Page 1

Page 2

TABLE OF CONTENTS

Preface ............................................................................................................................................... 2

Product Overview ............................................................................................................................. 2

Safety Instructions ........................................................................................................................... 3

1. Introduction ............................................................................................................................... 6

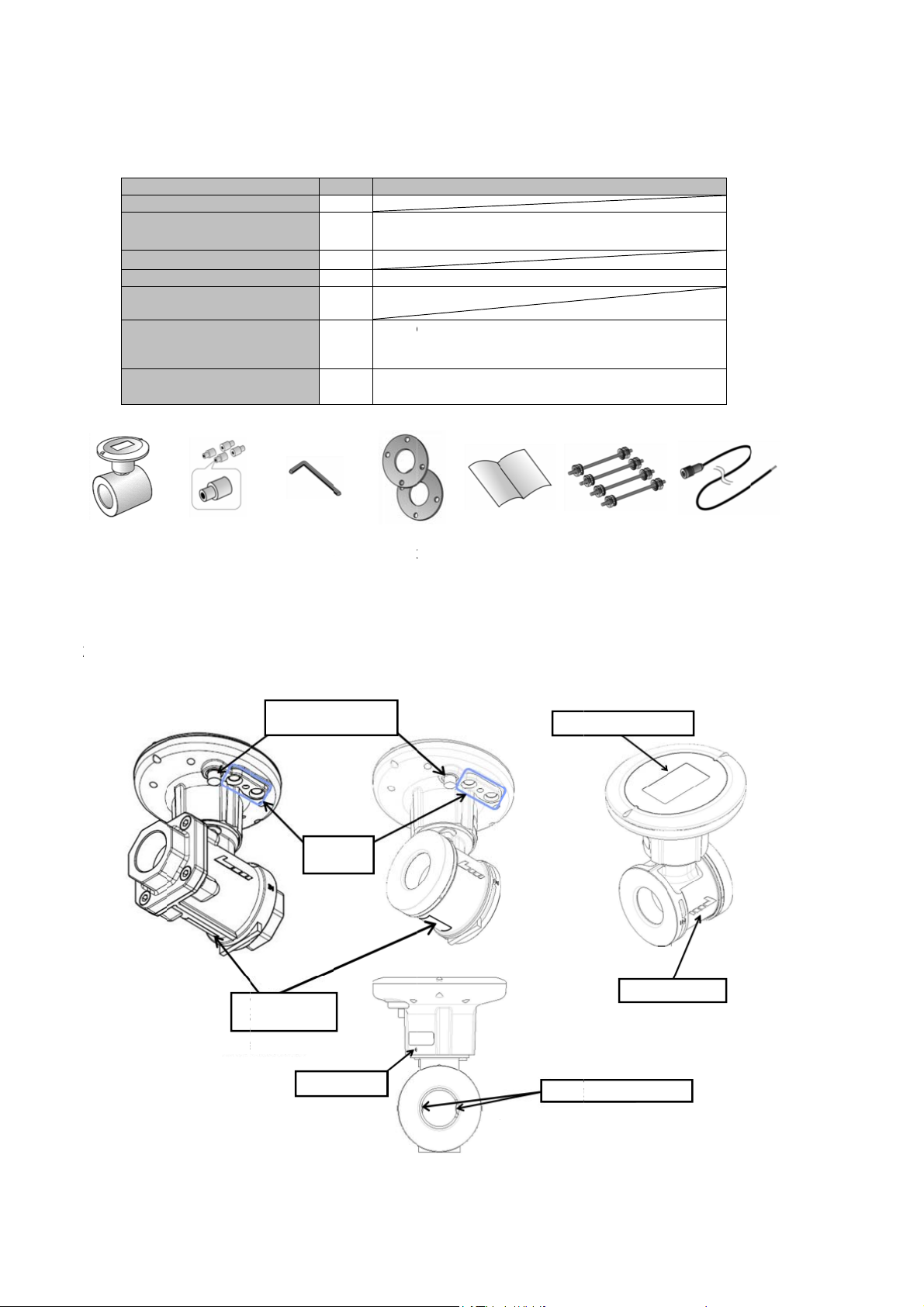

1-1. Scope of supply .............................................................................................................. 6

1-2. Name of each part ........................................................................................................... 6

2. Installation ................................................................................................................................. 7

3. Setting Up ................................................................................................................................ 12

3-1. Measurement and indication setting ........................................................................... 13

3-2. Output setting (for external power supply type) ........................................................ 14

4. Display ..................................................................................................................................... 16

4-1. Button operations ......................................................................................................... 16

4-2. Operation modes .......................................................................................................... 18

4-3. Setting items ................................................................................................................. 21

5. Wiring (External Power Supply Type) .................................................................................... 27

6. Operation ................................................................................................................................. 29

7. Alarm ........................................................................................................................................ 30

7-1. Aberration in flow measurement ................................................................................. 30

7-2. Aberrant pressure value ............................................................................................... 31

7-3. Aberrant temperature value .........................................................................................

7-4. Memory aberration ........................................................................................................ 32

8. Power Interruption (External Power Supply Type) ............................................................... 33

9. Battery Life (Built-In Battery Type) ........................................................................................ 34

10. Troubleshooting ...................................................................................................................... 35

11. Outline Diagram ...................................................................................................................... 37

Warranty and Maintenance ............................................................................................................ 38

31

1

Page 3

Preface

Thank you very much for purchasing the Ultrasonic Flow Meter for Air FWD this time. Please be sure

to read this Instruction Manual to use this product correctly and safely and to prevent failures.

Please arrange for operators who actually use this product to know the context of this Instruction

Manual surely. This Instruction Manual is necessary for performing maintenance, too. Please keep

the Manual until this product is disposed of.

Product Overview

This flow meter is the ultrasonic flow meter for air capable of measuring the flow of air at pressure

from the atmospheric pressure to less than 1 MPa. The flow meter is installed to pipes by screwing its

taper pipe threads to the pipes or by being tightened between pipe flanges.

Screw connection type (Taper pipe threads): FWD025, FWD032

Wafer connection type (Installation between pipe flanges and by tightening with bolts):

FWD040, FWD050, FWD065, FWD080

Flange connection type (JIS 10K flange): FWD100, FWD150, FWD200

2

Page 4

Safety Instructions

To ensure the safe use of this flow meter and to prevent a failure or an unexpected situation,

instructions to which attention must be paid are indicated with the following symbols.

Definitions

Danger

Warning

Note

General

Danger

Working environment and applicable fluid

Note

Incorrect handling by failure to follow instructions with this sign may lead to

imminent danger of death or serious injury.

Incorrect handling by failure to follow instructions with this sign may lead to death

or serious injury.

Incorrect handling by failure to follow instructions with this sign may lead to injury,

properties loss (product damage, etc.), pecuniary loss, and/or punishment

according to a penal regulation for violation of laws and ordinances.

This symbol indicates that improper operation may results in an accident.

This symbol indicates prohibited acts.

This symbol indicates matters you should observe without fail.

Do not use for applications that require safety, such as nuclear, railroad, aircraft,

vehicle, playground equipment, etc.

Do not modify the product.

Do not use the product for foods, drinks, medical chemicals, etc., because it is

not of sanitary specifications.

Do not use the product in the atmosphere of an inflammable gas, etc., because it

is not of explosion-proof specifications.

Do not apply any fluid other than air (compressed air used in factories) to this

flow meter. (The meter can be applied for nitrogen by factory setting before

shipment from our factory.)

Observe the temperature and humidity ranges (-10 to +60C and 90%RH or

lower) and pressure range (the atmospheric pressure to less than 1 MPa) in

use.

Avoid usage in an ambient containing a corrosive gas (chlorine, hydrogen

sulfide, etc.) and/or for an application to a fluid containing a corrosive gas.

This flow meter is not of a perfect waterproof structure (IP64). Do not install it at

a place that may be submerged in water.

Install the flow meter as far away from an electric noise source as possible. If it is

installed near the electric noise source, ground the shield of the external

connection cable.

The installation of a sunshade is recommended if the flow meter is exposed to

direct sunlight.

3

Page 5

Operation

Note

Storage

Note

Piping

Warning

Note

This flow meter is not a specified measuring instrument defined in Japanese

measurement law. The product cannot be used for billing transactions or

certification.

When opening a valve to start fluid flow, open the valve not all at once but

gradually. Opening of the valve all at once may cause a failure of the flow meter

if a pressure difference is occurring between the upstream side and

downstream side of the valve.

Store the flow meter at a place away from fire and not exposed to direct

sunlight.

Do not place any combustible material, inflammable substance and heating

body in the periphery of the flow meter.

Store this flow meter at a place which ambient temperature is -20 to +70C and

where no dew condensation occurs.

Do not ride on this flow meter using it as a foothold.

Do not hold the display section of this flow meter.

In the case that a flow-regulating valve, etc., that may cause turbulence of the

flow is installed, its location must be on the downstream side of the flow

meter.

In the case of new piping, install the product after sufficient cleaning of the

pipe(s).

Vertical piping is recommended when mist, dust, etc. are contained in a large

amount. In horizontal piping, install the flow meter in such a way that the

display section faces upward.

Do not install the product in locations where strong compressive force, tensile

force, or load may be applied after its installation.

Arrange piping so that the flow direction conforms to the direction of arrow

indicated on the flow meter’s body.

Do not drop it or do not make it bumped. Do not apply excessive impact,

either.

When rotating the display section, do not apply a force in a direction other

than the rotating direction.

Keep hands off the ultrasonic sensors.

4

Page 6

Wiring

Danger

Note

Disassembling and inspection

Note

Disposal

Warning

When performing wiring work, follow the instructions in this Manual.

Use the product within the rating.

Do not use the product on a voltage exceeding permissible load.

Do not place the product’s external connection cable together with or near to

power supply line(s) or power line(s), etc.

Electrical isolation of a remote counter (a receiver) from others is

recommended.

Do not apply an excessive tensile force to the external connection cable.

Ensure that the cable tip is not soaked in water during wiring work, etc.

When connecting the power supply wire of the external connection cable to an

external power supply, be careful not to short-circuit it. Use an external power

supply having a short-circuit protecting function.

Be sure to perform the wiring work in a state that power supply from the

external power supply is interrupted.

Do not perform operation and the wiring work with wet hands.

Do not disassemble this flow meter.

Presence of fluid flow makes a pilot lamp light up in a normal state. In the case

of no indication of the pilot lamp, contact our branch or sales office nearby.

If mist and dust is contained in a large amount, disconnect the flow meter

periodically to check for the presence of dirt etc., and remove it as necessary.

Be careful not to touch the ultrasonic sensors during inspection.

A lithium ion battery is incorporated in this flow meter. NEVER dispose of this

flow meter through general disposal routes. [Built-in battery type]

NEVER throw this flow meter into a fire. Otherwise, it may catch a fire or

explode. [Built-in battery type]

5

Page 7

1.

F

2

c

e

e

o

e

e

c

d

e

/

n

n

2

y

r

e

n

n

p

G

p

P

N

i

4

2

N

C

L

E

T

T

S

s

s

o

s

r

N

K

F

C

P

e

a

a

n

e

a

n

A

W

o

o

o

C

e

S

A

e

g

O

O

A

I

Introdu

1-

1. Scop

tion

of suppl

Upon deliv

LOW METER

Ultras

Cente

M4 h

Flang

Instru

(This

Bolt s

(Bolts

Exter

(exter

ry of the p

Name

nic flowmet

ring collars

xagonal wre

gasket

tion Manual

ocument)

t

nuts/plain wa

al connectio

al power su

CENTERIN

COLLARS

oduct, conf

r 1

ch 1

shes)

cable

ply type)

HEXAGO

WREN

rm that the

Q’ty

Acce

1

set

1

5 m o

1

See

Acce

The b

of req

Acce

AL

H

FLA

GAS

(WA

CONNE

TY

following it

about usage.

sory of the w

sory of the w

olts/nuts/plai

uired quantiti

sory of the w

r 20 m (Optio

GE

ETS

ER

TION

E)

OPE

M

ms are con

Remarks

fer connecti

fer connecti

washers are

s

fer connecti

)

RATION

NUAL

ained in th

n type

n type

put into a ba

n type

BOLT SET

(WAFER

ONNECTION

TYPE)

package:

in a set

EXTERN

CONNECT

CABLE

L

ON

1-

. Name

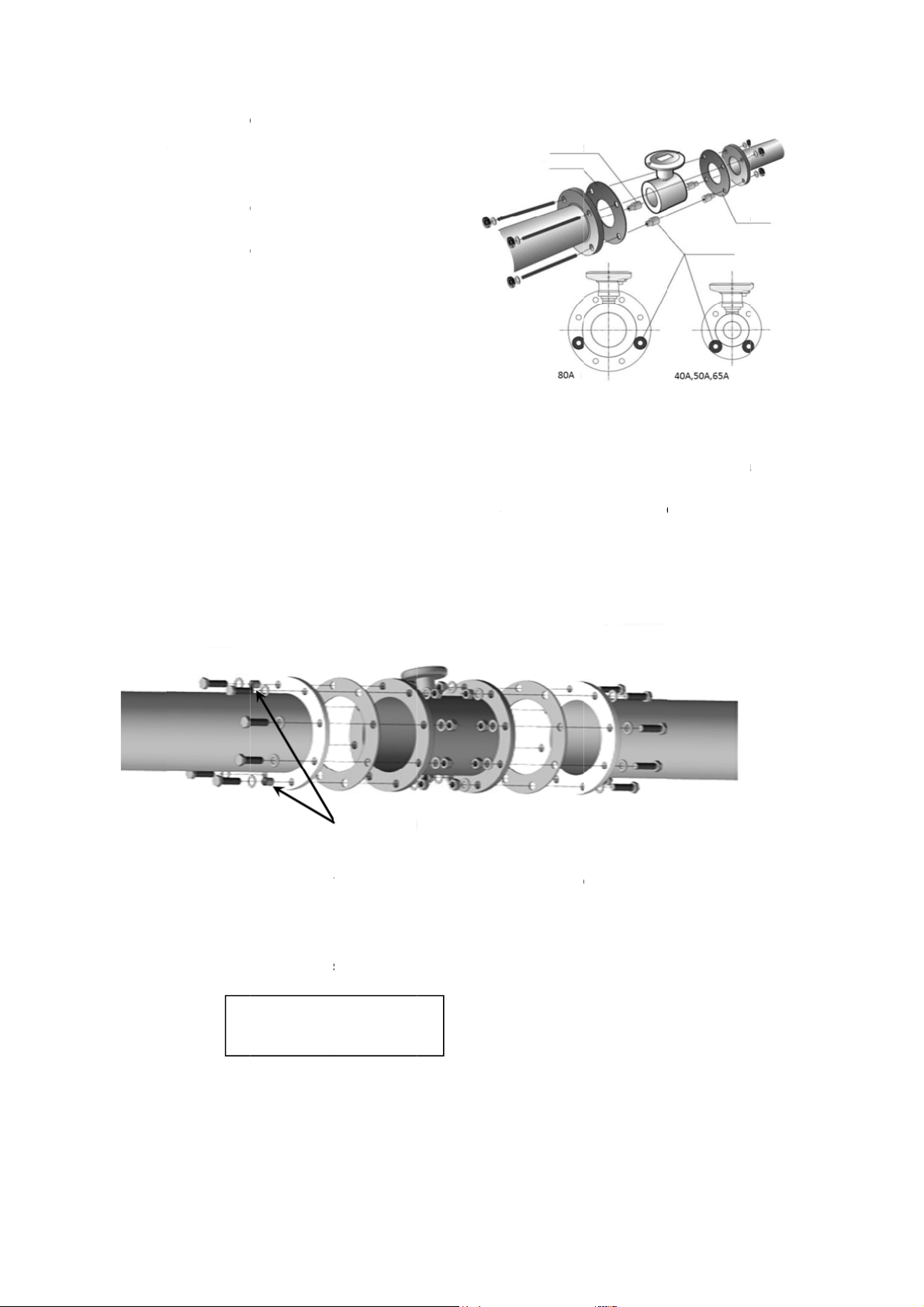

Screw con

type

of each

nection

art

EXTERNA

S

ECIFICATION

AME PLATE

CONN

SE

BU

SET

OUTPUT

CTOR

TING

TON

CREW

DI

ULTR

PLAY SECTI

BODY

SONIC SENS

N

CASING

R

afer conn

ction type

6

Page 8

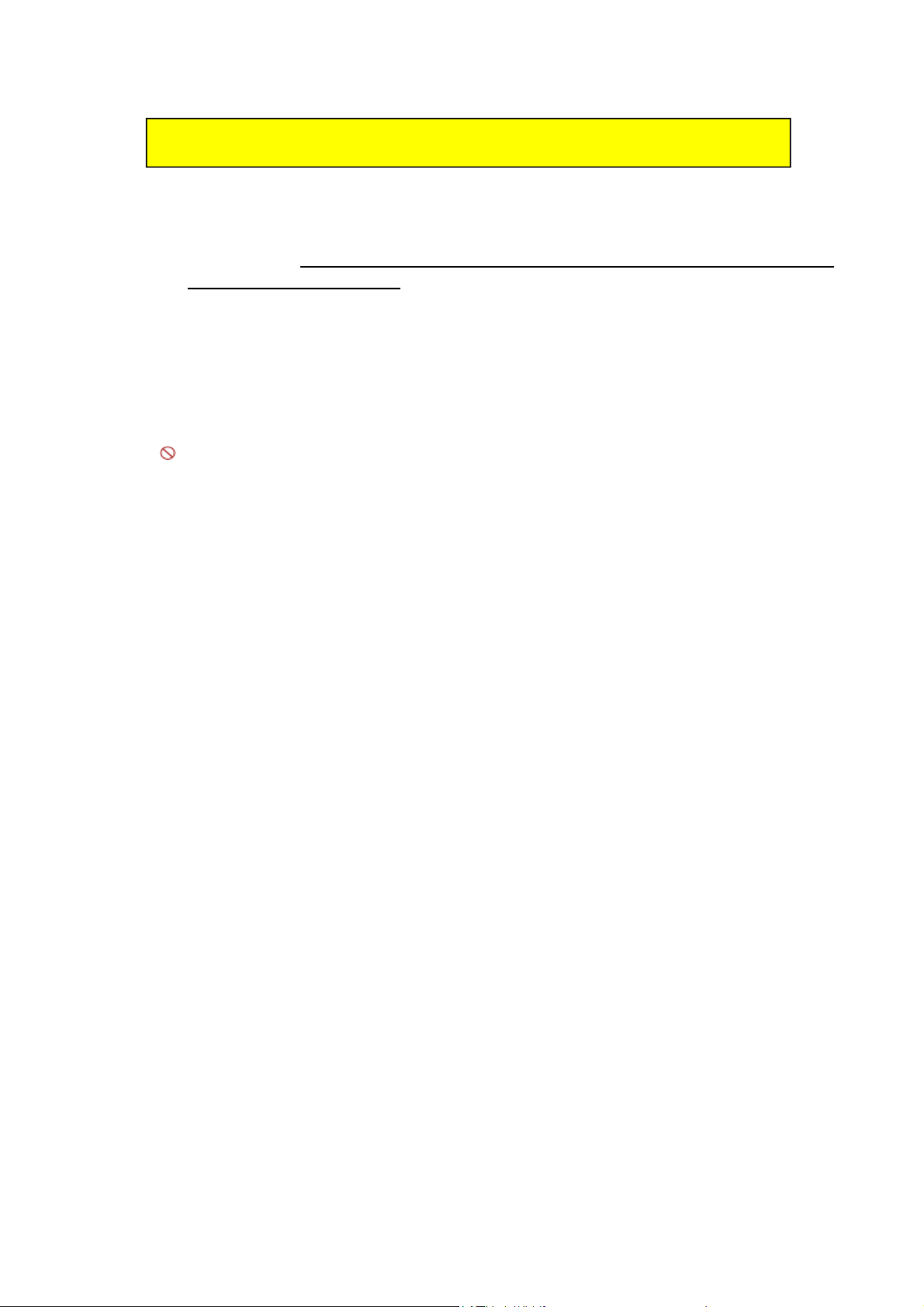

2. Installation

It is recommended that Setting Up (Page12 onward) and changing Panel angle

adjustment: (Page 11) are carried out before installation.

This flowmeter can be installed both indoors and outdoors and on a horizontal pipe and a

vertical pipe.

When a large amount of mist and/or dust exists inside pipe, the vertical piping is

recommended. When installing the flow meter horizontally, install it in such a way that the

display section faces upward.

This flow meter is not of a perfect waterproof structure (IP64). Do not install it at a place where

may be submerged in water.

The use of a sunshade is recommended if the flow meter is exposed to direct sunlight.

If you install the flowmeter in the place where it may get wet with rain, install the flowmeter so

that the display section does not face downward.

When you carry out the piping work, keep hands off inside the body and the ultrasonic

sensors (see Page 6) in particular.

Do not hold the display section of the flow meter.

Flow direction:

Mate the forward flow direction of a fluid to the arrow of the body.

7

Page 9

Straight run requirements:

Figure 2-1 Recommended straight pipe run

(D: nominal diameter)

8

Page 10

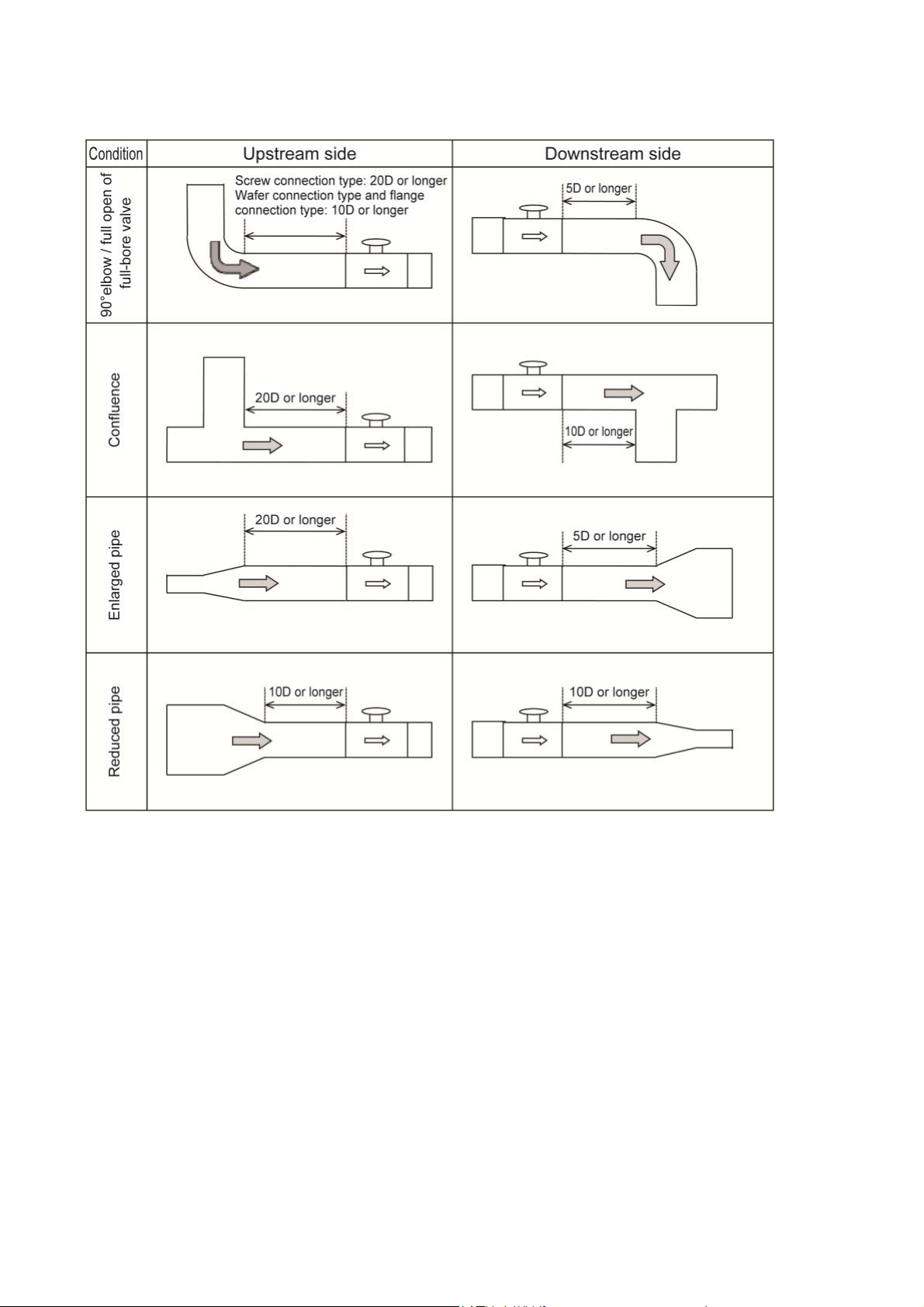

When the flow meter is installed near a pressure-reducing valve or a flow adjustment valve,

strictly observe the “required straight run L” as shown in Figure 2-2, because ultrasonic noise may

be generated inside the pipe.

Note that when the flow meter is installed at the downstream of the pressure-reducing

valve etc., there are many constraints. (If conditions are not satisfied, there is a possibility

that flow cannot be measured.)

Required straight run L (mm) =

10D differentialpressurekPa

⁄

20 ⁄

0.8

Figure 2-2 Required straight pipe run for installation near valve

9

Page 11

W

aFla

c

e

h

t

t

a

m

d

2

d

e

t

c

s

a

o

e

e

s

k

e

P

:

d

c

f

a

o

h

o

s

l

a

t

p

t

u

o

e

yFF

S

e

p

a

a

t

n

a

m

r

e

n

g

d

y

d

s

6

7

s

t

n

t

t

e

n

o

e

i

g

N

f

c

t

n

o

w

e

e

A

o

i

o

k

n

R

c

a

a

e

o

a

fer conn

nge type:

Install th

pipe. To

recomm

insert th

when in

Install t

flow me

connec

central

is reco

provide

Figure

provide

gaskets

to the c

flow me

it is diffi

both up

the mis

collars

ction type

e flowmete

er is aligne

ed. To redu

xes of the

mended th

as access

-3, insert t

as access

and flange

ntering col

er can be

ult to instal

tream and

lignment e

nly at the u

e flange ty

reduce the

nded that

centering

talling the

r so that th

to that of

e the displ

low meter

t the cente

ry be used

e centering

ry into the

. By fitting

ars, the ce

ligned to th

l the centeri

downstrea

c. of pipes,

pst

eam sid

e flow met

displaceme

he centerin

collars prov

pstream si

Figure

central axi

ipes to be

cement of

nd the pipe

ring collars

. As shown

collars

holes of fla

he flow me

tral axis of

t of the pip

ng collars a

sides due

install the

e.

r so that th

t of the ce

collars pr

ided as acc

e.

2-4 Attach

of the

he

s, it

in

ge

er

he

e. If

t

to

central axi

tral axes o

vided as a

ssory into

ng centeri

Figure 2-3

Centering c

Gasket

of the flo

the flow m

cessory be

he holes of

g collars

ttaching

llars

meter is al

ter and the

sed. As sh

flange pac

entering c

Centering co

igned to th

pipe, it is

own in Figu

ings and fl

llars

G

sket

llars

t of a

re 2-4,

nges

S

rew conn

Fix the fl

U

For

the wafer c

gas

owmeter b

STREAM

ets will not

ction typ

IDE

nnection t

extend insi

:

screwing it

WD025: 3

WD032: 4

CENTERI

pe and flan

e a pipe.

taper pipe

to 38 Nm

to 49 Nm

G COLLAR

e connecti

threads to

n type, tak

pipes within

DOWNST

care so th

the followi

EAM SIDE

at the flang

g torque ra

nge.

10

Page 12

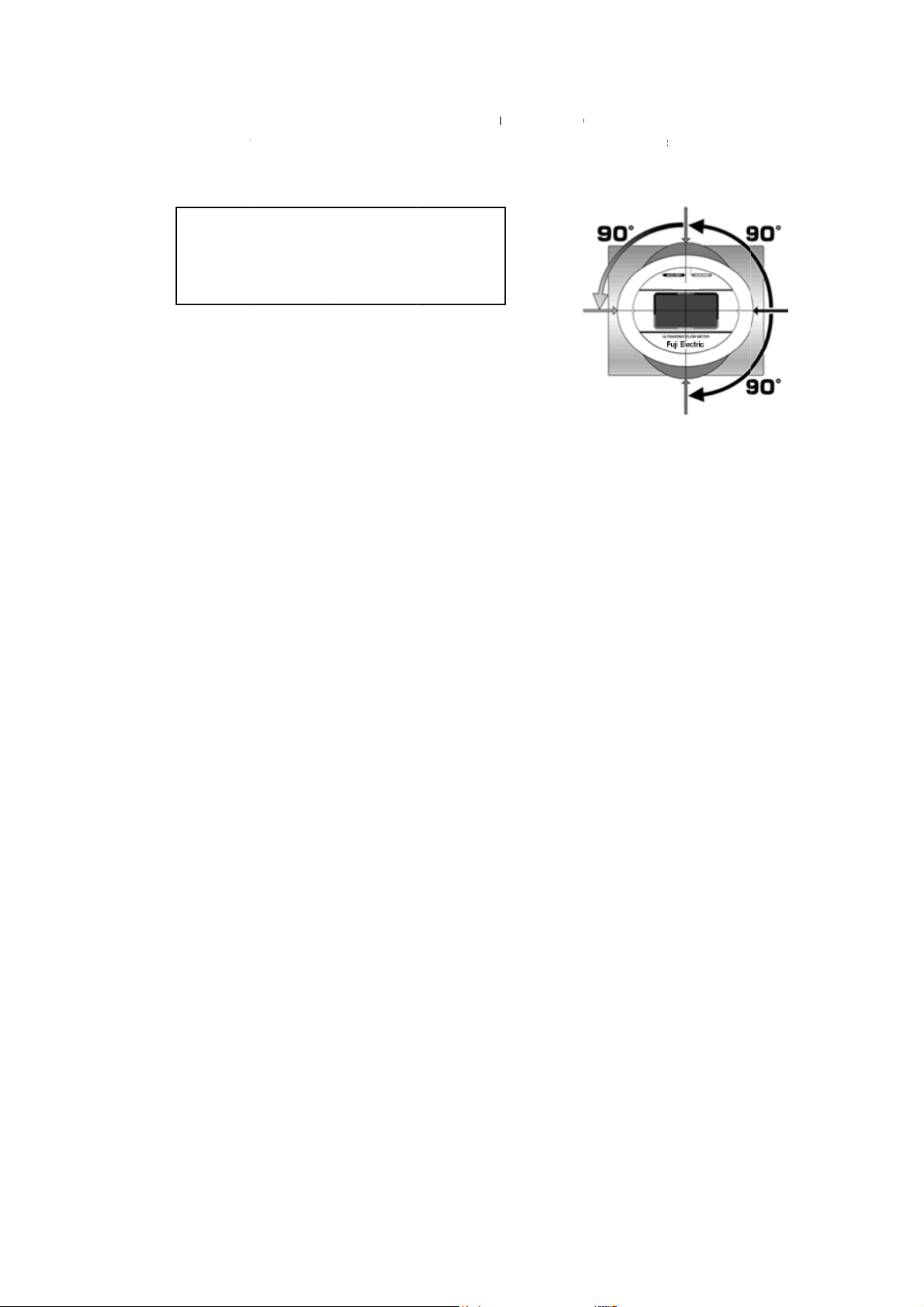

Pan

e

d

y

e

y

c

t

o

l

e

p

f

h

t

p

c

c

o

e

y

h

n

e

k

1

d

m

e

e

l

o

e

s

s

s

e

o

o

U

N

l angle a

The displa

change th

the displa

display se

position.

The disp

clockwis

the setu

When rota

in a directi

justment:

can be rot

direction o

section wit

tion. Do no

ay section

and 180

at the fact

ing the dis

n other tha

ted. It is r

the displa

the M4 he

fail to fix t

an be rotat

ountercloc

ry.

lay section,

n the rotati

commende

section, te

xagonal wr

e display s

d by 90

wise from

do not app

g direction.

to change

porarily lo

nch provid

ction by tig

y force

the directio

sen a set

d as acces

tening the

n before in

crew on th

sory, and th

set screw a

tallation. T

neck part

en rotate th

t a desired

DEFA

SETTI

f

e

LT

G

1

Page 13

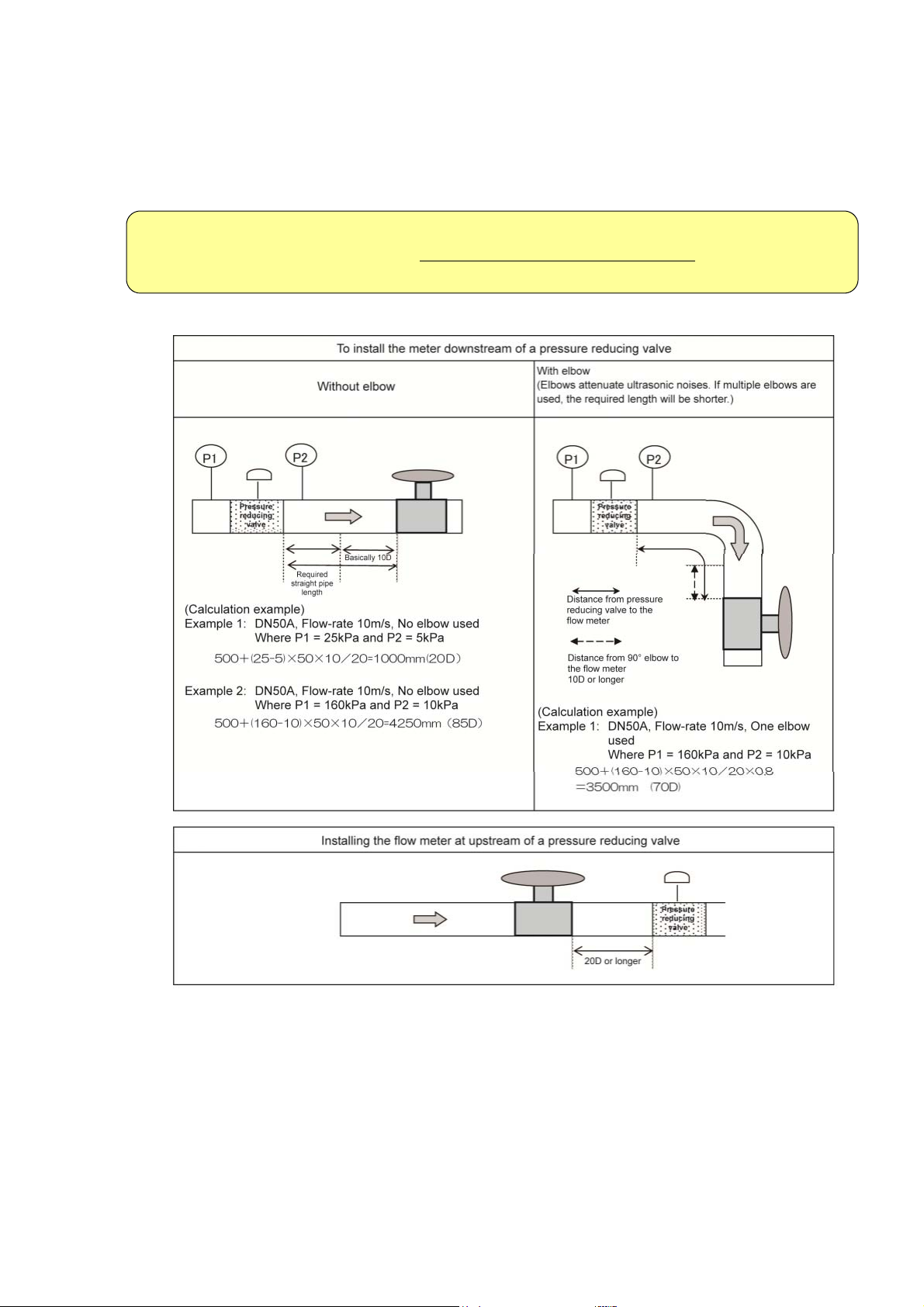

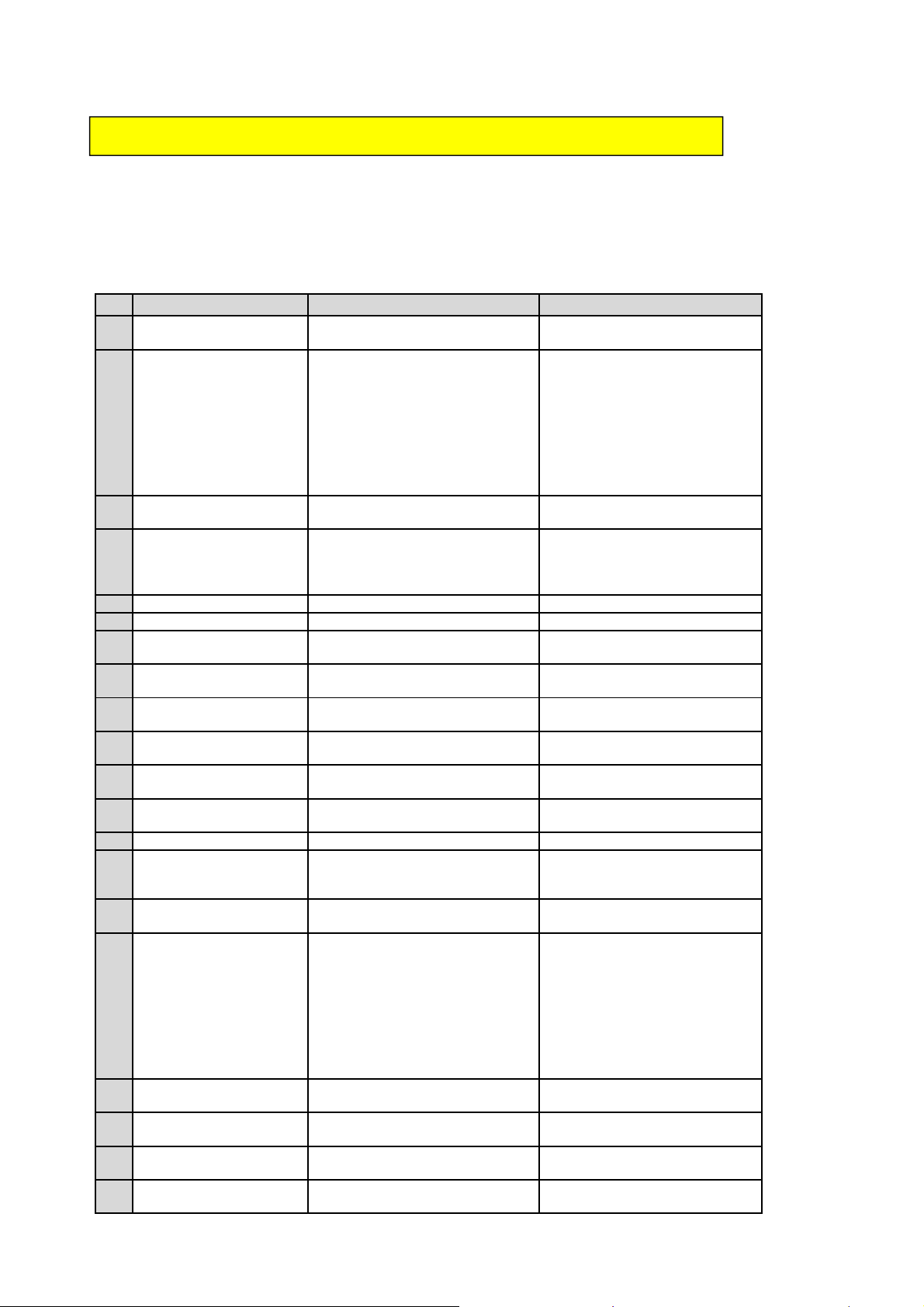

3. Setting Up

It is recommended that the setting of the flow meter be carried out before installation.

For this flow meter, 20 items shown in Table 3-1can be set. On delivery from factory, the “factory

default settings” in Table 3-1 are arranged, so that the flow meter can be used as it is. Change the

setting as necessary to make them suit to your working conditions.

See “4. Display” about button operations and setting methods.

Table 3-1 Setting items and standard factory settings

Setting item Setting options Factory settings

F1 Indication and output

Analog output

F2

full scale flow-rate

F3 State of contact output

F4 Contact output

F5 Lower limit alarm flow-rate -59999 to 59999 [m3/h] 0 [m3/h]

F6 Upper limit alarm flow-rate -59999 to 59999 [m3/h] 59999 [m3/h]

Alarm judgment value

F7

hysteresis width

Flow-rate moving average

F8

number of times

F9 Output pulse unit

F10 Pulse output method

Flow-value conversion

F11

selection

Standard conversion

F12

temperature

F13 Test mode time selection 3, 60, Unlimited [minutes] 3

F14 Fluid selection

Current output correlation

F15

value

F16 Low flow cutoff flow-rate 0 ≤ Set value ≤ Qmin*2 [m3/h]

Atmospheric pressure of

F17

the working environment

With or without pressure

F18

value averaging

Reset of all of

F00

accumulated values

Reset to standard factory

FFF

*1

delivery settings

Forward flow, forward and reverse

flow

0 to 99999 [m3/h]

Normal open,

Normal close

Reverse flow pulse, upper/lower

limit flow-rate alarm,

error alarm, electronic statement

output

3

0 to 9999 [m

01, 02, 04, 08, 16, 32, 64 [times] 04 [times]

Duty or one shot

50, 100, 125, 250, 500 [ms]

Yes (Normal),

Yes (Standard), No conversion

-10 to 60 [°C] 20 [°C]

Air (25A–200A)

Nitrogen (25A–80A)

Instantaneous flow-rate, pressure,

temperature

000.0 to 999.9 [kPa] 101.3

With (10 times), without (1 time) With (10 times)

To be cleared, not to be cleared Not to be cleared

To be reset, not to be reset Not to be reset

/h] 0 [m3/h]

Forward flow

25A:300

32A:600

40A:700

50A:1200

65A:2000

80A:2500

100A: 5000

150A: 10000

200A: 20000

Normal open

Upper/lower limit flow-rate alarm

100 [L]

1000 [L] for 100A and larger

Duty

Yes (Normal)

The kind of gas is set as the kind

specified at the time of order.

Instantaneous flow-rate

25A:0.1

32A:0.2

40A:0.2

50A:0.4

65A:0.6

80A:0.8

100A: 2.6

150A: 5.0

200A: 9.0

12

Page 14

Notes:

1. After resetting, "F9: Output pulse unit" will be set to 1000 [L], and “F14: Fluid selection” will be

set to Air.

2. Qmin is the following value depending on the nominal diameter.

25A 32A 40A 50A 65A 80A 100A 150A 200A

0.6 1.1 1.3 2.5 4.0 5.0 10.0 24.0 40.0

Setting items include the one related to fluid to be applied, the ones related to measurement and

indication, and the ones related to outputs.

[m3/h]

3-1. Measurement and indication setting

Settingrelatedtomeasurementandindication

Forwardflowor

Forward/reverseflow

Indicationandoutput

F1

Flowrateconversion

orActualflowrate

Flow‐rateconversion

F11

Indication of “Forward flow” or “Forward/reverse flow” [F1]

Indication of a main display is set.

When the “Forward flow” is selected, forward accumulated flow volume (total) or accumulated

flow volume (trip) can selectively be indicated on the main display by button operation.

When the “Forward/reverse flow” is selected, forward accumulated flow volume (total) or reverse

accumulated flow volume (total) can selectively be indicated on the main display by button

operation. When the analog output (4-20 mA) is selected for the flow-rate output, the electric

current value of the zero flow-rate output becomes 12 mA.

Flow-rate conversion

Select one among “actual flow-rate (OFF)”, "normal conversion flow-rate (Normal)", or "standard

conversion flow-rate (Standard)". If you select "normal conversion flow-rate (Normal)" or

"standard conversion flow-rate (Standard)", both indication and output of accumulated flow rate

and instantaneous flow rate are converted into the values under normal conditions or standard

conditions.

13

Page 15

3-2. Output setting (for external power supply type)

Pulseoutput

(reverseflow)

Alarmoutput

Instantaneous

flow‐rate

Pressure

Temperature

F3

Alarmoutput

F5

Lowerlimitalarm

F6

Upperlimitalarm

F7

Alarmjudgmentvalue

F2

AnalogoutputFSflow‐rate

Unitofoutputpulse

Opendrainoutput2

Currentoutput

Outputsettings

F9

Outputpulseunit

F4

Contactoutput

F15

Currentoutput

It is recommended that the setting of the flow meter be carried out before installation.

Current output [F15]

One of three output forms of instantaneous flow-rate, pressure and temperature can be

selected for the current output to suit your usage.

When the instantaneous flow-rate is selected, electric current corresponding to the setting of

the maximum flow-rate value of the analog output is outputted.

When the pressure is selected, 4 mA is outputted at the atmospheric pressure, and 20 mA is

outputted at 1 MPa.

When the temperature is selected, 4 mA is outputted at -10C, and 20 mA is outputted at

+60C.

Maximum flow-rate value of the analog current output (Analog output FS flow-rate) [F2]

When the analog output is used by setting to the instantaneous flow-rate, it is recommended

that full scale flow-rate (FS flow-rate) of the analog current output be set with a value

corresponding to maximum flow-rate used.

It is recommended that a numerical value having a margin be set as a set value of the FS

flow-rate.

(Setting example of the FS flow-rate: A set value at the time of nominal diameter 50mm,

flow-rate conversion “With(ON)”, room temperature (30°C), pressure 0.7 MPa, flow speed

10m/s: 600 m

3

/h)

14

Page 16

As a reference, Table 3-2 shows examples of conversion.

Table 3-2 Flow rate conversion examples

FWD025

FWD032

FWD040

FWD050

FWD065

FWD080

FWD100

FWD150

FWD200

Pressure

(MPa)

Temperature

(C)

0.6(m3/h) 0.6 0.5 3.6 3.2 4.7 4.3 6.4 5.8

35(m3/h) 35 32 210 190 280 250 370 330

1.1(m3/h) 1.1 1.0 6.5 5.9 8.7 7.8 12 11

65(m3/h) 65 59 390 350 510 460 690 630

1.3(m3/h) 1.3 1.2 7.7 7.0 10 9.3 14 13

80(m3/h) 80 72 470 430 630 570 850 770

2.5(m3/h) 2.5 2.3 15 13 20 18 27 24

150(m3/h) 150 135 890 800 1180 1070 1600 1440

4(m3/h) 4.0 3.6 24 21 32 29 43 39

240(m3/h) 240 220 1420 1280 1900 1710 2560 2310

5(m3/h) 5.0 4.5 30 27 40 36 53 48

300(m3/h) 300 270 1780 1600 2370 2140 3200 2880

10(m3/h) 10 9 59 53 79 71 110 96

500(m3/h) 500 450 2970 2670 3950 3560 5340 4810

24(m3/h) 24 22 140 130 190 170 260 230

1200(m3/h) 1200 1080 7120 6420 9490 8550 12810 11540

40(m3/h) 40 36 240 210 320 290 430 390

2000(m3/h) 2000 1800 11870 10700 15820 14250 21340 19230

0 (Atmospheric

pressure)

0 30 0 30 0 30 0 30

0.5 0.7 0.98

Output pulse unit [F9]

When a pulse output of the open drain output 1 (forward pulse output) is used, set the output

pulse unit in advance so as to suit your working conditions. The output pulse unit set here is

reflected in the open drain output 2 (reverse flow pulse output), too.

Contact output [F4]

You can select from the pulse output (reverse flow), the flow-rate upper/lower limit alarm output,

and the main unit aberration output. When the pulse output (reverse flow) is selected, set the

output pulse unit. However, when the output pulse unit is set in advance for the use of the open

drain output 1 (forward flow pulse output), it is not necessary to set it here.

For the upper/lower limit alarm output, an alarm can be outputted or stopped with a desired

flow-rate value.

When this function is selected, set the alarm output contact state (F3), the lower limit alarm

flow-rate (F5) and the upper limit alarm flow-rate (F6), and the alarm judgment value hysteresis

width (F7).

15

Page 17

4.

B

B

B

y

n

y

o

i

r

o

n

SBAC

P

o

y

a

t

b

t

e

CaainCare(t(L

P

C

C

R

z

T

m

p

c

a

o

r

f

f

m

a

f

m

o

o

t

h

c

t

s

o

r

m

o

o

l

u

e

o

u

p

w

s

W

w

m

oin

g

s

g

o

g

g

a

e

c

n

h

W

g

a

a

l

CBABABACMAI(UPSUB

W

o

r

s

n

f

f

a

o

U

T

U

M

u

o

m

d

o

v

e

]

W

]

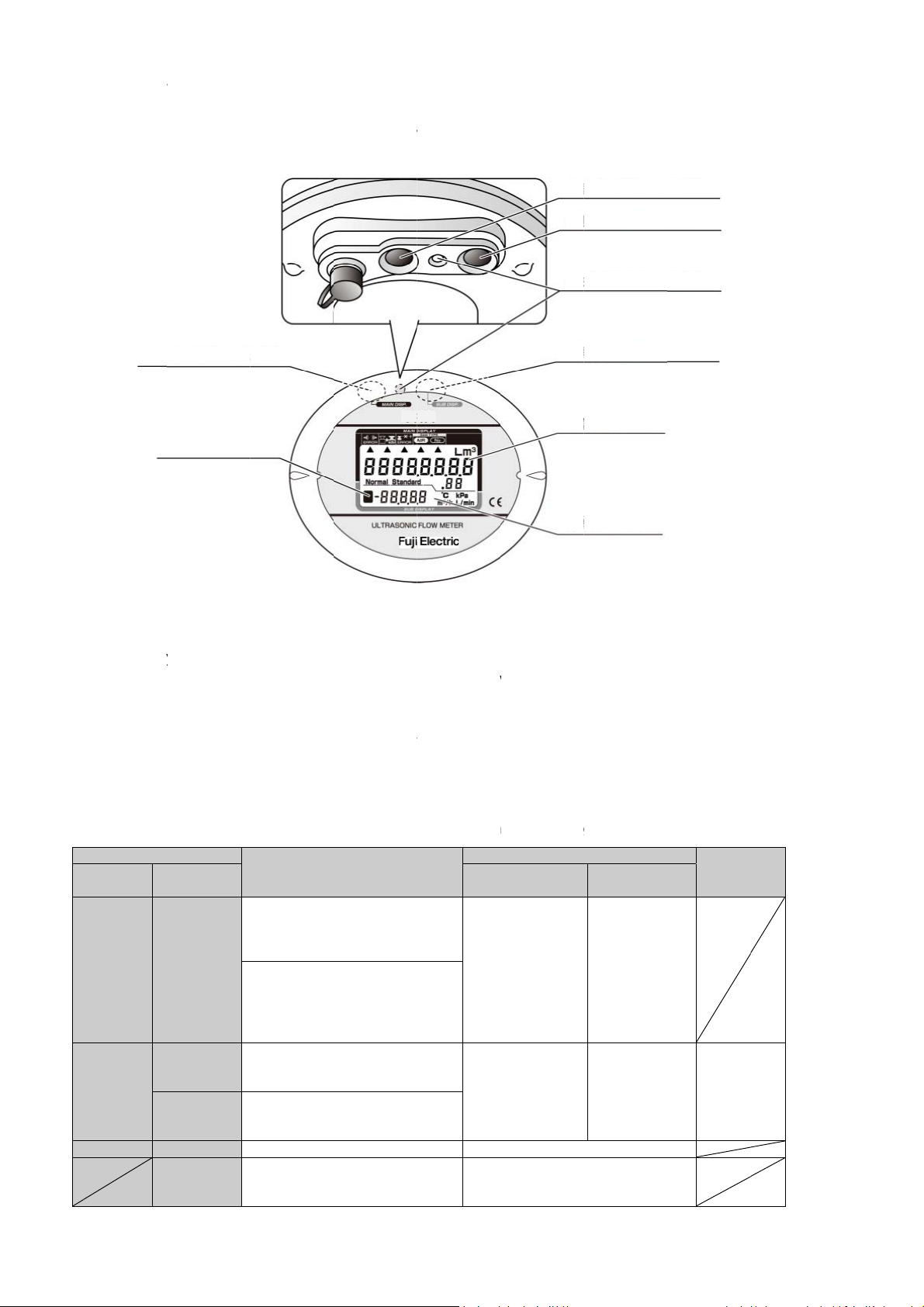

Displa

Fig

Back side of

ure 4-1 Dis

he panel

play and b

ttons

BA

K RIGHT B

TTON [SW2

4-

1. Butto

Usuall

Variou

See F

By pe

Table 4-1

flow v

on the

as sh

K LEFT BUT

ILOT LAMP

operati

is the me

lume, and

s individual

back of the

gure 4-1 a

forming but

wn in Figur

How to op

ON [SW1]

ns

surement

he sub-dis

setting item

display se

out the arr

on operati

4-2.

erate butto

ode, and t

lay (lower

s can be se

tion.

ngement of

ns in Table

ns in mea

e main dis

olumn) sho

t at a local

“SW1”, “S

4-1, the flo

urement

(LO

lay (upper

s instanta

ite by the t

2” and “S

meter can

ode, settin

CK LEFT BU

CK CENTER

K RIGHT B

N DISPLAY

PER COLUM

-DISPLAY

ER COLU

olumn) sh

eous flow-

ree button

3.”

be shifted t

mode, a

TON [SW1]

BUTTON [S

TTON [SW2

N)

N)

ws accum

ate.

witches pr

o various

d test mo

3]

lated

vided

odes

e

utton positio

Button

position

Back left

ack right

ack center

and name

Name

SW1

SW2 Cfl

SW2 for

three

seconds

SW3

W1+SW2

hangeover o

ccumulated fl

ccumulated fl

stantaneous

hangeover o

ccumulated fl

verse accu

otal) / instant

/min)

hangeover o

ow-late (m3/h

ressure / te

hangeover t

hangeover t

esetting of tri

1)

ero3)

Measu

ement mode

Forward

ow volume (t

ow volume (t

flow-late (L/

Forward

ow volume (t

ulated flow v

neous flow-

Instantaneo

/

perature

test mode

setting mod

p accumulati

2)

tal) /

ip) /

in)

ate

Chan

next

tal) /

lume

s

Chan

previ

item

Chan

Chan

n to

indic

and s

L

cal setting

dication

eover to the

etting item

eover to the

us setting

eover to me

eover of loc

tion

tting of detai

Setting

mode

Setting o

details

Changeover

setting detail

Movement o

blinking digit

Change of a

numerical v

at a blinking

portion

surement m

l setting

s

f

of

s,

f

lue

de

Test m

Switcho

measur

mode

de

er to

ment

16

Page 18

Notes:

(

[

]

1. “SW1+SW2” indicates that two switches are pressed simultaneously.

2. Indication cannot be changeover when the main display shows the instantaneous flow-rate

[L/min].

3. Accumulated flow volume (trip) is reset to zero in the following cases:

When SW1+SW2 are pressed during the indication of accumulated flow volume (trip)

If power supply is interrupted by a power failure [External power supply type]

Figure 4-2 Transitions between each operation mode

Main display (Forward flow

メイン表示(正流表示モード)

display mode)

Accumulated flow

正積算流量

volume

計

測

Sub-display (When main display displays Accumulated flow volume (Forward flow), Trip accumulated flow

モ

サ ブ 表示( メイン 表示が正 積算流量、 トリッ プ積 算流量、 逆積算流 量のい ずれかの 場合)

volume, or Accumulated flow volume (Reverse flow))

|

Instantaneous flow

瞬時流量 圧力 温度

ド

Forward flow)

SW1

SW2

Measuring modes

SW3

Transition to settings mode

設定モードへ遷移

Clear trip accumulated flow volum e

SW1+SW2/ トリップ積算クリア

Trip accumulated flow

トリ ップ積 算流量

volume

SW1

Pressure

SW3 or three minutes of

SW3 or3min

inaction.

SW1

SW2

1min

One minute

elapses.

経過

SW2 or one minute elapses.

SW2

無操作

Instantaneous flow-rate

瞬時流量

Temperature

or1min経過

Switchover using

settings mode [F1]

[L/min]

SW2 (3s)

設定モード[F1]で切換

Transition to test mode

テストモードへ遷移

メイ ン表示(正逆流表示モード)

Main display (Forward flow display m ode)

ブランク

Blank

SW1

Accumulated flow rate

逆積算流量

(Reverse flow)

SW1

[L/min]

)

Accumulated flow

正積算流量

volume (Forward flow)

Sub-display (main display) under insta ntaneous flow-rate [L/min]

サブ 表示(メイン表示:瞬時流量の場合

SW2 (3 sec.) or test mode

SW 2 (3s ) or テス トモ ード

time ended.

時間終了

SW1

Instantaneous flow-rate

瞬時流量 [L/min]

L/min

17

Page 19

4-

2

e

a

n

m

m

e

c

W

•

e

r

s

y

h

o

m

s

e

r

0

o

a

t

u

3

s

p

o

4

a

u

a

4

m

p

y

s

e

n

m

d

m

w

o

e

u

w

a

n

m

r

a

e

r

a

s

l

o

u

w

d

]

t

m

e

d

e

e

n

l

e

9

i

f

m

o

o

u

a

u

i

. Oper

M

asureme

tion mod

This

mode is fo

this

The

(low

r column) s

Swit

• Each ti

t mode

ode unles

ain displa

hover of t

hen the f

to insta

flow).

s

measuring

you opera

(upper col

hows the in

Figure 4-

e main di

rward flow i

e SW1 is

ntaneous fl

Figure

flow-rate,

e any of its

mn) displa

tantaneou

Exampl

play

s selected i

ressed, the

w-rate [L/

-4 Main

ressure, a

buttons.

s the accu

flow-rate.

of measu

[F1: Indic

display will

in] and th

isplay (fo

d temperat

ulated flo

ement mo

tion/output

cycle from

n to accu

ard flow)

re. The m

volume, a

e

rip accumu

ulated flow

ter will re

d the sub-d

lated flow v

volume (f

ain in

isplay

lume

rward

Accumul

tedflowvolu

e

Tri p

ccumulatedfl

wvolume

Instantaneous

flow‐rate[L/m

n]

By pre

display

If the t

show

operati

sing SW1

d, trip acc

ip accumul

000000.0

ns.

nd SW2 si

mulated flo

ted flow v

without z

ultaneous

volume c

lume overfl

ro suppre

ly while trip

n be canc

ows beyon

sion and

accumulat

led.

9999999.

continue

d flow vol

, the displ

its accum

me is

y will

lation

Figure

-5 Trip acc

mulated f

ow volum

No overflo

Overflow

18

Page 20

h

s

h

h

nWhe

o

m

t

t

o

r

t

a

s

a

s

b

t

a

l

c

en forward

/

e

o

g

e

M

n

2

a

c

o

e

e

d

c

f

d

y

y

a

n

a

w

w

r

s

)

a

a

d

a

d

h

t

e

s

m

e

e

e

e

e

n

n

r

4

4

9

d

d

a

-

n

f

t

w

e

2

e

w

e

s

l

/

t

v

i

L

e

e

p

a

e

W

/

d

t

d

t

d

m

u

)

e

o

m

i

e

o

”

a

o

a

r

o

a

e

c

c

o

c

a

t

e

f

3

t

e

n

r

n

s

W

•

Each tim

(Reverse

volume (f

reverse flo

SW1 is p

flow) to in

rward flow

Fi

ure 4-6 M

is selecte

essed, the

tantaneous

.

in display

in [F1: Ind

display will

flow-rate [

(forward/r

cation/outp

cycle from

/min] and

verse flow

t]:

accumulat

then to ac

)

d flow volu

umulated f

me

low

Test

mode

The test m

‒ Perfor

‒ During

‒ Test m

‒ When

‒ When

‒ An inst

Sub-di

In t

volu

Eac

mai

the i

during

flow-ra

interval

setting

measu

during

there i

there i

*Possi

convec

place.

Examp

A

cumulatedflo

(Forwardfl

play (low

e case of [

me (trip), a

time “SW

tenance

n one minu

ndication is

de is a fun

the test m

he measur

e can be m

the test mo

s of 0.5 se

de times o

mode. Whe

ement mod

he test mo

n indicated

a possibilit

n indicated

a possibilit

ility of leak

ion, etc., it

ntaneous f

e) Indicatio

Indic

volume

ow)

r column)

ain display

d reverse

” is presse

*1)

nd instant

te elapses

shifted to t

tion that re

de in a sta

ment mod

asured.

e, a unit of

onds.

three kind

n the set ti

e [F13]. Wh

e, it is shift

value of th

of leakag

value of th

of leakag

ge: As an i

indicates o

low-rate du

: 0 to 0.00

tion: -0.00

Accumula

(Re

: Forward a

ccumulate

,” the indic

neous flow

uring the i

e instantan

leases low

e of no flo

, the mode

the sub-dis

of 3 minut

e elapses,

en the “SW

d to the m

instantane

* at the do

instantan

* at the up

dicated va

ly a possibi

ing the test

[m3/h] →

to 0 [m

3

h]

edflowvolum

erseflow)

ccumulated

flow volum

tion chang

rate.

dication of

eous flow-r

low cutoff t

. When “S

is shifted to

3

play (“m

h”

s, 60 minut

the test mo

” is presse

asurement

ous flow-ra

nstream si

ous flow-ra

tream side.

ue includes

lity.

mode is in

0.00 [m3/h]

→ -0.00 [

e

Instant

flow volum

e (total)]

s in order

ressure, te

te automat

mporarily.

2” is press

the test m

, “kPa”, “C

s, and no l

e is autom

for 3 sec

mode.

e is a flow-r

e.

e is a flow-

offset of ze

icated by r

3

/h]

neousflow‐ra

(total), ac

f pressure,

mperature

ically.

ed for 3 se

de so that

, “L/min”) b

imit can be

atically shif

nds or mor

ate value of

ate value o

ro flow-rate

unding at

e[L/min]

umulated fl

temperatur

r maintena

onds or mo

very small

inks at the

selected in

ed to the

once agai

(+)0.1 or m

-0.1 or les

inside

rd

decimal

ow

,

ce,

e

the

ore,

,

1

Page 21

Setting mode

‒ Press “SW3” to shift the flow meter to the setting mode. To shift from the setting mode to the

measurement mode, press the “SW3” again. When no operation is made for 3 minutes in

the setting mode, it is shifted to the measurement mode automatically. Press the“SW3” with

the M4 hexagonal wrench provided as accessory, etc. Note: “SW3” may be broken if

pressed by a sharp pointed tool.

‒ In the setting mode, setting details shown in the “Table 3-1 Setting items and standard factory

settings” (Page 12) can be changed.

‒ See figures of changeover of indication of various setting modes in Figure 4-2 for button

operation methods in the setting mode.

20

Page 22

4-3. Setting items

[F1] Indication/output

In the indication/output, “forward flow (d.F.)” measurement or “forward/reverse flow (d.r.F)”

measurement is selected.

When the “forward flow” measurement is selected, the “forward accumulated flow volume (Total)”

or the “accumulated flow volume (Trip)” can be indicated on the main display by button operation.

When the instantaneous flow-rate is set with the analog output (4-20 mA), 4 mA becomes zero

flow-rate.

When the “forward/reverse flow” is selected, the “forward accumulated flow volume (Total)” or

“reverse accumulated flow volume (Total)” can be indicated on the main display by button

operation. The trip function cannot be used. When the instantaneous flow-rate is set with the

analog output (4-20 mA), 12 mA becomes the zero flow-rate.

See “4. Description of operation of display section” about the button operation.

[F2] Analog output FS (Full Scale) flow-rate

This function sets a full scale flow-rate value when the instantaneous flow-rate is set with the

analog output. On delivery from factory, the flow-rate value shown in the Table 3-1 or Table 3-2 is

set. When in use with the NORMAL conversion set to “With (ON)” set a NORMAL conversion

value.

[F3] State of contact output

Select "Normal open (n. OP)" or "Normal close (n. CL)."

Set this to "Normal open" in case of using a battery-powered signal receiving device.

[F4] Contact output

Select the output signal of open drain output 2 from “pulse output (reverse flow) (PULS),”

“main unit aberration output (Err),” “upper/lower limit flow-rate alarm output (AL),” and

“electronic statement output (COdE).”

“Main unit aberration output (Err)” outputs signals when one of the following occurs: ultrasonic

measurement aberration, pressure measurement aberration, temperature measurement

aberration, battery voltage reduction (for the built-in battery version only), and elapse of 11

years.

[F5] Lower limit alarm flow-rate

Use this to set the lower limit alarm flow-rate (5 digits) as the lower limit flow-rate value for the

upper/lower limit flow-rate alarm.

* This is the judgment value for flow-rate lower limit alarm output of open drain output 2.

[F6] Upper limit alarm flow-rate

Use this to set the upper limit alarm flow-rate (5 digits) as the upper limit flow-rate value for the

upper/lower limit flow-rate alarm.

* This is the judgment value for flow-rate upper limit alarm output of open drain output 2.

[F7] Alarm judgment value hysteresis width

With regard to the flow-rate value defined for the upper/lower limits of the upper/lower limit

flow-rate alarms, a hysteresis width range (4 digits) is defined for the alarm judgment value as

the range of flow-rates for terminating the alarm.

*This is the judgment value for flow-rate upper/lower limit alarm output of open drain output 2.

21

Page 23

[F8] Flow-rate moving average number of times

This denotes the moving average number of times for the instantaneous flow-rate

measurement results.

Instantaneous flow-rate for display and output is the value that the moving average is applied

for the defined number of times of the most recently measured instantaneous flow-rate.

While this is usually set to “4 times (04)” and does not need to be changed,

you can choose from “No moving average (01),” “2 times (02),” “4 times (04),” “8 times (08),”

“16 times (16),”

“32 times (32),” and “64 times (64).”

[F9] Output pulse unit

Select the weight (unit: L/P) of the output pulse from 10 L/P, 100 L/P, and 1000 L/P.

The range of the setting is limited depending on the nominal diameter and settings you have

made in [F10] Pulse output mode or [F11] Flow-value conversion selection. Please see the

following table for details.

Figure 4-7 Output pulse unit selections

22

Page 24

[F10] Pulse output method

Select from one of the five one-shot modes (ON time “50ms,” “100ms,” “125ms,” “250ms,” or

“500ms”) or Duty mode. Selecting one of the one-shot modes is recommended in case the

signal receiving instrument you are using is battery-powered. Make sure to check the

specifications of the signal receiving instrument and set the appropriate ON time from Figure

4-7.

[F11] Flow-rate conversion selection

Select "actual flow-rate (OFF)", "normal conversion flow-rate (Normal)", or "standard

conversion flow-rate (Standard)" for flow value conversion. If you select “normal conversion

flow-rate (Normal),” the “Normal” lamp above the partition line will flash. If you select “standard

conversion flow-rate (Standard),” the “Standard” lamp will flash. If you select “No conversion,”

both lamps will turn off. The accumulated flow volume display, instantaneous flow-rate display,

and output signal will all correspond to the selection of whether to convert the flow-rate or not.

See below for the definition of flow-rate conversion and the conversion equation.

/h

273.15

273.15

Q

: Normal conversion flow-rate [m3/h]

2

t: Measured temperature [°C]

P

: Measured pressure [kPa]

1

q

: Actual flow-rate [m3/h]

1

/h

273.15

273.15

Q

: Standard conversion flow-rate [m3/h]

2

T: Standard conversion temperature [°C] [F12]

t: Measured temperature [°C]

P

: Measured pressure [kPa]

1

q

: Actual flow-rate [m3/h]

1

[F12] Standard conversion temperature

This is used to set the temperature [ºC] to use as the basis for standard conversion. The

temperature can be set within a range between -10ºC and +60ºC in 1ºC increments. This

setting is not available if an option other than standard conversion is selected in [F11].

[F13] Test mode time selection

Test mode times available for selection are "3 min. (3)," "60 min. (60)," and "Unlimited (--)."

During test mode, the unit on sub display blinks.

[F14] Fluid selection

Select either "Air (Air)" or "Nitrogen (N2)." Even if you specified a flow meter for air in your

initial order, you can change this setting so that it can be used for nitrogen.

[F15] Current output correlation value

Select "Instantaneous flow-rate (FLo)", "Pressure (PrS)", or "Temperature (tEP)" for the

functional assignment of the current output. When instantaneous flow-rate is selected, the

instantaneous flow-rate correlation value that you have selected in [F11] Flow-value

conversion selection will be used.

17

101.33

17

101.33

23

Page 25

[F16] Low flow cutoff flow-rate

This is for setting the low flow cutoff flow-rate (Qcut) where the instantaneous flow-rate is

0m3/h.

The settable range is defined as 0 ≤ Qcut ≤ Qmin.

The set flow-rate will be the flow-rate you selected in [F11] Flow-value conversion selection.

[F17] Atmospheric pressure of the working environment

This is used to set the atmospheric pressure value (4 digits) [kPa] of the working environment

in absolute pressure. The standard factory setting has been set to 101.3 [kPa]. Leave this

setting unchanged unless you are operating the meter at higher elevations, etc.

[F18] With or without pressure value averaging

Set with or without pressure value averaging to either "With averaging (10)" or "No averaging

(1)." If "With averaging" is selected, the moving average value of the 10 most recently

measured pressures is used for display and output.

[F00] Reset of all of accumulated values

By selecting "Clear (cLr)", the values for Accumulated flow volume (Forward flow),

Accumulated flow volume (Reverse flow), and Trip accumulated flow volume are reset to zero.

[FFF] Reset to standard factory delivery settings

By selecting "Reset (SEt)", settings are reset to standard factory settings shown in Tab le 3-1.

However, "F9 Output pulse unit" alone will be set to 1000L/P for all nominal diameters, and

“F14 Fluid selection” will be set to Air.

24

Page 26

Fi

g

m

n

n

g

A

v

s

5

v

g

u

A

s

e

put

e

c

S

m

o

m

e

W

n

n

SW3

Setting

ure of cha

or no operation for

3 minutes

ode

geover of i

Fi

Measurement

mode

Display · output

nalog output

dication of

ure 4-8 Di

Forward flow outpu

Flickering

arious sett

play chan

Forward/reverse flow outp

t

Flickering

ing modes i

eover in s

t

Flickering

shown bel

tting mod

Flickering Fl

ow.

e

ickering

* Use SW2

portion.

* Displays t

as select

conversio

to increment flickering

he converted informatio

d in F11 “Flow rate

selection."

State of contact

output

Contact output

Alarm output lower

limit flow-rate

Alarm output upper

limit flow-rate

Alarm judgment

value hysteresis

width

Flow-rate moving

average number of

times

Normal open

Pulse

Normal close

larm

Main unit

aberration out

lectronic

* Use S

2 to increment

flickeri

g portion.

Flickering

Flickering

Flickering

Flickering

4 times

Flickering

Flickering

Flickering

8 times

Flickering

Flickering

Flickering

16 times

Flickering

Flickering Fli

Flickering

* Use

incre

porti

32 times 64 ti

Flickering Fli

kering

W2 to

ent flickering

n.

mes 1 time

Flickeri

ckering

* Use SW2 to

increment

flickering

portion.

2 times

Output pulse

unit

2

Page 27

)

At

t

)

出力パルス

Output pulse unit

F9

単位

SW1

(Other than standard

(スタンダード換算以外)

conversion)

SW2

(Other than standard

(スタンダード換算以外)

conversion)

SW2 SW1

出力パルス

F10

SW2

F11

SW2

F12

SW2

SW2

(Standard

(スタンダード換算)

conversion

Test mode time

テストモード

F13

SW2 SW1

F14

SW2 SW1

Current output

F15

correlating value

SW2

Low flow cutoff

F16

カットオフ値

SW2

使用環境の

pressure in the

F17

SW2

With or without

pressure value

F18

平均化有無

SW2

Clear accumulated

積算値クリア

F00

SW2

Reset parameters

FFF

Output pulse

selection

選択

Flow-rate

流量換算

conversion

有無選択

selection

Standard

スタンダード

conversion

換算温度

temperature

selection

時間選択

Kind of gas

ガス種

電流出力

相関値

ローフロー

mospheric

operating

大気圧

environmen

圧力値

averaging

values

パラメータ

リセット

SW1+SW2

SW1+SW2

SW1

SW1+SW2

SW1+SW2

SW1

SW1

(Standard

(スタンダード換算)

conversion

SW1+SW2

SW1+SW2

SW1

SW1+SW2

SW1+SW2

SW1+SW2

SW1+SW2

SW1+SW2

SW1+SW2

SW1

SW1+SW2

SW1+SW2

SW1

SW1+SW2

SW1+SW2

SW1

SW1+SW2

SW1+SW2

SW1

SW1+SW2

SW1+SW2

SW1

SW1+SW2

SW1+SW2

One-shot pulse:

ワンショットパルス:50ms

50 ms

No conversion

換算なし

SW2 SW2

3 min

3分

Air

Flow-rate

流量

Flickering Flickering Flickering

Flickering Flickering Flickering Flickering

With averaging No averaging

有り(10回)

Not to be

クリアしない

Not to be reset

One-shot pulse:

ワンショットパルス:100m s

100 ms

SW1

Normal conversion Standard conversion

ノルマル換算

SW1

Flickering

点滅

SW1

Flickering

点滅

SW1

空気

SW1

SW2

Pressure

SW1

点滅

SW1

SW1

無し(1回)

SW1

SW2

To be cleared

クリアする

SW1

SW2

To be reset

リセットするリセットしない

SW1

SW2

One-shot pulse:

ワンショットパルス:125ms

125 ms

SW1 SW1 SW1

SW1

スタンダード換算

SW1

SW1

Flickering

点滅

SW1

SW1

60 min

60分

SW1

Nitrogen

窒素

圧力 温度

SW1

点滅点滅 点滅

SW1

点滅

Unlimited

無制限

SW1

Temperature

SW1SW1

SW1

SW1 SW1

点滅

One-shot pulse:

ワンショットパルス:250ms

点滅

Flickering

* Use SW2 to increment f lickering

※SW2で点滅部

インクリメント

* Displays the converted inf ormation as

※F11「流量換算選択有無」にて

One-shot pulse:

ワンショットパルス:500ms

※SW2で点滅部

flickering portion.

インクリメント

500 ms

SW1

250 ms

* Use SW2 to increment

portion.

selected in F11 “Flow rate conversion

選択した換算情報が表示される

selection.”

点滅

* Use SW2 to increment

※SW2で点滅部

flickering portion.

インクリメント

duty

26

Page 28

5. Wiring (External Power Supply Type)

Please be sure to conduct the wire connection using the optional cable for external connection

as follows.

Figure 5-1 Wiring diagram

The main body and GND are electrically common.

Use an isolated power supply and a remote display as necessary.

Notes:

1. When installing the flow meter around an electric noise source, ground the braided

shield of the external connection cable.

2. Cut off the brown lead wire at its root to prevent it from contacting others.

3. Do not perform the insulation resistance and withstand voltage test.

27

Page 29

Note on open drain output setting

This meter gives you a choice of two types of outputs: duty output and one-shot output. The

meter is set to duty output when it leaves the factory.

Under duty output, the ON:OFF times are 1:1. Under one-shot output you can set the ON

times shorter between 50 to 500ms (Figure 5-2). Therefore, if you are using a battery-powered

pulse receiving signal receiver, using a one-shot pulse output is recommended to improve

battery life.

Please keep the following points in mind with regard to selecting one-shot.

Check the waveform corruption caused by the cable (line capacity, line resistance) and

the minimum input signal width of the signal receiver to choose the appropriate ON

time.

ON/OFF will reverse if you choose "Normal close."

Figure 5-2 One-shot output and duty output

(Example with pulse constant at 1000L/P, and Normal open)

Example of pull-up resistance calculation

Check the pulse receiving signal receiver's specifications (power supply voltage Vdd [V] and

ON current Ion [mA]) and select the pull-up resistance constant using equation (1).

R[Ω]=[(Vdd-0.2)/(Ion×10-3)]-24.7・・・(Equation 1)

*Do not allow the current Ion to exceed the maximum load of 24 VDC and 50 mA.

Example where Vdd=24V and Ion=10mA

R[Ω]=[(24-0.2)/(10×10-3)]-24.7=2355[Ω]≒2.2[kΩ]

28

Page 30

6.

O

n

r

n

c

n

p

u

t

a

e

m

a

u

t

e

9

s

a

w

a

n

r

a

t

m

f

a

r

g

Ope

diffe

Whe

(A fli

peratio

Do not o

ing or closi

ence is occ

you are r

kering pilo

en or close

ng of the v

urring betw

nning the

lamp indic

valves abr

lve all at on

en the ups

eter for the

tes that th

Figure

ptly. Make

ce may cau

ream side

first time, c

fluid is flo

6-1 Indic

ure to ope

se a failure

nd downst

heck that th

ing.)

tion at st

and close

of the flow

eam side o

e pilot lamp

rt-up

hem gradu

eter if a p

the valve.

is flickerin

lly.

essure

.

2

Page 31

7.7- Alarm

a

e

p

TAa

p

eOnmeatm

o

o

a

a

c

p

d

s

s

l

p

t

u

u

-

A

n

t

i

F

t

h

w

g

f

e

g

e

r

u

p

o

i

i

s

t

t

b

e

s

u

b

c

s

m

s

a

o

r

h

g

l

m

e

o

g

a

m

1. Aberr

[Stat

[Dis

[Out

[Cau

tion in fl

] Unable

lay] The tri

he instant

s for the a

nd the dis

ut] Analog

Open

se] There i

to or is

of ultra

If the a

branch

Fi

w meas

to receive

ngle in the

neous flow

cumulated

lay shows t

output: 4m

rain output:

a possibili

being retai

onic.

arm persis

or sales off

gure 7-1

rement

ltrasonic si

upper left o

rate value i

flow volum

he value im

Stopped

y that forei

ed in the m

s even afte

ce.

low meas

nals.

the LCD fl

n the sub-d

value disp

mediately p

n material

easuremen

removing

rement a

ckers.

splay show

ay, the acc

rior to the a

(liquids su

pipe, and i

he foreign

erration di

"0.00."

mulation p

erration.

h as oils)

obstructin

aterials, p

play

ocess is st

as become

the propa

lease conta

pped

stuck

ation

ct our

(Not

ce the flow

asurement

w

rking condi

) Actions w

ospheric

hen the me

meter is in

aberration

ressure. T

ions. (This

er is first ru

stalled and

display" d

is will sto

ill return t

n

measurem

ue to the

once the

normal.)

nts begin,

sudden ch

pressure

the meter

nge in pr

f the fluid

ay show

essure fro

stabilizes

"flow

the

under

30

Page 32

7-2.

n

y

n

m

o

s

t

]

a

a

n

y

a

s

t

]

e

e

s

u

a

m

u

i

]

s

e

o

m

a

a

e

e

u

u

m

s

u

i

]

r

m

n

F

f

h

v

)

A

t

e

o

m

e

h

p

s

A

t

a

e

T

r

1

s

d

l

m

c

o

p

u

e

u

m

m

a

e

a

d

h

w

m

p

s

n

v

u

y

a

g

s

n

m

e

a

0

b

n

s

b

0

h

a

i

u

t

s

n

r

u

t

f

m

e

e

k

a

r

m

p

e

n

l

t

r

s

F

e

Aberra

t pressur

value

[State]

[Displa

The i

of te

As f

stop

[Outpu

[Cause

Accumul

This stat

] The pres

stantaneo

perature v

r the accu

and the dis

] Analog o

Open dra

The pres

Other pot

or sales

ted flow volu

nd accumul

indicates t

ure display

s flow-rate

lue flashes

ulated flow

play shows

tput: 4m

n output: S

ure used m

ntial caus

ffice.

Figure 7-2

e (forward fl

ted flow volu

at the pres

in the sub-

alue in the

volume va

the value i

opped

ay have ex

s include p

Pressure

ow), trip accu

e (reverse fl

ure value

isplay sho

sub-display

ue in the

mediately

eeded the

ressure se

aberration

mulated flow

w) displays

as exceed

s the aberr

shows "0.0

ain display,

rior to the a

pecified ra

sor failure,

displays

olume, In

d the mea

ant value a

" and flicke

the accum

erration.

ge.

please con

tantaneous

(L/

urement li

d flickers.

s. (The dis

lation proc

act our bra

low- rate disp

in)

its.

lay

ss

ch

ay

7-3.

Aberra

[State]

[Displa

The i

displ

As fo

stop

[Outpu

[Cause

t temper

This stat

limits.

] The temp

nstantaneo

y of press

r the accu

and the di

] Analog o

Open dra

The aber

does not

getting a

ture valu

indicates t

rature dis

s flow-rate

re value fla

ulated flow

play shows

tput: 4m

n output: S

ant temper

atch the fl

aberrant t

igure 7-3

at the tem

lay in the s

value in th

hes)

volume val

the value i

opped

ture alarm

uid being

mperature

emperatur

erature val

b-display s

sub-displa

e in the m

mediately

may be trig

easured. If

larm, plea

aberratio

e has exce

hows the a

shows "0.

in display, t

prior to the

ered if sett

the setting

e contact o

displays

eded the m

errant valu

0" and flic

he accumul

berration.

ing of Fluid

is correct a

ur branch o

asuremen

and flicke

ers. (The

tion proce

selection [

nd you are

sales offic

s.

s

14]

still

.

Accumulated

flow volume (

and

accumulated

forward flow),

low volume (

trip accumul

everse flow)

ted flow volu

isplays

e, Instan

aneous flow-

(L/min)

rate display

3

Page 33

7-

4

o

e

p

p

s

t

a

a

e

s

y

s

y

h

h(Re

aRe

aRe

h

u

s

e

rMem(S

a

a

u

w

o

d

o

h

eFig

r

r

t

a

s

t

e

s

e

i

g

g

b

n

n

e

e

b

s

r

t

An

t

o

-

h

o

e

h

o

m

w

s

t

n

o

2

r

m

s

e

h

e

t

p

r

e

u

e

r

a

a

tStSt

o

t

s

a

e

c

e

"

"

. Mem

[Stat

[Dis

[Out

[Cau

ry aberra

] There is

[1]

User's are

[2]

System ar

lay] [1] U

ut] [1] U

e] [1] In t

: An

a: An

er's area:

[2] S

stem area:

er's area:

[2] S

stem area:

e case of a

C

If

eck to see

ny aberrati

set to stan

If

set of all of

*Pl

ease note t

[2] In t

Please

e case of a

contact our

ion

n aberratio

ch

dat

by

fer to Table

ny aberrati

Figure

in the dat

berration i

nged by bu

upon pow

berration i

sers is not

The tr

nitrog

The d

Analo

Open

Analo

Open

memory a

hether the

3-1.)

ns are fou

ard factory

ns are fou

accumulat

at this res

memory a

branch or

7-4 Memo

in the non

found in t

ton operati

ring the m

found in t

available).

iangle that i

n) flickers.

isplay show

output: N

drain outpu

output: 4

drain outpu

erration in t

set data is

d with the

delivery set

nd with the

d values" a

ts your sett

erration in t

ales office.

y aberrati

volatile me

e data for

ns, or in th

ter on.

e data for t

ndicates th

s "E-2."

rmal opera

t: Normal o

t: Stopped

he user’s a

ithin the s

et data, yo

ings." (*)

accumulat

d power th

ings data o

he system

n display

ory.

ettings that

accumulat

e system (

Kind of G

ions

erations

ea

ttable rang

can reset t

d value dat

meter ba

accumulat

rea

were

ed value

etting

s (air or

e.

hem using

a, perform

k on. (*)

d value.

[FFF]

[F00]

[1] Us

r’s area

[

] System a

rea

Meas

Pre

Te mp

Memo

rement abe

sure aberra

rature aber

y aberration

area)

ory aberra

ystem area

ure 7-5 Ou

ration

ion

ation

(User

ion

)

put at abe

alog output

4mA

4mA

4mA

Normal

perations

4mA

rations

Open dr

Normal

in output

S

op

op

op

perations

S

op

32

Page 34

8. Power Interruption (External Power Supply Type)

Detection of power failure

The drop of a power source voltage to 18±1.1V or lower is judged to be a power failure. As a

result, the measurement is stopped, and the last accumulated value is stored, and the LED

display is turned off.

Reset from power failure

When a power source voltage rises to 18.8±1.1V or higher, the measurement is resumed with

the total value recorded right before the power interruption, and the LED is turned on.

33

Page 35

9. Battery Life (Built-In Battery Type)

The life of the built-in battery is 10 years. (This is the life at the environment temperature of 20C.

The battery life fluctuates depending on conditions such as the ambient temperature and output

settings.)

* In the case the battery run out earlier due to reasons of high environment temperature, etc., the

battery is possible to be replaced at our plant as a fare-paying service. Contact our branch or

sales office nearby.

34

Page 36

10.

ycon

n

e

b

t

a

e

v

a

o

u

c

a

e

a

t

t

l

e

v

t

t

e

m

a

o

i

m

o

a

h

s

m

u

u

o

o

h

p

p

h

t

n

t

g

t

5

s

s

t

e

r

s

r

p

e

n

f

d

m

o

a

k

Cntls

v

C

s

C

b

fIufc

a

Cst

COp

Mts

w

K

S

f

p

m

a

t

d

d

n

t

a

t

u

o

h

a

o

t

a

e

s

a

a

d

a

h

d

m

f

e

p

e

e

e

o

p

o

0

p

s

a

rpag

212

0

7

8

8

7

If

Setti

Insta

Wirin

conn

Trou

ou encoun

tact our br

P

Even op

gs

buttons,

settings

The me

aberrati

llation

It starts

start ac

immedia

The inst

flow-rat

value.

Pulses

incorrec

g

ction

The curr

4-20mA

leshoo

er any prob

nch or sal

henomenon

rating the

unable to set a

alue.

surement

n indicator ligh

▲

p but does not

umulation

tely.

ntaneous

shows a nega

re counted

ly.

ent value of th

output is too s

ing

ems that c

s office.

Attempting

the range

Using a flu

Using the

specificati

s.

conditions,

Foreign m

interior of t

ultrasonic

There is a

noise near

Carrying o

pressure fl

The directi

ive

flow directi

of each ot

The pull-u

The pull-u

The one-s

or smaller

minimum i

Load resis

The settin

all.

FS flow-ra

nnot be re

Possible cau

to set a value

f settable valu

id other than ai

eter outside it

ns (such as fo

pressure, tem

terial is attach

he measureme

ensors.

major source o

the flow meter.

t adjustments

ctuations.

n of the fluid fl

on of the meter

er.

resistor is too

resistor is too

ot pulse ON ti

han the signal

put signal widt

ance is 400Ω

value for the

e is too large.

olved by ta

e

hat is outside

s.

or nitrogen.

range of

installation

erature).

d to the

t pipe or

electrical

ue to

ow and the

are opposite

large.

small.

e is equal to

receiver's

h.

r larger

nalog output

ing the ste

Re

heck to see th

itrogen) indica

ime of settings

ights, this is in

et a value outs

alues.

heck all remin

pecifications a

heck to see if

etween the m

lickering.

f it is, it means

ndergoing adj

luctuations. Thi

omplete in ab

ccumulation s

heck to see th

urface of the fl

he direction of

heck the sign

N current and

ull-up resistor.

ake sure to s

ime sufficiently

ignal receiver'

idth.

eep the resist

et an appropri

low-rate [F2] to

s describe

edial action

at the kind of g

or does not lig

mode. If this in

ication of atte

ide the range o

ders regarding

nd installation.

the partition lin

in and sub-dis

that the meter i

stments for pr

s should typica

ut 1 minute aft

ould begin.

at the arrow on

w meter is poi

he fluid flow.

l receiver's sp

select an appr

t the one-shot

large enough f

minimum inpu

nce below 40

te analog out

suit your need

below, ple

s (air or

t at the

icator

pting to

settable

lays is

s

ssure

lly

r which

the

ting in

cified

priate 2

ulse ON

r the

t signal

Ω 2

ut FS

.

Refe

1

3

2

2

se

ence

e

1

3

Page 37

Phenomenon Possible cause Remedial action

Check to see that the operating pressure

falls between 0 to 1MPa (Gauge

pressure).

Check to see that the operating

temperature falls between -20ºC and

70ºC.

Do not use gases other than air or

nitrogen.

This is normal. Installation of the meter

farther away from the pressure governor

is recommended to take accurate

measurements.

Check to see that the value unit on the

sub-display is not flickering.

Please make sure to properly install

straight pipe sections up and

downstream of the meter to suit your

specific piping conditions.

Check to see that the correct value unit

for the application is used.

Use the meter within the scope of its

specifications.

Please make sure to properly install

straight pipe sections up and

downstream of the meter to suit your

specific piping conditions.

Check to see that the correct value unit

for the application is used.

If it is, it means that the meter is

undergoing adjustments for pressure

fluctuations. This should typically

complete in about 1 minute.

(The partition line may also flicker

momentarily during other actions, such

as when a valve is opened or closed)

This is normal.

Refer to the page indicated to the right to

revert to accumulated flow volume

(forward flow) or accumulated flow

volume (reverse flow) display.

After

start

operation

Sub-display flickers

(pressure and

instantaneous flow-rate)

Sub-display flickers

(temperature and

instantaneous flow- rate)