Fuji Electric FVR0.75AS1S-4, FVR-Micro, FVR0.4AS1S-4, FVR1.5AS1S-4, FVR2.2AS1S-4 Brief Manual

...Page 1

Advanced simple Inverter

FVR-Micro

Thank you for purchasing our FVR-Micro of inverters.

This product is designed to drive a three-phase induction motor. Read through this

instruction manual and be familiar with the handling procedure for correct use.

Improper handling might result in incorrect operation, a short life, or even a failure of this

product as well as the motor.

Deliver this qui ck guide to the end user of this product. Keep this in a safe place until this

product is discarded.

For more details, refer to the instruction manual on website.

Web site : https://felib.fujielectric.co.jp/download/search.htm?site=global&lang=en

QR code :

Fuji Electric Co., Ltd. INR-SI47-2142a-E

Brief Manual

Page 2

Safety precautions

Read this manual thoroughly before proceeding with installation, connections (wiring), operation, or

maintenance and inspection. Ensure you have sound knowledge of the device and familiarize

yourself with all safety information and precautions before proceeding to operate the inverter.

Safety precautions are classified into the following two categories in this manual.

Failure to heed the information indicated by this

symbol may lead to dangerous conditions, possibly

resulting in death or serious bodily injuries.

Failure to heed the information indicated by this

symbol may lead to dangerous conditions, possibly

resulting in minor or light bodily injuries and/or

substantial property damage.

Failure to heed the information contained under the CAUTION title can also resu lt in s erious consequences. These safety precautions are of utmost importance and must be observed at all times.

Operation

Be sure to install the terminal block cover before turning the power on. Do not remove the

cover while power is applied.

Otherwise electric shock could occur.

Do not operate switches with wet hands.

Doing so could cause electric shock.

If the retry function has been selected, the inverter may automatically restart and drive

the motor depending on the cause of tripping.

(Design the machinery or equipment so that human safety is ensured after restarting.)

If the stall prevention function (current limiter), automatic deceleration, and overload

prevention control have been selected, the inverter may operate at an acceleration

/deceleration time or frequency different from the set ones. Design the machine so that

safety is ensured even in such cases.

Otherwise an accident could occur.

The STOP key is only effective when function setting (Function code F02) is established

to enable the STOP key. Prepare an emergency stop switch separately. If you disable

the STOP key priority function and enable operation by external commands, you cannot

emergency-stop the inverter using the STOP key on the built-in keypad.

If an alarm reset is made with the operation signal turned on, a sudden start will occur.

Ensure that the operation signal is turned off in advance.

Otherwise an accident could occur.

1

Page 3

Item

Specifications

Site location Indoors

Ambient

temperature

-10 to +50°C (IP20) (Note 1)

Relative

humidity

5 to 95% (No condensation)

Atmosphere

The inverter must not be exposed to dust,

direct sunlight, corrosive gases, flammable

gas, oil mist, vapor or water drops.

(Note 2)

The atmosphere can contain only a low

level of salt.

(0.01 mg/cm

2

or less per year)

The inverter must not be subjected to

sudden changes in temperature that will

cause condensation to form.

Altitude 1,000 m max. (Note 3)

Atmospheric

pressure

86 to 106 kPa

Vibration

3 mm (Max. amplitude) 2 to less than 9 Hz

9.8 m/s

2

9 to less than 20 Hz

2 m/s

2

20 to less than 55 Hz

1 m/s

2

55 to less than 200

Hz

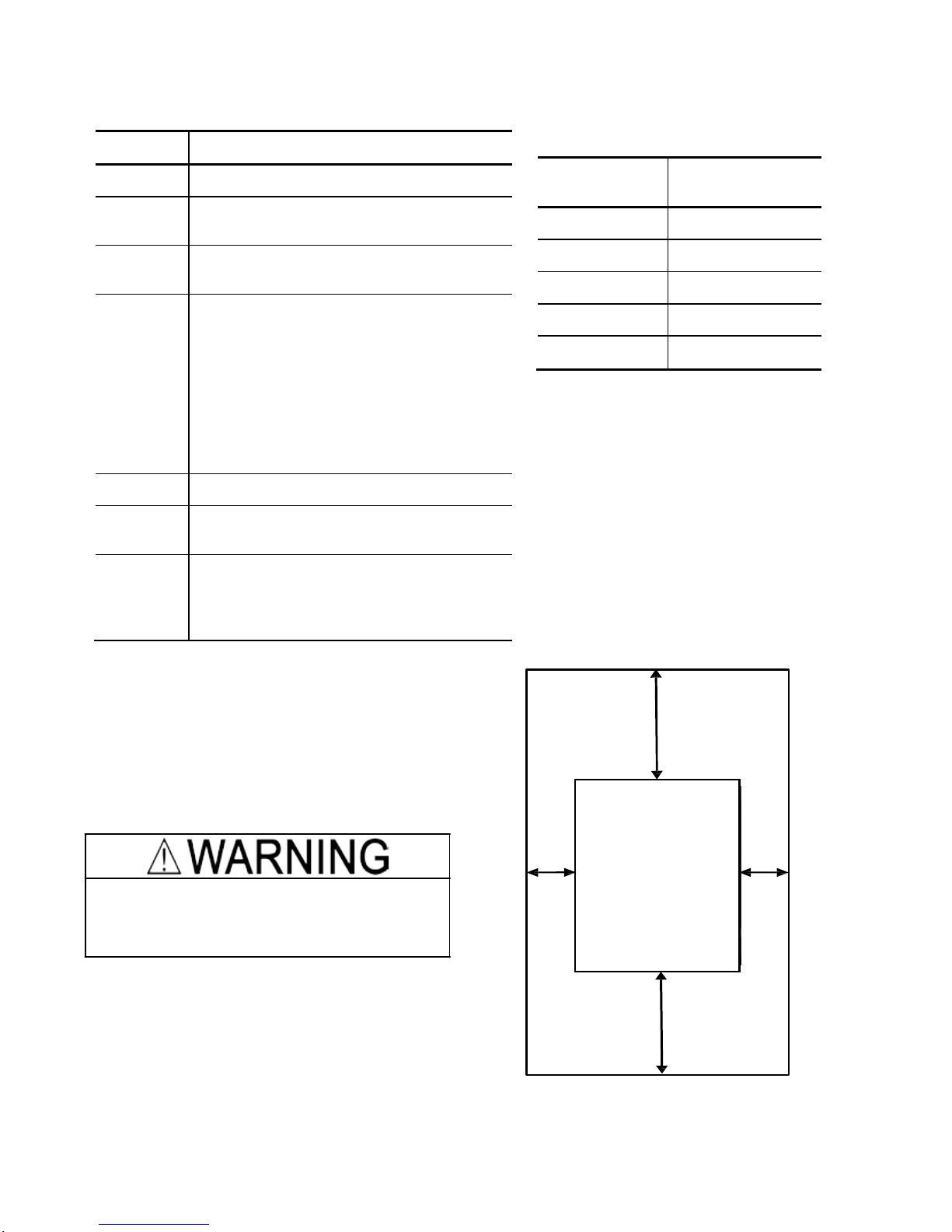

1. Operating Environment

Install the inverter in an environment that satisfies the requirements listed in

Table 1.1 Environmental Requirements

Table 1.2 Output Current Derating Factor

in Relation to Altitude

2. Installing the Inverter

(1) Mounting base

The temperature of the heat sink may rise up to

approx. 90°C during operation of the inverter, so the

inverter should be mounted on a base made of

material that can withstand temperatures of this

level.

Install the inverter on a base made of metal or

other non-flammable material.

A fire may result with other material.

(2) Clearances

Ensure that the minimum clearances indicated in

Figure 2.1 are maintained at all times. When

installing the inverter in the panel of your system,

take extra care with ventilation inside the panel as

the temperature around the inverter tends to

increase.

Figure 2.1 Mounting Direction and

Required

Clearances

Altitude

Output current

derating factor

1000 m or lower

1.00

1000 to 1500 m

0.97

1500 to 2000 m

0.95

2000 to 2500 m

0.91

2500 to 3000 m

0.88

(Note 1)

When inverters are mounted side-by-

side without any gap between them, the

ambient temperature should be within the

range from -10 to +40°C.

(Note 2)

Do not install the inverter in an

environment where it may be exposed to

cotton waste or moist dust or dirt which will

clog the heat sink in the inverter. If the

inverter is to be used in such an

environment, install it in the panel of your

system or other dustproof containers.

(Note 3)

If you use the inverter in an altitude

above 1000 m, you should apply an output

current derating factor as listed in Table 2.2.

Left

10 mm

Right

10 mm

Bottom 100 mm

FVR-Micro

Top 100 mm

2

Page 4

When mounting two or more inverters

When mounting two or more inverters in the same unit or panel, basically lay them out s ide by

side. As long as the ambient temperature is 40°C or lower, inverters can be mounted side by

side without any clearance between them. When the inverters necessarily mounted one above

the other be sure to separate them with a partition plate or the like so that any heat radiating

from an inverter will not affect the one(s) above.

(3) Mounting direction

Secure the inverter to the mounting base with four screws or bolts (M4) so that the FVR-Micro logo

faces outwards. (FVR0.4AS1S-7 and

FVR0.75AS1S-7 use t wo screws or bolts.) Tighten those

screws or bolts perpendicular to the mounting base. (Maximum torque is 0.6N∙m)

Do not mount the inverter upside down or horizontally. Doing so will reduce the

heat dissipation efficiency of the inverter and cause the overheat protection function to

operate, so the inverter will not run.

Prevent lint, paper fibers, sawdust, dust, metallic chips, or other foreign materials from getting

into the inverter or from accumulating on the heat sink.

This may result in a fire or accident.

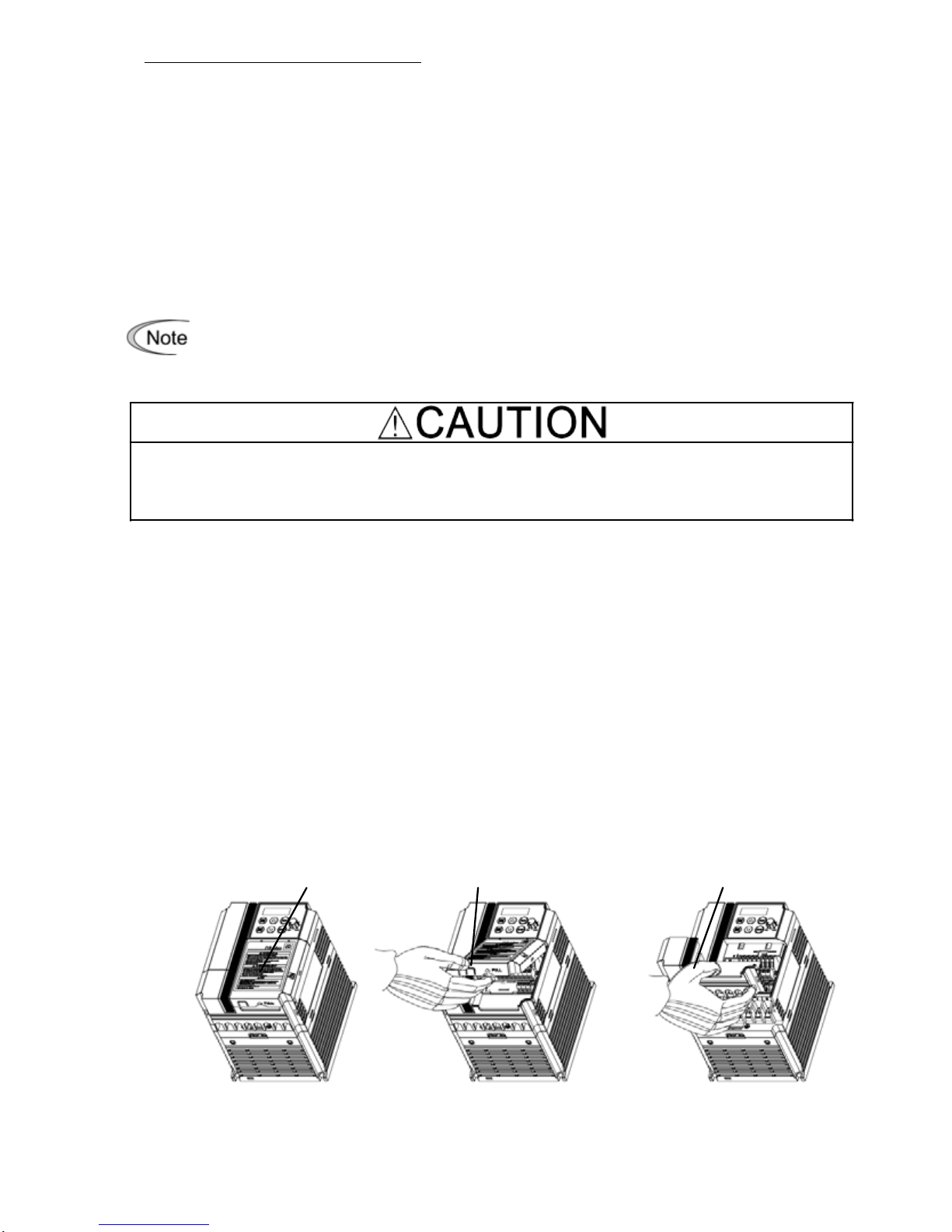

3. Wiring

Follow the procedure below. (In the following description, the inverter has already been installed.)

3.1 Removing and mounting the terminal block covers

(1) Loosen the screw securing the control circuit terminal block cover.

(2) Insert your finger in the cutout (near "PULL") in the bottom of the control circuit terminal

block cover, and then pull the cover towards you.

(3) Hold both sides of the main circuit terminal block cover between thumb and forefinger and

slide it towards you.

(4) After performing wiring, mount the main circuit terminal block cover and control circuit

terminal block cover in the reverse order of removal.

[ Removing the Terminal Block Covers ]

Control circuit terminal

block cover screw

Control circuit terminal

block cover

Main circuit terminal

block cover

3

Page 5

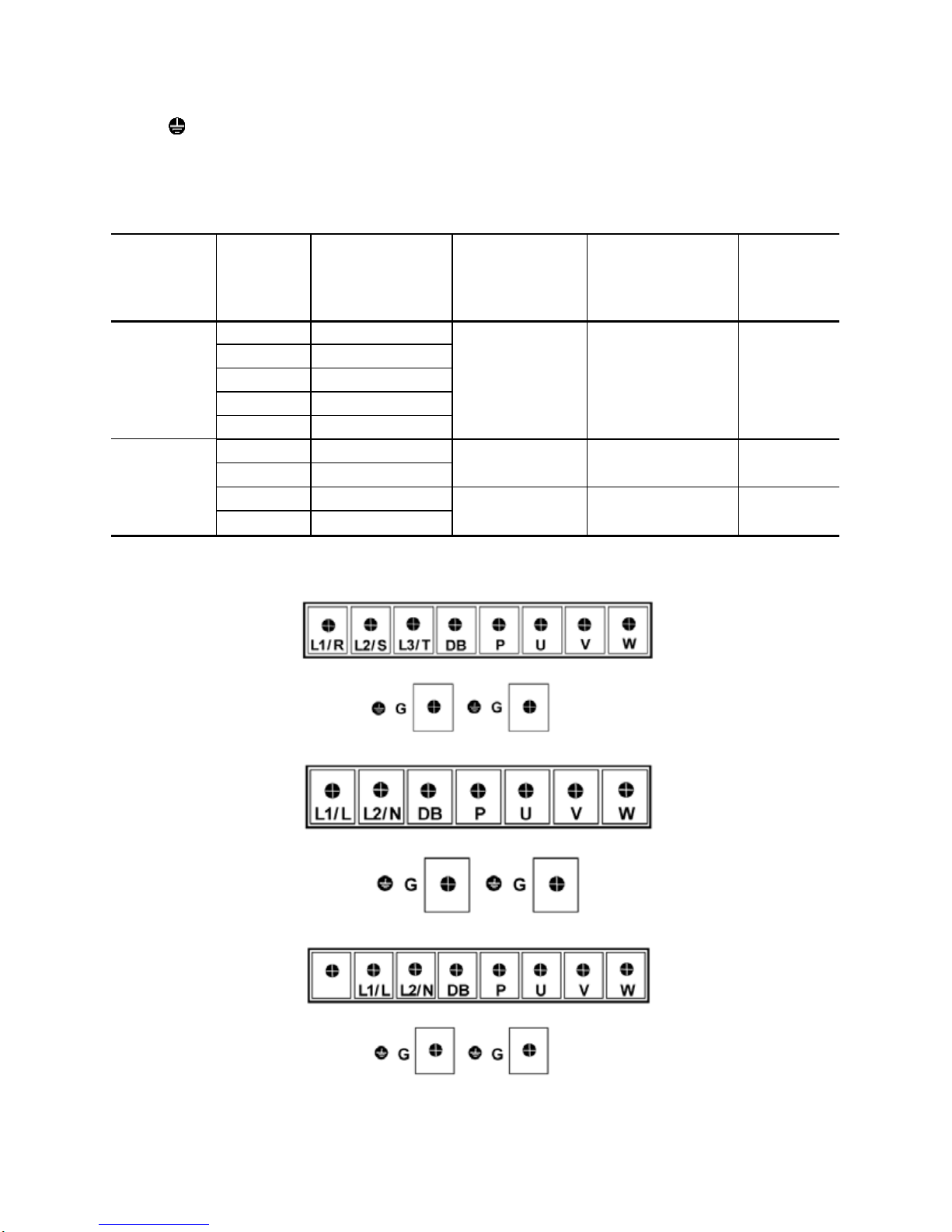

3.2 Terminal arrangement and screw specifications

The figures below show the arrangement of the main and control circuit terminals which differ

according to inverter type. The two terminals prepared for grounding, which are indicated by the

symbol G in Figures A to C, make no distinction between the power supply side (primary circuit)

and the motor side (secondary circuit).

(1) Arrangement of the main circuit terminals

Table 3.1 Main Circuit Terminals

Power supply

voltage

Nominal

Ap

plied

m

otor(kW)

Inverter type

Terminal screw

size

Tightening torque

(N·m)

Refer to:

Three- phase

400 V

0.4

FVR0.4AS1S-4

M4 1.2 Fig A

0.75

FVR0.75AS1S-4

1.5

FVR1.5AS1S-4

2.2

FVR2.2AS1S-4

3.7

FVR3.7AS1S-4

Single- phase

200 V

0.4

FVR0.4AS1S-7

M3 0.5 Fig B

0.75

FVR0.75AS1S-7

1.5

FVR1.5AS1S-7

M4 1.2 Fig C

2.2

FVR2.2AS1S-7

Figure A

Figure B

Figure C

4

Page 6

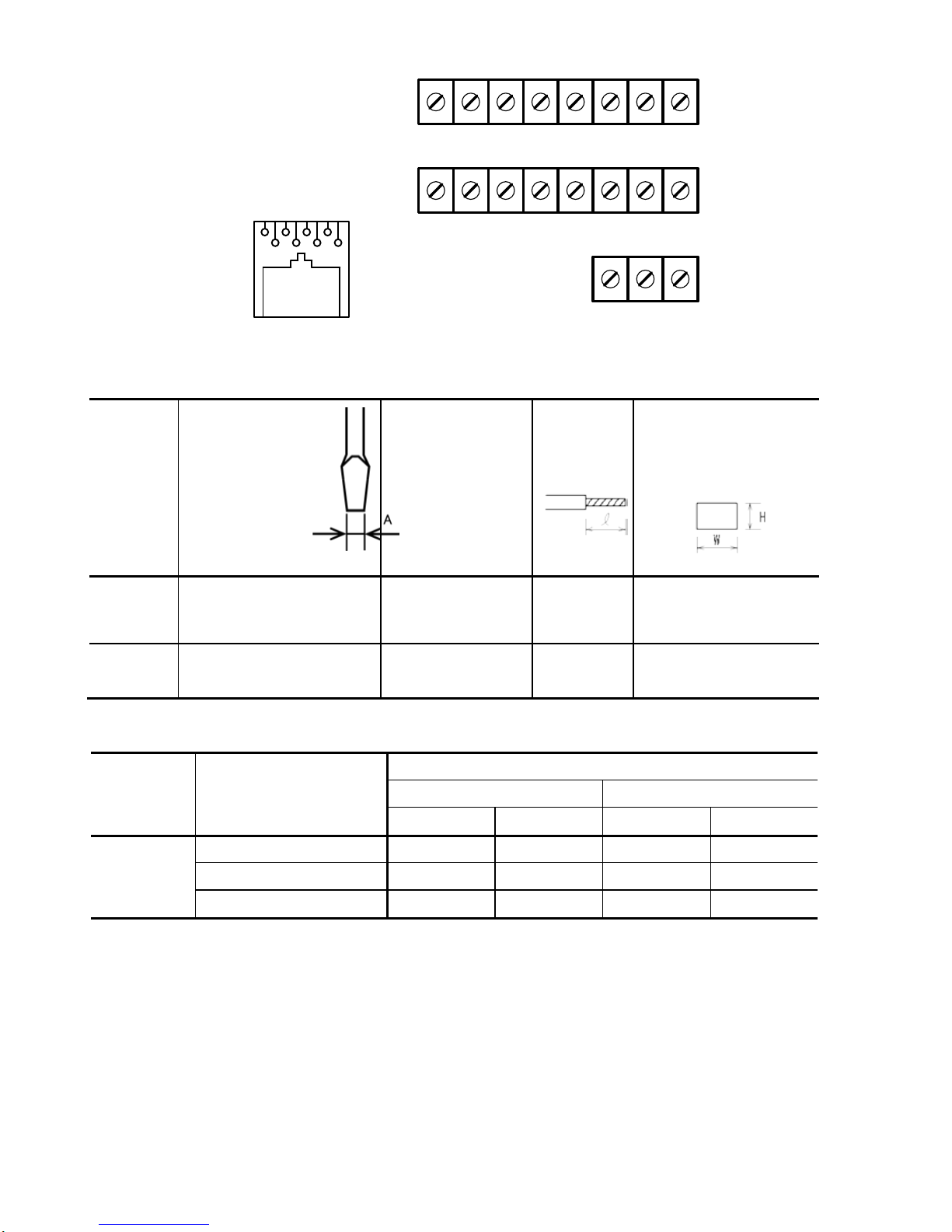

(2) Arrangement of the control circuit termi nal s (c om m on to all FVR-Micro models)

Y1 Y1E FMA C1 PLC X1 X2 X3

DX+ DX- 13 12 11 FWD REV CM

30A 30B 30C

8 7 6 5 4 3 2 1

1 : 5V

2 : Ground

3 : NC

4 : DX5 : DX+

6 : NC

7 : Ground

8 : 5V

Screw size : M2.5 Tightening torque : 0.4Nm

Table 3.2 Control Circuit Terminals

Terminal

symbol

Screwdriver

(Shape of

tip,

B x A)

Thickness of tip: B

Allowable wire size

Bare wire

length

Ferrule

terminal*

Opening dimension in

the terminal

block

First row in

the box

[Y1]~[X3]

Flat screwdriver

(0.6 x 3.5 mm)

AWG22 to AWG14

(0.34 to 2.1 mm

2

)

4.5 to 5 mm 5 (W) x 2.5 (H) mm

Other than

the above

Flat screwdriver

(0.6 x 3.5 mm)

AWG24 to AWG14

(0.25 to 2.1 mm

2

)

5 to 6 mm 2.3 (W) x 2.5 (H) mm

Table 3.3 Recommended Ferrule Terminals

Screw size Wire

size

Type

(216- )

With insulated collar Without insulated collar

Short type Long type Short type Long type

M2 or M2.5

AWG22 (0.34 mm2 )

322 302 152 132

AWG20 (0.50 mm2 )

221

201

121

101

AWG18 (0.75 mm2 )

222 202 122 102

The length of bared wires to be inserted into ferrule terminals is 5.0 mm or 8.0 mm for the short

or long type, respectively.

The following crimping tool is recommended: Variocrimp 4 (Part No. 206-204).

5

Page 7

3.3 Recommended wire sizes

Table 2.6 lists the recommended wire sizes. The recommended wire sizes for the main circuit

terminals for an ambient temperature of 50°C are indicated for two types of wire: HIV single wire (for

the maximum allowable temperature 75°C).

Table 3.4 Recommended Wire Sizes

Power supply

voltage

Nomi-

nal

applied

motor

(kW)

Inverter type

*1

Recommended wire size (mm

2

)

Main

Control

circuit

Main circuit power

input

[L1/R, L2/S, L3/T]

[L1/L,

L2/N]

Grounding

[ G]

Inverter

output

[U, V, W]

Braking

resistor

[P, DB]

w/o DCR

Three-phase

400 V

0.4

FVR0.4AS1S-4

2.0(2.0)

0.5

0.75

FVR0.75AS1S-4

1.5

FVR1.5AS1S-4

2.2

FVR2.2AS1S-4

3.7

FVR3.7AS1S-4

Single-phase

200 V

0.4

FVR0.4AS1S-7

2.0(2.0)

2.0(2.0)

2.0(2.5)

0.75

FVR0.75AS1S-7

1.5

FVR1.5AS1S-7

2.0(3.5)

2.2

FVR2.2AS1S-7

5.5(5.5)

*1 Use crimp terminals covered with an insulated sheath or insulating tube. Recommended wire sizes are for

HIV/IV (PVC in the EU).

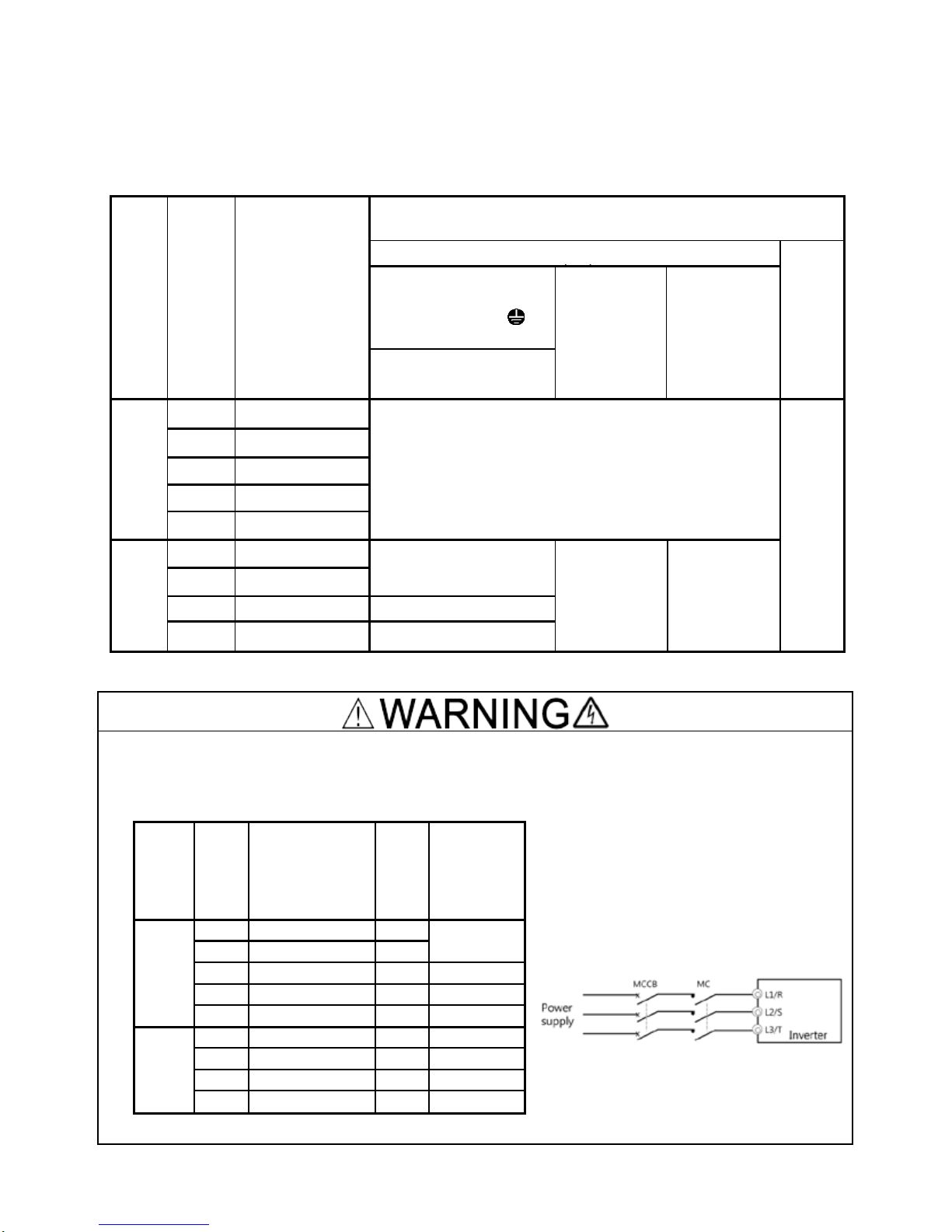

To prevent the risk of hazardous accidents that could be caused by damage of the inverter,

install the specified MCCB in the supply side (primary side) according to the following tables.

- Breaking capacity: Min. 10 kA

- Rated voltage: Min. 500 V

Power

supply

voltage

Appli-

cable

motor

rating

(kW)

Inverter type

Fuse

Rating

(A)

Rated

Current(A)

of MCCB

(w/o DCR)

Three-

phase

400 V

0.4

FVR0.4AS1S-

4

3

6

0.75

FVR0.75AS1S

-4

6

1.5

FVR1.5AS1S

-4

10

10

2.2

FVR2.2AS1S

-4

15

15

3.7

FVR3.7AS1S

-4

20

20

Single-

phase

200 V

0.4

FVR0.4AS1S

-7

10

10

0.75

FVR0.75AS1S

-7

15

15

1.5

FVR1.5AS1S

-7

30

20

2.2

FVR2.2AS1S

-7

40

35

6

Page 8

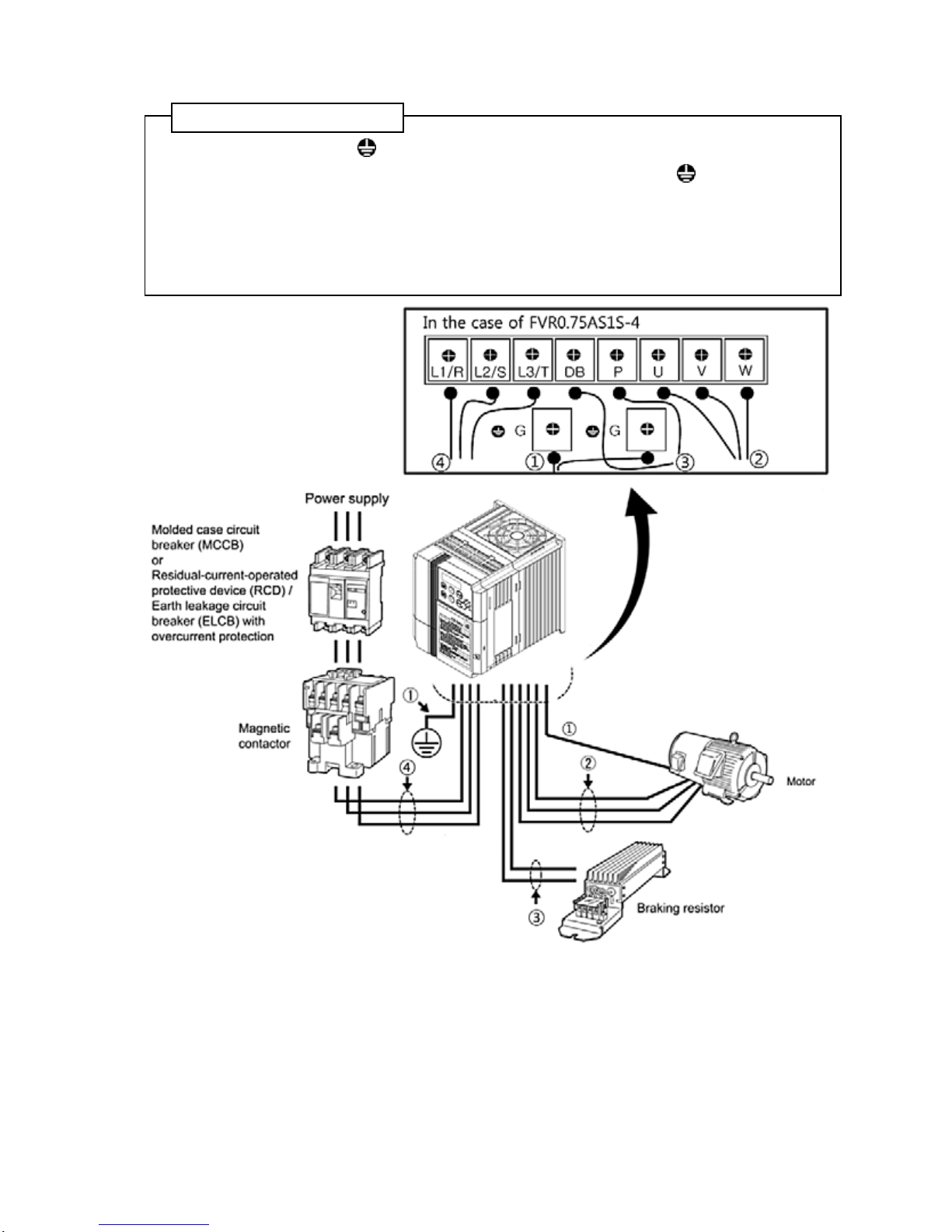

3.4 Wi ring for main circuit terminals and grounding terminals

Follow the procedure below. Figure 3.1 illustrates the wiring procedure with peripheral equipment.

Wiring procedure

①

Grounding terminal G*

1

② Inverter output terminals (U, V, and W) and grounding terminal G*1

③ Braking resistor connection terminals (P and DB)*2

④ Main circuit power input terminals (L1/R, L2/S and L3/T) or (L1/L and L2/N)

*

1

Use either one of these two grounding terminals on the main circuit terminal block.

*

2

Perform wiring as necessary.

Figure 3.1 Wiring procedures for Peripheral Equipment

7

Page 9

The wiring procedure for the FVR0.75AS1S-4 is given below as an example. For other inverter

types, perform wiring in accordance with their individual terminal arrangement.

①

Grounding terminal ( G)

Be sure to ground either of the two grounding terminals for safety and noise reduction. It is

stipulated by the Electric Facility Technical Standard that all metal frames of electrical equipment

must be grounded to avoid electric shock, fire and other disasters.

Grounding terminals should be grounded as follows:

1) Ground the inverter in compliance with the national or local electric code.

2) Connect a thick grounding wire with a large surface area. Keep the wiring length as short as

possible.

②

Inverter output terminals, U, V, W and grounding terminal ( G)

1) Connect the three wires of the three-phase motor to terminals U, V, and W, aligning phases

each other.

2) Connect the grounding wire of terminals U, V, and W to the grounding terminal ( G).

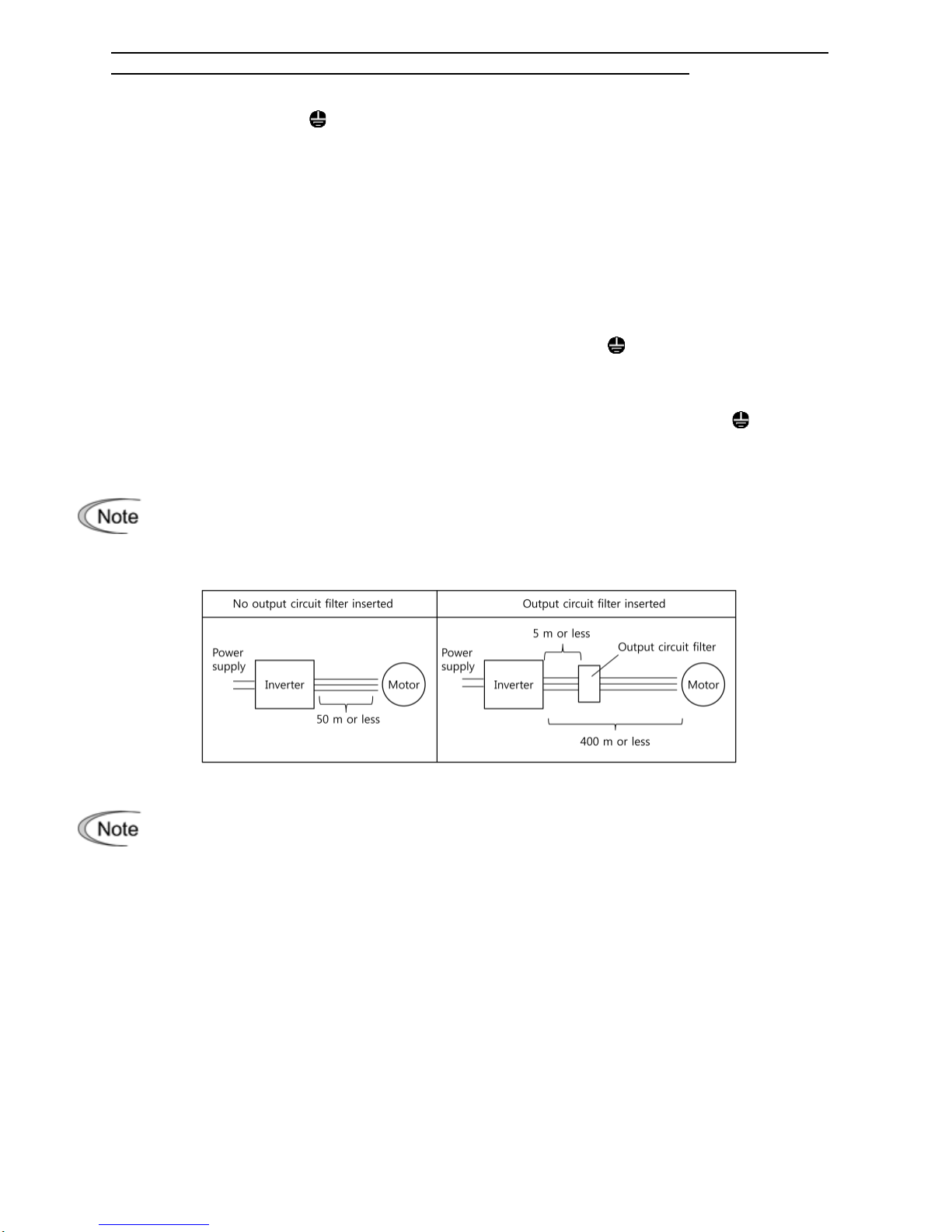

The wiring length between the inverter and motor should not exceed 50 m. If it exceeds

50 m, it is recommended that an output circuit filter (option) be inserted.

Do not use one multicore cable to connect several inverters with motors.

Do not connect a phase-advancing capacitor or surge absorber to the inverter’s output

lines (secondary circuit).

If the wiring length is long, the stray capacitance between the wires will increase,

resulting in an outflow of the leakage current. It will activate the overcurrent protecti on,

increase the leakage current, or will not assure the accuracy of the current display. In

the worst case, the inverter could be damaged.

If more than one motor is to be connected to a single inverter, the wiring length should

be the total length of the wires to the motors.

8

Page 10

Driving 400 V series motor

If a thermal relay is installed in the path between the inverter and the motor to protect

the motor from overheating, the thermal relay may malfunction even with a wiring

length shorter than 50 m. In this situation, add an output circuit filter (option) or lower

the carrier frequency (Function code F26: Motor sound (Carrier frequency)).

If the motor is driven by a PWM-type inverter, surge voltage that is generated by

switching the inverter component may be superimposed on the output voltage and may

be applied to the motor terminals. Particularly if the wiring length is long, the surge

voltage may deteriorate the insulation resistance of the motor. Consider any of the

following measures.

- Use a motor with insulation that withstands the surge voltage.

- Connect an output circuit filter (option) to the output terminals (secondary circuits) of

the inverter.

- Minimize the wiring length between the inverter and motor (10 to 20 m or less).

③

Braking resistor terminals, P and DB

1) Connect terminals P and DB of a braking resistor (option) to terminals P and DB on the main

circuit terminal block.

2) Arrange the inverter and braking resistor to keep the wiring length to 5 m or less and twist the

two wires or route them together in parallel.

④

Main circuit power input terminals, L1/R, L2/S, and L3/T ( for thre e-phase volta ge input) or

L1/L and L2/N (for single-phase voltage i nput )

1) For safety, make sure that the molded case circuit breaker (MCCB) or magnetic contactor

(MC) is turned off before wiring the main circuit power input terminals.

2) Connect the main circuit power supply wires (L1/R, L2/S and L3/T or L1/L and L2/N) to the

input terminals of the inverter via an MCCB or residual-current-operated protective device

(RCD)/earth leakage circuit breaker (ELCB)*, and MC if necessary.

It is not necessary to align phases of the power supply wires and the input terminals of the

inverter with each other.

* With overcurrent protection

It is recommended that a magnetic contactor be inserted which can be manually

activated.

This is to allow you to disconnect the inverter from the power supply in an emergency

(e.g., when the protective function is activated) so as to prevent a failure or accident

from causing the secondary problems.

9

Page 11

4. Names and Functions of Keypad Components

As shown in the figure at right, the

keypad consists of a four-digit 7-segment

LED monitor, a potentiometer (POT), and

six keys.

The keypad allows you to start and stop

the motor, monitor running status,

configure the function code data, check

I/O signal states, and display

maintenance information and alarm

information.

Table 4.1 Names and Functions of Keypad Components

Monitor,

Potentiometer

and

Keys

Functions

Four-digit, 7-segment LED monitor which displays the following according to the

operation modes *.

In Running mode: Running status information (e.g., output frequency,

current, and

voltage)

In Programming mode: Menus, function codes and their data

In Alarm mode: Alarm code which identifies the error factor if the

protective function is activated.

Potentiometer (POT) which is used to manually set a reference frequency, auxiliary

frequencies 1 and 2 or PID process command.

RUN key. Press this key to run the motor.

STOP key. Press this key to stop the motor.

UP/DOWN keys. Press these keys to select the settin g items and change the function

code data displayed on the LED monitor.

Program/Reset key which switches the operation modes* of the inverter.

In Running mode: Pressing this key switches the inverter to Programming mode.

In Programming mode: Pressing this key switches the inverter to Running

mode.

In Alarm mode: Pressing this key after removing the error factor

switches the inverter to Running mode.

Function/Data key which switches the operation you want to do in each mode as

follows:

In Running mode: Pressing this key switches the information to be displayed

concerning the status of the inverter (output freque ncy, output current, output voltage,

etc.).

In Programming mode: Pressing this key displays the function codes and sets their data

entered with the and keys or the POT.

In Alarm mode: Pressing this key displays detailed alarm information.

* FVR-Micro features three operation modes: Running, Programming, and Alarm.

10

Page 12

5. If an Alarm Code Appears on the LED Monitor

Quick reference table of alarm codes

Alarm

code

Name

Alarm

code

Name

OC1

Instantaneous overcurrent

dbH

Braking resistor overheated

OC2 OL1

Motor 1 overload

OC3 OLU

Inverter overload

OU1

Overvoltage

Er1

Memory error

OU2 Er2

Keypad communications error

OU3 Er3

CPU error

LU

Undervoltage

Er6

Operation protection

Lin

Input phase loss

Er7

Tuning error

OPL

Output phase loss

Er8

RS-485 communications error

OH1

Heat sink overheat

ErF

Data saving error during

under voltage

OH2

External alarm

Err

Mock alarm

OH4

Motor protection

(PTC thermistor)

CoF

PID feedback wire break

11

Page 13

6. Specifications

6.1

Single-phase 200 V class series

Item

Specifications

Type

0.4

0.75

1.5

2.2

Applicable motor rating (kW)

*1

0.4 0.75 1.5 2.2

Output Ratings

Rated capacity (kVA)

*2

0.9 1.6 2.8 3.8

Rated voltage (V) *3

Three-phase, 200 to 240 V (with AVR function)

Rated current (A) *4

3.5 (2.5) 4.2 (4.2) 9.2 (7.5) 10.0 (10.0)

Overload capability

150% of rated output current for 1 min (for the rated current given in

parentheses)

Rated frequency (Hz)

50/60 Hz

Input Ratings

Phases, voltage,

frequency

Single-phase, 200 to 240 V, 50/60 Hz

Voltage and

frequency variations

Voltage: +10 to -10%, Frequency: +5 to -5%

Rated

current(A)

*6

(w/o

DCR)

5.4 9.7 16.4 24.0

Required power

supply capacity (kVA)

0.7 1.3 2.4 3.5

Braking

Torque (%) *8

100

50 30

DC braking

Braking starting frequency*9: 0.0 to 60.0 Hz,

Braking time: 0.0 to 30.0 s, Braking level: 0 to 100%

Braking transistor

Built-in

Applicable safety standards

UL61800-5-1, IEC 61800-5-1(under application)

Enclosure

IP20 (IEC 60529), UL open type (UL50)

Cooling method

Fan cooling

Mass (kg)

0.6

0.6

1.0

1.0

*1 Fuji 4-pole standard motor s

*2 Refers to the rated capacity assuming the rated output voltage as 220 V.

*3 Output voltages cannot exceed the power supply voltage.

*4 The load shall be reduced so that the continuous operating current is the rated current in parentheses or less if

the carrier frequency is set to 3 kHz or above or the ambient temperature exceeds 40°C.

*

5

Interphase voltage unbalance (%)

=

Max. voltage (V) - Min.voltage

(V)

× 67

(Refer to

IEC 61800

- 3)

3 phase average voltage (V)

If this value is 2 to 3%, use an optional AC reactor (ACR).

*6 Refers to the estimated value to apply when the power supply capacity is 500 kVA (inverter capacity x 10 when

the inverter capacity exceeds 50 kVA) and the inverter is connected to the %X = 5% power supply.

*8 Refers to the average braking torque to apply when the motor running alone decelerates from 60 Hz with the

AVR control being OFF. (It varies with the efficiency of the motor.)

*9 Available only for induction motor drive.

12

Page 14

6.2

Three-phase 400 V class series

Item

Specifications

Type

0.4

0.75

1.5

2.2

3.7

Applicable moto r rating (kW)

*1

0.4 0.75 1.5 2.2 3.7

Output Ratings

Rated capacity (kVA)

*2

1.1 1.9 3.2 4.1 6.8

Rated voltage (V ) *3

Three-phase, 380 to 480 V (with AVR function)

Rated current (A )

1.8

(1.5)

2.5

(2.5)

4.3

(4.2)

6.3

(5.5)

10.5

(9.0)

Overload capability

150% of rated outp ut current for 1 min (fo r the rated current given in

parentheses)

Rated frequency ( Hz)

50/60 Hz

Input Ratings

Phases, voltage,

frequency

Three-phase, 380 to 480 V, 50/60 H z

Voltage and

frequency variatio ns

Voltage: +10 to -15% (Interphase voltage unbalance: 2% or less) *5,

Frequency: +5 to -5%

Rated

current (A)

*6

(w/o

DCR)

1.7 3.1 5.9 8.2 13.0

Required power supply

capacity (kVA)

0.6 1.1 2.0 2.9 4.9

Braking

Torque (%) *8

100

50

30

DC braking

Braking starting f requency*9: 0.0 to 60. 0 Hz,

Braking time: 0.0 to 30.0 s, Braking level: 0 to 100%

Braking transistor

Built-in

Applicable safety standards

UL61800-5-1, IEC 61800-5-1 (under application)

Enclosure

IP20 (IEC 60529), UL open type (UL50)

Cooling method

Natural cooling

Fan cooling

Mass (kg)

0.8

0.8

0.9

1.0

1.3

*1 Fuji 4-pole standard motor s

*2 Refers to the rated capacity assuming the rated output voltage as 440 V.

*3 Output voltages cannot exceed the power supply voltage.

*5

Interphase voltage unbalance (%)

=

Max. voltage (V) - Min.voltage

(V)

× 67

(Refer to

IEC 61800

- 3)

3 phase average voltage (V)

If this value is 2 to 3%, use an optional AC reactor (ACR).

*6 Refers to the estimated value to apply when the power supply capacity is 500 kVA (inverter capacity x 10 when the

inverter capacity exceeds 50 kVA) and the inverter is connected to the %X = 5% power supply.

*8 Refers to the average braking torque to apply when the motor running alone decelerates from 60 Hz with the AVR

control being OFF. (It varies with the efficiency of the motor.)

*9 Available only for induction motor drive.

13

Page 15

7. Connection diagram in operation by external signal inputs

Voltage Input

0 to 10 VDC

[Y1]

[Y1E]

[DX+]

Analog input

Analog Meter

[DX-]

Current Input

+4(0) to +20 mADC

[FWD]

[REV]

[CM]

[X1]

[X2]

[X3]

[PLC]

RJ-45

[FMA]

Digital input

[13]

[12]

[C1]

30A

30B

30C

Alarm output

(for any fault)

Transistor Output

Power supply

Single-phase

200 to 240V

50/60Hz

R

[11]

(+)

(-)

3

2

1

Power supply to

potentiometer

RS-485

Communication port

*With a built-in

resistor switch

SINK

SOURCE

L1/L

L2/N

MC (Note 2)

MCCB or

RCD/ELCB

(Note 1)

Control Circuit

Main Circuit

(Note 5)

(Note 6)

ELCB : Earth Leakage Circuit Braker

MC : Magnetic Contactor

MCCB : Molded Case Circuit Braker

RCD : Residual-current- operated

Protective Device

U

V

W

Grounding termical (Note 7)

G

M

Motor

Power supply

Three-phase

380 to 480V

50/60Hz

G

L1/R

L2/S

L3/T

MC (Note 2)

MCCB or

RCD/ELCB

(Note 1)

Grounding termical

P DB

DBR (Dynamic Braking Resistor)

P

DB

2

1

[CM]

[THR]

(Note 4)

(Note 1) Install a recommended molded case circuit breaker (MCCB) or a residual-current-

o

perated protective device (RCD)/earth leakage circuit breaker (ELCB) (with overcurrent

prot

ection) in the primary circuit of the inverter to protect wiring. Do not use an MCCB or

RCD/ELCB whose capacity exceeds the recommended rated current.

(Note 2) A magnetic contactor (MC) should, if necessary, be mounted independent of the MCCB or

ELCB to

cut off the power fed to the inverter. MCs or solenoids that will be installed close to

the inverter require surge absorbers to be connected in parallel to their coils.

(Note 4)

T

he THR function can be used by assigning "9" (External alarm) to any of terminals [X1] to

[X3],[FWD] or [REV] (function code E01 to E03, E98, or E99).

(Note 5)

Frequ

ency can be set by connecting a frequency setting device (external potentiometer)

b

etween terminals [11], [12] and [13] instead of inputting voltage signal (0 to +10 VDC or 0 to

+5VDC) between terminals [12] and [11].

(Note 6)

For the wiring of the control

circuit, use shielded or twisted wires. When shielded wires are

used

, connect the shields to earth. To prevent malfunction due to noise, keep the control

circuit wiring away from the main circuit wiring as far as possible (recommended: 10 cm or

longer),

and never set them in the same wire duct. When crossing the control circuit wiring with

the main circuit wiring, set them at right angles.

14

Page 16

8. External Dimensions

[unit: mm]

[FVR0.4AS1S-7/FVR0.75AS1S-7] [FVR1.5AS1S-7/FVR2.2AS1S-7/

FVR0.4AS1S-4~FVR2.2AS1S-4]

[FVR3.7AS1S-4]

15

Page 17

9. Function Code Tables

Function codes enable the FVR-Micro of inverters to be set up to match your system requirements.

Each function code consists of a 3-letter alphanumeric string. The first letter is an alphabet that

identifies its group and the following two letters are numerals that identify each individual code in the

group. The function codes are classified into seven groups: Fundamental Functions (F codes),

Extension Terminal Functions (E codes), Control Functions (C codes), Motor 1 Parameters (P codes),

High Performance Functions (H codes), Application Functions (J codes) and Link Functions (y

codes). To determine the property of each function code, set data to the function code.

(This manual only shows F functions, refer to the instruction on website for more functions,)

Changing, validating, and saving function code data when the motor is running

Function codes are indicated by the following based on whether they can be changed or not when the

inverter is running:

Notation Change when running Validating and saving function code data

Y*

Possible

If the data of the codes marked with Y* is changed, the change

will immediately take effect; however, the change is not saved

into the inverter's memory. To save the change, press the

(Function/Data) key. If you press the (Program/Reset) key

without pressing the (Function/Data) key to exit the current

state, then the changed data will be discarded and the pre vious

data will take effect for the inverter operation.

Y

Possible

The data of the codes marked with Y can be changed with the

or keys regardless of whether the motor is running or not.

Pressing the (Function/Data) key will make the change

effective and save it into the inverter's memory.

N Impossible

—

Using negative logic f or programmable I/O terminals

The negative logic signaling system can be used for digital input terminals and transistor output

terminals by setting the function code data specifying the properties for those terminals. Negative

logic refers to the inverted ON/OFF (logical value 1 (true)/0 (false)) state of input or output signal. An

active-ON signal (the function takes effect if the terminal is short-circuited.) in the normal logic

system is functionally equivalent to active-OFF signal (the function takes effect if the terminal is

opened.) in the negative logic system. An active-ON signal can be switched to active-OFF signal,

and vice versa, with the function code data setting.

To set the negative logic system for an input or output terminal, enter data of 1000s (by adding 1000

to the data for the normal logic) in the corresponding function code.

Example: "Coast to a stop" command BX assigned to any of digital input terminals [X1] to [X3] using

any of function codes E01 through E03.

Function code data BX

7 Turning BX ON causes the motor to coast to a stop. (Active ON)

1007 Turning BX OFF causes the motor to coast to a stop. (Active OFF)

16

Page 18

Limitation of data displayed on the LED monitor

Only four digits can be displayed on the 4-digit LED monitor. If you enter more than 4 digits of data

valid for a function code, any digits after the 4th digit of the set data will not be displayed; however

they will be processed correctly.

The following tables list the function codes available for the FVR-Micro inverters.

F codes: Fundamental Functions

Code Name Data setting range

Incre-

ment

Unit

Change

when

running

Data

copying

Defaul

t

setting

F00

Data

Protection

0: Disable both data protection and digital reference

protection

1: Enable data protection and disable digital reference

protection

2: Disable data protection and enable digital reference

protection

3: Enable both data protection and digital reference

protection

– – Y Y 0

F01

Frequency

Command 1

0: UP/DOWN keys on keypad

1: Voltage input to terminal [12] (0 to +10VDC)

2: Current input to terminal [C1] (4 to 20 mA DC)

3: Sum of voltage and current inputs to terminals [12]

and [C1]

4: Built-in potentiometer (POT)

7: Terminal command UP/DOWN control

– – N Y 4

F02

Operation

Method

0: RUN/STOP keys on keypad (Motor rotational

direction specified by terminal command FWD/REV)

1: Terminal command FWD or REV

2: RUN/STOP keys on keypad (forward)

3: RUN/STOP keys on keypad (reverse)

– – N Y 2

F03

Maximum

Frequency 1

25.0 to 400.0

0.1 Hz N Y 60.0

F04

Base

Frequency 1

25.0 to 400.0

0.1 Hz N Y 60.0

F05

Rated Voltage at

Base

Frequency 1

0: Output a voltage in proportion to input voltage

80 to 240: Output an AVR-controlled voltage (for 200 V

class series)

160 to 500: Output an AVR-controlled voltage (for 400

V class series)

1 V N Y2

0

F06

Maximum Output

Voltage 1

80 to 240: Output an AVR-controlled voltage (for 200 V

class series)

160 to 500: Output an AVR-controlled voltage (for 400

V class series)

1 V N Y2

220

(380)

F07

Acceleration Time 1

0.01 to 3600

Note: Entering 0.00 cancels the acceleration time,

requiring external soft-start.

0.01 s Y Y 6.00

F08

Deceleration Time 1

0.01 to 3600

Note: Entering 0.00 cancels the deceleration time,

requiring external soft-start.

0.01 s Y Y 6.00

F09

Torque Boost 1

0.0 to 20.0

(percentage with respect to "F05: Rated Voltage at

Base Frequency 1")

Note: This setting takes effect when F37 = 0, 1, 3, or 4.

0.1 % Y Y

See

Table

A.

17

Page 19

(F codes continued)

Code Name Data setting range

Increment

Unit

Change

when

running

Data

copying

Defaul

t

setting

F10

Electronic Thermal

Overload

Protection for

Motor 1

(Motor

characteristics)

1: For a general-purpose motor with shaft-driven

cooling fan

2: For an inverter-driven motor with separately

powered cooling fan

– – Y Y 1

F11

(Overload detection

level)

0.00: Disable, 0.01 to 100.0

1 to 135% of the rated current (allowable continuous

drive current) of the motor

0.01 A Y

Y1

Y2

See

Table

A.

F12

(Thermal time

constant)

0.5 to 75.0

0.1 min Y Y 5.0

F14

Restart Mode after

Momentary Power

Failure

(Mode selection)

0: Disable restart (Trip immediately)

1: Disable restart (Trip after a recovery from power

failure)

2: Trip after decelerate-to-stop *2

4: Enable restart (Restart at the frequency at which the

power failure occurred, for general loads)

5: Enable restart (Restart at the starting frequency)

– – Y Y

1

F15

Frequency Limiter

(High

)

0.0 to 400.0

0.1 Hz Y Y 70.0

F16

(Low)

0.0 to 400.0

0.1 Hz Y Y 0.0

F18

Bias(Frequency

command 1)

-100.0 to 100.0 *1

0.01 % Y* Y 0.00

F20

DC Braking 1

(Braking startin

g

frequency)

0.0 to 60.0

0.1 Hz Y Y 0.0

F21

(Braking level)

0 to 100 *2

1 % Y Y 0

F22

(Braking time)

0.00 (Disable), 0.01 to 30.00

0.01 s Y Y 0.00

F23

Starting Frequency

0.1 to 60.0

0.1 Hz Y Y 1.0

F24

(Holding time)

0.00 to 10.00

0.01 s Y Y 0.00

F25

Stop Frequency

0.1 to 60.0

0.1 Hz Y Y 0.2

F26

Motor Sound

(Carrier frequency

)

0.75 to 16

1 kHz Y Y

2

F27

(Tone)

0: Level 0 (Inactive)

1: Level 1

– – Y Y 0

F30

Analog Output

[FMA]

(Voltage

adjustment)

0 to 300

1 % Y* Y 100

F31

(Function)

Select a function to be monitored from the followings.

0: Output frequency 1 (before slip compensation)

1: Output frequency 2 (after slip compensation)

2: Output current

3: Output voltage

7: PID feedback amount (PV)

9: DC link bus voltage

14: Calibration

15: PID command (SV)

16: PID output (MV)

– – Y Y 0

18

Page 20

(F codes continued)

Code Name Data setting range

Incre-

ment

Unit

Change

when

running

Data

copying

Defaul

t

setting

F37

Load Selection/Auto

Torque Boost

0: Variable torque load

1: Constant torque load

2: Auto-torque boost

– – N Y 1

F39

Stop Frequency

(Holding Time)

0.00 to 10.00

0.01 s Y Y 0.00

F42

Control Mode

Selection 1

0: V/f control with slip compensation inactive

1: Dynamic torque vector control

2: V/f control with slip compensation active

– – N Y 0

F43

Current Limiter

(Mode selection)

0: Disable (No current limiter works.)

1: Enable at constant speed (Disable during ACC/DEC)

2: Enable during ACC/constant speed operation

– – Y Y 2

F44

(Level)

20 to 180 : 3.7 kW(5HP)

(The data is interpr eted as the rated output current of

the inverter for 100%.) *2

1 % Y Y 160

F50

Electronic Thermal

Overload Protection

for Braking Resistor

(Discharging

capability)

1 to 900, OFF (Cancel)

1 kWs Y

Y1

Y2

OFF

F51

(Allowable average

loss)

0.001 to 50.00

0.001 kW Y

Y1

Y2

0.001

*1 When you make settings from the keypad, the incremental unit is restricted by the number of digits that the LED monitor can

display.(Example) If the setting range is from -200.00 to 200.00, the incremental unit is:

"1" for -200 to -100, "0.1" for -99.9 to -10.0 and for 100.0 to 200.0, and "0.01" for -9.99 to -0.01 and for 0.00 to 99.99.

*2 The percentage is relative to the rated output current.

19

Page 21

10. Compliance with standards

10.1 Conformity to the Low Voltage Directive in the EU

If installed according to the guidelines given below, inverters marked with CE are considered as compliant

with the Low Voltage Directive in Europe.

1. The ground terminal G should always be connected to the ground. Do not use only a

residual-current-operated protective device (RCD)/earth leakage circuit breaker (ELCB)*

as the sole method of electric shock protection. Be sure to use ground wires whose size is

greater than power supply lines.

* With overcurrent protection.

2. When used with the inverter, a molded case circuit breaker (MCCB), residual-currentoperated protective device (RCD)/earth leakage circuit breaker (ELCB) or magnetic

contactor (MC) should conform to the EN or IEC standards.

3. When you use a residual-current-operated protective device (RCD)/earth leakage circuit

breaker (ELCB) for protection from electric shock in direct or indirect contact power lines

or nodes, be sure to install t ype B of RCD/ELCB on the input (primary) of the inverter if

the power source is three-phase 200/400 V. For single-phase 200 V power supplies, use

typ e A.

When you use no RCD/ELCB, take any other protective measure that isolates the electric

equipment from other equipment on the same power supply line using double or

reinforced insulation or that isolates the power supply lines connected to the electric

equipment using an isolation transformer.

4. The inverter should be used in an environment that does not exceed Pollution Degree 2

requirements. If the environment conforms to Pollution Degree 3 or 4, install the inverter in

an enclosure of IP54 or higher.

5. I nstall the inverter, input or output filter in an enclosure with minimum degree of protection

of IP2X (Top surface of enclosure shall be minimum IP4X when it can be easily

accessed), to prevent human body from touching directly to live parts of these equipment.

6. To make an inverter with no integrated EMC filter conform to the EMC directive, it is

necessary to connect an external EMC filter to the inverter and install them properly so

that the entire equipment including the inverter conforms to the EMC directive.

7. Do not connect any copper wire directly to grounding terminals. Use crimp terminals with

tin or equivalent plating to connect them.

8. When using inverters at an altitude of more than 2000 m (6600 ft), note that the basic

insulation applies to the insulation degree of the control circuitry. At an altitude of more

than 3000 m (9800 ft), inverters cannot be used.

9. The power supply mains neutral has to be earthed for the three-phase 400 V class

inverter.

10. The inverter has been tested with EN61800-5-1 5.2.3. 6.3 Shor t-circuit Current Test under

the following conditions.

Short-circuit current in the supply: 5 kA

Maximum 240 V

Maximum 480 V

20

Page 22

10.1 Conformity to the Low Voltage Directive in the EU (Continued)

Use wires listed in IEC60364-5-52.

MCCB: Molded case circuit breaker

RCD: Residual-current-operated protective device

ELCB: Earth leakage circuit breaker

*1 The frame size and model of the MCCB or RCD/ELCB (with overcurrent protection) will vary,

depending on the power transformer capacit y. Refer to the related technical documentation for

details.

*2 The recommended wire size for main circuits is for t he “Use Copp er Conductors Only, 75 °C.”

at an ambient temperature of 50°C.

Power supply voltage

Appli-

cable

motor

rating

(kW)

Inverter type

Recommended wire size (mm2 )

*2

Main circuit

power input

[L1/R, L2/S,

L3/T]

[L1/L, L2/N]

Grounding

[ G]

*2

Inverter output

[U, V, W]

*2

Braking resistor

[P, DB]

Control circuit

(30A,

30B,

30C)

Three-phase

400 V

0.4

FVR0.4AS1S-4

2.0(2.0)

0.5

0.75

FVR0.75AS1S-4

1.5

FVR1.5AS1S-4

2.2

FVR2.2AS1S-4

3.7

FVR3.7AS1S-4

Single-phase

200 V

0.4

FVR0.4AS1S-7

2.0(2.0)

2.0(2.0) 2.0(2.5)

0.75

FVR0.75AS1S-7

1.5

FVR1.5AS1S-7

2.0(3.5)

2.2

FVR2.2AS1S-7

5.5(5.5)

21

Page 23

10.1 Conformity to the Low Voltage Directive in the EU (Continued)

To prevent the risk of hazardous acci dent s that c ou ld be c aused by damage of the inverter, install th e

specified fuses in the supply side (primary side) according to the following tables.

- Breaking capacity: Min. 10 kA

- Rated voltage: Min. 500 V

Power

supply

voltage

Appli-

cable

motor

rating

(kW)

Inverter type

Rated

Current(A)

of MCCB

(w/o DCR)

Three-

phase

400V

0.4

FVR0.4AS1S-

4

6

0.75

FVR0.75AS1S

-4

1.5

FVR1.5AS1S

-4

10

2.2

FVR2.2AS1S

-4

15

3.7

FVR3.7AS1S

-4

20

Single-

phase

200V

0.4

FVR0.4AS1S

-7

10

0.75

FVR0.75AS1S

-7

15

1.5

FVR1.5AS1S

-7

20

2.2

FVR2.2AS1S

-7

35

10.2 Conformity with UL standards and cUL-listed for Canada

UL/cUL-listed inverters are subject to the regulations set forth by the UL standards and CSA standards

(cUL-listed

for Canada) by installation within precautions listed below.

Integral solid state sh ort cir c uit pr otection does not provide branch circuit pr ote c ti on. Branc h cir c ui t

protection must be provided in a ccordance with the National Electrical Code and any additional loc a l

codes.

1. Solid state motor overload protection (motor protection by electronic thermal overload relay) is

provided in each model.

Adjust function codes F10 to F 12 and H89 to set the protection level.

2. Connect the power supply satisfy ing the character istics shown in the table below as an input power

supply of the inverter. (Short circuit rating)

3. Use 75°C

(167°F) Cu wire only.

4. Use Class 1 wire only for control circuits.

22

Page 24

10.2 Conformity with UL standards and cUL-listed for Canada (Continued)

Short circuit rating

When protected by a circuit breaker, suitable for use on a circuit capable of delivering not

more than B rms symmetrical amperes, A volts maximum.

■kW rating

Power

supply

voltage

Inverter type Power supply max. voltage

Power supply current

Three-phase

400V

FVR0.4AS1S-4

480VAC 5,000 A or less

FVR0.75AS1S-4

FVR1.5AS1S-4

FVR2.2AS1S-4

FVR3.7AS1S-4

Single-phase

200V

FVR0.4AS1S-7

240VAC 5,000 A or less

FVR0.75AS1S-7

FVR1.5AS1S-7

FVR2.2AS1S-7

23

Page 25

10.2 Conformity with UL standards and cUL-listed for Canada (Continued)

5. Install UL certified circuit breaker rated 240V or more for 200V input, 480V or more for 400V

input, between the power supply and the inverter, referring to the table below.

*1 First row in the box [Y1]~[X3]

*2 Other than the TERM1

*3 Values in [ ] mean the size (AWG) of Grounding wire if exist.

Power

supply

voltage

Inverter type

Required torque

Ib-in (N・m)

Wire size

AWG or kcmil (mm

2

)

Circuit Breaker(A)

Main

terminal

Control circuit

*3

Main

terminal

Control circuit

*1

TERM1

*2

TERM2-1

TERM2-2

*1

TERM1

*2

TERM2-1

TERM2-2

Three-phase 400V

FVR0.4AS1S-4

10.6

-12.4

(1.2-1.4)

3.6

(0.4)

4.5

(0.5)

AWG20

to

AWG10

AWG

22 to

AWG

14

(0.34

to 2.1

mm

2

)

AWG26

to

AWG14

(0.25 to

2.1 mm

2

)

6

FVR0.75AS1S-4

6

FVR1.5AS1S-4

10

FVR2.2AS1S-4

15

FVR3.7AS1S-4

20

Single-phase 200V

FVR0.4AS1S-7

8.7

(0.98)

3.6

(0.4)

4.5

(0.5)

AWG22

to

AWG16

10

FVR0.75AS1S-7

15

FVR1.5AS1S-7

10.6

-12.4

(1.2-1.4)

3.6

(0.4)

4.5

(0.5)

AWG20

to

AWG10

20

FVR2.2AS1S-7

35

24

Page 26

10.2 Conformity with UL standards and cUL-listed for Canada (Continued)

6. To comply with CSA for 200 VAC input models, transient surge suppression shall be installed on

the line side of this equipment and shall be rated 240 V (phase to ground), 240 V (phase to phase),

suitable for overvoltage category 3, and shall provide protection for a rated impulse withstand

voltage peak of 4 kV. (3.7 kW (5 HP) or below)

To comply with CSA for 400 VAC input models, transient surge suppression shall be installed on

the line side of this equipment and shall be rated 278 V (phase to ground), 480 V (phase to phase),

suitable for overvoltage category 3, and shall provide protection for a rated impulse withstand

voltage peak of 4 kV.

7. All models rated 380-480 V input voltage ratings shall be connected to TN-C system power source,

i.e. 3-phase, 4-wire, wye (480Y/277V), so that the phase-to-ground rated system voltage is limited

to 300 V maximum.

8. Maximum surrounding air temperature rati ng of 50 ºC (122 °F)..

9. For use in pollution degree 2 e nvironments only.

25

Page 27

installation

Power

supply

M

3~

Motor

MCCB or

RCD/ELCB

*

Metal panel

Three-

or

single-

phase

Shielded

cable

(Note 1)

* with overcurrent protection

(Note 2)

(Note 3)

EMC-

compliant

filter

(optional)

G

G

N-Micro

L1/R

L2/S

L3/T

U

V

W

G

(L1/L)

(L2/N)

G

(Note 3)

Figure 10.1 Installing the Inverter with EMC-compliant Filter into a Metal Panel

Note 1: Pass the EMC filter input wires (shielded cable and grounding wire in a bundle) through the

ferrite bead core for reducing radio noise two times.

Note 2: Pass the EMC filter output wires (shielded cable and grounding wire in a bundle) through the

ferrite bead core for reducing radio noise two times.

Note 3: Connect the shielding layer of the shielded cable to the motor and panel electrically and

ground the motor and panel.

Radiated noise varies greatly depending upon the installation environment. When no

ferrite

bead core

is used, make sure that the radiated noise does not exceed the

permissible level.

Leakage current

Table 11.2 Leakage Current of EMC-compliant Filter

Input power Inverter type Filter type Leakage current (mA)

Three-phase 400 V

FVR0.4AS1S-4

B84143A0010A166

3.1

FVR0.75AS1S-4

B84143A0010A166

3.1

FVR1.5AS1S-4

B84143A0010A166

3.1

FVR2.2AS1S-4

B84143A0010A166

3.1

FVR3.7AS1S-4

B84143AC020A166

3.1

Single-phase 200 V

FVR0.4AS1S-7

B84142A0010A166

2.59

FVR0.75AS1S-7

B84142A0010A166

2.59

FVR1.5AS1S-7

B84142A0030R166

1.73

FVR2.2AS1S-7

B84142A0030R166

1.73

26

Page 28

11. Product warranty

To all our customers who purchase Fuji Electric Co., Ltd. products included in this

documentation:

Please take the following items into consideration when placing your order.

When requesting an estimate and placing your orders for the products included in these materials,

please be aware that any items such as specifications which are not specifically mentioned in the

contract, catalog, specifications or other materials will be as mentioned below.

In addition, the products included in these materials are limited in the use they are put to and the

place where they can be used, etc., and may require periodic inspection. Please confirm these

points with your sales representative or directly with this company.

Furthermore, regarding purchased products and delivered products, we request that you take

adequate consideration of the necessity of rapid receiving inspections and of product management

and maintenance even before receiving your products.

[ 1 ] Free of charge warranty period and warranty range

(1) Free of charge warranty period

1) The product warranty period is ''1 year from the date of purchase'' or 18 months from the

manufacturing date imprinted on the name place, whichever date is earlier.

2) However, in cases where the use environment, conditions of use, use frequency and times

used, etc., have an effect on product life, this warranty period may not apply.

3) Furthermore, the warranty period for parts restored by Fuji Electric Co., Ldt.’s Service

Department is ''6 months from the date that repairs are completed.''

(2) Warranty range

1) In the event that breakdown occurs during the product's warranty period which is the

responsibility

of Fuji Electric Co., Ltd., Fuj i Electric Co., Ltd. will replace or repair the part of the

product that has broken down free of charge at the place where the product was purchased or

where it was delivered. However, if the following cases are applicable, the terms of this

warranty may not apply.

①

The breakdown was caused by inappropriate conditions, environment, handling or use

methods, etc. which are not specified in the catalog, operation manual, specifications or

other relevant documents.

②

The breakdown was caused by the product other than the purchased or delivered

Fuji Electric Co., Ltd.

's

product.

③

The breakdown was caused by the product other than

Fuji Electric Co ., Lt d.

's product,

such as the

customer's equipment or software design, etc.

④

Concerning the

Fuji Electric Co., Ltd.

's programmable products, the breakdown was caused

by a program

other than a program supplied by this company, or the results from using such a

program.

⑤

The breakdown was caused by modifications or repairs affected by a party other than

Fuji Electric Co., Ltd.

⑥

The breakdown was caused by improper maintenance or replacement using

consumables, etc. specified in the operation manual or catalog, etc.

⑦

The breakdown was caused by a science or technical problem that was not foreseen

when making practical application of the product at the time it was purchased or

delivered.

⑧

The product was not used in the manner the product was originally intended to be used.

⑨

The breakdown was caused by a reason which is not this company's responsibility, such

as lightning or other disaster.

27

Page 29

2) Furthermore, the warranty specified herein shall be limited to the purchased or delivered

product alone.

3) The upper limit for the warranty range shall be as specified in item (1) above and any

damages (damage to or loss of machinery or equipment, or lost profits from the same, etc.)

consequent to or resulting from breakdown of the purchased or delivered product shall be

excluded from coverage by this warranty.

28

Page 30

Appendix

Compatibility with Revised EMC Directive and Low Voltage Directive

In the revised EMC Directive (2014/30/EU) and Low Voltage Directive (2014/35/EU), it is necessary

to clearly state the name and the address of manufactures and importers to enhance traceability.

Importers shall be indicated as follows when exporting products from Fuji Electric to Europe.

(Manufacturer)

Fuji Electric Co., Ltd.

5520, Minami Tamagaki-cho, Suzuka-city, Mie 513-8633, Japan

(Importer in Europe)

Fuji Electric Europe GmbH

Goethering 58, 63067 Offenbach / Main, Germany

< Precaution When exporting to Europe >

Not all Fuji Electric products in Europe are necessarily imported by the above importer. If any

Fuji Electric products are exported to Europe via another importer, please ensure that the

importer is clearly stated by the customer.

29

Page 31

[MEMO]

Page 32

Fuji Electric Co., Ltd.

Gate City Ohsaki, East Tower, 11-2, Osaki 1-chome, Shinagawa-ku, Tokyo 141-0032, Japan

Phone: +81-3-5435-7058 Fax: +81-3-5435-7420

URL http://www.fujielectric.com

Loading...

Loading...