Fuji Electric FVR-C11S-7EN Series, FVR0.1C11S-7EN, FVR0.2C11S-7EN, FVR0.4C11S-7EN, FVR0.75C11S-7EN Instruction Manual

...Page 1

Solutions for Drives

C11S

FVR

+PUVTWEVKQPOCPWCN

Fuji Electric-General-Purpose Inverter FVR-C11S-7EN Series

Single-phase 230V 0.1 - 2.2kW

Page 2

FVR-C11S-EN

g

g

ying

g

g

g

g

g

g

g

g

g

y

g

y

Contents

Safety Instructions

1 Before Using This Product

1-1 Receivin

1-2 Appearance

1-3 Handlin

1-4 Carr

1-5 Stora

2 Installation and Connection

2-1 Operatin

2-2 Installation Method ........................ 2-2

2-3 Connection .................................... 2-3

2-3-1 Basic connection .................... 2-3

2-3-2 Connectin

and

2-3-3 Connectin

control terminals ..................... 2-6

2-3-4 Connection examples ........... 2-12

2-4 Others ......................................... 2-21

2-4-1 Harmonic component ........... 2-21

2-4-2 Noise .................................... 2-21

2-4-3 Leaka

3 Operation

3-1 Inspection and Preparation

3-2 Operation Method ......................... 3-1

3-3 Trial Run ....................................... 3-2

............................................ 3-1

before Operation ........................... 3-1

4Keypad Panel

4-1 Names and Functions ................... 4-1

4-2 Operatin

5 Selecting Function

5-1 Function Selection List .................. 5-1

5-2 Details of Each Function ............... 5-7

6 Protective Function

6-1 List of protective functions ............ 6-1

6-2 Alarm Reset .................................. 6-3

7 Troubleshootin

7-1 In case of trippin

7-2 Other trouble ................................. 7-7

................................... 1

........... 1-1

Inspections ................... 1-1

.................................. 1-2

the Product .................... 1-3

........................................ 1-4

e and transportation ........... 1-4

........... 2-1

Environment ................. 2-1

the main circuit

round terminals ............. 2-4

the

e current ................... 2-21

.................................... 4-1

Keypad Panel ............... 4-1

........................... 5-1

......................... 6-1

............................... 7-1

......................... 7-1

8 Maintenance and Inspection

8-1 Dail

8-2 Periodic Inspection ........................ 8-1

8-3 Electrical measurements

8-4 Insulation Test ............................... 8-6

8-5 Parts Replacement ....................... 8-7

8-6 Inquiries about the Product and

9 Specifications

9-1 Standard Specifications ................ 9-1

9-2 Common Specifications ................ 9-2

9-3 Dimensions ................................... 9-8

9-4 Selection of Peripheral Device .... 9-11

10 Options

10-1 Built-in Options ............................ 10-1

10-2 External Options ......................... 10-1

11 Applicable reactors

Inspection ............................. 8-1

in the Main Circuit ......................... 8-5

Guarantee of the product .............. 8-7

.................................... 9-1

............................................ 10-1

....................... 11-1

12 Compliance with standards

12-1 UL/cUL standards [Applicable to

products with UL/cUL mark]......... 12-1

12-1-1 General ................................. 12-1

12-1-2 Precautions ........................... 12-1

12-2 Compliance with EMC directive

in EU [Applicable to products

with CE mark] .............................. 12-2

12-2-1 General ................................ 12-2

12-3 Compliance with low volta

in EU [Applicable to products

with TÜV or CE mark] .................. 12-2

12-3-1 General ................................. 12-2

12-3-2 Precautions ........................... 12-2

.......... 8-1

........ 12-1

e directive

13 Electromagnetic

Compatibilit

13-1 General ....................................... 13-1

13-2 RFI Filters ................................... 13-1

13-3 Recommended Installation

Instructions .................................. 13-3

(EMC)

....................... 13-1

Page 3

FVR-C11S-EN

y

g

y

y

g

y

g

y

y

y

Safety Instructions

Read this operation manual carefully and familiarize

before installation, connection (wirin

tion or maintenance and inspection of the device. Be familiar with the inverter, safet

information, and safety signs before using the inverter.

In this instruction manual, safet

sified into the followin

ourself with the operation of the inverter

), opera-

signs are clas-

categories.

WARNING

Improper operation may result in death

or serious injur

.

CAUTION

Improper operation may result in slight

to medium injur

Note: More serious situations than those cov-

ered b

dependin

important that

structions.

the CAUTION sign can result

or property damage.

on the circumstances. It is

ou always follow the in-

Safety Instructions 1

Page 4

FVR-C11S-EN

g

g

g

g

g

g

g

y

)

)

y

y

g

y

g

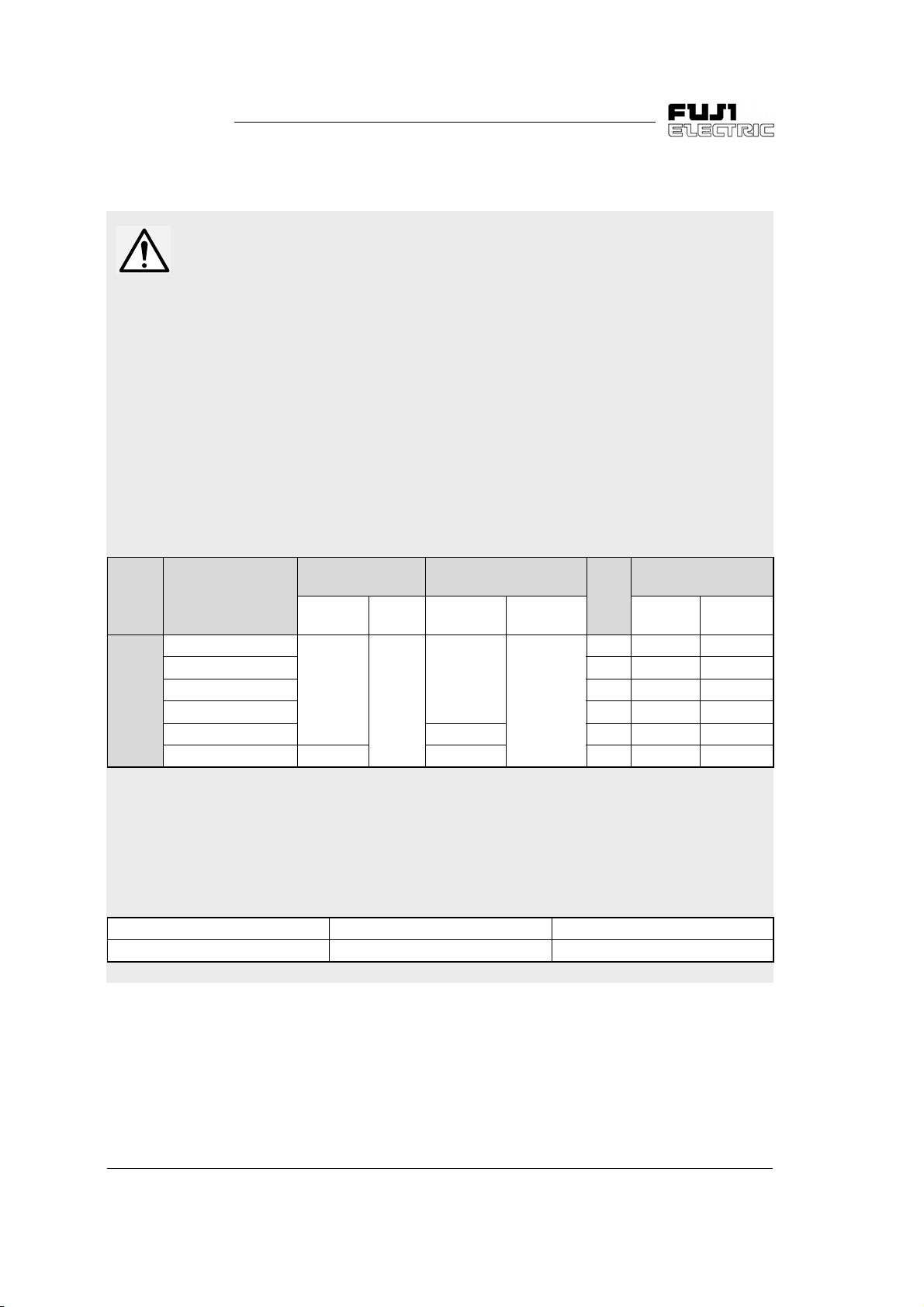

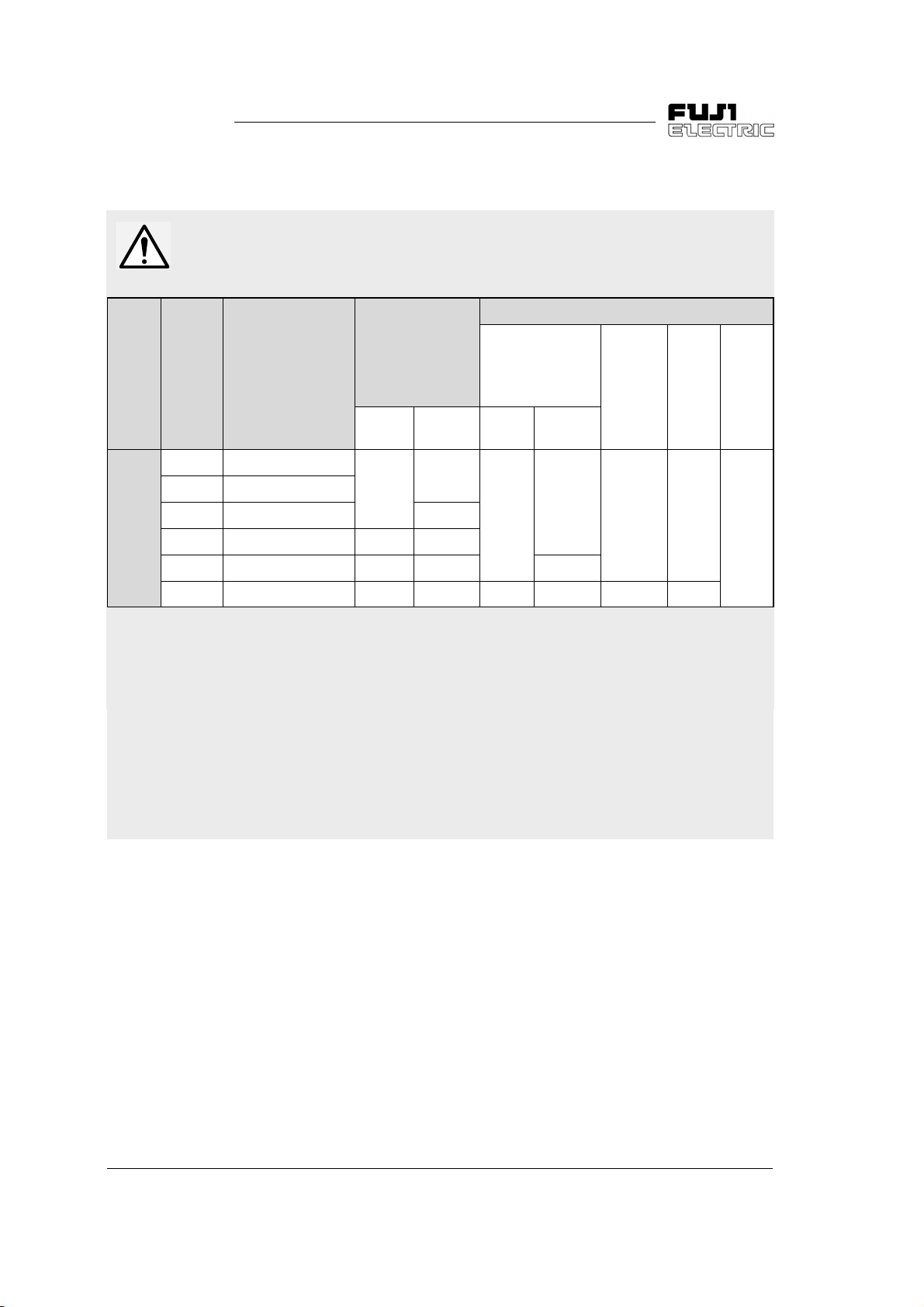

Compliance with UL/cUL standards [Applicable to products with UL/cUL mark]

1. [WARNING] Take care of electric shock. Be sure to turn the

CAUTION

inverter off before startin

2. [CAUTION] When the char

at a dan

erous voltage.

3. [WARNING] There are two or more live parts inside the inverter.

4. The inverter is approved as a part used inside a panel. Install it inside a panel.

work.

e lamp is lit, the inverter is still charged

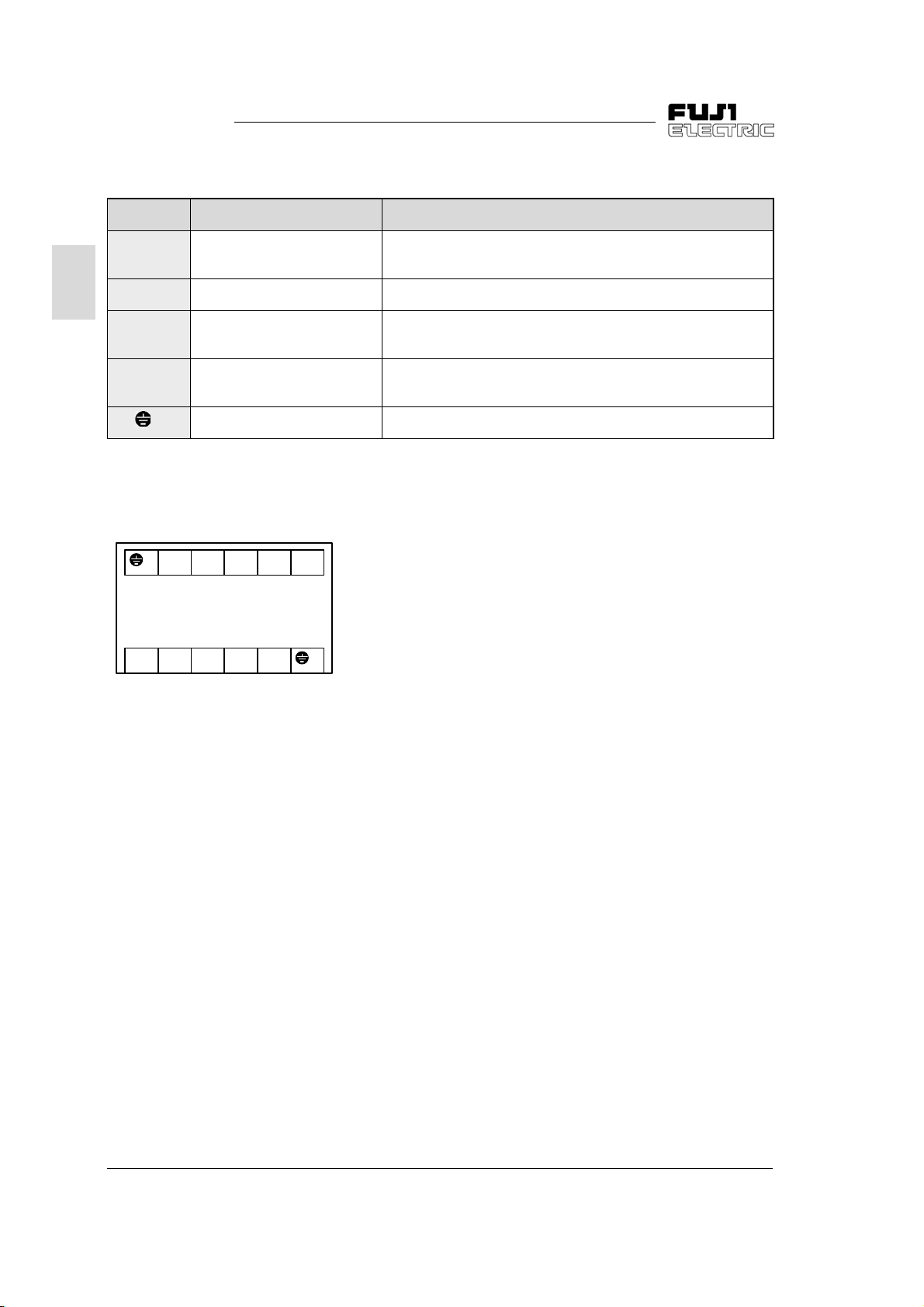

Voltage Inverter type

FVR0. 1C11S-7EN

Single-

phase

200V

input

FVR0. 2C11S-7EN 6 A4J6 JKS6

FVR0. 4C11S-7EN 10 A4J10 JKS10

FVR0. 75C11S-7EN 15 A4J15 JKS15

FVR1. 5C11S-7EN 12 (3.3) 30 A4J30 JKS30

FVR2. 2C11S-7EN 1.8 10 (5.3) 40 A4J40 JKS40

5. Perform wirin

verter, referrin

to the input, output and control terminals of the in-

to the table below. Use UL certified round crimp

terminal to the input and output terminals with insulation cover or

covered with reduced tube to obtain the insulation distance. Use a

crimpin

fabricatin

6. Install a fuse in the power suppl

tool recommended by the terminal manufacturer when

crimp terminals.

to the inverter, referring to the ta-

ble below.

Tightening torque

[Nm]

L1/L, L2/N

U, V, W

1.2

1) Use copper wires of allowable maximum temperature 60 or75 °C.

2) Use UL certified "quick breakin

Control

section

Applicable wire diameter

[AWG] (mm

L1/L, L2/N

U, V, W

14 (2.1)

0.4

2)1

Control

section

20 (0.5)

fuse".

Fuse

[A]

Recommended fuse

2

Gould

Compan

6 A4J6 JKS6

Bussmann

Compan

7. Connect the power supply satisfying the characteristics shown in

the table below as an input power suppl

circuit ratin

Inverter type Input max. voltage Input current

FVR0. 1-2. 2C11S-7EN AC240V 5,000 A or less

2 Safety Instructions

)

of the inverter. (Short

Page 5

FVR-C11S-EN

Ü

g

g

y

y

g

y

y

g

g

y

y

y

y

y sy

y

g

g

g

g

g

y

y

g

g

y

g

g

y

g

y

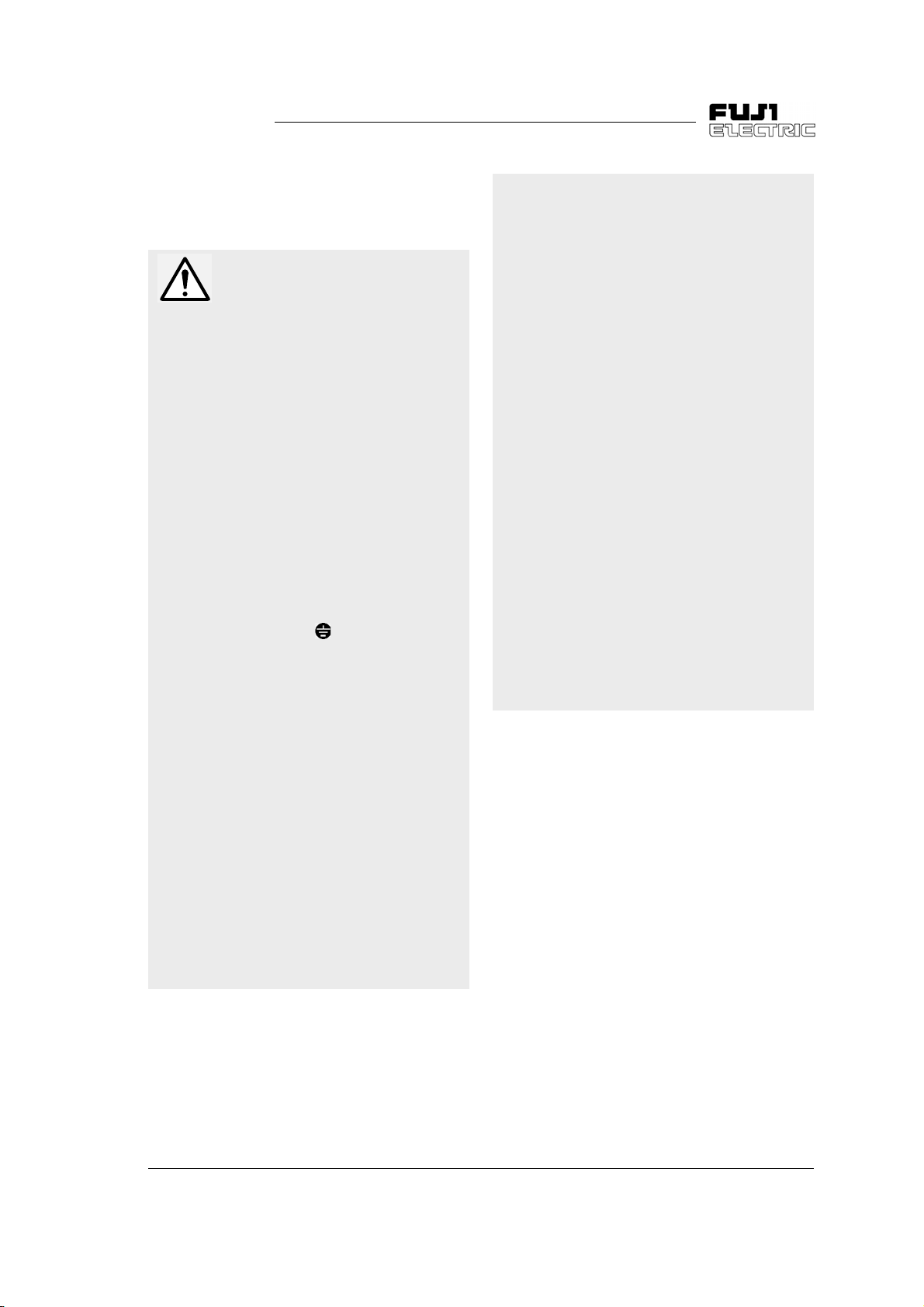

Compliance with low voltage directive in

EU [Applicable to products with T

V

mark]

CAUTION

1. Safe separation for control interface of this

inverter is provided when this inverter is installed in overvolta

(Protective Extra Low Volta

SELV (Safet

from external controller is connected to the

interface directl

2. Basic insulation for control interface of this

inverter is provided when this inverter is installed in overvolta

lation transformer has to be installed

between power suppl

verter when SELV circuit from external

controller is connected to this inverter directl

. Otherwise supplementary insulation

between control interface of this inverter

and environment must be provided.

3. The

round terminal G should always be

connected to the

RCD as the sole method of electric shock

protection. Dimensions of external PE conductor should be same as dimensions of

input phase conductor and capable for

possible fault.

Extra Low Voltage) circuit

e category II. PELV

e) circuit or

.

e category III. An insu-

mains and this in-

round. Don’t use onl

6. The inverter has to be installed in environment of pollution de

ment is pollution de

inverter has to be installed in a cabinet of

IP54 or hi

7. Use a prescribed wire accordin

EN60204 Appendix C.

8. Install the inverter, AC or DC reactor, output filter in an enclosure that meets the

followin

man bod

equipment.

1) When a person can touch easil

connectin

the inverter, AC or DC reactor, output filter in an enclosure with minimum de-

2) When a person can not touch easil

each connectin

install the inverter, AC or DC reactor,

output filter in an enclosure with a minimum de

9. It is necessar

propriate method usin

RFI filter to conform to the EMC directive.

It is customer’s responsibilit

whether the equipment, the inverter is installed in, conforms to EMC directive.

her.

requirement, to prevent a hu-

from touching directly to these

terminal or live parts, install

ree of protection of IP4X.

ree of protection of IP2X.

ree 2. If the environ-

ree 3 or 4, the

to the

on each

on

terminal or live parts,

to install the inverter in ap-

an appropriate

to check

4. Use MCCB or MC that conforms to EN or

IEC standard.

5. Where RCD (Residual-current-operated

protective device) is used for protection in

case of direct or indirect contact, onl

of t

pe B is allowed on the supply side of

this EE (Electric equipment). Otherwise another protective measure shall be applied

such as separation of the EE from the environment b

tion or isolation of EE and suppl

b

the transformer.

Safety Instructions 3

double or reinforced insula-

RCD

stem

Page 6

FVR-C11S-EN

y

g

)

)

)

)

g

)

)

)

)

)

)

)

)

)

)

)

g

g

g

y

y

y

g

g

g

y

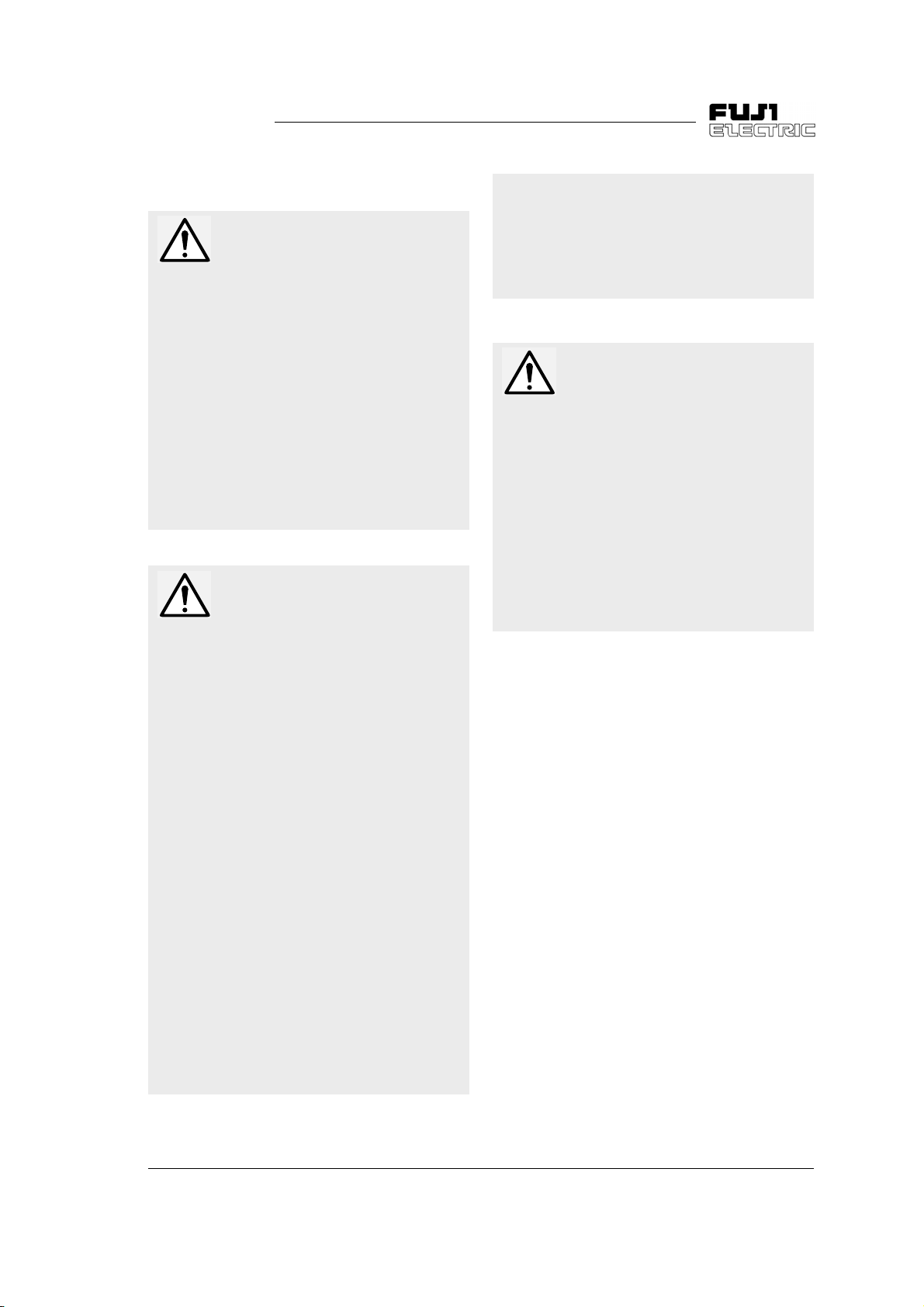

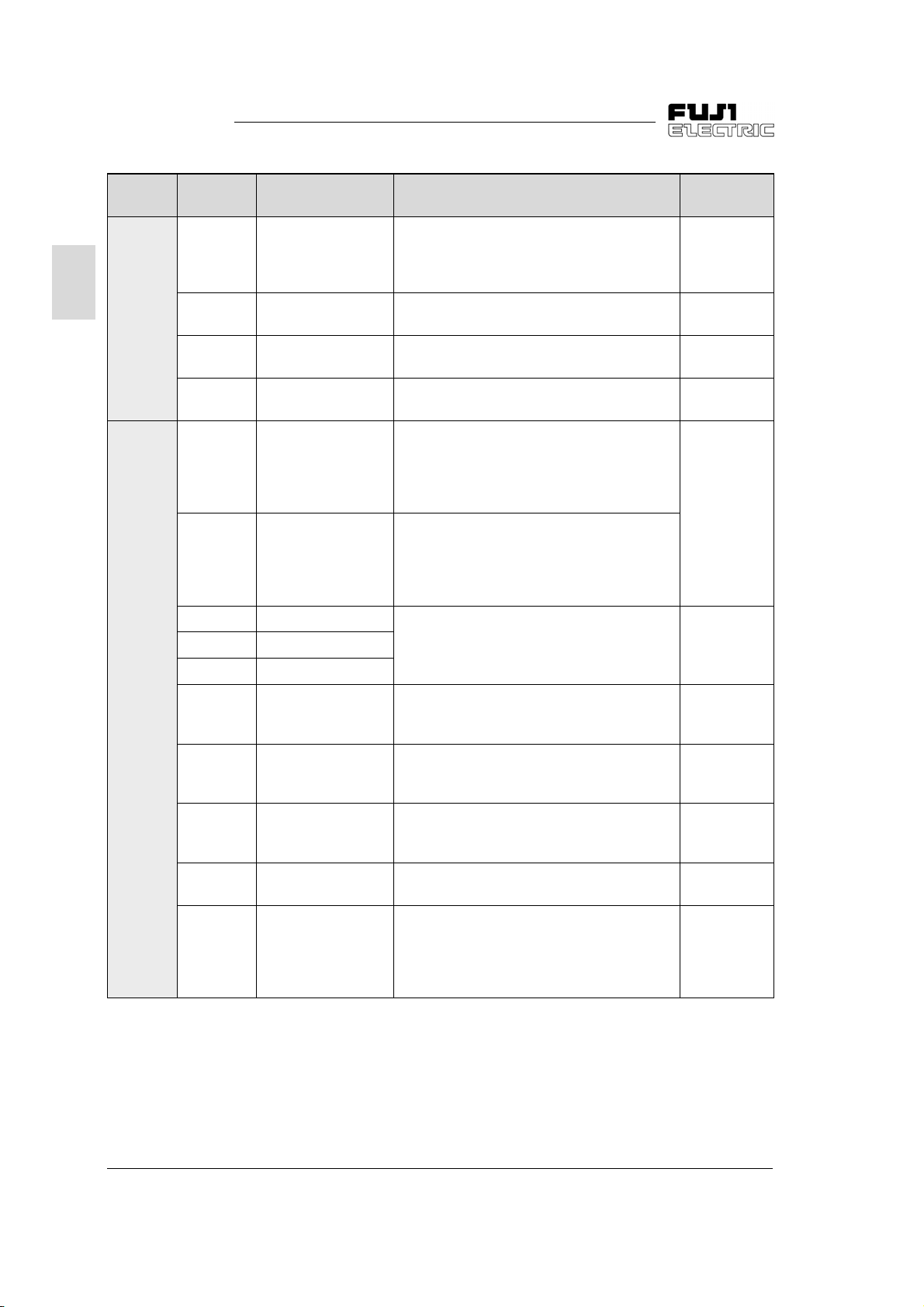

Compliance with low voltage directive in EU [Continued]

Power

suppl

voltage

Single

phase

200V

CAUTION

Use of wires specified in Appendix C of EN 60204 is recommended.

Molded case circuit

breaker (MCCB) or

Nominal

applied

motor

[kW]

Inverter type

earth leaka

circuit breaker

(ELCB)

Rated current [A]

With

DCR

0.1 FVR0. 1C11S-7EN

0.2 FVR0. 2C11S-7EN

6

0.4 FVR0. 4C11S-7EN 10

0.75 FVR0. 75C11S-7EN 10 16

1.5 FVR1. 5C11S-7EN 16 20

2.2 FVR2. 2C11S-7EN 20 32

1) The applicable frame and series of the molded case circuit breaker (MCCB) and

earth leaka

transformer of the equipment. For details of selection, refer to the concernin

technical documents.

2) The recommended wire size for the main circuit is the case for the low volta

directive at ambient temperature 40 °C.

3) The power suppl

equivalent of 0.1% of the inverter capacit

accompanied b

4) Crimp terminals up to 7.4 mm in width (includin

5) Crimp terminals up to 9.5 mm in width (includin

6) Use the

suppl

e circuit breaker (ELCB) vary according to the capacity of the

the voltage imbalance.

rounding cable of a size equal to or larger than that of the input power

cable.

Recommended wire size [mm2]

e

1

Without

reactor

Input circuit

single phase

200V [L1/L, L2/N]

With

3

DCR

2

Without

reactor

[U, V, W]

3

Output

circuit

2

DCR

circuit

2

[P1]

[P(+)]

6

4

2.5

4

2.5

4

4.0

5

4.0

impedance without a reactor is considered to be the

5

6.0

, with 10% current imbalance

tolerance) can be used.

tolerance) can be used.

2.5

2.5

4

5

2.5

4.0

4

5

Control

wirin

0.5

e

4 Safety Instructions

Page 7

FVR-C11S-EN

g

y

y

y

y

y

y

g

g

g

g

jury

jury

g

g

jury

Instructions on use

CAUTION

WARNING

1. This inverter is designed to drive a threephase induction motor and is not usable for

a sin

le-phase motor or any other pur-

poses.

There is a risk of fire.

2. This inverter ma

elevator, life-support s

pose directl

mans.

Safet

precautions should be established

and practiced in terms of the entire s

rather than the independent device.

Otherwise, an accident could occur.

not be used as is for an

stem, or other pur-

affecting the safety of hu-

stem,

Instructions on transport/installation

WARNING

1. Attach the device to an incombustible material such as metal.

Otherwise fire could occur.

1. Do not carry the device by holding just the

surface cover.

Inverter ma

2. Do not allow forei

per dust, small chips of wood or metal, and

dust to enter the inverter or adhere to the

heat sink.

Otherwise, a disaster such as burnin

could occur.

3. Do not install or operate dama

or an inverter with a missin

Otherwise in

4. Do not step on the product.

Otherwise in

5. When stackin

the number of tiers indicated on the pack-

carton.

in

Otherwise in

be dropped causing injury.

n matter such as lint, pa-

ed inverter

part.

could occur.

could occur.

up in tiers, do not exceed

could occur.

2. Do not place the device near inflammables.

Otherwise fire could occur.

Safety Instructions 5

Page 8

FVR-C11S-EN

g

g

g

g

g

y

jury

g

y

g

g

y

y

jury

y

g

g

g

Instructions on wirin

CAUTION

WARNING

1. When the inverter is connected to power,

connect it via a line-protection molded case

circuit breaker or an earth-leaka

breaker (Residual current operated protective device).

Otherwise fire could occur.

2. Be sure to connect the

Otherwise electric shock or fire could

occur.

3. Ensure that a licensed specialist

performs the wirin

4. Check before startin

power is off (OPEN).

Otherwise electric shock could occur.

5. Do not wire up the inverter until it has been

installed securel

Otherwise electric shock or in

occur.

6. The inverter has to be

ance with the national and local safet

specification.

Otherwise electric shock could occur.

.

round wire.

work.

the wiring that the

rounded in accord-

e circuit

could

1. Check that the number of phases and the

rated volta

the number of phases and volta

AC power suppl

Otherwise fire could occur.

2. Do not connect the AC power suppl

output terminals (U, V, W).

Otherwise in

3. Check the output terminals (U,V,W) for the

phase order and connect them to the motor

correctl

Otherwise fire could occur.

4. Do not connect a brakin

the DC terminals [P(+), N(-)].

Otherwise fire could occur.

5. Noise is

tor, and wirin

does not cause malfunctions in peripheral

sensors and equipment.

Otherwise accidents could occur.

e of this product correspond to

e of the

.

to the

could occur.

.

resistor directly to

enerated from the inverter, mo-

. Take care that this noise

6 Safety Instructions

Page 9

FVR-C11S-EN

g

g

y

g

g

y

g

g

y

g

y

g

y

g

g

y

g

y

y

g

g

g

y

y

g

y

ging

g

j

g

j

Instructions on operation

WARNING

1. Be sure to put on the surface cover before

the power ON (CLOSE).

turnin

Never remove the cover while the power is

applied to the inverter.

Otherwise electric shock could occur.

2. Never operate switches with wet fin

ers.

Otherwise electric shock could occur.

3. The interior of the inverter ma

char

ed after turning off the power.

remain

Therefore, never attempt to remove the

surface cover except for wirin

service and

periodic maintenance.

Otherwise electric shock could occur.

WARNING

I

5. Never touch the inverter terminals when

ized even if it has stopped.

ener

Otherwise electric shock could occur.

6. Never touch the ke

s on the keypad panel

with a pointed object such as a needle.

Otherwise electric shock could occur.

CAUTION

1. Never touch the heat sink because the

become very hot.

Otherwise burns could occur.

2. The inverter can set hi

. Carefully check the limit of the mo-

easil

tor and machine before chan

tin

.

Otherwise in

uries could occur.

3. Do not use the inverter brake function for

mechanical holdin

Otherwise in

uries could occur.

h-speed operation

the set-

.

1. When the retry function is selected, the inverter ma

pin

(Desi

safet

automatically restart after trip-

, depending on the cause of the trip.

n the machine to secure personal

in the event of restart.)

Otherwise accident could occur.

2. Operatin

conditions may occasionally be

different from the preset acceleration/deceleration time or speed because of activation of the stall prevention function.

In such a case, personal safet

cured throu

h adequate machine design.

must be se-

Otherwise accident could occur.

3. The stop ke

tion settin

Therefore install an emer

dependentl

ternal si

ke

on the keypad panel will be disabled.

is effective only when a func-

has been established.

ency switch in-

. When operation via the ex-

nal terminal is selected, the STOP

There is a risk of accidents.

4. Operation starts suddenl

done with an runnin

that no runnin

signal is input before alarm

if alarm reset is

signal input. Check

reset.

Otherwise accidents could occur.

Safety Instructions 7

Page 10

FVR-C11S-EN

g

g

g

y

g

g

jury

y

jury

g

g

y

y

g

g

Instruction on maintenance/inspection,

and replacement

WARNING

1. Do not commence inspection work until at

least five minutes after the power has been

turned off (OPEN).

(In addition, make sure that the char

lamp has

volta

does not exceed 25V DC.)

Otherwise electric shock could occur.

2. Onl

maintenance and inspection or replacement operations.

(Take off all metal objects (watch, rin

etc.) before startin

(Use well-insulated tools.)

Otherwise electric shock or in

occur.

3. Never modif

Otherwise electric shock or in

occur.

one off and check that the DC

e between terminals P(+) and N(-)

qualified personnel should perform

.)

could

the product.

could

Instruction on disposal

CAUTION

Since this product contains lead solder,

it must be treated as industrial waste

when it is disposed of. Entrust it to a

waste processin

posin

e

General instructions

The figures in this operation manual ma

show the inverter with covers and safet

,

screens removed to explain the structure in

details. Therefore, be sure to replace the covers and screens to their ori

operate the inverter accordin

tion manual.

company when dis-

it.

inal positions and

to the instruc-

8 Safety Instructions

Page 11

FVR-C11S-EN

g

y

y

g

g

g

y

y

g

y

y

y

g

g

y

1Before Using This Product

1-1 Receivin

Inspections

Unpack and check the product as explained below.

If

ou have any questions or problems with this product, please contact

FUJI ELECTRIC Co., Ltd., or

1) Check the ratin

the ordered one.

Figure 1-1-1 Ratings nameplate

TYPE: Inverter Type

0.75 C11S - 7 EN

FVR

Series name

s name plate to confirm that the delivered product is

our local FUJI inverter distributor.

Series Extension (EN series)

Power volta

씯

7 Sin

Nominal applied motor: 0.75 0.75kW

Product t

e series:

le-phase 200V input series

씯

pe

1

SOURCE: Number of input phases, rated input voltage, rated in-

put frequenc

OUTPUT: Number of output phases, rated output capacity, rat-

ed output volta

put current, overload capacit

SER. No.: Product number

1 1725R0001

9

2) Check for dama

on the covers or the main unit upon deliver

ed parts, missing parts, and dents or other damage

, rated input current

e, output frequency range, rated out-

Production lot serial number

Production month:

1 to 9: Januar

X: October, Y: November, Z: December

Production

Last di

it of year (9: 1999)

to September,

ear:

.

1 Before Using This Product 1-1

Page 12

FVR-C11S-EN

g

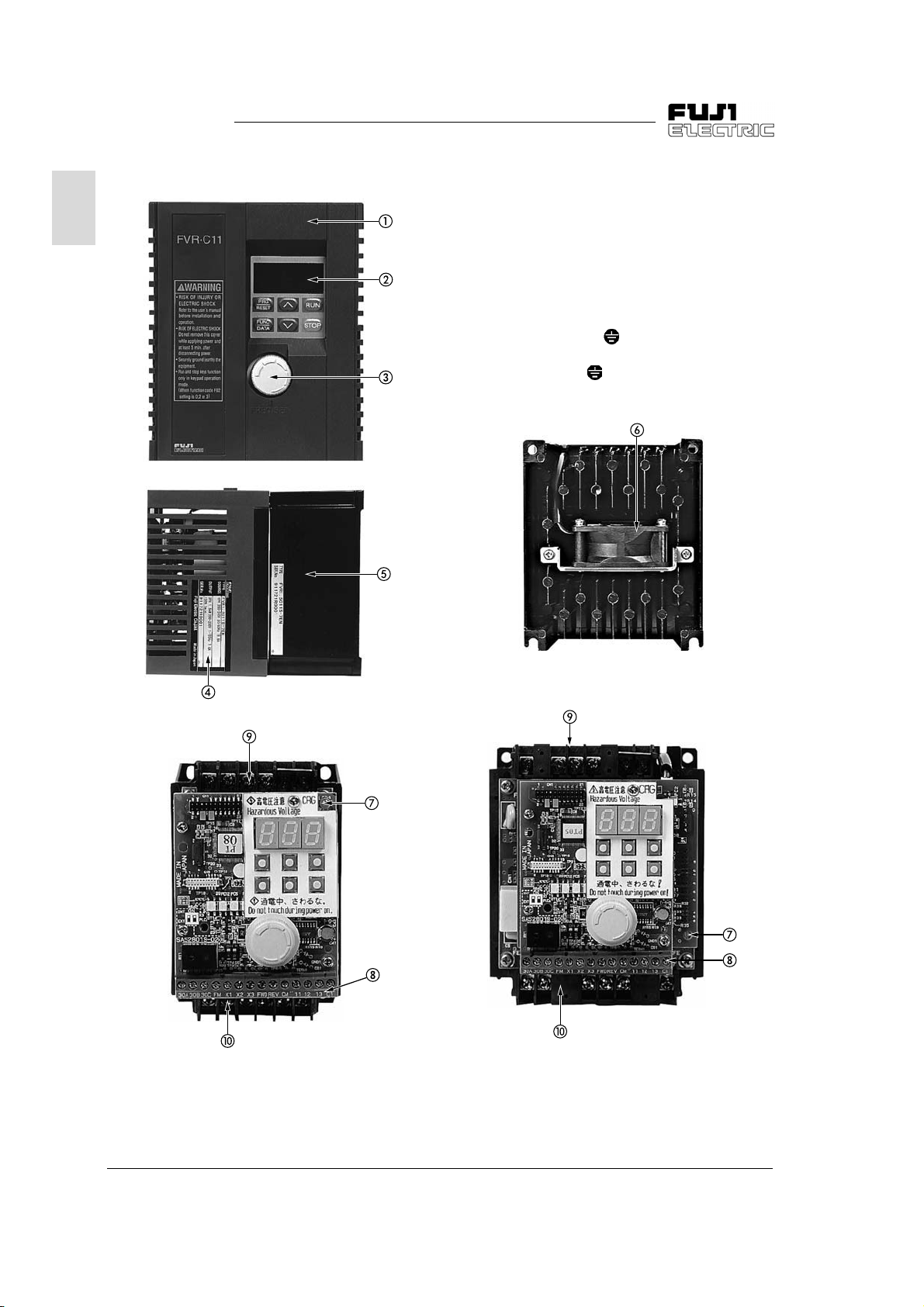

1-2 Appearance

1

Surface cover

Keypad panel

Frequency setting POT (VR) (built-in POT)

Ratings nameplate

Heat sink

Cooling fan (1.5 kW or more)

Charge lamp CRG

Control terminal block

Main circuit terminal block

le-phase 200V[ G,L1/L,L2/N,P1,P(+)]

Sin

Main circuit terminal block

[P(+),N(-),U,V,W, G]

1-2 1 Before Using This Product

Page 13

FVR-C11S-EN

y

1-3 Handling the Product

Remove the surface cover as explained below.

1) For FVR0.1 to 0.75C11S-7EN

Grasp the upper and lower parts of the cover

with both hands and pull it to the front of the

inverter.

2) For FVR1.5 to 2.2C11S-7EN

Expand the lower part of the cover horizontal-

, lift the cover to the front, and then remove

l

it.

1

1 Before Using This Product 1-3

Page 14

FVR-C11S-EN

g

y

y

g

y

y

g

g

g

y

y

y

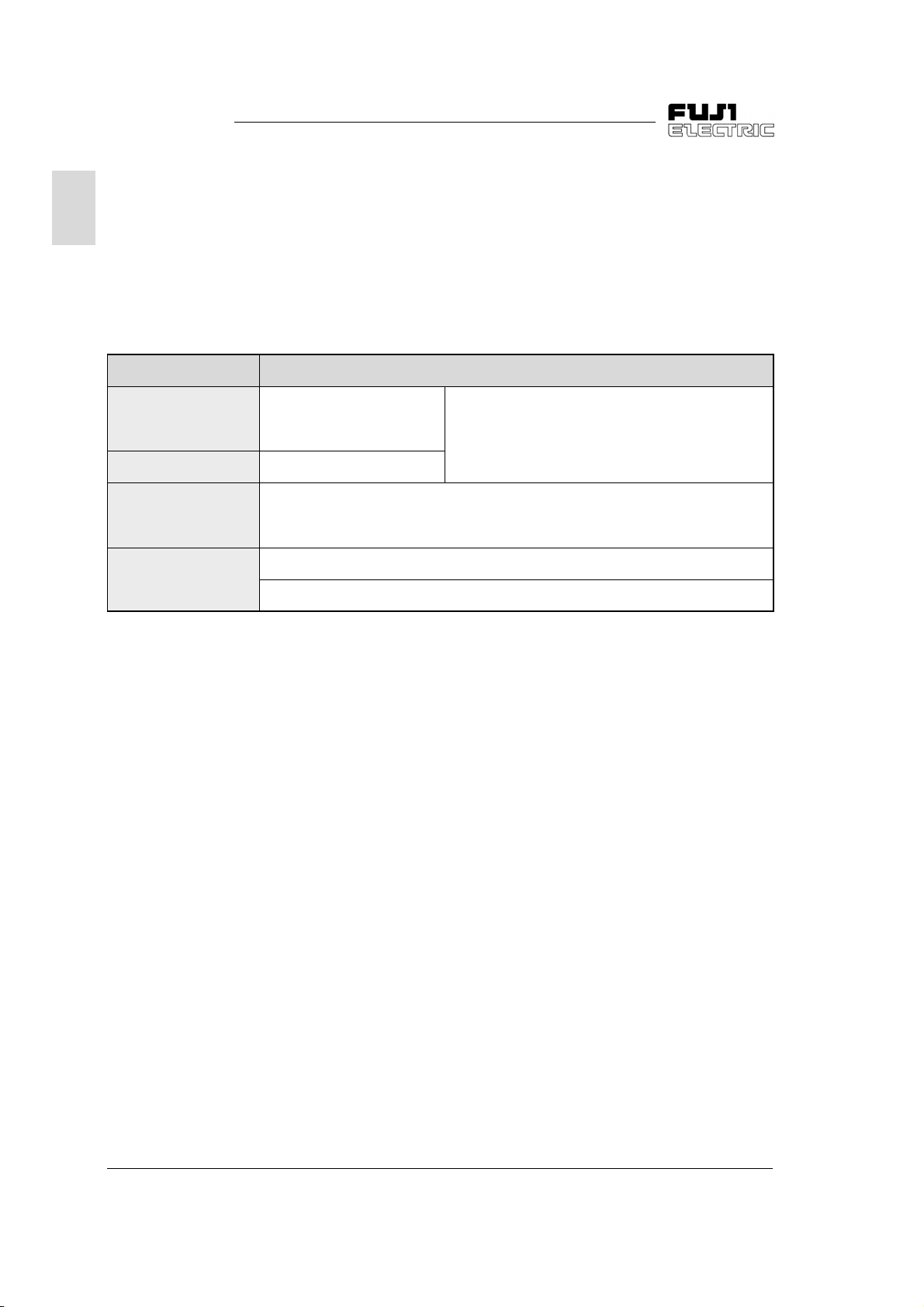

1-4 Carryin

1

1-5 Storage and

transportation

Item Specifications

Storage temperature Transportation

temperature

Relative humidit

Atmosphere The product must not be exposed to dust, direct sunlight, corrosive gas, in-

Air pressure 86 to 106kPa (During storage)

Always hold the main unit while carrying this product.

If it is carried b

be damaged or dropped.

ma

Force must not be applied to the inverter cover durin

it is made of plastic.

Store and transportation this product under the conditions listed in

Table 1-5-1.

-25 to +65 °C Condensation or formation of ice must not be

5 to 95%

flammable

salt in the atmosphere.

70 to 106kPa (Durin

1)

as, oil mist, vapor, water drops, or vibration. There must be no

the cover or parts and not the main unit, the product

carrying because

caused b

transportation)

sudden temperature changes.

Table 1-5-1 Storage and transportation environment

1) A large change in temperature within this humidity range may cause condensation

or formation of ice. Do not store this product at a place where such chan

[Storage precautions]

1. Do not locate this product directly on a floor; place it on a rack or

shelf.

2. To store the product in a severe atmosphere, pack it in vin

3. If the product must be stored at a place where it ma

humidity, insert a drying agent such as silica gel and pack it in vinyl

sheet.

es occur.

l sheet.

be affected b

1-4 1 Before Using This Product

Page 15

FVR-C11S-EN

g

y

g

y

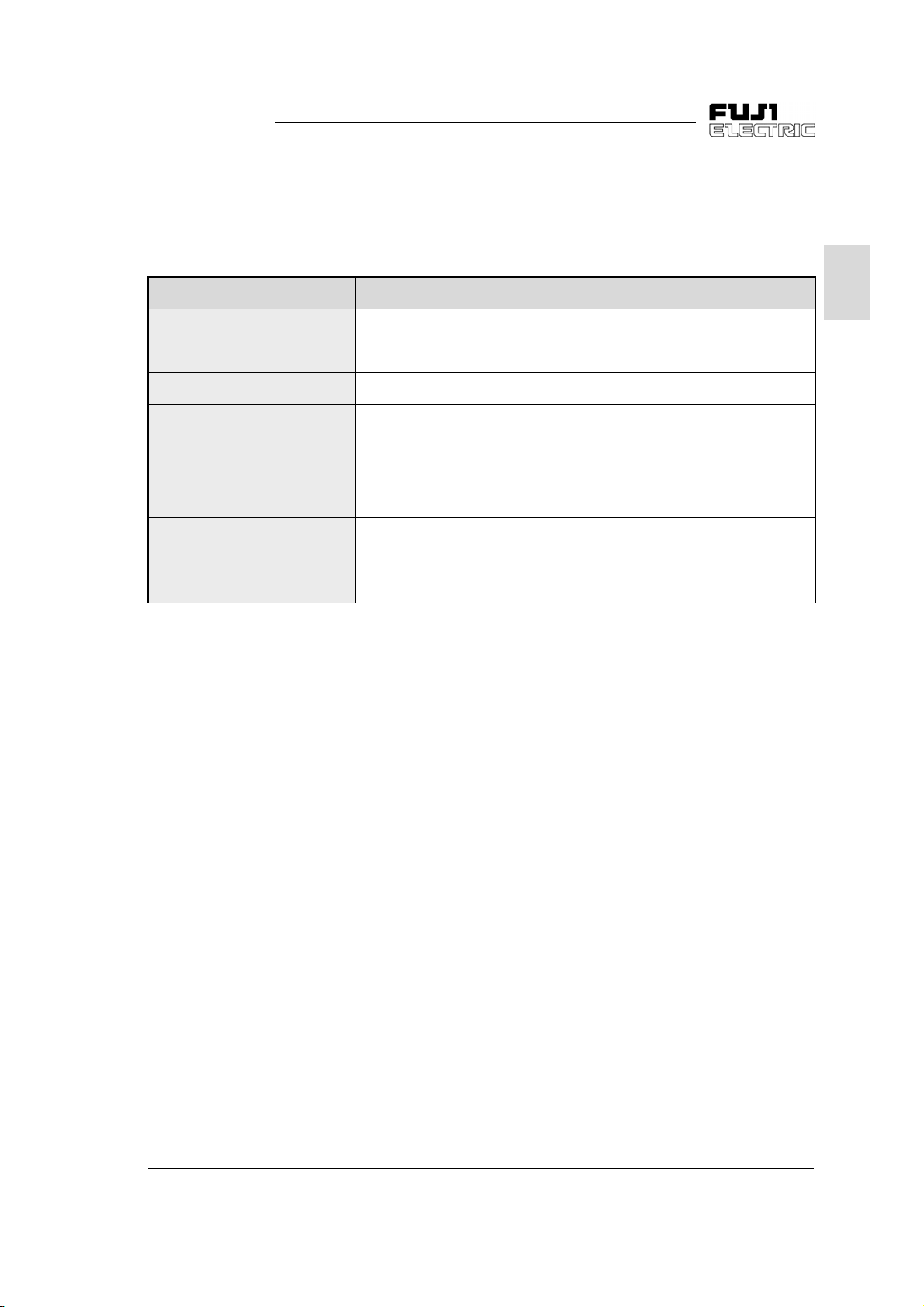

2 Installation and Connection

2-1 Operatin

Environment

Item Specifications

Place Indoor

Ambient temperature -10 to +50 °C

Ambient relative humidit

Atmosphere The product must not be exposed to dust, direct sunlight, corrosive

Altitude 1000 m or less (Air pressure : 86kPa to 106kPa)

Vibration 3mm: 2 ~ 9 Hz or less

Table 2-1-1 Operating environment

Install this product at a place satisfying the conditions listed in

Table 2-1-1.

5 to 95%RH (No condensation allowed)

as, inflammable gas, oil mist, vapor, or water drops.

There must be no salt in the atmosphere. Condensation must not

be caused b

9.8 m/s

2

2 m/s

2

1 m/s

sudden changes in temperature.

2

: 9 ~ 20 Hz or less

: 20 ~ 55 Hz or less

: 55 ~ 200 Hz or less

2

2 Installation and Connection 2-1

Page 16

FVR-C11S-EN

g

g

g

g

y

g

g

g

g

y

g

y

y

y

g

y

g

g

y

y

y

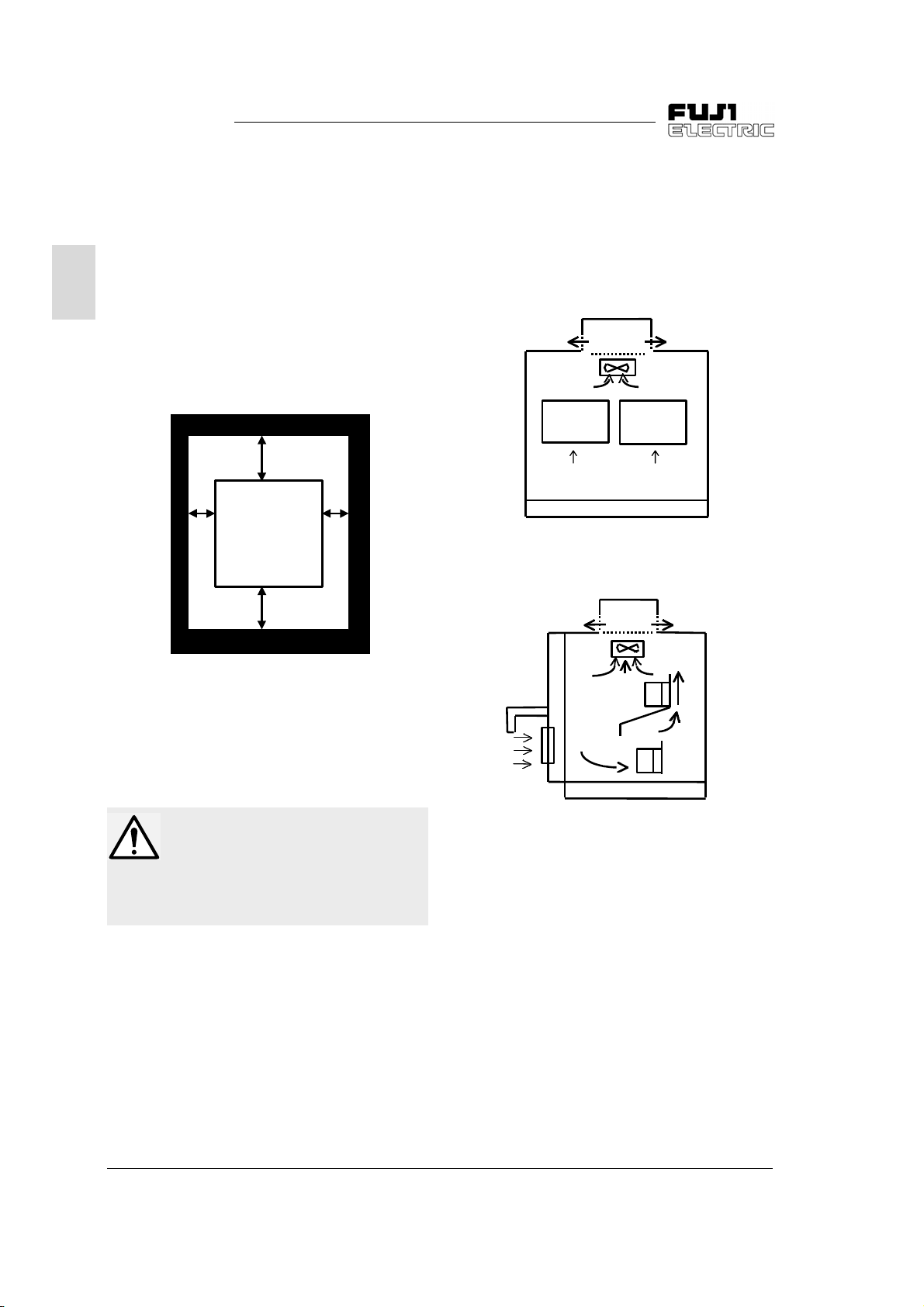

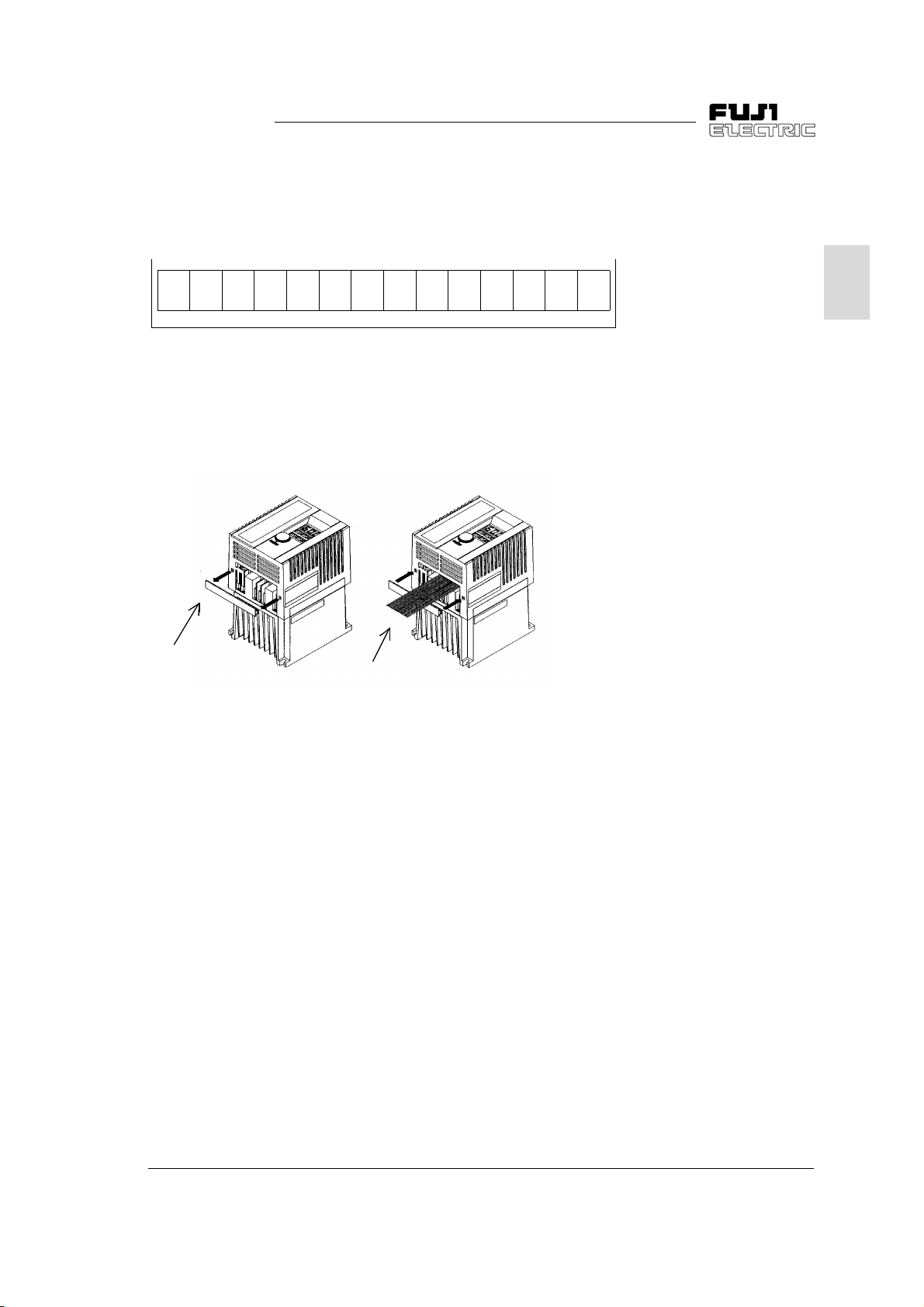

2-2 Installation Method

1. Tightly fasten the product in the upright posi structure using four bolts

fan, so do not install this prod-

10cm

2

tion on a stron

(M4) with the characters FVR-C11 facin

front. Be sure not to turn the product upside

down, and install it on a horizontal surface.

2. Heat is

in

necessar

enerated while the inverter is operat-

, so the gaps shown in Figure 2-2-1 are

for the passage of cooling air. The

enerated heat is radiated upward by the

built-in coolin

uct below a device that is sensitive to heat.

10cm

1cm FVR-C11 1cm

the

5. If two or more inverters need to be installed in

the same device or control panel, the

be arran

ed horizontally to minimize the influ-

should

ence of heat between them. If two or more inverters must be installed verticall

, place a

plate between them to prevent the upper inverter from bein

affected by heat from the

lower inverter.

Inverter

Air suppl

a) Horizontal arrangement

Inverter

Air suppl

Figure 2-2-1 Installation direction and surrounding space

3. The temperature of the heat sink increases to

about 90 °C while the inverter is operatin

Therefore, the surface behind where the

product is located must be able to withstand

this temperature increase.

WARNING

Install this product on a nonflammable

material such as metal.

Otherwise fire could occur.

4. When installin

el, carefull

vent the ambient temperature of the inverter

from exceedin

install it in a hermeticall

which heat is not radiated full

this product in a control pan-

consider the ventilation to pre-

the specified value. Do not

sealed box from

.

Inverter

Plate

.

Air

suppl

b) Vertical arran

Figure 2-2-2 How to install two or more inverters

Inverter

ement

2-2 2 Installation and Connection

Page 17

FVR-C11S-EN

y

g

y

g

ysg

g

g

y

g

g

g

y

g

y

g

g

g

y

g

g

g

CAUTION

Do not allow foreign matter such as

lint, paper dust, small chips of wood or

metal, and dust to enter the inverter or

adhere to the heat sink.

Otherwise, a disaster such as burnin

could occur.

2-3 Connection

Remove the surface cover to connect the terminal blocks. Correctl

the followin

procedures.

2-3-1 Basic connection

1. Always connect the power to the main power

suppl

input terminal of the inverter. If it is

connected to another terminal, the inverter

will be dama

2. Alwa

disasters such as fire and electric shock and

to minimize noise.

round the ground terminal to prevent

connect them according to

ed (see Figure 2-3-1).

WARNING

1. Always connect the ground wire.

Otherwise electric shock and fire could

occur.

2. Ensure that a licensed specialist performs

the wirin

3. Check before startin

power is off.

Otherwise electric shock could occur.

work.

the wiring that the

2

3. Use a reliable crimp terminal for connection

between a terminal and wire.

4. After terminatin

check the followin

a. Whether the connection is correct

b. Whether all necessar

been made

c. Whether there is a short-circuit or

fault between terminals and wires

5. Connection modification after power-on

The smoothin

part of the main circuit cannot be dischar

quickl

multimeter to check that the volta

rect current (DC) is reduced to the safet

range (25V DC or less) after the charge lamp

a

cause the residual volta

ma

after the power is turned off. Use a

oes off to avoid danger. Check that the volt-

e is zero before short-circuiting a circuit be-

cause sparks.

the connection (wiring),

items:

connections have

round

capacitor in the direct current

ed

e of the di-

e (electric charge)

2 Installation and Connection 2-3

Page 18

FVR-C11S-EN

g

g

y

g

y

g

g

g

g

y

g

g

y

y

y

y

g

g

y

g

y

g

g

g

y

g

y

g

2-3-2 Connecting the main circuit and ground terminals

Symbol Name Explanation

L1/L,L2/N Main power supply input Connects single-phase power

le-phase 200V input).

2

U, V, W Inverter output Connects 3-phase motor.

(Sin

P1, P(+) For connection of DC

reactor

P(+), N(-) For DC intermediate

circuit

G For inverter groundin

Table 2-3-1 Functions of main circuit and ground terminals

1) Main power suppl

Sin

le-phase 200V [L1/L,L2/N]

For single-phase 200V input

FVR-C11S-7EN

Figure 2-3-1 Arrangement of main circuit and ground

terminals

input terminal

P(+)P1L2/NG L1/L

GWVUN(-)P(+)

Connects input power- factor correcting DC reactor

(optional).

Connected to DC link circuit terminal

(for DC bus connection).

Ground terminal for inverter chassis (case).

1. Connect the main power supply input ter-

minals to the power suppl

via a molded

case circuit breaker for circuit protection or

earth leaka

leaka

e circuit breaker. An earth-

e circuit breaker which can also detect DC current is recommended. Phasesequence matchin

2. It is recommended that a ma

tor is connected to prevent an

accident from becomin

nectin

the inverter from the power suppl

is unnecessary.

netic contac-

failure or

serious by discon-

when the inverter protective function operates.

3. Do not turn on or off the main power suppl

to start or stop the inverter; instead, use the

control circuit terminal FWD/REV or the

RUN/STOP ke

on the keypad panel. If it

is unavoidable to turn the main power sup-

on or off to start or stop the inverter, it

pl

must not exceed once per hour.

2) Inverter output terminal [U, V, W]

1. Connect these terminals to the 3-phase

motor with the correct phase-sequence. If

a motor rotation direction does not correspond to the correct rotation direction, exchan

e any two of the U, V, and W phases.

2. Do not connect a phase-advance capacitor or sur

3. A ver

e absorber to the inverter output.

long wiring length between the inverter and the motor causes a hi

quenc

current to flow due to floatin

capacity between cables, making the inverter trip, increasin

and deterioratin

rent displa

wirin

. To prevent such trouble, the

length to the motor should not ex-

the leakage current

the accuracy in the cur-

ceed 50 meters.

When the inverter is operated in the low

noise mode (carrier frequenc

kHz) and the wirin

length is long, add an

: 8 to 15

optional output circuit filter (OFL filter).

h fre-

2-4 2 Installation and Connection

Page 19

FVR-C11S-EN

g

y

g

g

g

ysg

y

g

y

y

g

g

g

g

y

y

y

g

g

g

g

g

g

y

y

jury

g

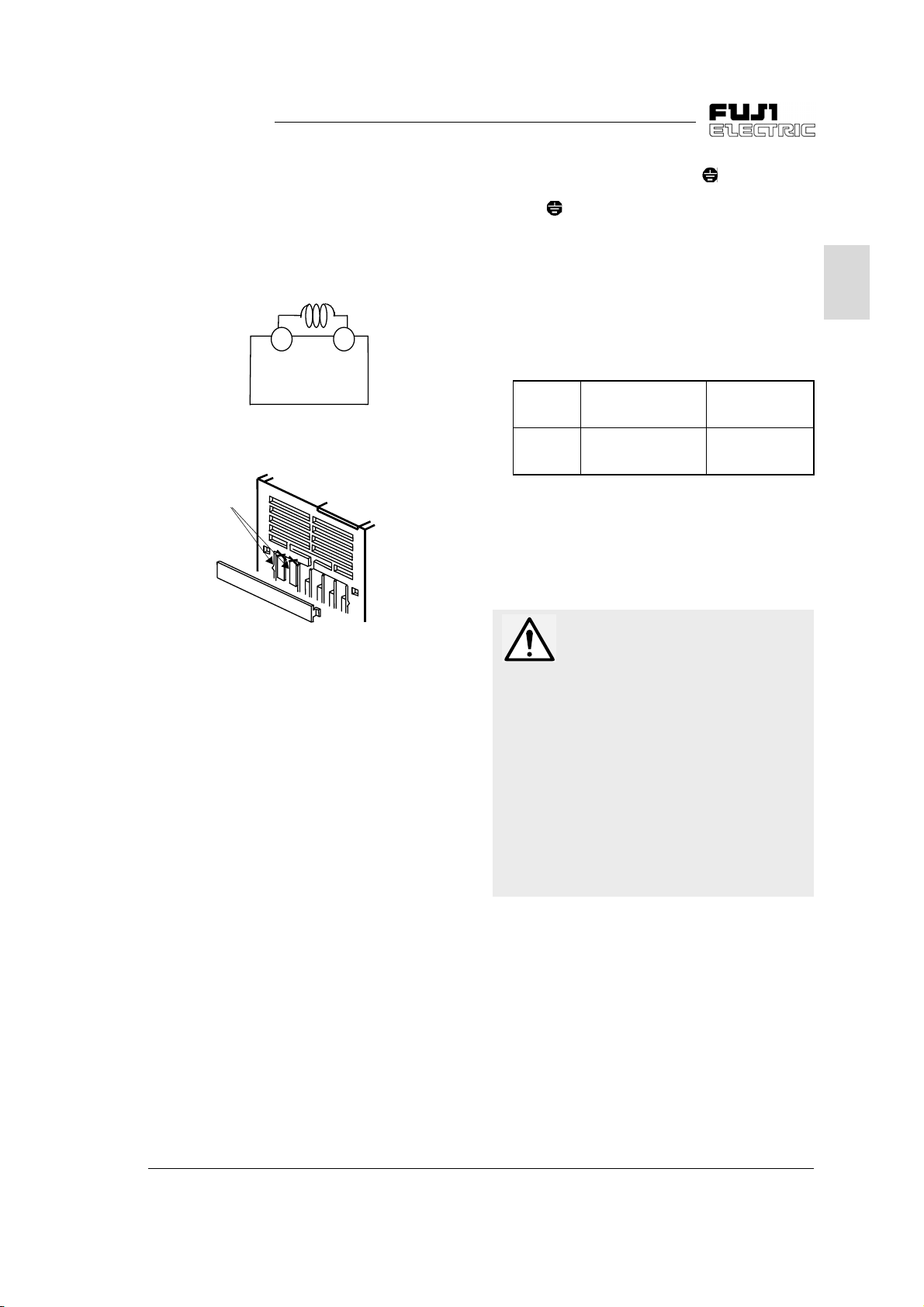

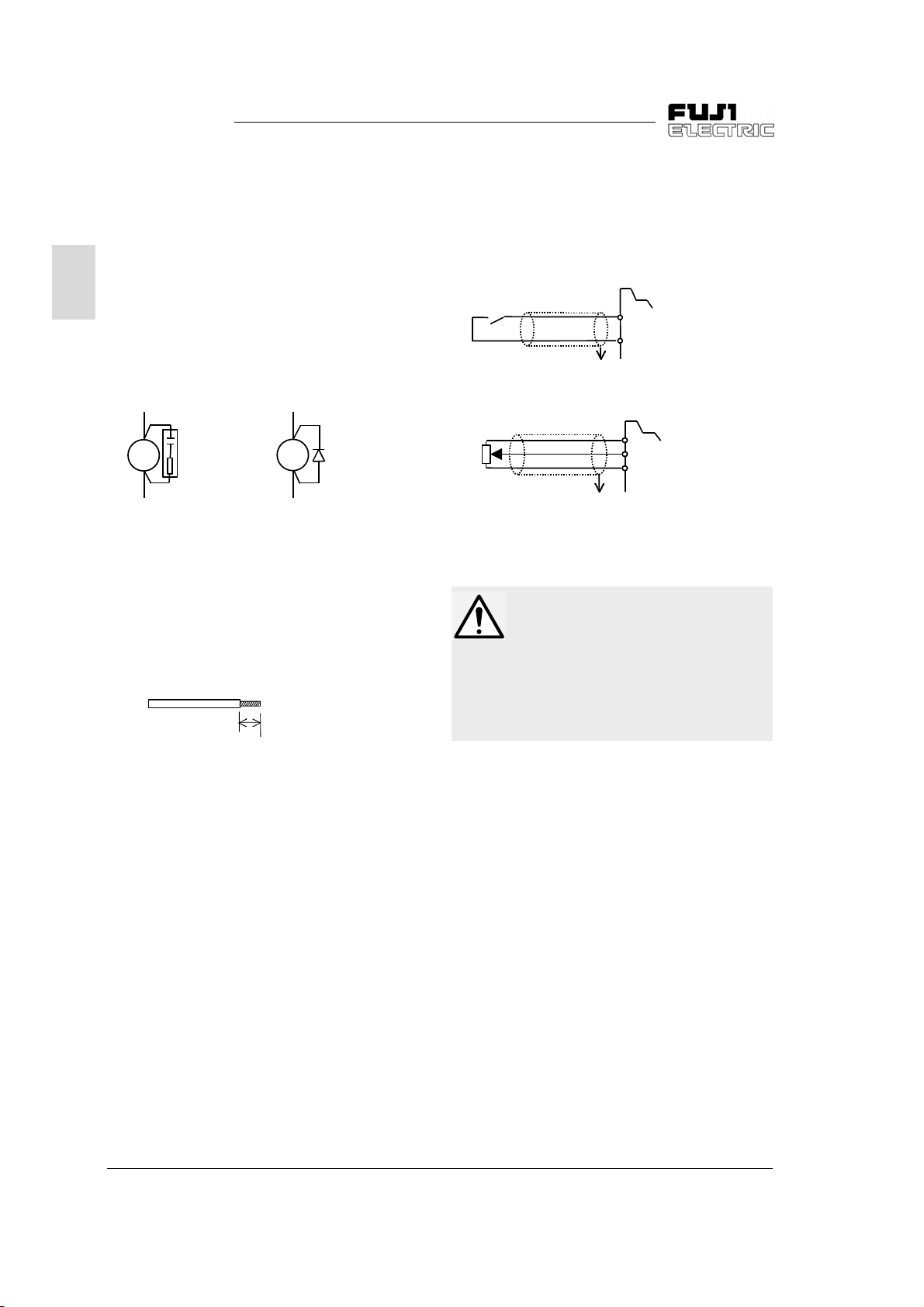

3) DC reactor connecting terminal [P1, P(+)]

1. Use this terminal to connect a input powerfactor correctin

DC reactor (optional).

Remove the jumper connected in the factor

before connecting the DC reactor (see

ure 2-3-2).

Fi

P1

FVR-C11S-7EN

a) Connection diagram

Top of inverter

Barrier

P(+)

4) Inverter

Alwa

nal [ G] for safet

Groundin

rounding terminal [ G]

round the inverter grounding termi-

and noise reduction.

of the metal frames of electric

equipment has to be done in accordance with

the national and local safet

specifications in

force.

1. In Japan, the 200V s

nected to a

class D

round electrode provided with

rounding, according to the electri-

stem must be con-

cal equipment technical standard.

Voltage

stem

s

200V

Table 2-3-2 Grounding of device according to

T

pe of ground-

work

in

Class D

roundin

electrical equipment technical standard

Groundin

resistance

100

Ω

maximum

2. Connect a thick and short wire to the

rounding terminal of the inverter for connection with a

exclusivel

round electrode prepared

for the inverter system.

2

b) Cuttin

Figure 2-3-2 Connection of DC reactor

of barrier

2. Use diagonal cutting pliers to cut the surface cover barriers from P1, P(+) terminals

before connection.

3. If no DC reactor is used, do not remove the

jumper.

CAUTION

1. Check that the number of phases and the

rated volta

to the number of phases and volta

AC power suppl

Otherwise fire could occur.

2. Do not connect the AC power suppl

output terminals (U, V, W).

Otherwise in

3. Do not connect a brakin

the DC terminals P(+), N(-).

Otherwise fire could occur.

e of this product correspond

e of the

.

to the

could occur.

resistor directly to

2 Installation and Connection 2-5

Page 20

FVR-C11S-EN

g

g

g

g

y

y

g

2-3-3 Connecting the control terminals

Table 2-3-4 lists the functions of the control circuit terminals.

The method of connectin

nal depends on how its function is set.

Connect the control circuit terminals accordin

2

to the set functions.

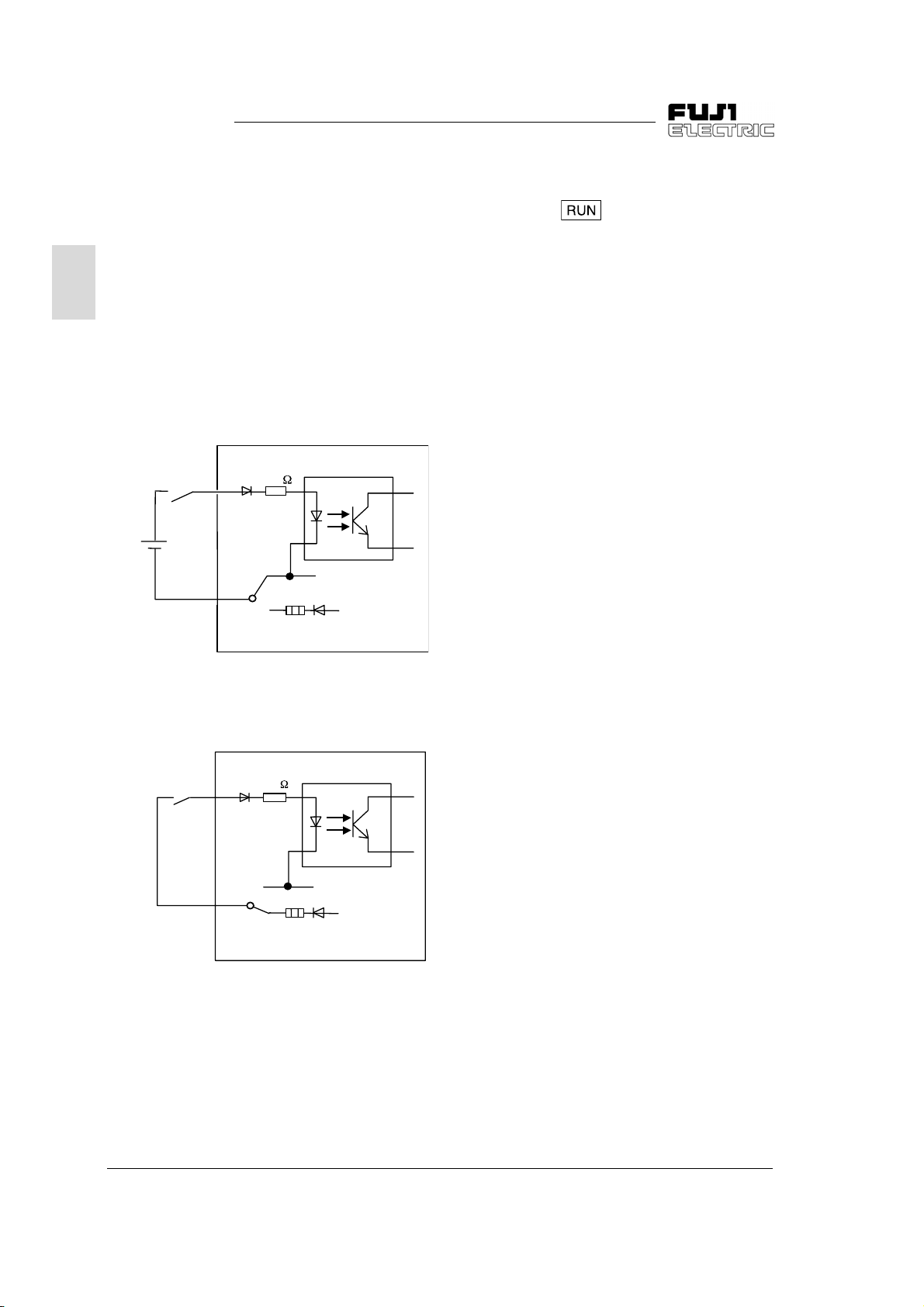

1) Di

ital input terminal

Fi

ure 2-3-3 shows the circuit configuration.

Use a reliable contact without poor contact for

input.

Example: FUJI control rela

FWD or others

+24 to

+27VDC

SW7

P24/CM

FVR-C11S-7EN

a control circuit termi-

HH54PW

4.7k

CM

P24

0 V

F1

+24 to

+27VDC

2) Run/stop command terminal [FWD, REV]

These terminals are left open in the factor

Pressin

the key on the keypad panel

starts forward operation. When function F02

is set at 0 or 1, the terminal functions are as

shown in Table 2-3-3.

.

a) When SW7 is set to CM (factory setting)

FWD or others

P24/CM

40mA max.

4.7k

CM

SW7

FVR-C11S-7EN

F1

P24

0 V

+24 to

+27VDC

b) When SW7 is set at P24

Figure 2-3-3 Digital input terminal

2-6 2 Installation and Connection

Page 21

FVR-C11S-EN

g

y

g

y

y

y

g

g

g

y

g

g

y

y

g

g

g

g

y

F02 When SW7 is set at CM When SW7 is set at P24

When +24 to +27 VDC is supplied to

FWD - P24/CM, pressin

ke

pad panel starts forward operation.

When +24 to +27 VDC is supplied to

0

REV - P24/CM, pressin

pad panel starts reverse operation.

ke

When +24 to +27 VDC is supplied to both

FWD - P24/CM and REV - P24/CM, the inverter

decelerates to stop.

When +24 to +27 VDC is supplied to

FWD - P24/CM, forward operation starts.

When +24 to +27 VDC is supplied to

1

REV - P24/CM, reverse operation starts.

When +24 to +27 VDC is supplied to both

FWD - P24/CM and REV - P24/CM, the inverter

decelerates to stop.

Table 2-3-3 Description of function F02

the key on the

the key on the

CAUTION

In case P24 is short-circuited with 0V

outer circuit when SW7 is set to P24

b

side, pol

off. To recover the power, open the

short circuit and turn the inverter off to

allow the temperature to lower.

3) Analog input terminal (13, 12, 11, C1)

Use these terminals to connect external input

voltage and analog current and fre-

analo

quenc

setting device (POT). For connectin

a contact to this circuit, use a twin contact for

fine current si

Do not use a contact for terminal 11.

switch (F1) turns the power

nal.

When FWD is short-circuited to P24/CM and the

on the keypad panel is pressed, for-

ke

ward operation starts.

When REV is short-circuited to P24/CM and the

on the keypad panel is pressed, re-

ke

verse operation starts.

When both FWD - P24/CM and REV - P24/CM

are short-circuited, the inverter decelerates to

stop.

Short-circuit FWD to P24/CM for forward operation, or REV to P24/CM for reverse operation.

Short-circuitin

P24/CM brin

stop.

both FWD - P24/CM and REV -

s the inverter to deceleration and

WARNING

The STOP key is valid only when the

function has been set. Prepare

another switch for emer

When operation usin

nal terminal is selected, the operation

cannot be stopped usin

ke

on the keypad panel.

Otherwise accidents could occur.

ency stop.

an external si-

the STOP

2

2 Installation and Connection 2-7

Page 22

FVR-C11S-EN

g

g

y

g

g

g

y

g

g

g

y

g

y

y

y

g

g

g

g

g

y

y

y

g

g

g

*Note the following when wiring:

1) Sur

e absorber connection

When the excitin

in the control circuit or inverter

e. Due to this surge voltage,

2

tactor or rela

peripheral circuit is opened or closed, a sur

e (noise) is generated with a sudden

volta

current chan

the inverter control circuit or peripheral equipment ma

a sur

(See Fi

AC rela

MC

SK: Surge absorber D: Diode

Figure 2-3-4 Surge absorber connection diagram

malfunction. If so, directly connect

e absorber to both ends of the coil.

ure 2-3-4).

SK

2) Control circuit wirin

1. Wires connected to control circuit terminals must be 0.5mm

twisted vin

shown in Fi

l wire. Remove the sheath as

ure 2-3-5 and then connect it.

coil of the magnetic con-

DC rela

+

Ry

D

-

2

shielded wire or

e

3) Shieldin

Connect one end of the shieldin

sheath connection

sheath of a

shielded or twisted-pair shielded wire to the

round terminal as shown in Figure 2-3-6. Do

not connect the other end.

Contact

Frequenc

setting POT

Figure 2-3-6 Connection of sheath of shielded wire

Shield

round terminal

To

Shield

To

round terminal

FWD

P24/CM

13

12

11

CAUTION

Noise is generated from the inverter,

motor, and wirin

noise does not cause malfunctions in

peripheral sensors and equipment.

Otherwise accidents could occur.

. Take care that this

6 ±1mm

Figure 2-3-5 End treatment

2. Keep the wiring of the main circuit, external rela

cuit as far awa

possible. If the

them at ri

sequence circuit and control cir-

from each other as

must be adjacent, cross

ht angles.

3. Use a twisted-pair shielded wire for lon

wiring distances.

2-8 2 Installation and Connection

Page 23

FVR-C11S-EN

g

g

g

g

g

g

g

g

g

g

4) Control terminal arrangement, screw size,

htening torque.

and ti

ure 2-3-7 shows the control terminal block

Fi

ement.

arran

REV

P24

/CM

30A 30B 30C FM X1 X2 X3

Figure 2-3-7 Control terminal block arrangement

FWD

5) Remove the plate at the bottom of the surface

cover before performin

and reinstall it after the wiring as shown in

in

ure 2-3-8.

Fi

inverter control wir-

Screw size: M2.5

htening torque: 0.4 Nm

Ti

11 12 13 C1

2

Plate

Control wirin

ure 2-3-8 How to pull out the control wirin

Fi

2 Installation and Connection 2-9

Page 24

FVR-C11S-EN

y

g

y

y

y

g

y

g

g

g

g

y

g

g

y

g

g

g

y

g

y

2

Classifi-

cation

Analo

input

Digital

input

Terminal

s

mbol

13

12

C1

Terminal name

Power suppl

variable resistor

Frequenc

voltage input

Frequenc

current input

11 Analo

FWD

Forward operation

/Stop command

Reverse

REV

operation

/Stop command

X1 Di

X2 Di

X3 Di

(SS1)

(SS2)

(BX)

ital input 1

ital input 2

ital input 3

Multistep

frequenc

selection

Coast to stop

command

(RST) Alarm reset

(THR)

External alarm

input

Write-enable com-

(WE-KP)

mand for ke

(data chan

lowed)

settin

settin

common

e al-

Detailed specifications

Used as power supply for frequenc

z

for

setting device

(POT: 1 to 5 k

(+10VDC 10mADC max.)

0 to +10VDC/0 to 100%,0 to +5VDC/0

z

to 100% (Input impedance : 22 k

4 to 20mADC/0 to 100%

z

(Input impedance : 250

Common terminal for analog input

z

nals

si

Forward operation with

z

FWD-P24/CM ON and

deceleration-stop with

FWD-P24/CM OFF

(Switch SW7 to P24)

Reverse operation with

z

REV-P24/CM ON and

deceleration-stop with

REV-P24/CM OFF

(Switch SW7 to P24)

The functions listed below can be set

z

the X1 to X3 terminal functions.

b

Up to four steps speed operation can

z

be selected with SS1 and SS2

ON/OFF si

Inverter output is cut immediately and

z

the motor coasts to a stop (no alarm

output) if BX

The inverter releases the status held

z

after stop with an alarm when RST

chan

The inverter stops with an alarm if

z

THR is set to OFF.

Data rewriting for each function with

z

pad

the ke

is OFF.

Rewriting with keypad panel is

z

allowed if WE-KP is ON.

).

Ω

Ω

)

Ω

nals.

oes on.

es from ON to OFF.

pad panel is rejected if WE-KP

Remarks

)

Deceleration-stop

with

FWD-P24/

CM and

REV-P24/

CM ON

Set with

functions

E01 to E03

2-10 2 Installation and Connection

Page 25

FVR-C11S-EN

y

g

g

g

g

g

g

g

y

g

y

g

y

y

y

g

g

g

g

g

Classifi-

cation

Digital

input

Output/

Input

Analo

output

Contact

output

Optional

Terminal

s

mbol

Terminal name

(Hz/PID) PID control cancel

(LE)

P24/CM

FM, 11 Analo

30A

30B

30C

DX+

DX-

Link operation

selection

Power Supply/

Di

ital Common

monitor

Alarm output for

fault

an

RS485 communication input/output

Detailed specifications

z

PID control cancel with Hz/PID ON

z

PID control with Hz/PID OFF

z

Operation based on command from

RS485 with LE ON

z

Inverter single operation with LE OFF

z

DC Power supply (SW7 set to P24)

(+24 to +27 VDC, 40mA max.)

z

Common terminal for digital input

si

nal (SW7 set to CM) (factory set-

)

tin

Data selected between the followin

items is output with DC voltage:

z

Output frequenc

z

PID feedback value

z

Output current

z

DC link circuit voltage

* Up to two analo

impedance : 10 k

voltmeters (input

Ω)

can be connected.

Note: Output waveform: An AC pulse

is output with consistent frequenc

and variable duty.

The avera

portional to output frequenc

e DC voltage is pro-

and

output current

(frequenc

: 121.6 Hz).

If the inverter is stopped with an alarm,

the non-volta

e contact signal (1SPDT)

is output

(Contact ratin

: 250V AC, 0.3 A, Power

factor = 0.3)

(48V DC, 0.5A for Low-volta

e Directive

or 42V DC, 0.5A for UL/cUL)

* Whether an alarm is

excitin

operation or non-exciting opera-

enerated with an

tion can be switched.

z

Terminal for RS485 communication

(when option board is installed)

z

DX+ : Non-inverted signal,

z

DX- : Inverted signal

Remarks

Switchin

of

P24/CM terminal with

switch SW7

Installed

on optional

board.

2

Table 2-3-4 Functions of control circuit terminals

2 Installation and Connection 2-11

Page 26

FVR-C11S-EN

g

g

y

g

y

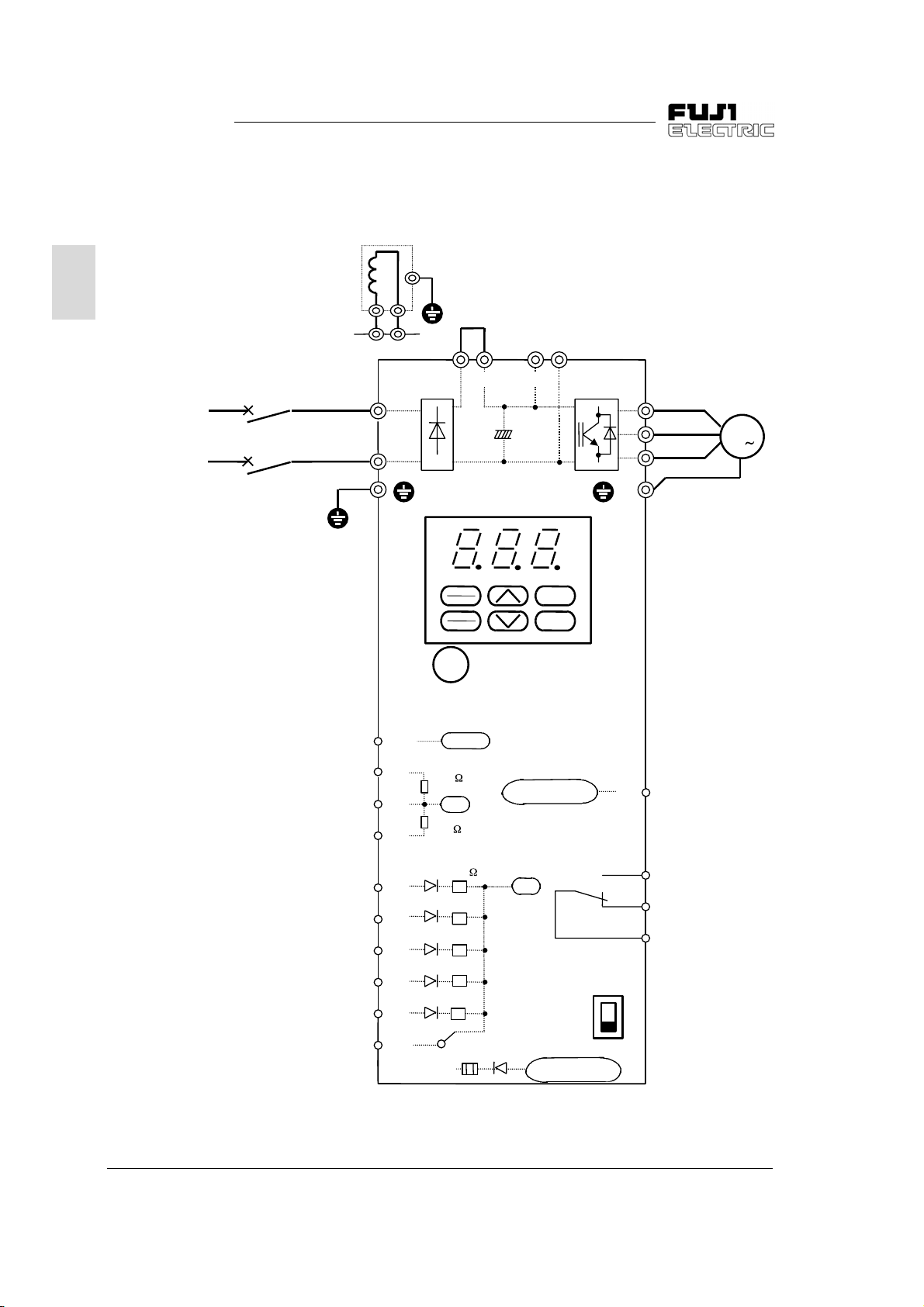

2-3-4 Connection examples

1) Keypad panel operation

2

le-phase

Sin

200V input

series

200 to 240V

50/60Hz

When power-factor

correctin

DC reactor is used

MCCB

P1

E

P(+)

L1/L

L2/N

G

Frequenc

P(+) P(+)

P1

PRG

RESET

FUNC

DATA

setting POT (VR)

2)

N(-)

U

V

W

M

3

G

RUN

STOP

13

12

11

C1

FWD

REV

X1

X2

X3

P24/

CM

Figure 2-3-9 Wiring diagram of keypad panel operation

SW7

+10VDC

22k

0V

250

4.7k

CM

P24

F1

Pulse output

0V

+24 to +27 VDC

SW7

P24

CM

FM

30A

30B

30C

Analo

monitor

Alarm output for

fault

an

2-12 2 Installation and Connection

Page 27

FVR-C11S-EN

y

y

g

y

y

g

g

g

g

1) The RUN and STOP keys on the keypad panel can be used to start and stop the operation

and the frequenc

used to set a frequenc

the power supply and motor with functions set

in the factor

.

factor

2) Remove the jumper between the P1 and P(+)

terminals before connectin

er-factor correctin

setting POT (VR) can be

only by connectin

. Forward rotation is set in the

the optional pow-

DC reactor.

2

3) Connect the sur

(such as coils of the ma

solenoid) near the inverter.

e absorber in parallel to coils

netic contactor and

2 Installation and Connection 2-13

Page 28

FVR-C11S-EN

y

g

g

y

g

y

g

g

g

y

g

2) External operation

(When external power suppl

is used)

2

When power-factor

correctin

DC reactor is used

le-phase

Sin

200V input

series

200 to 240V

50/60Hz

Frequency settin

voltage input

(0 to +10VDC)

Frequenc

current input

(4 to +20mADC)

Forward

operation

command

Reverse

operation

command

settin

MCCB

P1

E

P(+)

L1/L

L2/N

Frequenc

13

12

C1

FWD

REV

X1

X2

P1 P(+) N(-)P(+)

PRG

RESET

FUNC

DATA

setting POT (VR)

10VDC

22k

0V

250Ω

4.7k

Ω

3)

RUN

STOP

Pulse output

0V

30A

30B

30C

SW7

P24

U

V

W

M

3

GG

Analo

Analo

monitor

To

To 11 terminal

Alarm output for

an

fault

meter

round terminal

24VDC

X3

P24/

CM

SW7

P24

CM

F1

+24 to +27 VDC

CM

Toground terminal

Figure 2-3-10 Wiring diagram of external operation (When external power supply is used)

2-14 2 Installation and Connection

Page 29

FVR-C11S-EN

y

g

g

g

g

g

g

1) Use this connection to start, stop the operation and set the frequenc

nals. 0 to 10V DC can be set while function

F01 is set to 1 and +4 to +20mA DC can be

set while function F01 is set to 2. Set function

F02 to 1.

2) Set SW7 at CM

3) Remove the jumper between the P1 and P(+)

terminals before connectin

er-factor correctin

DC reactor.

with external sig-

the optional pow-

2

4) Connect the sur

(such as coils of the ma

solenoid) near the inverter.

5) Use twisted or shielded wire as control si

wire. Connect the shield to the

nal.

e absorber in parallel to coils

netic contactor and

round termi-

nal

2 Installation and Connection 2-15

Page 30

FVR-C11S-EN

y

(+)

g

g

y

g

y

g

g

g

y

g

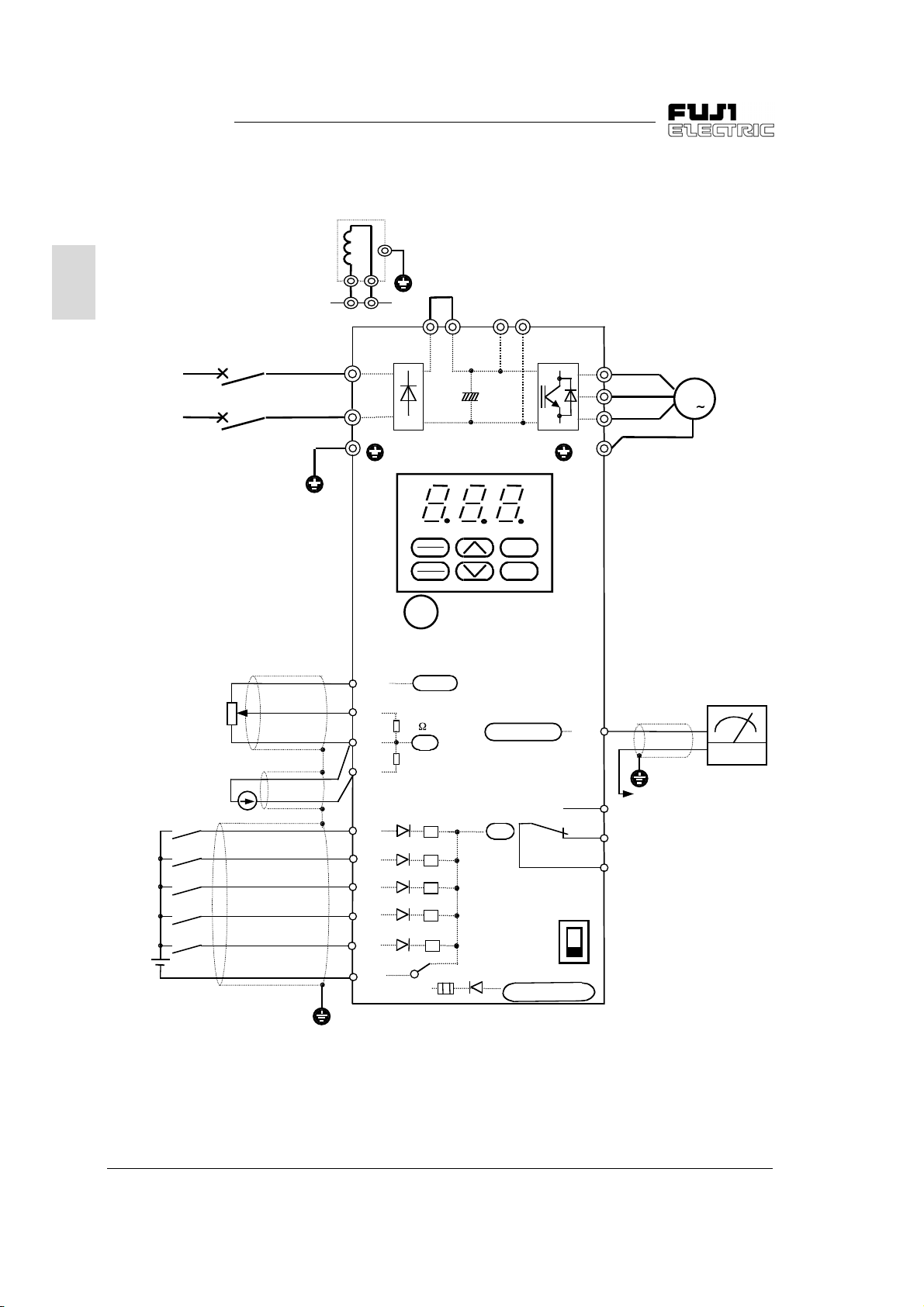

3) External operation

(When internal power suppl

is used)

2

When power-factor

correctin

DC reactor is used

le-phase

Sin

200V input

series

200 to 240V

50/60Hz

Frequency settin

voltage input

(0 to +10VDC)

Frequenc

current input

(4 to +20mADC)

Forward

operation

command

Reverse

operation

command

settin

P1

E

P

L1/L

L2/N

G

Frequenc

13

12

C1

FWD

REV

X1

X2

3)

P1 P(+) N(-)P(+)

PRG

RESET

FUNC

DATA

setting POT (VR)

10VDC

22k

0V

250

4.7k

RUN

STOP

Pulse output

0V

30A

30B

30C

SW7

P24

U

V

W

M

3

G

Analo

Analo

monitor

To

To 11 terminal

Alarm output for

an

fault

meter

round terminal

X3

P24/

CM

SW7

P24

CM

F1

+24 to +27 VDC

CM

Toground terminal

Figure 2-3-11 Wiring diagram of external operation (When internal power supply is used)

2-16 2 Installation and Connection

Page 31

FVR-C11S-EN

y

g

g

g

g

g

g

1) Use this connection to start, stop the operation and set the frequenc

nals. 0 to 10V DC can be set while function

F01 is set to 1 and +4 to +20mA DC can be

set while function F01 is set to 2. Set function

F02 to 1.

2) Set SW7 at P24.

3) Remove the jumper between the P1 and P(+)

terminals before connectin

er-factor correctin

DC reactor.

with external sig-

the optional pow-

2

4) Connect the sur

(such as coils of the ma

solenoid) near the inverter.

5) Use twisted or shielded wire as control si

wire. Connect the shield to the

nal.

e absorber in parallel to coils

netic contactor and

round termi-

nal

2 Installation and Connection 2-17

Page 32

FVR-C11S-EN

y

3

y

y

y

y

g

g

y

g

g

4) Connection to PLC

(When external thermal O/L rela

is used)

2

le-phase

Sin

200V input

series

200 to 240V

50/60Hz

MCCB

L1/L

L2/N

G

Frequenc

13

12

11

C1

FWD

REV

P1

PRG

RESET

FUNC

DATA

setting POT (VR)

+10VDC

22k

0V

250

4.7k

P(+) N(-)P(+)

RUN

STOP

Pulse output

0V

External thermal O/L

rela

U

V

W

G

To X3

terminalTooutput

Analo

monitor

FM

30A

30B

30C

To 11 terminal

Alarm output for

an

fault

terminal

of PLC

To

round

terminal

M

Analo

meter

DC24V

X1

X2

X3

(THR)

P24/

CM

F1

P24

SW7

P24

CM

+24 to +27 VDC

PLC

DC24V :

External thermal

O/L rela

Toground terminal

PLC power suppl

Figure 2-3-12 Connection example of PLC terminal (using THR function terminal)

2-18 2 Installation and Connection

Page 33

FVR-C11S-EN

g

y

y

g

y

y

1) Set SW7 at CM.

2) In the fi

the external thermal rela

suppl

PLC is turned off while the inverter remains

turned on, OH2 trips.

3) To prevent OH2 from trippin

of the PLC, deselect the THR terminal function and use the electronic rela

er.

ure above, the power is supplied to

from the power

of the PLC. If the power supply of the

upon shutdown

of the invert-

CAUTION

When SW7 is set at P24, possibl

causing inner parts to damage.

2

2 Installation and Connection 2-19

Page 34

FVR-C11S-EN

y

y

g

y

y

g

y

y

g

y

g

g

5) Connection to PLC (When analog signal is input from PLC)

2

le-phase

Sin

200V input

series

200 to 240V

50/60Hz

MCCB

P1

L1/L

L2/N

+

P

+

P

G

PRG

RESET

FUNC

DATA

Frequency setting POT (VR)

13

12

11

C1

FWD

REV

+10VDC

22k

V

250

4.7k

RUN

STOP

Pulse output

0V

N

-

External thermal rela

U

V

W

G

To X3

M

3

terminalTooutput

terminal

of PLC

Analo

Analo

meter

monitor

FM

round

To

30A

terminal

To 11 terminal

30B

30C

Alarm output for

fault

an

X1

X2

X3

DC24V

PLC

DC24V :

PLC power suppl

Figure 2-3-13 Connection example of PLC terminal (when analog signal is input from PLC)

1) Set SW7 at CM.

2) With this connection, the power is supplied from the PLC power suppl

So, OH2 trip is activated b

3) To prevent inverter trip with OH2 when the PLC power bein

use the inverter electronic thermal O/L rela

External

thermal

O/L rela

PLC power-off with the inverter turned on.

(THR)

P24/

CM

P24

Toground terminal

.

F1

turned off, do not select the THR terminal function and

SW7

P24

CM

+24 to +27 VDC

to the external thermal O/L relay.

When SW7 is set at P24, poly switch (F1) activates a current limit to

CAUTION

2-20 2 Installation and Connection

turn the power off.

Page 35

FVR-C11S-EN

g

y

g

g

y

g

g

y

y

g

g

g

g

g

g

g

g

y

g

y

g

y

y

g

y

g

y

y

y

y

2-4 Others

2-4-1 Harmonic component

A harmonic component which may influence the

phase-advance capacitor and

cluded in the inverter input current. If necessar

connect a power-factor correctin

(DCR) (option) for the inverter.

2-4-2 Noise

When noise generated from the inverter may affect peripheral equipment, and noise

from peripheral equipment ma

inverter, the followin

should be taken.

1) When noise affects other devices via power

and

round wires

z

Separate the ground of the inverter and

that of the affected device.

z

Connect a noise filter to the inverter power

wire.

z

Use an isolation transformer to separate

the power suppl

the affected device.

2) When another device is affected b

or radiation

z

Separate the main circuit wiring of the inverter from the control wirin

the affected device.

z

Encase the inverter main circuit wiring in a

metal tube and

the inverter.

z

Encase the inverter in a metal rack and

round the rack.

z

Connect a noise filter to the inverter power

wire.

basic countermeasures

of the inverter and that of

round the metal tube near

enerator is in-

DC reactor

enerated

malfunction the

induction

and wiring of

2-4-3 Leakage current

Leakage current flows through the inverter I-O

wirin

and motor stray capacitance when the inverter transistor is turned on and off.

Table 2-3-3 lists the countermeasures for the

problems caused b

,

Problem Countermeasures

Trip of earth

leaka

e

circuit

1

breaker

on main

power

suppl

side

Trip of exter-

2

nal thermal

O/L rela

Table 2-3-3 Countermeasures for leakage current

the leakage current.

1. Set the carrier

frequenc

lower.

2. Shorten the wirin

between the inverter

and motor.

3. Increase the

ELCB/RCD sensitivit

current.

4. Replace the

ELCB/RCD with an

ELCB/RCD that is de-

ned for high frequen-

si

cies.

1. Set the carrier frequen-

lower.

c

2. Increase the thermal

O/L rela

set value.

3. Use the inverter electronic thermal O/L

.

rela

2

3) When noise

enerated from peripheral equip-

ment affects the inverter

z

Use twisted or twisted-pair shielded wires

for the inverter control wirin

. Ground the

shields.

z

Connect a surge absorber in parallel to the

coil of the ma

netic contactor and sole-

noid.

z

If the power supply includes much distortion of the waveform or sur

impedance matchin

AC reactor for coor-

dination of power suppl

2 Installation and Connection 2-21

e, connect an

.

Page 36

FVR-C11S-EN

g

y

g

g

g

y

g

y

g

g

g

y

g

y

g

y

y

y

g

g by

g

y

y

y

3 Operation

3-1 Inspection

and Preparation before

Operation

3

3-2 Operation

Method

WARNING

Check the following before operation:

1) Check whether the connection is correct.

For sin

connected correctl

whether the inverter

2) Check for short-circuits and

tween live parts.

3) Check for loose terminals, connectors, and screws.

4) Check whether the motor is separated from mechanical equipment.

5) Set switches to OFF before turnin

will not start or operate abnormall

6) Check the followin

a) Check for alarms displa

1. Always install the surface cover before turning on the power.

Do not remove the surface cover durin

Otherwise electric shock could occur.

2. Do not operate a switch with wet hands.

Otherwise electric shock could occur.

There are various operation methods. Select a method depending on

the purpose and operation specifications with reference to Chapters 4

and 5. Table 3-2-1 lists operation methods used

le-phase 200V series, check whether the power supply is

to the L1/L and L2/N terminals. Also check

rounding terminal G is securely connected.

round faults between terminals and be-

on the power so that the inverter

at power-on.

after power-on:

ed on the keypad panel.

conduction.

enerally.

Operation method Frequency settin

Operation b

keypad

usin

panel

Operation b

using external

nal terminal

si

Table 3-2-1 General operation method

Built-in frequenc

POT (VR) or UP/DOWN

ke

Settin

voltage, analog current,

and external POT (VR)

using analo

settin

Running command

RUN/STOP ke

Contact input (switch)

z

When SW7 is set at CM

Connect external power suppl

terminal FWD with the (+) terminal of the

external power suppl

or connect terminal REV with the (+)

terminal of the external power suppl

z

When SW7 is set at P24

Connect terminal FWD with P24/CM or

connect terminal REV with P24/CM.

Refer to section 2-3-3.

,

and connect

.

3-1 3 Operation

Page 37

FVR-C11S-EN

y

y

y

g

y

g

y

y

g

y

y

y

y

y

y

y

g

y

g

g

g

y

3-3 Trial Run

Operation method Frequency settin

Operation b

using keypad

panel

Operation b

using external

si

nal terminal

(When built-in POT (VR) is used)

The frequenc

the variable resistor is turned

clockwise and reduces when it is

turned counterclockwise.

The motor accelerates when the

variable resistor is turned clockwise durin

erates when it is turned

counterclockwise.

(When the UP/DOWN ke

used)

Frequenc

UP ke

It reduces when the DOWN ke

is pressed.

The motor rotates when a frequency value and running command are

input from the ke

Refer to Table 3-3-1.

Use a low frequenc

A frequenc

and forward/stop can be performed usin

functions set in the factor

operation and decel-

increases when the

is pressed.

pad panel or external signal terminal.

(about 5Hz) for trial runs.

can be set using the built-in frequency setting POT (VR) ,

the keypad panel with the

.

Running command

Operation starts when the RUN ke

increases when

pressed.

The motor decelerates and stops when

is pressed.

the inverter to deceleration

the inverter to deceleration

is

the STOP ke

z

When SW7 is set at CM

Connect external power suppl

turn FWD (REV) on to start. Turn it off

to brin

and stop.

z

When SW7 is set at P24

Turn FWD (REV) on to start. Turn it off

to brin

and stop.

is

and

3

Table 3-3-1 Running command

Operation is not stopped althou

STOP ke

Refer to section 2-3-3.

is pressed.

h the

3 Operation 3-2

Page 38

FVR-C11S-EN

g

g

g

y

g

y

g

y

g

g

g

g

g

y

g

g

y

g

g

Check the following items:

a) Rotation direction

b) Whether rotation is smooth (whether there

is a motor buzzin

bration)

c) Whether acceleration and deceleration are

smooth

d) Whether the inverter coolin

(1.5kW or more)

3

If no abnormalit

a

ain by increasing the frequency.

Even if the output from the inverter is stopped,

ou will be get an electric shock when you touch

the main circuit terminals such as inverter output

terminals U, V and W if the volta

the main power suppl

The smoothin

been char

it is not dischar

in

the electric circuit, wait until at least five min-

utes have elapsed after power-off and the

e lamp is off, indicating the voltage is al-

char

read

low.

After checkin

start operation.

is detected, check the item

capacitor in the inverter has

ed when the power is turned off and

ed immediately. Before touch-

normality in the above trial run,

noise or abnormal vi-

fan is rotatin

e is supplied to

input terminal.

WARNING

1. The STOP key is valid only when the function has been set.

n another switch to emergency stops.

Assi

Otherwise accidents could occur.

2. Operation starts suddenl

done with an runnin

that no runnin

reset.

Otherwise accidents could occur.

signal is input before alarm

if alarm reset is

signal input. Check

CAUTION

Do not touch the heat sink.

Otherwise burns could occur.

3-3 3 Operation

Page 39

FVR-C11S-EN

g

y

y

g

g

y

g

y

y

g

y

y

g

y

g

y

g

y

y

g

y

y

y

g

y

y

g

g

y

)

)

4Keypad Panel

4-1 Names and Functions

ital displa

Di

In program mode: Shows function codes and data

codes.

In Operation mode: Shows the output frequenc

and output current, etc.

In Trip mode: Shows a code indicatin

of the trip.

ram (Reset) ke

Pro

Switches between Operation mode and Program

mode.

In Trip mode: Resets the trip status and chan

to Operation mode.

Function/Data ke

In Operation mode: Switches between frequenc

display and output current display during stopped

and runnin

write various function codes and function data

items.

Up/down ke

In Operation mode: Used to increase and reduce

the frequenc

Used to chan

RUN ke

This key is used to start operation.

The LED is on durin

This ke

from the external si

(F02 = 1).

STOP ke

This key is used to stop operation.

This ke

from the external si

(F02 = 1).

. In Program mode: Used to read and

s

(motor speed).In Program mode:

e a function code and data value.

operation.

does not function when the data code

nal (digital input) is selected

does not function when the data code

nal (digital input) is selected

the causes

4-2 Operating Keypad Panel

1) Switching monitor

The displa

quenc

pressing the in Operation mode.

60.0 1. 2 A

Frequenc

1) Frequency is displayed as a percentage with the least

si

nificant digit in PID control operation (function H20

is set to 1 or 2):

2) The reference frequenc

is pressed in current indication.

ke

2) Stopping operation

Operation is started when the is

pressed, and is stopped when the is

pressed while function is set to a val-

e

ue other than .

The rotation direction is:

F02 0

F02 2

F02 3

can be switched between fre-

display and output current display b

1

10.0.

100.

Current

for 10%

for 100%

is displayed when the

F02

1

= : Forward rotation with

FWD-P24/CM ON, and

reverse rotation with

REV-P24/CM ON

= : Forward rotation

(FWD/REV input is i

nored.)

= : Reverse rotation

(FWD/REV input is i

nored.)

2

4

-

-

4 Keypad Panel 4-1

Page 40

FVR-C11S-EN

y

g

g

g

y

y

)

ging

g

y

3) Changing frequenc

The frequency increases when the is pressed and decreases

when the is pressed while function is set to .

F01 0

4

The chan

e speed is increased when the is pressed at the

same time as the or .

Note: Do not turn the power off for five seconds after monitor switch-

in

or function setting, to prevent Er1 occurrence.

4) Settin

function

Procedure Displa

Press the ke

1

mode.

to set the program

2 Press the key to select a function.

3 Press the key to display data.

4 Press the key to change the data.

5 Press the to save the data.

Chan

6

Press the to cancel the pro

another function

ram

60.0

F00

F01

F02

60.0

1

1

2

mode.

1) The function code display changes as shown below.

The to are displa

o01 o11 o00 1

ed only with set to .

F00 F01 F36 E01 E03 C01

o11 o00 H25 H01 P00 C07

4-2 4 Keypad Panel

Page 41

FVR-C11S-EN

g

g

y

g

g

g

g

y

y

g

g

g

y

y

g

y

y

y

g

5Selecting Function

5-1 Function Selection List

F: Fundamental functions

Func-

Min.

unit

Factor

settin

tion

code

No.

F00 Data protection

F01

F02

F03

F04 Base frequency25 to 120Hz Hz 1 50 X

F05

F06 0

F07

F08

F09 Torque boost

Name Setting range Unit

Frequenc

command

Operation

method

Maximum output frequenc

- Data cannot be chan

Acceleration

time

Deceleration

time

0: Data chan

1: Data protected

0: Ke

1: Volta

(0 to +10VDC)

2: Current input (terminal[C1])

(4 to 20mADC)

3: Volta

(terminals[12]+[C1])

4: Analo

0: Ke

(rotation direction: B

1: External si

2: Ke

(forward rotation)

3: Ke

(reverse rotation)

50 to 120Hz Hz 1 50 X

0.0 to 60.0s

0.01 second is set when 0.0 is specified.

0.1 to 60.0s s 0.1 6.0

0,1 : Variable torque characteristic

2 to 31: Constant torque characteristic

e enabled,

operation (

e input (terminal [12])

e input + current input

(VR built in inverter)

operation

nal (digital input)

operation

operation

key)

,

terminal block)

ed. - -

-- 0 X

-- 4 X

-- 2 X

s0.1 6.0

-1 13

Change

opera-

0

durin

tion

-

User

settin

5

Change during operation: X = impossible, = possible (enabled by usin

5 Selecting Function 5-1

), = possible (enabled by usin

)

Page 42

FVR-C11S-EN

g

g

y

g

g

g

y

y

y

g

y

g

y

g

y

y

g

g

g

y

y

5

Function

code No.

F10

F11 (Level) 20 to 135% of inverter rated current A 0.01

F12

F14

F15

F16 (Low) 0 to 120Hz 0

F17

F18 Bias frequenc

F20

F21 (Level) 0 to 100% % 1 50

F22

F23

F24 - Data cannot be changed. - - 0.0 F25 Stop frequenc

Name Setting range Unit

Electronic

thermal overload

for motor

rela

(Select)

(Thermal

time

constant)

Restart after momentary power

failure (Select)

Frequenc

limiter

h)

(Hi

Gain

(for frequenc

setting signal)

DC injection brake

(Startin

freq.)

(Brakin

time)

Startin

frequenc

0: Inactive

1: Active (for 4-pole standard motor)

2: Active (for 4-pole FUJI inverter motor)

0.5 to 10.0min min 0.1 5.0

0: Inactive (Trip and alarm when power fail-

ure occurs)

1: Inactive (Trip and alarm when power re-

covers)

2: Active (Momentaril

3: Active (Momentaril

0 to 120Hz

0: For 0 to 10VDC (4 to 20 mA DC)

1: For 0 to 5VDC (4 to 12 mA DC)

-120 to 120Hz Hz 1 0

Fixed to 3Hz Hz - 3.0 -

0.0 s (Inactive), 0.1 to 30.0 s s 0.1 0.0

1 to 6Hz Hz 1 1 X

1 to 6Hz Hz 1 1 X

frequency of before power failure)

settin

frequency)

startin

stops and restarts at

stops and restarts at

Min.

Factor

settin

unit

-- 1