Page 1

HYBRID ULTRASONIC FLOWMETER <Duosonics>

(Pulse Doppler method + Transit Time method)

DATA SHEET

This meter is the world’s first non-intrusive type ultrasonic

flowmeter utilizing Pulse Doppler method along with Transit

Time method. It enables measurement of velocity profile directly resulting in high accuracy. This makes it suitable for undeveloped flow and for short straight pipes. Pulse Doppler

method requires reflectors in the liquid and is utilized on

opaque liquids while Transit Time method requires ultrasound

penetration and is ideal for clean liquids. The new hybrid technology utilizes both methods in a complementary fashion thus

enabling a wider range of applications than it is possible now.

In addition, thanks to Fuji’s new state-of-the-art algorithm, either method can be automatically switched to accommodate

for varying fluid conditions such as concentration of particles

and/or air bubbles and flow velocity.

FEATURES

1. Automatic switchover function between Pulse Doppler method utilizing ultrasound reflection and Transit

Time method utilizing ultrasound penetration

• Applicable to various kinds of liquids with/without air

bubbles and/or solid particles

• Applicable to liquid flow that changes in nature frequently

or periodically

2. High-accuracy non-intrusive (non-contact) volumetric

flow rate measurement of liquid flow in closed pipes.

• Accuracy of 0.5% to 1% (depending on the measuring

mode and pipe size)

• Clamp-on sensor

3. Direct measurement of velocity profile in case of

Pulse Doppler method

• High accuracy of 0.5% to 1% (correction coefficient un-

necessary)

• Applicable to undeveloped flow (short straight pipe)

• Applicable to flow hovering in the transitional region be-

tween laminar flow and turbulent flow

4. High speed response: 0.2sec (pulse Doppler method)/

0.5sec (transit time method)

5. Real time monitoring of velocity profile by PC in case

of Pulse Doppler method (option)

6. Dual-path option improves performance

SPECIFICATIONS

Operational specifications

System configuration:

The system is composed of one/two detectors (Model: FSW) and one Flow transmitter

(Model: FSH), realizing single-path/two-path

measurement.

Hybrid mode or transit time mode is selectable.

In case of hybrid mode, ether Pulse Doppler

method or transit time method is automatically selected depending on conditions of

measured liquid and magnitude of velocity.

FSH, FSW, FLY

Flow transmitter

(FSH)

Detector

(FSW)

Application: Uniform liquid in which ultrasonic waves can

propagate.

Air bubble quantity: Pulse Doppler method: 0.02 to

15% of volume at 1 m/s

Transit time method: 0 to 12%

of volume at 1 m/s

Fluid temperature: -40 to +100°C (FSW12), -40 to

80°C (FSW21, FSW40,FSW50)

Type of flow: P u l se Doppler method:

axisymmetric flow in a filled

pipe.

Transit time method: well-developed turbulent or laminar

flow in a filled pipe.

Applicable flow pipe:

Material: Plastics (PVC, FRP, etc.) or

Metals (carbon steel, SS, copper, aluminum, etc.)

Pipe size: 50 to 1000 mm

(inside diameter)

Liner: Tar epoxy, mortar, etc.

Straight pipe length: Typically 10D for upstream and

5D for downstream. Refer to

JEMIS-032 in detail.

(Note) JEMIS: Japan Electric

Measuring Instruments

Manufactures' Associations Standard

Velocity: Hybrid mode: 0 to ±0.3 --- ±Maximum Velocity

(depending on pipe diameter) (Note) Maximum measurement range in Hybrid mode

(see page 4)

Transit time mode: 0 to ±0.3 --- ±32 m/s

Power supply:

100 to 240 Vac+10%/-15%, 50/60Hz or 20 to

30 Vdc

EDS6-132a

Date

Aug. 31, 2005

Page 2

FSH, FSW, FLY

Signal cable: Single-path system :

A pair of RF co-axial cables for ultrasound signals and a three-core shield cable for temperature sensor,

Two-path system: Two pairs of RF co-axial

cables for ultrasound signals and a three-core

shield cable for temperature sensor,

Maximum cable length: 150m

Temperature range : 80°C

Environment: Non-explosive environment without direct

sunlight, corrosive gas and heat radiation

Ambient temperature:

-10 to +50°C for flow transmitter,

-20 to +80°C for detector

Ambient humidity:

95%RH or less for flow transmitter, 100%RH

or less for detector

Grounding: Class D (less than 100 ohm)

Arrester: Surge absorbers for outputs and power supply

incorporated as standard

Performance specifications

Accuracy :

Pulse Doppler method :

Pipe size (inside diameter)

ø50mm to ø1000mm

(Detector FSWS12)

ø100mm to ø1000mm

(Detector: FSWS21,40,50)

Velocity

1.5 m/s to

Max. Velocity (Note)

0 m/s to 1.5 m/s

1 m/s to

Max. Velocity (Note)

0 m/s to 1 m/s

Accuracy

±0.5% of rate

±0.0075m/s

±1.0% of rate

±0.01m/s

(Note) Maximum velocity is depend on a pipe diamecer.

See Maximum measurement range in Hybrid mode

(page 4).

Transit time method :

Pipe size (inside diameter)

ø50mm to ø300mm

or less

ø300mm to ø1000mm

Velocity

2 to 32 m/s

0 to 2 m/s

1 to 32 m/s

0 to 1 m/s

Accuracy

±1.0% of rate

±0.02m/s

±1.0% of rate

±0.01m/s

Response time:

Pulse Doppler method: 0.2sec

(depending on pipe

diameter and measuring condition)

Transit time method: 0.5sec

Power consumption:

20W or less

Short-term thermal stability:

140°C, 30 min (FSWS12),

100°C, 30 min (FSWS21, FSWS40, FSWS50)

Functional specifications

Analog output: 4 to 20 mAdc (1 point)

Max. load resistance: 1k ohm

Digital output:+total, -total, alarm, acting range, flow switch

or total switch -- arbitrarily selectable

Mechanical relay contact:

1 point with socket (replaceable)

Normally closed/open selectable

Capacity:240 Vac/30 Vdc, 1 A

Total pulse: less than 1 p/s

(Pulse width: 50, 100 or 200 ms

selectable)

Transistor open collector: 2 points

Capacity: 30 Vdc, 0.1 A

Normally off/on selectable

Total pulse: less than 1000 p/s

(Pulse width: 0.5, 1, 2, 5, 10, 20,

50, 100 or 200 ms selectable)

Communication interface:

RS-232C equivalent / RS-485 (selectable)

Number of connectable units: one (RS-232C)/

up to 31 (RS-485)

Baud rate: 9600/19200/38400 bps selectable

Parity: none/odd/even selectable

Stop bit: 1 or 2 bits selectable

Distance: up to 15 m (RS-232C)/up to 1k m

(RS-485)

Data: velocity, flow rate, +total, -total, status

(standard), velocity profile (option)

Display device:

Graphic LCD (number of pixels: 240x64) with

back light,

Display language:

Japanese, English, French, German or Spanish

selectable

Velocity/Flow rate display:

Display of velocity and/or flow rate with flow

direction

Data: up to 10 digits (decimal point to be

counted as 1 digit)

Unit: Metric/English system selectable

Metric system English system

Velocity m/s ft/s

3

Flow rate

L/s, L/min, L/h, L/d,

kL/h, ML/d, m

3

m

/min, m3/h, m3/d,

3

km

/d, Mm3/d, BBL/s,

3

/s,

BBL/min, BBL/h,

kBBL/d, MBBL/d

ft

/s, ft3/min, ft3/h,

3

Mft

/d, gal/s, gal/min,

gal/h, Mgal/d, BBL/s,

BBL/min, BBL/h,

BBL/d, kBBL/d,

MBBL/d

Note: “gal” means US gal.

Total display: Display of forward or reverse total

Data: up to 10 digits (decimal point to be

counted as 1 digit)

Unit: Metric/English system selectable

Metric system English system

3

ft

Total

mL, L, m3, km3, Mm3,

mBBL, BBL, kBBL

, kft3, Mft3, gal, kgal,

mBBL, BBL, kBBL,

ACRf

Configuration:

Fully configurable on keyboard by menu-driven

software

Zero adjustment:

Set zero/Clear available. (transit time method)

Damping: 0 to 100s (every 0.1s) configurable for analog

output and display

Low flow cut off:

0 to 5 m/s configurable

2

Page 3

Alarm: Hardware fault/process fault can be tied to

digital output

Burnout: Analog output: Hold/Upper limit/Lower limit/

Zero/Not-used selectable

Total: Hold/Count selectable

Timer: 0 to 900s (every 1s) configurable

Bi-directional range:

Forward and reverse ranges configurable independently

Hysteresis: 0 to 20% of working range

configurable

Working range applicable to digital output

Auto-2 ranges:

Forward 2 ranges configurable independently

Hysteresis: 0 to 20% of working range

configurable

Working range applicable to digital output

Flow switch: Lower and upper switching points

configurable independently

Acting point applicable to digital output

Total switch: +total switching point configurable

Acting point applicable to digital output

Physical specifications

Enclosure protection:

Flow Transmitter: IP67,

Detector: IP67

Mounting: Flow Transmitter: wall mount

Detector: clamped on pipe surface

Acoustic coupler:

Silicon compound (RTV)

Material: Flow Transmitter: aluminum alloy

Detector: PBT for housing, aluminum alloy for

frame and SS for fastening belt

Sensor cable(FLY6):

RF coaxial cable (double shielded)

External sheath: Black flame-resistant vinyl

External diameter: About 7.3 mm

Terminal treatment: Water-resistant BNC con-

nector (detector side), M3.5 amplifier

terminal (converter side)

Weight: About 90 g/m

Temperature sensor cable(FLY7):

3-core shield cable

External sheath: Gray flame-resistant vinyl

External diameter: About 6.9 mm

Terminal treatment: Round waterproof con-

nector (detector side), M3.5 amplifier

terminal (converter side)

Weight: About 56 g/m

Dimensions: Flow Transmitter : H240 x W247 x D134 mm

Detector: H70 x W57 x L360 mm (FSWS12)

H72 x W57 x L540 mm (FSWS21)

H90 x W85 x L640 mm (FSWS40)

H82 x W71 x L258 mm (FSWS50)

Mass: Flow Transmitter: 5 kg

Detector: 1.7 kg (FSWS12), 1.9 kg (FSWS21),

5 kg (FSWS40), 1.5 kg (FSWS50)

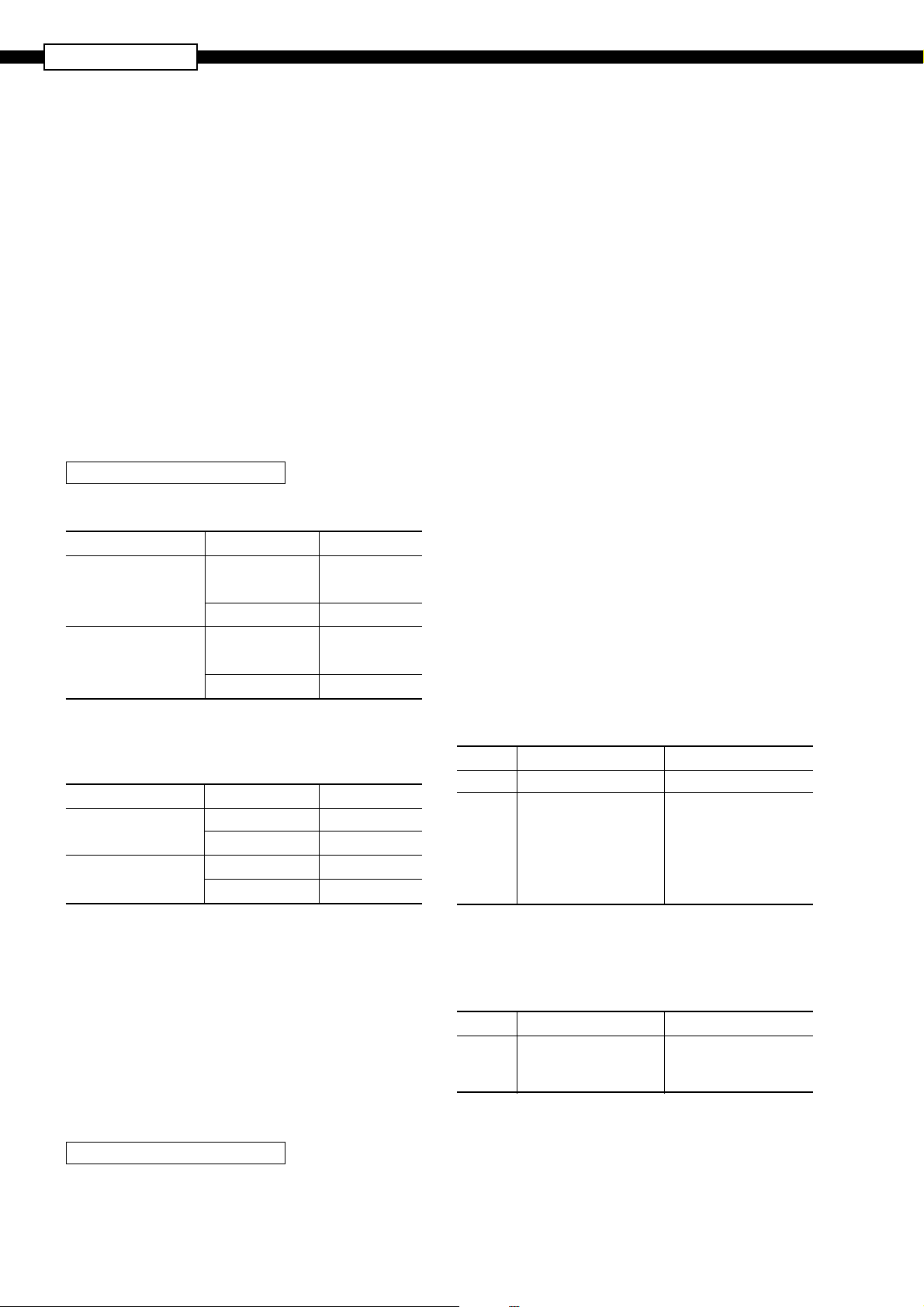

Conditions on straight pipe

( D : Inside diameter of pipe)

Classification Upstream side Downstream side

L≧5D

L≧10D

90° bend

Tee

Diffuser

Reducer

10D or more

10D

10D or more

or

0.5D

more

or

≧1.5D

more

Detector

L≧50D

L≧30D

D

L≧10D

L≧30D

L≧10D

L≧5D

L≧5D

L≧10D

Various Valve

In case that flow control valve exists on

upstream side.

Pump

(Note) The source : JEMIS-032

Stop valve

Check valve

P

In case that flow control valve exists on

downstream side.

L≧50D

3

Page 4

FSH, FSW, FLY

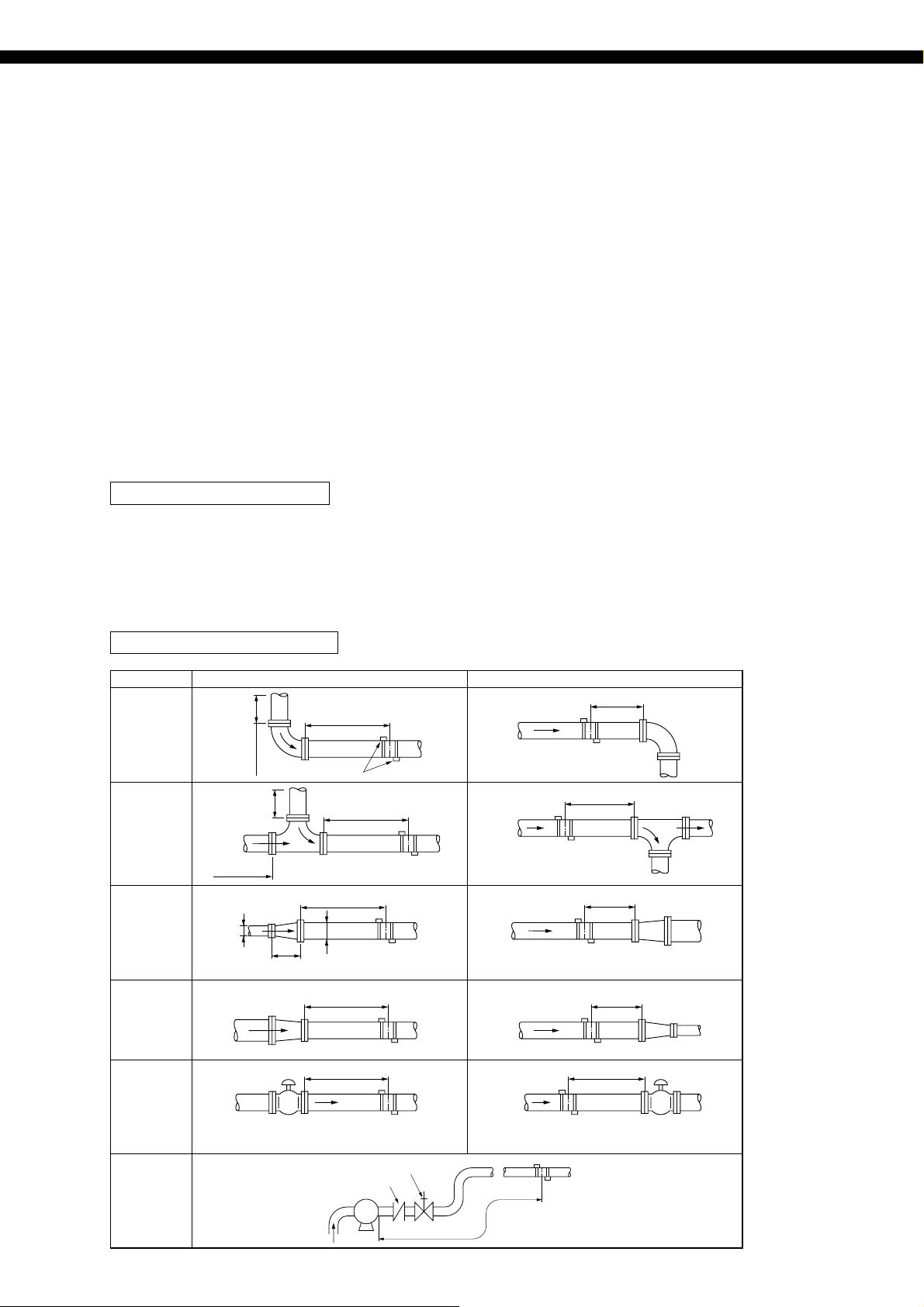

<Pulse Doppler method>

• Ultrasound pulses are transmitted into a liquid, and

flow velocity profile is found and the flow rate is measured by using the characteristics that Doppler frequency of the echo from reflectors such as air

bubbles and particles in the liquid changes according

to flow velocity.

Sensor 1

Air

bubbles

Reflection

Flow

velocity

Flow velocity

Profile 2

Piping wall Center Piping wall

Flow

velocity

Profile 1

<Transit Time method>

• Ultrasound pulses are propagated slanted both from the

upstream and downstream, and flow rate is measured by

detecting the time difference generated with the flow.

Sensor 1

Flow

Sensor 2

Block diagramMeasurement principle

(1) Single path system (Z method)

Cable

Detector

Flow

Transmitter

(2) 2-path system (Z method)

Cable

Detector

Power

supply

Power

supply

4 to 20mA DC

Flow

Transmitter

Contact

(Up to 3 points

are allowed.)

Temperature

sensor cable

4 to 20mA DC

Contact

(Up to 3 points

are allowed.)

Temperature

sensor cable

Flow

Sensor 2

Transmission

Sensor 2

Sensor 1

1

2

Time difference ∆T

Receiving

Maximum measurement range in hybrid mode

When stainless steel is selected as pipe material, nominal wall thickness is Sch20s, and the fluid is water

<Maximum measurable flow velocity>

Caliber

1000A 1.76

FSWS12

50A

65A 4.99

80A 4.40

90A 3.92

100A 3.45 6.95

125A 5.86

150A 5.04

200A 3.96 7.59

250A 6.26

300A 5.32

350A 4.82

400A 4.25

450A 3.80

500A 3.54 3.54

550A 3.14

600A 2.89

650A 2.69

700A 2.50

750A 2.34

800A 2.19

850A 2.07

900A 1.95

FSWS21 FSWS40 FSWS50

6.04

Unit: m/s

<Maximum measurable flow rate>

FSWS12

FSWS21 FSWS40 FSWS50

48.5

67.8

81.8

97.1

110.2 222.0

279.2

343.2

462.8 887

1,146

1,404

1,572

1,831

2,091

2,393 2,393

Unit: m

2,587

2,850

3,067

3,325

3,590

3,839

4,112

4,357

4,852

3

/h

4

Page 5

CODE SYMBOLS

<Flow transmitter>

12345678 9101112

F

SH Y YY

1S

E

Y

A

Y

1

4

1

S

Y

Y

Description

Type (4th digit)

Standard

Velocity profile output (5th digit)

None

Available

Use (6th digit)

Single path or Changeover two-path (Note)

2 sets of detectors and coaxial cables

Note:

(FLY6) needed for two-path system.

Power supply (7th digit)

100 to 240 Vac, 50/60 Hz

20 to 30 Vdc

Modification No. (8th digit)

Mark 1

Case structure (9th digit)

IP67

Conduit connection (10th digit)

G1/2 (female screw) with water-proof

connection

For use with explosion-proof detector

None

Parameter setting, Tag Plate (12th digit)

None

Y

With setting

A

With setting and Tag Plate

B

With Tag Plate

C

(11th digit)

<Signal cable>

12345678

F

LY

1

6

7

5

0

0

0

1

0

5

1

0

0

2

0

5

2

0

0

3

0

5

3

0

0

4

0

5

4

0

0

5

0

5

5

0

0

6

0

5

6

0

0

7

0

5

7

0

0

8

0

5

8

0

0

9

0

5

9

0

0

0

1

0

1

1

0

2

1

0

3

1

0

4

1

0

5

1

1

Description

Kind of cable (4th digit)

Coaxial cable (for ultrasonic sensors)

Three-core cable (for temperature sensor)

Cable length (5th to 7th digit)

5m

10m

15m

20m

25m

30m

35m

40m

45m

50m

55m

60m

65m

70m

75m

80m

85m

90m

95m

100m

110m

120m

130m

140m

150m

Length in m to be designated with 3 digits

Modification No. (8th digit)

Mark 1

<Detector>

12345678 91011

F

SSW0Y

1

S

1

2

2

1

4

0

5

0

0

1

Y

(Note) Select silicone compound (A) for acoustic

Description

Type (4th digit)

Standard

Kind of detector (5th and 6th digit)

Small diameter detector (φ 50 to 100 mm)

Small size detector (φ 100 to 200 mm)

Middle size detector (φ 200 to 500 mm)

Large size detector (φ 500 to 1000mm)

Use (7th digit)

Standard (IP67)

Modification No. (8th digit)

Mark 1

Signal cable (9th digit)

None

Acoustic coupler (10th digit) (Note)

Y

None

A

Silicone compound

Option (11th digit)

None

Y

Tag Plate

A

coupler in ordinary cases. Silicon compound is

supplied in a tube (150g). If one or more

detectors one ordered, silicon compound may

be selected onece every 5 orders or so.

Loader software for PCs

Equipped as standard

• Works on PC/AT compatible machines.

• Operation on PC98-series machines (NEC) cannot be

guaranteed.

• Operation on self-made PCs or shop-brand PCs cannot be

guaranteed.

•Major functions: Setting/changing of various parameters

for the main unit

If no flow velocity profile output is selected,

the following functions are not available.

“Detailed setting” and “flow velocity profile

display” in pulse Doppler measurement

“Detailed setting” and “ receved signal display” in Transit time measurement

• O/S: Windows2000/XP

• Memory requirement: 128MB or more

• Disk unit: Windows2000/XP-compatible CD-ROM drive

• Hard disk drive capacity: Free space of 52MB or more

Note: PC loader communication cable

(type ZZP*FSH TK4H6253) is separately required.

Detector frame installation fixture

Installation fixture is provided to facilitate the positioning of

the frame to the piping.

Select a desired type from the following according to the detector to be used.

Type

ZZP FSW TK7M7071C1

Applicable detector

FSWS12

ZZP FSW TK7M7071C2 FSWS21

ZZP FSW TK7M7071C3 FSWS40

Note: The installation fixture cannot be used for detector type

FSWS50, which is not provided with a frame.

5

Page 6

FSH, FSW, FLY

OUTLINE DIAGRAM

(Unit:mm)

<Flow transmitter (type: FSH)>

3

134

352

332

4-

φ

9

240

Duosonics

14

3333

Mtg. plate

(273) 30

72

233

CONNECTION DIAGRAM

Power supply terminals (AC)

2344

L1N

100 to 240V AC

Power supply terminals (DC)

123

+–

20 to 30V DC

2

1

HF

UP STR

34

HF

GND

DOWN STR

LINE1 LINE2

GND

56

HF GND

UP STR

HF GND

DOWN STR

30 30 30 24

48 48 48

B

Cable

(Black)

To temp sensor

78

* Use LINE1 terminals in case of single measuring path.

Cable

(Black)

312

BA

Cable

(Yellow/

Green)

1

DO1

SERIAL

SERIAL

No. RS485

4

5

6

2

3

–+

+

DO2

7654

+

Iout

TRX2 (

–

)

TRX1 (

+

)

SHILD

4–56–7

+

DO3

98

–

RS232C

TXD

RXD

COM

6

Page 7

OUTLINE DIAGRAM

(Unit:mm)

<Detector (type: FSWS12, 21)>

BNC Connector

Temp sensor

Sensor unit

Absorber unit

Frame

Type

FSWS12

FSWS21

W

(H)L

Pipe size (mm)

φ50 to φ100 360

φ

100 to φ200 540

L

WH

5770

5772

<Detector (type: FSWS40)>

BNC Connector

Temp Sensor

Sensor unit

640

Absorber unit

Frame

85

(90)

7

Page 8

FSH, FSW, FLY

OUTLINE DIAGRAM

(Unit:mm)

<Detector (type: FSWS50)>

BNC Connector

Temp sensor

Sensor unit

258

Absorber unit

71

82

8

Page 9

<Signal cable (type: FLY6)> <Signal cable (type: FLY7)>

L ± 1 (m)

φ11

φ7.3

φ15

BNC Connector

φ21.5

Connector

φ6.9

L ± 1 (m)

3-

φ

6.6

SCOPE OF DELIVERY

• Flow transmitter (Type: FSH):

Flow transmitter

CD-ROM (Instruction manual,

Loader software)

•Detector (Type: FSW): Sensor unit

Mounting belt

Silicon compound (option)

• Signal cable (Type: FLY6): Cable (2 wires)

3-

φ

6.6

ITEMS DESIGNATED ORDERING

• Flow transmitter code symbols

• Detector code symbols

• Signal cable code symbols

• Signal cable (Type: FLY7): Cable for temperature sensor (1)

9

Page 10

FSH, FSW, FLY

<Parameter specification table>

Outer diameter1

2

3

4

5

6

7

Pipe material

Wall thickness

Lining material

Lining thickness

PiPing specificationOutput setting

Kind of Fluid

Range unit

Setting itemNo.

10.00 to 6200.00mm

(0.393 to 244.100 inch)

12 menus

Settable range Initial value Settable value

60.00mm

(2.362 inch)

PVC

Carbon steel, Stainless steel, PVC, Copper,

[mm, inch]

Castiron, Aluminum, FRP, Ductileiron, PEEK,

Pipe S.V. : 1000 to 3700m/s

(3280 to 12140 ft/s)

0.10 to 100.00mm

(0.003 to 3.940 inch)

8 menus

Lining S.V. : 1000 to 3700m/s

(3280 to 12140 ft/s)

0.01 to 100.00mm

4.00mm

(0.157 inch)

No lining

PVDF, Acrylic

Others (Sound velocity : [m/s, ft/s])

[mm, inch]

No lining, Tar epoxy, Mortar, Rubber,

Teflon, Pyrex glass, PVC,

Others (Sound velocity : [m/s, ft/s])

[mm, inch]

(0.000 to 3.940 inch)

17 menus

Water

Water, Seawater, DIST. water, Ammonia,

Alcohol, Benzene, Bromide, Ethanol, Glycol,

Kerosene, Milk, Methanol, Toluol,

Fluid S.V. : 500 to 2500m/s

(1641 to 8203 ft/s)

Kinematic viscosity :

0.001 to 999.9999 x 10

-6m2

(0.0107 to 10763.9088 x 10

19 menus

/s

-6ft2

/s)

m/s

(ft/s)

Lube oil,

Fuel oil, Petrol,

Others (Sound velocity : [m/s, ft/s])

(Kinematic viscosity [x10

m/s, L/s, L/min, L/h, L/d, kL/d, ML/d, m

3

m

/min, m3/h, m3/d, km3/d, Mm3/d, BBL/s,

BBL/min, BBL/h, BBL/d, KBBL/d, MBBL/d,

3

(ft/s, ft

/s, ft3/min, ft3/h, ft3/d, kft3/d, Mft3/d,

-6m2

/s, ft2/s])

3

/s,

gal/s, gal/min, gal/h, gal/d, kgal/d, Mgal/d,

BBL/s, BBL/min, BBL/h, BBL/d, kBBL/d,

MBBL/d)

8

9 In terms of flow velocity 0.00 ···

Range type

Full scale or

Full scale 1

4 menus

±0.30 to ±32.00m/s

(±0.98 to ±104.98 ft/s)

Full scale 210 In terms of flow velocity 0.00 ···

±0.30 to ±32.00m/s

(±0.98 to ±104.98 ft/s)

Output burnout14 5 menus Hold

(0.00 to 16.40 ft/s)

in terms of flow velocity

1 : Display kind19 7 menus Flowrate (m3/s)

2 : Display kind20 7 menus Flow velocity (m/s)

Display setting

Single

2.00m/s

(6.56 ft/s)

4.00m/s

(13.12 ft/s)

0.00m/s

(0.00 ft/s)

Single, Auto 2, Bi-dir, Bi-dir Auto 2

[ ]

[ ]

%Range HYS.11 0.00 to 20.0% 10.00%

%Output limit LO.12 -20 to 0% -20%

%Output limit HI.13 100 to 120% 120%

Not use, Hold, Upper, Lower, Zero

secBurnout timer15 0 to 900sec 10sec

[ ]Rate limit16 0.00 to 5.00m/s

secRate limit timer17 0 to 900sec 0sec

secDamping18 0.0 to 100.0sec 5.0sec

Flow velocity, Flowrate, Total forward,

Total reverse,

F : Total pulse, R : Total pulse, Flow rate (%)

Flow velocity, Flowrate, Total forward,

Total reverse,

F : Total pulse, R : Total pulse, Flow rate (%)

10

(0.00 to 16.40 ft/s)

in terms of flow velocity

0.01m/s

(0.03 ft/s)

[ ]Low flow cut21 0.00 to 5.00m/s

Page 11

Setting itemNo.

Settable range Initial value Settable value

Total mode22 3 menus

Total stop

Total unit23 8 menus mL

25 0.000 to 9999999999.999 0.000

F : Total preset

F : Total SW

27 0.000 to 9999999999.999 0.000

R : Total preset

Output burnout29 2 menus Hold

Pulse width 131 3 menus 50ms

Pulse width 232 9 menus 50ms

Flow sw high33 In terms of flow velocity

0.00m/s

0.00 to ±32.00m/s

(0.00 to ±104.98 ft/s)

Flow sw low34 In terms of flow velocity

4.00m/s

0.00 to ±32.00m/s

Flow switchStatus output Total

(0.00 to ±104.98 ft/s)

Total stop, Total run, Total reset

mL, L, m

ft

3

, km3, Mm3, mBBL, BBL, kBBL,

3

, kft3, Mft3, kgal, gal, mBBL, BBL, kBBL,

ACRF

[ ]Total rate24 0.000 to 999999.999 0.000

[ ]

[ ]26 0.000 to 9999999999.999 0.000

[ ]

[ ]R : Total SW28 0.000 to 9999999999.999 0.000

Not use, Hold

50, 100, 200

0.5, 1.0, 2.0, 5.0, 10.0, 20.0, 50.0, 100.0,

200.0

[ ]

[ ]

secBurnout timer30 0 to 900sec 10sec

%Flow sw HYS.35 0 to 20% 10%

Output DO136 15 menus Not use

Mode DO137 2 menus Normal

Output DO238 15 menus Not use

Mode DO239 2 menus Normal

Output DO340 15 menus

Not use

Mode DO341 2 menus Normal

Not use, Signal error, F : Total pulse,

R : Total pulse, F : Total alarm,

R : Total alarm, F : Total overflow,

R : Total overflow, Flow SW high,

Flow SW Low, Full scale2, AO range over,

Pulse range over, R : Flow direction,

Device error

Normal, Reverse

Not use, Signal error, F : Total pulse,

R : Total pulse, F : Total alarm,

R : Total alarm, F : Total overflow,

R : Total overflow, Flow SW high,

Flow SW Low, Full scale2, AO range over,

Pulse range over, R : Flow direction,

Device error

Normal, Reverse

Not use, Signal error, F : Total pulse,

R : Total pulse, F : Total alarm,

R : Total alarm, F : Total overflow,

R : Total overflow, Flow SW high,

Flow SW Low, Full scale2, AO range over,

Pulse range over, R : Flow direction,

Device error

Normal, Reverse

11

Page 12

FSH, FSW, FLY

Setting itemNo.

System unit42 2 menus

Language43 5 menus English

Settable range Initial value Settable value

Metric

Metric, English

Japanese, English, German, French,

spanish

9600BPS, 19200BPS, 38400BPSCOM. speed44 3 menus 38400BPS

45 3 menus None

COM. parity

COM. stop bit

47 2 menus RS232C

System

Serial method

Serial com.

None, Even, Odd

1 bit, 2bits46 2 menus 1 bit

RS232C, RS485

1 to 31Station No.48 31 menus 1

49

Measurement

2 menus 1 Path

1 Path, 2 Path

mode

mode

AO Definition50 3 menus Line 1

Measuremant

51 4 menus FSW12

Note1: When total pulse output has been selected for DO1, DO2 or DO3 specify total pulse value and total pulse width so that conditions 1

Sensor Type

and 2 shown below are satisfies.

Condition 1 : 1000 [In the case of DO1 and DO2]

Condition 2 :

Flow span-1*[m

total pulse value*[m

Flow span-1*[m3/s]

total pulse value*[m

3

/s]

3

]

1 [In the case of DO3]

3

]

2 × total pulse width [ms]

1000

Average, Line 1, Line 2

FSW12, FSW21, FSW40, FSW50

* In the case of 2 ranges, perform calculations using either flow span-1 or flow span-2, whichever is greater.

Caution on Safety

*Before using this product, be sure to read its instruction manual in advance.

Head Office

6-17, Sanbancho, Chiyoda-ku, Tokyo 102-0075, Japan

http://www.fesys.co.jp/eng

Instrumentation Div.

International Sales Dept.

No.1, Fuji-machi, Hino-city, Tokyo, 191-8502 Japan

Phone: 81-42-585-6201, 6202 Fax: 81-42-585-6187

http://www.fic-net.jp/eng

Information in this catalog is subject to change without notice.

Printed in Japan

Loading...

Loading...