Page 1

Page 2

Introduction

We thank you very much for purchasing Fuji Electric’s ultrasonic flow meter.

The instruction manual concerns the installation, operation, checkup and maintenance of the Flow transmitter

(FSV) of ultrasonic flow meter. Read it carefully before operation.

First read this instruction manual carefully until an adequate understanding is acquired, and then

proceed to installation, operation and maintenance of the flow meter. Improper handling may result in an

accident or a failure.

The specifications of this flow meter are subject to change without prior notice for improvement of the

product.

Do not attempt to modify the flow meter without permission. Fuji will not bear any responsibility for a

trouble caused by such a modification. If it becomes necessary to modify the flow meter, contact our

office in advance.

This instruction manual should always be kept on hand by the operator.

After reading the manual, be sure to store it at a place easier to access.

This instruction manual should be delivered to the end user.

If the instruction manual has been lost, request another one (with charge) to our local business office.

Manufacturer: Fuji Electric Co., Ltd.

Type: Described in the nameplate put on the main body

Date of manufacture: Described in the nameplate put on the main body

Product nationality: Japan

Issued in Dec., 2012

Note

Reproduction of any part or the whole of this manual without

permission is strictly prohibited by laws.

Contents of the manual are subject to change without prior notice.

©Fuji Electric Co., Ltd. 2012

Rev. 1st edition May, 2014

Rev. 2nd edition Jun., 2016

-i-

Page 3

SAFETY PRECAUTIONS

Before using this product, read the following safety precautions and use the product correctly.

The following items are important for safe operation and must be fully observed.

These safety precautions are ranked in 2 levels; "DANGER" and "CAUTION".

Warning/Symbol Meaning

DANGER

CAUTION

The items noted under "

All the items must be fully observed.

Incorrect handling of the device may result in death or serious injury.

Incorrect handling may lead to a risk of medium or light injury, or to a risk of

physical damage.

CAUTION

" may also result in serious trouble depending on circumstances.

Caution on mounting and piping

This unit is not explosion-proof type. Do not use it in a place with explosive

DANGER

CAUTION

gases. Otherwise, it may result in serious accidents such as explosion,

fire, etc.

The unit should be installed in a place conforming to the installation

requirements noted in this instruction manual. Otherwise, it may cause

electric shocks, fire or malfunction of the unit.

Install the flow meter according to the following steps to prevent it from

damage, and to avoid error or malfunction.

During installation, make sure that the inside of the unit is free from cable

chips and other foreign objects. Otherwise, it may cause fire, failure or

malfunction.

The items under "Caution on Installation" noted in the manual must be

fully observed. Careless installation may result in trouble or malfunction of

the unit.

Auxiliary insulation is necessary for analog output (Iout) and serial

communication (RS485) of this device.

-ii-

Page 4

Cautions in wiring

When performing wiring termination to prevent output trouble caused by

CAUTION

moisture, dew condensation or water leak, follow “Section 3.3. Flow

transmitter wiring” described in this manual.

Before performing the wiring work, be sure to turn OFF the main power.

Otherwise, it may cause electric shock.

Do not perform wiring work outdoors in rainy days to prevent insulation

deterioration and dew condensation. Otherwise, it may result in trouble,

malfunction, etc.

Be sure to connect a power source of correct rating. Use of power source

out of rating may cause fire.

The unit must be grounded as specified. Otherwise, it may cause electric

shocks, malfunction, etc.

The signal cable and analog output signal cable should be wired as far

away as possible from high-voltage lines to prevent entry of noise signals

as it will cause malfunction of the unit.

To prevent malfunction of the unit, the analog output signal cable and

power cable should be wired using separate conduits.

Be careful not to touch electronic components other than the terminal

block and the fuse holder.

Electronic components can get hot during operation and cause skin burns.

Caution on maintenance and inspection

CAUTION

The unit should be inspected every day to always obtain good results of

measurements.

When measuring the insulation resistance between the power/output terminal and the

case, follow “Section 6.2.3. How to measure the insulation resistance” described in this

manual.

If the fuse is blown, detect and eliminate the cause, and then replace the fuse with a

spare. If there are no spares, replace the fuse with the one specified in this manual

“Section 6.3. How to replace the fuse ” (that must be aquired separately). Use of a fuse

other than specified or its short-circuit may cause an electric shock or fire. The fuse

should be replaced according to “Section 6.3. How to replace the fuse” described in

this manual.

Replacement of electrolytic capacitor

An electrolytic capacitor has a service life of approx. 10 years under general

operating condition (annual average ambient temperature of 30°C).

The life will be shortened by half when the temperature rises by 10°C.

Do not use capacitor beyond its life. Otherwise, electrolyte leakage or

depletion may cause odor, smoke, or fire.

For replacement, contact Fuji Electric.

Limited warranty

The warranty term of this product including accessories is one year. Please

note that this warranty does not cover the following cases where:

a) The product is improperly used.

The product is repaired or remodeled not by Fuji Electric.

b) The product is used beyond its specifications.

c) The product is damaged due to transportation or fall after purchase.

d) The product is damaged by natural disasters such as earthquake, fire,

storm and flood, thunderbolt, abnormal voltage, or as such, or their

secondary disasters.

-iii-

Page 5

Exclusion of liability for loss of opportunity

Regardless of the time period of the occurrence, Fuji Electric is not liable for

the damage caused by the factors Fuji Electric is not responsible for,

opportunity loss of the purchaser caused by malfunction of Fuji Electric

product, passive damages, damage caused due to special situations

regardless of whether it was foreseeable or not, and secondary damage,

accident compensation, damage to products that were not manufactured by

Fuji Electric,and compensation towards other operations.

Repair service and spare parts supply after product discontinuation

The discontinued models (products) can be repaired for five years from the

month of discontinuation.

Also, most spare parts used for repair are provided for five years from the

month of discontinuation. However, some electric parts may not be obtained

due to their short life cycle. In this case, repair or provision of the parts may be

difficult even within the above period.

Please contact Fuji Electric or its service providers for further information.

Service life

The service life of this product excluding limited-life parts and consumable

parts is 10 years under general operating condition (annual average ambient

temperature of 30°C).

Please note that the above mentioned life may affected by operating environment and

operating conditions of the system.

-iv-

Page 6

CAUTION ON INSTALLATION LOCATION

CAUTION

(1) A place that provides enough space for periodic inspection and wiring work.

(2) A place not exposed to direct sunshine nor inclement weather.

(3) A place free from excessive vibration, dust, dirt and moisture.

(4) A place not subjected to radiated heat from a heating furnace, etc.

(5) A place not subjected to corrosive atmosphere.

(6) A place not to be submerged.

(7) A place remote from electrical devices (motor, transformer, etc.) which generate electromagnetic induction

noise, electrostatic noise, etc.

(8) A place not subjected to excessive fluid pulsation such as pump discharge side.

(9) A place that provides enough place for the length of the straight pipe.

(10) A place where ambient temperature and humidity are -20 to +55°C and 95% RH or less for flow transmitter

(FSV).

(11) Altitude: up to 2000m

(12) Installation category: II

(13) Pollution degree: 2

-v-

Page 7

Contents

Introduction ······························································ i

SAFETY PRECAUTIONS ··········································· ii

CAUTION ON INSTALLATION LOCATION ···················· v

1. PRODUCT OUTLINE ············································ 1

1.1. Checking delivered items ·································· 1

1.2. Check on type and specifications························ 2

1.3. NAME AND FUNCTION OF EACH PART ············· 3

1.3.1. Flow transmitter : FSV···S (IP66) ·················· 3

1.3.2. Flow transmitter : FSV···H (IP67) ·················· 4

2. INSTALLATION AND BEFORE START OF

OPERATION OF THE FLOW TRANSMITTER ········· 5

2.1. Outline of installation procedure ························· 5

3. INSTALLATION ···················································· 6

3.1. Installation location of flow transmitter ················· 6

3.2. Installation of flow transmitter ····························· 7

3.2.1. Wall mounting (Flow transmitter : FSV···S

(IP66)) ·············································· 7

3.2.2. 2B pipe stand mounting (Flow transmitter :

FSV···S (IP66)) ·································· 7

3.2.3. Wall mounting (Flow transmitter : FSV···H

(IP67)) ·············································· 8

3.2.4. 2B pipe stand mounting (Flow transmitter :

FSV···H (IP67)) ·································· 8

3.3. Flow transmitter wiring ····································· 9

3.3.1. Cautions in wiring ······································ 9

3.3.2. Applicable wires ········································ 9

3.3.3. Treatment of wiring port ······························ 9

3.3.4. Wiring to each terminal ····························· 10

3.3.4.1. Flow transmitter : FSV···S (IP66) ··········· 10

3.3.4.2. Flow transmitter : FSV···H (IP67) ············ 11

3.3.5. How to connect to terminal block. ················ 12

3.3.5.1. Cable treatment ································· 12

3.3.5.2. How to connect to power supply/terminal

block for signal. ··························· 12

3.3.5.3. How to connect to communication

terminal block. ····························· 13

4. Parameter ·························································· 14

4.1. Description of display/setting unit······················· 14

4.1.1. Flow transmitter : FSV···S (IP66)

display/setting unit ···························· 14

4.1.2. Flow transmitter : FSV···H (IP67)

display/setting unit ···························· 14

4.1.3. Description of display/setting unit ················ 15

4.2. Composition of key operation···························· 16

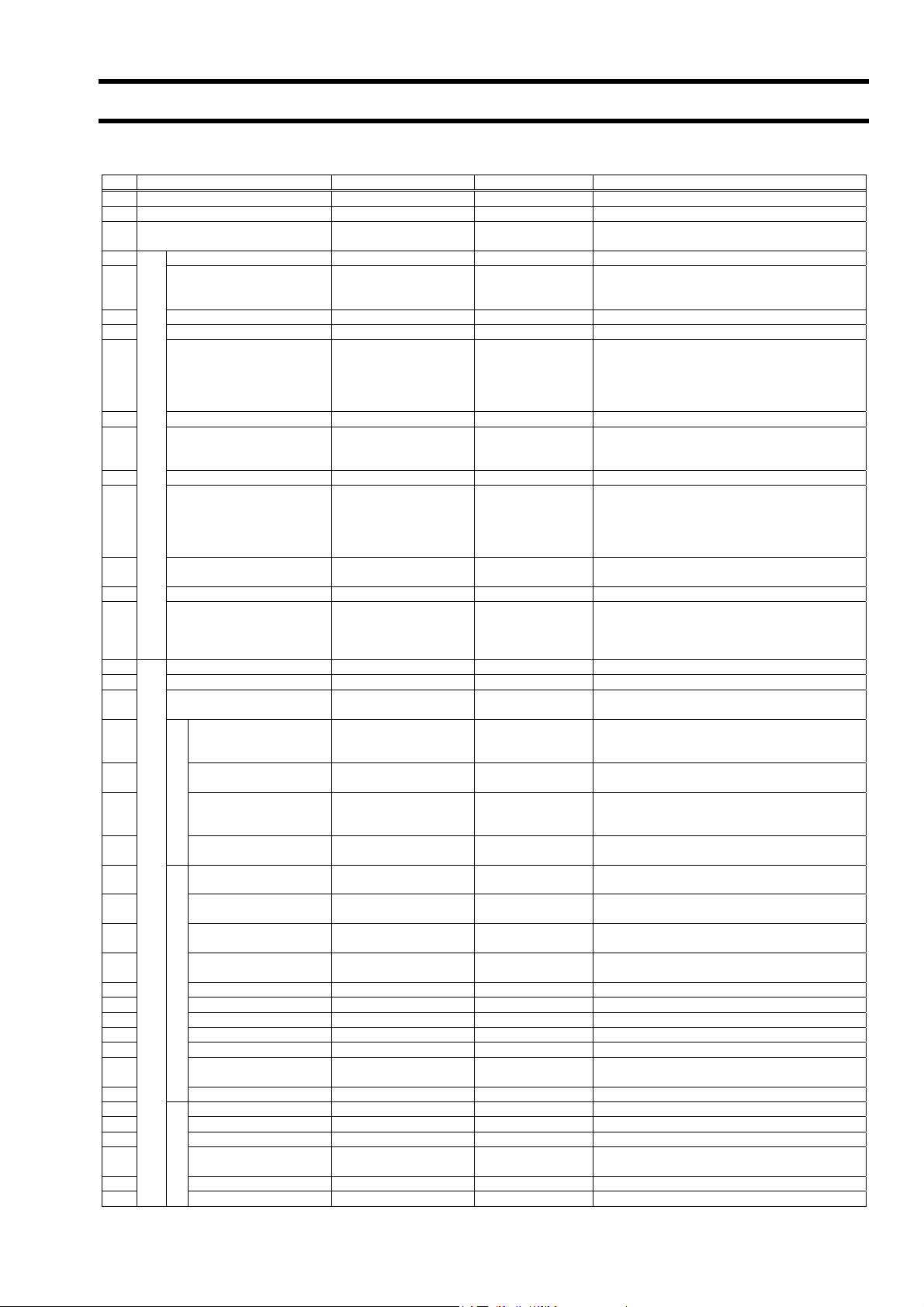

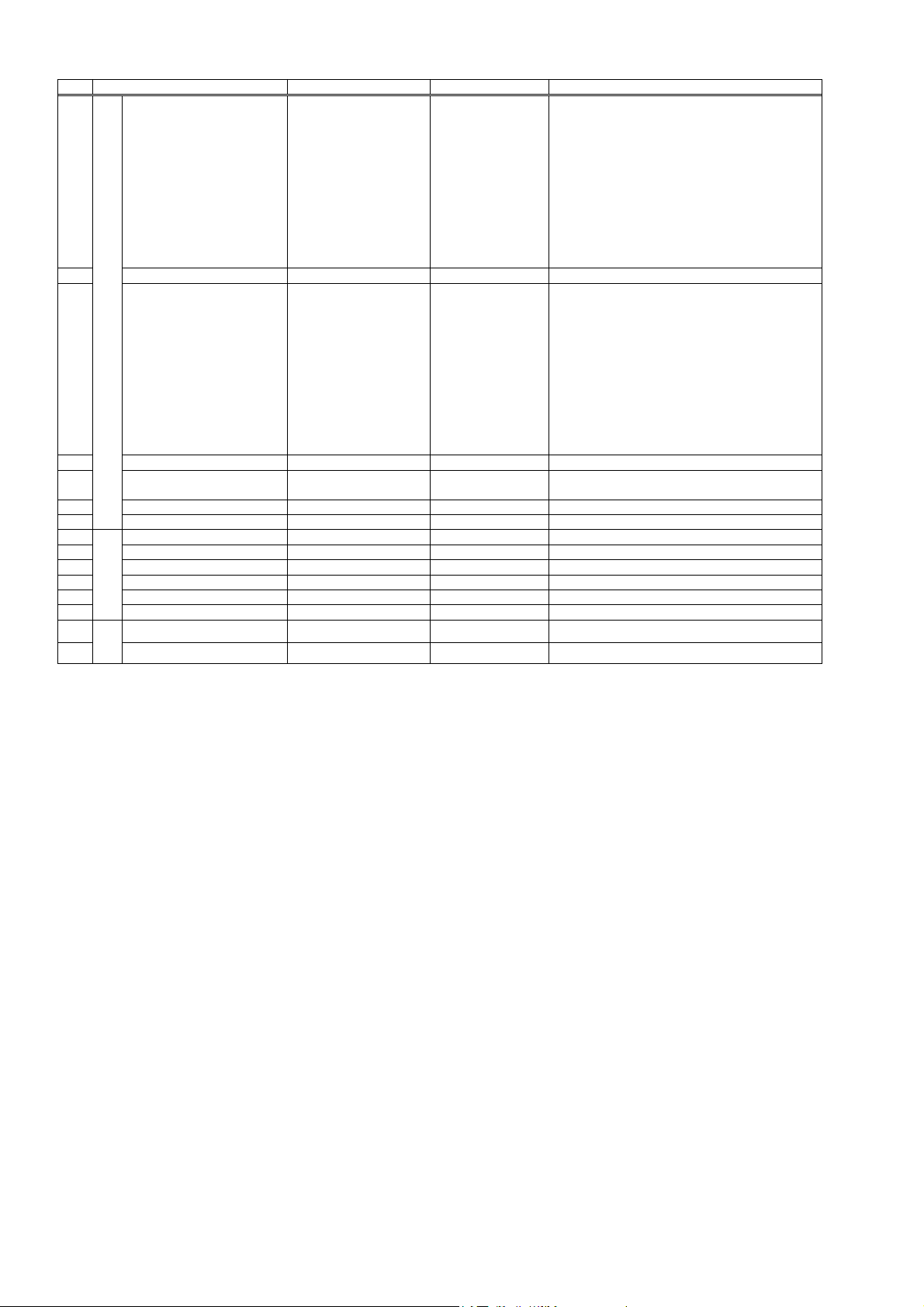

4.3. Parameter initial value list ································ 21

4.4. Parameter protection ······································ 23

4.4.1. Protection ON/OFF ·································· 23

4.5. Display language ··········································· 24

4.5.1. How to select the language ························ 24

4.6. Checking and Setting of Piping

Specifications/Detector ······························ 25

4.6.1. Checking piping parameter ························ 25

4.6.2. Piping parameter setting method ················· 26

4.7. Zero Adjustment ············································ 29

4.8. Setting of unit ··············································· 30

4.8.1. How to set the unit system ························· 30

4.8.2. How to set the flow rate unit ······················· 31

4.8.3. How to set the total unit ····························· 32

4.9. Output Setting ·············································· 33

4.9.1. Setting of flow rate range ··························· 33

4.9.1.1. Setting of flow rate range (single range) ·· 33

4.9.1.2. Setting of analog output at error

(Burnout) ···································· 35

4.9.1.3. Output limit ······································· 36

4.9.2. Setting the total(actual) ····························· 37

4.9.2.1. Setting the total pulse (total rate, pulse

width)········································· 37

4.9.2.2. Setting the preset value ······················· 39

4.9.2.3. TOTAL mode ····································· 40

4.9.2.4. Determining how to dispose of total at

error (BURNOUT) ························ 41

4.9.3. Setting the DO output ······························· 42

4.9.3.1. How to validate the total pulse output ····· 42

4.9.4. Setting the LCD indication ························· 44

4.9.5. Setting the damping ································· 45

4.9.6. Setting the low flow rate cutting ··················· 46

4.10. Application operation of parameter ·················· 47

4.10.1. Setting automatic 2 ranges ······················· 47

4.10.2. Setting the Bi-directional range ················· 49

4.10.3. Setting the Bi-directional auto 2 range ········ 51

4.10.4. Rate limit ·············································· 53

4.10.5. Setting the DO output ······························ 55

4.10.5.1. How to validate outputting the FULL

SCALE 2 ···································· 55

4.10.5.2. How to validate the alarm output ·········· 56

4.10.5.3. Setting the flow switch ······················· 57

4.10.5.4. How to validate the total switch ············ 59

4.10.5.5. How to validate the range over output

and pulse range over output ··········· 60

4.10.5.6. How to validate the output at the minus

direction action ···························· 61

4.10.6. How to compensate the measurement

value ·············································· 62

4.10.7. Setting of the operation mode ··················· 63

4.11. MAINTENANCE MODE ································ 64

4.11.1. How to calibrate the analog output ············· 64

4.11.2. How to set the constant current output ········ 65

4.11.3. How to check the action of total pulses ········ 66

4.11.4. How to check the status output ·················· 67

4.11.5. How to validate the test mode (simulated

flow rate output) ································ 68

4.11.6. How to validate a serial transmission (RS-

485) ··············································· 70

4.11.7. How to set the ID No. ······························ 72

4.11.8. How to confirm the software version ··········· 72

4.11.9. Initializing setting parameters ···················· 73

4.11.10. LCD backlight setting ····························· 74

-vi-

Page 8

4.11.11. How to set the detailed setting ················· 75

5. Mounting of detector ············································ 77

5.1. Detector mounting procedure ··························· 77

5.1.1. Mounting of detector ································· 78

5.1.2. Image figure of mounting dimension ············· 78

5.2. Selection of mounting method ·························· 79

5.3. Mounting method on the pipe ··························· 79

6. CHECK AND MAINTENANCE ······························· 80

6.1. Daily Check ·················································· 80

6.2. Periodic Inspection ········································· 80

6.2.1. Checking zero point ·································· 80

6.2.2. Reapplying grease ··································· 80

6.2.3. How to measure the insulation resistance ······ 81

6.2.3.1. Flow transmitter : FSV···S (IP66) ··········· 81

6.2.3.2. Flow transmitter : FSV···H (IP67) ··········· 82

6.3. How to replace the fuse ·································· 83

6.3.1. Flow transmitter : FSV···S (IP66) ················· 83

6.3.2. Flow transmitter : FSV···H (IP67) ················· 84

6.4. How to replace the LCD ·································· 85

6.4.1. Flow transmitter : FSV···S (IP66) ················· 85

6.4.2. Flow transmitter : FSV···H (IP67) ················· 86

6.5. ERROR AND REMEDY ·································· 87

6.5.1. Display error ··········································· 87

6.5.1.1. Checking the LCD/LED ························ 87

6.5.1.2. Checking the LED lit in red ··················· 88

6.5.1.3. Checking the RAS information ··············· 89

6.5.2. Displaying the data in maintenance mode ····· 90

6.5.3. Keying is abnormal ··································· 91

6.5.4. Error in measured value ···························· 92

6.5.5. Error in analog output ································ 94

6.5.6. Checking received waveforms ···················· 95

6.5.6.1. How to connect the oscilloscope ············ 95

6.5.6.2. Checking sending/receiving ·················· 96

6.5.7. Remedying a hardware fault ······················· 98

7. Appendix ··························································· 99

7.1. Specifications ················································ 99

7.2. OUTLINE DIAGRAM ···································· 101

7.3. ORDERING INFORMATION ·························· 102

7.4. Piping data ················································· 103

-vii-

Page 9

1. PRODUCT OUTLINE

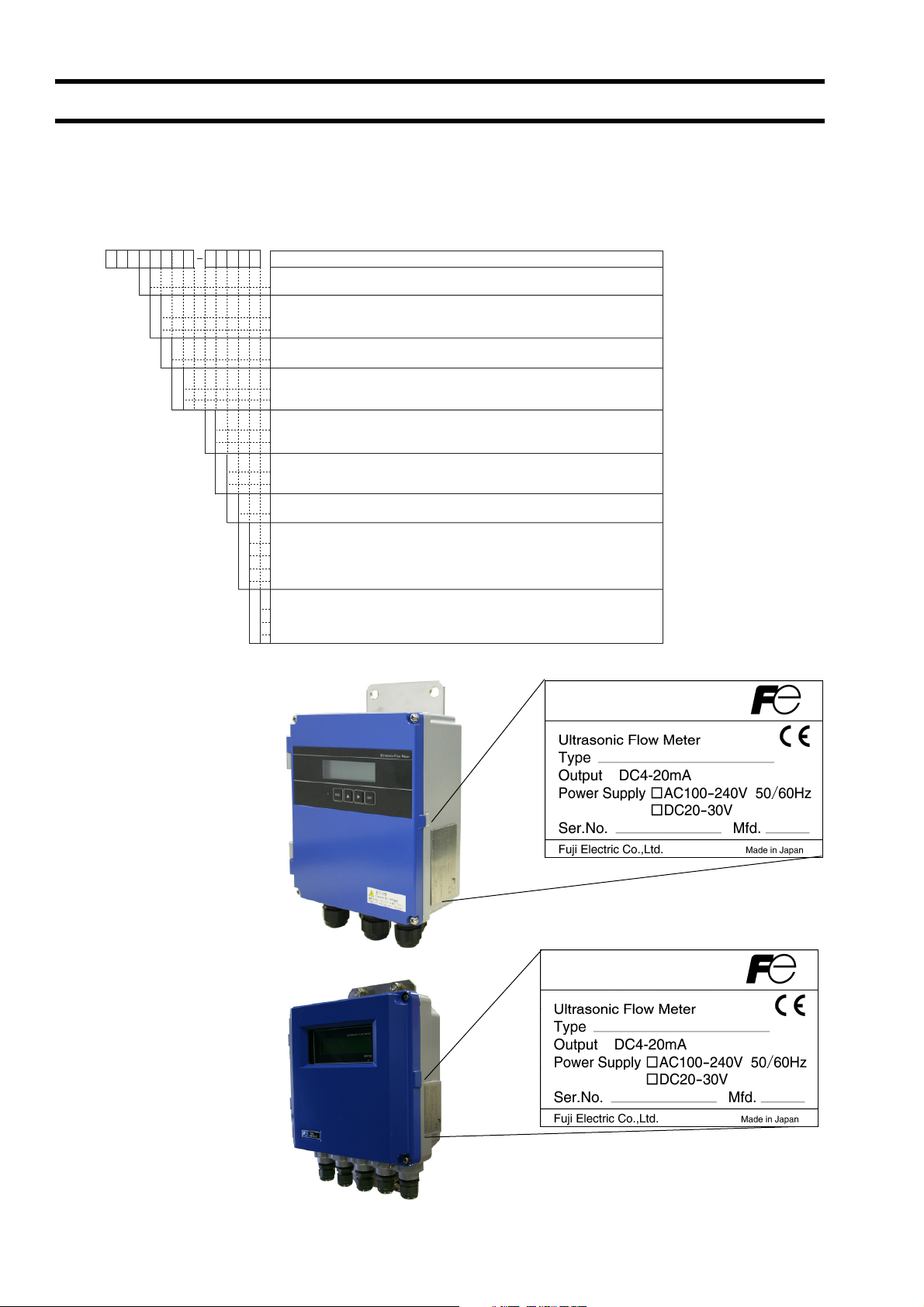

1.1. Checking delivered items

After opening the package, check if all following parts are present.

Note that the delivered parts vary according to the model type.

Flow transmitter (FSV)

Flow transmitter main unit ·································· 1 set

Waterproof gland (Built into the main unit) ············· 1 set

Wall mount frame (Built into the main unit) ············· 1 set

Panel mounting bracket (option)

(U bolt, support fixture, butterfly nut 2 pieces,

spring washer 2 pieces, plain washer 2 pieces) ······· 1 set

Flow transmitter (FSV)

FSV···S FSV···H

(IP66) (IP67)

CD-ROM (Instruction manual and loader software) ·· 1 piece

Out of delivery

Power cable

Output signal cable

RS-485 communication cable

Pipe mounting bracket

(option)

-1-

Page 10

1.2. Check on type and specifications

The type and specifications of product are indicated on the specifications plate mounted on the flow transmitter and detector

frame.

Check that they represent the type you ordered, referring to the following code symbols.

<Flow transmitter (FSV)>

12345678 910111213

2YFSV Y

E

Y

D

Y

1

4

Flow transmitter : FSV···S (IP66)

Description

(Destination) (4th digit)

Standard (English)

(Communication) (5th digit)

None

RS485

(Use) (6th digit)

Single measuring path

(Power supply) (7th digit)

AC100 to 240V 50/60Hz

DC20 to 30V

S

H

Y

A

Y

(Case structure) (9th digit)

IP66

IP67

(Wire connection port) (10th digit)

Weatherproof gland provided [G1/2 and G3/8 (internal threads)]

Union (for pilica) with gland [G1/2 female screw] (when "H" is specified 9th digit)

(Combination with explosion-proof detector) (11th digit)

None

(Parameter setting) (12th digit)

None

Y

Setting provided

A

Setting provided + tag

B

Ta g

C

(Mounting method) (13th digit)

Pipe mount (if the 9th digit is S)

A

Wall mount

B

Pipe mount (if the 9th digit is H)

C

Flow transmitter : FSV···H (IP67)

-2-

Page 11

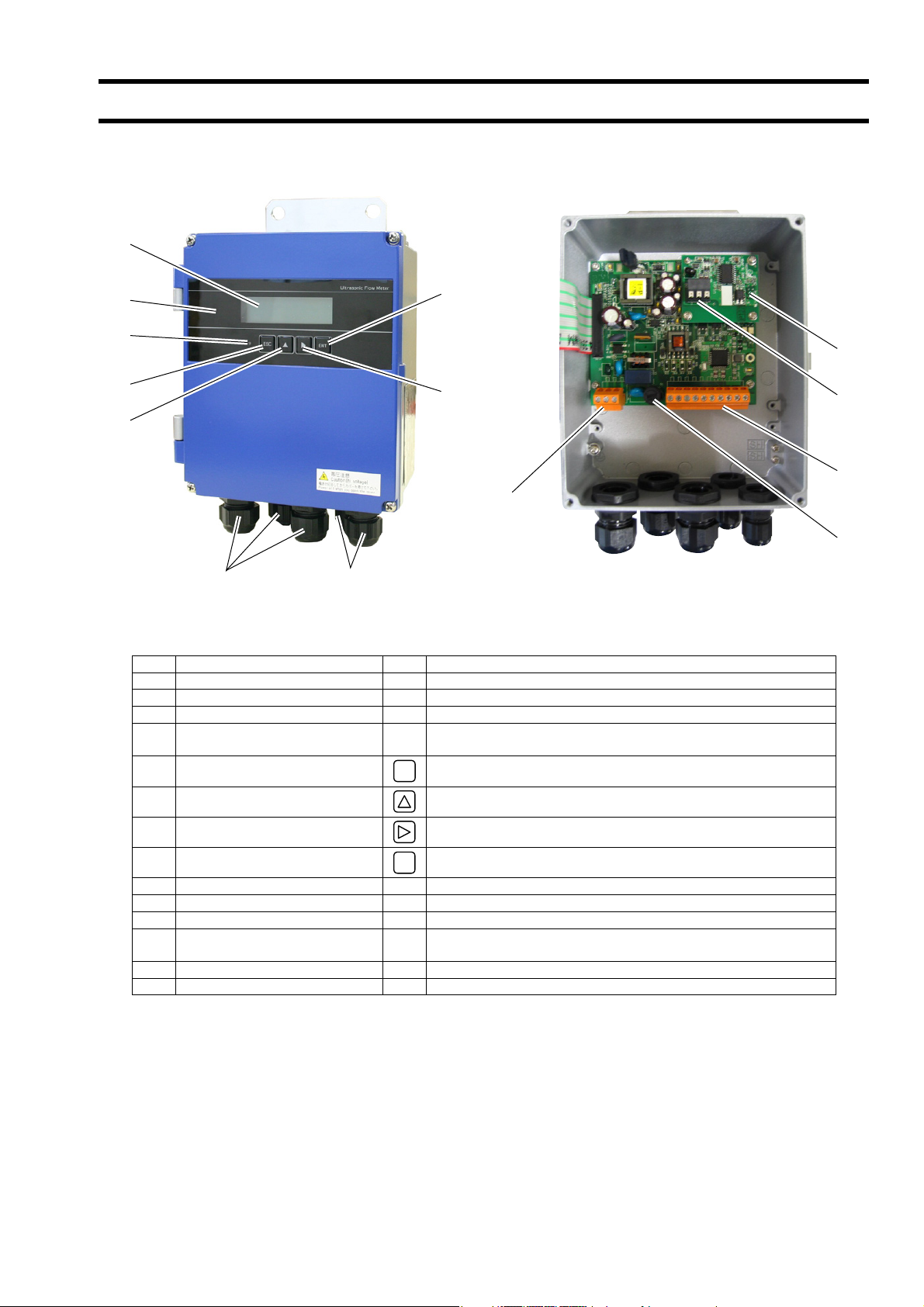

1.3. NAME AND FUNCTION OF EACH PART

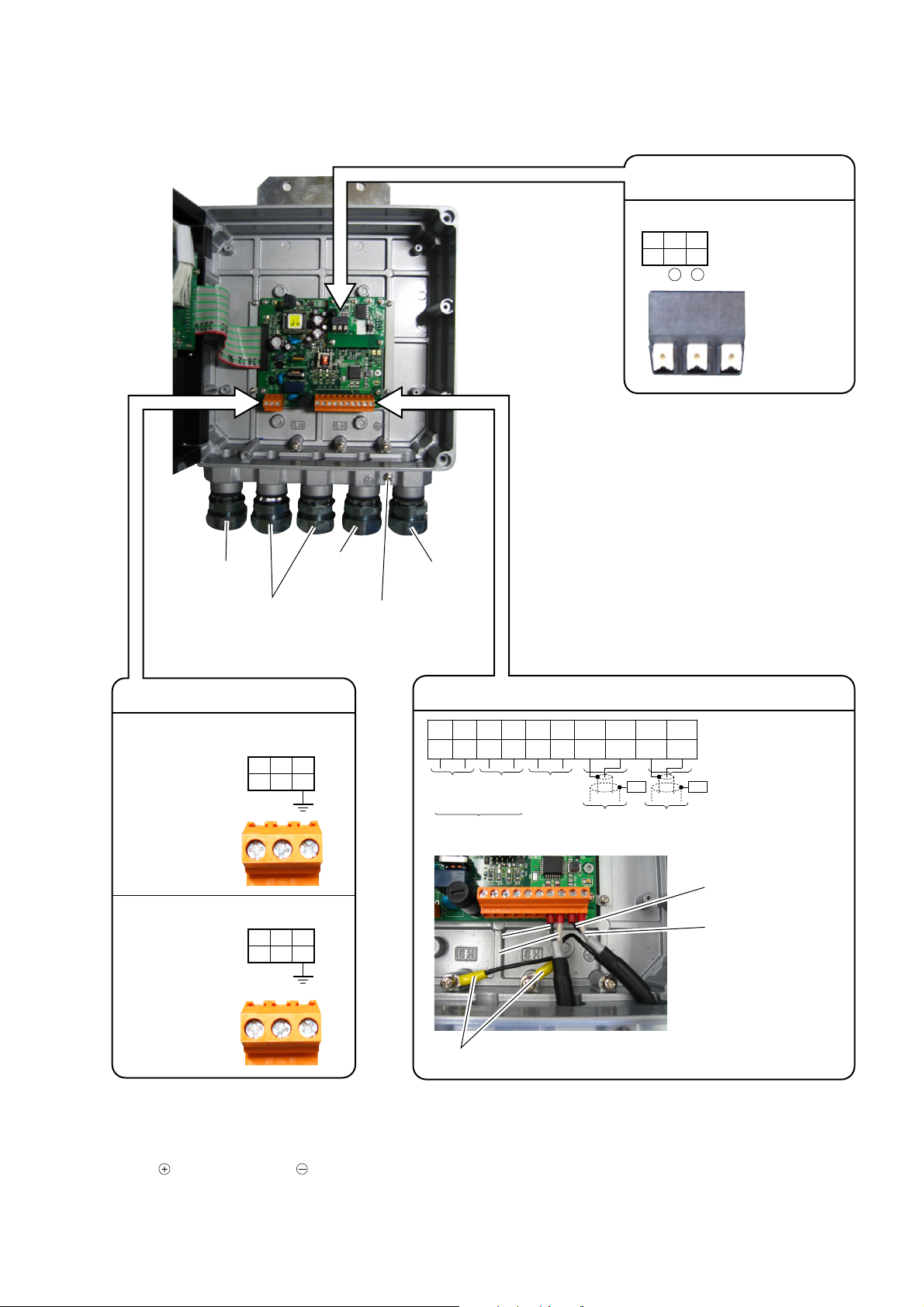

1.3.1. Flow transmitter : FSV···S (IP66)

(9)

(3)

(4)

(5)

(6)

(1)

No. Name Key Description

(1) Wiring connection port, large Wiring connection port for power cable and output cable.

(2) Wiring connection port, small Wiring connection port for signal cable only.

(3) Indication and setting unit Indicates and sets the flow rate, etc.

Received wave diagnostic

(4)

indication (LED)

(5) Escape key

(2)

ESC

(8)

(7)

(10)

Indicates whether received wave is normal (green) or abnormal

(red).

Returns to the next-higher menu level or cancels the set status.

(14)

(12)

(11)

(13)

(6) UP key Selects items, numeric values and symbols.

(7) Shift key Moves the cursor and selects decimal place.

(8) Entry key

(9) LCD display Indicates the flow rate or setting.

(10) Power terminal Connects the power cable.

(11) Input/output terminal Connects signal cable, analog output or DO output cable.

(12) Communication board terminal

(13) Fuse holder Fuse holder

(14) Communication board Mounted if communication is optionally designated.

ENT

Enters a selection or registers a setting.

Connects communication cable.

(A communication board is optional)

-3-

Page 12

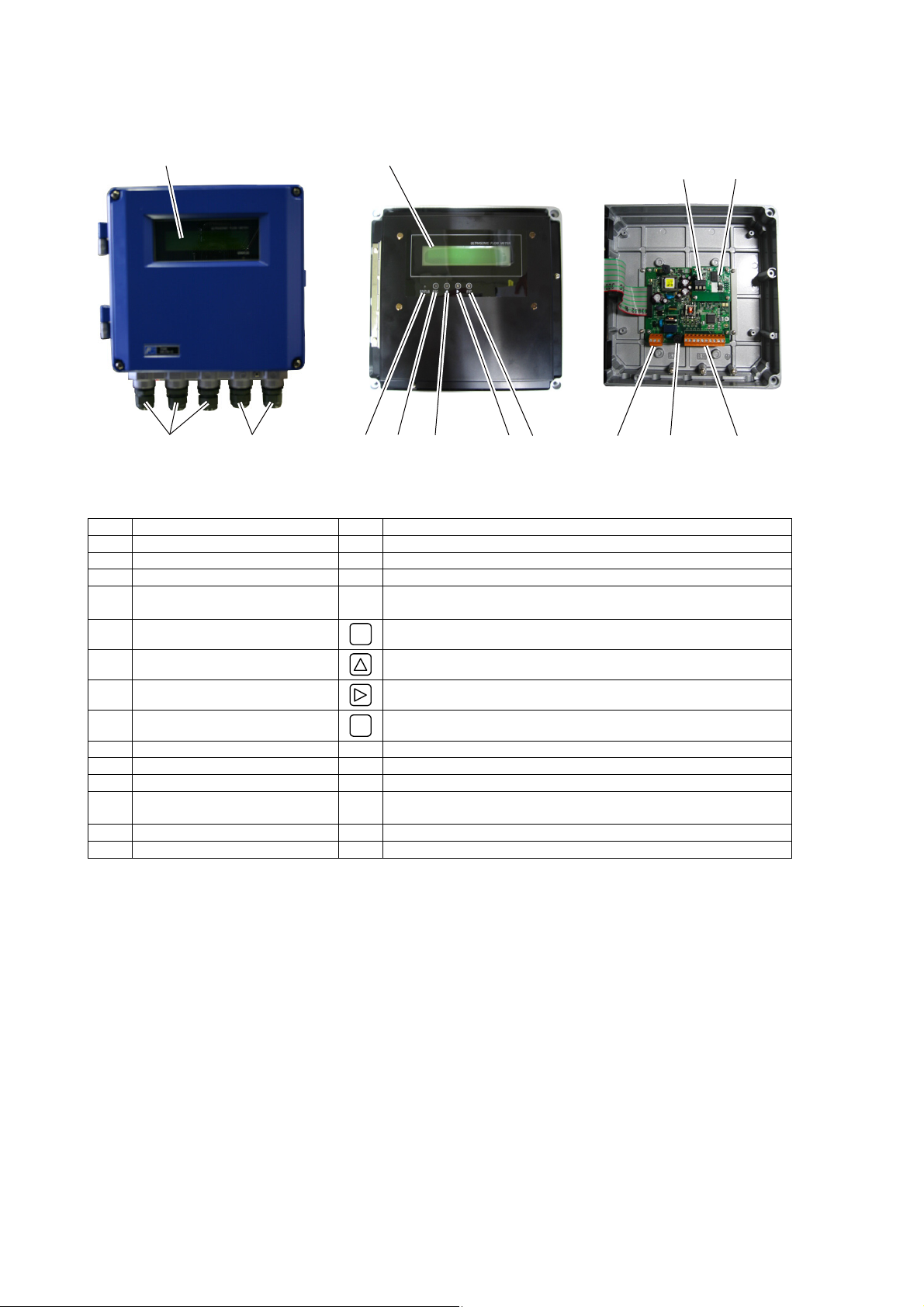

1.3.2. Flow transmitter : FSV···H (IP67)

(9)

(3)

(12)

(14)

(1)

No. Name Key Description

(1) Wiring connection port Wiring connection port for power cable and output cable.

(2) Wiring connection port Wiring connection port for signal cable only.

(3) Indication and setting unit Indicates and sets the flow rate, etc.

Received wave diagnostic

(4)

indication (LED)

(5) Escape key

(6) UP key

(7) Shift key

(8) Entry key

(9) LCD display Indicates the flow rate or setting.

(10) Power terminal Connects the power cable.

(11) Input/output terminal Connects signal cable, analog output or DO output cable.

(12) Communication board terminal

(13) Fuse holder Fuse holder

(14) Communication board Mounted if communication is optionally designated.

(2) (4) (5) (6) (7) (8) (10) (13) (11)

Indicates whether received wave is normal (green) or abnormal

(red).

ESC

Returns to the next-higher menu level or cancels the set status.

Selects items, numeric values and symbols.

Moves the cursor and selects decimal place.

ENT

Enters a selection or registers a setting.

Connects communication cable.

(A communication board is optional)

-4-

Page 13

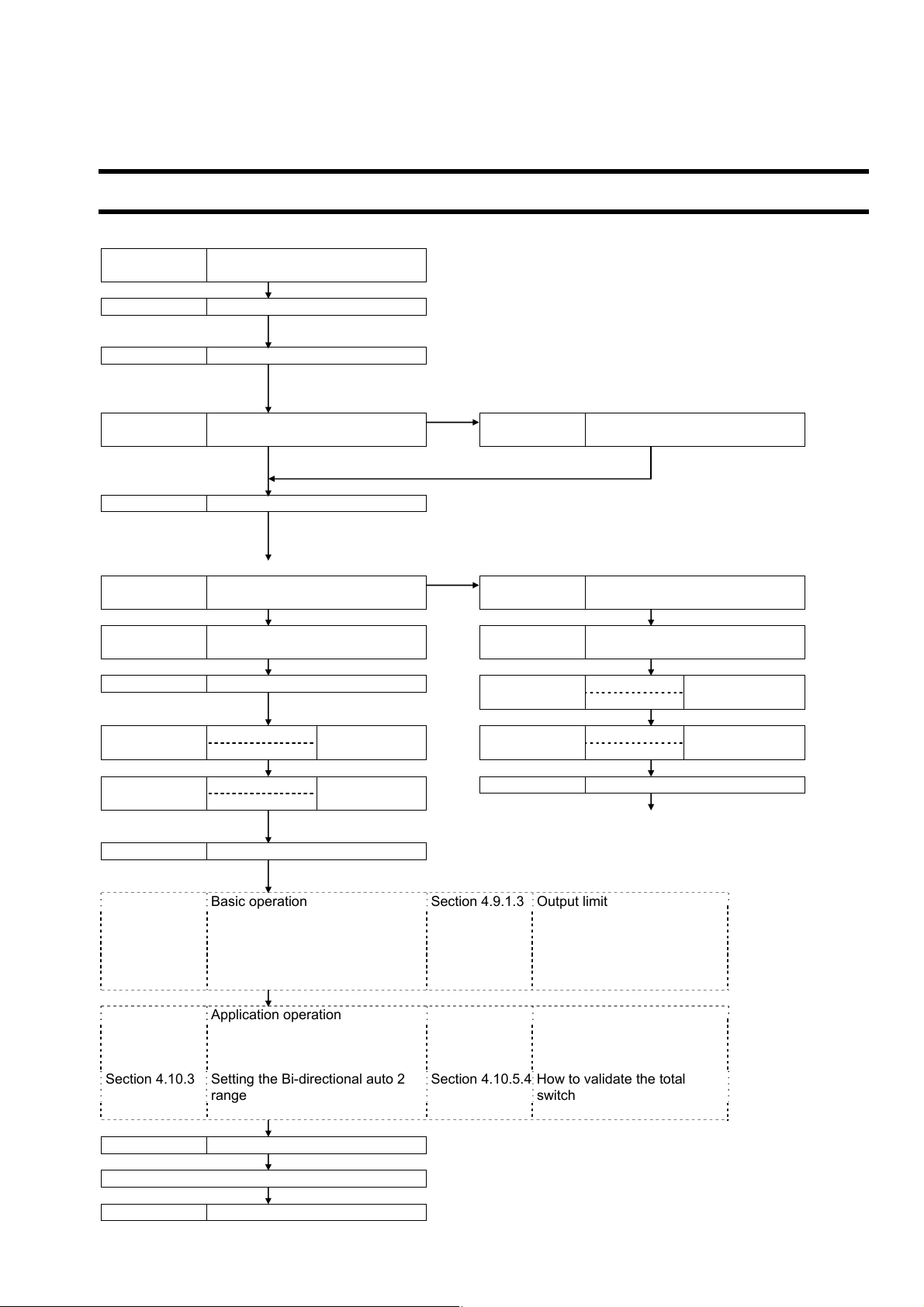

2. INSTALLATION AND BEFORE START OF OPERATION OF THE FLOW TRANSMITTER

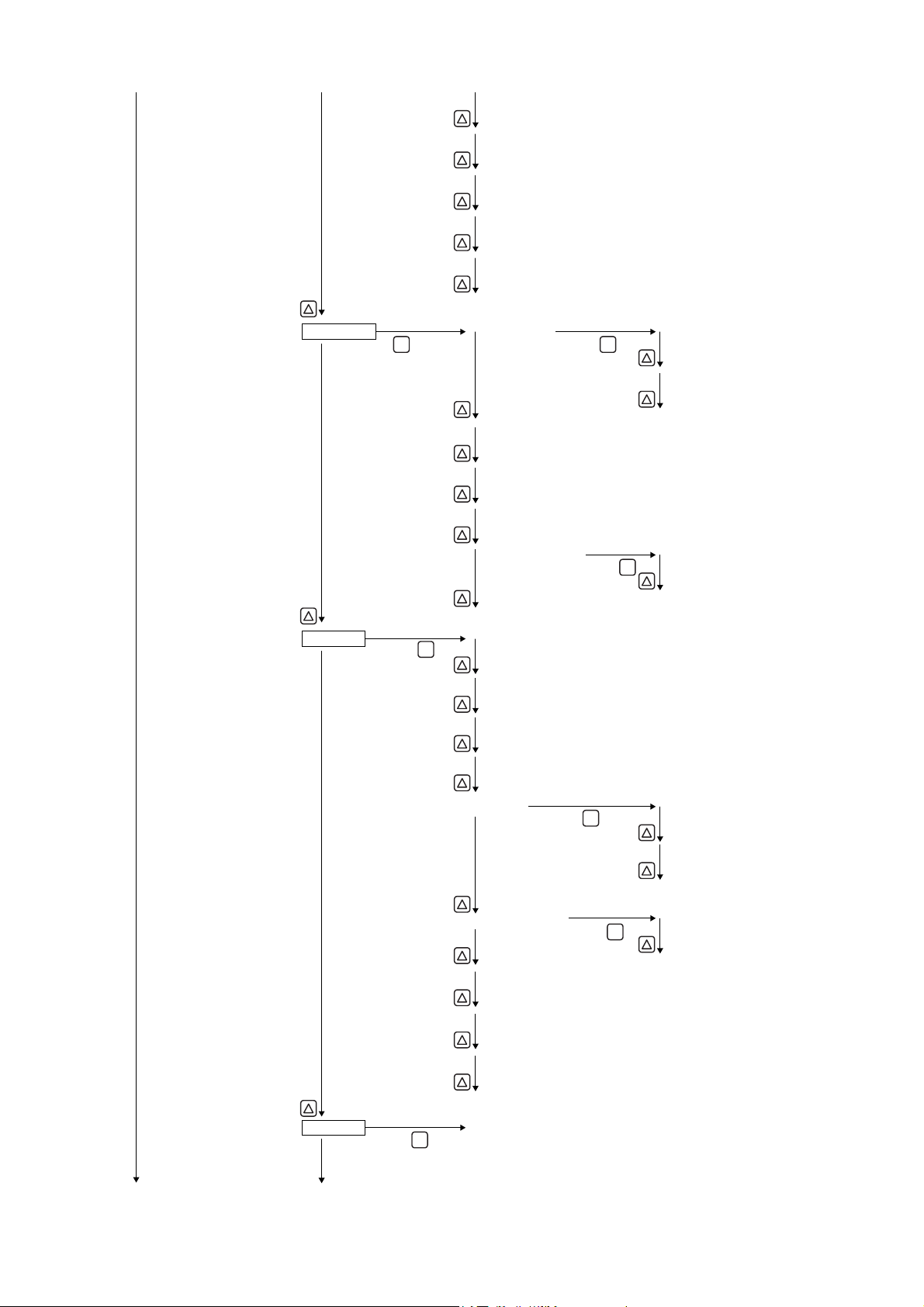

2.1. Outline of installation procedure

Install the flowmeter according to the following procedure.

Section 3.2

Section 3.3

Power ON * Check the power supply specifications and wiring before

Section 4.4 Parameter protection * Metric system is selected for unit.

* The initial display language is English. Switch the languages

NG When Y or C is selected for the 12th digit

Section 4.6

OK When A or B is selected for the

Section 5 Mounting of detector * Be careful not to mount the sensor units with wrong mounting

NG (LED display is red)

Section 6.5.1.3 Checking the RAS information

OK (LED display is green)

Section 6.5.2

Check the data display AGC U

AGC D

AGC U

AGC D P/H D

P/H U

P/H D

Contact Fuji Electric’s service representative.

Section 4.7 Zero Adjustment *

Basic operation Section 4.9.1.3 Output limit * Check A, B for

Section 4.8 Setting of unit Section 4.9.2 Setting thee

Section 4.9.1.1 Setting of flow rate range (single

Section 4.9.1.2 Setting of analog output at error

Application operation

Section 4.9.1 Setting of flow rate range Section 4.10.5.2 How to validate the alarm

Section 4.10.1 Setting automatic 2 ranges

Section 4.10.2 Setting the Bi-directional range Section 4.10.5.3 Setting the flow switch

Section 4.10.3 Setting the Bi-directional auto 2

Section 7.3 ORDERING INFORMATION

Section 6 CHECK AND MAINTENANCE

Note) Set the parameter protection to OFF before you change settings or perform zero adjustment.

Installation of flow transmitter

Flow transmitter wiring

Checking and Setting of Piping

Specifications/Detector

12th digit

Displaying the data in

maintenance mode

45% or more

5528 to 6758

range)

(Burnout)

range

Run (Measurement)

turning on the power. (Refer to “1.2.Check on type and

specifications”.)

as required.

P/H U

Section 6.5.6 Checking received waveforms

Section 4.9.3 Setting the DO output

Section 4.9.3.1 How to validate the total pulse

Section 4.9.4 Setting the LCD indication

Section 4.10.5.4 How to validate the total

Section 4.6.2 Piping parameter setting method

dimension. Mount it with the dimension displayed at the

process setting of the piping parameter. (Refer to “5.

Mounting of detector”.)

Section 6.5.2

Before performing zero point adjustment, check that the pipe

is filled with fluid, the fluid is in still state, and that the

measurement status is normal.

output

output

switch

Displaying the data in

maintenance mode

Check the data display

45% or more

Outside the range

of 5528 to 6758

the 12th digit of

code symbol

only.

-5-

Page 14

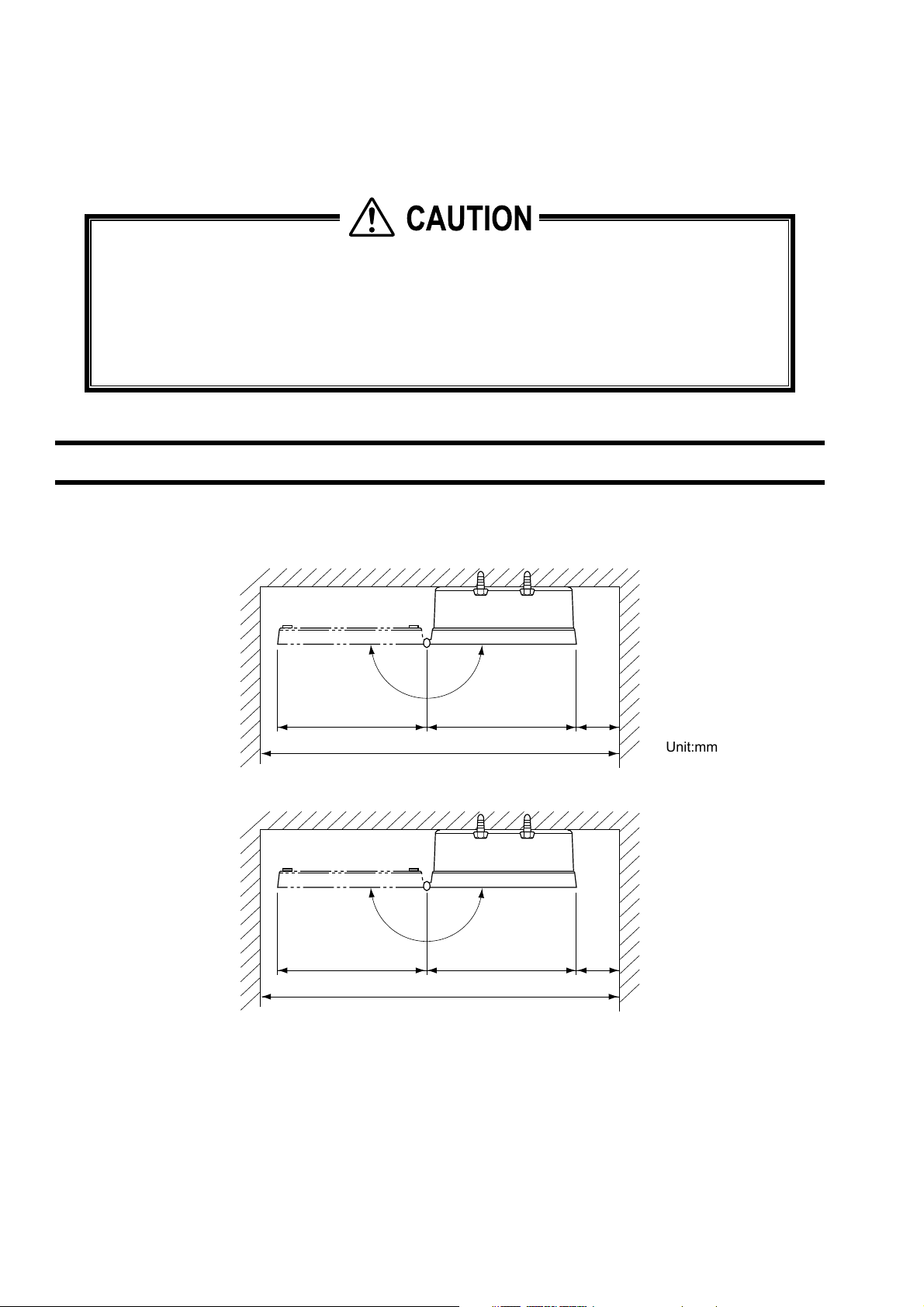

3. INSTALLATION

Select an installation location that satisfies the following conditions for ease of maintenance and inspection, service life of

the instrument, and assurance of reliability all considered.

CAUTION

(1) A place where ambient temperature and humidity are -20 to +55°C and 95% RH or less for flow transmitter

(FSV)

(2) A place not exposed to direct sunshine nor inclement weather.

(3) Space for periodic inspection and wiring work is available.

(4) A place not subjected to radiated heat from a heating furnace, etc.

(5) A place not subjected to corrosive atmosphere.

(6) A place not to be submerged.

(7) A place free from excessive vibration, dust, dirt and moisture.

3.1. Installation location of flow transmitter

Secure at least 100 mm of space between the flow transmitter and nearby wall. Also secure a space of opening the front

cover in case of maintenance.

Allow space for cable wiring under the case.

N

E

P

O

O

P

E

147

N

240

147

400 or more

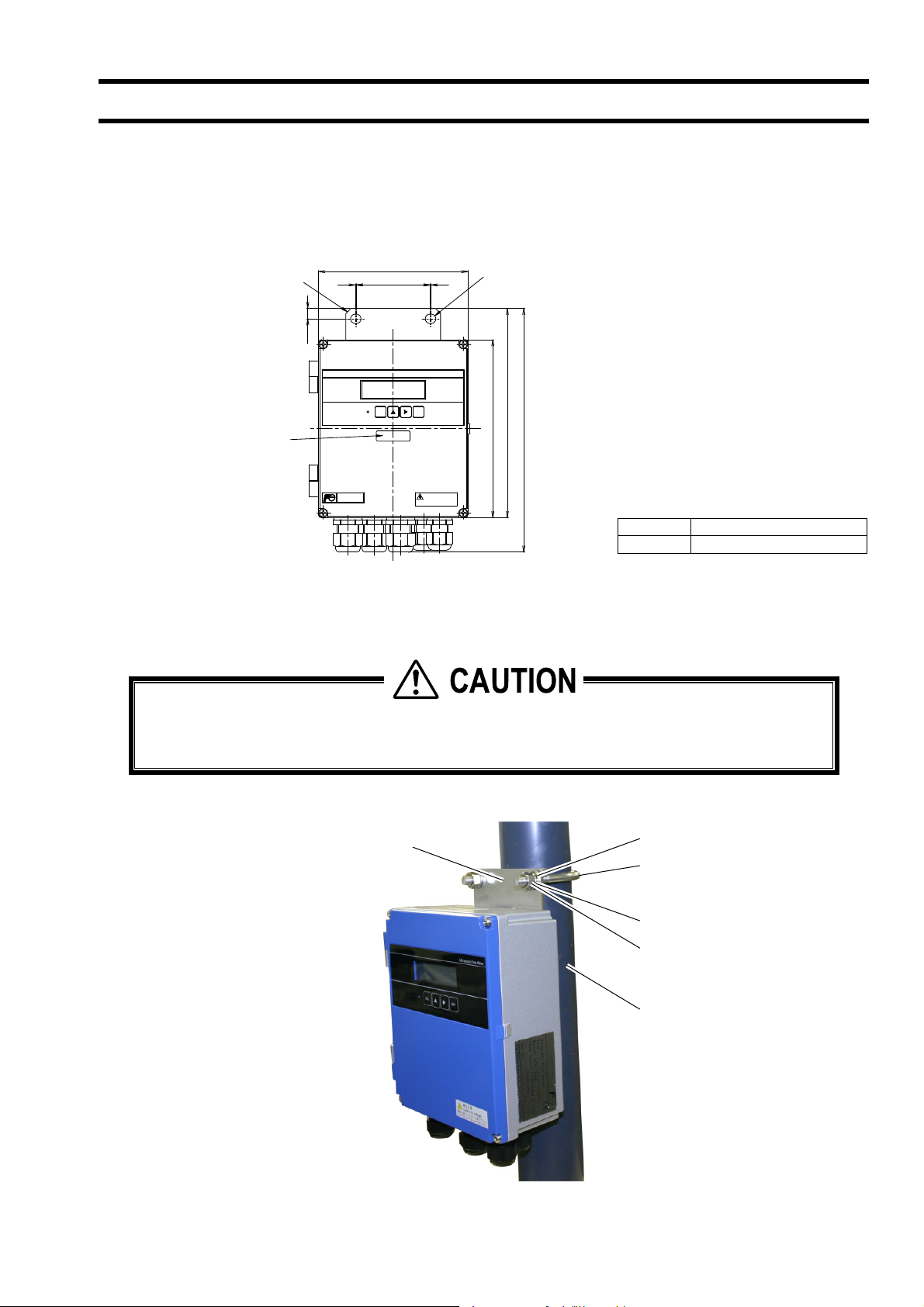

Fig. 3.1 Top view of mounting (Flow transmitter : FSV···S (IP66))

240

100 or

more

100 or

more

Unit:mm

580 or more

Fig. 3.2 Top view of mounting (Flow transmitter : FSV···H (IP67))

-6-

Unit:mm

Page 15

3.2. Installation of flow transmitter

The flow transmitter may be mounted on a wall or 2B pipe stand (option).

3.2.1. Wall mounting (Flow transmitter : FSV···S (IP66))

For wall mounting, use two M8 bolts.

Drill holes according to the mounting hole dimensions shown below, and fasten the flow transmitter using the M8 bolts.

Mounting plate

Stainless tag

(option)

1

10

ESC

142

70

ENT

1

Ultrasonic Flow Meter

Mounting hole 9 × 10

200

170

(233)

TIME

DELTA-C

高圧注意

Caution(hi voltage)

電源を切断してからカバーを開けて下さい。

Power off when you open the cover.

Norminal Standard tightening torque

M8

12.5 [Nm]

3.2.2. 2B pipe stand mounting (Flow transmitter : FSV···S (IP66))

CAUTION

When mounting on 2B pipe, be sure to use a complete set of fixtures (U bolt, support fixture, plain washer,

spring washer, nut) furnished if optionally designated. Tighten the nut by hand. If any support fixture is not used

or if the assembly is excessively tightened by tool, the wall mounting fixture may be deformed.

Mount the instrument on 2B pipe stand as illustrated below.

Support fixture

Plain washer

U bolt (M8)

Spring washer

-7-

Nut

2B pipe stand

Page 16

r

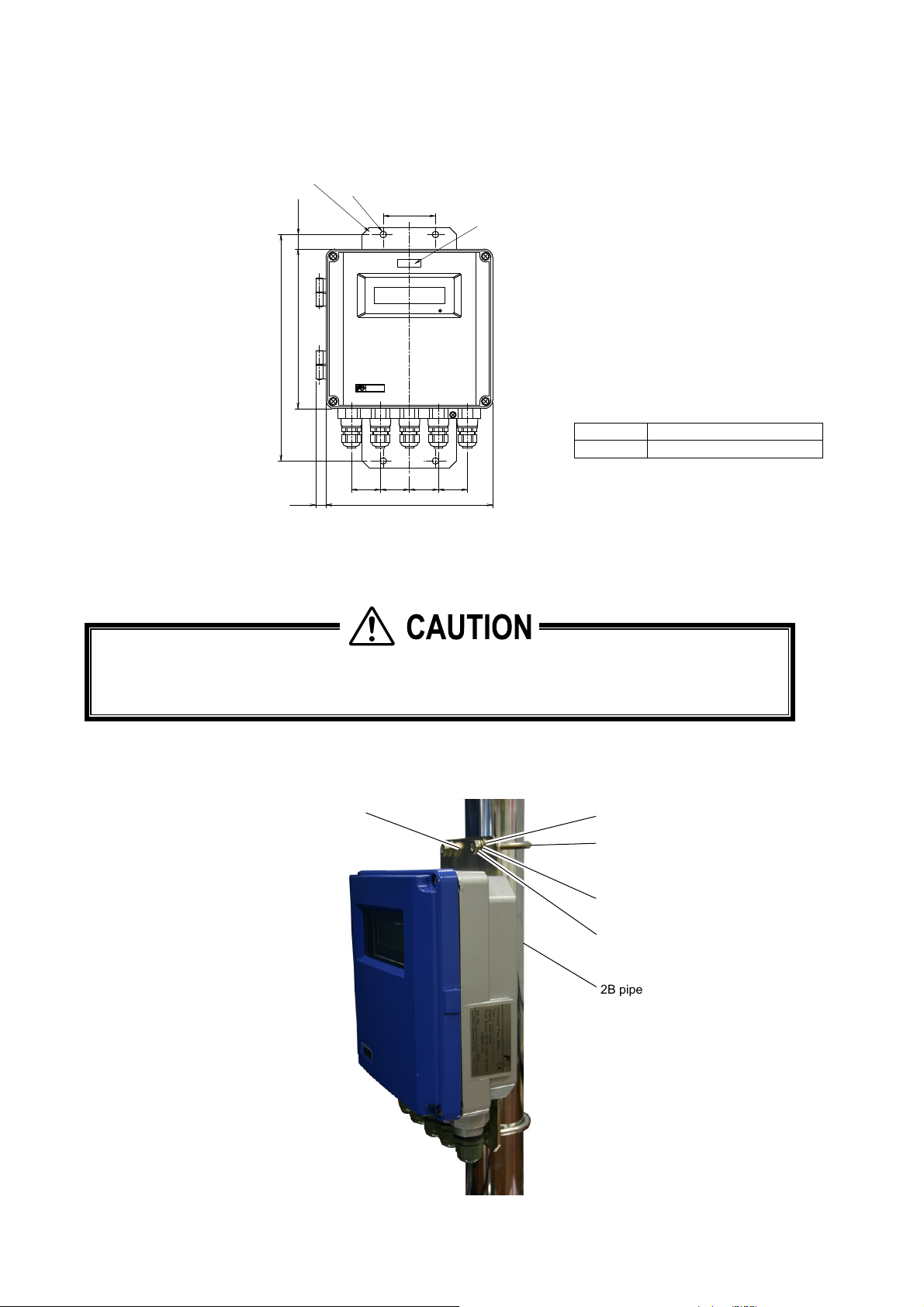

3.2.3. Wall mounting (Flow transmitter : FSV···H (IP67))

For wall mounting, use four M8 bolts.

Drill holes according to the mounting hole dimensions shown below, and fasten the flow transmitter using the M8 bolts.

Mounting plate

Mounting hole 2-φ9

20

72

Stainless tag

(option)

ULTRASONICFLOWMETER

STATUS

312

220

TIME

DELTA‑C

Norminal Standard tightening torque

12.5 [Nm]

14

40

230

40

M8

4040

3.2.4. 2B pipe stand mounting (Flow transmitter : FSV···H (IP67))

CAUTION

When mounting on 2B pipe, be sure to use a complete set of fixtures (U bolt, support fixture, plain washer,

spring washer, nut) furnished if optionally designated. Tighten the nut by hand. If any support fixture is not used

or if the assembly is excessively tightened by tool, the wall mounting fixture may be deformed.

Mount the instrument on 2B pipe stand as illustrated below.

Support fixture

Plain washer

-8-

U bolt (M8)

Spring washe

Nut

2B pipe stand

Page 17

3.3. Flow transmitter wiring

3.3.1. Cautions in wiring

(1) Use a special coaxial cable (FLYC) as a signal cable between the detector and flow transmitter (FSV). Do

not provide a junction or splice of the signal cable midway.

(2) The signal cable between the detector or flow transmitter should be run in metallic conduits. Upstream and

downstream signal cables may be put in the same conduit but, to avoid interference, do not put the power

cable together.

(3) For output signal, use a shielded cable, where possible.

(4) To avoid noise interference, do not put the cables together with heavy duty line or the like into the same

duct.

(5) If a ground wire is included in the power cable, connect it to ground as it is.

(6) A power switch is not provided on the instrument and must be mounted separately.

(7) Seal unused wiring ports by furnished caps.

CAUTION

3.3.2. Applicable wires

Use the following cables.

Power cable : 3-wire or 2-wire cabtyre cable (Allowable temperature: 65°C or more)

Nominal sectional area 0.75mm2 or more

Outside diameter Ф11 m m

Output signal cable : 2-wire or multi-wire cabtyre cable as required (Allowable temperature: 65°C or more)

Outside diameter Ф11 m m

Detector-flow transmitter cable : Signal cable by type designation

In case of detector FSSA : High-frequency coaxial double shield cable with

FSSC characteristic impedance of 50Ω

FSSD With one-side waterproof BNC connector

FSSH Outside diameter Ф7.3mm

In case of detector FSSE High-frequency coaxial double shield cable with

characteristic impedance of 50Ω

Outside diameter Ф7.3mm

3.3.3. Treatment of wiring port

The casing of the flow transmitter is IP66 and IP67. However, if installed in a humid place, the wiring ports must be made

airtight to avoid ingress of moisture, condensation, etc. Be sure to use the waterproof glands furnished with the instrument

in order to ensure the waterproof means. A gland, which is not ready to be used, should be sealed by supplied cover.

CAUTION

Do not install the instrument where there is a risk of flooding.

-9-

Page 18

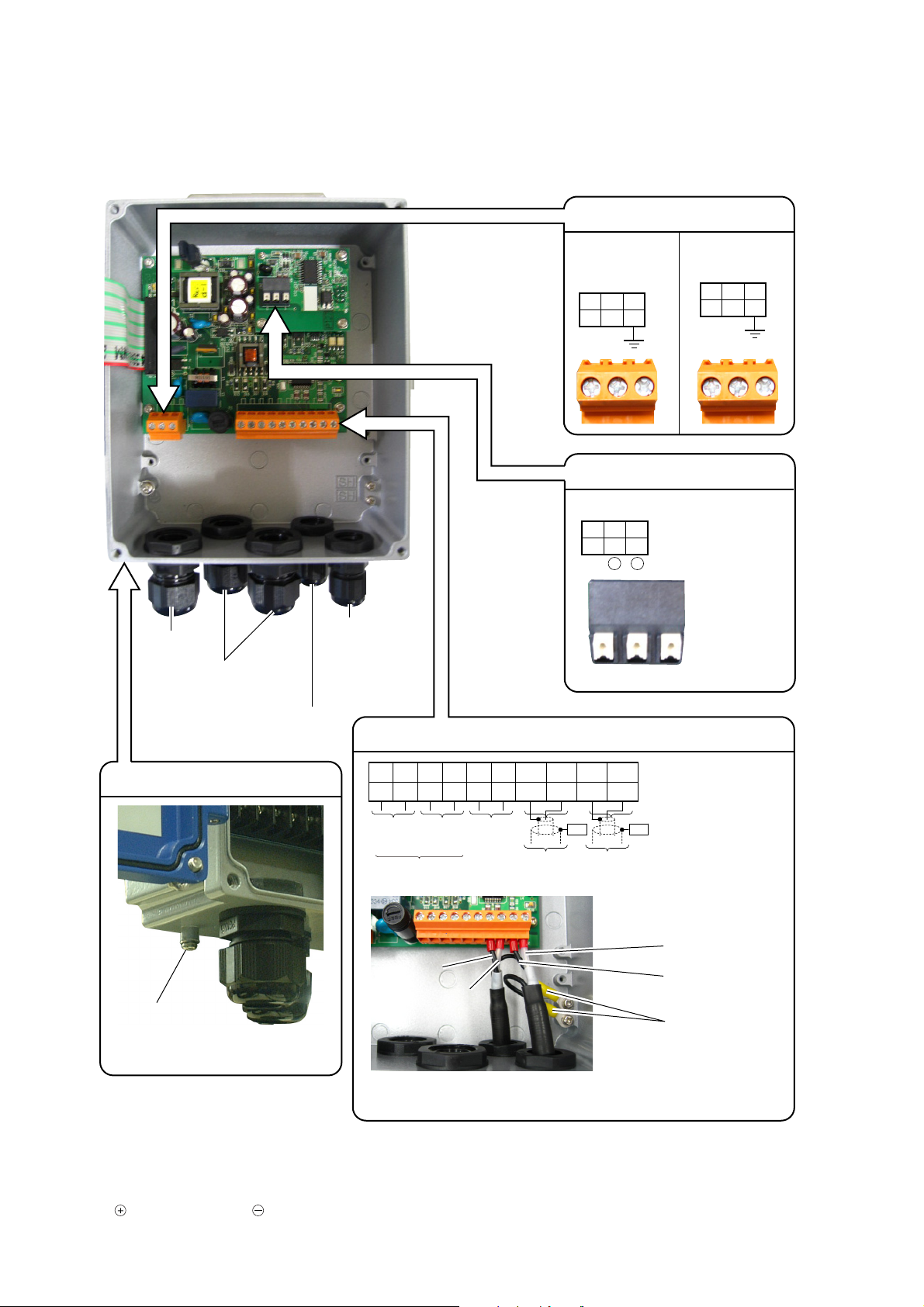

3.3.4. Wiring to each terminal

3.3.4.1. Flow transmitter : FSV···S (IP66)

Carry out wiring to each terminal according to the following figure.

Power supply board terminal block

Power cable

Output signal cable

(analog output, DO1,

DO2, Communication)

Upstream

sensor cable

Downstream

sensor cable

Main board terminal block

AC power supply

100 to 120V AC

or 200 to 240V AC

50/60Hz

123

L N FG

DC power supply

20 to 30V DC

123

+

-

Communication board terminal

block (option)

RS-485

123

SG A-B

+

+

-

FG

External ground terminal

Ground terminal (M4)

123456 7 8 910

--

+

+

DO1 DO2

TROUT

DC30V, 50mA

Black

White

-

+

I out

To upstream

sensor

GND

HF1 HF2

TO SENSOR

To downstream

sensor

GND

SHSH

DOWN STRUP STR

White

Black

Yellow

Iout : Analog output

DO1, 2 : Transistor/open

collector

Note 1) Terminal block is insertion type to connect a cable. Use bar terminal as crimp-style terminals.

Note 2) Be sure to connect ground terminal to external ground terminal. (Class D grounding)

Note 3) For output signal, use multiple core cable as required.

Note 4) Differential signal line of RS-485 consists of two pins.

means B+, and means A-.

-10-

Page 19

3.3.4.2. Flow transmitter : FSV···H (IP67)

Carry out wiring to each terminal according to the following figure.

Communication board terminal

block (option)

RS-485

123

SG A-B

+

-

+

Power cable

Output signal cable

(analog output, DO1,

DO2, Communication)

Downstream

sensor cable

Power supply board terminal block

AC power supply

100 to 120V AC

or 200 to 240V AC

50/60Hz

DC power supply

20 to 30V DC

123

L N FG

123

+

-

FG

sensor cable

External

ground terminal

(M4)

Upstream

Main board terminal block

123456 7 8 910

--

+

+

DO1 DO2

TROUT

DC30V, 50mA

Black

White

+

I out

-

GND

GND

HF1 HF2

DOWN STRUP STR

TO SENSOR

SHSH

Black

White

Iout : Analog output

DO1, 2 : Transistor/open

collector

Yellow

To upstream

sensor

To downstream

sensor

Note 1) Terminal block is insertion type to connect a cable. Use bar terminal as crimp-style terminals.

Note 2) Be sure to connect ground terminal to external ground terminal. (Class D grounding)

Note 3) For output signal, use multiple core cable as required.

Note 4) Differential signal line of RS-485 consists of two pins.

means B+, and means A-.

-11-

Page 20

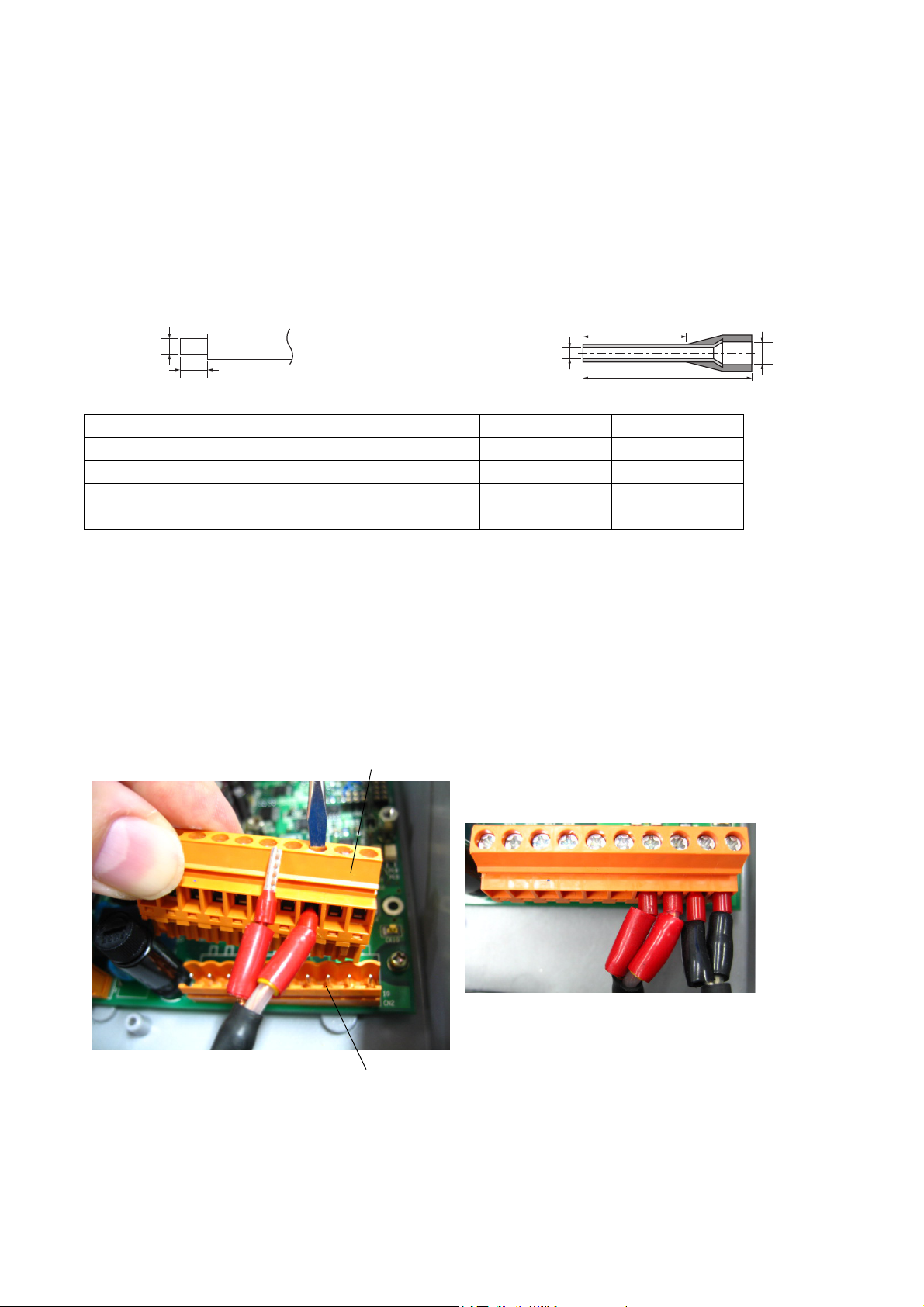

3.3.5. How to connect to terminal block.

3.3.5.1. Cable treatment

The cable connecting to the terminal block is available to connect with bare wire but for safety’s sake please crimp the bar

terminal to connect.

When you cut and use the signal cable, make sure to cut the cable in same length of upstream and downstream.

Note) if cable lengths are different, it may adversely affect the output.

Usable wiring materials

• Wire

Gauge: AWG20 (0.5mm

Strip-off length: 8 to 10mm

2

) to AWG16 (1.5mm2)

• Bar terminal

Weidmuller

www.weidmuller.com

AWG20

to

AWG16

øD1

8 to 10mm

10

16

Wire size (mm2) AWG øD1 (mm) øD2 (mm) Type

0.5 20 1 2.6 H0.5/16

0.75 18 1.2 2.8 H0.75/16

1 17 1.4 3 H1/16

1.5 16 1.7 3.5 H1.5/16

Note1) Make sure to use PZ6/5(H0.25 to H6 for sleeve) as a crimp tool for caulking.

Note2) Applicable sleeve is required for electric wire.

Note3) Insert the electric wire to the end of H sleeve so as to crimp.

Note4) Length of stripped wire is 12mm.

3.3.5.2. How to connect to power supply/terminal block for signal.

Please prepare the flathead screwdriver (head size: 0.6 x 3.5mm) so as to tighten the cable.

(1) Pull off the cable socket side from the plug on the substrate with holding the right side of the socket by hand.

(2) If cable connector is closed, turn the screw to the left on the top to open.

(3) Insert the cable and turn the screw to the right on the top to fix.

(4) Install the cable socket side to the plug on the substrate.

Cable socket side

øD2

Note) Make sure to conduct the procedure not to damage the printed-circuit board when you remove and install the cable

socket side.

Plug on substrate

-12-

Page 21

3.3.5.3. How to connect to communication terminal block.

Please prepare the flathead screwdriver (head size: 0.6 x 3.5mm) so as to connect the cable.

1. Push the clamp so as to open the connector.

2. Insert the cable to the connector and release the clamp to fix the cable.

Clamp

-13-

Page 22

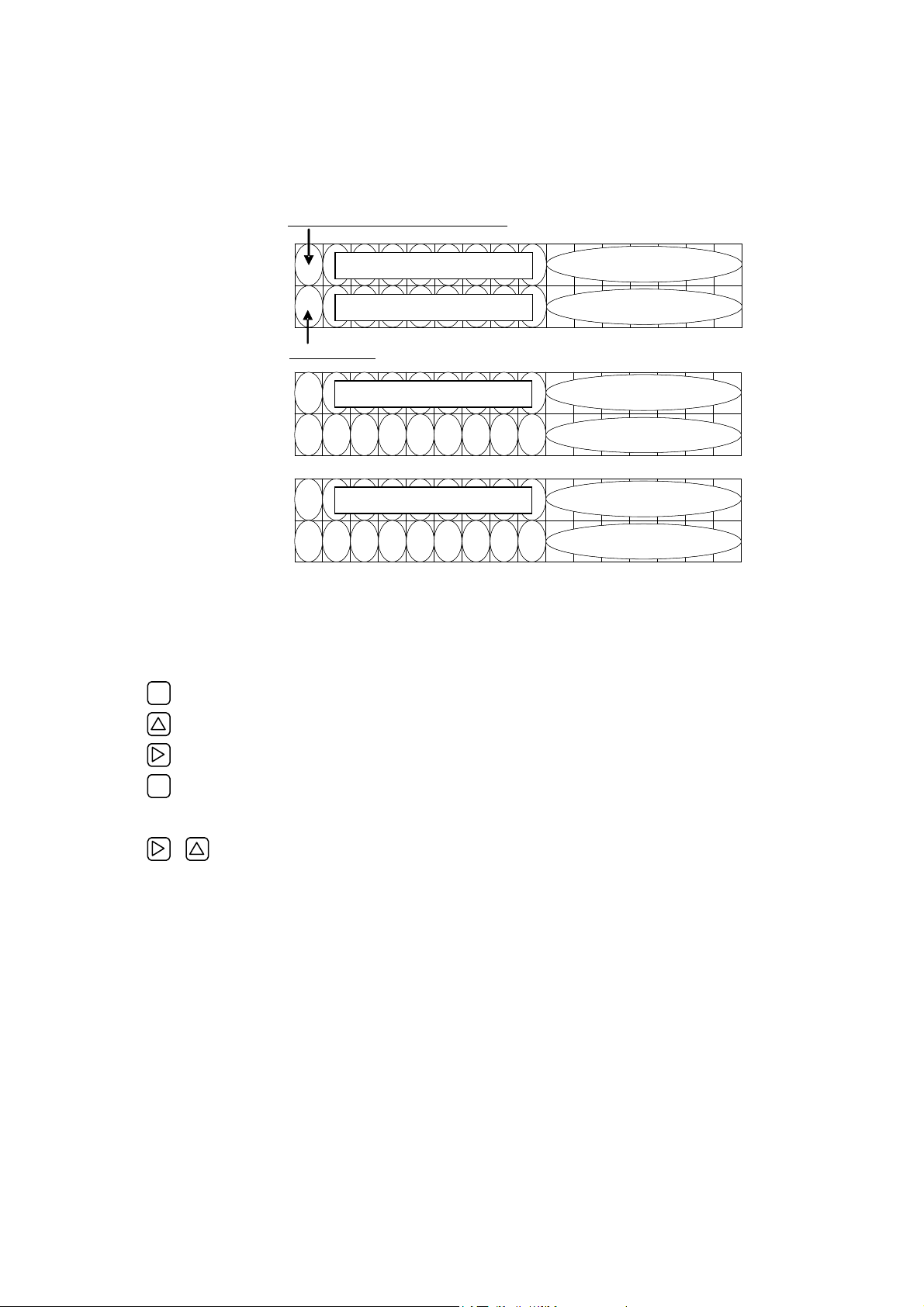

4. Parameter

4.1. Description of display/setting unit

Display unit and setting unit are as shown below.

4.1.1. Flow transmitter : FSV···S (IP66) display/setting unit

LED

4.1.2. Flow transmitter : FSV···H (IP67) display/setting unit

LED

-14-

Page 23

4.1.3. Description of display/setting unit

○ LCD display: Displays the measurement and setting (indication in 16 digits, 2 line).

“Measurement display”

Up to 8 digits including the decimal point are displayed in the data field. When the displayed

digits exceed, “<” is displayed at the first digit. When the range exceeds maximum or is below

minimum setting, “OVERFLOW” or “UNDERFLOW” is displayed blinking on the Display 2.

Flow direction, during test mode “T”

Display 1

Display 2

Flow direction

Display 1

Display 2

Display 1

Display 2

○ LED display: Indicates whether the received wave is normal or not.

Set the parameter by setting switches.

ESC

ESCAPE key : Return to the next-higher menu level or cancels the set status.

O

U D

(Green) : Received wave is normal.

(Red) : Received wave is abnormal.

Data

Data

Data Unit

V E R L O WF

Data Unit

N E R L O WF

Unit

Unit

UP key : Selects items, numeric values and symbols.

SHIFT key : Moves the cursor and selects decimal place.

ENT

ENTRY key : Enters a selection or registers a setting.

Note) For changing the parameter, enter the changed value, and press this key to confirm

that it is registered.

Uses DOWN key for selecting the items, values and codes.

+

DOWN key : DOWN key function is conducted by holding down SHIFT key and press DOWN key.

-15-

Page 24

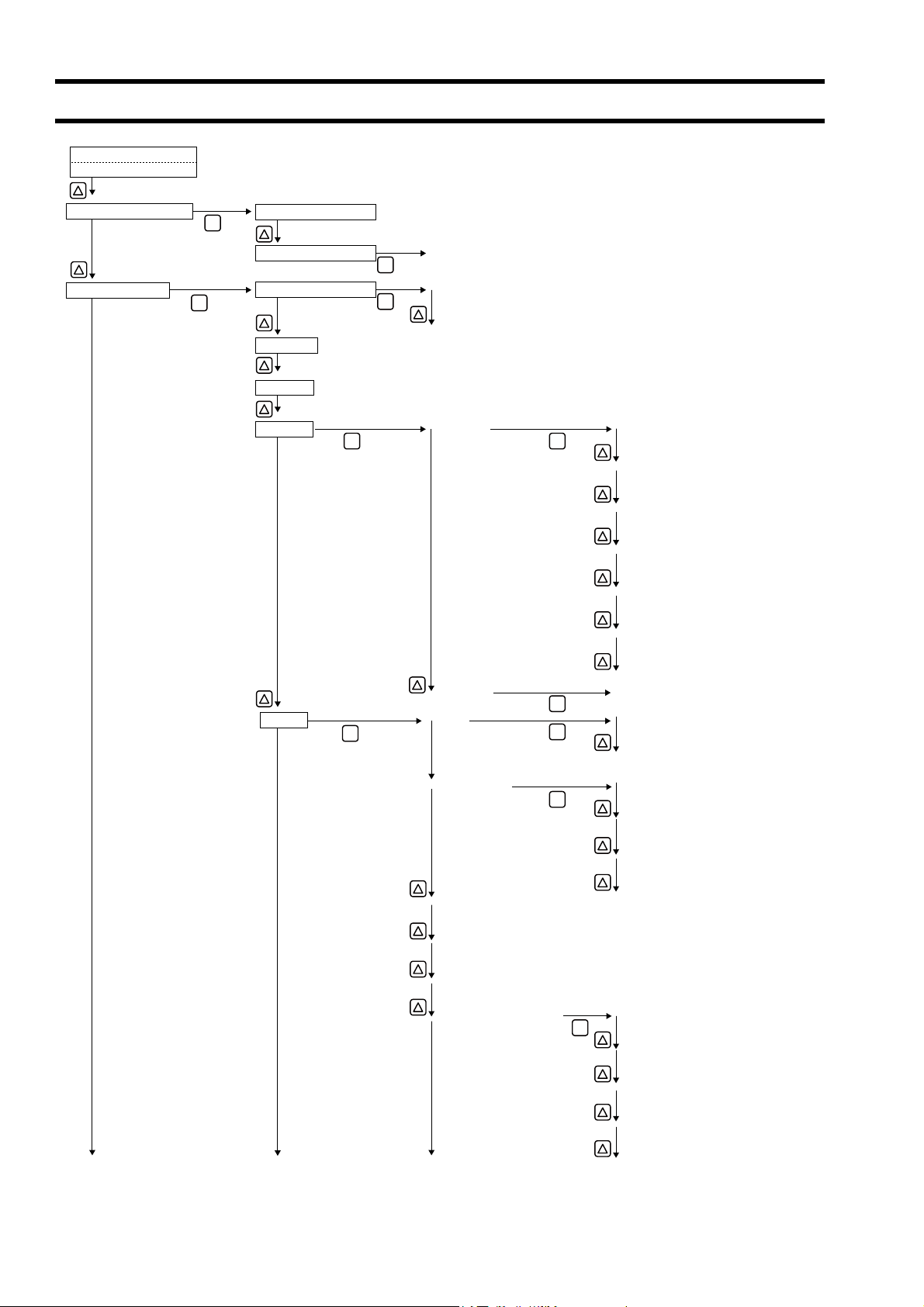

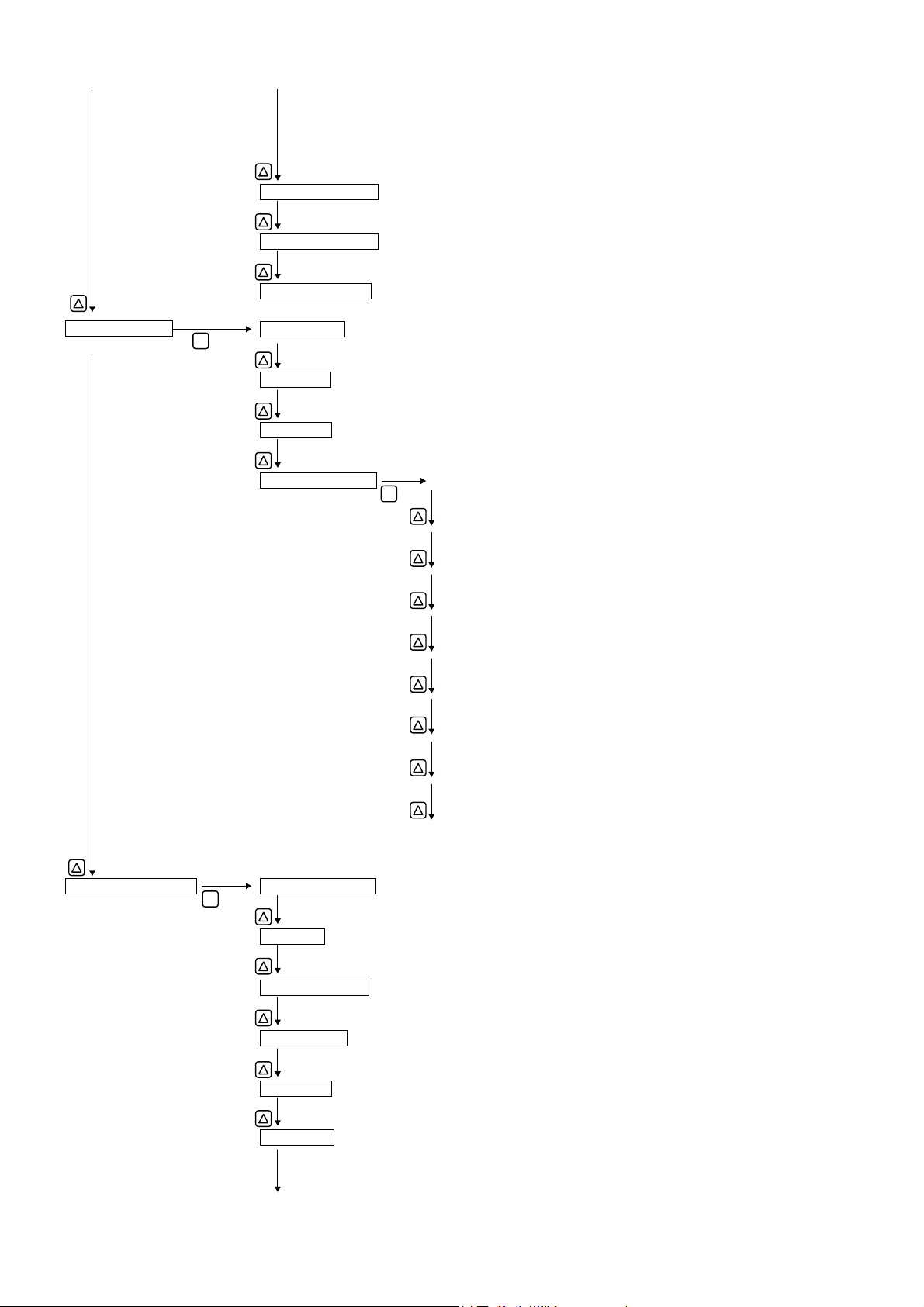

4.2. Composition of key operation

0.000 m/s

0.000 m3/h

Measurement mode

PAR.PROTECTIO PROTECTION ON

ENT

ENT

PROTECTION OFF

DAMPING

CUT OFF

ENT

RANGE

ENT

ENT

ENT

INPUT ID.NO

CLEARZERO ADJUSTMENTOUTPUT SET UP

SET ZERO

KIND

ENT

ENT

ENT

VELOCITY1ST ROWDISPLAY

FLOW RATE

FLOW RATE(%)

+TOTAL(ACTUAL)

+TOTAL PULSE

-TOTAL(ACTUAL)

-TOTAL PULSE

(Same as "1ST")2ND ROW

VELOCITY

FLOW RATE

ENT

SINGLERANGE TYPE

AUTO 2

BI-DIR

FULL SCALE 1

BI-DIR AUTO 2

FULL SCALE 2

RANGE HYS.

BURNOUT (CURRENT) NOT USED

ENT

HOLD

UPPER

LOWER

ZERO

-16-

Page 25

BURNOUT TIMER

OUTPUT LIMIT LOW

OUTPUT LIM.HIGH

RATE LIMIT

RATE LIMIT TIMER

ENT EN T

TOTAL RATE

TOTAL PRESET

PULSE WIDTH

BURNOUT (TOTAL) HOLD

BURNOUT TIMER

ENT

NOT USEDDO1 OUT

+TOTAL PULSE

-TOTAL PULSE

FULL SCALE 2

STARTTOTAL MODETOTAL UNIT

STOP

TOTAL RESET

ENT

NOT USED

ENT

ENT

LLAMRALA

HARDWARE FAULT

PROCESS ERROR

FLOW SWITCH FLOW SW HIGH

ENT

FLOW SW LOW

TOTAL SWITCH

AO RANGE OVER

PULSE RANGE OVER

-FLOW DIRECTION

(Same as "DO1 OUT")DO2 OUT

-17-

Page 26

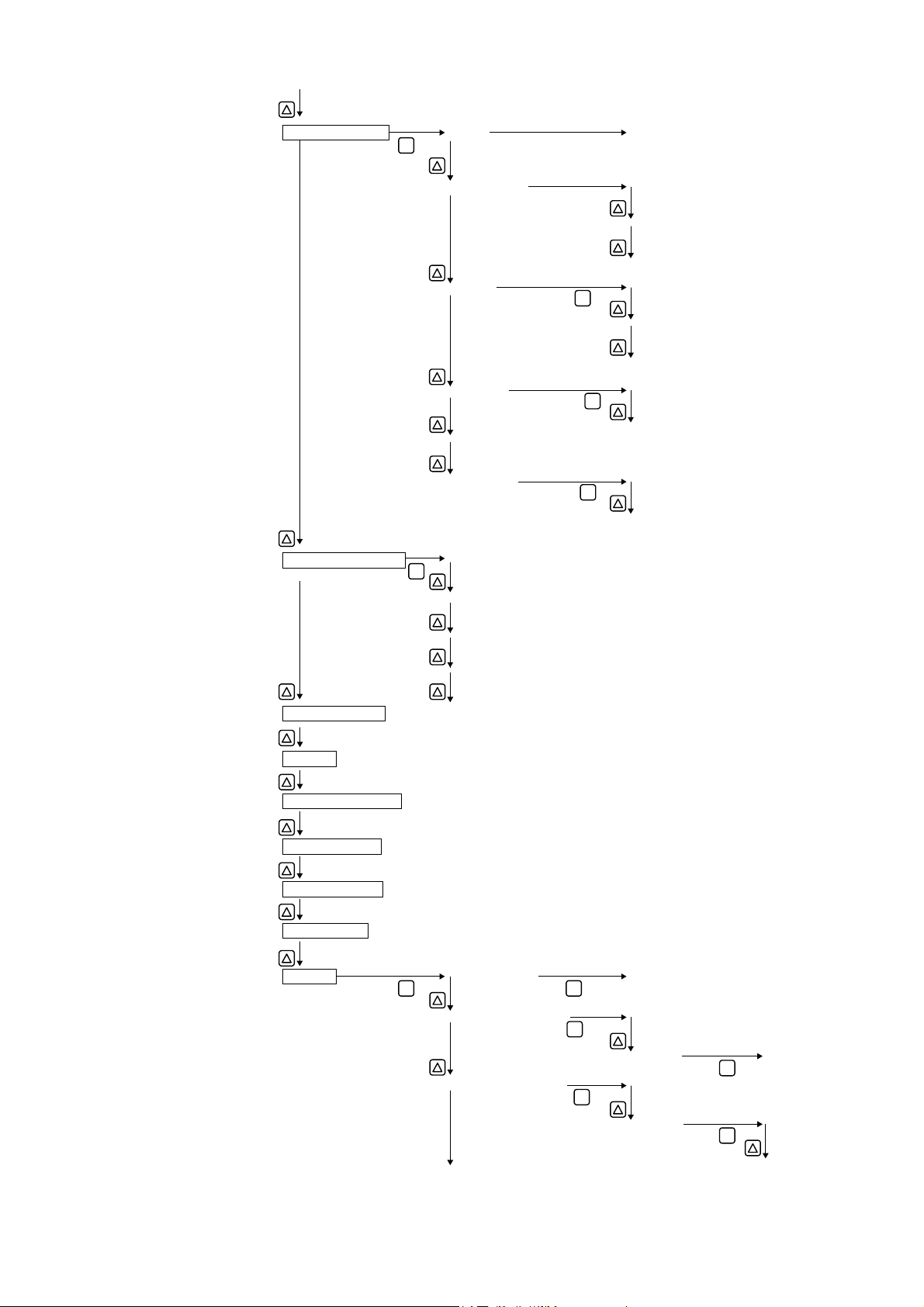

CALIBRATION ZERO

CALIBRATION SPAN

OPERATION MODE

MEASURE SETUP

ENT

SYSTEM UNIT

FLOW UNIT

TOTAL UNIT

PROCESS SETTING OUTER DIAMETER

ENT

PIPE MATERIAL

WALL THICKNESS

LINING MATERIAL

LINING THICKNESS (Except for "NO LINING")

KIND OF FLUID

VISCOSITY

SENSOR MOUNT

MAINTENANCE MODE RAS INFORMATION

ENT

CURRENT

OUTPUT SETTING

TOTAL PULSE

DO CHECK

TEST MODE

SENSOR TYPE

-18-

Page 27

SYSTEM LANGUAGE

ENT

MODECOMMUNICATION RS-485

BOUAD RATE 9600bps

ENT

STOP BIT

STATION No.

ENT

ENGLISH

ENT

ENT

19200bps

38400bps

NONEPARITY

ODD

EVEN

1 BIT

2 BITS

MODBUSPROTOCOL

M-Flow

REGISTER ID NO.

VER. NO.

MEMORY INITIALIZE

*

LCD BACKLIGHT

LCD/LED CHECK

DATA DISPLAY

*

ENT

JAPANESE

GERMAN

FRENCH

SPANISH

* Only for service technician

ENT

TRIGGER CONTROL

ENT

128 (Initial value)TRANS.COUNTDETAILS

AUTO (Initial value)

WINDOW CONTROL

-19-

ENT

MANUAL

ENT

AUTO (Initial value)

MANUAL

ENT

TRIGGER LEVEL

U:OPEN TIME

D:OPEN TIME

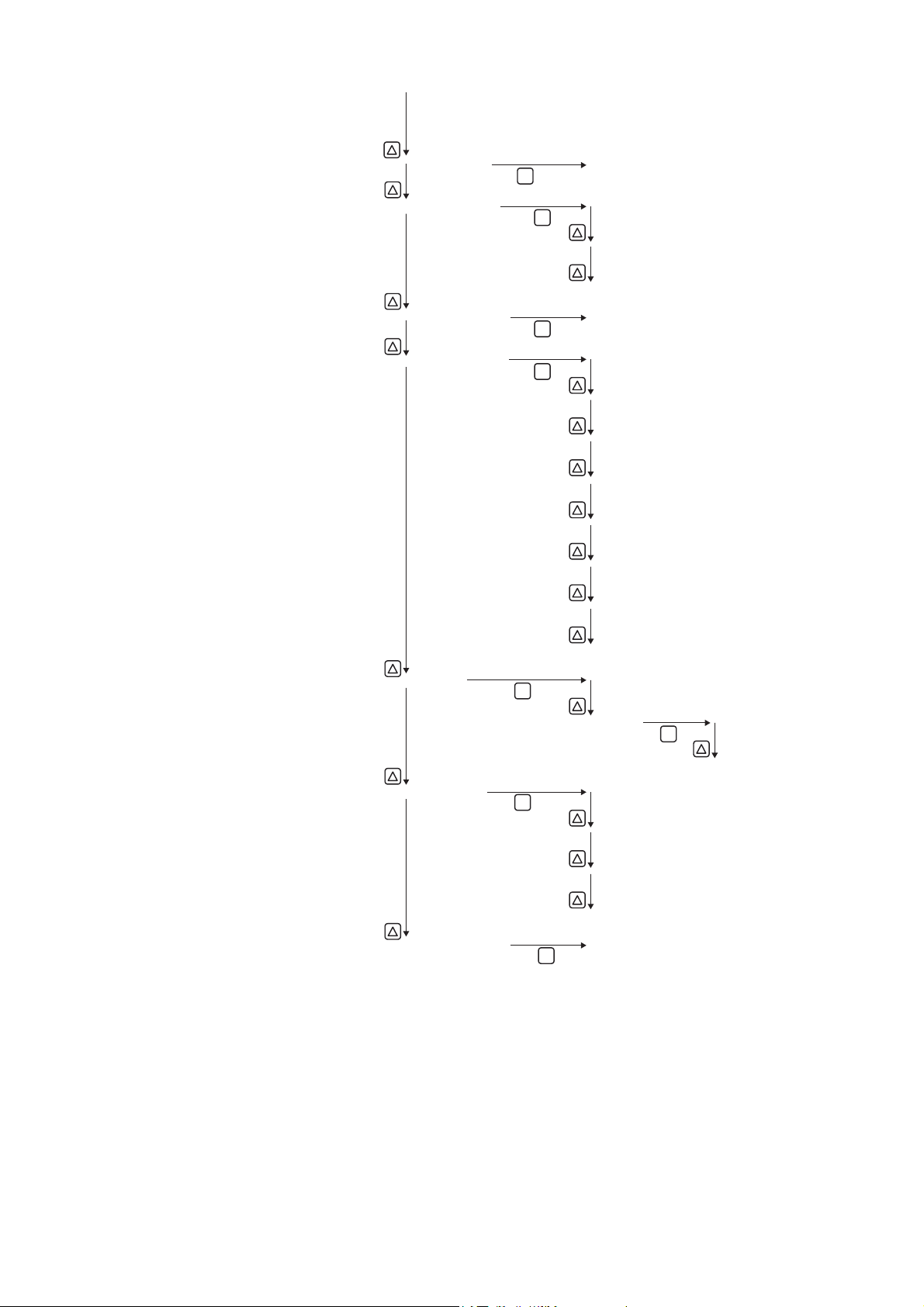

Page 28

SATURATION

MEAS.METHOD

SIGNAL BALANCE

TRANS.PATTERN

ENT

ENT

ENT

ENT

128 (Initial value)

METHOD 1

METHOD 2 (Initial value)

METHOD 3

25% (Initial value)

BURST 1

BURST 2

BURST 3 (Initial value)

BURST 4

BURST 5

CHIRP 4

CHIRP 8

SIGNAL PEEK

TRANS.WAIT TIME

ENT

ENT

ENT

RESERVE

AUTO (Initial value)AGC GAIN

MANUAL

ENT

U: AGC

D: AGC

0.125V (1024)

0.25V (2048)

0.375V (3072) (Initial value)

0.5V (4096)

5msec (Initial value)

-20-

Page 29

4.3. Parameter initial value list

Factory-set value is shown below. (When parameter setting is not provided.)

Setting unit Setting range Initial value Setting value

1 Parameter protection No. of menu: 2 PROTECTION ON PROTECTION ON, PROTECTION OFF

2 ID No 0000 to 9999 0000 ID No. is invalid when 0000 is selected.

3 Language No. of menu: 5 English *1 English, Japanese, German, French and

4

5 Flow unit No. of menu: 18 m3/h L/s, L/min, L/h, L/d, kL/d, ML/d, m3/s, m3/min,

6 Total unit No. of menu: 8 m3 mL, L, m3, km3, Mm3, mBBL, BBL, kBBL

7 Outer diameter 6.00 to 6200.00mm 60.00mm [mm, in]

8 Pipe material No. of menu: 13

9 Wall thickness 0.10 to 100.00mm 4.00mm [mm, in]

10 Lining material No. of menu: 8

11 Lining thickness 0.01 to 100.00mm – [mm, in]

12 Kind of fluid No. of menu: 18

13 Dynamic viscosity

14 Sensor mounting method No. of menu: 2 V method V method, Z method

15 Sensor type No. of menu: 10 FSSA/FSSG FSSA/FSSG, FLS_12,/FLS_22,FSSC,

16

17 Damping 0.0 to 100.0sec 5.0sec sec

18 Low flow cut 0 to 5m/s in terms of

19

20 Decimal point position

21 Content of display 2nd

22 Decimal point position

23

System unit No. of menu: 2 Metric Metric or inch

Sound velocity: 1000 to

3700m/s

Sound velocity: 1000 to

3700m/s

Measuring condition

coefficient

Zero adjustment No. of menu: 2 Clear (unadjusted) Clear, adjustment (Clear has been factory-set.)

Content of display 1st

line

of display 1st line

Display

line

of display 2nd line

Kind No. of menu: 2 Flow rate Flow verocity, Flow rate

Sound velocity: 300 to

2500m/s

0.001 to 999.999

-6m2

×10

/s

flow velocity

No. of menu: 7 Flow velocity (m/s) Flow velocity, Flow rate, Flow rate (%), +Total

No. of menu: 7 Flow rate (m/s) Flow velocity, Flow rate, Flow rate (%), +Total

PVC Carbon steel, Stainless, PVC, Copper,Cast

No lining No lining, Tar epoxy, Mortar, Rubber, Teflon,

Water Seawater, dist. water, ammonia, alcohol,

1.0038

×10-6m2/s

0.150m3/h [(5) unit]

.

.

Spanish

3

m

/h, m3/d, km3/d, Mm3/d, BBL/s, BBL/min,

BBL/h, BBL/d, kBBL/d, MBBL/d

iron, Aluminum, FRP, Ductile iron, PEEK,

PVDF, Acrylic and PP

Pipe sound velocity

(Sound velocity: [m/s, ft/s])

Pyrex glass, PVC

Lining S.V. (Sound velocity: [m/s, ft/s])

benzene, bromide, ethanol, glycol, kerosene,

milk, methanol, toluol, lube oil, fuel oil, petrol

and refrigerant R410

Fluid S.V. (Sound velocity: [m/s, ft/s])

-6m2

/s, ft2/s]

[×10

FSG_32, FSG_31/FSG_41,

FSSE/FSG_50,FSSF/FSG_51, FSD12, FSSD/

FSD22,FSSH/FSD32

(Actual), +Total pulse, -Total (Actual) and -Total

pulse

(Fill in the specified digit)

(Actual), +Total pulse, -Total (Actual) and -Total

pulse

(Fill in the specified digit)

24 Range type No. of menu: 4 Single range Single range, Auto 2 range, Bi-dir range and

25 Full scale 1 0, ±0.3 to ±32m/s in

26 Full scale 2 0, ±0.3 to ±32m/s in

Output condition

27 Hysteresis 0.00 to 20.00 10.00% %

28 Burnout (current) No. of menu: 5 Hold Not used, Hold, Lower, Upper and Zero

29 Burnout timer 10 to 900sec 10sec sec

30 Output limit low -20 to 0% -20% %

31 Output limit high 100 to 120% 120% %

32 Rate limit 0 to 5m/s in terms of

33 Rate limit timer 0 to 900sec 0sec sec

34

35 Total rate 0.000000 to 99999999 0m3 [(6) unit]

36 Total preset 0.000000 to 99999999 0m3 [(6) unit]

37 Pulse width No. of menu: 7 50.0msec 5.0msec, 10.0msec, 50.0msec, 100.0msec,

38 Burnout (total) No. of menu: 2 Hold Not used, hold

39 Burnout timer 10 to 900sec 10sec sec

Analog output

Total mode No. of menu: 3 Stop Start, Stop and Reset

Total output

terms of flow velocity

terms of flow velocity

flow velocity

15.000m3/h [(5) unit]

0.000m3/h [(5) unit]

0.000m3/h [(5) unit]

Bi-dir Auto 2 range

200.0msec, 500.0sec,1000msec.

-21-

Page 30

Setting unit Setting range Initial value Setting value

40

41 DO1 Output operation No. of menu: 2 Active ON Active ON, Active OFF

42 DO2 Output type No. of output content

43 DO2 Output operation No. of menu: 2 Active ON Active ON, Active OFF

44 Zero calibration -5 to 5m/s in terms of

45 Span calibration -200.00 to 200.00% 100.00% %

46 Operation mode No. of menu: 2 Standard Standard, High speed

47

48 Baud rate No. of menu: 3 9600bps 9600bps, 19200bps, 38400bps

49 Parity No. of menu: 3 Odd None, Odd, Even

50 Stop bit No. of menu: 2 1 bit 1 bit, 2 bits

51 Station No. 1 to 31 1 (In case of RS-485)

52 Communication protocol No. of menu: 2 MODBUS MODBUS, M-Flow

53

54

DO1 output type No. of output content

Output condition

Communication mode No. of menu: 1 RS-485 RS-485

Communication

LCD BACKLIGHT No. of menu: 2 ON ON, OFF

LCD

LIGHTS OUT TIME 0 to 99 min 5 min min

menu: 10

No. of alarm menu: 3

Flow switch range

0 to 32m/s in terms of

flow velocity

Total switch range

0.000000 to 99999999

menu: 10

No. of alarm menu: 3

Flow switch range

0 to 32m/s in terms of

flow velocity

Total switch range

0.000000 to 99999999

flow velocity

Not used

Not used

0.000m3/h [(5) unit]

Not used

+Total pulse

-Total pulse

Range full scale 2

Alarm [All, Device error, Process error]

Flow rate switch

Flow SW high [ [(5) unit]]

Flow SW low [ [(5) unit]]

Total switch [ [(6) unit]]

Range over

Pulse range over

–Flow direction

Not used

+Total pulse

-Total pulse

Range full scale 2

Alarm [All, Device error, Process error]

Flow rate switch

Flow SW high [ [(5) unit]]

Flow SW low [ [(5) unit]]

Total switch [ [(6) unit]]

Range over

Pulse range over

–Flow direction

*1) English is set when 4th digit of the type is “E”.

S : Japanese

FSV

□

E : English

FSV

□

-22-

Page 31

4.4. Parameter protection

4.4.1. Protection ON/OFF

Description

Parameters can be protected so that the flow meter settings will not carelessly be changed.

Parameters can be protected by setting the "ID No." (Note) in the maintenance mode.

Note) 4 digits are factory set at "0000". (Refer to Section 4.11.7.)

Setting range: PROTECTION ON : Parameter cannot be changed.

* 1 hour after “PROTECTION OFF” is set, “PROTECTION ON” is automatically set.

* Protection is set after turning power on.

For actual keying, refer to the typical operation indicated below.

Operation

(example)

Key operation Description Display

▼

ENT

▼

▼

ENT

▼

▼

▼

▼

ENT

▼

▼

PROTECTION OFF : Parameter can be changed.

Change the protection from ON to OFF (suppose ID No. is "2234").

Press the key in the measurement mode once to indicate “PAR.

PROTECTION”.

ENT

Press the

Press the key once to display "PROTECTION OFF".

Press the

Press the

Note) If ID No. is "0000" (as factory set), press the

▼ Enter ID No. “2234” by the key or the key.

key once to blink the 2nd line.

ENT

key once to display “PAR.PROTECTION”.

ENT

key once to indicate "0000" and blink the cursor.

the protection.

ENT

key to release

PAR.PROTECT

PAR.PROTECT

PAR.PROTECT

PAR.PROTECT

INPUT ID NO.

INPUT ID NO.

INPUT ID NO.

COMPLETE

PROTECTION ON

PROTECTION ON

PROTECTION OFF

↓

0000

2234

ENT

Press the

* If ID No. does not coincide, "INPUT ERROR!" appears, and the input

――― Protection canceled. ―――

screen is resumed.

ENT

key once.

INPUT ID NO.

PAR.PROTECT

COMPLETE

PROTECTION OFF

CAUTION

About the change of parameter setting

When you change parameters of converter in current use which analog output or alarm has been set, if you

change items which affect to the output or alarm, the output may change suddenly after display of

"**COMPLETE**" and may generate alarm. If, especially, the output signal is being used for control, perform the

signal lock on the system side prior to changing parameters.

Caution on change of parameter setting

When you change parameter settings, parameters will be saved in non-volatile memory on return to measuring

display. Saved parameters have been maintained even power is off. However, when you change the parameter

and turn off the power before returning to the measuring display, parameters will not be saved. Thus you should

set the parameter again.

↓

-23-

Page 32

4.5. Display language

4.5.1. How to select the language

Description

Indication language (English, Japanese, German, French, Spanish) is selectable.

Setting contents

English (default setting), Japanese, German, French, Spanish

For actual keying, refer to the typical operation indicated below. Set the protection to OFF beforehand. (See Section 4.4.1.)

Operation

(example)

Key operation Description Display

▼

ENT

▼

▼

ENT

▼

▼

ENT

▼

▼

▼

▼

ESC

Select English for the display language.

Press the key for 4 times to display “MAINTENANCE MODE”.

ENT

Press the

key once to display “RAS INFORMATION”.

Press the key for 8 times to display “SYSTEM LANGUAGE”.

ENT

Press the

key once to blink on the 2nd line.

Press the key for 4 times to display “ENGLISH”.

ENT

Press the

key once to register.

――― English has been registered. ―――

Press the

ESC

key or the key to display the measurement mode.

MAINTENANCE MODE

RAS INFORMATION

0000000000000000

SYSTEM LANGUAGE

SYSTEM LANGUAGE

SYSTEM LANGUAGE

SYSTEM LANGUAGE

COMPLETE

↓

SYSTEM LANGUAGE

0.000 m/s

0.000 m3/h

JAPANESE

JAPANESE

ENGLISH

ENGLISH

Operation

(example)

Key operation Description Display

▼

ENT

▼

▼

ENT

▼

▼

ENT

▼

▼

▼

▼

ESC

Select Japanese for the display language.

Press the key for 4 times to display “MAINTENANCE MODE”.

ENT

Press the

key once to display “RAS INFORMATION”.

Press the key for 8 times to display “SYSTEM LANGUAGE”.

ENT

Press the

key once to blink on the 2nd line.

Press the key for 4 times to display “JAPANESE”.

ENT

Press the

key once to register.

――― Japanese has been registered. ―――

Press the

ESC

key or the key to display the measurement mode.

MAINTENANCE MODE

RAS INFORMAITION

0000000000000000

SYSTEM LANGUAGE

SYSTEM LANGUAGE

SYSTEM LANGUAGE

SYSTEM LANGUAGE

(LANGUAGE)

ゲンゴ

0.000 m/s

0.000 m3/h

トウロク

↓

ニホンゴ

ENGLISH

ENGLISH

JAPANESE

(JAPANESE)

-24-

Page 33

4.6. Checking and Setting of Piping Specifications/Detector

4.6.1. Checking piping parameter

Key operation Description Display

▼

ENT

▼

▼

ENT

▼

▼

▼

▼

▼

▼

▼

▼

Press the key for 3 times to display “MEASURE SETUP”.

ENT

Press the

key once to display “SYSTEM UNIT”.

Press the key for 3 times to display “PROCESS SETTING”.

ENT

Press the

key once to display “OUTER DIAMETER”.

Press the key once to display “PIPE MATERIAL”.

Press the key once to display “WALL THICKNESS”.

Press the key once to display “LINING MATERIAL”.

Press the key once to display “KIND OF FLUID”.

Press the key once to display “VISCOSITY”.

Press the key once to display “SENSOR MOUNT”.

Press the key once to display “SENSOR TYPE ”.

0.000 m/s

0.000 m3/h

MEASURE SETUP

SYSTEM UNIT

PROCESS SETTING

S= 31( 93mm)

OUTER DIAMETER

PIPE MATERIAL

WALL THICKNESS

LINING MATERIAL

KIND OF FLUID

VISCOSITY

1.003800 E-6m2/s

SENSOR MOUNT

SENSOR TYPE

ENGLISH

60.00 mm

4.00 mm

NO LINING

V METHOD

FSSA/FSSG

PVC

WATER

ESC

Press the

measurement mode.

ESC

key twice, and press the key twice to return to the

0.000 m/s

0.000 m3/h

-25-

Page 34

4.6.2. Piping parameter setting method

Description

Set the parameters of piping and fluid to be measured to determine the sensor mounting spacing.

The mounting dimension of the sensor is automatically calculated. Refer to “5.1.1 PRODUCT OUTLINE”.

Be sure to set the following parameters before mounting the sensor on the pipe. Mount the sensor to match the sensor

mounting length.

Unless the sensor units are spaced accurately, the measurement error will be excessive.

Also, the received wave may be abnormal.

Setting items

1. Pipe outer diameter : 6.00 to 6200.00 [mm] (factory set at 60.00 [mm]).

2. Piping material : CARBON STEEL, STAINLESS STEEL, PVC (factory set), COPPER, CAST IRON, ALUMINIUM,

FRP, DUCTILE IRON, PEEK, PVDF, ACRYLIC, PP, Others (Sound velocity: 1000 to 3700[m/s])

3. Wall thickness : 0.10 to 100.00 [mm] (factory set at 4.00 [mm]).

4. Lining material : NO LINING (factory set), TAR EPOXY, MORTAR, RUBBER, TEFLON, PYREX GLASS, PVC,

Others (Sound velocity: 1000 to 3700[m/s])

5. Lining thickness : 0.10 to 100.00 [mm]

6. Measuring fluid : WATER, SEAWATER, DIST.WATER, AMMONIA, ALCOHOL, BENZENE, ETHANOL, GLYCOL,

KEROSENE, MILK, METHANOL, TOLUOL, LUBE OIL, FUEL OIL, PETROL, REFRIGERANT

R410, Others (Sound velocity: 300 to 2500[m/s])

7. Dynamic viscosity coefficient : 0.0010 to 999.999 × 10

8. Detector mounting method : V method (factory set), Z method Refer to “5.2.Selection of mounting method”

9. Detector type : FSSA/FSSG (factory set), FLS_12/FLS_22, FSSC,FSG_32, FSG_31/FSG-41, FSSE/FSG_50,

FSSF/FSG_51, FSD12, FSSD/FSD22,FSSH/FSD32

Note) If the sensor type is previous type, make a setting change for current type.

Previous type Current type Previous type Current type

FLD22 FSD22 FLW41 FSG_41

FLD32 FSD32 FLW50 FSG_50

FLW11 FSG_31 FLW51 FSG_51

FLW12 FSG_32

For concrete keying, refer to the typical operation indicated below. Set the protection to OFF beforehand. (See Section 4.4.1.)

(1) Setting method when sensor type is “FSSA”.

Operation

(example)

Key operation Description Display

▼

ENT

▼

▼

ENT

▼

ENT

▼

▼

Carry out setting for measuring the flow rate of water flowing through PVC pipe (for tap water) using FSSA detector.

Press the key for 3 times to display “MEASURE SETUP”.

ENT

Press the

key once to display “SYSTEM UNIT”.

Press the key for 3 times to display “PROCESS SETTING”.

ENT

Press the

Press the

Move the cursor by the key, and change the numeric value by

key once to display “OUTER DIAMETER”.

ENT

key once to blink the cursor.

the key. Operated to compose "114" because, from Piping data in

Section 7.4., the outer diameter of polyvinyl chloride pipe (tap water size)

is 114 mm.

CAUTION

-6

[m2/s] (factory set at 1.0038 x 10-6 [m2/s])

0.000 m/s

0.000 m3/h

MEASURE SETUP

SYSTEM UNIT

PROCESS SETTING

S= 16 ( 48mm)

OUTER DIAMETER

OUTER DIAMETER

OUTER DIAMETER

0160.00 mm

0160.00 mm

0160.00 mm

0110.00 mm

0110.00 mm

0114.00 mm

METRIC

60.00 mm

-26-

Page 35

ENT

▼

▼

▼

▼

▼

Press the

Press the key once to display “PIPE MATERIAL”.

Because PVC (factory set) is already registered, go to the next step.

Note) If the pipe is made of another material, press

ENT

key once to register the outer diameter.

――― Outer diameter has been registered. ―――

ENT

key, and select

OUTER DIAMETER

COMPLETE

OUTER DIAMETER

PIPE MATERIAL

↓

114.00 mm

PVC

▼

ENT

▼

a corresponding menu by the

Press the key once to display “WALL THICKNESS”.

ENT

Press the

key once to blink the cursor.

key.

WALL THICKNESS

WALL THICKNESS

4.00 mm

004.00 mm

004.00 mm

Move the cursor by the key, and change the numeric value by the

▼

key.

WALL THICKNESS

007.00 mm

Operated to compose "7" because, from Piping data in Section 7.4., the

wall thickness of polyvinyl chloride pipe (tap water size) is 7.0mm.

ENT

▼

▼

▼

▼

▼

Press the

Press the key once to display “LINING MATERIAL”.

"NO LINING" (factory set) is already registered. Because there is no

ENT

key once to register the wall thickness.

――― Wall thickness has been registered. ―――

WALL THICKNESS

COMPLETE

WALL THICKNESS

LINING MATERIAL

↓

7.00 mm

NO LINING

lining, go to the next step.

ENT

Note) If lining is provided, press the

key and key to select the

material or enter the sound velocity. Further, go to "LINING

THICKNESS", and input a lining thickness. Nothing is indicated in

case of "NO LINING".

▼

Press the key once to display "KIND OF FLUID". Because, also,

"WATER" (factory set) is already registered, go to the next step.

ENT

Note) If fluid to be measured is other than water, press the

key, and

KIND OF FLUID

WATER

select the menu or enter the sound velocity.

▼

Press the key once to display "VISCOSITY".

Input the kinematic viscosity of the fluid to be measured.

Because the kinematic viscosity 1.0038E

-6

[m2/s] of water at 20°C is

VISCOSITY

1.0038 E-6m2/s

already registered, go to the next step.

In case of fluid other than water, input the kinematic viscosity at a

measurement status of fluid to be measured referring to data in Section

7.4., etc.

ESC

▼

Press the

“S=31” is indicated on the 2nd line.

ESC

key once to display “PROCESS SETTING”.

PROCESS SETTING

S= 31 ( 93mm)

After mounting the frames on piping, insert into it 2 sensor units spaced

at 31 divisions.

ESC

Press the

measurement mode.

ESC

key once and the key twice to return to the

0.000 m/s

0.000 m3/h

-27-

Page 36

(2) Setting method when sensor type is not “FSSA”

Operation

(example)

Key operation Description Display

▼

ENT

▼

▼

ENT

▼

▼

ENT

▼

▼

ENT

▼

▼

▼

▼

ESC

▼

ESC

Carry out setting for measuring the flow rate of water flowing through PVC pipe (for tap water) having 100 mm of

nominal diameter, using FSSC detector.

* Settings of piping and fluid to be measured are omitted, since it is same as “(1) Setting method when sensor type

is “FSSA”

Press the key for 3 times to display “MEASURE SETUP”.

ENT

Press the

key once to display “SYSTEM UNIT”.

Press the key for 3 times to display “PROCESS SETTING”.

ENT

Press the

key once to display “OUTER DIAMETER”.

Press the key for 7 times to blink the cursor.

ENT

Press the

key once to blink the cursor.

Press the key for 2 times to display “FSSC” on the 2nd line.

ENT

Press the

key once to register “FSSC”.

――― “FSSC” has been registered. ―――

Press the

ESC

key once to display “PROCESS SETTING”.

“S=58.43mm” is displayed on the 2nd line.

MEASURE SETUP

SYSTEM UNIT

PROCESS SETTING

S= 31 ( 93mm)

OUTER DIAMETER

SENSOR TYPE

SENSOR TYPE

SENSOR TYPE

SENSOR TYPE

COMPLETE

SENSOR TYPE

PROCESS SETTING

S= 58.43mm

Align the sensor mounting spacing to 58.43mm, and attach the sensor to

the pipe.

Press the

measurement mode.

ESC

key once and the key twice to return to the

0.000 m/s

0.000 m3/h

METRIC

114.00 mm

FSSA/FSSG

FSSA/FSSG

FSSC

↓

FSSC

-28-

Page 37

4.7. Zero Adjustment

Description

Zero point is calibrated.

Settable range:

CLEAR : Clears the zero point calibration value to "0".

SET ZERO : A point where "SET ZERO" is carried out is regarded as zero, how condition used in case the flow cannot be stopped

For actual keying, refer to the typical operation indicated below. Set the protection to OFF beforehand. (See Section 4.4.1.)

Operation

(example)

Key operation Description Display

▼

ENT

▼

▼

ENT

▼

▼

▼

▼

ESC

Used in case the flow cannot be stopped when calibrating the zero point.

Note 1) Where possible, stop the flow and carry out "SET ZERO" stated below.

Otherwise, an error may occur in the zero point.

when calibrating the zero point.

Note 2) The flow must completely be stopped.

Otherwise, the flowing status is regarded as zero, thereby causing an error.

It takes ten seconds to several tens of seconds to complete adjustment, depending on pipe diameter.

Completely fill the piping, close the upstream and downstream valves, and proceed to zero point calibration.

Press the key twice to display “OUTPUT SETUP”.

ENT

Press the

key twice to display “ZERO ADJUSTMENT” and blink the

cursor.

Press the key once, and select “SET ZERO”.

ENT

Press the

key once to carry out “SET ZERO”.

* Be sure to completely stop the flow beforehand.

――― Zero adjustment has been completed. ―――

Press the

ESC

key once, and the key for 3 times to enter the

measurement mode.

OUTPUT SETUP

ZERO ADJUSTMENT

ZERO ADJUSTMENT

ZERO ADJUSTMENT

ZERO ADJUSTMENT

0.000 m/s

0.000 m3/h

COMPLETE

↓

CLEAR

SET ZERO

SET ZERO

-29-

Page 38

4.8. Setting of unit

4.8.1. How to set the unit system

Description

Measurement unit can be selected from metric or inch system.

Metric system (factory set)

Length ······································ mm

Flow velocity ······························ m/s

Flow rate ·································· L/s, L/min, L/h, L/d, kL/d, ML/d, m

Total unit ··································· mL, L, m

BBL/d, kBBL/d, MBBL/d

Kinematic viscosity coefficient ······· E

3

, km3, Mm3, mBBL, BBL, kBBL

-6m2

/s

<Note> When setting, stop status should be set at total mode. (See Section 4.9.2.)

For actual keying, refer to the typical operation indicated below. Set the protection to OFF beforehand. (See Section 4.4.1.)

Operation

(example)

Key operation Description Display

▼

ENT

▼

ENT

▼

▼

ENT

▼

▼

▼

▼

ESC

Change the unit system from inch system to metric system.

Press the key for 3 times to display “MEASURE SETUP”.

ENT

Press the

Press the

key once to display “SYSTEM UNIT”.

ENT

key once to blink the cursor.

Press the key once to display “METRIC”.

ENT

Press the

key once to register.

――― METRIC has been registered. ―――

Press the

ESC

key once and key twice to return to the measurement

mode.

3

/s, m3/min, m3/h, m3/d, km3/d, Mm3/d, BBL/s, BBL/min, BBL/h,

MEASURE SETUP

SYSTEM UNIT

SYSTEM UNIT

SYSTEM UNIT

SYSTEM UNIT

COMPLETE

↓

SYSTEM UNIT

0.000 m/s

0.000 m3/h

INCH

INCH

METRIC

METRIC

-30-

Page 39

4.8.2. How to set the flow rate unit

Description

Select the unit of flow rate.

Metric system

Flow rate ········ L/s, L/min, L/h, L/d, kL/d, ML/d, m

kBBL/d, MBBL/d

<Note> First, set the unit system (metric) according to Section 4.8.1.

For actual keying, refer to the typical operation indicated below. Set the protection to OFF beforehand. (See Section 4.4.1.)

Operation

(example)

Key operation Description Display

▼

ENT

▼

▼

ENT

▼

▼

ENT

▼

▼

▼

▼

ESC

Set a flow rate unit to “L/min”.

Press the key for 3 times to display “MEASURE SETUP”.

ENT

Press the

key once to display “SYSTEM UNIT”.

Press the key once to display “FLOW UNIT”.

ENT

Press the

key once to blink the cursor.

Press the key several times to display “L/min”.

ENT

Press the

key once to register.

――― “L/min” has been registered. ―――

Press the

ESC

key once and the key twice to return to the

measurement mode.

3

/s, m3/min, m3/h (factory set), m3/d, km3/d, Mm3/d, BBL/s, BBL/min, BBL/h, BBL/d,

MEASURE SETUP

SYSTEM UNIT

FLOW UNIT

FLOW UNIT

FLOW UNIT

FLOW UNIT

COMPLETE

↓

FLOW UNIT

0.000 m/s

0.000 L/min

METRIC

m3/h

m3/h

L/min

L/min

-31-

Page 40

4.8.3. How to set the total unit

Description

Select the unit of total volume.

Metric system

Total unit ········ mL, L, m

<Note> First, set the unit system (metric) according to Section 4.8.1.

When setting, stop status should be set at total mode. (See Section 4.9.2.)

For actual keying, refer to the typical operation indicated below. Set the protection to OFF beforehand. (See Section 4.4.1.)

Operation

(example)

Key operation Description Display

▼

ENT

▼

▼

ENT

▼

▼

ENT

▼

▼

▼

▼

ESC

Set a flow total unit to “L”.

Press the key for 3 times to display “MEASURE SETUP”.

Press the

Press the key once to display “TOTAL UNIT”.

Press the

Press the key twice to display “L”.

Press the

Press the

measurement mode.

3

(factory set), km3, Mm3, mBBL, BBL, kBBL

ENT

key once to display “SYSTEM UNIT”.

ENT

key once to blink the cursor.

ENT

key once to register.

――― “L” has been registered. ―――

ESC

key once and the key twice to return to the

MEASURE SETUP

SYSTEM UNIT

TOTAL UNIT

TOTAL UNIT

TOTAL UNIT

TOTAL UNIT

COMPLETE

↓

TOTAL UNIT

0.000 L

0.000 L/min

METRIC

m3

m3

L

L

-32-

Page 41

4.9. Output Setting

4.9.1. Setting of flow rate range

4.9.1.1. Setting of flow rate range (single range)

Description

The range (full scale) of flow rate to be measured is set.

20mA

* The analog output (4-20mA) corresponds to the range setting.

Settable range: 0.3 to 32 [m/s] in terms of flow velocity in piping

Full scale 1

* The piping parameters and FLOW UNIT must be set beforehand.

* If a value beyond the settable range is inputted, "INPUT ERROR" appears and then last

setting is resumed.

* If "piping parameters" or "FLOW UNIT" has been changed after setting the range,

recommence the range setting.

<Note> The flow rate unit is as selected by "FLOW UNIT" in the "MEASURE SETUP" mode.

(Refer to Section 4.8.2.)

4mA

0 100%

Flow rate

Setting range of the full scale frow rate

・

<Note> Converted flow rate in the Table 1 is the calculation results obtained

by using the internal diameters of pipes in the left columns.

Perform calculation using the actual internal diameters for accuracy.

Simple formula for calculation of flow verocity

Flow velocity range: 0.3 ~32 [m/s] <Table1>

Int. dia.

of pipes

[mm]

25 0.530 to 56.5 8.84 to 942

50 2.12 t o 226 35.3 to 3770

80 5.43 t o 579 90.5 to 9651

100 8.48 t o 905 141 to 15080

150 19.1 t o 2036 318 to 33929

200 33.9 t o 3619 565 to 60319

300 76.3 t o 8143 1272 to 135717

[ m

3

/h ]

Flow rate unit

For actual keying, refer to the typical operation indicated below. Set the protection to OFF beforehand. (See Section 4.4.1.)

Operation

(example)

Key operation Description Display

▼

ENT

▼

▼

ENT

▼

▼

Set the range type to single range and “FULL SCALE1” to flow rate 60m3/h.

* Set the piping parameters and "FLOW UNIT" beforehand.

Press the key twice to display “OUTPUT SETUP”.

ENT

Press the

key to enter the “ZERO ADJUSTMENT” mode.

Press the key for 4 times to display “RANGE”.

ENT

Press the

key once to display “KIND”.

Because flow rate (factory set) is already registered, go to the next step

Press the

key to display

“RANGE TYPE”

Because single range (factory set) is already registered, go to the next

step.

OUTPUT SETUP

ZERO ADJUSTMENT

RANGE

KIND

RANGE TYPE

[ L/min ]

SET ZERO

FLOW RATE

SINGLE

▼

ENT

▼

▼

▼

▼

▼

▼

▼

▼

▼

ENT

▼

▼

▼

▼

Press the key once to display “FULL SCALE1”.

ENT

Press the

Move the cursor by the key, and change the numeric value by the

key once to blink the cursor.

key.

Change the full scale1 to “60”.

Note) To change the decimal point position, align the cursor with a place

to change to and press the

ENT

Press the

key once to register.

key likewise.

――― FULL SCALE1 has been registered. ―――

FULL SCALE1

FULL SCALE1

FULL SCALE1

FULL SCALE1

FULL SCALE1

15.000 m3/h

00015.000 m3/h

00015.000 m3/h

00065.000 m3/h

00065.000 m3/h

0000060.0 m3/h

COMPLETE

↓

60.000 m3/h

-33-

Page 42

ESC

Press the

ESC

key for 2 times and then press the key for 3 times to

enter the measurement mode.

0.000 m/s

0.000 m3/h

-34-

Page 43

4.9.1.2. Setting of analog output at error (Burnout)

Description

Determine how to set the analog output when received wave error, etc. due to device error, accidental drain of piping or entry of

bubbles.

Settable range

(1) Analog output (4-20mA) at error

HOLD (factory set) : Outputs a current value preceding the error.

UPPER : Sets analog output to upper of the output limit (over scale).

LOWER : Sets analog output to lower of the output limit (under scale).

ZERO : Outputs 4mA.

(2) BURNOUT TIMER (time from error detection to BURNOUT processing) 10 to 900 seconds (factory set at 10 sec). Please set 10

seconds or more.

* Perform BURNOUT processing as shown below.

1. LCD display ······ Measured value operates with analog output.

For actual keying, refer to the typical operation indicated below. Set the protection to OFF beforehand. (See Section 4.4.1.)

Operation

(example)

Key operation Description Display

▼

ENT

▼

▼

ENT

▼

▼

ENT

▼

▼

ENT

▼

▼

▼

▼

▼

ENT

▼

▼

▼

ENT

▼

▼

▼

▼

ESC

Set “UPPER” to BURNOUT.

Set “20sec” to BURNOUT TIMER.

* Set the piping parameters and "FLOW UNIT" beforehand.

Press the key twice to display “OUTPUT SETTUP”.

ENT

Press the

key once to display “ZERO ADJUSTMENT”.

Press the key for 4 times to display “RANGE”.

ENT

Press the

key once to display “KIND”.

Press the key for 5 times to display “BURNOUT” (CURRENT).

ENT

Press the

key once to blink on the 2nd line.

Press the key once to display “UPPER”.

ENT

Press the

key once to register.

――― UPPER has been registered. ―――

Press the key once to display “BURNOUT TIMER”.

ENT

Press the

key once to blink the cursor.

Press the key once to align the cursor to “1”.

Press the key once to set “2”.

ENT

Press the

key once to register.

――― BURNOUT TIMER has been registered. ―――

Press the

ESC

key twice and then press the key for 3 times to enter

the measurement mode.

OUTPUT SETUP

ZERO ADJUSTMENT

RANGE

KIND

BURNOUT (CURRENT)

BURNOUT (CURRENT)

BURNOUT (CURRENT)

BURNOUT (CURRENT)

COMPLETE

↓

BURNOUT (CURRENT)

BURNOUT TIMER

BURNOUT TIMER

BURNOUT TIMER

BURNOUT TIMER

BURNOUT TIMER

COMPLETE

↓

BURNOUT TIMER

0.000 m/s

0.000 m3/h

SET ZERO

FLOW RATE

HOLD

HOLD

UPPER

UPPER

10 sec

010 sec

010 sec

020 sec

20 sec

-35-

Page 44