Page 1

ULTRASONIC FLOWMETER

TYPE: FSV-2, FSS, FLYD

The latest advance in high performance

The latest advance in high performance

transit time flow measurement

transit time flow measurement

Superior signal processing and

Superior signal processing and

best-in-class anti-bubble performance

best-in-class anti-bubble performance

in a compact and lightweight package

in a compact and lightweight package

TIME DELTA-C

Detector (FSSC)

■

High accuracy measurement : 1.0% of rate

■

Superior anti-bubble performance : Our Advanced ABM method

Maintenance free operation : Non-invasive setup with no moving parts

■

Compact and lightweight : Size and mass reduced by 2/3 (compared with model FLV).

■

Flexible communication functions : RS-485 (MODBUS) (option)

■

Wide application range : φ13 to φ6000mm applicable pipe diameters

■

Extendable rail type detector up to φ50 to φ1200mm

Quick and easy setup : Simple menu guided setup from the front panel or PC interface

■

* Advanced ABM method: anti-bubble measuring method.

*

Flow transmitter (FSV...S)

is adopted.

21A1-E-0016b

Page 2

12

●Advanced received signal digital processing results in higher performance

Applicable pipe diameter is

High accuracy measurement of fluid flow rate: 1.0% of rate

■

Quick response: 0.2 sec. or less (quick response mode)

■

Minimal Influence by the pressure of measured fluid and temperature

■

Superior anti-bubble performance

■

φ

13mm to

■

(Advanced AMB method * is adopted.)

Advanced ABM method: anti-bubble measurement method

*

flow measurement

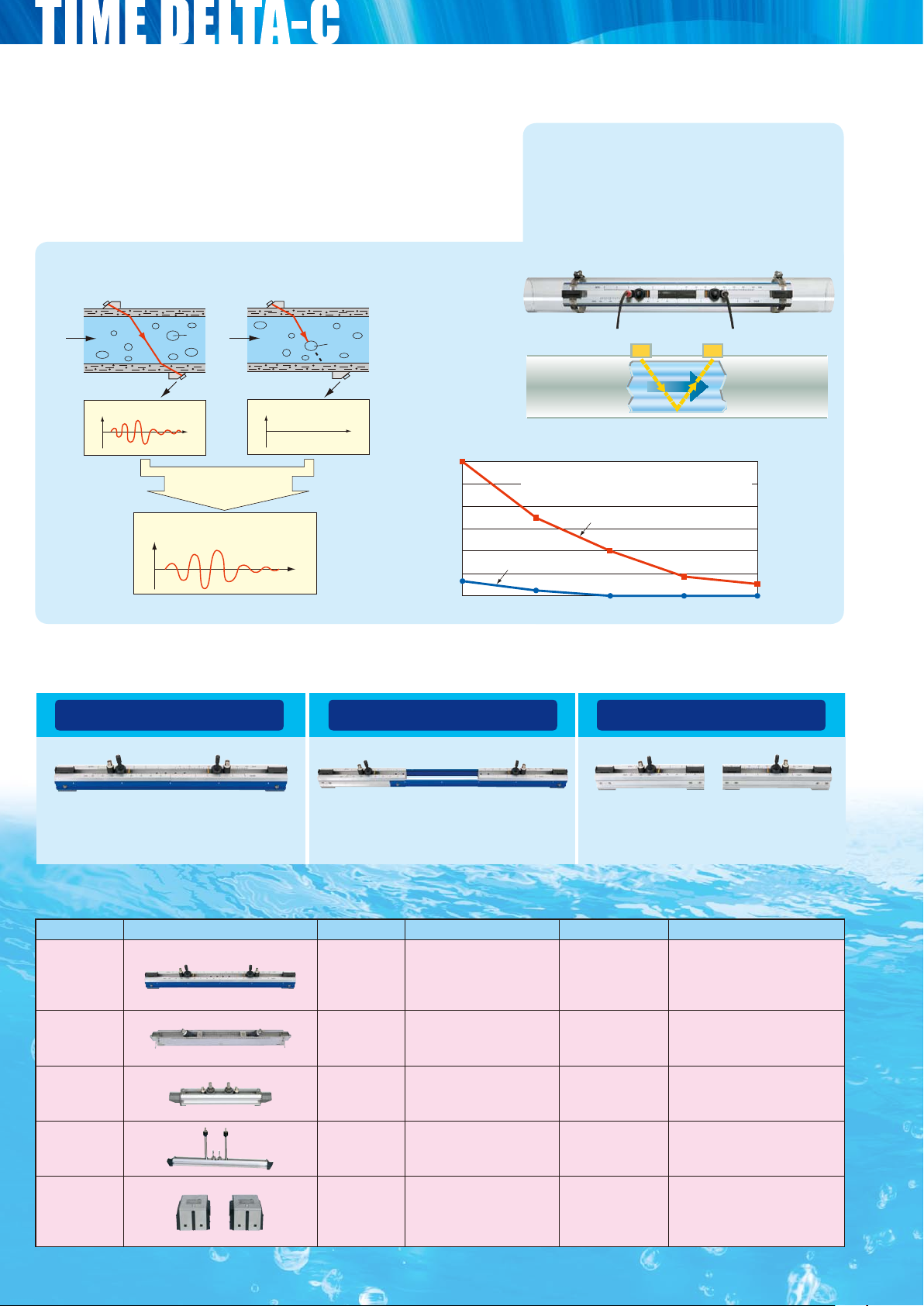

Normal propagation

Propagation interrupted by bubble

φ

6000mm

Measuring principle

With ultrasonic pulses propagated diagonally

between the upstream and downstream sensors

mounted on the exterior of the pipe, the flow rate

is measured by detecting the time difference

caused by the flow.

Flow

Received signal :

v

Summed 128 or 256 times

Digital data of the received signals :

v

Synchronized summation of received signals

Flow

Bubble

t

for a single output

Received signal :

v

Nothing

t

Bubble

In the case of an analog

system, measurement

t

failure will occur.

Sensor Sensor

12

Acceptable value

of bubble quantity

10

8

6

4

2

[vol.%]

1.2

1

1.0 2.0 3.0 4.0 5.0

(Note) Flowmeter indicates the volumetric flow

rate, including bubbles.

7.0

Advanced ABM method

4.0

Conventional method

0.4

0.03

1.5

0.02

Explanation of the extendable rail type detector

Normal Extended on rails Z method

1.0

0.02

Flow velocity

[m/s]

(type: FSSC)

pipe diameter φ50 to φ300mm <V method> pipe diameter up to φ600mm <V method> pipe diameter up to φ1200mm <Z method>

(A detector is simply attached to the exterior of the piping.)

Classification Appearance Detector type

Extendable rail

type

Compact type

Small

diameter type

High

temperature

type

Large

diameter type

FSSC

FSSA

FSSD

FSSH

FSSE

Applicable pipe inner diameter (mm)

50 to φ1200

φ

25 to φ225

φ

13 to φ100

φ

50 to φ400

φ

200 to φ6000

φ

(rail removed)

Measured fluid temperature

-

20 to 120°C

-

20 to 100°C

-

40 to 100°C

-

40 to 200°C

-

40 to 80°C

Mounting/structure

V or Z method mounting

・

Jet structure (equivalent to

・

IP65)

Submersible type available

・

V method mounting

・

Jet structure (equivalent to

・

IP65)

V mounting method

・

Splash-proof structure

・

(equivalent to IP52)

V or Z method mounting

・

Splash-proof structure

・

(equivalent to IP52)

V or Z method mounting

・

Watertight structure

・

(equivalent to IP67)

Submersible type available

・

2

Page 3

Normal: green / Extraordinary: Red

Instantaneous flow velocity

value (8-digit display)

Total flow rate value

(8-digit display)

Waterproof keypad

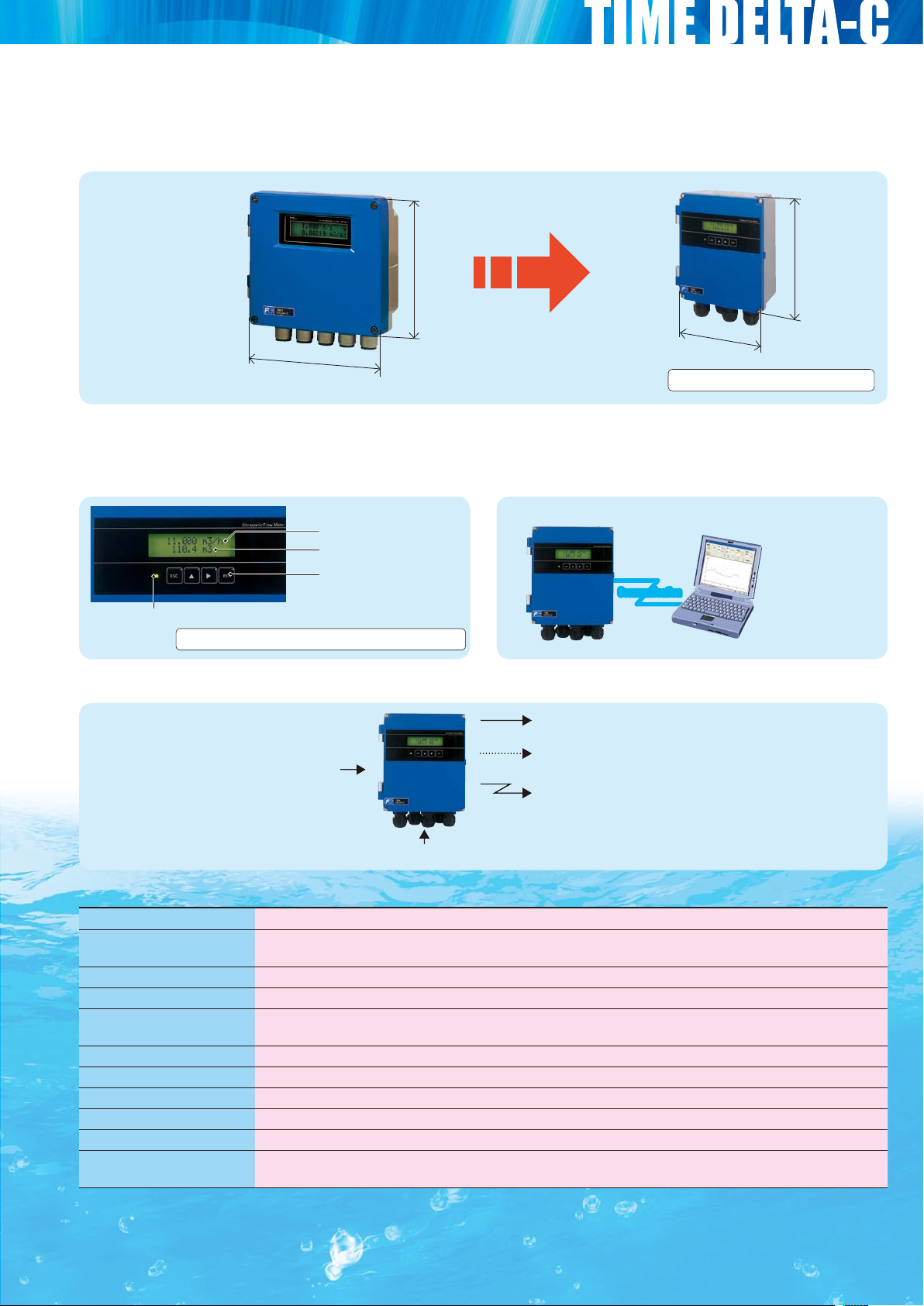

Both the mass and volume of the ow transmitter are reduced by 2/3!

Compact and lightweight flow transmitter (1/3 size of model FLV)

■

Easy to carry and install on a system

<Our FLV type> <Our FSV type>

170mm

220mm

Mass: approx 4.5kg Mass: approx 1.5kg

230mm

Operation can be performed from the outside panel

■

(In case of IP66 type)

Various settings can be made from the front side without opening the cover

of the flow transmitter. (Parameter setting , input of mou nted pipe data,

automatic calculation of mounting dimensions and similar)

LCD display with backlight is clearly legible, even in dark places.

Signal and process interfaces are designed with functionality as priority.

■

Input signal from the detector

Parameter setting and data collection can be

■

performed via optional PC communications

interface.

RS485

CommunicationCommunication

Analog output 1 point (4 to 20mA, insulated)

(max. load resistance: 600Ω)

Transistor contact 2 points (insulated)

Output frequency: 100P/s max., pulse width 5 to 1000ms)

Communication signal (RS485 communication)

(Insulated)

142mm

Mounting method: wall or pipe mounting

PC loader software

for the setting of

various parameters

and the collection of

measured data is a

standard accessory

Power supply voltage (with arrester, 100 to 240VAC or 20 to 30VDC)

Fully equipped with extensive functions

■

Zero adjustment one-touch adjustment while the flow is stopped

Damping

Low flow rate cut Output may be cut when the flow rate is low. Setting range: 0 to 5m/s (setting in 0.01m/s unit)

Alarm contact output Contact output at condition of hardware and process faults

Output burnout

Forward and backward ranges Ranges may be set arbitrarily. The digital output of the operation range is available.

Auto 2-range 2 forward ranges are independently configurable. Digital output of operation is available.

Flow switch Contact output is made when the upper or lower limit values of the instantaneous flow rate are reached

Total value switch Contact output is made when the upper limit value of the total flow rate (forward) exceeds the setting value.

Display of various units Unit may be set in

Multilingual display

Related products

■

Our product lineup includes such models as: consumed energy calculation, simultaneous measurement of 2 pipes, dual-path measurement.

Refer to the catalog No. 21A1-E-0024)

(

Used to reduce the fluctuation of the measured value.

Setting range: 0 to 100 sec. (setting per 0.1 sec.)

When measurement cannot be made because the pipe is empty or bubbles are entrained in the fluid, contact output is

activated while analog output is held.

m/s, L/s, L/min, L/h, L/d, KL/d, ML/d, m3/s, m3/min, m3/h, m3/d, Km3/d, Mm3/d

The display language may be selected from 5 choices, including Japanese (Katakana), English, French, Spanish and

German.

3

Page 4

Semi-conductor

underground water

condominiums and buildings

Pump

Application example

The ultrasonic flowmeter is a liquid flowmeter used in various applications.

■

1. Measuring system for the paint flow rate

The flow rate of thick paint is measured by a detector mounted on the pipe already constructed.

Ultrasonic

flowmeter

Paint

(red)

Flow

transmitter

Detector

Ultrasonic

flowmeter

Paint

(blue)

Flow

transmitter

Detector

Ultrasonic

flowmeter

Paint

(yellow)

Flow

transmitter

Detector

2. An energy-saving system for measuring and controlling the flow rate of a pump

A detector is attached to the already constructed pipe to measure the flow rate at the pump outlet, and a regulator is used to implement

inverter control of the pump.

Ultrasonic

flowmeter

Flow transmitter

(type: FSV)

Detector

(type: FSSC)

Pump

Inverter

Pump

Flow rate regulator

(type: PXH)

Water supplyWater supply

Application: To pump

3. Flow rate measurement in a water purifying

system for semi-conductors

Advantages of using an ultrasonic flowmeter for the system

Application: Water supply to high-rise

4.

Consumed energy calculation function

Calculates the thermal energy received and sent with liquid (water)

in cooling and heating.

1) It can be easily mounted on the exterior of a pipe, helping reduce

mounting cost.

2) As a sensor, it can operate without coming into contact with fluid, so the

fluid is not affected by metallic ions.

3) This meter, compact and lightweight, can be easily carried and mounted.

Ultrapure water

is supplied

manufacturing device

Electromagnetic

flowmeter

Raw

water

Ultrasonic

flowmeter

Detector

(type: FSSA)

Flow transmitter

(type: FSV)

Measurement of

the raw water

flow rate

Major applications

■

• Backup for the already constructed flowmeter

• Water supply and sewage systems ..........

• Power plant .................................................

• Various plants .............................................flow rate measurement of cooling water, plating solution and corrosive liquid

• Food manufacturing plan ...........................flow rate measurement of raw material and washing water

• Semiconductor manufacturing plant .........flow rate measurement of pure water

• Air-conditioning equipment .......................flow rate measurement of hot water and chilled water in heating and cooling

• Hot spring ...................................................Measurement of suction quantity

It can be mounted on the pipe already constructed.

・

Small, lightweight and easy to mount

・

Consumed heat quantity signal

Flow transmitter

(type: FSV...L)

Refer to the catalog

No. 21A1-E-0024

source

Heat

TR: Temperature of the heating

medium of the receiving side

leakage investigation of water pipe and investigation of the flow direction in the water distribution pipe

flow rate measurement of the boiler water supply, condenser circulating pump and turbine oil

)

Temperature

sensor

S: Temperature of the

T

heating medium on

the emitting side

Temperature

sensor

(4 to 20mADC)

Heat quantity total value pulse signal

(DO)

Consumed heat quantity

q = K · Q · |T

K : heat quantity (calorie)

conversion factor

(For heating K = 4.123)

(For cooling K = 4.186)

Q: Flow rate of the

heating medium

S–TR|

Detector

(type: FSSA)

Load

4

Page 5

Example of system conguration

5.5

Flow transmiter (Type: FSV)

Signal cable (Type: FLY)

Detector (Type: FSS)

< V method >

Detector (Type: FSS)

Power Supply

RS-485

Communication

4 to 20mA DC

Pulse output

Paperless recorder (Type: PHF)

Integrator

< Z method >

CODE SYMBOL

Flow transmitter

■

IP66

1 2 3 4 5 6 7 8 9 1011 1213

F S V Y 2 ー Y Description

E

Y

D

Y

1

4

S

H

Y

A

Detector

■

1 2 3 4 5 6 7 8 9 10

F S S 1 1 ー Description

C Extendable rail type (φ50 to φ1200mm)

A Compact type (φ25 to φ225mm)

D Small diameter type (φ13 to φ100mm)

E Large diameter type (φ200 to φ6000mm)

H High temperature type (φ50 to φ400mm)

1 Provided

Y None

A Stainless belt (1.0m×2)

C SS belt fasten with screws (1.0m×4)

D Wire ≤ φ1500mm

E Wire ≤ φ6000mm

Y None

A Silicon rubber (KE348)

B Silicone-free grease (HIGH-Z)

C Silicone grease (G40M)

Y None

A Provided (with signal cable 10m) *2

Y None

A Provided

(Language) (4th digits)

Standard

(Communication) (5th digit)

None

RS485

(6th digit)

Single measuring path

(Power supply) (7th digit)

100 to 240VAC 50/65H

20 to 30VDC

(Case structure) (9th digit)

IP66

IP67

(Wire connection port) (10th digit)

Weatherproof gland provided

Union (for plica) with gland [G1/ 2 female

screw] (when "H" is specied 9th digit)

(Combination with an explosion-proof detector) (11th digit)

None

Y

(Parameter setting) (12th digit)

None

Y

Setting provided

A

Setting provided + tag

B

Tag

C

(Mounting method) (13th digit)

Pipe mount (if the 9th digit is S)

A

Wall mount

B

Pipe mount (if the 9th digit is H)

C

<Senser type> (4th digit)

<Guide rall> (5th digit)

<Mounting belt> (6th digit)

<Acoustic coupler> (7th digit) *1

<Watwe-proof treatment> (9th digit)

<Tag plate> (10th digit)

(

) (

IP67

Contact output

Signal cable

■

)

1 2 3 4 5 6 7 8

F L Y 1 Description

D For FSSA, FSSC, FSSD, FSSH, FSSE (Note)

<Cable length: m> (5, 6, 7digits)

0 0 5 5m

0 1 0 10m

0 1 5 15m

0 2 0 20m

0 2 5 25m

0 3 0 30m

0 3 5 35m

0 4 0 40m

0 4 5 45m

0 5 0 50m

0 5 5 55m

0 6 0 60m

0 6 5 65m

0 7 0 70m

0 7 5 75m

0 8 0 80m

0 8 5 85m

0 9 0 90m

0 9 5 95m

1 0 0 100m

1 1 0 110m

1 2 0 120m

1 3 0 130m

1 4 0 140m

1 5 0 150m

Z Z Z Others (Contact us)

Note) When detector is FSSA,length of signal cable is up to 60 m.

Outline diagram det ecter signal cord

ø3.2

Bar terminal

<Type of detector> (4th digit)

L (cable length (m) : specified by order)

Relay

ø11

ø7.3

30

To DetectorTo Flow transmitter

SCOPE OF DELIVERY

• Flow transmitter

(provided with U-bolt and nuts for pipe mount)

•

Detector

(provided with mounting fixture and acoustic coupler)

• Signal cable

• CD-ROM (contains instruction manual, loader software)

*1) Normally select silicone rubber as acoustic coupler. Silicone rubber in tube (100g)

is furnished. If you place an order for several units, 1 tube may suce for every 5

units.

Select silicone -free grease for semiconductor manufacturing equipment or the

like that is vulnerable to silicone. The silicone-free grease is water-soluble and ,

therefore, cannot be used in environment exposed to water or on piping subjected

to a condensation. Since the grease does not set, a periodic maintenance

(cleaning, relling every about 6 months at normal temperature) is necessary.

* 2) It is selectable only for FS SC type and FSS E type.

ø14.5

BNC connector

5

Page 6

Specications

Applicable subjects and operation environment

■

Applicable fluid Homogeneous liquids capable of ultrasonic wave propagation

Bubble quantity: 0 to 12Vol% (reference diameter 50A, water and flow velocity of 1m/s)

Turbidity of fluid: 10000 degrees (mg/L) or less

Straight pipe length: upstream side 10D or more, downstream 5D or more (D: pipe inner diameter)

State of flow: fully developed turbulent or laminar flow in round pipe filled with fluid

Applicable piping and

fluid temperature

Flow velocity range 0 to ±0.3

Power supply voltage 100 to 240VAC 50/60Hz or 20 to 30VDC

Power consumption 15VA or less (AC power supply), 6W or less (DC power supply)

Signal cable (between the

detector and converter)

Installation environment Non-explosive area not exposed to direct sunlight, corrosive gas or heat radiation

Ambient temperature Flow transmitter: -20 to 55°C

Ambient moisture 90% RH max.

Grounding Class D (100Ω)

Arrester Provided as standard at the power supply

Classifi cation

Compact type FSSA

Extendable rail type FSSC

Small diameter type FSSD 13 to 100 V method -40 to +100

Large diameter type FSSE

High temperature type FSSH

Note 1) Please select the FSSC type and FSSE type if following condition.

- When pipe material is PP and pipe wall thickness is 15mm or more

- When pipe material is PVDF and pipe wall thickness is 9mm or more"

- When pipe material is cast iron pipe, lining pipe, old steel pipe or others through which the ultrasonic signal could not be transmitted easily.

Lining material: Tar epoxy, mortar, rubber, etc.

* If the lining is not properly glued to a pipe, the measurement may be impossible.

Note 2) If silicone-free grease is used as an acoustic couplant, the fl uid temperature range is 0 to 60°C, regardless of the detector.

Note 3) Please order a guide rail separately for Z method mounting. Order number : ZZP*TK4J5917C3

.....

±32m/s

Coaxial cable (60m max. for compact type detector (FSSA), 300m max. for others)

Heat resistance: 80°C

Detector: -20 to 60°C

Detector

type

Pipe size (inner diameter)

25to50

50to225

50to600

300to1200

200 to 1000 V method

500to6000

50to200

150 to 400 Z method

φ

(mm)

Mounting method

V method -20 to +100

V method

Z method

Z method

V method

Fluid temperature range

(°C) (Note 2)

-40 to +120

-40 to +80

-40 to +200

Applicable pipe material

(Note 1)

Plastic (PVC, Others)

Plastic (PVC, Others)

Metal pipe (Stainless

steel, Carbon steel,

Copper, Aluminum,

Others)

Performance specifications

■

Accuracy

rating

Response

time

Classifi cation Detector type Pipe size (inner diameter)

Compact

type

Extendable

rail type

Small

diameter

type

Large

diameter

type

High

temperature

type

0.5 sec. (standard mode), 0.2 sec. depending on setting (quick response mode)

FSSA

FSSC

FSSD

FSSE

FSSH

(mm)

φ

25to50

50to225

50to200

200to1200

13to50

50to100

200to300

300to1200

1200to6000

50to200

150to400

Flow velocity

(m/s)

3 to 32 ±2.0% of rate -

0 to 2 ±0.04m/s -

2 to 32 ±1.0% of rate ±2.0% of rate

0 to 2 ±0.02m/s ±0.04m/s

2 to 32 ±1.5% of rate

0 to 2 ±0.03m/s

2 to 32 ±1.0% of rate

0 to 2 ±0.02m/s

2 to 32 ±1.5% to ±2.5% of rate

0 to 2 ±0.03 to ±0.05m/s

2 to 32 ±1.5% of rate

0 to 2 ±0.03m/s

2 to 32 ±1.5% of rate

0 to 2 ±0.03m/s

0.75 to 32 ±1.5% of rate

0 to 0.75 ±0.0113m/s

1 to 32 ±1.0% of rate

0 to 1 ±0.02m/s

2 to 32 ±1.0% of rate

0 to 2 ±0.02m/s

0.75 to 32 ±1.0% of rate

0 to 0.75 ±0.0075m/s

Accuracy

Plastic pipe Metal pipe

6

Page 7

Functional specifications

■

Analog signal 4 to 20mA DC (1 point), Load resistance: 600Ω max.

Digital output

Serial communication

RS-485

(option)

Display device 2-color LED (Normal: green, Abnormal: red), LCD display (2 lines of 16 digits, back light provided)

Indication language Japanese (Katakana), English, French, German, Spanish (switchable)

Flow velocity / Instantaneous flow velocity / instantaneous flow rate indication (minus indication for reverse flow)

flow rate indication Numerals: 8 digits (decimal point is counted as 1 digit) English and metric units selectable.

Total indication Forward or reverse total value indication (negative indication for reverse direction)

Setting function Setting available with 4 keys (ESC, △, ▷, ENT) on the flowmeter front

Zero adjustment Set zero/Clear available

Damping 0 to 100s (setting per 0.1 sec.) for analog output and flow velocity/flow rate indication

Low flow rate cutoff 0 to 5m/s in terms of flow velocity

Alarm Digital output available for Hardware fault or Process fault

Burnout Analog output: Hold /Over-scale/Under-scale/zero (selectable)

Bi-directional range Forward and reverse ranges configurable independently / Hysteresis: 0 to 20% of working range / Working range applicable to digital output

Auto 2-range 2 forward ranges configurable independently / Hysteresis: 0 to 10% of working range / Working range applicable to digital output

Flow switch Lower limit, upper limit configurable independently (Digital output available for status at actuated point)

Total switch Upper limit of the forward total settable (Digital output available when actuated)

External total preset Preset total settable upon contact input setting

Backup of power failure backup by non-volatile memory

Forward total, reverse total, alarm, acting range, flow switch, total switch assignable arbitrarily

Transistor contact (isolated, open collector)

・Output: 2 points

・Normal: ON/OFF selectable

・Contact capacity: 30VDC, 50mA

・Output frequency: 100P/s max. (pulse width: 5, 10, 50, 100, 200, 500, 1000ms)

RS-485(MODBUS), isolated

Connectable quantity: 31 units

Baud rate: 9600, 19200, 38400bps

Parity: None/Odd/Even selectable

Velocity m/s ft/s

Unit:

Flow rate L/s, L/min, L/h, L/d, kL/d, ML/d, m

Numerals: 8 digits (decimal point is counted as 1 digit) English and metric units selectable.

Unit:

Total mL, L, m

Flow rate total: Hold/Count (selectable)

Burnout timer: 0 to 100s (every 1s)

Metric system Inch system

3

3

/d, BBL/s, BBL/min, BBL/h, BBL/d, kBBL/d, MBBL/d

Mm

Metric system Inch system

3

, km3, Mm3, mBBL, BBL, KBBL gal, kgal, ft3, kft3, Mft3, mBBL, BBL, kBBL, ACRE-ft

/s, m3/min, m3/d, km3/d,

Stop bits: 1 or 2 bits selectable

Cable length: 1km max.

Data: Flow velocity, flow rate, forward total, reverse total, status, etc.

gal/s, gal/min, gal/h, gal/d, kgal/d, Mgal/d, ft

3

/d, BBL/s, BBL/min, BBL/h, BBL/d, kBBL/d, MBBL/d

d, Mft

3

/s, ft3/min, ft3/d, Kft3/

Physical specifications

■

Type of enclosure Flow transmitter: IP66 or IP67

Mounting method Mounted on wall or by 2B pipe / Detector: Clamped on existing piping.

Acoustic couplant Silicone rubber, silicone grease or silicone-free grease

Note: The acoustic couplant

is a medium that eliminates

the gap between detector

and pipe.

Outer dimensions, mass See outline diagrams.

Loader software (standard accessory)

■

Compatible PC model PC/AT compatible instrument

Main function Software for setting/change of the main unit parameters and for collection of the measured data on PC

OS Windows 2000/XP/7/8

Memory requirement 125MB min.

Hard disk capacity Minimum free space of 52MB or more

Type

Fluid temperature -40 to +150˚C

Teflon piping Not usable Good Good Good

Silicone rubber (type:KE-348W)

Silicone grease (type:G40M)

30 to +150˚C 0 to +60˚C

-

Silicone-free grease (type:HIGH Z)

Connection diagram

Earth terminal

(M4)

AC power supply DC power supply

1

L

AC100 to 240V

32

N FG FG

+

DC20 to 30V

50/60Hz

<Plug terminal>

3

21

−

+

DO1

TR out

Max. DC30V, 50mA

3 421

− −

+

DO2

TR out

5 6

−

+

output

4 to 20mA

DC

7

GND

8

GND

HF1

To downstream-side

sensor

109

HF2

To upstream-side sensor

Grease for high temperature (type:KS62M)

30 to +250˚C

-

Option

●

21

SG

A

−

RS-485

3

B

+

7

Page 8

2-

U-bolt (M8) (option)

Mounting plate

Information in this catalog is subject to change without notice.

Outline diagram of the flow transmitter (unit: mm)

SS tag

BNC

Spacing 0 to 330

Saddle

Spacing

Name plate

10

TIME

DELTA-C

(Weight: 1.5kg)

142

701 1

ENT

ESC

10

9

Ultrasonic Flow Meter

IP66 type Flow transmitter Type: FSV...S

●

2.5

75

2.5

U-bolt (M8)

(option)

SS tag

Mounting Pipe

(2B)

(option)

Mounting hole 9x10

200

170

(233)

IP67 type flow transmitter Type FSV···H

●

20

220

312

277

25

(Weight: 4.5kg)

φ9

72

Cable gland

Earth terminal (M4)

For power supply/output cable (PG13.5)

Outline diagram of detector (unit: mm)

Extendable rail type detector Type: FSSC

●

±2

480

SPACING: 0 t o 300

mm

Scale (m m)

Lock nu t

Exte nded rail

Saddle

160 140 120 100 80 6 0 40 20

654321 inch

Name pl ate

53

54

Guide r ail

654321 inch

160 140 120 100 80 6 0 40 20

mm

Scale ( inch)

BNC CON N.

Rail end

Tag plate

<Shipmentstyle(Vmethod)>

High-temperature sensor

●

Type: FSSH

Scale

(inch)

(diameter φ50 to φ400, Weight: 1.6kg)

connector

Scale

(mm)

153

For sensor

cable (PF3/8)

(diameter φ50 to φ1200, Weight: 1kg)

(880)

700ma x.

400m ax.

Exte nded rail

mm

100 100

88ma x.

Rail end ( Accessor ies)

654321 inch

160 140 120 100 80 6 0 40 20

<Extendedstyle(Longest,Vmethod)>

240 2 40

<Sepalatestyle(Zmet hod)>

Small diameter sensor

●

Type: FSSD

(diameter φ13 to φ100, Weight: 0.6kg)

Bracket

(option)

240

100 100

14 230

5.7 95

Mounting Pipe

93

4040 40 40

For power supply/output cable (PF1/2) For sensor cable (PF1/2)

Compact type detector

●

Type: FSSA

mm

160 140 120 100 80 6 0 40 20

654321 inch

(option)

Large diameter sensor

●

Type: FSSE

(diameter φ25 to φ225, Weight: 0.4kg)

348

Sensor

BNC connector

Frame

Spacing

(Adjustment by every 3mm)

Lock clip

(diameter φ200 to φ6000, Weight: 1.2kg)

Earth terminal

30

(50)

34

28

Name plate

Scale

(inch)

530

Lock nut

Element holder

0 to 133

Cursor

Cursor

φ26

205max

90max

33

44

Caution on Safety

* Before using products in this catalog, be sure to read their instruction manuals in advance.

Grobal Sales Section

Instrumentation & Sensors Planning Dept.

1, Fuji-machi, Hino-city, Tokyo 191-8502, Japan

http://www.fujielectric.com

Phone: +81-42-514-8930 Fax: +81-42-583-8275

http://www.fujielectric.com/products/instruments/

inch

mm

52.5

Scale

(mm)

Element holder

90max

BNC

connector

Lock nut

320

78±1

Sensor

84±1

Wire rope

Mounting spring

114

67±1

36

φ4.3

8

150

BNC connector

φ7.3

±10

19

Signal cable conversion cord (accessories)

Printed in Japan 2015-5FOLS

Loading...

Loading...