Page 1

Instruction Manual

PC LOADER SOFTWARE

FOR MAINTENANCE

FOR HYBRID ULTRASONIC

FLOWMETER

<Duosonics>

TYPE: FSH-1

INF-TN514459-E

Page 2

Page 3

Contents

1. COPYRIGHT OF THIS SOFTWARE ...................................................................................1

2. OUTLINE .................................................................................................................................1

3. PC TO BE USED......................................................................................................................1

3.1. Computer .............................................................................................................................1

3.2. Memory capacity .................................................................................................................1

3.3. Interface...............................................................................................................................1

3.4. OS........................................................................................................................................1

3.5. Communication cable..........................................................................................................1

3.5.1. When using communication port for maintenance (RS232C)......................................1

3.5.2. When using communication port open to users (RS232C/RS485)...............................1

4. INSTALLING OF SOFTWARE .............................................................................................2

5. STARTUP METHOD ..............................................................................................................5

5.1. Communications..................................................................................................................6

5.2. Setting..................................................................................................................................7

5.2.1. Save setting...................................................................................................................7

5.2.2. Read setting ..................................................................................................................7

5.3. Version .................................................................................................................................8

6. STRUCTURE OF FUNCTION ..............................................................................................8

7. ESTABLISH SETTING...........................................................................................................9

8. RANGE SETTING ................................................................................................................11

9. TOTAL SETTING..................................................................................................................13

10. STATUS OUTPUT SETTING ............................................................................................15

11. DISPLAY SETTING............................................................................................................16

12. SYSTEM SETTING ............................................................................................................17

13. MEASUREMENT................................................................................................................18

14. PULSE DOPPLER MEASUREMENT..............................................................................19

14.1. Detailed setting................................................................................................................19

14.2. Flow velocity profile .......................................................................................................21

14.3. Operation Information.....................................................................................................22

15. TRANSIT TIME DIFFERENCE MEASUREMENT.......................................................24

15.1. Detailed Setting ...............................................................................................................24

15.2. Received Signal...............................................................................................................26

15.3. Operation Information.....................................................................................................27

16. RAS/STATUS........................................................................................................................29

16.1. RAS .................................................................................................................................29

16.2. Status ...............................................................................................................................30

16.3. RAS detail setting............................................................................................................31

17. MAINTENANCE .................................................................................................................33

18. SUPPORT.............................................................................................................................35

INF-TN514459-E

- i -

Page 4

19. END ...................................................................................................................................... 37

20. UNINSTALLING OF SOFTWARE ................................................................................... 37

- ii -

INF-TN514459-E

Page 5

1. COPYRIGHT OF THIS SOFTWARE

The copyright of this software belongs to Fuji Electric Systems Co., Ltd. No part of this software may be reproduced

or transmitted in any form.

2. OUTLINE

Using this software, you can set, read and display relevant graphs of the hybrid ultrasonic flow meter on your PC with

ease. Your data can be easily edited with Microsoft Excel because you can save your data in CSV file format.

Note: Microsoft Excel is the registered Trademark of the Microsoft Corporation in the United States.

3. PC TO BE USED

3.1. Computer

AT compatible-type with CPU Pentium IV 1 GHz/Celeron 1 GHz or more installed, display resolution of 1024 × 768,

and use of small font recommended.

3.2. Memory capacity

128 MB or more (256 MB or more recommended) [52 MB memory or more for free space required]

3.3. Interface

RS232C port or RS485 port

3.4. OS

Microsoft Windows2000 Professional (SP6a or more) or Microsoft WindowsXP Professional (SP1 or more)

3.5. Communication cable

There are two types of interfaces for flow transmitter.

3.5.1. When using communication port for maintenance (RS232C)

Use the following cable for communications between PC communication port and flow transmitter (control board CN6).

• Dedicated communication cable for digital controller

Type: PDZL1001

3.5.2. When using communication port open to users (RS232C/RS485)

Use the following cable for communications between PC communication port and flow transmitter (control board

terminal box).

• PC loader communication cable

Type: ZZP

B TK4H6253

*

INF-TN514459-E

- 1 -

Page 6

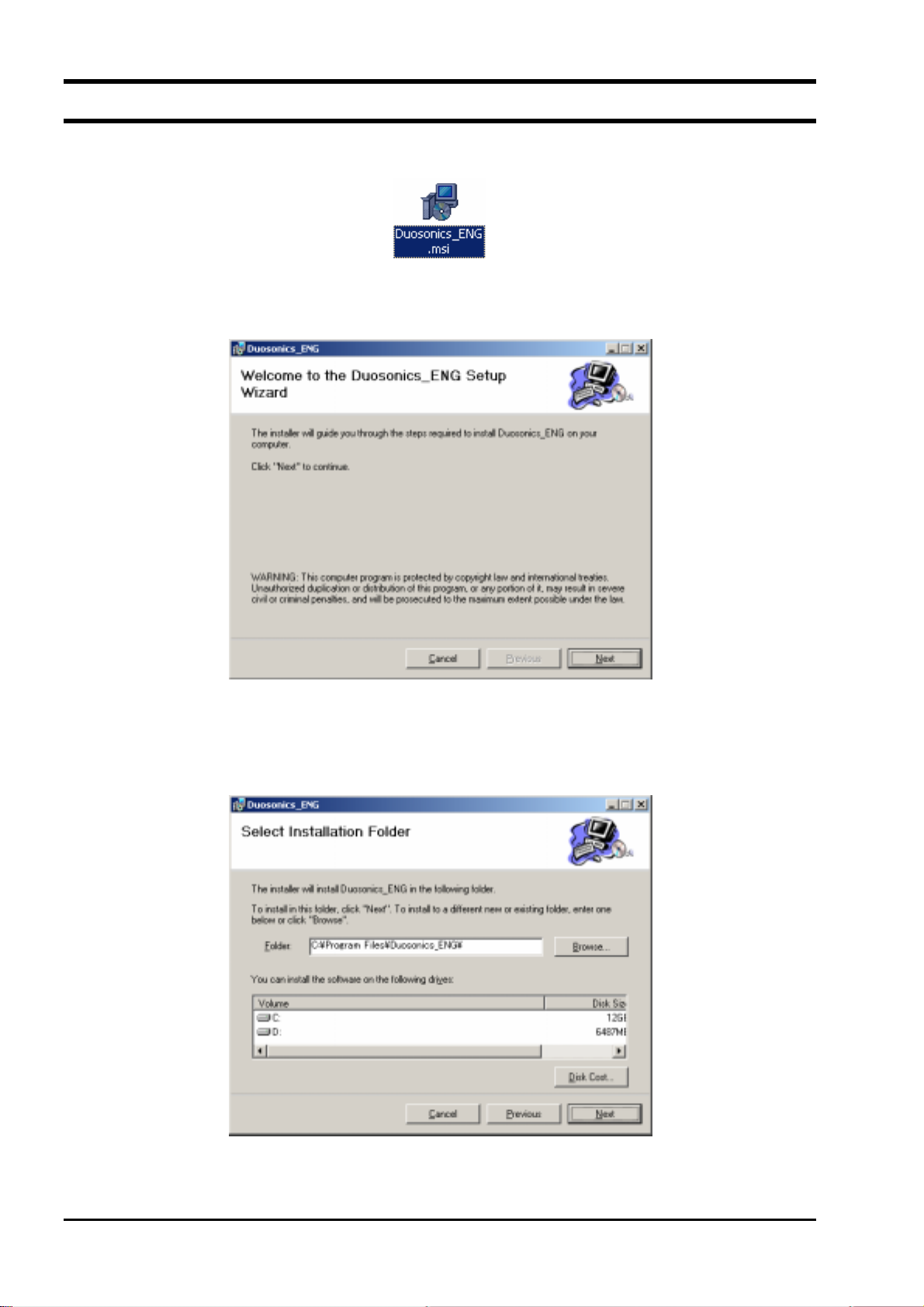

4. INSTALLING OF SOFTWARE

(1) Insert the setup disk into the drive, and double-click “Duosonics_ENG.msi”.

Fig. 1 <File Installation>

(2) Setting wizard will start up. Click the [Next] button. Click the [Cancel] button to cancel the installation.

Fig. 2 <Setup wizard screen>

(3) There is a query about selection of installation folder. Click the [Next] button to install the software in that folder.

To specify a folder click the [Browse] button and select, or enter directly. To return to the previous screen, click

the [Previous] button. Click the [Cancel] button to cancel the installation.

Fig. 3 <Select installation folder screen>

- 2 -

INF-TN514459-E

Page 7

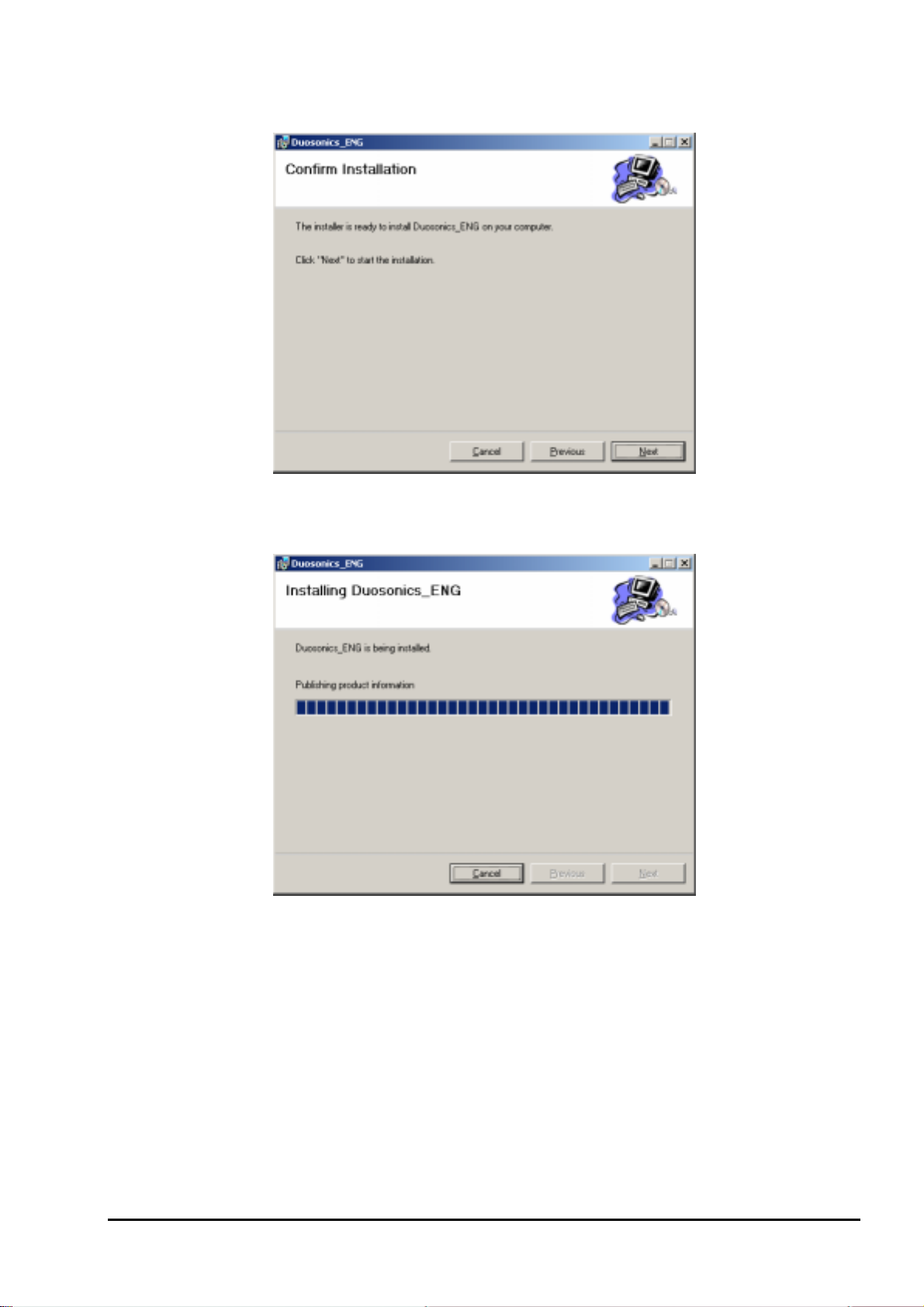

(4) Screen is displayed to confirm installation. Click the [Next] button to execute the installation. Click the

[Previous] button to return to the previous screen. Click the [Cancel] button to cancel the installation.

Fig. 4 <Installation confirmation screen>

(5) Execution of Installation

INF-TN514459-E

Fig. 5 <Installing screen>

- 3 -

Page 8

(6) The Installation Complete screen is displayed. Click the [Close] button to exit the installation screen.

Fig. 6 <Installation complete screen>

(7) After installation, the start menu and the application (“Duosonics_ENG”) that has been installed in the disktop are

created.

- 4 -

INF-TN514459-E

Page 9

5. STARTUP METHOD

Start “Duosonics_ENG” from the start menu to start up the loader.

Fig. 7 <Start screen>

Click the [Loader] button to start up the loader.

Click the [Download Program] button to start up the download program application. Click the button to upgrade

the software of the flow transmitter. Do not click it in ordinary cases.

Click the [Loader] button to start up the loader, and communication with the flow transmitter is carried out and the

system name, measurement method, language, and unit information is acquired.

If error occurs during communications, an error message is displayed to continue communication, select [Continue].

To stop communication, select [Cancel] on the menu screen that appears, check the setting for “Communication.”

Fig. 8 <Menu screen>

Click the menu bar and each function button to execute a desired function.

INF-TN514459-E

- 5 -

Page 10

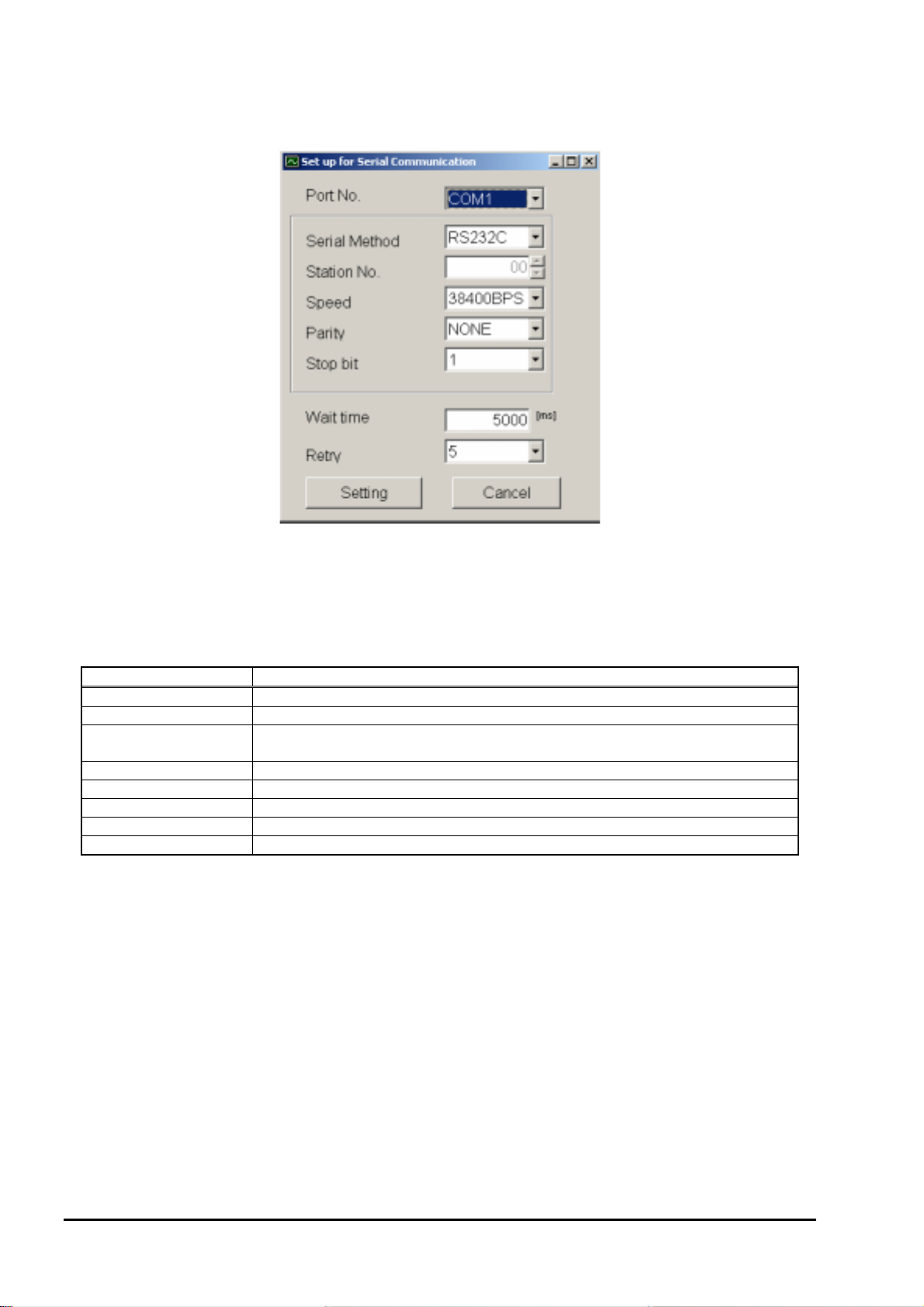

5.1. Communications

Click “Communication” on the menu bar on the Menu screen, and the following setup screen appears.

Fig. 9 <Serial communication setup screen>

Click the [Setting] button, and setting content is reflected; communications are executed with the flow transmitter and

information related to system name, measurement method, language and unit is obtained. Click the [Cancel] button to

invalidate the setting.

Table 1 <Measurement and Detailed Setting>

Item Content

Port No. Select either from COM1, COM2, COM3, COM4 and COM5.

Serial Method Select either RS232C or RS485.

Station No. Select one from 01 to 31. If communication method is RS232C, no selection is

allowed (fixed with 00).

Speed Select one from 9600BPS, 19200BPS and 38400BPS.

Parity Select one from NONE, EVEN and ODD.

Stop Bit Select either 1-bit or 2-bit.

Wait time Specify in the range from 1 to 65535. (Unit: msec)

Retry Specify in the range from 0 to 5.

- 6 -

INF-TN514459-E

Page 11

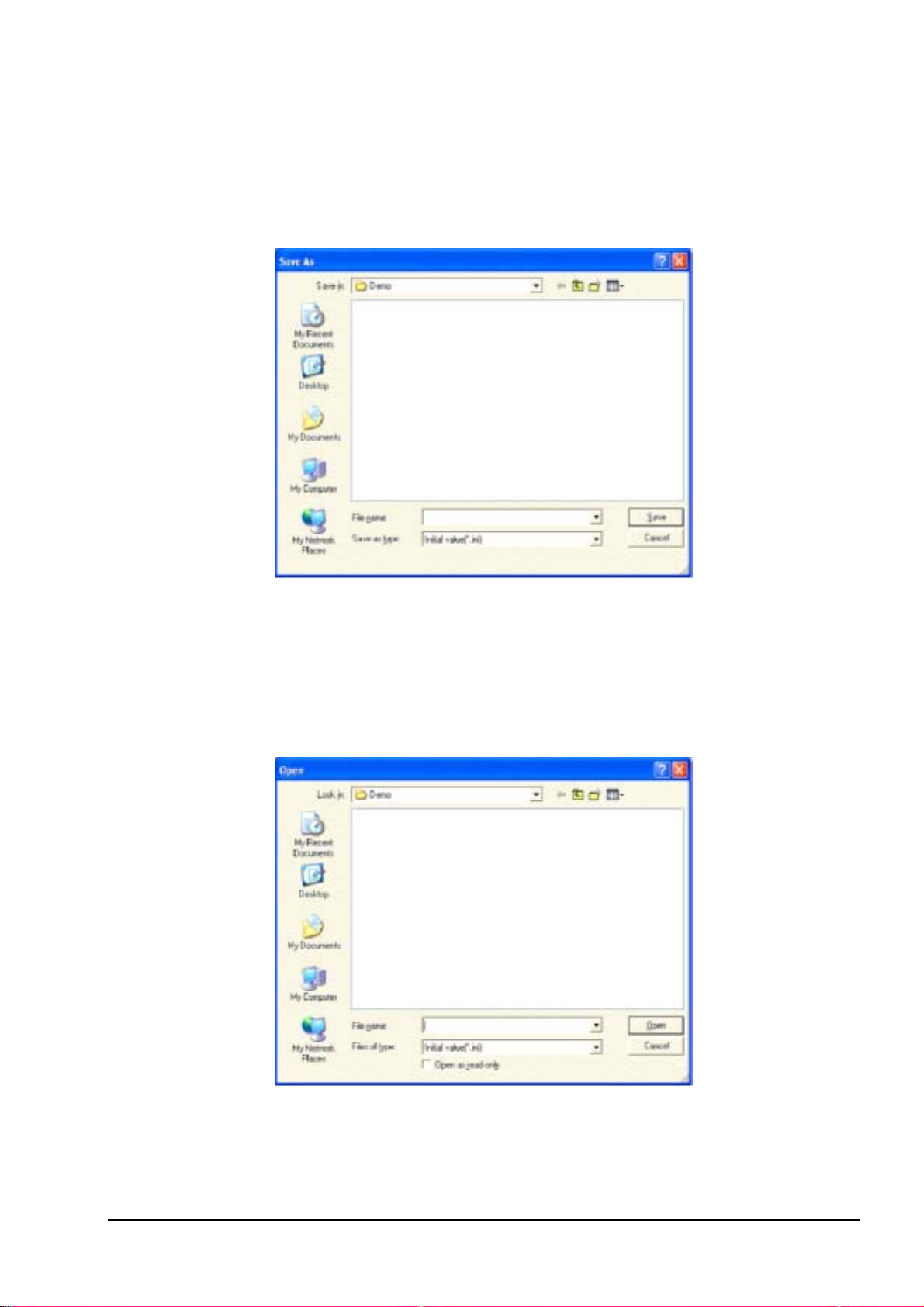

5.2. Setting

Click “Setting” on the menu bar on the Menu screen, and either “Save setting” or “Read setting” can be selected.

5.2.1. Save setting

Click “Save setting”, and the following screen appears. Specify saving location and file name, and setting content is

saved by clicking [Save] button. Click the [Cancel] button not to save the setting. File format is ini file.

Fig. 10 <Save setting: select save file screen>

* Note: Please be careful not to rewrite the setting file for loader (Hybrid USF.ini).

5.2.2. Read setting

Click “Read setting”, and the following screen appears. Specify the location and the name of the file saved previously.

Click the [Open] button to read the setting. Click the [Cancel] button not to read the setting. File format is ini file.

INF-TN514459-E

Fig. 11 <Read setting: select read file screen>

- 7 -

Page 12

5.3. Version

Click “Version” on the menu bar on the Menu screen, and the following screen appears.

Fig. 12 <Version screen>

Click the [OK] button to close the screen.

6. STRUCTURE OF FUNCTION

Functions with loader are as follows:

Table 2 <Function>

Function Outline

ESTABLISH Sets piping specifications, sensor type, etc.

RANGE Sets range-related matters.

TOTAL Sets total-related matters.

STATUS Sets status output-related matters.

DISPLAY Sets LCD display-related matters.

SYSTEM Sets system related to language, etc.

MEASURE Displays trend of flow rate, etc.

PULSE DOPPLER Displays graphs on Pulse Doppler detailed setting and operation information and

flow rate distribution, etc.

TRANSIT TIME Displays graphs on detailed setting of transit time difference, operation

information and received waveform, etc.

RAS/STATUS Reads status, or RAS, or performs detailed RAS setting.

MAINTENANCE Executes AO adjustment, AO and DO tests, etc.

SUPPORT Reads all the settings, and makes system mode setting.

- 8 -

INF-TN514459-E

Page 13

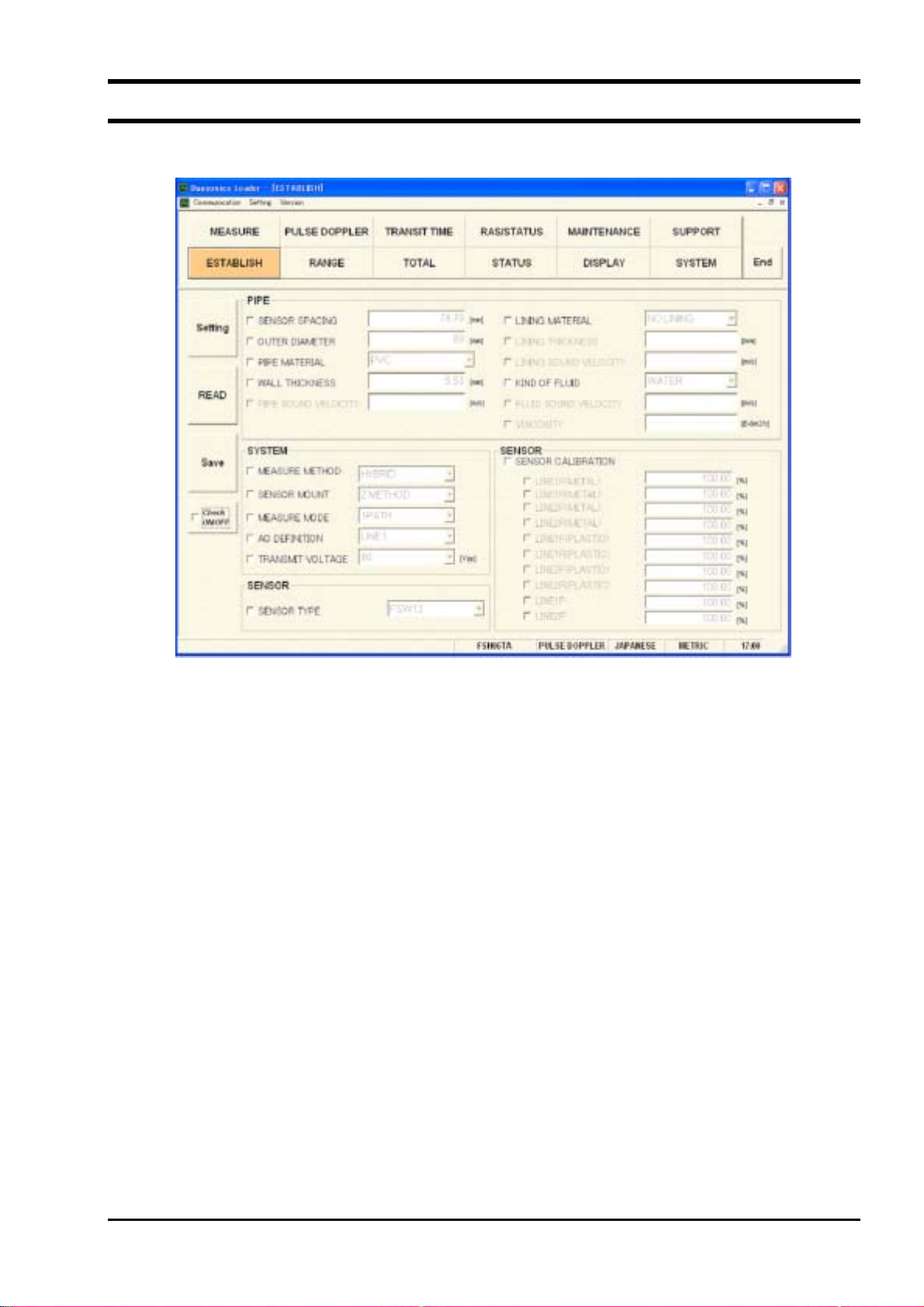

7. ESTABLISH SETTING

Click the “ESTABLISH” button on the Menu screen, and the following screen appears.

Fig. 13 <Establish setting screen>

To select an item to be set or read, set the relevant check box to ON (;). Not to select (or to reset the selection), set

the relevant check box to OFF (). If “Other” is selected as pipe material, pipe sound velocity becomes valid. If

“Other” is selected as fluid type, fluid sound velocity and dynamic viscous coefficient become valid.

[Setting]....................................... Sends the setting of the selected item (check box set to ON (;)), reflecting the

response value on the setting.

[READ] ....................................... Reads the setting of the selected item (check box set to ON (;)), reflecting the

response value on the setting.

[Save] ..........................................Reflects the setting sent by pressing the [Setting] button on the flow transmitter.

[Check ON/OFF] ......................... Set the check box to ON to select all the items (to set all the check boxes to ON

(;)). Set the check box to OFF () to release the selection of all the items (to set

all the check boxes to OFF ()).

INF-TN514459-E

- 9 -

Page 14

Table 3 <Piping Specifications>

Item Content

OUTER DIAMETER Enter in the range from 10.00 to 6200.00 mm.

PIPE MATERIAL Select from carbon steel, stainless steel, PVC, Copper, Cast iron, aluminum,

FRP, ductile iron, peek, PVDF, acrylic and others.

PIPE SOUND VELOCITY Enter in the range from 1000 to 3700 m/s (if piping material is “Others”.).

WALL THICKNESS Enter in the range from 0.10 to 100.00 mm.

LINING MATERIAL Select from no lining, tar epoxy, mortar, rubber, Teflon, pyrex, glass, PVC and

others.

LINING SOUND

Enter in the range from 1000 to 3700 m/s (if lining material is “Others”.).

VELOCITY

LINING THICKNESS Enter in the range from 0.01 to 100.00 mm (if lining material is other than “No

Lining”.).

KIND OF FLUID Select for water, seawater, dist. water, ammonia, alcohol, benzene, bromide,

ethanol, glycol, kerosene, milk, methanol, toluol, lube oil, fuel oil, petrol and

others.

FLUID S.V. Enter in the range from 500 to 2500 m/s (if fluid type is “Others”).

VISCOSITY

Enter in the range from 0.0010 to 999.9999 × 10

6 m2

/s (if fluid type is

“Others”).

SENSOR SPACING [Read] only is valid.

Table 4 <System>

Item Content

MEASURE METHOD Select from hybrid and transit time.

SENSOR MOUNT Select from Z method and V method.

MEASURE MODE Select from 1 path and 2 paths.

AO DEFINITION Select from average, line 1 and line 2. Line 1 only when 1 path is selected as

measurement mode.

TRANSMIT VOLTAGE Select from 20, 40, 80 and 160Vpp.

Table 5 <Sensor>

Item Content

SENSOR TYPE Select from FLW11, FLW41, FLW12, FLD12, FLD22, FLW32, FLW51,

FSW12, FSW21, FSW40 and FSW50.

SENSOR CALIB.

LINE 1F (METAL) Enter in the range from 0.00 to 300.00.

LINE 1R (METAL) Enter in the range from 0.00 to 300.00.

LINE 1F (PLASTIC) Enter in the range from 0.00 to 300.00.

LINE 1R (PLASTIC) Enter in the range from 0.00 to 300.00.

LINE 1P Enter in the range from 0.00 to 300.00.

LINE 2F (METAL) Enter in the range from 0.00 to 300.00.

LINE 2R (METAL) Enter in the range from 0.00 to 300.00.

LINE 2F (PLASTIC) Enter in the range from 0.00 to 300.00.

LINE 2R (PLASTIC) Enter in the range from 0.00 to 300.00.

LINE 2P Enter in the range from 0.00 to 300.00.

- 10 -

INF-TN514459-E

Page 15

8. RANGE SETTING

Click the “RANGE” button on the Menu screen, and the following screen appears.

Fig. 14 <Range setting screen>

To select an item to be set or read, set the relevant check box to ON (;). Not to select (or to reset the selection), set

the relevant check box to OFF ().

• Type: in case of single range;

Display Valid............................ Full scale

Display Invalid......................... Full scale 1, full scale 2 and histeresis

• Type: in case of automatic 2-range, forward and reverse range, forward and reverse automatic 2-range

Display Valid............................ Full scale 1, full scale 2 and histeresis

Display Invalid......................... Full scale

[Setting]................................ Sends the setting of the selected item (check box set to ON (;)), reflecting the

response value on the setting.

[READ] ................................ Reads the setting of the selected item (check box set to ON (;)), reflecting the

response value on the setting.

[Save] ................................... Reflects the setting sent by pressing the [Setting] button on the flow transmitter.

[Check ON/OFF].................. Set the check box to ON to select all the items (to set all the check boxes to ON

(;)). Set the check box to OFF () to release the selection of all the items (to set

all the check boxes to OFF ()).

INF-TN514459-E

- 11 -

Page 16

Table 6 <Range Setting>

Item Content

RANGE UNIT Select from m/s, L/s, L/min, L/h, L/d, kL/d, ML/d, m3/s, m3/min, m3/h, m3/d,

3

km

/d, Mm3/d, BBL/s, BBL/min, BBL/h, BBL/d, kBBL/d, MBBL/d

3

[ft/s, ft

/s, ft3/h, ft3/d, kft/d, Mft3/d, gal/s, gal/min, gal/h, gal/d, kgal/d, Mgal/d,

BBL/s, BBL/min, BBL/h, BBL/d, kBBL/d, MBBL/d]

* Of which [ ]: unit is in case of inch system.

RANGE TYPE Select from SINGLE, AUTO 2, BI-DIR, BI-DIR AUTO 2.

FULL SCALE

FULL SCALE 1

FULL SCALE 2

Enter 0, ±0.3 to 32 m/s fitting value (comply with range unit).

Enter 0, ±0.3 to 32 m/s fitting value (comply with range unit).

Enter 0, ±0.3 to 32 m/s fitting value (comply with range unit).

HYSTERISIS Enter in the range of 0 to 20%.

OUTPUT LIMIT LOW Enter in the range of -20 to 0%.

OUTPUT LIMIT HIGH Enter in the range of 100 to 120%.

OUTPUT BURNOUT Select from NOT USED, HOLD, UPPER, LOWER, ZERO.

BURNOUT TIMER Enter in the range of 0 to 900sec.

RATE LIMIT Enter 0 to 5 m/s fitting value (comply with range unit).

RATE LIMIT TIMER Enter in the range of 0 to 900 sec.

Table 7 <Damping>

Item Content

DAMPING Enter in the range of 0.0 to 100.0 sec.

Table 8 <Low Flow Rate Cut>

Item Content

CUT OFF Enter 0 to 5 m/s fitting value (comply with range unit).

Table 9 <High and Low Limit Switch>

Item Content

FLOW SW LOW Enter 0 to 32 m/s fitting value (comply with range unit).

FLOW SW HIGH Enter 0 to 32 m/s fitting value (comply with range unit).

HYSTERESIS Enter in the range of 0 to 20%.

Table 10 <Output Correction>

Item Content

ZERO Enter 0 to 5 m/s fitting value (comply with range unit).

SPAN Enter in the range of 0 to 200%.

- 12 -

INF-TN514459-E

Page 17

9. TOTAL SETTING

Click the “TOTAL” button on the Menu screen, and the following screen appears.

Fig. 15 <Total setting screen>

To select an item to be set or read, set the relevant check box to ON (;). Not to select (or to reset the selection), set

the relevant check box to OFF ().

[Setting]....................................... Sends the setting of the selected item (check box set to ON (;)), reflecting the

response value on the setting. Note that only when “STOP” mode is selected, the

setting of other items is reflected.

[READ] ....................................... Reads the setting of the selected item (check box set to ON (;)), reflecting the

response value together with the unit on the setting.

[Save] ..........................................Reflects the setting sent by pressing the [Setting] button on the flow transmitter.

[Check ON/OFF]......................... Set the check box to ON (;) to select all the items (to set all the check boxes to ON

(;)). Set the check box to OFF () to release the selection of all the items (to set

all the check boxes to OFF ()).

INF-TN514459-E

- 13 -

Page 18

Table 11 <Total Setting>

Item Content

TOTAL MODE Select from TOTAL STOP, TOTAL RUN, TOTAL RESET.

TOTAL UNIT Select from mL, L, m3, km3, Mm3, mBBL, BBL and kBBL,

3

[ft

, kft3, Mft3, kgal, gal, mBBL, BBL, kBBL and ACRf]

* Of which [ ]: unit is in case of inch system.

TOTAL RATE Enter in the range of 0 to 999999.999.

F: TOTAL PRESET Enter in the range of 0 to 9999999999.999.

F: TOTAL SW Enter in the range of 0 to 9999999999.999.

R: TOTAL PRESET Enter in the range of 0 to 9999999999.999.

R: TOTAL SW Enter in the range of 0 to 9999999999.999.

OUTPUT BURNOUT Select from NOT USED and HOLD.

BURNOUT TIMER Enter in the range of 0 to 900 sec.

PULSE WIDTH 1 Select from 50 msec, 100 msec and 200msec.

PULSE WIDTH 2 Select from 0.5 msec, 1 msec, 2 msec, 5 msec, 10 msec, 20 msec, 50 msec,

100 msec, 200 msec.

Note) When unit is changed, each unit indication of constant, F: total preset, F: total switch, R: total preset, R: total

switch are changed if [Read] is executed.

Note) When setting is changed, it should be executed with the mode stop.

- 14 -

INF-TN514459-E

Page 19

10. STATUS OUTPUT SETTING

Click the “STATUS” button on the Menu screen, and the following screen appears.

Fig. 16 <Status output setting screen>

To select an item to be set or read, set the relevant check box to ON (;). Not to select (or to reset the selection), set

the relevant check box to OFF ().

[Setting]....................................... Sends the setting of the selected item (check box set to ON (;)), reflecting the

response value on the setting.

[READ] ....................................... Reads the setting of the selected item (check box set to ON (;)), reflecting the

response value on the setting.

[Save] ..........................................Reflects the setting sent by pressing the [Setting] button on the flow transmitter.

[Check ON/OFF] ......................... Set the check box to ON to select all the items (to set all the check boxes to ON

(;)). Set the check box to OFF () to release the selection of all the items (to set

all the check boxes to OFF ()).

Table 12 <Status output setting>

Item Content

OUTPUT DO 1 Select from NOT USED, SIGNAL ERROR, F: TOTAL PULSE, R: TOTAL

PULSE, F: TOTAL SW, R: TOTAL SW, F: TOTAL OVERFLOW, R: TOTAL

OVERFLOW, FLOW SW HIGH, FLOW SW LOW, FULL SCALE 2, AO

RANGE OVER, PULSE RANGE OVER, R: FLOW DIRECTION and DEVICE

ERROR.

OUTPUT DO 2 Same as above

OUTPUT DO 3 Same as above

MODE DO 1 Select either NORMAL or REVERSE.

MODE DO 2 Same as above

MODE DO 3 Same as above

INF-TN514459-E

- 15 -

Page 20

11. DISPLAY SETTING

Click the “DISPLAY” button on the Menu screen, and the following screen appears.

Fig. 17 <Display setting screen>

To select an item to be set or read, set the relevant check box to ON (;). Not to select (or to reset the selection), set

the relevant check box to OFF (). If “Flow rate” is select in the selection items, flow rate unit becomes valid.

[Setting] ....................................... Sends the setting of the selected item (check box set to ON (;)), reflecting the

response value on the setting.

[READ]........................................Reads the setting of the selected item (check box set to ON (;)), reflecting the

response value on the setting.

[Save]...........................................Reflects the setting sent by pressing the [Setting] button on the flow transmitter.

[Check ON/OFF] .........................Set the check box to ON to select all the items (to set all the check boxes to ON

(;)). Set the check box to OFF () to release the selection of all the items (to set

all the check boxes to OFF ()).

Table 13 <Display Setting>

Item Content

DISPLAY 1

DISPLAY KIND Select from VELOCITY, FLOW RATE, TOTAL FORWARD, TOTAL

REVERSE, F: TOTAL PULSE, R: TOTAL PULSE, FLOW RATE (%).

Flow Unit Select from L/s, L/min, L/h, L/d, kL/d, ML/d, m

3

km

/d, Mm3/d, BBL/min, BBL/h, BBL/d, kBBL/d, MBBL/d

3

[ft/s, ft

/s, ft3/min, ft3/h, ft3/d, kft3/d Mft3/d, gal/s, gal/min, gal/h, gal/d,

3

/s, m3/min, m3/h, m3/d,

kgal/d, Mgal/d, BBL/s, BBL/h, BBL/d, kBBL/d, MBBL/d]

* Of which [ ]: unit is in case of inch system.

DISPLAY KIND Same as the selection of DISPLAY 1 DISPLAY 2

Flow Unit Same as the unit of DISPLAY 1

- 16 -

INF-TN514459-E

Page 21

12. SYSTEM SETTING

Click the “SYSTEM” button on the Menu screen, and the following screen appears.

Fig. 18 <System setting screen>

To select an item to be set or read, set the relevant check box to ON (;). Not to select (or to reset the selection), set

the relevant check box to OFF (). However, system name and version information can only be read.

* When changing unit, restart the loader to reflect the unit change.

[Setting]....................................... Sends the setting of the selected item (check box set to ON (;)), reflecting the

response value on the setting.

[READ] ....................................... Reads the setting of the selected item (check box set to ON (;)), reflecting the

response value on the setting.

[Save] ..........................................Reflects the setting sent by pressing the [Setting] button on the flow transmitter.

[Check ON/OFF] ......................... Set the check box to ON to select all the items (to set all the check boxes to ON

(;)). Set the check box to OFF () to release the selection of all the items (to set

all the check boxes to OFF ()).

Table 14 <System Setting>

Item Content

LANGUAGE Language is available in JAPANESE, ENGLISH, GERMAN,

FRENCH and SPANISH.

UNIT SYSTEM Select from METRIC and ENGLISH.

SYSTEM NAME Read only Without flow velocity profile output FSH###Y

CONTROL BOARD Read only With flow velocity profile output FSH###A VERSION

INFO.

MEASUREMENT BOARD Read only

INF-TN514459-E

- 17 -

Page 22

13. MEASUREMENT

Click the “MEASURE” button on the Menu screen, and the following screen appears.

Fig. 19 <Measure screen>

Select one from instantaneous value, total pulse, total value, or flow rate % first. Next, in case of moment value, select

either flow rate or flow velocity. In case of total pulse, select either normal direction or reverse direction. In case of

total value, select either normal direction or reverse direction.

In case of trend, the read measurement value and RAS columns are updated in specified cycles. Also, it is displayed in

trend (X axial displays collection time. The oldest is deleted and time is shifted to make the latest value to be seen

when specified points are reached. The vertical axial it displays with Y scale specifed. The grid line represents Pulse

Doppler in blue and transit time difference in green.

[Start]...........................................Starts measuring.

[Stop] ........................................... Stops measuring.

[Save as CSV]..............................Saves the measurement result in a file in CSV format. Click the button, and you

are prompted to enter the name of a file to which the data is to be saved. Specify

the destination to save and enter the file name, and a CSV file is created.

Table 15 <Measurement and Detailed Setting>

Item Content

Moment Value Select either FLOW RATE or VELOCITY.

TOTAL PULSE Select either FORWARD or REVERSE.

TOTAL Select either FORWARD or REVERSE.

FLOW RATE % -

Y: Scale Enter Max and Min. SCALE

X: Scale Enter Cycle and Point.

- 18 -

INF-TN514459-E

Page 23

14. PULSE DOPPLER MEASUREMENT

Click the “PULSE DOPPLER” button on the Menu screen, and the following screen appears. Click detailed setting

tab, flow speed distribution tab and/or operation information tab when necessary.

14.1. Detailed setting

CAUTION

• Do not change the setting by yourself. Otherwise measurement may be disabled.

• Make the detailed setting only when a problem should arise in flow rate measurement with factory default

settings. The setting need not be made in other cases.

Click “Detailed setting”, and the following screen appears.

Fig. 20 <Detail setting screen>

To select an item to be set or read, set the relevant check box to ON (;). Not to select (or to reset the selection), set

the relevant check box to OFF (). As to judgment, it can obtain with setting success ratio set, power and deviation

while setting ON with check box of setting lateral-line. However, when read it, disregard selection of multiple laterallines.

[Setting]....................................... Sends the setting of the selected item (check box set to ON (;)), reflecting the

response value on the setting.

[READ] ....................................... Reads the setting of the selected item (check box set to ON (;)), reflecting the

response value on the setting.

[Save] ..........................................Reflects the setting sent by pressing the [Setting] button on the flow transmitter.

[Check ON/OFF] ......................... Set the check box to ON to select all the items (to set all the check boxes to ON

(;)). Set the check box to OFF () to release the selection of all the items (to set

all the check boxes to OFF ()).

INF-TN514459-E

- 19 -

Page 24

Table 16 <Pulse and Doppler Measurement Detailed Setting>

Item Content

WEDGE SOUND

VELOCITY

With selection of AUTO/MANUAL, in case of MANUAL, input right side

column in the range of numeric 1000 to 3700 m/s.

PIPE SOUND VELOCITY With selection of AUTO/MANUAL, in case of MANUAL, input right side

column in the range of numeric 1000 to 3700 m/s.

LINING SOUND

VELOCITY

FLUID SOUND

VELOCITY

TRANSMIT

FREQUENCY

SAMPLING

FREQUENCY

With selection of AUTO/MANUAL, in case of MANUAL, input right side

column in the range of numeric 1000 to 3700 m/s.

With selection of AUTO/MANUAL, in case of MANUAL, input right side

column in the range of numeric 500 to 2500 m/s.

With selection of AUTO/MANUAL, in case of MANUAL, input right side

column in the range of numeric 0.1 to 5 MHz.

With selection of AUTO/MANUAL, in case of MANUAL, select numeric at right

side column.

RECEPTIVE WAIT TIME With selection of AUTO/MANUAL, in case of MANUAL, select numeric at right

side column.

REPETITION

FREQUENCY

With selection of AUTO/MANUAL, in case of MANUAL, input right side

column in the range of numeric 100 to 8000 Hz.

CHANNEL With selection of AUTO/MANUAL, in case of MANUAL, select from numeric

16, 32, 48, 64, 80, 96, 112 and 128 at right side column.

REFRENCE COUNT Select numeric.

TRANSMIT PULSE NO. Select from 0, 1, 2, 4, 8, 16, 32 and 64.

MEASUREMENT

Select from F RADIUS, N RADIUS and DIAMETER.

RANGE

PHASE ANGLE SHIFT Select from NORMAL 1, NORMAL 2, POSITIVE and NEGATIVE.

GAIN With selection of AUTO/MANUAL, in case of MANUAL, select numeric 0 to 18

in each column of START GAIN/END GAIN.

Table 17 <Pulse and Doppler Measurement Judgment Setting>

Item Content

SUCCESS RATIO Enter in the range of 0 to 100%.

POWER Enter in the range of 0.00 to 100.00.

DEVIATION Enter in the range of 0.00 to 1.00.

- 20 -

INF-TN514459-E

Page 25

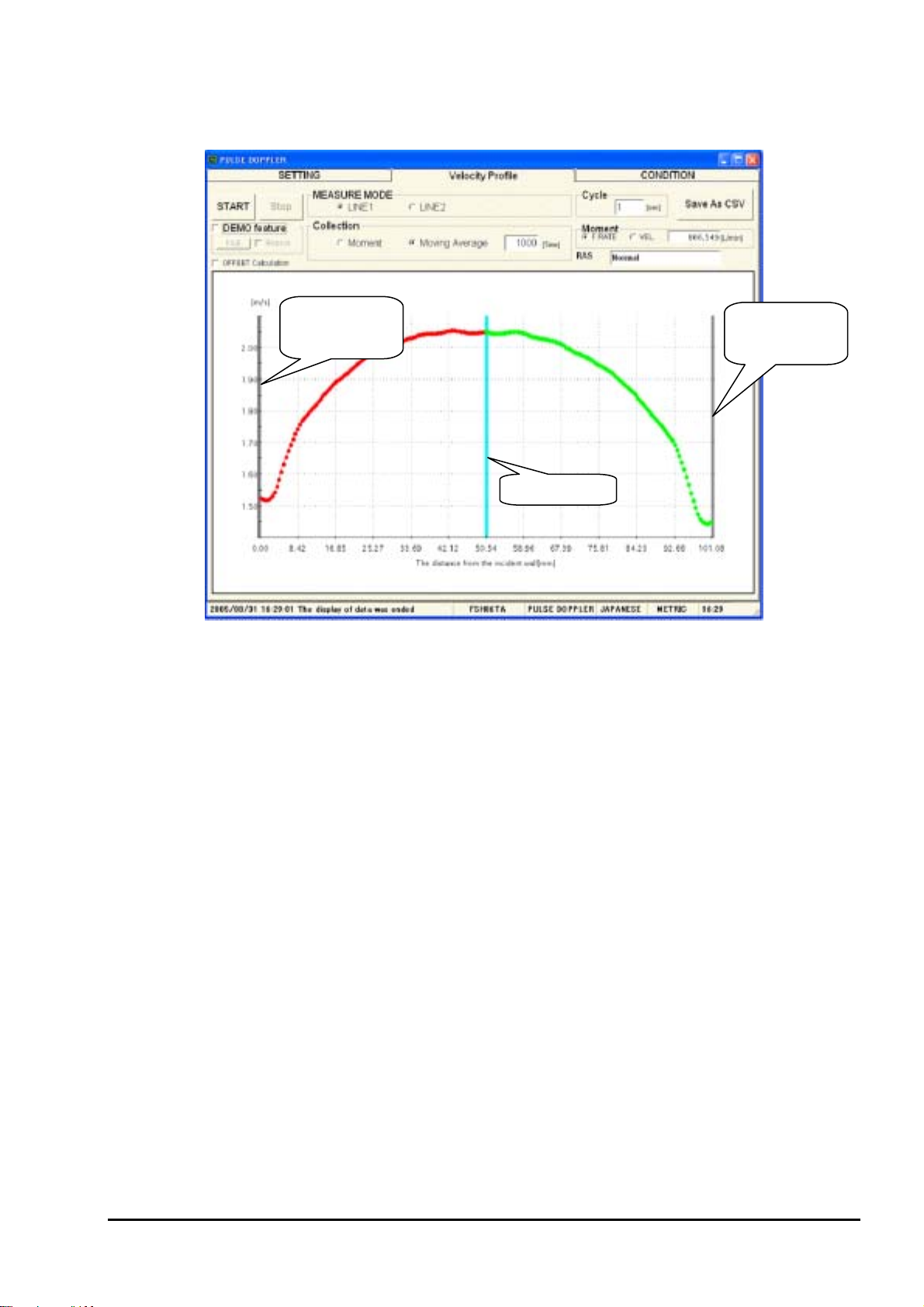

14.2. Flow velocity profile

Click “Velocity Profile”, and the following screen appears.

Internal pipe wall

of upper stream

sensor

Center of piping

Internal pipe wall

of down stream

sensor

Fig. 21 <Flow Rate Distribution screen>

Select either Moment or Moving Average first and then enter the range for reading from 1 to 60 sec. If Movingaverage is selected, set the number of times. Then, select either Line 1 or Line 2.

The line displays flow velocity distribution measured by upper flow side sensor in green, and flow speed distribution

measured by down flow side sensor in red.

Collection

Moment.................................... Displays data by each read

Moving Average....................... Displays data in moving average with the number of times set by channel in each

read data.

Moment

Flow velocity/flow rate............ Displays flow velocity or flow rate with each read

RAS ......................................... Displaying RAS with each read

Demonstration function ...........Displays read flow velocity distribution with [Save As CSV] file

Displays repeatedly by setting check box to ON (;)

Offset calculation..................... Displays flow velocity profile detected by the sensor on the upper stream side and

that on the lower stream side overlapped at the center of the piping.

[Start]....................................Starts reading in indicated cycle.

[Stop].................................... Stops reading.

[Save As CSV] ..................... Saves measurement results in file with CSV format. Click the button, and you are

prompted to enter the file name to which the data is to be saved.

INF-TN514459-E

- 21 -

Page 26

14.3. Operation Information

Click “CONDITION”, and the following screen appears.

Fig. 22 <Operation Information screen>

Select either Line 1 or Line 2 first.

[READ] ......................................Reads operation information in batch.

[Save As CSV]............................. Saves the measurement result in a CSV format file. Click the button, and you are

prompted to enter the name of a file to which the data is to be saved. Specify the

destination to save and enter the file name, and a CSV file is created.

- 22 -

INF-TN514459-E

Page 27

Table 18 <Operation Information>

Item Content

WEDGE SOUND

m/s [ft/s]

VELOCITY

WEDGE ANGLE

°

PIPE SOUND VELOCITY m/s [ft/s]

ANGLE IN PIPE

LINING SOUND

°

m/s [ft/s]

VELOCITY

ANGLE IN LINING

°

FLUID SOUND VELOCITY m/s [ft/s]

WEDGE TEMPERATURE

ANGLE IN FLUID

C [°F] displaying with “−” in case of measurement abnormal

°

°

TRANSMIT FREQUENCY MHz

SAMPLING FREQUENCY kHz

RECEPTIVE WAIT TIME

s

µ

REPETITION FREQUENCY Hz

TRANSMIT PULSE No.

REFERENCE COUNT

No. OF CHANNELS

MEASURE RANGE F RADIUS, N RADIUS, DIAMETER

PHASE ANGLE SHIFT NORMAL1, POSITIVE, NEGATIVE

START GAIN

END GAIN

START DIST. mm [inch]

CAHNNEL WIDTH mm [inch]

START CHANNEL 0 to 128

END CHANNEL 0 to 128

VEROCITY COEFF.

MEASURE

[104]

MODE1-F: POWER

MEASURE

MODE1-F: DEVIATION

MEASURE

[%]

MODE1-F: SUCCESS RATE

MEASURE

[104]

MODE1-R: POWER

MEASURE

MODE1-R: DEVIATION

MEASURE

[%]

MODE1-R: SUCCESS RATE

“Y” becomes “1” with Line 1 and “2” with Line 2.

INF-TN514459-E

- 23 -

Page 28

15. TRANSIT TIME DIFFERENCE MEASUREMENT

Click the [TRANSIT TIME] button on the Menu screen, and the following screen appears. Click detailed setting tab,

receiving waveform tab and operation information tab when necessary.

15.1. Detailed Setting

CAUTION

• Do not change the setting by yourself. Otherwise measurement may be disabled.

• Make the detailed setting only when a problem should arise in flow rate measurement with factory default

settings. The setting need not be made in other cases.

Click “SETTING”, and the following screen appears.

Fig. 23 <Detailed information screen>

Select either Line 1 or Line 2 first. As to selected Lateral-line, select the items to be set and read. Set the check box

items to be set to (;). Set the check box of the items not to be selected to reset the selection to OFF. ().

[Setting] ....................................... Sends the setting of the selected item (check box set to ON (;)), reflecting the

response value on the setting.

[READ]........................................Reads the setting of the selected item (check box set to ON (;)), reflecting the

response value on the setting.

[Save]...........................................Reflects the setting sent by pressing the [Setting] button on the flow transmitter.

[Check ON/OFF] .........................Set the check box to ON to select all the items (to set all the check boxes to ON

(;)). Set the check box to OFF () to release the selection of all the items (to set

all the check boxes to OFF ()).

- 24 -

INF-TN514459-E

Page 29

Table 19 <Detailed Setting>

Item Content

TRANSMIT PATTERN Select from BURST 1, BURST 2, BURST 3, BURST 4, BURST 5, CHIRP 4 and

CHIRP 8.

TRANSMIT COUNT Select from 8, 16, 32, 64, 128 and 256.

MEASURE METHOD Select from METHOD 1, METHOD 2 and METHOD 3.

SATURATION Enter in the range of numeric 0 to 256.

SIGNAL BALANCE Enter in the range of numeric 0 to 100%.

SIGNAL PEEK Select from 2048, 3071, 4096 and 5120.

TRIGGER LEVEL With selection of AUTO/MANUAL, in case of MANUAL, input range of numeric

10.00 to 90.00% at right column.

WINDOW CONTROL With selection of AUTO/MANUAL, in case of MANUAL, input range of numeric

1 to 16383 in each column of OPEN TIME (F)/OPEN TIME (R).

AGC GAIN With selection of AUTO/MANUAL, in case of MANUAL, input range of numeric

0.00 to 100.00% in each column of FORWARD/REVERSE.

TRANS. WAIT TIME Enter in the range of numeric 1 to 30 msec.

INF-TN514459-E

- 25 -

Page 30

15.2. Received Signal

Click “RECEIVED SIGNAL”, and the following screen appears.

Signal

waveform

Trigger level

Fig. 24 <Received signal screen>

Select either Line 1 or Line 2 first. Then, select one from forward direction received wave, reverse direction received

wave, forward direction filter, reverse direction filter and correlation waveform. Depending on measurement method

(method 1, method 2 and method 3), items which can be selected vary as shown below. Trigger level is also displayed.

Left-click the mouse while pressing the shift key to specify the screen range, and the selected range is magnified.

Press the R key to return to original status.

• Method 1: One from forward direction, reverse direction and correlation waveform can be selected.

• Method 2: One from forward direction, reverse direction, forward direction filter and reverse direction filter can be

selected.

• Method 3: One from forward direction, reverse direction, forward direction filter and reverse direction filter can be

selected.

[Start] .......................................Starts reading in idicated cycle.

[Stop]........................................Stops reading

[Save As CSV] .........................Saves the measurement result in a file in CSV format. Click the button, and you

are prompted to enter the name of a file to which the data is to be saved. Specify

the destination to save and enter the file name, and a CSV file is created.

- 26 -

INF-TN514459-E

Page 31

15.3. Operation Information

Click “CONDITION”, and the following screen appears.

Fig. 25 <Operation Information screen>

Select either Line 1 or Lline 2 first.

[Read].......................................... Reads operation information in a batch.

[Save As CSV]............................. Saves Operation Information in file with CSV format. Click the button, and you

are prompted to enter the name of a file to which the data is to be saved. Specify

the destination to save and enter the file name, and a CSV file is created.

INF-TN514459-E

- 27 -

Page 32

Table 20 <Operation Information>

Item Content

WEDGE SOUND

m/s [ft/s]

VELOCITY

WEDGE ANGLE

°

PIPE SOUND VELOCITY m/s [ft/s]

ANGLE IN PIPE

°

LINING SOUND VELOCITY m/s [ft/s]

ANGLE IN LINING

°

FLUID SOUND VELOCITY m/s [ft/s]

WEDGE TEMPERATURE

ANGLE IN FLUID

TOTAL TIME

WINDOW OPEN

TOTAL TIME

FORWARD TIME

RESERVE TIME

C [°F] displaying with “−” in case of measurement abnormal

°

°

s

µ

s

µ

s

µ

s

µ

s

µ

TRANSIT TIME ns

DELAY TIME

FLUID SOUND VELOCITY

ANGLE IN FLUID

s

µ

s

µ

°

REINOLDS No.

K

VELOCITY m/s [ft/s]

SIGNAL POWER (F)

SIGNAL POWER (R)

TRIG. LEVEL (F)

TRIG. LEVEL (R)

SIGNAL PEEK (F)

SIGNAL PEEK (R)

- 28 -

INF-TN514459-E

Page 33

16. RAS/STATUS

Click the [RAS/STATUS] button on the menu screen. Click the [RAS] tab, [STATUS] tab, or [RAS Detail Setting] tab

as required.

16.1. RAS

Click the [RAS] tab, and the following screen appears.

Fig. 26 <RAS screen>

The latest RAS and detailed RAS information can be displayed on the RAS screen.

(1) Latest RAS

Click the [RAS] option and then the [READ] button, and the latest RAS information

and/or 1) is displayed.

(2) RAS details

Click the [RAS Details] option and then the [READ] button, and all the RAS data is read. Up to 300 items out of

the latest RAS detail information can be displayed. Scroll the scroll bar to display older items. If [RAS No.] is

selected, RAS of the selected No. only is read.

[Save as File] button ................ Saves the displayed RAS detail data in a file.

[Read from File] button ...........Displays RAS detail data in the selected file as a table.

*1

(20 digits consisting of 0

INF-TN514459-E

- 29 -

Page 34

16.2. Status

Click the [STATUS] tab to display the following screen.

[READ] button.........................Display the status

Fig. 27 <Status screen>

*2

(20 digits consisting of 0 and/or 1).

- 30 -

INF-TN514459-E

Page 35

16.3. RAS detail setting

Click the [RAS Detail Setting] tab to display the following screen.

Fig. 28 <RAS detail setting screen>

Set the RAS collection method as follows.

(1) Item of collection

Check the check box for Item of Collection to ON (;). Then select items to be collected by checking the relevant

check box to ON (;). Leave the check box for the item not to be collected blank ().

[Setting] button ........................ Sends the items to be collected (check box set to ON [;]), and reflects the response

value to the check box of the relevant item.

[Read] button ........................... Reflects the current RAS items of collection to the check box.

[Save] button............................ Reflects the item of collection sent by clicking the [Setting] button to the flow

transmitter.

INF-TN514459-E

- 31 -

Page 36

*1) Composition of RAS information

*2) Composition of Status

Occurring ⇒ 1, Not occurring ⇒ 0

E1: DEVICE ERROR

E1: TEMPERATURE SENSOR ERROR

RESERVE

RESERVE

E2: DATA COLLECTION ERROR

E2: WINDOW SCAN

E2: NO SIGNAL

E2: SIGNAL ERROR

E2: SIGNAL RANGE OVER

E2: CALCULATION ERROR

RESERVE

RESERVE

E3: DATA COLLECTION ERROR

E3: SIGNAL ERROR

E3: FREQUENCY CALCULATION ERROR

E3: SUCCESS RATE

RESERVE

RESERVE

E4: RANGE OVER

E4: TEMPERATURE SPECIFICATION ERROR

Occurring ⇒ 1, Not occurring ⇒ 0

MEASUREMENT ERROR

F: TOTAL PULSE

R: TOTAL PULSE

F: TOTAL SW

R: TOTAL SW

F: TOTAL OVERFLOW

R: TOTAL OVERFLOW

FLOW SW HIGH

FLOW SW LOW

FULL SCALE 2

AO RANGE OVER

PULSE RANGE OVER

R: FLOW DIRECTION

RESERVE

DEVICE ERROR

RESERVE

RESERVE

RESERVE

RESERVE

RESERVE

- 32 -

INF-TN514459-E

Page 37

17. MAINTENANCE

Click the “MAINTENANCE” button on the Menu screen, and the following screen appears.

Note) If [Setting] and [Read] are executed on this screen, the instrument is in the Maintenance mode for flow rate

measurement. Be sure to reset the Maintenance mode of flow meter by clicking the [Release] button.

Fig. 29 <Maintenance screen>

(1) Analog output

There are two options: 4 to 20 mA adjustment and confirmation. Select one by pressing the option button.

• Adjustment

(1) Select either “4 mA” or “”20 mA”, read current setting at right column by clicking the [READ] button once.

Then, set value (1 to 65535) at right column and click the [Setting] button, and then click the [Save] button.

When setting is completed, setting value is redisplayed at right column. Click the [READ] button, and

selected setting values of “4 mA” and “20 mA” appear on the right column.

• Confirmation

(2) Selecting a value in the range from -20 to 120, and click the [Setting] button, when setting is completed,

and setting value is redisplayed: Click the [READ] button, and the setting value appears.

(2) DO output

Select one from the following option buttons: DO1 output confirmation, DO2 output confirmation and DO3 output

confirmation.

• DO1 output confirmation

(1) Set [DO1 Output Confirmation] check box to ON. Then select either ON or OFF from setting combo box,

and click the [Setting] button to change the selected value of DO1 output. Click the [READ] button, and

the setting value appears.

INF-TN514459-E

- 33 -

Page 38

• DO2 output confirmation

(2) Set [DO2 Output Confirmation] check box to ON. Then select either ON or OFF from setting combo box,

and click the [Setting] button to change to the selected value of DO2 output. Click the [READ] button,

and the setting value appears.

• DO3 output confirmation

(3) Set [DO3 Output Confirmation] check box to ON. Then select either ON or OFF from setting combo box,

and click the [Setting] button to change the selected value of DO3 output. Click the [READ] button, and

setting value is displayed.

(3) Test mode

Set input data and tracking time and click the [Setting] button, and you can enter the test mode.

Click the [Read] button to read the values in each column of the test mode.

[Release] button .......................Resets analog output, each DO output and Test mode.

* Note: Make sure to press the [Release] button when maintenance is completed.

- 34 -

INF-TN514459-E

Page 39

18. SUPPORT

Click the [SUPPORT] button, and the following screen appears.

Fig. 30 <Support screen>

Set the check box of the items to be selected for setting or reading to ON (;). Leave the check box of the items not to

be selected blank (). Reading only is allowed with the items for Read All Set Data and Wedge Temperature.

[Setting] button............................ Transmits the settings of selected items (check box set to ON [;]), and reflects the

response value to the settings.

[READ] button ............................ Reads the setting of selected items (check box set to ON [;]), and reflects the

response value to the setting.

[Save] button ............................... Reflects the setting transmitted by clicking the [Setting] button to the flow

transmiter.

INF-TN514459-E

- 35 -

Page 40

Table 21 <System setting>

Item Description

System mode Select from hybrid (with waveform data) and hybrid (without waveform data).

Application:

By changing the system mode to hybrid (with waveform data) when adjusting the flow

transmitter without flow velocity profile output, check of flow velocity profile and signal

waveform is allowed.

*Be sure to restore the original setting after the adjustment.

Sensor mode Select from Normal, Sensor F, and Sensor R.

Application:

Select the sensor mode when carrying out delivery test of the sensor unit at the factory.

Select Normal.

Read all set data Select Read All Set Data to read all the settings of the flow transmitter.

Click the [Save As] button, and you are prompted to enter the name of the file to which

the data is to be saved. Enter the destination to save and file name. Click the [Read]

button and a file in CSV format is created.

Check Displays the temperature measured with the temperature sensor. Wedge

temperature

Detail Displays the temperature measured with the temperature sensor and the internal constant.

- 36 -

INF-TN514459-E

Page 41

19. END

Click the [End] button on the Menu screen, and the following screen appears.

Fig. 31 <Menu screen>

Click either the [End] button or the (:) button, and a message asking you whether you want to save the loader setting

appears. To save setting value, select “Yes”. On the file designation window that appears, select a file, and the

setting is saved in the file. Then the loader is terminated. Not to save setting value, select “No”, and the loader is

terminated without saving the setting.

20. UNINSTALLING OF SOFTWARE

Select “Addition and Deletion of Application” from “Control Panel” of Windows, and click [Change and Deletion] to

uninstall the software.

INF-TN514459-E

- 37 -

Page 42

Page 43

Page 44

Head Office

Gate City Ohsaki, East Tower, 11-2, Osaki 1-chome,

Shinagawa-ku, Tokyo 141-0032, Japan

http://www.fesys.co.jp/eng

Instrumentation Div.

International Sales Dept.

No.1, Fuji-machi, Hino-city, Tokyo 191-8502, Japan

Phone: 81-42-585-6201, 6202 Fax: 81-42-585-6187

http://www.fic-net.jp/eng

Loading...

Loading...