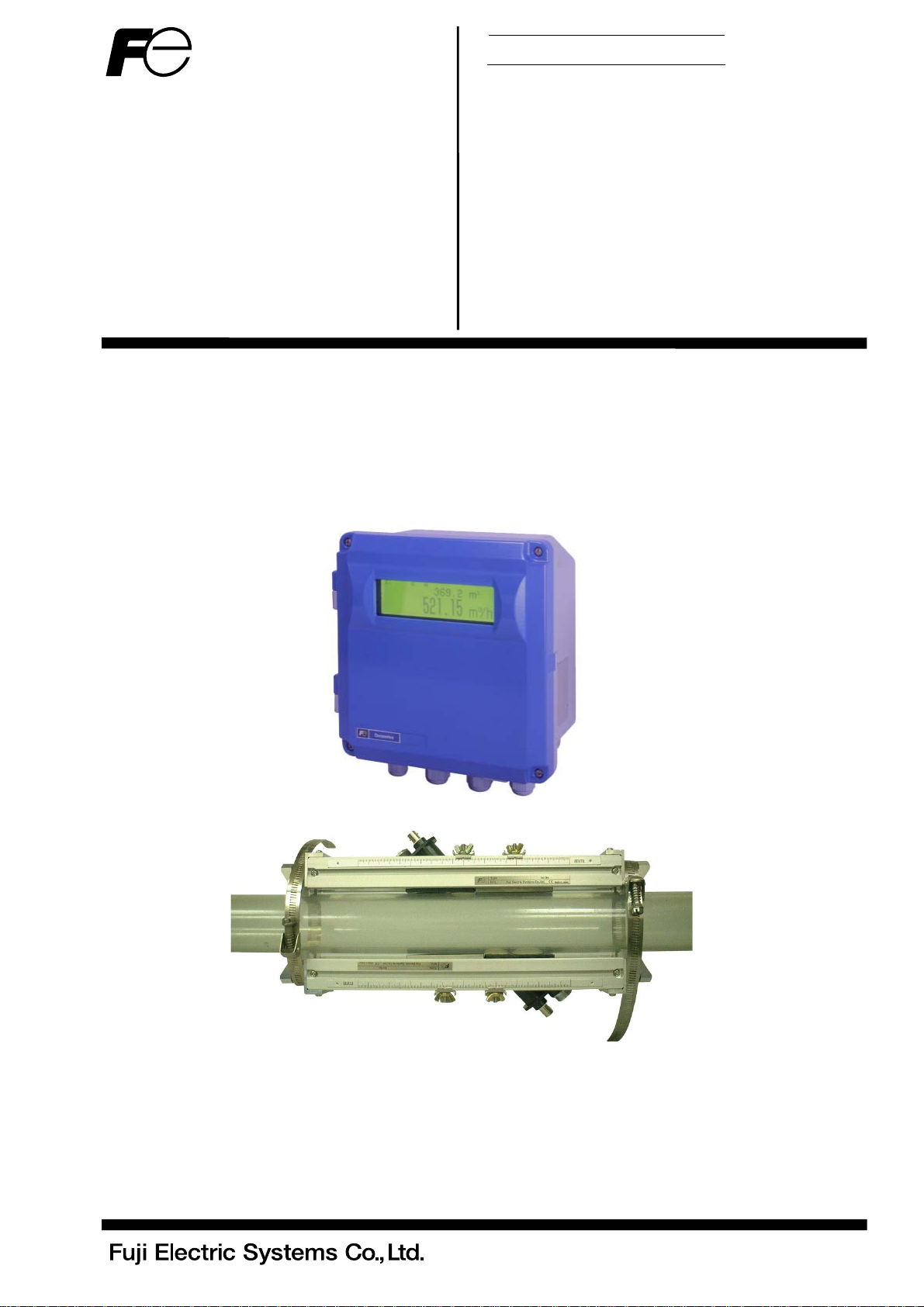

Page 1

Instruction Manual

HYBRID

ULTRASONIC FLOWMETER

<Duosonics>

TYPE: FSH (Flow transmitter)

FSW (Detector)

FLY (Signal cable)

INF-TN1FSH-E

Page 2

PREFACE

We thank you very much for purchasing Fuji’s ultrasonic flowmeter.

The instruction manual concerns the installation, operation, checkup and maintenance of the Flow transmitter

(FSH) and Detector (FSW) of ultrasonic flowmeter. Read it carefully before operation.

Before using, be sure to read this instruction manual carefully to ensure correct installation, operation

•

and maintenance of the flowmeter. Note that incorrect handling may lead to trouble or personal injury.

The specifications of this flowmeter are subject to change for improvement without prior notice.

•

Do not attempt to modify the flowmeter without permission. Fuji is not responsible for any trouble

•

caused by modification without permission. If it becomes necessary to modify the flowmeter, contact

our office in advance.

This instruction manual should always be kept on hand by the operator.

•

After reading, be sure to keep this manual in a place where it can easily be seen by the operator.

•

Make sure that this manual is presented to the end user.

•

If the instruction manual has been lost, request another one (with charge) to our local business office.

•

Manufacturer: Fuji Electric Instrumentation Co., Ltd.

Type: Shown on nameplate of Flowmeter

Date of manufacture: Shown on nameplate of Flowmeter

Product nationality: Japan

• It is strictly prohibited to reproduce any part or the whole of this

instruction manual.

• The contents of this manual may be changed without prior

notice.

NOTICE

Issued in July 2005

Fuji Electric Systems Co., Ltd. 2005

INF-TN1FSH-E

- i -

Page 3

SAFETY PRECAUTION

Before using, read the following safety precaution to ensure correct handling of the flowmeter.

• The following items are important for safe operation and must be fully observed. These items are

classified into "DANGER" and "CAUTION".

Warning & Symbol Meaning

DANGER

CAUTION

• The items noted under "

• All the items are important and must be fully observed.

DANGER

CAUTION

Incorrect handling may lead to a risk of death or heavy injury.

Incorrect handling may lead to a risk of medium or light injury, or to a risk of

physical damage.

CAUTION

Caution on Installation and Piping

• This product has not an explosion-proof structure. Do not use it in a place

with explosive gases, otherwise, it can result in serious accidents such as

explosion, fire, etc.

• The unit should be installed in a place conforming with the installation

requirements noted in this instruction manual. Installation in an improper

location may lead to a risk of electric shocks, fire, malfunction, etc.

• The unit should be installed as noted in the manual. Improper installation

will cause falling, trouble or malfunction of the unit.

• During installation, make sure that the inside of the unit is free from cable

chips and other foreign objects to prevent fire, trouble, malfunction, etc.

• The items under "Caution on Installation" noted in the manual must be fully

observed. Careless installation may result in trouble or malfunction of the

unit.

" may also result in serious trouble depending on circumstances.

- ii -

INF-TN1FSH-E

Page 4

Caution on Wiring

• When performing wiring termination to prevent output trouble caused by

CAUTION

moisture, dew condensation or water leak, follow “Section 3.3. Flow

transmitter wiring” described in this manual

• Before performing the wiring work, be sure to turn OFF the main power to

prevent electric shocks.

• Do not perform wiring work outdoors in rainy days to prevent insulation

deterioration and dew condensation. Otherwise, it can result in trouble,

malfunction, etc.

• Be sure to connect a power source of correct rating. Connection of a

power source of incorrect rating may lead to a risk of fire.

• The unit must be earthed as specified to prevent electric shocks or

malfunction.

• The analog output signal cable should be wired as far away as possible

from high-voltage lines to prevent entry of noise signals as it will cause

malfunction of the unit.

• To prevent malfunction of the unit, the analog output signal cable and power

cable should be wired using separate conduits.

Caution on Maintenance/Inspection

• The unit should be inspected everyday to always obtain good results of

CAUTION

measurements.

• When measuring the insulation resistance between the power/output

terminal and the case, follow “Section 5.2.4. Measuring insulation

resistance” described in this manual.

• If the fuse is blown, detect and eliminate the cause, and then replace the

fuse with a spare. If there are no spares, replace the fuse with the one

specified in this manual (that must be prepared by customer). Use of a

fuse other than specified or its short-circuit may cause an electric shock or

fire. The fuse should be replaced according to “Section 5.3. Replacing

fuse” described in this manual.

INF-TN1FSH-E

- iii -

Page 5

CAUTION ON INSTALLATION LOCATION

CAUTION

(1) Sufficient space for daily inspection, wiring, etc.

(2) A place not exposed to direct sunshine or weathering.

(3) Isolation from vibration, dust and moisture

(4) A place not subjected to radiated heat from a heating furnace etc.

(5) A place not subjected to explosive gas and corrosive atmosphere

(6) A place not submerged

(7) A place remote from electrical devices (motor, transformer, etc.) which generate

electromagnetic induction noise, electrostatic noise, etc.

(8) A place not subjected to excessive fluid pulsation (pump discharge side)

(9) A place that provides enough place for the length of the str aight pipe.

(10) A place where ambie nt temperature and humidity are • 10 to +50°C and 90% RH or less for

flow transmitter (FSH), and •20 to +80°C and 100% RH or less for detector (FSW).

- iv -

INF-TN1FSH-E

Page 6

Contents

PREFACE.......................................................................................................................................................................... I

SAFETY PRECAUTION ................................................................................................................................................II

CAUTION ON INSTALLATION LOCATION........................................................................................................... IV

1. PRODUCT OUTLINE..................................................................................................................................................1

1.1. Outline......................................................................................................................................................................1

1.1.1. Measurement principle......................................................................................................................................1

1.2. Checking delivered items.........................................................................................................................................3

1.3. Checking type and specifications.............................................................................................................................4

1.4. Names of each part and functions ............................................................................................................................7

2. SELECTING INSTALLATION LOCATION ............................................................................................................8

2.1. Flow transmitter .......................................................................................................................................................8

2.2. Detector....................................................................................................................................................................9

2.2.1. Length of straight section of pipe....................................................................................................................10

2.2.2. Mounting position ........................................................................................................................................... 11

2.2.3. Mounting the sensor........................................................................................................................................12

3. INSTALLATION AND BEFORE START OF OPERATION.................................................................................13

3.1. Before operation.....................................................................................................................................................13

3.2. Installing the flow transmitter ................................................................................................................................14

3.3. Flow transmitter wiring..........................................................................................................................................15

3.3.1. Cautions in wiring...........................................................................................................................................15

3.3.2. Applicable wires..............................................................................................................................................15

3.3.3. Treatment of wiring port .................................................................................................................................15

3.3.4. Removing and mounting the shield plate........................................................................................................16

3.3.5. Wiring to each terminal...................................................................................................................................17

3.4. Setting piping parameters and calculating the spacing between sensor units.........................................................18

3.4.1. Selecting sensor type, mounting the sensor.....................................................................................................18

3.4.2. Entering piping specifications.........................................................................................................................20

3.5. Installing Detector..................................................................................................................................................22

3.5.1. Outline of detector installation procedure .......................................................................................................22

3.5.2. Treatment of mounting surface .......................................................................................................................22

3.5.3. Mounting the detector by Z method using the frame ......................................................................................22

3.5.4. Mounting the sensor unit by V method using a frame (1 measurement line)..................................................29

3.5.5. Mounting the sensor unit by Z method using a frame (2 measurement lines).................................................31

3.5.6. Mounting the sensor unit by V method using a frame (2 measurement lines) ................................................32

3.5.7. Mounting the sensor unit to a large-diameter pipe ..........................................................................................33

3.6. Setting analog output range and total pulse............................................................................................................36

3.6.1. Analog output range setting.............................................................................................................................36

3.6.2. Total pulse output setting ................................................................................................................................38

3.7. Zero adjustment......................................................................................................................................................40

4. SETTING PARAMETERS ........................................................................................................................................41

4.1. Description of display/setting unit .........................................................................................................................41

4.1.1. Description of display .....................................................................................................................................41

4.1.2. Description of keys .........................................................................................................................................41

4.2. Setting item list ......................................................................................................................................................43

4.3. Parameter specification table .................................................................................................................................44

4.4. Setting parameters..................................................................................................................................................47

4.4.1. Measurement method and sensor ....................................................................................................................49

4.4.2. Pipe specifications...........................................................................................................................................51

4.4.3. Measurement mode (Measurement mode, AO definition) ..............................................................................53

4.4.4. Output setting..................................................................................................................................................54

4.4.4.1. Range (range unit, range type, full scale, hysteresis) setting....................................................................54

4.4.4.2. Output limit..............................................................................................................................................57

4.4.4.3. How to set analog output at error (BURNOUT) ......................................................................................58

4.4.4.4. Rate limit..................................................................................................................................................59

4.4.5. Damping..........................................................................................................................................................60

4.4.6. Zero adjustment...............................................................................................................................................61

4.4.7. Display setting.................................................................................................................................................62

INF-TN1FSH-E

- v -

Page 7

4.4.8. Cut off............................................................................................................................................................. 63

4.4.9. Integration ...................................................................................................................................................... 64

4.4.9.1. Total unit.................................................................................................................................................. 64

4.4.9.2. Setting total pulse (Total rate, pulse width) ............................................................................................. 65

4.4.9.3. Total preset .............................................................................................................................................. 67

4.4.9.4. Total SW.................................................................................................................................................. 68

4.4.9.5. Determining how to dispose of total at error (BURNOUT) .................................................................... 69

4.4.10. Flow switch .................................................................................................................................................. 70

4.4.11. Status output ................................................................................................................................................. 71

4.4.12. Output calibration......................................................................................................................................... 73

4.4.13. Measurement unit......................................................................................................................................... 74

4.4.14. System language selection............................................................................................................................ 75

4.4.15. Setting serial communication (RS232C/RS485) .......................................................................................... 76

4.4.16. Maintenance ................................................................................................................................................. 77

4.4.16.1. Analog output adjustment and check..................................................................................................... 77

4.4.16.2. Checking status output .......................................................................................................................... 78

4.4.16.3. Calibrating temperature sensor.............................................................................................................. 79

4.4.16.4. Checking temperature sensor................................................................................................................. 80

4.4.16.5. Test mode............................................................................................................................................... 81

4.4.17. LCD backlight.............................................................................................................................................. 82

4.4.18. Key lock ....................................................................................................................................................... 83

4.4.19. Checking system name................................................................................................................................. 84

4.4.20. Details of measurement................................................................................................................................ 85

4.4.20.1. Transit time............................................................................................................................................ 85

4.4.20.2. Pulse Doppler ........................................................................................................................................ 88

4.4.20.3. Initializing setting parameters ............................................................................................................... 92

4.4.20.4. Confirmation of software version.......................................................................................................... 92

5. MAINTENANCE AND INSPECTION .................................................................................................................... 93

5.1. Daily inspection..................................................................................................................................................... 93

5.2. Periodic inspection ................................................................................................................................................ 93

5.2.1. Checking zero point........................................................................................................................................ 93

5.2.2. Calibrating current output circuit ................................................................................................................... 93

5.2.3. Calibrating temperature sensor circuit............................................................................................................ 93

5.2.4. Measuring insulation resistance...................................................................................................................... 94

5.3. Replacing fuse....................................................................................................................................................... 95

5.4. Replacing relay...................................................................................................................................................... 96

5.5. Replacing LCD...................................................................................................................................................... 97

6. TROUBLESHOOTING............................................................................................................................................. 98

6.1. How to confirm normal operation......................................................................................................................... 98

6.1.1. Checking on LCD........................................................................................................................................... 98

6.1.2. Checking measurement status information..................................................................................................... 99

6.1.2.1. Define “RAS”.......................................................................................................................................... 99

6.1.2.2. Status information ................................................................................................................................. 101

6.1.2.3. Measurement data information.............................................................................................................. 102

6.2. Faults and remedies............................................................................................................................................. 104

6.2.1. Display error................................................................................................................................................. 104

6.2.2. Key failure.................................................................................................................................................... 104

6.2.3. Measurement value error.............................................................................................................................. 105

6.2.4. Analog output error ...................................................................................................................................... 107

6.3. Checking received waveform.............................................................................................................................. 108

6.3.1. Method by oscilloscope................................................................................................................................ 108

6.3.2. Checking signal waveform (TRANSIT TIME)............................................................................................ 109

6.3.3. Checking demodulated waves (Pulse Doppler) .............................................................................................111

6.3.4. Measures against hardware failure ................................................................................................................111

7. PC LOADER SOFTWARE ......................................................................................................................................112

7.1. Copyright of this software....................................................................................................................................112

7.2. Outline..................................................................................................................................................................112

7.3. PC to be used........................................................................................................................................................112

7.3.1. Computer.......................................................................................................................................................112

7.3.2. Memory capacity...........................................................................................................................................112

7.3.3. Interface.........................................................................................................................................................112

7.3.4. OS..................................................................................................................................................................112

- vi -

INF-TN1FSH-E

Page 8

7.4. Installing of Software........................................................................................................................................... 113

7.5. Startup Method.....................................................................................................................................................116

7.5.1. Communications ...........................................................................................................................................117

7.5.2. Setting ...........................................................................................................................................................118

7.5.2.1. Save setting ............................................................................................................................................118

7.5.2.2. Read setting............................................................................................................................................ 118

7.5.3. Version ..........................................................................................................................................................119

7.6. Structure of Function............................................................................................................................................119

7.7. Establish Setting...................................................................................................................................................120

7.8. Range Setting .......................................................................................................................................................122

7.9. Total Setting .........................................................................................................................................................124

7.10. Status Output Setting..........................................................................................................................................126

7.11. Display Setting...................................................................................................................................................127

7.12. System Setting....................................................................................................................................................128

7.13. Measurement......................................................................................................................................................129

7.14. Pulse Doppler Measurement ..............................................................................................................................130

7.14.1. Detailed setting (optional function).............................................................................................................130

7.14.2. Flow velocity profile (optional function) ....................................................................................................132

7.14.3. Operation Information.................................................................................................................................134

7.15. Transit Time Difference Measurement...............................................................................................................136

7.15.1. Detailed Setting (optional function) ............................................................................................................136

7.15.2. Received Signal (optional function)............................................................................................................138

7.15.3. Operation Information.................................................................................................................................139

7.16. Maintenance.......................................................................................................................................................141

7.17. End .....................................................................................................................................................................143

7.18. Uninstalling of Software ....................................................................................................................................143

8. APPENDIX ................................................................................................................................................................144

8.1. External communication specifications................................................................................................................144

8.1.1. Communication specifications......................................................................................................................144

8.1.2. Message configuration ..................................................................................................................................144

8.1.2.1. Receiving ...............................................................................................................................................144

8.1.2.2. Response ................................................................................................................................................144

8.1.2.3. Error response ........................................................................................................................................145

8.1.3. Error check....................................................................................................................................................145

8.1.4. Function code table .......................................................................................................................................146

8.1.5. Error code table.............................................................................................................................................147

8.1.6. Cable connection specifications (RS-232C)..................................................................................................147

8.2. Specifications.......................................................................................................................................................148

8.3. Outline diagram....................................................................................................................................................150

8.4. Items to be specified at placement of an order .....................................................................................................154

8.5. Composition of key operation..............................................................................................................................157

8.6. Piping data ...........................................................................................................................................................164

8.7. Making gauge paper.............................................................................................................................................172

INF-TN1FSH-E

- vii -

Page 9

1. PRODUCT OUTLINE

1.1. Outline

This high precision flowmeter is the world’s first clamp-on type ultrasonic flowmeter that adopts the pulse Doppler

method and the transit time method as its measurement principles. The ultrasonic flowmeter for industrial use

employs the pulse Doppler method, which directly measures flow distribution, thus easing straight pipe conditions and

allowing measurement of flows that have not grown into eddy or laminar flow. Combined use of the transit time

method allows the hybrid ultrasonic flowmeter to be used for measuring a significantly wide range of liquids. The

pulse Doppler method, which uses echoes coming from reflectors in a liquid to be measured, is ideal for the

measurement of liquids that contain air bubbles and particles. On the other hand, the transit time method, which

allows ultrasonic waves to pass through for measurement, is ideal for the measurement of clean liquids.

The new hybrid technique employing both the pulse Doppler and the transit time methods allows the flowmeter to be

used for wider range of applications. In addition, our self-developed switching algorithm ensures automatic switching

between the two methods depending on the conditions of a liquid to be measured (such as mixing status of air bubbles

or particles and flow rate), thus facilitating measurement.

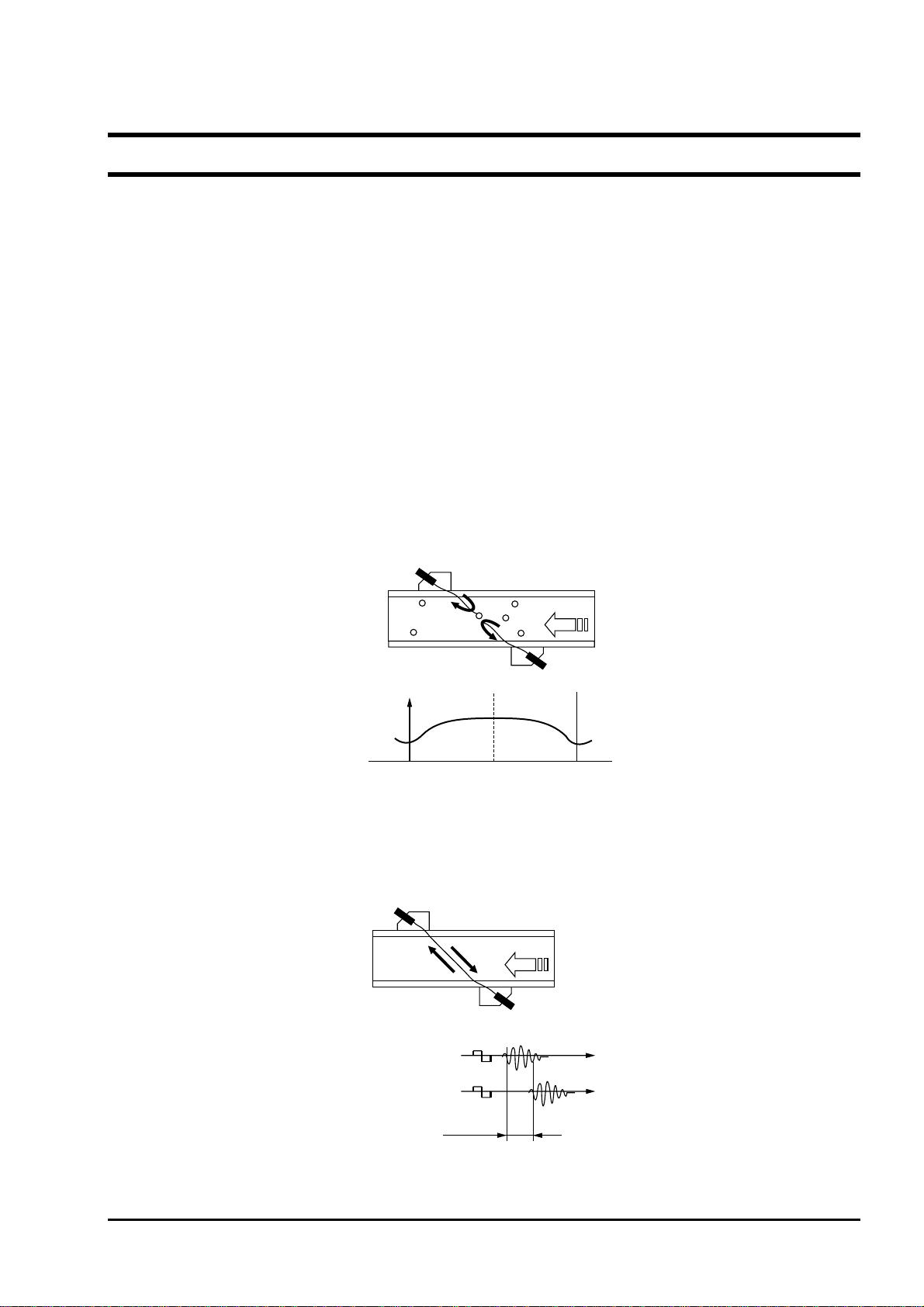

1.1.1. Measurement principle

<Pulse Doppler method>

The pulse Doppler method measures flow distribution and flow rate based on the fact that Doppler frequency of the

•

echo coming from reflectors such as air bubbles and particles in liquids changes with fluctuation of flow rate.

Sensor 2

Air bubble

Reflection

Flow velocity

distribution 2

Flow rate

Pipe wall Center Pipe wall

Flow velocity

distribution 1

Flow

Sensor 1

<Transit time method>

Under the transit time method, ultrasonic pulses are propagated slanted from both upstream and downstream sides,

•

and time difference of flows are detected to measure the flow rate.

Sensor 2

Flow

Sensor 1

Send Receive

Sensor 1 J 2

INF-TN1FSH-E

Sensor 2 J 1

Time difference ∆T

- 1 -

Page 10

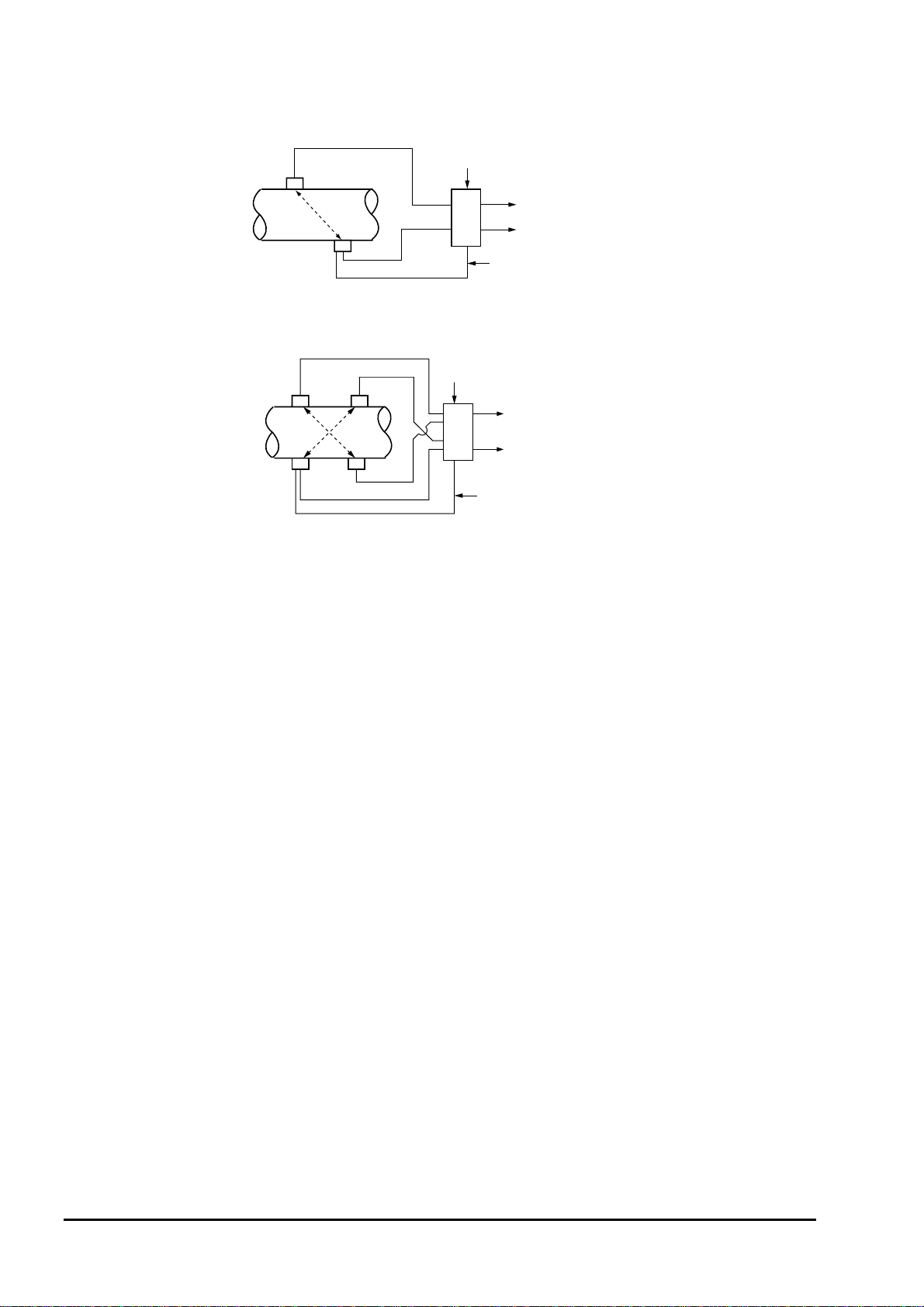

Configuration

(1) 1 measurement line method (Z method)

Detector

(2) 2 measurement line method (Z method)

Detector

Cable

Cable

Power supply

4 to 20 mA DC

Contact (3 points max.)

Flow

transmitter

Temperature sensor cable

Power

supply

4 to 20 mA DC

Flow

Contact (3 points max.)

transmitter

Temperature sensor cable

- 2 -

INF-TN1FSH-E

Page 11

1.2. Checking delivered items

Flow transmitter (FSH)

Flow transmitter main unit ··································1 set

Waterproof gland (Built into the main unit)·········1 set

Wall mount fittings (Built into the main unit)······1 set

Detector (FSWS12, 21, 40)

Detector main unit (FSWS12, 21) ·······················1 set

Detector main unit (FSWS40) ·····························1 set

Absorber unit ······················································1 set

Stainless steel belt ···············································1 set

Fittings ································································1 set

Silicon rubber······················································ 1 pc

Detector (FSWS50)

Detector main unit (FSWS50)····························· 1 set

Absorber unit······················································ 1 set

Wire rope···························································· 1 set

Spring for mounting············································ 1 set

Signal cable (FLY6)

Cable for ultrasonic signals··················· 1 pair (2 pcs.)

Signal cable (FLY7)

Cable for temperature sensor ··································· 1

CD-ROM (Instruction manual and Loader software)

······································ 1

Flow transmitter (FSH) Detector (FSWS12, 21, 40) Detector (FSWS50)

Detector (FSWS12, 21)

Frame

Absorber unit Sensor unit

Absorber unit

Detector (FSWS40)

Sensor unit

Frame

Wire rope

Absorber unit

Sensor unit

Stainless steel belt

Spring for mounting

Silicon rubber

Signal cable (FLY6)

Cable for ultrasonic signals

Signal cable (FLY7)

Cable for temperature sensor

INF-TN1FSH-E

- 3 -

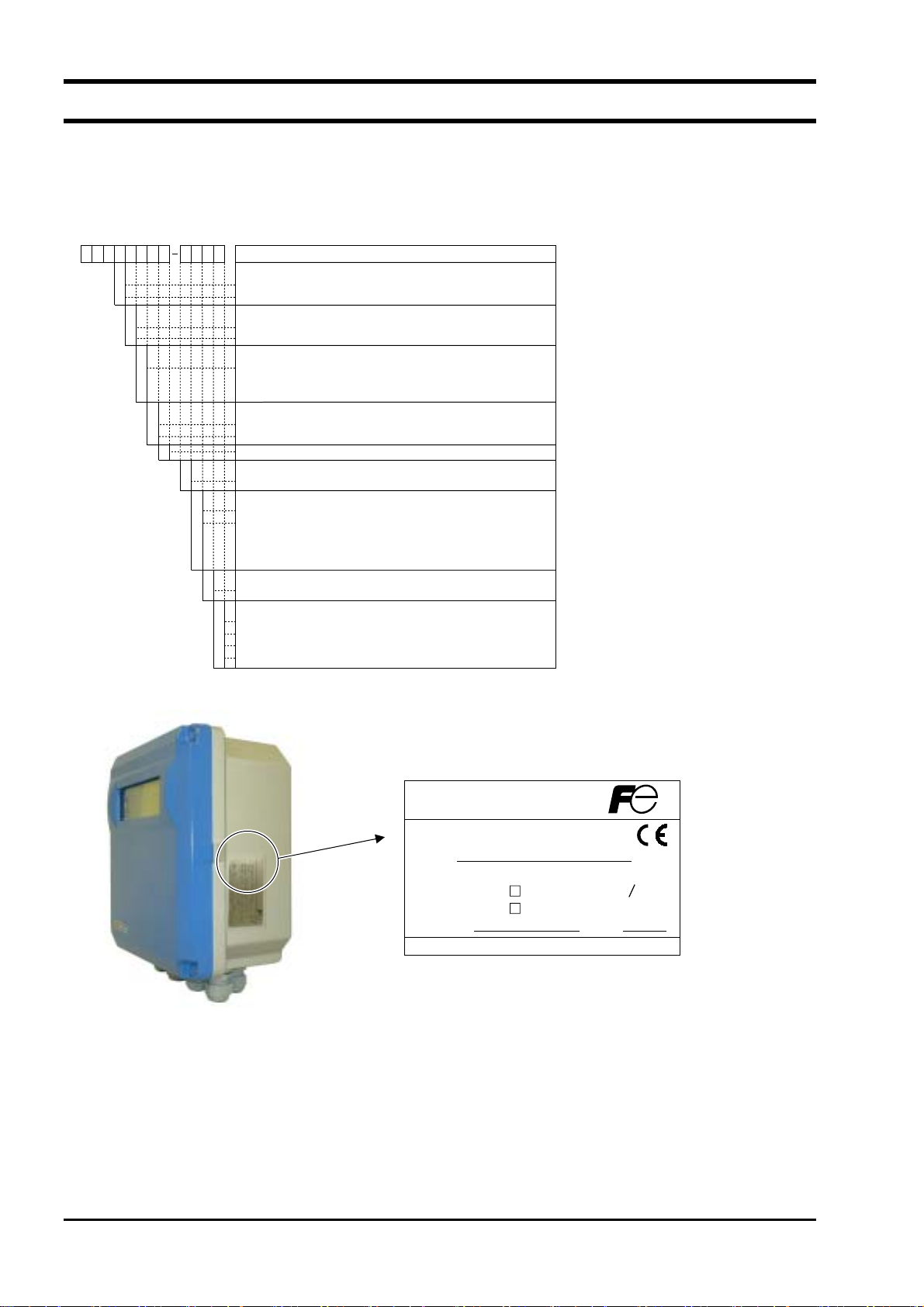

Page 12

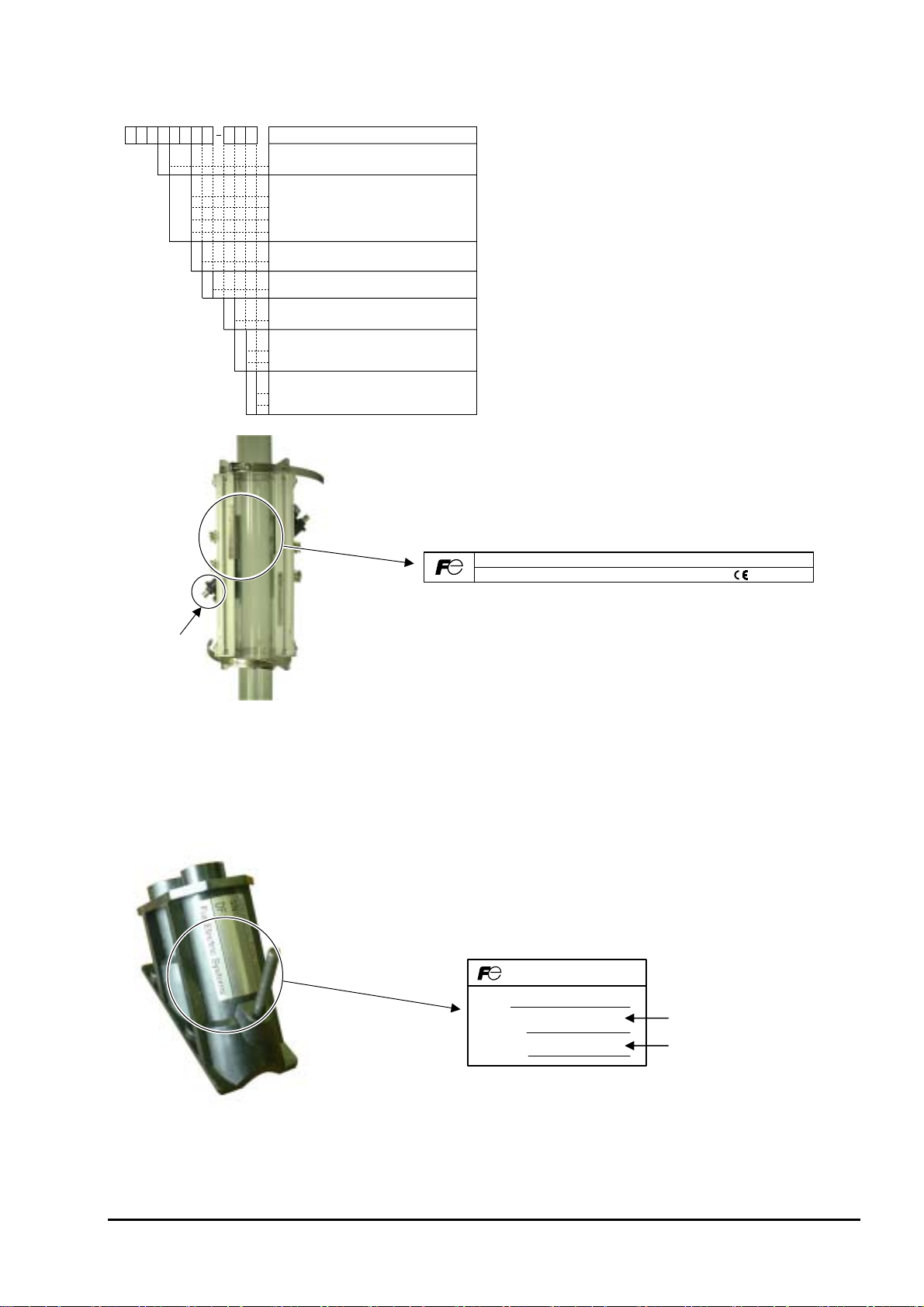

1.3. Checking type and specifications

The specification plates attached to the flow transmitter and the detector list the type and specifications of the product.

Check that they represent the type you ordered, referring to the following code symbols.

< Flow transmitter (FSH)>

12345678 9101112

F

SH

1S

S

E

Y

A

Y

1

4

1

S

Y

A

Type (4th digit)

Standard (Japanese)

Standard (English)

Velocity profile output (5th digit)

None

Available

Use (6th digit)

Single path or Changeover two-path (Note)

Note: 2 sets of detectors and coaxial cables (FLY6)

needed for two-path system

Power supply (7th digit)

100 to 240VAC, 50/60Hz

20 to 30VDC

Modification No. (8th digit)

Case structure (9th digit)

Watertight type (IP67)

Conduit connection (10th digits)

[G1/2 and G3/8 (female screw)] with waterproof gland

[G1/2 (female screw)] with union gland (for plica)

Note: The wiring port for coaxial cable (for ultrasonic

sensor) and 3-wire cable (for temperature

sensor) is provided with waterproof gland [G3/8 (female screw)].

For use with explosion-proof detector (11th digit)

None

Y

Parameter setting, Tag plate (12th digit)

None

Y

With setting

A

With setting + Tag plate

B

Tag plate

C

Description

Ultrasonic Flow Meter

Type

Output DC4-20mA

Power Supply AC100-240V 50 60Hz

DC20-30V

Ser.No.

Fuji Electric Systems Co.,Ltd.

Mfd.

Made in Japan

- 4 -

INF-TN1FSH-E

Page 13

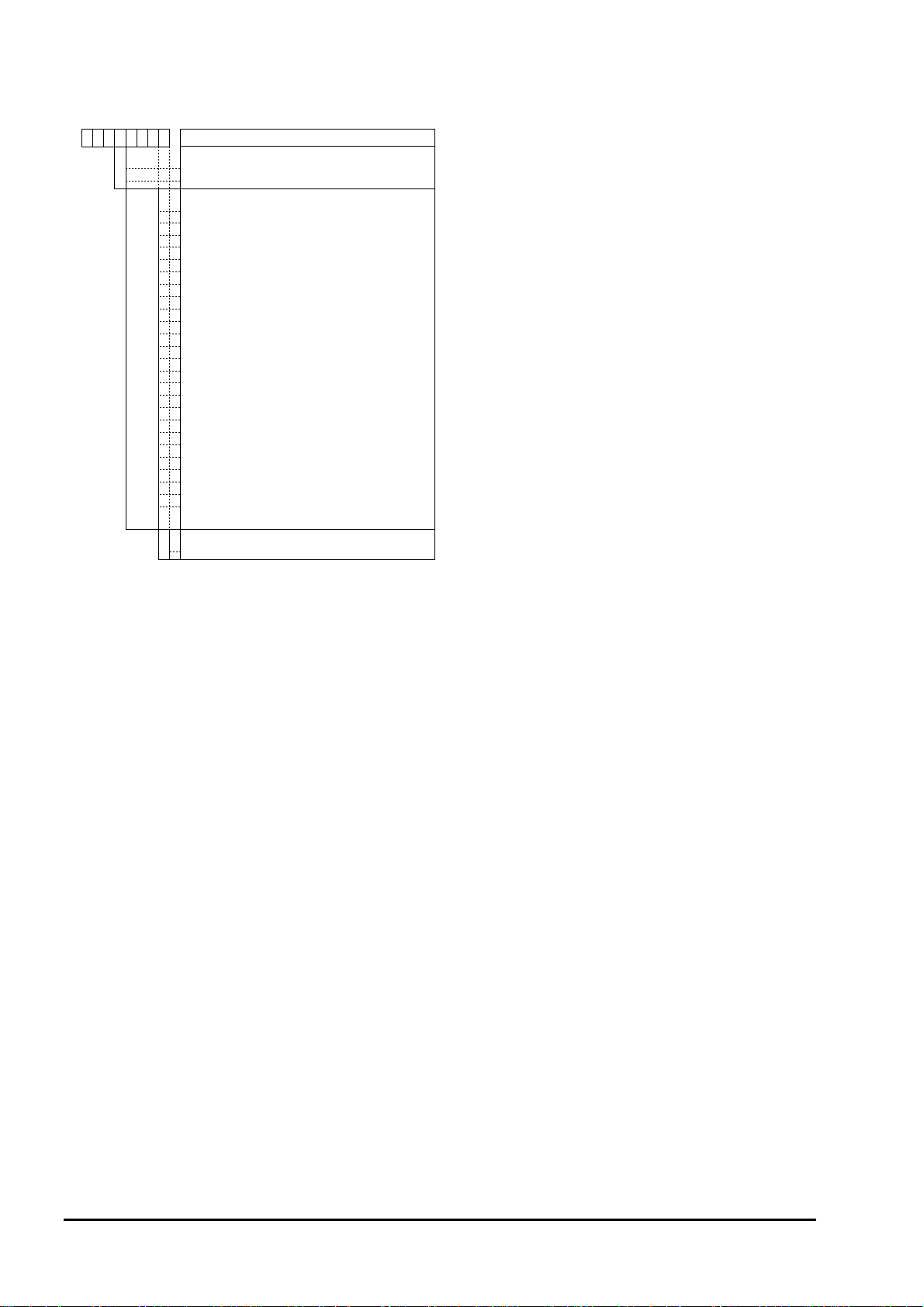

<Detector (FSW)>

12345678 910

F

S

W

1

S

1

2

2

1

4

0

5

0

0

1

Y

11

Description

Type (4th digit)

Standard

Kind of detector (5th and 6th digit)

Small diameter detector (φ 50 to 100 mm)

Small size detector (φ 100 to 200 mm)

Middle size detector (φ 200 to 500 mm)

Large size detector (φ 500 to 1000 mm)

Use (7th digit)

Watertight type (IP67)

Modification No. (8th digit)

Mark 1

Signal cable (9th digit)

None

Acoustic coupler (10th digit)

Y

None

Silicone compound

A

Option (11th digit)

None

Y

Tag Plate

A

Type.

Mfd.

Fuji Electric Systems Co.,Ltd.

Ser.No.

Made in Japan

Sensor unit

Note: To use the flowmeter employing the transit time method only, a detector (FLW) and a flow transmitter (FSH)

must be used in combination. See data sheet EDS6-71 or EDS6-111 for details of selection of the detector

(FLW) and dedicated cables (FLY1, FLY2).

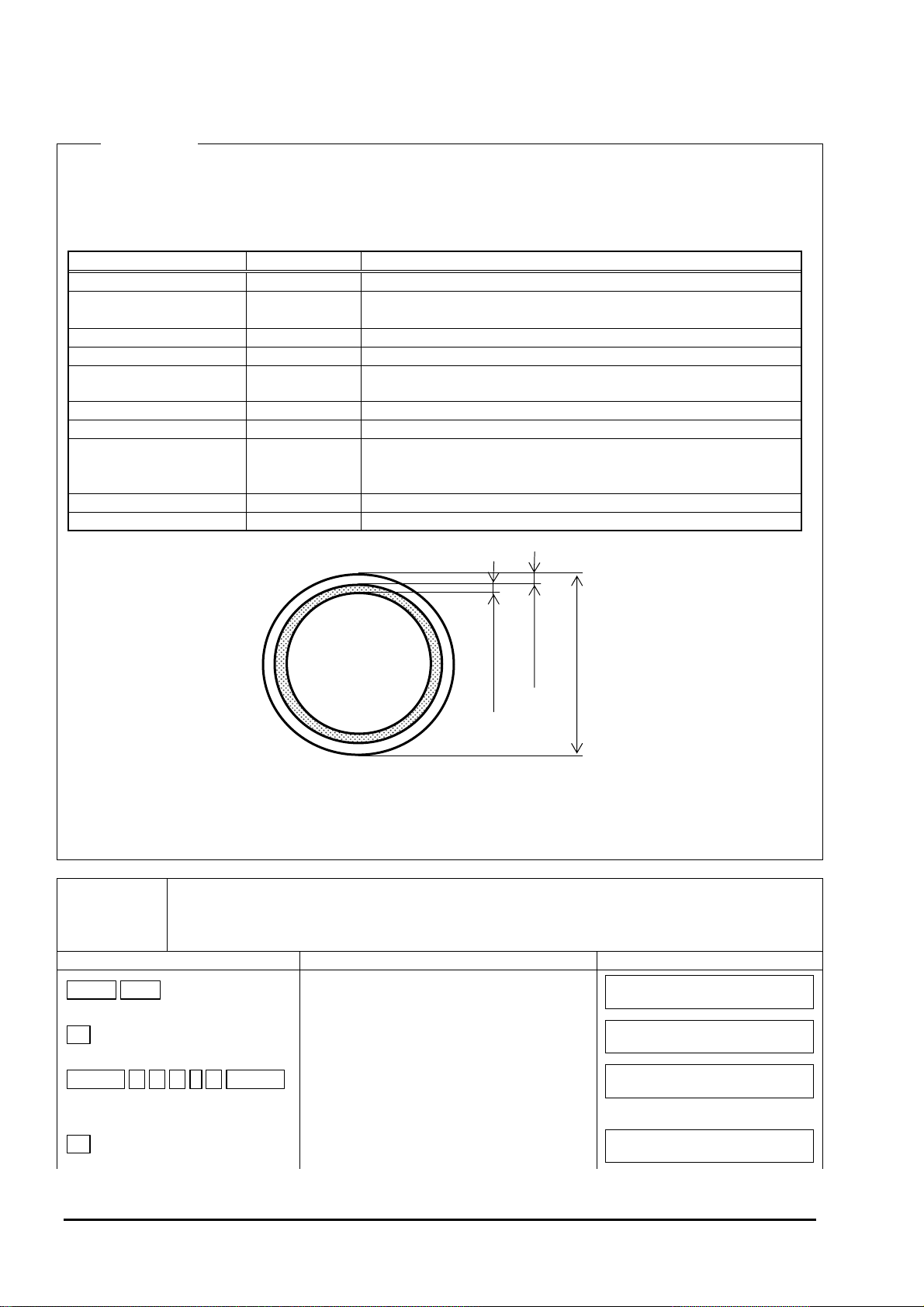

<Sensor unit>

The numeric value marked on the DF field of the nameplate of the sensor unit represents the sensor constant, which

is determined by actual current calibration performed as part of the delivery test at the factory.

Ultrasonic Flow Meter

SN :

DF

-

P :

DF-M :

Sensor constant for plastic pipe

Sensor constant for metal pipe

Note: Use a detector (FLW) and a transmitter (FSH) in combination to use the instrument by transit time method

only. Refer to data sheet EDS6-71 or EDS6-111 for details of selection of the detector (FLW) and

dedicated cables (FLY1, FLY2).

INF-TN1FSH-E

- 5 -

Page 14

<Signal cable (FLY)>

12345678

F

LY

1

6

7

0

0

1

0

1

0

2

0

2

0

3

0

3

0

4

0

4

0

5

0

5

0

6

0

6

0

7

0

7

0

8

0

8

0

9

0

9

0

0

1

1

1

2

1

3

1

4

1

5

1

Kind of cable (4th digit)

Coaxial cable (for ultrasonic sensors) 1 pair (2 pcs.)

Three-core cable (for temperature sonsor)

Cable length (5th to 7th digit)

5

5m

0

10m

5

15m

0

20m

5

25m

0

30m

5

35m

0

40m

5

45m

0

50m

5

55m

0

60m

5

65m

0

70m

5

75m

0

80m

5

85m

0

90m

5

95m

0

100m

0

110m

0

120m

0

130m

0

140m

0

150m

Description

Modification No. (8th digit)

Mark1

1

- 6 -

INF-TN1FSH-E

Page 15

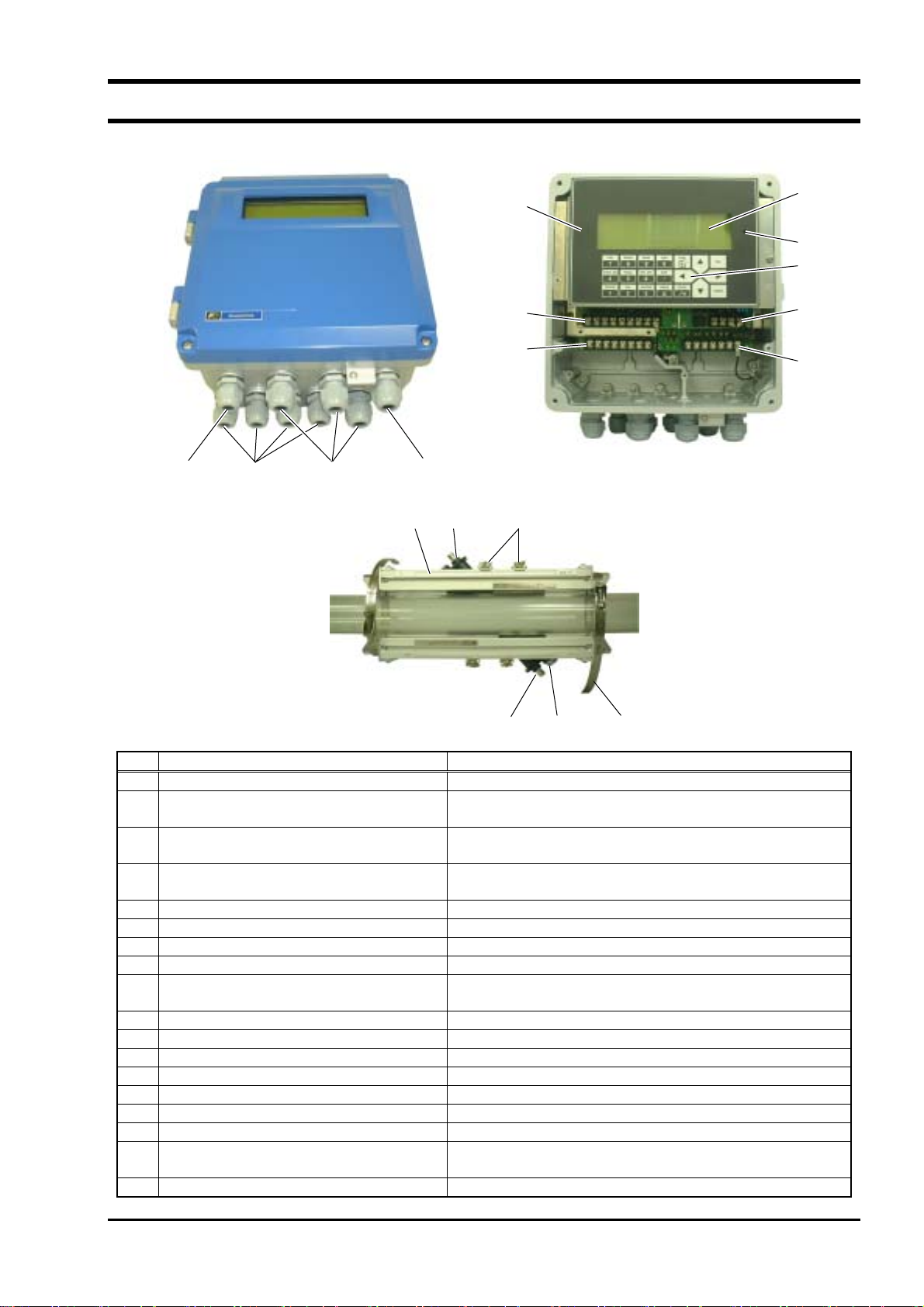

1.4. Names of each part and functions

(5)

(9)

(10)

(6)

(12)

(7)

(8)

(11)

(3) (2) (4) (1)

(15) (14) (13)

(16) (17) (18)

No. Name Description

(1)

Wiring connection port for power cable Wiring port for power cable

(2)

Wiring connection port for ultrasonic signal

Wiring port for ultrasonic signal cable

cable

(3)

Wiring connection port for temperature

Wiring port for temperature sensor cable

sensor cable

(4)

Wiring connection port for DO output

Wiring port for for DO output cable

cable

(5)

Display and setting unit Displays flow rate, etc. Used for various setting operations.

(6)

LCD Displays flow rate and various settings.

(7)

Setting key Used for making settings.

(8)

Power terminal Connect power cable to this terminal.

(9)

I/O terminal Connect power output cable, communication cable, and

temperature sensor cable to this terminal.

(10)

Input terminal Connect ultrasonic signal cable to this terminal.

(11)

Output terminal Connect Do output cable to this teminal.

(12)

LCD contrast adjusting knob Used for adjusting the contrast of the LCD.

(13)

Sensor unit Used for transmitting/receiving ultrasonic waves.

(14)

Sensor frame Used for fastening the sensor unit to the piping.

(15)

Unit arm Used for fastening the sensor by pressing it against the piping.

(16)

BNC connector for ultrasonic signal cable Transmits ultrasonic send/receive signals.

(17)

Water-tight connector for temperature

Transmits temperature sensor signals.

sensor cable

(18)

Stainless steel belt Used for fastening the sensor frame to the piping.

INF-TN1FSH-E

- 7 -

Page 16

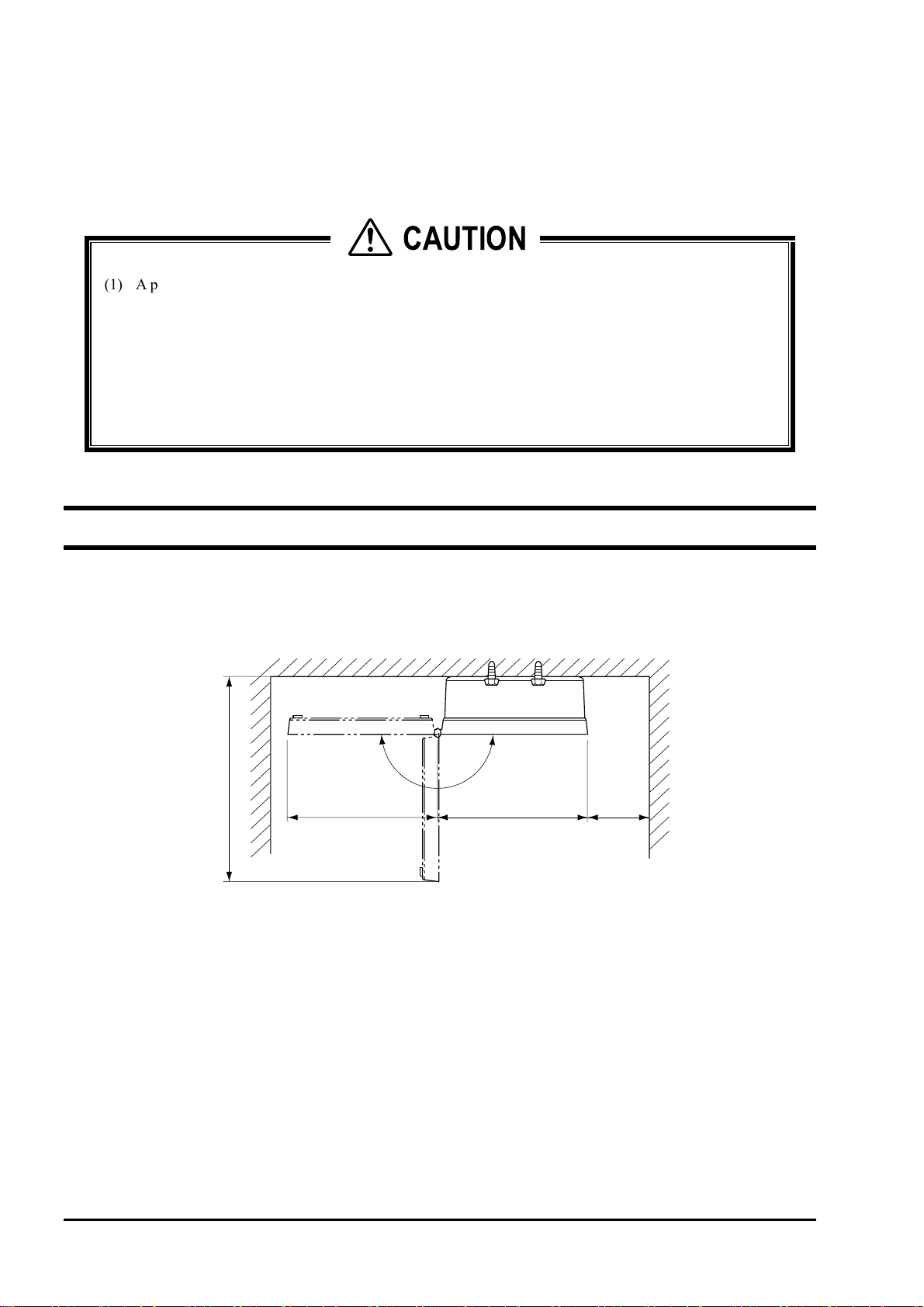

2. SELECTING INSTALLATION LOCATION

Select an installation location that satisfies the following conditions, with ease of maintenance and inspection, service

life of the instrument, and assurance of reliability taken into consideration.

CAUTION

(1) A place where ambient temperature and humidity are as follows:

Flow transmitter (FSH): −10 to +50°C, 90%RH or lower

Detector (FSW): −20 to +80°C, 100%RH or lower

(2) A place not subject to direct sunlight or weather

(3) A place provided with space for daily inspection and wiring work

(4) A place not subject to radiant heat from a heating furnace, etc.

(5) A place not in an atmosphere of corrosive or explosive gas

(6) A place not subject to flooding

(7) A place not subject to vibration, dust, or moisture

2.1. Flow transmitter

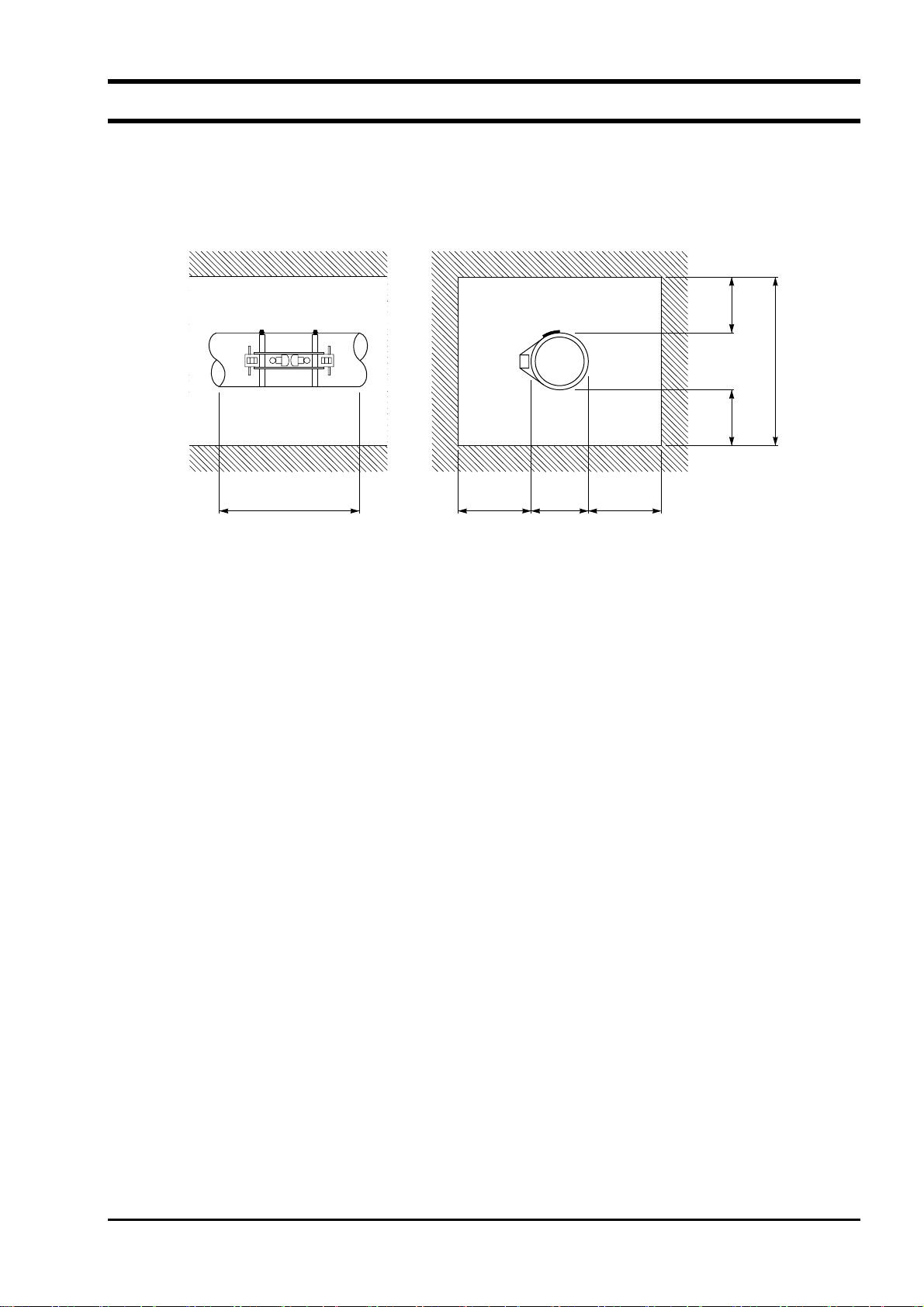

Allow space of 100 mm or more between the flow transmitter and the surrounding walls. Allow sufficient space for

opening of the front cover for maintenance.

Allow sufficient space for wiring at the bottom of the case.

N

E

P

O

348mm

245mm

244mm 100mm

or more

- 8 -

INF-TN1FSH-E

Page 17

2.2. Detector

The mounting position of the detector, in other words, the state of the piping where the flow rate is to be measured,

affects the accuracy of measurement to a great extent. Select a place that satisfies the conditions described in 2.2.1.

Length of straight section of pipe. Assure sufficient working space for installation and maintenance, referring to the

figures shown below.

200

or more

200 or more

Note

200

or more

D + 1200 or more

600

or more

D

600

or more

D: Pipe diameter

Space required for mounting of detector

INF-TN1FSH-E

- 9 -

Page 18

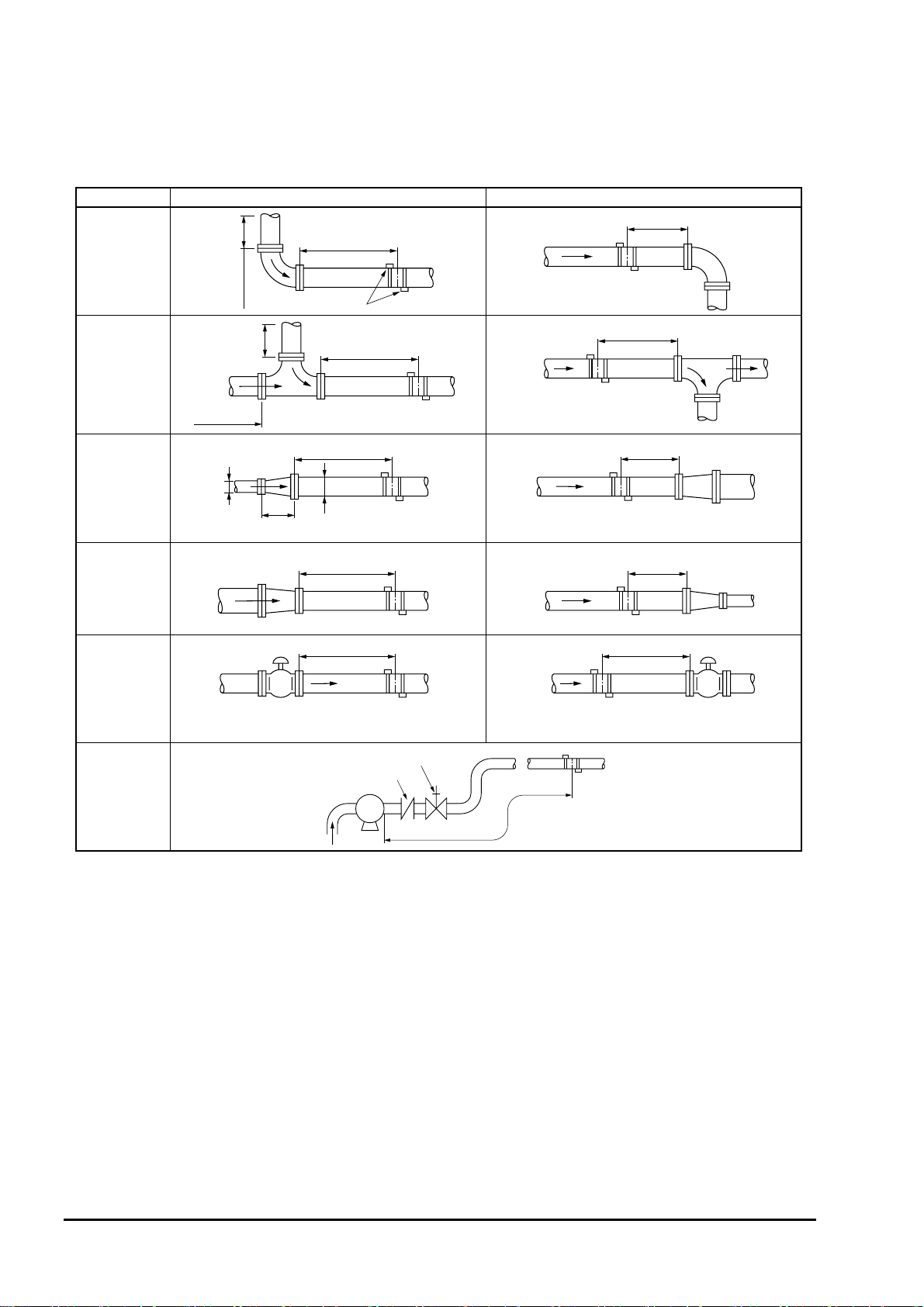

2.2.1. Length of straight section of pipe

To assure the accuracy of flow rate measurement, allow sufficient length of the straight section of the pipe on the

upper/lower stream side, referring to “straight pipe conditions” shown below.

Classification Upstream side Downstream side

L≧10D

90 bend

( D : Inside diameter of pipe)

L≧5D

Tee

Diffuser

Reducer

Various Valve

Pump

10D or more

or

10D

more

10D or more

or

0.5D

more

≧1.5D

In case that flow control valve exists on

upstream side.

Detector

L≧50D

L≧30D

D

L≧10D

L≧30D

Check valve

P

L≧10D

L≧5D

L≧5D

L≧10D

In case that flow control valve exists on

downstream side.

Stop valve

L≧50D

(Note) The source : JEMIS-032

- 10 -

INF-TN1FSH-E

Page 19

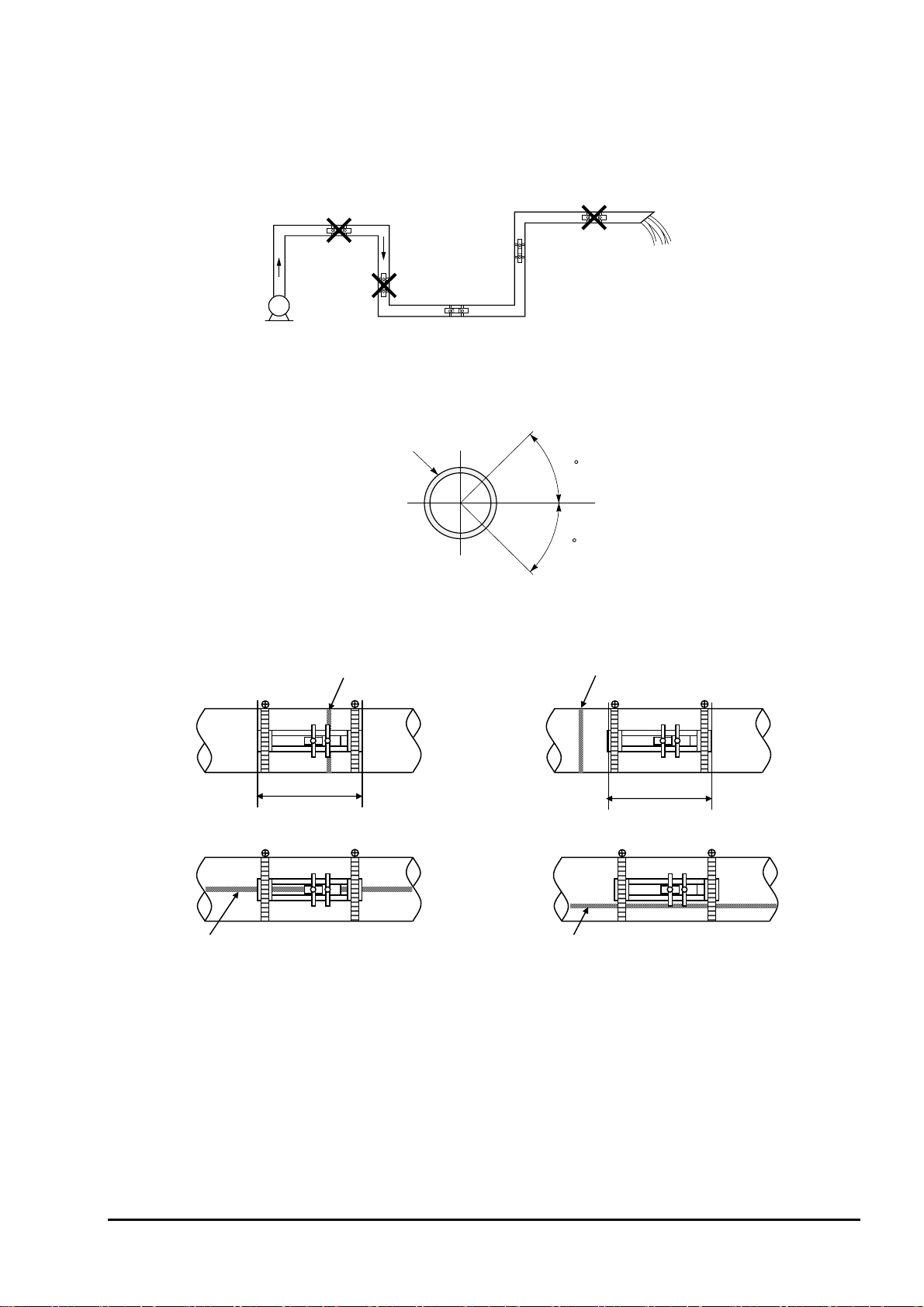

2.2.2. Mounting position

The instrument can be mounted horizontally or in any other position. However, pay attention to the following.

(1) Allow fluid to fill the pipe and keep it flowing at all times.

Air tends to pile up.

The pipe

may not be

filled with fluid.

The pipe may not be filled with fluid.

Good

Pipe

Good

45

45

Welded part

○

Does not include welded part.

○

Pump

(2) Mount the flowmeter within ±45° from the center plane in the case of horizontal pipe run.

Mount it at an arbitrary position on the outer periphery in the case of vertical pipe run.

Horizon

(3) Avoid mounting the flowmeter in a position where the pipe is deformed, or on a flange or welded part.

Overlaid on welded part. Not overlaid on welded part.

Includes welded part.

×

Welded part

INF-TN1FSH-E

- 11 -

Page 20

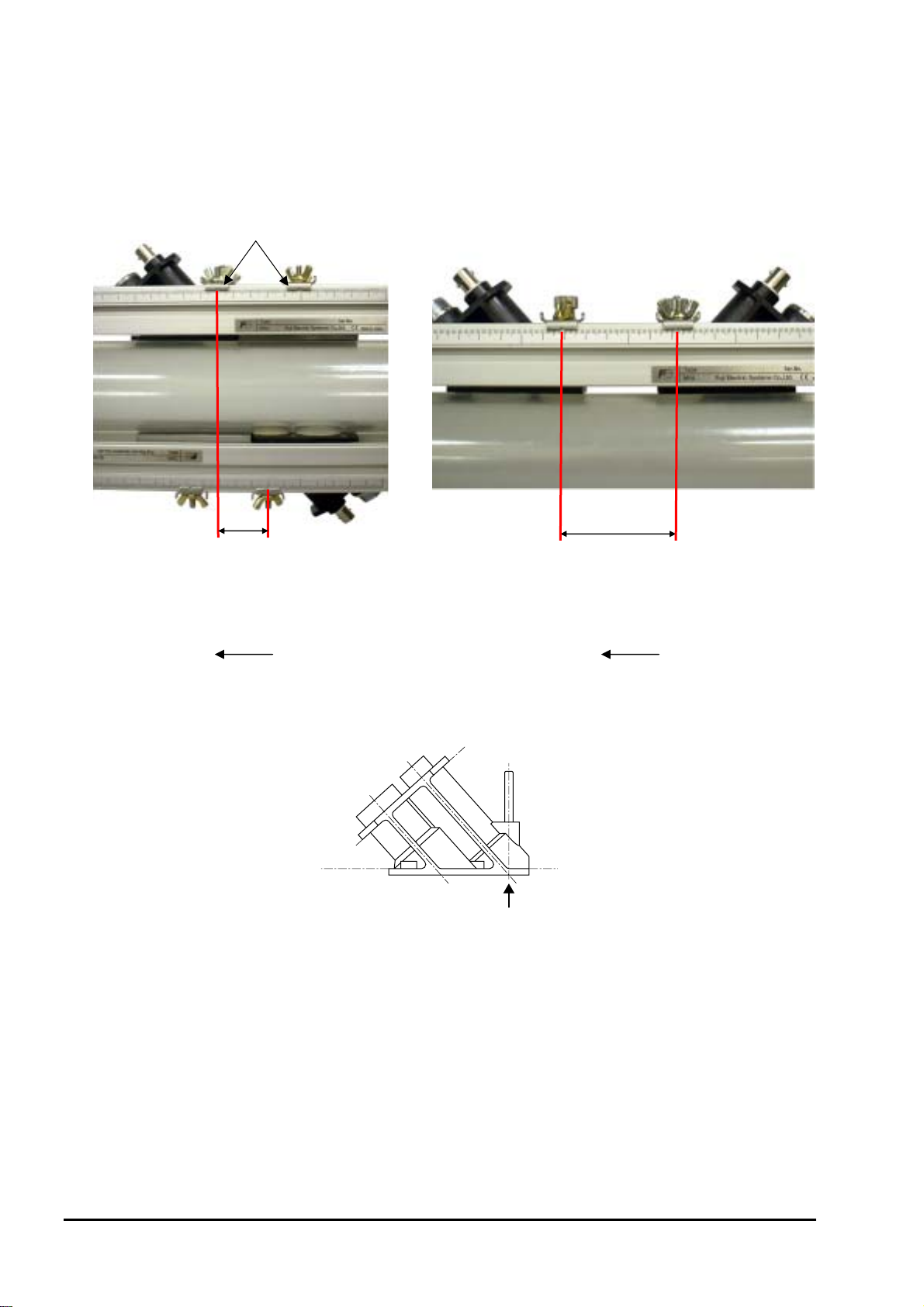

2.2.3. Mounting the sensor

The detector can be mounted either by Z method or V method as shown by Fig. 1.

The top surface of the sensor is referenced as shown by Fig. 2. Mount a pair of sensors, allowing the specified spacing

between the surfaces of both sensors.

Sensor R

on downstream side

(without temperature

sensor)

[Z method] [V method]

Cursor

Sensor R

on downstream side

Sensor F

on upstream side

Sensor F on upstream side

(with temperature sensor)

Sensor mounting spacing

Sensor mounting spacing

Flow direction

Flow direction

Fig. 1 Mounting of sensor

Reference

Fig. 2 Reference surface of sensor

Mount the sensor by Z method in the case of hybrid measurement system.

Mount it by Z method to take measurements under the following conditions by transit time method only.

To measure high turbidity fluids such as sewage influent

•

When the pipe is provided with mortar lining

•

When the pipe is old and thick scale is considered to have attached within the pipe

•

- 12 -

INF-TN1FSH-E

Page 21

3. INSTALLATION AND BEFORE START OF

OPERATION

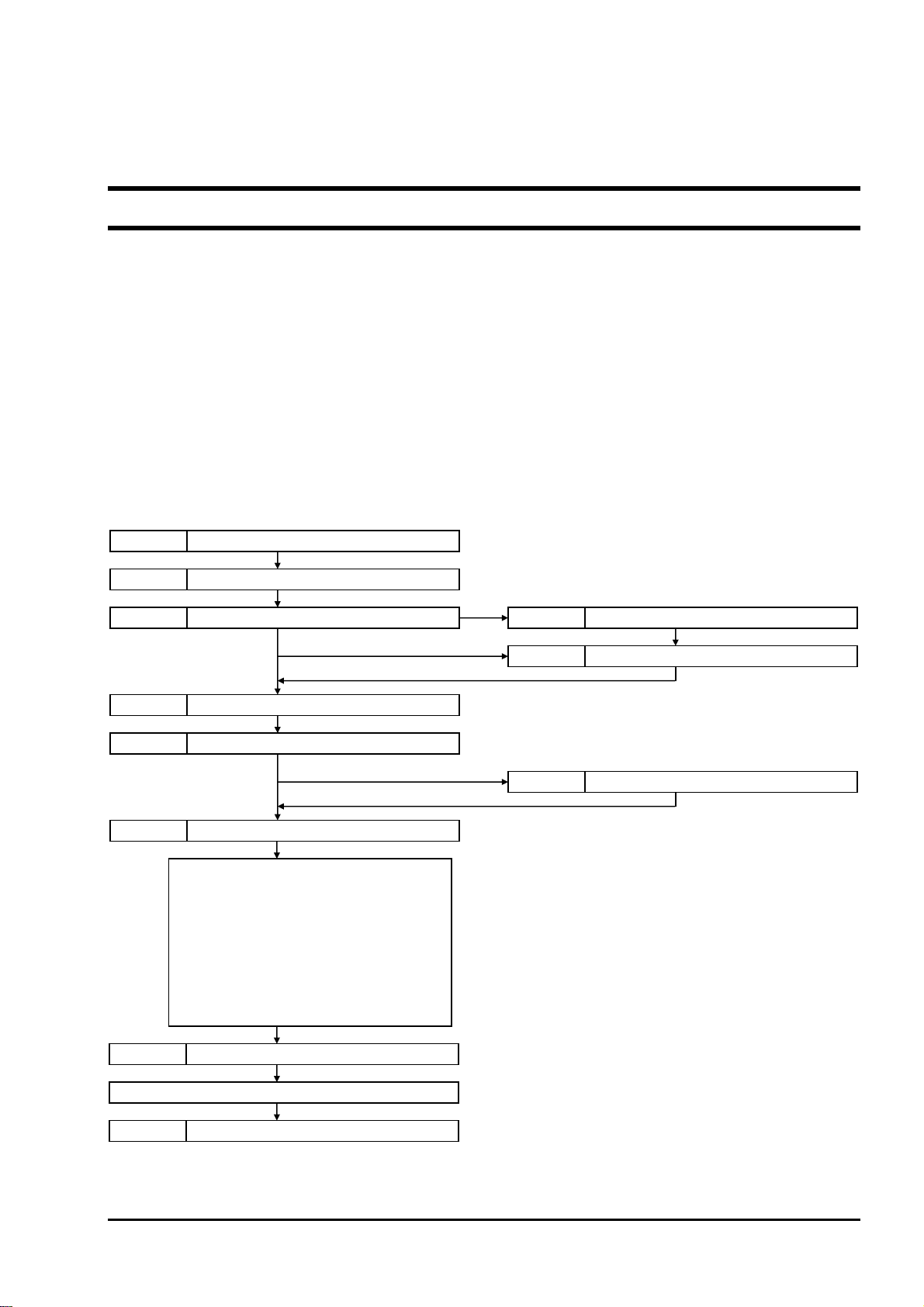

3.1. Before operation

(1) Selection of installation location of flow transmitter and detector

(2) Installation and wiring of flow transmitter

(3) Power ON

Check the power supply specifications and wiring before turning on the power.

(4) Entering of piping parameters and calculation of the spacing between the sensor units (*Check the spacing of

sensor units if parameter setting is provided.)

(5) Mounting of frame to measurement piping (*When using a frame for mounting)

(6) Mounting of sensor unit

Be careful not to mount the unit with wrong dimension.

(7) Setting of measurement range (*Not required if measurement range is specified by parameter setting provided.)

(8) Zero point adjustment

Before performing zero point adjustment, check that the pipe is filled with fluid, the fluid is in still state, and that

the measurement status is normal.

(9) Start of measurement

3.3. Flow transmitter wiring

3.1. Before operation

3.4.2. Entering piping specifications 4.4.1. Measurement method and sensor

3.5. Installing detector

6.3. Checking received waveform

3.7. Zero adjustment

8.5. Composition of key operation

Chapter 5. MAINTENANCE AND INSPECTION

Output specification setting

System setting

Total specification setting

Total alarm setting

Measurement display specification setting

Dumping setting

Low flow rate cut setting

Output correction setting

Status output setting

Measurement

3.4.2. Entering piping specifications

Chapter 6. TROUBLESHOOTING

INF-TN1FSH-E

- 13 -

Page 22

3.2. Installing the flow transmitter

The flow transmitter can be mounted on a wall or on a panel.

Use four M8 bolts to mount the flow transmitter on a wall or a panel. Drill holes according to the mounting hole

dimensions shown below, and fasten the flow transmitter using the M8 bolts.

352

332

14

240

4-

9

Duosonics

Mounting plate

72

233

- 14 -

INF-TN1FSH-E

Page 23

3.3. Flow transmitter wiring

3.3.1. Cautions in wiring

CAUTION

(1) Use a dedicated cable (FLY) as a signal cable between the detector (FSW) and the flow transmitter

(FSH). Do not join cable in the middle.

(2) Be sure to let the signal cables installed between the detector and the flow transmitter run through a

metal conduit tube. The signal cables for upper and the lower streams can be made to run through

the conduit tube together. However, do not let the power cable run through the conduit tube

together with the signal cables to avoid induction problems.

(3) Use shielded cables for output signals as far as possible.

(4) To prevent noise from coming in, avoid installing wiring in a duct together with the power cable.

(5) Directly ground the power cable that includes a ground lead.

(6) The flowmeter is not equipped with a power switch. Mount one separately.

(7) Tightly seal the unused wiring ports with supplied sealing caps.

3.3.2. Applicable wires

Use the following cables.

Power cable:

•

3-wire or 2-wire cabtyre cable

Nominal sectional area: 0.75 mm

Finished outer diameter: φ11 mm

Output signal cable:

•

2-wire or multi-wire cabtyre cable as required

Finished outer diameter: φ11 mm

Cable between detector and flow transmitter:

•

Cable for ultrasonic wave signals (High-frequency coaxial double shield cable with characteristic impedance

of 50 Ω, With waterproof BNC connector provided on one side)

Finished outer diameter: φ7.3 mm

Cable for temperature sensor (3-wire shielded cable, With waterproof connector provided on one side)

Finished outer diameter: φ6.9 mm

2

or more

3.3.3. Treatment of wiring port

The casing of the flow transmitter is of watertight type (IP67). However, to prevent entry of moisture and occurrence

of condensation, airtight processing of wiring ports is required. Be sure to take measures against entry of water using

the waterproof glands supplied with the instrument. Tightly seal unused glands using the supplied sealing caps.

CAUTION

Do not install the flow transmitter in a place subject to the occurrence of flooding.

INF-TN1FSH-E

- 15 -

Page 24

3.3.4. Removing and mounting the shield plate

Before installing wiring, remove the 4 M3 screws and then the shield plate.

Shield plate

Screw

Be sure to mount the shield plate back in position after wiring is completed.

- 16 -

INF-TN1FSH-E

Page 25

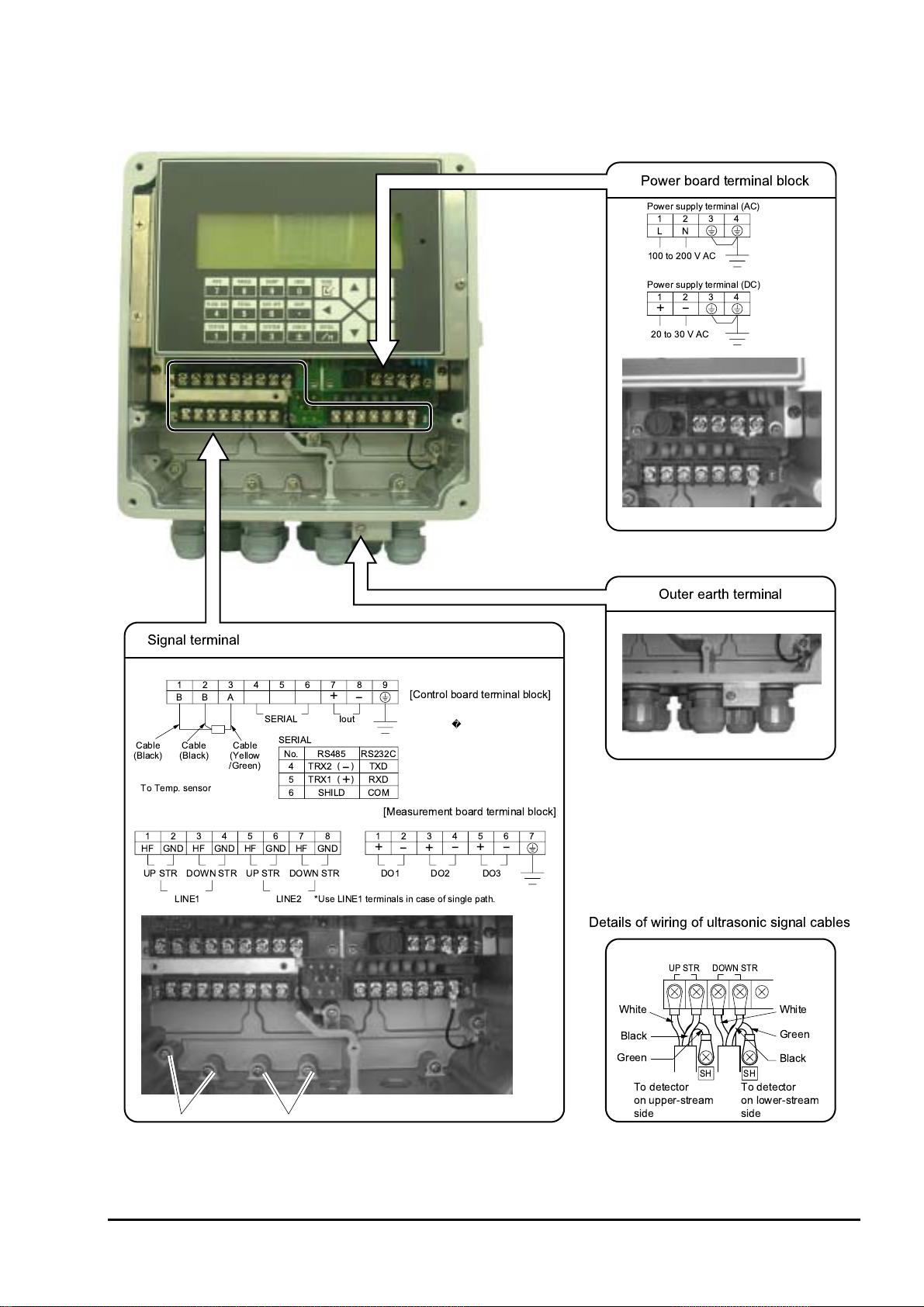

3.3.5. Wiring to each terminal

Install wiring according to the layout shown below.

( 2< 24

( ) *&'+

"$,,

## "## % &'

( ) *'+

"$

;

7

"# $# % &'

'2

*34+

!

3&

'2

$,

!

$"

'2

*5(

6-+

./

! -

&

3

*34+

-"-

"

0/.,

7

&

,1.

,

9"

()

.

9

()

/

01

! -

81

;

"$"'

9

;

9

7

':

=: 2< 24>

"

7

;

=' 2< 24>

$,./0

;;

"

7

$

7

( 2

34

-

<?

;

<

-

34

<

(;

<

INF-TN1FSH-E

- 17 -

Page 26

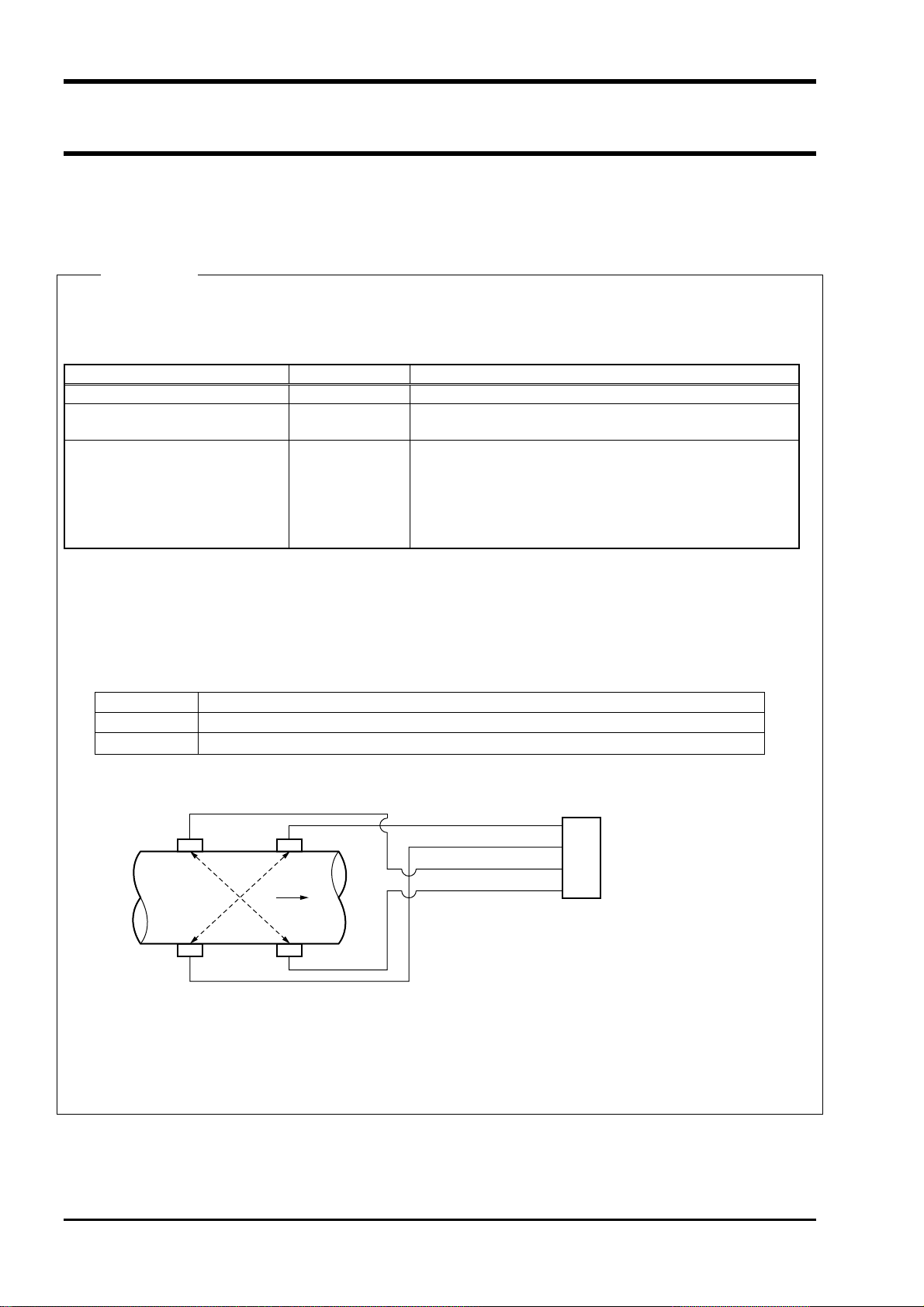

3.4. Setting piping parameters and calculating the

spacing between sensor units

Make the setting to calculate the spacing between the sensor units as follows.

3.4.1. Selecting sensor type, mounting the sensor

Description

The data of the sensor required for measurement can be set as follows.

If the sensor mounting method or sensor type is changed, the sensor spacing in piping specifications is also changed.

Enter the data for each item according to the display (see the table shown below).

Refer to 4.4.1 for details of the setting.

Item Input method Range or menu

Sensor mounting method Select V method, Z method

Sensor type Select FLW11, FLW41, FLW12, FLD12, FLD22, FLW32,

FLW50, FLW51, FSW12, FSW21, FSW40, FSW50

Sensor calibration

Line #-F: METAL PIPE

Line #-R: METAL PIPE

Line #-F: PLASTIC PIPE

Line #-R: PLASTIC PIPE

(#: Line No.)

*1) Select sensor type by the model of the sensor to be used in combination (5 digits).

*2) In sensor calibration, set the sensor constant calculated based on actual current calibration performed as part of the

delivery test at the factory. Set the sensor constant for each of the sensor units mounted to the pipe. The sensor

constant appears as the DF value marked on the nameplate of the sensor unit. The setting need not be changed

normally. (Make the setting when the detector or the flow transmitter is replaced.)

▪ It appears as the DF-P value on the nameplate of the sensor unit if the sensor is mounted on a plastic pipe.

▪ It appears as the DF-M value on the nameplate of the sensor unit if the sensor is mounted on a metal pipe.

Pipe material

Plastic Pipe PVC, FRP, PEEK, PVDF, Acrylic, Others

Metal Pipe Carbon steal, Stainless steel, Copper, Cast iron, Aluminium, Ductile iron

Refer to “1.3 Checking type and specifications” for sensor unit.

*3) The sensor calibration value is for the sensors in the following figure.

Numeric value

Numeric value

Numeric value

Numeric value

0.00% to 300.00%

0.00% to 300.00%

0.00% to 300.00%

0.00% to 300.00%

Sensor 3 Sensor 2

Direction of flow

Sensor 1 Sensor 4

Sensor calibration line 1-F: Sensor 1

Sensor calibration line 1-R: Sensor 2

Sensor calibration line 2-F: Sensor 3

Sensor calibration line 2-R: Sensor 4

*4) Perform sensor calibration only when the sensor type is FSW12, FSW21, FSW40, or FSW50.

To line 1

To line 2

- 18 -

Converter

INF-TN1FSH-E

Page 27

Operation (example) When Z method as sensor mount, FSW12 as sensor type, 102% for sensor calibration line 1-F

(METAL), 101% for 1-R (METAL)

Key operation Description Display

FUNC SYSTEM

S or T

ENTER S or T ENTER

Display System.

Select “SENSOR MOUNT”

Enter select/enter mode, select “Z

METHOD” and press ENTER.

UNIT & LANGUAGE

SENSOR MOUNT

SENSOR MOUNT

SKIP

V METHOD

Z METHOD

S or T

ENTER S or T ENTER

T

ENTER

ENTER 1 0 2 ENTER

or T

S

ENTER 1 0 1 ENTER

ESC

S

or

T

ENTER

ESC

Select “SENSOR TYPE”

Enter select/enter mode, select “FSW12”

and press ENTER.

Select “SENSOR CALIBRATION”

Enter select/enter mode, select “Setting,”

and press ENTER.

Enter numeric value enter mode, enter

“102” using ten keys, and press ENTER.

Select “LINE 1-R”

Enter numeric value enter mode, enter

“101,” and press ENTER.

Return to “SENSOR CALIBRATION”

Display measurement, reflecting the

setting.

SENSOR TYPE

SENSOR TYPE

SENSOR CALIBRATION

LINE 1-F: METAL

LINE 1-F: METAL

LINE 1-R: METAL

LINE 1-R: METAL

SENSOR CALIBRATION

(Measurement display screen)

FSW21

FSW12

SKIP

100.00%

102.00%

100.00%

101.00%

SKIP

INF-TN1FSH-E

- 19 -

Page 28

3.4.2. Entering piping specifications

Description

By setting the conditions of the piping where measurement is to be taken, the spacing between the sensor units to be

mounted can be calculated. The sensor spacing is calculated automatically.

Enter data for each item listed in the following table according to the display.

Item Input method Range or menu

Outer diameter Numeric value 10.00 mm to 6200.00 mm

Pipe material Select Carbon steel, stainless steel, PVC, copper, cast iron, aluminum,

FRP, ductile iron, PEEK, PVDF, acrylic, and others

Pipe S.V.*1 Numeric value 1000 m/s to 3700 m/s

Wall thickness Numeric value 0.10 mm to 100.00 mm

Lining material Select No lining, tar epoxy, mortar, rubber, Teflon, pyrex glass, PVC, and

others

Lining S.V.*2 Numeric value 1000 m/s to 3700 m/s

Lining thickness*3 Numeric value 0.01 mm to 100.00 mm

Kind of fluid Select Water, seawater, dist. water, ammonia, alcohol, benzene, bromide,

ethanol, glycol, kerosene, milk, methanol, toluol, lube oil, fuel oil,

petrol, and others

Fluid S.V.*4 Numeric value 500 m/s to 2500 m/s

Viscosity*4 Numeric value 0.0010E-6 m2/s to 999.9999E-6 m2/s

*1) When “others” is selected as pipe material only.

*2) When “others” is selected as lining material only.

*3) In the cases other than “No lining” only

*4) When “others” is selected for the kind of fluid only.

Operation

(example)

When outer diameter of the pipe is 114.3 mm, pipe material is carbon steel, wall thickness is 6.0 mm,

lining material is tar epoxy, lining thickness is 1.25 mm, kind of fluid is heavy water, sound velocity is

1388 m/s, and kinematic viscosity is 1.129E

(When the sensor is mounted by “Z method,” sensor type is “FSW12.”

Key operation Description Display

FUNC PIPE

T

ENTER 1 1 4 . 3 ENTER

Display sensor spacing.

Select “OUTER DIAMETER”

Enter numeric value enter mode, enter

114.30 using ten keys, and then press

ENTER.

6

−

m2/s

Lining thickness

Wall thickness

Outer diameter

SENSOR SPACING

OUTER DIAMETER

OUTER DIAMETER

9.17 mm

60.00 mm

114.30 mm

T

Select “PIPE MATERIAL”

- 20 -

PIPE MATERIAL

PVC

INF-TN1FSH-E

Page 29

ENTER

S or T ENTER

T

ENTER 6 ENTER

T

ENTER S or T ENTER

T

ENTER 1 . 2 5 ENTER

T

ENTER S or T ENTER

T

ENTER 1 3 8 8 ENTER

T

ENTER 1 . 1 2 9 ENTER

ESC

ESC

SENSOR SPACING

39.16 mm

Enter select/enter mode, select “CARBON

STEEL,” and then press ENTER.

Select “WALL THICKNESS”

Enter numeric value enter mode, enter “6”

using ten keys, and press ENTER.

Select “LINING MATERIAL”

Enter select/enter mode, select “TAR

EPOXY,” and press ENTER.

Select “LINING THICKNESS”

Enter numeric value enter mode, enter

“1.25” using ten keys, and press ENTER.

Select “KIND OF FLUID”

Enter select/enter mode, select “OTHERS,”

and press ENTER.

Select “FLUID S.V.”

Enter numeric value enter mode, enter

“1388” using ten keys, and press ENTER.

Select “VISCOSITY”

Enter numeric value enter mode, enter

“1.129” using ten keys, and press ENTER.

Select “SENSOR SPACING”

Display the measurement, reflecting the

setting.

PIPE MATERIAL

WALL THICKNESS

WALL THICKNESS

LINING MATERIAL

LINING MATERIAL

LINING THICKNESS

LINING THICKNESS

KIND OF FLUID

KIND OF FLUID

FLUID S.V.

FLUID S.V.

VISCOSITY

VISCOSITY

SENSOR SPACING

(Measurement display screen)

CARBON STEEL

4.50 mm

6.00 mm

NO LINING

TAR EPOXY

0.01 mm

1.25 mm

Water

OTHERS

1440 m/s

1388 m/s

6m2

1.0038 E

1.1290 E

39.16 mm

−

6m2

−

← Set the piping data, and then mount the detector at dimensions displayed.

/s

/s

INF-TN1FSH-E

- 21 -

Page 30

3.5. Installing Detector

3.5.1. Outline of detector installation procedure

1. Treatment of mounting surface of the detector

2-1 Mounting small-diameter and small/medium size sensor

(1) How to mount the frame (using a jig)

(2) How to mount the frame (not using a jig)

(2)-1 How to determine the mounting position

(2)-2 How to mount the frame

(3) How to mount the sensor unit

2-2 Mounting a large sensor

(1) Mounting position

(2) How to mount the sensor

3.5.2. Treatment of mounting surface

Using thinner and sand paper, remove rust, pitch, and irregularities, if any, on the surface of the piping to which the

detector is to be mounted over the length of the frame to be used.

Note 1: If the pipe is wrapped with jute, remove the jute wrapping over the entire circumference in width of frame

length (L) + 200 mm, and then perform surface treatment described above.

Jute wrapping

Pipe

L + 200 mm

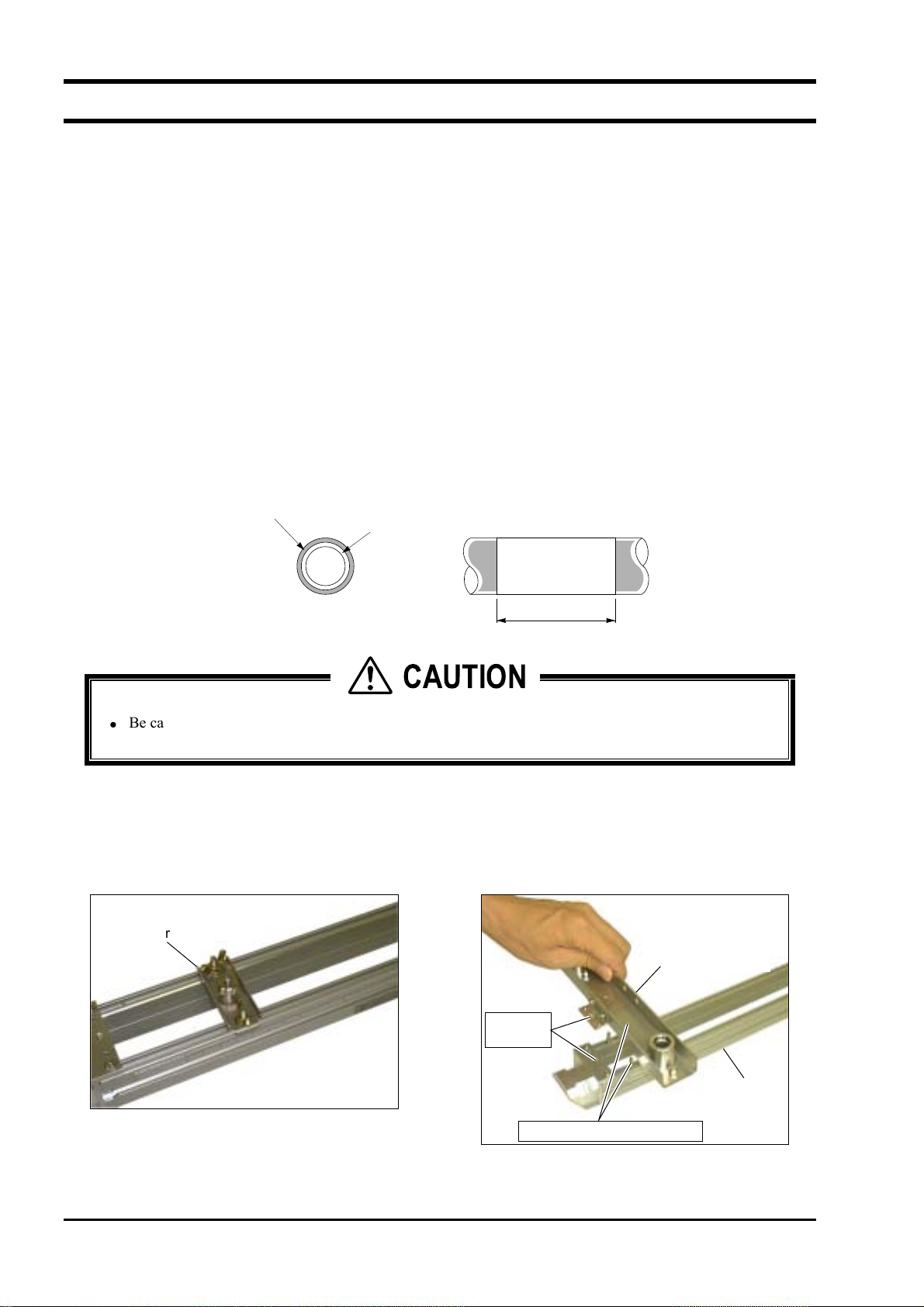

CAUTION

Be careful not to cut your hand with the stainless steel belt when mounting the frame.

•

Mount the sensor unit equipped with a temperature sensor on the upstream side.

•

3.5.3. Mounting the detector by Z method using the frame

(1) How to mount the frame (using a jig)

(1) Remove the butterfly nut of the cursor, and remove

it out of the frame.

Cursor

(2) Temporarily place the mounting jig (option) on the

frame.

Insert

the pins.

Mounting jig

Frame

- 22 -

Let the screws run through.

INF-TN1FSH-E

Page 31

w

(3) Fasten the mounting jig to the frame using the

butterfly nut and the screw.

Scre

Butterfly nut

(4) Mount the mounting jig on the opposite side of the

frame.

(6) Let the shaft run through the mounting jig on the

opposite side.

(7) Place the frame between the pipes.

(5) Let the shaft run through the mounting jig.

Note: Pay attention when letting the shaft run

through the jig so that the scale unit of the

frame coincides with that of the shaft.

Select the same scale (mm, inch).

Shaft

Mounting jig

(8) Let the shaft run through the holes at the bottom of

the mounting jig.

Shaft

INF-TN1FSH-E

- 23 -

Page 32

(9) Wrap the stainless belt around the frame end.

Frame end

(10) Lift the screw of the stainless belt to let the tip of the

belt run through it.

(11) Fasten the screw, wrapping the stainless belt around

the frame end.

(12) Fasten both ends of the frame with the stainless belt.

(13) Remove the mounting jig.

Remove the shaft first, and then remove the

mounting jig.

- 24 -

INF-TN1FSH-E

Page 33

(2) How to mount the frame (not using a jig)

Gage paper is required to mount the frame by this method. (See “8.7. Making gauge paper” for details.)

(2)-1 How to determine the mounting position

(1)

Align the edge of the gauge paper to the

place 100mm from one of the edges treated for

mounting, and wrap it around the pipe, keeping

the line on the gauge paper in parallel with the

axis of the pipe. (Fasten with tape to prevent it

from being dislocated.) Keep the edge of the

gauge paper at specified position.

Keep the line

in position.

100mm

(2)

Write straight line A on the pipe, extending

the line written on the gauge paper.

(3)

Write a line along one edge of the gauge

paper. Let the point of intersection of that line

and line A be A

0.

V method Z method

Example: When L=200mm

A2

(4)

Peel off the gauge paper,

A0

200mm

measure the sensor spacing from

A

0, and draw a line that intersects

with straight line A at right angles.

(Find A

2.)

From A0 to A2 is defined

as the mounting position.

Line A

A0

A0 B0, B1 A0, A1A1

B1

(4)

Measure the circumference beginning from A0 using a

B0

Straight line B

measure. Determine the points that equally divide the

circumference and let them be B

0 and B1 respectively.

Draw a line connecting these two points (straight line B).

Example: When L=100mm

100mm

B0B2

INF-TN1FSH-E

B0B2

A0

(5)

Mark point B

Measure the sensor spacing from B

intersects with straight line B at right angles. (Find B

From A

0, and then peel off the gauge paper.

0, and draw a line that

2.)

0 to B2 is defined as the mounting position.

- 25 -

Page 34

(2)-2 Mounting the Frame

(1) Checking the mark-off line

“In the case of 1 measurement line”

Draw a horizontal mark-off line that

includes the center point of the cross

sectional view of the pipe.

Mark-off line

Mark-off

line

(2) Wrap the stainless belt around the pipe.

“In the case of 2 measurement lines”

Draw a mark-off lines at an angle ±45°

from the horizon.

45°

45°

(4) Place the frame so that the marking line and the “V”

mark on the frame end are aligned, and then fasten it

with a band.

Mark-off line

Mark-off line

(3) Lift the screw of the stainless belt and let the tip of

the belt run through it.

Marking

line

Align the "▽" mark with

the marking line.

- 26 -

INF-TN1FSH-E

Page 35

(3) How to mount the sensor unit

Mount the sensor unit comprising of two sensors facing opposite to each other, keeping the spacing displayed after the

piping parameter setting is completed. See “2.2.3. Mounting the sensor” for details.

Note: Mount the sensor unit equipped with a temperature sensor on the upstream side.

(1) Before mounting the sensor unit to the frame, apply

silicon rubber evenly over the entire transmitting

surface of the sensor unit and the surface of the

thermometer that is to contact the pipe.

(4) Fasten the sensor unit with butterfly nuts. Then

bring the sensor unit into intimate contact with the

pipe, fastening the cap screw.

(2) Temporarily place the cursor on the sensor unit.

Cursor

(3) Insert the sensor unit into the frame, aligning the

holes of the cursor with the screws of the frame.

Cap screw

(5) Mount the sensor unit, paying attention to the

spacing of the sensors facing opposite to each other.

(6) Mount the two sensors with the front surface of each

facing to each other. Mount only one sensor to one

frame.

Mounting of resin piping has now been completed. In

the case of metal piping, mount the absorber unit as

shown below.

(7) Before mounting the absorber unit, apply silicon

rubber evenly over the entire installation surface of

the absorber unit.

Screw

INF-TN1FSH-E

Hole

- 27 -

Page 36

(8) Temporarily place the cursor onto the absorber unit.

Cursor

Absorber

unit

(9) Aligning the screws of the frame to the holes of the

cursor, insert the absorber unit into the frame.

Screw

(10) Fasten the absorber unit with the butterfly nut at the

position where the absorber unit comes in contact

with the sensor unit. Then fasten the cap screw.

(11) Fasten the absorber unit onto both frames.

Hole

- 28 -

INF-TN1FSH-E

Page 37

3.5.4. Mounting the sensor unit by V method using a frame

(1 measurement line)

(1) Mounting the frame

Unlike Z method, only one frame is used. No mounting jig is used.

(1) Wrap the stainless steel belt around the pipe.

(3) Wrap the stainless steel belt around the frame ends,

keeping the frame in parallel with the pipe, to fasten

the frame temporarily.

(2) Lift the screw of the stainless belt to let the tip of the

belt run through it.

Frame end

INF-TN1FSH-E

- 29 -

Page 38

(2) Mounting the sensor unit

Mount both sensor units at the spacing shown in “Sensor spacing” that is to be displayed after pipe parameter setting is

made. The spacing is the distance between the tips of both sensors.

Note: Mount the sensor unit equipped with a temperature sensor on the upstream side.

(1) Apply silicon rubber evenly over the entire

transmission surface of the sensor unit and the

contact surface of the pipe of the thermometer

before mounting the sensor unit to the frame.

(4) Fasten the sensor unit with butterfly nuts. Then

bring the sensor unit into intimate contact with the

pipe, fastening the cap screw.

(2) Temporarily place the cursor on the sensor unit.

Cursor

(3) Insert the sensor unit into the frame, aligning the

holes of the cursor with the screws of the frame.

Cap screw

(5) Mount the sensor unit opposing to each other,

paying attention to the mounting spacing. (Mount

the two sensors with the front of each facing

opposite to each other.)

Note:

The sensor can be mounted by V method only when

transit time method is employed. Consequently an

absorber is not used even if the pipe is made of metal.

Screw

Hole

- 30 -

INF-TN1FSH-E

Page 39

3.5.5. Mounting the sensor unit by Z method using a frame

(2 measurement lines)

(1) Mounting the frame

Two pairs of frames are required.

(1) Draw a mark-off line at an angle ±45° from the horizon. See 3.5.7. (1) how to draw a mark-off line.

45°

45°

(2) Align the center of the end frame so that it comes over the make-off line, and temporarily fasten it using cloth

belt, etc. not on the frame ends but on the frame.

(3) Then wrap a stainless steel belt around the frame end to fasten it securely. Follow the description in 3.5.3. to

fasten the stainless steel belt.

(2) Mounting the sensor unit

Two pairs of sensor units and two pairs of absorbers (in the case of a metal pipe) are required for mounting. Mount the

sensor units following the same procedure as “3.5.3.(3) How to mount the sensor unit.” Mount each pair of frames to

install the sensor unit.

Mark-off line

Mark-off line

45°

45°

Frame

INF-TN1FSH-E

- 31 -

Page 40

3.5.6. Mounting the sensor unit by V method using a frame

(2 measurement lines)

(1) Mounting the frame

The method is valid only when transit time method is employed. Two pairs of sensor units and 2 frames are required

for this measurement method. Mount the frames following the same procedure as Z method.

(2) Mounting the sensor unit

Follow the same procedure as “3.5.4.(2) Mounting the sensor unit.” to mount the sensor unit. Mount each frame to

install the sensor unit.

45°

45°

Mark-off line

Mark-off line

Frame

45°

45°

- 32 -

INF-TN1FSH-E

Page 41

3.5.7. Mounting the sensor unit to a large-diameter pipe

(1) How to determine the mounting position

Do not use a mounting jig to install the sensor unit to a pipe of diameter of 500 A or more. Mount the sensor with wire

in such cases. (Do not use a frame.)

Perform the following to determine the mounting position.

Gauge paper is required for the work. (See “8.7. Making gauge paper” for details.)

(1)

Align the edge of the gauge paper to the

place 100mm from one of the edges treated for

mounting, and wrap it around the pipe, keeping

the line on the gauge paper in parallel with the

axis of the pipe. (Fasten with tape to prevent it

from being dislocated.) Keep the edge of the

gauge paper at specified position.

Keep the line

in position.

100mm

(2)

Write straight line A on the pipe, extending

the line written on the gauge paper.

(3)

Write a line along one edge of the gauge

paper. Let the point of intersection of that line

0

and line A be A

.

V method Z method

Example: When L=200mm

A

A

2

200mm

(4)

Peel off the gauge paper,

0

measure the sensor spacing from

A

0

, and draw a line that intersects

with straight line A at right angles.

(Find A

2

.)

From A0 to A2 is defined

as the mounting position.

Line A

A

0

A

0

Straight line B

0

A

1

B

(4)

Measure the circumference beginning from A

B

1

B

0, B1

measure. Determine the points that equally divide the

circumference and let them be B

0 and B1 respectively.

Draw a line connecting these two points (straight line B).

Example: When L=100mm

100mm

B0B

2

A

0, A1

0 using a

INF-TN1FSH-E

A

B

0

2

0, and then peel off the gauge paper.

(5)

Mark point B

B

Measure the sensor spacing from B

intersects with straight line B at right angles. (Find B

From A

0

to B2 is defined as the mounting position.

0

0, and draw a line that

2.)

- 33 -

Page 42

(2) Mounting the sensor

Use sensor FSW50 for large-diameter pipes.

Note: Mount the sensor unit equipped with a temperature sensor on the upstream side.

(1) Checking the mark-off line

“In the case of 1 measurement line”

Draw a horizontal mark-off line that

includes the center point of the cross

“In the case of 2 measurement lines”

Draw a mark-off lines at an angle ±45°

from the horizon.

sectional view of the pipe.

Mark-off line

45°

Mark-off

line

(2) Provide a wire rope for the sensor unit on the

upstream and downstream sides and the absorber

unit. Allow the length of the wire rope to be the

same or longer than the pipe diameter.

(4) Apply silicon rubber evenly over the entire

transmitting surface of the sensor unit, paying