Fuji Electric FRN5.5LM1S-2, FRN15LM1S-2, FRN18.5LM1S-2, FRN22LM1S-2, FRN4.0LM1S-4 Instruction Manual

...Page 1

Designed for Elevating Machinery

Instruction Manual

Thank you for purchasing our FRENIC-Lift series of inverters.

• This product is designed to drive a three-phase induction motor and synchronous motor. Read through this

instruction manual and be familiar with the handling procedure for correct use.

• Improper handling might result in incorrect operation, a short life, or even a failure of this product as well as

the motor.

• Deliver this manual to the end user of this product. Keep this manual in a safe place until this product is

discarded.

• For how to use an option card, refer to the installation and instruction manuals for that option card.

Fuji Electric Co., Ltd. INR-SI47-1038g-E

Page 2

Copyright © 2005-2011 Fuji Electric Systems Co., Ltd.

All rights reserved.

No part of this publication may be reproduced or copied without prior written permission from Fuji Electric Co., Ltd.

All products and company names mentioned in this manual are trademarks or registered trademarks of their

respective holders.

The information contained herein is subject to change without prior notice for improvement.

Page 3

Preface

Thank you for purchasing our FRENIC-Lift series of inverters.

FRENIC-Lift is an inverter designed to drive a three-phase induction motor (hereafter called an induction motor)

and a three-phase permanent magnet synchronous motor (hereafter called a synchronous motor) for exclusively

controlling elevating machinery.

Improper handling might result in incorrect operation, a short life, or even a failure of this product as well as the

motor.

To drive a synchronous motor, a PG interface card option involving a pulse encoder is needed. For derails, refer

to the instruction manual of PG Interface Card.

Listed below are the other materials related to the use of the FRENIC-Lift. Read them in conjunction with this

manual as necessary.

• Multi-function Keypad "TP-G1-CLS" Instruction Manual (INR-SI47-1092-E)

• FRENIC-Lift Reference Manual (INR-SI47-1068-E)

• About compliance with standards (INR-SI47-1148-E)

The materials are subject to change without notice. Be sure to obtain the latest editions for use.

Safety precautions

Read this manual thoroughly before proceeding with installation, connections (wiring), operation, or maintenance

and inspection. Ensure you have sound knowledge of the device and familiarize yourself with all safety information and precautions before proceeding to operate the inverter.

Safety precautions are classified into the following two categories in this manual.

Failure to heed the information indicated by this symbol may lead to

dangerous conditions, possibly resulting in death or serious bodily injuries.

Failure to heed the information indicated by this symbol may lead to

dangerous conditions, possibly resulting in minor or light bodily injuries

and/or substantial property damage.

Failure to heed the information contained under the CAUTION title can also result in serious consequences.

These safety precautions are of utmost importance and must be observed at all times.

Application

• FRENIC-Lift is equipment designed to drive induction motors and synchronous motors for exclusively

controlling elevating machinery. Do not use it for single-phase motors or for other purposes.

Fire or accident could occur.

• FRENIC-Lift may not be used for a life-support system or other purposes directly related to the human

safety.

• Though FRENIC-Lift is manufactured under strict quality control, install safety devices for applications

where serious accidents or material losses are foreseen in relation to the failure of it.

An accident could occur.

i

Page 4

Installation

• Install the inverter on a nonflammable material such as metal.

Otherwise fire could occur.

• Do not place flammable matter nearby.

Doing so could cause fire.

• Using an optional DC reactor makes human body easily touch any live parts of inverters. In this case,

take countermeasures such as installing the inverter in a place that easily protects human body from

electric shock.

Otherwise, electric shock or injuries could occur.

• Do not touch the printed circuit boards in the product directly. Electronic devices on those boards are

easily affected by static electricity.

When touching those boards, put on a grounding wrist band and perform the job on a static mat.

Static electricity charged in your body may damage the product.

• Do not support the inverter by its terminal block cover during transportation.

Doing so could cause a drop of the inverter and injuries.

• Prevent lint, paper fibers, sawdust, dust, metallic chips, or other foreign materials from getting into the

inverter or from accumulating on the heat sink.

Otherwise, a fire or an accident might result.

• Do not install or operate an inverter that is damaged or lacking parts.

Doing so could cause fire, an accident or injuries.

• Do not get on a shipping box.

• Do not stack shipping boxes higher than the indicated information printed on those boxes.

Doing so could cause injuries.

Wiring

• When wiring the inverter to the power source, insert a recommended molded case circuit breaker

(MCCB) or residual-current-operated protective device (RCD)/earth leakage circuit breaker (ELCB)

(with overcurrent protection) in the path of power lines. Use the devices within the recommended current range.

• Use wires in the specified size.

Otherwise, fire could occur.

• Do not use one multicore cable in order to connect several inverters with motors.

• Do not connect a surge killer to the inverter's output (secondary) circuit.

Doing so could cause fire.

• Install inverters in compliance with the local regulation.

Otherwise, electric shock or fire could occur.

• Qualified electricians should carry out wiring.

• Be sure to perform wiring after turning the power OFF.

Otherwise, electric shock could occur.

• Be sure to perform wiring after installing the inverter body.

Otherwise, electric shock or injuries could occur.

ii

Page 5

• Ensure that the number of input phases and the rated voltage of the product match the number of

phases and the voltage of the AC power supply to which the product is to be connected.

Otherwise fire or an accident could occur.

• Do not connect the power source wires to output terminals (U, V, and W).

Doing so could cause fire or an accident.

• Generally, control signal wires are not enforced-insulated. If they accidentally touch any live power

lines, their insulation coat may break for any reasons. In such a case, an extremely high voltage may be

applied to the signal lines. Make a complete remedy to protect the signal line from contacting any live

high voltage lines.

Otherwise, an accident or electric shock could occur.

• Wire the three-phase motor to terminals U, V, and W of the inverter, aligning phases each other.

Otherwise injuries could occur.

• The inverter, motor and wiring generate electric noise. Take care of malfunction of the nearby sensors

and devices. To prevent the motor from malfunctioning, implement noise control measures.

Otherwise an accident could occur.

Operation

• Be sure to install the terminal block cover and the front cover before turning the power ON. Do not

remove the covers while power is applied.

Otherwise electric shock could occur.

• Do not operate switches with wet hands.

Doing so could cause electric shock.

• If the retry function has been selected, the inverter may automatically restart and drive the motor depending on the cause of tripping.

(Design the machinery or equipment so that human safety is ensured after restarting.)

• If the stall prevention function (current limiter), automatic deceleration, and overload prevention control

have been selected, the inverter may operate at an acceleration/deceleration time or frequency different from the commanded ones. Design the machine so that safety is ensured even in such cases.

Otherwise an accident could occur.

• If an alarm reset is made with the Run command signal turned ON, a sudden start will occur. Ensure that

the Run command signal is turned OFF in advance.

Otherwise an accident could occur.

• If you set the function codes wrongly or without completely understanding this instruction manual and

the FRENIC-Lift Reference Manual (INR-SI47-1068-E), the motor may rotate with a torque or at a

speed not permitted for the machine.

• In the tuning process of the inverter, no motor torque control for braking of the machinery takes effect.

Tune the inverter for the motor after disconnecting it from the machinery, or after mechanically brakes

the machinery. Anyway, do it after suppressing any dangerous factors.

An accident or injuries could occur.

• Never touch the inverter terminals while the power is applied to the inverter even if the inverter stops.

• Never touch the printed circuit boards in the product while the power is applied to the inverter. High

voltage is applied to those boards.

Doing so could cause electric shock.

iii

Page 6

• Do not turn the main circuit power (circuit breaker) ON or OFF in order to start or stop inverter operation.

Doing so could cause failure.

• Do not touch the heat sink because they become very hot.

Doing so could cause burns.

• Setting the inverter to high speeds is easy. Before changing the frequency (speed) setting, check the

specifications of the motor and machinery.

• The brake function of the inverter does not provide mechanical holding means.

Injuries could occur.

Setting control switches

• Before setting up any internal control switches, turn OFF the power, and wait for more than five minutes.

Further, check that the LED monitor is unlit, and make sure, using a multimeter or a similar instrument,

that the DC link bus voltage between the terminals P (+) and N (-) has dropped below a safe voltage

(+25 VDC).

Otherwise electric shock could occur.

Maintenance and inspection, and parts replacement

• Turn the power OFF and wait for more than five minutes, before starting inspection. Further, check that

the LED monitor is unlit, and check the DC link bus voltage between the P (+) and N (-) terminals to be

lower than 25 VDC.

Otherwise, electric shock could occur.

• Maintenance, inspection, and parts replacement should be made only by qualified persons.

• Take off the watch, rings and other metallic matter before starting work.

• Use insulated tools.

Otherwise, electric shock or injuries could occur.

Disposal

• Handle the inverter as an industrial waste when disposing of it.

Otherwise injuries could occur.

Others

• Never attempt to modify the inverter.

Doing so could cause electric shock or injuries.

Drawings in this manual may be illustrated without covers or safety shields for explanation of detail parts.

Restore the covers and shields in the original state and observe the description in the manual before

starting operation.

GENERAL PRECAUTIONS

iv

Page 7

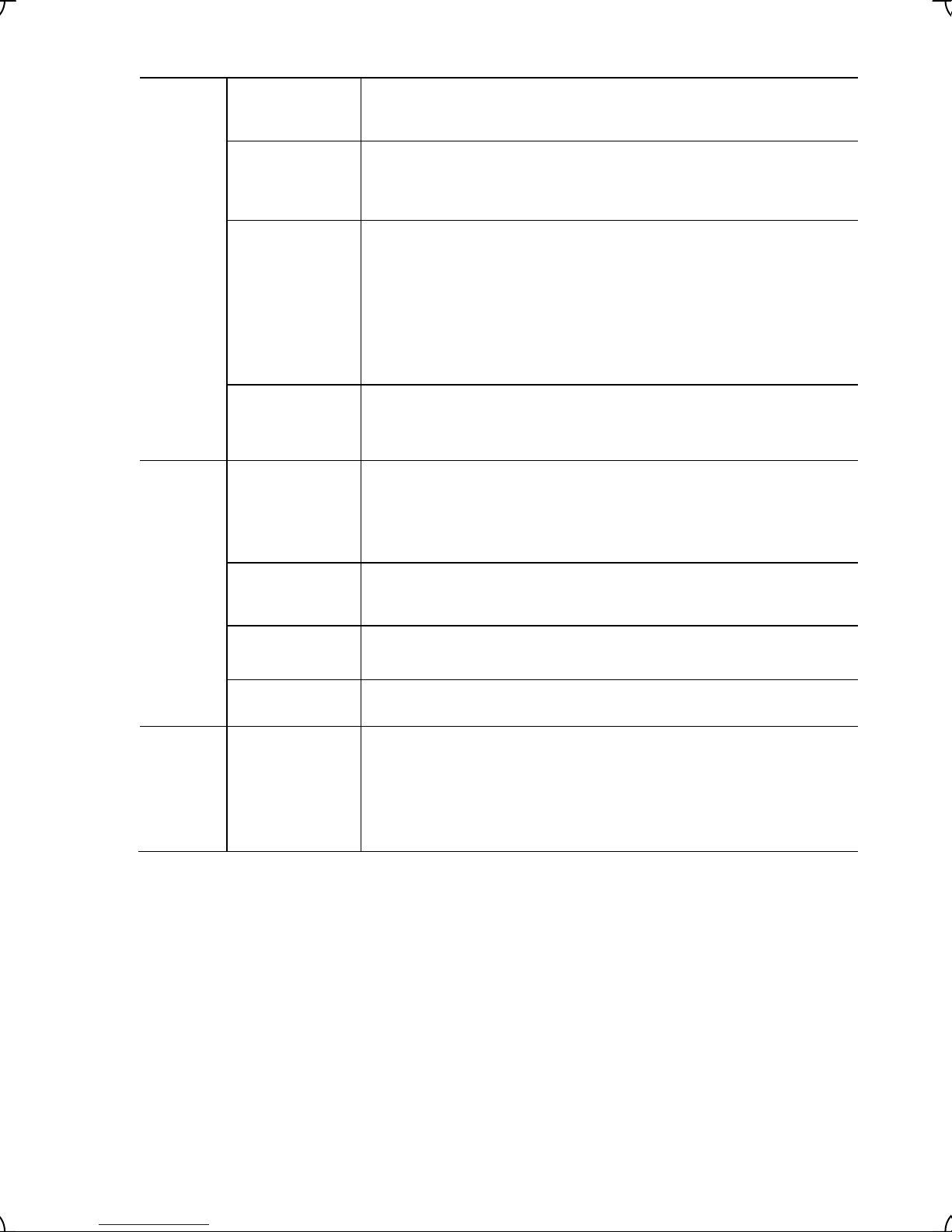

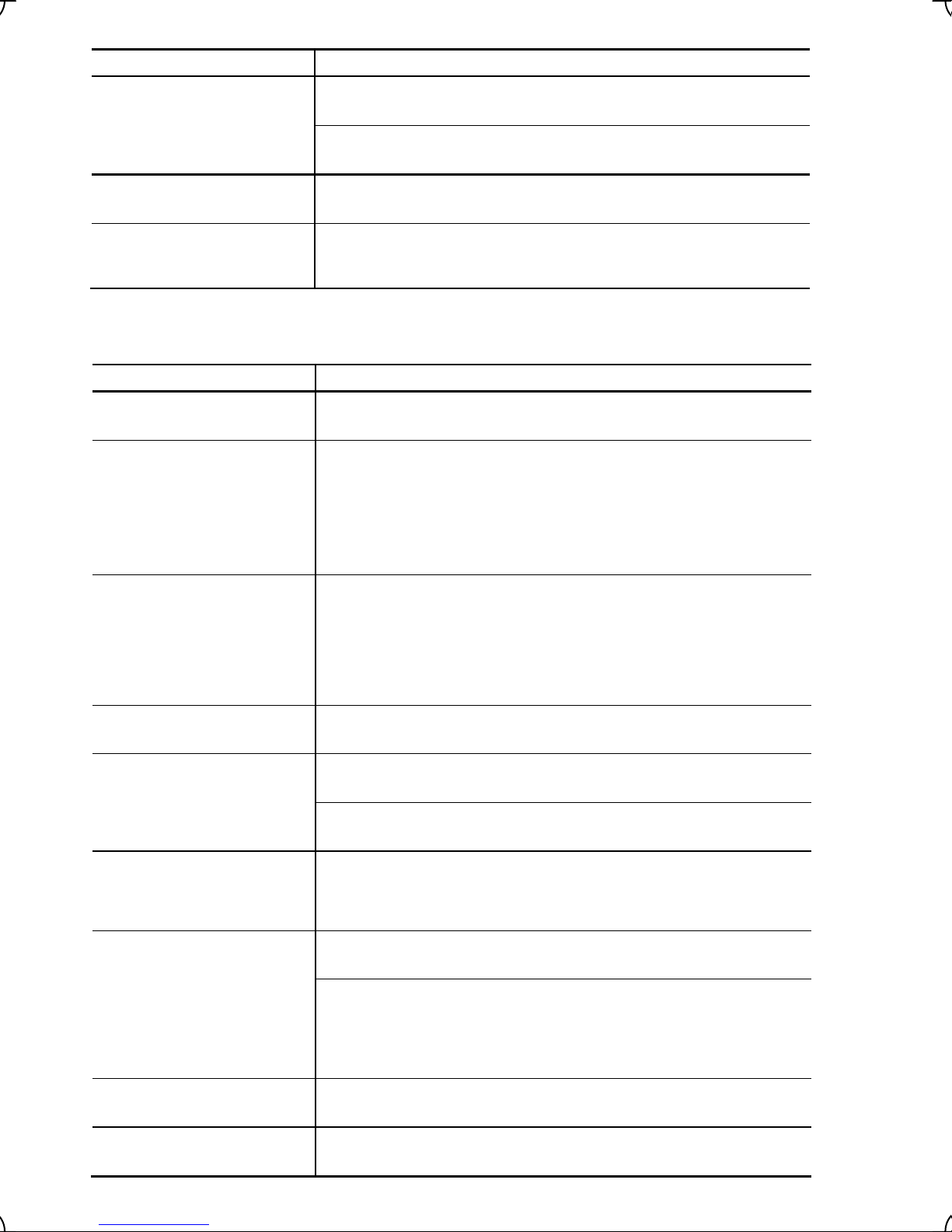

Precautions for use

In running

generalpurpose

motors

In running

special motors

Driving a 400V

general-purpose

motor

Torque characteristics and temperature rise

Vibration

Noise

Brake motors

Geared motors

When driving a 400V general-purpose motor with an inverter using extremely long wires, damage to the insulation of the motor may occur. Apply

the inverter after consulting the motor maker.

When the inverter is used to run a general-purpose motor, the temperature

of the motor becomes higher than when it is operated using a commercial

power supply. In the low-speed range, the cooling effect will be weakened,

so decrease the output torque of the motor.

When an inverter-driven motor is mounted to a machine, resonance may

be caused by the natural frequencies of the machine system.

Note that operation of a 2-pole motor at 60 Hz or higher may cause abnormal vibration.

* The use of a rubber coupling or vibration dampening rubber is recom-

mended.

* Run your machinery including FRENIC-Lift inverter so as to skip its re-

sonance frequency zone/s.

When an inverter is used with a general-purpose motor, the motor noise

level is higher than that with a commercial power supply. To reduce noise,

raise carrier frequency of the inverter. Operation at 60 Hz or higher can

also result in higher noise level.

For motors equipped with parallel-connected brakes, their braking power

must be supplied from the primary circuit. If the brake power is connected

to the inverter's output circuit by mistake, the brake will not work.

Do not use inverters for driving motors equipped with series-connected

brakes.

If the power transmission mechanism uses an oil-lubricated gearbox or

speed changer/reducer, then continuous motor operation at low speed

may cause poor lubrication. Avoid such operation.

Environmental conditions

Synchronous motors

Single-phase

motors

Installation location

The PG interface card (option) corresponding to the pulse encoder specfication is necessary. Read PG interface card (option) manual.

Single-phase motors are not suitable for inverter-driven variable speed

operation. Use three-phase motors.

Use the inverter within the ambient temperature range from -10 to +45°C.

The heat sink and braking resistor of the inverter may become hot under

certain operating conditions, so install the inverter on nonflammable material such as metal.

Ensure that the installation location meets the environmental conditions

specified in Chapter 2, Section 2.1 "Operating Environment."

v

Page 8

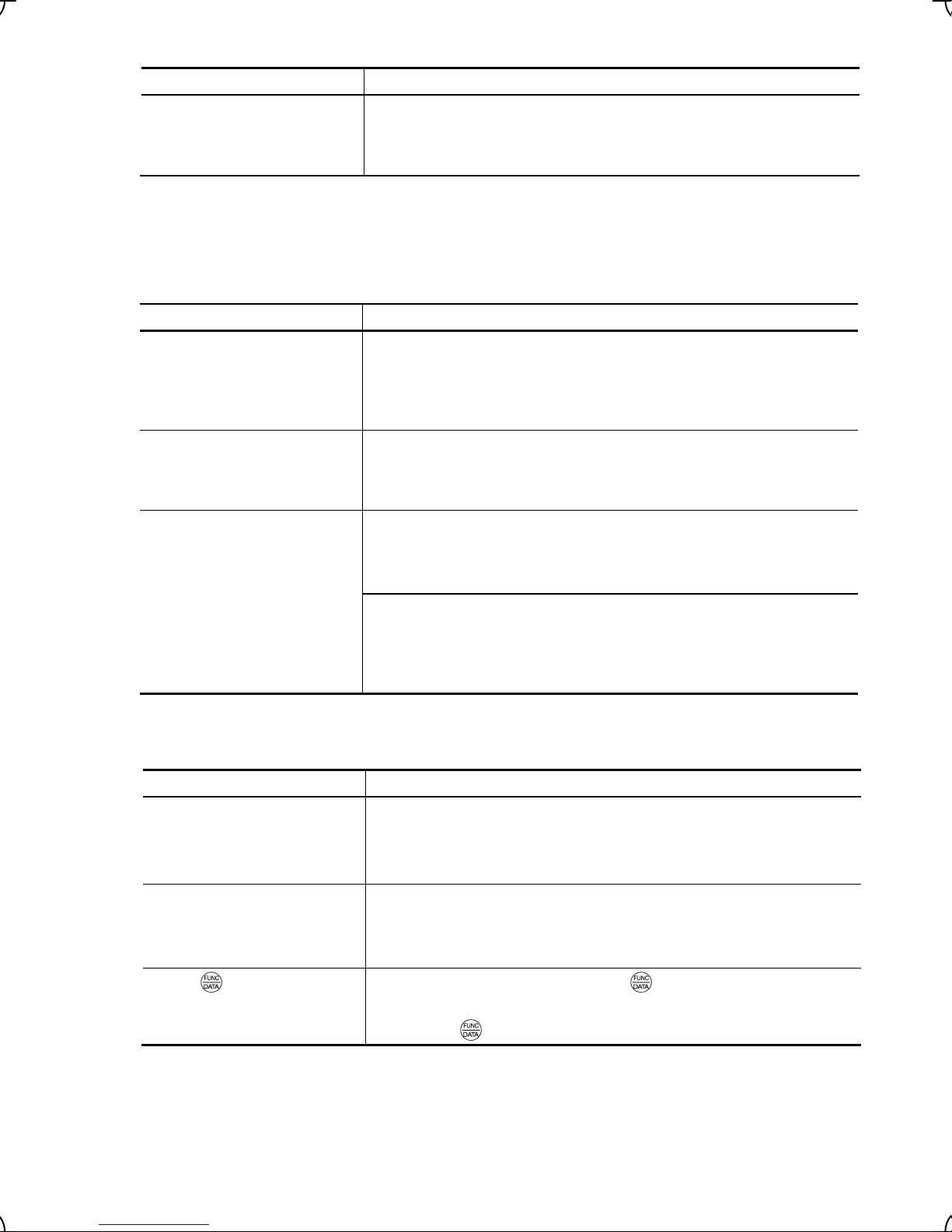

Install a recommended molded case circuit breaker (MCCB) or resi-

Installing an

MCCB or

RCD/ELCB

dual-current-operated protective device (RCD)/earth leakage circuit

breaker (ELCB) (with overcurrent protection) in the primary circuit of the

inverter to protect the wiring. Ensure that the circuit breaker capacity is

equivalent to or lower than the recommended capacity.

Combination with

peripheral

devices

Installing an MC

in the secondary

circuit

Installing an MC

in the primary

circuit

Protecting the

motor

Discontinuance

of power-factor

correcting capacitor

Discontinuance

of surge killer

Reducing noise

If a magnetic contactor (MC) is mounted in the inverter's output (secondary) circuit, ensure that both the inverter and the motor are completely

stopped before you turn the MC on or off.

Remove a surge killer built-in the MC.

Do not turn the magnetic contactor (MC) in the primary circuit ON or OFF

more than once an hour as an inverter failure may result.

If frequent starts or stops are required during motor operation, use FWD /

REV signals.

The electronic thermal function of the inverter can protect the motor. The

operation level and the motor type (general-purpose motor, inverter motor)

should be set. For high-speed motors or water-cooled motors, set a small

value for the thermal time constant and protect the motor.

If you connect the motor thermal relay to the motor with a long wire, a

high-frequency current may flow into the wiring stray capacitance. This

may cause the relay to trip at a current lower than the set value for the

thermal relay. If this happens, lower the carrier frequency.

Do not mount power-factor correcting capacitors in the inverter’s primary

circuit. (Use the DC reactor to improve the inverter power factor.) Do not

use power-factor correcting capacitors in the inverter’s output (secondary)

circuit. An overcurrent trip will occur, disabling motor operation.

Do not connect a surge killer to the inverter's output (secondary) circuit.

Use of a filter and shielded wires is typically recommended to satisfy EMC

Directives.

Wiring

If an overvoltage trip occurs while the inverter is stopped or operated under

Measures against

surge currents

a light load, it is assumed that the surge current is generated by open/close

of the phase-advancing capacitor in the power system.

* Connect a DC reactor to the inverter.

When checking the insulation resistance of the inverter, use a 500 V

Megger test

megger and follow the instructions contained in Chapter 7, Section 7.5

"Insulation Test."

Control circuit

wiring length

When using remote control, limit the wiring length between the inverter and

operator box to 20 m or less and use twisted pair or shielded wire.

If long wiring is used between the inverter and the motor, the inverter will

Wiring length

between inverter

and motor

overheat or trip as a result of overcurrent (high-frequency current flowing

into the stray capacitance) in the wires connected to the phases. Ensure

that the wiring is shorter than 20 m. If this length must be exceeded, lower

the carrier frequency.

Wiring size

Wiring type

Select wires with a sufficient capacity by referring to the current value or

recommended wire size.

When several inverters drive motors, do not use one multicore cable in

order to connect several inverters with motors.

Grounding Securely ground the inverter using the grounding terminal.

vi

Page 9

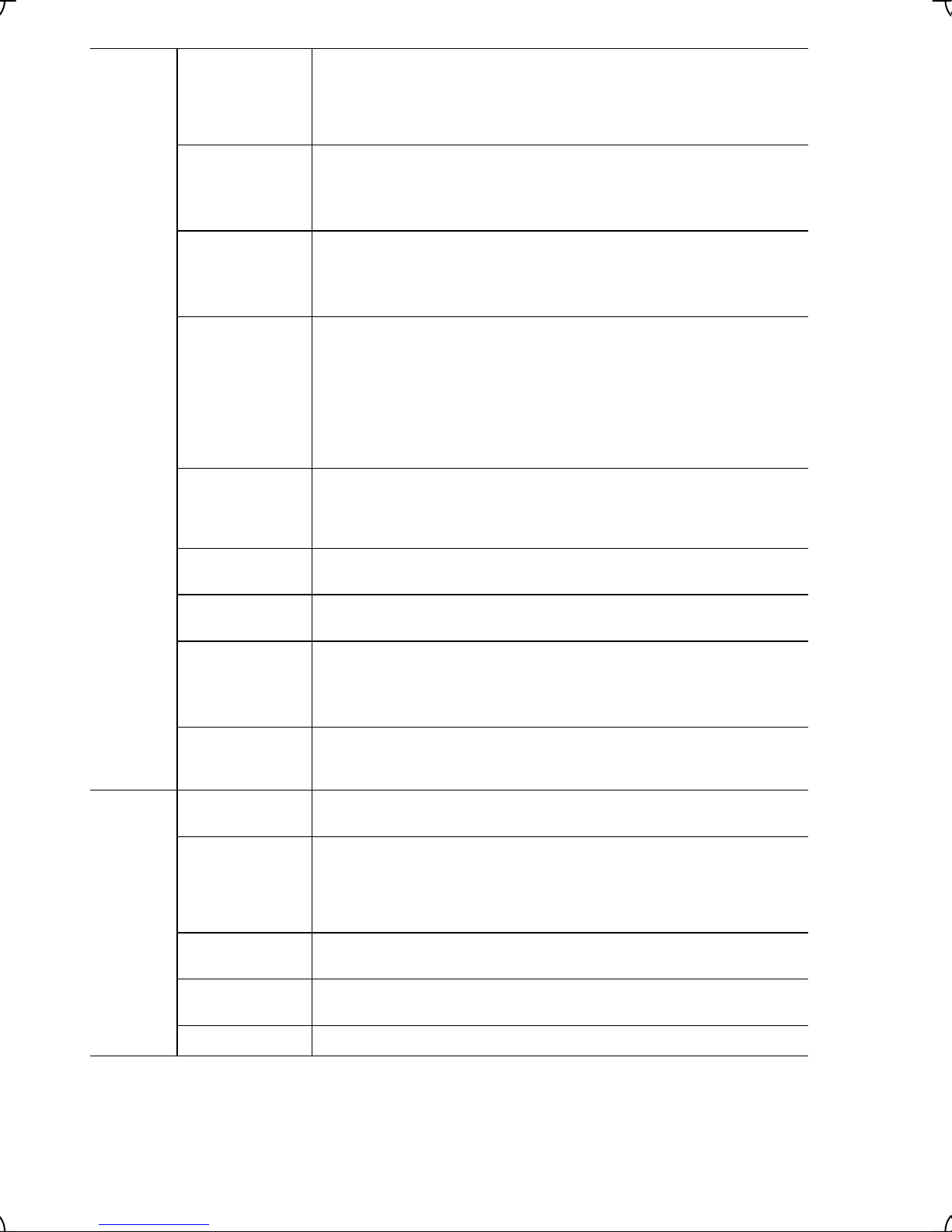

Selecting

inverter

capacity

Transportation and

storage

Select an inverter according to the applicable motor ratings listed in the

Driving general-purpose motor

standard specifications table for the inverter.

When high starting torque is required or quick acceleration or deceleration

is required, select an inverter with a capacity one size greater than the

standard.

Driving special

motors

Select an inverter that meets the following condition:

Inverter rated current > Motor rated current

Halogen compounds such as methyl bromide used in fumigation corrodes some parts inside the

inverter. When exporting an inverter built in a panel or equipment, pack them in a previously

fumigated wooden crate. When packing an inverter alone for export, use a laminated veneer

lumber (LVL).

When transporting or storing inverters, follow the procedures and select locations that meet the

environmental conditions listed in Chapter 1, Section 1.3 "Transportation" and Section 1.4

"Storage Environment."

vii

Page 10

How this manual is organized

This manual is made up of chapters 1 through 9.

Chapter 1 BEFORE USING THE INVERTER

This chapter describes acceptance inspection and precautions for transportation and storage of the inverter.

Chapter 2 MOUNTING AND WIRING OF THE INVERTER

This chapter provides operating environment, precautions for installing the inverter, wiring instructions for the

motor and inverter.

Chapter 3 OPERATION USING THE KEYPAD

The FRENIC-Lift has no standard keypad. Operating the FRENIC-Lift from a keypad requires an optional multi-function keypad. For details in operations, refer to the Multi-function Keypad "TP-G1-CLS" Instruction Manual

(INR-S147-1092-E).

Chapter 4 RUNNING THE MOTOR

This chapter describes preparation to be made before running the motor for a test and practical operation.

Chapter 5 FUNCTION CODES

This chapter provides a list of the function codes. For details of function codes, refer to the FRENIC-Lift Reference Manual (INR-S147-1068-E.)

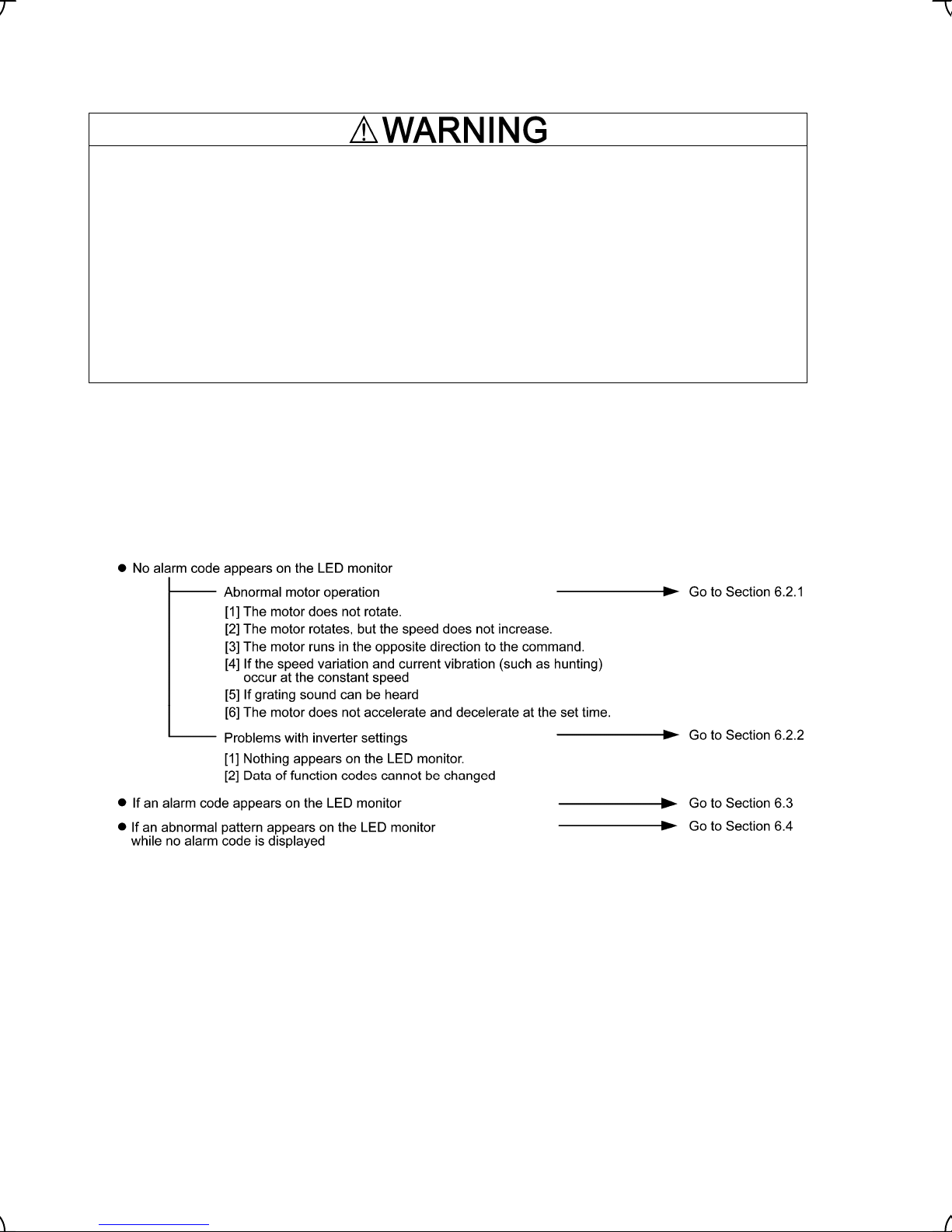

Chapter 6 TROUBLESHOOTING

This chapter describes troubleshooting procedures to be followed when the inverter malfunctions or detects an

alarm condition. In this chapter, first check whether any alarm code is displayed or not, and then proceed to the

troubleshooting items.

Chapter 7 MAINTENANCE AND INSPECTION

This chapter describes inspection, measurement and insulation test which are required for safe inverter operation.

It also provides information about periodical replacement parts and guarantee of the product.

Chapter 8 SPECIFICATIONS

This chapter lists specifications including output ratings, control system, external dimensions and protective

functions.

Chapter 9 LIST OF PERIPHERAL EQUIPMENT AND OPTIONS

This chapter describes main peripheral equipment and options which can be connected to the FRENIC-Lift series

of inverters.

Icons

The following icons are used throughout this manual.

This icon indicates information which, if not heeded, can result in the inverter not operating to full efficiency, as well as information concerning incorrect operations and settings which can result in accidents.

This icon indicates information that can prove handy when performing certain settings or operations.

This icon indicates a reference to more detailed information.

viii

Page 11

Table of Contents

Preface ................................................................... i

Safety precautions ............................................................. i

Precautions for use ........................................................... v

How this manual is organized .............................................viii

Chapter 1 BEFORE USING THE INVERTER .................. 1-1

1.1 Acceptance Inspection ........................................... 1-1

1.2 External View and Terminal Blocks ......................... 1-2

1.3 Transportation ........................................................ 1-4

1.4 Storage Environment .............................................. 1-4

1.4.1 Temporary storage ......................................... 1-4

1.4.2 Long-term storage ......................................... 1-4

Chapter 2 MOUNTING AND WIRING OF

2.1 Operating Environment .......................................... 2-1

2.2 Installing the Inverter .............................................. 2-1

2.3 Wiring ..................................................................... 2-5

2.4 Cautions Relating to Harmonic Component, Noise,

Chapter 3 OPERATION USING THE KEYPAD ............... 3-1

Chapter 4 RUNNING THE MOTOR ................................. 4-1

4.1 Running the Motor for a Test .................................. 4-1

4.2 Operation................................................................ 4-5

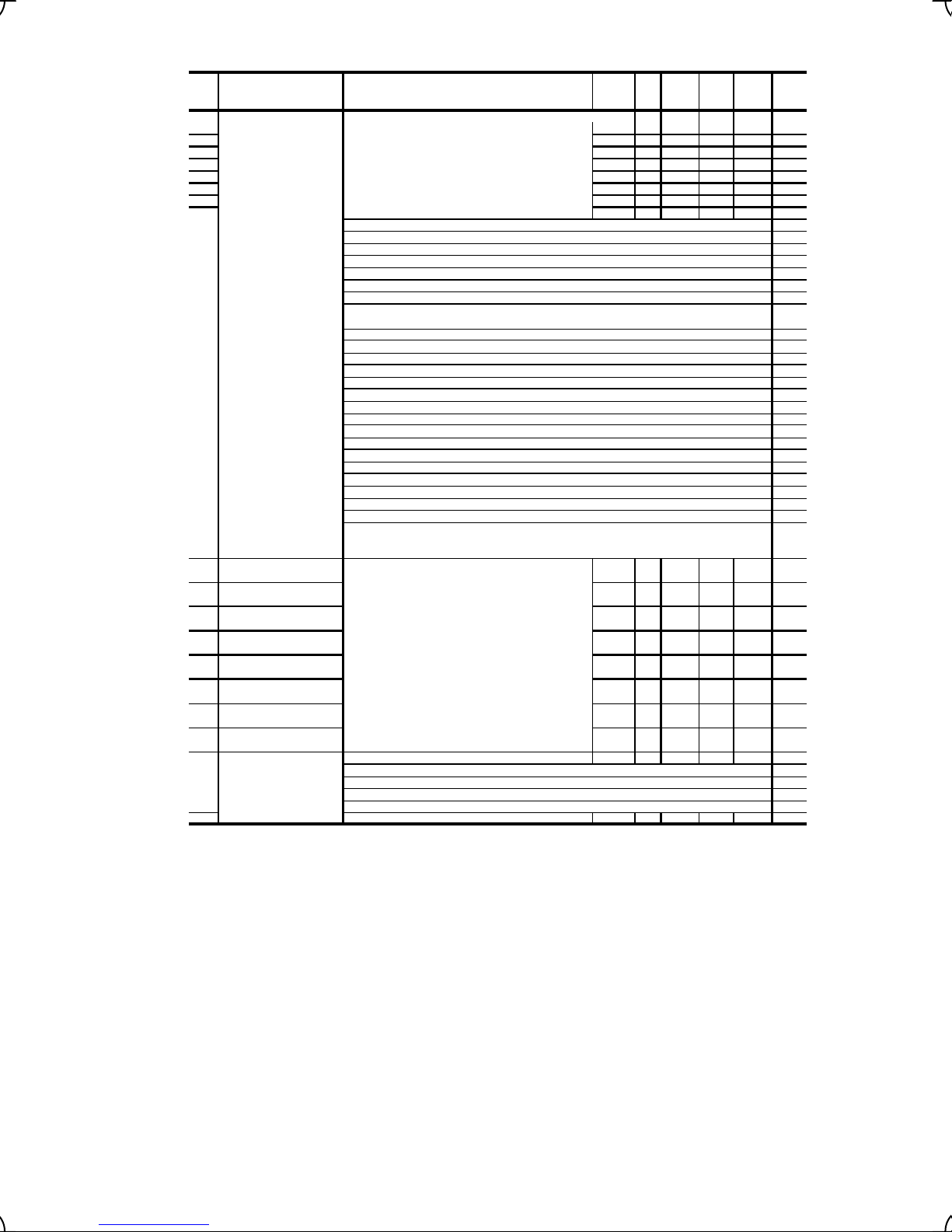

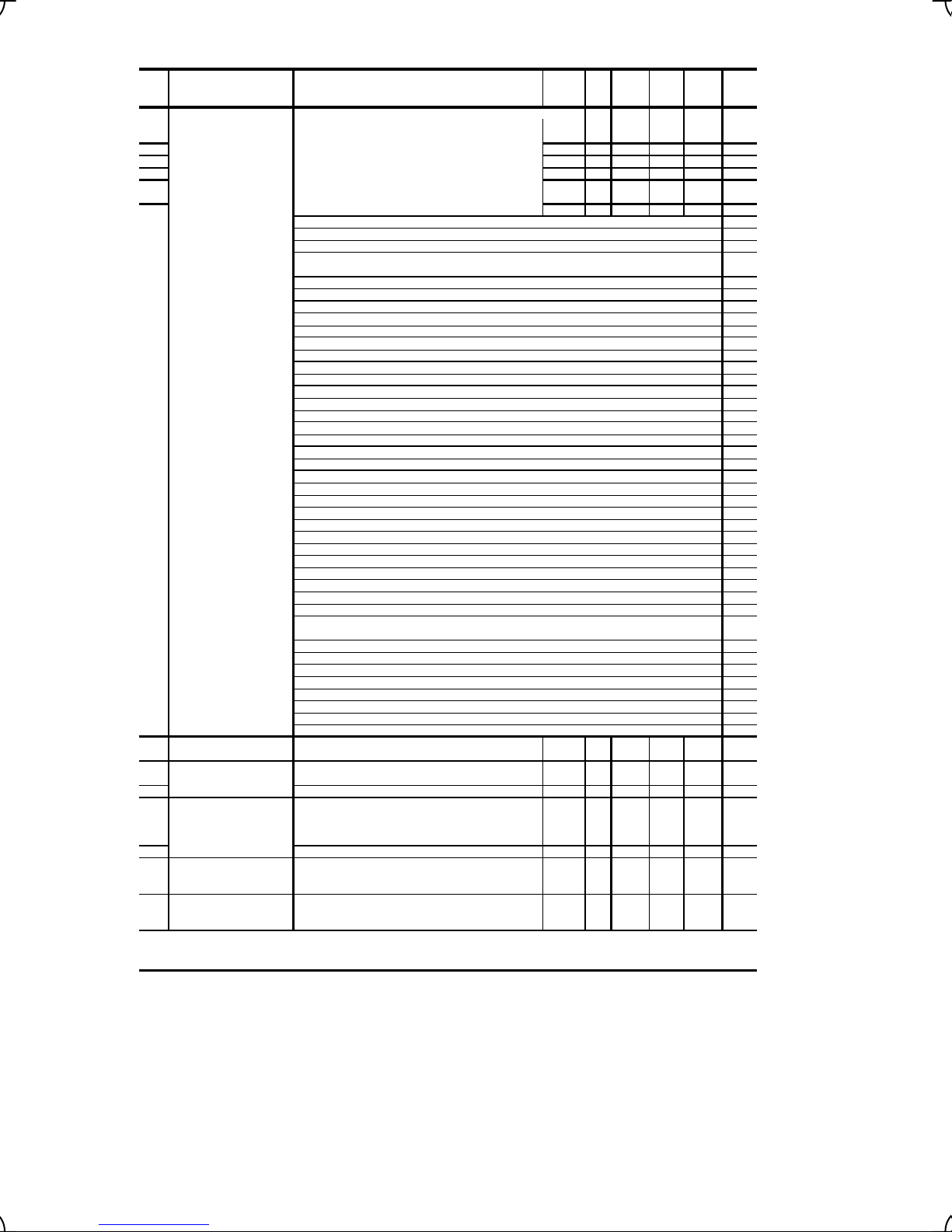

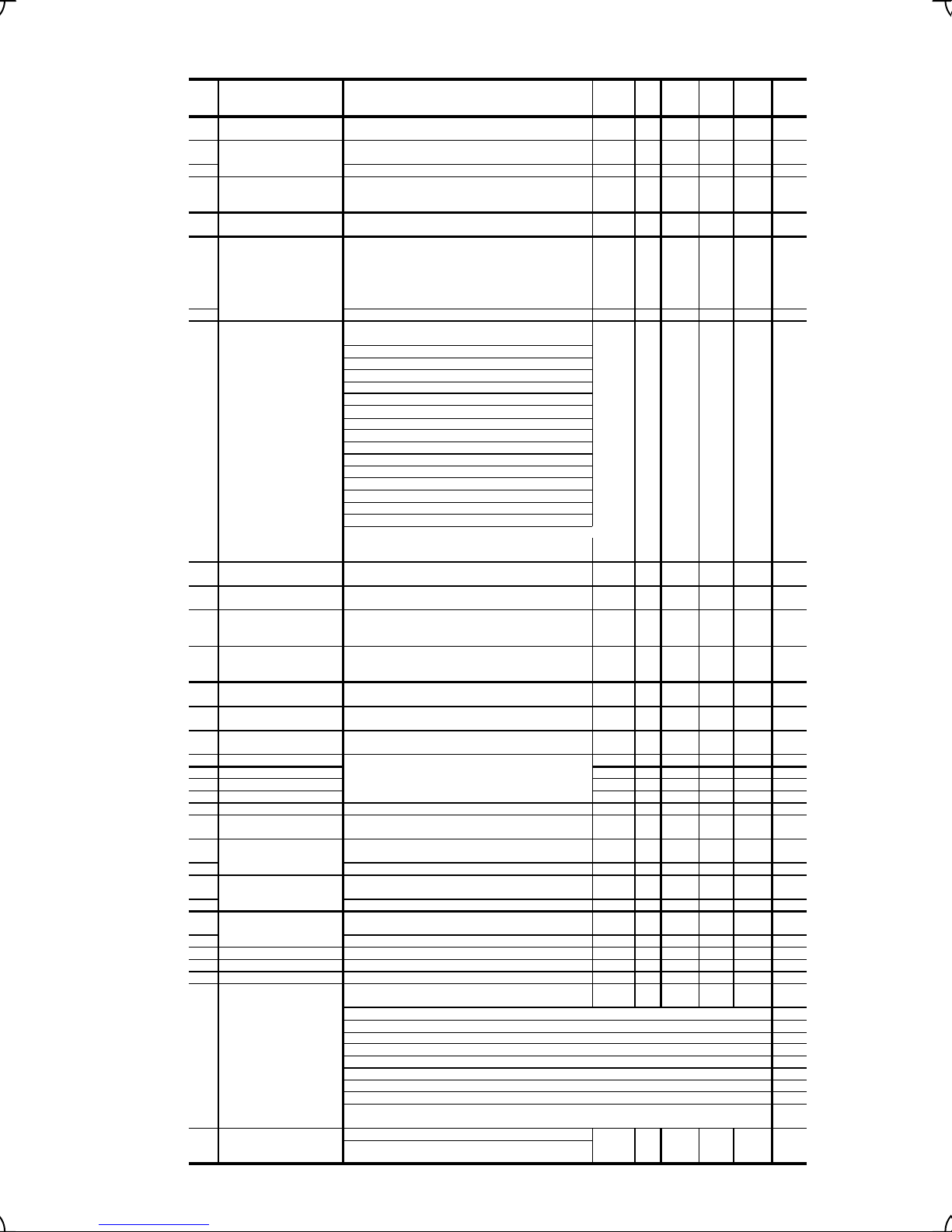

Chapter 5 FUNCTION CODES ........................................ 5-1

5.1 Function Code Tables ............................................. 5-1

THE INVERTER ............................................. 2-1

2.3.1 Removing and mounting the terminal block

(TB) cover and the front cover ....................... 2-5

2.3.2 Removing and retracting

the cable guide plate ...................................... 2-8

2.3.3 Terminal arrangement and

screw specifications ....................................... 2-9

2.3.4 Recommended wire sizes ............................ 2-12

2.3.5 Wiring precautions ....................................... 2-13

2.3.6 Wiring for main circuit terminals and

grounding terminals ..................................... 2-13

2.3.7 Wiring for control circuit terminals ................ 2-18

2.3.8 Setting up slide switches ............................. 2-27

and Leakage Current ............................................ 2-28

4.1.1 Inspection and preparation prior to

powering on ................................................... 4-1

4.1.2 Turning ON power and checking.................... 4-1

4.1.3 Preparation before running the motor

for a test--Setting function code data ............. 4-2

4.1.4 Test run .......................................................... 4-5

Chapter 6 TROUBLESHOOTING .................................... 6-1

6.1 Before Proceeding with Troubleshooting ................ 6-1

6.2 If No Alarm Code Appears on the LED Monitor ...... 6-2

6.2.1 Motor is running abnormally ........................... 6-2

6.2.2 Problems with inverter settings ...................... 6-6

6.3 If an Alarm Code Appears on the LED Monitor ....... 6-7

6.4 If an Abnormal Pattern Appears on the LED

Monitor while No Alarm Code is Displayed ........... 6-20

Chapter 7 MAINTENANCE AND INSPECTION ............... 7-1

7.1 Daily Inspection ...................................................... 7-1

7.2 Periodic Inspection ................................................. 7-1

7.3 List of Periodical Replacement Parts ...................... 7-3

7.3.1 Judgment on service life ................................ 7-3

7.4 Measurement of Electrical Amounts in

Main Circuit ............................................................ 7-5

7.5 Insulation Test ........................................................ 7-6

7.6 Inquiries about Product and Guarantee .................. 7-7

Chapter 8 SPECIFICATIONS .......................................... 8-1

8.1 Standard Models......................................................8-1

8.1.1Three-phase 200 V class series…………………8-1

8.1.2Three-phase 400 V class series…………………8-2

8.1.3Single-phase 200 V class series………………...8-3

8.2Common Specifications………………………………..8-4

8.3Terminal Specifications…………………………………8-5

8.3.1Terminal functions …………………………….8-5

8.3.2Basic wiring diagram …………………………….8-5

8.4External Dimensions…………………………………..8-7

8.4.1Standard models…………………………………8-7

8.5Protection Features………………………………….8-10

Chapter 9 LIST OF PERIPHERAL EQUIPMENT AND

OPTIONS ........................................................ 9-1

ix

Page 12

Chapter 1 BEFORE USING THE INVERTER

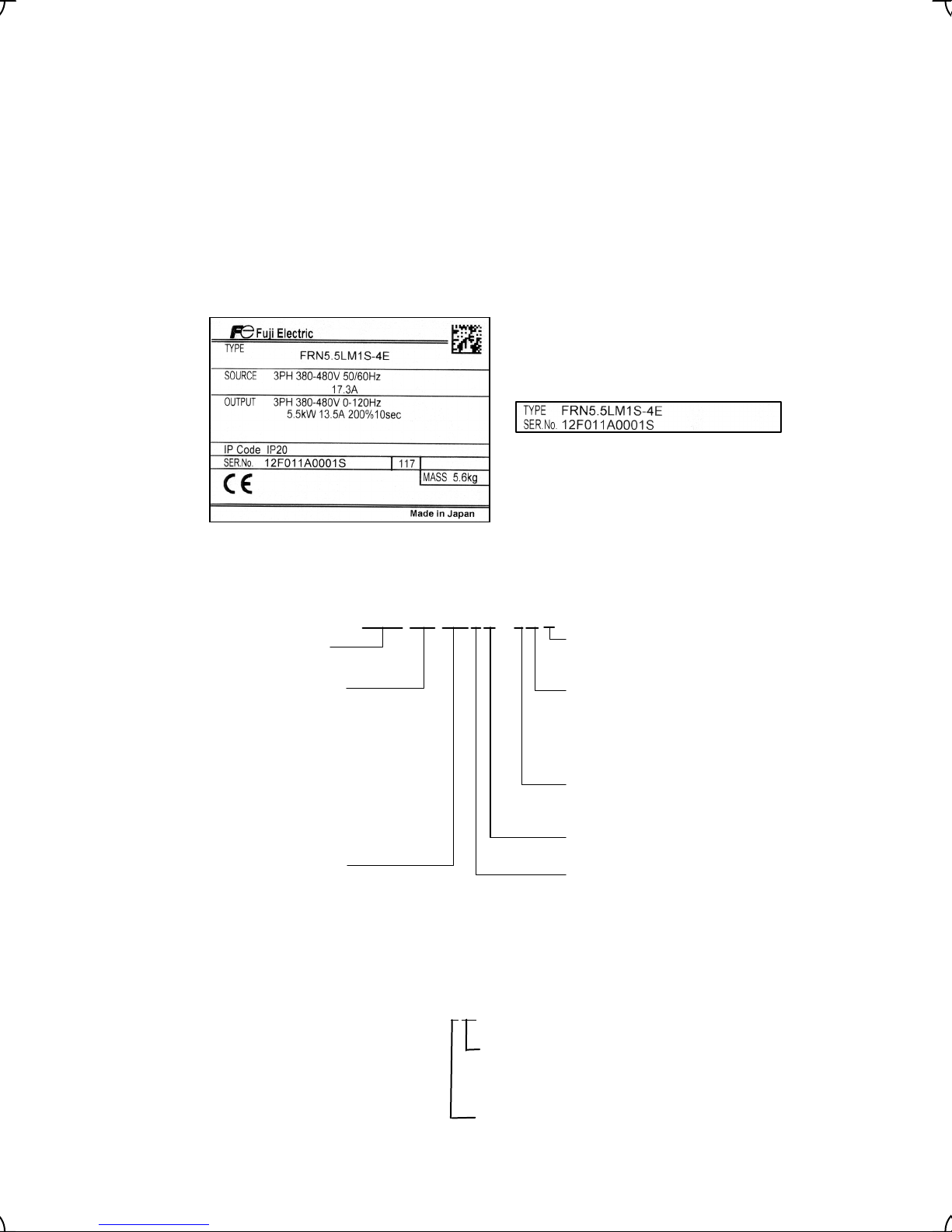

1.1 Acceptance Inspection

Unpack the package and check that:

(1) An inverter and accessories below are contained in the package.

• Cooling fan mounting screws (5.5 to 22 kW)

• Rubber bushes for cable guide plate (5.5 to 22 kW)

• Encoder wiring plug

(2) The inverter has not been damaged during transportation—there should be no dents or parts missing.

(3) The inverter is the model you ordered. You can check the model name and specifications on the main

nameplate. (Main and sub nameplates are attached to the inverter and are located as shown on the following

page.) For the inverter whose capacity is 37 kW or above, the mass of that is printed on the nameplate.

(a) Main Nameplate (b) Sub Nameplate

Figure 1.1 Nameplates

TYPE: Inverter model

F R N 5. 5 L M 1 S - 4 C

Code Series name

FRN FRENIC series

Code Nominal applied

motor

4.0 3.7 kW

5.5 5.5 kW

7.5 7.5 kW

11 11 kW

15 15 kW

18.5 18.5 kW

22 22 kW

30 30 kW

37 37 kW

45 45 kW

Code Applicable area

LM Elevating machinery

Code CAN port

With CAN port

(blank)

Without CAN port

A

Code Shipping destination/

Instruction manual version

C China/Chinese

E EU/English

A Asia/English

J Japan/Japanese

Code Power supply voltage

4 Three-phase 400 V

2 Three-phase 200 V

Code Enclosure

S Standard (IP20/IP00)

Code Development code

1 1

SOURCE: Number of input phases (three-phase: 3PH), input voltage, input frequency, input current

OUTPUT: Number of output phases, rated output capacity, rated output voltage, output frequency range, rated

output current, overload capacity

SER. No.: Product number manufacturing date

1 2 F 0 1 1 A 0 0 0 1 S 1 17

Production week

This indicates the week number that is numbered

from 1st week of January.

The 1st week of January is indicated as '01'.

Production year: Last digit of year

If you suspect the product is not working properly or if you have any questions about your product, contact your

Fuji Electric representative.

1-1

Page 13

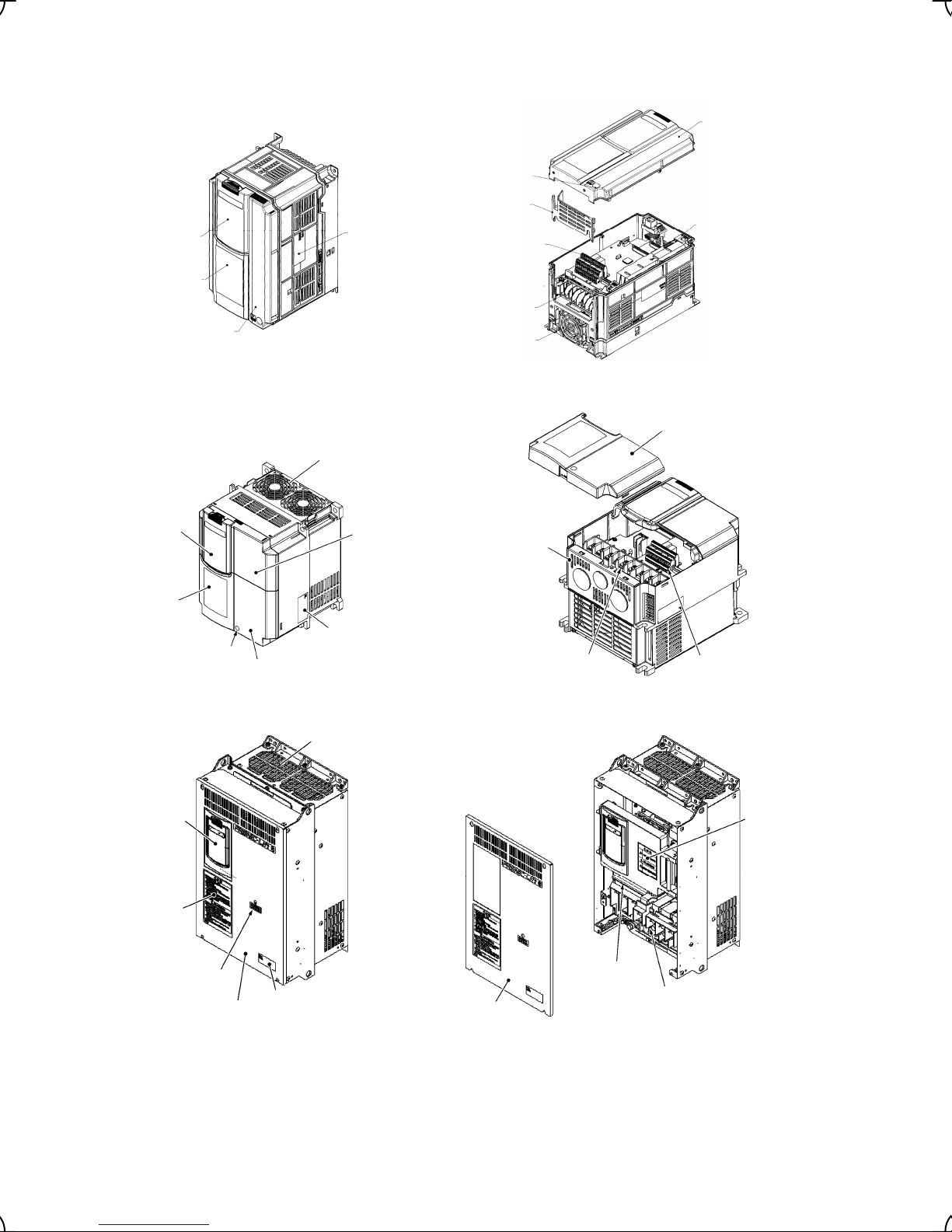

1.2 External View and Terminal Blocks

(1) Outside and terminal block views

Dummy cover

Warning plate

Front cover

Main nameplate

(a) FRN2.2LM1S-7. FRN4.0LM1S-4

Cooling fans

Front cover

Screw

Wiring guide

Sub nameplate

Control circuit

terminal block

Main circuit

terminal block

Cooling fans

Terminal block cover

Dummy cover

Warning plate

Dummy cover

Warning plate

Charging lamp

Note: A box (

Screw

Front cover

Main nameplate

Terminal block cover

Cable guide plate

Main circuit

terminal block

(b) FRN15LM1S-4

Front cover

Cooling fans

Main nameplate

Control circuit

terminal block

Front cover

(c) FRN30LM1S-4

Figure 1.2 Outside and Terminal Block Views of Inverters

) in the above figure replaces C, E, A or J depending on the shipping destination.

Control circuit

terminal block

Main circuit terminal block

Warning

plate

1-2

Page 14

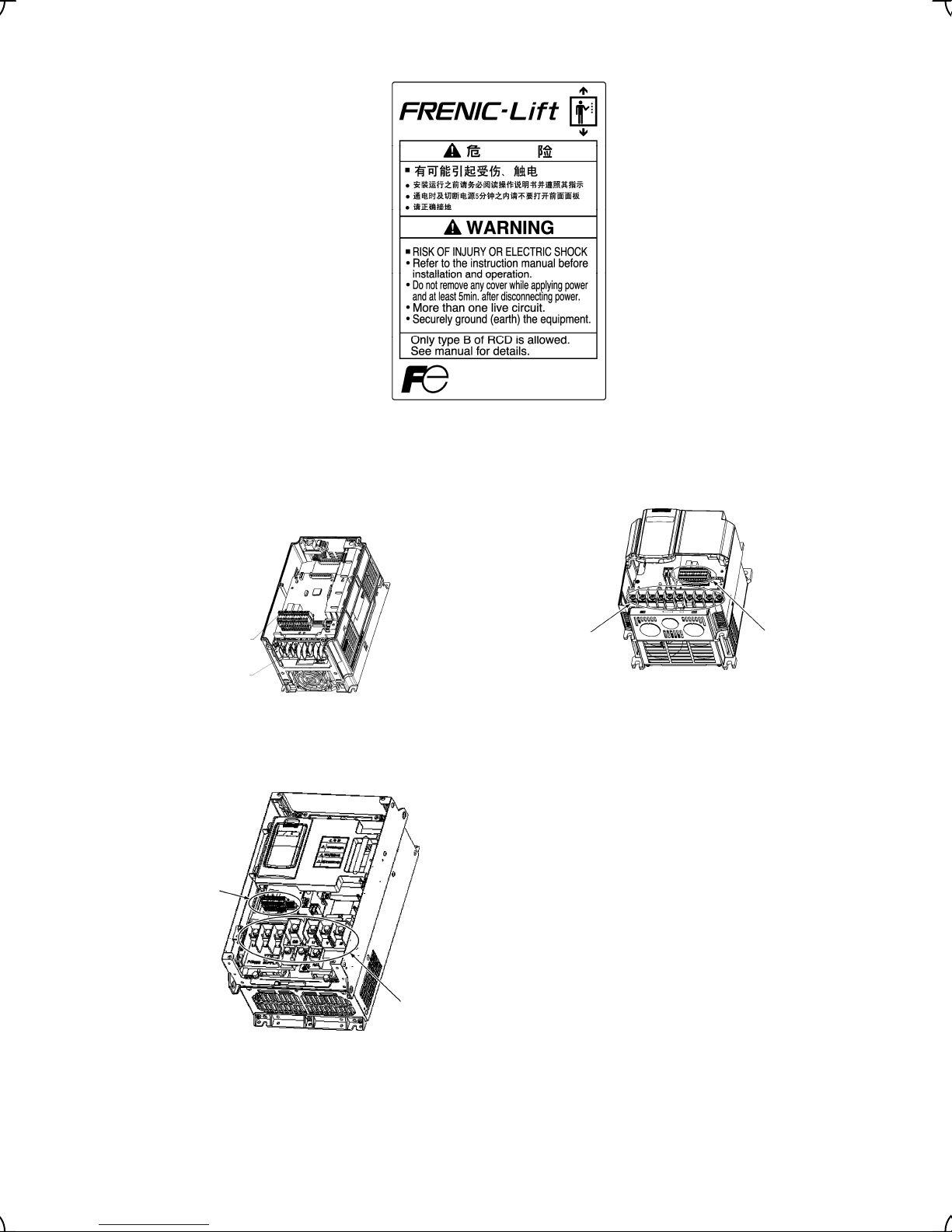

(2) Warning plates

(3) Terminal block location

Figure 1.3 Warning Plates

Control circuit

terminal block

Main circuit

terminal block

(a) FRN2.2LM1S-7, FRN4.0LM1S-4 (b) FRN15LM1S-4

Control circuit

terminal block

Note: A box (

Main circuit

terminal block

Control circuit

terminal block

Main circuit

terminal block

(c) FRN30LM1S-4

Figure 1.4 Main and Control Circuit Terminal Block Location

) in the above figure replaces C, E, A or J depending on the shipping destination.

1-3

Page 15

1.3 Transportation

• When carrying an inverter, always support its bottom at the front and rear sides with both hands. Do not hold

covers or individual parts only. You may drop the inverter or break it.

1.4 Storage Environment

1.4.1 Temporary storage

Store the inverter in an environment that satisfies the requirements listed in Table 1.1.

Table 1.1 Environmental Requirements for Storage and Transportation

Item Requirements

Storage temperature *1 -25 to +65°C

Relative humidity 5 to 95% *2

Atmosphere The inverter must not be exposed to dust, direct sunlight, corrosive or flammable gases,

oil mist, vapor, water drops or vibration. The atmosphere must contain only a low level of

salt. (0.01 mg/cm

Atmospheric pressure 86 to 106 kPa (in storage)

70 to 106 kPa (during transportation)

1

*

Assuming a comparatively short storage period (e.g., during transportation or the like).

2

*

Even if the humidity is within the specified requirements, avoid such places where the inverter will be subjected to

sudden changes in temperature that will cause condensation to form.

Precautions for temporary storage

A location where the inverter is not subject to abrupt changes in

temperature that would result in the formation of condensation or ice.

2

or less per year)

(1) Do not leave the inverter directly on the floor.

(2) If the environment does not satisfy the specified requirements, wrap the inverter in an airtight vinyl sheet or

the like for storage.

(3) If the inverter is to be stored in an environment with a high level of humidity, put a drying agent (such as silica

gel) in the airtight package described in item (2).

1.4.2 Long-term storage

The long-term storage methods for the inverter vary largely according to the environment of the storage site.

General storage methods are described below.

(1) The storage site must satisfy the requirements specified for temporary storage.

However, for storage exceeding three months, the ambient temperature should be within the range from -10

to +30 °C. This is to prevent the electrolytic capacitors in the inverter from deteriorating.

(2) The inverter must be stored in a package that is airtight to protect it from moisture. Include a drying agent

inside the package to maintain the relative humidity inside the package to within 70%.

(3) If the inverter has been installed in the equipment or control board at a construction site where it may be

subjected to humidity, dust or dirt, then remove the inverter and store it in a suitable environment specified in

Table 1.1.

Precautions for storage over 1 year

If the inverter will not be powered on for a long time, the property of the electrolytic capacitors may deteriorate.

Power the inverters on once a year and keep them on for 30 to 60 minutes. Do not connect the inverters to motors

or run the motor.

1-4

Page 16

r

y

Chapter 2 MOUNTING AND WIRING OF THE INVERTER

2.1 Operating Environment

Install the inverter in an environment that satisfies the requirements listed in Table 2.1.

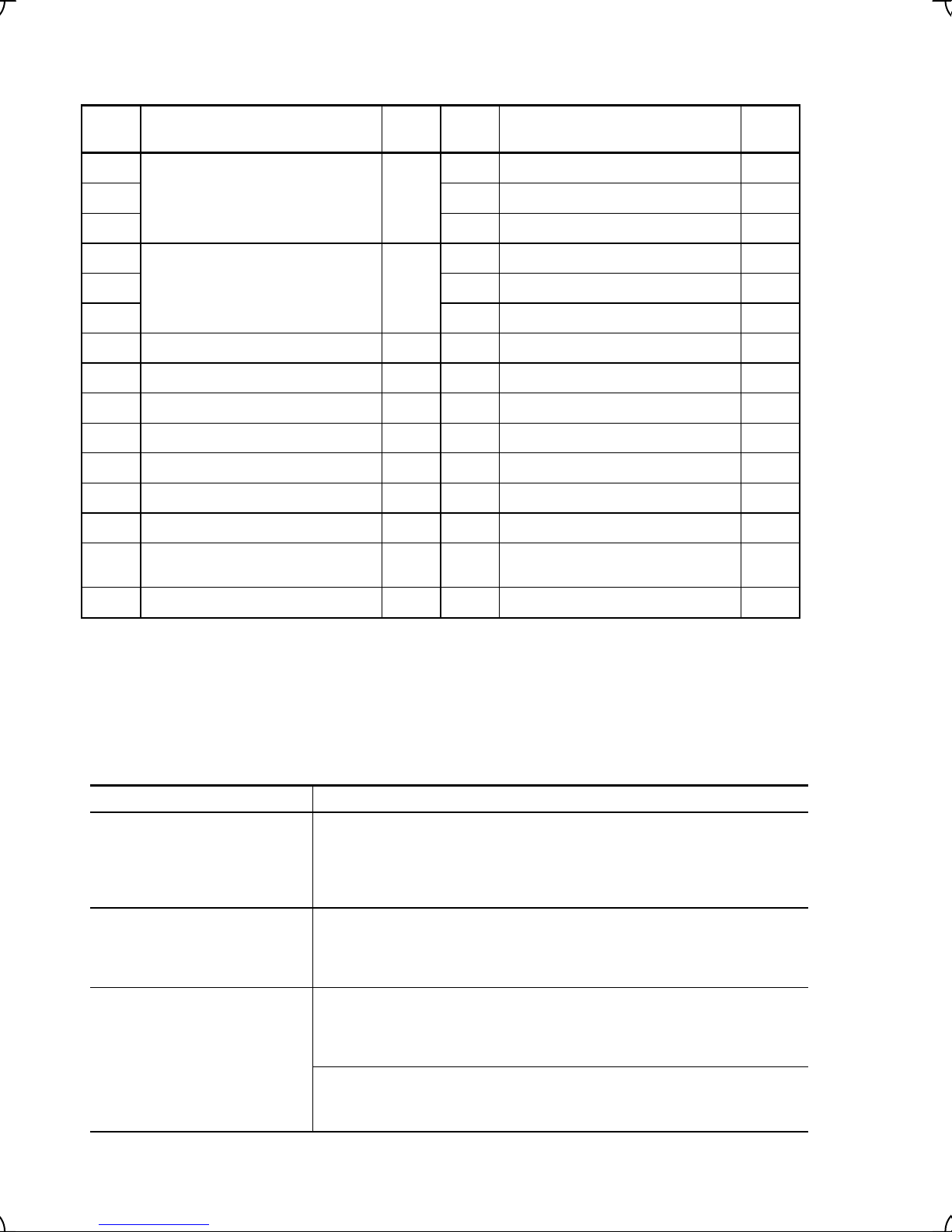

Table 2.1 Environmental Requirements

Item Specifications

Site location Indoors

Table 2.2 Output Current Derating Factor in

Relation to Altitude

Altitude

Output current

derating factor

Ambient

temperature

Relative

humidity

Atmosphere The inverter must not be exposed to dust, direct

Altitude 1,000 m max. (Note 2)

Atmospheric

pressure

Vibration

-10 to +45°C

5 to 95% (No condensation)

sunlight, corrosive gases, flammable gas, oil mist,

vapor or water drops. (Note 1)

The atmosphere must contain only a low level of salt.

(0.01 mg/cm

The inverter must not be subjected to sudden

changes in temperature that will cause condensation

to form.

86 to 106 kPa

3 mm (Max. amplitude) 2 to less than 9 Hz

9.8 m/s2 9 to less than 20 Hz

2 m/s2 20 to less than 55 Hz

1 m/s2 55 to less than 200 Hz

2

or less per year)

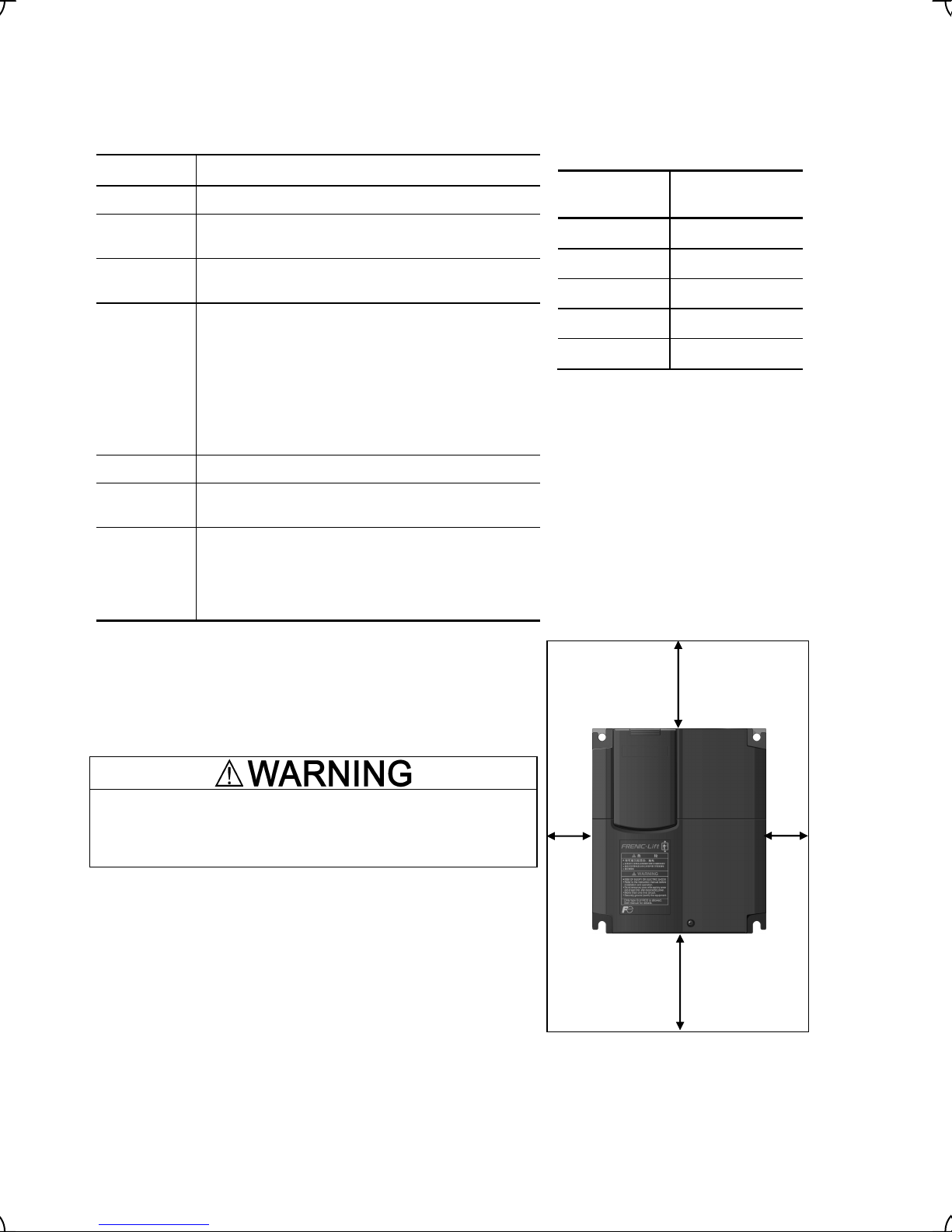

2.2 Installing the Inverter

(1) Mounting base

The temperature of the heat sink will rise up to approx. 90°C during

operation of the inverter, so the inverter should be mounted on a base

made of material that can withstand temperatures of this level.

1000 m or lower 1.00

1000 to 1500 m 0.97

1500 to 2000 m 0.95

2000 to 2500 m 0.91

2500 to 3000 m 0.88

(Note 1) Do not install the inverter in

an environment where it may be

exposed to cotton waste or moist dust

or dirt which will clog the heat sink in the

inverter. If the inverter is to be used in

such an environment, install it in the

enclosure of your system or othe

dustproof containers.

(Note 2) If you use the inverter in an

altitude above 1000 m, you should appl

an output current derating factor as

listed in Table 2.2.

Top 100 mm

Install the inverter on a base constructed from metal or other

non-flammable material.

A fire may result with other material.

(2) Clearances

Ensure that the minimum clearances indicated in Figure 2.1 are

maintained at all times. When installing the inverter in the enclosure

of your system, take extra care with ventilation inside the enclosure

as the temperature around the inverter will tend to increase. Do not

install the inverter in a small enclosure with poor ventilation.

Further,

do not install two or more inverters in single equipment or in

an enclosure.

Right

10 mm

2-1

Left

10 mm

Bottom 100 mm

Figure 2.1 Mounting Direction and

Required Clearances

Page 17

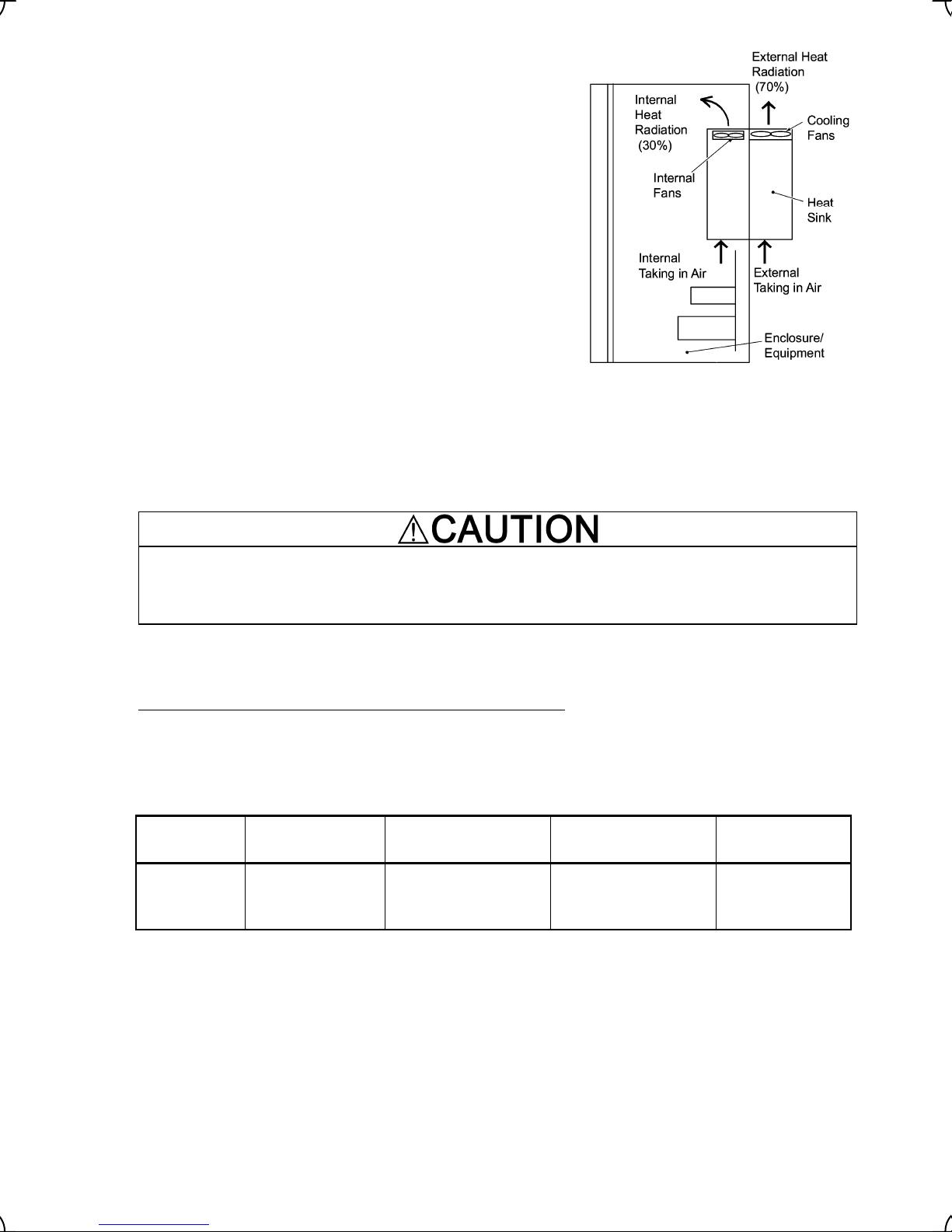

A

When employing external cooling

t the shipment time, the inverter is set up for mount inside your

equipment or enclosure so that cooling is done all internally.

To improve cooling efficiently, you can take the heat sink out of the

equipment or the enclosure (as shown on the right) so that cooling

is done both internally and externally (this is called "external

cooling").

To set up inverters with a capacity of 22 kW or below for "external

cooling," add the optional mounting adapter; to set up ones with a

capacity of 30 kW or above, change the position of the top and

bottom mounting bases as shown below.

For details about the optional mounting adapter, refer to the

Mounting Adapter for External Cooling "PB-F1" Installation

Manual (INR-SI47-0880).

In external cooling, the heat sink, which dissipates about 70% of

the total heat (total loss) generated into air, is situated outside the

equipment or the enclosure. As a result, much less heat is

Figure 2.2 External Cooling

radiated inside the equipment or the enclosure.

In an environment with high humidity or a lot of fibrous dust,

however, do not use external cooling, which tends to clog the heat

sink.

Prevent lint, paper fibers, sawdust, dust, metallic chips, or other foreign materials from getting into the

inverter or from accumulating on the heat sink.

This may result in a fire or accident.

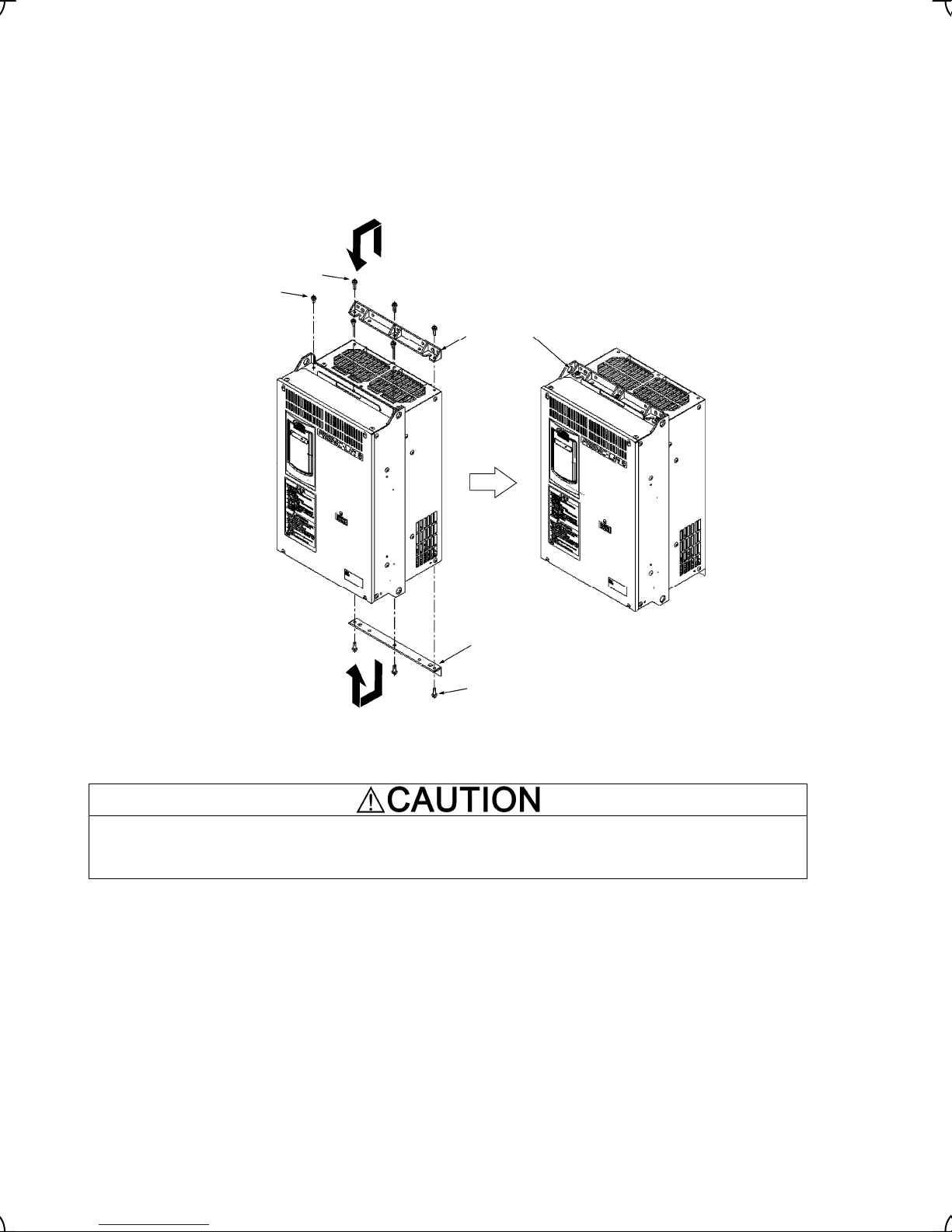

To utilize external cooling for inverters with a capacity of 30 kW

, change the position of the top and bottom

mounting bases from the edge to the center of the inverter as instructed on the next page.

Screws differ in size, length and count for each inverter. Be sure to refer to the table below.

Table 2.3 Screw Count and Tightening Torque

Power supply

voltage

Three-phase

400 V

Note: A box () in the above table replaces C (China), E (EU), A (Asia) or J (Japan) depending on the shipping

destination.

Inverter type

FRN30LM1S-4 to

FRN45LM1S-4

Base fixing screw

(Count)

M6 × 20

(3 pcs each for upper

and lower sides)

2-2

Case fixing screw

(Count)

M6 × 12

(3 pcs for upper side)

Tightening torque

•m)

(N

5.8

Page 18

g

g

1) Remove all of the base fixing screws from the top and bottom of the inverter. Also remove the case fixing

screws from the top. (The case fixing screws are not necessary in external cooling. Store them for future

use. On the bottom are no case fixing screws.)

2) Secure the top mounting base to the center of the inverter with the base fixing screws, using case fixing

screw holes.

3) Secure the bottom mounting base to the center of the inverter with the base fixing screws.

Base fixin

Case fixing screws

screws

Top

mounting

base

Bottom mountin

base

Base fixing screws

Figure 2.3 Relocating the Top and Bottom Mounting Bases

• Please use a specified screw for the change of Bottom mounting base.

Fire or accident could occur.

2-3

Page 19

A

A

(3) Mounting direction

Horizontal layout is recommended when two or more inverters are to be installed in an equipment or enclosure.

As long as the ambient temperature is 40°C or lower, inverters may be mounted side-by-side without any gap

between them. If it is necessary to mount the inverters vertically, install a partition plate or the like between the

inverters so that any heat radiating from an inverter will not affect the one/s above.

Do not mount the inverter upside down or horizontally. Doing so will reduce the heat dissipation

efficiency of the inverter and cause the overheat protection function to operate, so the inverter will not

run.

(4) Solving abnormal vibration after installation

If any vibration in the surroundings reaches the inverter and causes abnormal vibration to the cooling fan(s) or

the keypad, fix them firmly using the fixing screws provided as accessories.

Fixing the cooling fan(s)

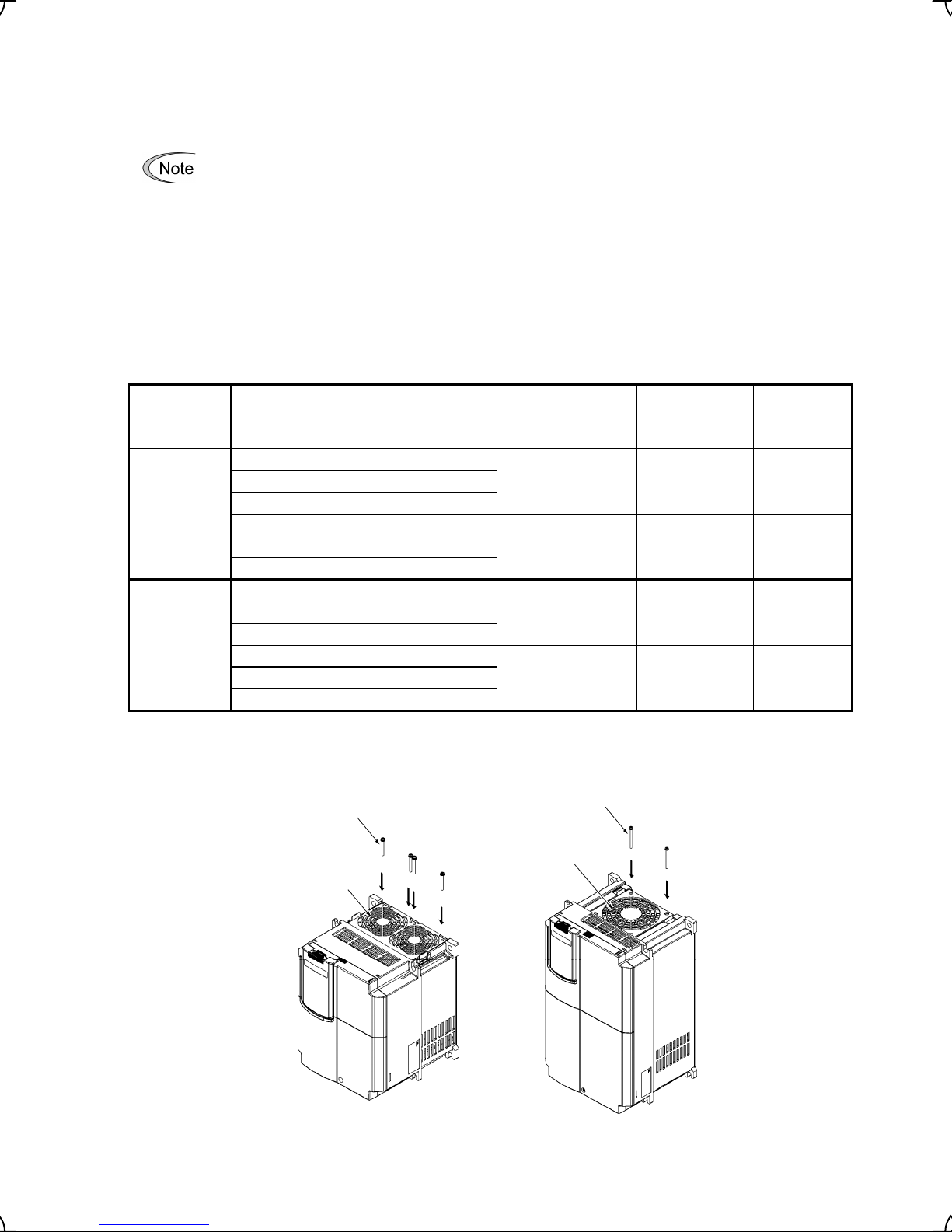

Table 2.4 Fixing Screws

Power

supply

voltage

Applicable

motor rating

(kW)

Inverter type

Screw size

(accessory)

Tightening

torque

(N·m)

Refer to:

5.5 FRN5.5LM1S-2

Threephase

200 V

7.5 FRN7.5LM1S-2

11 FRN11LM1S-2

15 FRN15LM1S-2

18.5 FRN18.5LM1S-2

M4x35 (4 pcs) 0.8 Figure A

M4x50 (2 pcs) 0.8 Figure B

22 FRN22LM1S-2

5.5 FRN5.5LM1S-4

Threephase

400 V

7.5 FRN7.5LM1S-4

11 FRN11LM1S-4

15 FRN15LM1S-4

18.5 FRN18.5LM1S-4

M4x35 (4 pcs) 0.8 Figure A

M4x50 (2 pcs) 0.8 Figure B

22 FRN22LM1S-4

Note: A box () in the above table replaces C (China), E (EU), A (Asia) or J (Japan) depending on the shipping

destination.

ttached screws

ttached screws

Cooling fans

Figure A Figure B

Cooling fan

Figure 2.4 Fixing the Cooling Fan(s)

2-4

Page 20

2.3 Wiring

Follow the procedure below. (In the following description, the inverter has already been installed.)

2.3.1 Removing and mounting the terminal block (TB) cover and the front cover

(1) For inverter with a capacity of 4.0 kW and Single Phase 2.2kW.

1) First loosen the front cover fixing screw, slide the cover downward holding its both sides, tilt it toward you,

and then pull it upward, as shown below.

2) While pressing the wiring guide upward, pull it out toward you.

3) After carrying out wiring (see Sections 2.3.2 through 2.3.7), put the wiring guide and the front cover back into place

in the reverse order of removal.

Screw

Front cover

Guide

The slide is done forward

while pressing it up.

Figure 2.5 Removing the covers and wiring guide

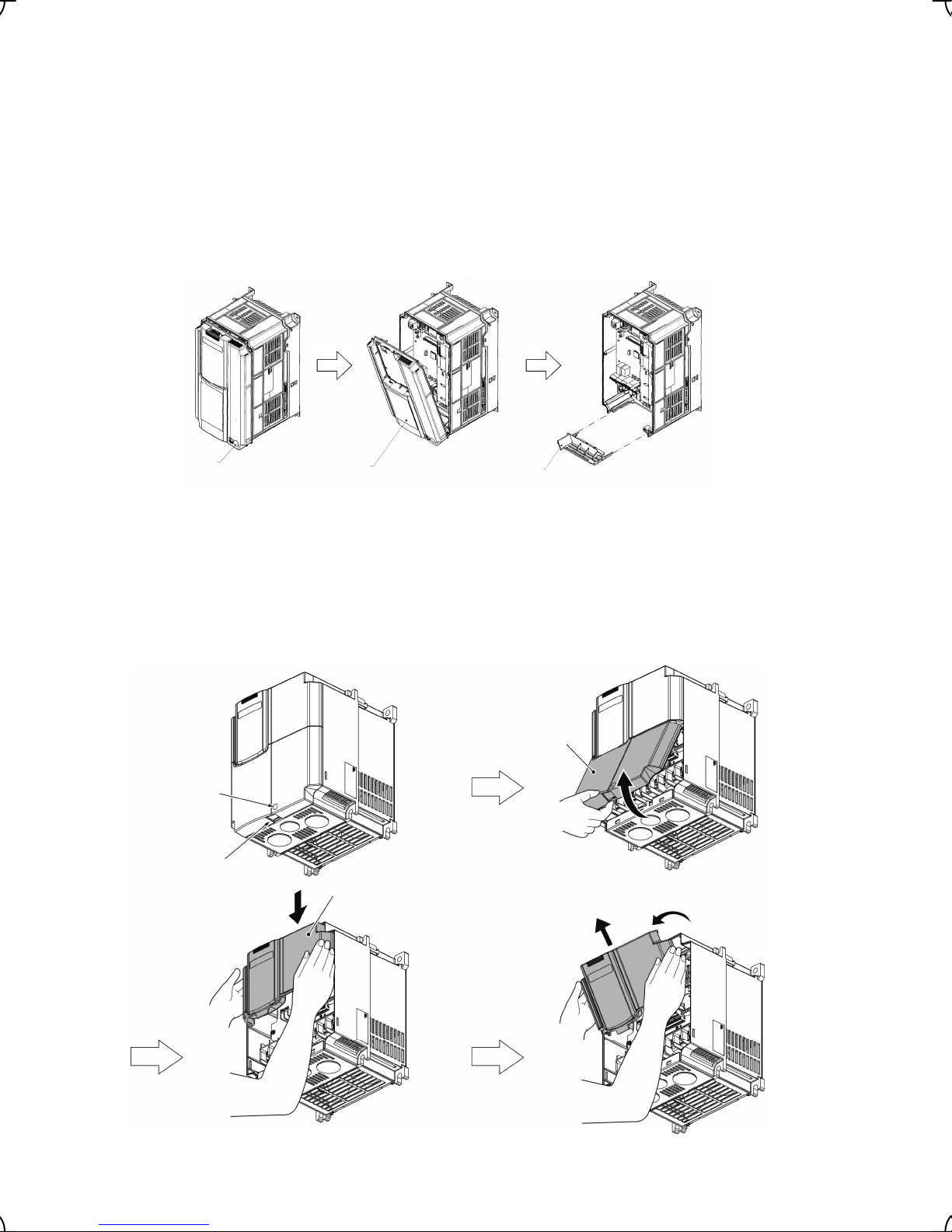

(2) For inverters with a capacity from 5.5 to 22 kW

Removing the covers

1) To remove the TB cover, loosen the fastening screw on it, hold the dimple (labeled “PULL”), and pull it up

toward you.

2) To remove the front cover, hold it with both hands, slide it downward, disengage the latch at the top from

the inverter, tilt the front cover toward you, and pull it upward.

Terminal block

cover

Terminal block

cover fastening

screw

"PULL"

mark

Front cover

Figure 2.6 Removing the Covers

2-5

Page 21

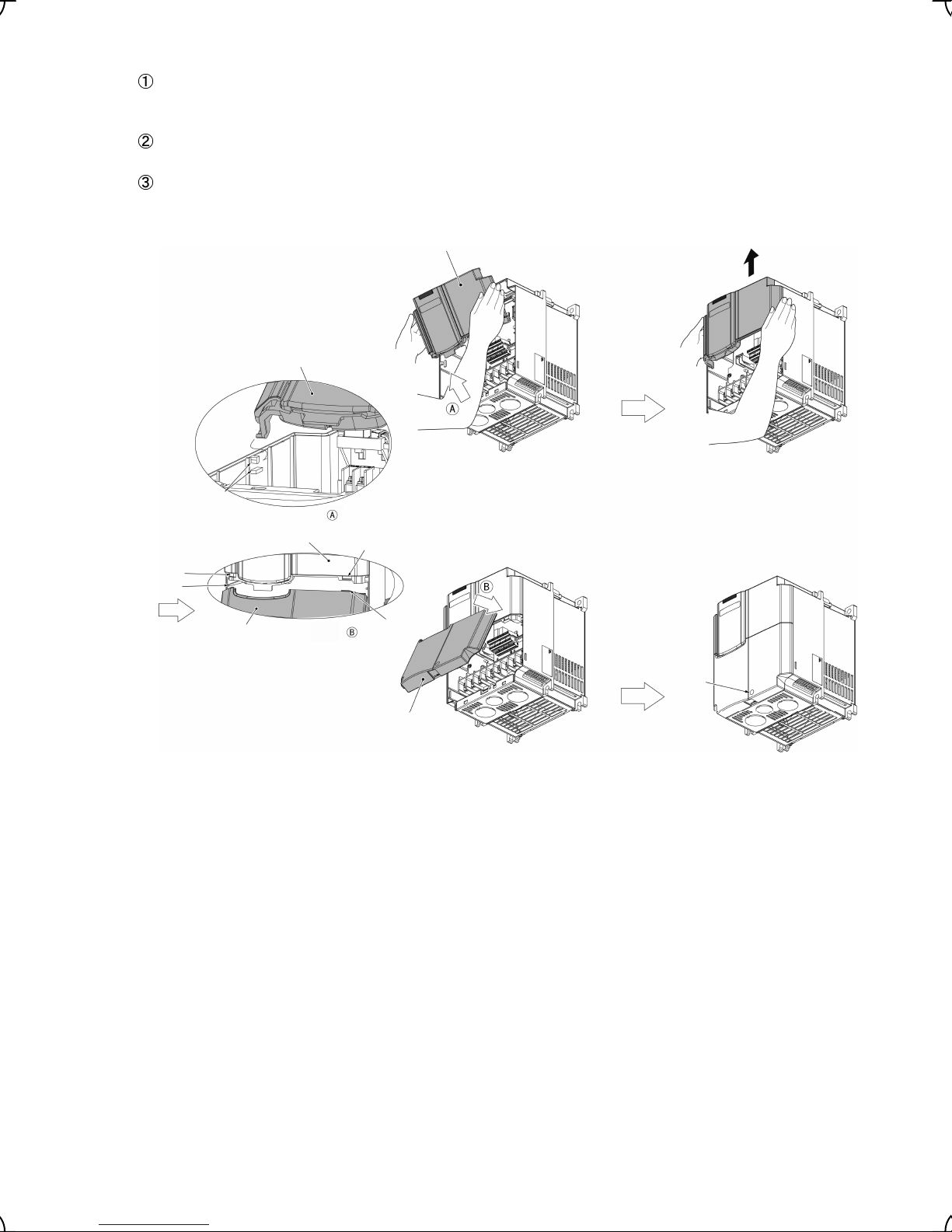

Mounting the covers

Put the front cover to the inverter case so that its bottom engages with the hinges provided on both sides of

the case. Push the front cover against the case of the inverter and slide it upward until the latch at its top

engages with the case.

Mount the TB cover onto the case of the inverter so that the latch at the top of the TB cover engages with a

hole provided at the bottom of the front cover.

Tighten the screw on the TB cover. (Tightening torque: 1.8 N·m)

Front cover

Front cover

Hole

Latch

Hinge

Terminal

block

cover

View from

Front cover

View from

Hole

Latch

Terminal block

cover

Cover

fastening

screw

(terminal

block cover)

Figure 2.7 Mounting the Covers

2-6

Page 22

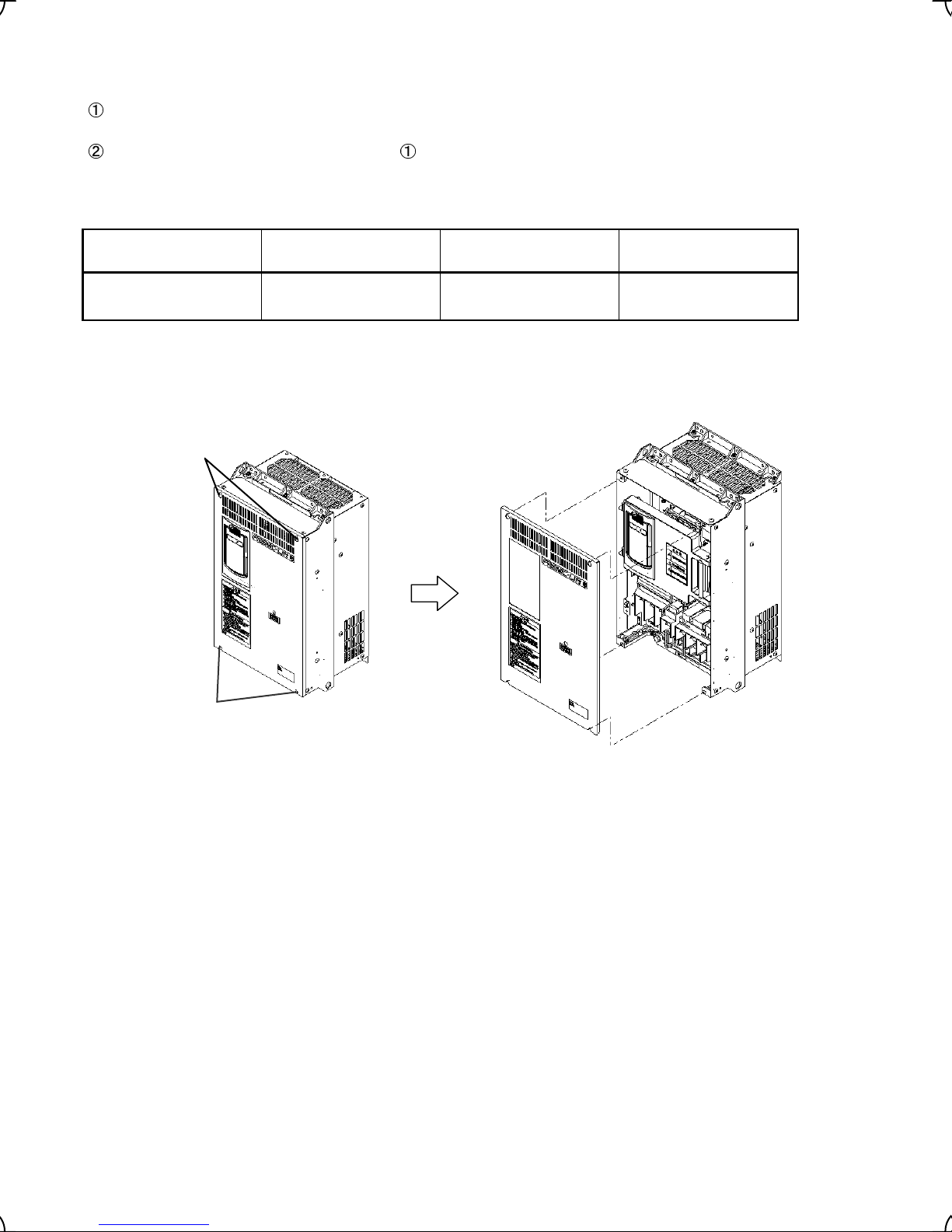

(3) For inverters with a capacity of 30 kW or above

Removing and mounting the cover

To remove the front cover, loosen the four fastening screws, hold it with both hands, and slide it upward.

(Refer to Figure 2.7.)

Put the front cover back in reverse order of . Make sure to properly match the position of the screw holes

on both of the front cover and inverter case.

Table 2.5 Screw Count and Tightening Torque

Power supply voltage Inverter type Front cover screw

Three-phase 400 V

Note: A box () in the above table replaces C (China), E (EU), A (Asia) or J (Japan) depending on the shipping

destination.

FRN30LM1S-4 to

FRN45LM1S-4

M4 x 8 (4 pcs) 1.8

Tightening torque

(N·m)

Fastening screws

Fastening screws

Figure 2.8 Removing and Mounting the Cover (FRN30LM1S-4)

Front cover

2-7

Page 23

A

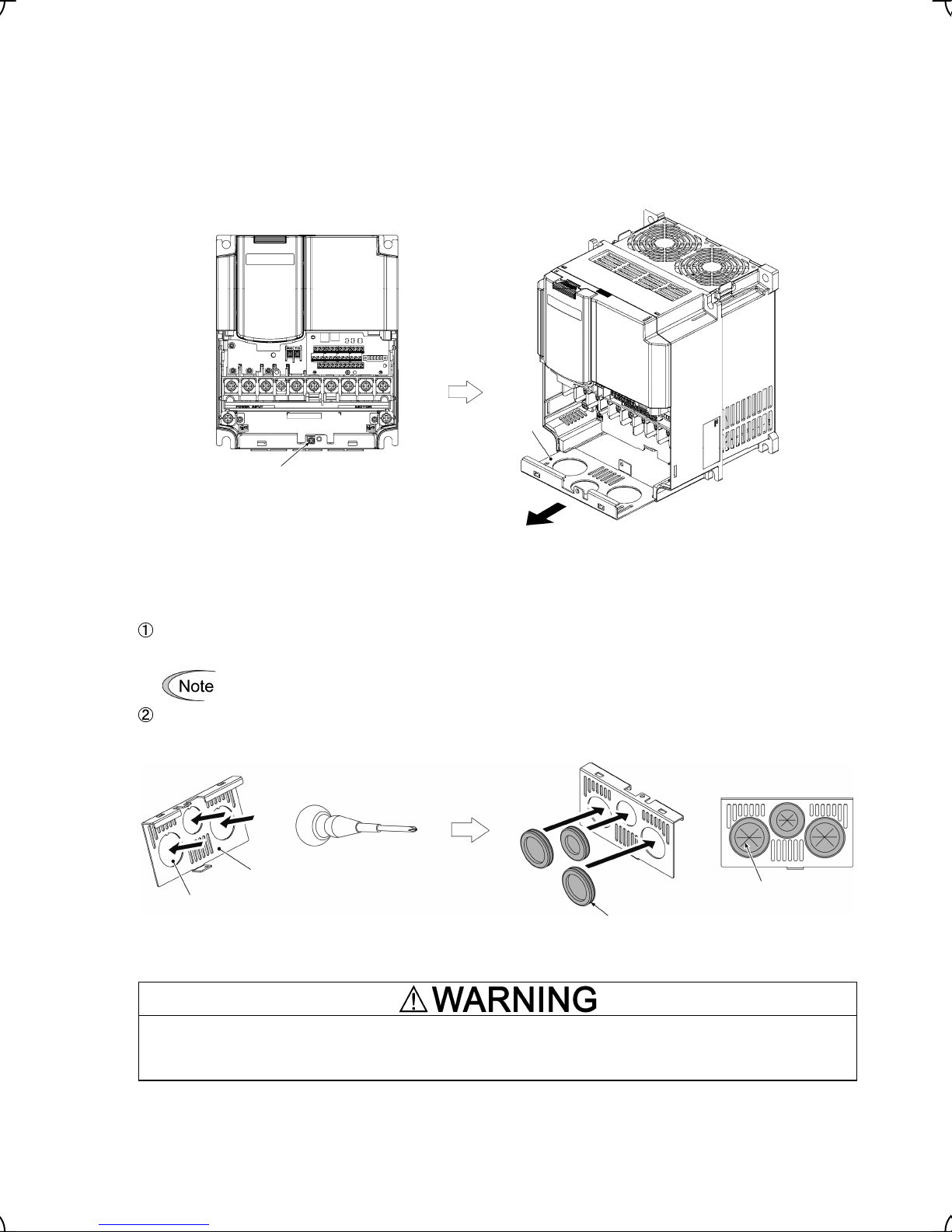

2.3.2 Removing and retracting the cable guide plate

To secure the protective structure IP20, FRENIC-Lift builds in the cable guide plate for external wiring

connections. To use it follow the steps listed below.

Removing the cable guide plate

Before to proceed, remove the terminal block cover as shown below left.

Remove the screw fastening the cable guide plate, and pull out the plate.

Cable

guide

plate

Cable guide plate

fastening screw

Figure 2.9 Removing the Cable Guide Plate

Opening half-punched holes and mounting rubber bushes

Tap an inside face of the half-punched hole by using a screwdriver grip end or the like to punch it out.

Punch out all 3 holes.

Be careful not to injure yourself by sharp cutting edges of parts.

Set 3 attached rubber bushes in the holes and cut in them by a cutting tool to make cut-outs as shown

below. All cables of an inverter should pass through any of cut-outs

Cable guide plate

Cut-outs

Half-punched

holes

Figure 2.10 Punching out the Holes and Mounting the Rubber Bushes

ttached rubber bushes

Be sure to use the rubber bushes. If not, a sharp cutting edge of the cable guide plate hole may damage the cable

sheath. This may induce a short-circuit fault or ground fault.

A fire or an accident may be caused.

Retracting the cable guide plate

Retract the cable guide plate following the steps illustrated in Figure 2.9 in reverse. (Tightening torque: 1.8 N

2-8

•

m)

Page 24

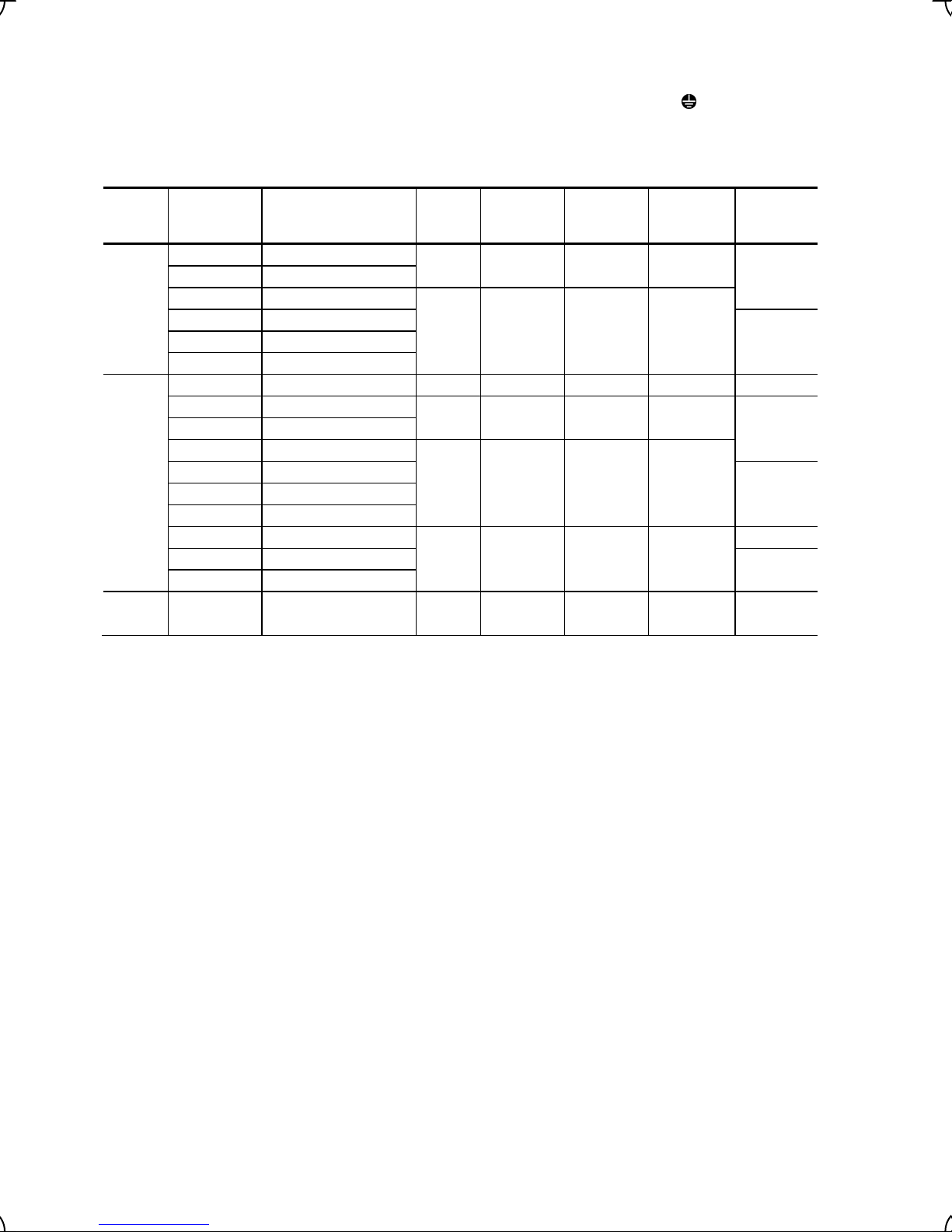

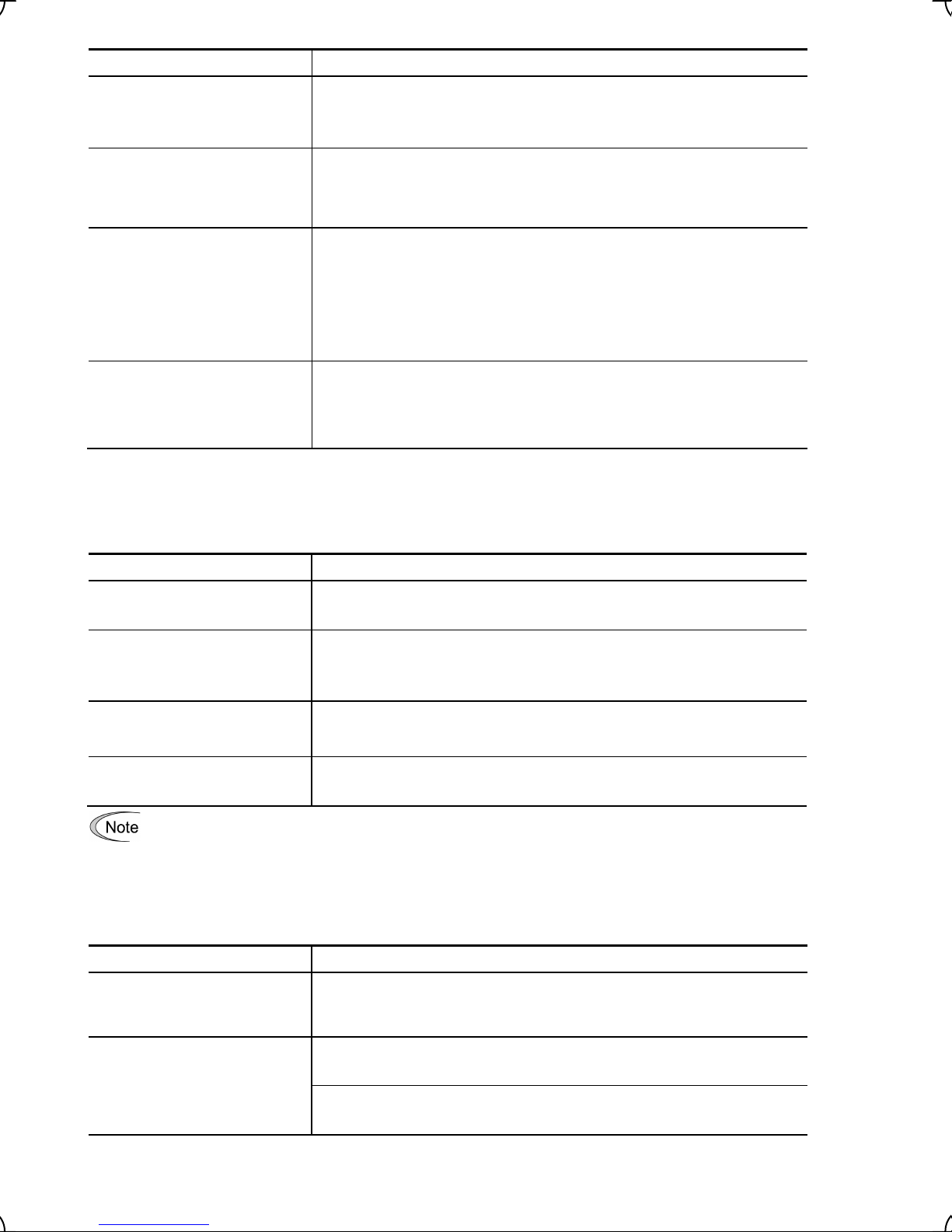

2.3.3 Terminal arrangement and screw specifications

The figures below show the arrangement of the main and control circuit terminals which differs according to

inverter type. The two terminals prepared for grounding, which are indicated by the symbol

G in Figures A to

C, make no distinction between the power supply side (primary circuit) and the motor side (secondary circuit).

(1) Arrangement of the main circuit terminals

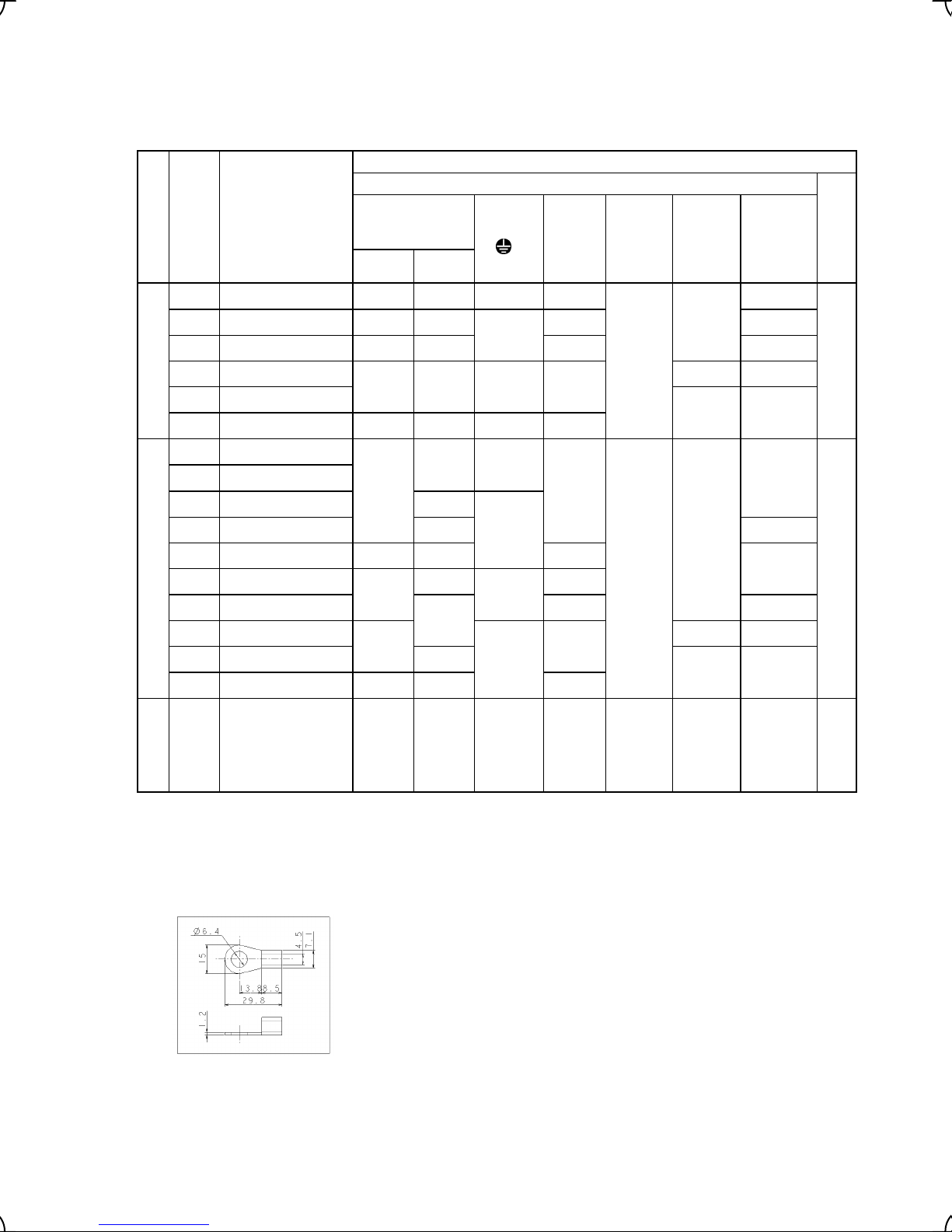

Table 2.6 Main Circuit Terminals

Power

supply

voltage

Threephase

200 V

Three-

phase

400 V

Singlephase

200 V

(*1)

Terminal DB on FRN11-LM1S-2/-4: Screw size M5, Tightening torque 3.8 N·m

Terminal R0, T0 (Common to all types): Screw size M3.5, Tightening torque 1.2 N·m

Note: A box (

Applicable

motor rating

(kW)

11 FRN11LM1S-2

15 FRN15LM1S-2

18.5 FRN18.5LM1S-2

22 FRN22LM1S-2

11 FRN11LM1S-4

15 FRN15LM1S-4

18.5 FRN18.5LM1S-4

22 FRN22LM1S-4

30 FRN30 LM1S-4

37 FRN37 LM1S-4

45 FRN45 LM1S-4

) in the above table replaces C (China), E (EU), A (Asia) or J (Japan) depending on the shipping

destination.

Inverter type

5.5 FRN5.5LM1S-2

3.7 FRN4.0LM1S-4

5.5 FRN5.5LM1S-4

M4 1.8 M4 1.8 Figure E

Terminal

screw

size

M5 3.8 M5 3.8

M6

(*1)

M5 3.8 M5 3.8

M6

(*1)

Tightening

torque

(N·m)

5.8

(*1)

5.8

(*1)

Grounding

screw size

M8 13.5 M8 13.5

2.2 FRN2.2LM1S-7 M4 1.8 M4 1.8 Figure F

M6 5.8

M6 5.8

Tightening

torque

(N·m)

Refer to:

Figure A 7.5 FRN7.5LM1S-2

Figure B

Figure A 7.5 FRN7.5LM1S-4

Figure B

Figure C

Figure D

2-9

Page 25

Terminal board illustrated in except Figure A. Take an attention for this structure to connect wires to main output

(secondary) terminals.

Figure A Figure B

Charging Light

Charging Light

Figure C

Figure E

Figure F

Charging Light

Charging Light

Charging Light

Figure D

Charging Light

L1/L

L2/N

2-10

Page 26

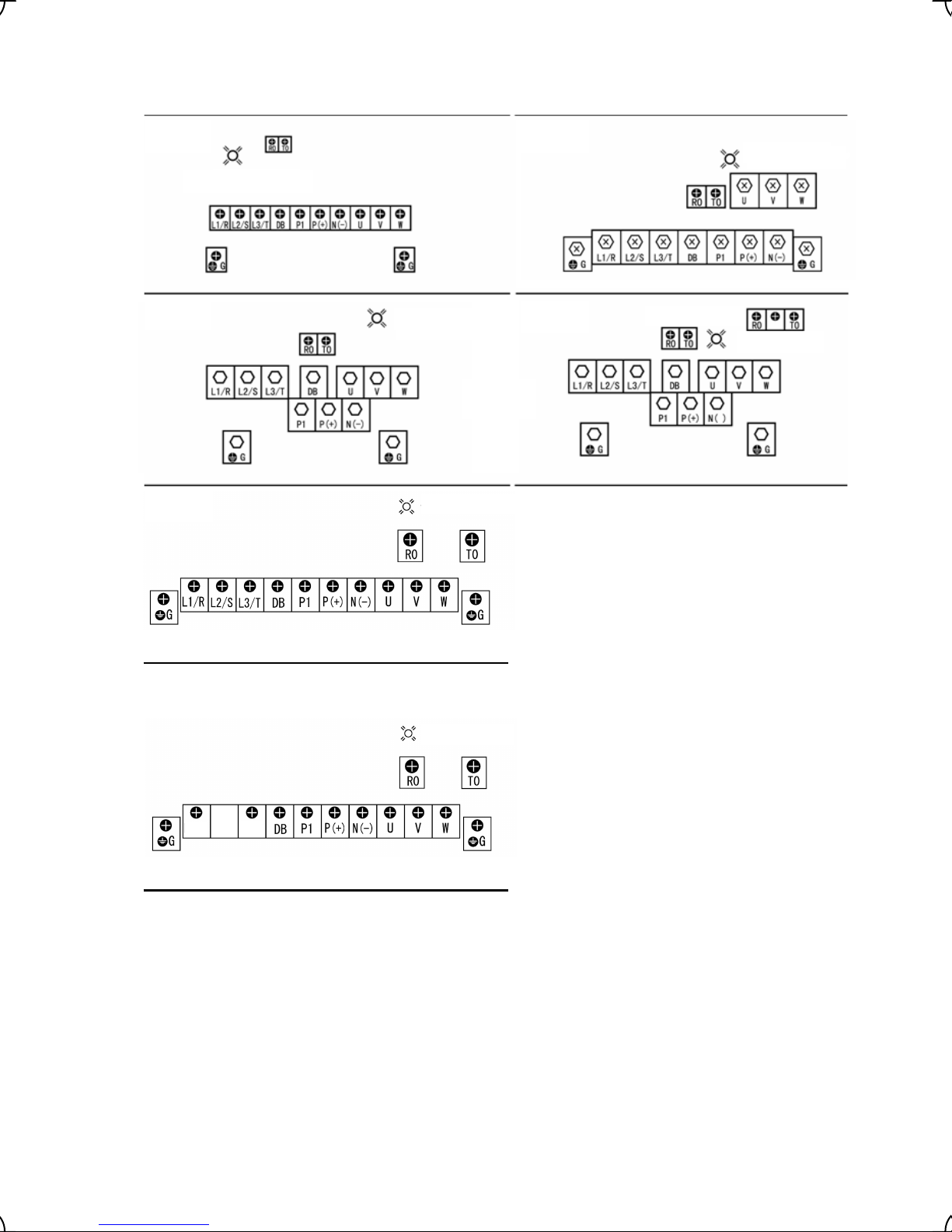

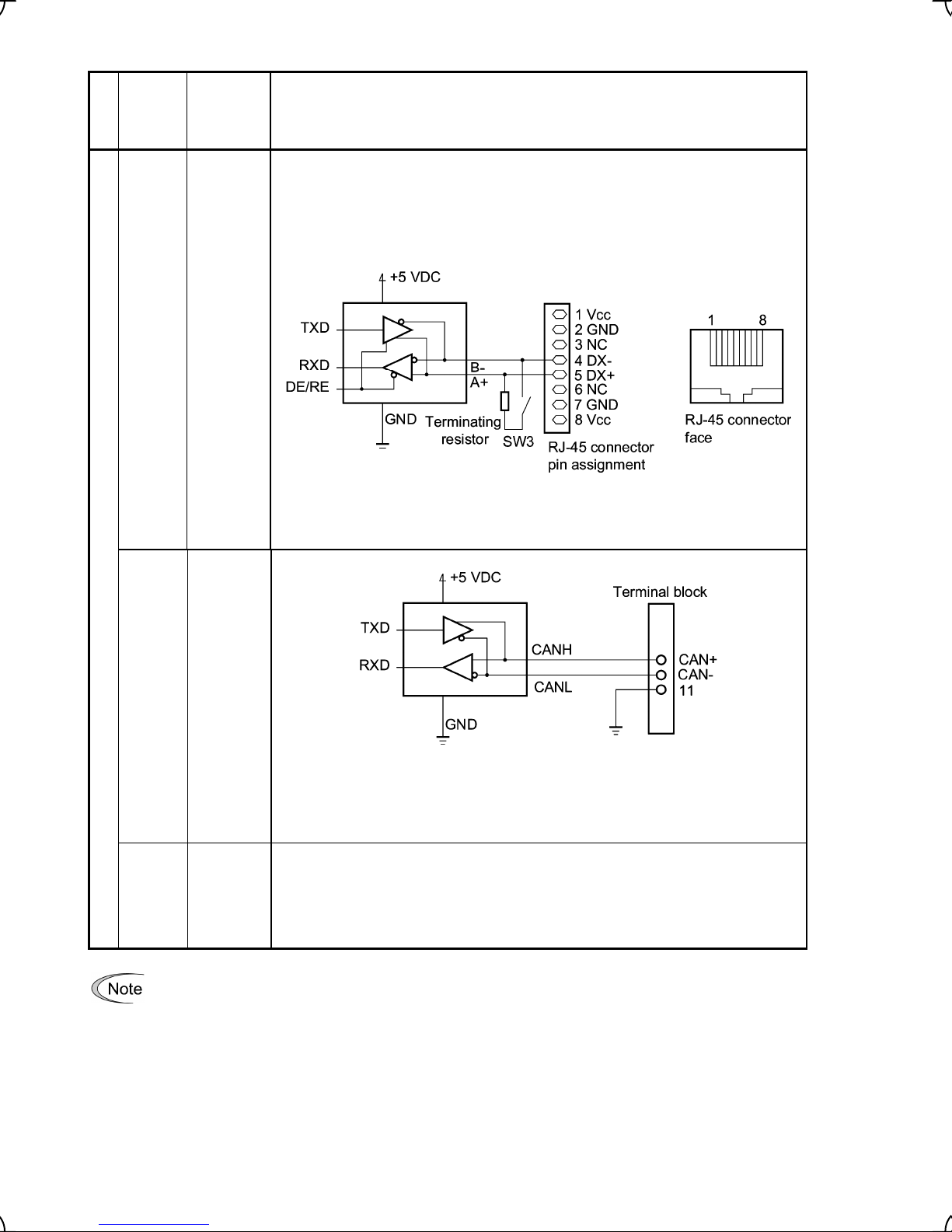

(2) The control circuit terminals (common to all models)

1) For inverters with CAN port (FRN _ _ _ LM1S-2C, -2E, -2A and -2J)

(FRN _ _ _ LM1S-4C, -4E, -4A and -4J)

2) For inverters without CAN port (FRN _ _ _ LM1S-2EA, -2AA and -2JA)

(FRN _ _ _ LM1S-4EA, -4AA and -4JA)

Screw size: M3

Tightening torque: 0.5 to 0.7 (N·m)

Table 2.7 Control Circuit Terminals

Terminal

group

* Manufacturer of ferrules: Phoenix Contact Inc. Refer to Table 2.8.

Screwdriver to be used

(Head style)

A

B

C

Flat head

(0.6 mm x 3.5 mm)

Flat head

(0.6 mm x 3.5 mm)

Flat head

(0.4 mm x 2.5 mm)

Allowable wire size

AWG26 to AWG16

(0.14 to 1.5 mm

AWG26 to AWG16

(0.14 to 1.5 mm

AWG28 to AWG16

(0.08 to 1.5 mm

Table 2.8 Recommended Ferrule Terminals

Type

Screw size

With insulated collar Without insulated collar

Bared wire length

2

)

2

)

2

)

Screw size: M2

Tightening torque: 0.22 to 0.25 (N·m)

Dimension of openings in the

control circuit terminals for ferrule

(for Europe type terminal block)*

6 mm 2.51 mm (W) x 1.76 mm (H)

7 mm 2.75 mm (W) x 2.86 mm (H)

7 mm 1.72 mm (W) x 2.7 mm (H)

AWG24 (0.25 mm2) AI0.25-6BU -

AWG22 (0.34 mm2) AI0.34-6TQ A0.34-7

AWG20 (0.5 mm2) AI0.5-6WH A0.5-6

AWG18 (0.75 mm2) AI0.75-6GY A0.75-6

AWG16 (1.25 mm2) AI1.5-6BK A1.5-7

3.5 mm

Head thickness: 0.6 mm

Screwdriver head style

2-11

Page 27

00

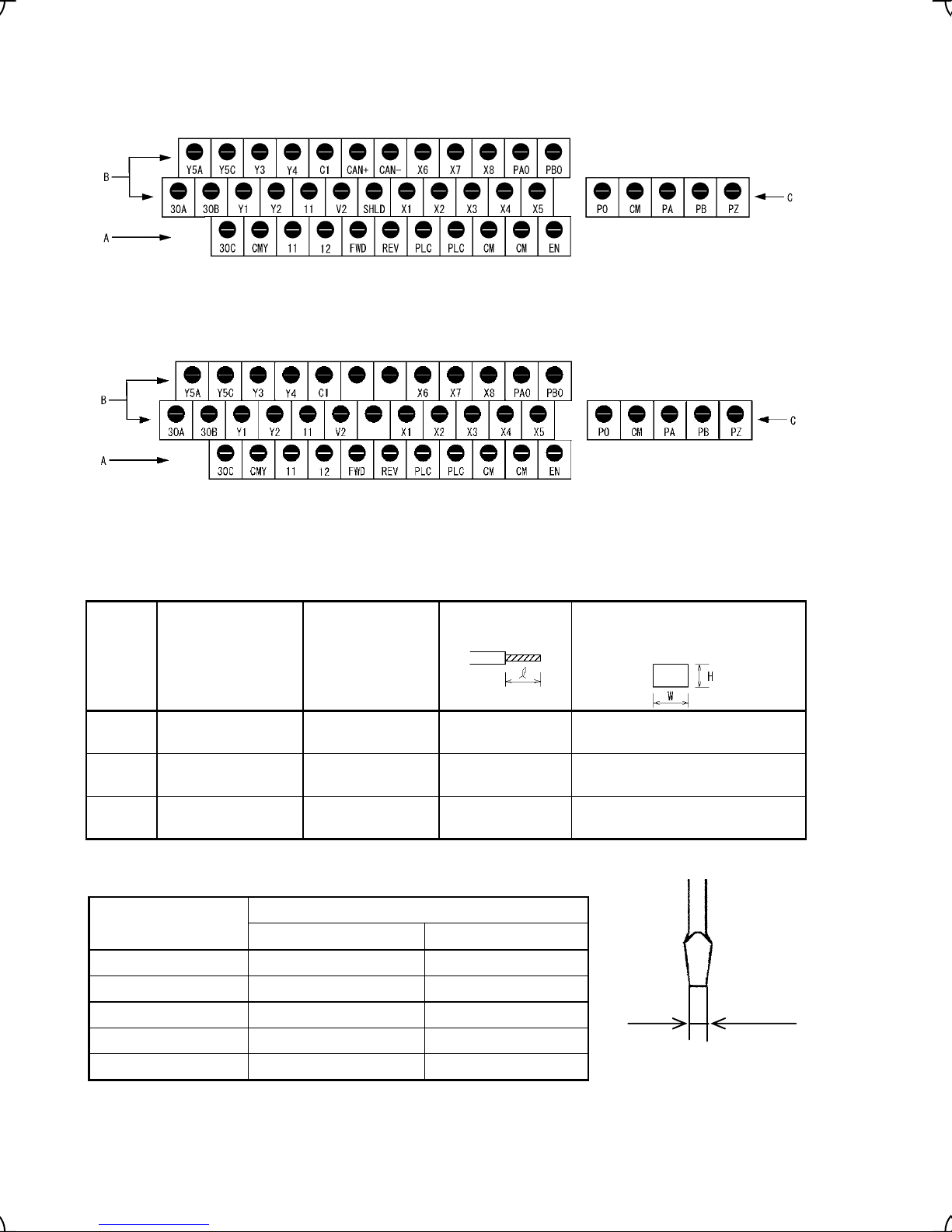

2.3.4 Recommended wire sizes

Table 2.9 lists the recommended wire sizes. The recommended wire sizes for the main circuits are examples of

using HIV single wire (for 75°C) at an ambient temperature of 50°C.

Table 2.9 Recommended Wire Sizes

Recommended wire size (mm2 ) *

G]

Main circuit

Inverter

[U, V, W]

Appli-

cable

motor

rating

voltage

(kW)

Power supply

5.5 FRN5.5LM1S-2 2 3.5 3.5 3.5

7.5 FRN7.5LM1S-2 3.5 5.5

Inverter type

Main circuit power

input

(L1/R, L2/S, L3/T)

w/ DCR w/ DCR

Grounding

[

Auxiliary

Power

output

Input

(Ctrl. cct.)

[R0, T0]

5.5 5.5

1

Braking

resistor

[DB]

2

DCR

[P1, P (+)]

3.5

Control circuit

5.5

11 FRN11LM1S-2 5.5 14 8 8

15 FRN15LM1S-2

2

1.25

3.5 14

14 22 8 14

18.5 FRN18.5LM1S-2

Three-phase 200 V

22 FRN22LM1S-2 22 38 14 22

3.7 FRN4.0LM1S-4

5.5 22

2 2

5.5 FRN5.5LM1S-4

7.5 FRN7.5LM1S-4 2

11 FRN11LM1S-4 3.5 3.5

15 FRN15LM1S-4 3.5 5.5 3.5

18.5 FRN18.5LM1S-4

22 FRN22LM1S-4

Three-phase 400 V

30 FRN30LM1S-4

37 FRN37LM1S-4

2

5.5

14

8

14

22

2

3.5

2

*

5.5

5.5

2

*

8 *2

8

2

2

3.5 14

14

8

2

5.5

1.25

5.5 22

45 FRN45LM1S-4 22

38

22

V

2.2 FRN2.2LM1S-7 2

2

Single-phase

Note: A box () in the above table replaces C (China), E (EU), A (Asia) or J (Japan) depending on the shipping

destination.

*1 Recommended wire sizes are calculated based on the specifications in Chapter 8.

*2 Use the "crimp terminal 8-L6 manufactured by J.S.T. Mfg Co., Ltd." or equivalent. (See the figure below.)

Dimensions of the crimp terminal 8-L6

Use the crimp terminal with an insulation sheath or with processing by the insulation tube. Use the wire of 75°C, 600

V, HIV-insulated. This selection assumes the inverter is used in ambient temperature at 50°C.

3.5

2 2 2 2 2

DCR: DC reactor

1.25

2-12

Page 28

2.3.5 Wiring precautions

Follow the rules below when performing wiring for the inverter.

(1) Make sure that the source voltage is within the rated voltage range specified on the nameplate.

(2) Be sure to connect the three-phase power wires to the main circuit power input terminals L1/R, L2/S and

L3/T of the inverter. If the power wires are connected to other terminals, the inverter will be damaged when

the power is turned on.

(3) Always connect the grounding terminal to prevent electric shock, fire or other disasters and to reduce

electric noise.

(4) Use crimp terminals covered with insulated sleeves for the main circuit terminal wiring to ensure a reliable

connection.

(5) Keep the power supply wiring (primary circuit) and motor wiring (secondary circuit) of the main circuit, and

control circuit wiring as far away as possible from each other.

• When wiring the inverter to the power source, insert a recommended molded case circuit breaker

(MCCB) or earth leakage circuit breaker (ELCB) (with overcurrent protection) in the path of each pair

of power lines to inverters. Use the devices recommended ones within the related current range.

• Use wires in the specified size.

• Tighten terminals with recommended torque.

Otherwise, fire could occur.

• Use a multi-core power cable (3- or 4-wires) to wire the inverter with a motor.

• Do not connect a surge killer to the inverter's output circuit.

Doing so could cause fire.

• According to the input power series install FRENIC-Lift in compliance with local regulations.

Otherwise, electric shock or fire could occur.

• Qualified electricians should carry out wiring.

• Be sure to perform wiring after turning the power off.

Otherwise, electric shock could occur.

• Be sure to perform wiring after installing the inverter.

Otherwise, electric shock or injuries could occur.

• Ensure that the number of input phases and the rated voltage of the product match the number of

phases and the voltage of the AC power supply to which the product is to be connected.

• Do not connect the power source wires to output terminals (U, V, and W).

Doing so could cause fire or an accident.

2.3.6 Wiring for main circuit terminals and grounding terminals

Table 2.10 shows the main circuit power terminals and grounding terminals.

Table 2.10 Symbols, Names and Functions of the Main Circuit Power Terminals

Symbol Name Functions

L1/R, L2/S, L3/T

and L1/L, L2/N

U, V, W Inverter outputs Connect a 3-phase motor.

R0, T0

P1, P(+) DC reactor connection Connect a DC reactor (DCR) for improving power factor.

P(+), N(-) DC link bus Connect an optional regenerative converter or the equivalent.

P(+), DB Braking resistor connection Connect a braking resistor.

G × 2

Main power inputs

Auxiliary power input for

the control circuit

Grounding for inverter and

motor

Connect the 3-phase input power lines or Single-phase input

power lines.

For the models of 200 V series 22 kW or below, and 400 V

series 30 kW or below.

For a backup of the control circuit power supply, connect AC

power lines same as that of the main power input.

For the models of 400 V series 37 kW or above.

For a control circuit, fan and contact a power supply, connect

AC power lines same as that of the main power input.

Grounding terminals for the inverter’s chassis (or case) and

motor. Earth one of the terminals and connect the grounding

terminal of the motor. Inverters provide a pair of grounding

terminals that function equivalently.

2-13

Page 29

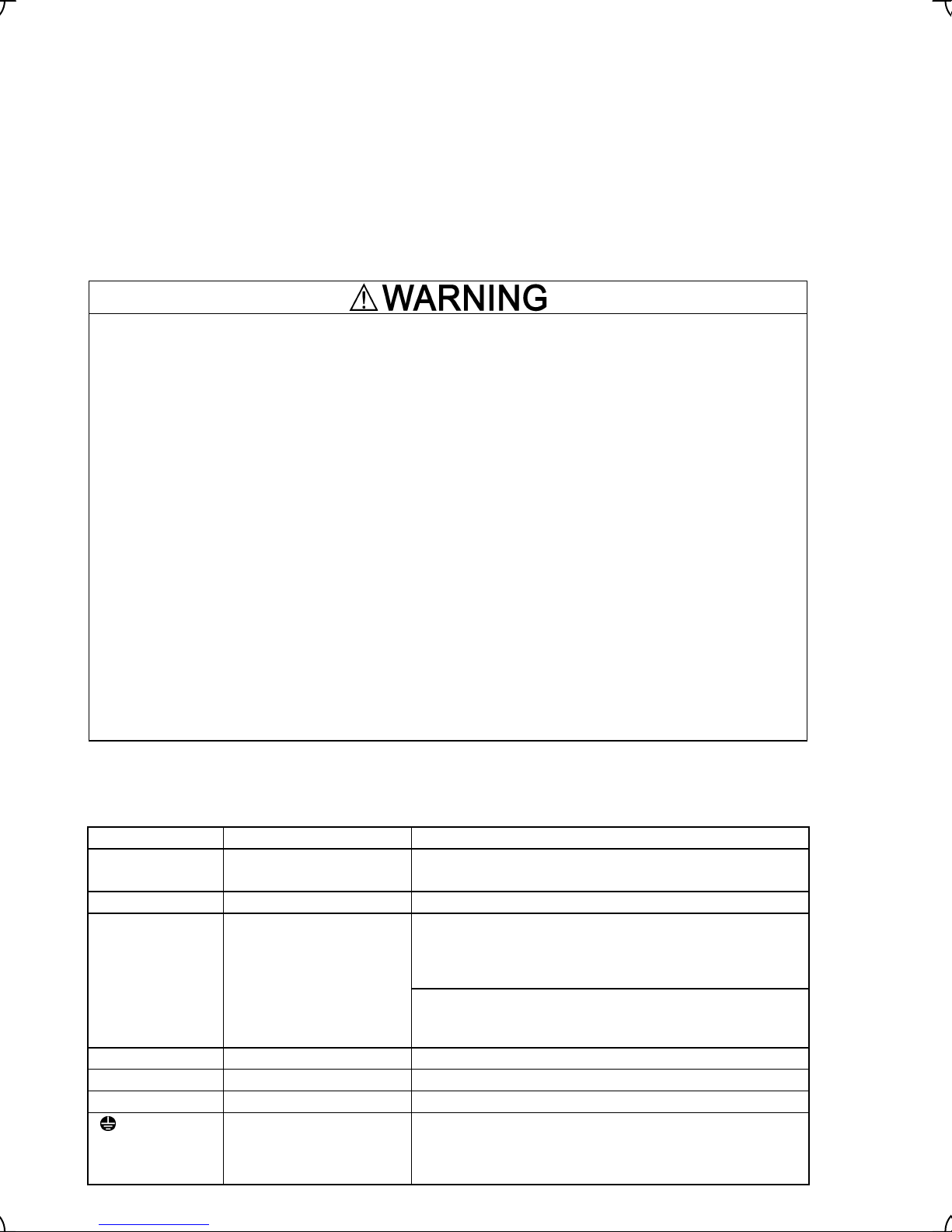

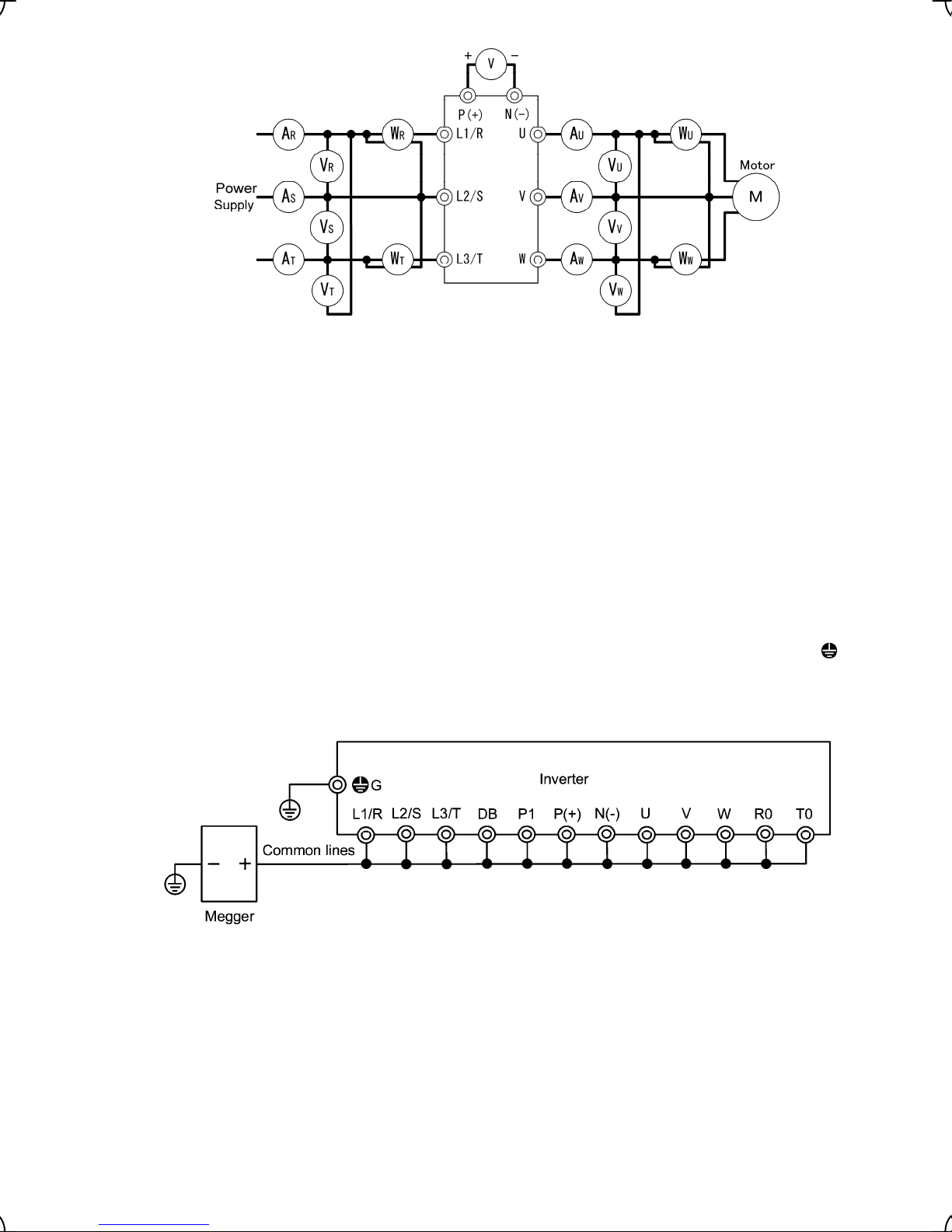

Follow the procedure below for wiring and configuration of the inverter. Figure 2.11 illustrates the wiring

procedure with peripheral equipment.

Wiring procedure

Grounding terminals ( G)

Inverter output terminals (U, V, W, and G)

DC reactor connection terminals (P1 and P(+))*

DC link bus terminals (P(+) and N(-))*

Main circuit power input terminals (L1/R, L2/S and L3/T or L1/L, L2/N)

Auxiliary power input terminals for the control circuit (R0 and T0)*

Braking resistor connection terminals (P(+) and DB)

*

Perform wiring as necessary

Molded

case circuit

breaker

(MCCB) or

earth

leakage

circuit

breaker

(ELCB) with

over current

protection

Magnetic

contactor

Power supply

CAUTION: Do not connect

more than 2 wires to

terminal P(+).

Regenerative

converter

Motor

Braking resistor

DC reactor (DCR)

Figure 2.11 Wiring Procedure for Peripheral Equipment

2-14

Page 30

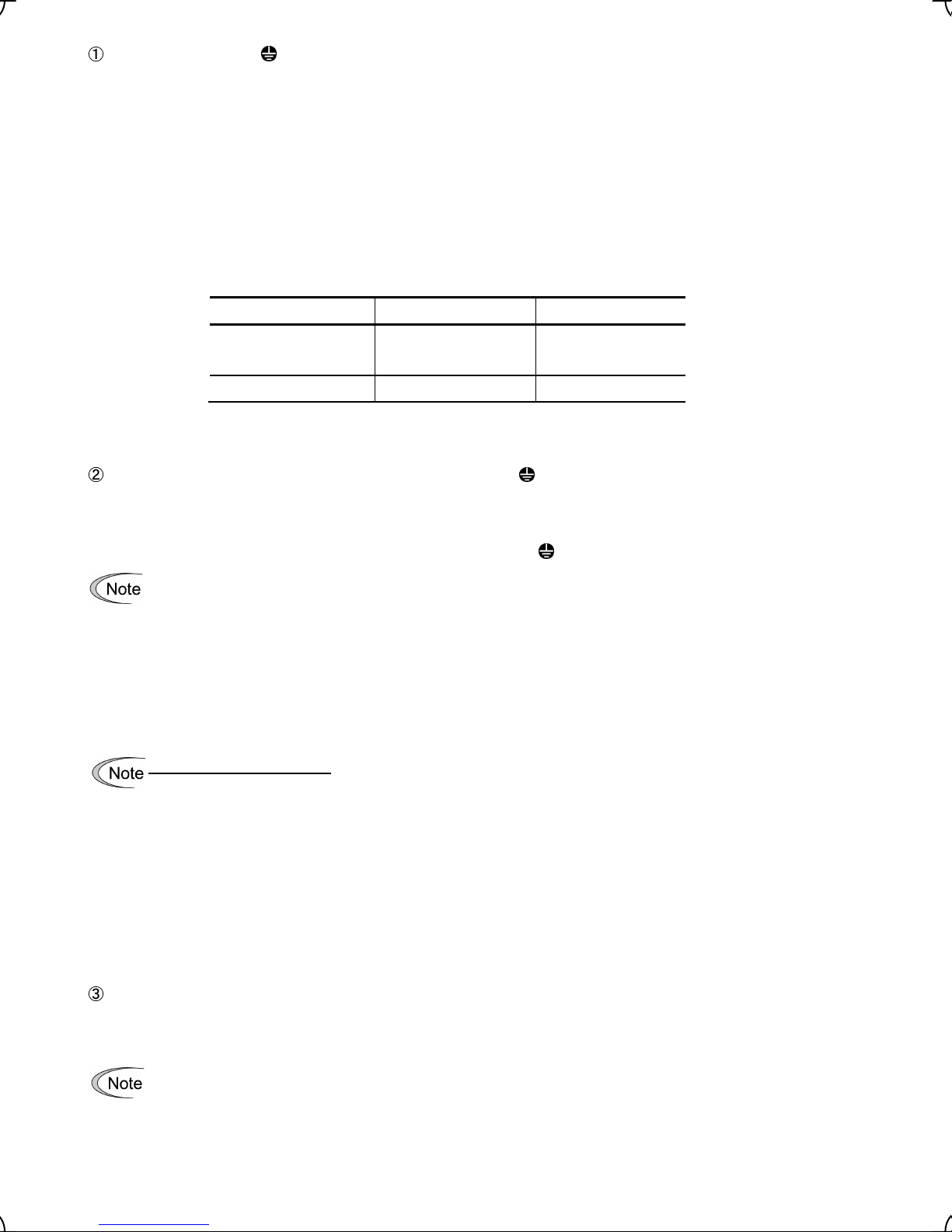

Grounding terminals ( G)

Be sure to ground either of the two grounding terminals for safety and noise reduction.

Install FRENIC-Lift in compliance with the local regulations, Described below for an example, a procedure

shows an installation of the inverter in compliance with regulations in Japan.

E.g. grounding terminals should be grounded as follows:

1) For the 200 V or 400 V series of inverters, connect the grounding terminal to a ground electrode on which

class D or C grounding work has been completed, respectively, with conformity to the Electric Facility

Technical Standard.

2) Connect a thick grounding wire with a large surface area and which meets the grounding resistance

requirements listed in Table 2.11. Keep the wiring length as short as possible.

Table 2.11 Grounding Stipulated in the Electric Facility Technical Standard

Supply voltage Grounding work class Grounding resistance

Single-phase 200V

Three-phase 200 V

Three-phase 400 V Class C 10 Ω or less

Class D 100 Ω or less

Inverter output terminals, U, V, W and grounding terminals ( G)

Inverter’s output terminals should be connected as follows:

1) Connect the three wires of the 3-phase motor to terminals U, V, and W, aligning phases each other.

2) Connect the secondary grounding wire to the grounding terminal (

• The wiring length between the inverter and motor should not exceed 50 m, when they are

connected directly.

• Do not connect a power factor correcting capacitor or surge absorber to the inverter’s output lines

(secondary circuit).

• If the wiring length is long, the stray capacitance between the wires will increase, resulting in an

outflow of the leakage current. It will activate the overcurrent protection, increase the leakage

current, or will not assure the accuracy of the current display. In the worst case, the inverter could

be damaged.

• Do not drive two or more motors by single inverter.

Driving 400 V series motor

• If a thermal relay is installed in the path between the inverter and the motor to protect the motor

from overheating, the thermal relay may malfunction even with a wiring length shorter than 50 m.

In this situation, lower the carrier frequency (Function code F26: Motor sound (Carrier frequency)).

• When a PWM-type inverter is driving a motor surge voltage that is generated by switching the

inverter component may be superimposed on the inverter output and may be applied to the motor

terminals. Particularly if the wiring length is long, the surge voltage may deteriorate the insulation

resistance of the motor. Consider any of the following measures.

- Use a motor with insulation that withstands the surge voltage.

- Minimize the wiring length between the inverter and motor.

DC reactor terminals, P1 and P (+)

G).

1) Remove the short bar from terminals P1 and P(+).

2) Connect a DC reactor (option) to terminals P1 and P(+).

• The wiring length should be 10 m or below.

• Do not remove the short bar installed across P1 and P(+) terminals if a DC reactor is not to be

used.

2-15

Page 31

DC link bus terminals, P (+) and N (-)

These are provided for the DC link bus powered system. Connect these terminals with terminals P(+) and N (-)

of an optional regenerative converter or the equivalent.

Consult your Fuji Electric representative if these terminals are to be used.

1) For safety, make sure that the molded case circuit breaker (MCCB) or magnetic contactor (MC) is turned off

2) Connect the main circuit power supply wires (L1/R, L2/S and L3/T or L1/L, L2/N (single-phase )) to the input

It is not necessary to align phases of the power supply wires and the input terminals of the inverter with

Main circuit power input terminals, L1/R, L2/S, and L3/T (three-phase input) or L1/L, L2/N

(single-phase input)

before wiring the main circuit power input terminals.

terminals of the inverter via an MCCB or residual-current-operated protective device (RCD)/earth leakage

circuit breaker (ELCB)*, and MC if necessary.

each other.

* With overcurrent protection

It is recommended that a magnetic contactor be inserted that can be manually activated. This is to

allow you to disconnect the inverter from the power supply in an emergency (e.g., when the protective

function is activated) so as to prevent a failure or accident from causing the secondary problems.

Auxiliary power input terminals R0 and T0 for the control circuit

For the models of single-phase 200V, 200V series 22kW or below, and 400V series 30kW or below

In general, the inverter will run normally without power supplied to the auxiliary power input for the control circuit.

However, if you share the input power for the control circuit with that for the main circuit, you would be lost when,

in the event of an error or alarm, you turn OFF the magnetic contactor between the inverter and the commercial

power supply. If the magnetic contactor is turned OFF, the input power to the control circuit is shut OFF, causing

the alarm signals (30A/B/C) to be lost and the display on the keypad to disappear. To secure input power to the

control circuit at all times, supply the power from the primary side of the magnetic contactor to control power

auxiliary input terminals R0 and T0. The method of connecting auxiliary power input terminals for the control

circuit refer to Section 2.3.8 "Setting up slide switches."

For the models of 400 V series 37 kW or above

The inverter will not run normally without power supplied to the auxiliary power input for the control circuit.

However, if you share the input power for the control circuit with that for the main circuit, you would be lost when,

in the event of an error or alarm, you turn OFF the magnetic contactor between the inverter and the commercial

power supply. If the magnetic contactor is turned OFF, the input power to the control circuit is shut OFF, causing

the alarm signals (30A/B/C) to be lost and the display on the keypad to disappear. To secure input power to the

control circuit at all times, supply the power from the primary side of the magnetic contactor to control power

auxiliary input terminals R0 and T0. The method of connecting auxiliary power input terminals for the control

circuit refer to Section 2.3.8 "Setting up slide switches."

When the DC power input is used, auxiliary power input terminals is used. The connected AC power is:

Single phase 380 to 460 V/50 Hz or 60 Hz for 400 V series 37 kW or above

Note: Allowable power input voltage range should be within – 15% to +10% of power source voltage.

Connect the power supply with R0 and T0 if the inverter of 37 kW or above is used, and the main

power supply is connected.

If you do not connect the power supply with Auxiliary power input terminals, the cooling fan will not run,

causing a heat sink overheating alarm "

0h1

" or a charger circuit error alarm "

2-16

pbf

."

Page 32

Braking resistor connection terminals, P(+) and DB

1) Connect terminals P and DB of an external braking resistor to terminals P(+) and DB on the main circuit

terminal block. (For the braking resistor built-in type, refer to the next page.)

2) When using an external braking resistor, arrange the inverter and braking resistor to keep the wiring length

to 5 m or less and twist the two wires or route them together in parallel.

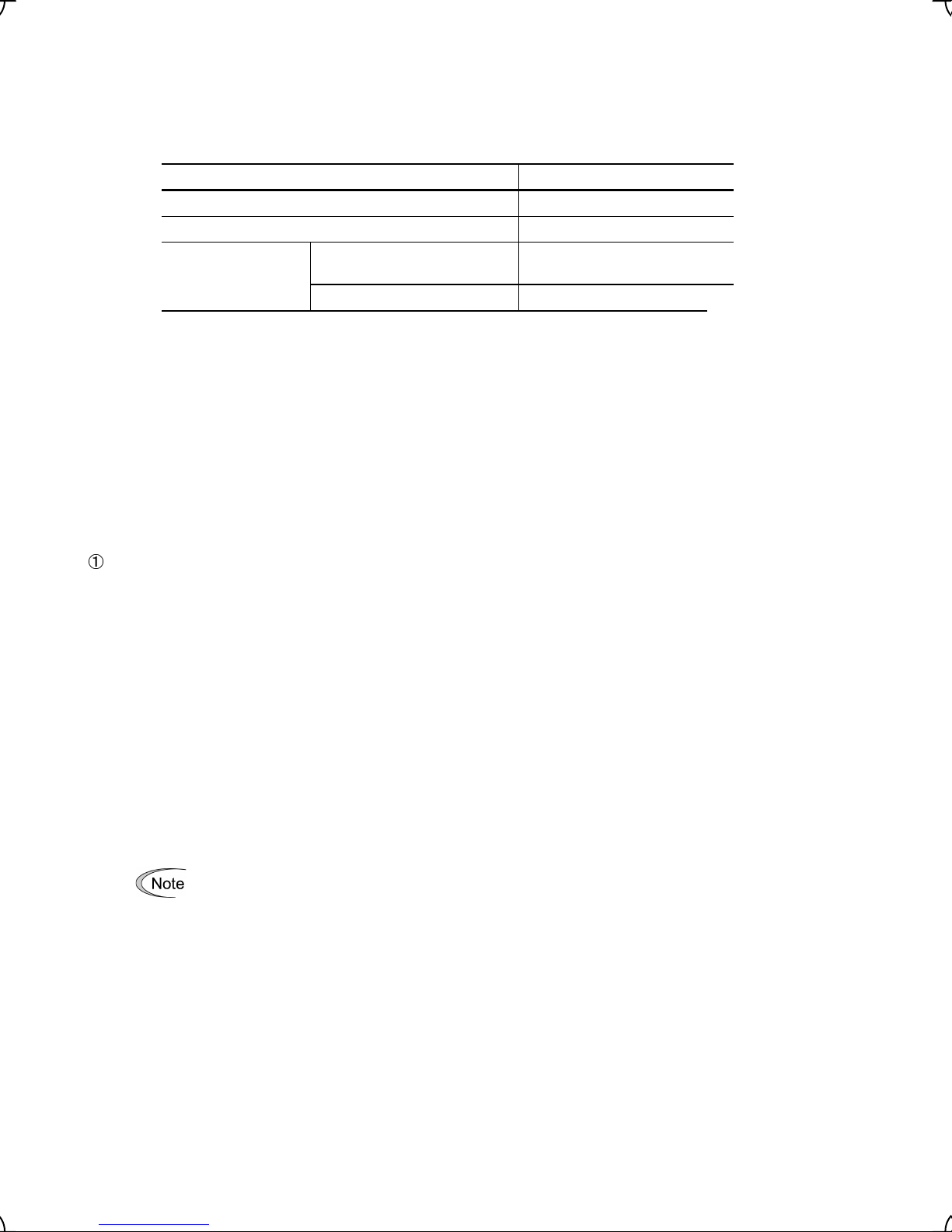

Never insert a braking resistor between terminals P(+) and N(-), P1 and N(-), P(+) and P1, DB and N(-), or

P1 and DB.

Doing so could cause fire.

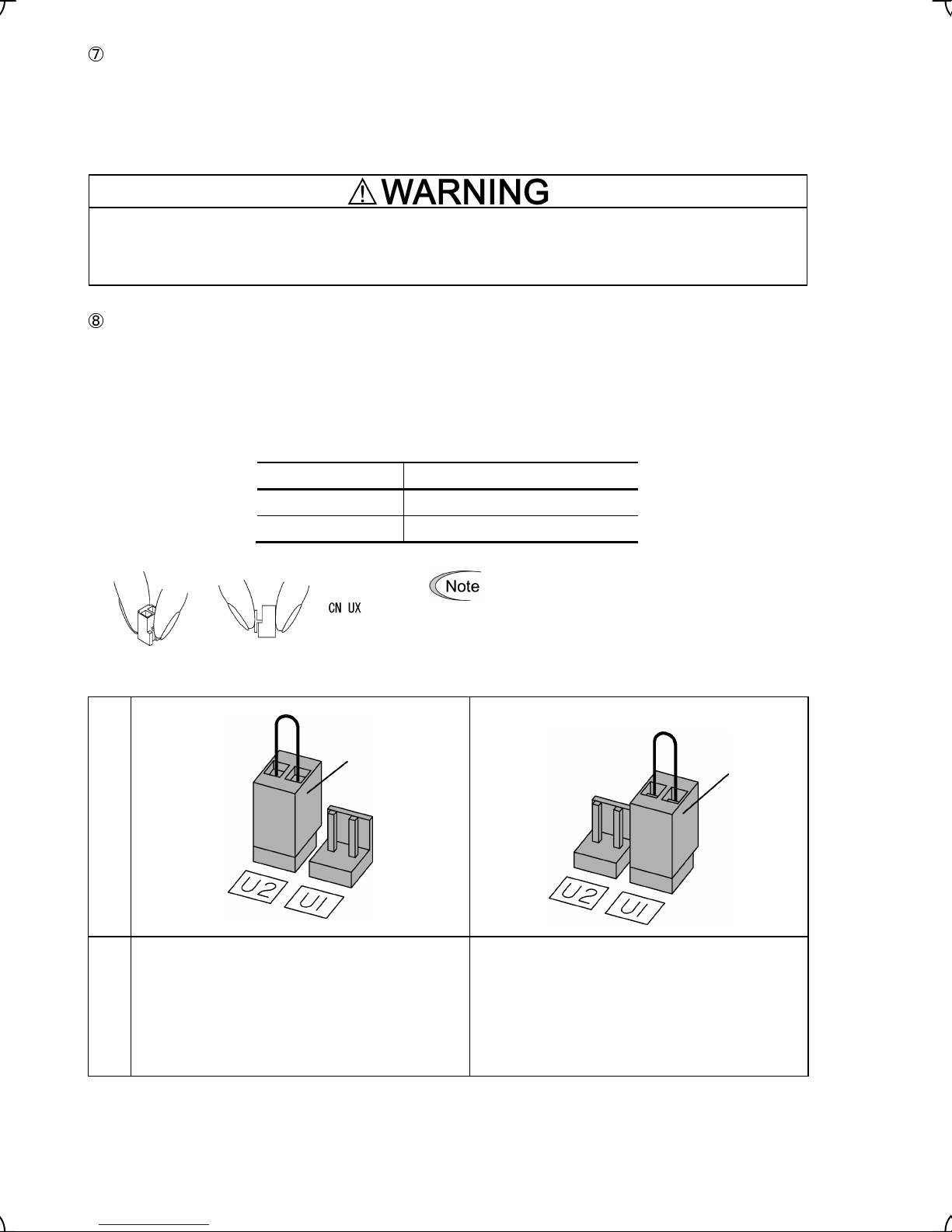

Power switching connectors [CN UX] (for the models of 400 V series 37 kW or above)

An inverter of 400 V series 37 kW or above is equipped with a set of switching connectors CN UX (male) which

should be configured with a jumper according to the power source voltage and frequency. Set the jumper to U1

or U2 depending upon the power source voltage applied to the auxiliary power input terminals (R0, T0), as

shown in Figure 2.13. Power switching connectors [CN UX] is arranged in the power supply printed wiring board

in the right part of the control printed wiring board. Please refer to figure 2.12 and Figure 2.13 for details.

Table 2.12 Voltage in which connection of Power switching connectors is changed

Frequency (Hz) Power supply voltage(V)

50 420~480

60 430~480

Figure 2.12 Inserting/Removing the Jumpers

Setting

380 to 420 V/50 Hz

380 to 430 V/60 Hz

CN UX (red)

To remove the jumper, pinch its upper side

between your fingers, unlock its fastener and pull

it up. To insert it, pull it down as firmly as it locks

with the connector until you will have heard a

click sound.

CN UX (red)

420 to 480 V/50 Hz

430 to 480 V/60 Hz

(

Factory default)

Volta ge

Note: Allowable power input voltage range should be

within – 15% to +10% of power source voltage.

Figure 2.13 Setting up the power switching connector [CN UX].

Note: Allowable power input voltage range should be

2-17

within – 15% to +10% of power source voltage.

Page 33

2.3.7 Wiring for control circuit terminals

In general, sheaths and covers of the control signal cables and wires are not specifically designed to

withstand a high electric field (i.e., reinforced insulation is not applied). Therefore, if a control signal cable or

wire comes into direct contact with a live conductor of the main circuit, the insulation of the sheath or the

cover might break down, which would expose the signal wire to a high voltage of the main circuit. Make sure

that the control signal cables and wires will not come into contact with live conductors of the main circuit.

Failure to observe these precautions could cause electric shock and/or an accident.

Noise may be emitted from the inverter, motor and wires.

Implement appropriate measure to prevent the nearby sensors and devices from malfunctioning due to such

noise.

An accident could occur.

Table 2.13 lists the symbols, names and functions of the control circuit terminals. The wiring to the control circuit

terminals differs depending upon the setting of the function codes, which reflects the use of the inverter.

2-18

Page 34

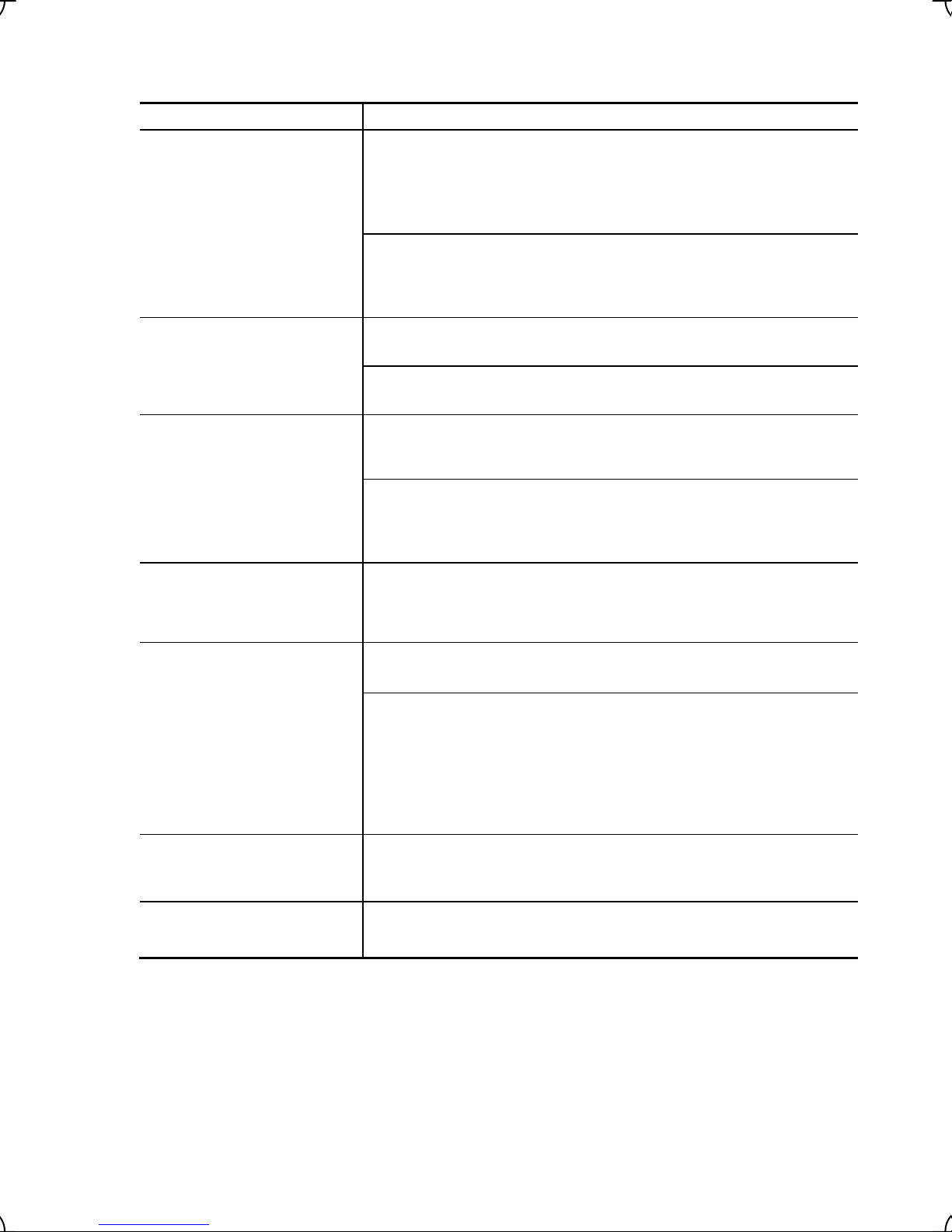

Table 2.13 Symbols, Names and Functions of the Control Circuit Terminals

Symbol Name Functions

cation

Classifi-

[12] Voltage

input

[C1] Current

input

[V2] Voltage

input

Analog input

(1) The reference speed (frequency) follows the input voltage level on terminal [12].

- 0 to ±10 VDC/0 to ±100 (%)

- Definition of 100%: Maximum speed (F03)

(2) The reference torque bias follows the input voltage level on terminal [12].

- 0 to ±10 VDC/0 to ±100 (%)

- Definition of the 100% torque bias: Rated output torque of the motor

(3) The reference torque current follows the input voltage level on terminal [12].

- 0 to ±10 VDC/0 to ±100 (%)

- Definition of 100% torque current: Rated overcurrent of the inverter

(1) The reference speed (frequency) follows the input current level on terminal [C1].

- +4 to +20 mA DC/0 to 100 (%)

- Definition of 100%: Maximum speed (F03)

(2) The reference torque bias follows the input current level on terminal [C1].

- +4 to +20 mA DC/0 to 100 (%)

- Definition of the 100% torque bias: Rated output torque of the motor

(3) The reference torque current follows the input current level on terminal [C1].

- +4 to +20 mA DC/0 to 100 (%)

- Definition of 100% torque current: Rated overcurrent of the inverter

* Input impedance: 250 Ω

* Allowable input current is +30 mA DC. If the input current exceeds +20 mA DC, the

inverter will limit it at +20 mA DC.

(1) The reference speed (frequency) follows the input voltage level on terminal [V2].

- 0 to ±10 VDC/0 to ±100 (%)

- Definition of 100%: Maximum speed (F03)

(2) The reference torque bias follows the input voltage level on terminal [V2].

- 0 to ±10 VDC/0 to ±100 (%)

- Definition of the 100% torque bias: Rated output torque of the motor

(3) The reference torque current follows the input voltage level on terminal [V2].

- 0 to ±10 VDC/0 to ±100 (%)

- Definition of 100% torque current: Rated overcurrent of the inverter

(4) This terminal is also used to connect a PTC (Positive Temperature Coefficient)

thermistor to protect the motor from an overheat failure. To do so, switch SW4 on the

control PCB to PTC side.

Figure shown at the right illustrates the

internal circuit diagram where the slide

switch SW4 (switching the input of

terminal [V2] between V2 and PTC)

selects PTC. For details of SW4 refer

to Section 2.3.8 “Setting up slide

switches.” In this case, you must

change data of the function code H26.

* Input impedance: 22 kΩ

* Allowable input voltage is +15 VDC. If the input voltage exceeds +10 VDC,

however, the inverter will limit it at +10 VDC.

Figure 2.14 Internal Circuit Diagram (SW4 Selecting PTC)

2-19

Page 35

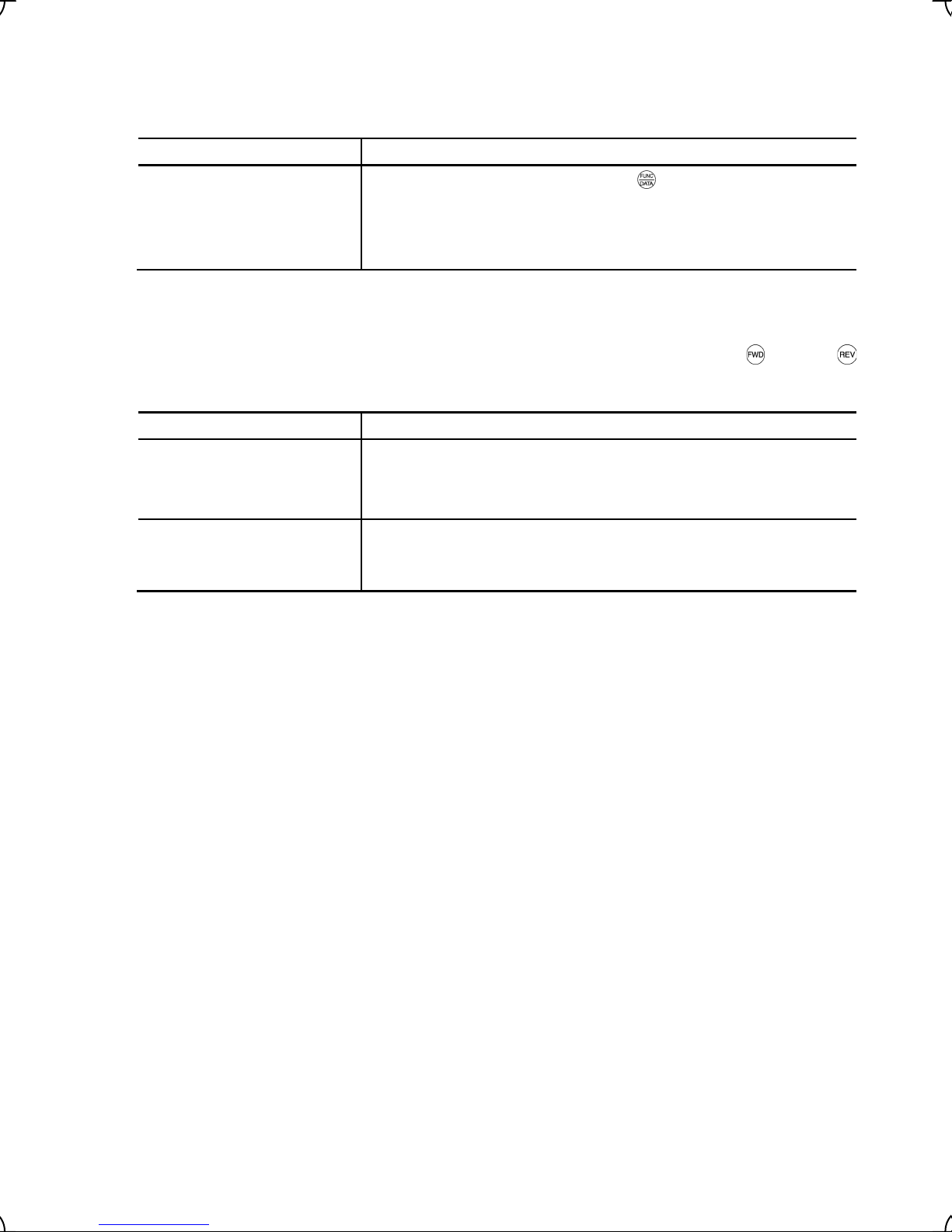

Table 2.13 Continued

Symbol Name Functions

Classifi-

cation

[11]

(Two

terminals)

Analog

common

Two common terminals for analog input and output signal terminals [12], [C1], and [V2].

These terminal are electrically isolated from terminals [CM]s and [CMY].

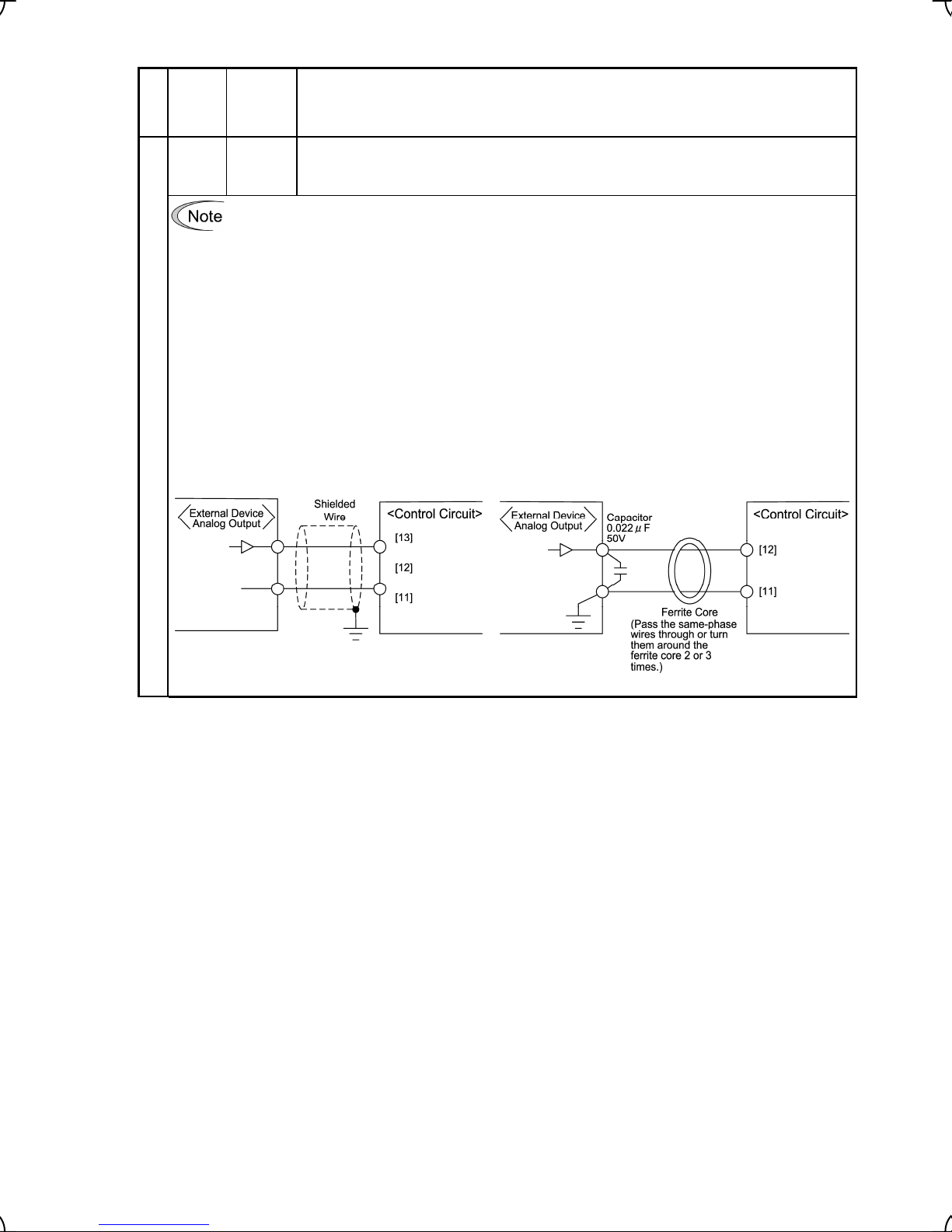

- Since low level analog signals are handled, these signals are especially susceptible to the external

noise effects. Route the wiring as short as possible (within 20 m) and use shielded wires. In

principle, ground the shielding layer of the shielded wires; if effects of external inductive noises are

considerable, connection to terminal [11] may be effective. As shown in Figure 2.15, ground the

single end of the shield to enhance the shielding effect.

- Use a twin contact relay for low level signals if the relay is used in the control circuit. Do not connect

the relay's contact to terminal [11].

- When the inverter is connected to an external device outputting the analog signal, a malfunction

may be caused by electric noise generated by the inverter. If this happens, according to the

circumstances, connect a ferrite core (a toroidal core or an equivalent) to the device outputting the

analog signal and/or connect a capacitor having the good cut-off characteristics for high frequency

components between control signal wires as shown in Figure 2.16.

Analog input

- Do not apply a voltage of +7.5 VDC or higher to terminal [C1]. Doing so could damage the internal

control circuit.

Figure 2.15 Connection of Shielded Wire Figure 2.16 Example of Electric Noise Reduction

2-20

Page 36

Table 2.13 Continued

Symbol Name Functions

Classifi-

cation

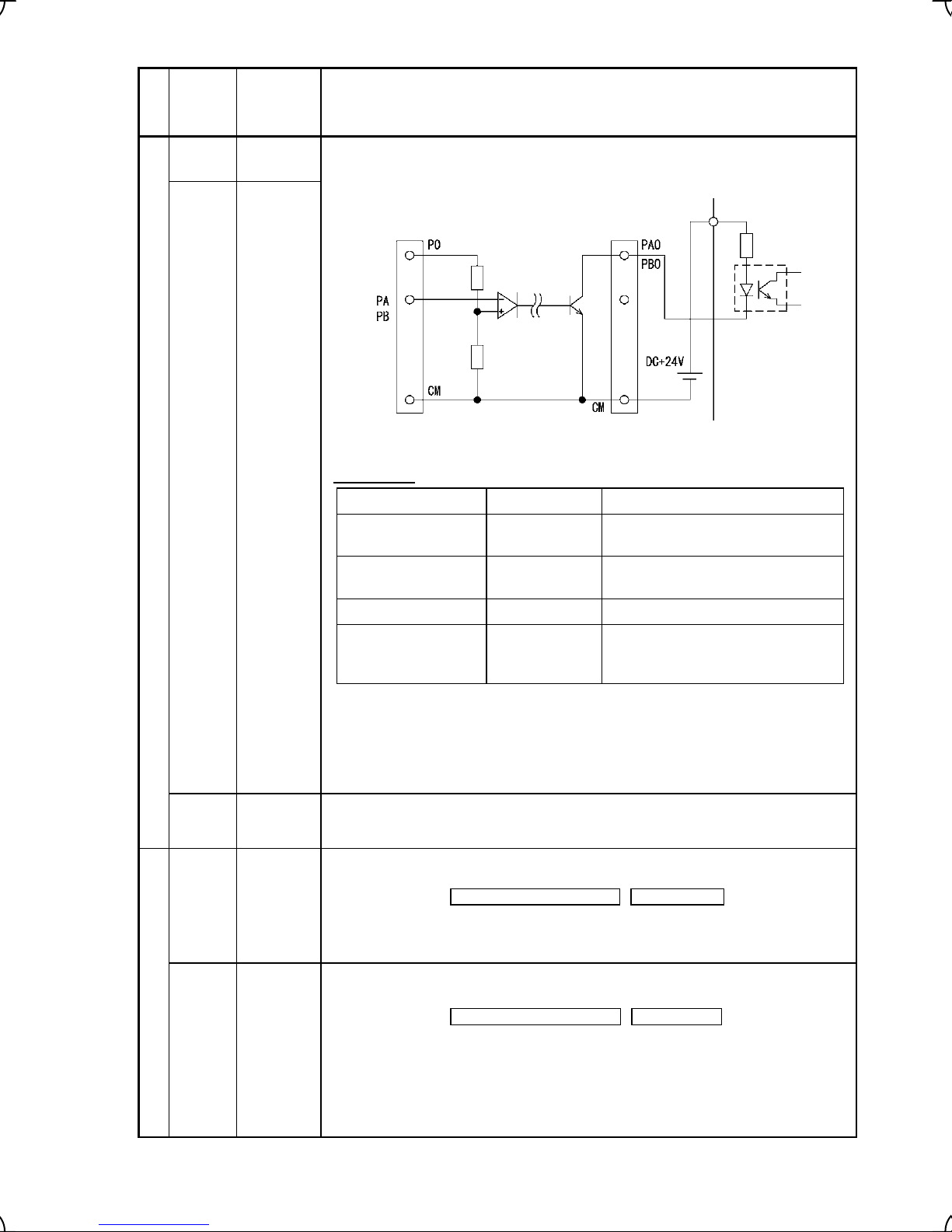

[X1] Digital

input 1

[X2] Digital

input 2

[X3] Digital

input 3

[X4] Digital

input 4

[X5] Digital

(1) The various signals such as coast-to-stop, alarm from external equipment, and

multistep speed commands can be assigned to terminals [X1] to [X8], [FWD], [REV],

and [EN] by setting function codes E01 to E08, E98, and E99. For details, refer to

Chapter 5, Section 5.2 "Overview of Function Codes."

(2) Input mode, i.e. Sink/Source, is changeable by using the internal slide switch SW1.

(3) Switches the logic value (1/0) for ON/OFF of the terminals between [X1] to [X8],

[FWD], [REV], or [EN] and [CM]. If the logic value for ON between [X1] and [CM] is 1

in the normal logic system, for example, OFF is 1 in the negative logic system and vice

versa.

(4) The negative logic signaling cannot be applicable to some signals such as [FWD] and

[REV].

input 5

[X6] Digital

(Digital input circuit specifications)

input 6

[X7] Digital

input 7

Operation

voltage

(SINK)

Item Min. Max.

ON level

0 V 2 V

OFF level 21 V 27 V

[X8] Digital

input 9

[FWD] Run

forward

command

[REV] Run

reverse

command

Operation

voltage

(SOURCE)

Operation current at ON

(Input voltage is at 0V)

Allowable leakage

current at OFF

ON level

OFF level

21 V 27 V

0 V 2 V

2.5 mA 5 mA

- 0.5 mA

Figure 2.17 Digital Input Circuit

Digital input

[EN] Enable If this terminal signal turns off, the inverter shut its power output down to absolutely stop

operation of the inverter.

[PLC]

(Two

terminals)

[CM]

(Two

terminals)

PLC

signal

power

Digital

common

Connects to PLC output signal power supply.

(Rated voltage: +24 VDC: Allowable range: +22 to +27 VDC)

Common terminals for digital input signal terminals

These terminals are electrically isolated from the terminals, [11]s and [CMY].

Figure 2.18 Digital Input Circuit

2-21

Page 37

Table 2.13 Continued

Symbol Name Functions

Classifi-

cation

Turning on or off [X1] to [X8], [FWD], [REV], or [EN] using a relay contact

Figure 2.19 shows two examples of a circuit that turns on or off control signal input [X1] to [X8],

[FWD], [REV], or [EN] using a relay contact. In the circuit (a), the slide switch SW1 has been turned

to SINK, whereas in the circuit (b) it has been turned to SOURCE.

NOTE: To configure this kind of circuit, use a highly reliable relay

(Recommended product: Fuji control relay Model HH54PW.)

(a) With the switch turned to SINK

(b) With the switch turned to SOURCE

Figure 2.19 Circuit Configuration Using a Relay Contact

Turning on or off [X1] to [X8], [FWD], [REV], or [EN] using a programmable logic controller

(PLC)

Figure 2.20 shows two examples of a circuit that turns on or off control signal input [X1] to [X8], [FWD],

Digital input

[REV], or [EN] using a programmable logic controller (PLC). In the circuit (a), the switch SW1 has been

turned to SINK, whereas in the circuit (b) it has been turned to SOURCE.

In circuit (a) below, short-circuiting or opening the transistor's open collector circuit in the PLC using an

external power source turns on or off control signal [X1] to [X8], [FWD], [REV], or [EN]. When using this

type of circuit, observe the following:

- Connect the + node of the external power source (which should be isolated from the PLC's power)

to terminal [PLC] of the inverter.

- Do not connect terminal [CM] of the inverter to the common terminal of the PLC.

(a) With the switch turned to SINK

For details about the slide switch setting, refer to Section 2.3.8 “Setting up slide switches.”

(b) With the switch turned to SOURCE

Figure 2.20 Circuit Configuration Using a PLC

2-22

Page 38

Table 2.13 Continued

Symbol Name Functions

Classifi-

cation

[Y1] Transistor

output 1

(1) Various signals such as inverter running, speed/freq. arrival and overload early

warning can be assigned to the terminal [Y1] by setting function code E20 to E23.

Refer to Chapter 5, Section 5.2 "Overview of Function Codes" for details.

(2) Switches the logic value (1/0) for ON/OFF of the terminals between [Y1] to [Y4] and

[CMY]. If the logic value for ON between [Y1] to [Y4] and [CMY] is 1 in the normal

logic system, for example, OFF is 1 in the negative logic system and vice versa.

Transistor output circuit specification

[Y2] Transistor

output 2

Item

Max.

[Y3] Transistor

output 3

[Y4] Transistor

output 4

Transistor output

[CMY] Transistor

output

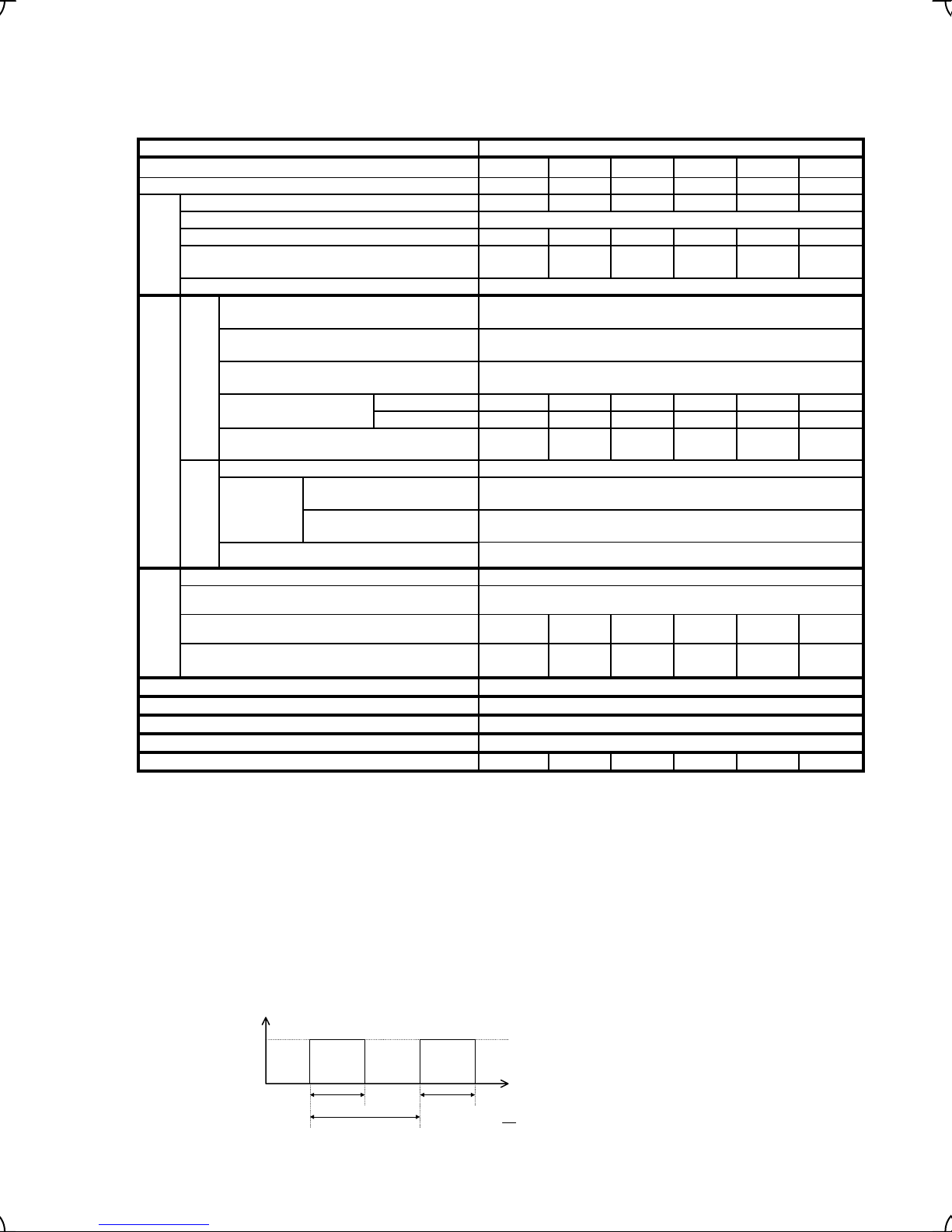

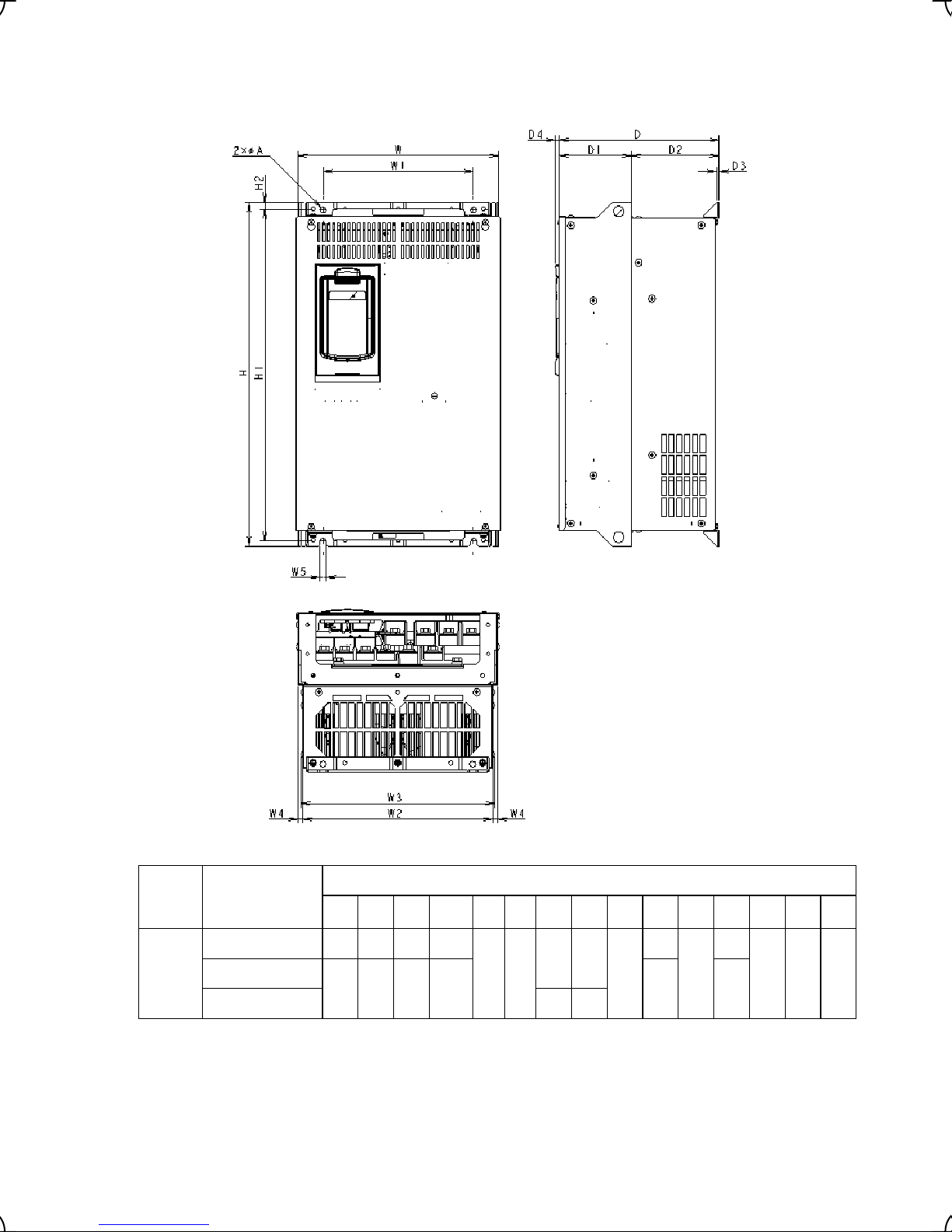

common