Page 1

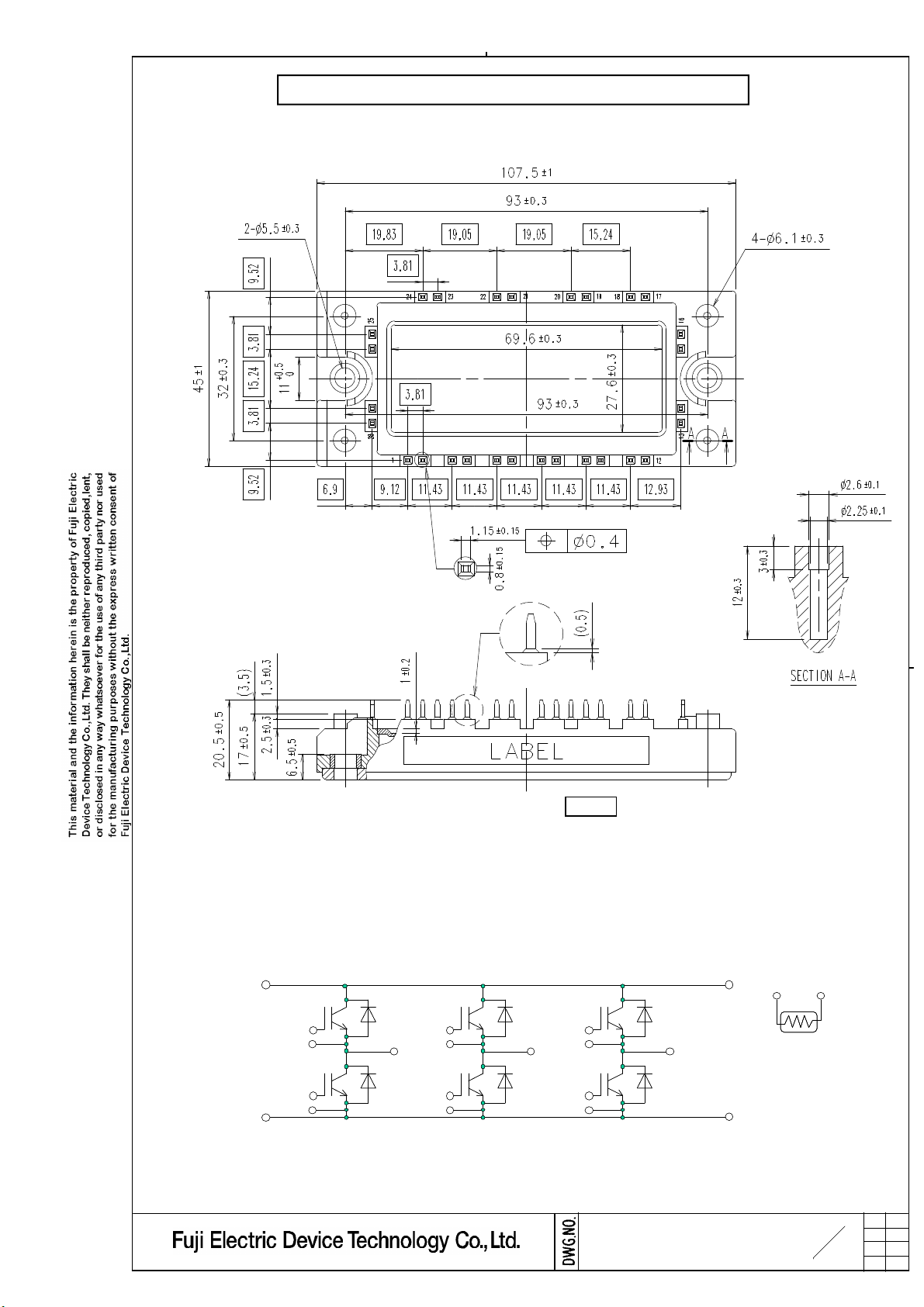

1. Outline Drawing ( Unit : mm )

6MBI75U4A-120

2. Equivalent circuit

222555,,,222666

222777,,,222888

shows theoretical dimension.

( ) shows reference dimension.

111555,,,111 666

111

222

333

444

555

666

UUU VVV WWW

222333,,,222 444

777

888

999

111000

111111

111222

111999,,,222000222111,,,222222

111333,,,111 444

MS5F6027

111777 111888

3

13

H04-004-03a

Page 2

Gate-Emitter

Gate-Emitter

)

C

3. Absolute Maximum Ratings ( at Tc= 25oC unless otherwise specified

)

o

o

C

Maximum

Ratings

1200

±20

100

75

200

150

75

150

390

+150

-40 to +125

3.5

Units

V

V

A

W

o

C

N m

Items

Collector-Emitter voltage

Gate-Emitter voltage

Collector current

Collector Power Dissipation 1 device

Junction temperature

Storage temperature

Isolation

voltage

Screw

Torque

(*1) All terminals should be connected together when isolation test will be done.

(*2) Two thermistor terminals should be connected together, each other terminals should be connected together

(*3) Recommendable Value : 2.5 to 3.5 Nm (M5)

between terminal and copper base (*1)

between thermistor and others (*2)

and shorted to base plate when isolation test will be done.

Symbols Conditions

VCES

VGES

Ic Continuous

Icp 1ms

-Ic

-Ic pulse 1ms

Pc

Tj

Tstg

Viso AC : 1min. 2500 VAC

-Mounting (*3)

Tc=25oC

Tc=80

Tc=80oC

4. Electrical characteristics ( at Tj= 25oC unless otherwise specified

Items ConditionsSymbols

Zero gate voltage

collector current

leakage current

threshold voltage

Collector-Emitter

saturation voltage

Input capacitance

Turn-on time

Inverter

Turn-off time

Forward on voltage

Reverse recovery time

Lead resistance,

terminal-chip (*4)

Resistance

B value B

Thermistor

(*4) Biggest internal terminal resistance among arm.

ICES - - 1.0

IGES

VGE(th)

VCE(sat)

(terminal)

VCE(sat)

(chip)

Cies VCE=10V,VGE=0V,f=1MHz ton Vcc=600V - 0.32 1.20

tr Ic=75A - 0.10

tr(i) VGE=±15V - 0.03 toff RG=9.1Ω -

tf - 0.07 0.30

VF

(terminal)

VF

(chip)

trr

R lead 4.10 - mΩ

R

VCE=1200V

VGE=0V

VCE=0V

VGE=±20V

VCE=20V

Ic=75mA

Ic=75A

VGE=15V

IF=75A

VGE=0V

IF=75A -

T=25oC

T=100oC

T=25/50oC

Tj=25oC

Tj=125oC

Tj=25oC

Tj=125oC

Tj=25oC

Tj=125oC

Tj=25oC

Tj=125oC

4.5

465 495 520

3305

Characteristics

typ.

- - 200

6.5 8.5

- 2.25 2.40

-

- 1.90 2.05

-

-

- 2.45 -

- 1.90 2.10

-

-

-

2.45

2.10 8 - nF

0.41 1.00

2.25 2.45

2.10 -

- 0.35

5000

3375 3450 K

max.

-

0.60

-

Units

mA

nA

V

V

us

V

us

Ω

MS5F6027

4

13

H04-004-03a

Page 3

)

5. Thermal resistance characteristics

Items Symbols Conditions Units

Thermal resistance(1device)

Contact Thermal resistance

(1 device) (*5)

Rth(j-c)

Rth(c-f) with Thermal Compound

IGBT FWD - -

(*5) This is the value which is defined mounting on the additional cooling fin with thermal compound.

Characteristics

min. typ. max.

-

-

0.05

6. Indication on module

Logo of production

6MBI75U4A-120

75A 1200V

Lot.No. Place of manufacturing (code

7. Applicable category

This specification is applied to IGBT-Module named 6MBI75U4A-120.

0.32

0.73

-

o

C/W

8. Storage and transportation notes

•

Store modules in a place with few temperature changes in order to avoid condensation on the

•

o

C and humidity of 45 to 75% .

module surface.

Avoid exposure to corrosive gases and dust.

•

Avoid excessive external force on the module.

•

Store modules with unprocessed terminals.

•

Do not drop or otherwise shock the modules when transporting.

•

9. Definitions of switching time

90%

~

~

0V

V

L

Vcc

R

G

V

GE

V

CE

Ic

GE

V

CE

Ic

0V

0A

t

r r

I

r r

Ic

~

90%

10%

10% 10%

t

r( i )

t

r

t

o n

~

V

CE

~

~

0V

90%

t

f

t

o f f

10. Packing and Labeling

Display on the packing box

- Products quantity in a packing box

MS5F6027

5

13

H04-004-03a

Page 4

11. Reliabi li ty test results

High temp. 125

( 0 : 1 )

-5

Reliability Test Items

Test

cate-

Test items Test methods and conditions

gories

1 Terminal Strength Pull force : 20N

(Pull test) Test time : 10±1 sec.

2 Mounting Strength Screw torque : 2.5 ~ 3.5 N・m (M5)

Test time : 10±1 sec.

3 Vibration Range of frequency : 10 ~ 500Hz

Sweeping time : 15 min.

Acceleration :

100m/s

Sweeping direction : Each X,Y,Z axis

Test time : 6 hr. (2hr./direction)

4 Shock Maximum acceleration :

5000m/s

Pulse width : 1.0msec.

Direction : Each X,Y,Z axis

Test time : 3 times/direction

Mechanical TestsEnvironment Tests

5 Solderabitlity Solder temp. : 235±5

Immersion time : 5±0.5sec.

Test time : 1 time

Each terminal should be Immersed in solder

within 1~1.5mm from the body.

6 Resistance to Solder temp. : 260±5

Soldering Heat Immersion time : 10±1sec.

Test time : 1 time

Each terminal should be Immersed in solder

within 1~1.5mm from the body.

1 High Temperature Storage temp. : 125±5 ℃

Storage Test duration : 1000hr.

2 Low Temperature Storage temp. : -40±5 ℃

Storage Test duration : 1000hr.

3 Temperature Storage temp. : 85±2 ℃

Humidity Relative humidity : 85±5%

Storage Test duration : 1000hr.

4 Unsaturated Test temp. : 120±2 ℃

Pressurized Vapor Test humidity : 85±5%

Test duration : 96hr.

5 Temperature

Cycle Test temp. : Low temp. -40±5

2

℃

℃

Reference

norms

EIAJ ED-4701

(Aug.- 2001 edit ion)

Test Method 401

Method

Test Method 402

method

Test Method 403

Reference 1

Condition code B

2

Test Method 404

Condition code B

Test Method 303

Condition code A

Test Method 302

Condition code A

Test Method 201

Test Method 202

Test Method 103

Test code C

Test Method 103

Test code E

Test Method 105

Number

sample

of

Acceptance

number

5 ( 0 : 1 )

Ⅰ

5 ( 0 : 1 )

Ⅱ

5 ( 0 : 1 )

5 ( 0 : 1 )

( 0 : 1 )

5

( 0 : 1 )

5

5 ( 0 : 1 )

5 ( 0 : 1 )

5 ( 0 : 1 )

5 ( 0 : 1 )

5 ( 0 : 1 )

℃

6 Thermal Shock

±5 ℃

RT 5 ~ 35

℃

Dwell time : High ~ RT ~ Low ~ RT

1hr. 0.5hr. 1hr. 0.5hr.

Number of cycles : 100 cycles

+0

Test temp. :

High temp. 100

+5

Low temp. 0 -0℃

Used liquid : Water with ice and boiling water

Dipping time : 5 min. par each temp.

Transfer time : 10 sec.

Number of cycles : 10 cycles

MS5F6027

℃

Test Method 307

Ⅰ

method

Condition code A

5

6

13

H04-004-03a

Loading...

Loading...