Fuji Bikes UG230H-SS4x, UG230H-TS4x, UG230, UG230H-LS4x, FEH381 User Manual

Create Tomorrow with

Trustworthy Technology

FUJI UG230 SERIES PROGRAMMABLE OPERATION DISPLAY

USER’S MANUAL <Hardware>

TYPE: UG230H-LS4x

UG230H-SS4x

UG230H-TS4x

FEH381

Preface

Thank you for selecting the Fuji Programmable Operation Display, POD UG230 Series (called as the UG230 or

POD hereafter).

This User’s Manual <UG230 Hardware> explains system configuration, specifications and handling of the UG230

Series. To enable you to fully utilize the display, carefully read this User’s Manual.

For more information on the UG230 Series, refer to the following manuals as well.

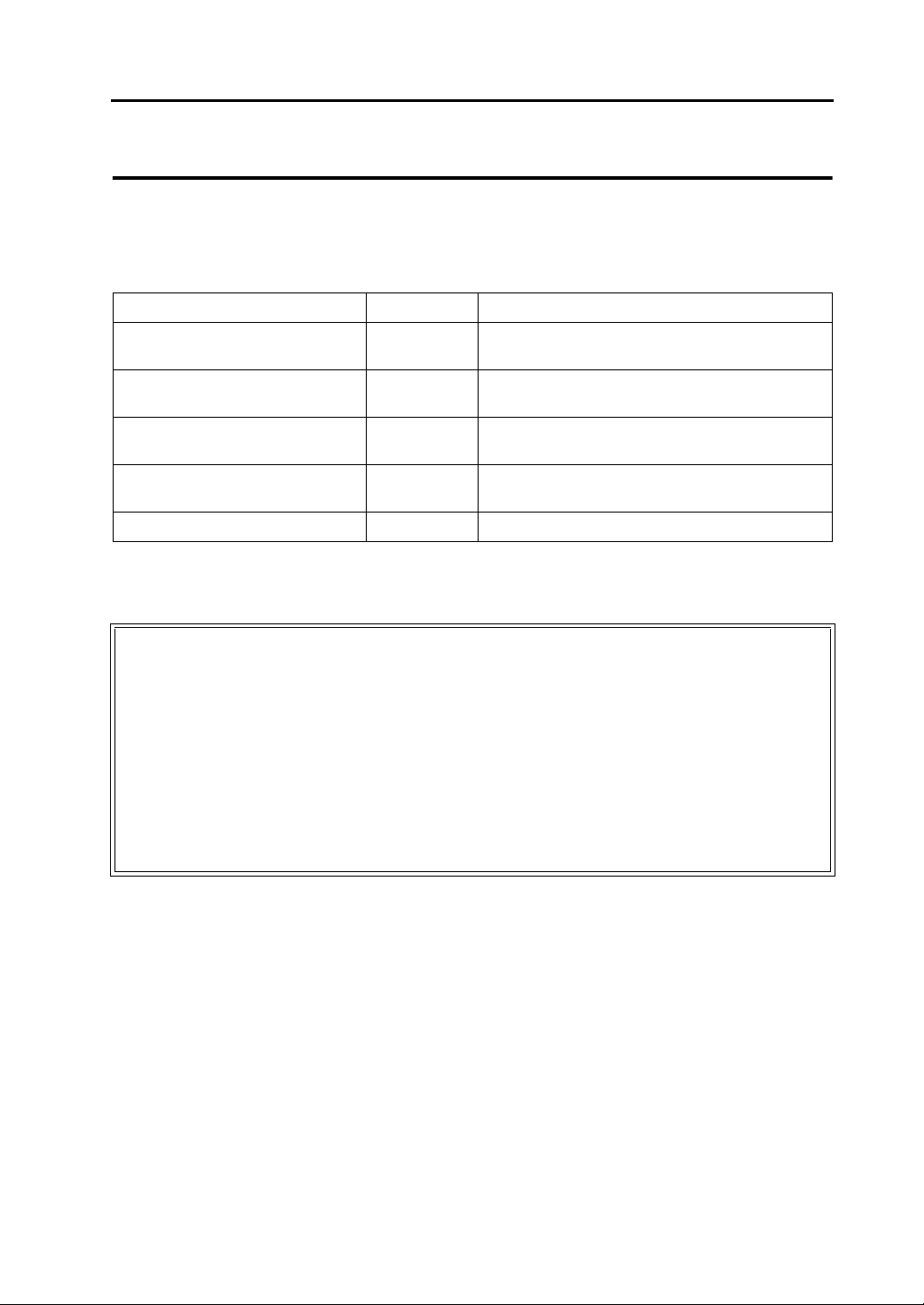

Name Manual No. Contents

UG Series <Operation> FEH375 Describes operating procedures of the screen editor

UG Series <Function> FEH376 Describes the functions available with the UG30/20

UG Series <PLC Connection> FEH380 Describes connections with PLCs, universal serial

UG Series <Supplementary Manual> FEH376-1 Supplementary information for the UG Series

UG Series <Tutorial> FEH350 Tutorial manual for novices in the UG Series

For further details about PLCs (programmable logic controllers), see the manual attached to each PLC.

Notes:

(UG00S-CW) for the UG Series.

Series.

communications, etc.

<Function>

1. This manual may not, in whole or in part, be printed or reproduced without the prior written consent of

Fuji Electric FA Components & Systems Co., Ltd.

2. The information in this manual is subject to change without prior notice.

3. Windows and Excel are registered trademarks of Microsoft Corporation in the United States and other

countries.

4. All other company names or product names are trademarks or registered trademarks of their

respective holders.

5. This manual is intended to give accurate information about POD hardware. If you have any

questions, please contact your local distributor.

Record of Revisions

Reference numbers are shown at the bottom left corner on the back cover of each manual.

Printing Date Reference No. Revised Contents

February, 2004 FEH381 First edition

Notes on Safe Use of POD

In this manual, you will find various notes categorized under the following levels with the signal words “DANGER,”

and “CAUTION.”

DANGER

CAUTION

Note that there is a possibility that the item listed with may have serious ramifications.

Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury and could cause property damage.

CAUTION

DANGER

• Never use the input function of POD for operations that may threaten human life or to damage the system,

such as switches to be used in case of emergency. Please design the system so that it can cope with

malfunction of a touch switch. A malfunction of the touch switch will result in machine accident or damage.

• Turn off the power supply when you set up the unit, connect cables or perform maintenance and inspection.

Otherwise, electrical shock or damage may occur.

• Never touch any terminals while the power is on. Otherwise, electric shock may occur.

• You must put a cover on the terminals on the unit when you turn the power on and operate the unit. Without

the terminal cover in place, an electric shock may occur.

• The liquid crystal in the LCD panel is a hazardous substance. If the LCD panel is damaged, never swallow

the leaked liquid crystal. If the liquid crystal spills on your skin or clothing, use soap and wash off thoroughly.

• For POD using a lithium battery, never disassemble, recharge, deform by pressure, short-circuit, nor reverse

the polarity of the battery, and never dispose of the battery in fire. Failure to follow these conditions will lead

to explosion or ignition.

• For POD using a lithium battery, never use a battery that is deformed, leaks, or shows any other signs of

abnormality. Failure to follow these conditions will lead to explosion or ignition.

CAUTION

• Check the appearance of the unit when it is unpacked. Do not use the unit if any damage or deformation is

found. Failure to do so may lead to fire, damage or malfunction.

• For use in a facility or for a system related to nuclear energy, aerospace, medical, traffic equipment, or

mobile installations, please consult your local distributor.

• Operate (or store) POD under the conditions indicated in this manual and related manuals. Failure to do so

could cause fire, malfunction, physical damage or deterioration.

• Understand the following environmental limits for use and storage of POD. Otherwise, fire or damage to the

unit may result.

- Avoid locations where there is a possibility that water, corrosive gas, flammable gas, solvents, grinding

fluids or cutting oil can come into contact with the unit.

- Avoid high temperature, high humidity, and outside weather conditions, such as wind, rain or direct

sunlight.

- Avoid locations where excessive dust, salt, and metallic particles are present.

- Avoid installing the unit in a location where vibration or physical shock may be transmitted.

• Equipment must be correctly mounted so that the main terminal of POD will not be touched inadvertently.

Otherwise, an accident or electric shock may occur.

• Tighten the fixtures of the POD with a torque in the specified range. Excessive tightening may distort the

panel surface. Loose tightening may cause POD to come off, malfunction or be short-circuited.

• Check periodically that terminal screws on the power supply terminal block and fixtures are firmly tightened.

Loosened screws may result in fire or malfunction.

• Tighten terminal screws on the power supply terminal block equally to a torque of 0.5 N•m. Improper

tightening of screws may result in fire, malfunction, or trouble.

• POD has a glass screen. Do not drop or give physical shock to the unit. Otherwise, the screen may be

damaged.

• Connect the cables correctly to the terminals of POD in accordance with the specified voltage and wattage.

Over-voltage, over-wattage or incorrect cable connection could cause fire, malfunction or damage to the

unit.

• Be sure to establish a ground of POD. Ground FG terminal which must be used for the unit. Otherwise,

electric shock or a fire may occur.

• Prevent any conductive particles from entering into POD. Failure to do so may lead to fire, damage or

malfunction.

• After wiring is finished, remove the paper used as a dust cover before starting to operate POD. Operation

with the cover attached may result in accident, fire, malfunction, or trouble.

• Do not attempt to repair POD at your site. Ask us or the designated contractor for repair.

• Do not disassemble or modify POD. Otherwise, it may cause a malfunction.

• Fuji Electric FA Components & Systems Co., Ltd. is not responsible for any damages resulting from repair,

overhaul or modification of POD that was performed by an unauthorized person.

• Do not use a sharp-pointed tool when pressing a touch switch. Doing so may damage the screen.

• Only experts are authorized to set up the unit, connect the cables or perform maintenance and inspection.

• For POD using a lithium battery, handle the battery with care. The combustible materials such as lithium or

organic solvent contained in the battery may generate heat, explode, or catch fire, resulting in personal injury

or fire. Read related manuals carefully and handle the lithium battery correctly as instructed.

• When using a POD that has analog switch resolution with resistance film, do not press two or more points on

the screen at the same time. If there is a switch between the two pressed points, it may be activated.

• Take safety precautions during such operations as setting change during running, forced output, start, and

stop. Any misoperation may cause unexpected machine motions, resulting in machine accident or damage.

• In facilities where a failure of POD could lead to accident threatening human life or other serious damage, be

sure that the facilities are equipped with adequate safeguards.

• At the time of disposal, POD must be treated as industrial waste.

• Before touching POD, discharge static electricity from your body by touching grounded metal. Excessive

static electricity may cause malfunction or trouble.

[General Notes]

• Never bundle control cables and input/output cables with high-voltage and large-current carrying cables such

as power supply cables. Keep these cables at least 200 mm away from the high-voltage and large-current

carrying cables. Otherwise, malfunction may occur due to noise.

• Plug connectors or sockets of POD in the correct orientation. Otherwise, it may cause a malfunction.

• Do not use thinners for cleaning because they may discolor the POD surface. Use alcohol or benzine

commercially available.

• If a data receive error occurs when POD and the counterpart (PLC, temperature controller, etc.) are started at

the same time, read the manual for the counterpart unit and handle the error correctly.

• Avoid discharging static electricity on the mounting panel of the POD. Static charges can damage the unit and

cause malfunctions. Otherwise, malfunction may occur due to noise.

• Avoid prolonged display of any fixed pattern. Due to the characteristics of the liquid crystal display, an

afterimage may occur. If a prolonged display of a fixed pattern is expected, use the auto OFF function of the

backlight.

Contents

Preface

Notes on Safe Use of POD

Chapter 1 Overview

1. Features............................................................................................................................................ 1-1

2. Models and Peripheral Equipment .................................................................................................... 1-2

POD Models ........................................................................................................................................................1-2

Peripheral Equipment..........................................................................................................................................1-3

3. System Composition......................................................................................................................... 1-6

System Composition of UG230...........................................................................................................................1-6

System Composition of UG230 + UG230A-DCL.................................................................................................1-7

Chapter 2 Specifications

1. Specifications.................................................................................................................................... 2-1

General Specifications ........................................................................................................................................2-1

Display Specifications .........................................................................................................................................2-2

Touch Switch Specifications ...............................................................................................................................2-2

Function Switch Specifications............................................................................................................................2-2

Interface Specifications.......................................................................................................................................2-3

Clock and Backup Memory Specifications ..........................................................................................................2-3

Drawing Environment ..........................................................................................................................................2-3

Display Function Specifications ..........................................................................................................................2-4

Function Performance Specifications..................................................................................................................2-5

2. Dimensions and Panel Cut-out ......................................................................................................... 2-6

UG230 External View and Dimensions ...............................................................................................................2-6

UG230 + UG230A-DCL External View and Dimensions.....................................................................................2-7

3. Names and Functions of Components.............................................................................................. 2-8

4. Modular Jack (MJ1/MJ2)................................................................................................................. 2-10

Modular Jack 1 (MJ1)........................................................................................................................................2-10

Modular Jack 2 (MJ2: Exclusive to the UG230) ................................................................................................2-11

Notes on Wiring.................................................................................................................................................2-14

Transferring Screen Data ..................................................................................................................................2-17

Barcode Reader Connection.............................................................................................................................2-17

Printer Connection (Serial Printer) ....................................................................................................................2-18

5. USB Connectors ............................................................................................................................. 2-19

USB-A (Master Port) .........................................................................................................................................2-19

USB-B (Slave Port) ...........................................................................................................................................2-20

6. D-sub 25-Pin Connector (CN1) (Optional) ...................................................................................... 2-25

Serial Connector (CN1) .....................................................................................................................................2-25

7. 10BASE-T (LAN) (Optional)............................................................................................................ 2-26

10BASE-T Connector........................................................................................................................................2-26

Notes on Wiring.................................................................................................................................................2-27

8. CF Card .......................................................................................................................................... 2-28

Recommended CF Cards .................................................................................................................................2-28

CF Card Insertion Position................................................................................................................................2-28

Mounting and Dismounting the CF Card...........................................................................................................2-29

Notes on Handling the CF Card ........................................................................................................................2-30

Chapter 3 Installation

1. Mounting Procedure .......................................................................................................................... 3-1

Mounting Procedure............................................................................................................................................3-1

Mounting Angle ...................................................................................................................................................3-1

2. Power Supply Cable Connection ...................................................................................................... 3-2

Power Supply Cable Connection ........................................................................................................................3-2

Grounding ...........................................................................................................................................................3-3

Chapter 4 Instructions

1. Coin-type Lithium Battery.................................................................................................................. 4-1

Battery Mounting Procedure ...............................................................................................................................4-1

Battery Replacement .......................................................................................................................................... 4-2

2. DIP Switch Setting ............................................................................................................................ 4-4

DIP Switch (DIPSW) Setting ...............................................................................................................................4-4

3. Function Switches ............................................................................................................................. 4-5

Types ..................................................................................................................................................................4-5

[SYSTEM] Switch................................................................................................................................................4-5

Chapter 5 Connections

1. 1 : 1 Connection ................................................................................................................................ 5-1

2. 1 : n Connection (Multi-drop)............................................................................................................. 5-2

3. n : 1 Connection (Multi-link 2) ........................................................................................................... 5-3

4. n : 1 Connection (Multi-link) .............................................................................................................. 5-4

5. Universal Serial Communications ..................................................................................................... 5-5

6. UG-Link ............................................................................................................................................. 5-6

7. PLC2Way.......................................................................................................................................... 5-7

8. Temperature Control Network........................................................................................................... 5-8

9. Ethernet............................................................................................................................................. 5-9

Chapter 6 POD Operations

1. Operational Procedures .................................................................................................................... 6-1

POD Operation ...................................................................................................................................................6-1

2. Main Menu Screen............................................................................................................................ 6-4

Displaying the M ain Menu Screen ......................................................................................................................6-4

Moving Back to the Screen in the RUN Mode ....................................................................................................6-4

Main Menu Screen..............................................................................................................................................6-5

1. I/O Test ............................................................................................................................... 6-5

1-1. USB Test................................................................................................................... 6-6

1-2. Serial Connection Test.............................................................................................. 6-7

1-3. SYSTEM & Function Switch Test ........................................................................... 6-13

1-4. Touch Switch Test .................................................................................................. 6-13

2. Card Menu Screen ............................................................................................................ 6-15

2-1. Card Recorder Menu Screen.................................................................................. 6-16

2-2. Transferring Screen Data from a CF Card.............................................................. 6-18

2-3. Saving Backup Copies of SRAM ............................................................................ 6-24

2-4. Messages during Data Transfer.............................................................................. 6-26

3. Communication Parameter Screen................................................................................... 6-27

4. Extension Program Information ........................................................................................ 6-28

5. Ethernet (Optional)............................................................................................................ 6-29

5-1. Ethernet Information Screen................................................................................... 6-29

5-2. IP Address Setting.................................................................................................. 6-30

6. SRAM/Clock...................................................................................................................... 6-36

7. Extended Function Setting................................................................................................ 6-38

Chapter 7 Error Correction

1. Error Messages................................................................................................................................. 7-1

1. Communication Error.......................................................................................................... 7-1

2. Check.................................................................................................................................. 7-3

3. Warning............................................................................................................................... 7-3

4. SYSTEM ERROR ............................................................................................................... 7-4

5. Touch Switch is Active........................................................................................................7-4

2. Troubleshooting ................................................................................................................................ 7-5

In the Event of an Error.......................................................................................................................................7-5

Probable Symptoms ............................................................................................................................................7-5

Chapter 8 Inspection and Maintenance

1. Inspection and Maintenance ............................................................................................................. 8-1

Daily Inspection ...................................................................................................................................................8-1

Periodical Inspection ...........................................................................................................................................8-1

2. Warranty Policy................................................................................................................................. 8-2

Inquiries about Failure.........................................................................................................................................8-2

Warranty Period ..................................................................................................................................................8-2

Free-of-charge Repair.........................................................................................................................................8-2

Chargeable Repair ..............................................................................................................................................8-2

1

1. Features

2. Models and Peripheral Equipment

3. System Composition

Overview

1. Features 1-1

1. Features

The UG230 series inherits and heightens the features of the UG20 series as described below.

1. 32k-color Display (except for UG230H-LS4x)

32,768-color display makes colorful expression possible.

JPEG files and bitmap files are clearly displayed in brilliant colors.

2. USB Master/Slave Port as Standard

Two ports are provided as standard for diverse applications.

At the master port, a USB-compatible EPSON STYLUS PHOTO series printer or CF card

reader/writer can be used.

On-site versatility is extended further.

At the slave port, large quantities screen data can be transferred from the computer at a high

speed.

3. SRAM and Clock Function as Standard

A 128 kbyte SRAM is standard, allowing backup copies of recipe data or sampling data to be

saved with ease.

4. CF Card Interface Supported (USB master port/optional)

The CF card can be used for saving multiple screen data, sampling data, recipe data, hard copy

images, and other various usages.

JPEG files and font files can also be saved.

5. 10BASE-T Connector Supported (optional)

This connector enables Ethernet connection with a host computer or PLC.

High-speed communications are possible via Ethernet for transferring screen data and

reading/writing data from/to the server.

1

Overview

6. Analog Switch/Matrix Switch Supported

The switch type can be selected from the lineup according to your application.

A variety of switch types is available to suit your requirements.

1-2 2. Models and Peripheral Equipment

2. Models and Peripheral Equipment

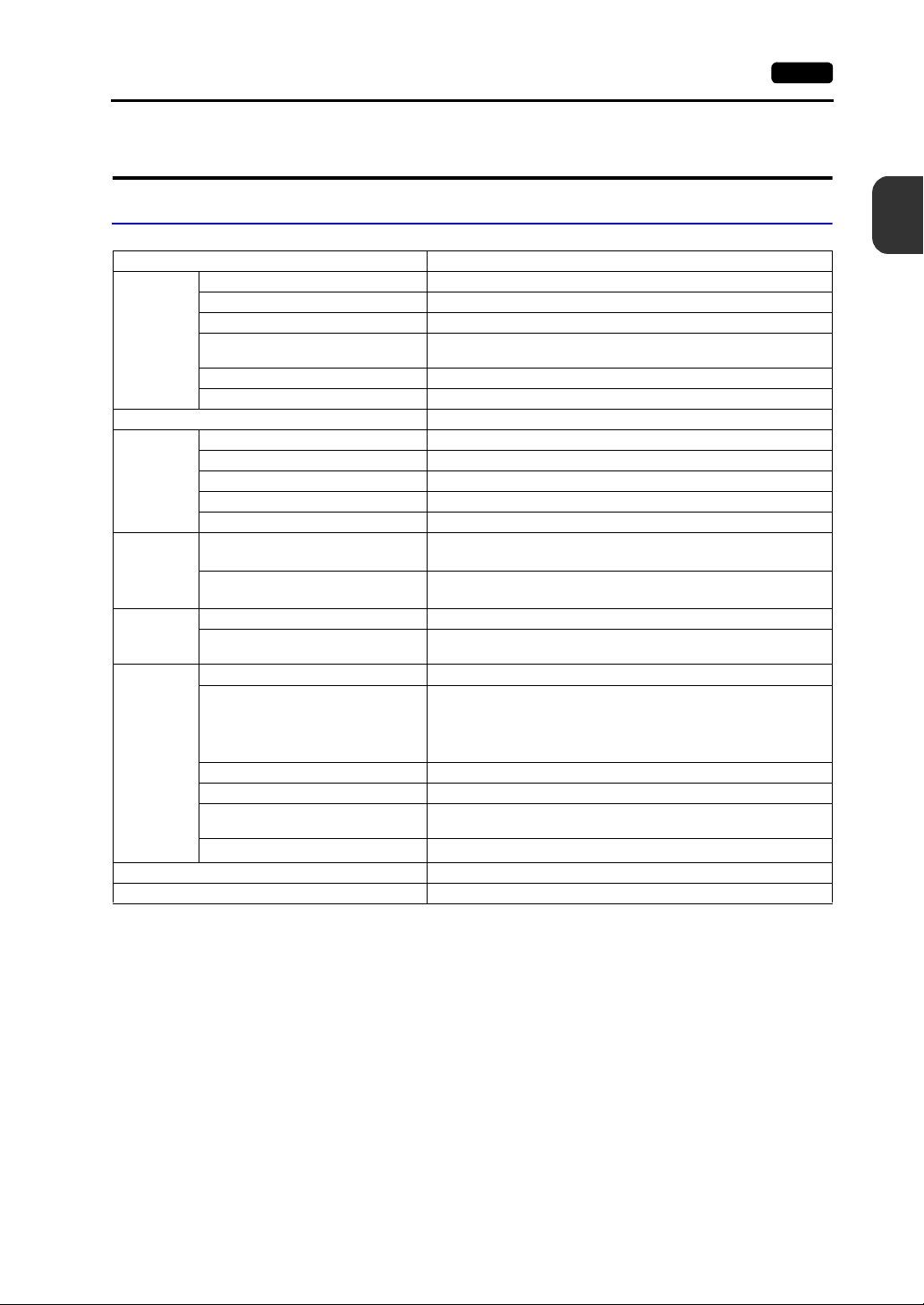

POD Models

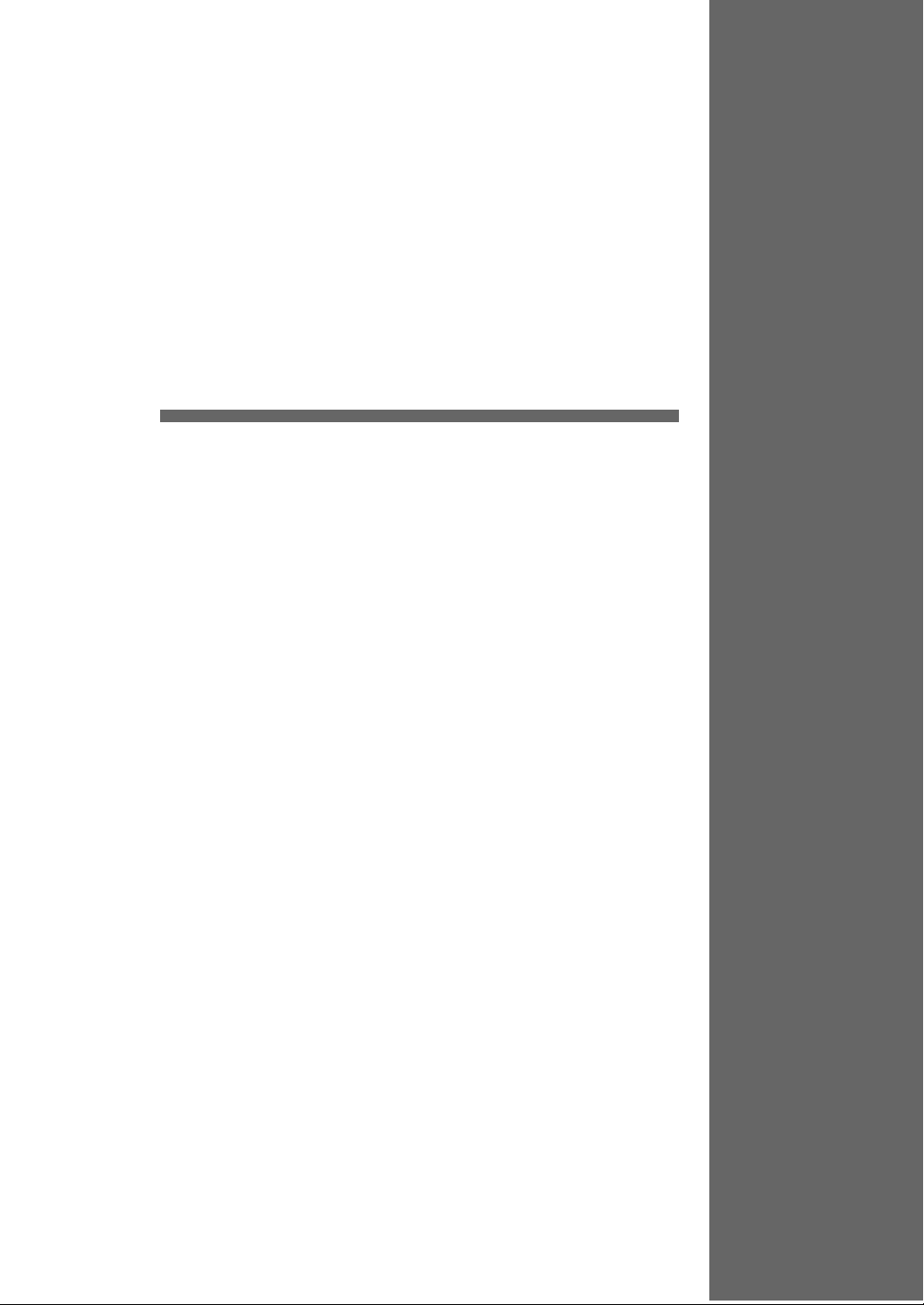

The model name consists of the following information.

UG 2 30 H - L S 4 D

Screen size

2: 5.7-inch

Version information

POD unit type

The following models are available.

Series and Size Model Name Specifications Remarks

UG230 series

5.7-inch

UG230H-TS4

UG230H-TS4D

UG230H-SS4

UG230H-SS4D

UG230H-LS4

UG230H-LS4D

Touch switch specification

None: Analog switch

D: Matrix switch

Power supply specification

4: 24 VDC specification

(in compliance with CE/UL/cUL)

Functional specification

S: Standard

Device specification

T: TFT color LCD (QVGA)

S: STN color LCD (QVGA)

L: STN monochrome LCD (QVGA)

TFT color, 320 × 240 dots, analog switch

DC power supply

TFT color, 320 × 240 dots, matrix switch

DC power supply

STN color, 320 × 240 dots, analog switch

DC power supply

STN color, 320 × 240 dots, matrix switch

DC power supply

STN monochrome, 320 × 240 dots, analog switch

DC power supply

STN monochrome, 320 × 240 dots, matrix switch

DC power supply

Compliant with

CE/UL/cUL

Compliant with

CE/UL/cUL

Compliant with

CE/UL/cUL

Compliant with

CE/UL/cUL

Compliant with

CE/UL/cUL

Compliant with

CE/UL/cUL

2. Models and Peripheral Equipment 1-3

Peripheral Equipment

The following options are available for using the UG230 series more effectively.

UG00S-CWV3 (configuration software: English/Japanese)

Application software for editing display data for the POD.

(Windows98/NT4.0/Me/2000/X P compatible)

The UG230 series is supported with ver. 3.2.0.0 and later.

UG230A-DCL (option unit)

Optional unit to be used for D-sub 25-pin connector, CF card and Ethernet.

UG230P-D4 (FLASH memory cassette)

Extension print circuit board to extend the memory for screen data.

The capacity of FLASH memory is 4 Mbyte.

* Only when the UG230A-DCL (option unit) is provided

UG00P-TC (terminal converter)

CN1

SW1

TB1

Used for connection between the UG30 series and a PLC at the RS-422/485 terminal block.

* Only when the UG230A-DCL (option unit) is provided

1

Overview

UG00P-MR (card recorder)

The card recorder creates a backup copy of screen data or works as an external memory

storage system for memory manager and data logging functions.

UG00K-xx (memory card) compliant with JEIDA ver. 4.0

Used with the card recorder when having a backup copy of screen data or saving data on an

external medium for memory manager and data logging functions.

SRAM 256 K, 512 K, 1 M, 2 M, 4 Mbyte

FLASH ROM 256 K, 512 K, 1 Mbyte

UG00P-MS (memory card editor: English/Japanese)

Application software for editing data stored on a memory card, SRAM or CF card.

(Windows98/NT4.0/Me/2000/X P compatible)

1-4 2. Models and Peripheral Equipment

UG00P-DI (ACPU/QnACPU/FXCPU dual port interface)

Add-on connector with two ports, specifically designed for the connector on the

PP

G

1 2 3

G

D

MITSUBISHI’s ACPU/QnACPU/FXCPU programmer. Operability can be improved when

directly connecting the POD to the ACPU/QnACPU/FXCPU programmer.

* Only when the UG230A-DCL (option unit) is provided

UG00P-U2 (serial extension I/O)

D

F

GI

C

2

4

V

I

N

1

I

N

3

I

N

5

N

0

I

N

7

I

N

I

2

N

9

I

N

I

4

N

1

1

IN

I

N

6

1

3

IN

I

8

N

1

5

I

N

1

0

I

N

1

2

I

N

1

4

C

O

M

+

M

J

1

O

U

T

1

O

U

T

3

O

U

T

5

O

U

O

T

U

0

T

7

O

U

O

T

U

2

T

8

O

U

O

T

U

4

T

1

0

O

U

O

T

U

6

T

1

2

C

O

O

M

U

1

T

1

4

O

U

C

T

O

9

M

2

O

U

T

1

1

O

U

T

1

3

O

U

T

1

5

Used as an external I/O unit for PLC. It has 16 inputs and 16 outputs.

UG00C-T (screen data transfer cable) 3 m

Used for connection between the POD and a personal computer, or a personal computer

and the card recorder (UG00P-MR).

UG00C-B (barcode reader connection cable) 3 m

Used for connection between the POD and a barcode reader.

This is also used for connection between the POD and a temperature controller via

RS-232C.

UG00C-H (multi-link 2 master cable/temperature controller connection cable) 3 m

Used for Multi-Link 2 connection between the POD master station and the POD slave

station.

This is also used for connection between the POD and a temperature controller via RS-422

(485).

UG00C-P (temperature controller connection cable) 3 m

Used for connection between the POD and a temperature controller or a PLC using the

PLC2Way function via RS-422 (4-wire connection).

This is also used for connection with a PLC at the MJ2 port on the UG230.

UG30C-J (MJ2-to-D-sub conversion cable) 0.3 m

Used for connection between the UG230 and a PLC at MJ2.

2. Models and Peripheral Equipment 1-5

UG30C-M (MJ-to-D-sub conversion cable) 0.3 m

Used for connection of the POD via PLC2Way.

UGxxP-PS (protective sheet)

This sheet protects the operation panel surface. (5 sheets/set)

UGxxP-PT (protective sheet)

This anti-glare sheet protects the operation panel surface. (5 sheets/set)

UG30P-BT (battery for replacement)

Replacement lithium battery for the UG30 series.

1

Overview

1-6 3. System Composition

3. System Composition

System Composition of UG230

The following illustration shows possible system configurations using the UG230.

UG series

configuration

softwar e

UG00S-CW

Creating screens

disc

RESET

Computer (PC)

(USB slave)

Transferring

screen data

UG00C-T

USB-B

UG230

(USB master)

USB-A

MJ2MJ1

During operation

(Link/universal serial communication)

RS-232C/RS-422

Temperature controller,

inverter

Barcode reader

UG00P-U2

Card recorder

UG00P-MR

UG00C-P

UG00C-B

D

C

2

4

V

I

N

1IN

F

G

3

I

N

5

I

N

0

I

N

7

I

N

I

2

N

9

I

N

I

4

N

1

I

N

6

I

N

8

I

N

1

0

I

N

1

MJ1

1

I

N

1

3

I

N

1

5

O

2

U

T

1

I

N

O

1

4

U

T

3

C

O

O

M

U

+

T

5

O

U

O

T

U

0

T

7

O

U

O

T

U

2

T

8

O

U

O

T

U

4

T

1

0O

O

U

T

U

6

T

1

2

C

O

O

M

U

1

T

1

4

O

U

C

T

O

9

M

2

O

U

T

1

1

O

U

T

1

3

O

U

T

1

5

Link unit/

general-purpose computer

CF card

reader/writer

C F R W

96

MB

Printer

3. System Composition 1-7

System Composition of UG230 + UG230A-DCL

The following illustration shows possible system configurations using the UG230 and the

UG230A-DCL.

UG series

configuration

softwa re

UG00S-CW

Creating screens

Temperature controller,

inverter

disc

RESET

Computer (PC)

disc

RESET

Computer (PC)

UG00C-T

Transferring

screen data

disc

RESET

Computer (PC)

UG230+UG230A-DCL

(USB slave)

USB-B

MJ1

UG00C-P

LAN

D-sub

USB-AMJ1/MJ2

(USB master)

Ethernet

During operation

(Link/universal serial

communication)

RS-232C/RS-422

1

Overview

Barcode reader

UG00P-U2

Card recorder

UG00P-MR

UG00C-B

Link unit/

general-purpose computer

D

C

2

4

V

I

N

1IN

F

G

3

I

N

5

I

N

0

I

N

7

I

N

I

2

N

9

I

N

I

4

N

1

1

I

N

6

I

N

8

I

N

1

0

I

N

1

2

MJ1

I

N

1

3

I

N

1

5

O

U

T

1

I

N

O

1

4

U

T

3

C

O

O

M

U

+

T

5

O

U

O

T

U

0

T

7

O

U

O

T

U

2

T

8

O

U

O

T

U

4

T

1

0O

O

U

T

U

6

T

1

2

C

O

O

M

U

1

T

1

4

O

U

C

T

O

9

M

2

O

U

T

1

1

O

U

T

1

3

O

U

T

1

5

CF card

C F R W

reader/writer

96

MB

Printer

1-8 3. System Composition

Please use this page freely.

2

1. Specifications

2. Dimensions and Panel Cut-out

3. Names and Functions of Components

4. Modular Jack (MJ1/MJ2)

5. USB Connectors

6. D-sub 25-Pin Connector (CN1) (Optional)

7. 10BASE-T (LAN) (Optional)

8. CF Card

Specifications

1. Specifications

1. Specifications 2-1

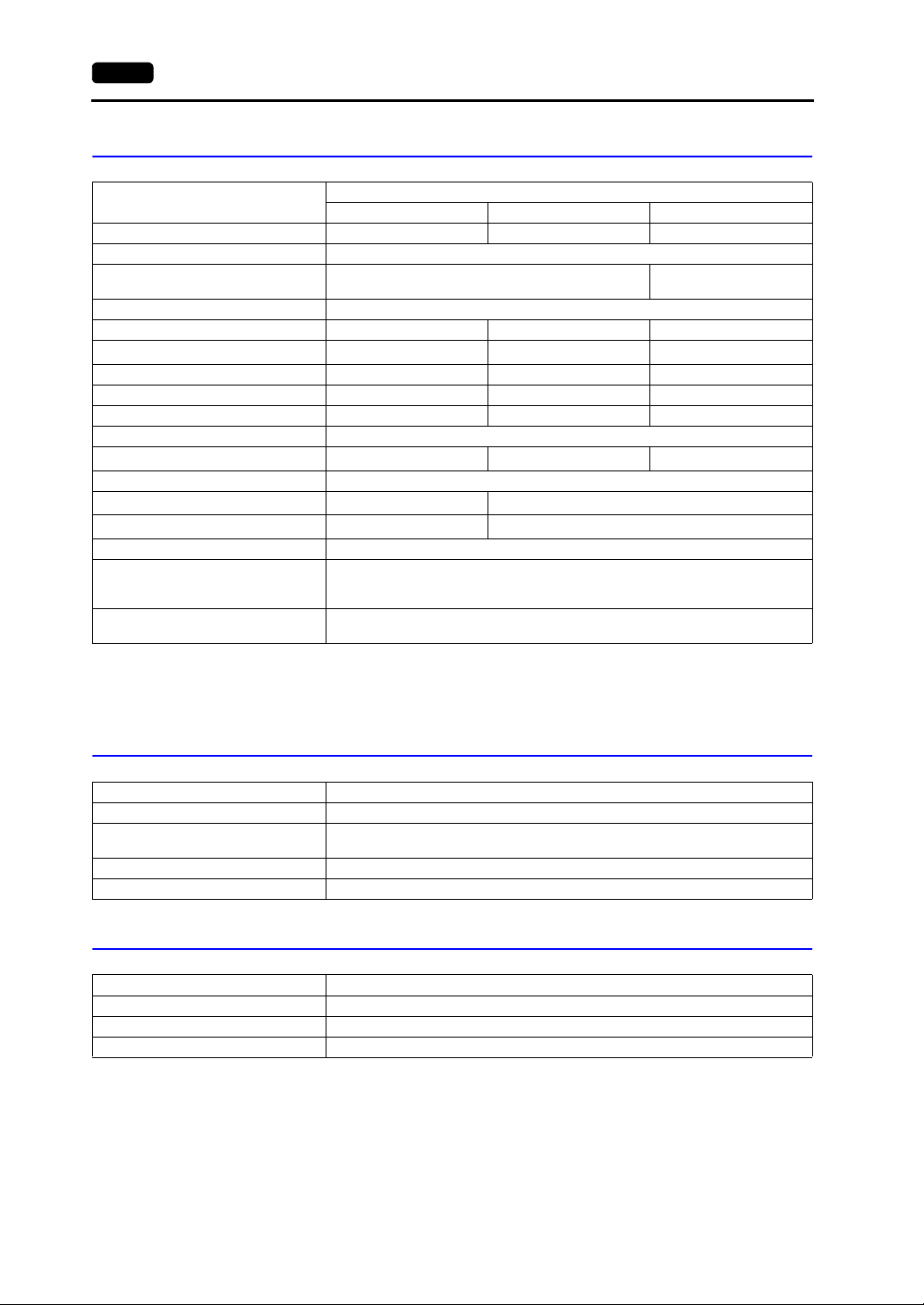

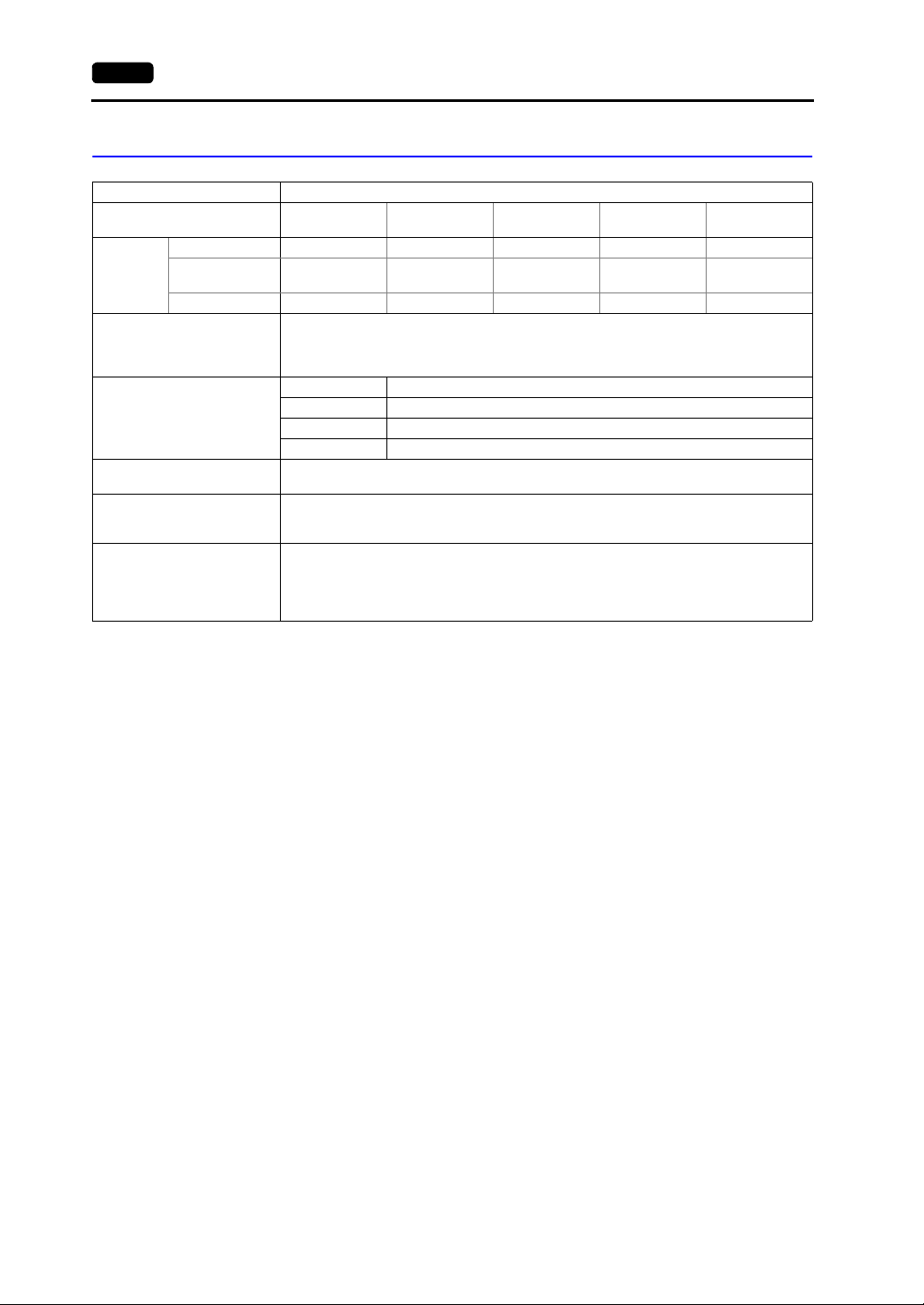

General Specifications

Item Specifications

Rated Voltage 24 VDC

Permissible Range of Voltage 24 VDC ± 10%

Power

Supply

Insulation Resistance 500 VDC, 10 MΩ or above

Physical

Environment

Mechanical

Working

Conditions

Electrical

Working

Conditions

Mounting

Conditions

Case Color Black (Munsell N2.0)

Material PC/PS resin (Tarflon)

Permissible Momentary Power Failure Within 1 ms

Power Consumption

(Maximum Rating)

Rush Current 20 A or less (with a rise time 0.1 ms)

Withstand Voltage DC external terminals to FG: 500 VAC, 1 minute

Ambient Temperature 0°C to +50°C *

Storage Ambient Temperature −10°C to +60°C

Ambient Humidity 85% RH or less (without dew condensation)

Solvent Resistance No cutting oil or organic solvent attached to the unit

Atmosphere No corrosive gas or conductive dust

Vibration Resistance

Shock Resistance

Noise Resistance 1000 Vp-p (pulse width 1µs, rise time: 1 ns)

Static Electricity Discharge Resistance

Grounding Grounding resistance: less than 100 Ω

Structure

Cooling System Cooling naturally

Weight Unit only : approx. 680 g, with UG230A-DCL installed: approx. 820 g

External Dimensions W × H × D (mm)

Panel Cut-out Dimensions (mm)

* As for UG230H-SS4x and UG230H-LS4x, operation for long hours at ambient temperatures of 40 to 50°C may

degrade the display quality, such as lowering contrast.

Vibration frequency: 10 to 150 Hz, Acceleration: 9.8 m/s

Single amplitude: 0.075 mm, X, Y, Z: 3 directions for one hour

Peak acceleration: 147 m/s

Protection structure: Front panel: compliant with IP65 (when using

Form: In a single body

Mounting procedure: Inserted in a mounting panel

with UG230A-DCL installed: 182.5 × 138.8 × 64.0

16 W or less

Pulse shape: Sine half wave

2

, X, Y, Z: 3 directions six times each

Compliant with IEC61000-4-2,

contact: 6 kV, air: 8 kV

+0.5

174 ×

−0

waterproof gasket)

+0.5

−0

131

Rear case: compliant with IP20

Unit only: 182.5 × 138.8 × 42.5,

2

Specifications

2

2-2 1. Specifications

Display Specifications

Item

Display Device TFT color LCD STN color LCD STN monochrome LCD

Display Size 5.7-inch

Colors

Resolution W × H (dots) 320 × 240

Dot Pitch W × H (mm) 0.36 × 0.36 0.36 × 0.36 0.36 × 0.36

Brightness (cd/m

Contrast Ratio 60 : 1 30 : 1 5 : 1

Angle of Vertical Visibility (°) +65, −40 +20, −35 +20, −40

Angle of Horizontal Visibility (°) ±65 ±50 ±45

Backlight Cold cathode rectifier (cannot be replaced by users)

Average Backlight Life

Backlight Auto OFF Function Always ON, random setting

Contrast Adjustment Not provided

Brightness Adjustment

Surface Sheet Material: Polycarbonate, 0.3 mm thick

POWER Lamp

MJ2 Function Selection

2

)

*1

*1 When the normal temperature is 25°C, and the surface luminance of the display is 50% of the initial

setting

*2 Adjustable with function switches

*3 By using the macro command

UG230H-TS4x UG230H-SS4x UG230H-LS4x

32,768 colors

+16-color blinks

350 160 220

Approx. 50,000 h Approx. 54,000 h Approx. 58,000 h

128 levels

Illuminated in green when the power is on;

illuminated in orange when the voltage of the battery (with its cable connected) has

become low.

*3

Slide switch Down: RS-422 (4-wire)

Model

Up: RS-232C

Provided

Not provided

Monochrome 8-grade

+ blink

*2

Touch Switch Specifications

Item Specifications

Method Analog resistance film type, matrix resistance film type

Switch Resolution

Mechanical Life One million activations or more

Surface Treatment Hard-coated, anti-glare treatment 5%

Analog: 1024 (W) × 1024 (H)

Matrix: 20 (W) × 12 (H)

Function Switch Specifications

Item Specifications

Number of Switches 6

Method Digital resistance film

Mechanical Life One million activations or more

1. Specifications 2-3

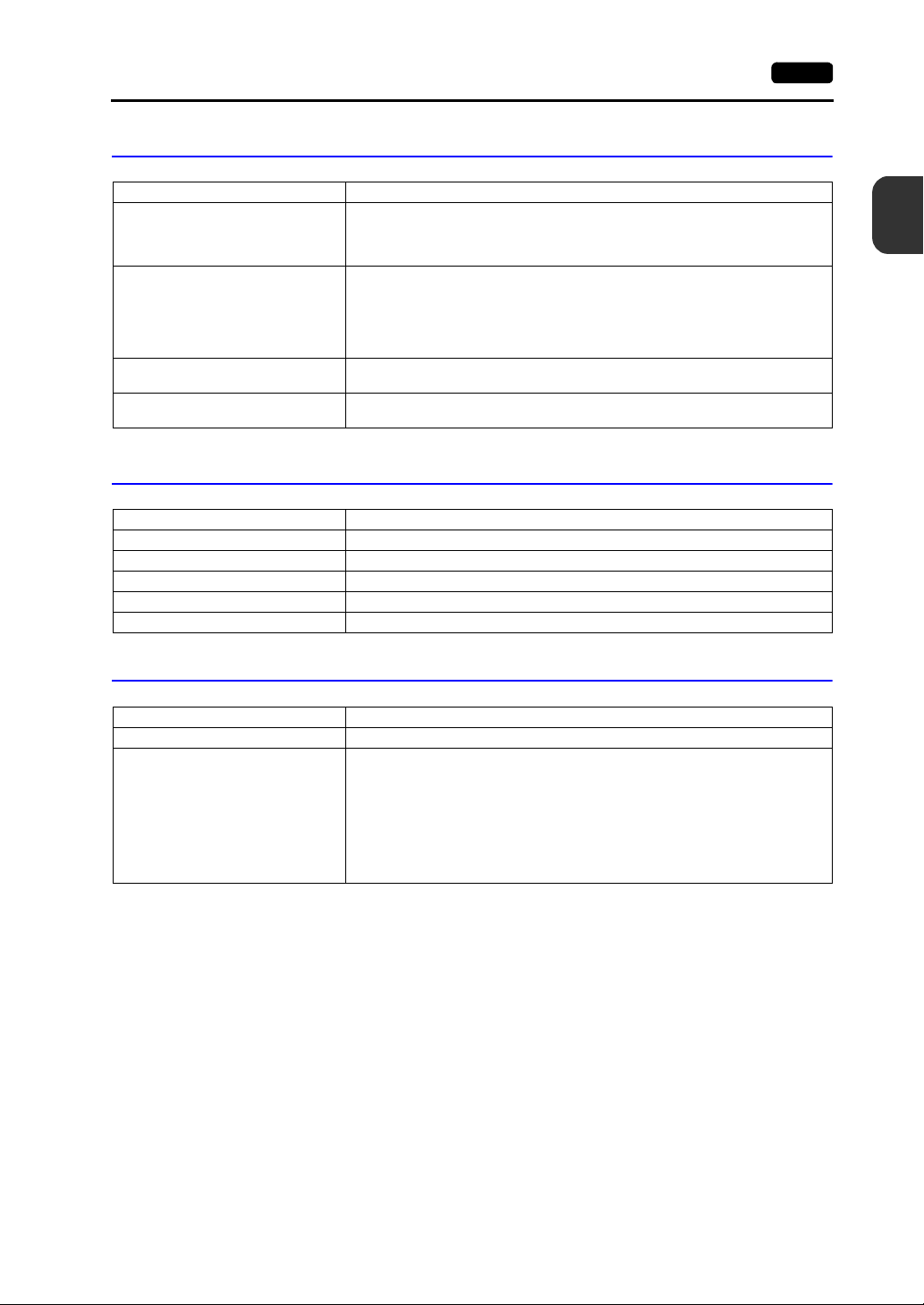

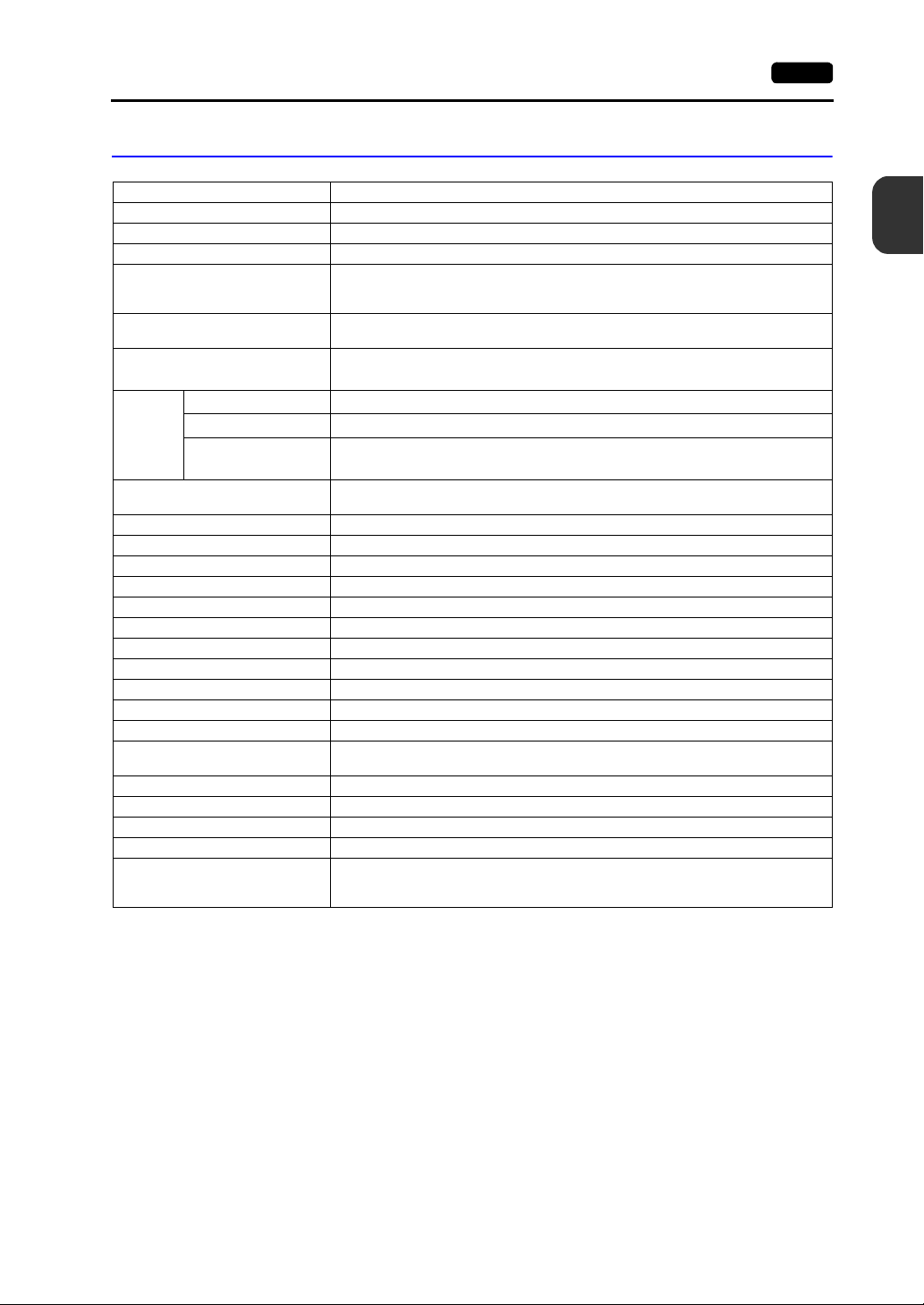

Interface Specifications

Item Specifications

Screen Data Transfer/External

Connection

Serial Interface

(Modular jack, 8-pin: MJ1)

PLC Connection

Serial Interface

(Modular jack, 8-pin: MJ2)

Printer/CF Card Reader Connection

USB Master Port (USB-A)

Screen Data Transfer

USB Slave Port (USB-B)

RS-232C, RS-422/485 (2-wire connection)

UG00P-MR, Barcode, UG00P-U2, Multi-link 2,

Temperature control network/PLC2Way, UG-link, etc.

RS-232C, RS-422 (4-wire connection)

Asynchronous ty pe

Data length: 7, 8 bits

Parity: Even, odd, none

Stop bit: 1, 2 bits

Baud Rate: 4800, 9600, 19200, 38400, 57600, 76800, 115200 bps

Type A, USB Ver. 1.1

Type B, USB Ver. 1.1

Clock and Backup Memory Specifications

Item Specifications

Battery Specification Coin-type lithium primary cell

Backup Memory SRAM 128 kbyte

Backup Time Period 5 years (ambient temperature at 25°C)

Battery Voltage Drop Detection Provided (internal memory allocated)

Calendar Accuracy Monthly deviation ±90 sec (ambient temperature at 25°C)

2

Specifications

Drawing Environment

Item Specifications

Drawing Method Exclusive drawing software

Name of exclusive configuration software: UG00S-CW (Ver. 3.2.0.0 and later)

Personal computer: Pentium II 450 MHz or above

Drawing Tool

OS: Windows98/Me/NT Ver.4.0/2000/XP

Capacity of hard disk required: Free space of approx. 460 Mbyte or more

Display: Resolution 800 × 600 or above

recommended

(For minimum installation:

approx. 105 Mbyte)

recommended

2-4 1. Specifications

Display Function Specifications

Item Specifications

Display Language* USEnglish

1/4-size, 1-byte ANK code Latin1 ASCII code ASCII code ASCII code

Characters

Character Size

Number of Displayable

Characters

Characters Properties

Graphics

Graphic Properties

2-byte 16-dot JIS #1, 2 levels −

2-byte 32-dot JIS #1 level −−−−

Resolution 320 × 240

1/4-size 40 characters × 30 lines

1-byte 40 characters × 15 lines

2-byte 20 characters × 15 lines

Display properties: Normal, reverse, blink, bold, shadow

Colors: 32,768 colors + blink 16 colors / monochrome 8-grade + blink

Lines: Line, continuous line, box, parallelogram, polygon

Circles: Circle, arc, sector, ellipse, elliptical arc

Others: Tile patterns

Line types: 6 (thin, thick, dot, chain, broken, two-dot chain)

Tile patterns: 16 (incl. user-definable 8 patterns)

Display properties: Normal, reverse, blink

Colors: 32,768 colors + blink 16 colors / monochrome 8-grade + blink

Color selection: Foreground, background, boundary (line)

* In addition, the follow ing fonts are available. For more information, refer to the User’s Manual <Operation>

(FEH375) and the User’s Manual <Supplementary Manual> (FEH376-1).

Gothic, English/Western Europe (HK Gothic), English/Western Europe (HK Times), Central Europe, Cyrillic,

Greek, Turkish

English/Western

Europe

1/4-size: 8 × 8 dots

1-byte: 8 × 16 dots

2-byte: 16 × 16 dots or 32 × 32 dots

Enlarge: W: 1 to 8 times, H: 1 to 8 times

Chinese

(traditional)

Chinese

(traditional)

(simplified)

(simplified)

Chinese

Chinese

Korean

Hangul

(without Kanji)

1. Specifications 2-5

Function Performance Specifications

Item Specifications

Screens Max. 1024

Screen Memory Flash memory: Appox. 1,472 kbyte (varies depending on the font)

Switches 192 per screen

Switch Actions

Lamps

Graphs

Numerical Data Display

Data

Setting

Sampling

Graphic Library Max. 2560

Multi-Overlaps Max. 1024

Data Blocks Max. 1024

Messages Max. 6144 lines

Patterns Max. 1024

Macro Blocks Max. 1024

Page Blocks Max. 1024

Direct Blocks Max. 1024

Screen Blocks Max. 1024

Data Sheets Max. 1024

Screen Library Max. 1024

Temperature Control Network/

PLC2Way Table

Time Display Time display function: provided

Hard Copy Screen hard copy function: provided

Buzzer Buzzer: provided, 2 sounds (short beep, long beep)

Auto OFF Function Always ON, random setting

Self-diagnostic Function

Character Display

Message Display

*1 The number of setting memory locations is limited to 256 per screen.

*2 Layer: 4 per screen (base + 3 overlaps)

Set, reset, momentary, alternate, to light

(Possible to press a function switch and a switch on the display at the same time)

(Matrix type: Possible to press two switches on the display at the same time)

Reverse, blink, exchange of graphics

192 per screen

Pie, bar, panel meter and closed area graph: No limitation within 256 kbyte per screen

Statistics and trend graphs: Max. 256 per layer

No limitation within 256 kbyte per screen

No limitation within 256 kbyte per screen

Resolution: Max . 40 1-byte characters

No limitation within 256 kbyte per screen

Sampling display of buffer data

(Constant sample, bit synchronize, bit sample, relay sample, alarm function)

Max. 32

Switch self-test function

Communication parameter setting check function

Communication check function

*1

*1

*1

2

Specifications

*1

*2

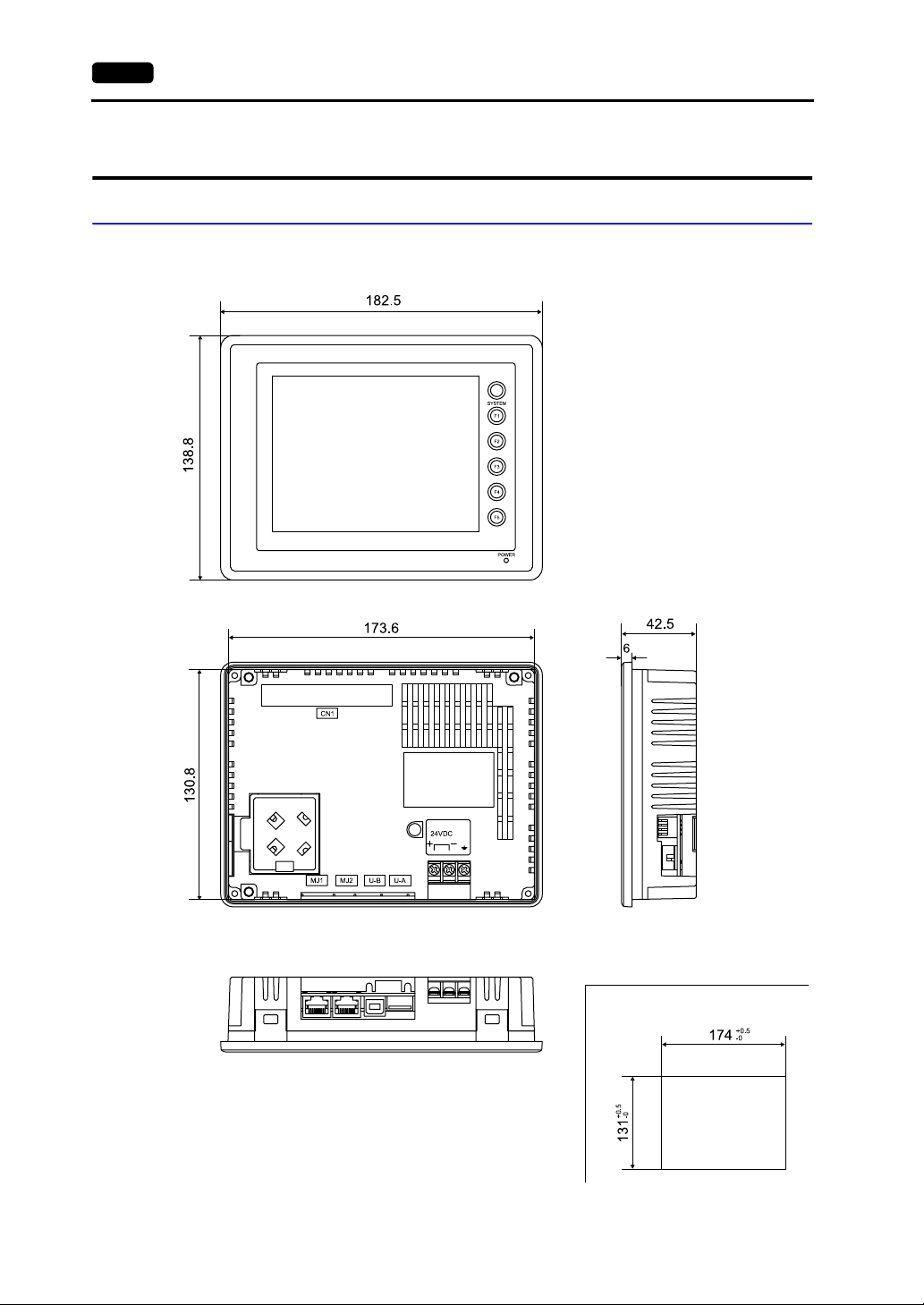

2-6 2. Dimensions and Panel Cut-out

2. Dimensions and Panel Cut-out

UG230 External View and Dimensions

(Unit: mm)

• Front View

• Side View

• Rear View

• Bottom View

• Panel Cut-out Dimensions

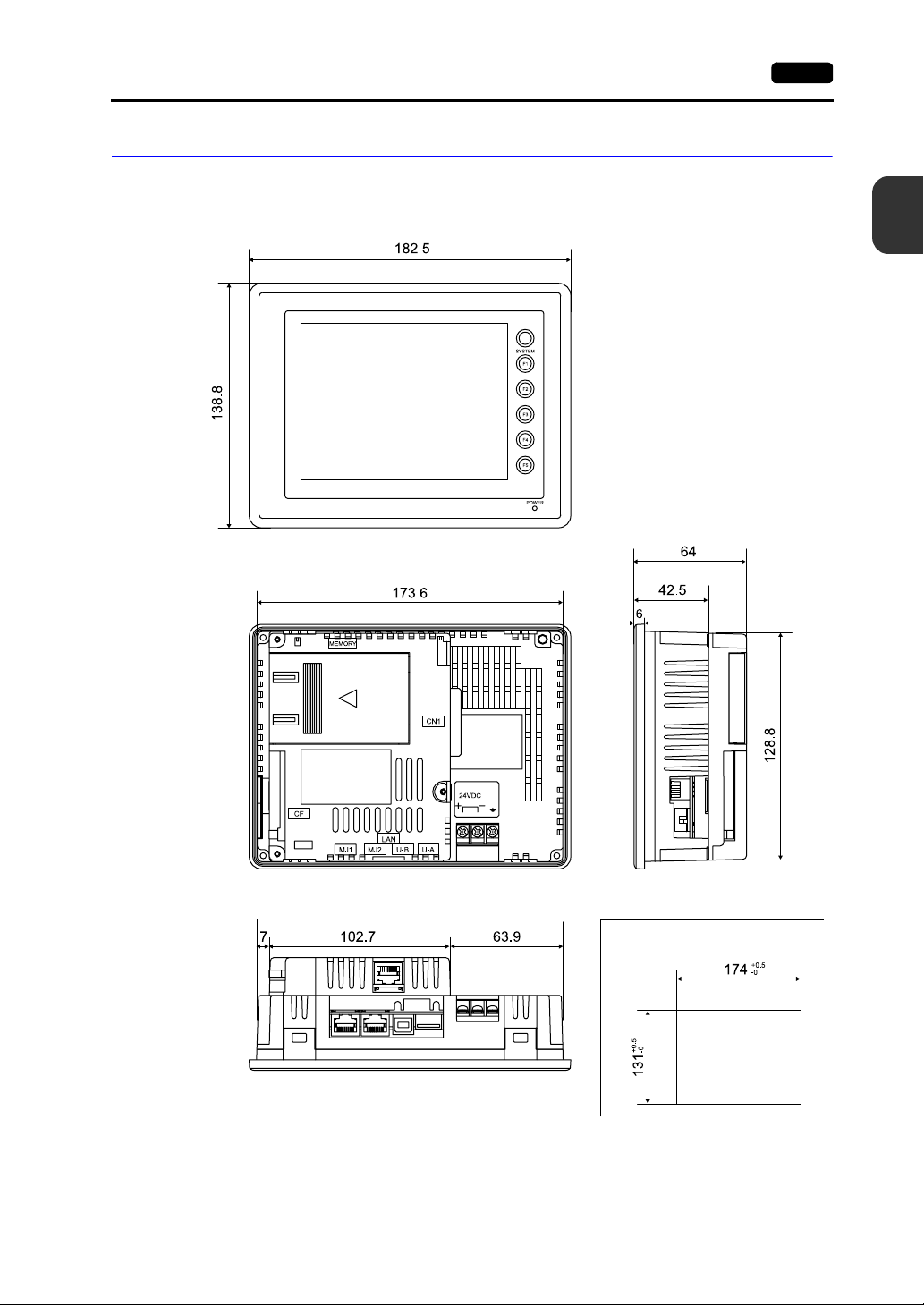

2. Dimensions and Panel Cut-out 2-7

UG230 + UG230A-DCL External View and Dimensions

(Unit: mm)

• Front View

• Rear View

2

Specifications

• Side View

• Bottom View

• Panel Cut-out Dimensions

2-8 3. Names and Functions of Components

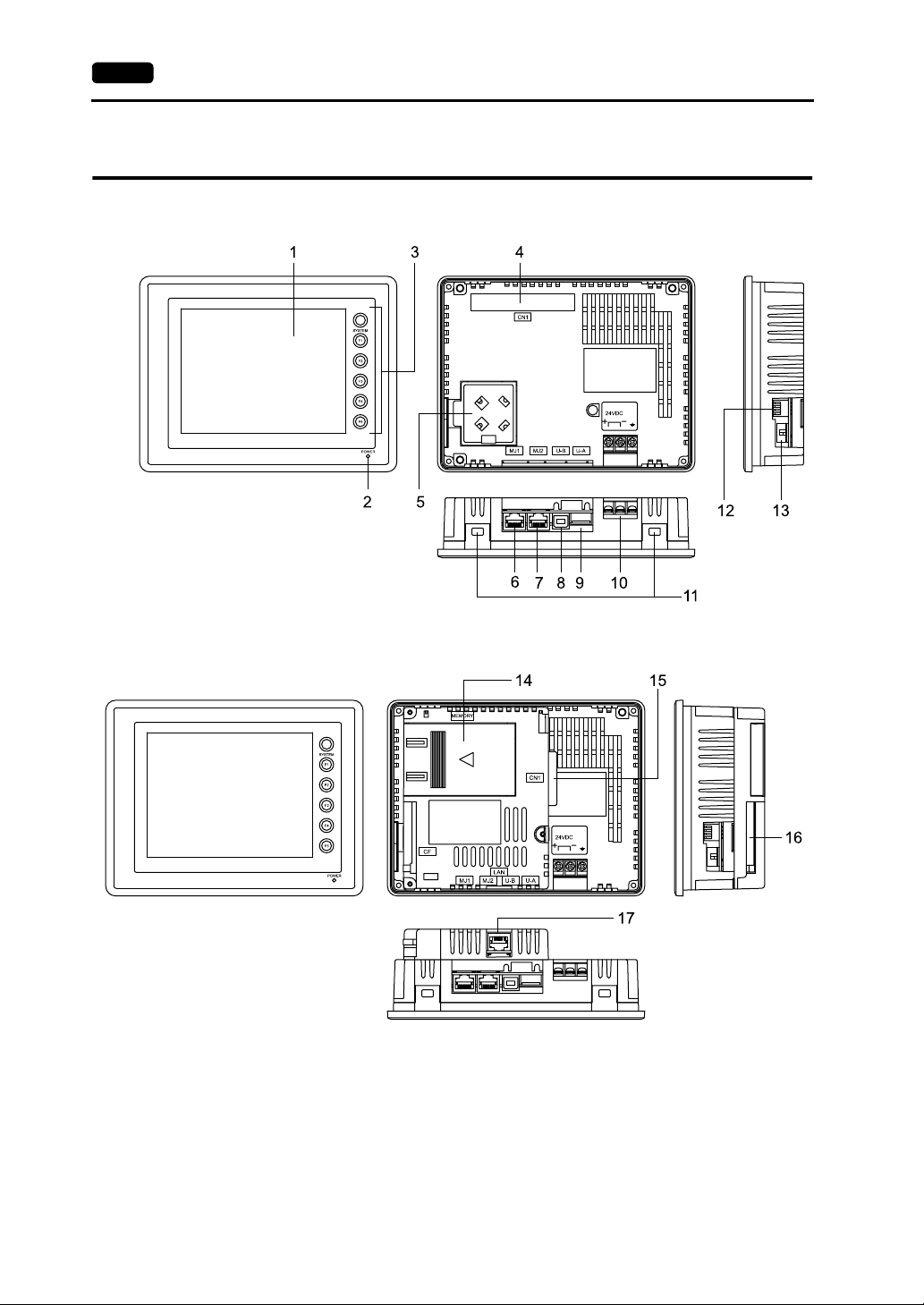

3. Names and Functions of Components

UG230

UG230+UG230A-DCL

1. Display

This is the display unit.

2. Power lamp (POWER)

Illuminates (green) when the power is supplied. The lamp illuminates (orange) when the voltage of

the battery set in the POD has become low.

3. Function switches

Used for RUN /STOP selection, contrast adjustment, brightness adjustment and backlight ON/OFF

(according to the setting). These switches can be used as user switches in the RUN mode.

3. Names and Functions of Components 2-9

4. Option unit connector (CN1)

This is the connector where the option unit UG230A-DCL is mounted.

5. Battery holder

Contains a backup battery for SRAM and clock.

When the battery voltage drops, replace the battery with a new one (UG30P-BT).

6. Modular jack connector (MJ1)

This is used for screen data transfer and connection with temperature controller, barcode reader,

UG00P-MR, etc.

7. Modular jack connectors (MJ2)

This is used for connection with the PLC.

With the option unit UG230A-DCL mounted, the modular jack allows you to connect a barcode

reader, serial printer, etc.

8. USB-B (slave port)

This is the connector for screen data transfer.

9. USB-A (master port)

This is the connector where a printer or a CF card reader/writer is connected.

10. Power supply terminal block

Supplies the power (24 VDC) to the UG230.

11. Mounting holes

Used for inserting fixtures when securing the POD to the mounting panel.

12. DIP switch

This is used for setting the terminating resistors of the MJ1/MJ2 RS-422/485 signal line.

13. Slide switch

This is used for switching between the RS-232C and RS-422 ports for the MJ2.

14. Add-on memory connector (MEMORY) (optional)

With the option unit UG230A-DCL mounted, this is used for mounting an optional FLASH memory

cassette (UG230P-D4).

15. PLC communication connector (CN1) (optional)

With the option unit UG230A-DCL mounted, this is used for connecting the UG230 and a PLC or

an external control unit (computer, custom controller, etc.).

16. CF card connector (CF) (optional)

This is the connector where the CF card is inserted when the option unit UG230A-DCL is installed.

17. 10BASE-T connector (LAN) (optional)

With the option unit UG230A-DCL mounted, this is used for Ethernet connection.

2

Specifications

2-10 4. Modular Jack (MJ1/MJ2)

4. Modular Jack (MJ1/MJ2)

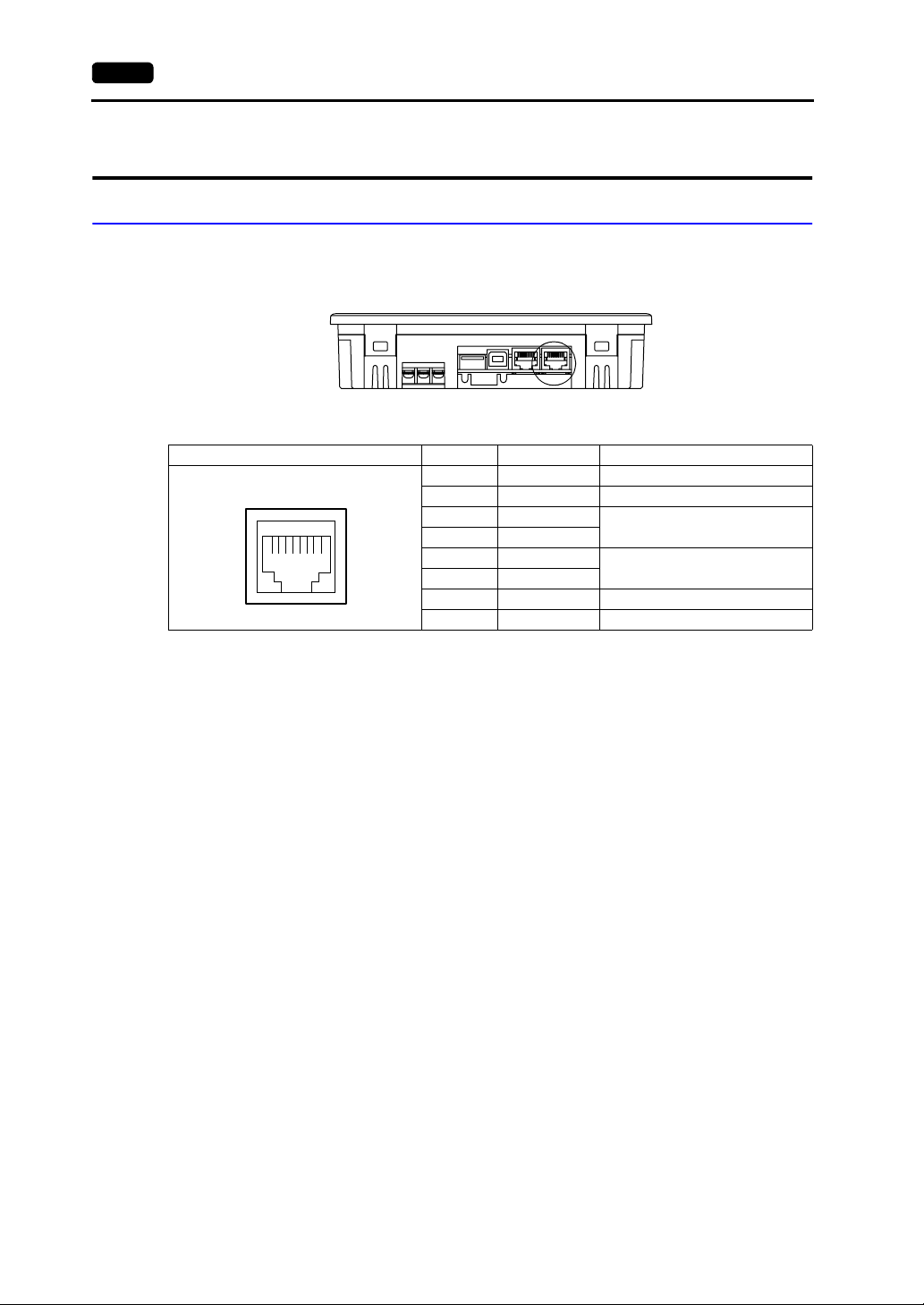

Modular Jack 1 (MJ1)

This is a modular connector used for connection for screen data transfer, temperature controller,

barcode reader, card recorder (UG00P-MR) or serial extension I/O (UG00P-U2).

Bottom View

The pins of modular jack 1 correspond to signals as given below.

MJ1 Pin No. Signal Name Contents

1 +SD/RD RS-485 +data

12345678

* The maximum current for external supply (+5V) is 150 mA when the MJ1 or MJ2 is used.

2 −SD/RD RS-485 − data

3+5V

4+5V

5SG

6SG

7 RD RS-232C receive data

8 SD RS-232C send data

Externally supplied +5 V

Max. 150 mA

Signal ground

*

Editor (UG00S-CW) Setting

1. The use of modular jack 1 can be set on the editor.

2. Select [Modular] from the [System Setting] menu. The [Modular Jack] dialog is displayed. Select

the use of modular jack 1 from the following options.

*1 Refer to “Transferring Screen Data” (page 2-17).

*2 Select this option w hen connecting the card recorder (UG00P-MR).

*3 Refer to “Barcode Reader Connection” (page 2-17).

*4 Select this open when “Multi-link 2” is selected for [Connection] and “1” is set for [Local Port] on the

[Comm. Parameter] dialog.

*5 Select this option w hen using the ladder transfer function.

*6 Select this option for Modbus slave connection.

*7 Select this option w hen connecting the printer with serial interface.

Refer to page 2-18.

Modular Jack 1

[Editor Port]

[Card Recorder]

[Barcode]

*1

*2

*3

[UG00P-U2]

[Multi-Link]

*4

[Temp. /PLC2Way]

[UG-Link]

[Ladder Tool]

[Modbus Slave]

*5

*6

[Printer (Serial Port)]

*7

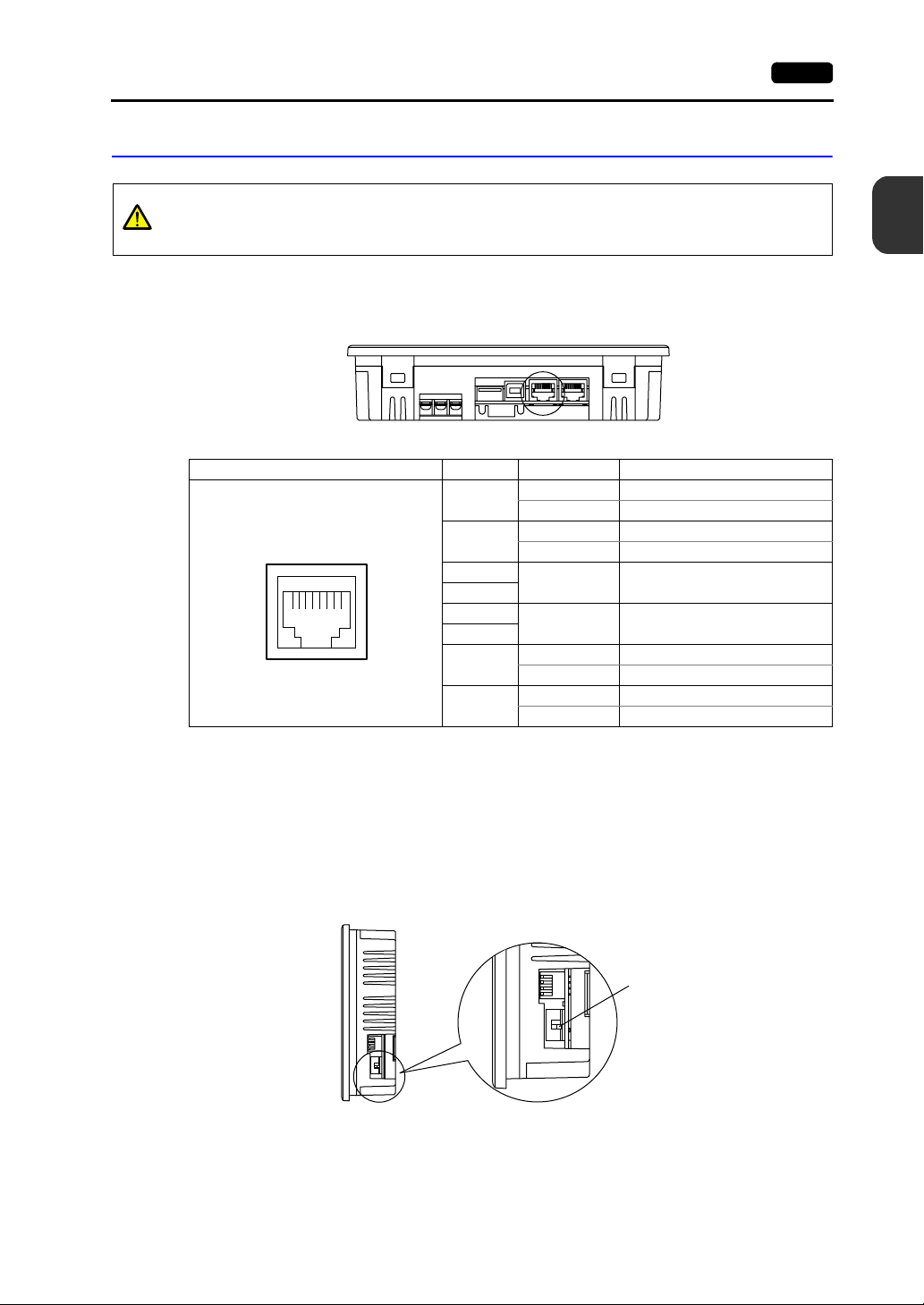

Modular Jack 2 (MJ2: Exclusive to the UG230)

Before using the MJ2, select whether it is used as an RS-232C or RS-422 port using the

CAUTION

slide switch.

The switch is factory-set to RS-422.

4. Modular Jack (MJ1/MJ2) 2-11

2

This is a modular jack connector used for connection with the PLC.

Unlike the MJ1, the connector is available as an RS-422 (4-wire) port.

Bottom View

The pins of modular jack 2 correspond to signals as given below.

MJ2 Pin No. Signal Name Contents

Not used Not used

*1

1

*1

12345678

*1 Switch between RS-232C and RS-422 for pin Nos. 1, 2, 7, and 8 with the slide switch on the POD.

*2 The maximum current for the output power supply (+5 V) is 150 mA when MJ1 or MJ2 is used.

2

3

4

5

6

*1

7

*1

8

+SD RS-422 + send data

Not used Not used

−SD RS-422 −send data

+5V

SG Signal ground

RD RS-232C receive data

+RD RS-422 + receive data

SD RS-232C send data

−RD RS-422 − receive data

Externally supplied +5 V

Max. 150 mA

Specifications

*2

Without the Option Unit UG230A-DCL

The MJ2 is usable as a port for PLC connection.

Slide switch

• Use the switch to set the signal level for the MJ2.

Side View

Wiring

For more information, refer to page 2-14.

Slide switch

Lower position: RS-422 (4-wire)

Upper position: RS-232C

Loading...

Loading...