Fuerst FB42 Operator's Manual

FB42

ROTARY MOWER

Published 08/01 Serial No. FB42-10017 Through Current P/N 00768114C

OPERATOR'S MANUAL

This Operator's Manual is an integral part of the safe operation

of this machine and must be maintained with the unit at all

times. READ, UNDERSTAND, and FOLLOW the Safety and

Operation Instructions contained in this manual before

operating the equipment.

FUERST

1020 S. Sangamon Ave.

Gibson City, IL 60936

217-784-4261

© 2004 Alamo Group Inc.

$0.00

TO THE OWNER/OPERATOR/DEALER

All implements with moving parts are potentially hazardous. There is no substitute for a cautious, safe-minded operator

who recognizes the potential hazards and follows reasonable safety practices. The manufacturer has designed this

implement to be used with all its safety equipment properly attached to minimize the chance of accidents.

BEFORE YOU START!! Read the safety messages on the implement and shown in your manual. Observe

the rules of safety and common sense!

WARRANTY INFORMATION:

Read and understand the complete Warranty Statement found in this Manual. Fill out the Warranty Registration Form

in full and return it to within 30 Days. Make certain the Serial Number of the Machine is recorded on the Warranty Card

and on the Warranty Form that you retain.

TABLE OF CONTENTS

SAFETY SECTION ....................................................................................................................................... 1-1

Safety Information .................................................................................................................................. 1-2

Safety Decal Location ............................................................................................................................ 1-11

INTRODUCTION SECTION ......................................................................................................................... 2-1

ASSEMBLY SECTION ................................................................................................................................. 3-1

Dealer Set-up Instructions ...................................................................................................................... 3-2

Shear Pin Driveline Installation ............................................................................................................... 3-2

Shield Assembly ..................................................................................................................................... 3-2

A-Frame Installation ................................................................................................................................ 3-3

Tailwheel Installation ............................................................................................................................... 3-3

Hydraulic Relief Assembly ...................................................................................................................... 3-4

OPERATION SECTION................................................................................................................................ 4-1

MAINTENANCE SECTION ........................................................................................................................... 5-1

Lubrication ............................................................................................................................................. 5-2

Gearbox .................................................................................................................................................. 5-3

Driveline ................................................................................................................................................. 5-4

Blades Sharpening ................................................................................................................................. 5-5

Blade & Carrier Removal ........................................................................................................................ 5-6

Blade Carrier Installation ........................................................................................................................ 5-6

Storage .................................................................................................................................................. 5-7

Torque Chart .......................................................................................................................................... 5-7

Gearbox Service Instructions .................................................................................................................. 5-8

SAFETY

SECTION

Safety Section 1-1

SAFETY

A safe and careful operator is the best operator. Safety is of primary importance to the

manufacturer and should be to the owner/operator. Most accidents can be avoided by being

aware of your equipment, your surroundings, and observing certain precautions. The first

section of this manual includes a list of Safety Messages that, if followed, will help protect the

operator and bystanders from injury or death. Read and understand these Safety Messages

before assembling, operating or servicing this mower. This equipment should only be operated

by those persons who have read the Manual, who are responsible and trained, and who know

how to do so safely and responsibly.

SAFETY

The Safety Alert Symbol combined with a Signal Word, as seen below, is used throughout this

manual and on decals which are attached to the equipment. The Safety Alert Symbol means:

“ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!” The Symbol and Signal

Word are intended to warn the owner/operator of impending hazards and the degree of

possible injury faced when operating this equipment.

Practice all usual and customary safe working precautions and

above all---remember safety is up to YOU. Only YOU can prevent

serious injury or death from unsafe practices.

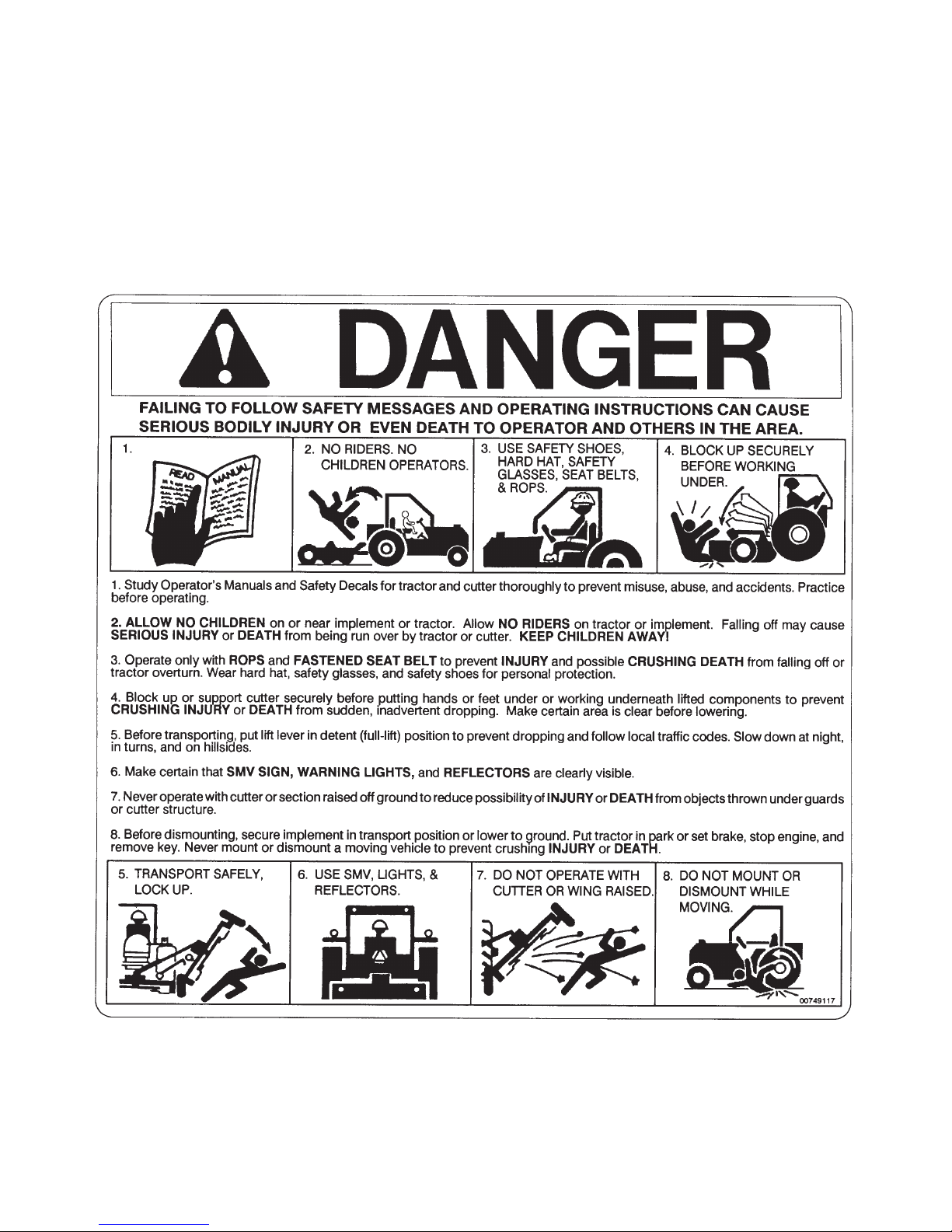

CAUTION! The lowest level of Safety Message; warns of possible injury. Decals

located on the Equipment with this Signal Word are Black and Yellow.

WARNING! Serious injury or possible death! Decals are Black and Orange.

DANGER! Imminent death/critical injury. Decals are Red and White. (SG-1)

© 2004 Alamo Group Inc.

Safety Section 1-2FB42 08/01

SAFETY

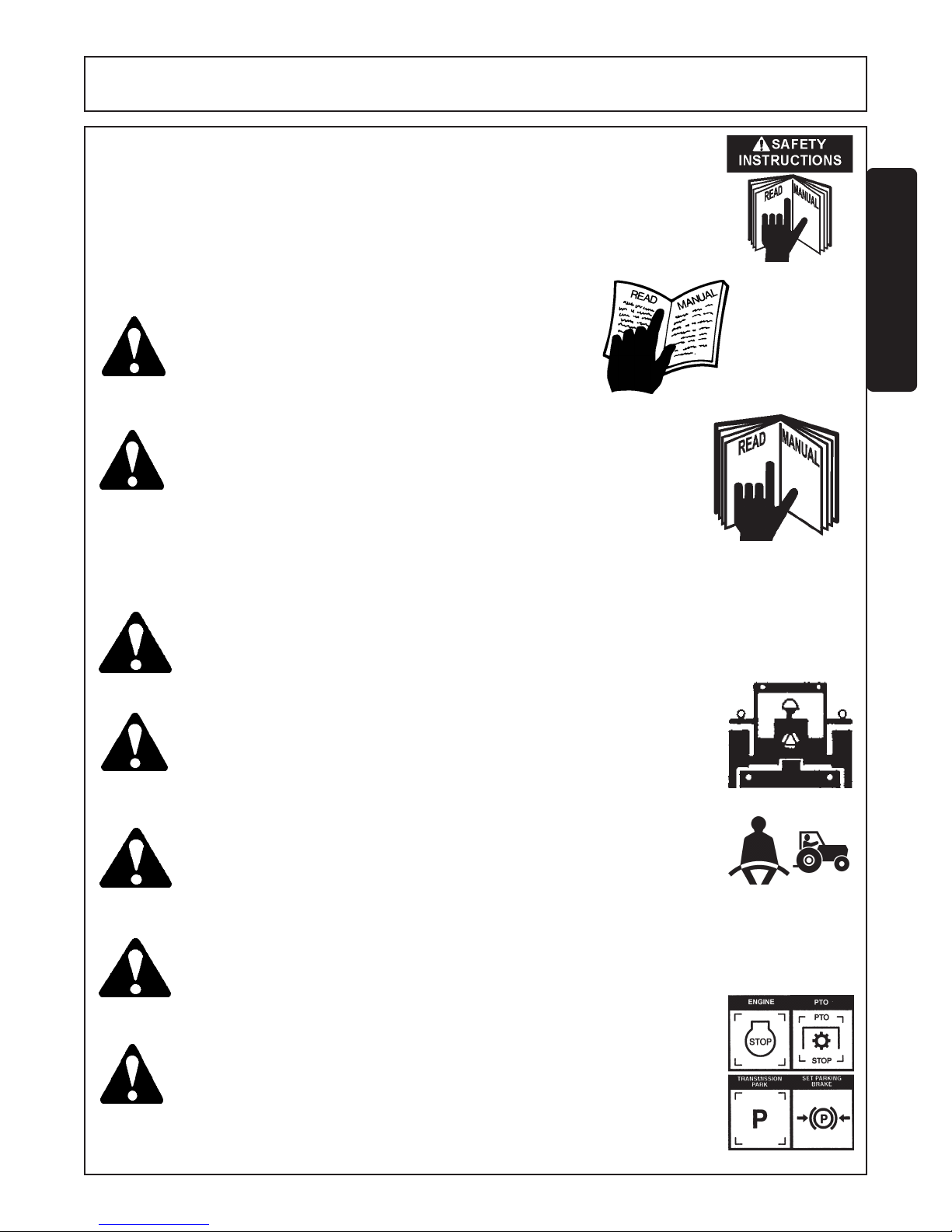

READ, UNDERSTAND, and FOLLOW the following Safety

Messages. Serious injury or death may occur unless care is

taken to follow the warnings and instructions stated in the Safety

Messages. Always use good common sense to avoid hazards.

(SG-2)

SAFETY

SAFETY

PELIGRO!

DANGER! Never operate the Tractor or Implement until you have read and

WARNING! Always maintain the safety decals in good readable condition. If the decals are missing, damaged,

WARNING! Make certain that the “Slow Moving Vehicle” (SMV) sign is installed in such

Si no lee Ingles, pida ayuda a alguien que si lo lea

para que le traduzca las medidas de seguridad. (SG-3)

completely understand this Manual, the Tractor Operator’s Manual,

and each of the Safety Messages found in the Manual or on the Tractor

and Implement. Learn how to stop the tractor engine suddenly in an

emergency. Never allow inexperienced or untrained personnel too

operate the Tractor and Implement without supervision.

the operator has fully read and understood the manuals prior to

operation. (SG-4)

or unreadable, obtain and install replacement decals immediately. (SG-5)

a way as to be clearly visible and legible. When transporting the

Equipment use the Tractor flashing warning lights and follow all local traffic

regulations. (SG-6)

Make sure

¡LEA EL

INSTRUCTIVO!

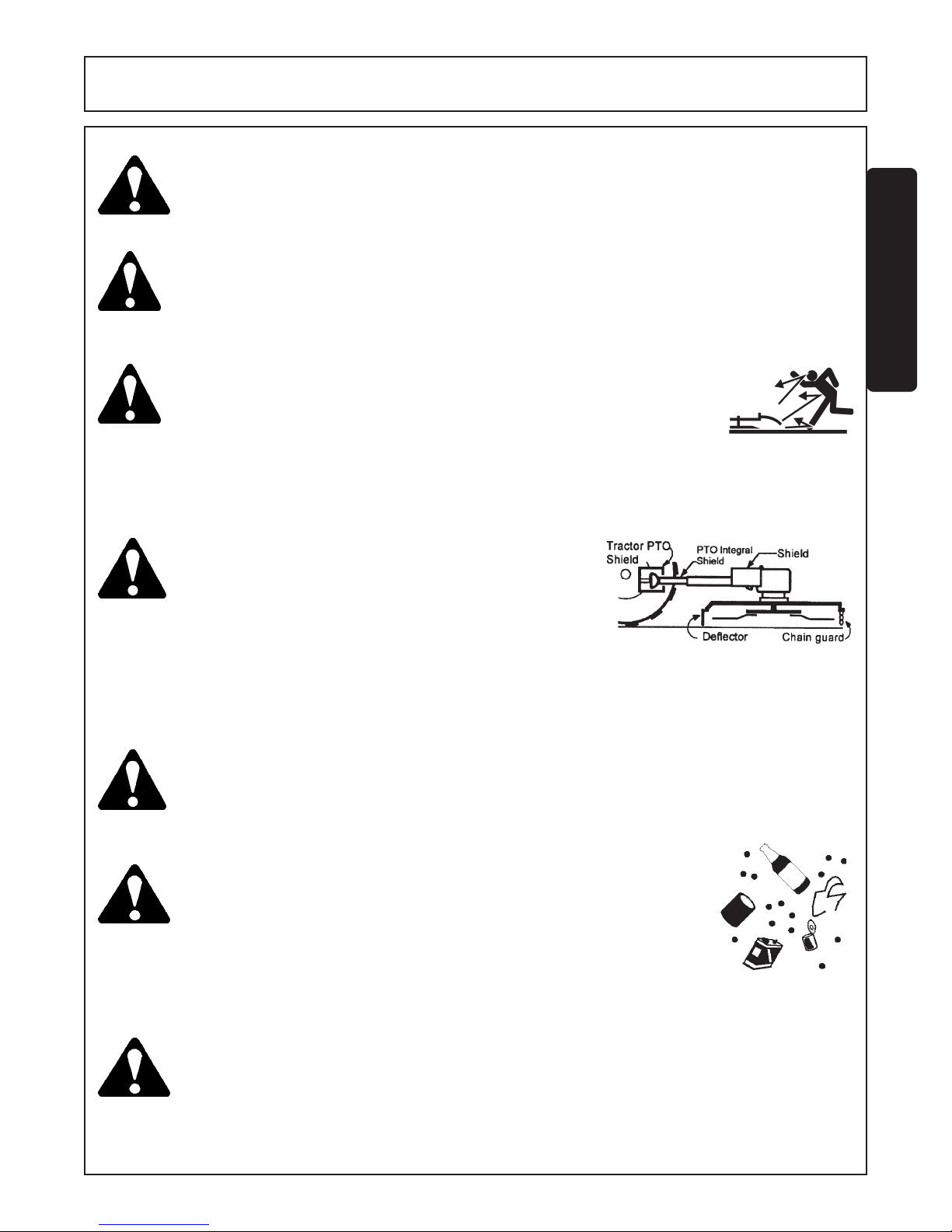

WARNING! Operate this Equipment only with a Tractor equipped with an approved

roll-over-protective system (ROPS). Always wear seat belts. Serious

injury or even death could result from falling off the tractor--particularly

during a turnover when the operator could be pinned under the ROPS.

(SG-7)

WARNING!

DANGER!

FB42 08/01

© 2004 Alamo Group Inc.

Do not modify or alter this Implement. Do not permit anyone to modify or alter this Implement,

any of its components or any Implement function. (SG-8)

BEFORE leaving the tractor seat, always engage the brake and/or set the

tractor transmission in parking gear, disengage the PTO, stop the engine,

remove the key, and wait for all moving parts to stop. Place the tractor

shift lever into a low range or parking gear to prevent the tractor from rolling.

Never dismount a Tractor that is moving or while the engine is running.

Operate the Tractor controls from the tractor seat only. (SG-9)

Safety Section 1-3

SAFETY

DANGER!

DANGER!

SAFETY

WARNING!

DANGER!

Never allow children or other persons to ride on the Tractor or Implement.

Falling off can result in serious injury or death. (SG-10)

Never allow children to operate or ride on the Tractor or Implement.

(SGM-11)

Do not mount the Tractor while the tractor is moving. Mount the Tractor

only when the Tractor and all moving parts are completely stopped.

(SG-12)

Start tractor only when properly seated in the Tractor seat. Starting a

tractor in gear can result in injury or death. Read the Tractor operators

manual for proper starting instructions. (SG-13)

DANGER!

WARNING! The operator and all support personnel should wear hard hats, safety

© 2004 Alamo Group Inc.

Never work under the Implement, the framework, or any lifted

component unless the Implement is securely supported or blocked up

to prevent sudden or inadvertent falling which could cause serious

injury or even death. (SG-14)

shoes, safety glasses, and proper hearing protection at all times for

protection from injury including injury from items thrown by the

equipment. (SG-16)

Safety Section 1-4FB42 08/01

SAFETY

CAUTION!

WARNING!

PROLONGED EXPOSURE TO LOUD NOISE MAY CAUSE

PERMANENT HEARING LOSS! Tractors with or without an

Implement attached can often be noisy enough to cause permanent

hearing loss. We recommend that you always wear hearing

protection if the noise in the Operator’s position exceeds 80db.

Noise over 85db over an extended period of time will cause severe

hearing loss. Noise over 90db adjacent to the Operator over an

extended period of time will cause permanent or total hearing loss.

Note: Hearing loss from loud noise [from tractors, chain saws,

radios, and other such sources close to the ear] is cumulative over

a lifetime without hope of natural recovery.

Transport only at safe speeds. Serious accidents and injuries can

result from operating this equipment at unsafe speeds. Understand the

Tractor and Implement and how it handles before transporting on streets

and highways. Make sure the Tractor steering and brakes are in good

condition and operate properly.

Before transporting the Tractor and Implement, determine the safe

transport speeds for you and the equipment. Make sure you abide

(SG-I7)

by the following rules:

1. Test the tractor at a slow speed and increase the speed slowly.

Apply the Brakes smoothly to determine the stopping characteristics

of the Tractor and Implement. As you increase the speed of the

Tractor the stopping distance increases. Determine the maximum

safe transport speed for you and this Equipment.

2. Test the equipment at a slow speed in turns. Increase the speed

through the turn only after you determine that it is safe to operate at

a higher speed. Use extreme care and reduce your speed when

turning sharply to prevent the tractor and implement from turning

over. Determine the maximum safe turning speed for you and this

equipment before operating on roads or uneven ground.

3. Only transport the Tractor and Implement at the speeds that you

have determined are safe and which allow you to properly control

the equipment.

SAFETY

SAFETY

Be aware of the operating conditions. Do not operate the Tractor with

weak or faulty brakes. When operating down a hill or on wet or rain

slick roads, the braking distance increases: use extreme care and

reduce your speed. When operating in traffic always use the Tractor’s

flashing warning lights and reduce your speed. Be aware of traffic

around you and watch out for the other guy. (SG-19)

WARNING!

FB42 08/01

© 2004 Alamo Group Inc.

Never attempt to lubricate, adjust, or remove material from the Implement while it is in motion

or while tractor engine is running. Make sure the tractor engine is off before working on the

Implement. (SG-20)

Safety Section 1-5

SAFETY

WARNING! Periodically inspect all moving parts for wear and replace when

necessary with authorized service parts. Look for loose fasteners,

worn or broken parts, and leaky or loose fittings. Make sure all pins

have cotter pins and washers. Serious injury may occur from not

maintaining this machine in good working order. (SG-21)

SAFETY

WARNING!

DANGER!

DANGER!

DANGER!

WARNING!

Always read carefully and comply fully with the manufacturers instructions

when handling oil, solvents, cleansers, and any other chemical agent.

(SG-22)

Never run the tractor engine or mower engine in a closed building or without adequate

ventilation. The exhaust fumes can be hazardous to your health. (SG-23)

KEEP AWAY FROM ROTATING ELEMENTS to prevent entanglement

and possible serious injury or death. (SG-24)

Never allow children to play on or around Tractor or Implement. Children can slip or fall off the

Equipment and be injured or killed. Children can cause the Implement to shift or fall crushing

themselves or others. (SG-25)

Do not exceed the rated PTO speed for the Implement. Excessive PTO speeds can cause

Implement driveline or blade failures resulting in serious injury or death. (SG-26)

DANGER!

© 2004 Alamo Group Inc.

NEVER use drugs or alcohol immediately before or while operating the

Tractor and Implement. Drugs and alcohol will affect an operator’s

alertness and coordination and therefore affect the operator’s ability to

operate the equipment safely. Before operating the Tractor or

Implement, an operator on prescription or over-the-counter medication must consult a medical professional regarding any side effects

of the medication that would hinder their ability to operate the

Equipment safely. NEVER knowingly allow anyone to operate this

equipment when their alertness or coordination is impaired. Serious

injury or death to the operator or others could result if the operator is

under the influnce of drugs or alcohol. (SG-27)

Safety Section 1-6FB42 08/01

SAFETY

DANGER! Operate the Tractor and/or Implement controls only while properly seated in the Tractor seat with

the seat belt securely fastened around you. Inadvertent movement of the Tractor or Implement may

cause serious injury or death. (SG-29)

WARNING!

Mow only in conditions where you have clear visibility in daylight or with adequate artificial lighting.

Never mow in darkness or foggy conditions where you cannot clearly see at least 100 yards in front

and to the sides of the tractor and mower. Make sure that you can clearly see and identify passersby,

steep slopes, ditches, drop-offs, overhead obstructions, power lines, debris and foreign objects.

If you are unable to clearly see this type of items discontinue mowing.

(SGM-1)

SAFETY

SAFETY

DANGER!

DANGER!

DANGER!

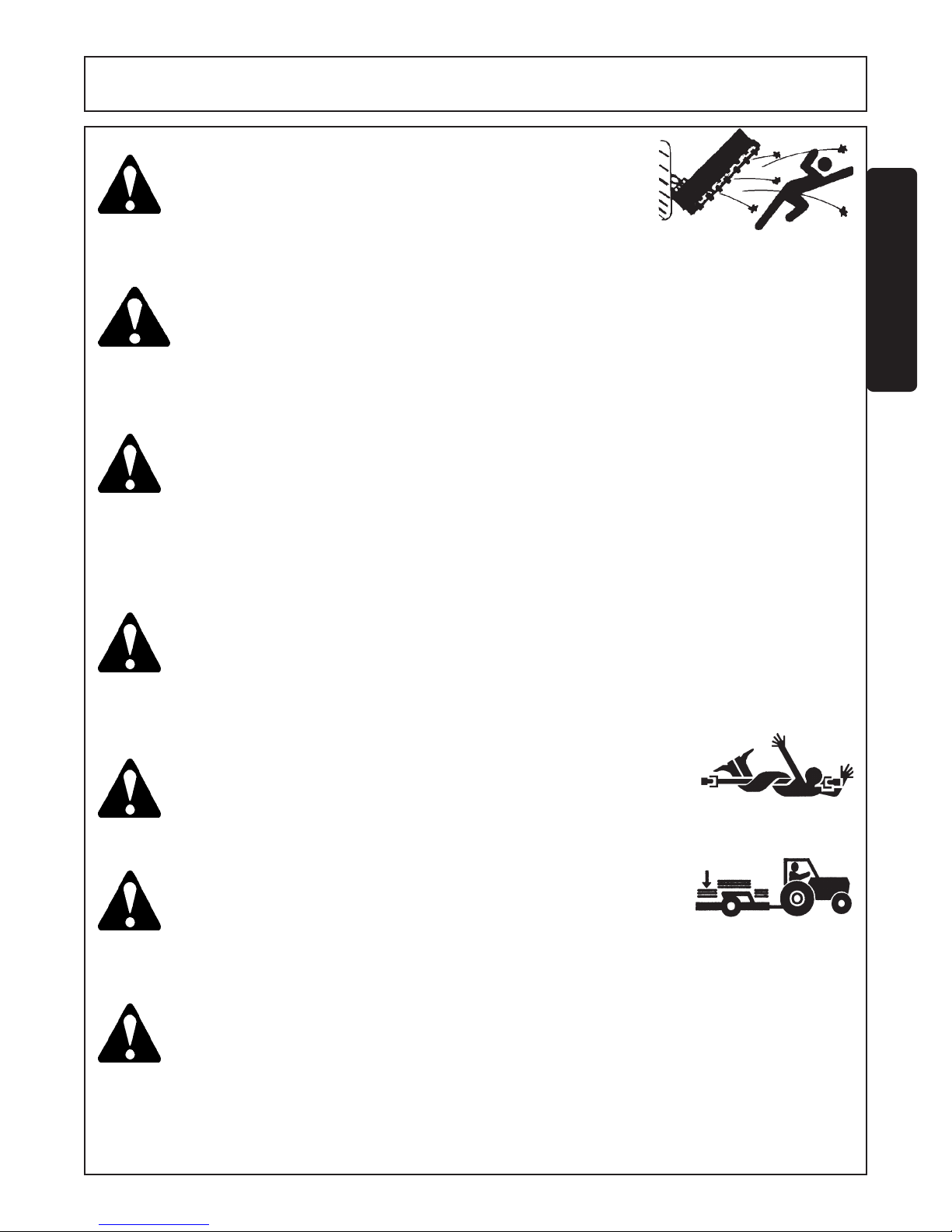

There are obvious and hidden potential hazards in the operation of this

Mower. REMEMBER! This machine is often operated in heavy brush

and in heavy weeds. The Blades of this Mower can throw objects if

shields are not properly installed and maintained. Serious injury or

even death may occur unless care is taken to insure the safety of the

operator, bystanders, or passersby in the area. Do not operate this

machine with anyone in the immediate area. Stop mowing if anyone

is within 100 yards of mower. (SGM-2)

All Safety Shields, Guards and Safety devices including

(but not limited to) - the Deflectors, Chain Guards, Steel

Guards, Gearbox Shields, PTO integral shields , and

Retractable Door Shields should be used and maintained

in good working condition. All safety devices should be

inspected carefully at least daily for missing or broken

components. Missing, broken, or worn items must be

replaced at once to reduce the possibility of injury or

death from thrown objects, entanglement, or blade

contact. (SGM-3)

The rotating parts of this machine have been designed and tested for rugged use. However,

the blades could fail upon impact with heavy, solid objects such as metal guard rails and

concrete structures. Such impact could cause the broken objects to be thrown outward at

very high velocities. To reduce the possibility of property damage, serious injury, or even

death, never allow the cutting blades to contact such obstacles. (SGM-4)

WARNING!

WARNING!

FB42 08/01

© 2004 Alamo Group Inc.

Extreme care should be taken when operating near loose objects such

as gravel, rocks, wire, and other debris. Inspect the area before

mowing. Foreign objects should be removed from the site to prevent

machine damage and/or bodily injury or even death. Any objects that

cannot be removed must be clearly marked and carefully avoided by

the operator. Stop mowing immediately if blades strike a foreign

object. Repair all damage and make certain rotor or blade carrier is

balanced before resuming mowing. (SGM-5)

Many varied objects, such as wire, cable, rope, or chains, can become entangled in the operating

parts of the mower head. These items could then swing outside the housing at greater velocities

than the blades. Such a situation is extremely hazardous and could result in serious injury or even

death. Inspect the cutting area for such objects before mowing. Remove any like object from the

site. Never allow the cutting blades to contact such items. (SGM-6)

Safety Section 1-7

SAFETY

WARNING! Mow at the speed that you can safely operate and control the tractor and mower. Safe mowing

speed depends on terrain condition and grass type, density, and height of cut. Normal ground

speed range is from 0 to 5 mph. Use slow mowing speeds when operating on or near steep slopes,

ditches, drop-offs, overhead obstructions, power lines, or when debris and foreign objects are to

be avoided.

WARNING! Avoid mowing in reverse direction when possible. Check to make sure there are no persons behind

the mower and use extreme care when mowing in reverse. Mow only at a slow ground speed where

you can safely operate and control the tractor and mower. Never mow an area that you have not

inspected and removed debris or foreign material.

(SGM-7)

(SGM-8)

SAFETY

WARNING! Do not put hands or feet under mower decks. Blade Contact can result

serious injury or even death. Stay away until all motion has stopped and

the decks are securely blocked up. (SGM-9)

DANGER!

WARNING! Do not mow with two machines in the same area except with Cab tractors with the windows closed.

DANGER!

Replace bent or broken blade with new blades. NEVER ATTEMPT TO STRAIGHTEN OR WELD

ON BLADES SINCE THIS WILL LIKELY CRACK OR OTHERWISE DAMAGE THE BLADE

WITH SUBSEQUENT FAILURE AND POSSIBLE SERIOUS INJURY FROM THROWN BLADES.

(SGM-10)

(SGM-11)

Rotary Mowers are capable under adverse conditions

of throwing objects for great distances (100 yards

or more) and causing serious injury or death. Follow

safety messages carefully.

STOP MOWING IF PASSERSBY ARE

WITHIN 100 YARDS UNLESS:

-Front and Rear Deflectors, Chain Guards, or Bands are installed and in good, workable

condition;

-Mower sections or Wings are running close to and parallel to the ground without exposed

Blades;

-Passerby are outside the existing thrown-object zone;

-All areas have been thoroughly inspected and all foreign material such as rocks, cans,

glass, and general debris has been removed.

NOTE: Where there are grass and weeds high enough to hide debris that could be struck

by the blades, the area should be: inspected and large debris removed, mowed at an

intermediate height, inspected, closely with any remaining debris being removed, and

mowed again at desired final height. (This will also reduce power requiredto mow, reduce

wear and tear on the Mower drivetrain, spread cut material better, eliminate streaking, and

make the final cut more uniform.) (SRM-1)

© 2004 Alamo Group Inc.

Safety Section 1-8FB42 08/01

SAFETY

WARNING!

WARNING! Never leave Tractor and Implemented unattended while the implement is in the lifted position.

WARNING! Be particularly careful when transporting the Implement with the Tractor. Turn curves or go up

Do not let the Blades turn when the Mower Deck is raised for any

reason, including clearance or for turning. Raising the Mower

deck exposes the Cutting Blades which creates a potentially

serious hazard and could cause serious injury or even death

from objects thrown from the Blades. (SRM-7)

Accidental operation of lifting lever or a hydraulic failure may cause sudden drop of unit with

injury or death by crushing. To properly park the implement when disconnecting it from the tractor,

lower the stand and put the retaining pin securely in place, or put a secure support under the AFrame. Lower the implement carefully to the ground. Do not put hands or feet under lifted

components. (S3PT-1)

hills only at a low speed and using a gradual steering angle. Rear mounted implements move the

center of gravity to the rear and remove weight from the front wheels. Make certain, by adding

front ballast, that at least 20% of the tractor’s weight is on the front wheels to prevent rearing up,

loss of steering control or Tractor tip-over. Slow down on rough or uneven surfaces to prevent

loss of steering control which could result in property damage or possible injury. Do not

transport unless 3-Point lift lever is fully raised and in the latched transport position. Dropping

implement in transport can cause serious damage to the tractor and/or Implement and possibly

cause the operator or others to be injured or killed. (S3PT-2)

SAFETY

SAFETY

DANGER!

DANGER! Make sure the PTO shield, integral driveline shields, and input shields are

WARNING!

WARNING!

There are obvious and hidden potential hazards in the operation of this Implement as in all

power-driven or pulled equipment. REMEMBER! This machine is often operated in rough terrain

conditions that include tall grass, weeds, gullies, holes, slopes, hidden obstructions and the like.

Serious injury or even death may occur unless care is taken to assure the safety of the operator

and bystanders in the area. Do not operate this machine with anyone in the immediate area.

(S3PT-7)

is installed when using PTO-driven equipment. Always replace any

shield if it is damaged or missing. (S3PT-8)

Relieve hydraulic pressure prior to doing any maintenance or repair

work on the Implement. Place the Implement on the ground or

securely blocked up, disengage the PTO, and turn off the tractor

engine. Push and pull the Remote Cylinder lever in and out several

times prior to starting any maintenance or repair work. (S3PT-9)

The rotating parts of this machine continue to rotate even after the PTO has been turned off. The

operator should remain in his seat for 60 seconds after the brake has been set, the PTO

disengaged, the tractor turned off, and all evidence of rotation has ceased. (3PT-10)

FB42 08/01

© 2004 Alamo Group Inc.

“Wait a minute...Save a life!”

Safety Section 1-9

SAFETY

DANGER!

In addition to the design and configuration of this Implement, including Safety Signs and Safety Equipment,

hazard control and accident prevention are dependent upon the awareness, concern, prudence, and proper

training of personnel involved in the operation, transport, maintenance, and storage of the machine. Refer also to

Safety Messages and operation instruction in each of the appropriate sections of the Tractor and Equipment

SAFETY

Manuals. Pay close attention to the Safety Signs affixed to the Tractor and Equipment. (SG-18)

Fuerst implement use matched system components for blades, hangers, rollers, and bearings. These parts

are made and tested to Fuerst specifications. Non-genuine "will fit" parts do not consistently meet these

specifications. The use of “will fit” parts may reduce implements performance, void warranties, and present

a safety hazard. Use genuine Fuerst mower parts for economy and safety. (SPFB-1)

Always disconnect the main PTO Driveline from the Tractor before performing service on the

Implement. Never work on the Implement with the tractor PTO driveline connected and running.

Rotating Parts, Blades or Drivelines could turn without warning and cause immediate

entanglement, injury or death. (S3PT-11)

PARTS INFORMATION

SEE YOUR FUERST DEALER

© 2004 Alamo Group Inc.

Safety Section 1-10FB42 08/01

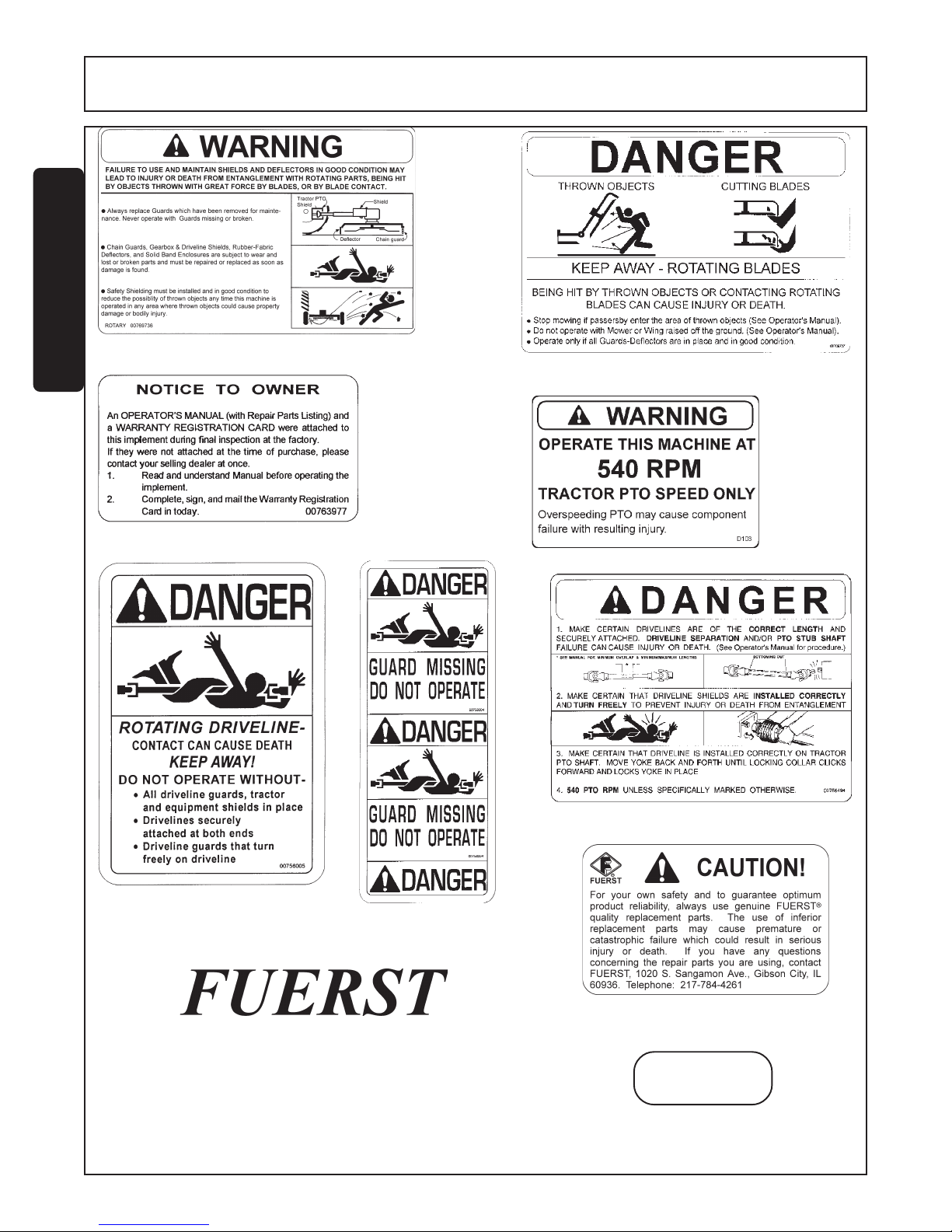

DECALS

10

8

7

16

11

13

15

ITEM PART NO. QTY TYPE DESCRIPTION

12

SAFETY

SAFETY

8

2

1

6

20

21

9

17

22

1 00725746 1 DANGER Peligro - Spanish Translation

2 00773723 1 DANGER Peligro - Spanish Driveline

3 00749117 1 DANGER Multi-Hazard

4 00756004 1 DANGER Shield Missing (Not Shown)

5 00756005 1 DANGER Rotating Driveline (Not Shown)

6 00756494 1 DANGER Driveline

7 00769737 1 DANGER Blades Thrown

8 00769736 1 WARNING Shields & Deflector

9 00760657 1 IMPORTANT Genuine Parts

10 03200347 * SIGN SMV

11 00763977 1 INSTRUCT Notice to Owner

12 D103 1 INSTRUCT 540 RPM

13 00768111 2 NAME FB42

15 IJ1835 2 LOGO Fuerst

16 nfs 1 S/N PLATE Serial Number Plate

17 00776481 1 INSTRUCT Operators Manual Inside

18 00776031 1 --------------- Canister, Operators Manual

19 00768114C 1 --------------- Operators Manual

20 10058000 3 --------------- Bolt

21 00024100 6 --------------- Flatwasher

22 02959924 3 --------------- Locknut

* Furnished by the Tractor Manufacturer

18

FB42 08/01

© 2004 Alamo Group Inc.

Safety Section 1-11

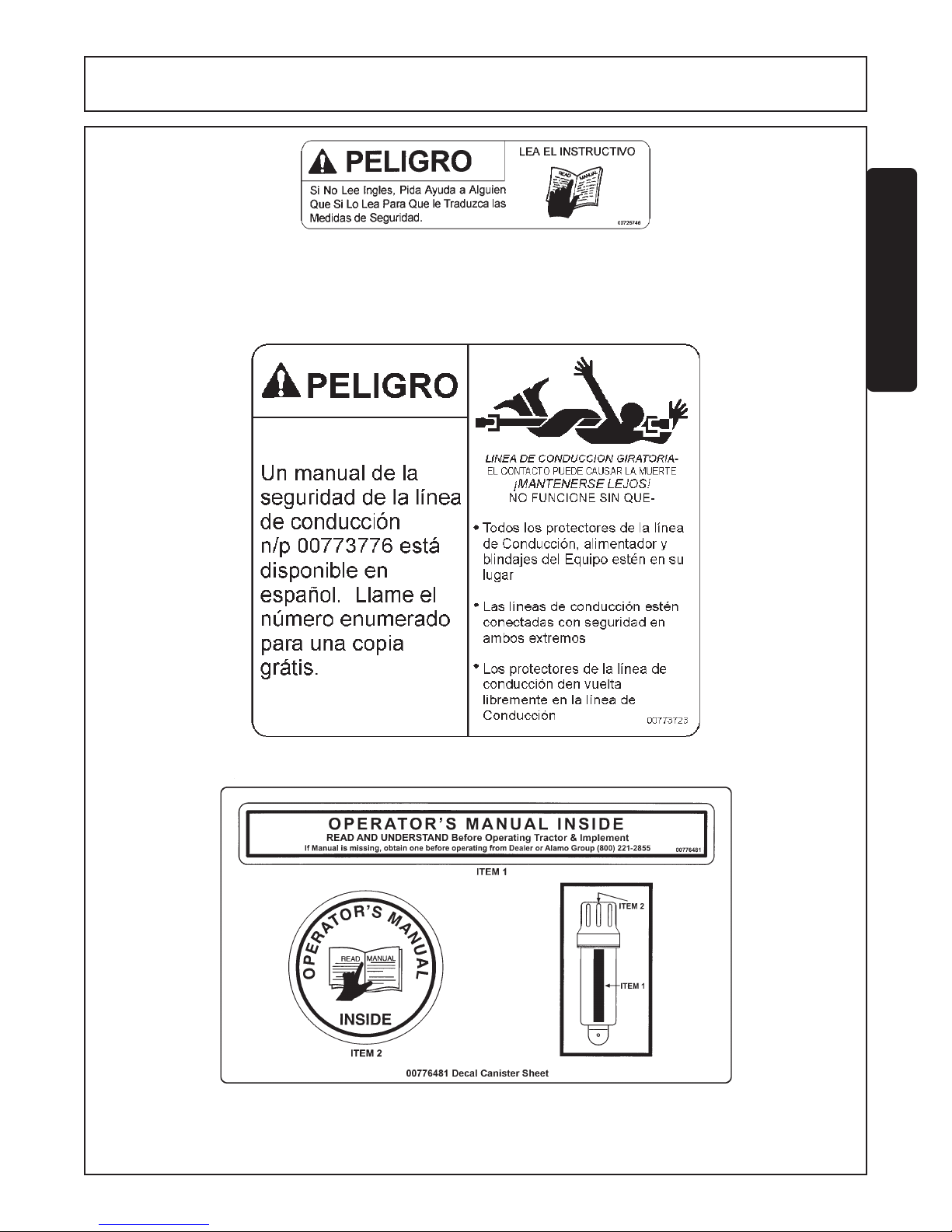

SAFETY

DECALS

8 - 00769736

7 - 00769737

12 - D103

11 - 00763977

5 - 00756005

15 -IJ1835

3 - 00749117 - Not Shown

(See Inside Front Cover of Manual)

© 2004 Alamo Group Inc.

6 - 00756494

4 - 00756004

9 - 3438305

FB42

13 - 00768111

Safety Section 1-12FB42 08/01

DECALS

1 - 00725746

SAFETY

SAFETY

FB42 08/01

© 2004 Alamo Group Inc.

2 - 00773723

17 - 00776481

Safety Section 1-13

SAFETY

FEDERAL LAWS AND REGULATIONS

This section is intended to explain in broad terms the concept and effect of federal laws and regulations concerning

employer and employee equipment operators. This section is not intended as a legal interpretation of the law and

should not be considered as such.

Employer-Employee Operator Regulations

U.S. Public Law 91-596 (The Williams-Steiger Occupational and Health Act of 1970) OSHA

This Act Seeks:

SAFETY

“...to assure so far as possible every working man and woman in the nation safe and healthful

working conditions and to preserve our human resources...”

DUTIES

Sec. 5 (a) Each employer(1) shall furnish to each of his employees employment and a place of employment which are free

from recognized hazards that are causing or are likely to cause death or serious physical harm to

his employees;

(2) shall comply with occupational safety and health standards promulgated under this Act.

(b) Each employee shall comply with occupational safety and health standards and all rules,

regulations and orders issued pursuant to this Act which are applicable to his own actions

and conduct.

OSHA Regulations

OSHA regulations state in part: “At the time of initial assignment and at least annually thereafter,

the employer shall instruct every employee in the safe operation and servicing of all equipment with

which the employee is, or will be involved.”

Employer Responsibilities:

To ensure employee safety during Tractor and Implement operation, it is the employer’s responsibility to:

1. Train the employee in the proper and safe operation of the Tractor and Implement.

2. Require that the employee read and fully understand the Tractor and Implement Operator’s manual.

3. Permit only qualified and properly trained employees to operate the Tractor and Implement.

4. Maintain the Tractor and Implement in a safe operational condition and maintain all shields and guards on the

equipment.

5. Ensure the Tractor is equipped with a functional ROPS and seat belt and require that the employee operator

securely fasten the safety belt and operate with the ROPS in the raised position at all times.

6. Forbid the employee operator to carry additional riders on the Tractor or Implement.

7. Provide the required tools to maintain the Tractor and Implement in a good safe working condition and provide

the necessary support devices to secure the equipment safely while performing repairs and service.

8. Require that the employee operator stop mowing if bystanders or passerbys come within 100 yards.

Child Labor Under 16 Years of Age

Some regulations specify that no one under the age of 16 may operate power machinery. It is your responsibility

to know what these regulations are in your own area or situation. (Refer to U.S. Dept. of Labor, Employment

Standard Administration, Wage & Home Division, Child Labor Bulletin #102.)

© 2004 Alamo Group Inc.

Safety Section 1-14FB42 08/01

INTRODUCTION

SECTION

Introduction Section 2-1

INTRODUCTION

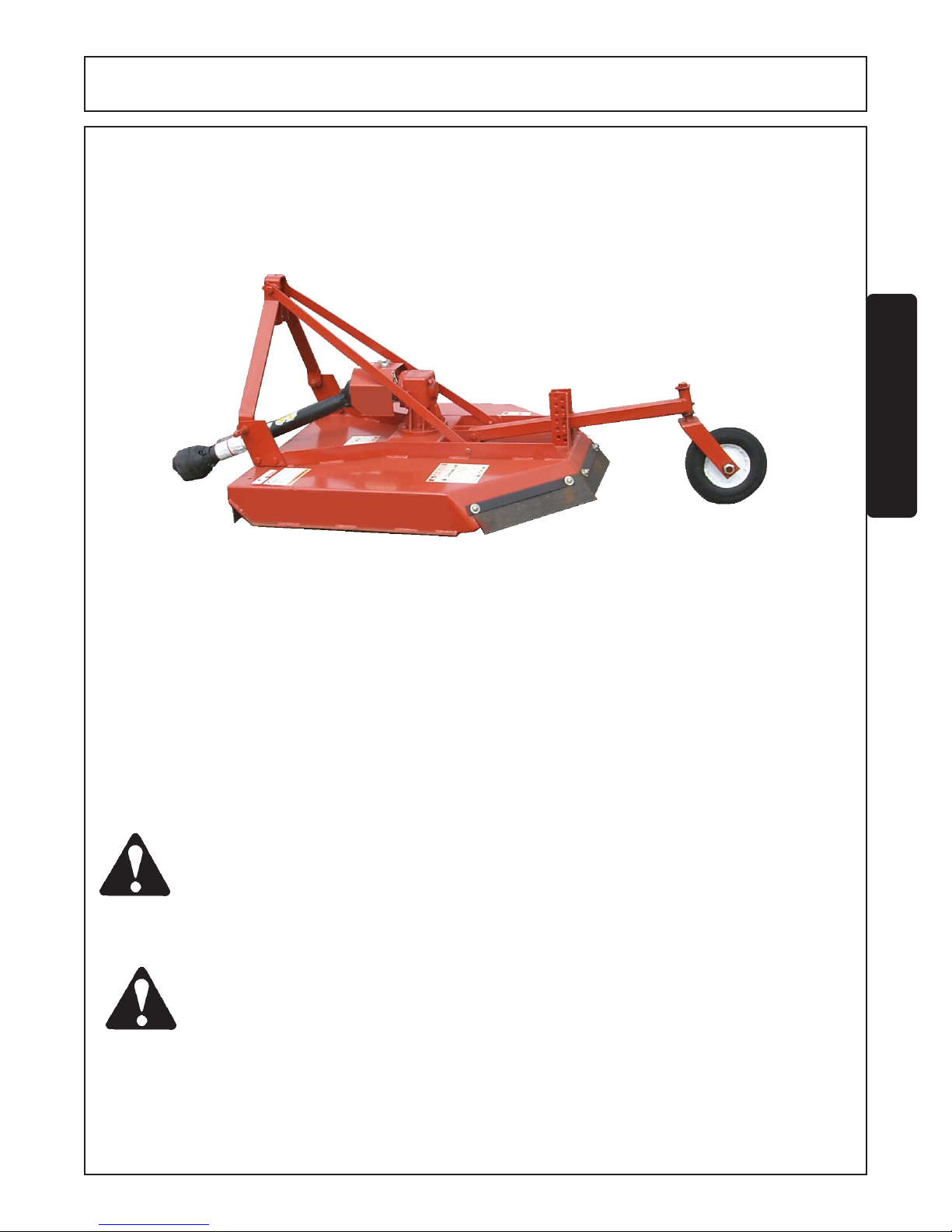

This Rotary Mower is designed with care and built with quality materials by skilled workers. Proper assembly,

maintenance, and operating practices, as described in this manual, will help the owner/operator get years of

satisfactory service from the machine.

The purpose of this manual is to familiarize, instruct, and train. The Assembly Section instructs the owner/

operator in the correct assembly of the Mower using standard and optional equipment. The Parts Listing section

is designed to familiarize the owner/operator with replaceable parts on the Mower. This section provides exploded

assembly drawings of each mower component illustrating each piece and the corresponding part number.

Careful use and timely service saves extensive repairs and costly downtime losses. The Operation and

Maintenance Sections of the manual train the owner/operator how to work the Mower correctly and attend to

appropriate maintenance. The Trouble Shooting Guide helps diagnose difficulties with mower and offers solution

INTRODUCTION

to the problems.

Safety is of primary importance to the owner/operator and to the manufacturer. The first section of this manual

includes a list of Safety Messages, that, if followed, will help protect the operator and bystanders from injury or

death. Many of the Safety Messages will be repeated throughout the manual. The owner/operator/dealer should

know these Safety Messages before assembly and be aware of the hazards of operating this mower during

assembly, use, and maintenance. The Safety Alert Symbol combined with a Signal Word, as seen below, is

intended to warn the owner/operator of impending hazards and the degree of possible injury faced when operating

this machine.

CAUTION

The lowest level of Safety Message; warns of possible minor injury. Decals

located on the Mower with this Signal Word are Black and Yellow.

WARNING

DANGER

Serious injury or possible death! Decals are Black and Orange.

Imminent death/critical injury. Decals are Red and White.

FB42 08/01

© 2004 Alamo Group Inc.

Introduction Section 2-2

INTRODUCTION

INTRODUCTION

Your FUERST FB42 mower is designed for light-duty cutting such as pasture mowing, weed, and grass control.

With a reasonable amount of preventive maintenance, your Mower will provide years of dependable service.

DANGER

WARNING

FB42 08/01

© 2004 Alamo Group Inc.

For Non-Agricultural use, OSHA, ASAE, SAE, and ANSI standards require the use of Chain

Guards, Deflectors, or Solid Skirts at all times. The Mower manufacturer strongly recommends

the use of Chain Guards or Solid Skirts for Agricultural purposes as well, to reduce the risk of

property damage, serious bodily injury, or even death from objects thrown out by or from contact

with the Cutting Blades.

At least 20% or the tractor’s weight must be on the front tires with the Mower lifted to provide

adequate traction for safe steering under good conditions. Slow down on hills, rough terrain,

and curves.

Front and rear and left and right are determined by the normal direction of travel, the same as

driving an automobile.

Introduction Section 2-3

INTRODUCTION

ATTENTION OWNER/OPERATOR

BEFORE OPERATING THIS MACHINE:

1. Carefully read the Operator’s Manual, completely understand the Safety Messages and instructions, and know

how to operate correctly both the tractor and Mower.

2. Fill out the Warranty Card in full. Be sure to answer all questions, including the Serial Number of the Mower.

Mail within 30 days of delivery date of this implement.

INTRODUCTION

NOTE: Warranties are honored only if completed “Owner Registration and Warranty” forms are received by

Alamo Group within thirty days of delivery of the mower.

3. Record the Mower Model and Serial Numbers on the Warranty page at the front of the Operator’s Manual.

Keep this as part of the permanent maintenance file for the Mower.

FB42 08/01

© 2004 Alamo Group Inc.

Introduction Section 2-4

ASSEMBLY

SECTION

Assembly Section 3-1

ASSEMBLY

DEALER SET-UP INSTRUCTIONS

Set up mower as received from factory with these instructions. Refer to complete check list when set -up is

finished.

Select a suitable working area. Open parts box and lay out parts to make location easy. Refer to Parts Lists in

Section 6 of manual and packing list. Cut all wire ties.

This mower is shipped partially assembled. Assembly will be easier if components are aligned and loosely

assembled before tightening hardware. Refer to bolt torque chart in Maintenance Section. All bolts are Grade 5

unless otherwise specified.

1. Position on flat surface.

2. Apply light oil to gear box input shaft.

SHIELD ASSEMBLY

4

2

4

3

4

Before installing gearbox shields, check lubricant level in

gearbox. Refer to Maintenance Section - Gearbox. Attach

cotter pin and cable assembly (#5) through top shield

bracket (#2) from outside in. Remove the top two bolts (#6)

on the front of the gearbox housing. Align holes in the top

shield bracket (#2) and gearbox. Reinstall the bolts &

lockwasher (torque to 33 ft. lbs.) Attach cotter pin (#5)

ASSEMBLY

through top shield (#1) from outside in. Attach shield (#1) to

top bracket (#2) and secure with flatwasher (#3 not shown)

and nut (#4). See Figure 1.

FIGURE 1. Gearbox Shield Attachment

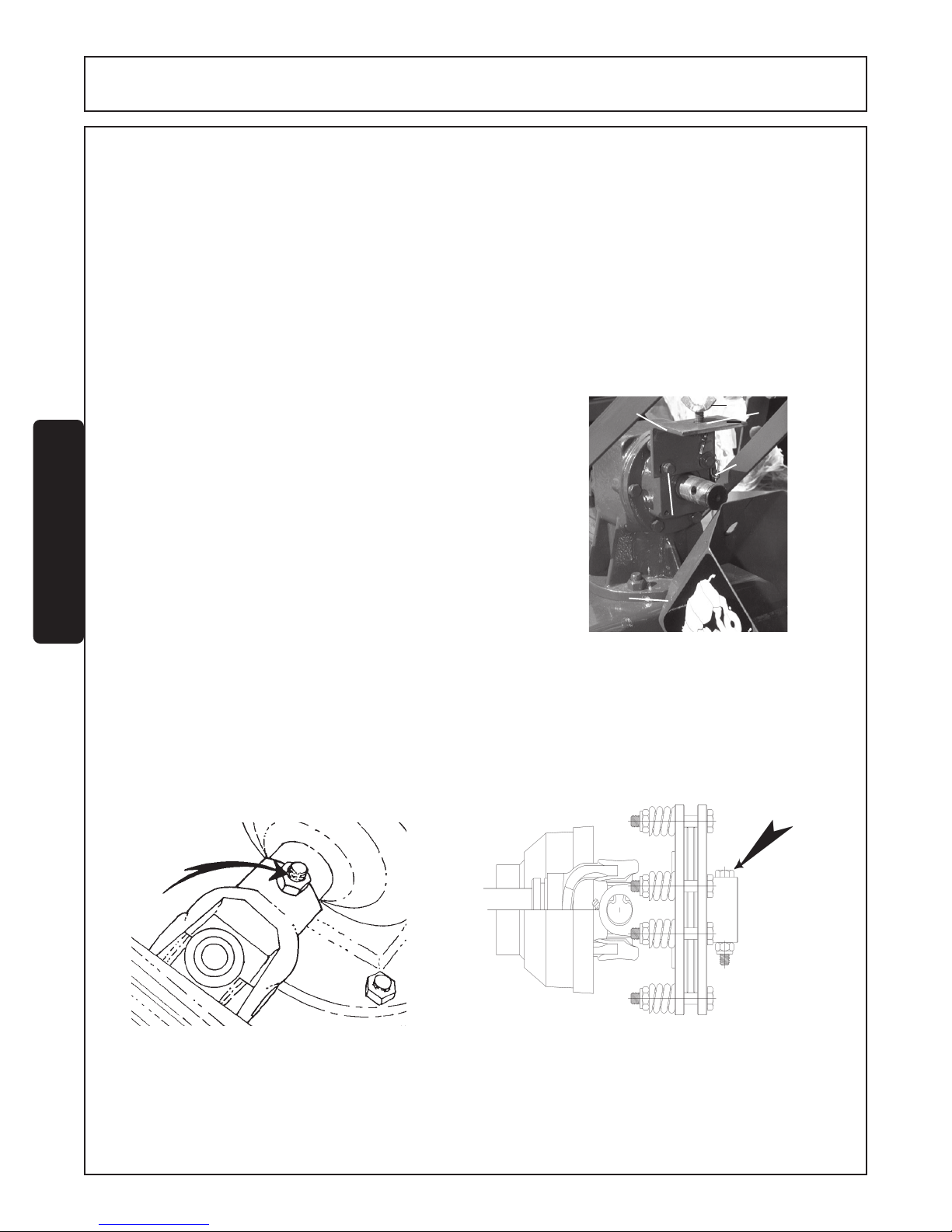

SHEAR BOLT or SLIP CLUTCH DRIVELINE INSTALLATION

Attach rear driveline of U-Joint to input Shaft on gearbox, install Snap Ring in groove on Input Shaft. NOTE:

Check that Snap Ring is properly seated in groove. This Snap Ring retains Driveline when shear bolt shears.

Install Grade 2 (only) shear bolt 1/2" by 3-1/2". Use of a stronger shear bolt than Grade 2, will result in

driveline failure and will void warranty. Figure 2.

1

6

5

FIGURE 2. Grade 2 Shear Bolt

Attach slip clutch driveline to input shaft on gearbox with Grade 8 Bolt Figure 3. Refer to proper Torque Chart in

Maintenance Section of this manual.

FB42 08/01

© 2004 Alamo Group Inc.

FIGURE 3. Grade 8 Bolt used with Slip Clutch

Assembly Section 3-2

R 09-21-99

ASSEMBLY

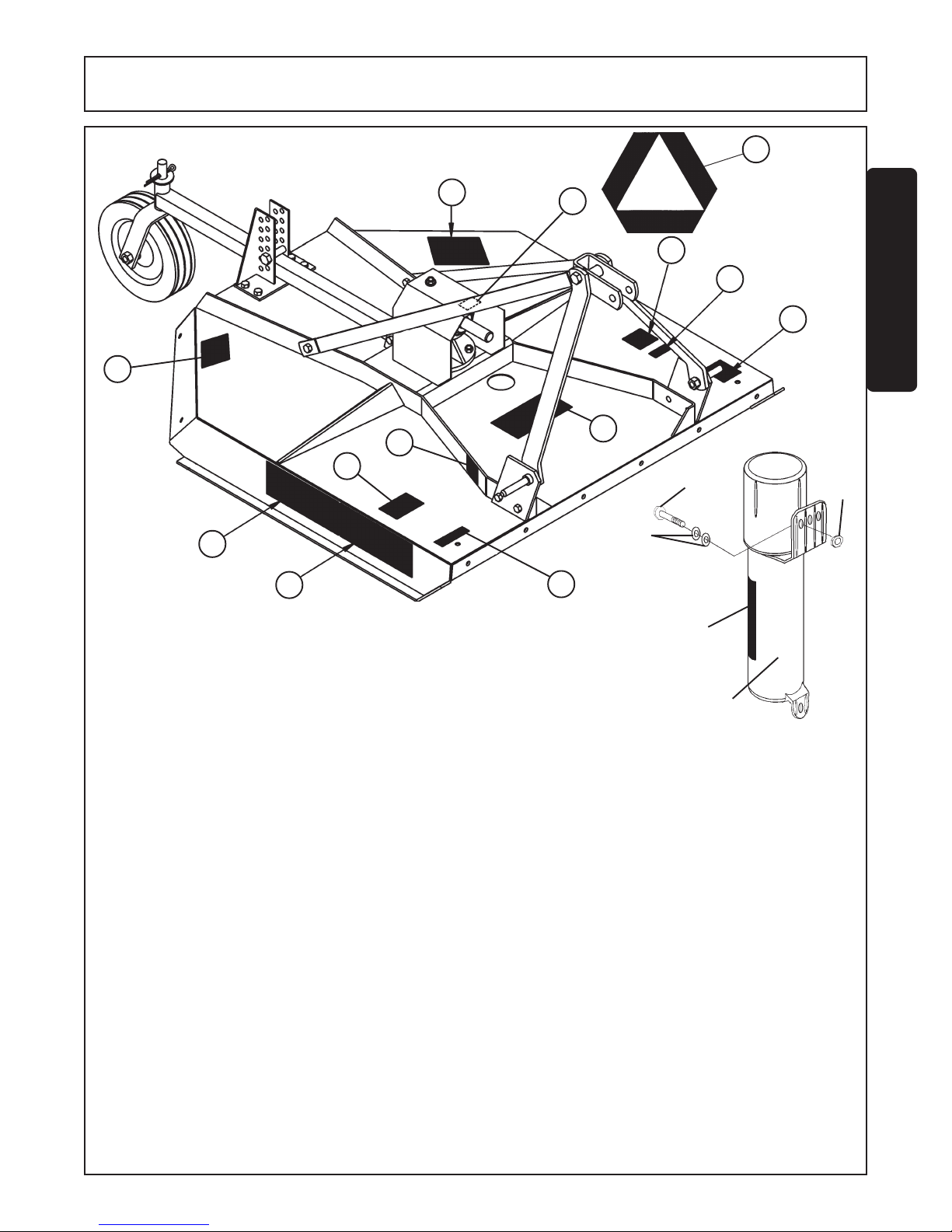

A-FRAME INSTALLATION (FIGURE 4)

1. Attach “A” Frames (1) to inside of welded hitch

brackets on Mainframe, insert Hitch Pin (12), Bushing (15), flatwasher (11), lockwasher (14) and install

nut (13). Then attach to lug hitch with bolt (22) and

locknut (23).

2. Install the lift straps (3) on inside of top rails on

mainshield (behind gearbox mount) and attach with

1/2" x 1-1/2" bolts (10) and locknuts (9).

3. Insert spacer (7) between A- frames (1). Insert

3/4" x 6" bolts (8) thru hole in lift straps and spacer

(7). Secure with 3/4" locknut (9).

TAIL WHEEL INSTALLATION (FIGURE 5)

3

9,10

FIGURE 4. A-Frame Installation

22, 23

7,8,9

1

11,12,13

14,15

ASSEMBLY

5. Align tailwheel beam weldment (16) between pivot brackets located behind gearbox mount on mainshield

weldment. NOTE: Long side of caster fork pivot tube is positioned up. Attach tailwheel beam weldment to

mainshield with 5/8" x 3-1/2" bolt (5) and locknut (6).

6. Insert caster fork assembly (19) into tailwheel beam weldment (16). Install washer (17) and secure with cotter

pin (18).

7. Place tailwheel adjusting brackets on to deck and secure with bolt (20) and locknut (21).

7. Position tailwheel beam weldment between tailwheel adjusting brackets on mainshield weldment and secure

with two 1/2" x 3" bolts (8) and locknut (9).

8. Tighten all bolts to the proper torque.

17, 18

16

8,9

20, 21

5,6

19

FB42 08/01

© 2004 Alamo Group Inc.

FIGURE 5. Tail Wheel Installation.

Assembly Section 3-3

R 08-12-99

Loading...

Loading...