Page 1

Сварочная горелка TIG

TIG welding torch

FB TIG 17

FB TIG 26

TIG KIT

Operator's Manual

Инструкция по эксплуатации

www.fubag.ru

Page 2

Omperator's anual

www.fubag.ru

WARNING! BEFORE USING THE WELDING READ THE INSTRUCTION

MANUAL CAREFULLY! FOR QUALIFIED AND SPECIALLY TRAINED PERSONS

ONLY AFTER PROPER READING OF THIS MANUAL IS ALLOWED TO USE AND TO

MAINTAIN THIS WELDING .

The detailed description, safety rules and all required information necessary for proper operation

and maintenance of FUBAG welding are provided below. Keep this instruction manual by

and refer to it by any doubts concerning safety operation, maintenance storage and handling of

FUBAG welding .

torch

TORCH

torch torch

TORCH

1. Safety perationo

-

It is highly recommended always to follow the safety rules. Wear protective clothes and

special means to avoid injuries to eyes and skins.

-

Use the welding mask or special protective glasses while working with the welding

machine. Only by viewing through the filter lens on the welding mask your eyes are

secured by your operation.

-

Under no circumstance allow any part of your body to touch the welder's output bipolarity

(torch and work piece).

-

Do not operate under water or more humid place.

-

Fumes and gases produced when welding are hazardous to health. Make sure to work in

places where there are exhaust or ventilation facilities to keep fumes or emissions away

from the breathing zone.

-

Please remember to keep arc rays away from the other nearby people when welding. This

is only due to the interference from arc rays.

-

There will be high temperature when welding work piece, so please don't directly touch on it

-

No touching on the electrification parts after turning on the power. Cut off the power supply

after operation or before leaving the welding site.

-

No welding in the dangerous site where easily get an electrical shock.

-

No welding for the container loaded inflammable or explosive materials.

-

Safe measures should be adoptted while operating in high place to avoid accident.

-

No entering the welding site for persons not concerned.

In order to avoid the explosion of the gas bottle:

- make sure that the gas type corresponds to the required

- use faultless hoses and fittings

- place the torch so that there was no contact with the gas bottle

- close the stop valve of the tank when the gas is not used.

WARNING

- it is necessary to shorten the length of welding and ground cables as much as possible;

- the welding cable is to be situated as close to the ground as possible

- the ground cable and the torch cables are to be situated parallel and should not cross.

:

WARNING. The welder voltage is always higher, so the safety precaution should be taken

before repair to avoid accidental shock. Switch off the power supply before each type of

maintenance work. The untrained people are not allowed to make maintenance of the

.torch

;

;

;

;

- 1 -

Page 3

Omperator's anual

2. Technical Specification

www.fubag.ru

Тype

Duty cycle, % 35% 35% 35% 35%

Tungsten electrodes 0,5 - 2,4 mm 0,5 - 3,2 mm 0,5 - 2,4 mm 0,5 - 2,4 mm

Cable assembly lengths 4 m 4 m 4 m 4 m

Gas cable lengths 6 m 6 m

Torch connection 35/50 35/50 10/25 35/50

The manufacturer reserves himself the right to make the manual's content or function

change without any preliminary notification of theusers.

FB TIG 17 FB TIG 26

Kit for TIG (IN 176/IN

196) vent

Kit for TIG (IN

206/IN 206 LVP/ IN

226) vent

torch

3.Application

Th is intended for connection to the power source and for the gas-shielded reusable

is TIG torch

electrode welding. The torch enable the possibility of gas-shielded welding with the use of welding

machines.

The torch application is permitted under the following climatic conditions:

a) The ambient temperature:

while welding: –10 … +40°C,

while storing and shipping: - 25 … +55°C.

-

b) Relative air humidity:

at +40°C – less than 50%,

at +20°C – less than 90%.

-

The torch is designed for . While connecting the torch to power source observe the rules

tig welding

indicated in the welding machine manual. The rated duty cycle is 60%, this means that within 10minutes' welding cycle the torch temperature reaches acceptable limit. In order to prevent the

insulation failure and premature wear of the torch, it is recommended to use it in rated duty cycle

only.

WARNING

! Operation in the mode above the rated is prohibited since it causes the torch

destruction. Diameter of an opening of a grip and the holder have to correspond to diameter of an

electrode.

- 2 -

Page 4

Omperator's anual

www.fubag.ru

4. Maintenance

In order to ensure the secure and efficient operation the torch requires periodical maintenance

service. Before performing the maintenance work, disconnect the torch from the welding machine.

All parts are to cool down to the safe temperature. Regularly check the joints in order to ensure that

there is no rust, check the reliability of the components tightening. Make sure there are no leakages

and signs of wear in the torch cable or the cable tube. The insulation breakdown can cause

accidents and equipment damage.

5. Warranty

Warranty refer to defects of materials and components and do not refer to components subject to

natural wear and maintenance work.

torch

Only cleaned from dust and dirt in original factory packing fully completed, provided with

instruction manual, warranty card with fixed sales date with a shop stamp factory serial number and

originals of sales and ware receipt issued by salesman are subjects of warranty. Within the warranty

period the service center eliminate free of charge all detected production defects. The manufacturer

disclaims warranty and legal responsibilities if nonobservance of the instruction manual by user,

unqualified disassembling repair or maintenance of the as well does not bear responsibility for

caused injury to persons or damages.

torch

- 3 -

Page 5

Инструкция по эксплуатации

www.fubag.ru

ВНИМАНИЕ! ПЕРЕД ИСПОЛЬЗОВАНИЕМ СВАРОЧНОЙ ГОРЕЛКИ

ВНИМАТЕЛЬНООЗНАКОМЬТЕСЬ С ДАННОЙ ИНСТРУКЦИЕЙ.

К использованию и обслуживанию оборудования допускается только

квалифицированный и специально обученный персонал, ознакомленный с данной

инструкцией.

В этой инструкции содержится описание, правила безопасности и вся необходимая

информация для правильной эксплуатации сварочной горелки FUBAG. Сохраняйте данную

инструкцию и обращайтесь к ней при возникновении вопросов по безопасной эксплуатации,

обслуживанию, хранению итранспортировке горелки FUBAG.

1. Правила безопасности

- Всегда соблюдайте правила безопасности. Носите защитную одежду и специальные

средства защиты, чтобы избежать повреждения глаз и кожных покровов.

- Всегда надевайте сварочную маску во время работы.

- Избегайте контактов с открытыми токоведущими кабелями, не к свариваемой

поверхности.

- Не работайте под водой или в месте с повышенной влажностью.

- Дым и газ, которые попадают в воздух при сварке, опасны для здоровья. Перед

началом работ убедитесь, что вытяжка и вентиляция исправно работают.

- Убедитесь, что излучение дуги не попадет на других людей, находящихся поблизости

от места сварки.

- Помните, что при сварке температура обрабатываемой поверхности повышается,

поэтому старайтесь не прикасаться к обрабатываемым деталям во избежание ожогов.

- Никогда не работайте там, где существует опасность получения электрошока.

- Никогда не производите сварку емкостей, в которых могут содержаться

легковоспламеняющиеся или взрывоопасные материалы.

- При высотных работах во избежание несчастного случая соблюдайте правила техники

безопасности работы на высоте.

- Следите за тем, чтобы на рабочей площадке не было посторонних людей.

Во избежание взрыва газовых баллонов:

- необходимо убедиться в том, что газ соответствует необходимому;

- необходимо использовать исправные шланги и соединительную арматуру;

- размещать горелку только так чтобы она не касалась баллонов;

- необходимо закрывайте запорный вентиль баллона, когда газ не используется.

ВНИМАНИЕ:

- необходимо максимально сократить длину сварочных и заземляющих кабелей;

- сварочный кабель должен располагаться как можно ближе к земле;

- кабели заземления и горелки должны располагаться параллельно и не пересекаться.

ВНИМАНИЕ. Оборудование находится под напряжением, поэтому прежде, чем

приступить к его обслуживанию, следует обесточить его во избежание электрошока.

Перед проведением любых работ всегда необходимо отключать источник питания. К

работам допускаются только специалисты.

--4

Page 6

Инструкция по эксплуатации

2. Технические характеристики

www.fubag.ru

Набор для TIG (IN

Тип

Номинальный цикл режима работы, % 35% 35% 35% 35%

Применяемые вольфрамовые электроды 0,5 - 2,4 мм 0,5 - 3,2 мм 0,5 - 2,4 мм 0,5 - 2,4 мм

Длина шланг пакета 4 м 4 м 4 м 4 м

Длина газового шланга 6 м 6 м

Тип коннектора 35/50 35/50 10/25 35/50

Производитель имеет право вносить изменения как в содержание данной инструкции, так и в конструкцию

горелкибезпредварительного уведомления пользователей.

FB TIG 17 FB TIG 26

176/IN 196)

вентильная

Набор для TIG (IN

206/IN 206 LVP/ IN

226) вентильная

3. Назначение и область применения

Готовая к эксплуатации горелка предназначена для подключения к источнику тока

сварки неплавящимся электродом в среде защитных газов. Горелка обеспечивает

возможность выполнения сварочных работ с использованием сварочных аппаратов.

Разрешается эксплуатация горелки при следующих климатических условиях:

а) Температура окружающей среды:

- при сварке: –10…+40°С;

- при хранении/транспортировке: –25…+55°C.

б) Относительная влажность воздуха:

- при 40°С: менее 50%;

- при 20°С: менее 90%.

TIG

Горелка предназначена для ручной аргоннодуговой сварки неплавящимся электродом в

среде инертных газов. При подключении горелки к источнику тока соблюдайте правила

подключения, указанные в документации сварочного аппарата. Номинальный рабочий цикл

составляет 60%, это значит, что в течение 10-минутного цикла сварки температура горелки

достигает допустимого предела. Чтобы предотвратить нарушение изоляции и

преждевременный износ горелки, следует использовать ее только в номинальном рабочем

цикле.

ВНИМАНИЕ!

Работа в режиме, превышающем номинальный, недопустима, так как приводит

к разрушению горелки. Диаметр отверстия в цанге и цангодержателе должны

соответствовать диаметру неплавящегося электрода.

--5

Page 7

Инструкция по эксплуатации

www.fubag.ru

4. Техническоеобслуживание

Для обеспечения безопасной и эффективной работы горелка нуждается в периодическом

техническом обслуживании. Перед проведением технического обслуживания отключите

горелку от сварочного аппарата. Все детали горелки должны остыть до безопасной

температуры. Регулярно проверяйте соединения на отсутствие коррозии и надежность

затяжки элементов. Убедитесь в отсутствии утечек и признаков старения в кабеле горелки.

Разрушение изоляции может привести к несчастным случаям и повреждению оборудования.

5. Гарантийные обязательства

Гарантийный срок на оборудование указывается в прилагаемом сервисном талоне

Гарантия относится к дефектам в материалах и узлах и не распространяется на компоненты

подверженные естественному износу и работы по техническому обслуживанию

Гарантийному ремонту подлежат только очищенные от пыли и грязи горелки в заводской

упаковке полностью укомплектованные имеющие инструкцию по эксплуатации гарантийный

талон с указанием даты продажи при наличии штампа магазина заводского номера и

оригиналов товарного и кассового чеков выданных продавцом

В течение гарантийного срока Сервисный центр устраняет за свой счёт выявленные

производственные дефекты Производитель снимает свои гарантийные обязательства и

юридическую ответственность при несоблюдении потребителем инструкций по эксплуатации

самостоятельной разборки ремонта и технического обслуживания оборудования а также не

несет никакой ответственности за причиненные травмы и нанесенный ущерб

,, ,

,,

,.

.

,,

.

.

.

,

,

--6

Page 8

FB TIG 17

www.fubag.ru

1 Torch head brass Корпус шейки

2 Reduction 9/17 14,8 Редуктор 9/17 14,8

3 TIG handle Корпус ручки

4 Assembly of TIG four switch horizontal Панель переключателей

5 Сover for TIG handle Покрытие для панели переключателей

6 Set for four switches Защитный корпус переключателей

7 Screw D3*8 UNI9707 Винт D3*8 UNI9707

8 TIG Joint small Шарнир с кольцом

9 Female trigger wire connector / 5holes "Мама" триггер коннектор с кабелем

10 Insulator Tube Изолятор

11 Complete outer cover 6 holes control wires Оплетка пакета шлангов

12 Plug TIG 50 M12x1 L=0,6m Байонет "папа" M12x1 L=0,6m

14 Accessory kit Набор аксессуаров

FB0066 Long cap FB TIG 17-26 Хвостовик горелки длинный FB TIG 17-26

FB0056 Medium cap FB TIG 17-26 Хвостовик горелки средний FB TIG 17-26

FB0067 Short cap FB TIG 17-26 Хвостовик горелки короткий FB TIG 17-26

FB0001.16 Collet 1,6 FB TIG 17-26 (10N23) Цанга 1,6 FB TIG 17-26 (10N23)

FB0001.24 Collet 2,4 FB TIG 17-26 (10N24) Цанга 2,4 FB TIG 17-26 (10N24)

FB0001.32 Collet 3,2 FB TIG 17-26 (10N25) Цанга 3,2 FB TIG 17-26 (10N25)

FB0001.40 Collet 4,0 FB TIG 17-26 (54N20) Цанга 4,0 FB TIG 17-26 (54N20)

FB0002 Insulator Tube FB TIG 17-26 Изолятор FB TIG 17-26

FB0706.0001.16 Collet body 1,6 FB TIG 17-26 (10N31) Корпус цанги 1,6 FB TIG 17-26 (10N31)

FB0706.0001.24 Collet body 2,4 FB TIG 17-26 (10N32) Корпус цанги 2,4 FB TIG 17-26 (10N32)

FB0706.0001.32 Collet body 3,2 FB TIG 17-26 (10N28) Корпус цанги 3,2 FB TIG 17-26 (10N28)

FB0706.0001.40 Collet body 4,0 FB TIG 17-26 Корпус цанги 4,0 FB TIG 17-26

FB0004 Ceramic nozzle №6 9,5 FB TIG 17-26 (10N48) Сопло керамическое №6 9,5 FB TIG 17-26 (10N48)

FB0005 Ceramic nozzle №7 1 1 FB TIG 17-26 (10N47) Сопло керамическое №7 1 1 FB TIG 17-26 (10N47)

FB0006 Ceramic nozzle №8 12,5 FB TIG 17-26 (10N46) Сопло керамическое №8 12,5 FB TIG 17-26 (10N46)

FB0007 Ceramic nozzle №10 16 FB TIG 17-26 (10N45) Сопло керамическое №10 16 FB TIG 17-26 (10N45)

FB0003 Insulator for gaslens FB TIG 17-26 Изолятор для газовой линзы FB TIG 17-26

FB0006.16 Collet body gaslens 1,6 FB TIG 17-26 Корпус цанги c газовой линзой 1,6 FB TIG 17-26

FB0006.24 Collet body gaslens 2,4 FB TIG 17-26 Корпус цанги c газовой линзой 2,4 FB TIG 17-26

FB0006.32 Collet body gaslens 3,2 FB TIG 17-26 Корпус цанги c газовой линзой 3,2 FB TIG 17-26

FB0006.40 Collet body gaslens 4,0 FB TIG 17-26 Корпус цанги c газовой линзой 4,0 FB TIG 17-26

FB0033 Ceramic nozzle gaslens №6 9,5 FB TIG 17-26 (54N16) Сопло керамическое для газовой линзы №6 9,5 FB TIG 17-26 (54N16)

FB0034 Ceramic nozzle gaslens №7 1 1 FB TIG 17-26 (54N15) Сопло керамическое для газовой линзы №7 1 1 FB TIG 17-26 (54N15)

FB0035 Ceramic nozzle gaslens №8 12,5 FB TIG 17-26 (54N14) Сопло керамическое для газовой линзы №8 12,5 FB TIG 17-26 (54N14)

Spare parts / Расходные запчасти

--7

Page 9

FB TIG 17 5P

www.fubag.ru

1 Torch head brass Корпус шейки

2 Reduction 9/17 14,8 Редуктор 9/17 14,8

3 TIG handle Корпус ручки

4 Assembly of TIG four switch horizontal Панель переключателей

5 Сover for TIG handle Покрытие для панели переключателей

6 Set for four switches Защитный корпус переключателей

7 Screw D3*8 UNI9707 Винт D3*8 UNI9707

8 TIG Joint small Шарнир с кольцом

9 Female trigger wire connector / 5holes "Мама" триггер коннектор с кабелем

10 Insulator Tube Изолятор

11 Complete outer cover 6 holes control wires Оплетка пакета шлангов

12 Plug TIG 50 M12x1 L=0,6m Байонет "папа" M12x1 L=0,6m

13 Connector 5 holes XS12 J5P Разъем управления 5-ти полюсной

15 Accessory kit Набор аксессуаров

FB0066 Long cap FB TIG 17-26 Хвостовик горелки длинный FB TIG 17-26

FB0056 Medium cap FB TIG 17-26 Хвостовик горелки средний FB TIG 17-26

FB0067 Short cap FB TIG 17-26 Хвостовик горелки короткий FB TIG 17-26

FB0001.16 Collet 1,6 FB TIG 17-26 (10N23) Цанга 1,6 FB TIG 17-26 (10N23)

FB0001.24 Collet 2,4 FB TIG 17-26 (10N24) Цанга 2,4 FB TIG 17-26 (10N24)

FB0001.32 Collet 3,2 FB TIG 17-26 (10N25) Цанга 3,2 FB TIG 17-26 (10N25)

FB0001.40 Collet 4,0 FB TIG 17-26 (54N20) Цанга 4,0 FB TIG 17-26 (54N20)

FB0002 Insulator Tube FB TIG 17-26 Изолятор FB TIG 17-26

FB0706.0001.16 Collet body 1,6 FB TIG 17-26 (10N31) Корпус цанги 1,6 FB TIG 17-26 (10N31)

FB0706.0001.24 Collet body 2,4 FB TIG 17-26 (10N32) Корпус цанги 2,4 FB TIG 17-26 (10N32)

FB0706.0001.32 Collet body 3,2 FB TIG 17-26 (10N28) Корпус цанги 3,2 FB TIG 17-26 (10N28)

FB0706.0001.40 Collet body 4,0 FB TIG 17-26 Корпус цанги 4,0 FB TIG 17-26

FB0004 Ceramic nozzle №6 9,5 FB TIG 17-26 (10N48) Сопло керамическое №6 9,5 FB TIG 17-26 (10N48)

FB0005 Ceramic nozzle №7 1 1 FB TIG 17-26 (10N47) Сопло керамическое №7 1 1 FB TIG 17-26 (10N47)

FB0006 Ceramic nozzle №8 12,5 FB TIG 17-26 (10N46) Сопло керамическое №8 12,5 FB TIG 17-26 (10N46)

FB0007 Ceramic nozzle №10 16 FB TIG 17-26 (10N45) Сопло керамическое №10 16 FB TIG 17-26 (10N45)

FB0003 Insulator for gaslens FB TIG 17-26 Изолятор для газовой линзы FB TIG 17-26

FB0006.16 Collet body gaslens 1,6 FB TIG 17-26 Корпус цанги c газовой линзой 1,6 FB TIG 17-26

FB0006.24 Collet body gaslens 2,4 FB TIG 17-26 Корпус цанги c газовой линзой 2,4 FB TIG 17-26

FB0006.32 Collet body gaslens 3,2 FB TIG 17-26 Корпус цанги c газовой линзой 3,2 FB TIG 17-26

FB0006.40 Collet body gaslens 4,0 FB TIG 17-26 Корпус цанги c газовой линзой 4,0 FB TIG 17-26

FB0033 Ceramic nozzle gaslens №6 9,5 FB TIG 17-26 (54N16) Сопло керамическое для газовой линзы №6 9,5 FB TIG 17-26 (54N16)

FB0034 Ceramic nozzle gaslens №7 1 1 FB TIG 17-26 (54N15) Сопло керамическое для газовой линзы №7 1 1 FB TIG 17-26 (54N15)

FB0035 Ceramic nozzle gaslens №8 12,5 FB TIG 17-26 (54N14) Сопло керамическое для газовой линзы №8 12,5 FB TIG 17-26 (54N14)

Spare parts / Расходные запчасти

--8

Page 10

FB TIG 26

www.fubag.ru

1 Torch head brass Корпус шейки

2 TIG handle Корпус ручки

3 Assembly of TIG four switch horizontal Панель переключателей

4 Сover for TIG handle Покрытие для панели переключателей

5 Set for four switches Защитный корпус переключателей

6 Screw D3*8 UNI9707 Винт D3*8 UNI9707

7 TIG Joint small Шарнир с кольцом

8 Female trigger wire connector / 5holes "Мама" триггер коннектор с кабелем

9 Insulator Tube Изолятор

10 Complete outer cover 6 holes control wires Оплетка пакета шлангов

11 Plug TIG 50 M12x1 L=0,6m Байонет "папа" M12x1 L=0,6m

13 Accessory kit Набор аксессуаров

FB0066 Long cap FB TIG 17-26 Хвостовик горелки длинный FB TIG 17-26

FB0056 Medium cap FB TIG 17-26 Хвостовик горелки средний FB TIG 17-26

FB0067 Short cap FB TIG 17-26 Хвостовик горелки короткий FB TIG 17-26

FB0001.16 Collet 1,6 FB TIG 17-26 (10N23) Цанга 1,6 FB TIG 17-26 (10N23)

FB0001.24 Collet 2,4 FB TIG 17-26 (10N24) Цанга 2,4 FB TIG 17-26 (10N24)

FB0001.32 Collet 3,2 FB TIG 17-26 (10N25) Цанга 3,2 FB TIG 17-26 (10N25)

FB0001.40 Collet 4,0 FB TIG 17-26 (54N20) Цанга 4,0 FB TIG 17-26 (54N20)

FB0002 Insulator Tube FB TIG 17-26 Изолятор FB TIG 17-26

FB0706.0001.16 Collet body 1,6 FB TIG 17-26 (10N31) Корпус цанги 1,6 FB TIG 17-26 (10N31)

FB0706.0001.24 Collet body 2,4 FB TIG 17-26 (10N32) Корпус цанги 2,4 FB TIG 17-26 (10N32)

FB0706.0001.32 Collet body 3,2 FB TIG 17-26 (10N28) Корпус цанги 3,2 FB TIG 17-26 (10N28)

FB0706.0001.40 Collet body 4,0 FB TIG 17-26 Корпус цанги 4,0 FB TIG 17-26

FB0004 Ceramic nozzle №6 9,5 FB TIG 17-26 (10N48) Сопло керамическое №6 9,5 FB TIG 17-26 (10N48)

FB0005 Ceramic nozzle №7 1 1 FB TIG 17-26 (10N47) Сопло керамическое №7 1 1 FB TIG 17-26 (10N47)

FB0006 Ceramic nozzle №8 12,5 FB TIG 17-26 (10N46) Сопло керамическое №8 12,5 FB TIG 17-26 (10N46)

FB0007 Ceramic nozzle №10 16 FB TIG 17-26 (10N45) Сопло керамическое №10 16 FB TIG 17-26 (10N45)

FB0003 Insulator for gaslens FB TIG 17-26 Изолятор для газовой линзы FB TIG 17-26

FB0006.16 Collet body gaslens 1,6 FB TIG 17-26 Корпус цанги c газовой линзой 1,6 FB TIG 17-26

FB0006.24 Collet body gaslens 2,4 FB TIG 17-26 Корпус цанги c газовой линзой 2,4 FB TIG 17-26

FB0006.32 Collet body gaslens 3,2 FB TIG 17-26 Корпус цанги c газовой линзой 3,2 FB TIG 17-26

FB0006.40 Collet body gaslens 4,0 FB TIG 17-26 Корпус цанги c газовой линзой 4,0 FB TIG 17-26

FB0033 Ceramic nozzle gaslens №6 9,5 FB TIG 17-26 (54N16) Сопло керамическое для газовой линзы №6 9,5 FB TIG 17-26 (54N16)

FB0034 Ceramic nozzle gaslens №7 1 1 FB TIG 17-26 (54N15) Сопло керамическое для газовой линзы №7 1 1 FB TIG 17-26 (54N15)

FB0035 Ceramic nozzle gaslens №8 12,5 FB TIG 17-26 (54N14) Сопло керамическое для газовой линзы №8 12,5 FB TIG 17-26 (54N14)

Spare parts / Расходные запчасти

--9

Page 11

FB TIG 26 5P

www.fubag.ru

1 Torch head brass Корпус шейки

2 TIG handle Корпус ручки

3 Assembly of TIG four switch horizontal Панель переключателей

4 Сover for TIG handle Покрытие для панели переключателей

5 Set for four switches Защитный корпус переключателей

6 Screw D3*8 UNI9707 Винт D3*8 UNI9707

7 TIG Joint small Шарнир с кольцом

8 Female trigger wire connector / 5holes "Мама" триггер коннектор с кабелем

9 Insulator Tube Изолятор

10 Complete outer cover 6 holes control wires Оплетка пакета шлангов

11 Plug TIG 50 M12x1 L=0,6m Байонет "папа" M12x1 L=0,6m

12 Connector 5 holes XS12 J5P Разъем управления 5-ти полюсной

14 Accessory kit Набор аксессуаров

FB0066 Long cap FB TIG 17-26 Хвостовик горелки длинный FB TIG 17-26

FB0056 Medium cap FB TIG 17-26 Хвостовик горелки средний FB TIG 17-26

FB0067 Short cap FB TIG 17-26 Хвостовик горелки короткий FB TIG 17-26

FB0001.16 Collet 1,6 FB TIG 17-26 (10N23) Цанга 1,6 FB TIG 17-26 (10N23)

FB0001.24 Collet 2,4 FB TIG 17-26 (10N24) Цанга 2,4 FB TIG 17-26 (10N24)

FB0001.32 Collet 3,2 FB TIG 17-26 (10N25) Цанга 3,2 FB TIG 17-26 (10N25)

FB0001.40 Collet 4,0 FB TIG 17-26 (54N20) Цанга 4,0 FB TIG 17-26 (54N20)

FB0002 Insulator Tube FB TIG 17-26 Изолятор FB TIG 17-26

FB0706.0001.16 Collet body 1,6 FB TIG 17-26 (10N31) Корпус цанги 1,6 FB TIG 17-26 (10N31)

FB0706.0001.24 Collet body 2,4 FB TIG 17-26 (10N32) Корпус цанги 2,4 FB TIG 17-26 (10N32)

FB0706.0001.32 Collet body 3,2 FB TIG 17-26 (10N28) Корпус цанги 3,2 FB TIG 17-26 (10N28)

FB0706.0001.40 Collet body 4,0 FB TIG 17-26 Корпус цанги 4,0 FB TIG 17-26

FB0004 Ceramic nozzle №6 9,5 FB TIG 17-26 (10N48) Сопло керамическое №6 9,5 FB TIG 17-26 (10N48)

FB0005 Ceramic nozzle №7 1 1 FB TIG 17-26 (10N47) Сопло керамическое №7 1 1 FB TIG 17-26 (10N47)

FB0006 Ceramic nozzle №8 12,5 FB TIG 17-26 (10N46) Сопло керамическое №8 12,5 FB TIG 17-26 (10N46)

FB0007 Ceramic nozzle №10 16 FB TIG 17-26 (10N45) Сопло керамическое №10 16 FB TIG 17-26 (10N45)

FB0003 Insulator for gaslens FB TIG 17-26 Изолятор для газовой линзы FB TIG 17-26

FB0006.16 Collet body gaslens 1,6 FB TIG 17-26 Корпус цанги c газовой линзой 1,6 FB TIG 17-26

FB0006.24 Collet body gaslens 2,4 FB TIG 17-26 Корпус цанги c газовой линзой 2,4 FB TIG 17-26

FB0006.32 Collet body gaslens 3,2 FB TIG 17-26 Корпус цанги c газовой линзой 3,2 FB TIG 17-26

FB0006.40 Collet body gaslens 4,0 FB TIG 17-26 Корпус цанги c газовой линзой 4,0 FB TIG 17-26

FB0033 Ceramic nozzle gaslens №6 9,5 FB TIG 17-26 (54N16) Сопло керамическ ое для газовой линзы №6 9,5 FB TIG 17-26 (54N16)

FB0034 Ceramic nozzle gaslens №7 1 1 FB TIG 17-26 (54N15) Сопло керамическое для газовой линзы №7 1 1 FB TIG 17-26 (54N15)

FB0035 Ceramic nozzle gaslens №8 12,5 FB TIG 17-26 (54N14) Сопло керамическое для газовой линзы №8 12,5 FB TIG 17-26 (54N14)

Spare parts / Расходные запчасти

- 10 -

Page 12

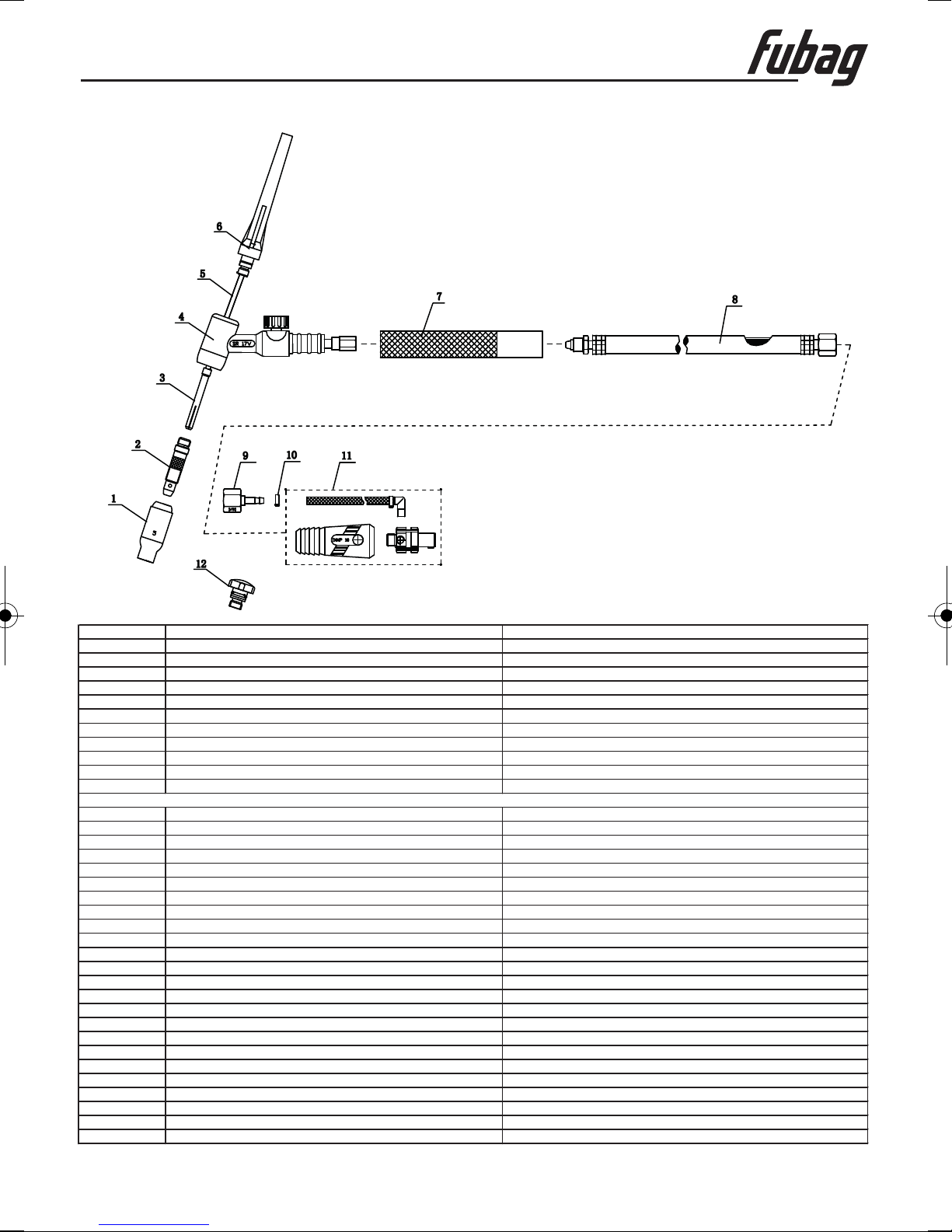

TIG KIT

www.fubag.ru

1 Alumina Cup GR5 TIG 17 Сопло GR5

2 Collet Body 2.4 TIG 17 Держатель цанги 2.4

3 Collet Body 2.4 50mm TIG 17 Цанга 2,4 50мм

4 Torch head with Valve TIG 17 Корпус шейки c вентелем

5 Pure tungsten 2,4x175 Вольфрамовый электрод 2,4x175

6 Long back cup TIG 17 Хвостовик горелки

7 Handle TIG 17 Корпус ручки

8 Cable gas 4m m12x1 TIG 17 Газовый шланг 4m m12x1

9 Connector with hexagen nut 3/8G Коннектор с разъемом 3/8G

10 Clamp D9mm Хомут D9mm

11 Plug TIG 25 M12x1 2m Разъем 25 M12x1 2m

12 Valve Вентиль

FB0066 Long cap FB TIG 17-26 Хвостовик горелки длинный FB TIG 17-26

FB0056 Medium cap FB TIG 17-26 Хвостовик горелки средний FB TIG 17-26

FB0067 Short cap FB TIG 17-26 Хвостовик горелки короткий FB TIG 17-26

FB0001.16 Collet 1,6 FB TIG 17-26 (10N23) Цанга 1,6 FB TIG 17-26 (10N23)

FB0001.24 Collet 2,4 FB TIG 17-26 (10N24) Цанга 2,4 FB TIG 17-26 (10N24)

FB0001.32 Collet 3,2 FB TIG 17-26 (10N25) Цанга 3,2 FB TIG 17-26 (10N25)

FB0001.40 Collet 4,0 FB TIG 17-26 (54N20) Цанга 4,0 FB TIG 17-26 (54N20)

FB0002 Insulator Tube FB TIG 17-26 Изолятор FB TIG 17-26

FB0706.0001.16 Collet body 1,6 FB TIG 17-26 (10N31) Корпус цанги 1,6 FB TIG 17-26 (10N31)

FB0706.0001.24 Collet body 2,4 FB TIG 17-26 (10N32) Корпус цанги 2,4 FB TIG 17-26 (10N32)

FB0706.0001.32 Collet body 3,2 FB TIG 17-26 (10N28) Корпус цанги 3,2 FB TIG 17-26 (10N28)

FB0706.0001.40 Collet body 4,0 FB TIG 17-26 Корпус цанги 4,0 FB TIG 17-26

FB0004 Ceramic nozzle №6 9,5 FB TIG 17-26 (10N48) Сопло керамическое №6 9,5 FB TIG 17-26 (10N48)

FB0005 Ceramic nozzle №7 1 1 FB TIG 17-26 (10N47) Сопло керамическое №7 1 1 FB TIG 17-26 (10N47)

FB0006 Ceramic nozzle №8 12,5 FB TIG 17-26 (10N46) Сопло керамическое №8 12,5 FB TIG 17-26 (10N46)

FB0007 Ceramic nozzle №10 16 FB TIG 17-26 (10N45) Сопло керамическое №10 16 FB TIG 17-26 (10N45)

FB0003 Insulator for gaslens FB TIG 17-26 Изолятор для газовой линзы FB TIG 17-26

FB0006.16 Collet body gaslens 1,6 FB TIG 17-26 Корпус цанги c газовой линзой 1,6 FB TIG 17-26

FB0006.24 Collet body gaslens 2,4 FB TIG 17-26 Корпус цанги c газовой линзой 2,4 FB TIG 17-26

FB0006.32 Collet body gaslens 3,2 FB TIG 17-26 Корпус цанги c газовой линзой 3,2 FB TIG 17-26

FB0006.40 Collet body gaslens 4,0 FB TIG 17-26 Корпус цанги c газовой линзой 4,0 FB TIG 17-26

FB0033 Ceramic nozzle gaslens №6 9,5 FB TIG 17-26 (54N16) Сопло керамическое для газовой линзы №6 9,5 FB TIG 17-26 (54N16)

FB0034 Ceramic nozzle gaslens №7 1 1 FB TIG 17-26 (54N15) Сопло керамическое для газовой линзы №7 1 1 FB TIG 17-26 (54N15)

FB0035 Ceramic nozzle gaslens №8 12,5 FB TIG 17-26 (54N14) Сопло керамическое для газовой линзы №8 12,5 FB TIG 17-26 (54N14)

Spare parts / Расходные запчасти

--11

Page 13

Горячая линия FUBAG

òåë.: (495) 641-31-31

info@fubag.ru

www.fubag.ru

Loading...

Loading...