Page 1

Аэрограф

Air brush

110101

110107

110108

Operator's Manual

Инструкция по эксплуатации

www.fubag.ru

Page 2

Omperator's anual

www.fubag.ru

WARNING! READ THE INSTRUCTION MANUAL CAREFULLY BEFORE USING THE

AEROGRAPH.

QUALIFIED AND SPECIALLYTRAINED PERSONS ONLYAFTERPROPER READING

OF THIS MANUAL ISALLOWED TOUSEANDTOMAINTAINTHISAEROGRAPH.

The detailed description, safety rules and all required information necessary for proper operation

and maintenance of FUBAG pneumatic aerographs are provided in this manual. Keep this

instruction manual by machine and refer to it if by any doubts concerning safe operation,

maintenance, storage and handling ofFUBAGaerographs. Failure to follow these instructions could

result in the damages of aerograph andinjuryofthe operator.

1. Safety rules

-

The aerograph must be used in a well operated area and kept away from sources of ignition

(open fire, lighted cigarettes, electric equipment).

- If you use solvents and detergents, it is important to pay special attention to the chemical

compatibility with aluminum and zinc. Don't use halogenated hydrocarbon-based solvents

and detergents (e.g., ethyl chloride, 1.1.1- trichlor), as explosive chemical reactions could

result from the contact of these agents with aluminum and zinc.

- Before disassembly make sure the aerograph is disconnected from compressed air and

fluid supply. To ensure immediate air supply cut-off use the ball valve.

- Some materials can cause intoxication, thus to work with them please use special

protective means: gloves, respirator, goggles, etc. One should also use ear protection

device when the appliance is used at the higher pressure.

Danger:

-

Never direct the pneumatic tool or the jet of compressed air towards people, animals or

your own body. (Always wear safety goggles to protect your eyes from small dust particles

that may be lifted by the jet).

- Never direct the jet of compressed air towards the compressor.

- Never use the appliance in your bare feet or with wet hands or feet

- Never exceed the recommended operating pressure.

- Never use the spare parts and removable nozzles which are not original.

- Never use aerograph in food or chemical industry.

Caution:

-

When connecting an air-powered tool to a hose of compressed air supplied by the

compressor, interruption of the flow of air from the hose is compulsory.

- Use of the compressed air requires compliance with the safety rules

.

- 1 -

Page 3

Omperator's anual

www.fubag.ru

2. Description

FUBAG aerographs are used to apply the coating by paint or lacquer spraying. These aerographs

can be used only if they are connected to the compressor or the similar compressed air supply. The

use for other purposes can cause failures of the appliance, and besides can be a hazard to other

people. Do not introduce any design changes into the product and do not use it for other purposes

other than that intended. Strictly follow thesafetyrules.

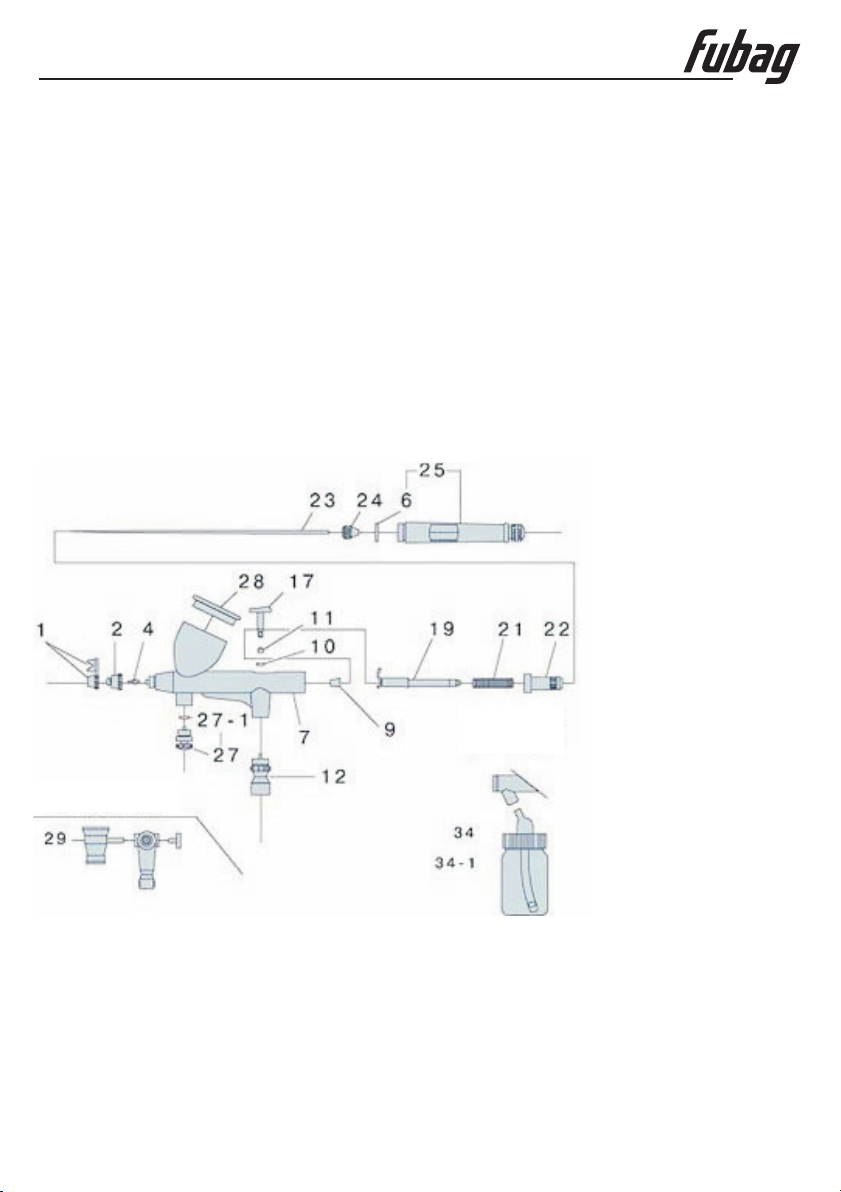

1. Needle head

2. Nozzle head

4. Nozzle

7. Housing

9. Needle guide

10. Piston

11. Piston ring

12. Air feed presetting

valve

17. Push button

19. Auxiliary guide for

needle clamping

22. Spring guide

21. Needle spring

23. Needle

24. Needle holder

25. Needle cap with

material supply control

27. Air feed regulator

28. Tank cover

29. Side tank 1.5 mm

32. Nozzle key

33. Material supply

control

34. Glass reservoir,

lower tank

--2

Page 4

Omperator's anual

www.fubag.ru

3s. Technical pecifications

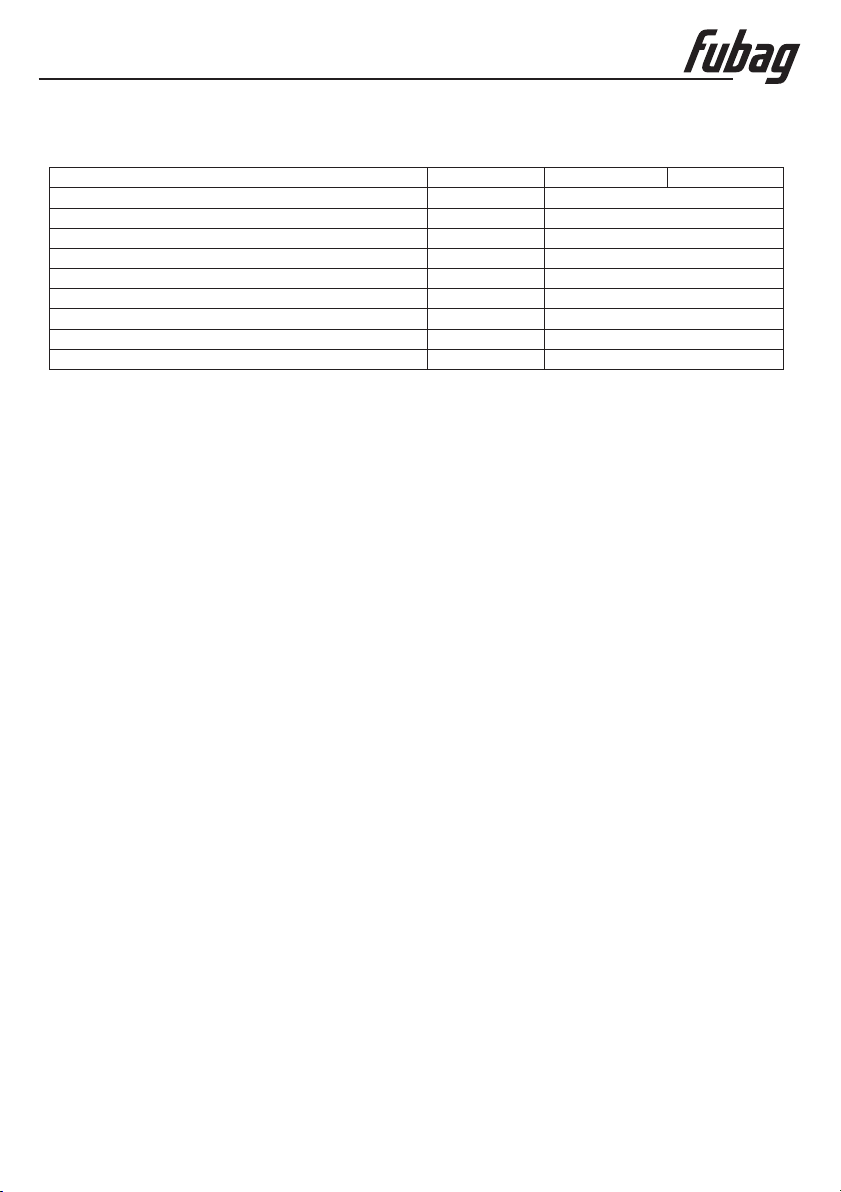

MODEL 110101 110107 110108

Action type

Diameter of the standard nozzle, mm 0,5 0,2, 0,3

Inlet diameter, inch 1/4 1/8

Air consumption at the operating pressure, l/min 11,0 9,0

Operating pressure, bar 2,0 1,0

Paint consumption, ml/min 2 1,5

Tank capacity, ml 22 7

Overall dimensions, mm 141х84х37 174х85х15

Weight, kg 0,184 0,3

The manufacturer reserves himself the right to make the manual's content or function

change without any preliminary notification oftheusers.

single independent dual

tools

4. Installation and functioning

Connections

- This device has the protective coating Before usingcleanitwith the appropriate solution.

- Aerograph is intended for the operation with dry and clean air. As the compressed air can contain

moister and foreign substances causing corrosion and early wear out of the pneumatic tool it is

recommended to use the airline filter moister oil separator to be installed very close to the

aerograph.

- Pressure in the air duct is to be 2,5-3,0 bar Greater or smaller pressure may result in damages of

the aerograph and poor painting quality.

- Check and, if necessary, replace the damaged and worn-out parts of the tool.

- Make sure, that the push buttonandthenozzle is the operative condition

- Connect air hose to the airduct The recommended hose size is 8 mm

- Make sure that the connections with the air duct, tank and cover are tight. Leakage of paint and

compressed air is not accepted.

- Mix spraying material as provided bythemanufacturer s instruction manual.

- It is possible to use all serial production paints for spraying or the lacquers having consistency as

an emulsion. If necessary water is to bediluted

,.

.

,-,

(/ ),

.

.

.–.

'

Control::

1. Single control aerographs

Push trigger button to supply air /paint.

- 3 -

Page 5

Omperator's anual

2. Dual independent control aerographs

www.fubag.ru

Press trigger to deliver air.

Move the trigger backwards to deliver

air / paint.

Operation:

Thin line. tart from air delivery, move the trigger backwards only together with the hand to avoid

ripples . Whencompleting, move the trigger first forward and then completely pull it down.

“”

Thick line/line contour. Together with the hand move the trigger still more. Movements of the hand

have to besmooth. When completing switch off theappliance and make a coating by spraying in the

opposite direction.

Circular motions. Start to apply paint in small quantity, making a thin part of the line with the circular

movements; then increase quantity of paint/distance, painting the bigger area with circular

movements. Then, again reduce the quantity of the paintappliedandreduce the distance.

Making points by spraying. Use the other hand for stabilization. Start from air delivery, and then

carefully pull the trigger alittle bit backwards. For the bigger size pointsuse longer distance and take

more paint.

- After use do not forget tocutoffdeliveryofthe compressed air.

S

Move the trigger forward to stop paint

delivery.

Remove the fingers from the trigger to

stop air delivery.

5 aintenance.M

Most of the problems which can arise during operation of the aerograph result from incorrect

cleaning. Unsatisfactory spraying process or the clogged nozzle are the usual results of the

incorrect and irregular cleaning. Clean your aerograph with water before every change of the paint

color if using water-based paint and with the appropriate cleaning agents or solvents if you use

(),

special paints. You can leave paint in the reservoir of the aerograph only for a short time.

If you use paints containing pigments e g acrylic their residuals are quickly accumulated on the

needle and on the inner walls of the needle-protection cap. Therefore the needle and the protective

cap have to be frequently washed washing frequencydependsonthe types of the paints used.

(.. ),

,

;

- 4 -

Page 6

Omperator's anual

www.fubag.ru

For cleaning proceed as follows:

- Remove paint residuals from aerograph. Release the collet clamp and carefully take out the

needle. Carefully wipe the needle towards theneedlepoint,turning it when wiping.

- Put some water or cleaning agentintothereservoir of the aerograph.

- Use wad of cotton wool towipeoutthe paint reservoir of the aerograph.

- Use the cleaning agent to purgeaerograph.

- Remove the protective cap and clean it inside with a wad of cotton wool, wet with water or the

cleaning solution.

- Tighten the cap.

- Carefully,applylight pressing force to insert the needle and fix it with the colletclamp.

- Finally clean the aerograph with thecleaningsolution.

6. Troubleshooting

Fault Cause Remedy

Air bubbles or foam appear in

the paint reservoir

No paint spraying

Air supply control is not

possible

Low spraying quality

A lot of small paint runs form

during spraying

The nozzle not tightened Tighten the nozzle

The nozzle is dirty Clean the nozzle

The nozzle has damaged Replace the nozzle

The paint is over in the tank Fill the reservoir with paint

The needle not tightened Tighten the needle

Dirty needle

The nozzle is dirty Clean the nozzle

Paint is too heavy Add the solvent into the paint

Air supply valve is dirty Clean the valve

Not enough oil on the trigger

stem

The needle is dirty Clean the needle

The nozzle is dirty Clean the nozzle

The needle or nozzle damaged.

Low quality of the used air,

pressure of the supplied air has

been set in the wrong way

Pressing force on the trigger is

too high

Appliance is too close to the

painted surface

Paint is too thin

Remove the cap; unscrew the nut

of the needle collet clamp, push the

trigger down and repeatedly move

the needle forward/ backwards.

Then firmly insert the needle and

tighten the clamping nut.

Unscrew air valve and apply the

engine oil on the seals of the air

valve stem

Change the needle or the nozzle.

Check moisture- / oil separation

filters, adjust pressure of the inlet

air

Reduce pressing force on the

trigger

Take away the appliance from the

painted surface

Add less paint thinner into the paint

or reduce air pressure

- 5 -

Page 7

Omperator's anual

www.fubag.ru

7s

. Transport & torage

Before storage the aerograph has to be disassembled and thoroughly cleanedfrom the residuals of

the sprayed liquids. During transportation and storage of the tool keep it away from humidity. It is

recommended to store the tool in the dry, well-ventilated area and not to expose to moister,

corrosion-hazardous gases and dust.

After unpacking it is recommendedagainto pack the tool if it is not supposed tobetransported to the

operation or storage area.

8

. Warranty

Warranty refer to defects of materials and components and do not refer to components subject to

natural wear and maintenance work.

Only machines cleaned from dust and dirt in original factory packing fully completed, provided with

instruction manual, warranty card with fixed sales date with a shop stamp factory serial number and

originals of sales and ware receipt issued by salesmanare subjects of warranty. Within the warranty

period the service centereliminate free of charge all detectedproduction defects. The manufacturer

disclaims warranty and legal responsibilities if nonobservance of the instruction manual by user,

unqualified disassembling repair or maintenance ofthemachineas well does not bear responsibility

for caused injury to persons or damages.

- 6 -

Page 8

Инструкция по эксплуатации

www.fubag.ru

ВНИМАНИЕ ПЕРЕД ИСПОЛЬЗОВАНИЕМ АЭРОГРАФА ВНИМАТЕЛЬНО!

ОЗНАКОМЬТЕСЬСДАННОЙИНСТРУКЦИЕЙ.

К ИСПОЛЬЗОВАНИЮ И ОБСЛУЖИВАНИЮ ИНСТРУМЕНТА ДОПУСКАЕТСЯ

ТОЛЬКО КВАЛИФИЦИРОВАННЫЙ И СПЕЦИАЛЬНО ОБУЧЕННЫЙ ПЕРСОНАЛ,

ОЗНАКОМЛЕННЫЙ С ДАННОЙ ИНСТРУКЦИЕЙ.

В этой инструкции содержится описание правила безопасности и вся необходимая,

информация для правильной эксплуатации пневматических аэрографов FUBAG.

Сохраняйте даннуюинструкциюи обращайтесь к ней при возникновении вопросов по

безопасной эксплуатации обслуживанию хранению и транспортировке аэрографов, , FUBAG.

Несоблюдение указанных рекомендаций может привести к повреждениям аэрографа и

травмам оператора.

1. Правила безопасности

- Работы проводите в хорошо проветриваемых помещениях вдали от источников

возгорания открытого огня зажженных сигарет электрического оборудования(, , ).

- При использовании растворителей и моющих средств необходимо обращать особое

внимание на их химическуюсовместимость с алюминием и цинком Нельзя.

использовать растворители и моющие средства на основе галогензамещенных

углеводородов например этил хлорид трихлор так как при контакте этих( , , 1.1.1- ),

веществ с алюминием и цинком могут протекать химические реакции взрывного

характера.

- Перед разборкой необходимо отключить аэрограф от подачи сжатого воздуха и

жидкости При необходимости немедленного прекращения подачи воздуха возле.

аэрографа следует установить шаровой клапан.

-,Некоторые материалы могут вызвать интоксикациюорганизма поэтому при работе с

ними необходимо иметь специальнуюзащиту перчатки респиратор очки и т д:, ,..

Также следует использовать устройство для защиты слуховых органов так как,

работы проводятся при высоком давлении.

Запрещается:

-,Направлять пневмоинструмент или струюсжатого воздуха на людей животных или на

собственное тело Чтобы со струей сжатого воздуха в глаза не попали мелкие.(

частицы пыли надевайте защитные очки,).

-.Направлять струюсжатого воздуха в сторону компрессора

-,Работать без защитной обуви касаться работающего компрессора мокрыми руками

и или ногами/.

-.Превышать рекомендованное рабочее давление

-.Устанавливать не оригинальные запасные части и сменные сопла

- Использование аэрограф в пищевой или химической промышленности

Важно:

-,Подсоединяя к шлангу компрессора пневмоинструмент не забывайте перекрывать

воздушный кран.

- .При использовании сжатого воздуха соблюдайте все правила техники безопасности

--7

Page 9

Инструкция по эксплуатации

www.fubag.ru

2. Описание

Аэрографы применяются для нанесения покрытия напылением красок или лаковFUBAG .

Использование этих аэрографов возможно только при подключении к компрессору или

подобному источнику сжатого воздуха Использования в других целях может привести к.

возникновениюнеисправностей прибора и кроме того представлять собой опасность для,,

окружающих Не разрешается вносить какие либо конструктивные изменения в изделие.- ,

перестраивать или использовать его не по назначению Следует неукоснительно.

придерживатьсяправил техники безопасности.

1. Головка иглы

2. Головка сопла

4. Сопло

7. Корпус

9. Направляющая для

иглы

10. Поршень

11. Поршневое кольцо

12. Клапан

предварительной

настройки подачи

воздуха

17. Кнопка курок

19. Вспомогательная

направляющая для

зажима иглы

22. Направляющая

пружины

21. Пружина для иглы

23. Игла

24. Держатель иглы

25. Колпачок иглы гриф

с регулятором подачи

материала

27. Регулятор подачи

воздуха

28. Крышка бачка

29. 1.5Боковой бачок мм

32. Ключ для сопла

33. Регулятор подачи

материала

34. Стеклянная емкость

нижний бачок

-

()

--8

Page 10

Инструкция по эксплуатации

www.fubag.ru

3. Техническиехарактеристики

МОДЕЛЬ 110101 110107 110108

Тип действия

Диаметр стандартного сопла мм,

Диаметр впускного отверстия дюйм,

Расход воздуха при рабочем давлении л мин,/

Рабочее давление бар,

Расход краски мл мин,/

Емкость бачка мл,

Габаритные размеры мм,

Масса кг,

Производитель имеет право вносить изменения как в содержание данной инструкции, так и в конструкцию

инструментабезпредварительногоуведомления пользователей.

одинарный независимый двойной

0,5 0,2, 0,3

1/4 1/8

11,0 9,0

2,0 1,0

2 1,5

22 7

141 84 37 174 85 15хх хх

0,184 0,3

4. Подключениеи работа

Подключение:

-.Данное оборудование содержит защитное покрытие Перед использованием промойте

оборудование подходящим раствором.

-.Аэрограф предназначен для работы с сухим и чистым воздухом Поскольку сжатый воздух

может содержать влагу и посторонние примеси приводящие к коррозии и,

преждевременному износу пневмоинструмента рекомендуется использовать в воздушной,

линии фильтр влаго маслоотделитель который необходимо устанавливать как можно(/ ),

ближе к аэрографу.

- 2,5-3,0 .Давление в воздухопроводе должно поддерживаться бар Слишком низкое или

слишком высокое давление могут повредить аэрограф иухудшить результат покраски.

- Проверьте и при необходимости замените поврежденные и изношенные части

инструмента.

-.Убедитесьчто куроки сопло в исправности

-.–Прикрепите воздушный шланг к воздухоприемнику Рекомендованный размер шланга

8.мм

-,.Убедитесь что соединения с воздухопроводом бачок и крышка надежно затянуты Утечки

краски и сжатоговоздуха не допускаются.

- .Смешайте материал для распыления согласно инструкции изготовителя

Возможно применение всех серийно выпускаемых красок для распыления или лаков с

консистенцией в виде эмульсии При необходимостикраску следует разбавлять..

Управление:

1. Аэрографы одинарногоуправления

При нажатии на кнопку триггера подается воздух краска/.

--9

Page 11

Инструкция по эксплуатации

2.Аэрографы двойного независимогоуправления

www.fubag.ru

- При нажатии триггера подается воздух

- При отведении триггера назад подается

воздух краска/

Работа:

Тонкая линия Начать с подачи воздуха триггер отводится назад только вместе с рукой во., ,

избежание появления ряби По завершении сместить триггер сначала вперед а затем«». ,

полностьюотпустить.

Широкая линия очертание линии Вместе с рукой отвести триггер еще дальше назад/. .

Движения руки должны быть плавными По завершении отключить прибор и нанести.

покрытие напылением в обратном направлении.

Круговые движения Начать с нанесения небольшого количества краски выводя круговыми.,

движениями тонкуючасть линии увеличивая подачу краски расстояние перейти к,/,

окрашиваниюкруговыми движениями более широкой площади Затем снова уменьшить.

количествоподаваемой краски исократить расстояние.

Нанесение точек распылением Использовать вторуюруку для стабилизации Начать с..

подачи воздуха затем осторожно потянуть триггер немного назад Для точек большего,.

размера следуетсоблюдать большее расстояние и брать больше краски.

-.После использования не забудьте выключить подачусжатоговоздуха

- При смещении триггера вперед

прекращается подача краски

- При снятии пальцев с триггера

прекращается подача воздуха

5. Техническоеобслуживание

Большинство проблем которые могут возникнуть при использовании аэрографа являются,.

результатом неправильной его чистки Неудовлетворительный процесс распыления или.

забитое сопло обычные результаты неправильной и нерегулярной чистки Ваш аэрограф-.

необходимо промывать водой перед каждой сменой цвета краски при использовании(

красок на водной основе а при использовании специальных красок соответствующими), чистящими растворами или растворителями Оставлять краску в емкости аэрографа.

можно только на короткое время.

При использовании красок содержащих пигменты например акриловых их остатки,(,),

быстро собираются на игле и внутренних стенках колпачка предохраняющего иглу,.

Поэтому иглу и предохранительный колпачок следует часто промывать частота промывок;

зависит от типов используемых красок.

--10

Page 12

Инструкция по эксплуатации

www.fubag.ru

Чистка должна выполняться следующим образом:

-.Продуйте аэрограф от остатков краски Освободите цанговый зажим иглы и аккуратно

вытащите иглу Осторожно протрите иглу по направлениюк острию поворачивая ее во..

время протирки.

- .Налейте немного воды или очищающего раствора в емкость аэрографа

-.Протрите ватным тампоном емкость аэрографа для краски

-.Продуйте аэрограф с чистящим раствором

- ,Отверните предохранительный колпачок и протрите его изнутри тампоном смоченным

водой или чистящим раствором.

-.Накрутите колпачок

-, .Аккуратно с легким нажимом вставьте иглу и закрепите цанговым зажимом

- В завершении еще раз продуйте аэрограф с чистящим раствором.

6. Неисправности и их устранение

Неисправность Возможные причины Способы устранения

В бачке с краской

появляются пузырьки

воздуха или пена.

Прибор не распыляет

краску

Невозможна регулировка

подачи воздуха

Низкое качество

напыления

В процессе напыления

образуются

множественные мелкие

потеки краски

Не затянута форсунка Затянуть форсунку

Форсунка загрязнена Прочистить форсунку

Форсунка повреждена Заменить форсунку

Закончилась краска в бачке Заполнить бачок краской

Не затянута игла Затянуть иглу

Загрязнена игла

Загрязнена форсунка Прочистить форсунку

Краска слишком густая Разбавить краску растворител ем

Загрязнен клапан подачи воздуха Прочистить клапан

Не достаточно смазки штока

триггера

Загрязнена игла Прочистить иглу

Загрязнена форсунка Прочистить форсунку

Повреждение иглы или форсунки.

Низкое качество используемого

воздуха не правильно выставлено,

давление подаваемого воздуха

Слишком сильное нажатие на

триггер

Прибор слишком близко к

окрашиваемой поверхности

Краска слишком жидкая

Снять наконечник отвинтить,

гайку цангового зажима иглы,

нажать триггер вниз и

многократно подвигать иглу

вперед назад Затем вставить/.

иглу до упора и затянуть

зажимнуюгайку.

Отвинтить воздушный клапан и

смазать уплотнения на штоке

воздушного клапана машинным

маслом

Заменить иглу или форсунку.

Проверить фильтры влаго-

маслоотделе ния отрегулировать,

давление поступающего воздуха

Уменьшить нажатие на триггер

Отвести прибор от окрашиваемой

поверхности

Разбавлять краску в меньшей

степени или уменьшить давление

воздуха

- 1 -1

Page 13

Инструкция по эксплуатации

www.fubag.ru

7. Хранение и транспортировка

Перед хранением аэрограф должен быть разобран и тщательно очищен от остатков

распыляемых жидкостей.

Во время транспортировки и хранения инструмента старайтесь беречь его от попадания

влаги Рекомендуется хранить инструмент в сухом хорошо проветриваемом помещении и не.,

подвергать его воздействиюповышенной влажности коррозионно опасных газов и пыли,- .

После вскрытия упаковки рекомендуется снова упаковать инструмент если предполагается,

перевозить его к месту работы или на хранение.

8. Гарантийные обязательства

Гарантийный срок на оборудование указывается в прилагаемом сервисном талоне

Гарантия относится к дефектам в материалах и узлах и не распространяется на компоненты,

подверженныеестественному износу иработы по техническому обслуживанию.

Гарантийному ремонту подлежат только очищенные от пыли и грязи инструменты в заводской

упаковке полностьюукомплектованные имеющие инструкциюпо эксплуатации гарантийный,, ,

талон с указанием даты продажи при наличии штампа магазина заводского номера и,,

оригиналов товарного и кассовогочеков выданных продавцом,.

В течение гарантийного срока Сервисный центр устраняет за свой счёт выявленные

производственные дефекты Производитель снимает свои гарантийные обязательства и.

юридическую ответственность при несоблюдении потребителем инструкций по эксплуатации,

самостоятельной разборки ремонта и технического обслуживания а также не несет никакой,,

ответственности запричиненные травмы и нанесенный ущерб.

.

- 1 -2

Page 14

Горячая линия FUBAG

тел.: (495) 641-31-31

info@fubag.ru

www.fubag.ru

Loading...

Loading...