OPERATION AND PARTS MANUAL

DRUM PUMP MOTORS

Models: M3 M5 M3T M3X M5T M5X M6 M6X M7T M7X M10X M15-M40 M58P M59P

EU Declaration of Conformity

Finish Thompson Inc. hereby declares that the following electrical equipment fully complies

with the applicable health and safety requirements as specified by the EU directives listed.

The product may not be taken into service until it has been established that the driven

Drum and Container Pump complies with the provisions of all relevant EU Directives

provided pumps manufactured by Finish Thompson are used.

This declaration is valid provided that the devices are fully assembled and no modifications

are made to these devices.

Type of Device:

Electric Motors for Driving Drum

and Container Pumps

Models:

M3V-UK M5 M5T M5V M5X M10X

M13 M59P M59H S2 S3

EU Directives (and their applicable amendments):

Low Voltage (2014/35/EU)

Electromagnetic Compatibility (2014/30/EU)

Specific standards applied:

EN 60335-1 EN60335-2-41

EN 55014-1 EN 55014-2

EN 60529

Signed,

_________________________________

Casey D. Bowes

CEO and President

20 April 2016

Person(s) Authorized to Compile Technical File: Finish Thompson GmbH

Otto-Hahn-Strasse 16

Maintal, D-63477 DEU

Telephone: 49 (0)6181-90878-0

2

EU DECLARATION OF CONFORMITY

Finish Thompson Inc. hereby declares that the following machines fully comply with the applicable

health and safety requirements as specied by the EU Directives listed. This declaration is valid

provided that the devices are fully assembled and no modications are made to these machines.

Type of Device:

Pump Motor

Pump Motor Models:

M10X

EU Directives:

Equipment and protective systems intended for use in potentially

explosive atmospheres (2014/34/EU)

EC-Type Examination:

Physical Technical Testing Institute 1026

Ostrava-Radvanice

FTZU 08 ATEX 0083X

Product Quality Assurance Notication:

Physical Technical Testing Institute 1026

Ostrava-Radanice

FTZU 08 ATEX Q 003

Applicable Harmonized Standards:

EN 60079-0:2012

EN 60079-1:2014

Signed,

Casey D. Bowes

CEO and President

April 20, 2016

3

EU Declaration of Conformity

Finish Thompson Inc. hereby declares that the following machine(s) fully comply with the

applicable health and safety requirements as specified be the EC Directives listed. The

product may not be taken into service until it has been established that the driven Drum

and Container pump complies with the provisions of all relevant EC Directives. The

complete product complies with the provisions of the EC Directive on machinery safety

provided

pumps manufactured by Finish Thompson Inc. are used.

This declaration is valid provided that the devices are fully assembled and no

modifications are made to these devices.

Type of

Device:

Air Motors for Driving

Drum

and Container

Pumps

Models:

M6 M6X M18 M19 M20 M57

M65 M66 S4

EC

Directives:

Machinery Safety

(2006/42/EC)

Applied Harmonized

Standards:

EN ISO 12100 Part

1

EN ISO 12100 Part

2

EN

983

Manufacturer:

Finish

Thompson

Inc.

921 Greengarden

Road

Erie, Pennsylvania 16501-1591

U.S.A

Signed,

_

President

27 February 2015

Person(s) Authorized to Compile Technical File: Finish Thompson GmbH

Otto-Hahn-Strasse 16

Maintal, D-63477 DEU

Telephone: 49 (0)6181-90878-0

4

TABLE OF CONTENTS

TABLA DE CONTENIDO

Introduction ........................................................ 6

Warranty and Return Policy ............................... 6

Safety Precautions .............................................. 7

Maintenance Precautions ................................... 7

Installation .......................................................... 8

M3 & M5 Models .............................................. 9

Assembly Drawing and Parts List

M3T & M5T Models ........................................ 10

Assembly Drawing and Parts List

M7T Models ......................................................11

Assembly Drawing and Parts List

M6 Model......................................................... 12

Assembly Drawing and Parts List

M6X Model ...................................................... 13

Assembly Drawing and Parts List

M3X, M5X, M7X & M10X Models ................ 14

Introducción ....................................................... 6

Garantía y Póliza de Devolución ....................... 6

Precauciones de Seguridad ................................ 7

Precauciones de Mantenimiento ........................ 7

Instalación .......................................................... 8

Modelos M3& M5 ............................................. 9

Dibujo de Armadura y Lista de Partes

Modelos M3T & M5T ...................................... 10

Dibujo de Armadura y Lista de Partes

Modelos M7T ....................................................11

Dibujo de Armadura y Lista de Partes

Modelo M6....................................................... 12

Dibujo de Armadura y Lista de Partes

Modelo M6X .................................................... 13

Dibujo de Armadura y Lista de Partes

Modelos M3X, M5X, M7X & M10X .............. 14

BT Models ....................................................... 14

Assembly Drawing and Parts List

M58P-M59P Models ........................................ 15

Assembly Drawing and Parts List

Static Protection Kit ......................................... 16

Modelo BT ....................................................... 14

Dibujo de Armadura y Lista de Partes

Modelos M58P, M59P ...................................... 15

Dibujo de Armadura y Lista de Partes

Guias para el Equipo de Protección Estático ... 17

5

INTRODUCTION

INTRODUCCIÓN

FTI has been an international designer and manufacturer of drum

pumps and mixers for over twenty years. We make drum pump

selection easy with our complete line of interchangeable motors

and tubes. When properly installed and operated, your Finish

Thompson drum pump or mixer will provide long, trouble free

service.

FTI ha sido diseñador y fabricante internacional de bombas de

tambor y mezcladoras por más de veinte años. Hacemos selección

de bombas de tambor fácil con nuestra línea completa de motores

y tubos intercambiables. Cuando se instala y se maneja correctamente, su bomba de tambor o mezcladora Finish Thompson le

dará servicio por un largo tiempo y sin problemas.

WARRANTY GARANTÍA

Finish Thompson, Inc (manufacturer) warrants this product to

be free of defects in materials and workmanship for a period of

one year from date of purchase by original purchaser. If a warranted defect, which is determined by manufacturer’s inspection,

occurs within this period, it will be repaired or replaced at the

manufacturer’s option, provided (1) the product is submitted with

proof of purchase date and (2) transportation charges are prepaid

to the manufacturer. Liability under this warranty is expressly

limited to repairing or replacing the product or parts thereof and

is in lieu of any other warranties, either expressed or implied.

This warranty does apply only to normal wear of the product or

components. This warranty does not apply to products or parts

broken due to, in whole or in part, accident, overload, abuse,

chemical attack, tampering, or alteration. The manufacturer accepts no responsibility for product damage or personal injuries

sustained when the product is modied in any way. If this warranty

does not apply, the purchaser shall bear all cost for labor, material

and transportation.

Manufacturer shall not be liable for incidental or consequential

damages including, but not limited to process down time, transportation costs, costs associated with replacement or substitution

products, labor costs, product installation or removal costs, or loss

of prot. In any and all events, manufacturer’s liability shall not

exceed the purchase price of the product and/or accessories.

Finish Thompson, Inc (el fabricante) garantiza este producto contra

todo defecto de materiales y mano de obra durante un periodo de un

año des de la fecha de adquisición por parte del comprador original.

Si, dentro de este periodo, se detecta algún defecto cubierto por la

garantía mediante una inspección del fabricante, éste se encargará de

corregirlo, mediante reparación o sustitución, a su elección, siempre

y cuando: (1) el producto le sea devuelto con algún comprobante de

la fecha de compra y (2) a portes pagados. La responsabilidad de

esta garantía se limita expresamente a la reparación o sustitución

del producto o de partes del mismo, y sustituye a cualquier otra

garantía expresa o implícita. Esta garantía sólo se aplica al desgaste

del producto o de sus componentes derivado del uso normal. No es

aplicable a productos o piezas cuya rotura se deba, en todo o en parte,

a accidentes, sobrecargas, abusos, agresión química, manipulación

o alteración. El fabricante declina toda responsabilidad por daños

en el producto o lesiones personales que se produzcan después de

modicar el producto en cualquier forma. Si el comprador no hace

valer esta garantía, deberá asumir todos los gastos de mano de obra,

material y transporte.

El fabricante no es responsable de los daños consecutivos o resultantes incluidos, aunque sin limitación, los relacionados con

la parada de procesos, costes de transporte, costes asociados a la

sustitución de productos, costes de mano de obra, costes de retirada

o instalación de productos, o perdida de benecios. En cualquier

caso, la responsabilidad del fabricante no sobrepasará el precio

de compra del producto y/o los accesorios.

RETURN POLICY

Should you have any problems with this product, please contact

the distributor in your area. The distributor will then determine

if a return to the factory is necessary and will contact the factory

for a return authorization number.

Call our toll free Technical Service Hot Line, 1-800-888-3743,

if you have any questions regarding product operation or

repair.

PÓLIZA DE DEVOLUCIÓN

Si usted tiene cualquier problema con este producto, por favor

póngase en contacto con el distribuidor en su area. Entonces el

determinará si una devolución a la fábrica es necesaria y se pondrá

en contacto con la fábrica para obtener un número de autorización

de devolución.

Llame nuestro servicio técnico al numero 814-455-4478 si tiene

pregunts de operación o reparación.

6

SAFETY

PRECAUCIONES DE

PRECAUTIONS

ALWAYS wear protective clothing, eye protection and follow

standard safety procedures when handling corrosive or personally

harmful materials.

NEVER use a plastic pump or an open, splashproof or TEFC motor

when pumping or mixing ammable or combustible material.

ALWAYS use and store in an upright position.

NEVER immerse motor in liquid.

ALWAYS place motor in the OFF position prior to connecting the

power source.

ALWAYS check motor label plate for the correct power supply

requirements.

ALWAYS have manufacturer, its service agent or similarly qualied

persons replace supply cord if damaged in order to avoid a hazard.

ALWAYS use an approved plug for Class I, Division 1, Group C

& D applications on the X Series motors.

Noise level at a distance of 3 feet:

S Series - M3, M5 73 db (Splash proof)

T Series - M3T, M5T 77 db (Totally enclosed

fan cooled)

A Series - M6 at 80 psi line pressure 90 db (Air)

M58P & M59P 85 db (800 watt)

SEGURIDAD

SIEMPRE use ropa protectiva, protección para los ojos y siga

procedimentos de seguridad básicos cuando maneje materiales

corrosivos.

NUNCA use una bomba de plástico en los motores abiertos, contra

salpiqueos o TEFC cuando se bombéa o se mezcla materiales

combustibles o inamables.

SIEMPRE use y almacene recto.

NUNCA sumerga el motor en líquido.

SIEMPRE ponga el motor en la posición OFF antes de conectar

la corriente electrica.

SIEMPRE revise la placa por los requerimientos correctos de

corriente electrica.

SIEMPRE use un enchufe aprovado para la Clase I, la Division 1,

las aplicaciones de los Grupos C & D en el motor de la Serie X.

Nível de ruido a una distancia de 3 pies:

Serie S - M3, M5 73 db (Contra alpiqueos)

Serie T - M3T, M5T 77 db (TEFC -Totalmente

sellada con ventilación)

A Series M6 at 80 psi línea

de presión 90 db (Aire)

M58P y M59P 85 db (800 watt)

MAINTENANCE

PRECAUTIONS

ALWAYS store motor upright and away from corrosive liquids

and vapors.

ALWAYS use an automatic air line lubricator, moisture trap

and lter in the airline ahead of an air motor. (Use detergent

SAE #10 in lubricator). Do not exceed 80 psi (551 kPa) on

M6 and 100 psi (689 kPa) on all other air motors.

Motor Models M3, M3T, M5, M5T, M58P and M59P are

10,000 rpm. Motor brushes in these models should be replaced every 200-300 operating hours to assure trouble free

service.

Motor Models M3, M3T, M5, M5T, M7T, M8T, M58P

andM59P contain a circuit breaker (overload). If motor will

not operate, check the circuit breaker.

Motor Models M3X and M5X have a 400-600 operating hour

brush life. Model M10X has a 200-300 operating hour brush

life. M3X, M5X and M10X motor brushes require factory

replacement.

PRECAUCIONES DE

MANTENIMIENTO

SIEMPRE guarde el motor en una posición vertical lejos de

líquidos o vapores corrosivos.

SIEMPRE use un lubricador automático con trampa de hu-

medad y ltro en la línea de aire antes del motor. (Use el

detergente SAE número 10 en el lubricador). No excede de

80 psi (551 kPa) con el motor M6 o 100 psi (689 kPa) con

todos los otros motores de aire.

Modelos de motor M3, M3T, M5, M5T, M58P y M59P operan

a 10,000 rpm. Los cepillos de motor en estos modelos deben

ser reémplazados cada 200-300 horas de operación para asegurarse de un servicio libre de problemas.

Modelos de motor M3, M3T, M5, M5T, M7T, M8T, M58P

y M59P contenen un disyuntor (sobrecarga). Si el motor no

opera, revise el disyuntor.

Los modelos M3X y M5X del motor tienen una vida del cepillo

de la hora de funcionamiento 400-600. El modelo M10X tiene

una vida del cepillo de la hora de funcionamiento 200-300. Los

cepillos del motor de M3X, de M5X y de M10X requieren el

reemplazo de la fábrica.

7

INSTALLATION INSTALACIÓN

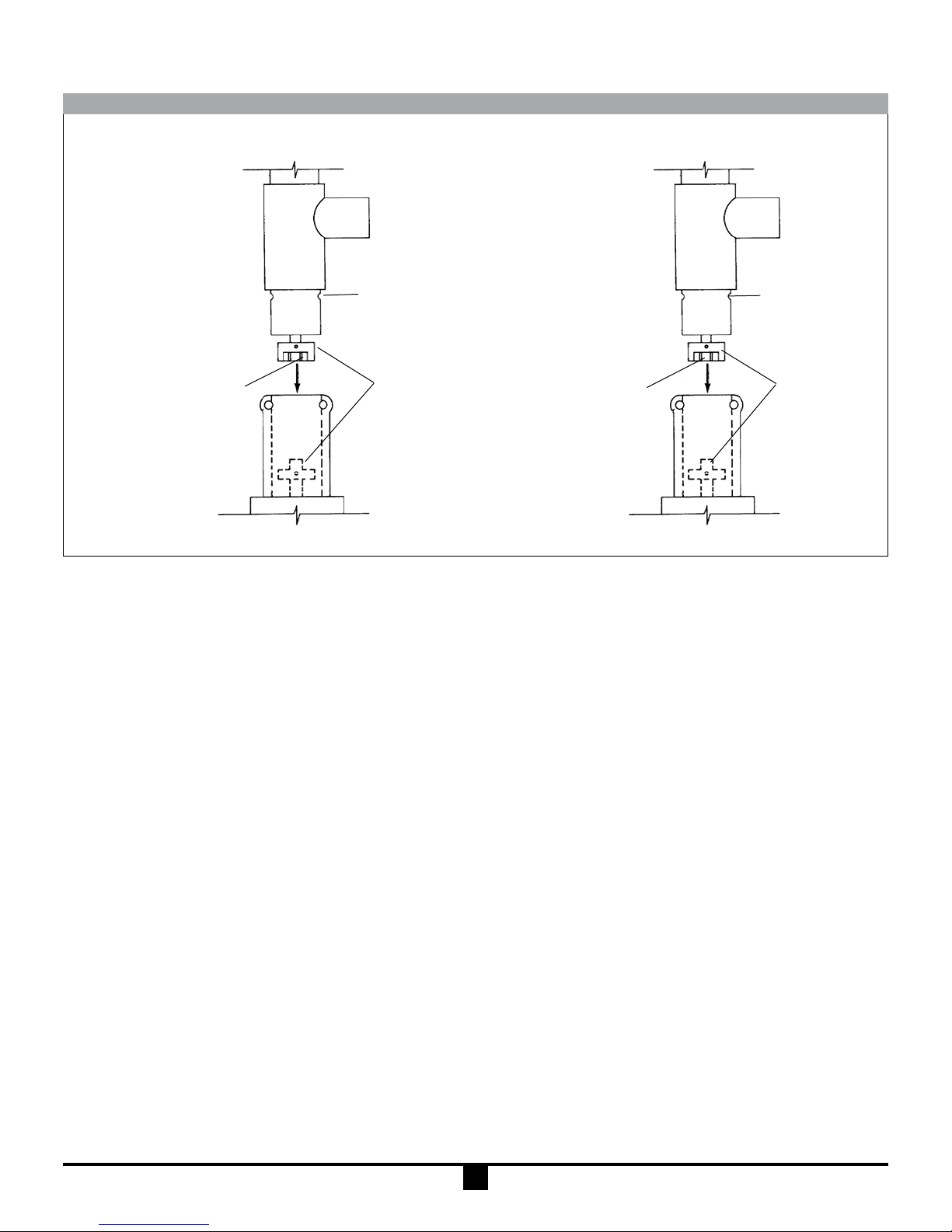

TUBE

GROOVE

COUPLING

INSERT

2 PRONG

COUPLING

MOTOR WITH ADAPTER

Unpack motor from carton and check for shipping damage.

Unpack pump/mixer from carton. Check for shipping damage.

If any shipping damage is found, save the packaging and notify

the carrier immediately.

1. Ensure motor and pump compatibility. I.E., labeling.

2. Remove 2 socket head screws and nuts.

3. Ensure no obstructions on the coupling of either motor or

pump/mixer.

4. Position couplings and coupling insert for proper alignment.

5. Slide pump/mixer down into motor until couplings mate

and pump/mixer is seated properly. Refer to Figure 1.

6. Position motor so mounting holes line up with corresponding grooves on pump/mixer. (Note: Always position

electric cord away from discharge spout of pump.)

7. Install 2 socket head screws and nuts in mounting holes

and tighten securely.

8. Check to ensure that the motor is secured to the pump/mixer before operating. If not, repeat steps 1-6.

TUBO

RANURA

2 PUNTA

ACOPLADORA

Figure 1

INSERTO

ACOPLADOR

MOTOR CON ADAPTADOR

Saque el motor del cartón y revise por daños de embarque.

Saque la bomba (o mezclador) del cartón y revise por daños

de embarque.

Si se encuentran daños de embarque, póngase en contacto

con el suplidor del producto para reémplazarlo o reparario.

1. Asegúrese de la compatibilidad entre el motor y la

bomba. I.E. La etiqueta.

2. Remove 2 tornillos de cabeza de caquillo y tuercas.

3. Asegúrese de que no haya obstrucciones en el acoplador

de el motor o la bomba (o mezclador).

4. Coloque el acoplador y el inserto acoplador para una alineación correcta.

5. Deslize la bomba (o mezclador) hacia abajo en el motor

hasta que el acoplador y la bomba (o mezclador) esten

asentadas correctamente. Vea la Figura 1.

6. Coloque el motor para que los huecos de la estructura y las

ranuras correspondientes esten alineadas en la bomba (o

mezclador). (Note: Siempre coloque la conexión electrica

lejos del caño de descargar de la bomba.)

7. Instale 2 tornillos de cabeza de caquillo y tuercas en los

huecos de la estructura y aprietelos seguros.

8. Revise para asegurarse que el motor esté amarrado a la

bomba (o mezclador) antes de operar. Si no está, repita los

pasos 1-6.

8

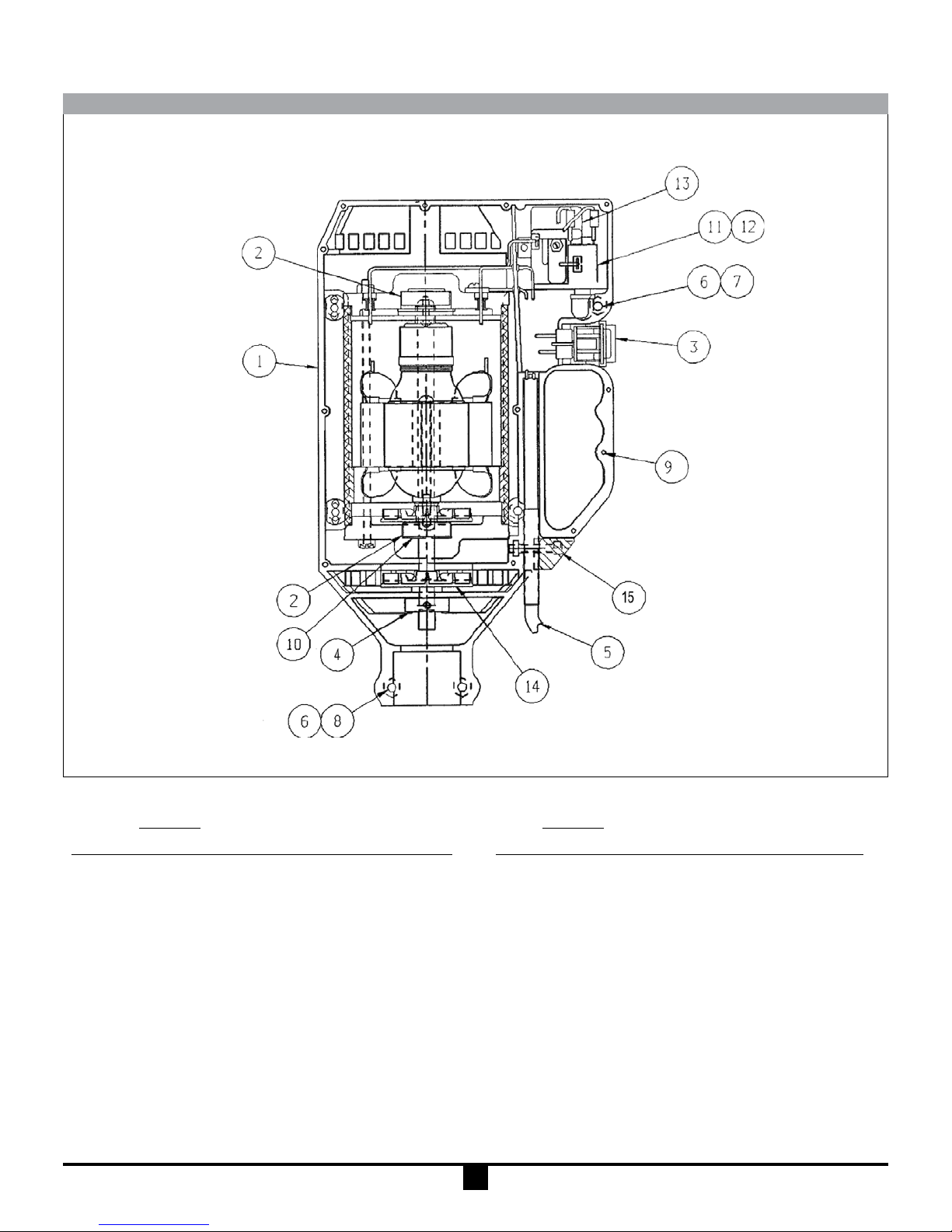

M3 & M5 MODELS

Item M3 M5 Description Part Number

1 1 1 HSG Repair Kit A101493

2 1 1 Handle M101668

3 1 1 Switch A101690

4 1 1 Half Coupling J100012

5 1 – Cord Assembly A102050

5 – 1 Cord Assembly A102051

6 2 2 Brush 107764

7 6 6 Housing Nut J100990

8 4 4 Housing Screw J100022

9 2 2 Socket Head Cap Screw 108392

QuantityQuantity

Item M3 M5 Description Part Number

10 3 3 Screw J102275

11 1 1 Bearing Kit A101018

12 1 – Circuit Breaker w/Cover A100854

12 – 1 Circuit Breaker w/Cover A102182

13 1 1 Fan Blade J101510

14 1 1 Motor Fan Cover M101710

15 4 4 Cover Screw J101020

16 1 1 Handle Mounting Block M101666

17 2 2 Screw J103715

Note: Motor housing repair kits include motor covers, labels

and screws to repair the motor should it be damaged.

9

M3T & M5T MODELS

Quantity Quantity

Item M3T M5T Description Part Number

1 1 1 HSG Repair Kit A101416

2 2 2 Ball Bearing J101069

3 1 1 Switch A101690

4 1 1 Half Coupling J100013

5 1 – Cord Assembly A101738

5 – 1 Cord Assembly A101740

6 2 2 Brush J101107

7 6 6 Housing Nut J100990

Note: Motor housing repair kits include motor covers, labels and screws to repair the motor should it be damaged.

Item M3T M5T Description Part Number

8 4 4 Socket Head Cap Screw 108392

9 2 2 Mounting Bolt J101690

10 2 2 Screw J101530

11 1 1 Wave Washer J101126

12 1 – Circuit Breaker J103796

12 – 1 Circuit Breaker J101149

13 1 1 Cover J100789

14 1 1 Fan Blade J101094

15 2 2 Housing Bolt J100022

10

M7T MODELS

Quantity Quantity

Item M7T Description Part Number

1 1 Housing Repair Kit A101416

2 2 Ball Bearing J101069

3 1 Switch A101690

4 1 Half Coupling J100013

5 1 Cord Assembly A101748

5 – Cord Assembly A101751

6 6 Housing Nut J100990

7 4 Socket Head Cap Screw 108392

8 2 Mounting Bolt J101690

Notes: (1) Motor housing repair kits include motor covers, labels and screws to repair the motor should it be damaged.

(2) Contact factory for information on M8T.

Item M7T Description Part Number

9 2 Screw J101530

10 1 Wave Washer J101126

11 1 Circuit Breaker J101150

11 – Circuit Breaker J101149

12 1 Cover J100789

13 1 Start Relay J101147

13 – Start Relay J101804

14 1 Fan Blade A102024

15 2 Housing Bolt J100022

11

M6 MODEL

Quantity

Item M6 Description Part Number

1 1 Air Motor M101717

2 1 Pipe Nipple J100107

3 1 Hex Red. Bushing J100057

4 1 Ball Valve J100073

5 1 Hose Fitting J100036

6 1 Mufer J100033

7 2 Set Screw J100040

Not Shown: Air Motor Repair Kit J100060

Quantity

Item M6 Description Part Number

8 1 Air Motor Mount M100013-1

9 2 Socket Head Cap Screw 108392

10 2 Hex Nut J100990

11 1 Half Coupling J100013

12 1 Lubricator J100035

13 2 Pipe Nipple J102463

14 1 Filter J100034

12

M6X MODEL

Quantity

Item M6X Description Part Number

1 1 Air Motor M101720

2 1 Pipe Nipple J102463

3 1 Ball Valve J100073

4 1 Hose Fitting J100036

5 1 Mufer J100074

6 2 Set Screw J100040

7 1 Air Motor Mount M100013-2

Not Shown: Air Motor Repair Kit J100075

Quantity

Item M6X Description Part Number

8 2 Socket Hd. Cap Screw 108392

9 2 Hex Nut J100990

10 1 Half Coupling J101500

11 1 Lubricator J100035

12 2 Pipe Nipple J102463

13 1 Filter J100034

13

M3X, M5X, M7X & M10X MODELS

The “X” Series motor housing repair kit number is A101455.

Repairs to any item other than the thermoplastic enclosure

voids warranty.

Note: Motor housing repair kits include motor covers, labels

and screws to repair the motor should it be damaged.

M15-M40 MODELS

BT AIR

El kit de reparación del motor de la Serie “X” es A101455. El

hacer reparaciones a cualquier cosa aparte de la cubierta termoplástico anula la garantía.

M18 M15 M24

M19 M16 M25

M20 M17 M26

M27 M33

M28 M34

M29 M35

M39 (50 Hz)

M40 (50 Hz)

Air TEFC EXP

BT ELECTRIC

Please consult factory for repairs to any of the above listed

motors.

14

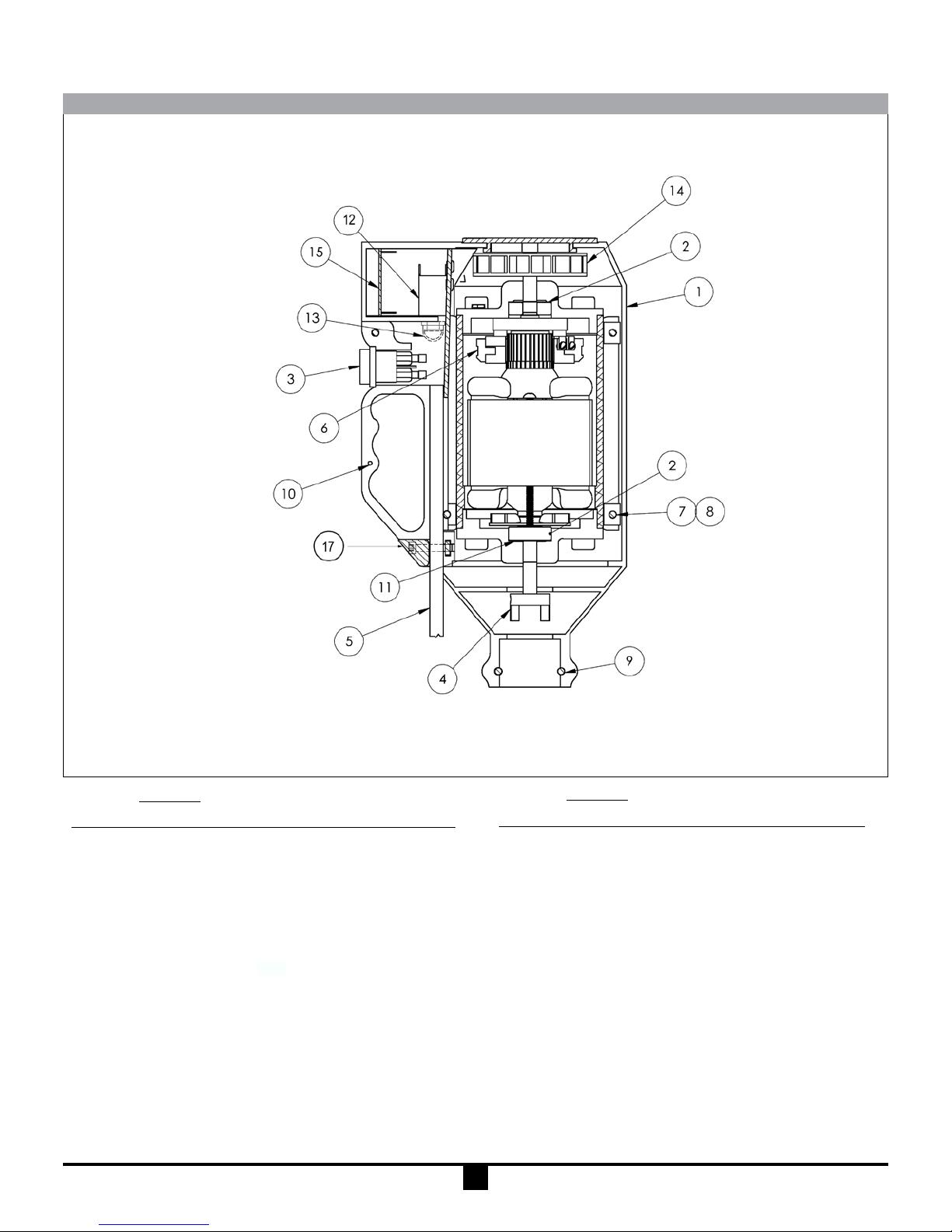

M58P-M59P MODELS

Quantity

Item M58P M59P Description Part Number

1 1 1 Housing Repair Kit 105145

2 1 1 Ball Bearing J101069

3 1 1 Switch A101690

4 1 1 Half Coupling J100013

5 1 – Cord Assembly A101738

5 – 1 Cord Assembly 106732

6 2 2 Brush J101107

7 6 6 Housing Nut J100024

8 4 4 Socket Head Cap Screw 108392

9 2 2 Mounting Bolt J101690

10 3 3 Screw J101530

Note: Housing Repair Kit includes motor covers, labels, & screws to

repair the motor should it be damaged.

Quantity

Item M58P M59P Description Part Number

11 1 1 Wave Washer J101126

12 1 – Circuit Breaker J103796

12 – 1 Circuit Breaker J101149

13 1 1 Cover J100789

14 1 1 Fan 105105

15 1 1 Speed Control 106086

15 1 – Potentiometer 108176-3

15 – 1 Potentiometer 108176-4

*16 1 1 Speed Control 108414

Knob & Cover

17 2 2 Housing Bolt J100022

*Not shown

15

STATIC PROTECTION KIT

EXPLOSION PROOF OR

GROUND WIRE ASSEMBLY

CLAMPED TO EARTH

GROUND

AIR MOTOR

GROUNDED HOSE

WITH GROUND WIRE

ASSEMBLY

GROUND WIRE ASSEMBLY

CLAMPED TO EARTH

GROUND

EXPLOSION PROOF OR

AIR MOTOR

GROUND

WIRE (NOT

INCLUDED)

EARTH GROUND

BONDING

WIRE (NOT

PROVIDED)

NO

SPLASHING

DRUM PUMP MIXER

DRUM PUMP INSTALLATION

1. Install the pump and Static Protection Kit as described and

shown.

2. Connect ground wire assembly to earth ground using supplied clamp.

3. Connect ground wire between drum and earth ground.

4. Connect ground wire between receiving container and earth

ground (or use bonding wire to connect to drum).

CAUTION - Check electrical continuity of all components

before pumping. All should be one (1) ohm or less.

GROUND WIRE

WITH PIPE

CLAMP (NOT

INCLUDED)

EARTH GROUND

OPERATION AND SAFETY GUIDELINES

• Use only metallic pump tubes with explosionproof motors to

transfer ammable or combustible liquids.

• Area for use must comply with NFPA 30 guidelines for safe

storage and use of ammable and combustible liquids.

• All containers and other equipment must be metal and

grounded.

• Follow NFPA 77 guidelines for control of static electricity.

• Avoid splashing. Splash lling can create static electricity

and is extrememly hazardous.

• Fluid velocity must be 3 feet/second maximum (7 GPM in

1" hose).

TUBE MIXER INSTALLATION

1. Install the mixer and Static Protection Kit as described and

shown.

2. Connect ground wire assembly to earth ground using supplied clamp.

3. Connect ground wire between drum and earth ground.

CAUTION - Check electrical continuity of all components

before pumping. All should be one (1) ohm or less.

1616

EQUIPO DE PROTECCIÓN ESTÁTICO

MOTOR CONTRA EXPLOSION

O DE AIRE

ALAMBRE DE CONEXION

A TIERRA

ALAMBRE

DE LINEA

(NO ESTA

INCLUIDO)

CONECCION DE TIERRA

MANGUERA CON

ALAMBRE DE LINEA

DE MONTAJE

ALAMBRE DE

PEGAR (NO

INCLUIDO)

NO SALPIQUEO

DRUM PUMP MIXER

INSTALACIÓN DE LA BOMBA DE MOTOR

1. Instale la bomba y el Equipo de Protección Estático como se

describe y se muestra.

2. Conecte el alambre a la conección de tierra, usando la grapa

que se le ha surtido.

3. Conecte el alambre de tierra entre el tambor y la conexión de

tierra.

4. Conecte el alambre de tierra entre el recipiente recibidor y la

conección de tierra (o use alambre de pegar para conectar al

tambor).

CUIDADO - Revise la continuadad eléctrica de todos los

componentes antes de bombear. Todos deben ser un (1) ohm

o menos.

MOTOR CONTRA EXPLO-

SION O DE AIRE

ALAMBRE DE CONEXION

A TIERRA

ALAMBRE

DE LINEA

CON GRAPA

DE PIPA (NO

INCLUIDA)

CONECCION DE TIERRA

GUIAS DE OPERACIÓN Y SEGURIDAD

• Use solamente tubos de bomba metálicos con motores contra

explosivos para transferir líquidos combustibles o inam-

ables.

• El lugar de uso debe estar de acuerdo con las normas NFPA

30, para almacener seguramente líquidos combustibles y

inamables.

• Todo recipiente y otro equipo debe ser de metal y conectado

a tierra.

• Siga las guias NFPA 77 para el control de electricidad estática.

• Evite salpiquear. El llenar con salpiquéo puede crear electricidad estática y es extremamente peligroso.

• La velocidad del fuido debe ser de 3 pies/segundo máximo

(7 GPM en manguera de 1").

INSTALACIÓN DEL MEZCLADOR

1. Instale la mezcladora y el Equipo de Protección Estático

como se describe y se muestra.

2. Conecte el alambre a la conección de tierra, usando la grapa

que se le ha surtido.

3. Conecte el alambre de línea entre el tambor y la conexión de

tierra.

CUIDADO - Revise la continuadad eléctrica de todos los

componentes antes de bombear. Todos deben ser un (1) ohm

o menos.

17

TECH SERVICE 1-800-888-3743

FT96-593M, J102516, Rev. 27, 7/15/2016

18

Loading...

Loading...