401 Andover Park East

USA (206) 246-2010

Original Instruction

UNCONTROLLED IF PRINTED

Seattle, Washington 98188-7605

FTI OPERATIONS, MAINTENANCE, AND REPAIR MANUAL

Little Brute Right Angle Puller (LBRA-7)

Part #2720-114, Log #36106

#568209 Revision C

February 27, 2019

NO REVISIONS WILL BE ISSUED

This manual should be used in conjunction with the FTI

“Little Brute Puller Unit Operations, Maintenance, and Repair Manual”

© Copyright 2019

Fatigue Technology

Al

l Rights Reserved

UNCONTROLLED IF PRINTED

ABOUT FATIGUE TECHNOLOGY

Fatigue Technology (FTI) is a world-leading aerospace engineering and manufacturing company. FTI pioneered cold

expansion technology (which provides solutions to fatigue problems associated with holes in metal structures) back in 1969

and has advanced this science to develop innovative bushing and fastener products. These proprietary products and

associated tooling may be covered by patents or agreements owned by or exclusively licensed to Fatigue Technology. Use of

tooling procured from other than a licensed source may constitute patent infringement.

The detailed tooling information in this manual was compiled and written by FTI. The tooling was designed specifically for

use with FTI’s Cold Expansion (Cx™) Systems. FTI cannot be held responsible for damage or injury as a result of operating

this equipment if it is used for other than the process intended, with any other tooling not provided by FTI, or not used in

accordance with the instructions contained in this manual. To avoid personal injury, please observe all safety precautions and

instructions. FTI reserves the right to change specifications or configurations of equipment detailed in this manual as part of

our ongoing technical and product improvement programs. If you have any questions about the use or serviceability of this

equipment, please contact our Sales Department.

FTI’s systems and processes are the subject matter of one or more of the following patents: 4,809,420, 4,885,829,

4,934,170, 5,083,363, 5,096,349, 5,103,548, 5,127,254, 5,129,253, 5,218,854, 5,245,743, 5,305,627, 5,341,559,

5,380,136, 5,405,228, 5,433,100, 5,468,104, 6,077,010, 6,183,180, 6,487,767, 6,792,657, 6,990,722, 7,024,908,

7,100,264; 1,061,276, 513,898, 692015124, 581,385, 69310828, 468,598, 69105390, 643,231, 69414946, 696,686,

785,366, 1032769, and other patents pending. These systems and processes are tooling critical and must be performed in

accordance with FTI’s specifications or controlling documents. To ensure proper results from FTI’s cold expansion systems

and to be licensed to use FTI’s patented processes, it is essential that FTI’s complete integrated system of tooling be

purchased and utilized. The use of tooling purchased from other than a licensed supplier could jeopardize fatigue life

enhancement and may constitute patent infringement.

Fatigue Technology Inc. 401 Andover Park East Seattle, WA • USA 98188-7605 Tel: (206)246-2010 Fax: (206)244-9886

568209-REV C

UNCONTROLLED IF PR

F

TI reserves the right to change the specifications or configurations of tooling detailed in this manual as part of its ongoing

INTED

technical and product information program. Should inconsistencies occur between your tooling and this manual, please

contact our Sales Department.

atigue Technology (FTI) has provided innovative solutions to fatigue problems in metal structures since 1969. Complete

F

systems of tooling are used worldwide to enhance the fatigue life of holes in airframes, turbine engines, and other critical

structures.

T

he FTI staff of professionals provides a full range of support services including:

• Application engineering

etailed project planning, implementation, and management

• D

• On-site assistance, including training and tool room setup

T

he Sales Department is always available to assist with special fatigue enhancement requirements. Please contact FTI with

questions at any time.

Fatigue Technology Inc. 401 Andover Park East Seattle, WA • USA 98188-7605 Tel: (206)246-2010 Fax: (206)244-9886

568209-REV C

This page intentionally left blank for two-sided printing.

Fatigue Technology Inc. 401 Andover Park East Seattle, WA • USA 98188-7605 Tel: (206)246-2010 Fax: (206)244-9886

568209-REV C

UNCONTROLLED IF PRINTED

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE

1.0 Introductory Information - Little Brute Right Angle Puller.......................................................................................................................... 1

2.0 Safety ........................................................................................................................................................................................................... 2

3.0 LBRA-7 Specifications and Dimensions ...................................................................................................................................................... 5

4.0 Assembly of the LBRA-7 onto a Little Brute Puller .................................................................................................................................... 6

5.0 Assembly and Maintenance ......................................................................................................................................................................... 9

6.0 Illustrated Parts Breakdown ....................................................................................................................................................................... 12

FIGURES

Figure 2.0-1 Safety Stickers ............................................................................................................................................................................................. 3

Figure 3.0-1 LBRA-7 Dimensions ................................................................................................................................................................................... 5

Figure 4.0-1 Little Brute Puller Unit, Endcap Removed ................................................................................................................................................... 6

Figure 4.0-2 Little Brute Puller Unit and Threaded Adapter ............................................................................................................................................ 7

Figure 4.0-3 LBR A-7, Installation Diagram ..................................................................................................................................................................... 8

Figure 5.1-1 Retaining Ring Removal .............................................................................................................................................................................. 9

Figure 5.2-1 Greased Internals ....................................................................................................................................................................................... 10

Figure 6.0-1 LBRA-7 Illustrated Parts Breakdown ........................................................................................................................................................ 12

Fatigue Technology Inc. 401 Andover Park East Seattle, WA • USA 98188-7605 Tel: (206)246-2010 Fax: (206)244-9886

568209-REV C

UNCONTROLLED IF PRINTED

TABLE OF CONTENTS (CONTINUED)

SECTION DESCRIPTION PAGE

TABLES

Table 3.0-1 LBRA-7 Specifications ................................................................................................................................................................................. 5

Table 6.0-1 LBRA-7 Parts List ...................................................................................................................................................................................... 13

Fatigue Technology Inc. 401 Andover Park East Seattle, WA • USA 98188-7605 Tel: (206)246-2010 Fax: (206)244-9886

568209-REV C

UNCONTROLLED IF PR

INTED

SECTION 1.0: INTRODUCTORY INFORMATION—LITTLE BRUTE RIGHT ANGLE PULLER

This instruction manual contains information on the operation and maintenance of the Little Brute Right Angle Puller (LB RA-7) designed by Fatigue

Technology Inc. (FTI) for use with the patented Split Sleeve Cold Expansion™ (SsCx™) process. To obtain optimum performance and many years of

trouble-free service, carefully follow maintenance procedures and operate the LBRA properly.

R

ead this manual before operating the LBRA, and retain the manual for future reference. If requested, FTI will provide this manual in the language of the

end-user.

T

he Little Brute Right Angle Puller is a compact, durable tool that enables coldworking in restricted access areas that are difficult or impossible to get to

with conventional tools.

• Is capable of cold expanding holes in restricted access areas up to 0.40-inch (10.16 mm) in diameter in aluminum and mild steel.

• Attaches to the Little Brute (LB) series of puller units. See the Little Brute Puller Unit Operations, Maintenance, and Repair Manual for additional

safety information.

• The Right Angle Puller alone weighs approximately 2.0 pounds (0.91 kg); with the Little Brute Puller Unit, it weighs approximately 12.0 pounds

(5.44 kg).

equires only 0.350-inch (8.89 mm) lateral clearance (see Figure 3.0-1).

• R

• Head can rotate 360 degrees on the puller unit.

• Has a maximum pull force of 3,400 pounds (maximum generated by the Little Brute Puller Unit).

• T

he LBRA-10 is capable of much more pull force than the LBRA-7 and is physically larger. For high-force applications, an LBRA-10 may be better

suited. This manual only covers the LBRA-7 and does NOT apply to the LBRA-10.

Fatigue Technology Inc. 401 Andover Park East Seattle, WA • US A 98188-7605 Tel: (206)246-2010 Fax: (206)244-9886

568209-REV C 1

UNCONTROLLED IF PRI

NTED

SECTION 2.0: SAFETY

afe operation of the LBRA is of paramount concern. Along with standard shop safety practices (eye protection, safe handling of high-pressure equipment,

S

etc.), the following items are peculiar to the LBRA/puller unit assembly:

1

. Wear eye protection when operating the puller unit.

. Disconnect the air supply when:

2

Maintenance is to be performed

Hydraulic hose is disconnected

PowerPak is not in use

. Disconnect the LB Puller Unit from the PowerPak before attaching the LBRA.

3

. Set the maximum operating pump pressure to 4,250 psi (29.31 MPa). Refer to the FT-200 PowerPak Operations, Maintenance, and Repair

4

Manual.

. In the event of a ruptured or leaking hydraulic hose, IMMEDIATELY RELEASE THE TRIGGER AND DISCONNECT THE AIR LINE at the air

5

coupler from the PowerPak. Never use your hands to grasp a leaking hose under pressure. The force of escaping hydraulic fluid could cause serious

injury.

6. Keep hands away from the nosecap assembly while holding the nosecap against the workpiece.

7

. Release the puller unit trigger when the mandrel clears the workpiece or becomes stuck.

8

. The Little Brute end cap must always be in place while in use. Injury may occur if the end cap is removed during operation.

. Before operating the pump, tighten all hose connections using the proper tools. Do not over-tighten the connections. Connections need only be

9

tightened securely and leak-free. Over-tightening may cause premature thread failure or high-pressure fittings to split at pressures lower than their

rated capacities.

Fatigue Technology Inc. 401 Andover Park East Seattle, WA • US A 98188-7605 Tel: (206)246-2010 Fax: (206)244-9886

568209-REV C 2

UNCONTROLLED IF PRINTED

0. Operators must read this manual in its entirety before using the Little Brute Right Angle Puller. Eye and ear protection must be worn while operating

1

the Little Brute. Three safety stickers on the Little Brute Puller Unit series act as a reminder to these instructions. The symbols are shown in Figure

2.0-1.

11. Do not use in potentially explosive atmospheres.

R

ead manual before using Always wear eye protection Always wear ear protection

Figure 2.0-1

Safety Stickers

Fatigue Technology Inc. 401 Andover Park East Seattle, WA • US A 98188-7605 Tel: (206)246-2010 Fax: (206)244-9886

568209-REV C 3

UNCONTROLLED IF PRINTED

Hydraulic Hose Safety

1. Inspect the hydraulic hose for signs of wear (cuts, abrasions, or kinks) to the outer shell material. Pump clean oil through the entire length.

Pressurize the hose and check for leaks at the crimped connectors, between the hose material and the fitting, and between the fitting and the coupler.

. DO NOT attempt to disconnect the hydraulic hose while it is under pressure.

2

DO NOT expose hoses to potential hazards, such as extreme heat or cold, sharp surfaces, or heavy impact.

D

O NOT allow hoses to kink, twist, curl, or bend so tightly that the oil flow within the hose is blocked or reduced. Periodically inspect the hose for

wear or damage that could cause premature failure of the hose and possibly result in injury. Damaged hoses must be replaced immediately.

DO NOT use the hose to move attached equipment.

D

O NOT remove the strain reliever from hoses.

3

. Hose strain relievers must be placed around hose fittings during use. Hoses with damaged strain relievers must be replaced immediately.

. Hose material and coupler seals must be compatible with hydraulic fluid that meets the requirements of MIL-PRF-5606.

4

. Hoses must not come in contact with toxic materials, such as creosote-impregnated objects and some paints. Keep couplers and hoses clean and fr

5

o

f paint. Hose deterioration due to chemical degradation may cause the hose to fail under pressure. Damaged hoses must be replaced immediately.

. Before operating the PowerPak, make sure all hose connections are tightened securely. DO NOT over-tighten.

6

. If hoses require replacement, contact the FTI Sales Department.

7

MPORTANT: FTI completed a risk assessment on this unit at our factory. Any modifications done by a third party or the final user are excluded from

I

that risk assessment.

ee

Fatigue Technology Inc. 401 Andover Park East Seattle, WA • US A 98188-7605 Tel: (206)246-2010 Fax: (206)244-9886

568209-REV C 4

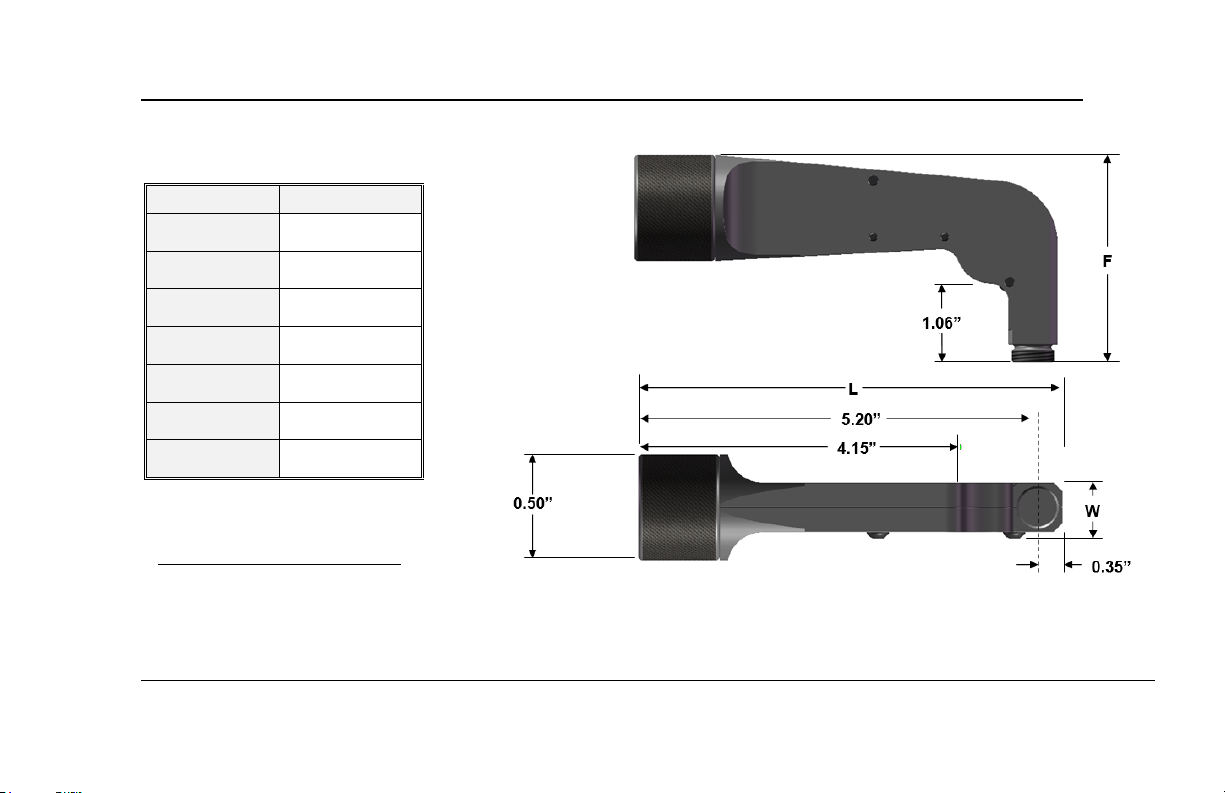

Right Angle

Width [W]

Adapter Length

[L]

Frontside

Clearance [F]

Maximum Pull

Force

Mini mum Edge

Distance

Max Stackup:

4-0-N to 8-1-N

Max Stackup:

8-2-N to 12-3-N

Mandrel and Nosecap Selection

UNCONTROLLED IF PRINTED

SECTION 3.0: LBRA-7 SPECIFICATIONS AND DIMENSIONS

Table 3.0-1

LBRA-7 Specifications

Model Number LBRA-7

0.80"

5.55"

3.0"

3,400 Pounds

0.350"

0.840"

0.715"

The LBRA uses special LBRA mandrels and nosecaps.

Refer to the FTI Tooling Catalog.

Nosecaps: Section 2.3.40

Mandrels: Section 2.3.22

Figure 3.0-1

LBRA-7 Dimensions

Fatigue Technology Inc. 401 Andover Park East Seattle, WA • US A 98188-7605 Tel: (206)246-2010 Fax: (206)244-9886

568209-REV C 5

UNCONTROLLED IF PRINTED

SECTION 4.0: ASSEMBLY OF THE LBRA-7 ONTO A LITTLE BRUTE PULLER

o install the LBRA-7 onto the Little Brute puller:

T

CAUTION: Before attempting any maintenance operations on the puller unit disconnect the PowerPak from the air supply or disconnect the puller

. Remove all tooling from the barrel end of the Little Brute.

1

. Using a spanner wrench, loosen the lock ring on the back of the Little Brute and remove the endcap (Figure 4.0-1). A large flat screwdriver fits into

2

the slot on the back of the piston to keep it from rotating.

from the PowerPak or hand pump.

Figure 4.0-1

Little Brute Puller Unit, Endcap Removed

Fatigue Technology Inc. 401 Andover Park East Seattle, WA • US A 98188-7605 Tel: (206)246-2010 Fax: (206)244-9886

568209-REV C 6

LB-D10 Threaded Adapter

UNCONTROLLED IF PRINTED

3. Ensure the threaded adapter, LB-D10, is attached to the piston rod of the LB puller unit (Figure 4.0-2). Tighten securely while using a large flat

screwdriver on the back of the Little Brute to keep the piston from rotating.

Figure 4.0-2

Little Brute Puller Unit and Threaded Adapter

Fatigue Technology Inc. 401 Andover Park East Seattle, WA • US A 98188-7605 Tel: (206)246-2010 Fax: (206)244-9886

568209-REV C 7

UNCONTROLLED IF PRINTED

4. Thread the LBRA rod into the threaded adapter while using a large flat screwdriver on the back of the Little Brute to keep the piston from rotating

(Figure 4.0-3 - Top). Once the LBRA rod is fully threaded onto the unit, thread the LBRA end cap onto the male threads on the Little Brute Puller

Unit barrel. Re-install the Little Brute endcap and tighten the lock ring securely with a pinwrench. THE ENDCAP MUST BE IN PLACE DURIN

ERATION. The installation is now complete.

OP

5. See Little Brute Manual for operation and use of assembled tooling.

Figure 4.0-3

LBRA-7, Installation Diagram

G

Fatigue Technology Inc. 401 Andover Park East Seattle, WA • US A 98188-7605 Tel: (206)246-2010 Fax: (206)244-9886

568209-REV C 8

UNCONTROLLED IF PRINTED

SECTION 5.0: ASSEMBLY AND MAINTENANCE

CAUTION: Before attempting any maintenance operations on the puller unit disconnect the PowerPak from the air supply or disconnect the puller

efer to Figure 6.0-1 for identification of the components.

R

5. 1 D

. To disassemble the LBRA-7, first remove it from the Little Brute. If a nosecap is mounted, take it off as well.

1

. Remove the retaining ring (9) using retaining ring pliers (Figure 5.1-1). The end cap (10) can now be removed along with the O-ring (7) and

2

washer (8).

from the PowerPak or hand pump.

isassembly

Figure 5.1-1

Retaining Ring Removal

. Remove the two screws in the left half of the housing. The left housing can now be removed and the internal parts accessed for maintenance.

3

Fatigue Technology Inc. 401 Andover Park East Seattle, WA • US A 98188-7605 Tel: (206)246-2010 Fax: (206)244-9886

568209-REV C 9

Grease

ONTROLLED IF PRINTED

UNC

5.2 Cleaning and Lubrication

The puller requires routine checking and periodic preventative maintenance to ensure safe, trouble-free operation. No special maintenance is required. The

following maintenance actions are suggested.

. Periodically clean the outer surfaces of the unit. Keep all hose connections free of dirt and grime. Doing so will dramatically extend the life of

1

pumps and puller seals.

. The internal moving parts should be periodically lubricated with Mobil-HP or equivalent grease to ensure smooth operation and extend the life of

2

the unit (Figure 5.2-1).

Figure 5.2-1

Greased Internals

. Whenever the puller unit is to be stored for any length of time, maintain a thin coat of 10-weight oil on the outside surfaces to prevent rusting.

3

Fatigue Technology Inc. 401 Andover Park East Seattle, WA • US A 98188-7605 Tel: (206)246-2010 Fax: (206)244-9886

568209-REV C 10

UNC

ONTROLLED IF PRINTED

5.3 Replacing Parts/Repair

If parts need replacing or the unit needs repair, please contact FTI’s Sales Department. FTI will work with the operator to try to troubleshoot over the phone,

but a return of the LBRA unit may be required.

5.4 Reassembly

. Replace all internal components into the right half housing.

1

. Attach the left housing half using the two screws.

2

3. Install the end cap (10), followed by the O-ring (7) and washer (8). Ensure that the O-ring and washer are fully seated all the way down.

4

. Install the retaining ring (9) using retaining ring pliers. The O-ring must be compressed to fit the retaining ring on, so it may be necessary to tap

the retaining ring with a blunt pin until the ring is fully snapped into the groove.

Fatigue Technology Inc. 401 Andover Park East Seattle, WA • US A 98188-7605 Tel: (206)246-2010 Fax: (206)244-9886

568209-REV C 11

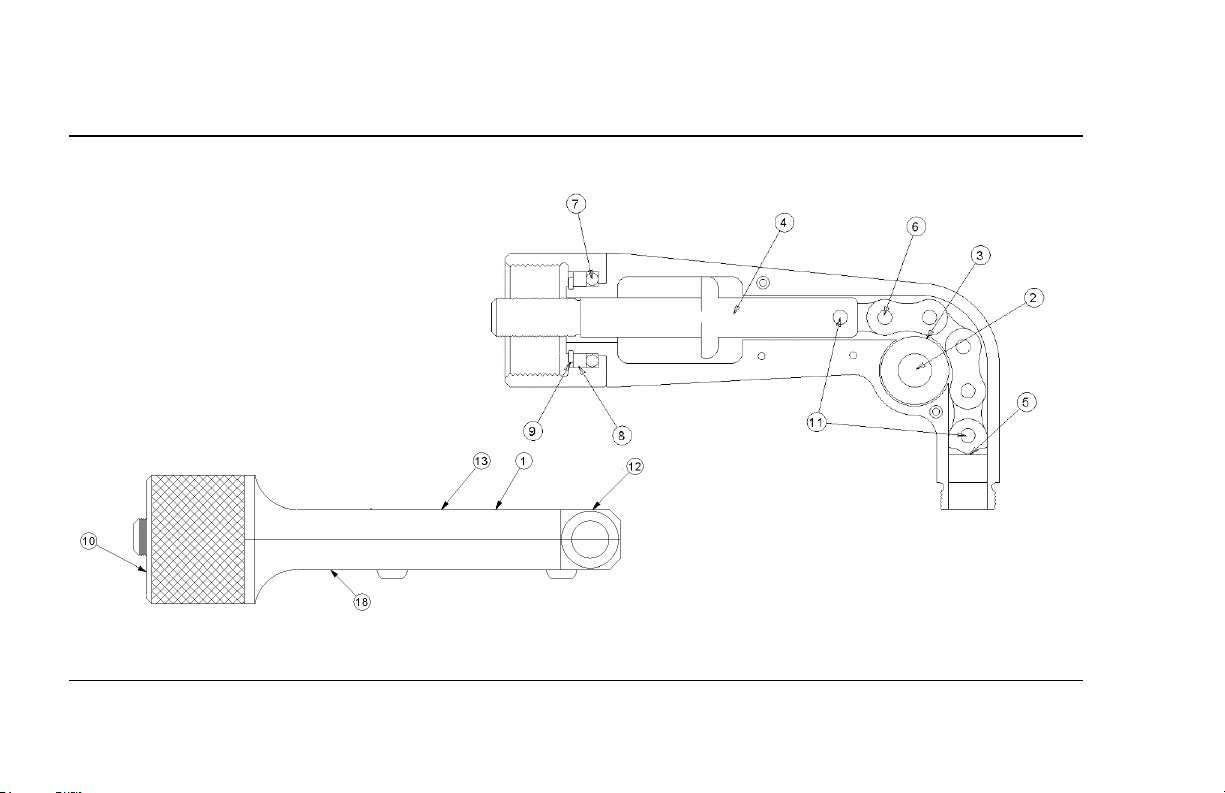

Figure 6.0-1

LBRA-7 Illustrated Parts Breakdown

UNCONTROLLED IF PR

INTED

SECTION 6.0: ILLUSTRATED PARTS BREAKDOWN

diagram is provided in Figure 6.0-1 and parts list in Table 6.0-1. The Little Brute Right Angle Puller Unit is compact and tight, and as a result, it could be

A

difficult to open and repair. Please contact FTI for any assistance.

Fatigue Technology Inc. 401 Andover Park East Seattle, WA • US A 98188-7605 Tel: (206)246-2010 Fax: (206)244-9886

568209-REV C 12

Quantity

LBRA-7

LBRA-7-PC-12

LBRA-7-BH-1

LBRA-7-PC-8

1 1 -

1

5295-001

- - 1

-

5295-002 2 1 1 1

1

5300-001

Pin, Roller

3 1 1 1 1

5299-001

Roller

4 1 1 1 1

5298-001

Adapter, Puller

1 - 1

-

5294-001

- 1 -

-

5294-002 - - - 1

5294-003 6 1 1 1

1

5305-001

Chain

7 1 1 1 1

1046-120

O-Ring

8 1 1 1 1

5301-001

Washer, LBRA Tension

9 1 1 1 1

1045-366

Ring, External Retaining

10 1 1 1 1

5304-001

LBRA End Cap

11 2 2 2 2

1045-367

Dowel Pin

12 1 1 1 1

1009-185

Caution Label

13 1 1 1 1

1009-255

Pressure Label

14 1 1 1 1

1199-452

Case

15

1

1 1 1

1009-293

FTI Label

16 1 1 1 1

1009-307

LBRA-7 Label

17 1 1 1 1

2720-114

Manual, LBRA-7

18 1 1 1 1

1166-001

Label, CE

UNCONTROLLED IF PRI

Table 6.0-1

LBRA-7 Parts List

NTED

Item Number

1

5

Fatigue Technology Inc. 401 Andover Park East Seattle, WA • US A 98188-7605 Tel: (206)246-2010 Fax: (206)244-9886

568209-REV C 13

Part

Number

Description

Housing Sub-Assembly

Adapter, Mandrel Link

E.C. DECLARATION OF CONFORMITY

FATIGUE TECHNOLOGY INC.

Manufacturer: Fatigue Technology Inc.

401 Andover Park East

Seattle, WA 98188-7605

Telephone: (206) 246-2010

Fax: (206) 244-9886

Responsible Person in E.C.: Jean-Michel Derisson

4 rue d’Austerlitz

31490 Léguevin

FRANCE

Telephone: 33 5-34-559-916

Fax: 33 5-34-569-047

401 Andover Park East

Seattle, Washington 98188-7605

USA

The undersigned declares that the machinery described:

Type:

Serial Number:

Conforms to the following directives:

Council Directive 2006/42/EC (the Machinery Directive)

ISO 11148-1 Hand-Held Non-Electric Power Tools – Safety Requirements – Part 1

ISO 4413 Hydraulic fluid power – General rules and safety requirements for

systems and their components

ISO 4414 Pneumatic fluid power – General rules and safety requirements for

systems and their components

And complies with the relevant health and safety requirements.

Jeff Sageman Date

Logistics Manager

4/25/19

Loading...

Loading...