™

Future Technology Devices International Ltd.

FT245R USB FIFO I.C.

Incorporating FTDIChip-ID™ Security Dongle

The FT245R is the latest device to be added to FTDI’s range of USB FIFO interface Integrated Circuit Devices.

The FT245R is a USB to parallel FIFO interface, with the new FTDIChip-ID™ security dongle feature. In addition,

asynchronous and synchronous bit bang interface modes are available. USB to parallel designs using the FT245R

have been further simplified by fully integrating the external EEPROM, clock circuit and USB resistors onto the device.

The FT245R adds a new function compared with its predecessors, effectively making it a “2-in-1” chip for some

application areas. A unique number (the FTDIChip-ID™) is burnt into the device during manufacture and is readable

over USB, thus forming the basis of a security dongle which can be used to protect customer application software

from being copied.

The FT245R is available in Pb-free (RoHS compliant) compact 28-Lead SSOP and QFN-32 packages.

Copyright © Future Technology Devices International Ltd. 2005

1. Features

1.1 Hardware Features

• Single chip USB to parallel FIFO bidirectional data

transfer interface.

• Entire USB protocol handled on the chip - No

USB-specific firmware programming required.

• Simple interface to MCU / PLD / FPGA logic with

simple 4-wire handshake interface.

• Data transfer rate to 1 Megabyte / second - D2XX

Direct Drivers.

• Data transfer rate to 300 kilobyte / second - VCP

Drivers.

• 256 byte receive buffer and 128 byte transmit

buffer utilising buffer smoothing technology to allow

for high data throughput.

• FTDI’s royalty-free VCP and D2XX drivers

eliminate the requirement for USB driver

development in most cases.

• New USB FTDIChip-ID™ feature.

• FIFO receive and transmit buffers for high data

throughput.

• Adjustable receive buffer timeout.

• Synchronous and asynchronous bit bang mode

interface options with RD# and WR# strobes allow

the data bus to be used as a general purpose I/O

port.

• Integrated 1024 Bit internal EEPROM for storing

USB VID, PID, serial number and product

description strings.

• Device supplied preprogrammed with unique USB

serial number.

Page 2

• Support for USB suspend / resume through

PWREN# pin and Wake Up pin function.

• In-built support for event characters.

• Support for bus powered, self powered, and high-

power bus powered USB configurations.

• Integrated 3.3V level converter for USB I/O .

• Integrated level converter on FIFO interface and

control pins for interfacing to 5V - 1.8V Logic.

• True 5V / 3.3V / 2.8V / 1.8V CMOS drive output

and TTL input.

• High I/O pin output drive option.

• Integrated USB resistors.

• Integrated power-on-reset circuit.

• Fully integrated clock - no external crystal,

oscillator, or resonator required.

• Fully integrated AVCC supply filtering - No separate

AVCC pin and no external R-C filter required.

• USB bulk transfer mode.

• 3.3V to 5.25V Single Supply Operation.

• Low operating and USB suspend current.

• Low USB bandwidth consumption.

• UHCI / OHCI / EHCI host controller compatible

• USB 2.0 Full Speed compatible.

• -40°C to 85°C extended operating temperature

range.

• Available in compact Pb-free 28 Pin SSOP and

QFN-32 packages (both RoHS compliant).

1.2 Driver Support

Royalty-Free VIRTUAL COM PORT

(VCP) DRIVERS for...

• Windows 98, 98SE, ME, 2000, Server 2003, XP.

• Windows Vista / Longhorn*

• Windows XP 64-bit.*

• Windows XP Embedded.

• Windows CE.NET 4.2 & 5.0

• MAC OS 8 / 9, OS-X

• Linux 2.4 and greater

The drivers listed above are all available to download for free from the FTDI website. Various 3rd Party Drivers are

also available for various other operating systems - see the FTDI website for details.

* Currently Under Development. Contact FTDI for availability.

Royalty-Free D2XX Direct Drivers

(USB Drivers + DLL S/W Interface)

• Windows 98, 98SE, ME, 2000, Server 2003, XP.

• Windows Vista / Longhorn*

• Windows XP 64-bit.*

• Windows XP Embedded.

• Windows CE.NET 4.2 & 5.0

• Linux 2.4 and greater

1.3 Typical Applications

• Upgrading Legacy Peripherals to USB

• Cellular and Cordless Phone USB data transfer

cables and interfaces

• Interfacing MCU / PLD / FPGA based designs to

USB

• USB Audio and Low Bandwidth Video data transfer

• PDA to USB data transfer

• USB Smart Card Readers

• USB Instrumentation

• USB Industrial Control

• USB MP3 Player Interface

• USB FLASH Card Reader / Writers

• Set Top Box PC - USB interface

• USB Digital Camera Interface

• USB Hardware Modems

• USB Wireless Modems

• USB Bar Code Readers

• USB Software / Hardware Encryption Dongles

FT245R USB UART I.C. Datasheet Version 1.05 © Future Technology Devices International Ltd. 2005

Page 3

2. Enhancements

2.1 Device Enhancements and Key Features

This section summarises the enhancements and the key features of the FT245R device. For further details, consult

the device pin-out description and functional description sections.

Integrated Clock Circuit - Previous generations of FTDI’s USB to parallel FIFO interface devices required an external

crystal or ceramic resonator. The clock circuit has now been integrated onto the device meaning that no crystal or

ceramic resonator is required. However, if required, an external 12MHz crystal can be used as the clock source.

Integrated EEPROM - Previous generations of FTDI’s USB to parallel FIFO interface devices required an external

EEPROM if the device were to use USB Vendor ID (VID), Product ID (PID), serial number and product description

strings other than the default values in the device itself. This external EEPROM has now been integrated onto the

FT245R chip meaning that all designs have the option to change the product description strings. A user area of the

internal EEPROM is available for storing additional data. The internal EEPROM is programmable in circuit, over USB

without any additional voltage requirement.

Preprogrammed EEPROM - The FT245R is supplied with its internal EEPROM preprogrammed with a serial number

which is unique to each individual device. This, in most cases, will remove the need to program the device EEPROM.

Integrated USB Resistors - Previous generations of FTDI’s USB to parallel FIFO interface devices required two

external series resistors on the USBDP and USBDM lines, and a 1.5 kΩ pull up resistor on USBDP. These three

resistors have now been integrated onto the device.

Integrated AVCC Filtering - Previous generations of FTDI’s USB to parallel FIFO interface devices had a separate

AVCC pin - the supply to the internal PLL. This pin required an external R-C filter. The separate AVCC pin is now

connected internally to VCC, and the filter has now been integrated onto the chip.

Less External Components - Integration of the crystal, EEPROM, USB resistors, and AVCC filter will substantially

reduce the bill of materials cost for USB interface designs using the FT245R compared to its FT245BM predecessor.

Transmit and Receive Buffer Smoothing - The FT245R’s 256 byte receive buffer and 128 byte transmit buffer utilise

new buffer smoothing technology to allow for high data throughput.

Enhanced Asynchronous Bit Bang Mode with RD# and WR# Strobes - The FT245R supports FTDI’s BM chip bit

bang mode. In bit bang mode, the eight parallel FIFO data bus lines can be switched from the regular interface mode

to an 8-bit general purpose I/O port. Data packets can be sent to the device and they will be sequentially sent to the

interface at a rate controlled by an internal timer (equivalent to the baud rate prescaler). With the FT245R device this

mode has been enhanced so that the internal RD# and WR# strobes are now brought out of the device which can be

used to allow external logic to be clocked by accesses to the bit bang I/O bus. This option will be described more fully

in a separate application note

Synchronous Bit Bang Mode - Synchronous bit bang mode differs from asynchronous bit bang mode in that the

interface pins are only read when the device is written to. Thus making it easier for the controlling program to measure

the response to an output stimulus as the data returned is synchronous to the output data. The feature was previously

seen in FTDI’s FT2232C device. This option will be described more fully in a separate application note.

Lower Supply Voltage - Previous generations of the chip required 5V supply on the VCC pin. The FT245R will work

with a Vcc supply in the range 3.3V - 5V. Bus powered designs would still take their supply from the 5V on the USB

bus, but for self powered designs where only 3.3V is available, and there is no 5V supply, there is no longer any need

for an additional external regulator.

Integrated Level Converter on FIFO Interface and Control Signals - VCCIO pin supply can be from 1.8V to 5V.

Connecting the VCCIO pin to 1.8V, 2.8V, or 3.3V allows the device to directly interface to 1.8V, 2.8V or 3.3V and other

logic families without the need for external level converter I.C.s

5V / 3.3V / 2.8V / 1.8V Logic Interface - The FT245R provides true CMOS Drive Outputs and TTL level Inputs.

FT245R USB UART I.C. Datasheet Version 1.05 © Future Technology Devices International Ltd. 2005

Page 4

Integrated Power-On-Reset (POR) Circuit- The device incorporates an internal POR function. A RESET# pin is

available in order to allow external logic to reset the FT245R where required. However, for many applications the

RESET# pin can be left unconnected, or pulled up to VCCIO.

Wake Up Function - If USB is in suspend mode, and remote wake up has been enabled in the internal EEPROM (it is

enabled by default), the RXF# pin becomes an input. Strobing this pin low will cause the FT245R to request a resume

from suspend on the USB bus. Normally this can be used to wake up the host PC from suspend

Lower Operating and Suspend Current - The device operating supply current has been further reduced to 15mA,

and the suspend current has been reduced to around 70μA. This allows a greater margin for peripherals to meet the

USB suspend current limit of 500μA.

Low USB Bandwidth Consumption - The operation of the USB interface to the FT245R has been designed to use

as little as possible of the total USB bandwidth available from the USB host controller.

High Output Drive Option - The parallel FIFO interface and the four FIFO handshake pins can be made to drive

out at three times the standard signal drive level thus allowing multiple devices to be driven, or devices that require a

greater signal drive strength to be interfaced to the FT245R. This option is configured in the internal EEPROM.

Power Management Control for USB Bus Powered, High Current Designs- The PWREN# signal can be used to

directly drive a transistor or P-Channel MOSFET in applications where power switching of external circuitry is required.

An option in the internal EEPROM makes the device gently pull down on its FIFO interface lines when the power

is shut off (PWREN# is high). In this mode any residual voltage on external circuitry is bled to GND when power is

removed, thus ensuring that external circuitry controlled by PWREN# resets reliably when power is restored.

FTDIChip-ID™ - Each FT245R is assigned a unique number which is burnt into the device at manufacture. This ID

number cannot be reprogrammed by product manufacturers or end-users. This allows the possibility of using FT245R

based dongles for software licensing. Further to this, a renewable license scheme can be implemented based on the

FTDIChip-ID™ number when encrypted with other information. This encrypted number can be stored in the user area

of the FT245R internal EEPROM, and can be decrypted, then compared with the protected FTDIChip-ID™ to verify

that a license is valid. Web based applications can be used to maintain product licensing this way. An application note

describing this feature is available separately from the FTDI website.

Improved EMI Performance - The reduced operating current and improved on-chip VCC decoupling significantly

improves the ease of PCB design requirements in order to meet FCC, CE and other EMI related specifications.

Programmable FIFO TX Buffer Timeout - The FIFO TX buffer timeout is used to flush remaining data from the

receive buffer. This timeout defaults to 16ms, but is programmable over USB in 1ms increments from 1ms to 255ms,

thus allowing the device to be optimised for protocols that require fast response times from short data packets.

Extended Operating Temperature Range - The FT232R operates over an extended temperature range of -40º to

+85º C thus allowing the device to be used in automotive and industrial applications.

New Package Options - The FT245R is available in two packages - a compact 28 pin SSOP ( FT245RL) and an

ultra-compact 5mm x 5mm pinless QFN-32 package ( FT245RQ). Both packages are lead ( Pb ) free, and use a

‘green’ compound. Both packages are fully compliant with European Union directive 2002/95/EC.

FT245R USB UART I.C. Datasheet Version 1.05 © Future Technology Devices International Ltd. 2005

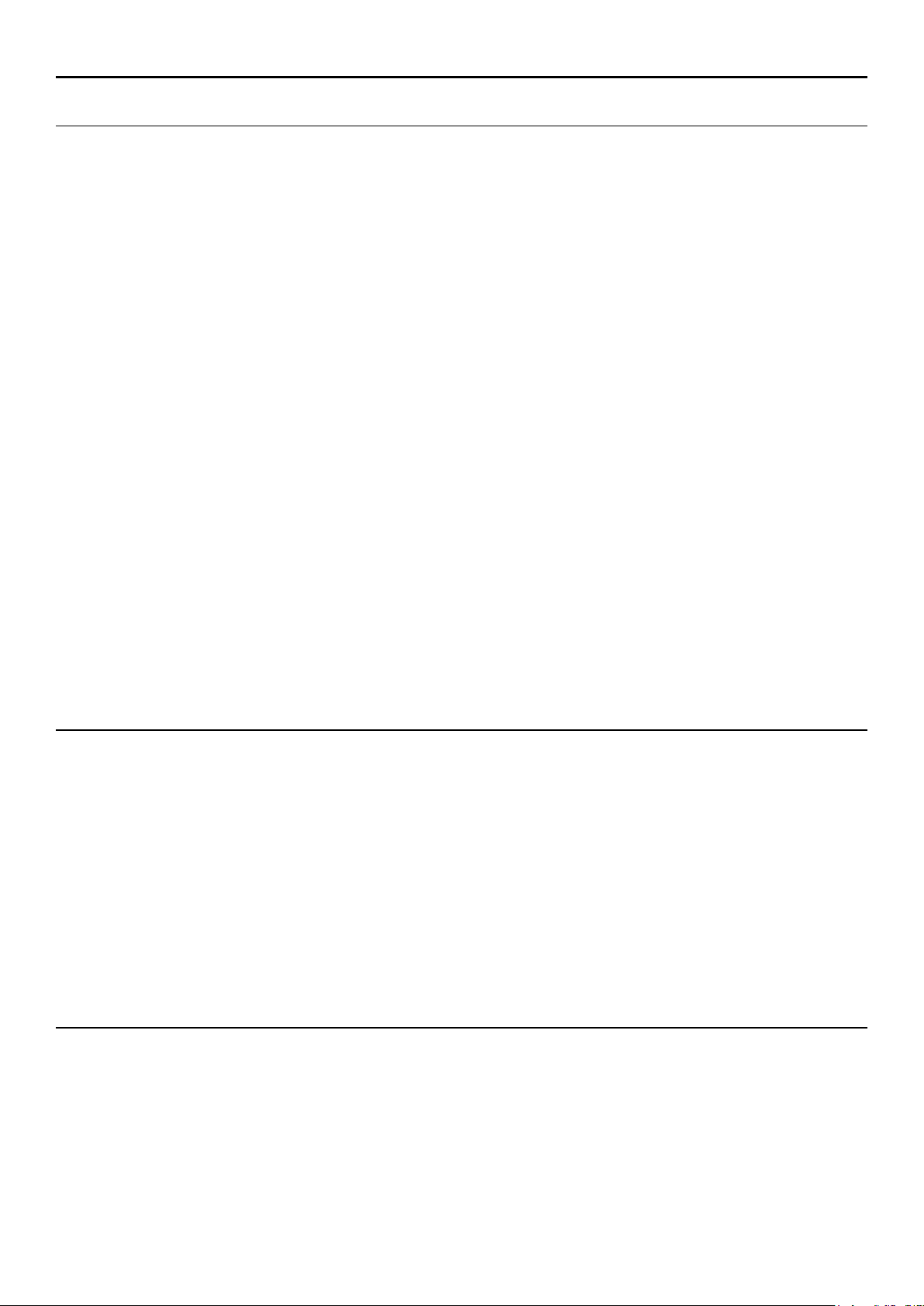

3. Block Diagram

Clock

Multiplier

Serial Interface

Engine

( SIE )

USB

Protocol Engine

3.3 Volt

LDO

Regulator

USB

Transceiver

with

Integrated

Series

Resistors

and 1.5K

Pull-up

USB DPLL

Internal

12MHz

Oscillator

48MHz

OCSI

(optional)

OSCO

(optional)

USBDP

USBDM

3V3OUT

VCC

D0

D1

D2

D3

D4

D5

D6

D7

RD#

RXF#

TXE#

RESET#

TEST

GND

RESET

GENERATOR

3V3OUT

WR

FIFO TX Buffer

128 bytes

FIFO RX Buffer

256 bytes

Internal

EEPROM

To USB Transceiver Cell

PWREN#

To USB

Transceiver

Cell

VCCIO

FIFO Controller

with

Programmable

High Drive

3.1 Block Diagram (Simplified)

Page 5

Figure 1 - FT245R Block Diagram

3.2 Functional Block Descriptions

3.3V LDO Regulator - The 3.3V LDO Regulator generates the 3.3V reference voltage for driving the USB transceiver

cell output buffers. It requires an external decoupling capacitor to be attached to the 3V3OUT regulator output pin. It

also provides 3.3V power to the 1.5kΩ internal pull up resistor on USBDP. The main function of this block is to power

the USB Transceiver and the Reset Generator Cells, rather than to power external logic. However, external circuitry

requiring 3.3V nominal at a current of around 50mA could also draw its power from the 3V3OUT pin if required.

USB Transceiver - The USB Transceiver Cell provides the USB 1.1 / USB 2.0 full-speed physical interface to the USB

cable. The output drivers provide 3.3V level slew rate control signalling, whilst a differential receiver and two single

ended receivers provide USB data in, SEO and USB Reset condition detection. This Cell also incorporates internal

USB series resistors on the USB data lines, and a 1.5kΩ pull up resistor on USBDP.

USB DPLL - The USB DPLL cell locks on to the incoming NRZI USB data and provides separate recovered clock and

data signals to the SIE block.

Internal 12MHz Oscillator - The Internal 12MHz Oscillator cell generates a 12MHz reference clock input to the x4

Clock multiplier. The 12MHz Oscillator is also used as the reference clock for the SIE, USB Protocol Engine and FIFO

controller blocks

Clock Multiplier - The Clock Multiplier takes the 12MHz input from the Oscillator Cell and generates the 48MHz clock

reference used for the USB DPLL block.

Serial Interface Engine (SIE) - The Serial Interface Engine (SIE) block performs the Parallel to Serial and Serial to

Parallel conversion of the USB data. In accordance to the USB 2.0 specification, it performs bit stuffing / un-stuffing

and CRC5 / CRC16 generation / checking on the USB data stream.

FT245R USB UART I.C. Datasheet Version 1.05 © Future Technology Devices International Ltd. 2005

Page 6

USB Protocol Engine - The USB Protocol Engine manages the data stream from the device USB control endpoint. It

handles the low level USB protocol (Chapter 9) requests generated by the USB host controller and the commands for

controlling the functional parameters of the FIFO.

FIFO TX Buffer (128 byte) - Data written into the FIFO using the WR pin is stored in the FIFO TX (transmit) Buffer.

The USB host controller removes data from the FIFO TX Buffer by sending a USB request for data from the device

data In endpoint.

FIFO RX Buffer (256 byte) - Data sent from the USB host controller to the FIFO via the USB data Out endpoint is

stored in the FIFO RX (receive) buffer and is removed from the buffer by reading the contents of the FIFO using the

RD# pin.

FIFO Controller - The FIFO controller handles the transfer of data between the external FIFO interface pins (D0 - D7)

and the FIFO transmit and receive buffers. A new feature, which is enabled in the internal EEPROM allows high signal

drive strength on the FIFO parallel data bus and handshake control pins.

RESET Generator - The integrated Reset Generator Cell provides a reliable power-on reset to the device internal

circuitry on power up. A RESET# input is provided to allow other devices to reset the FT245R. RESET# can be tied

to VCCIO or left unconnected, unless there is a requirement to reset the FT245R device from external logic or an

external reset generator I.C.

Internal EEPROM - The internal EEPROM in the FT245R can be used to store USB Vendor ID (VID), Product ID

(PID), device serial number, product description string, and various other USB configuration descriptors. The device is

supplied with the internal EEPROM settings preprogrammed as described in Section 10.

FT245R USB UART I.C. Datasheet Version 1.05 © Future Technology Devices International Ltd. 2005

4. Device Pin Out and Signal Descriptions

USBDP

USBDM

3V3OUT

GND

RESET#

VCC

GND

NC

AGND

TEST

OSCI

OSCO

TXE#

RXF#

D0

D2

D1

D4

VCCIO

D7

GND

NC

D5

D6

D3

PWREN#

RD#

WR

FT245RL

YYXX-A

1

14

15

28

FTDI

FT245RL

A

G

N

D

G

N

D

G

N

D

G

N

D

T

E

S

T

25

7 18 21 26

3V3OUT

VCCIO

4

17

NC

RESET#

NC

24

19

8

D0

D1

D2

D3

D4

D5

D6

D7

1

5

3

11

2

9

10

6

RXF#

WR

RD#

TXE#

23

22

13

14

20

16

15

USBDP

USBDM

VCC

OSCI

27

OSCO

28

PWREN#

12

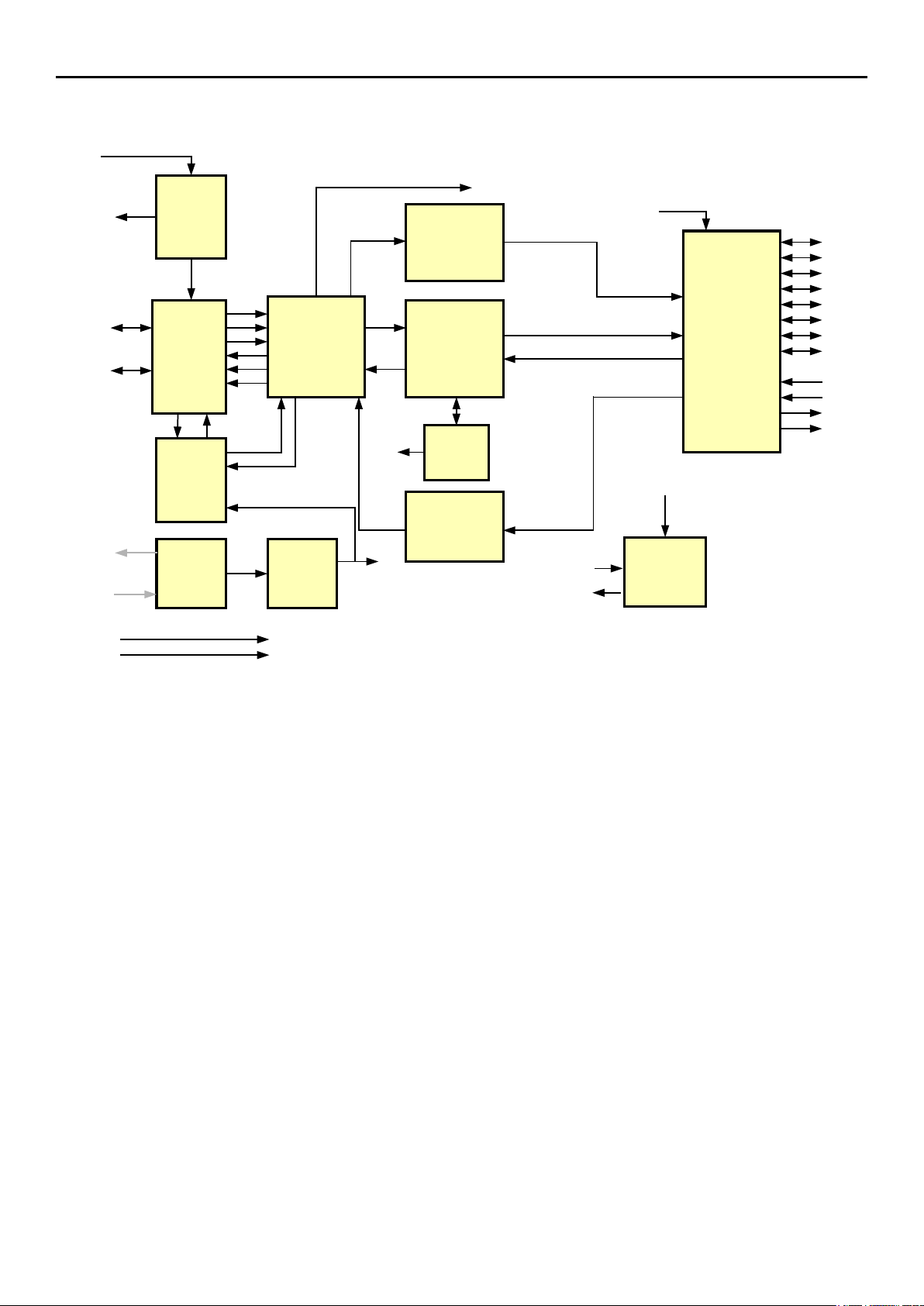

4.1 28-LD SSOP Package

Page 7

Figure 2 - 28 Pin SSOP Package Pin Out

Figure 3 - 28 Pin SSOP Package Pin Out (Schematic Symbol)

FT245R USB UART I.C. Datasheet Version 1.05 © Future Technology Devices International Ltd. 2005

Page 8

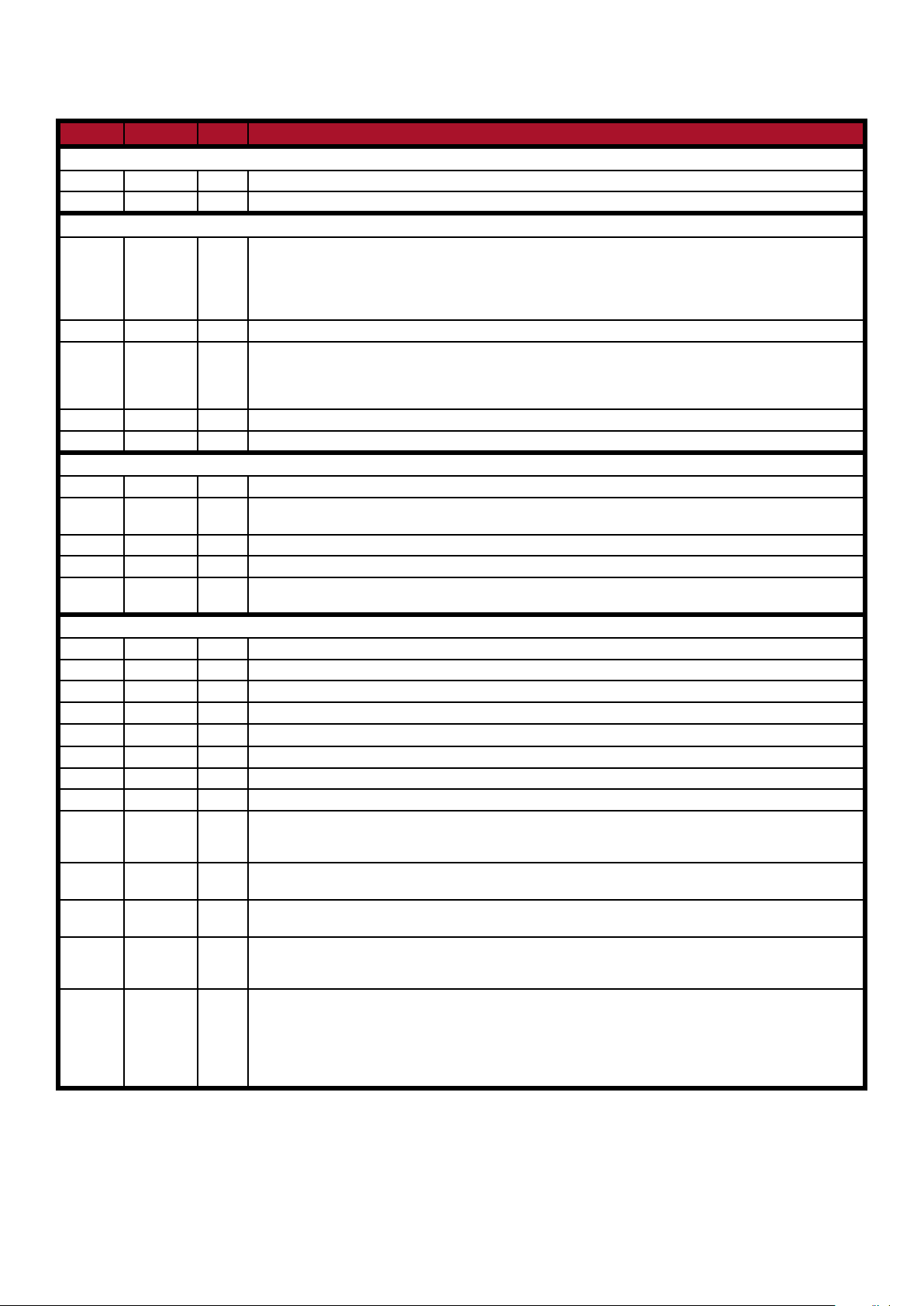

4.2 SSOP-28 Package Signal Descriptions

Table 1 - SSOP Package Pin Out Description

Pin No. Name Type Description

USB Interface Group

15 USBDP I/O USB Data Signal Plus, incorporating internal series resistor and 1.5kΩ pull up resistor to 3.3V

16 USBDM I/O USB Data Signal Minus, incorporating internal series resistor.

Power and Ground Group

4 VCCIO PWR +1.8V to +5.25V supply to the FIFO Interface and Control group pins (1...3, 5, 6, 9...14, 22, 23). In USB bus

powered designs connect to 3V3OUT to drive out at 3.3V levels, or connect to VCC to drive out at 5V CMOS

level. This pin can also be supplied with an external 1.8V - 2.8V supply in order to drive out at lower levels. It

should be noted that in this case this supply should originate from the same source as the supply to Vcc. This

means that in bus powered designs a regulator which is supplied by the 5V on the USB bus should be used.

7, 18, 21 GND PWR Device ground supply pins

17 3V3OUT Output 3.3V output from integrated L.D.O. regulator. This pin should be decoupled to ground using a 100nF capacitor.

The prime purpose of this pin is to provide the internal 3.3V supply to the USB transceiver cell and the internal

1.5kΩ pull up resistor on USBDP. Up to 50mA can be drawn from this pin to power external logic if required.

This pin can also be used to supply the FT245R’s VCCIO pin.

20 VCC PWR 3.3V to 5.25V supply to the device core.

25 AGND PWR Device analog ground supply for internal clock multiplier

Miscellaneous Signal Group

8, 24 NC NC No internal connection.

19 RESET# Input Can be used by an external device to reset the FT245R. If not required can be left unconnected or pulled up

to VCCIO.

26 TEST Input Puts the device into I.C. test mode. Must be grounded for normal operation.

27 OSCI Input Input to 12MHz Oscillator Cell. Optional - Can be left unconnected for normal operation. *

28 OSCO Output Output from 12MHz Oscillator Cell. Optional - Can be left unconnected for normal operation if internal oscilla-

tor is used.*

FIFO Interface and Control Group

1 D0 I/O FIFO Data Bus Bit 0**

2 D4 I/O FIFO Data Bus Bit 4**

3 D2 I/O FIFO Data Bus Bit 2**

5 D1 I/O FIFO Data Bus Bit 1**

6 D7 I/O FIFO Data Bus Bit 7**

9 D5 I/O FIFO Data Bus Bit 5**

10 D6 I/O FIFO Data Bus Bit 6**

11 D3 I/O FIFO Data Bus Bit 3**

12 PWREN# Output Goes low after the device is configured by USB, then high during USB suspend. Can be used to control power

to external logic P-Channel logic level MOSFET switch. Enable the interface pull-down option when using the

PWREN# pin in this way.

13 RD# Input Enables the current FIFO data byte on D0...D7 when low. Fetched the next FIFO data byte (if available) from

the receive FIFO buffer when RD# goes from high to low. See Section 4.5 for timing diagram. **

14 WR Input Writes the data byte on the D0...D7 pins into the transmit FIFO buffer when WR goes from high to low. See

Section 4.5 for timing diagram. **

22 TXE# Output When high, do not write data into the FIFO. When low, data can be written into the FIFO by strobing WR high,

then low. During reset this signal pin is tri-state, but pulled up to VCCIO via an internal 200kΩ resistor. See

Section 4.5 for timing diagram.

23 RXF# Output When high, do not read data from the FIFO. When low, there is data available in the FIFO which can be read

by strobing RD# low, then high again. During reset this signal pin is tri-state, but pulled up to VCCIO via an

internal 200kΩ resistor. See Section 4.5 for timing diagram.

If the Remote Wakeup option is enabled in the internal EEPROM, during USB suspend mode (PWREN# = 1)

RXF# becomes an input which can be used to wake up the USB host from suspend mode. Strobing the pin

low will cause the device to request a resume on the USB bus.

*Contact FTDI Support for details of how to use an external crystal, ceramic resonator, or oscillator with the FT245R.

** When used in Input Mode, these pins are pulled to VCCIO via internal 200kΩ resistors. These can be programmed

to gently pull low during USB suspend ( PWREN# = “1” ) by setting this option in the internal EEPROM.

FT245R USB UART I.C. Datasheet Version 1.05 © Future Technology Devices International Ltd. 2005

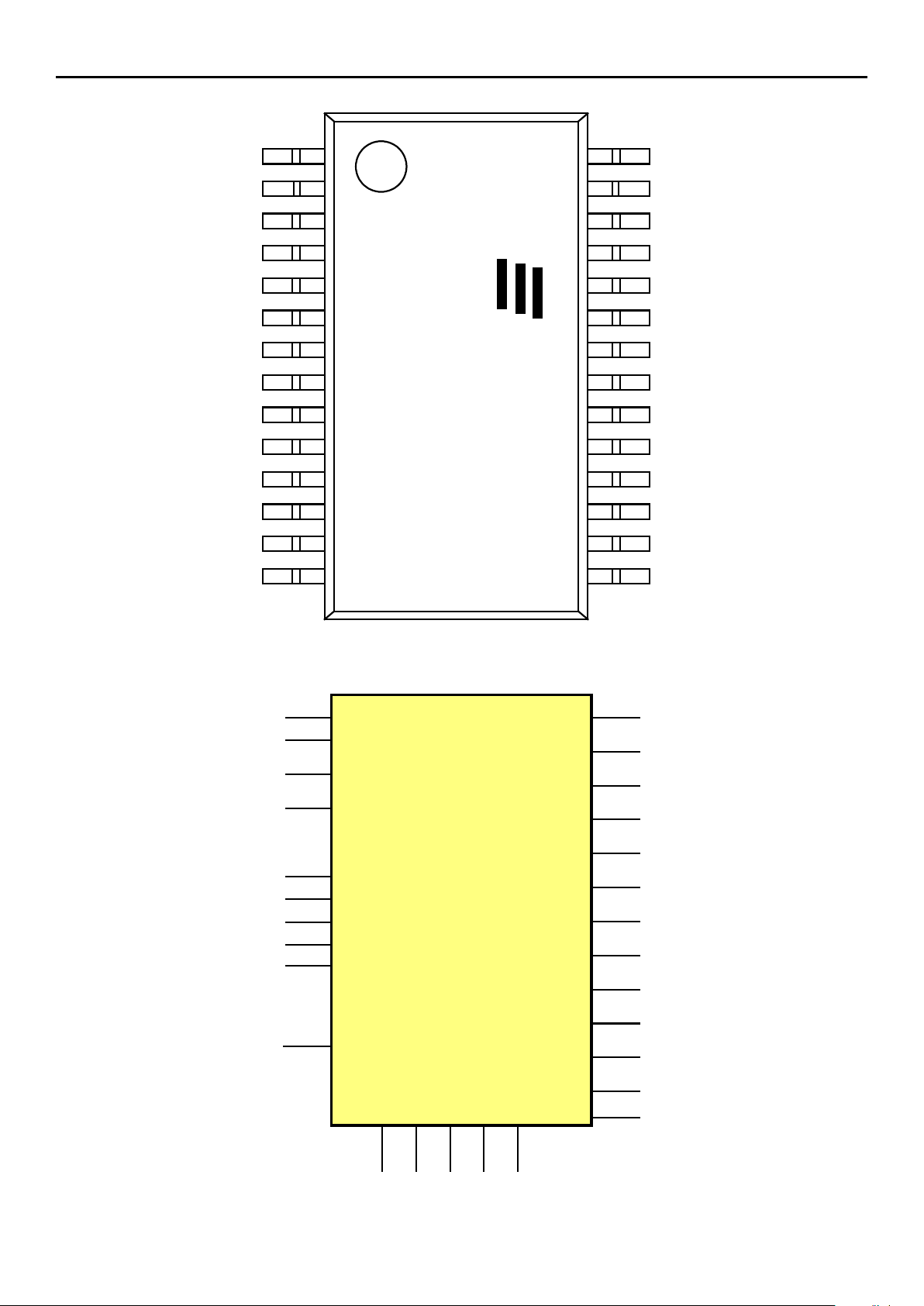

4.3 QFN-32 Package

FT245RQ

A

G

N

D

G

N

D

G

N

D

G

N

D

T

E

S

T

24

4 17 20 26

3V3OUT

VCCIO

1

16

NC

RESET#

NC

23

18

13

D0

D1

D2

D3

D4

D5

D6

D6

30

2

32

8

31

6

7

3

RXF#

WR

RD#

TXE#

22

21

10

11

19

15

14

USBDP

USBDM

VCC

OSCI

27

OSCO

28

PWREN#

9

NC

12

NC

5

NC

29

NC

25

FT245RQ

32

25

24

17

16

9

8

1

YYXX-A

18

9

1

2

3

4

5

6

7

8

10111213141516

17

19

20

21

22

23

24

25 26 27 28 29 30 31 32

USBDP

USBDM

3V3OUT

RESET#

VCC

NC

AGND

TEST

OSCI

OSCO

TXE#

RXF#

D0

D2D1D4

VCCIO

D7

GND

NC

D5

D6

D3

PWREN#

RD#

WR

GND

GND

NC

NC

NC

NC

FTDI

TOP

BOTTOM

Page 9

Figure 4 - QFN-32 Package Pin Out

Figure 5 - QFN-32 Package Pin Out (Schematic Symbol)

FT245R USB UART I.C. Datasheet Version 1.05 © Future Technology Devices International Ltd. 2005

Page 10

4.4 QFN-32 Package Signal Descriptions

Table 2 - QFN Package Pin Out Description

Pin No. Name Type Description

USB Interface Group

14 USBDP I/O USB Data Signal Plus, incorporating internal series resistor and 1.5kΩ pull up resistor to 3.3V

15 USBDM I/O USB Data Signal Minus, incorporating internal series resistor.

Power and Ground Group

1 VCCIO PWR +1.8V to +5.25V supply to FIFO Interface and Control group pins (2,3, 6, ...,11, 21, 22, 30,..32). In USB bus

powered designs connect to 3V3OUT to drive out at 3.3V levels, or connect to VCC to drive out at 5V CMOS

level. This pin can also be supplied with an external 1.8V - 2.8V supply in order to drive out at lower levels. It

should be noted that in this case this supply should originate from the same source as the supply to Vcc. This

means that in bus powered designs a regulator which is supplied by the 5V on the USB bus should be used.

4, 17, 20 GND PWR Device ground supply pins

16 3V3OUT Output 3.3V output from integrated L.D.O. regulator. This pin should be decoupled to ground using a 100nF capacitor.

The prime purpose of this pin is to provide the internal 3.3V supply to the USB transceiver cell and the internal

1.5kΩ pull up resistor on USBDP. Up to 50mA can be drawn from this pin to power external logic if required.

This pin can also be used to supply the FT245R’s VCCIO pin.

19 VCC PWR 3.3V to 5.25V supply to the device core.

24 AGND PWR Device analog ground supply for internal clock multiplier

Miscellaneous Signal Group

5, 12, 13,

23, 25, 29

18 RESET# Input Can be used by an external device to reset the FT245R. If not required can be left unconnected or pulled up

26 TEST Input Puts the device into I.C. test mode. Must be grounded for normal operation.

27 OSCI Input Input to 12MHz Oscillator Cell. Optional - Can be left unconnected for normal operation. *

28 OSCO Output Output from 12MHz Oscillator Cell. Optional - Can be left unconnected for normal operation if internal oscilla-

FIFO Interface and Control Group

30 D0 I/O FIFO Data Bus Bit 0**

31 D4 I/O FIFO Data Bus Bit 4**

32 D2 I/O FIFO Data Bus Bit 2**

2 D1 I/O FIFO Data Bus Bit 1**

3 D7 I/O FIFO Data Bus Bit 7**

6 D5 I/O FIFO Data Bus Bit 5**

7 D6 I/O FIFO Data Bus Bit 6**

8 D3 I/O FIFO Data Bus Bit 3**

9 PWREN# Output Goes low after the device is configured by USB, then high during USB suspend. Can be used to control power

10 RD# Input Enables the current FIFO data byte on D0...D7 when low. Fetched the next FIFO data byte (if available) from

11 WR Input Writes the data byte on the D0...D7 pins into the transmit FIFO buffer when WR goes from high to low. See

21 TXE# Output When high, do not write data into the FIFO. When low, data can be written into the FIFO by strobing WR high,

22 RXF# Output When high, do not read data from the FIFO. When low, there is data available in the FIFO which can be read

NC NC No internal connection.

to VCCIO.

tor is used. *

to external logic P-Channel logic level MOSFET switch. Enable the interface pull-down option when using the

PWREN# pin in this way.

the receive FIFO buffer when RD# goes from high to low. See Section 4.5 for timing diagram. **

Section 4.5 for timing diagram. **

then low. During reset this signal pin is tri-state, but pulled up to VCCIO via an internal 200kΩ resistor. See

Section 4.5 for timing diagram.

by strobing RD# low, then high again. During reset this signal pin is tri-state, but pulled up to VCCIO via an

internal 200kΩ resistor. See Section 4.5 for timing diagram.

If the Remote Wakeup option is enabled in the internal EEPROM, during USB suspend mode (PWREN# = 1)

RXF# becomes an input which can be used to wake up the host from suspend mode. Strobing the pin low will

cause the device to request a resume on the USB bus.

*Contact FTDI Support for details of how to use an external crystal, ceramic resonator, or oscillator with the FT245R.

** When used in Input Mode, these pins are pulled to VCCIO via internal 200kΩ resistors. These can be programmed

to gently pull low during USB suspend ( PWREN# = “1” ) by setting this option in the internal EEPROM.

FT245R USB UART I.C. Datasheet Version 1.05 © Future Technology Devices International Ltd. 2005

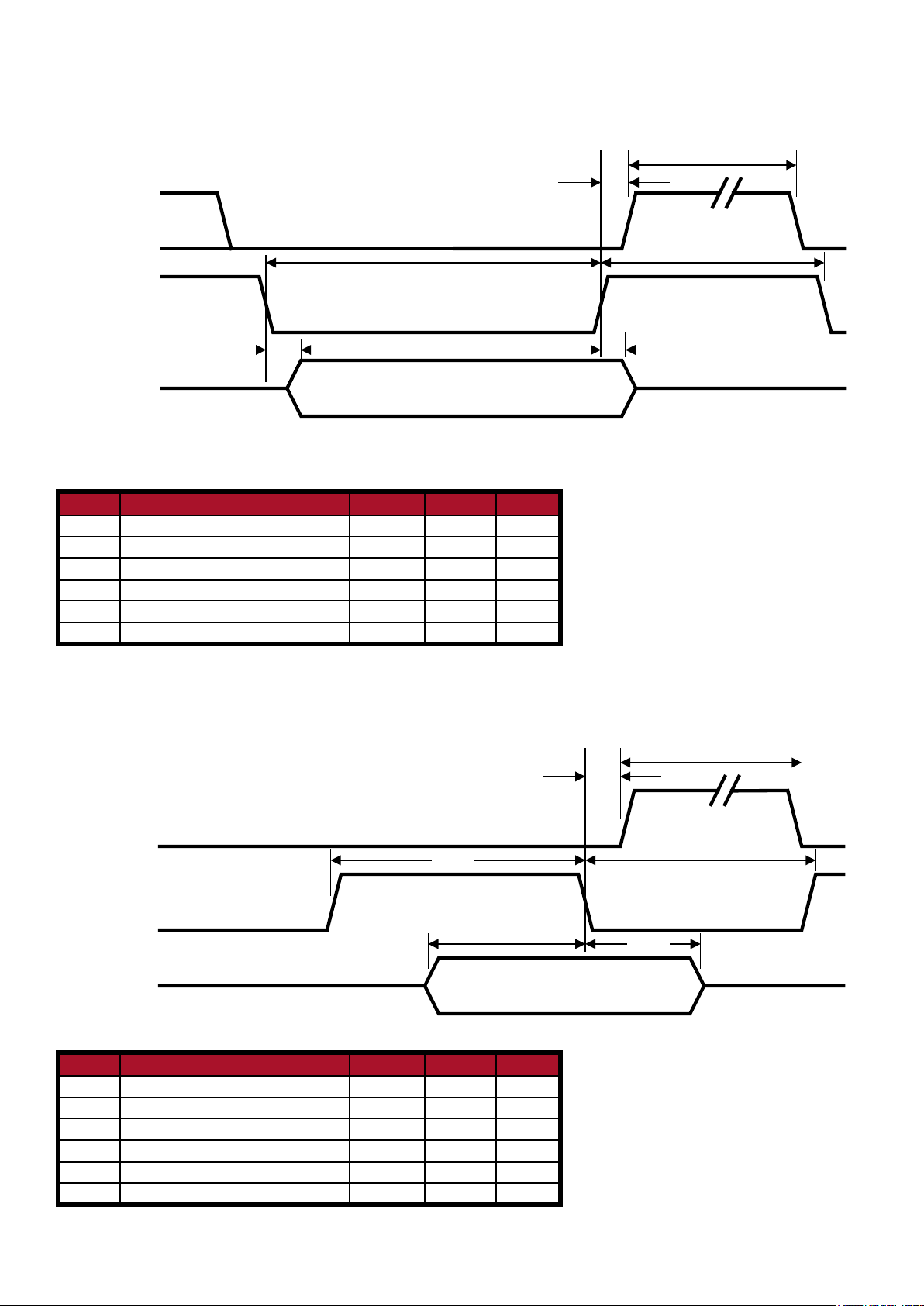

4.5 FT245R FIFO Timing Diagrams

RXF#

RD#

D[7...0]

T3

T1

T5

T6

T2

T4

Valid Data

Valid Data

D[7...0]

WR

TXE#

T7

T12

T11

T8

T9

T10

Figure 6 - FIFO Read Cycle

Table 3 - FIFO Read Cycle Timings

Time Description Min Max Unit

T1 RD Active Pulse Width 50 ns

T2 RD to RD Pre-Charge Time 50 + T6 ns

T3 RD Active to Valid Data* 20 50 ns

T4 Valid Data Hold Time from RD Inactive* 0 ns

T5 RD Inactive to RXF# 0 25 ns

T6 RXF Inactive After RD Cycle 80 ns

Page 11

* Load = 30pF

Figure 7 - FIFO Write Cycle

Table 4 - FIFO Write Cycle Timings

Time Description Min Max Unit

T7 WR Active Pulse Width 50 ns

T8 WR to RD Pre-Charge Time 50 ns

T9 Data Setup Time before WR Inactive 20 ns

T10 Data Hold Time from WR Inactive 0 ns

T11 WR Inactive to TXE# 5 25 ns

T12 TXE Inactive After WR Cycle 80 ns

FT245R USB UART I.C. Datasheet Version 1.05 © Future Technology Devices International Ltd. 2005

Page 12

12° Typ

0° - 8°

0.25

0.75 +/-0.20

0.09

2.00 Max

1.75

+/- 0.10

0.05 Min

1.25 +/-0.12

FT245RL

YYXX-A

1

14

15

28

FTDI

5.30 +/-0.30

7.80 +/-0.40

10.20 +/-0.30

1.02 Typ.

0.30 +/-0.012

0.65 +/-0.026

5. Package Parameters

The FT245R is supplied in two different packages. The FT245RL is the SSOP-28 option and the FT245RQ is the

QFN-32 package option. The solder reflow profile for both packages is described in Section 5.3.

5.1 SSOP-28 Package Dimensions

Figure 8 - SSOP-28 Package Dimensions

The FT245RL is supplied in a RoHS compliant 28 pin SSOP package. The package is lead ( Pb ) free and uses a

‘green’ compound. The package is fully compliant with European Union directive 2002/95/EC.

This package has a 5.30mm x 10.20mm body ( 7.80mm x 10.20mm including pins ). The pins are on a 0.65 mm pitch.

The above mechanical drawing shows the SSOP-28 package – all dimensions are in millimetres.

The date code format is YYXX where XX = 2 digit week number, YY = 2 digit year number.

FT245R USB UART I.C. Datasheet Version 1.05 © Future Technology Devices International Ltd. 2005

5.2 QFN-32 Package Dimensions

Indicates Pin #1

(Laser Marked)

FT245RQ

32

25

24

17

16

9

8

1

YYXX-A

FTDI

5.000

5.000

18

9

1

2

3

4

5

6

7

8

10111213141516

17

19

20

21

22

23

24

25 26 27 28 29 30 31 32

3.200 +/-0.100

3.200 +/-0.100

0.500

0.250

+/

-0.050

0.200 Min

0.500

+/

-0.050

0.150 Max

Pin #1 ID

0.800

+/-0.050

0.200

0.050

0.900

+/

-0.100

TOP

BOTTOM

Page 13

SIDE

Figure 9 - QFN-32 Package Dimensions

The FT245RQ is supplied in a RoHS compliant leadless QFN-32 package. The package is lead ( Pb ) free, and uses

a ‘green’ compound. The package is fully compliant with European Union directive 2002/95/EC.

This package has a compact 5.00mm x 5.00mm body. The solder pads are on a 0.50mm pitch. The above mechanical

drawing shows the QFN-32 package – all dimensions are in millimetres.

The centre pad on the base of the FT245RQ is not internally connected, and can be left unconnected, or connected to

ground (recommended).

The date code format is YYXX where XX = 2 digit week number, YY = 2 digit year number.

FT245R USB UART I.C. Datasheet Version 1.05 © Future Technology Devices International Ltd. 2005

5.3 QFN-32 Package Typical Pad Layout

1

17

25

0.500

0.30

0.200 Min

0.500

+/

-0.050

0.150 Max

0.20

0.100

3.200 +/-0.100

3.200 +/-0.100

2.50

2.50

Optional GND

Connection

Optional GND

Connection

9

0.500

0.30

0.200 Min

0.500

+/-0.050

0.150 Max

0.20

0.100

2.50

2.50

0.20

0.30

0.60

0.40

0.70

0.60

1

17

25

9

Top View

Page 14

Figure 10 - Typical Pad Layout for QFN-32 Package

5.4 QFN-32 Package Typical Solder Paste Diagram

Top View

Figure 11 - Typical Solder Paste Diagram for QFN-32 Package

FT245R USB UART I.C. Datasheet Version 1.05 © Future Technology Devices International Ltd. 2005

Page 15

Critical Zone: when

T is in the range

T to T

Temperature, T (Degrees C)

Time, t (seconds)

25

P

T = 25º C to T

t

p

T

p

T

L

t

Preheat

S

t

L

Ramp Up

L

p

Ramp

Down

T Max

S

T Min

S

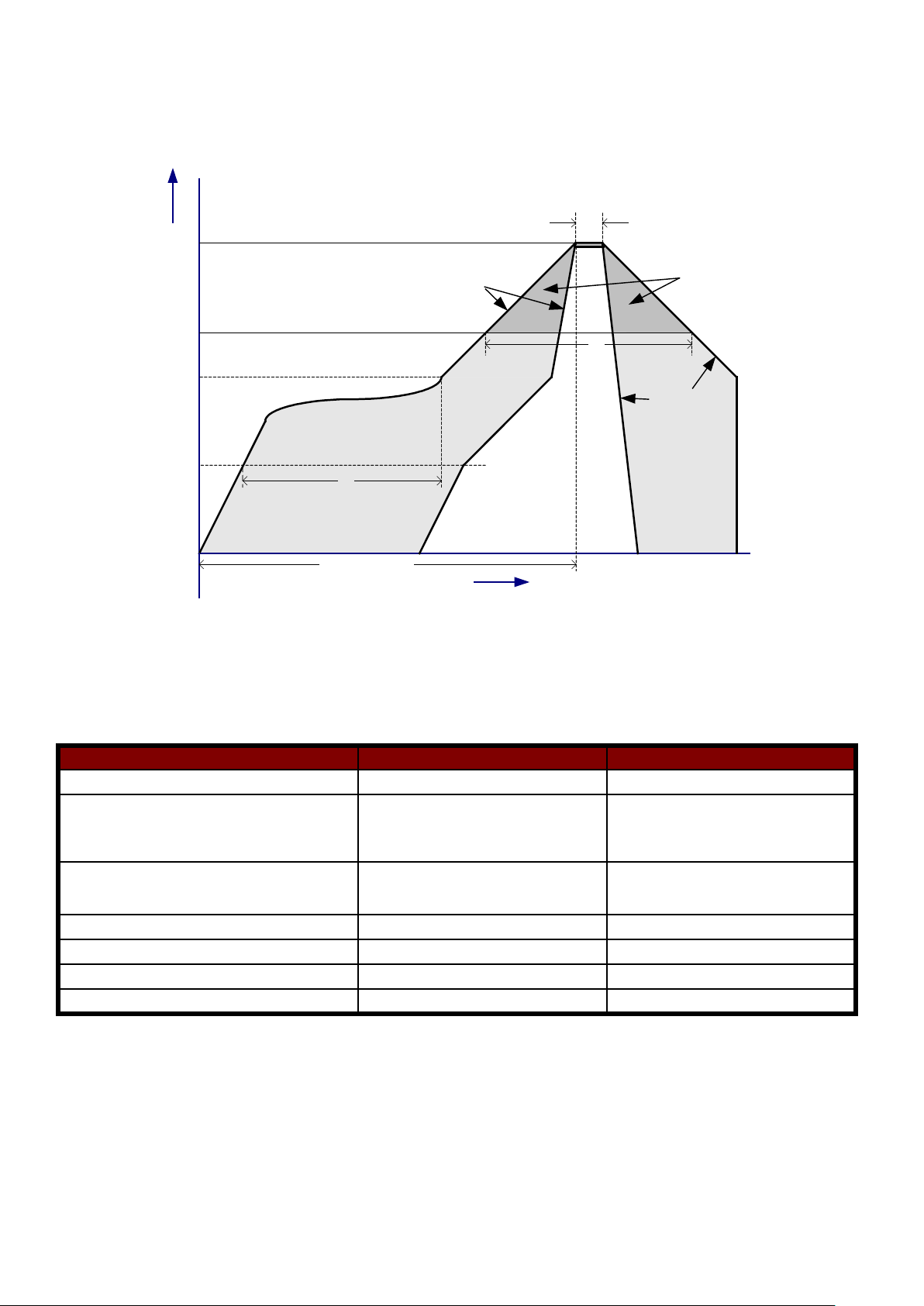

5.5 Solder Reflow Profile

The FT245R is supplied in Pb free 28 LD SSOP and QFN-32 packages. The recommended solder reflow profile for

both package options is shown in Figure 12.

Figure 12 - FT245R Solder Reflow Profile

The recommended values for the solder reflow profile are detailed in Table 5. Values are shown for both a completely

Pb free solder process (i.e. the FT245R is used with Pb free solder), and for a non-Pb free solder process (i.e. the

FT245R is used with non-Pb free solder).

Table 5 - Reflow Profile Parameter Values

Profile Feature Pb Free Solder Process Non-Pb Free Solder Process

Average Ramp Up Rate (Ts to Tp) 3°C / second Max. 3°C / Second Max.

Preheat

- Temperature Min (TS Min.)

- Temperature Max (TS Max.)

- Time (tS Min to tS Max)

Time Maintained Above Critical Temperature TL:

- Temperature (TL)

- Time (tL)

Peak Temperature (TP) 260°C 240°C

Time within 5°C of actual Peak Temperature (tP) 20 to 40 seconds 20 to 40 seconds

Ramp Down Rate 6°C / second Max. 6°C / second Max.

Time for T= 25°C to Peak Temperature, T

p

150°C

200°C

60 to 120 seconds

217°C

60 to 150 seconds

100°C

150°C

60 to 120 seconds

183°C

60 to 150 seconds

8 minutes Max. 6 minutes Max.

FT245R USB UART I.C. Datasheet Version 1.05 © Future Technology Devices International Ltd. 2005

Page 16

6. Device Characteristics and Ratings

6.1 Absolute Maximum Ratings

The absolute maximum ratings for the FT245R devices are as follows. These are in accordance with the Absolute

Maximum Rating System (IEC 60134). Exceeding these may cause permanent damage to the device.

Table 6 - Absolute Maximum Ratings

Parameter Value Unit

Storage Temperature -65°C to 150°C Degrees C

Floor Life (Out of Bag) At Factory Ambient

( 30°C / 60% Relative Humidity)

Ambient Temperature (Power Applied) -40°C to 85°C Degrees C.

Vcc Supply Voltage -0.5 to +6.00 V

D.C. Input Voltage - USBDP and USBDM -0.5 to +3.8 V

D.C. Input Voltage - High Impedance Bidirectionals -0.5 to +(Vcc +0.5) V

D.C. Input Voltage - All other Inputs -0.5 to +(Vcc +0.5) V

D.C. Output Current - Outputs 24 mA

DC Output Current - Low Impedance Bidirectionals 24 mA

Power Dissipation (Vcc = 5.25V) 500 mW

168 Hours

(IPC/JEDEC J-STD-033A MSL

Level 3 Compliant)*

Hours

* If devices are stored out of the packaging beyond this time limit the devices should be baked before use. The

devices should be ramped up to a temperature of 125°C and baked for up to 17 hours.

6.2 DC Characteristics

DC Characteristics ( Ambient Temperature = -40oC to +85oC )

Table 7 - Operating Voltage and Current

Parameter Description Min Typ Max Units Conditions

Vcc1 VCC Operating Supply Voltage 3.3 - 5.25 V

Vcc2 VCCIO Operating Supply Voltage 1.8 - 5.25 V

Icc1 Operating Supply Current - 15 - mA Normal Operation

Icc2 Operating Supply Current 50 70 100

μA

Table 8 - FIFO Interface and Control Bus Pin Characteristics (VCCIO = 5.0V, Standard Drive Level)

Parameter Description Min Typ Max Units Conditions

Voh Output Voltage High 3.2 4.1 4.9 V I source = 2mA

Vol Output Voltage Low 0.3 0.4 0.6 V I sink = 2mA

Vin Input Switching Threshold 1.3 1.6 1.9 V **

VHys Input Switching Hysteresis 50 55 60 mV **

USB Suspend

Table 9 - FIFO Interface and Control Bus Pin Characteristics (VCCIO = 3.3V, Standard Drive Level)

Parameter Description Min Typ Max Units Conditions

Voh Output Voltage High 2.2 2.7 3.2 V I source = 1mA

Vol Output Voltage Low 0.3 0.4 0.5 V I sink = 2mA

Vin Input Switching Threshold 1.0 1.2 1.5 V **

VHys Input Switching Hysteresis 20 25 30 mV **

FT245R USB UART I.C. Datasheet Version 1.05 © Future Technology Devices International Ltd. 2005

Table 10 - FIFO Interface and Control Bus Pin Characteristics (VCCIO = 2.8V, Standard Drive Level)

Parameter Description Min Typ Max Units Conditions

Voh Output Voltage High 2.1 2.6 3.1 V I source = 1mA

Vol Output Voltage Low 0.3 0.4 0.5 V I sink = 2 mA

Vin Input Switching Threshold 1.0 1.2 1.5 V **

VHys Input Switching Hysteresis 20 25 30 mV **

Table 11 - FIFO Interface and Control Bus Pin Characteristics (VCCIO = 5.0V, High Drive Level)

Parameter Description Min Typ Max Units Conditions

Voh Output Voltage High 3.2 4.1 4.9 V I source = 6mA

Vol Output Voltage Low 0.3 0.4 0.6 V I sink = 6mA

Vin Input Switching Threshold 1.3 1.6 1.9 V **

VHys Input Switching Hysteresis 50 55 60 mV **

Table 12 - FIFO Interface and Control Bus Pin Characteristics (VCCIO = 3.3V, High Drive Level)

Parameter Description Min Typ Max Units Conditions

Voh Output Voltage High 2.2 2.8 3.2 V I source = 3mA

Vol Output Voltage Low 0.3 0.4 0.6 V I sink = 8mA

Vin Input Switching Threshold 1.0 1.2 1.5 V **

VHys Input Switching Hysteresis 20 25 30 mV **

Page 17

Table 13 - FIFO Interface and Control Bus Pin Characteristics (VCCIO = 2.8V, High Drive Level)

Parameter Description Min Typ Max Units Conditions

Voh Output Voltage High 2.1 2.8 3.2 V I source = 3mA

Vol Output Voltage Low 0.3 0.4 0.6 V I sink = 8mA

Vin Input Switching Threshold 1.0 1.2 1.5 V **

VHys Input Switching Hysteresis 20 25 30 mV **

**Inputs have an internal 200kΩ pull-up resistor to VCCIO.

Table 14 - RESET#, TEST Pin Characteristics

Parameter Description Min Typ Max Units Conditions

Vin Input Switching Threshold 1.3 1.6 1.9 V

VHys Input Switching Hysteresis 50 55 60 mV

Table 15 - USB I/O Pin (USBDP, USBDM) Characteristics

Parameter Description Min Typ Max Units Conditions

UVoh I/O Pins Static Output ( High) 2.8 3.6 V RI = 1.5kΩ to 3V3OUT ( D+ )

RI = 15kΩ to GND ( D- )

UVol I/O Pins Static Output ( Low ) 0 0.3 V RI = 1.5kΩ to 3V3OUT ( D+ )

RI = 15kΩ to GND ( D- )

UVse Single Ended Rx Threshold 0.8 2.0 V

UCom Differential Common Mode 0.8 2.5 V

UVDif Differential Input Sensitivity 0.2 V

UDrvZ Driver Output Impedance 26 29 44 Ohms ***

***Driver Output Impedance includes the internal USB series resistors on USBDP and USBDM pins.

FT245R USB UART I.C. Datasheet Version 1.05 © Future Technology Devices International Ltd. 2005

6.3 EEPROM Reliability Characteristics

The internal 1024 Bit EEPROM has the following reliability characteristics-

Table 16 - EEPROM Characteristics

Parameter Description Value Unit

Data Retention 15 Years

Read / Write Cycles 100,000 Cycles

6.4 Internal Clock Characteristics

The internal Clock Oscillator has the following characteristics.

Table 17 - Internal Clock Characteristics

Parameter Value Unit

Min Typical Max

Frequency of Operation 11.98 12.00 12.02 MHz***

Clock Period 83.19 83.33 83.47 ns

Duty Cycle 45 50 55 %

Page 18

***Equivalent to +/-1667ppm.

Table 18 - OSCI, OSCO Pin Characteristics (Optional - Only applies if external Oscillator is used****)

Parameter Description Min Typ Max Units Conditions

Voh Output Voltage High 2.8 - 3.6 V Fosc = 12MHz

Vol Output Voltage Low 0.1 - 1.0 V Fosc = 12MHz

Vin Input Switching Threshold 1.8 2.5 3.2 V

****When supplied the device is configured to use its internal clock oscillator. Users who wish to use an external

oscillator or crystal should contact FTDI technical support.

FT245R USB UART I.C. Datasheet Version 1.05 © Future Technology Devices International Ltd. 2005

Page 19

FT245R

A

G

N

D

G

N

D

G

N

D

G

N

D

T

E

S

T

100nF

3V3OUT

VCCIO

NC

RESET#

NC

+

100nF

10nF

Vcc

D0

D1

D2

D3

D4

D5

D6

D7

RXF#

WR#

RD#

TXE#

USBDP

USBDM

VCC

1

2

3

4

5

OSCI

OSCO

PWREN#

Ferrite

Bead

+

4.7uF

SHIELD

GND

GND

GND

GND

Vcc

7. Device Configurations

Please note that pin numbers on the FT245R chip in this section have deliberately been left out as they vary between

the FT245RL and FT245RQ versions of the device. All of these configurations apply to both package options for the

FT245R device. Please refer to Section 4 for the package option pin-out and signal descriptions.

7.1 Bus Powered Configuration

Figure 13 - Bus Powered Configuration

Figure 13 illustrates the FT245R in a typical USB bus powered design configuration. A USB Bus Powered device gets

its power from the USB bus. Basic rules for USB Bus power devices are as follows –

i) On plug-in to USB, the device must draw no more than 100mA.

ii) On USB Suspend the device must draw no more than 500μA.

iii) A Bus Powered High Power USB Device (one that draws more than 100mA) should use the PWREN# pin to keep

the current below 100mA on plug-in and 500μA on USB suspend.

iv) A device that consumes more than 100mA can not be plugged into a USB Bus Powered Hub

v) No device can draw more that 500mA from the USB Bus.

The power descriptor in the internal EEPROM should be programmed to match the current draw of the device.

A Ferrite Bead is connected in series with USB power to prevent noise from the device and associated circuitry (EMI)

being radiated down the USB cable to the Host. The value of the Ferrite Bead depends on the total current required by

the circuit – a suitable range of Ferrite Beads is available from Steward (www.steward.com) for example Steward Part

# MI0805K400R-00.

FT245R USB UART I.C. Datasheet Version 1.05 © Future Technology Devices International Ltd. 2005

7.2 Self Powered Configuration

FT245R

A

G

N

D

G

N

D

G

N

D

G

N

D

T

E

S

T

100nF

3V3OUT

VCCIO

NC

RESET#

NC

+

100nF

VCC

D0

D1

D2

D3

D4

D5

D6

D7

RXF#

WR#

RD#

TXE#

USBDP

USBDM

VCC

1

2

3

4

5

OSCI

OSCO

PWREN#

4.7uF

SHIELD

GND

GND

GND

GND

VCC = 3.3V - 5V

GND

10k

4k7

100nF

Page 20

Figure 14 Self Powered Configuration

Figure 14 illustrates the FT245R in a typical USB self powered configuration. A USB Self Powered device gets its

power from its own power supply and does not draw current from the USB bus. The basic rules for USB Self power

devices are as follows –

i) A Self Powered device should not force current down the USB bus when the USB Host or Hub Controller is

powered down.

ii) A Self Powered Device can use as much current as it likes during normal operation and USB suspend as it has its

own power supply.

iii) A Self Powered Device can be used with any USB Host and both Bus and Self Powered USB Hubs

The power descriptor in the internal EEPROM should be programmed to a value of zero (self powered).

In order to meet requirement (i) the USB Bus Power is used to control the RESET# Pin of the FT245R device. When

the USB Host or Hub is powered up the internal 1.5kΩ resistor on USBDP is pulled up to 3.3V, thus identifying the

device as a full speed device to USB. When the USB Host or Hub power is off, RESET# will go low and the device will

be held in reset. As RESET# is low, the internal 1.5kΩ resistor will not be pulled up to 3.3V, so no current will be forced

down USBDP via the 1.5kΩ pull-up resistor when the host or hub is powered down. Failure to do this may cause some

USB host or hub controllers to power up erratically.

Figure 10 illustrates a self powered design which has a 3.3V - 5V supply. A design which is interfacing to 2.8V - 1.8V

logic would have a 2.8V - 1.8V supply to VCCIO, and a 3.3V - 5V supply to VCC

Note : When the FT245R is in reset, the FIFO interface and control pins all go tri-state. These pins have internal

200kΩ pull-up resistors to VCCIO, so they will gently pull high unless driven by some external logic.

FT245R USB UART I.C. Datasheet Version 1.05 © Future Technology Devices International Ltd. 2005

7.3 USB Bus Powered with Power Switching Configuration

FT245R

A

G

N

D

G

N

D

G

N

D

G

N

D

T

E

S

T

100nF

3V3OUT

VCCIO

NC

RESET#

NC

+

100nF

10nF

5V VCC

D0

D1

D2

D3

D4

D5

D6

D7

TXE#

WR#

RD#

RXF#

USBDP

USBDM

VCC

1

2

3

4

5

OSCI

OSCO

PWREN#

Ferrite

Bead

+

4.7uF

SHIELD

GND

GND

GND

GND

0.1uF

0.1uF

1k

Soft Start

Circuit

d

g

s

Switched 5V Power

to External Logic

5V VCC

P-Channel Power

MOSFET

Page 21

Figure 15 - Bus Powered with Power Switching Configuration

USB Bus powered circuits need to be able to power down in USB suspend mode in order to meet the <= 500μA

total USB suspend current requirement (including external logic). Some external logic can power itself down into a

low current state by monitoring the PWREN# signal. For external logic that cannot power itself down in this way, the

FT245R provides a simple but effective way of turning off power to external circuitry during USB suspend.

Figure 15 shows how to use a discrete P-Channel Logic Level MOSFET to control the power to external logic circuits.

A suitable device would be an International Rectifier (www.irf.com) IRLML6402, or equivalent. It is recommended that

a “soft start” circuit consisting of a 1kΩ series resistor and a 0.1μF capacitor are used to limit the current surge when

the MOSFET turns on. Without the soft start circuit there is a danger that the transient power surge of the MOSFET

turning on will reset the FT245R, or the USB host / hub controller. The values used here allow attached circuitry to

power up with a slew rate of ~12.5V per millisecond, in other words the output voltage will transition from GND to 5V in

approximately 400 microseconds.

Alternatively, a dedicated power switch I.C. with inbuilt “soft-start” can be used instead of a MOSFET. A suitable power

switch I.C. for such an application would be a Micrel (www.micrel.com) MIC2025-2BM or equivalent.

Please note the following points in connection with power controlled designs –

i) The logic to be controlled must have its own reset circuitry so that it will automatically reset itself when power is re-

applied on coming out of suspend.

ii) Set the Pull-down on Suspend option in the internal EEPROM.

iii) The PWREN# pin should be used to switch the power to the external circuitry.

iv) For USB high-power bus powered device (one that consumes greater than 100mA, and up to 500mA of current

from the USB bus), the power consumption of the device should be set in the max power field in the internal

EEPROM. A high-power bus powered device must use this descriptor in the internal EEPROM to inform the

system of its power requirements.

v) For 3.3V power controlled circuits the VCCIO pin must not be powered down with the external circuitry (the

PWREN# signal gets its VCC supply from VCCIO). Either connect the power switch between the output of the

3.3V regulator and the external 3.3V logic or power VCCIO from the 3V3OUT pin of the FT245R.

FT245R USB UART I.C. Datasheet Version 1.05 © Future Technology Devices International Ltd. 2005

7.4 USB Bus Powered with 3.3V / 5V Supply and Logic Drive / IO Supply Voltage

FT245R

A

G

N

D

G

N

D

G

N

D

G

N

D

T

E

S

T

100nF

3V3OUT

VCCIO

NC

RESET#

NC

10nF

D0

D1

D2

D3

D4

D5

D6

D7

TXE#

WR#

RD#

RXF#

USBDP

USBDM

VCC

1

2

3

4

5

OSCI

OSCO

PWREN#

Ferrite

Bead

+

SHIELD

GND

GND

GND

3.3V or 5V Supply

to External Logic

100nF

+

100nF

Vcc

4.7uF

GND

1

Jumper

2

3

Vcc

Page 22

Figure 16 - Bus Powered with 3.3V / 5V Supply and Logic Drive

Figure 16 shows a configuration where a jumper switch is used to allow the FT245R to be interfaced with a 3.3V or

5V logic devices. The VCCIO pin is either supplied with 5V from the USB bus, or with 3.3V from the 3V3OUT pin. The

supply to VCCIO is also used to supply external logic.

Please note the following in relation to bus powered designs of this type -

i) The PWREN# signal should be used to power down external logic during USB suspend mode, in order to comply

with the limit of 500μA. If this is not possible, use the configuration shown in Section 7.3.

ii) The maximum current source from USB Bus during normal operation should not exceed 100mA, otherwise a bus

powered design with power switching (Section 7.3) should be used.

Another possible configuration would be to use a discrete low dropout regulator which is supplied by the 5V on the

USB bus to supply 2.8V - 1.8V to the VCCIO pin and to the external logic. VCC would be supplied with the 5V from

the USB bus. With VCCIO connected to the output of the low dropout regulator, would in turn will cause the FT245R

I/O pins to drive out at 2.8V - 1.8V logic levels.

For USB bus powered circuits some considerations have to be taken into account when selecting the regulator –

iii) The regulator must be capable of sustaining its output voltage with an input voltage of 4.35V. A Low Drop Out

(L.D.O.) regulator must be selected.

iv) The quiescent current of the regulator must be low in order to meet the USB suspend total current requirement of

<= 500μA during USB suspend.

An example of a regulator family that meets these requirements is the MicroChip / Telcom TC55 Series of devices

(www.microchip.com). These devices can supply up to 250mA current and have a quiescent current of under 1μA.

FT245R USB UART I.C. Datasheet Version 1.05 © Future Technology Devices International Ltd. 2005

8. Example Interface Configurations

FT245R

A

G

N

D

G

N

D

G

N

D

G

N

D

T

E

S

T

100nF

3V3OUT

VCCIO

NC

RESET#

NC

+

100nF

4.7uF

Vcc

D0

D1

D2

D3

D4

D5

D6

D7

RXF#

WR#

RD#

TXE#

USBDP

USBDM

VCC

1

2

3

4

5

OSCI

OSCO

PWREN#

Microcontroller

I/O10

I/O11

I/O12

I/O13

Ferrite

Bead

GND

GND

GND

+

GND

10nF

Vcc

Vcc

I/O14

I/O15

I/O16

I/O17

I/O20

I/O21

I/O22

I/O23

I/O24

8.1 USB to MCU FIFO Interface Example

Page 23

Figure 17 -Example USB to MCU FIFO Interface

Figure 17 illustrates a typical interfacing between the FT245R and a Microcontroller (MCU) FIFO interface. This

example uses two I/O ports: one port (8 bits) to transfer data, and the other port (4 or 5 bits) to monitor the TXE# and

RXF# status bits and generate the RD# and WR strobes to the FT245R, as required. Using PWREN# for this function

is optional.

If the Remote Wakeup option is enabled in the internal EEPROM, during USB suspend mode RXF# becomes an input

which can be used to wake up the USB host controller by strobing the pin low.

FT245R USB UART I.C. Datasheet Version 1.05 © Future Technology Devices International Ltd. 2005

Page 24

10. Internal EEPROM Configuration

Following a power-on reset or a USB reset the FT245R will scan its internal EEPROM and read the USB configuration

descriptors stored there. The default values programmed into the internal EEPROM in a brand new device are defined

in Table 19.

Table 19 - Default Internal EEPROM Configuration

Parameter Value Notes

USB Vendor ID (VID) 0403h FTDI default VID (hex)

USB Product ID (PID) 6001h FTDI default PID (hex)

Serial Number Enabled? Yes

Serial Number See Note A unique serial number is generated and programmed into the EEPROM

during device final test.

Pull Down I/O Pins in USB Suspend Disabled Enabling this option will make the device pull down on the FIFO interface

lines when the power is shut off (PWREN# is high)

Manufacturer Name FTDI

Manufacturer ID FT Serial number prefix

Product Description FT245R USB FIFO

Max Bus Power Current 90mA

Power Source Bus Powered

Device Type FT245R

USB Version 0200 Returns USB 2.0 device descriptor to the host. Note: The device is be

a USB 2.0 Full Speed device (12Mb/s) as opposed to a USB 2.0 High

Speed device (480Mb/s).

Remote Wake up Enabled Taking RXF# low will wake up the USB host controller from suspend.

High Current I/Os Disabled Enables the high drive level on the FIFO data bus and control I/O pins

Load VCP Driver Enabled Makes the device load the VCP driver interface for the device.

The internal EEPROM in the FT245R can be programmed over USB using the utility program MPROG. MPROG can

be downloaded from the FTDI website. Version 2.8a or later is required for the FT245R chip. Users who do not have

their own USB Vendor ID but who would like to use a unique Product ID in their design can apply to FTDI for a free

block of unique PIDs. Contact FTDI support for this service.

FT245R USB UART I.C. Datasheet Version 1.05 © Future Technology Devices International Ltd. 2005

Page 25

Disclaimer

Copyright © Future Technology Devices International Limited , 2005.

Version 0.90 - Initial Datasheet Created August 2005

Version 0.94 - Revised Pre-release datasheet October 2005

Version 1.00 - Full datasheet released December 2005

Version 1.02 - Minor revisions to datasheet released 7th December 2005

Version 1.03 - Manufacturer ID added to default EEPROM data January 2006

Version 1.04 - 9th January 2006 Buffer sizes added.

Version 1.05 - 30th January 2006 QFN-32 Package pad layout and solder paste diagrams added.

Neither the whole nor any part of the information contained in, or the product described in this manual, may be

adapted or reproduced in any material or electronic form without the prior written consent of the copyright holder.

This product and its documentation are supplied on an as-is basis and no warranty as to their suitability for any

particular purpose is either made or implied.

Future Technology Devices International Ltd. will not accept any claim for damages howsoever arising as a result of

use or failure of this product. Your statutory rights are not affected.

This product or any variant of it is not intended for use in any medical appliance, device or system in which the failure

of the product might reasonably be expected to result in personal injury.

This document provides preliminary information that may be subject to change without notice.

Contact FTDI

Head Office -

Future Technology Devices International Ltd.

373 Scotland Street,

Glasgow G5 8QB,

United Kingdom

Tel. : +(44) 141 429 2777

Fax. : +(44) 141 429 2758

E-Mail (Sales) : sales1@ftdichip.com

E-Mail (Support) : support1@ftdichip.com

E-Mail (General Enquiries) : admin1@ftdichip.com

Regional Sales Offices -

Future Technology Devices International Ltd.

(Taiwan)

4F, No 16-1,

Sec. 6 Mincyuan East Road,

Neihu District,

Taipei 114,

Taiwan, R.o.C.

Future Technology Devices International Ltd.

(USA)

5285 NE Elam Young

Parkway, Suite B800

Hillsboro,

OR 97124-6499

USA

Tel.: +886 2 8791 3570

Fax: +886 2 8791 3576

E-Mail (Sales): tw.sales@ftdichip.com

E-Mail (Support): tw.support@ftdichip.com

E-Mail (General Enquiries): tw.admin@ftdichip.com

Tel.: +1 (503) 547-0988

Fax: +1 (503) 547-0987

E-Mail (Sales): us.sales@ftdichip.com

E-Mail (Support): us.support@ftdichip.com

E-Mail (General Enquiries): us.admin@ftdichip.com

Website URL : http://www.ftdichip.com

FT245R USB UART I.C. Datasheet Version 1.05 © Future Technology Devices International Ltd. 2005

Loading...

Loading...