Fracture Technology

Associates

Non-Linear Fracture Toughness Testing and Analysis

Version 3+.16.01

Users’ Reference Manual

January 2016

Keith Donald

Amy Blair

Fracture Technology Associates

2412 Emrick Boulevard

Bethlehem, PA 18020

610-868-3054

www.FractureTech.com

Page 2 of 148

NLFT Testing - Series 2015 - V3+.16.01

Table of Contents

1.0 The FTA NLFT Testing and Analysis System .............................................7

1.1 Introduction .................................................................................7

1.2 Software .....................................................................................7

1.2 The ADwin Gold .........................................................................7

1.4 Other Hardware Requirements ...................................................9

1.5 License Agreement.....................................................................9

1.6 Manual Layout ............................................................................9

2.0 Installation Guide ...................................................................................... 11

2.1 Hardware and Drivers ............................................................... 11

2.1.1 Analog input and output connections ............................. 11

2.1.2 Digital input and output connections .............................. 12

2.2 Connecting the FTA-DCPD Current Supply and Amplifier ........ 13

2.3 PC Setup and Installation of the FTA Software ........................ 15

2.4 Installing the ADWin Drivers on the PC .................................... 16

2.5 Testing in Simulation ................................................................ 18

2.5 Tuning ...................................................................................... 18

3.0 Using the NLFT Testing Software ............................................................. 19

3.1 Understanding Testing Files ..................................................... 19

3.2 Running a Test Using the FTA NLFT Software ........................ 20

3.2.1 Setup ............................................................................. 20

3.2.2 Running The Test .......................................................... 25

4.0 NLFT Testing Software: Description of Menus and Tabs ......................... 29

4.1 Splash Screen .......................................................................... 29

4.2 Main Menu ................................................................................ 30

4.3 File ............................................................................................ 30

4.3.1 Save Analysis File ......................................................... 30

4.3.2 Exit ................................................................................. 31

4.4 Config ....................................................................................... 31

4.4.1 Hardware Configuration ................................................. 32

4.4.1.1 Calibration (compliance) .................................. 32

4.4.1.2 Calibration (DCPD).......................................... 33

4.4.1.3 Configuration (Compliance and DCPD) ........... 34

4.4.2 Test Set-up .................................................................... 36

4.4.2.1 Initialize ........................................................... 37

4.4.2.2 Calibration ....................................................... 40

4.4.2.3 Coefficients ..................................................... 44

4.4.2.4 Dimensions ..................................................... 46

4.4.2.5 Compliance ..................................................... 48

4.4.2.6 DCPD .............................................................. 50

4.4.2.7 Storage ............................................................ 52

4.4.2.8 Limits ............................................................... 54

4.4.3 General information ....................................................... 55

4.4.3.1 General ........................................................... 56

4.4.3.2 Precrack .......................................................... 57

Page 3 of 148

NLFT Testing - Series 2015 - V3+.16.01

4.5 Control ...................................................................................... 58

4.5.1 Ramp Generator: Compliance and DCPD ..................... 58

4.6 Display ...................................................................................... 63

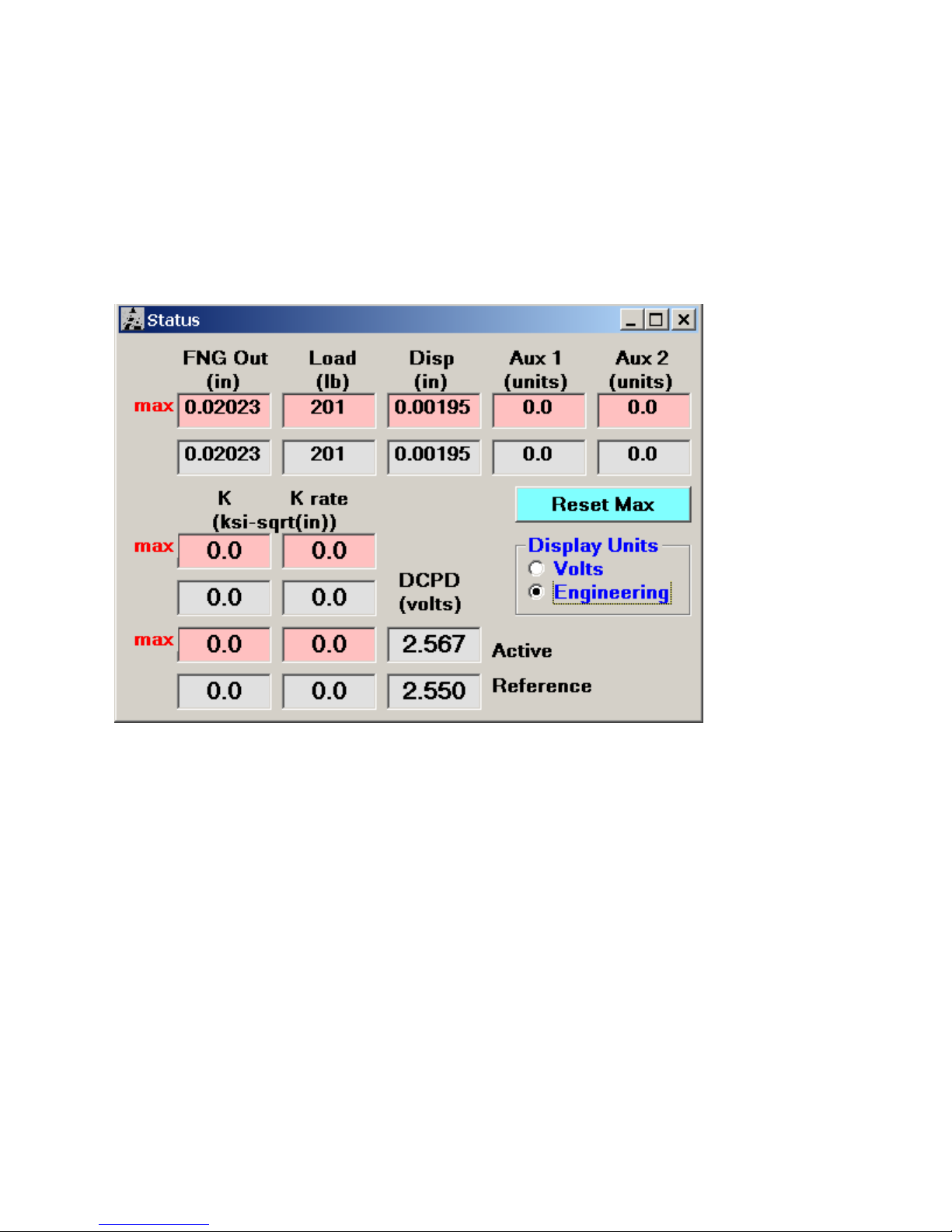

4.6.1 Status ............................................................................ 63

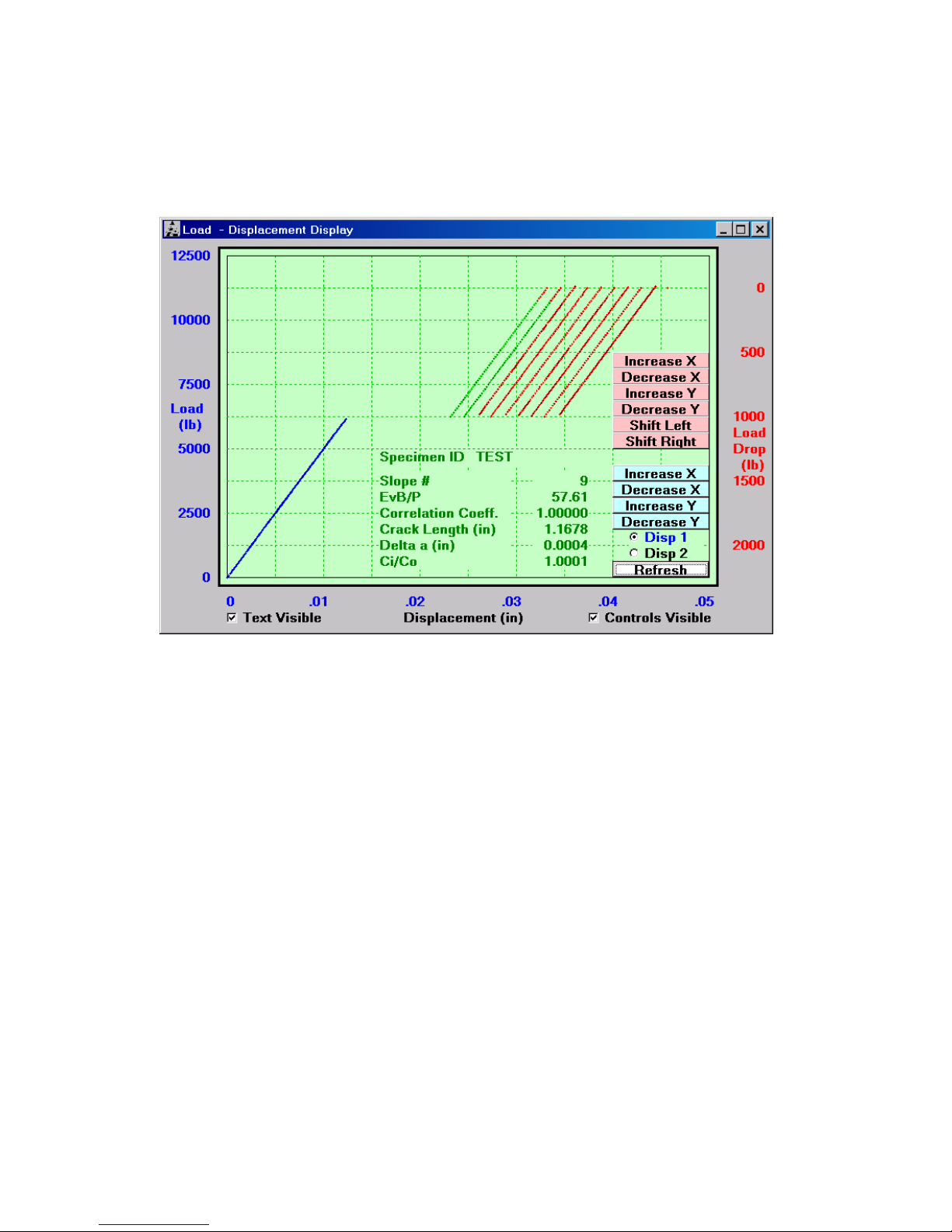

4.6.2 Load-Displacement ........................................................ 64

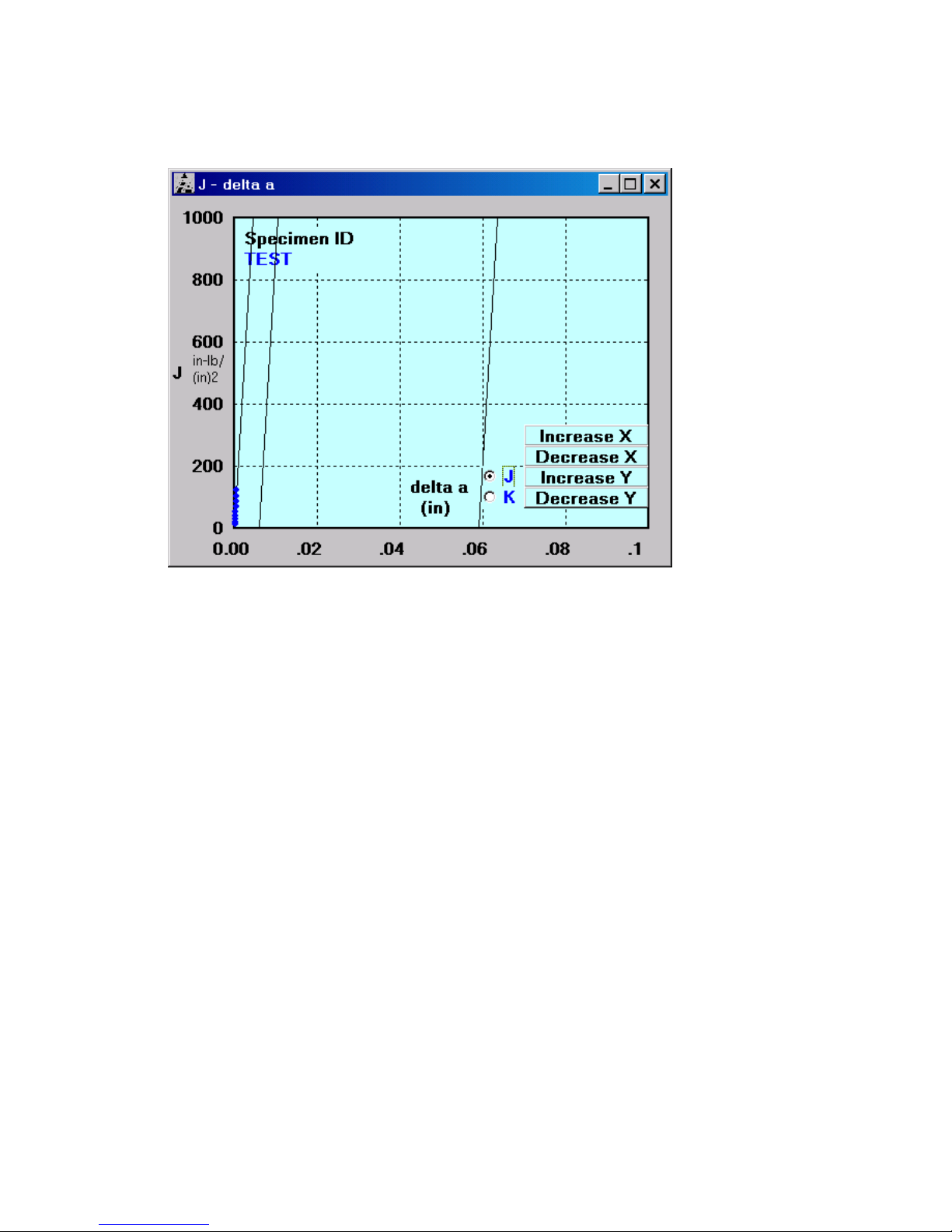

4.6.3 J – Delta a...................................................................... 66

4.7 Comments ................................................................................ 67

4.8 Help .......................................................................................... 67

5.0 Using the FTA Analysis Software ............................................................. 69

5.1 How the NLFT Analysis Program Works ................................ .. 69

5.2 Understanding the Files Used by the Analysis Program ........... 70

5.3 E1820 Analysis Procedure ....................................................... 71

5.4 E399 Analysis Procedure ......................................................... 74

6.0 NLFT Analysis Software: Description of Menus and Tabs ........................ 79

6.1 Splash Screen .......................................................................... 79

6.2 Main Form: Menu Items ............................................................ 79

6.2.1 File ................................................................................. 80

6.2.1.1 Open ............................................................... 81

6.2.1.2 Save ................................................................ 81

6.2.2 Display ........................................................................... 81

6.2.3 Help ............................................................................... 81

6.2.4 Quit ................................................................................ 81

6.3 Main Form: Tabs ...................................................................... 82

6.3.1 Control ........................................................................... 82

6.3.2 Coeff[icient]s .................................................................. 85

6.3.3 General .......................................................................... 86

6.3.4 Dimensions .................................................................... 88

6.3.5 Visuals, Etc. ..................................................................... 89

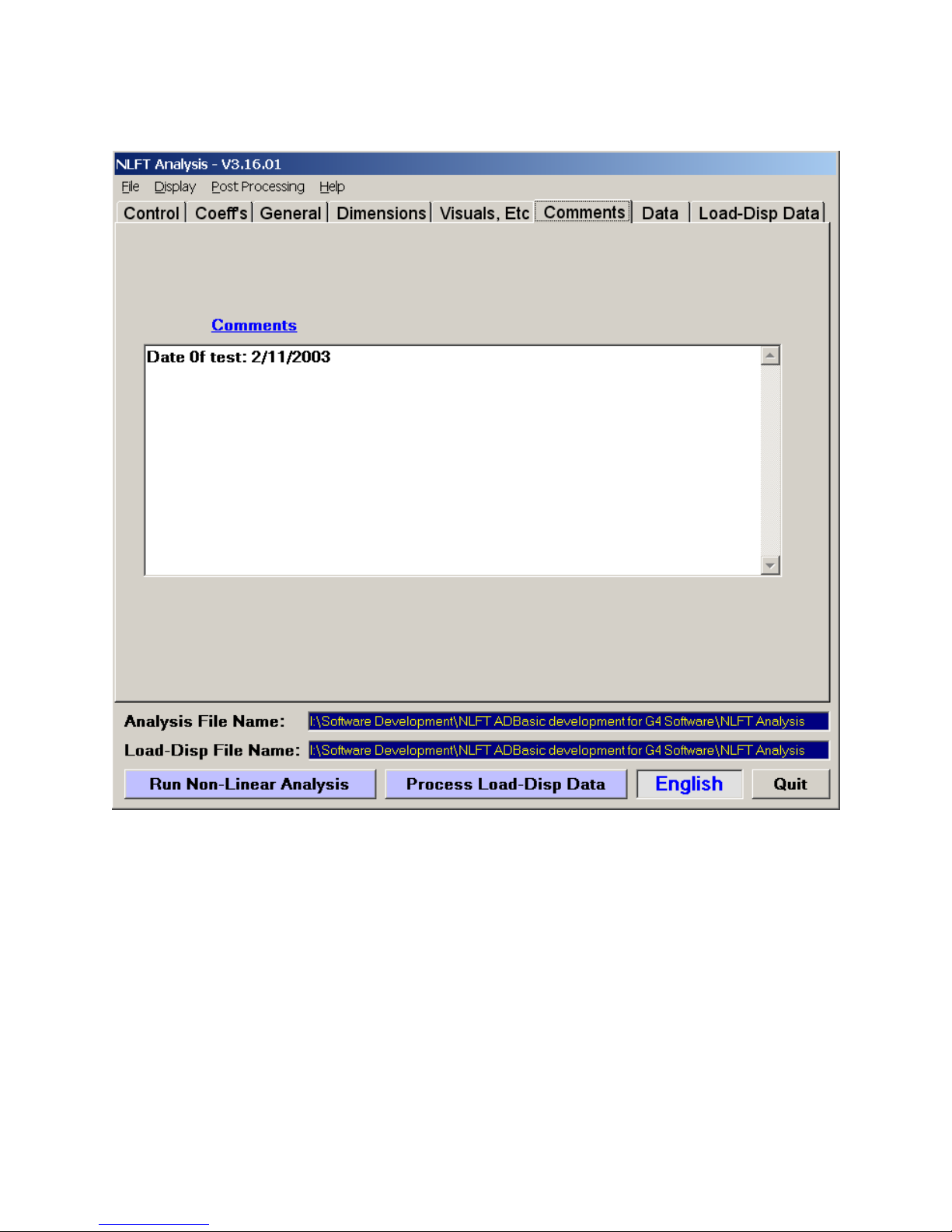

6.3.6 Comments ..................................................................... 91

6.3.7 Data ............................................................................... 92

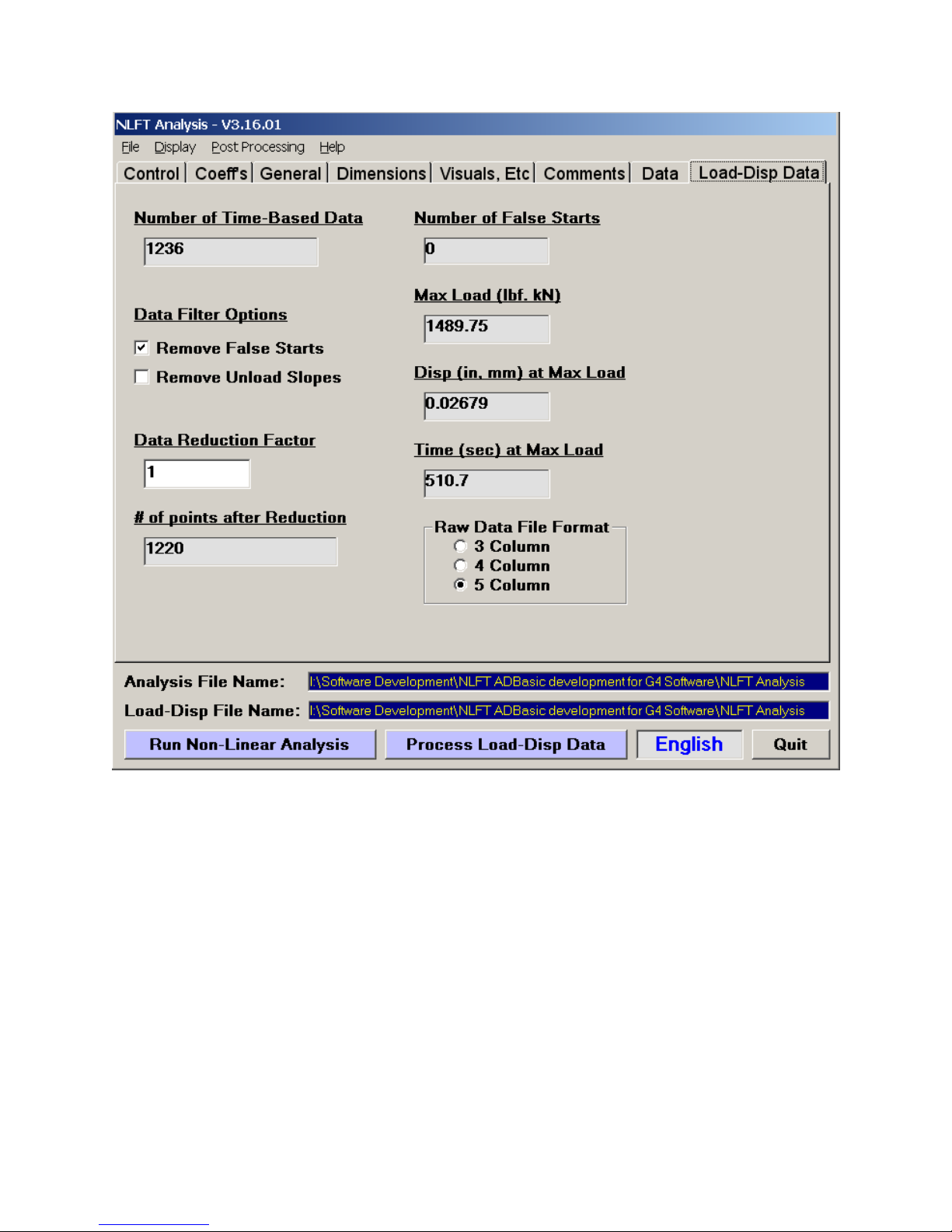

6.3.8 Load-Disp Data .............................................................. 94

6.4 Processing The Data ................................................................ 96

6.4.1 Run Non-Linear Analysis ............................................... 96

6.4.2 Process Load-Disp Data ................................................ 96

6.5 Display ...................................................................................... 96

6.5.1 J – delta a Display ......................................................... 97

6.5.2 Output Display ............................................................... 98

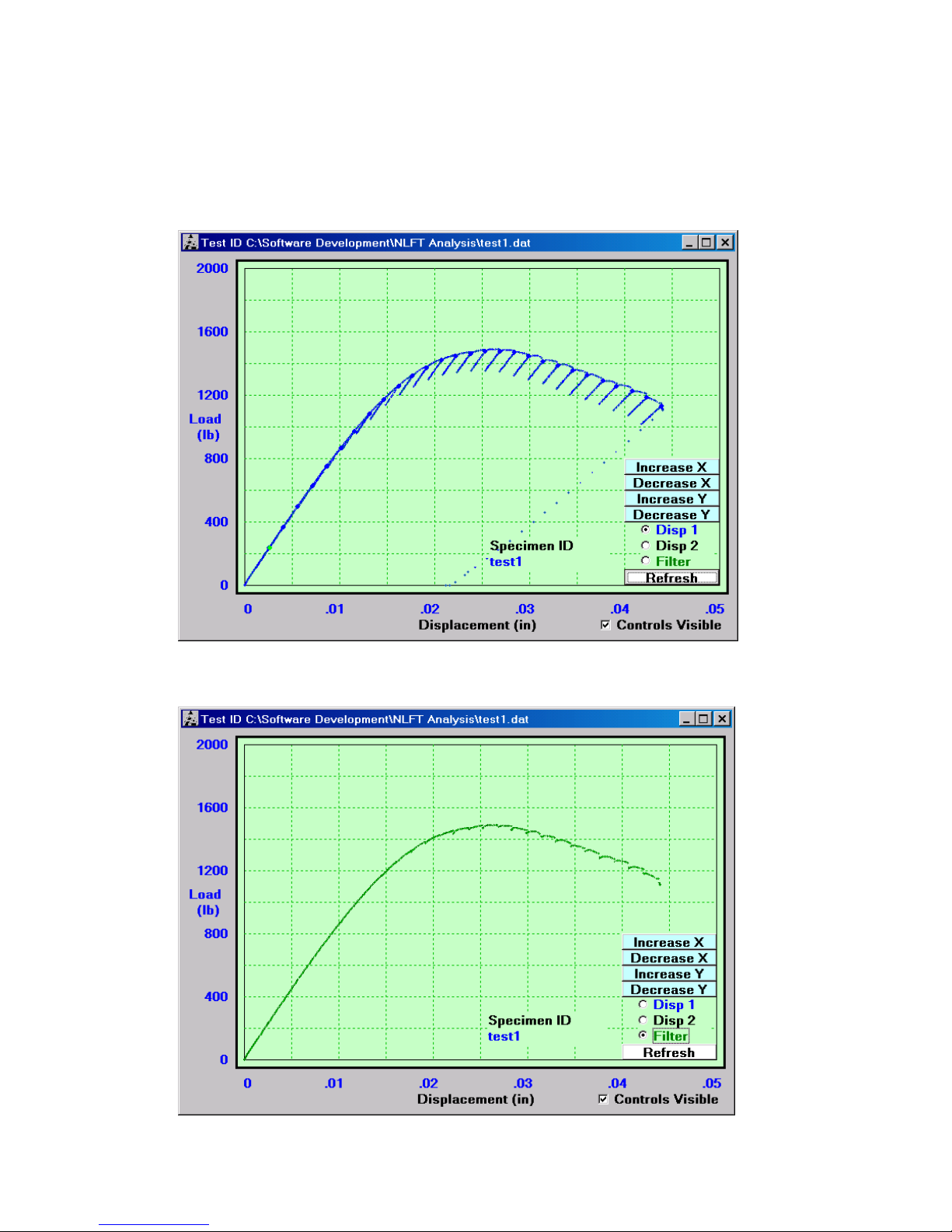

6.5.3 Load-displacement Display ............................................ 99

6.6 Post Processing ..................................................................... 101

7.0 Analysis Utility ........................................................................................ 103

7.1. Non-Linear Report .................................................................. 103

7.1.1 User Input .................................................................... 105

7.1.2 Reduced Data .............................................................. 106

7.1.3 J-plot ............................................................................ 107

7.1.4 Cover page .................................................................. 108

7.1.5 Raw Data ..................................................................... 110

Page 4 of 148

NLFT Testing - Series 2015 - V3+.16.01

7.1.6 Additional Data ............................................................ 111

7.1.7 Variables ...................................................................... 112

7.2. Load-Disp and Linear Report ................................................. 113

7.2.1 Load Disp..................................................................... 114

7.2.2 Load Time .................................................................... 115

7.2.3 User Input .................................................................... 116

7.2.4 Cover Page .................................................................. 117

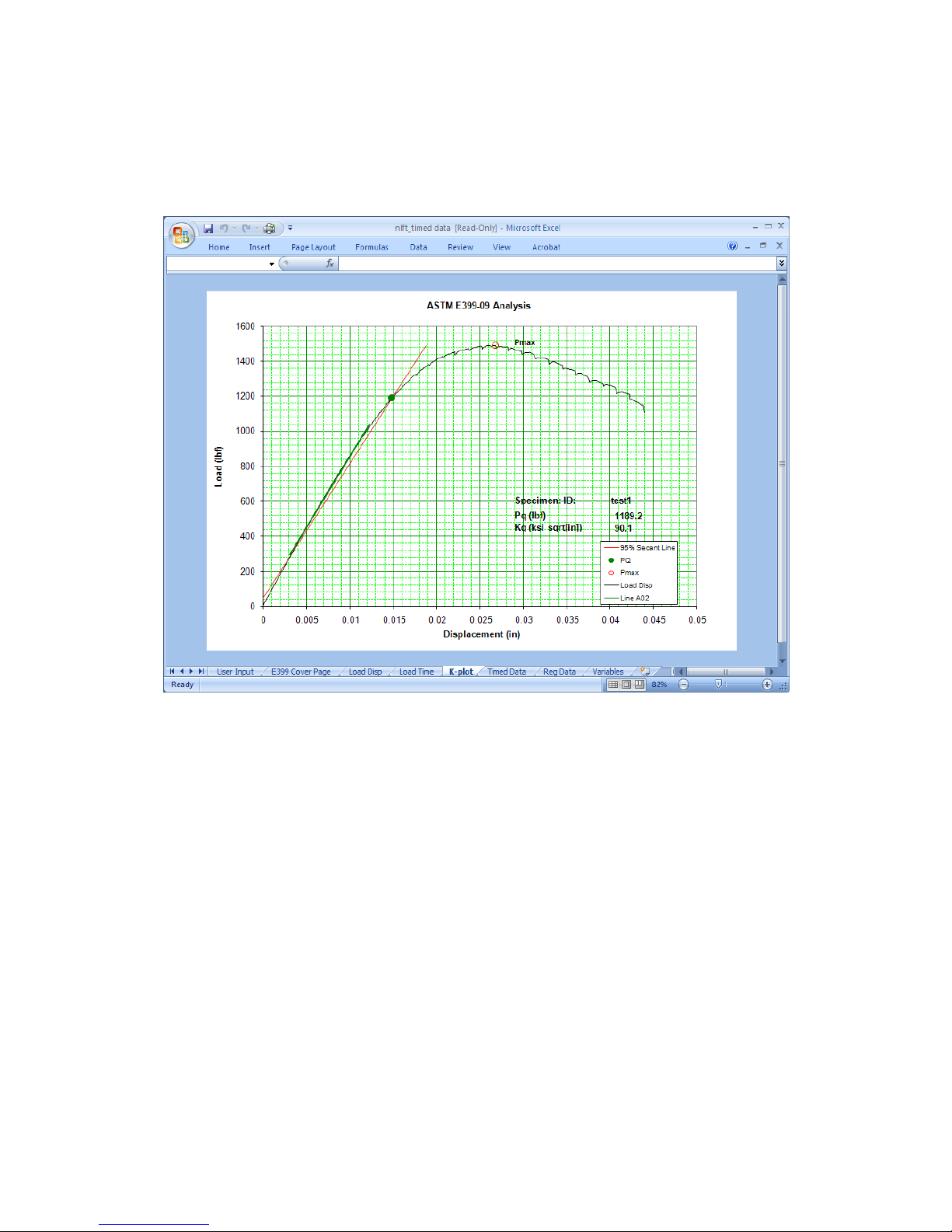

7.2.5 K-Plot ........................................................................... 118

7.2.6 K-Plot ........................................................................... 119

7.2.7 Reg Data...................................................................... 120

7.2.8 Variables ...................................................................... 121

8.0 The NLFT Testing PLAYBACK software ................................................ 123

8.1 Using the Testing Playback Software ..................................... 123

8.2 Description of Menus and Tabs .............................................. 124

8.2.1 Splash Screen ............................................................. 124

8.2.2 Main Menu ................................................................... 125

8.2.2.1 File ................................................................ 125

8.2.2.2 Open ............................................................. 126

8.2.2.3 Save Analysis File As .................................... 126

8.2.2.4 Save Metric Load-Displacement ................... 126

8.2.3 Input ............................................................................. 126

8.2.3.1 Data ............................................................... 127

8.2.3.1.1 Initialize ........................................ 127

8.2.3.1.2 Coefficients .................................. 128

8.2.3.1.3 Dimensions .................................. 129

8.2.3.1.4 Calibration ................................... 130

8.2.3.2 Options .......................................................... 131

8.2.4 Display ......................................................................... 132

8.2.4.1 Load-Displacement ....................................... 132

8.2.4.2 J – Delta a ..................................................... 133

8.2.5 Help ............................................................................. 133

Appendix A: Recovery from System Crash ................................................. 135

Appendix B: Descriptions of Analysis Files ................................................. 137

B1: Log file .................................................................................... 137

B1a: Compliance .................................................................. 137

B1b: Potential Drop .............................................................. 139

B2: Compliance .in5 file ................................................................ 141

B2a: Field Descriptors .......................................................... 142

B2b: Glossary of Variables ................................................... 142

B3: RAW file ................................................................................. 146

B4: UNL file ................................................................................... 147

Page 5 of 148

NLFT Testing - Series 2015 - V3+.16.01

Page 6 of 148

NLFT Testing - Series 2015 - V3+.16.01

1.0 The FTA NLFT Testing and Analysis System

1.1 Introduction

Fracture Technology Associates’ fourth-generation Non-Linear Fracture Toughness

(NLFT) system is an updated hardware and software package designed primarily for

non-linear fracture toughness testing and analysis (ASTM E1820, E1921), ), although

linear elastic testing and analysis is supported (ASTM E399). Each system consists of

an ADwin Gold signal processor and a computer running the FTA NLFT software.

Enhancements to the software include the ability to perform cyclic J and da/dt with a K

profile, desirable for accelerated environmentally assisted cracking tests (K

Two analysis packages are included with each system: 1) standard analysis and 2)

testing playback software, which allows the user to reprocess unloading slopes that may

have captured non-linear crack measurement data during testing.

FTA’s basic NLFT (ASTM E1820, E1921) testing application is designed to run with the

ADwin Gold and any closed loop servo-hydraulic mechanical test machine and

controller, suitably configured for non-linear fracture toughness testing. It is important to

note that the fourth-generation software requires an ADwin with an integrated USB port:

older Adwins are not supported.

Ieac

).

1.2 Software

The basic software application uses either compliance (NLFT-C) or DC potential drop

(NLFT-D) for non-linear fracture toughness testing with a single crack monitor. The

combined application (NLFT-C/D) includes either, independent or simultaneous

compliance unloading and DC potential drop monitor of crack size.

The FTA NLFT analysis program runs independently of the Adwin Gold and has been

upgraded as well. The analysis program can run analysis files created by the new

testing software as well as previous versions.

1.3 The ADwin Gold

The hardware component of FTA’s testing system is the ADwin-Gold signal processor,

manufactured by the German company Jäger. The ADwin takes over from the test

machine controller and performs all function generation, data acquisition, and real-time

data processing, using the ADbasic programming language. ADbasic controls both high

(such as command control and data acquisition) and low priority processes (such as

determination of crack length). The ADwin performs all tasks on a priority basis

regardless of the computer’s workload and time-critical processes run independently of

Page 7 of 148

NLFT Testing - Series 2015 - V3+.16.01

the PC operating system. Thus, if the computer running the FTA software crashes, the

ADwin continues to maintain control and collect data. When the computer is rebooted, it

can access the ADwin process and tests continue uninterrupted.

The ADwin has a dedicated Analog Devices SHARC DSP processor; local memory; and

high-speed 16-bit resolution analog input and output. It provides real-time response

within one microsecond. Further documentation can be found in the ADwin manuals

provided with FTA systems.

Page 8 of 148

NLFT Testing - Series 2015 - V3+.16.01

1.4 Other Hardware Requirements

Required hardware for the FTA testing package includes the ADwin Gold and a

computer running the FTA software. A computer (either 32-bit or 64-bit) with a Pentium

3 processor and 256M memory (or better) and a CD/DVD drive is recommended.

Windows versions 98 thru 7 are supported, although ADwin drivers will differ according

to the OS used (see section 2.4 of this manual for further details).

For potential drop methods of crack measurement, FTA supplies its own high-quality,

DC potential drop instrumentation (FTA-DCPD). The FTA-DCPD was specifically

designed for the precise current and amplifier stability necessary for the reversing DC

potential drop method of monitoring crack length and consists of two units: a

programmable linear DC power supply with built-in solid-state polarity-reversing relays

and a two channel precision differential DC amplifier

Please consult FTA for additional details regarding system requirements.

1.5 License Agreement

Familiarization with the background and theory of fracture toughness testing as well as

the American Society for Testing and Materials (ASTM) standards for fracture

toughness testing (E1820, E1921, E399) is strongly recommended. Fracture

Technology Associates (FTA) assumes no liability for inappropriate use of this software

and hardware system. It is the user’s responsibility to provide back-up verification of the

performance and accuracy of this software package (i.e., visual checking of crack

length, independent monitoring of the applied loads, and redundant checking of the

analysis).

Each test system requires a software license for each of the two required testing

applications. Permission is granted to make copies of the software for back-up

purposes. The analysis software does not require a license for multiple copies and may

be loaded on additional computers for convenience of use. All rights and title to the

application software shall remain the sole and exclusive property of FTA. Distribution of

this software to another party is prohibited.

1.6 Manual Layout

This manual is intended as a beginning reference for new users of the FTA testing and

analysis software. The following section describes setup and installation of the ADwin

Gold; FTA-DCPD current supply and amplifier; and FTA software. Section 3.2 provides

step-by-step instructions to guide new users through the running of a room temperature

E1820 test, including the option of DCPD crack measurement. Section 4 provides

detailed descriptions of each of the testing software menus and displays in the order in

Page 9 of 148

NLFT Testing - Series 2015 - V3+.16.01

which they are typically opened by the user. Sections 5 through 8 detail use of the

analysis software, including testing playback.

This manual includes discussion of the E399 and E1820 standards only. Please contact

FTA for more details on using the NLFT software for E1921 testing and analysis.

Operation and troubleshooting of laboratory controllers and test frames are outside the

scope of this document: for guidance, users are encouraged to contact their equipment

manufacturers.

Page 10 of 148

NLFT Testing - Series 2015 - V3+.16.01

2.0 Installation Guide

2.1 Connecting the ADwin to the Controller and FTA-DCPD

The ADwin-Gold is factory-calibrated and configured for differential inputs, although

FTA can provide a calibration procedure upon request. The ADwin must be grounded

for use in conjunction with a test machine: it should be grounded to the system console

or the common ground of the controller (refer to the ADwin hardware manual Start Up

section for details).

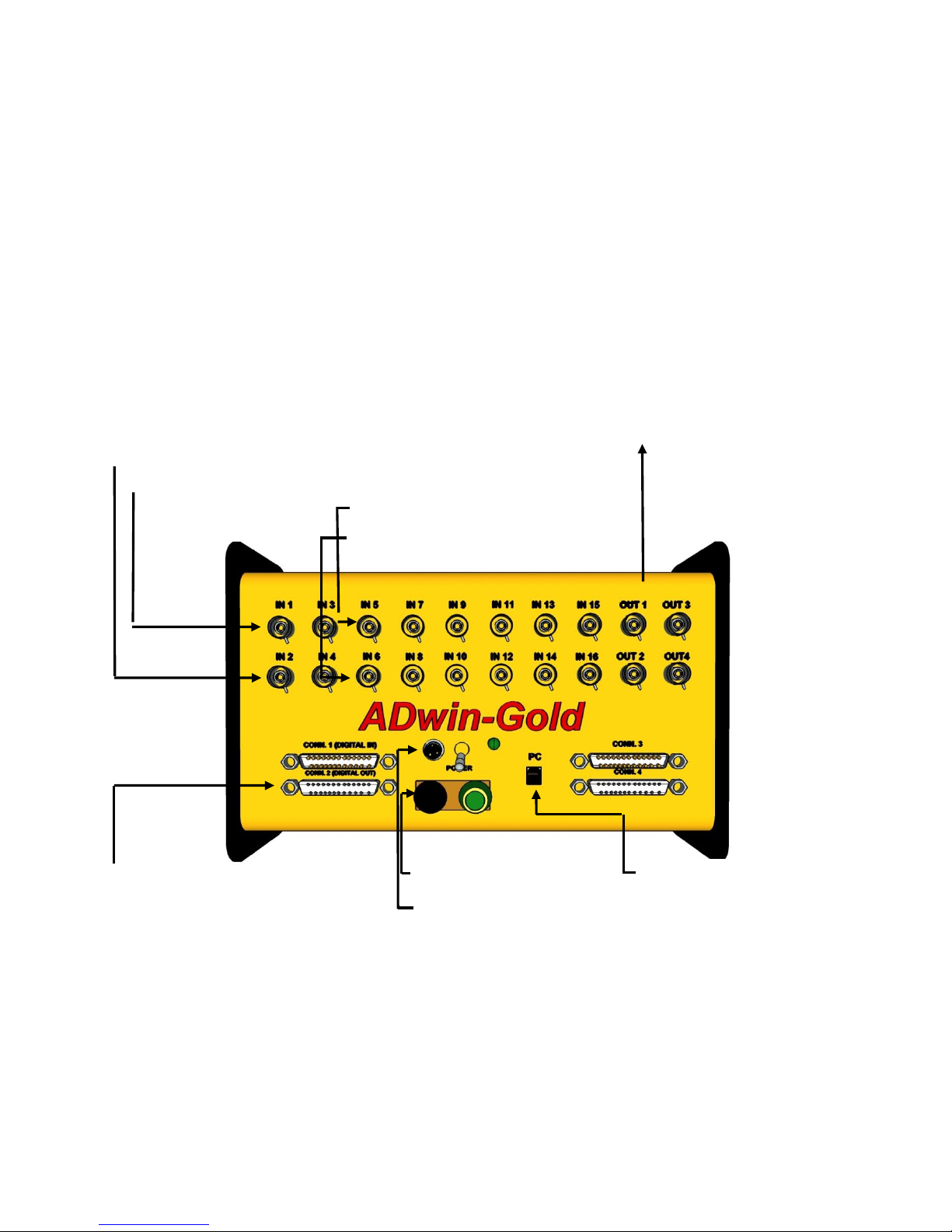

2.1.1 ANALOG INPUT AND OUTPUT CONNECTIONS

For fracture toughness applications, the following analog BNC connections are required

(refer to ADwin hardware manual Connector section for details). Note that these

connections are different than those required by FTA’s previous testing applications.

load cell signal from the test controller: connects to the IN 1 connector on the

ADwin

external function generator input on the test machine controller: connects to the

OUT 1 connector on the ADwin

[for compliance] the displacement signal from the test controller or auxiliary

instrumentation: connects to the IN 2 connector on the ADwin.

[for DC potential drop] active probe amplifier output: connects to the IN 5

connector on the ADwin.

[for DC potential drop] reference probe amplifier output (if required): connects to

the IN 6 connector on the ADwin.

in addition, the ADwin’s IN3 and IN4 connectors may be used as auxiliary

channels for display and/or data logging

The software is configured for a 10 volt range. It is therefore recommended that only

active inputs be connected to the ADwin, since an unused displacement or DC potential

drop signal may have an off-scale output (greater than 10 volts). This condition

influences the analog input multiplexer settling time and may affect the readings of the

other channels.

Page 11 of 148

NLFT Testing - Series 2015 - V3+.16.01

2.1.2 DIGITAL INPUT AND OUTPUT CONNECTIONS

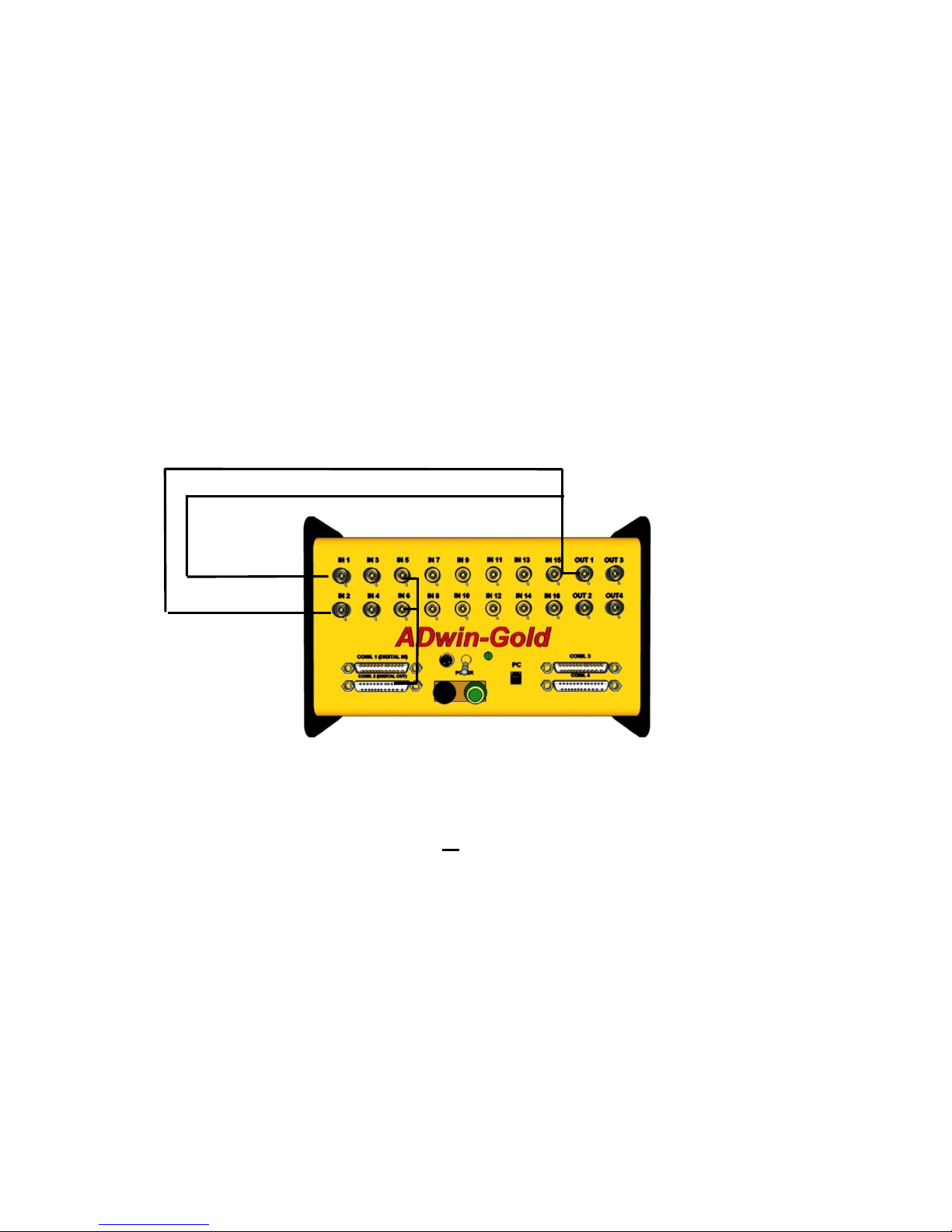

EXTERNAL FUNCTION GENERATION INPUT (OUT 1)

DISPLACEMENT SIGNAL (IN2)

LOAD CELL SIGNAL FROM TEST CONTROLLER (IN1)

ACTIVE DCPD (IN5)

REFERENCE DCPD (IN6)

CONTROLLER RUN STOP,

FTA-DCPD

POWER SUPPLY

CONTROLLER GROUND

PC USB

With each system, FTA supplies a 25-pin run-stop cable, which connects to CONN 2

(digital out) of the ADwin. Pins 5 and 13 of this connector (short red and black wires)

monitor the run state of the controller (pin 5 connects to ‘high’ and pin 13 to ‘low/ground’

of a digital-in logic signal – else, the wires are interchangeable). The nine-pin connector

goes to the back of the FTA-DCPD power supply if required. See Section 2.2 for FTADCPD hook-up.

An ADwin connection diagram appears below:

Page 12 of 148

NLFT Testing - Series 2015 - V3+.16.01

2.2 Connecting the FTA-DCPD Current Supply and Amplifier

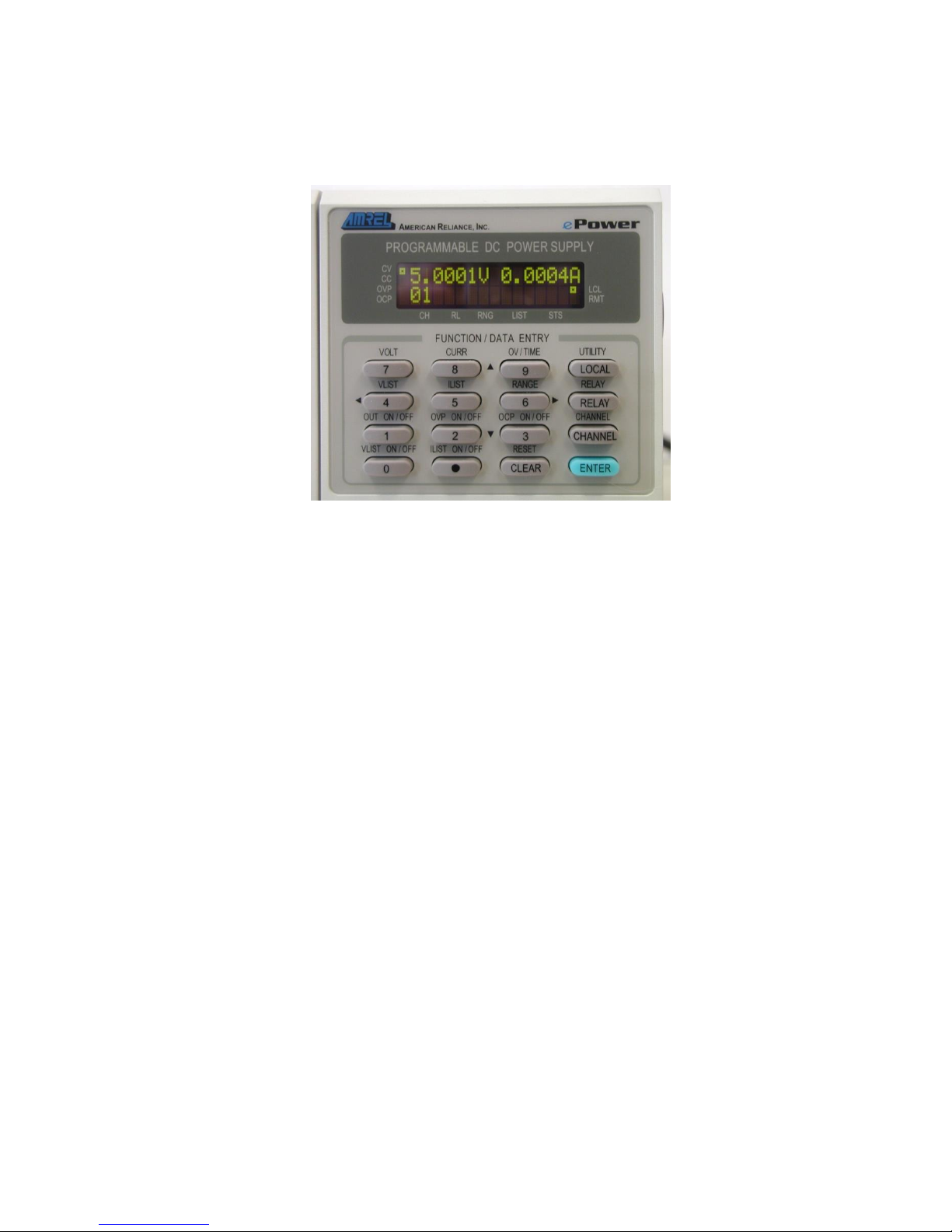

The figure below shows the front panel of the power supply. Programming functions are

activated by the keypad (see the DCPD options described in the test procedure in

Section 3.2 of this manual for details). The voltage/current output on the lower left side

has been disabled.

On the back of the unit, the current output is located on the left side beneath the 120

volt AC power cord. Use the FTA-provided current wire from the Current Out connector

to the test specimen or terminal strip. A cable-tie strain relief is recommended. On the

upper right side of the unit is a 9-pin connector labeled DCPD control, which is

connected to the nine-pin connector from the 25-pin CONN 2 connector on the cabling

to the ADwin-Gold. Note that pin 25 of CONN 2 goes to pin 1 of DCPD control; pin 1 of

CONN 2 goes to pin 3 of DCPD control, and pin 14 of CONN 2 goes to pin 2 of DCPD

control. Do not use the voltage/current outputs on the right side below the DCPD

control connector. Grounding of the unit is provided through the AC power cord.

However, an additional chassis ground terminal is provided next to the power cord and

use of that additional ground is recommended. FTA provides ground cabling in all

shipments.

Page 13 of 148

NLFT Testing - Series 2015 - V3+.16.01

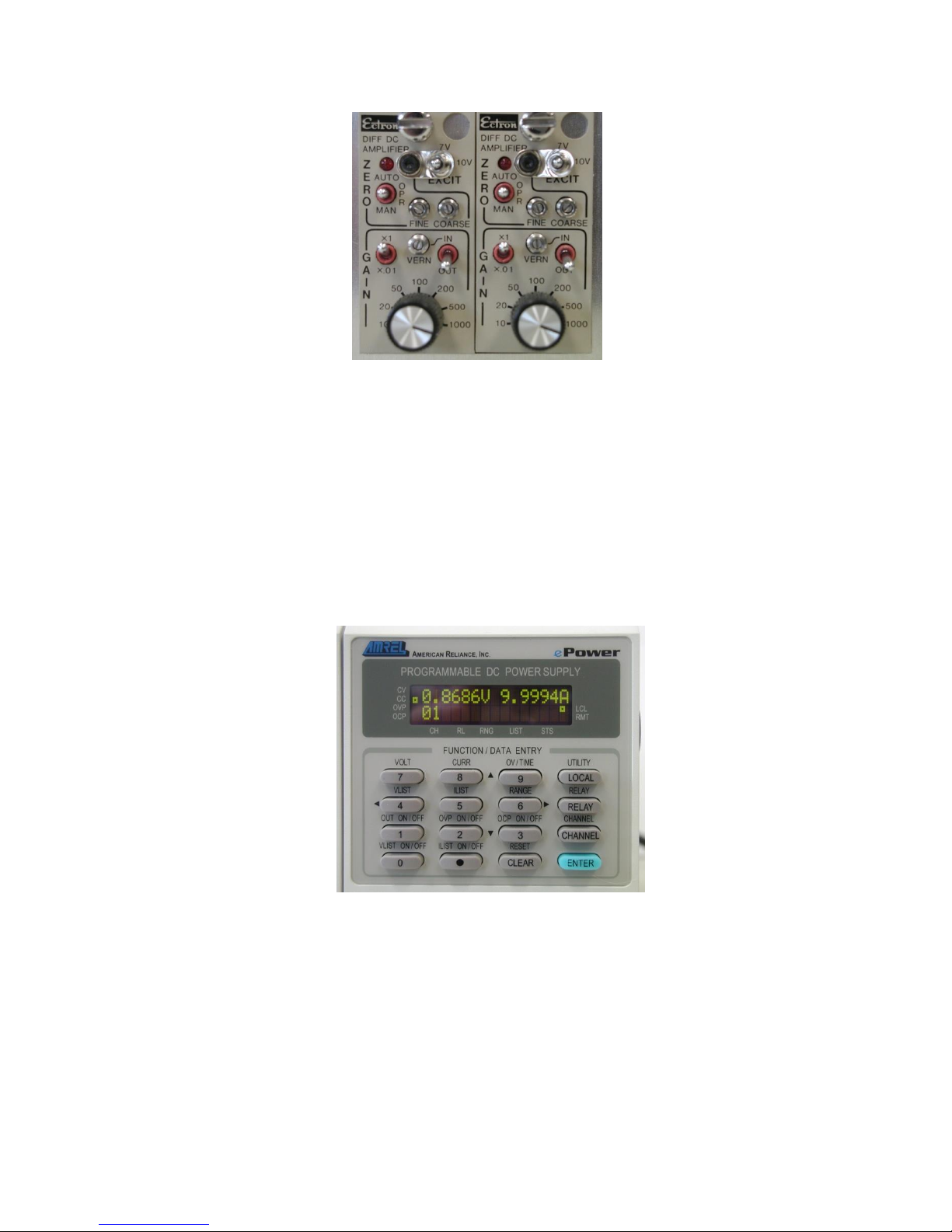

On the FTA DCPD amplifier, gain selection and auto zero are provided using the panel

controls on the Ectron modules. The two shielded Input connectors above the toggle

switches (left and right) connect to the active and reference probes. The active probe

senses the voltage drop across the crack while the reference probe senses the voltage

drop at a location not significantly affected by crack growth. The left-side Ectron module

is linked to the left-side connector and the right-hand module is linked to the right-side

connector. Active/reference assignment is at the discretion of the user.

The two BNC Output connectors below the toggle switches are the amplified and

conditioned voltage outputs for the active and reference probes respectively. They are

each paired with the shielded connector above. The channel designated ‘active’ by the

user connects with IN5 on the ADwin-Gold. The channel designated ‘reference’ by the

user connects with IN6 on the ADwin-Gold.

The toggle switch between the Input and BNC Output connectors is the Filter Switch

for each channel. Filter ‘out’ is the down position, filter ‘in’ is the up position.

Page 14 of 148

NLFT Testing - Series 2015 - V3+.16.01

On the back panel of the amplifer may be found the illuminated power switch; a fuse

holder with a 2-amp fuse; and a 12-volt DC power cord. A 120-volt AC to 12-volt DC

power supply is provided with the system.

To the left of the DC power cord is a ground terminal. The unit must be connected to

ground to function properly: FTA provides ground cabling in all shipments.

Note that the unit is ready for operation only after all the cables have been installed.

This includes attaching the potential drop and current wires to the specimen. In addition,

the FTA DCPD testing software must be open and all test parameters entered before

the system’s power is turned on. Activation of the FTA software sends a logic signal to

the DC power supply enabling the polarity switching relays to start in the forward

position. Detailed instructions for use of the FTA-DCPD system are included in the test

procedure provided in Section 3.2 of this manual.

2.3 PC Setup and Installation of the FTA Software

1. Deactivate the computer’s power saving modes, including standby and

hibernation. The settings of the Windows display should be high color, 800 by

600 pixels (small fonts) or 1024 by 768 (large fonts). The Theme/Appearance

should be set to Windows Classic, regardless of the computer’s OS.

2. From the FTA CD, execute the three setup files for Testing, Analysis, and

Testing Playback from their respective folders. It is recommended the software

be permitted to create the default directories of c:\Program Files\NLFT Testing

and c:\Program Files\NLFT Analysis.

3. Each program can now be launched from the Start Programs menu. To launch

the applications from the desktop, right click on their filename in the Start

Programs menu and Send them to the desktop (create shortcut). Icon files

FTAlogo3.bmp or FTAlogo4.bmp may be used for customization. These icons

can be found in the NLFT Testing folder in the Programs directory.

Page 15 of 148

NLFT Testing - Series 2015 - V3+.16.01

2.4 Installing the ADWin Drivers on the PC

Use the ADwin drivers contained on the FTA-provided CD rather than the gold-colored

CD provided with the ADwin. Version 3.20.1200 should be used for 32-bit systems with

Windows 98 through Windows XP; for Windows 7 use version 5.00.10.00. Users of

older Adwins with ISA-link-to-USB adaptors must use the ADwin driver version

3.00.2332. Adwin drivers for 64-bit systems can be provided by FTA or found on the

web at www.adwin-downloads.de.

Copy the entire ADwin folder onto the PC desktop and carry out installation from there.

Before installing the drivers, connect the ADwin (powered off) to the computer.

1. Run the installation program in the ADWin folder. From the ADWin splash

screen, execute the complete Driver and ADbasic setup.

2. V. 3.20.1200 users will be prompted to restart the computer at this point. Do not

do so. Return to the splash screen, choose Developer-Software setup, and

repeat installation. Exit the installation program.

3. Restart the computer with the ADwin powered off.

4. Power up the ADwin. When prompted by the ‘new hardware wizard’, choose to

find the drivers from a specific location. Go the ADwin folder on the desktop and

choose to search. Ignore warnings about Windows logo testing and finish the

installation.

5. The installation window will reappear when this first stage of installation is

complete. Click ‘next’, choose not to search the internet, and continue with all

defaults.

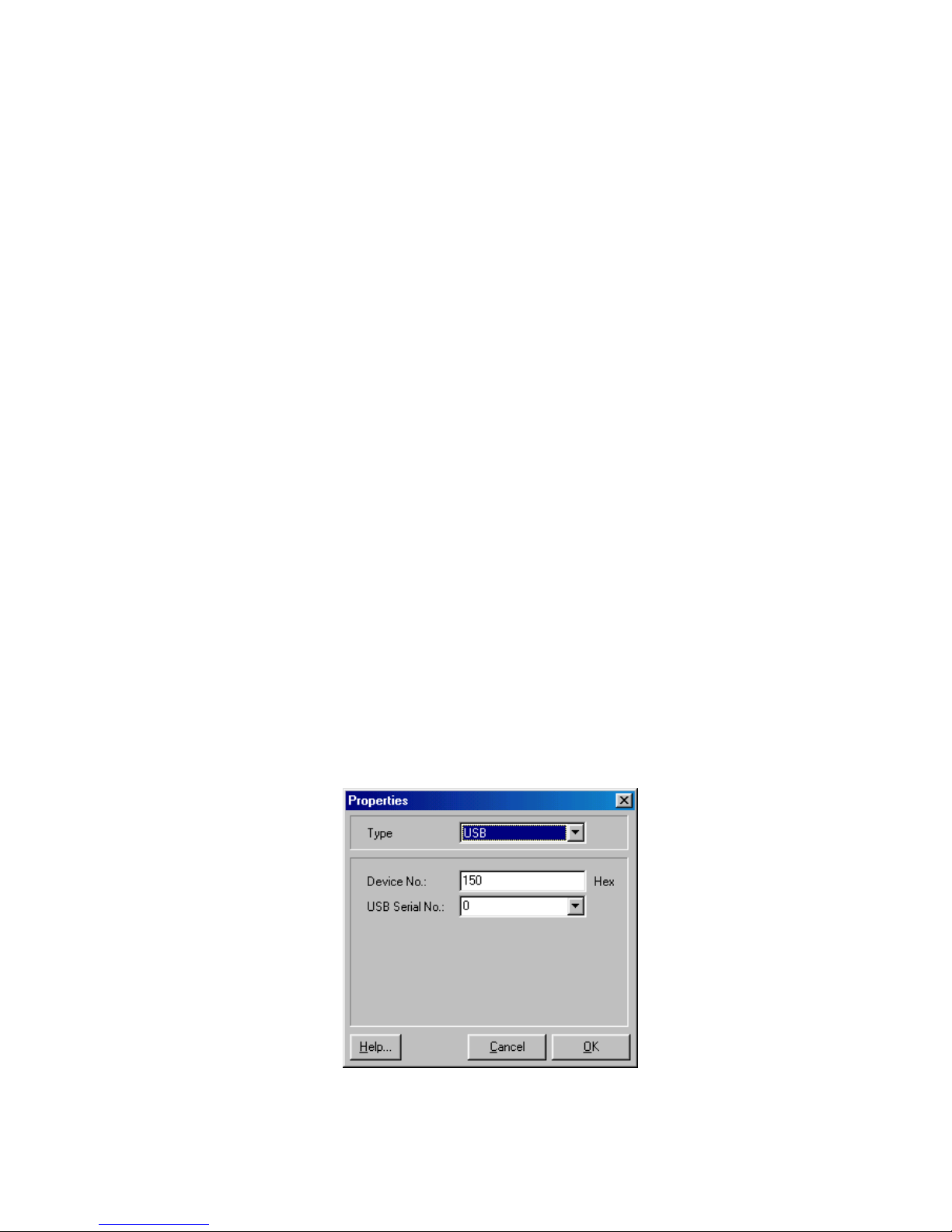

6. Next, go to Start\Programs\ADwin\ADconfig. For v. 3.20.1200, remove the two

default ‘Link’ type connections. Add USB from the drop-down menu and click OK

to exit the form.

Page 16 of 148

NLFT Testing - Series 2015 - V3+.16.01

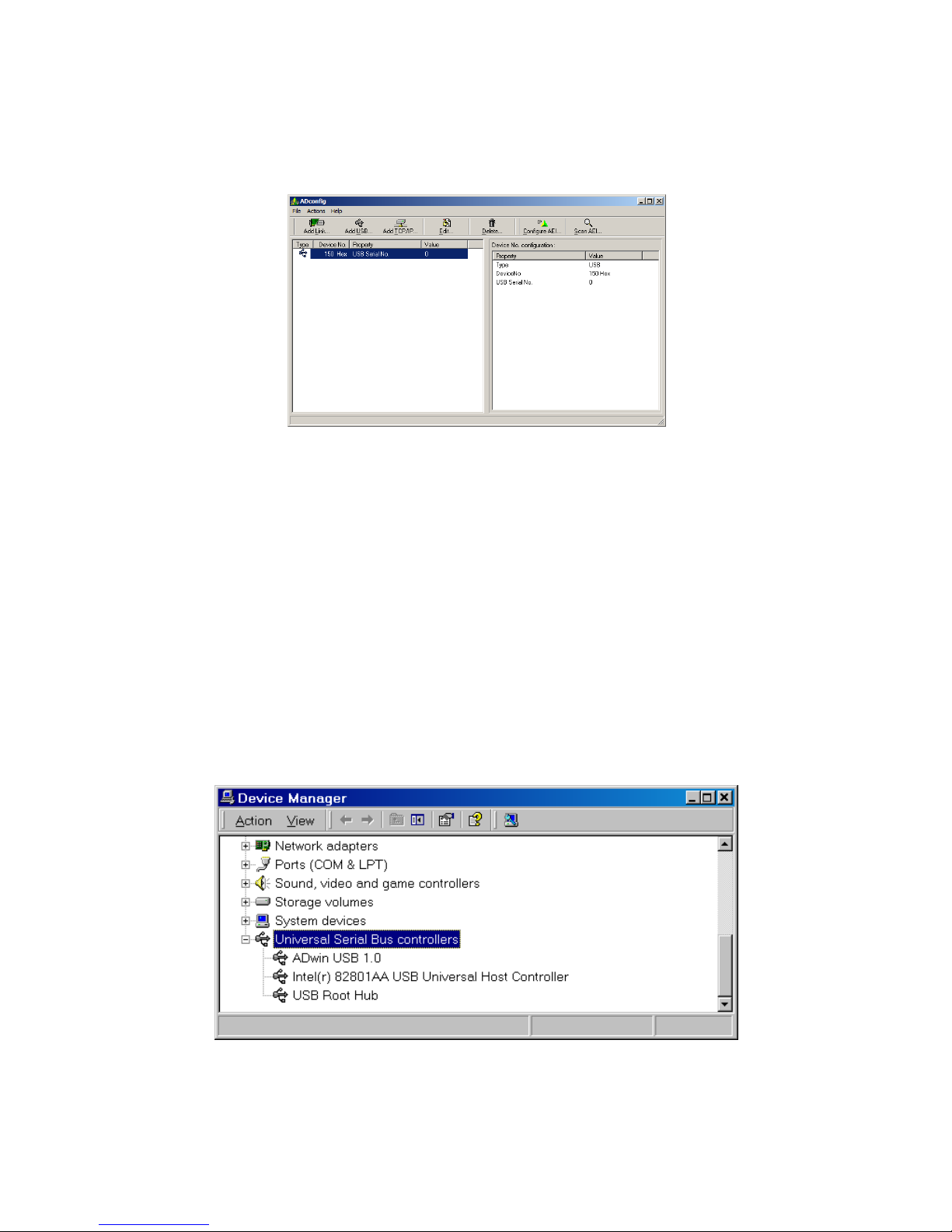

For v. 5.00.10.00, on the ADconfig screen choose ‘Add USB’ from the menu

across the top. Choose Device #150 [hex] and USB Serial #0.

7. Double click on the Adbasic icon on the computer desktop. Leave the license key

blank and click ‘OK’ twice to open the ADbasic program. For v. 3.20.1200, go

straight to step 8. For v. 5.00.10.00, go to the ‘options’ tab at the top of the

window and choose ‘compiler’. Make sure ‘System’ = ADwin Gold; ‘Processor’ =

T9; and ‘Device No.’ = 150 Hex. Close the window.

8. Press the red ‘B’ button on the Adbasic screen to boot the ADWin.

9. A flashing green LED on the ADwin-Gold unit means a successful connection

has been established. Unless the hardware is changed, booting the system from

this point forward will be done automatically when the FTA testing software is

opened.

10. The final installation may be confirmed by viewing the following form in the

Windows’ Device Manager.

Page 17 of 148

NLFT Testing - Series 2015 - V3+.16.01

2.5 Testing in Simulation

Note that it is possible to disconnect the ADwin from the test machine and operate the

NLFT program in simulation mode. Thus, users may familiarize themselves with the

FTA software and evaluate operation of the system without endangering the test

machine or expensive specimens. See Section 3.2 of this manual for sample test

procedures.

To simulate a compliance test, use BNC cables to jumper the ADwin’s OUT 1 to IN 1

and IN 2. To simulate a DCPD test, jumper OUT 1 to IN 1 and connect PIN 1 of

connector 2 to both of the center posts only of [PD active] IN 5 and [PD reference] IN 6.

Run the program as normal: new users may benefit from experimenting with the sample

test procedures provided in Section 3.2 of this manual.

2.6 Tuning

Make sure the machine controller is in displacement (actuator) control. Tune the system

as you normally would for a displacement controlled test. Since loading is static, some

dither might be required.

Page 18 of 148

NLFT Testing - Series 2015 - V3+.16.01

3.0 Using the NLFT Testing Software

The following section of this manual opens with a discussion of the six file-types

associated with the testing program. Section 3.2 contains an illustrative test procedures,

which detail the use of both the compliance and DCPD testing software. Analysis of test

results is covered in sections 5 through 8.

3.1 Understanding Testing Files

It is important to note that six different types of file are associated with the testing

program, each with its own extension. Some of these files are created automatically

during testing, while others must be configured and saved by the user. Several are

required by the FTA analysis software. Procedures for using these files are detailed

throughout this manual, but a summary of the different files is given briefly, for

information, below.

Test Parameter file (.pr5 extension): key information unique and necessary to

the test, such as specimen dimensions and initial test conditions. Although the

information is required, the files themselves are optional, and may be loaded,

modified and saved by the user for ease of use.

General Information file (.gn2 extension): general information not required for

testing, but that may be common across tests (such as test temperature or

material description). These optional files may be loaded, modified and saved by

the user. General information may also be added at analysis time.

Log file (.log extension): details of the test including test parameters and data

that are part of the analysis file (.in5). A log file is appended, rather than

overwritten, every time it is saved. See Appendix B1 for a description of log files.

Analysis file (.in5 extension): data required for the Windows Visual BASIC

analysis software. See Appendix B2.

Unloading Data file (.unl extension): calibration factors and the voltages of the

load-displacement unloading slopes. See Appendix B3.

Raw Data file (.raw extension): load-displacement information including elapse

time; load; displacement; and auxiliary channel information recorded in

engineering units. See Appendix B4.

Page 19 of 148

NLFT Testing - Series 2015 - V3+.16.01

3.2 Running a Test Using the FTA NLFT Software

The following is a general outline illustrating use of the FTA software to conduct a nonlinear fracture toughness test (E1820) at room temperature, using both a clip gage and

DC potential drop. These steps are meant as guidelines only in order to demonstrate

use of the FTA testing software. For detailed descriptions of the menus and forms

referred to below, see Section 4 of this manual. For an analysis procedure, see Section

5.3.

Note that when data are entered in a text box on a program menu, the data are not

transferred to the corresponding variable until another text box or command button

(such as Send to DSP) is clicked. If data have been entered in a text box but Send to

DSP has not been clicked, a blinking red reminder message will appear.

The following step-by step guide to test execution applies both to compliance and

DCPD testing. Where the process differs, directions for compliance testing appear in

blue and directions for DCPD testing appear in red. These steps are a guideline only: a

thorough knowledge of governing ASTM standards is essential.

3.2.1 SETUP

1. Turn on power to the ADwin.

2. Power to the FTA-DCPD amplifer and power supplies should be on, but the

power supply’s Output (number 1 on keypad) should be toggled to Off (the

front LED panel on the power supply should display ‘Output Off’). The unit will

start with a default voltage of 5 volts, which is recommended for most

applications. The default current is 1 amp. With Output set to off, the current

may be changed using the keypad. To input a current of 10 amps, for example,

press CURR (number 8 on the keypad) to bring up a new menu. Press the

numbers 1 and 0. Press the blue ENTER key to confirm the new setting.

3. On the FTA-DCPD amplifer, set the desired gain with the black dial on the

appropriate Ectron module (left module for left channel, right module for right

channel). Remember that the actual gain is 10 times that displayed on the

module. Also ensure that the amplifier’s VERN toggle switch is in the OUT

position and the left-hand toggle switch is in the X1 position. Note that the

toggle switch for the excitation has been locked in the 5 volt position. Do not

tamper with this lockout.

4. Open the NLFT testing program. If the program is already open from a previous

test, skip straight to step 7 of this procedure. Ensure the green light on the

Adwin is blinking, which indicates communication with the computer. Reboot

the Adwin to establish communication, if necessary. On the initial Splash

Screen, choose the crack monitor type: Compliance (for clip gage

Page 20 of 148

NLFT Testing - Series 2015 - V3+.16.01

measurement of crack length and J) or DC Potential Drop (for DCPD

measurement of crack length and clip gage measurement of J).

5. Select New Test (select Resume only if restarting a test, for example, after a

system crash).

6. The Main Menu appears: select Unit Type (English or Metric).

7. From the Input menu, select Data from the dropdown list. The Data Input form

appears, with the Initialize tab foremost. Note that the form has six tabs, which

are typically addressed from left to right.

If the program is already open from a previous test, ensure

FNG OUT on the Status screen reads zero. Ensure STOP

is active on the Ramp Generator and that the three boxes

under Data Acquisition Status are unticked. On the

Initialize tab of the Data Input form, Initialize the new test

by ticking Set Delta a to Zero and Clear Data Storage

Buffer. Press Send to DSP to clear the Adwin of data from

the previous test.

8. Select the Initialize tab of the Data Input form and enter the Test ID.

9. Press Start Data Files: this enables you to save .log files; .unl files (compliance

only); and .raw files as well as specify their data storage path.

10. Press Load Test Parameters (.pr2 files for common specimen geometries may

be found in the NLFT testing program directory).

11. Ensure the K-Calibration Type and PD Calibration Type are appropriate for

the application.

12. The Send to DSP button will blink when changes are made, reminding you to

send the changes to the ADwin by pressing Send to DSP. As an option, press

Print to Log to send data input to the .log file.

13. Address the remaining five tabs on the Data Input form (details may be found

in Section 4 of this manual). Go first to the Coefficients tab and confirm correct

values.

14. Go to the Dimensions tab. Ensure values are correct and change as

necessary. The program will automatically calculate limit load based upon the

values entered. The limit load is based on the plastic limit derived from the

specimen’s yield strength and geometry and is useful for determining the

maximum load range for the test.

15. Address the Calibration tab. Review and adjust values as required. It is

important to note that values in red must correspond to settings on the

controller and PD instrumentation. A full scale of 10 volts is assumed for all

controller settings and entry must be 10% of full-scale range. For a load range

Page 21 of 148

NLFT Testing - Series 2015 - V3+.16.01

of 25,000 lbs, for example, the entry in the Load Cell Calibration text box

should be 2500. PD gain (if running a DCPD test) should be the same as the

gain set on the FTA amplifier x10 (a gain of 500 on the amplifier should be

entered as 5000 on the Calibration tab). Initial PD should be set to zero.

16. Select the Data Acquisition tab, on which criteria for and characteristics of

automatic unloading slopes or DCPD crack length measurements are

determined. For example, if Load under Unloading Slope/DCPD Acquisition

Interval is set to 500 pounds, then that action will be taken every time the load

increases by 500 pounds. Please see Section 4.4.1.5 for more details on the

Data Acquisition tab.

17. Go to the Limits tab. The parameters on this tab specify the limits (Transducer

Limits, Load Drop Limit) at which the command signal will go to STOP or the

test will be terminated (Delta a Limit).

Load Limit Hold determines the initial ramp-up load level (which in most

cases should not exceed the Pmax of the precrack), at which point the

system can be tested for signal quality and correct crack-length reading

before the start of the test proper.

Ramp Down Amount specifies how much the load will ramp down upon

test termination (before going into Hold mode).

Automatic Preload is a useful alternative to the controller setpoint and

applies a [typically low] constant load to the specimen when, for

example, it is coming to test temperature or being held steady for other

purposes before testing commences.

18. Press Send to DSP to send all changes on the Data Input form to the ADwin.

Print to Log.

19. Return to the Initialize tab and press Save Test Parameters. This updates the

.pr2 file for future use.

20. Minimize the Data Input form, but do not close it.

21. Return to the Main Menu and select the Options form from the Input

dropdown list. The default settings are appropriate for most applications. Apply

Rotation Correction to Delta a should always be ticked when compliancetesting a C(T) specimen. For bend-bar testing, Normal Load Cell Polarity and

Normal Stroke Polarity should be unticked. See Section 4.4.2.2 for more

details on the Options menu.

22. Press Send to DSP regardless of whether any changes have been made.

Minimize but do not close the Options menu.

23. Return to the Main Menu and select General Information from the Input

dropdown list. Load a previously-saved .gn2 file or input new values and save

the file for future use. Information about both the test and precracking regime

Page 22 of 148

NLFT Testing - Series 2015 - V3+.16.01

can be recorded. Note that some precracking parameters are necessary for

fulfilling validity requirements during analysis. The General Information form

may be closed before proceeding.

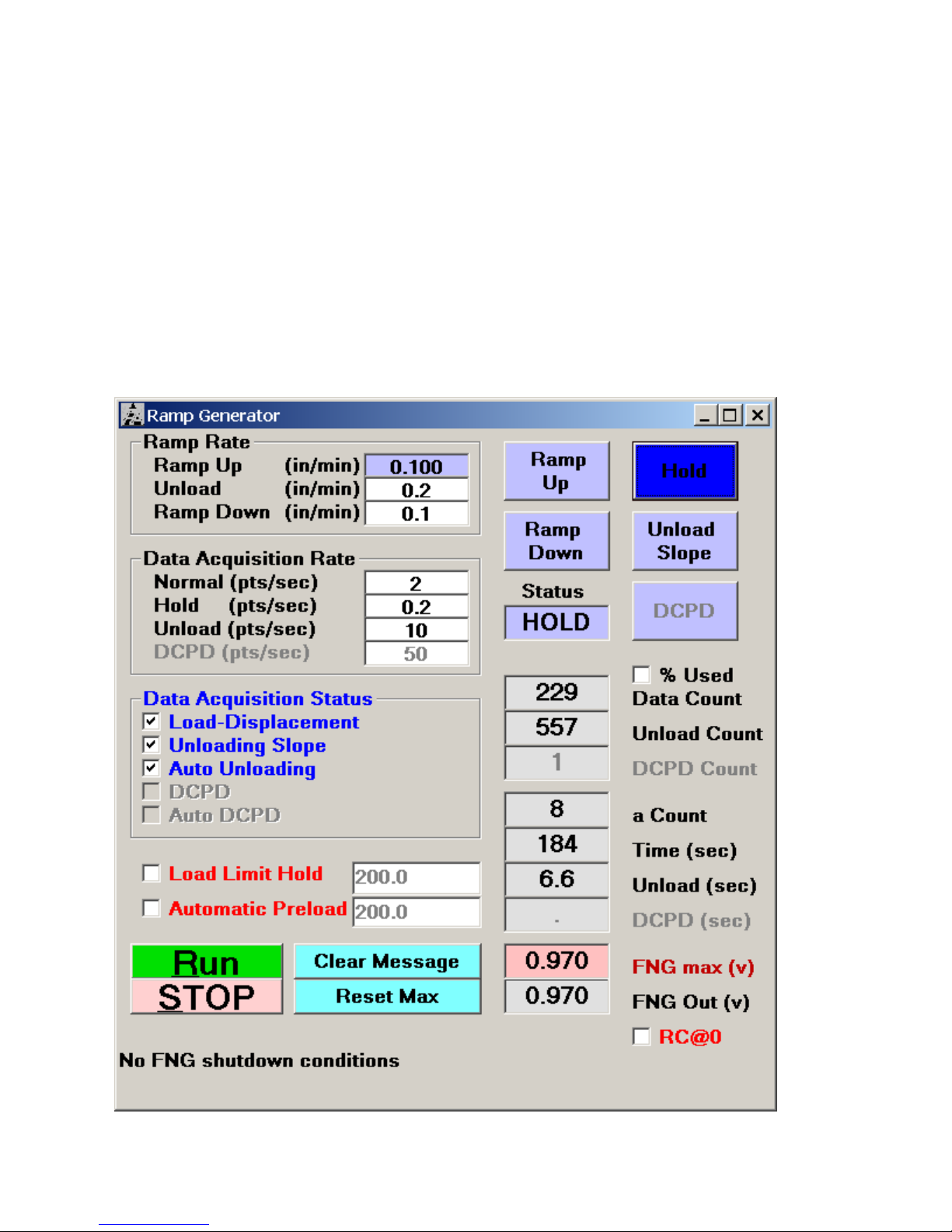

24. Return to the Main Menu and open the Ramp Generator from the Control

drop-down list. The Ramp Generator is the form from which the test is

controlled and must not be closed while the test is running. Changes on this

form are sent immediately to the ADwin.

25. On the Ramp Generator, verify the Ramp and Data Acquisition Rates and

change as appropriate (see details in Section 4.5). These rates may also be

changed on-the-fly while the test is running, if necessary. Ensure once again

that none of the check-boxes is selected and that the program is in STOP

mode. Minimize but do not close the Ramp Generator.

26. Return to the Main Menu and open the Status; Load-displacement; and J-da

(J-delta a) forms from the Display drop-down list.

27. Observe the Status display. Verify that the load and displacement channels are

active and reading correctly. FNG Out should read zero. Load should also

indicate zero.

28a. COMPLIANCE ONLY. Set the test controller to stroke control. Turn on the test

machine hydraulics. Enable the external command for full-scale input. Mount

the specimen in the test machine. Attach the clip gage and use the controller to

adjust the signal to read zero (Disp 1 on the FTA testing software’s Status

display). If more than 10v will be required for the test, adjust the signal for a

negative voltage.

28b. DCPD ONLY. Set the test controller to stroke control. Turn on the test machine

hydraulics. Enable the external command for full-scale input. Mount the

specimen in the test machine. Attach the clip gage and use the controller to

adjust the signal to read zero (Disp 1 on the FTA testing software’s Status

display). If more than 10v will be required for the test, adjust the signal for a

negative voltage.

Attach current and potential drop leads to the specimen.

With the FTA-DCPD power supply Output still Off, zero the volts on the Status

screen by toggling up the ‘auto/man zero’ switch at the top left of the amplifier’s

Ectron module. When the red light has activated, return the switch to its central

position. Voltage should now read zero on the NLFT testing software’s Status

screen (DCPD volts).

Page 23 of 148

NLFT Testing - Series 2015 - V3+.16.01

Activate the current output, (OUT ON/OFF or keypad number 1 on the power

supply). If the FTA software is running and the sample installed correctly, the

LED display should appear similar to the figure below, in which a 10 amp

current has been selected. In this figure, the voltage of 0.8686 volts is due

almost entirely to the voltage drop through the 10-12 AWG wire from the DC

power supply to the test sample. Constant current is assured as long as the

display voltage is less than the default setting of 5 volts. Note that in addition to

displaying the designated current of ~10 amps, the left side of the display

shows a square symbol next to the letters ‘CC’, indicating the constant current

mode.

The figure below shows the power supply display if the current wires are not

hooked up to the specimen or the FTA software is not running. Note that the left

side of the display shows a square symbol next to the letters ‘CV’, indicating the

constant voltage mode. If the system cannot maintain constant current due to

the resistance of the current loop then it defaults to the constant voltage mode.

The constant voltage mode with a current value lower than desired is most

likely due to insufficient wire size in the current path. A current value near zero

Page 24 of 148

NLFT Testing - Series 2015 - V3+.16.01

indicates an open current path or a low logic signal state on pins 2 and 3 of the

DCPD control connector.

Using the black knob on the amplifier’s Ectron module(s), adjust the gain

setting such that the amplified signal displayed on the NLFT testing software’s

Status screen is between 0.5 and 1.0 volts. Be sure to enter the final gain

setting in the FTA software on the Calibration tab, remembering to multiply the

selected amplifier gain by 10. (Note that the proper gain setting is also a

function of the applied current and must take into account the actual PD

calibration and range of crack size. It is important not to reach the ±10 volt

amplifier output limit during a crack growth rate experiment). For gains above

10,000, select the VERN IN position of the toggle switch. The vernier

adjustment can be used to increase the gain to ~25,000.

3.2.2 RUNNING THE TEST

1. Press Reset MAX on the Status form to reset the FNG Out and Load on the

Status display.

2. Return to the Ramp Generator and Clear Message if necessary.

3. Press Run on the Ramp Generator to activate the command signal.

4. Press Load Limit Hold to ensure that loading will stop when the load limit (set

on the Limits tab of the Data Input form) is reached.

5. Press Load-Displacement to begin data acquisition and ensure real-time

plotting of load on the Load-Displacement Display.

6. Press Ramp Up to begin loading the specimen to the load limit hold level.

Page 25 of 148

NLFT Testing - Series 2015 - V3+.16.01

7. Observe the Load-displacement display and Status screen (Load) to ensure

loading stops at the load limit hold. The HOLD indicator on the Ramp

Generator will flash when the load limit has been reached. The Loaddisplacement display may be scaled using the blue buttons.

8a. COMPLIANCE ONLY. Return to the Ramp Generator. Press the blue Unload

Slope button once to apply an unload slope to the specimen (the

characteristics of the unload slope were determined on the Data Acquisition

tab of the Data Input menu). Observe the green trace on the Load-

displacement display to verify correct operation:

the correlation coefficient should 0.9999 or better

the crack length should be accurate

Repeat unloading slopes as necessary to ensure repeatability of crack length

and quality of signal. Scale the unloading slopes as necessary (using the pink

buttons). Press Refresh to bring up the full display. Delta a should be within ±

0.001 inches and there should be no change in Ci/Co greater than 0.003. When

the system is stable, tick Set Delta a to Zero on the Initialize tab of the Data

Input form. Send to DSP.

Activate Unloading Slope on the Ramp Generator (Data Acquisition Status)

and apply one more unload slope to the specimen. This will be the first active

data point in the .in5 file.

8b. DCPD ONLY. Return to the Ramp Generator. Press the blue DCPD Acqu.

button once to take a DCPD reading (the characteristics of the acquisition were

determined on the Data Acquisition tab of the Data Input menu). Observe the

green trace on the Load-displacement display to verify correct operation.

Press DCPD Acqu. several more times. Observe the DCPD Active Voltage on

the Load-Displacement Display form. Readings should be consistent within

0.1%. Compute the mean of the final three readings and enter the value as

Initial PD on the Calibration tab of the Data Input form. Send to DSP.

Activate another DCPD acquisition cycle. The Load-Displacement Display

should now indicate the correct crack length. Apply at least two more cycles

and observe changes in crack length. Verify that the variation in delta a is

consistently within ±0.001 inches.

Page 26 of 148

NLFT Testing - Series 2015 - V3+.16.01

Activate DCPD Data on the Ramp Generator (Data Acquisition Status) and

press DCPD Acqu. once more. This will be the first active data point in the .in5

file.

9. When the quality of the signal and repeatability of crack length readings is

satisfactory, it is time to start the test. On the Ramp Generator disable Load

Limit Hold. Enable Auto Unloading [compliance] [or] Enable Auto DCPD Acq.

[DCPD] and press Clear Message.

10. Press Ramp Up to start the test. Unload slopes/DCPD acquisition cycles will

occur at the intervals and durations set on the Data Acquisition tab of the

Data Input form. View the Load-Displacement trace to verify correct

operation.

11. Observe the J-da (J-delta) display from the Display and adjust the scale as

required.

12. When the final test limit has been achieved (typically the Delta a Limit

specified on the Limits tab of the Data Input form), the test is complete. The

machine will automatically ramp down to the load specified under Ramp Down

Amount on the Limits tab. When this load is reached, the test will HOLD.

13. On the Ramp Generator, disable Unloading Slope and Auto Unloading/DCPD

data and Auto DCPD Acqu. On the Limits tab of the Data Input form, disable

Displacement 1 Limit and Send to DSP.

14. Press Run and then Ramp Down to ramp the load to zero. When the load

reaches zero press Hold. Disable Load-Displacement and remove the

specimen from the test machine (if DCPD, turn off the current before removing

the specimen). If necessary, press Ramp Down again until FNG Out reads

zero on the Status display.

15. Press Stop.

16. Return to the Main Menu. Using the File drop-down list, save the analysis

(.in5) file in Version 3 Format. Also save the load-displacement (.raw) data file

and the unload (.unl) data file.

Page 27 of 148

NLFT Testing - Series 2015 - V3+.16.01

17. Choose Exit if you wish to quit the program. For a new test, return to the

Initialize tab on the Data Input form. Enter a new Test ID and go straight to

step 7 of the preceding section, Setup.

Page 28 of 148

NLFT Testing - Series 2015 - V3+.16.01

4.0 NLFT Testing Software: Description of Menus and Tabs

The following section of the manual offers a complete description of the menus and tabs

comprising both the compliance and potential drop NLFT testing applications. The

menus are presented in the order in which they would normally be opened during test

setup.

For a step-by-step procedure detailing how the software may be used for running an

E1820 test, see preceding Section 3.2.

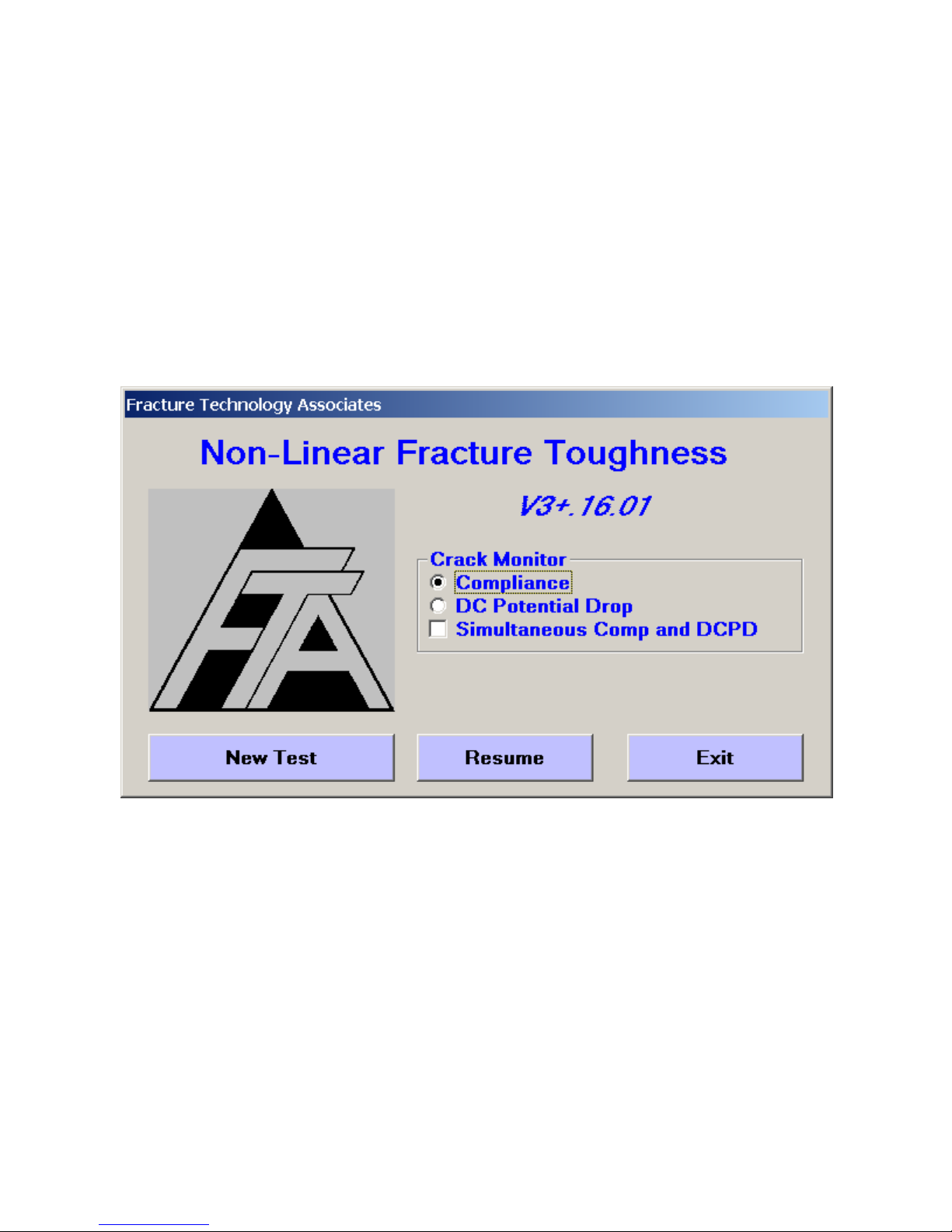

4.1 Splash Screen

The splash screen is displayed upon start-up. The application title and version number

are identified at the top of this form. From this form the Crack Monitor type

(Compliance or DC Potential Drop) is selected. If a different crack monitor type is

required for subsequent tests, the program must be shut down completely and

restarted. Simultaneous Compliance and DC Potential Drop if desired.

Once the test selection has been made, select New Test to call up the Main Menu and

begin a test from scratch. The Resume options allows the operator to resume a test

that may already have been in progress (for example, after a system crash or power

outage). See Appendix A for details. The establishment of a successful link between the

PC and the ADwin is confirmed when the green LED on the Adwin begins to flash.

Page 29 of 148

NLFT Testing - Series 2015 - V3+.16.01

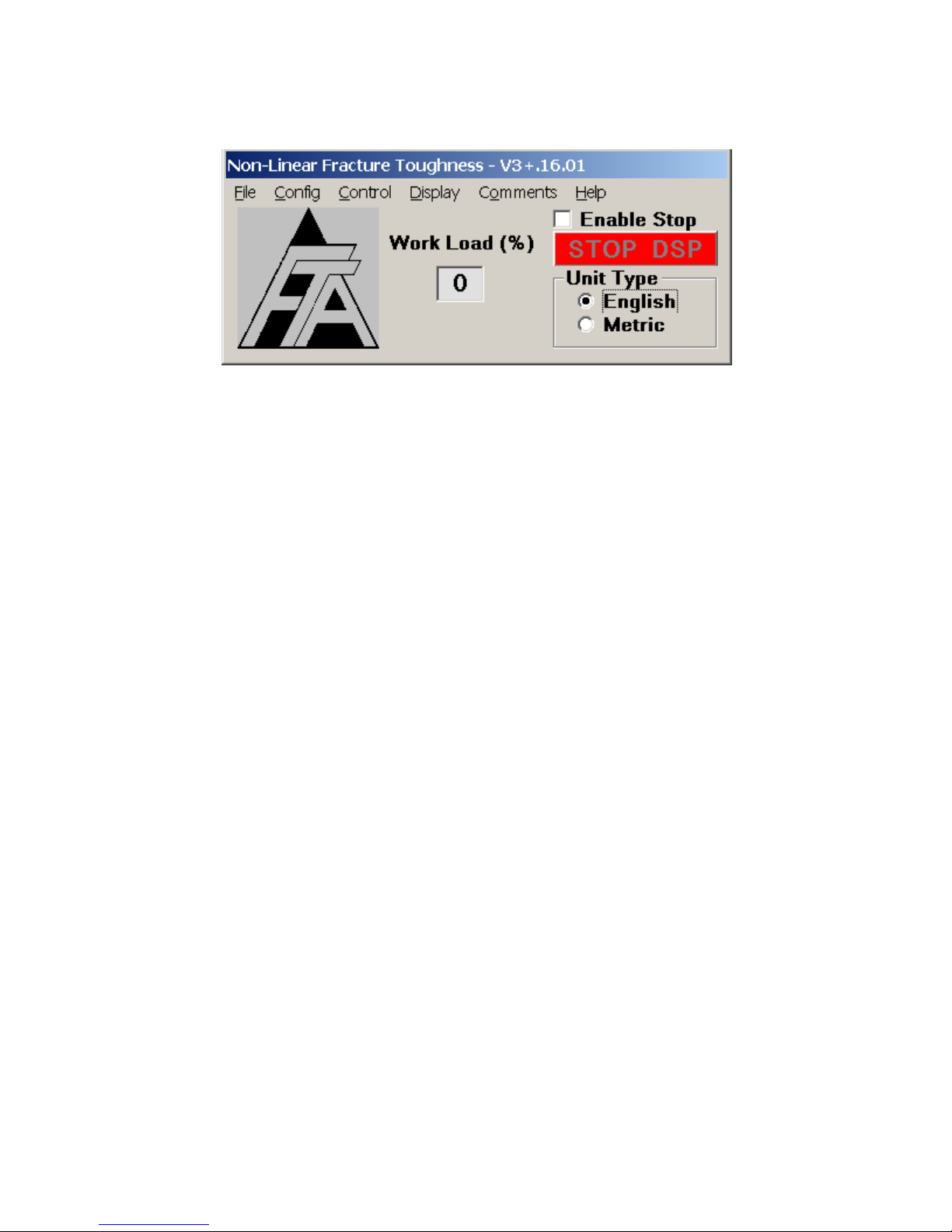

4.2 Main Menu

The Main Menu is always displayed while the program is running: its default position is

in the upper left-corner of the computer screen. The Unit Type (English or Metric)

must be selected before other forms may be opened. The Unit Type can be changed

while the test is in progress or the program is open, but such a change requires closing

and reopening all of the other forms. Note that all processing and data storage are done

in English units, even if the Metric option is chosen: the unit conversion takes place as

data are entered or displayed.

The Work Load displays the ADwin workload in % for both high and low priority

processes and is for reference only.

Pressing the red STOP DSP button terminates all DSP processes. This is not

recommended for normal operation and the button is disabled by default. To activate,

tick the Enable Stop box. Sometimes, if the ADwin does not appear to be responding,

enabling stop can reset the Adwin so normal functioning can resume. All DSP

processes are then restarted when the Run Button is pressed on the Main Function

Generator. Use with caution.

4.3 File

The first drop-down menu on the Main Menu is File. See Section 3.1 of this manual for

a full discussion of the files produced by the testing software.

4.3.1 SAVE ANALYSIS FILE

Analysis files with the .in5 extension must be saved manually, although they are held in

memory until the data buffer has been cleared. The user may save the analysis file at

any time during the test, noting that saving an analysis file overwrites any previous

versions.

Page 30 of 148

NLFT Testing - Series 2015 - V3+.16.01

Analysis files contain the header and raw test data that will be processed using the

analysis program. In addition to the analysis file (which is not saved automatically), the

program produces a .raw file containing load-displacement data and time data in

engineering units; a .unl file containing unloading slope data in volts; and a .log file that

automatically records all data taken during the test. It is nonetheless good practice to

save the .raw and .unl files at test completion using the Save As feature. Log files are

automatically produced and saved as long as this process is activated on the Options

form. It is also possible to save the analysis file in the FCGR format for da/dt analysis

using the FCGR analysis software.

Saving an analysis file overwrites the previous file. Analysis files are held in memory

until manually saved or the data buffer is cleared. Log files are saved automatically:

however, data dumps between automatic saving intervals (determined on the Options

form) must be done manually by pressing Print to Log on the Data Input form.

4.3.2 EXIT

When Exit is chosen, the user is prompted to save the analysis files even if they have

been previously saved. If Exit is selected inadvertently and the ADwin system power

remains on, the test can be continued without losing data by selecting Resume on the

splash screen.

4.4 Config

From the Main Menu, the Config dropdown menu accesses the Hardware

Configuration form; the Test Set-up form; and the General Information form. These

forms are addressed in sequence during test setup. All testing configuration (but not

function generation or control) is determined on the Config forms. Entries are

transferred between the PC and the ADwin when the Send to ADwin and Receive

from ADwin buttons are pressed. When a change is made to the input forms, the Send

to ADwin button will flash indicating that the change has not yet been sent to the

ADwin. When the Receive from ADwin button is pressed, the user will notice that all

fields in blue will be updated with the latest information from the ADwin. Pressing

Receive from ADwin does not alter test conditions and may be done at any time during

a test. All Config entries can be dumped to the .log file using the Print to Log button on

each of the three forms.

NB Text box entries are not transferred to the corresponding variable until you click on

another text box or command button such as Send to ADwin.

Page 31 of 148

NLFT Testing - Series 2015 - V3+.16.01

4.4.1 HARDWARE CONFIGURATION

The Hardware Configuration form is used to assign and configure the ADwin’s analog

input channels. All channels are pre-assigned and cannot be changed by the user.

Channels one through six are used, as detailed in the following sections.

The form consists of two tabs: Calibration and Configuration. These tabs are slightly

different depending on whether the compliance or DCPD application is in use, as

detailed below.

Hardware configuration entries are not transferred between the ADwin and computer

until the Send to ADwin or Receive from ADwin buttons are pressed. Hardware

configuration files (.pr8 extension) may be saved and loaded for subsequent tests using

the blue buttons at the bottom of the form.

4.4.1.1 Calibration (compliance)

Page 32 of 148

NLFT Testing - Series 2015 - V3+.16.01

The Calibration tab displays the active ADwin analog input compliance channels IN1

through IN4 and their function under the Channel Designation heading. These

assignments may not be changed by the user in the steady state single-monitor

application. The two auxiliary channels (IN3 and IN4) are optional and should be set to

zero when not in use (in this case, the BNC connectors on the ADwin should be empty).

IN5 and IN6 are used by the DCPD application only.

The channels are calibrated by the user using the text boxes under Calibration Factor,

using units/volt.

Enable Run-Stop Interlock is ticked by default and may not be changed.

4.4.1.2 Calibration (DCPD)

The Calibration tab displays the active ADwin analog input DCPD channels IN1

through IN6 and their function under the Channel Designation heading. Channel

assignments may not be changed by the user. The two auxiliary channels and DCPD

Page 33 of 148

NLFT Testing - Series 2015 - V3+.16.01

Ref[erence] (IN3, IN4, and IN6) are optional and should be set to zero when not in use

(in this case, the BNC connectors on the ADwin should be empty).

The channels are calibrated by the user using the text boxes under Calibration Factor.

All calibration factors are in units/volt except DCPD Active and DCPD Ref[erence],

which relate directly to the proportional gain selected on the amplifier. When using the

FTA DCPD system, the number entered for IN5 and IN6 must be 10X that selected on

the associated Ectron module: that is, if a gain of 500 is selected on the amplifier, then a

gain of 5000 should be entered on the Calibration tab).

Enable Run-Stop Interlock is ticked by default and may not be changed.

4.4.1.3 Configuration (Compliance and DCPD)

Page 34 of 148

NLFT Testing - Series 2015 - V3+.16.01

For each of the ADwin input channels, the Configuration tab allows designation of

Polarity and programmable Gain. Default selections are appropriate for most

applications with the following exceptions:

Polarity

IN1: increasing voltage with increasing load is the default setting for most

geometries with the exception of the compressive loading of bend bars, for

which polarity should be reversed. If the IN1 polarity is reversed, then the load

cell polarity must also be reversed by unticking the Normal Command

Polarity option below it. Use this option with caution. Do not change the

polarity while the ADwin is in control. The polarity cannot be changed while

the function generator is running.

IN2: increasing voltage with increasing displacement is the default setting and

appropriate for most applications.

IN3: normal polarity is chosen by default

IN4: normal polarity is chosen be default

IN5: specifies the polarity of the active DCPD signal. This option should be

Reversed if the potential signal is negative when the current is in the forward

direction (for example, if the hardware configuration has been accidentally

reversed)

IN6: specifies the polarity of the Reference DCPD signal. This option should

be Reversed if the potential signal is negative when the current is in the

forward direction (for example, if the hardware configuration has been

accidentally reversed)

Gain: the default gain of x1 provides + to -10 volt inputs, which is appropriate for

most steady-state testing. Higher gains allow for greater resolution but offer less

range: lower-level signals could benefit from gains of x2 (+ to -5 volts), x4 (+ to -

2.5 volts) or x8 (+ to -1.25 volts). Changes to the Gain on the Configuration tab

do not require any alterations on the Calibration tab.

Page 35 of 148

NLFT Testing - Series 2015 - V3+.16.01

4.4.2 TEST SET-UP

The Test Set-up form consists of eight tabs: Initialize; Calibration; Coefficients;

Dimensions; Compliance; DCPD; Storage; and Limits. When organized in a single

row, these tabs appear in the logical order in which parameters would be entered to

start a test. Inactive data fields are displayed in gray.

NB It is important to remember that entries are not automatically transferred between

the PC and the ADwin, but must be sent manually using the Send to ADwin and

Receive from ADwin buttons at the bottom of the form. Once a test has been started, it

is extremely important, before changing any test conditions, to Receive from ADwin in

order to ensure the PC and ADwin are in agreement.

Page 36 of 148

NLFT Testing - Series 2015 - V3+.16.01

4.4.2.1 Initialize

The tabs of the Test Set-up form are organized logically and, when displayed in a

single row, addressed from left to right by the user. Initial test setup is accomplished on

the Initialize tab. First, the Test ID must be entered, establishing the name of all the

test’s associated files (analysis files (.in5), log files (.log), load-displacement files (.raw)

and unloading slope files (.unl)). An extension is not entered in this field because it will

be automatically appended by the software. When changing the Test ID, the user will

be prompted to save the current analysis file. The Send to ADwin button must be

pressed a second time to confirm the name change.

Three blue buttons at the top of the tab establish the data storage path and allow

creation and saving of parameter files:

Page 37 of 148

NLFT Testing - Series 2015 - V3+.16.01

Start Log File: starting a log file also establishes the data storage path

(prompted by a pop-up window when the button is pressed) for all files created

by the testing program. It is recommended that users create discreet storage

folders out with the PC’s program directory, since some computers require

administrator privileges to access such files later on. Once initiated, log files are

saved and updated automatically by the program.

Load Test Parameters: loading a parameter (.pr5) file populates the Data Input

form with all the information necessary to start a test (except the Test ID), edited

as required. Parameter files contain geometry designations, specimen

dimensions, initial Pmax values, and other specific test information. Use of

parameter files can save time and reduce the risk of errors when entering

repetitive information. FTA supplied parameter files can be used for either

Compliance or DC Potential Drop. However, once these files are saved, they

become unique to the crack monitor type. Note that .par files from previous

versions of the software are not compatible with the current version 3+.16.

Several parameter files for commonly-used specimen geometries are supplied in

the program directory for the testing software. These files may be modified for

users’ particular needs. Refer to the latest ASTM E1820 and E647 test standards

for corresponding formulas and coefficients. Test parameter files supplied by

FTA include:

C(T) FF.pr5: compact tension with front face clip gage

C(T) LL.pr5: compact tension with load line clip gage

M(T) 4W.pr5: middle crack tension, 0.6” gage length, 4” panel width

SE(B).pr5: single edge 3-point bend

SE(T) PIN LOADED.pr5: single edge tension (pin loaded)

SE(T) RIGID.pr5: single edge tension (rigid grip)

ESE(T).pr5: eccentrically load single edge tension

SF.pr5: surface flaw tension

CC.pr5: corner crack tension

Save Test Parameters: pressing this button saves the current information with

the Test ID for future reference and/or loading. Parameter files may also be

saved from the Limits tab when all test setup fields are complete.

The Initialize tab also includes the following three check boxes at the upper right:

Initialize: sets to zero the values of crack length and current a/W (used only at

the start of a new test, after the previous test’s data have been saved).

Page 38 of 148

NLFT Testing - Series 2015 - V3+.16.01

Clear Data Buffer: clears all previously calculated data stored in memory. This is

typically used when starting a new test. Ticking Clear Data Buffer automatically

issues a prompt to store the data to an analysis file.

Clear Elapse Timer: resets the hour and day-elapse timer on the Status display.

After a box is ticked, the Send to ADwin button must be pressed to communicate the

change to the ADwin. The box is then cleared automatically so the action is not

repeated accidentally. All of these selections may be made without stopping a test and

may be carried out individually or in combination.

If the data buffer has been cleared unintentionally (or the operator has second

thoughts!) it may be restored using the Restore Data Buffer checkbox. This is

particularly useful if the analysis file was not manually saved before the buffer was

cleared.

The Data Buffer display shows the current status of the buffer, either as an absolute

value or % Used. Data stored include elapsed time; force; displacement; auxiliary1;

auxiliary2; crack size; unloading compliance; DCPD active; DCPD reference; and DCPD

normalized. The buffer allows for a maximum of 50,000 lines of data in the analysis

(.in5) file.

If the data buffer has been cleared accidentally (by activating the Clear Data Buffer box

in the Initialize frame), it may be restored by activating the Restore Data Buffer box

and sending to the ADwin. If too few data points reappear, more may restored by

entering the total desired number in the Specify Data Buffer Size field. Caution should

be exercised when using this capability, however, as it is possible to include data from

previous tests if too many points are specified.

Page 39 of 148

NLFT Testing - Series 2015 - V3+.16.01

4.4.2.2 Calibration

The K Calibration Type is selected automatically when the appropriate test parameter

file is loaded. It may be changed, however, when the user is testing a specimen

geometry for which a test parameter file does not exist or when creating a new test

parameter file from scratch. To change a K calibration, tick the Enable Cal Type box,

make the desired selection, then untick the Enable Cal Type box. Send to ADwin. Do

not forget to untick the Enable Cal Type box once all changes are made!

See Appendix G of the FCGR manual for the stress intensity solutions used by the FTA

software.

Page 40 of 148

NLFT Testing - Series 2015 - V3+.16.01

Polynomial (Type 1): allows the user to enter coefficients of a polynomial

expression up to the 5th order. The form of the expression is taken from the

ASTM E647 stress intensity (K) solution for the compact tension, C(T), geometry.

However, the user can apply other coefficients for different geometries such as

the disk-shaped compact tension, DC(T), as long as the K expression is of the

same form. Type 1 Type 1 is the form suitable for the compact tension sample as

follows:

K = (P /(BW)) ((2+a/W)/(1-a/W)^1.5) f(a/W)

Polynomial (Type 2): a more general form suitable for custom K calibrations:

K = a f(a/W) = (P/(BW)) a f(a/W)

Polynomial (Type 3): an alternative form suitable for custom K calibrations:

K = (P /(BW)) f(a/W)

Center Crack, M(T): the K solution is taken from ASTM E 647

Single Edge Crack, SE(T): assumes a pin-loaded specimen with the K solution

taken from: H. Tada, P. Paris, G. Irwin, Stress Analysis of Cracks Hankbook,

Second Edition, 1985.

SEN rigid for a rigidly gripped single edge notch

Bend, SE(B): K solution is taken from ASTM E399

Extended Compact, ESE(T): K solution is taken from ASTM E 647.

Surface Crack the solution assumes an aspect ratio of 1.

Corner Crack the solution assumes an aspect ratio of 1.

Look-up Table (see further details below)

The DCPD version of the Test Set-up form (shown at the beginning of this section)

includes PD Calibration Type options. When a standard test parameter file is loaded,

the selection of PD calibration type is automatic. However, when creating a unique

parameter file, the user may change the PD calibration. To change a PD calibration, tick

Enable Cal Type, make the desired selection, then untick the Enable Cal Type box.

Send to ADwin. Do not forget to untick the Enable Cal Type box once all changes are

made!

Polynomial: requires the input of user-supplied coefficients. The form of the

equation in terms of a/W is:

a/W = B0+B1(Va/V

B3(Va/V

0,a

V

V

0,a

)3 + B4(Va/V

0,r/Vr

) + B2(Va/V

0,r/Vr

0,a

0,a

V

V

0,r/Vr

0,r/Vr

4

)

)2 +

Page 41 of 148

NLFT Testing - Series 2015 - V3+.16.01

Where:

Va = instantaneous active voltage

V

= starting active voltage

0,a

Vr = instantaneous reference voltage (equal to 1 when reference

probe is not used)

V

= starting active voltage (equal to 1 when reference probe is

0,r

not used)

Johnson’s formula: may be selected for most specimen geometries. This is a

closed form solution for crack length and can be found in ASTM E647. It should

be noted that when applying Johnson’s formula to the C(T) geometry, a starting

a/W > 0.3 and a probe spacing to width ratio of 0.35 gives the most accurate

result.

Surface Crack: for a surface crack or corner crack. The solution assumes an

aspect ratio of 1.0.

Look-up Table: for situations where a polynomial expression or Johnson’s

formula are not sufficiently accurate. The data pairs are entered in a file with the

.dat extension in tabular form as shown in the example below:

Page 42 of 148

NLFT Testing - Series 2015 - V3+.16.01

The first column is the normalized DCPD reading and the second column is the

corresponding crack-length to width ratio (a/W).

The Geometry Type is selected automatically when the appropriate test parameter file

is loaded. It may be changed, however, when the user is testing a specimen geometry

for which a test parameter file does not exist or when creating a new test parameter file

from scratch. To change a Geometry calibration, tick the Enable Cal Type box, make

the desired selection, then untick the Enable Cal Type box. Send to ADwin. Do not

forget to untick the Enable Cal Type box once all changes are made!

The Geometry Type is necessary to assign eta and gamma functions for non-linear

fracture toughness. It is not necessary to assign a geometry for linear elastic fracture

toughness.

C(T): compact of similar type

M(T): center crack

SEN(B): single edge crack bend

SEN(pin): single edge crack tension (pin loaded)

SEN(rigid): single edge crack tension (clamped)

Neutral: no geometry adjustment

Page 43 of 148

NLFT Testing - Series 2015 - V3+.16.01

4.4.2.3 Coefficients

This tab displays the coefficients of fifth-order polynomial expressions used to calculate

stress intensity and crack length. When a selection other than Polynomial is made on

the Initialize tab, the coefficient fields on this tab are disabled and appear in gray.

Compliance coefficients are required in all cases for the compliance method of cracklength determination. DCPD applications using polynomial expressions for crack length

will require input of user-supplied coefficients.

The Coefficients tab shown displays the correct values for a C(T) specimen with a

front-face mounted clip gage (CT-comp-load line.pr5).

Page 44 of 148

NLFT Testing - Series 2015 - V3+.16.01

When using an FTA-provided parameter file, the Stress Intensity and Compliance

ranges displayed at the bottom of the tab are for information only. Consult FTA for more

information on user-generated look-up tables.

Page 45 of 148

NLFT Testing - Series 2015 - V3+.16.01

4.4.2.4 Dimensions

The following values must be entered by the user:

Specimen Thickness, B (NB When testing surface-crack or corner-crack

specimens, width and thickness dimensions are reversed)

Net Specimen Thickness, B

grooves, Net Specimen Thickness must equal Specimen Thickness, as in the

example above.

Specimen Width, W. For center-crack specimens enter half the full panel width.

(NB When testing surface-crack or corner-crack specimens, width and thickness

dimensions are reversed)

Span to Width Ratio(bend bars)

Page 46 of 148

NLFT Testing - Series 2015 - V3+.16.01

, for side-grooved samples. If there are no side-

net

Pin Spacing.

Modulus of Elasticity, E.

Yield Stress ys.

Tensile Stress

ult

.

Crack Length

Limit Load is automatically calculated by the program in reference to the other

dimensions entered by the user.

The ADC Data Burst Count parameter specifies the number of analog-to-digital

conversions that are averaged for each data point. A value of 83 is recommended since

this number cancels 60 Hz AC noise.

Page 47 of 148

NLFT Testing - Series 2015 - V3+.16.01

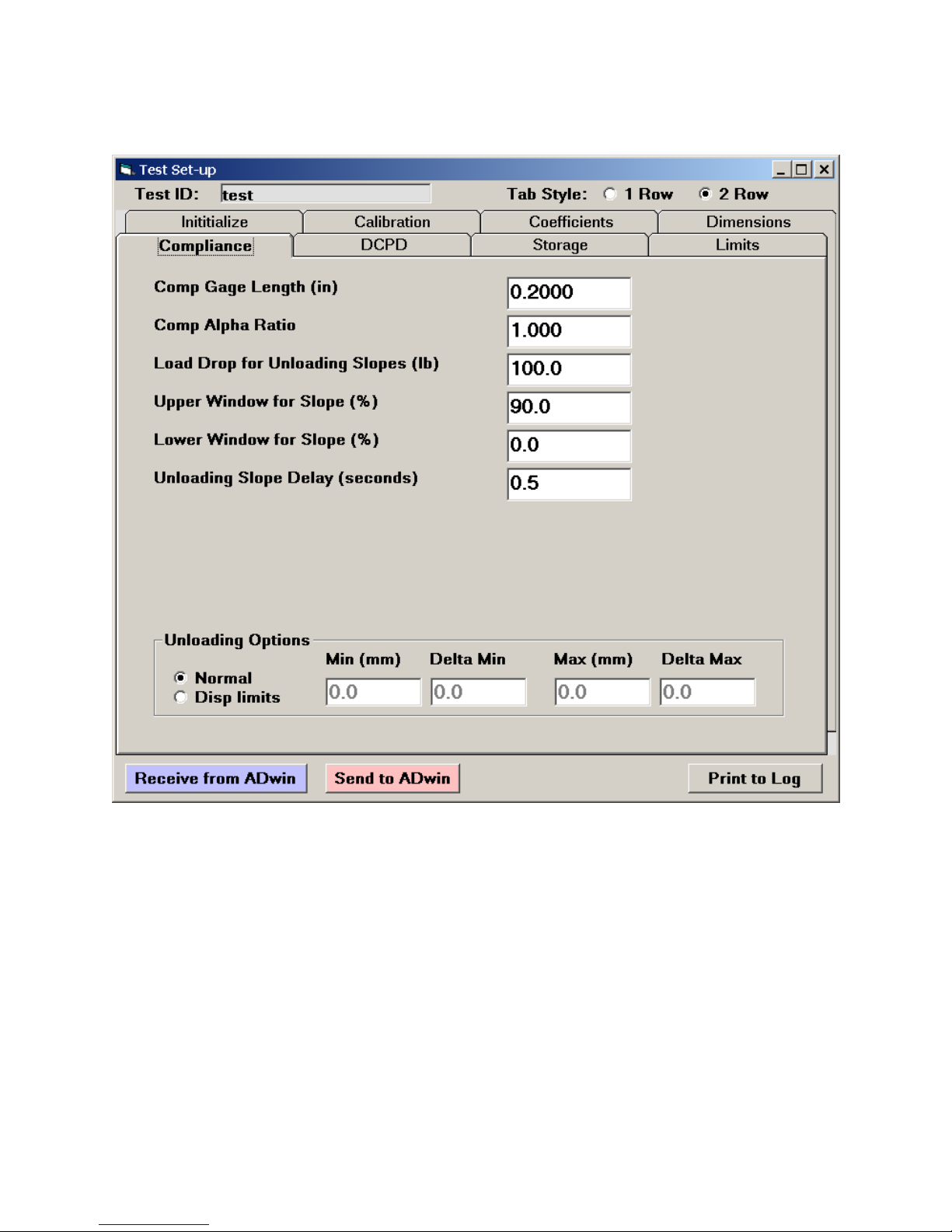

4.4.2.5 Compliance

The Compliance tab defines the parameters related to crack measurement using

unloading slopes.

The following values must be entered by the user:

Comp[liance] Gage Length.

Comp[liance] Alpha Ratio: the ratio between the gage location to back edge

distance divided by the specimen width. For example, when testing a C(T)

specimen with displacement measured on the load line, alpha = 1. If a front-face

displacement measurement is made, alpha = 1.25.

Page 48 of 148

NLFT Testing - Series 2015 - V3+.16.01

Load Drop for Unloading Slopes: the load drop value, expressed in pounds,

should not exceed 20% of the limit load. If no unloading slopes are required

during the test, enter zero.

Upper Window for Slope: specifies the upper cutoff for unloading compliance

slope measurement based upon percentage of load drop. The excluded portion

of the slope is displayed in red on the Load-displacement Display. During a

long test, it can be useful to decrease this window to capture the linear part of the

slope only. The default value of 90% (corresponding to the lower 90% of the

slope) is recommended at the start of tests, but this window can be decreased to

as much as 50% if the specimen undergoes severe deformation (it is good

practice to increase the Load Drop in this case). Slopes can also be

reprocessed during analysis using the Testing Playback software (discussed in

Section 8 of this manual).

Lower Window for Slope: specifies the lower cutoff for unloading compliance

slope measurement based upon percentage of load drop. The excluded portion

of the slope is displayed in red on the Load-displacement Display. Generally a

value of 0% is recommended.

Unloading Slope Delay: specifies the time interval between holding the

command signal at load and starting the unloading slope. The default value of 1

second is recommended for most applications where no creep effect is expected

Unloading Options: allows optional displacement limits for unloading slopes.

This is used for cyclic J and is beyond the scope of this manual.

Page 49 of 148

NLFT Testing - Series 2015 - V3+.16.01

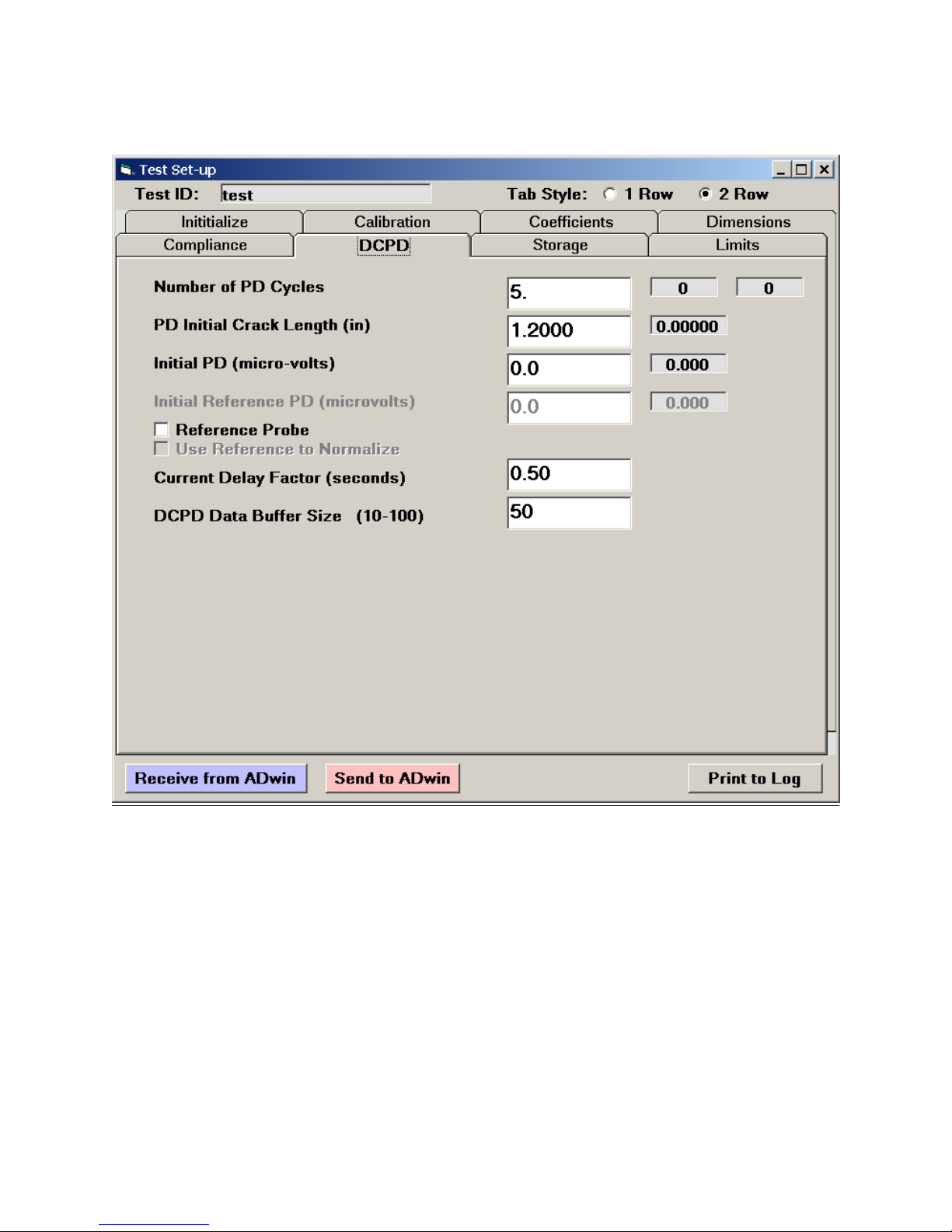

4.4.2.6 DCPD

The DCPD tab defines the parameters related to crack measurement using DC potential

drop.

The following values must be entered by the user:

PD Number of PD Cycles: … required to determine crack length. A large

number gives greater crack length precision but does not update the crack length

as often. A value of 2 to 5 is appropriate for most applications.