Page 1

www.fsm.ag

Telefon +49 7661 9855 0

vertrieb@fsm.ag

FSM AG

Erich-Rieder-Straße 2

D-79199 Kirchzarten

1

Operating instructions

Pressure sensor | Type DPS/ APS

1612_02

Page 2

www.fsm.ag

Telefon +49 7661 9855 0

vertrieb@fsm.ag

FSM AG

Erich-Rieder-Straße 2

D-79199 Kirchzarten

2

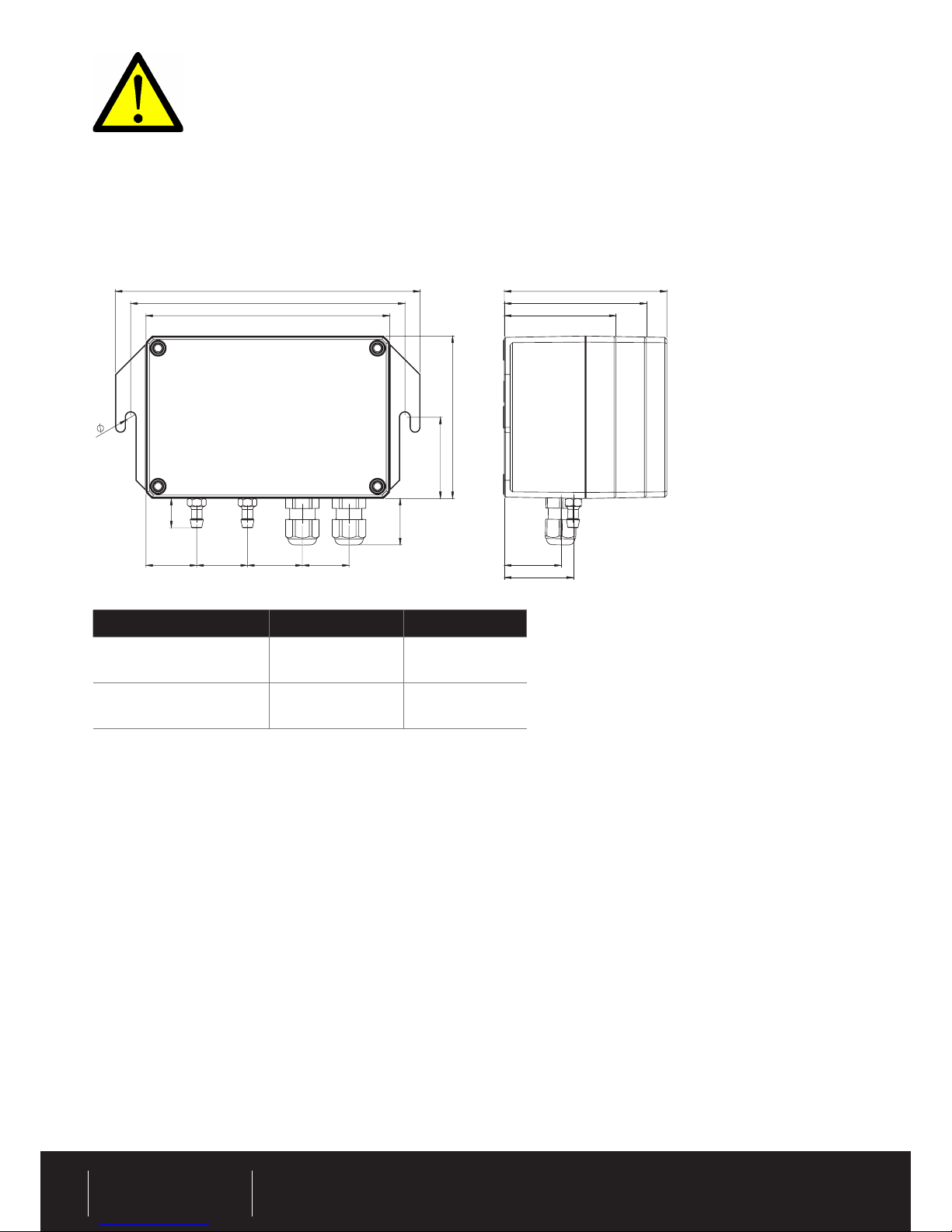

Drawing

Version Supply Output

Four-wire

1 = N

2 = L1

3 = 0

4 = output

Three-wire

1 = 0

2 = VDC

3 = 0

4 = output

Calibration

The pressure sensors are calibrated in the factory. If necessary recalibrate according to the calibration instructions.

Safety precautions and personnel protection

For the correct and safe use of this instrument it is important that the VDE (or similar association) safety precautions as

well as the safety precautions of the professional/trade association having liability for industrial safety regarding the operation

of electrical instruments and equipment be observed.

Installation

Using both straps the pressure sensors are connected to the mounting ttings. Avoid having interference sources (transformers,

transmitters, motors etc.) or heat sources in the neighbourhood. Shocks or vibrations at the mounting connection

can cause distortions to the output signals. Connections should be vertical, i.e. the pressure connections should point

downwards. The sensors are calibrated in the factory for such mounting conditions. In addition the formation of condensation

in the pressure tubing of the sensor is also reduced.

Preparations befor operation

Prior to operation remove the housing cover. Electrical connections are made using terminal connections. Take care when

connecting the power supply. Do not connect the power supply to the output connectors. Instruments with a DC power

supply are reverse-connect protected. The output signal of the sensors is short-circuit protected.

The pressure transducers of the DPS type series are suitable for detection of excess pressure, low pressure or differential pressure of non-aggressive gasses. Pressure measurement is carried out using CuBe membranes sensitive to the respective pressure

range. Using an inductive system the membrane systems are ‘force-free’ scanned.

Note: Commissioning may only be reliable, trained or assigned personnel.

25 25 27 23

23

14,50

150

135

120

40

80

5

80

55

70

28

34

Page 3

www.fsm.ag

Telefon +49 7661 9855 0

vertrieb@fsm.ag

FSM AG

Erich-Rieder-Straße 2

D-79199 Kirchzarten

3

After switching on the power supply the output signal can be measured. Variations in the output signals may be due to two

possible causes:

1) The warm-up time of the sensor is about one hour. After this period the sensor signal should be stable for zero

differential pressure and constant ambient temperature.

2) For small pressure ranges a measurable zero-point shift due to ambient conditions can occur. This error can be

corrected for by adjusting the zero-point potentiometer of the sensor after the warm-up time is completed. (Set the output

signal of the sensor with both pressure inputs open to the nominal value).

Connection the pressure to be measured

The pressure to be measured should be connected to the „+“ input. APS sensors (absolute pressure) have only one pressure

connection. Do not blow into this pressure connection. This can damage or destroy measuring cells for pressures up to

100 hPa.

Transport and storage

Ambient storage temp. range: -10 °C to + 70 °C For transport make sure that both pressure inputs of differential pressure

sensors are open. Air transport of absolute pressure sensors should only be done in pressure compensated cabin.

Calibration instructions

Use the following tools for calibration of the pressure sensor:

Reference pressure

Precision manometer, digital manometer, DPC-pressure calibtraor; for APS use absolute pressure

reference

Pressure source Pumps, bellows or DCP-pressure calibrator

Supply Depending on the pressure measuring transducers

Measuring instruments Multimeter to measure the output current or voltage signals

Calibration of type DPS

1. Connect the correct power supply between terminals 1 and 2.

2. Connect the multimeter to measure the output signals (current or voltage) between terminals 3 and 4.

3. Wait for the sensor to warm-up (ca. 1 hour).

4. To adjust the zero-point both pressure inputs must be open. Using the trimmer TP1 set the display of the multimeter to 0 Volt

(for current output 0 (4) mA).

5. To adjust the full-scale deection using a T-connector apply the rated pressure to the pressure connection of the sensor, the

pressure source and the pressure reference. Using the trimmer TP2 set the display of the multimeter to 10 Volt (for current

output 20 mA).

Page 4

www.fsm.ag

Telefon +49 7661 9855 0

vertrieb@fsm.ag

FSM AG

Erich-Rieder-Straße 2

D-79199 Kirchzarten

4

www.fsm.ag

Calibration of type APS

1. Connect the correct power supply between terminals 1 and 2.

2. Connect the multimeter to measure the output signals (current or voltage) between terminals 3 and 4.

3. Wait for the sensor to warm-up (ca. 1 hour).

4. Using a T-connector connect the pressure input of the sensor with the pressure source and the absolute pressure reference.

Adjust the absolute pressure so that the output signal of the sensor is 0 Volt (for current output 0(4) mA). Using the trimmer

TP1 set the multimeter display to the corresponding value.

5. Apply an absolute pressure to the pressure input to the sensor so that the output signal is 10 Volt (for current output20 mA).

Using the trimmer TP2 set the multimeter display to the corresponding value.

Response times

C14: Capacitor for electronic attenuation

Response times (t):

> t ≈ R x C

> C ≈ t / 50 kOhm

> R = 50 k

Notes

Additional trimmers (TP3 to TP7) are installed in some options:

> TP3: Matching trimmer for sensors with „+/-„ measurement ranges.

> TP4: Adjustment of the internal resistance for current output.

> TP5/TP6: Adjustment trimmer for special pressure ranges and special output signals.

> TP7: Scaling and matching of analog and digital displays.

These trimmers are initially set in the factory. Adjusting these trimmers should only be done after consultation with the

supplier. Readjustment of the sensor does not require readjustment of the trimmers TP3 to TP7. Only the trimmers TP1

and TP2 must be readjusted if necessary according to the calibration instructions.

Loading...

Loading...