FScurtis CA series, ES03, ES05, ES06, ES10 Installation And Operating Instruction Manual

...

CAP600AE

NOVEMBER, 2008

AIR COMPRESSOR

INSTALLATION AND

OPERATING INSTRUCTION

MANUAL

Before installing and operating this compressor, read

and understand the safety precautions contained in

LV-474 supplement to and part of CAP-600

IMPORTANT

Make a permanent record of the

Model and Serial number of

your machine here. You’ll save

time and expense by including

this reference identification on

replacement part orders.

*CONSULT FACTORY FOR SPECIAL APPLICATIONS

WARNING

CURTIS-TOLEDO, INC.

1905 Kienlen Avenue

St. Louis, MO 63133

REFER TO MODEL & SERIAL NUMBER.

READ INSTAL. & OPERATION INSTR.

DO NOT OPERATE LOW ER THAN 500

R.P.M. OR ABOVE MAX. AS STIPULATED

BY PERFORMANCE DATA SHEET.

SERIAL NO.MODEL NO.

CURTIS-TOLEDO, INC.

1905 Kienlen Avenue, St. Louis, Missouri 63133

phone: 314-383-1300 fax: 314-381-1439

email:info@curtistoledo.com website: www.fscurtis.com

Sales representatives in principal cities

CAP-600

INSTALLATION

CONGRATULATIONS on your new Curtis

Challenge Air Compressor. Please examine the

compressor for shipping damage(s) and if any are

found report it immediately to the carrier.

Select a clean dry location with a rigid floor strong

enough to support the compressor. If the

compressor is to be located in an area where

vibration is critical, properly engineered vibration

mounts and flexible piping should be used.

Remove the skid. NOTE: The compressor should

never be operated on the shipping skid. Level

the compressor so it can be bolted down securely.

Before tightening the bolts, check to see that all

four feet are resting on the foundation. Shim as

necessary to eliminate stress on the receiver or

base when the bolts are tightened. We suggest

using a level for proper alignment.

Maximum ambient temperature in which the

compressor and motor should be operated is

104°F. Therefore, adequate ventilation must be

provided.

The suction openings of the compressor are

equipped with a combination air filter-muffler to

protect the compressor from normal dust and other

harmful substances. If the air around the

compressor is excessively hot, dusty, humid or

contaminated with foreign gases (such as ammonia

or acid fumes) move the filter-muffler to a remote

point where the air is clean, cool and dry. Run a

pipe to the compressor suction opening. If the run

is over 50 feet in length, use a larger pipe to avoid

excessive pressure drop. In order to fit the filter to

the compressor, bush down the connections. Be

sure piping and fittings are clean and free from dirt

and chips. If the filter is installed outside, check to

insure that it is located above the normal outside

dust level, and that rain cannot enter the filter

element. Where the relocation of the filter-muffler

is not possible or feasible, an oil bath filter is

recommended and is available from Curtis.

LIMITED SAFETY PRECAUTIONS

(Also see supplement LV-474)

The following safety precautions are recommended

in the use of this compressor:

1. Use a totally enclosed OSHA-approved belt

guard to cover the drive assembly. Where

possible, place the flywheel toward the wall, and

mount the unit a minimum distance of 2 feet from

the wall for maintenance convenience.

2. Turn off & lock out the electrical disconnect

switch before working on the unit to prevent the

unit from starting unexpectedly

WARNING: Read and understand supplement LV-474 before installing and operating the compressor.

On basic or base mounted compressors run a

discharge pipe to the receiver or optional

aftercooler and bush up or down as necessary.

The pipe should enter near the top of the receiver.

Keep in mind that condensate may form in the

discharge line; therefore, the lines should always

be pitched to drain condensate away from the

compressor. Always provide a safety relief valve in

the discharge line between the compressor and inline shutoff valves. If more than one compressor

pumps into a common system, a check valve in the

discharge line of each compressor is recommended

to prevent moisture from entering the cylinder head

when one compressor is idle. A globe or gate valve

installed in the discharge line will allow compressor

isolation from plant air system for compressor

maintenance. (Note: A safety relief valve should be

located between the compressor and the

globe/gate valve.)

Check the electrical supply for voltage, phase, and

frequency to see that they match the nameplate

stampings on the motor, magnetic starter,

solenoids, and other controls. Use electrical wires

of adequate size to carry the full load current of the

motor without excessive voltage drop. Charts are

available from Curtis (upon request) to provide

information on this. The motor must always be

protected by a starter with properly sized thermal

overload(s). The starter should protect the motor

from overheating and burnout due to an overload,

low voltage or single phasing of a 3-phase circuit.

Failure to install the proper starter and

overloads will void the motor manufacturers

warranty. Follow the National Electric Code or

local electric code in providing wiring, fusing and

disconnect switches. NOTE: Do not close the

disconnect switch to start the compressor until

the procedures outlined under "Startup

Procedures" have been completed.

3. Release all air pressure from the system before

working on the unit and red tag all electrical

control switches, for safety precaution.

4. Do not by-pass motor over-current protection.

5. Do not change the setting or in any way affect

the operation of the safety valve.

6. Keep unit securely anchored so that movement

will not put a strain on piping, wiring, or air

receiver.

2

START-UP PROCEDURES

OIL RECOMMENDATION

Use Genuine CURTISLUBEPLUS Lubricants. Specially

formulated for Curtis Reciprocating Air Compressors. NonDetergent type with anti-foam, anti-rust and oxidation inhibitors.

Recommended ISO68 RC-1000 Premium Reciprocating

Compressor Lubricant, Part no. VO411-3, 12-quart case or

VO411-2, 4 gallon case.

Recommended ISO100 RC-1000A Premium Reciprocating

Compressor Lubricant Part no. VO421-3, 12-quart case or

VO421-2, 4 gallon case.

CURTISLUBEPLUS Lubricants are available through your

authorized Curtis distributor.

CAP-600

If the compressor is equipped with an automatic start-stop

control (with pressure switch unloading), it is automatically

unloaded upon starting, and will automatically load after

attaining running speed. If the compressor is equipped with

a constant speed control (pilot valve unloading), it is

necessary to manually unload the compressor, if there is

pressure in the discharge line, in order to achieve an

unloaded start. The compressor must be manually loaded

after the compressor has attained full running speed, there

after, it functions automatically to maintain operating

pressure until the unit is shut off.

Close the disconnect switch and start the compressor.

Observe the direction of rotation, which should be

counterclockwise when viewed from the flywheel side of the

compressor on all models. For single-phase units, the

direction of rotation is determined by the motor nameplate

instructions, and is adjusted at the factory. For three-phase

units, if the rotation is incorrect, stop the unit and

interchange any two of the three wires to the motor at the

disconnect switch. This will reverse the direction of rotation

of the motor and compressor.

PREVENTIVE MAINTENANCE

A good maintenance program will add years of service to your air

compressor. The following is recommended as a minimum

maintenance program. (TURN OFF POWER BEFORE

SERVICING.)

LUBRICATION

1. For proper lubrication the compressor shall not be

operated below the minimum or above the maximum R. P.M.

recommended for the various models.

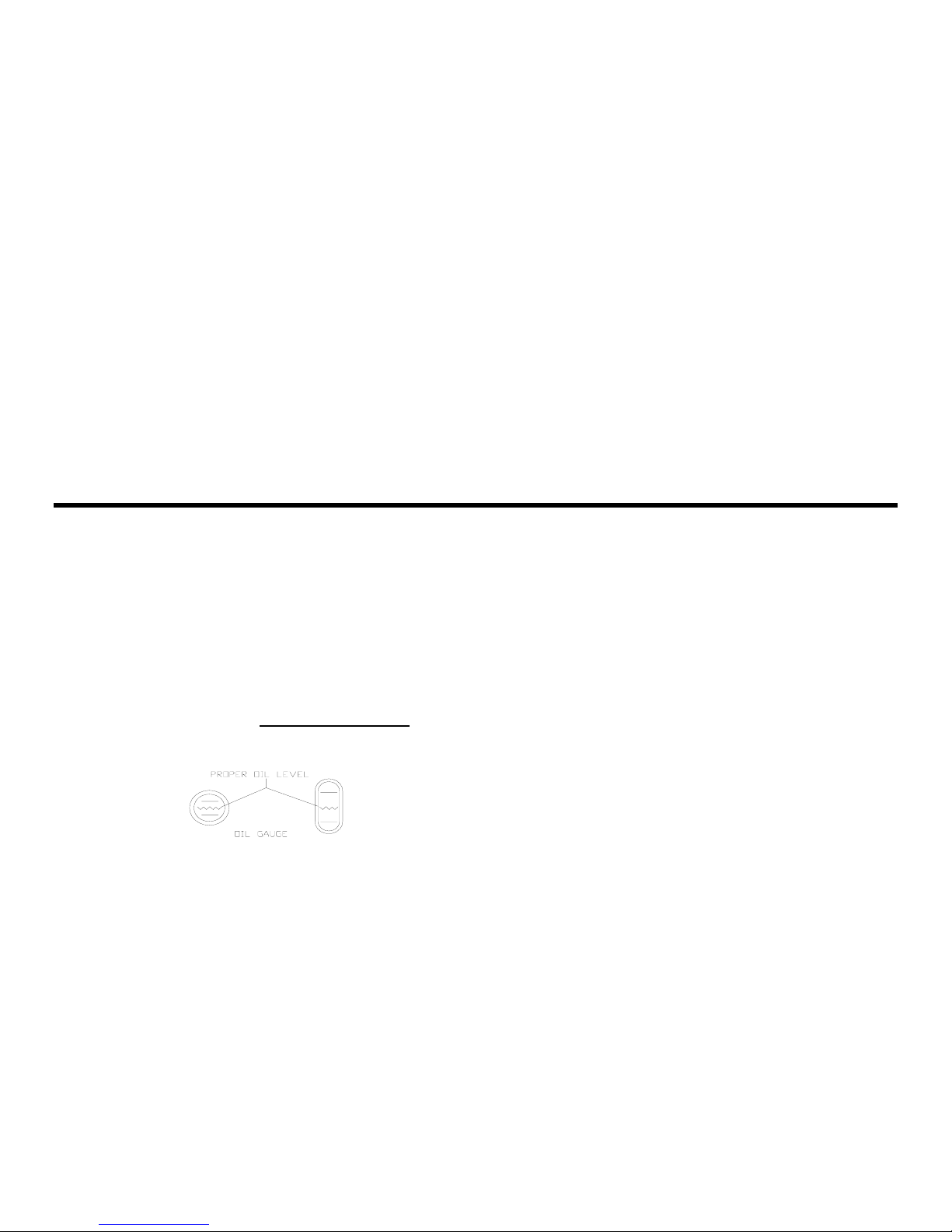

2. Maintain oil level mid-way between the upper and lower lines

of the crankcase sight gage.

3. Stop compressor to add and gauge oil.

4. Do not fill above the upper line and do not operate compressor

with oil level below the lower line.

DO NOT OVER FILL

5. Change oil at the first 100 hours of operation and 1000 hours

thereafter, or as required. It may be necessary to change oil

more frequent due to abnormal humid and contaminated

conditions.

DAILY MAINTENANCE

1. Check and maintain oil level at centerline of sight glass and

add oil as necessary.

2. Drain condensate from receiver unless it is equipped with an

automatic tank drain, in which case the drain should be

checked weekly to see that it is operating. See automatic tank

drain instructions.

NOTE ILLUSTRATION:

WARNING: Read and understand supplement LV-474 before installing and operating the compressor.

3. Check for unusual noise or vibration (See "Trouble Shooting".)

WEEKLY MAINTENANCE

1. Clean the air filters. A clogged air filter can seriously affect the

efficiency of the compressor and cause overheating and oil

usage.

2. Clean all external parts of the compressor and driver. Be sure

to clean the intercooler-finned surface on two-stage

compressors. A dirty compressor will cause abnormally high

discharge temperature and resulting oil carbonization on

internal valve components

3. Check the safety valve manually (by pulling ring or lever) to

see that it is not stuck.

MONTHLY MAINTENANCE

1. Inspect the entire air system for leaks.

2. lnspect condition of oil and change if necessary.

3. Check drive belt tension and tighten if needed.

EVERY 3 MOS. OR 1,000 HRS. OF OPERATION

1. Change oil.

2. lnspect valves. Clean the carbon from valves and head if

necessary.

3. Check and tighten if necessary all bolts, nuts, etc.

4. Check unloader operation.

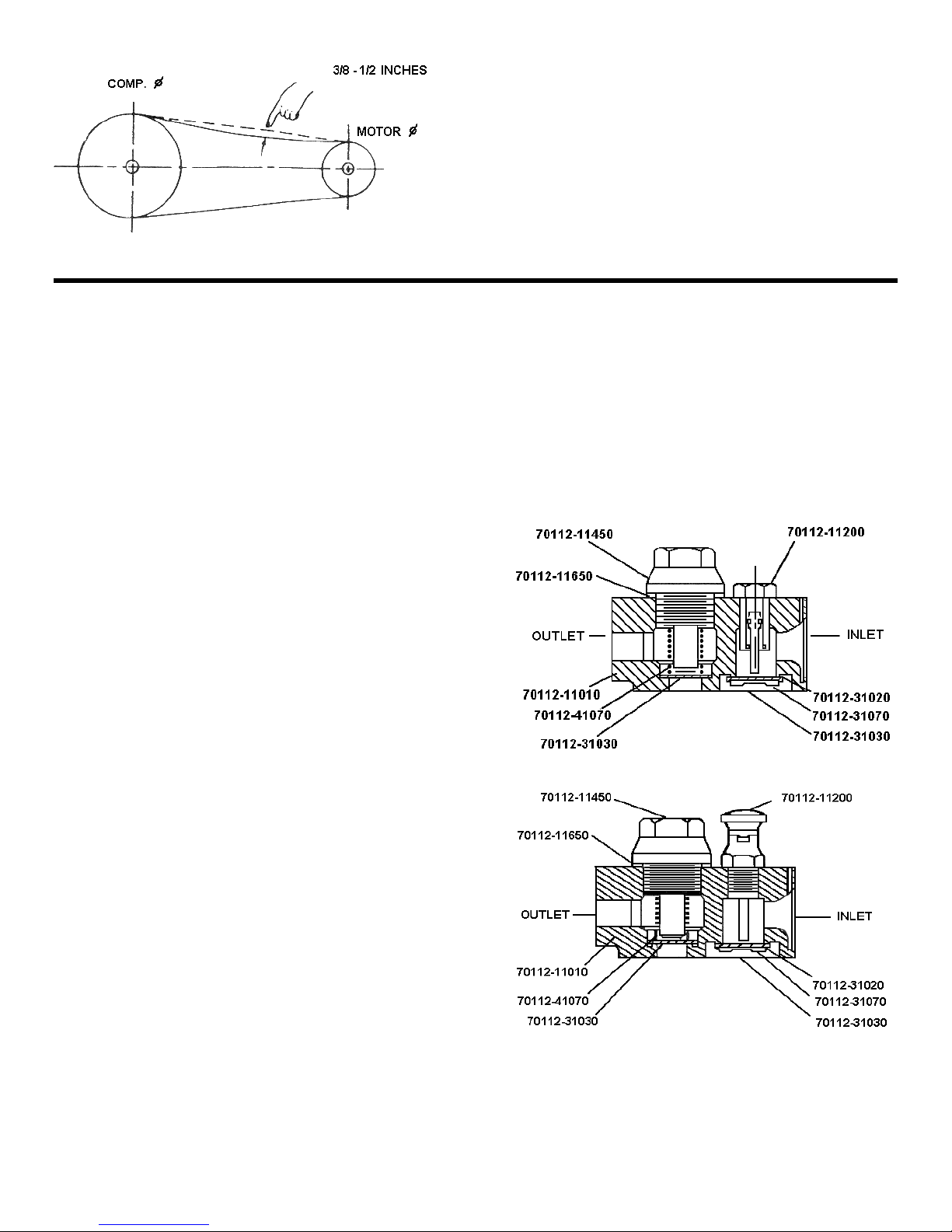

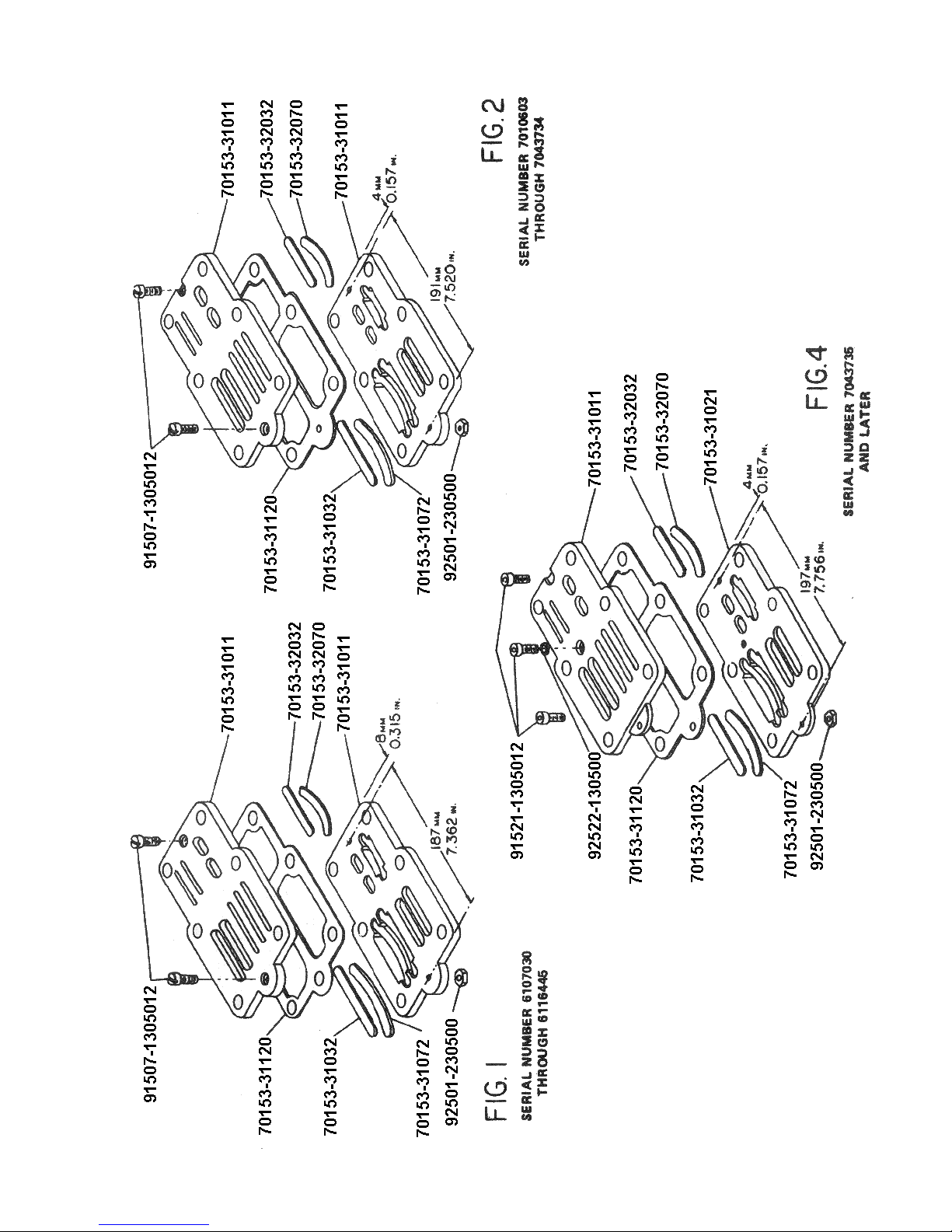

*CHECKING BELT TENSION

The v-belt(s) should be adjusted so that a declination of about 3/8

– 1/2 inch will be obtained when it is pushed by a finger at the

middle point as shown in Figure 1.

CAUTION: Over tightening the v-belt(s) will result in

overloading of the motor and belt failure, while a loose belt

will be slipping and resulting in an unstable speed,

overheating the belt and high amp draw.

3

Figure 1

VALVE INSPECTION AND MAINTENANCE

Valves should be inspected at regular intervals as

recommended under "Maintenance" and cleaned or

replaced when necessary. The valve can be serviced

without disconnecting air piping or removing the head.

(Be sure the power to the motor is disconnected and

all pressure released before starting to work on the

compressor.)

On constant run models, it is necessary to remove the

unloader piping before the valve plugs can be removed.

MODELS E-11 AND E-23 (Figures 2 and 3)

A. Disassembly:

1. Unbolt the outlet valve push cover (70112- 11450).

2. Remove the outlet valve push cover packing (70112-

11650), spring (70112-41070) and valve plate (70112-

31030). CAUTION: Steps 1 and 2 are for outlet

valve.

3. Remove the unloading connecting tube for Models

E-11 and E-23.

4. Untighten four cylinder head fixed bolts.

5. Remove cylinder head carefully and turn it over.

6. Unbolt inlet valve receiver (70112-31020).

7. Remove valve spring (70112-31070) and valve plate

(70112-31030).

Valves should be inspected approximately every 1,000

hours of operation. Inspect the valve seats on

cylinder head for dents, cracks or wear. Replace all

defective parts. Remove carbon deposits and wash all

valve components in a suitable non-flammable

cleaning fluid.

B. Assembly:

1. Place outlet valve plate (70112-31030) in position.

2. Place the outlet valve push cover packing (70112-

11650) in position.

3. Insert the spring (70112-41070) into outlet valve push

cover (70112-11450).

4. Turn outlet valve push cover (70112-11450) in position

carefully.

CAP-600

To change tension, loosen the motor hold-down bolts and

slide the motor on the base, using a lever if necessary, or

by turning the adjusting bolt at the end of the base.

Retighten motor hold-down bolts.

NOTE: Do not over tighten belts.

ELECTRIC MOTOR

Grease once a year with a good grade of lithium ball

bearing grease, or as directed by the motor manufacturer.

5. Check the valves to see if they can move freely in their

guides.

6. Turn over the cylinder head (70112-11010).

7. Place the inlet valve plate (70112-31030) in position.

8. Insert the small end of inlet valve spring (70112-

31070) into position of valve receiver (70112- 31020).

9. Screw inlet valve receiver in position.

10. Check the valves to see if they can move freely in their

guides and do not pinch or bind between the seat and

guard legs.

Figure 2

WARNING: Read and understand supplement LV-474 before installing and operating the compressor.

Figure 3

4

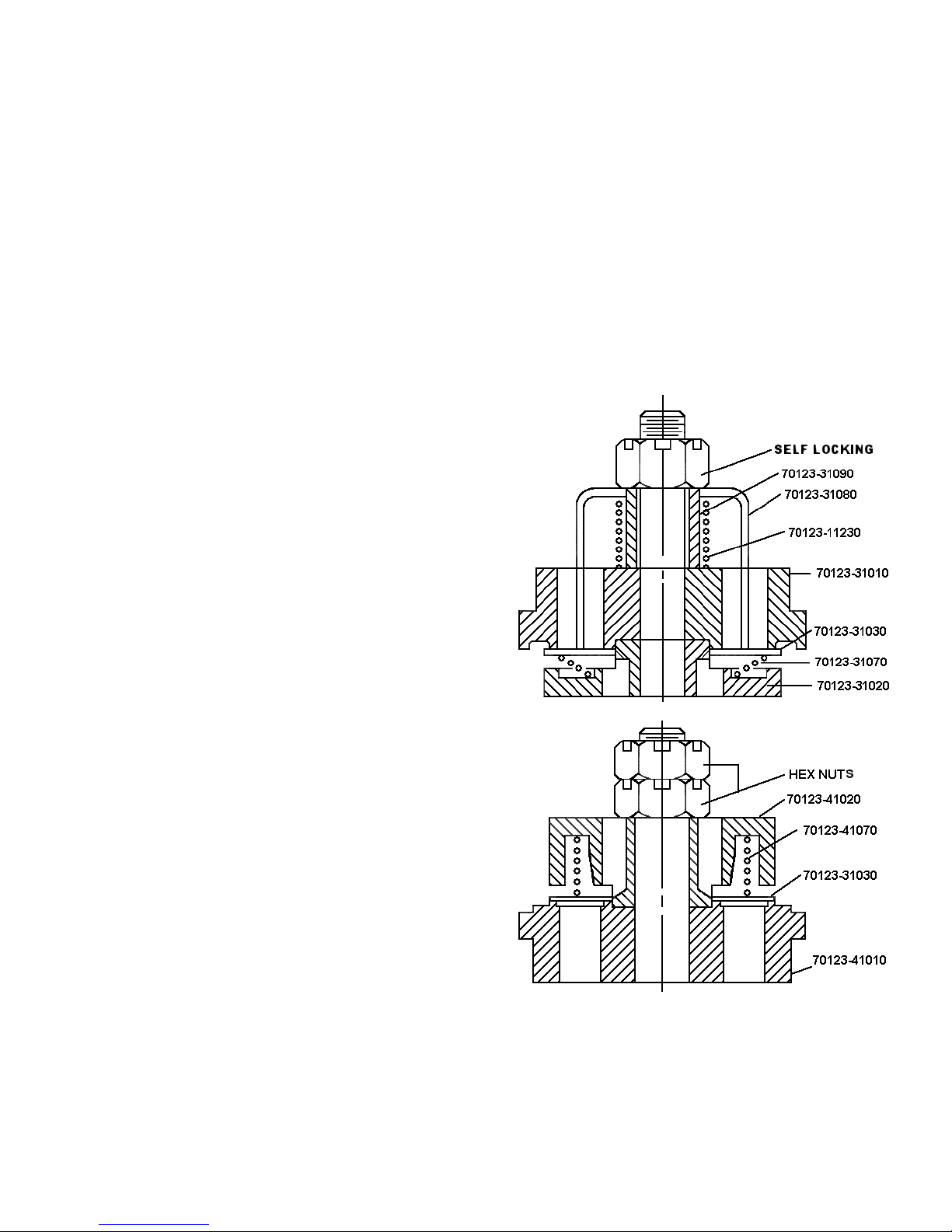

MODELS E-50, E-71 AND E-15 (Figures 4 and 5)

A. Disassembly of Inlet Valve Assembly (Figure 4).

1. Untighten the hex nut.

2. Remove unloading fork (70123-31080), unloading fork

guide (70123-31090), unloading spring (70123-11230)

and valve seat (70123-31010).

CAUTION:

1. If a vise is used to hold the valve assembly, be

careful not to clamp the assembly too tight.

2. Valve assembly should be inspected approximately

every 1,000 hours of operation.

3. Inspect the valve seat for dents, cracks or wear.

4. Replace all defective parts.

5. Valve seats that might be worn after years of

operation can be re-lapped or re-ground, in this

case the recess in which the valve guard legs fit

must also be cut down accordingly to ensure a

same valve lift.

6. Remove carbon deposits and wash all valve

components in a suitable non-flammable cleaning

fluid.

B. Reassembly of Inlet Valve Assembly

1. Place valve spring (70123-31070) and valve plate

(70123-31030) on valve receiver (70123-31020).

2. Place valve seat (70123-31010), unloading fork guide

70123-31090), unloading spring (70123- 11230) and

unloading fork (70123-31080) respectively.

3. Tighten the valve assembly by tightening the hex nut.

4. Check the valves to see if they can move freely in their

guides and do not pinch or bind between the seat and

guard legs.

C. Disassembly of Outlet Valve Assembly (Figure 5)

1. Untighten the hex nuts.

2. Remove valve receiver (70123-41020), valve spring

(70123-41070) and valve plate (70123-31030).

CAUTION: Refer to disassembly of inlet valve assembly

(paragraph B).

CAP-600

D. Reassembly of Outlet Valve Assembly

1. Place valve spring (70123-41070) in valve receiver

70123-41020).

2. Place valve plate (70123-31030) in valve receiver.

(70123-41020).

3. Insert the sub-assembled part (assembled in

step I and 2) into valve seat (70123-41010).

4. Tighten the hex nuts.

5. Check the valves to see if they can move freely in their

guides and do not pinch or bind between the seat and

guard legs.

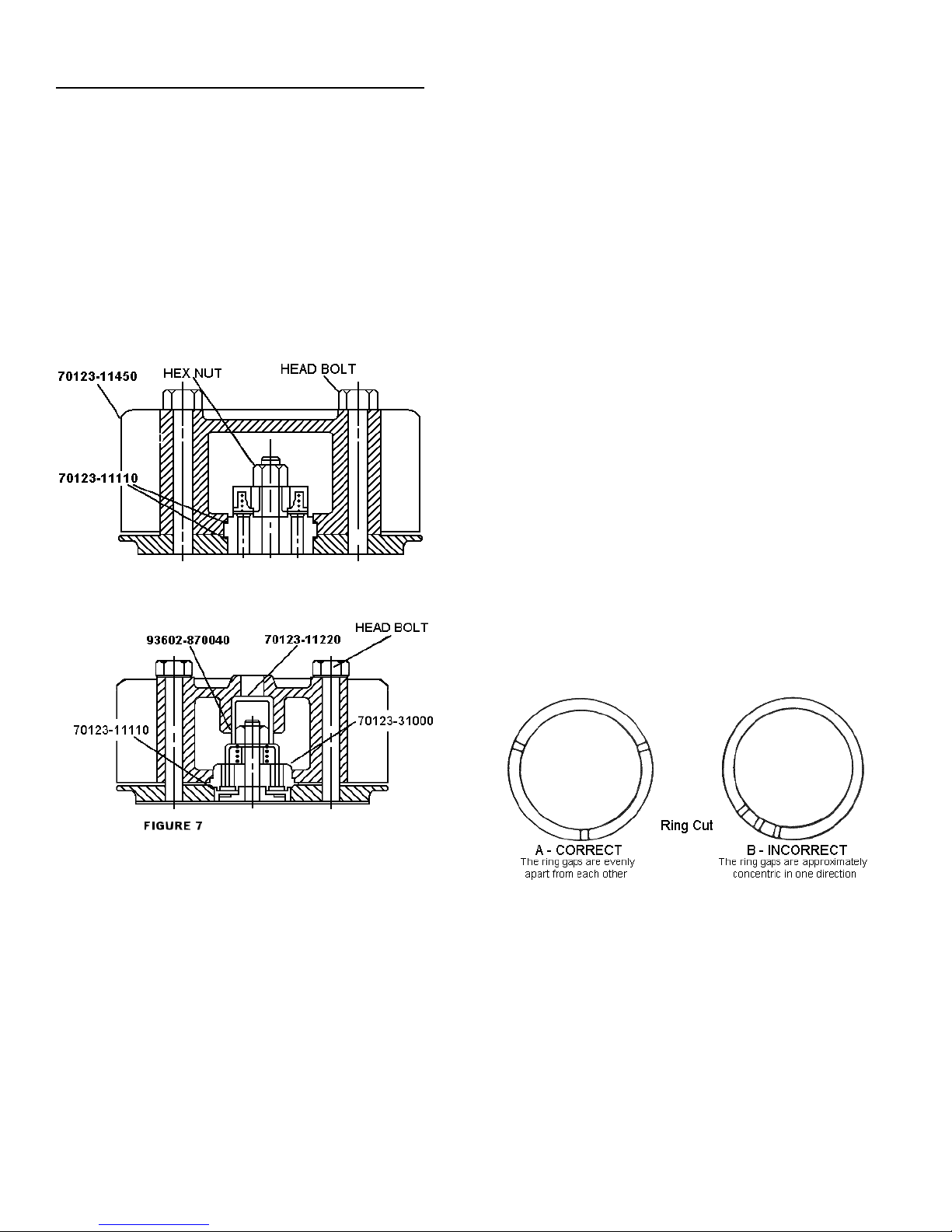

FIGURE 4 (EXAMPLE SHOWN E-50)

WARNING: Read and understand supplement LV-474 before installing and operating the compressor.

FIGURE 5

5

(EXAMPLE SHOWN E-50)

VALVE ASSEMBLY INSTALLATION - E-50 MODEL

(Figures 6 and 7)

1. Install valve assembly gasket (70123-11110)

2. Install valve assembly (70123-31000).

3. Install valve push cover (70123-11150).

4. Install head bolt and tighten evenly and securely.

It is strongly recommended that a Preventative

Maintenance Kit & Valve/Gasket Maintenance Kit be kept

on hand. In this manner, the valves can be used in turn to

keep the compressor always in good condition and a

minimum downtime.

FIGURE 6

CAP-600

PISTON RINGS (Rebuild Kit)

To inspect or replace piston rings as follows:

1. Remove cylinder head.

2. Remove cylinder.

3. Loosen the connecting rod bolts.

4. Push out the piston with piston rings and connecting

rod.

5. To remove the old rings, pry them out of their grooves

and slide them over the piston. Care should be taken

not to damage the piston.

6. Inspect the ring grooves for nicks and carbon deposits.

Clean the ring grooves and remove the obstructions,

which might prevent the rings from moving freely.

To install new rings on the piston as follows: (Be

careful not to damage the piston and rings).

1. Install the oil control ring (70123-61050) first. Rotate

ring in groove to make sure it is free.

2. Install the Compression ring (70123-61030). Make sure

the "top" or "R" mark is exactly on top. If not, it might

cause excessive oil consumption.

3. Repeat the process with other rings, if any.

4. Assemble connecting rod into the crankshaft. Be sure

that the connecting rod and its cap are in original pair

and position, since the connecting rod cap and

crankshaft pin bushing are selected fitted and are not

interchangeable.

5. Check if the ring gaps are in proper positions (Figure 8).

FIGURE 8

WARNING: Read and understand supplement LV-474 before installing and operating the compressor.

6

CAP-600

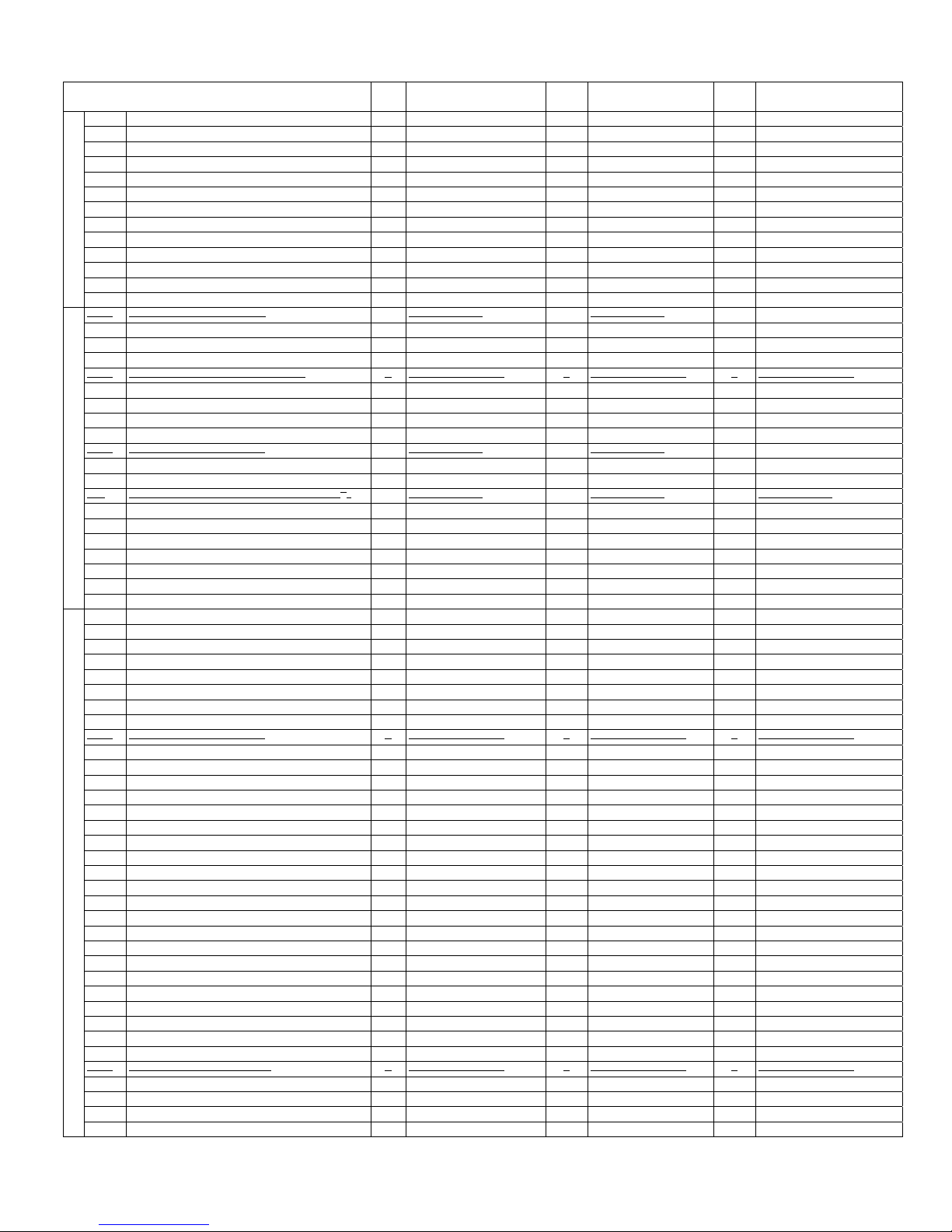

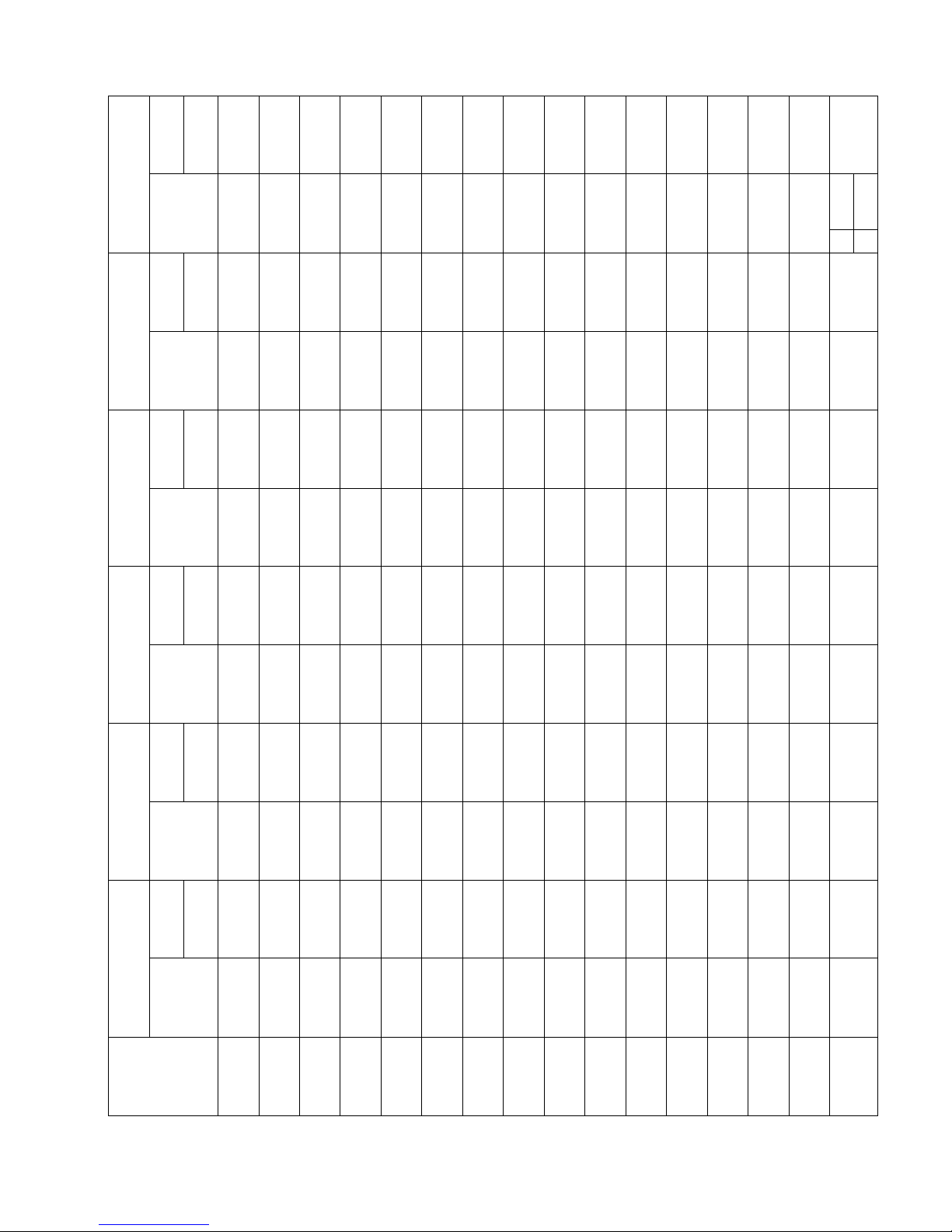

• REBUILD KITS

AIR COOLED SINGLE STAGE MODELS

PART

NO.

CF1237

1 70112-11461 Copper Gasket

ES05

CONSISTS OF:

PART

NO.

CF1299

ES03

CONSISTS OF:

1 70111-66140 Filter Element 1 70111-66140 Filter Element

2 70111-31030 Valve Disc 2 70112-31030 Valve Disc

1 70111-31070 Spring 1 70112-31070 Spring

1 70111-41070 Spring 1 70112-41070 Spring

1 70111-11461 Gasket 2 70112-61030 Comp. Ring

1 70111-11612 Head Gasket 1 70112-61050 Oil Ring

2 70111-61030 Comp. Ring 1 70112-11612 Head Gasket

1 70111-61050 Oil Ring 1 70112-51610 Crankcase Gasket

1 70111-57970 Bottom Cover Gasket 1 70112-57950 Front Cover Gasket

1 70111-57950 Front bearing cover gasket 1 70112-57960 Rear Cover Gasket

1 70111-57080 Front Oil Seal 1 70112-57080 Oil Seal

1 70111-57960 Rear Cover Gasket 12 92521-190800 Copper Washer

10 92521-190600 Copper Washer

ES06 ES10, ES10P ES20

PART

NO.

CF1302

CONSISTS OF:

2 70111-66140 Filter Element 2 70111-66140 Filter Element 3 70111-66140 Filter Element

4 70111-31030 Valve Disc 4 70112-31030 Disc 6 70112-31030 Disc

2 70111-31070 Spring 2 70112-31070 Spring 3 70112-31070 Spring

2 70111-41070 Spring 2 70112-41070 Spring 3 70112-41070 Spring

2 70111-11461 Gasket 4 70112-61030 Compression Ring 6 70112-61030 Compression Ring

2 70111-11612 Head Gasket 2 70112-61050 Oil Ring 3 70112-61050 Oil Ring

2 70121-51610 Crankcase Gasket 2 70112-11612 Head Gasket 3 70112-11612 Head Gasket

4 70111-61030 Comp. Ring 2 70112-51610 Crankcase Gasket 3 70112-51610 Crankcase Gasket

2 70111-61050 Oil Ring 1 70122-57950 Front Cover Gasket 1 70122-57950 Front Cover Gasket

1 70121-57950 Front Cover Gasket 1 70122-57960 Rear Cover Gasket 1 70122-57960 Rear Cover Gasket

1 70111-57960 Rear Cover Gasket 1 70122-57080 Front Oil Seal 1 70122-57080 Front Oil Seal

1 70121-57970 Bottom Cover Gasket 24 92521-190800 Copper Washer 26 92521-190800 Copper Washer

24 92521-190600 Copper Washer 2 70112-11461 Copper Gasket 3 70112-11461 Copper Gasket

PART

NO.

CF1238

CONSISTS OF:

PART

NO.

CF1239

CONSISTS OF:

PART

NO.

CF1246 REBUILD KIT INCLUDES:

2 70123-66140 Filter Kit

4 70123-31030 Disc

2 70123-31070 Spring

2 70123-41070 Spring

4 70123-61030 Compression Ring

4 70123-61050 Oil Ring 6 70123-31030 Disc 6 70124-31030 Disc 6 70125-31030 Disc 3 70125-31030 Disc I / V

4 70123-11110 Seat Gasket 3 70123-31070 Spring 3 70124-31070 Spring 3 70125-31070 Spring 3 70125-31070 Spring

2 70123-11612 Head Gasket 3 70123-41070 Spring 3 70124-41070 Spring 9 70125-41074 Spring 9 701212A1-41075 Spring

2 70123-51610 Crankcase Gasket 6 70123-11110 Seat Gasket 6 70124-11110 Seat Gasket 6 70125-11110 Seat Gasket 6 70125-11110 Seat Gasket

1 70123-57950 Front Cover Gasket 3 70123-11612 Head Gasket 3 70124-11612 Head Gasket 3 70125-87510 Manifold Gasket 3 70125-41030 Disc O / V

1 70123-57960-01 Rear Cover Gasket 3 70125-11610 Head Gasket 3 70125-11612 Head Gasket

1 70123-57080 Front Oil Seal ** 70125-11612 Head Gasket

*2 70123-61081 Bushing

2 70123-61090 Set, Rod Bearing

26 92521-191000 Copper Washer

1 70123-57080 Front Oil Seal 1 70124-57950

6 70123-61030 Compr.Ring 6 70124-61030 Compr.Ring 6 70125-61030 Compression Ring 6 70125-61030 Compression Ring

6 70123-61050 Oil Ring 6 70124-61050 Oil Ring 6 70125-61050 Oil Ring 6 70125-61050 Oil Ring

*3 70123-61081 Bushing 3 70124-61080 Bushing *3 70125-61081 Bushing *3 70125-61081 Bushing

3 70123-61090 Set, Rod Bearing 6 70124-61090 Set, Rod Bearing 3 70125-61090 Set, Bearing 6 70125-61090 Set, Bearing

3 70123-51610 Crankcase Gasket 3 70124-51610 Crankcase Gasket *3 70135-51610 Crankcase Gasket *3 70135-51610 Crankcase Gasket

1 70123-57950

1 70133-57960

ES-30 ES-50 ES-100 ES-150 ES-150A

CONSISTS OF:

PART

NO.

CF1252

3 70123-66140 Filter Element 3 70123-66140 Filter Element 3 70123-66140 Filter Element 3 70123-66140 Filter Element

CF1245

CF1244 REBUILD KIT INCLUDES: CF1242 REBUILD KIT INCLUDES: CF1244 REBUILD KIT INCLUDES: CF1244 REBUILD KIT INCLUDES:

34

CONSISTS OF:

PREVENTATIVE MAINTENANCE

KIT INCLUDES

VALVE / GASKET MAINT. KIT INCLUDES

92521-191000

Frt. Brg. Cvr. Gasket

Rear Brg. Cvr. Gasket

Copper Washer

PART

NO.

CF1252

CF1243

1 70134-57080 Front Oil Seal 1 70135-57950 Frt. Brg.Cvr Gasket 1 70135-57950 Frt. Brg.Cvr Gasket

1 70134-57960

34

CONSISTS OF:

PREVENTATIVE MAINTENANCE

KIT INCLUDES

VALVE / GASKET MAINT. KIT INCLUDES:

Frt. Brg. Cvr. Gasket

92521-191000

Rear Brg. Cvr. Gasket

Copper Washer

PART

NO.

CF1252

CF1241

1 70134-57080 Front Oil Seal 1 70134-57080 Front Oil Seal

1 70134-57960 Rear Brg.Cvr Gasket 1 70134-57960 Rear Brg.Cvr Gasket

24 92521-191000 Copper Washer 24 92521-191000 Copper Washer

CONSISTS OF:

PREVENTATIVE MAINTENANCE

KIT INCLUDES

VALVE / GASKET MAINT. KIT INCLUDES:

PART

NO.

PREVENTATIVE MAINTENANCE

CF1252

KIT INCLUDES

VALVE / GASKET MAINT. KIT INCLUDES:

CF1320

CONSISTS OF:

* WARNING – THESE ITEMS INTERCHANGE WITH PARTS ON SERIAL #3020000 & HIGHER ONLY.

CONTACT FACTORY FOR EARLIER SERIES.

** USE WITH SERIAL #A311XXXX AND LATER

70135-11610 REPLACES 70125-11610

.

7

CAP-600

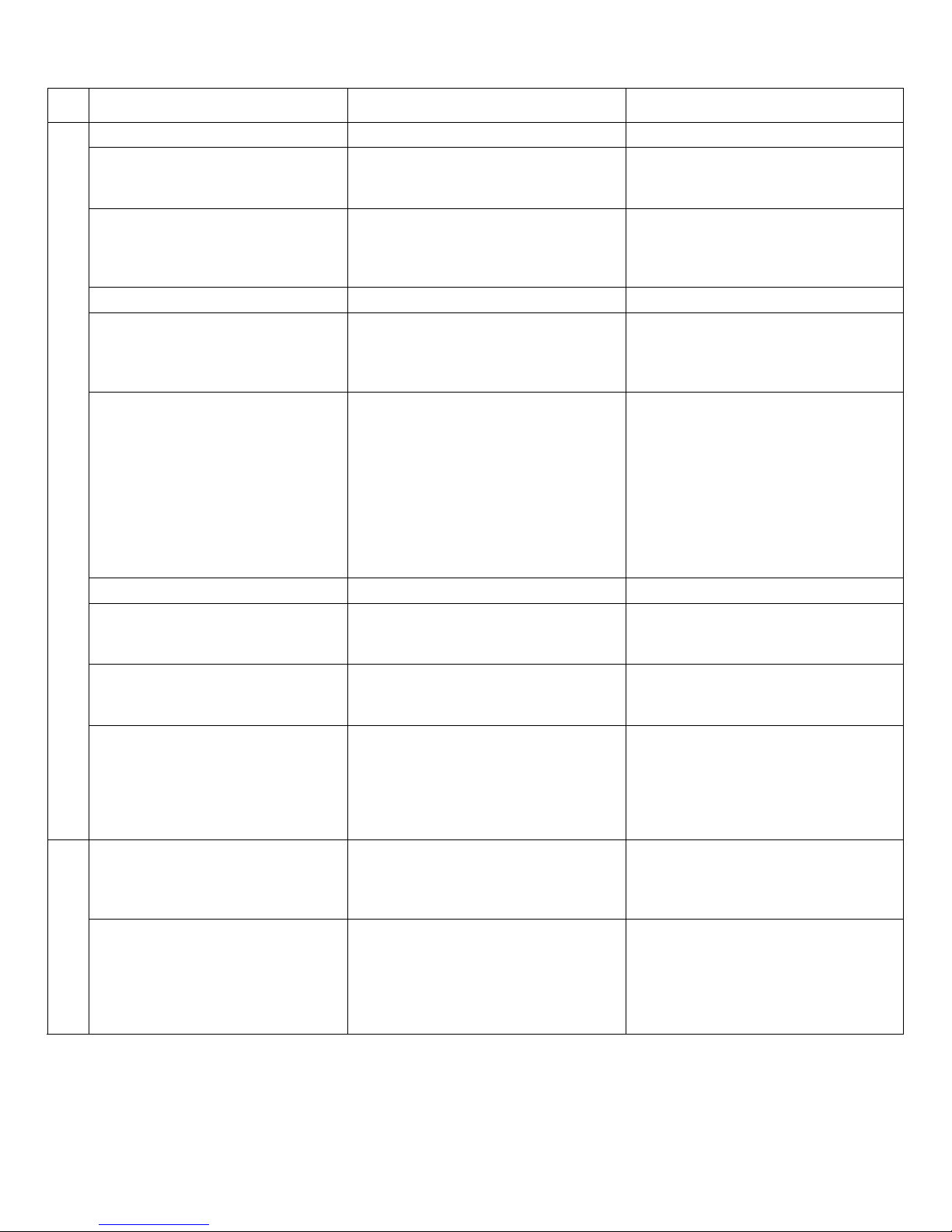

• REBUILD KITS

AIR COOLED TWO STAGE MODELS

E-11 E-23

PART

NO.

CF1250 1 70111-66140 Filter Element CF1251 2 70111-66140 Filter Element

2 70112-31030 Disc 4 70112-31030 Disc

2 70162-32030 Disc 2 70111-31030 Disc

1 70112-31070 Spring 2 70112-31070 Spring

1 70162-42070 Spring 2 70112-41070 Spring

1 70112-41070 Spring 1 70172-32070 Spring

1 70162-32070 Spring 1 70172-42070 Spring

2 70112-61030 Compression Ring 4 70112-61030 Compression Ring

1 70112-61050 Oil Ring 2 70112-61050 Oil Ring

2 70162-62030 Compression Ring 2 70111-61030 Compression Ring

2 70162-62050 Oil Ring 2 70111-61050 Oil Ring

1 70112-11612 Head Gasket (1st) 2 70112-11612 Head Gasket (1st)

1 70162-12610 Head Gasket (2nd) 1 70111-11612 Head Gasket (2nd)

2 70112-51610 Crankcase Gasket 3 70112-51610 Crankcase Gasket

1 70122-57950 Front Cover Gasket 1 70122-57950 Front Cover Gasket

1 70122-57960 Rear Cover Gasket 1 70122-57960 Rear Cover Gasket

1 70122-57080 Front Oil Seal 1 70122-57080 Front Oil Seal

24 92521-190800 Copper Washer 32 92521-190800 Copper Washer

1 70112-11461 Copper Gasket 1 70111-11461 Copper Gasket

2 70112-11461 Copper Gasket

CONSISTS OF:

PART

NO.

CONSISTS OF:

PART

NO.

CF1306

1 70152-66141 Element

CF1307

4 70152-31030 Disc

2 70152-32030 Disc

4 70152-31070 Spring

2 70152-32070 Spring

1 70152-11612 Head Gasket

1 70152-31120 Seat Gasket

1 70152-11622 Seat Gasket

CF1308 REBUILD KIT INCLUDES:

1 70152-51610 Case Gasket

1 70152-57960 Rear Cover Gasket

2 70152-61030 Comp. Ring

1 70152-61050 Oil Ring

1 70152-61080 Bushing (L.P.)

1 70152-62080 Bushing (H.P.)

2 70152-61090 Rod Bearing Set

3 70152-62030 Compression Ring

1 70152-62050 Oil Ring

1 70152-57950 Front Cover Gasket

1 70127-57080 Front Oil Seal

6 92521-190800 Copper Washer

E-35

CONSISTS OF:

PREVENTATIVE MAINTENANCE

KIT INCLUDES:

VALVE/GASKET MAINT KIT

INCLUDES:

E-57 E-50 E-71 E-15

PART NO. CONSISTS OF:

CF1291

CF1292

CF1293 REBUILD KIT INCLUDES: CF1254 REBUILD KIT INCLUDES: CF1256 REBUILD KIT INCLUDES: CF1258 REBUILD KIT INCLUDES:

26 92521-191000 Copper Washer 34 92521-191000 Copper Washer 34 92521-191000 Copper Washer 1 93503-NK28/30 Needle Bearing ***

PREVENTATIVE MAINTENANCE KIT

1 70153-66142 Element 2 70123-66140 Element 2 70123-66140 Element 2 70123-66140 Element

4 70153-31032 Disc 6 70123-31030 Disc 4 70124-31030 Disc 4 70125-31030 Disc

2 70153-32032 Disc 3 70123-31070 Spring 2 70123-31030 Disc 2 70175-42030 Disc

4 70153-31072 Spring 3 70123-41070 Spring 2 70124-31070 Spring 2 70125-31070 Spring

2 70153-32072 Spring 6 70123-11110 Seat Gasket 1 70123-31070 Spring 1 70124-31070 Spring

1 70153-31120 Head Gasket 3 70123-11612 Head Gasket 2 70124-41070 Spring 6 70125-41070 Spring

1 70153-11612 Seat Gasket 1 70123-41070 Spring 1 70124-41072 Spring

1 70153-11622 Seat Gasket 4 70124-11110 Seat Gasket 4 70125-11110 Seat Gasket

2 70123-11110 Seat Gasket 2 70124-11110 Seat Gasket

2 70124-11612 Head Gasket 4 70125-87510 Manifold Gasket

1 70123-11612 Head Gasket 2 70125-11610 Head Gasket

1 70124-11612 Head Gasket

** 70135-11610 Head Gasket

1 70153-57951 Front Bearing Gasket 1 70123-57950 Front Bearing Gasket 1 70124-57950 Front Bearing Gasket 4 70125-61030 Compression Ring

2 70124-61030 Compression Ring 4 70123-61030 Compression Ring 4 70124-61030 Compression Ring 4 70125-61050 Oil Ring

2 70124-61050 Oil Ring 4 70123-61050 Oil Rings 4 70124-61050 Oil Ring 3 70124-61030 Compression Ring

3 70153-62030 Compression Ring 3 70112-61030 Compression Ring 3 70123-61030 Compression Ring 2 70124-61050 Oil Ring

1 70153-62050 Oil Ring 1 70112-61050 Oil Ring 2 70123-61050 Oil Ring 2 70125-61081 Bushing

1 70153-61081 Bushing (L.P.) 2 70123-61081 Bushing 2 70124-61080 Bushing 3 70125-61090 Rod Bearing (2 Halves)

1 70153-62081 Bushing (H.P.) 1 93503TA1725 Needle Bearing 1 70174-62081 Bushing 3 70135-51610 Gasket

4 70153-61090 Rod Bearing (Halves) 6 70123-61090 Rod Bearing (Halves) 3 70124-51610 Gasket 1 70134-57080 Oil Seal

1 70153-51611 Case Gasket 3 70123-51610 Crankcase Gasket 1 70134-57080 Oil Seal 1 70135-57950 Front Bearing Gasket

1 70123-57080 Oil Seat 1 70123-57080 Oil Seal 6 70124-61090 Bearing (Halves) 1 70134-57960 Rear Bearing Gasket

1 70153-57961 Rear Bearing Gasket 1 70133-57960 Rear Bearing Gasket 1 70134-57960 Rear Bearing Gasket 24 92521-191200 Copper Washer

1 70173-62080 Bushing 1 70175-62080 Bushing ****

INCLUDES

VALVE/GASKET MAINT KIT

INCLUDES:

PART

NO.

CF1315

CF1253

CONSISTS OF:

PREVENTATIVE MAINTENANCE

KIT INCLUDES:

VALVE/GASKET MAINT KIT

INCLUDES:

PART

NO.

CF1315

CF1255

CONSISTS OF:

PREVENTATIVE MAINTENANCE

KIT INCLUDES:

VALVE/GASKET MAINT KIT

INCLUDES:

PART

NO.

CF1315

CF1257

CONSISTS OF:

PREVENTATIVE MAINTENANCE

KIT INCLUDES:

VALVE/GASKET MAINT KIT

INCLUDES:

* WARNING – THESE ITEMS INTERCHANGE WITH PARTS ON SERIAL #3020000 & HIGHER ONLY.

CONTACT FACTORY FOR EARLIER SERIES.

** USE WITH SERIAL #A311XXXX AND LATER

70135-11610 REPLACES 70125-11610

*** USE WITH SERIAL #A409XXXX AND LATER

**** USE FOR UNITS PRIOR TO SERIAL #A409XXXX

.

8

CAP-600

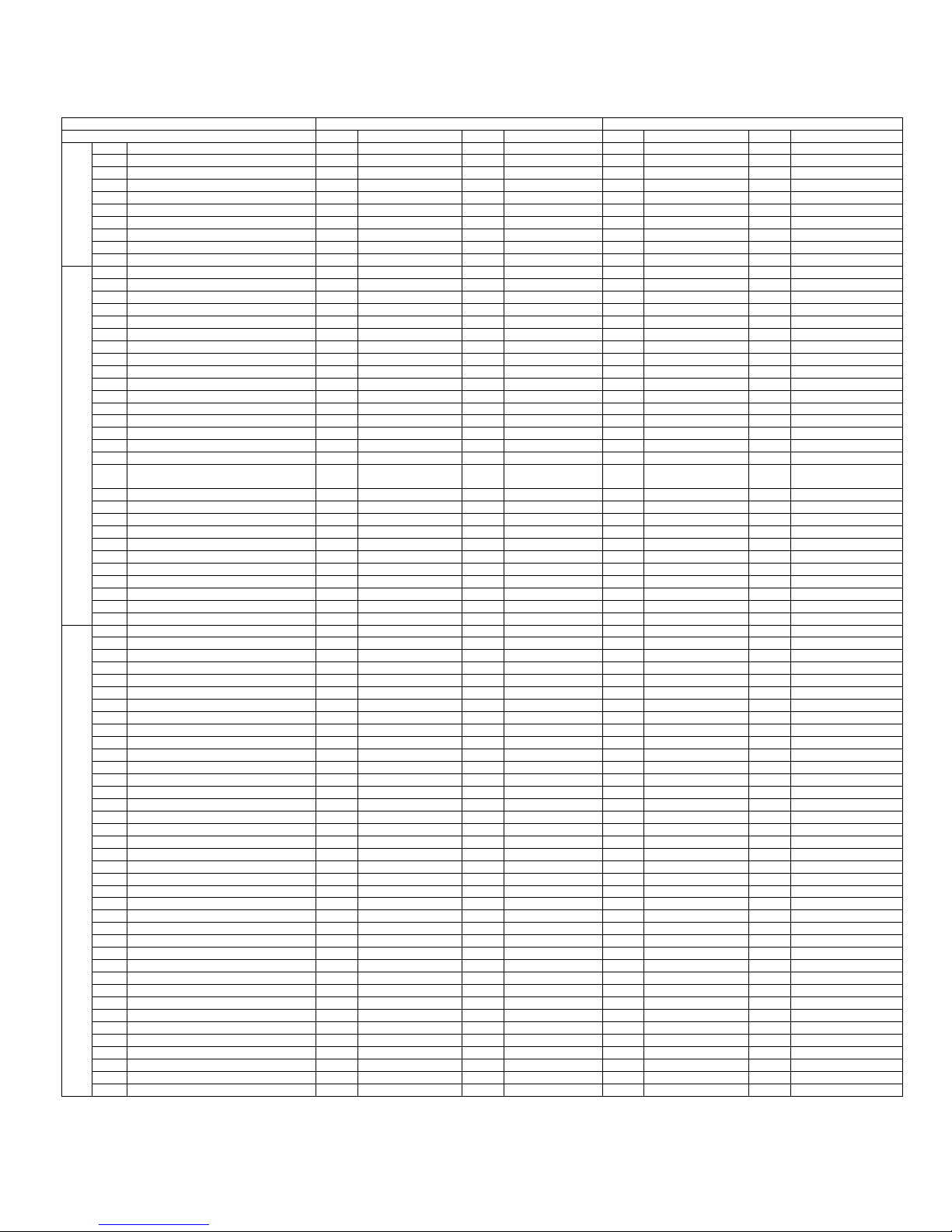

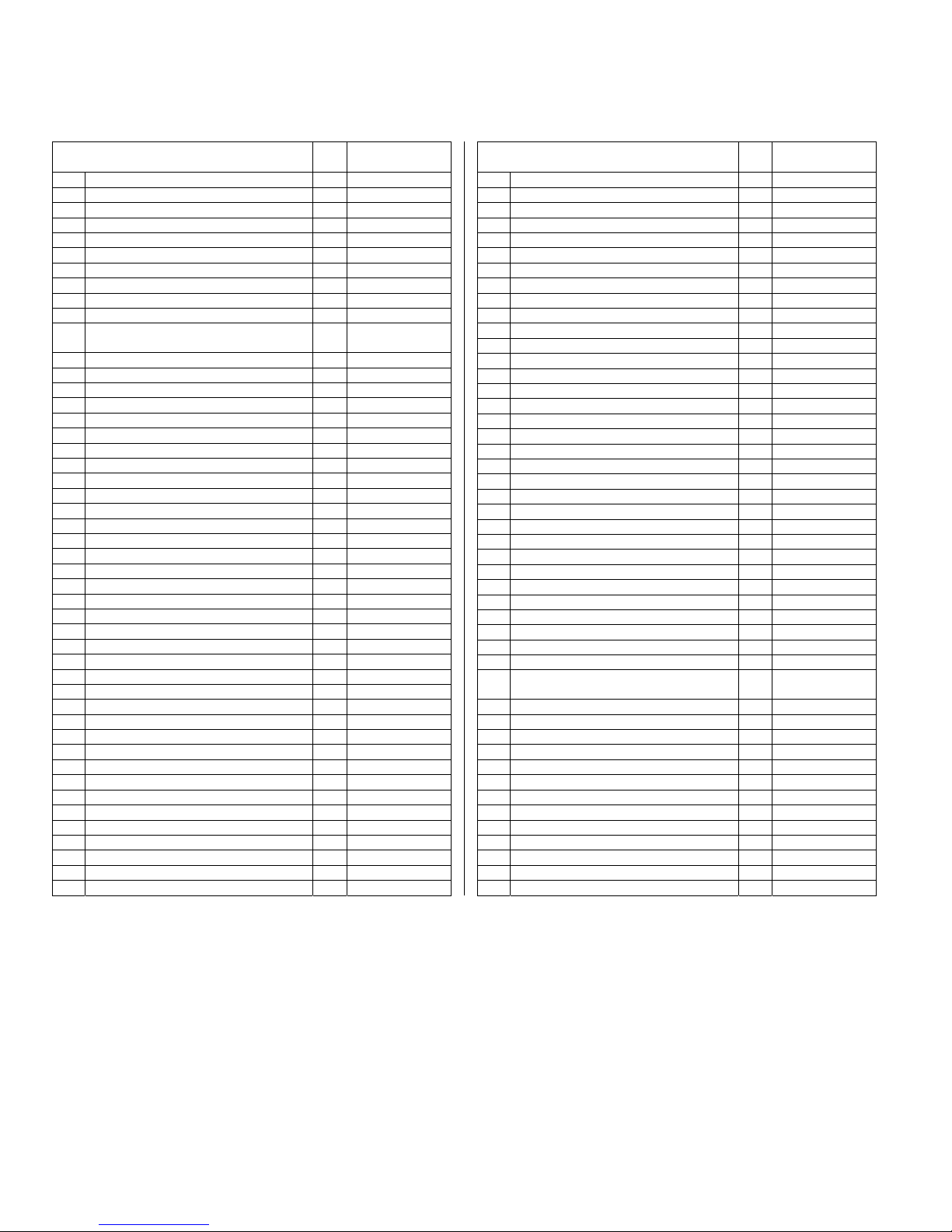

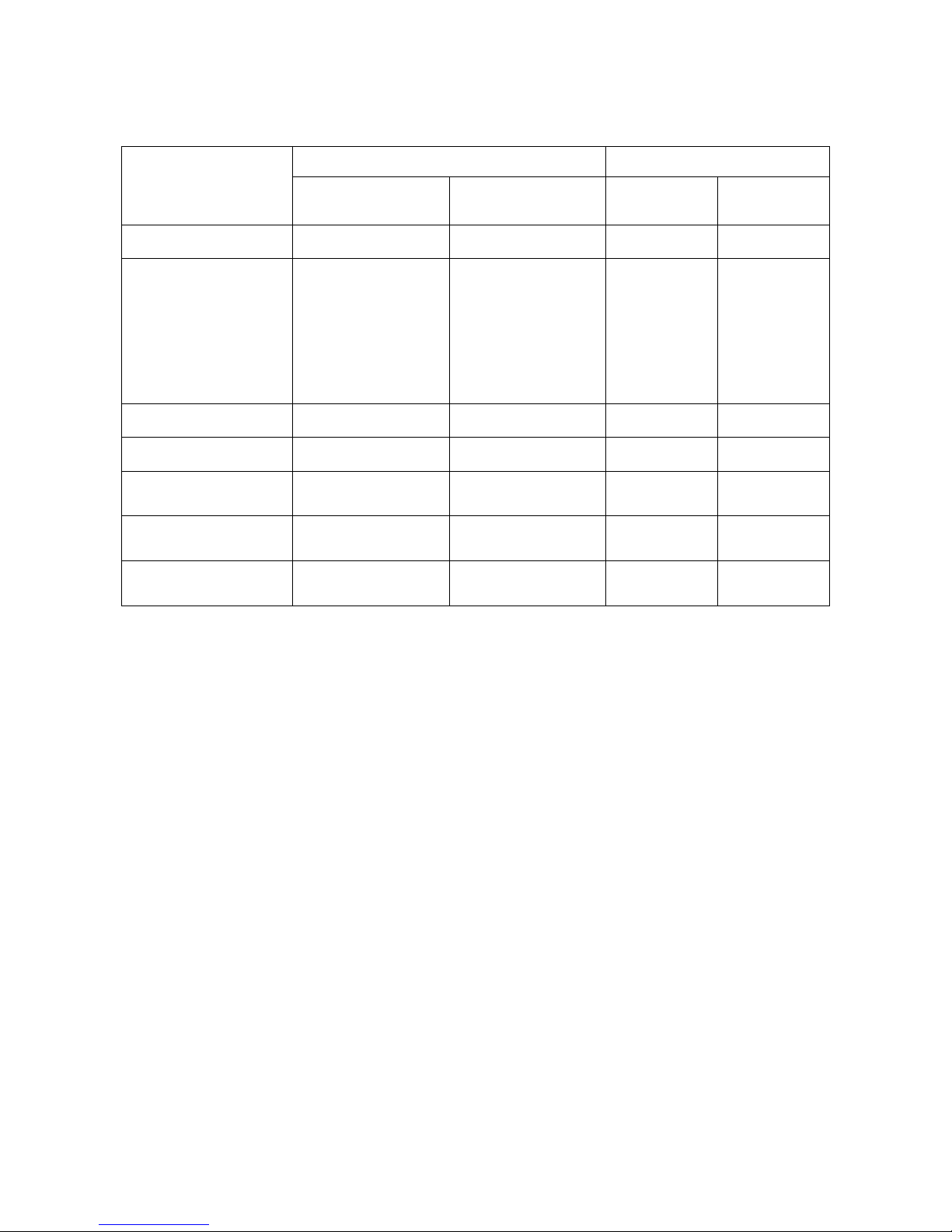

RING SETS & GASKET SETS

SINGLE STAGE

QUANTITY

MODEL PART NO. DESCRIPTION

ES03

ES05

ES06

ES10

ES20

ES30

ES50

ES100

ES150 &

ES150A

CF1297

CF1298

CF1259

CF1276

CF1300

CF1301

CF1260

CF1277

CF1261

CF1278

CF1262

CF1279

CF1263

CF1280

CF1264

CF1281

CF1265

CF1282

*CF1311

Ring set

Gasket set

Ring set

Gasket set

Ring set

Gasket set

Ring set

Gasket set

Ring set

Gasket set

Ring set

Gasket set

Ring set

Gasket set

Ring set

Gasket set

Ring set

Gasket set

*Gasket set

REQ’D

1

1

1

1

2

1

2

1

3

1

2

1

3

1

3

1

3

1

1

TWO-STAGE

MODEL PART NO. DESCRIPTION

CF1266

E11

E23

E35

E50

E57

E71

E15

* USE WITH SERIAL #A311XXXX AND LATER

CF1267

CF1283

CF1268

CF1269

CF1284

CF1303

CF1304

CF1305

CF1270

CF1271

CF1285

CF1288

CF1289

CF1290

CF1272

CF1273

CF1286

CF1274

CF1275

CF1287

*CF1313

Ring set (LP)

Ring set (HP)

Gasket set

Ring set (LP)

Ring set (HP)

Gasket set

Ring set(LP)

Ring set(HP)

Gasket set

Ring set(LP)

Ring set(HP)

Gasket set

Ring set(LP)

Ring set(HP)

Gasket set

Ring set(LP)

Ring set(HP)

Gasket set

Ring set(LP)

Ring set(HP)

Gasket set

*Gasket set

QUANTITY

REQ’D

1

1

1

2

1

1

1

1

1

2

1

1

1

1

1

2

1

1

2

1

1

1

9

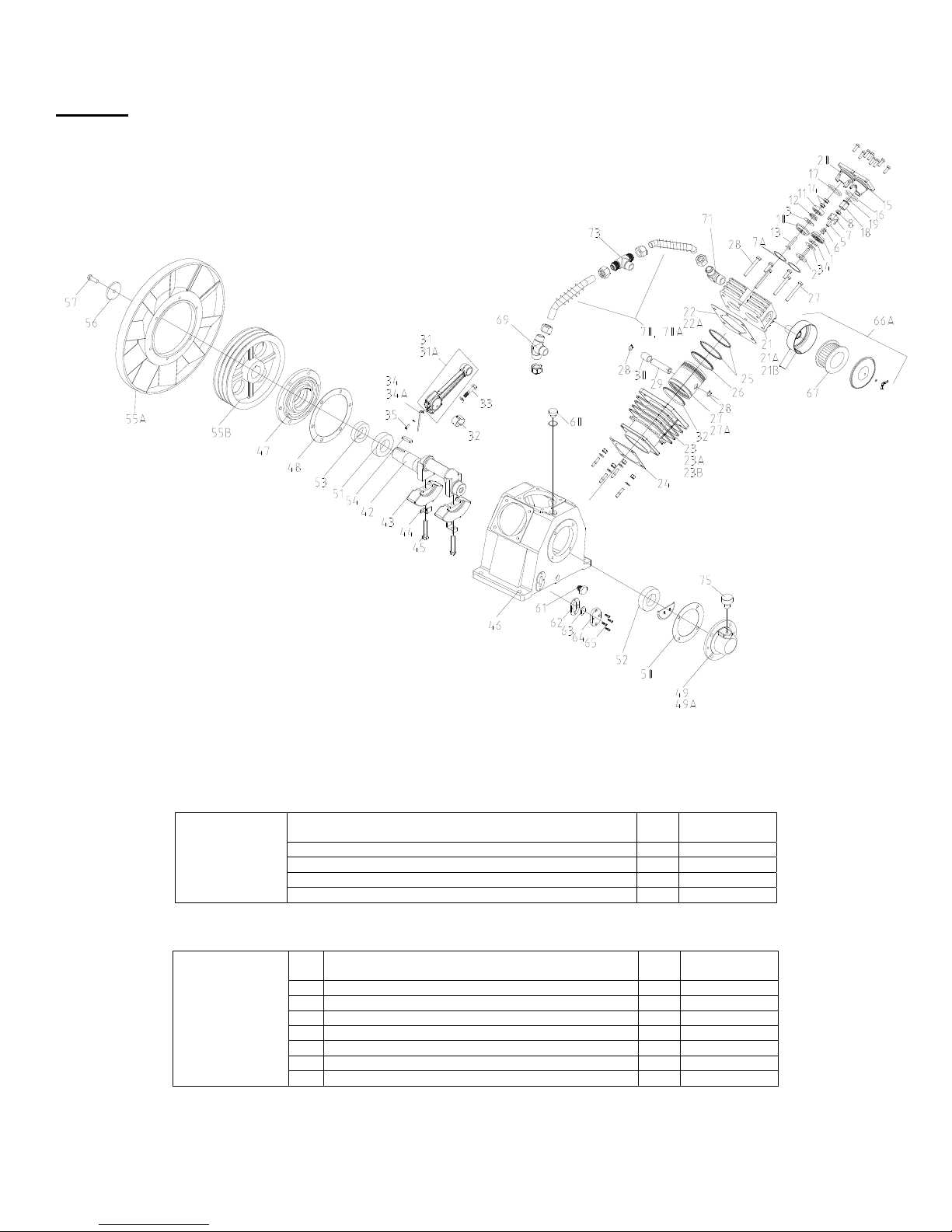

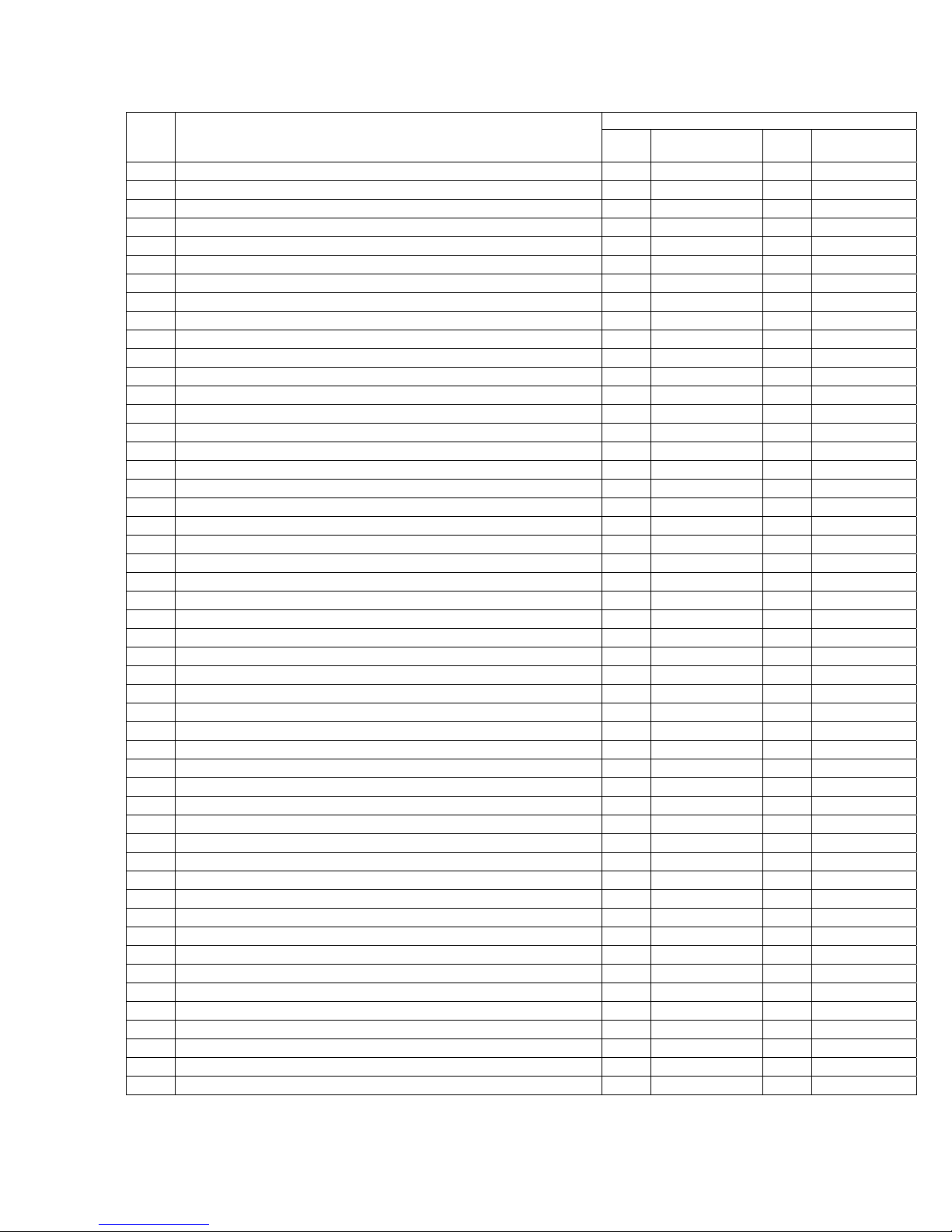

MODEL ES-03

AIR COOLED, SINGLE STAGE, SINGLE CYLINDER

CAP-600

Description QTY PART NO.

VALVES

1. Inlet & Outlet Valve Plate 2 70111-31030

2. Inlet Valve Spring 1 70111-31070

3. Inlet Valve Receiver 1 70111-31020

4. Inlet Valve Snap Ring 1 93610-130225

5. Outlet Valve Spring 1 70111-41070

6. Outlet Valve Push Cover Gasket 1 70111-11461

7. Outlet Valve Push Cover 1 70111-11450

8. Manual Unloader Assembly 1 70111-11300

9.

CYLINDERS

9A. Cylinder Head Assembly (Includes Valves) 1 70111-11000-4024

9B. Cylinder Head (Bare Casting) 1 70111-11010

10. Cylinder Head Bolt (Not Shown) 4 (Hardware Item)

11. Cylinder Head Gasket 1 70111-11612

12. Cylinder & Crankcase 1 70111-57010-4024

13. Compression Ring 2 70111-61030

14. Oil Control Ring 1 70111-61050

15. Piston 1 70111-61011

16. Piston Pin 1 70111-61120

17. Piston Pin Snap Ring 2 70111-61070

18. Connecting Rod Assembly 1 70111-61200

19. Connecting Rod Bolt 2

20. Oil Splash Dipper 1 70111-61282

21. Oil Splash Dipper Bolt 1 91507-2304010

22. Oil Splash Dipper Bolt Washer (Not Shown) 1 92522-130400

CRANKCASE AND CRANK ASSEMBLY

(furnished on conn.

Rod only)

23. Crankshaft 1 70111-56010

24. Front Bearing Cover 1 70111-57030

25. Front Bearing Cover Gasket 1 70111-57950

26. Front Cover Bolts (Not Shown) 4 91501-1306016

27. Front Bearing #6203 1 93501-6203

28. Rear Bearing Cover 1 70111-57060

29. Rear Bearing Cover Gasket 1 70111-57960

30. Rear Bearing #6201 1 93501-6201

31. Rear Bearing Cover Bolts (Not Shown) 3 93501-1306016

32. Front Oil Seal 1 70111-57080

33. Compressor Pulley 1 70111-76010

34. Compressor Pulley Thrust Washer 1 70111-76210

35. Compressor Pulley Thrust Bolt 1 91501-1306020

36. Crankcase Bottom Cover (Not Shown) 1 70111-57220

37.

38. Compressor Pulley Pin NA (Not Required)

39. Oil Level Gauge And Cover 1 70111-57700

40. Gauge Cover Seal 1 70111-57730

41. Crankcase Oil Plug (1/4” PT) 1 90112-100202

42. Breather Assembly 1 70191-57600-4024

AIR STRAINER ELEMENT

43. Air Strainer Assembly 1 70111-66001

44. Air Strainer Element (Not Shown) 1 70111-66140

10

Description QTY PART NO.

CRANKCASE AND CRANK ASSEMBLY

Crankcase Bottom Cover Gasket (Not

Shown)

1 70111-57970

MODEL ES-06

AIR COOLED, SINGLE STAGE, TWO CYLINDER

CAP-600

DESCRIPTION QTY PART NO. DESCRIPTION QTY PART NO.

VALVES

1. Inlet And Outlet Valve Plate 4 70111-31030 29 Front Bearing Cover Bolt 4 91501-1306016

2. Inlet Valve Spring 2 70111-31070 30 Front Bearing #6204 1 93501-6204

3. Inlet Valve Receiver 2 70111-31020 32 Rear Bearing Cover 1 70111-57060

4. Inlet Valve Snap Ring 2 93610-130225 33 Rear Bearing Cover Gasket 1 70111-57960

5. Outlet Valve Spring 2 70111-41070 34 Rear Bearing Cover Bolt (Not Shown) 3 91501-1306016

6. Outlet Valve Push Cover Gasket 2 70111-11461 35 Rear Bearing #6203 1 93501-6203

7. Outlet Valve Push Cover 2 70111-11450 36 Crankcase Bottom Cover (Not Shown) 1 70121-57220

37 Crankcase Bottom Cover Bolt (Not Shown) 1 70121-57970

CYLINDERS, CRANKCASE AND CRANK ASSEMBLY

8a. Cylinder Head Assy. (Includes Valves) 2 70111-11000-4024 39 Front & Rear Cover Bolt Washer (Not Shown) 10 92521-190600

8b. Cylinder Head (Bare Casting) 2 70111-11010 40 Compressor Pulley Pin 1 70112-56060

9. Cylinder Head Gasket 2 70111-11612 41 Compressor Pulley 1 70121-76011

10 Cylinder Head Bolt 8 91501-1306055 42 Compressor Pulley Thrust Washer 1 70112-76210

11 Cylinder 2 70121-51010 43 Compressor Pulley Thrust Bolt 1 91501-1306025

12 Cylinder To Case Gasket 2 70121-51610 44 Oil Level Gauge & Gauge Cover 1 70111-57700

13 Cylinder To Case Bolt (Not Shown) 8 91501-1306016 *44A Oil Level Gauge Assy 1 70704-57700

14 Cylinder To Case Bolt Washer (Not Shown) 16 92521-190600 45 Oil Level Gauge Cover Seal 1 70111-57730

15 Compression Ring 4 70111-61030 *45A Oil Level Gauge “O” Ring 1 93602-8126026

16 Oil Control Ring 2 70111-61050 46 Crankcase Oil Plug (1/4” NPT) 1 90112-100202

17 Piston 2 70111-61011 47 Breather Assembly 1 CCC1357

18 Piston Pin 2 70111-61120

19 Piston Pin Snap Ring 4 70111-61070 48 Auto – Unloader Assembly 2 70112-11201

20 Connecting Rod Assembly 2 70111-61200 49 Unloading Elbow* (Includes Nut & Sleeve) 1 VA786

21 Connecting Rod Bolt 4

22 Oil Splash Dipper 2 70121-61282

23 Oil Splash Dipper Bolt 2 91507-2304010 51 Air Strainer Assembly 2 70111-66001

24 Oil Splash Dipper Lock washer 2 92522-130400 52 Air Strainer Element (Not Shown) 2 70111-66140

25 Crankshaft 1 70121-56010 53 Compressor Body Discharge Pipe Assembly 1 70121-87100

26 Crankcase 1 70121-57010-4024 54 Outlet Pipe Elbow 1 70121-87010

27 Front Bearing Cover 1 70121-57030 55 Outlet Pipe Tee 1 70121-87020

56 Outlet Pipe Tee Nut 1 79922-130404

(Furnished On

Conn, Rod Only)

* START S/N AS 4030001

28 Front Bearing Cover Gasket 1 70121-57950

38 Crankcase Bottom Cover Washer (Not Shown) 4 (Hardware Item)

UNLOADERS(* Indicates Not Included On Basic Units)

50 Unloading Tee* (Includes Nut & Sleeve) 1 VA787

AIR STRAINER ASSEMBLY & DISCHARGE PIPING

11

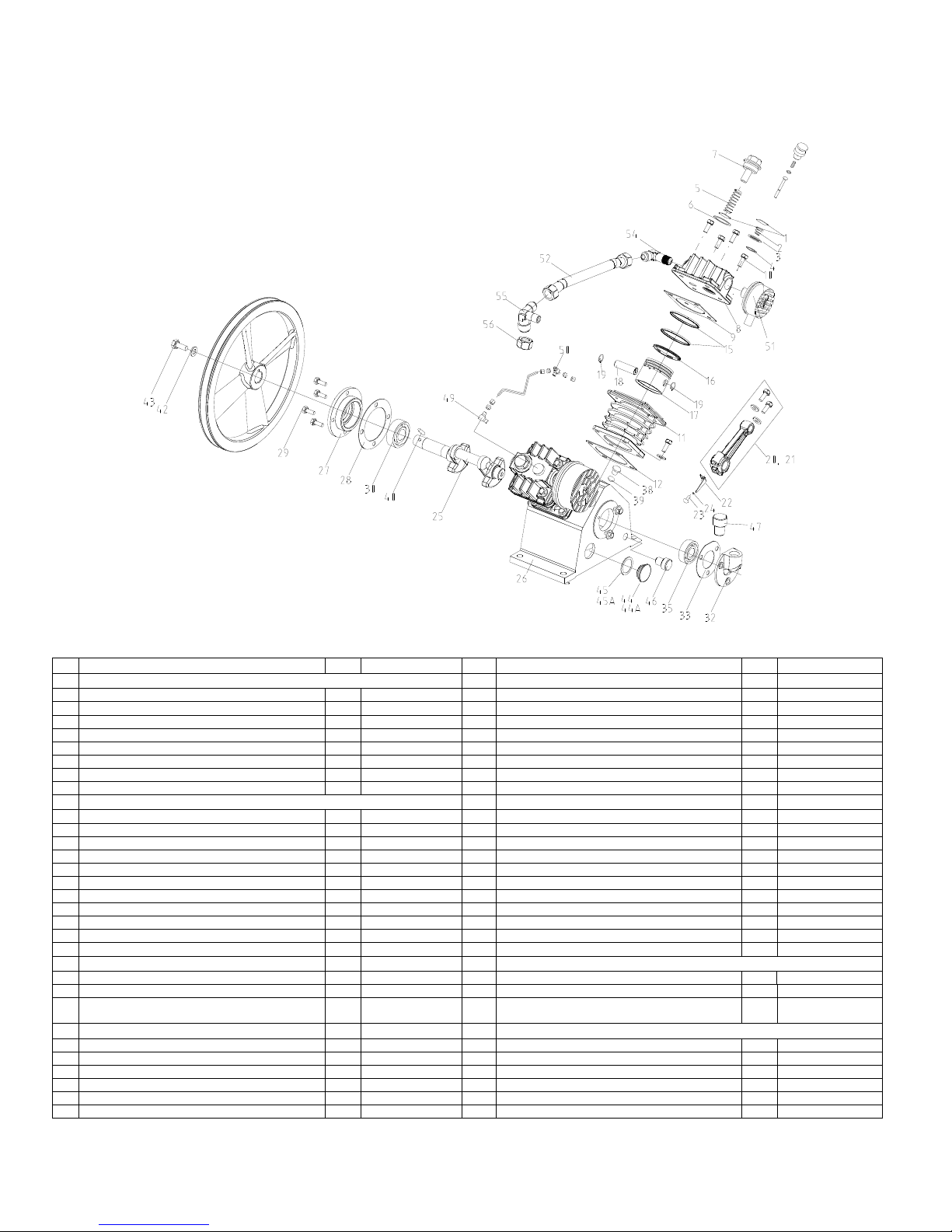

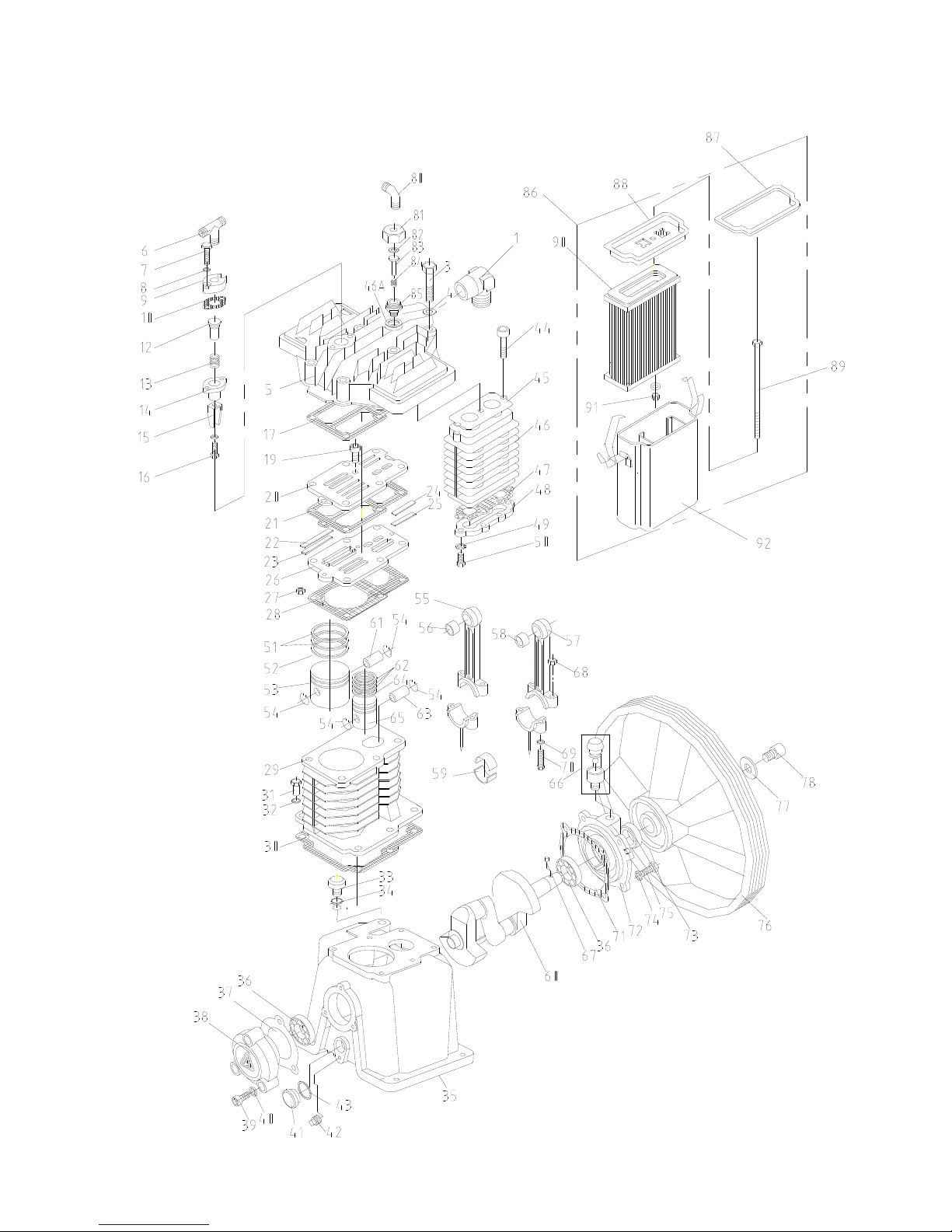

AIR COOLED, SINGLE STAGE MODELS

ES-05, ES-10 & ES-20

CAP-600

12

CAP-600

MAIN PARTS LISTING FOR

SINGLE STAGE MODELS

ES-05, ES-10 & ES-20

VALVES

1. Inlet And Outlet Valve Plate 2 70112-31030 4 70112-31030 6 70112-31030

2. Inlet Valve Spring 1 70112-31070 2 70112-31070 3 70112-31070

3. Inlet Valve Receiver 1 70112-31020 2 70112-31020 3 70112-31020

4. Inlet Valve Snap Ring 1 93610-130232 2 93610-130232 3 93610-130232

5. Outlet Valve Spring 1 70112-41070 2 70112-41070 3 70112-41070

6. Outlet Valve Push Cover Gasket 1 70112-11461 2 70112-11461 3 70112-11461

7. Outlet Valve Push Cover 1 70112-11450 2 70112-11450 3 70112-11450

CYLINDER AND CYLINDER HEADS

16A. Cylinder Head Assembly 1

16B. Cylinder Head 1 70112-11010 2 70112-11010 3 70112-11010

17. Cylinder & Head Gasket 1 70112-11612 2 70112-11612 3 70112-11612

18. Cylinder 1 70112-51010 2 70112-51010 3 70112-51010

19. Cylinder And Case Gasket 1 70112-51610 2 70112-51610 3 70112-51610

20. Compression Ring 2 70112-61030 4 70112-61030 6 70112-61030

21. Oil Control Ring 1 70112-61050 2 70112-61050 3 70112-61050

22. Piston 1 70112-61011 2 70112-61011 3 70112-61011

23. Piston Pin 1 70112-61120 2 70112-61120 3 70112-61120

24. Piston Pin Snap Ring 2 70112-61070 4 70112-61070 6 70112-61070

25. Connecting Rod Assembly 1 70112-61200-1 2 70112-61200-1 3 70112-61200-1

26. Connecting Rod Bolt 1 70112-61250 4 70112-61250 6 70112-61250

27. Oil Splash Dipper 1 70111-61282 2 70122-61282 2 70122-61282

27A. Oil Splash Dipper 1 70132-61290

28. Oil Splash Dipper Bolts 1 91507-2304010 2 91507-2304010 3 91507-2304010

29. Cylinder Head Bolt 4 (Hardware Item) 8 (Hardware Item) 12 (Hardware Item)

CRANK ASSEMBLY

39. Crankcase 1

40. Crankshaft 1 70112-56010 1 70122-56010 1 70132-56010

41. Front Bearing Cover 1 70112-57030 1 70122-57030 1 70122-57030

42. Front Bearing Cover Gasket 1 70112-57950 1 70122-57950 1 70122-57950

43. Rear Bearing Cover 1 70112-57060 1 70122-57060 1 70122-57060

44. Rear Bearing Cover Gasket 1 70112-57960 1 70122-57960 1 70122-57960

45A. Bearing – Front 1 93501-6205 1 93501-6205 1 93501-6205

45B. Bearing – Rear 1 93501-6204 1 93501-6204 1 93501-6204

46. Front Oil Seal 1 70112-57080 1 70122-57080 1 70122-57080

47. V-Pulley Pin 1 70112-56060 1 70112-56060 1 70112-56060

48. Compressor Pulley 1 70112-76010 1 70122-76011 1 70122-76011

49. Compressor Pulley Thrust Washer 1 70112-76210 1 70112-76210 1 70112-76210

50. Compressor Pulley Thrust Bolt 1 91501-1308025 1 91501-1308025 1 91501-1308025

51. Breather Assembly 1

52. Oil Gauge & Gauge Cover 1 70111-57700 1 70111-57700 1 70111-57700

٭52 A Oil Level Gauge Assembly - 1 70704-57700 1 70704-57700

53. Gauge Cover Seal 1 70111-57730 1 70111-57730 1 70111-57730

٭53 A Oil Level Gauge “O” Ring - 1 93602-8126026 1 93602-8126026

54. Crankcase Oil Plug 1 90112-100202 1 90112-100202 1 90112-100202

54A. Oil fill cap - - 1

54B. “O” Ring - - 1 93601-810016

UNLOADERS

55. Auto – Unloader Assembly 1 70112-11201

56. Auto – Unloader Spring 1 70112-11230 2 70112-11230 3 70112-11230

57. Auto – Unloader Piston 1 70112-11221 2 70112-11221 3 70112-11221

58. O-Ring (Unloader) 1 93601-810004 2 93601-810004 3 93601-810004

AIR STRAINER

61. Air Strainer Element (not shown) 1 70111-66140

62. Air Strainer Assembly 1 70111-66001 2 70111-66001 3 70111-66001

63. Discharge Piping Assembly 1 (Not Required) 2 70122-87100 2 70132-87100

64. Outlet Pipe Joint A - 1 70122-87010 1 70122-87010

65. Outlet Pipe Joint B - 1 70122-87020 1 70132-87020

66. Outlet Pipe Joint C - - 1 70132-87030

QTY

REQ’D

MODEL ES05

70112-11000-4024

70112-57010-4024

CCC1375

• ES10, START S/N AS 4030043

• ES20, START S/N AS 4030061

QTY

REQ’D

2

1

1

2 70112-11201

2 70111-66140

MODEL ES10

70112-11000-4024

70122-57010-4024

CCC1375

QTY

REQ’D

3

1

1

3 70112-11201

3 70111-66140

MODEL ES20

70112-11000-4024

70132-57010-4024

CCC1375

70101-57190-4010

13

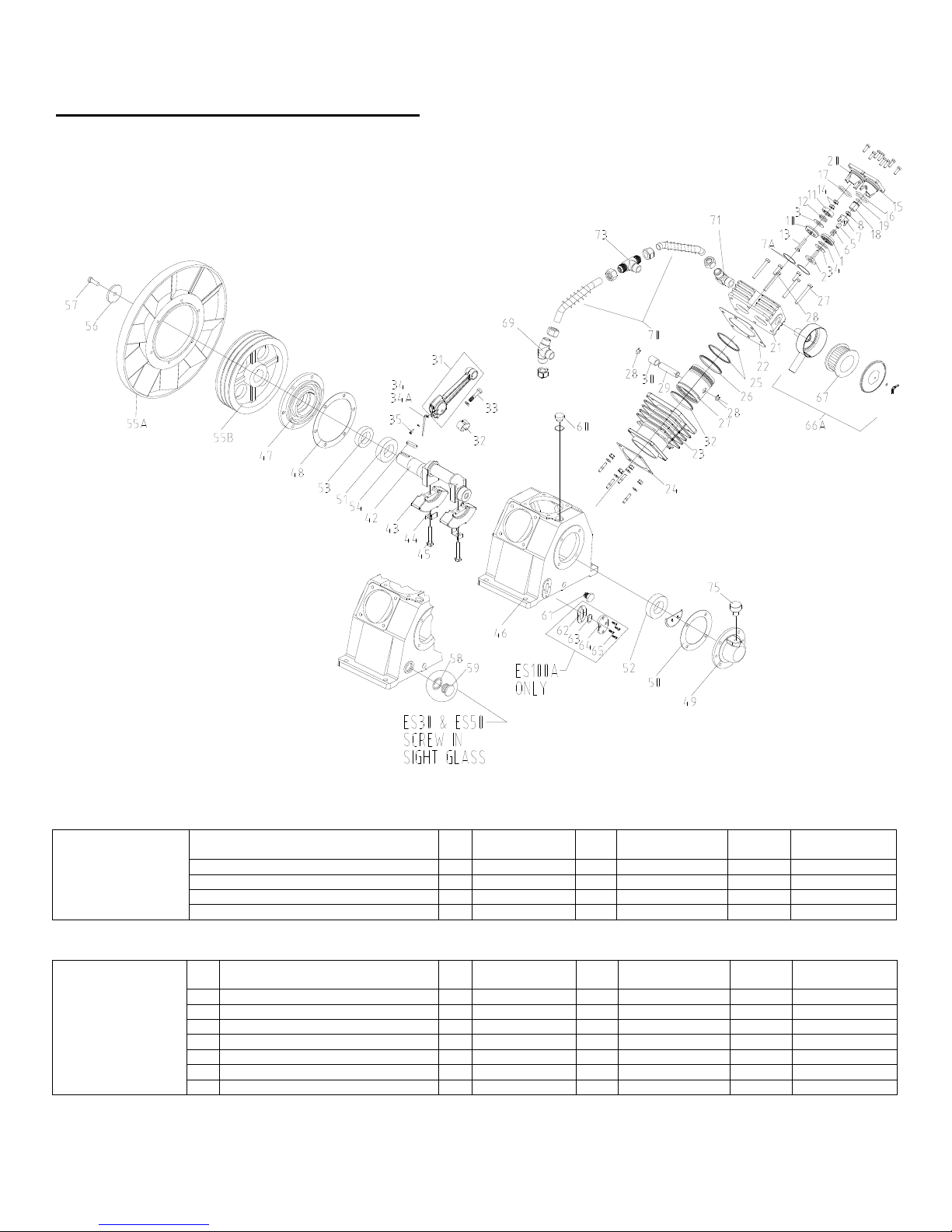

AIR COOLED SINGLE STAGE

t

t

MODELS ES-30, ES-50, ES-100

CAP-600

VALVE ASSEMBLIES

VALVE &

UNLOADERS

Description

Inlet Valve Assembly, 1

Outlet Valve Assembly, 1

Breather Assembly 1

s

Stage 2 70123-31000 3 70123-31000 3 70124-31000

s

Stage 2 70123-41000 3 70123-41000 3 70124-41000

Qty.

Req.

MODEL

ES30

70103-57600-4024

Qty.

Req.

70103-57600-4024

1

MODEL

ES50

Qty.

Req.

MODEL

ES100

1 70124-57600

MAIN PARTS LISTING FOR MODELS

ES-30, ES-50, ES-100

Item

Description

No.

1. Inlet Valve Seat 2 70123-31010 3 70123-31010 3 70124-31010

2. Inlet Valve Receiver 2 70123-31020 3 70123-31020 3 70124-31020

3. Inlet & Outlet Valve Plate 4 70123-31030 6 70123-31030 6 70124-31030

4. Inlet Valve Spring 2 70123-31070 3 70123-31070 3 70124-31070

5. Inlet Valve Unloading Fork Guide 2 70123-31090 3 70123-31090 3 70124-31090

6. Unloading Spring 2 70123-11230 3 70123-11230 3 70124-11230

7A. Valve Gasket 4 70123-11110 6 70123-11110 6 70124-11110

Qty.

Req.

MODEL

ES30

Qty.

Req.

MODEL

ES50

Qty.

Req.

MODEL

ES100

14

CAP-600

t

t

t

t

t

t

t

t

t

t

t

t

MAIN PARTS LISTING FOR MODELS

ES-30, ES-50 & ES-100 (Continued)

Qty.

Req.

7B Inlet Valve Unloading Fork 2 70123-31080 3 70123-31080 3 70124-31080

8. Locknut 2 92518-230800 3 92518-230800 3 92518-230800

10. Outlet Valve Seat 2 70123-41011 3 70123-41011 3 70124-41011

11. Outlet Valve Receiver 2 70123-41020 3 70123-41020 3 70124-41020

12. Outlet Valve Spring 2 70123-41070 3 70123-41070 3 70124-41070

13. Outlet Valve Bolt 2 70123-41810 3 70123-41810 3 70124-41810

14. Nut (Outlet Valve) 4 92502-130800 6 92502-130800 6 92502-130800

15. Inlet Valve Push Cover, 1

(Cont’d)

16. O – Ring G 40 2 93602-810040 3 93602-810040 3 93602-810055

17. Viton O – Ring G 40 (Outlet Valve) 2 93602-870040 3 93602-870040 3 93602-870055

18. Unloading Piston, 1

VALVES & UNLOADERS

19. O – Ring P 20 2 93601-810020 3 93601-810020 3 93601-810021

20. Outlet Valve Push Cover, 1

21A. Cylinder Head Assembly 2 70123-11000 3 70123-11000 -

21. Cylinder Head (1

22. Cylinder & Head Gasket, 1

23. Cylinder (1

s

s

) 2 70123-51012 3 70123-51012 3 70124-51011

s

Stage 2 70123-11150 3 70123-11150 3 70124-11150

s

Stage 2 70123-11220 3 70123-11220 3 70124-11220

s

Stage 2 70123-11450 3 70123-11450 3 70124-11450

) 2 70123-11010 3 70123-11010 3 70124-11010

s

Stage 2 70123-11612 3 70123-11612 3 70124-11612

23A. S/N 3020000 THRU A311XXXX 2 70123-51011 3 70123-51011 3 70124-51011

24. Cylinder & Case Gasket 2 70123-51610 3 70123-51610 3 70124-51610

25. Compression Ring (1

26. Oil Control Ring (1

27. Piston (1

s

) 2 70123-61011 3 70123-61011 3 70124-61011-1

s

) 4 70123-61030 6 70123-61030 6 70124-61030

s

) 4 70123-61050 6 70123-61050 6 70124-61050

27A. S/N 3020000 & later use 2 70123-61011 3 70123-61011 3 70124-61011

28. Piston Pin Snap Ring 4 70123-61070 6 70123-61070 6 70124-61070

29. Piston Pin (1

CYLINDERS

30. Connecting Rod Piston Pin Bushing (1

31. Connecting Rod Assembly, 1

s

) 2 70123-61120 3 70123-61120 3 70124-61120

s

s

) 2 70123-61081 3 70123-61081 3 70124-61080

Stage 2 70123-61200 3 70123-61200 3 70124-61201

31A. S/N 3020000 & later use 2 70123-61201 3 70123-61201 3 70124-61201

32. Connecting Rod Crank Pin Metal 4 70123-61090 6 70123-61090 6 70124-61090

33. Connecting Rod Bolt 4 70123-61250 6 70123-61250 6 70125-61250

34A. Oil Splash Dipper H.P. - 1 70122-61290 1 70134-62290

34. Oil Splash Dipper 2 70122-61282 2 70122-61282 2 70134-61281

35. Oil Splash Dipper Bolt 2 91507-2304012 3 91507-2304012 3 91507-2305016

42. Crankshaft 1 70123-56010 1 70133-56011 1 70134-56010

43. Counterweight - - 2 70134-56030

44. Lockwasher - - 2 70124-56830

45. Bolt - - 2 70124-56810

46. Crankcase 1 70123-57010-4024 1 70133-57010-4024 1 70134-57010-4024

47. Front Bearing Cover 1 70123-57030 1 70133-57030 1 70134-57031

48. Front Bearing Cover Gasket 1 70123-57950 1 70123-57950 1 70124-57950

49. Rear Bearing Cover 1 70123-57061 1 70133-57060 1 70134-57061

49A. S/N 3020000 & later use 1 70123-57061 1 70133-57061 1 70134-57061

50. Rear Bearing Cover Gasket 1 70123-57960-01 1 70133-57960 1 70134-57960

51. Front Bearing 1 93501-6206 1 93501-6206 1 93502-32210

52. Rear Bearing 1 93501-6206 1 93501-6206 1 93502-32210

53. Front Oil Seal 1 70123-57080 1 70123-57080 1 70134-57080

54. V – Pulley Pin 1 70123-56061 1 70123-56061 1 70134-56060

55A. Compressor Fan 1 (Not Required) 1 (Not Required) 1 70124-76310

55B. Compressor Pulley 1 70123-76010 1 70133-76010 1 70134-76011

56. Compressor Pulley Washer 1 70123-76210 1 70124-76210 1 70124-76210

57. Compressor Pulley Set Bolt 1 91501-1312030 1 91501-1312030 1 91501-1312040

58. O-Ring (oil level glass) 1 93602-81260-3065 1 93602-81260-3065 - -

59. Screw in Oil Level Glass 1 70A109B1-57702 1 70A109B1-57702 - -

60. Crankcase Oil Cap 1 CCC1257 1 CCC1257 1 CCC1257

61. Crankcase Oil Plug 1 90112-100404 1 90112-100404 1 90112-100404

62. Oil Level Glass Gasket 1 701210A1-57730 1 701210A1-57730 1 701210A1-57730

63. Oil Level Glass Assy. 1 701210A1-57700 1 701210A1-57700 1 701210A1-57700

CRANKCASE & CRANK ASSEMBLY

64. Oil Level Glass, Push Cover 1 701210A1-57740 1 701210A1-57740 1 701210A1-57740

65. Screw, Metric Pan Head 4 VH1470 4 VH1470 4 VH1470

66A Air Strainer Assembly 2 70123-66000 3 70123-66000 3 70123-66000

67. Air Strainer Filter 2 70123-66140 3 70123-66140 3 70123-66140

69. Outlet Pipe Joint B 1 70123-87020 1 70133-87020 1 70134-87020

70. Compressor Body Discharge Piping Assy. 1 70123-87100 2 70133-87101 2 70134-87100

70A. S/N 3020000 & Later Use 1 70123-87101 2 70133-87101 2 70134-87101

71. Outlet Pipe Joint A 1 70123-87010 1 70123-87010 1 70124-87010

73. Outlet Pipe Joint C - 1 70133-87030 1 70134-87030

74. Gasket (Manifold) - - -

75. Breather Assembly 1 CCC1375 1 CCC1375 1 CCC1375

MODEL

ES30

15

Qty.

Req.

MODEL

ES50

Qty.

Req.

MODEL

ES100

AIR COOLED SINGLE STAGE

t

t

MODELS ES-30A, ES-50A, ES-100A

CAP-600

Description

VALVE ASSEMBLIES

Inlet Valve Assembly, 1

Outlet Valve Assembly, 1

Breather Assembly 1 701105A1-57600 1 701105A1-57600 1 701210A1-57601

MAIN PARTS LISTING FOR MODELS

ES-30A, ES-50A, ES-100A

Item

Description

No.

1. Inlet Valve Seat 2 701208A1-31010 3 701208A1-31010 3 701210A1-31010

VALVE &

UNLOADERS

2. Inlet Valve Receiver 2 701208A1-31020 3 701208A1-31020 3 701210A1-31020

3. Inlet & Outlet Valve Plate 2 701208A1-31030 6 701208A1-31030 6 501210A1-31030

4. Inlet Valve Spring 2 701208A1-31070 3 701208A1-31070 3 701210A1-31070

5. Inlet Valve Unloading Fork Guide 2 701208A1-31090 3 701208A1-31090 3 701210A1-31090

6. Unloading Spring 2 701208A1-11230 3 701208A1-11230 3 701210A1-11230

7A. Valve Gasket 4 701208A1-11110 6 701208A1-11110 6 701210A1-11110

Qty.

s

Stage 2 701208A1-31000 3 701208A1-31000 3 701210A1-31000

s

Stage 2 701208A-41000 3 701208A1-41000 3 701210A1-41000

Req.

Qty.

Req.

14A

MODEL

ES30A

MODEL

ES30A

Qty.

Req.

Qty.

Req.

MODEL

ES50A

MODEL

ES50A

Qty. Req.

Qty. Req.

MODEL

ES100A

MODEL

ES100A

MAIN PARTS LISTING FOR MODELS

t

t

t

t

t

t

t

t

t

t

t

t

ES-30A, ES-50A & ES-100A (Continued)

Qty.

Req.

7B. Inlet Valve Unloading Fork 2 701208A1-31080 3 701208A1-31080 3 70210A1-31080

8. Locknut 2

10. Outlet Valve Seat 2 701208A1-41011 3 701208A1-41011 3 701210A1-41011

11. Outlet Valve Receiver 2 701208A1-41020 3 701208A1-41020 3 701210A1-41020

12. Outlet Valve Spring 2 701208A1-41070 3 701208A1-41070 3 701210A1-41070

13. Outlet Valve Bolt 2 701208A1-41810 3 701208A1-41810 3 9152613-1110050-5608

14. Nut (Outlet Valve) 4 9250113-150800-532 6

15. Inlet Valve Push Cover, 1

s

Stage 2 701208A1-11150 3 701208A1-11150 3 701210A1-11150

16. O – Ring G 40 (G55 ES100) 2 9360281-310394 3 9360281-310394 3 9360281-310544

17. Viton O – Ring G 40 (Outlet Valve) 2 9360287-310394 3 9630287-310394 3 9360287-310544

18. Unloading Piston, 1

19. O – Ring P 20 (P21 ES100) 2 9360181-240198 3 9360181-240198 3 9360187-240208

VALVES & UNLOADERS (Cont’d)

20. Outlet Valve Push Cover, 1

21A. Cylinder Head Assembly 2 70123-11000 3 70123-11000 -

21. Cylinder Head (1

22. Cylinder & Head Gasket, 1

23. Cylinder (1

s

s

Stage 2 701208A1-11220 3 701208A1-11220 3 701210A1-11220

s

Stage 2 701208A1-11450 3 701208A1-11450 3 701210A1-11450

s

) 2 701208A2-11010 3 701208A2-11010 3 701210A2-11010

s

Stage 2 701208A1-11020 3 701208A1-11020 3 701210A1-11020

) 2 701208A2-51010 3 701208A2-51010 3 701210A2-51010

23A. S/N 3020000 THRU A311XXXX 2 701208A1-51010 3 701208A2-51010 3 701210A2-51010

24. Cylinder & Case Gasket 2 701208A1-51030 3 701208A1-51030 3 701210A1-51030

25. Compression Ring (1

26. Oil Control Ring (1

27. Piston (1

s

) 2 701208A1-61012 3 701208A1-61012 3 701210A1-61011

s

) 4 701208A1-61030 6 701208A1-61030 6 701210A1-61030

s

) 4 701208A1-61050 6 701208A1-61050 6 701210A1-61050

27A. S/N 3020000 & later use 2 70123-61011 3 70123-61011 3 701210A1-61011

28. Piston Pin Snap Ring 4 701208A1-61070 6 701208A1-61070 6 701210A1-61070

29. Piston Pin (1

CYLINDERS

30. Connecting Rod Piston Pin Bushing (1

31. Connecting Rod Assembly, 1

s

) 2 701208A1-61120 3 701208A1-61120 6 701210A1-61120

s

s

) 2 70123-61081 3 70123-61081 3 70124-61080

Stage 2 701208A1-61201 3 701208A1-61201 3 701210A1-61201

31A. S/N 3020000 & later use 2 701208A1-61201 3 701208A1-61201 3 701210A1-61201

32. Connecting Rod Crank Pin Metal 4 70123-61090 6 70123-61090 6 70124-61090

33. Connecting Rod Bolt 4 70123-61250 6 70123-61250 6 70125-61250

33A. Oil Splash Dipper H.P. - 1 70130FA1-61290 1 701310A1-61290

34. Oil Splash Dipper 2 70120FA1-61282 2 70120FA1-61282 2 701310A1-61281

35. Oil Splash Dipper Bolt 2

42. Crankshaft 1 701208A1-56011 1 701308A1-56011 1 701310A1-56010

43. Counterweight - - 2 701310A1-56030

44. Lockwasher - - 2 701210A1-56830

45. Bolt - - 2 701210A1-56810

46. Crankcase 1 701208A2-57010 1 701308A2-57010 1 701310A2-57010

47. Front Bearing Cover 1 701208A1-57030 1 701308A1-57030 1 701310A1-57031

48. Front Bearing Cover Gasket 1 701208A1-57040 1 701208A1-57040 1 701210A1-57040

49. Rear Bearing Cover 1 701208A1-57061 1 701308A1-57061 1 701310A1-57061

49A. S/N 3020000 & later use 1 701208A1-57061 1 701308A1-57061 1 701310A1-57061

50. Rear Bearing Cover Gasket 1 701208A1-57070 1 701308A1-57070 1 701310A1-57070

51. Front Bearing 1 9350104-6206 1 9360112-6306 1 9354501-32210

52. Rear Bearing 1 9350104-6206 1 9360112-6306 1 9354501-32210

53. Front Oil Seal 1 701208A1-57080 1 701208A1-57080 1 701310A1-57080

54. V – Pulley Pin 1 701208A1-56061 1 701208A1-56061 1 701310A1-56060

55A. Compressor Fan 1 (Not Required) 1 (Not Required) 1 70121071-76311

55B. Compressor Pulley 1 701208A1-76010 1 701308A1-76010 1 701310A1-76011

56. Compressor Pulley Washer 1 701208A1-76210 1 70124-76210 1 701210A1-76210

57. Compressor Pulley Set Bolt 1

58. O-ring (Oil Level Glass) 1

59. Screw In Oil Level Glass 1

60. Crankcase Oil Cap 1 CCC1257 1 CCC1257 1 CCC1257

61. Crankcase Oil Plug 1 9156310-400800 1 9156310-400800 1 9156310-400800

62. Oil Level Glass Gasket 1 701210A1-57730 1 701210A1-57730 1 701210A1-57730

63. Oil Level Glass Assembly 1 701210A1-57700 1 701210A1-57700 1 701210A1-57700

CRANKCASE & CRANK ASSEMBLY

64. Oil Level Glass, Push Cover 1 701210A1-57740 1 701210A1-57740 1 701210A1-57740

65. Screw, Metric Pan Head 4 VH1470 4 VH1470 4 VH1470

66A Air Strainer Assembly 2 701208A1-66000 3 701208A1-66000 3 701312A1-66000

67. Air Strainer Filter 2 701208A1-66140 3 701208A-66110 3 701208A1-66110

69. Outlet Pipe Joint B 1 70123-87020 1 70133-87020 1 70134-87020

70. Compressor Body Discharge Piping Assy. 1 70123-87100 2 701308A1-87101 2 70134-87100

70A. S/N 3020000 & Later Use 1 701208A1-87101 2 701308A1-87101 2 701310A1-87101

71. Outlet Pipe Joint A 1 701208A1-87011 1 70123-87010 1 70124-87010

73. Outlet Pipe Joint C - 1 70133-87030 1 70134-87030

74. Gasket (Manifold) - - -

75. Breather Assembly 1 CCC1375 1 CCC1375 1 CCC1375

MODEL

ES30A

9251313-150800-532

9151313-1104012-5602

9150113-1112030-5608

93602-81260-3065

70A109B1-577002

Qty.

Req.

9251313-150800-532

3

9250113-150800-532

9151313-1104012-5602

3

9150113-1112030-5608

1

93602-81260-3065

1

70A109B1-577002

1

MODEL

ES50A

Qty.

Req.

MODEL

ES100A

3 9251313-151000-532

9250113-121000-532

6

9151313-1105016-5602

3

9150113-1112040-5608

1

-

-

-

-

15A

CAP-600

AIR COOLED, SINGLE STAGE MODEL

t

t

ES-150

CAP-600

DESCRIPTION

VALVE

ASSEMBLIES

Inlet Valve Assembly, 1

Outlet Valve Assembly, 1

Breather Assembly 1 70124-57600

MAIN PARTS LISTING FOR MODEL ES-150

VALVE &

UNLOADERS

DESCRIPTION

1. Inlet Valve Seat 3 70125-31010

2. Inlet Valve Receiver 3 70125-31021

3. Inlet & Outlet Valve Plate 6 70125-31030

4. Inlet Valve Spring 3 70125-31070

5. Inlet Valve Unloading Fork Guide 3 70125-31090

6. Unloading Spring 3 70125-11230

7A. Valve Gasket 6 70125-11110

Qty.

s

Stage 3 70125-31000

s

Stage 3 70125-41000

Req.

Qty.

Req.

16

MODEL

ES150

MODEL

ES150

MAIN PARTS LISTING FOR MODEL CAP-600

t

t

t

t

t

t

t

t

t

t

t

t

ES-150 (Continued)

VALVES & UNLOADERS

CYLINDERS

DESCRIPTION Qty. Req. MODEL ES150

7B Inlet Valve Unloading Fork 3 70125-31080

8. Locknut 3 92517-231200

10. Outlet Valve Seat 3 70125-41011

11. Outlet Valve Receiver 3 70125-41025

12. Outlet Valve Spring 3 70125-41074

13. Outlet Valve Bolt 3 70124-41810

14. Nut (Outlet Valve) 6 92502-131000

(Cont’d)

15. Inlet Valve Push Cover, 1

s

Stage 3 70125-11151

16. O – Ring G 65 3 93602-810065

17. Viton O – Ring G 65 (Outlet Valve) 3 93602-870065

18. Unloading Piston, 1

19. O – Ring P 22A 3 93601-870022A

20. Outlet Valve Push Cover, 1

21A. Cylinder Head Assembly 70135-11000A

21. Cylinder Head (1

21B. S/N A311XXXX AND LATER 3 70135-11011

22. Cylinder & Head Gasket, 1

22A. S/N A311XXXX AND LATER 3 70135-11612

23. Cylinder (1

s

Stage 3 70125-11220

s

Stage 3 70125-11451

s

) 3 70125-11010

s

Stage 3 70125-11612

s

) 3 70135-51011

23A. S/N 3020000 THRU A311XXXX 3 70135-51010

23B. S/N A311XXXX AND LATER 3 70135-51011

24. Cylinder & Case Gasket 3 70135-51610

25. Compression Ring (1

26. Oil Control Ring (1

27. Piston (1

s

) 3 70125-61010

s

) 6 70125-61030

s

) 6 70125-61050

27A. S/N 3020000 & later use 3 70135-61010-1

28. Piston Pin Snap Ring 6 70125-61070

29. Piston Pin (1

30. Connecting Rod Piston Pin Bushing (1

31. Connecting Rod Assembly, 1

s

) 3 70125-61120

s

s

) 3 70125-61081

Stage 3 70125-61200

31A. S/N 3020000 & later use 3 70125-61200

32. Connecting Rod Crank Pin Metal 6 70125-61090

33. Connecting Rod Bolt 6 70125-61250

34A. Oil Splash Dipper H.P. -

34. Oil Splash Dipper 3 70135-61281

35. Oil Splash Dipper Bolt 3 92501-130800

42. Crankshaft 1 70135-56011

43. Counterweight 2 70135-56031

44. Lockwasher 2 70135-56830

45. Bolt 2 70135-56811

46. Crankcase 1 70135-57010-4024

47. Front Bearing Cover 1 70135-57030

48. Front Bearing Cover Gasket 1 70135-57950

49. Rear Bearing Cover 1 70134-57061

49A. S/N 3020000 & later use 1 70134-57061

50. Rear Bearing Cover Gasket 1 70134-57960

51. Front Bearing 1 93502-30310

52. Rear Bearing 1 93502-32210

53. Front Oil Seal 1 70134-57080

54. V – Pulley Pin 1 70134-56060

55A. Compressor Fan 1 70135-76310

55B. Compressor Pulley 1 70135-76011

56. Compressor Pulley Washer 1 70124-76210

57. Compressor Pulley Set Bolt 1 91501-1312050

60. Crankcase Oil Cap 1 CCC1257

61. Crankcase Oil Plug 1 90112-100404

62 Oil Level Glass Gasket 1 701210A1-57730

63. Oil Level Glass Assembly 1 701210A1-57700

64. Oil Level Glass, Push Cover 1 701210A1-57740

65. Screw, Metric Pan Head 4 VH1470

66A. Air Strainer Assembly 3 70123-66001

67. Air Strainer Filter 3 70123-66140

69. Outlet Pipe Joint B 1 70135-87021

70. Compressor Body Discharge Piping Assy. 2 70135-87100 (Long)

70A. S/N 3020000 & Later Use 2 70135-87200 (Short)

71. Outlet Pipe Joint A 1 70135-87011

73. Outlet Pipe Joint C 1 70135-87031

74. Gasket (Manifold) 3 70125-87510

Discharge Piping Assembly 1 70135-87700

Discharge Piping Assembly 1 70135-87800

Discharge Piping Assembly 1 70135-87900

75. Breather Assembly 1 CCC1258

17

AIR COOLED SINGLE STAGE

MODEL ES-150A

CAP-600

18

MAIN PARTS LISTING FOR

MODEL ES150A

ITEM

NO.

1

2 92521-191000 COPPER WASHER 22

3 70134-57061

4

4a

4b

5 70134-57590

6 70134-57960

7

8

9 70124-57740 OIL GLASS & COVER 1

9a 70124-57700 OIL COVER 1

10 70124-57750 OIL COVER GLASS 1

11 70124-57730 GAUGE COVER SEAL 1

12

13

14 93502-30310 BEARING #30310 1

15 70135-56011 CRANKSHAFT 1

16 701312A1-56032

17 70135-56830 CT R WGT LK WASHER 2

18 70135-56811 CT R WGT MGT BOLT 2

19 70134-56060 V-PULLEY KEY 1

20 93502-32210 BEARING #32210 1

21 70135-57950

22 70134-57080 FRONT OIL SEAL 1

23 70135-57030

24 70135-76011

25 70135-76310 COMP PULLEY FAN 1

26

27

28 70124-76210

29

30

31 70135-51610 CYL & CASE PACKING 3

32 70135-51810 CYL & CASE BOLT 12

33 70135-61281 OIL SPLASH DIPPER 3

34

35 70125-61090

36 70125-61200 CONN.ROD ASS’Y 3

37 70125-61250

38 50135-61081

39 70125-61070

40 70125-61120 PISTON PIN 3

41 70135-61010-1 PISTON 3

42 70135-61050 OIL CONT ROL RING 6

43 70135-61030 COMPRESSION RING 6

44 70135-51011 CYLINDER 3

45

46 70135-11610 CYL & HEAD PACKING 3

47

48 70135-11011 CYLINDER HEAD 3

49 70125-11110

50 70125-31023

PART

NO.

91501-1310025

70131B81-57670

70131BA1-57670

CCC1697

70123-57190-4010

91507-2305016

90112-100404

70135-57010-4024

92522-130800

91501-2308030

92522-131200

91501-1312050

92501-130800

92501-131200

91501-1312035

DESCRIPTION QTY

BOLT, M10 X 25 10

REAR BEARING COVER

TUBE & BRTHR. ASSY. 1

TUBE, BREATHER 1

BREATHER, ASSY. 1

REAR COVER OIL BAFFLE

REAR BRG CVR PACKING

CRANKCASE OIL CAP 1

GAUGE SET BOLT 4

CRANKCASE OIL PLUG 1

CRANKCASE 1

CRANKSHAFT CTR. WGT.

FRONT BEARING GASKET

FRONT BEARING COVER

COMPRESSOR PULLEY

WASHER 6

BOLT 6

PULLEY THRUST WASHER

SPRING WASHER 31

BOLT 1

NUT 3

CONN.ROD CRANK PIN METL

CONN.ROD ASS’Y BOLT

CONN.ROD CRANK PIN METL

PISTON PIN SNAP RING

NUT 12

BOLT 18

I/O VALVE SEAT GASKET

INLET VALVE RECEIVER

CAP-600

ITEM

NO.

51 70125-31070 INLET VALVE SPRING 3

52 70125-31030 PLAT E, INLET VALVE 3

1

53 70125-31010 INT E R VALVE SEAT 3

54 70125-31090

55 70125-11230 UNLOADING SPRING 3

56 70125-31080 I.VALVE UNLOAD FORK 3

1

1

57

58

59 70125-11220 UNLOADING PISTON 3

60 93602-810065 O-RING G#65 3

61 70125-11151 I. VALVE PUSH COVER 3

62

63 90112-100101 SCREW PLUG 3

64 70124-41810 BOLT 3

65 70125-41012 OUT LET VALVE SEAT 3

66

67 70125-41025

68 92501-231000 NUT 6

2

69 93602-870065 VITON O-RING G#65 3

70 70125-11451

71

72 70135-87101

1

73

74 70135-87201

1

1

75

76 70125-41030 PLAT E, OUTLET VALVE 3

77 70125-41001 OUT LET, VALVE ASSY. 3

78 70125-31000 INLET , VALVE ASSY. 3

79 70123-66001 AIR ST RAINER ASSY. 3

1

80 70123-66140 AIR ST RAINER FILTER 3

6

6

3

6

6

3

PART

NO.

92517-231200

93601-810022A

91501-1310025

701212A-41075 OUTLET VALVE SPRING

701312A1-87032

701312A1-87022

701312A2-87011

DESCRIPTION QTY

I. VALVE UNLOAD FORK GUIDE

SLOTTED NUT 3

O-RING P#22A 3

BOLT 24

OUTLET VALVE RECEIVR

O. VALVE PUSH COVER

DIST. MANIFOLD #C 1

COMP.BODY DIS. PIPING

ASSEMBLY

DIST. MANIFOLD #B 1

COMP.BODY DIS. PIPING

ASSEMBLY

DIST. MANIFOLD #A 1

3

9

3

3

1

1

19

AIR COOLED SINGLE STAGE

MODEL ES-150B

CAP-600

18A

ITEM

NO.

91501-1310025

1

9252615-101000-0

2

701310A1-57061 REAR BEARING COVER

3

70131B81-57670

4

70131BA1-57670

4a

CCC1697

4b

701310A1-57590 REAR COVER OIL BAFFLE

5

701310A1-57070 REAR BRG CVR GASKET

6

70123-57190-4010

7

VH1470

8

701210A1-57740

9

701210A1-57700

9a

70124-57750

10

701210A1-57730

11

9156310-400800

12

701312A3-57010

13

9354504-30310

14

701312A1-56011

15

701312A1-56032 CRANKSHAFT CTR. WGT.

16

701312A1-56830

17

701312A1-56811

18

701310A1-56060

19

9354501-32210

20

70135-57950 FRONT BEARING GASKET

21

701310A1-57080

22

701312A1-57030 FRONT BEARING COVER

23

701312A1-76011 COMPRESSOR PULLEY

24

70131283-76310

25

9253113-100800-8

26

9150113-1108030-5202

27

701210A1-76210

28

9253113-101200-8

29

9150113-1112050-5608

30

701312A1-51030

31

701312A1-51810

32

701312A1-61281

33

9250113-120800-538

34

701212A1-61090

35

701212A1-61200

36

70125-61250 CONN.ROD ASS’Y BOLT

37

501312A1-61081

38

701212A1-61070 PISTON PIN SNAP RING

39

701212A1-61120

40

701312A1-61010

41

701212A1-61050

42

701212A1-61030

43

701312A3-51010

44

92501-131200

45

701312A3-11020

46

9250113-121200-538

47

701312A3-11010

48

701212A1-11110

49

PART

NO.

DESCRIPTION QTY

BOLT, M10 X 25 10

COPPER WASHER 10

TUBE & BRTHR. ASSY. 1

TUBE, BREATHER 1

BREATHER, ASSY. 1

CRANKCASE OIL CAP 1

GAUGE SET BOLT 4

OIL GLASS & COVER 1

OIL COVER ASSY 1

OIL COVER GLASS 1

GAUGE COVER SEAL 1

CRANKCASE OIL PLUG 1

CRANKCASE 1

BEARING #30310 1

CRANKSHAFT 1

CTR WGT LK WASHER 2

CTR WGT MGT BOLT 2

V-PULLEY KEY 1

BEARING #32210 1

FRONT OIL SEAL 1

COMP PULLEY FAN 1

WASHER 6

BOLT 6

PULLEY THRUST WASHER

SPRING WASHER 1

BOLT 1

CYL & CASE PACKING 3

CYL & CASE BOLT 12

OIL SPLASH DIPPER 3

NUT 3

CONN.ROD CRANK PIN METL

CONN.ROD ASS’Y 3

CONN.ROD CRANK PIN METL

PISTON PIN 3

PISTON 3

OIL CONTROL RING 6

COMPRESSION RING 6

CYLINDER 3

NUT 12

CYL & HEAD GASKET 3

BOLT 12

CYLINDER HEAD 3

I/O VALVE SEAT GASKET

MAIN PARTS LISTING FOR

MODEL ES150B

ITEM

NO.

701212A1-31023 INLET VALVE RECEIVER 3

50

701212A1-31070

51

1

1

1

2

1

1

1

1

501212A1-31030

52

701212A1-31010

53

701212A1-31090

54

701212A1-11230

55

701212A1-31080

56

9250413-151200-532

57

9360187-350217

58

701212A1-11220

59

9360287-310644

60

701212A1-11151

61

91501-1310025

62

90112-100101

63

70124-41810

64

701212A1-41012

65

701212A1-41075 OUTLET VALVE SPRING

66

701212A1-41025 OUTLET VALVE RECEIVR

67

92501-231000

68

9360287-310644

69

701212A1-11451 O. VALVE PUSH COVER

70

701312A1-87032

71

70135-87101

72

701312A1-87022

73

701312A2-87100

74

701312A2-87011

75

70125-41030

76

701212A1-41001

77

701212A1-31000

78

701312A1-66000

79

701208A1-66110

80

6

6

3

6

6

PART

NO.

CAP-600

DESCRIPTION QTY

INLET VALVE SPRING 3

PLATE, INLET VALVE 3

INTER VALVE SEAT 3

I. VALVE UNLOAD FORK GUIDE

3

UNLOADING SPRING 3

I.VALVE UNLOAD FORK 3

SLOTTED NUT 3

O-RING P#22A 3

UNLOADING PISTON 3

O-RING G#65 3

I. VALVE PUSH COVER 3

BOLT 3

SCREW PLUG 24

BOLT 3

OUTLET VALVE SEAT 3

3

9

NUT 3

VITON O-RING G#65 6

3

DIST. MANIFOLD #C 3

COMP.BODY DIS. PIPING

ASSEMBLY

1

DIST. MANIFOLD #B 1

COMP.BODY DIS. PIPING

ASSEMBLY

1

DIST. MANIFOLD #A 1

PLATE, OUTLET VALVE 1

OUTLET, VALVE ASSY. 3

INLET, VALVE ASSY. 3

AIR STRAINER ASSY. 3

AIR STRAINER FILTER 3

19A

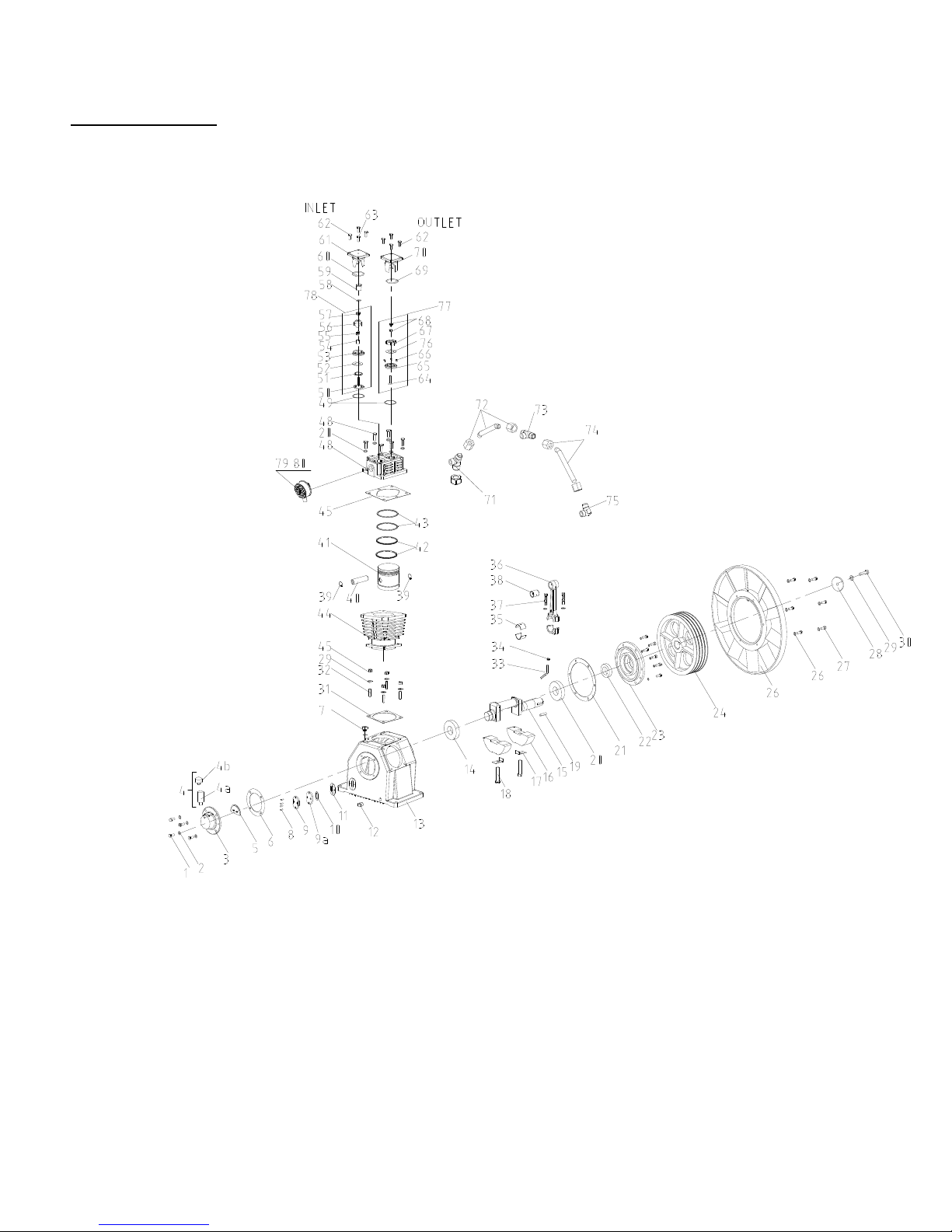

AIR COOLED

TWO STAGE MODELS E-11 & E-23

CAP-600

20

MAIN PARTS LISTING FOR

t

t

t

t

t

t

d

d

d

d

d

d

d

t

t

t

t

t

t

t

t

d

d

d

d

d

d

d

d

TWO STAGE MODELS E-11 & E-23

VALVES

1. Inlet & Outlet Valve Plate (1

2. Inlet Valve Spring (1

3. Inlet Valve Receiver (1

4. Inlet Valve Snap Ring (1

5. Outlet Valve Spring (1

6. Outlet Valve Push Cover Gasket (1

7. Outlet Valve Push Cover 1 70112-11450 2 70112-11450

8. Inlet & Outlet Valve Plate (2

9. Inlet Valve Spring (2

10. Inlet Valve Receiver (2

11. Inlet Valve Snap Ring (2

12. Outlet Valve Spring (2

14. Outlet Valve Push Cover Gasket (2

15. Outlet Valve Push Cover (2

CYLINDERS

16. Cylinder Head (1

17. Cylinder & Head Gasket (1

18. Cylinder (1

19. Cylinder & Case Gasket 2 70112-51610 3 70112-51610

20. Compression Ring (1

21. Oil Control Ring (1

22. Piston (1

23. Piston Pin (1

24. Piston Pin Snap Ring 4 70112-61070 6 70112-61070

25. Connecting Rod Assembly (1

26. Connecting Rod Bolt 2 70112-61250 3 70112-61250

27. Oil Splash Dipper 70122-61282 2 70122-61282

27A. Oil Splash Dipper - 1 70132-61290

28. Oil Splash Dipper Bolt 2 91507-2304010 3 91507-2304010

29. Cylinder Head Bolt 8 91501-1308025 12 91501-1308025

30. Cylinder Head (2

31. Cylinder & Head Gasket (2

32. Cylinder (2

34. Compression Ring (2

35. Oil Control Ring (2

36. Piston (2

37. Piston Pin (2

38. Connecting Rod Assembly (2

39. Crankcase 1 70122-57010-4024 1 70132-57010-4024

40. Crankshaft 1 70122-56010 1 70132-56010

41. Front Bearing Cover 1 70122-57030 1 70122-57030

42. Front Bearing Cover Gasket 1 70122-57950 1 70122-57950

43. Rear Bearing Cover 1 70122-57060 1 70122-57060

44. Rear Bearing Cover Gasket 1 70122-57960 1 70122-57960

45. Bearing 2 93501-6205 2 93501-6205

46. Front Oil Seal 1 70122-57080 1 70122-57080

47. V–Pulley Pin 1 70112-56060 1 70112-56060

48. Compressor Pulley 1 70122-76011 1 70132-76010

49. Compressor Pulley Thrust Washer 1 70112-76210 1 70112-76210

50. Compressor Pulley Thrust Bolt 1 91501-1308025 1 91501-1308025

51. Breather Assembly 1 CCC1375 1 CCC1375

52. Oil Gauge & Gauge Cover 1 70111-57700 1 70111-57700

٭52 A. Oil Level Gauge Assy. 1 70A109B1-57701 1 70704-57700

53. Gauge Cover Seal 1 70111-57730 1 70111-57730

٭53 A. Oil Level Gauge “O” Ring 1 93602-8126026 1 93602-8126026

54. Crankcase Oil Plug 1 90112-100202 1 90112-100202

54A. Oil fill cap - 1 70101-57190-4010

54B. “O” Ring - 1 93601-810016

55. Auto-Unloader Assembly 2 70112-11201 3 70112-11201

56. Auto-Unloader Spring 2 70112-11230 3 70112-11230

57. Auto-Unloader Piston 2 70112-11221 3 70112-11221

58. O-Ring (Unloader) 2 93601-810016 3 93601-810016

AIR STRAINER ASSEMBLY

61. Air Strainer Filter (not shown) 1 70111-66141 2 70111-66141

63A. Discharge Piping Assembly - 1 70132-87100

63B. Discharge Piping Assembly 1 70172-87300 1 70172-87300

64. Air Strainer Assembly 1 70111-66001 2 70111-66001

65. Outlet Pipe Joint #A 2 70122-87010 3 70122-87010

65A. Outlet Pipe Joint #B 1 70132-87020

• E11, START S/N AS4040633

• E23, START S/N AS4030313

s

s

) 1 70112-51010 2 70112-51010

s

) 1 70112-61011 2 70112-61011

s

) 1 70112-61120 2 70112-61120

n

n

) 1 70162-52010 1 70172-52010

n

) 1 70162-62010 1 70172-62010-1

n

) 1 70162-62120 1 70172-62120

CRANK ASSEMBLY

UNLOADERS

s

) 2 70112-31030 4 70112-31030

s

) 1 70112-31070 2 70112-31070

s

) 1 70112-31020 2 70112-31020

s

) 1 93610-130232 2 93610-130232

s

) 1 70112-41070 2 70112-41070

n

) 1 70162-32070 2 70172-32070

n

) 1 70162-32020 1 70111-31020

n

n

) 1 70162-42070 1 70172-42070

) 1 70112-11010 2 70112-11010

s

) 2 70112-61030 4 70112-61030

s

) 1 70112-61050 2 70112-61050

) 1 70162-12010 1 70172-12010

n

) 2 70162-62030 2 70111-61030

n

) 2 70162-62050 2 70111-61050

s

) 1 70112-11461 2 70112-11461

n

) 2 70162-32030 2 70111-31030

) 1 93610-130222 1 93610-130225

n

) 1 70162-12650 1 70111-11461

n

) 1 70112-12450 1 70111-11450

s

) 1 70112-11612 2 70112-11612

s

) 2 70112-61200-1 2 70112-61200-1

n

) 1 70162-12610 1 70111-11612

n

) - 1 70182-62200

Qty.

Req.

MODEL E11

Qty.

Req.

CAP-600

MODEL E23

21

AIR COOLED, TWO STAGE CAP600

t

d

t

d

MODELS E-50 & E-71

DESCRIPTIONS Qty. Req.

Inlet Valve Assembly, 1

Inlet Valve Assembly, 2

Outlet Valve Assembly, 1

VALVE

Outlet Valve Assembly, 2

ASSEMBLIES

Breather Assembly 1 70103-57600-4024 1 70124-57600-4010

DESCRIPTIONS

1. Inlet Valve Seat 2 70123-31010 1 70123-31010 2 70124-31010 1 70123-31010

2. Inlet Valve Receiver 2 70123-31020 1 70123-31020 2 70124-31020 1 70123-31020

3. Inlet & Outlet Valve Plate 4 70123-31030 2 70123-31030 4 70124-31030 2 70123-31030

4. Inlet Valve Spring 2 70123-31070 1 70123-31070 2 70124-31070 1 70123-31070

5. Inlet Valve Unloading Fork Guide 2 70123-31090 1 70123-31090 2 70124-31090 1 70123-31090

6. Unloading Spring 2 70123-11230 1 70123-11230 2 70124-11230 1 70123-11230

7. Inlet Valve Unloading Fork 2 70123-31080 1 70123-31080 2 70124-31080 1 70123-31080

8. Slotted Nut 2 92502-230800 1 92502-230800 2 92502-230800 1 92502-230800

9. Cotter Pin (not shown) 2 93701-130220 1 93701-130220 2 93701-130220 1 93701-130220

10. Outlet Valve Seat 2 70123-41011 1 70123-41011 2 70124-41011 1 70123-41011

VAVLES & UNLOADERS

11. Outlet Valve Receiver 2 70123-41020 1 70123-41020 2 70124-41020 1 70123-41020

12A. Seat Gaskets 4 70123-11110 2 70123-11110 4 70124-11110 2 70123-11110

MODEL

s

Stage 2 70123-31000 2 70124-31000

n

Stage 1 70173-32000 1 70173-32000

s

Stage 2 70123-41000 2 70124-41000

n

Stage 1 70123-41000 1 70123-41000

E50

Qty. Req.

MODEL

E71

MAIN PARTS LISTING FOR

TWO STAGE MODELS E-50 & E-71

MODEL E50 MODEL E71

Qty

Req’d

st

1

Stage

22

Qty

Req’d

2nd Stage

Qty

Req’d

1st Stage

Qty

Req’d

2nd Stage

CAP-600

MAIN PARTS LISTING FOR

TWO STAGE MODELS E-50 & E-71 (CONTINUED)

MODEL E-50 MODEL E-71

12B Outlet Valve Spring 2 70123-41070 1 70123-41070 2 70124-41070 1 70123-41070

13 Outlet Valve Bolt 2 70123-41810 1 70123-41810 2 70124-41810 1 70123-41810

14 Nut (Outlet Valve) 2 92502-230800 1 92502-230800 2 92502-230800 1 92502-230800

15 Inlet Valve Push Cover 2 70123-11150 1 70123-11150 2 70124-11150 1 70123-11150

16 O-ring G-40(Inlet Valve) 2 93602-810040 1 93602-810040 2 93602-810055 1 93602-810055

17 Viton O-ring G-40 (Outlet Valve) 2 93602-870040 1 93602-870040 2 93602-870055 1 93602-870040

18 Unloading Piston 2 70123-11220 1 70123-11220 2 70124-11220 1 70123-11220

19 O-ring P-20 2 93601-810020 1 93601-870020 2 93601-810021 1 93601-870020

20 Outlet Valve Push Cover 2 70123-11450 1 70123-11450 2 70124-11450 1 70123-11450

Valves & Unloaders

20A Iinterstage Safety Valve (E71 only) - N/A - N/A 1 93132-15006-40101 - N/A

21 Cylinder Head (1st) 2 70123-11010 2 70124-11010

22 Cylinder & Head Gasket 2 70123-11612 1 70123-11612 2 70124-11612 1 70123-11612

23 Cylinder (1st) 2 70123-51012 2 70124-51011

23A S/N A311xxxx & Later Use 2 70123-51012 2 70124-51011

24 Cylinder & Case Gasket 2 70123-51610 1 70123-51610 2 70124-51610 1 70124-51610

25 Compression Ring (1st) 4 70123-61030 4 70124-61030

26 Oil Control Ring (1st) 4 70123-61050 4 70124-61050

27 Piston (1st) 2 70123-61011 2 70124-61011-1

27A S/N 3020000 & Later Use 2 70123-61011 2 70124-61011-1

28 Piston Snap Ring 4 70123-61070 2 70123-61070 4 70124-61070 2 70124-61070

29 Piston Pin (1st) 2 70123-61120 2 70124-61120

30 Con’cting Rod Pist. Pin Bushing 2 70123-61081 1 70173-62080 2 70124-61080 1 70174-62081

30A Bushing S/N 3020000 & Later use 2 70123-61081