FRÄNKISCHE profi-air Series Installation And Operating Instructions Manual

profi-air® defroster heating DN 125

Installation and operating instructions

DRAINAGE SYSTEMS

ELECTRICAL SYSTEMS

BUILDING TECHNOLOGY

INDUSTRIAL PRODUCTS

Table of contents

1 General 3

1.1 Introduction 3

1.2 Safety 3

2 Intended use 4

3 Structure 4

4 Scope of delivery 4

5 Technical data 5

5.1 Device specifications 5

5.2 Dimensional drawing 5

5.3 Pressure loss diagram 5

6 Safety instructions 6

7 Installation instructions 6

7.1 Installation position 6

7.2 Installation in the fresh air pipe 7

7.3 Installation of the defroster heating 8

7.4 Putting into operation 11

8 Maintenance and cleaning 11

9 Declaration of Conformity 12

10 Warranty 13

11 Liability 13

12 Disposal 13

All infor mation in this p ublicatio n generally reflects the st ate of the art at th e time of printin g. Further more, consid erable care w as taken when pre paring this publication. Neverthe less, typ esetting

and trans lation error s cannot be entirely excluded . We also reser ve the right to make c hanges to our products, sp ecificati ons and other da ta. Changes may also beco me necessar y as a result of legal,

materia l-relate d or other techn ological re quirements, which cannot o r can no longe r be considered in this publi cation. For t his reason, we c annot assume a ny liability which is base d solely on the d ata

provide d in this publication. The d ecisive role w ith regard to the data on produ cts and ser vices is alway s played by the or der placed , the product a ctually purc hased and the d ocumentat ion in connec tion wit h it, or the information provid ed by our spec ialist staf f in each spec ific indivi dual case.

2

MBA profi-air defroster heating

FRÄNKISCHE

1 General

The profi-air defroster heating DN 125

ensures that the heat exchanger in the

profi-air 180 flat ventilation unit is pro-

1.1 Introduction

These installation and operating instructions are intended to help you install a

fully functional profi-air defroster heating and properly operate it. We recommend that you read these instructions

carefully before you commence installation. These installation and operating

1.2 Safety

If used as intended, the device is safe and

reliable to operate. The construction and

design are state of the art and comply

with all relevant DIN / VDE regulations

tected against frost without having to

temporarily turn off the supply air fan.

instructions can also serve as a reference for service and maintenance work

and guarantee smooth and efficient

operation.

and safety provisions. All safety regulations, warnings and notices of these

installation and operating instructions,

have to be complied with; non-compli-

ance may result in personal injury and/or

damage to the profi-air defroster heating.

1.2.1 Safety regulations

n

Installation, connection, putting into

operation as well as maintenance of

the profi-air defroster heating may

be performed by authorised and

qualified personnel only.

n

Installation of the profi-air defroster

heating must be carried out according to applicable local construction,

safety and installation regulations.

n

Changes or modifications to the

profi-air defroster heating are not permitted.

n

Keep these installation and operat-

ing instructions near the profi-air

defroster heating during the entire

life of the device.

1.2.2 Safety equipment and measures

n

The profi-air defroster heating cannot

be opened without tools.

n

Make sure that the heating spiral

cannot be touched with hands if the

system is connected to power.

n

During maintenance, the defroster

heating may be opened in the “dead”

state only, and may only be operated

with the installed duct network.

MBA profi-air defroster heating

3FRÄNKISCHE

1 General

1.2.3 Symbols used

Risk of personal injury

Risk of:

n

damage to equipment

n

errors while operating the device if the instructions are not complied with

correctly

n

other material damage

Additional notices

Reference to other sections and/or guidelines of the manufacturer

Disposal instructions

2 Intended use

The profi-air defroster heating DN 125 /

900 W is an air pre-heating device which

can be integrated into the fresh air pipe

of ventilation systems (profi-air 180 flat)

and which is intended to protect the

heat exchanger from freezing conden-

3 Structure

The profi-air defroster heating DN 125

consists of a galvanised steel-plate

housing with an integrated heating spiral. With the help of the insulation kit

included with the delivery, thermal insu-

4 Scope of delivery

sate. The defroster heating can be

switched on and off through the frost

protection control incorporated in the

ventilation device. To do so, the electric

heater coil must be connected to the

profi-air 180 flat control.

lation of the defroster heating is provided in order to prevent condensate

development. To insure protection

against overheating, a safety temperature monitor (with an automatic reset

This control ensures that the defroster

heating only operates if there is a risk

that the cross-flow heat exchanger can

freeze.

function) and a safety temperature limiter (with a manual reset function) are

integrated into the terminal box of the

defroster heating.

n Defroster heating DN 125 / 900 W

with integrated heating spiral and

two safety equipment units

n 1 m connection cable

4

MBA profi-air defroster heating

n Insulation kit incl. one set of infor-

mation and type plates

FRÄNKISCHE

5 Technical data

5.1 Device specifications

Electrical connection: 1~230 V / 50 Hz; 1 m cable with connector plugs

Heating performance: 900 Watt

Power consumption: 4.1 A

Safety components: 1 x safety temperature monitor

1 x safety temperature limiter

integrated into the circuit of the heater coil

Air volume flow rate: 70 to 220 m³/h

Air pipe connection: 2 x DN 125 connecting nipples

Weight: 2.8 kg

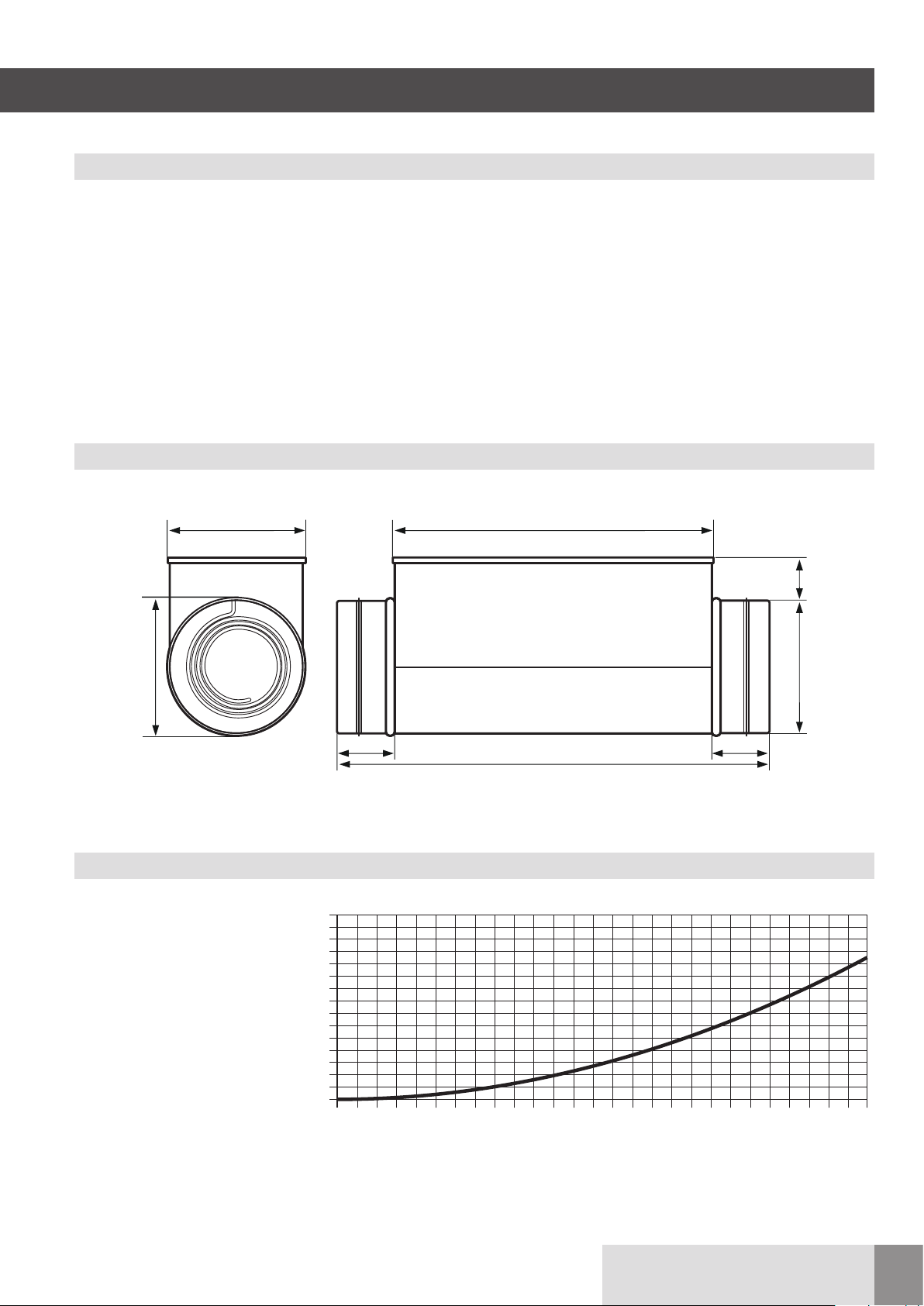

5.2 Dimensional drawing

125

Ø125

5.3 Pressure loss diagram

30

270

50 50

370

32

125

20

10

Pressure loss [Pa]

0

0

50 100 150 200 250

Volume flow rate [m3/h]

5FRÄNKISCHE

MBA profi-air defroster heating

Loading...

Loading...