Page 1

Y/KSCF/C/HC18G High Efficiency

Installation and Operation Manual

Cool Zone Series Gas Fryers

Frymaster, a member of the Commercial Food Equipment Service Association, recommends

using CFESA Certified Technicians.

24-Hour Service Hotline 1-800-551-8633

Price: $10.00

APR 2011

*8196329*

Page 2

Please read all sections of this manual and retain for future reference.

NOTICE

This appliance is intended for professional use only and is to be operated by qualified

personnel only. A Frymaster and Dean Factory Authorized Servicer (FAS) or other qualified

professional should perform installation, maintenance, and repairs. Installation, maintenance,

or repairs by unqualified personnel may void the manufacturer’s warranty. See Chapter 1 of

this manual for definitions of qualified personnel.

NOTICE

IF, DURING THE WARRANTY PERIOD, THE CUSTOMER USES A PART FOR THIS MANITOWOC

FOOD SERVICE EQUIPMENT OTHER THAN AN UNMODIFIED NEW OR RECYCLED PART

PURCHASED DIRECTLY FROM FRYMASTER DEAN, OR ANY OF ITS AUTHORIZED SERVICE

CENTERS, AND/OR THE PART BEING USED IS MODIFIED FROM ITS ORIGINAL

CONFIGURATION, THIS WARRANTY WILL BE VOID. FURTHER, FRYMASTE R DEAN AND ITS

AFFILIATES WILL NOT BE LIABLE FOR ANY CLAIMS, DAMAGES OR EXP ENSES INCUR RED B Y

THE CUSTOMER WHICH ARISE DIRECTLY OR INDIRECTLY, IN WHOLE OR IN PART, DUE TO

THE INSTALLATION OF ANY MODIFIED PART AND/OR PART RECEIVED FROM AN

UNAUTHORIZED SERVICE CENTER.

NOTICE

This equipment must be installed in accordance with the appropriate national and local codes of

the country and/or region in which the appliance is installed.

NOTICE

Drawings and photos used in this manual are intended to illustrate operational, cleaning and

technical procedures and may not conform to onsite management operational procedures.

NOTICE TO OWNERS OF UNITS EQUIPPED WITH CONTROLLERS

U.S.

This device complies with Part 15 of the FCC rules. Operation is subject to the following two

conditions: 1) This device may not cause harmful interference, and 2) This device must accept

any interference received, including interference that may cause undesired operation. While

this device is a verified Class A device, it has been shown to meet Class B limits.

Canada

This digital apparatus does not exceed the Class A or B limits for radio noise emissions as set

out by the ICES-003 standard of the Canadian Department of Communications.

Cet appareil numerique n’emet pas de bruits radioelectriques depassany les limites de classe A

et B prescrites dans la norme NMB-003 edictee par le Ministre des Communications du Canada.

DANGER

Improper installation, adjustment, maintenance or service, and unauthorized alterations or

modifications can cause property damage, injury, or death. Read the installation, operating and

service instructions thoroughly before installing or servicing this equipment. Only qualified

service personnel may convert this appliance to use a gas other than that for which it was

originally configured. See Chapter 1 of this manual for definition of qualified service personnel.

Page 3

DANGER

Adequate means must be provided to limit the movement of this appliance without depending

upon the gas line connection. Single fryers equipped with legs must be stabilized by installing

anchor straps. All fryers equipped with casters must be stabilized by installing restraining

chains. If a flexible gas line is used, an additional restraining cable must be connected at all

times when the fryer is in use.

DANGER

The front ledge of the fryer is not a step. Do not stand on the fryer. Serious injury can result

from slips or contact with the hot oil.

DANGER

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any

other appliance.

DANGER

Instructions to be followed in the event the operator smells gas or otherwise detects a gas leak

must be posted in a prominent location. This information can be obtained from the local gas

company or gas supplier.

DANGER

The crumb tray in fryers equipped with a filter system must be emptied into a fireproof container

at the end of frying operations each day. Some food particles can spontaneously combust if left

soaking in certain shortening material. Additional information can be obtained in the filtration

manual included with the system.

WARNING

No structural material on the fryer should be altered or removed to accommodate placement of

the fryer under a hood. Questions? Call the Frymaster Dean Service Hotline at 1-800-551-8633.

WARNING

Do not bang fry baskets or other utensils on the fryer’s joiner strip. The strip is present to seal

the joint between the frypot. Banging fry baskets on the strip to dislodge shortening will distort

the strip, adversely affecting its fit. It is designed for a tight fit and should only be removed for

cleaning.

Page 4

Y/KSCF/C/HC18G Cool Zone Gas Fryers

INSTALLATION & OPERATION MANUAL

TABLE OF CONTENTS

Page #

1. INTRODUCTION 1-1

2. IMPORTANT INFORMATION 2-1

3. INSTALLATION INSTRUCTIONS 3-1

4. DAILY OPERATION 4-1

5. FILTRATION 5-1

6. PREVENTATIVE MAINTENANCE 6-1

7. TROUBLESHOOTING 7-1

Page 5

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS

FRYERS

CHAPTER 1: INTRODUCTION

1.1 After Purchase

In order to improve service, have the following chart filled in by the Factory Authorized Servicer

who installed this equipment.

Authorized Servicer

Technician/FAS

Address

Telephone/Fax

Model Number

Serial Number

Gas Type

1.2 Ordering Parts

Customers may order parts directly from their local factory authorized servicer (FAS). If the

telephone number of your FAS is not listed above, call the Frymaster Service Hotline telephone

number, 1-800-551-8633.

To speed up your order, provide the model number, serial number, gas type, part needed, item part

number (if known), and quantity needed.

1-1

Page 6

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS FRYERS

CHAPTER 1: INTRODUCTION

1.3 Service Information

Call the Frymaster Service Hotline, 1-800-551-8633, for the location of your nearest factory

authorized servicer (FAS). To assist you more efficiently, always provide the service technician with

the model number, gas type, serial number, and the nature of the problem.

1.4 Controller Information

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC rules. While this device is a verified Class A device, it has been

shown to meet the Class B limits. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference to radio communications. Operation of

the equipment in a residential area is likely to cause harmful interference in which case the user will

be required to correct the interference at his own expense.

The user is cautioned that any changes or modifications not expressly approved by the party

responsible for compliance could void the user's authority to operate the equipment.

If necessary, the user should consult the dealer or an experienced radio and television technician for

additional suggestions.

The user may find the following booklet prepared by the Federal Communications Commission

helpful: "How to Identify and Resolve Radio-TV Interference Problems". This booklet is available

from the U.S. Government Printing Office, Washington, DC 20402, Stock No. 004-000-00345-4.

1.5 Safety Information

Before attempting to operate your unit, read the instructions in this manual thoroughly.

Throughout this manual, you will find notations enclosed in double-bordered boxes similar to the

ones below.

CAUTION

CAUTION boxes contain information about actions or conditions that may cause or result in a

malfunction of your system.

WARNING

WARNING boxes contain information about actions or conditions that may cause or result in

damage to your system, and which may cause your system to malfunction.

1-2

Page 7

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS FRYERS

CHAPTER 1: INTRODUCTION

1.5 Safety Information (cont.)

DANGER

DANGER boxes contain information about actions or conditions, which may cause or result in

injury to personnel, may cause damage to your system, and/or cause your system to malfunction.

1.6 Service Personnel

A. Qualified and/or Authorized Operating Personnel: Qualified/authorized operating personnel

are those who have carefully read the information in this manual and have familiarized

themselves with the equipment functions, or have had previous experience with the operation of

equipment covered in this manual.

B. Qualified Installation Personnel: Qualified/authorized personnel are those who have carefully

read the information in this manual and have familiarized themselves with the equipment

functions, or who have had previous experience with the operation of the equipment covered in

this manual.

C. Qualified Service Personnel: Qualified service personnel are those who are familiar with

Frymaster equipment and are authorized by Frymaster to perform service on Frymaster

equipment. All authorized service personnel are required to be equipped with a complete set of

service parts manuals and stock a minimum amount of parts for Frymaster equipment. A list of

Frymaster Factory Authorized Servicers (FAS’s) was included with the fryer when shipped from

the factory. Failure to use qualified service personnel will void the Frymaster warranty on

your equipment.

1-3

Page 8

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS

FRYERS

CHAPTER 2: IMPORTANT INFORMATION

2.1 Receiving and Unpacking Equipment

A. Check that the container is upright. Use an outward prying motion - no hammering - to

remove the carton. Unpack the fryer carefully and remove all accessories from the carton.

Do not discard or misplace these, as they will be needed.

B. After unpacking, immediately check the equipment for visible signs of shipping damage. If

damage has occurred, contact the carrier and file the appropriate freight claims. Do not

contact the factory. Shipping damage responsibility is between the carrier and the dealer.

If your equipment arrives damaged:

1. File claim for damages immediately, regardless of extent of damage.

2. Visible loss or damage: Be sure this is noted on the freight bill or express receipt and is

signed by the person making the delivery.

3. Concealed loss or damage: If damage is unnoticed until equipment is unpacked, notify

freight company or carrier immediately, and file a concealed damage claim. This should

be done within fifteen (15) days of date of delivery. Be sure to retain container for

inspection.

NOTE: Frymaster Does Not Assume Responsibility for Damage or Loss Incurred in Transit.

C. Frying systems with built-in filtration: Take off the filter support brace and remove the

filter pan from the cabinet.

D. Remove all plastic skin from sides, front, and doors of the fryer(s). Failure to do this prior to

initial fryer operation will make it very difficult to remove later.

2.2 General

Upon arrival, inspect the fryer carefully for visible or concealed damage. (See Receiving and

Unpacking Equipment, Section 2.1.)

The Frymaster Y/KSCF/C/HC18G High Efficiency Cool Zone Series Fryers are energy-efficient,

gas-fired units, design-certified by the International Approval Services (AGA/CGA), Gaz de France,

and NSF International and manufactured to their basic performance and application specifications.

All units are shipped completely assembled with accessories packed inside the frypots. All units are

adjusted, tested, and inspected at the factory before shipment. Sizes, weights, and input rates of all

models are listed in this manual.

2-1

Page 9

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS FRYERS

CHAPTER 2: IMPORTANT INFORMATION

2.3 Principles of Operation

The incoming gas flows through orifices and is mixed with air in the burners to create the correct ratio

for proper combustion. The mixture is ignited at the front end of each heat tube by the pilot light.

Internal diffusers slow the flame as it goes through the burner tube. This slow, turbulent flame

increases heat transfer to the walls of the tubes to heating the oil more efficiently.

2.4 Rating Plate

This is attached to the inside of the front door panel. Information provided includes the model and

serial number of the fryer, BTU/hr (kW/hr) input of the burners, outlet gas pressure in inches W.C.

(mbars), and whether the unit has natural (G20/25) or propane (G31) gas orifices.

2.5 Pre-Installation

DANGER

This appliance is equipped with a three-prong (grounding) plug for your protection

against electrical shock and must be plugged directly into a properly grounded

three-prong receptacle. Do not cut, remove, or otherwise bypass the grounding

prong on this plug.

A. General: Only licensed personnel should install any gas-fired equipment.

1. A manual gas shut-off valve must be installed in the gas supply line ahead of the fryers for

safety and ease of future service.

2. The Frymaster Y/KSCF/C/HC18G gas fryers require 120 volts (AC) 60-cycle electrical

service for U.S./Canada/Mexico installations. Fryers are equipped with a 16-3 SJT

grounded flexible power cord for a direct connection to the power supply. Amperage draw

for each unit depends on the accessories supplied with the unit. See detailed instructions

packaged with the fryer line-up.

DANGER

No structural material on the fryer should be altered or removed to accommodate

placement of the fryer under a hood. Questions? Call the Frymaster Service Hotline

at 1-800-551-8633.

2-2

Page 10

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS FRYERS

CHAPTER 2: IMPORTANT INFORMATION

2.5 Pre-Installation (cont.)

DANGER

This appliance must be installed with sufficient ventilation to prevent the occurrence

of unacceptable concentrations of substances harmful to the health of personnel in

the room in which it is installed.

B. Clearances: The fryer area must be free of all combustibles. This unit is design-certified for

the following installations:

1. Commercial installation only; not for household use.

2. Non-combustible floor installation equipped with factory-supplied 6-inch (15-cm)

adjustable legs or 5-inch (13-cm) casters;

3. Combustible construction with a minimum clearance of 6-inches (15-cm) side and 6-inches

(15-cm) rear, and equipped with factory-supplied 6-inch (15-cm) adjustable legs or 5-inch

(13-cm) casters.

C. Installation Standards

1. U.S. installations must meet: 2. Canadian installations must meet:

American National Standard Institute CAN 1-B149 Installation Codes

ANSI Z83.11 Canadian Gas Association

American Gas Association 55 Scarsdale Road

8501 E. Pleasant Valley Road Don Mills, ONT, M3B 2R3

Cleveland, OH 44131

National Electrical Code Canadian Electric Code c22.1, part 1

ANSI/NFPA #70 Canadian Standards Association

American National Standard Institute 178 Rexdale Blvd.

1430 Broadway Rexdale, ONT, M9W 1R3

New York, NY 10018

NFPA Standards #96 and #211

National Fire Protection Association

3. Australian installations must meet:

470 Atlantic Avenue AS5601/AG601 Installation Codes

Boston, MA 02110

Standards Australia International

25RaglanStreet

South Melbourne, VIC 3205

2-3

Page 11

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS FRYERS

CHAPTER 2: IMPORTANT INFORMATION

2.6 Air Supply and Ventilation

DANGER

Do not connect this appliance to the gas supply before reviewing each step in this

section.

A. Keep the area around the fryer clear to prevent obstruction of combustion and ventilation airflow

and to allow for service and maintenance. Always adhere to the following:

1. Do not connect this fryer to an exhaust duct.

2. Follow installation and adjustment procedure to ensure adequate airflow to the fryer system.

3. A heavy-duty, commercial fryer’s combustion wastes must vent to the outside of the

building. A deep-fat fryer must be installed under a powered exhaust hood, or an exhaust

fan must be provided in the wall above the unit. Exhaust gas temperatures are

approximately 800-1000°F (427-538°C). Check air movement during installation. Strong

exhaust fans in the exhaust hood or in the overall air conditioning system can produce

slight air drafts in the room and cause erratic burner flames or improper fryer operation.

4. Do not place the fryer’s flue outlet directly into the plenum of the hood, as it will affect the

gas combustion of the fryer.

5. Never use the interior of the fryer cabinet for storage or store items on shelving over or

behind the fryer. Exhaust temperatures can exceed 800°F (427ºC) and may damage or

melt items stored in or near the fryer.

6. Adequate distance must be maintained from the flue outlet of the fryer(s) to the lower edge

of the filter bank. Per NFPA Standards No. 96, a minimum of 18-inches (45-cm) should be

maintained between the flue(s) and the lower edge of the exhaust hood filter.

7. Filters and drip troughs should be part of an industrial hood, but consult local codes before

constructing and installing any hood. The duct system, the exhaust hood, and the filter

bank must be cleaned on a regular basis and kept free of grease.

2.7 Equipment Installed at High Altitudes

A. The fryer input rating [BTU/hr (kW/hr)] is for elevations up to 2,000 feet (610 m). For

elevations above 2,000 feet (610 m), the rating should be reduced 4% for each additional

1,000 feet (305 m) above sea level.

B. The correct orifices are installed at the factory if operating altitude is known at time of the

customer’s order.

2-4

Page 12

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS FRYERS

CHAPTER 2: IMPORTANT INFORMATION

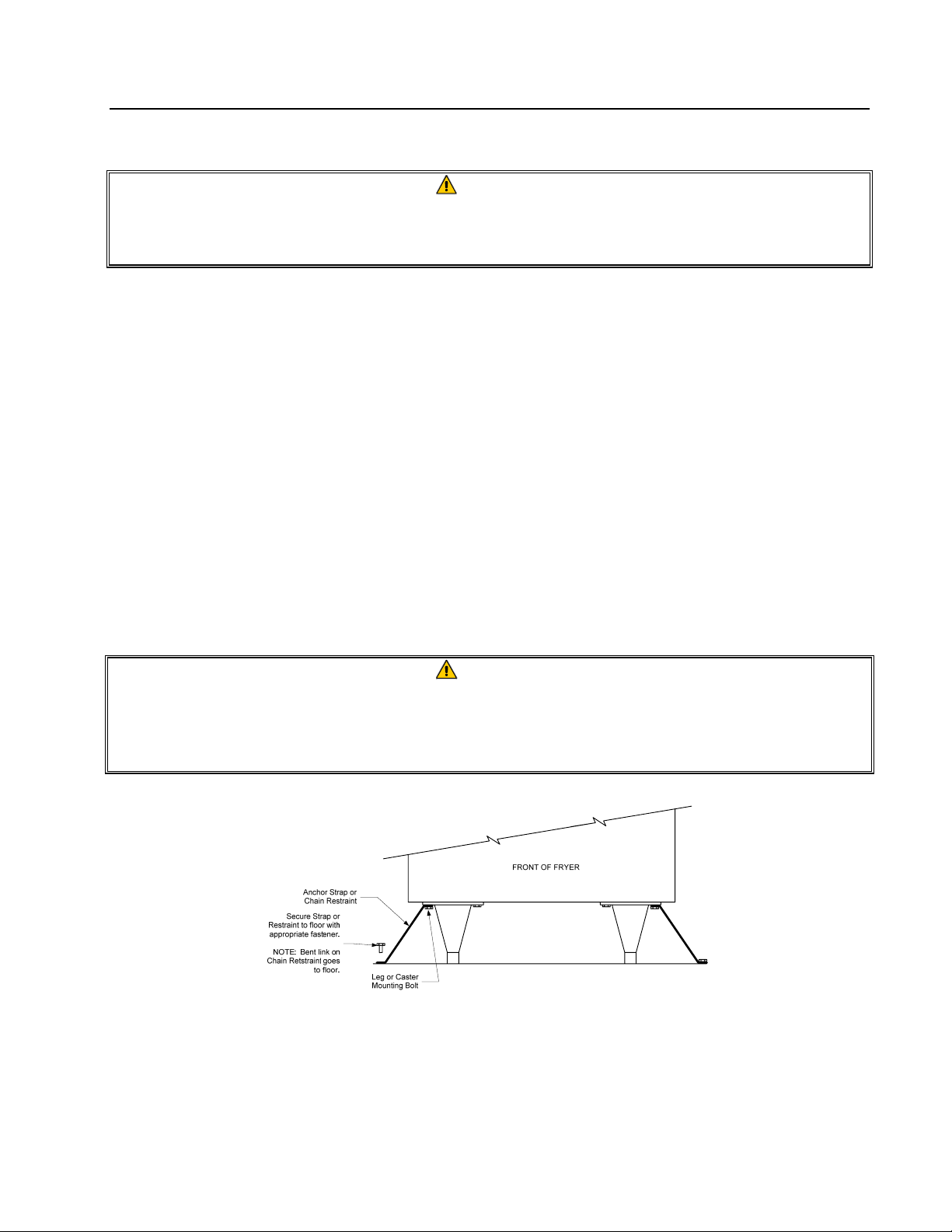

2.8 Restraining the Fryer

DANGER

No structural material on the fryer should be altered or removed to accommodate

placement of the fryer under a hood. Questions? Call the Frymaster Dean Service

Hotline at 1-800-551-8633.

1. Once the fryer has been positioned at the frying station, use a carpenter’s level placed across the

top of the frypot to verify that the unit is level, both side-to-side and front-to-back.

• To level fryers equipped with legs, the bottom of the legs can be screwed out up to one inch for

leveling. Legs should also be adjusted so that the fryer(s) are at the proper height in the frying

station.

• For fryers equipped with casters, there are no built-in leveling devices. The floor where the

fryers are installed must be level.

2. With the fryer level in its final position, install the restraints provided with the unit to limit its

movement so that it does not depend on or transmit stress to the electrical conduits/connections

or the gas supply line. Install the restraints in accordance with the provided instructions (see

illustration below). If disconnected for service or other reasons, the restraints must be

reconnected before the fryer is used.

DANGER

Adequate means must be provided to limit the movement of this appliance without

depending on or transmitting stress to the electrical conduit. A restraint kit is

provided with the fryer. If the restraint kit is missing contact your local Frymaster

Factory Authorized Servicer (FAS) for part number 826-0900.

NOTE: If you need to relocate a fryer installed with legs, remove all weight from each leg

before moving. If a leg is damaged, contact your service agent for immediate repair or

replacement.

2-5

Page 13

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS FRYERS

CHAPTER 2: IMPORTANT INFORMATION

DANGER

Hot oil can cause severe burns. Avoid contact. Under all circumstances, oil must be

removed from the fryer before attempting to move it to avoid oil spills, falls and

severe burns. This fryer may tip and cause personal injury if not secured in a

stationary position.

DANGER

Do not attach an apron drain board to a single unit. The appliance may become

unstable, tip over, and cause injury. The appliance area must be free and clear of

combustible material at all times.

2-6

Page 14

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS

FRYERS

CHAPTER 3: INSTALLATION INSTRUCTIONS

3.1 Installing the Fryer

Qualified, licensed, authorized installation or service personnel only (as defined in Section 1.6)

should perform the following:

1. Installation and service of Frymaster equipment;

2. Conversion of this appliance from one gas type to another.

Failure to use qualified, licensed, and/or authorized installation or service personnel to install,

convert to another gas type, or otherwise service this equipment will void the Frymaster

warranty and may result in damage to the equipment or injury to personnel.

Where conflicts exist between instructions and information in this manual and local code or

national codes and regulations, installation and operation shall comply with the codes or

regulations in force in the country in which the equipment is installed.

A. Initial Installation: If installed with legs, do not push against any unit edges to adjust its

position. Use a pallet or lift jack to lift it slightly and place it where it is to be installed.

B. Relocating the Fryer: If relocating a fryer installed with legs, remove all weight from ea ch leg

before moving.

NOTE: If a leg becomes damaged during movement, contact your service agent for

immediate repair or replacement.

DANGER

Building codes prohibit a fryer with an open tank of oil being installed beside an

open flame of any type, including those of broilers and ranges.

3.2 Leg and Caster Installation

DANGER

Frymaster fryers equipped with legs are for permanent installations. Fryers fitted

with legs must be lifted during movement to avoid damage and possible bodily

injury. For a moveable or portable installation, optional equipment casters must be

used. Questions? Call 1-800-551-8633

A. General

1. Because neither legs nor rigid rear casters are secure for long transit, install them near the

area of use. This unit cannot be curb mounted and must be equipped with the legs and rear

rigid casters provided.

3-1

Page 15

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS FRYERS

CHAPTER 3: INSTALLATION INSTRUCTIONS

3.2 Leg and Caster Installation (cont.)

2. When positioning the fryer, gently lower it into position to prevent undue strain to the legs

and internal mounting hardware. If possible, use a pallet or lift jack to lift and position the

fryer. Tilting the fryer may damage the legs.

3. The rigid casters must be installed on the fryer rear channel assembly only.

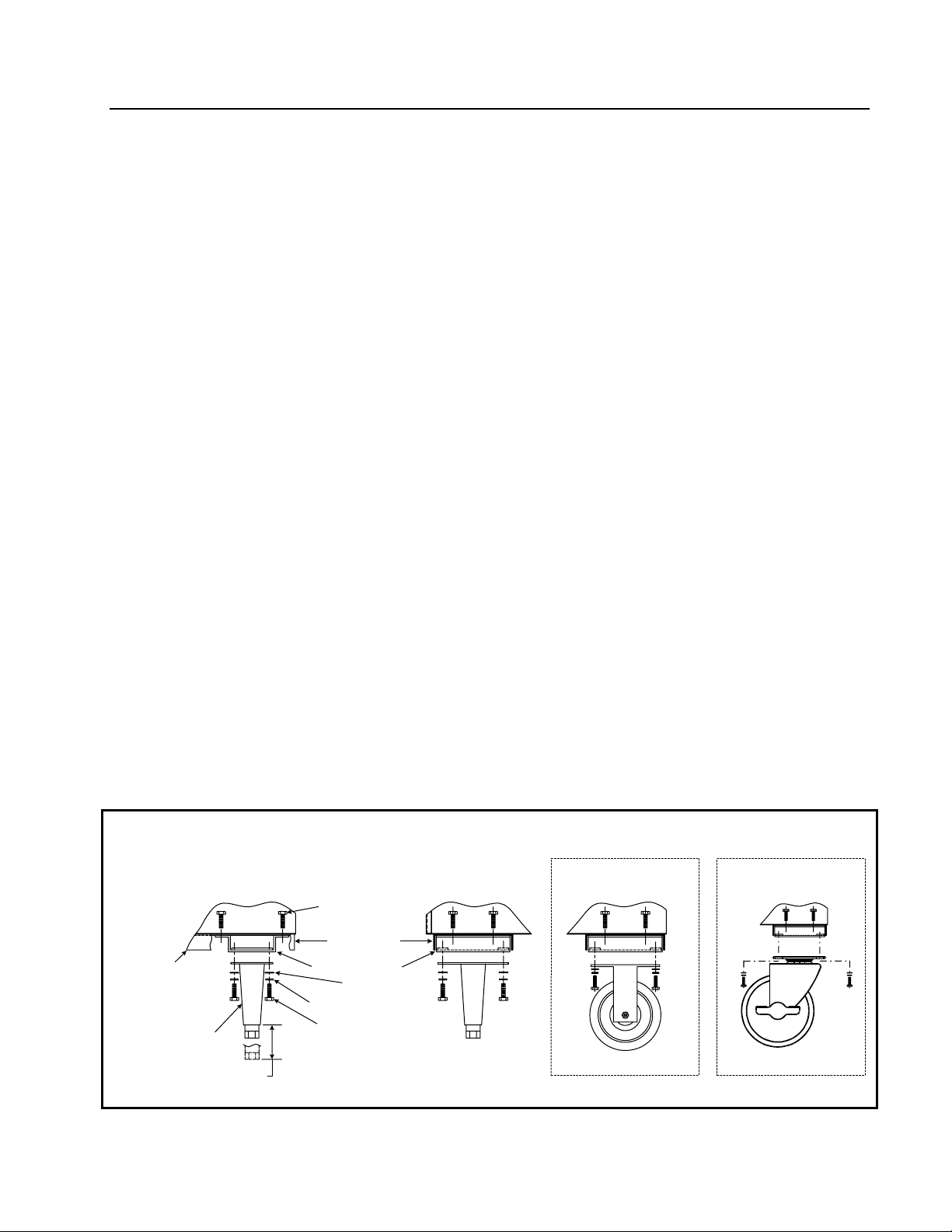

B. Installation

1. Remove unit from pallet.

2. Carefully raise unit with forklift, pallet jack, or other steady means.

3. Place one lock washer on each hex head screw.

4. Insert hex head screws with lock washers [1/4-20 threads by ¾" (19 mm) long] through bolt

holes of leg mounting plates and mount to the front channel. Mount rigid casters to the rear

channel following the same procedure. Locknuts have been attached to the topside of the

base mounting plates at the factory to capture hex head screws as they are screwed in.

5. Tighten the bolts to 50 in-lbf (5.65 joules) minimum torque.

6. After legs and rear rigid casters are installed, proceed to Step 3.3, Leveling the Fryer, to

ensure the fryer is level before use.

WARNING

For caster retrofit, the unit must be at room temperature and drained of shortening

before installing the casters.

3.3 Leveling the Fryer

A. Place a level across the top of the fryer and level the unit front-to-back. If the fryer is uneven

side-to-side, a platform or other surface adjustment is needed; there is no side-to-side level

adjustments on a fryer equipped with caster/leg combinations (If a fryer is equipped with legs

only, side to side level adjustments can be made. If a fryer is equipped with casters only, no level

adjustments to the fryer can be made.). If the fryer is not level, the unit may not function

efficiently, the oil may not drain properly for filtering, and it may not match adjacent units in a

multi-fryer battery.

3-2

Page 16

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS FRYERS

CHAPTER 3: INSTALLATION INSTRUCTIONS

3.3 Leveling the Fryer (cont.)

• Legs (Only)

1. Adjust leg height with an adjustable or 11/16-inch (27-mm) open-end wrench by turning

the hex bullet on the bottom of the leg.

2. The hex bullet is for minor leg height adjustment only. Do not adjust more than 1 inch

(25 mm).

3. When leveling the unit, the leg body should be held firmly to keep the leg from bending

or rotating while turning the hex bullet foot to the required height.

• Rigid Casters (Only)

1. Install rigid casters on the fryer rear channel only. Legs must be installed on the front channel.

2. There are no level-adjustments for the rigid casters.

B. If the floor is uneven or has a decided slope, place the fryer on a smooth platform.

C. If the fryer is moved, re-level the fryer following the instructions given in Steps 3.3, A-C.

D. Installing Optional Swivel Casters

1. Install non-locking casters only at the rear of the unit.

2. Locking casters must be installed at the front of the unit. Locking casters allow the fryer

to be "locked" in position for safe operations.

3. Follow the same instructions for leg installations as given above in Steps 3.2, B1-B5.

Front View

1/4-20 x 3/4 Hex Bolt

Rear Side View

Optional Caster-

Rear Only

Optional Caster-

Front Only

Front Channel

or Rear Channel

Front or Rear Leg with

Mounting Plate

Adjust as needed

Front Channel or

Rear Channel

Leg Support Assembly

Washer

1/4-20 Hex Head Locknut

1/4-20 x 3/4 Hex Bolt

Rear Caster—5" Rigid

Leg and Caster (Optional) Mounting Installation

3-3

Front Caster—5" Swivel

w/Brake

Page 17

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS FRYERS

CHAPTER 3: INSTALLATION INSTRUCTIONS

3.3 Leveling the Fryer (cont.)

ANSI Z83.11/11a-(Latest Edition) requires a fryer be restrained to prevent tipping when

installed in order to avoid the splashing of hot liquid. The means of restraint may be the

manner of installation, such as connection to battery of appliances or installing the fryer in an

alcove, or by separate means, such as adequate ties (chains, straps, etc.). A bracket has been

provided on the fryer back panel for this purpose.

NOTE: The installation must be inspected after it is complete to ensure it meets the intent of

these instructions. The on-site supervisor and/or operator(s) should be informed that the

appliance is installed with restraints. If restraints are removed to move fryer (e.g., to clean

beneath and behind, to relocate) ensure that they are re-installed when fryer is returned to its

permanently installed position.

For information on fryer restraints, see Section 2.8.

3.4 Gas Connections

The gas supply (service) line must be the same size or greater than the fryer inlet line. YSCFH18G

gas fryers are equipped with a ¾-inch (22-mm) male inlet. The gas supply line must be sized to

accommodate all gas-fired equipment connected to that gas supply. Consult local gas

companies/suppliers or your local contractor for minimum supply line requirements.

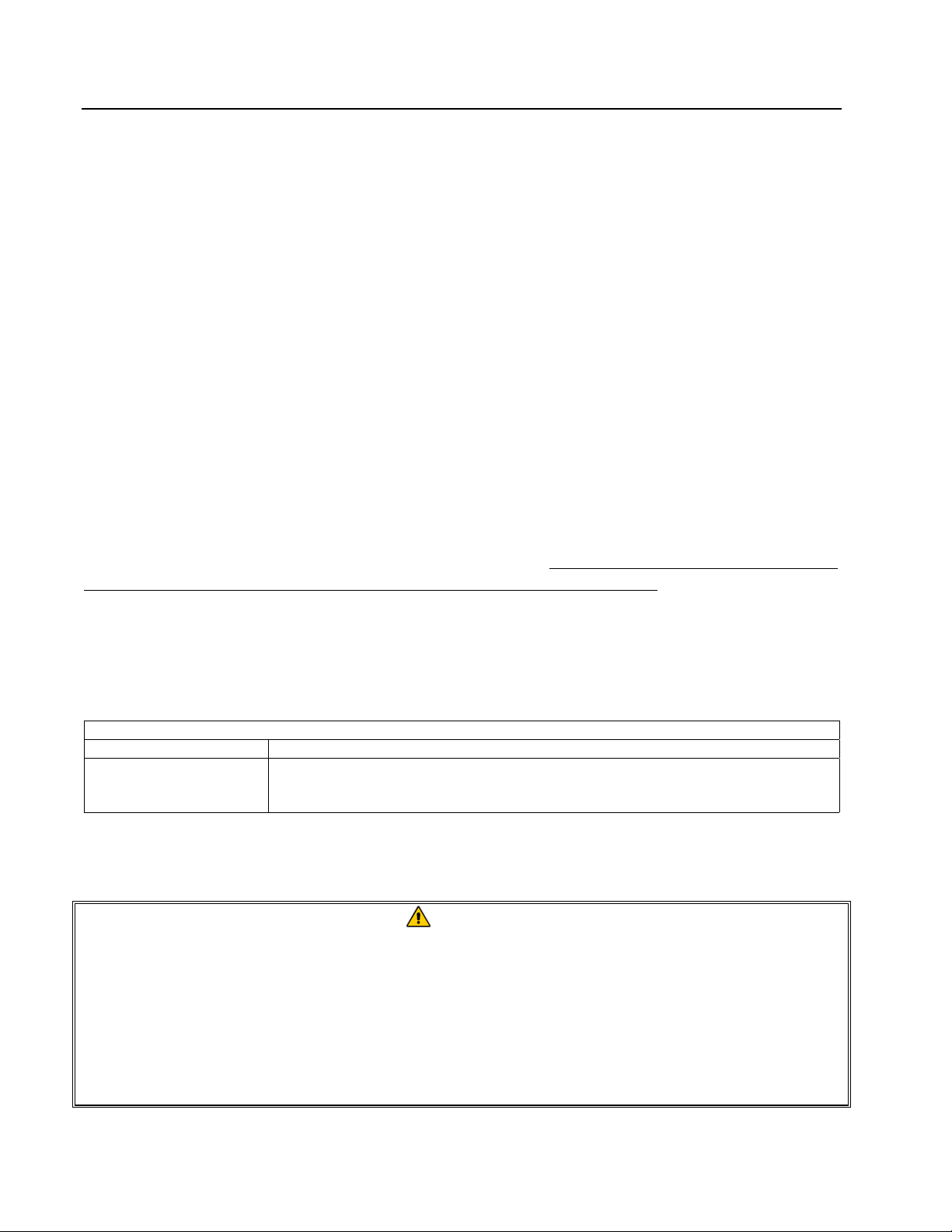

Supply Line Specifications

The gas supply lines must be sized as indicated in the chart below, based on the total number of

fryers connected to the main gas supply.

Gas Types Number of Fryers

1 2 to 3 4 or more*

Natural Gas ¾" (22 mm) 1" (28 mm) 1¼ " (35 mm)

Propane Gas ½" (15 mm) ¾" (22 mm) 1" (28 mm)

* When exceeding 18 feet (6 meters) for a configuration of more than four fryers, it is necessary to provide

a 1¼" (35 mm) rigid gas connection.

Recommended Gas Supply Line Sizes

DANGER

All connections must be sealed with a joint compound suitable for the gas being

used and all connections must be tested with a solution of soapy water before

lighting any pilots.

Never use matches, candles, or any other ignition source to check for leaks. If gas

odors are detected, shut off the gas supply to the appliance at the main shut-off

valve and immediately contact the local gas company or an authorized service

agency for service.

3-4

Page 18

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS FRYERS

CHAPTER 3: INSTALLATION INSTRUCTIONS

3.4 Gas Connections (cont.)

DANGER

"Dry-firing" your unit will cause damage to the frypot and can cause a fire. Before

firing the unit, always ensure that melted shortening, cooking oil, or water is in the

frypot.

DANGER

Before connecting new pipe to this appliance, the pipe must be blown out

thoroughly to remove all foreign material. Foreign material in the burner and gas

controls will cause improper and dangerous operation.

Rigid Connections

Check any installer-supplied intake pipe(s) visually and clean metal particles or other foreign matter

from the threads before installing into a service line. If the intake pipes are not clear of all foreign

matter, the orifices will clog when gas pressure is applied. When using thread compound on gas

piping, use very small amounts and only on male threads. Use a pipe thread compound that is not

affected by the chemical action of LP gases. DO NOT apply thread compound to the first two pipe

threads—doing so will cause clogging of the burner orifices and control valve.

Manual Shut-off Valve

This gas service supplier-installed valve must be installed in the gas service line ahead of the fryers

in the gas stream and in a position where it can be reached quickly in the event of an emergency.

Regulating Gas Pressure

The fryer and its individual shut-off valve must be disconnected from the gas supply piping system

during any pressure testing of the gas supply system, especially if the test pressures are in excess of

½ PSI (3,45 kPa/35 mbar).

External gas regulators are not normally required on this fryer. A safety control valve protects the

fryer against pressure fluctuations. If the incoming pressure is in excess of ½ PSI (3,45 kPa/35

mbar), a step-down regulator is required.

DANGER

When pressure-testing incoming gas supply lines, disconnect the fryer from the gas

line if the test pressure is 3,45 kPa (½ PSI, 14" W.C.) or greater to avoid damage to

the fryer’s gas piping and gas valve(s).

3-5

Page 19

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS FRYERS

CHAPTER 3: INSTALLATION INSTRUCTIONS

3.4 Gas Connections (cont.)

A. Manifold Pressure: Your local service technician should check the manifold pressure with

a manometer.

1. Check the rating plate for manifold gas pressures. Natural gas units normally require 4"

W.C., and propane units normally require 11" W.C. gas pressure.

2. Confirm that the arrow forged into the bottom of the regulator body, which indicates gas

flow direction, is pointed downstream towards the fryers. The air vent cap is also part of the

regulator and should not be removed.

3. If a vent line from the gas pressure regulator is used, it should be installed in accordance

with local codes or in the absence of local codes, with the National Fuel Gas Code, ANSI

Z223.1-(Latest Edition).

WARNING

Use a diluted soap solution to find potentially dangerous gas leaks when making

new connections.

B. Regulators: Gas regulators can be adjusted in the field, but no adjustments should be made

unless the regulator is out of adjustment or serious pressure fluctuations are observed.

C. Only qualified service personnel should make adjustments to the regulators.

D. Orifices: The fryer can be ordered to operate on any available gas. The correct

combination gas valve, appropriate burner orifices, and pilot burners are installed at the

factory. While the valve can be adjusted in the field, only qualified service personnel should

make any adjustments with the proper test equipment.

DANGER

If gas odors are detected, the gas supply must be shut off at the main shut-off valve.

The local gas company or FAS should be contacted immediately to fix the problem.

E. Flexible Couplings, Connectors and Casters:

1. If the fryer is to be installed with flexible couplings and/or quick-disconnect fittings, the

installer must use a heavy-duty AGA design-certified commercial flexible connector of

at least ¾" NPT (with suitable strain-relief attachments), in compliance with the

Standard for Connectors for Movable Gas Appliances, ANSI Z21.69-(Latest Edition)

and Addenda Z21.69a-(Latest Edition). Quick disconnect devices must comply with the

Standard for Quick-Disconnect Devices for Use with Gas Fuel, ANSI Z21.41-(Latest

Edition).

3-6

Page 20

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS FRYERS

CHAPTER 3: INSTALLATION INSTRUCTIONS

3.4 Gas Connections (cont.)

2. For an appliance equipped with casters, the installation shall be made with a connector

that complies with the Standard for Connectors for Movable Gas Appliances, ANSI

Z21.69, or Connectors for Moveable Gas Appliances, CAN/CGA-6.16. A quickdisconnect device that complies with the Standard for Quick-Disconnect Devices for Use

with Gas Fuel, ANSI Z21.41, or Quick-Disconnect Devices for Use with Gas Fuel,

CANI-6.9, must be used. Under no circumstances are the connector and the quickdisconnect device or its associated piping to be used to limit fryer movement.

3. The fryer must be restrained by means independent of the flexible coupling or connector

in order to limit the movement of the fryer. Clips are located on the back panel of the

fryer for the attachment of restraints.

4. If it is necessary to disconnect the restraint, it must be reconnected after the fryer has

been returned to its originally installed position.

WARNING

Do not attach accessories to this fryer unless fryer is secured from tipping.

Personal injury may result.

F. After hook-up, bleed the gas line of air to ensure that the pilot light will ignite quickly and

evenly.

WARNING

Qualified personnel MUST perform any adaptation, modification, or gas conversion,

if required. Failure to use qualified personnel will void the Frymaster warranty.

3.5 Adjustments/Adaptation To Different Gases

A. Proper operation of appliances requires the operator to scrupulously inspect the following:

1. Gas inputs and pressures;

2. Voltage and polarities of electrical power supplies.

B. Frymaster gas fryers are manufactured to use the type of gas and pressure specified on the

rating plate. When changing gas, adaptation must be performed by qualified personnel

Failure to use qualified personnel will void the Frymaster warranty.

Nominal "Qn" Heat Input for the Y/KSCF/C/HC18G High Eff iciency C ool Zone Gas fryer is 25 kW.

.

3-7

Page 21

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS FRYERS

CHAPTER 3: INSTALLATION INSTRUCTIONS

3.6 Gas Conversion: Procedures

DANGER

This appliance was configured at the factory for a specific type of gas. Converting

from one gas type to another requires the installation of specific gas-conversion

components.

Switching to a different type of gas without installing the proper conversion

components may result in fire or explosion. NEVER ATTACH THIS APPLIANCE TO A

GAS SUPPLY FOR WHICH IT IS NOT CONFIGURED!

Conversion of this appliance from one type of gas to another should only be

performed by qualified, licensed, and authorized installation or service personnel, as

defined in Section 1.6 of this manual.

See below for gas valve illustration when performing the following conversions.

Conversion from one gas family to another (e.g. changing from natural gas to propane) requires

special components and parts. Contact a Factory Authorized Service Agent for requirements and part

numbers.

Conversions can only be executed by qualified, factory-authorized personnel.

Pilot pressure adjustment

(remove cover screw to access)

Pressure flow adjustment

(remove cover screw to access)

Non-CE Gas Valve

3-8

Regulator Vent

ON/OFF Gas-Cock KnobPilot gas supply connection.

Page 22

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS FRYERS

CHAPTER 3: INSTALLATION INSTRUCTIONS

3.7 Electrical Connections

DANGER

This fryer is equipped with a three-prong (grounding) plug for protection against

electrical shock and must be plugged directly into a properly grounded, three-prong

receptacle. DO NOT CUT, REMOVE, OR OTHERWISE BYPASS THE GROUNDING

PRONG ON THIS PLUG!

DANGER

This appliance requires electrical power for operation. Place the gas valve in the

OFF position in case of a prolonged power outage. Do not attempt to operate this

appliance during a power outage.

Refer to the rating plate and wiring diagram located inside the front door. The fryer is equipped with

a 120VAC/60Hz system for USA/Canada/Mexico operations. All electrically operated appliances

must be electrically grounded in accordance with local codes or, in the absence of local codes, with

the National Electrical Code (ANSI/NFPA 70) or the Canadian Electrical Code (CSA C22.2). Do

not cut or remove the ground prong from the power cord plug. Do not attempt to use this appliance

in a power outage.

3.8 Safety Switches

A. Fryer with KFC-1 Computer

NOTE: For FAST-equipped fryers, see the Fast manual for operation instructions.

This fryer/filter system is equipped with a drain valve safety switch and a frypot float-switch on

each of the two-batteried fryers. Drain-valve safety switches de-energize the control circuit

during the filter process, thus providing an additional safety feature. Always leave the computer

when filtering.

ON

The KFC-1 computer monitors cooking operations. The computer logs the number of cook

sequences and locks out the cook cycle after a preset number is reached. The drain-valve must

be opened, the oil must be filtered, and the drain-valve closed before the KFC-1 computer will

allow a cook cycle. After filtering, always allow the frypot to refill with oil and heat to setpoint

before engaging a cook cycle.

See the accompanying KFC-1 SMS Cooking Computer User Manual for more detailed

information.

3-9

Page 23

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS FRYERS

CHAPTER 3: INSTALLATION INSTRUCTIONS

3.8 Safety Switches (cont.)

B. Other Fryer/Filter Switches

1. Drain Valve Microswitch: The computer

will display DRAIN OPEN when the

drain valve is opened. The computer will

lockout, preventing any cooking operation

until EXIT/COOL FILTER is pressed.

Float-Switch: Located in the frypot.

2.

Designed as a safety switch, it deactivates

the gas valve, preventing burner ignition

until the oil level extends above the

heating tubes.

3. High-limit Reset: Located in the right

fryer cabinet under the control panel.

This switch is used to reset the high-limit

if the cooking medium has reached high

temperature safety limits. The high-limit

sensor bulb is mounted inside the frypot

between the two left-most burner tubes.

A microswitch is located on the red handle at the

drain valve.

Frypot Front

High-Limit

Probe

Float

Switch

Temperature

Probe

3-10

The hi-limit reset is accessible in the fryer cabinet

under the controller.

Page 24

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS FRYERS

CHAPTER 3: INSTALLATION INSTRUCTIONS

3.8 Safety Switches (cont.)

C. Filtering: Drain Valve and Oil Return Handles

1. Drain Valve Handle: RED HANDLE.

Push the red handle (located in the fryer

cabinet) to the right to open the drain

valve when filtering. After all oil has

drained from the frypot and/or polishing

is complete, push the red handle left to

close the drain valve.

2.

Oil Return Handles: YELLOW LABEL.

The oil-return handles to the left and right

in the fryer cabinet return oil at the rear of

the pot, which flushes oil across the

bottom of the vat, washing debris toward

the drain. The oil-return handles in the

center of the cabinet return oil through the

over-the-top system. Ensure the faucet is

positioned over the emptied vat before

running oil through the over-the-top

return system.

See Chapter 5 for more information on filtering.

See Chapter 7 for troubleshooting information.

Rear flush

handle

Over-the-top return

handles

Drain valve handles (red). Rear flush

handle

DANGER

Always ensure that the over-the-top oil return faucet is located over the frypot or an

appropriate container before activating the over-the-top oil return system. If not, the

hot oil will spill and may cause burns.

DANGER

Allow oil to cool to 100°F (38°C) before draining into a metal container, stockpot, or

disposal unit.

DANGER

When draining oil into a disposal unit or portable filter unit, do not fill above the

maximum fill line located on the container.

3-11

Page 25

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS FRYERS

CHAPTER 3: INSTALLATION INSTRUCTIONS

3.9 Initial Cleaning Before Startup

New units are wiped clean with solvents at the factory to remove any visible signs of dirt, oil, and

grease remaining from the manufacturing process. Then, they are coated lightly with oil. Wash

thoroughly with hot, soapy water to remove any film residue and dust or debris before food

preparation. Then, rinse and wipe dry. In addition, wash any accessories shipped with the unit. Close

the drain valve completely and remove the crumb screen. Ensure the screws securing the

temperature probe to the bracket between heating tubes are tight.

WARNING

All droplets of water must be removed from the frypot before filling with shortening.

Failure to do so will cause hot oil to splatter and injure the operator.

3.10 Final Preparation

1. The Y/KSCF/C/HC18G frypot shortening capacity is approximately 40.5 kg (90 lb).

2. Ensure fryer power switches are OFF.

3. Cooking Oil: Fill the fryer to the bottom OIL LEVEL line scribed into the back of the

frypot. Replace the basket support screen.

WARNING

Never operate fryer without enough oil, shortening, or water in the frypot to cover

the heating tubes.

WARNING

NEVER set a complete block of solid shortening on top of heating tubes. To do so

will damage the frypot and increase the potential for flash-point shortening

temperatures and subsequent fire.

4. Solid Shortening: Either pre-melt solid shortening on another appliance first or cut it into

small pieces and pack it tightly into the cool zone at the bottom of the frypot. Take care not

to disturb the temperature probe or high-limit thermostat. If solid shortening is packed into

the frypot, ensure the float switch is in the "up" position.

5. FAST Controller: See the Fast manual for operation of a Fast-equipped fryer.

3-12

Page 26

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS FRYERS

CHAPTER 3: INSTALLATION INSTRUCTIONS

3.10 Final Preparation (cont.)

NOTE: If the float switch is blocked in "down position" with solid shortening, the fryer will not heat.

Always ensure that the float switch is in the "up" position when packing solid shortening into frypot.

6. KFC-1 Cooking Computer:

Turn computer ON (this also

turns the fryer ON if equipped

with electronic ignition). The

computer will cycle the

burners ON and OFF (melt

cycle). This is indicated by

heat icons located on either

side of the KFC-1 product

buttons, which will cycle ON

and OFF with the fryer. The

computer will display LOw

until the shortening reaches

180°F (82°C).

At 180° F (82°C), the fryer goes into continuous heat mode. The computer will display actual oil

temperature until setpoint is reached. At setpoint temperature, the computer will display

drop.

NOTE: For FAST-equipped fryers, see the Fast manual for operation instructions.

7. After shortening reaches the setpoint temperature, let the burners cycle at least four times,

then insert a thermometer or pyrometer near the temperature sensing probe within 1 inch of

the temperature probe and approximately 3-in. (7.5-mm) deep into the shortening. When the

burners cycle on after the fourth time, the thermometer should read within ±5°F (±2°C) of

the computer temperature setting.

8. When the frypot is filled and the shortening melted, replace the basket-support screen over

the heating tubes.

Heat Icon Indicators

Product Buttons

WARNING

Do not bang fry baskets or other utensils on the fryer’s joiner strip. The strip is

present to seal the joint between the frypots. Banging fry baskets on the strip to

dislodge shortening will distort the strip, adversely affecting its fit. It is designed for

a tight fit and should only be removed for cleaning.

For pilot lighting instructions, see Chapter 4.

For filtration instructions, see Chapter 5.

3-13

Page 27

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS

FRYERS

CHAPTER 4: DAILY OPERATION

4.1 General Use

1. At opening, always check that the power switch and the controller are OFF.

2. For consistent quality product, convenience, and long-term savings, use a high-quality liquid

shortening.

3. If using solid shortening, never melt a block of shortening by placing an entire block in the

fryer vessel. Cut it into small pieces and pack it around fryer components.

4. Although 350°F (177°C) is the recommended temperature for most cooking operations, set

the fryer at the lowest possible temperature which produces a high quality end product while

ensuring maximum life for your oil.

4.2 Start-Up Procedures

1. If the fryer is empty, pour enough oil into the frypot to fill it to the bottom OIL LEVEL line

scribed on the rear wall. If solid shortening is used, melt the shortening following

procedures in Section 3.10, Final Preparation.

2. A. Pilot lighting procedures – Standing Pilot:

a. Turn off the manual shut-off valve on the incoming service line.

b. Turn the operating thermostat to OFF.

c. Depress the Pilot Off button (red) on the combination safety gas valve to turn it off.

d. Wait at least five minutes for any accumulated gas to disperse.

e. Open the manual shut-off valve on the incoming service line.

f. Press and hold the white pilot light button and repeatedly press the piezo ignitor

button until the pilot lights. Release the white button after approximately 45-60

seconds.

g. If the pilot does not stay lit, depress the white pilot light button and re-light the pilot

(repeat Step f above). Hold the button in longer before releasing. Trapped air may

necessitate re-lighting the pilot several times until gas flow is constant.

h. When the pilot stays lit, release the white pilot light button.

i. Turn the thermostat to any ON setting and ensure the main burner ignites from the

pilot.

4-1

Page 28

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS FRYERS

CHAPTER 4: DAILY OPERATION

4.2 Start-Up Procedures (cont.)

B. Pilot lighting procedure – Electronic Ignition

a. Turn gas "ON."

b. Turn electric power "ON" with the appropriate rocker switch or

controller/controller.

c. The ignition module will energize the pilot gas supply and the ignitor. The ignitor

spark will ignite the pilot gas. The presence of the pilot flame is then proven by a

flame sensor, which sends a signal to the main gas supply, opening the valve. The

operating thermostat or controller/controller controls the fryer after ignition.

WARNING

In the event of prolonged power failure, the ignition module will shut down and lock

out the system. Turn the unit power "OFF" and then back "ON" after power has

been re-established.

d. If the pilot flame fails, the ignition module will shut down and lock out the system.

To restart, turn the electric power "OFF,” wait approximately 5 minutes for the

system to recycle itself, and then turn the power "ON" again. Repeat Steps a-c.

3. KFC-1 Cooking Controller: Turn the controller ON and select cooking program as

described in the KFC-1 SMS Cooking Controller User Guide.

ON/OFF Buttons

NOTE: For FAST-equipped fryers, see the Fast manual for operation instructions.

4-2

Page 29

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS FRYERS

CHAPTER 4: DAILY OPERATION

4.3 Filtering

DANGER

When filtering, never leave the filter unattended. The filtered oil is at or near 350°F

(177°C). Ensure all hoses are connected properly and drain handles are in their

proper position prior to operating any switches or valves.

DANGER

The crumb tray in fryers equipped with a filter system must be emptied into a

fireproof container at the end of frying operations each day. Some food particles can

spontaneously combust if left soaking in certain shortening material.

WARNING

Filter one frypot at a time. The filter pan is designed to safely hold the oil from one

fryer only.

1. The KFC-1 Controller must remain ON during filter operations for proper filter function.

NOTE: For FAST-equipped fryers, see the Fast manual for operation instructions.

2. Filter the shortening at least once daily or more frequently if cooking is heavy. This assures

the longest life possible for the shortening, a better taste to the food being prepared, and

minimizes flavors being transferred from batch to batch.

3. If using solid shortening, clear return lines before turning off the filter motor by allowing the

pump to run for approximately 15-30 seconds once air bubbles appear in the frypot from the

oil return line. Failure to do so increases the likelihood that solid shortening will solidify and

clog the lines.

NOTE: If using over-the-top oil return, allow the faucet to sputter for 15-30 seconds.

See Chapter 5 for detailed filtration procedures.

4.4 Closing

1. When closing at night, filter shortening in all fryers and drain the filter lines. Cover the

open tanks of oil. Turn the controller OFF.

2. When shutting down for periods longer than overnight, drain shortening and clean the frypot

thoroughly. After cleaning, discard the shortening or filter it and return it to the frypot.

Cover the frypot with the appropriate frypot cover. Turn both the power switch and

controller OFF.

4-3

Page 30

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS

FRYERS

CHAPTER 5: FILTRATION

5.1 General

WARNING

The on-site supervisor is responsible for ensuring that operators are made aware of

the inherent hazards of operating a hot oil filtering system, particularly the aspects

of oil filtration, draining, and cleaning procedures.

To conduct filter operations with the KFC-1 Cooking Computer installed on the fryer,

ALWAYS leave the computer ON when filtering. The computer must sense the drain valves

opening and closing in order to allow fryer operation.

For consistent product quality, convenience, and long-term savings use a high-quality liquid

shortening or vegetable oil.

If using solid shortening, always ensure the return lines are clear before turning off the filter pump.

Hang any flexible lines up to drain. Solid shortening will solidify as it cools and clog the lines.

5.2 Filter Preparation

Assemble filtering tools. These are supplied with

the filter starter kit (at right):

• L-shaped Teflon Brush: Used to clean

frypot sides, heating tubes, and to dislodge

sediment during filtration or oil change.

• Clean-out Rod: Used to dislodge heavy

debris in the drain tube (when needed).

• Filter Powder.

• Filter Paper.

The following tools are not required, but are recommended to make the filtering task easier.

• Measuring Cup: Used to measure filter powder.

• Stainless Steel Crumb Scoop: Used to remove large debris from oil prior to filtering.

NOTE: Always wear oil-resistant, insulated gloves and/or protective gear when working with

hot oil.

5-1

Page 31

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS FRYERS

CHAPTER 5: FILTRATION

5.2 Filter Preparation (cont.)

1. Put on protective gear/gloves. Pull the filter pan out of the filter cabinet. Remove cover.

2. Remove crumb screen. If crumbs are present in

the crumb screen, empty the screen into a

fireproof container. Thoroughly wash the

screen in hot, soapy water, rinse, then dry.

3. Remove the hold-down ring.

4.

Remove and discard old filter paper sheet from

the filter pan.

5-2

Page 32

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS FRYERS

CHAPTER 5: FILTRATION

5. Remove the filter screen from the bottom of

the pan.

6.

Thoroughly clean the pan and all pan

components as described for the crumb screen

(Step 2).

7.

Inspect the pickup tube and ensure vent hole is

open and free of shortening/debris.

8. Replace filter screen and drape one sheet of

filter paper across the filter pan. The filter

screen must be installed prior to filter paper

placement or the filter won’t operate

correctly.

5-3

Page 33

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS FRYERS

CHAPTER 5: FILTRATION

9.

Reinstall the hold-down ring. Ensure filter

paper is properly aligned under the hold-down

ring. Press the filter paper into place with the

hold-down ring, ensuring the paper laps against

the walls of the filter pan.

10. Sprinkle 1 cup (8 ounces/227 grams) of filter

powder evenly over the paper.

Use a measuring

cup or scoop to evenly distribute filter powder

over the filter sheet.

11. Replace the crumb screen . Ensure crum b

screen is cleaned throughout the workday.

12. Return pan cover to the filter pan.

13. Return filter pan to fryer cabinet, ensuring that

the two drainpipe extensions are directly over

the opening in the filter pan cover.

5.3 Filter Operations

NOTE: When left and right are indicated, refer to the operator’s left and right.

DANGER

Draining and filtering of cooking oil or shortening must be accomplished with care to

avoid a serious burn caused by careless handling. The oil to be filtered is at or near

350°F (177°C). Ensure all hoses are connected properly and drain handles are in

their proper position before operating any switches or valves. Wear all appropriate

safety equipment when draining and filtering oil.

5-4

Page 34

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS FRYERS

CHAPTER 5: FILTRATION

DANGER

Always ensure that the over-the-top oil return faucet is located over the frypot or an

appropriate container before activating the over-the-top oil return system. If not, the

hot oil will spill and may cause burns.

DANGER

Allow oil to cool to 100°F (38°C) before draining into a metal container, stockpot, or

disposal unit.

DANGER

Do not drain more than one frypot at a time into the built-in filtration unit to avoid

overflow and spillage of hot oil.

DANGER

When draining oil into a disposal unit or portable filter unit, do not fill above the

maximum fill line located on the container.

1. Remove large debris floating in the oil.

NOTE: Always heat oil to operating temperature

before filtering.

Remove large debris from frypot prior to filtering.

5-5

Page 35

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS FRYERS

CHAPTER 5: FILTRATION

5.3 Filter Operations (cont.)

2. Remove the support grid from the frypot

using the clean-out rod. Stir the oil with the

L-shaped Teflon brush to suspend debris

prior to draining.

3. Open the fryer drain valve by pushing the

red handle (under the frypot to be filtered) to

the right until it is completely open.

Continue stirring the oil.

Removing support grid from frypot prior to

draining.

Push the red handle right to open drain valve. Oil

will start to drain into filter pan.

5-6

Page 36

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS FRYERS

CHAPTER 5: FILTRATION

5.3 Filter Operations (cont.)

4. Use the L-shaped brush to scrub the frypot, and to

assist in sediment removal. Brush the frypot sides

and between the tubes to remove debris. Use the

clean-out rod to clear the drain if necessary.

5. Open the oil return valve by pushing one of the oil

return valves to the left. Oil-return handles on the far

sides of the cabinet return oil to the frypot through

rear ports, which flush debris from the bottom of the

frypot. The two return valve handles in the center of

the cabinet return oil through the top- mounted faucet.

Ensure the faucet is over the drained frypot before

attempting to return oil through the faucet.

The levers on the right and left of the cabinet return oil through rear ports in the

frypot. The center-mounted levers return oil through a top-mounted faucet. In all

cases, a yellow lever returns oil to the frypot directly above it.

Use the L-shaped brush to loosen

debris as oil drains from the frypot.

DANGER

Always ensure that the over-the-top oil return faucet is located over the frypot or an

appropriate container before activa ting the over-the- top oil return syste m. If not, the

hot oil will spill and may cause burns.

5-7

Page 37

g

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS FRYERS

CHAPTER 5: FILTRATION

5.3 Filter Operations (cont.)

6. Close the red drain valve by pushing the handle to the right until it stops. The fryer will not operate

unless the computer senses a closed drain microswitch circuit. Leave the oil return handle (yellow

label) open to allow pump to run and frypot to fill with filtered oil.

7. When filtering is complete:

• Rear Flush Oil Return: Allow the filter to

pump bubbles into the fryer for 15-30 seconds

to ensure the oil return lines are clear of oil.

• Over-the-top Oil Return: Allow the faucet to

sputter for 15-30 seconds to ensure the oil

return lines are clear of oil.

8. Turn off the filter by turning the oil return handle to the left, into the CLOSED position. This

closes the oil return valve under the filtered frypot and stops the filter pump motor.

DANGER

The crumb tray in fryers equipped with a

filter system MUST be emptied into a

fireproof container at the end of frying

operations each day. Some food particles

can spontaneously combust if left

soakin

in oil.

Empty contents of the crumb screen

into a fireproof container immediately

after filtering is complete.

5-8

Page 38

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS FRYERS

CHAPTER 5: FILTRATION

9. Repeat Steps 1 and 2 in Section 5.2. Remove crumb screen and empty debris into a fireproof

container. If possible, wash all filter pan components in hot, soapy water. Rinse and dry

thoroughly (Section 5.2, Step 7). If not, the filter pan should be thoroughly cleaned at the

close of each day, as previously described.

Filtration system troubleshooting information can be found in Chapter 7.

5-9

Page 39

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS

FRYERS

CHAPTER 6: PREVENTATIVE MAINTENANCE

Well-maintained equipment operates more efficiently and lasts longer. Keep the fryer clean during

the day and thoroughly clean it at the end of each day.

DANGER

Never attempt to clean the fryer during the cooking process or when the frypot is

filled with hot oil. If water comes in contact with oil heated to cooking temperature, it

will cause spattering of the oil, which can result in severe burns to nearby personnel.

6.1 Daily

Wash all removable parts. Clean all exterior surfaces. Do not use cleansers, steel wool, or any other

abrasive material on stainless steel. Filter the oil and replace it if necessary. Filter oil more often

under heavy use conditions (e.g., frying heavily breaded products).

WARNING

Use a commercial-grade cleaner formulated to effectively clean and sanitize food-

contact surfaces. Read the directions for use and precautionary statements before

use. Particular attention must be paid to the concentration of cleaner and the length

of time the cleaner remains on the food-contact surfaces.

WARNING

Water MUST NOT be allowed to drain into the filter pan or filter system. Irreversible

damage will result if water is allowed into the system, and all applicable warranties

will be voided.

6.2 Weekly

Completely drain the frypot into either the filter or a steel container. Do not use a plastic bucket or

glass container.

• Clean the frypot with a high grade cleaner or hot water and a strong detergent.

• Close the drain valve and refill with either the cleaning solution or water and detergent.

• Scrub frypot walls and heating tubes. Then drain frypot and rinse in clear water.

• Once cleaning is completed, drain, rinse, and dry thoroughly.

• Refill with shortening as directed in Section 3.10 of this manual.

6-1

Page 40

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS FRYERS

CHAPTER 6: PREVENTATIVE MAINTENANCE

6.3 Periodic/Annual

This appliance should be inspected and adjusted periodically by qualified service personnel as part

of a regular kitchen maintenance program.

Frymaster and Dean recommend that a Factory Authorized Servicer should inspect this

appliance at least annually, as follows:

• Inspect the cabinet inside-and-out, front-and-rear for excessive oil build-up.

• Verify that debris or accumulations of solidified oil or shortening do not obstruct the flue

opening.

• Verify that burners and associated components (e.g., gas valves, pilot assemblies, ignitors)

are in good condition and functioning properly. Inspect all gas connections for leaks and

verify that all connections are properly tightened.

• Verify that the burner manifold pressure matches the pressure specified on the fryer’s rating

plate.

• Verify that the temperature and high-limit probes are connected, tightened, and functioning

properly, and that mounting hardware and probe guard are present and properly installed.

• Verify that component box components (e.g., computer/controller, transformers, relays,

interface boards) are in good condition and free of oil build-up and other debris. Inspect the

component box wiring and verify that connections are tight and that wiring is in good

condition.

• Verify that all safety features (e.g., drain safety switches, reset switches) are present and

functioning properly.

• Verify that the frypot/cookpot is in good condition and free of leaks and that the

frypot/cookpot insulation is in serviceable condition. Verify that the frypot tube diffusers are

present and in good condition (i.e. no visible deterioration or damage).

• Verify that wiring harnesses and connections are tight and in good condition.

Built-in Filtration:

• Inspect all oil-return and drain lines for leaks and verify that all connections are tight.

• Inspect the filter pan for leaks and cleanliness. If there is a large accumulation of crumbs in

the crumb basket, advise the owner/operator that the crumb basket should be emptied into a

fireproof container and cleaned daily.

• Verify that all O-rings and seals, including those on quick-disconnect fittings, are present and

in good condition. Replace O-rings and seals if worn or damaged.

6-2

Page 41

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS FRYERS

CHAPTER 6: PREVENTATIVE MAINTENANCE

6.3 Periodic/ Annual (cont.)

Check filtration system integrity as follows:

• With the filter pan empty, place each oil return handle in the OPEN position, one at a time.

Using rear flush oil return, verify that the pump activates and that bubbles appear in the oil of

the associated frypot. Using over-the-top oil return, verify that the pump activates and that

the faucet sputters.

• Close all oil return valves (i.e., place all oil return handles in the CLOSED position). Verify

proper functioning of each oil return valve by activating the filter pump using the lever on

one of the oil return handle microswitches. No air bubbles should be visible in any frypot and

the over-the-top faucet should not sputter.

• Verify that the filter pan is properly prepared for filtering, then drain a frypot of oil heated to

350°F (177°C) into the filter pan and close the frypot drain valve. Place the oil return handle

in the OPEN position. Allow all oil to return to the frypot. The frypot should refill in no more

than 2 minutes and 30 seconds. Move the oil return handle to the CLOSED position when the

oil return lines are clear of oil (indicated by bubbles in the oil in the frypot or sputtering in

the over-the-top faucet).

To ensure good fryer health and a safe environment, the fryer should be checked and adjusted

periodically by qualified service personnel as part of a regular kitchen maintenance program.

6.4 Stainless Steel

All stainless steel fryer outer parts should be wiped regularly with hot, soapy water during the day

and with a liquid cleaner designed for this material at the end of each day.

• Do not use steel wool, abrasive cloths, cleansers, or powders!

• Do not use a metal knife, spatula, or any other metal tool to scrape stainless steel! Scratches

are almost impossible to remove.

• If it is necessary to scrape the stainless steel to remove any encrusted materials, soak the area

to loosen the material and use a wood or nylon scraper only.

6-3

Page 42

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS

FRYERS

CHAPTER 7: TROUBLESHOOTING

7.1 Introduction

This section provides an easy reference guide to some of the common problems that may occur

during the operation of this equipment. The troubleshooting guides that follow are intended to help

correct, or at least accurately diagnose, problems with this equipment. Although this chapter covers

the most common problems reported, you may encounter problems, which are not addressed. In

such instances, the Frymaster Dean Technical Service staff will make every effort to help you

identify and resolve the problem.

When troubleshooting a problem, always use a process of elimination starting with the simplest

solution and working through to the most complex. Never overlook the obvious – anyone can forget

to plug in a cord or fail to close a valve completely. Most importantly, always try to establish a clear

idea of why a problem has occurred. Part of any corrective action involves taking steps to ensure

that it doesn’t happen again. If a controller malfunctions because of a poor connection, check all

other connections, too. If a fuse continues to blow, find out why. Always keep in mind that the

failure of a small component may often be indicative of potential failure or incorrect functioning of a

more important component or system.

Before calling a service agent or the Frymaster Dean HOTLINE (1-800-551-

8633):

• Verify that electrical cords are plugged in and that circuit breakers are on;

• Verify that frypot drain valves are fully closed;

• Verify that gas line is properly connected.

DANGER

Never attempt to move a fryer containing hot cooking oil or to transfer hot cooking

oil from one container to another.

DANGER

Use extreme care when testing electrical circuits. Live circuits will be exposed.

WARNING

Inspection, testing, and repair of electrical components should be performed only by

qualified service personnel. The equipment should be unplugged when servicing,

except when electrical tests are required.

DANGER

NEVER use open flame to melt solidified shortening-blockage in the filtration

system. Open flame increases the chance of fire and operator injury.

7-1

Page 43

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS FRYERS

CHAPTER 7: TROUBLESHOOTING

7.2 Fryer Troubleshooting

For FAST-equipped fryers, consult the FAST controller manual. These steps apply to the KFC-1

SMS controller only.

1. Check wall circuit breakers. Reset, if

needed.

2. Check fryer connection to external

7.2.1

Controller fails to turn ON

when ON/OFF button is

pressed.

power source.

3. Disconnect fryer from power supply.

4. A power surge or outage may have

temporarily locked out controller.

If the fryer still fails to turn ON when the

ON/OFF button is pressed, contact an

authorized service agent.

7.2.2

Controller is ON, but the

gas valves fail to energize.

1. Ensure float-switch is not stuck in

"down" position. Contact a FAS for

service if float-switch is defective.

2. If the KFC-1 SMS controller displays

HELP, reset high-limit thermostat

(located in the fryer cabinet under the

control panel). Contact a FAS for

service if high-limit will not reset.

7-2

Page 44

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS FRYERS

CHAPTER 7: TROUBLESHOOTING

7.2 Fryer Troubleshooting (cont.)

Actual frypot temperature

7.2.3

differs from the controller

setpoint temperature.

1. Turn fryer ON.

2. Select a product number and allow the

fryer to heat for approximately 30 minutes

to stabilize shortening temperature at

desired setpoint.

3. Place a thermometer near the temperature

sensing probe within 1 inch of the

temperature probe and approximately 3in. (75-mm) deep into the shortening. (see

illustration, Page 7-3).

4. Press the KFC-1 SMS controller

temperature button to check the frypot

temperature. Press the controller temperature

button twice to view setpoint temperature

for the product number chosen.

7.2.3

(cont.)

Actual frypot temperature

differs from controller

setpoint temperature.

5. The thermometer temperature should be

within ±10°F (±5°C) of the KFC-1

SMS controller display temperature.

Yes: System is maintaining temperature

properly.

7-3

Page 45

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS FRYERS

CHAPTER 7: TROUBLESHOOTING

7.2 Fryer Troubleshooting (cont.)

Frypot Front

Temperature

Probe

High-Limit

Probe

Temperature Probe

Probe Bracket

Burner Tube

No: Ensure the probe tip is ⅛" from the

top of the burner tubes (see illustration).

If the probe adjustment is correct, the

controller probe circuit may be faulty.

If probe adjustment is incorrect, it will

require adjustment.

6. Contact your authorized service agent if

any of the following occurs during this test:

a. Controller probe circuit is suspected

as faulty.

b. Temperature probe needs adjustment.

c. KFC-1 SMS controller fails to call

for heat during the calibration test.

7-4

Page 46

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS FRYERS

CHAPTER 7: TROUBLESHOOTING

7.2 Fryer Troubleshooting (cont.)

DRAIN OPEN message

7.2.4

7.2.5

remains after closing drain

valve.

Pump motor won’t start or

stops during filtering.

1. KFC-1 SMS controller was turned OFF

while draining frypot.

2. Close drain valve. Turn KFC-1 SMS

controller OFF and ON again.

Controller display will read ON.

3. Open drain valve. The KFC-1 SMS

controller display will read DRAIN

OPEN. After 30 seconds the controller

display will read FILL.

4. Close drain valve.

5. Fill frypot with shortening. Press

EXIT/COOL FILTER when ready to

cook.

6. If the KFC-1 SMS controller message

DRAIN OPEN remains after Steps 1-

4, contact an authorized service agent.

Possible malfunctions are:

a. Drain microswitch may be faulty.

b. Drain circuit is suspect.

c. KFC-1 SMS controller is suspect.

1. The motor thermal overload has tripped. If

the thermal overload trips, wait

approximately 45 minutes. Press the

button on the end of the filter motor.

2. If you have to do this repeatedly, stop

resetting the overload and contact an

authorized service agent.

NOTE: This is usually caused by allowing

large particles of food to enter the pump

during filtering. Ensure that the filter paper

and crumb screen are properly in place.

7-5

Page 47

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS FRYERS

CHAPTER 7: TROUBLESHOOTING

Fryer Troubleshooting (cont.)

7.2.6

Main burner malfunctions.

A. Main burner will not ignite; no gas is

present at main burner.

1. Check that float switch is not stuck

in the "down" position.

2. Check and reset the high-limit

switch.

3. The combination gas valve and/or

electronic ignition system may be

defective; Contact a FAS for

service.

B. Main burner flames are small and

appear lazy; shortening does not come

up to temperature quickly. Contact a

FAS for service.

C. Fryer will not reach setpoint

temperature and/or runs erratically.

1. Incorrect location or adjustment of

sensor probe. Contact a FAS for

service.

2. Defective temperature sensor. Contact

a FAS for service.

D. Fryer shortening temperature cannot be

controlled; fryer runs at high-limit

temperature. Possible causes are:

1. Defective operating thermostat.

Contact a FAS for service.

2. Defective temperature probe.

Contact a FAS for service.

7-6

Page 48

Y/KSCF/C/HC18G HIGH EFFICIENCY COOL ZONE SERIES GAS FRYERS

CHAPTER 7: TROUBLESHOOTING

7.3 Filtration System Troubleshooting

• Return valve not fully opened.

Pump won't

start.

Pump stops

during filtering

process. Motor

is hot.

• Tripped circuit breaker.

• Incorrect or no line voltage.

• Failed or misadjusted return microswitch.