Page 1

YFG255 Rethermalizer

Service & Parts Manual

Frymaster, a member of the Commercial Food Equipment Service Association, recommends

using CFESA Certified Technicians.

24-Hour Service Hotline

1-800-551-8633

www.frymaster.com

Email: service@frymaster.com

*8196900*

05/2016

Page 2

Please read all sections of this manual and retain for future reference.

This product has been certified as commercial cooking equipment and MUST be installed by

professional personnel as specified. Installation, maintenance and repairs should be performed

by your Frymaster Factory Authorized Servicer (FAS).

DANGER

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any

other cooking appliance.

DANGER

Instructions explaining procedures to be followed MUST be posted in a prominent location in

the event the operator detects a gas leak. This information can be obtained from the local gas

company or gas supplier.

DANGER

Safe and satisfactory operation of your equipment depends on proper installation. Installation

MUST conform with local codes, or in absence of local codes, with the National Fuel Gas Code,

ANSI Z223.1; The Natural Gas Installation Code, CAN/CGA-B149.1; The Propane Installation

Code, CAN/CGA-B149.2; or The latest edition of the National Electric Code, N.F.P.A. 70.

NOTICE

If, during the warranty period, the customer uses a part for this Manitowoc Food Service

equipment other than an unmodified new or recycled part purchased directly from Frymaster or

any of its authorized servicers, and/or the part being used is modified from its original

configuration, this warranty will be void. Further, Frymaster and its affiliates will not be liable

for any claims, damages or expenses incurred by the customer which arise directly or

indirectly, in whole or in part, due to the installation of any modified part and/or part received

from an unauthorized servicer.

DANGER

The front ledge of the rethermalizer is not a step. Do not stand on the rethermalizer. Serious

injury can result from slips or contact with the hot water.

WARNING

Drawings and photos used in this manual are intended to illustrate operational, cleaning and

technical procedures and may not conform to on-site management operational procedures.

WARNING

No structural material on the rethermalizer should be altered or removed to accommodate

placement of the rethermalizer under a hood. Questions? Call the Frymaster Service Hotline at

1-800-551-8633.

NOTICE

This equipment is to be installed in compliance with the basic plumbing code of The Building

Officials and Code Administrators International, Inc. (BOCA) and the Food Service Sanitation

Manual of the Food and Drug Administration.

NOTICE

The Commonwealth of Massachusetts requires any and all gas products to be installed by a

licensed plumber or pipe fitter.

Page 3

CONTROLLERS

FCC

This device complies with Part 15 of the FCC rules. Operation is subject to the following two conditions:

1) This device may not cause harmful interference, and 2) This device must accept any interference

received, including interference that may cause undesired operation. While this device is a verified Class

A device, it has been shown to meet the Class B limits.

CANADA

This digital apparatus does not exceed the Class A or B limits for radio noise emissions as set out by the

ICES-003 standard of the Canadian Department of Communications.

Cet appareil numerique n’emet pas de bruits radioelectriques depassany les limites de classe A et B

prescrites dans la norme NMB-003 edictee par le Ministre des Communcations du Canada.

DANGER

THIS PRODUCT CONTAINS CHEMICALS KNOWN TO THE STATE OF CALI FORNIA TO CAUSE

CANCER AND/OR BIRTH DEFECTS OR OTHER REPRODUCTIVE HARM.

Operation, installation, and servicing of this product could expose you to airborne particles of

glasswool or ceramic fibers, crystalline silica, and/or carbon monoxide. Inhalation of airborne

particles of glasswool or ceramic fibers is known to the State of California to cause cancer.

Inhalation of carbon monoxide is known to the State of California to cause birth defects or other

reproductive harm.

WARNING

Do not bang rethermalizer baskets or other utensils on the rethermalizer’s joiner strip. The strip

is present to seal the joint between the cookpot vessels. Banging rethermalizer baskets on the

strip will distort the strip, adversely affecting its fit. It is designed for a tight fit and should only

be removed for cleaning.

DANGER

Improper installation, adjustment, maintenance or service, and unauthorized alterations or

modifications can cause property damage, injury, or death. Read the installation, operating and

service instructions thoroughly before installing or servicing this equipment. Only qualified

service personnel may convert this appliance to use a gas other than that for which it was

originally configured.

DANGER

Adequate means must be provided to limit the movement of this appliance without depending

upon the gas line connection or transmitting stress to the electrical conduit. Single

rethermalizers equipped with legs must be stabilized by installing anchor straps. All

rethermalizers equipped with casters must be stabilized by installing restraining chains. If a

flexible gas line is used, an additional restraining cable must be connected at all times when the

rethermalizer is in use.

Page 4

YFG255 Series Rethermalizers

Service & Parts Manual

TABLE OF CONTENTS

Page #

1. SERVICE PROCEDURES 1-1

1.1 Functional Description 1-1

1.2 Accessing Fryers for Service 1-3

1.3 Cleaning the Gas Valve Vent Tube (if applicable) 1-3

1.4 Adjusting Burner Manifold Gas Pressure 1-3

1.5 Replacing Rethermalizer Components 1-4

1.6 Troubleshooting and Problem Isolation 1-13

1.7 Troubleshooting Guides 1-18

1.8 Probe Resistance Chart 1-20

1.9 Wiring Diagram 1-21

2. PARTS LIST 2-1

2.1 YFG255 Cabinet and Related Components 2-1

2.2 Cookpot Assemblies and Components 2-3

2.3 Transformer Boxes and Control Frame Assemblies 2-4

2.4 Harnesses 2-5

2.5 Plumbing, Incoming Water 2-6

2.6 Plumbing, Drain 2-7

2.7 Plumbing, Gas Manifold 2-8

2.8 Fasteners 2-9

Page 5

)

)

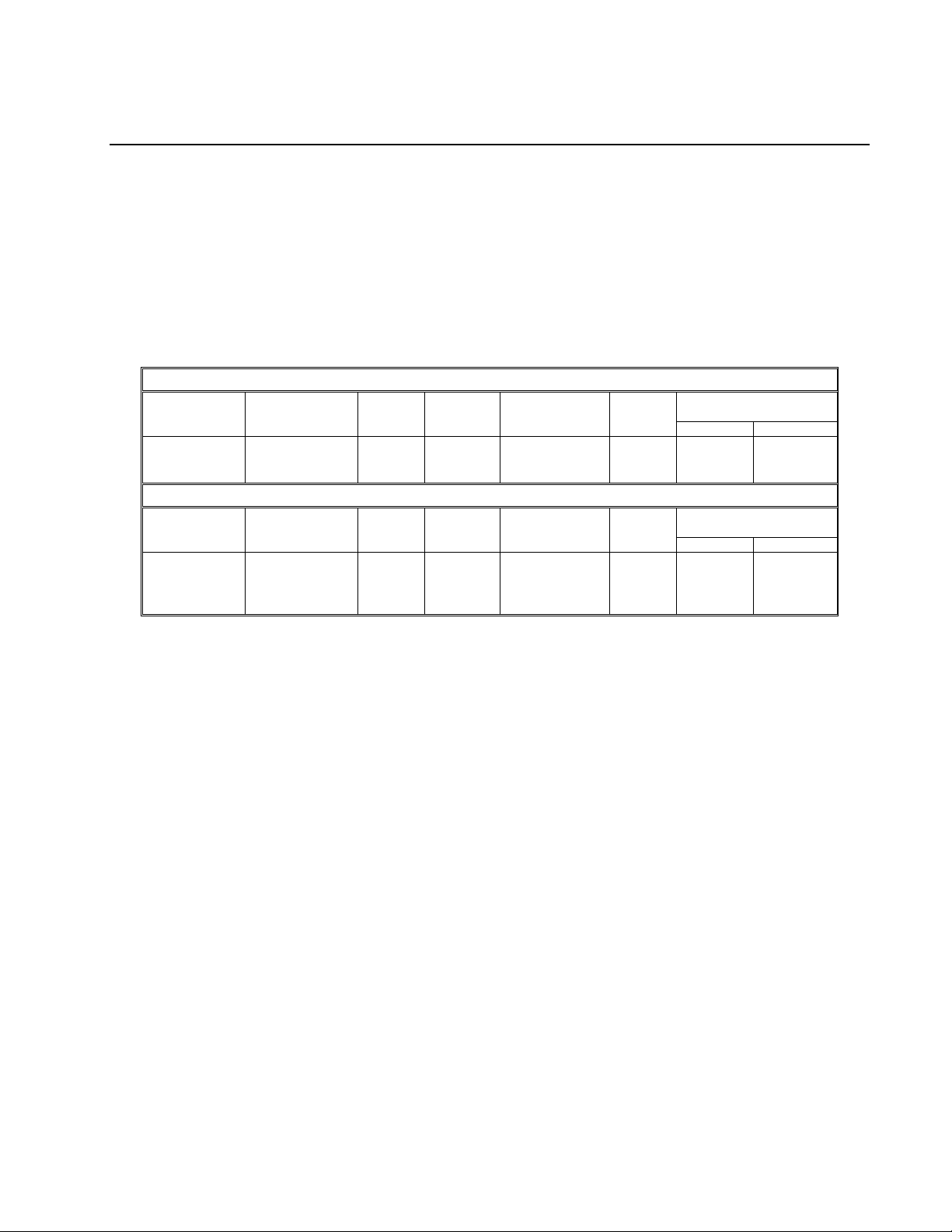

YFG255 SERIES GAS RETHERMALIZERS

CHAPTER 1: SERVICE PROCEDURES

1.1 Functional Description

YFG255 Series gas rethermalizers contain a welded stainless steel cookpot that is heated by gas

flames diffused evenly through tubes built into the cookpot.

Flames originate from orifices in a burner manifold positioned beneath the burners. The burners are

positioned in the tube openings, at the front of the cookpot. The diameter of the orifices differs for

natural (CE:G20/G25) and LP (CE:G31) gas as indicated in the accompanying table.

NON-CE (Altitudes of 2000 feet or less

MODEL

YFG255 90

INPUT

(BTU)

GAS

TYPE

NAT

LP

ORIFICE

MM

(INCH)

2.38(#42)

1.51(#53)

ORIFICE

PART NO.

810-2926

810-2941

QTY

2

2

EQUIPMENT

PRESSURE

MBAR INCH W.C.

10

27.5

4

11

CE ONLY (Altitudes of 2000 feet or less

MODEL

YFG255 26.4

INPUT

(kW)

GAS

TYPE

G20

G25

G31

ORIFICE

MM

(INCH)

2,38

2,38

1,51

ORIFICE

PART NO.

810-2926

810-2926

810-2941

QTY/

COLOR

2/BLUE

2/BLUE

2/RED

EQUIPMENT

PRESSURE

MBAR INCH W.C.

10,0

15,0

27,0

4,0

6,0

10,8

An electromechanical gas valve regulates gas flow to the manifold. YFG255 Series gas

rethermalizers are equipped with a 24-volt valve system with an electronic ignition system.

Electronic Ignition Configuration

An ignition module connected to an ignitor assembly controls ignition. The ignition module

performs three important functions: it provides an ignition spark, supplies voltage to the gas valve,

and proofs the pilot flame.

The module contains a 60-second time delay circuit and a coil that activates the gas valve. The

ignitor assembly consists of a spark plug, a pilot, and a flame sensor element.

At start-up the power switch is placed in the "ON" position, supplying 12 VDC to the heat control

circuitry in the controller. Current is supplied to the other leg of the heat relay coil which then closes

an electronic switch in the 24 VAC circuit to provide current to the ignition module.

Circuitry in the ignition module sends 24 VAC current to the gas valve via a normally closed float

switch. Simultaneously, the module causes the ignitor to spark for up to 60 seconds to light the pilot

flame. A flame sensor verifies that the pilot is lit by measuring the flow of microamps through the

flame. If the pilot does not light (or is extinguished), current to the ignition module is interrupted,

preventing the main valve from opening, and the ignition module "locks out" until the power switch

is turned "OFF", then back "ON".

1-1

Page 6

YFG255 SERIES GAS RETHERMALIZERS

CHAPTER 1: SERVICE PROCEDURES

A temperature probe monitors the temperature in the cookpot. When the programmed setpoint

temperature is reached, resistance in the probe causes the heat cycle circuitry in the controller to

interrupt current flow through the heat relay. This in turn interrupts the 24 VAC current to the

ignition module, resulting in closure of the gas valve.

Control Options

YFG255 Series gas rethermalizers are equipped with a factory preset temperature controller. These

are unique in that the components are wired directly to the controller and do not require an interface

board.

Temperature Probe

YFG255 rethermalizers are equipped with a temperature probe with resistance values that

correspond directly with the temperature. That is, as the temperature rises, so does resistance. See

the resistance table on page 1-20. Circuitry in the controller monitors the probe resistance and

controls burner firing when the resistance exceeds or falls below programmed temperatures

(setpoints).

1-2

Page 7

YFG255 SERIES GAS RETHERMALIZERS

CHAPTER 1: SERVICE PROCEDURES

1.2 Accessing Rethermalizers for Servicing

DANGER

Moving a rethermalizer filled with water may cause spilling or splattering of the hot

liquid. Follow the draining instructions included with the rethermalizer before

attempting to relocate a rethermalizer for servicing.

1. Shut off the gas supply to the unit. Unplug the power cords. Remove any attached restraining

devices.

2. Disconnect the unit from the gas supply.

3. Relocate the rethermalizer for service accessibility.

4. After servicing is complete, reconnect the unit to the gas supply, reattach restraining devices, and

plug in the electrical cords.

1.3 Cleaning the Gas Valve Vent Tube (if applicable)

1. Set the rethermalizer power switch and the gas valve to the "OFF" position.

2. Carefully unscrew the vent tube from the gas valve. NOTE: The vent tube may be straightened

for ease in removal.

3. Pass a piece of ordinary binding wire (.052 inch diameter) through the tube to remove any

obstruction. Remove the wire and blow through the tube to ensure it is clear.

4. Reinstall tube and bend so that the opening is pointing downward.

1.4 Adjusting Burner Manifold Gas Pressure

WARNING

This task should be performed by qualified service personnel only.

1. Ensure that the gas valve knob is in the "OFF" position.

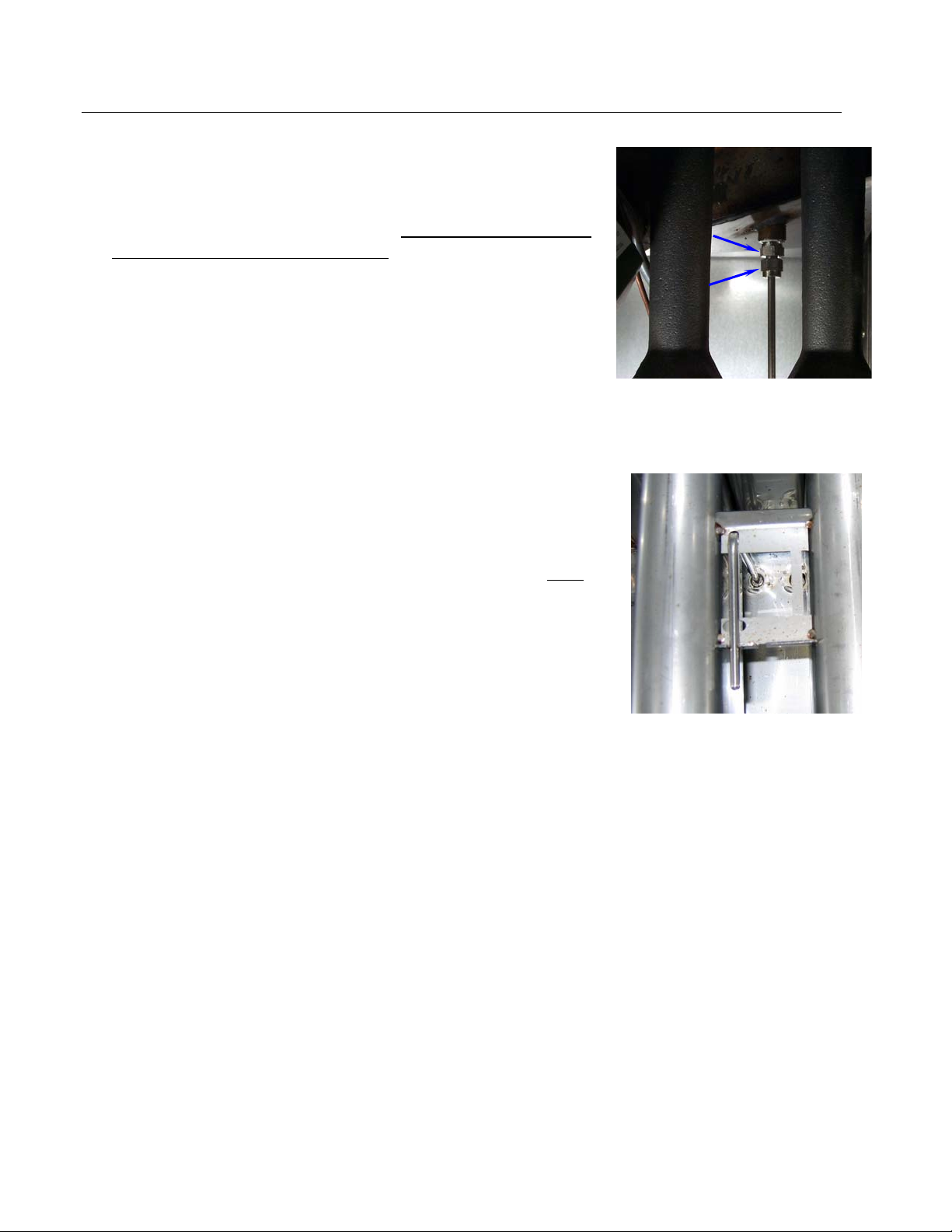

2. Remove the pressure tap plug from the gas valve (see arrows in photos on the following page for

location).

1-3

Page 8

YFG255 SERIES GAS RETHERMALIZERS

CHAPTER 1: SERVICE PROCEDURES

1.4 Adjusting Burner Manifold Gas Pressure (cont.)

3. Insert the fitting for a gas pressure-measuring device into the pressure tap hole.

4. Place the gas valve in the "ON" position then place the rethermalizer power switch in the "ON"

position. When the burner lights and continues to burn, note gas pressure reading for correct

pressure in accordance with the table on page 1-1.

5. To adjust burner gas pressure, remove the cap from the gas valve regulator and adjust to correct

pressure.

6. Place the rethermalizer power switch and the gas valve in the "OFF" position. Remove the

pressure-measuring device fitting from the pressure tap hole and reinstall the pressure tap plug.

1.5 Replacing Rethermalizer Components

1.5.1 Replacing the Controller or Solid State

Relays

1. Disconnect the rethermalizer from the electrical supply.

2. Open the cabinet doors and unscrew the three controller

panel screws located beneath the bezel. The controller

panel will drop down and will rest on the open doors.

3. Mark the wires for reassembly and using a small

screwdriver loosen and remove the wires from the rear

of the controller. If replacing the relays disconnect the

wires and replace the faulty relay.

Remove the three bezel screws.

1-4

Mark wires for reassembly.

Page 9

p

YFG255 SERIES GAS RETHERMALIZERS

CHAPTER 1: SERVICE PROCEDURES

1.5.1 Replacing the Controller or Solid State Relays cont.

4. Remove the controller from the bezel.

5. Reverse the procedure to install a new controller.

1.5.2 Replacing the Temperature Probe

1. Disconnect the rethermalizer from the electrical supply.

2. Drain the water from the cookpot. Allow the cookpot to cool

completely before proceeding.

3. Remove the rethermalizer door for easier access to the temperature

probe. Lift door up, disengage rod from lower door bracket, and

then remove door.

4. Gain access to probe wires in control box behind

controller using the steps in the previous section 1.5.1.

5. Disconnect the probe harness connector (see right).

Unplug connector.

6. Use a pin pusher to remove probe wires from the plug.

Remove probe wires.

Remove door for easier access

to tem

erature probe.

1-5

Page 10

YFG255 SERIES GAS RETHERMALIZERS

CHAPTER 1: SERVICE PROCEDURES

1.5.2 Replacing the Temperature Probe (cont.)

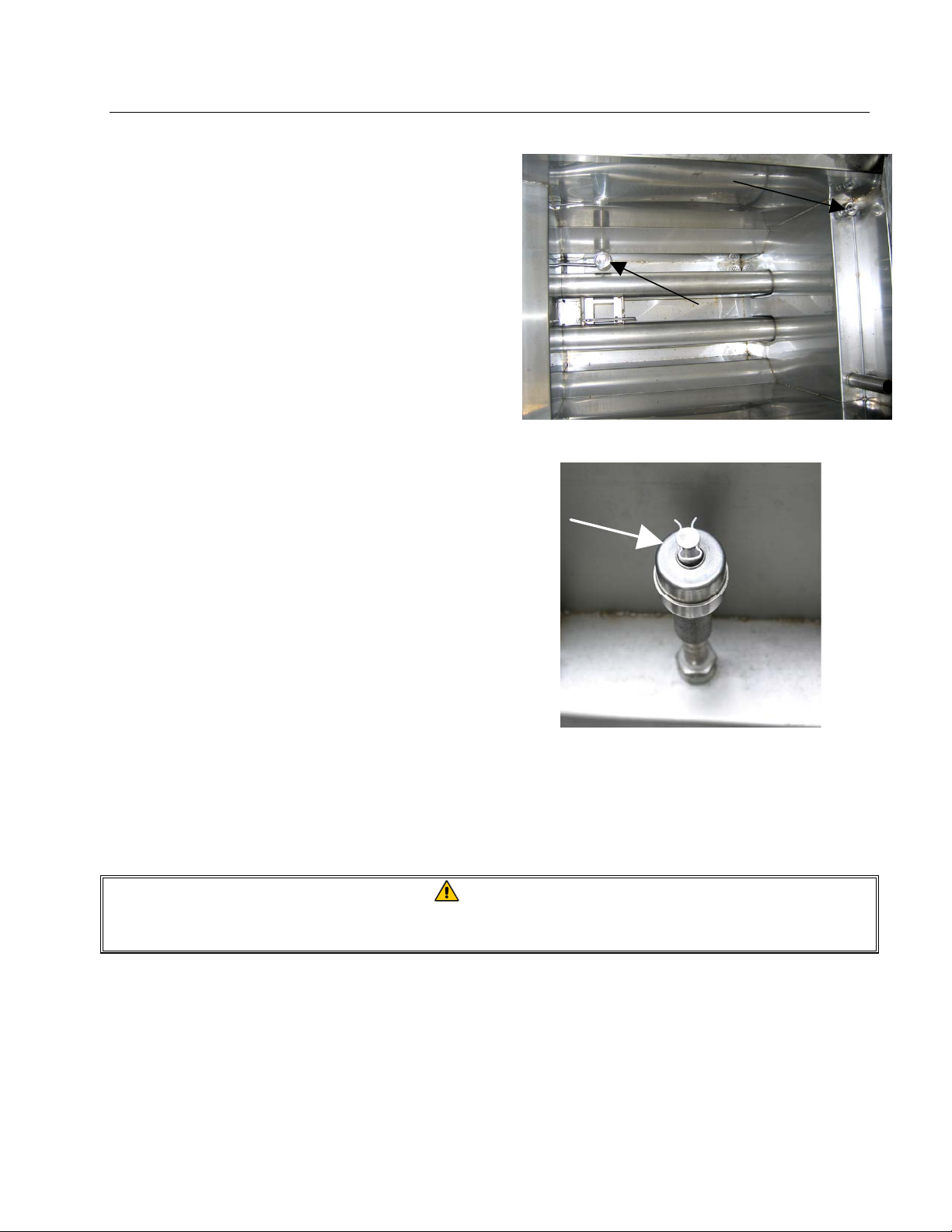

7. Loosen and unscrew completely the compression nut, then the

pass-through nut from the cookpot. Proceed to the next step

before removing probe from cookpot.

Note: The temperature probe can be removed through the top

of the cookpot as follows: Ensure the probe wires have been

removed from the connector (step 6). Remove the harness

insulation. The probe can be pulled through the cookpot from

the top (complete step 7 in this section, prior to removing

probe).

8. Carefully remove the probe from the cookpot.

9. Reverse steps for installation of new probe.

IMPORTANT: When installing new probe, ensure probe is

positioned properly with the mounting hardware installed prior to

tightening the compression nut. Once tightened, the probe cannot

be repositioned.

Loosen and unscrew completely

the compression nut (bottom arrow)

first. Loosen the pass-through nut

(top arrow).

Remove the temperature probe.

1-6

Page 11

YFG255 SERIES GAS RETHERMALIZERS

CHAPTER 1: SERVICE PROCEDURES

1.5.3 Replacing Float Switches

1. Disconnect the rethermalizer from the

electrical power supply.

2. Drain the water from the cookpot. Allow

the cookpot to cool completely before

proceeding.

3. Unplug the low float switch connector

from behind the controller (See section

1.5.1 for instructions on removing the

bezel.), or the high level float from the

The lower float switch (left), the high level float (right).

rear of the rethermalizer near the fresh

water connection.

4. Remove the clip and float from float switch shaft.

5. Remove the rethermalizer back to gain access to the

high level float compression nut. Removal of a

burner may be necessary to access the low level

float compression nut.

6. Loosen and completely unscrew the compression

nut from the cookpot.

7. Carefully pull the float switch shaft out of the

cookpot.

Remove the clip

8. Reverse the above steps for float switch installation.

1.5.4 Replacing the Gas Valve

DANGER

Drain the cookpot or remove the handle from the drain valve before proceeding

further.

1. Disconnect rethermalizer from electrical and gas supplies.

2. Disconnect the wires from the gas valve terminal block, marking each wire to facilitate

reconnections.

3. Remove the pilot gas line fitting from the gas valve.

1-7

Page 12

YFG255 SERIES GAS RETHERMALIZERS

CHAPTER 1: SERVICE PROCEDURES

4. Remove the pipe union collars to the left and right of the gas valve and remove the valve.

5. Remove the pipefitting from the old gas valve and install on the replacement valve, using

Loctite™ PST567 or equivalent pipe thread sealant on threads. Do not apply sealant to the first

two pipe threads. Doing so will clog and damage the gas valve.

6. Reverse steps 1-4 to install the replacement gas valve.

1.5.5 Replacing the Pilot Assembly

1. Remove the pilot tubing from the bottom of the pilot assembly.

2. Disconnect the ignition cable and the sense wire.

3. Remove the two pilot mounting screws from the pilot mounting-bracket and remove the pilot.

4. Reverse the procedure to replace the pilot assembly.

1.5.6 Replacing the Cookpot

1. Ensure controller and all power switches are off. Drain water from all cookpots prior to moving

rethermalizer.

DANGER

Hot water will cause severe burns. Never attempt to move this appliance when filled

with hot water or to transfer hot water from one container to another.

2. Turn gas valve off, then turn gas off at supply valve or meter. Disconnect supply line from gas

manifold at rear of rethermalizer.

NOTE: If restraints are installed on the rethermalizer, disconnect restraints prior to

disconnecting the gas supply line.

3. Unplug rethermalizer from electrical supply source.

4. Remove rethermalizer door for access to cabinetry components. Lift door up, disengage rod

from lower door bracket, remove and set door aside.

1-8

Page 13

YFG255 SERIES GAS RETHERMALIZERS

CHAPTER 1: SERVICE PROCEDURES

1.5.6 Replacing the Cookpot (cont.)

5. Remove upper cookpot cover and bracket.

6. Carefully pry up and remove

capping strip.

7. Locate all screws securing back panels.

Removing capping strip.

Screw location/orientation will vary

according to rethermalizer model.

8. Remove back panels on rethermalizer. Retain screws for re-assembly.

9. Remove screw securing back-

panel brace to flue cap. Support

brace with hand while removing

screw to prevent brace from

falling away. Remove brace and

set aside for reassembly.

Removing back panel to flue cap brace (arrow).

10. Remove screws securing flue-cap braces to cookpot (a nut-driver

with an extension or long screwdriver is required). Use care not to

drop the screws into the flues. If this happens, the screws can be

retrieved when the flue is removed (Step 12). Use a screwdriver

or similar tool to free flue cap from cookpots. Remove flue cap by

lifting up and off of rethermalizer.

11. Remove gas manifold pipe for access to gas manifold shield by

disconnecting at the unions. Ensure gas supply is shut off and

supply line is disconnected prior to removing. Set gas manifold

aside. Remove screws securing gas manifold shield. Remove

shield to access water-return plumbing components connected to

the cookpots.

Removing flue cap.

Removing gas manifold shield.

1-9

Page 14

YFG255 SERIES GAS RETHERMALIZERS

CHAPTER 1: SERVICE PROCEDURES

1.5.6 Replacing the Cookpot (cont.)

12. Remove four bolts securing flue

to the cookpot being removed.

Remove the flue by sliding back

and away until clear of cookpot.

Retrieve any screws dropped into

the flue during removal of the flue

cap to cookpot bracket.

13. Remove the burner shield.

Loosen burner bolts (two per

burner) that secure burners to the

burner support rail.

NOTE: On most rethermalizers,

do not remove bolts from burners.

14. Lift each burner upward to clear

the orifice, then slant the top of

the burner inward to clear the

burner-brace keyholes.

Removing bolts (arrows) securing flue to cookpot.

Loosening burner bolts prior to burner removal.

Removing burners from rethermalizer.

1-10

Page 15

p

YFG255 SERIES GAS RETHERMALIZERS

CHAPTER 1: SERVICE PROCEDURES

1.5.6 Replacing the Cookpot (cont.)

15. Remove screw(s) securing the electronic or

standing pilot bracket to the cookpot bracket.

Reposition ignitor assembly down and away

from cookpot. Use care not to bend, kink or

damage the electronic ignition lines and

wiring.

16. Remove nut from drain valve linkage, then

disconnect actuator rod from drain valve

Removing electronic/standing pilot assembly.

actuator.

17. Remove the temperature probe from cookpot. (see Section

1.5.2, Replacing Temperature Probe for specific instructions.

18. Disconnect the fresh water line from the cookpot.

19. The rethermalizer is equipped with float-valve switches, mark

the wires and terminals, then disconnect wires from the

switch. Secure the wires to prevent damage when cookpot is

removed.

20. Remove bolts from brackets securing burner manifold to

cookpot. Leave the manifold in place.

21. Using a sharp knife or box-cutter, cut the silicon seal between

and in front of the two cookpots. Use care not to scratch

stainless steel surfaces.

22. Remove cookpot from rethermalizer by lifting up and out.

23. Position the cookpot

upside down on a

suitable work surface.

24. Record position of the valve stem in relation to the cookpot

prior to removing the drain valve. Using a suitable wrench,

remove the drain valve from the cookpot. Use Loctite

Lift cook

ot from rethermalizer.

PST567 sealant when installing drain valve on replacement

cookpot.

25. Reverse the above steps to install replacement cookpot.

Removing bolts (arrows) from

burner manifold support brackets

(both sides). Leave the burner

manifold in place after removing

bolts.

Cut cookpot seal prior to cookpot

removal.

1-11

Page 16

YFG255 SERIES GAS RETHERMALIZERS

CHAPTER 1: SERVICE PROCEDURES

1.5.7 Annotated Cookpot Bottom

1-12

Page 17

YFG255 SERIES GAS RETHERMALIZERS

CHAPTER 1: SERVICE PROCEDURES

1.6 Troubleshooting and Problem Isolation

This section is intended to provide technicians with a general knowledge of the broad problem

categories associated with this equipment, and the probable causes of each. With this knowledge, the

technician should be able to isolate and correct any problem encountered.

Problems you are likely to encounter can be grouped into seven broad categories:

1. Ignition failures

2. Improper burner functioning

3. Improper temperature control

4. Controller-related problems

5. Leakage

The probable causes of each category are discussed in the following sections. Troubleshooting

guides are included in Section 1.7 to assist in identifying some of the more common problems.

1.6.1 Ignition Failures

Ignition failure occurs when the ignition module fails to sense a flame within the 60-second time

delay period and locks out. Turn the rethermalizer off, locate and fix the problem, then turn

rethermalizer back on to clear the module lock.

There are three primary reasons for ignition failure, listed in order of probability:

1. Problems related to the gas and/or electrical power supplies.

2. Problems related to the electronic circuits.

3. Problems related to the gas valve.

Problems Related to the Gas and/or Electrical Power Supplies

The main indicators of this are that an entire battery of rethermalizers fails to light. Verify that the

quick disconnect hose is properly connected, the rethermalizer is connected to power, the main gas

supply valve is open, and the circuit breaker for the rethermalizer electrical supply is not tripped.

1-13

Page 18

YFG255 SERIES GAS RETHERMALIZERS

CHAPTER 1: SERVICE PROCEDURES

1.6.1 Ignition Failures (cont.)

Problems Related to the Electronic Circuits

If gas and electrical power are supplied to the rethermalizer, the next most likely cause of ignition

failure is a problem in the 24 VAC circuit. First verify that the float switch valve is fully closed and

not sticking. (The float switch must be closed for power to reach the gas valve. Often, a starch build

up will cause the float switch to stick, impeding movement up and down the shaft. Simple cleaning

of the shaft will fix the problem.) If the float switch is fully closed, refer to the troubleshooting

guides in this chapter.

Problems Related to the Gas Valve

If the problem is not in the 24 VAC circuit or pilot system, it is most likely in the gas valve itself, but

before replacing the gas valve refer to the troubleshooting guides in this chapter.

1.6.2 Improper Burner Functioning

With problems in this category, the burner ignites but exhibits abnormal characteristics such as

"popping", incomplete lighting of burner, fluctuating flame intensity, and flames "rolling" out of the

rethermalizer.

"Popping" indicates delayed ignition. In this condition, the main gas valve is opening but the burner

is not immediately lighting. When ignition does take place, the excess gas "explodes" into flame,

rather than smoothly igniting.

The primary causes of popping are:

• Incorrect or fluctuating gas pressure

• Misdirected or weak pilot flame

• Clogged burner orifices

• Clogged burners

• Inadequate make-up air

• Heat damage to the controller or ignition module

• An out-of-adjustment ignitor or broken ignition wire

• A defective ignition module

1-14

Page 19

YFG255 SERIES GAS RETHERMALIZERS

CHAPTER 1: SERVICE PROCEDURES

1.6.2 Improper Burner Functioning (cont.)

If popping occurs only during peak operating hours, the problem may be incorrect or fluctuating gas

pressure. Verify that the incoming gas pressure (pressure to the gas valve) is in accordance with the

appropriate CE or Non-CE requirements listed in the Installation and Operation manual that came

with the rethermalizer, and that the pressure remains constant throughout all hours of usage. Refer

to Adjusting Burner Manifold Pressure in Section 1.4 if burner manifold pressure is suspected of

being incorrect.

If popping is consistent during all hours of operation, verify that the pilot is properly positioned

above the burner orifice and that the pilot pressure is correct. Correct pilot pressure is indicated by a

flame 1 to 1½" long. Also verify that ignitor is properly adjusted (electrode tip 1/8" from pilot hood

corner).

Clogged burners and/or burner orifices are also likely causes of delayed ignition. Clogged burners

are indicated by uneven flame or partial flame on the burner face. Clogged orifices are indicated by

no flame.

Another cause of popping is an insufficient air supply or drafts that are blowing the pilot flame away

from the burner. Check for "negative pressure" conditions in the kitchen area. If air is flowing into

the kitchen area, this indicates that more air is being exhausted than is being replenished and the

burners may be starved for air.

If the rethermalizers gas and air supplies are okay, the problem most likely is with one of the

electrical components. Examine the ignition module for signs of melting/distortion and/or

discoloration due to excessive heat build-up in the rethermalizer. (This condition usually indicates

improper flue performance.). Also, examine the controller for the same conditions. A melted or

distorted ignition module is automatically suspect and should be replaced, but unless the condition

causing excessive heat in the rethermalizer is corrected, the problem is likely to recur.

Next, ensure the ignition wire is tightly connected at both ends and examine it for obvious signs of

damage. Again, if damage is due to excessive heat in the rethermalizer, that problem must also be

corrected.

Check for proper operation by disconnecting the wire from the ignitor, inserting the tip of a

screwdriver into the terminal, and holding it near the frame of the rethermalizer as the power switch

is placed in the "ON" position. A strong, blue spark should be generated for at least 60 seconds.

DANGER

MAKE SURE YOU ARE HOLDING THE INSULATED HANDLE OF THE SCREWDRIVER

AND NOT THE BLADE. THE SPARKING CHARGE IS APPROXIMATELY 25,000

VOLTS.

Ensure the gap setting of the ignitor is correct (electrode tip 1/8" from pilot hood corner).

Burners lighting on the left side only may be caused by a trailing pilot problem or improper burner

manifold pressure.

1-15

Page 20

YFG255 SERIES GAS RETHERMALIZERS

CHAPTER 1: SERVICE PROCEDURES

Fluctuating flame intensity is normally caused by either improper or fluctuating incoming gas

pressure, but may also be the result of variations in the kitchen atmosphere. Verify incoming gas

pressure in the same way as for "popping", discussed in the preceding paragraphs. Variations in the

kitchen atmosphere are usually caused by air conditioning and/or ventilation systems starting and

stopping during the day. As air conditioning/ventilation systems start and stop, the pressure in the

kitchen may change from positive or neutral to negative, or vice versa. Changes in airflow patterns

may affect flame intensity.

Flames "rolling" out of the rethermalizer are usually an indication of negative pressure in the

kitchen. Air is being sucked out of the rethermalizer enclosure and the flames are literally following

the air. If negative pressure is not the cause, check for high burner-manifold gas pressure in

accordance with the procedures in Section 1.4. An obstructed flue, which prevents the rethermalizer

from properly exhausting, may also be the cause.

Excessively noisy burners, especially with flames visible above the flue opening, may indicate that

the burner gas pressure is too high, the tube diffusers are defective or burned out, or it may simply be

that the gas valve vent-tube is blocked (if applicable). If the gas pressure is correct, the tube

diffusers are intact and in good condition, and the vent-tube is unobstructed (if applicable), the gas

valve regulator is probably defective.

1.6.3 Improper Temperature Control

Temperature control is a function of several interrelated components, each of which must operate

correctly. The principal component is the temperature probe. Depending upon the specific

configuration of the rethermalizer, other components may include the controller itself, the

temperature probe, and the ignition module.

Improper temperature control problems can be failure to control at setpoint.

Failure to Control at Setpoint

The problem may be with the temperature probe or the controller. Refer to the troubleshooting

guides in this chapter.

1-16

Page 21

YFG255 SERIES GAS RETHERMALIZERS

CHAPTER 1: SERVICE PROCEDURES

1.6.4 Leakage

Cookpot leaks are almost always due to an improperly sealed temperature probe, float switches and

drain fittings. When installed or replaced, each of these components must be sealed with Loctite

PST567 sealant or equivalent to prevent leakage. In very rare cases, a leak may develop along one

of the welded edges of the cookpot, or where the tube is welded to the cookpot. When this occurs,

the cookpot must be repaired or replaced.

If the sides or ends of the cookpot are coated with water minerals, the most likely cause is spillage

over the top of the cookpot rather than leakage.

Cookpot locations (indicated by arrows) where potential leaks could occur.

1-17

Page 22

YFG255 SERIES GAS RETHERMALIZERS

CHAPTER 1: SERVICE PROCEDURES

1.7 Troubleshooting Guides

The following troubleshooting guides are intended to assist service technicians in quickly isolating

the probable causes of equipment malfunctions by following a logical, step-by-step process.

1.7.1 General Troubleshooting

PROBLEM PROBABLE CAUSES CORRECTIVE ACTION

A. Press the ON/OFF switch to turn the

controller on.

B. Verify that the rethermalizer is

plugged in and that the circuit breaker

is not tripped.

C. If available, substitute a controller

known to be working for the suspect

controller. If the rethermalizer

functions correctly, order replacement

from FAS.

A. Ensure float switch circuit is fully

closed and is functioning. Make sure

float is moving freely up and down

and does not have a starch build up

and that the shaft is not bent. Replace

float switch if defective.

C. Check temperature probe against

standard Minco probe resistance chart

on page 1-20. If found defective

replace temperature probe. .

No display on

controller.

The controller is

illuminated, but there is

no output to gas valve.

A. Rethermalizer is not turned on.

B. No power to rethermalizer.

C. Failed controller.

A. Float switch circuit is open.

B. Failed controller. B. Replace the controller.

C. Temperature probe defective.

D. Gas valve is suspect. D. Go to "No burner flame" section.

1-18

Page 23

YFG255 SERIES GAS RETHERMALIZERS

CHAPTER 1: SERVICE PROCEDURES

1.7.1 General Troubleshooting (cont.)

PROBLEM PROBABLE CAUSES CORRECTIVE ACTION

A. Press the ON/OFF switch off. Clean

float switch and make sure that the

float switch is not bent and that the

float moves freely up and down. Then

press the ON/OFF switch on. Replace

if defective.

B. Turn the gas valve knob to the ON

position.

C. Verify that any in-line manual shut off

valve is open. Verify that gas main

cut off valve is open.

A. If available, substitute a controller

known to be working for the suspect

controller. If the rethermalizer

functions correctly, order replacement

from FAS.

A. Check temperature probe against

standard Minco probe resistance chart

on page 1-20. If defective replace

temperature probe.

Heating indicator is on,

but burners will not

light.

Heating indicator cycles

on and off normally,

but burners will not

light.

Display shows a low

temperature,

and the rethermalizer

appears to operate

normally.

A. Float switch stuck or defective.

B. Gas valve is not turned on.

C. Manual gas shut off valve closed.

A. Failed controller.

A. Defective probe.

A. Water solenoid defective. A. Replace the defective solenoid valve.

Unit won’t fill with

water.

Fluctuating or erratic

lighting of burner

flame.

B. Float switch stuck or defective.

C. Water supply turned off.

A. Incoming gas supply pressures are not

within range [Natural- 6-14" W.C.

(1.49-3.49 kPa); Propane- 11-14"

W.C. (2.74-3.49 kPa)]

B. Air in gas supply lines (new

installation).

B. Press the ON/OFF switch off. Clean

float switch and make sure that the

float switch is not bent and that the

float moves freely up and down. Then

press the ON/OFF switch on. Replace

if defective.

C. Check water supply valve. Use

bypass switch to fill.

A. Inspect gas supply to rethermalizer.

Repair and/or replace faulty

components (defective supply shut-off

valves, incorrect piping size, etc.)

B. Allow unit to cy cle on and off for

approximately 30 minutes to force air

from gas manifold and lines.

1-19

Page 24

YFG255 SERIES GAS RETHERMALIZERS

CHAPTER 1: SERVICE PROCEDURES

1.7.1 General Troubleshooting (cont.)

PROBLEM PROBABLE CAUSES CORRECTIVE ACTION

A. Flame sensor possibly out of

A. Pilot does not stay lit.

alignment. Realign flame sensor.

Check flame sensor for loose wires.

B. Pilot stay s lit, and the flame sensor is

working, but burners fail to light.

No burner flame.

C. Gas valve is known to be good, but

there is not 24 VAC at the gas valve

terminals.

D. Continuity from ignition module

block to gas valve is not "0".

1.8 Probe resistance Chart

Probe Resistance Chart

For use with rethermalizers using the Control Products Controller.

F°

50 1059 16

68 1070 18

77 1080 21

86 1091 24

104 1101 27

122 1112 29

140 1122 32

158 1133 35

176 1143 38

194 1154 41

212 1164 43

OHMS

B. Inspect gas valve and replace if

defective.

C. Inspect temperature probe sensor

(while still in cookpot) for damage.

Replace if bent, dented or cracked.

Inspect leads for fraying, burning,

breaks and/or kinks. If found, remove

and replace temperature probe.

D. Inspect wiring for breaks or shorts and

repair if necessary.

C°

1-20

Page 25

YFG255 SERIES GAS RETHERMALIZERS

1.9 Wiring Diagram

Note: The diagram in this section depict wiring as of the date of manual publication. It

may not reflect design changes made to the equipment after publication. Refer to the

wiring diagram affixed to the unit when actually troubleshooting this equipment.

CHAPTER 1: SERVICE PROCEDURES

1-21

Page 26

YFG255 SERIES GAS RETHERMALIZERS

CHAPTER 2: PARTS LIST

2.1 YFG255 Cabinet and Related Components

See Page 2-3 for

Cookpot

Assemblies and

components.

ITEM PART # COMPONENT

1 231-8755 Side Panel, Left Side

2 232-8755 Side Panel, Right Side

3 108-1803 Door Assembly

106-4067 Pin Assembly

230-5472 Handle, Door

230-7249 Panel, Door

230-7324 Panel, Door Liner

810-0275 Spring, Door Hinge

* 810-2346 Magnet, Door

4 108-1111 Cover Assembly, Cookpot Right – includes item 6

5 108-1110 Cover Assembly, Cookpot Left – includes item 6

6 810-1374 Handle, Cover attaches with SS 3/8 Screw 809-0603

7 810-3879 Shock, Gas Spring

8 810-3881 Mount, Ball Stud 10MM

* Not illustrated

2-1

Page 27

YFG255 SERIES RETHERMALIZERS

CHAPTER 2: PARTS LIST

2.1 YFG255 Cabinet and Related Components (cont.)

ITEM PART # COMPONENT

9 231-8098 Strip, Cookpot Rim Left

10 230-7244 Strip, Joiner

11 232-8098 Strip, Cookpot Rim Right

12 823-7899 Fluecap

13 823-7944 Topcap

14 230-8183 Fascia, Control Panel

15 807-0012 Relay, 18A 1/3 HP 24V Coil, Float

16 826-2117 Module, Ignition (Dean) Honeywell

* 106-3553SP Cable, Ignition with Rajah Connector

17 231-6531 Hinge, Frypot Cover Outer Left

18 231-8049 Hinge, Cover Inner Left

19 220-8050 Back

20 232-8049 Hinge, Cover Inner Right

21 232-6531 Hinge, Frypot Cover Outer Right

22 826-1117 Caster, 5-inch w/o Brake Kit – includes washers and screws

23 826-1118 Caster, 5-inch with Brake Kit – includes washers and screws

24 230-8039 Pivot, Cover Front

25 220-7231 Box, Component

26 230-7383 Seal, Cookpot Cover

27 221-8051 Plate, Hinge Backing Left

28 222-8051 Plate, Hinge Backing Right

29 220-8081 Support, Fluecap

30 220-2773 Divider, Cookpot

31 220-7229 Brace, Back

32 220-7228 Brace, Horizontal Cabinet

33 220-7423 Post, Cabinet Rear

34 220-8126 Brace, Cabinet Lower

35 220-8186 Shield, Vapor

36 220-6033 Bracket, Component Box Support

37 220-7230 Brace, Rear Cabinet

38 230-7192 Hinge, Lower

39 220-2793 Channel, Base

40 220-7227 Channel, Front Base

41 220-7226 Channel, Rear Base

42 803-0325 Insert, Master Rack

43 803-0324 Master Rack 9⅛” x 13.00”

44 823-8148 Strainer

* 803-0278 L-Brush

* Not illustrated

2-2

Page 28

YFG255 SERIES RETHERMALIZERS

CHAPTER 2: PARTS LIST

2.2 Cookpot Assemblies and Components

ITEM PART # COMPONENT

1 823-7641SP Cookpot

2 108-0129 Flue Box Assembly

3 826-2622 Upper Float Switch (requires 813-0619)

* 813-0619 Flareless Male Tube Connection SS

4 108-0934 Lower Float Switch

* 826-2705 Snap Rings, Float Pkg. 5

5 826-2787 Kit, Probe, Temp with Controller (see item 6 on page 2-4)

* 810-3912 Fitting, Compression ¼” NPT

6 231-8164 Support, Hinge Left

7 232-8164 Support, Hinge Right

8 230-6251 Baffle, Burner

9 230-6301 Bracket, Pilot Burner

10 824-2228 Support, Burner Manifold

11 810-3221 Manifold, Burner

12 810-2926 Orifice, Natural Gas (G20/25) 2.38mm (#42)

810-2941 Orifice, Propane (G30/31) 1.51mm (#53)

13 813-0154 Plug ⅛” NPT

14 108-2612 Burner, Cast Iron with Clip Assy.

15 809-0459 Bolt, 5/16 -18 x ¾

16 200-1330 Burner, Heat Shield

17 220-5955 Bracket, Burner Cast Iron

18 108-2481 Assembly, Pilot Natural Gas (use 108-2614 for LP)

* 807-1310 Flame Sensor

* 106-1238SP Assembly, Ignitor Natural Gas ( use KIT6627 for LP)

* Not illustrated

2-3

Page 29

YFG255 SERIES RETHERMALIZERS

CHAPTER 2: PARTS LIST

2.3 Transformer Boxes and Control Frame Assemblies

ITEM PART # COMPONENT

1 807-2176 Transformer, 100/120V 12/24VAC Dual Voltage

2 807-1973 Terminal, Post

3 807-0070 Terminal, Ground Lug

4 823-7781 Box, Transformer

* 220-7698 Cover, Transformer Box

5 108-0959 Assembly, Harness

6 826-2787 Kit, Controller, Digital with Probe and fitting

7 106-4729 Assembly, Green Indicator 24V Light

8 807-3576 Switch, Fill

9 807-4036 Switch, Power

10 230-8183 Fascia

* 108-2801 Harness Controller, Switch, Light

* 106-7649 Cordset 68”

* Not illustrated

2-4

Page 30

2.4 Harnesses

YFG255 SERIES RETHERMALIZERS

CHAPTER 2: PARTS LIST

ITEM PART # COMPONENT

1 108-2800 Harness, Transformer, Solenoid and Float

2 108-2801 Harness, Controller, Switch and Light

3 108-2802 Harness, Ignition Module and Gas Valve

2-5

Page 31

YFG255 SERIES RETHERMALIZERS

CHAPTER 2: PARTS LIST

2.5 Plumbing, Incoming Water

ITEM PART # COMPONENT

1 108-0933 Solenoid Valve Assembly

2 810-3199 Fitting, ¼” NPT x ⅜” Tube Hose Barb

3 810-3244 Clamp, ⅝” Hose

4 811-1141 Tubing, Clear Plastic ⅜” ID (sold by the foot)

5 810-3243 Valve, In-line Check

6 810-3258 Adaptor, ⅜” Barb x ½” NPT Brass

7 813-0582 Nipple, ¼” NPT Close Brass

8 813-0449 Tee, ¼” NPT Brass

9 810-3573 Adaptor, Pipe to Hose ¼” NPT x ¾”

10 813-0502 Elbow, 90° Street NPT Brass

11 220-6016 Mount Solenoid

2-6

Page 32

2.6 Plumbing, Drain

YFG255 SERIES RETHERMALIZERS

CHAPTER 2: PARTS LIST

12

5

10

11

3

4

6

2

14

8

1

13

3

5

6

ITEM PART # COMPONENT

7

1 220-8186 Shield, Vapor Front

2 809-0374 Clamp, Hose

3 813-0138 Nipple

4 813-0202 Elbow, 90° 1”

5 813-0314 Tee, 1”

6 813-0525 Barb Fitting, 1” Pipe to Hose

7 816-0779 Hose, Drain 10.25”

8 816-0787 Hose, Drain 6.75”

9 823-7649 Plate Assembly

10 810-3569 Valve, Drain Brass 1” NPT

11 813-0266 Elbow, Street 1” NPT

12 816-0910 Hose, Drain 12.50”

13 823-6279 Handle, Drain Valve

14 816-0639 Cap, Vinyl Red

4

9

2-7

Page 33

YFG255 SERIES RETHERMALIZERS

CHAPTER 2: PARTS LIST

2.7 Plumbing, Gas Manifold

2

To burner

manifold.

15

11

3

12

5

8

1

7

9

10

14

13

6

4

ITEM PART # COMPONENT

1 807-3552 Valve, Gas Natural 24V Honeywell

807-3628 Valve, Gas Propane 24V Honeywell

2 200-1450 Bracket, Gas Valve Support

3 810-2808 Clamp, ¾”

4 810-3722 Clamp, ½” Pipe Heavy

5 813-0066 Elbow, ¾” NPT 90°

6 813-0096 Nipple, ½” x 6.00” NPT

7 813-0112 Nipple, ¾” x 2.00” NPT

8 813-0114 Nipple, ¾” x 2.50 NPT

9 813-0174 Union, ¾” NPT

10 813-0251 Nipple, ½” x 4.50 NPT

11 813-0257 Nipple, ¾” x 24.50” NPT

12 813-0382 Nipple, ¾” x 11.50” NPT

13 813-0387 Tee, ¾” NPT

14 813-0763 Bushing, ¾” x ½” ID NPT

15 810-2542 Flexline, ¾” NPT x 18.50"

* 810-0703 Gas Line ¼” x 20.00” (Gas Valve to Pilot Assy.)

* 810-0691 Vent Tube

* 810-2734 Gas Line, ¾” x 48.00" with Quick Disconnect

* Not illustrated

2-8

Page 34

YFG255 SERIES RETHERMALIZERS

CHAPTER 2: PARTS LIST

2.8 Fasteners

ITEM PART # COMPONENT

* 809-0428 Bolt, ¼-inch – 20 x ½-inch Hex Head ZP Tap

* 809-0429 Bolt, ¼-inch – 20 x 2.00-inch Hex Head ZP Tap

* 809-0514 Capscrew, 5/16-inch-18 NC Hex

* 809-0448 Clip, Tinnerman

* 826-1366 Nut, 4-40 Keps Hex (Pkg. of 25) (809-0237)

* 826-1358 Nut, 6-32 Keps Hex (Pkg. of 25) (809-0049)

* 809-0247 Nut, 8-32 Keps Hex

* 826-1376 Nut, 10-32 Keps Hex (Pkg. of 10) (809-0256)

* 809-0766 Nut, 10-32 Keps Hex SS

* 809-0581 Nut, ½ NPT Locking

* 809-0020 Nut Cap 10-24 NP

* 826-1372 Nut Grip ¼-inch 1/4-20 Hex NP (Pkg. of 10) (809-0059)

* 809-0417 Nut Flange ¼-inch 1/4-20 Serr

* 809-0535 Nut, "T" ¼-inch-20 x 7/16 SS

* 826-1389 Nut, Nylock ¼-inch-20 (Pkg. of 10) (809-0803)

* 809-0540 Nut, Lock ½-inch-13 Hex 2-Way ZP

* 813-0154 Plug, Pipe ⅛-inch Brass, Hex Head

* 826-1359 Screw, 4-40 x ¾-inch Slotted Round Head (Pkg. of 25) (809-0354)

* 826-1365 Screw, 6-32 x ⅜-inch Slot Head (Pkg. of 25) (809-0095)

* 809-0357 Screw, 6 x ⅜-inch Phillips Head NP

* 809-0359 Screw, 8 x ¼-inch Hex Washer Head

* 809-0360 Screw, 8 x ⅜-inch Hex Washer Slot Head

* 826-1371 Screw, 8 x ½-inch Hex Head ZP (Pkg. of 25) (809-0361)

* 809-0818 Screw, 8 x ½-inch Type B

* 809-0364 Screw, 8 x ⅝-inch Hex Washer Head ZP

* 809-0518 Screw, 8-32 x ⅜-inch Hex Washer Slotted Head SS

* 809-0104 Screw, 8-32 x ½-inch Slotted Head ZP

* 826-1363 Screw, 8-32 x ½-inch NP (Pkg. of 25) (809-0103)

* 826-1360 Screw, 10-24 x 5/16-inch Round Slot Head ZP (Pkg. of 25) (809-0024)

* 826-1330 Screw, 10-32 x ⅜-inch Slot Head SS (809-0117)

* 809-1003 Screw, 10-32 x ⅜-inch Hex Trim Head SS

* 826-1375 Screw, 10-32 x ¾-inch Hex Trim Head SS (Pkg. of 5) (809-0401)

* 809-1000 Screw, 10-32 x 1¼-inch Hex Sck C/S

* 826-1374 Screw, 10 x ½-inch Hex Head (Pkg. of 25) (809-0412)

* 809-0266 Screw, 10 x ½-inch Phillips Head ZP

* 809-0434 Screw, 10 x ⅜-inch Hex Washer Head NP

* 809-0123 Screw, 10 x ¾-inch Slot Head

* 826-1389 Screw, 1/4-20 x ¾-inch Hex Head ZP (Pkg. of 10) (809-0131)

* 809-0582 Washer ½ NPT Locking

* 809-0184 Washer, #10 LK ZP

* 809-0190 Washer, .625 X .275 X 40 Flat SS

* 809-0191 Washer, Lock 1/4 Spring ZP

* 809-0193 Washer, Flat 1/4 Nylon

* 809-0194 Washer, Flat 5/16 ZP

2-9

Page 35

THIS PAGE INTENTIONALLY LEFT BLANK

Page 36

Frymaster, L.L.C., 8700 Line Avenue, Shreveport, Louisiana 71106

TEL 1-318-865-1711 FAX (Tech Support) 1-318-219-7135

PRINTED IN THE UNITED STATES

SERVICE HOTLINE

1-800-551-8633

819-6900

05/2016

Loading...

Loading...