Page 1

SERVICE MANUAL

UNIVERSAL HOLDING CABINET (UHC)

MANUFACTURED BY

P.O. BOX 51000

SHREVEPORT, LOUISIANA

71135-1000

PHONE 1-318-865-1711

1-800-24 FRYER

Universal Holding Cabinet 1-1

Power Up 2-1

Operational Overview 3-1

Operator Mode 4-1

Timer Operation 5-1

Cook More Prompts 6-1

Switching Between Breakfast. Lunch, Clean Mode and Slot Off 7-1

Slot Temperature Display 8-1

Temperature Alarms 9-1

Product Selection 10-1

Program Mode 10-1

Page Selection 10-2

Meal Selection 10-3

Exiting Program Mode 10-5

Example of Production Selection Change 10-6

Entering and Editing Product Information 11-1

Entering Password 11-1

Entering Product Name 11-1

Entering Product Holding Time 11-3

Enter Meal Usage 11-4

Display Adjustments 12-1

Change Display Time 12-1

Change Display Intensity 12-1

Change F° to C°

Troubleshooting Guide 13-1

Diagnostic Tests 14-1

Service Procedures 15-1

Parts Lists, Exploded Views 16-1

Wiring Diagram 17-1

Appendices 18-1

Appendix A: Food Item Default Settings 18-1

Appendix B: Cleaning and Preventive Maintenance 18-2

Appendix C: RTD Resistance Chart 18-4

Appendix D: SOC for Universal Holding Cabinet 18-5

Appendix E: Production Charts 18-6

Appendix F: Quick Reference Guide 18-7

Appendix G: Typical Setups/Stacked Arrangements 18-8

12-1

Frymaster L.L.C., 8700 Line Avenue 71106, 5489 Campus Drive 71129

P.O. Box 51000, Shreveport, Louisiana 71135-1000

PHONE 318-865-1711 FAX 318-219-7135

PRINTED IN THE UNITED STATES SERVICE HOTLINE 1-800-24-FRYER 819-5551A 10/00

Page 2

1 Universal Holding Cabinet

The Frymaster Universal Holding Cabinet (UHC) developed and manufactured exclusively for

McDonald’s, is a short-term holding device to extend the freshness of a wide variety of cooked

products. The UHC meets all McDonald’s standards for safety, efficiency, and cleanliness.

1.1 Warranty Statement

A. Frymaster L.L.C. makes the following limited warranties to the original purchaser only for

this equipment and replacement parts:

1.1.1 Warranty Provisions – Universal Holding Cabinet

A. Frymaster L.L.C. warrants all components against defects in material and workmanship for a

period of two years.

B. All parts, with the exception of fuses, are warranted for two years after installation date of

cabinet

C. If any parts, except fuses, become defective during the first year after installation date,

Frymaster will also pay straight-time labor costs to replace the part, plus up to 100 miles/160

km of travel (50 miles/80 km each way).

1.1.2 Parts Return

A. All defective in-warranty parts must be returned to a Frymaster Authorized Factory Service

Center within 60 days for credit. After 60 days, no credit will be allowed.

1.2.3 Warranty Exclusions

• This warranty does not cover equipment which has been damaged due to misuse, abuse,

alteration, or accident such as:

• Improper or unauthorized repair;

• Failure to follow proper installation instructions and/or scheduled maintenance

procedures as prescribed in your MRC cards;

• Improper maintenance;

• Damage in shipment;

• Abnormal use;

• Removal, alteration, or obliteration of the rating plate;

This warranty also does not cover:

• Transportation or travel over 100 miles/160 km (50 miles/80 km each way), or travel

time over two hours;

• Overtime or holiday charges;

• Consequential damages (the cost of repairing or replacing other property that is

damaged), loss of time, profits, use or any other incidental damages of any kind.

1-1

Page 3

There are no implied warranties or merchantability or fitness for any particular use of purpose.

For international warranty, the above procedures apply, except that the customer is responsible for

freight and duty charges.

PARTS ORDERING AND SERVICE INFORMATION

Parts orders may be placed directl y with your local Frymaster Factory Authorized Service Center

(FASC)/Distributor. A list of Frymaster FASC/Distributors was included with the cabinet when

shipped from the factory. If you do not have access to this list, please contact the Frymaster Service

Department at 1-800-24-FRYER or 1-318-865-1711.

Please note that orders for wi re/plastic trays, stacking kits, carts and casters should be p laced

with your local Kitchen Equipment Supplier (KES). Frymaster does not supply these

accessory items.

To speed up your order, the following information is required:

Model Number_____________________________________

Serial Number_____________________________________

Voltage___________________________________________

Item Part Number___________________________________

Quantity Needed____________________________________

Service may be obtained by contacting your local Frymaster Authorized Service Cent er/Distributor.

Service information may be obtained by calling the Frymaster Service Department. The following

information will be needed in order to assist you quickly and efficiently:

Model Number_____________________________________

Serial Number______________________________________

Nature of the

Problem___________________________________________________________________

Also any other information which may be helpful in solving your service problem.

RETAIN AND STORE THIS MANUAL IN A SAFE PLACE FOR FUTURE USE.

1-2

Page 4

1.2 Product Trays

There are 3 product tray sizes. See Appendices A and C for specific product volumes and

recommended holding sizes and times. Use the tray that is designed for the specific product

described below:

A. 1/3-size plastic tray – Holds meat and egg products that are grilled (hamburger patties,

bacon, eggs, sausage, etc.) There are two important procedures to rememb er when storing

grilled products:

• The product should not be drained when picked up from the grill.

• The product is stacked when placed in the proper tray. 10-1 and sausage patties can be

stacked up to six high. Eggs (except scrambled), grilled chicken and 4-1 patties can be

stacked up to three high.

B. 1/2-size wire tray – holds fried products (McNuggets, McChicken, Filet-O-Fish, etc.)

Remember this important procedure when storing fried products:

• Fried products are to be placed on the wire rack. The rack should be placed on a crumb

tray. No tray liners are required for these trays.

C. Full-size plastic tray – holds baked products (biscuits, muffins, etc.) Follow these

procedures for baked products:

• After the biscuits have been removed from the biscuit oven, remove the wrapper and

open the cardboard box.

• Put a tray liner in the tray and slide the biscuits onto the liner. The biscuit trays can hold

up to 30 frozen biscuits, 20 scratch biscuits or 20 muffins.

Important Operational Tips

When placing a tray into the cabinet, make sure the slot line on the tray handle lines up with the edge

of the slot.

Discard cracked or damaged trays.

When removing portions from a tray, slide the tray only as far as needed, then quickly return the tray

to the slot line.

1-3

Page 5

1.3 Install Grill Clip

The grill clip is shipped in the accessory package and is

designed to hold the 1/3-size grill tray. It attaches to the

grill to make transfer from the grill to the UHC faster and

safer.

• Position the front of the grill clip under the lip

of the grill.

• Lower the back of the clip until the grooves rest

over the grill bar. The grill clip should firmly

seat on the front of the grill. If the clip doesn’t

fit snuggly, simply loosen the four nuts under

the clip and slide it in or out as needed to tighten

against the bar. Tighten the nuts after the clip is

properly adjusted.

The grill clip attaches to the grill and holds

grilled product in a UHC tray, making

transfer to the holding cabinet easier.

1.4 Installation of 4” Legs

CAUTION

Use caution when handling the cabinet or tilting the unit to/from the floor to install

the legs. Maneuvering the cabinet should be accomplished by at least tw o people.

A. Carefully place the Universal Holding Cabinet on its right side (direction is determined with

you facing the front of the unit), exposing the base of the cabinet.

B. Mount the leg pads to the bottom of the base using the 16-¼"-20 x ½" long screws and

lockwashers provided.

C. Screw the leg into the mounted leg pad until fully tight.

D. Carefully turn the UHC upright until the unit stands on its legs. Perform Step 2, Power Up.

IF THE UHC IS INSTALLED WITH THE COUNTERTOP OPTION, ENSURE THE

AREA WHERE THE UHC BASE AND COUNTERTOP MEET IS PROPERLY SEALED

WITH A FOOD GRADE TYPE SEALANT.

1-4

Page 6

2 Power Up

ALL ELECTRICALLY OPERATED APPLIANCES MUST BE ELECTRICALLY

GROUNDED IN ACCORDANCE WITH LOCAL CODES, OR IN THE ABSENCE OF

LOCAL CODES, WITH NATIONAL ELECTRIC CODE, ANSI/NFPA NO. 70-1990.

A. Power Requirements:

• Voltage – 208/240 VAC

• 2620 Watts @ 208V – 3420 Watts @ 240V

• Frequency – 50/60 Hertz

• Single Phase

• 20 amp Service

THIS APPLIANCE IS EQUIPPED WITH A THREE-PRONG GROUNDING PLUG FOR

YOUR PROTECTION AGAINST SHOCK HAZARD AND MUST BE PPLUGGED INTO A

PROPERLY GROUNDED THREE-PRONG RECEPTACLE. DO NOT CUT OR REMOVE

THE GROUNDING PRONG FROM THIS PLUG.

B. Plug the Universal Holding Cabinet into the power source.

C. Place the power switch in the ON position. All control displays will illuminate green

approximately 2 seconds after the power switch is activated.

D. Monitor the temperature of the slots. The time it takes the slot(s) to heat from ambient (room)

temperature to a 155°F (68°C) setpoint should be approximately 15 minutes. It should take

approximately 25 minutes to reach a 200°F (93°C) setpoint. If setpoint is not consistently

achieved within these limits, call your local Factory Authorized Service Center for repair.

2-1

Page 7

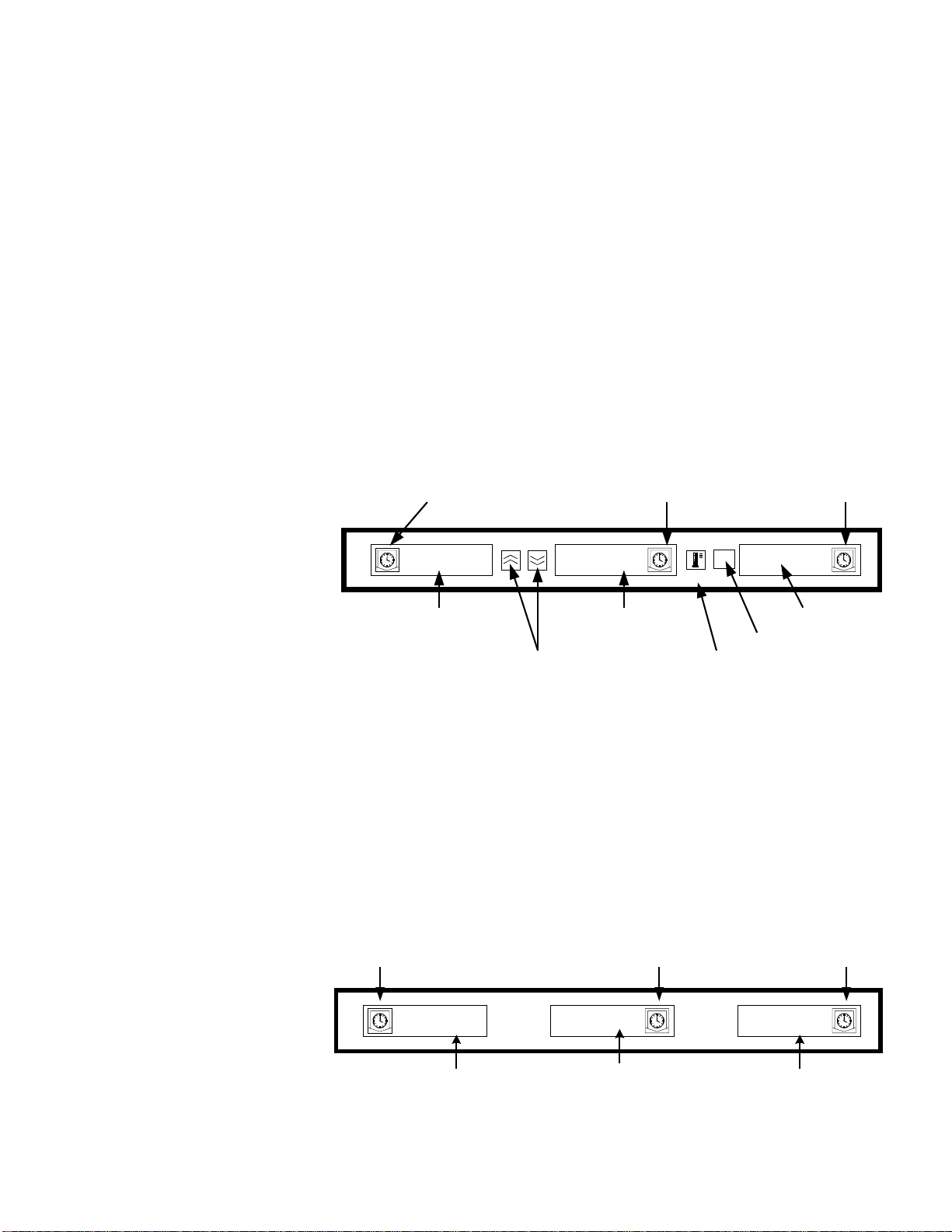

3 Operational Overview

The Universal Holding Cabinet (UHC) has either four slots that can hold up to three trays of product per slot

or two slots, which hold up to three trays. Each slot has a controller that indicates the holding time and

product selection for each tray position.

Universal Holding Cabinet (UHC)

The operator enters information into the controller via the display and keypad shown below. Each product

selection has a temperature setpoint and product holding time. All product timers run independently. The

slot temperature is controlled by the temperature setpoint of the leftmost product entry in each slot as

viewed from the front of the cabinet. Product selections that have a holding temperature different that

the leftmost product selection will not be available for entry into that slot’s configuration.

Most UHC’s have a front and rear display for each slot. All operator mode selections can be made from

either display. Program changes can only be made from the front display. A Special Point of Distribution

(SPOD) cabinet has only a front controller for each slot.

UHC Controller (Front Display and Keypad)

Timer keys (Left, Center, and

Left Timer Key

Center Timer Key

Right Timer Key

Right) start and stop the timer

associated with each tray

position. The timer keys also

turn off audible alarms.

Displays (Left, Center, and

Right) show product selection

and holding time for each tray

position. The displays also

provide programming

SAUS

SAUS SAUS

SAUSSAUS

Left Display

UP/DOWN Arrow Keys

SAUS SAUS

SAUSSAUS

Center Display

ENTER

MENU

PAGE

Temperature/Enter

SAUS

SAUSSAUS

Right Display

Menu Key

/Page Key

information in program mode.

MENU key is used to select meal transitions (breakfast to lunch), Clean Mode operation and to turn

individual slots on or off. The MENU key also provides access to program mode.

TEMPERATURE/ENTER/PAGE key has three functions. 1) Display slot temperature information; 2)

Enter operational changes; and 3) Select Page parameters in program mode.

Up and Down ARROW keys are used to increase/decrease variables or change selections.

UHC Controller (Rear

Display and Keypad,

Traditional UHC Only)

Left Timer Key

Center Timer Key

SAUS SAUS SAUS

Left Display

Center Display Right Display

3-1

Right Timer Key

Page 8

4 Operator Mode

Operator Mode is the normal operating mode of the controller when all slots are at the proper

temperature and no alarm conditions exist. Product information and holding time is displayed.

4.1 Display of Product Information

In Operator Mode the slot display indicates the following:

1. The product selection for a tray location.

2. The holding time remaining (in minutes) for active timers.

An active timer alternately displays the product selection and the time remaining. Inactive timers

display only product selection.

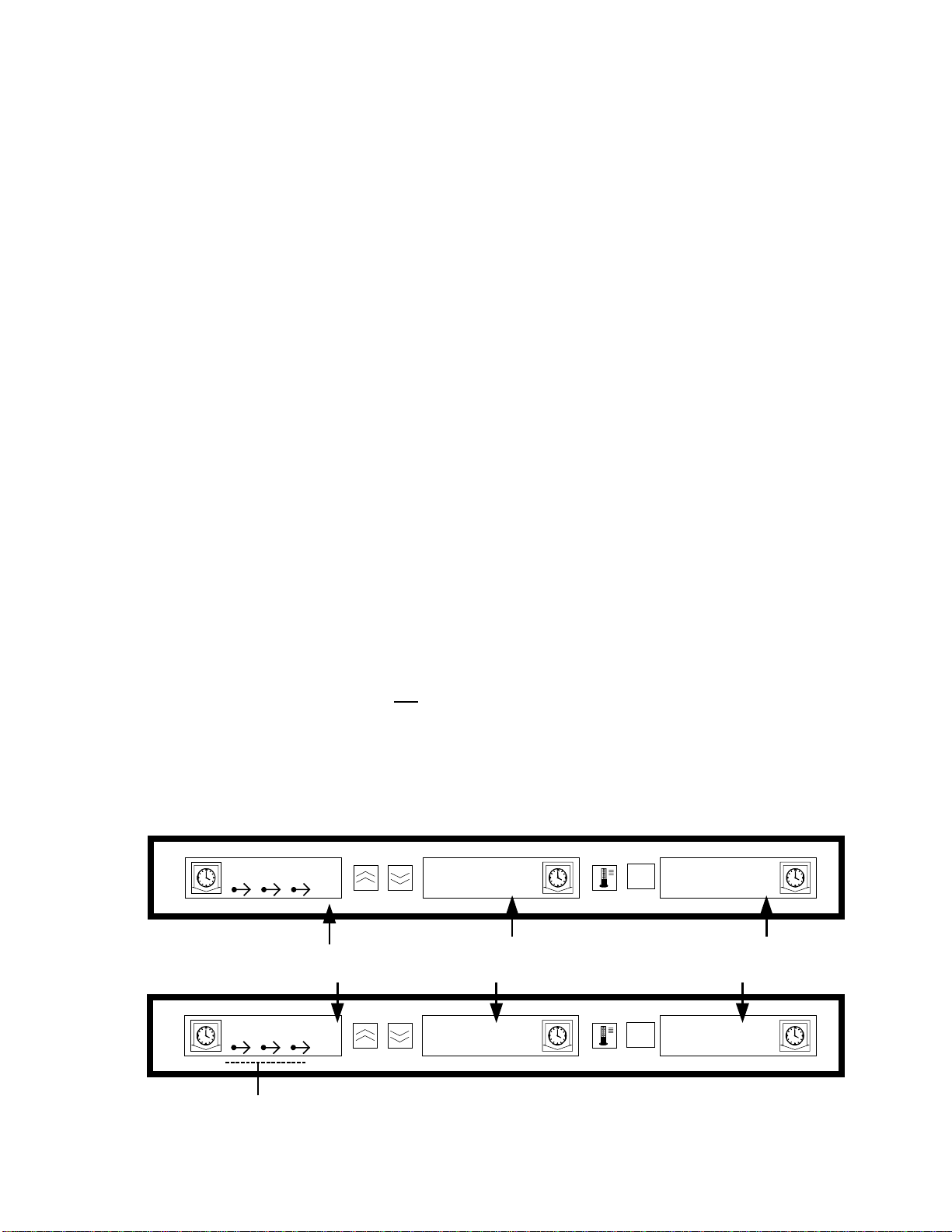

4.2 Product Information and the Use First Display

The Operator Mode indicates product selection and holding time status by changing the display

intensity.

The “Use First Display” indicates the product with the least amount of holding time remaining.

There are two levels of display intensity used to indicate product status.

1. Brighter level of display intensity and running dots indicate the “use first” product

selection.

2. Lower level of display intensity indicates:

a. An active timer that is not the product selection with the least holding time remaining.

b. An inactive timer where only the product selection is displayed.

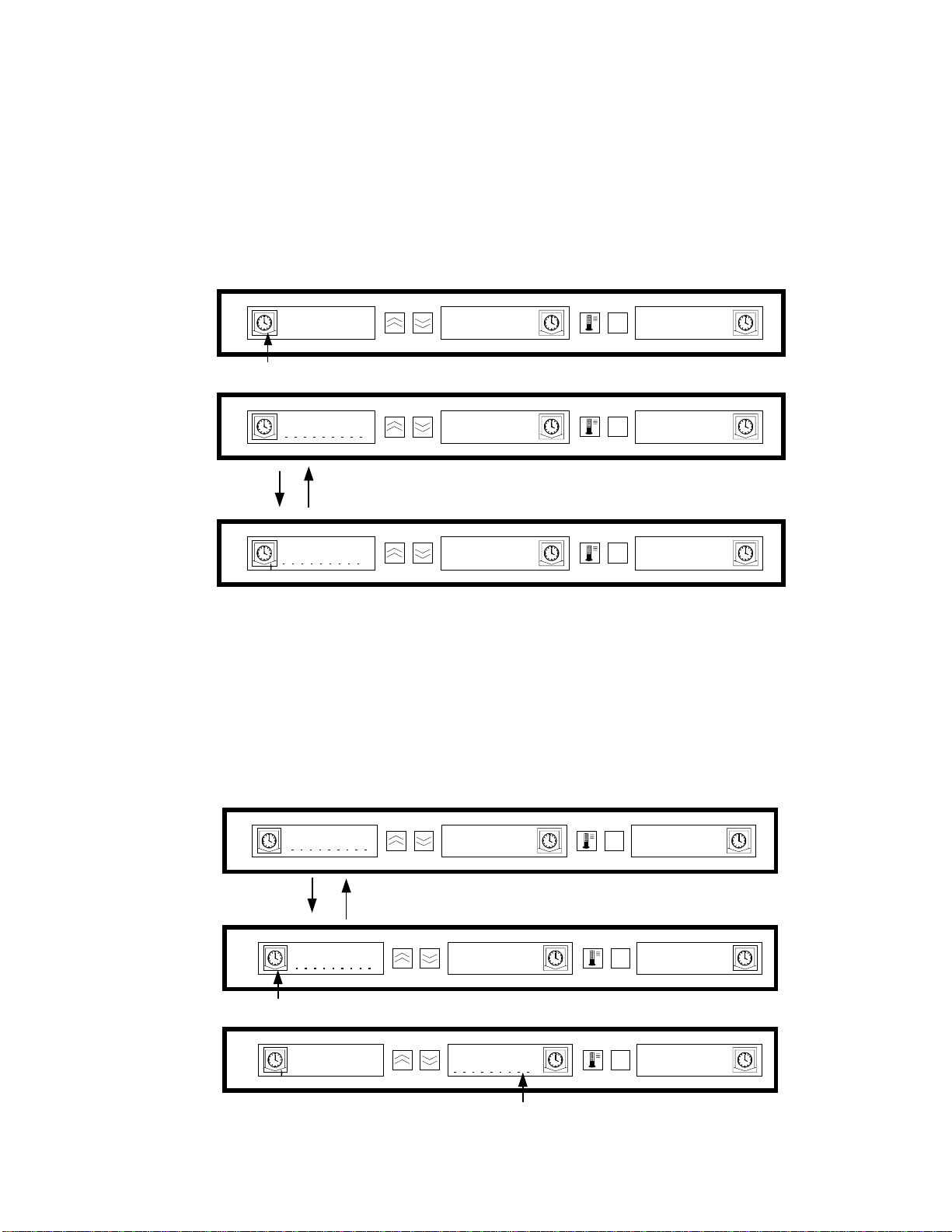

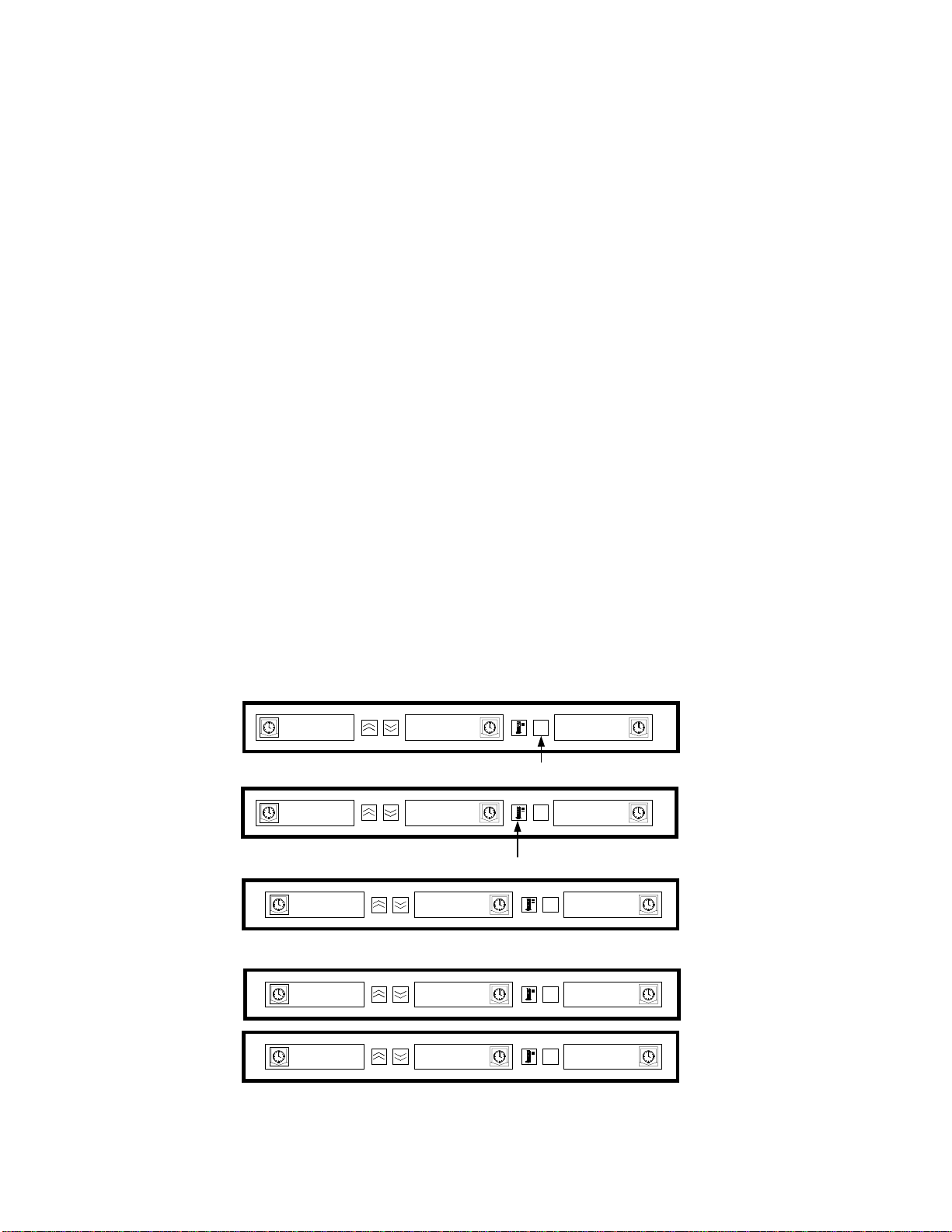

Timer Status Indicators

SAUS

SAUS

SAUSSAUS

Use-First Timer

Higher Intensity

12

12

1212

ENTER

PAGE

ENTER

PAGE

MENU

SAUS

SAUSSAUS

Inactive Timer

Lower Intensity

MENU

SAUS

SAUSSAUS

SAUS

SAUS SAUS

SAUSSAUS

Active Timer

Lower Intensity

20

20 SAUS

2020

Running Dots

4-1

Page 9

5 Timer Operation

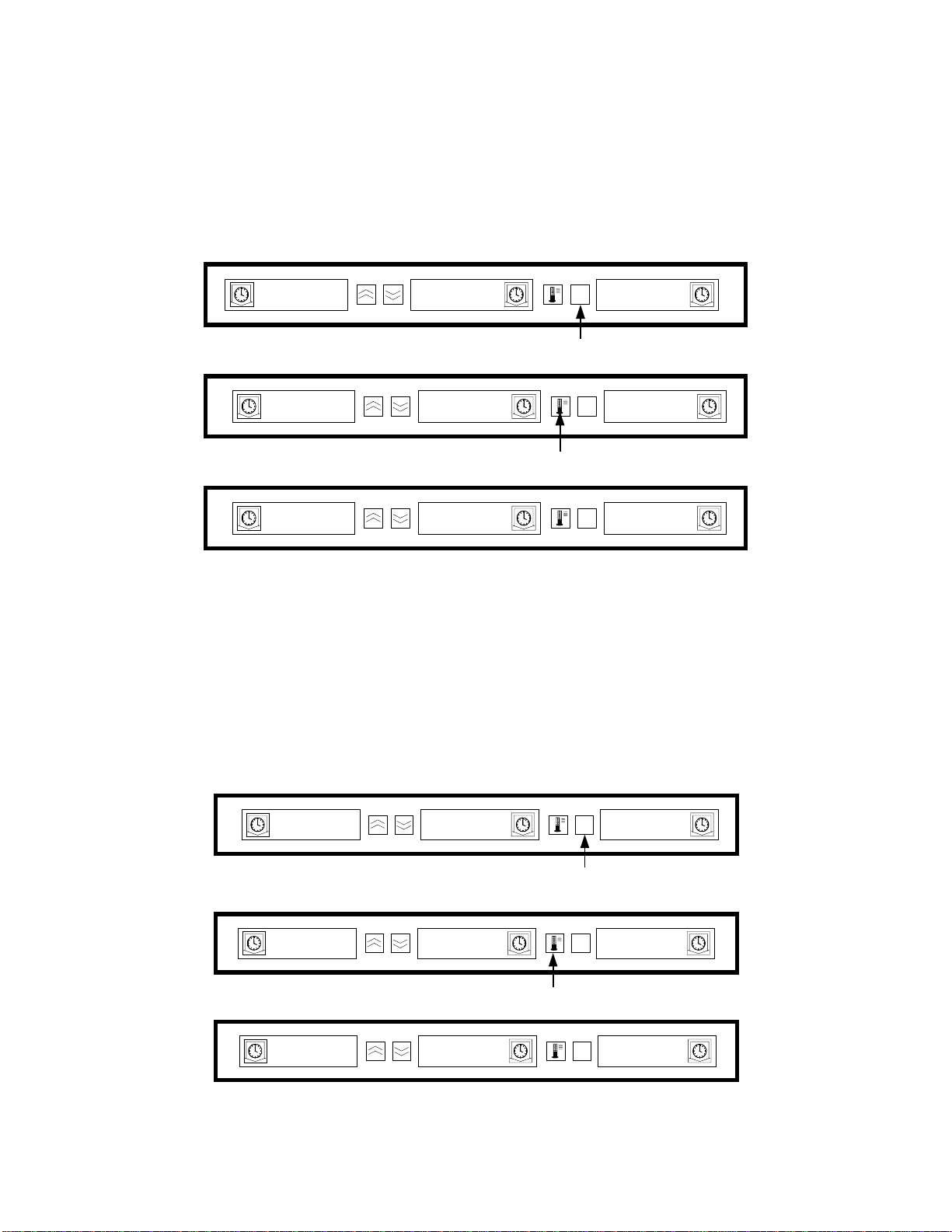

5.1 Starting A Timer

Press the Timer key above the tray position to start a timer. The timer will time down from a

preset value and alternately display product selection and the holding time remaining. If more than

one tray of a product selection is timing, the location of the product with the least remaining holding

time is indicated by the Use First display status.

ENTER

SAUS

SAUS SAUS

SAUSSAUS

Press TIMER key to start a timer

60

60 SAUS

6060

Active display alternately indicates

holding time and product selection

SAUS

SAUS SAUS

SAUSSAUS

SAUS SAUS

SAUSSAUS

SAUS SAUS

SAUSSAUS

SAUS SAUS

SAUSSAUS

PAGE

ENTER

PAGE

ENTER

PAGE

MENU

MENU

MENU

SAUS

SAUSSAUS

SAUS

SAUSSAUS

SAUS

SAUSSAUS

5.2 Stopping A Timer

Press the Timer key above the slot position to turn off an active timer. The timer stops timing

and the display changes to the inactive timer status. If more than one tray of a product selection is

timing, use first indication changes to next active timer.

Timer to Stop

SAUS

SAUS SAUS

SAUSSAUS

Active display alter n ately indicates

holding time and product selection

19

19 24

1919

Press TIMER key to stop timer

SAUS

SAUS SAUS

SAUSSAUS

Next Shortest Time

ENTER

SAUS SAUS

SAUSSAUS

24 SAUS

2424

SAUS SAUS

SAUSSAUS

PAGE

ENTER

PAGE

ENTER

PAGE

Inactive Timer

MENU

SAUS

SAUSSAUS

MENU

MENU

SAUS

SAUSSAUS

SAUS

SAUSSAUS

Use-First indication changes to next

active timer

5-1

Page 10

5.3 Timing Out

Time out indication alerts the operator that the product holding time has expired. When the

holding time remaining reaches zero an audible alarm sounds and the display indicates -00-

-00-. All

-00--00-

other active displays in the cabinet will switch to the lowest intensity level until the audible alarm is

turned off.

Press the Timer key of the timed-out timer to clear th e timer an d turn off the audibl e alarm. If

other timers in the cabinet have timed out, the audible alarm will remain on until all timers are

cleared. When all timers are cleared, active timers return to normal status. Use First status is

switched to the next timer with the least holding time remaining.

Timed Out Timer Next Shortest Time Inactive Timer

ENTER

-00-

-00-

-00--00-

Press TIMER key to turn of audible alarm

SAUS

SAUS

SAUS

SAUS

SAUSSAUS

PAGE

ENTER

PAGE

MENU

MENU

SAUS

SAUS

Display returns

to inactive

Use first status changes

to the next active timer.

5.4 Buffer Timer

This feature allows an operator to adjust the holding time for a specified product by pressing the

timer key. This means product can be transferred from a remote holding cabinet and the remaining

hold time entered into another UHC. Time adjustments are in 5-minute increments.

ENTER

60

6060

Initial Timer Display:

saus

saus

saussaus

Shown when timer

PAGE

MENU

saus

saus60

saussaus

is pressed after placing product in slot.

ENTER

Buffer Timer:

saus

saus

30

30

3030

saussaus

Pressing the timer button a

MENU

PAGE

saus

saus

saussaus

second time within three seconds allows 5minute decrease in holding time.

5-2

Page 11

5.4 Buffer Timer (cont.)

When the "Use First" tray of a product is placed in the cabinet, the product timer is activated by

pressing the corresponding timer key. The display immediately indicates the maximum holding time

for the product and changes to Display Intensity three (brightest). If the timer key is pressed within

3 seconds of activating the timer, the product holding time will decrease by 5 minutes for each key

press. If no timer key press occurs within 3 seconds, the display then alternately displays the

remaining holding time and product mnemonic.

The Timer Display Time (TIMR TIME) and Product Display Time (PROD TIME) v alues det ermine

how long (in seconds) that each message is displayed. Default settings for these values are 5

seconds and 1 second respectively.

To decrease the preset time, the holding time for each product, press the timer key and th e displayed

time will decrease in 5-minute increments each time the key is pressed. The timer key must be

pressed within 3 seconds. If you wait longer than three seconds, the timer will reset. Preset times are

the established holding times for each product. The Buffer Timer Feature is extremely useful when

transferring product from another holding cabinet.

5-3

Page 12

6 Cook More Prompts

The Cook More Prompts feature provides the operator with visual and audible notification that the

last tray of a specific food product will be expiring soon and it is time to cook more. This feature is

programmable, in one-minute increments, at the restaurant level.

ENTER

PAGE

ENTER

PAGE

MENU

MENU

saus

sauscook

saussaus

30

30cook

3030

more

more

cook

cookcook

When the holding time of a product equals a preset "cook more" time, an audible

alarm sounds for 3 seconds and the display will alternately display: the remaining

holding time / product mnemonic / COOK MORE.

- No acknowledgment of the audible alarm is required. It occurs only to get the

attention of the operator.

muff

muff

muffmuff

moremore

cook

cookcook

Cook More:

After accessing the Cook More feature, use the UP and DOWN arrow keys to

change the cook more time.

To change the cook more

- Press and hold the MENU key for 5 seconds

- Press the PAGE key to scroll to View Page

- Press MENU key to scroll to the Security Lock

- Press the Up and Down arrow keys to enter the manager security code 247

- Press the PAGE key to scroll to the Cook Page

- Press the MENU key to scroll to the Product Selection

- Press the Up and Down arrow keys to change the product cook more time

- Press and hold the MENU key for 5 seconds to return to normal operation

cook more time:

cook morecook more

6-1

Page 13

7 Switching Between Breakfast, Lunch, Clean Mode and Slot On/Off

Pressing the MENU key scrolls the following information for each slot.

1. The inactive meal product selection (breakfast or lunch).

2. Clean Mode.

3. Slot On/Off status.

Pressing the MENU key again returns the display to Operator Mode.

7.1 Selecting Breakfast and Lunch

To establish the breakfast and/or lunch menu, determine the type and number of product tray(s) to

use. The following is the established configuration of trays and products:

1/3-size plastic tray – holds meat and egg products that are grilled (hamburger patties,

bacon, eggs, sausage, etc.). Each slot can hold up to three trays of this type.

1/2 size plastic tray with wire insert – holds breaded fried products (McNuggets,

McChicken, Filet-O-Fish, etc.). Each slot can hold up to two trays of this type.

Full-size plastic tray – holds baked products (biscuits, muffins, etc.). Each slot can hold one

tray of this type.

To change the product selection of a slot from Breakfast to Lunch, press the MENU key to display

the lunch product selections. Press the ENTER key to activate the meal selection. If the ENTER

key is not pressed within 5 seconds, the product selection will return to the Breakfast meal selection.

Changing Meal Selection

ENTER

SAUS

NUGG

NUGG NUGG

NUGGNUGG

NUGG

NUGG NUGG

NUGGNUGG

NUGG

NUGGNUGG

NUGG

NUGGNUGG

Press ENTER key to enter meal selection

and return to normal display mode.

MENU

MENU

MENU

SAUSSAUS

NUGG

NUGG

NUGGNUGG

NUGG

NUGG

NUGGNUGG

PAGE

Press MENU key to display

inactive meal selection

ENTER

PAGE

ENTER

PAGE

NOTE: Active timers will not change to the new meal selection until the timer(s) are stopped or

timed out and reset. Active timer(s) are stopped by pressing the timer key. The default menu at

start up is for breakfast items.

7-1

Page 14

7.1 Selecting Breakfast and Lunch (cont.)

NOTE: Active timers will not change to the new meal selection until the timer(s) are stopped or

timed out and reset. Active timer(s) are stopped by pressing the timer key. The Breakfast menu is

the default at power up.

If the product selection for the meal has a holding temperature different that the curr ent meal, a hi gh

or low temperature-alarm message displays to alert the operator that the holding temperature is being

changed. To turn off the audible alarm pr ess any Timer Key. The display alternately indicates the

product selection and the alarm message until the slot temperature is within the preset limits. The

alarm message automatically resets when the slot temperature is within the preset limits.

To change the product selection of a slot from Lunch to Breakfast, press the MENU key to display

the Breakfast product selections. Press the ENTER key to activate the meal selection. If the ENTER

key is not pressed within 5 seconds the product selection will return to the Lunch meal selection.

7.2 Clean Mode

Clean Mode changes the temperature setpoint of all slots in the cabinet to 125°F (52°C).

Starting Clean Mode

To start the Clean Mode press the MENU key to scroll to the Clean Mode message CLN MODE.

Press the ENTER key to activate the Clean Mode. All slots in the cabinet will change to Clean

Mode. If the ENTER key is not pressed within 5 seconds, the product selection will return to the

previous meal selection. If the slot temperature is above 125°F (52°C), the display will alternately

indicate SLOT CLN MODE and NOT SAFE YET. Th e display will indicate SAFE TO CLN

when the slot temperature is 125°F (52°C).

ENTER

SAUS

Press MENU key to scroll to clean mode message

CLN

CLN

CLNCLN

Press ENTER key to enter start Clean Mode

SLOT

SLOT CLN

SLOTSLOT

Display alternates messages if temperature is above safe level.

NOT

NOT SAFE

NOTNOT

CLN

CLNCLN

SAFE

SAFESAFE

PAGE

ENTER

PAGE

ENTER

PAGE

ENTER

PAGE

MENU

MENU

MENU

MENU

SAUSSAUS

MODE

MODE

MODEMODE

MODE

MODE

MODEMODE

YET

YET

YETYET

ENTER

MENU

CLN

CLN

SAFE

SAFE TO

SAFESAFE

To exit Clean Mode, press the MENU key to display the Clean Mode message. Press ENTER to exit

the Clean Mode and return to normal operation. The slot will alternately display SLOT TEMP LOW

and the product selection until the temperature is within normal operating limits. If the ENTER key is

not pressed within 5 seconds, the slot will return to the Clean Mode.

TO

TOTO

PAGE

CLNCLN

7-2

Page 15

Exit Clean Mode

To exit Clean Mode press the MENU Key to display the Clean Mode message. Press ENTER to

exit the Clean Mode and return to normal operation. The Slot will alternately display SLOT

TEMP LOW and the product selection until the temperature is within normal operating limits. If

the ENTER key is not pressed within 5 seconds the slot will return to the Clean Mode.

ENTER

TO

CLN

CLN

EXIT

EXIT

EXITEXIT

SAUS

SAUS SAUS

SAUSSAUS

CLNCLN

SAUS

SAUSSAUS

Press MENU key to display exit

CLN Mode message

Press ENTER key to exit Clean Mode and

return to normal display mode

PAGE

ENTER

ENTER

PAGE

PAGE

MENU

MENU

MENU

CLNSAFE

MODE

MODE

MODEMODE

SAUS

SAUS

SAUSSAUS

7.3 Slot On/Off

To turn a slot off, press the MENU key to scroll to the slot off message TURN SLOT OFF.

Press the ENTER key to enter the selection. The display will read SLOT IS OFF. If the ENTER

key is not pressed within 5 seconds, the product selection returns to the Operator Mode.

Turning Slot Off

ENTER

SAUS

SAUS

SAUS

SAUSSAUS

EXIT

EXIT

EXITEXIT

SLOT

SLOT 15

SLOTSLOT

SAUSSAUS

CLN

CLN

CLNCLN

15

1515

Press MENU key to scro ll to Slo t

Off message.

Press ENTER key to turn slot off.

PAGE

ENTER

PAGE

ENTER

PAGE

MENU

MENU

MENU

SAUS

SAUSSAUS

SAUSSAUS

MODE

MODE

MODEMODE

OFF

OFF

OFFOFF

7-3

Page 16

Turning Slot On To turn a slot on, press the MENU key to scroll to the slot on message (TURN SLOT ON). Press the

ENTER key to enter the selection and return to the Operator Mode. The slot alternately displays

SLOT TEMP LOW and the product selection until the temperature is within normal operating limits.

If the ENTER key is not pressed within 5 seconds the slot returns to the SLOT OFF status.

ENTER

15

15

SLOT

SLOTSLOT

TURN

TURN

TURNTURN

SAUS

SAUS SAUS

SAUSSAUS

1515

SLOT

SLOT

SLOTSLOT

SAUS

SAUSSAUS

Press MENU key to scroll to Slot

ON message.

Press ENTER key to turn slot ON and

return to normal display mode.

PAGE

ENTER

PAGE

ENTER

PAGE

MENU

MENU

MENU

OFF

OFFSLOT

OFFOFF

ON

ON

ONON

SAUS

SAUS

SAUSSAUS

7-4

Page 17

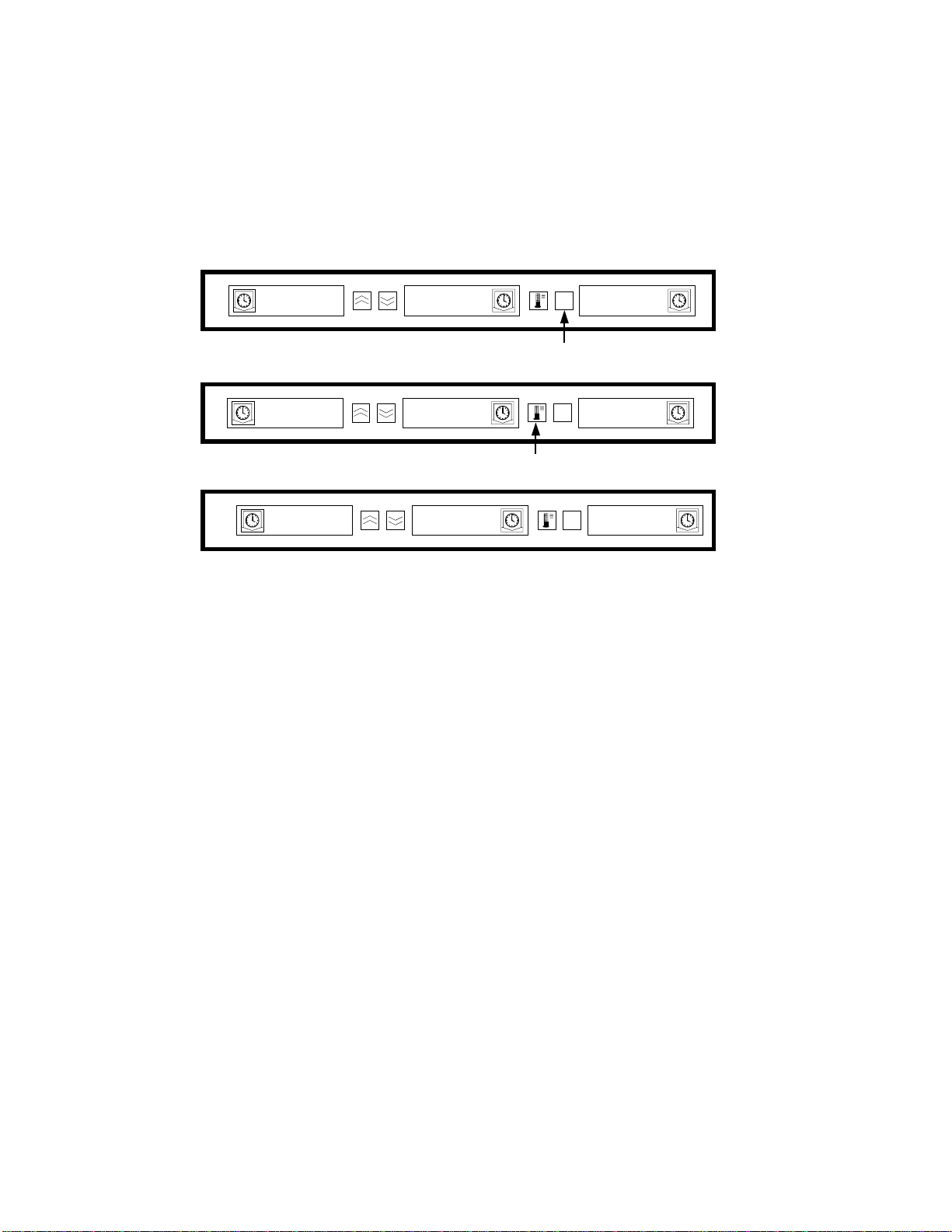

8 Displaying Slot Temperature Information (Temperature Key)

Pressing the Temperature/ENTER/PAGE key scrolls the following temperature information for

each slot.

1. Top plate temperature

2. Bottom plate temperature

3. Top plate setpoint

4. Bottom plate setpoint

Pressing the ENTER key again will return the display to Operator Mode. The display will

automatically return to Operator Mode if no key is pressed for 5 seconds.

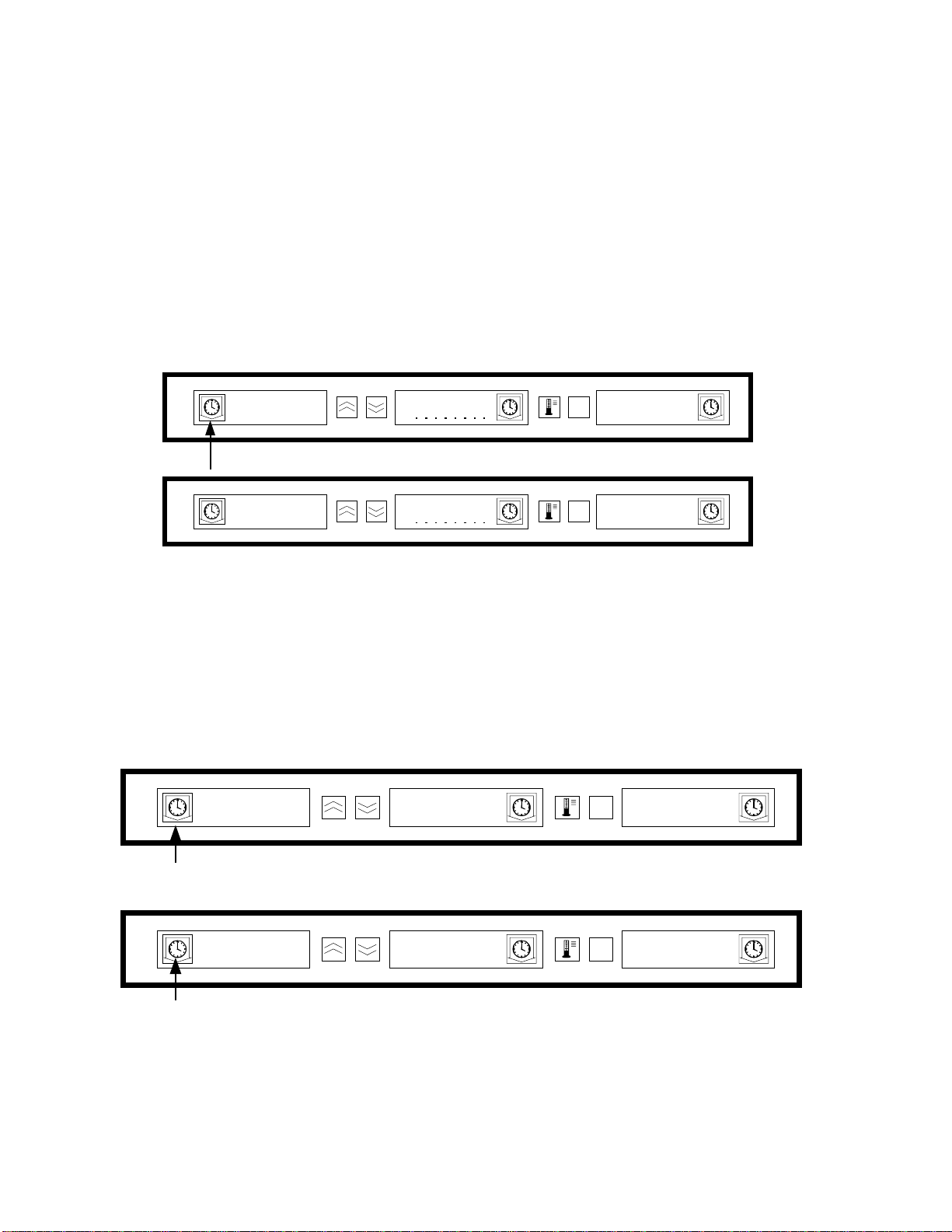

Shelf Temperature Display

ENTER

SAUS

SAUSSAUS

SAUS

SAUS

SAUSSAUS

Press temperature key to display top plate

temperature.

PAGE

MENU

SAUS

SAUSSAUS

SAUSSAUS

TEMP

TEMP

TOP

TOP

TOPTOP

BOT

BOT TEMP

BOTBOT

top

top tset

toptop

saus

saus saus

saussaus

TEMPTEMP

Press temperature key to display bottom

plate temperature.

TEMP

TEMPTEMP

Press temperature k ey to display top plate

setpoint temperature.

tset

tsettset

Press temperature key to display bottom

plate setpoint temperat ure.

saus

saussaus

Press temperat ure key to return to normal

display mode.

ENTER

PAGE

ENTER

PAGE

ENTER

PAGE

ENTER

PAGE

MENU

MENU

MENU

MENU

160

160

160160

160

160

160160

160

160

160160

saus

saus

saussaus

SAUS

SAUS saus

SAUSSAUS

saus

saussaus

8-1

ENTER

PAGE

MENU

saus

saus

saussaus

Page 18

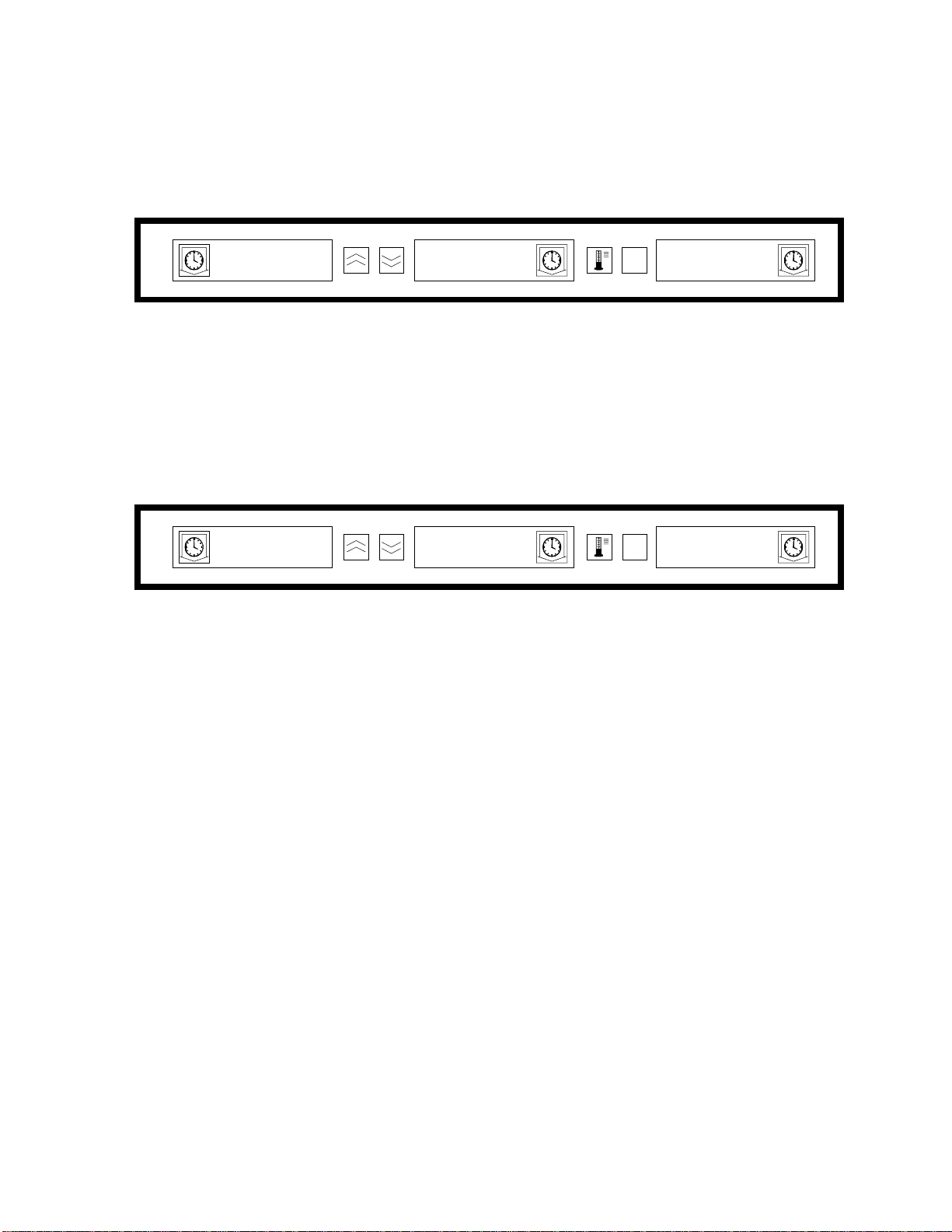

9 Temperature Alarms

There are five temperature alarm functions:

1. High Temperature Alarm

2. Low Temperature Alarm

3. FDA Alarm

4. Sensor Alarm

5. Rise Time Alarm

If alarm conditions occur an audible alarm will sound and the displays will alternately display the

product selection and alarm message. Timers cannot be started when a slot is in alarm condition.

9.1 High and Low Temperature Alarm

If the slot temperature is above or below the preset limits for product selection, the controller will

enter the High or Low alarm condition. The audible alarm will sound and the alarm message will

read either SLOT TEMP HIGH or SLOT TEMP LOW.

To turn off the audible alarm , pr ess any Timer key. The displays will alternately display the product

selection and the alarm message until the slot temperature is within the preset limits. The alarm

message will be displayed until the slot temperature is within the preset limits.

Alarm Display Messages

ENTER

TEMP

TEMP

SLOT

SLOTSLOT

Press any TIMER key to turn off the audible alarm.

SLOT

SLOT

SLOTSLOT

Press any TIMER key to turn off the audible alarm.

TEMPTEMP

TEMP

TEMP

TEMPTEMP

PAGE

ENTER

PAGE

MENU

MENU

LOW

LOWSLOT

LOWLOW

HIGH

HIGH

HIGHHIGH

NOTE: The low temperature audible alarm is inhibited at power-up. The SLOT TEMP LOW

message will be displayed until the slot temperature is within the preset limits.

9-1

Page 19

9.2 Food and Drug Administration (FDA) Alarm

The FDA Alarm indicates the slot temperature is below the preset limit to hold the product. The

audible alarm will sound and the alarm message will read TEMP UNDR FDA. Active timers are

automatically reset.

To turn off the audible alarm, press an y Timer key. The alarm message will remain until the slot

temperature is within the preset limits. If no keys are pressed the audible alarm and alarm message

will remain. A Timer Key must be pressed to clear a FDA Alarm.

ENTER

TEMP

TEMPTEMP

UNDR

UNDR

UNDRUNDR

PAGE

MENU

FDA

FDATEMP

FDAFDA

Press any TIMER key to turn off the audible alarm.

9.3 Sensor Range Alarm

The Sensor Fail alarm indicates a sensor temperature value above or below the operating limit 90°F

(32°C) to 250°F (121 °C) of the slot. The alarm message is SENS ALRM.

To turn off the audible alarm, press an y Timer key. The alarm message will be displayed until the

slot temperature is within the operating limits. Power to the slot’s heaters will be turned off until the

sensor is repaired. Service will be required to correct a sensor alarm.

ENTER

SENS

SENSSENS

MENU

PAGE

ALRM

ALRMSENS

ALRMALRM

Press any TIMER key to turn off the audible alarm.

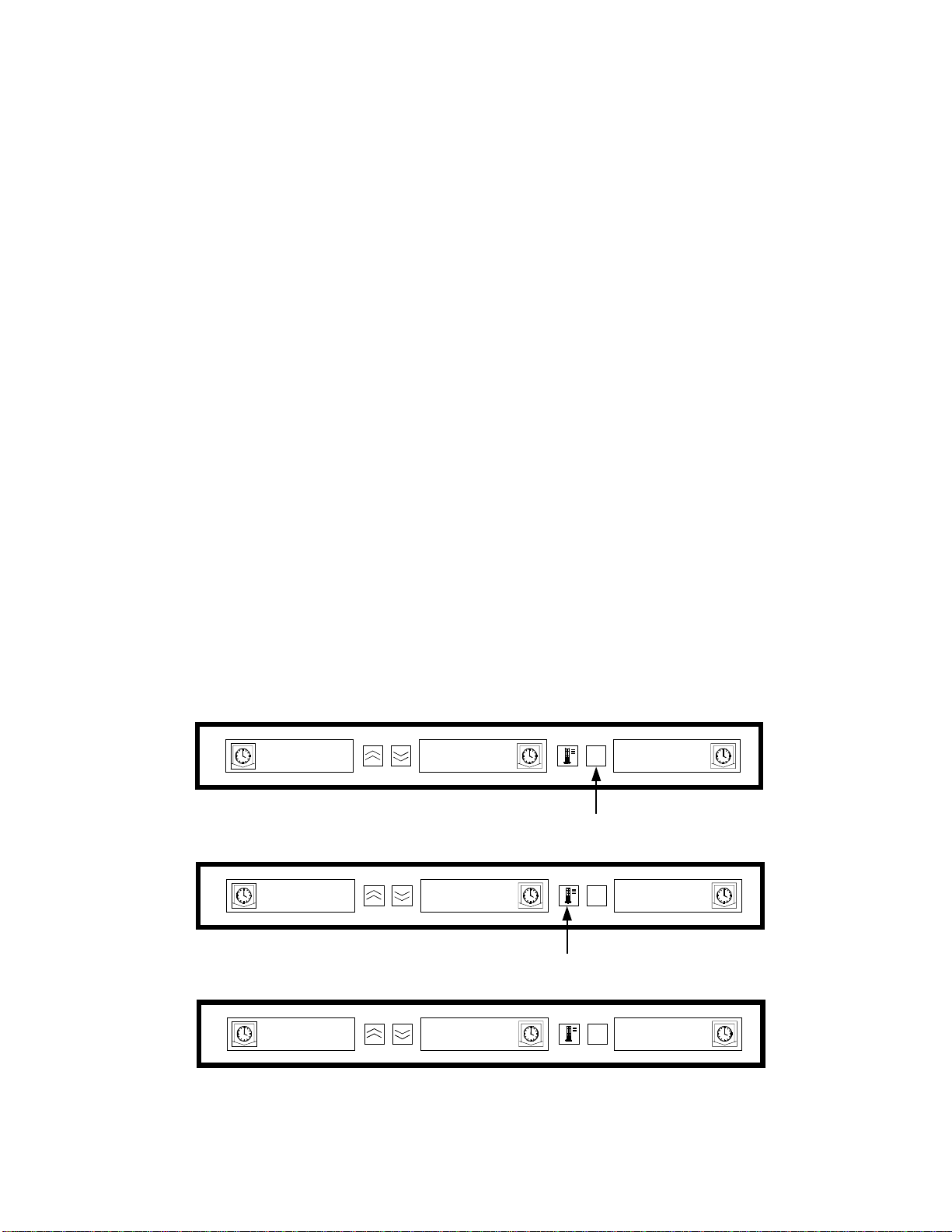

9.4 Rise Time Alarm

The Rise Time Alarm indicates that t he slot temp er ature fail ed to r each operating temperature w it hi n

the preset time limits of the system at power up.

To turn off the audible alarm, press any Timer key. Service will be required to correct a Rise

Time Alarm.

ENTER

SLOT

SLOTSLOT

RISE

RISE RATE

RISERISE

PAGE

MENU

RATESLOT

RATERA TE

Press any TIMER key to turn off the audible alarm and clear alarm message.

9-2

Page 20

9.5 Additional Out of Tolerance Displays

9.5.1 HHHH

HHHH is the display indicates a sensor error. Service will be required to correct this condition.

9.5.2 LLLL

LLLL in the display indicates either a senso r error or a slot that is below 50°F (10°C). Allow the

slot to operate for 30 minutes. If the LLLL remains, service will be required.

9-3

Page 21

10 Product Selection For Each Slot

10.1 Program Mode

The following is the correct locations to program the slot controls based on the configuration of trays

and products:

• 1/3-size plastic tray – Since each slot can accommodat e 3 trays, all displays can be p ro grammed

for a product. Remember, the temperature parameters established by the left display product will

be in effect for the entire slot, but the timing and product settings can be different for each

display within a slot.

• 1/2-size plastic tray with wire insert – Since each slot can only accommodate two trays, the left

and right displays will be used for controlling/monitoring the products. The center display

should be voided by selecting NONE; the left and right displays should be active with selected

product. Again, the temperature parameters established by the left display product will be in

effect for the right display but the timing and product settings can be different for each display

within a slot.

• Full-size plastic tray – Since each slot can accommodate one tray, the center display will be

used to establish product parameters. The center display establishes the product parameter for the

slot. The left and right displays should be voided by choosing NONE with only the center

display active with the selected product.

Program Mode is used to select the products for each slot location. All selections are accomplished

through simple PAGE and MENU selections. Each slot position has a page of configuration menus.

The top slot in the cabinet is Slot 1. The PAGE key is used to select slots 1 – 4. The MENU key

selects the configuration menu items (meal and tray location). Th e Up/Down arrow keys are used to

select the available product selections for each meal. To enter the pro gram mode, press and hold the

MENU key for at least 5 seconds. The display will indicate the PROG MODE message.

To Enter Program Mode

ENTER

SAUS

SAUSSAUS

SAUS

SAUS

SAUSSAUS

PAGE

MENU

SAUS

SAUSSAUS

SAUSSAUS

Press and hold the MENU key for at least 5

seconds to enter Program mode

ENTER

PROG

PROG

PROGPROG

MENU

PAGE

MODE

MODE

MODEMODE

10-1

Page 22

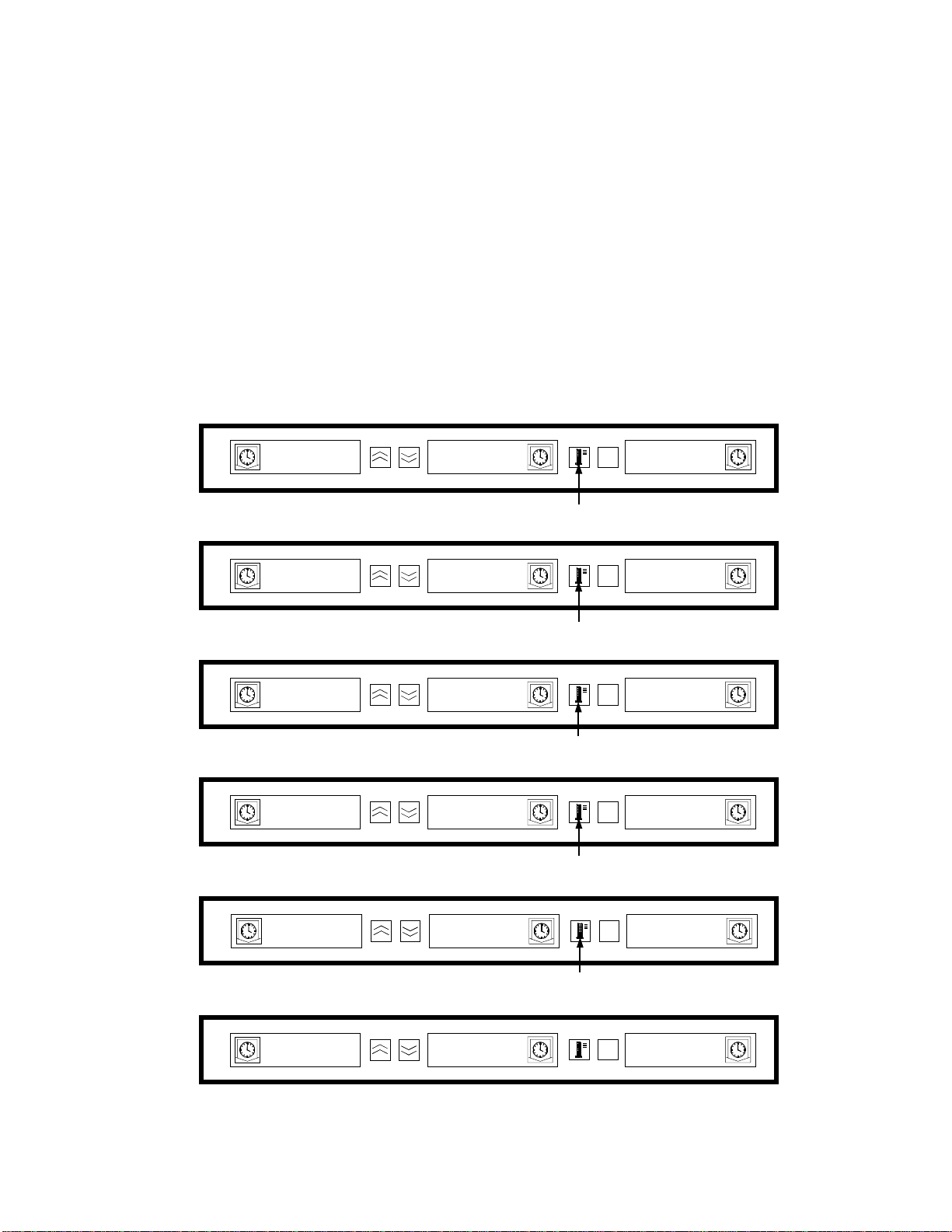

10.2 Page Selection

Each slot contains product selections for each meal (Breakfast or Lunch). To select the page press

the PAGE key to scroll to the desired slot 1 – 4.

To Select the Slot Page:

ENTER

PROG

PROGPROG

MENU

PAGE

MODE

MODEPROG

MODEMODE

Press the PAGE key to scroll to

slot page selections.

ENTER

SLOT

SLOT

SLOTSLOT

1111

MENU

PAGE

Press the PAGE key to scroll slot

page selections.

slot

slot 2222

slotslot

slot

slot 3333

slotslot

slot

slot 4444

slotslot

ENTER

Press ENTER key to turn slot ON and

return to normal display mode.

MENU

PAGE

Press the PAGE key to scroll slot

page selections.

ENTER

MENU

PAGE

Press the PAGE key to scroll slot

page selections.

ENTER

MENU

PAGE

10-2

Page 23

10.3 Meal Selection and Tray Position

Pressing the MENU key scrolls the meal and tray position in the left and center displays. The current

product selection is indicated in the right display.

To Select the Meal and Tray Position:

ENTER

SLOT

SLOT

SLOTSLOT

1111

MENU

PAGE

Press MENU key to scroll to

meal selection and tray position.

ENTER

BFST

BFST

BFSTBFST

LEFT

LEFT

LEFTLEFT

MENU

PAGE

saus

saus

saussaus

Meal Selection Tray position

bfst

bfst cent

bfstbfst

cent

centcent

Meal Selection Tray position

bfst

bfst rght

bfstbfst

rght

rghtrght

Meal Selection Tray position

lnch

lnch left

lnchlnch

left

leftleft

Meal Selection Tray position

lnch

lnch cent

lnchlnch

cent

centcent

Press MENU key to scroll to

meal selection and tray position.

ENTER

MENU

PAGE

SAUS

SAUS

SAUSSAUS

Press MENU key to scroll to

meal selection and tray position.

ENTER

MENU

PAGE

saus

saus

saussaus

Press MENU key to sc roll to

meal selection and tray position.

ENTER

MENU

PAGE

10-1

10-1

10-110-1

Press MENU key to scroll to

meal selection and tray position.

ENTER

MENU

PAGE

10-1

10-1

10-110-1

Meal Selection Tray position

rght

rght 10-1

lnch

lnch

lnchlnch

rghtrght

Meal Selection Tray position

10-3

Press MENU key to scroll to

meal selection and tray position.

ENTER

MENU

PAGE

10-1

10-110-1

Press MENU key to sc roll to

meal selection and tray position.

Page 24

10.4 Product Selection

The Up/Down arrow keys are used to scroll the available product selections for each meal and tray

position.

The product selected for the left tray position of each meal determines the holding temperature

for the slot. Only products that have holding temperatures within 5°°°°F (3°°°°C) of the left most

product selection will be displayed for selection in the center and right tray position.

If the left most product selection is changed, and the left product is now a different temperature, the

center and right positions must be re-entered. If the product selection for an active timer is chan ged,

the timer is automatically reset.

To Enter a Product Selection:

ENTER

ENTER

PAGE

PAGE

MENU

MENU

saus

sausbfst

saussaus

roun

roun

rounroun

bfst

bfstbfst

Press Up/Down arrow keys to

scroll product selections

bfst

bfst

bfstbfst

left

left

leftleft

left

left

leftleft

Press Up/Down arrow keys to

scroll product selections

bfst

bfst left

bfstbfst

Press Up/Down arrow keys to

scroll product selections

bfst

bfst left

bfstbfst

left

leftleft

left

leftleft

ENTER

PAGE

ENTER

PAGE

Product selections

MENU

fold

fold

foldfold

Product selections

MENU

scra

scra

scrascra

Product selections

10.5 Exiting Program Mode

To return to operating mode press and hold the MENU key for 5-8 seconds. The controller will

automatically exit the program mode if no entries occur for 5 seconds.

To Exit Program Mode:

ENTER

bfst

bfstbfst

left

left

leftleft

PAGE

MENU

scra

scrabfst

scrascra

scra

scra

scrascra

Press and hold the MENU key for at

least 5 seconds to exit program mode.

ENTER

MENU

saus

saus

PAGE

saussaus

10-4

Page 25

10.6 Product Selection Change (Example)

This example changes the lunch product selection in the left position of slot three from 10-1 to

NUGG. Because the holding temperature for NUGG is different than 10-1, the cent er and right

product selections will be cleared. Only items with holding temperatures within 5°F (3°C) o f the left

product selection can be entered for the center and right position.

ENTER

MENU

PAGE

ENTER

MENU

mode

mode

MENU

MENU

MENU

MENU

MENU

MENU

MENU

MENU

MENU

MENU

modemode

saus

saus

saussaus

saus

saus

saussaus

saus

saus

saussaus

10-1

10-1

10-110-1

4-1

4-1

4-14-1

nugg

nugg

nuggnugg

PAGE

Press the PAGE key to scroll the

slot selections.

ENTER

PAGE

Press the PAGE key to scroll the

slot selections.

ENTER

PAGE

Press the PAGE key to scroll the

slot page selections.

ENTER

PAGE

Press the MENU key to scroll

meal selection and tray position.

ENTER

PAGE

Press the MENU key to scroll

meal selection and tray position.

ENTER

PAGE

Press the MENU key to scroll

meal selection and tray position.

ENTER

PAGE

Press the MENU key to scroll

meal selection and tray position.

ENTER

PAGE

Press the MENU key to scroll

meal selection and tray position.

ENTER

PAGE

ENTER

PAGE

ENTER

PAGE

prog

prog

progprog

slot

slot 1111

slotslot

slot

slot 2222

slotslot

slot

slot 3333

slotslot

bfst

bfst left

bfstbfst

Meal Selection

bfst

bfst cent

bfstbfst

Meal Selection

bfst

bfst rght

bfstbfst

Meal Selection

lnch

lnch left

lnchlnch

lnch

lnch left

lnchlnch

lnch

lnch left

lnchlnch

nugg

nugg

nuggnugg

10-1

10-1 10-1

10-110-1

Press Up/Down arrow keys to

scroll product selections

10-1

10-110-1

Press and hold the MENU key for at least 5

seconds to enter Program mode.

left

leftleft

Tray Position

cent

centcent

Tray Position

rght

rghtrght

Tray Position

left

leftleft

Tray PositionMeal Selection

left

leftleft

left

leftleft

Press and hold the MENU key for at least 5

seconds to exit Program mode.

10-5

Page 26

11 Entering and Editing Product Information

Changing or entering new product selections, holding times and temperature settings are passwordprotected functions. To enter the password, press and hold the MENU key for five seconds and enter

Program Mode. Press the Page key to scroll to View PAGE. Press the MENU key to select the

Security Lock (SECR LOCK).

11. 1 Entering password

ENTER

SAUS

SAUS

SAUSSAUS

prog

prog

progprog

Saus

Saus

SausSaus

MENU

PAGE

Press and hold MENU key for 5 seconds to

enter Program Mode

ENTER

MENU

PAGE

Press PAGE key to scroll to the VIEW

page

saus

saus

saussaus

mode

mode

modemode

view

view

viewview

secr

secr

secrsecr

Press Up/Down arrow keys to enter

password.

secr

secr lock

secrsecr

*Security code 247 is the manager-level password.

lock

locklock

ENTER

MENU

PAGE

page

page

pagepage

Press MENU key to scroll to the VIEW

page

ENTER

MENU

PAGE

ENTER

MENU

PAGE

156

156

156156

247

247

247247

11-1

Page 27

11.2 Entering a Product Name

A new product entry requires entry of the product name, holding time, holding temperature, meal

selection and cook more time. The following example enters a new product (named XXY) with a

holding time of 25 minutes, holding temperature of 1800F (820C) and cook more time of five

minutes.

ENTER

secr

secr lock

secrsecr

edit

edit

editedit

prod

prod name

prodprod

lock

locklock

name

namename

MENU

PAGE

Press PAGE key to scroll

to the Edit Page

ENTER

MENU

PAGE

Press MENU key to scroll to

an unused product space.

ENTER

MENU

PAGE

247

247

247247

page

page

pagepage

....

Press Up arrow key to scroll

to the letter X.

prod

prod

prodprod

Press Down arrow key to

scroll to next display segment.

prod

prod name

prodprod

Press Up arrow key to scroll

to the letter X.

prod

prod name

prodprod

Press Down arrow key to

scroll to next display segment.

prod

prod name

prodprod

name

name

namename

name

namename

name

namename

name

namename

Note: The decimal point indicates which

display segment is being entered.

ENTER

MENU

PAGE

ENTER

MENU

PAGE

ENTER

MENU

PAGE

ENTER

MENU

PAGE

x

x

x x

x

x

x x

xx

xx

xx xx

xx

xx

xxxx

....

....

....

....

Press Up arrow key to scroll

to the letter Y.

prod

prod name

prodprod

name

namename

11-2

ENTER

PAGE

MENU

xxy

xxy

xxyxxy

....

Page 28

11.3 Entering Product Holding Time

name

name

prod

prodprod

time

time

timetime

xxy

xxy time

xxyxxy

Press Up/Down arrow key to change time

to 25 minutes.

xxy

xxy time

xxyxxy

namename

Press PAGE key to scroll to the Time page.

Press MENU key to scroll to product time

selection.

time

timetime

time

timetime

11.4 Entering Product Holding Temperature

ENTER

PAGE

ENTER

PAGE

ENTER

PAGE

ENTER

PAGE

MENU

MENU

MENU

MENU

xxy

xxyprod

xxyxxy

page

page

pagepage

20

20

2020

25

25

2525

xxy

xxyxxy

temp

temp

temptemp

xxy

xxy ttop

xxyxxy

Press Up/Down arrow key to change top

plate temperature.

xxy

xxy ttop

xxyxxy

xxy

xxy tbot

xxyxxy

Press Up/Down arrow key to change

bottom plate temperature.

xxy

xxy tbot

xxyxxy

ENTER

time

time

timetime

PAGE

MENU

25

25xxy

2525

Press PAGE key to scroll to the Temp page.

ENTER

MENU

page

page

PAGE

pagepage

Press MENU key to scroll to product top

plate temperature selection.

ENTER

ttop

ttopttop

ttop

ttopttop

PAGE

ENTER

PAGE

MENU

MENU

155

155

155155

180

180

180180

Press MENU key to scroll to product

bottom plate temperature selection.

ENTER

tbot

tbottbot

tbot

tbottbot

PAGE

ENTER

PAGE

MENU

MENU

155

155

155155

180

180

180180

11-3

Page 29

11.5 Enter Meal Usage

xxy

xxy tbot

xxyxxy

meal

meal

mealmeal

xxy

xxy meal

xxyxxy

Press Up/Down a rro w key to sele c t BF S T .

xxy

xxy meal

xxyxxy

ENTER

tbot

tbottbot

Press PAGE key to scroll to the Meal page.

Press MENU key to scroll to product meal sel ection.

meal

mealmeal

meal

mealmeal

MENU

PAGE

ENTER

MENU

PAGE

ENTER

MENU

PAGE

ENTER

MENU

PAGE

180

180

180180

page

page

pagepage

all

all

allall

bfst

bfst

bfstbfst

11.6 Enter Cook Time

ENTER

xxy

xxy meal

xxyxxy

meal

mealmeal

PAGE

Press PAGE key to scroll to the Cook Page.

ENTER

cook

cook

cookcook

PAGE

Press MENU key to scroll to the cook product selection.

ENTER

xxy

xxy cook

xxyxxy

cook

cookcook

PAGE

Press Up/Down arrow k ey s to center desired cook warning time.

ENTER

xxy

xxy cook

xxyxxy

cook

cookc ook

PAGE

MENU

MENU

MENU

MENU

all

all

allall

page

page

pagepage

0000

5555

Press and hold MENU key for 5 seconds to exit Program Mode, return to normal

operation.

11-4

Page 30

12 Display Adjustments

12.1 Change Display Time

The rate at which an active timer alternately displays product selection and holding time may be

adjusted as follows:

ø Press and hold MENU key for 5 seconds

ø Press PAGE key to scroll to View Page

ø Press MENU key to scroll to the Security Lock

ø Press Up and Down Arrow keys to enter the security code

ø Press MENU key to scroll to Product Display time (PROD TIME)

ø Press Up and down Arrow keys to change Product Display Time

ø Press MENU key to scroll to Timer display Time (TIMR TIME)

ø Press Up and Down Arrow keys to change Timer Display time

ø Press and hold MENU key for 5 seconds to return to normal operation

12.2 Change Display Intensity

The brightness of each of the intensity levels used for product status may be adjusted as follows:

ø Press and hold MENU key for 5 seconds ø Press PAGE key to scroll to View Page ø Press MENU key to scroll to the Security Lock ø Press Up and Down Arrow keys to enter the security code ø Press MENU key to scroll to Display Intensity Level ø Press Up and Down Arrow keys to change intensity level ø Press and hold MENU key for 5 seconds to return to normal operation

12.3 Change °°°°F to °°°°C

The following changes temperature indications from °F to °C.

NOTE: You must enter the Service code to setup or change a cook time.

ø Press and hold MENU key for 5 seconds

ø Press PAGE key to scroll to View Page

ø Press MENU key to scroll to the Security Lock

ø Press Up and Down Arrow keys to enter the security code 247

ø Press MENU key to scroll to Display Units

ø Press Up and Down Arrow keys to change °F to °C

ø Press and hold MENU key for 5 seconds to return to normal operation

12-1

Page 31

13 Troubleshooting Guide for the Universal Holding Cabinet

Press the rocker switch to

the ON position.

Broken or improper wire

1.

Are all displays

lit?

Yes

No

1. No power to power cord.

2. Blown 20 amp fuse.

3. Defective power switch.

4. Broken or improper wire connection (Check

CN2).

5. Defective transformer.

6. Defective master control board.

Do all displays

fail to light?

Yes

No

connection.

Defective display.

2.

Defective display driver

3.

board.

Are slot(s)

heating

properly?

Yes

Are timers

operating?

Yes

Operation Normal

1.Broken or improper wire connection.

No

2. Defective display (defective button).

3. Defective master control board.

13-1

Page 32

14 Tests

14.1 Transformer

1. Disconnect power to cabinet. Remove side and top panels, unless stacked. If stacked, see the

service procedures for access instructions.

2. Mark for re-assembly, then remove the two bottom leads. Connect an AC meter across the

outside terminals of the secondary. Apply power and note the voltage. If voltage is

approximately 16 VAC, the transformer is operating normally. If zero or incorrect voltage is

measured, measure the input voltage at the top two terminals (primary). The acceptable input

voltage range is 177 to 264 VAC.

14.2 Master Control Board

Input Power

1. Disconnect power to the cabinet. Remove side and top panels unless stacked. If stacked, see the

service procedures for access instructions.

2. Visually check all terminals and connections for loose or disconnected wires.

3. Apply power and measure AC voltage to board on connector CN1. Correct measurement is 16

volts across the two outside connectors and 8 volts from either outside connector to the center

connector.

14.3 RTD/Master Board

1. Normally only one or two plates will be suspect. To isolate between a defective RTD, bad wiring

connection or defective master board, first perform the heater plate test described in section 14.7.

2. If the plate tests OK (heater and RTD ), isolate further by swapping the l eads (heater and RTD)

from the suspect slot with a slot that operates correctly.

3. If both slots operate correctly after swapping, a poor wire connection is the probable c ause of the

malfunction. (Reconnect the wires to their original slots and retest.)

4. If the original slot continues to malfunction with swapped leads, the master board is defective.

5. If the malfunction moves to the other slot, the heater plate/RTD assembly is defective.

NOTE: After testing, reconnect all leads to their original positions.

14-1

Page 33

14.4 Master Board/Display Driver

1. To isolate between a defective master board or display driver, disconnect the front and rear

ribbon cables (FC1 and FC2) and the CN2 connector on the suspect displa y driver. Disconnect

the front and rear ribbon cables and the CN2 connector on the nearest display driver, which

operates correctly.

2. Connect the connectors from the suspect display driver to a known good display driver and test

the operation. If the malfunction continues, replace the master board. If the malfunction is

corrected, replace the defective display driver.

NOTE: After testing, reconnect all connections to their original positions.

14.5 Shorted Triac

1. Turn the suspect slot off and measure voltage from the white terminal block to the top (black

lead) heater plate. Also, measure voltage to the bottom heater plate. With slot off, there should be

no line voltage. If the triac is shorted, you will measure AC line voltage. If the triac is half

waving, you will get DC voltage of approximately one-half the line AC voltage. Also, with the

slot off, measure the slot temperature. If the slot is heating, it is miswired or the master control

board is defective (shorted triac).

14.6 Display Driver/Display Isolation Test

1. On stand-alone units, disconnect power to the cabinet and remove side and top panels. If unit is

stacked, see service procedures for instructions on accessing the top panel.

2. Disconnect CN2 connector on the suspect display driver. Apply power. The selected display will

indicate Disp Test Mode. (Note: All slots below the selected slot will not operate.) Press

each functional button on the selected display, starting with the timer key at the left. Each button

must be pressed in sequential order, starting at the left on the front display and continuing to the

rear display on all slots. After all buttons have been pressed, each LED display segment should

illuminate sequentially.

3. If the unit does not perform as described in step 2, isolate between a bad display or display driver

by connecting the ribbon connector form the suspect display to one or the know good display

drives and repeat the test.

NOTE: There is no output from the master control board during this test. If t he unit does not

operate as described in step 2, the problem cannot be the master control board.

14-2

Page 34

14.7 Heater Plate

1. Disconnect power to the cabinet. On stand-alone units, remove side and top panels. On stacked

units, see Service Procedures for instructions on accessing the top panel.

2. Disconnect the black heater lead and the two RTD leads (brown and red) of the suspect plate

from the master board. Measure resistance of the heater from the black lead to an y terminal on

the white terminal block. Resistance should be 140-150 ohms.

3. Measure resistance across the brown and red RTD leads. Resistanc e must be within a range of

104-148 ohms. Resistance at room temperature is approximately 107 ohms. See chart on Page

18-5 for resistance at different temperatures. If either resistance is incorrect, replace the heate r

plate.

14.8 Display Meanings

1. SLOT TEMP HIGH OR SLOT TEMP LOW and no audible alarm. This is normal when

the slot is changing temperature in association with a menu change.

2. LLLL means the RTD indicates a temperature below 50°F (10°C). Unit will automatically heat

at 20 percent until temperature is above 50°F (10°C), then operate normally.

3. HHHH means RTD indicates the temperature is above 255°F (124°C), but below "Open" circuit

resistance, which causes SENS ALARM.

4. UHC VERSION _ _ _ (version numbe r will vary) appears for five seconds when the unit

is turned on. This is normal. If the UHC VERSION _ _ _ stays in the display, the normal

cause is 120 VAC is applied instead of the nominal 200 to 250 VAC.

14-3

Page 35

15 Service Procedures

15.1 Removing/Replacing Shelf Components

DANGER!! Failure to disconnect the power supply before servicing could result in serious

injury or death. The cabinet power switch DOES NOT disconnect all incoming power to the

cabinet.

1. Turn the UHC off, disconnect the power supply and allow the unit to cool (approximately 60

minutes).

2. Use a #2 Phillips-head screwdriver to remove two

#10 truss-head screws from each side of the unit (Fig.

1).

3. Remove the side panels and set aside, being careful

not to mar the panel finish.

Fig. 1. Removing side panel.

4. Removing the side panels allows access to display

driver boards (removable by disconnecting the wire

harnesses and removing the securing screws), fascia

mounting screws and slot mounting screws (Fig. 2).

5. Use a 5/16” nut driver to remove the four cabinet

screws holding the equipment shelf in place. The

screws are located on each side of the unit, near the

top corners of the inner panel.

6. Use 5/16” nut driver to remove the two #10-32 hex-

head screws from each side of the front fascia.

7. Pull the front fascia out (you may use the Production

Chart Holder as a grip to free the fascia from the

cabinet) and up to reveal the front edge of the

equipment shelf. (It is not necessary to disconnect the

switch wiring. Fig. 3)

NOTE: For accessibility of the fascia, the top of

the unit may be removed if the configuration is

either a single stand-alone unit or the top unit of

a stacked arrangement.

8. Grab the edge of the shelf and pull out slightly.

Remove the wire and wire harnesses to free the shelf.

Mark each wire for reassembly. Pull the shelf until it

engages the stops. Place the fascia on top of the shelf

(Fig. 4-5).

Fig. 2. Side panel removed.

15-1

Fig. 3. Removing front fascia.

Page 36

9. This exposes the transformer, cooling fans, terminal

blocks, fuses and main control board. These

components are accessible and easily

removable/replaceable.

10. Reassemble the unit by reversing the previous steps.

Ensure all wiring connections are tight and in

accordance with the wiring diagram. Ensure that all

screws and other fasteners are snug.

11. Before reconnecting power to the unit, clean all

stainless steel surfaces and the interior of the slots

using approved cleansing agents. (See Appendix B).

12. Reconnect power, turn the power switch to the ON

position and reprogram the controllers as necessary to

the desired menu selections.

Fig. 4. Component shelf slid forward.

15.2 Replacing Membrane Switch/Switches

Perform steps 1-5 in Section 15.1

1. Release ribbon cable from top of driver board on left

side of unit. Feed ribbon cable into space between

slots (Fig. 6-7).

2. Remove Allen screw (not on early units) locking

display bezel in place.

3. Loosen bolt-holding bezel.

4. Remove bezel, which contains the display, from the

unit (Fig. 7).

Fig. 5. Component shelf with UHC lid

removed.

Fig. 6. Remove ribbon cable from driver

board.

15-2

Fig. 7. Feed ribbon cable out of UHC

when bezel is removed.

Page 37

5. Place bezel face down on table with slot hole

at bottom and remove metal frame holding

display. Note position of rib on metal frame

and position of ribbon connection on display

(Fig. 8).

6. Remove old display assembly.

7. Clean bezel.

8. Remove screws connecting the membrane

switch to the display board (Fig. 9).

9. Gently separate the membrane switch from

the display board (Fig. 10).

Fig. 8. Note ribbon cable is at top of bezel

opening.

Fig. 9. Remove two screws securing the display

board to the membrane switch.

10. Disconnect the non-terminated ribbon, which

connects the membrane switch to the display

board, by gently pulling the cable from the

connector on the display board (Fig. 11).

Note: Early production units (prior to S/N

9703) had the membrane switch soldered

to the display assembly. For these units,

the complete display assembly must be

replaced. (Front Display Assembly: 8073309; Rear Display Assembly: 807-3310.)

Fig. 10. Separate the display board and the

membrane switch.

Fig. 11. The ribbon on the membrane switch is

pulled free of the connector on the display board.

15-3

Page 38

11. Attach the new membrane switch to the

display board by sliding the non-terminated

ribbon into the connector on the display

board.

Note: The ribbon must be held flat during

insertion. If it bows, it will not seat correctly

(Fig. 12).

12. Replace screws securing display board to the

membrane switch.

13. Return the display assembly to the bezel with

ribbon connection at top.

14. Reposition metal frame (Fig. 13).

15. Return bezel to UHC, feeding ribbon cable

through slot and back to the display driver

board.

16. Reconnect ribbon cable to driver board.

17. When all membranes have been replaced,

perform this test to ensure the displays are

operating correctly:

With the cabinet’s sides still off, disconnect

CN2 connector from the display driver(s)

to be tested (Fig. 14). Plug unit in and turn

on power switch. The selected display will

show Disp Test Mode. Press each

function button on the selected membrane

switch, starting with the timer key at the

left. Each button must be pressed in

sequential order, starting at the left on the

front display and continuing to the rear

display. After all buttons have been

pressed, each LED (Light Emitting Diode)

display should illuminate sequentially (Fig.

15).

Fig. 12. Hold the ribbon cab le fla t when a ttach ing

the new membrane to t he displa y board. The nonterminated cable will not seat properly if it is

allowed to bow while inserting into connector.

Fig. 13. Position metal framework as shown.

CN2

Fig. 14. CN2 connectors are disconnected from

the driver board to test new displays.

15-4

Page 39

Fig: 15: In the test mode, aster isk-like symbols will illum inate in the displays, appearing to m arch from

g

display to display from left to right. In units with rear displays, this light motion is repeated on the rear

displays.

Note: The rear displa y is differentiated f rom the front by t he absence of UP/DOWN arrows and a M ENU

switch.

18. If the display fails to perform in this manner, check connection between ribbon cable and displa y

driver, ribbon cable and display assembly and non-terminated ribbon cable and membrane

switch.

19. Turn off power. Reconnect CN2 connector. Install sides and return unit to operation.

15.3 Removing a Slot

1. Perform steps in Section 15-1, Steps 1-7.

Disconnect heater and control wiring to the slot

being removed (Fig. 16).

2. Using a 7/16” nut driver, loosen the four ¼ - 20

hex-head mounting screws from each corn er of the

slot to be removed. Loosen one full turn, but do not

remove.

3. Remove wire wraps from wiring harness holding

heater and control wires for affected slot.

4. Lifting slightly, carefully slide the malfunctioning

slot out of the cabinet. Do not allow the slot to

contact and damage the controls of the unit below.

5. Perform Section 15-1, Steps 9 – 11.

Fig. 16. Disconnect heater and control

from component shelf.

wirin

Fig. 17. Slide malfunctioning slot from

cabinet.

15-5

Page 40

15.4 Replace Heater Plate

1. Perform Section 15-2, Steps 1–7.

2. Run your fingers around the outside surface of

the slot assembly. There will be four raised

areas. These are the setscrews that hold the

heater plate to the spacer. Punch 4 holes in the

insulation, directly above the location of the

setscrews (Fig. 18).

3. Use a 5/64” Allen wrench to loosen the four

spacer-setscrews along the edges of the plate

(Fig. 19).

4. Slide the malfunctioning plate out of the spacer

(Fig. 20).

Fig. 18. Locate

setscrews under

heater plate covering.

Fig. 19. Puncture foil

with Allen wrench to

loosen slot.

5. Slide the replacement plate into position. Make

sure the plate is inserted squarely.

CAUTION

Ensure the heater plate setscrews are

tightened securely to the spacer.

Tightening the setscrews will ensure the

plate is properly grounded.

6. Perform Section 15.2, Steps 9–11.

Fig. 20. Slide the loosened heater plate from

the spacer.

15-6

Page 41

16 Parts Lists, Exploded Views

16.1 Universal Holding Cabinet Illustrated Parts Breakdown

17

16

12

4

9

13

7

6

8

18

15

2

22

21

20

19

14

11

10

5

3

4

1

Item

Part Number Qty/Slot Description

1 806-8162SP 1 Bottom Pan Assembly

2 806-7904 1 Pan Base

3 See Page 16-2 4 Slot Assembly

4 910-4876SP 2 Cabinet Side, 4-slot unit (Right and Left)

Not Shown 106-0266 2 Cabinet Side, 2-slot unit (Right and Left)

5 900-4880SP 2 Inner Panel, 4-slot unit

Not Shown 900-9453 1 Inner Panel, 2-slot unit

6 910-4875 4 Vertical Support, 4-slot unit

Not Shown 910-9451 4 Vertical support, 2-slot unit

16-1

Page 42

16.1 Universal Holding Cabinet Illustrated Parts Breakdown (cont.)

Item

7 807-2444E 4 Display Driver

8 816-0267 1 Driver Board Cover, 4-slot unit

Not Shown 816-0506 1 Driver Board Cover, 2-slot unit

Not Shown 807-2448 1 Driver Board AC/Data Harness, 4-slot unit

Not Shown 807-3413 1 Driver Board AC Harness, 2-slot unit

Not Shown 807-3414 1 Driver Board Data Harness, 2-slot unit

9 806-0618 8 Button Hanger

Not Shown 806-0256 8 Button Hanger Nut

10 807-3308 1 ON/OFF Switch

11 806-8654 SP 1 Front Fascia

12 900-4946 2 Slide Bracket

13 816-0265 4 Bushing .75 ID Snap-in

14 See next page 1 Shelf Assembly

Part Number Qty/Slot Description

15 807-3238 1 Power Cord Strain Relief

16 823-2375 1 Rear Fascia

17 807-2473 1 Pin & Sleeve Power Cord, 12 ½ Feet

18 807-2474 1 Twist Lock Power Cord, 12 ½ Feet

19 902-4882 2 Right Bracket

19 902-4882 2 Left Bracket

20 816-0262 4 VHB Tape, 3.75 x 1”

21 806-7906 1 Top Cap Assembly

22 210-0047 1 Cord Support Bracket

Not Shown 900-5217 1 Air Flow Closure

Not Shown 900-5218 1 Full Baffle

Not Shown 901-5219 1 Left Baffle

Not Shown 902-5219 1 Right Baffle

Not Shown 826-1288 4 Leg Kit

Not Shown 809-0428 16 Leg Plate Mounting Screws

16-2

Page 43

16.2 Domestic Component Shelf

5

14

9

7

1

2

12

15

6

16

4

13

3

11

Item Part Number Quantity Description

1 807-0263 2 Connector, terminal

2 807-2443 1 Motherboard

Not Shown 826-1529 1 Alarm Buzzer Kit

3 807-2460 1 Transformer

4 807-2665 2 Exhaust blower

5 807-2812 1 Terminal block

6 807-2819 2 Fuse, 20 amp

7 807-2820 1 Fuse block

8 809-0094 2 Screw, 6-32 x 3/8

9 826-1366 2 Nut, hex keps

10 809-0250 1 #6-32

11 809-0360 4 Screw, #8 x ¾

12 809-0580 5 Stand-off, Circuit Board

13 809-0607 4 Screw, #8 x 2

14 809-0675 2 Screw, 4-40 x ½

15 812-1306 1 Metal oxide varistor

16 900-5511 1 Equipment shelf

16-3

Page 44

16.3 Components

2 3

1

Item Part number Quantity Description

1 807-2767 1 Bead Shield, CE only

2 807-2766 1 Power Line Filter, CE only

3 807-2769 1 Power Transformer, CE only

16.4 Pre-1997 Components

2 3

1

Item Part number Quantity Description

1 807-2278 2 20-Amp Fuse

2 807-2447 1 Fuse Holder

3 807-2462 2 Terminal Block

16-4

Page 45

16.5 Slot Assembly

Item

4

1

8

2

9

5

6

10

11

3

7

Part Number Qty/Slot Description

1 807-2880 2 Heater Plate (includes RTD)

1 807-2906 2 Heater Plate CSA

2 807-3309 1

Not Shown 807-3311 1

3 807-3310 1

Not Shown 807-3312 1

Display Assembly., Front Slot

(All, including pre- S/N 9703)

Membrane Switch, Front Display

(Not for pre- S/N 9703)

Display Assembly., Rear Slot

(All, including pre- S/N 9703)

Membrane Switch, Rear Display

(Not for pre- S/N 9703)

4 809-0593 8 Screw, set #6 x 1/2

5 809-0609 8 Screw, set #8 x 3/8 Phillips

6 809-0610 4 Washer, #8

7 809-0612 8 Screw, #8-32 x 3/16

8 810-1286 2 Spacer

9 816-0239 2 Slot Bezel

10 900-5109 2 Display bracket

11 900-5234 2 Bezel support bracket

Not Shown 812-1455 1 Filler, SPOD Bezel

Not Shown 816-0243 1 Insulation

16-5

Page 46

17 Wiring Diagram, UHC

17-1

Page 47

18 Appendices

Appendix A: Food Item Default Settings

Food Item

Sausage SAUS BFST

Round Eggs ROUN BFST

Folded Eggs FOLD BFST

Scrambled Eggs SCRA BFST

Canadian Bacon CBAC BFST

English Muffins MUFF BFST

Biscuits BISC BFST

Burritos BURR BFST

Display Name

Meal Selection Temperature Setpoint

185°F (85°C) top plate

185°F (85°C) bottom plate

175°F (79°C) top plate

175°F (79°C) bottom plate

175°F (79°C) top plate

175°F (79°C) bottom plate

175°F (79°C) top plate

175°F (79°C) bottom plate

175°F (79°C) top plate

175°F (79°C) bottom plate

175°F (79°C) top plate

175°F (79°C) bottom plate

175°F (79°C) top plate

175°F (79°C) bottom plate

185°F (85°C) top plate

185°F (85°C) bottom plate

Time

(Min)

60

20

20

20

30

20

60

30

Regular Patties 10-1 LNCH

Quarter Pound Patties

and Big Xtra! Patties

Grilled Chicken NUGG LNCH

Fish FISH LNCH

McChicken Patties McCK LNCH

4-1 LNCH

200°F (93°C) top plate

200°F (93°C) bottom plate

200°F (93°C) top plate

200°F (93°C) bottom plate

200°F (93°C) top plate

200°F (93°C) bottom plate

200°F (93°C) top plate

200°F (93°C) bottom plate

200°F (93°C) top plate

200°F (93°C) bottom plate

20

20

60

30

30

18-1

Page 48

Appendix B: Cleaning and Preventive Maintenance

After Each Use – Clean Trays/Racks

1. Remove all plastic and wire trays. Take trays/racks to the sink for cleaning.

2. Clean trays by washing in a hot McD All-Purpose Super Concentrate (APSC) (HCS) solution

drawn through the sink proportioner or mix 0.3 fl. McD APSC (HCS) for each gallon of solution.

Rinse trays/racks thoroughly under hot water.

3. Sanitize trays/racks by dipping in McD Sink Sanitizer (HCS) solution, (one pack per 10 gallons

of water) or McD Sanitizer (HCS) solution (four packs per 10 gallons of water), for at least 1

minute. Remove from sanitizer solution and allow to air dry.

Daily – Clean Cabinet

1. At the end of the operating day, turn unit to Clean Mode (see Clean Mode, Section 7.2 on Pa ges

7-2 — 7-3).

Note: Do not use McD Sink Sanitizer (HCS) to clean the exterior of the Universal Holding

Cabinet.

2. Let the unit cool until SAFE to CLN is displayed. Use brush to remove any remaining

buildup on the slot surface by pushing the particles out the opposite end of the cabinet.

Note: Use only the cabinet cleaning brush to clean the cabinet slots. Wire brushes, abrasive

pads, or metal scrapers will permanently damage the surface of the cabinet slot.

Note: Do Not use any other cleaner than McD (APSC)(HCS). Using other compounds may

result in damage to control components.

3. With the cabinet cleaning brush push all loose particles out the opposite end of the cabinet.

4. Use a wet, clean/sanitized towel and the cabinet cleaning brush to clean each slot. Clean the

bottom and top surface of each slot.

5. Wipe clean all exterior cabinet surfaces with a clean, sanitized towel that has been soaked in

McD ASPC (HCS).

6. Turn the unit off.

18-2

Page 49

Weekly – Cabinet Slots

Calibrate the top and bottom plates in all four UHC slots by performing the following procedure