Page 1

Installation, Operation, Service and Parts Manual

(SDU 50, 90, 100 and BKSDU)

Shortening Disposal Unit

www.frymaster.com

Frymaster, a member of the Commercial Food Equipment Service Association,

recommends using CFESA Certified Technicians.

24-Hour Service Hotline 1-800-551-8633

E-mail:

service@frymaster.com

*8195703A*

OCT 11

Page 2

NOTICE

IF, DURING THE WARRANTY PERIOD, THE CUSTOMER USES A PART FOR THIS

MANITOWOC FOOD SERVICE EQUIPMENT OTHER THAN AN UNMODIFIED NEW OR

RECYCLED PART PURCHASED DIRECTLY FROM FRYMASTER DEAN, OR ANY OF ITS

AUTHORIZED SERVICERS, AND/OR THE PART BEING USED IS MODIFIED FROM ITS

ORIGINAL CONFIGURATION, THIS WARRANTY WILL BE VOID. FURTHER,

FRYMASTER DEAN AND ITS AFFILIATES WILL NOT BE LIABLE FOR ANY CLAIMS,

DAMAGES OR EXPENSES INCURRED BY THE CUSTOMER WHICH ARISE DIRECTLY

OR INDIRECTLY, IN WHOLE OR IN PART, DUE TO THE INSTALLATION OF ANY

MODIFIED PART AND/OR PART RECEIVED FROM AN UNAUTHORIZED SERVICER.

NOTICE

Drawings and photos used in this manual are intended to illustrate operational, cleaning

and technical procedures and may not conform to on-site management operational

procedures.

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause property

damage, injury or death. Read the installation, operating and maintenance instructions

thoroughly before installing, operating or servicing this equipment.

DANGER

Hot vegetable oil will cause severe burns. Allow vegetable oil to cool to 100°F (38°C)

before transporting to the disposal site. Use extreme caution when transporting and

disposing of spent vegetable oil.

DANGER

Before each use inspect the cover to ensure the cover gasket is present and properly

placed. DO NOT use the disposal unit if this gasket is damaged or missing.

ii

Page 3

Shortening Disposal Unit (SDU)

Installation, Operation, Service, and Parts Manual

TABLE OF CONTENTS

Page

1. INTRODUCTION 1

1.1 Service Information and Parts Ordering ..............................................1

1.2 Installation, Operating and Service Personnel .....................................1

1.3 Definitions ................................................................................................1

1.4 Shipping Damage Claim Procedure ......................................................2

1.5 What To Do If Your Equipment Arrives Damaged .............................2

2. ASSEMBLY AND OPERATION ..........................................................2

2.1 Equipment Description ...........................................................................2

2.2 Equipment Assembly ..............................................................................3

2.3 Equipment Operation .............................................................................3

2.4 Cleaning ....................................................................................................5

3. SERVICE PROCEDURES .....................................................................5

3.1 General .....................................................................................................5

3.2 Replacing Worn or Damaged O-Rings ..................................................5

3.3 Replacing Worn Pump Vanes and/or Pump Shaft Seal ......................5

4. PARTS LIST ............................................................................................7

iii

Page 4

SHORTENING DISPOSAL UNIT

(SDU 100, 90 50, AND BKSDU)

INSTALLATION, OPERATION, SERVICE AND PARTS

1. INTRODUCTION

1.1 Service Information and Parts Ordering

Included with the unit when shipped from the factory is a list of Factory Authorized Servicers

(FAS). Refer to this list to find the FAS nearest you. If you do not have access to this list, contact

the Frymaster Technical Service Department at 1-800-551-8633 or 1-318-865-1711.

Service information may be obtained by contacting your local FAS. Information may also be

obtained by calling the Frymaster Technical Service Department at 1-800-551-8633 or 1-318-8651711 or by e-mail: service@frymaster.com. In order to assist you as quickly as possible, the FAS or

Service Department representative requires certain information about your equipment. The

information is printed on a data plate located on the tank cover. When requesting service, please

have the following information ready:

Model Number:

Serial Number:

In addition to the model number, and serial number, please be prepared to describe the nature of the

problem and have ready any other information that you think may be helpful in solving your

problem. Parts orders may be placed directly with your local FAS or distributor. When ordering

parts, the following information is required:

Model Number:

Serial Number:

Item Part Number:

Quantity Needed:

RETAIN AND STORE THESE INSTRUCTIONS IN A SAFE PLACE FOR FUTURE USE.

1.2 Installation, Operating and Service Personnel

Installation, Operating, and Service information for this equipment has been prepared for use by

qualified and/or authorized personnel only, as defined in Section 1.3.

1.3 Definitions

QUALIFIED AND/OR AUTHORIZED OPERATING PERSONNEL

Qualified/authorized operating personnel are those who have carefully read the information in this

manual and have familiarized themselves with the equipment functions, or who have had previous

experience with the operation of the equipment covered in this manual.

QUALIFIED SERVICE PERSONNEL

Qualified service personnel are those who are familiar with this equipment and who have been

authorized by Frymaster L.L.C. to perform service on equipment manufactured by Frymaster. All

authorized service personnel are required to be equipped with a complete set of service and parts

1

Page 5

manuals, and to stock a minimum amount of parts for Frymaster equipment. A list of Factory

Authorized Service Centers (FAS’s) is located on the Frymaster website at www.frymaster.com.

Unless specifically indicated otherwise in this manual, failure to use qualified service personnel

will void the Frymaster Warranty on this equipment.

1.4 Shipping Damage Claim Procedure

This equipment was carefully inspected and packed before leaving the factory. The transportation

company assumes full responsibility for safe delivery upon acceptance of the equipment for

transport.

1.5 What to Do If Your Equipment Arrives Damaged

1. File a claim for damages immediately, regardless of the extent of damages.

2. Inspect for and record all visible loss or damage and ensure that this information is noted on

the freight bill or express receipt and is signed by the person making the delivery.

3. Concealed loss or damage that was unnoticed until the equipment was unpacked should be

recorded and reported to the freight company or carrier immediately upon discovery. A

concealed damage claim must be submitted within 15 days of the date of delivery. Ensure that

the shipping container is retained for inspection.

FRYMASTER DOES NOT ASSUME RESPONSIBILITY

FOR DAMAGE OR LOSS INCURRED IN TRANSIT.

2. ASSEMBLY AND OPERATION

2.1 Equipment Description

The Shortening Disposal Unit (SDU) is designed for the safe transportation of used shortening or

cooking oil from the kitchen to a disposal container. There are three sizes –SDU 50 (50 lbs./23 kg),

SDU 90 (90 lbs./41 kg) and SDU 100 (100 lbs./45kg). All sizes are similar in construction and

operation. The units consist of a tank and a heavy-duty manual pump. All models are equipped with

6 " (150 mm) wheels.

The BKSDU is equipped with a 120VAC or 240VAC tank heater to prevent solid shortening from

solidifying prior to disposal. The BKSDU is equipped with a receptacle that accepts a three-prong,

grounded plug for protection against shock hazard. The power cord should be plugged directly into

a properly grounded, three-hole wall or floor receptacle. Do not cut off, remove, or otherwise

bypass the grounding prong on the power cord plug. CAUTION: Risk of fire and electric shock.

Replace only with manufacturer’s cord set, part number 8071224 for 120V or part number

106-4697 for 240V.

With the cover open, the top of the tank is 9¾ inches (248 mm) above the floor, permitting it to be

positioned directly beneath the drains of most fryers.

2

Page 6

2.2 Equipment Assembly

Assembly of the unit is a four-step process:

1. Remove the two bolts from the handle-mounting bracket and raise the handle to the upright

position. Reinstall the bolts in the bracket and tighten to 8 ft/lbs.

2. Ensure the O-rings and the bottom 2 inches of the suction tube are lubricated with Accrolube

with Teflon or an equivalent light oil or grease.

3. Turn the pump and suction tube upside down and carefully pour no more than one cup of

cooking oil down the tube. Rotate the pump handle slowly three or four times to prime the

pump.

4. Insert the suction tube through the pipe bracket on the handle and into the pickup tube on top of

the reservoir. Push down on the pump assembly and ensure the suction tube is fully seated.

2.3 Equipment Operation

WARNING

DO NOT use this unit to dispose of water or Boil-out solution. Introduction of water

or solvents into the unit will permanently damage the pump.

1. Turn the fryer off prior to draining into SDU. If so equipped, ensure the fryer drainpipe is firmly

threaded into the frypot drain valve.

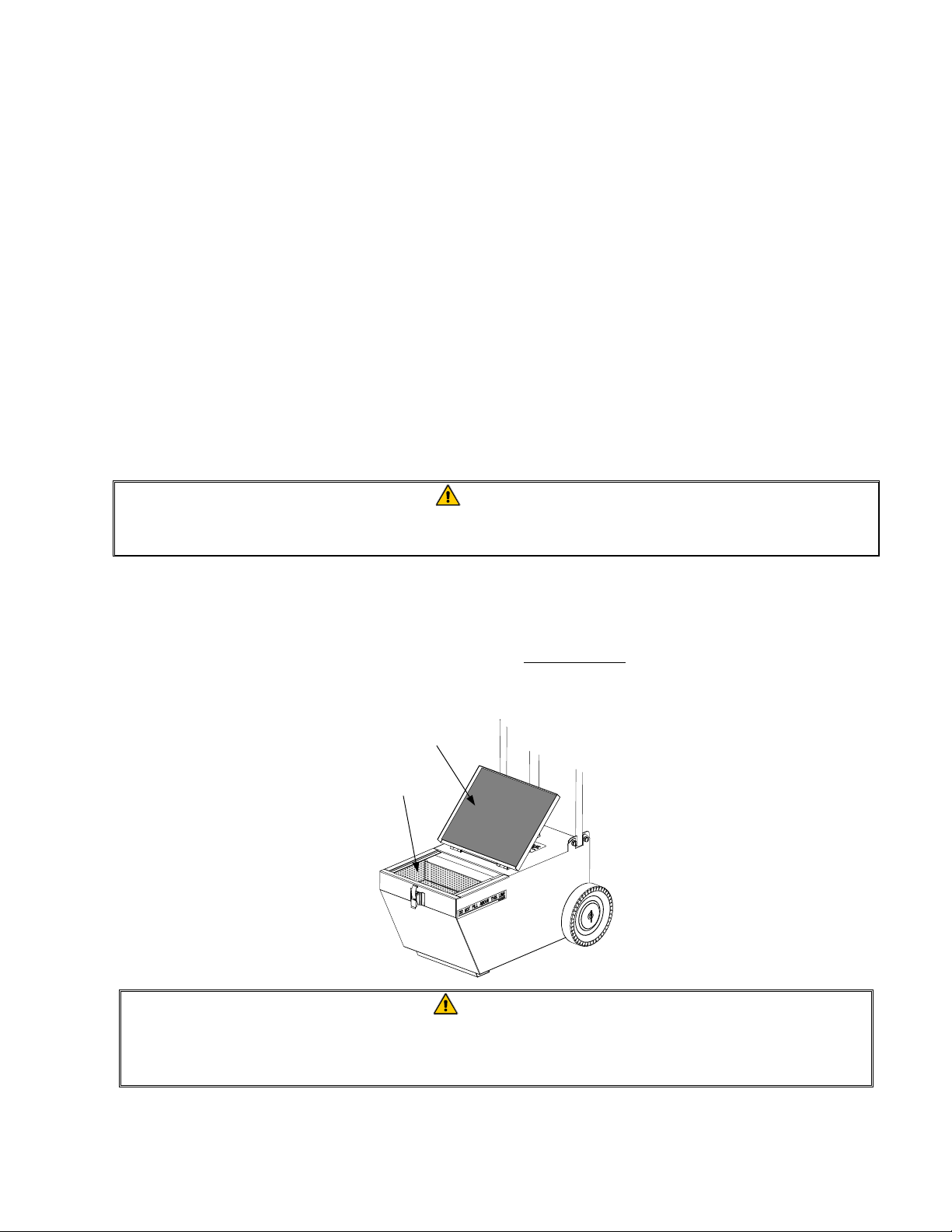

2. Open the cover, verify that the crumb screen and rubber gasket on the inside cover are in place,

and position the unit so that the opening is directly under the frypot drainpipe.

Cover Gasket

Crumb Tray

DANGER

Before each use inspect the cover to ensure the cover gasket is present and

properly placed. DO NOT use the disposal unit if this gasket is damaged or

missing.

3. Slowly open the drain valve. Regulate flow with the drain valve to prevent splashing.

3

Page 7

DANGER

DO NOT OVERFILL! Do not fill the reservoir above the fill lines on the sides of the

reservoir. Moving the SDU with an overfilled reservoir may result in spills and injury

to personnel who come in contact with the spilled shortening.

4. Carefully withdraw the unit far enough to allow the cover to be closed. Latch the cover in the

closed postion. Using the handle, carefully tip the unit back slightly for ease of handling and roll

the unit to the disposal site.

WARNING

DO NOT use the pump or discharge piping assembly as a handle!

DANGER

To minimize the potential for burns, oil must always be allowed to cool below 100°F

(38°C) before draining into the SDU and transporting to the disposal area. However,

DO NOT allow shortening to solidify in the SDU.

The unit is designed to be moved, when properly filled, at an average walking pace on a flat

surface. Care must be taken at all times when moving hot shortening or oil. Rough terrain or

sudden stops and starts may cause the contents of the reservoir to spill or splash out of the

reservoir, possibly causing serious injury to personnel. Always ensure that the cover is latched

shut when moving the unit.

5. At the disposal site, lift the pump assembly lock pin and rotate the discharge pipe as necessary to

position the discharge nipple over the opening of the disposal container. Release the lock pin to

secure the pump assembly in position. Turn the pump handle clockwise. The pump should start

discharging oil after a few turns. Continue turning the handle until the MSDU reservoir is empty.

6. On BKSDU units, the built-in heater may be connected to a grounded 120VAC or 240VAC

receptacle to prevent shortening from solidifying in the tank when immediate transfer to a

disposal container is not possible.

2.4 Cleaning

Clean the crumb screen with a solution of detergent and water. Clean the exterior surfaces of the

SDU with a soft cloth and a solution of detergent and water. It is not necessary to clean the interior

of the reservoir, but if desired it may be wiped down with clean paper towels to remove excess

residual shortening.

4

Page 8

WARNING

DO NOT clean the interior of the reservoir with water or detergent. Introduction of

water or detergent into the unit will permanently damage the pump.

3. SERVICE PROCEDURES

3.1 Introduction

Other than routine cleaning and the replacement of worn suction tube O-rings, the SDU is

maintenance free. After long use, the pump vanes and pump shaft seal may require replacement due

to wear. Frymaster recommends worn pump vanes and/or pump shaft seals be replaced by an FAS,

but store personnel may perform these service actions without voiding the warranty.

3.2 Replacing Worn or Damaged O-Rings

If pump efficiency degrades, it is likely that the O-rings on the suction tube are worn or damaged.

To replace the O-rings, follow the steps below.

1. Lift the pump assembly straight up and out of the handle assembly.

2. Remove the worn or damaged O-rings from the grooves at the bottom of the suction tube and

replace with new O-rings. Apply Accrolube with Teflon grease or equivalent to bottom 2 inches

of the suction tube.

3. Insert the suction tube through the tube bracket in the handle and into the receiver on top of the

reservoir. Push down on the pump assembly to make sure the suction tube is fully seated.

3.3 Replacing Worn Pump Vanes and/or Pump Shaft Seal

Depending upon the amount of use, the vanes in the pump assembly will eventually wear, reducing

the efficiency of the pump. The pump shaft seal can also become worn and start to leak. A kit for

replacing the vanes and the seal is available. The pump shaft seal can also be purchased as a

separate item. To replace the pump vanes, and/or the pump shaft seal, follow the steps below (refer

also to the illustration on Page 6).

1. Loosen the setscrew securing the pump handle to the pump shaft and slip the handle off the shaft.

If unit is a BKSDU remove the eight screws that secure the pump cover in place and remove the

cover.

2. Remove the five screws securing the front cover and remove the cover.

If replacing the pump shaft seal only, remove the old seal and install the replacement as shown in

the illustration below, then go to Step 5.

If replacing the pump vanes, go to Step 3.

3. Grasp the pump shaft and carefully pull the rotor assembly straight out of the pump housing far

enough to expose the vanes. IMPORTANT: The vanes are spring-loaded. Use one hand to

hold the vanes while pulling the rotor assembly the rest of the way out of the housing. Carefully

release the vanes and discard the worn vanes, springs, and rods.

5

Page 9

Pump shaft seal fits into the

recess of the pump cover.

Step 5 - Replace gasket.

Step 1 - Loosen

setscrew and

remove handle.

Step 3 - Grasp

shaft and pull

Step 4 - Replace

vanes, spring,

and rod.

rotor assembly

out of housing.

Step 2 - Remove cover

screws and cover.

4. Assemble the replacement vanes, spring and rod into the rotor assembly. Compress the vane

spring and carefully insert the rotor assembly back into the pump housing.

5. Position the replacement gasket on the pump body, slip the cover over the shaft, and align the

pins in the cover with the holes in the pump housing. Reinstall the five screws removed in Step

2 and tighten securely (torque to approximately 60 inch-pounds).

6. Slip the pump handle back onto the shaft and align the screw hole in the handle with the screw

hole in the shaft. Tighten the setscrew loosened in Step 1 securely.

6

Page 10

4. PARTS LIST

10

9

8

7

6

5

11

12

SDU 50, 90, 100 and

BKSDU units built April

2010 and later.

4

3

13

14

15

16

17

2

1

18

7

Page 11

Item Part # Component

1 810-3784 Wheel, 6” x 2”

2 809-0200 Washer, flat, ½”

3 809-1001 Screw, ¼ x 20 x ½”

4 823-2421 Handle, SDU 90, 100

* 823-2038 Handle, SDU 50, BKSDU

5 810-0777 Spring-loaded plunger

6 810-3858 Check valve, ¾” NPT (Added August 2010)

7 813-0032 Bushing, hex 1 x 3/4

8 810-0657 Pump handle

9 813-0109 Nipple, ¾ NPT close

10 823-4600 Discharge pipe, SDU 50, SDU 90

* 823-7935 Discharge pipe, SDU 100

* 823-4617 Discharge pipe, BKSDU

* 108-2580 SDU 100 Complete discharge assembly: pump, discharge pipes, check valve

* 108-2303 SDU 50/90 Complete discharge assembly: pump, discharge pipes, check valve

* 106-3767 BKSDU Complete discharge assembly: pump, discharge pipes

11 810-0784 Pump

* 826-1053

12 823-7849 Suction pipe, SDU 50, 90, 100

See BKSDU Pump Enclosure on page 11

* 823-4581 Suction pipe, BKSDU

13 816-0132 O-ring

14 809-1001 Screw, 1/4x20x1/2

* 809-0047 Cap, nut 1/4x20

* 809-0193 Flat washer, ¼ nylon

15 809-0119 Screw, 10x32x1/2

16 823-2422 Cover assembly, SDU 90

* 823-7804 Cover assembly, SDU 100

* 823-1683 Cover assembly, SDU 50, BKSDU

* 816-0877 Cover gasket, SDU 100

* 816-0264 Cover gasket, SDU 90

* 816-0134 Cover gasket, SDU 50, BKSDU

* 816-0133 Cover hinge gasket

* 108-2210 Crumb screen, SDU 100

* 108-0706 Crumb screen, SDU 90

* 108-0705 Crumb screen, SDU 50, BKSDU

17 810-0742 Latch

18 823-2420 Tank assembly, SDU 90

* 823-7803 Tank assembly, SDU 100

* 823-4580 Tank assembly, SDU 50

* 823-6268 Tank assembly, BKSDU

* 823-6267 Heater assembly for BKSDU (other BKSDU heater components on page 10,11)

* Not illustrated.

** CAUTION: Risk of fire and electric shock. Replace only with manufacturer’s cord set, part No. 8071224 for 120V.

Kit, Pump Repair (includes two vanes, one spring, one rod, one gasket.)

8

Page 12

NOTE: See Page 6 for BKSDU

pump assembly components.

SDU 50, 90, 100

and BKSDU units

built before April

2010.

1

3

2

5

6

7

8

9

11

4

10

14

12

13

(Crumb Basket

17

24

19

27

28

29

1611

383736

16

20

21

34

35

optional)

15

22 23

25

26

30

31

32

33

18

9

Page 13

Item Part # Component

1 Pipe Assembly, Discharge

823-4600

823-4598

2 813-0115 Nipple, ¾-inch x 3-inch Toe

3 813-0031 Bushing, ¾-inch x ½-inch

4 810-1845

5 813-0109 Nipple, ¾-inch x Close

6 810-0784

* 826-2774 Check valve kit

* 826-1053

* 816-0401 Seal, Pump Shaft

7 813-0032 Bushing 1-inch x ¾-inch Hex

8 823-4581 Pipe Assembly, Suction

9 810-0777 Pin, Plunger

10 Handle Assembly

823-2038 SDU50 and BKSDU

823-2421 SDU90

11 809-0119 Screw, 10-32 x ½-inch Slotted Head

12 Cover and Hinge Assembly

823-1683SP

823-2422SP

13

816-0134 SDU50 and BKSDU

816-0264 SDU90

14 816-0133 Gasket, Cover Hinge

15 Crumb Basket (optional)

824-0438 SDU50 and BKSDU

824-0615 SDU90

16 826-1376 Nut, 10-32 Keps Hex (Pkg. of 10)

17 816-0132

18 809-0200 Washer, Wheel ½” SAE

19 809-0193 Washer, ¼-inch Nylon Flat

20 809-0191 Lock Washer, ¼-inch

21 809-0047 Nut, ¼-20 S/S Cap

22 810-0742 Latch, Tank Cover

23 809-0359 Screw, #8 x ¼-inch

24 809-1001 Screw, ¼-20 x ½” Slotted Head

25 802-0227 Label, Fill Line

26 Tank and Axle Assembly

823-4580SP SDU50 and BKSDU

826-2103 SDU50 Retrofit Kit for SDU’s manufactured before Jan. 2004.

823-4583 SDU90 If replacing tank manufactured pre-Jan.2004, 823-4581 will also be needed.

27x 823-1911

28x 807-1219

29 809-0266

30 810-0783 Cotter Pin, Wheel

31 809-0054

32 814-0051

33 809-0122

34 810-1112 Wheel, 7-inch x 1½-inch

35 807-1577

* 807-1224

36 823-1915

37 809-0104

38 809-0247

* 815-0661 Adhesive, 3M 1300L

* Not illustrated.

** CAUTION: Risk of fire and electric shock. Replace only with manufacturer’s cord set, part No. 8071224 for 120V.

Standard (includes Item 2) (use 823-4617 for BKSDU)

For use with Item 4 (Hose Discharge) (includes Item 3)

Hose, 24-inch Discharge (Optional) (use 810-2797 for 48-inch hose)

Pump (includes handle 810-0657, which may be ordered separately)

Kit, Pump Repair (includes two vanes, one spring, one rod, one gasket.)

SDU50 and BKSDU (does not include gasket (Item 13))

SDU90 (does not include gasket (Item 13))

Gasket, Cover (attach with 3M 1300L adhesive or equivalent)

O-ring, Suction Pipe Assembly (2 required)

Housing, 120VAC Receptacle (BKSDU only) (use 823-5060 for 240VAC)

Receptacle, 120V 3-wire (BKSDU only) (use 807-4108 for 240VAC)

Screw, #10 x ½-inch Phillips Truss Head (use 809-0396 for 240VAC Receptacle)

Nut, 10-32 Elastic Lock (BKSDU only)

Bumper, Rubber (BKSDU only)

Screw, 10-32 x ⅝-inch Slotted Round Head (BKSDU only)

Heater, 120V 50W 5” x 10” (BKSDU only)

Cord, Power – 120VAC (BKSDU only)** (use 106-4697 for 240VAC)

Shield Heater (BKSDU only)

Screw, 8-32 x ½-inch Slotted Truss Head (BKSDU only)

Nut, 8-32 Keps Hex (BKSDU only)

10

Page 14

5

1

NOTE: The BKSDU pump

assembly is identical to the SDU

50/SDU 90 pump assembly except

for the addition of the pump cover

and insulation and the modified

6

discharge pipe assembly.

ITEM PART # COMPONENT

1 823-1847 Cover and Handle Assembly, BKSDU

2 900-4429 Box, BKSDU Pump

3 811-0861 Insulation, 3-inch X 50-foot Adhesive-Backed Foam

4 823-4617 Pipe Assembly, BKSDU Discharge

5 809-0477 Screw, #10 X ¼-inch Philips Truss Head

6 809-0266 Screw, #10 X ½-inch Philips Truss Head

4

6

2

3

11

Page 15

THIS PAGE INTENTIONALLY LEFT BLANK

Page 16

Frymaster, L.L.C., 8700 Line Avenue, Shreveport, Louisiana 71106

TEL 1-318-865-1711 FAX (Parts) 1-318-688-2200 FAX (Tech Support) 1-318-219-7135

PRINTED IN THE UNITED STATES

SERVICE HOTLINE

1-800-551-8633

819-5703A

OCT 2011

Loading...

Loading...