Page 1

*819

6666

*

(HPRE) RE80 Electric

E4 High Production RE

Service & Parts Manual

Frymaster, a member of the Commercial Food Equipment Service Association, recommends using

CFESA Certified Technicians.

www.frymaster.com E-mail: service@frymaster.com

24-Hour Service Hotline 1-800-551-8633

JAN 2011

Page 2

NOTICE

IF, DURING THE WARRANTY PERIOD, THE CUSTOMER USES A PART FOR THIS ENODIS

EQUIPMENT OTHER THAN AN UNMODIFIED NEW OR RECYCLED PART PURCHASED DIRECTLY

FROM FRYMASTER DEAN, OR ANY OF ITS AUTHORIZED SERVICE CENTERS, AND/OR THE

PART BEING USED IS MODIFIED FROM ITS ORIGI NAL CONFIGUR ATION, THI S WARRANTY WI LL

BE VOID. FURTHER, FRYMASTER DEA N AND ITS AFFILIATES WILL NOT BE LIABLE FOR ANY

CLAIMS, DAMAGES OR EXPENSES INCURRED BY THE CUSTOMER WHICH ARISE DIRECTLY OR

INDIRECTLY, IN WHOLE OR IN PART, DUE TO THE INSTALLATION OF ANY MODIFIED PART

AND/OR PART RECEIVED FROM AN UNAUTHORIZED SERVICE CENTER.

DANGER

Copper wire suitable for at least 167°F (75°C) must be used for power connections.

DANGER

The electrical power supply for this appliance must be the same as indicated on the rating and

serial number plate located on the inside of the fryer door.

DANGER

This appliance must be connected to the voltage and phase as specified on the rating and serial

number plate located on the inside of the fryer door.

DANGER

All wiring connections for this appliance must be made in accordance with the wiring diagrams

furnished with the equipment. Wiring diagrams are located on the inside of the fryer door.

DANGER

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any

other appliance.

WARNING

Do not attach accessories to this fryer unless fryer is secured from tipping. Personal injury may

result.

WARNING

Frymaster fryers equipped with legs are for permanent installations. Fryers fitted with legs

must be lifted during movement to avoid damage and possible bodily injury. For a moveable or

portable installation, Frymaster optional equipment casters must be used.

Questions? Call 1-800-551-8633 or email at service@frymaster.com.

WARNING

Do not use water jets to clean this equipment.

WARNING

This equipment is intended for indoor use only. Do not install or operate this equipment in

outdoor areas.

i

Page 3

DANGER

Adequate means must be provided to limit the movement of this appliance without depending

on or transmitting stress to the electrical conduit. A restraint kit is provided with the fryer. If

the restraint kit is missing contact your local Frymaster Factory Authorized Service Center

(FASC) for part number 826-0900.

DANGER

Prior to movement, testing, maintenance and any repair on your Frymaster fryer, disconnect all

electrical power from the fryer.

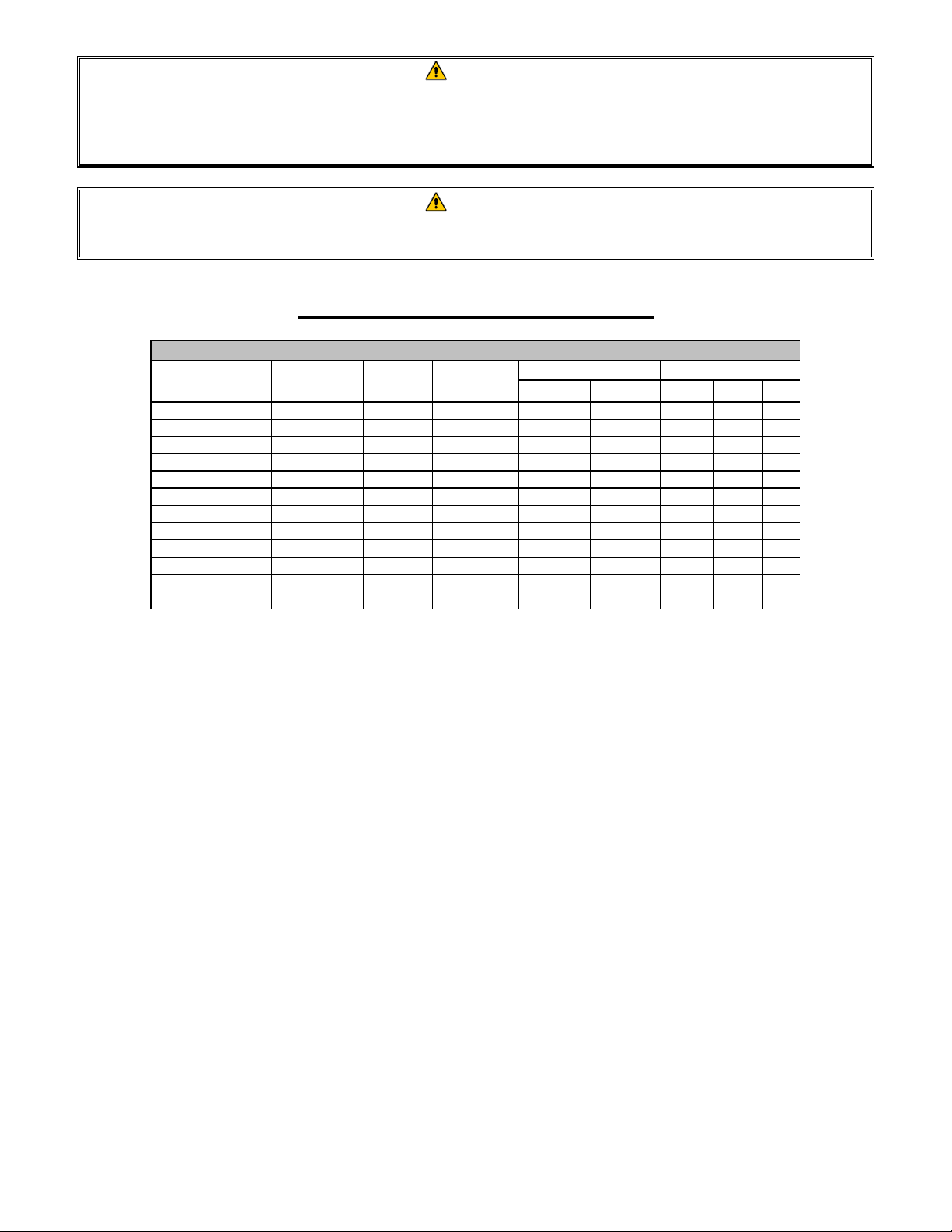

ELECTRICAL POWER SPECIFICATIONS

Three (3) Phase Requirements

WIRE

kW VOLTAGE PHASE

17 208 3 3 6 16 48 48 48

17 240 3 3 6 16 41 41 41

17 480 3 3 6 16 21 21 21

17 220/380 3 4 6 16 26 26 26

17 240/415 3 4 6 16 24 24 24

17 230/400 3 4 6 16 25 25 25

21 208 3 3 4 25 57 57 57

21 240 3 3 4 25 50 50 50

21 480 3 3 6 16 25 25 25

21 220/380 3 4 6 16 N/A N/A N/A

21 240/415 3 4 6 16 29 29 29

21 230/400 3 4 6 16 27 27 27

SERVICE

MINIMUM SIZE AMPS PER LEG

AWG mm2 L1 L2 L3

ii

Page 4

E4 SERIES HIGH PRODUCTION RE ELECTRIC FRYERS TABLE OF

CONTENTS

CAUTIONARY STATEMENTS ........................................................................................................ i

ELECTRICAL POWER SPECIFICATIONS ................................................................................. ii

CHAPTER 1: Service Procedures

1.1 General .............................................................................................................................. 1-1

1.2 Replacing a Controller ....................................................................................................... 1-1

1.3 Replacing Component Box Components .......................................................................... 1-1

1.4 Replacing a High-Limit Thermostat .................................................................................. 1-3

1.5 Replacing a Temperature Probe ........................................................................................ 1-3

1.6 Replacing a Heating Element ............................................................................................ 1-5

1.7 Replacing Contactor Box Components ............................................................................. 1-6

1.8 Replacing a Frypot ............................................................................................................ 1-7

1.9 Built-In Filtration System Service Procedures .................................................................. 1-9

1.9.1 Filtration System Problem Resolution ............................................................... 1-9

1.9.2 Replacing the Filter Motor, Filter Pump and Related Components ................. 1-10

1.9.3 Replacing the Filter Transformer or Filter Relay ............................................. 1-12

1.10 Basket Lift Service Procedures ....................................................................................... 1-12

1.11 Interface Board Diagnostic Chart .................................................................................... 1-15

1.12 Probe Resistance Chart .................................................................................................... 1-16

1.13 Wiring Diagrams ............................................................................................................. 1-17

1.13.1 Basket Lift (480V/120V Control Supply) ........................................................ 1-17

1.13.2 PBI Basket Lift ................................................................................................. 1-18

1.13.3 Standard Component Wiring ............................................................................ 1-18

1.13.4 Component Wiring – Single Phase .................................................................. 1-18

1.13.5 Component Wiring – 480V Non-Filter ............................................................ 1-21

1.13.6 Component Wiring – Fast Ready ..................................................................... 1-22

1.13.7 Component Wiring – KFC-1 ............................................................................ 1-23

1.13.8 Contactor Box – Domestic 17 kW ................................................................... 1-24

1.13.9 Contactor Box – Domestic 21 kW ................................................................... 1-24

1.13.10 Contactor Box – Export .................................................................................... 1-25

CHAPTER 2: Parts List

2.1 Accessories ........................................................................................................................ 2-1

2.2 Cabinetry ........................................................................................................................... 2-2

2.2.1 Backs, Control Panel Frames, Doors, Sides, Tilt Housings and Top Caps ........ 2-2

2.2.2 Cabinet Bases, Braces and Associated Parts ...................................................... 2-5

2.2.3 Basket Lift Assembly and Associated Parts ....................................................... 2-7

2.3 Filtration System Components .......................................................................................... 2-9

2.3.1 Filter Pan ............................................................................................................ 2-9

2.3.1 Filter Pump ....................................................................................................... 2-11

2.4 Drain System Components .............................................................................................. 2-12

2.4.1 Drain Valves and Associated Parts .................................................................. 2-12

2.4.2 Drain Tube Sections and Associated Parts ....................................................... 2-14

2.5 Oil Return System Components ...................................................................................... 2-15

2.5.1 Oil Disposal Wand ........................................................................................... 2-15

2.5.2 KFC Over-the-Top Return ............................................................................... 2-18

2.5.3 Drain Flush ....................................................................................................... 2-19

iii

Page 5

E4 SERIES HIGH PRODUCTION RE ELECTRIC FRYERS

TABLE OF CONTENTS (cont.)

2.6 Heating Elements ............................................................................................................ 2-20

2.6.1 Element Assemblies and Hardware .................................................................. 2-20

2.6.2 Element Tube Assembly .................................................................................. 2-22

2.7 Frypots and Associated Components .............................................................................. 2-33

2.8 Controllers ....................................................................................................................... 2-24

2.9 Electronics and Electrical Components ........................................................................... 2-25

2.9.1 Component Boxes ............................................................................................ 2-25

2.9.2 Contactor Boxes ............................................................................................... 2-27

2.9.3 Fuse Boxes ....................................................................................................... 2-29

2.9.4 Terminal Blocks ............................................................................................... 2-30

2.9.5 Cordsets ............................................................................................................ 2-31

2.10 Wiring ............................................................................................................................. 2-31

2.10.4 Contactor Box Wiring Assemblies 6-Pin (Left) & 9-Pin (Right) Elements ..... 2-31

2.10.5 Main Wiring Harnesses .................................................................................... 2-32

2.11 Pin Connectors ................................................................................................................ 2-33

2.12 Fasteners .......................................................................................................................... 2-34

iv

Page 6

E4 SERIES HIGH PRODUCTION RE ELECTRIC FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.1 General

Before performing any maintenance on your Frymaster fryer, disconnect the fryer from the electrical

power supply.

When electrical wires are disconnected, it is recommended that they be marked in such a way as to

facilitate re-assembly.

1.2 Replacing a Controller

1. Disconnect the fryer from the electrical power supply.

2. The controller bezel is held in place by tabs at the top and bottom. Slide the metal bezel up to

disengage the lower tabs. Then slide the bezel down to disengage the upper tabs.

3. Remove the two screws from the upper corners of the control panel. The control panel is hinged

at the bottom and swings open from the top.

4. Unplug the wiring harness from the connector on the back of the controller and disconnect the

grounding wire from terminal adjacent to the connector. Remove the control panel assembly by

lifting it from the hinged slots in the control panel frame.

5. Remove the controller from the control panel assembly and install the replacement controller.

Reinstall the control panel assembly by reversing steps 1 and 2.

1.3 Replacing Component Box Components

1. Disconnect the fryer from the electrical power supply.

2. The controller bezel is held in place by tabs at the top and bottom. Slide the metal bezel up to

disengage the lower tabs. Then slide the bezel down to disengage the upper tabs.

3. Remove the two screws from the upper corners of the control panel and allow the control panel

to swing down.

4. Unplug the wiring harness from the 15-pin connector on the interface board and disconnect the

grounding wire from terminal adjacent to the 15-pin connector on the back of the controller.

Remove the control panel assembly by lifting it from the hinge slots in the control panel frame.

5. Disconnect the wiring from the component to be replaced, being sure to make a note of where

each wire was connected.

6. Dismount the component to be replaced and install the new component, being sure that any

required spacers, insulation, washers, etc. are in place.

1-1

Page 7

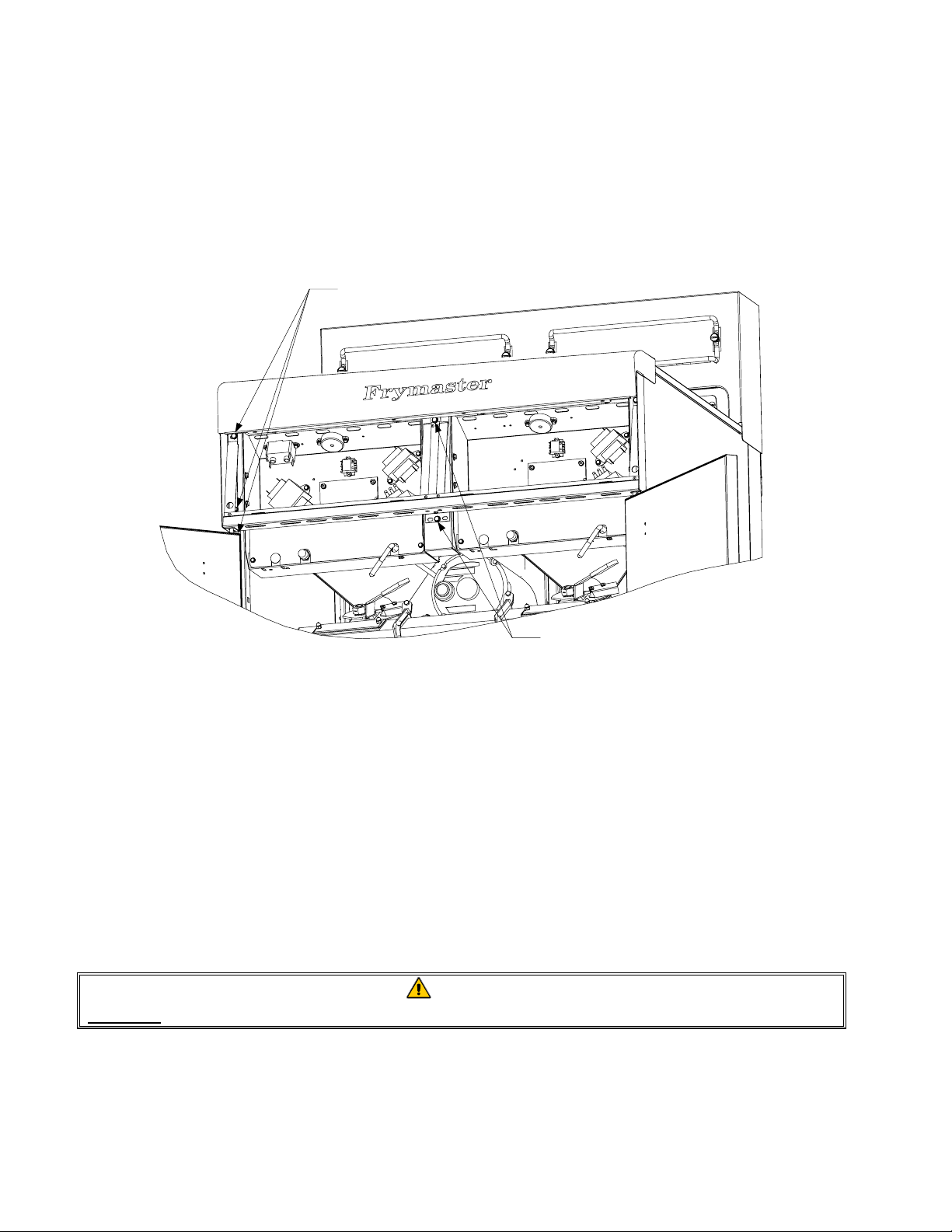

NOTE: If more room to work is required, the control panel frame assembly may be removed by

removing the hex head screws that secure it to the fryer cabinet (see illustration below). If this

option is chosen, all control panel assemblies must be removed per steps 1 and 2 above. The

cover plate on the lower front of the component box may also be removed if desired. Removing

the component box itself from the fryer is not recommended due to the difficulty involved in

disconnecting and reconnecting the oil-return valve rods, which pass through openings in the

component box.

Remove these three

screws at each end.

Remove these two screws

from the center supports.

Removing the Control Panel Frame and Top Cap Assembly

7. Reconnect the wiring disconnected in Step 3, referring to your notes and the wiring diagrams on

the fryer door to ensure that the connections are properly made. Also, verify that no other wiring

was disconnected accidentally during the replacement process.

8. Reverse steps 1 through 4 to complete the replacement and return the fryer to service.

1.4 Replacing a High-Limit Thermostat

1. Remove the filter pan and lid from the unit. Drain the frypots into a Shortening Disposal Unit

(SDU) or other appropriate metal container.

DANGER

DO NOT drain more than one full frypot or two split frypots into the SDU at one time.

2. Disconnect the fryer from the electrical power supply and reposition it to gain access to the rear

of the fryer.

3. Remove the four screws from both the left and right sides of the lower back panel.

1-2

Page 8

4. Locate the high-limit that is being replaced and follow the two-black wires to the 12-pin

connector C-6. Note where the leads are connected prior to removing them from the connector.

Unplug the 12-pin connector C-6 and using a pin-pusher push the pins of the high-limit out of

the connector.

5. Using a wrench, carefully unscrew the high-limit thermostat to be replaced.

6. Apply Loctite

™

PST 567 or equivalent sealant to the threads of the replacement and screw it

securely into the frypot.

7. Insert the leads into the 12-pin connector C-6 (see illustration below). For full-vat units or the

left half of a dual-vat unit (as viewed from the rear of the fryer) the leads go into positions 1 and

2 of the connector. For the right half of a dual-vat unit (as viewed from the rear of the fryer), the

leads go into positions 7 and 8. In either case, polarity does not matter.

8. Reconnect the 12-pin connecting plug C-6. Use wire ties to secure any loose wires.

9. Reinstall the back panels reposition the fryer under the exhaust hood, and reconnect it to the

electrical power supply to return the fryer to service.

1.5 Replacing a Temperature Probe

1. Remove the filter pan and lid from the unit. Drain the frypots into a Shortening Disposal Unit

(SDU) or other appropriate metal container.

DANGER

DO NOT drain more than one full frypot or two split frypots into the SDU at one time.

2. Disconnect the fryer from the electrical power supply and reposition it to gain access to the rear

of the fryer.

3. Remove the four screws from both sides of the lower back panel. Then remove the two screws

on both the left and right sides of the back of the tilt housing. Lift the tilt housing straight up to

remove from the fryer.

4. Locate the red and white wires of the temperature probe to be replaced. Note where the leads

are connected prior to removing them from the connector. Unplug the 12-pin connector C-6 and

using a pin-pusher push the pins of the temperature probe out of the connector.

1-3

Page 9

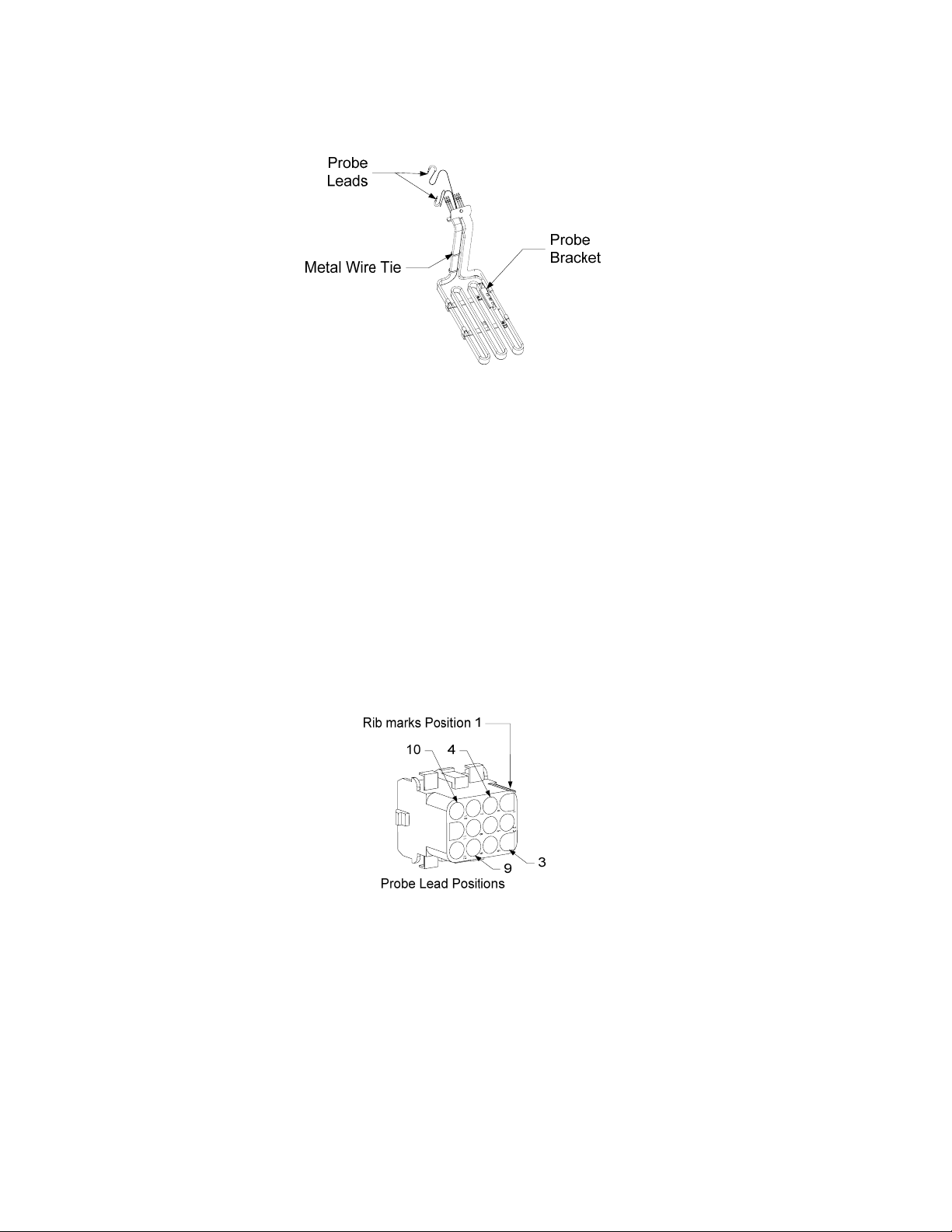

5. Raise the element and remove the securing probe bracket and metal tie wraps that secure the

probe to the element (see illustration below).

6. Gently pull on the temperature probe and grommet, pulling the wires up the rear of the fryer and

through the element tube assembly.

7. Insert the replacement temperature probe (wires first) into the tube assembly ensuring that the

grommet is in place. Secure the probe to the elements using the bracket which was removed in

Step 5 and the metal tie wraps which were included in the replacement kit.

8. Route the probe wires out of the tube assembly following the element wires down the back of the

fryer through the Heyco bushings to the 12-pin connector C-6. Secure the wires to the sheathing

with wire ties.

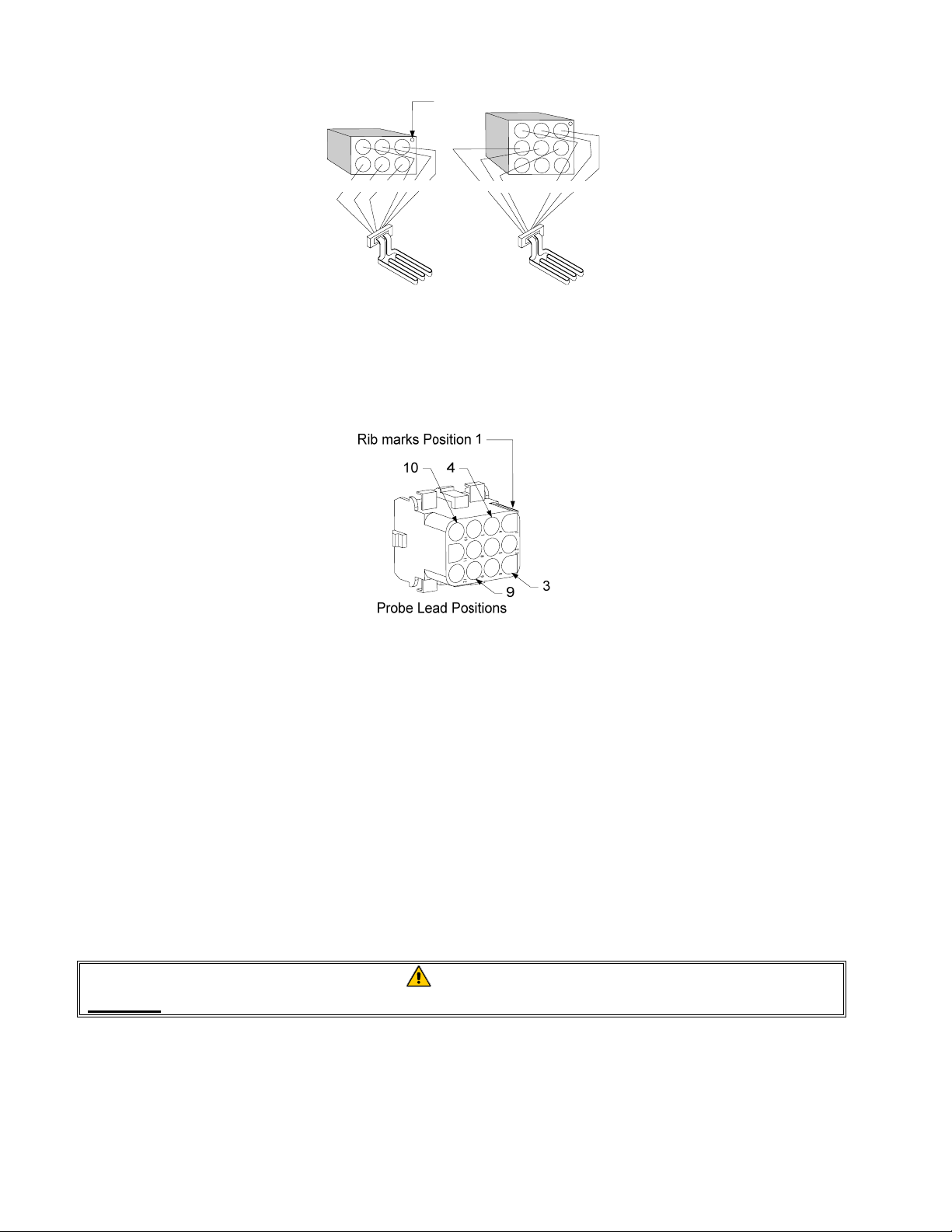

9. Insert the temperature probe leads into the 12-pin connector C-6 (see illustration below). For

full-vat units or the right half of a dual-vat unit (as viewed from the rear of the fryer) the red lead

goes into position 3 and the white lead into position 4 of the connector. For the left half of a

dual-vat unit (as viewed from the rear of the fryer), the red lead goes into position 9 and the

white lead into position 10. NOTE: Right and left refer to the fryer as viewed from the rear.

10. Secure any loose wires with wire ties making sure that the lead wires will not interfere with the

movement of the springs. Rotate the elements up and down making sure that movement is not

restricted and that the wires are not pinched.

11. Reinstall the tilt housing and back panels, reposition the fryer under the exhaust hood, and

reconnect it to the electrical power supply to return the fryer to service.

1.6 Replacing a Heating Element

1. Perform steps 1-3 of section 1.5, Replacing a Temperature Probe.

1-4

Page 10

2. On dual-vat fryers, and on full-vat fryers where the temperature probe is attached to the element

being replaced, disconnect the wire harness containing the probe wiring. Using a pin pusher,

disconnect the probe wires from the 12-pin connector C-6.

3. Remove screws holding element wiring cover in place and remove cover.

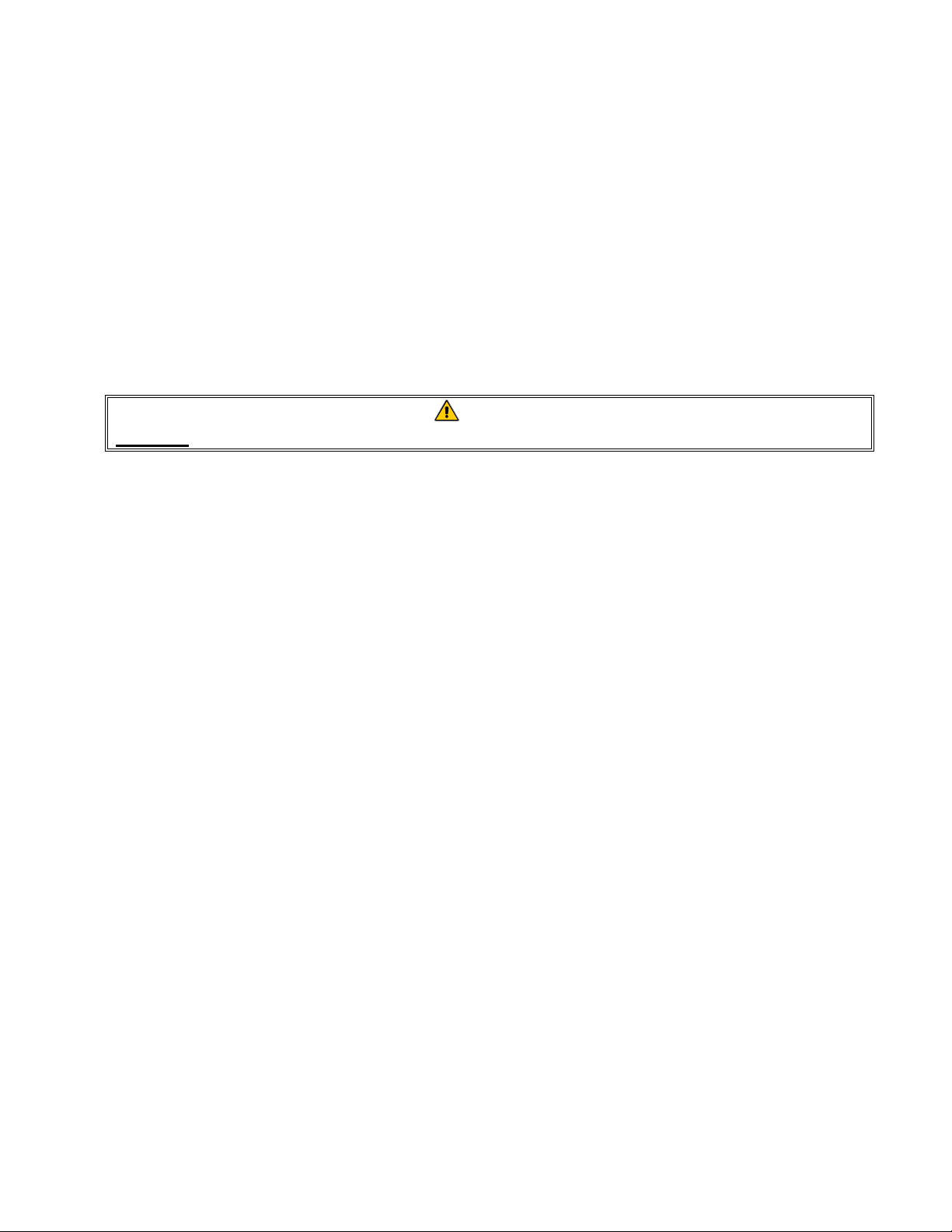

4. In the rear of the fryer directly behind the frypot disconnect the 6-pin connector for the left

element (as viewed from the front of the fryer) or the 9-pin connector for the right element.

Press in on the tabs on each side of the connector while pulling outward on the free end to extend

the connector and release the element leads (see photo below). Pull the leads out of the

connector and out of the wire sleeving.

5. Raise the element to the full up position and support the elements.

6. Remove the hex head screws and nuts that secure the element to the tube assembly and pull the

element out of the frypot. NOTE: Full-vat elements consist of two dual-vat elements clamped

together. For full-vat units, remove the element clamps before removing the nuts and screws that

secure the element to the tube assembly.

7. If applicable, recover the probe bracket and probe from the element being replaced and install

them on the replacement element. Install the replacement element in the frypot, securing it with

the nuts and screws removed in Step 5 to the tube assembly. Ensure the gasket is between the

tube and element assembly.

8. Route the element leads through the element tube assembly and into the wire sleeving to prevent

chafing. Ensure that the wire sleeving is routed back through the Heyco bushing keeping it clear

from the lift springs. Also ensure that the wire sleeving extends into the tube assembly to

prevent the edge of the tube assembly from chafing the wires. Press the pins into the connector

in accordance with the diagram on the following page, and then close the connector to lock the

leads in place. NOTE: It is critical that the wires be routed through the sleeving to prevent

chafing.

1-5

Page 11

Index Marker marks

Position 1

14253

14253

6

5L 4L6L 1L2L3L

6

789

5

6

4R

R

R

2

1R

3R

R

9. Reconnect the element connector ensuring that the latches lock.

10. Insert the temperature probe leads into the 12-pin wiring harness connector C-6 (see illustration

below). For full-vat units or the right half of a dual-vat unit, the red lead goes into position 3 and

the white into position 4. For the left half of a dual-vat unit, the red lead goes into position 9 and

the white into position 10. NOTE: Right and left refer to the fryer as viewed from the rear.

10. Reconnect the 12-pin connector C-6 of the wiring harness disconnected in Step 2.

11. Lower the element down onto the basket rack.

12. Reinstall the tilt housing, upper cover and back panels, reposition the fryer under the exhaust

hood, and reconnect it to the electrical power supply.

1.7 Replacing Contactor Box Components

1. If replacing a contactor box component above the built-in filter system, remove the filter pan and

lid from the unit. Drain the frypots into a Shortening Disposal Unit (SDU) or other appropriate

metal container. If replacing a contactor box component in a non-filter unit or a frypot that’s not

over the filter pan, drain the frypot above the box into a Shortening Disposal Unit (SDU) or other

appropriate metal container.

DANGER

DO NOT drain more than one full frypot or two split frypots into the SDU at one time.

2. Disconnect the fryer from the electrical power supply.

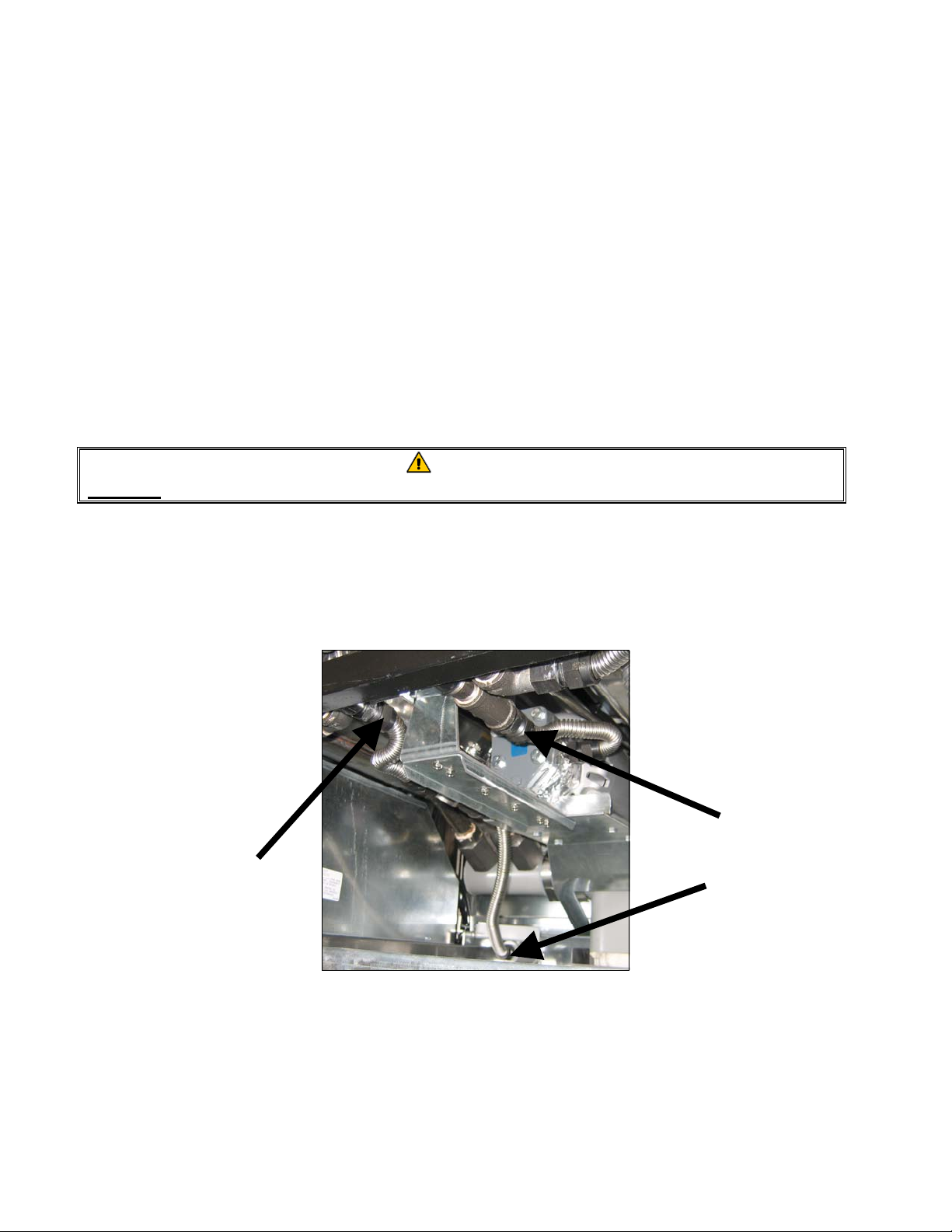

3. Remove the two screws securing the cover of the contactor box. The contactor boxes above the

filter pan are accessed by sliding under the fryer. They are located to the left and right above the

1-6

Page 12

guide rails (see photo below). The contactor boxes of non-filter units or frypots not over the

filter pan are accessed by opening the fryer door directly under the affected frypot.

4. The contactors and relays are held on by threaded pin studs so that only removal of the nut is

required to replace the component.

5. After performing necessary service, reverse steps 1-4 to return the fryer to operation.

1.8 Replacing a Frypot

1. Drain the frypot into the filter pan or, if replacing a frypot over the filter system, into a

Shortening Disposal Unit (SDU) or other appropriate metal container. If replacing a frypot over

the filter system, remove the filter pan and lid from the unit.

DANGER

DO NOT drain more than one full frypot or two split frypots into the SDU at one time.

2. Disconnect the fryer from the electrical power supply and reposition it to gain access to both the

front and rear.

3. Slide the metal bezel up to release the bottom tabs, then slide the bezel down to disengage the

upper tabs.

4. Remove the two screws from the upper corners of the control panels and allow them to swing

down (see illustration and photo on page 1-1).

5. Unplug the wiring harnesses and ground wires from the backs of the controllers. Remove the

controllers by lifting them from the hinge slots in the control panel frame.

6. Remove the tilt housing and back panels from the fryer. The tilt housing must be removed first in

order to remove the upper back panel.

7. To remove the tilt housing remove the hex head screws from the rear edge of the housing. The

housing can be lifted straight up and off the fryer.

8. Remove the control panel by removing the screw in the center and the nuts on both sides.

9. Loosen the component boxes by removing the screws, which secure them in the cabinet.

10. Dismount the top cap by removing the nuts at each end that secure it to the cabinetry.

11. Remove the hex head screw that secures the front of the frypot to the cabinet cross brace.

12. Remove the top-connecting strip that covers the joint with the adjacent frypot.

13. Unscrew the Teflon vent/vacuum-breaker tube fitting, unscrew the nut located on the front of

each section of drain tube, and remove the tube assembly from the fryer.

1-7

Page 13

14. Remove the covers from the drain safety switch(es) and disconnect the switch wiring at the

switch(es).

15. At the rear of the fryer, unplug the 12-pin connector C-6 and, using a pin pusher, disconnect the

high-limit thermostat leads.

16. Disconnect the oil return flexline(s) at the frypot end(s).

17. Raise the elements to the “up” position and disconnect the element springs.

18. Remove the machine screws and nuts that secure the element tube assembly to the frypot.

Carefully lift the element assembly from the frypot and secure it to the cross brace on the rear of

the fryer with wire ties or tape.

19. Carefully lift the frypot from the fryer and place it upside down on a stable work surface.

20. Recover the drain valve(s), oil return flexline connection fitting(s), and high-limit thermostat(s)

from the frypot. Clean threads and apply Loctite™ PST 567 or equivalent sealant to the threads

of the recovered parts and install them in the replacement frypot.

21. Carefully lower the replacement frypot into the fryer. Reinstall the hex head screw removed in

step 7 to attach the frypot to the fryer.

22. Position the element tube assembly in the frypot and reinstall the machine screws and nuts

removed in step 14.

23. Reconnect the oil return flexlines to the frypot, and replace aluminum tape, if necessary, to

secure heater strips to the flexlines.

24. Insert the high-limit thermostat leads disconnected in step 13 (see illustration on page 1-3 for pin

positions).

25. Reconnect the drain safety switch wiring to the switch(es) in accordance with the diagram below

then reinstall the switch covers.

RIGHT

ORANGE Pin 15 J4

BLUE Pin 1 C6

ORANGE Pin 7 J4

BLUE Pin 7 C6

26. Reinstall the drain tube assembly.

DRAIN SAFETY SWITCH

LEFT

DRAIN SAFETY SWITCH

(DUAL-VAT ONLY)

27. Reinstall the top connecting strips, top cap, control panel, component box, tilt housing and back

panels.

28. Reinstall controllers in the control panel frame and reconnect the wiring harnesses and ground

wires.

29. Reposition the fryer under the exhaust hood and reconnect it to the electrical power supply.

1-8

Page 14

1.9 Built-in Filtration System Service Procedures

1.9.1 Filtration System Problem Resolution

One of the most common causes of filtration problems is placing the filter paper on the bottom of the

filter pan rather than over the filter screen.

CAUTION

Ensure that filter screen is in place prior to filter paper placement and filter pump

operation. Improper screen placement is the primary cause of filtration system

malfunction.

Whenever the complaint is “the pump is running, but no oil is being filtered,” check the installation

of the filter paper, and ensure that the correct size is being used. While you are checking the filter

paper, verify that the O-rings on the pick-up tube of the filter pan are in good condition. Missing or

worn O-rings allow the pump to take in air and decrease its efficiency.

If the pump motor overheats, the thermal overload will trip and the motor will not start until it is

reset. If the pump motor does not start, press the red reset switch (button) located on the rear of the

motor at the front of the fryer.

If the pump starts after resetting the thermal overload switch, then something is causing the motor to

overheat. A major cause of overheating is when several frypots are filtered sequentially, overheating

the pump and motor. Allow the pump motor to cool at least 30 minutes before resuming operation.

Pump overheating can be caused by:

• Solidified shortening in the pan or

Sediment Particle

filter lines, or

• Attempting to filter unheated oil

(cold oil is more viscous,

Oil Flow

overloading the pump motor and

causing it to overheat).

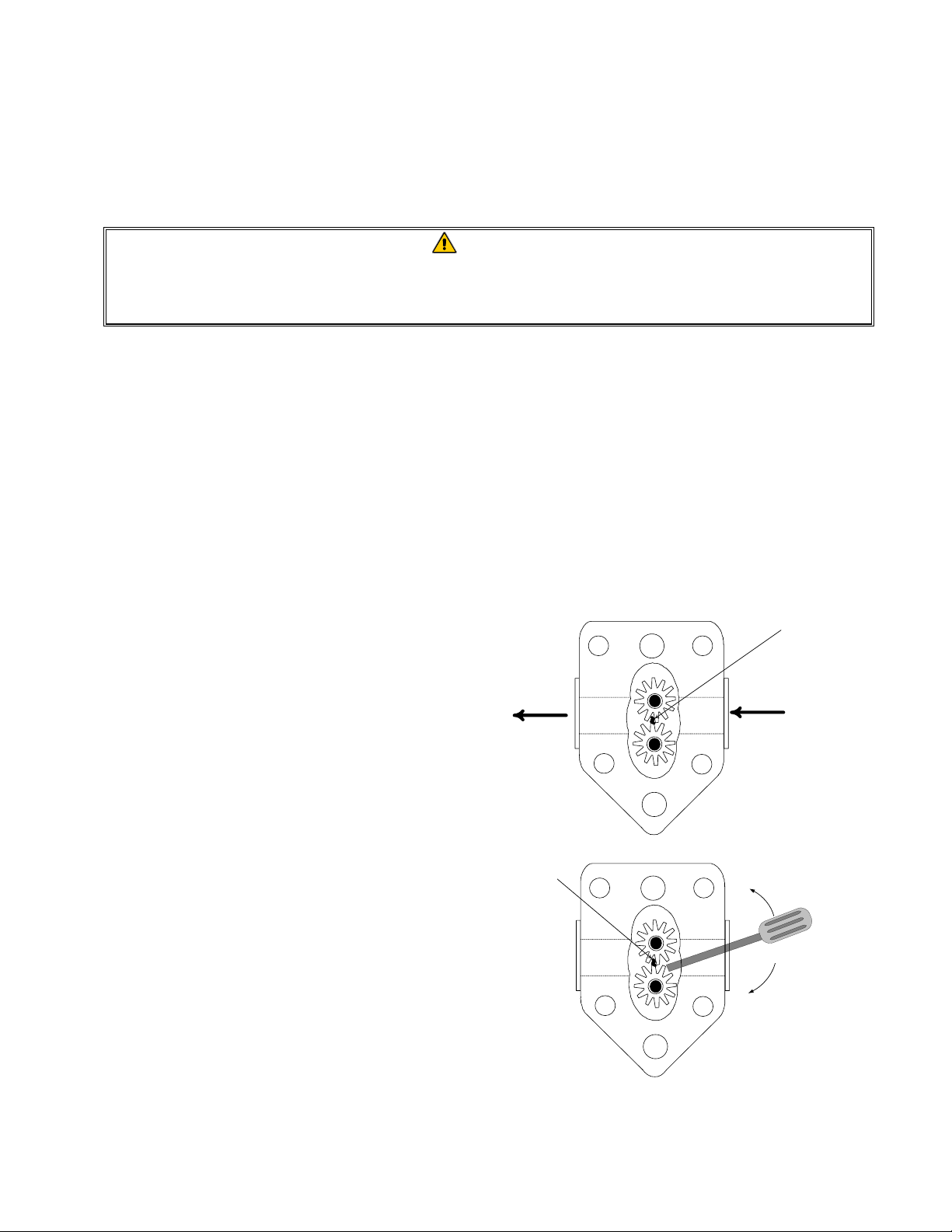

If the motor runs but the pump does not

return oil, there is a blockage in the pump.

Incorrectly sized or installed paper/pads will

allow food particles and sediment to pass

through the filter pan and into the pump.

Sediment Particle

Up for reverse

When sediment enters the pump, the gears

bind, causing the motor to overload, again

tripping the thermal overload. Shortening

that has solidified in the pump will also

Down for forward

cause it to seize, with the same result.

A pump seized by debris or hard shortening

can usually be freed by manually moving

the gears with a screwdriver or other

instrument.

1-9

Page 15

Disconnect power to the filter system, remove the input plumbing from the pump, and use a

screwdriver to manually turn the gears.

● Turning the pump gears in reverse will release a hard particle.

● Turning the pump gears forward will push softer objects and solid shortening through the

pump and allow free movement of the gears.

Incorrectly sized or installed paper/pads will also allow food particles and sediment to pass through

and clog the suction tube on the bottom of the filter pan. Particles large enough to block the suction

tube may indicate that the crumb tray is not being used. Pan blockage can also occur if shortening is

left in the pan and allowed to solidify. Blockage removal can be accomplished by forcing the item

out with an auger or drain snake. Compressed air or other pressurized gases should not be used to

force out the blockage.

1.9.2 Replacing the Filter Motor, Filter Pump, and Related Components

1. Drain the frypots into a Shortening Disposal Unit (SDU) or other appropriate metal container.

DANGER

DO NOT drain more than one full frypot or two split frypots into the SDU at one time.

2. Disconnect the fryer from the electrical power supply and reposition it to gain access to both the

front and rear.

3. Disconnect the two flexlines running to the oil-return manifold at the rear of the fryer as well as

the pump suction flexline at the end of the filter pan connection (see photo below).

Disconnect flexlines indicated by the arrows.

4. Remove the cover plate from the front of the motor and disconnect the motor wires.

5. Unplug the pump motor assembly 6-pin connector C-2 and, using a pin pusher, disconnect the

vent vacuum-breaker solenoid (pins 2 and 5) that is attached to the oil return manifold.

1-10

Page 16

6. When complete, reverse steps to reinstall the bridge. NOTE: The black motor wires go on the

top terminal, the white on the bottom. The pump solenoid valve wires go in positions 1 and 4 of

the 6-pin connector C-2; the vent vacuum-breaker solenoid valve wires go in positions 2 and 5;

the red/black heater tape wires go into position 3 and the violet/white wires go into position 6

(see illustration on the following page).

7. Disconnect any heater tape wiring from connectors and remove heater tape. Motor and pump can

be separated and removed individually or as one unit.

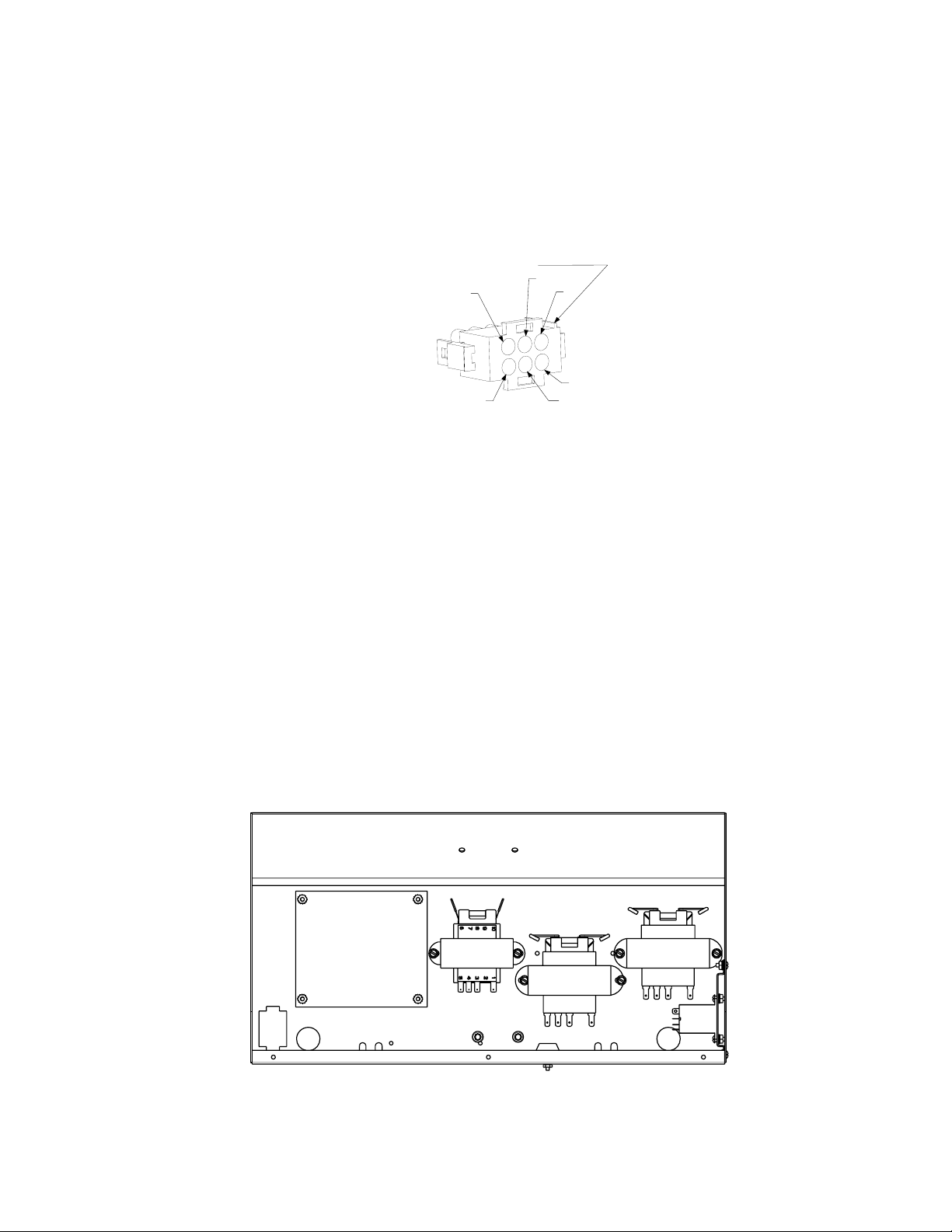

Rib marks position 1

3

Oil Return Solenoid, Vent Solenoid

and Heater Lead Positions

6

2

1

4

5

8. Reconnect the unit to the electrical power supply, and verify that the pump is functioning

correctly (i.e., when a filter handle is placed in the ON position, the motor should start and there

should be strong suction at the intake fitting and outflow at the rear flush port.)

9. When proper operation has been verified, reinstall the back panels and the filter pan and lid.

10. Reposition the fryer under the exhaust hood and reconnect it to the electrical power supply to

return the fryer to service.

1.9.3 Replacing the Filter Transformer or Filter Relay

Disconnect the fryer from the electrical power supply. Remove the left controller from the fryer to

expose the interior of the left component box. The filter transformer and relay are behind the

controller on a single fryer or just right of the filter in a bank of two or more. The filter transformer

and relay are located as shown in the illustration below. .

RE Control Box

1-11

Page 17

1.10 Basket Lift Service Procedures

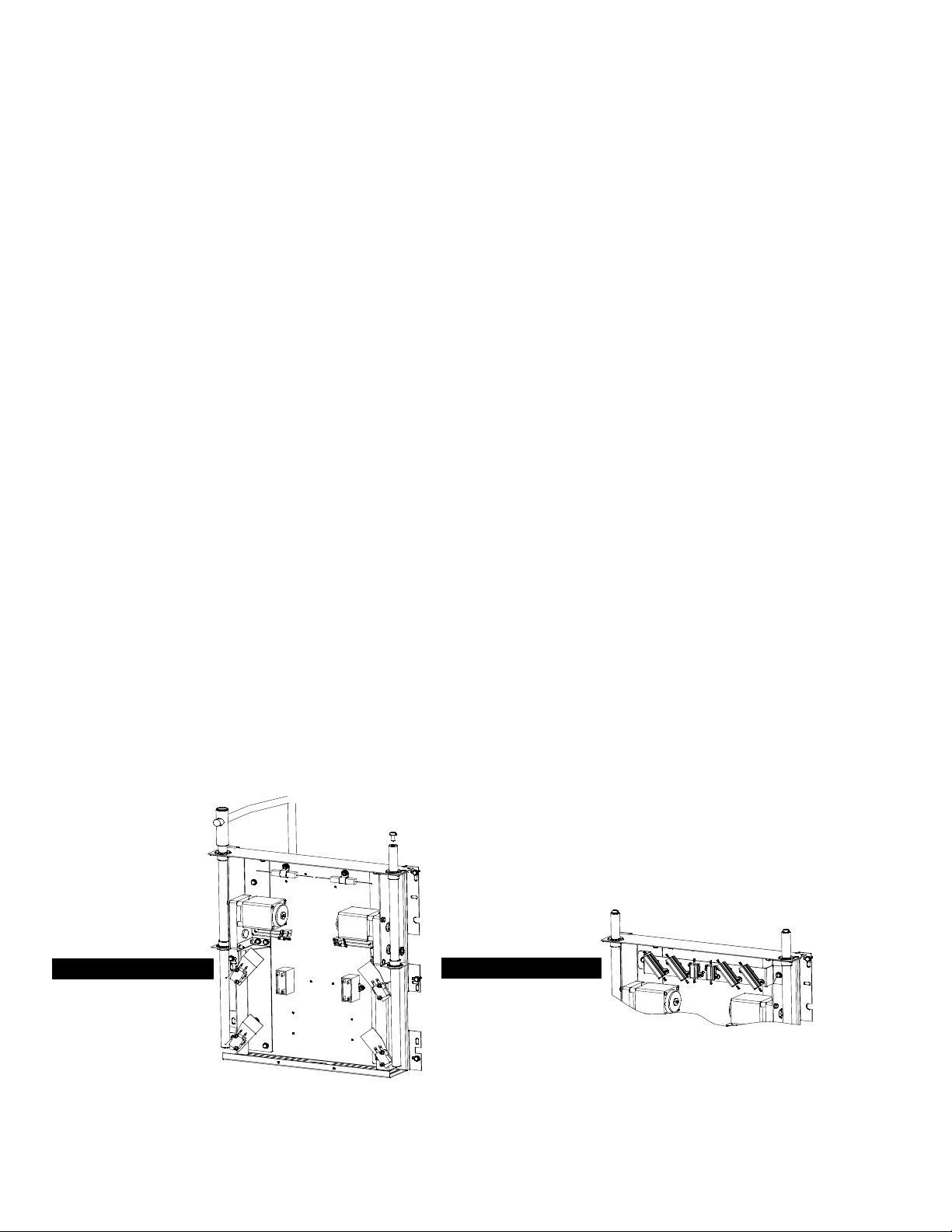

High Production RE Series electric fryers may be equipped with automatic basket lifts. Basket lifts

always come in pairs, although each operates independently.

A modular basket lift (illustrated on the following page) is a self-contained sub-assembly

consisting of a pair of toothed rods which support removable basket lift arms, a pair of reversibledrive gear motors, and four microswitches. The gear motors engage the teeth of the rods, moving

them up or down depending upon the motors’ direction of rotation. The microswitches at the upper

and lower limits of movement stop the motors when the basket is in the full up or full down position.

Timing circuitry in the controller initiates and stops basket lift operation depending upon the

variables programmed by the operator. When the product button is pressed, the timing circuitry

activates a coil in the basket lift relay to supply power to the lower microswitch. The microswitches

stop the motor at the lift’s upper and lower travel limits and reverse the direction of current flow thus

reversing the motor direction.

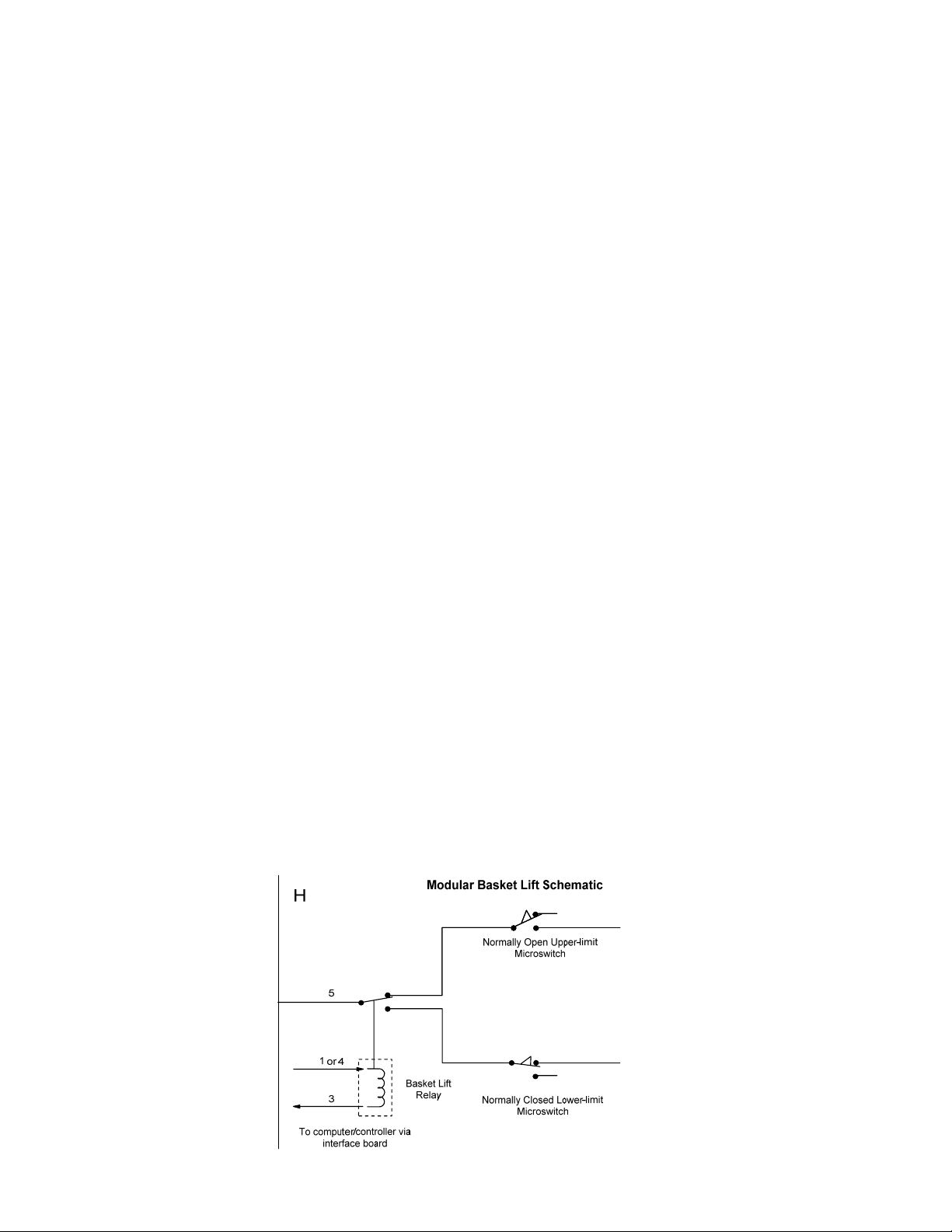

When the product button is pushed on the computer/controller, current flows through a coil in the

basket lift relay, causing the lower circuit to be activated. The basket lift lowers, closing the

normally open upper-micro-switch. When the downward-moving rod opens the lower normally

closed microswitch, the power to the motor ceases to flow. When the computer/controller times out,

the current to the relay coil is cut, allowing the upper circuit to be activated. The basket lift then

raises and re-closes the lower microswitch. When the basket lift rod clears the upper microswitch,

the microswitch reopens, power to the circuit is cut, and the motor stops. Pushing the product button

restarts the cycle.

Problems with the basket lift can be grouped into three categories:

● Binding/jamming problems

● Motor and gear problems

● Electronic problems

100-120V Configuration

208-250V Configuration

1-12

Page 18

BINDING/JAMMING PROBLEMS

Noisy, jerky or erratic movement of the lifts is usually due to lack of lubrication of the rods and their

bushings. Apply a light coat of Lubriplate® or similar lightweight white grease to the rod and

bushings to correct the problem.

With the modular basket lift, another possible cause of binding is improper positioning of the motor,

which prevents the gear from correctly engaging the teeth in the rod. To correct the problem, loosen

the screws that hold the motor in place and move it forward or backward until the rod has just

enough slack to be rotated slightly.

MOTOR AND GEAR PROBLEMS

With the modular basket lift, the most likely problem to be encountered in this category is erratic

motion of the lift due to a worn drive gear. Failure to keep the lift rod and bushings properly

lubricated will cause unnecessary wear of the gear. The problem is corrected by replacing the worn

gear.

If the lift cycles correctly but fails to remain in the up position (i.e., goes up, but then slowly settles

back down into the frypot), the problem is a failed motor brake. A failed motor brake cannot be

repaired and requires replacement of the motor itself.

If power is reaching the motor but the motor fails to run, the motor is burned out and must be

replaced.

ELECTRONIC PROBLEMS

Within this category are problems associated with the relays, microswitches, capacitors, resistors,

interface board, wiring, and controls. The most common problem in this category is a lift that

continuously travels up and down. This is usually caused by a microswitch that is out of adjustment.

Troubleshooting the electronics of a modular basket lift is simply a process of verifying current flow

through the individual components up to and including the motor. Using a multimeter set to the 250

VAC range, check the connections on both sides of the component for the presence of the applied

line voltage. The schematic below and the wiring diagram on page 1-16 can identify the

components and wiring connection points.

1-13

Page 19

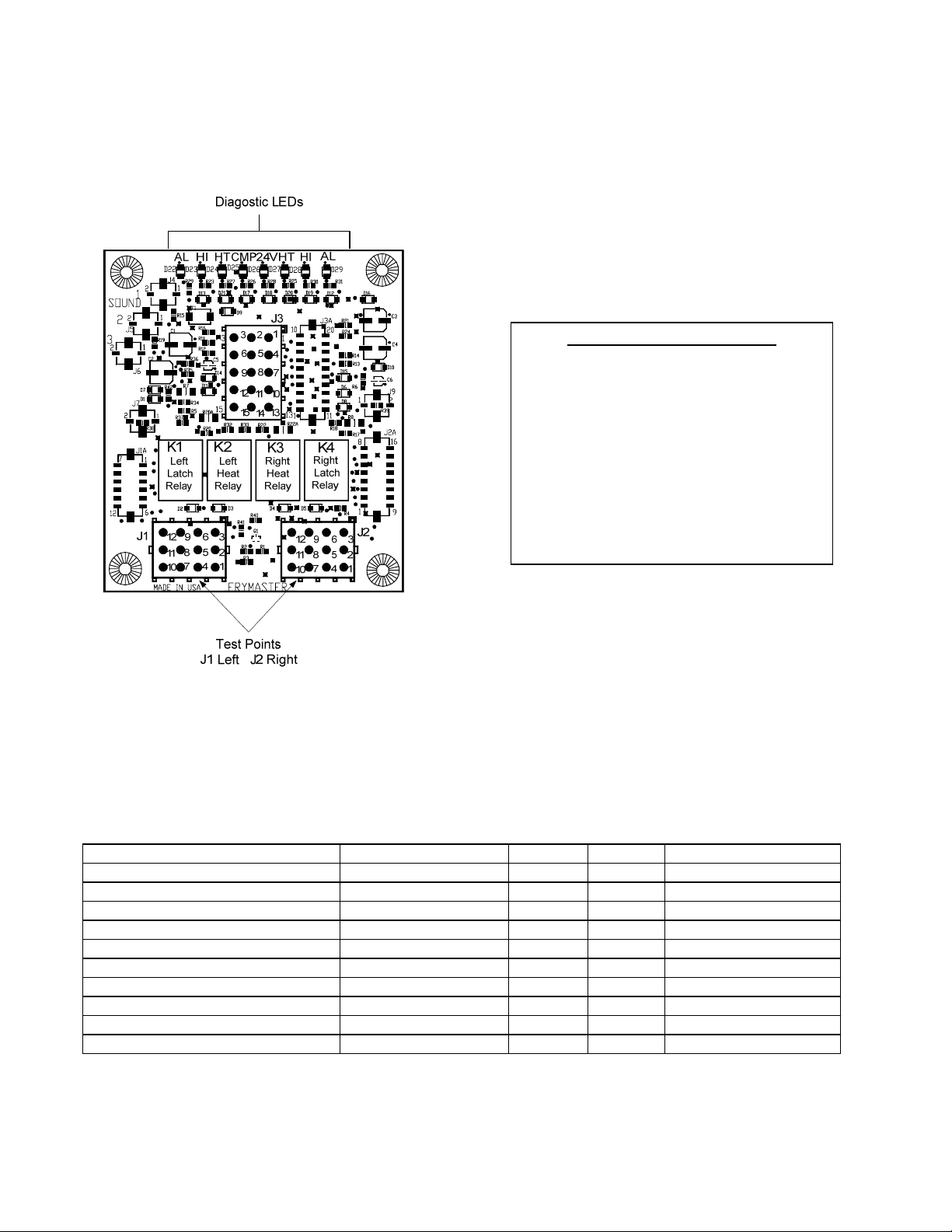

1.11 Interface Board Diagnostic Chart

The following diagram and charts provide ten quick system checks that can be performed using only

a multimeter.

Diagnostic LED Legend

CMP indicates power from 12V transformer

24 indicates power from 24V transformer

HI (RH) indicates output (closed) from right latch

relay

HI (LH) indicates output (closed) from left latch relay

HT (RH) indicates output from right heat relay

HT (LH) indicates output from left heat relay

AL (RH) indicates output (open) from right latch relay

AL (LH) indicates output (open) from left latch relay

PN 106-6664

NOTE – When testing the test points on J1

and J2 test use the illustration above disregarding any silk-screened numbers on

the board depicting the location of Pin 1.

Pin 1 is located in the bottom right corner of

both J1 and J2. These test points are ONLY

for RE Series boards with J1 and J2 plugs on

the front of the board.

Meter Setting Test Pin Pin Results

12 VAC Power 50 VAC Scale 3 of J2 1 of J2 12-16 VAC

24 VAC Power 50 VAC Scale 2 of J2 Chassis 24-30 VAC

*Probe Resistance (RH) R X 1000 OHMS 11 of J2 10 of J2 See Chart

*Probe Resistance (LH) R X 1000 OHMS 1 of J1 2 of J1 See Chart

High-Limit Continuity (RH) R X 1 OHMS 9 of J2 6 of J2 0 - OHMS

High-Limit Continuity (LH) R X 1 OHMS 6 of J1 9 of J1 0 - OHMS

Latch Contactor Coil (RH) R X 1 OHMS 8 of J2 Chassis 3-10 OHMS

Latch Contactor Coil (LH) R X 1 OHMS 5 of J1 Chassis 3-10 OHMS

Heat Contactor Coil (RH) R X 1 OHMS 7 of J2 Chassis 11-15 OHMS

Heat Contactor Coil (LH) R X 1 OHMS 4 of J1 Chassis 11-15 OHMS

* Disconnect 15-Pin harness from the computer/controller before testing the probe circuit.

1-14

Page 20

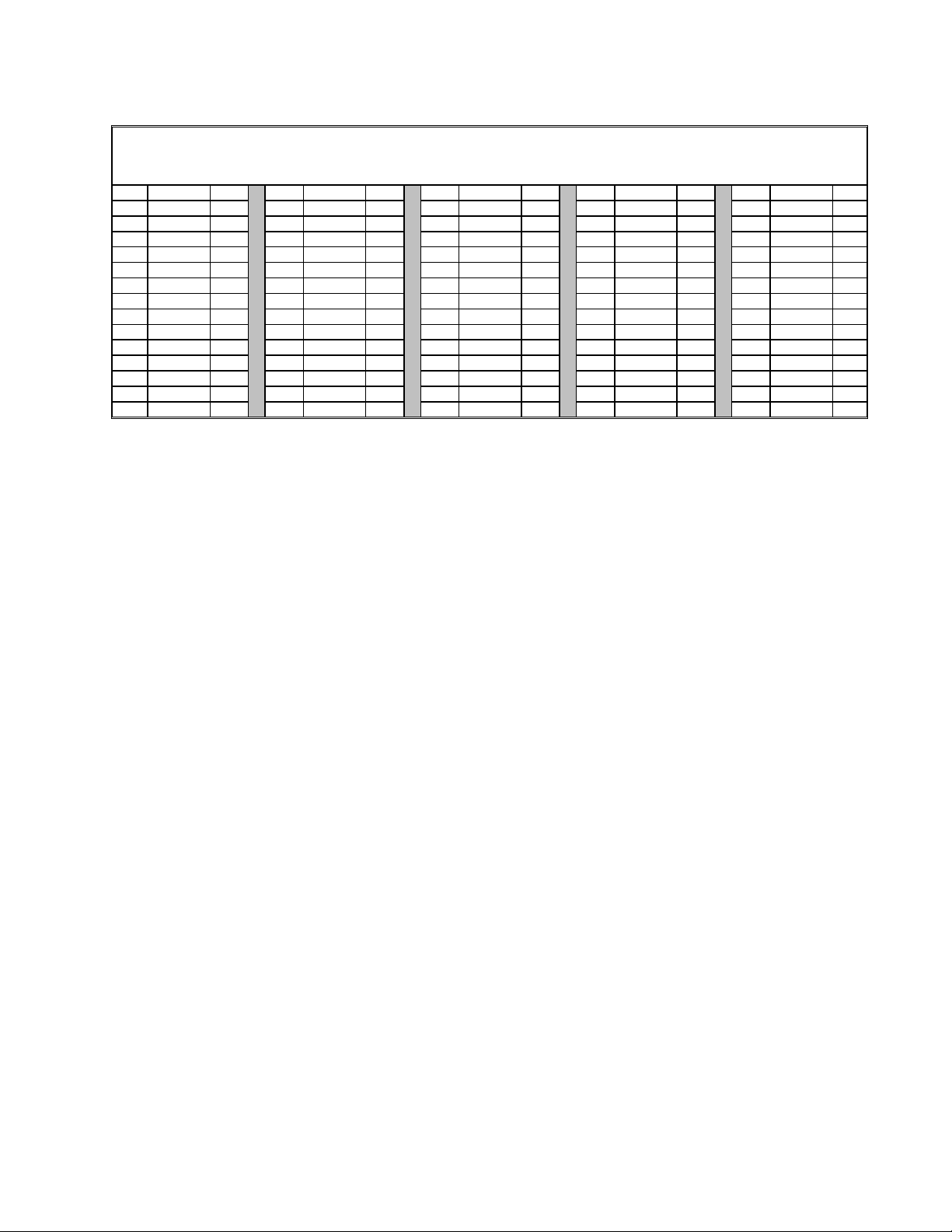

1.12 Probe Resistance Chart

Probe Resistance Chart

For use with fryers manufactured with Minco Thermistor probes only.

F OHMS C F OHMS C F OHMS C F OHMS C F OHMS C

60 1059 16 130 1204 54 200 1350 93 270 1493 132 340 1634 171

65 1070 18 135 1216 57 205 1361 96 275 1503 135 345 1644 174

70 1080 21 140 1226 60 210 1371 99 280 1514 138 350 1654 177

75 1091 24 145 1237 63 215 1381 102 285 1524 141 355 1664 179

80 1101 27 150 1247 66 220 1391 104 290 1534 143 360 1674 182

85 1112 29 155 1258 68 225 1402 107 295 1544 146 365 1684 185

90 1122 32 160 1268 71 230 1412 110 300 1554 149 370 1694 188

95 1133 35 165 1278 74 235 1422 113 305 1564 152 375 1704 191

100 1143 38 170 1289 77 240 1432 116 310 1574 154 380 1714 193

105 1154 41 175 1299 79 245 1442 118 315 1584 157 385 1724 196

110 1164 43 180 1309 82 250 1453 121 320 1594 160 390 1734 199

115 1174 46 185 1320 85 255 1463 124 325 1604 163 395 1744 202

120 1185 49 190 1330 88 260 1473 127 330 1614 166 400 1754 204

125 1195 52 195 1340 91 265 1483 129 335 1624 168 405 1764 207

1-15

Page 21

1.13 Wiring Diagrams

1.13.1 Basket Lift

1-16

Page 22

1.13.2 PBI Basket Lift

1-17

Page 23

1.13.3 Standard Component Wiring

1-18

Page 24

1.13.4 Component Wiring – Single Phase

805-1786

1-19

Page 25

1.13.5 Component Wiring – 480V Non-Filter

805-1776

1-20

Page 26

1.13.6 Component Wiring - Fast Ready

1-21

Page 27

1.13.7 Component Wiring – KFC-1

1-22

Page 28

1.13.8 Contactor Box – Domestic, 17 kW

1.13.9 Contactor Box – Domestic, 21 kW

1-23

Page 29

1.13.10 Contactor Box – Export

1-24

Page 30

E4 SERIES HIGH PRODUCTION RE ELECTRIC FRYERS

2.1 Accessories

CHAPTER 2: PARTS LIST

1

2

3

4

5

7

8

9

ITEM PART # COMPONENT

1 809-0985 Thumbscrew, ¼ -20 X 1⅜-inch

2 810-2794 Basket Hanger

* 230-4318 Basket Hanger, KFC

* 809-0941 Spacer, Basket Hanger

3 803-0197 Cleanout Rod, 27-inch

4 803-0278 Brush, Teflon, L-shaped

5 Joiner Strip

230-4766 Standard

823-7066 Church’s/Popeye’s

230-5382 Battering Strip (Standard, 1 per 5-vat or 6-vat unit)

823-7100 Battering Strip (Church’s, 1 per 5-vat or 6-vat unit)

823-6341 Caster Battering Plate

6 108-0220 Frypot Cover

* 108-0217 Frypot Cover, Church’s

7 803-0304 Basket, Twin

8 803-0387 Grid, Basket Support

9 810-3066 Grid, Basket Support, Church’s

* 803-0293 Gloves, Hot Oil/Neoprene (pair)

* 803-0342 Powder, Filter (25 count box)

* 823-7169 Splash Guard, Church’s or Popeye’s

* Not illustrated.

6

2-1

Page 31

2.2 Cabinetry

2.2.1 Back Panels, Tilt Housings, Top Caps, and Doors

2-2

Page 32

2.2.1 Back Panels, Tilt Housings, Top Caps, and Doors (cont.)

ITEM PART # COMPONENT

1

220-5033 x1

220-5034 x2, x4 (2), x5 (1)

220-5149 x3, x5 (1), x6 (2)

220-5618

220-5313 x1

220-5314 x2, x5 (1), x4 (2)

220-5315 x3, x5 (1), x6 (2)

220-7582

220-5617

2

823-7019 x1

823-6947 x2

823-6874 x3

823-7022 x4

823-7014 x1

823-6782 x2

823-7133 x3

823-7022 x1

823-7073 x2, x5 (1)

823-7074 x3, x5 (1), x6 (2)

823-7075 x4

3 823-5440 Cove, Element Tilt Housing

4

108-0026 x1

106-9429 x2, x5 (1)

106-9602 x3, x5 (1), x6 (2)

108-0027 x4

108-0034 x1

108-0040 x2, x5 (1)

108-0042 x3, x5 (1), x6 (2)

108-0036 x4

108-0128 x1

108-0126 x2, x5 (1)

108-0127 x3, x5 (1), x6 (2)

108-0130 x4

5

106-5492 x1

106-5907 x2, x5 (1)

106-6085 x3, x5 (1), x6 (2)

106-4574 x4

* Not illustrated.

Back, Cabinet

Standard

KFC with Over the Top Filtration (2-vat)

Church’s/Popeye’s

Single Filter Cabinet

With Basket Lift

Tilt Housing

KFC with Over the Top Filtration

Church’s/Popeye’s

Top Cap

Frymaster

Dean

Church’s/Popeye’s

Control Frame

Standard

2-3

Page 33

2.2.1 Back Panels, Tilt Housings, Top Caps, and Doors (cont.)

ITEM PART # COMPONENT

106-8427 x1

106-7166 x2

6

230-0489 x1, x3 (1), x5 (1)

210-8175 x2, x3 (1), x4 (2), x5 (2), x6 (3)

230-5478 x1, x3 (1), x5 (1)

230-5477 x2, x3 (1), x4 (2), x5 (2), x6 (3)

230-7720 x1, x3 (1), x5 (1)

230-7721 x2, x3 (1), x4 (2), x5 (2), x6 (3)

230-4771 With Switch Cut-out (1 per wand connection for Church’s/Popeye’s)

106-4309 Door, Left or Right (Left shown – move handle to opposite side for Right) - Standard

7 210-8075 Panel, Door

8 200-8076 Panel, Liner

9 106-4067 Pin Assembly

10 810-0275 Spring, Door Hinge/Pin

11 210-8077 Handle

12 810-2346 Magnet

* Not illustrated.

FAST

Computer Bezel

Standard

KFC

K3000

2-4

Page 34

2.2.2 Cabinets, Bases, Braces, and Associated Parts (FINAL)

8

13

3

6

2

11

9

12

5

4

1

16

15

10

7

20

17

Three-vat unit shown here.

ITEM PART # COMPONENT

1

106-8224 x1, Filter Cabinet

106-6534 x2, Filter Cabinet

106-5622 x3, Filter Cabinet

106-4424 x4, Filter Cabinet

106-5622 x5, Filter Cabinet

106-5622 x6, Filter Cabinet

106-6643 x1, Non-filter Cabinet

106-6436 x2, Non-filter Cabinet

106-9425 x3, Non-filter Cabinet

2

810-3118 x2, x5 (1)

810-3121 x3, x5 (1), x6 (2)

810-3120 x4

3 220-2082 Strap, Manifold Brace (x2, x3)

* Not illustrated.

Base Assembly

Oil Return Manifold

19

18

14

2-5

Page 35

2.2.2 Cabinets, Bases, Braces, and Associated Parts cont.

ITEM PART # COMPONENT

4 231-4896 Side, Stainless Steel, Left

5 232-4896 Side, Stainless Steel, Right

221-5073 Side, Painted, Left

222-5073 Side, Painted, Right

221-5170 Side, Inner, Left (x5 and x6 units)

222-5170 Side, Inner, Right (x5 and x6 units)

6 220-5983 Divider (multi-vat units)

7 220-5112 Front (all x2, x4, x5, x6 units and x3 filter cabinet)

8 220-2250 Front (x3 non-filter cabinet)

9 220-5032 Rear, Standard

* 220-5210 Rear, Church’s/Popeye’s

10 220-4937 Brace, Frypot Locating

* 220-5979 Brace, Pump Motor Support

* 220-5490 Mount, Contactor Box (x1)

11 220-4860 Bracket, Lower Spring

12

220-0274 x1

200-9590 x2, x5 (1)

220-0608 x3, x5 (1), x6 (2)

x4

13

220-0274 x1

220-1809 x2, x3, x4, x5, x6

14

220-5267 x1

220-4999 x2, x3 (1), x5 (1)

200-8100 x3 (1), x4 (2), x5 (3), x6 (4)

220-4570 x2

220-4569 x3

15 824-1966 Bridge, Filter

16 Filter Pan Lid (see next section)

17 221-2576 Rail, Left

18 222-2576 Rail, Right

19 823-3347 Frame, Slide Base

20 823-6450 Bracket, Disconnect

* 826-1115 Leg Assembly (includes 810-3168)

* 826-1118 Caster Assembly with Brake (includes 810-0357)

* 826-1117 Caster Assembly without Brake (includes 810-0356)

* 826-0900 Chain Restraint Kit (required for all caster installations)

* Not illustrated.

Cabinet Sides

Post

Brace, Upper Cabinet, Front

Brace, Upper Cabinet, Rear

Brace, Lower Cabinet, Front

Brace, Lower Cabinet, Rear

2-6

Page 36

2.2.3 Basket Lift Assembly and Associated Parts

33

30

29

28

34

31

32

35

17

24

26

1

25

4 17

17

15

3

20

3

14

27

2

222110

16

181298

175

11

2-7

Page 37

2.2.3 Basket Lift Assembly and Associated Parts (cont.)

ITEM PART # COMPONENT

106-3775

106-4147

106-4148

1 810-1012 Rod, Basket Lift

2 813-0035 Bushing, Bronze

3 807-2513 Capacitor, 12.5 μFarad 330VAC

4 901-8499 Chassis, Left Basket Lift

5 902-8499 Chassis, Right Basket Lift

6 807-0159 Connector, 12-Pin Female

7 900-5529 Gusset, Basket Lift Motor

8 812-0442 Insulation, Microswitch

9 807-2572 Microswitch

10 806-5964SP Motor Assembly, 208-240VAC Modular Basket Lift

11 200-6455 Mount, Modular Basket Lift

12 826-1366 Nut, 4-40 Hex Keps (Pkg. of 25)

13 809-0247 Nut, 8-32 Hex Keps

14 807-1683 Relay, 12VDC

15

806-8530SP 100-120VAC Modular Basket Lift

106-2770SP 208-220VAC Modular Basket Lift

106-2771SP 230-250VAC Modular Basket Lift

16 809-0082 Ring, Bushing Retainer

17 826-1374 Screw, #10 X ½-inch Hex Washer Head (Pkg. of 25)

18 826-1359 Screw, 4-40 X ¾-inch Slotted Round Head (Pkg. of 25)

19 826-1361 Screw, 8-32 X 1-inch Slotted Truss Head (Pkg. of 25)

20 826-1371 Screw, #8 X ½-inch Drill Point Hex Head (Pkg. of 25)

21 809-0503 Screw, 8-32 X ½-inch Hex Head

22 809-0186 Washer, #8 Lock

23 WIR-0166SP Wire Bundle, 200-250VAC Basket Lift w/Relay

24 910-4776 Cover, Modular Basket Lift Rear S/S (Use 900-4776 for Mild Steel)

25 809-0127 Screw, ¼-20 X ½-inch Slotted Round Head

26 823-2704 Arm, Left Basket Lift

27 823-2705 Arm, Right Basket Lift

28 810-0179 Button, Plug

29 806-9110SP

30 910-8112 Bracket, Basket Lift Roller

31 810-0194 Roller, Basket Lift

32 810-0374 Spacer, Basket Lift Roller

33 809-0508 Bolt, ¼-20 X 1¼ -Inch

34 809-0190 Washer, ¼-inch Flat

35 809-0047 Nut, ¼-20 Cap

* 106-3776 Wiring Harness, RE Series Electric Basket Lift (Plugs into Item 6)

* 824-1353 Basket Lift Drip Weldment, Right

* 824-1351 Basket Lift Drip Weldment, Left

* Not illustrated.

Basket Lift Assembly, 100-120VAC

Basket Lift Assembly, 208-220VAC

Basket Lift Assembly, 230-240VAC

Resistor Assembly

Roller Assembly, Basket Lift

2-8

Page 38

2.3.1 Filter Pan Assemblies

6

7

8

9

10

2

1

3

4

11

12

Single-vat Filter Assembly

11

12

Multi-vat Filter Assembly

5

2-9

Page 39

2.3.1 Filter Pan Assemblies (cont.)

ITEM PART # COMPONENT

106-7674SP

1 823-6943 Lid, Filter Pan

2 823-6172 Crumb Basket

3 810-3195 Hold-down Ring

4 106-7330 Sana Grid

5 823-7534 Filter Pan

106-8398

6 823-6508 Lid, Filter Pan

7 823-7386 Crumb Basket

8 810-3328 Hold-down Ring

9 108-1029 Sana Grid

10 823-7359 Filter Pan

108-0253

* 823-6466 Crumb Basket

* 810-2350 Filter Screen/Leaf

* 823-7112 Suction Tube

* 810-2583 Fitting, Bottom, Filter Screen/Leaf

* 810-2582 Fitting, Bulk Head, Filter Screen/Leaf

* 823-7111 Filter Pan

11 809-0823 Nut

12 810-2805 Caster

* 826-1979 Roller Kit (includes 4 rollers, 4 nuts and 4 lock washers)

* 826-1979 Filter Pan Roller Kit (four each of Items 7 and 8)

* Not illustrated.

Filter Assembly, Multi-vat, Paper Filtration

Filter Assembly, Single-vat, Paper Filtration

Filter Assembly, Multi-vat, Screen Filtration

2-10

Page 40

2.3.2 Filter Pump

ITEM PART # COMPONENT

1

816-0093 Pump Gasket

810-3347 8GPM Pump

826-1264 4 GPM Pump

826-1712 120V Filter Motor, Gasket

826-1756 208V Filter Motor, Gasket

826-1270 220-240V Filter Motor, Gasket

809-1020 Cap Screw to Connect Pump to Motor

2 106-9918 Harness Assembly, Filter Pump

3

4

5

6 813-0838 Nipple, ¼” NPT BM, Close

7 813-0304 Bushing, ½” x ¼” BM, Flush

* 813-0763 Bushing, ¾” OD x ½” ID NPT, Flush

* 813-0889

8

9

10 813-0331 Elbow, Side Outlet, ½” NPT

11 813-0003 Tee, ½” x ½” x ½” BM

12 810-3257 Fitting, ¼” NPT

13 810-1339 Flexline, ⅝” x 4.5” Long

14 810-1680 Flexline, ⅝” OD x 4.5” Long

15 810-1668 Adaptor, Male, ⅝” OD x ½”

16 810-1669 Adaptor, Female, ⅞” OD x ½”

17 106-3470 Solenoid Valve (with Female Pins)

* 813-0436 Plug, ½” Counter Sink

* Not illustrated.

813-0265 Nipple, ½” x 2.5” NPT BM

813-0298 Nipple, ½” x 2.0” NPT BM

813-0698 Nipple, ½” x 10.5” NPT BM

813-0342 Elbow, Street, 45°, ½”NPT

813-0165 Elbow, Street, ½” x ½” NPT, 90° BM

Filter Pump Components

Elbow, ½”, 90°

2-11

Page 41

2.4 Drain System Components

2.4.1 Drain Valve Assemblies

6

7

12

1

810-2126

22

23

10

4

8

3

21

20

11

14

2

5

108-0179

9

17

15

13

16

108-0124

12

26

24

19

25

108-1999 &

108-2086

18

2-12

Page 42

2.4.1 Drain Valve Assemblies (cont.)

ITEM PART# COMPONENT

1 810-2783 Valve, 1 ½” Full Port

2 816-0544PK O-ring (pack of 5)

3 807-2103 Microswitch, Straight Lever, Drain Safety Switch

4 106-3745 Bracket, Drain Safety Switch

5 200-5694 Cover, Drain Safety Switch

6 210-7077 Handle (multi-vat unit)

* 230-7413 Handle (single unit)

7 816-0405 Sleeve, Drain Handle, Red

8 809-0349 Spacer, 4.0 mm x 6.0 mm

9 809-0237 Nut, 4-40 Keps Hex (with extended teeth)

10 809-0988 Washer, 1" x .525" ID, Teflon

11 200-6116 Strap, Drain Valve Connecting, 1 ½” (single unit)

12 810-2126 Valve, 1 ¼” Full Port

13 807-2103 Microswitch, Straight Lever, Drain Safety Switch

14 106-9017 Bracket, Drain Safety Switch

15 901-2348 Cover, Drain Safety Switch

16 809-0349 Spacer, 4.0 mm x 6.0 mm

17 809-0237 Nut, 4-40 Keps Hex (with extended teeth)

18 810-2783 Valve, 1 ½” Full Port

19 816-0544PK O-ring (pack of 5)

20 807-2103 Microswitch, Straight Lever, Drain Safety Switch

21 807-4936 Microswitch, Gold Plated, Sealed

22 823-7749 Handle

23 809-0237 Nut, 4-40 Keps Hex (with extended teeth)

24 200-6116 Strap, Drain Valve Connecting, 1 ½” (single unit)

25 108-2006 Stud Assembly

26 816-0220 Insulation, Drain Safety Switch

* 106-9924 Standard, K3000

* 108-0250 KFC

* 807-5123 K3000

* 106-7718 Wire Assembly, Jumper (for units with no float switch or drain switch)

* Not illustrated.

Drain Valve (units equipped with filtration)

Drain Valve (units NOT equipped with filtration)

Drain Valve (K3000)

Drain Safety Harness

2-13

Page 43

2.4.2 Drain System Plumbing

ITEM PART# COMPONENT

27 812-2078 Downspout, Center

28 823-4681 Right, 8” Long (with coupling)

29 823-5188 Right, 10.5” Long

30 200-9365 Right, 9” Long (no drain connection)

31 823-4844 Left, 12.5” Long (with coupling)

34 812-2078 Downspout, Center

35 823-7016 Right, 8” Long

36 823-5188 Right, 10.5” Long

37 200-9365 Right, 9” Long (no drain connection)

38 823-7015 Left, 12.5” Long

* 823-4844 Left, 12.5” Long (with coupling)

39 200-6615 9” Long (no drain connection)

40 812-2131 Downspout, Multi-height

41 816-0772 Sleeve, Drain Connecting

42 809-0969 Clamp, T-bolt

* 816-0665 Vinyl Cap

* 812-1226 Drain Extension, 1.25-inch

* 220-5944 Drain Support (for spreader cabinets)

* Not illustrated.

Drain Plumbing

With Drain Flush

Without Drain Flush

2-14

Page 44

2.5 Oil Return System Components

20

1

18

12

15

16

13

14

19

10

11

9

8

7

2

6

5

3

4

2-15

Page 45

2.5 Oil Return System Components (cont.)

ITEM PART # COMPONENT

1

106-9711

106-9712

108-0717

* 106-9928 Rear Harness

* 106-9929 Jumper Harness

2 220-4955 Handle Mount

3 200-8929 Handle, Oil Return

4 816-0638 Vinyl Cap, Yellow

5 809-0601 Clevis Clip, Rod End

6 810-1668 Adapter, Male, 5/8” OD x ½”

7 813-0062

* 813-0165

8 813-0265 Nipple, ½ NPT x 2½” BM

* 813-0087 Nipple, ½ NPT x 1½” BM

* 813-0247 Nipple, ½ NPT x 3.5” BM

9 813-0281 Nipple, ½ NPT x 5” BM

10 810-1067 Flexline, 8.5”

* 813-0003 Tee, ½ NPT BM

11 106-4006

12 901-2772 Handle

13 807-2103 Microswitch, Straight Lever

14 220-2459 Cover, Drain Safety Switch

15 106-3962 Bracket Assembly, Microswitch

16 816-0220 Insulation, Oil Return Microswitch

17 826-1366 Nut, 4-40 Keps Hex (Pkg. of 25)

18 900-2935 Retainer, Nut

19 810-0278 Valve, ½” Ball

20

810-3118 x2, x5 (1)

810-3121 x3, x5 (1), x6 (2)

810-3120 x4

* Not illustrated.

Oil Return Plumbing Assembly

Left Assembly

Right Assembly

Single Assembly

Elbow, ½”, 90° BM

Elbow, Street, ½ NPT, 90° BM

Valve Assembly

Oil Return Manifold

2-16

Page 46

2.5.1 Oil Disposal Wand

1

3

4

5

2

ITEM PART # COMPONENT

108-0528

1 106-1454 Nozzle assembly with handle

2 810-1434 Hose assembly

3 816-0631 Cap, red vinyl

4 823-7153 Handle

5 810-0487 Coupling

* Not illustrated.

Oil Disposal Wand Assembly

2-17

Page 47

2.5.2 Over-the-Top Oil Return (KFC)

ITEM PART # COMPONENT

106-9693

Plumbing Assembly

1 810-3468 Tubing, Over the Top

2 810-2513 Tubing, Faucet Upper

3 813-0165 Elbow, Street, ½” x ½” NPT, 90°

4 810-1668 Adapter, Male, ⅝” OD x ½”

5 810-2700 Nipple, Quick Disconnect

6 810-2699 Coupling, Quick Disconnect

7 106-3470 Valve, Solenoid, Female Pins

8ump 106-4006 Valve, ½” Oil Return

9 826-1712 120V Motor, Gasket

* 810-3347 8 GPM Pump

10 810-1159 Flexline, 5” Oil Return

11 810-1669 Adapter, Female, ⅞ OD x ½”

12 810-3160 Adaptor, ½” NPT x 15

13 810-3257 Fitting, ¼” NPT, ⅜” OD

14 813-0003 Tee, ½” x ½” BM

2-18

Page 48

2.5.3 Drain Flush Plumbing

ITEM PART # COMPONENT

1 106-4006 Valve Assembly, Oil Return, 1/2"

2 200-8929 Handle, Oil Return

3 809-0601 Clevis Clip, Rod End

4 810-1069 Flexline, 5/8" x 29.50" Long

5 810-1668 Adapter, Male 5/8" OD x 1/2"

6 810-3160 Adapter, 1/2" NPT

7 813-0022 Nipple, 1/2" x Close NPT BM

8 813-0062 Elbow, 1/2", 90

9 813-0165 Elbow, Street, 1/2" x 1/2" NPT, 90 BM

10 813-0460 Nipple, 1/2" x 3.00 NPT BM

11 816-0637 Cap, Vinyl, Blue

* 220-4955 Handle Mount

* 106-9929 Wiring Harness, Drain Flush

* Not illustrated.

2-19

Page 49

2.6 Heating Element Assemblies and Associated Parts

2.6.1 Element Assemblies and Hardware

NOTE: These elements apply only to the RE series fryers.

For the previous model elements see manual PN 819-5990.

2-20

Page 50

2.6.1 Heating Element Assemblies and Associated Parts (cont.)

ITEM PART # COMPONENT

1

106-9757 208V, 17kW

106-9974 208V, 21kW

106-9961 240V, 17kW

106-9963 240V, 21kW

106-9962 480V, 17kW

106-9964 480V, 21kW

807-3652 Element, 208V/8.5kW (for 17kW)

807-4656 Element, 208V/10.25kW (for 21kW)

807-5185 Element, 230V/10.25kW (for 21kW)

807-4711 Element, 240V/8.5kW (for 17kW)

807-4713 Element, 240V/10.25kW (for 21kW)

807-4712 Element, 480V/8.5kW (for 17kW)

807-4714 Element, 480V/10.25kW (for 21kW)

* 812-1794 Element Sleeving

2

807-4955 Standard

807-4757 FAST

809-0567 Ty-wrap

3 816-0681 Grommet, Probe

4 816-0480 Plug, .375-inch Dome

5 816-0688 Gasket, Element

6 230-5041 Bracket, Temperature Probe

7 910-2042 Clamp, Element (Short)

8 230-0781 Clamp, Element (Long)

9 230-4902 Support, Full-Vat Element Rear

10 230-4101 Support, Full-Vat Element Front (use 823-5621 for 17kW Front Support)

11 809-0567 Ty-Wrap, Metal

12 810-1212 Pin, .125 X .5-inch Split

13 810-3030 Spring, Element Lift Left

* 810-3031 Spring, Element Lift Right

14 220-4860 Bracket, Lower Spring

15 220-0733 Bracket, Wire Mating

16 810-2189 Handle, Element Lift

* 108-0317 Tilt Switch Assembly

* Not illustrated.

Element Assemblies

Elements

Temperature Probe

2-21

Page 51

2.6.2 Element Tube Assemblies

ITEM PART # COMPONENT

106-7653SP

1 106-5329 Bracket Assembly, LH Element Tube Support

2 106-5330 Bracket Assembly, RH Element Tube Support

3 220-0122 Plate, Element Tube Support Inner

4 220-0123 Plate, Element Tube Support Outer

5 106-7651 Bracket Assembly, LH Upper Spring (use 106-6569 for 17kW)

6 106-7652 Bracket Assembly, RH Upper Spring (use 106-6570 for 17kW)

7 810-2992 Tube, FV Element Mounting

8 810-2993 Bushing, Tube End Teflon

9 809-0766 Nut, 10-32 Hex HD SS

* 106-6587 Magnetic Position Sensor Assembly

* 106-6588 Magnetic Position Sensor Assembly with Bracket

* 810-3007 Magnet

* 230-0794 Bracket, Magnetic Position Sensor Wire

* Not illustrated.

Tube Assembly RE Element, Full-Vat

2-22

Page 52

2.7 Frypot Assemblies and Associated Parts

ITEM PART # COMPONENT

1

Frypot Assembly

823-6935SP Frypot, Non-filter

823-6721SP Frypot, Filter

823-6936SP Frypot, Church’s/Popeye’s

2 806-8035 Thermostat Assembly, High-Limit (CE, 806-8132)

* 816-0785 Side Insulation

* 816-0786 Center Insulation

* 221-7274 Heat Shield, Left

* 222-7274 Heat Shield, Right

* Topcap Heat Shield

* 220-5464 x1

* 220-5460 x2, x4 (2), x5 (1)

* 220-5461 x3, x5 (1), x6 (2)

* 823-7109 Splash Guard, Standard

* 823-7169 Splash Guard, Church’s/Popeye’s

* 108-0213 Float Switch

* Not illustrated.

2-23

Page 53

2.8 Controllers

ITEM PART # COMPONENT

1 826-2429 Computer Magic III.5, Full-Vat, non-CE

* 106-4343 Computer Magic III.5, Full-vat, CE

2 826-2329 Digital Controller, Full-Vat

3 108-0267 FAST Computer

4 106-4070 KFC-1 Computer

5 108-0232 Church’s CM4S Computer

6 108-0218 Popeye’s CM4S Computer

7 826-2401 Basket Lift Timer

8 108-2087 K3000

*

108-0485 Position 2

108-0486 Position 3

108-0487 Position 6

108-0488 Position 8

108-0489 Position 10

* 802-2021 Graphic Sheet of Symbols

* Not illustrated.

Computers

K3000 Locator Harness

2-24

Page 54

2.9 Electronics and Wiring Components

2.9.1 Component Boxes

2-25

Page 55

2.9.1 Component Boxes

ITEM PART # COMPONENT

106-9730 208/240V, Filter

106-9732 208/240V, Non-filter

108-0279 220/250V, Filter

108-0278 220/250V, Non-filter

108-0420 480V, Filter

108-0421 480V, Non-filter

108-0330 480V, no switch, no basket lift

1 106-6666 Interface Board

* 106-9930 Harness, Filter

* 106-9965 Harness, Non-filter

2 220-4465 Panel, Switch

3 230-4346 Guard, Switch

4 807-4036 Switch

5 220-5805 Standoff, Relay, Filter

6 807-4114 Relay, 24VAC Coil, Filter

7 807-0922 Holder, Screw-Type Buss Fuse

* 807-4765 Harness, Control

8 809-0963 Standoff, 6-32, ¼” x 2.00 NP

9 810-1164 Block, Screwless Terminal

10 823-6745 Box, Component

11 807-2278 Fuse, 20 Amp

12 807-1597 Fuse, Slo-blo, Filter (220-250V)

13

807-0979 208/240V, 12V

807-0680 208/240V

807-2180 208/240V, 24V, 50VA

807-2191 V&F, 208/230/240V, 12V

807-0800 120V, 50/60 Hz-24V, 50VA

807-0855 120V, 50/60 Hz-12V, 20VA

807-3892 440/480V to 12/24V

14 810-3141 Sound Device, SMT

* 108-0273 Sound Device, KFC

* Not illustrated.

Component Box Assemblies (for reference)

Component Box Parts

Transformers

2-26

Page 56

2.9.2 Contactor Boxes

2-27

Page 57

NOTES: Left and right contactor box assemblies are mirror images of one another. With the exception of the

box itself, most components of a left-hand assembly are the same as those in the corresponding right-hand

assembly and vice versa. The configuration illustrated shows most possible components, but a particular

configuration may not have all the components shown.

ITEM PART # COMPONENT

106-9967 17 kW, 3-wire, Left

106-9966 17 kW, 3-wire, Right

106-9756 21kW, 3-wire, Left

106-9755 21kW, 3-wire, Right

108-0427 17 kW, 4-wire, Left

108-0426 17 kW, 4-wire, Right

108-0037 21kW, 4-wire

108-1861 17kW, Single

108-0684 21kW, Single

108-0868 21kW, 4-wire, Single, Export

1 106-9601 Stud Assembly, Left Contactor Box

* 106-9600 Stud Assembly, Right Contactor Box

2 106-9735 Harness, 6-pin

3 106-9736 Harness, 9-pin

4 200-6648 Bracket, Fuse Block

5 200-6809 Bracket, Ground Lug Holder

6 221-5553 Cover, 21kw Contactor Box

* 220-5103 Cover, 17kw Contactor Box

7 807-0070 Terminal Lug

8 807-0501 Fuse Block

9 807-2283 Contactor, 63 AMP, Mechanical, 24V Coil (21kw)

* 807-2284 Contactor, 50 AMP, Mechanical, 24V Coil (17kw)

10 807-3610 Terminal Block

* 807-1268 Terminal Block, Splicer Single (4-wire)

11 807-4017 Fuse, 50 AMP, 300 VDC

12 810-1202 Contactor, 40 AMP, 3-pole

13 108-1786 Harness, Contactor Box

14 220-6545 Door, Fuse Access

15 810-0519 Hinge, Fuse Access

* 220-5484 Mount, Contactor Box (2 per box)

* Not illustrated. ** Full Vat has three relays 826-1562, Dual-Vat has six relays.

Contactor Box Assemblies (for reference only)

Contactor Box Parts

2-28

Page 58

2.9.3 Fuse Boxes

Left 22kW and

Single Phase

Fuse Box Assembly

106-5505/106-6678

10

Right 22kW and

Single Phase

Fuse Box Assembly

106-5506/106-6679

11

9

8

6

7

12

5

1

3

2

ITEM PART # COMPONENT

1 200-2334 Door

2 810-0519 Hinge

3 221-0523 Cover, LH Fuse Box

4 222-0523 Cover, RH Fuse Box (Used on Single Station Fryers also)

5 809-0434 Nut, RH Fuse Holder

6 823-5585 Box, LH Fuse

7 823-5557 Box, RH Fuse

823-5797 Box, Single Station Fryer Only

8 807-3970 Block, 3 Pole 600V 175A Terminal

9 807-0501 Fuse Block, Buss #2968 3-Pole

10 807-2240 Fuse, 60 AMP 300VAC

11 807-0070 Terminal, Ground Lug

12 807-0128 Bushing, Insulating Heyco

4

2-29

Page 59

2.9.4 Terminal Blocks

ITEM PART # COMPONENT

1 823-5631 Box, LH Rear Terminal Block

2 823-5632 Box, RH Rear Terminal Block

823-5797 Box, Single Station Fryer Only (see previous page for cover 222-0523)

3 220-0801 Cover, Rear Terminal Block Box

4 807-3970 Block, 3 Pole 600V 175A

5 807-0070 Terminal, Ground Lug

6 807-0128 Bushing, Insulating Heyco

2-30

Page 60

2.9.5 Cordsets

ITEM PART # COMPONENT

* 807-4658 Domestic

* OPT11295 Generic Export

* OPT37413 Church’s Cord Connect Box

* Not illustrated.

2.10 Wiring

2.10.1 Contactor Box Wiring Assemblies (Left Element)

1

2

1

2

3

4

5

6

1

2

3

4

5

6

7

8

9

BLUE

BLUE

BLUE

BLACK

BLACK

BLACK

BLUE

BLUE

BLUE

BLACK

BLACK

BLACK

ITEM PART # COMPONENT

1 106-9735 6-pin

106-9736 9-pin

2-31

Page 61

2.10.2 Component Box, Filter Pump and Basket Lift Wiring Harnesses

ITEM PART # COMPONENT

1 106-9930 Component Box Harness, Filter

2 106-9965 Component Box Harness, Non-filter

3 807-4765 Component Box Harness, Control

4 106-9918 Filter Pump Harness

5 106-9924 Drain Safety Harness

* 108-0255 Drain Safety Harness, KFC-1, Popeye’s, Church’s

6 106-9928 Oil Return Harness, Rear

2-32

Page 62

2.11 Wiring Connectors and Pin Connectors

ITEM PART # COMPONENT

1 807-1068 2-Pin Female

2 807-0158 6-Pin Female

3 807-0156 9-Pin Female

4 807-0159 12-Pin Female

5 807-0875 15-Pin Female

6 807-1067 2-Pin Male

7 807-0157 6-Pin Male

8 807-0155 9-Pin Male

9 807-0160 12-Pin Male

10 807-0804 15-Pin Male

11 826-1341 Terminal, Female Split Pin (pkg. of 25)

12 826-1342 Terminal, Male Split Pin (pkg. of 25)

13 807-2518 Plug, Mate-N-Lock (Dummy Pin)

14

807-0928

Extract Tool Pin Pusher

15 806-4855 Pin Pusher Screwdriver Assembly

16 230-2345 SMT Pin Extractor

* 807-4660PK SMT Pin Service Repair Kit

* Not illustrated.

2-33

Page 63

2.12 Fasteners

ITEM PART # COMPONENT

* 809-0429 Bolt, ¼-inch – 20 x 2.00-inch Hex Head ZP Tap

* 809-0514 Capscrew, 5/16-inch-18 NC Hex

* 809-0448 Clip, Tinnerman

* 826-1366 Nut, 4-40 Keps Hex (Pkg. of 25) (809-0237)

* 826-1358 Nut, 6-32 Keps Hex (Pkg. of 25) (809-0049)

* 809-0247 Nut, 8-32 Keps Hex

* 826-1376 Nut, 10-32 Keps Hex (Pkg. of 10) (809-0256)

* 809-0766 Nut, 10-32 Keps Hex SS

* 809-0581 Nut, ½ NPT Locking

* 809-0020 Nut Cap 10-24 NP

* 826-1372 Nut Grip ¼-inch 1/4-20 Hex NP (Pkg. of 10) (809-0059)

* 809-0417 Nut Flange ¼-inch 1/4-20 Serr

* 809-0535 Nut, "T" ¼-inch-20 x 7/16 SS

* 809-0540 Nut, Lock ½-inch-13 Hex 2-Way ZP

* 826-1359 Screw, 4-40 x ¾-inch Slotted Round Head (Pkg. of 25) (809-0354)

* 826-1365 Screw, 6-32 x ⅜-inch Slot Head (Pkg. of 25) (809-0095)

* 809-0357 Screw, 6 x ⅜-inch Phillips Head NP

* 809-0359 Screw, 8 x ¼-inch Hex Washer Head

* 809-0360 Screw, 8 x ⅜-inch Hex Washer Slot Head

* 826-1371 Screw, 8 x ½-inch Hex Head ZP (Pkg. of 25) (809-0361)

* 809-0364 Screw, 8 x ⅝-inch Hex Washer Head ZP

* 809-0518 Screw, 8-32 x ⅜-inch Hex Washer Slotted Head SS

* 809-0104 Screw, 8-32 x ½-inch Slotted Head ZP

* 826-1363 Screw, 8-32 x ½-inch NP (Pkg. of 25) (809-0103)

* 826-1360 Screw, 10-24 x 5/16-inch Round Slot Head ZP (Pkg. of 25) (809-0024)

* 826-1330 Screw, 10-32 x ⅜-inch Slot Head SS (809-0117)

* 809-1003 Screw, 10-32 x ⅜-inch Hex Trim Head SS

* 826-1375 Screw, 10-32 x ¾-inch Hex Trim Head SS (Pkg. of 5) (809-0401)

* 809-1000 Screw, 10-32 x 1¼-inch Hex Sck C/S

* 826-1374 Screw, 10 x ½-inch Hex Head (Pkg. of 25) (809-0412)

* 809-0266 Screw, 10 x ½-inch Phillips Head ZP

* 809-0434 Screw, 10 x ⅜-inch Hex Washer Head NP

* 809-0123 Screw, 10 x ¾-inch Slot Head

* 826-1389 Screw, 1/4-20 x ¾-inch Hex Head ZP (Pkg. of 10) (809-0131)

* 809-0582 Washer ½ NPT Locking

* 809-0184 Washer, #10 LK ZP

* 809-0190 Washer, .625 X .275 X 40 Flat SS

* 809-0191 Washer, Lock 1/4 Spring ZP

* 809-0193 Washer, Flat 1/4 Nylon

* 809-0194 Washer, Flat 5/16 ZP

2-34

Page 64

Frymaster, L.L.C., 8700 Line Avenue, Shreveport, Louisiana 71106

TEL 1-318-865-1711 FAX (Parts) 1-318-219-7140 (Tech Support) 1-318-219-7135

PRINTED IN THE UNITED STATES

SERVICE HOTLINE

1-800-551-8633

819-6666

JAN 2011

Loading...

Loading...