Page 1

INSTALLATION, OPERATION,

Return to Cover

SERVICE, AND PARTS MANUAL

H50 SERIES GAS FRYERS

(Series Codes AY through BE)

Frymaster, L.L.C., 8700 Line Avenue, PO Box 51000, Shreveport, Louisiana 71135-1000

Shipping Address: 8700 Line Avenue, Shreveport, Louisiana 71106

TEL 318-865-1711 FAX (Parts) 318-219-7140 (Tech Support) 318-219-7135

PRINTED IN THE UNITED STATES

SERVICE HOTLINE

1-800-551-8633

819-0001 11/00

Page 2

DANGER

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE, OR

MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY, OR DEATH. READ THE

INSTALLATION, OPERATING, AND SERVICE INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING THIS EQUIPMENT.

DANGER

FOR YOUR SAFETY, DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE

LIQUIDS OR VAPORS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

DANGER

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN THE

EVENT THE USER SMELLS GAS. THIS INFORMATION SHALL BE OBTAINED BY

CONSULTING THE LOCAL GAS SUPPLIER.

THIS EQUIPMENT IS TO BE INSTALLED IN COMPLIANCE WITH THE BASIC

PLUMBING CODE OF THE BUILDING OFFICIALS AND CODE ADMINISTRATORS

INTERNATIONAL, INC. (BOCA) AND THE FOOD SERVICE SANITATION MANUAL OF

THE FOOD AND DRUG ADMINISTRATION.

COMPUTERS

FCC

This device complies with Part 15 of the FCC rules. Operation is subject to the following two

conditions: 1) This device may not cause harmful interference, and 2) This device must accept any

interference received, including interference that may cause undesired operation. While this device is

a verified Class A device, it has been shown to meet the Class B limits.

CANADA

This digital apparatus does not exceed the Class A or B limits for radio noise emissions as set out by

the ICES-003 standard of the Canadian Department of Communications.

Cet appareil numerique n’emet pas de bruits radioelectriques depassany les limites de classe A et B

prescrites dans la norme NMB-003 edictee par le Ministre des Communcations du Canada.

DANGER

THIS PRODUCT CONTAINS CHEMICALS KNOWN TO THE STATE OF CALIFORNIA

TO CAUSE CANCER AND/OR BIRTH DEFECTS OR OTHER REPRODUCTIVE HARM.

Operation, installation, and servicing of this product could expose you to airborne

particles of glasswool or ceramic fibers, crystalline silica, and/or carbon monoxide.

Inhalation of airborne particles of glasswool or ceramic fibers is known to the State

of California to cause cancer. Inhalation of carbon monoxide is known to the State

of California to cause birth defects or other reproductive harm.

FRYMASTER FRYERS EQUIPPED WITH LEGS ARE FOR PERMANENT

INSTALLATION. FOR MOVEABLE OR PORTABLE INSTALLATION, FRYMASTER

OPTIONAL EQUIPMENT CASTERS MUST BE USED.

QUESTIONS??? CALL 1-800-551-8633.

Page 3

H50 SERIES GAS FRYERS

TABLE OF CONTENTS

CHAPTER 1: General Information

1.1 Parts Ordering and Service Information............................................................................ 1-1

1.2 Safety Information............................................................................................................. 1-1

1.3 European Community (CE) Specific Information............................................................. 1-2

1.4 Equipment Description...................................................................................................... 1-3

1.5 Installation, Operating, and Service Personnel ................................................................. 1-3

1.6 Definitions......................................................................................................................... 1-4

1.7 Shipping Damage Claim Procedure.................................................................................. 1-4

CHAPTER 2: Installation Instructions

2.1 General Installation Requirements.................................................................................... 2-1

2.2 Caster/Leg Installation ......................................................................................................2-3

2.3 Pre-Connection Preparations............................................................................................. 2-3

2.4 Connection to Gas Line..................................................................................................... 2-5

2.5 Converting to Another Gas Type ...................................................................................... 2-7

CHAPTER 3: Operating Instructions

3.1 Start-Up Procedure............................................................................................................ 3-2

3.2 Boiling Out the Frypot ...................................................................................................... 3-4

3.3 Shutting the Fryer Down...................................................................................................3-5

3.4 Controller Operation and Programming............................................................................ 3-5

Computer Magic III Controller ......................................................................................... 3-6

Analog Controller............................................................................................................ 3-11

Digital Controller ............................................................................................................ 3-12

Solid-State Basket Lift Timer ......................................................................................... 3-13

CHAPTER 4: Filtration Instructions

4.1 Draining and Manual Filtering.......................................................................................... 4-1

4.2 Built-In Filtration System Operation................................................................................. 4-2

Preparing the Filter Unit for Use....................................................................................... 4-2

Operation of the Filter Unit............................................................................................... 4-4

Changing the Filter Paper.................................................................................................. 4-6

CHAPTER 5: Preventive Maintenance

5.1 Fryer Preventive Maintenance Checks and Service.......................................................... 5-1

Daily Checks and Service.................................................................................................. 5-1

Weekly Checks and Service..............................................................................................5-1

Monthly Checks and Service............................................................................................. 5-3

Quarterly Checks and Service........................................................................................... 5-5

Semi-Annual Checks and Service..................................................................................... 5-7

5.2 Built-In Filtration System Preventive Maintenance Checks and Service ......................... 5-9

i

Page 4

H50 SERIES GAS FRYERS

TABLE OF CONTENTS

CHAPTER 6: Operator Troubleshooting

6.1 Introduction........................................................................................................................6-1

6.2 Troubleshooting Fryers and Controllers............................................................................6-2

6.3 Troubleshooting the Built-In Filtration System .................................................................6-5

6.4 Replacing the Ignition Module Fuse..................................................................................6-8

6.5 Replacing the Controller or Controller Wiring Harness....................................................6-8

CHAPTER 7: Service Procedures

7.1 Functional Description.......................................................................................................7-1

The Electronic Ignition System.........................................................................................7-1

Interface Boards.................................................................................................................7-2

Thermostats........................................................................................................................7-5

7.2 Accessing Fryers for Servicing..........................................................................................7-5

7.3 Cleaning the Gas Valve Vent Tube ...................................................................................7-5

7.4 Checking the Burner Manifold Gas Pressure ....................................................................7-5

7.5 Measuring Flame Current..................................................................................................7-6

7.6 Replacing Fryer Components............................................................................................7-6

7.6.1 Replacing the Controller or the Controller Wiring Harness...............................7-6

7.6.2 Replacing the Temperature Probe or High-Limit Thermostat............................7-6

7.6.3 Replacing the Interface Board ...........................................................................7-7

7.6.4 Replacing an Ignition Module............................................................................7-7

7.6.5 Replacing an Ignitor Assembly...........................................................................7-8

7.6.6 Replacing a Combustion Air Blower..............................................................................7-8

7.6.7 Replacing a Gas Valve........................................................................................7-8

7.6.8 Replacing a Burner Assembly............................................................................7-9

7.6.9 Replacing the Frypot.........................................................................................7-10

7.6.10 Replacing Frypot Insulation and/or Upper Burner Rails..................................7-12

7.7 Troubleshooting and Problem Isolation...........................................................................7-17

7.7.1 Ignition Failures................................................................................................7-17

7.7.2 Improper Burner Functioning........................................................................... 7-18

7.7.3 Improper Temperature Control.........................................................................7-20

7.7.4 Computer-Related Problems.............................................................................7-21

7.7.5 Filtration Problems ...........................................................................................7-22

7.7.6 Leakage Problems.............................................................................................7-27

7.7.7 Basket Lift Malfunctions..................................................................................7-27

7.7.8 Interpretation of Digital Controller Lights........................................................7-32

7.8 Troubleshooting Guides...................................................................................................7-32

7.8.1 Troubleshooting the 24 VAC Circuit in Units..................................................7-33

7.8.2 Troubleshooting the 24 Gas Valve ...................................................................7-35

7.8.3 Troubleshooting the Temperature Probe ..........................................................7-36

ii

Page 5

H50 SERIES GAS FRYERS

TABLE OF CONTENTS

Probe Resistance Chart.................................................................................................... 7-37

7.9 Simplified Wiring Diagrams........................................................................................... 7-39

7.10 Principal Wiring Connections......................................................................................... 7-41

7.11 Wiring Diagrams – Main ................................................................................................ 7-42

7.12 Wiring Diagrams – Transformer Boxes.......................................................................... 7-47

7.13 Wiring Diagrams – Basket Lifts...................................................................................... 7-49

7.14 Wiring Diagrams – Filter Boxes .....................................................................................7-52

CHAPTER 8: Parts List

8.1 Accessories........................................................................................................................ 8-1

8.2 Basket Lift Assemblies and Component Parts.................................................................. 8-2

8.2.1 Bell Crank Basket Lifts...................................................................................... 8-2

8.2.2 Modular Basket Lifts.......................................................................................... 8-3

8.3 Blower Assemblies and Associated Components............................................................. 8-6

8.4 Burner Ignition System Components and Associated Hardware...................................... 8-8

8.5 Cabinet Assemblies and Component Parts........................................................................ 8-9

8.5.1 FPH150............................................................................................................... 8-9

8.5.2 FPH50 Batteries ...............................................................................................8-10

8.5.3 FMH150 and MJH150 ..................................................................................... 8-12

8.5.4 FMH50 and MJH50 Batteries .......................................................................... 8-13

8.5.5 Filter Magic II ..................................................................................................8-14

8.6 Casters, Legs, and Associated Hardware ........................................................................8-16

8.7 Component Box Assemblies and Associated Component Parts..................................... 8-17

8.8 Control Panel Assemblies, Flue Caps, Top Caps, and Related Components.................. 8-18

8.9 Controller Assemblies.....................................................................................................8-19

8.10 Door Assemblies.............................................................................................................8-20

8.11 Drain System Components.............................................................................................. 8-21

8.11.1 Filter Magic II Square Drain Components, Standard Configuration ............... 8-21

8.11.2 Filter Magic II Square Drain Components, Foodmaker Configuration ........... 8-22

8.11.3 FootPrint III Square Drain Components, Standard Configuration................... 8-23

8.11.4 FootPrint III Square Drain Components, Rear Flush Configuration................ 8-24

8.11.5 FootPrint III Square Drain Components, Foodmaker Configuration............... 8-25

8.12 Drain Valve Assemblies.................................................................................................. 8-26

8.12.1 MJH50 Dual Vat Valve Assemblies, 1”, Domestic and Export Models.......... 8-26

8.12.2 MJH50 Full Vat Valve Assemblies, 1 ¼”, Domestic and Export Models.......8-26

8.12.3 FMH50 (CE) Dual Vat Valve Assemblies, 1”................................................. 8-27

8.12.4 FMH50 Domestic and Non-CE Export Dual Vat Valve, 1”............................ 8-28

8.12.5 FMH50 (CE) Full Vat Valve Assembly, 1 ¼”................................................. 8-28

8.12.6 FMH50 Domestic and Non-CE Export Full Vat Valve Assembly, 1 ¼” ........ 8-29

8.12.7 FPH50 (CE) Dual Vat Valve Assemblies, 1”................................................... 8-30

8.12.8 FPH50 Domestic and Non-CE Export Dual Vat Valve Assemblies, 1”..........8-31

8.12.9 FPH50 Domestic and Export Full Vat Valve Assemblies, 1 ¼”...................... 8-32

iii

Page 6

H50 SERIES GAS FRYERS

TABLE OF CONTENTS

8.13 Filtration Systems and Component Parts (Other Than Drain Components) ...................8-33

8.13.1 Filter Magic II/Single FootPrint III Filter Pan Assembly.................................8-33

8.13.2 FootPrint III Filter Pan Assembly.....................................................................8-34

8.13.3 FootPrint III Filter Base Assemblies................................................................8-35

8.13.4 Filter Magic Oil Return Plumbing Components (Including Pump & Motors).8-36

8.13.5 FootPrint III Filter Motors and Pump Plumbing Components.........................8-38

8.13.6 FootPrint III with Power Shower Oil Return Plumbing Components..............8-40

8.13.7 FootPrint III with Rear Flush Oil Return Plumbing Components....................8-42

8.13.8 FPH150 Oil Return Plumbing (Including Handle)...........................................8-44

8.13.9 Oil Return Handle Assembly, Filter Magic & Standard FootPrint III..............8-46

8.13.10 Oil Return Handle Assembly, Rear Flush Units...............................................8-47

8.13.11 Power Shower Assemblies (All Systems) ........................................................8-48

8.13.12 Oil Disposal Systems Plumbing .......................................................................8-49

8.14 Frypot Assemblies and Component Parts........................................................................8-51

8.14.1 Replacement Frypots and Frypot Insulation Kits.............................................8-51

8.14.2 Full Vat Frypot Assembly, with Power Shower, Component Parts.................8-52

8.14.3 Dual Vat Frypot Assembly, with Power Shower, Component Parts................8-54

8.15 Gas Manifold Assemblies and Component Parts ............................................................8-56

8.15.1 CE Units............................................................................................................8.56

8.15.2 Non-CE Units ...................................................................................................8-58

8.16 Gas Valve Assemblies and Associated Parts...................................................................8-60

8.16.1 CE Gas Valve Assemblies................................................................................8-60

8.16.2 Non-CE Gas Valve Assemblies........................................................................8-62

8.16.3 Gas Supply Lines and Enrichment Tubes.........................................................8-63

8.17 Thermostats, Temperature Probes, and Related Components.........................................8-64

8.18 Transformer Box and Filter Box Component Parts.........................................................8-64

8.19 Wiring Harnesses, Wiring Assemblies, and Plug Assemblies.........................................8-66

8.19.1 Filter Box Wiring..............................................................................................8-66

8.19.2 Main Wiring Harnesses ....................................................................................8-66

PARTS LIST INDEX.................................................................................................................8-67

iv

Page 7

H50 SERIES GAS FRYERS

CHAPTER 1: GENERAL INFORMATION

1.1 Parts Ordering and Service Information

In order to assist you quickly, the Frymaster Factory Authorized Service Center (FASC) or Service

Department representative requires certain information about your equipment. Most of this information is printed on a data plate affixed to the inside of the fryer door. Part numbers are found in the

Installation, Operation, Service, and Parts Manual. Parts orders may be placed directly with your

local FASC or distributor. Included with fryers when shipped from the factory is a list of Frymaster

FASCs. If you do not have access to this list, contact the Frymaster Service Department at 1-800551-8633 or 1-318-865-1711.

When ordering parts, the following information is required:

Model Number:

Serial Number:

Type of Gas or Voltage:

Item Part Number:

Quantity Needed:

Service information may be obtained by contacting your local FASC/Distributor. Service may also

be obtained by calling the Frymaster Service Department at 1-800-551-8633 or 1-318-865-1711.

When requesting service, please have the following information ready:

Model Number:

Serial Number:

Type of Gas:

In addition to the model number, serial number, and type of gas, please be prepared to describe the

nature of the problem and have ready any other information that you think may be helpful in solving

your problem.

RETAIN AND STORE THIS MANUAL IN A SAFE PLACE FOR FUTURE USE.

1.2 Safety Information

Before attempting to operate your unit, read the instructions in this manual thoroughly.

Throughout this manual, you will find notations enclosed in double-bordered boxes similar to the

one below.

CAUTION boxes contain information about actions or conditions that may cause or result in a

malfunction of your system.

CAUTION

Example of a CAUTION box.

1-1

Page 8

H50 SERIES GAS FRYERS

CHAPTER 1: GENERAL INFORMATION

WARNING boxes contain information about actions or conditions that may cause or result in damage

to your system, and which may cause your system to malfunction.

WARNING

Example of a WARNING box.

DANGER boxes contain information about actions or conditions that may cause or result in injury to

personnel, and which may cause damage to your system and/or cause your system to malfunction.

DANGER

Hot cooking oil or shortening causes severe burns. Never attempt to move a fryer

containing hot cooking oil/shortening or to transfer hot cooking oil/shortening from

one container to another.

Your fryer is equipped with automatic safety features:

1. High temperature detection shuts off gas to the burner assembly should the controlling thermostat

fail.

2. An optional safety switch built into the drain valve prevents burner ignition with the drain valve

even partially open.

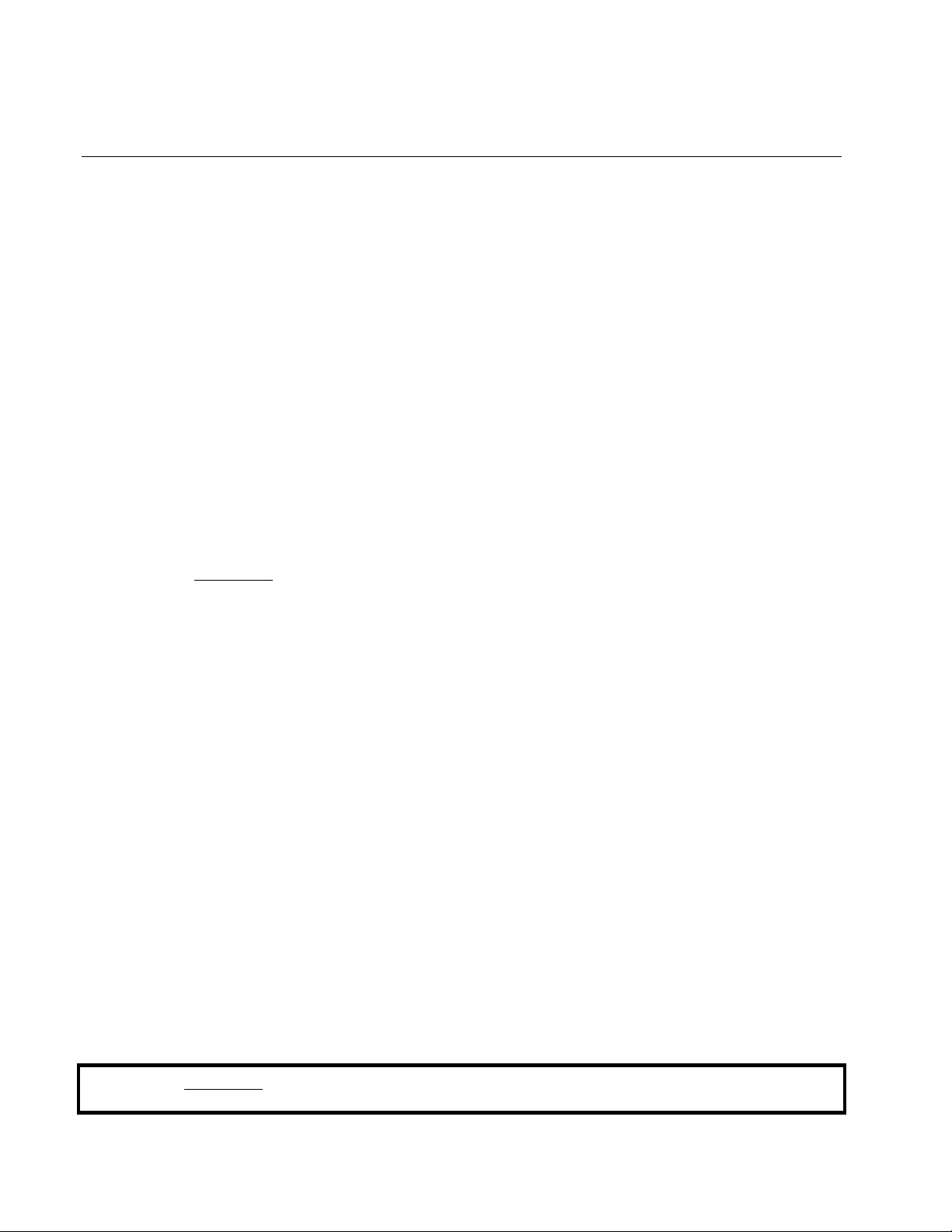

1.3 European Community (CE) Specific Information

The European Community (CE) has established certain specific standards regarding equipment of

this type. Whenever a conflict exists between CE and non-CE standards, the information or instructions concerned are identified by means of shadowed boxes similar to the one below.

Non-CE Standard

for Incoming Ga s Pressures

Ty pe Minimum Maximum

6" W.C. 14" W.C.

Na tural 1.49 k Pa 3.49 kPa

14.68 mbar 34.72 mbar

11" W.C. 14" W.C.

LP 2.74 kPa 3.49 kPa

27.28 mbar 34.84 mbar

1-2

Page 9

H50 SERIES GAS FRYERS

CHAPTER 1: GENERAL INFORMATION

1.4 Equipment Description

H50 Series high-efficiency gas fryers employ a unique infrared burner system that uses up to 43%

less energy to cook the same volume as conventional fryers. Models in this series include MJH50,

FMH50, and FPH50 variants. MJH50 variants have no built-in filtration system. FMH50 variants

have a built-in Filter Magic II filtration system. The Filter Magic system is housed in its own cabinet, which may be attached to either side of a fryer and which can be located anywhere in a battery of

fryers. The FPH50 variants have a built-in FootPrint III filtration system that is located underneath

the fryer to conserve floor space. (In batteries of fryers, the FootPrint III syste m is always loc ated

under the leftmost two fryers.)

All H50 Series fryers are of an open-pot design with no tubes and have a hand-sized opening into the

deep cold zone, which makes cleaning the stainless frypot quick and easy.

Frypots are constructed of welded, heavy-gauge stainless steel, and may be configured with a single

(full) vat or dual vats. A drain valve is tapped into the center of the frypot, with a front-operated

manual ball valve. Heating is supplied by a pair of infrared burner assemblies mounted on each side

of the frypot. Combustion air for the burners is supplied by a dedicated blower mounted on the front

of the frypot. H50 Series fryers can be configured for natural gas, propane (LP), or manufactured

gas, as required by the customer.

Each frypot is equipped with a temperature probe for precise temperature control. The probe is located on the centerline of the frypot for rapid response to changes in loads, and to provide the most

accurate temperature measurement.

All H50 Series fryers come standard with electronic ignition, melt cycle, and boil-out mode. Control

opt ion s i n c l u de Comp u ter Ma g i c III c o mpu t e r s , so l id- s t a t e a nal o g c o n t r o lle r s , d igi t a l c o n tro l ler s , a n d

basket lift timers. Each type is covered in detail in Chapter 3, Fryer Operating Instructions.

All fryers in this series require an external source of AC electrical power. Uni ts can be configured

for voltages ranging from 120 VAC to 220 VAC.

Fryers equipp ed with FootPrint III built-in filtration systems are shipped completely assembled. Fryers without the FootPrint III req ui r e i n s t al l a t io n o f l e gs o r o p t i on a l ca s t er s at p o i nt o f us e . A l l f rye rs

are shipped with a package of standard accessories. Each fryer is adjusted, tested, and inspected at

the factory before crating for shipment.

1.5 Installation, Operating, and Service Personnel

Operating information for Frymaster equipment has been prepared for use by qualified and/or

authorized personnel only, as defined in Section 1.6.

All installation and servi ce on Frymaster equipment must be performed by qual ifi ed, certi fied,

licensed, and/or authorized installation or service personnel, as defined in Section 1.6.

1-3

Page 10

H50 SERIES GAS FRYERS

CHAPTER 1: GENERAL INFORMATION

1.6 Definitions

QUALIFIED AND/OR AUTHORIZED OPERATING PERSONNEL

Qualified/authorized operating personnel are those who have carefully read the information in this

manual and have familiarized themselves with the equipment functions, or who have had previous

experience with the operation of the equipment covered in this manual.

QUALIFIED INSTALLATION PERSONNEL

Qualified installation personnel are individuals, firms, corporations, and/or companies which, either

in person or through a representative, are engaged in and are responsible for the installation of gasfired appliances. Qualified personnel must be experienced in such work, be familiar with all gas

precautions involved, and have complied with all requirements of applicable national and local

codes.

QUALIFIED SERVICE PERSONNEL

Qualified service personnel are those who are familiar with Frymaster equipment and who have been

authorized by

Frymaster

Frymaster

FrymasterFrymaster

Corporation to perform service on Frymaster equipment. All authorized

service personnel are required to be equipped with a complete set of service and parts manuals, and

to stock a minimum amount of parts for Frymaster equipment. A list of Frymaster Factory Authorized Service Centers (FASC) was included wit h the fryer when shipped from the fact ory. Failure to

use qualified service personnel will void the Frymaster Warranty on your equipment.

1.7 Shipping Damage Claim Procedure

Your Frymaster equipment was carefully inspected and packed before leaving the factory. The

transportation company assumes full responsibility for safe delivery upon its acceptance of the

equipment for transport.

What to do if your equipment arrives damaged:

1. File a claim for damages immediately, regardless of the extent of damages.

2. Inspect for and record all visibl e loss or damage, and ensure that this information is noted on

the freight bill or express receipt and is signed by the person making the delivery.

3. Concealed loss or damage that was unnoticed until the equipment was unpacked should be re-

corded and reported to the freight company or carrier immediately upon discovery. A concealed

damage claim must be submitted within 15 days of the date of delivery. Ensure that the shipping

container is retained for inspection.

Frymaster

Frymaster

FrymasterFrymaster

DOES NOT ASSUME RESPONSIBILITY FOR DAMAGE OR LOSS

INCURRED IN TRANSIT.

1-4

Page 11

H50 SERIES GAS FRYERS

CHAPTER 2: INSTALLATION INSTRUCTIONS

2.1 General Installation Requirements

PROPER INSTALLATION IS ESSENTIAL FOR EFFICIENT, TROUBLE-FREE OPERATION OF YOUR

FRYER. ANY UNAUTHORIZED ALTERATIONS MADE TO THIS EQUIPMENT W ILL VOID THE FRYM AS-

WARRANTY.

TER

Upon arrival, inspect the fryer carefully for visible or concealed damage. (See Shipping Damage

Claim Procedure in Chapter 1.)

CLEARANCE AND VENTILATION

The fryer(s) must be installed with a 6” (150 mm) clearance at both sides and back when installed

adjacent to combustible construction; no clearance is required when installed adjacent to noncombustible construction. A minimum of 24” (600 mm) clearance should be provided at the front of the

fryer.

One of the most important considerations of efficient fryer operation is ventilation. Make sure the

fryer is installed so that products of combustion are removed efficiently, and that the kitchen ventilation system does not produce drafts that interfere with proper burner operation.

The fryer flue opening must not be placed close to the intake of the exhaust fan, and the fryer must

never have its flue extended in a “chimney” fashion. An extended flue will change the combustion

characteristics of the fryer, causing longer recovery time. It also frequently causes delayed ignition.

To provide the airflow necessary for good combustion and burner operation, the areas surrounding

the fryer front, sides, and rear must be kept clear and unobstructed.

Fryers must be installed in an area with an adequate air supply and adequate ventilation. Adequate

distances must be maintained from the flue outlet of the fryer to the lower edge of the ventilation

filter bank. Filters should be installed at an angle of 45º. Place a drip tray beneath the lowest edge of

the filter. For U.S. installation, NFPA standard No. 96 states, “A minimum distance of 18 in. (450

mm) should be maintained between the flue outlet and the lower edge of the grease filter.”

Frymaster recommends that the minimum distance be 24 in. (600 mm) from the flue outlet to the

bottom edge of the filter when the appliance consumes more than 120,000 BTU per hour.

For installations in the United States, information on construction and installation of ventilating

hoods can be found in the NFPA standard cited above. A copy of the standard may be obtained from

the National Fire Protection Association, Battery March Park, Quincy, MA 02269.

DANGER

Do not attach an apron drainboard to a single fryer. The fryer may become unstable,

tip over, and cause injury. The appliance area must be kept free and clear of com-

bustible material at all times.

2-1

Page 12

H50 SERIES GAS FRYERS

CHAPTER 2: INSTALLATION INSTRUCTIONS

NATIONAL CODE REQUIREMENTS

The type of gas for which the fryer is equipped is stamped on the data plate attached to the inside of

the fryer door. Connect a fryer stamped “NAT” only to natural gas, those stamped “PRO” only to

propane gas, and those stamped “MFG” only to manufactured gas.

Installation shall be made with a gas connector that complies with national and local codes, and,

where applicable, CE codes. Quick-disconnect devices, if used, shall likewise comply with national,

local, and, if applicable, CE codes.

ELECTRICAL GROUNDING REQUIREMENTS

All electrically operated appliances must be grounded in accordance with all applicable national and

local codes, and, where applicable, CE codes. A wiring diagram is located on the inside of the fryer

door. Refer to the rating plate on the inside of the fryer door for proper voltages.

DANGER

If this appliance is equipped with a three-prong (grounding) plug, it must be plugged

directly into a properly grounded receptacle.

Do not cut or remove the grounding prong from the plug.

DANGER

This equipment requires electrical power for operation.

Place the gas control valve in the OFF position in case of a prolonged power outage.

Do not attempt to use the equipment during a power outage.

FCC COMPLIANCE

The user is cautioned that any changes or modifications to Frymaster computers not expressly approved by the party responsible for compliance could void the user’s authority to operate the equipment.

Frymaster computers have been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC rules. Whil e these devices are verified as C lass A devices, t hey

have been shown to meet the Class B limits. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of the equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

2-2

Page 13

H50 SERIES GAS FRYERS

CHAPTER 2: INSTALLATION INSTRUCTIONS

If necessary, the user should consult the dealer or an experienced radio and television technician for

additional suggestions.

The user may find the booklet “How to Identify and Resolve Radio-TV Interference Problems” helpful. It is prepared by the Federal Communications Commission and is available from the U.S. Government Printing Office, Washington, DC 20402, Stock No. 004-000-00345-4.

2.2 Caster/Leg Installation

Depending upon the specific configuration ordered your fryer may have been shipped without installed casters or legs. If casters or legs are installed, you may skip this section and proceed to section 2.3, Pre-Connection Preparations.

If your fryer requires the installation of casters/legs, install them in accordance with the instructions included in your accessory package.

2.3 Pre-Connection Preparations

DANGER

Do not connect fryer to gas supply before completing each step

in this section.

After the fryer has been positioned under the fry station exhaust hood, ensure the following has been

accomplished:

1. Adequate means must be provided to limit the movement of fryers without depending upon the

gas line connections. If a flexible gas hose is used, a restraining cable must be connected at all

times when the fryer is in use. The restraining cable and installation instructions are packed with

the flexible hose in the accessories box that was shipped with your unit.

2. Single unit fryers must be stabilized by installing restraining chains on fryers equipped with

casters or anchor straps on fryers equipped with legs. Follow the instructions shipped with the

casters/legs to properly install the chains or straps.

3. Level fryers equipped with legs by screwing out the legs approximately 1 inch then adjusting them so that the fryer is level and at the proper height in the exhaust hood. Frymaster

recommends that the minimum distance from the flue outlet to the bottom edge of the hood be 24 in. (600 mm) when the appliance consumes more than 120,000 BTU per hour.

NOTE: There are no built-in leveling devices on fryers equipped with casters. The floor where the fryer is to be installed must be level.

4. Test the fryer electrical system:

a. Plug the fryer electrical cord(s) into a grounded electrical receptacle.

b. Place the power switch in the ON position.

• For fryers equipped with analog controls, verify that the power and heat lights are lit.

2-3

Page 14

H50 SERIES GAS FRYERS

(1)

(1)

CHAPTER 2: INSTALLATION INSTRUCTIONS

• For fryers having computer or digital displays, verify that the display indicates CYCL.

c. Place the fryer power switch in the OFF position. Verify that the power and heat lights are

out, or that the display is blank.

5. Refer to the data plate on the inside of the fryer door to determine if the fryer burner is config-

ured for the proper type of gas before connecting the fryer quick-disconnect device or piping

from the gas supply line.

6. Verify the minimum and maximum gas supply pressures for the type of gas to be used in accor-

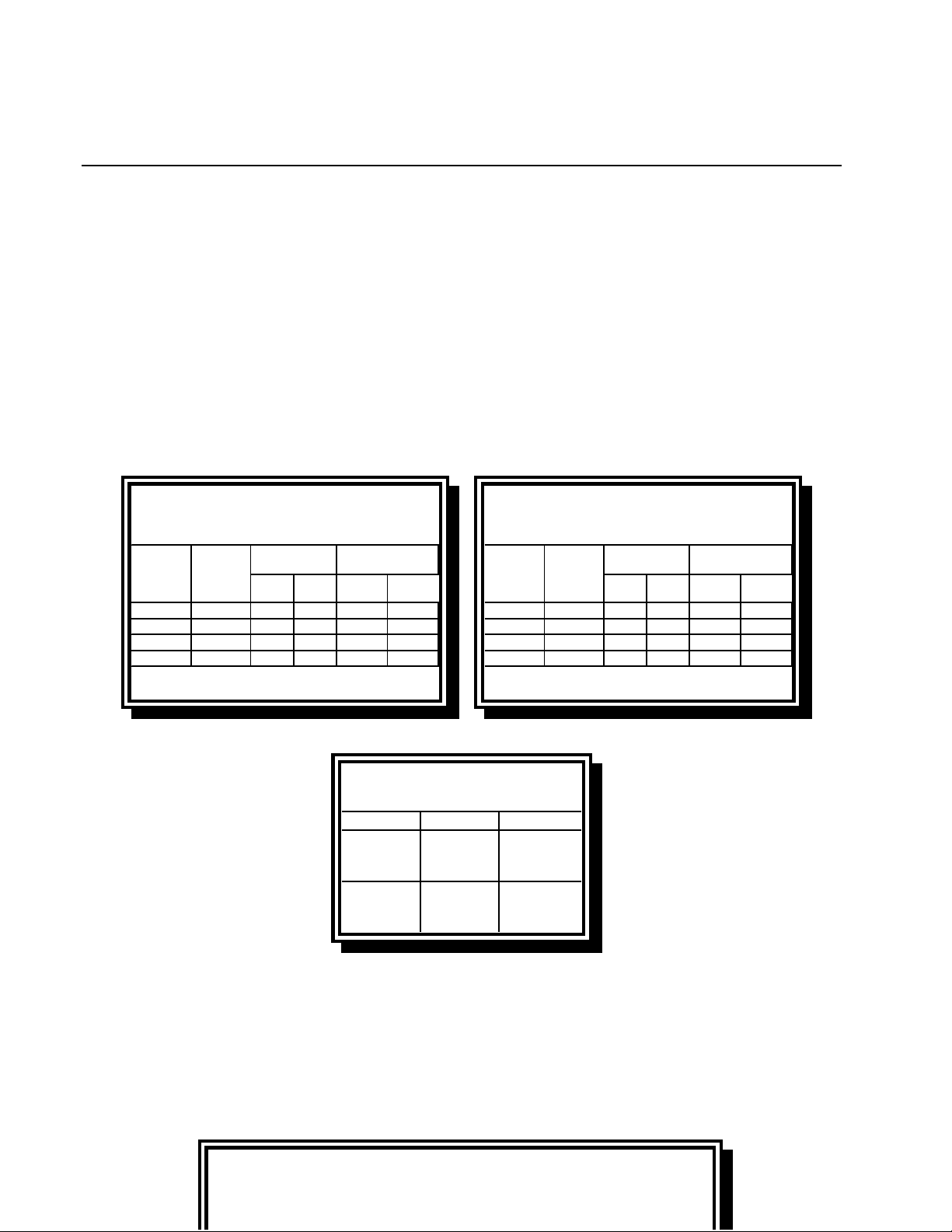

dance with the accompanying tables.

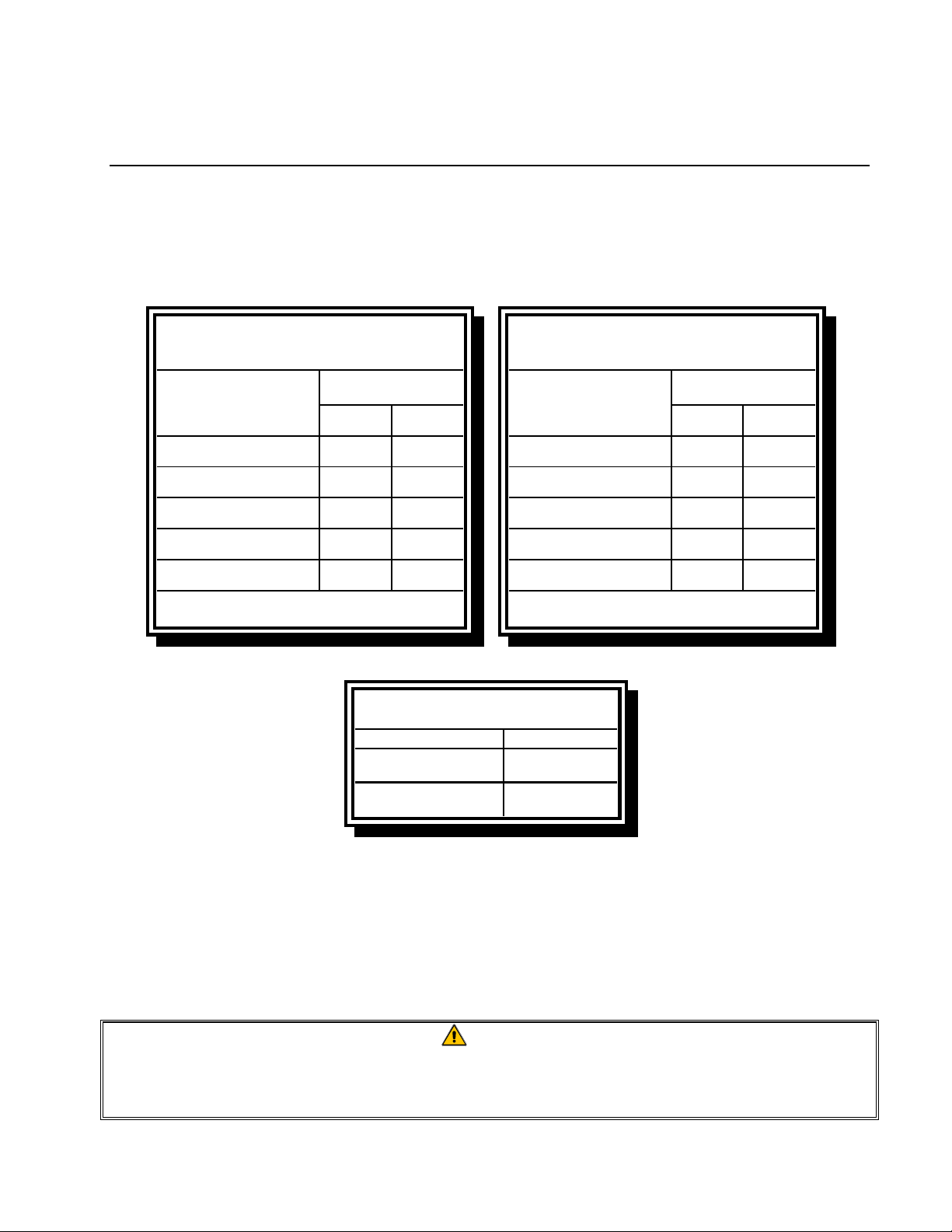

CE Standard

for Incom in g Gas Pressu res

for Fryers Manufactured After April 1999

Pressure

Gas

G20 20 2 x 3.40 2 x 3.40 7 mbar 7 mbar

G25 20 or 25 2 x 3.40 2 x 3.40 10 mbar 10 mbar

G30 28/30 or 50 2 x 2.05 2 x 2.05 17 mbar 17 mbar

G31 37 or 50 2 x 2.05 2 x 2.05 20 mbar 20 mbar

mbar = 10,2 mm H2O

(mbar)

Orifice Diameter

Single

(1)

Vat

Dual

Vat

Regulator Pressure

Single

Vat

Dual

Vat

Non-CE Standard

for Incoming Gas Pressures

Gas Minimum Maximum

Natural

LP

6" W.C.

1.49 kPa

14.93 mbar

11" W.C.

2.74 kPa

27.37 mbar

CE Standard

for Incom in g Gas Pressu res

for Fryers Manufactured Through April 1999

Pressure

Gas

G20 20 2 x 3.40 2 x 3.40 7 mbar 7 mbar

G25 20 or 25 2 x 3.40 2 x 3.40 10 mbar 9 mbar

G30 28/30 or 50 2 x 2.05 2 x 2.05 17 mbar 16,5 mbar

G31 37 or 50 2 x 2.05 2 x 2.05 20,2 mbar 18,5 mbar

mbar = 10,2 mm H2O

34.84 mbar

34.84 mbar

(mbar)

14" W.C.

3.48 kPa

14" W.C.

3.48 kPa

Orifice Diameter

Single

(1)

Vat

Dual

Vat

Regulator Pressure

Single

Vat

Dual

Vat

7. F or fr yers e quip ped with a Foo tPr int III syste m or b ask et li fts , pl ug t he el ect rica l co rd(s ) in to a

power receptacle behind the fryer.

2.4 Connection to Gas Line

The H50 Series has received the CE mark for the countries and gas categories indicated in the

accompanying table. NOTE: The nominal heat input (QN) is 21kW except for AT, DE, LU and

category 3P/B, which is 23kW.

CE Approved Gas Categories by Country

2-4

Page 15

H50 SERIES GAS FRYERS

CHAPTER 2: INSTALLATION INSTRUCTIONS

COUNTRIES CATEGORIES G AS PRESSURE (MBAR)

AUSTRIA (AT) II2H3B/P

BELGIUM (BE)

DENMARK (DK) II2H3B/P

FRANCE (FR)

FINLAND (FI) II2H3B/P

GERMANY (DE)

GREECE (GR) II2H3+

ITALY (IT) II2H3+

IRELAND (IE) II2H3+

LUXEMBOURG (LU) II2E3B/P

NETHERLANDS (NL)

NORWAY (NO) I3B/P G30, G31 30

PORTUGAL (PT) II2H3+

SPAIN (ES)

SWEDEN (SE) II2H3B/P

UNITED KINGDOM (UK) II2H3+

I2E(R)B G20, G25 20, 25

I3+ G30, G31 28-30, 37

II2Esi3+

II2Esi3P

II2ELL3B/P

I3P G31 50

II2L3P

II2L3B/P

II2H3+

II2H3P

G20 20

G30, G31 50

G20 20

G30, G31 30

G20, G25 20, 25

G30, G31 28-30, 37

G20, G25 20, 25

G31 50

G20 20

G30, G31 30

G20, G25 20

G30, G31 50

G20 20

G30, G31 28-30, 37

G20 20

G30, G31 28-30, 37

G20 20

G30, G31 28-30, 37

G20 20

G30, G31 50

G25 25

G31 50

G25 25

G30, G31 30

G20 20

G30, G31 28-30, 37

G20 20

G30, G31 28-30, 37

G20 20

G31 37, 50

G20 20

G30, G31 30

G20 20

G30, G31 28-30, 37

The size of the gas line used for installation is very important. If the line is too small, the gas pressure at the burner manifold will be low. This may cause slow recovery and delayed ignition. The

incoming gas supply line should be a minimum of 1½” (38 mm) in diameter. Refer to the chart on

the following page for the minimum sizes of connection piping.

Gas Connection Pipe Sizes

(Minimum incoming pipe size should be 1 1/2" (38 mm))

4 or more

Gas Single Unit 2 - 3 Units

Natural

3/4" (19 mm)

1" (25 mm) 1 1/4" (33 mm)

Propane 1/2" (13 mm) 3/4" (19 mm) 1" (25 mm)

Manufactured 1" (25 mm) 1 1/4" (33 mm) 1 1/2" (38 mm)

units*

2-5

Page 16

H50 SERIES GAS FRYERS

CHAPTER 2: INSTALLATION INSTRUCTIONS

* For distances of more than 20 feet (6 m) and/or more

than 4 fittings or elbows, increase the connection by one

pipe size.

Before connecting new pipe to your unit, the pipe must be thoroughly blown out to remove any foreign particles. If these foreign particles get into the burner and controls, they will cause improper

and sometimes dangerous operation.

CE Standard

Required airflow for the combustion air supply is 2m3/h per kW.

1. Connect the quick-disconnect hose to the fryer quick-disconnect fitting under the front of the

fryer and to the building gas line.

NOTE: Some fryers are configured for a rigid connection to the gas supply line. These units are

connected to the gas supply line at the rear of the unit.

When using thread compound, use very small amounts on male threads only. Use a pipe thread

compound that is not affected by the chemical action of LP gases (Loctite™ PST56765 Sealant is

one such compound). DO NOT apply compound to the first two threads. This will ensure that

the burner orifices and control valve do not become clogged.

2. Open the gas supply to the fryer and check all piping, fittings, and gas connections for leaks. A

soap solution should be used for this purpose.

DANGER

Never use matches, candles, or any other ignition source to check for leaks.

If gas odors are detected, shut off the gas supply to the fryer

at the main shut-off valve and contact the local gas company or an authorized

service agency for service.

3. Close the fryer drain valve and fill the frypot with water and boil-out solution to the bottom OILLEVEL line at the rear of the frypot. Light the fryer and perform the boil-out procedures that are

described in the “Lighting Instructions” and “Boiling Out the Frypot” topics found in Chapter 3

of this manual.

WARNING

“Dry-firing” your unit will cause damage to the frypot. Always ensure that melted

shortening, cooking oil, or water and boil-out solution is in the frypot before firing

your unit for any extended period.

2-6

Page 17

H50 SERIES GAS FRYERS

CHAPTER 2: INSTALLATION INSTRUCTIONS

4. It is suggested that the burner manifold pressure be checked at this time by the local gas company

or an authorized service agent. Refer to “Check Burner Manifold Pressure” in Chapt er 5 of this

manual for the proper procedure. The accompanying tables list the burner manifold gas pressures

for the various gas types that can be used with this equipment.

CE Standard

Burner Manifold Gas Pressures

for Fryers Manufactured After April 1999

Pressure (mbar)

Single

Natural Gas Lacq

Gas

(G20) under 20 mbar

Natural Gas Groningue *

(G25) under 25 mbar

Natural Gas Groningue

(G25) under 20 mbar

Butane

(G30) at 28/30 or 50 mbar

Propane

(G31) under 37 or 50 mbar

* Belgian G25 = 7,0 mbar (single or dual)

Vat

77

10 10

10 10

17 17

20 20

Burner Manifold Gas Pressures

for Fryers Manufactured Through April 1999

Dual

Vat

Natural Gas Lacq

(G20) under 20 mbar

Natural Gas Gronigue *

(G25) under 25 mbar

Natural Gas Gronigue

(G25) under 20 mbar

Butane

(G30) at 28/30 or 50 mbar

Propane

(G31) under 37 or 50 mbar

* Belgian G25 = 7,0 mbar (single) or 6,5 (dual)

Gas

Non-CE Standard

Burner Manifold Gas Pressures

Gas Pressure

Natural

Propane

3" W.C.

0.73 kPa

8.25" W.C.

2.5 kPa

CE Standard

Pressure (mbar)

Single

Vat

76,5

10 9

10 9

17 16,5

20,2 18,5

Dual

Vat

5. Check the programmed temperature or analog controller thermostat setting. (Refer to Chapter 3,

Operating Instructions, for the setpoint programming instructions for your particular controller.)

2.5 Converting to Another Gas Type

Your fryer is configured at the factory for either natural gas or propane (LP) gas. If you desire to

switch from one type of gas to another, a gas conversion kit must be installed by a Factory

Authorized Service Center technician.

DANGER

Switching to a different type of gas without installing the proper conversion kit may

result in fire or explosion! NEVER attach your fryer to a gas supply for which it is

not configured.

2-7

Page 18

H50 SERIES GAS FRYERS

CHAPTER 2: INSTALLATION INSTRUCTIONS

H50 Series Fryers manufactured for Non-CE countries use different burners for each type gas. The

burners in fryers built for Propane gas have a special gray-colored coating on the burner tiles to enable them to withstand the higher caloric value of the Propane gas. Burners designed for use in Propane units may be used in natural gas applications, but not vice versa.

Non-CE Gas Conversion Kits

Natural Gas to Propane (LP) Gas Propane (LP) Gas to Natural Gas

Full Vat: Part Number 826-1145 Full Vat: Part Number 826-1146

Dual Vat: Part Number 826-1147 Dual Vat: Part Number 826-1148

Units manufactured for export to CE countries are equipped with “universal” burners that may be

used with either natural (G20, G25) gas or Butane (G30) and Propane (G31) gasses.

CE Gas Conversion Kits for Units with Gas Valve 810-1011

G20 or G25 (Natural) to G30 or G31 Gas: G30 or G31 to G20 or G25 (Natural) Gas:

Part Number 826-1196 Part Number 826-1197

CE GAS CONVERSION INSTRUCTIONS

1. Between G20- and G25-type Natural Gas, adjust the gas pressure at the regulator. (Refer to the

CE Standard Burner Manifold Gas Pressure Chart.) Do not change the orifice.

2. Between a 2nd family (G20 or G25) and a 3rd family gas (G30 Butane or G31 Propane):

a. Change the orifices.

b. Change the gas valve spring (units with valve part number 810-1011only)

c. Adjust the manifold pressure.

3. Remove the rating plate and install a new one. Call your local service agency or KES for a new

rating plate.

4. If the destination language changes, replace the labels. Call your local service agency or KES for

a label kit. The language of reference will be on the corner of the label.

2-8

Page 19

H50 SERIES GAS FRYERS

p

n

)

CHAPTER 3: OPERATING INSTRUCTIONS

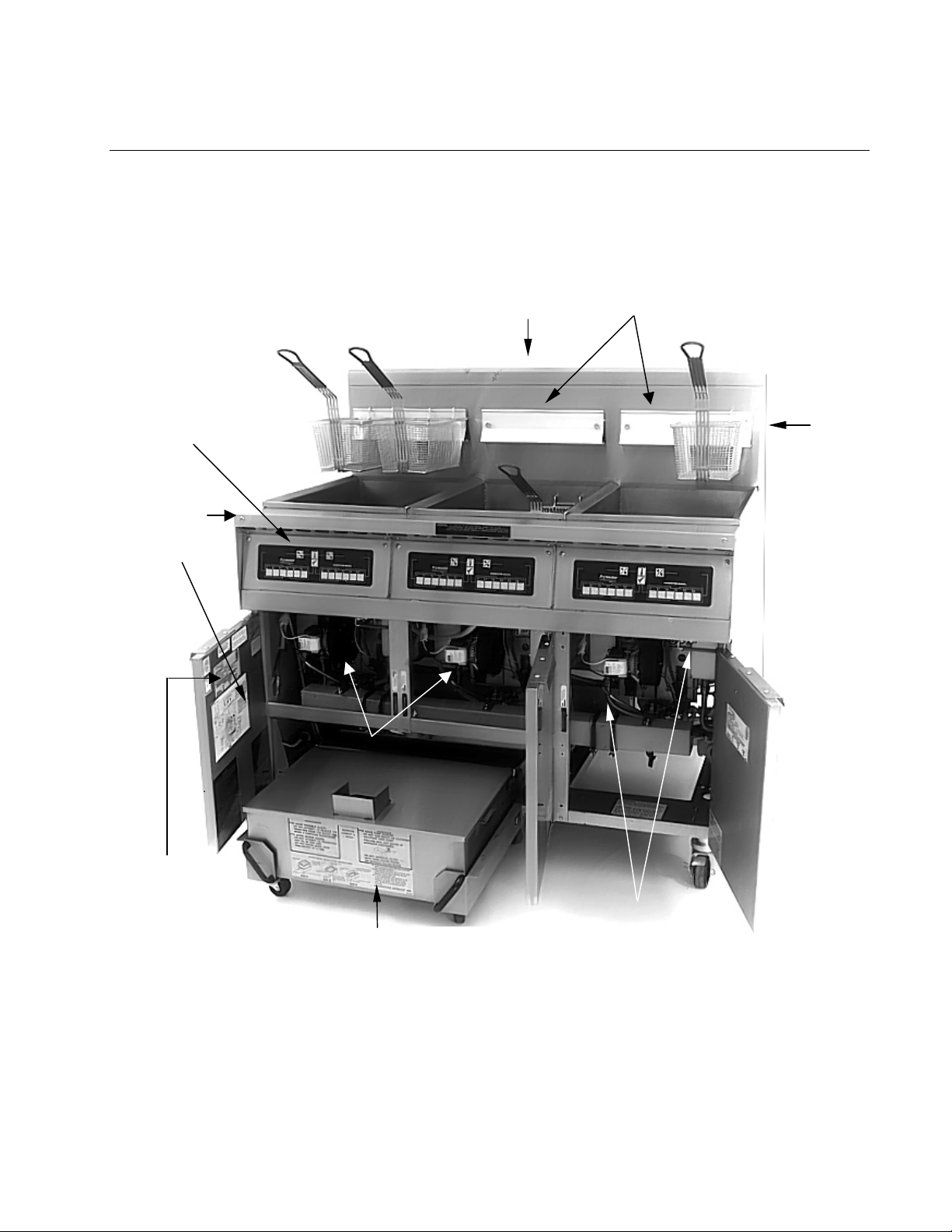

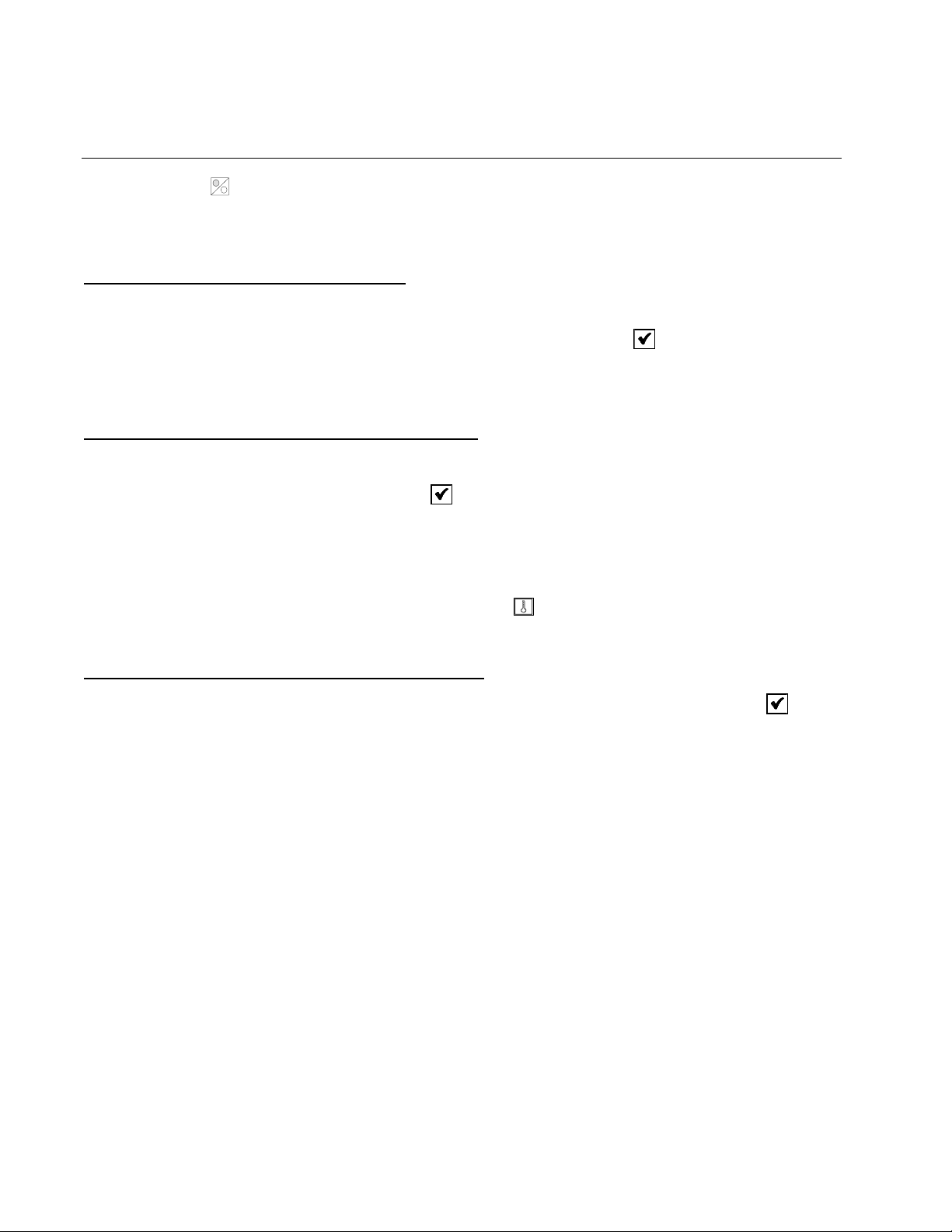

FINDING YOUR WAY AROUND THE H50 SERIES FRYER

Control Panel (CM III

uter show

Com

Top Cap

Wiring Diagrams

Flue Cap

Basket Hangers

Flue

Fryer Identification

Data Labels (Model

and Serial Number)

Combustion Blowers

Drain and Filter Control Handles.

FootPrint III Built-in Filtration Unit

TYPICAL CONFIGURATION

(FPH350 SHOWN)

3-1

Page 20

H50 SERIES GAS FRYERS

CHAPTER 3: OPERATING INSTRUCTIONS

3.1 Start-Up Procedure

CAUTION

If this is the first time the fryer is being used a fter installation, refer to Sec ti on 3.2,

Boil-Out Procedure.

CAUTION

The cooking oil/shortening capacity of the H50 Series fryer is 50 lbs (25 liters) at

70ºF (21ºC) for a full pot and 25 lbs (12.5 liters) at 70ºF (21ºC) for each half of a split

pot.

Before lighting the fryer, make sure the fryer is OFF and the frypot drain valve(s)

is/are closed. Remove the basket support rack(s), if installed, and fill the frypot to

the bottom OIL-LEVEL line.

If solid shortening is being used, make sure it is packed down into the bottom of the

frypot.

Lighting the Fryer

1. Press the computer/controller POWER switch to the OFF position.

Non-CE Fryers

After placing the ON/OFF switch in the OFF

position, turn the gas valve knob to the OFF

position. Wait 5 minutes, then turn the knob to

the ON position.

ON

OFF

Honeywell

Honeywell

ON

OFF

2. Press the computer/controller POWER switch to the ON position and set the thermostat or pro-

gram the computer for normal cooking temperature.

3. If the burners fail to light, press the POWER switch to the OFF position and wait 60 seconds.

Repeat step 2.

3-2

Page 21

H50 SERIES GAS FRYERS

CHAPTER 3: OPERATING INSTRUCTIONS

4. The fryer will automatically enter the Melt Cycle mode if the frypot temperature is below 180ºF

(82ºC). (NOTE: During the melt cycle, the burners will repeatedly fire for a few seconds, then

go out for a longer period.) When the frypot temperature reaches 180ºF (82ºC), the unit will

automatically switch to the Heating mode. The burners will remain lit until the frypot temperature reaches the programmed cooking temperature.

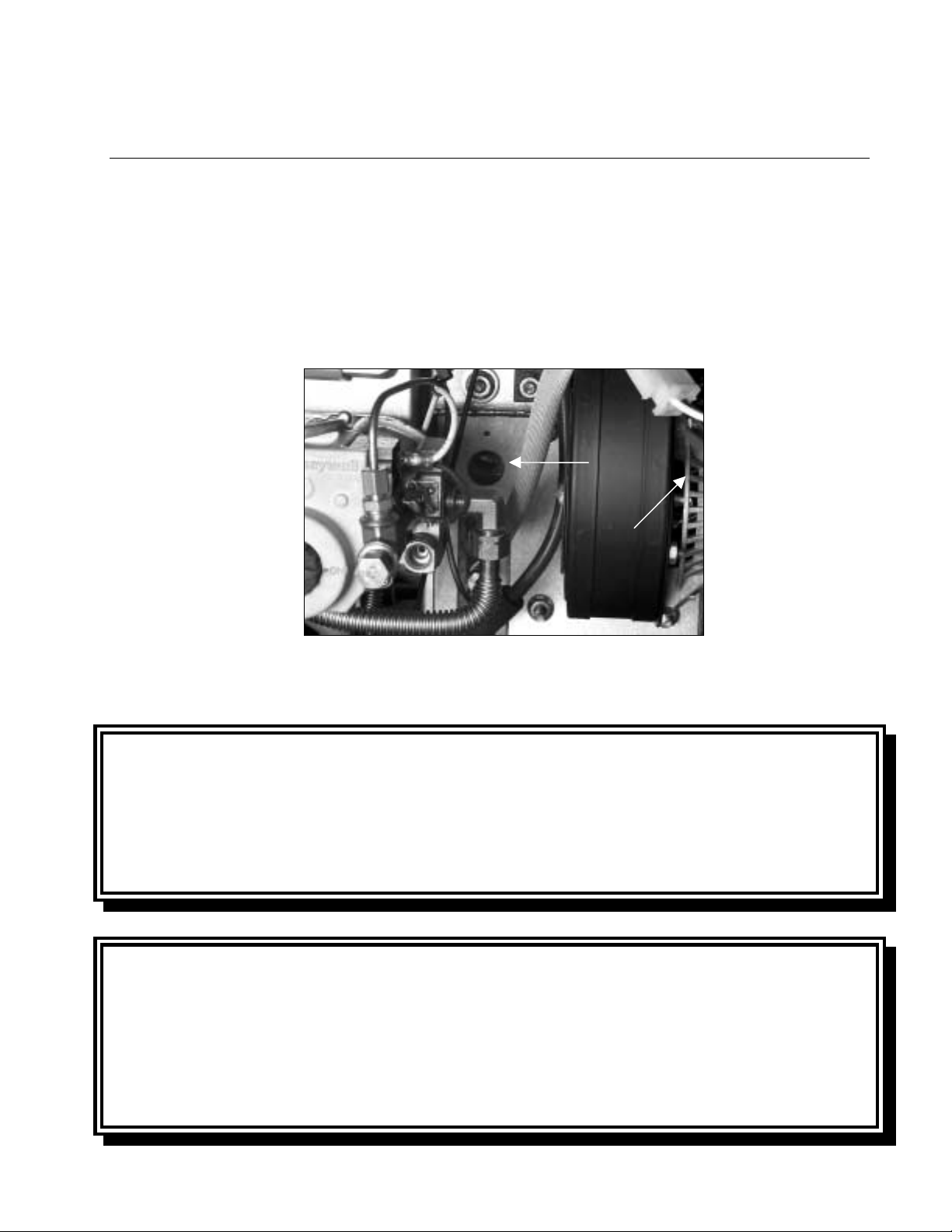

5. After the burners have been lit for at least 90 seconds, observe the flames through the burner

viewing ports located on each side of the combustion air blower.

Left

Viewing

Port

Right

Viewing

Port

Behind

Motor

The optimum burn is a bright orange-red glow. If a blue flame is observed, or if there are dark

spots on a burner face, the air/gas mix requires adjustment. Adjustment procedures are different

for CE and Non-CE units.

Adjusting Air/Gas Mix:

Non-CE Units and CE Units Built After April 1999

On the side of the blower housing opposite the motor is a plate with one or two locking nuts. Loosen

the nut(s) enough to allow the plate to be moved, then adjust the position of the plate to open or close

the air intake opening until a bright orange-red glow is obtained. Carefully hold the plate in position

and tighten the locking nut(s).

Adjusting Air/Gas Mix:

CE Units Built Before May 1999

CE units built before May 1999 are equipped with a shield assembly in front of the blowers. An air

shutter plate on the face of the shield assembly regulates the amount of airflow to the blower intake.

To adjust the shutter plate, loosen the locking screws and slide the shutter to the left or right as necessary to obtain a bright orange-red glow. Carefully hold the shutter plate in position and tighten the

locking screws.

3-3

Page 22

H50 SERIES GAS FRYERS

CHAPTER 3: OPERATING INSTRUCTIONS

3.2 Boiling Out the Frypot

To ensure that the frypot is free of any contamination resulting from its manufacture, shipping, and

handling during installation, the frypot must be boiled out before first use. Frymaster recommends

boiling out the frypot each time the oil or shortening is changed.

1. Before lighting the burners, close the fryer drain valve(s) and fill the frypot to the bottom OIL-

LEVEL line with a mixture of cold water and Frymaster FRYER ‘N’ GRIDDLE cleaner or detergent.

2. For units equipped with other than Computer Magic III controllers or Solid-State Basket Lift

Timers, set the thermostat to, or program the controller for, 200ºF (93ºC).

For units equipped with Computer Magic III controllers, select the Boil-Out feature in accordance with the procedure Using the Boil-Out Feature on page 3-10.

For units equipped with Solid-State Basket Lift Timers, press the Boil-Out Mode button to

begin the boil-out process.

3. Place the fryer into operation in accordance with Section 3.1 and simmer the solution for 1 hour.

DANGER

Never leave the fryer unattended during the boil-out process. If the boil-out solution

boils over, turn off power to the fryer immediately and let the solution cool for a few

minutes before resuming the process.

4. After the solution simmers for 1 hour, turn the fryer off, allow the solution to cool, then add 2

gallons (7.75 liters) of cold water and stir. Drain the solution into a suitable container and clean

the frypot thoroughly.

WARNING

Do not drain boil-out solution into the built-in filtration system. Doing so may cause

damage to the filtration pump.

5. Rinse the frypot at least twice by filling the frypot with clean water and draining. Dry the frypot

thoroughly with a clean, dry towel.

DANGER

Remove all drops of water from the frypot before filling with cooking oil/shortening.

Failure to do so may cause spattering of hot liquid when the oil/shortening is heated

to cooking temperature.

3-4

Page 23

H50 SERIES GAS FRYERS

CHAPTER 3: OPERATING INSTRUCTIONS

3.3 Shutting the Fryer Down

For short-term shut down during the workday, place the fryer power switch in the OFF position and

put the frypot covers in place (if the fryer is so equipped).

When shutting the fryers down at closing time, place the controller power switch in the OFF position.

Non-CE Fryers

After placing the POWER switch in the OFF

position, turn the gas valve knob to the OFF

position.

ON

OFF

Honeywell

Honeywell

ON

OFF

Put the frypot covers in place (if the fryer is so equipped).

3.4 Controller Operation and Programming

Fryers in the H50 Series can be equipped with any of the following controlling devices:

• Computer Magic III

• Analog Controller

• Digital Controller

• Basket Lift Timer

Each type is discussed in detail in the following pages.

3-5

Page 24

H50 SERIES GAS FRYERS

N

CHAPTER 3: OPERATING INSTRUCTIONS

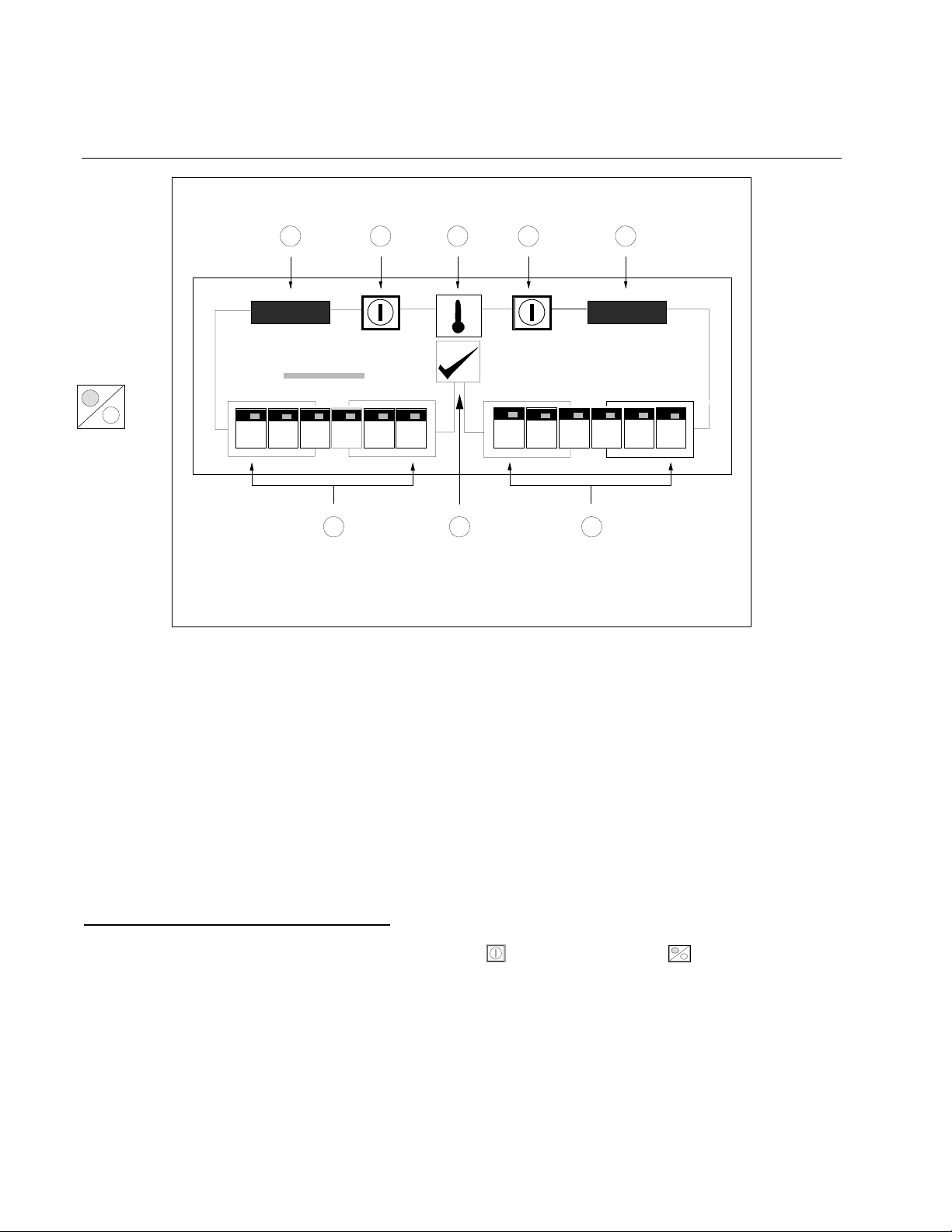

1 234 5

OTE:

Some computers

may have this

earlier style

ON/OFF Switch:

ON

OFF

c y c l c y c l

Frymaster

L1 23445

6 78

COMPUTER MAGIC III

6

COMPUTER MAGIC

78 9

0R

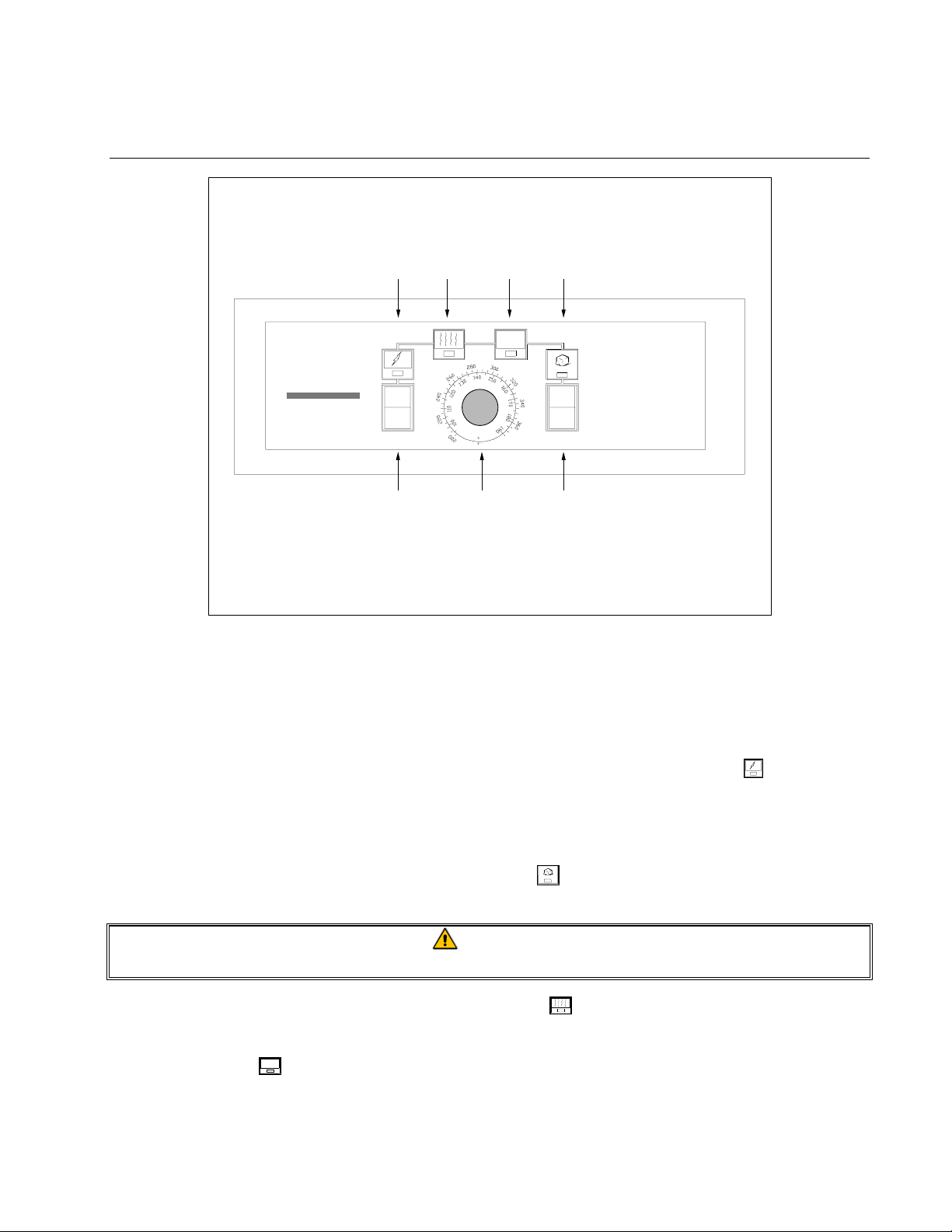

COMPUTER MAGIC III CONTROLLER

The Computer Magic III control panel includes the following items:

1/2. Left and Right LED Displays

1/3. Temperature Check and Program Lock Switch

4/5. Left and Right Frypot Power Switches NOTE: On single vat units, either switch will turn the

fryer on and off.

6/7. Left and Right Product Selection and Coding Keys

1/8. Program Mode Switch

COMPUTER OPERATING INSTRUCTIONS

ON

Turn the computer on by pressing the Power Switch (or ON/ OFF Switch

OFF

). NOTE: A deci-

mal between digits 1 and 2 in either LED Display indicates that the burners are on.

1. One of the following will be displayed:

a. cycl

cycl, indicating that the fryer is operating in the melt cycle mode. The fryer will remain in

cyclcycl

the melt cycle mode until it reaches 180ºF (82ºC).

3-6

Page 25

H50 SERIES GAS FRYERS

CHAPTER 3: OPERATING INSTRUCTIONS

b. hi

hi, indicating that the frypot temperature is 21ºF (12ºC) higher than the setpoint.

hihi

c. LO

LO, indicating that the frypot temperature is 21ºF (12ºC) lower than the setpoint.

LOLO

d. “- - - -,” indicating that the frypot temperature is in the cooking range. NOTE: For best re-

sults, cooking should not be attempted unless the display indicates “- - - -.”

e. help

help, indicating a heating problem.

helphelp

f. hot

hot, indicating the frypot temperature is in excess of 410ºF (210ºC).

hothot

g. prob

prob, indicating that the computer has detected a problem in the tem perature measuring and

probprob

control circuits.

2. Press a product switch to initiate a cook cycle.

a. The basket lift (on fryers so equipped) will lower the product into the frypot.

b. The display will indicate the previously programmed cook time and begin countdown.

c. If shake time is programmed, the operator will be notified of the need to shake the product

“X” seconds after the cook cycle has begun (X = amount of time programmed). An alarm

will sound, and the display will read SH#

time has been programmed, sh

canceling.

d. At the end of the cooking cycle, an audible alarm will sound, cooc

associated product switch indicator will flash. To cancel the cook alarm, press the appropriate switch.

e. At this time, the hold time will be displayed (if programmed greater than zero), and the

countdown will begin. When the countdown reaches zero, hD

the switch number) and an alarm will sound. The hold alarm is canceled by pressing the Programming Switch . NOTE: If the display is in use, the hold time countdown will not be

displayed.

3. To check the frypot temperature at any time, press the Temperature Check Switch once. To

check the setpoint, press the switch twice. If you suspect the temperature probe is defective,

check the temperature of the frypot with a thermometer or pyrometer to verify that the computer

readout is reasonably close to the measured reading.

sh#### will not appear during the cook cycle. The alarm is self-

shsh

SH#, where “#” will be the switch number. If no shake

SH#SH#

cooc will be displayed, and the

cooccooc

hD#### will be displayed (# will be

hDhD

4. During idle periods when the fryer is on but not in use, “- - - -” should appear in both displays. If

not, check the actual temperature and setpoint.

3-7

Page 26

H50 SERIES GAS FRYERS

CHAPTER 3: OPERATING INSTRUCTIONS

CAUTION

The electronic circuitry in your computer can be affected adversely by current

fluctuations and electrical storms. Should it fail to function or program properly for

no apparent reason, the computer should be reset by unplugging the computer and

plugging it back in. This could prevent a service call.

COMPUTER PROGRAMMING INSTRUCTIONS

ON

1. Turn the computer on by pressing the Power Switch (or ON/OFF

OFF

Switch).

2. Enter the programming mode by pressing the Program Mode Switch

. Code

Code will appear in the

CodeCode

left display. If you enter the programming mode by mistake, press the switch again to exit the

programming mode. NOTE: If you try to enter the programming mode while the computer is

cooking, the display will flash busy

busy.

busybusy

3. Enter the number 1 6 5 0 by pressing the number keys. Unless this code is entered, programming

will not be accepted. This is to prevent unauthorized persons from changing your current instructions.

4. sp-

sp-r (Setpoint) will appear in the left display. Any previously programmed temperature setpoint

sp-sp-

will appear in the right display. To change the setpoint, enter the desired setpoint temperature

using the number keys. For CE units, the highest setpoint allowed is 370ºF (188ºC). For Non-CE

units the number is 375ºC (191ºC). Press the Program Mode Switch to lock in the new setpoint (or the old setpoint, if it was not changed). If the unit is a dual vat fryer, sp-L

sp-L will appear,

sp-Lsp-L

allowing the setpoint for the left vat to be adjusted or confirmed.

5. selp

selp (Select Product) will appear in the left display. Press the product button to be programmed

selpselp

(or press

6. sens

sens (Sensitivity) appears in the left display. Any previously programmed sensitivity setting will

senssens

to return to the normal operating mode).

appear in the right display. To change the sensitivity setting, enter the new setting and press

to lock it in. If the setting was not changed, pressing accepts the previous setting.

Sensitivity is a built-in feature that adjusts cooking time to compensate for the drop in frypot

temperature when a basket of product is placed into it. Different food products will vary in

density, basket load size, and initial temperature. Food products will also vary in how long it is

required to be cooked. A proper sensitivity setting for each product will assure a high-quality

product each time. For example: four ounces of fries can be programmed to be cooked to the

same quality as two and one-half pounds. Some experimenting with the range of 0 - 9 (0 being

least sensitive and 9 being most sensitive) may be required to obtain the desired quality to meet

your specifications, but setting 5 is the recommended starting point.

3-8

Page 27

H50 SERIES GAS FRYERS

CHAPTER 3: OPERATING INSTRUCTIONS

7. cooc

cooc (Cook Time) will now show in the left display. Any previously programmed cooking time

cooccooc

will appear in the right display. Pressing

cooking time, enter the new time using the Number keys. Press

8. sh_

sh_ (Shake Time) appears in the left display. If your product requires shaking during the cook-

sh_sh_

will accept the current cooking time. To change the

to lock in the new time.

ing process, set the number of minutes to cook before shaking using the number keys.

For example, entering “30” means the product needs to be shaken after it has been cooking for 30

seconds. At the end of 30 seconds, an alarm will sound and the product switch will flash for 3

seconds. If your product does not require shaking, enter “0”. The number entered will appear in

the right display. Press to lock in the programmed time.

9. hd_

hd_ (Hold Time) will appear in the left display. Set the time the product may be held before

hd_hd_

serving, anything from 13 seconds to 60 minutes. If you do not wish to use the hold time feature,

enter 0. Press to lock in the time.

In the event the same product is being cooked in more than one basket, any product button can

be programmed to use the hold timer normally used with a different product button. Example:

Program button 3 for 7:00 minutes hold time. Then, when programming button R for hold time,

press address 4. Both product button 3 and product button R will then use the same hold time of

7:00 minutes. The button numbers and their assigned address numbers are:

Button: L 1 2 3 4 5 6 7 8 9 0 R

Address: 1 2 3 4 5 6 7 8 9 10 11 12

10. selp

selp (Select Product) will again appear in the left display. If more products are to be pro-

selpselp

grammed, return to Step 5 and follow all instructions to this point, repeating for each product.

11. When you complete your programming, lock in the whole program by pressing the Temperature

Check/Program Lock Switch .

USING THE BOIL-OUT FEATURE

CAUTION

Before using this feature, ensure the frypot is filled with a mixture of cold water and

Frymaster FRYER ‘N’ GRIDDLE cleaner or detergent.

ON

1. To program the fryer for boil-out, press the Power Switch (or ON/OFF

by the Program Mode Switch . Code

2. Enter the code number 1 6 5 3. The right display will read boil

Code will appear in the left display.

CodeCode

boil. The temperature is automatically

boilboil

OFF

Switch) followed

set for 195ºF (91ºC). The fryer will attain this temperature and remain there until the Power

3-9

Page 28

H50 SERIES GAS FRYERS

CHAPTER 3: OPERATING INSTRUCTIONS

ON

(or ON/OFF

OFF

) Switch is pressed, which cancels the boil-out mode. In high-altitude locations,

the fryer must be monitored constantly for boil-over conditions. If boil-over occurs, turn off the

fryer immediately, allow it to cool, then re-enter the boil-out mode to continue the process.

FRYER RECOVERY TIME CHECK FEATURE

The computer automatically checks the recovery time each time the frypot temperature drops below

250ºF (121ºC). To check recovery time, press the Program Mode Switch . C ode

Code will appear in the

CodeCode

left display. Enter the code number 1 6 5 2 on the number keypad. The recovery time will appear in

both displays for 5 seconds.

SELECTING FAHRENHEIT– CELSIUS DISPLAY MODE

1. The computer can display temperatures in either Fahrenheit or Celsius. To change from one to

the other, press the Program Mode Switch . Code

Code will appear in the left display.

CodeCode

2. Enter the code number 1 6 5 8 on the number keypad. The computer will toggle the temperature

display from Celsius to Fahrenheit or from Fahrenheit to Celsius.

3. Press the Temperature Check/Program Lock Switch to display the temperature in the newly

selected mode.

SELECTING FRYPOT TEMPERATURE DISPLAY MODE

1. To display the actual frypot temperature at all times, press the Program Mode Switch . Code

Code

CodeCode

will appear in the left display.

2. Enter code 1 6 5 L in both number keypads. The computer will display the actual frypot temperature. NOTE: During the product cooking process, the cooking time will not be displayed, but

timing is taking place.

3. To return to setpoint display, repeat Steps 1 and 2.

3-10

Page 29

H50 SERIES GAS FRYERS

CHAPTER 3: OPERATING INSTRUCTIONS

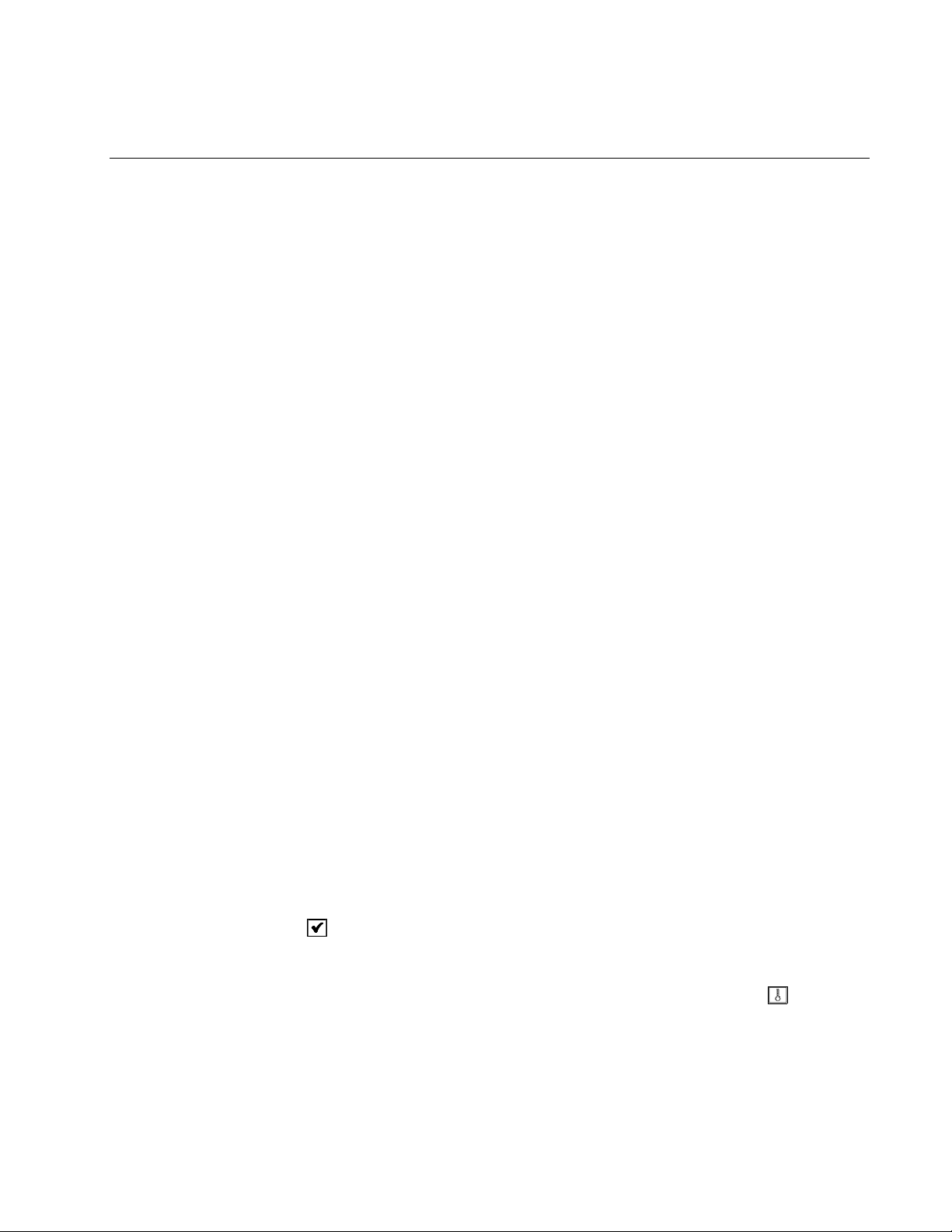

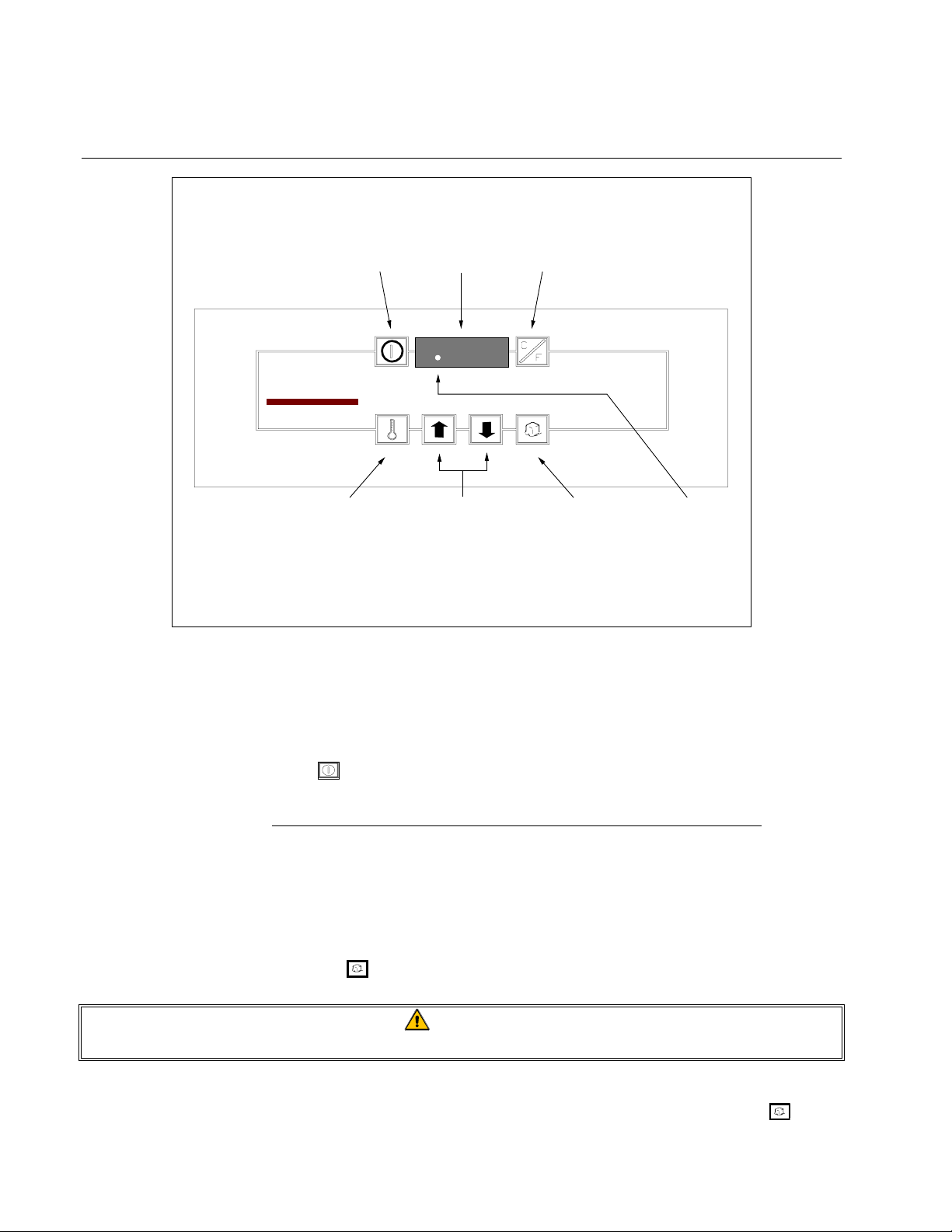

ANALOG CONTROLLER

Frym as te r

Power

Light

Power

Switch

Heat

Mode

On

Light

ANALOG CONTROLLER

Trouble

Light

C

F

Temperature

Knob

Melt

Cycle

Light

?

SOLID STATE

Melt Cycle

Switch

Like th e C omp ut er Mag ic III, th e a nal og con tr ol le r utilizes a frypot-mounted temperature probe and

solid-state electronics mounted on the control panel. The temperature probe is connected to the control circuitry via an interface board behind the control panel. Rotating the Temperature Knob to the

desired temperature sets the cooking temperature. When the Power Switch is placed in the ON posi-

tion, electrical current is supplied to the fryer’s components and the Power On Light illuminates.

Placing the Melt Cycle Switch in the ON position causes the burners to cycle on for a few seconds

and off for a longer period until the temperature in the frypot reaches 180ºF (82ºC). At that time the

unit automatically enters the heat mode, causing the burners to remain lit until the setpoint is

reached. When in the melt cycle, the Melt Cycle Light

will alternately illuminate and go out as

the burners cycle on and off.

CAUTION

Do not cancel the Melt Cycle if solid shortening is being used.

When the unit enters the heat mode, the Heat Mode Light will illuminate and remain on until the

setpoint is reached.

The Trouble Light ? will illuminate if there is an ignition failure. To reset the controller after an

ignition failure, place the Power switch in the OFF position for 30 seconds, then place it back in the

ON position. The Trouble Light is also used to indicate the presence of a probe circuit or high-limit

circuit problem.

3-11

Page 30

H50 SERIES GAS FRYERS

CHAPTER 3: OPERATING INSTRUCTIONS

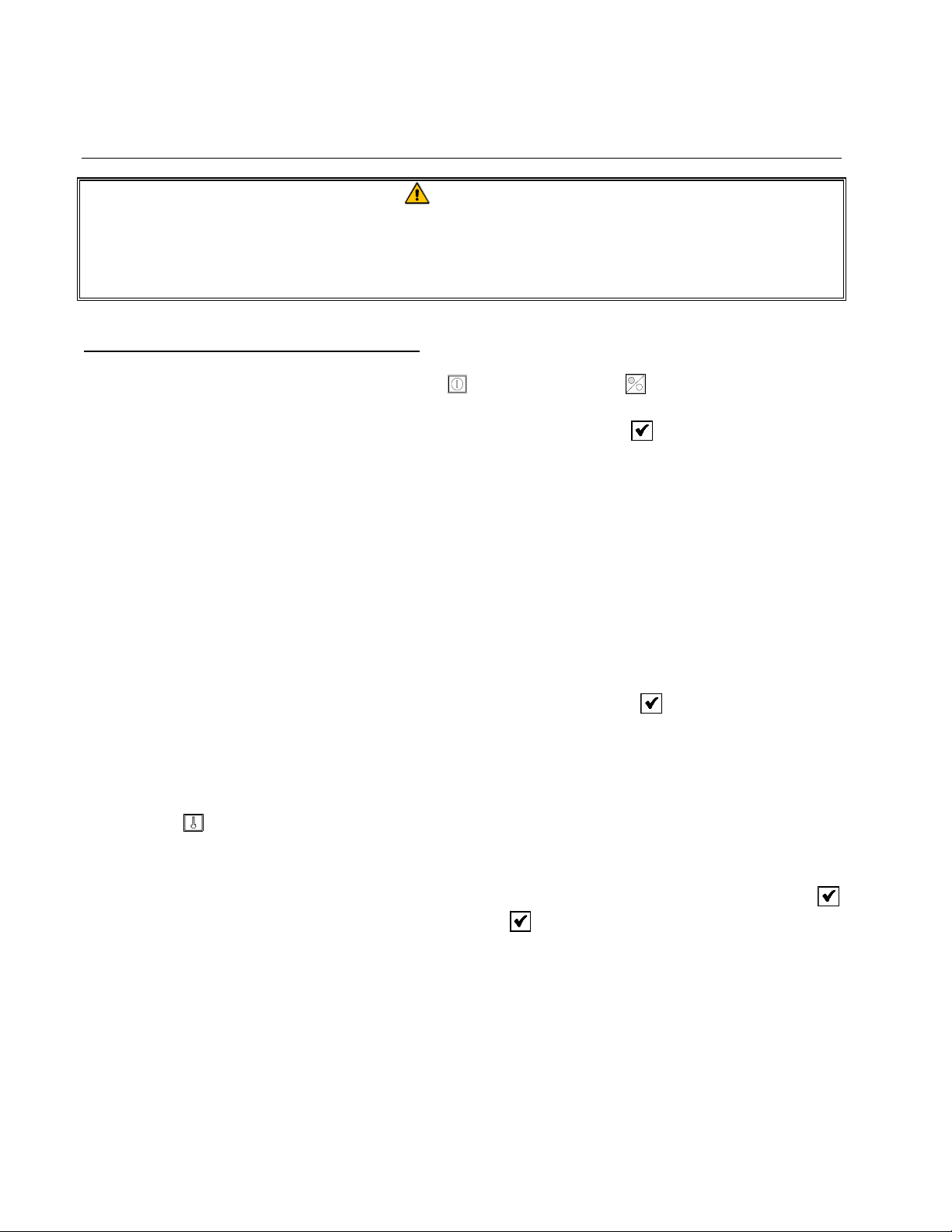

Celcius or

ON/OFF

Switch

Digital

Display

Fahrenheit

Display Switch

9 . 9 9 9

Frym as te r

Heating

Mode

Indicator

DIGITAL CONTROLLER

Temperature

or Setpoint

Display Switch

Setpoint

Adjustment

Arrows

DIGITAL CONTROLLER

Melt

Cycle

Switch

On the digital controller, the thermostat knob has been replaced with a digital display and a pair of

keys for increasing or decreasing the setpoint.

Pressing the ON/OFF Switch

supplies electrical power to the fryer, and causes the controller

software version number to display for 4 seconds in the Digital Display. Following the software version number display, the SETPOINT TEMPERATURE WILL DISPLAY CONSTANTLY. Pressing

the Temperature/Setpoint Display Switch will display the actual frypot temperature.

The fryer will automatically enter the melt cycle mode and will continue to cycle on for a few

seconds and off for a longer period until the temperature in the frypot reaches 180ºF (82ºC). At that

time, it will enter the heat mode. The purpose of the melt cycle is to gradually melt solid shortening

to prevent its scorching, and to prevent creation of “hot spots” on the frypot. To cancel the melt

cycle, press the Melt Cycle Switch .

CAUTION

Do not cancel the Melt Cycle if solid shortening is being used.

NOTE: If solid shortening is not being used, the controller can be programmed to bypass the Melt

Cycle as follows: With the controller in the OFF mode, press the Melt Cycle Switch . The

display will show either a “0” (meaning that the melt cycle can be bypassed) or a “1” (meaning that

3-12

Page 31

H50 SERIES GAS FRYERS

CHAPTER 3: OPERATING INSTRUCTIONS

the melt cycle cannot be bypassed). To change the bypass option setting, press and hold the Melt

Cycle Switch for 5 to 6 seconds to toggle “0” to “1” or “1” to “0”. When the display shows the

desired setting, release the switch.

The fryer will remain in the heat mode until the setpoint is reached. The Heat Mode Indicator is a

decimal point that appears between the first two numbers of the digital display to indicate the unit is

heating. When the setpoint is reached, the decimal will go out, indicating the fryer is ready for

cooking.

To enter or change the setpoint temperature, press the Up Arrow or Down Arrow keys to raise or

lower the temperature setting. The display will change at a rate of about 1 degree per second for approximately the first 12 degrees, then change to a faster rate if the arrow is continuously pressed.

The temperature can be displayed in either Fahrenheit or Celsius. To change from one to the other,

press the C/F Switch .

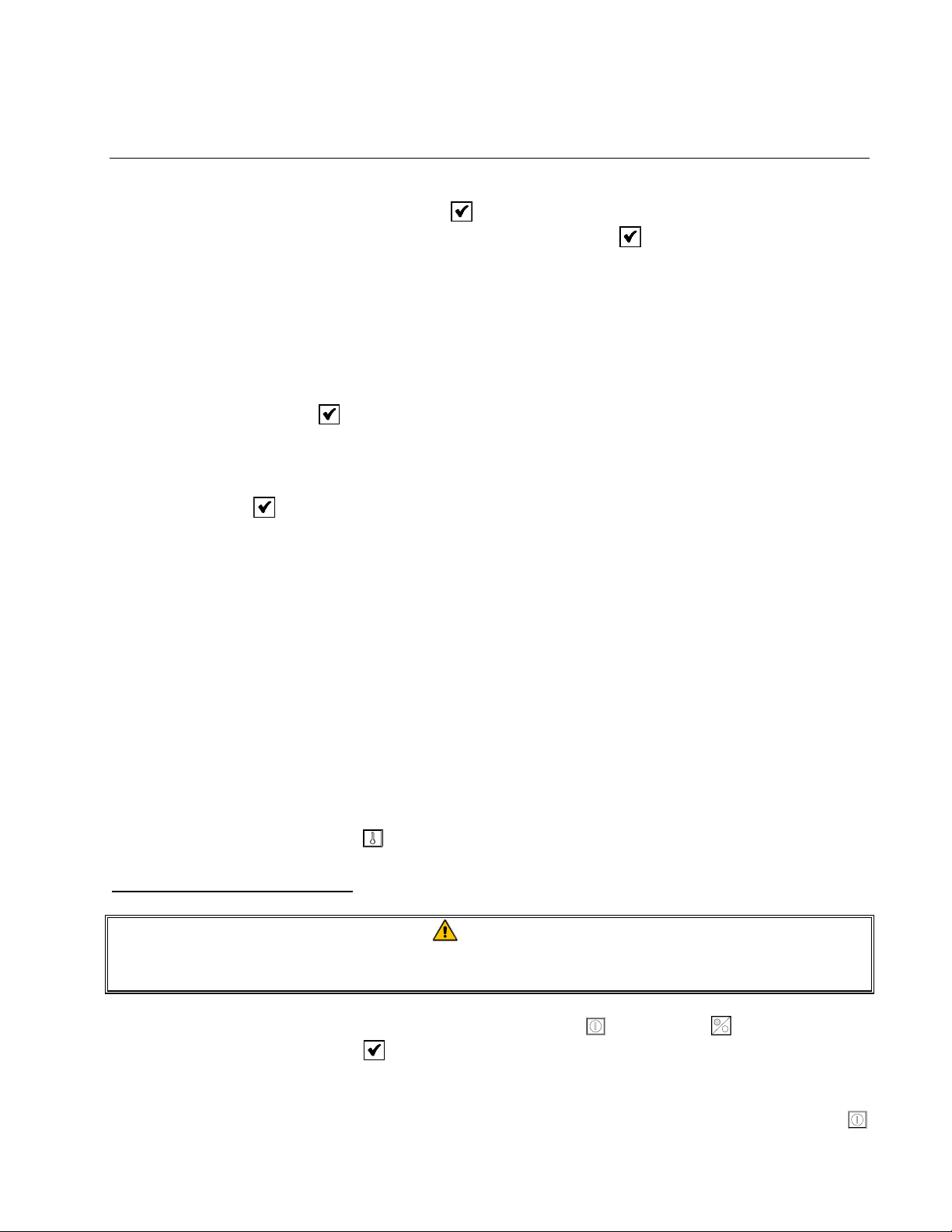

Digital

Display

Programming

SOLID-STATE BASKET LIFT TIMER

ON/OFF

Button

Cook Time

Buttons

Temperature

Check Button

Left

Basket

Button

BASKET LIFT TIM ER

Temperature

Check Button

Boil-Out

Button

Right

Basket

Button

ON/OFF

Button

Cook Time

Programming

Buttons

Digital

Display

The Basket Lift Timer allows the operator to specify individual cooking times for each vat and independently control the operation of each basket lift.

3-13

Page 32

H50 SERIES GAS FRYERS

CHAPTER 3: OPERATING INSTRUCTIONS

Pressing the ON/OFF buttons supplies electrical power to the fryer components. The fryer will

automatically go into the melt cycle mode if the temperature in the frypot is below 180ºF (82ºC), cycling on for a few seconds and off for a longer period. The purpose of the melt cycle is to gradually

melt solid shortening to prevent its scorching, and to prevent the creation of “hot spots” in the frypot.

To cancel the melt cycle mode, press the Right Basket button.

The cook time for each basket is always shown in the Digital Displays except when the Temperature

Check buttons

To view the setpoint for a frypot, press the corresponding Temperature Check button . The

setpoint for the frypot will be shown in the corresponding Digital Display.

NOTE: For full pot (single vat) units, the setpoint will be shown in the right display only.

To change the setpoint, enter the new temperature using the number keys, then press the Temperature

Check button

Pressing a Basket button initiates a cooking cycle. The basket is automatically lowered into the

frypot and the cook time in the Digital Display begins to count down. When the countdown reaches

zero, the basket is raised from the frypot and a buzzer sounds to alert the operator that cooking is

completed. Pressing the Basket button silences the alarm.

are pressed. To change a cook time, enter the new time with the number keys.

again to lock in the setpoint and return to the cook time mode.

The controller also displays the following trouble messages in the Digital Display of the vat functioning abnormally:

• HELP

HELP is displayed continuously if there is a heating failure.

HELPHELP

• hot

hot is displayed if the frypot temperature rises above 385ºF (196ºC).

hothot

• PROB

PROB indicates a problem with the temperature probe circuit.

PROBPROB

3-14

Page 33

H50 SERIES GAS FRYERS

CHAPTER 4: FILTRATION INSTRUCTIONS

4.1 Draining and Manual Filtering

DANGER

Allow oil/shortening to cool to 100ºF (38ºC) or lower before draining to an appropriate container for disposal.

If your fryer is not equipped with a built-in filtration system (FootPrint III or F ilter Magic II), the

cooking oil or shortening must be drained into another suitable container. (For safe, convenient

draining and disposal of used cooking oil or shortening, Frymaster recommends using the

Shortening Disposal Unit (SDU). The SDU is available through your local distributor.)

1. Turn the fryer power switch to the OFF position. Screw the drainpipe (provided with your fryer)

into the drain valve. Make sure the drainpipe is firmly screwed into the drain valve and that the

opening is pointing down.

2. Position a metal container with a sealable cover under the drainpipe. The metal container must

be able to withstand the heat of the cooking oil/shortening and hold hot liquids. If you intend to

reuse the oil or shortening, Frymaster recommends that a Frymaster

cone be used when a filter machine is not available. If you are using a Frymaster filter cone

holder, be sure that the cone holder rests securely on the metal container.

filter cone holder and filter

Frymaster

3. Open the drain valve slowly to avoid splattering. If the drain valve becomes clogged with food

particles, use the Fryer’s Friend (poker-like tool) to clear the blockage.

DANGER

DO NOT insert anything into the drain from the front to unclog the valve. Hot

oil/shortening will rush out, creating an extreme hazard.

WARNING

DO NOT hammer on the drain valve with the Fryer’s Friend. This will damage the

drain valve ball and prevent the valve from sealing securely, resulting in a leaky

valve.

4. After draining the oil/shortening, clean all food particles and residual oil/shortening from the fry-

pot. BE CAREFUL, this material may still cause severe burns if it comes in contact with bare

skin.

5. Close the drain valve securely and fill the frypot with clean, filtered or fresh cooking oil or solid

shortening to the bottom OIL-LEVEL line.

4-1

Page 34

H50 SERIES GAS FRYERS

CHAPTER 4: FILTRATION INSTRUCTIONS

DANGER

When using solid shortening, pack the shortening down into the bottom of the

frypot. DO NOT operate the fryer with a solid block of shortening sitting in the upper

portion of the frypot. This will cause damage to the frypot and may cause a flash

fire.

4.2 Built-In Filtration System Operation

Bot h t he Fo o tP ri n t III ( FP III) a nd Filter Magic II (FM II) filtration systems allow the cooking oil or

shortening in one frypot to be safely and efficiently filtered while the other frypots in a battery remain in operation. Although different in design and appearance, the operation of the FootPrint III

and Filter Magic II systems is identical. Operation of the FootPrint III syste m is illustrated in this

discussion, but the steps described apply equally to the Filter Magic II system.

Most reported problems with these systems have been found to be caused by improper operation.

Careful attention to the step-by-step instructions that follow will ensure that your system operates as

intended.

PREPARING THE FILTER UNIT FOR USE

1. Pull the filter unit from the cabinet, open the cover, remove the crumb tray, and remove the paper

hold-down ring.

4-2

Page 35

H50 SERIES GAS FRYERS

CHAPTER 4: FILTRATION INSTRUCTIONS