Page 1

Series MJCF, MJCFE, MJCFEC, FMCFE,

FMCFEC, JCFX, KJ3FC, J3F & J65X.

Master Jet CF Series Atmospheric

Service & Parts Manual

Gas Fryers

NON-CE &

Frymaster, a member of the Commercial Food Equipment Service Association, recommends

using CFESA Certified Technicians.

24-Hour Service Hotline 1-800-551-8633 APRIL 2005

PRINTED IN THE USA

www.frymaster.com

Email: service@frymaster.com

*8195186*

Page 2

Please read all sections of this manual and retain for future reference.

NOTICE

This appliance is intended for professional use only and is to be operated by qualified

personnel only. A Frymaster Factory Authorized Service Center (FASC) or other qualified

professional should perform installation, maintenance, and repairs. Installation, maintenance,

or repairs by unqualified personnel may void the manufacturer’s warranty.

NOTICE

Drawings and photos used in this manual are intended to illustrate operational, cleaning and

technical procedures and may not conform to onsite management operational procedures.

NOTICE

IF, DURING THE WARRANTY PERIOD, THE CUSTOMER USES A PART FOR THIS ENODIS

EQUIPMENT OTHER THAN AN UNMODIFIED NEW OR RECYCLED PART PURCHASED

DIRECTLY FROM FRYMASTER/DEAN, OR ANY OF ITS AUTHORIZED SERVICE CENTERS,

AND/OR THE PART BEING USED IS MODIFIED FROM ITS ORIGINAL CONFIGURATION, THIS

WARRANTY WILL BE VOID. FURTHER, FRYMASTER/DEAN AND ITS AFFILIAT ES WILL NOT BE

LIABLE FOR ANY CLAIMS, DAMAGES OR EXPENSES INCURRED BY THE CUSTOMER WHICH

ARISE DIRECTLY OR INDIRECTLY, IN WHOLE OR IN PART, DUE TO THE INSTALLATION OF

ANY MODIFIED PART AND/OR PART RECEIVED FROM AN UNAUTHORIZED SERVICE CENTER.

DANGER

Improper installation, adjustment, maintenance or service, and unauthorized alterations or

modifications can cause property damage, injury, or death. Read the installation, operating and

service instructions thoroughly before installing or servicing this equipment. Only qualified

service personnel may convert this appliance to use a gas other than that for which it was

originally configured.

DANGER

Adequate means must be provided to limit the movement of this appliance without depending

upon the gas line connection. Single fryers equipped with legs must be stabilized by installing

anchor straps. All fryers equipped with casters must be stabilized by installing restraining

chains. If a flexible gas line is used, an additional restraining cable must be connected at all

times when the fryer is in use.

DANGER

The front ledge of the fryer is not a step. Do not stand on the fryer. Serious injury can result

from slips or contact with the hot oil.

DANGER

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any

other cooking appliance.

WARNING

No structural material on the fryer should be altered or removed to accommodate placement of

the fryer under a hood. Questions? Call the Frymaster Service Hotline at 1-800-551-8633.

ii

Page 3

DANGER

Instructions explaining procedures to be followed MUST be posted in a prominent location in

the event the operator detects a gas leak. This information can be obtained from the local gas

company or gas supplier.

DANGER

The crumb tray in fryers equipped with a filter system must be emptied into a fireproof container

at the end of frying operations each day. Some food particles can spontaneously combust if left

soaking in certain shortening material. Additional information can be obtained in the filtration

manual included with the system.

WARNING

Do not bang fry baskets or other utensils on the fryer’s joiner strip. The strip is present to seal

the joint between the frypot. Banging fry baskets on the strip to dislodge shortening will distort

the strip, adversely affecting its fit. It is designed for a tight fit and should only be removed for

cleaning.

IMPORTANT

Safe and satisfactory operation of Frymaster equipment depends upon its proper installation.

Installation MUST conform with local codes, or in the absence of local codes, to European

Community (CE) Standards.

COMPUTERS

FCC

This device complies with Part 15 of the FCC rules. Operation is subject to the following two conditions:

1) This device may not cause harmful interference, and 2) This device must accept any interfere nce

received, including interference that may cause undesired operation. While this device is a verified Class

A device, it has been shown to meet the Class B limits.

CANADA

This digital apparatus does not exceed the Class A or B limits for radio noise emissions as set out by the

ICES-003 standard of the Canadian Department of Communications.

Cet appareil numerique n’emet pas de bruits radioelectriques depassany les limites de classe A et B

prescrites dans la norme NMB-003 edictee par le Ministre des Communcations du Canada.

DANGER

THIS PRODUCT CONTAINS CHEMICALS KNOWN TO THE STATE OF CALIFORNIA TO CAUSE

CANCER AND/OR BIRTH DEFECTS OR OTHER REPRODUCTIVE HARM.

Operation, installation, and servicing of this product could expose you to airborne particles of

glasswool or ceramic fibers, crystalline silica, and/or carbon monoxide. Inhalation of airborne

particles of glasswool or ceramic fibers is known to the State of California to cause cancer.

Inhalation of carbon monoxide is known to the State of California to cause birth defects or other

reproductive harm.

iii

Page 4

Master Jet CF Series Atmospheric Gas Fryers

TABLE OF CONTENTS

PAGE #

1.

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.8.1

1.8.2

1.8.3

1.8.4

1.8.5

1.8.6

1.8.7

1.8.8

1.8.9

1.8.10

1.8.11

1.8.12

1.9

1.9.1

1.9.2

1.9.3

1.9.4

1.9.5

1.9.6

1.9.7

1.10

1.10.1

1.10.2

1.11

1.12

1.12.1

1.12.2

1.12.3

1.12.4

1.12.5

SERVICE PROCEDURES

Functional Description

Accessing Fryers for Servicing

Cleaning Burner Manifold Gas Pressure

Adjusting Pilot Flame

Cleaning Gas Valve Vent Tube

Adjusting Burner Ceramic Target Spacing and Alignment

Calibrating Thermostat Control

Replacing Fryer Components

Replacing Computer

Replacing Operating Thermostat

Replacing Temperature Probe

Replacing High-Limit Thermostat – Operating Thermostat Controls

Replacing High-Limit Thermostat – Computer Controls

Replacing Heat Mode Indicator Light – Operating Thermostat Controls

Replacing Power/Melt Cycle Switch – Operating Thermostat Controls

Replacing Melt Cycle Timer – Operating Thermostat Controls

Replacing Burner Ceramic Targets

Replacing Gas Valve

Replacing Pilot Assembly or Thermopile

Replacing Frypot

Troubleshooting and Problem Isolation

Pilot/Ignition Failures

Improper Burner Functioning

Improper Temperature Control

Computer Related Problems

Filtration Problems

Leakage Problems

Millivolt Problems

Troubleshooting Guides

Initial Troubleshooting, Millivolt Frying Systems

Initial Troubleshooting, 24VAC Frying Systems

Probe Resistance Chart

Wiring Diagrams

MJCF Millivolt Wiring Diagram, Non-CE

MJCF Millivolt Wiring Diagram, CE

MJCFE 24V Wiring Diagram

MJCFEC 24V Wiring Diagram

FAST-Ready Constant Pilot

1–1

1–1

1–4

1–5

1–6

1–7

1–7

1–8

1–9

1–9

1–10

1–11

1–11

1–12

1–13

1–13

1–14

1–15

1–17

1–17

1–18

1–20

1–20

1–22

1–23

1–24

1–26

1–28

1-28

1–31

1–31

1–33

1–34

1–32

1–35

1–36

1–37

1–38

1–39

iv

Page 5

Master Jet CF Series Atmospheric Gas Fryers

TABLE OF CONTENTS (cont.)

PAGE #

1.12.6

2.

2.1

2.2

2.3

2.3.1

2.3.2

2.4

2.5

2.5.1

2.5.2

2.5.3

2.6

2.7

2.7.1.1

2.7.1.2

2.7.2

2.7.3

2.7.4

2.7.5

2.7.6

2.7.7

2.7.8.1

2.7.8.2

2.7.9

2.8

2.9

A.

A.1

A.1.1

A.1.2

A.1.3

A.1.4

A.1.5

A.1.6

A.1.7

A.2

Filter Magic II Wiring Diagram

PARTS LIST

Accessories

Burner Manifold Components

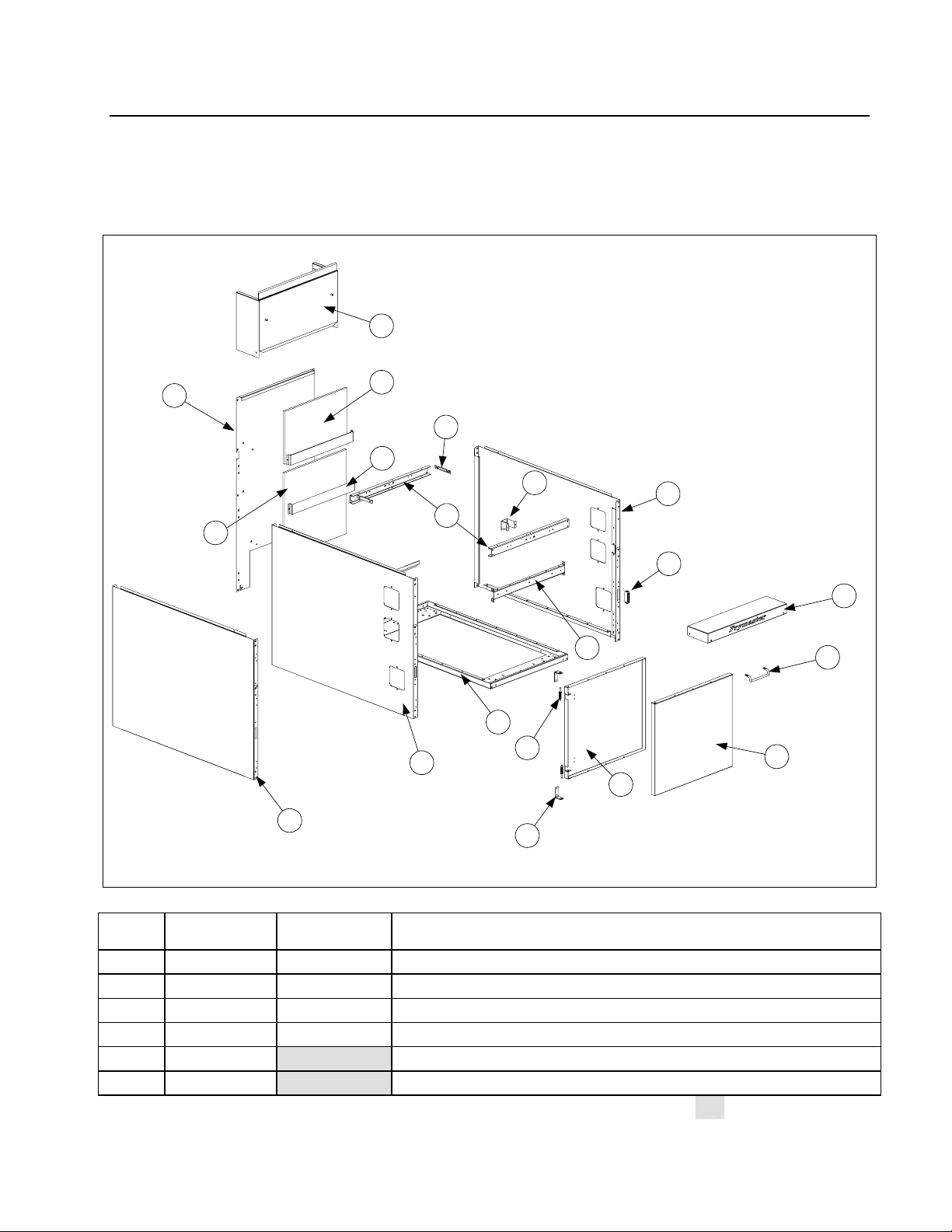

Cabinetry Components

Fryer Cabinetry

Filter Magic II and Spreader Cabinet Cabinetry

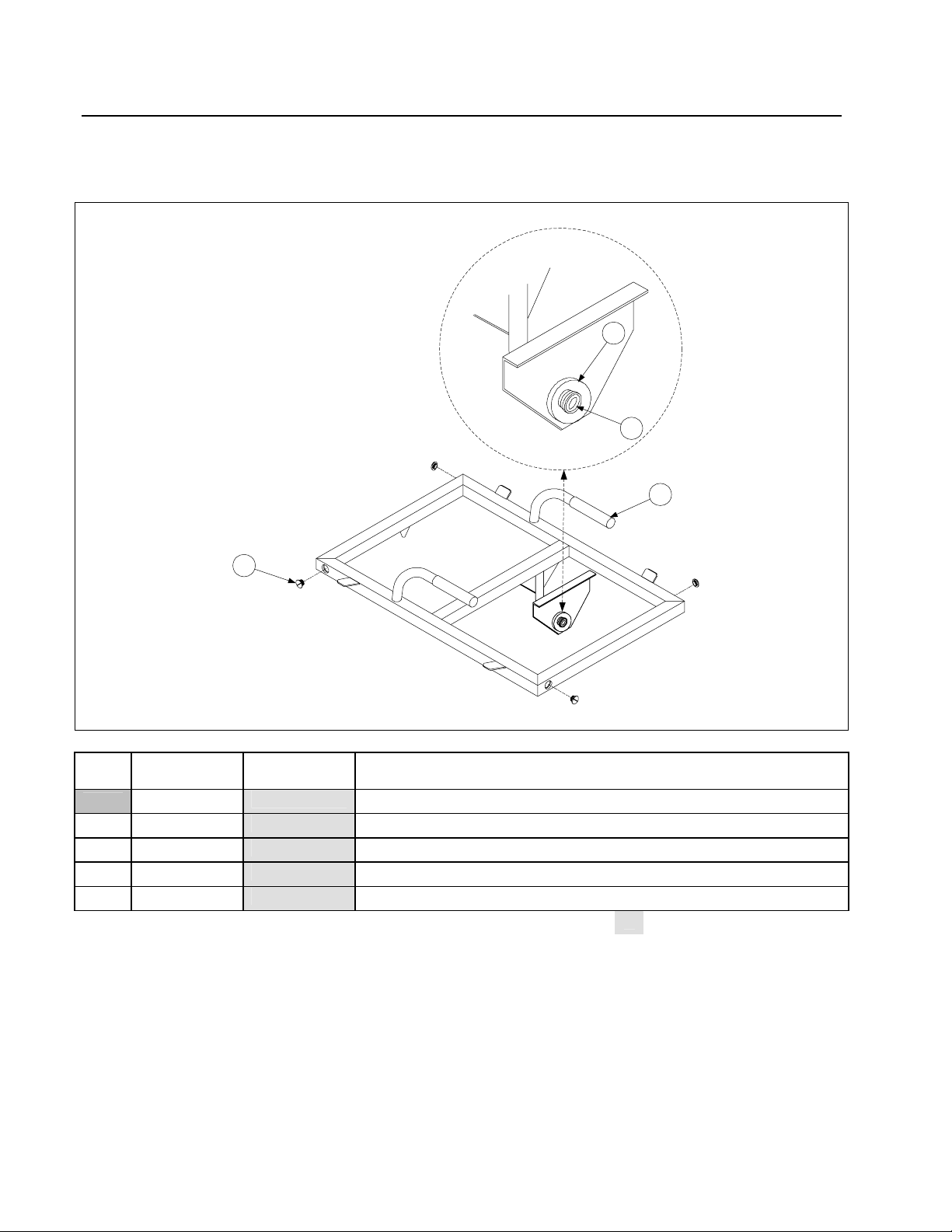

Casters, Legs and Associated Hardware

Component Shield, Filter Box Assemblies and Components

Component Shield Assemblies – No Interface Board

Component Shield Assemblies – With Interface Board

Filter Box Assemblies

Control Panel Assemblies and Related Components

Filtration System Components

Filter Magic II Drain Manifold Components

Euro-Look Drain Manifold Components

Filter Magic II Filter Pan Components – Outer Pan Components

Filter Magic II Filter Pan Components – Inner Pan Components

Oil Return Handle Components – Units Built Prior to April 2001

Oil Return Handle Components – Units Built April 2001 and After

Oil Return Plumbing

Filter Pump and Motor Components

Drain Valves and Related Components

Euro-Look Drain Valves and Related Components

Power Shower Components

Frypot, High-Limit and Probe Components

Wiring Connectors, Pin Terminals and Power Cords

APPENDIX

KJ3FC & J3F Variants – Wiring Diagrams

Computer Wiring Diagram – KJ3FC Fast-Ready

J3F Wiring Diagram – (Fast/Fast-Computer Modified; For Reference Only)

KFC-1 Computer Wiring Diagram – 120V

KFC-1 Computer Wiring Diagram – 220V

KSCF Wiring Diagram w/ Float (CE)

KFC-1 Harness Diagram

Transformer/Filter Box Wiring for FAST Controller

Parts List – KJ3FC Variant

v

1–40

2–1

2–1

2–3

2–5

2–5

2–7

2–9

2–10

2–10

2–11

2–12

2–13

2–15

2–15

2–17

2–18

2–19

2–21

2–22

2–23

2–24

2–26

2–27

2–28

2–29

2–31

A–1

A–1

A–1

A–2

A–3

A–4

A–5

A–6

A–7

A–8

Page 6

MASTER JET CF SERIES ATMOSPHERIC GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.1 Functional Description

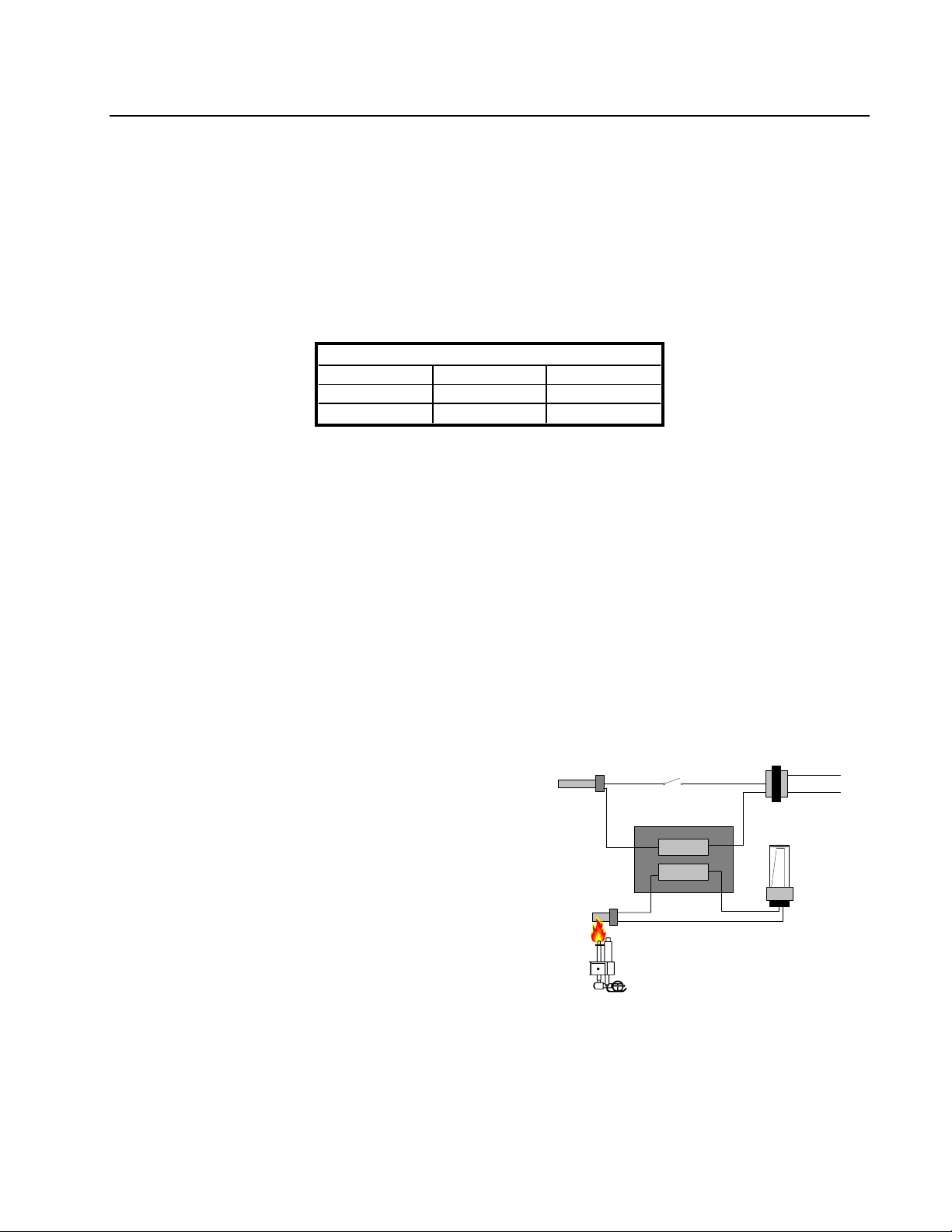

Master Jet (MJ) CF Series Atmospheric gas fryers contain a welded stainless steel frypot that is

directly heated by gas flames that are diffused evenly over its lower surface by ceramic targets.

The flames originate from orifices in a U-shaped burner manifold positioned beneath the frypot. The

orifice diameters differ for natural and propane gas as shown in the table below. For altitudes of

2000 feet and greater, contact factory for correct orifice part number.

CF Series Orifice Sizes (0-1999 ft/609 m)

Gas Inches Millimeters

Natural 0.055 1.4

Propane 0.035 0.9

Gas flow to the manifold is regulated by an electromechanical gas valve. MJCF Series gas fryers are

equipped with millivolt gas valves, and MJCFE Series gas fryers are equipped with 24-volt gas

valves. All models use a pilot ignition system.

Pilot Ignition System

The pilot ignition system consists of the pilot orifice, pilot hood, and a thermopile (a thermocouple is

also used in CE units per CE requirements). The pilot serves two purposes. The first is to light the

burner, the second is to heat the thermopile. In operation, the thermopile is in contact with the pilot

flame and generates millivolts. The millivolt output passes through a normally closed high-limit

switch and energizes the gas valve pilot coil, which in turn opens the pilot valve. If the pilot flame is

extinguished, voltage is lost to the gas valve pilot coil and the pilot valve closes.

On MJCFE models, a separate 24-volt circuit,

Operating Thermostat

activated by the fryer On/Off switch,

provides voltage through the thermostat or

controller to the gas valve main coil, which

opens the main valve. The gas valve is

constructed so that the main valve will not

open if the pilot valve is not open. The pilot

flame must be manually lit (either with a

Thermopile

match or with an optional built-in piezo

ignitor) when the fryer is first placed into

operation.

Pilot

The Pilot System (24V Circuit, Non-CE).

ON/OFF Switch

Gas Valve

Main Valve Magnet

Pilot Magnet

24VAC Transformer

Line Voltage

High-Limit

1-1

Page 7

MASTER JET CF SERIES ATMOSPHERIC GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.1 Functional Description (cont.)

CONTROL OPTIONS

MJCF Series gas fryers may be equipped with thermostat controllers or Computer Magic III.5

computers. KJ3FC variants are equipped with user-supplied or KFC-1 computers.

MJCF fryers equipped with thermostat controls are turned on and off with the gas valve control knob

(an On/Off switch is optional). The temperature is set by means of a knob connected directly to the

frypot-mounted thermostat. MJCFE models come equipped with a rocker switch to turn the fryer on

and off. Units equipped with thermostat controllers have no interface board.

MJCFE Series with Melt-Cycle option: When the melt cycle switch is placed in the ON position, the

fryer stays in the melt cycle mode until the switch is manually placed in the OFF position, even if the

frypot is at setpoint temperature.

Fryers equipped with computers have an interface board located in the component shield behind the

control panel.

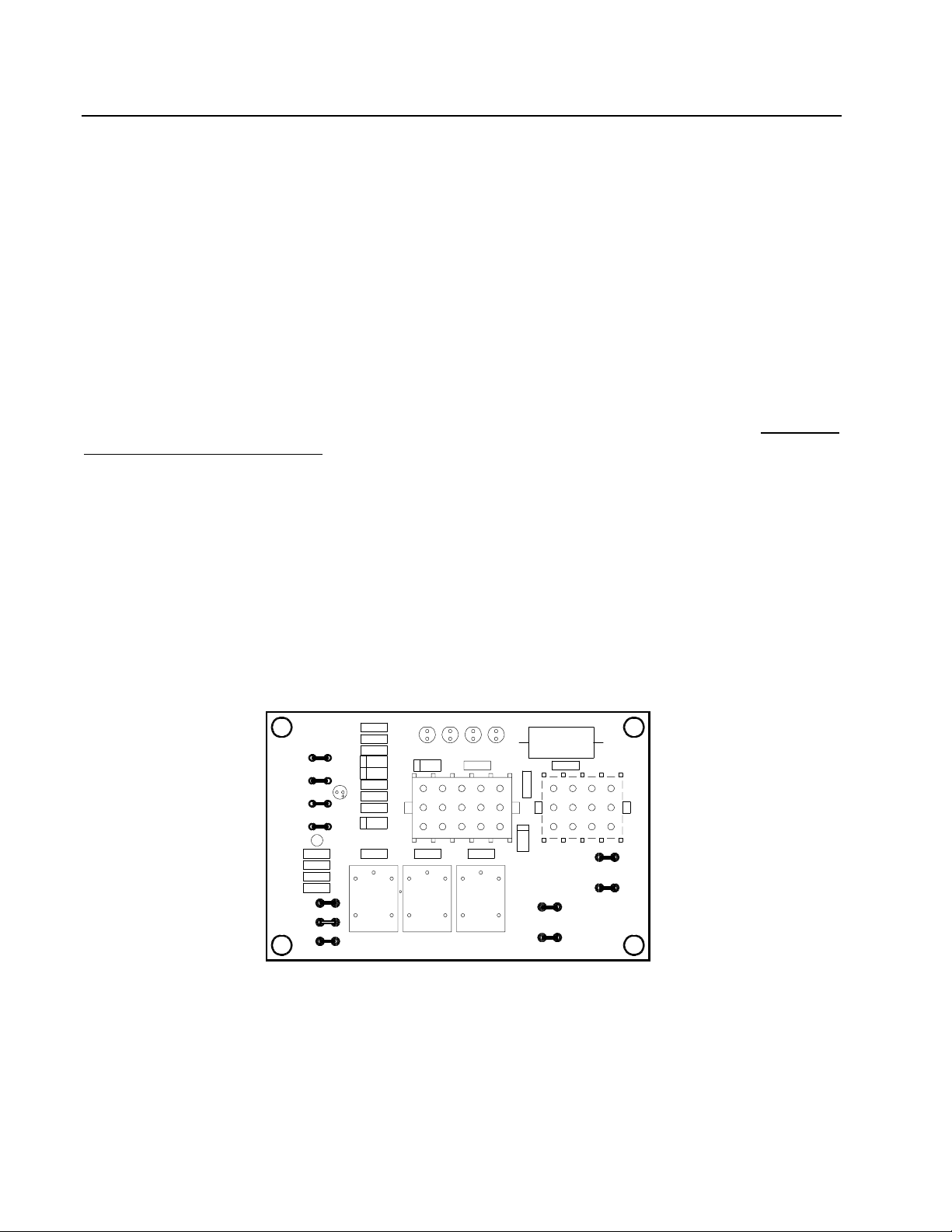

INTERFACE BOARDS

The interface board provides the link between the computer and the fryer’s components without

requiring excessive wiring, and allows the computer to execute commands from one central point.

Depending upon the configuration of the fryer, any of three boards may be used. Regardless of the

particular board installed when the fryer was built, P/N 806-3548 is the universal replacement

part (not applicable to user-supplied computers).

AL 24V

7

8

9

52

4

3

COMP

R6

10

11

12

R11

1

D1

R7

13

14

15 1

1

J1

D9

52

4

MADE IN U.S.A.

AC

R1

R5

12

6

9

3

5

2

8

11

4

7

10

COM

AC

HOT

COM

HOT

R2

R3

R4

C1

2000

Frymaster

3

2

3

K3

1

D5

R8

R10

R13

D7

R9

D8

1

24VAC

COMP AC

C

R14

R15

R16

R17

SOUND

NOTES:

1. RELAYS K1 AND K2 ARE FOR BELL CRANK BASKET LIFTS.

THEY ARE NOT PRESENT ON BOARDS 806-5490 (U.S. & NONCE EXPORT UNITS W/O BASKET LIFTS) OR 806-7501 (CE UNITS,

WITH OR WITHOUT BASKET LIFTS).

2. RESISTORS R1, R10, AND R15 ARE NOT USED ON ANY OF THE

THREE BOARDS.

3. RESISTORS R11 AND R12 ARE NOT USED ON 806-5490

BOARDS.

GV

D4

D6

J2

1

1

2

3

R12

1

52

4

3

K2 K1

4

5

6

INTERFACE BOARDS 806-3548, 806-5490 & 806-7505

1-2

Page 8

MASTER JET CF SERIES ATMOSPHERIC GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.1 Functional Description (cont.)

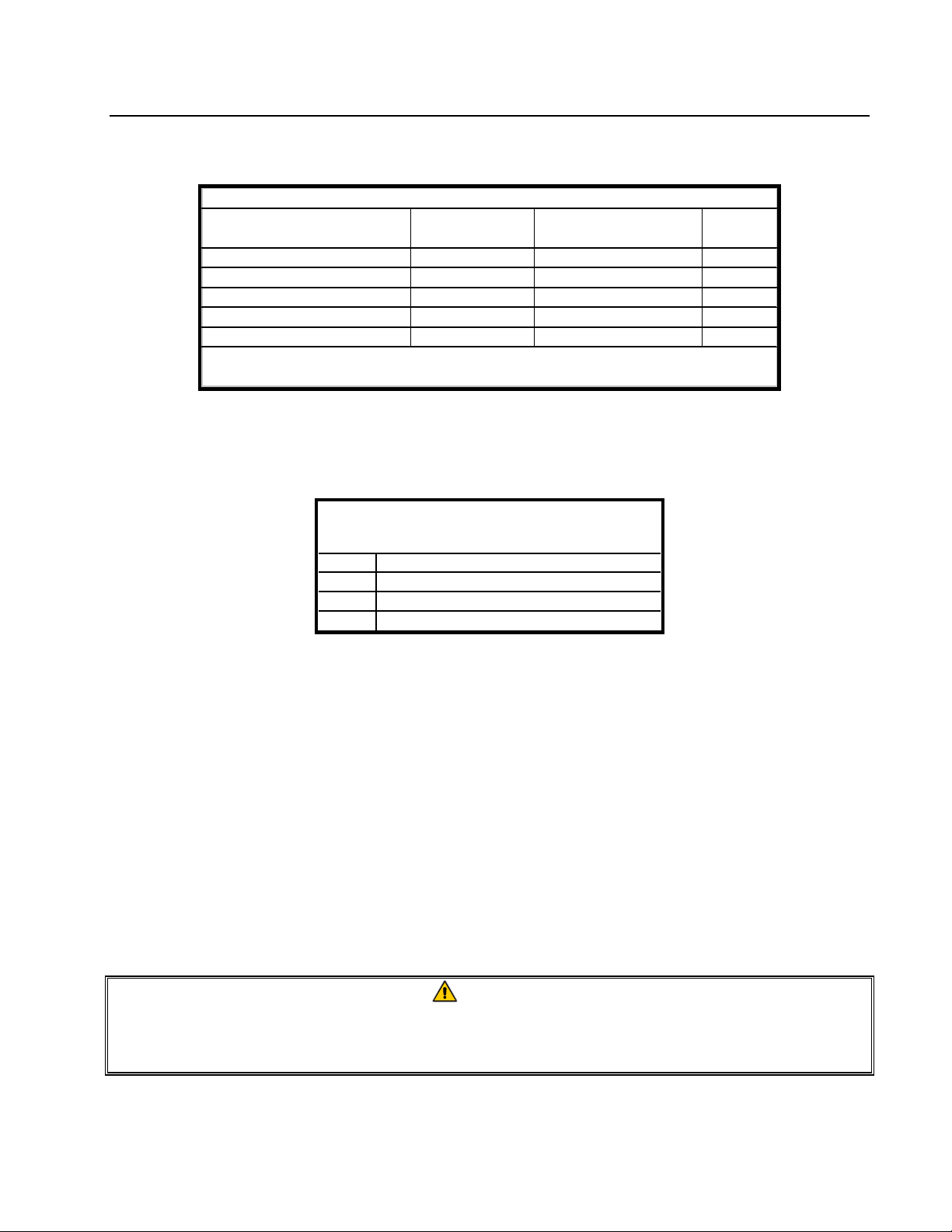

FREQUENTLY USED TEST POINTS FOR MODELS WITH INTERFACE BOARDS

Meter

Test

12 VAC P ower t o Cont rol ler 50 V AC S cal e 1 and 3 of J2 12-18

24 VAC P ower 50 VAC S cal e 24 VAC Terminal s 22-28

24 VAC P ower t o Gas V a l ve 50 VAC S cal e 6 on J1 and GROUND 22-2 8

120 VAC Po wer 250 VAC S cale 7 and 12 of J1 110-125

Probe Resi s tanc e* R x 1000 OHMS 2 and 3 of J1 **

** Disconnec t 15-Pi n harnes s from controller before tes ting probe c i rc ui t .

** S ee Probe Res i stance Chart at end of c ha pt e r.

Four LEDs, arranged across the top of the boards and identified in the table below, are provided to

assist in troubleshooting.

Setting Pins Results

MASTER JET SERIES INTERFACE BOARD

LED DIAGNOSTIC LIGHTS

Indicates 24 VAC to t he gas val ve

GV

Indicates open Drain Safety Switc h (i f installed)

AL

Indicates 24 VAC from transformer

24V

Indicates 12 VAC to computer

COMP

Every board contains one heat relay (K3), and may contain two basket lift relays (K1 and K2). As

shipped from the factory, fryers with bell-crank basket lifts will have relays K1, K2, and K3. All

other factory-original fryers will have boards with only relay K3.

NOTE: The basket lift option is not available on MJCF Series fryers. The above diagnostic

tables are not applicable to user-supplied or KFC-1 computers.

THERMOSTATS AND TEMPERATURE PROBES

MJCF Series fryers equipped with thermostat controls have an adjustable controlling (operating)

thermostat. The temperature at which the thermostat opens and closes is adjusted by changing the

setting of the thermostat with an attached knob. When new, the Fenwal controlling thermostat is

sensitive to one-degree changes in temperature.

CAUTION

Fenwal thermostats are used in a number of Frymaster products. The thermostat for

the MJCF Series is 4 inches long. Do not use 3-inch Fenwal thermostats in MJCF

Series fryers.

1-3

Page 9

MASTER JET CF SERIES ATMOSPHERIC GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.1 Functional Description (cont.)

MJCFE Series fryers equipped with computers have a temperature probe. In these units, the probe

resistance varies directly with the temperature. That is, as the temperature rises, so does resistance at

a rate of approximately 2 ohms for every 1° (F or C). Circuitry in the computer monitors the probe

resistance and controls burner firing when the resistance exceeds or falls below programmed

temperatures (setpoints). The temperatures are programmed by means of a keypad on the face of the

computer.

All MJCF Series Atmospheric gas fryers are equipped with a high-limit thermostat. In the event

that the fryer fails to properly control the oil temperature, the high-limit thermostat prevents the fryer

from overheating to the flash point. The high-limit thermostat acts as a normally closed power

switch that opens when exposed to temperatures in the range of 415°F to 435°F (213°C to 224°C).

The high-limit thermostat is the same for CE and Non-CE applications. When a replacement highlimit thermostat is ordered, ensure the kit appropriate for the valve in use is ordered.

1.2 Accessing Fryers for Servicing

DANGER

Moving a fryer filled with oil may cause spilling or splattering of hot liquid. Follow

the draining instructions in the Operator’s manual that shipped with the fryer.

1. Shut off the gas supply to the unit. Unplug the power cord(s). Disconnect the unit from the gas

supply.

2. Remove any attached restraining devices.

3. Relocate the fryer for service accessibility.

4. After servicing is complete, reconnect the unit to the gas supply, reattach restraining devices,

and plug in the electrical cords.

1-4

Page 10

(

)

(

/H)

MASTER JET CF SERIES ATMOSPHERIC GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.3 Checking Burner Manifold Gas Pressure

WARNING

This task should be performed by qualified service personnel only.

1. Ensure that the gas valve knob or button is in the OFF position.

2. Remove the pressure tap plug from the end of the manifold (see illustration below) and connect a

gas pressure-measuring device to the port.

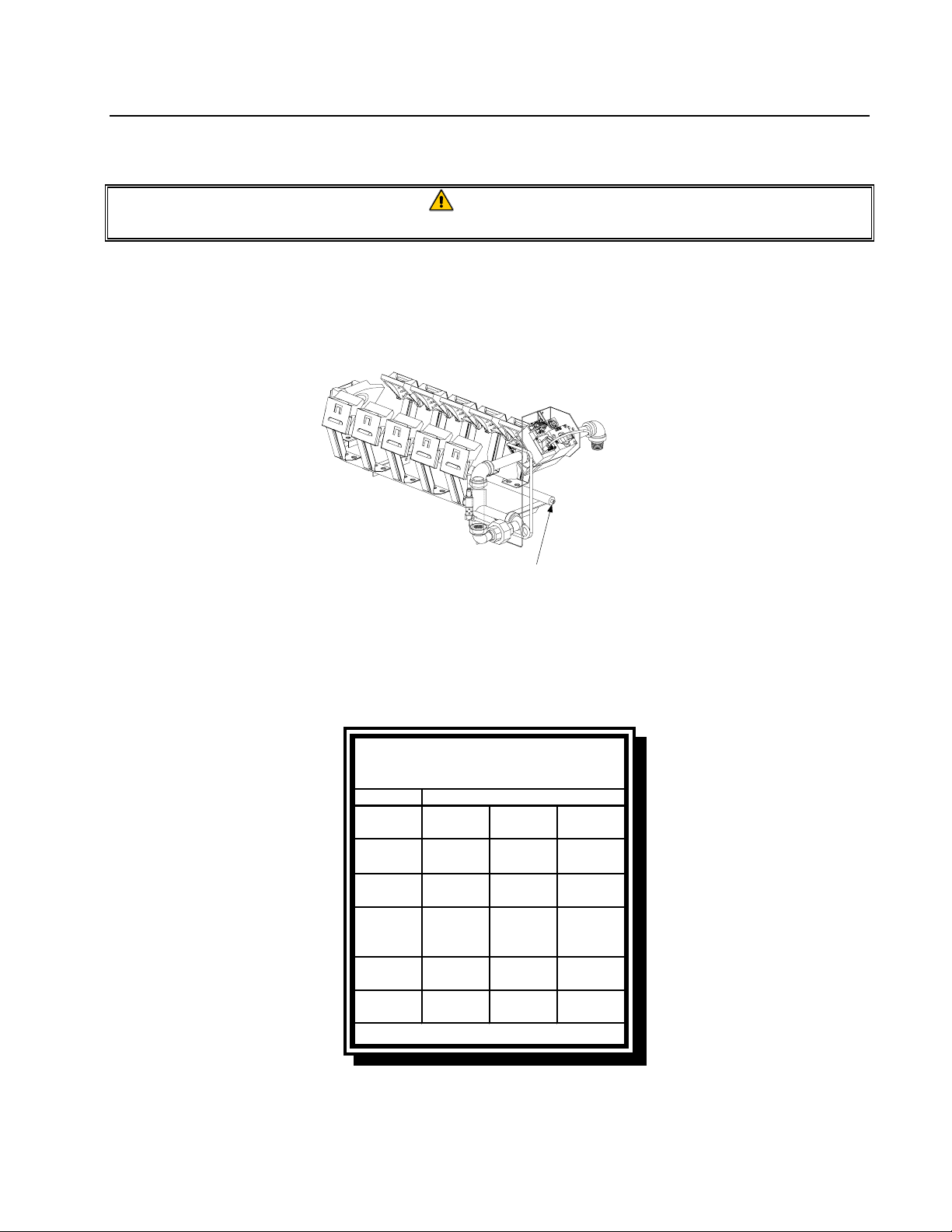

Remove plug to connect a gas

pressure-measu ring devi c e t o th e port.

3. Place the gas valve in the ON position then place the fryer power switch in the ON position

(where applicable). When the burner lights and continues to burn, compare the pressure reading

to that for the corresponding gas in the tables below and on the next page.

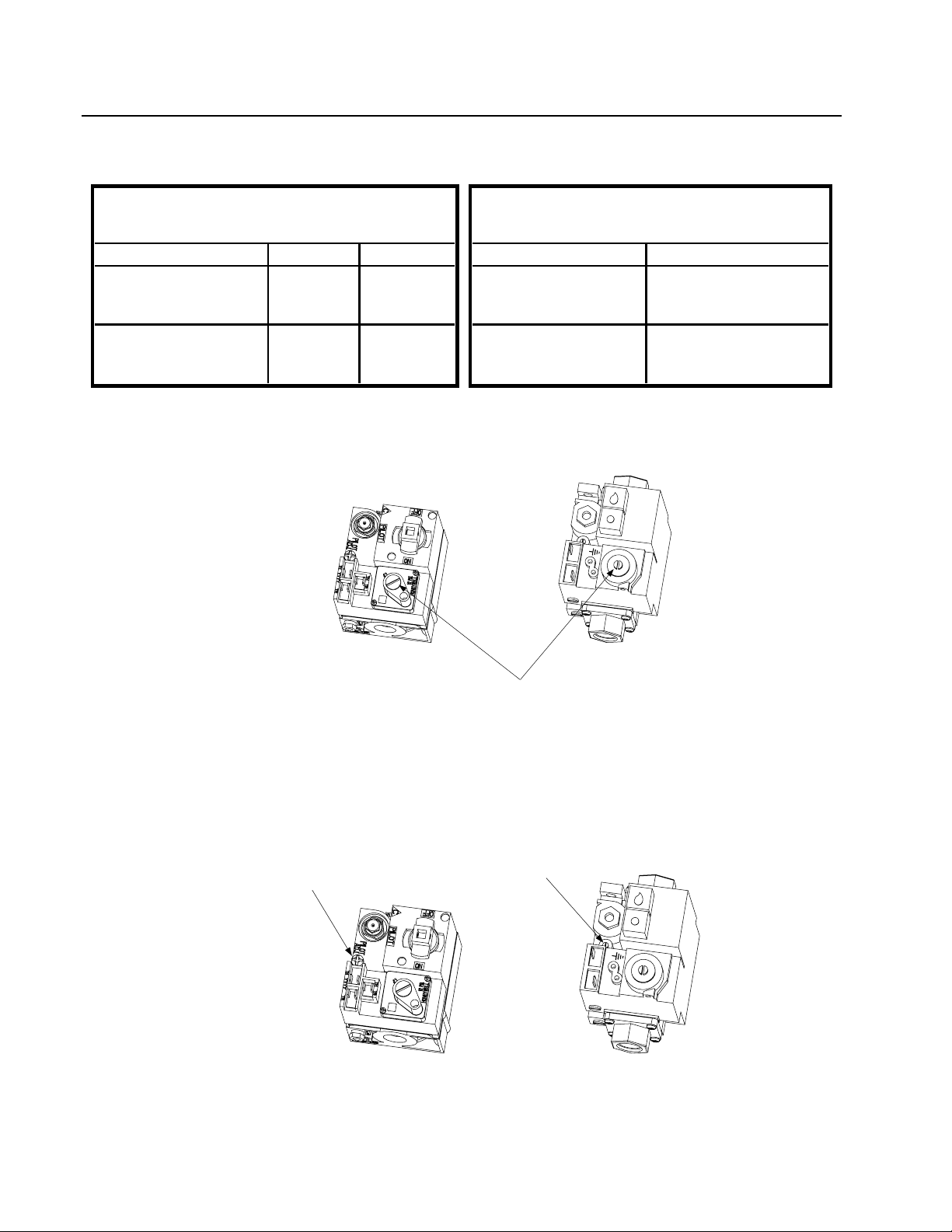

CE Standards for Incoming Ga s

Pressures

Model

Gas Type G20 G25 G31

Pressure

Manifold

Pressure

1

(mbar) = 10,2 mm CE

mbar

Orifice

Size

Number

of

Orifices

Air Flow

3

m

1

MJCF/J65 CE

20 20-25 37-50

1,40 1,40 0,95

21 21 21

7,5 10 14,9

3,62 4,18 2,35

1-5

Page 11

MASTER JET CF SERIES ATMOSPHERIC GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.3 Checking Burner Manifold Gas Pressure (cont.)

Non-CE Standard

for Incoming Gas Pressures

Gas Minimum Maximum

Natural

LP

6" W.C.

1.49 kPa

14.93 mbar

11" W.C.

2.74 kPa

27.37 mbar

14" W.C.

3.48 kPa

34.84 mbar

14" W.C.

3.48 kPa

34.84 mbar

for Burner Manifold Gas Pressures

Non-CE Standard

Gas

Natural

LP

Pressure

3.5" W. C.

.75 kPa

7.5 mbar

8.25" W. C.

2.0 kPa

20.0 mbar

4. If the measured manifold gas pressure does not match the appropriate pressure in the preceding

tables, remove the cap from the gas valve regulator and adjust to the correct pressure.

Honeywell Valve

(Non-CE Units)

Honeywell Valve

(CE Units)

Regulator Adjustment Screw Cap

1.4 Adjusting Pilot Flame

1. On non-CE valves, remove the cap covering the pilot adjustment screw. On all valves, turn the

pilot adjustment screw counterclockwise to increase the length of the flame or clockwise to

decrease the length of the flame. Adjust the flame to a length of 1 to 1-½ inches (25 to 38 mm).

On Non-CE gas valves, remove this cap to

access Pilot Adjustment Screw.

Honeywell Valve

(Non-CE Units)

2. On Non-CE valves, reinstall the pilot adjustment screw cap.

Pilot Adjustment Screw

Honeywell Valve

(CE Units)

1-6

Page 12

MASTER JET CF SERIES ATMOSPHERIC GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.5 Cleaning Gas Valve Vent Tube

1. Carefully unscrew the vent tube from the gas valve. NOTE: The vent tube may be straightened

for ease in removal.

2. Pass a piece of ordinary binding wire (.052 inch diameter) or equivalent through the tube to

remove any obstruction.

3. Remove the wire, and then blow through the tube to ensure it is clear.

4. Reinstall tube and bend it so that the opening is pointing downward.

1.6 Adjusting Burner Ceramic Target Spacing and Alignment

DANGER

Drain the frypot or remove the handle from the drain valve before proceeding further.

Proper spacing of the top edge of the burner ceramic targets is ¾-inch (13 mm) from the frypot side

[The rear target should be adjusted to 1-inch (25 mm) from the frypot back]. To adjust target

spacing, bend the brackets to which they are attached away or toward the frypot to the proper

distance. (A length of board of the proper thickness is useful as a gauge to verify spacing and

alignment.)

3/4-inch

1-inch

There should be about 3/4-inch spacing between the top edge of the targets

and the side of the frypot, and 1-inch between the rear target and the frypot

back.

1-7

Page 13

MASTER JET CF SERIES ATMOSPHERIC GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.7 Calibrating Thermostat Control

1. Fill the frypot to the lower OIL-LEVEL line with oil. If solid shortening is used, it must be

tightly packed into the frypot.

2. Light the pilot. (Refer to Installation and Operation Manual that shipped with the fryer for

detailed lighting instructions.)

3. Insert a good grade thermometer or pyrometer into the frypot, about one inch from the

thermostat.

4. Set the thermostat to 325°F (163°C).

5. Allow the fryer to heat to 325°F (163°C) and cycle on and off three times.

6. With the oil temperature at 325°F (163°C) turn the flexible shaft slowly clockwise until the

burner shuts off. (Turning the shaft counterclockwise causes the temperature to increase and the

burner to light; turning it clockwise causes the temperature to decrease and shut off.)

7. Allow the fryer to sit for a few minutes and then slowly turn the flexible shaft counterclockwise

until the burner lights.

8. Repeat steps 6 and 7 at least three times to ensure an accurate setting is obtained. The thermostat

control is calibrated if the burner lights as the oil cools to 325°F (163°C) – not when the burner

shuts off as the temperature rises.

9. Compare the reading of the pyrometer to the setting on the thermostat plate. The position of the

knob on the thermostat and the reading from the pyrometer should be within 5°F (3°C) of each

other.

10. If not, loosen the setscrew and stop screw securing the thermostat shaft extension to the flexible

shaft. Remove the extension to expose the slot in the end of the flexible shaft. Use a flat-blade

screwdriver to adjust the thermostat.

11. Once the calibration point of 325°F (163°C) is determined, allow the burner to cycle on and off

at least three times to ensure it will light at the calibrated temperature.

12. Carefully replace the thermostat shaft extension, ensuring that the stop screw is pointed straight

up. Tighten the stop screw and locking nut and the setscrew, being careful not to rotate the

flexible shaft.

CAUTION

The thermostat flexible shaft must not be rotated while installing the thermostat

shaft extension!

When handling the thermostat, do not rotate the shaft more than two turns in either

direction. Doing so will cause damage to the thermostat.

1-8

Page 14

MASTER JET CF SERIES ATMOSPHERIC GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.7 Calibrating Thermostat Control (cont.)

13. Close the fryer control panel and replace the screws in the upper corners.

14. Reinstall the thermostat knob with its pointer aligned with the 325°F (163°C) index mark on the

temperature dial.

15. Reconnect the fryer to the electrical power supply.

1.8 Replacing Fryer Components

1.8.1 Replacing Computer

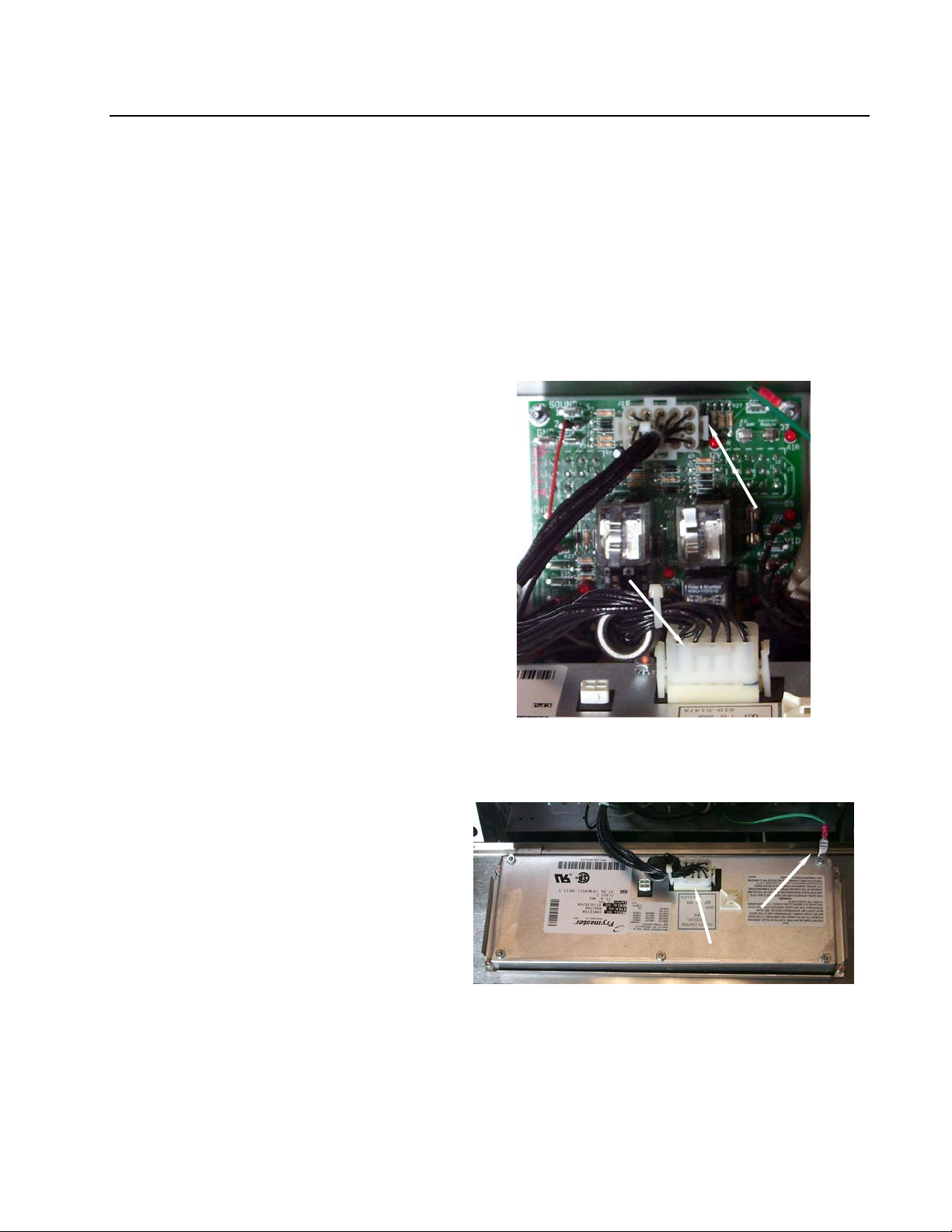

1. Disconnect the fryer from the electrical

supply.

2. The controller bezel is held in place by

tabs at the top and bottom. Slide the

bezel up to disengage the lower tabs.

Then slide the bezel down to disengage

the upper tabs.

3. Remove the two screws in the upper

corners of the control panel and swing

the panel open from the top, allowing it

to rest on its hinge tabs.

4. Disconnect the wiring harness from the

back of the controller and, if replacing

the harness, disconnect it from the

interface board (arrows).

5. Disconnect the ground wire, and then

remove the controller by lifting it from

the hinge slots in the control panel

frame.

6. Ensure the new computer is properly

configured for the fryer on which it is

installed (i.e., gas or electric, full or

split pot and Celsius or Fahrenheit.

Although identical in appearance,

computers configured for use on one

type of fryer are not directly

interchangeable with those configured

for use on another type.

7. Reverse the procedure to install a new

controller or wiring harness.

If replacing harness, disconnect the harness from

the controller and interface board (arrows).

If replacing controller, disconnect the ground wire

and the 15-pin connector (arrows).

1-9

Page 15

MASTER JET CF SERIES ATMOSPHERIC GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.8.2 Replacing Operating Thermostat

CAUTION

The thermostat must be calibrated after installation is complete. Refer to Section 1.7

for calibration instructions.

When handling the thermostat, do not rotate the shaft more than two turns in either

direction. Doing so will cause damage to the thermostat.

1. Disconnect the fryer from the electrical supply and drain the frypot.

2. Loosen the setscrew securing the thermostat knob and remove the knob. Remove the screws

from the upper left and right corners of the control panel. The control panel is hinged at the

bottom and will swing open from the top.

3. Disconnect the 9-pin connector and remove the control panel from the fryer by disengaging its

tabs from the hinge slots in the mounting frame.

4. Loosen the setscrews (2) securing the

flexible shaft to the thermostat shaft and

slip the flexible shaft off the thermostat

shaft (arrow).

5. Remove the flexible shaft guide by

removing the two sheet metal screws

securing it to the upper frame.

6. Disconnect the thermostat leads from pin

14 in the 20-pin terminal block and from

the gas valve terminal.

NOTE: If the fryer is configured with a

melt cycle, the thermostat leads will be

connected to the melt cycle timer motor

or PC board rather than to the terminal

block and gas valve. Disconnect the leads

from the motor or PC board if this is the

Remove setscrews (arrow) to remove flexible shaft

from thermostat shaft.

case.

7. Unscrew the thermostat from the frypot and remove.

8. Apply Loctite PST567 thread sealant or equivalent to the replacement thermostat threads.

9. Reverse steps 1 through 7 to install the replacement.

1-10

Page 16

MASTER JET CF SERIES ATMOSPHERIC GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.8.3 Replacing Temperature Probe

1. Disconnect the fryer from the electrical supply.

2. Drain the frypot.

3. Remove the screws from the upper left and right corners of the control panel. The panel is

hinged at the bottom and will swing open from the top.

4. Unplug the wiring harness from the back of the controller and disconnect the grounding wire

(see Section 1.8.1, Step 4).

5. Remove the controller from the fryer by lifting it from the hinge slots in the control panel frame.

5. Remove the two screws from the base of the interface board mounting-bracket.

6. Disconnect the 12-pin plug from the back of the interface board and lay the board in the left end

of the compartment with all other wires still connected.

7. Remove the 12-volt transformer from the component shield and lay it in the left end of the

compartment with wires still connected.

8. Using a pin-pusher, remove the temperature probe wires (pins 1 and 2) from the 12-pin plug

disconnected in step 7.

9. Unscrew the temperature probe from the frypot and remove.

10. Apply Loctite PST567 thread sealant or equivalent to new probe threads.

11. Reverse steps 1 through 10 to install the replacement probe.

1.8.4 Replacing High-Limit Thermostat – Operating Thermostat Controls

1. Disconnect the fryer from the electrical supply.

2. Drain the frypot.

3. Loosen the setscrew securing the thermostat knob and remove the knob. Remove the screws

from the upper left and right corners of the control panel. The control panel is hinged at the

bottom and will swing open from the top.

4. Disconnect the 9-pin connector and remove the control panel from the fryer by disengaging its

tabs from the hinge slots in the mounting frame.

5. Disconnect the high-limit thermostat leads from the gas valve pilot coil.

1-11

Page 17

MASTER JET CF SERIES ATMOSPHERIC GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.8.4 Replacing High-Limit Thermostat – Operating Thermostat Controls (cont.)

6. Unscrew the high-limit thermostat from the frypot and remove.

7. Apply Loctite PST567 thread sealant or equivalent to the replacement thermostat threads.

8. Reverse steps 1 through 7 to install the replacement.

1.8.5 Replacing High-Limit Thermostat – Computer Controls

1. Disconnect the fryer from the electrical power supply.

2. Drain the frypot.

3. Remove the screws from the upper left and right corners of the computer panel. The computer is

hinged at the bottom and will swing open from the top.

4. Unplug the wiring harness and disconnect the grounding wire from the controller.

5. Remove the controller from the fryer by lifting it from the hinge slots in the fryer control panel

frame.

6. Remove the two screws from the base of the interface board-mounting bracket.

7. Disconnect the 12-pin plug from the back of the interface board and lay the board in the right end

of the compartment with all other wires still connected.

8. Remove the 12-volt transformer and lay it in the right end of the compartment with wires still

connected.

9. Remove the high-limit thermostat wires from the gas valve pilot coil and pull them up through

the control shield.

10. Unscrew the high-limit thermostat from the frypot and remove.

11. Apply Loctite PST567 thread sealant or equivalent to the replacement thermostat’s threads and

screw it into the frypot.

12. Attach the appropriate terminals (furnished in the replacement thermostat kit) to the thermostat

leads.

13. Reverse steps 1 through 9 to complete installation of the replacement thermostat.

1-12

Page 18

MASTER JET CF SERIES ATMOSPHERIC GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.8.6 Replacing Heat Mode Indicator Light – Operating Thermostat Controls

1. Disconnect the fryer from the electrical supply.

2. Loosen the setscrew securing the thermostat knob and remove the knob. Remove the screws

from the upper left and right corners of the control panel. The control panel is hinged at the

bottom and will swing open from the top.

3. Disconnect the 9-pin connector and remove the control panel from the fryer by disengaging its

tabs from the hinge slots in the mounting frame.

4. Carefully press the light out from the back of the control panel. Disconnect one wire at a time

and reconnect it to the replacement light until all wires are transferred.

5. Carefully press the light back into the control panel.

6. Reverse steps 1-3 to reassemble the fryer.

1.8.7 Replacing Power/Melt Cycle Switch – Operating Thermostat Controls

NOTE: The Power/Melt-Cycle Switch, P/N 807-1404, has been replaced with a new switch, P/N

807-3498. When ordering the new switch, order Kit 826-1792, which contains the new switch and

wiring instructions. The new switch is wired differently than the old one. Ensure the new switch is

wired properly before operating fryer. Consult P/N 819-5889 (MJCF, MJ45 Switch Replacement

Instructions) for further detail.

1. Disconnect the fryer from the electrical supply.

2. Loosen the setscrew securing the thermostat knob and remove the knob. Remove the screws

from the upper left and right corners of the control panel. The control panel is hinged at the

bottom and will swing open from the top.

3. Disconnect the 9-pin connector and remove the control panel from the fryer by disengaging its

tabs from the hinge slots in the mounting frame.

4. Using a flat-tipped screwdriver, disconnect the chrome bezel from the tabs on the switch and

press the switch out from the front.

5. Carefully press the new switch back into the chrome bezel, ensuring the tabs on the switch

engage the slots in the bezel.

6. Disconnect the wires from the old switch and reconnect to the new switch until all wires have

been transferred (see note at the beginning of this procedure).

7. Reverse steps 1-3 to reassemble the fryer.

1-13

Page 19

MASTER JET CF SERIES ATMOSPHERIC GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

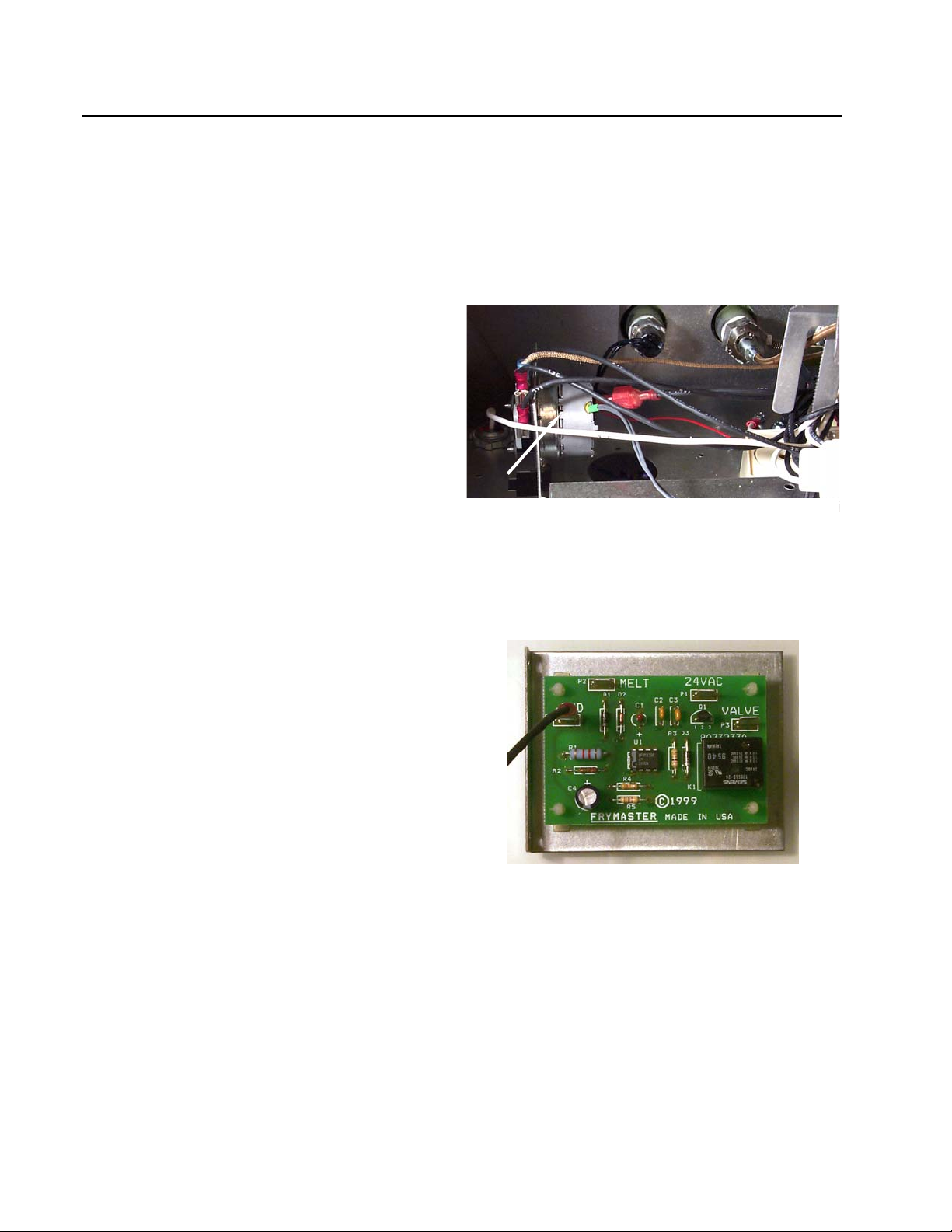

1.8.8 Replacing Melt Cycle Timer – Operating Thermostat Controls

The mechanical melt cycle timer is no longer available. A solid-state timer replaces the

mechanical unit. To replace the mechanical melt-cycle timer:

1. Remove all electrical power from the fryer. Unplug fryer and ensure all power switches are off.

2. Access timer by removing the control

panel. Remove timer by removing two

screws that hold it in place. Detach wires.

3. Attach wires to the new timer as follows:

Remove the control panel to reveal the mechanical

timer (arrow). The metal plate that holds the timerunit in place is secured with two screws. Remove

the screws, lift out the timer and detach the wires.

Ground -To number 4 of clip terminals.

24VAC - To wire 28C.

Melt - To wire 29C.

Valve - To thermostat.

4. Bolt new timer into place. Reattach

The solid-state timer mounted on a metal plate,

bolts into the space previously occupied by the

mechanical timer.

control panel.

1-14

Page 20

MASTER JET CF SERIES ATMOSPHERIC GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

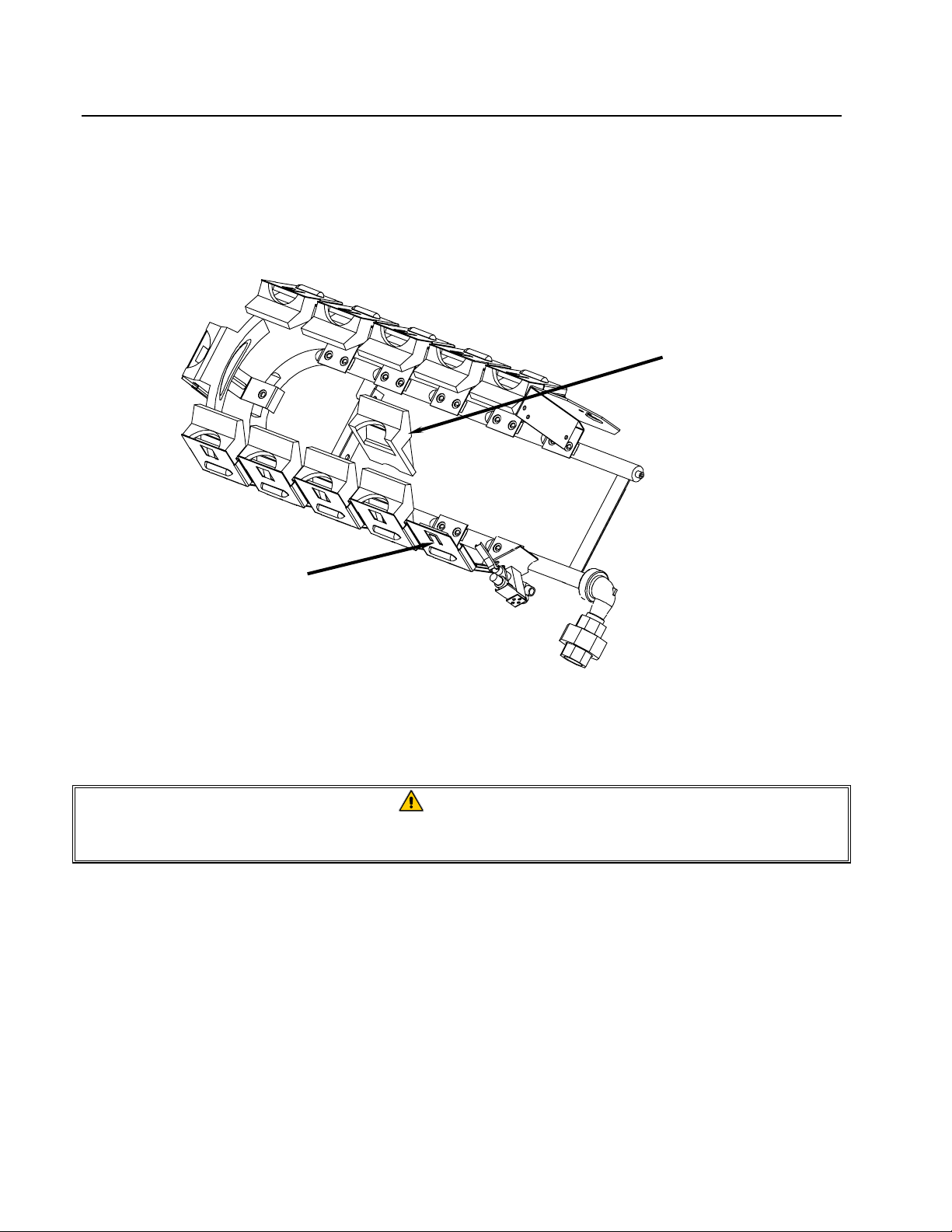

1.8.9 Replacing Burner Ceramic Targets

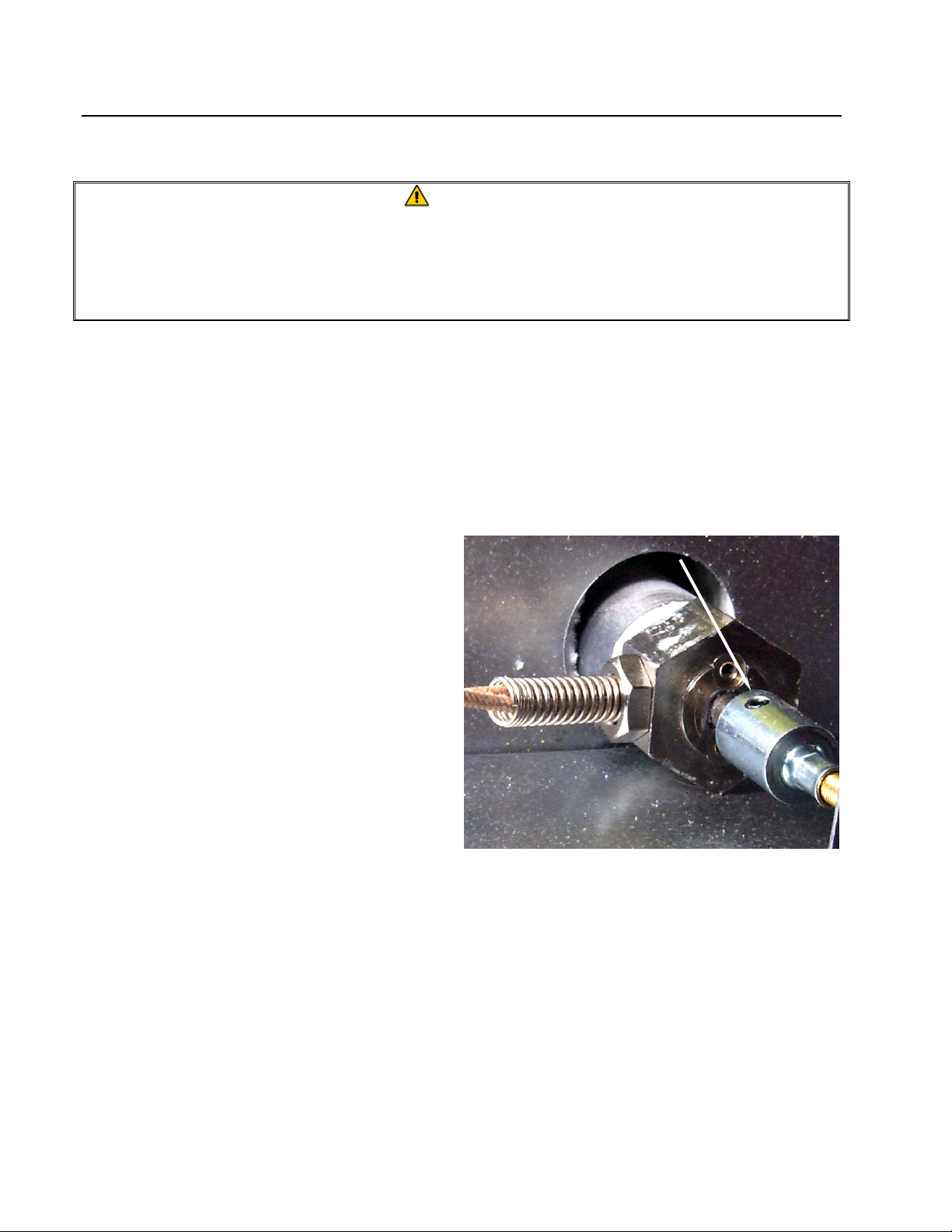

DANGER

Drain the frypot or remove the handle from the drain valve before proceeding further.

1. Disconnect fryer from electrical and gas supplies.

2. On FMCF fryers, remove square-drain sections as necessary to expose burner.

3. Disconnect the wires from the gas valve terminal block, marking each wire to facilitate

connections.

4. Remove the high-limit thermostat wires from the gas valve pilot coil.

5. Disconnect the pipe union collar at the left side of the gas valve (arrow).

Disconnect union (arrow) to remove burner manifold assembly.

6. Remove front burner shields to access burner assembly.

7. Remove the burner heat shield hanger screws at the front of the burner and remove the heat

shield.

8. Remove the burner hanger screws and lower the front of the main burner. Pull it forward to clear

the rear burner hanger, and then lower the burner to the floor.

9. Raise the front of the fryer enough to slide the burner from under the fryer cabinet.

1-15

Page 21

MASTER JET CF SERIES ATMOSPHERIC GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.8.9 Replacing Burner Ceramic Targets (cont.)

10. To replace only the ceramic targets, straighten the target locking tabs with a pair of needle nose

pliers or a screwdriver, and slide the target up and off the bracket. Slide the replacement target

onto the bracket and bend the locking tabs inward towards the burner target.

Remove

damaged target

by lifting up from

bracket. Install

new target and

bend lock-tab in

to lock target in

bracket.

Straighten lock-tab

to remove ceramic

target.

To replace the entire target assembly, use a ½-inch (13 mm) box end wrench to remove the two

brass orifices that hold the assembly to the burner manifold. Position the new assembly and

replace the orifices.

WARNING

Use extreme care to prevent cross-threading and stripping when reinstalling the

brass orifices.

11. Reverse steps 1-8 to reinstall the burner assembly. Check spacing and alignment of targets in

accordance with Section 1.6.

1-16

Page 22

MASTER JET CF SERIES ATMOSPHERIC GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.8.10 Replacing Gas Valve

DANGER

Drain the frypot or remove the handle from the drain valve before proceeding further.

1. Disconnect fryer from electrical and gas supplies

2. Disconnect the wires from the gas valve terminal block, marking each wire to facilitate

reconnections.

3. Remove the high-limit thermostat wire from the gas valve pilot coil.

4. Disconnect the pilot gas line fitting from the gas valve.

5. Disconnect the pipe union collars to the left and right of the gas valve and remove the valve.

6. Remove the pipefittings from the old gas valve and install on the replacement valve, using

Loctite PST567 or equivalent pipe-thread sealant on threads.

7. Reverse steps 1-5 to install the replacement gas valve.

1.8.11 Replacing Pilot Assembly or Thermopile

1. Remove the burner assembly in accordance with steps 1-8 of Section 1.8.9.

2. To replace only the thermopile:

a. Bend the clip at the bottom of the pilot

assembly and press the thermopile out

of the pilot assembly from the top.

b. Disconnect the thermopile fitting from

the gas valve pilot coil.

c. Reverse the above two steps to install

the replacement thermopile.

Bend the clip (arrow) outward, and then press

the thermopile out of the pilot assembly.

1-17

Page 23

MASTER JET CF SERIES ATMOSPHERIC GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.8.11 Replacing Pilot Assembly or Thermopile (cont.)

3. To replace the complete pilot assembly:

a. Disconnect the pilot tubing from the bottom of the pilot assembly.

b. Remove the screw from the pilot mounting-bracket to release the pilot assembly.

c. Disconnect the thermopile fitting from the gas valve pilot coil.

d. Reverse steps a through c to install the replacement pilot assembly.

4. Reinstall the burner assembly by reversing steps 1-8 of Section 1.8.9.

1.8.12 Replacing Frypot

1. Drain the frypot.

2. Remove all accessories (e.g., frypot covers, basket lift arms, etc.) from the fryer.

3. Disconnect the fryer from gas and electrical supplies.

4. Remove the screws from the top-cap above the control panel and lift it up and off the fryer(s).

5. If the fryer is equipped with other than a thermostat control, skip to Step 10.

6. Perform steps 1-6, section 1.8.2.

CAUTION

When handling the thermostat, do not rotate the shaft more than two turns in either

direction. Doing so will cause damage to the thermostat.

7. For fryers with other than thermostat controls, perform steps 1-4, section 1.8.1.

8. Disconnect the 12-pin plug from the back of the interface board. Use a pin pusher to remove the

temperature probe leads (pins 1 and 2) and the high-limit thermostat leads (pins 6 and 8) from

the plug. Leave all other wires connected. Leave the interface board lying on the shield.

9. Remove the louvered frame above the control panel opening.

10. Remove the screws securing the component shield to the fryer.

11. Disconnect the wires from components in component shield and mark to facilitate reconnection.

12. Disconnect the wires from the gas valve terminal block. Mark each wire to facilitate

reconnection.

1-18

Page 24

MASTER JET CF SERIES ATMOSPHERIC GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.8.12 Replacing Frypot (cont.)

13. Remove the cover from the safety drain switch, disconnect the wires from the switch, and pull

them out of the switch box.

14. Pull up and forward on the component shield to clear the rear mounting stud on the front of the

frypot and remove it from the fryer by rotating its right side up and to the left.

15. Disconnect the pipe union on the right side of the gas valve.

16. On FMCF fryers, remove the section of square drain from the drain valve of the frypot to be

removed.

17. Remove the frypot hold-down bracket.

18. Remove the screws from the flue cap sides and back, and lift it clear of the fryer(s).

19. Remove the oil return line from the front of the frypot to be removed.

20. Lift the complete frypot assembly (frypot, burner, gas valve, and flue) from the fryer cabinet.

21. Transfer the burner heat shield and burner to the replacement frypot.

22. Remove the drain valve, thermostat or temperature probe, and high-limit thermostat and install

on replacement frypot.

CAUTION

Before installing the thermostat/temperature probe, high-limit thermostat, and drain

valve on the replacement frypot, clean their threads and apply Loctite PST567 thread

sealant or equivalent to the threads.

23. Reverse steps 1-22 to reassemble the fryer.

1-19

Page 25

MASTER JET CF SERIES ATMOSPHERIC GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.9 Troubleshooting and Problem Isolation

Because it is not feasible to attempt to include in this manual every conceivable problem or trouble

condition that might be encountered, this section is intended to provide technicians with a general

knowledge of the broad problem categories associated with this equipment, and the probable causes

of each. With this knowledge, the technician should be able to isolate and correct any problem

encountered.

Problems likely encountered can be grouped into six broad categories:

1. Pilot/Ignition failures

2. Improper burner functioning

3. Improper temperature control

4. Computer-related problems

The probable causes of each category are discussed in the following sections. Troubleshooting

charts are included at the end of the chapter to assist in identifying some of the more common

problems.

1.9.1 Pilot/Ignition Failures

There are two categories: no pilot flame and unreliable flame.

No pilot flame

1. No gas or insufficient gas supply.

2. Clogged pilot orifice.

3. Air in gas lines (usually in new installations).

4. Open or grounded high limit.

Unreliable flame

1. Loose/corroded wire connections.

2. Low or no voltage out of thermopile / thermocouple (CE units).

3. Defective gas valve.

5. Filtration problems

6. Leakage

1-20

Page 26

MASTER JET CF SERIES ATMOSPHERIC GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.9.1 Pilot/Ignition Failures (cont.)

Ignition failures occur when the 24VAC power supply to the gas valve is interrupted, when the gas

supply is interrupted, or when the pilot flame is extinguished.

There are three primary reasons for ignition failure, listed in order of probability:

1. Problems related to the gas and/or electrical power supplies.

2. Problems related to the electronic circuits.

3. Problems related to the gas valve.

PROBLEMS RELATED TO THE GAS AND/OR ELECTRICAL POWER SUPPLIES

The main indicators of this are that an entire battery of fryers fails to light and/or there are no

indicator lights illuminated on the fryer experiencing ignition failure. Verify that the quick

disconnect hose is properly connected, the fryer is plugged in, the main gas supply valve is open,

and the circuit breaker for the fryer electrical supply is not tripped.

PROBLEMS RELATED TO THE ELECTRONIC CIRCUITS

If gas and electrical power are being supplied to the fryer, the next most likely cause of ignition

failure is a problem in the 24 VAC circuit of the pilot system. If the fryer is equipped with a Filter

Magic II filtration system, first verify that the drain valve is fully closed. (The valve is attached to a

microswitch that must be closed for power to reach the gas valve. Often, although the valve handle

appears to be in the closed position, the microswitch is still open.) If the valve is fully closed, or the

fryer does not have a filtration system, refer to the troubleshooting tables in this chapter.

PROBLEMS RELATED TO THE GAS VALVE

If the problem is not in the 24 VAC circuit of the pilot system, it is most likely in the gas valve itself,

but before replacing the gas valve refer to the troubleshooting tables in this chapter.

1-21

Page 27

MASTER JET CF SERIES ATMOSPHERIC GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.9.2 Improper Burner Functioning

The burner ignites but exhibits abnormal characteristics such as "popping", incomplete lighting of

the burner, fluctuating flame intensity, and flames "rolling" out of the fryer.

"Popping" indicates delayed ignition. In this condition, the main gas valve is opening but the

burner is not immediately lighting. When ignition does take place, the excess gas "explodes" into

flame, rather than smoothly igniting.

The primary causes of popping are:

• Incorrect or fluctuating gas pressure

• Misdirected or weak pilot flame

• Burner deflector targets out of alignment or missing

• Clogged burner orifices

• Inadequate make-up air

• Clogged vent tube, causing incorrect gas pressure

If popping occurs only during peak operating hours, the problem may be incorrect or fluctuating gas

pressure. Verify that the incoming gas pressure (pressure to the gas valve) is in accordance with the

appropriate CE or Non-CE standards found in the tables on Pages 1-5 and 1-6, and that the pressure

remains constant throughout all hours of usage. Refer to Section 1.3 for the procedure for checking

the burner gas pressure.

If popping is consistent during all hours of operation, verify that the pilot is properly positioned

above the burner orifice and that the pilot pressure is correct. Correct pilot pressure is indicated by a

flame 1 to 1-½" (25 to 38 mm) long. Refer to Section 1.4 for the pilot flame adjustment procedure.

Clogged burner orifices, especially those near the pilot, are also likely causes of delayed ignition.

Clogged orifices are indicated by no flame, flames that are orange-colored, and flames that shoot out

at an angle from the rest.

Another cause of popping is an insufficient air supply or drafts that are blowing the pilot flame away

from the burner. Check for "negative pressure" conditions in the kitchen area. If when the door is

opened to the kitchen and a rush of incoming air is felt, this indicates that more air is being

exhausted than is being replenished and the burners may have insufficient combustion air.

If the fryer’s gas and air supplies are okay, the problem most likely is with one of the electrical

components. Examine the computer for signs of melting/distortion and/or discoloration due to

excessive heat buildup in the fryer. (This condition usually indicates improper flue performance.).

A discolored or distorted computer should be replaced immediately. To prevent recurring problems,

correct the condition immediately.

The burner lighting on one side only may be caused by a missing or misaligned rear deflector target

or improper burner manifold pressure. Clogged burner orifices are usually the cause of gaps in

burner firing.

1-22

Page 28

MASTER JET CF SERIES ATMOSPHERIC GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.9.2 Improper Burner Functioning (cont.)

Fluctuating flame intensity is normally caused by either improper or fluctuating incoming gas

pressure, but may also be the result of variations in the kitchen atmosphere. Verify incoming gas

pressure in the same way as for "popping", discussed in the preceding paragraphs. Variations in the

kitchen atmosphere are usually caused by air conditioning and/or ventilation unit air-exchange. As

the systems start and stop, the pressure in the kitchen may change from positive or neutral to

negative, or vice versa. They may also cause changes in airflow patterns that may affect flame

intensity.

Flames "rolling" out of the fryer are usually an indication of negative pressure in the kitchen. Air

is being sucked out of the fryer enclosure and the flames are literally following the air. If negative

pressure is not the cause, check for high burner manifold gas pressure in accordance with the

procedures in Section 1.3. An obstructed flue, which prevents the fryer from properly exhausting,

may also be the cause.

An excessively noisy burner, especially with flames visible above the flue opening, may indicate

that the burner gas pressure is too high, or it may simply be that the gas valve vent tube is blocked.

If the gas pressure is correct and the vent tube is unobstructed, the gas valve regulator is probably

defective.

Occasionally a burner may apparently be operating correctly, but the fryer has a slow recovery rate.

[The recovery rate is the length of time required for the fryer to increase the oil temperature from

250°F to 300°F (121°C to 149°C)]. Low burner manifold pressure and/or misaligned or missing

deflector targets are usually the main causes. If both of these causes are ruled out, the probable

cause is a gas valve regulator that is out of adjustment. See Section 1.3 to adjust regulator.

1.9.3 Improper Temperature Control

Temperature control, including the melt cycle, is a function of several interrelated components, each

of which must operate correctly. The principle component is the thermostat (in thermostat control

units) or the temperature probe (in fryers equipped with computers). Depending upon the specific

configuration of the fryer, other components may include the interface board and the computer.

Improper temperature control problems can be categorized into melt cycle problems and failure to

control at setpoint problems.

1-23

Page 29

MASTER JET CF SERIES ATMOSPHERIC GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.9.3 Improper Temperature Control (cont.)

MELT CYCLE PROBLEMS

NOTE: In early 1999, PC board melt cycle timers replaced melt-cycle timer motors in new fryers.

See Section 1.8.8 for retrofit information.

In fryers equipped with thermostat controls, the melt cycle is controlled by a mechanical timer or a

PC board. Three components that that can fail are the melt-cycle timer, the melt-cycle timer

microswitch or the control panel melt cycle On/Off switch. Isolate the defect and replace defective

component.

In fryers equipped with computers, the problem may be with the computer itself, the temperature

probe, or a malfunctioning heat relay on the interface board. Refer to the troubleshooting tables in

this chapter.

FAILURE TO CONTROL AT SETPOINT

In fryers equipped with thermostat controls, the problem will be with the thermostat itself. Possible

causes are that the thermostat is out of calibration, the knob or flexible shaft is loose on the

thermostat shaft, a thermostat wire is disconnected or broken, or the thermostat is defective. Refer to

Section 1.7 for instructions on calibrating the thermostat.

In fryers equipped with other types of controls, the problem may be with the temperature probe, the

interface board, or the controller. Refer to the troubleshooting tables in this chapter.

1.9.4 Computer-Related Problems

Computer Magic III.5 Features

Sensitivity or "Stretch Time"

Sensitivity or stretch time is a programmable feature that increases the cook time countdown based

on variations in the oil temperature from the setpoint.

The sensitivity for each product button has 10 settings (0 through 9). A "0" sensitivity setting will

disable the feature (no change in cooking time), while a nine will provide the highest sensitivity or

most change. The correct sensitivity for any product is based on the product, its density, the setpoint

temperature, and the customer’s own requirements.

1-24

Page 30

MASTER JET CF SERIES ATMOSPHERIC GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.9.4 Computer-Related Problems (cont.)

Recovery Time

Recovery time is a method of measuring a fryer’s performance. Put simply, it is the time required for

the fryer to increase the oil temperature from 250°F to 300°F (121°C to 149°C). This range is used

as a standard since ambient kitchen temperatures can affect the test if lower ranges are used.

The Computer Magic III.5 performs the recovery test each day as the fryer warms up. An operator

can view the results of the test any time the fryer is above the 325°F (163°C) point by pressing the

button and entering the code 1652. The test results will be displayed in the computer’s LED

panel in minutes and seconds. An acceptable recovery time for the MJCF Series fryers is 3 minutes,

30 seconds.

Common Computer Complaints

Most problems concerning computers have to do with programming them. There are four common

complaints. The complaints, their causes, and corrective actions are:

1. Fryer constantly displays "

".

Cause: Setpoint incorrect or missing.

Corrective Action: Press 1 6 5 0, enter the correct setpoint using keypad, press again, then

press to lock in the setpoint.

2. Temperature is displayed in Celsius.

Cause: Computer is programmed to display in Celsius.

Corrective Action: Press

1 6 5 8.

3. Temperature is constantly displayed.

Cause: Computer is programmed for constant temperature display.

Corrective Action: Press 1 6 5 L.

4. Computer times down too slowly or too quickly.

Cause: Computer is compensating for oil temperature via the sensitivity setting.

Corrective Action: Reprogram sensitivity setting for each product in accordance with

programming instructions in the Frymaster Fryer Controllers User’s Manual that shipped with

the computer.

1-25

Page 31

MASTER JET CF SERIES ATMOSPHERIC GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.9.5 Filtration Problems

The majority of filtration problems arise from operator error. One of the most common errors is

placing the filter paper on the bottom of the filter pan rather than over the filter screen.

Whenever the complaint is "the pump is running, but no oil is being filtered", check the installation

of the filter paper, and the paper size. While you are checking the filter paper, verify that the O-rings

on the bottom of the filter pan, and on the male disconnect (at inside rear of filter cabinet) are present

and in good condition. Missing or worn O-rings will allow the pump to suck air and decrease its

efficiency.

If the pump motor overheats, its thermal overload will trip and the motor will not start until it is

reset. If the pump motor does not start, press the red reset switch located on the end of the motor

nearest the operator. If the pump then starts, something caused the motor to overheat. It may be just

that several frypots were being filtered one after the other and the pump got hot. Letting the pump

cool down for at least a half-hour is all that is required in this case. More often, the pump

overheated for one of the following reasons:

• Shortening has solidified in the pan or filter lines.

• Attempt to filter unheated oil or shortening. Cold oil and shortening are thicker and cause the

pump motor to work harder and overheat.

If the motor tries to run but the pump does not, there is a blockage in the pump. Incorrectly sized or

installed paper will allow food particles and sediment to pass through the filter pan and into the

pump. When sediment enters the pump, the gears can bind up causing the motor to overload, again

tripping the thermal overload. Solidified shortening in the pump will also cause it to seize, with the

same result.

A pump seized by debris or hard shortening can

usually be freed by manually moving the gears

Sediment

Particle

with a screwdriver or other instrument.

1. Disconnect power to the filter system.

Oil Flow

2. Remove the input plumbing from the

pump.

3. Use a screwdriver to manually turn the

gears.

Sediment

Particle

Up for reverse

• Turning the pump gears backwards

will release a hard particle and allow

its removal.

Down for

forward

• Turning the pump gears forward will

push softer objects and solid shortening

through the pump and allow free

movement of the gears.

1-26

Page 32

MASTER JET CF SERIES ATMOSPHERIC GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.9.5 Filtration Problems (cont.)

Incorrectly sized or installed paper will also allow food particles and sediment to pass through and

clog the suction tube on the bottom of the filter carriage. Particles large enough to block the suction

tube may indicate that the crumb tray is not installed in the pan during filtering.

Pan blockage can also occur if shortening is left in the pan and allowed to solidify. The heater strip

on the suction tube is designed to prevent solidification of residual shortening left in the tube. It will

not melt or prevent solidification of shortening in the pan.

Blockage removal can be accomplished by forcing the item out with an auger or drain snake.

Compressed air or other pressurized gases should not be used to force out the blockage.

Possible problems with the Power Shower include clogged openings, shortening solidified in the

tubes, missing clean-out plugs, and missing or worn O-rings. Cleaning the unit and replacing

missing plugs and missing or worn O-rings will correct these problems.

The electronics of the Filter Magic II are simple and straightforward. Microswitches, attached to the

oil-return valve handles of each vat and wired in parallel, provide the 24 VAC needed to activate the

pump relay coil when the handles are moved to the ON position. The activated coil pulls in the

pump motor switch, supplying power to the motor.

The suction tube heater and flexible hose heater are wired directly into the 24VAC source. They

remain energized as long as the unit is plugged in (see diagram below).

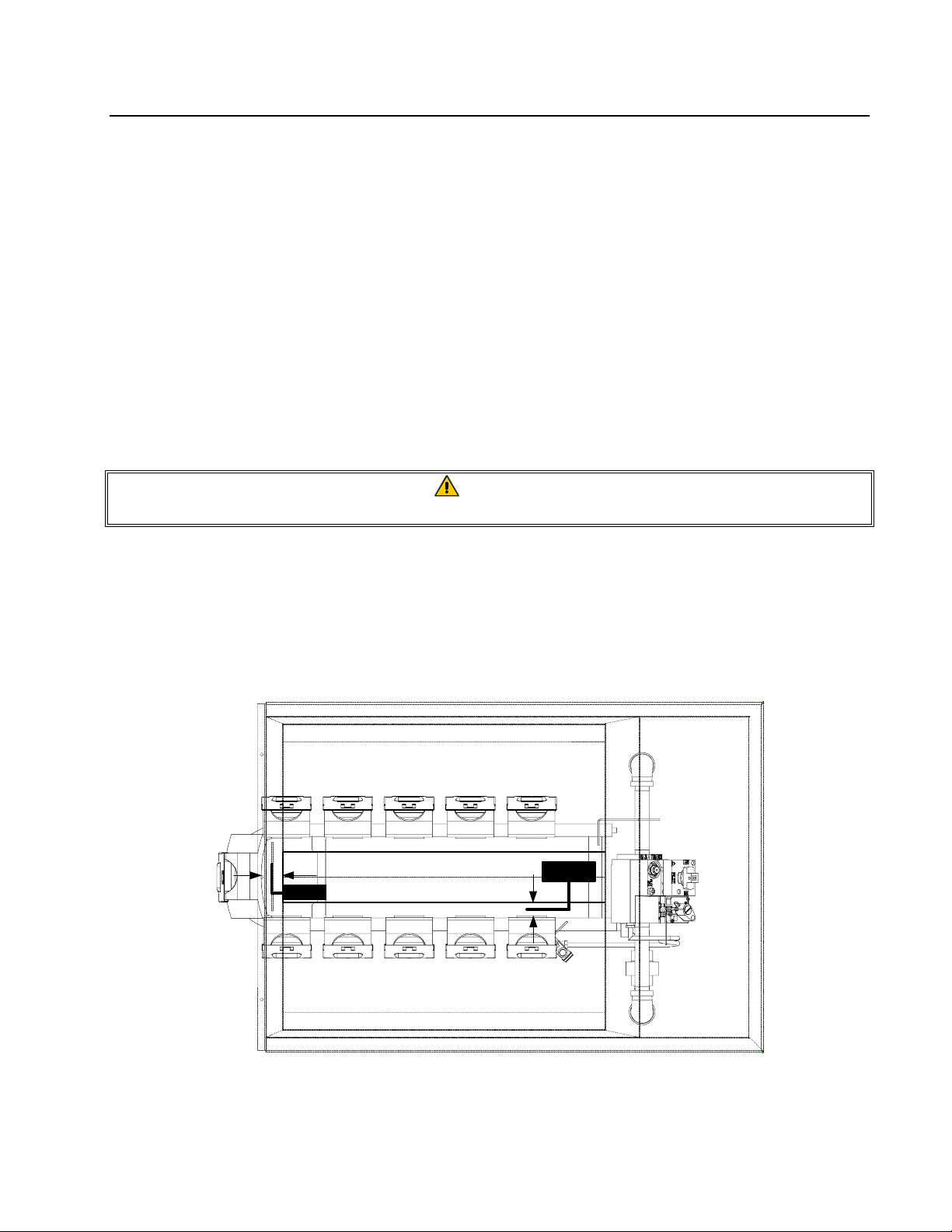

Line VAC

Return Line Heater Tapes

24 VAC

Suction Tube (Pan) Heater Tape

Micro-switches

Pump Relay Coil

Pump Motor

M

Pump Motor Switch

Filter Magic Simplified Wiring Diagram

1-27

Page 33

MASTER JET CF SERIES ATMOSPHERIC GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.9.6 Leakage

Leakage of the frypot is mostly due to improperly sealed high-limits, thermostats/temperature

probes, and drain fittings. When installed or replaced, each of these components must be sealed with

Loctite PST567 sealant or equivalent to prevent leakage. In very rare cases, a leak may develop

along one of the welded edges of the frypot. When this occurs, the frypot must be replaced.

If the sides and/or ends of the frypot are coated with oil, the most likely cause is spillage over the top

of the frypot rather than leakage.

The clamps, which hold the drain tube sections together, may loosen over time as the tubes expand

and contract with heating and cooling during use. If the section of drain tube connected to the drain

valve is removed for whatever reason, make sure that its grommet is in good condition and properly

fitted around the nipple of the drain when it is reinstalled. Also, ensure that the drain tube runs

downward from the drain along its whole length and has no low points where oil may accumulate.

1.9.7 Troubleshooting, Millivolt Frying Systems

How the Millivolt Circuit Works

The voltage output of a thermopile powers the coil of a millivolt gas valve. This output is measured

in millivolts or thousandths of one volt.

The high-limit thermostat acts as a safety switch. It will de-energize the gas valve when the oil in the

fryer’s frypot climbs to 425°F to 450°F.

An operating thermostat controls the main coil actuation and acts as the burner control.

Gas Valve

Operating Thermostat

Main Valve Magnet

Pilot Magnet

Thermopile

Pilot

High-Limit

1-28

Page 34

MASTER JET CF SERIES ATMOSPHERIC GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

High-limit

High-Limit

Thermostat

Pilot

Generator

Optional ON-OFF switch

Operating

Thermostat

Pilot

Generator

HONEYWELL

Adj.

Pilot

1/2 PSI

HONEYWELL

PILOT

C

ON

1/2 PSI

HONEYWELL 1/2 P.S.I.

OFF

12C

Thermostat

17C

17C

In Line Splice

Safety Drain

Switch

In Line Spl ice

ON/OFF Switch

(Optional)

FENWALL

Operating

Thermostat

When troubleshooting millivolt systems, always check these areas before performing diagnostic

checks on either the Robertshaw or Honeywell systems:

A. Inspect all wires and component leads for damage (heat, oil, moisture, etc.). On capillary

tube-type thermostats, check for resistance on the thermostat lead wires. Wire nuts and other

connectors cannot be present in a millivolt circuit as they can cause resistance. If resistance

is found, solder the connectors to the wires or replace the wires.

B. Clean and verify that all wire connections and gas valve terminal connections are tight.

C. Check the length of the pilot flame (it should be about 1½-inches (38mm) long) and verify

that it contacts the top one third of the thermopile. Clean the pilot orifice and adjust the pilot

strength if needed.

D. Measure thermopile output with no load (i.e., with the thermopile disconnected from the gas

valve). Measurements must be made with a multimeter having a 0-1000 DC millivolt (MV)

range. Light the pilot and have someone hold the gas cock knob in the depressed position. If

the thermopile is a single lead (coaxial) type, measure from the lead’s end contact to its

screw-in threads. If the thermopile has two leads, measure across the end terminals. The

reading should be within the range of 500-800 millivolts. If not, replace the thermopile.

Performing diagnostic checks on Robertshaw and Honeywell Systems are described on the following

page.

1-29

Page 35

MASTER JET CF SERIES ATMOSPHERIC GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

ROBERTSHAW-UNITROL 7000 SYSTEM CHECK

1. Complete System Check

With thermostat contacts closed and gas cock

dial in the “ON” position, the main burner

should ignite. Measure the reading between

the 2 & 3 terminals. If the reading is more

than 100MV, replace the gas valve.

2. System Resistance Check

With thermostat contacts closed and main

burner “ON”, measure the millivolt reading

between the 1 and 3 terminals. The reading

should be less than 80MV. If not, recheck the

thermostat leads and connections. Replace

with new or heavier gauge wires if necessary.

If the reading is still greater than 80MV,

replace the thermostat.

3. Automatic Pilot Dropout Check

With the thermostat contacts open, hold the

gas cock knob depressed with the pilot lit until

the maximum millivolt output is observed

between the 1 and 2 terminals. Then

extinguish the pilot and observe the meter.

The sound of the pilot magnet dropping should

be audible. This dropout should occur

between 120MV and 30MV. If it occurs

outside these limits, change the gas valve.

HONEYWELL SYSTEM CHECK

1. Complete System Check

With thermostat contacts closed and gas cock

dial in the “ON” position, main burner should

ignite. If not, measure across terminals 2 and

3 as indicated in the diagram. If the reading is

more than 180MV, replace the gas valve.

2. System Resistance Check

With thermostat contacts closed and main

burner “ON”, measure the millivolt reading

between terminals 1 and 3 as indicated in the

diagram. The reading should be 220MV or

less. If not, recheck thermostat leads and

connections. Replace with new or heavier

gauge wires if necessary. If the reading is still

greater than 220MV, replace the thermostat.

3. Automatic Pilot Dropout Check

With the thermostat contacts open, hold the

gas cock knob depressed with the pilot lit until

the maximum millivolt output is observed

between terminals 1 and 2. Then extinguish

the pilot and observe the meter. The sound of

the pilot magnet dropping should be audible.

This dropout should occur between 110MV

and 36MV. If it occurs outside these limits,

change the gas valve.

TH

TH

TP

THTP TH

Test

1

Meter

Setting

2

TP

Millivolt Operator

Terminal Panel

(Robertshaw)

Meter Leads

On Terminals

3

TP

Acceptable

Results

1 MV 2 & 3 <100MV

2 MV 1 & 3 <80MV

3 MV 1 & 2 30-120MV

4

TH

3

TH

Millivolt Opera tor

Terminal Panel

PP

PP

1

2

(Honeywell)

Test

Meter

Setting

Meter Leads On

Terminals

Acceptable

Results

1 MV 2 & 3 <180MV

2 MV 1 & 3 <220MV

3 MV 1 & 2 36-110MV

1-30

Page 36

MASTER JET CF SERIES ATMOSPHERIC GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.10 Troubleshooting Guides

The troubleshooting guides found in the pages that follow are intended to assist service technicians

in quickly isolating the probable causes of equipment malfunctions by following a logical, step-bystep process.

1.10.1 Initial Troubleshooting, Millivolt Frying Systems

PROBLEM PROBABLE CAUSES CORRECTIVE ACTION

A. Pilot is not lit. A. Light pilot.

Burner won’t ignite.

Burner partially ignites.

B. Loose, dirty, or corroded terminals on

gas valve.

C. Loose, dirty, or corroded terminals on

thermostat.

D. Thermostat, gas valve, or high-limit

wires broken or shorted.

E. Thermostat out of calibration. E. Check calibration of thermostat in

F. Thermostat or gas valve is suspect. F. Inspect and replace components if

A. One or more burner orifices clogged. A. Turn gas valve knob to OFF position.

B. Blocked flue outlet. B. Clear blockage from flue outlet.

C. Fryer flue connected directly to vent

hood with a chimney-like duct.

B. Clean and tighten terminals on gas

valve.

C. Clean and tighten terminals on

thermostat.

D. Examine wires for signs of abrasions,

cuts, kinks, etc. If the wiring is

damaged, replace the affected

component.

accordance with procedures in

Section 1.7 of this manual.

necessary.

Use a thin wire to clear obstruction

from burner orifices.

C. Remove duct and allow for at least 18"

(45.7cm) between flue outlet and vent

hood filters.

D. Broken or missing ceramic targets, or

incorrect burner gas pressure.

D. Replace broken/missing ceramic

targets if required. If not required,

check burner gas pressure and adjust

to correct pressure if required.

1-31

Page 37

MASTER JET CF SERIES ATMOSPHERIC GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.10.1 Initial Troubleshooting, Millivolt Frying Systems (cont.)

PROBLEM PROBABLE CAUSES CORRECTIVE ACTION

Burner ignition is

delayed.

Pilot won’t remain lit.

A. Inadequate make-up air in cooking

area.

B. Pilot flame directed away from first

orifice of burner.

C. One or more burner orifices is

clogged.

D. Low pilot flame [less than 1” (25mm)],

low incoming gas pressure, or

inadequate incoming gas supply line.

A. Clogged pilot orifice. A. Use a small wire to clear obstruction

B. Pilot flame blowing away from pilot

generator (excessive draft in kitchen).

C. Pilot generator not inserted fully into

pilot burner.

D. Corroded connection where pilot

generator connects to gas valve.

A. Adjust ventilation system to increase

make-up air.

B. Reposition pilot hood to direct flame

toward first burner orifice.

C. Use a thin wire to clear obstruction

from orifices.

D. Adjust pilot flame height to 1–1-½"

(25– 38.1mm), if required. If pilot

flame is adequate, check incoming

gas pressure and adjust to proper

pressure, if required. If proper

pressure cannot be achieved, check

incoming-gas supply line and increase

to proper size if required.

from pilot orifice.

B. Eliminate draft in kitchen.

C. Reinsert pilot generator into pilot

burner until flame surrounds tip.

D. Clean pilot generator connection at

gas valve.

Flames rolling out of

fryer.

Pilot ignites, but fails to

remain lit after gas

valve knob/button is

released.

Setpoint temperature

cannot be attained.

E. Low pilot flame, pilot generator, high-

limit thermostat contacts, or gas valve

pilot magnet is suspect.

A. Flue obstructed. A. Remove obstruction from flue.

B. Inadequate make-up air in cooking

area.

A. Loose, dirty or corroded high-limit

wires.

B. Gas valve, pilot generator or high-limit

thermostat is suspect.

A. Thermostat out of calibration. A. Check calibration of thermostat in

B. Failed thermostat. B. Replace defective thermostat as

E. Adjust pilot flame as instructed in

“Burner ignition is delayed”, if

required. If pilot flame is adequate,

inspect and replace pilot generator, if

required. Inspect and clean high-limit

contacts, if required. Replace gas

valve if pilot magnet is defective.

B. Adjust ventilation system to increase

make-up air.

A. Clean/tighten high-limit wires on gas

valve.

B. Inspect and replace any or all

defective components, if required.

accordance with procedures in

Section 4.2 of this manual.

outlined in Section 1.8.2.

1-32

Page 38

MASTER JET CF SERIES ATMOSPHERIC GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.10.2 Initial Troubleshooting, 24VAC Frying Systems

PROBLEM PROBABLE CAUSES CORRECTIVE ACTION

Burner won’t ignite.

Light in ON/OFF switch

is not illuminated.

A. ON/OFF switch is off. A. Turn ON/OFF switch on.

ON/OFF switch is on,

but the switch light is

not illuminated.

ON/OFF switch is on

and the switch light is

illuminated, but there is

no output to gas valve.

A. No 24 VAC output from transformer. A. Check 24VAC circuit. Replace

transformer if defective.

A. Drain microswitch circuit (filter-

equipped units) is open.

B. 24VAC is present at ON/OFF switch,

but continuity of the switch in ON

position is not "0".

C. Continuity of thermostat is not "0"

(cooking oil/shortening temperature is

at least 15°F below thermostat

setting).

D. Gas valve is suspect. D. Go to "No burner flame".

A. Pilot does not stay lit (fryer is on and

thermopile output is approximately

400 millivolts.

B. Pilot does not stay lit (fryer is on and

thermopile output is not

approximately 400 millivolts.

A. Ensure drain valve is fully closed and

microswitch is functioning. Replace

microswitch if defective.

B. On/Off switch is defective. Replace

switch with a known working switch.

C. Thermostat is defective. Replace with

a known working thermostat.

A. Check high-limit switch. Switch

continuity should be "0". If not, highlimit switch is defective. Replace highlimit switch.

B. Inspect thermopile (units without

interface board) and replace if

defective.

No burner flame.

C. Pilot stays lit, and the high-limit and

thermopile are known working, but

burners fail to light.

D. Gas valve is known to be good, but

there is not 24 VAC at the gas valve

terminals.

E. Continuity from terminal block to gas

valve thermostat wire is not "0".

1-33

C. Inspect gas valve and replace if

defective.

D. Inspect thermostat body (while still in

frypot) for damage. Remove and

replace thermostat if bent, dented or

cracked. Inspect leads for fraying,

burning, breaks and/or kinks. If found,

remove and replace thermostat.

Remove leads from terminal block,

allow oil to cool 15°F below thermostat

setting and check continuity. If

continuity is not "0", then thermostat

has failed. Replace thermostat.

E. Inspect wiring for breaks or shorts and

repair if necessary.

Page 39

MASTER JET CF SERIES ATMOSPHERIC GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.10.2 Initial Troubleshooting, 24VAC Frying Systems (cont.)

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

Fluctuating or erratic

lighting of burner

flame.

A. Incoming gas supply pressures are

not within range [Natural- 6-14" W.C.

(1.49-3.49 kPa); Propane- 11-14"

W.C. (2.74-3.49 kPa)]