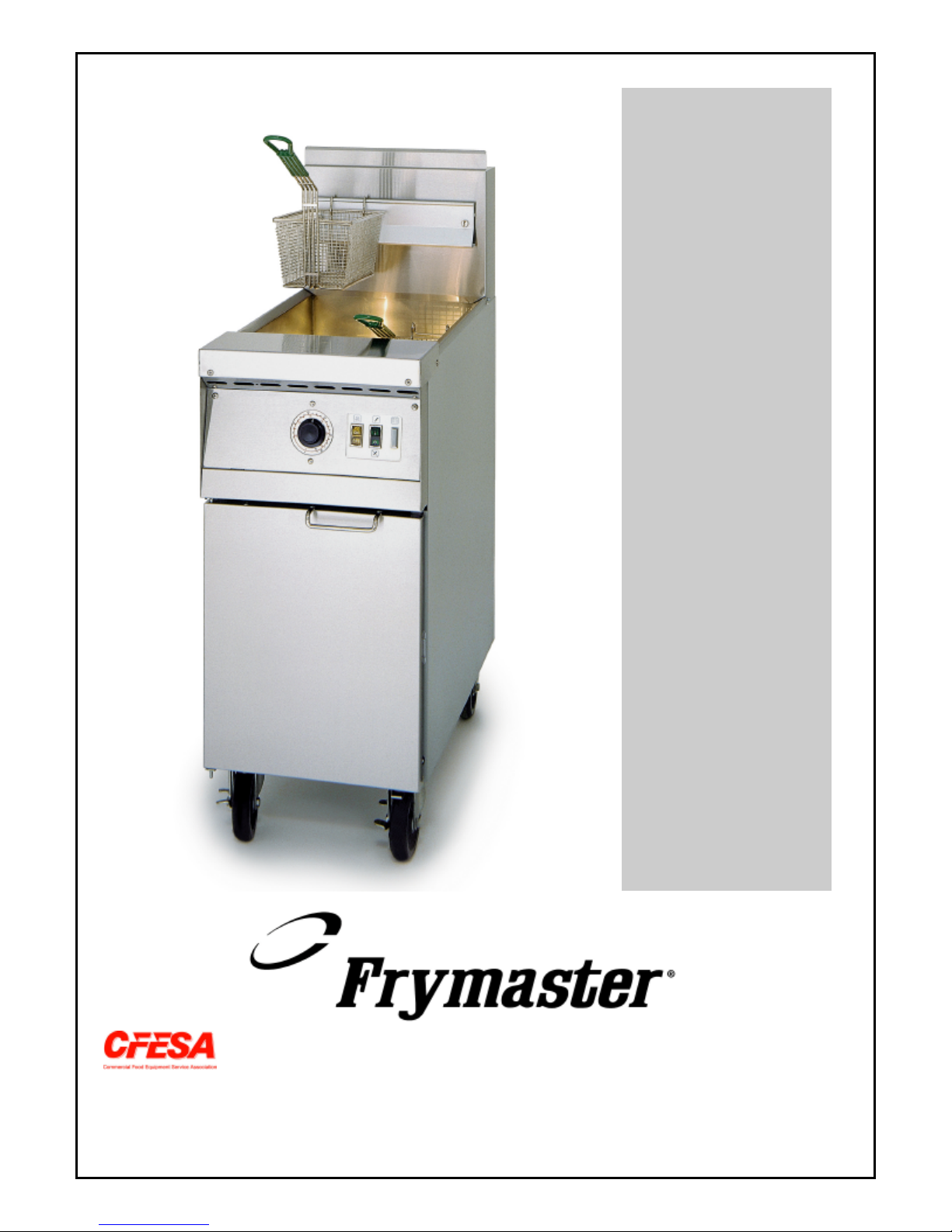

Frymaster FM45E, MJ45E, MJ45EC, FM45EC Installation & Operation Manual

45 Series Gas Fryers

Installation & Operation Manual

Frymaster, a member of the Commercial Food Equipment Service Association, recommends

using CFESA Certified Technicians.

24-Hour Service Hotline 1-800-551-8633

819-0002

08-00

DANGER

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE, OR

MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY, OR DEATH. READ THE

INSTALLATION, OPERATING, AND SERVICE INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING THIS EQUIPMENT.

DANGER

FOR YOUR SAFETY, DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE

LIQUIDS OR VAPORS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

DANGER

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN THE

EVENT THE USER SMELLS GAS. THIS INFORMATION SHALL BE OBTAINED BY

CONSULTING THE LOCAL GAS SUPPLIER.

THIS EQUIPMENT IS TO BE INSTALLED IN COMPLIANCE WITH THE BASIC

PLUMBING CODE OF THE BUILDING OFFICIALS AND CODE ADMINISTRATORS

INTERNATIONAL, INC. (BOCA) AND THE FOOD SERVICE SANITATION MANUAL OF

THE FOOD AND DRUG ADMINISTRATION.

COMPUTERS

FCC

This device complies with Part 15 of the FCC rules. Operation is subject to the following two

conditions: 1) This device may not cause harmful interference, and 2) This device must accept any

interference received, including interference that may cause undesired operation. While this device is

a verified Class A device, it has been shown to meet the Class B limits.

CANADA

This digital apparatus does not exceed the Class A or B limits for radio noise emissions as set out by

the ICES-003 standard of the Canadian Department of Communications.

Cet appareil numerique n’emet pas de bruits radioelectriques depassany les limites de classe A et B

prescrites dans la norme NMB-003 edictee par le Ministre des Communcations du Canada.

DANGER

THIS PRODUCT CONTAINS CHEMICALS KNOWN TO THE STATE OF CALIFORNIA

TO CAUSE CANCER AND/OR BIRTH DEFECTS OR OTHER REPRODUCTIVE HARM.

Operation, installation, and servicing of this product could expose you to airborne

particles of glasswool or ceramic fibers, crystalline silica, and/or carbon monoxide.

Inhalation of airborne particles of glasswool or ceramic fibers is known to the State

of California to cause cancer. Inhalation of carbon monoxide is known to the State

of California to cause birth defects or other reproductive harm.

FRYMASTER FRYERS EQUIPPED WITH LEGS ARE FOR PERMANENT

INSTALLATION. FOR MOVEABLE OR PORTABLE INSTALLATION, FRYMASTER

OPTIONAL EQUIPMENT CASTERS MUST BE USED.

QUESTIONS??? CALL 1-800-551-8633.

45 SERIES GAS FRYERS

TABLE OF CONTENTS

CHAPTER 1: General Information

1.1 Parts Ordering and Service Information............................................................................ 1-1

1.2 Safety Information............................................................................................................. 1-1

1.3 European Community (CE) Specific Information............................................................. 1-2

1.4 Equipment Description...................................................................................................... 1-2

1.5 Installation, Operating, and Service Personnel ................................................................. 1-3

1.6 Definitions......................................................................................................................... 1-3

1.7 Shipping Damage Claim Procedure.................................................................................. 1-3

CHAPTER 2: Installation Instructions

2.1 General Installation Requirements.................................................................................... 2-1

2.2 Caster/Leg Installation ......................................................................................................2-2

2.3 Pre-Connection Preparations............................................................................................. 2-3

2.4 Connection to Gas Line..................................................................................................... 2-4

2.5 Converting to Another Gas Type ...................................................................................... 2-6

CHAPTER 3: Operating Instructions

3.1 Start-Up Procedure............................................................................................................ 3-1

3.2 Boiling-Out the Frypot......................................................................................................3-2

3.3 Shutting the Fryer Down...................................................................................................3-3

3.4 Controller Operation and Programming............................................................................ 3-3

Computer Magic III Controller ......................................................................................... 3-4

Thermostat Controller....................................................................................................... 3-8

Analog Controller.............................................................................................................. 3-9

Digital Controller ............................................................................................................ 3-10

Solid State Basket Lift Timer.......................................................................................... 3-11

CHAPTER 4: Filtration Instructions

4.1 Draining and Manual Filtering.......................................................................................... 4-1

4.2 Filter Magic II Filtration System Operation...................................................................... 4-1

Preparing the Filter Unit for Use....................................................................................... 4-2

Operation of the Filter Unit............................................................................................... 4-3

Changing the Filter Paper.................................................................................................. 4-4

CHAPTER 5: Preventive Maintenance

5.1 Fryer Preventive Maintenance Checks and Services ........................................................ 5-1

Daily Checks and Services................................................................................................ 5-1

Weekly Checks and Services ............................................................................................ 5-1

Quarterly Checks and Services.......................................................................................... 5-2

Semi-Annual Checks and Services.................................................................................... 5-4

5.2 Filter Magic II Filtration System Preventive Maintenance Checks and Services............. 5-5

i

45 SERIES GAS FRYERS

TABLE OF CONTENTS

CHAPTER 6: Operator Troubleshooting

6.1 Introduction........................................................................................................................6-1

6.2 Troubleshooting Fryers with Thermostat Controls............................................................6-2

6.3 Troubleshooting Fryers with Analog, Digital, or CM III Controllers...............................6-4

6.4 Troubleshooting the Filter Magic II Filtration System......................................................6-7

6.5 Troubleshooting Abnormal Burner Operation.................................................................6-11

6.6 Replacing the Controller or Controller Wiring Harness..................................................6-12

ii

45 SERIES GAS FRYERS

CHAPTER 1: GENERAL INFORMATION

1.1 Parts Ordering and Service

Information

In order to assist you as quickly as possible,

the Frymaster Factory Authorized Service

Center (FASC) or Service Department representative requires certain information about

your equipment. Most of this information is

printed on a data plate affixed to the inside of

the fryer door.

Parts orders must be placed directly with your

local FASC or distributor. Included with

fryers when shipped from the factory is a list

of Frymaster FASCs. If you do not have

access to this list, contact the Frymaster

Technical Service Department at 1-800-5518633 or 1-318-865-1711.

When ordering parts, the following information is required:

ready any other information that you think

may be helpful in solving your problem.

RETAIN AND STORE THIS MANUAL IN A SAFE

PLACE FOR FUTURE USE.

1.2 Safety Information

Before attempting to operate your unit, read

the instructions in this manual thoroughly.

Throughout this manual, you will find notations enclosed in double-bordered boxes

similar to the ones below.

CAUTION boxes contain information about

actions or conditions that may cause or result

in a malfunction of your system.

CAUTION

Example of a CAUTION box.

Model Number:

Serial Number:

Type of Gas or Voltage:

Item Part Number:

Quantity Needed:

Service information may be obtained by

contacting your local FASC. Information may

also be obtained by calling the Frymaster

Technical Service Department at 1-800-5518633 or 1-318-865-1711.

When requesting service, please have the following information ready:

Model Number:

Serial Number:

Type of Gas:

In addition to the model number, serial number, and type of gas, please be prepared to describe the nature of the problem and have

WARNING boxes contain information about

actions or conditions that may cause or result

in damage to your system, and which may

cause your system to malfunction.

WARNING

Example of a WARNING box.

DANGER boxes contain information about ac-

tions or conditions that may cause or result in

injury to personnel, and which may cause

damage to your system and/or cause your system to malfunction.

DANGER

Hot cooking oil or shortening causes

severe burns. Never attempt to move a

fryer containing hot cooking

oil/shortening or to transfer hot

cooking oil/shortening from one

container to another.

1-1

45 SERIES GAS FRYERS

CHAPTER 1: GENERAL INFORMATION

Your fryer is equipped with automatic safety

features:

1. High temperature detection shuts off gas to

the burner assembly should the controlling

thermostat fail.

2. A safety switch built into the drain valve

of units with built-in filtration systems

prevents burner ignition with the drain

valve even partially open.

1.3 European Community (CE)

Specific Information

The European Community (CE) has established certain specific standards regarding

equipment of this type. Whenever there is a

difference between CE and non-CE standards,

the information or instructions concerned are

identified by shadowed boxes similar to the

one below.

Non-CE Standard

for Incoming Gas Pr essur es

Gas Minimum Maximum

6" W.C.

Natural

LP

1.49 kPa

14.93 mbar

11" W.C.

2.74 kPa

27.37 mbar

1.4 Equipment Description

45 Series gas fryers are specifically designed

for high volume frying. Models in this series

include FM45E, FM45EC, MJ45E, and

MJ45EC variants. Fryers in this series may be

equipped with built-in Filter Magic filtration

14" W.C.

3.48 kPa

34.84 mbar

14" W.C.

3.48 kPa

34.84 mbar

systems (FM45E and FM45EC variants), or

may be configured for manual filtration

(MJ45E and MJ45EC variants). All models

may be configured for electrical power supplies ranging from 120 to 240 VAC.

45 Series fryers utilize a combination gas

valve to control the burner and require an external source of AC electrical power. On the

FM45E and MJ45E models, the electrical

power supply to the gas valve is controlled by

a manually operated thermostat controller or

an electronic controller. The FM45EC and

MJ45EC models are equipped with Computer

Magic III computers.

All models are of an open-pot design with no

tubes and have a hand-sized opening into the

deep cold zone, which makes cleaning the

stainless frypot quick and easy.

Fryers equipped with built-in filtration systems are shipped completely assembled. Fryers without built-in filtration require installation of legs or optional casters at point of use.

All fryers are shipped with a package of standard accessories. Each fryer is adjusted,

tested, and inspected at the factory before

crating for shipment.

Frypots are constructed of welded, heavygauge stainless steel. Heating is supplied by a

burner assembly having multiple gas jets,

which are focused on ceramic targets located

around the lower side of the frypot. The burner

assembly can be configured for natural gas,

propane, or manufactured gas, as required by

the customer. A drain is tapped into the center

of the frypot, with a front-controlled manual

ball valve.

Each fryer is equipped with a thermostat probe

for precise temperature control. The probe is

located on the centerline of the frypot for rapid

1-2

45 SERIES GAS FRYERS

CHAPTER 1: GENERAL INFORMATION

response to changes in loads and to provide

the most accurate temperature measurement.

45 Series fryers may be equipped with an optional melt cycle feature which pulses the

burner on and off at a controlled rate. The

melt cycle feature is designed to prevent

scorching and uneven heating of the frypot for

customers who use solid shortening.

The controls on your fryer vary depending on

the model and configuration purchased. Control options include thermostat controls (standard), analog controllers, digital controllers, or

Com puter Magic III compu ters. Each t ype is

covered in detail in Chapter 3, Fryer Operating

Instructions.

1.5 Installation, Operating, and

Service Personnel

Operating information for Frymaster equipment has been prepared for use by qualified

and/or authorized personnel only, as defined in

Section 1.6.

All installation and service on Frymaster

equipment must be performed by qualified,

certified, licensed, and or/authorized installation or service personnel, as defined in

Section 1.6.

1.6 Definitions

operation of the equipment covered in this

manual.

QUALIFIED INSTALLATION PERSONNEL

Qualified installation personnel are individuals, or firms, corporations, or companies

which, either in person or through a representative, are engaged in and are responsible for

the installation of gas-fired appliances. Qualified personnel must be experienced in such

work, be familiar with all gas precautions involved, and have complied with all requirements of applicable national and local codes.

QUALIFIED SERVICE PERSONNEL

Qualified service personnel are those that are

familiar with Frymaster equipment and who

have been authorized by Frymaster to perform service on Frymaster equipment. All

authorized service personnel are required to be

equipped with a complete set of service and

parts manuals, and to stock a prescribed

minimum amount of Frymaster equipment

parts.

A list of Frymaster Factory Authorized Service Centers (FASC) was included with the

fryer when it was shipped from the factory.

Failure to use qualified service personnel

will void the Frymaster Warranty on your

equipment.

QUALIFIED AND/OR AUTHORIZED OPERATING

PERSONNEL

Qualified/authorized operating personnel are

those who have carefully read the information

in this manual and have familiarized

themselves with the equipment functions, or

who have had previous experience with the

1.7 Shipping Damage Claim

Procedure

Your Frymaster equipment was carefully inspected and packed before leaving the factory.

The transportation company assumes full responsibility for safe delivery upon acceptance

of the equipment for transport.

1-3

45 SERIES GAS FRYERS

CHAPTER 1: GENERAL INFORMATION

What to do if your equipment arrives

damaged:

1. File a claim for damages immediately,

regardless of the extent of damages.

2. In spect for and record all vi sible loss or

damage, and ensure that this information

is noted on the freight bill or express receipt and is signed by the person making

the delivery.

Frymaster DOES NOT ASSUME

RESPONSIBILITY FOR DAMAGE OR LOSS

INCURRED IN TRANSIT.

3. Concealed loss or damage that was un-

noticed until the equipment was unpacked

should be recorded and reported to the

freight company or carrier immediately

upon discovery. A concealed damage

claim must be submitted within 15 days of

the date of delivery. Ensure that the shipping container is retained for inspection.

1-4

45 SERIES GAS FRYERS

CHAPTER 2: INSTALLATION INSTRUCTIONS

2.1 General Installation

Requirements

PROPER INSTALLATION IS ESSENTIAL FOR

EFFICIENT, TROUBLE-FREE OPERATION OF

YOUR FRYER. ANY UNAUTHORIZED ALTERATIONS MADE TO THIS EQUIPMENT WILL

VOID THE FRYMASTER

WARRANTY.

Upon arrival, inspect the fryer carefully for

visible or concealed damage. (See Shipping

Damage Claim Procedure in Chapter 1.)

CLEARANCE AND VENTILATION

The fryer(s) must be installed with a 6” (150

mm) clearance at both sides and back when

installed adjacent to combustible construction;

no clearance is required when installed adjacent to noncombustible construction. A

minimum of 24” (600 mm) clearance should

be provided at the front of the fryer.

Adequate distances must be maintained from

the flue outlet of the fryer to the lower edge of

the ventilation filter bank. Filters should be

installed at an angle of 45º. Place a drip tray

beneath the lowest edge of the filter. For U.S.

installation, NFPA standard No. 96 states, “A

minimum distance of 18 in. (450 mm) should

be maintained between the flue outlet and the

lower edge of the grease filter.” Frymaster

recommends that the minimum distance be 24

in. (600 mm) from the flue outlet to the bottom

edge of the filter when the appliance consumes

more than 120,000 BTU per hour.

Information on construction and installation of

ventilating hoods can be found in the NFPA

standard cited above. A copy of the standard

may be obtained from the National Fire Protection Association, Battery March Park,

Quincy, MA 02269.

One of the most important considerations of

efficient fryer operation is ventilation. Make

sure the fryer is installed so that products of

combustion are removed efficiently, and that

the kitchen ventilation system does not produce drafts that interfere with proper burner

operation.

The fryer flue opening must not be placed

close to the intake of the exhaust fan, and the

fryer must never have its flue extended in a

“chimney” fashion. An extended flue will

change the combustion characteristics of the

fryer, causing longer recovery time. It also

frequently causes delayed ignition. To provide the air flow necessary for good combustion and burner operation, the areas surrounding the fryer front, sides, and rear must be kept

clear and unobstructed.

Fryers must be installed in an area with an

adequate air supply and adequate ventilation.

DANGER

Do not attach an apron drainboard to a

single fryer. The fryer may become

unstable, tip over, and cause injury.

The appliance area must be kept free

and clear of combustible materials at

all times.

NATIONAL CODE REQUIREMENTS

The type of gas for which the fryer is equipped

is stamped on the data plate attached to the

inside of the fryer door. Connect a fryer

stamped “NAT” only to natural gas, those

stamped “PRO” only to propane gas, and

those stamped “MFG” only to manufactured

gas.

Installation shall be made with a gas connector

that complies with national and local codes,

and, where applicable, CE codes. QuickDisconnect devices, if used, shall likewise

2-1

45 SERIES GAS FRYERS

CHAPTER 2: INSTALLATION INSTRUCTIONS

comply with national, local, and, if applicable,

CE codes.

ELECTRICAL GROUNDING REQUIREMENTS

All electrically operated appliances must be

grounded in accordance with all applicable

national and local codes, and, where applicable, CE codes. A wiring diagram is located on

the inside of the fryer door. Refer to the rating

plate on the inside of the fryer door for proper

voltages.

DANGER

If this appliance is equipped with a

three-prong (grounding) plug, it must

be plugged directly into a properly

grounded receptacle.

Do not cut or remove the grounding

prong from the plug.

DANGER

This equipment requires electrical

power for operation.

Place the gas control valve in the OFF

position in case of a prolonged power

outage.

limits for a Class A digital device, pursuant to

Part 15 of the FCC rules. While these devices

are verified as Class A devices, they have been

shown to meet the Class B limits. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses, and

can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of

the equipment in a residential area is likely to

cause harmful interference in which case the

user will be required to correct the interference

at his own expense.

If necessary, the user should consult the dealer

or an experienced radio and television technician for additional suggestions.

The user may find the booklet “How to Identify and Resolve Radio-TV Interference Problems” helpful. It is prepared by the Federal

Communications Commission and is available

from the U.S. Government Printing Office,

Washington, DC 20402, Stock No. 004-00000345-4.

2.2 Caster/Leg Installation

Do not attempt to use the equipment

during a power outage.

FCC COMPLIANCE

The user is cautioned that any changes or

modifications to Frymaster computers not expressly approved by the party responsible for

compliance could void the user’s authority to

operate the equipment. Frymaster computers

have been tested and found to comply with the

Depending upon the specific configuration

ordered, your fryer may have been shipped

without installed casters or legs. If casters or

legs are installed, you may skip this section

and proceed to Section 2.3, Pre-Connection

Preparations.

If your fryer requires the installation of

casters/legs, install them in accordance with

the instructions inclu ded in your accessory

package.

2-2

45 SERIES GAS FRYERS

CHAPTER 2: INSTALLATION INSTRUCTIONS

2.3 Pre-Connection Preparations

DANGER

Do not connect fryer to gas supply

before completing each step

in this section.

After the fryer has been positioned under the

fry station exhaust hood, ensure the following

has been accomplished:

1. Adequate means must be provided to limit

the movement of fryers without depending

upon the gas line connections. If a flexible

gas hose is used, a restraining cable must

be connected at all times when the fryer is

in use. The restraining cable and installation instructions are packed with the flexible hose in the accessories box that was

shipped with your unit.

4. Test the fryer electrical system:

a. Plug the fryer electrical cord(s) into a

grounded electrical receptacle.

b. Place the power switch in the ON

position.

• For fryers equipped with thermo-

stat controls, verify that the power

and heat lights are lit.

• For fryers having computer or

digital displays, verify that the display indicates CYCL.

c. Place the fryer power switch in the

OFF position. Verify that the power

and heat lights are out, or that the display is blank.

2. Single unit fryers must be stabilized by

installing restraining chains on fryers

equipped with casters or anchor straps on

fryers equipped with legs. Follow the instructions shipped with the casters/legs to

properly install the chains or straps.

3. Level fryers equipped with legs by screwing out the legs approximately 1 inch then

adjusting them so that the fryer is level and

at the proper height in the exhaust hood.

Frymaster recommends that the minimum

distance from the flue outlet to the bottom

edge of the filter be 24 in. (600 mm) when

the appliance consumes more than 120,000

BTU per hour.

For fryers equipped with casters, there are

no built-in leveling devices. The floor

where the fryer is to be installed must be

level.

5. Refer to the data plate on the inside of the

fryer door to determine if the fryer burner

is configured for the proper type of gas before connecting the fryer quick-disconnect

device or piping from the gas supply line.

6. Verify the minimum and maximum gas

supply pressures for the type of gas to be

used in accordance with the accompanying

tables.

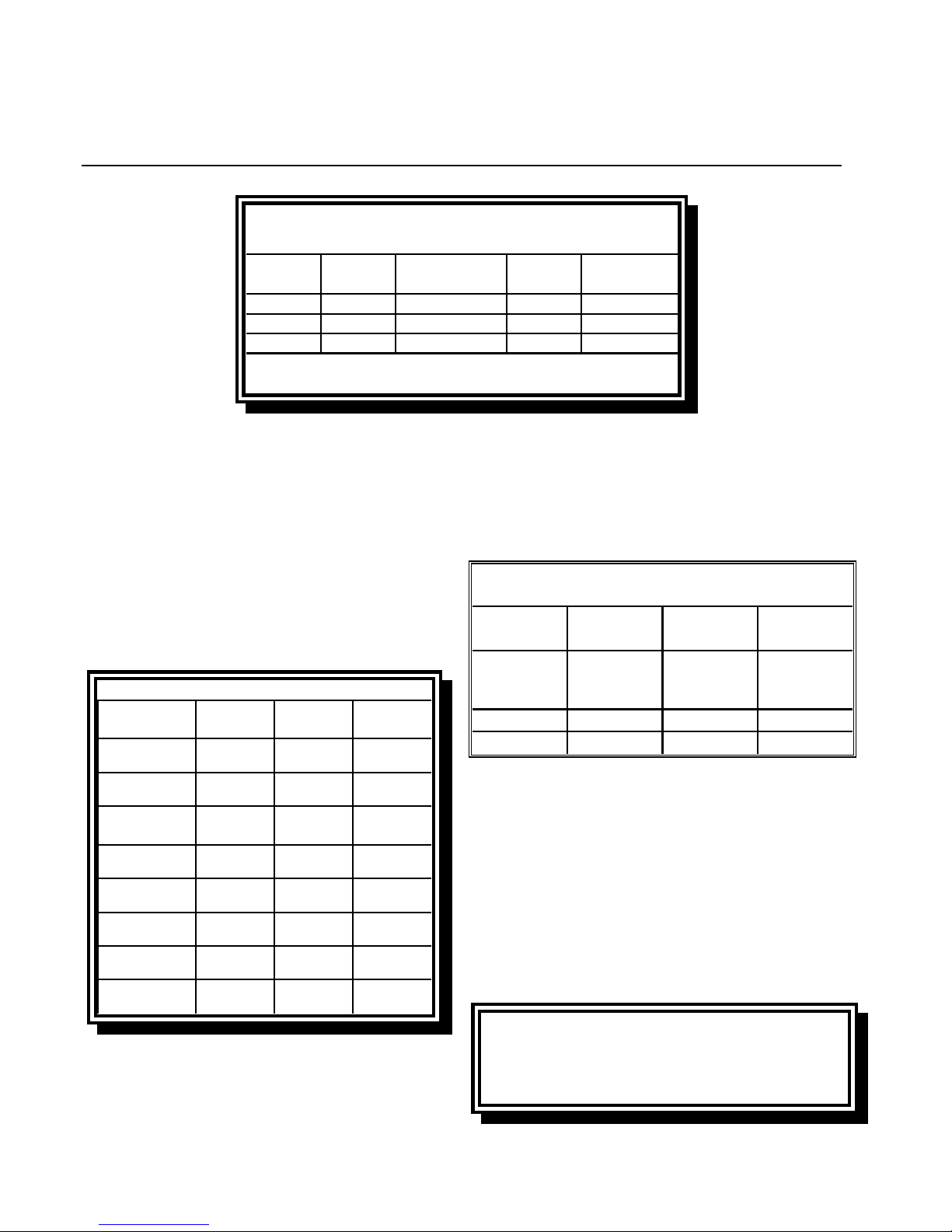

Non-CE Standard

for Incoming Gas Pressures

Gas Minimum Maximum

Natural

LP

6" W.C.

1.49 kPa

14.93 mbar

11" W.C.

2.74 kPa

27.37 mbar

14" W.C.

3.48 kPa

34.84 mbar

14" W.C.

3.48 kPa

34.84 mbar

2-3

45 SERIES GAS FRYERS

d

O

CHAPTER 2: INSTALLATION INSTRUCTIONS

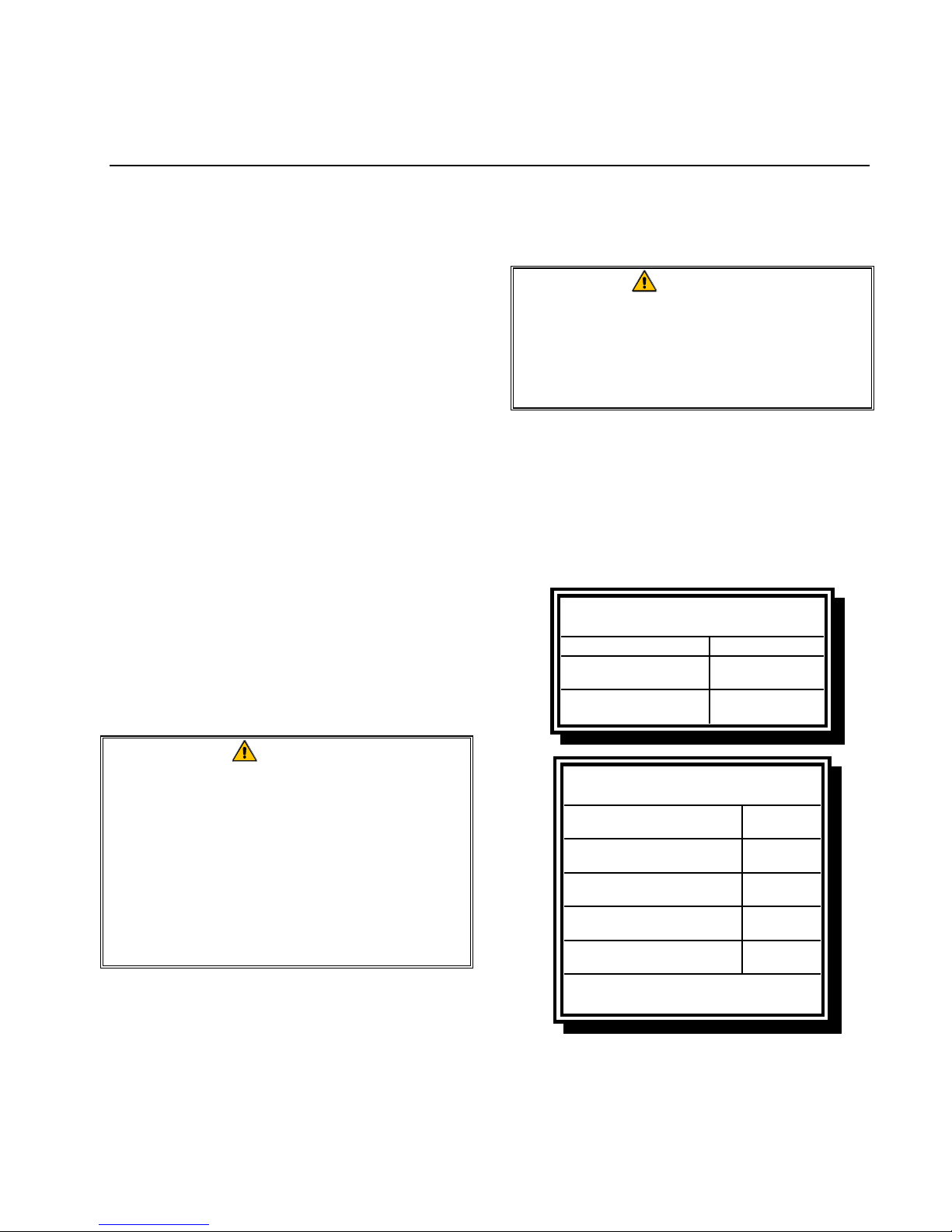

CE Standar

for Incoming G as Pressure s

Pressure

Gas

G20 20 18 x 1,40 mm 7,5 mbar

G25 20 - 25 18 x 1,40 mm 10 mbar

G31 37 - 50 18 x 0,86 mm 20,6 mbar

(mbar )

(1)

Regulator

Pressure ConsumptionOrifice Diameter

3

3,00 m

3

3,50 m

2,21 kg/h

/h

/h

(1) mbar = 10,2 m m H

2

7. For fryers equipped with a Filter Magic II

system and/or basket lifts, plug the electrical cord(s) into a power receptacle behind

the fryer.

2.4 Connection to Gas Line

The 45 Series fryer has received the CE mark

for the countries and gas categories indicated

in the accompanying table.

CE Approved Gas Categories

Pressure

Country Category Gas

BE

DE

DK-GR-IT

I2E+(S)

I3P

I2 ELL

13P

I2 H G20 20

G20/G25

G31

G20/G25

G31

(mbar)

20/25

37

20

50

This may cause slow recovery and delayed

ignition. The incoming gas supply line should

be a minimum of 1½” (38 mm) in diameter.

Refer to the chart below for the minimum

sizes of connection piping.

Gas Connection Pipe Sizes

(Minimum incoming pipe size should be 1 1/2" (38 mm))

4 or more

Gas Single Unit 2 - 3 Units

Natural

Propane 1/2" (13 mm) 3/4" (19 mm) 1" (25 mm)

Manufactured 1" (25 mm) 1 1/4" (33 mm) 1 1 /2" (38 mm)

3/4

" (19 mm) 1" (25 mm)

* For distances of more than 20 feet (6 m ) and/or

more than 4 fittings or elbows, increase the connection by one pipe size.

units*

Use two 1"

(25mm)

connections

FR

LU

ES

NL

IE-PT-GB

II2Esi3P

I2E G20/G25 20/25

II2H3P

II2L3P

II2H3P

G20/G25

G31

G20

G31

G25

G31

G20

G31

The size of the gas line used for installation is

very important. If the line is too small, the gas

pressure at the burner manifold will be low.

20/25

37 ET 50

20

37 ET 50

25

50

20

37

Before connecting new pipe to your unit, the

pipe must be thoroughly blown out to remove

any foreign particles. If these foreign particles

get into the burner and controls, they will

cause improper and sometimes dangerous operation.

CE Standard

CE regulations require a combustion air supply of 2m3/h per kW per fryer. (See rating

plate affixed to door for kW rating.)

2-4

45 SERIES GAS FRYERS

CHAPTER 2: INSTALLATION INSTRUCTIONS

1. Connect the quick-disconnect hose to the

fryer quick-disconnect fitting under the

front of the fryer and to the building gas

line.

NOTE: Some fryers are configured for a

rigid connection to the gas supply line.

These units are connected to the gas supply line at the rear of the unit.

When using thread compound, use very

small amounts on male threads only. Use

a pipe thread compound that is not affected by the chemical action of LP gases

(Loctite™ PST56765 Sealant is one such

compound). DO NOT apply compound to

the first two threads. This will ensure that

the burner orifices and control valve do

not become clogged.

2. Open the gas supply to the fryer and check

all piping, fittings, and gas connections for

leaks. A soap and water solution should

be used for this purpose.

the “Lighting Instructions” and “Boiling

Out the Frypot” topics found in Chapter 3

of this manual.

WARNING

“Dry-firing” your unit will cause

damage to the frypot. Always ensure

that melted shortening, cooking oil, or

water and boil-out solution is in the

frypot before firing your unit.

4. It is suggested that the burner manifold

pressure be checked at this time by the local gas company or an authorized service

agent. Refer to “Check Burner Manifold

Pressure” in Chapter 5 of this manual for

the proper procedure.

Non-CE Standard

Burner Manifold Gas Pressures

Gas Pressure

Natural

LP

3.5" W.C.

0.87 kPa

8.25" W.C.

2.05 kPa

DANGER

Never use matches, candles, or any

other ignition source to check for

leaks.

If gas odors are detected, shut off the

gas supply to the fryer at the main

shut-off valve and contact the local gas

company or an authorized service

agency for service.

3. Close the fryer drain valve and fill the fry-

pot with water and boil-out solution to the

bottom OIL-LEVEL line at the rear of the

frypot. Light the fryer and perform the

boil-out procedures that are described in

CE Standard

Burner Manifold Gas Pressures

Gas

Natural Gas Lacq

(G20) under 20 mbar

Natural Gas Gronique *

(G25) under 25 mbar

Natural Gas Gronique

(G20) under 20 mbar

Propane

(G31) under 37 or 50 mbar

* Belgian G25 = 7,0 mbar

Pressure

(mbar)

7,5

10

10

20,6

5. Check the thermostat calibration or tem-

perature programmed into the computer.

2-5

45 SERIES GAS FRYERS

CHAPTER 2: INSTALLATION INSTRUCTIONS

• For units equipped with thermostat

controls, refer to the Thermostat Calibration instructions in Chapter 7.

• For units equipped with other types of

controllers, refer to the Set Point programming instructions in Chapter 3.

2.5 Converting to Another Gas Type

Your fryer is configured at the factory for either natural gas or Propane (LP) gas.

If you desire to switch from one type of gas to

another, a gas conversion kit must be installed by a Factory Authorized Service

Center technician.

CE Gas Conversion Instructions

1. Between G20- and G25-type Natural Gas,

adjust the gas pressure at the regulator.

(Refer to the CE Standard Burner Manifold Gas Pressure Chart.) Do not change

the orifice or pilot.

2. Between a 2nd family gas (G20 or G25)

and a 3rd family gas (G31 Propane):

a. Change the orifices.

b. Change the pilot.

c. Change the gas valve regulator.

d. Adjust the manifold pressure.

DANGER

Switching to a different type of gas

without installing the proper

conversion kit may result in fire or

explosion!

NEVER ATTACH YOUR FRYER TO A

GAS SUPPLY FOR WHICH IT IS NOT

CONFIGURED!

Non-CE Gas Conversion Instructions

Call

Frymaster

Frymaster

FrymasterFrymaster

Service (1-800-551-8633) to

determine the conversion kit appropriate for

your configuration and altitude. Contact your

local FASC to order the kit and arrange for

installation.

3. Remove the rating plate and install a new

one. Call your local service agency or

KES for a new rating plate.

4. If the destination language changes, re-

place the labels. Call you local service

agency of kitchen equipment supplier for a

label kit. The language of reference will

be on the corner of the label.

The following gas-conversion components and

kits are available from your FASC:

Propane (G31) to Natural (G20/G25)

Regulator only: P/N 810-1288

Pilot, regulator, and orifices kit: P/N 826-1201

Natural (G20/G25) to Propane (G31)

Regulator only: P/N 810-1292

Pilot, regulator, and orifices kit: P/N 826-1200

2-6

45 SERIES GAS FRYERS

CHAPTER 3: OPERATING INSTRUCTIONS

3.1 Start-Up Procedure

CAUTION

If this is the first time the fryer is being

used after installation, refer to Section

3.2, Boil-Out Procedure.

Knob is shown in

OFF position.

CAUTION

The cooking oil/shortening capacity of

the 45 Series fryer is 50 lbs (25 liters)

at 70ºF (21ºC).

Before lighting the fryer, make sure the

fryer is OFF and the frypot drain valve

is closed. Remove the basket support

rack, if installed, and fill the frypot to

the bottom OIL-LEVEL line.

To prevent scorching, if solid

shortening is being used, make sure it

is tightly packed down into the bottom

of the frypot.

Non-CE Standard

Units configured to Non-CE standards are

equipped with Robertshaw valves.

Note index mark.

3. Place a flame near the pilot assembly, push

and hold the knob in, light the pilot, and

continue to depress the knob for at least 60

seconds after the pilot lights. Failure to

hold the knob in long enough will cause

the pilot to go out when the knob is released. If the pilot goes out when the knob

is released, wait at least 5 minutes then repeat this step.

4. Turn the gas valve knob to the ON position.

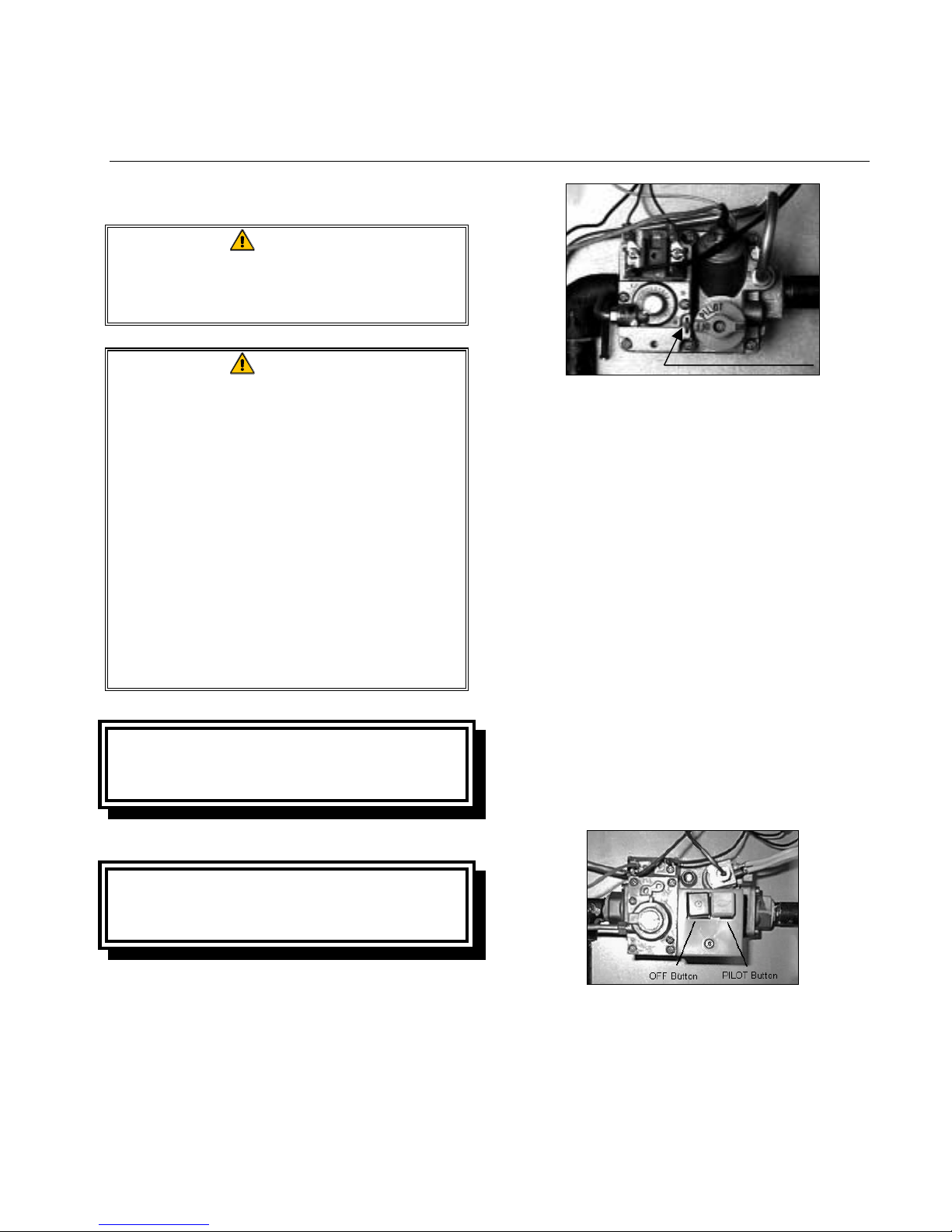

Lighting the Pilot on Honeywell Valves:

1. Ensure power to the unit is OFF.

2. Press the OFF (red) button. Wait 5 minutes.

CE Standard

Units configured to CE standards are

equipped with Honeywell valves.

Lighting the Pilot on Robertshaw Valves:

1. Ensure power to the unit is OFF.

2. Turn the gas valve knob to the OFF position. Wait 5 minutes, then turn the knob

to the PILOT position.

3. Place a flame near the pilot assembly, push

and hold the PILOT (white) button in,

light the pilot, and continue to depress the

button for at least 60 seconds after the

pilot lights. Failure to hold the button in

long enough will cause the pilot to go out

3-1

Loading...

Loading...