Page 1

FilterQuick™

Controller

Operation Manual

This manual is updated as new information and models are released. Visit our website for the latest manual.

*8197050*

Part Number: FRY-IOM-8197050 2/15

OriginalInstructions

Page 2

NOTICE

IF, DURING THE WARRANTY PERIOD, THE CUSTOMER USES A PART FOR THIS MANITOWOC

FOOD SERVICE EQUIPMENT OTHER THAN AN UNMODIFIED NEW OR RECYCLED PART

PURCHASED DIRECTLY FROM FRYMASTER, OR ANY OF ITS AUTHORIZED SERVICE

CENTERS, AND/OR THE PART BEING USED IS MODIFIED FROM ITS ORIGINAL

CONFIGURATION, THIS WARRANTY WILL BE VOID. FURTHER, FRYMASTER AND ITS

AFFILIATES WILL NOT BE LIABLE FOR ANY CLAIMS, DAMAGES OR EXP ENSES INCUR RED B Y

THE CUSTOMER WHICH ARISE DIRECTLY OR INDIRECTLY, IN WHOLE OR IN PART, DUE TO

THE INSTALLATION OF ANY MODIFIED PART AND/OR PART RECEIVED FROM AN

UNAUTHORIZED SERVICE CENTER.

NOTICE

This appliance is intended for professional use only and is to be operated by qualified

personnel only. A Frymaster Factory Authorized Servicer (FAS) or other qualified professional

should perform installation, maintenance, and repairs. Installation, maintenance, or repairs by

unqualified personnel may void the manufacturer’s warranty.

NOTICE

This equipment must be installed in accordance with the appropriate national and local codes of

the country and/or region in which the appliance is installed.

NOTICE TO OWNERS OF UNITS EQUIPPED WITH CONTROLLERS

U.S.

This device complies with Part 15 of the FCC rules. Operation is subject to the following two

conditions: 1) This device may not cause harmful interference, and 2) This device must accept

any interference received, including interference that may cause undesired operation. While

this device is a verified Class A device, it has been shown to meet the Class B limits.

CANADA

This digital apparatus does not exceed the Class A or B limits for radio noise emissions as set

out by the ICES-003 standard of the Canadian Department of Communications.

Cet appareil numerique n’emet pas de bruits radioelectriques depassany les limites de classe A

et B prescrites dans la norme NMB-003 edictee par le Ministre des Communcations du Canada.

DANGER

Prior to movement, testing, maintenance and any repair on your Frymaster fryer, disconnect

ALL electrical power from the fryer.

NOTICE

The instructions in this manual for using a bulk oil system for filling and discarding oil are for a

Frontline or RTI systems. These instructions may not be applicable to other bulk oil systems.

DANGER

Keep all items out of drains. Closing actuators may cause damage or injury.

DANGER

Remove all drops of water from the frypot before filling with oil. Failure to do so will cause spattering of

hot liquid when the oil is heated to cooking temperature.

Page 3

WARNING

Do not add HOT or USED oil to a JIB.

WARNING

NEVER drain boil-out solution into an SDU. Boil-out solution can cause damage to an SDU and void the

warranty.

DANGER

When draining oil into a disposal unit, do not fill above the maximum fill line located on the container.

DANGER

Allow oil to cool to 100°F (38°C) before draining into an appropriate METAL container for disposal.

DANGER

When draining oil into an appropriate SDU or METAL container, ensure the container will hold at least

FOUR gallons (15 liters) or more. Otherwise oil could overflow and can cause injury.

DANGER

When draining boil out solution oil into an appropriate METAL container, ensure the container will hold at

least FOUR gallons (15 liters) or more. Otherwise boil out solution could overflow and can cause injury.

DANGER

Open the filter pan slowly to avoid splashing of hot oil that may cause severe burns, slipping and falling.

DANGER

Ensure that the frypot and filter pan are completely dry and free of water before filling with oil. Failure to

do so will cause splattering of hot liquid when the oil is heated to cooking temperature.

WARNING

The on-site supervisor is responsible for ensuring that operators are made aware of the inherent hazards of

operating a hot oil filtering system, particularly the aspects of oil filtration, draining and cleaning

procedures.

DANGER

Do not drain more than one frypot at a time into the built-in filtration unit to avoid overflow and spillage of

hot oil that may cause severe burns, slipping and falling.

WARNING

Never drain water into the filter pan. Water will damage the filter pump

WARNING

Ensure a filter paper/pad is in place prior to filtering, draining or disposing of oil. Failure to insert a filter

paper/pad may result in clogged lines and/or pumps.

DANGER

DO NOT drain more than one full frypot or two split frypots into the SDU at one time to avoid overflow and

spillage of hot oil that may cause severe burns, slipping and falling.

Page 4

WARNING

Never operate the filter system without oil in the system.

WARNING

Never use the filter pan to transport old oil to the disposal area.

WARNING

Never leave the fryer unattended during the boil out process. If the solution overflows, press the ON/OFF

switch to the OFF position immediately.

Page 5

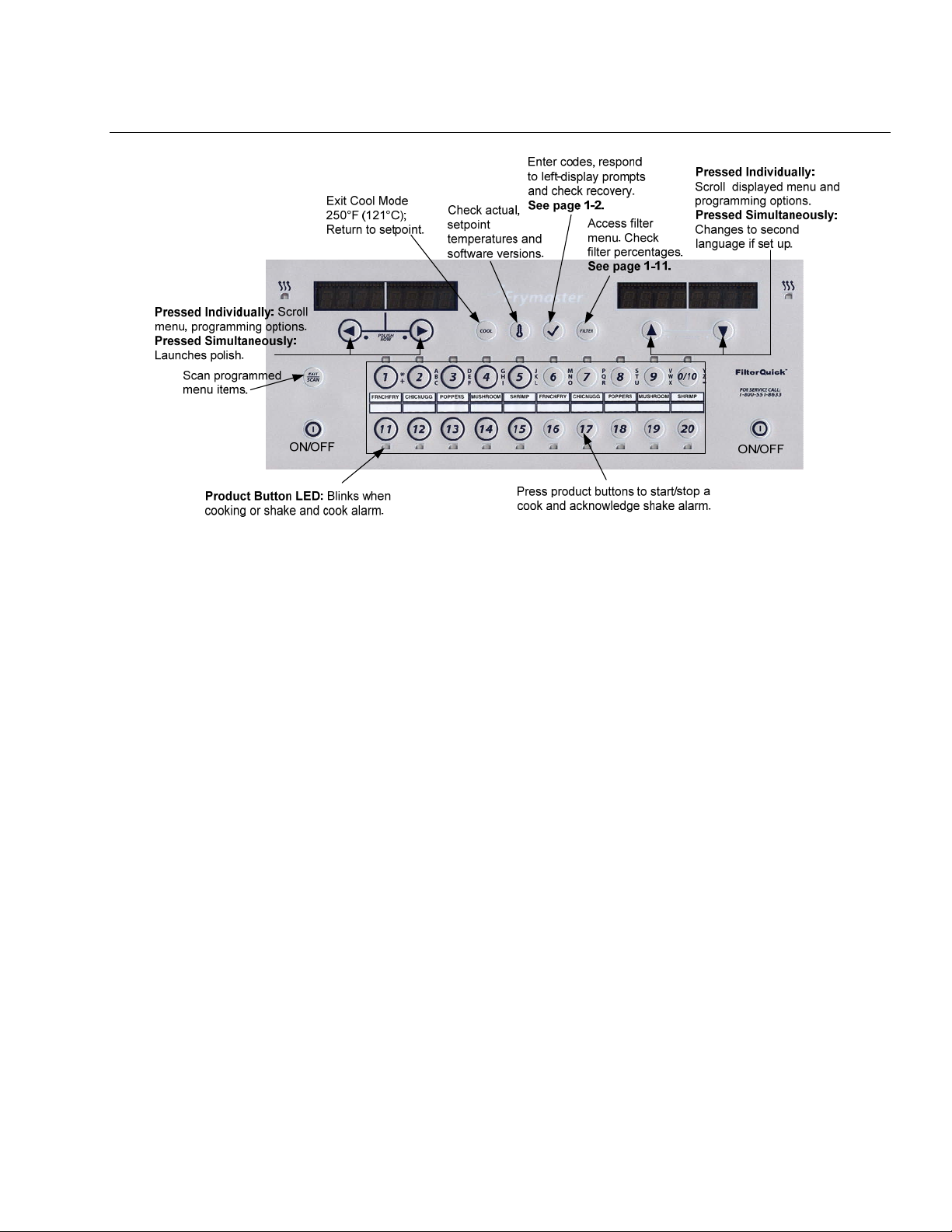

CHAPTER 1: FILTERQUICK™ CONTROLLER INSTRUCTIONS

1.1 Using the FilterQuick™ Controller

ON/OFF

Press ON/OFF button. Fryer begins melt cycle to slowly heat solid shortening to programmed temperature before s witching to full

temperature and heating to setpoint or idle temperature and displays: READY.

Exit melt cycle, when using liquid oil, by pressing and releasing the E xit Co ol button or any programmed product button. Displays Exit

Melt? on left and YES NO on the right. Press (YES) arrow to exit.

Cooking

COOL displayed: Press product button or Exit Cool; fryer heats to setpoint and displays READY.

READY displayed: Press product button and drop product.

----- displayed: The vat temperature is out of the Ready zone.

DONE displayed: Press blinking product button to cancel alarm and end a cook.

HOLD displayed: Press blinking product button to cancel hold alarm.

Cancel a Cook: Press and hold blinking product button to cancel cook cycle.

Change Cook Temperature: Press and hold a product button with the desired different cooking temperature for 3 seconds. An audible will

confirm that the temperature has changed. Press the product button again to start a cook at the new temperature.

NOTE: When a product button with a setpoint different than a currently cooking product is pressed, a low tone is heard indicating the new

cook won’t start until the cook is finished and the cook temperature is changed.

Controller Button Navigation

Product: Press to start a cook cycle. Active when adjacent LED is lit. LED flashes during a cook cycle. Press and hold to cancel a cook

cycle. Press at end of cook cycle to cancel an alarm. Press and hold a product with different setpoint to change setpoint temperature.

Exit/ Scan: Press once; all product buttons are lit. Select Product displayed. Press product button to view product name. Press to

advance through all product parameters. Press Exit Scan again to repeat. Press Exit Scan twice to escape.

Left/Right Arrows: Navigate options in left display. Press both simultaneously to start a polish cycle.

Up/Down Arrows: Navigate options in right display. Press both simultaneously to change to a second language if one is selected in

setup.

Exit Cool: Exits cool mode, returns fryer to setpoint temperature.

Thermometer: Fryer ON: Press and release for setpoint in left display and vat temperature in right display.

Thermometer: Fryer OFF: Press to display temperature, time, date, system version, controller and circuit board software versions.

Thermometer: Fryer OFF: Press and hold. Will display AIF/ATO Temp

Checkmark: Fryer OFF: Press to check recovery; Press and hold 3 seconds: Scroll filter usage; Press and hold 10 seconds: Product

setup.

Checkmark: Fryer ON: Press to check recovery; Enter Codes and Respond to left display prompts.

Filter: Press and release: Displays total percentage of products cooked and cooks remaining to filter cycle. Press and hold: Filter

options: Filter, Clean and Filter, Dispose, Drain to Pan, Fill from Pan, Boil Out, Fill Vat from Bulk (Bulk only) and Pan to Waste (Bulk

only).

1-1

Page 6

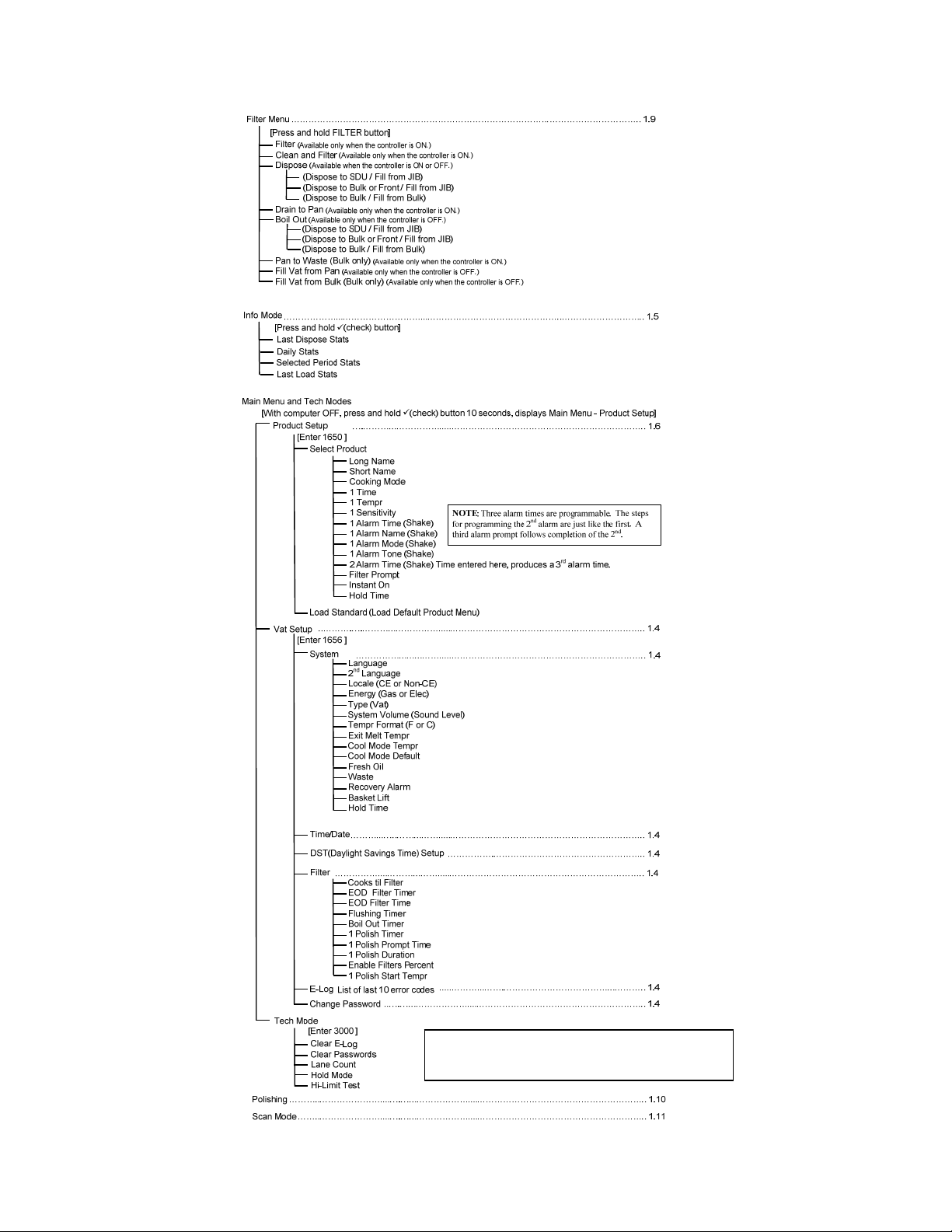

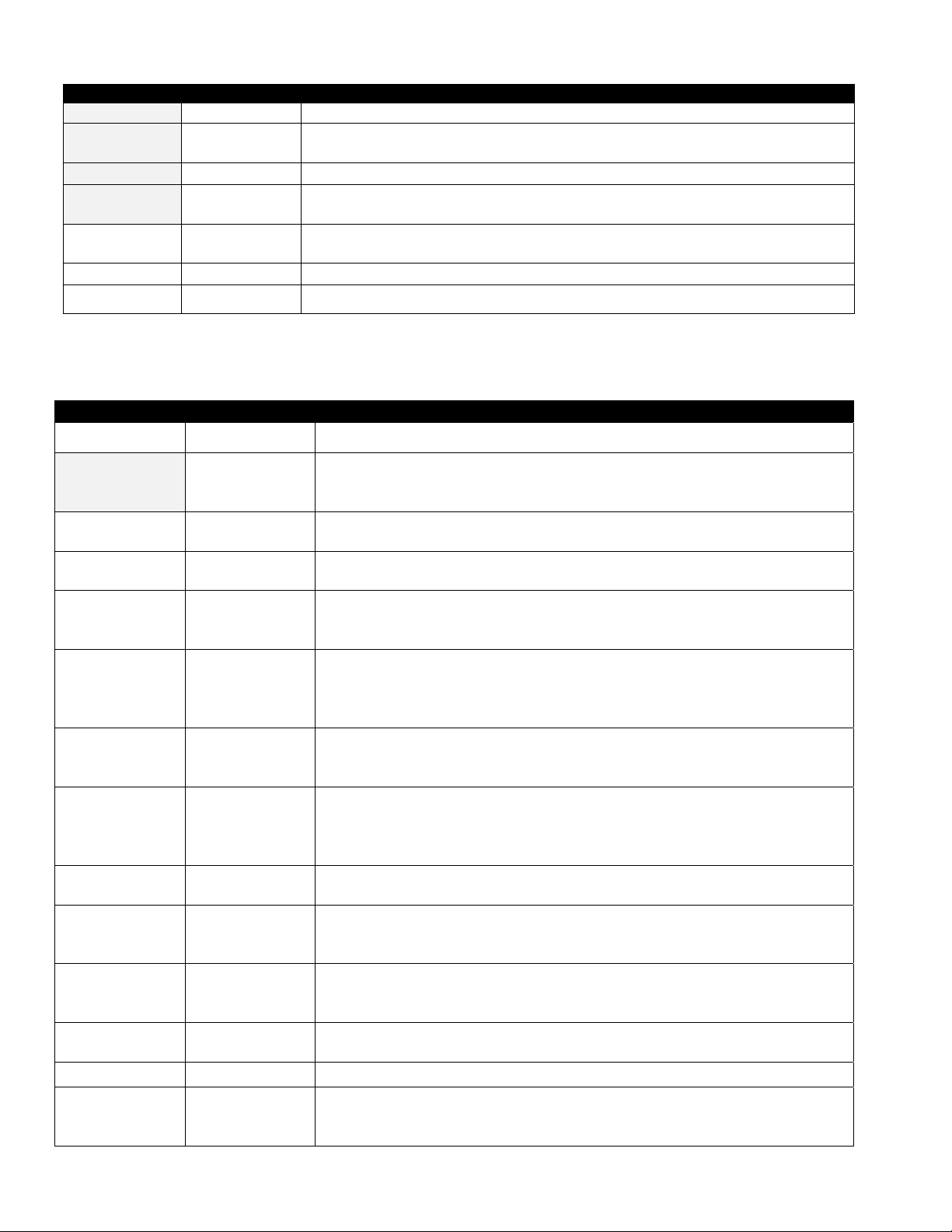

1.2FilterQuick™ControllerMenuSetupTree

NOTE: If the lane count doesn’t change,

set the basket lift to disabled in Vat Setup.

1-2

Page 7

1.3 Setup: Main Menu

Pressing and holding the checkmark key for 10 seconds produces the setup mode, which first displays Product Setup. Turn

the controller off and follow the steps below to navigate the options.

Left Display Right Display Action

OFF OFF

Product Setup

Start with the far left controller. Press until the controller scrolls INFO MODE,

changing to MAIN MENU and then PRODUCT SETUP.

Press to scroll to Product Setup, Vat Setup, Tech Mode, and Exit. With the desired

selection displayed, press .

Product Setup Used to program menu items and cooking parameters.

vat setup Vat set up is described below in section 1.4.

Tech Mode Tech mode is used to enable and disable Cooks and Filters options.

Exit Exit Press Exit/Scan button to return the controller to OFF.

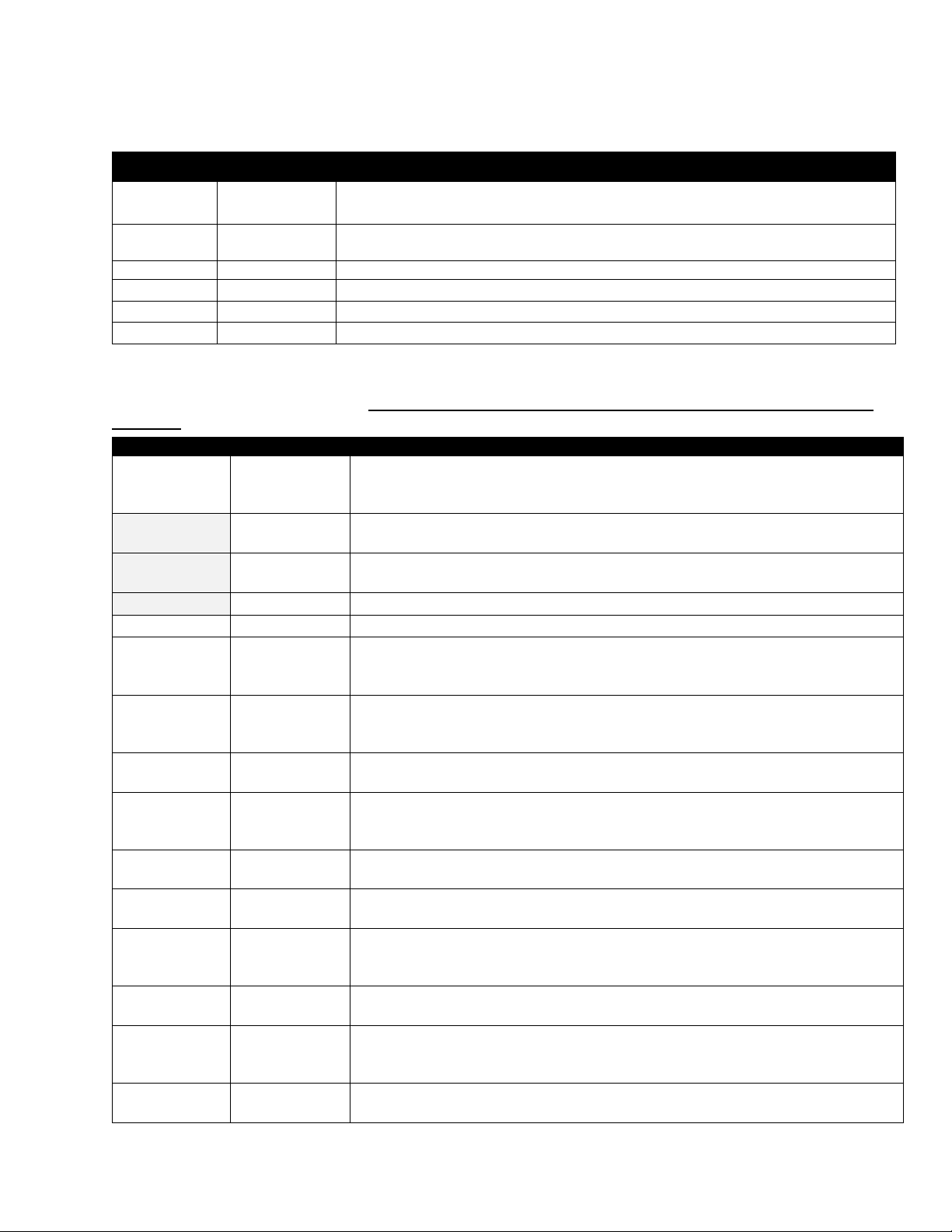

1.4 Vat Setup

Vat Setup mode allows the controller to be set for language displays, vat sizes, and temperature range displays. With the

controller OFF, follow the steps below. *NOTE: Most of the system choices are only available on the far left (Master)

controller.

Left Display Right Display Action

Start with the far LEFT controller on an OCF fryer, any controller on a legacy model.

OFF OFF

Press until the controller scrolls Info Mode, changing to Main and then PRODUCT

SETUP.

PRODUCT

SETUP

VAT SETUP

Enter

code

SYSTEM

Language English

2nd

language

SPANISH

Press to scroll to Vat setup and press .

Enter 1656.

Press .

Press to scroll to choice and press .

Press to scroll to choice and press . (This option allows another language to

be toggled from the front panel. (ex. Spanish as a second language.) Default is

Spanish.

Press to scroll to choices: CE (European Conformity standards), or Non-CE

Locale Non-CE

(non-European standards) and press . This option is available only on the far left

controller.

Energy Gas

Press to scroll to choices: Gas or Electric and press . This option is available

only on the far left controller.

Press to scroll choices: Gas- GL30 Full, GL30 Split, GL30 OSP Full, GL30

Type GL30 Full

OSP Split Electric- EL30-14 Full, EL30-14 Split, EL30-17 Full, EL30-17 Split.

With the current fryer vat type displayed, press .

SYSTEM

volume

Tempr

format

Exit Melt

Tempr

COOL MODE

TEMPR

COOL MODE

DEFAULT

FRESH OIL JIB

5

F

180º

(82 ºC)

250F (121

ºC)

0

Sets sound level for controller. Enter level, 1-9 (1=Lowest/ 9=Loudest). Press .

Press to scroll choices: F for Fahrenheit; C for Celsius. Press .

Use numbered keys to change default setting. Press . (This is the temperature for

the fryer to exit the melt cycle.) Range is 100°F (38°C) to 200°F (93°C). Default is

180°F (82°C).

Use numbered keys to change default setting. Press . (This is the temperature

during setback or idle mode.) Default is 250°F (121°C).

Use numbered keys to change default setting. (This is the amount of minutes the

fryers sits idle before going to cool mode. The default, 0, disables the feature.) Press

.

Press to scroll choices JIB or Bulk. Default is JIB. Press . This option is

available only on the far left controller.

1-3

Page 8

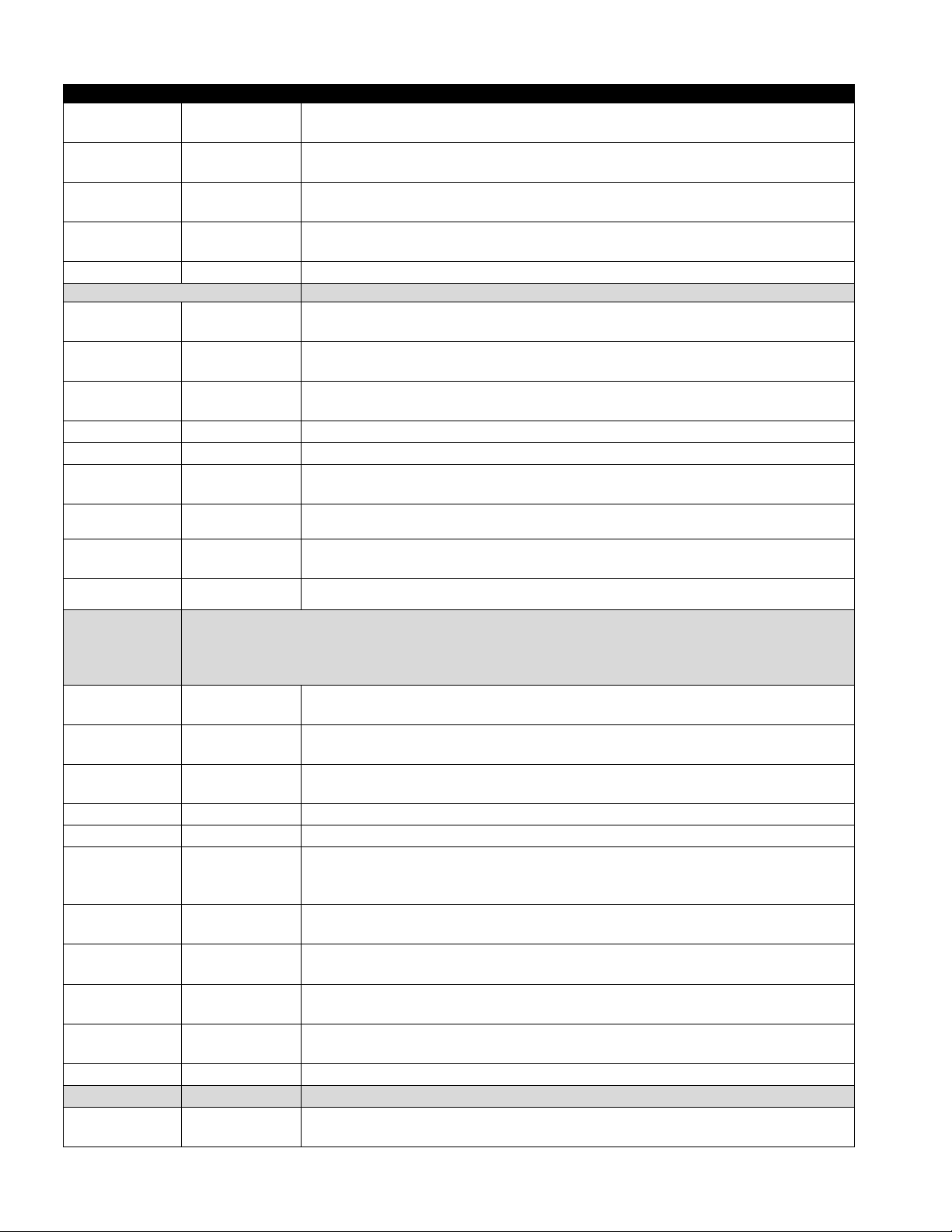

Left Display Right Display Action

WASTE SDU

RECOVERY

ALARM

BASKET

LIFT

DISABLED

DISABLED

HOLD TIME AUTO

Exit Exit

Press to scroll choices SDU, BULK or FRONT. Default is SDU. Press . This

option is available only on the far left controller.

Press to scroll choices DISABLED and ENABLED. Press . (This is a

recovery alarm that locks out the fryer if it does not heat properly. Default is disabled.

Press to scroll choices DISABLED and ENABLED. Press . Default is

disabled.

Press to scroll choices AUTO and MANUAL. Press . (This is the hold timer

cancel alarm.) If set to auto, the alarm will auto cancel. Default is auto.

Press button once to return the controller to OFF.

Time/date Programming

OFF OFF

PRODUCT

SETUP

VAT SETUP

Enter

code

SYSTEM

TIME/DATE

TIME

ENTRY

DATE

FORMAT

ENTER

DATE

Time

Mm/dd/yy

date

EXIT Exit

Press until the controller scrolls INFO MODE, changing to MAIN and then

PRODUCT SETUP.

Press to scroll to Vat setup and press .

Enter 1656.

Press to scroll to TIME/DATE.

Press .

Use numbered keys to change time. Enter the time in 24 hour format. Press .

Press to scroll choices. With the desired date format displayed, press .

Use numbered keys to change date. Press .

Press the Exit/Scan button three times to return the controller to OFF.

This is daylight savings time setup. In the United States, daylight saving time begins at 2:00 A.M. on the

DST SETUP

second Sunday in March. Clocks move ahead one hour. Daylight saving time ends at 2:00 A.M. on the

first Sunday in November. Clocks move back one hour. For the two U.S. states and international

locations that do not use DST, set to disabled.

OFF OFF

PRODUCT

SETUP

VAT SETUP

Enter

code

SYSTEM

DST SETUP

Press until the controller displays INFO MODE, changing to MAIN and then

PRODUCT SETUP.

Press to scroll to Vat setup and press .

Enter 1656.

Press to scroll to DST Setup.

Press

Press to scroll choices DISABLED and ENABLED. Press . (Default is

DST Enabled

enabled.) If disabled is chosen, pressing the button, displays exit. Press the exit

scan button three times to exit.

DST START

MONTH

DST START

SUNDAY

DST END

MONTH

DST END

SUNDAY

3

2

11

1

EXIT Exit

Filter

OFF OFF

Enter the daylight savings time starting month using the 1-10 keys. (Default is US

starting month: 3.) Press .

Enter the daylight savings time starting Sunday using the 1-10 keys. (Default is US

starting Sunday 2.) Press .

Enter the daylight savings time ending month using the 1-10 keys. (Default is US

ending month 11.) Press .

Enter the daylight savings time ending Sunday using the 1-10 keys. (Default is US

ending Sunday 1.) Press .

Press the Exit/Scan button three times to return the controller to OFF.

Press until the controller scrolls INFO MODE, changing to MAIN and then

PRODUCT SETUP.

1-4

Page 9

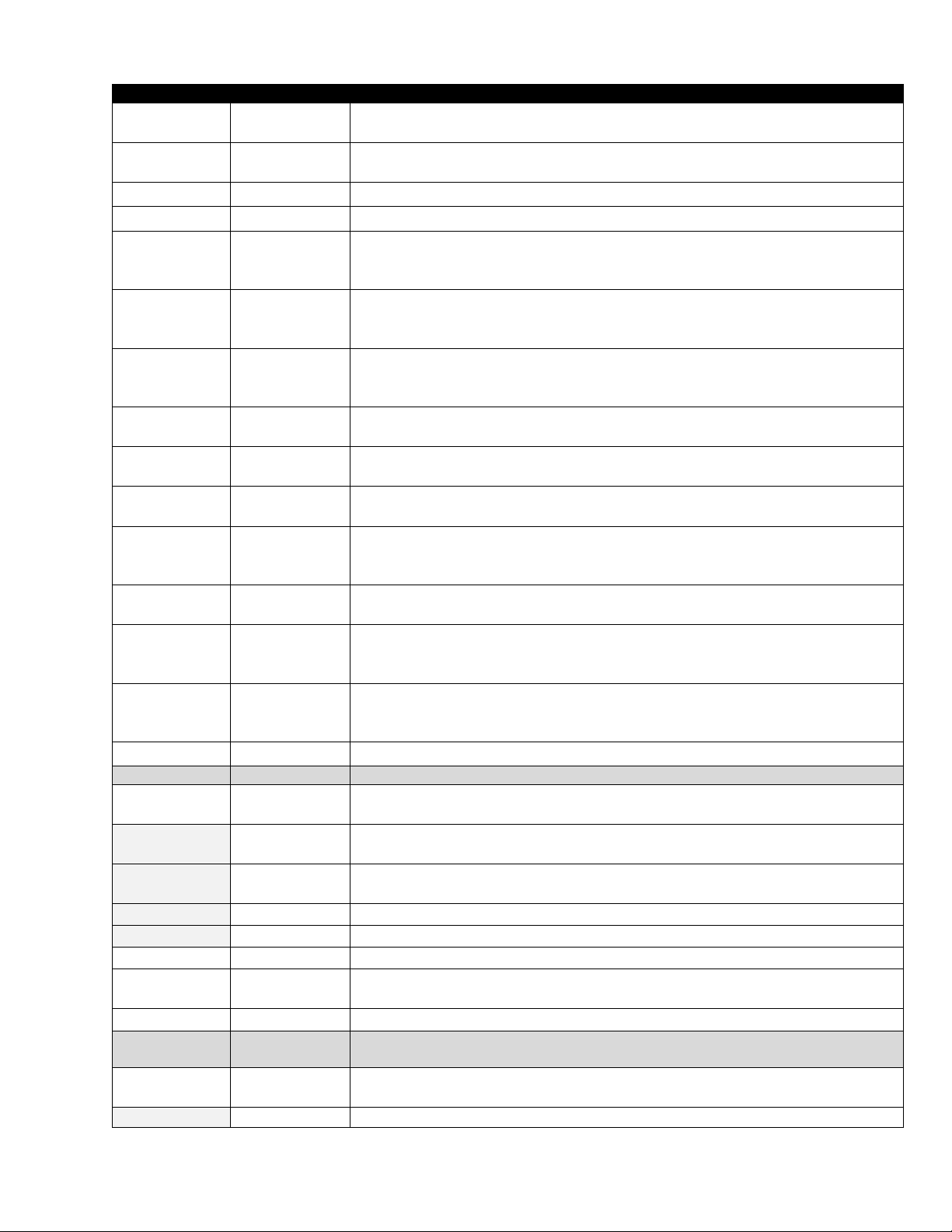

Left Display Right Display Action

PRODUCT

SETUP

VAT SETUP

Enter

code

SYSTEM

FILTER

Press to scroll to Vat setup and press .

Enter 1656.

Press to scroll to FILTER.

Press .

Cooks

till

Filter

0

(This is the total number of cooks that occur before a filter prompt. The default is 0.)

Enter the number of cooks before a filter prompt is desired. Press .

EOD

FILTER

DISABLED

Press to scroll to choice enable or disable and press . Default is DISABLED)

TIMER

EOD

filter

time

FLUSHING

TIMER

Boil out

timer

1 polish

TIMER

23:59

5

30

DISABLED

Use numbered keys to program end of day filter alert time. Enter time in 24 hour

format. After this time, the controller prompts for filter when user presses the power

button to go to OFF. Enter 23:59 if no end of day filter prompt is desired. Press .

Use numbered keys to change default setting for the flushing timer. Enter the time in

minutes. Default is five minutes. Press .

Use numbered keys to change default setting for the boil out timer. Enter the time in

minutes. Default is 30 minutes. Press .

Press to scroll to choice enable or disable and press . Default is

DISABLED). Press .

1 polish

prompt

time

1 polish

duration

23:59

15

Use numbered keys to enter polish prompt time. (This is the time the polish prompt

will occur each day.) 23:59 is disabled. Enter time in 24 hour format. Press .

Use numbered keys to change. (This is the duration, in minutes for a polish.) Default

is 15 minutes. Press .

ENABLE

FILTERS

NO

PERCENT

1 polish

start

TEMPR

(300F)

(149°C)

Exit Exit

Press to scroll to choice YES or NO and press . Default is NO. Press . This

is the total percentage of products cooked and cooks remaining to filter cycle.

Use numbered buttons to change temperature. (This is the minimum temperature

required for a polish to begin.) Default is 300F (149C). Press .

Press the Exit/Scan button once to return the controller to OFF.

E-LOG

OFF OFF

PRODUCT

SETUP

VAT SETUP

Enter

code

SYSTEM

E-LOG

NOW Time/date

A

E

Time/date

Exit Exit

Press until the controller scrolls INFO MODE, changing to MAIN and then

PRODUCT SETUP.

Press to scroll to Vat Setup. Press .

Enter 1656.

Press to scroll to E-LOG.

Press . (This is a log of the ten most recent error codes.)

Press . (Current time and date)

Errors listed A-J. Press to scroll through errors. Error codes are listed on page 2-4.

If no errors exist, pressing will display No errors. Press .

Press the Exit/Scan button three times to return the controller to OFF.

Change

password

OFF OFF

PRODUCT

Press until the controller scrolls INFO MODE, changing to MAIN and then

PRODUCT SETUP.

Press to scroll to Vat Setup. Press .

1-5

Page 10

Left Display Right Display Action

SETUP

VAT SETUP

SYSTEM

CHANGE

PASSWORD

Product

setup

Vat setup 1656

Exit Exit

Enter

code

1650

Enter 1656.

Press to scroll to Change Password.

Press .

Use numbered keys to change code. Press .

Use numbered keys to change code. Press .

Press the Exit/Scan button three times to return the controller to OFF.

1.5 INFO MODE: Viewing Operational Stats

The FilterQuick™ collects and stores information on cook and filter cycles. This data is in the info mode, and is accessed by

pressing the checkmark key with the controller off or on. The steps to view the data are detailed below.

Left Display Right Display Action

OFF/ON OFF/ON

LAST

DISPOSE

STATS

Total

cooks

Last

dispose

Number

date

Press until INFO MODE is displayed and release.

Press to scroll: Last Dispose Stats, Daily Stats, Selected Period Stats, Last Load

Stats. With the desired stats displayed, press .

Press . (This is the number of cooks since the last dispose.)

Press . (This is the date of the last dispose.)

FILTERS—

since

Number

Press . (This is the number of filters since oil disposal.)

dispose

Filters by-

passed –

SINCE

Number

Press . (This is the number of by-passed filters since oil disposal . )

DISPOSE

Polishes—

since

Number

Press . (This is the number of polishes since oil disposal.)

dispose

Polishes

by-passed

– SINCE

Number

Press . (This is the number of by-passed polishes since oil disp osal . )

DISPOSE

Oil Life

Oil Life- 1

dispose

prior

Oil Life – 2

disposes

prior

Avg Oil

Life

Avg cooks Number

Number

Days

Number

Days

Number

Days

Number

Days

Press . (This is the number of days since the last dispose.)

Press . (This is the oil life in days 1 dispose prior.)

Press . (This is the oil life in days 2 disposes prior.)

Press . (This is the average oil life of past 3 disposes.)

Press . (This is the average cooks over past 3 disposes.)

Reset Last

dispose

Yes no

Press to scroll or to reset Last Dispose stats.

stats

1-6

Page 11

Left Display Right Display Action

Reset Last

dispose

stats

Enter

code

Enter 1656

complete

Press button once and press to scroll to desired choice. Once desired choice is

Exit Exit

displayed, press button or press the Scan button once to return the controller to

OFF.

DAILY

STATS

MON date

Filters

Filters –

prior week

Filters

bypass

Cooks

Number

and day

Number

and day

Number

and day

Number

and day

With the desired stats displayed, press .

Press to scroll a day within the prior week. With the desired date displayed,

press .

Press to scroll number of times the vat was filtered on that day of the prior

week. Press .

Press to scroll number of daily filter cycles in the prior week. Press . Press

button once to return to Info Mode menu, or Exit/Scan button once to return the

controller to OFF.

Press to scroll number of times the filter prompt was bypassed on that day in

the prior week. Press .

Press to scroll number of cook cycles on that day of the prior week occurred.

Press .

Press button once and press to scroll to desired choice. Once desired choice is

Exit Exit

displayed, press button or press the Scan button once to return the controller to

OFF.

SELECTED

PERIOD

STATS

Date TIME

COOKS Number

QUIT COOKS Number

On HOURS Number

Reset

usage

Reset

usage

Yes no

Enter code

Complete

Press to scroll Info Mode Menu: Last Dispose Stats, Daily Stats, Selected Period

Stats, Last Load Stats with the desired stats displayed, press .

Press . (This is the date and time the selected period started.)

Press . (This is the total number of cooks since start of selected period.)

Press . (This is the total number of cooks that were cancelled since start of the

selected period.)

Press . (This is the total number of hours the fryer was on since start of the

selected period.)

Press to scroll or to set start of new selected period stats.

Enter 1656.

Press button once and press to scroll to desired choice. Once desired choice is

Exit Exit

displayed, press button or press the Scan button once to return the controller to

OFF.

LAST LOAD

STATS

Product

Started

Actual

time

Program

time

Product

Name

Number

Minutes

Number

Minutes

Number

Minutes

Max TEMP Number

Min TEMP Number

With the desired stats displayed, press .

Press .

Press . (This is the time the last cook started.)

Press . (This is the actual cook time including stretch time.)

Press . (This is the programmed cook time.)

Press . (This is the maximum temperature of the oil during the last cook.)

Press . (This is the minimum temperature of the oil during the last cook.)

1-7

Page 12

Left Display Right Display Action

Avg TEMP Number

Heat on %

Ready for

Cook

Yes or no

Press . (This is the average temperature of the oil during the last cook.)

Press . (This is the percentage of the cook time the heat source was on during the

last cook.)

Press . (This displays yes if the fryer was back to set temperature before the cook

cycle was started.)

Press button once and press to scroll to desired choice. Once desired choice is

Exit Exit

displayed, press button or press the Scan button once to return the controller to

OFF.

1.6 Main Menu: Product Setup (Single Setpoint Cooking)

Programming food items is shown below. Ensure the controller is OFF and follow the steps. The right column has the

action necessary to continue. Exit from a programming step at any time by pressing the Exit/Scan key until the display

returns OFF

Left Display Right Display Action

OFF OFF

PRODUCT SETUP

Product Setup Enter Code

Select

Product

Long Name

Short Name

COOKING MODE

1 Time

1 TEMPR

1 Sensitivity

1 alarm time

(Shake Time)

1 ALARM NAME SHAKE

1 ALARM MODE

(Shake Alarm Mode)

1 ALARM TONE

(Shake Alarm tone)

2 alarm time 0:00

Filter PROMPT

Press until the controller scrolls INFO MODE, changing to MAIN and then

PRODUCT SETUP.

Press .

Enter 1650. If loading a default menu on a legacy fryer, use the steps in the gray

fields below. If not, skip gray fields.

Press desired product button.

Product name or

button number

Abbreviated

Product name or

button number

SINGLE

SETPOINT

0:00 or

previously entered

time

350F or

previously entered

temperature

Number

0:00 or

previously entered

time

AUTO

Short

0 or previously

entered number.

Enter product name with letter keys. Advance cursor with . Press to

advance to next product set up feature.

Enter four character product name which alternates with the timer during a

cook. Press .

Press . If multiple setpoint or segmented cooking is desired press

MULTIPLE SETPOINT and go to 1.8 and follow the instructions. Default is

SINGLE SETPOINT.

Enter total cook time with numbered keys. Press .

Enter cooking temperature. Press .

Enter the level of sensitivity, 0-9, for the product. Press .

Enter time in cook cycle for audible alarm for shaking. Press . If set to 0:00

skip to FILTER PROMPT.

Press to scroll through the alarm names (ex. Shake, Stir). Press .

Press . Default is auto. Press to scroll to Manual shake alarm mode.

Press . Alarm (Shake) Mode when set to auto, cancels the alarm

automatically after a few seconds. Manual requires user action.

Press to scroll choice of shake alarm tones. Press . Default is SHORT.

Press . Leave at 0:00 if a second alarm is not needed. Enter time if needed

and follow steps above for entering other parameters. Repeat for third alarm

time. (If 0:00 is entered for second alarm, the steps for the third alarm do not

appear.)

Enter number of cook cycles before a filter prompt and press .

1-8

Page 13

Left Display Right Display Action

This is the time, in seconds, the fryer heats at 100%, after the product button is

Instant On

HOLD TIME

Exit Exit

Select

Product

To access menu strip, remove screws attaching bezel. Lower bezel and remove strip from back of controller. Once the

menu strip is updated, reverse the steps to reassemble. To unassign a product from a button set the cook time to 0:00 and

press EXIT/SCAN.

5 or previously

set number

0 or previously

entered time.

pressed before the controller adjusts the temperature. Enter value and press .

(Default is 5. 0=OFF). NOTE: Instant on time may need to be adjusted for

light cooking loads.

Enter time in minutes to hold product before discarding. Press .

Press the button to save changes.

For additional programming refer back to Product Setup above. To exit press

the EXIT SCAN button twice to OFF.

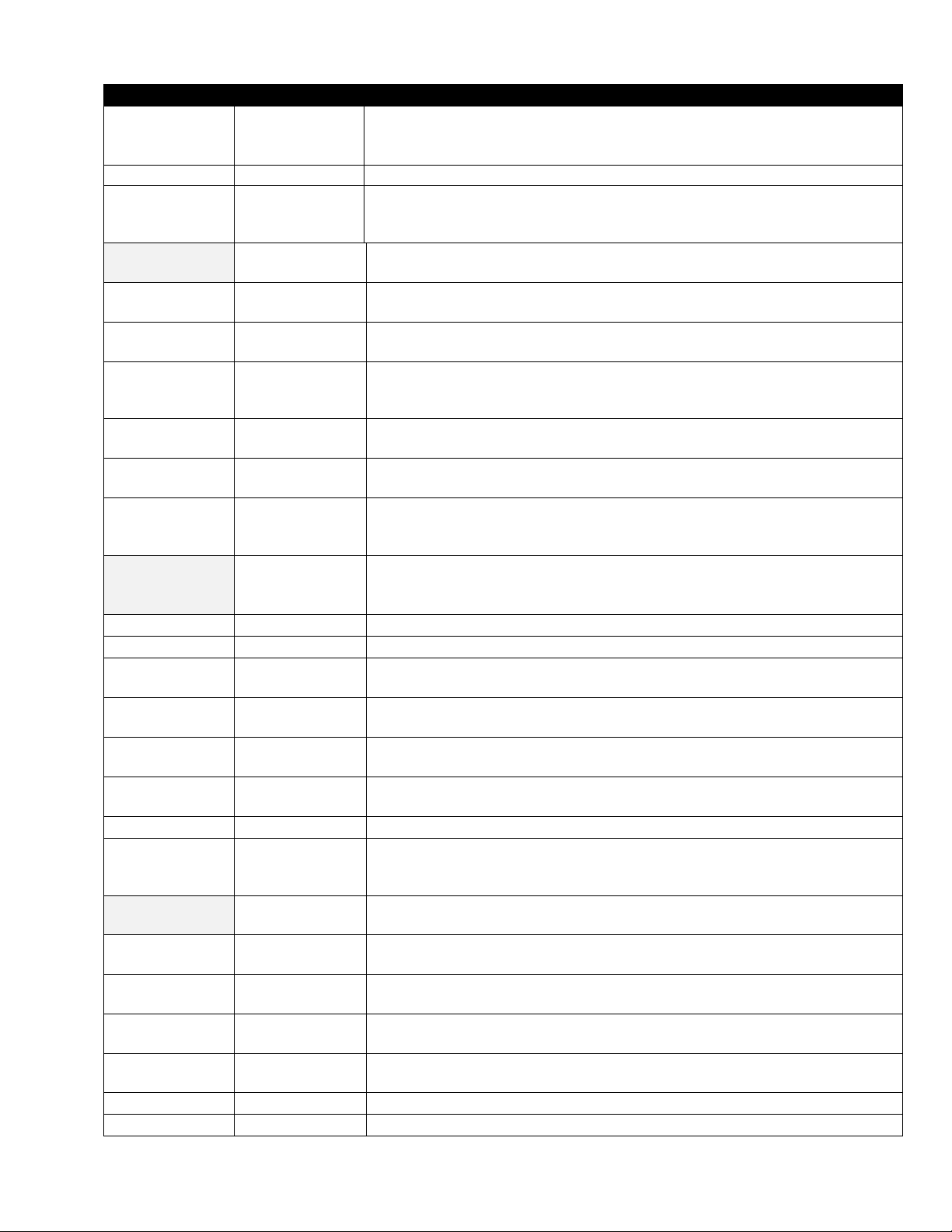

1.7 Multiple Setpoint (Segmented) Cooking Overview

When segmented cooking is selected, the product can cook at a variety of cooking temperatures with the temperature

changes occurring at user programmable points in the cook cycle.

When programming for segmented cooking, it is easiest to think of the entire cook cycle occurring on a countdown timer.

The cook cycle begins with its full time allotment, say, 13 minutes and it is completed when the countdown timer reaches

zero. The desired temperature changes are entered based on when they are to occur relative to the remaining cooking time.

The time entries for temperature changes are for the time remaining in the cook cycle, not the time elapsed. The graphic

below breaks down a 13-minute cook cycle. It’s best to create a similar table of time/temperature changes before beginning

the programming process.

Step 1 sets total cook time and initial setpoint.

Step 2 sets the duration of the first cooking segment, 2 minutes, and the setpoint of the first

temperature change.

Step 3 sets the duration of the second cooking segment, 4 minutes, and the setpoint of the

second temperature change.

Step 4 sets the duration of the third cooking segment, 3 minutes, and the setpoint of the third

temperature change.

The four remaining minutes in the cook time elapse at the final temperature. No entry is required to

use the final minutes

1-9

Page 14

1.8 Main Menu: Product Setup (Multiple Setpoint (Segmented) Cooking)

Left Display Right Display Action

OFF OFF

PRODUCT

SETUP

Product

Setup

Select

Product

Long Name

Short Name

COOKING MODE SINGLE SETPOINT

1 Time

1 TEMPR

1 sensitivity

2 Time

2 TEMPR

2 sensitivity

3 Time

3 TEMPR

3 sensitivity

4 Time

4 TEMPR

4 sensitivity

5 Time

5 TEMPR

5 sensitivity

1 ALARM time

1 alarm name shake

Enter Code

Product name or button

number

Abbreviated product name

or button number

0:00 or previously entered

time

350F or previously

entered temperature

Number

0:00 or previously entered

time

0 or previously entered

temperature

0 or previously entered

value

0:00 or previously entered

time

0 or previously entered

temperature

0 or previously entered

value

0:00 or previously entered

time

0 or previously entered

temperature

0 or previously entered

value

0:00 or previously entered

time

0 or previously entered

temperature

0 or previously entered

value

0:00 or previously entered

time

Press until the controller scrolls INFO MODE, changing to

MAIN and then PRODUCT SETUP.

Press .

Enter 1650.

Press desired product button.

Enter product name with letter keys. Advance cursor with

. Press to advance to next product set up feature.

Enter with letter keys abbreviated 4-character product name,

which alternates with cook time. Press .

Press . If multiple setpoint or segmented cooking is desired

press Multiple Setpoint (Segmented) and follow the

instructions in the next section. (Default is SINGLE

SETPOINT)

Enter total cook time for segmented item and press .

Enter initial cooking temperature and press .

Enter the level of sensitivity, 0-9, for the product. Press .

Default is 0.

Enter time remaining after first temperature change (see page

1-9) and press .

Enter first temperature change and press .

Enter the flex value, 0-9, for the product and press . Default

is 0.

Enter time remaining after second temperature change and

press .

Enter temperature of the second segment and press .

Enter the flex value, 0-9, for the product and press . Default

is 0.

Enter time remaining after third temperature change and press

.

Enter temperature of the third segment and press .

Enter the flex value, 0-9, for the product and press . Default

is 0.

Leave at zero if no more segments are needed and press . If

more segments are needed, continue programming as shown

above. Five is the limit.

Enter temperature of the third segment and press .

Enter the flex value, 0-9, for the product and press . Default

is 0.

Enter time in cook cycle for audible alarm for shaking. Press

.

Press to scroll through the alarm names (ex. Shake). Press

.

1-10

Page 15

Left Display Right Display Action

1 alarm mode auto

1 Alarm Tone Short

2 SHAKE time

0:00 or previously entered

time

2 Alarm name shake

2 alarm mode auto

2 Alarm Tone Short

3 time

0:00 or previously entered

time

3 Alarm name shake

3 alarm mode auto

3 Alarm Tone Short

Filter PROMPT

0 or previously entered

number.

Press to scroll to confirm Auto or Manual shake alarm

mode. Press . The default is auto.

Press to scroll to choice of shake alarm tones. Press .

Enter time in cook cycle for a second audible alarm for

shaking. Press .

Press to scroll through the alarm names (ex. Shake). Press

.

Press to scroll to confirm Auto or Manual shake alarm

mode. Press . The default is auto.

Press to scroll to choice of shake alarm tones. Press .

Enter time for third audible alarm for shaking. Press .

Press to scroll through the alarm names (ex. Shake). Press

.

Press to scroll to confirm Auto or Manual shake alarm

mode. Press . The default is auto.

Press to scroll to choice of alarm tones. Press .

Enter number of cook cycles before a filter prompt and press

.

This is the time, in seconds, the fryer heats at 100%, after the

Instant ON 0

product button is pressed, before the controller adjusts the

temperature. Enter value and press . Default is 0.

HOLD TIME

Exit Exit

Select

Product

0 or previously entered

time.

Enter time to hold product before discarding. Press .

Press the button to save changes.

For additional programming refer back to Product Setup above.

To exit press the EXIT SCAN button twice to OFF.

To access menu strip, remove screws attaching bezel. Lower bezel and remove strip from back of controller. Once the

menu strip is updated, reverse the steps to reassemble. To remove a product from a button set the cook time to 0 :00 and

press EXIT/SCAN.

1.9 Filter Menu

The FilterQuick™ controller has eight Filter menu options: Filter, Clean and Filter, Dispose (SDU or alternate container /

Manually Fill Vat From JIB, Dispose to Bulk or Front / Manually Fill Vat From JIB, Dispose to Bulk / Fill From Bulk),

Drain to Pan, Boil Out (Dispose to SDU or alternate container / Manually Fill Vat From JIB, Dispose to Bulk or Front /

Manually Fill Vat From JIB, Dispose to Bulk / Fill From Bulk), Fill From Pan, Pan to Waste (Bulk only), and Fill Vat from

Bulk (Bulk only). All are accessed by pressing and holding the Filter button until the display becomes Filter Menu. If fryer

temp is below 300°F the, controller displays “WAIT FOR FILTER”. The controller must be on and at or above 300°F to

execute a Filter, a Clean and Filter or a Polish. All messages need to be confirmed or cleared on all controllers prior to

starting any filtration process. NOTE: Some functions are only available when the controller is on, while others are

only available when the controller is OFF. See menu tree on page 1-2.

Entering Filter Menu Mode

Left Display Right Display Action

READY READY

Press the FILTER button until FILTER MENU is displayed for three seconds

changing to FILTER.

Press to scroll to Clean and Filter, Dispose, Drain To Pan, Fill From Pan,

Fill Vat from Bulk (Bulk only), Pan to Waste (Bulk only), Boil Out, or Exit.

FILTER

With the desired choice displayed press . Follow instructions on the

following pages to navigate the modes. If the filter pan is not fully engaged,

the controller displays INSERT PAN. Once the filter pan is pushed fully into

place, and the MIB board displays an “A”, the filter function continues.

1-11

Page 16

1.9.1 Filter

Left Display Right Display Action

FILTER

LEFT (Split vats only)

RIGHT (Split vats

only)

FILTER

FILTER NOW? YES / NO

SKIM VAT or OIL

TOO LOW.

CONFIRM is only

shown with OIL

TOO LOW display

START

FILTRATION

DRAINING

FLUSHING

CLOSE DRAIN

FILLING

-------- or LOW

TEMP alternating with

the temperature.

-------- or LOW

TEMP alternating

with the temperature.

Press and hold FILTER button until FILTER is displayed.

Press appropriate arrow to select side.

Press the button.

Press (YES) arrow to continue. Press (NO) arrow to bypass

filtration and return to previous state.

Skim the vat. If the oil level is too low, the controller displays

“OIL TO LOW”. Fill the vat and press either arrow under

CONFIRM.

Pull knob next to flashing light.

None required. If the drain becomes clogged, use the Fryer’s Friend

to clear the blockage.

None required.

Push knob next to flashing light in.

None required.

Fryer starts heating back to setpoint. Once back to setpoint the

controller displays READY.

1.9.2 Clean and Filter

Left Display Right Display Action

Follow steps to Entering Filter Menu Mode on page 1-11.

LEFT (Split vats only)

CLEAN AND

FILTER

CLEAN NOW? YES / NO

SKIM VAT

START

FILTRATION

DRAINING

CLEAN OIL

SENSOR

FLUSHING

SCRUB VAT

COMPLETE?

POLISHING 5:00 TIMER

CLOSE DRAIN

FILLING

IS VAT FULL? YES / NO

OFF OFF

RIGHT (Split vats

only)

CONFIRM

CONFIRM

Press appropriate arrow to select side.

Press .

Press (YES) arrow to continue. Press (NO) arrow to cancel and

return to previous state.

Skim the vat.

Pull knob next to flashing light.

None required. If the drain becomes clogged, use the Fryer’s

Friend to clear the blockage

Clean oil sensor with a no scratch pad and press arrow under

CONFIRM.

Use brush and hot oil to wash down crumbs and residue from the

frypot walls and foam deck. Use no scratch pad to remove

residue. Frypot surface will be hot, use thermal gloves and

extreme care.

Press arrow under CONFIRM.

None required. The oil flows from the filter pan to the frypot and

back to the filter pan for 5 minutes.

Push knob next to flashing light in.

None required.

Press (YES) if the vat is full. Press (NO) to continue filling.

1-12

Page 17

1.9.3 Dispose (to SDU or alternate container / Manually fill vat from JIB)

For safe, convenient draining and disposal of used oil or shortening, Frymaster recommends using the Frymaster Shortening

Disposal Unit (SDU). The SDU is available through your local distributor.

Left Display Right Display Action

Follow steps to Entering Filter Menu Mode on page 1-11. DANGER: When draining oil into an appropriate METAL

container, make sure the container will hold at least FOUR gallons (15 liters) or more, otherwise hot liquid could

overflow and cause injury.

LEFT (Split vats only) RIGHT (Split vats only)

DISPOSE

DISPOSE NOW? YES / NO

REMOVE FILTER

PAN

INSERT

DISPOSAL UNIT

CONFIRM

START DISPOSE

DISPOSING

VAT EMPTY AND

CLEAN?

CONFIRM

CLOSE DRAIN

Remove

Disposal Unit

CONFIRM

INSERT Filter

PAN

FILL VAT CONFIRM

OFF OFF

1.9.4 Dispose (to Bulk or Front / Manually fill vat from JIB)

Press appropriate arrow to select side.

Press .

Press (YES) arrow to continue. Press (NO) arrow to cancel and

return to previous state.

Remove filter pan.

Insert (SDU) shortening disposal unit or METAL pan large

enough to contain FOUR gallons (15 liters) or more under the

drain and press arrow under CONFIRM.

Pull knob next to flashing light.

None required. If the drain becomes clogged, use the Fryer’s

Friend to clear the blockage.

Press arrow under CONFIRM.

Push knob next to flashing light in.

Remove disposal unit and press arrow unde r CONFIRM.

Insert Filter pan

Manually fill vat with fresh oil and press arrow under

CONFIRM when full.

Left Display Right Display Action

Follow steps to Entering Filter Menu Mode on page 1-11.

LEFT (Split vats only) RIGHT (Split vats only)

DISPOSE

DISPOSE NOW? YES / NO

WASTE TANK

FULL

CONFIRM

START DISPOSE

DRAINING

VAT EMPTY AND

CLEAN?

CONFIRM

CLOSE DRAIN

Press appropriate arrow to select side.

Press .

Press (YES) arrow to continue. Press (NO) arrow

to cancel and return to previous state.

If waste tank is full, this message is displayed.

Press button to CONFIRM and call waste oil

provider. Controller displays OFF.

Pull the knob next to the blinking light.

None required. If the drain becomes clogged, use

the Fryer’s Friend to clear the blockage.

Press arrow under CONFIRM.

Push the knob next to the blinking light in.

Pull the dispose handle. (Note: If using front

OPEN DISPOSE

VALVE

dispose, ensure t he wand is connected to the

quick disconnect port. Press and hold switch

after pulling the dispose handle to dispose oil.)

1-13

Page 18

Left Display Right Display Action

DISPOSING

REMOVE FILTER

4:00 countdown timer None required.

Open the door and pull filter pan out of the cabinet.

PAN

IS PAN EMPTY? YES / NO

Ensure the pan is empty and press (YES),

otherwise press (NO) and follow the prompts

(returns to DISPOSING).

INSERT FILTER

Insert the pan.

PAN

CLOSE DISPOSE

VALVE

FILL VAT? CONFIRM

Push the dispose handle in. (Note: If using front

dispose, disconnect the dispose wand.)

Manually fill vat with fresh oil and press arrow

under CONFIRM when full.

OFF OFF

1.9.5 Dispose (to Bulk or Front / Fill Vat from Bulk)

Left Display Right Display Action

Follow steps to Entering Filter Menu Mode on page 1-11.

LEFT (Split vats only) RIGHT (Split vats only)

DISPOSE

DISPOSE NOW? YES / NO

WASTE TANK

FULL

CONFIRM

START DISPOSE

DRAINING

VAT EMPTY and

clean?

CONFIRM

CLOSE DRAIN

Press appropriate arrow to select side.

Press .

Press (YES) arrow to continue. Press (NO) arrow

to cancel and return to previous state.

If waste tank is full, this message is displayed.

Press button to CONFIRM and call waste oil

provider. Controller displays OFF.

Pull the knob next to the blinking light.

None required. If the drain becomes clogged, use

the Fryer’s Friend to clear the blockage.

Press arrow under CONFIRM when empty.

Push the knob next to the blinking light.

Pull the dispose handle. (Note: If using front

OPEN DISPOSE

VALVE

dispose, ensure t he wand is connected to the

quick disconnect port. Press and hold switch

after pulling the dispose handle to dispose oil.)

DISPOSING

REMOVE FILTER

PAN

4:00 countdown timer

None required while the oil is disposing as the

timer counts down.

Open the door and pull filter pan out of the cabinet.

Ensure the pan is empty and press (YES) arrow,

IS PAN EMPTY? YES / NO

otherwise press (NO) arrow and follow the

prompts (returns to DISPOSING).

INSERT Filter

PAN

CLOSE DISPOSE

VALVE

FILL VAT FROM

BULK?

PRESS AND HOLD

YES TO FILL

FILLING

CONTINUE

FILLING?

Yes / No

Yes

Yes / No

Insert the pan.

Push the dispose handle. (Note: If using front

dispose, disconnect the dispose wand.)

Press (YES) arrow to fill vat or (NO) arrow to go

to OFF.

Press and hold (YES) arrow to fill.

Displayed while filling vat.

Press (NO) arrow when full, otherwise press (YES)

arrow to continue filling.

1-14

Page 19

Left Display Right Display Action

OFF OFF

1.9.6 Drain to Pan

Left Display Right Display Action

Follow steps to Entering Filter Menu Mode on page 1-11.

LEFT (Split vats only) RIGHT (Split vats only)

DRAIN TO PAN

DRAIN NOW? YES / NO

OPEN DRAIN

VALVE

DRAINING

VAT EMPTY? CONFIRM

CLOSE DRAIN

FILL FROM PAN? YES / NO

FILLING

IS THE VAT

FULL?

REMOVE FILTER

PAN

Countdown timer

YES / NO

Press appropriate arrow to select side.

Press .

Press (YES) arrow to continue. Press (NO) arrow to

cancel and return to previous state.

Pull the knob next to the blinking light.

Displayed while draining. If the drain becomes clogged,

use the Fryer’s Friend to clear the blockage.

Press arrow under CONFIRM.

Push the knob next to the blinking light in.

Press (YES) to fill vat from pan. Press (NO) to go to OFF.

Displayed while filling vat.

Press (YES) if vat is full, otherwise press (NO) and follow

the prompt (returns to FILLING for another 45 seconds).

If vat is not full after two attempts go to next line.

Open the door and pull filter pan out of the cabinet.

Ensure the pan is empty and press (YES) arrow and go to

IS PAN EMPTY? YES / NO

next line, otherwise press (NO) arrow and follow prompt

to CHANGE FILTER PAPER.

INSERT Filter

PAN

OFF OFF

Insert the pan.

1.9.7 Fill Vat from Pan

Left Display Right Display Action

Follow steps to Entering Filter Menu Mode on page 1-11. WARNING: Ensure the oil is at or near operating

temperature to prevent damage to the pump.

LEFT (Split vats only) RIGHT (Split vats only)

FILL FROM PAN

FILL VAT FROM

PAN?

YES / NO

FILLING

IS THE VAT

FULL?

YES / NO

OFF OFF

Press appropriate arrow to select side.

Press .

Press (YES) arrow to continue. Press (NO) arrow to

cancel and return to OFF.

None required.

Press (YES) arrow if vat is full, otherwise press (NO)

arrow and follow the prompt (returns to FILLING).

1-15

Page 20

1.9.8 Fill Vat from Bulk (Bulk only)

Left Display Right Display Action

Follow steps to Entering Filter Menu Mode on page 1-11.

LEFT (Split vats only) RIGHT (Split vats only)

FILL VAT FROM

BULK

FILL VAT FROM

BULK?

PRESS AND HOLD

YES TO FILL

YES/NO

Yes

FILLING

CONTINUE

FILLING?

Yes / No

Press appropriate arrow to select side.

Press .

Press (YES) arrow to continue. Press (NO) arrow

to cancel and return to OFF.

Press and hold (YES) arrow to fill.

Displayed while filling vat.

Once the button is released while filling this

message is displayed. Press (NO) arrow when full,

otherwise press (YES) arrow to continue filling.

OFF OFF

1.9.9 Pan to Waste (Bulk only)

Left Display Right Display Action

Follow steps to Entering Filter Menu Mode on page 1-11.

LEFT (Split vats only) RIGHT (Split vats only)

PAN TO WASTE

PAN TO WASTE? YES/NO

WASTE TANK

FULL

OPEN DISPOSE

VALVE

COMFIRM

Pull the dispose handle.

DISPOSING

REMOVE FILTER

PAN

IS PAN EMPTY? YES / NO

INSERT Filter

PAN

CLOSE DISPOSE

VALVE

OFF OFF

Press appropriate arrow to select side.

Press .

Press (YES) arrow to continue. Press (NO) arrow

to cancel and return to previous state.

If waste tank is full, this message is displayed.

Press button to CONFIRM and call waste oil

provider. Controller displays OFF.

None required while the oil is disposing.

Open the door and pull filter pan out of the cabinet.

Ensure the pan is empty and press (YES) arrow,

otherwise press (NO) arrow and follow the

prompts (returns to DISPOSING).

Insert the pan.

Push the dispose handle in.

1-16

Page 21

1.9.10 Boil Out (Dispose to SDU or Alternate container / Manually Fill Vat from JIB)

Left Display Right Display Action

Follow steps to Entering Filter Menu Mode on page 1-11. WARNING: To prevent injury, ensure adjacent vats that

contain oil are OFF and covered prior to performing a boil out.

LEFT (Split vats only) RIGHT (Split vats only)

BOIL OUT

Boil Out Now? YES / NO

IS OIL REMOVED? YES / NO

REMOVE FILTER

PAN

INSERT

DISPOSAL UNIT

CONFIRM

START DISPOSE

DISPOSING

VAT EMPTY AND

CLEAN?

Countdown timer

CONFIRM

CLOSE DRAIN

REMOVE

DISPOSAL UNIT

IS SOLUTION IN

THE VAT?

CONFIRM

CONFIRM

BOIL OUT 30:00 countdown timer

BOIL OUT DONE CONFIRM

INSERT

DISPOSAL PAN

OPEN DRAIN

VALVE

DRAINING

IS SOLUTION

REMOVED?

RINSE

COMPLETE?

CONFIRM

Countdown timer

CONFIRM

CONFIRM

CLOSE DRAIN

VAT AND PAN

DRY?

REMOVE

DISPOSAL PAN

INSERT FILTER

PAN

CONFIRM

CONFIRM

FILL VAT CONFIRM

Press appropriate arrow to select side.

Press .

Press (YES) arrow to continue. Press (NO) arrow to

cancel and return to OFF.

Press (YES) arrow and g o to “IS SOLUTION IN THE

VAT?”. Press (NO) arrow to continue to next line.

Remove filter pan and press arrow under CONFIRM.

Insert (SDU) shortening disposal unit or METAL pan

large enough to contain FOUR gallons (15 liters) or more

under the drain and press arrow under CONFIRM.

Pull knob next to flashing light.

If the drain becomes clogged, use the Fryer’s Friend to

clear the blockage.

Press arrow under CONFIRM.

Push knob next to flashing light in.

Remove disposal unit and press arrow under

CONFIRM.

Ensure solution is in the vat and press arrow under

CONFIRM.

The boil-out timer starts and heats to 195ºF (91ºC).

Press arrow under CONFIRM to cancel the alarm.

Insert disposal pan large enough to contain FOUR gallons

(15 liters) or more under the drain and press arrow under

CONFIRM.

Pull knob next to flashing light.

None required.

Press arrow under CONFIRM.

Rinse the vat with water and press arrow under

CONFIRM.

Push knob next to flashing light in.

Ensure the vat and filter pan are completely dry and press

arrow under CONFIRM.

Remove the disposal pan and press arrow under

CONFIRM.

Insert Filter pan

Fill vat with fresh oil and press arrow under CONFIRM

when full.

OFF OFF

1-17

Page 22

1.9.11 Boil Out (Dispose to Bulk or Front / Manually Fill Vat from JIB)

Left Display Right Display Action

Follow steps to Entering Filter Menu Mode on page 1-11. WARNING: To prevent injury, ensure adjacent vats that

contain oil are OFF and covered prior to performing a boil out.

LEFT (Split vats only) RIGHT (Split vats only)

BOIL OUT

Boil Out Now? YES / NO

WASTE TANK

FULL

CONFIRM

Press appropriate arrow to select side.

Press .

Press (YES) arrow to continue. Press (NO) arrow to

cancel and return to OFF.

If waste tank is full, this message is displayed. Press

button to CONFIRM and call waste oil provider.

Controller displays OFF.

Press (YES) arrow and go to “IS SOLUTION IN THE

IS OIL REMOVED? YES / NO

VAT?”. Press (NO) arrow to continue to “START

DISPOSE” prompt.

START DISPOSE

DRAINING

VAT EMPTY and

clean?

CLOSE DRAIN

Countdown timer

CONFIRM

Pull the knob next to the blinking light.

If the drain becomes clogged, use the Fryer’s Friend to

clear the blockage.

Press arrow under CONFIRM when empty.

Push the knob next to the blinking light in.

Pull the dispose handle. (Note: If using front dispose,

OPEN DISPOSE

valve

ensure the wand is connected to the quick disconnect

port. Press and hold switch after pulling the dispose

handle to dispose oil.)

DISPOSING

REMOVE FILTER

PAN

4:00 countdown timer

None required.

Open the door and pull filter pan out of the cabinet.

Ensure the pan is empty and press (YES) arrow, otherwise

IS PAN EMPTY? YES / NO

press (NO) arrow and follow the prompts (returns to

DISPOSING).

INSERT Filter

PAN

CLOSE DISPOSE

VALVE

IS SOLUTION IN

THE VAT?

BOIL OUT 30:00 countdown timer

BOIL OUT DONE CONFIRM

REMOVE FILTER

PAN

INSERT

DISPOSAL PAN

OPEN DRAIN

valve

DRAINING

IS SOLUTION

REMOVED?

RINSE

COMPLETE?

CLOSE DRAIN

CONFIRM

CONFIRM

Countdown timer

CONFIRM

CONFIRM

Insert the pan.

Push the dispose handle.

Ensure solution is in the vat and press arrow under

CONFIRM.

The boil-out timer starts. Vat heats to 195ºF (91 ºC).

Press arrow under CONFIRM to cancel the alarm.

Open the door and pull filter pan out of the cabinet.

Insert disposal pan large enough to contain FOUR gallons

(15 liters) or more under the drain and press arrow under

CONFIRM.

Pull knob next to flashing light.

None required.

Press arrow under CONFIRM.

Rinse the vat with water and press arrow under

CONFIRM.

Push knob next to flashing light in.

1-18

Page 23

Left Display Right Display Action

VAT AND PAN

DRY?

REMOVE

DISPOSAL PAN

INSERT FILTER

PAN

CONFIRM

CONFIRM

FILL VAT CONFIRM

Ensure the vat and filter pan are completely dry and press

arrow under CONFIRM.

Remove the disposal pan and press arrow under

CONFIRM.

Insert Filter pan

Fill vat with fresh oil and press arrow under CONFIRM

when full.

OFF OFF

1.9.12 Boil Out (Dispose to Bulk or Front / Fill Vat from Bulk)

Left Display Right Display Action

Follow steps to Entering Filter Menu Mode on page 1-11. WARNING: To prevent injury, ensure adjacent vats that

contain oil are OFF and covered prior to performing a boil out.

LEFT (Split vats only) RIGHT (Split vats only)

BOIL OUT

Boil Out Now? Yes/no

WASTE TANK

FULL

CONFIRM

Press appropriate arrow to select side.

Press .

Press (YES) arrow to continue. Press (NO) arrow to

cancel and return to OFF.

If waste tank is full, this message is displayed. Press

button to CONFIRM and call waste oil provider.

Controller displays OFF.

Press (YES) arrow and g o to “IS SOLUTION IN THE

IS OIL REMOVED? YES / NO

VAT?”. Press (NO) arrow to continue to START

DISPOSE.

START DISPOSE

DRAINING

VAT EMPTY AND

CLEAN?

CLOSE DRAIN

Countdown timer

CONFIRM

Pull the knob next to the blinking light.

If the drain becomes clogged, use the Fryer’s Friend to

clear the blockage.

Press arrow under CONFIRM when empty.

Push the knob next to the blinking light.

Pull the dispose handle. (Note: If using front dispose,

OPEN DISPOSE

VALVE

ensure the wand is connected to the quick disconnect

port. Press and hold switch after pulling the dispose

handle to dispose oil.)

DISPOSING

REMOVE FILTER

PAN

IS PAN EMPTY? YES / NO

INSERT Filter

PAN

CLOSE DISPOSE

valve

IS SOLUTION IN

THE VAT?

BOIL OUT 30:00 countdown timer

BOIL OUT DONE CONFIRM

REMOVE FILTER

PAN

4:00 countdown timer

CONFIRM

None required.

Open the door and pull filter pan out of the cabinet.

Ensure the pan is empty and press (YES), otherwise press

(NO) and follow the prompts (returns to DISPOSING).

Insert the pan.

Push the dispose handle in.

Ensure solution is in the vat and press arrow under

CONFIRM.

Turns on and heats to 195ºF (91 ºC). The boil-out timer

starts.

Press arrow under CONFIRM to cancel the alarm.

Open the door and pull filter pan out of the cabinet.

1-19

Page 24

Left Display Right Display Action

INSERT

DISPOSAL PAN

OPEN DRAIN

valve

DRAINING

IS SOLUTION

REMOVED?

RINSE

COMPLETE?

CONFIRM

Countdown timer

CONFIRM

CONFIRM

CLOSE DRAIN

VAT AND PAN

DRY?

REMOVE

DISPOSAL PAN

INSERT FILTER

PAN

FILL VAT FROM

BULK?

PRESS AND HOLD

YES TO FILL

CONFIRM

CONFIRM

Yes / No

Yes

FILLING

CONTINUE

FILLING?

Yes / No

Insert disposal pan large enough to contain FOUR gallons

(15 liters) or more under the drain and press arrow under

CONFIRM.

Pull knob next to flashing light.

None required.

Press arrow under CONFIRM.

Rinse the vat with water and press arrow under

CONFIRM.

Push knob next to flashing light in.

Ensure the vat and filter pan are completely dry and press

arrow under CONFIRM.

Remove the disposal pan and press arrow under

CONFIRM.

Insert Filter pan

Press (YES) arrow to fill vat or (NO) arrow to go to OFF.

Press and hold (YES) to fill.

Displayed while filling vat.

Press (NO) arrow when full, otherwise press (YES) arrow

to continue filling.

OFF OFF

1.10 Polishing

The FilterQuick™ controller displays a series of prompts when a polish filter cycle is under way. To initiate a polish, press

and hold the arrows simultaneously when the controller displays READY. The steps are detailed below. A “WAIT

TO POLISH” message may appear until the signal is received that the vat is ready for polish cycle to begin.

Left Display Right Display Action

LEFT (Split vats

only)

RIGHT (Split vats only)

POLISH NOW? Yes / NO

SKIM VAT or

OIL LEVEL TOO

LOW.

CONFIRM (only shown if oil

level too low)

START POLISH

DRAINING

POLISHING

15:00 countdown timer

CLOSE DRAIN

Press appropriate arrow under side to filter.

Respond to prompt with button push. Press (YES) arrow to

continue. Press (NO) arrow to cancel and return to previous

state. Yes starts a polish, detailed below. No delays filter for 30

minutes and cooking continues. Answering NO after two

prompts cancels polish.

Skim the vat. If the oil level is too low, pressing CONFIRM

will turn off controller.

Pull the knob next to the blinking light.

None required.

None required. The oil flows from the filter pan to the frypot

and back to the filter pan for15 minutes. Default is 15 minutes.

Push the knob next to the blinking light in.

1-20

Page 25

Left Display Right Display Action

FILLING

-------- or LOW

TEMP alternating

with the temperature.

-------- or LOW TEMP

alternating with the

temperature.

None required.

Fryer starts heating back to temperature.

1.11 SCAN Mode

The daily stats mode can be used to see current stats about any product quickly throughout the day. Follow the steps below

to view stats.

Left Display Right Display Explanation/Action

READY READY

SELECT

PRODUCT

Long name

Short

Name

COOKS

REMAINING

COOKS

TODAY

Press the Exit/Scan button.

8 character product name Press to progress to next product stat.

4 character abbreviated

product name

Number or DISABLED Number of cooks remaining until filter prompt. Press .

Number Number of cooks completed today. Press .

Press a product button to check daily stats.

Press to progress to next product stat.

COOKS

SINCE LAST

DISPOSE

1 TIME

1 TEMPR

1

Sensitivity

1 ALARM

TIME

1 ALARM

NAME

1 ALARM

MODE

1 ALARM

TONE

FILTER

PROMPT

*

*

*

*

Number Numbers of cooks since last dispose. Press .

Time Time that product is programmed to cook. Press .

Temperature Temperature that product is programmed to cook. Press .

Number The level of sensitivity the product is programmed to cook at. Press .

Shake Time The time during a cook till a product shake alarm occurs. Press .

Shake, stir, or

numbered alarm

AUTO or MANUAL

Short, medium,

long, double or

long short,

none

Number

This is the name of the alarm. Press .

The alarm mode the product is programmed with. Press .

The shake alarm tone the product is programmed with. Press .

The number of cook cycles before a filter prompt occurs. Press .

INSTANT ON 0

This is the time, in seconds, the fryer heats before the controller checks

1-21

Page 26

Left Display Right Display Explanation/Action

the temperature. NOTE: An incorrect entry may cause the fryer to

overshoot temperature and over cook some products. Press .

HOLD time

Exit Exit

0:00 or previously

entered time.

The time to hold product before discarding. Press .

Press Exit/Scan button twice to exit.

* NOTE: If no alarm time is programmed these fields are hidden.

1-22

Page 27

CHAPTER 2: FILTERQUICK™

OPERATOR TROUBLESHOOTING

2.1 Introduction

This chapter provides an easy reference guide to some of the common problems that may occur

during the operation of your equipment. The troubleshooting guides that follow are intended to help

you correct, or at least accurately diagnose, problems with your equipment. Although the chapter

covers the most common problems reported, you may encounter problems that are not covered. In

such instances, the Frymaster Technical Services staff will make every effort to help you identify

and resolve the problem.

When troubleshooting a problem, always use a process of elimination starting with the simplest

solution and working through to the most complex. Most importantly, always try to establish a clear

idea of why a problem has occurred. Part of your corrective action involves taking steps to ensure

that it doesn’t happen again. If a controller malfunctions because of a poor connection, check all

other connections while you’re at it. If a fuse continues to blow, find out why. Always keep in mind

that failure of a small component may often be indicative of potential failure or incorrect functioning

of a more important component or system.

If you are in doubt as to the proper action to take, do not hesitate to call the Frymaster Technical

Service Department or your local Frymaster Authorized Servicer for assistance.

Before calling a servicer or the Frymaster HOTLINE (1-800-551-8633):

Verify that electrical cords are plugged in and that circuit breakers are on.

Verify that gas line quick-disconnects are properly connected.

Verify that any gas line cutoff valves are open.

Verify that frypot drain valves are fully closed.

Have your fryer’s model and serial numbers ready to give to the technician assisting

you.

DANGER

Hot oil will cause severe burns. Never attempt to move this appliance when filled

with hot cooking oil or to transfer hot cooking oil from one container to another.

DANGER

This equipment should be unplugged when servicing, except when electrical circuit

tests are required. Use extreme care when performing such tests.

This appliance may have more than one electrical power supply connection point.

Disconnect all power cords before servicing.

Inspection, testing, and repair of electrical components should be performed by an

factory authorized servicer only.

2-1

Page 28

2.2 Troubleshooting Fryers

2.2.1 Error Messages and Display Problems

PROBLEM PROBABLE CAUSES CORRECTIVE ACTION

No display on the

controller.

Fryer repeatedly cycles

on and off when first

started with MLT

CYCL displayed.

Heat indicator is on

and blower is running,

but burner will not

ignite.

Fryer does not heat

after filtering.

Controller displays

Hot hi-1.

Controller displays Hi

temp.

A. Controller not turned on.

B. No power to fryer.

C. Failed controller or other

component

Fryer is in melt-cycle mode.

Blown fuse on interface board

or ignition module.

Drain valve is open. Verify that the drain valve is fully closed.

Frypot temperature is more than

410ºF (210ºC) or, in CE countries,

395ºF (202ºC).

Frypot temperature is more than

40 ºF (4ºC) over setpoint.

A. Press the ON/OFF switch to turn the controller

on.

B. Verify that the fryer is plugged in and that the

circuit breaker is not tripped.

C. Call your FAS for assistance.

This is normal when fryer is turned on with oil

temperature below 100 F° (38C°).

Contact your FAS for service.

Shut the fryer down immediately and call your

FAS for assistance.

Press the power button to turn off fryer and let

cool before returning power to fryer. If issue

continues call your FAS for assistance.

Controller displays

RECOVERY

FAULT/ YES and

alarm sounds.

Controller display is in

wrong temperature

scale (Fahrenheit or

Celsius).

Controller displays

High limit

failure

disconnect

power.

Controller displays

TEMPR PROBE

FAILURE.

Recovery time exceeded maximum

time limit.

Incorrect display option

programmed.

Failed high limit

Problem with the temperature

measuring circuitry including the

probe or damaged controller

wiring harness or connector.

Clear error and silence the alarm by pressing the

(YES) button. If the error continues call your FAS

for assistance.

Toggle between F° to C° by pressing the button

until Product setup is displayed. Press to scroll

to Tech Mode and press . Enter 1658. Press the

scan button. The controller displays OFF. Turn

the controller on to check temperature. If the

desired scale is not displayed, repeat.

Shut the fryer down immediately and call your

FAS for assistance.

Shut the fryer down and call your FAS for

assistance.

2-2

Page 29

PROBLEM PROBABLE CAUSES CORRECTIVE ACTION

Controller displays

HEATING

FAILURE.

Controller displays

SERVICE

REQUIRED followed

by an error message.

Controller displays

IS VAT FULL?

YES NO during a

cook or in idle mode

with an audible

alarm.

Controller displays

IS OIL

SENSOR

CLEAM?

CONFIRM during

a cook or in idle

mode with an

audible alarm.

Contactor issue, gas valve off,

failed controller, failed

transformer, open high-limit

thermostat.

An error has occurred which

requires a service technician.

A. An error has occurred due to

carbon buildup on oil level

sensor.

B. CAN communication issues,

component failure issues.

A. The oil level sensor may be

coated with caramelized oil.

B. CAN communication issues,

component failure issues.

It is normal for this message to appear during

startup if a gas fryer’s lines have air in them.

Check that the gas valve is on. If it continues,

shut the fryer down and call your FAS for

assistance.

(NO) to continue cooking and call

Press

your FAS for assistance. In some cases,

cooking may not be allowed.

A. If answering yes directs to IS OIL

SENSOR CLEAN? CONFIRM, clean the

oil level sensor with a scratch pad and

power cycle the controller.

B. If the issue persists contact your FAS for

assistance.

A. Clean sensor with scratch pad.

B. If the issue persists contact your FAS for

assistance.

2.2.2 Filtration Problems

PROBLEM PROBABLE CAUSES CORRECTIVE ACTION

A. An error has occurred due to

carbon buildup on oil level

A. If answering yes directs to clean oil sensor,

clean oil level sensor with a scratch pad and

retry. Otherwise press (YES) if the vat is

full, otherwise press (NO) and follow

prompts.

B. Check to ensure that the probable causes

are remedied. Follow the prompts to refill

the vat.

A. Ensure fryer is at 250°F (121°C) or setpoint

before starting; ensure the controller is ON.

B. Clear messages and errors on other

controllers.

C. Ensure the filter pan is in position and fully

inserted into the fryer and “A” is displayed

on the MIB board.

Controller

displays IS VAT

FULL? YES

NO after a filter

function.

CLEAN, POLISH,

FILTER OR

DISPOSE won’t

start.

sensor. Normal after some filter

menu functions when filling.

B. All the oil may not have returned

during a filter function due to

dirty or clogged filter paper,

clogged filter pump, filter pump

thermal overload, improperly

installed filter pan components,

worn or missing O-rings, cold oil

or an actuator problem.

A. Temperature too low or

controller displays OFF.

B. Messages or errors on other

controllers.

C. Filter pan not fully engaged.

Controller displays

A. Another function is still in A. Wait until the previous function ends to

2-3

Page 30

PROBLEM PROBABLE CAUSES CORRECTIVE ACTION

WAIT FOR

Filter, CLEAN

AND FILTER,

DISPOSE, DRAIN

TO PAN, POLISH,

FILL VAT FROM

BULK, FILL VAT

FROM PAN, BOIL

OUT, PAN TO

WASTE

Controller displays

CHANGE FILTER

PAPER?

Controller displays

INSERT pan.

Controller displays

OIL IN DRAIN

PAN / CONFIRM

process.

B. MIB has not cleared checking

system.

C. Messages or errors on other

controllers.

D. Filter pan not fully engaged.

Filter error has occurred, filter

paper clogged, 25 hour filter paper

change prompt has occurred or

change filter paper was ignored on

a prior prompt.

A. Normal during Change Filter

Paper routine.

Drain valve open or possibility that

oil is in drain pan.

start another filtration cycle.

B. Wait one minute and try again.

C. Clear messages and errors on other

controllers.

D. Ensure the filter pan is in position and

fully inserted into the fryer and “A” is

displayed on the MIB board.

Press (YES), follow prompts and change

the filter paper. Ensure the filter pan has been

removed from the fryer for a minimum of 30

seconds. Do NOT ignore CHANGE

FILTER PAPER prompts.

A. Insert pan and press (CONFIRM)

button.

Press (CONFIRM) and follow directions for

FILL VAT FROM DRAIN PAN.

Controller displays

FLT DYLD

Controller displays

POL DYLD

Controller displays

CANCEL

FILTER?

YES/NO

A filter cycle has been delayed.

A polish cycle has been delayed.

A filter menu function has been

requested while another function is

in process.

This is a normal display when a filter has been

delayed. After the next filter prompt press

YES to filter.

This is a normal display when a polish has

been delayed. After the next polish prompt

press YES.

Press YES to keep the desired function in

memory. Once the current function is

complete, the second requested function will

prompt to start. Press NO to cancel requested

function and return to OFF.

2.2.3 Using Tech Modes

The FilterQuick™ controller has a Tech Mode menu accessed with Code 3000, which allows

clearing of E-log, password reset, lane count, hold mode and high limit test.

Left Display Right Display Action

OFF OFF

Start with the far LEFT controller. Press until the controller

scrolls Info Mode, changing to Main and then PRODUCT SETUP.

Product Setup Blank

Press to scroll to Tech Mode. Press .

Tech Mode Enter Code

Clear E-Log Blank

Enter 3000

Press to clear error codes. Press . Clears captured error codes.

2-4

Page 31

Left Display Right Display Action

Clear passwords Blank

Lane count 2

HOLD MODE STANDARD

Hi limit test* Blank

Hi limit test* YES NO

Exit Exit

OFF OFF

*This test will ruin the oil and should only be conducted by a technician.

Press to clear passwords. Press .

Press to change Lane Count. Press .

Press to toggle to LANE. Press .

Press to initiate Hi-Limit test.

Press to start; press to decline. Press .*

Press Exit/Scan twice.

2.2.4 Error Log Codes

Code ERROR MESSAGE EXPLANATION

E03 ERROR TEMP PROBE FAILURE Temp probe reading out of range

E04 HI 2 BAD High limit reading is out of range.

E05 HOT HI 1 High limit temperature is past more than 410°F

(210°C), or in CE countries, 395°F (202°C)

E06 HEATING FAILURE A component has failed such as controller, interface

board, contactor, gas valve, ignition module or

open-high limit.

E07 ERROR MIB SOFTWARE Internal MIB software error

E08 ERROR ATO BOARD MIB detects ATO board connection lost; ATO board

failure

E09 ERROR PUMP NOT FILLING Dirty pad and it needs changed or it was bypassed;

filter pump problem

E10 ERROR DRAIN VALVE NOT OPEN Drain valve was trying to open and confirmation is

missing

E11 ERROR DRAIN VALVE NOT CLOSED Drain valve was trying to close and confirmation is

missing

E12 ERROR RETURN VALVE NOT OPEN Return valve was trying to open and confirmation is

missing

E13 ERROR RETURN VALVE NOT

CLOSED

E14 ERROR AIF BOARD MIB detects AIF missing; AIF board failure

E15 ERROR MIB BOARD Cooking computer detects MIB connections lost;

Return valve was trying to close and confirmation is

missing

MIB board failure

E16 ERROR AIF PROBE AIF RTD reading out of range

E17 ERROR ATO PROBE ATO RTD reading out of range

E20 INVALID CODE LOCATION SD card removed during update

E21 FILTER PAPER PROCEDURE ERROR

(Change Filter Paper)

E22 OIL IN PAN ERROR Oil may be present in the filter pan.

24 hour timer has expired

2-5

Page 32

Code ERROR MESSAGE EXPLANATION

E23 CLOGGED DRAIN (Gas) Vat did not empty during filtration

E24 OIL LEVEL SENSOR FAILED (Gas) Oil level sensor failed.

E25 RECOVERY FAULT Recovery time exceeded maximum time limit.

E26 RECOVERY FAULT CALL SERVICE Recovery time exceeded maximum time limit for two

or more recovery tests.

E28 HIGH TEMP ALARM Oil has exceeded 40 ºF (4ºC) over setpoint.

2-6

Page 33

THIS PAGE INTENTIONALLY LEFT BLANK

Page 34

8700LINEAVENUE,SHREVEPORT,LA71106‐6800

FRYMASTER

EMAIL:SERVICE@FRYMASTER.COM

WWW.FRYMASTER.COM

318‐865‐1711

844‐724‐CARE(2273)

*8197050*

Every new piece of Manitowoc Foodservice equipment comes with KitchenCare™ and you choose the level of service that meets

your operational needs from one restaurant to multiple locations.