Page 1

Installation, Operation, Service, and Parts Manual

FBR18 & FBRA18 Series

Gas Rethermalizers

Frymaster, a member of the Commercial Food Equipment Service Association, recommends

using CFESA Certified Technicians.

24-Hour Service Hotline 1-800-551-8633

819-5278

May 2003

Page 2

NOTICE

IF, DURING THE WARRANTY PERIOD, THE CUSTOMER USES A PART FOR THIS ENODIS

EQUIPMENT OTHER THAN AN UNMODIFIED NEW OR RECYCLED PART PURCHASED

DIRECTLY FROM FRYMASTER/DEAN, OR ANY OF ITS AUTHORIZED SERVICE CENTERS,

AND/OR THE PART BEING USED IS MODIFIED FROM ITS ORIGINAL CONFIGURATION, THIS

WARRANTY WILL BE VOID. FURTHER, FRYMASTER/DEAN AND ITS AFFILIAT ES WILL NOT BE

LIABLE FOR ANY CLAIMS, DAMAGES OR EXPENSES INCURRED BY THE CUST OMER WHICH

ARISE DIRECTLY OR INDIRECTLY, IN WHOLE OR IN PART, DUE TO THE INSTALLATION OF

ANY MODIFIED PART AND/OR PART RECEIVED FROM AN UNAUTHORIZED SERVICE CENTER.

NOTICE

This appliance is intended for professional use only and is to be operated by qualified

personnel only. A Frymaster/DEAN Factory Authorized Service Center (FASC) or other qualified

professional should perform installation, maintenance, and repairs. Installation, maintenance,

or repairs by unqualified personnel may void the manufacturer’s warranty. See Chapter 1 of

this manual for definitions of qualified personnel.

NOTICE

This equipment must be installed in accordance with the appropriate national and local codes of

the country and/or region in which the appliance is installed. See NATIONAL CODE

REQUIREMENTS in Chapter 2 of this manual for specifics.

NOTICE TO U.S. CUSTOMERS

This equipment is to be installed in compliance with the basic plumbing code of the Building

Officials and Code Administrators International, Inc. (BOCA) and the Food Service Sanitation

Manual of the U.S. Food and Drug Administration.

NOTICE

Drawings and photos used in this manual are intended to illustrate operational, cleaning and

technical procedures and may not conform to onsite management operational procedures.

NOTICE TO OWNERS OF UNITS EQUIPPED WITH COMPUTERS

U.S.

This device complies with Part 15 of the FCC rules. Operation is subject to the following two

conditions: 1) This device may not cause harmful interference, and 2) This device must accept

any interference received, including interference that may cause undesired operation. While

this device is a verified Class A device, it has been shown to meet the Class B limits.

CANADA

This digital apparatus does not exceed the Class A or B limits for radio noise emissions as set

out by the ICES-003 standard of the Canadian Department of Communications.

Cet appareil numerique n’emet pas de bruits radioelectriques depassany les limites de classe A

et B prescrites dans la norme NMB-003 edictee par le Ministre des Communcations du Canada.

CAUTION

Do not use deliming solution to clean these units. Use of deliming solution will damage all stainless steel

parts.

Page 3

DANGER

Improper installation, adjustment, maintenance or service, and unauthorized alterations or

modifications can cause property damage, injury, or death. Read the installation, operating,

and service instructions thoroughly before installing or servicing this equipment. Only

qualified service personnel may convert this appliance to use a gas other than that for which it

was originally configured. See Chapter 1 of this manual for definition of qualified service

personnel.

DANGER

No structural material on the rethermalizer should be altered or removed to accommodate

placement of the rethermalizer under a hood. Questions? Call the Frymaster/Dean Service

Hotline at 1-800-551-8633.

DANGER

Adequate means must be provided to limit the movement of this appliance without depending

upon the gas line connection. Single rethermalizers equipped with legs must be stabilized by

installing anchor straps. All rethermalizers equipped with casters must be stabilized by

installing restraining chains. If a flexible gas line is used, an additional restraining cable must

be connected at all times when the rethermalizer is in use.

DANGER

The front ledge of the rethermalizer is not a step! Do not stand on the rethermalizer. Serious

injury can result from slips or contact with the hot water.

DANGER

Do not store or use gasoline or other flammable liquids or vapors in the vicinity of this or any

other appliance.

DANGER

Instructions to be followed in the event the operator smells gas or otherwise detects a gas leak

must be posted in a prominent location. This information can be obtained from the local gas

company or gas supplier.

DANGER

This product contains chemicals known to the State of California to cause cancer and/or birth

defects or other reproductive harm.

Operation, installation, and servicing of this product could expose you to airborne particles of

glasswool or ceramic fibers, crystalline silica, and/or carbon monoxide. Inhalation of airborne

particles of glasswool or ceramic fibers is known to the State of California to cause cancer.

Inhalation of carbon monoxide is known to the State of California to cause birth defects or other

reproductive harm.

NOTICE

The Commonwealth of Massachusetts requires any and all gas products to be installed by a

licensed plumber or pipe fitter.

Page 4

FBR18 & FBRA18 SERIES GAS RETHERMALIZERS

TABLE OF CONTENTS

CHAPTER 1: General Information

1.1 Parts Ordering and Service Information ............................................................................1-1

1.2 Safety Information .............................................................................................................1-1

1.3 Equipment Description ......................................................................................................1-2

1.4 Installation, Operating, and Service Personnel ..................................................................1-2

1.5 Definitions..........................................................................................................................1-2

1.6 Shipping Damage Claim Procedure...................................................................................1-3

CHAPTER 2: Installation Instructions

2.1 General Installation Requirements.....................................................................................2-1

2.2 Caster/Leg Installation .......................................................................................................2-2

2.3 Pre-Connection Preparations .............................................................................................2-2

2.4 Connecting to the Gas Supply............................................................................................2-4

2.5 Converting to Another Gas Type.......................................................................................2-5

CHAPTER 3: Operating Instructions

3.1 Introduction........................................................................................................................3-1

3.2 FBR18/FBRA18 Digital Controller...................................................................................3-1

Operating the FBR18/FBRA18 Digital Controller ............................................................3-1

Operating the FBR18/FBRA18 Timers .............................................................................3-2

3.3 Start-Up Procedure.............................................................................................................3-2

3.4 Boiling Out the Cookpot....................................................................................................3-3

3.5 Shutting the Rethermalizer Down......................................................................................3-4

CHAPTER 4: Preventive Maintenance

4.1 Daily Checks and Services.................................................................................................4-1

4.2 Quarterly Checks and Services ..........................................................................................4-1

4.3 Semi-Annual Checks and Services ....................................................................................4-2

Clean Combustion Air Blower...........................................................................................4-2

Clean Gas Valve Vent Tube ..............................................................................................4-2

Check Burner Manifold Pressure.......................................................................................4-3

CHAPTER 5: Operator Troubleshooting

5.1 Introduction........................................................................................................................5-1

5.2 Operator Troubleshooting Guides......................................................................................5-2

5.3 Replacing the Computer or Computer Wiring Harness.....................................................5-6

CHAPTER 6: Service Procedures

6.1 Functional Description.......................................................................................................6-1

The Electronic Ignition System .........................................................................................6-1

Controller and Mechanical Timers ....................................................................................6-2

Interface Boards .................................................................................................................6-2

i

Page 5

Temperature Probe ............................................................................................................ 6-3

Water Level Sensors (FBRA18 Only)............................................................................... 6-3

6.2 Accessing the Rethermalizer for Servicing ....................................................................... 6-4

6.3 Cleaning the Gas Valve Vent Tube................................................................................... 6-4

6.4 Checking the Burner Manifold Gas Pressure .................................................................... 6-4

6.5 Measuring Flame Current.................................................................................................. 6-4

6.6 Replacing Components...................................................................................................... 6-5

6.6.1 Replacing the Controller or Controller Wiring Harness ................................................... 6-5

6.6.2 Replacing the Temperature Probe ..................................................................................... 6-5

6.6.3 Replacing the Interface Board........................................................................................... 6-5

6.6.4 Replacing an Ignition Module........................................................................................... 6-6

6.6.5 Replacing an Ignitor Assembly ......................................................................................... 6-6

6.6.6 Replacing the Combustion Air Blower ............................................................................. 6-7

6.6.7 Replacing the Gas Valve ...................................................................................................6-7

6.6.8 Replacing a Burner Assembly........................................................................................... 6-7

6.6.9 Replacing the Cookpot ...................................................................................................... 6-8

6.7 Troubleshooting and Problem Isolation ............................................................................ 6-8

6.7.1 Ignition Failures ................................................................................................................ 6-9

6.7.2 Improper Burner Functioning.......................................................................................... 6-10

6.7.3 Improper Temperature Control ....................................................................................... 6-12

6.8 Troubleshooting Guides .................................................................................................. 6-12

6.8.1 Troubleshooting the Gas Valve....................................................................................... 6-13

6.8.2 Troubleshooting the 24 VAC Circuit in FBR18 Units.................................................... 6-14

6.8.3 Troubleshooting the 24 VAC Circuit in FBRA18 Units................................................. 6-16

6.8.4 Troubleshooting the Temperature Probe......................................................................... 6-21

Probe Resistance Chart.................................................................................................... 6-22

6.9 Wiring Diagram for FBR18 Units................................................................................... 6-23

6.10 Wiring Diagram for FBRA18 Units................................................................................ 6-24

CHAPTER 7: Parts List

7.1 Burner System Components.............................................................................................. 7-1

7.2 Cabinetry and Associated Components............................................................................. 7-2

7.3 Control Box Assembly and Associated Parts, FBR18/FBRA18....................................... 7-3

7.4 Controller and Component Box Assemblies..................................................................... 7-4

7.5 Cooking Timer Control Panel Components ...................................................................... 7-5

7.6 Cookpot, FBR18................................................................................................................ 7-6

7.7 Cookpot, FBRA18.............................................................................................................7-7

7.8 Gas Supply Components ................................................................................................... 7-8

7.9 Plumbing Components ...................................................................................................... 7-9

ii

Page 6

FBR18 & FBRA18 SERIES GAS RETHERMALIZERS

CHAPTER 1: GENERAL INFORMATION

1.1 Parts Ordering and Service Information

In order to assist you as quickly as possible, the Frymaster Factory Authorized Service Center

(FASC) or Service Department representative requires certain information about your equipment.

Most of this information is printed on a data plate affixed to the inside of the door.

Parts orders may be placed directly with your local FASC or distributor. Included with the unit

when shipped from the factory is a list of FASCs. If you do not have access to this list, contact the

Frymaster Technical Service Department at 1-800-551-8633 or 1-318-865-1711.

When ordering parts, the following information is required:

Model Number:

Serial Number:

Gas Type:

Item Part Number:

Quantity Needed:

Service information may be obtained by contacting your local FASC/Distributor. Information may

also be obtained by calling the Frymaster Technical Service Department at 1-800-551-8633 or

1-318-865-1711. When requesting service, please have the following information ready:

Model Number:

Serial Number:

Gas Type:

In addition to the model number, serial number, and gas type, please be prepared to describe the nature of the problem and have ready any other information that you think may be helpful in solving

your problem.

RETAIN AND STORE THIS MANUAL IN A SAFE PLACE FOR FUTURE USE.

1.2 Safety Information

Before attempting to operate your unit, read the instructions in this manual thoroughly.

Throughout this manual, you will find safety notations enclosed in double-bordered boxes similar to

the ones illustrated on the following page.

1-1

Page 7

CAUTION

CAUTION boxes contain information about actions or conditions that may cause or

result in a malfunction of your system.

WARNING

WARNING boxes contain information about actions or conditions that may cause or

result in damage to your system, and which may cause your system to malfunction.

DANGER

DANGER boxes contain information about actions or conditions that may cause or

result in injury to personnel, and which may cause damage to your system and/or

cause your system to malfunction.

1.3 Equipment Description

The FBR18 and FBRA18 Series Gas Rethermalizers are specifically designed to rethermalize meats,

sauces, and other vacuum packaged foods at a safe temperature range that prevents overcooking.

They can be configured for either natural or LP (Propane) gas, and their efficient infrared burners

deliver 90,000 BTUs (94.9 MJ – 26.4 kW).

The two models are identical except that the FBRA18 has an automatic filling (AutoFill) feature.

Both models feature digital temperature controls with continuous temperature display and individual

color-coded timer controls with corresponding color-coded baskets. Each unit can rethermalize up

to 15 lbs. (7 kg) of food an hour in large capacity 2-5 lb. (0.9-2.3 kg) baskets.

The rethermalizers are safeguarded against boil-over by a standpipe overflow drain, and come with a

1¼” cookpot drain for fast, clog-free emptying. The unit has a rethermalizing area of 18” x 24”

(457mm x 609mm) and holds 25 gallons (94.6 liters) of water.

1.4 Installation, Operating, and Service Personnel

Operating information for Frymaster equipment has been prepared for use by qualified and/or authorized personnel only, as defined in Section 1.5.

All installation and service on Frymaster equipment must be performed by qualified, certified,

licensed, and or/authorized installation or service personnel, as defined in Section 1.5.

1.5 Definitions

QUALIFIED AND/OR AUTHORIZED OPERATING PERSONNEL

Qualified/authorized operating personnel are those who have carefully read the information in this

manual and have familiarized themselves with the equipment functions, or who have had previous

experience with the operation of the equipment covered in this manual.

1-2

Page 8

QUALIFIED INSTALLATION PERSONNEL

Qualified installation personnel are individuals, or firms, corporations, or companies which, either in

person or through a representative, are engaged in and are responsible for the installation of electrical and gas appliances. Qualified personnel must be experienced in such work, be familiar with all

electrical precautions involved, and have complied with all requirements of applicable national and

local codes.

QUALIFIED SERVICE PERSONNEL

Qualified service personnel are those that are familiar with Frymaster equipment and who have been

authorized by

sonnel are required to be equipped with a complete set of service and parts manuals, and to stock a

prescribed minimum amount of Frymaster equipment parts.

A list of Frymaster Factory Authorized Service Centers (FASC) was included with the unit when it

was shipped from the factory. Failure to use qualified service personnel will void the Frymaster

Warranty on your equipment.

1.6 Shipping Damage Claim Procedure

Your Frymaster equipment was carefully inspected and packed before leaving the factory. The

transportation company assumes full responsibility for safe delivery upon acceptance of the equipment for transport.

What to do if your equipment arrives damaged:

Frymaster

to perform service on Frymaster equipment. All authorized service per-

1. File a claim for damages immediately, regardless of the extent of damages.

2. Inspect for and record all visible loss or damage and ensure that this information is noted on

the freight bill or express receipt and is signed by the person making the delivery.

3. Concealed loss or damage that was unnoticed until the equipment was unpacked should be re-

corded and reported to the freight company or carrier immediately upon discovery. A concealed

damage claim must be submitted within 15 days of the date of delivery. Ensure that the shipping

container is retained for inspection.

Frymaster

DOES NOT ASSUME RESPONSIBILITY

FOR DAMAGE OR LOSS INCURRED IN TRANSIT.

1-3

Page 9

FBR18 & FBRA18 SERIES GAS RETHERMALIZERS

CHAPTER 2: INSTALLATION INSTRUCTIONS

2.1 General Installation Requirements

PROPER INSTALLATION IS ESSENTIAL FOR EFFICIENT, TROUBLE-FREE OPERATION OF YOUR

RETHERMALIZER. ANY UNAUTHORIZED ALTERATIONS MADE TO THIS EQUIPMENT WILL VOID

Frymaster WARRANTY.

THE

Upon arrival, inspect the rethermalizer carefully for visible or concealed damage. (See Shipping

Damage Claim Procedure in Chapter 1.)

CLEARANCE AND VENTILATION

This equipment must be installed with a 6” (150mm) clearance at both sides and back when installed

adjacent to combustible construction. No clearance is required when installed adjacent to noncombustible construction. A minimum of 24” (600mm) clearance should be provided at the front of the

unit.

One of the most important considerations of efficient operation is ventilation. Make sure the equipment is installed so that products of combustion are removed efficiently, and that the kitchen ventilation system does not produce drafts that interfere with proper burner operation.

The equipment flue opening must not be placed close to the intake of the exhaust fan, and the flue

must never be extended in a “chimney” fashion. An extended flue will change the combustion characteristics of the equipment, causing longer recovery times. It also frequently causes delayed ignition. To provide the airflow necessary for good combustion and burner operation, the areas surrounding the front, sides, and rear of the unit must be kept clear and unobstructed.

This equipment must be installed in an area with an adequate air supply and adequate ventilation.

For U.S installations, information on construction and installation of ventilating hoods can be found

in NFPA Standard 96. This document can be ordered from the National Fire Protection Association,

Battery March Park, Quincy, MA 02269. For installations in countries other than the U.S., the appropriate regulating authority should be contacted for information related to hood construction and

installation.

DANGER

Do not attach an apron drain to a single rethermalizer. The rethermalizer may become unstable, tip over, and cause injury to personnel.

NATIONAL CODE REQUIREMENTS

This equipment is to be installed in compliance with the Basic Plumbing Code of the Building Officials and Code Administrators International, Inc. (BOCA) and the Food Service Sanitation Manual

of the U.S. Food and Drug Administration.

2-1

Page 10

This equipment is manufactured to use the type of gas specified on the rating plate attached to the

door. Connect equipment stamped “NAT” only to natural gas and that stamped “PRO” only to LP

(Propane) gas.

Installation shall be made with a gas connector that complies with national and local codes. Quick

disconnect devices, if used, shall likewise comply with national and local codes.

ELECTRICAL GROUNDING REQUIREMENTS

All electrically operated appliances must be grounded in accordance with all applicable national and

local codes. A wiring diagram is located on the inside of the door. In the United States and Canada,

the electrical supply must be 120VAC, 60 Hz. In other countries, refer to the rating plate on the inside of the door for proper voltages.

FCC COMPLIANCE

The user is cautioned that any changes or modifications to Frymaster computers not expressly approved by the party responsible for compliance could void the user’s authority to operate the equipment. Frymaster computers have been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC rules. While these devices are verified as Class A devices,

they have been shown to meet the Class B limits. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of the equipment in a residential area is likely to cause harmful interference

in which case the user will be required to correct the interference at his own expense. If necessary,

the user should consult the dealer or an experienced radio and television technician for additional

suggestions.

The user may find the booklet “How to Identify and Resolve Radio-TV Interference Problems” helpful. It is prepared by the Federal Communications Commission and is available from the U.S. Government Printing Office, Washington, DC 20402, Stock No. 004-000-00345-4.

2.2 Caster/Leg Installation

Your unit requires casters or legs to be installed. IT MAY NOT BE CURB MOUNTED!

If casters or legs are not already installed, install them in accordance the instructions included

in your accessory package. FAILURE TO INSTALL CASTERS OR LEGS WILL RESULT

IN IMPROPER OPERATION OF YOUR UNIT.

2.3 Pre-Connection Preparations

DANGER

Do not connect this equipment to the gas supply before completing each step in this

section.

2-2

Page 11

After the unit has been positioned in the area where it will be used, ensure the following has been

accomplished before connecting the unit to the gas supply:

1. Adequate means must be provided to limit the movement of this equipment without depending

upon the gas line connections. If a flexible gas hose is used, a restraining cable must be connected at all times when the equipment is in use.

2. The rethermalizer must be stabilized by installing restraining chains on units equipped with cast-

ers or anchor straps on units equipped with legs. Follow the instructions shipped with the casters/legs to properly install the chains or straps.

3. Level rethermalizers equipped with legs by screwing out the legs approximately 1 inch then ad-

justing them so that the rethermalizer is level.

4. For rethermalizers equipped with casters, there are no built-in leveling devices. The floor where

the rethermalizer is to be installed must be level.

5. Connect the water hose to the fitting at the rear of the unit.

NOTE 1: The hose comes with a quick-disconnect coupling. The quick disconnect may be attached to the rethermalizer or to the water supply line, or it may be left off entirely, whichever

you prefer. Whichever of the options is chosen, Teflon thread-seal tape or Loctite™ PST56765

or equivalent thread sealer must be used when installing the fittings.

NOTE 2: Either hot or cold water may be connected to the unit. Connecting to hot water will

minimize the amount of time required to bring the unit to boil when filling with fresh water.

NOTE 3: In order for the water level sensors to work properly, a certain amount of mineral content in necessary in the water. For that reason, purified, deionized, or highly filtered water

should not be used.

4. Connect the desired drain plumbing to the 1¼” drain valve.

5. Test the equipment electrical system by plugging the power cord into a grounded 120VAC outlet

and pressing the controller’s ON/OFF button. After four (4) seconds, the last programmed setpoint temperature will display constantly.

6. Turn the controller off. Verify that the display is blank.

7. Verify th at t h e mi ni mu m a n d ma x i mu m i nc o mi n g g a s pressures for the type of gas to be used are

in accordance with the accompanying table.

Incoming Gas Pressures

Gas Minimum Maximum

Natural

LP

6" W.C.

1.49 kPa

14.93 mbar

11" W.C.

2.74 kPa

27.37 mbar

14" W.C.

3.48 kPa

34.84 mbar

14" W.C.

3.48 kPa

34.84 mbar

2-3

Page 12

2.4 Connecting to the Gas Supply

GAS CONNECTIONS AND PIPE SIZES

The size of the gas supply pipe is very important. If the pipe is too small, the gas pressure at the

burner manifold will be low. This will cause slow recovery and delayed ignition. The incoming gas

supply line should be a minimum of 1½ inches (38mm) ID.

When configured for natural gas, this equipment requires a standard gas pipe size of ¾ inch (19mm)

ID for connections within 20 feet (6m) of the supply line, provided no more than 4 fittings or elbows

are used in the run. For a pipe run over 20 feet (6m), increase the pipe size to 1 inch (25.4mm). For

use with LP (Propane) gas, the next smaller pipe size may be used.

IF IN DOUBT ABOUT THE PIPE SIZE TO BE USED, CONSULT YOUR LOCAL GAS

COMPANY.

DANGER

Before connecting new pipe to this equipment, the pipe must be blown out

thoroughly to remove all foreign material. Foreign material in the burner and gas

controls may cause improper and dangerous operation.

1. Connect the equipment to the gas supply line.

When making connections, apply a small amount of Loctitite® PST 56765 or equivalent thread

compound to the male threads only. DO NOT apply the compound to the first two threads. This

will prevent clogging of the burner orifices and control valve.

2. Open the gas supply to the fryer and check all piping, fittings, and gas connections for leaks. A

soap and water solution should be used for this purpose.

DANGER

Never use matches, candles, or any other ignition source to check for leaks.

If gas odors are detected, shut off the gas supply to the fryer at the main shut-off

valve and contact the local gas company or an authorized service agency for service.

The rethermalizer and any shut-off valves installed between the rethermalizer and

the gas supply line must be disconnected from the gas supply line during any

pressure testing of the supply line at pressures equal to or greater than ½ PSIG

(3.45kPa, 13.84 inches W.C.).

3. Close the drain valve and fill the cookpot with water and boil-out solution to the overflow. Light

the burners and perform the boil-out procedures that are described in the “Start-Up Procedure”

and “Boiling Out the Cookpot” sections in Chapter 3 of this manual.

2-4

Page 13

WARNING

“Dry-firing” this equipment will cause damage to the cookpot. Always ensure that

the cookpot is filled with water before firing your unit.

4. It is suggested that the burner manifold pressure be checked at this time by the local gas com-

pany or an authorized service agent. Refer to “Check Burner Manifold Pressure” in Chapter 4 of

this manual for the proper procedure.

2.5 Converting to Another Gas Type

This equipment is configured at the factory for either natural gas or LP (Propane) gas.

If you desire to switch from one type of gas to the other, a gas conversion kit must be installed by a

Factory Authorized Service Center technician.

DANGER

Switching to a different type of gas without installing the proper conversion kit may

result in fire or explosion! NEVER attach your fryer to a gas supply for which it is

not configured.

2-5

Page 14

FBR18 & FBRA18 SERIES GAS RETHERMALIZERS

CHAPTER 3: OPERATING INSTRUCTIONS

3.1 Introduction

Mechanically, the FBR18 and FBRA18 rethermalizers are virtually identical, the only difference

being that the FBRA18 units have an automatic filling (AutoFill) feature. Both units use the same

digital temperature controller and mechanical timers.

In operation, a setpoint is programmed into the controller which then regulates burner firing to

maintain the water in the cookpot at the desired temperature. Six individual color-coded mechanical timers allow different types or quantities of product to be rethermalized simultaneously. The

timers are equipped with an alarm to notify the operator that rethermalizing is complete. The product baskets have color-coded handles that correspond to the timers to eliminate confusion.

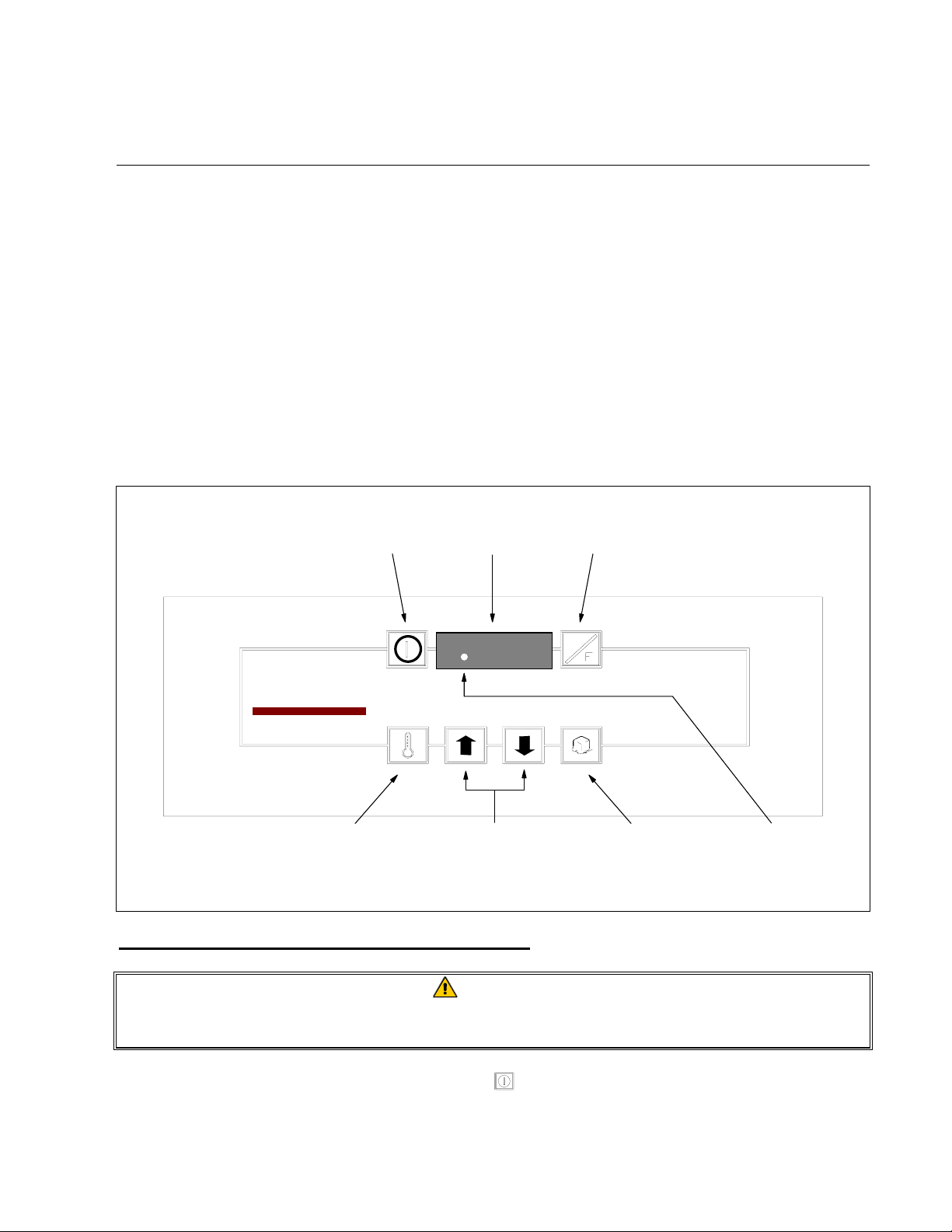

3.2 FBR18/FBRA18 Digital Controller

Celsius or

Power

Switch

Digital

Display

Fahrenheit

Display Switch

9 . 9 9 9

C

Frymaster

Temperature

or Setpoint

Display Switch

OPERATING THE FBR18/FBRA18 DIGITAL CONTROLLER

Setpoint

Adjustment

Arrows

Melt

Cycle

Switch

WARNING

Ensure the cookpot is filled with water before turning the controller on. “Dry firing”

will cause damage to the cookpot!

1. Turn the controller on by pressing the Power

switch. The controller software version num-

ber will display for 4 seconds in the digital display then change to the last programmed setpoint

temperature.

Heating

Mode

Indicator

3-1

Page 15

NOTE: The unit comes from the factory configured to display in degrees Fahrenheit. To toggle

back and forth between Fahrenheit and Celsius, press the Celsius/Fahrenheit display switch.

2. The controller will automatically cycle the burners on and off seven times or until the tempera-

ture in the cookpot reaches 160°F (71°C), whichever comes first. At that time, it will enter the

continuous heat mode. When in the continuous heat mode the Heat Mode indicator (a decimal

point between the first two digits of the temperature display) will appear. When the setpoint is

reached, the Heat Mode indicator will go out, indicating the rethermalizer is ready for use.

3. To enter or change the setpoint temperature, press the up arrow key to raise the setpoint or

the down arrow keys to lower the setpoint. The display will change at a rate of about 1

degree per second for approximately the first 12 degrees, then change at a faster rate if the

arrow is continuously pressed.

4. Pressing the Temperature/Setpoint display switch toggles the display back and forth be-

tween constant temperature display and constant setpoint display. Use this feature if you want

to check the actual cookpot temperature.

5. To turn the controller (and burners) off, press the Power

switch.

OPERATING THE FBR18/FBRA18 TIMERS

1. Place a packet of product in one of the rethermalizing baskets and note the handle color of the

basket.

2. Place the basket into the water and rotate the correspondingly colored timer knob to the desired

rethermalizing time, up to 60 minutes.

3. An alarm will sound when the rethermalizing time has elapsed.

3.3 Start-Up Procedure

CAUTION

If this is the first time the unit is being used after installation, refer to Section 3.4,

Boiling-Out the Cookpot.

Before turning the rethermalizer on, ensure that:

• the unit is connected to the water supply

• the water supply is turned on

• the unit is plugged into a 120VAC outlet

• the electrical power supply to the rethermalizer is turned on

• the gas supply to the rethermalizer is turned on.

3-2

Page 16

1. Turn the gas valve to the ON position (see illustration below).

ON

OFF

Hone yw ell

2. Press the controller Power switch.

On FBR18 models, the burners will light for several seconds then go out. A few seconds later

they will light again. This cycle will repeat seven times or until the water in the cookpot

reaches 160°F (71°C), whichever comes first, at which time the burners will remain lit until the

setpoint is reached.

On FBRA18 models, if the cookpot is not already full of water, the AutoFill feature will immediately begin adding water. When the water level reaches the upper water level sensor, the

AutoFill solenoid valve will cut off the water flow. (If the water level drops below the upper

water level sensor during operation, the AutoFill solenoid valve will open and add water to the

cookpot). When the water level is above the lower water level sensor, the burners will light for

several seconds then go out. A few seconds later they will light again. This cycle will repeat

seven times or until the water in the cookpot reaches 160°F (71°C), whichever comes first, at

which time the burners will remain lit until the setpoint is reached.

3. When the burners have been lit continuously for at least 90 seconds, observe the burners

through the burner viewing ports. The burners should display a bright orange-red glow. If a

blue flame is observed, or if there are dark spots on a burner face, the air/gas mixture requires adjustment. Refer to Chapter 4, Section 4.4, Clean Combustion Air Blower for ad-

justment procedures.

3.4 Boiling-Out the Cookpot

CAUTION

Do not use deliming solution to clean these units. Use of deliming solution will

damage all stainless steel parts.

To ensure that the cookpot is free of any contamination resulting from its manufacture, shipping,

and handling during installation, the cookpot must be boiled out before first use.

1. Close the drain valve and fill the cookpot with a solution of cold water and 1 cup of Frymaster

FRYER ‘N’ GRIDDLE cleaner or detergent. NOTE: Do not use deliming solution to clean

these units. Use of deliming solution will damage all stainless steel parts.

2. Place the unit into operation in accordance with Section 3.3.

3. Program the setpoint for 200°F (93°C). When the Heat Mode indicator (decimal between the

first two digits of the display) goes out, set one of the product timers for 60 minutes.

3-3

Page 17

4. After the solution simmers for an hour, turn the unit off, allow the solution to cool, then add 2

gallons (7.75 liters) of cold water and stir. Drain the solution and clean the cookpot thoroughly.

5. Rinse the cookpot at least twice by filling with clean water and draining.

6. Reprogram the setpoint to the appropriate temperature.

3.5 Shutting Down the Rethermalizer

1. Turn the unit off by pressing the Power switch.

2. If shutting down at the end of the day, turn the gas valve to the OFF position (see illustration

below).

ON

OFF

Honey w ell

3. Drain and clean the cookpot. NOTE: Do not use deliming solution to clean these units. Use of

deliming solution will damage all stainless steel parts.

CAUTION

Do not use deliming solution to clean these units. Use of deliming solution will

damage all stainless steel parts.

CAUTION

The electronic circuitry in your controller can be adversely affected by current

fluctuations and electrical storms. Should it fail to function or program properly for

no apparent reason, unplug the controller and plug it back in to reset it. This could

prevent a service call.

3-4

Page 18

FBR18 & FBRA18 SERIES GAS RETHERMALIZERS

CHAPTER 4: PREVENTIVE MAINTENANCE

4.1 Daily Checks and Services

Inspect Rethermalizer and Accessories for Damage

Look for loose or frayed wires and cords, leaks, foreign material in cookpot or inside cabinet, and

any other indications that the rethermalizer and accessories are not ready and safe for operation.

Clean Cabinet Inside and Out

Clean inside the cabinet with a dry, clean cloth. Wipe all accessible metal surfaces and components

to remove accumulations of oil, dust, or cooking residue.

Clean the outside of the cabinet with a clean cloth dampened with dishwashing detergent, removing

oil, dust, or cooking residue.

DANGER

Never attempt to clean rethermalizer during the rethermalizing process or when the

cookpot is filled with hot water and/or food products.

CAUTION

Do not use deliming solution to clean these units. Use of deliming solution will

damage all stainless steel parts.

Clean Water-Level Sensors, Temperature Probe, and Cookpot

NOTE: Do not use deliming solution to clean these units. Use of deliming solution will damage all

stainless steel parts.

Press the controller power switch to the OFF position.

FBRA18 Units: Remove the cap nut at the top of the shield (located on the left front of the cook-

pot) and remove the shield by lifting up until it can be removed from the stud that holds it at the

bottom. Clean the exposed screw heads with a solution of detergent and water. A Scotchbrite™ or

equivalent nylon pad may be used to scrub away any accumulated mineral deposits.

FBR18 & FBRA18 Units: Clean the temperature probe, located on the lower front centerline of

the cookpot, using a small bottlebrush wet with a solution of detergent and water.

Using a Scotchbrite™ or similar abrasive pad and a solution of detergent and water, clean the inside

of the cookpot.

Rinse the cookpot thoroughly with clean water at least twice.

4-1

Page 19

4.2 Quarterly Checks and Services

Check Digital Controller Set Point Accuracy

1. Fill the cookpot with water. Press the controller power switch. When the Heat Mode indicator

(decimal between the first and second digits of the display) goes out, insert a good-grade

thermometer or pyrometer probe into the cookpot, with the end touching the temperature probe

at the lower front centerline of the cookpot and wait one minute.

2. Press the Temperature Display switch once to display the temperature of the water as sensed

by the temperature probe. Press the Temperature Display switch again to display the set

point. The displayed water temperature should be within ±10°F (5°C) of the setpoint and the

temperature shown on the thermometer or pyrometer should be within ± 5ºF (2ºC) of the

displayed water temperature. If either set of readings is outside its range, contact a Factory

Authorized Service Center for assistance.

4.3 Semi-Annual Checks and Services

Clean Combustion Air Blower

1. Unplug the rethermalizer.

2. There are 4 wires (2 orange, 1 white, and 1 black) running from the motor. Remove the wire

nuts and disconnect these wires from the rethermalizer wiring harness, marking each to ensure

proper reconnection.

3. Remove the 4 nuts and bolts securing the blower to its mounting bracket and remove the blower

from beneath the rethermalizer.

4. Remove the 3 motor flange nuts from the side of the blower housing and remove the motor and

blower wheel from the housing.

5. Wrap the motor with plastic wrap to prevent water from entering it. Spray degreasing detergent

on the blower wheel and blower housing. Wait 5 minutes, then rinse under hot water, being

careful not to get water into the motor. Dry with a clean cloth.

6. Reverse steps 1-5 to reinstall the blower.

7. Light the rethermalizer in accordance with the procedure described in Chapter 3, Section 3.1.

8. After the burners have been lit for at least 90 seconds, observe the flames through the burner

viewing ports. The air/gas mixture is properly adjusted when the burner manifold gas pressure

is in accordance with the table on page 4-3 and the burners display a bright orange-red glow. If

a blue flame is observed, or if there are dark spots on a burner face, the air/gas mix requires adjustment.

On the side of the blower housing opposite the motor is a plate with one or two locking nuts.

Loosen the nut(s) enough to allow the plate to be moved, then adjust the position of the plate to

4-2

Page 20

open or close the air intake opening until a bright orange-red glow is obtained. Carefully hold

the plate in position and retighten the nut(s).

Clean Gas Valve Vent Tube

1. Set the rethermalizer power switch and the gas valve to the OFF position.

2. Carefully unscrew the vent tube from the gas valve. NOTE: The vent tube may be straightened

for ease in removal.

Vent Tube

3. Pass a piece of ordinary binding wire (.052 inch diameter) through the tube to remove any

obstruction.

4. Remove the wire, then blow through the tube to ensure it is clear.

5. Reinstall tube and bend so that the opening is pointing downward.

Check Burner Manifold Pressure

WARNING

Frymaster recommends that this task be performed by the local gas company or an

authorized service technician only.

1. Ensure that the gas valve knob is in the OFF position.

2. Remove the pressure tap plug from the gas valve assembly and attach the fitting for a gas

pressure-measuring device to the tap.

Pressure

Tap Plug

Regulator Cap

4-3

Page 21

3. Place the gas valve in the ON position. Place the controller power switch in the ON position.

When the burner lights and continues to burn, compare the indicated pressure to the table

below.

Burner Manifold Gas

Pressures

Gas Pressure

Natural

LP

3.5" W.C.

0.8 kPa

8.25" W.C.

2.5 kPa

4. If necessary, adjust the burner gas pressure by removing the cap from the gas valve regulator

and turning the regulator screw to obtain the correct pressure. When the correct pressure is

obtained, reinstall the cap.

5. Place the controller power switch and the gas valve in the OFF position. Remove the fitting

from the pressure tap hole and reinstall the pressure tap plug.

4-4

Page 22

FBR18 & FBRA18 SERIES GAS RETHERMALIZERS

CHAPTER 5: OPERATOR TROUBLESHOOTING

5.1 Introduction

This chapter provides an easy reference guide to the more common problems that may occur during

the operation of your equipment. The troubleshooting guides in this chapter are intended to help you

correct, or at least accurately diagnose, problems with your equipment. Although the chapter covers

the most common problems reported, you may very well encounter a problem not covered. In such

instances, the Frymaster Technical Service Department will make every effort to help you identify

and resolve the problem.

When troubleshooting a problem, always use a process of elimination starting with the simplest

solution and working through to the most complex. Never overlook the obvious. Anyone can forget

to plug a cord into a receptacle or open the valve on the water supply line. Don’t assume that you

are exempt from such occurrences.

Always try to establish a clear idea of why a problem has occurred. Part of your corrective action

involves taking steps to ensure that it doesn’t happen again. If a controller malfunctions because of

a poor connection, check all other connections while you’re at it. If a fuse continues to blow, find

the cause. Keep in mind that failure of a small component may often be indicative of potential

failure or incorrect functioning of a more important component or system.

Each guide begins with a description of a common problem in a six-sided figure. Simply follow the

arrows and answer the questions to determine the corrective action to take. If you have doubts as to

the proper action to take, do not hesitate to call the Frymaster Technical Service Department or your

local Frymaster Factory Authorized Service Center for assistance.

DANGER

Hot water can cause severe burns. Never attempt to move a rethermalizer

containing hot water or to transfer hot water from one container to another.

DANGER

Use extreme care when performing electrical circuit tests. Live circuits will be

exposed.

WARNING

Inspection, testing, and repair of electrical equipment should be performed only by

qualified service personnel. The equipment should be unplugged when servicing,

except when electrical tests are required.

5-1

Page 23

5.2 Troubleshooting Guides

NOTE: This guide applies

to FBRA18 units only.

COOKPOT DID NOT FILL

WHEN UNIT WAS TURNED ON.

WATER SUPPLY TO UNIT

VERIFIED TO BE ON.

Controller is not functioning.

Probable causes are failed 12V

transformer, failed interface

board, or failed controller.

Probable causes are a failed

interface board or

failed/loose high-level water

sensor wiring.

No

Did anything appear

in controller display when unit

was turned on?

Open control panel by

removing screws in

each upper corner.

LED on interface board

Use bottlebrush to

clean water level

No

Yes

Is WATER

illuminated?

No

sensors.

Did LED

illuminate?

Yes

Yes

Call FASC.

Problem

resolved.

5-2

Did unit begin

to fill?

NoYes

Probable causes are a failed

water solenoid or a failed

interface board.

Page 24

WATER DID NOT SHUT

OFF WHEN COOKPOT

WAS FULL.

NOTE: This guide applies

to FBRA18 units only.

Use bottlebrush to clean

water level sensors.

Problem

resolved.

Mineral content of water is

insufficient for water sensor to

detect it. Whenever cookpot is

refilled, add 1/8 cup of salt.

Remove the cover over the

water sensors and thoroughly

clean the sensors with a

Scotchbrite or similar pad.

Yes

Yes

Yes No

Did water

stop?

No

Add 1/8 cup of salt to

water in cookpot and

stir.

Did water

stop?

No

Open control panel by

removing screws in each

upper corner.

Is WATER

LED on interface board

illuminated?

Probable cause is failed

water solenoid.

If water still does not stop,

probable cause is

failed/loose high water

sensor wiring.

Call FASC.

5-3

Page 25

WATER NOT HEATING.

AUTOFILL (IF INSTALLED)

WORKED PROPERLY.

Press the Temperature

Check button twice to

display setpoint.

Has the correct setpoint

been programmed?

Yes

Did burners

light?

Yes

Did water reach

setpoint temperature?

Yes

Problem

resolved.

No

No

No

Insert a good grade thermometer into

the Temperature Check button once to

Program setpoint in

accordance with instructions

in Chapter 3.

Refer to troubleshooting

guide "BURNERS DO NOT

LIGHT".

cookpot with tip near temperature

probe and wait two minutes. Press

display cookpot temperature.

Is temperature

displayed reasonably

close to thermometer

reading?

No

There is a problem in

temperature probe

circuit. Call FASC.

Yes

Temperature control

features are working properly.

If water still fails to reach

setpoint, call FASC.

5-4

Page 26

BURNERS DO

NOT LIGHT.

Verify that correct setpoint has

been programmed, that main gas

supply valve is open, and that

equipment gas valve is set to ON.

Press ON/OFF button.

Did burners

light?

No

Use bottlebrush to clean low water

sensor. If burners still do not light,

remove the cover over the water

sensors and thoroughly clean them

with a Scotchbrite or similar nylon pad.

Did burners

light?

No

Open control panel by

removing screws in

each upper corner.

Yes

Yes

Problem

resolved.

Problem

resolved.

Is HEAT LED

on interface board

illuminated?

No

Problem is with a

failed interface board or a

malfunctioning computer.

Call FASC.

Yes

5-5

Problem is with the gas

supply or ignition system.

Call FASC.

Page 27

5.3 Replacing the Controller or Controller Wiring Harness

1. Disconnect the rethermalizer from the electrical supply.

2. Remove the two screws in the upper corners of the control panel and swing the panel open from

the top, allowing it to rest on its hinge tabs.

3. Disconnect the wiring harness from the back of the controller. If replacing the harness, discon-

nect it from the interface board, install the new harness, and then reverse steps 1 and 2 to

complete the process.

4. Disconnect the ground wire from the controller. Remove the control panel by lifting it from the

hinge slots in the frame.

If substituting one complete control panel for another, reverse steps 1-4 to complete the

procedure.

If replacing the controller, remove the nuts securing the controller to the control panel and install

the replacement controller on the control panel. Reverse steps 1-4 to complete the procedure.

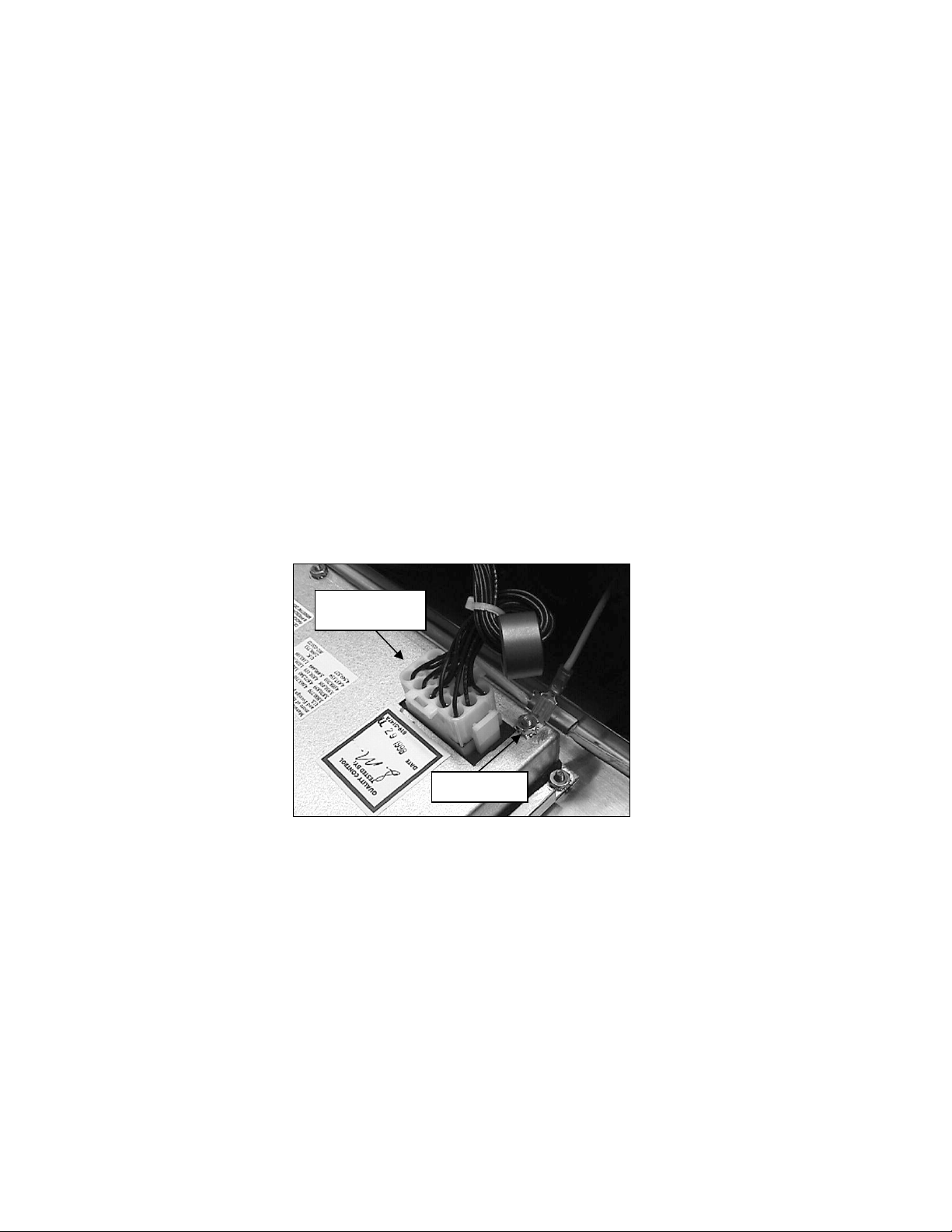

Wiring Harness

Connection

Ground Wire

5-6

Page 28

FBR18 & FBRA18 SERIES GAS RETHERMALIZERS

CHAPTER 6: SERVICE PROCEDURES

6.1 Functional Description

These rethermalizers contain a welded stainless steel cookpot that is directly heated by a high efficiency burner system requiring approximately 43% less energy than conventional burner systems to

heat the same volume of water.

Two self-contained combustion chambers (referred to as “burners”) are located beneath the cookpot.

Each combustion chamber is fitted with special ceramic tiles that are heated by the burning of a

forced air/gas mixture. The tiles transfer their heat to the cookpot by means of infrared radiation,

providing much more constant and uniform heat dispersion over the surface of the cookpot than do

conventional burners. Because relatively less heat is lost to the atmosphere in the process, compared

to “open-burner” designs, less fuel is required to achieve and maintain a given cookpot temperature.

Gas flow to both of the burners is regulated by one electromechanical gas valve.

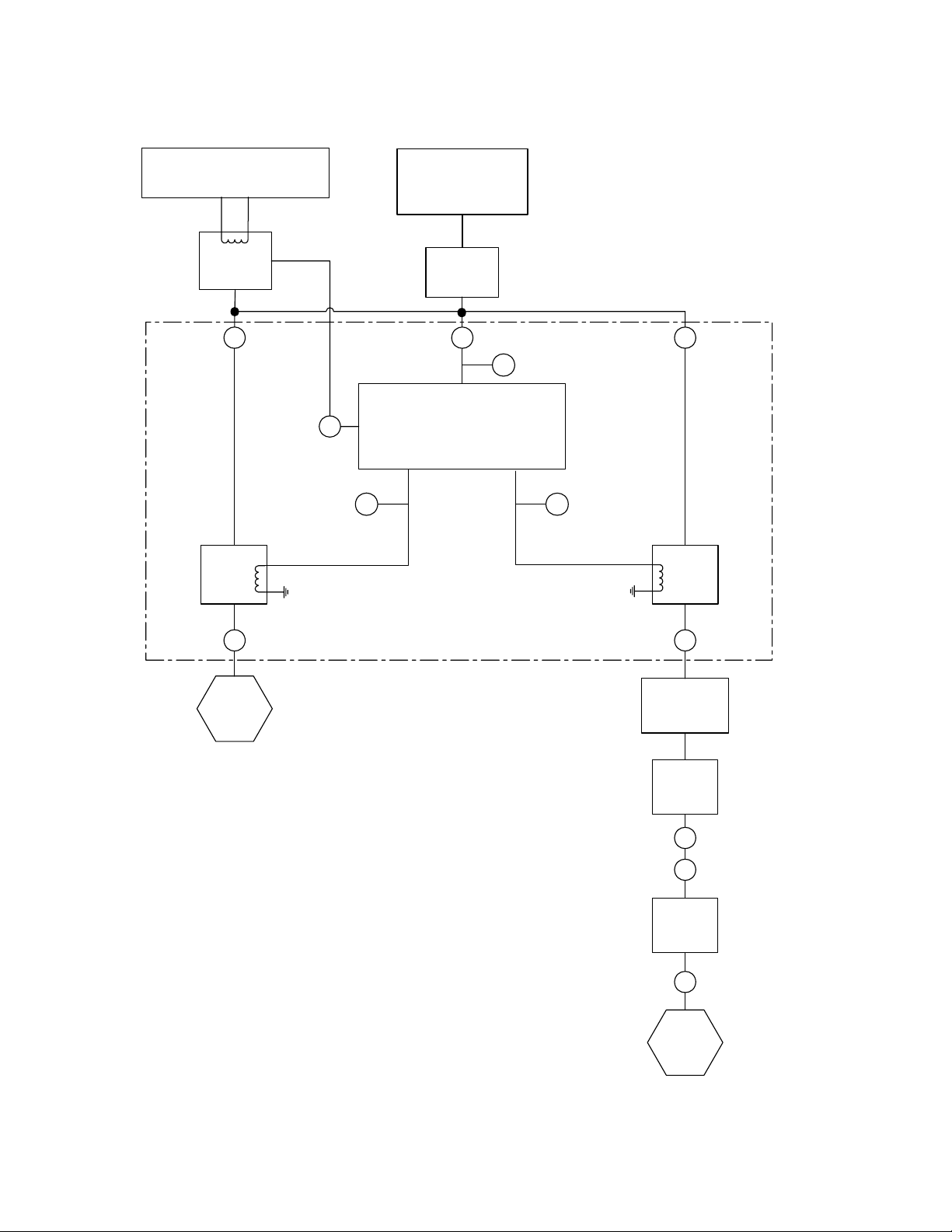

THE ELECTRONIC IGNITION SYSTEM

Ignition modules, located in the component box, are

connected to ignitor assemblies at each burner. An

ignition module performs four important functions: it

provides fuse protection for the 24-volt circuit, provides

an ignition spark, supplies voltage to the gas valve, and

proofs the burner flame. The module contains a 4second time delay circuit and a coil that activates the

gas valve.

The ignitor assembly consists of a spark plug, an

enrichment tube, and a flame sensor.

At start-up, the power switch is placed in the ON

position, supplying approximately 12-volts DC to the

heat control circuitry in the controller and to one side of

the heat relay coil on the interface board. If resistance

in the temperature probe indicates the temperature in the cookpot is below 160ºF (71ºC), the current

flows through a warm-up circuit containing a timer switch that alternately closes for 4 seconds and

opens for 24 seconds. If the temperature is 160ºF (71ºC) or above, the current flows through a heat

circuit, bypassing the timer switch. In either case, ground is supplied to the other leg of the heat relay coil, which then closes an electronic switch in the 24 VAC circuit to provide current to the ignition module.

Circuitry in the ignition module sends 24 VAC to the gas valve. Simultaneously, the module causes

the ignitor to spark for 4 seconds to light the burner. A flame sensor verifies that the burner is lit by

measuring the flow of microamps through the flame. If the burner does not light (or is extin-

Inside the Ignition Module

Out to

Gas Valve

To Alarm

25 V +

Coil

TD

HV

25 V GND

Ignition Wire Flame Sensor

6-1

Page 29

guished), current to the ignition module is cut, preventing the main valve from opening, and the ignition module “locks out” until the power switch is turned off and then back on.

A probe monitors the temperature in the cookpot. When the programmed setpoint temperature is

reached, resistance in the probe causes the heat cycle circuitry in the controller to cut off current

flow through the heat relay. This in turn cuts off the 24 VAC to the ignition module, causing the gas

valve to close.

CONTROLLER AND MECHANICAL TIMERS

FBR18 and FBRA18 Series rethermalizers are equipped with a digital controller that allows the operator to enter or adjust a specific rethermalizing temperature for the cookpot. The controller does

not control rethermalizing times. Rethermalizing times for up to six different products are specified

by means of 60-minute mechanical timers arrayed across the front of the unit.

INTERFACE BOARDS

An interface board is located in the component box directly behind the control panel. The interface

board provides a link between the controller and the rethermalizer’s individual components without

requiring excessive wiring, and it allows the controller to execute commands from one central point.

FBR18 and FBRA18 models use different interface boards. The boards are not interchangeable.

FBR18 rethermalizers have been manufactured with two different interface boards, similar in appearance to the ones illustrated below. Regardless of the board used when manufactured, the uni-

versal replacement part is 806-3398. Earlier design boards may be replaced with later design

boards and vice versa.

SOUND

1

2

GND

3

3 6 9 12

2 5 8 11

J1

1 4 7 10

GND

V2D

PWR

AD

AS

V2S

GND GV PWR

EARLIER DESIGN INTERFACE BOARD P/N 806-3398

J2

K3 K5

NOT

USED

NOT

USED

12 6 3 45

AL 12V AIR 24V AL

K4

BLOWER

MOTOR

RELAY

K1 K2

10741

11852

12963

13

14

15

NOT

USED

HEAT

RELAY

PWR

J3

GV

GND

3 6 9 12

2 5 8 11

1 4 7 10

GND

GND

V1D

PWR

ALR

V1S

SOUND

1

2

GND

3

3 6 9 12

2 5 8 11

J1

1 4 7 10

D1

GND

V2D

PWR

AD

AS

D2

V2S

GND

LATER DESIGN INTERFACE BOARD P/N 806-3398

GV

PWR

J2

K1

NOT

USED

D3

NOT

USED

24V

K2 K3

10741

11852

12963

K4

13

14

D6

15

12V

NOT

USED

HEAT

RELAY

AND

BLOWER

MOTOR

RELAY

3 6 9 12

2 5 8 11

1 4 7 10

Blower

Motor

2 Amp

D4

PWR

GND

GND

D5

GV

D7

AIR

J3

GND

V1D

PWR

ALR

V1S

In earlier versions, nine diagnostic LEDs are arrayed along the bottom edge of the board. Each of

the LEDs is labeled with two or three letters indicating its function, and six of them are numbered.

In later versions, there are seven LEDs scattered around the board. All of these LEDs are labeled

and numbered. The diagnostic purposes of LEDs 1 through 6 on one board correspond directly to

those of LEDs 1 through 6 on the other board. When lit, LED 3 indicates the 24VAC is being received from the transformer. LEDs 2 and 4, when lit, indicate that 24VAC is being supplied to the

left and right ignition modules respectively. LED 5, when lit, indicates that 24VAC is being supplied to the gas valve. A lit LED 6 indicates that 12VAC is being received from the transformer.

All other LEDs have no diagnostic purpose in rethermalizer applications.

6-2

Page 30

The relays in earlier design boards are soldered on and cannot be replaced. Later design boards feature replaceable plug-in relays. In earlier designs boards, a heat relay (K2) switches 24VAC to the

ignition and gas valve circuits when the controller heat logic circuit calls for heat. Simultaneously, a

blower motor relay (K4) switches 120VAC to the blower motor. In later design boards, relay K3

serves as both the heat relay and blower motor relay.

FBRA18 rethermalizers use interface board 806-9592, often referred to as a water board.

J2

1

K1

HEAT

1

J1

INTERFACE BOARD P/N 806-9592

WATER

CYCLE WATER BLOWER

K2

K3

BLOWER

J3

POWER

On interface board 806-9592, the heat (or cycle) relay (K1) switches 24VAC to the ignition and gas

valve circuits when the controller’s heat logic circuit calls for heat and the lower water level sensor

is grounded (i.e., the water level in the cookpot is above the lower water level sensor). If the water

level in the cookpot is below the upper water level sensor, the water relay (K2) closes, switching

power to the normally closed water solenoid valve, causing it to open. When the water level reaches

the upper sensor, the relay opens, cutting power to the valve, causing it to close. The blower relay

(K3) closes and switches 120VAC to the blower motor only when the heat relay (K1) is closed. The

board has four LEDs to assist in troubleshooting. Three of the LEDs (CYCLE, WATER, and

BLOWER) are arrayed along the lower edge of the board. The fourth LED (POWER) is located at

the right edge of the board. When the cycle, water, and blower LEDs are illuminated, they indicate

that the associated relay is closed. The power LED indicates that 24VAC is being supplied to the

interface board by the transformer.

TEMPERATURE PROBE

A temperature probe is located on the front centerline of the cookpot. The probe is a type of thermo-

stat in which the resistance varies directly with the temperature. That is, as the temperature changes,

so does resistance, at a rate of approximately 2 ohms for every 1° of rise or fall. Circuitry in the

controller monitors the probe resistance and controls burner firing when the resistance exceeds or

falls below a programmed temperature (setpoint). The temperature is programmed by means of up

or down arrow buttons on the face of the controller.

WATER LEVEL SENSORS (FBRA18 Only)

A pair of water level sensors is arranged one above the other on the left front of the FBRA18 cook-

pot. When water contacts the sensors they are grounded. The lower sensor acts as a safety device to

keep the burner from firing when there is no water in the cookpot. When the sensor is grounded by

contact with water, a transistor on the interface board is biased and the heat relay (K1) pulls in, supplying power to the blower via relay K3 and to the gas valve via the ignition modules. Grounding

the upper water level sensor causes the water relay (K2) to open. This cuts power to the water solenoid valve, which closes, cutting off water flow into the cookpot.

6-3

Page 31

6.2 Accessing the Rethermalizer for Servicing

DANGER

Moving a rethermalizer filled with hot water may cause spilling or splattering of the

hot water. Always drain the cookpot before attempting to relocate the unit for servicing.

1. Shut off the gas supply to the unit. Unplug the electrical power cord. Disconnect the unit from

the gas supply.

2. Remove any attached restraining devices.

3. Relocate the rethermalizer for service accessibility.

4. After servicing is complete, reconnect the unit to the gas supply, reattach restraining devices, and

plug in the electrical power cord.

6.3 Cleaning the Gas Valve Vent Tube

Refer to Semi-Annual Checks and Services in Chapter 4, Preventive Maintenance.

6.4 Checking the Burner Manifold Gas Pressure

Refer to Semi-Annual Checks and Services in Chapter 4, Preventive Maintenance.

6.5 Measuring Flame Current

When the burner flame is properly adjusted, it will produce a current between 3.5 μA and 6.5 μA.

Flame current is measured by placing a microamp (not milliamp) meter in series with the white sensing wire on the ignitor. This is accomplished as follows:

1. Turn the unit OFF (press the

2. Disconnect the white flame sensor wire

button).

Ignitor Wire

Flame Sensor

Wire

from one of the burner ignitor assemblies

and connect it to the positive lead of the

meter. Connect the negative lead of the

meter to the terminal from which the

sensing wire was removed.

3. Turn the unit ON (press the

button).

When a cold unit is first turned on, the

burner will cycle on and off repeatedly

until the temperature in the cookpot

reaches 180°F (82°C). When the water in

the unit exceeds that temperature, the burner will stay on until the setpoint is reached. Check the

reading when the burner has been on continuously for at least one minute.

6-4

Page 32

6.6 Replacing Components

6.6.1 Replacing the Controller or Controller Wiring Harness

Refer to Chapter 5, Section 5.3 for this procedure.

6.6.2 Replacing the Temperature Probe

1. Unplug the rethermalizer and drain the cookpot.

2. Remove the screws from the upper corners of the timer panel and swing the panel open from the

top, allowing it to rest on its hinge tabs. Cut the probe leads off at the rear of the probe. NOTE:

Once the probe leads have been cut, the probe cannot be reused. Work the Tinnerman retaining

clip rearward off the probe.

3. Remove the two screws securing the probe cover to the probe block and remove the cover. Slip

the failed probe out of the block from the cookpot side and replace with a new probe. Carefully

remove the Tinnerman retaining clip from the replacement probe to allow the leads and short end

of the probe to be inserted through the probe block from cookpot side. When the replacement

probe has been inserted, work the retaining clip onto the probe until the probe is held securely in

place. Reinstall the probe cover and timer panel.

4. Remove the screws from the upper corners of the control panel and swing the panel open from

the top, allowing it to rest on its hinge tabs. Remove the two upper screws securing the component box to the rethermalizer. Rotate the box forward and outward to expose the 12-pin connector on the rear of the interface board.

5. Unplug the 12-pin connector from the interface board. Using a pin pusher, remove the cut off

pieces of wire from the connector one at a time, and insert the corresponding wire from the new

probe.

6. Reattach the 12-pin connector to the interface board, rotate the component box back into posi-

tion, and replace and tighten the mounting screws. Close the control panel and replace the

screws in each upper corner.

6.6.3 Replacing the Interface Board

1. Unplug the rethermalizer and drain the cookpot.

2. Remove the screws from the upper corners of the control panel and swing the panel open from

the top, allowing it to rest on its hinge tabs.

3. Detach the grounding wire from the controller, unplug the 15-pin connector from the interface

board, and remove the control panel from the unit by lifting it up and out of the hinge slots in the

control panel frame.

4. Remove the two upper screws securing the component box to the rethermalizer. Rotate the box

forward and outward to expose the 12-pin connector on the rear of the interface board, and unplug it from the board.

6-5

Page 33

5. On FBRA18 models only, mark the water level sensor wires and disconnect them from terminals

J1-1 (upper sensor) and J1-2 (lower sensor).

6. Remove the nuts in each corner of the interface board and carefully pull the board off the mount-

ing studs, being careful not to dislodge the spacers on the studs.

7. Position the replacement board on the studs and replace the four nuts.

8. Reconnect the water level sensor wires (FBRA18 models only) and the 12-pin connector to the

interface board.

9. Rotate the component box back into position and replace and tighten the mounting screws. Re-

mount the control panel to the component box and reattach the grounding wire.

10. Reattach the 15-pin connector to the interface board.

11. Close and secure the control panel.

6.6.4 Replacing an Ignition Module

1. Unplug the rethermalizer and drain the cookpot.

2. Disconnect the ignitor wire and flame sensor wire from the right burner assembly.

3. Remove the five screws from the rear of the transformer box and pull the box out of the unit suf-

ficiently to allow the removal of the five screws in the cover of the box. Remove the cover.

4. Unplug the ignitor wire and flame sensor wire from the module to be replaced. Disconnect the

remaining wires from the ignition module one at a time and mark them to facilitate reconnection.

5. Remove the four screws securing the module in place and lift the module out of the box. Re-

move the four spacers from the back of the failed module and insert them into the holes on the

replacement module, tapered end in.

6. Reverse steps 1 through 5 to complete the procedure.

6.6.5 Replacing an Ignitor Assembly

1. Unplug the rethermalizer and drain the cookpot.

2. Remove the ignitor wire and flame sensor wire from the ignitor assembly. Disconnect the gas

enrichment tube from the assembly.

3. Remove the two mounting screws and pull the ignitor assembly out of the burner.

4. Install the replacement ignitor assembly.

5. Reconnect the ignitor wire, flame sensor wire, and gas enrichment tube.

6-6

Page 34

6.6.6 Replacing the Combustion Air Blower

Refer to Chapter 4, Section 4.4, Clean Combustion Air Blower, for instructions on removing and reinstalling the combustion air blower.

6.6.7 Replacing the Gas Valve

1. Turn off the gas supply to the rethermalizer, unplug the unit, and drain the cookpot.

2. Disconnect the unit from the gas supply line and remove any fitting that may be attached to the

gas manifold at the rear of the unit.

3. Disconnect the gas lines at each burner orifice.

4. Disconnect the gas enrichment tubes at the gas valve cross fitting.

5. Disconnect the wires from the gas valve terminal, marking each wire to facilitate reconnection.

6. Remove the two nuts securing the gas manifold bracket to the base frame.

7. Pull the gas manifold assembly out the front of the unit.

8. Remove the gas valve from the manifold assembly and remove all fittings from the old valve.

9. Install the fittings removed from the old valve on the new valve, using Loctite® PST56765 or

equivalent pipe thread sealant.

10. Apply Loctite® PST56765 pipe thread sealant or equivalent to the threads of the manifold and

install the new gas valve.

11. Position the gas manifold system in the unit and replace the two nuts removed in step 6.

12. Reverse steps 1-5 to complete installation.

13. Check burner manifold gas pressure in accordance with procedure given in Chapter 4.

6.6.8 Replacing a Burner Assembly

NOTE: If space permits, it is recommended that the unit be disconnected from the gas line and laid

(

on its back when performing this procedure. Be sure to place blocks under the unit to protect the

end of the gas line.)

1. Unplug the rethermalizer.

2. Disconnect the flexible gas line at the burner orifice.

3. Remove both air hoses from the blower assembly and the burner assemblies.

6-7

Page 35

4. Remove the four screws from the blower stabilizing bracket attached to the blower assembly and

to each burner. Remove the stabilizing bracket from the unit.

5. Remove the screw securing the blower support bracket to the cookpot assembly and lower the

blower assembly out of the way. It is not necessary to disconnect the blower wiring.

6. Remove the two screws at the front of the burner assembly to be replaced, then pull the assembly

toward the front of the unit slightly to free it from its rear support. Remove the assembly

through the bottom of the unit.

7. Reverse steps 1-6 to install replacement burner assembly, being careful to get the insulation strip

running along the top of the blower support bracket back in place.

6.6.9 Replacing the Cookpot

1. Remove the cookpot insert.

2. Remove the top cap by removing the two screws on the front and the screw on each end.

3. Remove the flue cap and lid assembly by removing the two screws on each side and the two out-

ermost screws on the back. Rotate the bottom of the flue cap forward slightly to allow the top of

the flue cap to slip out from under the back panel.

4. Remove the four screws securing the upper flue assembly to the back panel.

5. Remove the blower motor by removing the four nuts securing it to blower mounting bracket.

6. Disconnect the flexible gas lines, gas enrichment tubes, ignitor wires, and flame sensor wires

from the burner assemblies.

7. Remove the temperature probe from the cookpot. Leave wires attached.

8. Disconnect the water fill line at the cookpot and at the solenoid valve inlet.

9. Disconnect the wires from the water level sensors, marking them to facilitate reconnection.

10. Lift the cookpot assembly out of the cabinet and set it, top down, on a suitable work surface.

11. Remove all other hardware from the old cookpot and install the components on the replacement

®

cookpot, using Loctite

PST56765 on the drain valve threads. (NOTE: Install any replacement

insulation that might be required before installing components.)

12. Reverse steps 1-10 to install the replacement cookpot.

6.7 Troubleshooting and Problem Isolation

Because it is not feasible to attempt to include in this manual every conceivable problem or trouble

condition that might be encountered, this section is intended to provide technicians with a general

6-8

Page 36

knowledge of possible problems, and the probable causes of each. With this knowledge, the technician should be able to isolate and correct any problem encountered.

Problems that are likely to be encountered can be grouped into five broad categories:

1. Ignition failures

2. Improper burner functioning

3. Improper temperature control

4. Controller-related problems

5. Autofill system problems.

The probable causes of each category are discussed in the following sections. A series of troubleshooting guides (decision trees) is also included at the end of the chapter to assist in identifying

some of the more common problems.

6.7.1 Ignition Failures

Ignition failure occurs when the ignition module fails to sense a flame within 4 seconds and locks

out. When this happens, the module sends 24 VAC through the interface board alarm circuit to the

controller and the trouble light on the timer control panel lights.

The three primary reasons for ignition failure, listed in order of probability, are:

1. Problems related to the gas and/or electrical power supplies.

2. Problems related to the electronic circuits.

3. Problems related to the gas valve.

PROBLEMS RELATED TO THE GAS AND/OR ELECTRICAL POWER SUPPLIES

The main indicator of a problem with the electrical power supply is that there are no indicator lights

illuminated on the unit. The main indication of a problem with the gas supply is failure of the unit to

fire. Verify that the gas line quick-disconnect fitting (if used) is properly connected, the unit is

plugged in, the main gas supply valve is open, and the circuit breaker for the unit’s electrical supply

is not tripped.

PROBLEMS RELATED TO THE ELECTRONIC CIRCUITS

If gas and electrical power are being supplied to the rethermalizer, the next most likely cause of ignition failure is a problem in the 24 VAC circuit. First, verify that the drain valve is fully closed. (The

drain valve assembly includes a microswitch that must be closed for power to reach the gas valve.

Often, although the valve handle appears to be in the closed position, the microswitch is still open.)

If the drain valve is fully closed, refer to the troubleshooting guide

CIRCUIT

.

TROUBLESHOOTING THE 24 VAC

Some typical causes of ignition failure in this category include a defective sensing wire in the ignitor

assembly, a defective module, a defective ignition wire, or a defective ignitor. Occasionally an igni-

6-9

Page 37

tion failure situation may be encountered in which all components appear to be serviceable and the

microamp reading is within specification, but the unit nevertheless goes into ignition failure during