Page 1

CONTROLLER

YUM F3000

Operation Manual

Frymaster, a member of the Commercial Food Equipment Service Association, recommends using

CFESA Certified Technicians.

www.frymaster.com E-mail: service@frymaster.com

24-Hour Service Hotline 1-800-551-8633

*8196710*

FEB 2013

Page 2

NOTICE

IF, DURING THE WARRANTY PERIOD, THE CUSTOMER USES A PART FOR THIS MANITOWOC

FOOD SERVICE EQUIPMENT OTHER THAN AN UNMODIFIED NEW OR RECYCLED PART

PURCHASED DIRECTLY FROM FRYMASTER DEAN, OR ANY OF ITS AUTHORIZED SER VICERS,

AND/OR THE PART BEING USED IS MODIFIED FROM ITS ORIGINAL CONFIGURATION, THIS

WARRANTY WILL BE VOID. FURTHER, FRYMASTER DEAN AND ITS AFFILIATES WILL NOT BE

LIABLE FOR ANY CLAIMS, DAMAGES OR EXPENSES INCURRED BY THE CUST OMER WHICH

ARISE DIRECTLY OR INDIRECTLY, IN WHOLE OR IN PART, DUE TO THE INSTALLATION OF

ANY MODIFIED PART AND/OR PART RECEIVED FROM AN UNAUTHORIZED SERVICER.

NOTICE

This appliance is intended for professional use only and is to be operated by qualified

personnel only. A Frymaster Authorized Servicer (FAS) or other qualified professional should

perform installation, maintenance, and repairs. Installation, maintenance, or repairs by

unqualified personnel may void the manufacturer’s warranty.

NOTICE

This equipment must be installed in accordance with the appropriate national and local codes of

the country and/or region in which the appliance is installed.

NOTICE TO OWNERS OF UNITS EQUIPPED WITH CONTROLLERS

U.S.

This device complies with Part 15 of the FCC rules. Operation is subject to the following two

conditions: 1) This device may not cause harmful interference, and 2) This device must accept

any interference received, including interference that may cause undesired operation. While

this device is a verified Class A device, it has been shown to meet the Class B limits.

CANADA

This digital apparatus does not exceed the Class A or B limits for radio noise emissions as set

out by the ICES-003 standard of the Canadian Department of Communications.

Cet appareil numerique n’emet pas de bruits radioelectriques depassany les limites de classe A

et B prescrites dans la norme NMB-003 edictee par le Ministre des Communcations du Canada.

DANGER

Prior to movement, testing, maintenance and any repair on your Frymaster fryer, disconnect

ALL electrical power from the fryer.

NOTICE

The instructions in this manual for using a bulk oil system for filling and discarding oil are for a

Frontline or RTI system. These instructions may not be applicable to other bulk oil systems.

Page 3

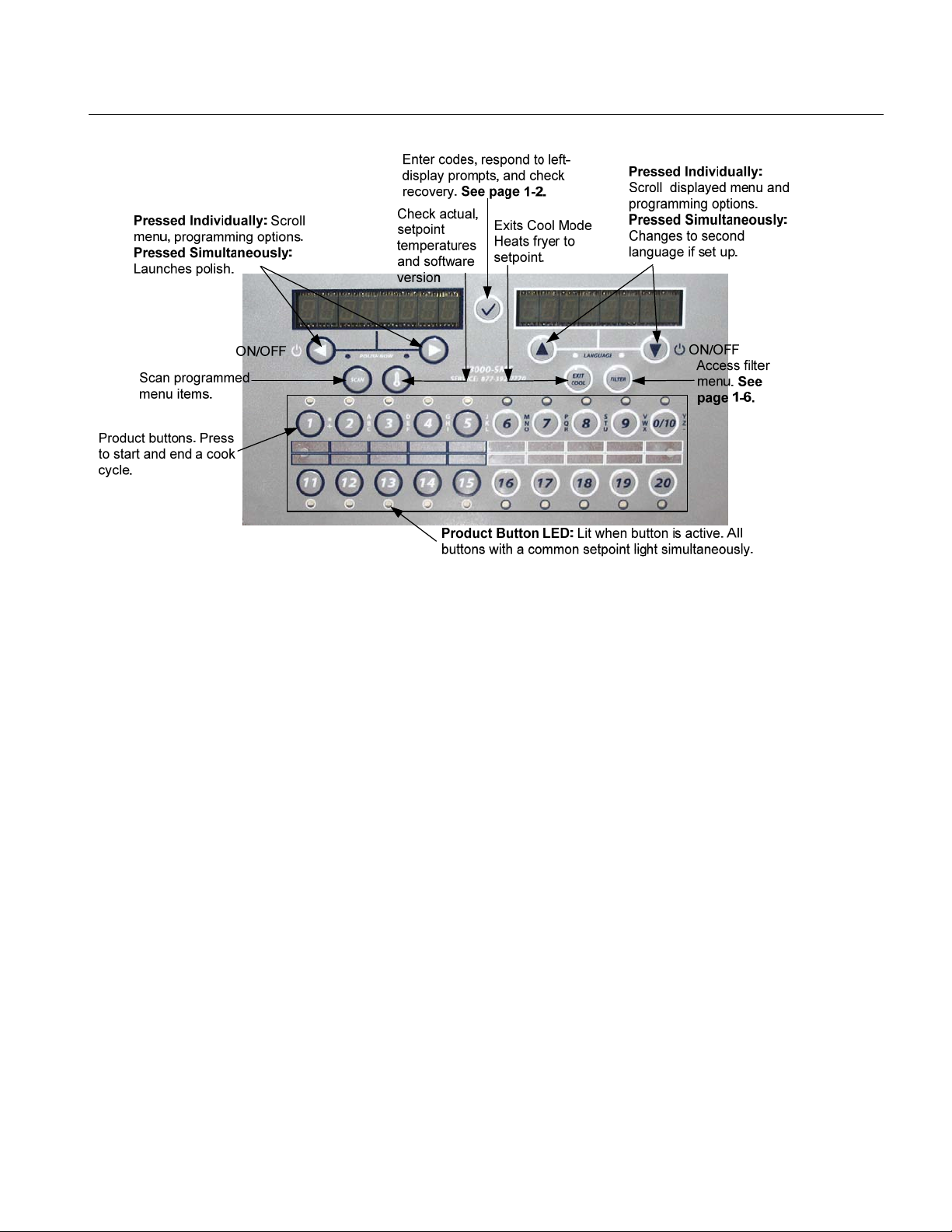

CHAPTER 1: F3000 CONTROLLER INSTRUCTIONS

1.1 Using the F3000

ON/OFF

ON - Press ON/OFF button fryer heats to setpoint or idle temperature and displays: COOL or DROP.

OFF- Press and hold ON/OFF button. Controller displays OFF.

Cooking

Fryer displays COOL or DROP

COOL display: Press product button; fryer heats to setpoint and displays DROP.

DROP display: Press product button and drop product.

DONE display: Press product button to cancel alarm.

CANCEL: Press and hold product button to cancel a cook cycle.

Responding to Polish Prompt

Computer displays Polish Now, alternating with Yes No.

Press Yes (button under Yes display) and the polish cycle launches.

Computer displays Cool after polish cycle.

Computer Button Navigation

Product: Active when adjacent LED is lit. Press to launch cook cycle. Press and hold to cancel a launched cook

cycle. Press at end of cook cycle to halt alarm and end cook.

Scan: Press once, all product buttons are lit; Select Product displayed. Press product button to view product

name. Press Scan again to repeat. Press Scan twice to return to normal operation.

Left/Right Arrows: Navigate options in left display.

Up/Down Arrows: Navigate options in right display. Press the up/down a rrow simultaneously to change to a

second language if one is selected in setup.

Exit Cool: Exits cool mode and sets fryer’s temperature to setpoint.

Thermometer: Fryer ON: Press and release for setpoint/left; vat temp/right.

Thermometer: Fryer OFF: Press to display temperature, time, date, system version, F3000 version and circuit

board versions.

Checkmark: Fryer OFF: Press and hold 3 seconds: Scroll filter usage; Press and hold 10 seconds: Product

setup.

Checkmark: Fryer ON: Check recovery and respond to prompts.

Filter: Press and release: Cooks remaining to filter cycle. Press and hold: Filter options: Filter, Clean,

Dispose, Drain to Pan and Fill Vat from Pan.

1-1

Page 4

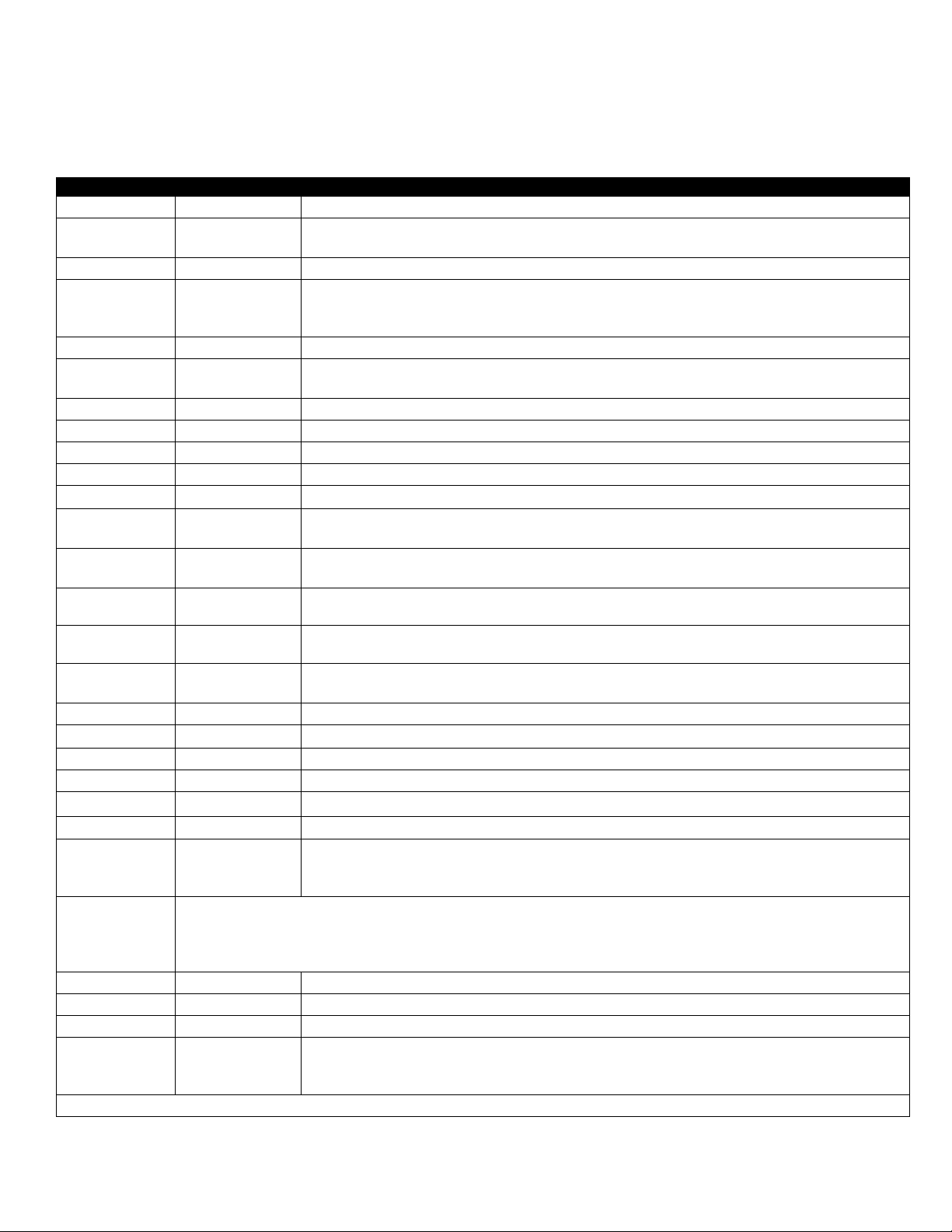

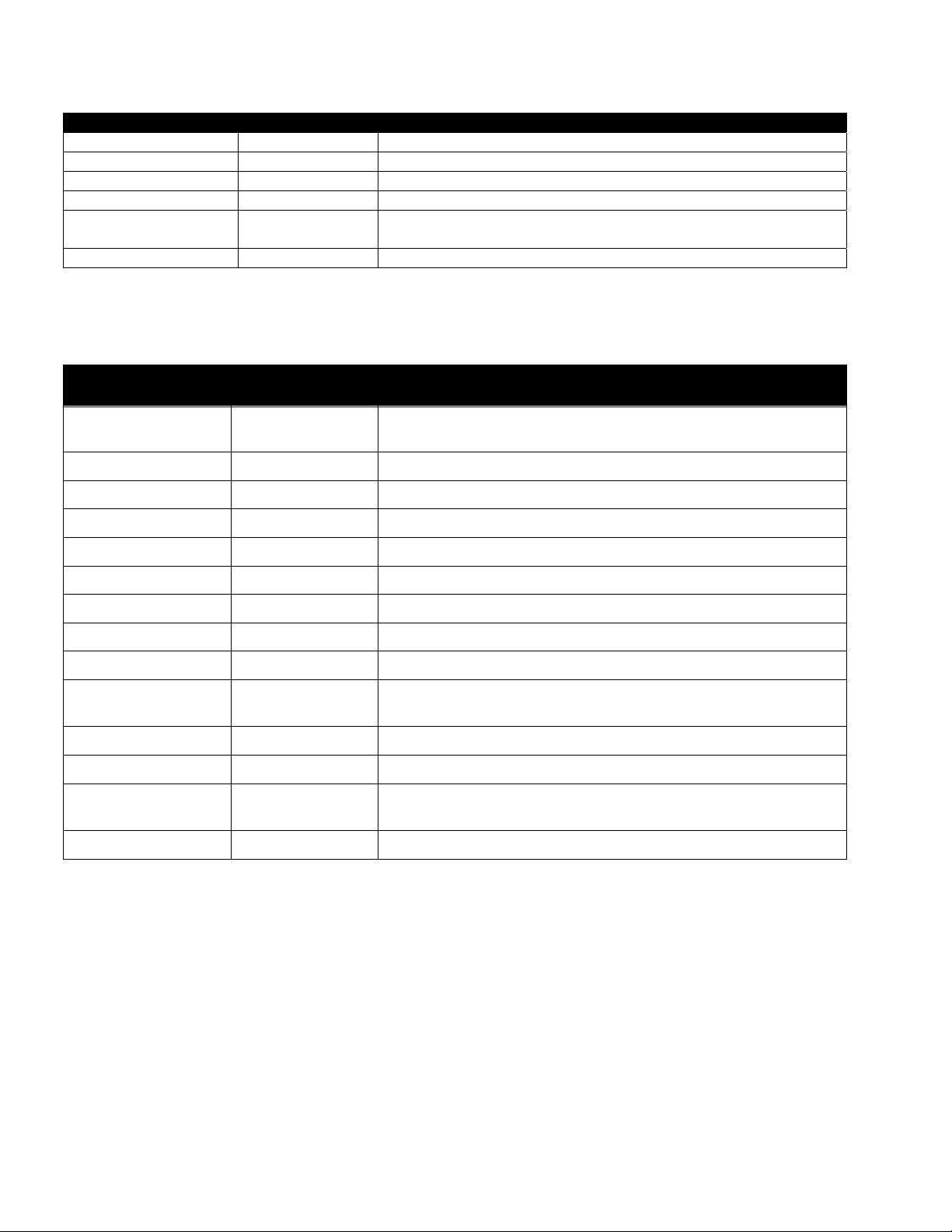

1.2 Navigating controller

Press and hold the checkmark button for 10 seconds produces the setup mode, which first displays Product Setup. Follow the

steps below to navigate the options. Unpopulated fields indicate a blank display.

Left Display Right Display Action

OFF OFF

Product Setup

Product Setup

Press to scroll: Vat Setup, Tech Mode, and Exit. With the desired selection displayed,

Product setup (entering and editing menu items) is described on page 1-11 through 1-14.

Press and hold until Product Setup is displayed.

press .

vat setup

Tech Mode

Exit Exit

Vat Setup is described on page 1-4.

Tech mode is for technicians only.

Press Scan button until the controller displays OFF.

1.3 Viewing Operational Stats

The F3000 collects and stores information on the cook cycles and filter cycles. This data is accessed in the info mode, which is

accessed by pressing the checkmark button. The steps to view the data are detailed below:

Left Display Right Display Action

OFF OFF

Oil stats

Total cooks - last

dispose

Total heads—last

dispose

Last dispose date

TEMP > 300F—TODAY

TEMP > 300f– Since

dispose

TEMP > 300F—1 back

TEMP > 300f—2

baCK

FILTERS—since

dispose

Filters—1 back

Filters—2 back

Press to scroll: Oil Stats, Filter Stats, Review Usage, Last Load. With the desired stats

Number Press . (This is the number of cooks since the last dispose.)

Number Press . (This is the number of heads cooked since the last dispose.)

Number Hrs Press . (This is the number of hours the temperature of the oil rose above 300°F during

Number Hrs Press . (This is the number of hours the oil temperature was above 300°F since oil

Number Hrs Press . (This is the number of hours the oil temperature was above 300°F since the

Number Hrs Press . (This is the number of hours the oil temperature was above 300°F since two oil

Number Press . (This is the number of filters since oil disposal.)

Number Press . (This is the number of filters that have occurred since the previous oil

Number Press . (This is the number of filters that have occurred since two oil disposals ago.)

Press and hold until INFO MODE is displayed. Release and press .

displayed, press .

Press . (This is the date of the last dispose.)

operation today.)

disposal.)

previous oil disposal.)

disposals ago.)

disposal.)

Polishes—since

dispose

Polishes—1 back

Polishes—2 back

Reset oil stats Yes no

Reset oil stats Enter code

Continued on the following page

Number Press . (This is the number of polishes since oil disposal.)

Number Press . (This is the number of polishes that have occurred since the previous oil

Number Press . (This is the number of polishes that have occurred since two oil disposals ago.)

disposal.)

Press to scroll or to reset oil stats.

Enter 3228.

1-2

Page 5

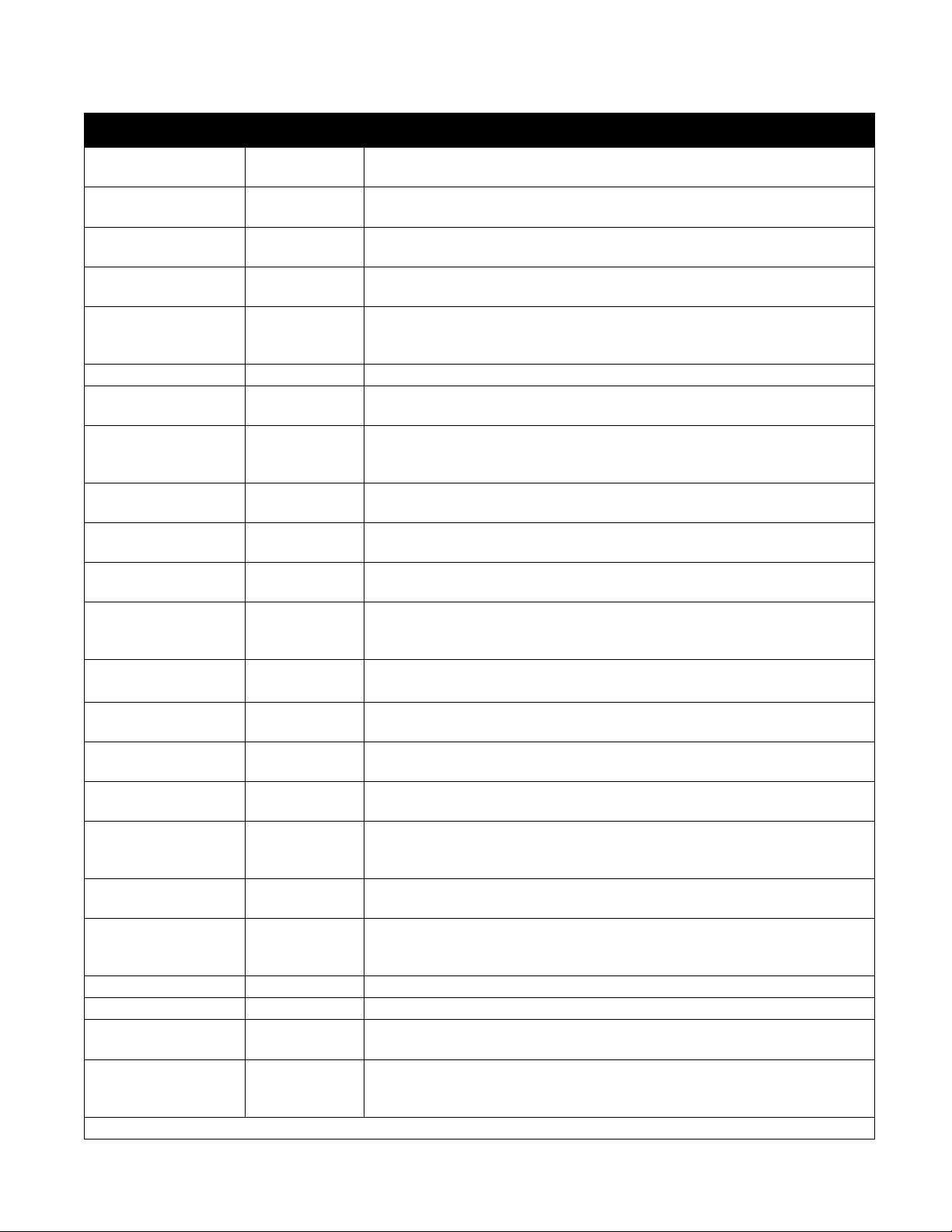

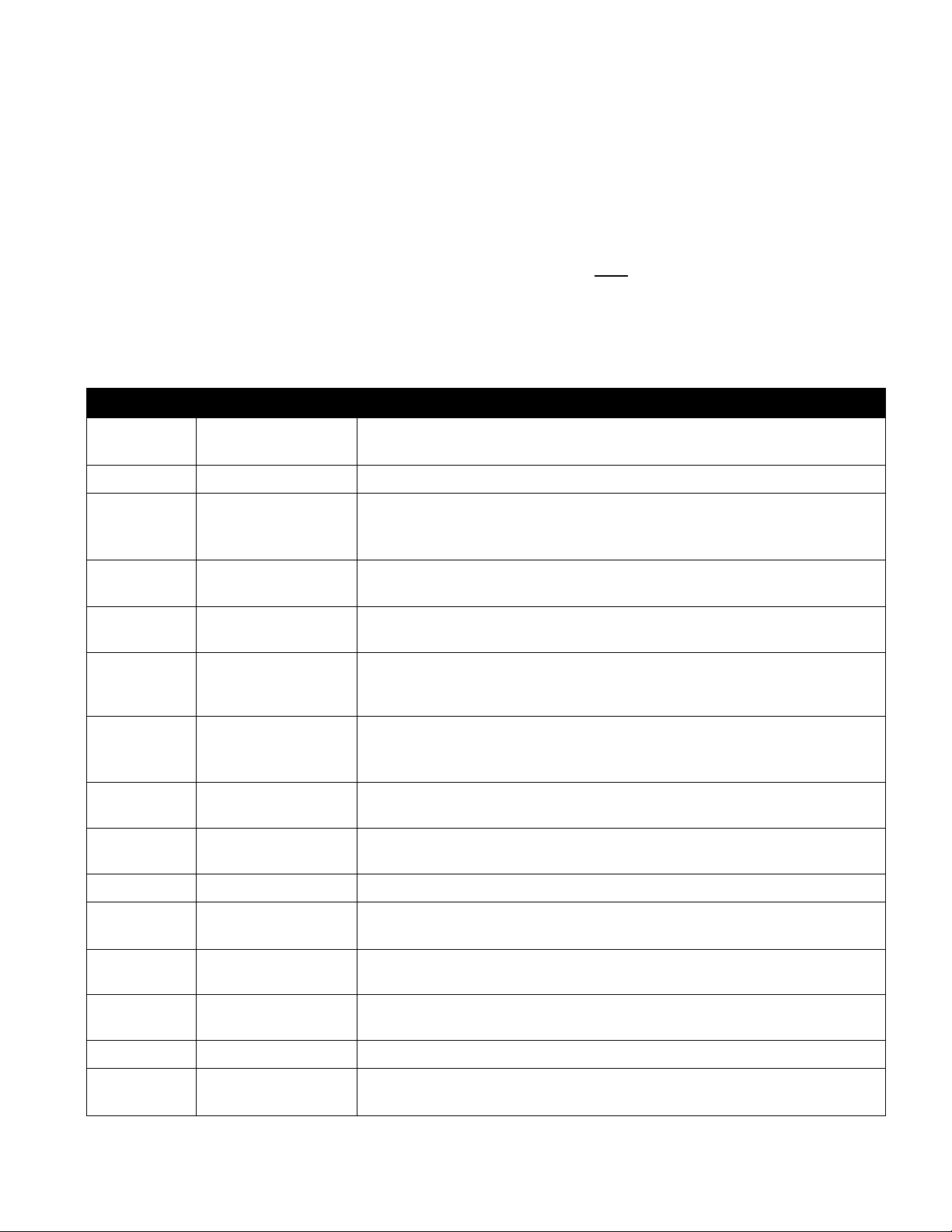

1.3 Viewing Operational Stats cont.

Left Display Right Display Action

complete

None required.

Exit Exit

Filter Stats

MON date

Filtered Number and day

Flt bpsd Number and day

Cooks Number and day

Heads Number and day

FLT AVG Number and day

REVIEW USAGE

USAGE SINCE

DATE TIME

TOTAL COOKS

QUIT COOKS

On HOURS

Reset usage Yes no

Reset usage Enter code

Complete

Exit Exit

Last load

Product Product name

Started

Actual time

Progtime

Max temp

Min temp

Avg temp

Heat on

Ready Yes or no

Exit Exit

Number

Number

Number

Time

Number Minutes

Number Minutes

Number

Number

Number

Number

Press button once to return to menu, or Scan button once to return the controller

to OFF.

Press to scroll: Filter Stats, Review Usage, Last Load. With the desired stats

displayed, press .

Press to scroll seven days of data. With the desired date displayed, press .

Press to scroll number of times the vat was filtered in the seven -day period.

Press .

Press to scroll number of times the filter prompt was bypassed in the sevenday period. Press .

Press to scroll number of cook cycles that occurred in the seven-day period.

Press .

Press to scroll number of heads that were cooked in the seven-day period.

Press .

Press to scroll average number of daily filter cycles that occurred in the sevenday period. Press . Press button once to return to menu, or Scan button once to

return the controller to OFF.

Press to scroll: Filter Stats, Review Usage, Last Load. With the desired stats

displayed, press .

None required.

Press . (This is the date and time of the last usage reset.)

Press . (This is the total number of cooks since the last usage reset.)

Press . (This is the total amount of cooks that were cancelled since the last reset

usage.)

Press . (This is the total amount of hours the fryer was on since the last reset.)

Press to scroll or to reset oil stats usage.

Enter 3228.

None required.

Press to scroll: Filter Stats, Review Usage, Last Load. With the desired stats

displayed, press or press Scan to return the controller to OFF.

Press .

Press . (This is the product last cooked.)

Press . (This is the time the last cook started.)

Press . (This is the actual cook time including flex time.)

Press . (This is the actual programmed cook time.)

Press . (This is the maximum temperature of the oil during the last cook.)

Press . (This is the minimum temperature of the oil during the last cook.)

Press . (This is the average temperature of the oil during the last cook.)

Press . (This is the percentage of the cook time the heat source was on during the

last cook.)

Press . (If the fryer was back to proper temperature before the cook cycle was

started.)

Press to scroll: Filter Stats, Review Usage, Last Load. With the desired stats

displayed, press or press Scan button to return the controller to OFF.

1-3

Page 6

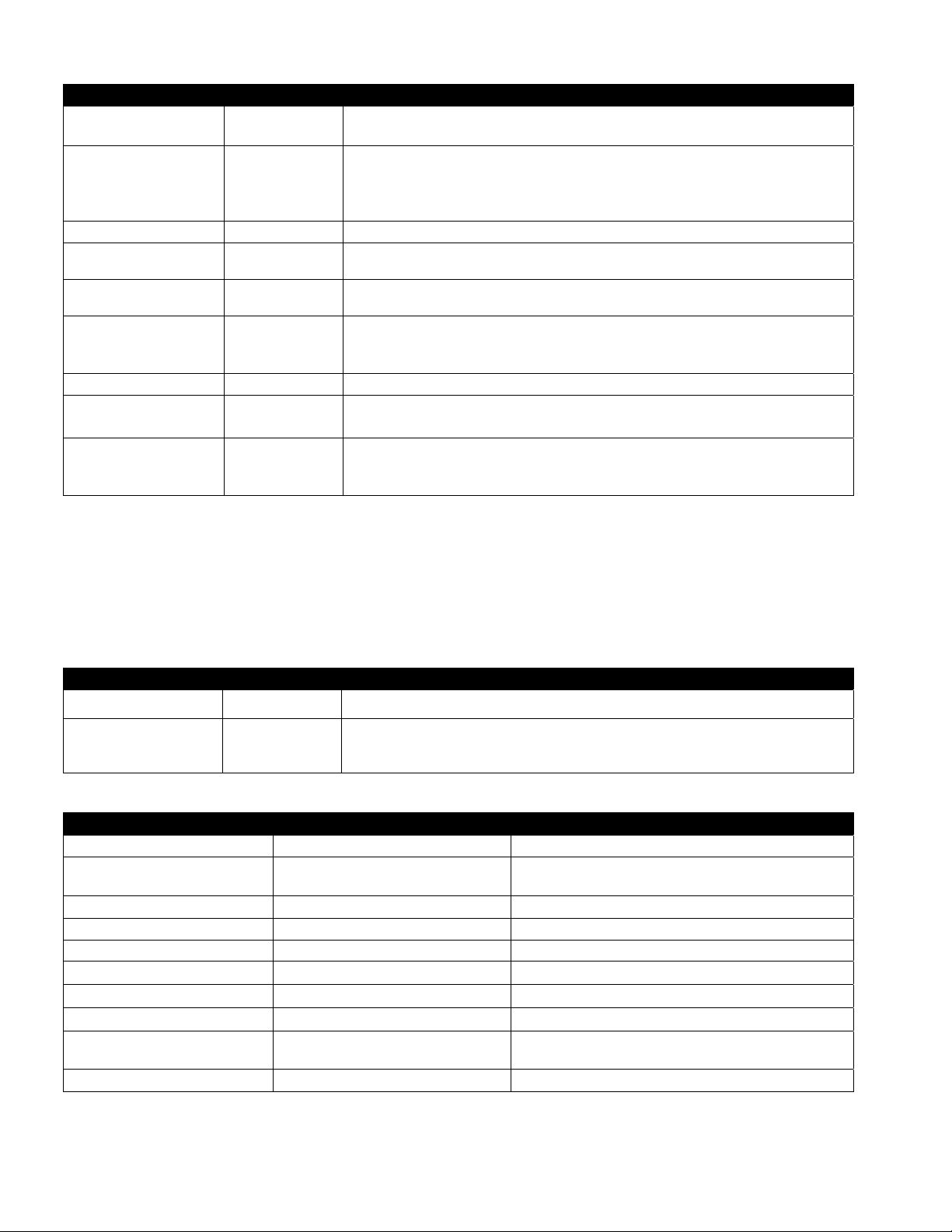

1.4 F3000 Vat Setup

Setup mode allows the controller to be set for language displays, vat sizes, and temperature range displays. Follow the steps

below to enter and navigate Vat Setup.

Vat Set Up

Left Display Right Display Action

OFF OFF

Product Setup

Press and hold until Product Setup is displayed.

Press to scroll to Vat setup and press . Product setup is described on pages 1-11 through

1-14.

Vat setup Enter code

System

Enter 3228.

Press button or press to scroll to Time/Date, Filter, E-Log, Change Password or Edit

Alarm Names. With desired choice displayed, press . If SYSTEM is not chosen skip to the

relevant selection.

Language English

2nd language English

Press to scroll to choice and press .

Press to scroll to choice and press . (This option allows another language to be toggled

easily from the front panel (ex. Spanish as a second language.)).

Locale Non-ce

ENERGY Gas

type KJ3 Full

System volume 9

Tempr format F

Exit Melt Tempr 100F

Press to scroll to choice Non-CE or CE and press .

Press to scroll to choice Gas or Electric and press .

Press to scroll choices. Once the fryer type is chosen, press .

Sets sound level for controller. Enter level, 1-9 (0=Lowest/ 9=Loudest). Press .

Press to scroll choices: F for Fahrenheit; C for Celsius. Press .

Use numbered buttons to change default setting (use 10 for 0). Press . (This is the

temperature for the fryer to exit the melt cycle.) Default is 100F (38C).

Setback tempr 250F

Use numbered buttons to change default setting (use 10 for 0). Press . (This is the

temperature during setback or idle mode.) Default is 250F (121C).

Fresh oil None

waste NONE

RECOVERY ALARM DISABLED

Press to scroll choices JIB, Bulk-RTI, Bulk-F (Frontline) or None. Press .

fryers should be set to NONE.

Press to scroll choices JIB, Bulk-RTI, Bulk-F (Frontline) or None. Press .

fryers should be set to NONE.

Press to scroll choices DISABLED and ENABLED. (This is a recovery alarm that locks

out the fryer if the fryer does not heat properly. The default is disable d) . Pr ess .

Exit Exit

OFF OFF

Time/date

Time entry time

Date format Mm/dd/yy

Enter date date

Exit Exit

Press button.

None required.

Press .

Use numbered buttons to change time (use 10 for 0). Press .

Press to scroll choices. With the date format displayed, press .

Use numbered buttons to change date (use 10 for 0 ). Press .

Press button once and press to scroll to System, Time/Date, Filter, E-Log, Change

Password or Edit Alarm Names. With desired choice displayed, press or press the Scan

button once to return the controller to OFF.

DST SETUP

This is daylight savings time setup. In the United States, daylight savings time begins each year at 2:00 A.M. on

the second Sunday in March, with clocks moving ahead one hour. Daylight savings time ends each year at 2:00

A.M. on the first Sunday in November, with clocks moving back one hour. For the two states and international

locations, which do not use DST, set to disabled.

OFF OFF

Product Setup

Blank

Vat setup Enter code

DST ENABLED

Press and hold until Product Setup is displayed.

Press to scroll to Vat setup and press .

Enter 3228.

Press to scroll choices DISABLED and ENABLED. Press . (This enables or disabled

daylight savings time. Default is enabled.) If disabled is chosen, pressing the button,

displays exit. Press the exit scan button three times to exit.

Continued on the following page

NOTE:. All

NOTE:. All

1-4

Page 7

1.4 F3000 Vat Setup cont.

Left Display Right Display Action

DST START MONTH

3

Enter the daylight savings time starting month using the 1-10 keys. (Default is

US government starting month “3”.) Press .

DST START SUNDAY

2

Enter the daylight savings time starting Sunday using the 1-10 keys. (Default is

US government starting Sunday “2”.) Press .

DST END MONTH

11

Enter the daylight savings time ending month using the 1-10 keys. (Default is

US government ending month “11”.) Press .

DST END SUNDAY

1

Enter the daylight savings time ending Sunday using the 1-10 keys. (Default is

US government ending Sunday “1”.) Press .

EXIT Exit

Press button once and press to scroll to System, Time/Date, Filter, E-Log

or Change Password. With desired choice displayed, press or press the

Exit/Scan button three times to return the controller to OFF.

filter

Global filter count

20

Press .

Press . (Changes the total number of cooks that occur before a filter prompt.

The default is 20.)

Eod filter time 21:00

Use numbered buttons to change end of day filter alert time. Press . After

this time, the controller prompts for filter when user presses the power button

to go to the OFF state.

1 polish timer EnableD

Press to scroll to choice and press . (This enables or disables the polish

timer.)

1 polish time 08:00

Use numbered buttons to change time (use 10 for 0). (This is the time the first

polish prompt will occur each day. The default is 8:00 AM.) Press .

1 polish duration

30

Use numbered buttons to change (use 10 for 0). (This is the duration, in

minutes for a polish. The default is 30 minutes.) Press .

1 polish delay time 00:00

Use numbered buttons to change time (use 10 for 0). (This is the amount of

time that an operator can delay the start of a polish.) Press . After the delay

the operator must polish.

1 polish start tempr 300F

Use numbered buttons to change temperature (use 10 for 0). (This is the

temperature required for a polish to begin.) Press .

2 polish timer enabled

Press to scroll to choice and press . (This enables or disables the

second polish timer.)

2 polish time 14:00

Use numbered buttons to change time (use 10 for 0). (This is the time the

second polish prompt will occur each day.) Press .

2 polish duration

30

Use numbered buttons to change (use 10 for 0). (This is the duration, in

minutes for a polish. The default is 30 minutes.) Press .

2 polish delay time 01:00

Use numbered buttons to change time (use 10 for 0). (This is the amount of

time that an operator can delay the start of the second polish. The default is one

hour.) Press . After the delay the operator must polish.

2 polish start tempr 300F

Use numbered buttons to change temperature (use 10 for 0). (This is the

required temperature for the second polish to begin.) Press .

Exit Exit

Press button once and press to scroll to System, Time/Date, Filter, ELog, Change Password or Edit Alarm Names. Wit h desired choice displayed,

press or press the Scan button once to return the controller to OFF.

E-Log

NOW Time/date

A E# Time/date

Press . (This is a log of the ten most recent error codes.)

Press . (Current time and date)

Errors listed A-J. Press to scroll through errors. If no errors exist, pressing

will display No Errors.

Exit Exit

Press button once and press to scroll to System, Time/Date, Filter, ELog, Change Password or Edit Alarm Names. Wit h desired choice displayed,

press or press the Scan button once to return the controller to OFF.

Continued on the following page

1-5

Page 8

Left Display Right Display Action

C-Log

Blank

Press . (This is a reserved internal data collection feature that only exists in

pressure fryers.)

Exit Exit

Press button once and press to scroll to System, Time/Date, Filter, ELog, C-Log, Change Password or Edit Alarm Names. With desired choice

displayed, press or press the Scan button once to return the controller to

OFF.

Change password

Product setup

Current code

Press .

Use numbered buttons to change code (use 1 0 for 0) . P ress .

(1724)

Vat setup

Current code

Use numbered buttons to change code (use 1 0 for 0) . P ress .

(3228)

Exit Exit

Press button once and press to scroll to System, Time/Date, Filter, ELog, Change Password or Edit Alarm Names. Wit h desired choice displayed,

press or press the Scan button once to return the controller to OFF.

Edit alarm names

Alarm 1 NUM1

Press .

Enter or edit alarm name with letter buttons. Press . Continue scrolling

through names up to alarm 10. (Ex. Shake, Stir, etc.)

Exit Exit

Press button once and press to scroll to System, Time/Date, Filter, ELog, Change Password or Edit Alarm Names. Wit h desired choice displayed,

press or press the Scan button once to return the controller to OFF.

1.5 Navigating Filter Menu

The F3000 has five functions in the Filter Menu: Filter, Clean, Dispose, Fill Vat from Pan and Drain to Pan. They are accessed

by pressing and holding the Filter button until FILTER is displayed. The first matrix below steps through the initial

navigation. Navigation of the functions are covered in separate matrices. The controller must be on and at setpoint to use all

the functions of the filter menu. If the fryer is not at setpoint the controller displays WAIT FOR FILTER.

Entering Filter Mode

Left Display Right Display Action

DROP DROP

Press and hold the filter button until Filter is displayed.

filter

Press to scroll to choices: Filter, Clean, Dispose, Drain to Pan, Fill Vat from

Pan and Exit. With the desired choice displayed press . Follow the

instructions below to navigate the modes.

Filter

Left Display Right Display Action

filter

Filter Now? alternating with

Press .

Press YES.

yes/no

OPEN DRAIN VALVE

Draining

OPEN RETURN VALVE

POLISHING COUNTDOWN TIMER

CLOSE DRAIN VALVE CONFIRM

Filling

CLOSE RETURN VALVE when full

CONFIRM

Open drain valve.

None required.

Open return valve.

None required.

Close drain valve and press CONFIRM.

None required.

Press CONFIRM.

and press confirm

COOL COOL

1-6

Page 9

Clean

Left Display Right Display Action

CLEAN

Clean now? Yes NO

Open drain valve

Draining

Scrub vat complete? Yes

OPEN RETURN VALVE

Polishing 5-minute countdown timer

Fill vat? YES

CLOSE DRAIN VALVE CONFIRM

filling

CLOSE RETURN VALVE WHEN

CONFIRM

Press .

Press YES.

Open drain valve

None required.

Press YES.

Open return valve.

None required.

Press YES.

Close drain valve and press CONFIRM.

None required.

Press YES.

FULL AND PRESS CONFIRM

off off

Dispose

Left Display Right Display Action

dispose

Dispose now? Yes NO

REMOVE PAN CONFIRM

Insert disposal unit Confirm

OPEN DRAIN VALVE

DISPOSING

VAT EMPTY? CONFIRM

Clean vat complete? Confirm

CLOSE DRAIN VALVE CONFIRM

REMOVE DISPOSAL UNIT CONFIRM

INSERT PAN CONFIRM

Manually fill vat Confirm

off off

Press .

Press YES.

Remove the filter pan and press CONFIRM.

Insert disposal unit under the drain and press CON FIR M .

Open the drain valve.

None required.

Press CONFIRM once the vat is empty.

Press CONFIRM once the vat is clean.

Close drain valve and press CONFIRM.

Remove disposal unit from the fryer and press CONFIRM.

Insert the filter pan and press CONFIRM.

Fill vat with oil to the bottom fill line and press CONFIRM when full.

Drain to Pan

Left Display Right Display Action

Drain to pan

DRAIN TO PAN? Yes NO

OPEN DRAIN VALVE

draining

VAT EMPTY? CONFIRM

CLOSE DRAIN VALVE CONFIRM

OIL IN DRAIN PAN CONFIRM

FILL VAT FROM DRAIN PAN? YES NO

OPEN RETURN VALVE

FILLING

CLOSE RETURN VALVE WHEN

CONFIRM

Press

Press YES.

Open the drain valve.

None required.

Press CONFIRM.

Close the drain valve and press CONFIRM

Press CONFIRM.

Press YES.

Open the return valve.

None required.

Press CONFIRM.

FULL AND PRESS CONFIRM

OFF OFF

1-7

Page 10

Fill Vat from Pan

Left Display Right Displa y Action

FILL VAT FROM PAN? YES NO

OPEN RETURN VALVE

FILLING

CLOSE RETURN VALVE WHEN

FULL AND PRESS CONFIRM

off off

FILL VAT FROM PAN

CONFIRM

Press

Press YES.

Open the return valve.

None required.

Press CONFIRM.

1.6 Polishing

The F3000 displays a series of prompts when a polish filter cycle is under way. The steps are detailed below.

Left Display Right Display Explanation/Action

Polish Now? Yes NO

Add FILTER POWDER CONFIRM

**

INSERT PAN CONFIRM

**

CHANGE FILTER PAPER CONFIRM

*

*

Add filter powder Confirm

Insert pan confirm

*

*

OPEN DRAIN VALVE

Draining

OPEN RETURN VALVE

POLISHING 15-MINUTE COUNTDOWN

TIMER

Close drain valve CONFIRM

FILLING

CLOSE RETURN valve when

full and press confirm

COOL COOL

CONFIRM

Respond to prompt with button push. Press YES or NO. Yes produces a

filter, detailed below. No delays filter and cooking continues.

Remove filter pan, add filter powder and press CONFIRM.

Insert filter pan and press CONFIRM.

Remove the filter pan and change the filter paper.

Add filter powder and press CONFIRM.

Insert filter pan into fryer.

Open the drain valve.

None required. The oil drains from the frypot to the filter pan.

Open the return valve.

None required. The oil flows from the filter pan to the frypot and back to

the filter pan for 15 minutes.

Close the drain valve and press CONFIRM.

None required. The oil returns from the filter pan to the frypot.

Close the return valve and press CONFIRM.

*NOTE: Occurs on first polish of the day.

**NOTE: Occurs on first polish after lunch and subsequent polishes during the day.

1-8

Page 11

1.7 Prompts Encountered While Programming

The F3000 can be programmed for single-segmented cooking, which is used for most products, and segmented cooking, which

is used for bone-in chicken. When programming for either product, the time prompts encountered are sequentially numbered.

For non-segmented products, enter 0:00 for the second time prompt (2 Time) and the additional programming steps associated

with segmented programming don’t appear.

For segmented products, the process is longer. As many as 10 segments can be introduced during the cook cycle of one

product. The complete cook cycle can be thought of as a timeline, with temperatures changes introduced at time-specific

points on the timeline.

As Time 2, Time 3, Time 4 appear in the programming steps, the time entered is NOT the duration of the specific cycle, but

the point a temperature change occurs on the timeline. For example, a Time 2 change that is to change a temperature in a 13

minute cycle after 2 minutes is entered as 11. The first temperature change will occur with 11 minutes remaining on the time

line. See graphic on page 1-12.

Below is a explanation of the prompts presented in the sequence they occur. Programming is detailed on pages 1-11 thorough

1-14.

Left Display Right Display Explanation/Action

Long name

Name or button number

Short Name Name or button number

COOKING MODE SINGLE SETPOINT

1 Time 0:00 or previously

entered #

1 Tempr Temperature

1 Flex number

1 PRESSURE

OPEN

SOLENOID

2 Time Time

2 Tempr Temperature

Enter the full name of the product

Enter the four character abbreviated name of the product

Segmented: If multiple setpoint or segmented cooking is desired press

MULTIPLE SETPOINT and go to 1.9 and follow the instructions.

Non-Segmented: Leave at default of SINGLE SETPOINT.

In segmented and non-segmented programming, the total cook time is entered here.

This is the setpoint for non-segmented products; the initial setpoint for segmented

products.

Flex is the feature in the controller that allows the fryer to react to large and small

loads with the same cooking curve. It is generally not used with bone-in chicken.

The default value is 5. The range is 0-9.

This option is only present on pressure fryers. During cooks it determines if the

pressure solenoid should be open or closed. For segmented or multi-setpoint

cooking it may be closed and open during different cycles during the cook.

Segmented: Enter time remaining in the cook cycle after the first temperature

change occurs.Non-Segmented: Enter 0:00

Segmented: This is the first temperature change, which occurs at the point entered

at the 2 Time prompt. Non-Segmented: Doesn’t appear

2 Flex On or Off

2 PRESSURE

OPEN

SOLENOID

3 Time Time

3 Tempr Temperature

3 Flex On or OFF

3 PRESSURE

OPEN

SOLENOID

See 1 Flex.

See 1 Pressure Solenoid.

Segmented: Enter time remaining in the cook cycle after the second temperature

change occurs. Non-Segmented: Doesn’t appear.

Segmented: This is the second temperature change, which occurs at the point

entered at the 3 Time prompt. Non-Segmented: Doesn’t appear

See 1 Flex.

See 1 Pressure Solenoid.

1-9

Page 12

1.7 Prompts Encountered While Programming cont.

Left Display Right Display Explanation/Action

4 Time Time

4 Tempr Temperature

4 Flex On or Off

4 PRESSURE

SOLENOID

5 Time Time

1 Alarm Time Time

1 Alarm Name Shake, stir, numbered alarm

1 Alarm Mode Manual or Auto

1 Alarm Tone Short, Medium, Long, double

2 Alarm Time Time

2 Alarm Name Shake, stir, numbered alarm

OPEN

or long short, none

Segmented: Enter time remaining in the cook cycle after the third

temperature change occurs.Non-Segmented: Doesn’t appear.

Segmented: This is the third temperature change, which occurs at the

point entered at the 3 Time prompt. Non-Segmented: Doesn’t appear

See 1 Flex.

See 1 Pressure Solenoid.

Segmented: Enter 0:00 if no more segments are needed.

Non-Segmented: Doesn’t appear.

An audible alarm in the cook cycle, indicating a need to shake or stir the

product.

Navigate choice with arrow buttons under display.

The alarm can be self cancelling (Auto) or manually canceled (Manual),

which requires a button push. Navigate choice with arrow buttons under

display.

The duration of the audible alarm is optional. Navigate choice with

arrow buttons under display.

The second point in the cook cycle an alarm sounds.

Navigate choice with arrow buttons under display.

2 Alarm Mode Manual or Auto

2 Alarm Tone Short, Medium, Long, double

or long short, none

3 Alarm Time Time

3 Alarm Name Shake, stir, numbered alarm

3 Alarm Mode Manual or Auto

3 Alarm Tone Short, Medium, Long, double

or long short, none

After Cooking Set Point or COOL

Filter Lockout Number

Head Count 0

Instant On 0

Exit Exit

Navigate choice with arrow buttons under display.

Navigate choice with arrow buttons under display.

The third point in the cook cycle an alarm sounds.

Navigate choice with arrow buttons under display.

Navigate choice with arrow buttons under display.

Navigate choice with arrow buttons under display.

Setpoint: Fryer remains at setpoint; Cool: Fryer holds at 250°F (121°C).

Number of cook cycles for the product before a filter prompt.

Number of head of chicken or the equivalent number for a non-chicken

product.

This is the time, in seconds, the fryer heats before the controller checks

the temperature.

Press or Scan button to exit programming.

1-10

Page 13

1.8 Programming for Single Setpoint (Non-Segmented) Items

Programming for non-segmented food items is shown below. The right column has the action necessary to continue. Exit from

a programming step at any time by pressing the Scan button until the display returns to its pre-programming status.

Left Display Right Display Action

OFF OFF

Product Setup

Product Setup Enter Code

Select Product

Long Name Product name or button

Short Name Abbreviated Product name or

COOKING MODE SINGLE SETPOINT

1 Time 0:00 or previously entered time

1 TempR Temp

1 Flex

1 PRESSURE

SOLENOID

2 Time 0:00 or previously entered time

1 Alarm TIME 0:00 or previously entered time

number

button number

Number

OPEN

Press and hold until Product Setup is displayed.

Press .

Enter 1724.

Press a desired product button 1-20 that is not currently used. Buttons

already programmed are indicated with an LED.

Enter product name with letter buttons. Advance cursor with .

Press .

Enter abbreviated four character product name with letter buttons. Press

.

Press . If multiple setpoint or segmented cooking is desired press

MULTIPLE SETPOINT and go to 1.9 and follow the instructions.

(Default is SINGLE SETPOINT)

Enter total cook time with numbered buttons. Press .

Enter cooking temperature. Press .

Enter the level of flex, 0-9, for the product. Press .

Press to scroll to OPEN or CLOSED. Enter the state of the

pressure fryer solenoid lid. Default is OPEN. (Option only for pressure

fryers.)

Enter 0:00. Press .

Subtract the time from the starting cook time when the alarm should

sound. (Example: If a cook time is 5:00 and the shake time should be

30 seconds into the cook time enter 4:30 as the alarm time). Enter that

time for shaking, stirring, etc. Press . (Note: If alarm time is set to

0:00 skip to After Cooking below.)

1 alarm name shake

1 ALARM MODE AUTO OR MANUAL

1 alarm tone Short, medium, long double or

long short, none

2 alarm time 0:00

After Cooking Cool or Setpt

Filter Lockout 0

QUANTITY? No

Head Count 0 or previously set number

Instant On 0

Exit Exit

Select Product

Product Setup

OFF OFF

Press to scroll through the alarm names (ex. Shake). Press .

Press to scroll to Auto or Manual alarm mode. Press .

Press to scroll to choice of alarm tones. Press .

Press . Leave at 0:00 for non-segmented cooking.

Press to scroll to Cool or Setpoint mode the fryer should exit to

after cook cycle: cool = 250; Setpoint = cooking temp. Press .

Enter number of cook cycles before a filter prompt and press .

Press to scroll to YES if a quantity per load is required, otherwise

leave to default NO.

Enter number of head or the equivalent value for the product . Press .

This is the time, in seconds, the fryer heats before the controller checks

the temperature. Enter value and press .

Press Scan button to exit or the button for additional programming.

More Programming? Press product button a nd fol l o w inst r uct i ons

above. Exit Programming? Press Scan Button.

Press Scan button to exit or the button for additional programming.

1-11

Page 14

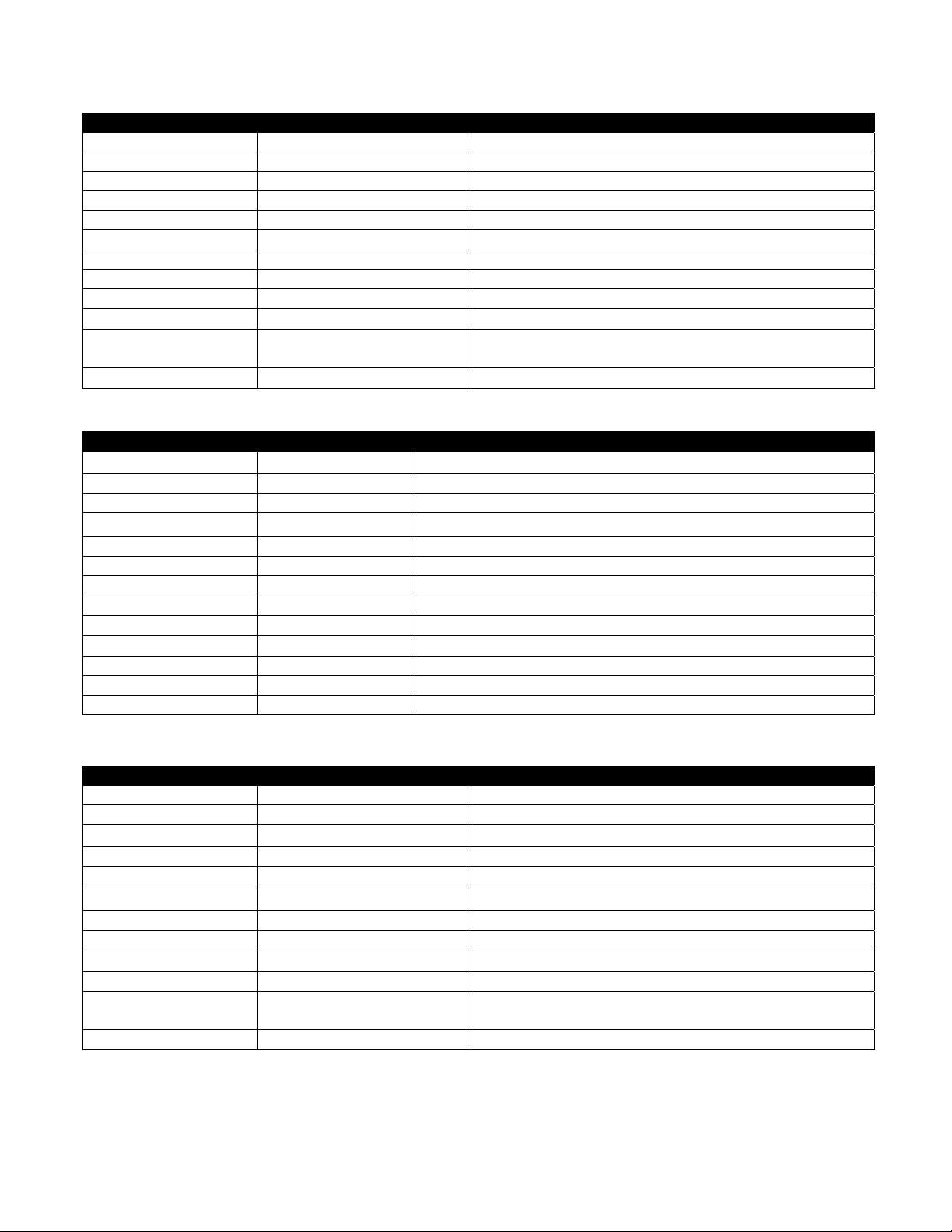

1.9 Multi-Setpoint (Segmented)

1.9.1 Cooking Programming Overview

The F3000 is capable of segmented cooking, a feature which allows a cooking cycle to be broken into a number of

parts, each with its own cooking temperature and time.

An abbreviated version of the programming for a 13-minute cook cycle with four cooking temperatures is

shown below. Steps are compressed for clarity. The cook times represent when on the timeline of the

total cook cycle the segment occurs. In this example, the first temperature change occurs with 11

minutes remaining in the total cook time; 11 is entered at the prompt for the second cook time. Two

minutes into the total cook cycle, the temperature will change;11 minutes will remain. Cook times for the

remaining segments are arrived at by subtracting the segment length from the remaining cook time. The

complete programming steps are shown on pages 14 and 15.

Step 1 sets total cook time and initial setpoint.

Step 2 sets the duration of the first cooking segment, 2 minutes, and the setpoint of the first

temperature change.

Step 3 sets the duration of the second cooking segment, 4 minutes, and the setpoint of the second

temperature change.

Step 4 sets the duration of the third cooking segment, 3 minutes, and the setpoint of the third

temperature change.

The four remaining minutes in the cook time elapse at the final temperature. No entry is required to use

the final minutes

1-12

Page 15

1.9.2 Alarm Programming Overview

Alarms are set to remind operators to shake fry baskets or tend to the product in some other way at points

during the cook cycle. The instructions below detail setting three alarms in a 13-minute cook cycle. To

enter a single alarm, exit the sequence after setting the first alarm.

Three alarms can be programmed for a cook cycle. The K3000 counts down cook times from

the total time to zero. Alarms are entered at the point in the countdown they are desired. The

example below is for alarms at 11:00, 6:00 and 2:00 on the countdown clock; the alarms will

occur two, seven and 11 minutes into the 13-minute cook cycle.

11:00

1:

At the Alarm 1

prompt, enter

11:00. The alarm

will occur with 11

minutes remaining

in the cook cycle;

two minutes have

passed.

2:

At the Alarm 2 prompt,

enter 6:00, The alarm will

occur with 6:00 remaining

in the cook cycle; seven

minutes have passed.

6:00

3:

At the Alarm 3

prompt, enter 2:00.

The alarm will

occur with 2:00

remaining in the

cook cycle; 11

minutes have

passed.

2:00

Cook

cycle

ends

2:00 7:00 11:00

Points in the cook cycle the alarms occur

13:00

1-13

Page 16

1.10 Programming for Multi-Setpoint (Segmented) Items

Left Display Right Display Action

OFF OFF

Product Setup

Product Setup Enter Code

Blank Press .

Press and hold until Product Setup is displayed.

Enter 1724

Select Product

Long Name Product name or button number

Short Name Abbreviated Product name or

COOKING MODE SINGLE SETPOINT

1 Time 0:00 or previously entered time

1 Tempr temperature

1 Flex 0 or previously entered value

1 PRESSURE

SOLENOID

2 Time 0:00 or previously entered time

2 Tempr 0:00 or previously entered

2 Flex 0 or previously entered value

2 PRESSURE

SOLENOID

3 Time O:00 or previously programmed

3 Tempr

3 Flex 0 or previously entered value

3 PRESSURE

SOLENOID

4 Time 00 or previously entered time

4 tempr 0:00 or previously programmed

4 Flex 0 or previously entered value

4 PRESSURE

SOLENOID

5 Time :00 or previously entered time

1 Alarm time :00 or previously entered time

1 Alarm Name SHAKE

1 alarm mode Manual or auto

Blank Press desired product button

button number

OPEN

temperature

OPEN

time

0:00 or previously programmed

temperature

OPEN

temperature

OPEN

Enter product name with letter buttons. Advance cursor with

. With name entered, press

Enter abbreviated four character product name with letter

buttons. Press .

Press . If multiple setpoint or segmented cooking is desired

press Multiple Setpoint (Segmented) and follow the

instructions in the next section. (Default is SINGLE

SETPOINT)

Enter total cook time for segmented item and press .

Enter initial cooking temperature and press .

Enter the flex value, 0-9, for the product and press .

Set to desired position with the buttons. Press the

button to change to CLOSED. (Option only for pressure

fryers.)

Enter time remaining after first temperature change (see page

1-11) and press .

Enter first temperature change and press .

Enter the flex value, 0-9, for the product and press .

See 1 Pressure solenoid.

Enter time remaining after second temperature change and

press .

Enter temperature of the second segment and press .

Enter the flex value, 0-9, for the product and press .

See 1 Pressure solenoid.

Enter time remaining after third temperature change and press

.

Enter temperature of the third segment and press .

Enter the flex value, 0-9, for the product and press .

See 1 Pressure solenoid.

Leave at zero if no more segments are needed and press . If

more segments are needed, 5 is the limit, continue

programming as shown above.

Subtract the time from the starting cook time when the alarm

should sound. (Example: If a cook time is 5:00 and the shake

time should be 30 seconds into the cook time enter 4:30 as the

alarm time). Enter that time for shaking, stirring, etc. Press .

Press to scroll through choices: Shake, Stir, Num1. With

NUM 1 displayed, scroll through number choices with .

Display name and press .

Choose mode with and press .

1-14

Page 17

1.10 Programming for Multi-Setpoint (Segmented) Items cont.

Left Display Right Display Action

1 Alarm Tone Short, medium, long double or

long short, none

2 Alarm time Time

2 Alarm name name

2 alarm mode Manual or auto

2 Alarm Tone Short, medium, long double or

long short, none

3 Alarm time name

3 alarm Mode Manual or auto

3 Alarm Tone Short, medium, long double or

long short, none

After cooking Set Point or cool

Filter Lockout 0

QUANTITY? No

Head count User prompt 00

Instant ON 0

Choose tone with and press .

Subtract the time from the starting cook time when the second

alarm should sound. (Example: If a cook time is 5:00 and the

shake time should be 30 seconds into the cook time enter 4:30

as the alarm time). Enter that time for shaking, stirring, etc.

Press .

Press to scroll through choices and press .

Choose mode with and press .

Choose tone with and press .

Subtract the time from the starting cook time when the third

alarm should sound. (Example: If a cook time is 5:00 and the

shake time should be 30 seconds into the cook time enter 4:30

as the alarm time). Enter that time for shaking, stirring, etc.

Press .

Choose mode with and press .

Choose tone with and press .

Choose fryer status after cook cycle with and press .

Enter number of cook cycles before a filter prompt and press

.

Press to scroll to YES if a quantity per load is required,

otherwise leave to default NO.

Enter chicken head count or equivalent number for nonchicken item and press .

This is the time, in seconds, the fryer heats before the

Controller checks the temperature. Enter value and press .

Exit Exit

Select Product

OFF OFF

Blank

Press .

Press Scan twice. Display goes to OFF.

1-15

Page 18

1.11 F3000 Menu Summary Tree

Filter Menu

Info Mode

Setup and Tech Modes

[With computer OFF, press and hold (check) button 10 seconds, displays Product Setup]

………………………………………………………………………………………………………….. 1.5

[With computer ON, press and hold FILTER button]

Filter

Clean

Dispose

Drain to Pan

Fill Vat From Pan

………………...………………………...………………………………………..……………………….. 1.3

[With computer OFF, press and hold (check) button]

Oil Stats

Filter Stats

Review Usage

Last Load

Product Setup

[Enter 1724 ]

Vat Setup

[Enter 3228 ]

…….………...…………….....………………………………………………………….. 1.4

Select Product

System

..….………...…….....………..……………………………………………….. 1.9 - 1.10

Long Name

Short Name

Cooking Mode

1 Time

1 Tempr

1 Flex

1 Pressure Solenoid

2 Time

1 Alarm Time

1 Alarm Name

1 Alarm Mode

1 Alarm Tone

2 Alarm Time

After Cooking Setpoint

Filter Lockout

Quantity

Head Count

Instant On

….………………...…...…….....………………………………………………………….. 1.4

Language

nd

Language

2

Locale (CE or Non-CE)

Energy

Type (Vat)

System Volume (Level)

Tempr Format (F or C)

Exit Melt Tempr

Setback Tempr

Fresh Oil

Waste

Recovery Alarm

Time/Date………...…..……...…….....………………………………………………………….. 1.4

DST (Daylight Savings Time) Setup..………...….………………………….. 1.4

Filter

…………………....………...…….....………………………………………………………….. 1.4

Global Filter Count

EOD Filter Time

1 Polish Timer

1 Polish Time

1 Polish Duration

1 Polish Delay Time

1 Polish Start Tempr

2 Polish Timer

2 Polish Time

2 Polish Duration

2 Polish Delay Time

2 Polish Start Tempr

Log of last 10 error codes

E-Log

Solenoid Activation Log (only on pressure fryers)

C-Log

Change Password

…...………………....………………………………………………….. 1.4

……….………….………………………….. 1.4

Edit Alarm Names…...………………....………………………………………………….. 1.4

Tech Mode

[Enter 1650 ]

Clear E-Log

Clear Passwords

Lane Count

Hi-Limit Test

…….. 1.4

1-16

Page 19

CHAPTER 1: F3000 CONTROLLER INSTRUCTIONS

1.1 Using the F3000

ON/OFF

ON - Press ON/OFF button fryer heats to setpoint or idle temperature and displays: COOL or DROP.

OFF- Press and hold ON/OFF button. Controller displays OFF.

Cooking

Fryer displays COOL or DROP

COOL display: Press product button; fryer heats to setpoint and displays DROP.

DROP display: Press product button and drop product.

DONE display: Press product button to cancel alarm.

CANCEL: Press and hold product button to cancel a cook cycle.

Responding to Polish Prompt

Computer displays Polish Now, alternating with Yes No.

Press Yes (button under Yes display) and the polish cycle launches.

Computer displays Cool after polish cycle.

Computer Button Navigation

Product: Active when adjacent LED is lit. Press to launch cook cycle. Press and hold to cancel a launched cook

cycle. Press at end of cook cycle to halt alarm and end cook.

Scan: Press once, all product buttons are lit; Select Product displayed. Press product button to view product

name. Press Scan again to repeat. Press Scan twice to return to normal operation.

Left/Right Arrows: Navigate options in left display.

Up/Down Arrows: Navigate options in right display. Press the up/down a rrow simultaneously to change to a

second language if one is selected in setup.

Exit Cool: Exits cool mode and sets fryer’s temperature to setpoint.

Thermometer: Fryer ON: Press and release for setpoint/left; vat temp/right.

Thermometer: Fryer OFF: Press to display temperature, time, date, system version, F3000 version and circuit

board versions.

Checkmark: Fryer OFF: Press and hold 3 seconds: Scroll filter usage; Press and hold 10 seconds: Product

setup.

Checkmark: Fryer ON: Check recovery and respond to prompts.

Filter: Press and release: Cooks remaining to filter cycle. Press and hold: Filter options: Filter, Clean,

Dispose, Drain to Pan and Fill Vat from Pan.

1-1

Page 20

1.2 Navigating controller

Press and hold the checkmark button for 10 seconds produces the setup mode, which first displays Product Setup. Follow the

steps below to navigate the options. Unpopulated fields indicate a blank display.

Left Display Right Display Action

OFF OFF

Product Setup

Product Setup

Press to scroll: Vat Setup, Tech Mode, and Exit. With the desired selection displayed,

Product setup (entering and editing menu items) is described on page 1-11 through 1-14.

Press and hold until Product Setup is displayed.

press .

vat setup

Tech Mode

Exit Exit

Vat Setup is described on page 1-4.

Tech mode is for technicians only.

Press Scan button until the controller displays OFF.

1.3 Viewing Operational Stats

The F3000 collects and stores information on the cook cycles and filter cycles. This data is accessed in the info mode, which is

accessed by pressing the checkmark button. The steps to view the data are detailed below:

Left Display Right Display Action

OFF OFF

Oil stats

Total cooks - last

dispose

Total heads—last

dispose

Last dispose date

TEMP > 300F—TODAY

TEMP > 300f– Since

dispose

TEMP > 300F—1 back

TEMP > 300f—2

baCK

FILTERS—since

dispose

Filters—1 back

Filters—2 back

Press to scroll: Oil Stats, Filter Stats, Review Usage, Last Load. With the desired stats

Number Press . (This is the number of cooks since the last dispose.)

Number Press . (This is the number of heads cooked since the last dispose.)

Number Hrs Press . (This is the number of hours the temperature of the oil rose above 300°F during

Number Hrs Press . (This is the number of hours the oil temperature was above 300°F since oil

Number Hrs Press . (This is the number of hours the oil temperature was above 300°F since the

Number Hrs Press . (This is the number of hours the oil temperature was above 300°F since two oil

Number Press . (This is the number of filters since oil disposal.)

Number Press . (This is the number of filters that have occurred since the previous oil

Number Press . (This is the number of filters that have occurred since two oil disposals ago.)

Press and hold until INFO MODE is displayed. Release and press .

displayed, press .

Press . (This is the date of the last dispose.)

operation today.)

disposal.)

previous oil disposal.)

disposals ago.)

disposal.)

Polishes—since

dispose

Polishes—1 back

Polishes—2 back

Reset oil stats Yes no

Reset oil stats Enter code

Continued on the following page

Number Press . (This is the number of polishes since oil disposal.)

Number Press . (This is the number of polishes that have occurred since the previous oil

Number Press . (This is the number of polishes that have occurred since two oil disposals ago.)

disposal.)

Press to scroll or to reset oil stats.

Enter 3228.

1-2

Page 21

1.3 Viewing Operational Stats cont.

Left Display Right Display Action

complete

None required.

Exit Exit

Filter Stats

MON date

Filtered Number and day

Flt bpsd Number and day

Cooks Number and day

Heads Number and day

FLT AVG Number and day

REVIEW USAGE

USAGE SINCE

DATE TIME

TOTAL COOKS

QUIT COOKS

On HOURS

Reset usage Yes no

Reset usage Enter code

Complete

Exit Exit

Last load

Product Product name

Started

Actual time

Progtime

Max temp

Min temp

Avg temp

Heat on

Ready Yes or no

Exit Exit

Number

Number

Number

Time

Number Minutes

Number Minutes

Number

Number

Number

Number

Press button once to return to menu, or Scan button once to return the controller

to OFF.

Press to scroll: Filter Stats, Review Usage, Last Load. With the desired stats

displayed, press .

Press to scroll seven days of data. With the desired date displayed, press .

Press to scroll number of times the vat was filtered in the seven -day period.

Press .

Press to scroll number of times the filter prompt was bypassed in the sevenday period. Press .

Press to scroll number of cook cycles that occurred in the seven-day period.

Press .

Press to scroll number of heads that were cooked in the seven-day period.

Press .

Press to scroll average number of daily filter cycles that occurred in the sevenday period. Press . Press button once to return to menu, or Scan button once to

return the controller to OFF.

Press to scroll: Filter Stats, Review Usage, Last Load. With the desired stats

displayed, press .

None required.

Press . (This is the date and time of the last usage reset.)

Press . (This is the total number of cooks since the last usage reset.)

Press . (This is the total amount of cooks that were cancelled since the last reset

usage.)

Press . (This is the total amount of hours the fryer was on since the last reset.)

Press to scroll or to reset oil stats usage.

Enter 3228.

None required.

Press to scroll: Filter Stats, Review Usage, Last Load. With the desired stats

displayed, press or press Scan to return the controller to OFF.

Press .

Press . (This is the product last cooked.)

Press . (This is the time the last cook started.)

Press . (This is the actual cook time including flex time.)

Press . (This is the actual programmed cook time.)

Press . (This is the maximum temperature of the oil during the last cook.)

Press . (This is the minimum temperature of the oil during the last cook.)

Press . (This is the average temperature of the oil during the last cook.)

Press . (This is the percentage of the cook time the heat source was on during the

last cook.)

Press . (If the fryer was back to proper temperature before the cook cycle was

started.)

Press to scroll: Filter Stats, Review Usage, Last Load. With the desired stats

displayed, press or press Scan button to return the controller to OFF.

1-3

Page 22

1.4 F3000 Vat Setup

Setup mode allows the controller to be set for language displays, vat sizes, and temperature range displays. Follow the steps

below to enter and navigate Vat Setup.

Vat Set Up

Left Display Right Display Action

OFF OFF

Product Setup

Press and hold until Product Setup is displayed.

Press to scroll to Vat setup and press . Product setup is described on pages 1-11 through

1-14.

Vat setup Enter code

System

Enter 3228.

Press button or press to scroll to Time/Date, Filter, E-Log, Change Password or Edit

Alarm Names. With desired choice displayed, press . If SYSTEM is not chosen skip to the

relevant selection.

Language English

2nd language English

Press to scroll to choice and press .

Press to scroll to choice and press . (This option allows another language to be toggled

easily from the front panel (ex. Spanish as a second language.)).

Locale Non-ce

ENERGY Gas

type KJ3 Full

System volume 9

Tempr format F

Exit Melt Tempr 100F

Press to scroll to choice Non-CE or CE and press .

Press to scroll to choice Gas or Electric and press .

Press to scroll choices. Once the fryer type is chosen, press .

Sets sound level for controller. Enter level, 1-9 (0=Lowest/ 9=Loudest). Press .

Press to scroll choices: F for Fahrenheit; C for Celsius. Press .

Use numbered buttons to change default setting (use 10 for 0). Press . (This is the

temperature for the fryer to exit the melt cycle.) Default is 100F (38C).

Setback tempr 250F

Use numbered buttons to change default setting (use 10 for 0). Press . (This is the

temperature during setback or idle mode.) Default is 250F (121C).

Fresh oil None

waste NONE

RECOVERY ALARM DISABLED

Press to scroll choices JIB, Bulk-RTI, Bulk-F (Frontline) or None. Press .

fryers should be set to NONE.

Press to scroll choices JIB, Bulk-RTI, Bulk-F (Frontline) or None. Press .

fryers should be set to NONE.

Press to scroll choices DISABLED and ENABLED. (This is a recovery alarm that locks

out the fryer if the fryer does not heat properly. The default is disable d) . Pr ess .

Exit Exit

OFF OFF

Time/date

Time entry time

Date format Mm/dd/yy

Enter date date

Exit Exit

Press button.

None required.

Press .

Use numbered buttons to change time (use 10 for 0). Press .

Press to scroll choices. With the date format displayed, press .

Use numbered buttons to change date (use 10 for 0 ). Press .

Press button once and press to scroll to System, Time/Date, Filter, E-Log, Change

Password or Edit Alarm Names. With desired choice displayed, press or press the Scan

button once to return the controller to OFF.

DST SETUP

This is daylight savings time setup. In the United States, daylight savings time begins each year at 2:00 A.M. on

the second Sunday in March, with clocks moving ahead one hour. Daylight savings time ends each year at 2:00

A.M. on the first Sunday in November, with clocks moving back one hour. For the two states and international

locations, which do not use DST, set to disabled.

OFF OFF

Product Setup

Blank

Vat setup Enter code

DST ENABLED

Press and hold until Product Setup is displayed.

Press to scroll to Vat setup and press .

Enter 3228.

Press to scroll choices DISABLED and ENABLED. Press . (This enables or disabled

daylight savings time. Default is enabled.) If disabled is chosen, pressing the button,

displays exit. Press the exit scan button three times to exit.

Continued on the following page

NOTE:. All

NOTE:. All

1-4

Page 23

1.4 F3000 Vat Setup cont.

Left Display Right Display Action

DST START MONTH

3

Enter the daylight savings time starting month using the 1-10 keys. (Default is

US government starting month “3”.) Press .

DST START SUNDAY

2

Enter the daylight savings time starting Sunday using the 1-10 keys. (Default is

US government starting Sunday “2”.) Press .

DST END MONTH

11

Enter the daylight savings time ending month using the 1-10 keys. (Default is

US government ending month “11”.) Press .

DST END SUNDAY

1

Enter the daylight savings time ending Sunday using the 1-10 keys. (Default is

US government ending Sunday “1”.) Press .

EXIT Exit

Press button once and press to scroll to System, Time/Date, Filter, E-Log

or Change Password. With desired choice displayed, press or press the

Exit/Scan button three times to return the controller to OFF.

filter

Global filter count

20

Press .

Press . (Changes the total number of cooks that occur before a filter prompt.

The default is 20.)

Eod filter time 21:00

Use numbered buttons to change end of day filter alert time. Press . After

this time, the controller prompts for filter when user presses the power button

to go to the OFF state.

1 polish timer EnableD

Press to scroll to choice and press . (This enables or disables the polish

timer.)

1 polish time 08:00

Use numbered buttons to change time (use 10 for 0). (This is the time the first

polish prompt will occur each day. The default is 8:00 AM.) Press .

1 polish duration

30

Use numbered buttons to change (use 10 for 0). (This is the duration, in

minutes for a polish. The default is 30 minutes.) Press .

1 polish delay time 00:00

Use numbered buttons to change time (use 10 for 0). (This is the amount of

time that an operator can delay the start of a polish.) Press . After the delay

the operator must polish.

1 polish start tempr 300F

Use numbered buttons to change temperature (use 10 for 0). (This is the

temperature required for a polish to begin.) Press .

2 polish timer enabled

Press to scroll to choice and press . (This enables or disables the

second polish timer.)

2 polish time 14:00

Use numbered buttons to change time (use 10 for 0). (This is the time the

second polish prompt will occur each day.) Press .

2 polish duration

30

Use numbered buttons to change (use 10 for 0). (This is the duration, in

minutes for a polish. The default is 30 minutes.) Press .

2 polish delay time 01:00

Use numbered buttons to change time (use 10 for 0). (This is the amount of

time that an operator can delay the start of the second polish. The default is one

hour.) Press . After the delay the operator must polish.

2 polish start tempr 300F

Use numbered buttons to change temperature (use 10 for 0). (This is the

required temperature for the second polish to begin.) Press .

Exit Exit

Press button once and press to scroll to System, Time/Date, Filter, ELog, Change Password or Edit Alarm Names. Wit h desired choice displayed,

press or press the Scan button once to return the controller to OFF.

E-Log

NOW Time/date

A E# Time/date

Press . (This is a log of the ten most recent error codes.)

Press . (Current time and date)

Errors listed A-J. Press to scroll through errors. If no errors exist, pressing

will display No Errors.

Exit Exit

Press button once and press to scroll to System, Time/Date, Filter, ELog, Change Password or Edit Alarm Names. Wit h desired choice displayed,

press or press the Scan button once to return the controller to OFF.

Continued on the following page

1-5

Page 24

Left Display Right Display Action

C-Log

Blank

Press . (This is a reserved internal data collection feature that only exists in

pressure fryers.)

Exit Exit

Press button once and press to scroll to System, Time/Date, Filter, ELog, C-Log, Change Password or Edit Alarm Names. With desired choice

displayed, press or press the Scan button once to return the controller to

OFF.

Change password

Product setup

Current code

Press .

Use numbered buttons to change code (use 1 0 for 0) . P ress .

(1724)

Vat setup

Current code

Use numbered buttons to change code (use 1 0 for 0) . P ress .

(3228)

Exit Exit

Press button once and press to scroll to System, Time/Date, Filter, ELog, Change Password or Edit Alarm Names. Wit h desired choice displayed,

press or press the Scan button once to return the controller to OFF.

Edit alarm names

Alarm 1 NUM1

Press .

Enter or edit alarm name with letter buttons. Press . Continue scrolling

through names up to alarm 10. (Ex. Shake, Stir, etc.)

Exit Exit

Press button once and press to scroll to System, Time/Date, Filter, ELog, Change Password or Edit Alarm Names. Wit h desired choice displayed,

press or press the Scan button once to return the controller to OFF.

1.5 Navigating Filter Menu

The F3000 has five functions in the Filter Menu: Filter, Clean, Dispose, Fill Vat from Pan and Drain to Pan. They are accessed

by pressing and holding the Filter button until FILTER is displayed. The first matrix below steps through the initial

navigation. Navigation of the functions are covered in separate matrices. The controller must be on and at setpoint to use all

the functions of the filter menu. If the fryer is not at setpoint the controller displays WAIT FOR FILTER.

Entering Filter Mode

Left Display Right Display Action

DROP DROP

Press and hold the filter button until Filter is displayed.

filter

Press to scroll to choices: Filter, Clean, Dispose, Drain to Pan, Fill Vat from

Pan and Exit. With the desired choice displayed press . Follow the

instructions below to navigate the modes.

Filter

Left Display Right Display Action

filter

Filter Now? alternating with

Press .

Press YES.

yes/no

OPEN DRAIN VALVE

Draining

OPEN RETURN VALVE

POLISHING COUNTDOWN TIMER

CLOSE DRAIN VALVE CONFIRM

Filling

CLOSE RETURN VALVE when full

CONFIRM

Open drain valve.

None required.

Open return valve.

None required.

Close drain valve and press CONFIRM.

None required.

Press CONFIRM.

and press confirm

COOL COOL

1-6

Page 25

Clean

Left Display Right Display Action

CLEAN

Clean now? Yes NO

Open drain valve

Draining

Scrub vat complete? Yes

OPEN RETURN VALVE

Polishing 5-minute countdown timer

Fill vat? YES

CLOSE DRAIN VALVE CONFIRM

filling

CLOSE RETURN VALVE WHEN

CONFIRM

Press .

Press YES.

Open drain valve

None required.

Press YES.

Open return valve.

None required.

Press YES.

Close drain valve and press CONFIRM.

None required.

Press YES.

FULL AND PRESS CONFIRM

off off

Dispose

Left Display Right Display Action

dispose

Dispose now? Yes NO

REMOVE PAN CONFIRM

Insert disposal unit Confirm

OPEN DRAIN VALVE

DISPOSING

VAT EMPTY? CONFIRM

Clean vat complete? Confirm

CLOSE DRAIN VALVE CONFIRM

REMOVE DISPOSAL UNIT CONFIRM

INSERT PAN CONFIRM

Manually fill vat Confirm

off off

Press .

Press YES.

Remove the filter pan and press CONFIRM.

Insert disposal unit under the drain and press CON FIR M .

Open the drain valve.

None required.

Press CONFIRM once the vat is empty.

Press CONFIRM once the vat is clean.

Close drain valve and press CONFIRM.

Remove disposal unit from the fryer and press CONFIRM.

Insert the filter pan and press CONFIRM.

Fill vat with oil to the bottom fill line and press CONFIRM when full.

Drain to Pan

Left Display Right Display Action

Drain to pan

DRAIN TO PAN? Yes NO

OPEN DRAIN VALVE

draining

VAT EMPTY? CONFIRM

CLOSE DRAIN VALVE CONFIRM

OIL IN DRAIN PAN CONFIRM

FILL VAT FROM DRAIN PAN? YES NO

OPEN RETURN VALVE

FILLING

CLOSE RETURN VALVE WHEN

CONFIRM

Press

Press YES.

Open the drain valve.

None required.

Press CONFIRM.

Close the drain valve and press CONFIRM

Press CONFIRM.

Press YES.

Open the return valve.

None required.

Press CONFIRM.

FULL AND PRESS CONFIRM

OFF OFF

1-7

Page 26

Fill Vat from Pan

Left Display Right Display Action

FILL VAT FROM PAN? YES NO

OPEN RETURN VALVE

FILLING

CLOSE RETURN VALVE WHEN

FULL AND PRESS CONFIRM

off off

FILL VAT FROM PAN

CONFIRM

Press

Press YES.

Open the return valve.

None required.

Press CONFIRM.

1.6 Polishing

The F3000 displays a series of prompts when a polish filter cycle is under way. The steps are detailed below.

Left Display Right Display Explanation/Action

Polish Now? Yes NO

Add FILTER POWDER CONFIRM

**

INSERT PAN CONFIRM

**

CHANGE FILTER PAPER CONFIRM

*

*

Add filter powder Confirm

Insert pan confirm

*

*

OPEN DRAIN VALVE

Draining

OPEN RETURN VALVE

POLISHING 15-MINUTE COUNTDOWN

TIMER

Close drain valve CONFIRM

FILLING

CLOSE RETURN valve when

full and press confirm

COOL COOL

CONFIRM

Respond to prompt with button push. Press YES or NO. Yes produces a

filter, detailed below. No delays filter and cooking continues.

Remove filter pan, add filter powder and press CONFIRM.

Insert filter pan and press CONFIRM.

Remove the filter pan and change the filter paper.

Add filter powder and press CONFIRM.

Insert filter pan into fryer.

Open the drain valve.

None required. The oil drains from the frypot to the filter pan.

Open the return valve.

None required. The oil flows from the filter pan to the frypot and back to

the filter pan for 15 minutes.

Close the drain valve and press CONFIRM.

None required. The oil returns from the filter pan to the frypot.

Close the return valve and press CONFIRM.

*NOTE: Occurs on first polish of the day.

**NOTE: Occurs on first polish after lunch and subsequent polishes during the day.

1-8

Page 27

1.7 Prompts Encountered While Programming

The F3000 can be programmed for single-segmented cooking, which is used for most products, and segmented cooking, which

is used for bone-in chicken. When programming for either product, the time prompts encountered are sequentially numbered.

For non-segmented products, enter 0:00 for the second time prompt (2 Time) and the additional programming steps associated

with segmented programming don’t appear.

For segmented products, the process is longer. As many as 10 segments can be introduced during the cook cycle of one

product. The complete cook cycle can be thought of as a timeline, with temperatures changes introduced at time-specific

points on the timeline.

As Time 2, Time 3, Time 4 appear in the programming steps, the time entered is NOT the duration of the specific cycle, but

the point a temperature change occurs on the timeline. For example, a Time 2 change that is to change a temperature in a 13

minute cycle after 2 minutes is entered as 11. The first temperature change will occur with 11 minutes remaining on the time

line. See graphic on page 1-12.

Below is a explanation of the prompts presented in the sequence they occur. Programming is detailed on pages 1-11 thorough

1-14.

Left Display Right Display Explanation/Action

Long name

Name or button number

Short Name Name or button number

COOKING MODE SINGLE SETPOINT

1 Time 0:00 or previously

entered #

1 Tempr Temperature

1 Flex number

1 PRESSURE

OPEN

SOLENOID

2 Time Time

2 Tempr Temperature

Enter the full name of the product

Enter the four character abbreviated name of the product

Segmented: If multiple setpoint or segmented cooking is desired press

MULTIPLE SETPOINT and go to 1.9 and follow the instructions.

Non-Segmented: Leave at default of SINGLE SETPOINT.

In segmented and non-segmented programming, the total cook time is entered here.

This is the setpoint for non-segmented products; the initial setpoint for segmented

products.

Flex is the feature in the controller that allows the fryer to react to large and small

loads with the same cooking curve. It is generally not used with bone-in chicken.

The default value is 5. The range is 0-9.

This option is only present on pressure fryers. During cooks it determines if the

pressure solenoid should be open or closed. For segmented or multi-setpoint

cooking it may be closed and open during different cycles during the cook.

Segmented: Enter time remaining in the cook cycle after the first temperature

change occurs.Non-Segmented: Enter 0:00

Segmented: This is the first temperature change, which occurs at the point entered

at the 2 Time prompt. Non-Segmented: Doesn’t appear

2 Flex On or Off

2 PRESSURE

OPEN

SOLENOID

3 Time Time

3 Tempr Temperature

3 Flex On or OFF

3 PRESSURE

OPEN

SOLENOID

See 1 Flex.

See 1 Pressure Solenoid.

Segmented: Enter time remaining in the cook cycle after the second temperature

change occurs. Non-Segmented: Doesn’t appear.

Segmented: This is the second temperature change, which occurs at the point

entered at the 3 Time prompt. Non-Segmented: Doesn’t appear

See 1 Flex.

See 1 Pressure Solenoid.

1-9

Page 28

1.7 Prompts Encountered While Programming cont.

Left Display Right Display Explanation/Action

4 Time Time

4 Tempr Temperature

4 Flex On or Off

4 PRESSURE

SOLENOID

5 Time Time

1 Alarm Time Time

1 Alarm Name Shake, stir, numbered alarm

1 Alarm Mode Manual or Auto

1 Alarm Tone Short, Medium, Long, double

2 Alarm Time Time

2 Alarm Name Shake, stir, numbered alarm

OPEN

or long short, none

Segmented: Enter time remaining in the cook cycle after the third

temperature change occurs.Non-Segmented: Doesn’t appear.

Segmented: This is the third temperature change, which occurs at the

point entered at the 3 Time prompt. Non-Segmented: Doesn’t appear

See 1 Flex.

See 1 Pressure Solenoid.

Segmented: Enter 0:00 if no more segments are needed.

Non-Segmented: Doesn’t appear.

An audible alarm in the cook cycle, indicating a need to shake or stir the

product.

Navigate choice with arrow buttons under display.

The alarm can be self cancelling (Auto) or manually canceled (Manual),

which requires a button push. Navigate choice with arrow buttons under

display.

The duration of the audible alarm is optional. Navigate choice with

arrow buttons under display.

The second point in the cook cycle an alarm sounds.

Navigate choice with arrow buttons under display.

2 Alarm Mode Manual or Auto

2 Alarm Tone Short, Medium, Long, double

or long short, none

3 Alarm Time Time

3 Alarm Name Shake, stir, numbered alarm

3 Alarm Mode Manual or Auto

3 Alarm Tone Short, Medium, Long, double

or long short, none

After Cooking Set Point or COOL

Filter Lockout Number

Head Count 0

Instant On 0

Exit Exit

Navigate choice with arrow buttons under display.

Navigate choice with arrow buttons under display.

The third point in the cook cycle an alarm sounds.

Navigate choice with arrow buttons under display.

Navigate choice with arrow buttons under display.

Navigate choice with arrow buttons under display.

Setpoint: Fryer remains at setpoint; Cool: Fryer holds at 250°F (121°C).

Number of cook cycles for the product before a filter prompt.

Number of head of chicken or the equivalent number for a non-chicken

product.

This is the time, in seconds, the fryer heats before the controller checks

the temperature.

Press or Scan button to exit programming.

1-10

Page 29

1.8 Programming for Single Setpoint (Non-Segmented) Items

Programming for non-segmented food items is shown below. The right column has the action necessary to continue. Exit from

a programming step at any time by pressing the Scan button until the display returns to its pre-programming status.

Left Display Right Display Action

OFF OFF

Product Setup

Product Setup Enter Code

Select Product

Long Name Product name or button

Short Name Abbreviated Product name or

COOKING MODE SINGLE SETPOINT

1 Time 0:00 or previously entered time

1 TempR Temp

1 Flex

1 PRESSURE

SOLENOID

2 Time 0:00 or previously entered time

1 Alarm TIME 0:00 or previously entered time

number

button number

Number

OPEN

Press and hold until Product Setup is displayed.

Press .

Enter 1724.

Press a desired product button 1-20 that is not currently used. Buttons

already programmed are indicated with an LED.

Enter product name with letter buttons. Advance cursor with .

Press .

Enter abbreviated four character product name with letter buttons. Press

.

Press . If multiple setpoint or segmented cooking is desired press

MULTIPLE SETPOINT and go to 1.9 and follow the instructions.

(Default is SINGLE SETPOINT)

Enter total cook time with numbered buttons. Press .

Enter cooking temperature. Press .

Enter the level of flex, 0-9, for the product. Press .

Press to scroll to OPEN or CLOSED. Enter the state of the

pressure fryer solenoid lid. Default is OPEN. (Option only for pressure

fryers.)

Enter 0:00. Press .

Subtract the time from the starting cook time when the alarm should

sound. (Example: If a cook time is 5:00 and the shake time should be

30 seconds into the cook time enter 4:30 as the alarm time). Enter that

time for shaking, stirring, etc. Press . (Note: If alarm time is set to

0:00 skip to After Cooking below.)

1 alarm name shake

1 ALARM MODE AUTO OR MANUAL

1 alarm tone Short, medium, long double or

long short, none

2 alarm time 0:00

After Cooking Cool or Setpt

Filter Lockout 0

QUANTITY? No

Head Count 0 or previously set number

Instant On 0

Exit Exit

Select Product

Product Setup

OFF OFF

Press to scroll through the alarm names (ex. Shake). Press .

Press to scroll to Auto or Manual alarm mode. Press .

Press to scroll to choice of alarm tones. Press .

Press . Leave at 0:00 for non-segmented cooking.

Press to scroll to Cool or Setpoint mode the fryer should exit to

after cook cycle: cool = 250; Setpoint = cooking temp. Press .

Enter number of cook cycles before a filter prompt and press .

Press to scroll to YES if a quantity per load is required, otherwise

leave to default NO.

Enter number of head or the equivalent value for the product . Press .