Page 1

Application Series

Service and Parts Manual

Frymaster, a member of the Commercial Food Equipment Service Association, recommends

using CFESA Certifi ed Technicians.

24-Hour Service Hotline 1-800-551-8633

www.frymaster.com Email: service@frymaster.com

SEPTEMBER 2006

*8196153*

Page 2

IF, DURING THE WARRANTY PERIOD, THE CUSTOMER USES A PART FOR THE ENODIS

EQUIPMENT OTHER THAN AN UNMODIFIED NEW OR RECYCLED P ART PURCHASED DIRECTL Y

FROM FRYMASTER DEAN, OR ANY OF ITS AUTHORIZED SERVICE CENTERS, AND/OR THE

P ART BEING USED IS MODIFIED FROM ITS ORIGINAL CONFIGURA TION, THIS WARRANTY WILL

BE VOID. FURTHER, FRYMASTER DEAN AND ITS AFFILIATES WILL NOT BE LIABLE FOR ANY

CLAIMS, DAMAGES OR EXPENSES INCURRED BY THE CUSTOMER WHICH ARISE DIRECTLY

OR INDIRECTLY, IN WHOLE OR IN PART, DUE TO THE INSTALLATION OF ANY MODIFIED PART

AND/OR PART RECEIVED FROM AN UNAUTHORIZED SERVICE CENTER.

NOTICE

This appliance is intended for professional use only and is to be operated by qualifi ed personnel only.

A Frymaster DEAN Factory Authorized Service Center (FASC) or other qualifi ed professional should

perform installation, maintenance, and repairs. Installation, maintenance, or repairs by unqualifi ed

personnel may void the manufacturer’s warranty.

NOTICE

This equipment must be installed in accordance with the appropriate national and local codes of the

country and/or region in which the appliance is installed.

NOTICE TO U.S. CUSTOMERS

This equipment is to be installed in compliance with the basic plumbing code of the Building Offi cials

and Code Administrators International, Inc. (BOCA) and the Food Service Sanitation Manual of the

U.S. Food and Drug Administration.

NOTICE

Drawings and photos used in this manual are intended to illustrate operational, cleaning and technical

procedures and may not conform to onsite management operational procedures.

NOTICE TO OWNERS OF UNITS EQUIPPED WITH COMPUTERS

U.S.

This device complies with Part 15 of the FCC rules. Operation is subject to the following two conditions:

1) This device may not cause harmful interference, and 2) This device must accept any interference

received, including interference that may cause undesired operation. While this device is a verifi ed

Class A device, it has been shown to meet the Class B limits.

CANADA

This digital apparatus does not exceed the Class A or B limits for radio noise emissions as set out by

the ICES-003 standard of the Canadian Department of Communications.

Cet appareil numerique n’emet pas de bruits radioelectriques depassany les limites de classe A et B

prescrites dans la norme NMB-003 edictee par le Ministre des Communcations du Canada.

DANGER

Improper installation, adjustment, maintenance or service, and unauthorized alterations or modifi cations

can cause property damage, injury , or death. Read the installation, operating, and service instructions

thoroughly before installing or servicing this equipment. Only qualifi ed service personnel may convert

this appliance to use a gas other than that for which it was originally confi gured.

Page 3

DANGER

Adequate means must be provided to limit the movement of this appliance without depending upon the

gas line connection. Single fryers equipped with legs must be stabilized by installing anchor straps. All

fryers equipped with casters must be stabilized by installing restraining chains. If a fl exible gas line is

used, an additional restraining cable must be connected at all times when the fryer is in use.

DANGER

No structural material on the fryer should be altered or removed to accommodate placement of the fryer

under a hood. Questions? Call the Frymaster Dean Service Hotline at 1-800-551-8633.

DANGER

The front ledge of the fryer is not a step! Do not stand on the fryer. Serious injury can result from slips

or contact with the hot oil.

DANGER

Do not store or use gasoline or other fl ammable liquids or vapors in the vicinity of this or any other ap-

pliance.

DANGER

Instructions to be followed in the event the operator smells gas or otherwise detects a gas leak must

be posted in a prominent location. This information can be obtained from the local gas company or

gas supplier.

DANGER

The crumb tray in fryers equipped with a fi lter system must be emptied into a fi reproof container at the

end of frying operations each day. Some food particles can spontaneously combust if left soaking in

certain shortening material.

WARNING

Do not bang fry baskets or other utensils on the fryer’s joiner strip. The strip is present to seal the joint

between the fry vessels. Banging fry baskets on the strip to dislodge shortening will distort the strip,

adversely affecting its fi t. It is designed for a tight fi t and should only be removed for cleaning.

DANGER

This product contains chemicals known to the state of California to cause cancer and/or birth defects

or other reproductive harm.

Operation, installation and servicing of this product could expose you to airborne particles of glass wool

or ceramic fi bers, crystalline silica, and/or carbon monoxide. Inhalation of airborne particles of glass

wool or ceramic fi bers in know to the State of California to cause cancer. Inhalation of carbon monox-

ide is known to the State of California to cause birth defects or other reproductive harm.

Page 4

THIS PAGE INTENTIONALLY LEFT BLANK

Page 5

APPLICATION SERIES FRYERS

Table of Contents

CHAPTER 1: Service Procedures

1.1 General and Model Number Matrix .....................................................................................................1-1

1.2 Wiring Diagrams ..................................................................................................................................1-2

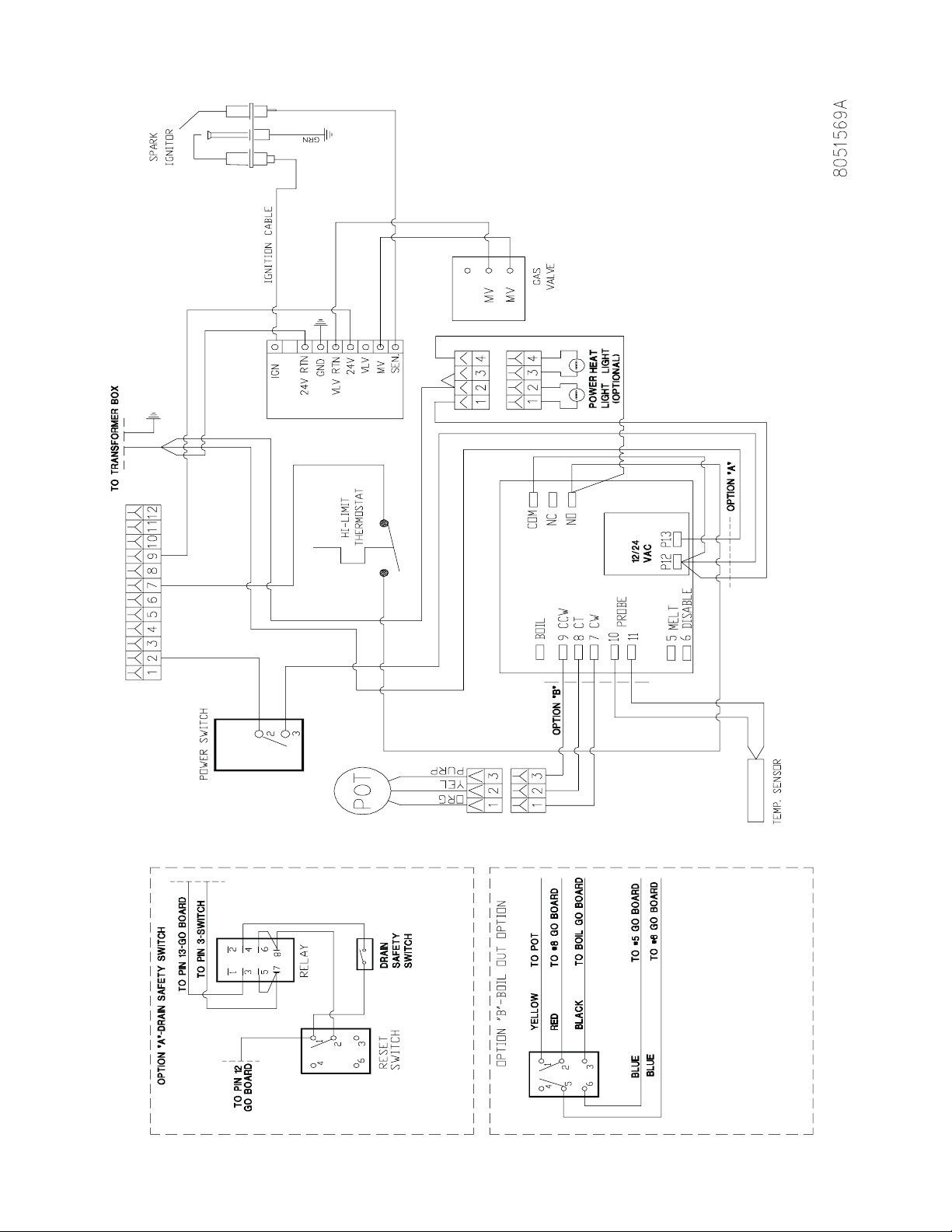

1.2.1 FPP35/45 Electric Ignition ........................................................................................................1-2

1.2.2 Flatbottom Wiring ......................................................................................................................1-3

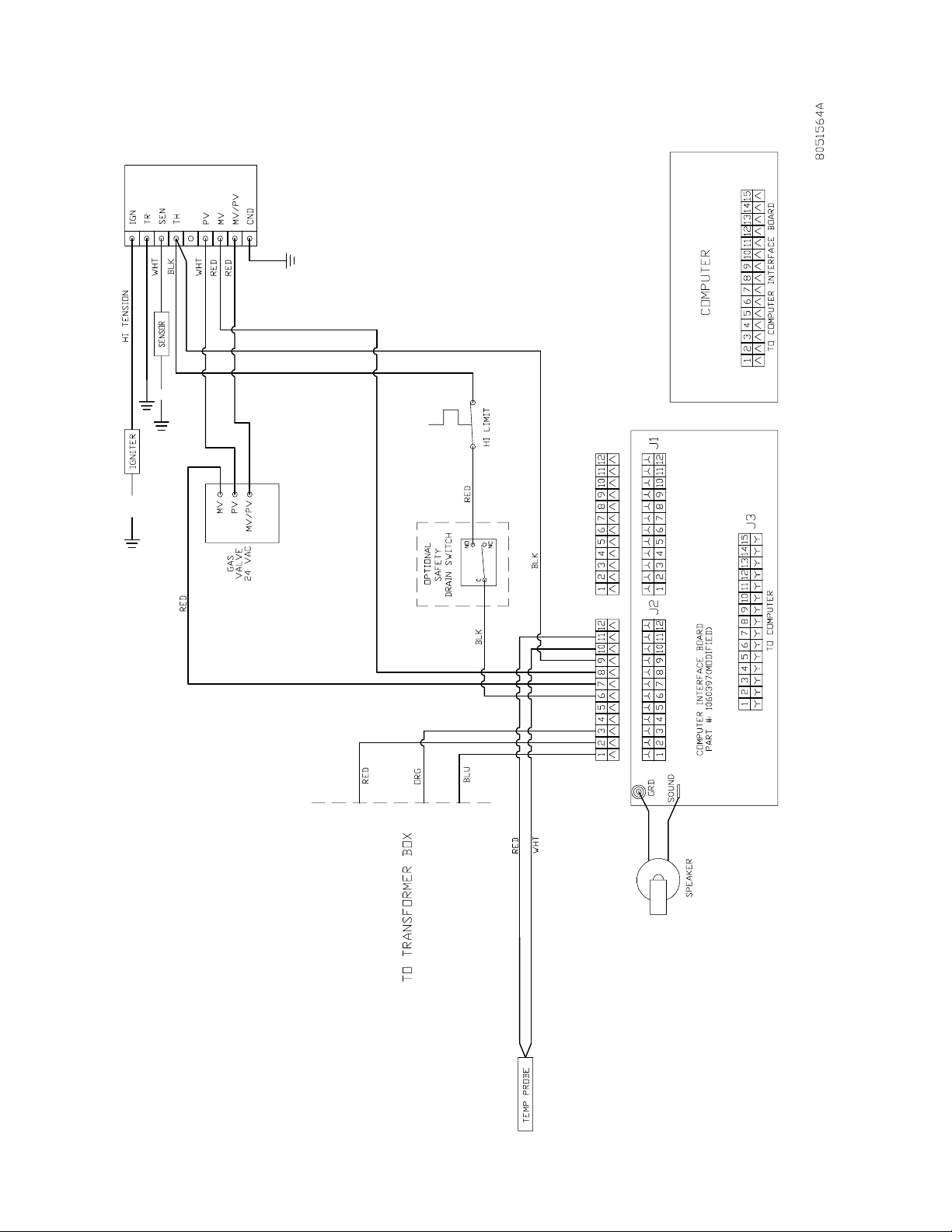

1.2.3 MJ35/45 Computer w/ Electronic Ignition Wiring ....................................................................1-4

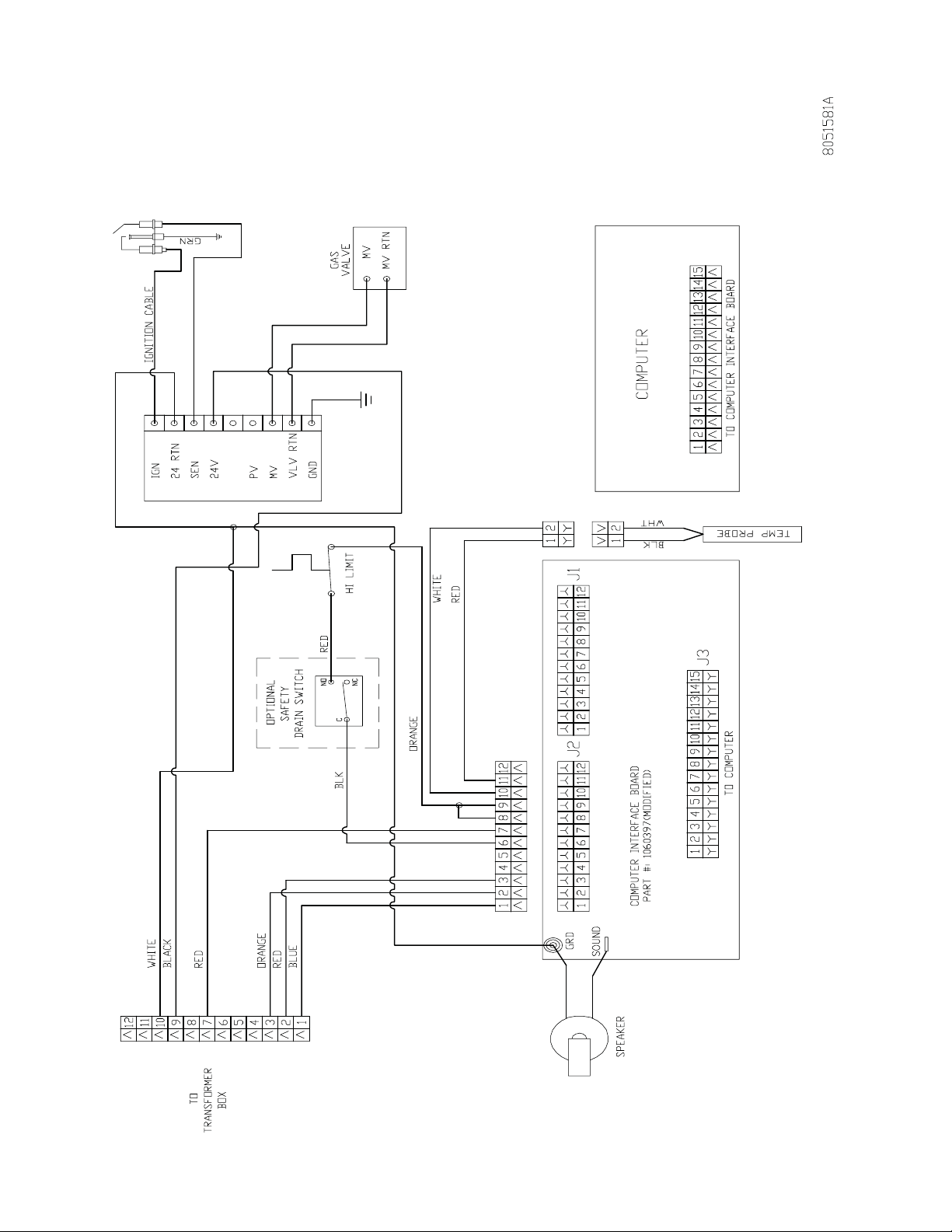

1.2.4 Dean Computer Wiring ..............................................................................................................1-5

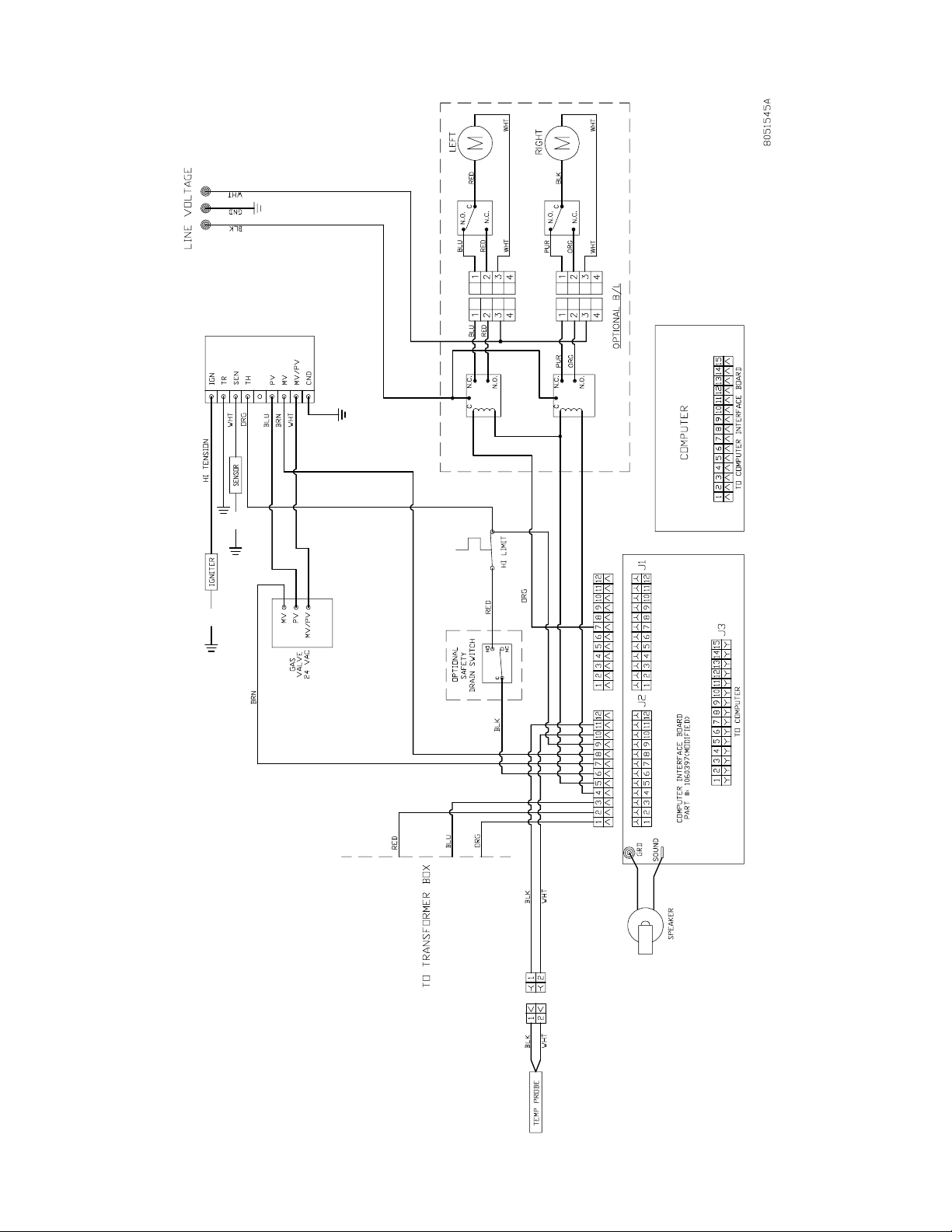

1.2.5 Flatbottom Computer Wiring .....................................................................................................1-6

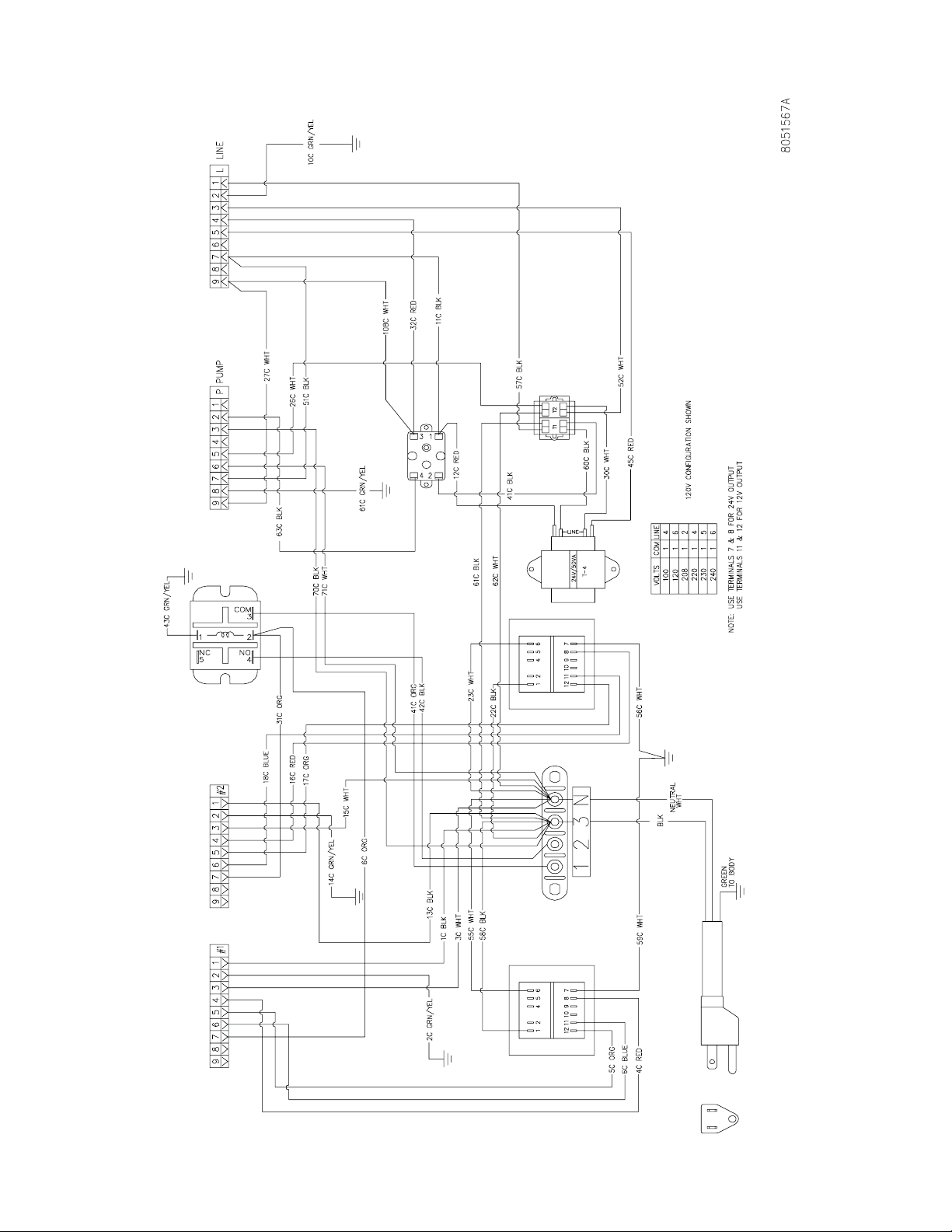

1.2.6 Dean/Frymaster Transformer/Filter Box Wiring .......................................................................1-7

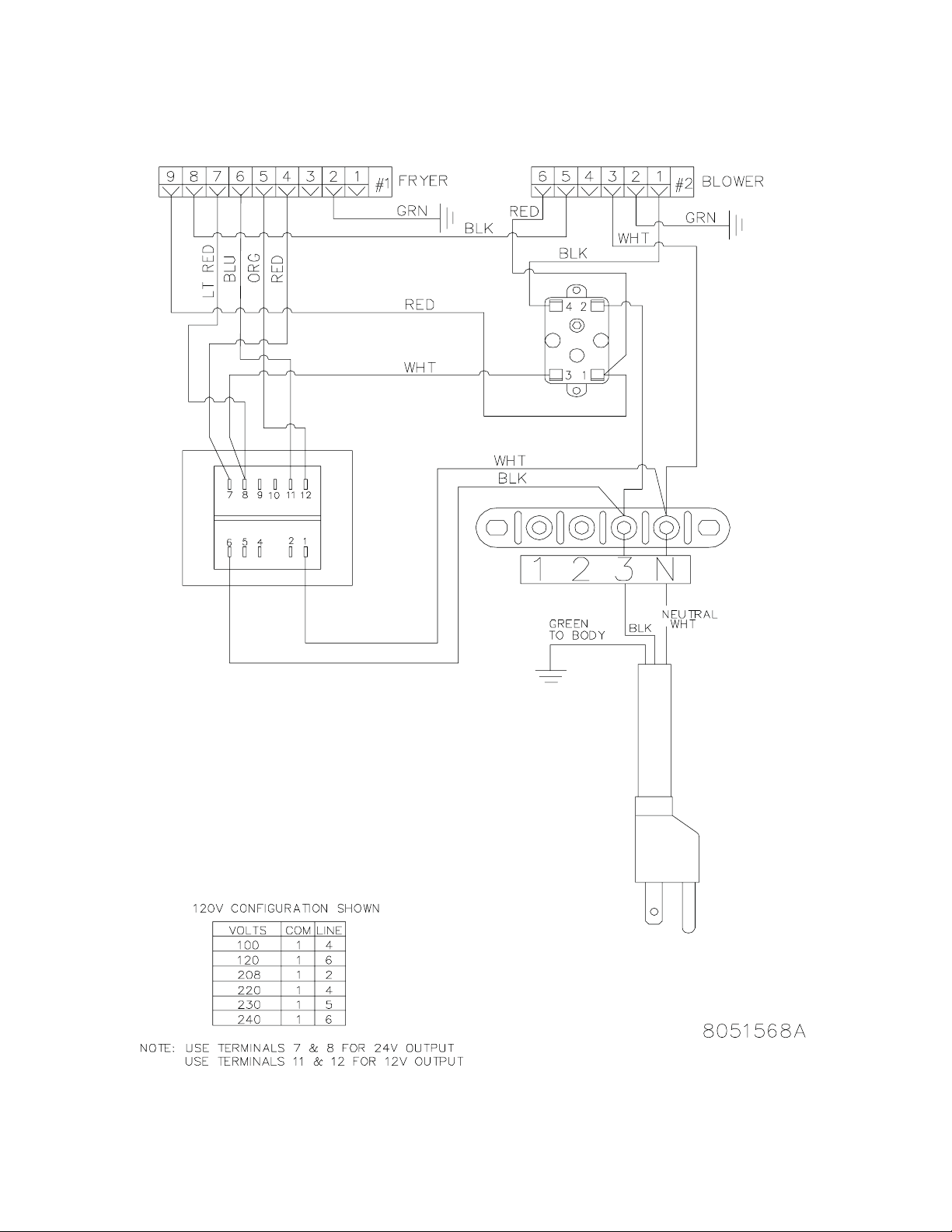

1.2.7 Flatbottom 18/24 Transformer Box Wiring ...............................................................................1-8

1.2.8 Flatbottom 24/24 Filter Box Wiring ..........................................................................................1-9

CHAPTER 2: Parts List

2.1 Accessories ..........................................................................................................................................2-1

2.2 Cabinetry ..............................................................................................................................................2-2

2.2.1 MJ35/45, H55 / D50, D60, D80 Combinations .........................................................................2-2

2.2.2 MJ35/45, H55, D50, D60, D80 and Flatbottom Combinations ................................................2-6

2.3 T op Cap Assemblies ...........................................................................................................................2-10

2.4 Flue Caps, Control Panel Frame Assemblies and Bezels ..................................................................2-12

2.5 Upper and Lower Cabinet Back Panels .............................................................................................2-14

2.6 Door Assemblies ................................................................................................................................2-16

2.7 Drain Assemblies ...............................................................................................................................2-17

2.8 Drain Valve Assemblies .....................................................................................................................2-20

2.9 Filter Pump Assemblies .....................................................................................................................2-22

2.10 Filter Plumbing ................................................................................................................................2-24

2.11 Filter Pan Assemblies .......................................................................................................................2-25

2.12 Transformer and Filter Box Assemblies ..........................................................................................2-26

i

Page 6

APPLICATION SERIES FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.1 General

Frymaster’s Application Series fryers combine many types of fryers such as MJ35/45, H55, D50/60/80,

Flatbottom 1824 and 2424 fryers. Service procedures for each of the specifi c fryers are covered in each

fryers respective service and parts manuals. These manuals are accessible online at www.frymaster.com

under online literature.

Fryer Service and Parts Manuals

Performance Pro-Series Gas Fryers MJ35/45 819-6092

Pro H50/55 Series Gas Fryers 819-6083

Decathlon Gas Fryers 819-5922

Flatbottom Gas Fryers 819-6031

Flatbottom Electric Fryers 819-6115

Pro Electric H14/17/22 Electric Fryers 819-5990

RE Series RE14/17/22 Electric Fryers 819-6150

1721/18UE Electric Fryers 819-5981

Application Series Model Number Matrix

Model* Confi guration

Two Station Fryers

DF2x1 D-HD160/MJ-H1x5CSC

DF2x2 D-HD150/MJ-H1x5

DF2x3 D-HD160/MJ-H1x5SC

DF2x5 D-HD160/MC/MJ-H1x5

DF2x6 MJ-H1x5/D-HD150

DF2x7 D-HD160/MJ-H1x5

DF2x# MJ-H1x5/D-HD160

Five Station Fryers

DF5x1 MJ-H2x5/D-HD360

DF5x# 22424/MC/MJ-H3x5

Six Station Fryers

DF6x1 MJ-H2x5/2424//32424

Three Station Fryers

DF3x1 D-HD160/MJ-H2x5

DF3x2 D-HD160/MJ-H2x5 Nat Gas

DF3x3 D-HD160/MJ-H2x5 LP Gas

DF3x4 MJ-H1x5/D-HD250

DF3x5 D-HD160/MJ-H2x5 Battered to Right of DF4x6

DF3x# D-HD250/MJ-H1x5

DF3x# 2424/MC/MJ-H2x5

Four Station Fryers

DF4x1 MJ-H2x5/D-HD260 Alz Back

DF4x2 MJ-H2x5/D-HD250

DF4x3 D-HD250/MJ-H2x5

DF4x4 MJ-H2x5/D-HD260 SS Back

DF4x5 MJ-H3x5/MC/2424

DF4x6 D-HD460 Battered to Left of DF3x5

DF4x# D-HD160/MC/MJ-H3x5

DF4x# 2424/MC/MJ-H3x5

DF4x# MJ-H2x5/21824

DF4x# 32424/D-HD160

1-1

*NOTE: To shorten model numbers the

zeros have been dropped.

Example: DF2x1 = DF20000001

Page 7

APPLICATION SERIES FRYERS

CHAPTER 1: SERVICE PROCEDURES

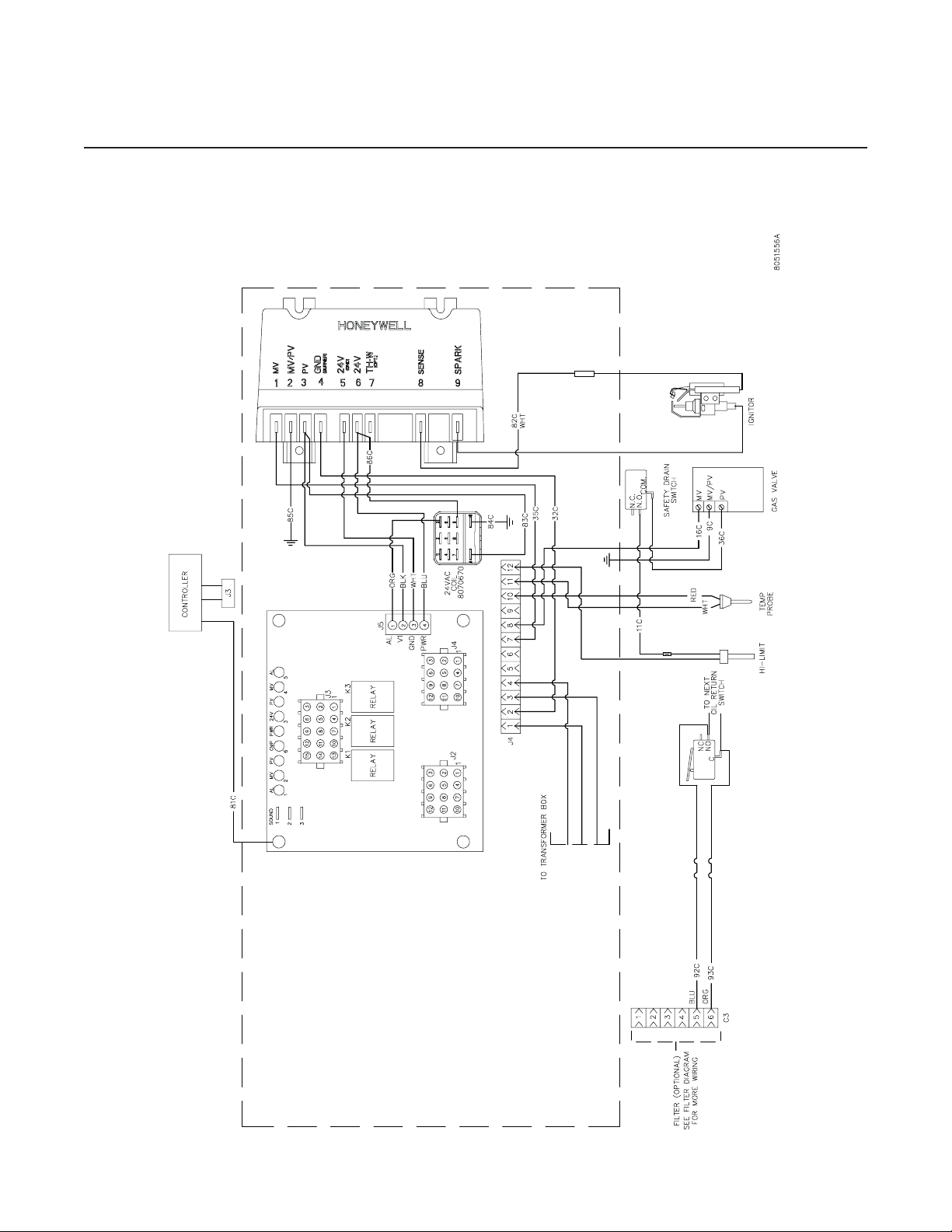

1.2 Wiring Diagrams

1.2.1 FPP35/45 Electronic Ignition

1-2

Page 8

1.2.2 Flatbottom Wiring

1-3

Page 9

1.2.3 MJ35/45 Computer w/ Electronic Ignition Wiring

1-4

Page 10

1.2.4 Dean Computer Wiring

1-5

Page 11

1.2.5 Flatbottom Computer Wiring

1-6

Page 12

1.2.6 Transformer/Filter Box Wiring Common Cabinet

1-7

Page 13

1.2.7 Flatbottom 18/24 Transformer Box Wiring

1-8

Page 14

1.2.8 Flatbottom 24/24 Filter Box Wiring

1-9

Page 15

APPLICATION SERIES FRYERS

CHAPTER 2: PARTS LIST

This manual lists the unique cabinet and fi ltration parts for the Application Series Fryers. For common

parts pertaining to the fryer, refer to the respective fryer’ s service and parts manual. (ie., H50/55, Decathlon,

etc.)

These manuals may be accessed online at www.frymaster.com.

Fryer Service and Parts Manuals

Performance Pro-Series Gas Fryers MJ35/45 819-6092

Pro H50/55 Series Gas Fryers 819-6083

Decathlon Gas Fryers 819-5922

Flatbottom Gas Fryers 819-6031

Flatbottom Electric Fryers 819-6115

Pro Electric H14/17/22 Electric Fryers 819-5990

RE Series RE14/17/22 Electric Fryers 819-6150

1721/18UE Electric Fryers 819-5981

2.1 Accessories and Connecting/Joiner Strips

3

1

2

4

5

6

ITEM PART # COMPONENT

1 810-2793 Wireform Basket Hanger

* 810-2794 Wireform Basket Hanger CF

2 809-0171 Basket Hanger Screw

3 809-0921 Spacer, Basket Hanger

4 803-0278 Brush, Tefl on / L-Shaped

Top Connecting and Joiner Strips

5 823-5036 SM/D60 Connecting (joins like frypots within a system)

823-1885 BK Type - H55, MJ Connecting (joins like frypots within a system)

* 210-4313 Flatbottom Connecting (joins like frypots within a system)

6 823-5429 D60 Left / MJ-H55 Right Joiner

823-5366 DD250 Left / MJ-H55 Right Joiner

7 823-5037 MJ-H55 Left / D60 Right Joiner

823-5080 MJ-H55 Left / Flatbottom (1824,2424) Right Joiner

* 826-1351 Nut Retainer, ¼-20 Nutsert (pkg. of 10)

* Not illustrated.

7

2-1

Page 16

2.2 Cabinetry

2.2.1 MJ35, MJ45, H55 / D50, D60, D80 Combinations

4

1

3

Front of fryer.

15

8

13

21

17

11

18

2

16

10

5

27

26

9

12

7

22

14

6

25

24

20

Rear of fryer.

23

19

H255/DD250 Four station fryer shown.

2-2

Page 17

2.2.1 MJ35, MJ45, H55 / D50, D60, D80 Combinations cont.

ITEM PART # COMPONENT

Cabinet Assemblies

Two Station Fryer

106-5324 DF2x1 (SCFD160/MJ-H1x5CSC), DF2x3 (SCFD160/MJ-H1x5SC)

106-6837 DF2x2 (SCFD150/MJ-H1x5)

106-6837 DF2x6 (MJ-H1x5/DD50)

106-7518 DF2x# (MJ-H1x5/D160)

Three Station Fryer

106-5452 DF3x1-DF3x2-DF3x3 (D160/MJ-H2x5), DF2x5 (D160/15MC/MJ-H1x5)

106-6834 DF3x4 (MJ-H1x5/DD250)

106-7599 DF3x5 (D160/MJ-H2x5)

106-7523 DF3x# (DD250/MJ-H1x5)

Four Station Fryer

106-4314 DF4x1 (MJ-H2x5/SCFD260), DF4x4 (MJ-H2x5/SCFD260)

106-4432 DF4x2 (MJ-H2x5/SCFD250)

106-5233 DF4x3 (SCFD250/MJ-H2x5)

106-7600 DF4x6 (D460 Filter Right)

106-7365 DF4x# (SCFD160/MC/MJ-H3x5)

Five Station Fryer

106-4454 DF5x1 (245E/SCFD360), DF5x# (MJ-H2x5/D360)

Base Assemblies

Two Station Fryer

106-5323 DF2x1 (SCFD160/MJ-H1x5CSC), DF2x3 (SCFD160/MJ-H1x5SC)

106-6836 DF2x2 (SCFD150/MJ-H1x5), DF2x6 (MJ-H1x5/D50)

Three Station Fryer

106-5451 DF3x1-DF3x2-DF3x3 (D60/MJ-H2x5), DF2x5 (D160/15MC/MJ-H1x5)

106-6833 DF3x4 (MJ-H1x5/DD250)

106-7522 DF3x# (DD250/ MJ-H1x5)

Four Station Fryer

106-4313 DF4x1 (MJ-H2x5/SCFD260), DF4x4 (MJ-H2x5/SCFD260)

106-4434 DF4x2 (MJ-H2x5/SCFD250), DF4x3 (SCFD250/MJ-H2x5)

106-7358 DF4x# (SCFD160/MC/MJ-H3x5)

Five Station Fryer

106-4455 DF5x1 (245E/SCFD360), DF5x# (MJ-H2x5/D360)

1 211-8078 Side, Left Cabinet

2 212-8078 Side, Right Cabinet

3 200-9929/8662 Post, Rear Com Cabinet (use 220-1799 for DF2x2, DF2x6, DF3x4)

4 200-8080 Divider, Frypot (use 220-1844 for DF3x4)

5 810-1494 Caster, w/o Brake Swivel 4” Wheel

6 810-0326 Caster, Adj. w/ Brake 4” Wheel

7 200-8168 Post, Front

8 200-8227 Brace, Left Lower Front H55 LT/RT

9 Brace, Center Lower Front

Two Station Fryer

220-0078 DF2x1 (SCFD160/MJ-H1x5CSC), DF2x3 (SCFD160/MJ-H1x5SC)

220-0882 DF2x2 (SCFD150/MJ-H1x5), DF2x6(MJ-H1x5/DD150)

220-0402 DF2x5 (D60/15MC/MJ-H1x5)

220-2210 DF2x (MJ-H1x5/D160)

Three Station Fryer

220-0402 DF3x1-DF3x2-DF3x3 (D60/MJ-H2x5)

2-3

continued on next page...

Page 18

2.2.1 MJ35, MJ45, H55 / D50, D60, D80 Combinations cont.

ITEM PART # COMPONENT

220-0882 DF3x4 (MJ-H1x5/DD250)

Four Station Fryer

200-8101 DF4x1 (MJ-H2x5/SCFD260), DF4x4 (MJ-H2x5/SCFD260)

200-8453 DF4x2 (MJ-H2x5/SCFD250), DF4x3 (SCFD250/MJ-H2x5)

220-2129 DF4x# (SCFD160/MC/MJ-H3x5)

Five Station Fryer

200-9938 DF5x1 (245E/SCFD360), DF5X# (MJ-H2x5/D360)

10 200-8452 Brace, Right Lower Front DD50 LT/RT

Three Station

200-8227 DF3x1-DF3x2-DF3x3 (D60/MJ-H2x5),

DF2x5 (D160/15MC/MJ-H1x5)

220-0891 DF3x4 (MJ-H1x5/DD250)

Four/Five Station

200-8100 DF4x1 (MJ-H2x5/SCFD260), DF4x4 (MJ-H2x5/SCFD260), DF5x

200-8452 DF4x2 (MJ-H2x5/SCFD250), DF4x3 (SCFD250/MJ-H2x5)

11 200-8736 Support, Left Filter Pan MJ-H/D50 - DF4x1 (MJ-H2x5/SCFD260),

DF4x4 (MJ-H2x5/SCFD260)

221-2194 Support, Left Filter Pan MJ-H/D60 - DF2x1 (SCFD160/MJ-H1x5CSC), DF2x3

(SCFD160/MJ-H1x5CSC), DF2x5 (D160/15MC/MJ-H1x5), DF3x1-DF3x2-DF3x3

(D60/MJ-H2x5) DF4x2 (MJ-H2x5/SCFD250), DF4x3 (SCFD250/MJ-H2x5), DF5x1

(245E/SCFD360), DF5x# (MJ-H2x5/D360)

221-2130 DF4x# (SCFD160/MC/MJ-H3x5)

221-1938 DF2x6 (MJ-H1x5/DD150), DF3x4 (MJ-H1x5/DD250)

12 200-8737 Support, Right Filter Pan MJ-H/D50 - DF4x1 (MJ-H2x5/SCFD260), DF4x4 (MJ-

H2x5/SCFD260)

222-2194 Support, Right Filter Pan MJ-H/D60 - DF2x1 (SCFD160/MJ-H1x5CSC), DF2x3

(SCFD160/MJ-H1x5CSC), DF2x5 (D160/15MC/MJ-H1x5), DF3x1-DF3x2-DF3x3

(D60/MJ-H2x5) DF4x2 (MJ-H2x5/SCFD250), DF4x3 (SCFD250/MJ-H2x5), DF5x1

(245E/SCFD360), DF5x# (MJ-H2x5/D360)

222-2130 DF4x# (SCFD160/MC/MJ-H3x5)

222-1938 DF2x6 (MJ-H1x5/DD150), DF3x4 (MJ-H1x5/DD250)

* 220-1687 Bridge, Filter Pump

13 823-4894 Hinge, Lower Left Door

14 823-4895 Hinge, Lower Right Door

15 823-4729 Hinge, Upper Left Door

16 823-4730 Hinge, Upper Right Door

17 Brace, Front/Rear Upper

Two Station Fryer

220-0077 DF2x1 (SCFD160/MJ-H1x5CSC), DF2x3 (SCFD160/MJ-H1x5SC)

220-1804 DF2x2 (SCFD150/MJ-H1x5), DF2x6 (MJ-H1x5/DD150 rear only)

220-0401 DF2x5 (D160/15MC/MJ-H1x5)

220-0878 DF2x6 (MJ-H1x5/DD150 front only)

Three Station Fryer

220-0401 DF3x1-DF3x2-DF3x3 (D60/MJ-H2x5)

220-1804 DF3x4 (MJ-H1x5/DD250 rear only)

220-0886 DF3x4 (MJ-H1x5/DD250 front only)

Four Station Fryer

200-8082 DF4x1 (MJ-H2x5/SCFD260), DF4x4 (MJ-H2x5/SCFD260)

200-8455 DF4x2 (MJ-H2x5/SCFD250), DF4x3 (SCFD250/MJ-H2x5)

220-2128 DF4x# (SCFD160/MC/MJ-H3x5)

* Not illustrated.

continued on next page...

2-4

Page 19

2.2.1 MJ35, MJ45, H55 / D50, D60, D80 Combinations cont.

ITEM PART # COMPONENT

200-8504 Five Station DF5x1 (245E/SCFD360), DF5x# (MJ-H2x5/D360)

18 200-2235 Bracket, Component Box Support

19 Channel, Base Rear

Two Station Fryer

220-2190 DF2x1 (SCFD160/MJ-H1x5CSC), DF2x3 (SCFD160/MJ-H1x5SC)

220-1335 DF2x2 (SCFD150/MJ-H1x5), DF2x6 (MJ-H1x5/DD150 front only)

220-2195 DF2x5 (D160/15MC/MJ-H1x5)

Three Station Fryer

220-2195 DF3x1-DF3x2-DF3x3 (D60/MJ-H2x5)

220-1939 DF3x4 (MJ-H1x5/DD250)

220-2219 DF3x# (DD250/MJ-H1x5)

Four Station Fryer

220-2198 DF4x1 (MJ-H2x5/SCFD260), DF4x4 (MJ-H2x5/SCFD260)

220-2199 DF4x2 (MJ-H2x5/SCFD250), DF4x3 (SCFD250/MJ-H2x5)

220-2126 DF4x# (SCFD160/MC/MJ-H3x5)

Five Station Fryer

220-2203 DF5x1 (245E/SCFD360), DF5X# (MJ-H2x5/D360)

20 823-4851/5790 Channel, Base Side DF2x6 (MJ-H1x5/DD150 front only), DF3x4 (MJ-H1x5/DD250)

21 200-8098 Channel, Base Front Left, Five Station, DF5x1 (245E/SCFD360), DF5x# (MJ-H2x5/

D360)

22 Channel, Base Front Right

Two Station Fryer

200-8450 DF2x5 (D160/15MC/MJ-H1x5)

Three Station Fryer

200-8450 DF3x1-DF3x2-DF3x3 (D60/MJ-H2x5)

220-0890 DF3x4 (MJ-H1x5/DD250)

Four Station Fryer

200-8095 DF4x1-DF4x4 (MJ-H2x5/SCFD260)

200-8450 DF4x2 (MJ-H2x5/SCFD250), DF4x3 (SCFD250/MJ-H2x5)

220-2127 DF4x# (SCFD160/MC/MJ-H3x5)

Five Station Fryer

200-8505 DF5x1 (245E/SCFD360), DF5x# (MJ-H2x5/D360)

23 Manifold, Assembly -Oil Return / Rear Support

Two Station Fryer

810-3155 DF2x1 (SCFD160/MJ-H1x5CSC), DF2x3 (SCFD160/MJ-H1x5SC)

810-3113 DF2x5 (D160/15MC/MJ-H1x5)

810-3117 DF2x6 (MJ-H1x5/DD150)

Three Station Fryer

810-3156 DF3x1-DF3x2-DF3x3-DF3x# (D60/MJ-H2x5)

810-3117 DF3x4 (MJ-H1x5/DD250)

Four Station Fryer

810-3157 DF4x1-DF4x4 (MJ-H2x5/SCFD260)

810-3158 DF4x2 (MJ-H2x5/SCFD250), DF4x3 (SCFD250/MJ-H2x5)

823-6015 DF4x# (SCFD160/MC/MJ-H3x5)

Five Station Fryer

823-4973 DF5x1 (245E/SCFD360), DF5x# (MJ-H2x5/D360)

24 826-1389 Screw, Hex Head 1/4-20 x 3/4 (Qty. of 10)

25 801-0189 Washer, 1/4 Flat

26 809-0821 Screw, Hex Head 1/4-20 x 3/4

27 823-4891 Plate, Front Caster Mounting

2-5

Page 20

2.2.2 MJ35, MJ45, H55, D50, D60, D80 and Gas Flatbottom Combinations

18

10

16

1

7

4

5

6

8

3

Front of fryer

2

20

19

12

14

25

11

26

28

15

13

27

29

21

17

30

9

31

24

Rear of fryer

22

23

H255/21824 Four station fryer shown.

2-6

Page 21

2.2.2 MJ35, MJ45, H55, D50, D60, D80 and Gas Flatbottom Combinations cont.

ITEM PART # COMPONENT

Cabinet Assemblies

Two/Four Station Fryer

106-5348 DF2x# (1824/2424 Left non-fi lter)

106-5153 DF2x# (22424 Left), DF4x# (Left 32424/D60)

106-5487 DF2x# (22424 Right)

106-5382 DF2x# (22424 Right non-fi lter)

106-5349 DF2x# (SCF22424 Right)

106-5154 DF2x# (2424/D60 Right), DF4x# (Right 32424/D60)

106-5136 DF2x# (2424/2424)

Three/Five/Six Station Fryer

106-4751 DF3x# (MJ-H2x5/FB), DF6x1 (Left MJ-H2x5/2424//32424)

106-5458 DF3x# (32424E), DF6x1 (Right MJ-H2x5/2424//32424)

106-4712 DF3x# (32424 Right)

106-5420 DF3x# (MJ-Hx5/D60/1824)

106-7028 DF5x# (Left 22424/26MC//MJ-H3x5)

106-7008 DF5x# (Right 22424/26MC//MJ-H3x5)

Four Station Fryer

106-5468/5349 DF4x5 (MJ-H3x5//MC24/2424) Four Station w/ spreader cabinet

106-5376 DF4x# (MJ-H2x5/21824)

Base Assemblies

Two/Four Station Fryer

106-5350 DF2x# (1824/2424L non-fi lter)

106-5381 DF2x# (22424 R non-fi lter)

106-4983 DF2x# (22424L, 22424R, 2424), DF4x# (Left 22424//2424/D60)

106-4986 DF2x# (2424 or 1824 and D60), DF4x# (Right 22424//2424/D60)

Three/Five/Six Station Fryer

106-4752 DF3x# (MJ-H2x5/FB), DF6x1(Left MJ-H 2x5/2424//32424)

106-5445 DF3x# (32424E)

106-5421 DF3x# (MJ-Hx5/D60/1824)

106-7029 DF5x#(Left 22424/26MC//MJ-H3x5)

106-4711 DF6x1 (Right MJ-H2x5/2424//32424)

Four Station Fryer

106-5472/4983 DF4x5 (MJ-H3x5//MC24/2424) Four Station w/ spreader cabinet

106-5377 DF4x# (MJ-H2x5 / 21824)

1 Side, Left Cabinet

211-8078 2424L, H2xx/21824, H255/FB, H55/D60/1824, MJ/H3x5L, 1824/2424L

221-0012 2424L, MJ-H3x5L, 2424L non-fi lter (has openings for connecting fryers)

201-8942 2424/D60 (has openings for connecting fryers)

231-0395 32424E - YUM

2 Side, Right Cabinet

202-8942 2424R, (has openings for connecting fryers)

212-8078 MJ-H2x5/21824, MJ-H2x5/FB, MJ-Hx5/D60/1824, SCF2424R, 2424R, 2424/

D60

222-0012 MJ/H3x5R, 1824/2424R (has openings for connecting fryers)

232-0395 32424E - YUM

3 Post, Rear

200-8882 MJ-H2x5/21824, MJ-H2x5/FB, MJ-Hx5/D60/1824, 2424R, 2424/D60, 2424L

continued on next page...

2-7

Page 22

2.2.2 MJ35, MJ45, H55, D50, D60, D80 and Gas Flatbottom Combinations cont.

ITEM PART # COMPONENT

200-8662 MJ/H3xxL

220-0404 32424E - YUM

200-9232 SCF2424R, 1824/2424L, 2424, 2424R non-fi lter

Divider, Frypot

4 200-8080 MJxxx, Hxxx Pot Divider

5 200-8873 MJxxx, H2xx / 1824, 2424 Divider

6 200-8912 1824, 2424 Flatbottom Pot Divider

7 200-8168 Post, Front Cabinet

8 200-8903 Brace, Firebox FB

9 Brace, Upper Front/Rear

Two Station Fryer

200-9229 DF2x# (2424L, SCF2424, 2424, 2424R, 2424R non-fi lter)

200-9239 DF2x# (2424/D60, 1824/2424L non-fi lter)

Three Station Fryer

200-8874 DF3x# (MJ-H2x5/FB)

220-0370 DF3x# (32424E)

220-0291 DF3x# (MJ-Hx5/D60/1824)

Four Station Fryer

220-0210 DF4x# (MJ-H2xx/21824)

10 200-8227 Brace, Left Lower Front MJ-Hx5 LT/RT

11 Brace, Right/Center Lower Front

Two Station Fryer

200-9240 DF2x# (1824/2424L non-fi lter, 2424/D60)

200-9231 DF2x# (2424, 2424/2424L, SCF2424R, 2424R, 2424R non-fi lter)

Three Station Fryer

200-8878 DF3x# (MJ-H2x5/FB)

220-0371 DF3x# (32424E)

220-0290 DF3x# (MJ-Hx5/D60/1824)

Four Station Fryer

220-0214 DF4# (MJ-H2x5/21824)

* Bridge, Filter Pump

* 200-8932 MJ-H2x5/FB

* 220-0380 32424E - YUM

12 201-9764 Rail, Filter Pan Left

* 221-0289 Rail, Filter Pan Left MJ-Hx5/D60/1824

13 202-9764 Rail, Filter Pan Right

* 222-0289 Rail, Filter Pan Right MJ-Hx5/D60/1824

14 201-9890 Guide, Filter Pan Left

15 202-9890 Guide, Filter Pan Right

16 823-4894 Hinge, Lower Left Door (all models)

17 823-4895 Hinge, Lower Right Door (all models)

18 823-4729 Hinge, Upper Left Door MJ-Hx5

823-5520 Hinge, Upper Left Door 24 (32424E)

823-5136 Hinge, Upper Left Door FB (1824/2424L)

19 823-4730 Hinge, Upper Right Door MJ-Hx5

823-5521 Hinge, Upper Right Door 24 (32424E)

823-5137 Hinge, Upper Right Door (SCF2424R, 2424R)

* Not illustrated.

continued on next page...

2-8

Page 23

2.2.2 MJ35, MJ45, H55, D50, D60, D80 and Gas Flatbottom Combinations cont.

ITEM PART # COMPONENT

20 Channel, Cabinet Base Front Left/Center

Two Station Fryer

200-9228 DF2x# (2424/2424L, 2424, SCF2424R, 2424R)

200-9241 DF2x# (1824/2424L non-fi lter, 2424/D60)

220-0036 DF2x# (2424R non-fi lter)

Three/Five Station Fryer

200-8098 DF3x# (MJ-H2x5/FB, MJ-Hx5/D60/1824)

200-9228 DF3x# (32424E)

220-2033 DF5x# (22424/26MC/MJ-H3x5)

Four Station Fryer

200-8098 DF4x# (MJ-H2xx/21824)

22 220-0207 Channel, Cabinet Base Front Right D60

Three Station Fryer

220-0331 DF3x# (32424E)

Four Station Fryer

220-0207 DF4x# (MJ-H2xx/21824)

23 Channel, Cabinet Base Rear

Two Station Fryer

823-5155 DF2x# (2424/2424L, 2424, SCF2424R, 2424R, 2424R non-fi lter)

823-5162 DF2x# (1824/2424L non-fi lter, 2424/D60 Right)

Three/Five Station Fryer

823-5102 DF3x# (MJ-H2x5/FB)

823-5518 DF3x# (32424E)

823-5498 DF3x# (MJ-Hx5/D60/1824)

220-2031 DF6x# (22424/26MC//MJ-H3x5)

Four Station Fryer

823-5466 DF4x# (MJ-H2x5/21824)

24 Manifold, Rear Support

Two Station Fryer

823-5158 DF2x# (22424L/R 2424R non-fi lter), DF4x#(Left 32424/D60)

823-5435 DF2x# (1824/2424L non-fi lter)

823-5161 DF2x# (2424/D60 Right), DF4x# (32424/D60 Right)

Four Station Fryer

823-5540 DF4x5 (MJ-H3x5/24MC/2424)

823-5468 DF4x# (MJ-H2x5/21824)

Five Station Fryer

823-5094 DF5x1 (MJ-H2x5/D360)

Six Station Fryer

823-5103 DF6x1 (MJ-H2x5/24/32424 Left)

823-5094 DF6x1 (MJ-H2x5/24/32424 Right)

25 200-8871 Bracket, Component Box Support

26 810-1494 Caster, w/out Brake 4” wheel

27 810-0944 Caster, w/ Brake 4” wheel

28 823-4891 Plate, Front Caster Mounting

29 809-0821 Screw, Hex Head 1/4-20 x 3/4

30 801-0189 Washer, 1/4 Flat

31 826-1389 Screw, Hex Head 1/4-20 x 3/4 (Qty. of 10)

2-9

Page 24

2.3 Top Cap Assemblies

3

2

6

5

9

8

12

11

14 15

1

4

7

10

13

continued on next page...

2-10

Page 25

2.3 Top Cap Assemblies cont.

ITEM PART # COMPONENT

Topcap Assemblies / Marine Edges

Two Station Topcaps

1 106-5318 DF2x1 (SCFD160/MJ-H1x5CSC), DF2x3 (SCFD160/MJ-H1x5SC)

5 106-5496 DF2x5 (D160/15MC/MJ-H1x5)

* 106-6798 DF2x6 (MJ-H1x5/DD150)

2 106-5471 DF4x5 (MC24/2424) Right Side

3 823-5301 DF4x# (2424/D60) Right Side

4 823-5308 DF4x# (22424) Right Side notched on left

* 823-5478 DF4x# (22424) Left Side notched on right

Three Station Topcaps

5 106-5496 DF3x1-DF3x2-DF3x3-DF3x5 (D60/MJ-H2x5)

6 106-5470 DF4x5 (MJ-H3x5) Left Side

7 823-5123 DF6x1 (32424) Right Side

8 823-5078 DF6x1 (MJ-H2x5/2424) Left Side

9 823-5504 DF3x# (MJ-Hx5/D60/1824)

10 823-5514 32424E - YUM

* 823-5989 DF5x# (22424/MC/MJ-H3x5 Notched Right) Left Side

* 823-5982 DF5x# (22424/MC/MJ-H3x5 Notched Left) Right Side

Four Station Topcaps

11 106-4653 DF4x1 (MJ-H2x5/SCFD260), DF4x4 (MJ-H2x5SC/SCFD260)

12 106-4654 DF4x2 (MJ-H2x5/SCFD250)

13 106-5234 DF4x3 (SCFD250/MJ-H2x5)

* 106-7638 DF4x6 (D460 Filter Right)

14 823-5467 DF4x# (MJ-H2x5/21824)

* 106-7368 DF4x# (SCFD160/MC/MJ-H3x5)

Five Station Topcaps

15 106-4655 DF5x1 (MJ-H2x5/D360)

* Not illustrated.

2-11

Page 26

2.4 Flue Caps, Control Panel Frame Assemblies and Bezels

1

2

6

5

3

ITEM PART # COMPONENT

1 Fluecap Assemblies

Two Station Fluecaps

106-5319 DF2x1 (SCFD160/MJ-H1x5CSC), DF2x3 (SCFD160/MJ-H1x5SC)

106-5137 DF4x5 (24MC/2424) Right Side

Three Station Fluecaps

106-5455 DF3x1-DF3x2-DF3x3 (D60/MJ-H2x5),

DF2x5 (D160/15MC/MJ-H1x5)

106-6827 DF3x4 (MJ-H1x5/DD250)

106-5432 DF3x# (MJ-Hx5/D60/1824)

106-5469 DF4x5 (MJ-H3x5) Left Side

106-4926 DF6x1 (MJ-H2x5/2424) Left Side

106-4927 DF6x1 (32424) Right Side

823-5514 32424E - YUM

106-7069 DF5x# (22424/MC/MJ-H2x5)

Four Station Fluecaps

106-4389 DF4x1 (MJ-H2x5/SCFD260), DF4x4 (MJ-H2x5SC/SCFD260)

106-4656 DF4x2 (MJ-H2x5/SCFD250)

106-5235 DF4x3 (SCFD250/MJ-H2x5)

106-5378 DF4x# (MJ-H2x5/21824)

106-7366 DF4x# (SCFD160/MC/MJ-H3x5)

Five Station Fluecaps

106-4657 DF5x1 (MJ-H3x5/SCFD360), DF5x# (MJ-H2x5/D360)

4

2-12

continued on next page...

Page 27

2.4 Flue Caps, Control Panel Frame Assemblies and Bezels

ITEM PART # COMPONENT

2 Control Panel Frame Assemblies

Two Station Assembly

106-5320 DF2x1 (SCFD160/MJ-H1x5CSC), DF2x3 (SCFD160/MJ-H1x5SC)

106-6826 DF2x6 (MJ-H1x5/DD150)

106-5495 DF2x5 (D160/15MC/MJ-H1x5)

106-4984 DF4x# (24MC/2424), DF4x# (32424/D60)

Three Station Assembly

106-5453 DF3x1-DF3x2-DF3-3 (D60/MJ-H2x5)

106-5431 DF3x# (MJ-Hx5/D60/1824)

106-6332 DF3x4 (MJ-H1x5/DD250)

106-5467 DF4x5 (MJ-H3x5) Left Side

106-4754 DF6x1 (MJ-H2x5/2424) Left Side

106-4918 DF6x1 (32424) Right Side

106-5446 32424E - YUM

Four Station Assembly

106-4315 DF4x1 (MJ-H2x5/SCFD260), DF4x4 (MJ-H2x5SC/SCFD260),

DF4x# (MJ-H2x5/21824)

106-5375 DF4x2 (MJ-H2x5/SCFD250)

106-4433 DF4x3 (SCFD250/MJ-H2x5)

106-7367 DF4x# (SCFD160/MC/MJ-H3x5)

Five Station Assembly

106-4456 DF5x1 (MJ-H2x5/SCFD360), DF5x# (MJ-H2x5/D360)

Bezels

3 Single

210-5046 MJ-Hx5 - DF4x5

210-9266 D60 - DF4x#

210-8971 Flatbottom - DF4x5, DF4x#, DF6x#

210-7002 MJ-Hx5 Blank

4 230-0439 2424 Blank - DF4x5

230-0394 2424E - 32424E - YUM

230-0394 2424 -with Thermatron

5 Two Station

230-0090 D160/MJ-H1x5 - DF2x1, DF2x2, DF2x3,

210-5819 MJ/Hxx5 - DF4x1, DF4x2, DF4x3, DF4x4, DF4x5, DF4x#,

DF5x1, DF5x#, DF6x1

210-8522 D250 - DF4x2, DF4x3

210-8175 D260 - DF4x1, DF4x4

230-1675 DF2x5 (D160/15MC/MJ-H1x5)

6 Three Station

230-0410 D60/MJ/H2x5 - DF3x1, DF3x2. DF3x3

230-1948 D350 - DF3x4 (MJ-H1x5/DD250)

230-0338 MJ-Hx5/D60/1824 - DF3x#

210-8509 D360 - DF5x1

2-13

Page 28

2.5 Upper and Lower Cabinet Back Panels

1

2

ITEM PART # COMPONENT

1 Upper Cabinet Backs

Single Station Backs

200-8886 2424 - DF4x# (32424/D60), DF6x1 (MJ-H2x5/FB24/32424)

** 220-0366 2424 - YUM

Two Station Backs

220-0093 D60/MJ-Hx5 - DF2x1 (SCFD160/MJ-H1x5CSC),

DF2x2 (SCFD150/MJ-H1x5SC), DF2x3 ( SCFD160/MJ-H1x5SC)

200-8593 D250 - DF4x1 (MJ-H2x5/SCFD260), DF4x2 (MJ-H2x5/SCFD250),

DF4x3 (SCFD250/MJ-H2x5), DF4x# (MJ245/21824),

DF5x1 (MJ-H2x5/SCFD360), DF5x# (MJ-H2x5/D360),

DF6x1 (MJ-H2x5/FB24/32424)

230-0241* D250/MJ-H2x5 - DF4x4 (MJ-H2x5SC/SCFD260)

200-8458 D260 - DF4x1 (MJ-H2x5/SCFD260)

230-0239* D260 - DF4x4 (MJ-H2x5SC/SCFD260)

200-8457 MJ-H2x5 - DF4x2 (MJ-H2x5/SCFD250)

200-9781 21824 or FB/D60 - DF4x# (MJ-H2x5/21824), DF4x# (32424/D60)

200-0481 22424- DF4x5 (MJ-H3x5/24MC/2424)

Three Station Backs

220-0413 D60/MJ-H2x5 - DF3x1 (D60/MJ-H2x5),

DF2x5 (D160/15MC/MJ-H1x5)

220-0337 MJ-Hx5/D60/1824 - DF3x# (MJ-Hx5/D60/1824)

220-0440 MJ-H3x5-DF4x5 (MJ-H3x5/24MC/2424)

200-8597 D360 - DF5x1 (MJ-H2x5/SCFD360), DF5x# (MJ-H2x5/D360)

* Stainless steel continued on next page...

** Not illustrated.

2-14

Page 29

2.5 Upper and Lower Back Panels cont.

ITEM PART # COMPONENT

2 Lower Cabinet Backs

Single Station Backs

200-8885 2424 - DF4x# (32424/D60), DF6x1 (MJ-H2x5/FB24/32424)

220-0365 2424 - YUM

Two Station Backs

220-0091 D60/MJ-Hx5 - DF2x1 (SCFD160/MJ-H1x5CSC),

DF2x2 (SCFD150/MJ-H1x5SC), DF2x3 ( SCFD160/MJ-H1x5SC)

200-8594 D250 - DF4x1 (MJ-H2x5/SCFD260), DF4x2 (MJ-H2x5/SCFD250),

DF4x3 (SCFD250/MJ-H2x5), DF4x# (MJ245/21824),

DF5x1 (MJ-H2x5/SCFD360), DF5x# (MJ-H2x5/D360),

DF6x1 (MJ-H2x5/FB24/32424)

230-0242* D250/MJ-H2x5 - DF4x4 (MJ-H2x5SC/SCFD260)

200-8595 D260 - DF4x1 (MJ-H2x5/SCFD260)

230-0240* D260 - DF4x4 (MJ-H2x5SC/SCFD260)

200-8539 MJ-H2x5 - DF4x2 (MJ-H2x5/SCFD250)

220-0180 21824 or FB/D60 - DF4x# (MJ-H2x5/21824), DF4x# (32424/D60)

200-0179 22424- DF4x5 (MJ-H3x5/24MC/2424)

Three Station Backs

220-0412 D160/MJ-H2x5 - DF3x1 (D160/MJ-H2x5), DF2x5 (D160/MC/MJ-

H1x5)

220-0336 MJ-H1x5/D160/1824 - DF3x# (MJ-H1x5/D160/1824)

220-0441 MJ-H3x5-DF4x5 (MJ-H3x5/24MC/2424)

200-8596 D360 - DF5x1 (MJ-H2x5/SCFD360), DF5x# (MJ-H2x5/D360)

* Stainless Steel

2-15

Page 30

2.6 Door Assemblies

3

1

2

4

ITEM PART # COMPONENT

1 Door Assemblies

106-3965 MJ35/45

106-3966 H55

106-4512 D50

106-4309 D60, 1824

106-5248 2424 Left

106-4753 2424 Right

2 Panel, Liner

200-6814 MJ35/45

200-6822 H55

200-8538 D50

200-8076 D60, 1824

200-8872 2424 Left, 2424 Right

3 Handle

210-9739 MJ35/45, H55

210-8077 D50, D60, 1824, 2424 Left, 2424 Right

4 809-0449 Screw #10 x 1/2” Phillips

5 Panel, Door

824-1344 MJ35/45

824-1342 H55

824-1435 D50

824-1386 D60, 1824

824-1480 2424 Left, 2424 Right

5

2-16

Page 31

2.7 Drain Assemblies

28

28

17

16

4

28

17

5

MJ-H1x5/DD150 (DF2x6)

17

13

5

MJ-H2x5/D150 (DF3x#)

28

19

23

16

12

18

23

5

MJ-H2x5/D260 (DF4x1 & DF4x4)

17

12

28

19

7

28

19

23

D250/MJ-H2x5 (DF4x3)

10

10

D160/15MC/MJ-H1x5 (DF2x5)

1

D160/MJ-H1x5 (DF2x1 & DF2x3)

5

12

3

10

MJ-H1x5/DD250 (DF3x4)

25

15

D160/MJ-H2x5 (DF3x1-3)

11

2

2-17

17

12

12

31

2424/26MC/MJ-H2x5 (DF3x#)

23

6

MJ-H2x5/D250 (DF4x2)

30

Page 32

2.7 Drain Assemblies cont.

22

29

9

21

25

12

29

12

20

25

24

25

12

25

25

20

25

MJ-H3x5/24MC/2424 (DF4x5)

11

26

24

15

2

22

2424/26MC/MJ-H3x5 (DF4x#)

35

29

34

18

24

2

32

28

18

23

15

22424/26MC/MJ-H3x5 (DF5x#)

22

9

12

24

25

20

24

20

MJ-H2x5/42424 (DF6x1)

29

20

13

8

14

18

24

23

8

5

MJ-H2x5/D360 (DF5x1)

13

32424E

20

16

24

32424/D60 (DF4x#)

8

25

12

MJ-H2x5/21824 (DF4x#)

2-18

Page 33

2.7 Drain Assemblies cont.

ITEM PART # COMPONENT

1 812-1880 Connector / Dump D60/MJ-Hx5 (823-5473)

2 812-1873 Connector / Dump 24MC/MJ-Hx5 (823-5984)

3 812-1881 Connector / Dump D60/MJ-Hx5 (823-5529)

4 812-1878 Connector / Dump D60/15MC/MJ-Hx5 (823-5938)

5 823-5046 Connector / Dump MJ-Hx / D60

6 823-4929 Connector / Dump MJ-Hx5/D50

7 812-1882 Connector / Dump D50/MJ-Hx5 (823-5464)

8 823-4876 Connector / Dump

9 823-4678 Connector / Dump

10 823-5506 Connecting Drain, Left/Upper D60/MJ-Hx5 - 7.0”

11 812-1876 Connecting Drain, Left/Upper 2424- 11.03” (823-5980)

12 823-4639 Connecting Drain, Left / Right - 15.55”

13 823-4853 Connecting Drain, Left - 9.06”

14 823-5066 Connecting Drain, Left MJ-Hx/D60 - 15.61”

15 812-1874 Connecting Drain, Center - 8.93” (823-5983)

16 200-8561 Connecting Drain, Center - 6.25”

17 200-8560 Connecting Drain, Center - 4.5”

18 200-6603 Connecting Drain, Center - 11.5”

19 200-6751 Connecting Drain, Center - 7.0”

20 200-8128 Connecting Drain, Center - 16.5”

21 200-0442 Connecting Drain, Center 24MC

22 823-5089 Connecting Drain, Center MJ-H2x5/FB - 8.05”

23 823-4682 Connecting Drain, Center 50/60/80 - 8.0”

24 823-4854 Connecting Drain, Center FB - 9.0”

25 823-4641 Connecting Drain, Center - 15.55”

26 823-5311 Connecting Drain, Right FB/D60

27 823-5474 Connecting Drain, Right MJ-Hx5/D60

28 823-4681 Connecting Drain, Right 50/60/80 - 8.06”

29 823-5084 Connecting Drain, Right FB - 4.0”

30 816-0625 Sleeve

31 809-0969 Clamp

* 816-0630 Vinyl Cap

32 812-1875 Connecting Drain, Center 22424/26MC - 10.97” (823-5990)

33 812-1879 Connector / Dump MJ-Hx5 / DD50 (823-5967)

34 823-5701 Connecting Drain, Left - 12.04”

35 220-2046 Connecting Drain, Center - 12.30”

* 811-1071 Tubing, Tefl on Vent (sold by the foot)

* KIT6214 3” Round Drain Boot Kit (includes 2 clamps and 1 sleeve)

* Not illustrated.

2-19

Page 34

2.8 Drain Valve Assemblies

9

5

4

5

4

11

3

2

6

10

14

3

8

8

1

6

7

12

15

13

1

2

7

18

22

16

21

17

9

5

4

106-1106106-4690

11

19

8

20

106-5430

2-20

Page 35

2.8 Drain Valve Assemblies cont.

ITEM PART # COMPONENT

106-4690 Drain Valve Assembly , MJ45/D50/D60

106-1106 Drain Valve Assembly, H55

106-5430 Drain Valve Assembly , Flatbottom

1 200-6496 Support, Drain Tube

2 806-8137 Bracket, Switch

3 807-2103 Switch, CE Micro Straight Lever

4 826-1366 Nut, 4-40 KEPS Hex (Qty. of 25)

5 809-0540 Nut, 2-Way Lock 1/2” - 13 ZN PL

6 810-1018 Valve, 1-1/4”

7 816-0135 O-Ring, Drain Valve

8 816-0220 Insulation, RF Switch

9 816-0547 Cap, Vinyl Red .375” x 3”

10 823-5064 Handle W/A, Drain Valve 45 Common Cabinet

11 901-2348 Cover, DV Safety Switch

12 816-0639 Cap, Vinyl Red 5/16” x 3”

13 824-1602 Handle W/A, Drain Valve Universal FV Elec.

14 900-2841 Cover, Switch Valve

15 900-2936 Retainer, Nut Drain Valve

16 106-3982 Bracket Assembly, 1-1/4” Microswitch

17 200-1257 Retainer, Nut Drain Valve

18 200-8867 Strap, 3” Drain 1-1/4” Valve

19 807-2104 Switch, CE Micro Roller Lever

20 810-2867 Valve, 1-1/4 Full Port w/o Ring FB Drain

21 816-0544 O-Ring, Drain Valve

22 823-4883 Handle W/A, Flatbottom 3” Drain Valve

2-21

Page 36

2.9 Filter Pump Assemblies

MJ-Hx5 and D50/60/80

Combinations

8

1

7

4

3

11

2

10

22

9

12

5

Filter Pump Wiring

17

4

MJ-H, D50/60/80 and Flatbottom

Combinations

21

15

14

6

1

20

2

9

13

18

19

16

2-22

12

Page 37

2.9 Filter Pump Assemblies cont.

ITEM PART # COMPONENT

Pump and Motor Assembly 115V 60Hz

1 826-1712 Motor 115V 60Hz

2 826-1264 Pump and Gasket Kit, Viking 4GPM 2-piece

816-0093 Gasket, Pump/Motor

3 106-5162 Pump, Wiring Assembly

4 810-1668 Adaptor, Male 5/8” OD x 1/2”

5 812-1497 Wrap, 3/8” x 20” Long Spiral

6 812-1500 Wrap, 3/8” x 6” Long Spiral

7 813-0022 Nipple, 1/2” x Close NPT BM

8 813-0165 Elbow, St. 1/2” x 1/2” NPT 90°

9 813-0304 Bushing, 1/2” x 1/4” BM Flush

10 813-0342 Elbow, Street 45° 1/2” NPT

11 813-0530 Tee, Reducing 1/2” x 1/4” x 1/2”

12 813-0838 Nipple, 1/4” NPT BM Close

13 813-0537 Nipple, 1/4” x 2” NPT BM

14 810-3071 Pump, Viking 8 GPM

816-0093 Gasket, Pump/Motor

15 810-1669 Adapter, Female 7/8” OD x 1/2”

16 813-0003 Tee, 1/2” x 1/2” x 1/2” BM

17 813-0031 Bushing, HX 3/4” NPT x 1/2” BM

18 813-0068 Elbow, Reducing 3/4” x 1/2”

19 813-0087 Nipple, 1/2” x 1.50” NPT BM

20 813-0112 Nipple, 3/4” x 2.00” NPT BM

21 813-0168 Elbow, Street 90° 3/4” x 3/4” NPT BM

22 106-3470 Valve, Solenoid w/ Female Pins

2-23

Page 38

2.10 Filter Plumbing

6

5

2

3

4

1

ITEM PART # COMPONENT

106-6646 Plumbing Assembly , Filter

1 106-4427 Bracket Assembly, Suction Tube

2 824-1618 Plate Weldment, Filter Pump

3 810-1669 Adapter, Female 7/8 OD x 1/2”

4 200-8404 Bridge, Suction Tube

5 810-1057 Flexline 5/8” OD x 13.00”

6 810-1159 Flexline, 5.00” Oil Return

2-24

Page 39

2.11 Filter Pan Assemblies

11

8

1

7

12

5

2

9

6

10

4

3

ITEM PART # COMPONENT

106-5388 Filter Pan Assembly, Com Cab 60 Filter - MJ-Hx5 and D50/60 Combinations

106-6130 Filter Pan Assembly, Flatbottom - Flatbottom Combinations (use 106-4720 for

DF6x1)

1 106-5313 Lid Assembly - (fi ts Pan Assembly 106-5388)

2 200-5726 Screen, Sana Grid

3 809-0070 Nut, 1/4 - 20 HEX SS

4 810-2805 Caster, 2”

5 823-3361 Ring W/A, Hold Down

6 823-5138 Pan W/A, Com Cab 60 Filter (Pan for Assy 106-5388 and 106-4937)

* 823-5737 Pan W/A, Filter 2424 (Pan for Assy 106-6130)

7 823-5471 Basket W/A, Crumb Com Cab - (fi ts Pan Assy 106-5388)

8 823-5546 Lid Assembly - (fi ts Pan Assy 106-4720) 32424E

9 106-3675 Filter Screen Assembly, 2424

10 823-3480 Pan W/A, Flatbottom (Pan for Assy 106-4720)

11 823-5833 Basket W/A, Crumb - (fi ts Pan Assy 106-6130)

12 823-5090 Lid Assembly - (fi ts Pan Assy 106-4720) DF6x1

* 106-6131 Lid Assembly - (fi ts Pan Assy 106-6130)

* Not illustrated.

2-25

Page 40

2.12 Transformer and Filter Box Assemblies

1

11

8

4 2

8

76

106-4839

24

7

106-5112

3

88

5

8

5 9

8

10

10

3

9

3

3

13

15

3

14

8

806-6150

7

106-5111

8

7 8

4

8

4

7

4

19

7412

3

106-5113

2

106-5109

7

5

8

32

4

16

3

181714

ITEM PART # COMPONENT

106-4839 Box Assembly, Transformer/Filter Common Cabinet 2xx

106-5112 Box Assembly, Transformer/Filter Tube/Flatbottom

106-5113 Box Assembly , Transformer/Filter Flatbottom/Flatbottom

806-6150 Box Assembly, Transformer 100/120V H255

106-511 1 Box Assembly, Transformer Tube/Open Single

106-4881 Box Assembly , Transformer 1824/2424

106-5109 Box Assembly, Transformer Flatbottom Single

106-4994 Box Assembly, Filter 1824/2424

1 824-1242 Box, Weldment, Transformer FPP255

* 200-1415 Cover, Transformer Box FPP H55

2 200-6721 Plate, Strain Relief

3 807-0012 Relay, 18AMP 1/3 HP 24V Coil

4 807-0070 Terminal Ground Lug

5 807-0800 Transformer 120V/24VAC, 50/60 HZ, 50VA

6 807-1683 Relay, 12VDC

* Not illustrated.

2-26

106-4994

14

8

106-4881

17

7

4

continued on next page...

Page 41

2.12 Transformer and Filter Box Assemblies cont.

ITEM PART # COMPONENT

7 807-1973

8 807-2176

9 810-1164

10 816-0217

11 824-1557

* 200-1415

12 824-1558

* 200-1415

13 900-2700

* 900-2702

14 900-2703

15 824-1530

* 200-9392

16 200-9288

* 900-2708

17 900-2709

18 200-9049

* 900-2708

19 824-1551

* 200-9392

Terminal Post

Transformer V/T Dual Voltage

Block, 1 PLC Screwless Terminal

Paper, Insulating Terminal Block CE

Box, Weldment, Tube/FB Filter

Cover, FPP H55 Transformer Filter Box

Box, Weldment, FB/FB and Filter

Cover, FPP H55 Transformer Filter Box

Box, Transformer H252

Cover, H255 Transformer Box

Cover, Transformer Box H155L, 255 L&R, 355L

Box, Weldment, Transformer Common Cabinet

Cover, Transformer Box Common Cabinet

Box, Transformer 1824/2424 Common Cabinet

Cover, H155 Transformer Box

Cover, Transformer Box H355R

Box, Transformer 1824/2424 Common Cabinet

Cover, H155 Transformer Box

Box W/A, Flatbottom Single

Cover, Transformer Box Common Cabinet

* Not illustrated.

2-27

Page 42

Frymaster, L.L.C., 8700 Line Avenue, PO Box 51000, Shreveport, Louisiana 71135-1000

Shipping Address: 8700 Line Avenue, Shreveport, Louisiana 71106

TEL 1-318-865-1711 FAX (Parts) 1-318-219-7140 FAX (Tech Support) 1-318-219-7135

PRINTED IN THE UNITED STATES

SERVICE HOTLINE

1-800-551-8633

819-6153

SEPTEMBER 2006

Loading...

Loading...