Page 1

Major Components Manual

• H50/55

• OPEN BURNER

• DECATHLON

• 24G

• DEAN MILLIVOLT

819-6367

Essential Parts For

• ELECTRIC/RE

• 2836

• 1721/18UE

• PUMPS

• GSMS

24-Hour Service Hotline 1-800-551-8633

or service@frymaster.com

Frymaster, a member of the Commercial Food Equipment Service Association, recommends using CFESA-certified technicians.

www.frymaster.com

• 8SMS

• UHC-P

• UHC

• SINBAD

• HLZ

JUL 08

Page 2

NOTICE

IF, DURING THE WARRANTY PERIOD, THE CUSTOMER USES A PART FOR THIS ENODIS

EQUIPMENT OTHER THAN AN UNMODIFIED NEW OR RECYCLED PART PURCHASED DIRECTLY

FROM FRYMASTER DEAN, OR ANY OF ITS AUTHORIZED SERVICE CENTERS, AND/OR THE

PART BEING USED IS MODIFIED FROM ITS ORIGINAL CONFIGURATION, THIS WARRANTY WILL

BE VOID. FURTHER, FRYMASTER DEAN AND ITS AFFILIATES WILL NOT BE LIABLE FOR ANY

CLAIMS, DAMAGES OR EXPENSES INCURRED BY THE CUSTOMER WHICH ARISE DIRECTLY OR

INDIRECTLY, IN WHOLE OR IN PART, DUE TO THE INSTALLATION OF ANY MODIFIED PART

AND/OR PART RECEIVED FROM AN UNAUTHORIZED SERVICE CENTER.

DANGER

Copper wire suitable for at least 167°F (75°C) must be used for power connections.

DANGER

The electrical power supply for this appliance must be the same as indicated on the

rating and serial number plate located on the inside of the fryer door.

DANGER

This appliance must be connected to the voltage and phase as specified on the rating

and serial number plate located on the inside of the fryer door.

DANGER

All wiring connections for this appliance must be made in accordance with the wiring

diagrams furnished with the equipment. Wiring diagrams are located on the inside of

the fryer door.

DANGER

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

WARNING

Do not attach accessories to this fryer unless fryer is secured from tipping. Personal

injury may result.

WARNING

Frymaster fryers equipped with legs are for permanent installations. Fryers fitted with

legs must be lifted during movement to avoid damage and possible bodily injury. For a

moveable or portable installation, Frymaster optional equipment casters must be used.

Questions? Call 1-800-551-8633

WARNING

Do not use water jets to clean this equipment.

DANGER

All wiring connections for this appliance must be made in accordance with the wiring

diagrams furnished with the equipment. Wiring diagrams are located on the inside of

the fryer door.

WARNING

This equipment is intended for indoor use only. Do not install or operate this

equipment in outdoor areas.

Page 3

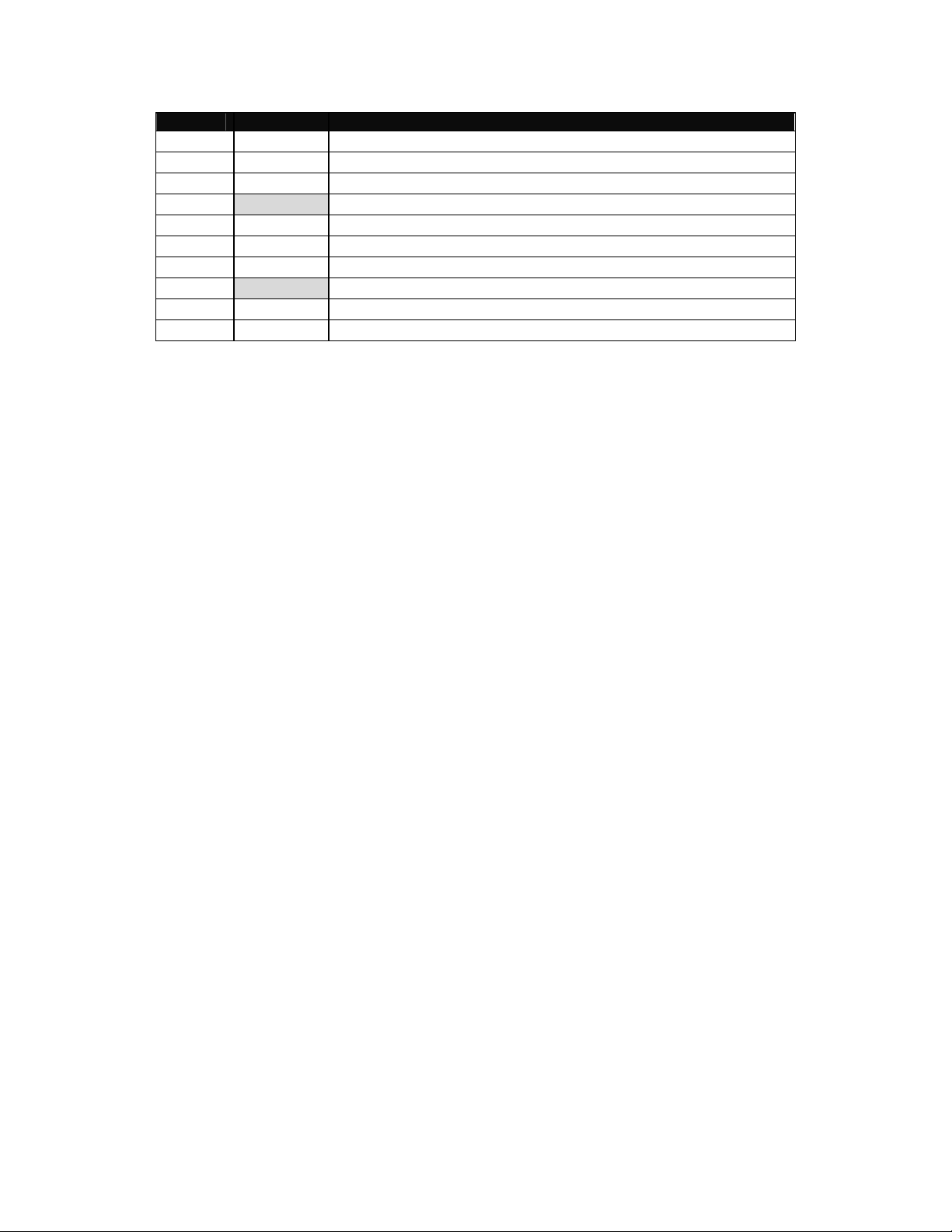

Frymaster and Dean Major Components

TABLE OF CONTENTS

Chapter Content Page

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

REPAIR ACCESSORIES

16

H50/52/55

Open Burner

Decathlon Series

24G Flatbottom

Dean Millivolt Fryers

Pro Series/RE Electric Fryers

2836 Series

1721/18UE

Filter Motors and Pumps

GSMS

8SMS Series

CABINETS/WARMERS/DISPENSERS

UHC-P

UHC

Sinbad

HLZ

Tools

GAS FRYERS

ELECTRIC FRYERS

WATER BATH UNITS

1-1

2-1

3-1

4-1

5-1

6-1

7-1

8-1

9-1

10-1

11-1

12-1

13-1

14-1

15-1

16-1

Page 4

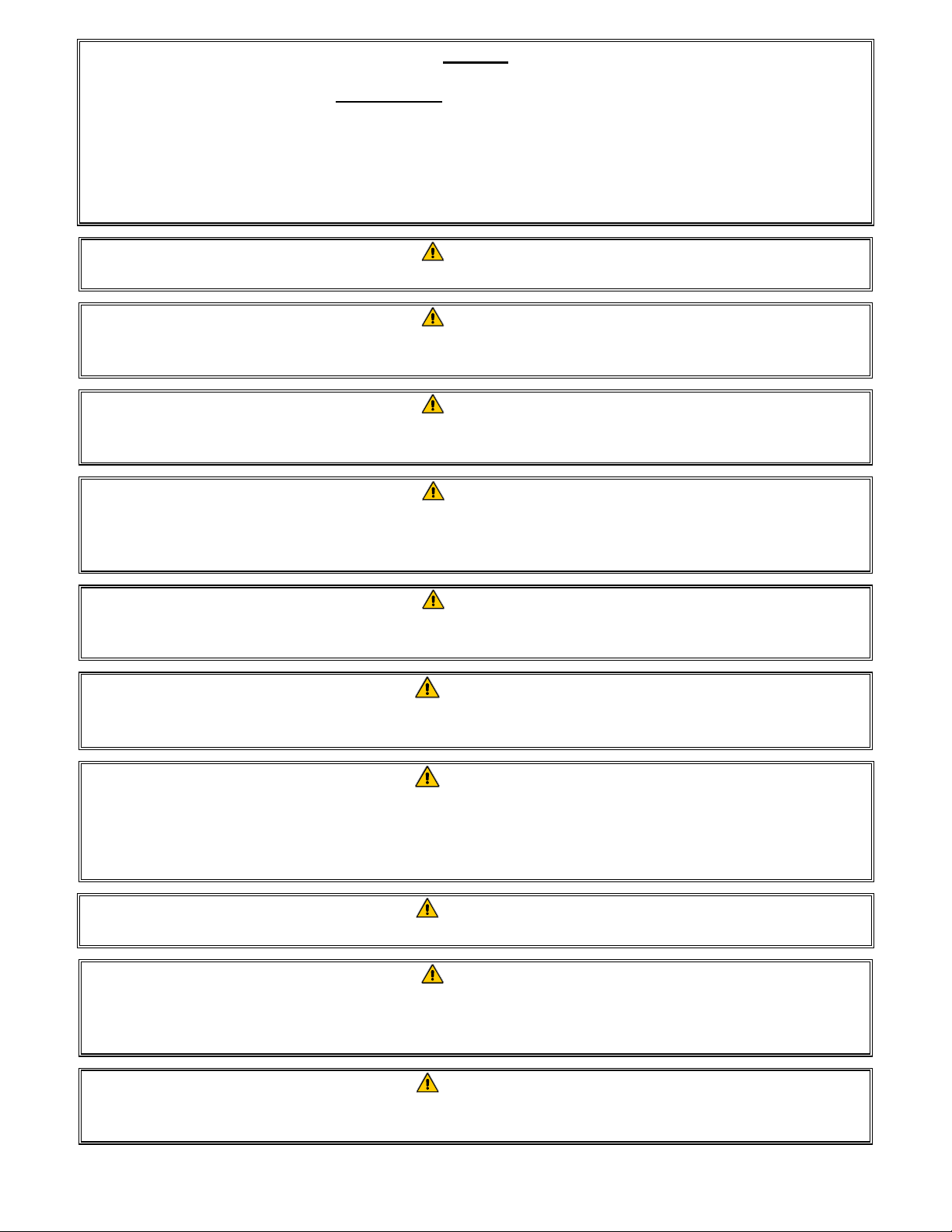

H50/55

The H50/55 series fryer is Frymaster’s flagship gas fryer.

Unique physical characteristic:

• Closed burner with blowers to enhance efficiency of

combustion.

Where Used:

• McDonald’s, Burger King, and other large fast-food

restaurants.

Common Model Numbers

• FPPH355

Burners are attached to either side of

the frypot. See arrow.

1-1

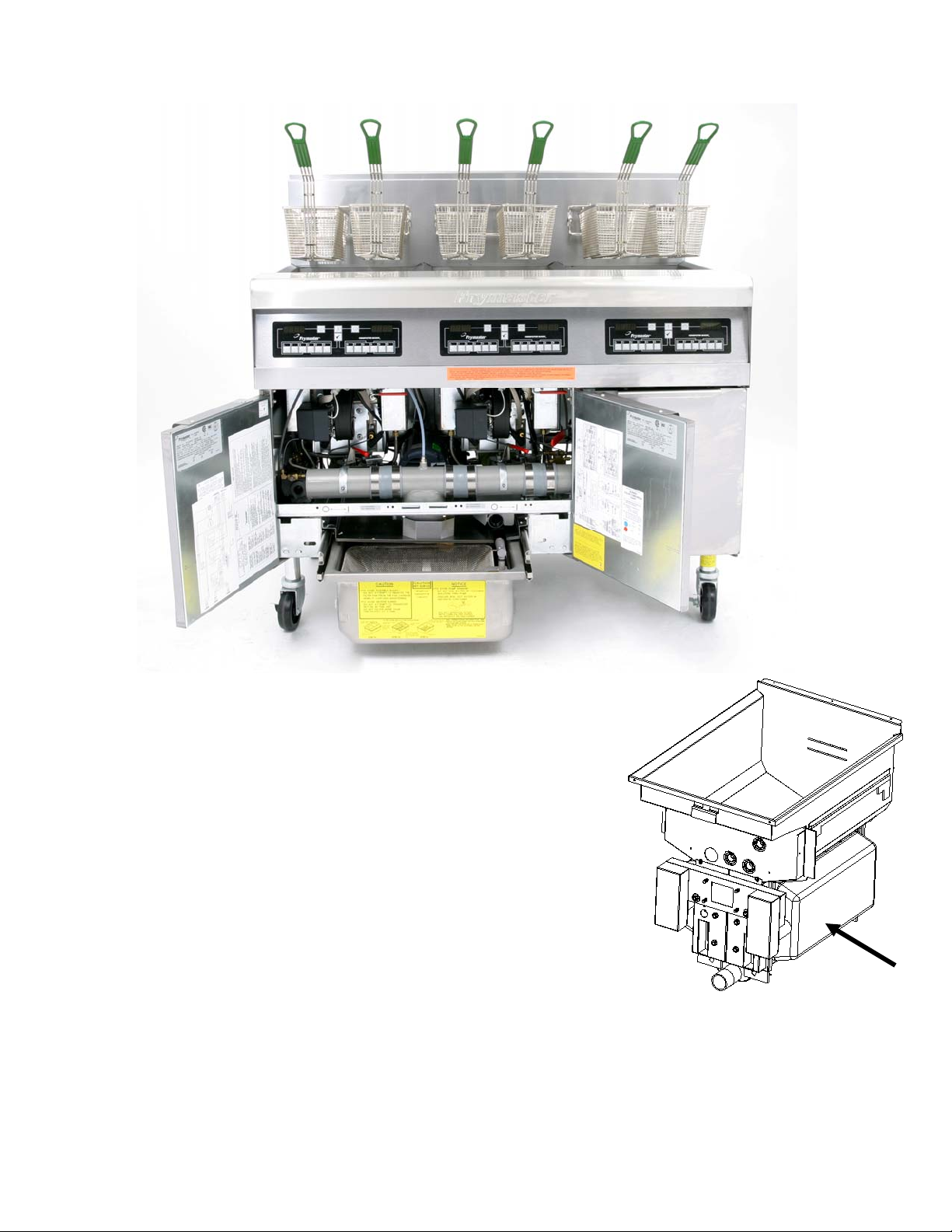

Page 5

H50/55

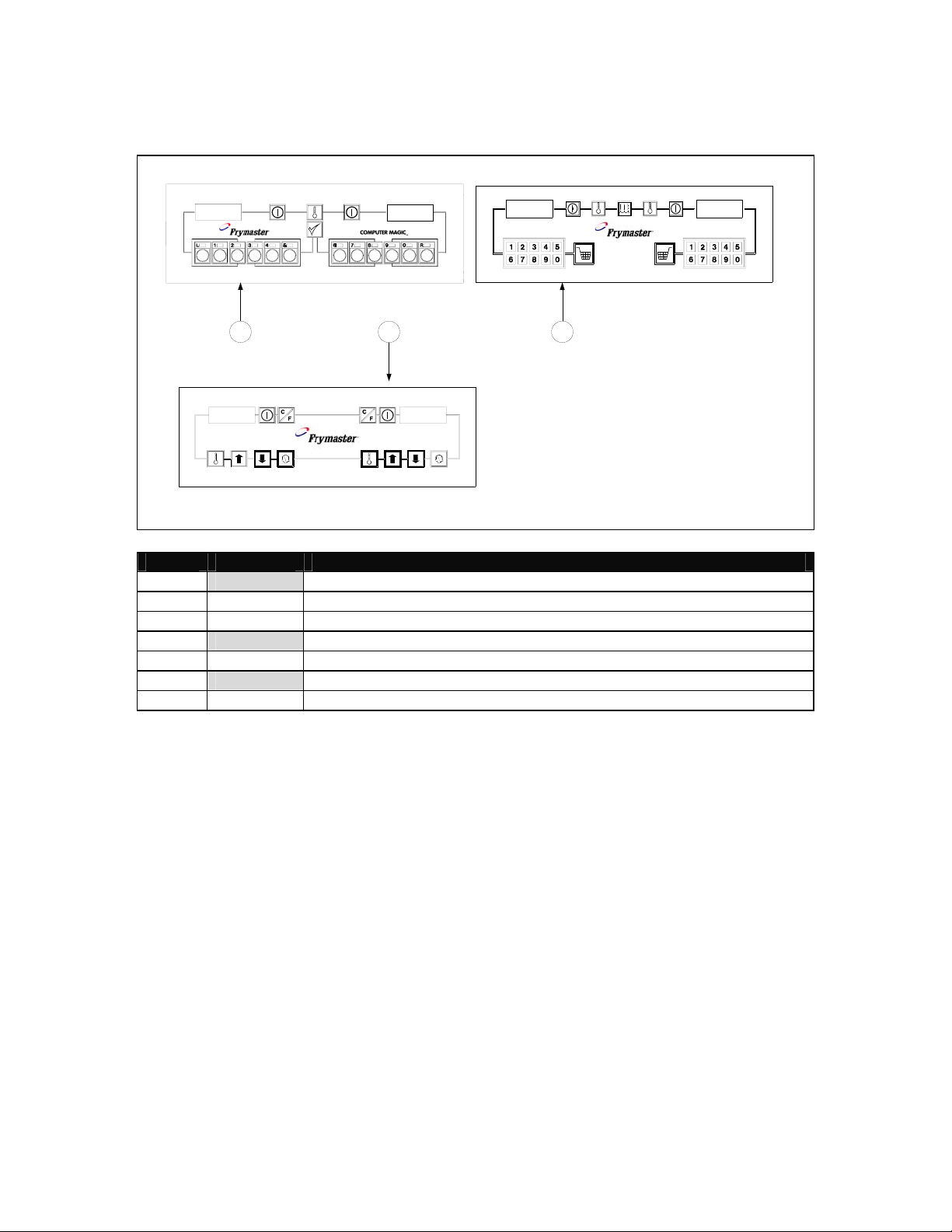

Controllers

Item **Standard

Part #

1

826-2296 826-2381 Dual-vat

826-2297 826-2325 Full-vat

2

106-2074SP 106-3580 Dual-vat

106-2073SP 106-3504 Full-vat

3

106-2081SP 106-3496 Dual-vat

106-2080SP 106-3495 Full-vat

* 806-2071 806-2071 15-pin Wiring Harness, Computer-to-Interface Board

* 807-4199 807-4199 SMT Wiring Harness, Computer-to-Interface Board

* 826-2278 826-2278 Remote Computer, Burger King

* 807-4397 807-4397 Remote Computer Adapter

4 826-2342 M2000 Full Vat

* 826-1810 M100 to M2000 Conversion Kit

** Pro H50/55-Series cabinets were manufactured with standard cabinets with the 90º-edge

topcap and the Euro-Look cabinets with the rounded topcap.

**Euro-look

Part #

Component

Computer Magic III.5

Digital Controller

Basket Lift Timer

McDonald’s Computer

1-2

Page 6

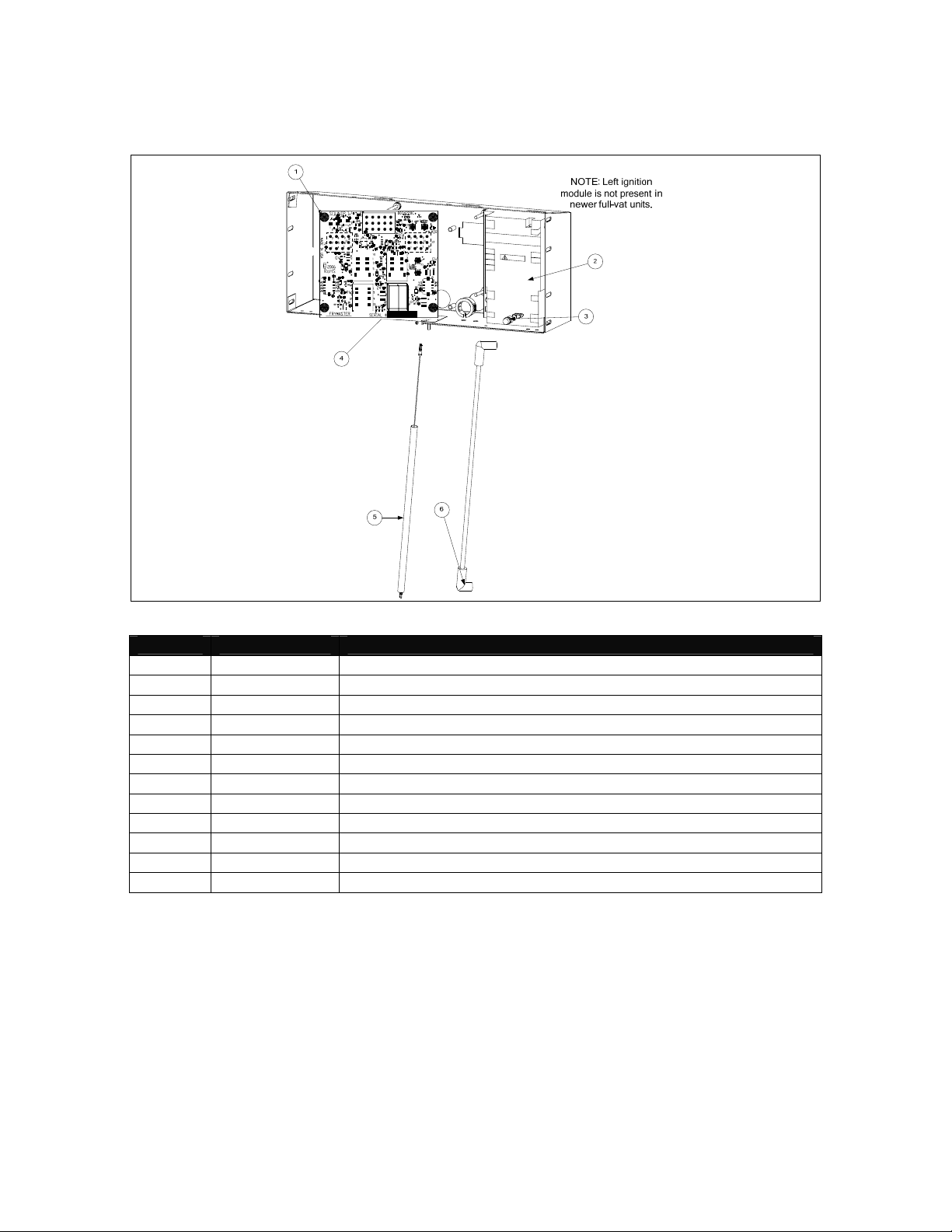

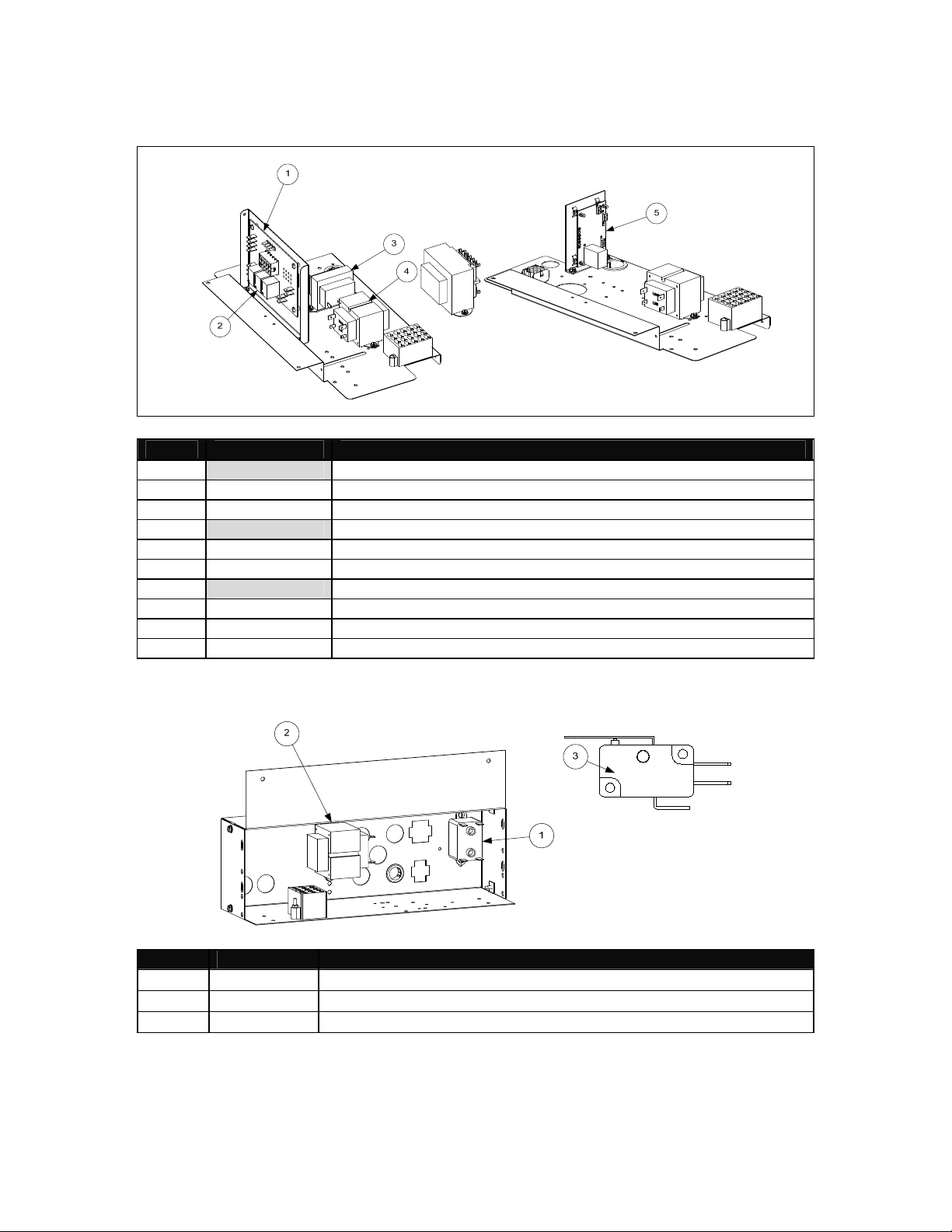

Gas Control Box Components

H50/55

Item Part # Component

1 826-2264 Interface Board

2 807-1006 Ignition Module

3 807-3484 Connector, Rajah

4 807-0833 Relay, DPDT 5A 12VDC Latch

* 807-0834 Relay, SPDT 15A 12VDC Basket Lift (See Note 2 below)

5 826-2024 Cable, 21-inch Ignition (comes with Rajah connector)

6 806-6085 Flame Sensor wire assembly

* 826-1721 Ignition Cable (2 ignition cables, 2 rajah connectors)

* 807-1200 Ignition Wires, 27-inch (used with 807-1006)

* 807-1878 Ignition Wires, 19-inch (used with 807-1006)

* 806-3660 Sound Device, High Output

* 826-2458 Speaker, McDonald’s

* Not illustrated.

1-3

Page 7

H50/55

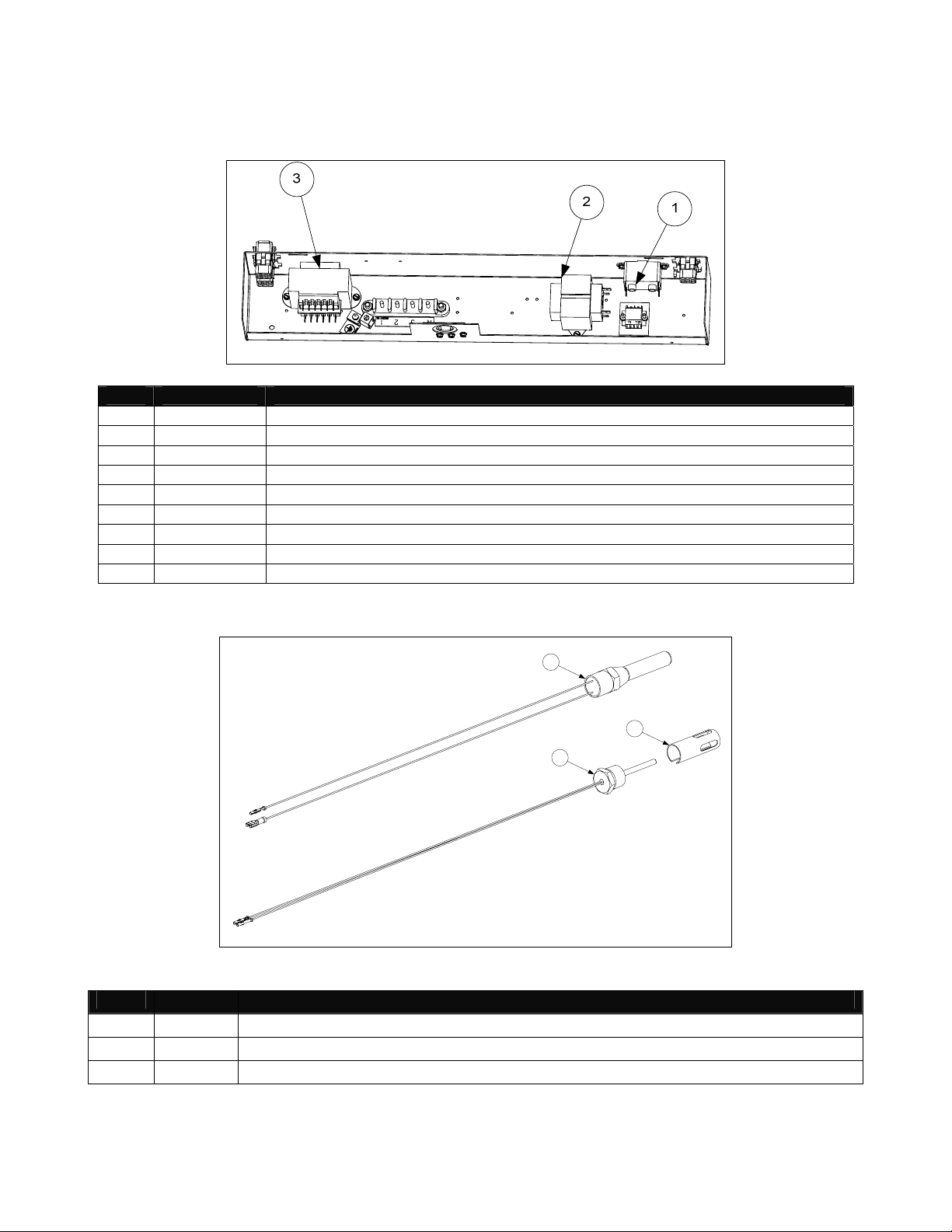

Transformer/Relays

Item Part # Component

1 807-0012 4-Terminal Relay, Filter Only

* 807-2434 5-Terminal Relay, Filter Only

2 807-2180 Transformer, 208-240V/24V 50/60Hz

* 807-0979 Transformer 208-240V/12V 50/60Hz

3 807-1999 Transformer, 208-240V/24/12V

* 807-1696 3-wire Power Cord (CE)

* 807-1683 Relay, 12V (Hood Relay, McDonald’s only. Can be located in transformer box.)

* 807-0012 Pump Relay, 24V Coil, 18A

* 807-2434 Pump/Heater Relay, 24V Coil, 18A

* Not illustrated.

High-Limit Thermostat and Temperature Probe

1

2

Item Part # Component

1 826-1177

2 806-4206 Temperature Probe

3 210-0681 Probe Guard

High Limit Thermostat - 425°F/218°C

3

1-4

Page 8

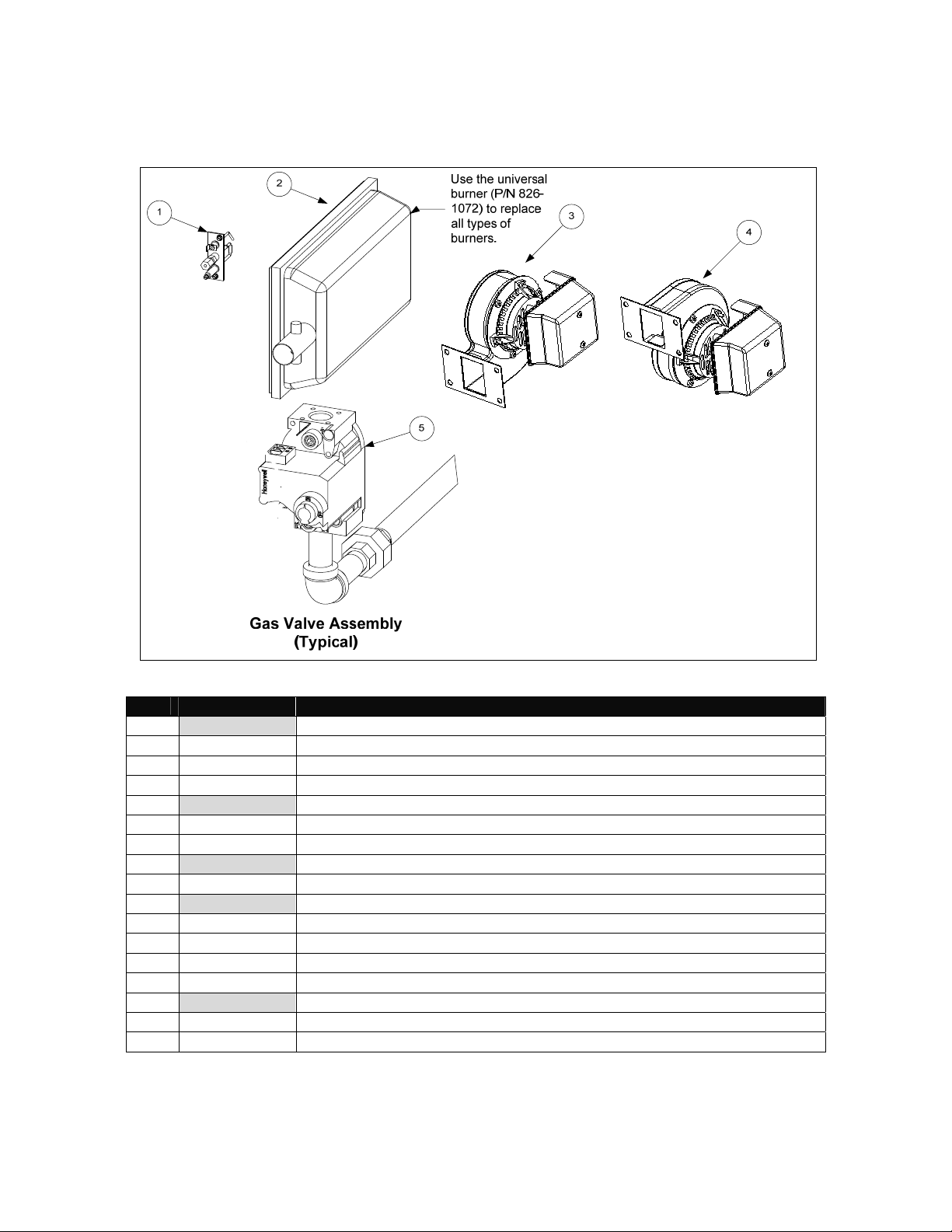

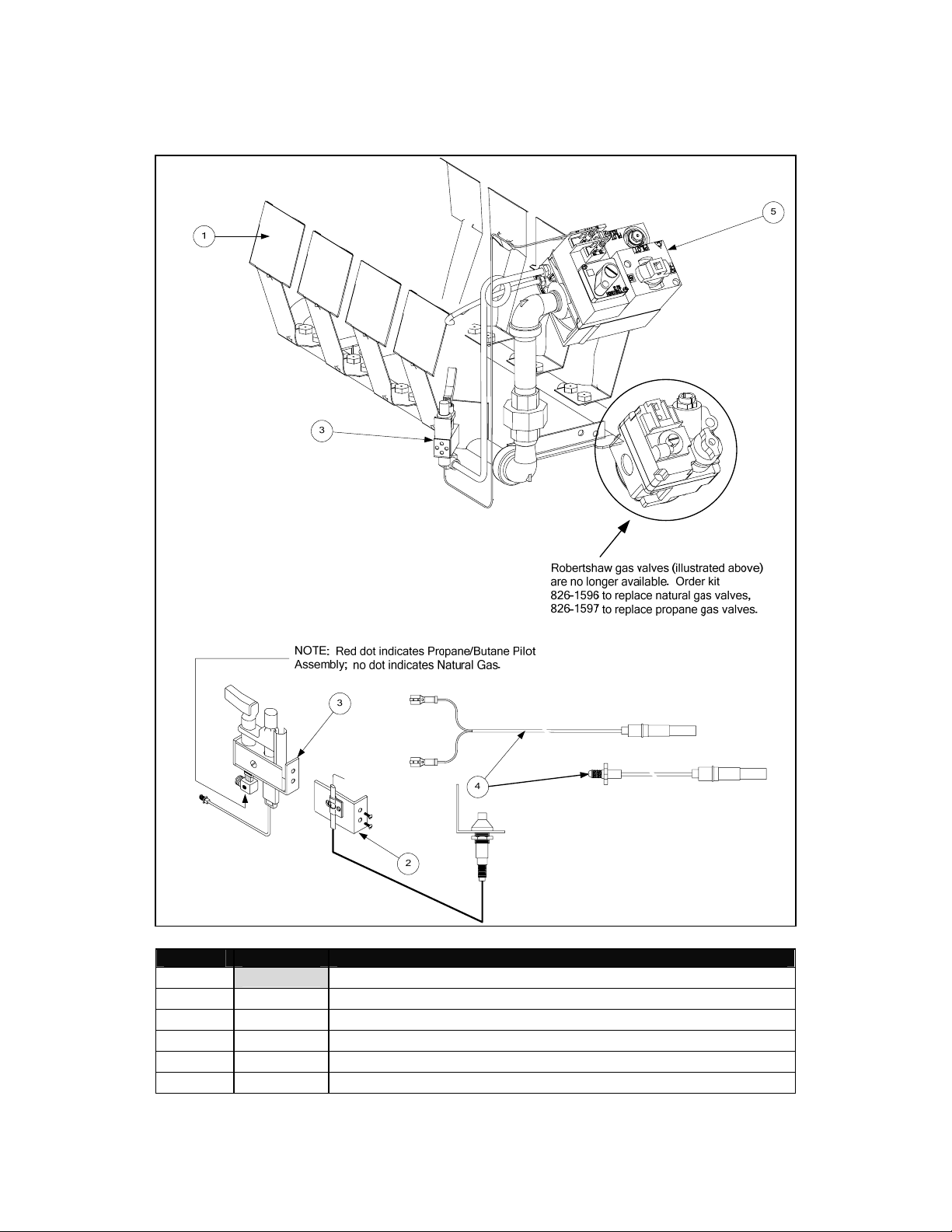

H50/55

Gas Supply and Combustion System Components

Item Part # Component

1 Igniter (includes gasket 816-0059, which may be ordered separately)

826-0981 Natural Gas

826-0982 Propane

2 826-1072 Universal Burner

Blower Assembly, Combustion Air (includes harness )

3 106-3001SP 230V (Right)

4 106-3000SP 230V (Left)

5 Gas Valve

826-1576 Gas Valve CE

*

826-1145 Natural Gas to Propane/Butane, Full-vat

826-1146 Propane/Butane to Natural Gas, Full-vat

826-1147 Natural Gas to Propane/Butane, Dual-vat

826-1148 Propane/Butane to Natural Gas, Dual-vat

*

826-0931 Burner Insulation Kit, Full Vat

826-0932 Burner Insulation Kit, Split Vat

* Not illustrated.

Conversion Kits

Insulation Kits

1-5

Page 9

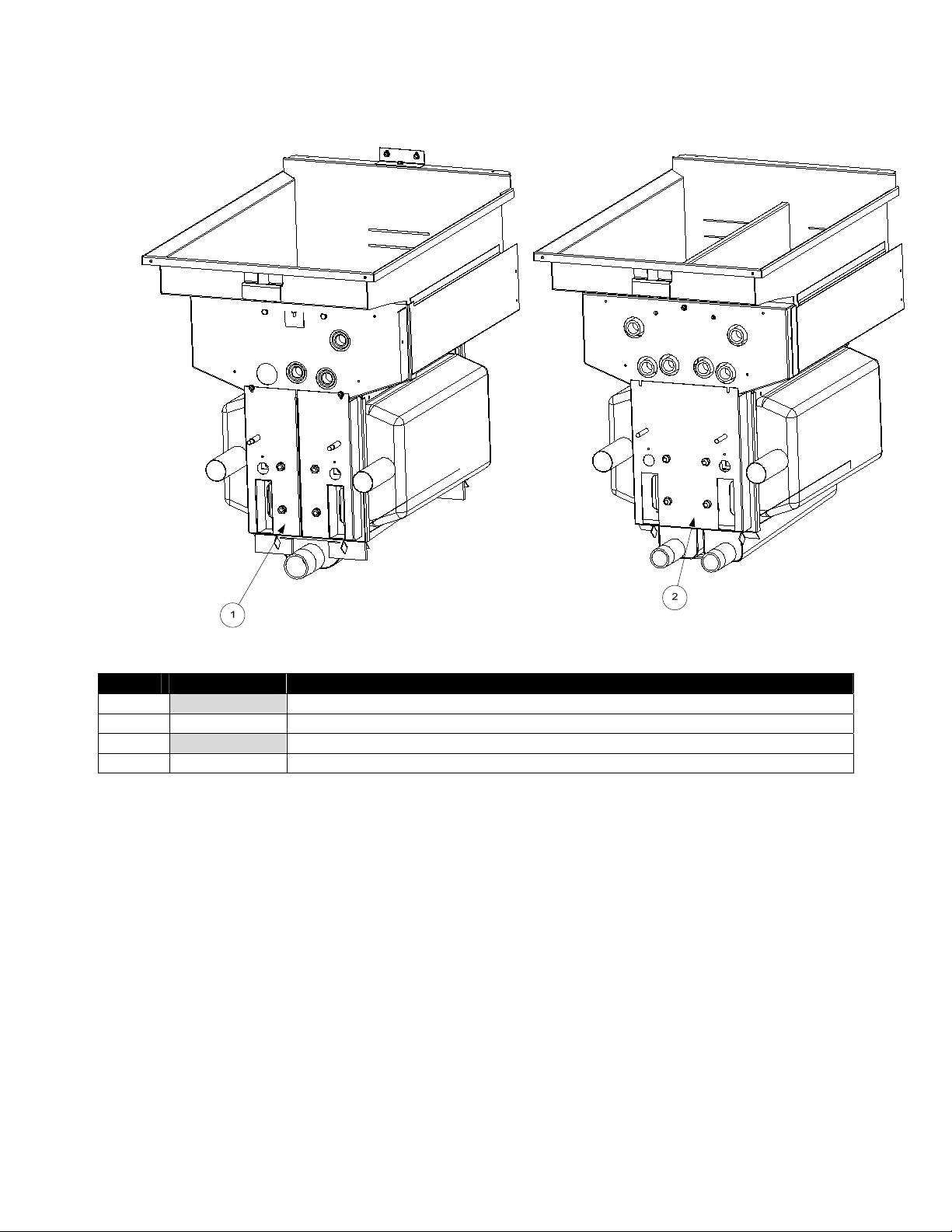

Frypots

H50/55

Item Part # Component

1

* 106-1050SP Frypot, Complete Assembly

2

* 106-1080SP Frypot, Complete Assembly

* Not illustrated.

Frypot, Full Vat, Complete Assembly

Frypot, Dual Vat, Complete Assembly

1-6

Page 10

Open Burner

The open burner, or Master Jet, family of fryers

includes the 35, 45, CF, and J1C series at the

upper end and the GF14 and GF40 at the lower

end.

Unique physical characteristic:

• A U-shaped burner manifold surrounds the

frypot, supplying flame to metal

deflectors, or targets, which direct the heat

to the frypot.

Where used:

• Burger King uses 45’s. The other models will be found in smaller restaurants.

Common Model Numbers: FPP235, FMP245, PMJ145, MJ1CF, KJ3FC, J1C,

An open burner surrounds the frypot of the MJ

series of fryers. Orifices secure the deflectors.

2-1

Page 11

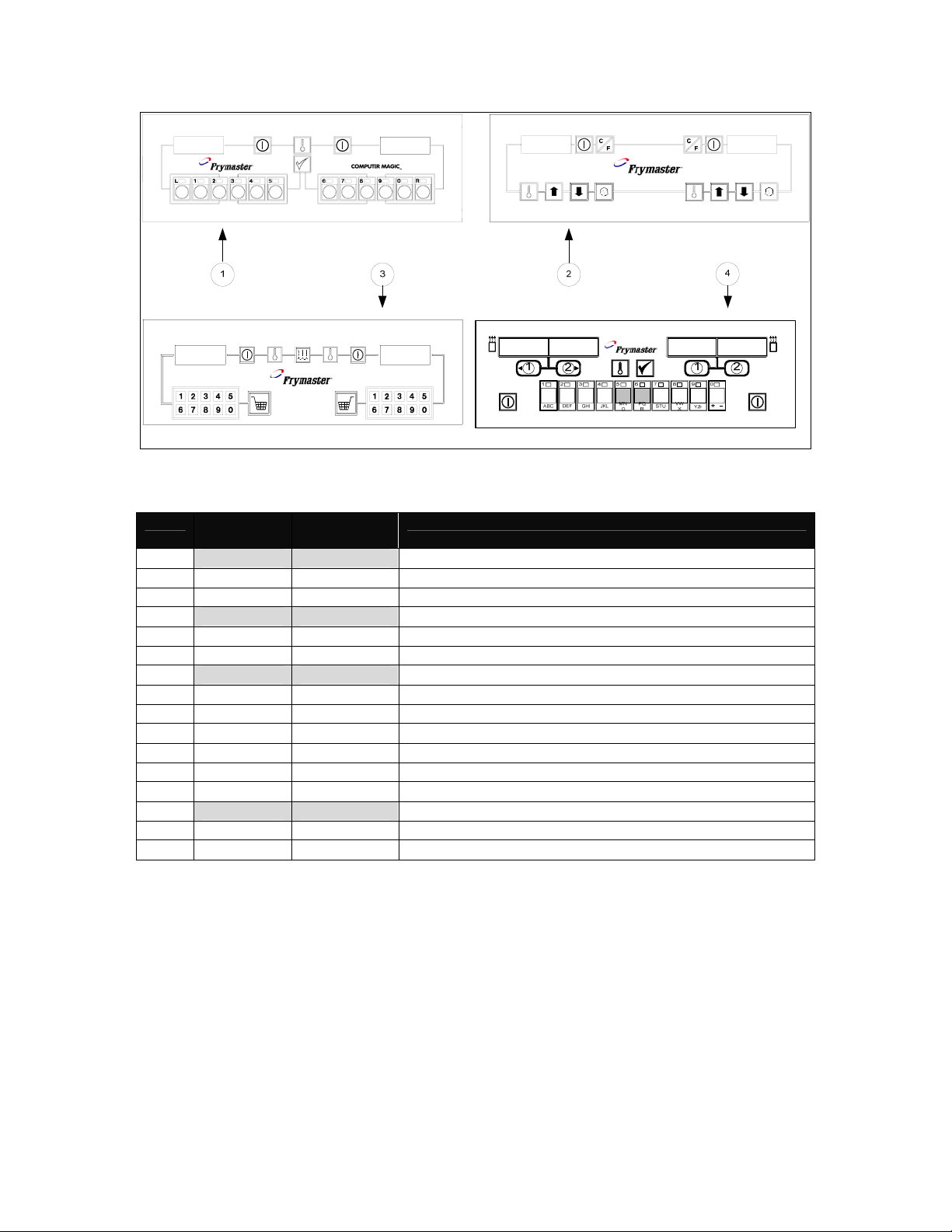

Open Burner

GF40Controller Assemblies (Other than Thermostat Controllers)

1 3 2

Item Part # Component

1

826-2300 Computer, 45 CE FV SMT, built-in

826-2392 CM 3.5 CE

2

106-3373 Controller, Basket Lift Timer, MJ45

3

826-2304 Controller, Digital

* Not illustrated.

Computer Magic III, MJ45, FM45 Series

Basket Lift Timers

Digital Controllers

2-2

Page 12

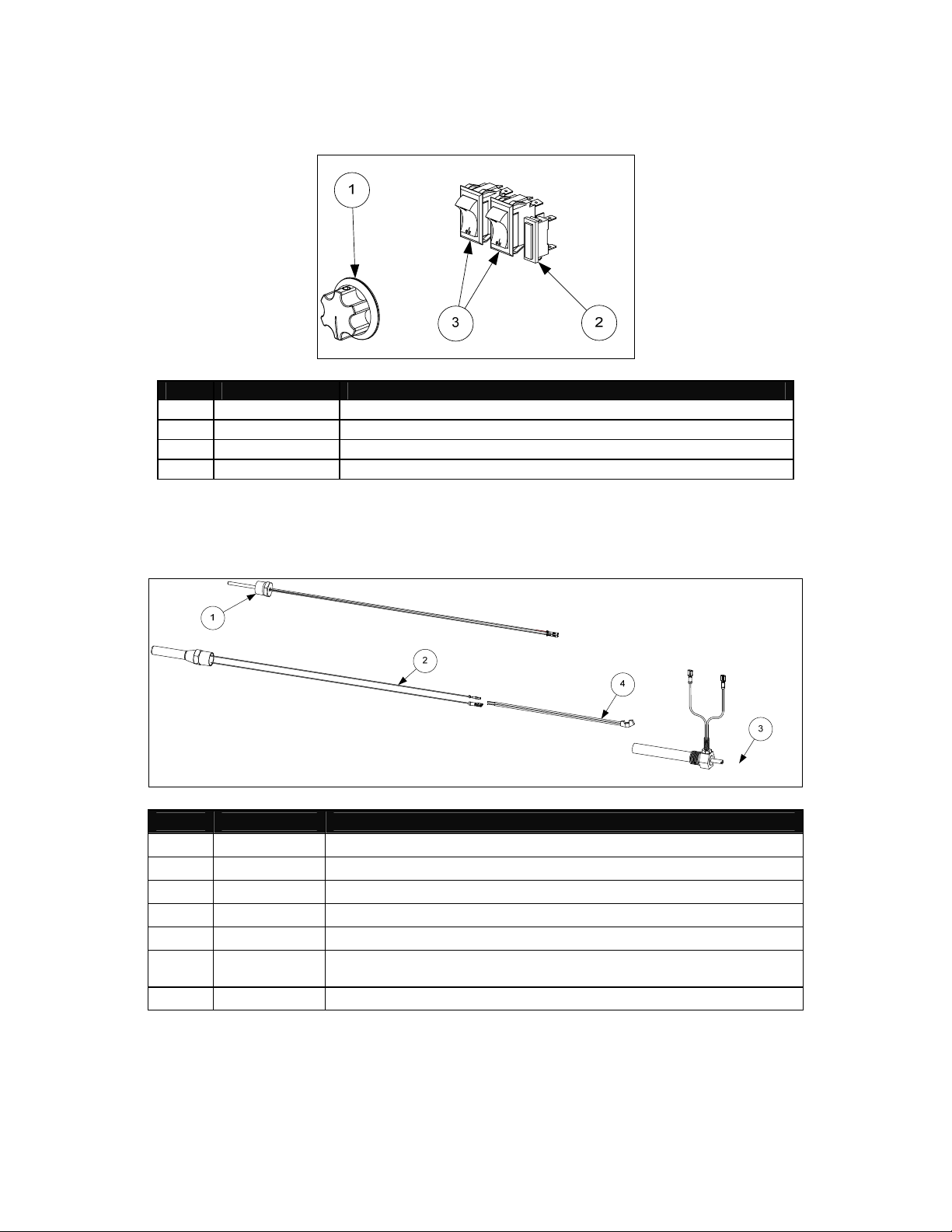

Open Burner

Component Parts

Item Part # Component

1

806-7505 Universal Replacement: MJ, FM, 45, CF

826-2425 Interface Board, FPP/FMP 35/45 with Standing Pilot

2

807-0833 Heat relay

807-0834 Basket Lift Relay

3 807-0979 208-240V 12V 50/60Hz

4 807-0680 208-240V 24V 50/60Hz

5 826-1546 Kit, Melt Cycle Timer, replaces electromechanical timer

* Not illustrated.

Interface Boards

Relays

Transformers

Item Part # Component

1 807-0012 Relay, 18 Amp, SPST, Filter

2 807-2180 Transformer, 230V Primary/24V Secondary 50/60Hz VA

3 807-2103 Micro Switch

2-3

Page 13

Open Burner

Controller Assemblies (Thermostat Controllers)

Item Part # Component

1 810-0334 Knob, Operating Thermostat

* 810-0110 Knob, MJ35 Operating Thermostat

2 807-1525 Light, White Melt Cycle Indicator, 24V

3 807-3498 Switch, 24V, Used for ON/OFF or Melt Cycle

* Not illustrated.

Temperature Probe, Thermostats, and Related Components

Item Part # Component

1 806-4206 Temperature Probe, Minco

2 826-1177

3 806-0183 Thermostat Assembly, Operating, MJ45/MJCF/MJ47

4 807-0280 Hi-limit Adapter

* 806-0184 Thermostat Assembly, MJ, FM, J1C with Robertshaw Gas Valve

* 806-5816

* 807-1692 Thermostat, GF14, GF40

* Not illustrated.

NOTE: Kit 826-1177 (Item 2) contains high-limit thermostat 806-7545 and an assortment of

connectors to allow it to be configured for use on several different Robertshaw valves.

Thermostat, 425°F High-Limit (see NOTE)

Thermostat Assembly, MJ, FM, FPP, FMP, J1C, GF14 Sysco, 35 with

Honeywell Gas Valve

2-4

Page 14

Open Burner

Burner Assembly Component Parts

Item Part # Component

1

230-1177 45 Deflector, Side

230-1206 45 Deflector, Rear

230-1178 35/CF Deflector, Side

230-1180 35/CF Deflector, Rear

230-1568 JIC Deflectors, all

Deflectors

2-5

Page 15

Open Burner

Item Part # Component

2 826-1155 Igniter Kit, Optional Piezo

807-1906 Electrode Assembly

810-1001 Trigger

3 Pilot Assembly

806-8688SP Nat Gas Pilot, CE

806-8689SP LP pilot, CE

4 810-1152 Thermopile/Thermocouple

5 Valve, Gas (see Note 1 below)

806-6710SP Natural Gas Valve, CE

806-6711SP LP Gas Valve, CE

NOTE: A gas valve capacitor (P/N 806-4781) is required on gas valves used on units with

Thermostat Controllers.

2-6

Page 16

Decathlon

The Decathlons are large tube fryers often used for bone-in

chicken. Flame passes through tubes in the frypot, which

transfer heat to the oil. Decathlon is indicated in the model

name with a D: D50’s, D60’s and D65’s are all models of the

Decathlon family.

Unique physical characteristics:

• Burner tubes rest on a gas manifold at the front of the

fryer, transferring heat to tubes in the frypot.

Where used:

• The Decathlon is common in Chili’s.

Common Model numbers:

• SCFHD250, SCFHD350, SCFHD460, HD160

3-1

Page 17

Decathlon

Common Primary Components and Controllers

Item

1 826-2013 Thermostat, Sunne

2 810-2035 Knob, Thermostat

* 826-2413 Computer, Compu-Fry III.5

* 826-2414 Computer, Compu-Fry, Dual vat

* 806-8308 Computer, CM4-S (FPD65) Popeye’s

* 806-8305 Computer, CM4-S

* 106-3028 Computer, CM4-S, with HD Bezel

* 806-5139 Computer, remote

* 106-6025 Analog Controller, Boston Market

* 806-4803 Cable Assembly, Compu-Fry to Interface Board

* 826-2269 Potentiometer, Thermatron

*

* Not illustrated.

Part # Component

Computers/Controllers/Thermostats

816-0534 Knob, Control, Thermatron

Pilot Components

3-2

Page 18

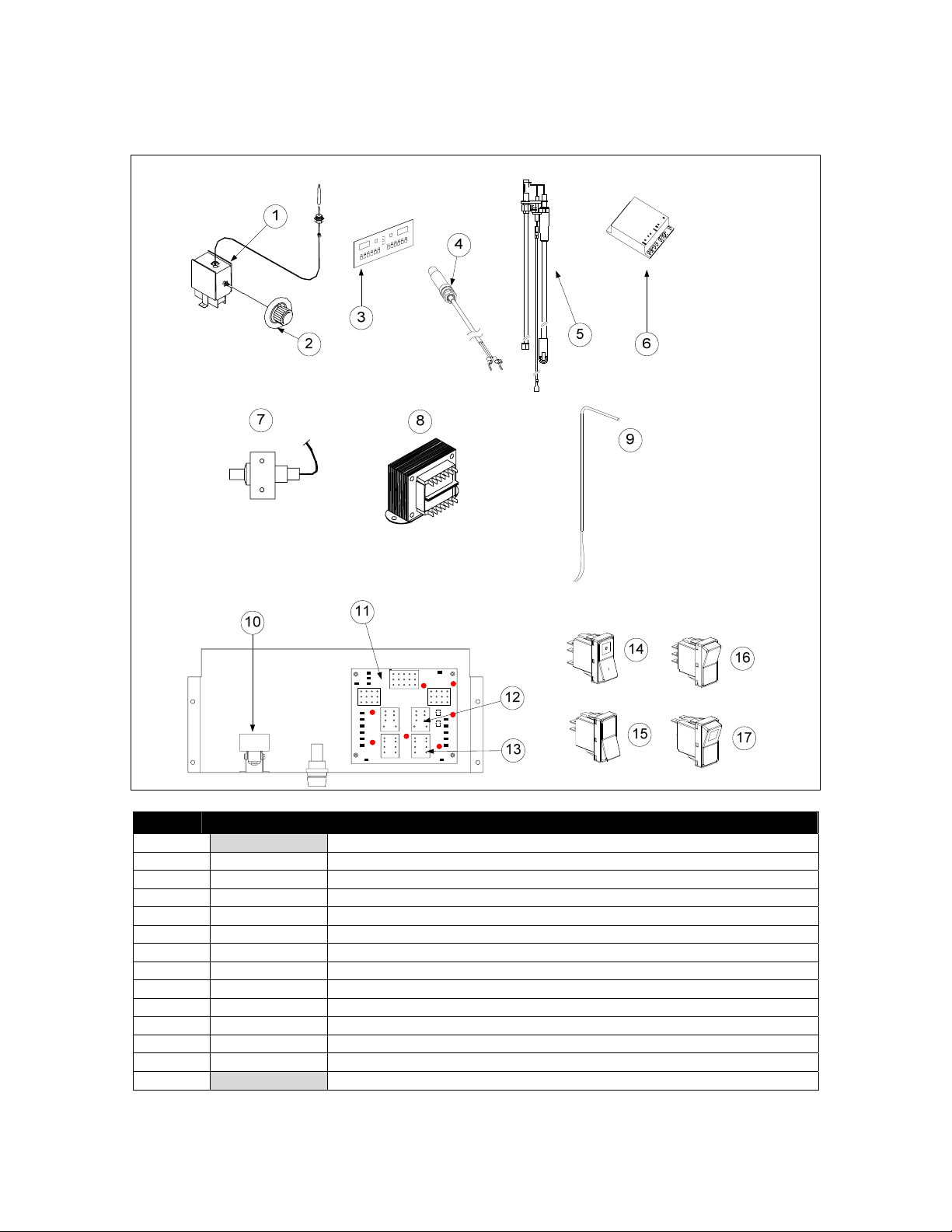

Decathlon

Item

4 807-3485 Thermopile

* 807-3550 Thermocouple

5 807-1311 Pilot Assembly- Natural Gas- Electronic Ignition

* 812-1676 Pilot Assembly- LP Gas- Electronic Ignition

6 826-2117 Spark Module

* 807-1315 Ignition Cable, D

* 106-7535 Ignition Cable, HD

7 810-1001 Piezo Ignitor (Trigger)

* 807-3540 Electrode, Piezo

8 807-1999 Transformer, CE

9 826-2423 Probe Assembly (RTD), Temperature, Dean Computer

* 106-5419 Probe Assembly, Temperature- Thermatron- D20 & D50

* 106-1976 Probe Assembly, Temperature- D60 & D80 (New Design)

10 8073560 High-Limit Thermostat. CE

11 826-2425 Interface Board, Dean Computer Only. Manual pilot

* 826-2434 Interface Board for Electronic Ignition

* 106-3287 Interface Board, Thermatron- 24 VAC

* 826-2086 Interface Board, Thermatron- 12/208-240

* 826-2031 Interface Board, Thermatron- 115/220V

* 807-3577 Circuit Breaker, 7 amp

* 807-3592 Fuse, 2 amp, Slo Blo

* 807-3750 Fuse, 5 amp

12 807-0834 Relay, 12VDC 15A 1PDT (Basketlift)

13 807-0833 Relay, 12VDC 5A 1PDT (Latching)

* 807-3611 Relay, Filter Pump

* 807-3640 Relay, Boil Out

* 807-2104 Microswitch

14 807-3574 Switch, Power- Green Lens

15 807-3580 Switch, Rocker- Manual Filter Power

16 807-3579 Switch, Boil-Out- 6-Terminal

17 807-3576 Switch, Fryer Reset (Momentary)

* 807-3552 Gas Valve, Natural Gas, Electronic Ignition 24 VAC D20-D50-D60-D80

* 807-3628 Gas Valve, LP Gas, Electronic Ignition 24 VAC D20-D50-D60-D80

* 810-2156 Gas Valve, Natural Gas 120 VAC D20-D50-D60-D80

* 810-2323 Gas Valve, LP Gas 120 VAC D20-D50-D60-D80

* 810-2158 Pilot Burner- Natural Gas, D20

* 810-2526 Pilot Burner- LP Gas, D20

* 810-2032 Pilot Burner- Natural Gas, D50-D60-D80 (Primary and Trailing)

* 810-2155 Pilot Burner- LP Gas, D50-D60-D80 (Primary and Trailing)

* Not illustrated.

Part # Component

Ignition Components

Transformers

Probe Assemblies

High Limit

Interface Boards

Fuses/ Circuit Breaker

Relays

Switches

Gas Valves

Pilot Burners

3-3

Page 19

Decathlon

Decathlon Frypot Components

1

Item

1 Diffusers

230-2593 Diffuser Assembly D20

210-5175 Diffuser Assembly D50

210-8387 Diffuser Assembly D60

210-5177 Diffuser Assembly D80

230-1342 Diffuser Assembly HD50

230-1431 Diffuser Assembly HD60 and FPHD65

Part # Component

3-4

Page 20

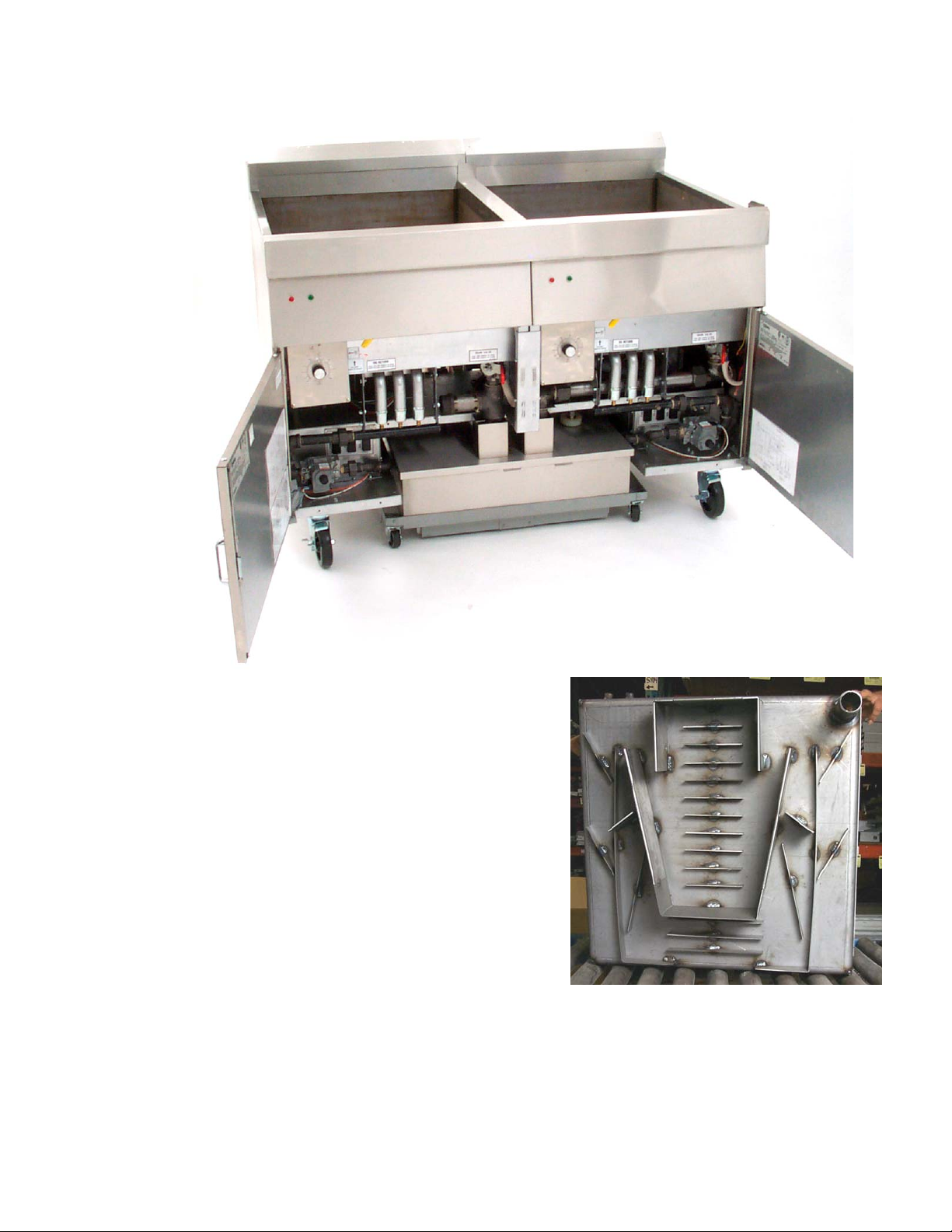

24G

The 24G is a large flatbottom fryer with draft

induction system, which draws heated air across the

bottom of the fryer. Baffles welded to the pot impede

the flow of the air and increase temperature transfer.

Unique physical characteristic:

• Rear draft system

Where used:

• KFC, LJS, Captain D’s and other fish chains

Common Model Numbers:

• 1824G, 2424G, KSCF42424G

Heated air is drawn across the bottom of the

24G frypot with a blower-driven draft system.

4-1

Page 21

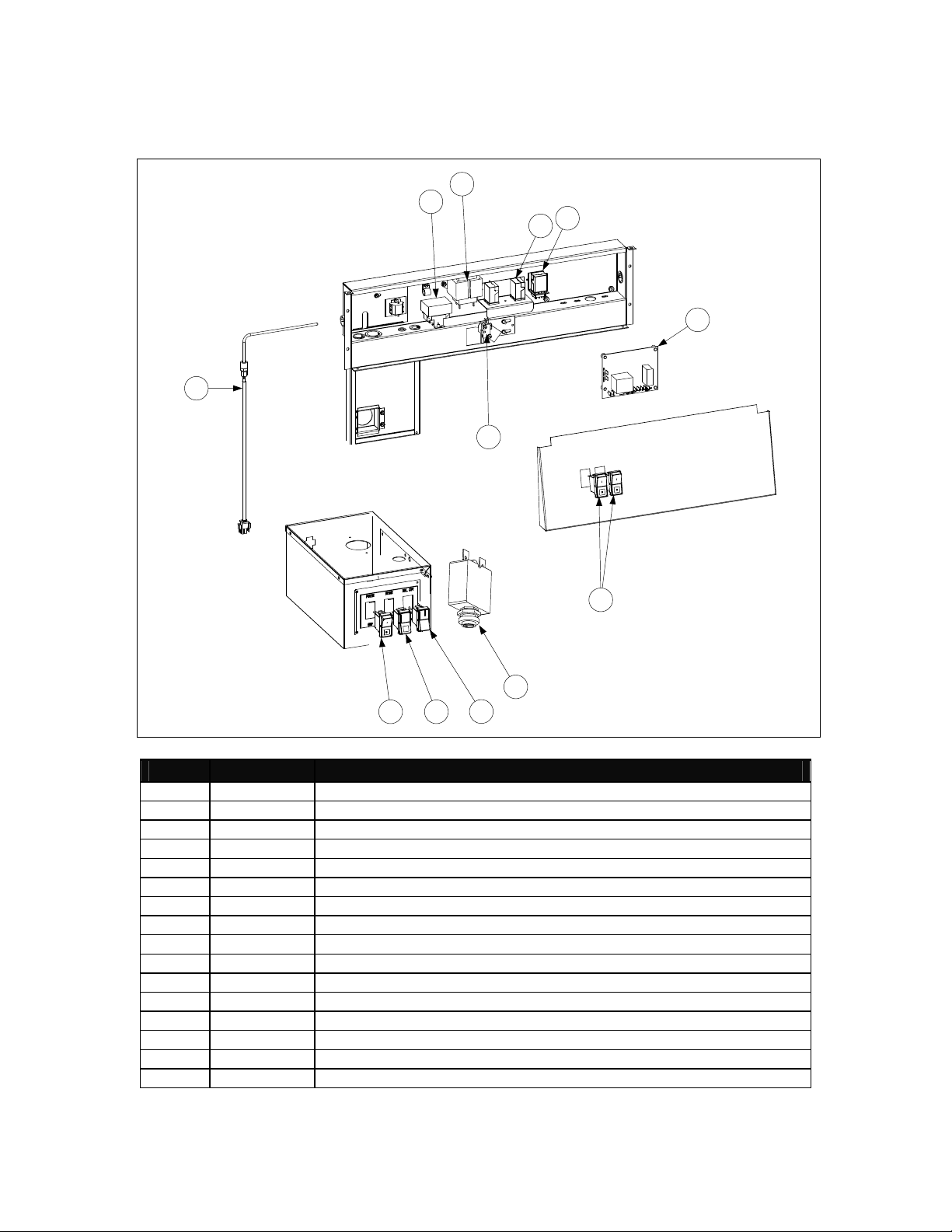

Electrical Components

1

24G

3

2

5

4

6

11

7

10

7

9

8

ITEM PART # COMPONENT

1 106-2607SP Thermatron Probe, 20” wires

* 106-0882 Thermatron Probe, 62 1/2” wires

2 807-3560 High-Limit Thermostat, CE

3 807-2180 Transformer, 208-240V 24V CE

4 807-3611 Relay

5 807-3611 Relay, 24VAC Coil (Latch or filter, plug-in style)

* 807-4114 Relay, 24VAC (left relay) Latch or Filter, used after Sept. 04

6 106-3287 Thermatron Board, 24V, CE

7 807-3574 Switch, Power ON/OFF Rocker

8 807-3576 Switch, Momentary Reset

9 807-3580 Switch, Boil-Out

10 807-3577 7-amp Circuit Breaker

11 807-2103 Oil-return Microswitch

* 106-4730 Lamp Assembly, white 24V

* 106-4729 Lamp Assembly, green 24V

* 807-3577 7-amp Circuit Breaker

* Not illustrated.

4-2

Page 22

24G

ITEM PART # COMPONENT

1

807-3555 24V Natural

807-3690 24V Propane (LP)

810-2156 120V Natural

810-2323 120V Propane (LP)

2 807-3556 Igniter and Flame Sensor Assembly

* 106-1645SP Flame Sensor Wire

3 106-1644SP Ignition Cable

4 807-0918 Module, Ignition (11-second spark module)

* 807-3551 Transformer, Electronic Ignition

5 Pilot Burner

810-2403 Natural Gas

810-2403 Propane (LP) Gas (Use 810-2400 LP burner orifice)

6 807-3550 Thermocouple, 120V

* 807-3294 24V gas valve, Honeywell

* 807-3295 24V propone gas valve, Honeywell

* 807-3485 Thermopile generator with adapter

* Not illustrated.

Valve, Gas

Electronic Ignition Components

Pilot Ignition Components

Post Fall 2005 24V Gas Valve-equipped Fryers

4-3

Page 23

24G

Blower Assembly, Combustion Air

ITEM PART # COMPONENT

1 Motor, Blower Assembly

807-3920 230V

2 807-3746 Switch, Sail (Air Prover Switch)

4-4

Page 24

Drain, Oil-Return Frypot Kits

24G

ITEM PART # COMPONENT

1 823-3174 Drain Plug, frypot

2 200-4725 Guard, probe and high-limit

3 210-1433 Clamp, probe and high limit bulb

4 823-4548 Retainer, probe

5 810-2125 Oil return valve, 3/8”

6 809-0884 Nut, slip joining

7 816-0544 O-ring (2 required per slip joint nut)

* 826-1823 Frypot Kit, 1824G (Front Drain, Front Return) (use 826-1821 for 2424G)

* 826-1822 Frypot Kit, 1824G (Front Drain, w/o Filtration) (use 826-1820 for 2424G)

* 826-1828 Frypot Kit, 1824G (Rear Drain, Front Return) (use 826-1842 for 2424G)

* Not illustrated.

4-5

Page 25

THIS PAGE INTENTIONALLY LEFT BLANK

Page 26

Dean Millivolt

The SR and SM-series of Dean fryers are millivolt-powered units.

Unique Physical Characteristics:

• A no-frills millivolt fryer.

Where used:

• IHOP uses SM fryers with filtration, small restaurants, bars, catering vehicles use

the SR series.

Common Model Numbers:

SR42, SR52, SR62, SM250, SM150, SCFSM250

5-1

Page 27

Dean Millivolt

Component Box Components and Related Components

Item

1 826-2013 Thermostat, Sunne

2 807-3485 Thermopile

3 810-1001 Piezo Ignitor (Trigger) (Wire Lead-807-3650) (Assembly-44970SP)

4 807-1990 Transformer, CE

5 807-3580 Switch, Rocker- Manual Filter Power

6 807-3516 High-Limit Thermostat- Automatic Reset 435° F SM20/35,SR40/42

* 807-3680 High-Limit Thermostat- Manual Reset 450° F

7 807-1321 Fuse Holder, Buss

* 807-3592 Fuse 2A 230V

* 826-1392 O-Rings (Pkg. of 5)

* 807-3611 Relay, Filter 24A DPDT

* 807-2103 Microswitch, Straight Lever

* Not illustrated.

Part # Component

5-2

Page 28

Dean Millivolt

Frypots and Related Components

Tab

210-5175

2

1

5

3

230-2593

6

Item Part # Description

1

2

210-5197 Diffuser, Burner Tube- SM80G

210-5215 Diffuser, Burner Tube- SM60G, SR62G

230-2593 Diffuser, Burner Tube- SR52G, SM/D50, SM/D20

210-5175 Diffuser, Burner Tube- SM50G, SM20 (with tab)

230-2592 Diffuser, Burner Tube- SR38G, SR42G, SM35G, SM40G

3

3

4

4 810-2038 Burner, Center- SR38G, SR42G, SM35G, SM40G

810-2689 Pilot Assembly Honeywell w/ Piezo- Natural (Use 810-2690 for LP) SM20G

106-4968 Pilot Assembly w/ Piezo-Natural SM20G

810-2158 Pilot Burner- SM20G- Natural(0.18 Orifice) (Use 810-2526 for LP)

810-2690 Pilot assembly, LP, SM20

810-2032

106-0692 Burner, Pilot Assembly- Natural & MFG SM60G, SR62G, SM80G

810-2155

810-2150 Burner, Right- SM60G, SM80G, SR62G, SM20, SR52G, SM50G

810-2039 Burner, Right- SR38G, SR42G, SM35G, SM40G

810-2149 Burner, Center- SM60G, SM80G, SR62G, SR52G, SM50G

Pilot Assemblies

Burner, Pilot- Natural & MFG (Also Used For Main Pilot) SM60G, SR62G,

SM80G, 50G

Burner, Pilot- LP (Also Used For Main Pilot) SM60G, SR62G, SM80G,

SM50

Diffusers

Burners

4

5-3

Page 29

Dean Millivolt

Item Part # Description

5 810-2151 Burner, Left- SM60G, SM80G, SR62G, SM20G, SR52G, SM50G

5 810-2037 Burner, Left- SR38G, SR42G, SM35G, SM40G

6

807-2122 CE Gas Valve, natural gas, 35,45,50

807-2121 CE Gas Valve, LP, 35-45-50

*

810-3101 2.40mm orifice, CE (SR42 after 4/07)

810-2138 Valve, Trailing Pilot- SM60G, SM80G, SR62G adjustment valve

*

826-1817 Natural to LP, SR42

826-2017 LP to Natural, SR42

826-2018 Natural to LP, SR52/SM50 (with Honeywell valve)

826-2019 LP to Natural, SR52/SM50 (with Honeywell valve)

826-2020 Natural to LP, SR62/SM60 (with Honeywell valve)

826-2021 LP to Natural, SR62/SM60 (with Honeywell valve)

* Not illustrated.

810-2060 G20-25 2.40mm orifice, CE

810-2059 G31 1.15mm orifice CE

810-3102 G31 1.15mm orifice, CE (SR42 after 4/07)

807-1846 Valve kit, Nat to Pro, SR 52,62, SM35, SM40, SM50

Valves

Orifices

Conversion Kits

5-4

Page 30

Pro Electric/RE

RE

Pro Electric

The Pro Electric fryer, which introduced a new filter pan

and a large drain manifold among other design changes,

was followed by the RE, which introduced a unique

rotating element. The units share many common electrical

components.

Unique physical characteristics:

Pro Electric — 3-inch drain manifold, filter pan redesign

RE — Recessed rotating element mounting mechanism,

repositioned and redesigned contactor boxes

Where used:

All major chains

Common Model numbers:

• Pro Electric — FPPH214, FPPH217, FMPH214; McDonald’s: BIPH214,

BIPH314

• RE — FPRE317, FPRE 217, FPRE214; McDonald’s: BIRE314, BIRE414,

BIRE214

The RE fryer has a recessed tubular

mounting point for the elements which

rotates. This is the most obvious

difference between the RE and the Pro

Electric.

6-1

Page 31

Controllers

Pro Electric/RE

Standard

Item

1

826-2333 826-2395 Full-Vat , CE

826-2334 826-2396 Dual-Vat, CE

826-2335 826-2397 Full-Vat (Triac/Solid State)

826-2336 826-2398 Dual-Vat (Triac/Solid State)

2

826-2303 826-2399 Full-Vat, CE

826-2362 826-2400 Dual-Vat, CE

3

106-2088SP 826-2330 Full-Vat, CE

106-2089SP 106-4366 Dual-Vat, CE

5

826-1810 826-2342 M2000 replacement

Part #

Euro-look

Part # Component

Computer Magic III.5

Digital Controller

Basket Lift Timer

McDonald’s Replacement Controllers (No bezel)

Interface Board to Controller Wiring Harness – 15-Pin

806-2071SP

6-2

For SMT

computer

Page 32

Pro Electric/RE

Component Boxes

Item Part # Component

1 807-0012 Relay, 18 Amp ⅓ HP 24V Coil

2 807-2180 Transformer, 208-240V 50VA

4 807-0680 Transformer, 208-240V/24V 20VA

* 807-0979 Transformer, 208-240V/12V 43VA

6

826-2256 Standard (Non-Triac), Full- or Dual-Vat

826-2257 Triac, Full- or Dual-Vat

106-5335 Fast Computer, Full- or Dual-Vat

6

826-2260 Standard, Full or Dual Vat

106-6501 Fallback Controller Assembly

807-3932 Relay, Heat and Latch 12 VDC SPDT 12A

7 806-7179SP Sound Device

* 826-2458 Speaker, McDonald’s

8 807-0069 Circuit Breaker, 10 Amp

*

* Not illustrated.

807-0680 208/240V/24V (no fuse)

807-1999 208/220/230/240V 20/50 VA 12/24

807-4036 Switch (used on RE control box)

826-2249 RE Hood/Ansul Interlock Kit (includes terminal block, wires,

Pro Series Interface Board

RE Interface Boards

24 Volt Transformers Used in Common Electric Units

connectors

6-3

Page 33

Contactor Boxes

Pro Electric/RE

Item Part # Component

1 807-1071 Contactor, 24V 30 Amp Mercury

2 807-0884 Contactor, 24V 35-50 Amp Mercury

3 807-2284 Contactor, 24V 50 Amp Mechanical (only in 14 & 17kW Navy units)

4 807-2283 Contactor, 24V 63 Amp Mechanical (only in 22kW Navy units)

5 810-1202 Contactor, 24V 40 Amp 3-Pole

6 807-0012 Relay, 18 Amp ⅓ HP 24V Coil

7 807-0064 Transformer, 480V/120V 150VA

8 807-1683 Relay, 12VDC

** 826-1562 Relay, Solid State 50 Amp 280V

* 807-0331 250V transformer

* Not illustrated.

** Dual-vat Assembly has six relays (826-1562); full-vat Assembly has three relays.

6-4

Page 34

Pro Electric/RE

Heating Element Assemblies and Associated Parts

NOTE: Pro-series

elements have flat

mounting flanges and

will not fit on newer REseries fryers.

1

2

1

Item Part # Component

1

Element

826-2152 230V 7kW

826-2150 208V 18.5 kW

826-2172 208V 11.0 kW

826-2154 240V 17.0 kW

826-2155 240V 18.5 kW

826-2166 240V 11.0 kW

826-2159 440V 17.0 kW

826-2160 440V 18.5 kW

826-2169 440V 11.0 kW

826-2161 480V 17.0 kW

826-2162 480V 18.5 kW

826-2170 480V 11.0 kW

2 826-1526 Probe, Temperature

3

Hi-limit

806-8132 218°C (415°F) Color-coded yellow

3

6-5

Page 35

Pro Electric/RE

RE Heating Element Assemblies and Associated Parts

NOTE: RE-series

elements have a curved

mounting flange and will

not fit on earlier Proseries models.

Item Part # Component

1 Element Kits – includes gaskets, grommets, tie wraps, screws and nuts.

826-2193 230V 7kW

826-2197 208V 18.5 kW

826-2210 208V 11.0 kW

826-2194 240V 17.0 kW

826-2207 240V 11.0 kW

826-2195 440V 17.0 kW

826-2202 440V 18.5 kW

826-2211 440V 11.0 kW

826-2196 480V 17.0 kW

826-2203 480V 18.5 kW

826-2209 480V 11.0 kW

2 826-2212 Probe, Temperature RE – includes tie wraps and grommet.

807-4324 Probe, Temperature Fast Ready

*

* Not Illustrated.

806-8132 213°C, CE

Probes

Hi Limit

6-6

Page 36

2836

The 2836 is a large electric fryer used principally in Wal-Mart

kitchens to prepare chicken in large quantities. The original

design used a round-bar element and had float switches; later

units have flat-bar elements and no float switch.

Unique Physical Characteristics:

• The unit is big. Wal-Mart cooks 100 pieces of chicken

at a time in the 36Kw frypot. The amp draw demands

special wiring for the store. The unit is also sold in a

two 28Kw frypot configuration.

Where Used:

• Wal-Mart, however, it is not marketed exclusively to Wal-Mart.

Common Model Numbers:

• FP128/236, FP228

The earlier 2836 units have round

heating elements and a float switch,

which is visible in the left corner above.

7-1

Page 37

2836

Computer and Related Components

Item Part Number

1 826-2389 Computer, Standard CM3.5

* 826-2388 Computer, FP28 SMT FV

* 826-2387 Computer, FP36 SMT FV

* 106-7177 Computer, FP28SV/SPR with Bezel SMT

* Not illustrated

Description

7-2

Page 38

2836

Contactor and Power Cord Box Assembly

Item Part # Description

1 807-0884 Contactor Mercury 240V 50A

2 810-1202 Contactor, 40 Amp 3 Pole

* 807-4017 Fuse, 50-amp 480V, 300VDC

* Not illustrated.

7-3

Page 39

Component Box Assembly

2836

Item Part # Description

1 806-3660 Sound Device, High Output

2 826-2256 PCB Assembly, Interface (FV) Common Elect

3 807-0012 Relay 18 Amp 1/3 Hp 24V Coil (On LT Only)

4 807-0670 Relay, Midtex DPDT 24V

5 807-0680 Transformer 208/240 50/60-24V 50VA

6 807-0979 Transformer 208/240 50/60-12V 20VA

7 807-2278 Fuse, 20 Amp

7-4

Page 40

2836

Elements (round) and related components for float-switch model

3

2

1

Item Part # Description

1 807-4009 Element, FP28/36S 480V 9.533 kW

* 807-4011 Element, FP28/36S 11.9 kW

2 809-0567 Tie Wrap, Metal

3 806-6849SP Switch, Tilt Safety

* 826-2104 Probe, 28 kW Temperature

* 826-2105 Probe, 36kW, Temperature

* KIT6078SP

* Not illustrated.

Float Switch Kit FP28 (Use KIT6079SP for FP36) - Both kits include

covers.

7-5

Page 41

2836

Elements (flat) and related components for non float-switch model

1

Item Part # Description

1 807-4038 Element, FP28, 480V

807-4051 Element, FP36, 480V

2 826-2106 Probe kit, FP28, temperature

826-2107 Probe kit, FP36, temperature

3 806-6849 Tilt switch assembly

2

3

7-6

Page 42

1721/18UE

The 18UE and the 1721 are Dean and Frymaster versions of very similar electric fryers.

Many components in the running gear are the same.

Unique Physical Characteristics:

• Large-capacity chicken fryer.

Where Used:

• The Frymaster 1721 is used in Church’s and Popeye’s.

Common Model Numbers:

• EH1721, SCF318UE, CF118UE

8-1

Page 43

1721/18UE

Computers, Controllers and Related Components

Item Part # Description

1 826-2310 Computer, CM-III Full-Vat

2 826-2303 Controller, Digital- Full-Vat

3 106-0063 Computer, KFC-1 Electric (Non-CE)

4 106-3028 Computer, CM4-S (Segmented Programming)

5 806-7422 Controller, Analog- Solid State (3 On, 12 Off)

8-2

Page 44

Electronics

1721/18UE

Item Part Number Description

1 826-2256

2 826-2031

3 807-0855 Transformer, 120V, 50/60 Hz –12V 20VA (480V Units)

* 807-0979 Transformer, 208-240V, 50/60Hz –12V 20VA

4 807-0800 Transformer, 120V 50/60 Hz –24V 50VA (480V Units)

* 807-0680 Transformer, 208-240V, 50/60Hz –24V 20VA

5 807-3611 Relay, 24VAC

6 807-1071 Contactor, Mercury- 240VAC 30-Amp (17 kW Units)

* 807-0884 Contactor, Mercury- 240VAC 50-Amp (21 kW Units)

7 810-1202 Contactor, Latching- 40-Amp, 3-Pole

* 807-2278 Fuse, 20-Amp

8 806-3660 Sound Device- All Except KFC18E

9 806-5974SP Speaker, Sound- KFC18E Only

* 807-3577 Breaker, Circuit 7 amp (120V Filter Circuit)

* 807-2104 Microswitch

* 807-3932 Relay, 12VDC

* Not illustrated.

Interface Board- (All Except Electronic Thermostat

Controller)

Thermatron Board- (Electronic Thermostat Controllers

Only)

8-3

Page 45

1721/18UE

Probes, High-Limits, Elements and Related Components

1

2

3

4

Item Part # Description

1 807-3652 Element- 208V 8.5 kW

807-3675 Element- 480V 10.25 kW

807-3655 Element- 240V 8.5 kW

807-3657 Element- 208V 9.0 kW

807-3658 Element- 240V 9.0 kW

807-2557 Element- 208V 10.25 kW

807-3655 Element- 240V 8.5 kW (USE FOR 220V 7 kW)

807-2637 Element- 240V 10.25 kW

2 826-1791 Probe, Temperature- 15" (With Ty Wrap)- All Except Thermatron

* 807-3653 Probe, Temperature- Thermatron Only

3 910-5022 Bracket, Probe Guard

4 826-2456 High-Limit Thermostat- 435°F

* Not illustrated.

8-4

Page 46

1721/18UE

Tilt Safety Switch Components

1

2

Item Part # Description

1 106-5876 Sensor assy

2 810-3007 Magnet

8-5

Page 47

THIS PAGE INTENTIONALLY LEFT BLANK

Page 48

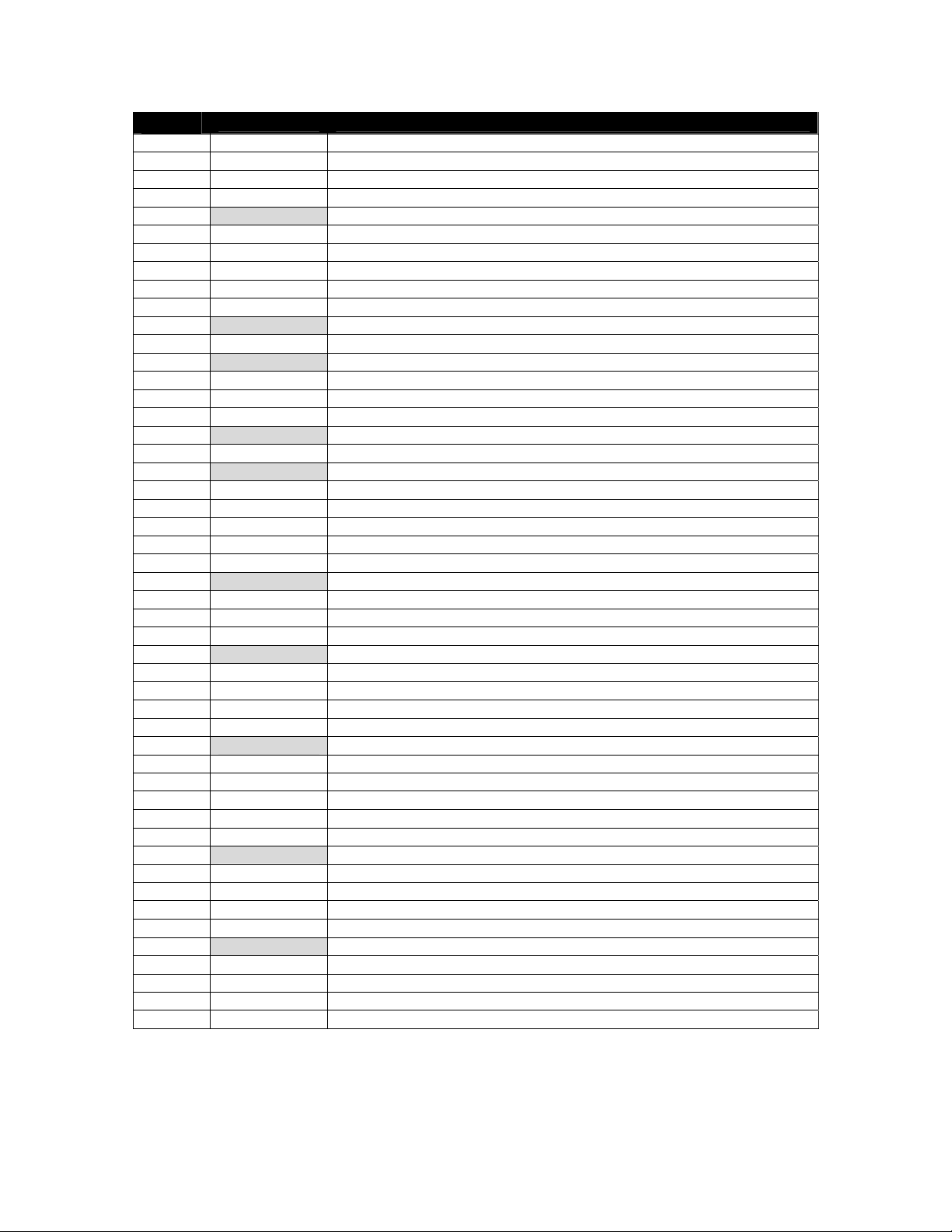

Pumps/Motors

Frymaster fryers use Viking pumps; Dean units have Haight

pumps. The 4 GPM pump used in Frymaster fryers will fit in

most units. The same can be said for Dean pumps, although

4GPM, 5GPM, and an 8 GPM pump are available.

What to Watch For:

• Pumps are easily clogged. Don’t replace a pump/motor

assembly without cleaning the pump.

How to Order:

• Frymaster doesn’t sell pump/motor assemblies,

essentially to deter needless replacement of both components. Pumps and motors

are listed separately, each with a gasket.

It doesn't take much debris

to clog a pump. The one

above was believed failed

and replaced. All it needed

was cleaning. Warranty

claims for functioning

pumps are rejected.

9-1

Page 49

Pumps/Motors

Item # Part # Component

1 810-2100 Motor, 120-230 1/3 HP used in 24G, Decathlon

2 810-2098 Pump, 8GPM, used in 24G, Decathlon

* 810-2252 Pump, 5GPM, used in Decathlon

3 826-1270 Motor, gasket kit, 220-240V

4 826-1264 Pump, 4 GPM, used in 45, 52/55, Pro/RE

* 816-0093

* 810-3071 Pump, 8 GPM, used in Dean Common Cabinet

* 826-1392 O-Rings, .739" I.D. (pkg. of 5) [816-0596]

* 826-1051 O-Ring Kit, for FMII or FPII Filter Systems

* 816-0597 O-Rings, 1.36" I.D., for Footprint III Filter Pan Check Valve

* Not illustrated.

Gasket, used in Frymaster filters/pumps, part of Items 3 & 4

9-2

Page 50

GSMS

The GSMS is a gas pasta cooker.

Unique Physical Characteristics:

The GSMS has a flat-bottom tank with sealed burners attached.

Where Used:

Carrabba’s and other pasta restaurants

Common Model Numbers:

GSMS

10-1

Page 51

GSMS

Combustion System Components

ITEM PART # COMPONENT

1 Igniter

826-1714 Natural Gas

826-1715 Propane Gas

2 Burner Assembly

810-1382 Natural or Propane Gas Burner w/o Orifice

* 812-0357 Burner Insulation

3 Motor, Blower

807-1712 230VAC/50 Hz

* Not illustrated.

10-2

Page 52

GSMS

Control Box and Related Components

ITEM PART # COMPONENT

1 807-1396 Relay, 24VDC SPDT (Basket Lift Relay – GSMS and GBC units only)

2 807-0680 Transformer, 208-240VAC/24VAC, 50/60 Hz, 43VA

3 807-3366 Module, Honeywell Dual-Spark FV Ignition (See NOTE below.)

4 807-0670 Relay, 24V DPDT (Heat Relay – all units)

5 106-0676SP Cable, Ignition (used with Item 3 – also requires Item 8)

6 807-1709 Cable, Ignition (used with 807-1006 Ignition Modules)

7 806-5316SP Wire Assembly, 20-inch High Temperature (Flame Sensor Wire)

8 807-3484 Connector, RAJAH (two required for each 807-3366 Ignition Module)

NOTE: Control box assemblies on units manufactured before October 2000 were built with

two single-spark ignition modules (P/N 807-1006). If an 807-1006 module fails, the control

box may be retrofitted with one dual-spark ignition module (P/N 807-3366) and two RAJAH

connectors (P/N 807-3484). If this option is chosen, the earlier style ignition cables (P/N 807-

1709) must also be replaced with the new ignition cables (P/N 106-0676SP).

10-3

Page 53

GSMS

Controllers and Control Panel Components

ITEM PART # COMPONENT

1 Controller, SMS III - GSMS

106-0376 Full Featured

106-0379 w/o Autoskim

106-0380 w/o Autofill or Autoskim

Controller, SMS III - GSMS

106-0376 Full Featured

106-0379 w/o Autoskim

106-0380 w/o Autofill or Autoskim

Water Sensors

ITEM PART # COMPONENT

1 823-1920 Sensor, Low Water Level

2 823-1921 Sensor, Normal Water Level

3 806-4764 Probe Assembly, Temperature

* 809-0193 Washer, ¼” Nylon, flat

* Not illustrated.

10-4

Page 54

GSMS

Gas Valves

ITEM PART # COMPONENT

1 Valve, Honeywell Gas (Non-CE)

826-1122 Natural or Manufactured Gas

826-1123 Propane Gas

10-5

Page 55

THIS PAGE INTENTIONALLY LEFT BLANK

Page 56

8SMS

The 8SMS is an 8Kw electric pasta cooker.

Unique Physical Characteristics:

Has basket lifts, rinse tank and a faucet.

Where Used:

Fazoli’s and other pasta restaurants

Common Model Numbers:

8SMS

11-1

Page 57

8SMS

ITEM PART # COMPONENT

1 810-1697 Block, Probe

* 826-1081 Kit, Probe Block (old style with pins and cover)

* 823-2791 Cover, Probe Block

* 823-1942 Cover, Probe (old style with holes for pins)

2 823-1920 Sensor, Lower Water Level (approximately 7 inches long)

3 823-1921 Sensor, Upper Water Level (approximately 4¼ inches long)

4 910-1804 Bracket, Temperature Probe Retaining

5 806-4764 Temperature Probe (with connectors)

6 900-5675 Bracket, High-Limit Thermostat Mounting

7 826-1601 Thermostat, High-Limit (includes high-limit, gasket, and tie wrap)

* 809-0193 Washer, ¼” Nylon, Flat

8 Element, 8kW, 1- or 3-Ø (includes mounting washer and nut and standoff)

807-1345 208VAC

807-1347 240VAC

* Not illustrated.

11-2

Page 58

8SMS

4

3

2

1

ITEM PART # COMPONENT

1 807-1396 Relay, 24VDC

2 807-0680 Transformer, 208/240VAC – 24VAC

3 806-4770 Valve Assembly, Solenoid

4 810-1202 Contactor, 40 Amp 3 Pole

* 806-4702 Cable, 8SMS Controller

* WIR0013SP Wire Assembly, SMSII 208/240V

5 807-1308 Fuse Holder

* 807-1555 Fuse

* Controller, 8SMS (Use smaller bezels)

106-0371 AutoFill and AutoSkim

106-0373 AutoFill but without AutoSkim

106-0374 Without Autofill or Autoskim

* Not illustrated.

5

11-3

Page 59

THIS PAGE INTENTIONALLY LEFT BLANK

Page 60

UHC-P

The UHC-P is the second generation of the holding cabinet, which, until recently, was

made exclusively for McDonald’s. This cabinet is programmed with a Palm Pilot.

Unique Physical Characteristics:

• Dark IR port on top right of the cabinet. Programming is beamed to the cabinet

through this port from a Palm Pilot. The unit is offered in four-slot (shown

above), two-slot and narrow configurations. There is no parts interchangeability

between the UHC-P and the earlier UCH.

Where Used:

• McDonald’s. A generic version called the Holdmaster is just being brought to

market. The bezels and heater plates are different on the generic model.

Common Model Numbers: UHC-P4, UHC-P2 and UHC-P Narrow

12-1

Page 61

UHC-P

ITEM PART # COMPONENT

1 807-4204 Distribution board

2 106-7956 Power supply board

3 807-4203 Communication board

4 807-4024 Transformer

5 807-4036 Switch

6 807-4202 Display, narrow (equipped with ribbon cable)

7 807-4201 Display, full (equipped with ribbon cable)

* 807-3918 Communication cable

* 826-2034 Palm Zire 22 with UHC-P software

* 807-2819 Fuse, 20 amp

* 819-6048 UHC-P software CD

* 807-2766 Line filter

* Not illustrated.

12-2

Page 62

UHC

The UHC is the first generation holding cabinet. This unit was built exclusively for

McDonald’s.

Unique Physical Characteristics:

• This unit is programmed with buttons on the bezel. There is no IR port. There is

no part interchangeability between the UHC and the newer UHC-P.

Where Used:

• McDonald’s only

Common Model Number:

• UHC

13-1

Page 63

UHC

ITEM PART # COMPONENT

1 807-2443 UHC Motherboard

2 807-2444 UHC Driver board

3 807-2460 Transformer

4 807-3308 Switch

5 807-3490 Relay, power

* 826-1718 Switch Kit with relay ( includes switch, relay, bracket and wiring)

6 807-3309 Front Display Assembly

* 807-3310 Rear display Assembly

* 807-3311 Front Membrane Switch

* 807-3312 Rear Membrane Switch

* 807-2448 CN1 and CN2 Harnesses

* 807-2665 Blower

* 807-2770 1.5 amp fuse

* 807-2819 20 amp fuse

* Not illustrated.

13-2

Page 64

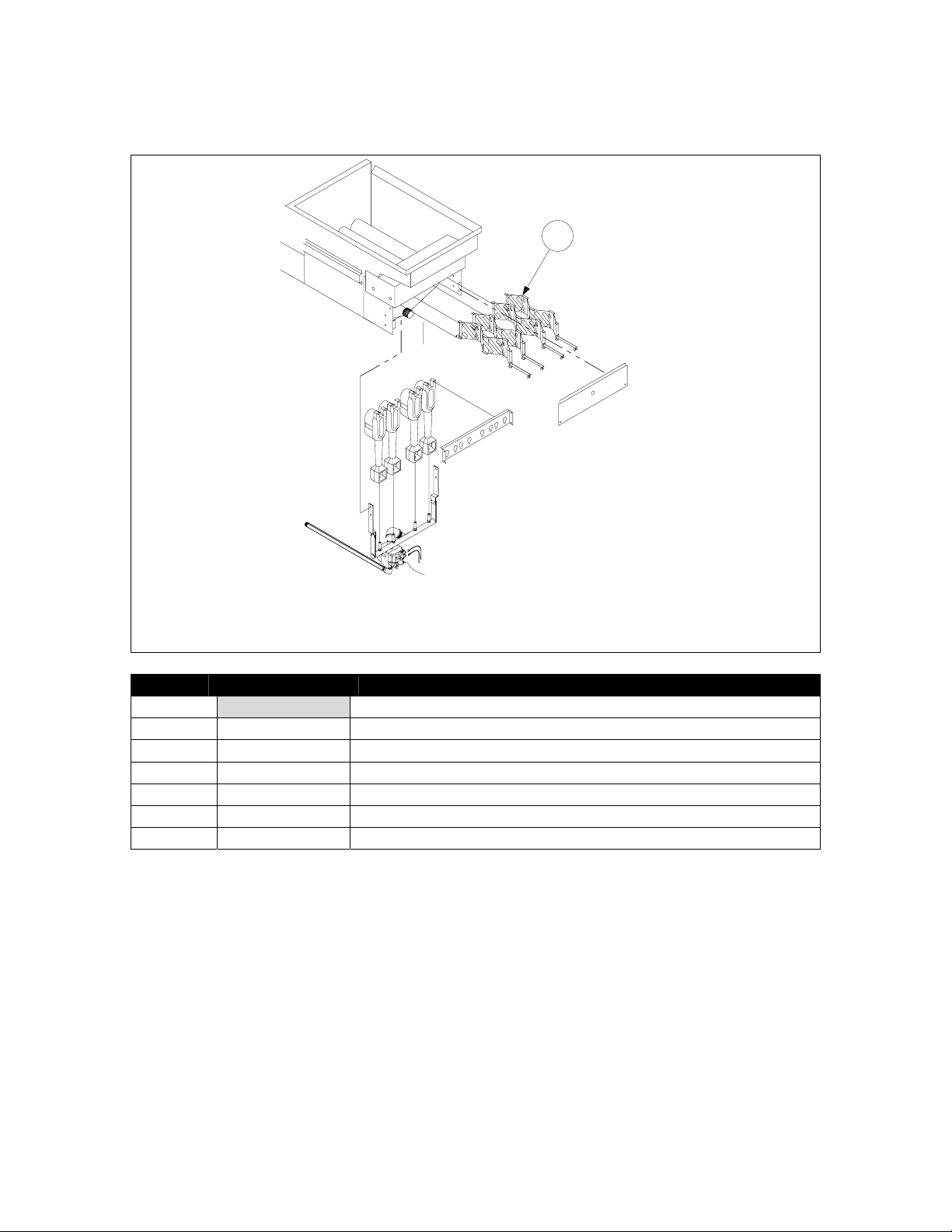

Sinbad

The Sinbad is a single-basket fry dispenser. It is used almost exclusively by Burger King.

Unique Physical Characteristics:

• The Sinbad uses a load cell to measure fries awaiting dispensing in the hopper.

Where Used:

• Burger King and a few in McDonald’s.

Common Model Number

• Sinbad

14-1

Page 65

Sinbad

ITEM PART # COMPONENT

1 106-1277 Sinbad II Controller (Burger King)

* 826-1571 Sinbad 1 Controller, (Burger King)

* 106-1480 Sinbad Controller, (McDonald’s

2 807-3436 Drum Motor

3 810-1571 Drum Rotator Arm

4 806-9258 Load Cell

5 106-6715 Motor Interface Board

6 807-3004 Dispense Motor

7 807-3185 Transformer

8 807-2734 ON/OFF Switch, Lighted, Green

9 806-8969SP Position Sensor Assembly, Hall Effect

10 106-0503SP Proximity Sensor Assembly

* 816-0568 Sight Glass, Sinbad II ( Tapered, wider at top)

* 816-0324 Sight Glass, Sinbad I (Parallel sides, not tapered)

* 807-2818 Line Filter

* Not illustrated.

14-2

Page 66

HLZ

The HLZ, or Heated Landing Zone, is a warming station sold exclusively to McDonald’s.

Unique Physical Characteristics:

• Supplies heat with a plate and heated air.

Where Used:

• McDonald’s

Common Model Number:

• HLZ

15-1

Page 67

HLZ

2

3

1

5

6

7

8

4

ITEM PART # COMPONENT

1 826-1549 Air heater kit, 208V

2 807-0979 Transformer 208/240/12V

3 807-3036 Air RTD Probe

4 807-3631 Hi-limit

5 807-3021 Latch, relay

6 826-2038 Air Relay Kit, 50-amp

* 826-1958 5-amp Plate relay kit

7 106-6713 Computer

8 826-1551 Blower kit

* 807-2818 Line filter

* Not illustrated.

15-2

Page 68

Tools

Part # Description

806-4855 Pin-pusher screwdriver

806-5023 Transformer mtb-310a 120v/12v

806-5093 MTB/310a test box 120v

806-5094 MTB/310A TEST BOX 240v

806-5095 5 ft. Ext remote cable assy

807-0928 Tool extract/pin pusher

807-1391 Multitester digital dm50a

826-1746 Load-Cell Simulator for Sinbad

810-0504 Fuse puller

810-0765 1" conduit wrench

810-0766 1.25" conduit wrench

230-4028 Spanner, element nut (used on RE elements)

815-0385 Socket 1" 6pt mld slot

815-0386 Socket 7/8" deep 6pt mld slot

815-0810 1 1/2"carbide-tipped hl cutter

817-0001 Tool roll Xcelite

817-0002 Gas pressure gauge

817-0003 Gas pressure gauge case

817-0005 Tool mini amp pin pusher

230-2345 Extractor pin, SMT, Micro amp

16-1

Frymaster sells a number of

tools for working on our

equipment. The complete list

is below. Not all tools

illustrated above are available

from Frymaster.

Page 69

THIS PAGE INTENTIONALLY LEFT BLANK

Page 70

Frymaster, a member of the Commercial Food Equipment Service Association,

recommends using CFESA-certified technicians.

Frymaster, L.L.C., 8700 Line Avenue, PO Box 51000, Shreveport, Louisiana 71135-1000

Shipping Address: 8700 Line Avenue, Shreveport, Louisiana 71106

Tel: 1-318-865-1711

Web: www.frymaster.com

PRINTED IN THE UNITED STATES

FAX Parts: 1-318-219-7140 Tech Support: 1-318-219-7135

SERVICE HOTLINE

1-800-551-8633

819-6367

JUL 2008

or service@frymaster.com

Loading...

Loading...