Page 1

INSTALLATION, OPERATION,

& MAINTENANCE MANUAL

COOL ZONE ELECTRIC FRYERS (CE)

A WELBILT Company

DEAN INDUSTRIES

14501 South Broadway, Gardena, California 90248

Dean Factory Service Center

1-800-551-8633

1-318-865-1711

Printed in the United States of America P/N 819-5729

English November 1999

Page 2

Please read all sections of this manual and retain for future reference.

NOTICE

IF, DURING THE WARRANTY PERIOD, THE CUSTOMER USES A PART FOR THIS ENODIS

EQUIPMENT OTHER THAN AN UNMODIFIED NEW OR RECYCLED PART PURCHASED

DIRECTLY FROM FRYMASTER DEAN, OR ANY OF ITS AUTHORIZED SERVICE CENTERS,

AND/OR THE PART BEING USED IS MODIFIED FROM ITS ORIGINAL CONFIGURATION, THIS

WARRANTY WILL BE VOID. FURTHER, FRYMASTER DEAN AND ITS AFFILIATES WILL NOT

BE LIABLE FOR ANY CLAIMS, DAMAGES OR EXPENSES INCURRED BY THE CUSTOMER

WHICH ARISE DIRECTLY OR INDIRECTLY, IN WHOLE OR IN PART, DUE TO THE

INSTALLATION OF ANY MODIFIED PART AND/OR PART RECEIVED FROM AN

UNAUTHORIZED SERVICE CENTER.

NOTICE

This appliance is intended for professional use only and is to be operated by qualified

personnel only. A Frymaster Dean Factory Authorized Service Center (FASC) or other

qualified professional should perform installation, maintenance, and repairs. Installation,

maintenance, or repairs by unqualified personnel may void the manufacturer’s warranty. See

Chapter 1 of this manual for definitions of qualified personnel.

NOTICE

All fryers shipped without factory supplied cords and plug assemblies must be hardwired

using flexible conduit to the terminal block located on the rear of the fryer. These fryers

should be wired to NEC specifications. Hardwired units must include installation of restraint

devices.

NOTICE

This equipment must be installed in accordance with the appropriate national and local codes

of the country and/or region in which the appliance is installed.

NOTICE

Drawings and photos used in this manual are intended to illustrate operational, cleaning and

technical procedures and may not conform to onsite management operational procedures.

NOTICE TO OWNERS OF UNITS EQUIPPED WITH COMPUTERS

U.S.

This device complies with Part 15 of the FCC rules. Operation is subject to the following two

conditions: 1) This device may not cause harmful interference, and 2) This device must accept

any interference received, including interference that may cause undesired operation. While

this device is a verified Class A device, it has been shown to meet Class B limits.

CANADA

This digital apparatus does not exceed the Class A or B limits for radio noise emissions as set

out by the ICES-003 standard of the Canadian Department of Communications.

Cet appareil numerique n’emet pas de bruits radioelectriques depassany les limites de classe

A et B prescrites dans la norme NMB-003 edictee par le Ministre des Communications du

Canada.

Page 3

DANGER

Improper installation, adjustment, maintenance or service, and unauthorized alterations or

modifications can cause property damage, injury, or death. Read the installation, operating

and service instructions thoroughly before installing or servicing this equipment. See Chapter

1 of this manual for definition of qualified service personnel.

DANGER

The front ledge of the fryer is not a step. Do not stand on the fryer. Serious injury can result

from slips or contact with the hot oil.

DANGER

Single fryers equipped with legs must be stabilized by installing anchor straps. All fryers

equipped with casters must be stabilized by installing restraining chains

DANGER

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any

other appliance.

DANGER

The crumb tray in fryers equipped with a filter system must be emptied into a fireproof

container at the end of frying operations each day. Some food particles can spontaneously

combust if left soaking in certain shortening material. Additional information can be obtained

in the filtration manual included with the system.

WARNING

No structural material on the fryer should be altered or removed to accommodate placement of

the fryer under a hood. Questions? Call the Frymaster Dean Service Hotline at 1-800-551-

8633.

WARNING

Do not bang fry baskets or other utensils on the fryer’s joiner strip. The strip is present to seal

the joint between the frypot. Banging fry baskets on the strip to dislodge shortening will

distort the strip, adversely affecting its fit. It is designed for a tight fit and should only be

removed for cleaning.

DANGER

Adequate means must be provided to limit the movement of this appliance without depending

on or transmitting stress to the electrical conduit. A restraint kit is provided with the fryer. If

the restraint kit is missing contact your local Frymaster Factory Authorized Service Center

(FASC) for part number 826-0900.

DANGER

This fryer may have two power cords and prior to movement, testing, maintenance and any

repair on your Frymaster fryer; disconnect BOTH electrical power cords from the electrical

power supply.

Page 4

DEAN

COOL ZONE ELECTRIC FRYERS (CE)

INSTALLATION, OPERATION, & MAINTENANCE MANUAL

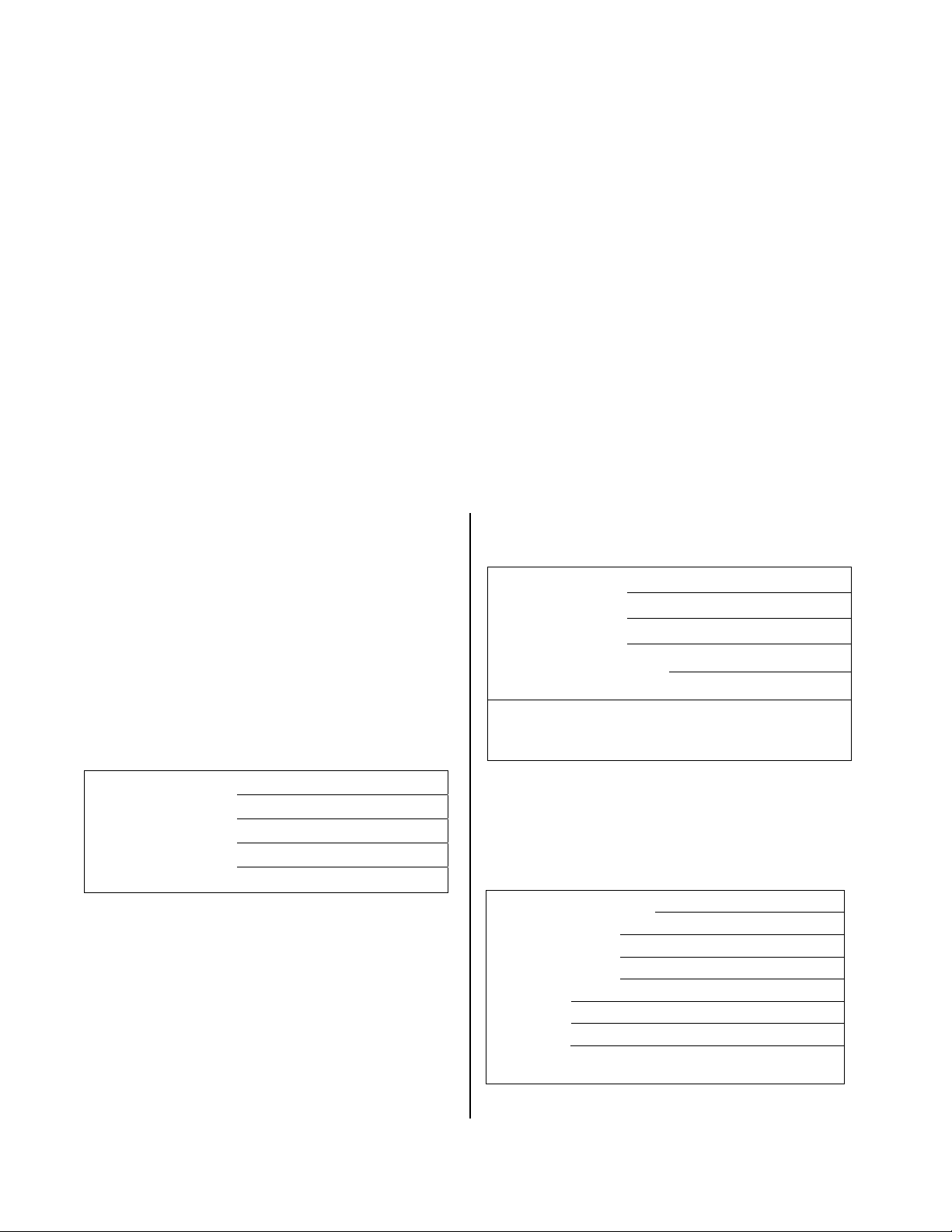

1 PARTS ORDERING/SERVICE INFORMATION 2

2 IMPORTANT INFORMATION 3

3 INSTALLATION 5

4 DAILY OPERATION 10

5 CLEANING AND MAINTENANCE 12

6 OPERATOR TROUBLESHOOTING 14

7 WIRING DIAGRAM 15

1. PARTS ORDERING AND SERVICE INFORMATION

1.1 ORDERING PARTS:

Customers may order parts directly from their

local Authorized Parts Distributor. For this

address and phone number, contact your

Maintenance & Repair Center or call the Dean

Factory Service Hotline. The factory address

and phone numbers are on the cover of this

booklet.

To speed up your order, the following

information is required:

Model Number

Serial Number

Type of Voltage

Item Part Number

Quantity Needed

1.2 SERVICE INFORMATION:

Call the Dean Factory Service Hotline number

on the cover of this booklet for the location of

your nearest Maintenance & Repair Center or

contact the factory direct. Always give the

model and serial numbers of your filter and

fryer.

TABLE OF CONTENTS

To assist you more efficiently, the following

information will be needed:

Model Number

Serial Number

Voltage

Nature of the Problem

Any other information which may be helpful

in solving your service problem.

1.3 AFTER SALES:

In order to improve service, have the following

chart filled in by the Dean Authorized Servicer

who installed this equipment.

Authorized Servicer

Address

Telephone/Fax

Model #

Serial #

Type:

Fryer Equipped For:

PAGE

Page 5

2. IMPORTANT INFORMATION

2.1 DESCRIPTION: The Dean Cool Zone

(CE) electric fryers are energy-efficient,

electrically heated units, certified by NSF

and the Underwriters Laboratory and

manufactured to their basic performance

and application specifications. The Dean

Cool Zone (CE) electric fryers are

certified for installation and operation in

the European Community (CE).

Units are shipped completely assembled

with any accessories packed inside the

fryer vessel. They are adjusted, tested,

and inspected at the factory prior to crating

for shipment. Sizes, weights and input

rates are listed in this manual.

2.2 DESIGN SPECIFICATIONS:

a. VESSEL CONSTRUCTION: Welded,

heavy gauge steel with three heater

elements fixed inside the vessel with a

protective, chromed wire mesh crumb

screen over the elements. A drain is

tapped into front right corner of vessel

with a front-controlled manual drain

valve.

b. BODY CONSTRUCTION: An

aluminized steel base with stainless

steel front and enamel sides. The

frame is supported by 15 cm (6 inches)

adjustable legs or optional 15 cm (6

inches) rigid rear casters.

c. OPERATING CONTROLS: Unit is

shipped standard with a liquid filled

bulb thermostat. The temperature

control is mounted in the cabinet

behind the front door on the bottom

left side of the cabinet.

d. AUTOMATIC SAFETY FEATURE:

High temperature detection to shut off

electric heater elements should the

controlling thermostat fail.

e. RATING PLATE: This is attached to

the inside front door panel.

Information provided includes the

kilowatt (kW) output of the heater

elements and electrical requirements.

THE FRYER MUST BE CONNECTED ONLY

TO THE TYPE OF ELECTRICAL SERVICE

IDENTIFIED ON THE ATTACHED RATING

DANGER!

2.3 PRE-INSTALLATION:

a. GENERAL: A licensed electrician

should install any commercial electric

cooking equipment.

b. CLEARANCES: The fryer area must

be kept free and clear of all

combustibles. This unit is designcertified for the following installations:

1. Other than household use.

2. Non-combustible floor installation

equipped with factory-supplied 15

cm (6 inch) adjustable legs,

optional 13 cm (5 inch) rigid rear

casters, or optional 13 cm (5 inch)

locking swivel casters.

3. Combustible construction with a

minimum clearance of 15 cm (6

inches) side and 15 cm (6 inches)

rear, and equipped with factorysupplied 15 cm (6 inches)

adjustable legs or 13 cm (5 inches)

casters.

Local building codes usually prohibit a fryer

with its open tank of hot oil from being

installed beside an open flame of any type,

whether a broiler or the open burner of a

range.

CAUTION

3

Page 6

c. STANDARDS: All electrical cooking

appliances must be electrically

connected and grounded in accordance

with local codes, or in the absence of

local codes, with the latest editions of

the European Community (CE)

standards.

2.4 AIR SUPPLY & VENTILATION:

a. The area around the fryer must be kept

clear to prevent any obstruction to

ventilation air flow as well as for

service and maintenance. Never use

the interior of the fryer’s cabinet for

storage.

b. A commercial, heavy-duty fryer

should be vented to the outside of the

building.

c. Filters and drip troughs should be part

of any industrial hood, but consult

local codes before constructing and

installing any hood.

2.5 RECEIVING AND UNPACKING:

Check that the container is upright.

Unpack the fryer carefully and remove all

accessories from the carton. Do not

discard or misplace these, as they will be

needed.

After unpacking, immediately check the

equipment for visible signs of shipping

damage. If such damage has occurred,

contact the carrier and file the appropriate

freight claims. Do not contact the factory,

as the responsibility of shipping damage is

between the carrier and the dealer or enduser.

If your equipment arrives damaged:

♦ File claim for damages immediately,

regardless of extent of damage.

♦ Visible loss or damage: Be sure this is

noted on the freight bill or express

receipt and is signed by the person

making the delivery.

♦ Concealed loss or damage: If damage

is unnoticed until equipment is

unpacked, notify freight company or

carrier immediately, and file a

concealed damage claim. This should

be done within fifteen (15) days of

date of delivery. Be sure to retain

container for inspection.

NOTE: Dean does not assume responsibility

for damage or loss incurred in transit.

4

Page 7

3. INSTALLATION

3.1 POSITIONING:

a. Initial Installation: If installed with

legs, do not push against any unit edges

to adjust its position. Use a pallet or lift

jack to lift it slightly and place it where

Note: If a leg becomes damaged during

THIS FRYER MAY TIP AND

CAUSE PERSONAL INJURY IF

NOT SECURED CORRECTLY IN

A STATIONARY POSITION.

REMOVE ALL SHORTENING

BEFORE MOVING FRYER AS IT

MAY CAUSE SEVERE BURNS

UPON CONTACT.

3.2 L E G A N D C A S TER INSTALLATION:

it is to be installed.

b. Relocating The Fryer: If relocating a

fryer installed with legs, remove all

weight from each leg before moving.

movement, contact your service agent

for immediate repair/replacement of that

leg.

DANGER!

a. General:

1. Install legs and and optional rear

rigid casters near where the fryer is

to be used, as neither are secure for

long transit. Unit cannot be curb

mounted and must be equipped with

the legs (or legs and optional rigid

casters) provided.

2. When positioning the fryer, gently

lower the fryer into position to

prevent undue strain to the legs and

internal mounting hardware. Use a

pallet or lift jack to lift and position

the fryer if possible. Tilting the

fryer may damage the legs.

3. If the optional rigid casters are to be

installed on single fryers, the casters must

be installed on the fryer rear channel

assembly only.

4. Proceed to Step 3.3, Leveling, after legs

and/or optional rear rigid casters are

installed to ensure the fryer is level

before using.

b. Leg Installation:

1. Remove unit from pallet.

2. Carefully raise unit with forklift, pallet

jack, or other steady means.

3. Place one lock washer on each hex head

screw.

4. Insert hex head screws with lockwashers

(1/4-20 threads by 19mm (¾") long)

through bolt holes of leg mounting plates

as shown in the Figure 3-1 on the next

page. A locknut has been attached to the

top side of the mounting plate at the

factory to capture the hex head screw as

it is screwed in.

5. Tighten the bolts and nuts to 5.65 joules

(50 inch-lbs.) minimum torque.

For leg and caster installations, the unit

must be at room temperature and drained of

shortening before installing the legs and/or

casters.

CAUTION

c. Installing Optional Rear Rigid Casters

1. Install rear rigid casters only at the rear

of the single fryer as shown in the Figure

3-1. Legs must be installed at the front

of the fryer.

2. Follow the same instructions for leg

installations as given above in steps

3.2.b.1-5.

:

5

Page 8

Side Panel

Front Channel

Rear Channel

Side Panel

Front Door

Front Channel

Front Leg

w/Mounting Plate

1/4-20 HX HD Lock Nut

Caster Shims

if required.

Lock Washer

1/4-20 HX HD

Screw

1/4-20 HX HD Lock Nut

Caster Shims

if required.

Lock Washer

1/4-20 HX HD Screw

Adjust as needed.

Locking Caster

13 cm/5 in

Rear Rigid Caster

13 cm/5 in

Leg and Caster Installations

Figure 3-1

d. Installing Optional Swivel Casters:

1. Swivel casters can only be used with

multiple fryer batteries (two or more

fryers battered together).

2. Install non-locking casters only at the rear

of the unit as shown in the Figure 3-1.

3. Locking casters must be installed at the

front of the unit. This allows the fryer

to be "locked" in position for safe

operations.

4. Follow the same instructions for leg

installations as given above in steps

3.2.b.1-5.

A FRYER MUST BE LEVEL BEFORE

FILLING WITH OIL. IF THE FRYER

IS NOT LEVEL, THE FRYER MAY

TIP OVER AND MAY CAUSE

INJURY TO THE OPERATOR.

WARNING!

6

3.3 LEVELING:

a. Place a carpenter’s spirit level across

the top of the fryer and level the unit

both front-to-back and side-to-side. If

the fryer is not level, the unit may not

function efficiently, the oil may not

drain properly for filtering and in a

line-up it may not match adjacent

units.

b. Legs (Only):

1. If the floor is smooth and level,

level the unit by using the caster

shims. Adjust to the high corner

and measure with the spirit level.

2. Adjust leg height with an

adjustable or 27mm (1-1/16”)

open end wrench by turning the

hex bullet on the bottom of the

leg. See figure 3-2 on page 7.

3. The hex bullet is for minor leg

height adjustment only. Do not

adjust more than 22mm (1").

Structural Back

Page 9

4. When leveling the unit, the leg

body should be held firmly to

keep the leg from rotating while

turning the hex bullet foot to the

required height.

Adjust leg height with an

adjustable wrench.

Figure 3-2

DO NOT USE MORE THAN TWO

METAL SHIMS PER LEG/CASTER.

USING MORE THAN TWO SHIMS

PER LEG/CASTER MAY CAUSE

THE FRYER TO BECOME

UNSTABLE, TIP OVER, AND MAY

CAUSE INJURY TO THE

OPERATOR.

IF OPTIONAL SWIVEL CASTERS

ARE USED ON A MULTIPLE

FRYER BATTERY, LOCKING

CASTERS MUST BE INSTALLED

ON THE FRYERS' FRONT

CHANNEL. FAILURE TO LOCK

CASTERS PRIOR TO OPERATING

THE FRYERS MAY CAUSE THE

FRYERS TO MOVE AND CAUSE

INJURY TO THE OPERATOR.

WARNINGS!

c. Rigid Casters (Only):

1. Install the optional rigid casters on

the fryer rear channel only. Legs

must be installed on the front

channel.

2. Do not use more than two metal

shims per caster.

3. There are no thread adjustments for

the rigid casters.

d. Swivel Casters (Only):

1. Multiple fryer batteries (only): If

optional swivel casters are used,

the locking swivel casters must be

installed on the fryer front channel.

Lock casters prior to operating

the fryer.

2. Install non-locking swivel casters

on the fryer rear channel only.

3. Do not use more than two metal

shims per caster.

4. There are no thread adjustments for

the swivel casters.

e. If the floor is uneven or has a decided

slope, it is recommended to place the

fryer on a smooth platform. Do not

rely on leg thread or caster shims for

adjustments.

f. If the fryer is moved, re-level the fryer

following the instructions given in

Steps 3.3.a-c.

g. This fryer must be restrained to

prevent tipping when installed in order

to avoid the splashing of hot liquid.

The means of restraint may depend on

the type of application, such as

connecting to a battery of appliances

or installing the fryer in an alcove, or

by separate means, such as restraining

devices. A bracket has been provided

on the fryer back panel for this

purpose.

The install must be reviewed at the

time of installation to ensure it meets

the intent of these instructions. The

on-site supervisor and/or operator(s)

should be made aware that there is a

7

Page 10

restraint on the appliance and, if

disconnection of the restraint is

necessary, to reconnect this restraint

after the appliance has been

returned to its originally installed

position.

The fryer MUST be connected to the voltage

and phase as specified on the rating and

serial number plate located on the back of

the fryer door.

A ground wire MUST be connected to the

ground terminal provided near the input

power terminal block.

CAUTION

3.4 ELECTRICAL CONNECTIONS:

Plan and carry out installation in

accordance with local codes.

a. Connections: Connections to the

terminal block and grounding lug

should be made through the hole

provided for this purpose in the

junction box. To install this fryer, the

servicer/installer must use a goose

neck and retainer to protect the cord

set.

b. Wiring Diagram: It is attached to the

inside of the fryer door. Amperage for

each unit depends on the type of

installation and accessories supplied

with the unit. A 230/400V Wiring

Diagram is provided in Chapter 7.

3.5 INITIAL START-UP:

a. CLEANING: New units are wiped

clean with solvents at the factory to

remove any visible signs of dirt, oil,

grease, etc. remaining from the

manufacturing process, then coated

lightly with oil. Wash thoroughly with

hot, soapy water to remove any film

residue and dust or debris before food

preparation, then rinse out and wipe

dry. Wash also any accessories

shipped with the unit. Close the drain

valve completely and remove the

crumb screen. Make sure the screws

holding the thermostat and hi-limit

control sensing bulbs are tight.

b. HEATING THE VESSEL: This step

checks heater element operation, initial

thermostat calibration, and cleans the

vessel for initial food production.

1. Fill the fryer vessel with hot or

cold water to the oil level line

scribed in the back of the tank.

2. Set the thermostat/temperature

controller dial to 104°C/220°F,

just above that of boiling water.

3. Toggle the power switch “ON”.

The heater elements will begin

heating.

4. When the water starts to boil, turn

the dial to below 99°C/210°F.

The elements will turn off and the

water will stop boiling.

5. When satisfied that the heaters

and thermostat operate properly,

drain the vessel of water and dry

thoroughly. Refill fry vessel with

shortening as directed in section

3.6, Final Preparation.

Temperature Controller

8

Figure 3-3

Power Switch

Page 11

3.6 FINAL PREPARATION:

a. When using liquid shortening

(cooking oil), fill the fryer to the “oil

level” line scribed into the back of the

fryer vessel.

b. When using solid shortening, either

melt it first, or cut into small pieces

and pack into cool zone (bottom) of

the frying vessel. Do not leave any

air spaces or disturb the sensing

bulbs. Melt shortening by turning the

heaters “ON” for five or ten seconds,

“OFF” for a minute, repeating cycle

until shortening is melted. If oil starts

to smoke while melting this way,

shorten the “ON” cycle and lengthen

the “OFF” cycle. Smoke indicates oil

scorching, shortening its useful life.

NOTE: Never melt a solid block of shortening

by setting it in the vessel or on top of

the heating elements. This is unsafe,

inefficient and dangerous.

c. When the fryer vessel is filled and

the shortening melted, replace the

crumb screen gently over the heater

elements to prevent splashing of hot

oil. Wear gloves when replacing the

crumb screen.

d. Before starting operation, turn the

temperature controller to the probable

working temperature; wait for the

temperature to stabilize then check

with a high-quality immersion

thermometer.

9

NEVER OPERATE FRYER

WITHOUT ENOUGH COOKING

COMPOUND OR WATER IN

THE VESSEL TO COVER THE

HEATING ELEMENTS.

ALWAYS WEAR OIL-PROOF,

INSULATED GLOVES WHEN

WORKING WITH THE FRYER

FILLED WITH HOT OIL.

ALWAYS DRAIN HOT OIL INTO

A METAL CONTAINER. HOT

OIL CAN MELT PLASTIC

BUCKETS AND CRACK GLASS

CONTAINERS.

WARNINGS!

Page 12

4. DAILY OPERATION

4.1 OPENING: At opening time, always

visually check that the power switch and

the thermostat are “OFF”.

If electrical power service is disrupted for

more than a few seconds, turn fryer OFF.

This will prevent the fryer from accidentally

heating oil when power service is resumed.

4.2 GENERAL USE:

a. For consistent quality product,

convenience and long-term savings,

use a high-quality liquid frying

compound.

IF USING SOLID SHORTENING,

NEVER MELT A BLOCK OF

SHORTENING BY SETTING IT

WHOLE IN THE FRYER

VESSEL. THIS IS DANGEROUS

AND CAN EASILY CAUSE THE

SHORTENING SCORCHING,

DAMAGE TO THE ELEMENTS

OR POSSIBILY A FIRE.

b. Although a temperature of 177°C

(350°F) is recommended for most

cooking operations, set the fryer at the

lowest possible temperature which

produces a high-quality end product

while ensuring maximum life of frying

compound.

c. When the fryer is not in use, the

thermostat should be set lower than that

used during cooking.

CAUTION

WARNING!

4.3 TURN ON PROCEDURES:

a. If fryer is empty, pour enough

shortening into the vessel to fill the

vessel to the "oil level” line scribed on

the rear wall. If solid shortening is to

be used, melt enough in a separate

container to cover the heating elements

in the bottom of the vessel, then melt

the rest in the vessel by turning power

switch off and on.

b. Turn the power switch on; set

temperature controller to 177°C

(350°F). In less than 30 minutes, the

frying compound temperature will

stabilize and be ready for production.

4.4 FILTERING:

a. General: Filtering the shortening

assures a better taste to the food,

minimizes flavors being transferred

from batch to batch, and increases

frying compound lifespan.

Filter the frying compound at least

once daily or more frequently if

cooking is heavy.

b. Prior to filtering, align the portable

filter unit under the drain valve.

Attach the drain valve extension to

ensure shortening flows into the filter

safely.

c. If using solid shortening, clear return

lines before turning off the filter motor

and hang any flexible lines up to drain.

As it cools, solid shortening solidifies

and clogs lines.

d. For more detailed information

concerning filtration, review the

operator's manual shipped with your

filter unit.

10

Page 13

When filtering, never leave the filter

unattended. Always point the flexible oil

return hose nozzle down into the fry vessel

to prevent spraying of hot oil which may

cause severe burns.

CAUTION

4.5 CLOSING: When closing at night, filter

oil in all fryers and drain the filter lines.

Cover the open tanks of oil. Turn power

switch “OFF”.

4.6 SHUTDOWN: When shutting down for

periods longer than overnight, drain the

frying compound and clean the vessel

thoroughly. Either discard the frying

compound or return it filtered to the vessel

and then cover it. Turn both the power switch

and temperature controller “OFF”.

11

Page 14

5. CLEANING & MAINTENANCE

IF FRYER IS NOT COMPLETELY

EMPTY OF OIL, ADJUSTMENT,

ALTERATION, SERVICE OR

MAINTENANCE CAN CAUSE

PROPERTY DAMAGE AND

PERSONAL INJURY.

WARNING

5.1 GENERAL: Any piece of equipment

works better and lasts longer when

maintained properly and kept clean.

Cooking equipment is no exception. The

fryer must be kept clean during the

working day and thoroughly cleaned at the

end of each day.

5.2 DAILY: Wash all removable parts.

Clean all exterior surfaces of the body.

Do not use cleansers, steel wool, or any

other abrasive material on the stainless

steel. Filter the cooking oil and replace if

necessary. The oil should be filtered more

often than daily under heavy use

conditions.

5.3 ACCESS FOR SERVICING:

The appliance is equipped with a bracket

attached on the center of the structural

back to connect a restraining device

supplied by the installer. The restraining

device should meet the requirements

specified in section 3.3.f of this manual.

In addition, if the installed fryers have

casters provided by Dean Industries, both

rear casters come with a locking

mechanism that prevents the fryer from

moving when the lever or each mechanism

is turned “ON”.

To gain access for servicing, the

restraining device has to be removed from

the bracket and both front caster's locking

mechanisms have to be turned “OFF”.

To return the unit to its previous installed

position see sections 3.3 and 5.3 of this

manual.

5.4 WEEKLY:

a. Completely drain the oil from the fry

vessel into either the filter or a steel

container. Do not use a plastic bucket

or glass container.

b. Clean the vessel with a good grade of

cleaner or hot water and a strong

detergent.

c. Close the drain valve and refill with

either the cleaning solution or water

and detergent.

d. Set operating thermostat to 104°C

(220°F). Bring to a rolling boil, then

turn the heat down and let the mixture

stand until deposits and/or carbon

spots can be rubbed off with the

Teflon brush.

e. Scrub tank walls, bottom and heating

tubes. Then drain vessel and rinse in

clear water.

CAUTION

Do not drain water into the filter. Water

will damage the filter pump.

f. Refill with clear water, set operating

thermostat to 104°C (220°F), and boil

again. Once boiling is completed, turn

operating thermostat “OFF”, drain,

rinse, and dry thoroughly.

Do not let water boil down to the point that

elements are exposed as this will damage

them.

CAUTION

g. Immediately refill with cooking oil or

frying compound as directed in

Section 4.3.

12

Page 15

DO NOT LET WATER SPLASH

INTO THE TANK OF HOT OIL. IT

WILL SPLATTER AND CAN

CAUSE SEVERE BURNS.

WARNING

5.5 PERIODIC: The fryer should be

checked and adjusted periodically by

qualified service personnel as part of a

regular kitchen maintenance program.

5.6 STAINLESS STEEL: All stainless

steel fryer body parts should be wiped

regularly with hot, soapy water during the

day and with a liquid cleaner designed for

this material at the end of each day.

a. Do not use

cleansers or powders!

b. Do not use a metal knife, spatula or

any other metal tool to scrape stainless

steel! Scratches are almost impossible

to remove.

c. If it is necessary to scrape the stainless

steel to remove any encrusted

materials, soak the area first to loosen

the material, then use a wood or nylon

scraper only.

steel wool, abrasive cloths,

13

Page 16

6. TROUBLESHOOTING GUIDE

The problems and possible solutions given below cover those most commonly encountered by

operators.

FOR DETAILED TROUBLESHOOTING AND SERVICE-RELATED INFORMATION, CALL

THE DEAN SERVICE HOTLINE AT 1-800-551-8633 (USA/Canada only) or 1-318-865-1711.

PROBLEM CORRECTIVE ACTION

Operator hears click sound

when the temperature

controller dial is turned but

vessel remains cold. No

evidence that elements are

warming the vessel.

With the power switch “ON”:

1. Manually reset the high temperature limit switch (push red button

on the panel above the drain valve). See Figure 6-1.

2. Check for tripped branch or main circuit breakers or blown fuses.

Check thermostat adjustment:

Poor temperature control

on the cold side or hot side;

excessive warm-up time;

temperature recovery is

slow or inadequate when

vessel is loaded; uneven

heating; excessive

temperature overshooting

during warm-up; scorching;

overheating; or high limit

switch must be reset often.

1. Check that the thermostat bulb/probe in the vessel has not been

knocked loose from its operating position. It should be clamped

to the second element with 1,5 mm (1/16 inch) spacing. See

Figure 6-2.

2. Place the sensing bulb of a high quality immersion thermometer

about 38 mm (1-1/2 inches) above the thermostat sensing bulb

and set the temperature controller dial to 177°C (350°F).

3. Wait at least 30 minutes for the oil temperature to stabilize.

4. If temperature is not within +/- 5°C (10°F) of the dial setting, call

service for a new operating thermostat/temperature controller.

High Limit

Reset Switch

Figure 6-1

Drain

Valve

Sensing Bulb in

Fryer Vessel

Figure 6-2

14

Page 17

7. WIRING DIAGRAM

P/N 2557

YEL

YEL

P/N 807-1999

Transformer

240V

24V

BRN

YEL

Oper Thermostat

PURPRED

BLK#2

WHT#2

P/N 1693

5 Amp

Fuse

WHT#2

BLK#2

P/N 2687

BRN

BLU

Hi-Limit

PURP

Power Switch (SPST)

P/N 807-2196

BLU

YEL

RED

K2K1

YEL

K2 = Heat Contactor

P/N 810-1202

K1 = Latch Contactor

P/N 810-1202

230/400V = 17.118 KW Total

P/N 14-0592-6

25.0 Amps

P/N 1501-1

Terminal

Ground

Leg 3

Leg 2

Leg 1

3 Phase

4 Wire

Neutral

Wiring Diagram Cool Zone Electric Fryer (CE)

Electric Fryer 230/400V 24V Contactors

Terminal

Block

June 1999

15

Page 18

8. COOL ZONE 1414E ELECTRIC (CE) PARTS LIST

ITEM PART NUMBER DESCRIPTION

1

2

3

4

5

6

7

8

2698 LEG, BLACK, ADJUSTABLE WITH MOUNTING PLATE, 6"

1942 CASTER, 5" W/BRAKE

1943 CASTER, 5" W/O BRAKE

44-1363 NIPPLE, DRAIN EXT. 1-1/4”

36004-1 DOOR ASSY

36-0014-1 DOOR PANEL

12-0097 DOOR PIN

1503 MAGNETIC DOOR CATCH

1039-2 HANDLE, CHROME/DOOR

9002949 SHIM CASTER

12220 GRID ASSEMBLY

12-0309-2 FRONT CNTRL PANEL

1501 TERMINAL BLOCK 3 WIRE

1501-1 TERMINAL BLOCK 4 WIRE

16

Page 19

ITEM PART NUMBER DESCRIPTION

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23 2687 HI LMT 410 DEG F,W/MAN RESET CE

24 12212 BOX RACEWAY/CONTCTR ASSY,SR38E (CE)

25 14248-2 VESSEL WELD ASSY SS

26 14-0592-6 HEAT ELEMENT 208V 4666W

27

28

29 18-0031 SPACER HEAT ELEMENT

30 12193 BRACKET ELEMENT SPRT, SR38E

31 18-0031 SPACER HEAT ELEMENT

32 18-0061 SUPPORT HEAT ELEMENT

33 12-0377 COVER, LOWER CNTRL BOX SR38E (CE Only)

24-0350 LOWER HINGE BRACKET

36-0012 FRT & REAR CHANNEL

8101202 40 AMP 3 POLE CONTACTOR (CE Only)

12-0311 CNTRL PANEL BACK SR38

50-0041-1 SIDE PANEL PP/GREY LH

50-0041-2 SIDE PANEL PP/GREY RH

2557 THERMOSTAT, SUNNE #TC125-004

1205 KNOB,THERMOS R/S KXD

2025 POWER SWITCH (ROCKER SWITCH, CARLING)

8072196 POWER SWITCH (GRN LIGHTED ROCKER SWITCH)

12-0376 MOUNTING PLATE CONTCTR, SR38ECE

12-0323 COVER CONTACTOR BOX, SR38E

12210 BOX, CONTACTOR WELD ASSY,SR38E (CE)

12-0322 COVER HEATER RACEWAY, SR38E

14-0193 GOOFER ROD DECLOGGER

2066-1 DRAIN VALVE,1-1/4"(1"STD PORT)

36-0048 STRUCTURAL BACK

12-0237 RESTRAINING BRACKET

1902 O RING SEAL (4 EA ELEMENT)

14-0695 O-RING RETAINER WASHER (4 EA ELEMENT)

2189 JAM NUT ¾-16 (2 EA ELEMENT)

18-0041 CLAMP; THERMOSTAT 1 EA USA, 2 EA CE

14-0883 SPRING/ROBERTSHAW/SPACER

18-0041 CLAMP; THERMOSTAT 1 EA USA, 2 EA CE

18-0040 HIGH LIMIT CLAMP USA

34 Not Used

35 Not Used

36 36-0026-2 BASKET HANGER

37 2608 FRY BASKET

39 8071999 TRANSFORMER PRIMARY 208/240V (CE Only)

40 1692 FUSE HOLDER W/LEADS

41 1693 FUSE 5 A

14673 OPERATIONAL THERMOSTAT WIRING HARNESS Not

Shown

44-1362 BRACKET,DRAIN NIPPLE EXTENSION

17

Page 20

Frymaster, L.L.C., 8700 Line Avenue, PO Box 51000, Shreveport, Louisiana 71135-1000

Shipping Address: 8700 Line Avenue, Shreveport, Louisiana 71106

TEL 1-318-865-1711 FAX (Parts) 1-318-219-7140 (Tech Support) 1-318-219-7135

PRINTED IN THE UNITED STATES

SERVICE HOTLINE

1-800-551-8633

Price: $6.00

*8195729*

NOV 1999

Loading...

Loading...