Frost Fighter IHS 1500 Installation, Operation, Maintenance Instructions & Parts List

FROSTFROSTFROSTFROST

OIL - FIRED CONSTRUCTION HEATER

MODEL IHS 1500

JULY 2014

TO PRESENT

Installation - Operation

Maintenance Instructions

and Parts List

READ INSTRUCTIONS PRIOR TO STARTING HEATERS

FROST FIGHTER INC.

100-1500 NOTRE DAME

WINNIPEG, MANITOBA

CANADA R3P 0E9

TEL : (204) 775-8252

FAX: (204) 783-6794

TOLL FREE: (888) 792-0374

WWW.FROST-FIGHTER.COM

JULY, 2014

FROSTFIGHTER WARRANTY

Frost Fighter Inc. warrants the Frostfighter heater to be free from defects in

workmanship and materials for a period of twelve (12) months from date of initial

service not to exceed fifteen (15) months from date of shipment.

If during the warranty period, the heat exchanger fails under normal use and service

due to a defect in material or workmanship said heat exchanger will be repaired or

replace free of charge F.O.B. the Winnipeg Factory..

All mechanical and electrical components are covered by a one (1) year limited

warranty. Normal maintenance items are excluded under the warranty. The

warranty does NOT include any freight, labor or sales taxes incurred by the

purchaser and is subject to the following conditions:

1. The heater shall be operated in accordance with the manufacturer’s

operating and maintenance manual.

2. The heater shall be subject to normal use in service and shall not have

been misused, neglected, altered or other wise damaged.

3. The unit shall be operated within the rated capacities and with the

prescribed fuel.

4. The unit has not been allowed to exceed its proper temperature limits due

to control malfunction or inadequate air circulation.

5. There is no evidence that the unit has been subject to tampering or

deliberate destruction.

No representative of Frost Fighter Inc., nor any of its distributors or dealers, is

authorized to assume for Frost fighter Inc. any other obligations or liability in

connection with this product, not alter the terms of the warranty in any way. This

warranty is limited to the express provisions contained herein and does not extend to

liability for labor costs incurred in replacing defective parts.

Parts can be obtained from Frost Fighter Inc., Winnipeg, Manitoba on the basis that

credit will be issued if the defective parts returned qualify for replacement pursuant to

the terms and conditions of this warranty. Authorization to return any alleged

defective parts must be first obtained from the factory prior to transporting the part.

The transportation charges for the alleged defective part must be prepaid by the

owner. Frost Fighter Inc. will not accept charges for parts purchased unless the

conditions of this warranty have been satisfied and prior authorization to purchase

the parts has been received from the factory.

100-1500 NOTRE DAME , WINNIPEG, MANITOBA

R3P 0E9, (204) 775-8252, 1-888-792-0374

INSTRUCTION MANUAL

INDIRECT FIRED CONSTRUCTION HEATER

HAZARD DEFINITIONS

The following will be used throughout this manual to bring attention to hazards and

their risk factors, or to special information.

Denotes presence of a hazard which, if ignored, will result in severe personalDANGER

injury, death or substantial property damage.

Denotes presence of a hazard, which, if ignored, could result in severeWARNING

personal injury, death or substantial property damage.

CAUTION Denotes presence of a hazard, which, if ignored, could result in minor

personal injury, or property damage.

NOTICE Intended to bring special attention to information, but not related to personal

injury or property damage.

To the owner-

WARNING Installation and adjustment of the burner requires technical knowledge and

the use of combustion test instruments. Do not tamper with the unit or controls. Call your

qualified service technician. Incorrect operation of the burner could result in severe

personal injury, death or substantial property damage.

Have your equipment inspected and adjusted annually by your qualified service technician

to assure continued proper operation.

Never store gasoline or combustible materials near the heating equipment. This could

result in explosion or fire, causing severe personal injury, death or substantial property

damage.

Never burn garbage or refuse in your heating appliance or try to light theWARNING

burner by tossing burning material into the appliance. This could result in severe personal

injury, death or substantial property damage.

Never restrict air openings on the burner or to the room in which the appliance is located.

This could result in fire hazard or flue gas leakage, causing severe personal injury, death

or substantial property damage.

THE INSTALLATION OF THE UNIT SHALL BE IN ACCORDANCE WITH THE REGULATIONS

OF THE AUTHORITIES HAVING JURISDICTION - Refer to CSA Standard B139-1962, Installation

Code for Oil-Burning Equipment for recommended installation practice.

2

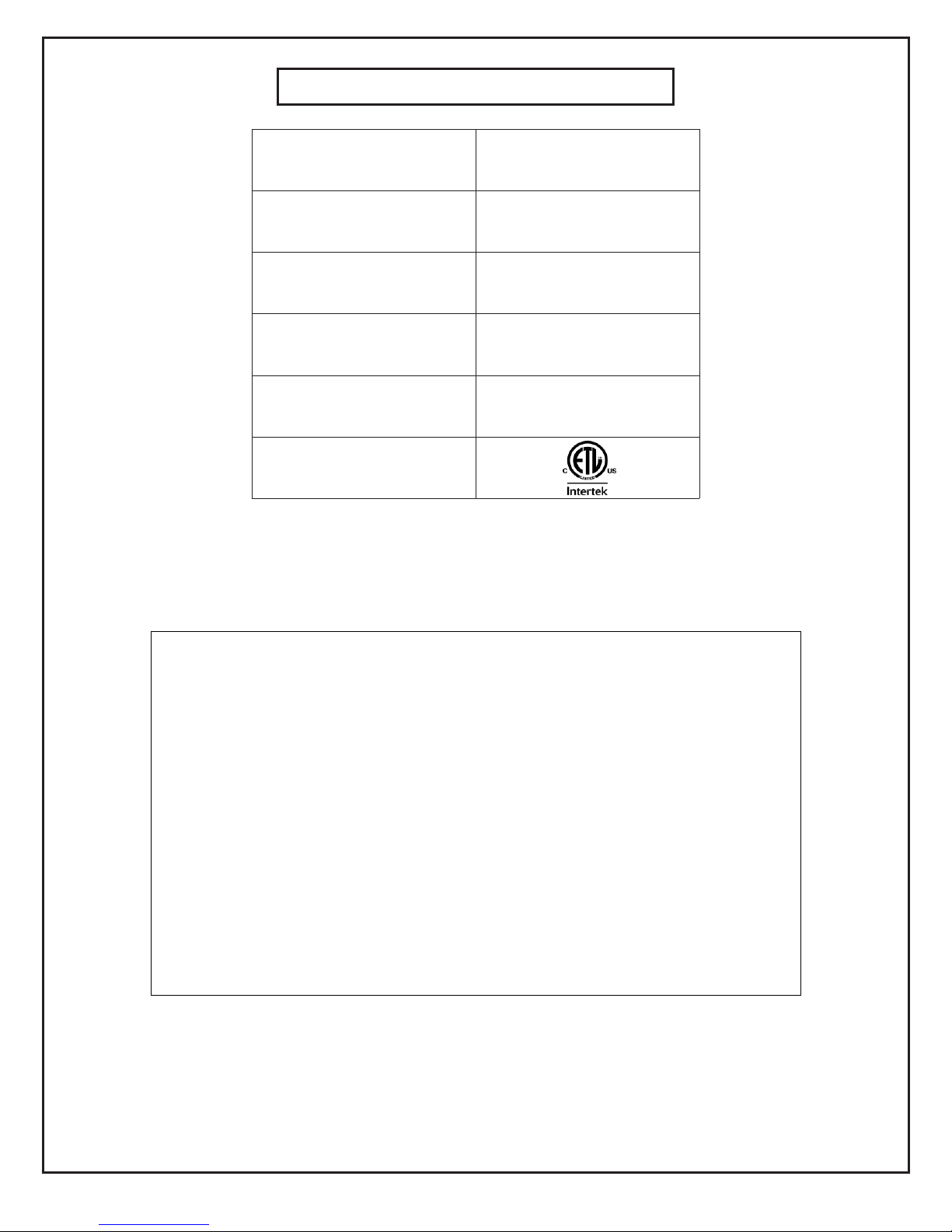

MODEL

IHS-1500

FUEL TYPES

#2 Fuel Oil / Diesel Fuel

NOZZLE

SIZE

6.50 USGPH

45’ B (SOLID)

PUMP

PRESSURE

High Fire 300 P.S.I.g *

Low Fire 140 P.S.I.g *

AIR SETTING

High Fire: 45

Low Fire: 30

Burner Slide Plate Setting: 2

APPROVAL

AGENCY

SPECIFICATIONS

* Pressure at the bleeder port. Subtract 10 PSI if measured at the pump discharge

port. See unit rating plate for exact specifications.

To the owner-

WARNING Read all the instructions before proceeding. Follow all instructions completely.

failure to follow these instructions could result in equipment malfunction, causing severe

personal injury, death or substantial property damage.

This equipment must be installed, adjusted and started only by a qualified service technician

– an Individual or agency, licensed and experienced with all the codes and ordinances, who

is responsible for the installation and adjustment of the equipment. The installation must

comply with all local codes and ordinances and with the National Fire Protection Standard

for Oil-Burning Equipment, NFPA 31 (or CSA B139-04).

NOTICE Concealed damage – If you discover damage to the burner or the controls

during Unpacking, notify the carrier at once and file the appropriate claim.

NOTICE High altitude installations – Accepted industry practice requires no derate of

Burner capacity up to 2000 feet above sea level. For altitudes higher than

2000 Feet, derate burner capacity 4% for each 1000 feet above sea level.

3

PRE-INSTALLATION CHECKLIST

COMBUSTION AIR SUPPLY

The burner requires combustion air and ventilation air for reliable operation. Assure that the

Building and/or combustion air openings comply with National Fuel Gas Code NFPA 54/CSA B149. For

appliance/burner units in confined spaces, the room must have an air opening near the top of the room

plus one near the floor, each with a free area at least one square inch per 1000 Btu/hr input of all fuel

burning equipment in the room. For other conditions, refer to NFPA 31 (CSA B1139-M91 in Canada).

If there is a risk of the space being under negative pressure or of exhaust fans or other devices depleting

available air for combustion and ventilation, the appliance/burner should be installed in an isolated room

provided with outside combustion air.

CLEARANCES

The unit must be installed with minimum clearances of 16 inches on the sides, 12 inches from the top of

the unit, 16 inches from the flue (venting), 48” from the front, 0” from the floor, 48” from ductwork and 36

inches from the burner access side. The unit must be installed on a level floor.

DUCT INSTALLATION

- Duct diameter is 20 inches

- Use belt cuff ducting. Slide the cuff overtop of the duct inlet/outlet and tighten with the belt.

- The top two connections are the heated supply air into the building.

- The bottom two duct connections are for cold air or return air into the heater.

- The heater is approved use with or without ducting.

- Maximum duct length is 100 feed per supply opening. If return air ducting is used the length of

the return air duct must be subtracted form the allowable supply ducting length (i.e. if the return

air duct length is 30 feet the maximum supply duct length is reduced to 70 feet).

- Ducts should be rated for 300 F. minimum.

HIGH LIMITS

- The heater is supplied with manual reset high limits located behind marked panels on the left

side of the heater

- The high limit contacts are normally closed and open on the over temperature condition

- If a high limit trips allow the heater to cool down and then reset the high limit by manually

depressing the reset button located in the centre of the high limit.

4

VENT SYSTEM

The flue gas venting system must be in good condition and must comply with all the applicable codes.

OUTDOOR INSTALLATIONS:

For outdoor installation, vent cap must be installed and fastened.

INDOOR INSTALLATIONS:

Must be done in accordance to NFPA 54 (or CSA B149) with local authorities having jurisdictions.

1. The flue must be securely attached to the unit with tight joints.

2. The flue must not be sized to have a cross-sectional area less then that of the flue

collar at the unit.

3. Other appliances must not be connected so as to vent through the vent of this unit.

4. Do not use 90-degree tees or elbows greater than 45 degrees.

5. Do not support the weight of the stack on the flue connection of the heating system.

6. The maximum flue gas temperature is 650 F. “A” vent, or single wall steel pipe must

be used.

7. Minimize connecting pipe length and the number of bends by locating the unit as close

to the flue pipe as possible.

8. Maintain clearances between the flue pipe and combustible materials that are

acceptable to the Federal, Provincial and local authorities having jurisdiction.

9. Unit must be connected to a flue having sufficient draft to ensure proper operation of

unit.

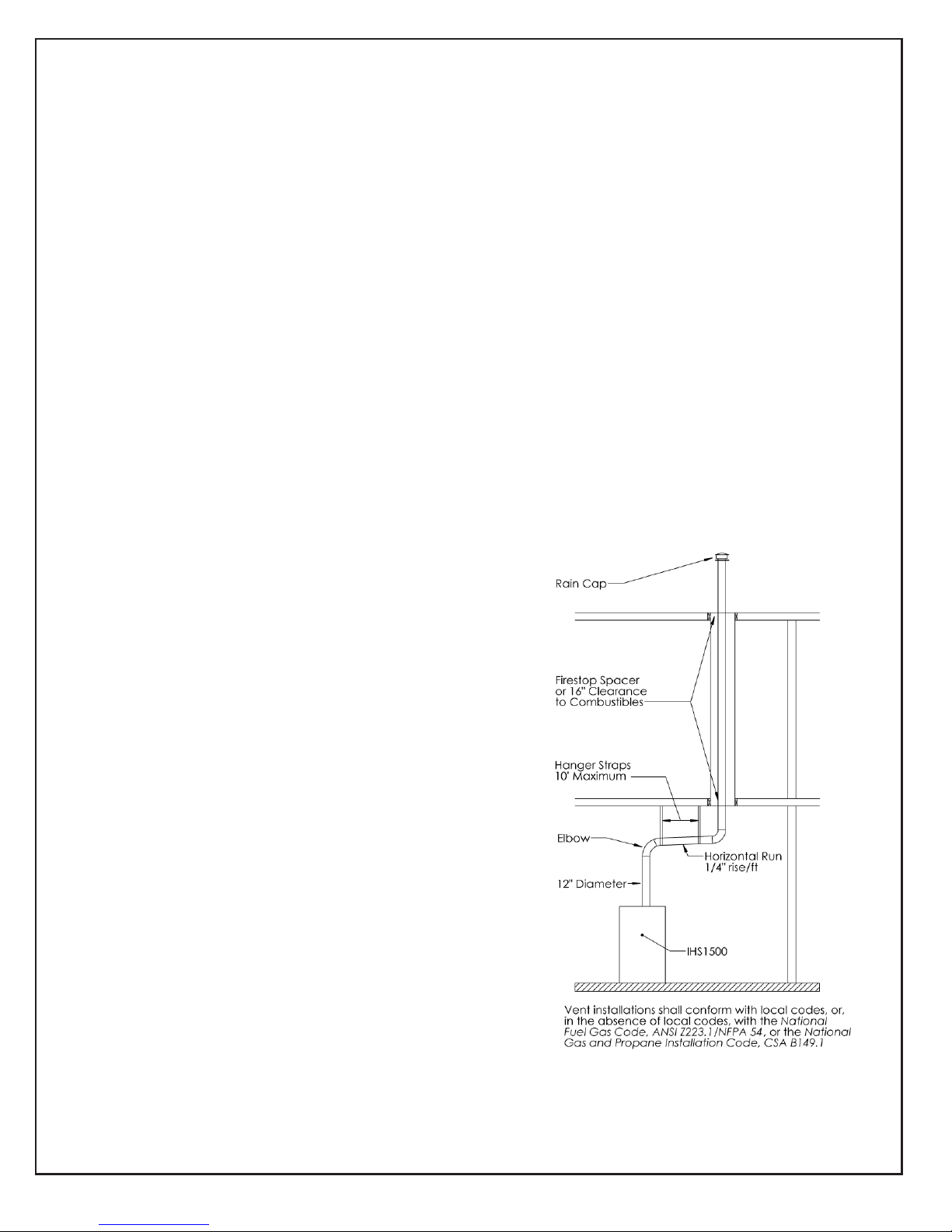

VERTICALLY VENTED UNITS

1. Maximize the height of the vertical run of

vent pipe. A minimum of five (5) feet

(1.5m) of vertical pipe is required. The

top of the vent must extend at least two

(2) feet (0.61m) above highest point on

the roof. A weatherproof vent cap must

be installed to the vent termination.

2. Horizontal runs must not exceed 75% of

the vertical height of the vent pipe, up to

a maximum of ten (10) feet (3m).

Horizontal runs should be pitched upward

¼” per foot

(21 mm) and should be supported at 3

foot (1m) maximum intervals.

3. Design vent pipe to minimize the use of

elbows. Each 90 is equivalent to 5 feet

(1.5m) of straight vent pipe run.

4. Vent pipe should not be run through

unheated spaces. If such runs cannot be

avoided, insulate vent pipe to prevent

condensation inside vent pipe. Insulation

should be a minimum of ½” (12.7mm)

thick foil faced fibreglass, minimum 1 ½#

density.

5. Dampers must not be used in vent piping

runs. Spillage of flue gases into the

occupied space could result.

6. Vent pressure must be negative.

7. The vent must be terminated vertically.

5

.

HORIZONTAL FLUE VENTING

25' Maximum

90 Degree elbow

3' Minimum

IHS 1500

Vent installations shall conform with local codes, or,

in the absence of local codes, with the National

Fuel Gas Code, ANSI Z223.1/NFPA 54, or the National

Gas and Propane installation Code, CSA B149.1

3' Minimum

Rise ratio

1/4" per foot

90 Degree elbow

Straight section

Vent Diameter: 12"`

Material: Single wall steel pipe or type A vent

6

ELECTRICAL SUPPLY

Lift “H”

3450 RPM Motor Speed

3/8” OD Tubing @ 7 GPM

0’

80’2’73’

4’

66’

6’

59’

8’

52’

10’

45’

12’

38’

14’

31’

16’

80’

Verify that the power connections available are correct for the Unit. All power must be supplied

through the disconnect.

INSTALLING THE OPTIONAL THERMOSTAT

Plug the thermostat directly into the receptacle. WARNING: THE RECEPTACLE IS USED FOR

INSTALLING THE THERMOSTAT ONLY! THIS IS NOT A POWER SOURCE.

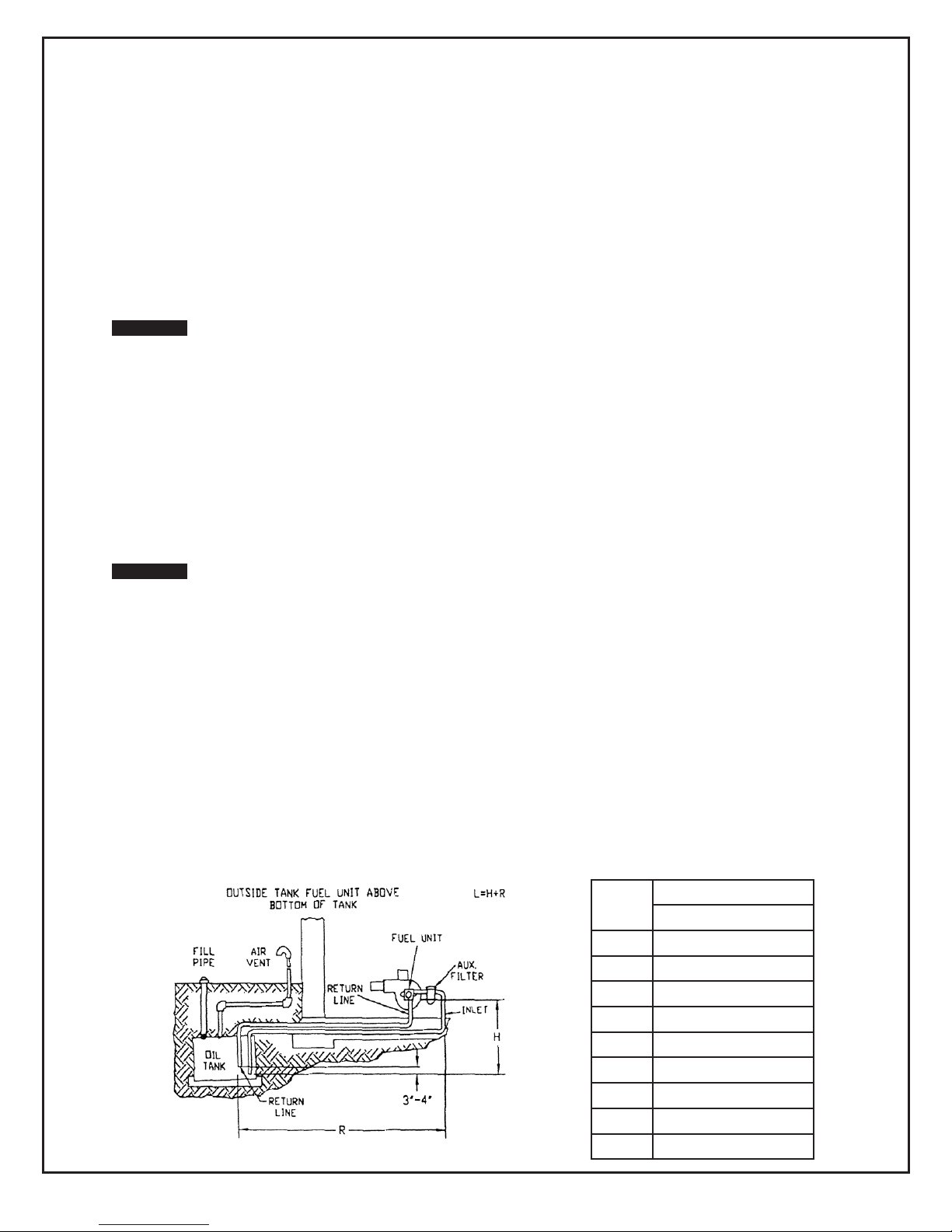

CONNECT THE FUEL LINE(S) - REFER TO CHART BELOW FOR FUEL LINE LENGTH

WARNING Install the oil lines using the following guidelines. Failure to comply could lead to equipment

damage and present a risk of sever personal injury, death or substantial property damage

due to leakage of oil and potential fire hazard.

Use only flare fittings at joints and connections. Never use compression fittings.

Install fittings only in accessible locations to assure any leak will be detected.

Where joint sealing is needed, use only pipes dope. Never use Teflon tape. Tape strands

can break free and damage the fuel unit.

On two-pipe oil systems verify that the suction line vacuum does not exceed the fuel

manufacturer's recommendation.

WARNING Do not operate the burner unless a return line or a by-pass loop is installed. Failure to

follow this guideline will cause damage to the fuel seals and consequent fuel leakage. This

could result in severe personal injury, death or substantial property damage.

OIL SUPPLY / RETURN LINES

Install the oil tank lines in accordance with all applicable codes.

Use continuous lengths of heavy wall copper tubing, routed under the floor, where possible. Do not attach

fuel lines to the fuel unit or to the floor joists if possible. This reduces vibration and noise transmission

problems.

Install a high quality shut-off valve in an accessible location on the oil supply line. Locate one valve close

to the tank.

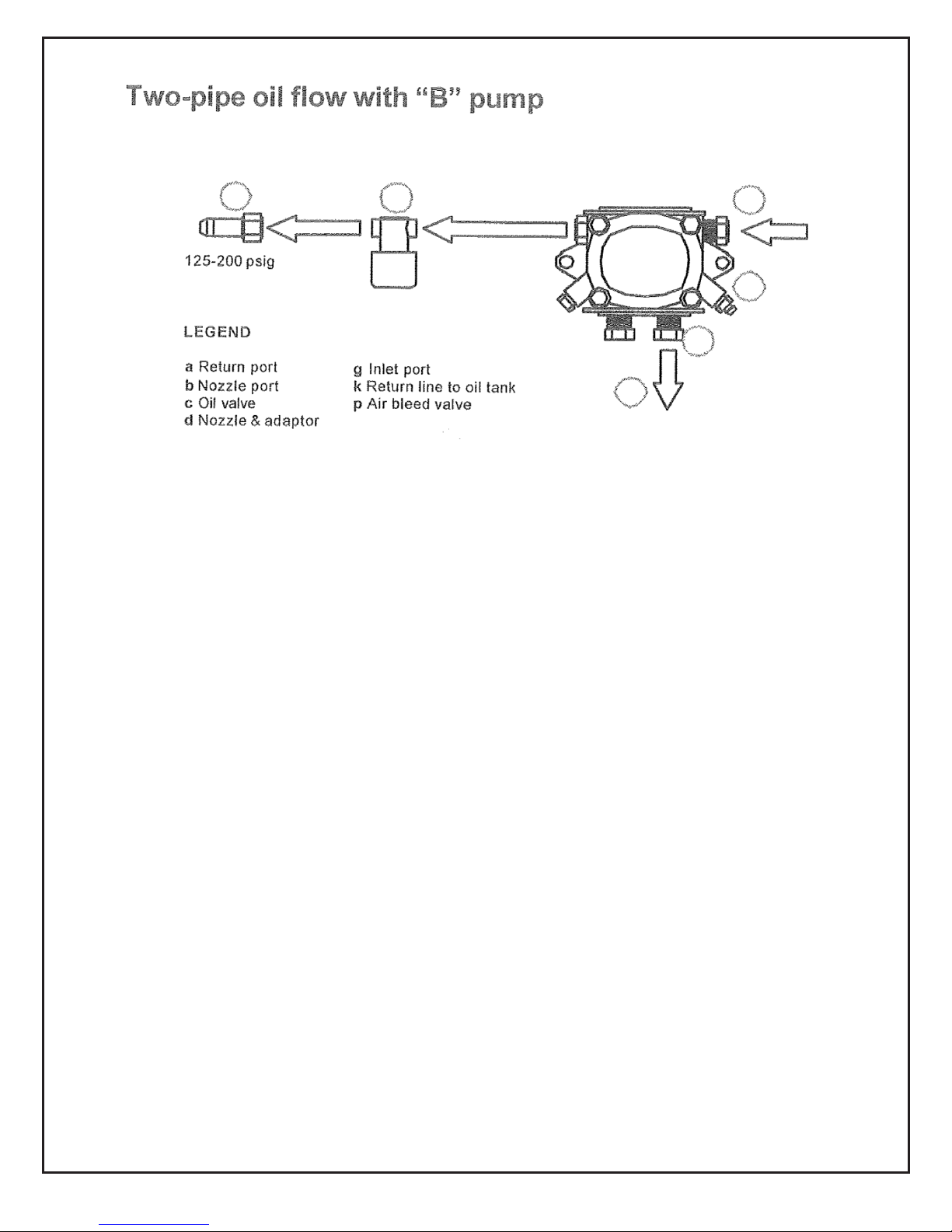

TWO-PIPE SYSTEM - (Bypass plug installed in pump) TWO-STAGE TWO-PIPE MAXIMUM

LINE LENGTH (H + R)

7

d c

SEQUENCE OF OPERATION – TYPICAL

1. Turn the unit switch to manual.

2. Power is applied to the R7184B black wire (BK).

3. After 10 seconds, the F7184B applies 120 volts to the orange wire (OR),

activating the burner motor (M1) and the ignition transformer (TR). The oil

pump is operated by the burner-motor, so oil pressure is delivered to the oil

valve inlets.

4. Power is applied to the oil valve circuit. After a ten second pre-purge. When

the timer times out, oil valves (S1 and S3) are activated, allowing oil to flow to

the nozzle.

5. Trail for ignition (TFI). A flame should be established within the 15-second

lockout time. If no flame is sensed after 15 seconds, the R7184B will terminate

all power to the blower and oil circuits, shutting the burner down. The control

will electrically lock out and has to be manually reset. If the control locks out

three times in a row, the control enters restricted lockout. Call a qualified

service technician.

6. After the flame is established, there is a 30 second warm-up. After the 30

seconds the main blower starts.

7. When the call for heat signal terminates (at the black wire of the R7184B), the

R7184B terminates power to all circuits, closing the oil valves and stopping the

burner motor. The main blower motor stays in operation for 3 minutes, then the

blower shut down.

140-300 psig

a

k

g

p

(Optional)

If a thermostat is used, the thermostat is plugged into the receptacle on the side of unit. The sensor unit

should be placed in the heated space. On a call for heat the unit will be activated as above.

8

Loading...

Loading...