Frost Fighter IDH200QR OIL, IDH200QR LP/NG Installation, Operation & Maintenance Instructions Manual

FROSTFROST

INDIRECT FIRED SPACE HEA

MODEL IDH200QR OIL

MODEL

IDH200QR LP/NG

TERS

Installation - Operation/Maintenance

Instructions and Parts List

READ INSTRUCTIONS PRIOR

TO STARTING HEATERS

FROST FIGHTER INC.

100-1500 NOTRE DAME AVE

WINNIPEG, MANITOBA

CANADA R3E 0P9

TEL : (204) 775-8252

FAX: (204) 783-6794

WWW.FROST-FIGHTER.COM

TOLL FREE 1-888-792-0374

1

VER. 1.3.3

SEPT. 2018

FROSTFIGHTER WARRANTY

Frost Fighter Inc. warrants the Frostfighter heater to be free from defects in workmanship

and materials for a period of twelve (12) months from date of initial service not to exceed

fifteen (15) months from date of shipment.

If during the warranty period, the heat exchanger fails under normal use and service due to a

defect in material or workmanship said heat exchanger will be repaired or replace free of

charge F.O.B. the Winnipeg Factory..

All mechanical and electrical components are covered by a one (1) year limited warranty.

Normal maintenance items are excluded under the warranty. The warranty does NOT

include any freight, labor or sales taxes incurred by the purchaser and is subject to the

following conditions:

1. The heater shall be operated in accordance with the manufacturer’s operating and

maintenance manual.

2. The heater shall be subject to normal use in service and shall not have been

misused, neglected, altered or other wise damaged.

3. The unit shall be operated within the rated capacities and with the prescribed fuel.

4. The unit has not been allowed to exceed its proper temperature limits due to

control malfunction or inadequate air circulation.

5. There is no evidence that the unit has been subject to tampering or deliberate

destruction.

6. The heat exchanger shows no signs of an implosion or explosion.

No representative of , nor any of its distributors or dealers, is authorized toFrost Fighter Inc.

assume for . any other obligations or liability in connection with this product,Frost Fighter Inc

no alter the terms of the warranty in any way. This warranty is limited to the expressr

provisions contained herein and does not extend to liability for labor costs incurred in

replacing defective parts.

Parts can be obtained from , Winnipeg, Manitoba on the basis that credit willFrost Fighter Inc

be issued if the defective parts returned qualify for replacement pursuant to the terms and

conditions of this warranty. Authorization to return any alleged defective parts must be first

obtained from the factory prior to transporting the part. A R.G.A.# must be provided from an

Frost Fighter Inc representative. The transportation charges for the alleged defective part

must be prepaid by the owner. will not accept charges for partsFrost Fighter Inc.

purchased unless the conditions of this warranty have been satisfied and prior authorization

to purchase the parts has been received from the factory.

100-1500 NOTRE DAME WINNIPEG, MANITOBA

R3 , (204) 775-8252E 0P9

2

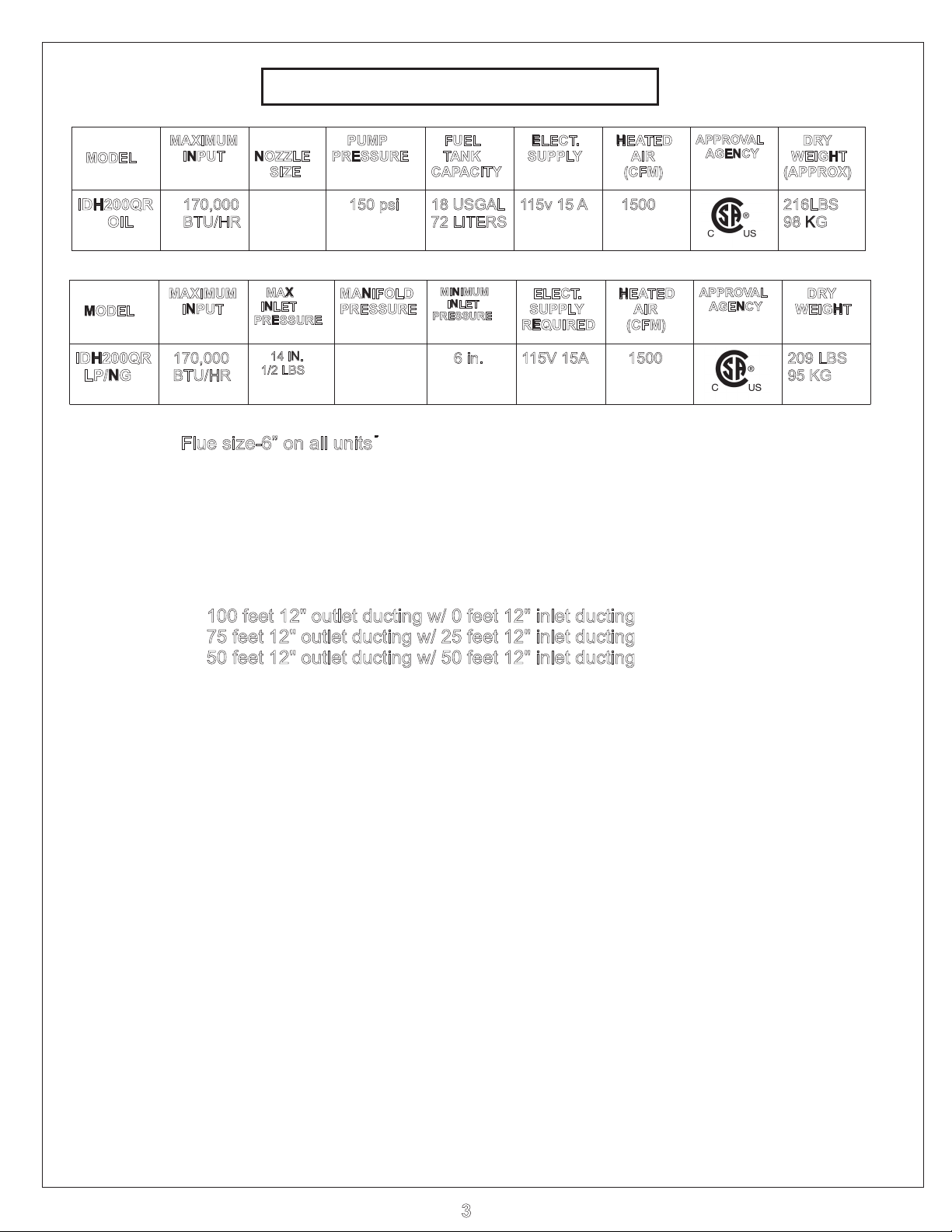

MODEL

MAXIMUM

INPUT

NOZZLE

SIZE

PUMP

PRESSURE

FUEL

TANK

CAPACITY

ELECT.

SUPPLY

HEATED

AIR

(CFM)

APPROVAL

AGENCY

DRY

WEIGHT

(APPROX)

IDH200QR

OIL

150 psi

18 USGAL

72 LITERS

115v 15 A

1500

216LBS

98 KG

MODEL

MAXIMUM

INPUT

MAX

INLET

PRESSURE

MANIFOLD

PRESSURE

MINIMUM

INLET

PRESSURE

ELECT.

SUPPLY

REQUIRED

HEATED

AIR

(CFM)

APPROVAL

AGENCY

DRY

WEIGHT

IDH200QR

LP/NG

0,00017

BTU/HR

14 IN.

1/2 LBS

6 in.

115V 15A

1500

209 LBS

95 KG

SPECIFICATIONS

0,00017

BTU/HR

.85 X 45°A

3.4

" NG

1.9" LP

Flue size-6” on all units

NOTE: -These heaters are intended for use primarily as temporary heating

of buildings under construction, alteration or repair

MAXIMUM ALLOWABLE DUCT LENGTHS ( )IDH200 OIL & LP/NG

100 feet 12" outlet ducting w/ 0 feet 12" inlet ducting

75 feet 12" outlet ducting w/ 25 feet 12" inlet ducting

50 feet 12" outlet ducting w/ 50 feet 12" inlet ducting

RECOMMENDED MANIFOLD GAS PRESSURE

SETTINGS FOR IDH200QR LP/NG MODELS

FOR APPLICATIONS ABOVE 0

Degrees C/32 Degrees F

Set manifold pressure to:

3.4” w.c. NG or 1.9” LP

FOR APPLICATIONS BELOW 0

Degrees C/32 Degrees F

Set manifold pressure to:

3.8” w.c. NG or 2.1” LP

3

POUR LES APPLICATIONS AU-

DESSUS DE 0 °C/32 °F

Régler la pression du collecteur à:

3,4 po GN ou jusqú à 1,9 po LP

POUR LES APPLICATIONS AU-

DESSOUS DE 0 °C/32 °F

Régler la pression du collecteur à:

3,8 po GN ou jusqú à 2,1 po LP

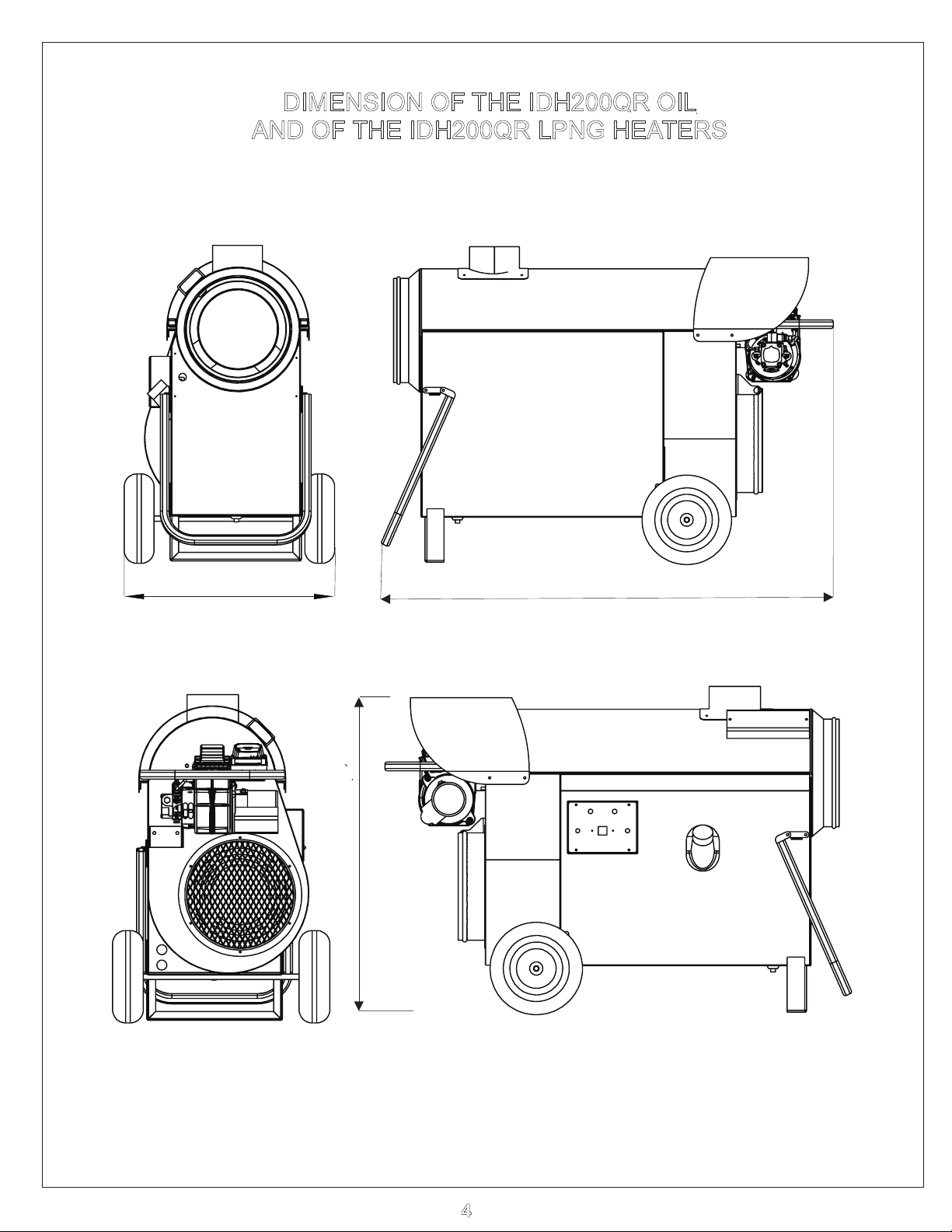

DIMENSION OF THE IDH200QR OIL

AND OF THE IDH200QR LPNG HEATERS

22”

52"

36.5”

4

INSTALLATION- OPERATION

MAINTENANCE INSTRUCTIONS FOR LP/NG

READ INSTRUCTIONS PRIOR TO OPERATING HEATER

GENERAL HAZARD WARNING

FAILURE TO COMPLY WITH PRECAUTIONS AND INSTRUCTIONS PROVIDED WITH

THIS HEATER CAN RESULT IN DEATH, SERIOUS BODILY INJURY AND PROPERTY

LOSS OR DAMAGE FROM HAZARDS OF FIRE, EXPLOSION, BURN, ASPHYXIATION,

CARBON MONOXIDE POISONING, AND/OR ELECTRICAL SHOCK.

ONLY PERSONS WHO CAN UNDERSTAND AND FOLLOW THE INSTRUCTIONS

SHOULD USE OR SERVICE THIS HEATING UNIT.

IF YOU REQUIRE ASSISTANCE OR HEATER INFORMATION SUCH ASAN

INSTRUCTION MANUAL, LABELS, ETC., CONTACT THE MANUFACTURER.

WARNING

FIRE, BURN INHALATION, AND EXPLOSION HAZARD. KEEP SOLID COMBUSTIBLES,

SUCH AS BUILDING MATERIAL, PAPER AND/OR CARDBOARD A SAFE DISTANCE

AWAY FROM THE HEATER AS RECOMMENDED BY THE INSTRUCTIONS. NEVER

USE THE HEATER IN SPACES WHICH MAY CONTAIN VOLATILE OR AIRBORNE

COMBUSTIBLES, OR PRODUCTS SUCH AS GASOLINE, SOLVENTS, PAINT

THINNER, ACETONE, DUST PARTICLES AND/OR UNKNOWN CHEMICALS.

WARNING

THIS PRODUCT IS NOT INTENDED FOR HOME OR RECREATIONAL VEHICLE USE.

FOR YOUR SAFETY

DO NOT USE THIS HEATER IN A SPACE WHERE GASOLINE OR OTHER LIQUIDS

HAVING FLAMMABLE VAPOURS ARE STORED OR USED.

GENERAL NOTES:

NATURAL/PROPANE GAS CODE: B149.1

ALL GAS INSPECTION AUTHORITIES IN CANADA REQUIRE THAT THE

INSTALLATION AND MAINTENANCE OF HEATER AND ACCESSORIES

SHALL BE ACCOMPLISHED BYA QUALIFIED GAS FITTER.

5

GENERAL NOTES:

1. The heater is designed and approved for use as a construction heater under ANSI Z83.7

with the applicable requirements of UL 795 and under CGA 2.14 with applicable

requirements of CAN/CSA 3.2. The intended use is for 5 the temporary heating of building or

structures under construction, alteration or repair.

2. ICE cannot anticipate every use, which may be made of our heaters. CHECK WITH

LOCAL FIRE AND SAFETY AUTHORITY IF YOU HAVE QUESTIONS ABOUT SAFE

APPLICATIONS.

3. Other standards govern the use of fuel gases and heat producing products in specific

applications.

4. Please retain this instruction manual for future reference.

5. The primary application of this heater is for temporary heating of construction sites and/or

applications of this type.

ELECTRICAL NOTES:

1. All electrical connections and grounding shall be in compliance with the National Electrical

Code and/or the Canadian Electrical Code (CSA Standard C22.1-98).

2. W

ARNING: Electrical grounding instructions... This appliance is equipped with a three

prong(grounding) plug for your added protection against electrical shock hazard and should

be plugged directly into a properly grounded three-prong receptacle.

Your local authority can advise you about this issue.

YOUR

ADDITIONAL INSTRUCTIONS FOR PROPANE GAS:

1. Reference the Storage and Handling of Liquefied Petroleum Gas,

National Standards of Canada CAN/CGA B149.2 installation codes for propane gas.

2. The heater must be located more than six (6) feet (1.83 meters) away from the propane

source or propane tank.

3. When the heater is not in use insure to shut o

propane tank.

4. Disconnect the heater from the propane source or propane tank when storing the heater

indoors.

5.

The heater must not discharge toward any propane gas container within 20 feet (6 M).

ff the gas supply from the propane source or

ANSI/NFPA 58 and/or the

6

INSTALLATION INSTRUCTIONS

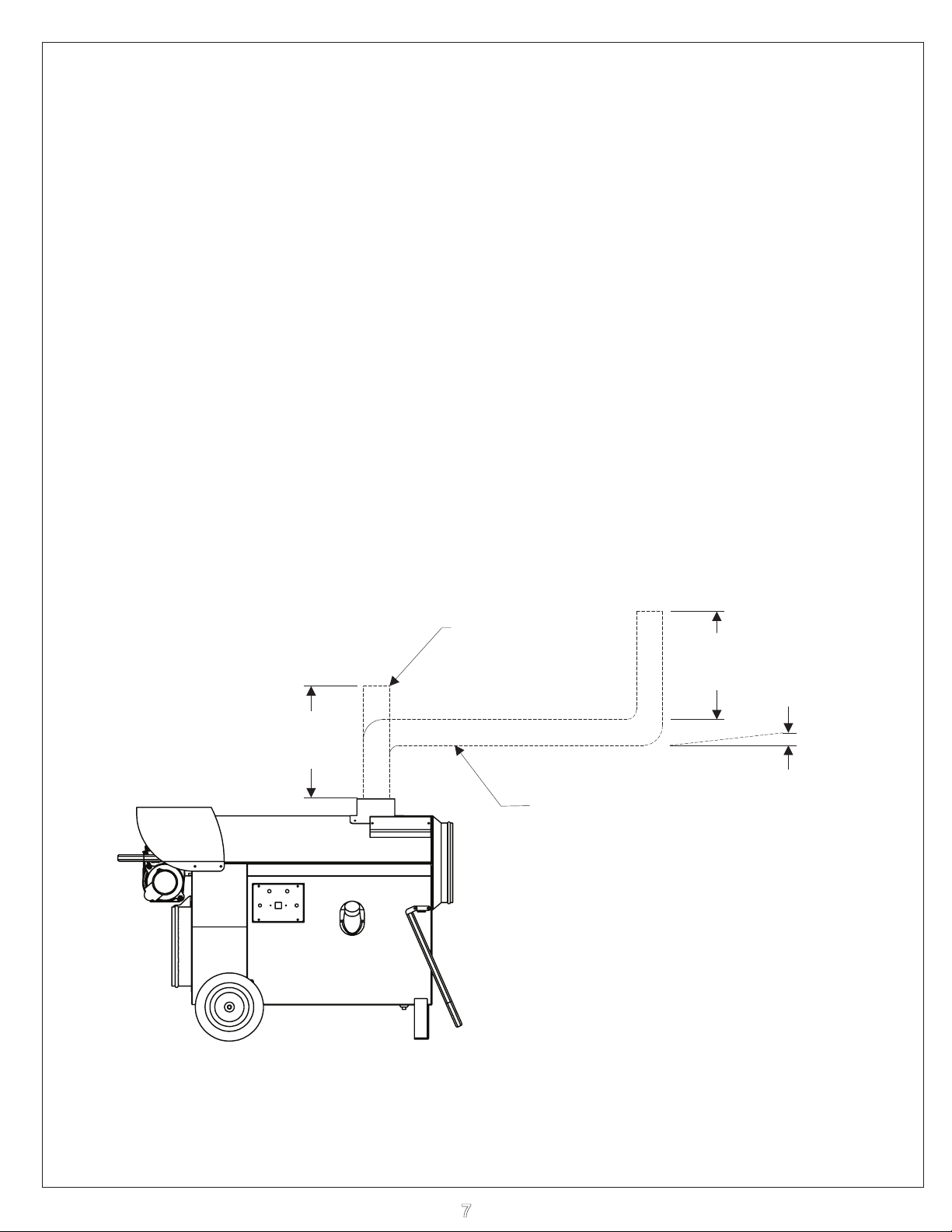

NOTE: Installation clearances are as follows:

Top - Discharge End - 10 feet2 feet

Sides - Vent Connector -2 feet 2 feet

Burner End - 2 feet Floor - Combustible

FLUE PIPE CONNECTIONS

When the heater is connected to a flue pipe the flue pipe shall terminate in a vertical

section at least two feet long. Horizontal runs should have rise ratio of 1 in 10 away

from the heater. The chimney should have .02” W.C. draft to ensure safe operation

of the unit. Where down drafts are liable to occur a vent cap should be used. All venting

Should correspond with the CSA B149 standard or local codes.(CANADA), NFPA 54 (US)

INSTALLATION CLEARANCES

FLUE WITH

VERTICAL RUN

2 FT.

MIN.

FLUE WITH

HORIZONTAL RUN

2 FT.

MIN.

RISE RATIO

1 IN 10

7

INSTALLATION INSTRUCTIONS cont.

LPNG

1. The National Fuel Code, ANSI 223.1/NFPA 54 and/or National Standards of Canada CAN/CGA B149.1

installation codes must be followed as well as the recommendations of local authorities having jurisdiction.

2. Inspect the heater before each use and have it annually inspected by a qualified agency.

3. Inspect the hose assembly for wear

4. When firing the unit in an enclosed area, three square feet (0.278 square meters), must be provided to

allow free entry of the air required for operation.

5. Do not operate the unit in partly ventilated areas without a flue pipe connected to the unit.

6. Do not operate the unit in close proximity to combustible surfaces and materials.

The cylinder supply system must be arranged to provide for vapor withdrawil from the operation

7.

cylinder.

8. Propane tank size should be minimum 100 lbs. (90 liters)

, cuts, etc. and replace if necessary.

OIL

1. The recommendations of local authorities having jurisdiction must be followed. For recommended

Installation practices refer to C.S.A. Standard B139 (CANADA)

2. When firing the unit in an enclosed area 3 square feet must be provided to allow the free entry of the air

required for operation.

or NFPA 54 (US)

3. For electrical supply

4. Do not operate the unit in partly ventilated areas without a flue pipe or in close proximity to combustible

surfaces or materials.

, use 3 wire receptacle with “U” ground.

8

MAINTENANCE INSTRUCTIONS

!WARNING!: Heaters should be fully serviced annually to ensure proper

erformance. Maintenance should be performed by trained personnelp

only. Incorrect maintenance may result in improper operation and

serious injury.

HIGH LIMIT SWITCH

The limit switch should be checked every heating season to ensure the burner will

shutdown if temperature exceeds 220 F. (This can be done by restricting the air

flow through the unit. After tests are complete, remove restriction for proper operation).

AN SWITCH

F

The fan switch has been selected to allow for preheating of the heat exchanger to ensure that

only heated air is allowed to enter the space. Upon satisfying the need for heat, the fan switch will

continue to run the supply fan until the heat exchanger has cooled sufficiently. This feature will

help prolong the life of your heat exchanger.

FUEL FILTER

Replace cartridge every usage or sooner, depending(48164 or 48164A)once week of normal

upon fuel .quality

BURNER

The electrode spacing must be checked and adjusted, if necessary after every nozzle

change. Nozzle should be replaced annually or sooner if burner cannot be set up to

operate properly. Nozzle size and type are marked on the rating plate.

ELECTRICAL

Ensure all conduit (BX) connectors are tight. Check inside connections in control box to ensure

good connections. Check marrettes.

FAN

Check for dust or dirt build up on blades. Run heater to check for fan vibration. Replace fan blade

if vibration is noticeable.

MOTORS

No lubrication is necessary since the bearings are the sealed type Clean motor of existing dust or dirt..

FUEL SYSTEM

Periodically remove fuel tank drain plug and clean tank. Do not store unit containing

furnace oil for long periods. The quality of fuel oil will affect light off at low ambient

temperatures, #1 fuel oil or kerosene are recommended for temperatures below -10

8 F.o(see page 7 for recommended settings if using #2 fuel oil in cold temperature)

FUEL PUMP

Check fuel pump pressure on a regular basis. This should be checked at the bleeder screw.

THE CLEANWITH CUT PUMP ADD 10 LBS TO THIS READING TO GET THE TRUE

PRESSURE. There is a pressure loss when fuel passes through solenoid valve. Example:

IDH200QR oil, 60 Ppressure should be read on the guage at 1 SI, reading at nozzle line will

50then be 1 . Units with the Suntec A2YA7916, pressure reading can be checked at the guage

port. This will provide a true reading.

HEAT EXCHANGER

If a smokey condition continues even after adjusting the air band assembly, the heat exchanger

should be thoroughly cleaned as per next page.

o

o

C /

CLEANING PROCEDURE ON HEAT EXCHANGER

1. Remove 4 bolts securing rear hood (21008) to heater and remove hood.

2. Remove exhaust gas vent trim plate (21206)

3. Remove the high limit cover

4. Remove the push on wires from the limit switch(s) (21006 & 21005 LP/NG) and note their

proper connection location for re-assembly.

5. Loosen the nut securing the connector for the armoured cable where it enters the thermostat

limit switch enclosure and pull entire wiring bundle our from opening in the enclosure end plate.

6. Remove the screws securing top half of the heat exchanger enclosure (21204A) to the bottom

half.

.

9

CLEANING PROCEDURE ON HEAT EXCHANGER cont.

7. Removing the top half of the heat exchanger enclosure will reveal the heat exchanger and the

burner mount tube.

8. Remove the four nuts securing the burner mount tube to the heat exchanger.

9. Heat exchanger can now be slid slightly forward to disengage the studs from the burner mount

tube and will lift out.

10. Clean heat exchanger by using a pressure washer want and hot water inside the opening

where the burner inserts into the heat exchanger and through the flue vent opening to remove

and build up.

1

1.

To reassemble, reverse the procedure. Ensure that the gasket material between the burner

mount tube and the heat exchanger and under the vent trim plate are in good condition when

re-assembling. If gaskets are deteriorated, replace gaskets.

12. Please contact the factory if you need assistance.

Ensure all wiring is re connected to their proper locations and all covers are properly secured

before re starting the unit.

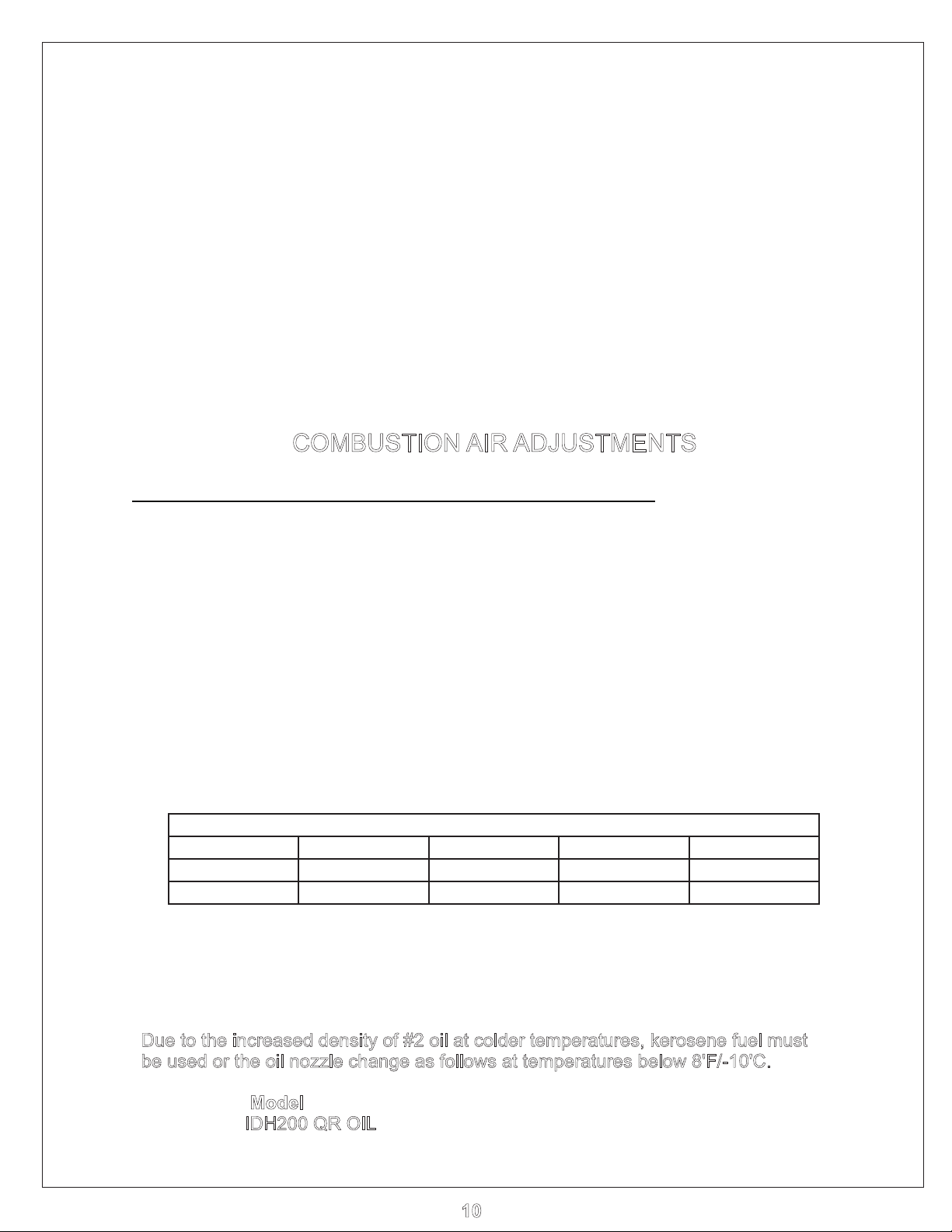

COMBUSTION AIR ADJUSTMENTS

****For proper combustion air adjustment a calibrated gas analyzer and/or smoke tester should be

used to ensure complete combustion. Air adjustment should be made at the correct input and be

adjusted to achieve 10% CO2.

control should be set to provide no more than a No. 1 smoke (Bacharach Scale). The Beckett burner has a

calibrated air band and air shutter, which will assist in adjusting the primary air for a good oil/air mixture.

Adjust shutter by loosening lock screws and moving air shutter (B20254) to the setting listed below. Check

for excessive heat build up in the heat exchanger and any visible smoke from the vent stack V. ery cold

operating conditions may require a slight reduction in air to aid ignition. Insufficient air will cause flame

impingement and reduced heat exchanger life. Increase air until heat build up has been eliminated. Check

for proper ignition. Once satisfied re- tighten all screws and locking mechanisms.

For optimum combustion efficiency on oil models the combustion air

This adjustment is to be carried out while the unit is operating and after 5 minutes of firing. Rotating the air

bands on the burner housing makes the adjustment.

PRELIMNARY AIR SETTINGS

UNIT MODEL SHUTTER BAND SLIDE PLATE BURNER MODEL

IDH200QR OIL 6 1 2 AFG

IDH200LPNGQR 9 0 n/a

CG4

***Note: The above settings are approximations based upon clean equipment in proper working order.

Combustion air adjustments will vary with location, altitude, air temperature and type of fuel

used. Colder ambient conditions may require less air while altitude increases will require more air.

ADJUST AIR AS NECESSARY TO OBTAIN CLEAN COMBUSTION AND CONSISTANT LIGHTOFF

- Use Combustion Analyzer or Smoke Tester -

Due to the increased density of #2 oil at colder temperatures, kerosene fuel must

be used or the oil nozzle change as follows at temperatures below 8'F/-10'C.

Model

IDH200 QR OIL

Nozzle (USGPH)

0.85 GPH x 45° A Delevan

10

OIL - OPERATING INSTRUCTIONS

T

O START HEAT WITH GENISYS OIL CONTROL

1. Ensure unit is on flat, level ground before starting, canopy and fan guards must be closed.

2.

3 Check fuel level ( 2-4 gallons to start)

4.

5. Flip switch to “MANUAL” position.

6. For thermostat operation flip switch to “THERM” position.

7 There will be a 5 second safe start check, a second pre purge then the burner will fire.. 15

IF HEATER FAILS TO START

1. Press manual reset button on burner relay.

2. Check for low voltage condition and 115 volt supply.

3. Check fuel filter suction tubing, and nozzle assembly

NOTE: If unit has been reset a number of times without ignition there will be an

1. Make sure unit is sitting on level ground to ensure excess oil drain out of secondary

2. Allow unit to drain for 15-20 minutes or until all oil has drained out.

3. Upon ignition excessive amounts of smoke will be present until all excess

4. When the unit has stabilized and the burner set up to operate properly, shut off

Flip switch to “OFF” position

Plug in supply cord to 115 volt outlet.

accumulation of oil in the combustion chamber! Do the Following:

exchanger by burner end(via small drain hole located on outer shell of heat exchanger ).

il has been burnt from the heat exchanger.o

the switch. Let the fan cool down the chamber and stop.

IF UNIT STILL DOES NOT START REFER TO THE TROUBLE SHOOTING GUIDE PAGE 13

CAUTION

1.

2. Do not fill tank while unit is operating.

3. Do not shut off by disconnecting supply cord. The heat exchanger

4. In no case should extension cords be smaller than 12 A.W.G. If cord

5. Do not use gasoline, crankcase oil or heavier than No. 2 furnace oil.

6. Always maintain adequate fuel supply.

ELECTRICAL REQUIREMENTS:

TO STOP HEATER

Flip switch to “OFF” position.

exchanger and electrodes.

cooled. Do not disconnect main power until supply fan has stopped running.

Do not start heater when excess oil has accumulated in chamber.

should be properly cooled before power shutdown.

is longer than 50’ use 10 A.W.G. minimum.

15 amp circuit IDH200QR MODELS

The burner motor will continue to run for approx. 1 minute to help cool the heat

The supply fan will continue to operate until the heat exchange has sufficiently

WARNING!: BEFORE MOVING ANY GUARDS OR SAFETIES DISCONNECT

POWER AS THE SUPPLY FAN WILL CYCLETHE MAIN

AUTOMATICALLY.

11

Loading...

Loading...