Frontiers From Glycerol to Value-Added User Manual

FROM GLYCEROL TO

VALUE-ADDED PRODUCTS

EDITED BY : Patrick Cognet and Mohamed Kheireddine Aroua

PUBLISHED IN : Frontiers in Chemistry

Frontiers eBook Copyright Statement

The copyright in the text of

individual articles in this eBook is the

property of their respective authors

or their respective institutions or

funders. The copyright in graphics

and images within each article may

be subject to copyright of other

parties. In both cases this is subject

to a license granted to Frontiers.

The compilation of articles

constituting this eBook is the

property of Frontiers.

Each article within this eBook, and

the eBook itself, are published under

the most recent version of the

Creative Commons CC-BY licence.

The version current at the date of

publication of this eBook is

CC-BY 4.0. If the CC-BY licence is

updated, the licence granted by

Frontiers is automatically updated to

the new version.

When exercising any right under the

CC-BY licence, Frontiers must be

attributed as the original publisher

of the article or eBook, as

applicable.

Authors have the responsibility of

ensuring that any graphics or other

materials which are the property of

others may be included in the

CC-BY licence, but this should be

checked before relying on the

CC-BY licence to reproduce those

materials. Any copyright notices

relating to those materials must be

complied with.

Copyright and source

acknowledgement notices may not

be removed and must be displayed

in any copy, derivative work or

partial copy which includes the

elements in question.

All copyright, and all rights therein,

are protected by national and

international copyright laws. The

above represents a summary only.

For further information please read

Frontiers’ Conditions for Website

Use and Copyright Statement, and

the applicable CC-BY licence.

ISSN 1664-8714

ISBN 978-2-88963-577-1

DOI 10.3389/978-2-88963-577-1

About Frontiers

Frontiers is more than just an open-access publisher of scholarly articles: it is a

pioneering approach to the world of academia, radically improving the way scholarly

research is managed. The grand vision of Frontiers is a world where all people have

an equal opportunity to seek, share and generate knowledge. Frontiers provides

immediate and permanent online open access to all its publications, but this alone

is not enough to realize our grand goals.

Frontiers Journal Series

The Frontiers Journal Series is a multi-tier and interdisciplinary set of open-access,

online journals, promising a paradigm shift from the current review, selection and

dissemination processes in academic publishing. All Frontiers journals are driven

by researchers for researchers; therefore, they constitute a service to the scholarly

community. At the same time, the Frontiers Journal Series operates on a revolutionary

invention, the tiered publishing system, initially addressing specific communities of

scholars, and gradually climbing up to broader public understanding, thus serving

the interests of the lay society, too.

Dedication to Quality

Each Frontiers article is a landmark of the highest quality, thanks to genuinely

collaborative interactions between authors and review editors, who include some

of the world’s best academicians. Research must be certified by peers before entering

a stream of knowledge that may eventually reach the public - and shape society;

therefore, Frontiers only applies the most rigorous and unbiased reviews.

Frontiers revolutionizes research publishing by freely delivering the most outstanding

research, evaluated with no bias from both the academic and social point of view.

By applying the most advanced information technologies, Frontiers is catapulting

scholarly publishing into a new generation.

What are Frontiers Research Topics?

Frontiers Research Topics are very popular trademarks of the Frontiers Journals

Series: they are collections of at least ten articles, all centered on a particular subject.

With their unique mix of varied contributions from Original Research to Review

Articles, Frontiers Research Topics unify the most influential researchers, the latest

key findings and historical advances in a hot research area! Find out more on how

to host your own Frontiers Research Topic or contribute to one as an author by

contacting the Frontiers Editorial Oce: researchtopics@frontiersin.org

Frontiers in Chemistry 1 March 2020 | From Glycerol to Value-Added Products

FROM GLYCEROL TO VALUE-ADDED PRODUCTS

Topic Editors:

Patrick Cognet, National Polytechnic Institute of Toulouse, France

Mohamed Kheireddine Aroua, Sunway University, Malaysia and

Lancaster University, UK

Citation: Cognet, P., Aroua, M. K., eds. (2020). From Glycerol to Value-Added

Products. Lausanne: Frontiers Media SA. doi: 10.3389/978-2-88963-577-1

Frontiers in Chemistry 2 March 2020 | From Glycerol to Value-Added Products

Table of Contents

05 Editorial: From Glycerol to Value-Added Products

Mohamed Kheireddine Aroua and Patrick Cognet

07 A Review on the Catalytic Acetalization of Bio-renewable Glycerol to Fuel

Additives

Amin Talebian-Kiakalaieh, Nor Aishah Saidina Amin, Neda Najaafi and

Sara Tarighi

32 Experimental Determination of Optimal Conditions for Reactive Coupling

of Biodiesel Production With in situ Glycerol Carbonate Formation in a

Triglyceride Transesterification Process

Luma Sh. Al-Saadi, Valentine C. Eze and Adam P. Harvey

43 Selective Electrooxidation of Glycerol Into Value-Added Chemicals: A

Short Overview

Christophe Coutanceau, Stève Baranton and Roméo S. Bitty Kouamé

58 Extending Catalyst Life in Glycerol-to-Acrolein Conversion Using

Non-thermal Plasma

Lu Liu, Xiaofei Philip Ye, Benjamin Katryniok, Mickaël Capron, Sébastien Paul

and Franck Dumeignil

71 Selective Electrochemical Conversion of Glycerol to Glycolic Acid and

Lactic Acid on a Mixed Carbon-Black Activated Carbon Electrode in a

Single Compartment Electrochemical Cell

Ching Shya Lee, Mohamed Kheireddine Aroua, Wan Ashri Wan Daud,

Patrick Cognet, Yolande Pérès and Mohammed A. Ajeel

82 Catalytic Dehydration of Glycerol to Acrolein in a Two-Zone Fluidized Bed

Reactor

Benjamin Katryniok, Roger Meléndez, Virginie Bellière-Baca, Patrick Rey,

Franck Dumeignil, Nouria Fatah and Sébastien Paul

94 Glycerol to Glyceraldehyde Oxidation Reaction Over Pt-Based Catalysts

Under Base-Free Conditions

Ayman El Roz, Pascal Fongarland, Franck Dumeignil and Mickael Capron

103 Esterification of Glycerol With Oleic Acid Over Hydrophobic

Zirconia-Silica Acid Catalyst and Commercial Acid Catalyst: Optimization

and Influence of Catalyst Acidity

Pei San Kong, Yolande Pérès, Wan Mohd Ashri Wan Daud, Patrick Cognet

and Mohamed Kheireddine Aroua

114 Peculiarities of Glycerol Conversion to Chemicals Over Zeolite-Based

Catalysts

Oki Muraza

125 A Novel Strategy for Selective O-Methylation of Glycerol in Subcritical

Methanol

Sophie Bruniaux, Rajender S. Varma and Christophe Len

Frontiers in Chemistry 3 March 2020 | From Glycerol to Value-Added Products

132 Recent Progress in Synthesis of Glycerol Carbonate and Evaluation of its

Plasticizing Properties

Pascale de Caro, Matthieu Bandres, Martine Urrutigoïty, Christine Cecutti

and Sophie Thiebaud-Roux

145 Two-Step Purification of Glycerol as a Value Added by Product From the

Biodiesel Production Process

Abdul Aziz Abdul Raman, Hooi W. Tan and Archina Buthiyappan

154 Techno-Economic Analysis of Glycerol Valorization via Catalytic

Applications of Sulphonic Acid-Functionalized Copolymer Beads

Luma Sh. Al-Saadi, Valentine C. Eze and Adam P. Harvey

Frontiers in Chemistry 4 March 2020 | From Glycerol to Value-Added Products

Editorial: From Glycerol to

5

Value-Added Products

published: 11 February 2020

doi: 10.3389/fchem.2020.00069

EDITORIAL

Edited and reviewed by:

Florent Allais,

AgroParisTech Institut des Sciences et

Industries du Vivant et de

L’environnement, France

*Correspondence:

Patrick Cognet

patrick.cognet@ensiacet.fr

Specialty section:

This article was submitted to

Green and Sustainable Chemistry,

a section of the journal

Frontiers in Chemistry

Received: 15 January 2020

Accepted: 21 January 2020

Published: 11 February 2020

Citation:

Aroua MK and Cognet P (2020)

Editorial: From Glycerol to

Value-Added Products.

Front. Chem. 8:69.

doi: 10.3389/fchem.2020.00069

Mohamed Kheireddine Aroua

1

Centre for Carbon Dioxide Capture and Utilisation, School of Science and Technology, Sunway University, Subang Jaya,

Malaysia,2Department of Engineering, Faculty of Science and Technology, Lancaster University, Bailrigg, United Kingdom,

3

Laboratoire de Génie Chimique, Université de Toulouse, CNRS, INPT, UPS, Toulouse, France

Keywords: glycerol, green chemistry, catalysis, process, activation, added value bio-based products,

electrochemical conversions

1,2

and Patrick Cognet

3

*

Editorial on the Research Topic

From Glycerol to Value-Added Products

Increases in biodiesel production and the demand for oleochemical-based products have led to the

generation of huge amounts of crude glycerol, whichhasgiven birth to new challenges regarding its

sustainable use. Although there is a wide range of potential uses for crude glycerol, there are limited

by its degree of purity, which affects its physical, chemical, and biological properties. The chemical

transformation of glycerol has thus become a major point of interest for crude glycerol valorization.

High added value products can be obtained from glycerol through different pathways, such

as oxidation, carbonylation, reforming, acetalyzation, etherification, esterification, dehydration,

hydrogenolysis, etc. Starting from a poly-hydroxylated molecule, all these chemical routes generally

lead to complex mixtures and are not selective. In order to develop further industrial processes,

progresses must be achieved to increase yield and selectivity, reduce reaction times, and ensure

that work in media is as clean as possible. The catalyst choice is also of great importance since it

impacts the selectivity. Heterogeneous ones must be preferred for an industrial process because

they can be easily separated. One other important aspect is the quality of the starting glycerol; it

has a great influence on the synthesis performance. This special issue gathers some contributions

focused on recent advances in some key aspects of glycerol transformation processes: the crude

glycerol purification prior to use for chemical transformation, the use of new synthesis media,

the use of non-thermal activation techniques such as electrochemistry and plasma, as well as the

synthesis, use, and characterization of new heterogeneous catalysts. These principles are applied to

the optimization of the synthesis of key added-value products, such as glycerol carbonate, glycerol

oleates, glyceraldehyde, acrolein, glycolic acid, and lactic acid. Process aspects are also considered,

such as the purification process or fluidized bed technology.

This special issue is a collection of 3 critical reviews and 10 original research articles.

The use of an electron as a clean reagent is of great interest to the goal of transforming glycerol

in added-value products in a sustainable manner. As direct electron transfer for a polyhydroxylated

molecule like glycerol would lead to the creationof a variety of products, an indirect electrocatalytic

process is envisaged in this special issue.

lack-activated carbon electrodes for glycolic and lactic acid production. Glycolic acid was then

b

Lee et al. have investigated the use of mixed carbon

obtained with good yield and selectivity. On the other hand, Coutanceau et al. have proposed an

overview of different catalytic systems and conditions to control the products selectivity obtained

from glycerol electrooxidation.

Catalyst deactivation is also a crucial issue to overcome on the road to a sustainable

industrial process. Liu et al. have demonstrated the benefits of non-thermal plasma technology

to avoid silice-supported silicotungstic acid catalyst deactivation during glycerol dehydration for

acrolein production.

Glycerol purity is crucial for its further selective transformation into various products.

Therefore, in order to valorize crude glycerol for synthetic purposes, a purification step is necessary.

Frontiers in Chemistry | www.frontiersin.org 1 February 2020 |

Volume 8 | Article 69

Aroua and Cognet Editorial: From Glycerol to Value-Added Products

6

Abdul Raman et al. propose, in this special issue, a dual-step

purification method t hat includes acidification and ion exchange

operations, which allows it to reach a 98.2% purity.

This special issue also focuses on targeted molecules derived

from glycerol. de Caro et al. have presented the recent advances

concerning glycerol carbonate (GC) synthesis. Amongst the

different routes, DMC and glycerol are good precursors,

leading to GC through transcarbonation under mild conditions.

Bruniaux et al. have reported the selective conversion of

glycerol into 3-methoxypropan-1,2diol in mild yields. Al-Saadi

et al. have investigated a reactive coupling that associates the

transesterification of rapeseed oil into a fatty acid methyl ester

and glycerol carbonate in a one-step process by introducing

triazabicyclodecene guanidine as a catalyst.

Viable industrial chemical processes imply the use of

heterogeneous catalysts for easy product recovery and catalyst

recycling. Moreover, catalyst activity strongly relies on its

physical properties, such as hydrophilicity/hydrophobicity,

acidity, stability to water, etc. Muraza et al. have investigated

the performances of natural zeolites and natural clays as lowcost catalysts. For a specific application, such as esterification

with oleic acid, new catalysts must be developed, and these

should exhibit good proprieties in terms of acidity and

hydrophobicity. Kong et al. have developed, characterized,

and studied hydrophobic zirconia-silica acid catalysts. They

obtained 80% glycerol conversion together with 60% monooleate selectivity. Pt-based solid catalysts deposited on various

supports have been studied by El Roz et al. when applied to the

synthesis of glyceraldehyde from glycerol. The best activity was

obtained for Pt/g-Al2O3, whereas best selectivity was obtained

using Pt/SiO2. Sulphonic acid-functionalized copolymer beads

were also synthetized, characterized, and used for solketal

synthesis from glycerol. Al-Saadi et al. succeeded in optimizing

the process using a two-step acetone feeding process. A technicoeconomic analysis revealed that this process could compete

with the current industrial one. This reaction—the acetalization

of glycerol through acid catalysis—was also investigated by

Talebian-Kiakalaieh et al. They give, in this special issue, a

comprehensive study of the impact of the different operating

parameters—a prerequisite for biorefinery development.

To succeed in these industrial implementations, a chemical

engineering approach has to be coupled with a chemical one.

For this purpose, Katryniok et al. de veloped a two-zone fluidized

bed reactor to carry out the gas-phase dehydration of glycerol

to acrolein, using phosphotungstic acid supported on silica

as a catalyst. The fluidization quality, the catalyst mechanical

stability, and the influence of the operating conditions were

successively studied, thus showing, for example, the crucial

part the O2/glycerol ratio plays for the purposes of conversion

and selectivity.

The contributions made to this special issue of "From Glycerol

to Value-Added Products” underline the variety of the research

work carried out in the field of the valorization of glycerol and

processing of raw material at low cost, and they tackle both

the re actional aspects as catalysis, processes, and even economic

aspects. Many chemical applications have been covered in this

special issue, thus showcasing all the potential of glycerol. We

hope that the issue will inspire the readers to further contribute

to this exciting field of glycerol valorization.

Finally, we would like to thank all authors for their valuable

contributions to this special issue, and we wish them success in

their research.

AUTHOR CONTRIBUTIONS

MA and PC thank all contributors for their original articles

submissions to this special issue.

ACKNOWLEDGMENTS

This special issue is the result of a long term collaboration

between University of Malaya and Sunway University in Malaysia

and Toulouse University in France. We strongly acknowledge the

French Embassy in Malaysia for its support and all contributors

to this collection.

Conflict of Interest: The authors declare that the research was conducted in the

absence of any commercial or financial relationships that could be construed as a

potential conflict of interest.

Copyright © 2020 Aroua and Cognet. This is an open-access article distributed

under the terms of the Creative Commons Attribution License (CC BY). The use,

distribution or reproduction in other forums is permitted, provided the original

author(s) and the copyright owner(s) are credited and that the original publication

in this journal is cited, in accordance with accepted academic practice. No use,

distribution or reproduction is permitted which does not comply with these terms.

Frontiers in Chemistry | www.frontiersin.org 2 February 2020 | Volume 8 | Article 69

published: 26 November 2018

7

doi: 10.3389/fchem.2018.00573

A Review on the Catalytic Acetalization of Bio-renewable Glycerol to Fuel Additives

REVIEW

Mohamed Kheireddine Aroua,

Edited by:

Sunway University, Malaysia

Reviewed by:

Abdul Aziz Abdul Abdul Raman,

University of Malaya, Malaysia

Maan Hayyan,

University of Malaya, Malaysia

*Correspondence:

Nor Aishah Saidina Amin

noraishah@cheme.utm.my

Specialty section:

This article was submitted to

Green and Sustainable Chemistry,

a section of the journal

Frontiers in Chemistry

Received: 27 August 2018

Accepted: 05 November 2018

Published: 26 November 2018

Citation:

Talebian-Kiakalaieh A, Amin NAS,

Najaafi N and Tarighi S (2018) A

Review on the Catalytic Acetalization

of Bio-renewable Glycerol to Fuel

Additives. Front. Chem. 6:573.

doi: 10.3389/fchem.2018.00573

Amin Talebian-Kiakalaieh

1

Faculty of Petrochemicals, Iran Polymer and Petrochemical Institute (IPPI), Tehran, Iran,2Chemical Reaction Engineering

Group, Faculty of Chemical and Energy Engineering, Universiti Teknologi Malaysia (UTM), Skudai, Malaysia,3Iran Industrial

Design Company, Tehran, Iran

1,2

, Nor Aishah Saidina Amin

2

*

, Neda Najaafi3and Sara Tarighi

1

The last 20 years have seen an unprecedented breakthrough in the biodiesel industry

worldwide leads to abundance of glycerol. Therefore, the economic utilization of

glycerol to various value-added chemicals is vital for the sustainability of the biodiesel

industry. One of the promising processes is acetalization of glycerol to acetals

and ketals for applications as fuel additives. These products could be obtained by

acid-catalyzed reaction of glycerol with aldehydes and ketones. Application of different

supported heterogeneous catalysts such as zeolites, heteropoly acids, metal-based

and acid-exchange resins have been evaluated comprehensively in this field. In this

review, the glycerol acetalization has been reported, focusing on innovative and potential

technologies for sustainable production of solketal. In addition, the impacts of various

parameters such as application of different reactants, reaction temperature, water

removal, utilization of crude-glycerol on catalytic activity in both batch and continuous

processes are discussed. The outcomes of this research will therefore significantly

improve the technology required in tomorrow’s bio-refineries. This review provides

spectacular opportunities for us to use such renewables and will consequently benefit

the industry, environment and economy.

Keywords: glycerol, acetalization, fuel additives, heterogeneous catalysts, acetone, ketone

INTRODUCTION

In the early Twentieth century, petroleum exploitation and its cracking to simple hydrocarbons

was one of the most influential factors on human life. Fossil fuel has been the main source of energy

for almost a century. Current oil production rate reach approximately 12 Mt/day and its demand

is predicted to rise dramatically to around 16 Mt/day by 2030 due to the significant increase in

the world population and industrial development (Lin and Huber, 2009; Talebian-Kiakalaieh et al.,

2014). Various types of environmental concerns such as massive amount of carbon dioxide and the

depletion of fossil fuel resources have become the main concerns in maintaining sustainability. Low

cost supply of fossil fuel (<100 USD/b arrel) will no longer be available by 2040 (Posada et al., 2009).

Many efforts are geared toward finding new sources of alternative energy to supplant the current

non-renewable fossil fuels. Biomass is selected as a promising alternative source of energy to meet

the significant energy demand as well as to reduce environmental concerns. As a result, a new term,

“bio-refinery,” has emerged recently to describe a facility for converting biomass to food, fuel, and

value-added chemicals.

Frontiers in Chemistry | www.frontiersin.org 1 November 2018

| Volume 6 | Article 573

Talebian-Kiakalaieh et al. Glycerol Acetalization to Value-Added Chemicals

8

Biodiesel is one of the most important and valuable alternative

liquid fuel in the transportation sector. As a substitute to fossil

fuels, biodiesel could reduce chemical emissions such as sulfur

dioxide (100%), unburned hydrocarbon (68%), and polycyclic

aromatic hydrocarbon (80–90%). In addition, biodiesel is

environmentally friendly, technically feasible and biodegradable

(

Fazal et al., 2011). The worldwide production of biodiesel is

edicted to increase to 141 billion liters by 2022 from 110

pr

billion liters in 2013, mainly due to the contribution of European

Renewable Energy Directive (EU-RED) and Renewable Fuel

Standard (RFS) in the United States. This would improve the

global production to almost 70% by the year of 2022, compared

to its average from 2010 to 2012 (SSI Review, 2014). Hence, it is

vital to enhance the economic feasibility of biodiesel production

through the modification of three major aspects of the process,

namely the raw materials used in the process, the synthesis

method, and the byproducts (De Torres et al., 2011).

Briefly, biodiesel is obtained via the transesterification of

animal fat or vegetable oils in the presence of methanol under

basic catalysis condition (Menchavez et al., 2017). Glycerol as a

byproduct is produced at a high 1:10 glycerol to biodiesel weight

ratio. The increasing demand for biodiesel caused a glycerol oversupply, thus reducing the commercial price of glycerol to almost

8 cents/lb recently compared to 25 cents/lb in 2004 (Clomburg

and Gonzalez, 2013). It is expected the global surge in biodiesel

production lead to production of >41.9 billion liter of crude

glycerol by 2020 (Nanda et al., 2014a). Fabrication of low cost

glycerol is important since it can be transformed to many valueadded chemicals (more than 2,000 products) in various reaction

pathways (Nanda et al., 2017; Nguyen et al., 2017; Tangestanifard

and Ghaziaskar, 2017). Traditionally, glycerol was produced from

the production of fatty acids (47%), followed by soaps (24%), fatty

alcohols (12%), and the biodiesel industry (9%). However, since

2009 the biodiesel industry is the main producer that supplies

over 64% of the glycerol (Abad and Turon, 2012). Thus, glycerol

consumption is expected to increase significantly by up to 50% in

2020. Its demand was 2,247.2 kilo tons in 2013 and is expected to

reach 3,469.2 kilo tons by 2020 (Ayoub and Abdullah, 2012; Villa

et al., 2015).

Traditional uses of glycerol include in the textiles (24%), food

and beverages (21%), cosmetics and toiletries (18%), drugs (18%),

tobacco (6%), and paper and printing (5%), and others, cannot

satisfy the dramatic surge in production of this compound. Thus,

it is necessary to find new routes of conversion for this chemical

in order to avoid market saturation. Table 1 lists the possible

catalytic processes and products that can be produced from

glycerol.

Undoubtedly, one of the most promising glycerol applications

is production of fuel additives such as cyclic acetals and ketals

with aldehydes and ketones, respectively (Deutsch et al., 2007).

Generally, fuel (Wang et al., 2004) and diesel additive (Ribeiro

et al., 2007) is a material that improves the cleanliness of different

parts of the engine (e.g., carburetor, fuel injector and intake

valve), promotes complete combustion, reduces fuel gelling and

choking of nozzle, as well as reducing corrosion impact on

different parts of the engine. The result is improved engine

performance, reduced emission and reduced fuel consumption.

It could significantly reduce the particulate emissions of diesel

fuel (Rakopoulos et al., 2008) (e.g., reduction of CO2and NO

emission) and increase oxygen and air concentration (Lin and

Chen, 2006). In addition, it could improve the thermal stability

of jet fuels as well as significantly reduce (1–70%) deposits in

jet engines (Forester et al., 2003). Methyl tertiary butyl ether

(MTBE) was widely used as octane accelerator in gasoline in

the early 1980’s (Franklin et al., 2000). For more than two

decades, it was the most economical oxygenate additive used

by the refineries to reduce production cost of Reformulated

Gasoline (RFG) (Romanow, 1999). However, the International

Agency of Research on Cancer (IARC) classified RFG as a major

health risk threat in 2000 (U.S. EPA, 1996). Thus, ketalization

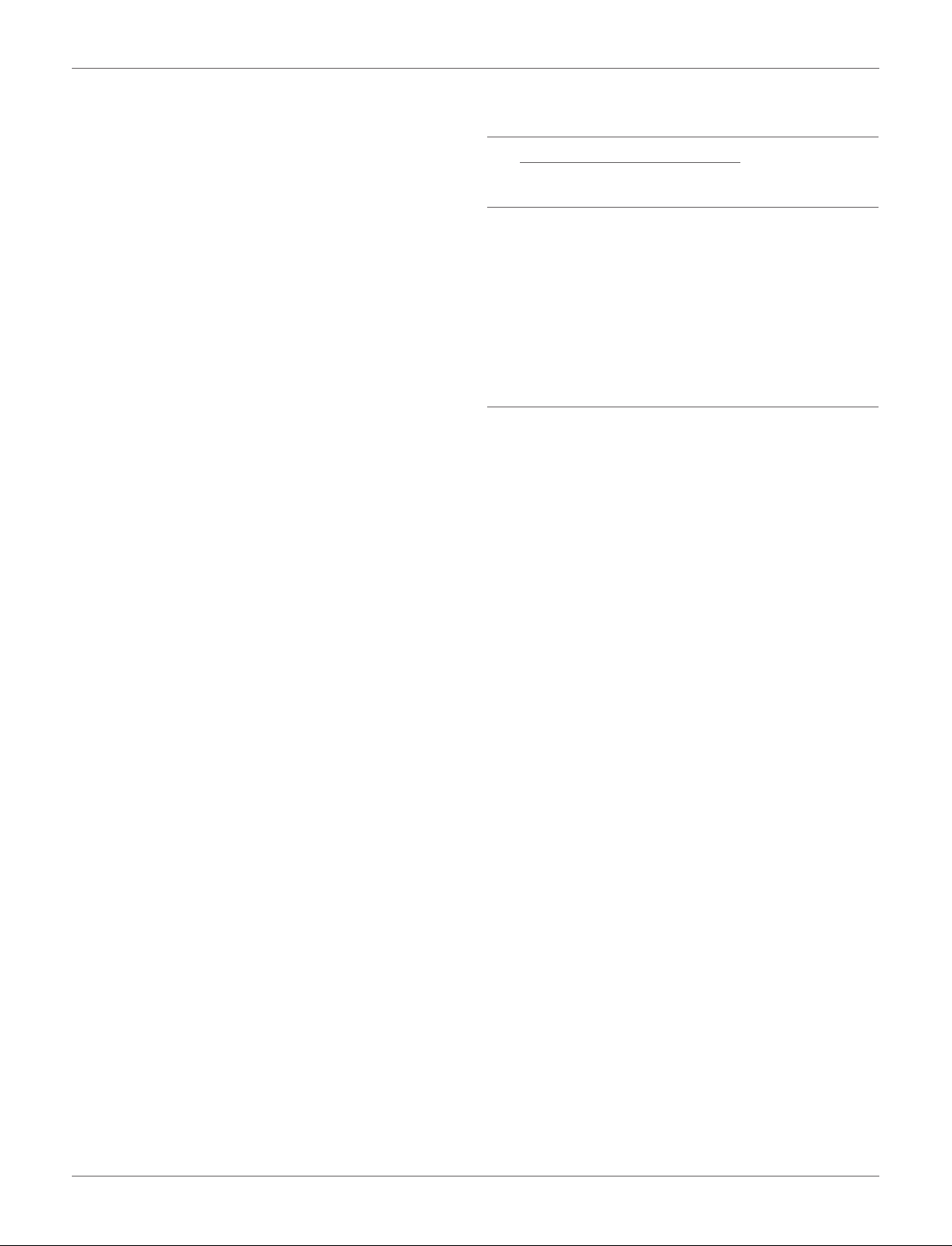

reaction between glycerol and acetone where 2, 2-dimethyl1, 3-dioxolane-4- methanol known as solketal, is formed as

the condensation product over an acid catalyst is shown in

Figure 1. Solketal, an oxygenate fuel additives, could reduce

the particulate emission and improve the cold flow properties

of liquid transportation fuels (Pariente et al., 2008). It helps

to reduce the gum formation, improves the oxidation stability,

and enhances the octane number when added to gasoline

(Mota et al., 2010). Maksimov et al. (2011) reported its use

as a versatile solvent and a plasticizer in the polymer industry

and a solubilizing and suspending agent in pharmaceutical

preparations. More importantly, the aquatox fish test on the

toxicity of the solketal showed that solketal (with a LC50 for

fish to be as hig h as 3,162 ppm) has demonstrated much less

environmental toxicity than the common fuel additive, MTBE,

with a LC50 of 1,000 ppm (Nanda et al., 2014a).

Thus, the main objective of this review is to collect

information about the latest advances in glycerol conversion

to oxygenated fuel additives from biomass sources. In

addition, the review addresses the critical knowledge gaps for

enhancing conversion and selectivity in glycerol acetalization.

Fundamentals of reaction mechanisms for the acid-catalyzed

conversion of glycerol into solketal are presented. Some aspects

such as the influence of various reaction parameters, reactant

selection, reaction temperature, catalyst acidity, water removal,

and reactor design are exclusively summarized and discussed.

Finally, the application of crude-glycerol is discussed in batch

and continuous-flow processes.

CATALYTIC ACETALIZATION OF GLYCEROL

Glycerol is an organic compound which is a low toxicity alcohol

that consists of a three-carbon chain with a hydroxyl group

attached to each carbon. These groups made glycerol hygroscopic

and water-soluble. Glycerol has low volatility and low vapor

pressure and is nontoxic to both humans and the environment.

Physically, glycerol is a clear, colorless, odorless, viscous,

and sweet-tasting liquid. Table 2 lists the physico-chemical

characteristics of glycerol (

rst discovered by K.W. Scheele, a Swedish researcher, in 1779.

fi

He produced a material with a sweet taste by heating olive oil

with lead oxide. Three decades later, a French chemist, Michel

Rahmat et al., 2010). Glycerol was

Frontiers in Chemistry | www.frontiersin.org 2 November 2018 | Volume 6 | Article 573

Talebian-Kiakalaieh et al. Glycerol Acetalization to Value-Added Chemicals

9

)

(C + H

2

Carbon+

)

2

(CO + H

ROH

(Continued)

Hydrogen

Syngas

Alcohol

TABLE 1 | Catalytic conversion of glycerol into value-added chemicals by different processes.

2n

H

n

C

Olefin

2n+2

H

n

C

Alkane

Oxidation

Hydrogenolysis

Dehydration

Pyrolysis, Gasification

Trans- Esterification

Frontiers in Chemistry | www.frontiersin.org 3 November 2018 | Volume 6 | Article 573

Talebian-Kiakalaieh et al. Glycerol Acetalization to Value-Added Chemicals

10

Etherification

TABLE 1 | Continued

Oligomerization, Polymerization Polyglycerol methacrylates

Carboxylation

Acetalization

Different catalytic conversion of glycerol into value-added chemicals.

Frontiers in Chemistry | www.frontiersin.org 4 November 2018 | Volume 6 | Article 573

Talebian-Kiakalaieh et al. Glycerol Acetalization to Value-Added Chemicals

11

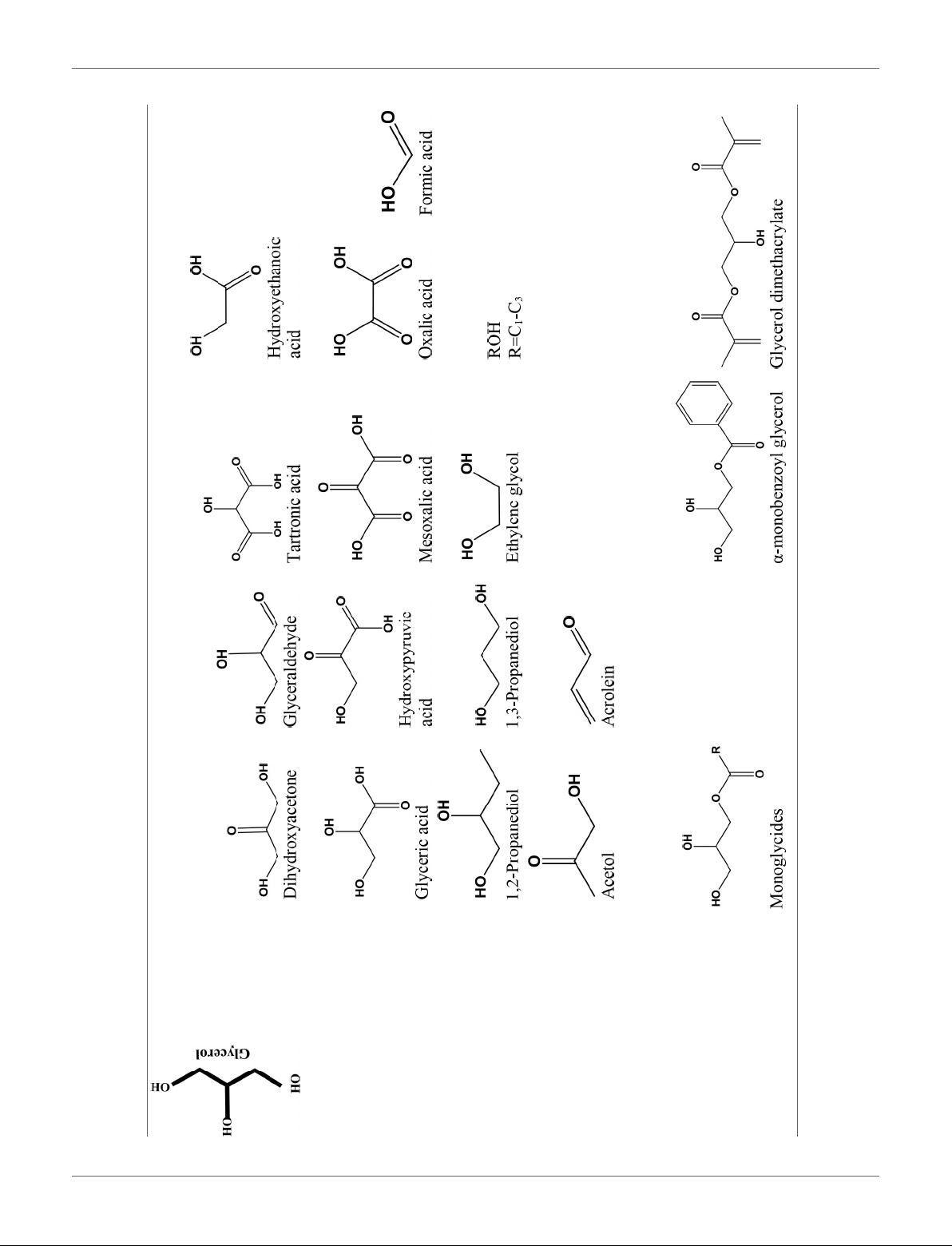

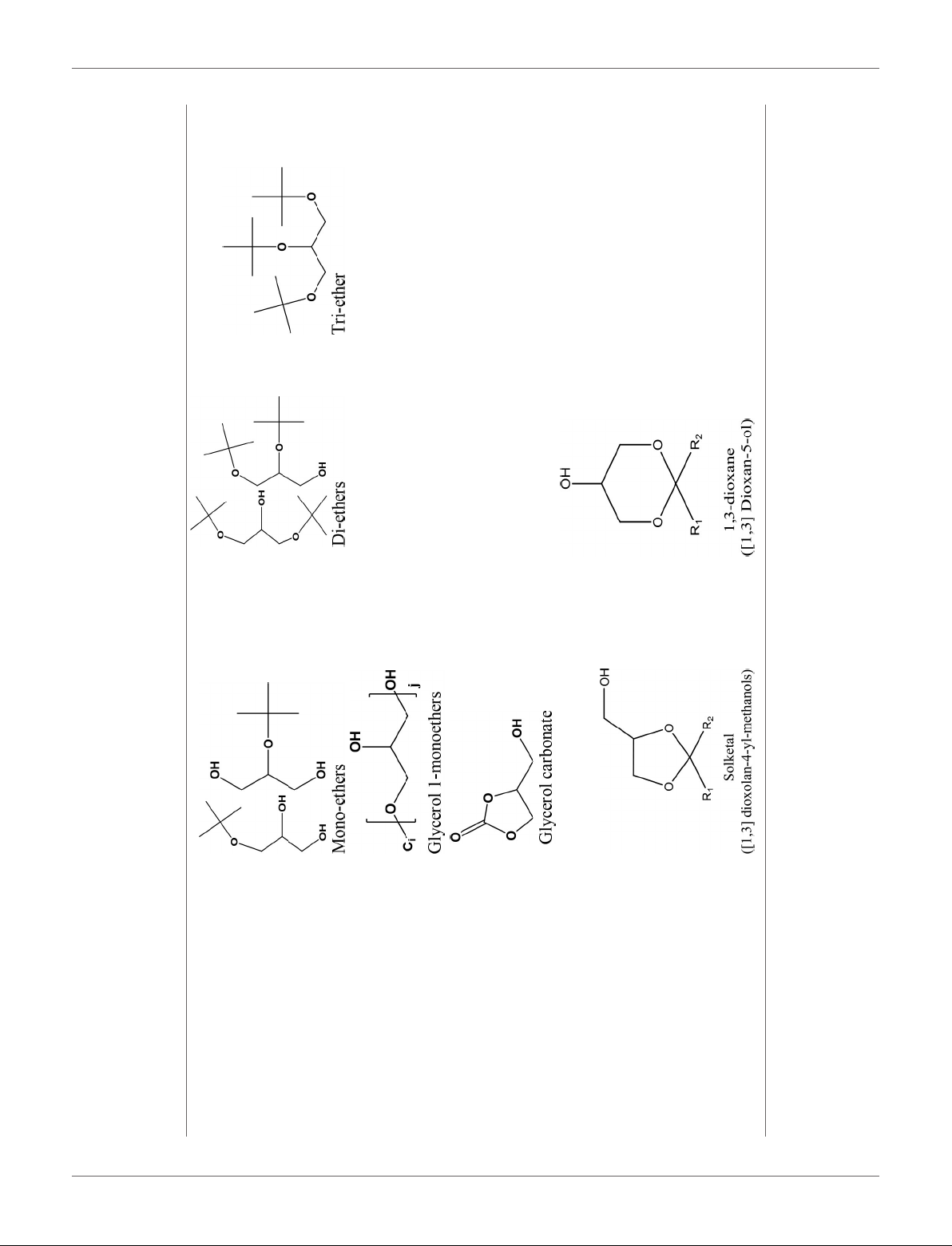

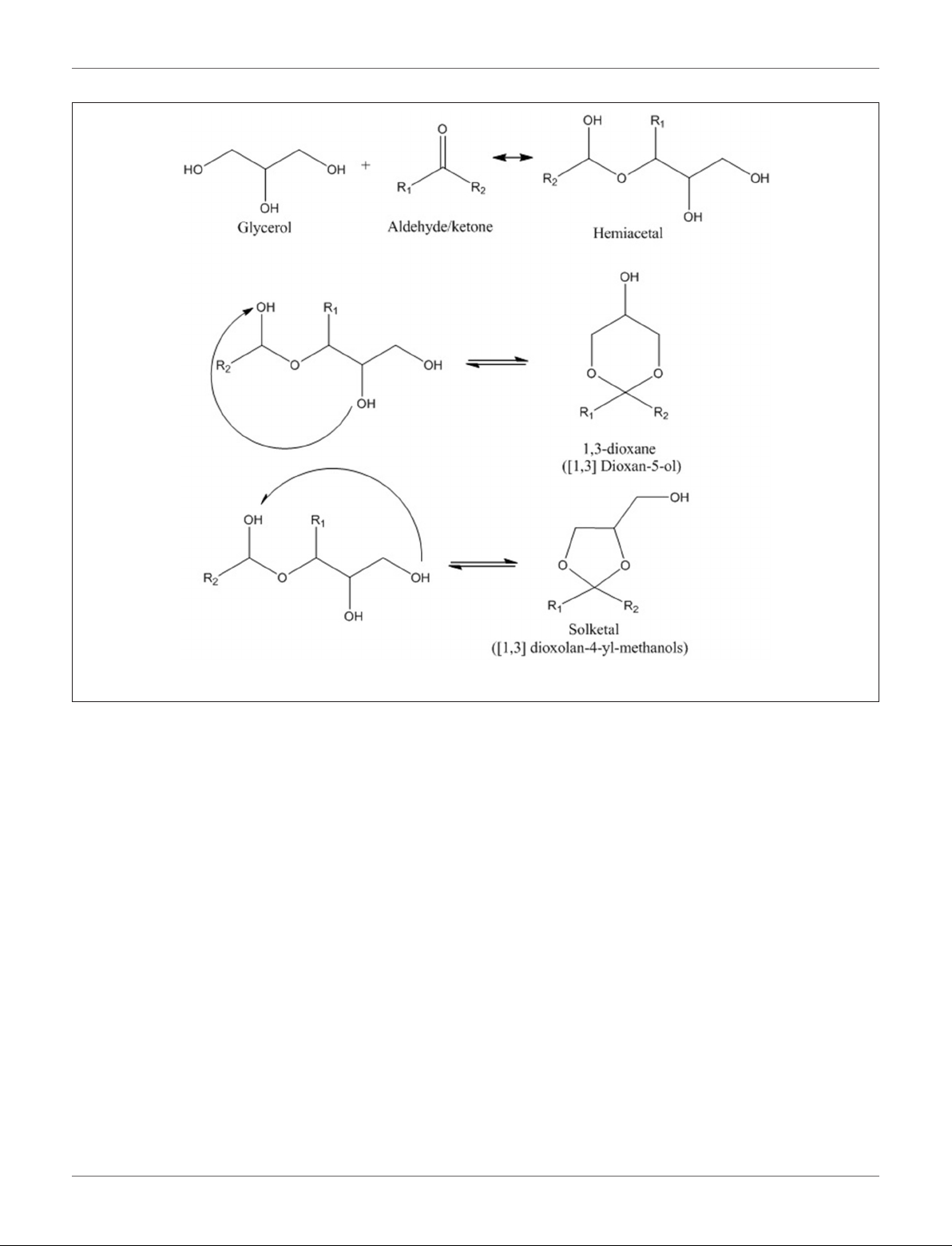

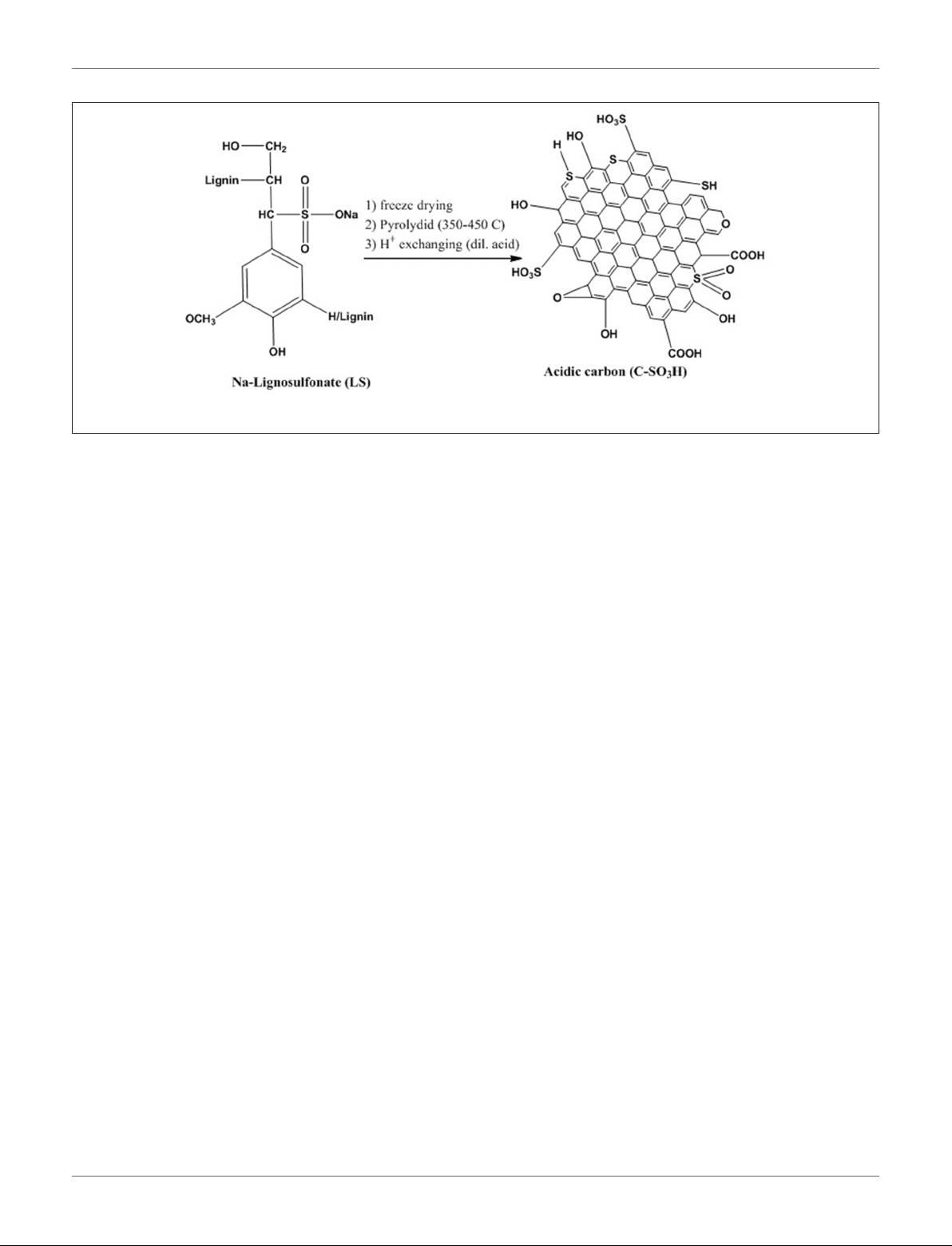

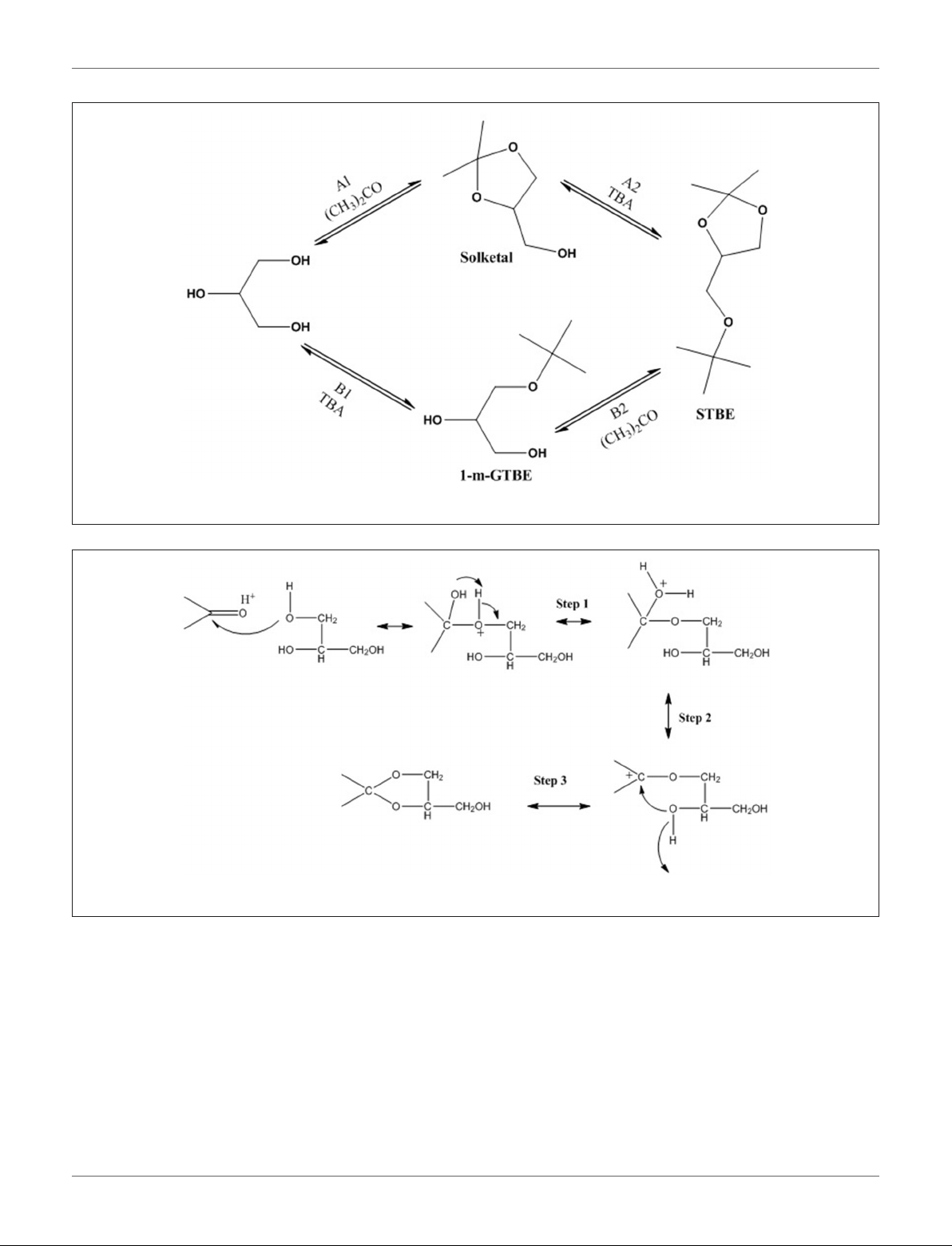

FIGURE 1 | Reaction mechanism of glycerol with aldehydes/ketones.

Eugene Chevrel, named it “glycerin.” He then proposed fatty

acids ethereous chemical formulas along with glycerin formulas

in vegetable oils and animal fats. Finally, his study on the

production of fatty acids (FA) from the reaction of fatty materials

with lime and alkali was reported, which was the first industrial

attempt in this field (Gesslein, 1999). It is an irrefutable fact that

the discovery of glycerol has brought significant breakthroughs

in the production different products. Re cent advances in catalyst

and bio-refinery industries have provided great opportunities

for industrialization of bio-based processes which could produce

food, fuel, and chemicals from glycerol.

Based on the literature in the last decades, catalytic

acetalization of glycerol process could be categorized by three

generations. In fact, the first generation of studies on the catalytic

acetalization of glycerol to fuel additives reported in the presence

of homogenous catalysts and a solvent. Fischer and co-workers

pioneered the synthesis of solketal from glycerol and acetone,

catalyzed by hydrogen chloride, in a batch reactor (Fischer,

1895). A few years later, a similar process by Fischer and Pfahler

(1920) was applied for the ketalizationof glycerol with anhydrous

sodium sulfate

(1945) reported the

and hydrogen chloride. Newman and Renoll

preparation of solketal in a three-neck flask

using reflux and mechanical stirrer in 1948. To obtain high

solketal yield, they used pTSA monohydrate as the catalyst and

petroleum ether as the reaction medium. After the reaction, the

products were separated by reducing the pressure and distilling.

The drawback of this system was its very long reaction time (21–

36 h). Generally, the reaction of glycerol with aldehydes/ketones

is conducted under homogenous Lewis catalysts (

010) or

2

mineral acids such as HF, HCl, H3PO4,H2SO4,and p-

Ruiz et al.,

toluenesulfonic acid (pTSA) to form solketal (1,2-isopropylidene

glycerol, 2,2-dimethyl-1, or 3-dioxolane-4-methanol) (Sato et al.,

2008; Coleman and Blankenship, 2010; Suriyapradilok and

Kitiyanan, 2011; Nanda et al., 2014a; Sun et al., 2017). The first

generation of studies was stopped more than half a century ago

due to the economic barriers. Indeed, availability of cheap fossil

fuels was the main obstacle for bio-based processes.

The second generation of catalytic acetalization of glycerol

performed in the presence of heterogeneous catalysts and a

solvent as reaction medium. Indeed, this group of investigations

on bio-based glycerol acetalization to fuel additives started

after the introduction of large amount of inexpensive glycerol

from biodiesel industry at the end of the Twentieth century.

Science and technological advances in synthesis of heterogeneous

Frontiers in Chemistry | www.frontiersin.org 5 November 2018 | Volume 6 | Article 573

Talebian-Kiakalaieh et al. Glycerol Acetalization to Value-Added Chemicals

12

TABLE 2 | Physico-chemical properties of glycerol.

Properties Values

Chemical formula CH2OH–CHOH–

Formula weight 92.09

Form and color Colorless and liquid

Specific gravity 1.260

Melting point 17.9◦C

Boiling point 290◦C

Solubility in 100 parts

Water Infinitely

Alcohol Infinitely

Ether Insoluble

Vapor pressure in 760 mmHg 290◦C

Heat of fusion at 18.07◦C 47.49 cal/g

Viscosity liquid glycerol

100%

50% 25 cP

Diffusivity in (DL×105sq.cm/s)

i-Amyl alcohol 0.12

Ethanol 0.56

Water 0.94

Specific heat glycerol in

aqueous solution (mol%)

2.12 0.961 0.960

4.66 0.929 0.924

11.5 0.851 0.841

22.7 0.765 0.758

43.9 0.670 0.672

100 0.555 0.576

15◦C (cal/g◦C) 30◦C(cal/g◦C)

CH2OH

50/4

10 cP

catalysts and their applications provide spectacular opportunities

for further investigations in this field. In fact, homogenous

catalysts like Lewis catalysts and strong mineral acids are

known to not only cause difficult purification and product

separation, but also environmental and corrosion problems.

Several studies were employed to solve the shortcomings

of homogenous catalysts using heterogeneous catalysts by

evaluating the most important characteristics of a catalyst

which are cost, accessibility, efficiency, easy removal, and good

activity at mild conditions. One of the earliest studies on the

use of heterogeneous acid catalyst was reported by Deutsch

et al. (2007). They applied Amberlyst-36 with various solvents

(dichloromethane, chloroform, toluene, and benzene) as organic

solvents to obtained >62% glycerol conversion in the presence

of three different reactants (acetone, benzene, and furfural) in

a batch reactor (Deutsch et al., 2007). Application of Hβ and

MMT-K10 zeolites were reported in catalytic acetalization of

glycerol to fuel additives in the presence of chloroform as solvent

and benzaldehyde as reactant. The results indicated that >95%

of solketal yield was obtained at glycerol to benzaldhyde molar

ratio of 1.1/1 and after 6 h of reaction time (Deutsch et al.,

2007). In addition,

in cat

alytic acetalization of glycerol by Umbarkar et al. (2009).

toluene is another solvent which was utilized

They reported about 72% glycerol conversion over MoO3/SiO

catalyst at optimum reaction of 1.1/1 molar ration of glycerol

to benzaldehyde, reaction temperature of 100◦C and in 8 h. As

mentioned earlier, simultaneous application of heterogeneous

catalysts and solvent is one of the old methods in catalytic

acetalization process and there are limited number of studies

in this field in the last decade. However,

Nanda et al. (2014b)

reported one of the successful studies on application of ethanol

s solvent in the presence of Amberlyst-35 as catalyst to reach

a

more than 74% solketal yield at 2/1 molar ratio of glycerol to

acetone and quite very low reaction temperature of 25–45◦C.

Indeed, they could significantly reduce the reaction temperature

by application of ethanol as solvent.

Finally, the third generation is solvent free glycerol

acetalization reaction by heterogeneous catalysts in batch

or continuous processes. In fact, new heterogeneous catalysts are

active enough to push the catalytic process to produce desired

products (solketal) at high reaction conversion even without

solvent (Chen et al., 2018a; Ferreira et al., 2018). In this regard,

different types of heterogeneous acid catalysts have been recently

applied in the acetalization of various carbonyl compounds with

glycerol such as activated carbons, montmorillonite (MMT),

zeolites, metal-based catalysts, ionic liquids, supported multiwalled carbon nano-tubes (MWCNTs) or, mesoporous silicates

with arylsulphonate group, heteropoly acids, rare-earth triflates,

and ion-exchange resins. Thus, the latest trend in catalytic

acetalization of glycerol to fuel-additives will be investigated in

the following sections. Table 3 summarizes some of the recent

studies related to glycerol acetalization with different aldehydes

and ketones in batch and continuous processes. All the reported

studies are organized into two main groups of homogenous and

heterogeneous catalysts. Also, the heterogeneous c atalysts are

divided into four categories of zeolite-, heteropoly acid-, metal-,

and polymers-based catalysts. As it can clearly be seen, the

highest catalytic activity (complete conversions) were observed

from the rare-earth triflate catalysts (Pierpont et al., 2015),

Ni-Zr/activated carbon catalyst (Khayoon and Hameed, 2013),

(L)Ru (II)@SBA-15 (Lazar et al., 2018), Amberlyst-47 (Guemez

et al., 2013), and [5%V] Si-ITQ-6 (Vieira et al., 2018). The detail

of each reaction process and optimum conditions reported in

Table 3.

Lack of research studies on different methods of catalyst

synthesize (e.g., sol-immobilization) is obvious, which has great

influence on the catalyst activity and selectivity. In fact, the

majority of reported heterogeneous catalysts synthesized through

simple impregnation approach. Also, the photo-catalytic process

is a promising strategy in various reaction processes and under

mild reaction conditions with altered selectivities, compared

with the conventional thermo-catalytic route. Unfortunately,

application of photo-catalytic acetalization of glycerol has rarely

been reported, while it definitively requires more attention in the

future.

In addition to investigating the synthesis of an effective

catalyst, the process engineering for economic evaluation was

also rarely investigated. The UNISimTMsoftware was used

2

Frontiers in Chemistry | www.frontiersin.org 6 November 2018 | Volume 6 | Article 573

Talebian-Kiakalaieh et al. Glycerol Acetalization to Value-Added Chemicals

13

TABLE 3 | Glycerol acetalization with different aldehydes and ketones in batch and continuous processes.

Type Catalyst Optimum condition Conc(%) Yd(%) Description References

Homogenous PTSA MRaGl/Fb= 1:1

T = 80◦C, t = 9 h

PTSA MR Gl/Ace= 1:4

t = 12 h

PTSA MR Gl/Benf= 1:2

T = 140◦C, t = 15 min

H2SO

4

MR Gl/F = 1.5/1

T = 100◦C, t = 4 h

Heterogeneous Zeolites Zeolite beta MR Gl/F = 1/1 T = 100◦C,

t = 2 h

Zeolite beta MR Gl/Ac = 1/2 T = 70◦C,

t = 1 h

H beta zeolite MR Gl/Ac = 1/2 T = 25◦C,

t = 2 h

Zeolite USY MR Gl/Bug= 1/2.5 T =

70◦C, t = 4 h

Zeolite BEA Con = 87

Zeolite ZSM Con = 28

MMT K10 MR Gl/Ben = 1/2 T =

140◦C, t = 15 min

Nb5-HUSY MR Gl/Ac = ½ T = 40◦C,

Cat = 2 wt%

MK-10S

MW

T = 40◦C, t = 2 h, Cat = 5

wt%, MR Gl/F = 1/1

[5%V]Si-ITQ-6 T = 60◦C, t = 120 min,

Ac/Gl = 3/1, Cat = 0.02 g

Zr-MO-KIT-6 T = 50◦C, t = 4 h, Ac/Gl =

8/1, Cat = 0.05 g

Immobilize sulfonic

T = 120◦C, t = 8 h Con = 78 Argon atmosphere in

acid on to silica

Zeolite beta

CP814E

MR Gl/Ac = 1/6 T = 35◦C,

t = 4 h

Zeolite beta

CP811T1

Zeolite HY Con = 37%

Heterogeneous Zeolites Hierarchical Zeolite

(H/BEA5)

T = 70◦C, t = 240 min, MR

G/F = 1/1.25, Cat = 10%

6.8v-MCM-41 T = 60◦C, t = 60 min,

Ac/Gl =6.5, Cat =20 mg

ITQ-2 T = 83◦C, HMF/Gl = 1/2,

Cat =20 wt%, Si/Al = 15

MCM-41 Con = 99

Heteropoly

acid

Cs

2.5H0.5PW12O40

T = 25◦C, MR Gl/Ac = 1/6,

Cat = 0.25 g/batch, t =

15 min

Cs

/KIT-6 T = 70◦C, MR Gl/F = 1/1.2,

2.5

Cs= 3.83 g/batch, t = 24 h

Y

= 80 – Ruiz et al., 2010

Acetal

Con = 82 – Suriyapradilok and

Kitiyanan, 2011

Con = 67 Microwave assisted,

Pawar et al., 2014

Power = 600 W; Con

= 95% without catalyst

Y

= 89 – Coleman and

Acetal

Y

= 25 – Ruiz et al., 2010

Acetal

Blankenship, 2010

Con = 90 – da Silva and Mota,

2011

Con = 86 – Manjunathan et al.,

2015

Con = 72 – Serafim et al., 2011

Con = 84 Microwave assisted,

Roldan et al., 2009

Power = 600 W

Con = 95 No catalyst

Con = 66

S

Solketal

Con = 68

S

Solketal

Con = 100

S

Solketal

= 98

= 66

= >95

– Ferreira et al., 2018

Microwave synthesis

enhanced reaction

Gutiérrez-Acebo et al.,

2018

conversion

Acetone washing could

Vieira et al., 2018

reduce the catalyst

deactivation after each

run

Con = 85.8

S

= 97.8

Solketal

– Li et al., 2018a

Adam et al., 2012

the presence of

Benzaldehyde

Con = 82% – Maksimov et al., 2011

Con = 85%

Con = 78

S

Solketal

Con = 92

S

Solketal

Con = 98

S

5R+6R

= 85

= 95

= 100

– Sonar et al., 2018

– Abreu et al., 2018

Products ratio 5R/6R =

Arias et al., 2018

2.8

Products ratio 5R/6R =

S

5R+6R

Con = 95

S

Solketal

Con = 95

=100

= 98

3.9

– Chen et al., 2018a

– Chen et al., 2018b

YGF= 60

(Continued)

Frontiers in Chemistry | www.frontiersin.org 7 November 2018 | Volume 6 | Article 573

Talebian-Kiakalaieh et al. Glycerol Acetalization to Value-Added Chemicals

14

TABLE 3 | Continued

Type Catalyst Optimum condition Conc(%) Yd(%) Description References

Acid

Nafion SAC 13 MR Gl/Ben = 1/2 T =

exchange

resins

Dowex MR Gl/Bu = 1/2.5 T =

Amberlyst 36 MR Gl/F =1/1, T = 100◦C,

Amberlyst 15 MR Gl/Ac = 1/2 T = 70◦C,

Amberlyst 15 MR Gl/Ac = 1/2 T = 50◦C,

Amberlyst 47 MR Gl/F = 2/1 T =

Amberlyst 47 MR Gl/Ac = 2/1 t =

Amberlyst 47 MR Gl/Buth= 3/1 T =

Amberlyst 15 MR Gl/F = 1/2 T = 75◦C, t

Heterogeneous Metal-based Ni-activated

carbon

Zr-activated

carbon

X%Ni-Y%Zr/

activated carbon

Ni-MWCNT

Pt-TNT T = 50◦C, t = 24 h, Ac/Gl

M-AlPO

4

M-ZnAlPO

M-CuAlPO

M-NiAlPO

M-CoAlPO

PTNT T = 50◦C, MR G/Ac = 1/1,

SO4/SnO

TiO2-SiO

2

MoX/TiO2-ZrO

Niobium

oxyhydroxyde

Nb2O

5

HC-SZ (SO

coated on

cordierite

honeycomb

monolith)

140◦C, t = 15 min

Con = 81 Microwave assisted,

Power = 600 W, Con =

Trifoi et al., 2016

95% without catalyst

Con = 66 – Serafim et al., 2011

70◦C, t = 4 h

Y = 55 – Ruiz et al., 2010

t = 4 h

Con = 95 –

t = 1 h

Con = 95 –

P = 8.0 bar t = 6 h

Con = 75 – Agirre et al., 2011

80–100◦C, t = 3 h

Con = 90

10–50◦C, t = 4 h

Con = 95 – Guemez et al., 2013

80◦C, t = 100 min

MR Gl/But = 0.5/1 T = 60

◦

C, t = 4 h

= 2 h

MR Gl/Ac = 1/8 T = 45◦C,

t = 3 h

Con = 100

Con = 100% Reactive distillation

process

Con = 98 3% reduction of

catalytic activity after

Hasabnis and

Mahajani, 2014

Khayoon and Hameed,

2013

the 4th run

Con = 67

Con = 100

i

MR Gl/Ac = 1/6 T = 40◦C,

t = 3 h

Con = 96 5% reduction of

catalytic activity after

Khayoon et al., 2014

4th run

= 1/1, Cat = 130 mg

MR Gl/Ac = 1/8 T = 80◦C,

4

4

4

4

t = 1 h

S

= 10

Solketal

Con = 75 80% reduction of

Con = 40

Con = 46.7

t = 6 h

j

2

Gl-Fur

MR Gl/Ac = 1/4 T =

S

= 20

Soketal

Con = 99 – Mallesham et al., 2014

Con = 98 Sel

40–90◦C, t = 3 h

MR Gl/Ben = 1/1 T =

2

60–100◦C, t = 90 min

MR Gl/Ac = 1/4 T = 40◦C,

Con = 74 – Sudarsanam et al.,

Con = 74 – Souza et al., 2014,

t = 1 h

MR Gl/Ac = 1/3 T = 70◦C,

Con = 80 Up to 4 time reusability Nair et al., 2012

– Gomes et al., 2018

Zhang et al., 2015

M-NiAlPO4activity

after the 5th run

– Gomes et al., 2018

k

5−memberedring

95%

=

Fan et al., 2012

2013

2015

t = 6 h

2

4

/ZrO

T = 60◦C, MR G/Ac = 1/3,

2

Cat = 0.2 g

Con = 96,

Y

Solketal

= 94

– Vasantha et al., 2018

(Continued)

Frontiers in Chemistry | www.frontiersin.org 8 November 2018 | Volume 6 | Article 573

Talebian-Kiakalaieh et al. Glycerol Acetalization to Value-Added Chemicals

15

TABLE 3 | Continued

Type Catalyst Optimum condition Conc(%) Yd(%) Description References

Meso-SnO2-350 T = 60◦C, t = 30 min, Ac/Gl

Heterogeneous Other

a

MR, Molar Ratio;bF, Formaldehyde;cCon, Conversion (%);dY, Yield (%);eAc, Acetone;fBen, Benzaldehyde;gBu, Butanal;hBut, Butiraldehyde;iMWCNTs, Multiwall carbon

nano-tubes;jFur, Furfural;kSel, Selectivity.

catalysts

Rare earth triflate Gl-Ac T = 25◦C Con = 100 – Pierpont et al., 2015

Organic-inorganic

hybrid catalyst

(L)Ru(II)@SBA-15 T = 25◦C, t = 20 min, MR

80LS20PS450H

PrSO3H-SBA-15400

Carbon-based

catalyst

Co(II)

(Co(III)

Purolite PD206 T = 40.66◦C, P = 42.31

KU-2 MR Gl/Ac = 1/6 T = 60◦C,

Purolite PD 206 MR Gl/Ac = 5/1 T = 20◦C,

1.25

)Al

2−0.75)O4

= 1/1, Cat = 0.125 g

MR Gl/Ac = 1/6 T = 30◦C,

t = 3 h

Al/MeOH = 1/250

+

T = 40◦C, Cat = 5 wt%,

MR G/Ac = 1/6, t = 60 min

T = 90◦C, t = 8 h, F/Gl =

1.5/1, Cat = 0.2 g

T = 28◦C, t = 30 min, Ac/Gl

=4/1, Cat = 3 wt%

T = 130◦C, t = 3 h, 2 g Gl

and 12.72 g AC, Cat = 0.1 g

bar, MR Gl/Ac = 1/4.97,

Feed flow rate = 0.49

ml/min, Cat = 0.5 g

t = 4 h

P = 120 bar

Con = 51.3

S

= 98

Solketal

Con = 94 Water resistance Sandesh et al., 2015

Con = 100

S

= 100

Solketal

Con = 90 S

S

= 60 – Li et al., 2018b

Solektal

Con = >78

S

= 73

Solketal

Con = 69.2

S

= 98.6

Solketal

Normalized exergy

destraction =

6.18%, Universal

Exergetic

efficiency =

90.36%

Con = 85% – Maksimov et al., 2011

Con = 95% Acetone-solvent Shirani et al., 2014

Higher selectivity to the

solketal in the presence

of Acetone compared

to the Furfuraldehyde

and benzaldehyde

– Lazar et al., 2018

=51–53%

Soketal

obtained over Furfural

and Methyl levulinate

instead of acetone

– Mantovani et al., 2018

– Li et al., 2018c

Optimization and

modeling of continuous

acetalization process

with subcritical acetone

Manjunathan et al.,

2018

Konwar et al., 2017

Aghbashloa et al., 2018

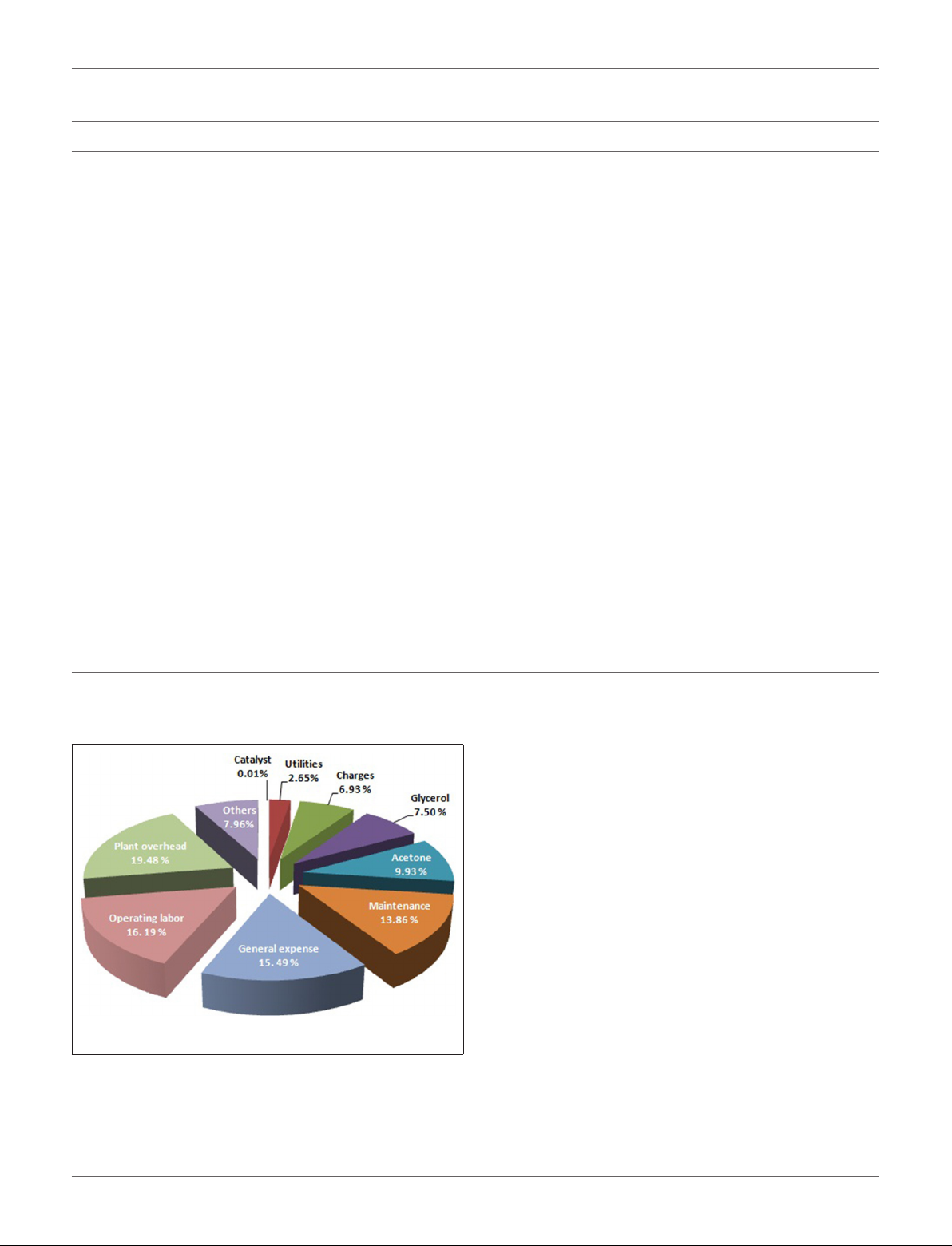

operation costs are shown in Figure 2. The results of this

study suggest t hat glycerol acetalization for the production

of solketal (fuel-additive) requires more attention and study.

Such simulation studies could provide valuable information

before large-scale industrialization of glycerol acetalization

process. Indeed, researchers could analyses and evaluate different

scenarios to evaluate the environmental and economic aspects of

this process such as material, energy and production cost.

Zeolite Based (Micro- and Mesoporous) Catalysts

Zeolite is a micro-porous, alumino-silicate mineral

conventionally used as commercial adsorbents due to its

unique porous characteristics (tunable pore size), acid sites,

FIGURE 2 | Annual operation costs.

for the material and energy balances. The proposed plant

could consume 432

t/y of glycerol and produce 620.9 t/y

of solketal. The solketal cost was 12.29US$/kg. The annual

Frontiers in Chemistry | www.frontiersin.org 9 November 2018 | Volume 6 | Article 573

and high thermal stability (Halgeri and Das, 1999). Zeolites

could be used

in various applications with a global market of

several million tons annually, which includes petrochemical,

water purification, gas separator, nuclear, and biogas industries.

Among different forms of zeolite, nano-crystalline zeolite Beta

and Y showed higher activity than micro-crystalline zeolites due

Talebian-Kiakalaieh et al. Glycerol Acetalization to Value-Added Chemicals

16

to their high surface area, lower diffusion path length and more

exposed active sites (Taufiqurrahmi et al., 2011).

Despite all the research studies which have been used

zeolite catalysts, some studies reported diffusion problems (mass

transfer resistance) by utilization of bulk zeolites due to the

presence of micro-porous network (Sharma et al., 2011). Thus,

researchers have decided to use different metal oxides, metals, or

metal nanoparticles as a support for zeolites to overcome these

limitations. However, the synthesis procedures are sometimes

laborious and require additional costs due to application of

noble metals or thermal treatment which in general consume

lots of time, energy, and cost. As a result, new concept of

“Hierarchical zeolites” have attracted much attention recently.

Based on our knowledge, application of supported hierarchical

zeolites acid catalysts is reported rarely in this field. Indeed,

hierarchical zeolites overcome the drawbacks related to hamper

mass transfer and limited accessibility of conventional zeolites

by the introduction of secondary, larger porosity within the

micro-porous framework (García-Martínez and Li, 2015). In

hierarchical meso-micro-porous zeolites, mesopores facilitate the

physical transport of reactant molecules, whereas micropores

act as nano-reactors to provide both active sites and shape

selectivity (Groen et al., 2007). Therefore, hierarchical zeolites

have recently been explored as catalysts for reactions t hat

involve bulky molecules and their outstanding activities have

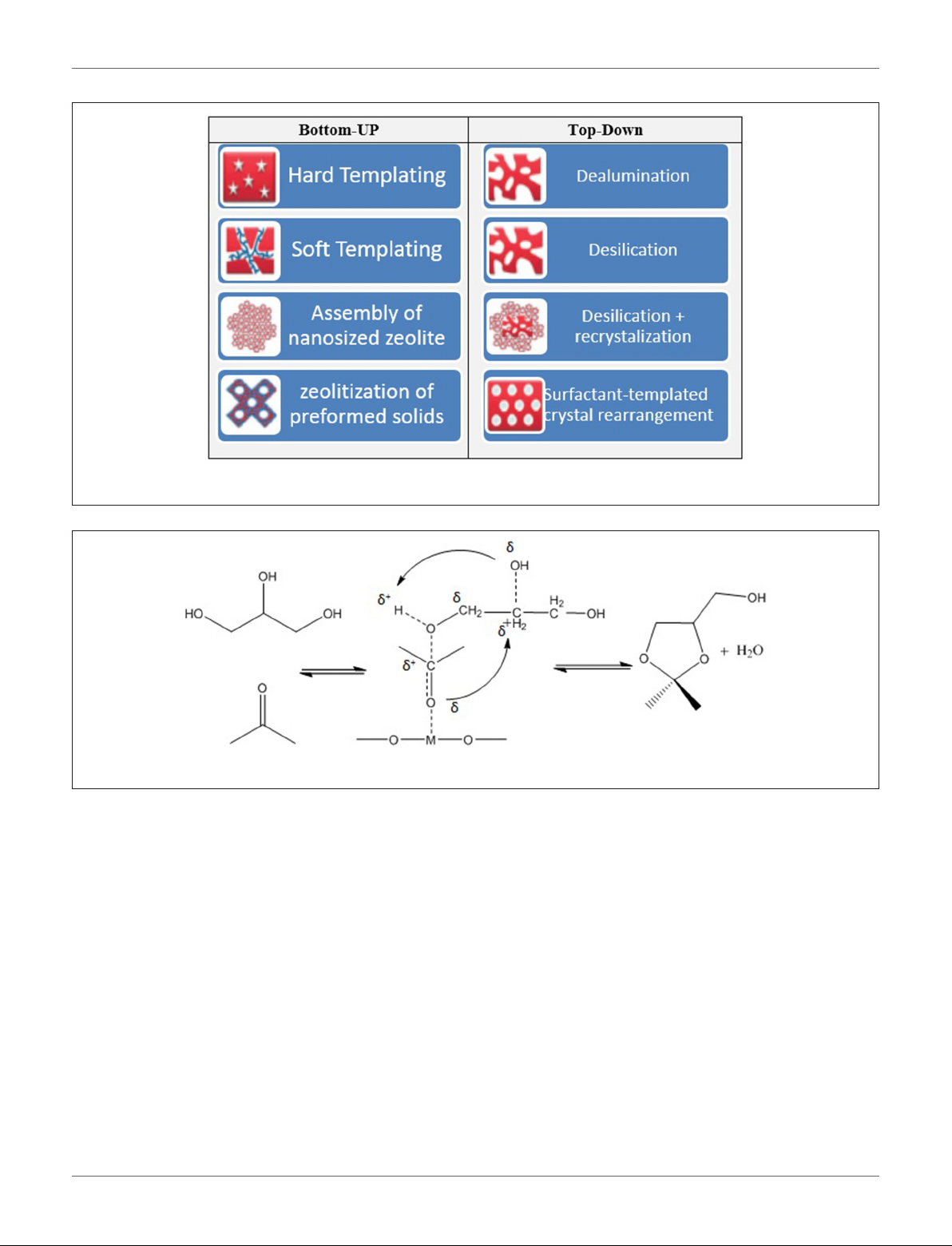

been reported (Zhou et al., 2010). There are two approaches

to introduce a hierarchical pore structure (connected pore

structure) in zeolites. In fact, the bottom up and the top-down

methods which hierarchical zeolites are synthesized directly from

a silica-alumina gel or by post-treatment of the existing zeolites,

respectively. Extra-crystalline, hard, templates such as carbon,

(Egeblad et al., 2008) starch, (Park et al., 2009) resins, (Tosheva

et al., 2000) and surfactants, (Choi et al., 2006) which are removed

by calcination after crystallization to create mesoporosity can be

used in the bottom-up approach (Fan et al., 2008). In the topdown approach to achieve hierarchical form, zeolites are posttreated after synthesis. The easiest way to introduce mesoporosity

is by dealumination, which can be achieved by steaming and

chemical treatments, such as acid leaching which remove the

resulting extra-framework alumina. The increased mesoporosity

may give rise to increasing rates in bimolecular and oligomeric

reaction pathways that require large transition states (Lupulescu

and Rimer, 2012). Another way of producing mesopores is

desilication which can be done by base leaching. Figure 3

illustrates bottom-up and top-down methods for synthesizing

hierarchical meso-porous zeolites (Vogt and Weckhuysen, 2015).

Undoubtedly, application of hierarchical zeolites as one of the

catalysts with high activity and selectivity to the desired product

should be more studied in the glycerol acetalization process due

to its characteristics and acceptable results in other chemical

processes particularly as a fluid catalytic cracking (FCC) catalyst

in petrochemical industry.

One of the early studies regarding application of zeolites, was

performed by da Silva et al. (2009) who investigated different

catalysts (K10 MMT, zeolite Beta, amberlyst 15, and p-toluene

sulfonic acid) for the conversion of glycerol to fuel-additives

in the presence of acetone or formaldehyde. Consequently, the

zeolite Beta (Si/Al = 16) reached conversion >95% in 1 h. In fact,

high content of Si/Al ratio led to the hydrophobic characteristic

of zeolite, which prevents the diffusion of water to inside

the pores and acid sites’ strength was preserved. Nevertheless,

with aqueous formaldehyde solution, the glycerol conversion

illustrated a drop to between 60 and 80% for different catalysts

(Amberlyst-15, K-10 montmorillonite, p-toluene-sulfonic acid).

Indeed the main reason was high amount of water in the reaction

medium, which shifts the equilibrium and weakens the acid sites.

Li et al. (2012) reported that mesoporous Lewis acid catalysts

could be active in acetalization of glycerol with acetone to

produce solketal. A series of three-dimensional mesoporous

silicate catalysts (Hf-TUD-1, Zr-TUD-1, Al-TUD-1, and SnMCM-41) synthesized and two of these catalysts (Hf-TUD1 and Zr-TUD-1) showed excellent catalytic activities in

solketal production. Indeed, 65 and 64% glycerol conversion

obtained over Hf-TUD-1 and Zr-TUD-1 catalysts, respe ctively,

at optimum reaction condition of 2/1 molar ratio of acetone

to glycerol, 25 mg of catalyst weigh, at 80◦C in 6 h reaction

time. The main reasons for such high activity of synthesized

catalysts were wide pores (Hf-TUD-1 = 0.6 cm2/g, Zr-TUD1 = 0.8 cm2/g), large specific surface area (Hf-TUD-1 = 715

m2/g, Zr-TUD-1 = 651 m2/g), large pore size (Hf-TUD-1 =

4 nm, Zr-TUD-1 = 13.3 nm), the amount of accessible acid sites,

and a relatively hydrophobic surface of catalyst. In addition,

the active mesoporous materials didn’t suffer from leaching

and could be efficiently reused in consecutive catalytic cycles.

They also proposed a reaction mechanism for acetalization

reaction in the presence of Lewis acid catalysts. The Lewis acid

metal sites coordinate and activate acetone’s carbonyl group.

Then, the carbon atom of the carbonyl group is attacked by

the primary alcoholic group of glycerol accompanied by the

formation of a bond between the carbonyl oxygen atom and

the secondary carbon atom of glycerol. Finally, solketal forms

through the dehydration step. Figure 4 displays the detailed

reaction mechanism.

Jamil et al. (2017) used different tailored forms of zeolite

Beta in the condensation of bio-glycerol with acetone for

production of the Solketal. The zeolite Beta catalysts treated with

acids (hydrochloric acid, nitric acid, and oxalic acid) exhibited

enhanced catalytic activity, irrespective of the nature of the acid

used for the de-alumination. The nitric acid-treated beta zeolite

sample (AB-2) exhibited a higher conversion than the other acidtreated samples. At optimum conditions (1:6 glycerol to acetone

molar ratio, 4 h reaction time, 60◦C reaction temperature) the

bio-glycerol conversion and solketal yield were 94.26% and

94.21 wt%, respectively. The AB-2 sample was reusable for at

least 4 times without any significant loss in its activity with

approximately >80% glycerol conversion and >80% solketal

yield.

Kowalska-Kus et al. (2017) investigated the glycerol

acetalization reaction with acetone in the presence of hierarchical

zeolites comprising pores of different diameters (MFI, BEA,

and MOR) at 343 K and 1:1 glycerol to acetone molar ratio.

The best catalytic performance for glycerol acetalization, which

was 100% solketal selectivity at 80% reaction conversion, was

achieved over hierarchical (micro/mesoporous) MFI zeolites. A

Frontiers in Chemistry | www.frontiersin.org 10 November 2018 | Volume 6 | Article 573

Talebian-Kiakalaieh et al. Glycerol Acetalization to Value-Added Chemicals

17

FIGURE 3 | Bottom-up and top-down models for synthesizing hierarchical mesoporous zeolites.

FIGURE 4 | Proposed reaction mechanism for the acetalization of glycerol and acetone over Lewis acid catalyst.

significant increase in reaction conversion and solketal selectivity

in the studied reaction resulted from the easier accessibility of

the active sites to reagents due to the formation of mesopores by

means of desilication of the micro-porous zeolites.

Heteropoly Acid Based Catalysts

Application of heteropoly acid (HPA) has attracted much

attention due to its wide applic ations in biodiesel industry and

production of value-added chemical from glycerol. HPAs are

highly stable against humidity and air,low toxicity, high solubility

in polar solvents, production of less residues than mineral acids,

less corrosive, and highly safer than other catalysts (Martin

et al., 2012). Tungstophosphoric acid (HPW), silicotungstic

acid (HSiW), and Phosphomolybdic acid (HPMo) are three

commercially available HPAs. The HPW is a common HPA

catalyst which is widely used. HPA catalysts have high ability

for adjustment by modifying their central atoms with various

Frontiers in Chemistry | www.frontiersin.org 11 November 2018 | Volume 6 | Article 573

compounds. Researchers have attempted to increase the catalytic

activity and long-life stability of the catalysts to achieve the

highest fuel-additive yield. The Cs/HPW catalyst displayed one of

the highest potential catalyst in acetalization of glycerol with 98%

selectivity to solketal at about 95% glycerol conversion (

t al., 2018a). HPA’spossessed Keggin structure. It is the structural

e

Chen

form of α-Keggin anions, which have a general formula of

[XM12O40]n−, where X, M, and O represent the heteroatom, the

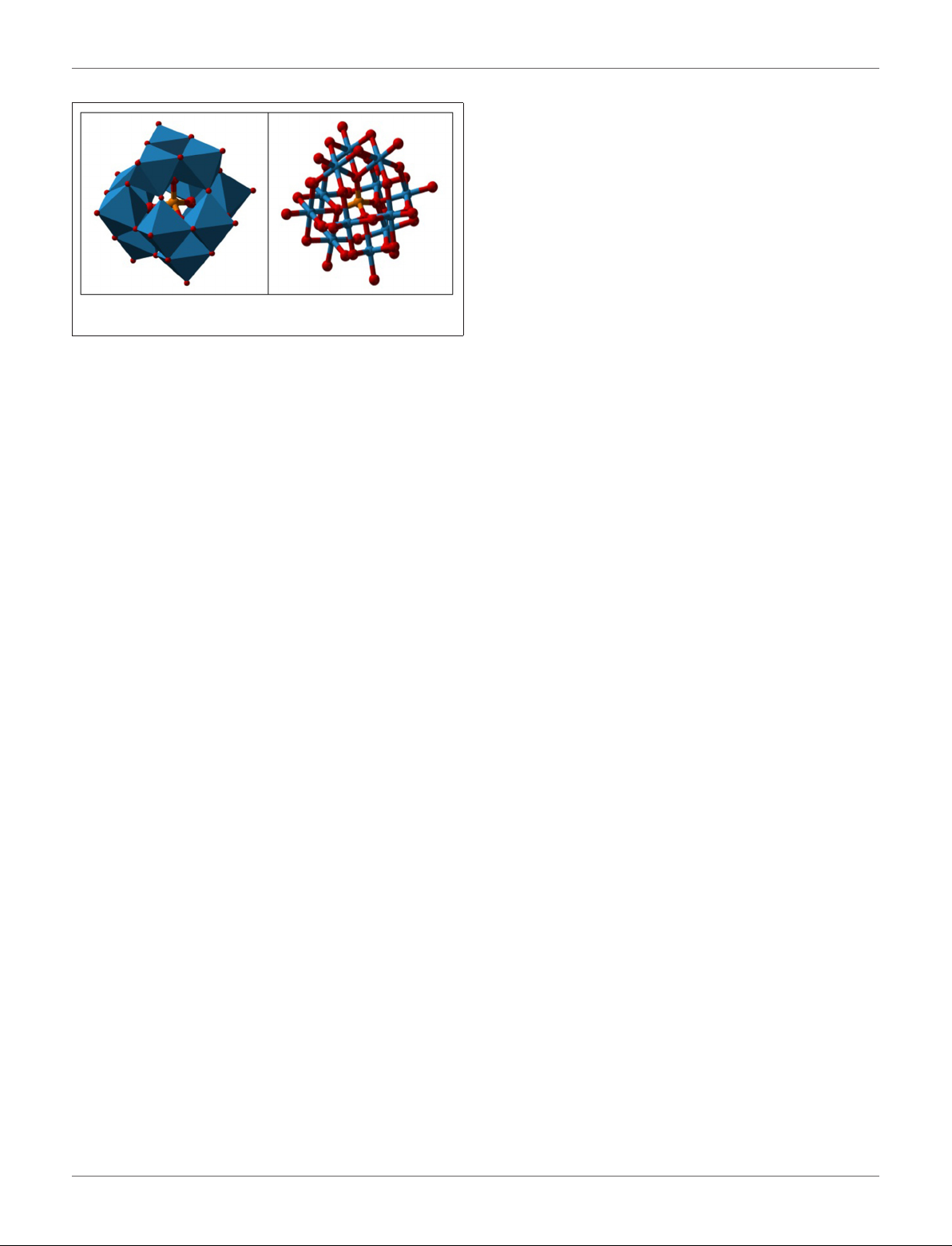

addenda atom, and oxygen, respectively (Figure 5). The structure

self-assembles in acidic aqueous solution and is the most stable

structure of polyoxometalate catalysts. Despite the enormous

applications of HPA catalysts as active components in various

heterogeneous catalytic processes [e.g., glycerol dehydration to

acrolein (Talebian-Kiakalaieh et al., 2014), glycerol oxidation to

glyceric acid (Talebian-Kiakalaieh et al., 2018)], application of

these type

s of catalysts are rarely reported in glycerol acetalization

reaction.

Talebian-Kiakalaieh et al. Glycerol Acetalization to Value-Added Chemicals

18

Metal Based Catalysts

Mixed oxides, phosphates, and pyrophosphates have been

used in glycerol acetalization to fuel-additives. Metal oxide

catalysts such as niobium oxide (Nb2O5), tungsten oxides

(WO3), silicon dioxide (SiO2) have been widely used in various

chemical processes. The most important factors about metalbased catalysts are their synthesis method (especially calcination

temperature) and their binary or tertiary combinations which

have detrimental impact on physicochemical characteristics

FIGURE 5 | HPA keggin structure.

The glycerol acetalization was studied using a series of

supported HPAs [HPW, HPMo, HSiW, and molybdosilisic

(SiMo)], immobilized in silica catalysts by sol–gel method

(Ferreira et al., 2010). As results, all catalysts exhibited high

solketal selectivities (near S

= 98%) at quite complete

Solketal

conversions at optimum reaction conditions of 70◦C reaction

temperature, 0.2 g catalyst weight, 6:1 molar ratio of acetone

to glycerol and after 4h reaction time. Also, the catalytic

activities decreased in the following order: HPW-S > SiW-S

>PMo-S > SiMo-S. All the catalysts exhibited high stability

even after the fourth consecutive run, having lost only 10–

13% of their initial activity. In another study, Narkhede and

Patel (2014) achieved high selectivity toward solketal using

supported SiW wit h MCM-41 catalysts (30% SiW11/MCM-41,

30% SiW12/MCM-41) in the presence of benzaldehyde. The

results indicated that the 30%-SiW11/MCM-41 could reach the

highest solketal selectivity of 82 at 85% glycerol conversion

at room temperature (30◦C), 1/1.2 molar ratio of glycerol to

benzaldehyde, 100 mg catalyst weight and in 1h. Also, tuning of

the acidity of the parent SiW led to an increase in the selectivity

toward solketal. High activity of t hese catalysts was attributed

to their strength of acidity, wide pores and large specific surface

area.

da Silva et al. (2015b) evaluated the activity of various

Brønsted acid catalysts e.g., HPW, H2SO4, p-toluene sulfonic

acid, PMo, or SiW on glycerol ketalization with different ketones

(e.g., propanone, butanone, cyclopentanone, and cyclohexanone)

at room temperature and in the absence of an auxiliary solvent.

The HPW sample exhibited the highest activity among the

Brønsted acid catalysts and exhibited high (> 85%) selectivity

toward five-membered (solketal) cyclic ketals. The highest (98%)

selectivity of solketal is obtained at 288 K reaction temperature,

1 mol% catalyst (HPW) loading, 1:30 glycerol to ketone

(propanone) molar ratio. The activity of different tested catalysts

was as follows HPW> p-toluene sulfonic acid > PMo > SiW

> H2SO4with 83% > 76% > 41% > 40% > 31%, respectively.

In addition, the results revealed that the application of various

ketones with Brønsted acid catalyst in absence of solvent for

ketalization of glycerol has significant influence on product

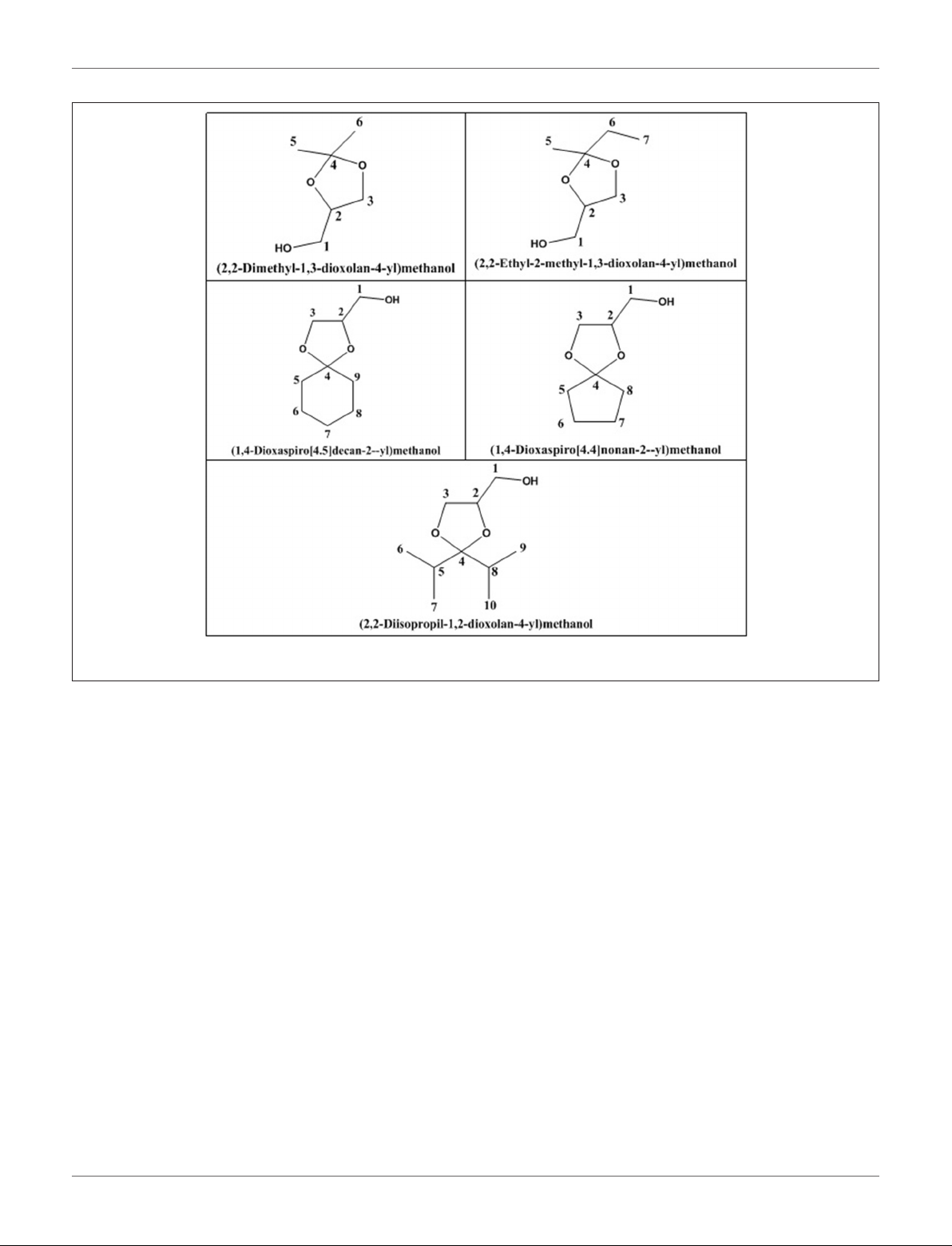

distribution. Figure 6 summarizes the possible products that can

be obtained as a result of different ketone application.

catalyst (

w

with two different methods of fusion and wet-impregnation.

XRD results suggested that solid solutions of nano-crystalline

SnO2were formed due to the incorporation of Mo and W

cations into the SnO2lattice. Textural characterization results

revealed that all the compounds showed smaller crystallite

size, large specific surface area (WO3-SnO2= 32 m2/g and

MoO3-SnO2= 56 m2/g), and high porosity. Moreover, Raman

measurements and TPR results confirmed the formation of

more oxygen vacancy defects in the doped catalysts along with

facile reduction of the doped SnO2, respectively. The positive

impact of Mo and W oxides on the acidic properties of the

SnO2was revealed by NH3-TPD. Total acidity of MoO3-SnO

and WO3-SnO2were 81.45 and 61.81 µmol/g, respectively.

The presence of larger number of Brønsted (B) acidic sites

vs. Lewis (L) sites (B/L = >95%) was confirmed by pyridineFTIR characterization. High selectivity to solketal (96%) at

approximately 70% glycerol conversion was achieved over the

MoO3-SnO2sample at the optimum reaction condition of 1:1

glycerol to acetone molar ratio, 5 wt% catalyst loading in 150 min.

In addition, this catalyst reached around 65% solketal selectivity

at almost complete glycerol conversion in the presence of

furfural (1:1 glycerol to furfural molar ratio) in 120 min. Finally,

applications of different mono-substituted furfural compounds

(e.g., 5-methylfurfural, 5-nitrofurfural, 5-chlorofurfural, and 5hydroxymethyl furfural) were evaluated for acetalization of

glycerol in the presence of MoO3/SnO2sample. The results

confirmed that all the substituted compounds reached lower

glycerol conversion than furfural. This observation confirms

the impact of steric hindrance induced with substitutes rather

than the electronic effects of the substituent (i.e., inductive,

resonance and hyper conjugation influences). In detail, the

acetalization reaction reached >61% solketal selectivity at >60%

glycerol conversion in the presence of different mono-substituted

furfural.

e

solventless/solvent-containing systems [Formalin (solvent-less),

Para-formaldehyde (water), Para-formaldehyde (solventless)] in

the presence of Zr-SBA-16 catalyst with three different Si/Zr

ratios (100, 50, and 25) for glycerol acetalization to glycerol

formal (GF). Results showed that the Zr–SBA-16(100) sample

exhibited 24 and 76% selectivity to the solketal and dioxane,

respectively, at 77% glycerol conversion at optimum reaction

conditions of 100◦C reaction temperature, 1:1 glycerol to paraformaldehyde molar ratio. In addition, the Zr–SBA-16(50)

Talebian-Kiakalaieh et al., 2014).

Mallesham et al. (2013) synthesized a series of supported SnO

ith molybdenum (Mo) and tungsten (W) solid acids catalysts

In another study,

Gonzalez-Arellano et al. (2014b) also

valuated the application of various formaldehyde sources and

2

2

Frontiers in Chemistry | www.frontiersin.org 12 November 2018 | Volume 6 | Article 573

Talebian-Kiakalaieh et al. Glycerol Acetalization to Value-Added Chemicals

19

FIGURE 6 | Products with application of various ketones.

sample could be successfully reused up to five times under

identical reaction conditions, without any noticeable decrease

in activity. The main reason for better stability of Zr-SBA-16

(50) compared to the Zr-SBA-16 (100) was acidity. Indeed, the

Zr-SBA-16(50) possessed higher amount of total acidity (116

µmol/g) with Lewis acidic nature (B/L = 36/80) compared to

the Zr-SBA-16 (100) with just 40 µmol/g total acidity and with

Bronsted acidic nature (B/L = 28/12).

Gonzalez-Arellano et al. (2014a) continued their study on

the acetalization of glycerol with different aldehyde sources

(para-formaldehyde, benzaldehyde, furfural, and acetone) in the

presence of another newly synthesized heterogeneous catalyst,

which was supported iron oxide nano-particle system of a

mesoporous alumino-silicate heterogeneous catalyst (Fe/Al-SBA-

15). The characterization results confirmed that Fe/Al-SBA-15

possessed high surface area (688 m2/g) with Brønsted acidic

nature (88 µmol−1g−1). Experimental results revealed that the

product distribution was totally dependent on the use of different

aldehyde sources. In fact, acetalization of glycerol with paraformaldehyde results in the production of dioxane (selectivity

66%) as the main product compared to the dioxolane with

just 34% selectivity at almost complete glycerol conversion. In

contrast, the use of other aldehyde sources led to production

of dioxolane (solketal) as the main product. The product’s

selectivities (dioxolane/dioxane) were 84%/16% at 70% glycerol

conversion, 60%/40% at >95% glycerol conversion, and 99%/1%

at 58% glycerol conversion in the presence of benzaldehyde,

furfural and acetone, respectively. Finally, the Fe/Al-SBA-15

showed the highest stability after five consecutive runs without

significant reduction in catalyst activity in the presence of acetone

as the aldehyde source.

Gadamsetti et al. (2015) synthesized a series of supported SBA-

5 with molybdenum phosphate (MoPO 5–50 wt%) catalysts

1

for the acetalization of glycerol with acetone. Synthesized

catalysts were characterized and the XRD results revealed that

unsupported MoPO exhibits the formation of (MoO2)2P2O

phase and is dispersed well on the SBA-15 surface. Also,

Raman spectra characterization confirmed the existence of

MoPO species [(MoO2)2P2O7] in samples with more than 40

wt% MoPO supported on SBA-15. In addition the UV-DRS

results revealed the presence of both isolated tetrahedrally and

isolated octahedrally coordinated Mo centers in the supported

and unsupported MoPO. Finally, the NH3-TPD analysis shows

that the total acidity surged from 0.2 to almost 1 mmol/g with

MoPO loading from 5 to 40 wt%; however, total acidity dropped

by increasing MoPO loading beyond 40 wt%. In contrast, specific

7

Frontiers in Chemistry | www.frontiersin.org 13 November 2018 | Volume 6 | Article 573

Talebian-Kiakalaieh et al. Glycerol Acetalization to Value-Added Chemicals

20

surface area of synthesized catalysts showed a downward trend

from 688 to 125 m2/g for 5 to 50 wt% of MoPO loading. Acidity

of catalysts had negative impact on catalytic performance. The

40 wt% MoPO/SBA-15 sample showed the best catalytic activity

with 98% Solketal selectivity at complete conversion (100%)

at optimal reaction condition of 3:1 molar ratio of acetone to

glycerol, 50 mg catalyst loading, room temperature, in 2h.

da Silva et al. (2017) used solid SnF2 catalyst for glycerol

etalization with propanone to solketal. The SnF2catalyst

k

reached 97% selectivity of solketal at 97% glycerol conversion at

optimum condition of glycerol (21.0 mmol), propanone (168.0

mmol) molar ratio (1:8), CH3CN (15mL), at room temperature

(298 K). Most importantly, this catalyst exhibited incredible

stability even after four times recycling and reuse with almost

constant reaction conversion and solketal selectivity.

Another recent study on a series of zirconia-based catalysts

for the acetalization of glycerol suggested that the activity

increased in the order of ZrO2< WOx/ZrO2< MoOx/ZrO

2−

<SO

/ZrO2. In particular, the use of a sulfated zirconia catalyst

4

led to ∼98% conversion of glycerol and ∼97% selectivity to

solketal. The surface acidity and crystalline state of ZrO2on

2−

the SO

/ZrO2catalyst were found to be very influential to the

4

catalytic performances (Reddy et al., 2011).

Kapkowski et al. (2017) synthesized a series of nano-silica

supported Re, Ru, Ir, Rh NPs along with different mixture of

the metal (Re, Ru, Ir, and Rh) catalysts for acetalization of

glycerol with acetone or butanone. It was found that nano-SiO

supported Re (1.0%Re/SiO2) was a highly efficient catalyst in

glycerol acetalization reaction for solketal production exhibiting

the highest activity (TOF = 620.7 h−1) with 94.1% selectivity

to solketal at 100% glycerol conversion. The addition of Ir

(1.0% Re.Ir (1:1)/SiO2) could also slightly improve the solketal

selectivity to 96% and catalyst activity to TOF = 630.5 h

−1

at complete conversion. Although 1.0%Re/SiO2favors fivemembered cycles, its substitution with Mo alters this selectivity

and both five- and six-membered products can be obtained. In

detail, the solketal selectivity and catalyst activity decreased to

about 78.9% and 336.9 h−1, respectively. Despite the addition of

Rh [1.0%RuRh(1:1)/Mo], the solketal selectivity did not increase

more than 93.4%.

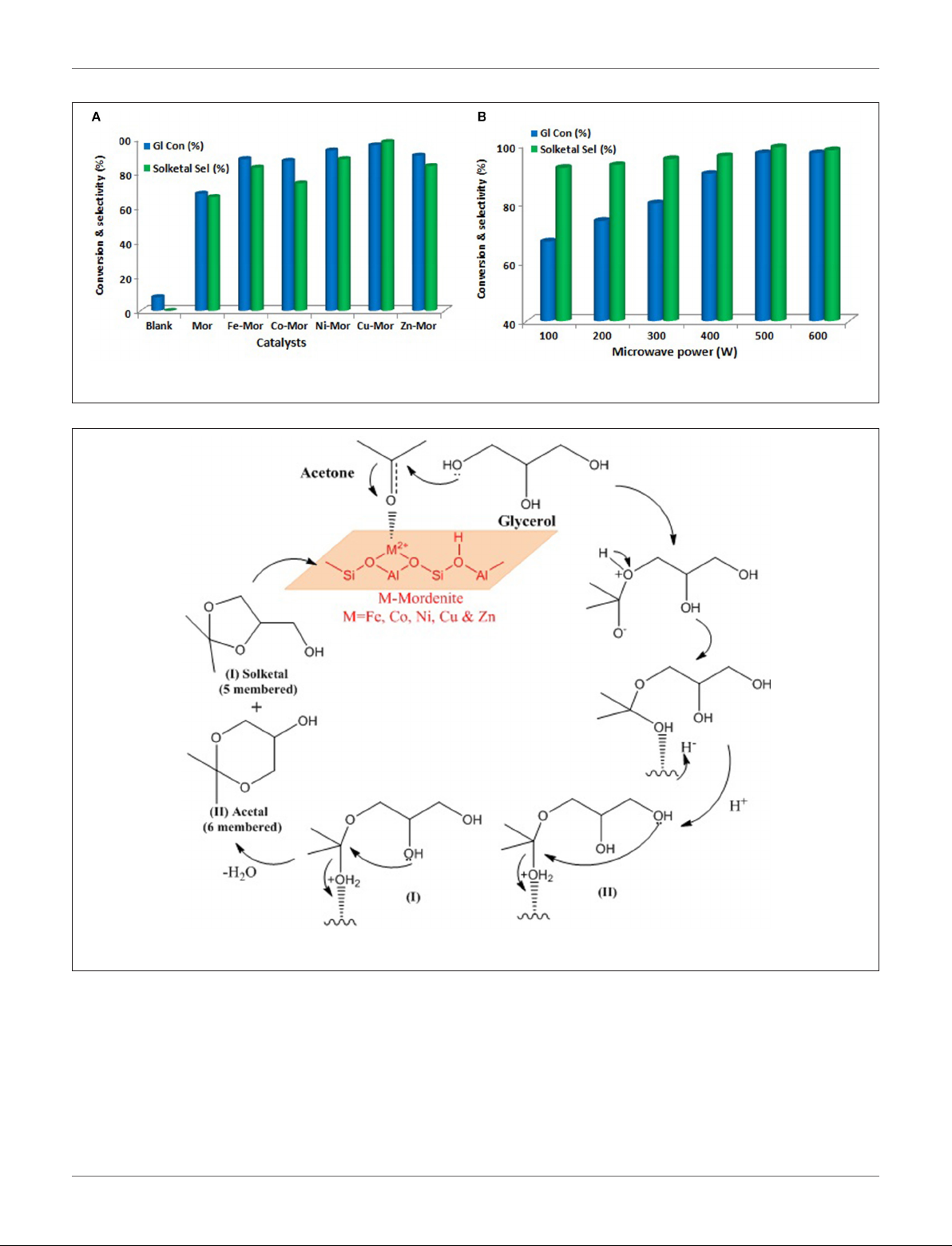

Priya et al. (2017) used microwave irradiation as a heating

source in glycerol acetalization to fuel-additives over different

transition-metal-ion-promoted mordenite solid acid catalysts

which were synthesized by wet impregnation method. The

transition metal ions include Fe, Co, Ni, Cu, and Zn. This

approach is considered notably clean and green in this field. The

results from the microwave irradiation system were compared to

those from other processes that use conventional heating sources

to ascertain its efficiency and efficacy. The Cu-Mor catalyst

showed the highest activity because of the large number of acidic

sites and the synergetic effects of metal particles interacting

with mordenite. The activity of synthesized s amples is shown in

Figure 7A. Using Cu-Mor sample and 3:1 acetone/glycerol molar

ratio, 98% solketal selectivity at 95% glycerol conversion was

obtained in only 15 min. Figure 7B illustrates how the glycerol

conversion and solketal selectivity in the presence of the best

sample of Cu-Mor varies with microwave power. The reaction

mechanism of glycerol acetalization using microwave irradiation

and using Cu-Mor catalyst was proposed (Figure 8). Finally,

the Cu-Mor sample exhibited an excellent reusability of up

to four reaction cycles with only a marginal drop in reaction

conversion.

Timofeeva et al. (2017) investigated glycerol acetalization with

acetone using iso-structural MOFs of the families MIL-100(M)

and MIL-53(M) (M = V, Al, Fe, and Cr) and mixed MIL53(Al/V). The results revealed that the metal ion’s type in MIL100(M) and MIL-53(M) has significant impact on the rate of

reaction and selectivity of desired product. The zero point of

charge of the surface (pH

) values are revealed that the acidity

PZC

of MIL-100(M) dropped in the following order: MIL-100(V)

> MIL−100(Al) > MIL-100(Fe) > MIL-100(Cr). As a result,

glycerol conversion decreases in the following order V3+> Al

> Fe3+> Cr3+. Indeed, literature analysis revealed that isomer

selectivity depends on the length of the M-O bond in MIL-53(M)

and MIL-100(M). Thus, length of M-O bond in MIL-53(M) and

2

MIL-100(M) change in the following order: (Å): MIL-53(Cr)

[2.08 (Serre et al., 2002)] > MIL-53(Al) [1.82–2.00 (Loiseau

et al., 2004)] > MIL-47(V) [1.946–1.998 (Karin et al., 2004)]

and MIL-100(Cr) [2.18 (Férey et al., 2004)] > MIL-100(Fe)

[2.065 (Horcajada et al., 2007)] > MIL-100(Al) [1.831–1.995

(Volkringer et al., 2009)], respectively. The decrease in the length

of the M-O bond favors increased formation of solketal for both

samples. The solketal selectivities increased from approximately

80, 87, and almost 90% over MIL-100(Cr), MIL-100(Fe), and

2

MIL-100(Al). Similarly, it surged from about 80 to 90%, and

then around 97% for MIL-53(Cr), MIL-53(Al), and MIL-53(V),

respectively. Evaluation of mixed MIL-53(Al,V) showed that the

reaction rate and solketal selectivity rise from 90 to 97.5% with

increasing V3+content from 0 to 1% in MIL-53(Al,V). Also, the

efficiencies of MIL-100(V) (87 mol/mol) and MIL-47(V) (106.1

mol/mol), were higher than those of H2SO4, SnCl2and p-toluene

sulfonic acid with 50.9, 89.6, and 58.9 mol/mol, respe ctively at

25◦C. The MIL-100(V) catalyst exhibited four times recycling

and reusability with negligible reduction in glycerol conversion

(>80%).

de Carvalho et al. (2017) synthesized a series of titanatenano-