OPERATOR’S MANUAL

CARTED RAKE

WR3008

WR3010

WR3012

HSMFG0908

TABLE OF CONTENTS

T ABLE OF CONTENTS...............................................................................................INSIDE COVER

WARRANTY & W ARRANTY ST A TEMENT ..........................................................................................1

DEALER PRE-DELIVERY & DELIVERY CHECKLIST.........................................................................3

SPECIFICATIONS..................................................................................................................................5

BOL T TORQUE CHART.........................................................................................................................6

BE ALERT SYMBOL................................................................................................................................7

SAFETY RULES...................................................................................................................................8-9

DANGER - WARNING DECALS........................................................................................................ ...10

OPERA TION WR3008, WR3010 & WR3012.................................................................................11-12

ADJUSTMENTS...............................................................................................................................13-14

OPTIONAL CENTER KICKER WHEEL...............................................................................................15

LUBRICA TION WR3008, WR3010 & WR3012...................................................................................16

DECAL LOCATION................................................................................................................. ...............17

TROUBLE SHOOTING ...........................................................................................................................18

ORDERING P ARTS - ABOUT IMPROVEMENTS..............................................................................19

P ARTS LISTS & DIAGRAMS WR3008, WR3010 & WR3012.....................................................20-27

SERVICE RECORDS...........................................................................................................................28

H&S WARRANTY

H&S Manufacturing Co., Inc. (“H&S”) warrants this product to be free from defect in material and

workmanship. Except as noted below, this warranty term is twelve (12) months from the date of delivery of the

product to the original purchaser by an authorized H&S dealer. Under this warranty, H&S will repair or replace, at

its option, any covered part which is found to be defective in material or workmanship during the applicable

warranty term. In no case will the covered repair cost of a part or parts exceed the replacement cost of that part.

Warranty service must be performed by H&S or a dealer authorized by H&S to sell and/or service the product

involved, which will use only new or remanufactured parts or components furnished by H&S. This warranty

includes approved parts and labor to fix the product but does not include, and the purchaser is responsible for,

any service call and/or transportation of the product to and from the dealer’s place of business, for any premium

charged for overtime labor requested by the purchaser, and for any service work not directly related to any defect

covered under this warranty . This warranty includes only those components of the product manufactured by H&S.

Warranty for any component not manufactured by H&S including, but not limited to, engines, batteries, tires, rims,

hydraulic motors, pumps, etc., are covered by the warranty, if any, provided separately by their respective

manufacturers.

This warranty in all its parts, is extended solely to the original purchaser of the product, is terminated upon

any subsequent transfer or sale from or by the original purchaser and extends no third party benefits or rights

whatsoever .

The warranty term for any product used in any commercial, custom, for hire or rental application, is limited to

six (6) months from the date of delivery of the product to the original purchaser by an authorized H&S dealer.

Polybonded (polyethylene and plywood) panels utilized in H&S Manure Spreaders are warrantied, to the

original purchaser, to not wear through and the polyethylene overlay to not tear free of the plywood for the

functional life of the spreader. This specific warranty on polybonded panels includes only replacement of any

defective panel part without any allowance for labor beyond the terms of the general warranty (12 or 6 months),

and is further limited to manure spreaders used to spread normal agricultural manure.

This warranty does not include: (1) Any product that has been altered or modified in ways not approved by

H&S; (2) Depreciation or damage caused by normal wear, misuse, improper or insuf ficient maintenance, improper

operation, accident or failure to follow the product Operator Manual recommendations and product decal

recommendations; (3) Normal maintenance parts and service; (4) Repairs made with parts other than those

available from H&S or performed by anyone other than H&S or a dealer authorized by H&S to sell and/or service

the product involved.

To secure warranty service the purchaser must report the product defect to a dealer authorized by H&S to

sell and/or service the product involved within the applicable warranty term together with evidence of the warranty

start date and make the product available to that dealer within a reasonable period of time.

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE OF THIS

WARRANTY. H&S and the companies affiliated with it makes no warranties, representations, or promises,

express or implied, as to the quality or performance or freedom from defect of its products other than those set

forth above and NO IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS OR FITNESS FOR A

PARTICULAR PURPOSE IS MADE. IN NO EVENT WILL THE DEALER, H&S OR ANY COMPANY

AFFILIATED WITH H&S BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. The ONLY

REMEDY the purchaser has in connection with the breach of performance of any warranty on H&S products are

those set forth above.

The selling dealer has no authority to make any representation or promise on behalf of H&S, or to modify the

terms or limitations of this warranty in any way .

-1-

-2-

AFTER COMPLETION, DEALER SHOULD REMOVE AND RETAIN FOR RECORDS

FRONTIER

DEALER PRE-DELIVERY CHECK LIST

After the Carted Rake has been completely set-up, check to be certain it is in correct operating order before

delivering to the customer. The following is a list of points to inspect. Check off each item as you have made

the proper adjustments and found the item operating satisfactorily.

All grease fittings have been lubricated

!

(See lubrication guide in this manual).

All mechanisms are operating trouble free.

!

Rake wheels touch ground in unison when lowered into position.

!

(Rake setting level)

All bolts and fasteners are tight.

!

All decals are in place and legible.

!

(Dealer’s Name) Model Number

Serial Number

(Signature of Pre-Delivery Inspector) (Inspection Date)

DEALER DELIVERY CHECK LIST

This check list that follows is an important reminder of valuable information that should be passed on to the

customer at the time this Carted Rake is delivered.

Check off each item as you explain it to the customer .

This delivery check list, when properly filled out and signed assures the customer that the Pre-delivery

service was satisfactorily performed.

Explain to the customer that the pre-delivery inspection was made.

!

Explain to the customer all the safety precautions they must excercise when operating this unit.

!

Explain raking and windrow width adjustments.

!

Explain to customer that regular lubrication is required for proper operation and long life of

!

machine. Show customer the lubrication section of Owner’s Manual.

Give the customer Owner’s Manual and make sure they read and understand all operating and

!

service instructions.

Record Serial Number on page 19 of this Manual.

!

Date Delivered Dealer’s Name

By

Signature of Original Buyer

-3-

-4-

FRONTIER WR3008, WR3010, WR3012

CARTED RAKE

Your new Frontier Carted Rake has been manufactured of the finest quality materials and

components. The performance you get from your machine is largely dependent upon how well you

read and understand this manual and apply this knowledge. There is a right and a wrong way to

do everything. Please do not assume that you know how to operate and maintain your Heavy Duty

Wheel Rake before reading this manual carefully . Keep this manual available for ready reference.

SPECIFICA TIONS

WR3008 WR3010 WR3012

Number of Wheels. . . . . . . . . . . . . . 8. . . . . . . . . . . . . . . . .. . . . . . 10. . . . . . . . . . . . . . . . . . . . . . . . . 12

Wheel Diameter . . . . . . . . . . . . . . . . 55”. . . . . . . . . . . . . . . . . . . . . 55”. . . . . . . . . . . . . . . . . . . . . . . . 55”

T eeth per Wheel. . . . . . . . . . . . . . . . 40. . . . . . . . . . . . . . . . . . . . . .40. . . . . . . . . . . . . . . . . . . . . . . . .40

T ooth Diameter . . . . . . . . . . . . . . . . .7mm. . . . . . . . . . . . . . . . . . . .7mm. . . . . . . . . . . . . . . . . . . . . 7mm

Transport Width. . . . . . . . . . . . . . . . 9’6”. . . . . . . . . . . . . . . . . . . . .9’6”. . . . . . . . . . . . . . . . . . . . . .10’6”

Transport Length. . . . . . . . . . . . . . . 13’. . . . . . . . . . . . . . . . . . . . . 15’6”. . . . . . . . . . . . . . . . . . . . . . .18’

Windrow Width Adjustment. . . . . . .4’-6’. . . . . . . . . . . . . . . . . . . . 4’-6’. . . . . . . . . . . . . . . . . . . . . . 4’-6’

Raking Width. . . . . . . . . . . . . . . . . . 16’-20’. . . . . . . . . . . . . . . . . . 18’-22’. . . . . . . . . . . . . . . . . .20’-24’

3 Settings. . . . . . . . . . . . . . . 3 Settings. . . . . . . . . . . . 3 Settings

Weight. . . . . . . . . . . . . . . . . . . . . . . .1125 lbs. . . . . . . . . . . . . . . . .1275 lbs. . . . . . . . . . . . . . .1440 lbs.

Number of Transport Wheels. . . . . 2. . . . . . . . . . . . . . . . . . . . . . .2. . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Center Kicker Wheel. . . . . . . . . . . . N/A. . . . . . . . . . . . . . . . . . . . .Optional. . . . . . . . . . . . . . . .Optional

Rake Wheel Hubs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Tapered Bearings. . . . . . . . . . . . . . . . . . .

Wing Flex. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Limited. . . . . . . . . . . . . . . . . . . . . . .

Hitch Jack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .St andard. . . . . . . . . . . . . . . . . . . . . . .

Tires. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ST175/80D13. . . . . . . . . . . . . . . . . . . .

NOTE:

Determine right or left side of Carted Rake by viewing it from the rear. If instructions or

parts lists call for hardened bolts see p age 6 to identify .

-5-

-6-

BE

YOUR SAFETY

ALERT!

THIS SYMBOL IS USED THROUGHOUT THIS BOOK WHENEVER YOUR PERSONAL SAFETY IS

INVOLVED. TAKE TIME TO BE CAREFUL. REMEMBER: THE CAREFUL OPERATOR IS THE BEST

OPERATOR. MOST ACCIDENTS ARE CAUSED BY HUMAN ERROR. CERTAIN PRECAUTIONS

MUST BE OBSERVED TO PREVENT THE POSSIBILITY OF INJURY OR DAMAGE.

TRACTORS

This operator’s manual uses the term “Tractor” when identifying the power source.

IS INVOLVED.

-7-

RECOGNIZE SAFETY INFORMA TION

This is the safety-alert symbol. When you see this symbol

on your machine or in this manual, be alert to the potential

for personal injury .

Follow recommended precautions and safe operating

practices.

UNDERST AND SIGNAL WORDS

A signal word- DANGER, WARNING, or CAUTION - is

used with the safety-alert symbol. DANGER identifies the

most serious hazards.

Safety signs with signal word DANGER or WARNING are

typically near specific hazards.

General precautions are listed on CAUTION safety signs.

FOLLOW SAFETY INSTRUCTIONS

Carefully read all safety messages in this manual,

and all safety signs on your machine. Follow all

recommended precautions and safe operating

procedures.

Keep signs in good condition. Immediately replace

any missing or damaged signs.

OBSERVE MAXIMUM TRANSPORT SPEED

The maximum transport speed for this

implement is 32 km/h (20 mph).

Some tractors are capable of operating at speeds that exceed

the maximum transport speed of this implement. Regardless of

the maximum speed capability of the tractor being used to tow

this implement, do not exceed the implement’s maximum

transport speed.

Exceeding the implements maximum transport speed can result in:

" Loss of control of the tractor/implement combination

" Reduced or no ability to stop during braking

" Implement tire failure

" Damage to the implement structure or its components

Use additional caution and reduce speed when towing under

adverse surface conditions, when turning, and when on inclines.

Do not attempt transport if the fully loaded implement weighs more

than 1.5 times the weight of the tractor.

-8-

TRACTORS

This operators manual uses the term “Tractor” when identifying the power source.

WARNING

TO PREVENT SERIOUS INJURY OR DEATH

BEFORE YOU ATTEMPT TO OPERATE THIS EQUIPMENT, READ AND STUDY THE FOLLOWING

INFORMATION. IN ADDITION, MAKE SURE THAT EVERY INDIVIDUAL WHO OPERATES OR WORKS

WITH THIS EQUIPMENT, WHETHER FAMILY MEMBER OR EMPLOYEE, IS FAMILIAR WITH THESE

SAFETY PRECAUTIONS.

DO NOT ALLOW PERSONNEL OTHER THAN THE QUALIFIED OPERATOR NEAR THE

MACHINE.

IF RAKE ARMS ARE IN THE RAISED POSITION, MAKE SURE TRANSPORT LOCK PINS

(5HP10WR4) ARE INSTALLED TO LOCK ARMS UP BEFORE CLEANING, WORKING ON, OR

ADJUSTING MACHINE.

DO NOT attempt to perform maintenance or repair with tractor running.

DO NOT step up on machine at any time.

DO NOT allow minors to operate or be near the machine.

Stop the tractor engine, remove ignition key, and allow all mechanisms to stop before cleaning,

working, or adjusting on machine.

Stay clear of rake when raising or lowering main rake beams.

Stay clear of hydraulic lines, they may be under extreme pressure or heat.

For transport and storage, always make sure that the transportation lock pins (5HP10WR4) are

positioned to lock the rake arms in the transport position.

Frontier always takes the operator and his safety into consideration and guards exposed moving

parts for their protection. However, some areas cannot be guarded or shielded in order to assure proper

operation. In addition, the operators manual and decals on the machine itself warn you of further

danger and should be read and observed closely.

Study The Above Safety Rules

ATTENTION - BE ALERT - YOUR SAFETY IS INVOLVED

-9-

-10-

OPERATION

1. Check for proper assembly and adjustment and make sure that all bolts are tightened. Securely

retighten after a few hours of operation as bolts can loosen up on new machinery. Check wheel bolts

upon delivery and periodically thereafter. Wheel bolts should be tightened at 95 ft./lbs. of torque.

2. Check tires and inflate to recommended pressure (ST175/80D13 to 35 PSI).

3. Adjust the tractor hitch (13 to 17 inches above ground) and attach to tractor with a hitch pin that

has a safety locking device.

4. Remove weight from lift jack. Rotate jack into storage position.

5. Connect hydraulic hose for raising and lowering rake arms.

6. Lubricate the rake completely (See Lubrication Section in This Manual).

7. On all rake wheels, tooth bolts must be torqued to 40 ft./lbs. to help prevent excessive tooth

breakage. Re-torque rake tooth bolts after first 100 acres. (Part No. HPT175) Check

periodically thereafter.

8. Check all bolts on rake after 100 acres. Re-torque if necessary.

NOTE: Determine right or left side of your Carted Rake by viewing it from the rear. If

instructions or parts lists call for hardened bolts, refer to bolt torque chart on page 6.

ADJUSTMENTS

There are four different positions to adjust the hitch on your new Carted Rake. The hitch should be

adjusted so the main rake beams are level, or parallel to the ground. Hitch (A) can be put in the lower set

of holes (B) or the upper set of holes (C). Also hitch (A) can be turned over and be used in holes (B) & (C).

This will give you two additional settings.

A

C

B

-11-

OPERATION (Continued)

TRANSPORT LOCKS

There are two (D) transport locks on the Carted Rake. The transport pins (5HP10WR4) lock the rake

beams into the up position for Cleaning or working on the rake and for transport and storage. The pins

should be in the storage position (E) during operation.

D

E

ONE SIDED RAKING

Raking with one side can be accomplished by locking the left rake arm in the transport position (F),

disconnecting the lifting linkage 5HP10WR35 or 5HP12WR5) (G), then putting it into the lifting linkage

storage position (H).

FHG

-12-

ADJUSTMENTS

RAKING WIDTH

There are three rake width adjustments on each rake beam. Width on each side can be set independently.

Each rake beam angle can be adjusted independently for multiple raking conditions. Fine tuning is

accomplished by adjusting the threaded ball end attached to the linkage arm.

Windrow Width Adjustments

WINDROW WIDTH

Remove locking pin (A). Remove the jack from jack storage position. Position jack mount tube on top of

rake beam pin (B) with jack foot in position as shown. Windrow width can now be adjusted from 4’ to 6’, in

6” increments on each side of the rake. After the desired windrow width has been reached, re-insert pin (A)

in desired hole. Remove jack and return to storage position.

BA

-13-

ADJUSTMENTS (Continued)

DOWN PRESSURE

Down pressure of the rake arms can be adjusted

by adjusting the stop (C) on the top of the spring

located at each end of the main frame. The stop

should be adjusted so there is approximately 1/4

of an inch of threads showing above the jam nut

(D). The carted rake can be adjusted for less

ground pressure by “raising” the stop.

TREAD WIDTH ADJUSTMENT (WR3012 ONLY)

Tread width (wheel spacing) can be adjusted by first jacking up one side of the main frame. Loosen nuts

(4) on the mounting bolts (HP16SV77) (E). The entire wheel assembly now can be positioned as desired.

Retighten nuts evenly. Repeat procedure on the opposite frame.

C

D

E

FLOATATION

The carted rake has been designed to be operated with the hydraulic cylinder in the float position. This

allows the rake beams to “float” up and down without the hydraulic cylinder restricting it’s motion. If your

tractor does not have a float position, you will need the second hose option. If rake is equipped with

second hose option, it is very important transport lock pins are removed prior to attempting to

lower rake arms. Failure to remove pins will result in damage to rake.

NOTE: If 2 hose system is desired, remove vent plug and install hose (3/8” x 145”) (Part No. 5HP10WR10)

between cylinder and tractor.

-14-

OPTIONAL CENTER KICKER WHEEL

An optional center kicker wheel is available for the WR3010 and WR3012 carted rake. If the hay is laying

out flat, the extra wheel allows you to raise the hay laying in the center of the rake out of the stubble for

easier pick-up. Attached to the right lifter arm with a cable, the center kicker wheel will raise and lower

when the hydraulics are activated. The center kicker wheel may locked in the up position when not needed.

Down Position

Up Position

-15-

LUBRICATION GUIDE

GREASE FITTINGS

There are twelve grease fittings on the Carted Rake. If lubricated properly and often enough, it will prolong

the life of your Carted Rake. Grease daily during normal use and before and after storage and after

power washing. Use a good grade of high quality grease. Make sure that grease comes out around the

shaft on sleeve type bearings. Wipe off excessive grease to prevent accumulation of chaff or grit around

the bearing.

LOCATION

Listed and shown are the description of location and number of grease fittings.

A. (2 ) One on each end fo left side lift linkage

B. (2 ) One on each pivot arm pivot point

C. (4) Two on each of lifter arms

D. (2) One on each horizontal pivot point at the end of lifter arms

E. (2 ) One on each vertical pivot point, rake arm mount

F. (1 ) Center kicker wheel arm (If Equipped)

G. (4 ) One on each rake arm (6 on WR3010 & WR3012)

E

D

C

A

B

A

G

F

-16-

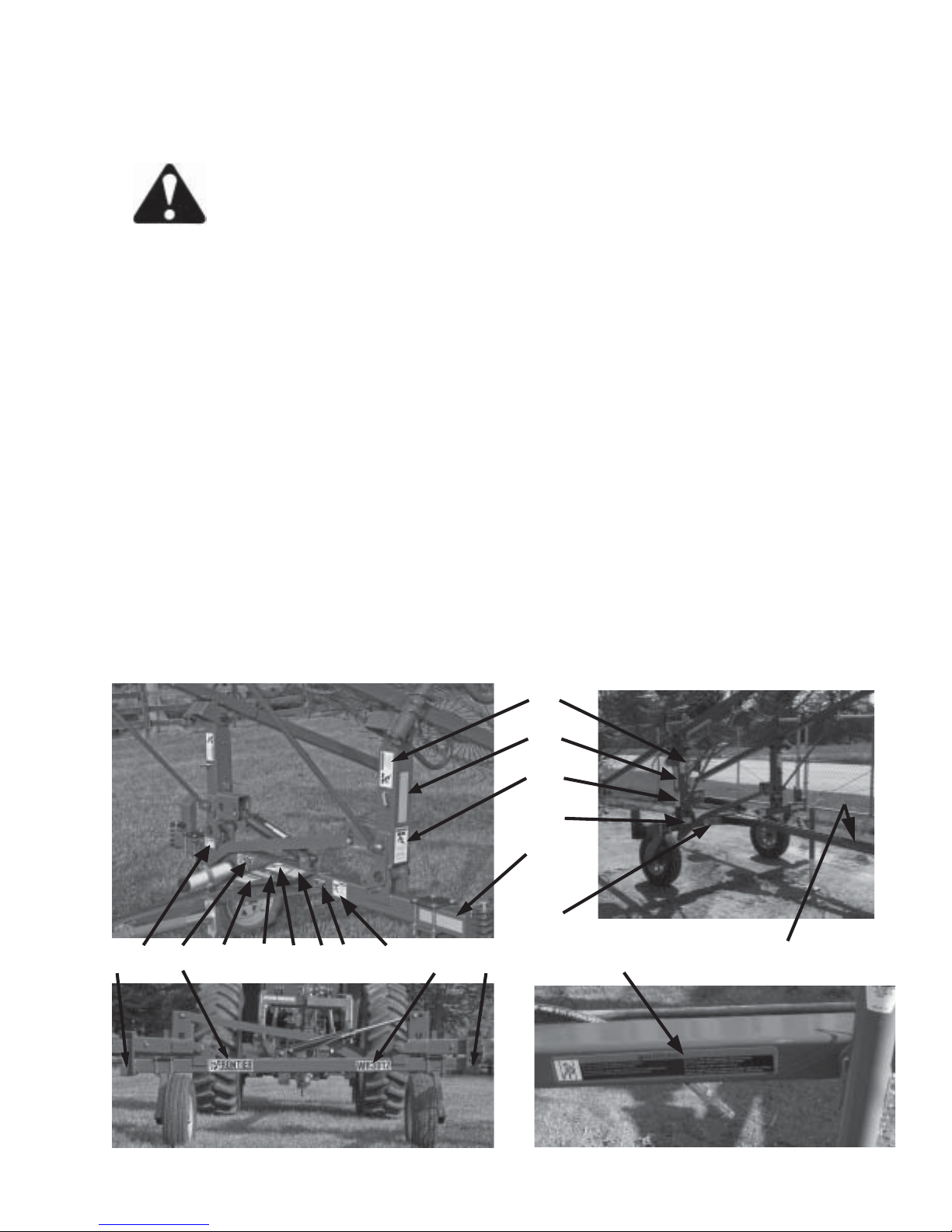

DECAL LOCATION

Your Frontier Carted Rake was manufactured with operator safety in mind. Located on the rake are

various decals to aid in operation, and warn of caution areas. Pay close attention to all decals.

DO NOT REMOVE ANY OF THESE DECALS. IF DECALS ARE LOST, DAMAGED,

OR IF HEAVY DUTY WHEEL RAKE IS REPAINTED, REPLACE DECALS.

REMEMBER: DECALS ARE FOR YOUR PROTECTION AND INFORMATION.

Listed below are the decals on your Carted Rake. These decals may be ordered individually by part

number or by ordering a complete set.

ITEM PART NO. DESCRIPTION

A. 5HP2700A (2) WARNING - Stay Clear of Rake

B. HPFRONTIER13 (2) Frontier Decal

C. 5HP3008WR Frontier Model Decal (WR3008)

5HP3010WR Frontier Model Decal (WR3010)

5HP3012WR Frontier Model Decal (WR3012)

D. 5HP2700B (2) WARNING - Stay Clear of Rake

E. HP2X9RED (2) Red Reflectors

F . HP2X9AMBER (3) Amber Reflectors

G. HP11599 WARNING - Do Not Go Near Leaks

H. HPHS404 Patent Numbers

I. Serial Number

J. HPFRON1 WARNING - Help Avoid Injury

K. 5HP73100A Locking Pin Storage

L. 5HP73100B WARNING - Install Locking Pins

M. 5HP73100C WARNING - Install Locking Pin

N. HP92606 WARNING - Do Not Exceed Transport Speed

O. 5HP51508 DANGER - Avoid Electrical Lines

5HP09083008 Complete Set of Decals (WR3008)

5HP09083010 Complete Set of Decals (WR3010)

5HP09083012 Complete Set of Decals (WR3012)

A

F

D

M

G

B

E L B J K G H I M C E N O

-17-

TROUBLE SHOOTING

WARNING

MAKE SURE THAT THE TRACTOR IS SHUT OFF AND THE RAKE CAN NOT MOVE

BEFORE SERVICING THE CARTED RAKE. MAINTENANCE AND REPAIR SERVICE WORK

TO BE PERFORMED BY A QUALIFIED SERVICE PERSON ONLY.

TROUBLE... POSSIBLE CAUSE... POSSIBLE REMEDY...

Rake Lifting Arms Will Not Transport Lock Pins Are In Lock Remove Transport Lock Pins And

Lower Position Place In Storage Position

Hydraulic Coupler Not Coupled Couple Hose To Tractor

To Tractor Properly (See Page #11)

Rake Lifting Arms Hange Up Install Second Hose Kit

And Will Not Lower On Uneven

Terrain

Some Tractors Do Not Operate Install Second Hose Kit

Single Acting Cylinders Well

Rake Lifting Arms Will Not Hydraulic Coupler Not Coupled Couple Hose To Tractor

Raise To Tractor Properly (See Page #11)

Tractor Hydraulics Do Not Tractor Should Have At Least 1500

Sufficient Pressure PSI To Operate Rake

-18-

INSTRUCTIONS FOR ORDERING PARTS

All service parts should be ordered through your authorized Frontier dealer. They will be able to

give you faster service if you will provide them with the following

1. Model & Serial number is located on the inside right pole mount, under center frame.

2. All reference to left or right apply to the machine as viewed from the rear.

3. Parts should not be ordered from illustration only. Please order by complete part number.

4. If your dealer has to order parts - give shipping instructions:

VIA truck - large pieces (please specify local truck lines)

VIA United Parcel Service (include full address)

PLEASE RECORD NUMBERS FOR YOUR UNIT FOR QUICK REFERENCE

ABOUT IMPROVEMENTS

FRONTIER IS CONTINUALL Y STRIVING TO IMPROVE IT’S PRODUCTS

We must therfore, reserve the right to make improvements or changes whenever it becomes practical to do so

without incuring any obligation to make changes or additions to the equipment previously sold.

-19-

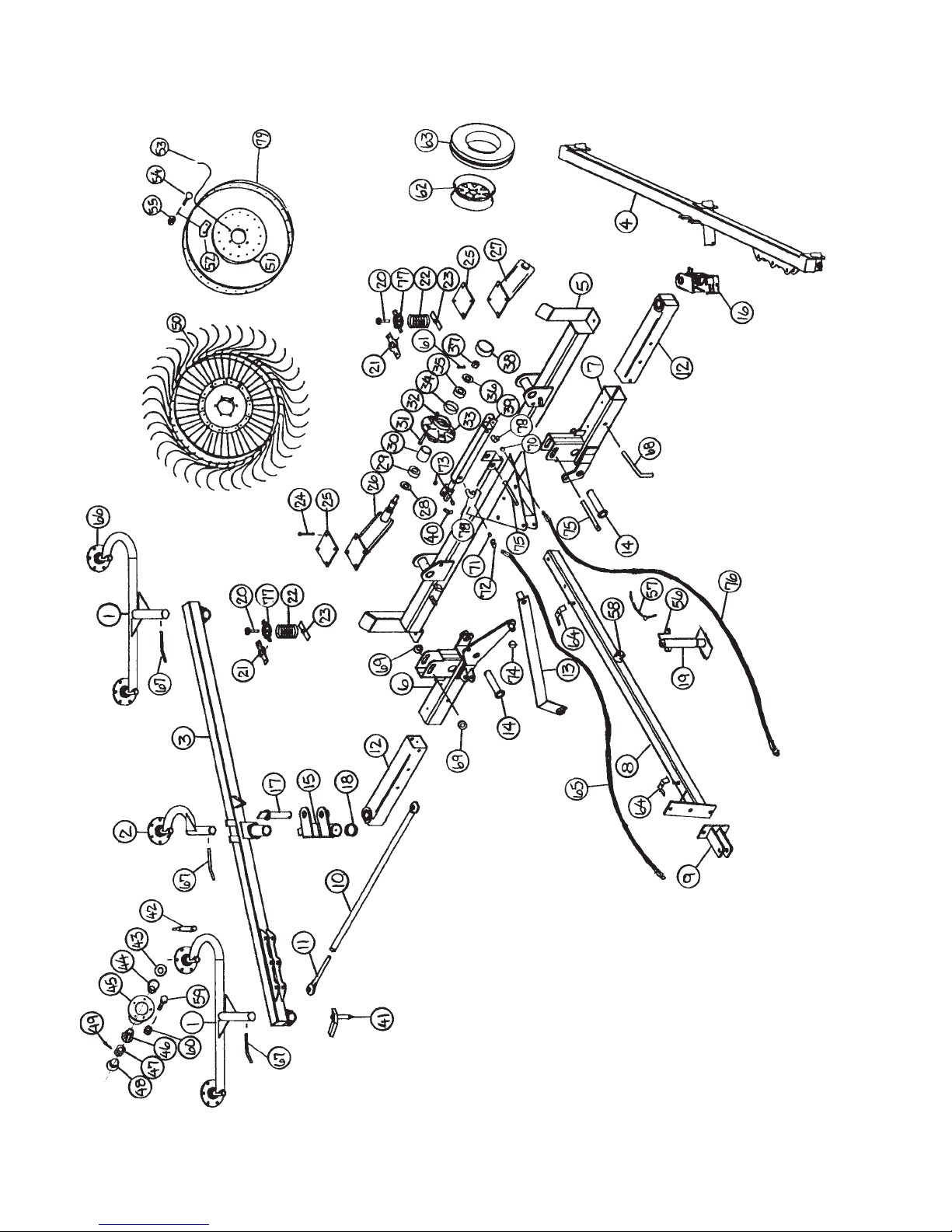

FIGURE 1

-20-

FIGURE 1

FRONTIER MODEL WR3008, WR3010 & WR3012

CARTED RAKE

ITEM WR3008 WR3010 WR3012 DESCRIPTION

1. 5HP10WR22 “ “ Rake Arm

2. - 5HP10WR23 - Single Rake Arm

3. 5HP8WR1 5HP10WR24 5HP12WR2 Right Rake Beam

4. 5HP8WR1 5HP10WR25 5HP12WR3 Left Rake Beam

5. 5HP8WR9 5HP10WR26 5HP12WR4 Main Frame

6. 5HP8WR7 5HP10WR27 “ Right Lifter Arm

7. 5HP8WR6 5HP10WR28 “ Left Pivot Arm Housing

8. 5HP10WR29 “ “ Pole

9. 5HP10WR30 “ “ Hitch

10. 5HP8WR8 5HP10WR31 “ Link Rod

11. 5HP10WR9 “ “ Adjusting Rod

12. 5HP8WR5 5HP10WR34 “ Slide Arm

13. 5HP10WR35 “ 5HP12WR5 Lifting Linkage

14. 5HP10WR7 “ “ Rake Arm Pins

15. 5HP10WR36 “ “ Right Pivot Bracket

16. 5HP10WR37 “ “ Left Pivot Bracket

17. 5HP10WR6 “ “ Rake Beam Pin

18. 5HP10WR8 “ “ Pivot Thrust Washer

19. HPBFR223 “ “ Jack

20. 5HP10WR16 “ “ Spring Adjustment

21. 5HP10WR46 “ “ Spring Bottom

22. 5HP10WR47 “ 5HP12WR1 Spring

23. 5HP10WR3 “ “ Spring Clamp

24 . HP16SV77 “ “ 1/2” x 6” Bolt GR.5

25. - - 5HP10WR38 Axle Plate

26. 5HP10WR32 “ “ Right Axle

27. 5HP10WR33 “ “ Left Axle

28. 5HPCAT5 “ “ Seal

29. 5HPCAT6 “ “ Inner Bearing

30. 5HPCAT7 “ “ Inner Race

31. 5HPCAT128A “ “ Hub Stud

32. HPCAT14 “ “ Hub Nut

33. 5HP10WR49 “ “ Ground Wheel Hub

34 . HPCAT9 “ “ Outer Race

35. HPCAT10 “ “ Outer Bearing

36 . HPBFR63 “ “ Washer

37 . HPBFR64 “ “ Nut

38. HPCAT13 “ “ Hub Cap

39. 5HP10WR11A “ “ 2-1/2” x 16” Cylinder

40. 5HP10WR4 “ “ Transport Pins

41. 5HP10WR5 “ “ Slide Lock Pin

42 . HPBFR36 “ “ Spindle

43. HPT163 “ “ Seal

NOTE: * (MEANS SHOWN)

- (MEANS NOT USED ON THIS MODEL)

“ (MEANS SAME P ART NO. AS PREVIOUS MODEL)

-21-

FIGURE 1

-22-

FIGURE 1

FRONTIER MODEL WR3008, WR3010 & WR3012

CARTED RAKE

ITEM WR3008 WR3010 WR3012 DESCRIPTION

44. HPT164 “ “ Inner Bearing

* HPT165 “ “ Inner Race

45 . HPBFR32 “ “ Rake Wheel Hub

46. HPT170 “ “ Outer Bearing

* HPT171 “ “ Outer Race

47. HPT172 “ “ Nut

48. HPT173 “ “ Hub Cap

49. HPT169 “ “ Cotter Pin

50 . HPBFR31 “ “ RH Rake Wheel

* HPT174 “ “ LH Rake Wheel

51. HPT179 “ “ Rake Wheel Center

52. HPT178 “ “ Rake Tooth Clip

53. HPT176 “ “ Rake Wheel Tooth

54. HPT175 “ “ 10mmx25mm Carriage Bolt

55. HPT166 “ “ 10mm Nut

56 . HPBFR3 “ “ Jack Handle

57 . HPBFR4 “ “ Jack Pin & Chain

58. HP12N14 “ “ Jack Mount

59. HPT168 “ “ 10mmx25mm Bolt

60. HPT166 “ “ 10mm Nut

61. HPT37 “ “ Cotter Pin

62. 5HPCAT195 “ “ 13 x 4-1/2 Wheel

63. 5HPCAT198 “ “ ST175x80D13 Tire

64 . HP23N67 “ “ Hose Hol d e r

65. 5HP10WR10 “ “ 3/8”x145” Hose

66. 5HPBFR76 “ “ Hub - Complete

67. 5HP10WR13 “ “ 3” Pin

68. 5HP10WR14 “ “ 5” Pin

69. HP16SV136 “ “ Washer

70 . HPBFR70 “ “ Vent Plug

71. HPBFR120 “ “ Orifice

72 . HPBFR12 “ “ Male Adapter Union

* HPBFR617 “ “ Adapter Union & Orifice

73 . HPBFR33 “ “ Washer

74. HPF56 “ “ Clip Pin

75. 5HPLW55 “ “ Pin

77. 5HP10WR15 “ “ Spring Holder

79. HPT177 “ “ Outer Ring

OPTIONAL DOUBLE ACTING CYLINDER:

76. 5HP10WR10 “ “ 3/8”x145” Hose

78 . - - HP23N234 90° Street Elbow

NOTE: #70 Vent Plug Not Used on Double Acting Cylinder

NOTE: * (MEANS NOT SHOWN)

- (MEANS NOT USED ON THIS MODEL)

“ (MEANS SAME PREVIOUS PART NO.)

-23-

FIGURE 2

-24-

FIGURE 2

FRONTIER MODEL WR3010 & WR3012

OPTIONAL KICKER WHEEL

ITEM WR3010 WR3012 DESCRIPTION

1. 5HP10WR41 “ Kicker Arm

2. 5HP10WR39 “ Mounting Bracket Top

3. 5HP10WR20 “ Mount

4. 5HP10WR19 “ Pulley Mount

5. HPBFR292 “ Poly Pulley

6. HPST81 “ Spacer

7. 5HP10WR40 “ Pivot Mount

8. 5HP10WR18 “ 5/16”x3” Bolt GR.5

9. 5HPF87 “ “S” Hook

10. HPES14 “ Cable Protector

11. HPES5 “ Crimp On Clamp

12. 5HP12WR6 “ Cable (57”)

13. 5HPT19 “ 3/8” x 2” Bolt GR.5

14. HPES10 “ I-Bolt (5/16” x 4” Overall)

15. HPBFR110 “ Spring

16. HPT163 “ Seal

17. HPT164 “ Inner Bearing

18. HPT165 “ Inner Race

19. HPT168 “ Hub Bolt

20 . HPBFR32 “ Hub

21. HPT166 “ Hub Nut

22. HPT171 “ Outer Race

23. HPT170 “ Outer Bearing

24. HPT172 “ Nut

25. HPT169 “ Cotter Pin

26. HPT173 “ Hub Cap

27. 5HP10WR17 “ 48” Kicker Wheel

28. HPT179 “ Rake Wheel Center

29. HPT178 “ Rake Tooth Clip

30. 5HP10WR42 “ Rake Wheel Tooth

31. HPT168 “ 10mmx25mm Bolt

32. HPT166 “ 10mm Lock Nut

33. HP3G22 “ Roll Pin

34. HP12V45 “ 1/2”x1-1/2” Bolt GR.5

35. HPS99 “ “O” Ring

36 . HPG16 “ Bro nz e Bus hi n g

37. HPBFR230 “ Bearing Spacer

38. HPBFR221 “ Poly Washer

39. 5HP10WR44 “ Chain (5 Links)

40. HPBFR295 “ Snap Hook

41. 5HP10WR43 “ 3/8”x1” Bolt

42. HPBFR229 “ Washer

43. HPT177 “ Outer Ring

NOTE: “ (MEANS SAME AS PREVIOUS PART NO.)

-25-

FIGURE 3

FIGURE 3

FRONTIER MODEL WR3010 & WR3012

HYDRAULIC CYLINDER

ITEM WR3008 WR3010 WR3012 DESCRIPTION

1. 5HPT181A “ “ Clevis Cap

2. 5HPT182A “ “ Rod Cap

3. 5HPT183 “ “ Piston

4. HP23N145A “ “ Rod

5. 5HP10WR45 “ “ Cylinder Tube

6. HP23N147 “ “ T ie Rod

7. HP23N148 “ “ Piston Nut

8. HP23N149 “ “ Plug

9. HP23N150A “ “ Rod Clevis

10. 5HPT187 “ “ Seal Kit

11. 5HP10WR11A “ “ Complete Cylinder

-26-

FIGURE 4

1 2 3 4 5 6

9

7 8 10 11

12

13 14 15

FIGURE 3

FRONTIER MODEL WR3008, WR3010 & WR3012

DECALS

ITEM PART NO. DESCRIPTION QTY.

1. 5HP2700B WARNING - Stay Clear of Rake Decal 2

2. 5HP73100B WARNING - Install Locking Pins Decal 1

3. 5HP2700A WARNING - Stay Clear of Rake Decal 2

4. 5HP73100C WARNING - Install Locking Pin Decal 1

5. HP11599 WARNING - Do Not Go Near Leaks Decal 1

6. HPFRON1 WARNING - Help Avoid Injury Decal 1

7. HP2X9RED Red Reflector Decal 2

8. HP2X9AMBER Amber Reflector Decal 3

9. 5HP73100A Locking Pin Storage Decal 1

10 . HPHS404 Pat en t Nu mb er De cal 1

11. HP92606 WARNING - Do Not Exceed Transport Speed Decal 1

12. 5HP3008WR Frontier Model Decal (WR3008) 1

13. 5HP3010WR Frontier Model Decal (WR3010) 1

14. 5HP3012WR Frontier Model Decal (WR3012) 1

15. HPFRONTIER13 Frontier Decal 2

16. 5HP51508 DANGER - Avoid Electrical Lines Decal 1

5HP09093008 Complete Set of Decals (WR3008) 1

5HP09083010 Complete Set of Decals (WR3010) 1

5HP09083012 Complete Set of Decals (WR3012) 1

16

-27-

SERVICE / MAINTENANCE RECORD

DATE DESCRIPTION NOTES

-28-

2608 S. Hume A ve.

P.O. Box 768 - Telephone (715) 387-3414

F AX (715) 384-5463

MARSHFIELD, WI 54449

Loading...

Loading...