Page 1

WOOD CHIPPER

O P E R A T O R ' S M A N U A L

WC1208

5PQ990126 (05/01/11)

Page 2

To the Owner;

Thank-You for choosing a quality product from Frontier Equipment. We strive

to give you the best equipment and the best level of service of any company.

With a little care and maintenance this machine will do your work for you for

many years. In this manual, we make an effort to get you better acquainted

with the machine so you can achieve maximum performance. We design

and build all of our equipment with the end user in mind so we welcome any

suggestions or ideas for improvement. Please note that it is within our rights

to make changes or improvements to our equipment without updating the

equipment that was manufactured before the change took place.

Please take a few minutes to ll out the area below. This information will be

valuable to you when ordering parts or requesting service from your dealer.

Dealer Name:_____________________________

Dealer Phone Number:______________________

Service Manager/Technician:_________________

Model# and Description:_____________________

Serial Number:____________________________

Date of Purchase:__________________________

Page 3

TABLE OF CONTENTS

Introduction ……………………………………………………………… 2

Intended Use ………………………………………………… 2

Serial Number …………………………………………….… 2

Specications ………………………………………………… 2

Safety …………………………………………………………………….… 3

Safety Decals ………………………………………………… 4

Inspection and Set-up ………………………………………………… 5

Operation …………………………………………………………………… 6

Startup ………………………………………………………… 6

Chipping Tips ………………………………………………… 6

Chip Chute Adjustments …………………………………… 7

Deector ……………………………………………………… 7

Feeding Material …………………………………………….. 8

Maintenance & Service ……………………………………………… 10

Belt Tension …………………………………………………… 10

Replacing the Belts …………………………………………… 10

Knives ……….………………………………………………… 11

Anvil …………………………………………………………… 11

Lubrication ……………………………………………………………….. 12

Bearings ……………………………………………………… 12

Feed Roller Slide …………………………………………… 13

Warranty …………………………………………………………………… 14

Notes ………………………………………………………………………… 15

Illustrated Parts Breakdown ……..………………………………… 16

Base Assembly Parts ….…………………………………… 17

Drum Housing ……………..………………………………… 18

Feed Roller Carriage ………………………….…………… 19

Hopper Assembly …………………………………………… 20

Chute Assembly……………………………………………… 21

Decals & Labels …………………………………………… 22

1

Page 4

INTRODUCTION

Intended Use

Frontier Chippers are designed to chip natural, untreated wood only. Materials that are processed

may contain chemicals or by-products that could corrode the machine, damage the blades, or spontaneously combust. Frontier Equipment will not cover under warranty any chipper that has been used

for anything besides natural wood.

Serial Number

The chipper’s serial number is located on the chipper housing just behind the 3-point tractor hookup.

This number helps us to track changes and improvements and must be mentioned when ordering

parts or requesting service. For your convenience, a space has been provided inside the front cover

of this manual to record the serial number, model number, purchase date, and dealer name.

Specications

Specications WC1103 WC1105 WC1205 WC1208

Chip Opening 3 x 5.5 in. (7.5 x 14cm) 5.5 x 8 in. (14 x 20cm) 9 x 16 in (23 x 40.6cm)

Drive System PTO PTO PTO

Engine N/A N/A N/A

Transport 3 Point Hitch

HP Required 16 35+ 80+

Rotor/Drum Size 65 lbs. 165 lbs. 490 lbs.

Knives (2) 2.5 x 3.25 x 5/16 in. (4) 2.5 x 3.25 x 5/16 in. (2) 4.5 x 9 x 5/8 in.

Knife Bolts 3/8” Recessed Head Hardened Bolts 5/8” Grade 8

Feed System Manual Hydraulic

Hydraulic Requirement N/A 6 GPM 8GPM

Feed Roller N/A 12” (30.5cm) 15.5” (39.4cm)

Hopper Opening 25 x 18 in. (62.5 x 45cm) 28 x 28 in. (70 x 70cm) 28 x 42 in (70 x 106cm)

Feed Height 38” (95cm) 41” (102.5cm) 21” (52.5cm) 29.5” (75cm)

Weight (lbs.) 375 650 775 2300

2

Page 5

SAFETY

Do not operate this machine until this manual has been read and fully understood;

serious injury or death can occur if these safety warnings are ignored!

Never allow more than one person to operate this machine at a time. If two people are working together it will increase the chance of your workmate engaging the machine or causing

you to fall into the machine.

Wood is much harder than human esh! If your hand is ever near the chipping or feeding area

serious injury can occur. NEVER place your hands on the machine while it is chipping.

Never place your hands or feet on or near the machine while it is engaged.

Never place your hands or feet on or near the material while it is feeding.

DO NOT wear loose clothing, jewelry, or anything that can catch a branch that is feeding into

the chipper.

DO NOT stand directly in front of the infeed hopper when loading material into the hopper;

always load from the side of the hopper. This will not allow any part of your body to be pulled

into the machine.

Do not go near any hydraulic leaks. Hydraulic oil is under extreme pressure and a small leak

can easily penetrate the skin, causing serious injury or infection.

Always wear safety hearing protection, eye wear, gloves, and long pants when operating the

chipper.

Never place your hands beyond the opening of the hopper while the chipper is running.

Never allow children, disabled, or untrained persons to operate the chipper.

Do not operate the chipper near bystanders, public roads, or anywhere that the debris may

travel far enough to injure another person.

Never move the chipper while it is running.

Shut off the tractor and allow the chipper to come to a complete stop before removing any

debris.

Never perform any maintenance or repair while the chipper is running.

The SMV (Slow Moving Vehicle) Triangle must be visible at all times when traveling on public

roads.

3

Page 6

SAFETY

903101

903100

Safety Decals

Warning decals are provided to insure safe and proper use of the machine and should be

heeded at all times. If at any time there are damaged and/or faded decals, contact your dealer

for replacements immediately. Below is an illustration of each decal.

4

Page 7

INSPECTION AND SET-UP

Follow the instructions in the lubrication section of this manual to make sure the chipper

•

is greased properly. The initial grease is applied at the factory, but a routine maintenance

schedule is the user’s responsibility.

Check all bolts and nuts to make sure everything is tight. All hardware is checked at the fac-

•

tory, but sometimes it will vibrate loose during shipment. Also check all fasteners periodically

between uses. A wood chipper produces high vibration levels which can cause hardware to

loosen.

Check the length of the PTO shaft. Some tractor 3-point hitch arms are shorter and require

•

a shorter PTO shaft. To determine whether your shaft needs to be cut down to t you will

need to connect the 3-point arms to the chipper, connect the PTO shaft to both the tractor

and chipper, and slowly raise the 3-point hitch. Watch closely to make sure that the PTO

shaft does not fully retract. If it does, you will need to remove it and cut it down accordingly.

If the PTO shaft is not tted properly it can “bottom out” and cause damage to the PTO shaft

or the chipper. Also check the PTO to make sure the tubes overlap at least 6 in. (15cm) (see

illustration below) when the chipper is in the operating position. (sitting level on the ground)

5

Page 8

OPERATION

Startup

Place tractor transmission in neutral and set the parking brake, then turn the tractor engine

•

off.

Connect the 3 pt. hitch linkages to the chipper and secure them with safety snap pins.

•

Adjust the top link so that the chipper sits level.

•

Connect the pto shaft to the tractor. Be sure that the balls are set in the ball groove of the

•

tractor pto shaft. Make sure that the pto safety chains are attached to both the tractor and

the chipper to keep the protective PTO shield from rotating.

Make sure the feed drive control bar on the chipper is in the ‘neutral’ position and connect

•

the hydraulic hoses to the tractor

Turn the chip chute in a safe direction and adjust the chip deector to the desired position.

•

Start tractor engine and hold the engine rpm’s at a strong idle. Engage the pto slowly. If

•

the tractor is running at a high speed when you engage the PTO you could damage the

drive belts. After the rotor is spinning freely raise the tractor rpm’s until the PTO speed is

around 540 rpm.

With the chipper now running at full speed you may begin chipping. Start by feeding small

•

diameter branches until you get better acquainted with the machine and its operation, then

you may begin feeding larger pieces.

Chipping tips

Feed the blunt end of the branch in rst.

•

Trim the side limbs that won’t t into the hopper before you feed the chipper.

•

Stand to the side of the hopper to feed the material so that debris doesn’t y back at you.

•

Never stand directly in front of the hopper when feeding the chipper.

If you have a lot of dry material try to mix in some green (fresh) limbs with the dry. The

•

moisture in the green wood will lubricate and cool the knives. Chipping only dry wood will

cause the knives to heat up. A hot knife will lose its edge much quicker.

6

Page 9

OPERATION

Chip chute adjustments

To position the chip chute, loosen the set bolt (Figure 3) and rotate the chute to the desired

position, then retighten the set bolt. The chute conveniently rotates a full 360 degrees. Be sure

the set bolt is tight and the chute is locked in place before transporting the chipper!

Deector

The chip deector easily adjusts to regulate the distance that the chips are thrown. Loosen the

locking handle and adjust as desired. (Figure 4)

Figure 3

Figure 4

7

Page 10

OPERATION

Feeding Material

The ow control valve (Figure 5) will control the speed of the material being fed into the chipper,

The tractor’s hydraulic pressure will also contribute to the speed of the feed.

To adjust the speed of the feed system, nd a small branch and feed it into the chipper with the

feed adjusted to 3 or 4 and keep adjusting up until the chips are 3/8 to 1/2 inch (9-12mm) thick.

The feed setting “0” will completely stop the ow of oil to the drive motors, stopping the feed roller.

The hydraulic system on the chipper requires at least 8 GPM to operate the chipper at full capacity.

Sometimes when the brush is wet or if there is a lot of small twigs and branches the feed roller can

slip because of the wet wood or the small size material. In this situation it is best to grab the control

bar and switch it from forward to reverse several times. You can even reverse the material and turn

it a different way so that the roller grabs a different part of the branch.

Figure 5 Figure 6

Hydraulic Flow Control Forward Neutral Reverse

Shown above (Figure 6) is the control bar that operates the feed roller. This control bar has three

positions, forward, neutral, and reverse. The feeding position is to the rear of the machine so that

in an emergency the operator can just push the control bar and it will either stop or reverse the

feed roller. Always keep the control bar in the neutral position whenever you are not feeding the

chipper to eliminate the chance of accidently feeding something into the machine

8

Page 11

OPERATION

Feeding Material, Cont’d

The optional tachometer(Figure 7) and shut off swith will stop the feed roller if the chipper rotor RPM

drops below the specied low speed setting. This feature keeps the tractor from stalling and eliminates undue stress on the drive system when the torque requirement is too high. The feed roller will

restart automatically after the tractor recovers to the specied high speed setting.

Only the Hi/Lo settings on the tachometer are eld modiable. All other settings are pre-pro-

grammed at the factory and should not need to be changed. In case of total memory loss, see factory calibration section below to re-set to factory settings.

FIELD OPERATION:

Normal Operation: Press “O” button to toggle between RPM display, hours, or volts

Programming: Press and hold “O” button for three seconds to enter programming mode. Press “O”

button momentarily to select parameter to adjust. Press “+” and “-” buttons to change setting. Only

the Hi/Lo settings are eld modiable. (“Hi” setting is 1800, “Lo” setting 1550)

FACTORY CALIBRATION

Factory calibration is performed quickly and easily using any Sony television compatible infrared

remote control. Factory calibration include number of pulses per revolution (4), mode of operation

(Mode 0, Output 1) and all eld adjustable parameters.

• Press “TV” on remote to select television mode

• Press “POWER” 5 times within 2 seconds to enter programming mode.

• Press CHANNEL +/- to select parameter to adjust

• Press VOLUME +/- to change value OR press number keys to enter values directly.

• Press ENT to save and exit programming mode

The magnetic sensor (Figure 8) should be within .0025” from the outer edge of the paddle to get an

accurate RPM reading.

Figure 7 Figure 8

9

Page 12

MAINTENANCE & SERVICE

Belt tension

The belt tension is adjusted by turning the turnbuckles (Figure 9) and raising or lowering the

drive gearbox. Be sure to adjust the turnbuckles the same amount on both sides. The belts

should be snug but not stretched too tightly.

Replacing the belts

Follow these steps to replace the drive belt (Figure 10). The WC1208 chipper uses a 5-section

banded B-78 belt.

Remove the belt shield on the left side of the chipper to gain access to the belt

•

Loosen the turnbuckle adjustment to relieve the belt tension.

•

Remove the belt and replace with new.

•

Retighten both turnbuckles until the belt is tight. Keep both turnbuckles extended to the

•

same length.

Figure 9

Shield has been removed to show detail. All shields must be on at all times during operation!!

Figure 10

10

Page 13

MAINTENANCE & SERVICE

Knives

The performance of the chipper will depend largely on the condition of the knives. If the knives are

dull or damaged you will create a lot of unnecessary stress on the machine and consumes more

power from the tractor. The knives are reversible and can easily be reversed or replaced by removing the four bolts. (Figure 11) The bolts thread into a removable threaded block. Torque setting for

knife bolts is 175 ft. lb. We recommend that the knives be resharpened by a precision sharpening

service to retain the proper angle. The angle of the cutting edge should be 30 degrees. It is good to

keep an extra set of knives on hand to use while the other set is being sharpened.

Anvil (Shear Bar)

The anvil setting will also affect the performance of your chipper. Follow these steps to adjust the

anvil. The anvil can also be reversed if the edge gets damaged. This is a two man job.

Stop the tractor and remove the PTO and hydraulic connections.

•

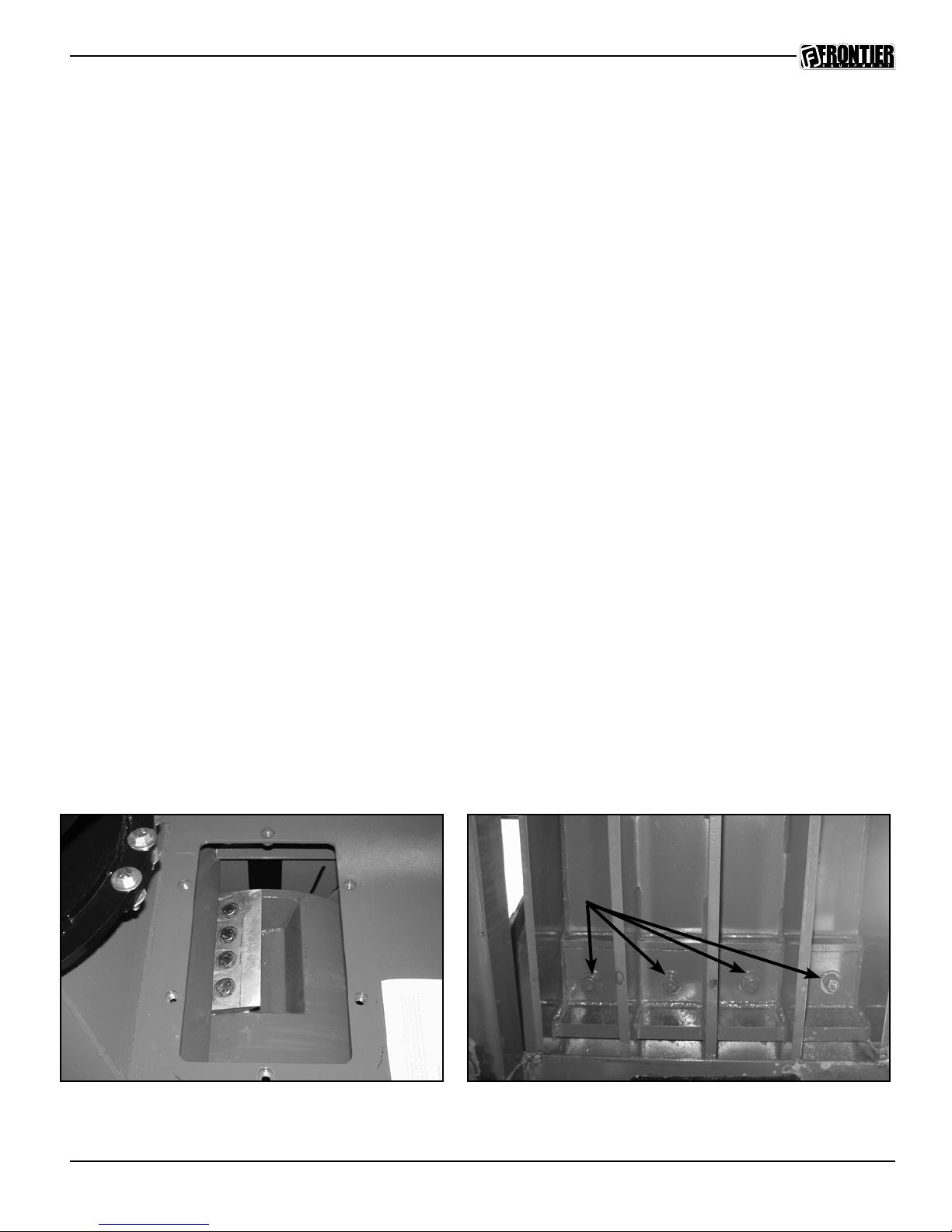

Remove the access cover on the side of the chipper base and loosen the bolts (Figure 12) that

•

clamp the anvil in position. The holes for these bolts are slotted to allow for adjustment.

Slide the feed roller carriage up so you can look beneath the feed roller to check the setting of

•

the anvil. Place a wooden block between the top of the feed chamber and the feed roller carriage to keep the roller up out of the way.

Place a .0040 shim between the knife and anvil and have the second person tighten the bolts

•

when the anvil is set. There will be excess vibration and torque requirement if the anvil is set too

far from the knives.

Retighten the bolts to secure the anvil. Tighten to 60 ft.lb.

•

Put the access cover back into position.

•

Remove the block that you used to hold up the feed roller.

•

Figure 11

Shield has been removed to show detail. All shields must be on at all times during operation!!

Figure 12

11

Page 14

LUBRICATION

Bearings

The WC1208 chipper has six bearings. Figure 13 shows the bearings on the output shaft going

to the large pulley. Figure 14 shows the feed roller bearing. There is one on each side of the

feed roller carriage. The shield may need to be removed to access this bearing. All sealed bear-

ings should be greased lightly every 20 hours of use. Be sure to wipe all the dirt off of the tting

before greasing.

Figure 13

Figures 15 & 16 show the rotor shaft bearings. These should also be greased lightly every 20

hours. When greasing a sealed bearing, be careful that you do not over-grease or the grease will

push the rubber seal away and expose the bearing to dirt and moisture.

Shields have been removed to show detail. All shields must be on at all times during operation.

Figure 14

Figure 15 Figure 16

12

Page 15

LUBRICATION

There are two grease ttings on the gearbox stand where it pivots on the base assembly (Figure

17). These ttings should be greased heavily every 10 hrs of operation and should always be wet

with grease.

Figure 11

Feed Roller Slide

The feed roller slide should always be wet with grease. Grease the feed slides every 10 hours

(this might be excessive but too much grease won’t damage the feed slide).

Figure 16 Figure 17

13

Page 16

WARRANTY

Warranty coverage is provided by John Deere according

to the terms of the Agricultural/Commercial & Consumer

Equipment Warranty Statement. Carefully read the warranty

statement on the back of your original purchase order for

details on coverage and limitations of this warranty.

14

Page 17

NOTES

15

Page 18

Illustrated

Parts

Breakdowns

16

Page 19

1

2

3

4

5

6

7

9

10

11

12

13

14

15

16

17

17

18

18

19

19

20

20

21

21

22

23

24

25

26

26

28

29

30

31

28

32

33

26

27

27

27

8

34

WC1208 Base Assembly

Ref# Description Part# Ref# Description Part#

1 Complete Gearbox 5PQ903000 18 Lock Washer, 5/8 5PQ000860

2 Drive Shaft 5PQ903428 19 Flat Washer, 5/8 5PQ001075

3 Nut, 9/16 5PQ000965 20 Spacer 5PQ903435

4 Lock Washer, 9/16 5PQ000850 21 Bolt, 5/8 x 4-1/2 5PQ000645

5 SAE Flat Washer, 9/16 5PQ001066 22 Turn Buckle 5PQ505259

6 1-3/4" Flange Bearing 5PQ903418 23 Belt 5PQ903497

7 Bolt, 9/16 x 2-3/4 5PQ000582 24 Chipper Base 5PQ903400

8 16" 5-Groove Pulley 5PQ903039 25 Belt Shield 5PQ903432

9 Key, .375 x 2.00 5PQ400857 26 Lock Washer, 1/2 5PQ000840

10 1-3/4" SF Bushing 5PQ903016 27 Bolt, 1/2 x 3/4 5PQ000406

11 Lock Washer, 1/2 5PQ000840 28 1-1/8" Hitch Pin 5PQ903437

12 Bolt, 1/2 x 1-1/4 5PQ000420 29 Lock Nut, 3/8 5PQ003000

13 Gearbox Base 5PQ903419 30 PTO Shaft Hook 5PQ902236

14 Pivot Pin 5PQ903436 31 Bolt, 3/8 x 1-1/4 5PQ000275

15 Machinery Bushing, 1-1/4 5PQ500185 32 1" Hitch Pin 5PQ903238

16 Ext. Retaining Ring 5PQ701173 33 Drive System Cover 5PQ903431

17 Nut, 5/8 5PQ000970 34 Complete PTO Shaft 5PQ903498

17

Page 20

WC1208 Drum Housing

1

2

3

4

5

6

7

2

8

10

9

9

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

26

35

36

37

39

38

40

41

17

18

29

30

31

31

30

29

34

33

Ref# Description Part#

1 Bolt, 1/2 x 1-1/4 5PQ000420

2 Lock Washer, 1/2 5PQ000840

3 Flat Washer, 1/2 5PQ001055

4 Knife Access Cover 5PQ903451

5 Drum Hood Weldment 5PQ903059

6 Rotor Weldment 5PQ903440

7 Blower Paddle, Left 5PQ903031

8 Bolt, 1/2 x 1 5PQ000405

Blower Paddle, Right 5PQ903020

9 Key 5PQ903442

10 Drum Shaft 5PQ903004

11 2-3/8 E-Style Bushing 5PQ903038

12 Lock Washer, 1/2 5PQ000840

13 Bolt, 1/2 x 2-1/2 5PQ000460

14 Grease Fitting 5PQ903450

15 Nipple, 1/8 x 4 5PQ903449 Ref# Description Part#

16 2-3/8 Flange Bearing 5PQ903024 29 Bolt, 1/2 x 1-1/4 5PQ000420

17 Lock Washer, 3/4 5PQ000870 30 Lock Washer, 1/2 5PQ000840

18 Hex Nut, 3/4 5PQ000975 31 Flat Washer, 1/2 5PQ001055

19 8" 5-Groove Pulley 5PQ903018 32 Speed Sensor Cover 5PQ903454

20 2-3/8" SF Bushing 5PQ903036 33 Jam Nut, 5/8 5PQ000681

21 Bed Knife 5PQ903002 34 Magnetic Pickup 5PQ900216

22 Flat Washer, 1/2 5PQ001055 35 Drum Housing 5PQ903023

23 Lock Washer, 1/2 5PQ000840 36 Bearing Slot Cover, Right 5PQ903446

24 Bolt, 1/2 x 1-3/4 5PQ000445 37 Knife Bar 5PQ903441

25 Feed Chamber Cover 5PQ903073 38 Chipper Knife 5PQ903001

26 Hose Holding Kit 5PQ903443 39 Bolt, 5/8 x 3 Grade 8 5PQ000628

27 Socket Screw, 3/8 x 1 5PQ000301 40 2-3/8 Flange Bearing 5PQ903024

28 Bulkhead Fitting 5PQ290257 41 Bearing Cover 5PQ903448

18

Page 21

4

5

6

6

6

6

7

8

9

12

13

14

15

15

14

12

13

21

22

16

17

19

20

22

21

16

17

18

19

20

10

3

2

1

WC1208 Feed Carriage Assembly

Ref# Description Part#

1 Lock Nut, 3/8 5PQ003000

2 Flat Washer, 3/8 5PQ001035

3 Feed Carriage Weldment 5PQ903065

4 Bolt, 1/4 x 6 5PQ000212

5 Flat Washer, 1/4 5PQ001020

6 Coupling Shield 5PQ903495

7 Lock Washer, 1/4 5PQ000805

8 Nut, 1/4 5PQ000900

9 Rubber Block 5PQ505269

10 Bolt, 3/8 x 1-1/2 5PQ000280

12 Hydraulic Fitting 5PQ900190

13 Hydraulic Motor 5PQ900178

14 Key, 1/4 x 1 5PQ400114

15 Coupling Chain 5PQ903490

16 1-1/2" Flange Bearing 5PQ400810

17 Key, 3/8 x 1-1/2 5PQ401580

19

18 Feed Roller 5PQ903027

19 Machinery Bushing, 1/2 5PQ000530

20 Bolt, 1/2 x 1 5PQ000405

21 Nut, 1/2 5PQ000940

22 Bolt, 1/42 x 1-3/4 5PQ000445

23 1" Coupling Sprocket 5PQ903056

24 1-1/2" Coupling Sprocket 5PQ903057

Page 22

WC1208 Hopper Assembly

1

2

3

4

2

5

6

7

8

9

10

11

12

14

13

16

15

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

17

16

38

38

39

36

23

18

17

16

34

33

1

20

Ref# Description Part# Ref# Description Part#

1 Lock Nut, 5/16 5PQ002999 21 Rotary Valve 5PQ291002

2 Flat Washer, 5/16 5PQ001030 22 Speed Sensor 5PQ900215

3 Valve Linkage Bar 5PQ902035 23 Bolt, 1/4 x 3/4 5PQ000175

4 Control Linkage 5PQ902036 24 Bypass Valve 5PQ830323

5 Nut, 5/16 5PQ000910 25 Manifold, Complete 5PQ903466

6 Lock Washer, 5/16 5PQ000810 26 Safety Bar 5PQ903480

7 Feed Control Cover 5PQ902039 27 Infeed Tray 5PQ903460

8 Feed Control Spring 5PQ902040 28 Latch Handle 5PQ903455

9 Feed Control Inner Plate 5PQ902038 29 Compression Spring 5PQ505316

10 Feed Control Outer Plate 5PQ902037 30 Flat Washer, 1/2 5PQ001055

11 Valve Cover 5PQ902034 31 Stainless Steel Roll Pin 5PQ000562

12 Hydraulic Fitting 5PQ290126 32 Hinge Pin 5PQ100323

13 Solenoid Valve Coil 5PQ830325 33 Roll Pin, 3/16 x 1-1/4 5PQ000563

14 Solenoid Valve 5PQ291001 34 Machinery Bushing, 3/4 5PQ400148

15 Check Valve 5PQ291003 35 Infeed Hopper 5PQ903473

16 Nut, 1/4 5PQ000900 36 Elbow Fitting 5PQ900171

17 Lock Washer, 1/4 5PQ000805 37 Directional Valve 5PQ900181

18 Flat Washer, 1/4 5PQ001020 38 Elbow Fitting 5PQ900172

19 Hydraulic Control Bracket 5PQ903463 39 Bolt, 1/4 x 1-1/2 5PQ000185

20 Valve Handle 5PQ291005

Page 23

WC1208 Chute Assembly

1

2

3

4

5

6

7

8

9

10

Ref# Description Part#

1 Set Bolt 5PQ500148

2 Bolt, 3/8 x 1-1/2 5PQ000280

3 Chip Chute 5PQ903486

4 Chip Deector 5PQ903197

5 Bolt, 3/8 x 7/8 5PQ000250

6 Flat Washer, 3/8 5PQ001035

7 Locknut, 3/8 5PQ003000

8 Clamp Handle 5PQ806039

9 Locknut, 3/8 5PQ003000

10 Chute Retainer 5PQ903487

21

Page 24

WC1205 Decals and Labels

903101

903100

1

9

10

2

3

4

11

12

13

5

6

14

7

8

Ref# Description Part#

1 Decal, Frontier Equipment 5PQ903110

2 Decal, WC1208 5PQ903118

3 Warning, do not ride 5PQ903104

4 Warning, crush/pinch hazard 5PQ903105

5 Warning, thrown objects 5PQ903106

6 Warning, do not place hands 5PQ903100

7 Warning, hydraulic pressure 5PQ903114

8 SMV Decal 5PQ903148

9 Decal, reverse-neutral-feed 5PQ903113

10 Decal, Red Retroreective 5PQ903112

11 Danger, do not remove shields 5PQ903101

12 Danger, PTO Entanglement 5PQ903102

13 Caution, 540 RPM PTO 5PQ903107

14 Caution, general information 5PQ903103

Complete Decal Kit 5PQ903205

22

Page 25

23

Page 26

24

Page 27

Page 28

Loading...

Loading...