Page 1

Fronius prints on elemental chlorine free paper (ECF) sourced from certified sustainable forests (FSC).

/ Perfect Charging / Perfect Welding / Solar Energy

WF 25i LaserHybrid 10 kW

SB 360i LaserHybrid

Operating Instructions

LaserHybrid

EN-US

[

42,0426,0279,EN 010-19032020

Page 2

2

Page 3

Table of contents

Safety Instructions ..................................................................................................................................... 7

Explanation of Safety Instructions......................................................................................................... 7

General ................................................................................................................................................. 7

Intended Use......................................................................................................................................... 8

Environmental Conditions..................................................................................................................... 8

Obligations of the Operating Company................................................................................................. 8

Obligations of Personnel....................................................................................................................... 8

Personal Protective Equipment............................................................................................................. 9

Danger from Toxic Gases and Vapors.................................................................................................. 9

Danger Posed by Shielding Gas Leak.................................................................................................. 9

Danger from Flying Sparks ................................................................................................................... 10

Danger from Welding Current ............................................................................................................... 10

Stray Welding Currents......................................................................................................................... 10

EMC Measures ..................................................................................................................................... 10

Particular Hazard Areas........................................................................................................................ 11

Informal Safety Measures..................................................................................................................... 12

Safety Measures at the Installation Location ........................................................................................ 13

Safety Measures in Normal Operation.................................................................................................. 13

Safety Inspection .................................................................................................................................. 13

Modifications ......................................................................................................................................... 14

Spare and Wearing Parts...................................................................................................................... 14

Calibrating Power Sources ................................................................................................................... 14

The CE label ......................................................................................................................................... 14

Copyright............................................................................................................................................... 14

EN-US

General Information 15

General ...................................................................................................................................................... 17

General ................................................................................................................................................. 17

Intended Use......................................................................................................................................... 17

Applications........................................................................................................................................... 17

Scope of Supply.................................................................................................................................... 18

Optional Components ........................................................................................................................... 19

Gas nozzle cross jet.............................................................................................................................. 19

Requirements............................................................................................................................................. 20

Mechanical Requirements .................................................................................................................... 20

Robot Requirements ............................................................................................................................. 20

Ground Connection............................................................................................................................... 20

Alignment .............................................................................................................................................. 21

System Overview ....................................................................................................................................... 22

System Overview .................................................................................................................................. 22

Other LaserHybrid Systems.................................................................................................................. 23

Setup Variants ...................................................................................................................................... 25

Operating controls and connections 27

Product description .................................................................................................................................... 29

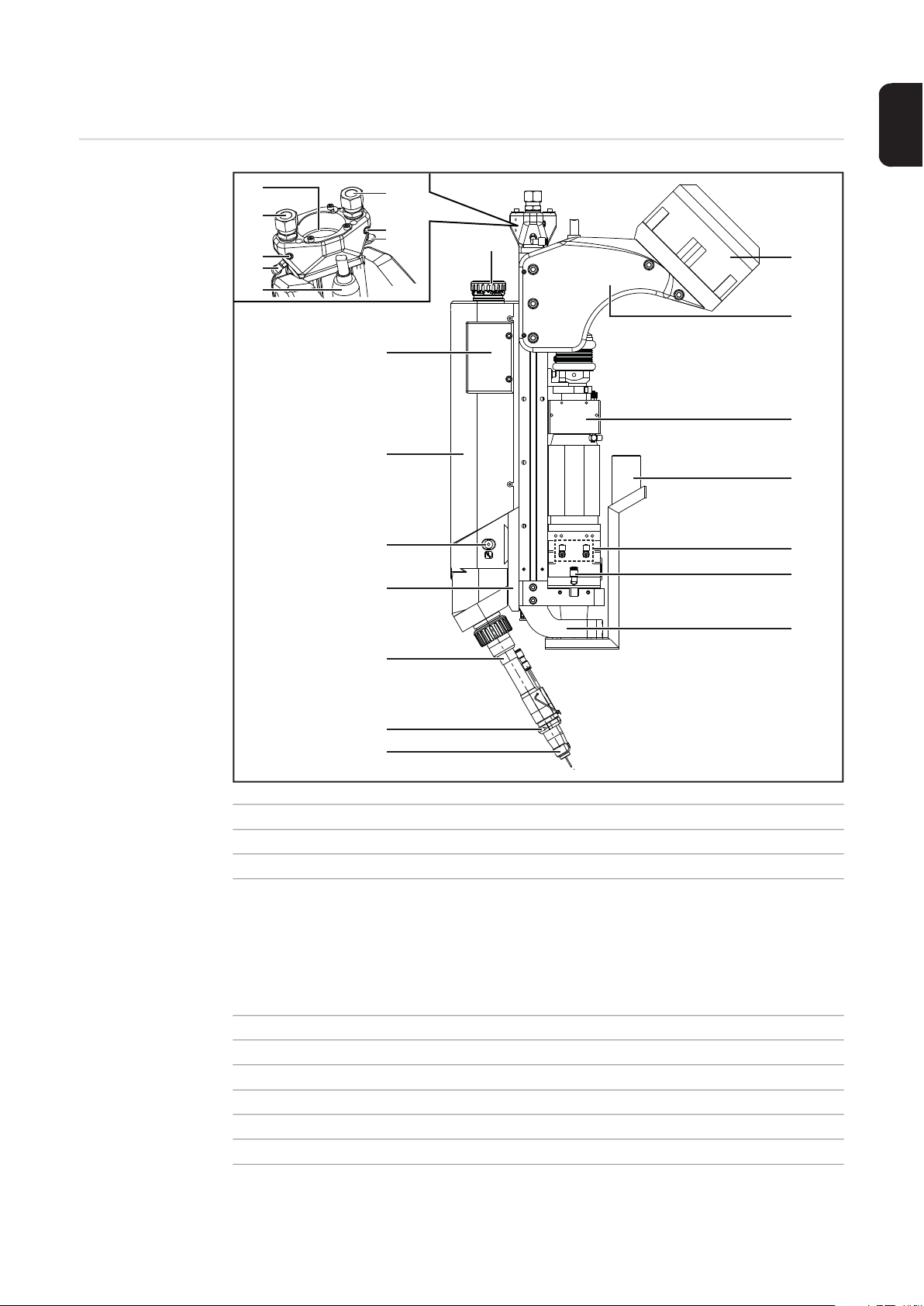

Device Description WF 25i LaserHybrid 10 kW .................................................................................... 29

Device Description, SB 360i LaserHybrid ............................................................................................. 30

Collision Protection .................................................................................................................................... 32

General ................................................................................................................................................. 32

Safety.................................................................................................................................................... 32

Checking the Reference Point after a Collision .................................................................................... 32

Signal Analysis...................................................................................................................................... 32

Connection Specifications.......................................................................................................................... 33

Connection Specifications..................................................................................................................... 33

Compressed Air Diagram...................................................................................................................... 35

Pressure Monitoring in the SplitBox SB 360i LaserHybrid.................................................................... 35

3

Page 4

Commissioning 37

General ...................................................................................................................................................... 39

Safety.................................................................................................................................................... 39

Setup Regulations................................................................................................................................. 39

Grid Connection .................................................................................................................................... 39

Set Up LaserHybrid Welding System.................................................................................................... 40

Installing the Laser Welding Head on the Robot........................................................................................ 41

Connection Options on the Robot......................................................................................................... 41

Installing the Laser Welding Head on the Robot................................................................................... 41

Installing and Connecting SplitBox SB 360i LaserHybrid .......................................................................... 42

Installing SplitBox SB 360i LaserHybrid on Robot................................................................................ 42

Connecting SplitBox SB 360i LaserHybrid............................................................................................ 44

Connecting Crossjet................................................................................................................................... 46

Connecting the CrossJet....................................................................................................................... 46

Connecting LaserHybrid Hosepack to Laser Welding Head...................................................................... 48

Connecting LaserHybrid Hosepack to Laser Welding Head................................................................. 48

Connecting/changing Wirefeeding Hose to/on Laser Welding Head.................................................... 49

Installing/Changing Wirefeed Rollers......................................................................................................... 50

Installing/Changing Wirefeed Rollers.................................................................................................... 50

Connecting Laser Optics and Extra Extraction .......................................................................................... 51

Connecting Laser Optics....................................................................................................................... 51

Connecting Extra Extraction ................................................................................................................. 54

Preparing Welding Torch ........................................................................................................................... 57

Preparing Welding Torch ...................................................................................................................... 57

Installing Hosepack on Robot .................................................................................................................... 59

Placing the Hosepack on the Robot...................................................................................................... 59

Threading the Wire Electrode .................................................................................................................... 61

Threading the Wire Electrode ............................................................................................................... 61

Setting up Laser Welding Head ................................................................................................................. 62

Stick Out ............................................................................................................................................... 62

Adjustable Axes .................................................................................................................................... 63

Adjustment Mechanisms on the Laser Welding Head .......................................................................... 64

Setting Up X-Axis.................................................................................................................................. 65

Setting Up Y-Axis.................................................................................................................................. 66

Setting Up Z-Axis .................................................................................................................................. 67

Creating Reference Program ..................................................................................................................... 68

Safety.................................................................................................................................................... 68

General ................................................................................................................................................. 68

Creating Reference Program ................................................................................................................ 68

Signal Sequence for LaserHybrid Welding ................................................................................................ 70

Safety.................................................................................................................................................... 70

Signal Sequence for LaserHybrid Welding ........................................................................................... 70

Measures before Starting Welding............................................................................................................. 72

Measures before Starting Welding........................................................................................................ 72

Operation Recommendations for LaserHybrid Welding System................................................................ 73

Operation Recommendations for LaserHybrid Welding System........................................................... 73

Specifications for the compressed-air supply ....................................................................................... 73

Maintenance 75

Replacing the Welding Torch and Welding Torch Wearing Parts.............................................................. 77

Safety.................................................................................................................................................... 77

Welding Torch Spare Parts................................................................................................................... 77

Replacing the Welding Torch................................................................................................................ 77

Replacing Welding Torch Wearing Parts .............................................................................................. 79

Replacing the Spatter Guard Plate and Extra Extraction........................................................................... 80

Replacing the Spatter Guard Plate ....................................................................................................... 80

Replacing the Extra Extraction.............................................................................................................. 80

Replacing the Laser Optics........................................................................................................................ 81

Safety.................................................................................................................................................... 81

Replacing the Trumpf Laser Optics ...................................................................................................... 81

Preparation ........................................................................................................................................... 81

4

Page 5

Removing the Laser Optics................................................................................................................... 84

Inserting the Laser Optics..................................................................................................................... 86

Checking/Adjusting Laser Optics Focus ............................................................................................... 89

Fixing the Laser Optics ......................................................................................................................... 91

Final Tasks............................................................................................................................................ 92

Laser Optics – Overview....................................................................................................................... 94

Checking Position of the Wire Electrode in relation to the Laser Focus .................................................... 95

Safety.................................................................................................................................................... 95

General ................................................................................................................................................. 95

Checking Position of the Wire Electrode in relation to the Laser Focus ............................................... 95

Example: Reference Program Application after Welding Torch Change.............................................. 96

Measures to Reduce Contamination of the Optics .................................................................................... 97

Measures to Reduce Contamination of the Optics ............................................................................... 97

Appendix 99

Technical Data ........................................................................................................................................... 101

WF 25i LaserHybrid 10 kW (laser welding head).................................................................................. 101

LaserHybrid hosepack MHP 360i LH.................................................................................................... 101

EN-US

5

Page 6

6

Page 7

Safety Instructions

EN-US

Explanation of

Safety Instructions

DANGER!

Indicates an immediate danger.

► Death or serious injury may result if appropriate precautions are not taken.

WARNING!

Indicates a possibly dangerous situation.

► Death or serious injury may result if appropriate precautions are not taken.

CAUTION!

Indicates a situation where damage or injury could occur.

► Minor injury or damage to property may result if appropriate precautions are not taken.

NOTE!

Indicates the possibility of flawed results and damage to the equipment.

General The LaserHybrid head has been manufactured using state-of-the-art technology and ac-

cording to recognized safety standards. If used incorrectly or misused, however, it can

cause

- injury or death to the operator or a third party,

- damage to the LaserHybrid head and other material assets belonging to the operating

company,

- inefficient operation of the LaserHybrid head.

All persons involved in the commissioning, operation, maintenance, and servicing of the

LaserHybrid head must

- be suitably qualified,

- have knowledge of welding and

- have read and implemented carefully these Operating Instructions and the OI for the

following system components:

Laser

Laser optics

Power source and associated wirefeeder

Robot and its controller

The Operating Instructions must always be at hand wherever the LaserHybrid head is being used. In addition to the Operating Instructions, all applicable local rules and regulations

regarding accident prevention and environmental protection must also be followed.

All safety instructions and warning signs on the LaserHybrid head itself must:

- be kept in a legible state

- not be damaged/marked

- not be removed

- not be covered, pasted, or painted over.

7

Page 8

For the location of the safety and danger notices on the LaserHybrid head, refer to the section headed "General" in the Operating Instructions for the LaserHybrid head.

Before switching it on, resolve any faults that could compromise safety.

Your personal safety is at stake!

Intended Use The LaserHybrid head is to be used exclusively for its intended purpose.

The LaserHybrid head is intended exclusively for LaserHybrid welding of aluminum, CrNi

and steel materials.

Any other use does not constitute proper use.

The manufacturer is not responsible for any damage resulting from improper use.

Proper use also means:

- Completely reading and obeying all instructions in the Operating Instructions

- Completely reading and obeying all safety instructions and danger notices

- Carrying out all the specified inspection and servicing work.

Never use the LaserHybrid head or the power source to thaw pipes.

The LaserHybrid head is designed for operation in industry and business. The manufac-

turer shall not be liable for any damage resulting from use in a living area.

The manufacturer shall not be liable for faulty or incorrect work results either.

Environmental

Conditions

Obligations of the

Operating Company

Operation or storage of the LaserHybrid head outside the stipulated area will be deemed

as not in accordance with the intended purpose. The manufacturer is not responsible for

any damage resulting from improper use.

Temperature range of the ambient air:

- During operation: -10°C to +40°C (14°F to 104°F)

- During transport and storage: -25°C to +55°C (-13°F to 131°F)

Relative humidity:

- Up to 50% at 40°C (104°F)

- Up to 90% at 20°C (68°F)

Ambient air: free of dust, acids, corrosive gases or substances, etc.

Altitude above sea level: up to 2000 m (6561 ft. 8.16 in.)

The operating company must only allow persons to work with the LaserHybrid head if they

- are familiar with the basic occupational safety and accident prevention regulations and

are trained in handling the LaserHybrid head

- have read and understood these Operating Instructions, especially the section "Safety

Rules," and have confirmed this with their signature

- are trained according to the requirements for the work results.

The safety-conscious work of the personnel must be checked regularly.

Obligations of

Personnel

8

All persons who are assigned to work with the LaserHybrid head must do the following before beginning work:

- Follow the basic regulations for occupational safety and accident prevention

- Read these Operating Instructions, especially the section "Safety Rules," and confirm

that they have understood and will follow them by signing

Before leaving the workplace, ensure that no personal injury or property damage can occur

in one's absence.

Page 9

Personal Protective Equipment

Please take the following precautions for your own personal safety:

Persons present in the sealed cell for the LaserHybrid process must

- wear rigid, wet-insulating footwear

- protect hands with appropriate gloves (featuring electrical insulation and thermal protection)

- protect their eyes from laser beams by wearing regulation-compliant safety glasses for

lasers. To protect their face and eyes against UV beams, further protection in the form

of a protective shield with regulation-compliant filter insert for laser protection class 4

must also be used in front of the safety glasses for lasers and the person's face. Do

not look into the laser beam, even with a regulation-compliant filter insert for laser protection class 4.

- Only wear suitable (flame-resistant) clothing

- Wear hearing protection designed for crossjet noise (120 dbA)

If there are persons present in the sealed cell for the LaserHybrid process,

- inform them of all the dangers that may be posed during operation (e.g. potential accumulation of gases hazardous to health, risk of asphyxiation due to lack of oxygen in

the breathable air, hazards posed by laser light, etc.)

- provide protective equipment

- construct protective walls or install protective curtains.

EN-US

Danger from Toxic Gases and Vapors

The fumes produced during welding contain toxic gases and vapors.

Welding fumes contain substances that may cause birth defects and cancer in some cir-

cumstances.

Keep your head out of the welding fumes and gases.

Take the following precautionary measures for fumes and harmful gases:

- Do not breathe them in.

- Extract them from the work area using appropriate equipment.

Ensure that there is sufficient fresh air.

Use breathing apparatus with air supply if there is insufficient ventilation.

When no welding is taking place, close the valve of the shielding gas cylinder or the main

gas supply.

If there is uncertainty as to whether the extraction capacity is sufficient, compare the measured toxic emission values against the permissible limit values.

The following components are factors that determine how toxic the welding fumes are:

- The metals used for the workpiece

- Electrodes

- Coatings

- Cleaning agents, degreasers, and the like

Danger Posed by

Shielding Gas

Leak

Consult the corresponding material safety data sheets and manufacturer's instructions for

the components listed above.

Keep flammable vapors (such as solvent vapors) out of the laser and arc radiation range.

Risk of asphyxiation due to uncontrolled shielding gas leak

9

Page 10

Shielding gas is colorless and odorless and may suppress the oxygen in the ambient air in

the event of leakage.

- Ensure there is a sufficient supply of fresh air with a ventilation flow rate of at least

20 m³ per hour.

- Please observe the safety and maintenance information for the shielding gas cylinder

or the main gas supply.

- When no welding is taking place, close the valve of the shielding gas cylinder or the

main gas supply.

- Always check the shielding gas cylinder or main gas supply for uncontrolled gas leakage before each start-up.

Danger from Flying Sparks

Danger from

Welding Current

Flying sparks can cause fires and explosions.

Never undertake welding near flammable materials.

Flammable materials must be kept at least 11 meters (35 ft.) from the LaserHybrid welding

process or protected with a certified cover.

Keep suitable, tested fire extinguishers on hand.

Sparks and pieces of hot metal may also get into surrounding areas through small cracks

and openings. Take appropriate measures to ensure that there is no risk of injury or fire.

Do not undertake welding in areas at risk of fire and explosion, or on sealed tanks, drums,

or pipes if these have not been prepared in accordance with corresponding national and

international standards.

Do not undertake welding on containers in which gases, fuels, mineral oils, and the like are/

were stored. Residues pose a risk of explosion.

An electric shock can be fatal. Every electric shock poses a risk of death.

All welding power-leads must be secured, undamaged, and insulated. Replace loose con-

nections and scorched cables immediately.

Stray Welding

Currents

EMC Measures WARNING! Electromagnetic field! Electromagnetic fields may cause health problems

If the following instructions are not observed, stray welding currents may occur, which can

result in the destruction of ground conductors, the power source used, the LaserHybrid

head, and other electrical equipment.

Ensure that the workpiece terminal is securely connected to the workpiece. If the floor is

electrically conductive, set up the power source so that it is insulated wherever possible.

that are not yet known.

The operator is responsible for ensuring that there is no electromagnetic interference with

electrical and electronic equipment.

If electromagnetic interference is discovered, the operator is obliged to take action to rectify

the situation.

10

Page 11

Check and evaluate possible problems and the interference immunity of equipment in the

vicinity according to national and international regulations:

- Safety devices

- Grid power lines, signal lines, and data transfer lines

- EMC and telecommunications equipment

- Devices for measuring and calibrating

- The health of persons close by, e.g., those with pacemakers and hearing aids

Persons with pacemakers must seek advice from their doctor before staying in the immediate vicinity of where the welding work is taking place.

Supporting measures to avoid EMC problems:

a) Grid power supply

- If electromagnetic interference occurs despite a grid connection that complies

with regulations, take additional measures (e.g., use a suitable grid filter).

b) Welding power-leads

- Keep them as short as possible

- Route them close together (also to avoid EMC problems)

- Route them far from other lines

c) Equipotential bonding

d) Workpiece grounding

- If necessary, establish grounding using suitable capacitors

e) Shield, if necessary

- Shield other devices in the vicinity

- Shield the entire welding installation

EN-US

Particular Hazard

Areas

Laser beam poses a risk of injury to the eyes. In addition to using the protective shield with

a regulation-compliant UV filter insert, eyes should be protected from laser beams using

regulation-compliant safety glasses for lasers. It must still be ensured, however, that no

one can accidentally look into the laser beam.

If the workpiece surface is especially bright or highly reflective, reflected laser-scattering

radiation poses a further risk. Take suitable precautions so that persons present have adequate protection from laser-scattering radiation also.

Keep hands, hair, loose clothing, and tools away from moving parts, such as:

- Ventilators

- Gear wheels

- Rollers

- Shafts

- Wirespools and welding wires

Do not insert body parts into rotating gear wheels on the wire drive or into rotating drive

parts.

Covers and side parts must only be opened/removed during maintenance and repair work.

During operation:

- Ensure that all covers are closed and all side parts have been mounted properly.

- Keep all covers and side parts closed.

Welding wire from the welding torch poses a high risk of injury (cuts to the hand, injuries to

the face and eyes, etc.).

For this reason, always hold the welding torch away from your body (devices with wirefeeder) and wear suitable protective goggles.

Do not touch workpieces during or after welding – risk of burns.

11

Page 12

Slag may fly off from workpieces that are cooling down. For this reason, be sure to wear

regulation-compliant protective equipment and ensure that other people are sufficiently

protected even when reworking workpieces.

Leave the welding torch and other parts with a high operating temperature to cool before

working on them.

Special regulations apply in areas where there is a risk of fire or explosion

– observe relevant national and international regulations.

Power sources for work in spaces where electrical hazards pose a greater risk (e.g. the

boiler room) must be marked with a (Safety) sign. The power source should not be located

in these types of spaces, however.

Risk of scalding due to coolant leakage. Before disconnecting connections for the coolant

supply hose or return connection, switch off the cooling unit.

When handling coolants, observe the specifications on the safety data sheet. The coolant

safety data sheet is available from your service center or from the manufacturer's homepage.

Only use suitable load-carrying equipment from the manufacturer for transporting devices

by crane.

- Attach chains or ropes to all designated suspension points on suitable load-carrying

equipment.

- Chains or ropes must be as close to perpendicular as possible.

- Remove the gas cylinder and wirefeeder (MIG/MAG and TIG devices).

Informal Safety

Measures

Always use a suitable wirefeeder hoisting attachment with insulation on the crane for hoisting the wirefeeder (MIG/MAG and TIG devices).

If the device is fitted with a carrier belt or handle, this should be used exclusively for transportation by hand. The carrier belt is not suitable for transportation by crane, counterbalanced lift truck or other mechanical chain hoists.

All lifting equipment (belts, straps, chains, etc.) used in connection with the device or its

components must be checked regularly (e.g., for mechanical damage, corrosion, or changes due to other environmental influences).

The test interval and scope must, as a minimum, comply with the respective valid national

standards and guidelines.

There is a risk of colorless, odorless shielding gas escaping without notice if an adapter is

used for the shielding gas connection. Use suitable Teflon tape to seal the thread of the

shielding gas connection adapter on the device side before installation.

The Operating Instructions must always be at hand wherever the LaserHybrid head is being used.

In addition to the Operating Instructions, all applicable local rules and regulations regarding

accident prevention and environmental protection must also be made available and be followed.

12

All safety and danger notices on the LaserHybrid head must be kept in a legible state.

Page 13

Safety Measures

at the Installation

Location

The cell for the LaserHybrid welding process must meet the following requirements:

- be light-proof in relation to surrounding rooms

- is shielded with at least 1 mm steel plate and/or approved laser protective glass to protect against UV and laser beams

- The laser welding process and the arc welding process must be stopped automatically

and immediately as soon as the cell is opened.

A toppling device can be deadly! Set up the device securely on an even, solid surface

- A tilt angle of no more than 10° is permitted

Special regulations apply in areas at risk of fire or explosion

- Follow the appropriate national and international regulations.

Use instructions and checks within the company to ensure that the vicinity of the workplace

is always clean and organized.

Only set up and operate the device in accordance with the degree of protection shown on

the rating plate.

When setting up the device, ensure an all-round clearance of 0.5 m (1 ft. 7.69 in.) so that

the cooling air can enter and leave unhindered.

Take care to ensure that the applicable national and regional guidelines and accident prevention regulations are observed when transporting the device, especially guidelines concerning hazards during transport and shipment.

Before transporting the device, always completely drain the coolant and dismantle the following components:

- Wirefeeder

- Wirespool

- Shielding gas cylinder

EN-US

It is essential to conduct a visual inspection of the device to check for damage after it has

been transported but before it is commissioned. Have any damage repaired by trained service technicians before commissioning the device.

Safety Measures

in Normal Operation

Safety Inspection The operator is required to have the LaserHybrid head tested by an electrician after every

Only operate the LaserHybrid head if all protective and safety devices are fully functional.

If the safety devices are not fully functional, there is a risk of

- injury or death to the operator or a third party,

- damage to the device and other material assets belonging to the operating company,

- inefficient operation of the device.

Safety devices that are not fully functional must be repaired before the device is switched

on.

Never bypass or disable safety devices.

Before conditioning the LaserHybrid head, ensure that no one can be put in danger.

The LaserHybrid head must be examined at least once a week for externally detectable

damage and functionality of the safety devices.

alteration, installation or modification, and all repairs and maintenance, and at least every

12 months, to ensure that it is in its correct state.

Regulation Title

IEC (EN) 60 974-1 Equipment for Arc Welding, Part 1: Welding Current Sources

13

Page 14

BGV A2, Section 5 Electrical Plants and Equipment

BGV D1, Sections 33 / 49Welding, Cutting and Related Work Methods

VDE 0701-1 Repairing, Modifying and Testing Electrical Devices;

General Requirements

VDE 0702-1 Repeating Tests on Electrical Devices

Modifications Do not carry out any alterations, installations, or modifications to the LaserHybrid head

without first obtaining the manufacturer’s permission.

Parts that are not in perfect condition must be replaced immediately.

Spare and Wearing Parts

Calibrating Power

Sources

The CE label The LaserHybrid head meets the basic requirements of the Low Voltage and Electromag-

Copyright Copyright of these operating instructions remains with the manufacturer.

Use only original spare and wearing parts (also applies to standard parts).

It is impossible to guarantee that externally procured parts are designed and manufactured

to meet the demands made on them, or that they satisfy safety requirements.

When ordering, specify the exact name and part number according to the Spare Parts List

as well as the serial number of your device.

Regular calibration of power sources is required in accordance with international standards. The manufacturer recommends a calibration interval of 12 months. Please contact

your service center if you require further details.

netic Compatibility Directives and therefore has CE sign.

Text and illustrations are technically correct at the time of going to print. The right to make

modifications is reserved. The contents of the operating instructions shall not provide the

basis for any claims whatsoever on the part of the purchaser. If you have any suggestions

for improvement, or can point out any mistakes that you have found in the operating instructions, we will be most grateful for your comments.

14

Page 15

General Information

Page 16

Page 17

General

EN-US

General

The laser welding head combines the benefits of a laser beam with the benefits of the

MIG/MAG welding process.

For the LaserHybrid process this results in

a high penetration depth, a narrow heat-affected zone, filler metal and good gap bridging.

Additional benefits of the laser welding head:

- high welding speed and great cost-effectiveness

- high process stability combined with a low level of rejects and reworking effort

- high quality weld seam

- low heat input, reduced distortion

- high availability of the welding system, high service life of the wearing parts

- flexible use

- high gap tolerance

- adaptation for fiber, disk, and diode laser possible.

Intended Use The WF 25i LaserHybrid 10 kW is designed exclusively for automated MIG/MAG welding

in connection with Fronius system components.

Any other use does not constitute proper use.

The manufacturer is not responsible for any damage resulting from improper use.

Proper use also means:

- Following all the instructions in these operating instructions for the individual components

- Carrying out all the specified inspection and servicing work

The WF 25i LaserHybrid 10 kW will be referred to as the "laser welding head" in the rest

of these Operating Instructions.

Applications The WF 25i LaserHybrid 10 kW welding head is used for the following applications:

- In the manufacturing of axles and bodies in the automotive industry, to make sheets

of 1–4 mm in thickness

- In rail vehicle manufacturing, for longitudinal seams and lap joints

- In shipbuilding, for butt welds

- In vehicle manufacturing, for lap joints and to weld wheel rims

- In container construction, for lap joints, circumferential welds and butt welds

- For corner joints on hoists

17

Page 18

Scope of Supply The following components are included as standard with the laser welding head:

- 1 x WF 25i LaserHybrid 10 kW laser welding head (complete)

- 1 x LaserHybrid hosepack

- 1 x stick out gauge

- 1 x flow volume meter (max. 25 l/min)

- 1 x Operating Instructions

- Tool and wirefeed end accessories, depending on the configuration

Tool and Wirefeeder Accessories:

Description No.

Extractor tool for register pins

44,0450,1223

Gauge for adjusting the focal spot

42,0201,1216

Stick out gauge

42,0201,1742

Allen key, size 6 mm (for adjusting the position on the holder unit)

42,0435,0001

Allen key, size 5 mm (for adjusting the position on the holder unit)

42,0410,0014

Allen key, size 4 mm (for adjusting the position on the holder unit)

42,0410,0013

Allen key, size 3 mm (for fixing the extraction hose)

42,0410,0012

Allen key, size 2.5 mm (for adjusting the laser optics)

42,0435,0002

Trimming aid for inner liners

42,0001,4936

Spanner for welding torch coupling and hosepack coupling

45,0200,1404

Flat spanner, wrench size 12 mm

42,0410,0007

Flat spanner, wrench size 8/10 mm

42,0410,0004

Drive wheel key

42,0200,9344

1

1

1

1

1

1

1

1

1

1

1

1

1

18

Page 19

Optional Components

Possible laser optics:

- Trumpf BEO D70

- Precitec YW52

- Highyag BIMO

The following components are optional for the WF 25i LaserHybrid 10 kW laser welding

head:

- Focus monitoring

- Temperature sensor

- Pressure sensor crossjet

- Extraction hose set

- Mounting plate 17.5 mm

- Gas nozzle crossjet

EN-US

Gas nozzle cross

jet

During welding, depending on the energy density and material, the laser triggers a plasma

flare of a varying height which absorbs the laser light.

At constant laser output a penetration of different depths is created.

To ensure constant penetration despite the plasma flare, it is possible to use the gas nozzle

cross jet.

The gas nozzle cross jet uses compressed air to generate a fine current of air that cuts off

the plasma flare at a defined height.

IMPORTANT!

- Because the gas nozzle cross jet is situated very closely to the opening of the gas outlet this can result in swirling gas and subsequently: pores.

- Furthermore, if the air current experiences resistance this can lead to acute pore formation.

- The plasma flare contains welding spatter and welding fume. If the plasma flare is

blown out, the surrounding area will be severely polluted.

Scope of Application:

- For freely accessible components

- For a laser output of at least 4 kW

- Mainly for butt welds with a full penetration root pass or where precise welding penetration depth is required

19

Page 20

Requirements

-

Mechanical Requirements

Robot Requirements

Ground Connection

The following mechanical requirements must be met in order to ensure a stable and repeatable LaserHybrid process:

- Accurate welding torch guidance for robots or single-purpose machines (e.g. longitudinal chassis)

- Precise weld seam preparation

- Low component tolerances

- Precise and very fast weld seam management systems with little deviation

The laser welding head weighs around 19 kg. The optics weigh a further 3 kg approximately. A total weight of around 30 kg should be expected for the complete laser welding head

when fitted with optics and hosepack.

It must therefore be possible for the robot axles to move a weight of 30 kg safely with the

accelerations specified.

IMPORTANT! The maximum permitted acceleration for the laser welding head is 3 g at 5–

150 Hz, based on use of the laser optics.

-

Grounding cable with bifilar winding Grounding cable coiled

20

Page 21

Alignment

y

5°

Example: Work angle 5° leading

CAUTION!

Danger of serious damage by laser radiation reflected directly into the laser optics!

This can cause serious damage to the fiber

optic.

► Always avoid 90° angles to the workpie-

ce surface when aligning the LaserHybrid head.

EN-US

21

Page 22

System Overview

System Overview LaserHybrid System with SplitBox SB 360i LaserHybrid Mounted on the Robot

(6)

(10)

(4)

(2)

(3)

(1)

(1) Welding wire drum *

(2) Wirefeeder reel:

WF 25i REEL 4R

+ OPT/i WF Wire straightening

path (4,100,880,CK)

+ WF MOUNTING Drum

(3) Control line for wirefeeder reel

(4) Remote control

(5) Power source TPS 500i

+ robot interface **

+ Cooling unit CU 1400i Pro MC or

CU 2000i MC Single

+ Upright bracket (screwed in

place)

(5)

(11)

(8)

(7)

(9)

(6) Wirefeeding hose

(7) Interconnecting hosepack

(8) Robot

(9) SplitBox SB 360i LaserHybrid

(10) Hosepack LaserHybrid

(11) WF 25i LaserHybrid 10 kW

(12) Cleaning station LaserHybrid

(12)

22

* The wire can also be fed via a wirespool (alternative to welding wire drum).

The following components are required for this:

Wirefeeder reel WF 25i REEL 4R

+ OPT/i WF reel carriage D300

** Example: RI FB Inside/i or RI FB Pro/i

Page 23

Other LaserHybrid Systems

LaserHybrid System with SplitBox SB 360i LaserHybrid Mounted on the Wall

(6)

(9)

(10)

EN-US

(2)

(4)

(5)

(3)

(1)

(1) Welding wire drum

(2) Wirefeeder reel:

WF 25i REEL 4R

+ OPT/i WF Wire straightening

path (4,100,880,CK)

+ WF MOUNTING Wall

(3) Control line for wirefeeder reel

(4) Remote control

(5) Power source TPS 500i

+ Robot interface

+ Cooling unit CU 1400i Pro MC or

CU 2000i MC Single

+ Upright bracket (screwed in

place)

(7)

(11)

(8)

(12)

(6) Wirefeeding hose

(7) Interconnecting hosepack

(8) Robot

(9) SplitBox SB 360i LaserHybrid

(10) Hosepack LaserHybrid

(11) WF 25i LaserHybrid 10 kW

(12) Cleaning station LaserHybrid

23

Page 24

LaserHybrid System with SplitBox SB 360i LaserHybrid Mounted on the Power

(5)

(6)

(2)

(1)

(3)

(8)

(10)

(7)

(9)

(4)

(11)

Source

(1) Remote control

(2) Control line for wirefeeder reel

(3) Power source TPS 500i

+ Robot interface

+ Cooling unit CU 1400i Pro MC or

CU 2000i MC Single

+ Upright bracket (screwed in

place)

+ Interconnecting hosepack

(4) SplitBox SB 360i LaserHybrid

(5) Wirespool D300

(6) Wirefeeder reel:

WF 25i REEL 4R

+ OPT/i WF reel carriage D300

(7) Hosepack LaserHybrid

(8) Wirefeeding hose

(9) Robot

(10) WF 25i LaserHybrid 10 kW

(11) Cleaning station LaserHybrid

24

Page 25

Setup Variants

Power Source Located in Welding Cell (I)

- TPS 500i – power source

- HP 95i CON W / 1.2 m / 95 mm² – interconnecting hosepack

- SB 360i LaserHybrid – SplitBox, mounted on the power source

- MHP 360i LH/W/FSC/FW 7.5m – LaserHybrid hosepack

- Welding wire drum

- WF 25i REEL 4R – wirefeeder reel

- WF MOUNTING Drum

- Wirefeeding hose L = 10 m

- Laser welding head

Area of application:

The robot only makes minor compensatory movements.

Robot axles 7 and 8 carry out the majority of the welding feed movements.

Example:

Circumferential welds on boilers, axles, etc.

Power Source Located in Welding Cell (II)

- TPS 500i – power source

- HP 95i CON W / 1.2 m / 95 mm² – interconnecting hosepack

- SB 360i LaserHybrid – SplitBox, mounted on the power source

- MHP 360i LH/W/FSC/FW 7.5m – LaserHybrid hosepack

- Wirespool

- WF 25i REEL 4R – wirefeeder reel

- WF reel carriage D300

- Wirefeeding hose L = 10 m

- Laser welding head

EN-US

Area of application:

For test systems only (no wirespool in series production)

Power Source Not Located in Welding Cell (I)

- TPS 500i – power source

- HP 95i CON W / 10 m / 95 mm² – interconnecting hosepack

- SB 360i LaserHybrid – SplitBox, mounted on the robot or the wall

- MHP 360i LH/W/FSC/FW 4.2m – LaserHybrid hosepack

- Welding wire drum

- WF 25i REEL 4R – wirefeeder reel

- WF MOUNTING Drum

- Wirefeeding hose L = 20 m

- Laser welding head

Area of application:

Robot axles 1–6 carry out the welding feed movements.

Example:

Longitudinal seams on boilers, battery trays, etc.

25

Page 26

Power Source Not Located in Welding Cell (II)

- TPS 500i – power source

- HP 95i CON W / 10 m / 95 mm² – interconnecting hosepack

- SB 360i LaserHybrid – SplitBox, wall mounting

- MHP 360i LH/W/FSC/FW 7.5m – LaserHybrid hosepack

- Welding wire drum

- WF 25i REEL 4R – wirefeeder reel

- WF MOUNTING Drum

- Wirefeeding hose L = 20 m

- Laser welding head

Area of application:

Robot axles 1–6 carry out the welding feed movements.

Example:

Longitudinal seams on boilers, battery trays, etc.

Power Source Is on a Gantry and Moves Too

- TPS 500i – power source

- HP 95i CON W / 10 m / 95 mm² – interconnecting hosepack

- SB 360i LaserHybrid – SplitBox, mounted on gantry

- MHP 360i LH/W/FSC/FW 4.2 m or 7.5m – LaserHybrid hosepack

- Welding wire drum

- WF 25i REEL 4R – wirefeeder reel

- WF MOUNTING Drum

- Wirefeeding hose L = 20 m

- Laser welding head

Area of application:

Robot axles 1–8 carry out the welding feed movements.

Example:

Longitudinal seams in rail vehicle construction, large base frames (e.g. press brakes),

etc.

26

Page 27

Operating controls and connections

Page 28

Page 29

Product description

EN-US

Device Description WF 25i LaserHybrid 10 kW

(1)

(2)

(3)

(4)

(6)

(8)

(9)

(10)

(11)

(2)

(3)

(5)

(7)

(15)

(16)

(17)

(18)

(19)

(20)

(12)

(13)

(14)

Item Description

(1) Exhaust for crossjet (must be connected to an extraction unit)

(2) Supply to crossjet

(3) Connection for optional pressure monitoring

A LaserHybrid hosepack with extra data line is needed for optional pressure monitoring.

Pressure is monitored in SplitBox SB 360i LaserHybrid (see page 35) for the laser

welding head and LaserHybrid hosepack.

(4) Supply to radial fan flow

(5) Supply to gas nozzle crossjet

(6) Fiber optic cable

(7) LaserHybrid hosepack connection

(8) Control box

(9) Drive unit cover

(21)

29

Page 30

Item Description

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(14)

(13)

(12)

(11)

(9)

(8)

(10)

(10) Gas-test button

Wire-return button*

Wire-threading button*

* The wire-return and wire-threading buttons are located on the opposite side of the

laser welding head.

(11) Mounting plate

Thickness 21 mm or 17.5 mm, depending on application

(12) LaserHybrid welding torch

(13) Gas nozzle crossjet (optional)

(14) Gas nozzle

(15) Robot holder

(16) Bracket for robot connection

(17) Laser optics

(18) Extra extraction

(19) Laser optics water cooling connections

(20) Connection to radial air stream

(21) Crossjet

Device Description, SB 360i LaserHybrid

30

Back Front

Item Description

(1) (+) Current socket with fine thread

for connecting the power cable from the interconnecting hosepack

(2) Shielding gas connection socket

(3) SpeedNet connection

for connecting the SpeedNet cable from the interconnecting hosepack

(4) SpeedNet connection

(5) Gas purging connection

(6) Connection for welding torch cooling – coolant return flow (red)

for connecting system add-ons e.g. the remote control

for connecting the coolant return flow hose from the interconnecting hosepack

Page 31

Item Description

(7) Connection for welding torch cooling – coolant supply line (blue)

for connecting the coolant supply line hose from the interconnecting hosepack

(8) SplitBox SB 360i LaserHybrid mount

(9) Welding torch connection (FSC)

for connecting the LaserHybrid hosepack

(10)

(11)

(12) Connection crossjet IN

(13) Interconnecting hosepack (for the power source)

(14) Connecting plug for welding torch cooling

Connection crossjet OUT

not included in the SB 300i LaserHybrid in its original state; the interconnecting

hosepack is inserted into SB 300i LaserHybrid during the assembly.

for connecting the welding torch cooling on the LaserHybrid hosepack

EN-US

31

Page 32

Collision Protection

1

General The laser welding head is fitted with collision protection to protect the LaserHybrid welding

torch and the entire laser welding head.

The collision protection works on the floating contact principle. Displacing the welding torch

a certain amount will open the circuit (ring line) between the two inputs for the robot control.

The ring line runs from the laser welding head, via the LaserHybrid hosepack, on to the

SplitBox SB 360i LaserHybrid, and from there on to the connection for the robot interface

used on the power source.

Safety

The collision protection and its digital analysis are not a substitute for an electromechanical emergency stop protection device.

► Just like with collision protection, the emergency stop protection device also has to

Checking the Reference Point after

a Collision

Signal Analysis The signal from the collision protection is sent to the robot control via a robot interface.

IMPORTANT! After a collision, check the reference point as follows:

2

3

Further information can be found on page 95.

In the event of a collision, the ring line will open and the signal level will drop. The robot

control must carry out the following program sequence:

- Stop the laser and arc welding process immediately

- Stop the robot movement immediately

WARNING!

shut off the arc process and the laser process.

Set a 14 / 20 mm stick out on the LaserHybrid welding torch depending on the application and design

Move to reference point

Using the gauge, check the position of the wire electrode in relation to the focal point

in the x/y/z direction

32

Page 33

Connection Specifications

EN-US

Connection Specifications

(1)

(2)

(3)

(5)

(2)

(4)

(6)

(8)

(9)

(10)

(7)

Item Description

(1) Crossjet extraction connection

for connecting a hose in accordance with the following data:

- Internal diameter Di = 51 mm

- External diameter Da = 57 mm

- Max. length = 10 m

(2) Crossjet supply

for connecting a hose in accordance with the following data:

- Internal diameter Di = 12 mm

- External diameter Da = 14 mm

- Atmospheric overpressure in flow condition:

= 4.5 bar at both connections

p

min

- V

(3) Radial air supply

for connecting a hose in accordance with the following data:

- External diameter Da = 6 mm

The hose connects the radial air supply (3) to the radial air connection (10).

total = 1460 Nl/min

min

33

Page 34

Item Description

(4) Crossjet gas nozzle supply

for connecting a hose in accordance with the following data

- External diameter Da = 4 mm

The hose connects the crossjet gas nozzle supply (4) to the crossjet gas nozzle

(7).

(5) Fiber optic cable for laser

bending radius > 200 mm.

(6) LaserHybrid hosepack connection

MHP 360i LH/W/FSC/4.2 m

MHP 360i LH/W/FSC/7.5 m

(7) Gas nozzle crossjet

(8) Extra extraction connection

for connecting a hose in accordance with the following data:

- Internal diameter Di = 40 mm

- Extraction capacity required Q

- Atmospheric underpressure p

min

min

(9) Laser optics water cooling connection

(10) Connection to radial air stream

NOTE!

= 280 m³/h

= 21000 Pa

The welding torch and gas nozzle are also cooled down by the power source cooling

unit.

The optics are cooled down by the laser cooling unit.

► Never cool the laser optics with the power source cooling unit.

34

Page 35

Compressed Air

WF 25i LaserHybrid 10 kWSB 360i LaserHybrid

MHP LH

(1)

(2)

(3) (4)

(5)

(6)

(7)

(8)

Diagram

MPH LH = LaserHybrid hosepack

EN-US

(7)

Item Description

(1) Compressed air supply

(7)

(8)

(2) Solenoid valve

(min. 6 bar)

(3) Internal pressure measurement

(4) Pressure measurement option

(9)

(4)

(4)

(6)

(5) Radial air stream branching

(6) Gas nozzle crossjet branching

(7) Crossjet air supply duct connections

(8) Exhaust air crossjet

(5)

(9) Extraction

NOTE!

The "VALVE ON" signal for controlling the solenoid valve (2) is transmitted to bit 26 (start counting with

0).

Pressure Monitoring in the SplitBox SB 360i

LaserHybrid

The pressure is monitored after the solenoid valve.

If the pressure falls below 4.5 bar for longer than two seconds, the "Powersource Ready"

bit is withdrawn and error code 16835 (laser crossjet air pressure supply low) issued.

35

Page 36

36

Page 37

Commissioning

Page 38

Page 39

General

EN-US

Safety

Setup Regulations

WARNING!

Work performed incorrectly can cause serious injury and damage to property.

► This setting work must only be carried out by trained and qualified personnel.

► Observe the safety rules in the OI, in particular the "Safety Inspection" section.

The power sources have been tested according to protection class IP 23. This means:

- Protection against solid foreign bodies larger than Ø 12 mm (0.47 in.)

- Protection against spraywater up to an inclined angle of 60°

The welding system can be set up and operated outdoors in accordance with protection

class IP 23. However, the effects of direct moisture (e.g. from rain) must be avoided.

WARNING!

Toppling or falling devices can be deadly.

► Securely set up the devices on a level and stable surface.

The ventilation channel of the power sources is an important safety device. When selecting

the setup location, ensure that the cooling air can enter and exit unhindered through the

vents on the front and back. Any electrically conductive dust (e.g. from grinding work) must

not be allowed to be sucked directly into the system.

Grid Connection The device is designed for the grid voltage listed on the rating plate. The fuse protection

required for the grid lead can be found in the "Technical Data" section. If mains cables or

mains plugs are not included with your version of the appliance, attach the appropriate

mains cable or mains plug in accordance with your country's standards.

CAUTION!

An under-dimensioned electrical installation can lead to serious damage.

► The grid lead and its fuse protection should be designed to suit the existing power sup-

ply.

► The technical data on the rating plate should be followed.

39

Page 40

Set Up LaserHy-

2

5

8

9

12

15

18

19

22

brid Welding System

WARNING!

If a power source is connected to the grid during installation, there is a danger of

serious injury and damage.

Please read the information in the "Safety Rules" chapter in the Operating Instructions for

the power source before starting for the first time. Only perform all of the preparation steps

if

► the power switch for the power source is set to – O – ,

► the mains cable is disconnected from the grid.

Initial situation:

Robot and robot control are present and ready for operation

Set up welding system:

Install upright brackets

1

Install cooling unit on upright bracket

Connect power source to cooling unit

3

Set up welding wire drum

4

Assemble WF Mounting Drum on welding wire drum

Set up and connect wirefeeder reel

6

Connect power source to robot control

7

Connect remote control

Set up laser welding head:

Installing the Laser Welding Head on the Robot

Installing and Connecting SplitBox SB 360i LaserHybrid

10

Connect crossjet

11

Connecting LaserHybrid Hosepack to Laser Welding Head

Connecting/changing Wirefeeding Hose to/on Laser Welding Head

13

Installing/Changing Wirefeed Rollers

14

Connect laser optics and extra extraction

Preparing Welding Torch

16

Install LaserHybrid hosepack on robot

17

Threading the Wire Electrode

Other activities prior to start-up:

Setting up Laser Welding Head

Creating Reference Program

20

Signal sequence for LaserHybrid welding

21

Measures before starting welding

Set up ground earth connection between workpiece and power source

23

40

Page 41

Installing the Laser Welding Head on the Robot

1

Connection Options on the Robot

90 mm

406,5 mm

EN-US

Installing the Laser Welding Head

on the Robot

Install the laser welding head in line

1

with the robot manufacturer's specifications for the robot.

41

Page 42

Installing and Connecting SplitBox SB 360i LaserHy-

2

3

3

3

3

3

4

4

brid

Installing SplitBox SB 360i LaserHybrid on Robot

Separate the SplitBox SB 360i LaserHybrid and SplitBox mount

1

Install a suitable holder for the SplitBox mount on your robot

IMPORTANT Please observe the robot manufacturer's assembly instructions.

Fit the SplitBox mount on the holder

using 4 x Allen screws size 6 mm

Tightening torque = 24 Nm

Insert the interconnecting hosepack

strain-relief device into the opening

and push forward

42

Page 43

Fix the interconnecting hosepack

5

7

6

5

5

6

7

8

8

8

9

10

10

10

10

10

10

9

10

strain-relief device in place using 2 x

Allen screws size 4 mm

Open the ear clamps (x 2)

Insert the interconnecting hosepack

into the ear clamps

Close the ear clamps

EN-US

Insert SplitBox SB 360i LaserHybrid

into the SplitBox mount as illustrated

Fix SplitBox in place in the SplitBox

mount using 3 x screws TX25 at the top

and 3 x screws TX25 at the bottom

Tightening torque = 3.5 Nm

43

Page 44

Connecting Split-

a

*

b

c

d

e

f

1

3

2

4

2

3

4

6

5

5

6

Box SB 360i LaserHybrid

Connect interconnecting hosepack to

SplitBox:

a) Power cable

b) Welding torch cooling return flow

(red)

c) Welding torch cooling supply line

(blue)

d) Protective gas shield

e) SpeedNet (from interconnecting

hosepack)

f) SpeedNet (remote control)

* Gas purging connection

Connect LaserHybrid hosepack to welding torch connection (FSC)

Close clamping lever

Open cover on LaserHybrid hosepack

Connect connecting plug for welding

torch cooling to the LaserHybrid hosepack

Connect crossjet air inlet

44

Page 45

IMPORTANT! When connecting crossjet

7

8

7

8

7

8

9

9

9

9

9

(1)

air outlet hoses, make sure that cutting

rings are present!

Connect crossjet air outlet (x 2)

Fix the hoses in place on the connec-

tion using hexagon nuts size 24 mm

Tightening torque = 50 Nm

IMPORTANT! Use flat spanner size 22 mm

to hold the items in place when fixing the

hexagon nuts in place on the connection

Connect hoses for optics cooling

(push-in)

Blue marking = coolant supply line

EN-US

Connecting Interconnecting Hosepack to Power Source

10

Option:

(1) Data line 3 x 0.5 mm²

(e.g. for analyzing additional pressure monitoring)

45

Page 46

Connecting Crossjet

2

1

1

2

3

3

3

4

6

5

4

5

6

7

8

Connecting the

CrossJet

Insert CrossJet exhaust air hose into

the opening

Position fixing plate so that it is in a

groove of the CrossJet exhaust hose

(x2 - also on the opposite side)

Secure fixing plate with 2 Allen screws,

3 mm

(x2 - also on the opposite side)

46

Depending on the robot movement,

determine the required length of the air

hoses and cut the air hoses accordingly to size

Withdraw protective hose

IMPORTANT! When connecting the

CrossJet air outlet hoses, ensure that

the cutting rings are present!

Connect CrossJet air outlet

Secure hose to the connection using a

hexagonal nut, 24 mm

Tightening torque = 50 Nm

IMPORTANT! When securing the hexagon nut to the 22 mm connection socket, counter with a 22 mm wrench.

Repeat process on the other side

Page 47

Pull protective hoses over the connec-

8

8

9

tions

EN-US

47

Page 48

Connecting LaserHybrid Hosepack to Laser Welding

1

1

2

2

45,0200,1404

4

3

3

4

5

3

4

5

Head

Connecting LaserHybrid Hosepack

to Laser Welding

Head

IMPORTANT! When connecting the LaserHybrid hosepack, ensure that pins and connec-

tions on the interface do not get bent or damaged.

Align the LaserHybrid hosepack to be as straight as possible.

Connect the LaserHybrid hosepack

Fix the LaserHybrid hosepack in place:

Tighten the union nut using a torch key

and torque wrench

Tightening torque = 11 Nm

Remove 2 x Allen screws size 2.5 mm

Remove 2 x Allen screws size 2.5 mm

on the opposite side

Remove drive unit cover

48

Page 49

Put CrashBox cable together

7

6

6

6

7

1

1

3

2

4

5

2

3

4

5

1

2

Lay cable in groove

EN-US

Connecting/

changing Wirefeeding Hose to/

on Laser Welding

Head

Insert wirefeeding hose into laser welding head

Press and hold locking button

Insert the wirefeeding hose into the lo-

cking device as far as is needed to release the locking button

Release the locking button

Keep pushing the wirefeeding hose un-

til the locking device locks in place and

the locking button pops out

Removal:

Press and hold locking button

Pull wirefeeding hose out of locking de-

vice

49

Page 50

Installing/Changing Wirefeed Rollers

3

2

4

5

6

1

1

2

3

4

5

6

Installing/Changing Wirefeed Rollers

IMPORTANT! The wire electrode has to be pulled out in order to change the wirefeed roll-

er.

Disconnect external wirefeeding hose

Swing the clamping stirrup open

Remove the screwable shaft

Remove the wirefeeder roller

Remove the hexagon nut size 10 mm –

use the driving wheel key supplied with

the laser welding head to hold this on

the wirefeeder roller

Remove the wirefeeder roller

The sequence is reversed for installation

NOTE!

Do not replace the supplied wirefeeder components with other models.

Failure to use the specified V groove rollers in particular may cause problems during the

wirefeed.

50

Page 51

Connecting Laser Optics and Extra Extraction

1

1

5x

1

1

1

1

b

a

a

c

c

2

EN-US

Connecting Laser

Optics

CAUTION!

Risk of damage to the laser welding head as a result of contamination from above.

► Please observe the Operating Instructions, specifications and safety instructions is-

sued by the manufacturer of the laser optics

► Prior to connection, position the laser welding head so that the longitudinal axis on the

laser welding head is outside of the horizontal (> 90°). This will ensure that no dirt can

get into the laser optics from above.

Remove 5 x Allen screws size 6 mm

For assembly:

the 3 x shorter screws are located one below the other; the 2 x longer screws opposite each other.

Remove 2 x register pins:

a) Position and connect extractor

tool for register pins

b) Hit the vibrating mass on the ex-

tractor tool backward and then remove the register pins

c) Remove bracket for robot connec-

tion

51

Page 52

Position the laser welding head so that

3

4

5

4

5

7

6

6

7

the longitudinal axis on the laser welding head is outside of the horizontal (>

90°)

Clean connection area using compressed air

Remove protective cover from fiber optic cable connection

Clean fiber optic cable plug using compressed air

Remove protective cover from fiber optic cable plug

52

Page 53

IMPORTANT! When connecting the fiber

b

a

b

c

8

9

10

10

10

optic cable, pay attention to the position of

the register pin on the plug.

Connect fiber optic cable:

a) Press the key

b) Pull the rubber sleeve back in the

direction of the optics

c) Connect the fiber optic cable plug

Check whether the rubber sleeve is

sealing neatly around the fiber optic

cable plug

IMPORTANT The illustration shows an

incorrectly positioned rubber sleeve.

The rubber sleeve shown forms a kink

in the area around the arrow, which

means that it does not seal completely.

EN-US

INCORRECTLY positioned rubber sleeve!

The rubber sleeve does not seal completely.

Connect optics cooling using Allen

screw size 2.5 mm

Tightening torque = 4 Nm

53

Page 54

Connect optics cooling supply line

11

11

11

12

12

12

12

2

1

1

2

(blue marking)

Connect optics cooling return flow

Connecting Extra

Extraction

Put the laser welding head into a vertical position

13

Push the hose across the connection

Fix the hose in place with the hose

clamp

54

Page 55

Position bracket for robot connection

3

4

3

4

5

5

5

6

7

7

8

6

7

8

Push the slot nut up so that the top hole

on the slot nut is positioned below the

top hole on the bracket for the robot

connection.

Fasten, but do not completely tighten,

the slot nut and bracket for the robot

connection using a short Allen screw

size 6 mm

EN-US

Insert 2 x register pins

Position and connect extractor tool for

register pins

Hit the vibrating mass on the extractor

tool forward and then position the register pins

55

Page 56

For assembly:

5x

10

9

9

9

9

10

the 3 x shorter screws are located one below the other; the 2 x longer screws opposite each other.

Insert the remaining 4 x Allen screws

size 6 mm

Fix the bracket for the robot connection

in place using 5 x Allen screws size 6

mm

Tightening torque = 24 Nm

56

Page 57

Preparing Welding Torch

1

1

2

2

3

3

EN-US

Preparing Welding Torch

Open knurled nut

Insert the inner liner into the welding

torch from underneath

Use the entire contact tip to insert the

entire inner liner into the welding torch

57

Page 58

Place the union nut over the contact tip

4

5

4

5

8

6

7

6

7

8

9

9

Tighten union nut

size 12 mm

Tightening torque = 3 Nm

Put the gas nozzle in position

Fix the gas nozzle in position using Al-

len screw size 4 mm

Fold the bracket downward

Tighten the knurled nut

58

Page 59

Installing Hosepack on Robot

EN-US

Placing the Hosepack on the Robot

IMPORTANT! The optional LaserHybrid hosepack holder is not included in the scope of

supply for the laser welding head.

6 x 5 Nm

44,0360,0099

(11)

(13)

8 Nm

(14)

2,9 Nm

(12)

27 Nm

2,9 Nm

(12)

(8)

(5)

(7)

(6)

(6)

(9)

(10)

(11)

(6)

(6)

(7)

(4)

(4)

44,0350,0254

(1) Robot arm

(2) Mounting HP LH xx

(3) Item profile 10 50 x 50 mm, 2 m

(4) Optional extension arm

(5) Opening for extraction hose

(6) Opening for wirefeeding hose

(7) Opening for fiber optic cable

(8) Opening for LaserHybrid hose-

M10

45 Nm

Mounting plate depending on robot

(42,1000,0112)

(44,0350,0254)

pack

42,1000,0112

(3)

(2)

(1)

(9) Adapter insert for extraction hose

set, diameter 41/51 mm

(42,0411,9036)

(10) Lower sheet metal part

(11) Slot nut

(12) Allen screw

M4 x 60 mm

(13) Allen screw

M8 x 20 mm

(14) Allen screw

M6 x 25 mm

59

Page 60

Installation

3

4

7

10

Mount the mounting plate (2) to the robot arm (1) according to the instructions of the

1

robot manufacturer

Cut the profile 10 50 x 50 mm (3) to length according to the robot arm

2

Mount the profile 10 50 x 50 mm (3) using slot nuts and 4 hexagonal bolts, size 17 mm,

to the mounting plate (2)

Tightening torque = 10 Nm

Remove Allen screw, size 3 mm (12), and dismantle the lower sheet metal part (10)

of the LaserHybrid hosepack holder

Loosen the 2 Allen screws, size 6 mm (13), between the lower sheet metal part (10)

5

and the slot nut (11) so that the slot nut (11) can be pushed into the top slot on the

profile 10 50 x 50 mm (3)