Operating

instructions

WeldCube Connector U/I

WeldCube Connector U/I/WFS

WSM

WeldCube Connector U/I/WFS

Euro

WeldCube Connector Advanced

EN-US

Operating instructions

42,0426,0363,EA 005-10062022

Table of contents

Safety Instructions 5

Explanation of Safety Instructions 5

General 5

Intended use 6

Grid Connection 6

Environmental Conditions 6

Obligations of the Operating Company 7

Obligations of Personnel 7

Residual current circuit breaker 7

Personal Protection and Protection of Others 7

Data on noise emission values 8

Danger from toxic gases and vapors 8

Danger from Flying Sparks 9

Risks from grid current and welding current 9

Stray welding currents 10

EMC Device Classifications 10

EMC measures 11

EMF measures 11

Particular hazard areas 11

Requirement for the shielding gas 13

Danger from Shielding Gas Cylinders 13

Danger Posed by Shielding Gas Leak 13

Safety Measures at the Setup Location and During Transport 14

Safety Measures in Normal Operation 14

Maintenance and repair 15

Safety Inspection 15

Disposal 15

Safety symbols 16

Data backup 16

Copyright 16

General 17

Device concept 17

Application areas 17

Operating principle 17

Safety symbols on the device 18

Requirements 19

Options 19

FCC/RSS/EU compliance 20

Bluetooth trademarks 21

System configurations 22

System configurations with WeldCube Connector U/I 22

System configurations with WeldCube Connector U/I/WFS Euro 25

System configurations with WeldCube Connector U/I/WFS WSM 26

System configurations with WeldCube Connector Advanced 26

Operating controls, connections and mechanical components 27

Operating controls, connections, and mechanical components 27

Power LED, status LED 29

Connection Options 30

Connection Options 30

Connection via LAN 30

Connection via WLAN 30

Instructions for installation and operation 31

Installation information 31

Operating Instructions 31

Fronius Data Channel 31

Commissioning 33

Safety 33

Requirements 33

Start-up 33

SmartManager - the website of the WeldCube Connector 36

EN-US

3

General 36

Starting and logging into SmartManager 36

Unlock function if logging in does not work 37

Changing the password/logging out 37

Settings 38

Selecting the language 38

Status display 39

Fronius 39

Current system data 40

Current system data 40

Documentation logbook 41

Documentation logbook 41

Basic settings 42

Device Options 43

Default settings 43

Designation & location 43

Date and time 43

Network settings 43

Save and restore 44

Save and restore 44

Automatic backup 44

User management 46

General 46

Users 46

User roles 46

Export & import 47

CENTRUM 47

Overview 48

Overview 48

Expanding all groups/collapsing all groups 48

Saving as an xml file 48

Update 49

Update 49

Finding the update file (performing an update) 49

Fronius WeldConnect 50

Troubleshooting 51

Error display 51

Troubleshooting 51

Service, maintenance and disposal 52

Safety 52

Monthly maintenance activities 52

Calibration 52

Disposal 52

Technical data 53

WeldCube Connector 53

Wire sensor 54

4

Safety Instructions

EN-US

Explanation of

Safety Instructions

DANGER!

Indicates an immediate danger.

Death or serious injury may result if appropriate precautions are not taken.

▶

WARNING!

Indicates a possibly dangerous situation.

Death or serious injury may result if appropriate precautions are not taken.

▶

CAUTION!

Indicates a situation where damage or injury could occur.

Minor injury or damage to property may result if appropriate precautions are

▶

not taken.

NOTE!

Indicates the possibility of flawed results and damage to the equipment.

General

NOTE!

The WeldCube Connector is integrated into an existing welding system for data

collection.

Therefore, all safety and warning notices relevant to the welding process apply to

the WeldCube Connector.

Observe the Operating Instructions for all system components of the weld-

▶

ing system, in particular the safety instructions and warning notices!

The device has been manufactured in line with the state of the art and according

to recognized safety standards. If used incorrectly or misused, however, it can

cause:

Serious or fatal injury to the operator or third parties

-

Damage to the device and other material assets belonging to the operating

-

company

Inefficient operation of the device

-

All persons involved in the commissioning, operation, maintenance, and servicing

of the device must

Be suitably qualified

-

Have knowledge of welding and

-

Have fully read and precisely followed these Operating Instructions

-

The Operating Instructions must always be kept to hand wherever the device is

being used. In addition to the Operating Instructions, all applicable local rules

and regulations regarding accident prevention and environmental protection

must also be followed.

5

All safety and danger notices on the device:

Must be kept in a legible state

-

Must not be damaged/marked

-

Must not be removed

-

Must not be covered, pasted, or painted over

-

For the location of the safety and danger notices on the device, refer to the section headed "General Information" in the operating instructions for the device.

Before switching on the device, eliminate any faults that could compromise

safety.

Your personal safety is at stake!

Intended use The device is intended exclusively for measuring welding data in the designated

power range as shown on the rating plate.

The device must be properly installed and set up to ensure it functions as intended.

Utilization for any other purpose, or in any other manner, shall be deemed to be

not in accordance with the intended purpose. The manufacturer accepts no liability for any damage resulting from improper use.

Intended use also means

Reading and adhering to all instructions in the Operating Instructions

-

Carefully reading and obeying all safety instructions and danger notices

-

Carrying out all the specified inspection and maintenance work.

-

Never use a welding system for the following:

Thawing pipes

-

Charging batteries

-

Starting motors

-

The manufacturer shall not be liable for faulty or incorrect work results.

Grid Connection Devices with a high output can influence the energy quality of the grid due to

their current consumption.

This may affect a number of device types in terms of:

connection restrictions

-

-

criteria regarding maximum permissible grid impedance

-

criteria regarding the minimum required short-circuit power

*)

both at the interface with the public grid

*)

*)

See technical data

Environmental

Conditions

6

In this case, the operator or the person using the device should check whether or

not the device is allowed to be connected, where appropriate through discussion

with the power supply company.

IMPORTANT! Ensure secure grounding of the grid connection!

Operation or storage of the device outside the stipulated area will be deemed as

not in accordance with the intended purpose. The manufacturer accepts no liability for any damage resulting from improper use.

Temperature range of the ambient air:

During operation: -10°C to +40°C (14°F to 104°F)

-

During transport and storage: -20°C to +55°C (-4°F to 131°F)

-

Relative humidity:

Up to 50% at 40°C (104°F)

-

Up to 90% at 20°C (68°F)

-

Ambient air: free of dust, acids, corrosive gases or substances, etc.

Altitude above sea level: up to 2000 m (6561 ft. 8.16 in.)

EN-US

Obligations of

the Operating

Company

Obligations of

Personnel

Residual current

circuit breaker

The operating company must only allow persons to work with the device if they

Are familiar with the basic occupational safety and accident prevention regu-

-

lations and are trained in handling the device

Have read and understood these Operating Instructions, especially the sec-

-

tion "Safety Rules," and have confirmed this with their signature

Are trained according to the requirements for the work results

-

The safety-conscious work of the personnel must be checked regularly.

All persons who are assigned to work with the device must do the following before beginning the work:

Follow the basic regulations for occupational safety and accident prevention

-

Read these Operating Instructions, especially the section "Safety Rules," and

-

confirm that they have understood and will follow them by signing

Before leaving the workplace, ensure that no personal injury or property damage

can occur in one's absence.

Local regulations and national guidelines may mean that a residual current circuit breaker is required when connecting a device to the public grid.

The residual current circuit breaker recommended for the device by the manufacturer can be found in the technical data.

Personal Protection and Protection of Others

You are exposed to numerous hazards while handling the device, for example:

Flying sparks and pieces of hot metal

-

Arc radiation that poses a risk of injury to the eyes and skin

-

Hazardous electromagnetic fields that pose a risk of death for individuals

-

with pacemakers

Electrical risks from grid current and welding current

-

Increased noise exposure

-

Harmful welding fumes and gases

-

Wear suitable protective clothing when dealing with the device. The protective

clothing must have the following properties:

Flame resistant

-

Insulating and dry

-

Covering the entire body and in good condition with no damage

-

Safety helmet

-

Cuffless pants

-

7

Protective clothing involves the following:

Protecting the face and eyes from UV radiation, heat and flying sparks with a

-

face guard featuring a regulation-compliant filter

Wearing regulation-compliant protective goggles with side protection behind

-

the face guard

Wearing rigid, wet-insulating footwear

-

Protecting hands with appropriate gloves (featuring electrical insulation and

-

thermal protection)

Wearing ear protection to reduce noise exposure and protect against injury

-

Keep persons, especially children, away during the operation of the devices and

during the welding process. If persons are in the vicinity, however:

Instruct them about all hazards (blinding hazard due to arcs, risk of injury

-

from flying sparks, welding fumes hazardous to health, noise exposure, possible hazard due to grid current or welding current, etc.)

Provide suitable protective equipment or

-

Construct suitable protective walls and curtains.

-

Data on noise

emission values

Danger from toxic gases and vapors

The device produces a maximum noise level of <80 dB(A) (ref. 1pW) when idling

and in the cooling phase following operation in relation to the maximum permitted operating point at standard loading in accordance with EN 60974-1.

A workplace-specific emission value for welding (and cutting) cannot be specified because this value depends on the welding process and the environmental

conditions. It is influenced by a wide range of parameters, such as the welding

process itself (MIG/MAG, TIG welding), the selected current type (direct current, alternating current), the power range, the type of weld metal, the resonance

properties of the workpiece, the workplace environment, and many other factors.

The fumes produced during welding contain toxic gases and vapors.

Welding fumes contain substances that cause cancer, as stated in monograph

118 from the International Agency for Research on Cancer.

Use at-source extraction source and a room extraction system.

If possible, use a welding torch with an integrated extraction device.

Keep your head out of the welding fumes and gases.

Take the following precautionary measures for fumes and harmful gases:

Do not breathe them in.

-

Extract them from the work area using appropriate equipment.

-

Ensure that there is a sufficient supply of fresh air. Ensure that there is a ventilation flow rate of at least 20 m³ per hour.

Use a welding helmet with air supply if there is insufficient ventilation.

If there is uncertainty as to whether the extraction capacity is sufficient, compare the measured toxic emission values against the permissible limit values.

The following components are factors that determine how toxic the welding

fumes are:

The metals used for the workpiece

-

Electrodes

-

Coatings

-

Cleaning agents, degreasers, and the like

-

The welding process used

-

8

Consult the corresponding material safety data sheets and manufacturer's instructions for the components listed above.

Danger from Flying Sparks

Recommendations for exposure scenarios, risk management measures and

identifying working conditions can be found on the European Welding Association website under Health & Safety (https://european-welding.org).

Keep flammable vapors (such as solvent vapors) out of the arc radiation range.

When no welding is taking place, close the valve of the shielding gas cylinder or

the main gas supply.

Flying sparks can cause fires and explosions.

Never undertake welding near flammable materials.

Flammable materials must be kept at least 11 meters (36 ft. 1.07 in.) from the

arc or protected with a certified cover.

Keep suitable, tested fire extinguishers on hand.

Sparks and pieces of hot metal may also get into surrounding areas through

small cracks and openings. Take appropriate measures to ensure that there is no

risk of injury or fire.

Do not undertake welding in areas at risk of fire and explosion, or on sealed

tanks, drums, or pipes if these have not been prepared in accordance with corresponding national and international standards.

EN-US

Risks from grid

current and

welding current

Do not undertake welding on containers in which gases, fuels, mineral oils, and

the like are/were stored. Residues pose a risk of explosion.

An electric shock can be fatal.

Do not touch voltage-carrying parts inside or outside the device.

During MIG/MAG welding and TIG welding, the welding wire, the wirespool, the

feed rollers, as well as all pieces of metal that are in contact with the welding

wire, are live.

Always place the wirefeeder on a sufficiently insulated base or use a suitable insulating wirefeeder holder.

Ensure suitable personal protection with dry temporary backing or cover with

sufficient insulation against the ground potential. The temporary backing or cover must completely cover the entire area between the body and the ground potential.

All cables and leads must be secured, undamaged, insulated, and adequately dimensioned. Replace loose connections and scorched, damaged, or inadequately

dimensioned cables and leads immediately.

Before every use, check power connections for secure fit by hand.

In the case of power cables with bayonet connectors, turn the power cable by at

least 180° around the longitudinal axis and pretension.

Do not wrap cables or leads around your body or parts of the body.

Concerning the electrode (rod electrode, tungsten electrode, welding wire, etc.)

Never immerse it in liquids to cool it

-

Never touch it when the power source is switched on.

-

9

The open circuit voltage of a welding system may double, for example, between

the electrodes of two welding systems. Touching the potentials of both electrodes at the same time may be life-threatening in some cases.

Have the grid and device supply lead regularly inspected by an electrician to ensure that the ground conductor is functioning properly.

Protection class I devices require a grid with a ground conductor and a connector

system with ground conductor contact for proper operation.

Operation of the device on a grid without a ground conductor and on a socket

without a ground conductor contact is only permitted if all national regulations

for protective separation are observed.

Otherwise, this is considered gross negligence. The manufacturer accepts no liability for any damage resulting from improper use.

Use suitable equipment to ensure that the workpiece is sufficiently grounded if

necessary.

Switch off unused devices.

When working at elevated heights, wear a safety harness to prevent falls.

Before working on the device, switch off the device and remove the grid plug.

Secure the device to prevent the grid plug from being connected and switched

on again by applying a clearly legible and understandable warning sign.

Stray welding

currents

After opening the device:

Discharge all electrically charged components

-

Ensure that all components are disconnected from the power supply.

-

If work is needed on voltage-carrying parts, bring in a second person who will

switch off the main switch at the correct time.

If the following instructions are not observed, stray welding currents may occur,

which pose a risk of the following:

Fire

-

Overheating of parts connected to the workpiece

-

Irreparable damage to ground conductors

-

Damage to the device and other electrical equipment

-

Ensure that the workpiece clamp is securely connected to the workpiece.

Secure the workpiece clamp as close to the spot to be welded as possible.

Position the device with sufficient insulation against electrically conductive environments, e.g., insulation against electrically conductive floors or electrically conductive mounts.

Observe the following when using power distribution boards, twin-head mounts,

etc.: Even the electrode of the welding torch/electrode holder not in use carries

electric potential. Ensure that there is sufficient insulation when the unused

welding torch/electrode holder is stored.

EMC Device

Classifications

10

In automated MIG/MAG applications, only guide the wire electrode from the

welding wire drum, large spool, or wirespool to the wirefeeder with insulation.

Devices in emission class A:

Are only designed for use in industrial settings

-

Can cause line-bound and radiated interference in other areas

-

Devices in emission class B:

Satisfy the emissions criteria for residential and industrial areas. This is also

-

true for residential areas in which the energy is supplied from the public lowvoltage grid.

EMC device classification as per the rating plate or technical data.

EMC measures In certain cases, even though a device complies with the standard limit values for

emissions, it may affect the application area for which it was designed (e.g., when

there is sensitive equipment at the same location, or if the site where the device

is installed is close to either radio or television receivers).

If this is the case, then the operating company is obliged to take appropriate action to rectify the situation.

Test and assess the immunity of equipment in the vicinity of the device in accordance with national and international provisions. Examples of interferenceprone equipment that could be affected by the device:

Safety devices

-

Grid power lines, signal lines, and data transfer lines

-

IT and telecommunications equipment

-

Devices for measuring and calibrating

-

Supporting measures to avoid EMC problems:

Grid power supply

1.

If electromagnetic interference occurs despite a grid connection that

-

complies with regulations, take additional measures (e.g., use a suitable

grid filter).

Welding power-leads

2.

Keep them as short as possible

-

Route them close together (also to avoid EMF problems)

-

Route them far from other lines

-

Equipotential bonding

3.

Workpiece grounding

4.

If necessary, establish grounding using suitable capacitors.

-

Shield, if necessary

5.

Shield other devices in the vicinity

-

Shield the entire welding installation

-

EN-US

EMF measures Electromagnetic fields may cause health problems that are not yet known:

Effects on the health of persons close by, e.g., those with pacemakers and

-

hearing aids

Persons with pacemakers must seek advice from their doctor before staying

-

in the immediate vicinity of the device and the welding process

Keep distances between welding power-leads and the head/torso of the

-

welder as great as possible for safety reasons

Do not carry welding power-leads and hosepacks over your shoulder or wrap

-

them around your body or body parts

Particular hazard areas

Keep hands, hair, loose clothing, and tools away from moving parts, such as:

Fans

-

Gears

-

Rollers

-

Shafts

-

Wirespools and welding wires

-

11

Do not reach into rotating gears of the wire drive or into rotating drive parts.

Covers and side panels must only be opened/removed during maintenance and

repair work.

During operation

Ensure that all covers are closed, and all side parts have been mounted prop-

-

erly.

Keep all covers and side parts closed.

-

The protrusion of welding wire from the welding torch represents a high risk of

injury (cuts to the hand, facial and eye injuries, etc.).

Therefore, always hold the welding torch away from the body (devices with

wirefeeder) and use suitable protective goggles.

Do not touch the workpiece during or after welding – risk of burns.

Slag may fly off cooling workpieces. Therefore, also wear regulation-compliant

protective equipment when reworking workpieces and ensure that other persons

are sufficiently protected.

Leave the welding torch and other parts with a high operating temperature to

cool before working on them.

Special regulations apply in areas at risk of fire or explosion

– follow the appropriate national and international regulations.

Power sources for work in areas with increased electrical hazard (e.g., boilers)

must be labeled with the symbol (Safety). However, the power source may not be

located in such areas.

Risk of scalding due to leaking coolant. Switch off the cooling unit before disconnecting connections for the coolant supply or return.

When handling coolant, observe the information on the coolant safety data

sheet. The coolant safety data sheet can be obtained from your service center or

via the manufacturer's website.

Only use suitable load-carrying equipment from the manufacturer to transport

devices by crane.

Attach chains or ropes to all designated attachments of the suitable load-

-

carrying equipment.

Chains or ropes must be the smallest angle possible from vertical.

-

Remove gas cylinder and wirefeeder (MIG/MAG and TIG devices).

-

In the event of crane attachment of the wirefeeder during welding, always use a

suitable, insulating wirefeeder hoisting attachment (MIG/MAG and TIG devices).

If the device is equipped with a carrier belt or handle, then this is used exclusively for transport by hand. The carrier belt is not suitable for transport by crane,

counterbalanced lift truck, or other mechanical lifting tools.

All lifting equipment (belts, buckles, chains, etc.), which is used in association

with the device or its components, must be checked regularly (e.g., for mechanical damage, corrosion, or changes due to other environmental influences).

The test interval and scope must at least comply with the respective valid national standards and guidelines.

12

There is a risk of colorless, odorless shielding gas escaping without notice if an

adapter is used for the shielding gas connection. Use suitable Teflon tape to seal

the thread of the shielding gas connection adapter on the device side before installation.

Requirement for

the shielding gas

Especially with ring lines, contaminated shielding gas can cause damage to

equipment and reduce welding quality.

Meet the following requirements regarding shielding gas quality:

Solid particle size < 40 µm

-

Pressure condensation point < -20 °C

-

Max. oil content < 25 mg/m³

-

Use filters if necessary.

EN-US

Danger from

Shielding Gas

Cylinders

Shielding gas cylinders contain compressed gas and may explode if damaged.

Shielding gas cylinders are an integral part of the welding equipment, so they

must be handled very carefully.

Protect shielding gas cylinders with compressed gas from excessive heat, mechanical impact, slag, open flames, sparks, and arcs.

Mount the shielding gas cylinders vertically and secure them in accordance with

instructions so they cannot fall over.

Keep shielding gas cylinders away from welding or other electrical circuits.

Never hang a welding torch on a shielding gas cylinder.

Never touch a shielding gas cylinder with an electrode.

Risk of explosion: Never weld on a compressed shielding gas cylinder.

Always use suitable shielding gas cylinders for the application in question and the

correct matching accessories (controller, hoses, and fittings, etc.) Only use

shielding gas cylinders and accessories that are in good condition.

If a valve on a shielding gas cylinder is open, turn your face away from the outlet.

When no welding is taking place, close the valve of the shielding gas cylinder.

Leave the cap on the valve of the shielding gas cylinder when the cylinder is not

connected.

Danger Posed by

Shielding Gas

Leak

Follow the manufacturer's instructions and applicable national and international

provisions for shielding gas cylinders and accessories.

Risk of asphyxiation due to uncontrolled shielding gas leak

Shielding gas is colorless and odorless and may suppress the oxygen in the ambient air in the event of leakage.

Ensure there is a sufficient supply of fresh air with a ventilation flow rate of

-

at least 20 m³ per hour.

Please observe the safety and maintenance information for the shielding gas

-

cylinder or the main gas supply.

When no welding is taking place, close the valve of the shielding gas cylinder

-

or the main gas supply.

Always check the shielding gas cylinder or main gas supply for uncontrolled

-

gas leakage before each start-up.

13

Safety Measures

at the Setup

Location and

During Transport

A toppling device can be deadly! Set up the device securely on an even, solid surface

The maximum permitted tilt angle is 10°.

-

Special regulations apply in areas at risk of fire or explosion

Follow the appropriate national and international regulations.

-

Use instructions and checks within the company to ensure that the vicinity of the

workplace is always clean and organized.

Only set up and operate the device in accordance with the protection class

shown on the rating plate.

When setting up the device, ensure that there is an all-round clearance of 0.5 m

(1 ft. 7.69 in.) to allow cooling air to circulate unhindered.

Take care to ensure that the applicable national and regional guidelines and accident prevention regulations are observed when transporting the device, especially guidelines concerning hazards during transport and shipment.

Do not lift or transport any active devices. Switch off devices before transport or

lifting.

Before transporting the device, completely drain the coolant and dismantle the

following components:

wirefeeder

-

wirespool

-

shielding gas cylinder

-

Safety Measures

in Normal Operation

It is essential to conduct a visual inspection of the device to check for damage

after it has been transported but before commissioning. Have any damage repaired by trained service technicians before commissioning the device.

Only operate the device when all safety devices are fully functional. If the safety

devices are not fully functional, there is a danger of:

Injury or death to the operator or a third party

-

Damage to the device and other material assets belonging to the operating

-

company

Inefficient operation of the device

-

Safety devices that are not fully functional must be repaired before the device is

switched on.

Never bypass or disable safety devices.

Before switching on the device, ensure that no one can be put in danger.

The device must be examined at least once a week for externally detectable damage and functionality of the safety devices.

Always secure the shielding gas cylinder well and remove before transporting by

crane.

14

Only the original coolant from the manufacturer is suitable for use in our devices

due to its properties (electrical conductivity, anti-freeze, material compatibility,

flammability, etc.)

Only use appropriate original coolant from the manufacturer.

Do not mix original coolant from the manufacturer with other coolants.

Only connect system components from the manufacturer to the cooling unit circuit.

Maintenance and

repair

If there is damage due to use of other system components or other coolants, the

manufacturer accepts no liability for this and all warranty claims are forfeited.

Cooling Liquid FCL 10/20 is not flammable. The ethanol-based coolant is flam-

mable in certain conditions. Only transport the coolant in closed original containers and keep away from sources of ignition.

Properly dispose of used coolant according to national and international regulations. The coolant safety data sheet can be obtained from your service center or

via the manufacturer’s website.

When the system is cool, always check the coolant level before starting welding.

It is impossible to guarantee that bought-in parts are designed and manufactured to meet the demands made of them, or that they satisfy safety requirements.

Use only original spare and wearing parts (also applies to standard parts).

-

Do not carry out any modifications, alterations, etc. to the device without the

-

manufacturer's consent.

Components that are not in perfect condition must be replaced immediately.

-

When ordering, please give the exact designation and part number as shown

-

in the spare parts list, as well as the serial number of your device.

The housing screws provide the ground conductor connection for earthing the

housing parts.

Only use original housing screws in the correct number and tightened to the specified torque.

EN-US

Safety Inspection

Disposal To comply with European directives and national law, waste electrical and elec-

The manufacturer recommends that a safety inspection of the device be performed at least every 12 months.

The manufacturer recommends calibrating power sources within the same 12month interval.

A safety inspection by a certified electrician is recommended:

After changes

-

After alterations

-

After repair, care, and maintenance

-

At least every 12 months

-

For the safety inspection, follow the appropriate national and international

standards and guidelines.

You can obtain more information about the safety inspection and calibration

from your service center. The service center will provide the necessary documents upon request.

tronic equipment must be collected separately and sent for environmentallyfriendly recycling. Used devices must be returned to a distributor or an approved

collection and recycling facility in your area. Proper disposal of used devices promotes the sustainable recycling of material resources. Ignoring this may have potentially adverse effects on the environment and your health.

15

Packaging materials

Materials collected separately. Check the regulations in your area. Reduce the

volume of cardboard.

Safety symbols Devices with the CE label satisfy the essential requirements of the low-voltage

and electromagnetic compatibility directive (e.g., relevant product standards of

the EN 60974 series).

Fronius International GmbH declares that the device complies with Directive

2014/53/EU. The full text of the EU Declaration of Conformity is available on the

following website: http://www.fronius.com

Devices marked with the CSA test mark satisfy the requirements of the relevant

standards for Canada and the USA.

Data backup The user is responsible for backing up any changes made to the factory settings.

The manufacturer accepts no liability for any deleted personal settings.

Copyright Copyright of these Operating Instructions remains with the manufacturer.

Text and illustrations were accurate at the time of printing. Fronius reserves the

right to make changes. The contents of the Operating Instructions shall not

provide the basis for any claims whatsoever on the part of the purchaser. If you

have any suggestions for improvement, or can point out any mistakes that you

have found in the Operating Instructions, we will be most grateful for your comments.

16

General

Device concept With the WeldCube Connector, all

welding systems involved in production

can be integrated into the Fronius

WeldCube Premium documentation

system, regardless of manufacturer.

If the power supply is lost, the WeldCube Connector stores the last data

and ensures a safe shutdown process.

The WeldCube Connector is available in the following versions:

WeldCube Connector U/I

4,044,056

Measurement of welding current and welding voltage

incl. voltage measurement adapter

EN-US

Application

areas

Operating principle

WeldCube Connector U/I/WFS WSM

4,044,057

Measurement of welding current, welding voltage, and wire speed

incl. wire sensor

(for the power sources TransSteel 3000c Pulse, TransSteel 3500c, and the

wirefeeder VR 5000)

WeldCube Connector U/I/WFS Euro

4,044,058

Measurement of welding current, welding voltage, and wire speed

incl. Euro wire sensor

WeldCube Connector Advanced

4,044,067

Measurement of welding current, welding voltage, and wire speed

Wire sensor optional (see options from page 19)

The WeldCube Connector is used in manual and automated MIG/MAG, TIG, and

MMA applications.

Regardless of the welding process, the WeldCube Connector is always integrated

between the power source and the grounding cable.

The current is measured at the current sockets of the power source.

For functional system integration, the following components must be connected:

17

Safety symbols

on the device

Connect the WeldCube Connector to the ground current socket of the

-

power source

Connect the grounding cable to the WeldCubeConnector

-

Voltage measurement by adapter cable or voltage/wire speed measurement

-

by wire sensor at the other pole

Power supply via "Power over Ethernet" using a suitable network cable

-

Connection to the network via LAN network cable or WLAN

-

The WeldCube Connector is powered via the network cable using Power over

Ethernet (PoE).

The power supply via PoE can be provided by the central IT infrastructure or a

PoE injector on site. The PoE injector is then integrated into the data line

between the network distributor and the WeldCube Connector.

Welding is dangerous. The following basic requirements must be met:

Adequate welding qualifications

-

Appropriate protective equipment

-

Exclusion of unauthorized persons

-

Do not use the functions described here until you have fully read and understood

the following documents:

These Operating Instructions

-

All system component Operating Instructions, especially the safety rules

-

18

Requirements

NOTE!

Installing and integrating the WeldCube Connector requires an understanding

of network technology.

For detailed information, consult your network administrator.

▶

Network cable requirements:

RJ45 / M12 connection, X-coding

-

Industrial cable version, min. CAT 5e

-

Requirements for the PoE injector according to IEEE 802.3at - PoE+ / 30 W:

Shielded RJ45 socket

-

Robust and enclosed plastic housing

-

Min. 100 Mbit/s data speed

-

EMC device class: EN55032 Class B, FCC part 15 Class B

-

Environmental conditions:

Ambient temperature in operation: -10 °C to +40 °C

-

Storage temperature: -20 °C to +55 °C

-

EN-US

Options

PoE injector RJ45 30 W / 802.3at /

PoE+

CE IEC power cable 2 m 43,0004,2951

Network cable M12-X / RJ45, 5 m 42,0411,0232

Network cable M12-X / RJ45, 10 m 42,0411,0233

Network cable M12-X / RJ45, 15 m 42,0411,0234

Network cable M12-X / RJ45, 20 m 42,0411,0235

OPT/WCC Sensor Cable EXT 5m

Extension cable for external sensors 5

m

OPT/WCC Sensor Cable EXT 10m

Extension cable for external sensors

10 m

OPT/WCC Mounting Set TSt

Mounting equipment for TransSteel

power sources

OPT/WCC Mounting Set 1

Mounting equipment for a welding

system

42,0411,0213

4,051,547

4,051,548

4,101,361

4,101,362

19

OPT/WCC Mounting Set 2

Mounting equipment for a welding

system

4,101,363

FCC/RSS/EU

compliance

OPT/WCC Wire Sensor EUR

Option wire sensor/Euro for WeldCube Connector Advanced

OPT/WCC Wire Sensor WSM

Option wire sensor/TSt for WeldCube

Connector Advanced

Holding magnet * 4,100,265

* 2 holding magnets are required for the WeldCube Connector.

FCC

This device conforms to the limits for a Class B digital device, pursuant to Part

15 of the FCC regulations. These limit values are designed to provide reasonable

protection against harmful interference in a residential installation. This device

generates and uses high frequency energy and, if not used in accordance with the

instructions, may interfere with radio communications. However, there is no guarantee that interference will not occur in a particular installation.

If this device does cause harmful interference to radio or television reception,

which can be determined by turning the device off and on again, the user is encouraged to try to correct the interference using one or more of the following

measures:

Align or reposition the receiving antenna

-

Increase the distance between the device and receiver.

-

Connect the device to a different circuit than the receiver.

-

Consult the dealer or an experienced radio/TV technician for help.

-

4,101,372

4,101,373

20

FCC ID: QKWSPB209A

Industry Canada RSS

This device complies with Industry Canada license-exempt RSS standards. Operation is subject to the following conditions:

(1) This device must not cause any harmful interference.

(2) This device must not be affected by external sources of interference, in-

cluding interference that may impair operation.

IC: 12270A-SPB209A

EU

Compliance with directive 2014/53/EU - Radio Equipment Directive (RED)

The antennas used for this transmitter must be installed in such a way that a

minimum distance of 20 cm from all persons is maintained. They must not be in-

stalled or operated in conjunction with another antenna or transmitter. OEM integrators and end users must ensure the operating conditions of the transmitter

comply with radio frequency exposure guidelines.

EN-US

Bluetooth trademarks

The word mark Bluetooth® and the Bluetooth® logos are registered trademarks

and property of Bluetooth SIG, Inc. and are used by the manufacturer under license. Other trademarks and trade names are the property of their respective

owners.

21

System configurations

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

+

(10)

(9)

System configurations with

WeldCube Connector U/I

MIG/MAG

Schematic illustration, interconnecting hosepack not shown in detail between power source and

wirefeeder

(1) Computer for access to WeldCube Premium

(2) Ethernet switch with PoE

(3) Power supply via PoE (Power over Ethernet)

(4) WeldCube Premium Server (physical or VM)

(5) Voltage measurement adapter

(6) Wirefeeder

(7) Power source

(8) WeldCube Connector U/I

(9) Grounding cable

(10) Welding torch

22

MIG/MAG with wire drive integrated in the power source

+

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

HF

+

*

(1) Computer for access to WeldCube Premium

(2) Ethernet switch with PoE

(3) Power supply via PoE (Power over Ethernet)

(4) WeldCube Premium Server (physical or VM)

(5) Voltage measurement adapter

(6) Power source

(7) WeldCube Connector U/I

(8) Grounding cable

(9) Welding torch

EN-US

TIG-DC, TIG-AC

HF = high frequency ignition; * = high-frequency-free current socket - e.g., for rod electrodes

(1) Computer for access to WeldCube Premium

(2) Ethernet switch with PoE

(3) Power supply via PoE (Power over Ethernet)

(4) WeldCube Premium Server (physical or VM)

(5) Voltage measurement adapter

(6) Power source

(7) WeldCube Connector U/I

23

(8) Grounding cable

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

HF

+

*

(9)

(9) Welding torch

MMA (with TIG power source)

HF = high frequency ignition; * = high-frequency-free current socket - e.g., for rod electrodes

(1) Computer for access to WeldCube Premium

(2) Ethernet switch with PoE

(3) Power supply via PoE (Power over Ethernet)

(4) WeldCube Premium Server (physical or VM)

(5) Voltage measurement adapter

(6) Power source

(7) WeldCube Connector U/I

(8) Grounding cable

(9) Electrode holder

24

System config-

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

+

(10)

(9)

(1)

(2)

(3)

(4)

(6)

(7)

(8)

(9)

(5)

urations with

WeldCube Connector U/I/WFS

Euro

MIG/MAG

EN-US

Schematic illustration, interconnecting hosepack not shown in detail between power source and

wirefeeder

(1) Computer for access to WeldCube Premium

(2) Ethernet switch with PoE

(3) Power supply via PoE (Power over Ethernet)

(4) WeldCube Premium Server (physical or VM)

(5) Power source

(6) Wirefeeder

(7) Euro wire sensor

(8) WeldCube Connector U/I

(9) Return lead cable

(10) Welding torch

MIG/MAG with wire drive integrated in the power source

(1) Computer for access to WeldCube Premium

(2) Ethernet switch with PoE

(3) Power supply via PoE (Power over Ethernet)

(4) WeldCube Premium Server (physical or VM)

(5) Euro wire sensor

(6) Power source

25

(7) WeldCube Connector U/I

(8) Return lead cable

(9) Welding torch

System configurations with

WeldCube Connector U/I/WFS

WSM

System configurations with

WeldCube Connector Advanced

The system configuration for TransSteel welding systems with WeldCube Connector U/I/WFS WSM is the same as the system configuration for WeldCube

Connector U/I/WFS Euro, except that instead of the Euro wire sensor, a wire

sensor is integrated into the power source or wirefeeder itself.

The wire sensor is either installed at the factory or can be retrofitted by suitably

trained and qualified personnel.

For details on installing the wire sensor, refer to the "WeldCube Connector wire

sensor TransSteel" Installation Instructions - 42,0410,2663.

The system configuration for welding systems with WeldCube Connector Advanced is the same as the system configuration for WeldCube Connector

U/I/WFS Euro.

Euro wire sensor or a wire sensor integrated into the TransSteel power sources

are optionally available.

26

Operating controls, connections and mechanical

(1) (2) (3) (4)

(5)

(6)

(7)

(2) (2) (2) (2) (2) (2)

(2)

(5)

M5

100 mm

184 mm

components

Operating controls, connections, and mechanical components

(1) M12 socket, X-coding

EN-US

For connecting a network cable

(2) M5 threaded bushing

4 pieces per side

For mounting the WeldCube Connector for the welding system

(3) Status LED

Warnings, errors, and current operating states are output via the status

LED

(4) Power LED

Information on the electrical supply to the WeldCube Connector is output via the Power LED

The LEDs are described in the following section

(5) Return lead cable with bayonet connector

For connecting to the ground current socket of the power source

NOTE!

The ground connection on the power source depends on the welding process

and does not necessarily have to coincide with the (-) current socket!

27

(6) Ground current socket with bayonet latch

(10)

(9)

(8)

(11) (12) (13)

For connecting the welding circuit return lead cable

(7) Sensor connection

Laboratory socket

(for WeldCube Connector U/I)

For connecting the voltage measurement adapter

19-pin sensor socket

(for WeldCube Connector U/I/WFS WSM, WeldCube Connector U/I/WFS

Euro, and WeldCube Connector Advanced)

For connecting the wire sensor

No. Function

(8) Measuring cable

(9) (+) Current socket with bayonet

For connecting to the laboratory socket for WeldCube Connect U/I

latch

For connecting the (+) welding

circuit cable from the interconnecting hosepack

Voltage measurement adapter (only in conjunction with WeldCube Connector U/I)

Euro wire sensor (only in conjunction with WeldCube Connector U/I/WFS Euro or as an option

for WeldCube Connector Advanced)

(10) (+) cable with bayonet connect-

or

For connecting to the (+) current socket of the power source

No. Function

(11) Measuring cable

For connecting to the 19-pin

sensor socket on WeldCube

Connector U/I/WFS WSM,

WeldCube Connector U/I/WFS

Euro, and WeldCube Connector

Advanced

(12) Euro adapter

For connecting to the power

source

(13) Euro torch connector

For connecting the welding

torch

28

Power LED,

status LED

Power LED

lights up green:

electrical supply available

lights up orange:

no electrical supply available - power is currently being supplied internally, until

all data is saved

does not light up:

no electrical supply available

Status LED

When the electrical supply is on, the status LED may light up or flash in the following colors:

lights up green:

device ready for operation, everything OK

flashes green (at 5 Hz):

initial connection established between WeldConnect app and WeldCube Connector, e.g., for commissioning or configuration purposes

lights up orange:

warning

EN-US

flashes orange (at 0.5 Hz):

device not yet in operation

lights up red:

error

a pending error can be checked in the SmartManager or WeldCube Premium logbook.

flashes in the current color (at 2.5 Hz):

welding detected

29

Connection Options

(1)

(2)

(3)

(4)

(6)

(7)

(5)

(1)

(2)

(3)

(4)

(6)

(7)

(5)

AP

Connection Options

Connection via

LAN

The WeldCube Connector can be integrated into a network as follows:

via LAN

-

via WLAN

-

(1) Computer for access to Weld-

Cube Premium

(2) Ethernet switch with PoE

(3) WeldCube Premium Server

(4) Power supply via PoE (Power

over Ethernet)

(5) Network cable

(6) WeldCube Connector

(7) Ground connection on the

power source

NOTE!

Connection via

WLAN

The ground connection on the power source depends on the welding process

and does not necessarily have to coincide with the (-) current socket!

(1) Computer for access to Weld-

Cube Premium

(2) Ethernet switch

(3) WeldCube Premium Server

(4) WLAN AccessPoint

(5) Power supply via PoE (Power

over Ethernet)

(6) WeldCube Connector

(7) Ground connection on the

power source

NOTE!

The ground connection on the power source depends on the welding process

and does not necessarily have to coincide with the (-) current socket!

30

Instructions for installation and operation

EN-US

Installation information

Operating Instructions

The WeldCube Connector must be attached to the power source or a com-

-

ponent of the welding system, e.g., the trolley.

The WeldCube Connector must not lie on the ground.

-

The WeldCube Connector can be mounted in any position.

-

Max. length between 2 active network components (e.g., between WeldCube

-

Connector and Ethernet switch with PoE): 90 m

Position the WeldCube Connector so that the LEDs are clearly visible.

-

Do not position the WeldCube Connector in the area of hot exhaust air from

-

the power source or in the area of heated system components.

Position the WeldCube Connector such that it is protected from welding

-

spatter.

Use an adequately dimensioned grounding cable.

-

Secure the network cable, sensor cable and measuring cable to the ground-

-

ing cable of the WeldCube Connector using cable ties (strain relief)

NOTE!

The WeldCube Connector suppresses HF high voltage pulses!

If a TIG welding process with integrated WeldCube Connector needs to be ignited by means of HF high-voltage pulses, HF ignition will not take place.

If available, only connect cable to an HF-free current socket (e.g. for manual

▶

metal arc welding).

If an HF-free current socket is not available, deactivate HF ignition.

▶

Fronius Data

Channel

HF = high frequency

Before each use of the WeldCube Connector:

Check all welding and measuring cables for damage.

-

Check connecting plugs are correctly and firmly connected.

-

Check LEDs

-

Monthly:

Visually inspect the housing and plug

-

NOTE!

When measuring TIG-AC welds, an arithmetically rectified value is documented.

Part designation, part serial number and weld seam number can be sent to the

WeldCube Connector via the Fronius Data Channel.

The Fronius Data Channel is a TCP / IP server that runs on the WeldCube Connector administration port. This port is used for documentation and communication as well as servicing purposes and this interface is monitored on TCP port

4714.

31

A PC program or a higher-level controller establishes a TCP socket connection to

the IP address of the WeldCube Connector at TCP port 4714. The parameters

are transmitted as key or set value text lists separated by semicolons.

The following parameters are supported:

No. Parameter

1 Process active

During an active welding process (from gas pre-flow at the start of welding to gas post-flow at the end of welding), the WeldCube Connector out-

puts the process active signal = 1 to the controller.

2 Current flow

When the current flow is active during welding, the WeldCube Connector

outputs the current flow signal = 1 to the controller.

3 Part item number

The controller gives the WeldCube Connector the item number of the

part being welded using ASCII characters A-Z, a-z and 0-9.

4 Part serial number

The controller gives the WeldCube Connector the serial number of the

part being welded using ASCII characters A-Z, a-z and 0-9.

5 Seam number

The controller gives the WeldCube Connector the seam being welded

(welding position) using ASCII characters 0-9.

Data transfer via the Fronius Data Channel can be tested using the following programs:

Windows® PuTTy

-

Linux Socat

-

A TCP socket connection must first be established for the data transfer.

Enter the IP address of the service

1

port of the WeldCube Connector

and the port number 4714

32

Example Windows® PuTTY

Commissioning

EN-US

Safety

Requirements

WARNING!

Danger from incorrect operation and work that is not carried out properly.

This can result in serious personal injury and damage to property.

All the work and functions described in this document must only be carried

▶

out by technically trained and qualified personnel.

Read and understand this document in full.

▶

Read and understand all safety rules and user documentation for this equip-

▶

ment and all system components.

NOTE!

Installing and integrating the WeldCube Connector requires an understanding

of network technology.

For detailed information, consult your network administrator.

▶

The WeldCube Connector must be integrated into the welding system ac-

-

cording to one of the system configurations.

Available PoE power supply

-

Fronius WeldConnect app installed on the smartphone

-

Bluetooth activated on the smartphone

-

Start-up The WeldCube Connector is commissioned using a smartphone and the Fronius

WeldConnect app.

NOTE!

If the power source has a function for determining the welding circuit resistance R, determine the welding circuit resistance of the welding system before

commissioning using the WeldCube Connector that is in place.

The welding circuit resistance value must be correct to get accurate measurement results!

Enter the welding circuit resistance value found using the Installation Wizard

▶

at Setup 5/6.

If there is no function for determining the welding circuit resistance on the

▶

power source, use the calculation tool in the Installation Wizard at Setup

5/6.

Determine the welding circuit resistance of the welding system incl. Weld-

1

Cube Connector

33

name1.name2@e-mailaddr.ess

2

4

3

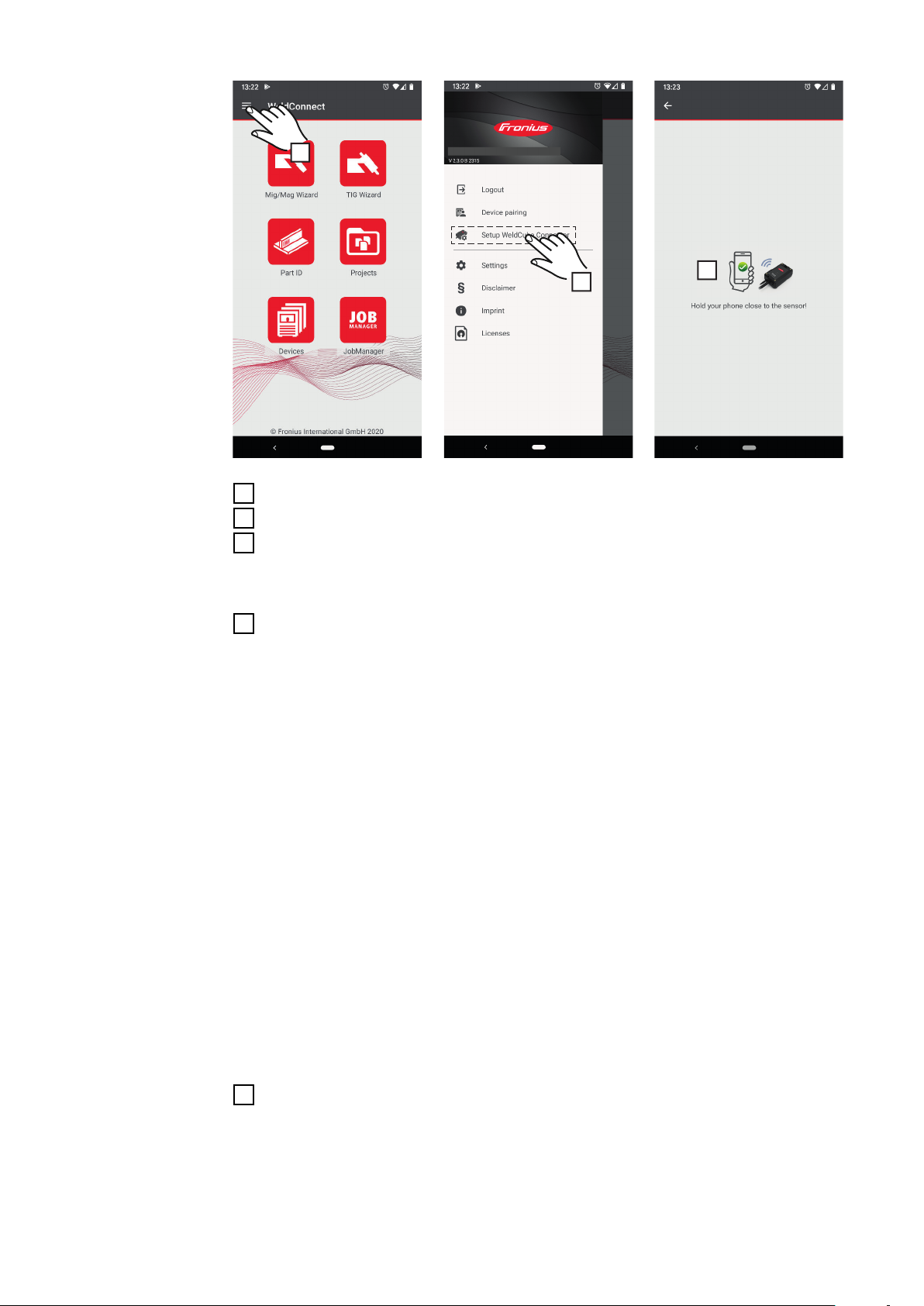

Start the WeldConnect app and open the menu

2

Select Setup WeldCube Connector

3

Bring smartphone into the immediate vicinity of the WeldCube Connector

4

A successfully started connection is indicated by a status LED on the WeldCube Connector flashing quickly at 5 Hz.

Follow the instructions in the Installation Wizard:

5

Setup 1/6

Enter name, site, hall, cell and additional information

Setup 2/6

Enter network data

Setup 3/6

Enter WLAN data

Setup 4/6

Enter date, time and time zone

Setup 5/6

Enter the welding circuit resistance determined in step 1

or

Start the calculation tool

Setup 6/6

Optionally enter wire diameter and filler metal

If wire diameter and filler metal are entered, they are also logged in WeldCube Premium.

Complete WeldCube Connector Setup

6

The documented data can now be viewed in the SmartManager or analyzed

with WeldCube Premium.

34

For data analysis with WeldCube Premium:

xx.x.xx.xx

EN-US

Enter the IP address of the WeldCube Connector under Administration / Ma-

7

chines / Machine IP-Addresses

The recorded welding operations are then available in the Fronius WeldCube

Premium documentation system under Machines / WeldCube Connector.

35

SmartManager - the website of the WeldCube

Connector

General With the SmartManager, the WeldCube Connector has its own website.

Once the WeldCube Connector is connected to a computer via a network cable

or WLAN or is integrated into a network, the SmartManager of the WeldCube

Connector can be accessed via the IP address.

IE 10 or higher or another modern browser is required in order to access the

SmartManager.

The following entries are available for the WeldCube Connector:

Starting and logging into SmartManager

Current system data

-

Documentation logbook

-

Device Options

-

Save and restore

-

Enter the IP address of the WeldCube Connector into the search field of the

1

browser

Enter user name and password

2

Factory setting:

User name = admin

Password = admin

Confirm the displayed message

3

The SmartManager of the WeldCube Connector is displayed.

User management

-

Overview

-

Update

-

36

Unlock function

if logging in does

not work

When logging into the SmartManager, the unlock function can be used to unlock

a WeldCube Connector that was unintentionally locked and enable it for all functions.

Click on "Start unlock function?"

1

Create a verification file:

2

click on "Store"

A .txt file with the following file name is saved in the computer's download folder:

unlock_SN[serial number]_YYYY_MM_DD_hhmmss.txt

Send this verification file via e-mail to Fronius Technical Support at:

3

welding.techsupport@fronius.com

Fronius will reply by e-mail with a one-time unlock file with the following file

name:

response_SN[serial number]_YYYY_MM_DD_hhmmss.txt

Save the unlock file to the computer

4

Click on "Find unlock file"

5

Save the unlock file

6

Click on "Load unlock file"

7

EN-US

Changing the

password/

logging out

The Admin password of the WeldCube Connector is reset once to factory settings.

Click on this symbol to

change the user password

-

log out of the SmartManager

-

Changing the password for the SmartManager:

Enter the old password

1

Enter a new password

2

Repeat the new password

3

Click on "Store"

4

37

Settings

Selecting the

language

By clicking on this symbol, the units and standards for the WeldCube Connector

can be set.

The settings depend on the user who is logged in.

Click on the language abbreviation to display the languages available for the

SmartManager.

38

The currently set language is highlighted in white.

To change the language, click on the desired language.

Status display The current status of the WeldCube Connector is displayed between the Fronius

logo and the displayed WeldCube Connector.

EN-US

Fronius

Caution/warning

Welding in progress WeldCube Connector is ready for op-

WeldCube Connector is not ready for

operation (offline)

* In the event of an error, a red error line with the error number appears

above the line with the Fronius logo.

After clicking on the error line, an error description is displayed.

Error on the WeldCube Connector *

eration (online)

Click on the Fronius logo to open the Fronius homepage: www.fronius.com

39

Current system data

Current system

data

Any current WeldCube Connector data is displayed:

Machine name

Installation location

Welding current Welding voltage Wire speed *

Arc time Total operating hours

* Only for WeldCube Connector U/I/WFS WSM and WeldCube Connector

U/I/WFS Euro

Hall Cell Additional information

ACTUAL

Current arc power

Current arc energy

40

Documentation logbook

(1) (2) (3) (4) (5) (6) (7) (10)(8) (9) (12)(11)

EN-US

Documentation

logbook

The Documentation logbook entry shows the last 100 logbook entries. These logbook entries can be welds, errors, warnings, notifications and events.

The "Time filter" button can be used to filter the displayed data by a specific time

period. This is entered with date (yyyy MM dd) and time (hh mm), each from - to.

An empty filter reloads the most recent welding operations.

The display of welding operations, errors, and events can be deactivated.

The following data is displayed:

(1) Log type

(2) Seam number

(3) Part item number

(4) Part serial number

(5) Start time (local time)

(6) Welding duration

(7) Welding current in A (rectified average)

(8) Welding voltage in V (rectified average)

(9) Wire speed in m/min *

(10) IP - arc power in W (based on real-time values according to ISO/TR

18491)

(11) IE - arc energy in kJ (as the total throughout the entire welding process

according to ISO/TR 18491)

(12) reserved for other data

* Only for WeldCube Connector U/I/WFS WSM and WeldCube Connector

U/I/WFS Euro

Additional values can be also displayed by clicking on the "Insert column" button:

I max / I min: maximum/minimum welding current in A

-

Power max / Power min: maximum/minimum arc power in W

-

Start time (power source time); date and time

-

U max / U min: maximum/minimum welding voltage in V

-

Vd max / Vd min: maximum / minimum wire speed in m/min

-

41

Basic settings In the Documentation logbook entry, the sampling rate for the documentation

and rules for hiding the ignition phase can be set under Basic settings.

Sampling rate

0.1 - 100 s / off

Factory setting: 0.1 s

0.1 - 100.0 s

Documentation is saved at the set sampling rate.

off

Sampling rate is deactivated, only average values are stored.

Hide ignition phase

Period of time for which the ignition phase of the weld is to be hidden

(e.g. in order to prevent the ignition phase from affecting the measurement results in the case of short welds)

0.1 - 2 s / off

0.1 - 2 s

The welding data is not documented until the set time value has elapsed.

off

The ignition phase is documented at the same time.

42

Device Options

Default settings The welding circuit resistance can be adjusted under the default settings.

The currently set resistance is displayed.

To calculate the resistance:

Click on the Start calculation aid button

1

Enter the length and cross section of the hosepack

2

Enter the grounding cable length and cross-section

3

Enter the number of separable connections

4

The calculated resistance value is displayed immediately.

Click on the Yes button to accept the calculated resistance

5

Finally, save or discard the changes

6

EN-US

Designation &

location

The power source configuration can be viewed and modified under Designation &

location.

Date and time Under Date and Time, the time zone, date, and time can be set.

The setting can be made manually or automatically.

Network settings Under Network settings, the data for integrating the WeldCube Connector into a

network can be entered:

Management

MAC address is displayed

-

Current IP address is displayed

-

DHCP can be enabled or disabled

-

Manual

With DHCP deactivated, the following data can be entered:

IP address

-

Network mask

-

Default gateway

-

DNS server 1

-

DNS server 2

-

WLAN

The following data can be entered with an active WLAN connection:

MAC address

-

Current IP address

-

43

Save and restore

Save and restore Starting a backup

Click on "Start backup" to save the WeldCube Connector data as a backup

1

By default, the data is saved in the format MCU1-YYYYMMDTHHmm.fbc in

the selected location.

YYYY = year

MM = month

DD = day

HH = hour

mm = minute

The following data is saved in the backup:

the documentation sampling rate

-

machine name and installation site

-

time and date

-

Finding a recovery file

Automatic

backup

Click on "Find recovery file" to transfer an existing backup to the power

1

source

Select the file and click on "Open"

2

The selected backup file appears in the SmartManager for the power source

under Restore.

Click on "Start restore"

3

Once the data has been successfully restored, a confirmation is displayed.

Enable interval settings

1

Enter the interval settings for the times at which the automatic backup

2

should take place:

Interval:

-

daily/weekly/monthly

at:

-

time (hh:mm)

44

Enter the data for the backup destination:

3

Protocol:

-

SFTP (Secure File Transfer Protocol) / SMB (Server Message Block)

Server:

-

Enter the IP address of the destination server

Port:

-

Enter port number; if no port number is entered, the standard port 22 is

automatically used.

If SMB is set under Protocol, leave the Port field blank.

Storage location:

-

Used to configure the subfolder where the backup will be stored.

If no location is entered, the backup is stored in the server root directory.

IMPORTANT! For SMB and SFTB, always enter the location with a slash

"/".

Domain/user, password:

-

User name and password - as configured on the server;

When entering a domain, first enter the domain, then backslash "\" and

then the user name (DOMAIN\USER)

If a connection via proxy server is required, activate and enter the proxy set-

4

tings:

Server

-

Port

-

User

-

Password

-

EN-US

Save changes

5

Activate automatic backup

6

If you have any questions about configuration, contact your network administrator.

45

User management

General Under the User administration entry

Users can be viewed, changed, and created.

-

User roles can be viewed, changed, and created.

-

Users and user roles can be exported or imported into the WeldCube Con-

-

nector.

During import, existing user management data on the WeldCube Connector

is overwritten.

A CENTRUM server can be activated.

-

User management is created on one WeldCube Connector and can then be saved

with the export/import function and transferred to other WeldCube Connectors.

Users Existing users can be viewed, changed and deleted, new users can be created.

Viewing/changing a user:

Select a user

1

Change user data directly in the display field

2

Save the changes

3

Deleting a user:

Select a user

1

Click on the "Delete user" button

2

Confirm the prompt with "OK"

3

Creating a user:

Click on the "Create new user" button

1

Enter user data

2

Confirm with OK

3

User roles Existing user roles can be viewed, changed and deleted, new user roles can be

created.

Viewing/changing a user role:

Select a user role

1

Change user role data directly in the display field

2

Save the changes

3

46

The "Administrator" role cannot be changed.

Deleting a user role:

Select a user role

1

Click on the "Delete user role" button

2

Confirm the prompt with "OK"

3

The "Administrator" and "locked" roles cannot be deleted.

Creating a user role:

Click on the "Create new user role" button

1

Enter a role name, apply values

2

Confirm with OK

3

Export & import Exporting users and user roles from a WeldCube Connector

Click on "export"

1

User management for the WeldCube Connector is stored in the computer's

download folder.

File format: userbackup_SNxxxxxxxx_YYYY_MM_DD_hhmmss.user

SN = serial number, YYYY = year, MM = month, DD = day

hh = hour, mm = minute, ss = second

Importing users and user roles into a WeldCube Connector

Click on "Find user data file"

1

Select the file and click on "open"

2

Click on "import"

3

EN-US

User management is stored on the WeldCube Connector.

CENTRUM To activate a CENTRUM server

(CENTRUM = Central User Management)

Activate CENTRUM Server

1

In the input field, enter the domain name or IP address of the server on

2

which Central User Management has been installed.

If a domain name is used, a valid DNS server must be configured under the

WeldCube Connector network settings.

Click on the "Verify server" button

3

The availability of the specified server is checked.

Save the changes

4

47

Overview

Overview The Overview entry displays the components of the WeldCube Connector with

all the available information, e.g., firmware version, item number, serial number,

production date, etc.

Expanding all

groups/

collapsing all

groups

Saving as an xml

file

Click on the "Expand all groups" button to see further details about the individual components.

Example SCU1:

Item number

-

RD SCU1

-

Item number, serial number, production date

Bootloader: version

Image version

Licenses

-

Click on the "Collapse all groups" button to hide the details of the system components.

Click on the "Save as xml file" button to create an XML file from the details of

the system components. This XML file can either be opened or saved.

48

Update

Update Under the Update entry, the firmware of the WeldCube Connector can be up-

dated.

The current firmware version is displayed.

To update the firmware of the WeldCube Connector:

Organize and save the update file

1

Click on "Find update file" to start the update process

2

Select the update file

3

Click on "Update"

After the update has been successfully completed, a confirmation message is

displayed.

EN-US

Finding the update file (performing an update)

After clicking on "Find update file", select the desired firmware (*.ffw)

1

Click on "Open"

2

The selected update file appears in the SmartManager under Update.

Click on "Update"

3

The progress of the update process is displayed.

Once this reaches 100%, the prompt to restart the power source appears.

The SmartManager is not available during the restart.

After the restart, the SmartManager may no longer be available.

If you select No, the new software functions will be activated the next time the

power is turned on/off.

After a successful update, a confirmation and the current firmware version is displayed.

Then log into the SmartManager again.

49

Fronius WeldConnect

Under the Update entry, the Fronius WeldConnect mobile application can also

be called up. Fronius WeldConnect supports welders, designers and work planners in estimating various welding parameters.

Fronius WeldConnect

Fronius WeldConnect is available as follows:

WeldConnect online (direct link)

-

As an app for Android

-

As an app for Apple/IOS

-

The parameters found for the mobile application can be transferred to the power

source via WLAN connection as a welding job (IP address input required).

50

Troubleshooting

Error display An error is indicated by a red lit or red flashing status LED on the WeldCube

Connector.

The error can be checked in the SmartManager or WeldCube Premium logbook.

EN-US

Troubleshooting

4

Sensor PC board could not be found

Cause:

Remedy:

53

WeldCube Connector backup power supply not available

Cause:

Remedy:

NOTE!

If the backup supply is not available, a disconnection of the electrical supply

may result the recorded welding data of the last 24 hours being lost!

A permanent connection of the WeldCube Connector to WeldCube Premium

▶

can reduce the loss of recorded welding data in the event of a fault.

56

Operating temperature of the WeldCube Connector is outside the permissible

range

Connection error to the sensor PC board

Contact the Fronius service team

The backup supply is defective.

Contact the Fronius service team

Cause:

Remedy:

Cause:

Remedy:

57

Time and date are not set

Cause:

Remedy:

Internal temperature of the WeldCube Connector is too low or too

high

Change the position of the WeldCube Connector

Poor contact due to oxidized or damaged contact surfaces on the

power plugs

Clean or replace power plugs

Time and date are not set

Set the time and date (e.g. in the SmartManager or using the Fronius

WeldConnect app.)

51

Service, maintenance and disposal

Safety

WARNING!

Danger from incorrect operation and work that is not carried out properly.

This can result in serious personal injury and damage to property.

All the work and functions described in this document must only be carried

▶

out by technically trained and qualified personnel.

Read and understand this document in full.

▶

Read and understand all safety rules and user documentation for this equip-

▶

ment and all system components.

WARNING!

Danger from electrical current.

This can result in serious personal injury and damage to property.

Before starting work, switch off all devices and components involved, and

▶

disconnect them from the grid.

Secure all devices and components involved so they cannot be switched back

▶

on.

After opening the device, use a suitable measuring instrument to check that

▶

electrically charged components (such as capacitors) have been discharged.

WARNING!

Danger due to insufficient ground conductor connection.

This can result in serious personal injury and damage to property.

The housing screws provide a suitable ground conductor connection for

▶

grounding the housing.

The housing screws must not under any circumstances be replaced by other

▶