Fronius prints on elemental chlorine free paper (ECF) sourced from certified sustainable forests (FSC).

/ Perfect Charging / Perfect Welding / Solar Energy

Virtual Welding 2.0

Operating Instructions

EN

Virtual welding system

[

42,0426,0089,EN 012-10072020

2

Contents

Safety rules ................................................................................................................................................ 7

Explanation of safety notices ................................................................................................................ 7

General ................................................................................................................................................. 7

Environmental conditions...................................................................................................................... 7

Obligations of the operator.................................................................................................................... 8

Obligations of personnel ....................................................................................................................... 8

Mains connection .................................................................................................................................. 8

Dangers from mains current ................................................................................................................. 8

EMC device classifications ................................................................................................................... 9

Specific hazards.................................................................................................................................... 10

Safety measures at the installation location and during transport ........................................................ 10

Safety measures in normal operation ................................................................................................... 11

Commissioning, maintenance and repair.............................................................................................. 11

Safety symbols...................................................................................................................................... 11

Data protection...................................................................................................................................... 11

Copyright............................................................................................................................................... 12

Disposal ................................................................................................................................................ 12

General information 13

General ...................................................................................................................................................... 15

Device concept ..................................................................................................................................... 15

Intended use ......................................................................................................................................... 15

Warning notices on the device.............................................................................................................. 16

Software and product updates.............................................................................................................. 17

Scope of delivery and optional function packages..................................................................................... 18

Scope of supply .................................................................................................................................... 18

Function packages................................................................................................................................ 19

EN

Controls, connections and mechanical components 21

Touchscreen and sensor ........................................................................................................................... 23

Touchscreen and sensor ...................................................................................................................... 23

Control elements and connections............................................................................................................. 24

Connection sockets on the StandUp Terminal...................................................................................... 24

Controls and connection sockets on the MobileCase........................................................................... 25

Location of the ventilation openings........................................................................................................... 27

Ventilation openings on the StandUp Terminal..................................................................................... 27

Ventilation openings on the MobileCase............................................................................................... 27

Installation 29

Before installation and commissioning....................................................................................................... 31

Safety.................................................................................................................................................... 31

Setup regulations .................................................................................................................................. 31

Installing the StandUp Terminal................................................................................................................. 33

Safety.................................................................................................................................................... 33

Screwing the mounting brackets to the StandUp Terminal................................................................... 33

Assembling the StandUp Terminal and tightening the screws.............................................................. 35

Waiting time until the power connection is established......................................................................... 38

Installing the MobileCase........................................................................................................................... 39

Safety.................................................................................................................................................... 39

Setting up the MobileCase, fitting the tool table.................................................................................... 39

Waiting time until the power connection is established......................................................................... 40

Fitting and connecting the system components......................................................................................... 41

Fitting and connecting the tool and other system components............................................................. 41

Switching on, getting started...................................................................................................................... 44

Connecting the mains cable and switching on the device .................................................................... 44

Getting started ...................................................................................................................................... 44

3

Start-up 45

Training concept and commissioning sequence ........................................................................................ 47

Training concept ................................................................................................................................... 47

Commissioning sequence..................................................................................................................... 47

First step of commissioning: creating a curriculum .................................................................................... 48

General ................................................................................................................................................. 48

Configuring a USB flash drive............................................................................................................... 48

Creating a knowledge check (test)........................................................................................................ 49

Saving content to the USB flash drive .................................................................................................. 50

Importing content .................................................................................................................................. 51

Merging content into a curriculum......................................................................................................... 55

Second step of commissioning: creating a course..................................................................................... 63

Uses of a course ................................................................................................................................... 63

Creating a course.................................................................................................................................. 63

Third step of commissioning: assigning courses ....................................................................................... 66

Assigning courses to the Virtual Welding system ................................................................................. 66

Assigning courses to multiple terminals................................................................................................ 67

Fourth step of commissioning: activating course mode, preparing the system for users .......................... 68

Activating course mode......................................................................................................................... 68

Preparing the system for users ............................................................................................................. 68

Ghost 69

Explanation and configuration options ....................................................................................................... 71

Explanation ........................................................................................................................................... 71

Creating a variable Ghost ..................................................................................................................... 71

Available modes on the Virtual Welding system 75

Course mode ............................................................................................................................................. 77

Explanation ........................................................................................................................................... 77

Activating course mode......................................................................................................................... 77

Profile.................................................................................................................................................... 78

Description of rankings lists, exporting course data.............................................................................. 80

Open mode ................................................................................................................................................ 82

Explanation ........................................................................................................................................... 82

Enabling open mode ............................................................................................................................. 82

Showroom mode........................................................................................................................................ 83

Explanation ........................................................................................................................................... 83

Enabling showroom mode .................................................................................................................... 83

Calibration 85

System calibration...................................................................................................................................... 87

Function ................................................................................................................................................ 87

Performing system calibration............................................................................................................... 87

Room calibration ........................................................................................................................................ 89

Function ................................................................................................................................................ 89

Performing room calibration.................................................................................................................. 89

Component calibration ............................................................................................................................... 91

Function ................................................................................................................................................ 91

Performing component calibration ........................................................................................................ 91

Changing the camera settings ................................................................................................................... 93

Function ................................................................................................................................................ 93

Changing the camera settings .............................................................................................................. 93

Additional settings 95

Licence management................................................................................................................................. 97

Function ................................................................................................................................................ 97

Opening licence management (Licensemanager) ................................................................................ 97

Installing a licence................................................................................................................................. 97

4

Changing the robot manufacturer .............................................................................................................. 98

Description ............................................................................................................................................ 98

Quiz............................................................................................................................................................ 99

Function ................................................................................................................................................ 99

Enabling/disabling or importing/exporting quizzes................................................................................ 99

Exporting a quiz .................................................................................................................................... 99

Creating a quiz...................................................................................................................................... 100

Importing a quiz .................................................................................................................................... 102

Setup menu 105

Permissions and opening the Setup menu ................................................................................................ 107

Different permissions ............................................................................................................................ 107

Access the Setup menu ........................................................................................................................ 107

Network menu item .................................................................................................................................... 108

Description ............................................................................................................................................ 108

Creating a cluster network .................................................................................................................... 108

Other settings menu item........................................................................................................................... 111

Viewing the licence list.......................................................................................................................... 111

Creating a backup (exporting data)....................................................................................................... 112

Management code ................................................................................................................................ 113

Language settings................................................................................................................................. 114

Importing data (only available to administrators) .................................................................................. 116

Viewing/changing country profiles (only available to administrators).................................................... 117

Restoring factory settings (only available to administrators)................................................................. 118

Performing sensor registration (only available to administrators) ......................................................... 119

Technical settings menu item .................................................................................................................... 122

Setting the time and date (only available to administrators) ................................................................. 122

Showing the NSB number..................................................................................................................... 122

Test screen (only available to administrators) ...................................................................................... 123

Setting the model .................................................................................................................................. 124

Enabling ScanDisk (only available to administrators) ........................................................................... 124

Performing touchscreen test (only available to administrators) ............................................................ 125

Adjusting the volume (only available to administrators)........................................................................ 126

EN

Troubleshooting, maintenance and disposal 129

Troubleshooting ......................................................................................................................................... 131

General ................................................................................................................................................. 131

Safety.................................................................................................................................................... 131

Troubleshooting .................................................................................................................................... 131

Maintenance and disposal ......................................................................................................................... 134

General ................................................................................................................................................. 134

Safety.................................................................................................................................................... 134

Maintenance at every start-up .............................................................................................................. 134

Disposal ................................................................................................................................................ 134

Update 135

Updating the software ................................................................................................................................ 137

Preparing for the update ....................................................................................................................... 137

Updating the software ........................................................................................................................... 146

Technical data 149

Technical data............................................................................................................................................ 151

Special voltages.................................................................................................................................... 151

StandUp Terminal, MobileCase ............................................................................................................ 151

Standards.............................................................................................................................................. 151

5

6

Safety rules

EN

Explanation of

safety notices

DANGER!

Indicates immediate danger.

► If not avoided, death or serious injury will result.

WARNING!

Indicates a potentially hazardous situation.

► If not avoided, death or serious injury may result.

CAUTION!

Indicates a situation where damage or injury could occur.

► If not avoided, minor injury and/or damage to property may result.

NOTE!

Indicates a risk of flawed results and possible damage to the equipment.

General The device has been manufactured in line with the state of the art and according to recog-

nised safety standards. If used incorrectly or misused, however, it can cause:

- Serious or fatal injury to the operator or third parties

- Damage to the device and other material assets belonging to the operating company

- Inefficient operation of the device

All persons involved in commissioning, operating, maintaining and servicing the device

must:

- Be suitably qualified

- Have fully read, understood and precisely followed these Operating Instructions

The Operating Instructions must always be at hand wherever the device is being used. In

addition to the Operating Instructions, all applicable local rules and regulations regarding

accident prevention and environmental protection must also be followed.

All safety and danger notices on the device:

- Must be kept in a legible state

- Must not be damaged/marked

- Must not be removed

- Must not be covered, pasted, or painted over

For the location of the safety and danger notices on the device, refer to the "General" chapter of the device Operating Instructions.

Before switching on the device, rectify any faults that could compromise safety.

This is for your personal safety!

Environmental

conditions

Operation or storage of the device outside the stipulated area will be deemed as not in accordance with the intended purpose. The manufacturer shall not be held liable for any damage arising from such usage.

7

The device must only be installed and operated inside dry and enclosed premises.

Ambient temperature range:

- during operation: - 10 °C to + 35 °C (14 °F to 95 °F)

- during transport and storage: - 25 °C to + 55 °C (-13 °F to 131 °F)

Relative humidity:

- up to 50 % at 35 °C (95 °F)

- up to 90 % at 20 °C (68 °F)

The surrounding air must be free from dust, acids, corrosive gases or substances, etc.

Can be used at altitudes of up to 2000 m (6500 ft)

Obligations of the

operator

Obligations of

personnel

The operator undertakes:

- To read and understand these Operating Instructions.

- To hand the key of the device only to persons who are familiar with the product

The operator must only allow persons to work with the device who:

- Are familiar with the fundamental instructions regarding safety at work and accident

prevention and have been instructed in how to use the device

- Have read and understood these Operating Instructions and have confirmed as much

with their signatures

- Are trained to produce the required results (live work or training)

Checks must be carried out at regular intervals to ensure that personnel are working in a

safety-conscious manner.

Before using the device, all persons instructed to do so undertake:

- To observe the basic instructions regarding safety at work and accident prevention

- To have read and understood these Operating Instructions

Before leaving the workplace, ensure that people or property cannot come to any harm in

your absence.

Mains connection The mains voltage and frequency must conform to the data on the rating plate.

The Virtual Welding system must be connected to a properly installed, fused and earthed

mains socket.

If the device is shipped without a standard domestic cable, fit and use a mains plug and

cable in accordance with local standards.

An electric shock is potentially life threatening and can be fatal. The mains plug must be

fitted and connected by trained personnel only.

Route the mains cable so as to avoid any risk of injury to persons (e.g. tripping) or damage

to the mains cable.

Dangers from

mains current

8

An electric shock is potentially life threatening and can be fatal.

Do not touch live parts either inside or outside the device.

All cables and leads must be secured, undamaged, insulated and adequately dimensioned. Loose connectors, scorched, damaged or inadequately dimensioned cables and

leads must be replaced immediately.

Do not wrap cables or leads around the body or parts of the body.

Arrange for the mains cable to be checked regularly by a qualified electrician to ensure the

ground conductor is functioning properly.

The device must only be operated on a mains supply with a ground conductor and a socket

with a ground conductor contact.

If the device is operated on a grid without a ground conductor and in a socket without a

ground conductor contact, this will be deemed gross negligence. The manufacturer shall

not be held liable for any damage arising from such usage.

Switch off unused devices.

Wear a safety harness if working at height.

Before working on the device, switch it off and pull out the mains plug.

EN

EMC device classifications

Attach a clearly legible and easy-to-understand warning sign to the device to prevent anyone from plugging the mains plug back in and switching it on again.

After opening the device:

- Discharge all components that store an electrical charge

- Ensure that all components in the device are de-energised.

If work on live parts is required, appoint a second person to switch off the main switch at

the right moment.

Repairs (e.g. opening of the device) must only be carried out by suitably trained and qualified personnel. In the event of a fault, disconnect the mains plug immediately and have

repairs carried out by trained and qualified personnel.

- The device must be disconnected from the power supply before carrying out repairs

- Use only original spare parts

- Switch off before removing the mains plug

Virtual Welding is an emission class A device.

Devices with emission class A

- Are only designed for use in an industrial setting

- Can cause conducted and emitted interference in other areas.

In certain cases, even though a device complies with the standard limit values for emissions, it may affect the application area for which it was designed (e.g. when there is sensitive equipment at the same location, or if the site where the device is installed is close to

either radio or television receivers).

If this is the case, then the operator is obliged to take appropriate action to rectify the situation.

9

Check for possible problems, and check and evaluate neighbouring devices' resistance to

interference according to national and international requirements. For example:

- Safety devices

- Network, signal and data transfer lines

- IT and telecommunications devices

- Measuring and calibrating devices

Supporting measures for avoidance of EMC problems:

a) Mains supply

- Use only with the power cable supplied

- If electromagnetic interference arises despite the correct mains connection, addi-

tional measures are necessary (e.g. use of a suitable line filter)

b) No changes to the device

- Changes made to the device without prior consent from the manufacturer may re-

sult in loss of type approval

c) If the device appears to be interfering with the reception of radio or TV signals or the

operation of other equipment:

- Turn the device on and off to confirm that it is a source of interference

- If this identifies the device as a source of interference, remedy the fault by the in-

terference suppression measures listed below

d) Interference suppression measures

- Shield other devices nearby

- Set up the device well away from the affected receiver

- Turn the device away from the affected receiver

- Turn the antenna of the affected receiver in a different direction

- Connect the device to a different AC socket so that the device and the affected

receiver use different circuits.

- Only connect the device to a socket that is earthed. Removing the earth can am-

plify high-frequency emissions and cause an electric shock with fatal consequences. Do not use an AC adapter or extension cable

- If the measures described above do not resolve the problem, contact the manu-

facturer or a qualified radio and TV technician

Specific hazards Special provisions apply in areas at risk of fire or explosion

- observe relevant national and international regulations.

Always keep ventilation openings clear. For more details on the position of the ventilation

openings, see section Location of the ventilation openings from page 27.

The ambient temperature must not exceed 35 °C (95 °F).

The device must not be moved using a crane.

If the StandUp Terminal is set up incorrectly it could topple over, leading to injury and material damage. The StandUp Terminal must only be set up by trained personnel on a firm,

horizontal surface and secured to the wall and the floor using the brackets provided.

For more details on installing the StandUp Terminal, see section Installing the StandUp

Terminal from page 33.

Safety measures

at the installation

location and during transport

When transporting the device, ensure that the relevant national and local guidelines and

accident prevention regulations are observed. This applies especially to guidelines regarding the risks arising during transport.

Transport the device only in the original packaging. The original packaging is available

from the manufacturer.

10

Do not lift or transport operational devices. Switch off devices before transport or lifting.

Safety measures

in normal operation

Use internal directives and checks to ensure that the workplace environment is always

clean, organised and tidy.

After transport, before installation and commissioning, it is essential to visually inspect the

device for damage. Have a trained service technician repair any damage before installation

and commissioning.

Only operate the device when all safety devices are fully functional. If the safety devices

are not fully functional, there is a risk of:

- Serious or fatal injury to the operator or third parties

- Damage to the device and other material assets belonging to the operating company

- Inefficient operation of the device

Any safety devices that are not functioning properly must be repaired before switching on

the device.

Never bypass or disable safety devices.

Before switching on the device, ensure that no one is likely to be endangered.

Check the device at least once a week for obvious damage and proper functioning of safety

devices.

EN

Commissioning,

maintenance and

repair

Safety symbols Devices with the CE mark satisfy the essential requirements of the low-voltage and elec-

It is impossible to guarantee that bought-in parts are designed and manufactured to meet

the demands made of them, or that they satisfy safety requirements.

- Use only original spare and wearing parts (also applies to standard parts).

- Do not carry out any modifications, alterations, etc. to the device without the manufacturer's consent.

- Components that are not in perfect condition must be replaced immediately.

- When ordering, please give the exact designation and part number as shown in the

spare parts list, as well as the serial number of your device.

The housing screws provide the ground conductor connection for earthing the housing

parts.

Only use original housing screws in the correct number and tightened to the specified

torque.

tromagnetic compatibility directives (e.g. relevant product standards of the EN 60 974 series).

Fronius International GmbH hereby declares that the device is compliant with Directive

2014/53/EU. The full text on the EU Declaration of Conformity can be found at the following

address: http://www.fronius.com

Devices marked with the CSA test mark satisfy the requirements of the relevant standards

for Canada and the USA.

Data protection The user is responsible for the safekeeping of any changes made to the factory settings.

The manufacturer accepts no liability for any deleted personal settings.

11

Copyright Copyright of these operating instructions remains with the manufacturer.

The text and illustrations are all technically correct at the time of printing. We reserve the

right to make changes. The contents of the operating instructions shall not provide the basis for any claims whatsoever on the part of the purchaser. If you have any suggestions for

improvement, or can point out any mistakes that you have found in the instructions, we will

be most grateful for your comments.

Disposal Do not dispose of this device with normal domestic waste! To comply with the European

Directive on Waste Electrical and Electronic Equipment and its implementation as national

law, electrical equipment that has reached the end of its life must be collected separately

and returned to an approved recycling facility. Any device that you no longer require must

either be returned to your dealer or given to one of the approved collection and recycling

facilities in your area. Ignoring this European Directive may have potentially adverse affects on the environment and your health!

12

General information

General

EN

Device concept

Virtual Welding is used to teach welding in

a realistic environment. The following benefits are provided by Virtual Welding:

- Very low cost of training No consumables are required (wire electrodes, welding gas, etc.)

- The trainees are not exposed to the

hazards of welding (heat, welding fumes, welding spatter, noise, etc.)

- The learning progress of the trainees is

documented and can be compared

with each other

- The learning content can be adapted to

suit your needs

- Many different tasks can be simulated

with the help of the different welding

torches and workpieces

- etc.

Virtual Welding is available as a StandUp

Terminal for stationary applications and as

a MobileCase for portable use.

StandUp Terminal

MobileCase

Intended use The device is to be used exclusively for its intended purpose.

15

The device is intended for welding simulation only with the software and hardware supplied

by the manufacturer.

Any use above and beyond this purpose is deemed improper.

The manufacturer shall not be held liable for any damage arising from such usage.

Intended use also means:

- Fully reading and understanding all the instructions given in the Operating Instructions

- Fully reading and understanding all warning notices on the device

- Performing all stipulated inspection and servicing work

- Establishing the mains connection according to the specifications on the rating plate

- Setting up in a dry and enclosed environment

The device must never be:

- Modified without authorisation

- Handled improperly

- Operated with software other than that supplied by the manufacturer

- Operated, maintained or repaired without observing the Operating Instructions

The device is designed for use in a dry and enclosed environment. The manufacturer is not

liable for any damage caused by use in a different environment.

The manufacturer accepts no liability for inadequate or incorrect training results.

Warning notices

on the device

Warning notices and safety symbols are affixed to the StandUp Terminal and MobileCase.

These warning notices and safety symbols must not be removed or painted over. They

warn against incorrect operation, as this may result in serious injury and damage.

16

Incorrect operation or poorly executed work can cause serious injury or damage. The device may only be installed, repaired and maintained by trained and qualified personnel. The

following documents must be completely read and understood:

- These Operating Instructions

- All the Operating Instructions for the system components, especially the safety rules

Do not dispose of used devices with domestic waste. Dispose of them according to the safety rules.

EN

Software and

product updates

Due to software updates, you may find that your device has certain functions that are not

described in these Operating Instructions or vice versa. Certain illustrations may also differ

slightly from the actual controls on your device, but these controls function in exactly the

same way.

17

Scope of delivery and optional function packages

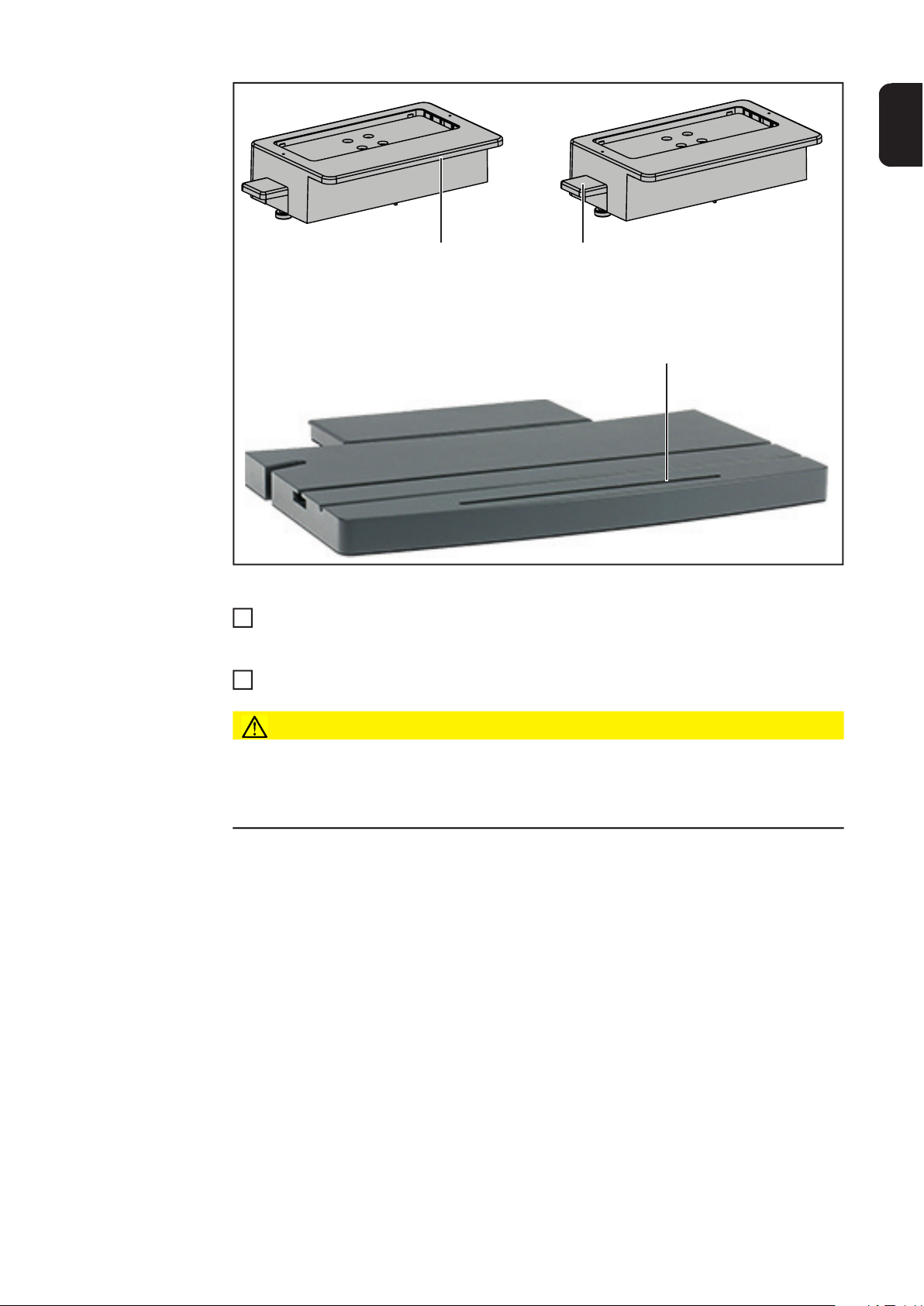

Scope of supply In addition to the StandUp Terminal or MobileCase, the following system components are

supplied:

Work table

Workpiece holder Single-V butt weld layer 1 (square butt weld) workpie-

ce

Fillet weld workpiece

18

Single-V butt weld layer 2 and 3 (square butt weld)

workpiece

EN

Function packages

Pipe workpiece

2 NFC keys

Supplied with the StandUp Terminal, but not shown:

- 3D glasses

- 4 keys

- 4 screws M8x80 mm with washers, for screwing together the upper and lower parts

- Mounting bracket including 4 screws M8x16 mm and washers

- This document

- Mains cable (for connecting to a power socket)

- Cable for 3D glasses

- Network cable

Supplied with the MobileCase, but not shown:

- 3D glasses

- 2 keys

- This document

- Mains cable (for connecting to a power socket)

- Cable for 3D glasses

- Network cable

The function packages are not included with the Virtual Welding system. At least one of the

following function packages must be ordered with the Virtual Welding system.

MIG/MAG function package TIG function package

Robotics function package

19

Rod electrode function package

20

Controls, connections and mechani-

cal components

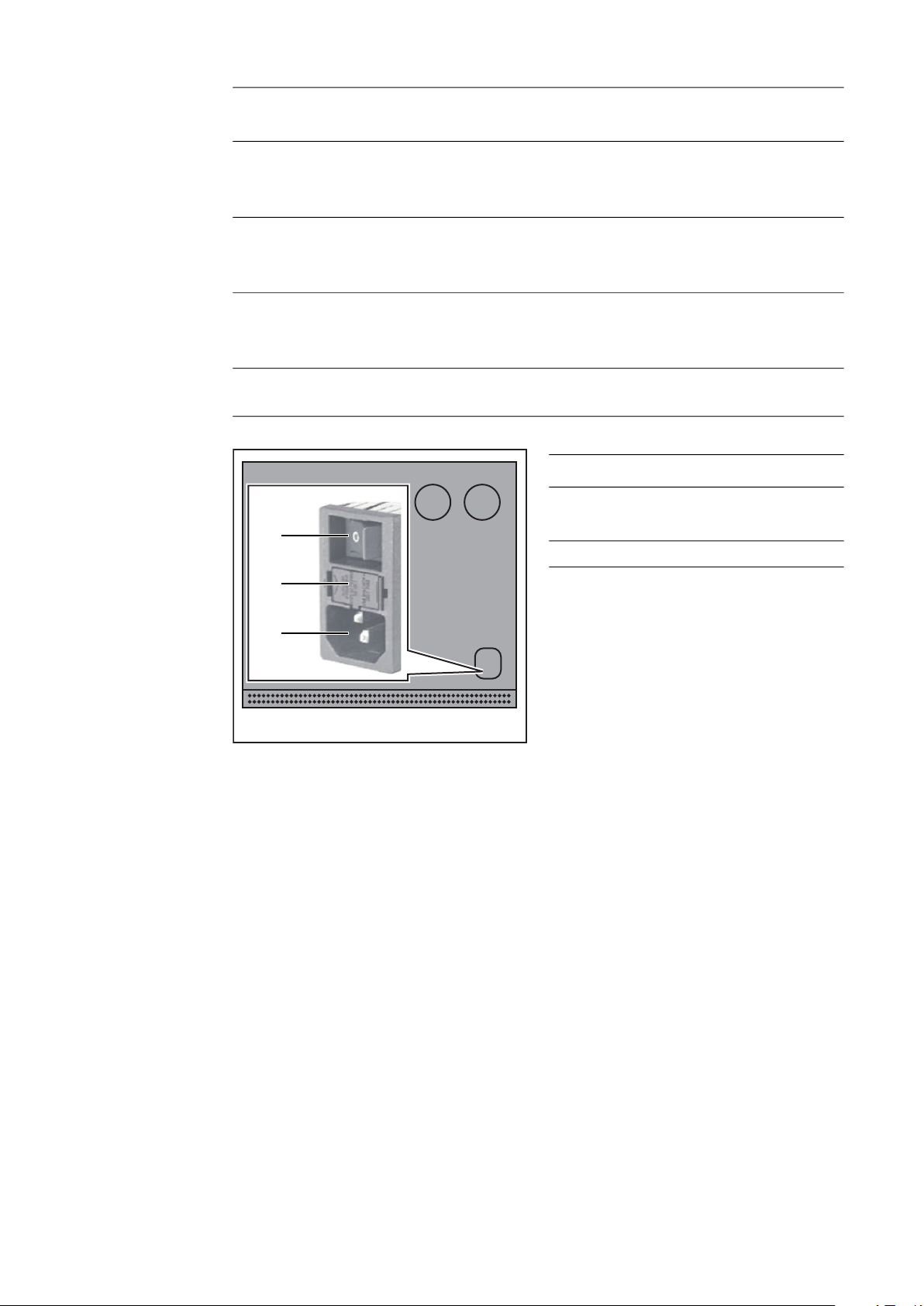

Touchscreen and sensor

(2)

(1)

(2)

Touchscreen and

sensor

EN

Touchscreen and sensor on the StandUp Terminal

The touchscreen (1) allows intuitive operation by means of virtual buttons.

The sensor (2), in conjunction with the supplied NFC keys, performs the following functions:

- Touch sensor with the NFC key once =

Open terminal management in order to create curricula, for example - see section

First step of commissioning: creating a curriculum from page 48

- Touch the sensor with the NFC key twice =

Open the Setup menu - for more details, see section Permissions and opening the

Setup menu from page 107

Sensor on MobileCase

23

Control elements and connections

(1) (2) (3) (4)

Connection sockets on the StandUp Terminal

(1) Connection for the workpiece

(2) Connection for robotics clip or

(3) Connection 1 for welding torch

(4) Connection 2 for welding torch

holder

for connecting the sensor cable of

the workpiece holder

filler material

for connecting the sensor cable of

the robotics clip;

for connecting the sensor cable of

the filler material (TIG)

for connecting the sensor cable of

the welding torch;

for connecting the sensor cable of

the electrode holder

for connecting the control cable of

the welding torch;

for connecting the control cable of

the electrode holder

Front of the StandUp Terminal

24

(5) LAN connection socket

(5) (6) (7) (8)

(9)

(10)

(11)

(4) (5)(3)(2)(1)

(7) (6)(8)(9)

for connecting a LAN network cable

(6) 3D glasses connection socket

for connecting the data cable of the

3D glasses

(7) USB port

for connecting the power cable of

the 3D glasses

(8) Connection for external display

provided

for connecting an external monitor

or projector

(After connecting the monitor/projector, restart the Virtual Welding

system)

(9) Mains switch

(10) Fuse

2 x 3.15 A slow-blow

(11) Mains connection

EN

Controls and connection sockets

on the MobileCase

Rear of StandUp Terminal

The controls and connection sockets illustrated below are located on the right side panel

of the MobileCase.

(1) Connection for external display

provided

for connecting an external monitor

or projector

(After connecting the monitor/projector, restart the Virtual Welding

system)

(2) Sensor

See section Touchscreen and

sensor on page 23

(3) 3D glasses connection socket

for connecting the data cable of the

3D glasses

(4) USB port

for connecting the power cable of

the 3D glasses

25

(5) LAN connection socket

(9)

(10)

(11)

for connecting a LAN network cable

(6) Connection 1 for welding torch

for connecting the control cable of the welding torch;

for connecting the control cable of the electrode holder

(7) Connection 2 for welding torch

for connecting the sensor cable of the welding torch;

for connecting the sensor cable of the electrode holder

(8) Connection for robotics clip or filler material

for connecting the sensor cable of the robotics clip;

for connecting the sensor cable of the filler material (TIG)

(9) Connection for the workpiece holder

for connecting the sensor cable of the workpiece holder

(10) Mains switch

(11) Fuse

2 x 3.15 A slow-blow

Rear of MobileCase

(12) Mains connection

26

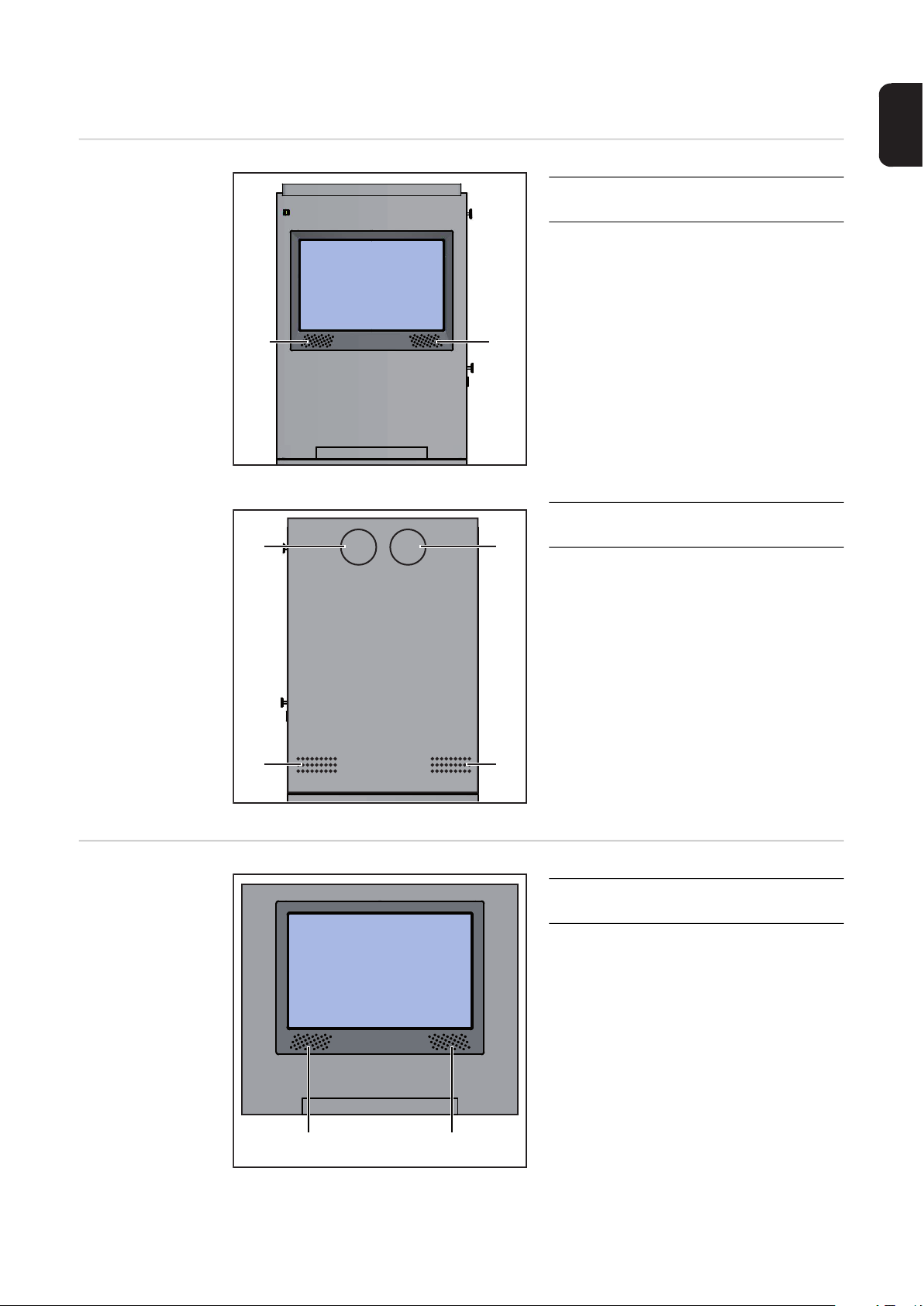

Location of the ventilation openings

(1)

(1)

(1)

(1)

(1)

(1)

(1)(1)

Ventilation openings on the StandUp Terminal

(1) Ventilation openings at the front

(2) Ventilation openings at the rear

EN

of the device

of the device

Ventilation openings on the MobileCase

(1) Ventilation openings at the front

of the device

27

(2) Ventilation openings at the rear

(2)

(2)

(2)

of the device

28

Installation

Before installation and commissioning

EN

Safety

Setup regulations

WARNING!

Danger due to incorrect operation and incorrectly performed work.

This can result in serious injury and damage to property.

► All the work and functions described in this document must only be carried out by

trained and qualified personnel in accordance with the applicable national and international standards.

► Read and understand this document.

► Read and understand all the Operating Instructions for the system components, espe-

cially the safety rules.

WARNING!

Danger from StandUp Terminal falling or toppling over.

This can result in serious injury and damage to property.

► Bolt StandUp Terminal securely to the ground and to a wall.

► The screws for fastening to the ground/wall are not included in the scope of supply of

the device. The installer is responsible for selecting the right type of screws or bolts.

► For more details on installing the StandUp Terminal, see section Installing the Stan-

dUp Terminal from page 33.

WARNING!

Danger due to unacceptable environmental conditions.

This can result in serious injury and damage to property.

► Observe the following requirements for all Virtual Welding systems.

Before installation, ensure that the following conditions are met:

- Dry and enclosed location

- Firm, level and supportive surface

- Unobstructed access to the device

- Device has no transport damage and is in fault-free condition

Do not set up the device close to life-saving facilities, such as:

- Emergency exits

- Fire extinguishers

- First-aid cabinets

Do not place the device near heat sources, such as:

- Radiators

- Air-conditioning units

- Sun terraces

- Strong sunlight

Protect the device from severe environmental impact, such as:

- Smoke and dirt

- Rain and moisture

- Strong magnetism or radio waves

- Cold

31

Ensure that the permissible environmental conditions are maintained at all times. For more

details on environmental conditions, see section Environmental conditions on page 7.

Special provisions apply in areas at risk of fire or explosion - observe relevant national and

international regulations.

NOTE!

Risk of frequency interference.

This can lead to malfunctions.

► Keep metallic objects away from the device.

► Ensure a minimum distance of 4 m (157.48 inches) between multiple Virtual Welding

devices.

32

Installing the StandUp Terminal

1

EN

Safety

Screwing the

mounting brackets to the StandUp Terminal

WARNING!

Danger from electric current.

This can result in serious injury or death.

► Before beginning work, switch off the device and disconnect from the mains supply.

► Secure the device against it being switched back on again.

WARNING!

Danger due to improper installation.

This can result in serious injury and damage to property.

► Observe the instructions in the section Setup regulations from page 31.

(1)(1)(1) (1)

Top of StandUp Terminal

Screw the supplied mounting brackets to the top of the StandUp Terminal (1) as

shown below, but do not yet tighten the screws

- Use four M8x16 mm screws and washers

- Do not tighten the four screws until the StandUp Terminal is in its final installation

position and the mounting brackets have been pushed against the wall

33

Top of StandUp Terminal, side view

(2)(3)(3)(3) (3) (2)

(2) = Mounting bracket

(3) = Screws with washers

34

Assembling the

(2)

(1)

(4)

(2)

(3) (3)(3) (3)

(4)

1

2

3

4

5

6

(5)(6) (6)(5)

(5)

(6)

(7)

(6)

(7)

(5)

9

StandUp Terminal

and tightening

the screws

Place the bottom part in its final installation position

- Make sure that the mounting bra-

ckets (2) extend to the wall

Place the upper part on the lower part

Screw the two parts together using the

four socket screws (1) M8x80 mm supplied

Screw the StandUp Terminal to the

wall at the mounting brackets (2)

- Fixings for securing the terminal to

the wall are not included in the

scope of supply. The installer is

responsible for selecting the right

fixings.

Tighten the four screws M8x16 mm (3)

of the mounting brackets

Screw the StandUp Terminal to the

ground through the holes (4)

- Fixings for securing the terminal to

the ground are not included in the

scope of supply. The installer is

responsible for selecting the right

fixings.

EN

Loosen the screws (5) while holding one of the brackets (6)

7

Guide the brackets (6) down until the screws (5) can be screwed through the holes (7)

8

Tighten the screws (5)

35

Tool table, standard mounting:

(9)

(8)

10

Slide the tool table (8) fully into the

opening (9)

Tool table, overhead mounting:

NOTE!

To aid clarity, the mounting brackets for wall mounting have been removed in the

following images. However, the StandUp Terminal must always be screwed to the

wall with the mounting brackets.

► For more details on the mounting brackets, see section Screwing the mounting brac-

kets to the StandUp Terminal from page 33.

36

(10)(11)

Top of StandUp Terminal

Lock the tool table in the holders (10) and (11) as shown below

5

EN

(11)

Top of StandUp Terminal with tool table fitted

(10) = Holder

(11) = Holder

(12) = Tool table

(12) (10)

CAUTION!

Danger from falling tool table.

This can result in injury and damage to property.

► Always make sure the tool table is locked in the holders (10) and (11) as shown above.

37

Waiting time until

the power connection is established

CAUTION!

Risk of poor acclimatisation of components by connecting the device to the mains

too early.

This can result in damage to the device

► Do not connect the device to the mains and switch it on until at least four hours after

the installation has been completed.

38

Installing the MobileCase

1

2

EN

Safety

Setting up the

MobileCase, fitting the tool table

WARNING!

Danger from electric current.

This can result in serious injury or death.

► Before beginning work, switch off the device and disconnect from the mains supply.

► Secure the device against it being switched back on again.

WARNING!

Danger due to improper installation.

This can result in serious injury and damage to property.

► Observe the instructions in the section Setup regulations from page 31.

Take the MobileCase and the tool table

out of the transport case

Place the MobileCase in the desired

position

39

(2)(1)

3

Slide the tool table (2) fully into the opening (1)

Refer to the Installation Instructions of the relevant installation kit for the overhead

4

mounting of the tool table

CAUTION!

Risk of poor acclimatisation of components by connecting the device to the mains

too early.

This can result in damage to the device

► Do not connect the device to the mains and switch it on until at least four hours after

the installation has been completed.

Waiting time until

the power connection is established

CAUTION!

Risk of poor acclimatisation of components by connecting the device to the mains

too early.

This can result in damage to the device

► Do not connect the device to the mains and switch it on until at least four hours after

the installation has been completed.

40

Fitting and connecting the system components

1

Fitting and connecting the tool

and other system

components

(2) (2)

(1)

EN

(2)

(2)

NOTE!

The workpiece holder (1) is shown in the standard mounting position. The workpiece holder (1) can be fitted in other positions on the tool table. These are displayed

at the end of this section.

Place the workpiece holder (1) on the tool table

- Make sure that the workpiece holder is locked in the guides (2)

Connect the workpiece holder sensor cable to the Virtual Welding system

2

(2) (2)

41

1

5

2

Insert the desired workpiece into the workpiece holder as shown above

3

Connect the 3D glasses to the Virtual Welding system

4

Connect the welding torch/electrode holder to the Virtual Welding system

For more information on the connection sockets

- on the StandUp Terminal, see section Connection sockets on the StandUp Termi-

nal from page 24

- on the MobileCase, see section Controls and connection sockets on the Mobi-

leCase from page 25

Alternative mounting positions of the workpiece holder:

42

EN

1

(3)

Alternative mounting positions of workpiece holder 1:

Insert the overhang (3) into the slot (4) on the tool table

Alternative mounting positions of workpiece holder 2:

Insert the overhang (5) into the slot (4) on the tool table

1

(5)

(4)

CAUTION!

Danger from falling workpiece holder.

This can result in injury and damage to property.

► The two alternative mounting positions must not be used for overhead exercises.

► For overhead exercises, only use the standard mounting position.

43

Switching on, getting started

(1)

(2)

1

2

3

2

5

Connecting the

mains cable and

switching on the

device

WARNING!

Danger from electric current.

This can result in serious injury or death.

► Use only the supplied mains cable to connect to the mains.

► Only plug the mains cable into a correctly earthed socket.

CAUTION!

Risk of poor acclimatisation of components by connecting the device to the mains

too early.

This can result in damage to the device

► Do not connect the device to the mains and switch it on until at least four hours after

the installation has been completed.

Plug the mains cable into the connection socket (1)

Plug the mains cable into a power socket

Set the mains switch (2) to the "I" position

Getting started Confirm the displayed licence agreement

44

1

Set time and date

- Follow the instructions on the touchscreen

Perform sensor registration

3

- Follow the instructions on the touchscreen

- Create at least one NFC key for administrators

Choose model/camera position:

4

- Follow the instructions on the touchscreen

Perform room calibration:

- See section Room calibration from page 89

Performing system calibration:

6

- See section Performing system calibration from page 87

The Virtual Welding system is now fully functional.

Start-up

Training concept and commissioning sequence

Training concept - The curriculum is used as the basis for all Virtual Welding learning content

- A curriculum is divided into individual chapters

- The chapters contain all relevant content for the trainees. This content includes:

- Theory: Explanation of welding processes, introductions, etc.

- Knowledge check: Tests to verify the knowledge acquired, etc.

- Training: Practical welding tasks, etc.

- WPS (Welding Procedure Specification): welding procedure specification

- Individual courses can be compiled for the desired group of trainees from the curricu-

lum

- If there are multiple Virtual Welding systems in a network, the courses can be as-

signed to different Virtual Welding systems, such as:

- Course A is assigned to the systems used for basic training

- Course B is assigned to the systems used for advanced training

EN

Commissioning

sequence

1. Create a curriculum and chapters

– This step is only necessary if no Fronius licences have been purchased with the

Virtual Welding system

– If Fronius licences have been purchased with the system, several curricula are

pre-installed on the system

2. Create individual courses from the curriculum

3. Assign the courses to the desired Virtual Welding systems (only necessary if multiple

Virtual Welding systems are in use)

4. Enable course mode (must be performed separately on each Virtual Welding system)

and prepare Virtual Welding systems for users

The above steps are described in detail in the following sections.

The following sections describe the MIG/MAG welding process. The procedure is the same

for the all other welding processes.

47

First step of commissioning: creating a curriculum

2

3

General - A curriculum needs to be created only if no Fronius licences have been purchased with

the Virtual Welding system.

- If you purchased Fronius licences with the system, this section can be skipped and

you can start with creating courses. For details, see section Creating a course from

page 63

- Even if you purchased Fronius licences with the system, you may still create your

own curricula. However, this is not necessary.

Configuring a

USB flash drive

Connect a USB flash drive to the USB port of the Virtual Welding system

1

Touch the NFC key on the Virtual Welding system sensor to open terminal management

- For the sensor location, see section Touchscreen and sensor on page 23

(2)

(1)

Select button (1)

Select tab (2)

4

(3)

48

Select button (3) to configure the USB flash drive

2

(1)

(2)

(1)

(3)

(4)

(5)

(6)

(7)

4

5

EN

Creating a knowledge check (test)

- The knowledge check is part of the course mode and is used to check whether the

learned theory content has been understood.

- It is recommended to include in the knowledge check only questions that can be answered through the theoretical content provided.

Disconnect the USB flash drive from the Virtual Welding system and plug it into a PC

1

Open the USB flash drive on the PC

Open "QuizEditor.exe"

3

Select button (1)

Fill in text boxes (2) - (6) for the first question of the knowledge check

5

Select button (7) to add another question

6

- Repeat these steps as many times as you like

NOTE!

It is recommended that the knowledge check be given a practical and unique file

name when saving, since this file name can be transferred to the Virtual Welding

system when later imported (this means that you do not have to re-enter the name

of the knowledge check on the Virtual Welding system).

49

(8)

Saving content to

the USB flash

drive

Select button (8) and save the knowledge check in the "knowledgecheck" folder on the

7

USB flash drive

- Saving is only possible once all the fields in theQuizEditor have been completed

If desired, a quiz can also be created. For details, see section Quiz from page 99.

NOTE!

It is recommended that the learning content and the WPS be given a practical and

unique file name when saving, since this file name can be transferred to the Virtual

Welding system when later imported (this means that you do not have to re-enter the

name of the learning content and the WPS on the Virtual Welding system).

50

Copy all desired learning content to the "theory" folder

1

(1)

(2)

(3)

3

1

- Use PDF only

Copy customer-specific WPS to the "wps" folder

2

- WPS from Fronius are already installed on the system

- The knowledge check created in the previous step is already in the "knowledgecheck"

folder

- the "quiz" folder already contains a Quiz, if this has been created

Importing content Connect the USB flash drive to the USB port of the Virtual Welding system

Touch the NFC key on the Virtual Welding system sensor to open terminal manage-

2

ment

- For the sensor location, see section Touchscreen and sensor on page 23

EN

Import theory content:

Select button (1)

Select tab (2)

4

Select button (3)

5

51

(4)

6

(6)

(7)

(8)

10

Import theory content:

Select the desired file, for example (4)

Select button (5)

7

(5)

52

Import theory content:

Make sure the correct welding process is selected (6)

8

Select checkbox (7) to use the original file name

9

Select button (8) to import the file

(10)

13

14

EN

(9)

Import a knowledge check:

Select button (9)

11

Select tab (10)

12

Select button (11)

(12)

(11)

(13)

Import a knowledge check:

Select the desired file, for example (12)

Select button (13)

15

53

(15)

17

(17)

(18)

(19)

21

(16)

Import a knowledge check:

Make sure that the correct welding process is selected (14)

16

Select checkbox (15) to use the original file name

Select button (16) to import the file

18

(14)

54

Import a WPS:

Select button (17)

19

Select tab (18)

20

Select button (19)

(20)

23

25

Import a WPS:

Select the desired file, for example (20)

22

Select button (21)

EN

(21)

(23)

(22)

(24)

Import a WPS:

Make sure that the correct welding process is selected (22)

24

Select checkbox (23) to use the original file name

Select button (24) to import the file

26

Plug the USB flash drive into the system

27

- The USB flash drive can be used to store curricula (backup copy), for example

Merging content

into a curriculum

- In the following section, the previously imported content is merged to form a curriculum.

55

- The curriculum can be divided into individual chapters as desired

(3)

- It is recommended that each chapter builds on previously learned knowledge. For

example, a chapter with easy welding tasks and related content, a chapter with

medium welding tasks and related contents, and so forth.

- Individual courses for users can be created from the curriculum. For details, see section Creating a course from page 63.

(1)

(2)

Select button (1)

1

Select button (2)

2

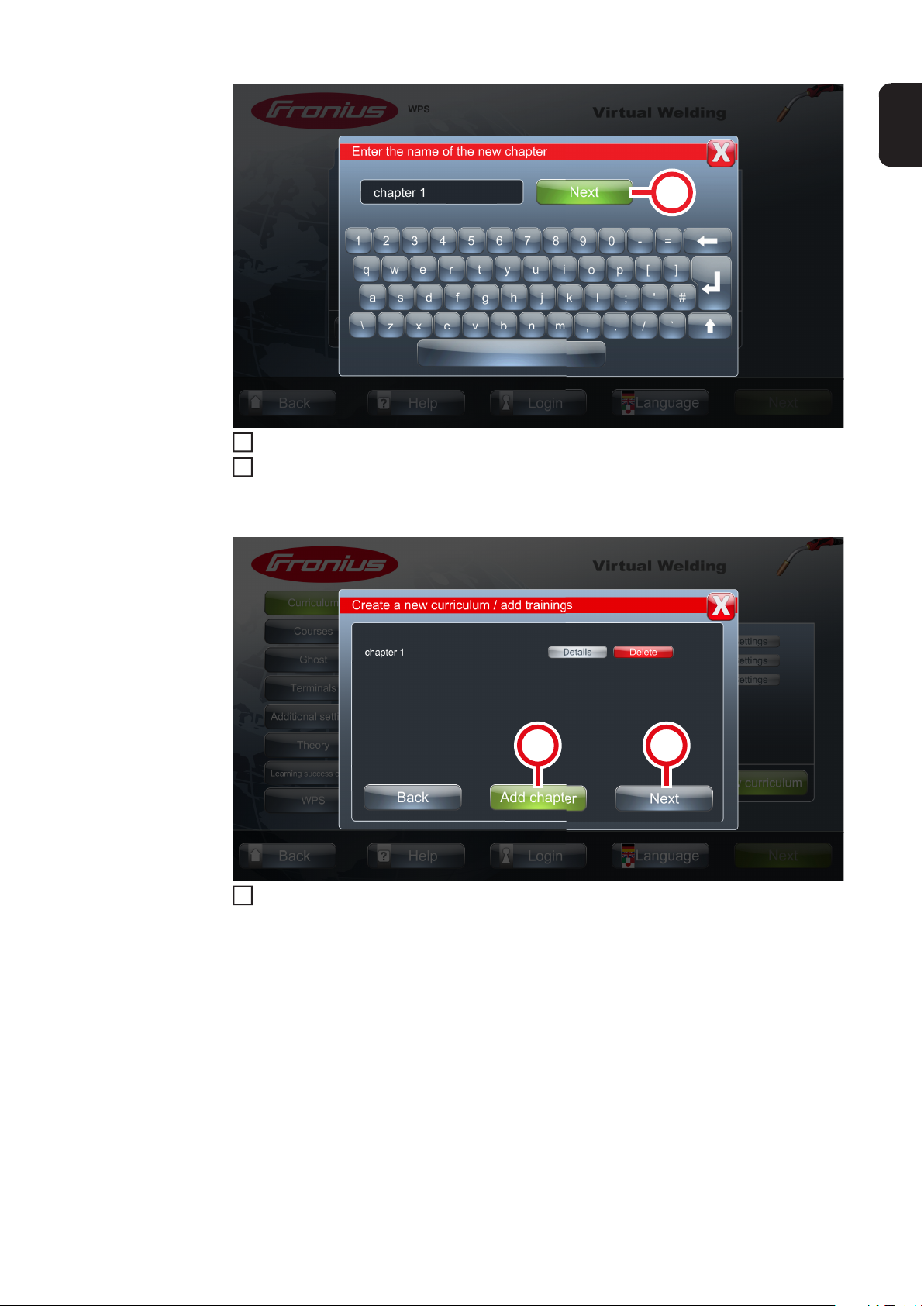

Create the first chapter for the new curriculum:

56

Select button (3)

3

(4)

(11)

7

(5)

Select which content types are to be inserted into the chapter (4)

4

- Depending on your needs, you can select individual content types or all content

types

Select button (5)

5

- In the next steps, the individual contents are inserted into the chapter

Add training content to the first chapter:

(Only possible if this content type was selected when the chapter was created)

EN

Use the arrow keys to make the desired settings

6

Select button (11)

57

(13)

10

11

(13)

(12)

Enable/disable the required tasks using the buttons (12)

8

- If a task is enabled, it can be disabled again when the course is created

- If a task is disabled, it will not be possible to later enable the task in this curriculum

Use the arrow keys (13) to select the extent of the permissible deviation (Ghost) (for

9

more details on the Ghost see section Ghost from page 69)

- The acceptable deviation can be set in a range of 60-90%

- 60% = Execution of the task may deviate by a maximum of 30% from the

Ghost to be evaluated positively

- 90% = Task must be executed exactly as specified by Ghost to be evaluated

positively

- The acceptable deviations can be edited again when the course is created

Select button (14)

(14)

(15)

Give this training content a name

Select button (15)

12

Add a WPS to the first chapter:

(Only possible if this content type was selected when the chapter was created)

58

(17)

(6)

(7)

16

(16)

Make sure the correct welding process is selected

13

- If necessary, select button (16) to change the welding process

Select button (17) to insert the desired WPS into the chapter

14

Add theory content to the first chapter:

(Only possible if this content type was selected when creating the chapter)

EN

Make sure the correct welding process is selected

15

- If necessary, select button (6) to change the welding process

Select button (7) to insert the desired theory content into the chapter

- Each chapter can contain only one piece of theory content

Add a knowledge check to the first chapter:

(Only possible if this content type was selected when creating the chapter)

59

(7)

(10)

(8)

(8)

(9)

(9)

20

(6)

Make sure the correct welding process is selected

17

- If necessary, select button (6) to change the welding process

Select button (7) to insert the desired knowledge check into the chapter

18

- Each chapter can contain only one knowledge check

60

Select the percentage of questions that need to be answered correctly in order for the

19

knowledge check to be passed (8)

- A value of 80% or more is recommended

- The settings can be adjusted again when the course is created

Set how much time will be allowed to answer a question (9)

- About 30 seconds per question is recommended

Select button (10)

21

Give the chapter a name:

Give this chapter a name

(19)(20)

22

Select button (18)

23

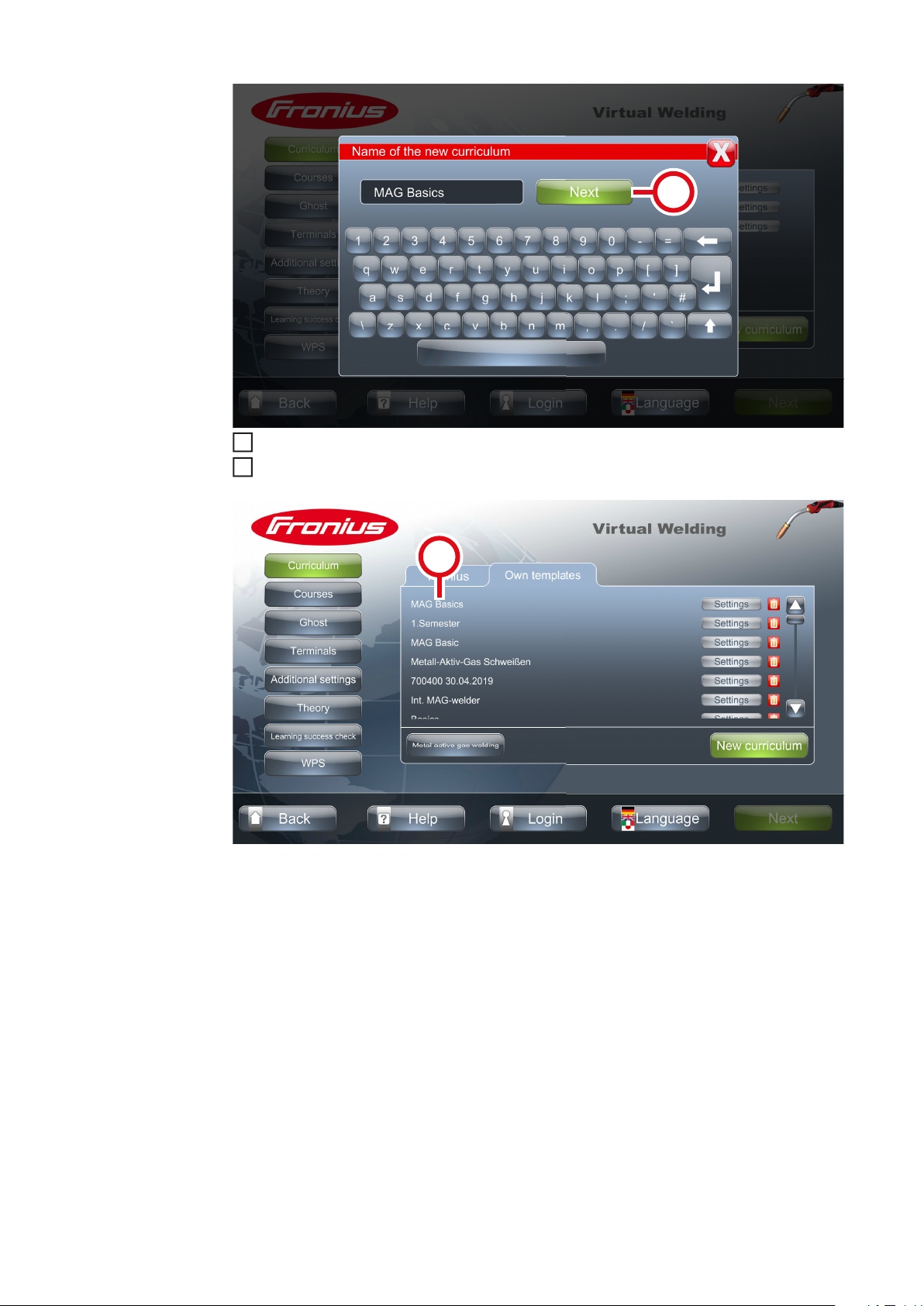

Complete the curriculum:

EN

(18)

Select button (19) to complete and create the curriculum

24

- If you wish, a new chapter can also be added to the curriculum at this point. In this

case, select the button (20) and repeat the previous steps

61

Give the curriculum a name

25

Select button (21)

26

(21)

(22)

62

- The new curriculum is displayed in the overview (22)

Second step of commissioning: creating a course

3

Uses of a course - Individual courses can be compiled for the desired group of trainees from the curricu-

lum

- If there are multiple Virtual Welding systems in a network, the courses can be as-

signed to different Virtual Welding systems, such as:

- Course A is assigned to the systems used for basic training

- Course B is assigned to the systems used for advanced training

EN

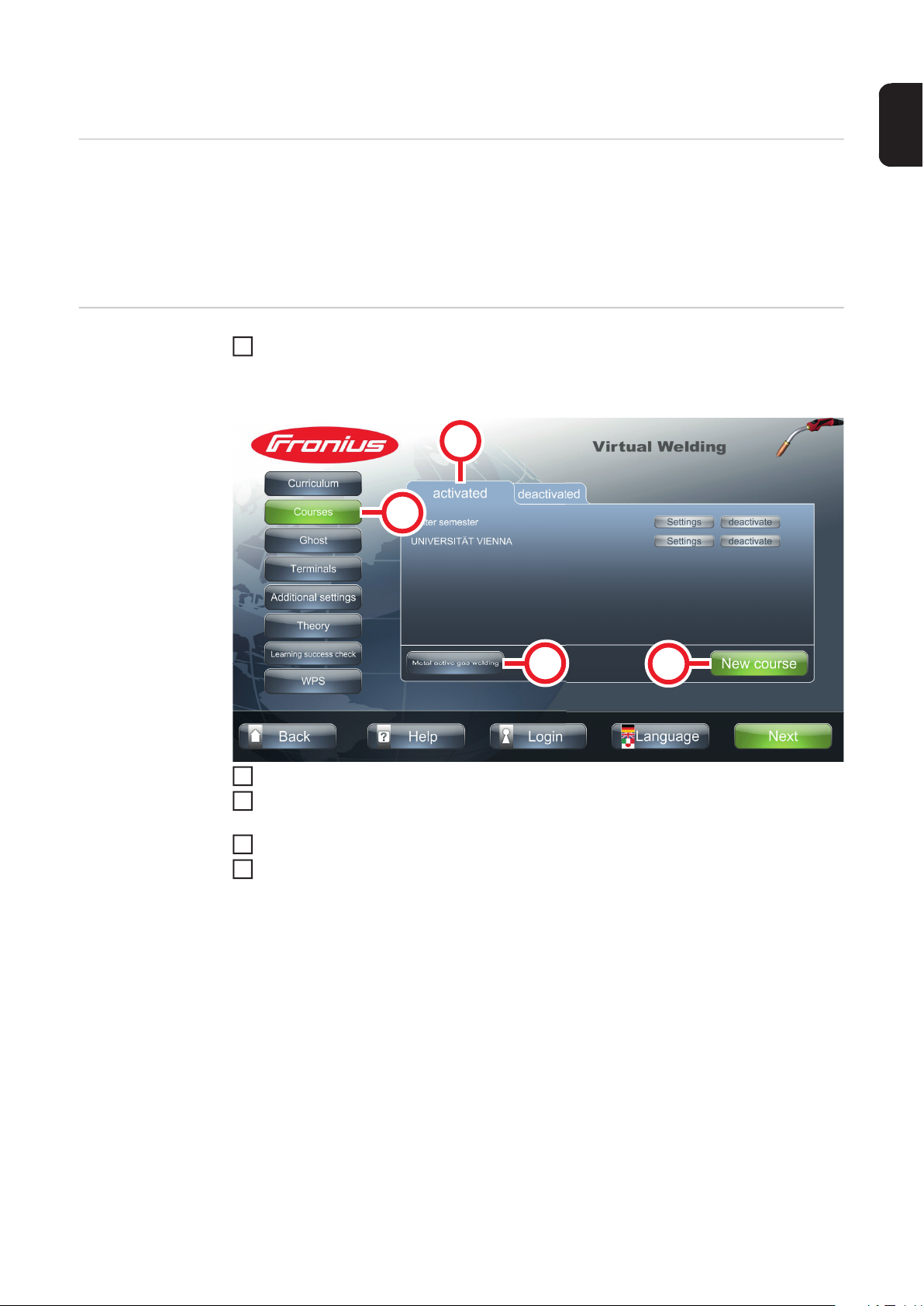

Creating a course Touch the NFC key on the Virtual Welding system sensor to open terminal manage-

1

ment

- For the sensor location, see section Touchscreen and sensor on page 23

(3)

(1)

(2)

Select button (1)

2

Make sure the correct welding process is selected

- If necessary, select button (2) to change the welding process

Select tab (3)

4

Select button (4)

5

(4)

63

(7) (8)

7

8

(9)

(6)

Make sure the correct welding process is selected

6

- If necessary, select button (6) to change the welding process

Select a curriculum to use as the basis for the course. For example (9)

- Fronius curricula are displayed on tab (7)

- Self-created curricula are displayed on tab (8)

(10)

(12)

Select the content you want to add to the course (10)

- Using the Settings button (11):

- Tasks in the curriculum can be disabled

- Acceptable deviations of the tasks can be set

- Acceptable deviations and time limits for the knowledge check can be set

Select button (12)

9

(11)

64

(13)

11

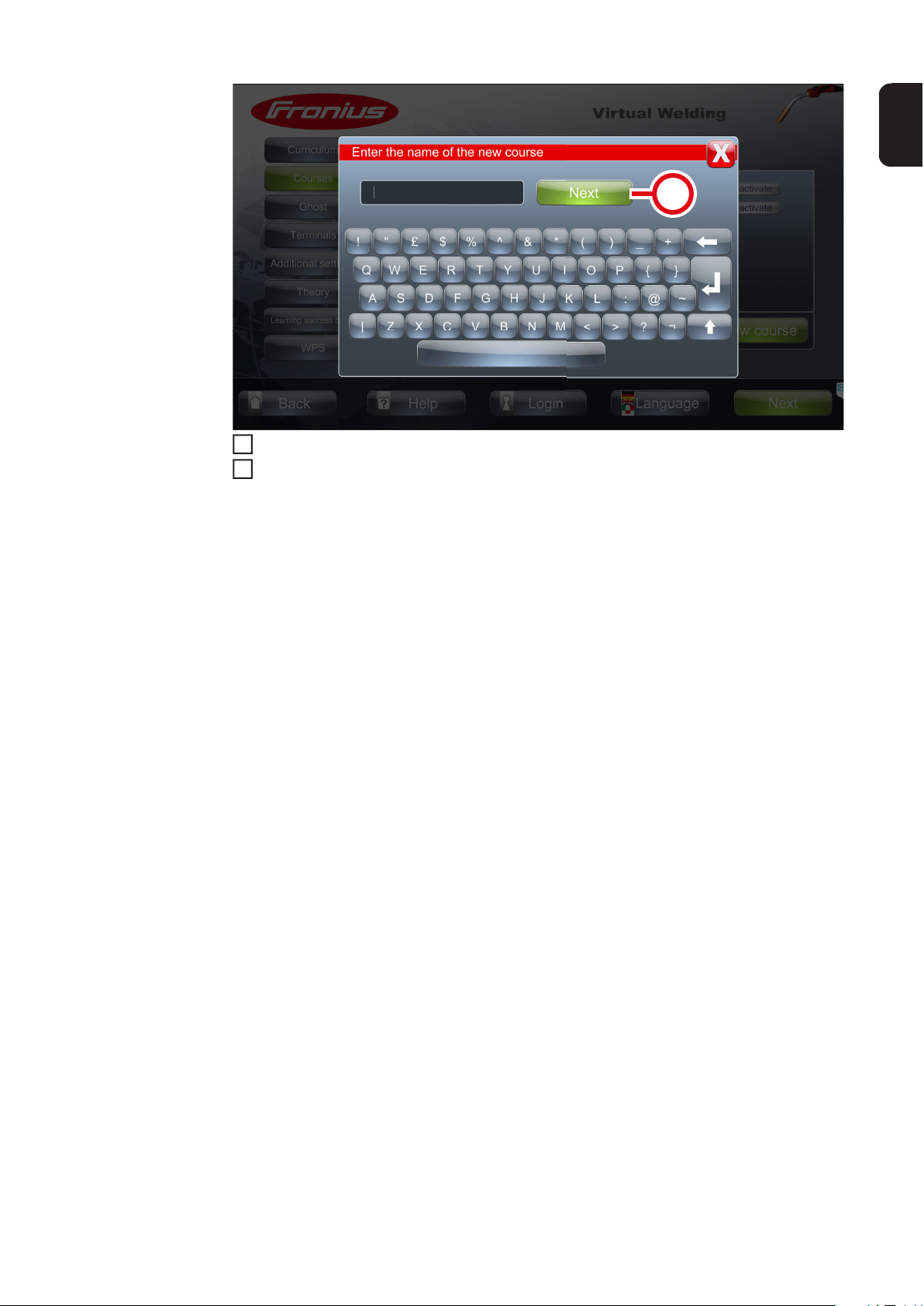

Give the course a name

10

Select button (13)

- The new course is now shown in the course overview

After creating all the courses you want, it is recommended that you back up your data. For

more details on this, see section Creating a backup (exporting data) from page 112.

EN

65

Third step of commissioning: assigning courses

1

2

(4)

(5)

5

Assigning courses to the Virtual

Welding system

Touch the NFC key on the Virtual Welding system sensor to open terminal management

- For the sensor location, see section Touchscreen and sensor on page 23

(1)

(2) (3)

Select button (1)

- Available terminals are displayed (2)

- If there is only one terminal on the network, the serial number is displayed as the

terminal name

Select button (3)

3

Make sure the correct welding process is selected

4

- If necessary, select button (4) to change the welding process

Select the course to be available on the previously selected terminal

- For example (5)

66

(6)

Select button (6)

6

- The course has been assigned to the terminal

EN

Assigning courses to multiple terminals

- If multiple Virtual Welding systems are being used, it is possible to combine them into

groups (cluster networking)

- See section Creating a cluster network from page 108 for a description of how to

create groups

- Courses are assigned to groups as described in the section above

67

Fourth step of commissioning: activating course

2

5

2

mode, preparing the system for users

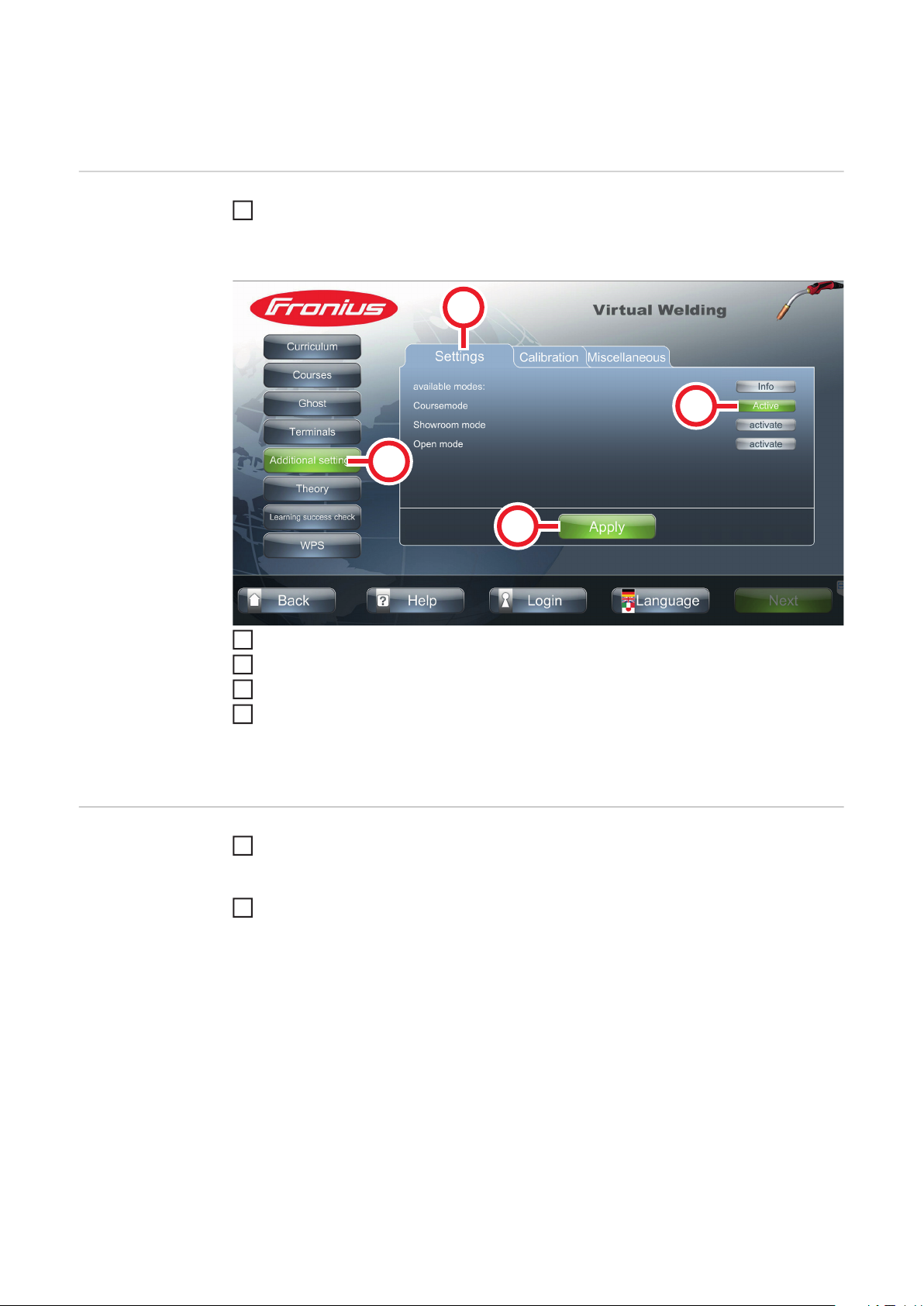

Activating course

mode

Touch the NFC key on the Virtual Welding system sensor to open terminal manage-

1

ment

- For the sensor location, see section Touchscreen and sensor on page 23

(2)

(3)

(1)

(4)

Select button (1)

Select tab (2)

3

Select button (3) to activate course mode

4

Select button (4) to save the entries

- The system is now fully set up

- Refer to the following section for the necessary settings to allow users to begin

the exercises

Preparing the

system for users

68

Create a profile

1

- Either each user creates their own profile, or

- The trainer creates the profiles for all users

User logs on to the system (performed by the users themselves)

- The practical exercises can now be started (read through theory content, com-

plete knowledge checks, complete welding tasks)

Ghost

Explanation and configuration options

2

Explanation - The Ghost is a virtual welding torch that is displayed during the welding tasks

- The Ghost shows the ideal movement when welding

- A Ghost is saved for all welding tasks as standard (default Ghost)

- The New Ghost button (1) allows you to create what is known as a variable Ghost

- A variableGhost can be created in addition to the default Ghost and adapted to your

own requirements

- A variable Ghost can be created for all welding processes

(1)

EN

Creating a variable Ghost

(1)

(2)

Select button (1)

1

Make sure the correct welding process is selected

- If necessary, select button (2) to change the welding process

Select button (3)

3

(3)

71

Use the arrow keys to make the desired settings

5

6

4

Select button (4)

(4)

(5)

Select button (5)

72

(6)

9

Enter a name for the variable Ghost

7

Select button (6)

8

Follow the instructions on the touchscreen

NOTE!

With Virtual Welding Robotics, a distinction is made between Polygon and Cycles

when creating a Ghost:

► Polygon: Enables a completely free path to be traced (inscription, etc.)

► Cycles: Equivalent to conventional welding

EN

73

74

Available modes on the Virtual Weld-

ing system

Course mode

2

5

Explanation In course mode, courses with varying degrees of difficulty can easily be configured or

adapted to individual requirements. The courses and the curricula on which they are based

are easy to access. The results can be compared with the help of ranking lists, so that it is

possible to address the precise needs of the trainee welder.

The course mode is used for training:

- Different courses can be assigned to individual terminals

- The results of each user can be compared in ranking lists

- For more details, see section Description of rankings lists, exporting course

data from page 80

- For more details on creating users, see section Profile from page 78

In course mode, the following functions are available:

- Training (practical welding tasks)

- Theory (learning content)

- Knowledge check (testing the knowledge learned)

- Rankings list - for more details, see Description of rankings lists, exporting course

data from page 80

- Profile - for more details, see Profile from page 78

EN

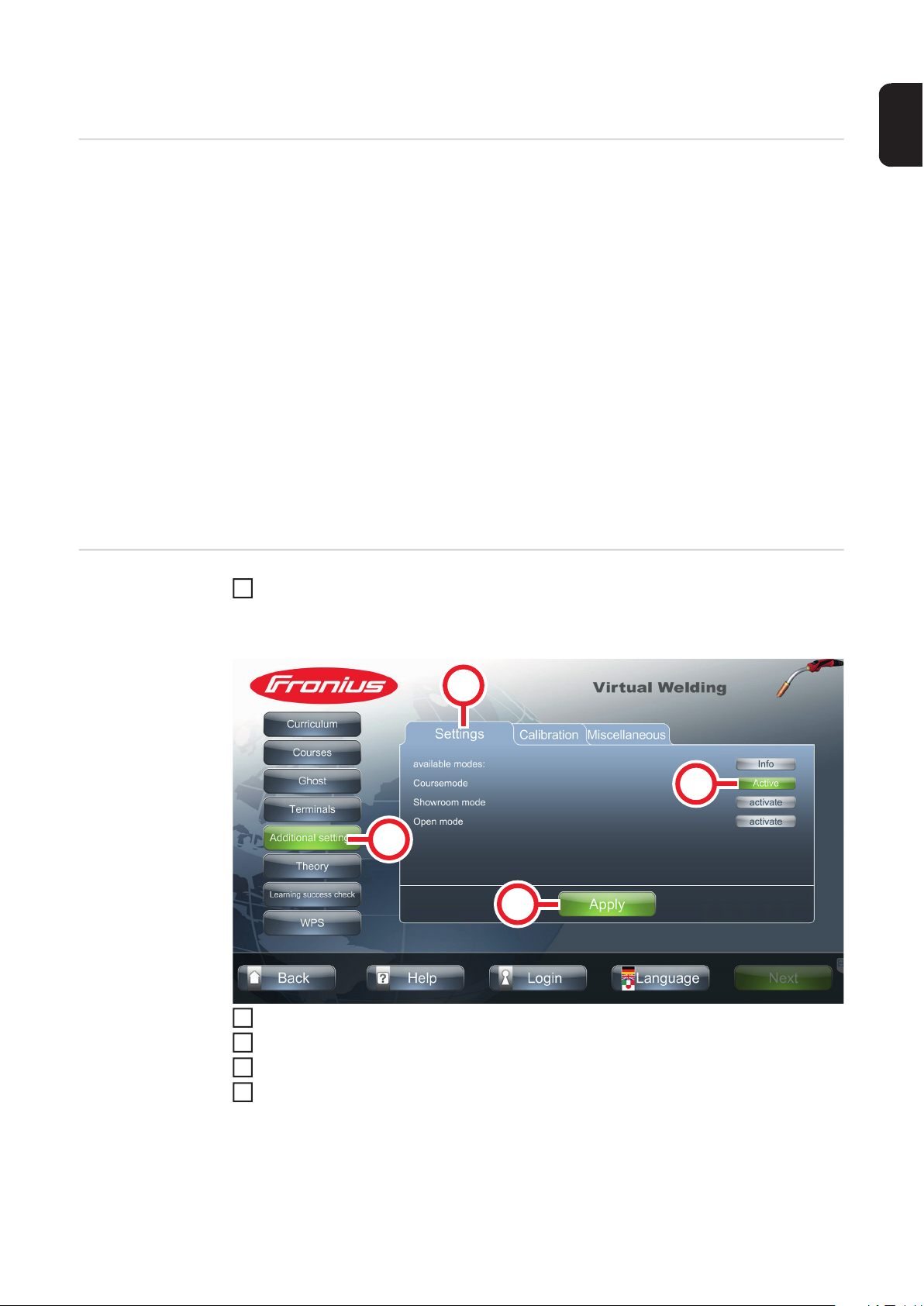

Activating course

mode

Touch the NFC key on the Virtual Welding system sensor to open terminal manage-

1

ment

- For the sensor location, see section Touchscreen and sensor on page 23

(2)

(3)

(1)

(4)

Select button (1)

Select tab (2)

3

Select button (3) to activate course mode

4

Select button (4) to save the entries

- The system is now fully set up

- Refer to the following section for the necessary settings to allow users to begin

the exercises

77

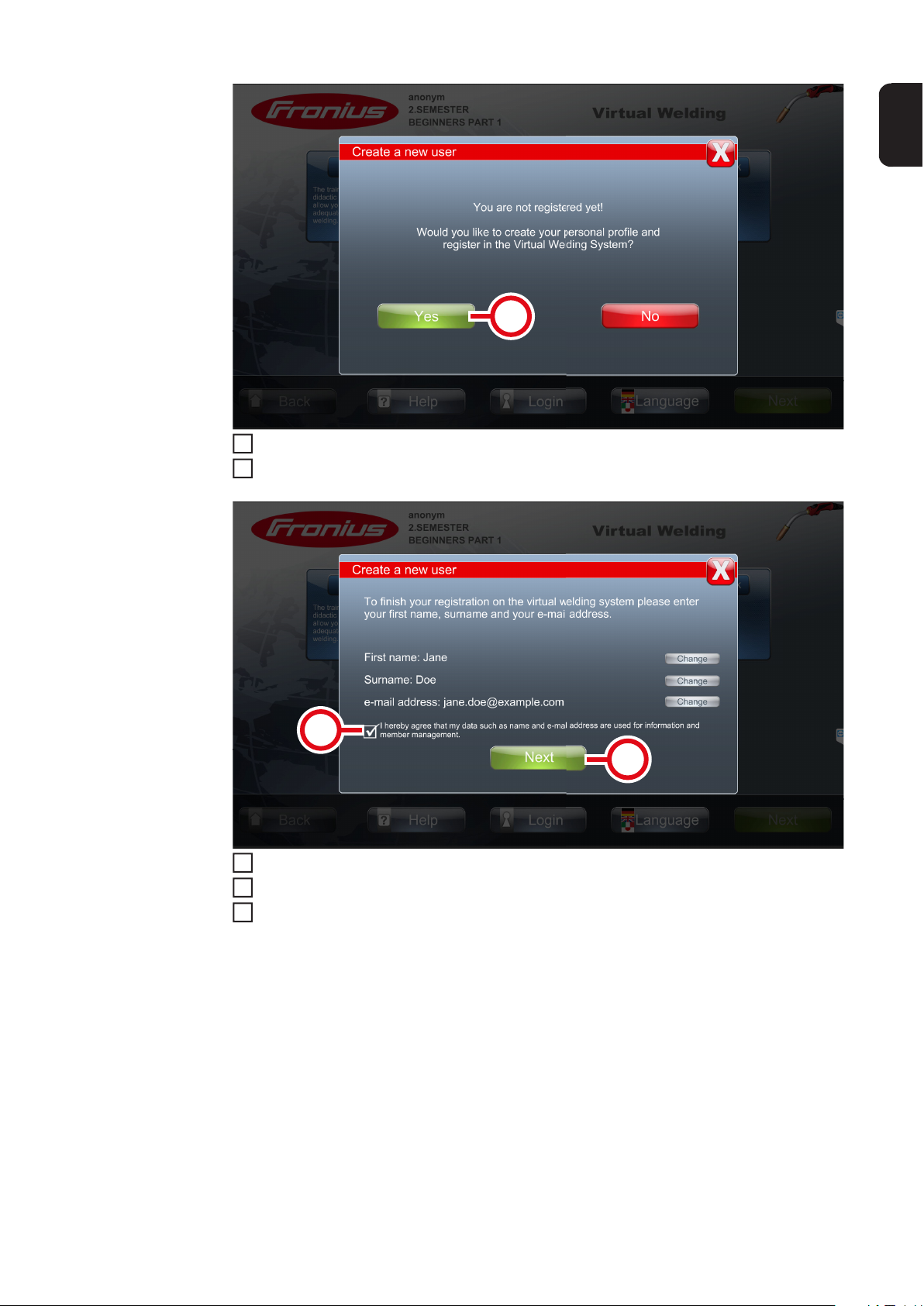

Profile To use the course mode properly, a profile must be created for each user. It is therefore

(1)

3

recommended to create a profile for each user.

A profile allows you to:

- Save data for each user (trainee)

- Follow-up on the latest welding results of each user

- Get an overview of each user via the latest ranking lists

Create a profile:

Select button (1)

1

Enter the name and password

2

Select button (2)

(2)

78

Select button (3)

7

4

Enter required data

5

EN

(3)

(4)

(5)

Read and understand the text next to the checkbox (4) and select the checkbox (4)

6

Select button (5)

Confirm the message displayed

8

79

(6)

Once the settings have been completed, the profile of the respective user can be opened

using button (6)

Description of

rankings lists, exporting course

data

- Each course has its own ranking list

- The ranking lists allow a user's welding results to compared with the welding results

of the other participants (allVirtual Welding systems in the network and their users are

visible in the ranking lists)

- For a user to be listed in the ranking lists, a profile must be created for each user and

the user must be logged in when completing the tasks

- See Profile from page 78

- Ranking lists can be exported with the respective courses

- The export data is only used for viewing/further processing on a PC and cannot

be imported again

- No course content is exported, only course data (students, score, etc.)

To export a course:

Connect a USB flash drive to the USB port of the Virtual Welding system

1

Touch the NFC key on the Virtual Welding system sensor to open terminal manage-

2

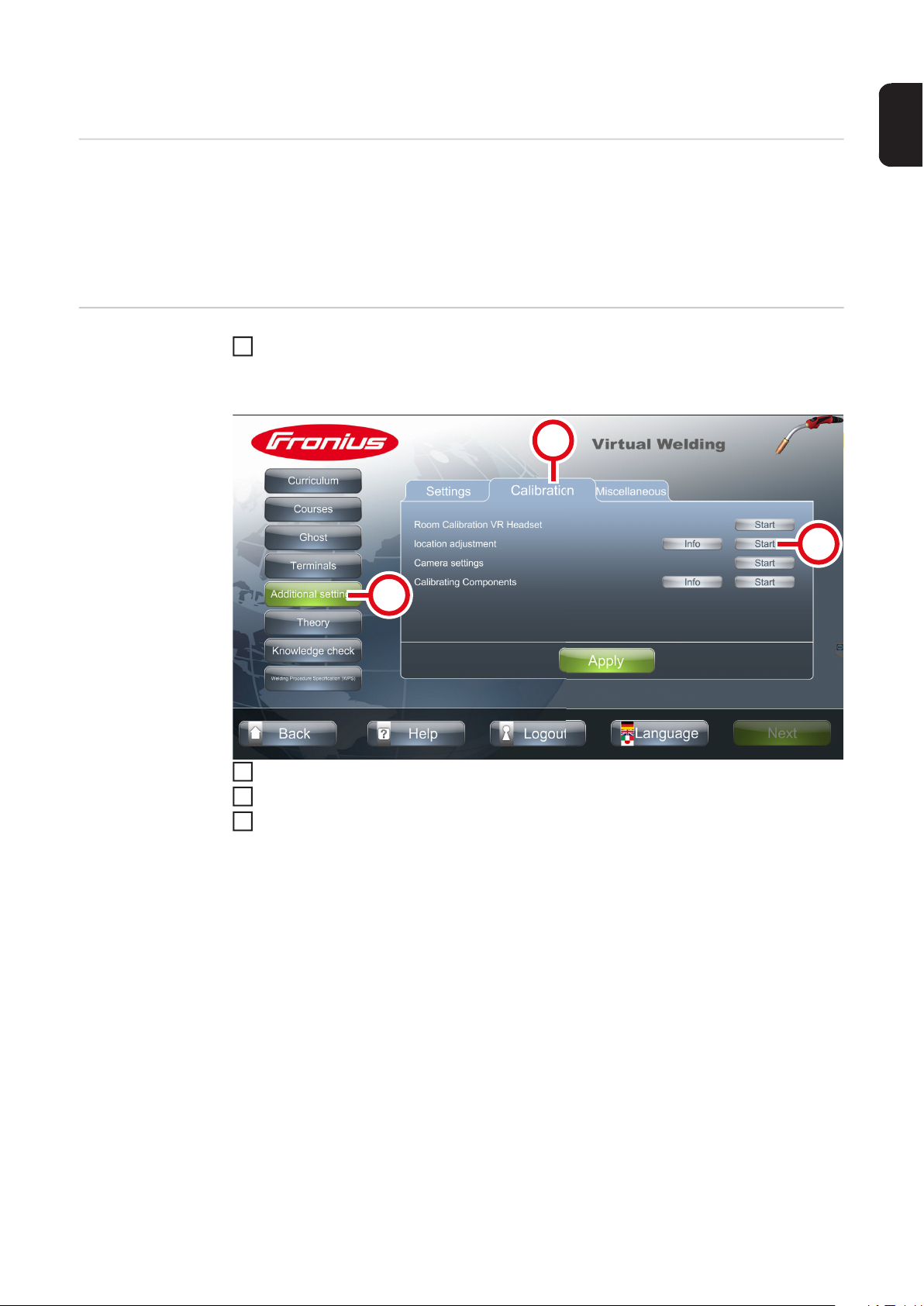

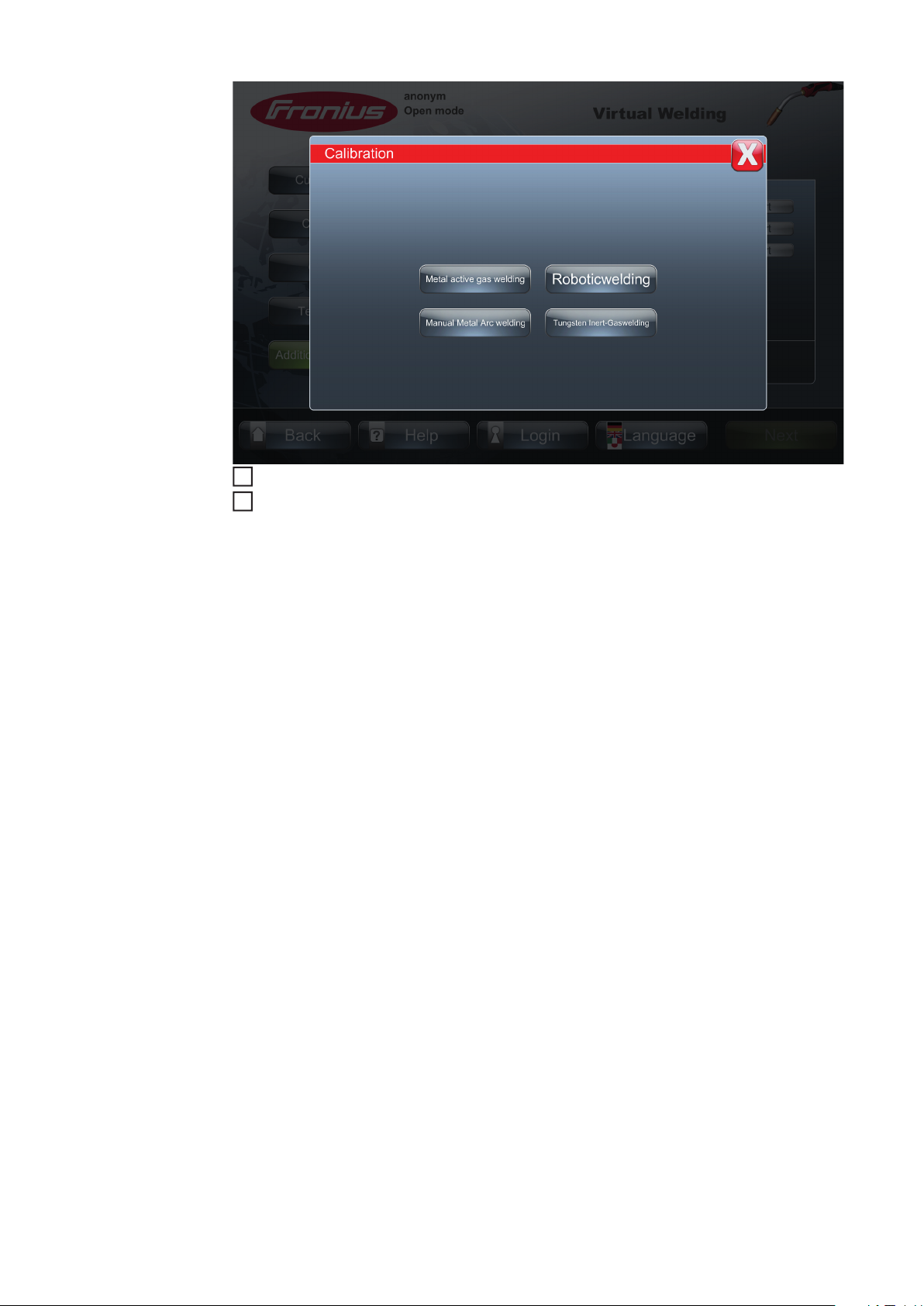

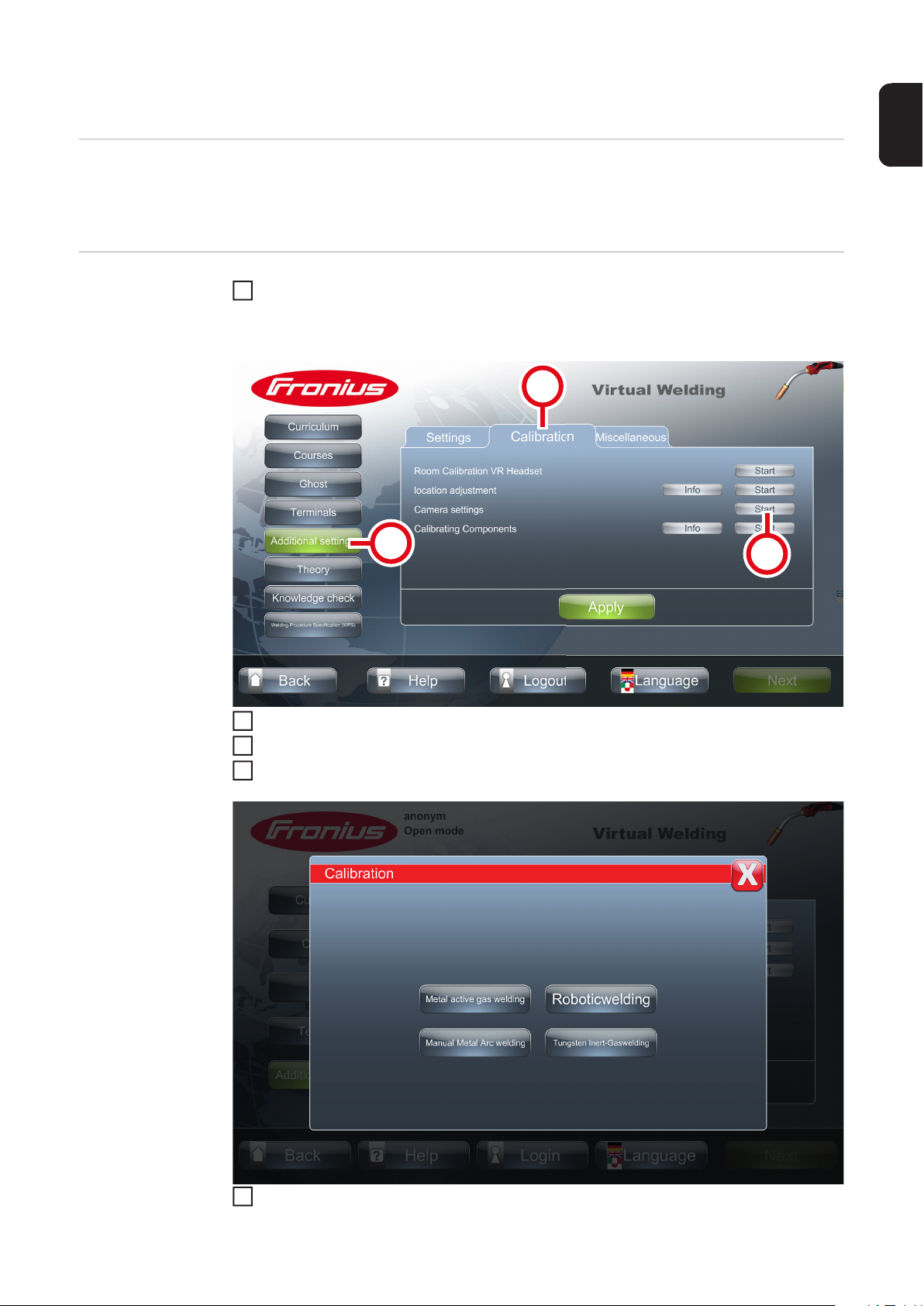

ment