ENA Engineering Recommendation G99

This form should be used by the Manufacturer to demonstrate and declare compliance with the

requirements of EREC G99. The form can be used in a variety of ways as detailed below:

1. To obtain Fully Type Tested status (≤50kW)

The Manufacturer can use this form to obtain Fully Type Tested status for a Power

Generating Module by registering this completed form with the Energy Networks Association

(ENA) Type Test Verification Report Register. Tests 1 – 15 must all be completed and compliant

for the Power Generating Module to be classified as Fully Type Tested.

2. To obtain Type Tested status for a product

This form can be used by the Manufacturer to obtain Type Tested status for a product which is

used in a Power Generating Module by registering this form with the relevant parts completed

with the Energy Networks Association (ENA) Type Test Verification Report Register.

Where the Manufacturer is seeking to obtain Type Tested status for an Interface Protection

device the appropriate section of Form A2-4 should be used.

3. One-off Installation

This form can be used by the Manufacturer or Installer to confirm that the Power Generating

Module has been tested to satisfy all or part of the requirements of this EREC G99. This form

shall be submitted to the DNO as part of the application.

A combination of (2) and (3) can be used as required, together with Form A2-4 where

compliance of the Interface Protection is to be demonstrated on site.

Note:

Within this Form A2-3 the term Power Park Module will be used but its meaning can be

interpreted within Form A2-3 to mean Power Park Module, Generating Unit or Inverter as

appropriate for the context. However, note that compliance must be demonstrated at the Power

Park Module level.

If the Power Generating Module is Fully Type Tested and registered with the Energy Networks

Association (ENA) Type Test Verification Report Register, the Installation Document (Form A3)

should include the Manufacturer’s reference number (the Product ID), and this form does not

need to be submitted.

Where the Power Generating Module is not registered with the ENA Type Test Verification

Report Register or is not Fully Type Tested this form (all or in parts as applicable) needs to be

completed and provided to the DNO, to confirm that the Power Generating Module has been

tested to satisfy all or part of the requirements of this EREC G99.

Manufacturer´s reference number

Tauro 50-3-P

PGM technology

IGBT power modules, transformerless

Manufacturer name

Fronius International GmbH

Adress

Guenter Fronius Str.1

4600 Wels-Thalheim, Austria

Tel

+43-7242-241-0

Fax

+43-7242-241-224

Issue 1 – Amendment 8 2021

R&D - TESTING TR31969 page 1 of 14

FORM A2-3 Compliance Verification Report for Type A Inverter

Connected Power Generating Modules

@BCL@40080E81.doc Backup: Tauro General

ENA Engineering Recommendation G99

E:mail

pv@fronius.com

Web site

www.fronius.com

Registered Capacity

50 kW

Manufacturer compliance declaration. - I certify that all products supplied by the company with the above

Type Tested Manufacturer’s reference number will be manufactured and tested to ensure that they

perform as stated in this document, prior to shipment to site and that no site Modifications are required

to ensure that the product meets all the requirements of EREC G99.

Signed

On behalf of

Fronius International GmbH

Note that testing can be done by the Manufacturer of an individual component or by an external test

house.

Where parts of the testing are carried out by persons or organisations other than the Manufacturer then

that person or organisation shall keep copies of all test records and results supplied to them to verify that

the testing has been carried out by people with sufficient technical competency to carry out the tests.

Issue 1 – Amendment 8 2021

R&D - TESTING TR31969 page 2 of 14

@BCL@40080E81.doc Backup: Tauro General

ENA Engineering Recommendation G99

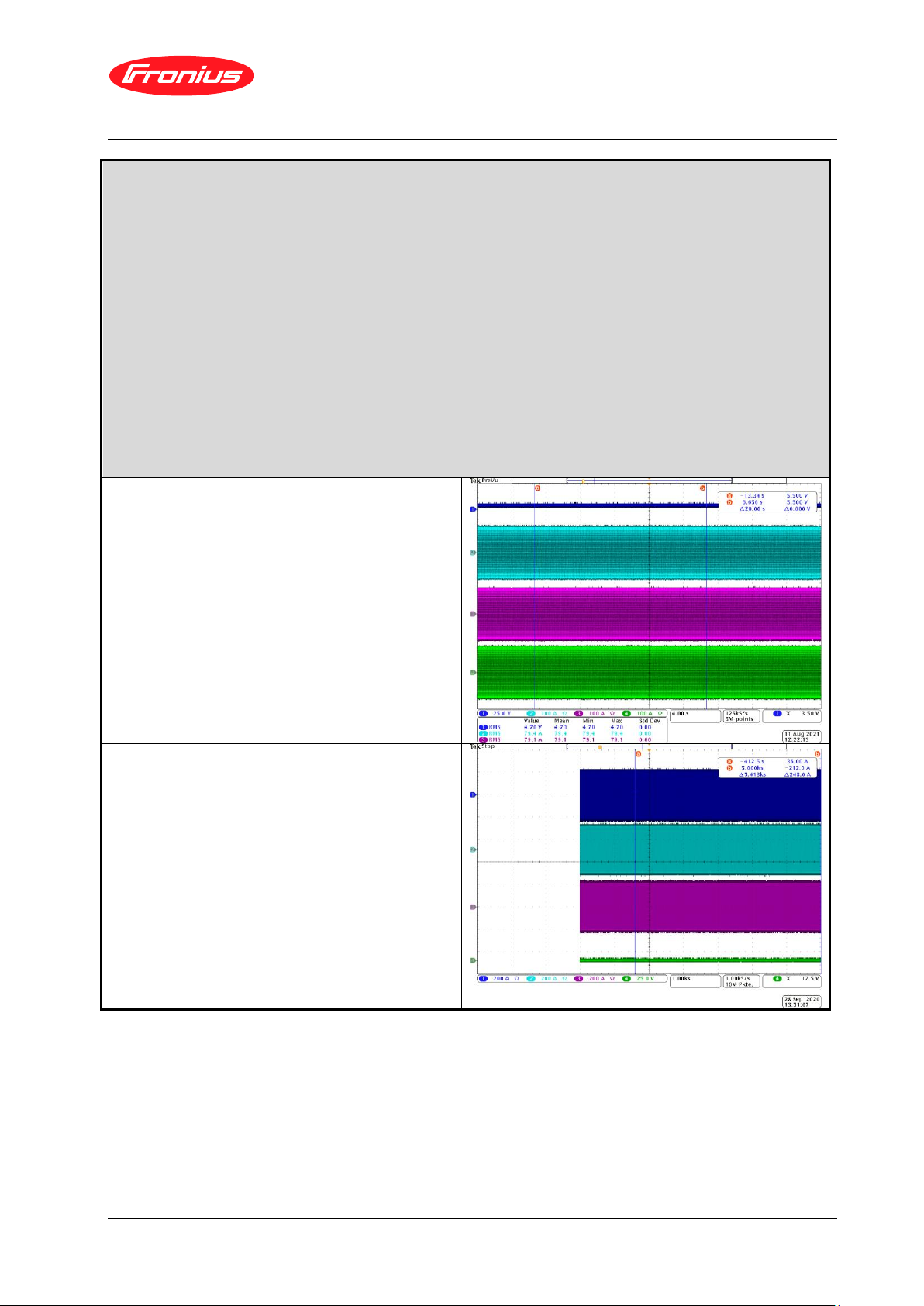

1. Operating Range: Tests should be carried with the Power Generating Module operating at

Registered Capacity and connected to a suitable test supply or grid simulation set. The power

supplied by the primary source shall be kept stable within ± 5 % of the apparent power value set for the

entire duration of each test sequence.

Frequency, voltage and Active Power measurements at the output terminals of the Power Generating

Module shall be recorded every second. The tests will verify that the Power Generating Module can

operate within the required ranges for the specified period of time.

The Interface Protection shall be disabled during the tests.

In case of a PV Power Park Module the PV primary source may be replaced by a DC source.

In case of a full converter Power Park Module (eg wind) the primary source and the prime mover

Inverter/rectifier may be replaced by a DC source.

Pass or failure of the test should be indicated in the fields below (right hand side), for example with the

statement “Pass”, “No disconnection occurs”, etc. Graphical evidence is preferred.

Note that the value of voltage stated in brackets assumes a LV connection. This should be adjusted for

HV as required.

Test 1

Voltage = 85% of nominal (195.5 V),

Frequency = 47.0 Hz,

Power factor = 1,

Period of test 20 s

Test 2

Voltage = 85% of nominal (195.5 V),

Frequency = 47.5 Hz,

Power factor = 1,

Period of test 90 minutes

Issue 1 – Amendment 8 2021

R&D - TESTING TR31969 page 3 of 14

@BCL@40080E81.doc Backup: Tauro General

ENA Engineering Recommendation G99

Test 3

Voltage = 110% of nominal (253 V),

Frequency = 51.5 Hz,

Power factor = 1,

Period of test 90 minutes

Test 4

Voltage = 110% of nominal (253 V),

Frequency = 52.0 Hz,

Power factor = 1,

Period of test 15 minutes

Test 5

Voltage = 100% of nominal (230 V),

Frequency = 50.0 Hz,

Power factor = 1,

Period of test 90 minutes

Issue 1 – Amendment 8 2021

R&D - TESTING TR31969 page 4 of 14

@BCL@40080E81.doc Backup: Tauro General

ENA Engineering Recommendation G99

Test 6 RoCoF withstand

Confirm that the Power Generating Module is

capable of staying connected to the Distribution

Network and operate at rates of change of

frequency up to 1 Hzs-1 as measured over a

period of 500 ms. Note that this is not expected to

be demonstrated on site.

Measurement before jump (50Hz)

Measurement jump (51Hz)

Remark: During the tests 1, 2, 3, 4,5 and 6 the unit does not disconnect, tests have been passed.

Issue 1 – Amendment 8 2021

R&D - TESTING TR31969 page 5 of 14

@BCL@40080E81.doc Backup: Tauro General

Loading...

Loading...