Fronius TTG 1600 S, TTG 1600 Pot, TTG 1600 FS/TL, TTG 1600 FS/UD, TTG 2200 S Operating Instruction

Page 1

Operating

Instructions

TTG 1600 S

TTG 1600 Pot

TTG 1600 FS/TL

TTG 1600 FS/UD

TTG 2200 S

DE

EN

FR

IT

ES

PT-BR

ZH

Bedienungsanleitung

Operating instructions

Instructions de service

Istruzioni per l'uso

Manual de instrucciones

Manual de instruções

操作说明书

42,0410,1504 002-15092022

Page 2

Page 3

Inhaltsverzeichnis

Allgemeines 4

Allgemeines 4

Sicherheit 4

Installation und Inbetriebnahme 5

Inbetriebnahme 5

WIG Gasschieber-Schweißbrenner - S 6

WIG-Schweißbrenner mit Potentiometer - Pot 7

JobMaster TIG 8

Verschleißteil-System 10

Verschleißteil-System A 10

Verschleißteil-System P 11

Fehlerdiagnose, Fehlerbehebung 12

Fehlerdiagnose 12

Pflege, Wartung und Entsorgung 14

Pflege und Wartung 14

Entsorgung 14

Technische Daten 15

DE

3

Page 4

Allgemeines

Allgemeines Die WIG Gasschieber-Schweißbrenner (S) und die WIG-Schweißbrenner mit Po-

tentiometer (Pot) eignen sich für das Schweißen von CrNi und Stahl und zeichnen sich durch vielfältige Ausführungen aus.

Die Schweißbrenner lassen sich an die unterschiedlichsten Aufgabenstellungen

anpassen und bewähren sich bestens in der manuellen Serien- und Einzelfertigung, sowie im Werkstättenbereich.

Sicherheit

WARNUNG!

Fehlerhaft durchgeführte Arbeiten können schwerwiegende Personen- und

Sachschäden verursachen.

Beschriebene Tätigkeiten dürfen nur von geschultem Fachpersonal durchgeführt

werden! Beachten Sie das beiliegende Dokument „Sicherheitsvorschriften“.

WARNUNG!

Ein elektrischer Schlag kann tödlich sein.

Beschriebene Tätigkeiten nur durchführen, wenn:

der Netzschalter der Stromquelle in Stellung - O - geschaltet ist

▶

die Stromquelle vom Netz getrennt ist.

▶

WARNUNG!

Ein elektrischer Schlag kann tödlich sein.

Vor dem Reinigen des Schweißbrenners und dem Überprüfen seiner Komponenten, Netzschalter der Stromquelle in Stellung - O - schalten.

VORSICHT!

Verbrennungsgefahr durch infolge des Betriebes stark erhitzten Schweißbrenner.

Die Reinigung des Schweißbrenners, und das Überprüfen seiner Komponenten,

darf nur in abgekühltem Zustand des Schweißbrenners erfolgen.

VORSICHT!

Verletzungsgefahr durch unzureichende Verbindungen.

Sämtliche Kabel, Leitungen und Schlauchpakete müssen fest, unbeschädigt, isoliert und ausreichend dimensioniert sein.

4

Page 5

Installation und Inbetriebnahme

1

2

3

0

°

1

2

d

d

3

2

3

1

DE

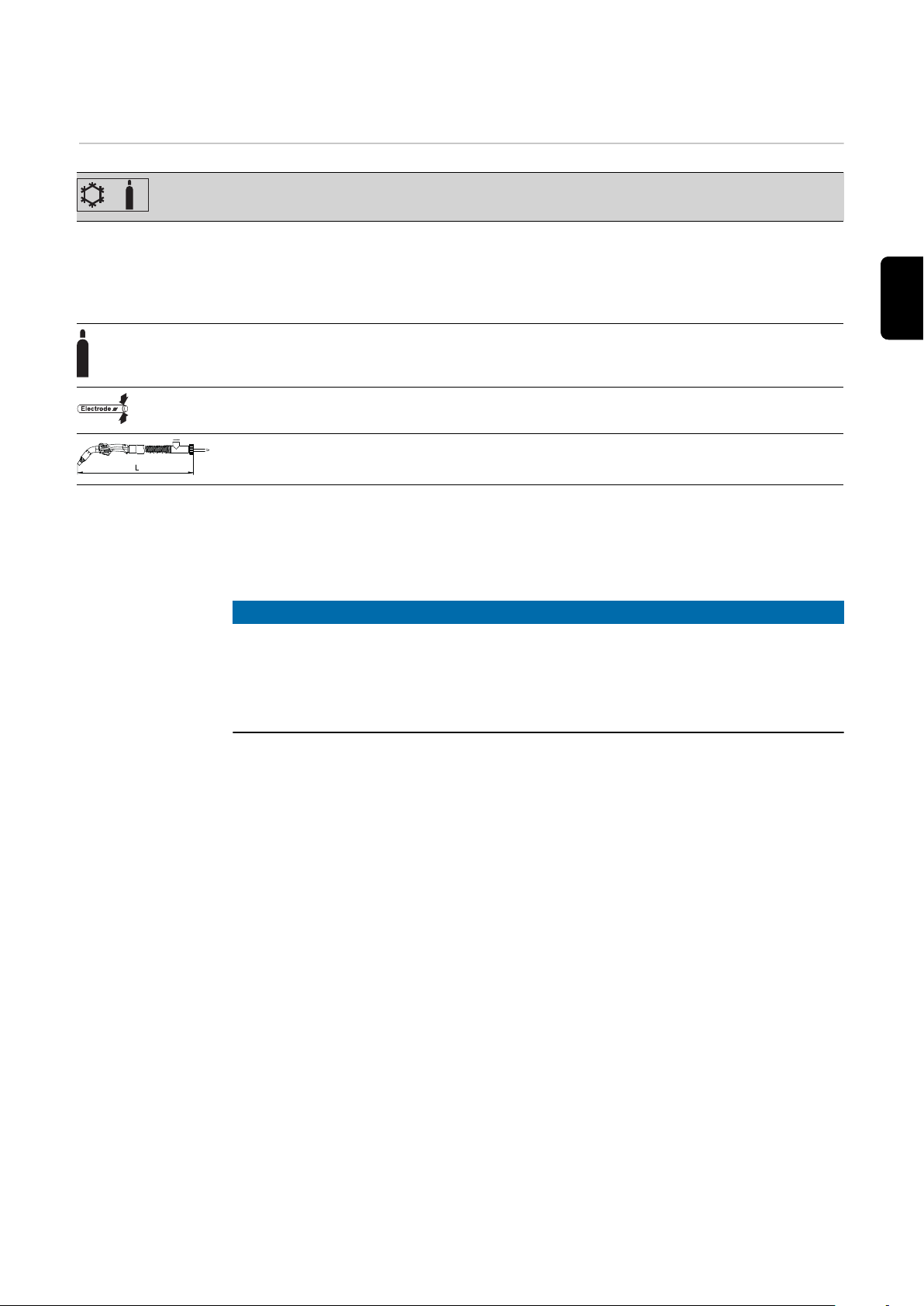

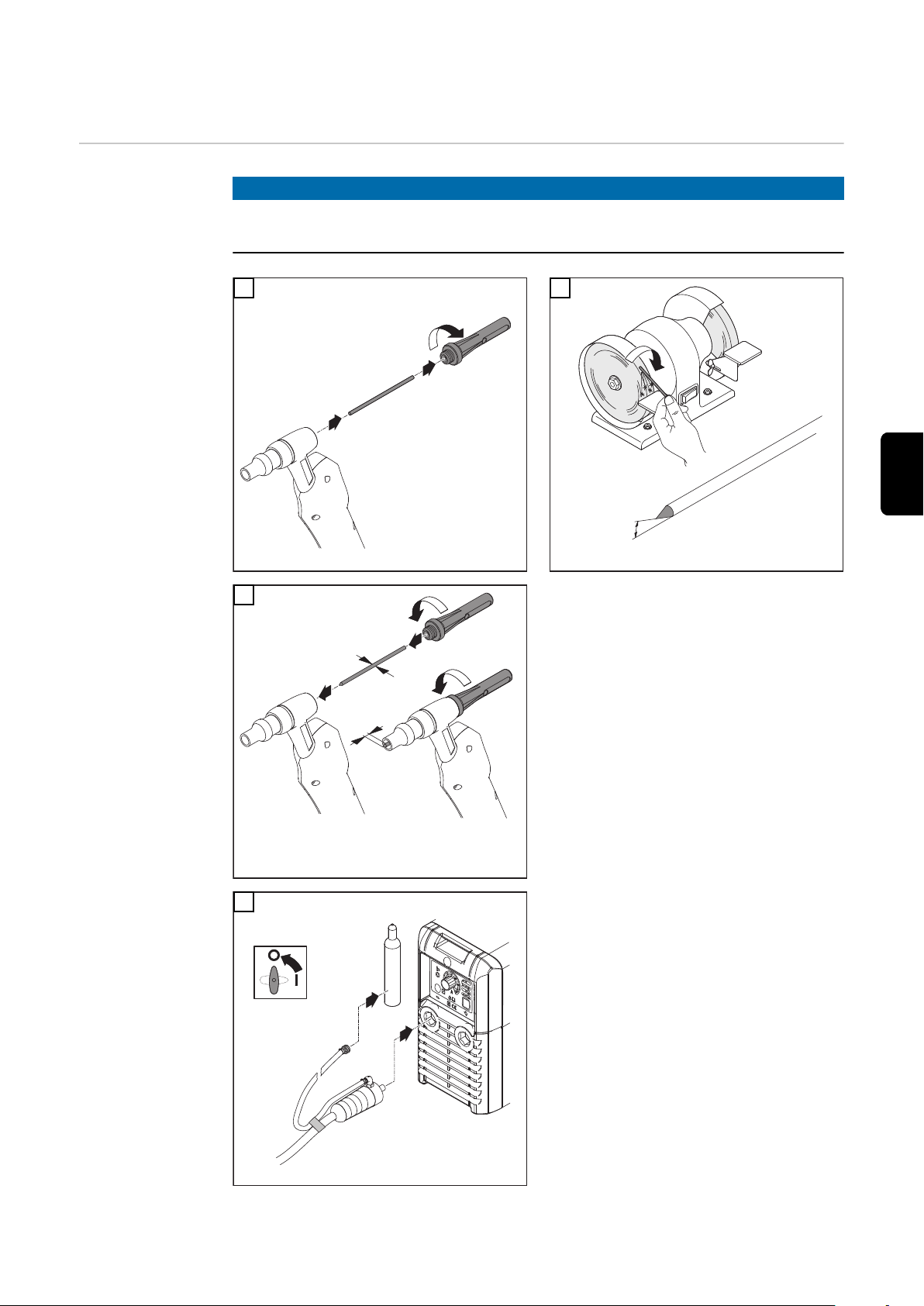

Inbetriebnahme

HINWEIS!

Vor jeder Inbetriebnahme den richtigen Sitz von Stromanschluss und Gasanschluss kontrollieren.

1

3

2

4

WIG Gasschieber-Schweißbrenner:

TTG 1600 / 2200 ... S

Betrieb möglich an folgenden Stromquellen:

TransPocket

-

TransPuls Synergic (außer CMT-

-

und Remote-Varianten)

5

Page 6

2

3

1

5

*

Gas

WIG Schweißbrenner mit Potentiometer: TTG 1600 ... Pot

Betrieb nur möglich an folgender

Stromquelle:

TransPocket 1500 TIG (Schutzgas

-

direkt an der Stromquelle anschließen)

WIG GasschieberSchweißbrenner

- S

6

WIG-Schweißbrenner: TTG 1600

FS/TL, TTG 1600 FS/UD

Betrieb nur möglich an folgender

Stromquelle:

AccuPocket 150/400 TIG (Schutz-

-

gas direkt an der Stromquelle anschließen)

HINWEIS!

Häufiges Biegen der flexiblen Brenner kann zu dauerhaften Beschädigungen

führen.

1

* nur für Varianten „F“

2

6

Page 7

3

2

Gas

1

*

0 = min

9 = max

1

2

3

4

5

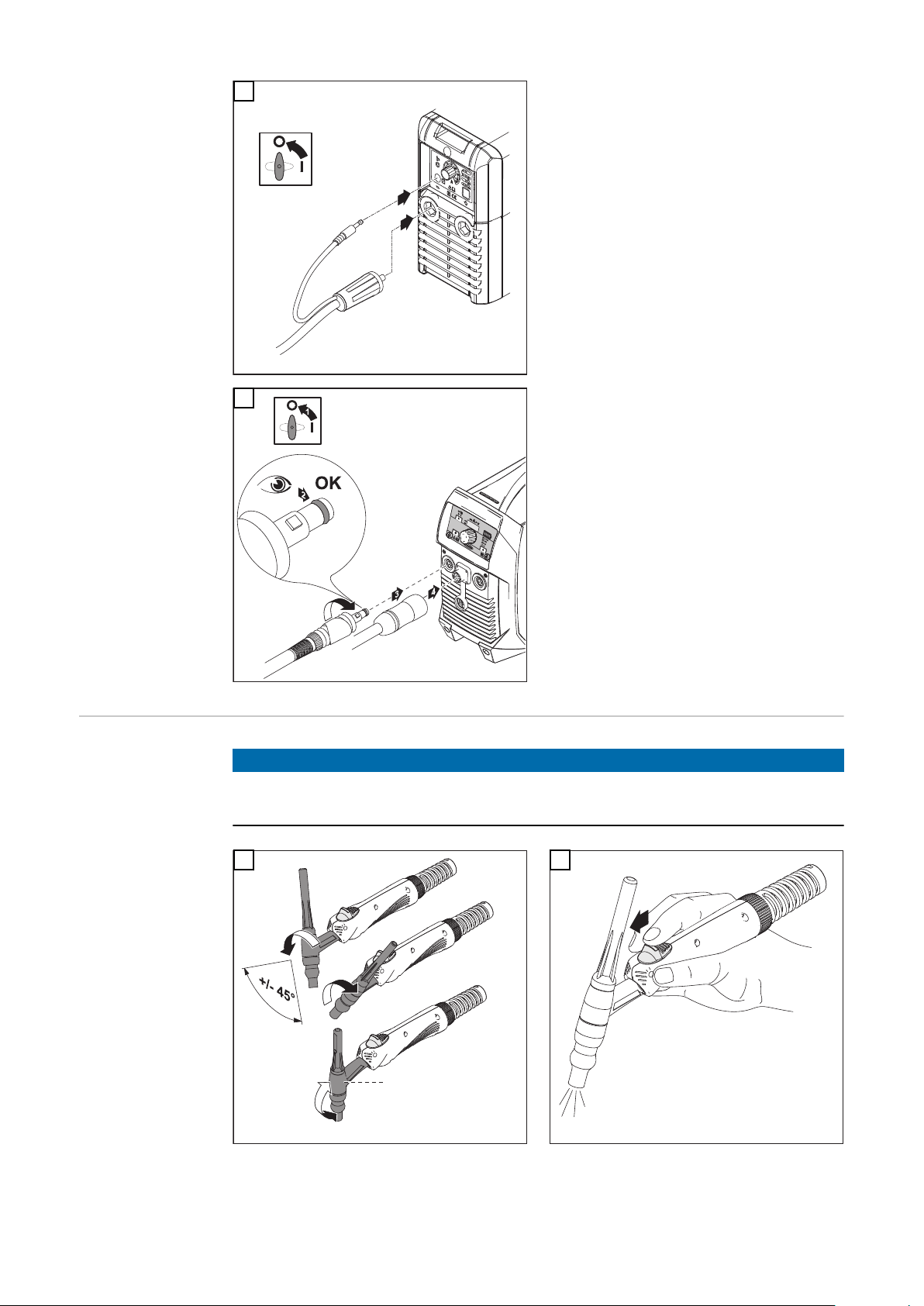

Schweißbrenner einrichten

1

Gasschieber öffnen: Gasströmung setzt ein

2

Berührungszünden

3

Schweißvorgang beenden:

4

Schweißbrenner abheben: Lichtbogen reißt ab

-

Gasschieber schließen

-

4

DE

WIGSchweißbrenner

mit Potentiometer - Pot

HINWEIS!

Häufiges Biegen der flexiblen Brenner kann zu dauerhaften Beschädigungen

führen.

1

* nur für Varianten „F“

2

7

Page 8

3

TCS

Schweißbrenner einrichten

1

Strom einstellen (auch während des Schweißvorganges möglich):

2

0 = min. Schweißstrom

-

9 = max. Schweißstrom

-

Werkstück mit Wolframelektrode berühren:

3

Gasströmung setzt aus

-

der Lichtbogen zündet

-

Beenden des Schweißvorganges mittels Funktion „TCS - TIG-Comfort-Stop“

4

4

(siehe Bedienungsanleitung TP 1500)

JobMaster TIG Mittels Taste „Mode“ einen der folgenden Parameter anwählen:

Parameter mittels Up/Down-Funktion einstellen

Voraussetzung für Kalottenbildung:

Verfahren „WIG-AC“

-

Voraussetzung für Zwischenabsenkung:

Betriebsart „Standard 4-Takt-Betrieb“

-

Setup-Parameter SFS auf „OFF“ (Werkseinstellung)

-

HINWEIS!

Häufiges Biegen der flexiblen Brenner kann zu dauerhaften Beschädigungen

führen (keine Garantieansprüche).

8

Page 9

*

1

+

-

1

+

-

2

+

-

1

+

-

2

l

1

l

2

* nur für Varianten „F“

3 4

2

DE

5

6

9

Page 10

Verschleißteil-

1

2

3

4

5

6

*

1

2

3

4

5

6

*

*

1

4

2

3

**

30°

2

1

d

d

3

1

d

2

System

1

2

VerschleißteilSystem A

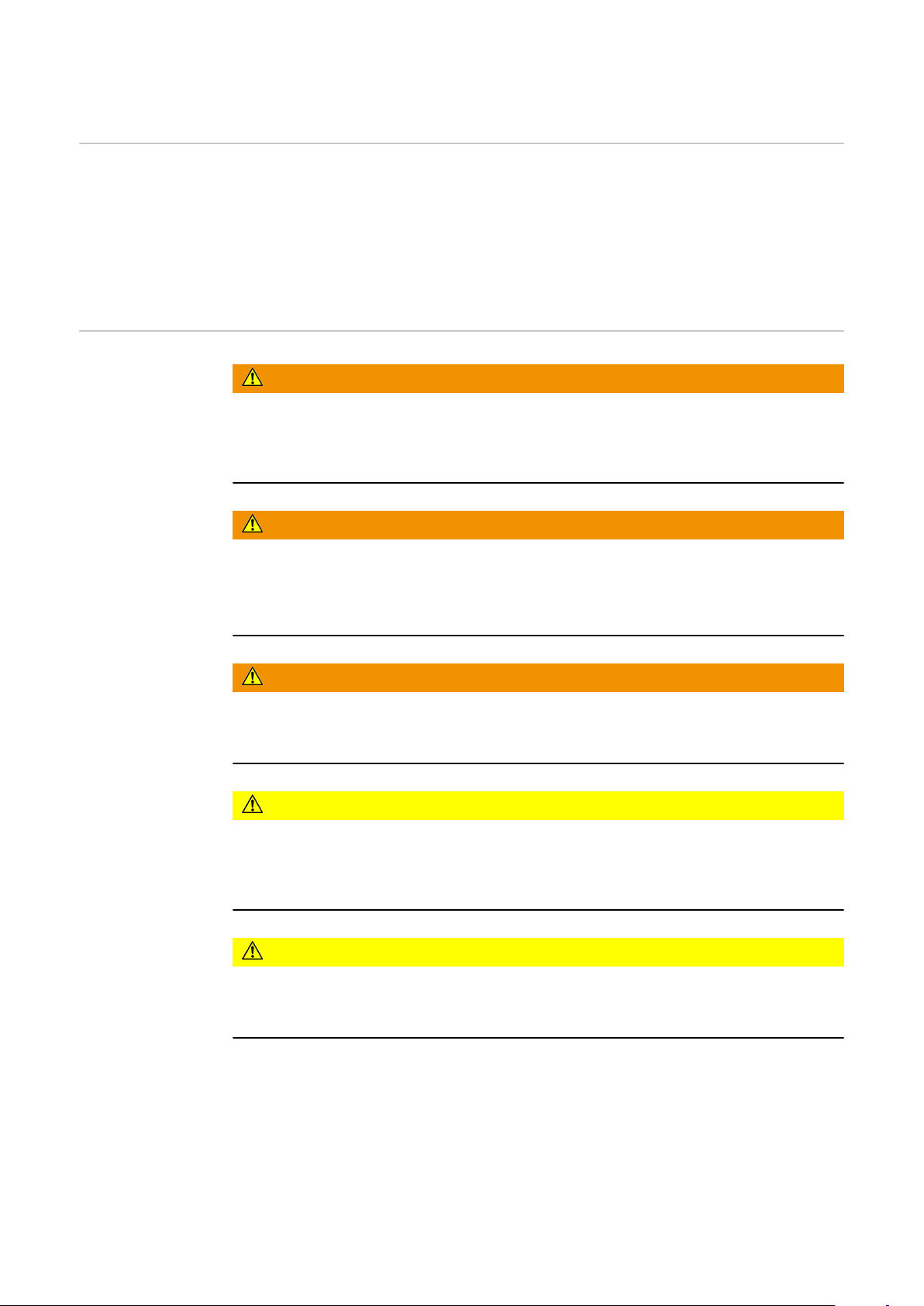

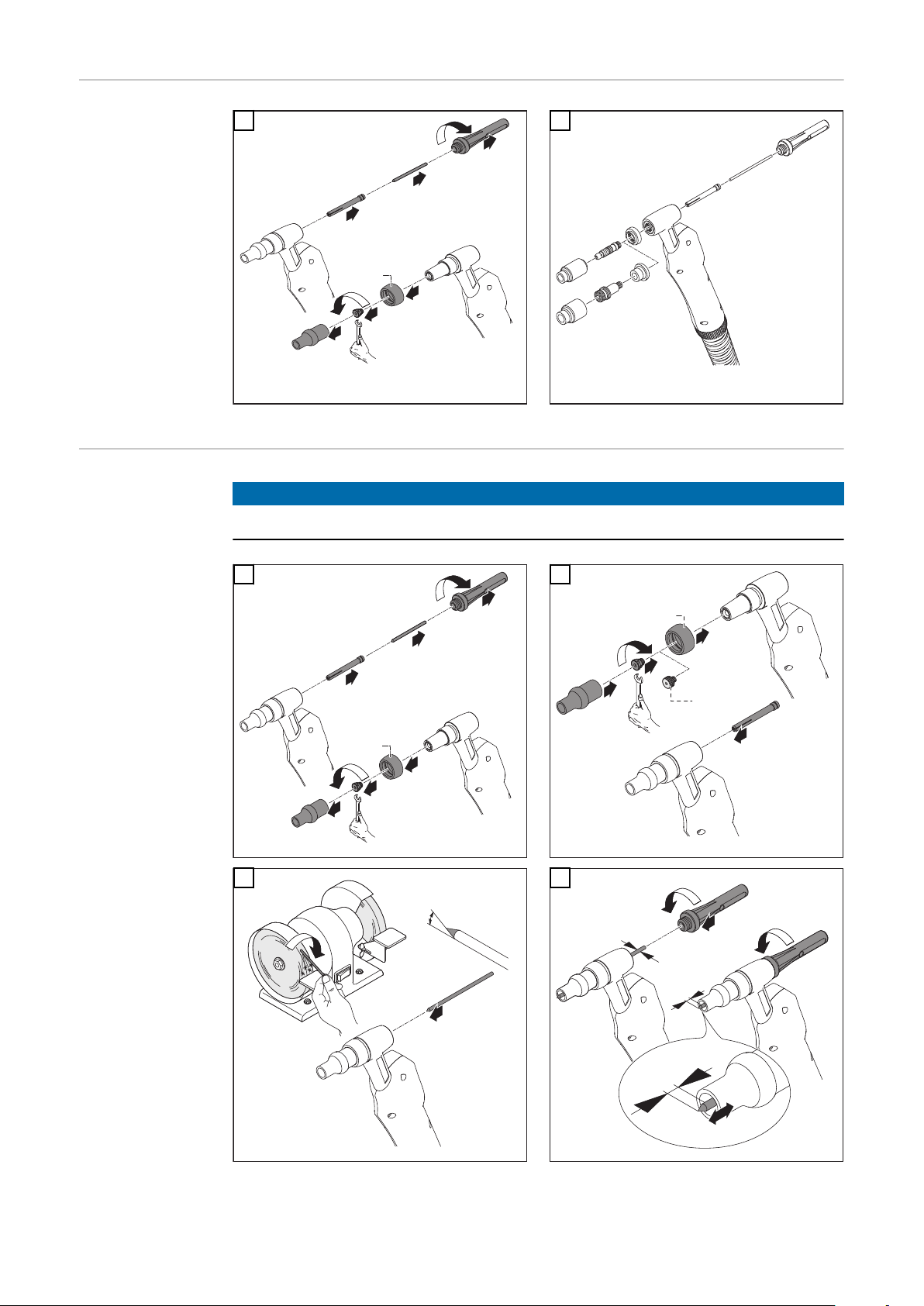

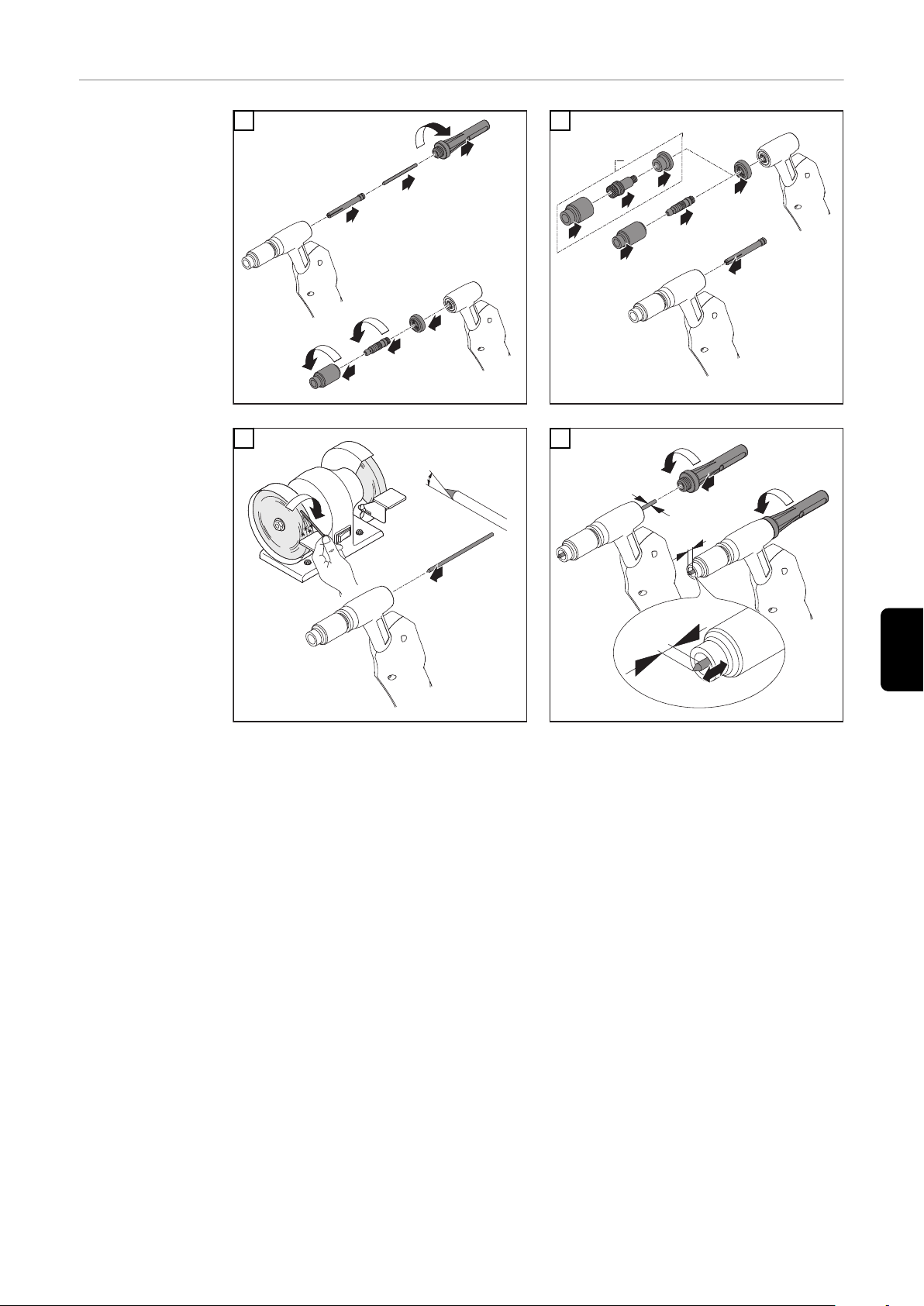

Verschleißteil-System A: Gasdüse gesteckt

Verschleißteil-System P: Gasdüse geschraubt

HINWEIS!

Gefahr der Beschädigung des Gewindes.

Spannmutter oder Gaslinse nur leicht festziehen.

1

2

3

4

10

Page 11

* Austauschbare Gummi-Dichthülse nur für TTG 2200 A

1

2

3

4

5

6

2

3

*

2

3

4

1

5

2

30°

1

d

d

3

1

d

2

** Je nach Ausführung des Schweißbrenners kann anstelle der Spannmutter

eine Gaslinse zum Einsatz kommen

DE

VerschleißteilSystem P

1

2

* nur für Gaslinse

3

4

11

Page 12

Fehlerdiagnose, Fehlerbehebung

Fehlerdiagnose

Schweißbrenner lässt sich nicht anschließen

Ursache:

Behebung:

Kein Schweißstrom

Netzschalter eingeschaltet, Anzeigen an der Stromquelle leuchten, Schutzgas

vorhanden

Ursache:

Behebung:

Ursache:

Behebung:

Ursache:

Behebung:

Ursache:

Behebung:

keine Funktion des Potentiometers

Netzschalter eingeschaltet, Anzeigen an der Stromquelle leuchten, Schutzgas

vorhanden

Bajonett-Verriegelung verbogen

Bajonett-Verriegelung austauschen

Masseanschluss falsch

Masseanschluss und Klemme auf Polarität überprüfen

Stromkabel im Schweißbrenner unterbrochen

Brenner tauschen

Wolframelektrode lose

Wolframelektrode mittels Brennerkappe festziehen

Verschleißteile lose

Verschleißteile festziehen

Ursache:

Behebung:

kein Schutzgas

alle anderen Funktionen vorhanden

Ursache:

Behebung:

Ursache:

Behebung:

Ursache:

Behebung:

Ursache:

Behebung:

Ursache:

Behebung:

Steckerverbindungen „Potentiometer / Steuerleitung / Stromquelle“

fehlerhaft

Steckerverbindung überprüfen / Stromquelle oder Schweißbrenner

zum Service

Gasflasche leer

Gasflasche wechseln

Gasdruckminderer defekt

Gasdruckminderer tauschen

Gasschlauch nicht montiert oder schadhaft, geknickt

Gasschlauch montieren, ausbiegen oder tauschen

Schweißbrenner defekt

Schweißbrenner austauschen

Gas-Magnetventil defekt

Gas-Magnetventil austauschen

12

Page 13

schlechte Schweißeigenschaften

Ursache:

Behebung:

falsche Schweißparameter

Einstellungen überprüfen

DE

Ursache:

Behebung:

Schweißbrenner wird sehr heiß

Ursache:

Behebung:

Porosität der Schweißnaht

Ursache:

Behebung:

Ursache:

Behebung:

Ursache:

Behebung:

Ursache:

Behebung:

Masseanschluss falsch

Masseanschluss und Klemme auf Polarität überprüfen

Schweißbrenner zu schwach dimensioniert

Einschaltdauer und Belastungsgrenzen beachten

Spritzerbildung in der Gasdüse, dadurch unzureichender Gasschutz

der Schweißnaht

Schweißspritzer entfernen

Löcher im Schutzgas-Schlauch oder ungenaue Anbindung des

Schutzgas-Schlauches

Schutzgas-Schlauch austauschen

O-Ringe an den Anschlüssen sind zerschnitten oder defekt

O-Ringe austauschen

Feuchtigkeit / Kondensat in der Schutzgas-Leitung

Schutzgas-Leitung trocknen

Ursache:

Behebung:

Ursache:

Behebung:

Schlechte Zündeigenschaften

Ursache:

Behebung:

Ursache:

Behebung:

Gasdüse bekommt Risse

Ursache:

Behebung:

Zu starke oder zu geringe Schutzgas-Strömung

Schutzgas-Strömung korrigieren

Zu viel Trennmittel aufgetragen

Überschüssiges Trennmittel entfernen / weniger Trennmittel auftra-

gen

Ungeeignete Wolframelektrode (z.B. WP-Elektrode beim DCSchweißen)

Geeignete Wolframelektrode verwenden

Spannmutter, Gasdüse oder Spannhülse lose

Spannmutter, Gaslinse oder Spannhülse festziehen

Wolframelektrode ragt nicht weit genug aus der Gasdüse

Wolframelektrode weiter aus der Gasdüse ragen lassen

13

Page 14

Pflege, Wartung und Entsorgung

Pflege und War-

tung

Entsorgung Die Entsorgung nur gemäß den geltenden nationalen und regionalen Bestimmun-

gen durchführen.

14

Page 15

Technische Daten

DE

Schweißstrom bei

10 min / 40°C

(104°F)

DC

TTG 1600

gasgekühlt

I (Ampere) 15 % ED* 160

35 % ED* 110

60 % ED* 80

100 % ED* 60

Norm EN 439 EN 439

[mm (in.)] 1,0 - 3,2 (.039 - .126) 1,0 - 4,0 (.039 - .158)

[m (ft. + in.)] 4,0 / 8,0 (13 + 1.48 / 26 +

2.96)

ED* Einschaltdauer

Spannungsbemessung (V-Peak):

für handgeführte Schweißbrenner: 113 V

-

HINWEIS!

Gilt für die Schweißbrenner TTG 1600 A / A F: Die Schweißstrom-Angaben gelten bei Verwendung von Gasdüsen mit einer Länge von 33 mm.

Bei Verwendung von Gaslinsen und 22 mm-Gasdüsen reduzieren sich die

Schweißstrom-Angaben um bis zu 20 %.

TTG 2200 S

gasgekühlt

15 % ED* 220

35 % ED* 150

60 % ED* 110

100 % ED* 90

4,0 / 8,0 (13 + 1.48 / 26 +

2.96)

Das Produkt entspricht den Anforderungen laut Norm IEC 60974-7.

15

Page 16

16

Page 17

Contents

General 18

General remarks 18

Safety 18

Installation and commissioning 19

Commissioning 19

TIG gas valve welding torch - S 20

TIG welding torch with potentiometer - Pot 21

JobMaster TIG 22

Wearing-parts system 24

Wearing-parts system A 24

Wearing-parts system P 25

Troubleshooting 26

Fault diagnosis 26

Care, maintenance and disposal 28

Care and maintenance 28

Disposal 28

Technical data 29

EN

17

Page 18

General

General remarks The TIG gas valve welding torch (S) and the TIG welding torch with potentiome-

ter (Pot) are available in many versions and are suitable for welding CrNi and

steel.

The welding torches can be used in an extremely wide range of applications. They

are ideally suited for manual series production and one-off jobs, such as in workshops.

Safety

WARNING!

Work that is not carried out correctly can cause serious injury and damage.

The actions described herein may ONLY be carried out by skilled, trained technicians! Observe the instructions given in the attached document “Safety rules”.

WARNING!

An electric shock can be fatal.

Only carry out the actions described here if:

the mains switch of the power source is in the - O - position, and

▶

the power source has been disconnected from the mains.

▶

WARNING!

An electric shock can be fatal.

Before cleaning the welding torch and inspecting its components, shift the mains

switch of the power source into the - O - position.

CAUTION!

The torch becomes extremely hot during welding - risk of burns! Cleaning of the

welding torch, and inspection of its components, may only be carried out once

the torch has cooled down.

CAUTION!

Risk of injury from inadequate connections.

All cables, leads and hosepacks must be firmly attached, undamaged, properly

insulated and adequately.

18

Page 19

Installation and commissioning

1

2

3

0

°

1

2

d

d

3

2

3

1

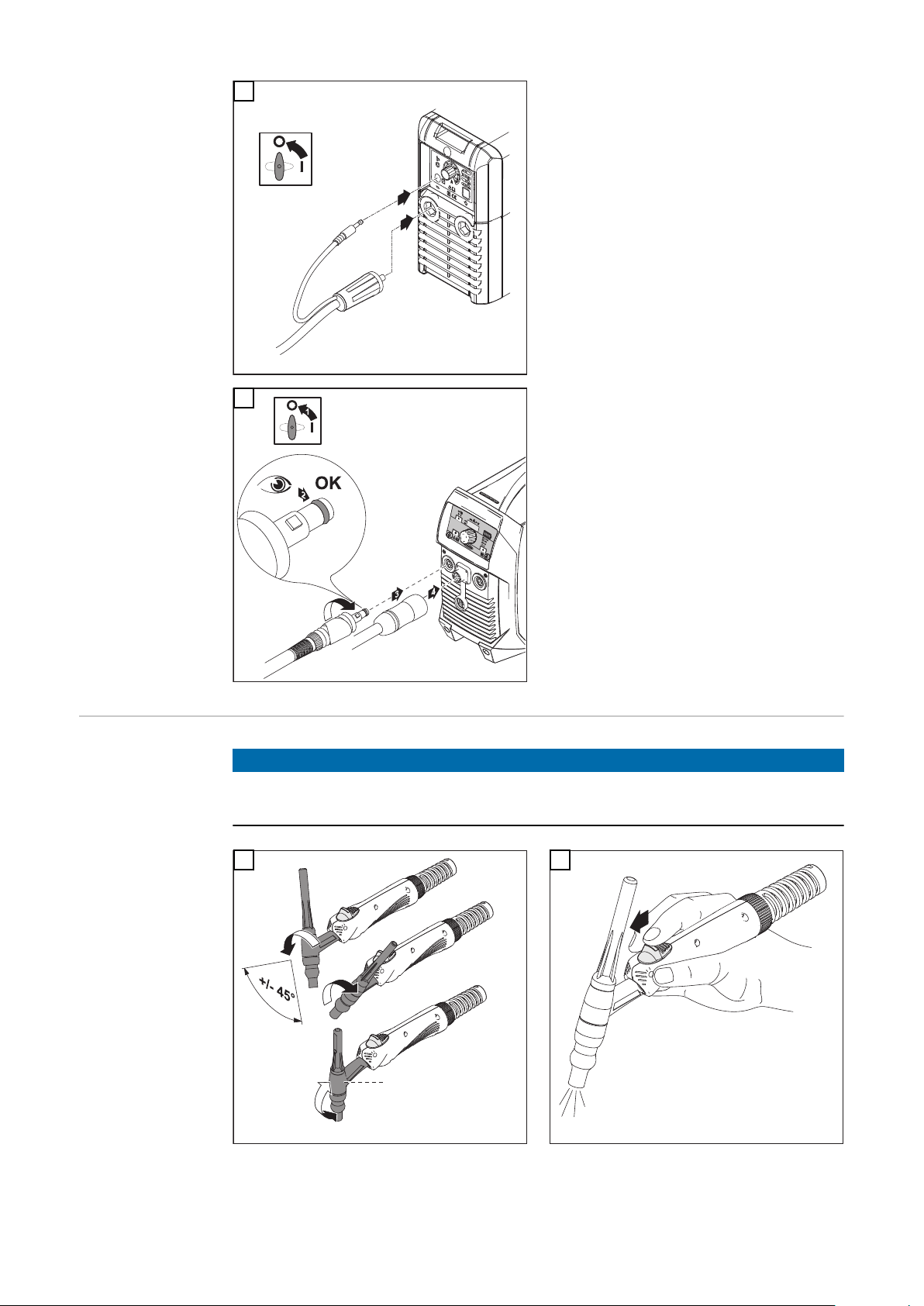

Commissioning

NOTE!

Check that the current connection and the gas connection are properly secured

before use.

1

3

2

EN

4

TIG gas valve welding torch: TTG

1600/2200 ... S

Can be used with the following power

sources:

TransPocket

-

TransPuls Synergic (except CMT

-

and Remote versions)

19

Page 20

2

3

1

5

*

Gas

TIG welding torch with potentiometer:

TTG 1600 ... Pot

Can only be used with the following

power source:

TransPocket 1500 TIG (connect

-

shielding gas directly to the power

source)

TIG gas valve

welding torch - S

6

TIG welding torch with potentiometer::

TTG 1600 FS/TL, TTG 1600 FS/UD

Can only be used with the following

power source:

AccuPocket 150/400 TIG (con-

-

nect shielding gas directly to the

power source)

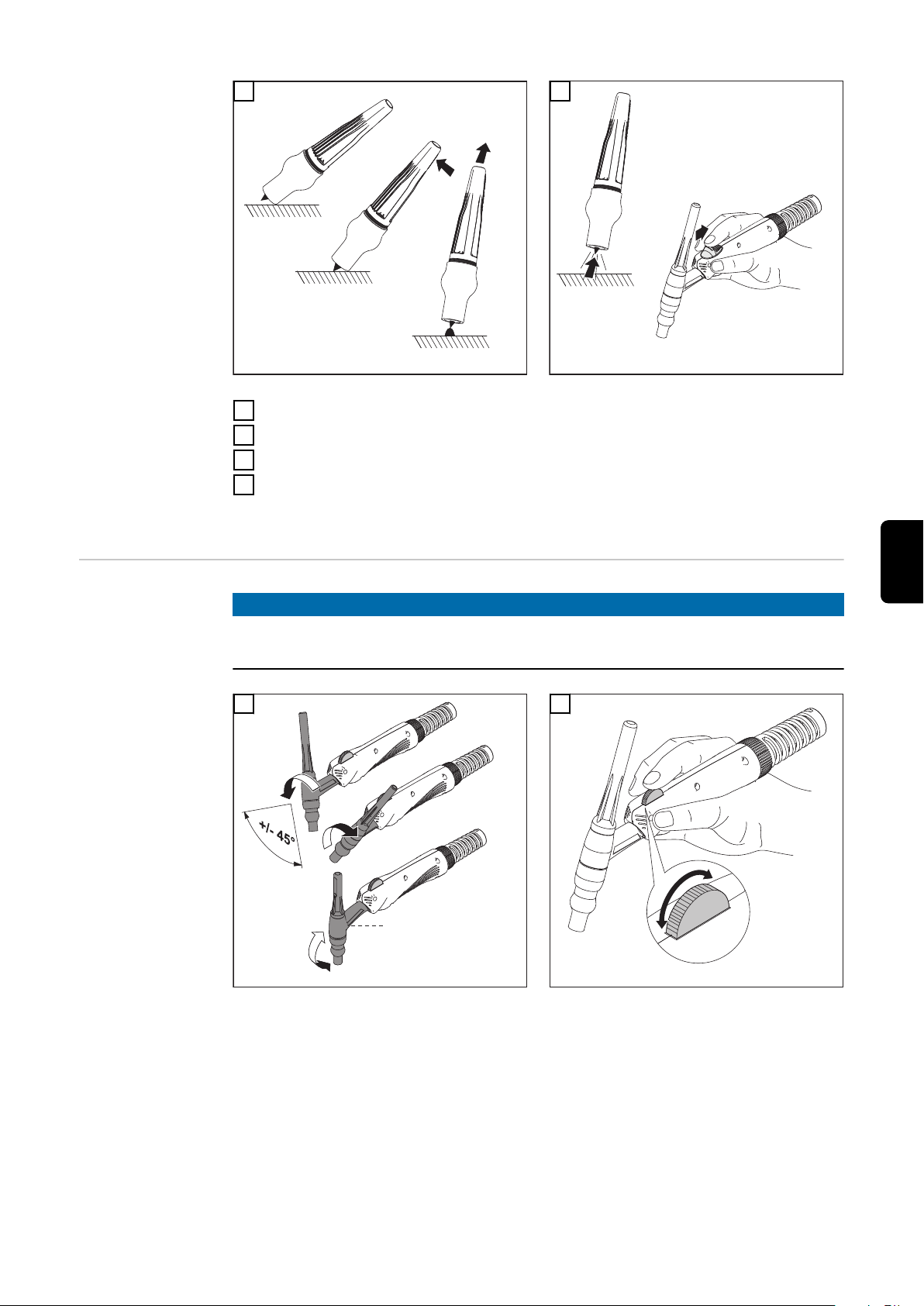

NOTE!

Frequent bending of the flexible burner can cause permanent damage.

1

2

* only on “F“ types

20

Page 21

3

2

Gas

1

*

0 = min

9 = max

1

2

3

4

5

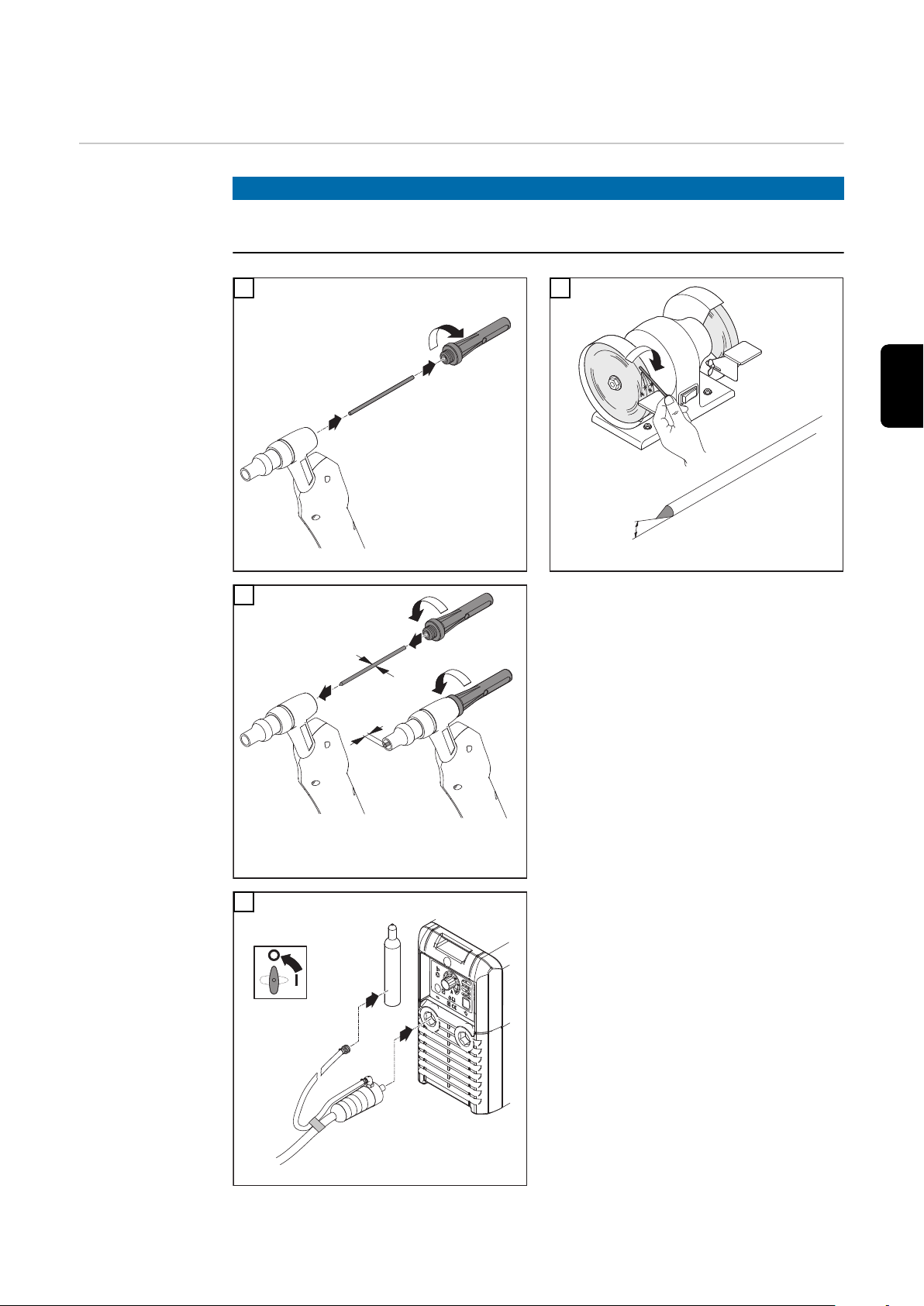

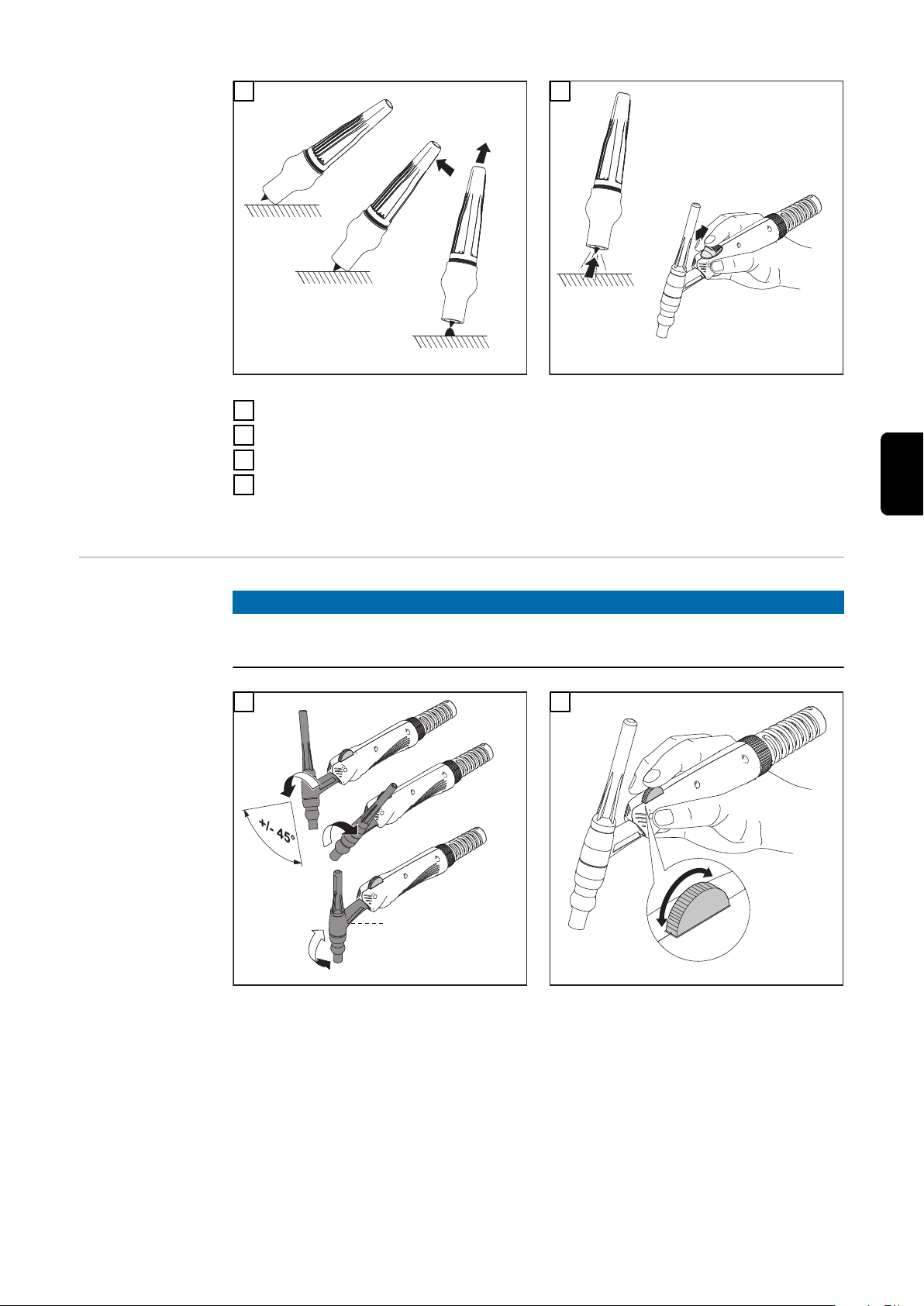

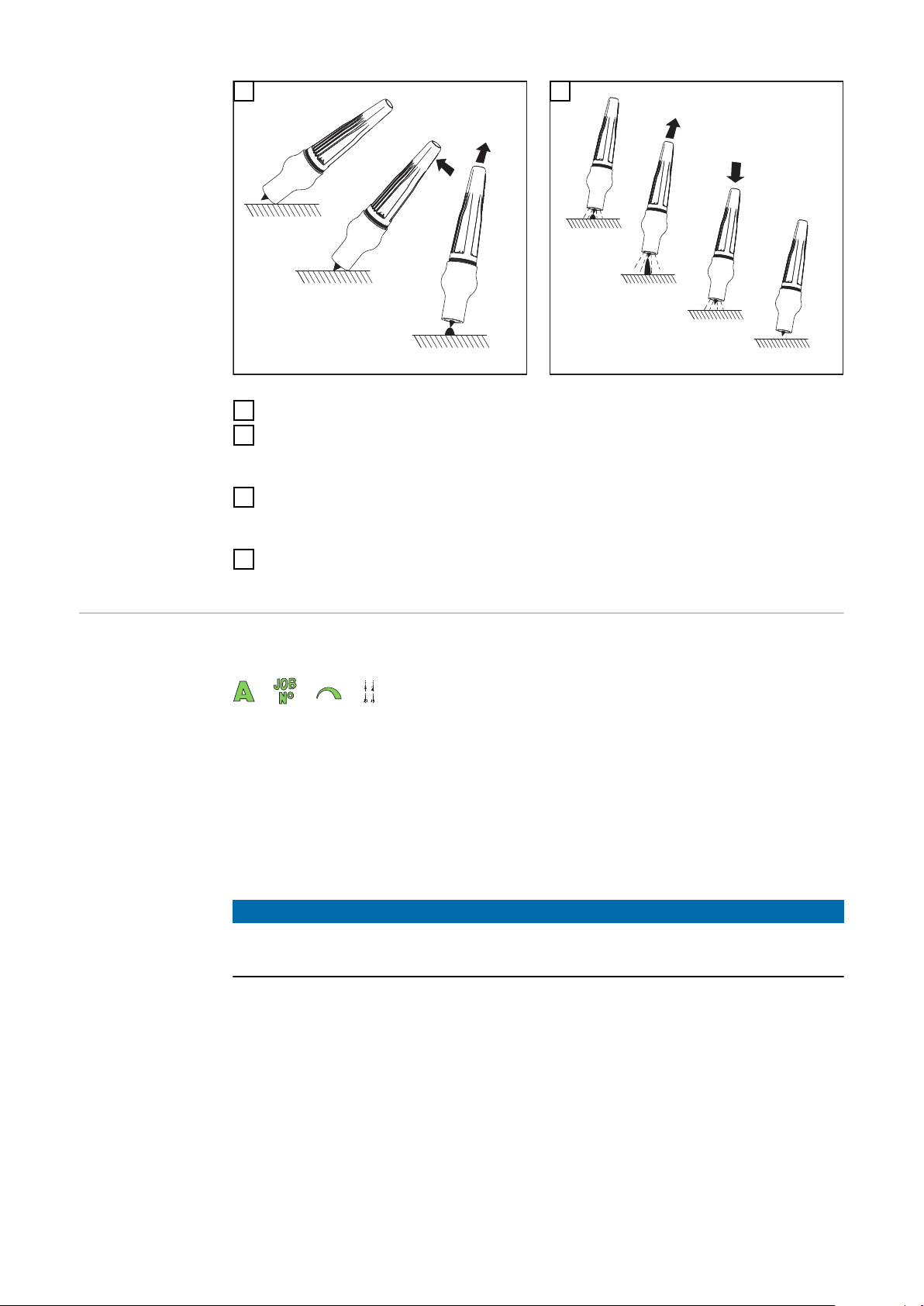

Set up welding torch

1

Open gas valve: gas flow starts

2

Touchdown ignition

3

End the welding process:

4

Lift the welding torch clear: arc breaks

-

Close gas valve

-

4

EN

TIG welding

torch with potentiometer Pot

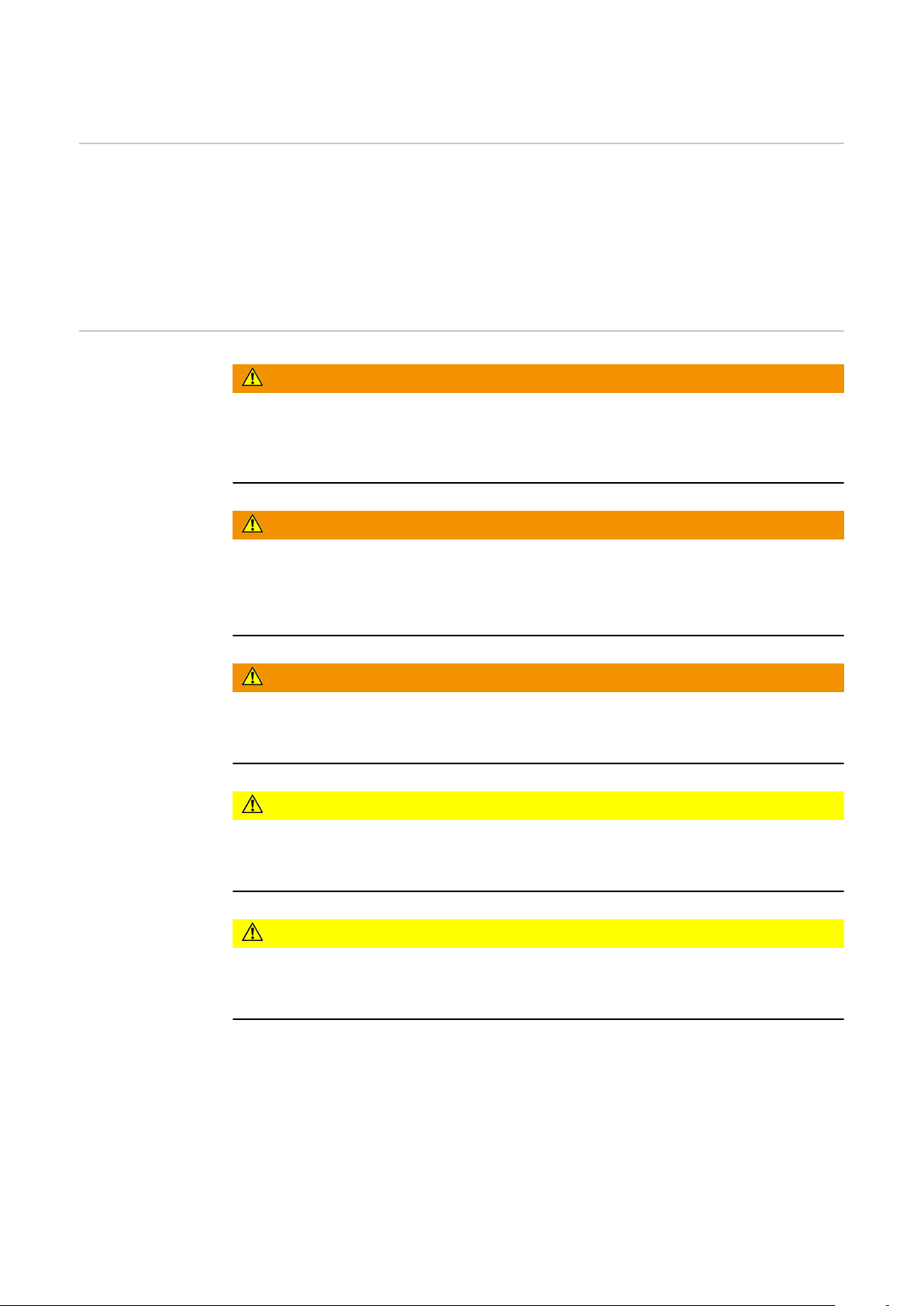

NOTE!

Frequent bending of the flexible burner can cause permanent damage.

1

* only on “F“ types

2

21

Page 22

3

TCS

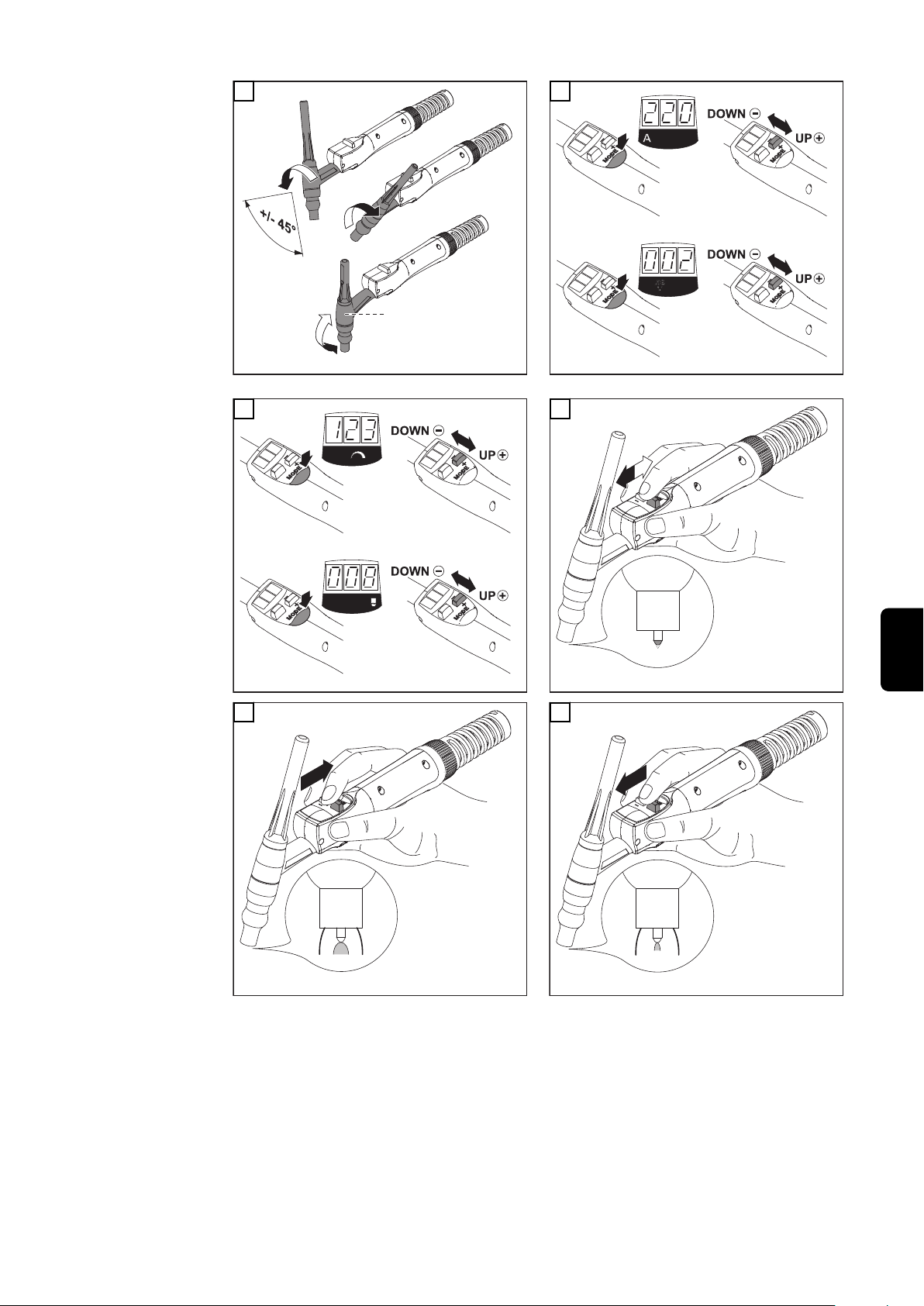

Set up welding torch

1

Adjust current (may also be adjusted during the welding process):

2

0 = min. welding current

-

9 = max. welding current

-

Touch the workpiece with the tungsten electrode:

3

gas flow starts

-

Arc ignites

-

End welding using the „TCS - TIG-ComfortStop“ feature (see TP 1500 opera-

4

4

ting instructions)

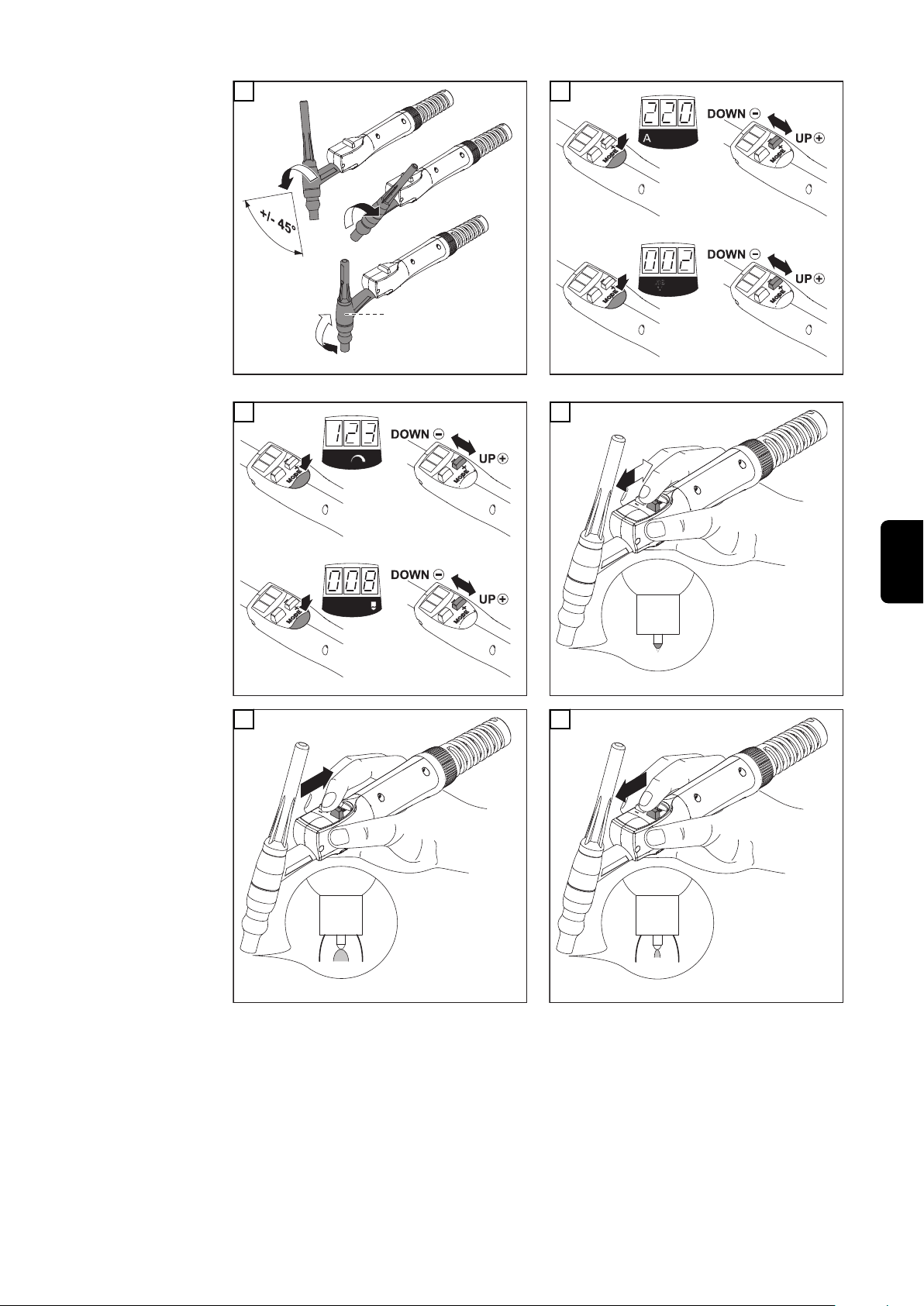

JobMaster TIG Using the „Mode“ button select one of the following parameters:

Set the parameters using the Up/Down function

Cap-shaping - precondition:

TIG-AC welding process

-

Intermediate lowering - precondition:

Standard 4-step mode

-

Set-up parameter SFS must be set to “OFF” (factory setting)

-

NOTE!

Frequent bending of the flexible burner can cause permanent damage (no guarantee).

22

Page 23

*

1

+

-

1

+

-

2

+

-

1

+

-

2

l

1

l

2

* only on “F“ types

3 4

2

EN

5

6

23

Page 24

Wearing-parts

1

2

3

4

5

6

*

1

2

3

4

5

6

*

*

1

4

2

3

**

30°

2

1

d

d

3

1

d

2

system

1

2

Wearing-parts

system A

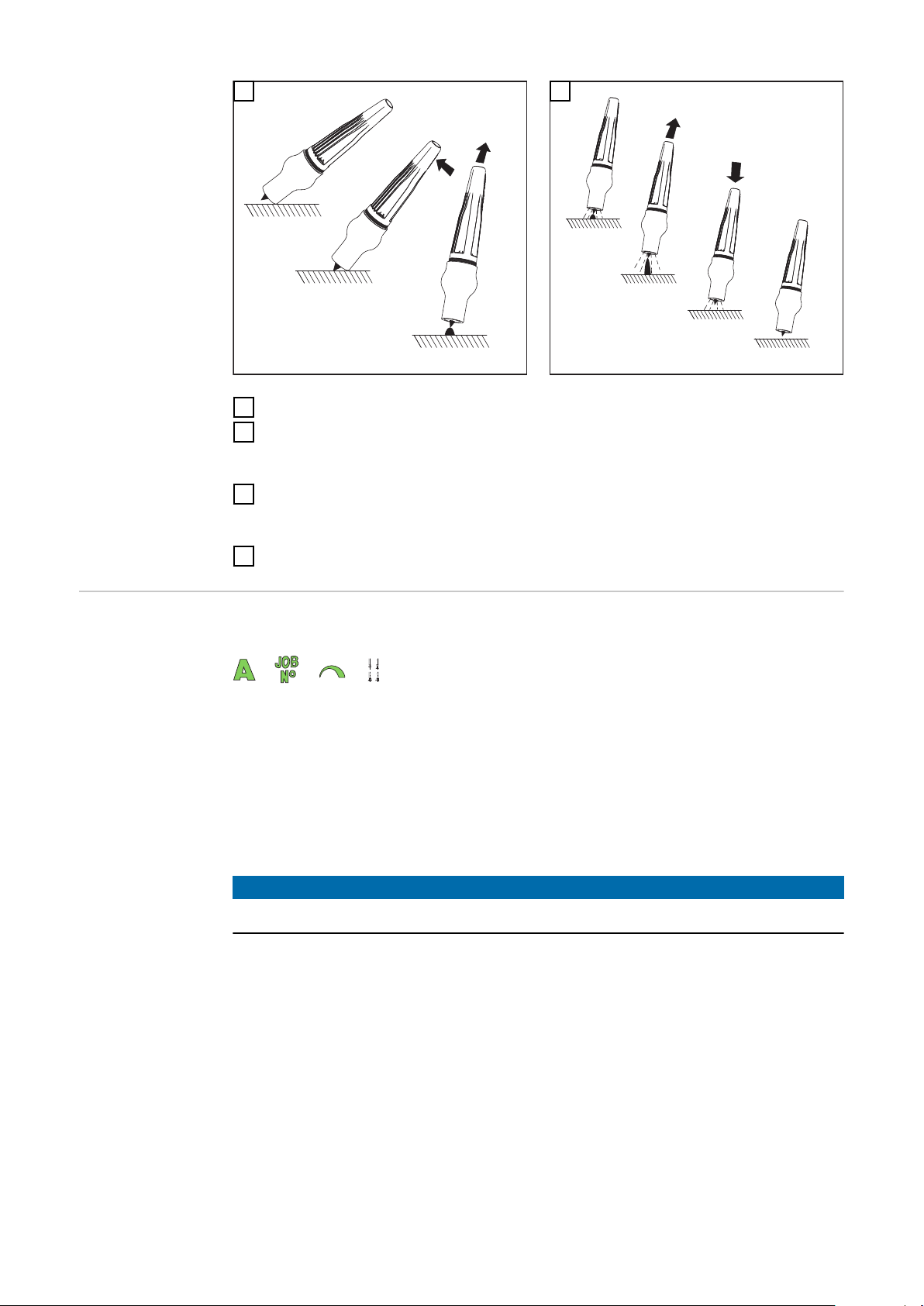

Wearing-parts system A: Plug-on gas nozzle

Wearing-parts system P: Screw-on gas nozzle

NOTE!

Risk of damage to the thread.

Tighten the clamping nut or gas lens only very gently.

1

2

3

4

24

Page 25

* interchangeable rubber sealing sleeve only on TTG 2200 A

1

2

3

4

5

6

2

3

*

2

3

4

1

5

2

30°

1

d

d

3

1

d

2

** Depending on the design of the welding torch, it may be possible to use a

gas lens instead of the clamping nut.

Wearing-parts

system P

1

2

EN

* only on gas lens

3

4

25

Page 26

Troubleshooting

Fault diagnosis

Welding torch cannot be connected

Cause:

Remedy:

No welding current

Mains switch ON, indicators on the power source are lit up, shielding gas flows

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Potentiometer not working

Mains switch is on, indicators on the power source are lit, shielding gas available

Bayonet fixing bent

Replace bayonet fixing

Faulty earth (ground) connection

Check the earth (ground) connection and clamp for correct polarity

There is a break in the current cable in the welding torch

Change the torch

Loose tungsten electrode

Tighten tungsten electrode using torch cap

Loose parts

Tighten parts

Cause:

Remedy:

No protective gas shield

All other functions are OK

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Plug-in connections of „potentiometer/control line/power source“

faulty

Check plug-in connection/have power source or welding torch serviced

The gas cylinder is empty

Change the gas cylinder

The gas pressure regulator is faulty

Replace the gas pressure regulator

The gas hose is not connected, damaged or kinked

Connect/replace the gas hose, or straighten out kinks

The welding torch is faulty

Replace welding torch

Gas solenoid valve is faulty

Replace gas solenoid valve

26

Page 27

Poor weld properties

Cause:

Remedy:

Incorrect welding parameters

Check the settings

Cause:

Remedy:

The welding torch becomes very hot

Cause:

Remedy:

Weld-seam porosity

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Grounding (earthing) connection is incorrect

Check the grounding (earthing) connection and terminal for correct

polarity

The design dimensions of the torch are not sufficient for this task

Respect the duty cycle and loading limits

Spatter accumulating in the gas nozzle, causing inadequate gas-shielding of the weld-seam

Remove the welding spatter

Either the shielding-gas hose has holes in it, or it is not connected up

properly

Change the shielding gas-hose

The O-ring seals on the connection points are cut or defective

Change the O-ring seals

Moisture / condensate in the shielding-gas hose

Dry the shielding-gas hose

EN

Cause:

Remedy:

Cause:

Remedy:

Poor ignition properties

Cause:

Remedy:

Cause:

Remedy:

Cracks in gas nozzle

Cause:

Remedy:

Shielding-gas flow is either too high or too low

Correct the shielding-gas flow

Too much parting agent applied

Wipe off excess parting agent / apply less parting agent

Unsuitable tungsten electrode (e.g. WP electrode for DC welding)

Use suitable tungsten electrode

Loose clamping nuts, gas lens or clamping sleeve

Tighten clamping nuts, gas lens or clamping sleeve

Tungsten electrode does not protrude far enough out of gas nozzle

Allow tungsten electrode to protrude further out of gas nozzle

27

Page 28

Care, maintenance and disposal

Care and maintenance

Disposal Dispose of in accordance with the applicable national and local regulations.

28

Page 29

Technical data

Welding current range at 10 min / 40°C

(104°F)

DC

TTG 1600

gas-cooled

I (Ampere) 15 % d.c.* 160

35 % d.c.* 110

60 % d.c.* 80

100 % d.c.* 60

Norm EN 439 EN 439

[mm (in.)] 1,0 - 3,2 (.039 - .126) 1,0 - 4,0 (.039 - .158)

[m (ft. + in.)] 4,0 / 8,0 (13 + 1.48 / 26 +

2.96)

d.c.* duty cycle

Voltage rating (V-Peak):

for manually guided torches: 113 V

-

NOTE!

When using TTG 1600 A / AF welding torches: the welding-amperage data apply

where 33 mm long gas nozzles are being used.

If gas lenses and 22 mm long gas nozzles are used, the welding-amperage data

are reduced by as much as 20 %.

TTG 2200 S

gas-cooled

15 % d.c.* 220

35 % d.c.* 150

60 % d.c.* 110

100 % d.c* 90

4,0 / 8,0 (13 + 1.48 / 26 +

2.96)

EN

The product complies with standard IEC 60974-7.

29

Page 30

30

Page 31

Sommaire

Généralités 32

Généralités 32

Sécurité 32

Installation et mise en service 33

Mise en service 33

Torche de soudage TIG avec vanne à gaz - S 34

Torche de soudage TIG avec potentiomètre - Pot 35

JobMaster TIG 36

Système de pièces d’usure 38

Système de pièces d’usure A 38

Système de pièces d’usure P 39

Diagnostic d’erreur, élimination de l'erreur 40

Diagnostic d'erreur 40

Maintenance, entretien et élimination 42

Entretien et maintenance 42

Élimination des déchets 42

Caractéristiques techniques 43

FR

31

Page 32

Généralités

Généralités La torche de soudage TIG avec vanne à gaz (S) et la torche de soudage TIG avec

potentiomètre (Pot) sont adaptées au soudage du CrNi et de l’acier et se distinguent par la diversité de leurs exécutions.

Ces torches de soudage conviennent pour les tâches les plus diverses et sont

idéales pour la fabrication manuelle en série et sur commande, ainsi que dans les

garages.

Sécurité

AVERTISSEMENT!

Les travaux mal exécutés peuvent entraîner de graves dommages corporels ou

matériels.

Seuls des techniciens spécialement formés par la société sont habilités à exécuter les procédures décrites ciaprès ! Veillez à respecter les indications fournies

dans le document ci-joint intitulé « Consignes de sécurité »..

AVERTISSEMENT!

Un choc électrique peut être mortel.

N’exécutez les procédures décrites que :

l’interrupteur d’alimentation de la source de courant est en position - O -

▶

et que la source de courant est débranchée.

▶

AVERTISSEMENT!

Un choc électrique peut être mortel.

Avant de procéder au nettoyage de la torche et à la vérification de ses composants, mettez l’interrup-teur d’alimentation de la source de courant en position O -.

32

ATTENTION!

Danger de brûlures pouvant être provoquées par la torche rendue extrêmement

chaude suite à son utilisation.

Ne procédez au nettoyage de la torche et à la vérification de ses composants que

lorsque celle-ci est refroidie.

ATTENTION!

Danger de blessures pouvant être provoquées par des connexions en mauvais

état.

Les câbles, conduites et faisceaux doivent être parfaitement fixés, en parfait

état, bien isolés, et correspondre aux dimensions requises.

Page 33

Installation et mise en service

1

2

3

0

°

1

2

d

d

3

2

3

1

Mise en service

REMARQUE!

Avant chaque mise en service, s’assurer que la connexion électrique et le raccordement de gaz sont bien fixés.

1

3

2

FR

4

Torche de soudage TIG avec vanne à

gaz : TTG 1600 / 2200 ... S

Fonctionnement possible sur les

sources de courant suivantes :

TransPocket

-

TransPuls Synergic (sauf procédés

-

CMT et Remote)

33

Page 34

2

3

1

5

*

Gas

Torche TIG avec potentiomètre : TTG

1600 ... Pot

Fonctionnement possible uniquement

sur la source de courant suivante :

TransPocket 1500 TIG (raccorder

-

le gaz protecteur directement sur

la source de courant)

Torche de soudage TIG avec vanne à gaz - S

6

Torche TIG : TTG 1600 FS/TL, TTG

1600 FS/UD

Fonctionnement possible uniquement

sur la source de courant suivante :

AccuPocket 150/400 TIG (raccor-

-

der le gaz protecteur directement

sur la source de courant)

REMARQUE!

Un pliage fréquent de la torche flexible peut provoquer des dommages

irrémédiables.

1

* uniquement pour les types «F»

2

34

Page 35

3

2

Gas

1

*

0 = min

9 = max

1

2

3

4

5

Positionner la torche de soudage

1

Ouvrir la vanne à gaz : le débit de gaz s’enclenche

2

Amorçage par contact

3

Terminer le processus de soudage :

4

Relever la torche de soudage : l’arc électrique s’interrompt

-

Fermer la vanne à gaz

-

4

FR

Torche de soudage TIG avec potentiomètre Pot

REMARQUE!

Un pliage fréquent de la torche flexible peut provoquer des dommages

irrémédiables.

1

* uniquement pour les types «F»

2

35

Page 36

3

TCS

Positionner la torche de soudage

1

Régler le courant (également possible durant le processus de soudage) :

2

0 = courant de soudage min.

-

9 = courant de soudage max.

-

Établir un contact entre l’électrode en tungstène et la pièce à usiner :

3

le débit de gaz s’enclenche

-

’arc électrique s’amorce

-

Terminer le processus de soudage à l’aide de la fonction „TCS - Tig-Comfort-

4

4

Stop“ (voir mode d’emploi TP 1500)

JobMaster TIG Au moyen de la gâchette „Mode“ sélectionnez l’un des paramètres suivants:

Configurez les paramètres au moyen de la fonction up/down

Formation de calotte - Condition:

Procédé soudage TIG-AC

-

Abaissement intermédiaire - Condition:

Service standard à 4 temps

-

Paramètre Setup SFS doit être mis sur «OFF» (réglage d’ usine)

-

REMARQUE!

Un pliage fréquent de la torche flexible peut provoquer des dommages

irrémédiables (aucune garantie).

36

Page 37

*

1

+

-

1

+

-

2

+

-

1

+

-

2

l

1

l

2

* uniquement pour les types «F»

3 4

2

FR

5

6

37

Page 38

Système de

1

2

3

4

5

6

*

1

2

3

4

5

6

*

*

1

4

2

3

**

30°

2

1

d

d

3

1

d

2

pièces d’usure

1

2

Système de

pièces d’usure A

Système de pièces d’usure A: tuyère à gaz

fichée

Système de pièces d’usure P: tuyère à gaz vissée

REMARQUE!

Danger d’endommagement du filetage.

Ne serrer que légèrement l’écrou de serrage ou la lentille de gaz.

1

2

3

4

38

Page 39

* manchon d’étanchéité en caoutchouc interchangeable uniquement pour

1

2

3

4

5

6

2

3

*

2

3

4

1

5

2

30°

1

d

d

3

1

d

2

TTG 2200 A

** En fonction du modèle de chalumeau, une lentille de gaz peut être utilisée

à la place de l’écrou de serrage.

Système de

pièces d’usure P

1

2

FR

* uniquement pour lentille de gaz

3

4

39

Page 40

Diagnostic d’erreur, élimination de l'erreur

Diagnostic d'erreur

Impossible de raccorder la torche de soudage

Cause:

Solution:

Pas de courant de soudage

Interrupteur d’alimentation enclenché, témoins de la source de courant allumés,

gaz de protection disponible

Cause:

Solution:

Cause:

Solution:

Cause:

Solution:

Cause:

Solution:

Le potentiomètre ne fonctionne pas

Interrupteur d’alimentation commuté, voyants allumés sur la source de courant,

gaz protecteur disponible

Le verrouillage baïonnette est tordu

Remplacer le verrouillage baïonnette

mauvaise connexion à la masse

vérifiez la polarité de la connexion à la masse et de la borne

coupure du câble électrique dans la torche

changez la torche

L’électrode en tungstène n’est pas fixée correctement

Fixer l’électrode en tungstène au moyen de l’extrémité de la torche

Les pièces d’usure sont desserrées

Resserrer les pièces d’usure

Cause:

Solution:

Pas de gaz de protection

Toutes les autres fonctions sont disponibles

Cause :

Remède :

Cause :

Remède :

Cause :

Remède :

Cause :

Remède :

Cause :

Remède :

Connexions „potentiomètre / câble de commande / source de courant“ défectueuses

Vérifier la fiche de connexion / Amener la source de courant ou la

torche de soudage au S.A.V.

Bouteille de gaz vide

Remplacer la bouteille de gaz

Détendeur défectueux

Remplacer le détendeur

Le tuyau de gaz n’est pas monté, est endommagé ou plié

Monter, détordre ou remplacer le tuyau de gaz

Torche défectueuse

Remplacer la torche de soudage

Électrovanne de gaz défectueuse

Remplacer l'électrovanne de gaz

40

Page 41

Mauvaises caractéristiques de soudage

Cause :

Remède :

Paramètres incorrects

Vérifier les réglages

Cause :

Remède :

La torche de soudage devient très chaude

Cause:

Solution:

Posrosité de la soudure

Cause :

Solution :

Cause :

Solution :

Cause :

Solution :

Cause :

Solution :

Connexion à la masse incorrecte

Vérifier la polarité de la connexion à la masse et de la borne

la torche n’a pas les dimensions suffisantes

respecter la durée maximale de fonctionnement et les limites de

charge

formation de projections dans la buse à gaz, d’où une protection gazeuse insuffisante de la soudure

enlevez les projections de soudure

trous dans le tuyau de gaz de protection ou mauvais raccordement de

ce même tuyau

changez le tuyau de gaz de protection

les joints toriques se trouvant au niveau des raccordements sont

coupés ou défectueux

changez les joints toriques

humidité ou condensation dans la conduite de gaz de protection

séchez la conduite de gaz de protection

FR

Cause :

Solution :

Cause :

Solution :

Mauvaises caractéristiques d’amorçage

Cause:

Solution:

Cause:

Solution:

La buse de gaz se fissure

Cause :

Solution :

courant trop faible ou trop important du gaz de protection

corrigez le courant du gaz de protection

vous avez utilisé une trop grande quantité d’antiagglomérant

enlevez l’excédent d’antiagglomérant / utilisez moins d’antiag-

glomérant

L’électrode en tungstène n’est pas adaptée (par ex. électrode WP

pour un soudage DC)

Utiliser une électrode en tungstène adaptée

L’écrou tendeur, la lentille de gaz ou la douille de serrage sont desserrés

Resserrer l’écrou tendeur, la lentille de gaz ou la douille de serrage

L'électrode en tungstène ne sort pas suffisamment de la buse de gaz

Faire davantage sortir l'électrode en tungstène de la buse de gaz

41

Page 42

Maintenance, entretien et élimination

Entretien et

maintenance

Élimination des

déchets

42

L'élimination doit être réalisée conformément aux prescriptions nationales et

régionales en vigueur.

Page 43

Caractéristiques techniques

Intensité de soudage

à

10 min / 40°C

(104°F)

DC

TTG 1600

refroidissement par gaz

I (Ampère) 15 % f.m.* 160

35 % f.m.* 110

60 % f.m.* 80

100 % f.m.* 60

Norme EN 439 EN 439

[mm (in.)] 1,0 - 3,2 (.039 - .126) 1,0 - 4,0 (.039 - .158)

[m (ft. + in.)] 4,0 / 8,0 (13 + 1.48 / 26 +

2.96)

f.m.* facteur de marche

Mesure de tension (V-Peak) :

pour les torches utilisées manuellement : 113 V

-

REMARQUE!

TTG 2200 S

refroidissement par gaz

15 % f.m.* 220

35 % f.m.* 150

60 % f.m.* 110

100 % f.m.* 90

4,0 / 8,0 (13 + 1.48 / 26 +

2.96)

FR

A observer pour les chalumeaux TTG 1600 A / AF: les indications de courant de

soudage sont valables en cas d’emploi de tuyères à gaz d’une longueur de 33

mm.

En cas d’utilisation de lentilles à gaz de tuyères à gaz de 22 mm, les indications

de courant de soudage diminuent de jusqu’à 20%.

Ce produit satisfait aux exigences de la norme IEC 60974-7.

43

Page 44

44

Page 45

Indice

In generale 46

In generale 46

Sicurezza 46

Installazione e messa in funzione 47

Messa in funzione 47

Torcia per saldatura TIG con valvola del gas - S 48

Torcia per saldatura TIG con potenziometro - Pot 49

JobMaster TIG 50

Sistema con pezzo sostituibile 52

Sistema con pezzo sostituibile A 52

Sistema con pezzo sostituibile P 53

Diagnosi e risoluzione degli errori 54

Diagnosi degli errori 54

Cura, manutenzione e smaltimento 56

Cura e manutenzione 56

Smaltimento 56

Dati tecnici 57

IT

45

Page 46

In generale

In generale Le torce per saldatura TIG con valvola del gas (S) e le torce per saldatura TIG

con potenziometro (Pot) sono adatte alla saldatura di CrNi e acciaio e si distinguono per la varietà delle versioni.

È possibile adattare le torce per saldatura alle lavorazioni più svariate e si dimostrano particolarmente efficaci nella produzione in serie e nella lavorazione singola

manuale, nonché nell’impiego nelle officine.

Sicurezza

PERICOLO!

I lavori effettuati in modo non corretto possono causare gravi danni alle persone

e alle cose.

Gli interventi descritti possono essere svolti soltanto dal personale specializzato!

Attenersi alle istruzioni contenute nel documento allegato „Norme di sicurezza“.

PERICOLO!

Uno schock elettrico può avere esiti mortali.

Effettuare gli interventi descritti soltanto se

l‘interruttore di rete della saldatrice è in posizione - O -

▶

la saldatrice è staccata dalla rete.

▶

PERICOLO!

Uno schock elettrico può avere esiti mortali.

La pulizia del cannello di saldatura e il controllo dei suoi componenti può avvenire soltanto quando l‘interruttore di rete della saldatrice è in posizione - O -.

PRUDENZA!

46

Pericolo di scottature a causa del forte riscaldamento del cannello durante il

funzionamento.

La pulizia del cannello di saldatura e il controllo dei suoi componenti può avvenire soltanto quando il cannello è freddo.

PRUDENZA!

Pericolo di danni personali per insufficienza di collegamenti.

Tutti i cavi, i condotti e i tubi devono essere solidi, integri, isolati e adeguatamente dimensionati.

Page 47

Installazione e messa in funzione

1

2

3

0

°

1

2

d

d

3

2

3

1

Messa in funzione

AVVERTENZA!

Prima di ogni messa in funzione controllare il corretto posizionamento del collegamento elettrico e dell’attacco del gas.

1

3

2

IT

4

Torcia per saldatura TIG con valvola

del gas:: TTG 1600 / 2200 ... S

Possibilità di funzionamento con i generatori seguenti:

TransPocket

-

TransPuls Synergic (escluse le ver-

-

sioni CMT e Remote)

47

Page 48

2

3

1

5

*

Gas

Torcia per saldatura TIG con potenziometro: TTG 1600 ... Pot

Possibilità di funzionamento solo con i

generatori seguenti:

TransPocket 1500 TIG (collegare il

-

gas inerte direttamente al generatore)

Torcia per saldatura TIG con valvola del gas - S

6

Torcia per saldatura TIG:: TTG 1600

FS/TL, TTG 1600 FS/UD

Possibilità di funzionamento solo con i

generatori seguenti:

AccuPocket 150/400 TIG (colle-

-

gare il gas inerte direttamente al

generatore)

AVVERTENZA!

La frequente piegatura della torcia flessibile può provocare danni duraturi.

1

2

* solo per varianti „F“

48

Page 49

3

2

Gas

1

*

0 = min

9 = max

1

2

3

4

5

Installare la torcia per saldatura

1

Aprire la valvola del gas: il flusso del gas ha inizio

2

Accensione a contatto

3

Terminare il processo di saldatura:

4

sollevare la torcia per saldatura: l’arco voltaico si spegne

-

chiudere la valvola del gas

-

4

IT

Torcia per saldatura TIG con potenziometro Pot

AVVERTENZA!

La frequente piegatura della torcia flessibile può provocare danni duraturi.

1

* solo per varianti „F“

2

49

Page 50

3

TCS

Installare la torcia per saldatura

1

Regolare la corrente (è possibile anche durante il processo di saldatura):

2

0 = corrente di saldatura min.

-

9 = corrente di saldatura max.

-

Mettere a contatto il pezzo da lavorare con l’elettrodo al tungsteno:

3

il flusso del gas ha inizio

-

l’arco voltaico si accende

-

Terminare il processo di saldatura con la funzione „TCS - TIG Comfort Stop“

4

4

(vedere le istruzioni per l’uso TP 1500)

JobMaster TIG Mediante il tasto „Mode“ selezionare uno dei seguenti parametri della fuente de

corriente:

Regolare i parametri mediante funzione up/down

Formazione della calotta - condizione necessaria:

Sistema di saldatura TIG-AC

-

Intervallo mediante - Condizione necessaria:

Funzionamento standard a 4 tempi

-

Parametro SFS si trova su „OFF“ (regolazione in fabbrica)

-

AVVERTENZA!

La frequente piegatura della torcia flessibile può provocare danni duraturi

(nessuna garanzia).

50

Page 51

*

1

+

-

1

+

-

2

+

-

1

+

-

2

l

1

l

2

2

* solo per varianti „F“

3 4

5

IT

6

51

Page 52

Sistema con pez-

1

2

3

4

5

6

*

1

2

3

4

5

6

*

*

1

4

2

3

**

30°

2

1

d

d

3

1

d

2

zo sostituibile

1

2

Sistema con pezzo sostituibile A

Sistema con pezzo sostituibile A: Applicare

l‘ugello del gas

Sistema con pezzo sostituibile P: Avvitare l‘ugello del gas

AVVERTENZA!

Pericolo di danno alla filettatura.

Stringere il dado di tensione e il limitatore del gas solo leggermente.

1

2

3

4

52

Page 53

* manicotto impermeabile in gomma sostituibile solo per TTG 2200 A

1

2

3

4

5

6

2

3

*

2

3

4

1

5

2

30°

1

d

d

3

1

d

2

** A seconda della versione del cannello di saldatura, si può utilizzare al pos-

to del dado di tensione un limitatore del gas.

Sistema con pezzo sostituibile P

1

2

IT

* solo per limitatore del gas

3

4

53

Page 54

Diagnosi e risoluzione degli errori

Diagnosi degli

errori

Impossibile collegare il cannello di saldatura

Causa:

Risoluzione:

Corrente di saldatura assente

L‘interruttore di rete è acceso, le spie della saldatrice sono accese, il gas inerte è

presente

Causa:

Risoluzione:

Causa:

Risoluzione:

Causa:

Risoluzione:

Causa:

Risoluzione:

Nessuna funzione del potenziometro

Interruttore di rete inserito, spie sul generatore accese, gas inerte presente

La chiusura a baionetta si deforma

Sostituire la chiusura a baionetta

collegamento a massa sbagliato

controllare le polarità del collegamento a massa e il morsetto

il cavo di corrente nel cannello di saldatura è interrotto

sostituire il cannello

Elettrodo al tungsteno puro allentato

Fissare l’elettrodo al tungsteno puro tramite la chiusura del

cannello

Pezzi soggetti a usura allentati

Fissare i pezzi soggetti a usura

Causa:

Risoluzione:

Gas inerte assente

Tutte le altre funzioni sono disponibili.

Causa:

Risoluzione:

Causa:

Risoluzione:

Causa:

Risoluzione:

Causa:

Risoluzione:

Causa:

Risoluzione:

Collegamenti a spina „Potenziometro / Cavo di comando / Generatore“ difettosi

Controllare i collegamenti a spina / Inviare il generatore o la

torcia per saldatura all’Assistenza

bombola del gas vuota.

sostituire la bombola del gas.

riduttore di pressione del gas difettoso.

sostituire il riduttore di pressione del gas.

il tubo del gas è smontato, danneggiato, piegato.

montare, sostituire, raddrizzare il tubo del gas.

torcia per saldatura guasta.

sostituire la torcia per saldatura.

valvola magnetica del gas difettosa.

sostituire la valvola magnetica del gas.

54

Page 55

Proprietà di saldatura scarse

Causa:

Risoluzione:

Parametri di saldatura errati.

Controllare le impostazioni.

Causa:

Risoluzione:

Il cannello di saldatura diventa molto caldo

Causa:

Risoluzione:

Porosità del giunto saldato

Causa:

Risoluzione:

Causa:

Risoluzione:

Causa:

Risoluzione:

Causa:

Risoluzione:

Collegamento a massa errato.

Controllare la polarità del collegamento a massa e del morset-

to.

cannello di saldatura sottodimensionato

rispettare il tempo d’accensione e i limiti di carico

formazione di spruzzi nell‘ugello del gas perciò insufficiente

protezione con il gas del giunto saldato

eliminare gli spruzzi di saldatura

fori nel tubo del gas inerte o allacciamento insufficiente del tubo del gas inerte

sostituire il tubo del gas inerte

le guarnizioni OR degli attacchi sono rovinate o difettose

sostituire le guarnizioni OR

umidità / condensato nel tubo del gas inerte

asciugare il tubo del gas inerte

IT

Causa:

Risoluzione:

Causa:

Risoluzione:

Proprietà d’accensione non efficaci

Causa:

Risoluzione:

Causa:

Risoluzione:

L'ugello del gas si crepa

Causa:

Risoluzione:

flusso troppo forte o debole del gas inerte

correggere il flusso del gas inerte

e‘ stato applicato troppo agente distaccante

eliminare l‘agente distaccante in eccesso / applicare meno

agente distaccante

Elettrodo al tungsteno puro non adatto (ad esempio, elettrodo

WP per saldatura DC)

Utilizzare un elettrodo al tungsteno puro adatto

Dado di bloccaggio, limitatore del gas o bussola di serraggio allentati

Fissare il dado di bloccaggio, il limitatore del gas o la bussola di

serraggio

l'elettrodo al tungsteno non sporge abbastanza sull'ugello del

gas.

far sporgere maggiormente l'elettrodo al tungsteno sull'ugello

del gas.

55

Page 56

Cura, manutenzione e smaltimento

Cura e manutenzione

Smaltimento Lo smaltimento va eseguito unicamente nel rispetto delle disposizioni nazionali e

regionali vigenti.

56

Page 57

Dati tecnici

Corrente di saldatura

a

10 min / 40°C

(104°F)

DC

TTG 1600

raffreddato a gas

I (Ampere) 15 % TA* 160

35 % TA* 110

60 % TA* 80

100 % TA* 60

Norma EN 439 EN 439

[mm (in.)] 1,0 - 3,2 (.039 - .126) 1,0 - 4,0 (.039 - .158)

[m (ft. + in.)] 4,0 / 8,0 (13 + 1.48 / 26 +

2.96)

TA* tempo di accensione

Taratura della tensione (V-Peak):

per cannelli di saldatura manuali: 113 V

-

AVVERTENZA!

TTG 2200 S

raffreddato a gas

15 % TA* 220

35 % TA* 150

60 % TA* 110

100 % TA* 90

4,0 / 8,0 (13 + 1.48 / 26 +

2.96)

IT

Per i cannelli di saldatura TTG 1600 A / AF attenzione: I dati relativi alla corrente di saldatura valgono se si utilizzano ugelli a gas della lunghezza di 33 mm.

Se si usano delle lenti gas e ugelli a gas da 22 mm i valori relativi alla corrente di

saldatura si abbassano fino al 20 %.

Questo prodotto è conforme allo standard IEC 60974-7.

57

Page 58

58

Page 59

Tabla de contenido

Generalidades 60

Generalidades 60

Seguridad 60

Instalación y puesta en servicio 61

Colocação em funcionamento 61

Antorcha de soplete TIG - S 62

Antorcha TIG con potenciómetro - Pot 63

JobMaster TIG 64

Sistema de desgaste 66

Sistema de desgaste A 66

Sistema de desgaste P 67

Diagnóstico de errores, solución de errores 68

Diagnóstico de errores 68

Cuidado, mantenimiento y eliminación 70

Cuidado y mantenimiento 70

Eliminación 70

Datos técnicos 71

ES

59

Page 60

Generalidades

Generalidades Las antorchas de soplete TIG (S) y las antorchas TIG con potenciómetro (Pot) re-

sultan adecuadas para la soldadura de CrNi y acero y se caracterizan por la variedad de sus versiones.

Las antorchas se pueden adaptar a los más diferentes planteamientos de las

tareas y muestran sus ventajas de forma óptima en la producción manual en serie

e individual, así como en el ámbito de los talleres.

Seguridad

¡PELIGRO!

Los trabajos realizados defectuosamente pueden causar daños personales y

materiales graves.

¡Las actividades descritas sólo deben ser realizadas por personal técnico formado! Tenga en cuenta el documento adjuntado „Normas de seguridad.

¡PELIGRO!

Un electrochoque puede ser mortal.

Realizar las actividades descritas sólo cuando:

el interruptor de red de la fuente de corriente se encuentre en posición - O -

▶

la fuente de corriente esté desconectada de la red.

▶

¡PELIGRO!

Un electroschock puede ser mortal.

Antes de la limpieza del soplete para soldar y de comprobar sus componentes,

colocar el interruptor de red de la fuente de corriente en posición - O -.

¡PRECAUCIÓN!

60

Riesgo de quemadura como consecuencia del soplete utilizado y altamente calentado.

La limpieza del soplete y la comprobación de sus componentes, sólo deberá realizarse estando este refrigerado.

¡PRECAUCIÓN!

Riesgo de lesión a través de conexiones insuficientes.

Todos los cables, tuberías y paquetes de latiguillos tienen que estar fijos, aislados

sin deterioros y suficientemente dimensionados.

Page 61

Instalación y puesta en servicio

1

2

3

0

°

1

2

d

d

3

2

3

1

Colocação em

funcionamento

¡OBSERVACIÓN!

Antes de cada colocação em funcionamento controlar o assento correto da

conexão de corrente e da conexão de gás.

1

3

2

ES

4

Tocha TIG-corrediça de gás: TTG

1600 / 2200 ... S

Possibilidade de operação com as seguintes fontes de solda:

TransPocket

-

TransPuls Synergic (exceto Varian-

-

te e Remota CMT)

61

Page 62

2

3

1

5

*

Gas

Tocha-TIG com potenciômetro: TTG

1600 ... Pot

Possibilidade de operação somente nas

seguintes fontes de solda:

TransPocket 1500 TIG (gás inerte

-

conectar diretamente na fonte de

solda)

Antorcha de soplete TIG - S

6

Antorcha TIG con: TTG 1600 FS/TL,

TTG 1600 FS/UD

Posibilidad de servicio sólo en la siguiente fuente de corriente:

AccuPocket 150/400 TIG (conec-

-

tar el gas protector directamente

en la fuente de corriente)

¡OBSERVACIÓN!

Un doblado frecuente de las antorchas flexibles puede provocar daños de

carácter permanente.

1

* sólo para variantes “F“

2

62

Page 63

3

2

Gas

1

*

0 = min

9 = max

1

2

3

4

5

Preparar la antorcha

1

Abrir el soplete: El flujo de gas comienza

2

Cebado por contacto

3

Finalizar el proceso de soldadura:

4

Elevar la antorcha: El arco voltaico se interrumpe

-

Cerrar el soplete

-

4

ES

Antorcha TIG

con potenciómetro - Pot

¡OBSERVACIÓN!

Un doblado frecuente de las antorchas flexibles puede provocar daños de

carácter permanente.

1

* sólo para variantes “F“

2

63

Page 64

3

TCS

Preparar la antorcha

1

Ajustar la corriente (también es posible durante el proceso de soldadura):

2

0 = min. corriente de soldadura

-

9 = max. corriente de soldadura

-

Tocar la pieza de trabajo con el electrodo de tungsteno:

3

El flujo de gas comienza

-

El arco voltaico se enciende

-

Finalizar el proceso de soldadura mediante la función „TCS - Tig-Comfort-

4

4

Stop“ (ver el manual de instrucciones TP 1500)

JobMaster TIG Por medio de la pulsador „Mode“ seleccionar uno de los siguientes parámetros en

la fuente de corriente:

Ajustar los parámetros por medio de la función Up/Down

Formación de calota - condición previa:

Procedimiento de soldadura TIG-A

-

Reducción intermedia - condición previa:

Operación estándar de 4 tiempos

-

Parámetro de configuración SFS debe estar en “OFF“ (ajuste de fábrica)

-

¡OBSERVACIÓN!

Un doblado frecuente de las antorchas flexibles puede provocar daños de

carácter permanente (no hay garantia).

64

Page 65

*

1

+

-

1

+

-

2

+

-

1

+

-

2

l

1

l

2

* sólo para variantes “F“:

3 4

2

ES

5

6

65

Page 66

Sistema de des-

1

2

3

4

5

6

*

1

2

3

4

5

6

*

*

1

4

2

3

**

30°

2

1

d

d

3

1

d

2

gaste

1

2

Sistema de desgaste A

Sistema de desgaste A: Inyector de gas insertado

Sistema de desgaste P: Inyector de gas roscado

¡OBSERVACIÓN!

Riesgo de dañar la rosca.

Apretar sólo ligeramente la tuerca de sujeción resp. la lente gaseosa.

1

2

3

4

66

Page 67

* manguito obturador intercambiable sólo para TTG 2200 A

1

2

3

4

5

6

2

3

*

2

3

4

1

5

2

30°

1

d

d

3

1

d

2

** Dependiendo del modelo del soplete para soldar, en lugar de la tuerca de

sujeción se puede utilizar una lente gaseosa.

Sistema de desgaste P

1

2

ES

* sólo para lente gaseosa

3

4

67

Page 68

Diagnóstico de errores, solución de errores

Diagnóstico de

errores

No se puede conectar la antorcha

Causa:

Solución:

Sin corriente de soldadura

Interruptor de red conectado, las indicaciones en la fuente de corriente se iluminan, existe gas protector

Causa:

Solución:

Causa:

Solución:

Causa:

Solución:

Causa:

Solución:

No hay función del potenciómetro

Interruptor de red conectado, indicaciones en la fuente de corriente iluminadas,

gas protector disponible

El bloqueo de bayoneta está deformado

Sustituir el bloqueo de bayoneta

Conexión a masa defectuosa

Comprobar la polaridad de la conexión a masa y del contacto

Cable de corriente en el soplete de soldadura interrumpido

Cambiar soplete

El electrodo de tungsteno está suelto

Apretar el electrodo de tungsteno por medio de la caperuza de

antorcha

Las piezas de desgaste están sueltas

Apretar las piezas de desgaste

Causa:

Solución:

No hay gas protector

Todas las demás funciones están disponibles

Causa:

Solución:

Causa:

Solución:

Causa:

Solución:

Causa:

Solución:

Causa:

Solución:

Uniones enchufables „Potenciómetro/cable de control/fuente de corriente“ defectuosas

Comprobar la unión enchufable/enviar la fuente de corriente o la

antorcha al servicio

Bombona de gas vacía

Cambiar la bombona de gas

Regulador de presión de gas defectuoso

Cambiar el regulador de presión de gas

Manguera de gas no montada, dañada o doblada

Montar, redoblar o cambiar la manguera de gas

Antorcha defectuosa

Sustituir la antorcha

Electroválvula de gas defectuosa

Sustituir la electroválvula de gas

68

Page 69

Propiedades de soldadura pobres

Causa:

Solución:

Parámetros de soldadura incorrectos.

Comprobar los ajustes.

Causa:

Solución:

El soplete se caliente demasiado

Causa:

Solución:

Porosidad del cordón de soldadura

Causa:

Solución:

Causa:

Solución:

Causa:

Solución:

Causa:

Solución:

Conexión de masa errónea.

Comprobar la polaridad de la conexión de masa y del borne.

Dimensiones insuficientes del soplete

Observar la duración de ciclo de trabajo y los límites de carga

Formación de proyecciones en la boquilla de gas, a través de ello,

protección de gas insuficiente del cordón de soldadura

Eliminar las proyecciones de soldadura

Agujeros en el tubo flexible de gas protector o conexión del tubo fle-

xible de gas no exacta

Cambiar el tubo flexible de gas

Las juntas tóricas de las conexiones están cortadas o defectuosas

Cambiar juntas tóricas

Humedad / Condensación en la tubería de gas protector

Secar la tubería de gas protector

ES

Causa:

Solución:

Causa:

Solución:

Pobres propiedades de cebado

Causa:

Solución:

Causa:

Solución:

La tobera de gas se está agrietando.

Causa:

Solución:

Corriente de gas muy débil o muy fuerte

Corregir la corriente del gas protector

Se ha aplicado demasiado agente separador

Eliminar el agente separador sobrante / aplicar menos agente separa-

dor

Electrodo de tungsteno inadecuado (por ejemplo, electrodo WP para

soldadura DC)

Utilizar un electrodo de tungsteno adecuado

Tuerca tensora, lente de gas o casquillo tensor suelto

Apretar la tuerca tensora, la lente de gas o el casquillo tensor

El electrodo de tungsteno no sobresale suficientemente de la tobera

de gas.

Dejar que el electrodo de tungsteno sobresalga más de la tobera de

gas.

69

Page 70

Cuidado, mantenimiento y eliminación

Cuidado y mantenimiento

Eliminación Efectuar la eliminación observando las normas nacionales y regionales aplica-

bles.

70

Page 71

Datos técnicos

Corriente de soldadura

con

10 min / 40°C (104°F)

DC

DC* Duración de ciclo de trabajo

Dimensionado de tensión (V-Peak):

-

¡OBSERVACIÓN!

Para los sopletes TTG 1600 A / AF observar: Las indicaciones de corriente de

soldadura se aplican al utilizar inyectores de gas con una longitud de 33 mm.

Al utilizar lentes gaseosas y inyectores de gas con una longitud de 22 mm las indicaciones de corriente de soldadura se reducen en hasta un 20 %.

TTG 1600

refrigerador por gas

I (Ampere) 15 % DC* 160

35 % DC* 110

60 % DC* 80

100 % DC* 60

Norm EN 439 EN 439

[mm (in.)] 1,0 - 3,2 (.039 - .126) 1,0 - 4,0 (.039 - .158)

[m (ft. +

in.)]

para soplete de guiado manual: 113 V

4,0 / 8,0 (13 + 1.48 / 26 +

2.96)

TTG 2200 S

refrigerador por gas

15 % DC* 220

35 % DC* 150

60 % DC* 110

100 % DC* 90

4,0 / 8,0 (13 + 1.48 / 26 +

2.96)

ES

El producto cumple los requisitos de la norma IEC 60974-7.

71

Page 72

72

Page 73

Índice

Informações gerais 74

Informações gerais 74

Segurança 74

Instalação e colocação em funcionamento 75

Comissionamento 75

Tocha de válvula de gás TIG - S 76

Tocha TIG com o potenciômetro - Pot 77

JobMaster TIG 78

Sistema de peça de desgaste 80

Sistema de peça de desgaste A 80

Sistema de peça de desgaste P 81

Diagnóstico de erro, eliminação de erro 82

Diagnóstico de Falhas 82

Conservação, Manutenção e Descarte 84

Conservação e manutenção 84

Descarte 84

Dados técnicos 85

PT-BR

73

Page 74

Informações gerais

Informações gerais

Segurança

A tocha de válvula de gás TIG (S) e a tocha de solda TIG com potenciômetro

(Pot) são adequadas para a soldagem de CrNi e aço e se destacam pelas versões

variadas.

As tochas de solda podem ser adaptadas às mais diferentes tarefas e dão bons

resultados na produção manual em série e individual, assim como na área de oficinas.

PERIGO!

Trabalhos executados de forma incorreta podem causar danos graves a pessoas

e materiais.

As atividades descritas a seguir deverão ser executadas apenas por pessoal

técnico formado! Respeite o documento em anexo „Diretrizes de segurança“.

PERIGO!

Um choque elétrico pode ser fatal.

Executar as atividades descritas somente se:

o interruptor de rede da fonte de solda estiver na posição - O -

▶

a fonte de solda estiver desligada da rede.

▶

PERIGO!

Um choque elétrico pode ser fatal.

Antes de efetuar a limpeza da tocha de solda e a verificação dos seus componentes, colocar o interruptor da fonte de solda na posição - O -.

CUIDADO!

Perigo de queimadura devido à operação com a tocha de solda muito aquecida.

Efetuar a limpeza da tocha de solda e a verificação dos seus componentes

apenas quando a mesma estiver fria.

CUIDADO!

Perigo de lesão devido a ligações insuficientes.

Todos os cabos, tubagens e jogos de mangueiras devem estar fixos, intactos, isolados e ter dimensões adequadas.

74

Page 75

Instalação e colocação em funcionamento

1

2

3

0

°

1

2

d

d

3

2

3

1

Comissionamento

AVISO!

Antes de cada comissionamento, controlar o assento correto da conexão de corrente e da conexão de gás inerte.

1

3

2

PT-BR

4

Tocha de válvula de gás TIG: TTG

1600 / 2200 ... S

Possibilidade de operação com as seguintes fontes de solda:

TransPocket

-

TransPuls Synergic (exceto Varian-

-

te e Remota CMT)

75

Page 76

2

3

1

5

*

Gas

Tocha TIG com potenciômetro: TTG

1600 ... Pot

Possibilidade de operação somente nas

seguintes fontes de solda:

TransPocket 1500 TIG (conectar o

-

gás de proteção diretamente à fonte de solda)

Tocha de válvula

de gás TIG - S

6

Tocha TIG: TTG 1600 FS/TL, TTG

1600 FS/UD

Possibilidade de operação somente nas

seguintes fontes de solda:

AccuPocket 150/400 TIG (conec-

-

tar o gás de proteção diretamente

à fonte de solda)

AVISO!

Flexão constante das tochas de solda flexíveis pode causar danificações permanentes.

1

* somente para as versões „F“

2

76

Page 77

3

2

Gas

1

*

0 = min

9 = max

1

2

3

4

5

Ajustar a tocha de solda

1

Abrir a corrediça de gás: Inicia-se o fluxo de gás

2

Ignição de contato

3

Término do processo de soldagem:

4

Levantar a tocha de solda: o arco voltaico se rompe

-

Fechar a válvula de gás

-

4

Tocha TIG com o

potenciômetro Pot

AVISO!

Flexão constante das tochas de solda flexíveis pode causar danificações permanentes.

1

* somente para as versões „F“

2

PT-BR

77

Page 78

3

TCS

Ajustar a tocha de solda

1

Ajustar a corrente (também possível durante o processo de soldagem):

2

0 = corrente de soldagem mín.

-

9 = corrente de soldagem máx.

-

Tocar a peça de trabalho com o eletrodo de tungstênio:

3

o fornecimento de gás é suspenso

-

o arco voltaico entra em ignição

-

Finalizar o processo de soldagem através da função „TCS - TIG-Comfort-

4

4

Stop“ (vide manual de instruções TP 1500)

JobMaster TIG Através da tecla „Mode“, selecione um dos seguintes parâmetros:

Ajustar o parâmetro através da função up/down

Pré-requisito para a formação de calota:

Método de soldagem „TIG-CA“

-

Pré-requisito para a redução intermediária:

Modo de operação „Operação de 4 ciclos padrão“

-

Parâmetro Setup SFS em „OFF“ (configuração de fábrica)

-

AVISO!

Flexão constante das tochas de solda flexíveis pode causar danificações permanentes (sem reivindicação de garantia).

78

Page 79

*

1

+

-

1

+

-

2

+

-

1

+

-

2

l

1

l

2

* somente para as versões „F“

3 4

2

PT-BR

5

6

79

Page 80

Sistema de peça

1

2

3

4

5

6

*

1

2

3

4

5

6

*

*

1

4

2

3

**

30°

2

1

d

d

3

1

d

2

de desgaste

1

2

Sistema de peça

de desgaste A

Sistema de peça de desgaste A: Bico de gás

conectado

Sistema de peça de desgaste P: Bico de gás parafusado

AVISO!

Perigo de dano da rosca.

Apertar a porca de aperto ou a lente de gás levemente.

1

2

3

4

80

Page 81

* Luva de vedação de borracha substituível somente para TTG 2200 A

1

2

3

4

5

6

2

3

*

2

3

4

1

5

2

30°

1

d

d

3

1

d

2

** Dependendo da versão da tocha de solda, ao invés da porca de aperto po-

de ser usada uma lente de gás

Sistema de peça

de desgaste P

1

2

* somente para lente de gás

3

4

PT-BR

81

Page 82

Diagnóstico de erro, eliminação de erro

Diagnóstico de

Falhas

Não é possível conectar a tocha de solda

Causa:

Solução:

Sem corrente de soldagem

Interruptor da rede ligado, indicações acesas na fonte de solda, gás de proteção

disponível

Causa:

Solução:

Causa:

Solução:

Causa:

Solução:

Causa:

Solução:

sem função do potenciômetro

Interruptor da rede ligado, indicações acesas na fonte de solda, gás de proteção

disponível

Fecho da baioneta dobrado

Substituir o fecho da baioneta

Conexão de massa incorreta

Verificar a conexão de massa e o borne de conexão quanto à pola-

ridade

Cabo de corrente na tocha de solda interrompido

Substituir a tocha de solda

Eletrodo de tungstênio solto

Apertar o eletrodo de tungstênio com a capa da tocha

Peças de desgaste soltas

Apertar peças de desgaste

Causa:

Solução:

Sem gás de proteção

Todos as outras funções existentes

Causa:

Eliminação:

Causa:

Eliminação:

Causa:

Eliminação:

Causa:

Eliminação:

Causa:

Eliminação:

Conectores „potenciômetro / linha de controle / fonte de solda“ defeituosos

Verificar conectores / fonte de solda ou tocha de solda para o serviço

Cilindro de gás vazio

Substituir o cilindro de gás

Redutor de pressão de gás com defeito

Substituir o redutor de pressão de gás

Mangueira de gás não montada ou com defeito, dobrada

Montar, desentortar ou trocar a mangueira de gás

Tocha de solda com defeito

Substituir a tocha de solda

Válvula solenóide de gás com defeito

Substituir a válvula solenóide de gás

82

Page 83

Características de soldagem ruins

Causa:

Solução:

Parâmetros de soldagem incorretos

Verificar os ajustes

Causa:

Solução:

A tocha de solda esquenta muito

Causa:

Solução:

Porosidade na costura de soldagem

Causa:

Solução:

Causa:

Solução:

Causa:

Solução:

Causa:

Solução:

Conexão de massa incorreta

Verificar a conexão de massa e o borne quanto à polaridade

Tocha de solda dimensionada muito fraca

Observar o ciclo de trabalho e os limites de carga

Formação de respingos no bico de gás, por isso a proteção de gás da

costura de soldagem é insuficiente

Remover os respingos de solda

Furos na mangueira do gás de proteção ou conexão inadequada da

mangueira de gás de proteção

Substituir a mangueira do gás de proteção

Os O-Rings nas conexões estão cortados ou com defeito

Substituir O-Rings

Umidade / condensado na tubulação de gás de proteção

Secar a tubulação de gás de proteção

PT-BR

Causa:

Solução:

Causa:

Solução:

Características ruins de ignição

Causa:

Solução:

Causa:

Solução:

Rachadura no bico de gás

Causa:

Solução:

Fluxo de gás de proteção forte ou fraco demais

Corrigir o fluxo de gás de proteção

Aplicação de agente separador em excesso

Retirar o agente separador em excesso / aplicar menos agente sepa-

rador

Eletrodo de tungstênio inadequado (por ex., eletrodo WP na soldagem CC)

Utilizar um eletrodo de tungstênio adequado

Porca de aperto, bico de gás ou luva de fixação soltos

Apertar porca de aperto, lente de gás ou luva de fixação

O eletrodo de tungstênio não está longe o suficiente do bico de gás

Afastar o eletrodo de tungstênio do bico de gás

83

Page 84

Conservação, Manutenção e Descarte

Conservação e

manutenção

Descarte O descarte pode ser executado somente de acordo com as determinações nacio-

nais e regionais em vigor.

84

Page 85

Dados técnicos

Corrente de soldagem a

10 min / 40°C

(104°F)

CC

TTG 1600

refrigerado a gás

I (ampère) 15 % CT* 160

35 % CT* 110

60 % CT* 80

100 % CT* 60

Norma EN 439 EN 439

[mm (in.)] 1,0 - 3,2 (.039 - .126) 1,0 - 4,0 (.039 - .158)

[m (ft. + in.)] 4,0 / 8,0 (13 + 1.48 / 26 +

2.96)

CT* Ciclo de trabalho

Medição da tensão (pico V):

para tochas de solda manuais: 113 V

-

AVISO!

TTG 2200 S

refrigerado a gás

15 % CT* 220

35 % CT* 150

60 % CT* 110

100 % CT* 90

4,0 / 8,0 (13 + 1.48 / 26 +

2.96)

PT-BR

Válido para as tochas de solda TTG 1600 A / A F: As indicações da corrente de

soldagem são válidas para o uso de bicos de gás com um comprimento de 33

mm.

No caso de uso de lentes de gás e bicos de gás de 22 mm, as indicações da corrente de soldagem diminuem em até 20%.

O produto está em conformidade com as exigências da norma IEC 60974-7.

85

Page 86

86

Page 87

目录

概述 88

一般说明 88

安全说明 88

安装和调试 89

调试 89

TIG 气阀焊枪 - S 90

带有电位计的 TIG 焊枪 - Pot 91

JobMaster TIG 92

成套易损件 94

成套易损件 A 94

成套易损件 P 95

错误诊断和错误排除 96

错误诊断 96

维护、保养和废料处理 98

维修与保养 98

废料处理 98

技术数据 99

ZH

87

Page 88

概述

一般说明 TIG 气阀焊枪 (S) 和带电位计的 TIG 焊枪 (Pot) 有多种版本可供选择,适用于焊接 CrNi 和

钢。

焊枪的应用范围十分广泛。它们非常适合在车间等场合执行手动连续生产以及一次性作

业。

安全说明

危险!

操作不当可能会造成严重的人身伤害和设备损坏。此处介绍的操作只能由技术熟练、经专

业培训的技术人员执行!请遵守随附文档“安全规程”中提供的说明。

危险!

电击可能致命。仅在以下几种情况下才能执行操作:

电源主开关位于 - O - 位置,且

▶

电源与输电干线的连接断开。

▶

危险!

电击可能致命。在清洁焊枪及检查其部件之前,请先将电源主开关切换至 - O - 位置。

小心!

在焊接过程中,焊枪会变得非常热 - 存在烫伤的危险!只能在焊枪冷却后,才能清洁焊枪

和检查其部件。

小心!

连接不良可能会造成人身伤害。所有电缆、引线及其他综合管线必须连接牢固、完好无

损、妥善和充分绝缘。

88

Page 89

安装和调试

1

2

3

0

°

1

2

d

d

3

2

3

1

调试

注意!

使用前,先检查通电接口和通气接口是否稳固连接。

1

3

2

ZH

4

TIG 气阀焊枪:TTG 1600/2200 ...S

可与下列电源配合使用:

-

TransPocket

-

TransPuls Synergic(CMT 和 Remote

型号除外)

89

Page 90

2

3

1

5

*

Gas

带有电位计的 TIG 焊枪:TTG 1600 ...Pot

只能与下列电源配合使用:

-

TransPocket 1500 TIG(将保护气体

直连至电源)

TIG 气阀焊枪 - S

6

注意!

频繁折弯挠性燃烧器会造成永久性损坏。

1

带有电位计的 TIG 焊枪:TTG 1600 FS/

TL、TTG 1600 FS/UD

只能与下列电源配合使用:

-

AccuPocket 150/400 TIG(将保护气

体直连至电源)

2

* 仅针对“F”类型

90

Page 91

3

2

Gas

1

*

0 = min

9 = max

1

2

3

4

5

设置焊枪

1

打开气阀:气流开始流动

2

接触式引弧

3

结束焊接过程:

4

-

抬起焊枪:断弧

-

关闭气阀

4

带有电位计的 TIG

焊枪 - Pot

注意!

频繁折弯挠性燃烧器会造成永久性损坏。

1

* 仅针对“F”类型

ZH

2

91

Page 92

3

TCS

设置焊枪

1

调节电流(也可以在焊接过程中调节):

2

-

0 = 最小焊接电流

-

9 = 最大焊接电流

将工件与钨极接触:

3

-

气流开始流动

-

电弧起燃

通过“TCS - TIG-ComfortStop”功能结束焊接(请参见 TP 1500 操作说明)

4

4

JobMaster TIG 使用“模式”按钮选择下列其中一个参数:

使用 Up/Down(上/下)功能设置参数

形成截球形 - 前提条件:

-

TIG-AC 焊接工艺

中间降低 - 前提条件:

-

标准四脉冲模式

-

设置参数 SFS 必须设为“OFF”(关)(出厂设置)

注意!

频繁折弯挠性燃烧器会造成永久性损坏(不保证)。

92

Page 93

*

1

+

-

1

+

-

2

+

-

1

+

-

2

l

1

l

2

* 仅针对“F”类型

3 4

2

ZH

5

6

93

Page 94

成套易损件

1

2

3

4

5

6

*

1

2

3

4

5

6

*

*

1

4

2

3

**

30°

2

1

d

d

3

1

d

2

1

2

成套易损件 A

成套易损件 A:插接式气体喷嘴

成套易损件 P:螺丝拧入式气体喷嘴

注意!

存在螺纹损坏的风险。只需轻轻用力即可拧紧夹紧螺母或气体透镜。

1

2

3

* 可替换的橡胶密封套仅针对 TTG 2200 A

** 根据焊枪设计,可以使用气体透镜来替代夹紧螺母。

4

94

Page 95

成套易损件 P

1

2

3

4

5

6

2

3

*

2

3

4

1

5

2

30°

1

d

d

3

1

d

2

1

2

* 仅针对气体透镜

3

4

ZH

95

Page 96

错误诊断和错误排除

错误诊断

无法连接焊枪

原因:

补救措施:

无焊接电流

主开关处于“打开”状态,电源上的指示灯点亮,保护气体流动

原因:

补救措施:

原因:

补救措施:

原因:

补救措施:

原因:

补救措施:

电位计不能正常工作

主开关处于打开状态,电源上的指示灯点亮,保护气体可用

卡口式固定件折弯

更换卡口式固定件

接地连接存在故障

检查接地连接和地线夹的极性是否正确

焊枪中的载流电缆损坏

更换焊枪

钨极松动

使用焊枪盖帽拧紧钨极

部件松动

拧紧部件

原因:

补救措施:

无保护气体

所有其他功能可用

原因:

措施:

原因:

措施:

原因:

措施:

原因:

措施:

原因:

措施:

焊枪性能差

原因:

措施:

“电位计/控制线/电源”的插入式连接存在故障

检查插入式连接/检修电源或焊枪

气瓶空了

更换气瓶

保护气流量计损坏

更换保护气流量计

气管未安装或受损,弯折

安装、拉直或更换气管

焊枪损坏

更换焊枪

气体磁阀损坏

更换气体磁阀

焊接参数错误

检查设置

96

原因:

措施:

接地连接错误

检查接地连接并检查接线夹极性

Page 97

焊枪变得很热

原因:

补救措施:

焊缝多孔

原因:

补救措施:

焊枪的设计尺寸不能胜任这样的任务

遵守占空比和负载的限制要求

焊渣在气体喷嘴处累积,造成焊缝保护气体不充分

清除焊渣

原因:

补救措施:

原因:

补救措施:

原因:

补救措施:

原因:

补救措施:

原因:

补救措施:

引弧性能差

原因:

补救措施:

原因:

补救措施:

保护气体软管上有孔洞,或其未正确连接

更换保护气体软管

连接点处的 O 形密封圈有切口或存在缺陷

更换 O 形密封圈

保护气体软管内有湿气 / 冷凝水

风干保护气体软管

保护气体流量过高或过低

校正保护气体流量

使用的分离剂过多

除去多余的分离剂 / 使用少量的分离剂

钨极不合适(例如,对于直流焊接使用 WP 电极)

使用合适的钨极

夹紧螺母、气体透镜或夹紧套管松动

拧紧夹紧螺母、气体透镜或夹紧套管

ZH

气体喷嘴上存在裂纹

原因:

补救措施:

钨极从气体喷嘴中伸出的长度不够长

让钨极从气体喷嘴中伸出的长度再长一些

97

Page 98

维护、保养和废料处理

维修与保养

废料处理 按照国家和地区的现行法规对废料进行处理。

98

Page 99

技术数据

10 min / 40°C (104°F)

时的焊接电流范围

DC

TTG 1600

气冷式

I (A) 15 % d.c.*160

35 % d.c.*110

60 % d.c.*80

100 % d.c.*60

标准 EN 439 EN 439

[mm (in)] 1.0 - 3.2 (0.039 - 0.126) 1.0 - 4.0 (0.039 - 0.158)

[m (ft + in)] 4.0 / 8.0 (13 + 1.48 / 26 + 2.96) 4.0 / 8.0 (13 + 1.48 / 26 + 2.96)

d.c.* 占空比

额定电压(峰值电压):

-

对于手动操作焊枪:113 V

TTG 2200 S

气冷式

15 % d.c.*220

35 % d.c.*150

60 % d.c.*110

100 % d.c* 90

注意!

使用 TTG 1600 A / AF 焊枪时:如果使用的是 33 mm 长的气体喷嘴,则上述焊接电流数据

适用。如果使用了气体透镜和 22 mm 长的气体喷嘴,焊接电流数据会减小多达 20 %。

本产品符合 IEC 60974-7 标准。

ZH

99

Page 100

Loading...

Loading...