Operating

Instructions

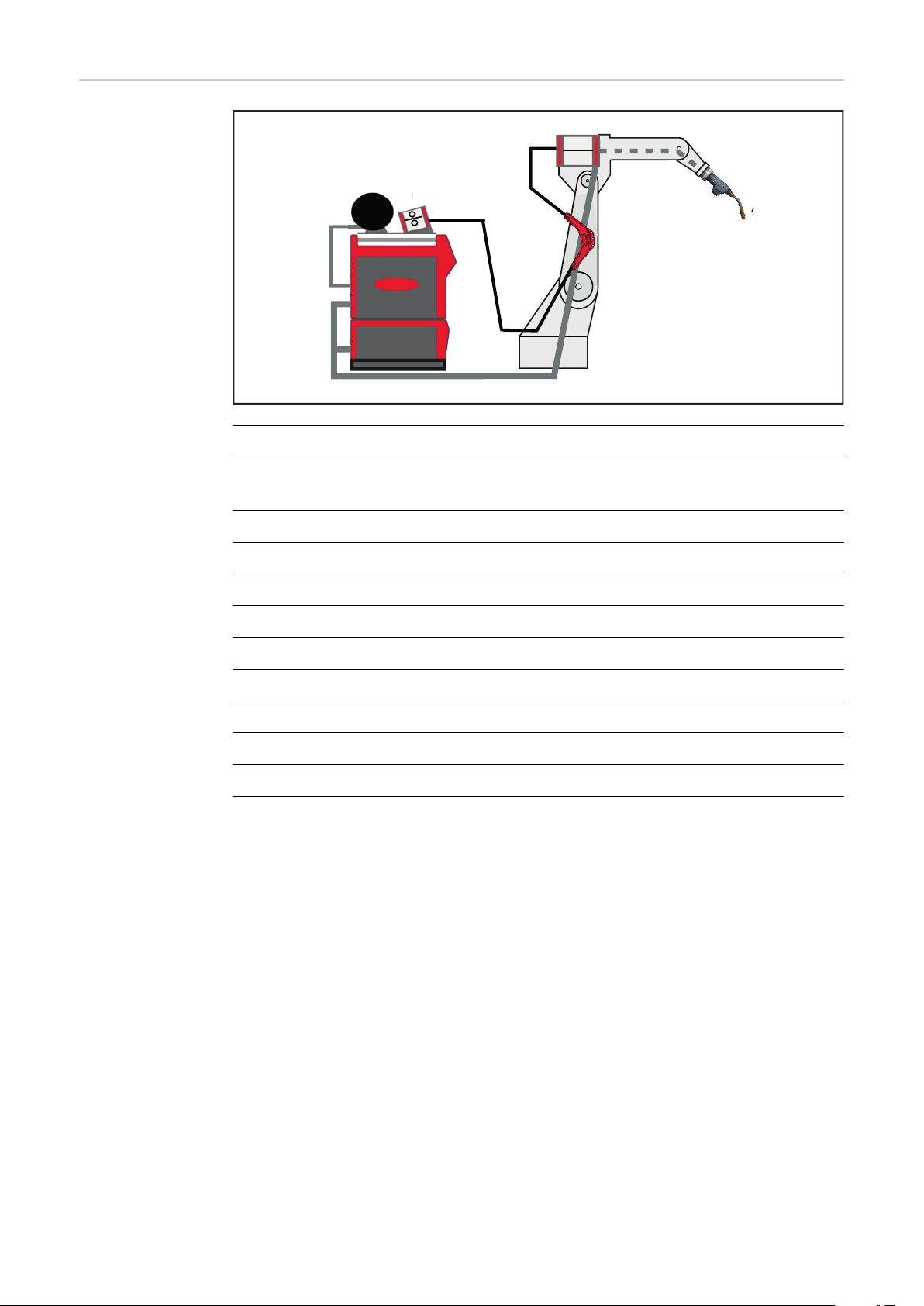

TPS/i Robotics welding system

Pull

PushPull CMT

Operating Instructions

EN

42,0426,0219,EN 024-07032023

Contents

Safety rules 8

Explanation of safety notices 8

General 8

Intended use 9

Environmental conditions 9

Obligations of the operator 9

Obligations of personnel 9

Mains connection 9

Protecting yourself and others 10

Danger from toxic gases and vapours 10

Danger from flying sparks 11

Risks from mains current and welding current 11

Meandering welding currents 13

EMC Device Classifications 13

EMC measures 13

EMF measures 14

Specific hazards 14

Requirement for the shielding gas 15

Danger from shielding gas cylinders 15

Danger from escaping shielding gas 16

Safety measures at the installation location and during transport 16

Safety measures in normal operation 17

Commissioning, maintenance and repair 17

Safety inspection 18

Disposal 18

Safety symbols 18

Data protection 18

Copyright 18

Description of the warning notices on the device 19

EN

System configurations 21

System configurations - conventional robot 23

PowerDrive with wire drum 23

PowerDrive with wire drum and external wirefeeding hose 24

PushPull with 4-roller unreeling wirefeeder and wire drum 25

PushPull with 4-roller unreeling wirefeeder and wirespool 26

PushPull with SB 60i, 4-roller unreeling wirefeeder and wirespool 27

PushPull with 2-roller unreeling wirefeeder, wire drum and external wirefeeding hose 28

CMT with SB 60i, 4-roller unreeling wirefeeder and wire drum 29

CMT with SB 500i, 4-roller unreeling wirefeeder, wire drum and external wirefeeding hose 30

CMT with SB 60i, 4-roller unreeling wirefeeder and wirespool 31

System configurations - PAP 32

PowerDrive with wire drum 32

PushPull with 4-roller unreeling wirefeeder and wire drum 33

PushPull with 4-roller unreeling wirefeeder and wirespool 34

PushPull with 2-roller unreeling wirefeeder and wire drum 35

PushPull with wire buffer, 4-roller unreeling wirefeeder and wire drum 36

PushPull with wire buffer, 4-roller unreeling wirefeeder and wirespool 37

CMT with SB 60i, 4-roller unreeling wirefeeder and wire drum 38

CMT with SB 500i, 4-roller unreeling wirefeeder and wire drum 39

CMT with SB 500i, 4-roller unreeling wirefeeder and wirespool 40

System components 41

SplitBox SB 500i R 43

Device concept 43

Proper use 43

Safety 43

Warning notices on the device 44

3

SplitBox SB 60i R 46

Device concept 46

Proper use 46

Safety 46

Warning notices on the device 47

TPSi wire buffer 49

General 49

CrashBox /i 50

General 50

Note on the correct operation of CrashBoxes 51

Also required for installation 51

Device concept 52

Areas of utilisation 52

Information on repairing CrashBoxes 52

Scope of supply 52

WF Robacta Drive 53

General 53

Warning notices on the device 53

PushPull hosepack 54

General 54

Scope of supply 54

Robot welding torch 55

Safety 55

General 55

WF 25i REEL R /4R, WF 30i REEL R /2R 57

Safety 57

Device concept 57

Application area 57

Proper use 57

Warning notices on the device 58

Interconnecting hosepack 60

General 60

General 60

PowerLiner 61

General 61

WireSense 62

General 62

Requirements 62

How it works 62

WireSense - edge detection 63

WireSense - contour detection 64

Technical details 65

OPT/i camera mount 66

General 66

Drilling template 66

Controls, connections and mechanical components 67

General 69

Safety 69

General 69

SplitBox SB 500i R / SB 500i R PAP 70

Controls, connections, and mechanical components of the SB 500i R 70

Controls, connections, and mechanical components of the SB 500i R PAP 71

SplitBox SB 60i R 73

SB 60i R:Controls, connections, and mechanical components 73

SB 60i R /L:Controls, connections, and mechanical components 74

WF 25i Robacta Drive / WF 60i Robacta Drive CMT 75

Control panel WF 25i Robacta Drive / WF 60i Robacta Drive CMT 75

Status indicators 75

WF 25i REEL R /4R, WF 30i REEL R /2R 77

Control elements, connections and mechanical components 77

Function of the gas-test, wire retract and wire threading buttons 79

4

Function of the gas-test, wire retract and wire threading buttons 79

Assembling system components - conventional robot 81

General 83

Safety 83

Assembly sequence, conventional robot 83

Fitting the SplitBox SB 500i R 84

Fitting the wirefeeder holder 84

Fitting the SB 500i R 84

Fitting the CrashBox /i to the robot 85

Fitting the CrashBox /i to the robot 85

Installing the CrashBox/i Dummy on the robot 86

Fitting the WF Robacta Drive to a conventional robot 88

Fitting the hosepack to the WF Robacta Drive (conventional) 88

Fitting the WF Robacta Drive to the robot (conventional) 89

Fitting the WF Robacta Drive to the robot 90

Optimum hosepack arrangement 91

Fitting the interconnecting hosepack 92

Fitting the Standard interconnecting hosepack to the robot 92

Connecting the MHP W hosepack 93

Connecting the MHP W hosepack 93

Connecting the SplitBox SB 500i R to the system components 96

Safety 96

General 96

Connecting the SplitBox SB 500i R to the system components 96

Assembling system components - PAP robot 99

EN

General 101

Safety 101

Assembly sequence, PAP robot 101

Maximum axis rotation 102

Fitting the SplitBox SB 500i R PAP 103

Fitting the SB 500i R PAP 103

Installing the CrashBox Drive /i PAP on the robot 104

Installing the CrashBox Drive /i PAP on the robot 104

Installing the CrashBox Drive /i PAP Dummy on the robot 105

Fitting the WF Robacta Drive to a PAP robot 107

Fitting the hosepack to the WF Robacta Drive (PAP) 107

Fitting the WF Robacta Drive to the robot (PAP) 108

Fitting the interconnecting hosepack 111

Fitting the PAP interconnecting hosepack to the robot 111

Connecting the SplitBox SB 500i R PAP to the system components 112

Safety 112

General 112

Connecting the SplitBox SB 500i R PAP to the system components 112

Assembling further system components 115

Fitting the SplitBox SB 60i R 117

Fitting the SB 60i R to the robot 117

Fitting the SB 60i R to the balancer 117

Mounting the SB 60i R on the wall 118

Connecting the torch hosepack to the SplitBox SB 60i R 119

Fitting the TPSi wire buffer 120

Fitting the TPSi wire buffer 120

Connecting the control line to the wire buffer 121

Fitting the unreeling wirefeeder 122

Fitting the unreeling wirefeeder 122

Connecting the extension hosepack 123

Connecting the extension hosepack 123

Fitting the torch body to the WF Robacta Drive 125

Fitting the gas-saver nozzle 125

5

Fitting the inner liner inside the torch body 126

Fitting the torch body to the WF Robacta Drive 128

Fitting the OPT/i camera mount 129

Load-bearing capacity of the OPT/i camera mount 129

Safety 129

Fitting the OPT/i camera mount 130

Fitting the inner liner 131

Fitting the inner liner (unreeling wirefeeder - SplitBox SB 500i R) 131

Fitting the inner liner (unreeling wirefeeder- WF Robacta Drive with external wirefeeding

hose)

Fitting the PowerLiner (unreeling wirefeeder - WF Robacta Drive with external wirefeeding hose)

Fitting the inner liner (unreeling wirefeeder - wire buffer) 133

Fitting the inner liner (SplitBox - WF 25i with internal inner liner) 134

Fitting the inner liner (wire buffer - WF Robacta Drive with internal wirefeeding hose) 135

Fitting the inner liner (wire buffer - WF Robacta Drive with external wirefeeding hose) 136

Fitting the inner liner inside the torch hosepack 137

Start-up 139

Inserting/replacing feed rollers 141

General 141

WF 25i Reel 4R: inserting/replacing feed rollers for the 4-roller drive 141

WF 30i Reel 2R: inserting/replacing feed rollers for the 2-roller drive 142

Inserting/replacing the WF 25i Robacta Drive feed rollers 143

Inserting/replacing the WF 60i Robacta Drive CMT feed rollers 145

Feeding in the wire electrode 148

Insulated routing of wire electrode to wirefeeder 148

Feeding in the wire electrode 148

Setting the contact pressure for the WF 25i Robacta Drive 149

Setting the contact pressure for the WF 60i Robacta Drive CMT 150

Start-up 151

Requirements 151

General 151

131

132

Troubleshooting, maintenance and disposal 153

Troubleshooting 155

Safety 155

Fault diagnosis 155

Care, maintenance and disposal 159

General 159

Safety 159

Every start-up 159

Special care of O-rings 159

Whenever the welding torch or torch hosepack is changed 160

Changing the torch hosepack, changing the interconnecting hosepack 160

Every 6 months 160

Recognising faulty wearing parts 161

Replacing the WF 25i Robacta Drive clamping lever 161

Replacing the WF 60i Robacta Drive CMT clamping lever 162

Replacing the WF Robacta Drive gas-saver nozzle 162

Replacing the SB 60i R inner liner 163

Replacing the TPSi wire buffer wire guide 165

Changing the direction of operation of the TPSi wire buffer 166

Replacing the TPSi wire buffer lever 167

Fitting wearing parts to the torch body 168

Fitting wearing parts to the torch body - MTW 700 i 168

Removing the CrashBox PAP from the robot 169

Entsorgung 170

Technical data 171

6

SB 500i R, R left variant, PAP 173

SB 500i R, R left-hand version, PAP 173

SB 60i R 174

SB 60i R 174

CrashBox /i 175

CrashBox /i 175

PushPull hosepack 178

Gas-cooled PushPull hosepacks 178

Water-cooled PushPull hosepacks 179

WF 25i Robacta Drive 181

WF 25i Robacta Drive /G 181

WF 25i Robacta Drive /W 181

WF 60i Robacta Drive CMT 182

WF 60i Robacta Drive CMT /G 182

WF 60i Robacta Drive /W CMT 182

WF 25i REEL R /4R/G/W 184

WF 30i REEL R /2R/G/W 185

Robot welding torch 186

Gas-cooled robot welding torches 186

Water-cooled robot welding torches 187

Interconnecting hosepacks 189

HP 70i 189

HP 95i 189

HP 120i 189

HP 70i, HP PC Cable HD 70 189

EN

7

Safety rules

Explanation of

safety notices

DANGER!

Indicates immediate danger.

If not avoided, death or serious injury will result.

▶

WARNING!

Indicates a potentially hazardous situation.

If not avoided, death or serious injury may result.

▶

CAUTION!

Indicates a situation where damage or injury could occur.

If not avoided, minor injury and/or damage to property may result.

▶

NOTE!

Indicates a risk of flawed results and possible damage to the equipment.

General The device is manufactured using state-of-the-art technology and according to

recognised safety standards. If used incorrectly or misused, however, it can

cause:

injury or death to the operator or a third party,

-

damage to the device and other material assets belonging to the operating

-

company,

inefficient operation of the device.

-

All persons involved in commissioning, operating, maintaining and servicing the

device must:

be suitably qualified,

-

have sufficient knowledge of automated welding, and

-

read and carefully follow these operating instructions as well as the operat-

-

ing instructions for all system components.

The operating instructions must always be at hand wherever the device is being

used. In addition to the operating instructions, attention must also be paid to any

generally applicable and local regulations regarding accident prevention and environmental protection.

All safety and danger notices on the device

must be in a legible state,

-

must not be damaged,

-

must not be removed,

-

must not be covered, pasted or painted over.

-

For the location of the safety and danger notices on the device, refer to the section headed "General" in the operating instructions for the device.

Before commissioning the device, rectify any faults that could compromise

safety.

This is for your personal safety!

8

Intended use The devices and components described in these Operating Instructions are in-

tended exclusively for automated MIG/MAG applications in conjunction with

Fronius components.

Any use above and beyond this purpose is deemed improper. The manufacturer

shall not be held liable for any damage arising from such usage.

Proper use also includes:

Carefully reading and following all the instructions given in the Operating In-

-

structions

Studying and obeying all safety instructions and danger notices carefully

-

Performing all stipulated inspection and servicing work

-

The manufacturer likewise accepts no liability for inadequate or incorrect results.

EN

Environmental

conditions

Obligations of

the operator

Operation or storage of the device outside the stipulated area will be deemed as

not in accordance with the intended purpose. The manufacturer shall not be held

liable for any damage arising from such usage.

Ambient temperature range:

during operation: -10 °C to + 40 °C (14 °F to 104 °F)

-

during transport and storage: -20 °C to +55 °C (-4 °F to 131 °F)

-

Relative humidity:

up to 50% at 40 °C (104 °F)

-

up to 90% at 20 °C (68 °F)

-

The surrounding air must be free from dust, acids, corrosive gases or substances,

etc.

Can be used at altitudes of up to 2000 m (6561 ft. 8.16 in.)

The operator must only allow persons to work with the device who:

are familiar with the fundamental instructions regarding safety at work and

-

accident prevention and have been instructed in how to use the device

have read and understood these operating instructions, especially the sec-

-

tion "safety rules", and have confirmed as much with their signatures

are trained to produce the required results.

-

Checks must be carried out at regular intervals to ensure that operators are

working in a safety-conscious manner.

Obligations of

personnel

Mains connection

Before using the device, all persons instructed to do so undertake:

to observe the basic instructions regarding safety at work and accident pre-

-

vention

to read these operating instructions, especially the "Safety rules" section and

-

sign to confirm that they have understood them and will follow them.

Before leaving the workplace, ensure that people or property cannot come to any

harm in your absence.

Devices with a higher rating may affect the energy quality of the mains due to

their current consumption.

9

This may affect a number device types in terms of:

Connection restrictions

-

-

Criteria with regard to the maximum permissible mains impedance

-

Criteria with regard to the minimum short-circuit power requirement

*)

at the interface with the public grid

*)

*)

see "Technical data"

In this case, the plant operator or the person using the device should check

whether the device may be connected, where appropriate by discussing the matter with the power supply company.

IMPORTANT! Ensure that the mains connection is earthed properly

Protecting yourself and others

Anyone working with the device exposes themselves to numerous risks, e.g.

flying sparks and hot pieces of metal

-

Arc radiation, which can damage eyes and skin

-

Hazardous electromagnetic fields, which can endanger the lives of those us-

-

ing cardiac pacemakers

Risk of electrocution from mains current and welding current

-

Greater noise pollution

-

Harmful welding fumes and gases

-

Suitable protective clothing must be worn when working with the device. The

protective clothing must have the following properties:

Flame-resistant

-

Insulating and dry

-

Covers the whole body, is undamaged and in good condition

-

Safety helmet

-

Trousers with no turn-ups

-

Protective clothing refers to a variety of different items. Operators should:

Protect eyes and face from UV rays, heat and sparks using a protective visor

-

and regulation filter

Wear regulation protective goggles with side protection behind the protect-

-

ive visor

Wear stout footwear that provides insulation even in wet conditions

-

Protect the hands with suitable gloves (electrically insulated and providing

-

protection against heat)

Wear ear protection to reduce the harmful effects of noise and to prevent in-

-

jury

Danger from toxic gases and vapours

10

Keep all persons, especially children, out of the working area while any devices

are in operation or welding is in progress. If, however, there are people in the vicinity:

Make them aware of all the dangers (risk of dazzling by the arc, injury from

-

flying sparks, harmful welding fumes, noise, possible risks from mains current and welding current, etc.)

Provide suitable protective equipment

-

Alternatively, erect suitable safety screens/curtains.

-

The fumes produced during welding contain harmful gases and vapours.

Welding fumes contain substances that cause cancer, as stated in Monograph

118 of the International Agency for Research on Cancer.

Use at-source extraction and a room extraction system.

If necessary, use a welding torch with an integrated extraction device.

Keep your face away from welding fumes and gases.

Fumes and hazardous gases

must not be breathed in

-

must be extracted from the working area using appropriate methods.

-

Ensure an adequate supply of fresh air. Ensure that there is a ventilation rate of

at least 20 m³ per hour at all times.

Otherwise, a welding helmet with an air supply must be worn.

If there is any doubt about whether the extraction capacity is sufficient, the

measured toxic emission values should be compared with the permissible limit

values.

The following components are responsible, amongst other things, for the degree

of toxicity of welding fumes:

Metals used for the workpiece

-

Electrodes

-

Coatings

-

Cleaners, degreasers, etc.

-

Welding process used

-

The relevant material safety data sheets and manufacturer's specifications for

the listed components should therefore be studied carefully.

Recommendations for trade fair scenarios, risk management measures and for

identifying working conditions can be found on the European Welding Association website under Health & Safety (https://european-welding.org).

EN

Danger from fly-

ing sparks

Flammable vapours (e.g. solvent fumes) should be kept away from the arc's radiation area.

Close the shielding gas cylinder valve or main gas supply if no welding is taking

place.

Flying sparks may cause fires or explosions.

Never weld close to flammable materials.

Flammable materials must be at least 11 metres (36 ft. 1.07 in.) away from the

arc, or alternatively covered with an approved cover.

A suitable, tested fire extinguisher must be available and ready for use.

Sparks and pieces of hot metal may also get into adjacent areas through small

gaps or openings. Take appropriate precautions to prevent any danger of injury or

fire.

Welding must not be performed in areas that are subject to fire or explosion or

near sealed tanks, vessels or pipes unless these have been prepared in accordance with the relevant national and international standards.

Do not carry out welding on containers that are being or have been used to store

gases, propellants, mineral oils or similar products. Residues pose an explosive

hazard.

Risks from mains

current and

welding current

An electric shock is potentially life threatening and can be fatal.

Do not touch live parts either inside or outside the device.

11

During MIG/MAG welding and TIG welding, the welding wire, the wirespool, the

feed rollers and all pieces of metal that are in contact with the welding wire are

live.

Always set the wirefeeder up on a sufficiently insulated surface or use a suitable,

insulated wirefeeder holder.

Make sure that you and others are protected with an adequately insulated, dry

base or cover for the earth or ground potential. This base or cover must extend

over the entire area between the body and the earth or ground potential.

All cables and leads must be secured, undamaged, insulated and adequately dimensioned. Replace loose connections and scorched, damaged, or inadequately

dimensioned cables and leads immediately.

Use the handle to ensure the power connections are tight before every use.

In the case of power cables with a bayonet connector, rotate the power cable

around the longitudinal axis by at least 180° and pretension.

Do not wrap cables or leads around the body or parts of the body.

The electrode (rod electrode, tungsten electrode, welding wire, etc.) must

never be immersed in liquid for cooling

-

Never touch the electrode when the power source is switched on.

-

Double the open circuit voltage of a power source can occur between the welding

electrodes of two power sources. Touching the potentials of both electrodes at

the same time may be fatal under certain circumstances.

Arrange for the mains cable to be checked regularly by a qualified electrician to

ensure the ground conductor is functioning properly.

Protection class I devices require a mains supply with ground conductor and a

connector system with ground conductor contact for proper operation.

Operation of the device on a mains supply without ground conductor and on a

socket without ground conductor contact is only permitted if all national regulations for protective separation are observed.

Otherwise, this is considered gross negligence. The manufacturer shall not be

held liable for any damage arising from such usage.

If necessary, provide adequate earthing for the workpiece.

Switch off unused devices.

Wear a safety harness if working at height.

Before working on the device, switch it off and pull out the mains plug.

Attach a clearly legible and easy-to-understand warning sign to the device to

prevent anyone from plugging the mains plug back in and switching it on again.

After opening the device:

Discharge all live components

-

Ensure that all components in the device are de-energised.

-

12

If work on live parts is required, appoint a second person to switch off the main

switch at the right moment.

Meandering

welding currents

If the following instructions are ignored, meandering welding currents can develop with the following consequences:

Fire hazard

-

Overheating of parts connected to the workpiece

-

Damage to ground conductors

-

Damage to device and other electrical equipment

-

Ensure that the workpiece is held securely by the workpiece clamp.

Attach the workpiece clamp as close as possible to the area that is to be welded.

Position the device with sufficient insulation against electrically conductive environments, such as insulation against conductive floor or insulation to conductive

racks.

If power distribution boards, twin-head mounts, etc., are being used, note the following: The electrode of the welding torch / electrode holder that is not used is

also live. Make sure that the welding torch / electrode holder that is not used is

kept sufficiently insulated.

In the case of automated MIG/MAG applications, ensure that only an insulated

wire electrode is routed from the welding wire drum, large wirefeeder spool or

wirespool to the wirefeeder.

EN

EMC Device

Classifications

EMC measures In certain cases, even though a device complies with the standard limit values for

Devices in emission class A:

Are only designed for use in industrial settings

-

Can cause line-bound and radiated interference in other areas

-

Devices in emission class B:

Satisfy the emissions criteria for residential and industrial areas. This is also

-

true for residential areas in which the energy is supplied from the public lowvoltage mains.

EMC device classification as per the rating plate or technical data.

emissions, it may affect the application area for which it was designed (e.g. when

there is sensitive equipment at the same location, or if the site where the device

is installed is close to either radio or television receivers).

If this is the case, then the operator is obliged to take appropriate action to rectify the situation.

Check and evaluate the immunity to interference of nearby devices according to

national and international regulations. Examples of equipment that may be susceptible to interference from the device include:

Safety devices

-

Network, signal and data transfer lines

-

IT and telecommunications devices

-

Measuring and calibrating devices

-

Supporting measures for avoidance of EMC problems:

Mains supply

1.

If electromagnetic interference arises despite the correct mains connec-

-

tion, additional measures are necessary (e.g. use of a suitable line filter)

Welding power-leads

2.

must be kept as short as possible

-

must be laid close together (to avoid EMF problems)

-

must be kept well apart from other leads

-

13

Equipotential bonding

3.

Earthing of the workpiece

4.

If necessary, establish an earth connection using suitable capacitors.

-

Shield, if necessary

5.

Shield other devices nearby

-

Shield the entire welding installation

-

EMF measures Electromagnetic fields may pose as yet unknown risks to health:

Effects on the health of persons in the vicinity, e.g. those with pacemakers

-

and hearing aids

Individuals with pacemakers must seek advice from their doctor before ap-

-

proaching the device or any welding that is in progress

For safety reasons, maintain as large a distance as possible between the

-

welding power-leads and the head/torso of the welder

Do not carry welding power-leads and hosepacks over the shoulders or wind

-

them around any part of the body

Specific hazards Keep hands, hair, clothing and tools away from moving parts. For example:

Fans

-

Cogs

-

Rollers

-

Shafts

-

Wirespools and welding wires

-

Do not reach into the rotating cogs of the wire drive or into rotating drive components.

Covers and side panels may only be opened/removed while maintenance or repair

work is being carried out.

During operation

Ensure that all covers are closed and all side panels are fitted properly.

-

Keep all covers and side panels closed.

-

The welding wire emerging from the welding torch poses a high risk of injury

(piercing of the hand, injuries to the face and eyes, etc.).

Therefore, always keep the welding torch away from the body (devices with

wirefeeder) and wear suitable protective goggles.

Never touch the workpiece during or after welding - risk of burns.

Slag can jump off cooling workpieces. The specified protective equipment must

therefore also be worn when reworking workpieces, and steps must be taken to

ensure that other people are also adequately protected.

Welding torches and other parts with a high operating temperature must be allowed to cool down before handling.

Special provisions apply in areas at risk of fire or explosion

- observe relevant national and international regulations.

14

Power sources for work in areas with increased electric risk (e.g. near boilers)

must carry the "Safety" sign. However, the power source must not be located in

such areas.

Risk of scalding from escaping coolant. Switch off cooling unit before disconnecting coolant flow or return lines.

Observe the information on the coolant safety data sheet when handling coolant.

The coolant safety data sheet may be obtained from your service centre or downloaded from the manufacturer's website.

Use only suitable load-carrying equipment supplied by the manufacturer when

transporting devices by crane.

Hook chains or ropes onto all suspension points provided on the load-carry-

-

ing equipment.

Chains and ropes must be at the smallest angle possible to the vertical.

-

Remove gas cylinder and wirefeeder (MIG/MAG and TIG devices).

-

If the wirefeeder is attached to a crane holder during welding, always use a suitable, insulated wirefeeder hoisting attachment (MIG/MAG and TIG devices).

If the device has a carrying strap or handle, this is intended solely for carrying by

hand. The carrying strap is not to be used if transporting with a crane, counterbalanced lift truck or other mechanical hoist.

All lifting tackle (straps, handles, chains, etc.) used in connection with the device

or its components must be tested regularly (e.g. for mechanical damage, corrosion or changes caused by other environmental factors).

The testing interval and scope of testing must comply with applicable national

standards and directives as a minimum.

Odourless and colourless shielding gas may escape unnoticed if an adapter is

used for the shielding gas connection. Prior to assembly, seal the device-side

thread of the adapter for the shielding gas connection using suitable Teflon tape.

EN

Requirement for

the shielding gas

Danger from

shielding gas cylinders

Especially with ring lines, contaminated shielding gas can cause damage to

equipment and reduce welding quality.

Meet the following requirements regarding shielding gas quality:

Solid particle size < 40 µm

-

Pressure condensation point < -20 °C

-

Max. oil content < 25 mg/m³

-

Use filters if necessary.

Shielding gas cylinders contain gas under pressure and can explode if damaged.

As the shielding gas cylinders are part of the welding equipment, they must be

handled with the greatest of care.

Protect shielding gas cylinders containing compressed gas from excessive heat,

mechanical impact, slag, naked flames, sparks and arcs.

Mount the shielding gas cylinders vertically and secure according to instructions

to prevent them falling over.

Keep the shielding gas cylinders well away from any welding or other electrical

circuits.

Never hang a welding torch on a shielding gas cylinder.

Never touch a shielding gas cylinder with an electrode.

Risk of explosion - never attempt to weld a pressurised shielding gas cylinder.

Only use shielding gas cylinders suitable for the application in hand, along with

the correct and appropriate accessories (regulator, hoses and fittings). Only use

shielding gas cylinders and accessories that are in good condition.

15

Turn your face to one side when opening the valve of a shielding gas cylinder.

Close the shielding gas cylinder valve if no welding is taking place.

If the shielding gas cylinder is not connected, leave the valve cap in place on the

cylinder.

The manufacturer's instructions must be observed as well as applicable national

and international regulations for shielding gas cylinders and accessories.

Danger from escaping shielding

gas

Safety measures

at the installation location and

during transport

Risk of suffocation from the uncontrolled escape of shielding gas

Shielding gas is colourless and odourless and, in the event of a leak, can displace

the oxygen in the ambient air.

Ensure an adequate supply of fresh air with a ventilation rate of at least

-

20 m³/hour.

Observe safety and maintenance instructions on the shielding gas cylinder or

-

the main gas supply.

Close the shielding gas cylinder valve or main gas supply if no welding is tak-

-

ing place.

Check the shielding gas cylinder or main gas supply for uncontrolled gas

-

leakage before every start-up.

A device toppling over could easily kill someone. Place the device on a solid, level

surface such that it remains stable

The maximum permissible tilt angle is 10°.

-

Special regulations apply in rooms at risk of fire or explosion

Observe relevant national and international regulations.

-

Use internal directives and checks to ensure that the workplace environment is

always clean and clearly laid out.

Only set up and operate the device in accordance with the degree of protection

shown on the rating plate.

When setting up the device, ensure there is an all-round clearance of 0.5 m (1 ft.

7.69 in.) to ensure that cooling air can flow in and out freely.

When transporting the device, observe the relevant national and local guidelines

and accident prevention regulations. This applies especially to guidelines regarding the risks arising during transport.

Do not lift or transport operational devices. Switch off devices before transport

or lifting.

Before transporting the device, allow coolant to drain completely and detach the

following components:

Wirefeeder

-

Wirespool

-

Shielding gas cylinder

-

After transporting the device, the device must be visually inspected for damage

before commissioning. Any damage must be repaired by trained service technicians before commissioning the device.

16

Safety measures

in normal operation

Only operate the device when all safety devices are fully functional. If the safety

devices are not fully functional, there is a risk of

injury or death to the operator or a third party

-

damage to the device and other material assets belonging to the operator

-

inefficient operation of the device

-

Any safety devices that are not functioning properly must be repaired before

switching on the device.

Never bypass or disable safety devices.

Before switching on the device, ensure that no one is likely to be endangered.

Check the device at least once a week for obvious damage and proper functioning of safety devices.

Always fasten the shielding gas cylinder securely and remove it beforehand if the

device is to be transported by crane.

Only the manufacturer's original coolant is suitable for use with our devices due

to its properties (electrical conductibility, anti-freeze agent, material compatibility, flammability, etc.).

Only use suitable original coolant from the manufacturer.

Do not mix the manufacturer's original coolant with other coolants.

EN

Commissioning,

maintenance and

repair

Only connect the manufacturer's system components to the cooling circuit.

The manufacturer accepts no liability for damage resulting from use of other system components or a different coolant. In addition, all warranty claims will be

forfeited.

Cooling Liquid FCL 10/20 does not ignite. The ethanol-based coolant can ignite

under certain conditions. Transport the coolant only in its original, sealed containers and keep well away from any sources of ignition.

Used coolant must be disposed of properly in accordance with the relevant national and international regulations. The coolant safety data sheet may be obtained from your service centre or downloaded from the manufacturer's website.

Check the coolant level before starting to weld, while the system is still cool.

It is impossible to guarantee that bought-in parts are designed and manufactured to meet the demands made of them, or that they satisfy safety requirements.

Use only original spare and wearing parts (also applies to standard parts).

-

Do not carry out any modifications, alterations, etc. to the device without the

-

manufacturer's consent.

Components that are not in perfect condition must be replaced immediately.

-

When ordering, please give the exact designation and part number as shown

-

in the spare parts list, as well as the serial number of your device.

The housing screws provide the ground conductor connection for earthing the

housing parts.

Only use original housing screws in the correct number and tightened to the specified torque.

17

Safety inspection

Disposal Waste electrical and electronic equipment must be collected separately and re-

The manufacturer recommends that a safety inspection of the device is performed at least once every 12 months.

The manufacturer recommends that the power source be calibrated during the

same 12-month period.

A safety inspection should be carried out by a qualified electrician

after any changes are made

-

after any additional parts are installed, or after any conversions

-

after repair, care and maintenance has been carried out

-

at least every twelve months.

-

For safety inspections, follow the appropriate national and international standards and directives.

Further details on safety inspection and calibration can be obtained from your

service centre. They will provide you on request with any documents you may require.

cycled in an environmentally responsible manner in accordance with the EU Directive and national law. Used equipment must be returned to the distributor or

through a local, authorised collection and disposal system. Proper disposal of the

old device promotes sustainable recycling of material resources. Ignoring this

may lead to potential health/environmental impacts.

Packaging materials

Collected separately. Check your municipality’s regulations. Reduce the volume

of the box.

Safety symbols Devices with the CE mark satisfy the essential requirements of the low-voltage

and electromagnetic compatibility directives (e.g. relevant product standards of

the EN 60 974 series).

Fronius International GmbH hereby declares that the device is compliant with

Directive 2014/53/EU. The full text on the EU Declaration of Conformity can be

found at the following address: http://www.fronius.com

Devices marked with the CSA test mark satisfy the requirements of the relevant

standards for Canada and the USA.

Data protection The user is responsible for the safekeeping of any changes made to the factory

settings. The manufacturer accepts no liability for any deleted personal settings.

Copyright Copyright of these operating instructions remains with the manufacturer.

18

The text and illustrations are all technically correct at the time of printing. We

reserve the right to make changes. The contents of the operating instructions

shall not provide the basis for any claims whatsoever on the part of the purchaser. If you have any suggestions for improvement, or can point out any mistakes that you have found in the instructions, we will be most grateful for your

comments.

Description of

A B

the warning notices on the

device

For certain device versions, warning notices are affixed to the device.

The arrangement of the symbols may vary.

! Warning! Attention!

The symbols represent possible dangers.

A Drive rollers can injure fingers.

B The welding wire and drive parts are live during operation.

Keep hands and metal objects away!

EN

1. An electric shock can be fatal.

1.1 Wear dry, insulating gloves. Do not touch the wire electrode with bare

hands. Do not wear wet or damaged gloves.

1.2 Use a base that is insulated from the floor and work area to protect

against electric shock.

1.3 Before working on the device, switch off the device and pull out the mains

plug or disconnect it from the power supply.

2. Inhalation of welding fumes can be harmful to health.

2.1 Keep your face away from any welding fumes.

19

2.2 Use forced-air ventilation or a local extraction system to remove welding

xx,xxxx,xxxx *

fumes.

2.3 Remove welding fumes with a fan.

3 Welding sparks can cause an explosion or fire.

3.1 Keep flammable materials away from the welding process. Never weld

close to flammable materials.

3.2 Welding sparks can cause a fire. Have fire extinguishers to hand. If neces-

sary, have a supervisor ready who can operate the fire extinguisher.

3.3 Do not weld on drums or closed containers.

4. Arc rays can burn the eyes and injure the skin.

4.1 Wear headgear and protective goggles. Use ear protection and a shirt col-

lar with button. Use a welding helmet with the correct tinting. Wear suitable protective clothing over the entire body.

5. Before working on the system or welding:

undertake training on the device and read the instructions!

6. Do not remove or paint over the warning sticker.

* Manufacturer order number of the sticker

20

System configurations

21

22

System configurations - conventional robot

(6)

(2)

(3)

(9)**

(8)

(4)

(5)

(1)*

(7)*

PowerDrive with

wire drum

(1) Wirefeeding hose with inner liner

(2) TPSi power source

EN

(3) CU cooling unit

(4) Upright console

(5) HP interconnecting hosepack

(6) SplitBox SB 500i R

(7) MHP /i R torch hosepack

(8) WF 25i Robacta Drive

(9) MTB /i R robot welding torch

Maximum wirefeed length:

max. 6 m between wire drum and drive unit

(max. 8 m with PowerLiner)

Possible wire diameters:

0.8 - 1.2 mm

Welding process:

Standard, Pulse, LSC, PMC, PMC-MIX-DRIVE

IMPORTANT! Do not use a wire straightening section or guide roller in this configuration.

* Use the largest inner liner (incl. basic kit)

** Use the inner liner corresponding to the wire diameter (incl. basic kit)

23

PowerDrive with

(6)

(9)**

(8)

(5)

(1)*

(7)*

(2)

(3)

(4)

wire drum and

external

wirefeeding hose

(1) Wirefeeding hose with inner liner

(2) TPSi power source

(3) CU cooling unit

(4) Upright console

(5) HP interconnecting hosepack

(6) SplitBox SB 500i R

(7) MHP /i R welding torch hosepack with external wirefeeding hose

(8) WF 25i Robacta Drive

(9) MTB /i R robot welding torch

Maximum wirefeed length:

max. 6 m between wire drum and drive unit

(max. 8 m with PowerLiner)

Possible wire diameters:

0.8 - 1.2 mm

Welding process:

Standard, Pulse, LSC, PMC, PMC-MIX-DRIVE

IMPORTANT! Do not use a wire straightening section or guide roller in this configuration.

* Use the largest inner liner (incl. basic kit)

** Use the inner liner corresponding to the wire diameter (incl. basic kit)

24

PushPull with 4-

(8)

(11)**

(10)

(1)*

(9)*

(2)

(3)

(1)*

(4)

(5)

(6)

(7)

roller unreeling

wirefeeder and

wire drum

EN

(1) Wirefeeding hose with inner liner

(2) SpeedNet cable COM

(3) Unreeling wirefeeder WF 25i REEL 4R

(4) TPSi power source

(5) CU cooling unit

(6) Upright console

(7) HP interconnecting hosepack

(8) SplitBox SB 500i R

(9) MHP /i R torch hosepack

(10) WF 25i Robacta Drive

(11) MTB /i R robot welding torch

Maximum wirefeed length:

max. 15 m between drive unit and unreeling wirefeeder

-

(max. 20 m with PowerLiner)

max. 8 m between unreeling wirefeeder and wire drum

-

(max. 10 m with PowerLiner)

Minimum length between unreeling wirefeeder and drive unit:

4 m

Possible wire diameters:

0.8 - 2.0 mm

Welding process:

Standard, Pulse, LSC, PMC

* Use the largest inner liner (incl. basic kit)

** Use the inner liner corresponding to the wire diameter (incl. basic kit)

25

PushPull with 4-

(8)

(3)

(4)

(11)**

(10)

(5)

(6)

(1)

(9)*

(2)

(7)*

roller unreeling

wirefeeder and

wirespool

(1) SpeedNet cable COM

(2) Unreeling wirefeeder WF 25i REEL 4R

+ OPT/i WF Reel carriage D300

(3) TPSi power source

(4) CU cooling unit

(5) Upright console

(6) HP interconnecting hosepack

(7) Wirefeeding hose with inner liner

(8) SplitBox SB 500i R

(9) MHP /i R welding torch hosepack with external wirefeeding hose

(10) WF 25i Robacta Drive

(11) MTB /i R robot welding torch

Maximum wirefeed length:

max. 15 m between drive unit and unreeling wirefeeder

(max. 20 m with PowerLiner)

Possible wire diameters:

0.8 - 2.0 mm

Welding process:

Standard, Pulse, LSC, PMC

* Use the largest inner liner (incl. basic kit)

** Use the inner liner corresponding to the wire diameter (incl. basic kit)

26

PushPull with

(10)

(11)**

(9)

(1)

(7)**

(2)

(8)

(3)

(4)

(5)

(6)

SB 60i, 4-roller

unreeling

wirefeeder and

wirespool

EN

(1) SpeedNet cable COM

(2) Unreeling wirefeeder WF 25i REEL 4R

+ OPT/i WF Reel carriage D300

(3) TPSi power source

(4) CU cooling unit

(5) Upright console

(6) HP interconnecting hosepack SB 60i

(7) Wirefeeding hose with inner liner

(8) SplitBox SB 60i R

(9) MHP /i R torch hosepack

(10) WF 25i Robacta Drive

(11) MTB /i R robot welding torch

Maximum wirefeed length:

max. 4 m between drive unit and SB 60i R

-

max. 6 m between SB 60i R and unreeling wirefeeder

-

Minimum length between SB 60i R and drive unit:

1 m

Possible wire diameters:

0.8 - 1.6 mm

Welding processes:

Standard, Pulse, LSC, PMC, PMC-MIX-DRIVE

* Use the largest inner liner (incl. basic kit)

** Use the inner liner corresponding to the wire diameter (incl. basic kit)

27

PushPull with 2-

(9)

(11)**

(8)

(1)

(7)*

(2)

(10)

(3)

(4)

(5)

(6)

roller unreeling

wirefeeder, wire

drum and external wirefeeding hose

(1) Unreeling wirefeeder WF 30i REEL 2R

+ WF Mounting Drum

(2) SpeedNet cable COM

(3) TPSi power source

(4) CU cooling unit

(5) Upright console

(6) HP interconnecting hosepack

(7) Wirefeeding hose with inner liner

(8) SplitBox SB 500i R

(9) MHP /i R welding torch hosepack with external wirefeeding hose

(10) WF 25i Robacta Drive

(11) MHP /i R robot welding torch

Maximum wirefeed length:

max. 8 m between drive unit and unreeling wirefeeder

(max. 10 m with PowerLiner)

Possible wire diameters:

0.8 - 1.6 mm

Welding process:

Standard, Pulse, LSC, PMC, PMC-MIX-DRIVE

IMPORTANT!

This configuration is only possible with wire drum. A wirespool cannot be

-

used.

Do not use a wire straightening section or guide roller in this configuration.

-

* Use the largest inner liner (incl. basic kit)

** Use the inner liner corresponding to the wire diameter (incl. basic kit)

28

CMT with SB 60i,

(9)*

(4)

(5)

(11)**

(8)

(6)

(7)

(1)*

(1)**

(2)

(10)

(3)

(1

(1(1

4-roller unreeling wirefeeder

and wire drum

EN

(1) Wirefeeding hose with inner liner

(2) SpeedNet cable COM

(3) Unreeling wirefeeder WF 25i REEL 4R

(4) TPSi power source

(5) CU cooling unit

(6) Upright console

(7) HP interconnecting hosepack SB 60i

(8) SplitBox SB 60i R

(9) MHP /i R torch hosepack

(10) WF 60i Robacta Drive CMT

(11) MTB /i R robot welding torch

Maximum wirefeed length:

max. 4 m between drive unit and SB 60i R

-

max. 6 m between SB 60i R and unreeling wirefeeder

-

max. 8 m between unreeling wirefeeder and wire drum

-

(max. 10 m with PowerLiner)

Minimum length between wirefeeder and drive unit:

1 m

Possible wire diameters:

0.8 - 1.6 mm aluminium, 0.8 - 1.4 mm steel

Welding process:

Standard, Pulse, LSC, PMC, PMC-MIX-DRIVE, PMC-RIPPLE-DRIVE, CMT

* Use the largest inner liner (incl. basic kit)

** Use the inner liner corresponding to the wire diameter (incl. basic kit)

29

CMT with SB

(9)

(4)

(5)

(12)**

(8)

(6)

(7)

(1)*

(1)**

(2)

(10)*

(3)

(11)

(1

500i, 4-roller unreeling wirefeeder, wire drum and

external

wirefeeding hose

(1) Wirefeeding hose with inner liner

(2) SpeedNet cable COM

(3) Unreeling wirefeeder WF 25i REEL 4R

(4) TPSi power source

(5) CU cooling unit

(6) Upright console

(7) HP interconnecting hosepack

(8) Wire buffer

(9) SplitBox SB 500i R

(10) MHP /i R welding torch hosepack with external wirefeeding hose

(11) WF 60i Robacta Drive CMT

(12) MTB /i R robot welding torch

Maximum wirefeed length:

max. 4 m between drive unit and wire buffer

-

max. 6 m between wire buffer and unreeling wirefeeder

-

max. 8 m between unreeling wirefeeder and wire drum

-

(max. 10 m with PowerLiner)

Minimum length between wirefeeder and drive unit:

1 m

Possible wire diameters:

0.8 - 1.6 mm aluminium, 0.8 - 1.4 mm steel

Welding process:

Standard, Pulse, LSC, PMC, CMT

30

* Use the largest inner liner (incl. basic kit)

** Use the inner liner corresponding to the wire diameter (incl. basic kit)

CMT with SB 60i,

(3)

(4)

(11)**

(8)

(5)

(6)

(1)

(7)**

(2)

(9)*

(2)

(10)

4-roller unreeling wirefeeder

and wirespool

EN

(1) SpeedNet cable COM

(2) Unreeling wirefeeder WF 25i REEL 4R

+ OPT/i WF Reel carriage D300

(3) TPSi power source

(4) CU cooling unit

(5) Upright console

(6) HP interconnecting hosepack SB 60i

(7) Wirefeeding hose with inner liner

(8) SplitBox SB 60i R

(9) MHP /i R torch hosepack

(10) WF 60i Robacta Drive CMT

(11) MTB /i R robot welding torch

Maximum wirefeed length:

max. 4 m between drive unit and SB 60i R

-

max. 6 m between SB 60i R and unreeling wirefeeder

-

Minimum length between wirefeeder and drive unit:

1 m

Possible wire diameters:

0.8 - 1.6 mm aluminium, 0.8 - 1.4 mm steel

Welding processes:

Standard, Pulse, LSC, PMC, CMT

* Use the largest inner liner (incl. basic kit)

** Use the inner liner corresponding to the wire diameter (incl. basic kit)

31

System configurations - PAP

(8)

(2)

(3)

(9)**

(7)*

(1)*

(4)

(6)

(5)

PowerDrive with

wire drum

(1) Wirefeeding hose with inner liner

(2) TPSi power source

(3) CU cooling unit

(4) Upright console

(5) HP interconnecting hosepack

(6) SplitBox SB 500i R

(7) MHP /i R torch hosepack

(8) WF 25i Robacta Drive

(9) MTB /i R robot welding torch

Maximum wirefeed length:

max. 6 m between wire drum and drive unit

(max. 8 m with PowerLiner)

Possible wire diameters:

0.8 - 1.2 mm

Welding process:

Standard, Pulse, LSC, PMC, PMC-MIX-DRIVE

IMPORTANT! Do not use a wire straightening section or guide roller in this configuration.

* Use the largest inner liner (incl. basic kit)

** Use the inner liner corresponding to the wire diameter (incl. basic kit)

32

PushPull with 4-

(8)

(4)

(5)

(11)**

(9)*

(1)*

(6)

(10)

(7)

(2)

(3)

(1)*

(1(1(1

(1(1(1

(1

roller unreeling

wirefeeder and

wire drum

EN

(1) Wirefeeding hose with inner liner

(2) SpeedNet cable COM

(3) Unreeling wirefeeder WF 25i REEL 4R

(4) TPSi power source

(5) CU cooling unit

(6) Upright console

(7) HP interconnecting hosepack

(8) SplitBox SB 500i R

(9) MHP /i R torch hosepack

(10) WF 25i Robacta Drive

(11) MTB /i R robot welding torch

Maximum wirefeed length:

max. 15 m between drive unit and unreeling wirefeeder

-

(max. 20 m with PowerLiner)

max. 8 m between unreeling wirefeeder and wire drum

-

(max. 10 m with PowerLiner)

Minimum length between wirefeeder and drive unit:

4 m

Possible wire diameters:

0.8 - 2.0 mm

Welding process:

Standard, Pulse, LSC, PMC

* Use the largest inner liner (incl. basic kit)

** Use the inner liner corresponding to the wire diameter (incl. basic kit)

33

PushPull with 4-

(8)

(11)**

(9)*

(1)

(10)

(2)

(7)*

(3)

(4)

(5)

(6)

roller unreeling

wirefeeder and

wirespool

(1) SpeedNet cable COM

(2) Unreeling wirefeeder WF 25i REEL 4R

+ OPT/i WF Reel carriage D300

(3) TPSi power source

(4) CU cooling unit

(5) Upright console

(6) HP interconnecting hosepack

(7) Wirefeeding hose with inner liner

(8) SplitBox SB 500i R

(9) MHP /i R torch hosepack

(10) WF 25i Robacta Drive

(11) MTB /i R robot welding torch

Maximum wirefeed length:

max. 15 m between drive unit and unreeling wirefeeder

(max. 20 m with PowerLiner)

Minimum length between wirefeeder and drive unit:

4 m

Possible wire diameters:

0.8 - 2.0 mm

Welding process:

Standard, Pulse, LSC, PMC

34

* Use the largest inner liner (incl. basic kit)

** Use the inner liner corresponding to the wire diameter (incl. basic kit)

PushPull with 2-

(8)

(4)

(5)

(11)**

(9)*

(3)*

(6)

(10)

(7)

(1)

(2)

roller unreeling

wirefeeder and

wire drum

EN

(1) Unreeling wirefeeder WF 30i REEL 2R

+ WF Mounting Drum

(2) SpeedNet cable COM

(3) Wirefeeding hose with inner liner

(4) TPSi power source

(5) CU cooling unit

(6) Upright console

(7) HP interconnecting hosepack

(8) SplitBox SB 500i R

(9) MHP /i R torch hosepack

(10) WF 25i Robacta Drive

(11) MHP /i R robot welding torch

Maximum wirefeed length:

max. 8 m between drive unit and unreeling wirefeeder

(max. 10 m with PowerLiner)

Minimum length between wirefeeder and drive unit:

4 m

Possible wire diameters:

0.8 - 1.6 mm

Welding process:

Standard, Pulse, LSC, PMC, PMC-MIX-DRIVE

IMPORTANT! This configuration is only possible with wire drum. A wirespool

cannot be used.

* Use the largest inner liner (incl. basic kit)

** Use the inner liner corresponding to the wire diameter (incl. basic kit)

35

PushPull with

(8)

(4)

(5)

(12)**

(10)*

(1)*

(6)

(11)

(7)

(2)

(3)

(1)**

(9)

(1)*

wire buffer, 4roller unreeling

wirefeeder and

wire drum

(1) Wirefeeding hose with inner liner

(2) SpeedNet cable COM

(3) Unreeling wirefeeder WF 25i REEL 4R

(4) TPSi power source

(5) CU cooling unit

(6) Upright console

(7) HP interconnecting hosepack

(8) SplitBox SB 500i R

(9) Wire buffer

(10) MHP /i R torch hosepack

(11) WF 25i Robacta Drive

(12) MTB /i R robot welding torch

Maximum wirefeed length:

max. 4 m between drive unit and wire buffer

-

max. 6 m between wire buffer and unreeling wirefeeder

-

max. 8 m between unreeling wirefeeder and wire drum

-

(max. 10 m with PowerLiner)

Possible wire diameters:

0.8 - 2.0 mm aluminium, 0.8 - 1.6 mm steel

Welding process:

Standard, Pulse, LSC, PMC, PMC-MIX-DRIVE

* Use the largest inner liner (incl. basic kit)

** Use the inner liner corresponding to the wire diameter (incl. basic kit)

36

PushPull with

(9)

(12)**

(10)*

(7)**

(8)

(1)

(2)

(7)*

(11)

(3)

(4)

(5)

(6)

wire buffer, 4roller unreeling

wirefeeder and

wirespool

EN

(1) SpeedNet cable COM

(2) Unreeling wirefeeder WF 25i REEL 4R

+ OPT/i WF Reel carriage D300

(3) TPSi power source

(4) CU cooling unit

(5) Upright console

(6) HP interconnecting hosepack

(7) Wirefeeding hose with inner liner

(8) Wire buffer

(9) SplitBox SB 500i R

(10) MHP /i R torch hosepack

(11) WF 25i Robacta Drive

(12) MTB /i R robot welding torch

Maximum wirefeed length:

max. 4 m between drive unit and wire buffer

-

max. 6 m between wire buffer and unreeling wirefeeder

-

Minimum length between wirefeeder and drive unit:

1 m

Possible wire diameters:

0.8 - 1.6 mm

Welding processes:

Standard, Pulse, LSC, PMC, PMC-MIX-DRIVE

* Use the largest inner liner (incl. basic kit)

** Use the inner liner corresponding to the wire diameter (incl. basic kit)

37

CMT with SB 60i,

(8)

(4)

(5)

(11)**

(9)*

(1)**

(6)

(7)

(3)

(2)(1)*

(10)

4-roller unreeling wirefeeder

and wire drum

(1) Wirefeeding hose with inner liner

(2) SpeedNet cable COM

(3) Unreeling wirefeeder WF 25i REEL 4R

(4) TPSi power source

(5) CU cooling unit

(6) Upright console

(7) HP interconnecting hosepack SB 60i

(8) SplitBox SB 60i R

(9) MHP /i R torch hosepack

(10) WF 60i Robacta Drive CMT

(11) MTB /i R robot welding torch

Maximum wirefeed length:

max. 4 m between drive unit and SB 60i R

-

max. 6 m between SB 60i R and unreeling wirefeeder

-

max. 8 m between unreeling wirefeeder and wire drum

-

(max. 10 m with PowerLiner)

Minimum length between wirefeeder and drive unit:

1 m

Possible wire diameters:

0.8 - 1.6 mm aluminium, 0.8 - 1.4 mm steel

38

Welding process:

Standard, Pulse, LSC, PMC, CMT

* Use the largest inner liner (incl. basic kit)

** Use the inner liner corresponding to the wire diameter (incl. basic kit)

CMT with SB

(8)

(12)**

(9)

(10)*

(7)

(3)

(2)(1)*

(11)

(1)**

(1)*

(4)

(5)

(6)

500i, 4-roller unreeling wirefeeder and wire drum

EN

(1) Wirefeeding hose with inner liner

(2) SpeedNet cable COM

(3) Unreeling wirefeeder WF 25i REEL 4R

(4) TPSi power source

(5) CU cooling unit

(6) Upright console

(7) HP interconnecting hosepack

(8) SplitBox SB 500i R

(9) Wire buffer

(10) MHP /i R torch hosepack

(11) WF 60i Robacta Drive CMT

(12) MTB /i R robot welding torch

Maximum wirefeed length:

max. 4 m between drive unit and wire buffer

-

max. 6 m between wire buffer and unreeling wirefeeder

-

max. 8 m between unreeling wirefeeder and wire drum

-

(max. 10 m with PowerLiner)

Minimum length between wirefeeder and drive unit:

1 m

Possible wire diameters:

0.8 - 1.6 mm aluminium, 0.8 - 1.4 mm steel

Welding process:

Standard, Pulse, LSC, PMC, CMT

* Use the largest inner liner (incl. basic kit)

** Use the inner liner corresponding to the wire diameter (incl. basic kit)

39

CMT with SB

(8)

(12)**

(9)

(10)*

(6)

(7)**

(2)

(1)

(11)

(7)*

(3)

(4)

(5)

500i, 4-roller unreeling wirefeeder and wirespool

(1) SpeedNet cable COM

(2) Unreeling wirefeeder WF 25i REEL 4R

+ OPT/i WF Reel carriage D300

(3) TPSi power source

(4) CU cooling unit

(5) Upright console

(6) HP interconnecting hosepack

(7) Wirefeeding hose with inner liner

(8) SplitBox SB 500i R

(9) MHP /i R torch hosepack

(10) WF 60i Robacta Drive CMT

(11) MTB /i R robot welding torch

Maximum wirefeed length:

max. 4 m between drive unit and wire buffer

-

max. 6 m between wire buffer and unreeling wirefeeder

-

Minimum length between wirefeeder and drive unit:

1 m

Possible wire diameters:

0.8 - 1.6 mm aluminium, 0.8 - 1.4 mm steel

Welding processes:

Standard, Pulse, LSC, PMC, CMT

40

* Use the largest inner liner (incl. basic kit)

** Use the inner liner corresponding to the wire diameter (incl. basic kit)

System components

41

42

SplitBox SB 500i R

Device concept The SplitBox (SB) 500i R, SB 500i R / L and SB 500i R PAP devices bring togeth-

er the welding media for automated MIG/MAG welding and have been specially

designed for mounting onto the robot. Two versions of the devices are available:

R = for applications in which the hosepack is externally mounted on the ro-

-

bot

PAP = for applications in which the hosepack is mounted in the robot arm

-

Proper use The device is designed exclusively for bringing together the welding media in

automated MIG/MAG welding applications in conjunction with Fronius system

components. Any use above and beyond this purpose is deemed improper. The

manufacturer shall not be held liable for any damage arising from such usage.

Utilisation in accordance with the intended purpose also comprises:

carefully reading these operating instructions

-

following all the instructions and safety rules in these operating instructions

-

performing all the stipulated inspection and maintenance work

-

EN

Safety

WARNING!

Danger from incorrect operation and work that is not carried out properly.

This can result in serious personal injury and damage to property.

All the work and functions described in this document must only be carried

▶

out by technically trained and qualified personnel.

Read and understand this document in full.

▶

Read and understand all safety rules and user documentation for this device

▶

and all system components.

43

Warning notices

40,0006,3035

Caution:

Attention:

Parts may be at welding

voltage

Les pièces peuvent être

à la tension de soudage

500 A/100% 600 A/60% 650A/40%

I2

0.8 A

I11

U11

60 V

U12 I12 0.5 A24 V

IEC 60 974-1/-10 Cl.A

IP 43

www.fronius.com

Ser.No.:

Part No.:

XXXXXXXXXX

4,040,080

SB 500i R /G/W/FSC

on the device

The device is fitted with safety symbols and a rating plate. The safety symbols

and rating plate must not be removed or painted over. The safety symbols warn

against operating the equipment incorrectly, as this may result in serious injury

and damage.

Welding is dangerous. The following basic requirements must be met to ensure

the equipment is used properly:

Welders must be sufficiently qualified

-

Suitable protective equipment must be used

-

All persons not involved must be kept at a safe distance from the wirefeeder

-

and the welding process

Do not dispose of used devices with domestic waste. Dispose of them according

to the safety rules.

Do not use the functions described here until you have fully read and understood

the following documents:

These Operating Instructions

-

All the Operating Instructions for the system components, especially the

-

safety rules

44

Keep hands, hair, clothing and tools away from moving parts. For example:

Cogs

-

Feed rollers

-

Wirespools and welding wires

-

Do not reach into rotating drive components.

Covers and side panels may only be opened/removed while maintenance or repair

work is being carried out.

During operation

Ensure that all covers are closed and all side panels are fitted properly.

-

Keep all covers and side panels closed.

-

EN

45

SplitBox SB 60i R

Device concept The SB 60i R and SB 60i R /L are devices for bringing together the welding media

in automated MIG/MAG welding and are specially designed for mounting on robots.

SB 60i R:

Right version of the appliance, for fitting to the right side of the robot

SB 60i R /L:

Left version of the appliance, for fitting to the left side of the robot

Proper use The device is designed exclusively for bringing together the welding media in

automated MIG/MAG welding applications in conjunction with Fronius system

components. Any use above and beyond this purpose is deemed improper. The

manufacturer shall not be held liable for any damage arising from such usage.

Utilisation in accordance with the intended purpose also comprises:

carefully reading these operating instructions

-

following all the instructions and safety rules in these operating instructions

-

performing all the stipulated inspection and maintenance work

-

Safety

WARNING!

Danger from incorrect operation and work that is not carried out properly.

This can result in serious personal injury and damage to property.

All the work and functions described in this document must only be carried

▶

out by technically trained and qualified personnel.

Read and understand this document in full.

▶

Read and understand all safety rules and user documentation for this device

▶

and all system components.

46

Warning notices

on the device

The device is fitted with safety symbols and a rating plate. The safety symbols

and rating plate must not be removed or painted over. The safety symbols warn

against operating the equipment incorrectly, as this may result in serious injury

and damage.

EN

Welding is dangerous. The following basic requirements must be met to ensure

the equipment is used properly:

Welders must be sufficiently qualified

-

Suitable protective equipment must be used

-

All persons not involved must be kept at a safe distance from the wirefeeder

-

and the welding process

Do not use the functions described here until you have fully read and understood

the following documents:

These Operating Instructions

-

All the Operating Instructions for the system components, especially the

-

safety rules

47

Do not dispose of used devices with domestic waste. Dispose of them according

to the safety rules.

48

TPSi wire buffer

General As its name implies, the wire buffer

acts as a buffer zone for the rapid reversing movements of the wire electrode needed during the CMT welding

process.

The wire buffer can also be used to

help coordinate two drive systems that

work in different ways. The rear drive

system steadily feeds the wire electrode into the wire buffer, while the

front highly dynamic drive motor

moves it to and fro up to 70 times per

second.

The wire electrode is therefore fed to

the front drive unit with hardly any

force being applied, thus guaranteeing

a high-quality welding process.

EN

The wire buffer is suitable for mounting on the side arm or on the balancer.

49

CrashBox /i

General

A CrashBox Drive /i PAP mounted onto the robot arm with Robacta Drive and MTB

The CrashBox Drive /i is a protection device for the torch body, the drive unit and

the welding torch interchangeable coupling. In the event of a collision, the

CrashBox sends a signal to the robot control, which stops the robot immediately.

The clamp system is used to hold the drive unit on conventional robots.

NOTE!

Always adjust the holding force of the CrashBox to the system weight.

Select the CrashBox size according to the following criteria:

L:

▶

for push systems with a torch body length of up to 249 mm.

XL:

▶

for push systems with a torch body length of up to 249 mm and with extension;

for push systems with a torch body length of 250–391 mm;

for push/pull systems with a torch body length of up to 249 mm.

XXL:

▶

for push/pull systems with a torch body length of 250–391 mm;

for push/pull systems with a torch body length of up to 249 mm and with extension.

If there is a TX/i torch-neck changeover system or WireBrake in the welding

▶

system, select the next larger CrashBox.

When cleaning the welding torch with the TC 2000, also select the next lar-

▶

ger CrashBox.

A CrashBox Drive /i mounted onto the robot arm

with clamp system, Robacta Drive und MTB

50

A robot-specific, isolated robot flange is necessary for fitting the CrashBox

Drive /i.

Note on the correct operation of

CrashBoxes

NOTE!

To avoid damage to the welding torch or the torch hosepack, or to prevent false

triggering of the CrashBox, consider the following points:

Avoid strong accelerations and maximum speeds during robot movements.

▶

Ensure the free movement of the torch hosepack during all robot move-

▶

ments;

The torch hosepack must not tighten in any position and thus exert a strain

on the CrashBox.

The torch hosepack must not whip around or get stuck when moving.

▶

If possible, clarify all movement situations with Fronius system components

▶

in a simulation as early as the concept phase.

EN

Also required for

installation

Depending on the particular robot:

1 x robot flange with screws

-

Robot flange as per price list

Observe torques:

Max. tightening torque for screws of

strength class 8.8

M4 3.3 Nm / 2.43 lb-ft

M5 5.0 Nm / 3.69 lb-ft

M6 6.0 Nm / 4.43 lb-ft

M8 27.3 Nm / 20.14 lb-ft

M10 54 Nm / 39.83 lb-ft

M12 93 Nm / 68.60 lb-ft

51

Device concept The CrashBox Drive /i is designed specifically for fitting to the robot arm and for

(1) (2)(3) (2)(3)(4) (5) (6)

(1) (2) (3) (4) (5)(6)(2)(3)

holding gas-cooled and water-cooled robot hosepacks with robot drive units. For

PAP systems, the torch hosepack runs through the CrashBox and then through

the robot arm. In conventional robot systems the torch hosepack runs along the

robot arm and is attached to the clamp. In the event of a crash, the magnetic

coupling smoothly deflects the forces along a large deflection path.

Areas of utilisation

Information on

repairing CrashBoxes

Scope of supply

The clamp system can be used for the following PushPull robot hosepacks:

MHP /i G/W RD hosepacks

-

NOTE!

Only send complete CrashBoxes for repair!

Incomplete CrashBoxes (e.g. without a magnetic ring) cannot be checked in the

course of a repair.

CrashBox Drive /i PAP scope of supply

(1) CrashBox Drive /i holder

(2) 1-ear clamp *

(3) Locking ring, 2-part *

(4) Bellows

(5) Cheese-head screws, M4 x 16 mm

(6) Magnetic ring

* A two-part locking ring and a 1-ear clamp are supplied fitted to the bel-

Do not fit the CrashBox Drive /i holder (1) and magnetic ring (4) together before

fitting to the robot. The components become even more difficult to release due

to the strong magnetism.

52

Conventional CrashBox /i scope of supply

lows (4).

WF Robacta Drive

General The WF 25i Robacta Drive and WF 60i

Robacta Drive CMT are designed for

gas or water-cooled systems. The builtin motor ensures precise wirefeeding

(pull system). The torch body is fitted

to the Robacta Drive.

EN

Warning notices

on the device

The device is fitted with safety symbols and a rating plate. The safety symbols

and rating plate must not be removed or painted over. The safety symbols warn

against operating the equipment incorrectly, as this may result in serious injury

and damage.

WF 25i Robacta Drive rating plate

Welding is dangerous. The following basic requirements must be met to ensure

the equipment is used properly:

Anyone performing automated welding must be sufficiently qualified

-

Suitable protective equipment must be used

-

All persons not involved must be kept at a safe distance from the wirefeeder

-

and the welding process

WF 60i Robacta Drive CMT rating plate

Do not use the functions described here until you have fully read and understood

the following documents:

These Operating Instructions

-

All the Operating Instructions for the system components, especially the

-

safety rules

53

PushPull hosepack

General The Robacta MHPi RD hosepack is designed for gas-cooled and water-cooled ro-

bot applications. It connects the SplitBox to the wirefeeder.

The length of the hosepack depends on the robot.

The following combinations are available:

Robacta MHPi RD conventional

-

SB500i -> WF 25i Robacta Drive

-

SB60i -> WF 60i Robacta Drive CMT

-

Robacta MHPi RD PAP

-

SB500i -> WF 25i Robacta Drive

-

SB500i -> WF 60i Robacta Drive CMT

-

SB60i -> WF 60i Robacta Drive CMT

-

Robacta MHPi RD conventional with external wirefeeding hose

-

SB500i -> WF 25i Robacta Drive

-

SB500i -> WF 60i Robacta Drive CMT

-

Scope of supply

Robacta MHPi RD conventional hosepack Robacta MHPi RD PAP hosepack

Not supplied:

Inner liners

-

Inlet nozzles

-

Robacta MHPi RD hosepack with external

wirefeeding hose

54

Robot welding torch

Standard OVT TXi TXM OPT CAM*

EN

Safety

Risk of burns from hot torch body, hot torch body coupling and other hot welding torch components.

Before starting work on the torch body, the torch body coupling and all other

welding torch components:

▶

▶

▶

General The following torch bodies are recommended for the CMT process:

-

-

The following maximum angles are permitted during the CMT process:

-

-

CAUTION!

Allow the torch body, torch body coupling and all other welding torch components to cool down to room temperature (+25 °C, +77 °F)

Wear electrically insulated and heat protective gloves

Use a suitable tool

MTB 250i / 320i / 400i / 500i / 700i: 22–36°

MTB 330i: 22°

MTB 250i / 320i / 400i / 500i / 700i: 45°

MTB 330i: 36°

*Optional (no torch body)

The robot welding torch transmits the arc power to the workpiece. The gascooled or water-cooled TPS /i welding torch is designed for use with the CrashBox /i.

The torch body has an integrated lead for gas nozzle touch sensing.