User

Information

TPS/i Interface Signal Descriptions

EN-US

User information

42,0426,0227,EA 027-08072022

Table of contents

General 6

Data types used 6

Behavior of the Power Source when an Interface is Connected 6

Availability of Functions 6

Signal Transmission Time 7

Safety 7

Digital Inputs 8

Welding start (Welding on) - Single Bit 8

Robot ready (Robot ready) - Single Bit 8

Working mode (Operating mode) - Single Bit 8

Gas on (Gas on) - Single Bit 10

Wire forward (Wire forwards) - Single Bit 10

Wire backward (Wire return) - Single Bit 11

Error reset (Reset error) 12

Touch sensing (TouchSensing) - Single Bit 12

Torch blow out (Blow out welding torch) - Single Bit 14

Welding simulation (Welding simulation) - Single Bit 14

Synchropulse on (SynchroPulse on) - Single Bit 14

WireBrake on (Wire brake on) - Single Bit 14

Torchbody Xchange (Change torch body) - Single Bit 15

Teach mode - Single Bit 15

ExtInput 1-8 (External input 1-8) - Single Bit 16

Job number (Job‑number) - Group Input 17

Welding characteristic (Characteristic number) - Group Input 17

Disable process control (Deactivate process-dependent correction) - Group Input 18

Processline select (Process line selection) - Group Input 18

TWIN mode (TWIN operating mode) - Group Input 18

Contact tip short circuit detection on (contact tip short circuit detection on) - Single Bit 19

Documentation mode (Documentation mode) - Single Bit 19

WireSense start - Single Bit 19

WireSense break - Single Bit 20

Analog Inputs 21

Wire feed speed command value (Wire speed set value) - Group Input / Analog Input 21

Arclength correction (arc length correction) - Group Input / Analog Input 21

Pulse-/ dynamic correction (Pulse/dynamic correction) - Group Input / Analog Input 22

Hotwire current (Hot-wire amperage) - Group Input / Analog Input 23

Wire retract correction (Wire retraction correction) - Group Input / Analog Input 23

Seam number (Seam number) - Group Input / Analog Input 24

Welding speed (Welding speed) - Group Input / Analog Input 24

WireSense edge detection - Group Input / Analog Input 24

Wire forward / backward length (length specification wire threading / wire retraction) Group Input / Analog Input

Digital Outputs 27

Definition 27

Heartbeat power source (Heartbeat power source) - Single Bit 27

Power source ready (Power source ready) - Single Bit 27

Warning (Warning) - Single Bit 27

Process active (Process active) - Single Bit 28

Current flow (current flow) - Single Bit 28

Robot motion release (Robot motion release) - Single Bit 29

Arc stable /Touch signal (Arc stable/touch signal) - Single Bit 30

Main current signal (main current signal) - Single Bit 33

Collisionbox active (CrashBox active) - Single Bit 34

Torchbody gripped (Torch body gripped) - Single Bit 34

Command value out of range (set value out of range) - Single Bit 34

Correction out of range (Correction out of range) - Single Bit 34

Process Bit (Process bit) - Group Output 34

ExtOutput 1-8 (External output 1-8) - Single Bit 35

Touch signal (Touch signal) - Single Bit 36

Characteristic number valid (Characteristic number valid) - Single Bit 36

25

EN-US

3

Sensor Status 1 (sensor status 1) - Single Bit 36

Sensor Status 2 (sensor status 2) - Single Bit 37

Sensor Status 3 (sensor status 3) - Single Bit 37

Sensor Status 4 (sensor status 4) - Single Bit 37

Wire stick workpiece (Wire stick workpiece) - Single Bit 37

Short circuit contact tip (contact tip short circuit) - Single Bit 38

Parameter selection internally (Internal parameter selection) - Single Bit 38

Limitsignal (Limit signal) - Single Bit 38

Main supply status (Mains voltage status) - Single Bit 39

Safety status - Single Bit 39

Twin synchronization active - Single Bit 39

System not ready - Single Bit 39

Touch signal gas nozzle - Single Bit 40

Notification (Notification) - Single Bit 40

Analog Outputs 41

Welding voltage (Welding voltage) - Group Output / Analog Output 41

Welding current (Welding current) - Group Output / Analog Output 41

Wire feed speed (Wire speed) - Group Output / Analog Output 42

Actual real value for seam tracking (Current actual value for seam tracking) - Group Output / Analog Output

Motor current M1 (Motor current M1) - Group Output / Analog Output 44

Motor current M2 (Motor current M2) - Group Output / Analog Output 45

Motor current M3 (Motor current M3) - Group Output / Analog Output 45

Error number (Error number) - Group Output / Analog Output 46

Warning number (Warning number) - Group Output / Analog Output 46

Wire position (wire position) - Group Output / Analog Output 46

Available Process Images 47

Process Image Types 47

Changing/assigning characteristic numbers/program numbers (Retro Fit mode) 47

Information on the use of the MIG/MAG standard manual, TIG, electrode, and ConstantWire

welding processes

MIG/MAG standard manual 49

TIG 49

Electrode 49

ConstantWire 49

Arc Break Monitoring 50

Arc break monitoring 50

Fronius Data Channel 52

Fronius Data Channel 52

Signal sequence when selected using "Job Mode" operating mode 53

Signal sequence when selected using "Characteristics Mode" operating mode 54

WireSense - more information 56

Process description WireSense (contour detection) 56

Process description WireSense edge detection (edge detection) 57

Signal curve of Edge Detection Mode on a level surface 58

Signal curve of Edge Detection Mode on a slanted surface 60

Signal curve of Sensing Mode for different surface geometries 62

Signal curve of WireSense break (during Sensing Mode) 64

Representation of the possible measurement range 65

Note on ignition timeout (Ignition Timeout) 66

Available signals for component scanning 67

Signal list 67

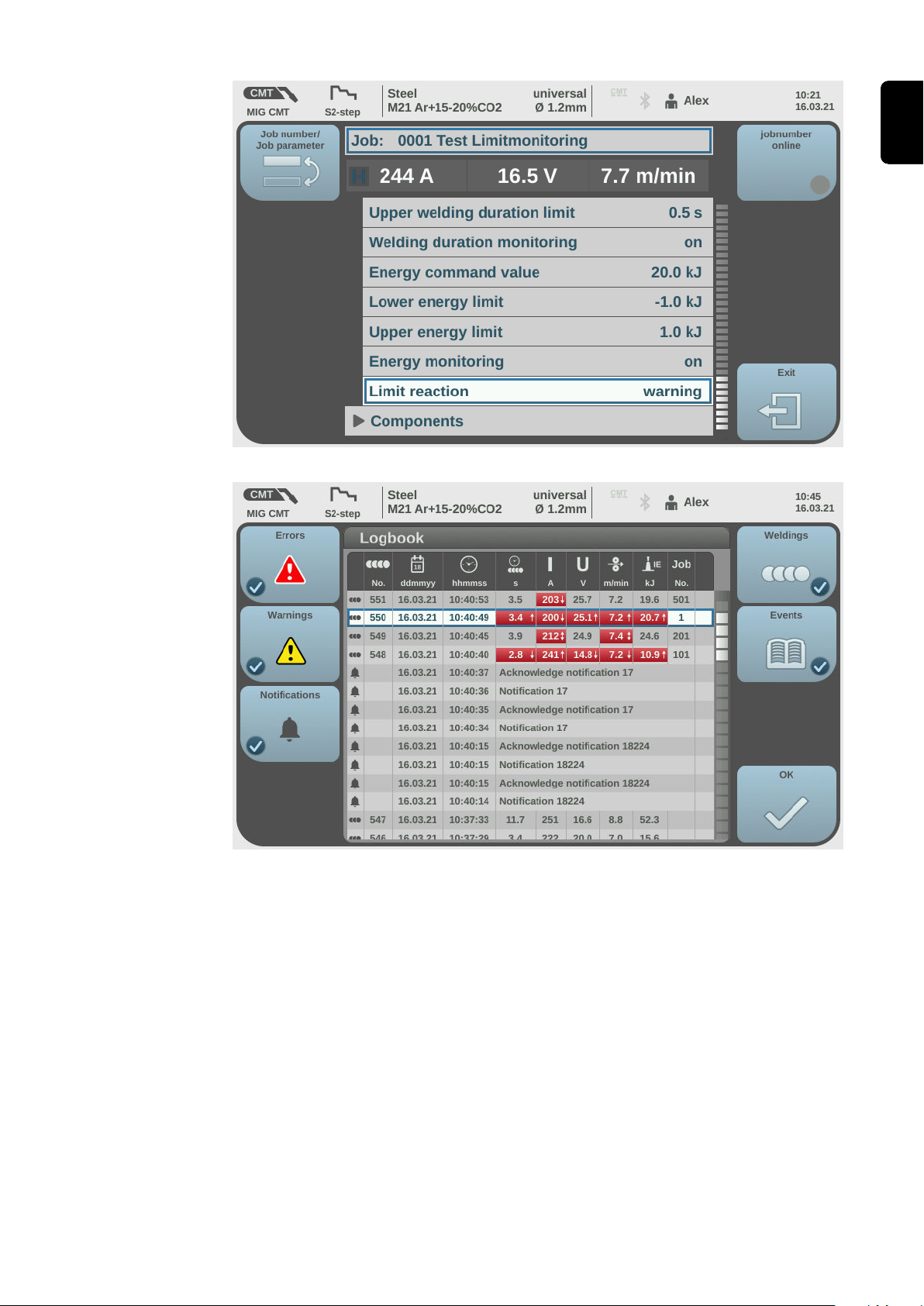

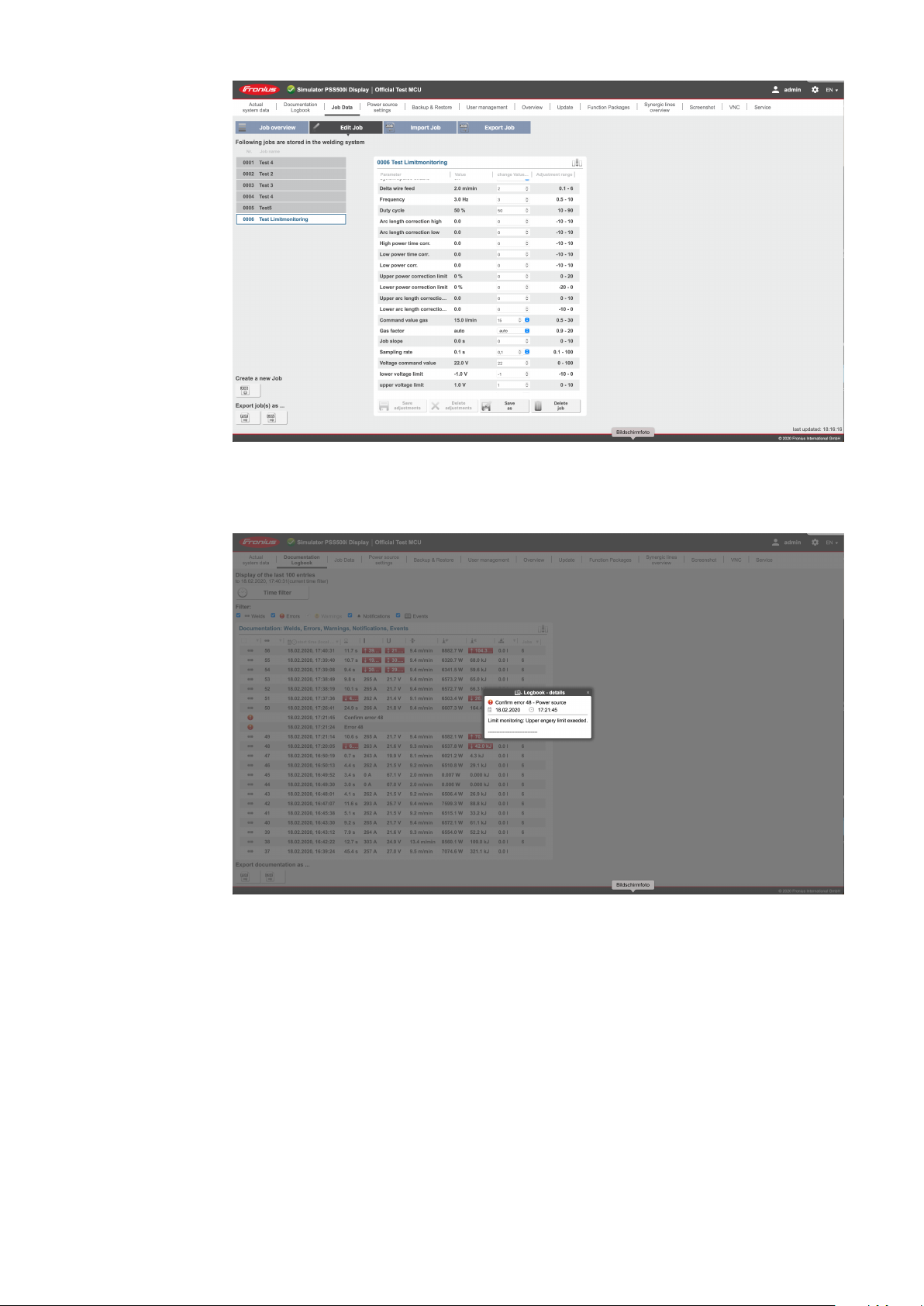

Limit Monitoring - functions and activation 68

Functions of Limit Monitoring 68

Available function packages 68

Prerequisites for the successful use of Limit Monitoring 69

Switch Limit Monitoring on / off 69

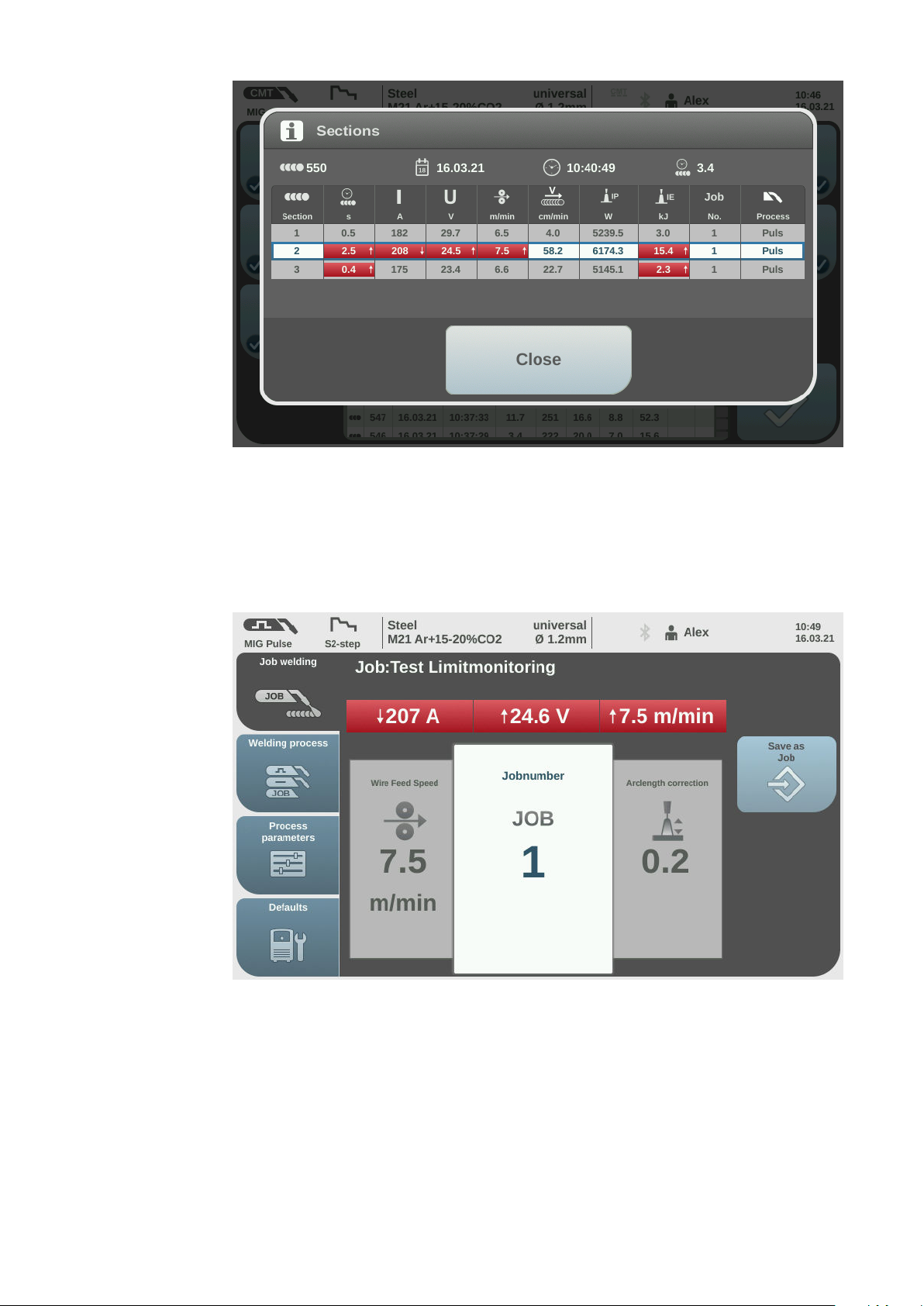

Detailed description of Limit Monitoring 70

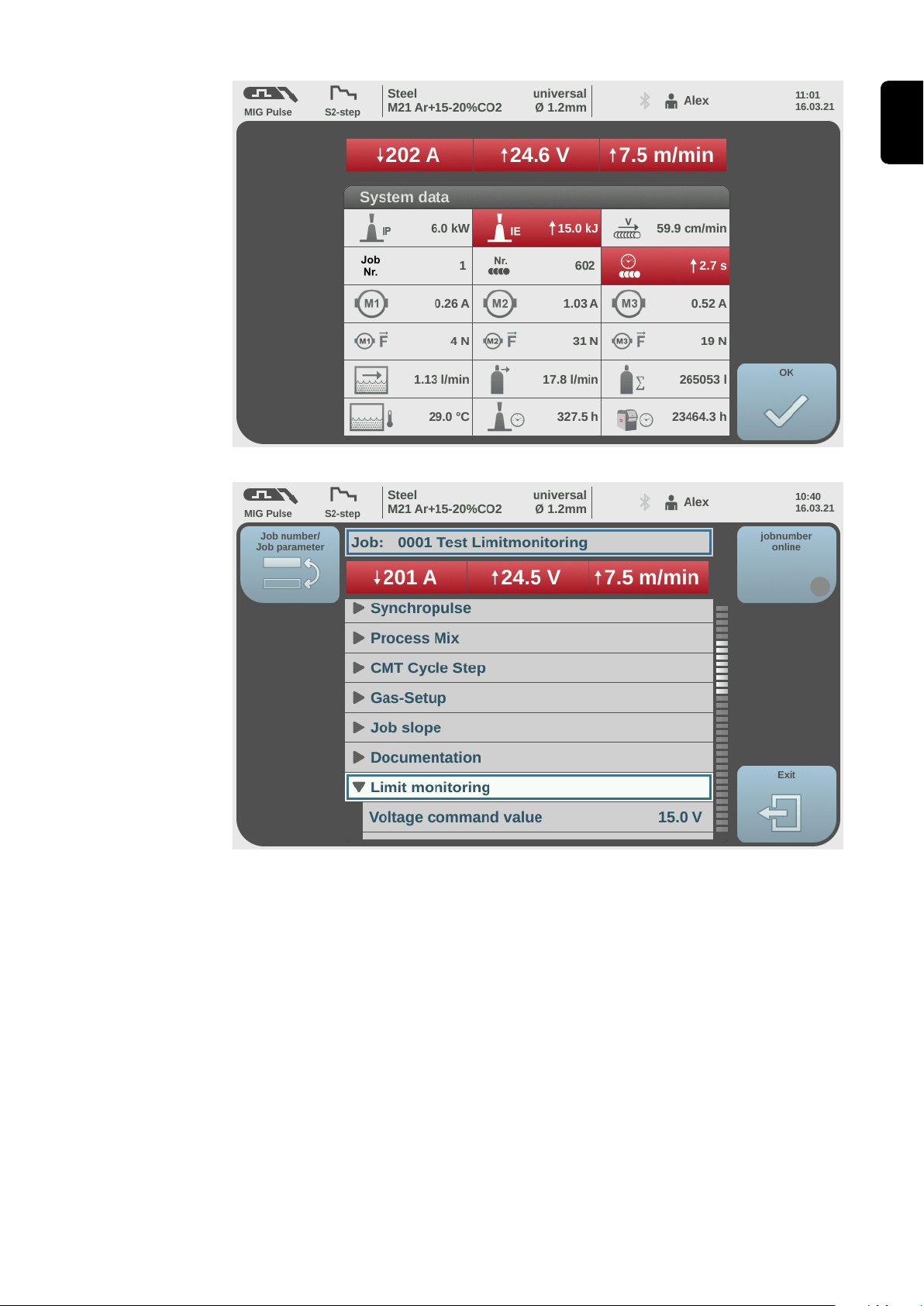

Limit Monitoring - details on the individual welding parameters 71

Voltage monitoring 71

Current monitoring 72

Wirefeeder monitoring 72

Welding time monitoring 73

Energy monitoring 75

42

49

4

Setting of the reaction when exceeding or falling below the limits: 76

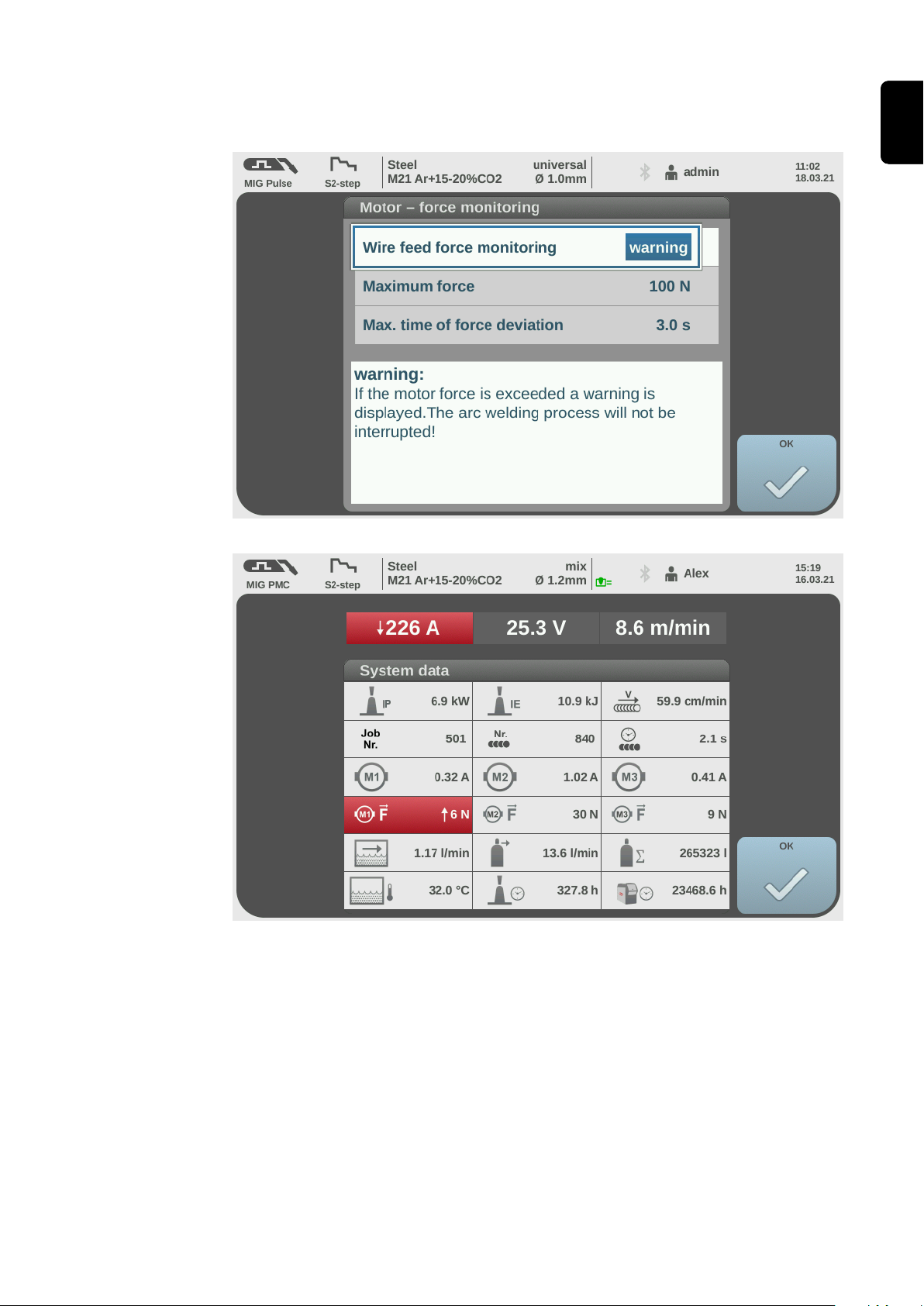

Setting of the reaction when exceeding or falling below the limits for the motor force 84

Smart Manager + OPT/i Jobs (4,067,002) 89

EN-US

5

General

Data types used UINT 16 (Unsigned Integer) = Whole number in the range from 0 to 65,535.

SINT 16 (Signed Integer) = Whole number in the range from -32,768 to 32,767.

Conversion examples:

For a positive value (SINT 16) = desired wirefeeder speed x factor = 12.3

-

m/min x 100 = 1230

For a positive value (SINT 16) = desired arc length correction x factor = -6.4 x

-

10 = -64

Unsigned (UINT): Signed (SINT):

= FFC0

dec

dec

hex

.

= 04CE

hex

.

Behavior of the

Power Source

when an Interface is Connected

Type: Unsigned 16 Bit integer =

16 bits

Range: 0 to 65,535 Range:-32,768 to 32,767

0000 -10 (00000000000000

00)

32,767 0 (0111111111111111)56 56 (0*00000000011100

65,535 +10 (1111111111111111)-64 -64 (1*111111111000000

If a power source from the TPS/i series is connected to a robot interface, the settings on the power source remain unchanged (2-step mode, special 2-step mode,

etc.).

If a power source from the TPS series is connected to a robot interface, the

power source automatically selects 2-step mode.

Type: Signed 16 Bit integer (15 bits

+ 1 Sign Bit*)

0000 0000 (0*0000000000000

00)

0)

)

* = if the value entered has a negative

sign, the sign is Bit High – see markings.

Availability of

Functions

6

As a result of updates, certain functions may be available on your device that are

not described in this document, or vice versa.

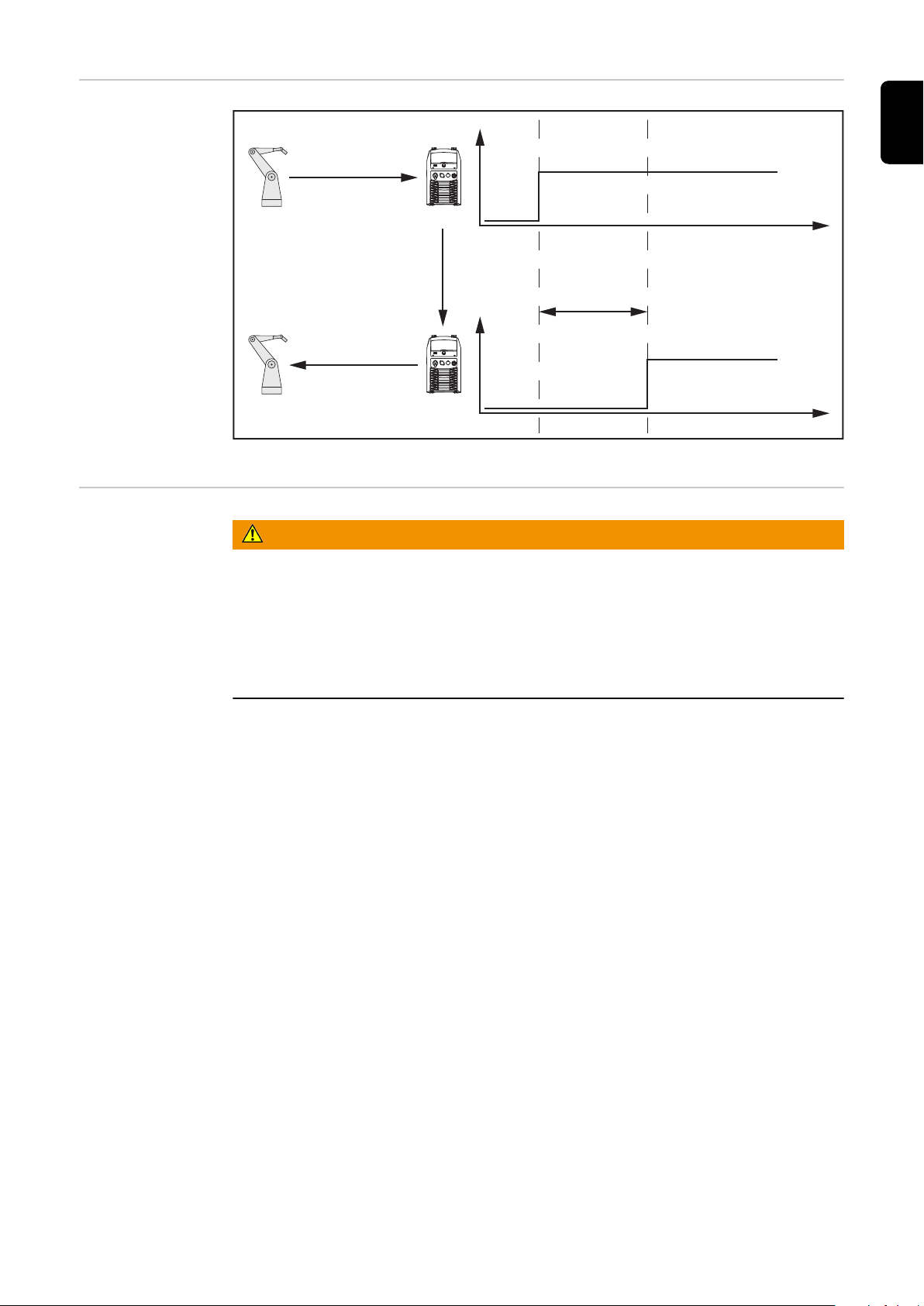

Signal Transmis-

TPS/i

t

t

TPS/i

<10 ms

Welding start

Process active

sion Time

EN-US

Representation of the signal transmission time; the signals shown are for illustrative purposes only

Safety

WARNING!

Danger from incorrect operation and work that is not carried out properly.

This can result in serious personal injury and damage to property.

All the work and functions described in this document must only be carried

▶

out by technically trained and qualified personnel.

Read and understand this document in full.

▶

Read and understand all safety rules and user documentation for this equip-

▶

ment and all system components.

7

Digital Inputs

Welding start

(Welding on) Single Bit

Robot ready (Robot ready) Single Bit

The rising edge of the Welding start signal starts the welding process.

The welding process runs for as long as the Welding start signal is active.

-

Exceptions: The Robot ready signal is deactivated or the power source is reporting an error (for example: overtemperature, too little coolant, etc.).

The Welding start signal can be activated independently of the operating

-

mode (internal parameter selection, special 2-step mode characteristics, Job

Mode, etc.).

Touch mode cannot be activated as long as the Welding start signal remains

-

set.

Additional information for TWIN systems:

In single wire mode, the welding process is started on the active power

-

source.

In TWIN mode, the welding process is started on both power sources.

-

The robot sets this signal as soon as it is ready to weld.

If the signal is reset by the robot during welding, the welding process is

-

ended in a controlled manner (without any crater filling routines).

In addition, the Robot not ready error is output. This error must either be re-

-

set on the power source control panel or using the robot interface.

It is still possible to specify the set values in the internal parameter selection

-

operating mode, even if the Robot ready signal is not set.

Working mode

(Operating

mode) - Single

Bit

This signal is used to select the operating mode of the power source.

Value range for operating mode:

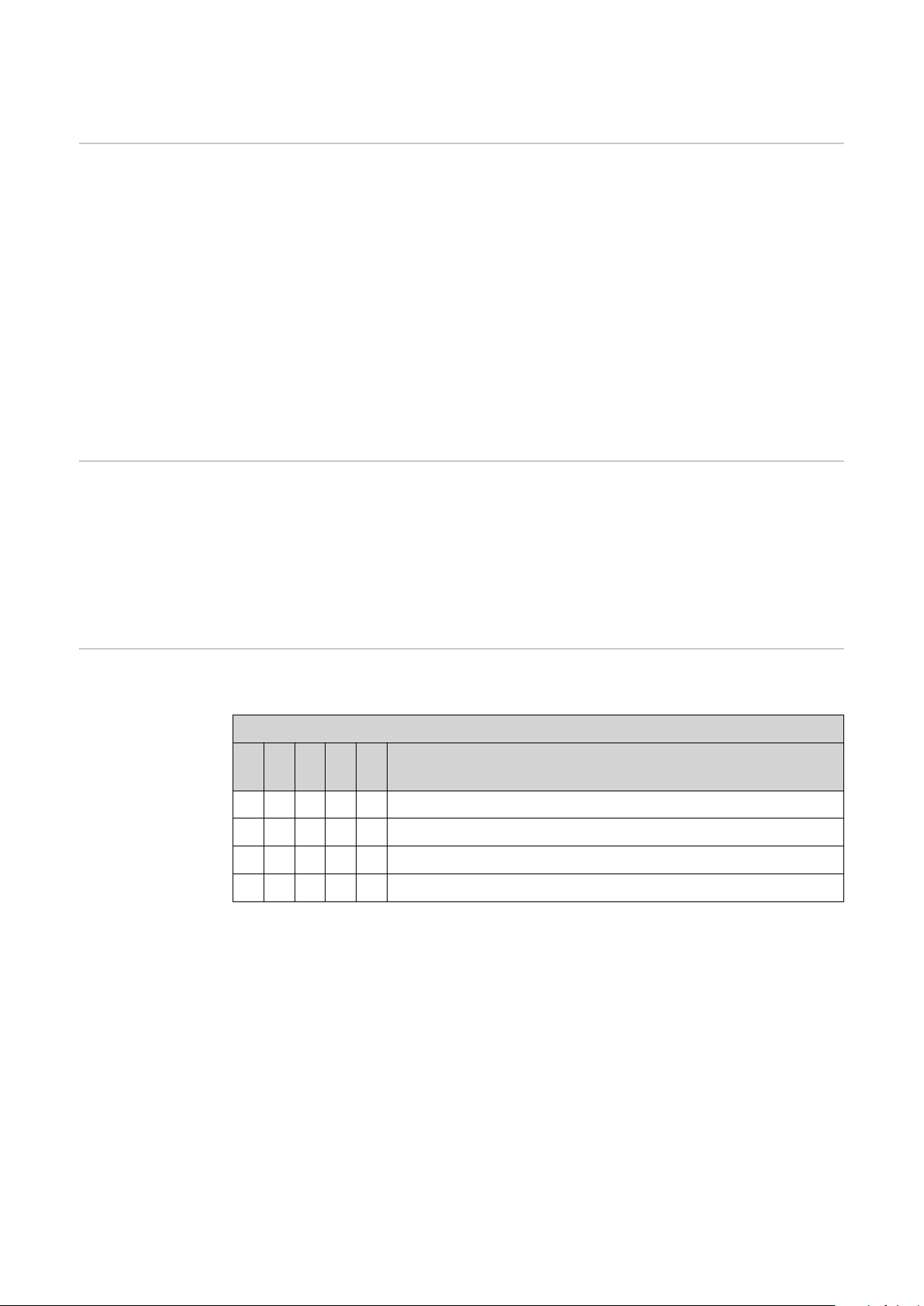

Bit 4

Bit 3

Bit 2

Bit 1

0 0 0 0 0 Internal parameter selection

0 0 0 0 1 Special 2-step mode characteristics

0 0 0 1 0 Job mode

0 1 0 0 0 2-step mode characteristics

Description of internal parameter selection:

The control panel or a remote control can be used to specify all the set val-

-

ues and material settings important for welding. This makes creating and saving jobs easy.

The robot outputs all other signals.

-

These values can also be specified during welding.

-

Internal parameter selection can be used to select:

4-step mode

-

Special 4-step mode

-

Electrode

-

TIG.

-

Description

Bit 0

8

Description of special 2-step mode characteristics:

I

I-S I-E

I

S

E

GPr GPoSL1 Main current SL2

t

t-S

Welding start

t-E

HIGH LOW

To select welding parameters using the analog set values and the character-

-

istic number (characteristic ID), the correct characteristic number must be

used. The characteristic numbers can be found on the website of the power

source, in the characteristics overview.

The welding process is also defined using the characteristic number

-

(MIG/MAG standard synergic, MIG/MAG pulse synergic, MIG/MAG LSC,

MIG/MAG PMC, MIG/MAG CMT, etc.).

Only characteristics that have previously been approved for the power

-

source can be selected.

The parameters from the start of welding/end of welding are used in the spe-

-

cial 2-step mode characteristics.

EN-US

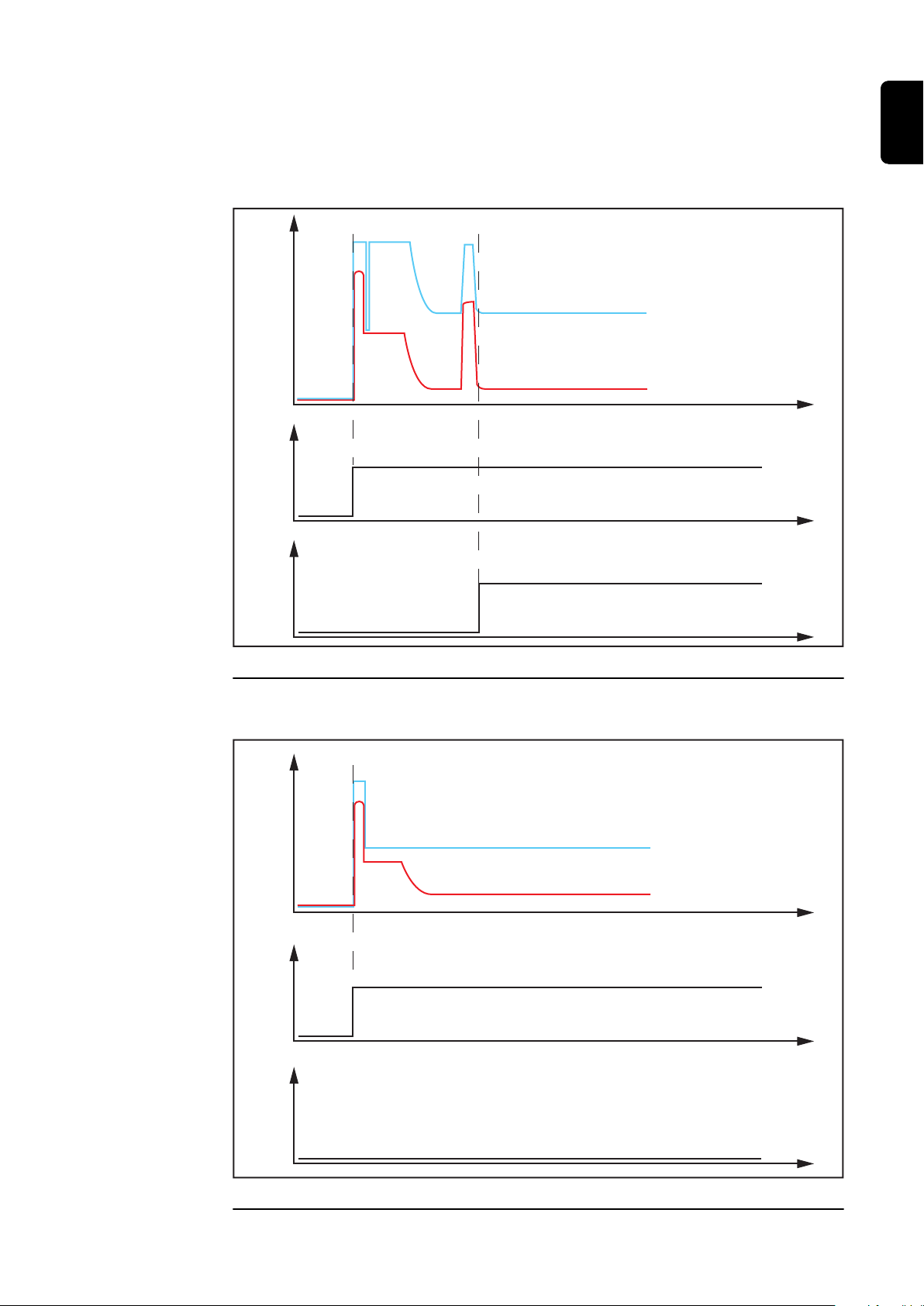

Special 2-step mode signal sequence

Description of Job Mode:

The welding parameters are selected using the data saved in the jobs.

-

The EasyJob function is deactivated as soon as a CC module (an RI IO/i or a

-

RI IO PRO/i) is connected.

There is no job with the number 0. Job number 0 can be used to select the

-

job on the control panel of the power source.

Description of 2-step mode characteristics:

To select welding parameters using the analog set values and the character-

-

istic number (characteristic ID), the correct characteristic number must be

used. The characteristic numbers can be found on the website of the power

source, in the characteristics overview.

The welding process is also defined using the characteristic ID (MIG/MAG

-

standard synergic, MIG/MAG pulse synergic, MIG/MAG LSC, MIG/MAG

PMC, MIG/MAG CMT, etc.).

Only characteristics that have previously been approved for the power

-

source can be selected.

9

t

I

I

GPr GPoMain current

HIGH LOW

Welding start

2-step mode signal sequence

For MIG/MAG standard manual characteristics, the 2-step mode characteristics

must be used.

Gas on (Gas on) Single Bit

Wire forward

(Wire forwards) Single Bit

The Gas on signal opens the gas solenoid valve and thus activates the gas flow.

As long as the signal is High, the gas solenoid valve remains open.

-

The gas flow can be activated independently of the operating mode (internal

-

parameter selection, special 2-step mode characteristics, Job Mode, etc.).

During welding, the gas pre-flow and the gas post-flow are controlled by the

-

power source. It is therefore not necessary to activate the gas pre-flow and

gas post-flow separately.

If the Gas on High signal is set before the Welding start signal, the gas pre-

-

flow of the power source is not active.

The Gas on signal can only be set if the Robot ready signal is set at the same

-

time. If this is not the case, the gas flow must be activated by pressing a button on one of the Fronius system components (power source, wirefeeder,

torch hosepack, etc.).

Additional information for TWIN systems:

In single wire mode with a Single-torch body, the gas solenoid valve of the

-

active process line is opened.

In TWIN mode, both gas solenoid valves are opened.

-

When welding with a TWIN torch body, both gas solenoid valves are always

-

opened.

The Wire forward signal activates the start of the wirefeeder.

10

The wire electrode is threaded into the hosepack without current or gas.

-

The wirefeeder can be activated independently of the operating mode (in-

-

ternal parameter selection, special 2-step mode characteristics, Job Mode,

etc.).

The signal corresponds to the wire threading button on the control panel of

-

the power source, on the wirefeeder, and on the torch hosepack. The precise

function of the wire threading button is described in the Operating Instructions of the respective system components/the documentation of the whole

welding system.

As long as the Wire forward signal is set, the Wire backward signal cannot be

-

set.

The Wire forward signal can only be set if the Robot ready signal is set at the

-

same time. If this is not the case, wire threading must be controlled using the

wire threading button on one of the Fronius system components (wirefeeder,

torch hosepack, etc.).

The wire electrode can be threaded a maximum of 50 m (164 feet 0.5 inches)

-

(=safety stop).

The signal can be set in two ways:

Pulse signal = wire electrode moves approx. 1 mm (0.039 inches) forwards.

-

Continuous signal = creep function – the wirefeeder is stopped as soon as

-

the wire electrode touches the welding material.

Additional information for TWIN systems:

In single wire mode, the wire electrode of the active process line is fed.

-

In TWIN mode, both wire electrodes are fed.

-

If the TWIN operating mode changes during wirefeeding, the wirefeeding is

-

adapted in line with the change.

EN-US

Wire backward

(Wire return) Single Bit

The Wire backward signal activates the retraction of the wire electrode.

It can be used to retract the wire electrode out of the welding torch com-

-

pletely or only by a specific length.

The retraction can be activated independently of the operating mode (intern-

-

al parameter selection, special 2-step mode characteristics, Job Mode, etc.).

The signal corresponds to the wire-return button on the control panel of the

-

power source, on the wirefeeder, and on the torch hosepack. The precise

function of the wire-return button is described in the Operating Instructions

of the respective system components/the documentation of the whole welding system.

As long as the Wire backward signal is set, the Wire forward signal cannot be

-

set.

The Wire backward signal can only be set if the Robot ready signal is set at

-

the same time. If this is not the case, retraction of the wire electrode must

be controlled using the wire-return button on one of the Fronius system

components (wirefeeder, torch hosepack, etc.).

The wire electrode can be retracted a maximum of 50 m (164 feet 0.5

-

inches) (=safety stop).

The signal can be set in two ways:

Pulse signal = wire moves approx. 1 mm (0.039 inches) backwards.

-

Continuous signal = permanent wire retraction.

-

Additional information for TWIN systems:

In single wire mode, the wire electrode of the active process line is fed.

-

In TWIN mode, both wire electrodes are fed.

-

If the TWIN operating mode changes during wirefeeding, the wirefeeding is

-

adapted in line with the change.

11

Error reset (Reset error)

If an error message is output on the power source, the error is reset using the Error reset signal.

In order to reset the signal successfully, the signal must remain set for at least

10 ms.

WARNING!

Danger due to welding processes starting unexpectedly.

This can result in severe personal injury and damage to property.

The cause of the error must always be resolved before the error message is

▶

reset using the Error reset signal.

WARNING!

Danger due to welding processes starting unexpectedly if the Error reset signal

is always active and the Welding start signal is set at the same time.

This can result in severe personal injury and damage to property.

Ensure that the Welding start signal is not set during troubleshooting if the

▶

Error reset signal is active at the same time.

Additional information for TWIN systems:

The signal resets the error on both power sources.

Touch sensing

(TouchSensing) Single Bit

CAUTION!

Danger from unexpected electric shock.

When Touch sensing is activated, a voltage of approx. 70 V (up to 3 A) is applied

to the wire electrode/gas nozzle.

If touched, a harmless but perceptible electric shock can be transmitted. An involuntary reaction to this shock can cause injuries.

Do not touch the wire electrode and the torch body (gas nozzle, contact tip)

▶

when Touch sensing is active.

When Teach mode is active, do not touch any electrically conductive parts

▶

that are touched by the wire electrode and the torch body (gas nozzle, contact tip, etc.).

The Touch sensing signal can be used to detect contact between the wire electrode or the gas nozzle and the workpiece = short circuit between workpiece and

wire electrode or gas nozzle.

If the Touch sensing signal is set, the control panel of the power source dis-

-

plays touch and a voltage of approx. 70 V (current limited to 3 A) is applied

to the wire electrode/the gas nozzle.

If a short circuit occurs, this is reported to the robot controller by the Arc

-

stable signal / Touch signal (see page 30) and Touch signal (see page 36).

The output of the Arc stable / Touch signals (see page 30) and Touch signal

-

(see page 36) lasts 0.3 seconds longer than the duration of the short circuit

current.

As long as the Welding start signal is set, the Touch sensing signal cannot be

-

activated.

The welding process can also be started if the TouchSensing signal is active.

-

This automatically deactivates the touch function.

TouchSensing can be activated independently of the operating mode (intern-

-

al parameter selection, special 2-step mode characteristics, Job Mode, etc.).

12

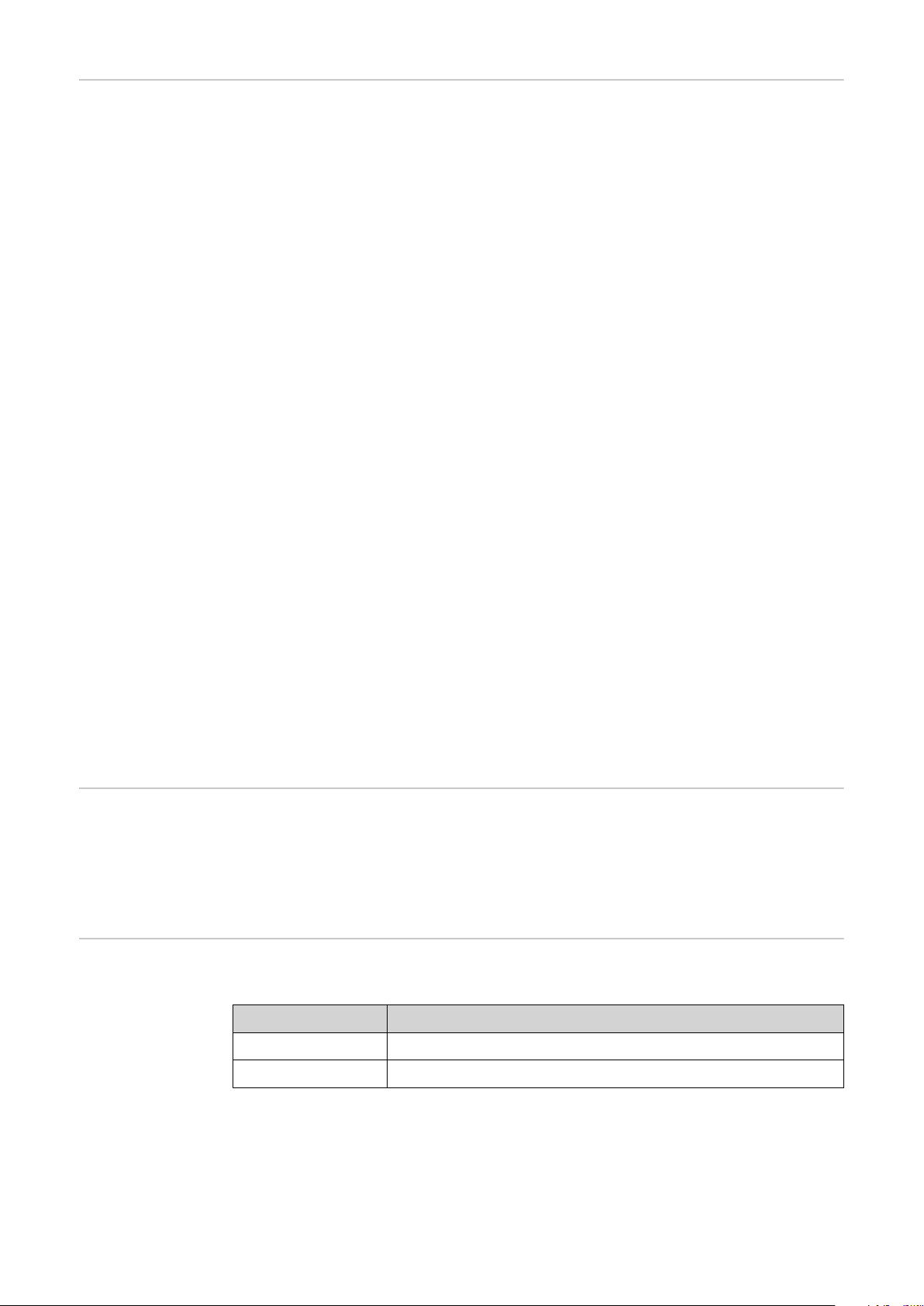

Touch sensing function/process:

t

t

t

U

plus. 300ms * or as long as the wire touches the work piece

I

< 15ms *

t

* timing depends Interface

delta u (rising voltage) --> delta t (time)

Condition: voltage drop i.e. 1,5 volt (adjustable)

max. Open circuit voltage

depends on PowerSource type (i.e. 60V)

max. current aprox. 3A

digital I/O

digital I/O

Touchvoltage

Touchcurrent

Output signal

Input signal

EN-US

NOTE!

Risk of signal overlap.

This can lead to problems in connection with the Wirebrake option.

▶

Additional information for TWIN systems:

-

-

-

After deactivating the Touch sensing signal, wait 4 seconds before setting

another signal.

Touch sensing is started on both power sources, but is only ever carried out

on one wire electrode.

In single wire mode, the wire electrode of the active process line is used.

In TWIN mode, the wire electrode of the leading process line (Lead) is used only when the wire electrode of the Lead-power source is touched are the

Touch Sensing signals generated.

13

Additional information for Touch sensing with the gas nozzle:

If the position detection is carried out by touching the workpiece with the

-

gas nozzle (instead of the wire electrode), the gas nozzle must be connected

to the welding current lead using an RC circuit or the Touch Sensing Adv. option.

The use of an RC circuit is required so that if the gas nozzle comes into con-

-

tact with the workpiece during welding:

Unacceptable currents in the connection between the gas nozzle and the

-

welding current lead are avoided.

The welding process is not influenced.

-

When the position is detected by contact with the gas nozzle, the short cir-

-

cuit current flows until the capacitors of the RC circuit are charged (a few

milliseconds). To ensure safe position detection by the robot controller, the

Arc stable and Touch sensing signals are on for 300 milliseconds longer than

the short circuit current.

Torch blow out

(Blow out welding torch) Single Bit

Welding simulation (Welding

simulation) Single Bit

Synchropulse on

(SynchroPulse

on) - Single Bit

If the robot wirefeeder is fitted with an additional solenoid valve for compressed

air, this is controlled using the Torch blow out signal.

The signal is used to remove contaminations from the gas nozzle during torch

cleaning.

The power source uses the Welding simulation signal to simulate an actual welding process.

This allows the user to follow a welding path that has been programmed in

-

the robot controller without any actual welding taking place.

All signals are set as if actual welding were taking place (no actual values)

-

Process active

-

Current flow

-

Arc stable

-

Robot motion release

-

Main current signal.

-

No arc is ignited (Welding start signal).

-

No wire electrode is moved (Wire forward and Wire backward signal).

-

The gas solenoid valve is not triggered ( Gas on signal).

-

The gas purging valve is not triggered ( Torch blow out signal).

-

The Synchropulse on signal activates/deactivates the SynchroPulse function set

in the power source. The signal can be set before or during welding.

WireBrake on

(Wire brake on) Single Bit

14

By activating the WireBrake on signal, the wire electrode is held by the OPT/i

MHP WireBrake.

OPT/i MHP WireBrake is a mechanical component that is installed between the

torch hosepack and the torch body.

WireBrake on can be activated independently of the operating mode (internal

parameter selection, special 2-step mode characteristics, Job Mode, etc.).

If OPT/i MHP WireBrake is detected in the system, the WireBrake on signal is

automatically set in Touch sensing.

NOTE!

Risk of signal overlap.

This may result in problems holding the wire electrode.

It is not recommended to activate any other signals while the WireBrake on

▶

signal is active.

After deactivating the WireBrake on signal, wait 4 seconds before activating

▶

another signal.

A detailed description of the program sequence can be found in the Robacta

▶

TX 10i/G/W Operating Instructions.

Additional information for TWIN systems:

WireBrake is not available for TWIN hosepacks.

EN-US

Torchbody

Xchange

(Change torch

body) - Single Bit

Teach mode Single Bit

The Torchbody Xchange signal is only available in conjunction with a torch body

change system.

If the signal is High,, the torch body coupling is opened.

Torchbody Xchange can be activated independently of the operating mode (internal parameter selection, S2-step mode characteristics, Job Mode).

NOTE!

Risk of signal overlap.

This may result in problems changing the torch body.

It is not recommended to activate any other signals while the Torchbody

▶

Xchange signal is active.

After deactivating the Torchbody Xchange signal, wait 3 seconds before ac-

▶

tivating another signal.

A detailed description of the program sequence can be found in the Operat-

▶

ing Instructions of the torch body change system.

WARNING!

Danger from electrical current due to Teach mode being active. When Teach

mode is active, a voltage of approx. 70 V (up to 3 A) is applied to the wire electrode/contact tip.

This may result in serious injuries or death.

Do not touch the wire electrode and the contact tip when Teach mode is act-

▶

ive.

When Teach mode is active, do not touch any electrically conductive parts

▶

that are touched by the wire electrode or the contact tip.

Teach mode can be used to create the robot program. Teach mode being activated (signal High) avoids the wire electrode becoming bent when setting up the

robot.

Teach mode can be activated independently of the operating mode (internal

parameter selection, special 2-step mode characteristics, Job Mode, etc.).

Teach mode function:

15

= 15 mm

(0.59 inch)

Ensure the desired distance (Stickout) to the

< 15 mm

(0.59 inch)

= 15 mm= 5 mm= 5 mm= 5

(0.59 inch)

mm

-

workpiece (cut the wire electrode to the correct Stickout , etc.).

If the distance between the gas nozzle and

-

the workpiece becomes smaller during robot

movement, the wirefeeder retracts the wire

electrode – this means that the wire electrode cannot be bent.

If the distance between the gas nozzle and

-

the workpiece becomes bigger during robot

movement, the wirefeeder unwinds the wire

electrode to the set Stickout .

The wire electrode will not be unwound any

-

further once the set Stickout-value has been

reached, even if the wire electrode is no

longer in contact with the workpiece.

The Touch signal is set as follows when using Teach mode:

As soon as the wire electrode touches the workpiece, the Touch signal is set

-

to High.

Only when the wire electrode is no longer in contact with the workpiece is

-

the Touch signal set to Low.

NOTE!

Danger from using Teach mode in conjunction with very soft wire electrodes.

This may result in unexpected welding results caused by bent wire electrodes.

Using Teach mode with very soft wire electrodes may result in the wire elec-

▶

trodes becoming bent. To prevent wire burn-back caused by the bent wire

electrode, unwind the wire electrode by approx. 50 mm (1.97 inch) before the

start of welding and shorten it.

Additional information for TWIN systems:

In single wire mode, Teach mode is activated for the active process line.

-

In TWIN mode, Teach mode is activated for both process lines

-

The scanning frequency of the wire electrode at a component contact

-

with the Lead-power source is higher than the scanning frequency with

the Trail-power source.

ExtInput 1-8

(External input

1-8) - Single Bit

16

Inputs used to control options, such as OPT/i RI FB REL.

Max. voltage = DC 113 V / AC 68 V

-

Max. current load 1 A

-

Example outputs: ExtInput1 = OPT_Output 1.

The inputs have no effect on other signals (for example Robot ready, etc.)

OPT/i RI

FB REL

(1)

External

Device

(2) (3)

(1) Robot output

(2) Power source input

(3) Options output

Additional information for TWIN systems:

TWIN systems are only compatible with the OPT/i RI FB REL EXT 8I/8O op-

-

tion.

The signals are forwarded to both power sources and are then available at

-

the outputs of the relay station used.

EN-US

Job number

(Job‑number) Group Input

Welding characteristic (Characteristic number)

- Group Input

This signal is used to carry out welding using the welding parameters that are

saved under the selected job number (1-1000).

Job number 0 can be used to select the job on the control panel of the power

source.

Additional information for TWIN systems:

Job numbers must be selected separately for both power sources.

This signal is used to specify the welding process using the characteristic number.

Characteristic number 0 can be used to select the material setting and the welding process on the control panel of the power source.

Examples of characteristic numbers:

2765 = G3Si1 / 1.2 mm / Ar 15-20%, CO2 / LSC

-

3189 = G3Si1 / 1.2 mm / Ar 15-20%, CO2 / PMC

-

Additional information for TWIN systems:

Characteristic numbers must be selected separately for both power sources.

17

Disable process

control (Deactivate process-dependent correction) - Group Input

If this signal is active, a process-dependent correction (Process controlled correction signal) can be manually selected on the power source.

Additional information for TWIN systems:

Process-dependent corrections must be activated separately for both power

sources.

Processline select (Process line

selection) Group Input

This signal is used to select the desired process line.

The signal is only available if:

The OPT/i TPS Dual Head Robotics option is present in the power source.

-

Each process line has its own wirefeeder.

-

Bit 1 Bit 0 Description

0 0 Wirefeeder 1 (factory setting)

0 1 Wirefeeder 2

1 0 Wirefeeder 3

Function information:

It is only possible to switch between the process lines using the robot.

-

The inactive wirefeeders are only supplied with voltage, the system bus is

-

switched off. This has the following limitations:

Available software updates will only be applied to the wirefeeder if the

-

wirefeeder is part of the process line selected.

The CAT signal of inactive wirefeeders is not evaluated.

-

It is not possible to carry out gas tests, wire threading, wire retraction,

-

etc. on the hosepacks of the inactive process lines.

The welding torch identification of hosepacks of the inactive process

-

lines is not read.

The remote controls of the inactive process lines are also inactive.

-

TWIN mode

(TWIN operating

mode) - Group

Input

This signal defines which TWIN mode will be used to operate the respective

power source.

The following can be specified using the signal:

Single wire / or TWIN welding.

-

Which process line is leading during TWIN welding (Lead).

-

Which process line is active during single wire welding.

-

The operating modes can be changed both before and during welding.

Bit 32 Bit 33 Description

0 0 Single wire mode, line 1

0 1 TWIN mode, line 1 leading (Lead)

1 0 TWIN mode, line 2 leading (Lead)

1 1 Single wire mode, line 2

Value range for TWIN mode

18

Contact tip short

circuit detection

on (contact tip

short circuit detection on) Single Bit

If this signal is set to High, a short circuit check between the two contact tips in

the TWIN welding torch starts.

If a short circuit is detected, the signal Short circuit contact tip is set high.

-

This signal is only available for TWIN systems operating in TWIN mode (not available for single wire operation).

EN-US

Documentation

mode (Documentation mode)

- Single Bit

WireSense start

- Single Bit

The signal is used to select whether the weld seams are counted by the power

source or the robot.

Signal level = Low:

The weld seams are counted by the power source.

-

Each time welding is completed, the weld seam count increases by 1. Switch-

-

ing the power source off and on again restarts the count at 0. In addition, it

is also possible to specify an initial value (starting the count at 10 instead of

0, for example).

With the exception of: If the Fronius Data Channel is used, the number

-

of weld seams is specified using the Fronius Data Channel and not the

power source.

Signal level = High:

The number of weld seams is specified using the robot.

-

WARNING!

Danger from electrical current. When the WireSense start signal is active, a

voltage of approx. 50 V (up to 1 A) is applied to the wire electrode/contact tip.

This may result in serious injuries or death.

Do not touch the wire electrode and contact tip when the WireSense start

▶

signal is active.

Do not touch any electrically conductive parts that are touched by the wire

▶

electrode or the contact tip when the WireSense start signal is active.

This signal starts one of the following two functions:

Function WireSense - Sensing Mode (= contour detection): Used for scan-

1.

ning the component surface / component geometry

This function is active when the Signal WireSense start is activated and a

-

height value less than 0.5 mm (0.019 inches) is specified for the WireSense edge detection signal.

Edge detection (WireSense - Edge Detection Mode function) is not active

-

with this function.

The Touch signal is not output for this function.

-

WireSense - Edge Detection Mode function (= edge detection): Used to de-

2.

tect a single edge

This function is active when the Signal WireSense start is activated and a

-

height value greater than / equal to 0.5 mm (0.019 inches) is specified

for the WireSense edge detection signal.

For more information, see WireSense edge detection - Group Input /

-

Analog Input on page 24.

19

Other effects of the WireSense start signal:

As soon as the signal is active, the forward and backward movement of the

-

wire electrode begins.

After the wire electrode has touched the workpiece for the first time, the

-

point of the first contact is used as a zero position (reference point) for the

WireSense height measurement.

Safety functions with WireSense:

If WireSense is already active (WireSense process already running), the wire

-

electrode can be conveyed a maximum of 25 mm (0.98 inches). If there is no

workpiece contact within 25 mm (0.98 inches), wirefeeding is stopped.

If WireSense is started for the first time (without previous workpiece con-

-

tact), the wire electrode can be conveyed a maximum of 450 mm (17.72

inches). If there is no workpiece contact within 450 mm (17.72 inches),

wirefeeding is stopped.

For more information on WireSense, see section WireSense - more information

from page 56.

Additional information for TWIN systems:

In single wire mode, WireSense is only activated and evaluated for the active

-

process line.

In TWIN mode, WireSense is activated for both process lines. Please note

-

the following:

The Touch signal, which can be output at the WireSense edge detection,

-

is only triggered by the Lead-power source.

The position signals during contour detection(WireSense - Sensing

-

Mode) are output at the interface with two individual output signals simultaneously - with the Signal Wire position for power source 1 and power

source 2.

WireSense break

- Single Bit

This signal only has an impact if the WireSense start signal is active at the

-

same time.

This signal is used to interrupt the WireSense process but at the same time

-

to obtain the reference point that was determined when the WireSense process was first started.

The WireSense break signal stops the wire movement while the Wire-

-

Sense start signal is active - for example, to bridge larger distances

between two workpieces (if the wire electrode is touching a workpiece

while the WireSense break signal is active, the wire electrode is still retracted to prevent bending).

The reference point, which was determined when the WireSense process

-

was first started, remains stored while the WireSense break signal is active.

After the WireSense break signal is deactivated, the wire movement

-

starts again and the height measurement continues.

When the WireSense break signal is set, the Arc stable signal is disabled at

-

the same time. As soon as the WireSense break signal is deactivated again,

the Arc stable signal is reactivated.

For more information on WireSense, see section WireSense - more information

from page 56.

Additional information for TWIN systems:

In single-wire operation, WireSense break nur die Drahtelektrode der aktiven

-

Prozesslinie stops.

In TWIN mode, WireSense break beide Drahtelektroden stops.

-

20

Analog Inputs

EN-US

Wire feed speed

command value

(Wire speed set

value) - Group

Input / Analog

Input

As described below, the set value can be specified on a Digital Interface or an

Analog Interface.

The following set value specifications apply to the MIG/MAG standard synergic,

MIG/MAG pulse synergic, MIG/MAG PMC, MIG/MAG LSC, CMT, and ConstantWire welding processes.

Digital Interface:

The wirefeeder set value is specified by entering a value between -32,768 and

+32,767 (SINT 16).

Value range Designation Min./max. possible value

-32,768 Wirefeeder -327.68 m/min (depending on wirefeeder)

+32,767 Wirefeeder +327.67 m/min (depending on wirefeeder)

Additional information for TWIN systems:

The digital set value must be entered separately for both power sources.

Analog Interface:

The wirefeeder set value is specified through an analog method by entering a

value between 0 and 10 V.

Value range Designation Min./max. possible value

0 V Wirefeeder 0% (depending on wirefeeder)

Arclength correction (arc

length correction) - Group Input / Analog Input

10 V Wirefeeder 100% (depending on wirefeeder)

Additional information for TWIN systems:

It is not possible to enter an analog set value on TWIN systems.

Job correction (specifications apply for Single- and TWIN welding):

Factor = 100

-

Data type SINT

-

Specified as a percentage. Example: 15% = 1500 step change.

-

As described below, the value for the arc length correction can be specified on a

Digital Interface or an Analog Interface.

The following specifications apply to the MIG/MAG standard synergic, MIG/MAG

pulse synergic, MIG/MAG PMC, and MIG/MAG LSC welding processes.

Digital Interface:

By entering a value between -32,768 and +32,767 (SINT 16) the arc length is

corrected, but the wire speed is not changed.

Value range Designation Min./max. possible value

-32,768 Arc length correction -10% = shorter arc

0 Arc length correction 0% = saved value

+32,767 Arc length correction +10% = longer arc

Additional information for TWIN systems:

The digital set value must be entered separately for both power sources.

21

Analog Interface:

By entering a value between 0 and 10 V using an analog method, the arc length

is corrected, but the wire speed is not changed.

Value range Designation Min./max. possible value

0 V Arc length correction -10% = shorter arc

5 V Arc length correction 0% = saved value

10 V Arc length correction +10% = longer arc

Additional information for TWIN systems:

It is not possible to enter an analog set value on TWIN systems.

Job correction (specifications apply for Single-and TWIN welding):

Factor = 10

-

Data type SINT

-

Specified as absolute value. Example: 1.5 = 150 step change.

-

Pulse-/ dynamic

correction

(Pulse/dynamic

correction) Group Input /

Analog Input

As described below, the value for the pulse/dynamic correction can be specified

on a Digital Interface or an Analog Interface.

The following specifications apply to the MIG/MAG standard synergic, MIG/MAG

pulse synergic, MIG/MAG PMC, and MIG/MAG LSC welding processes.

Digital Interface:

Entering a value between -32,768 and +32,767 (SINT 16) specifies the pulse/

dynamic correction, the wire speed is not changed.

Value range Designation Min./max. possible value

-32,768 Pulse/dynamic correction -10% = pulse/dynamic correction

0 Pulse/dynamic correction 0% = saved value

+32,767 Pulse/dynamic correction +10% = pulse/dynamic correc-

tion

Additional information for TWIN systems:

The digital set value must be entered separately for both power sources.

Analog Interface:

Entering a value between 0 and 10 V using an analog method specifies the

pulse/dynamic correction, the wire speed is not changed.

22

Value range Designation Min./max. possible value

0 V Pulse/dynamic correction -10% = pulse/dynamic correc-

tion

5 V Pulse/dynamic correction 0% = saved value

10 V Pulse/dynamic correction +10% = pulse/dynamic correc-

tion

Additional information for TWIN systems:

It is not possible to enter an analog set value on TWIN systems.

Hotwire current

(Hot-wire amperage) - Group Input / Analog Input

As described below, the value for the hot-wire amperage can be specified on a Digital Interface or an Analog Interface.

The following specifications apply to the ConstantWire welding process.

Digital Interface:

The hot-wire amperage is specified by entering a value between 0 and 65,535

(UINT 16).

Value range Designation Min./max. possible value

0 Hot-wire amperage 0

65,535 Hot-wire amperage 6553.5 A

Additional information for TWIN systems:

The digital value must be entered separately for both power sources.

Analog Interface:

The hot-wire amperage is specified by using an analog method to enter a value

between 0 and 10 V.

Value range Designation Min./max. possible value

0 V Hot-wire amperage 0

10 V Hot-wire amperage 100%

(the effective current value de-

pends on the output of the

power source

EN-US

Wire retract correction (Wire retraction correction) - Group Input / Analog Input

Additional information for TWIN systems:

It is not possible to enter an analog value on TWIN systems.

As described below, the value for the wire retraction correction can be specified

on a Digital Interface or an Analog Interface.

The following specifications apply to the MIG/MAG standard synergic, MIG/MAG

pulse synergic, MIG/MAG PMC, MIG/MAG LSC, CMT, and ConstantWire welding

processes.

Digital Interface:

The wire retraction correction is specified by entering a value between 0 and

65,535 (UINT 16).

Value range Designation Min./max. possible value

0 Wire retraction correction 0

65,535 Wire retraction correction +10

Additional information for TWIN systems:

The digital value must be entered separately for both power sources.

Analog Interface:

The wire retraction correction is specified by using an analog method to enter a

value between 0 and 10 V.

Value range Designation Min./max. possible value

0 V Wire retraction correction 0

23

10 V Wire retraction correction +10

Additional information for TWIN systems:

It is not possible to enter an analog value on TWIN systems.

Seam number

(Seam number) Group Input /

Analog Input

Welding speed

(Welding speed)

- Group Input /

Analog Input

WireSense edge

detection Group Input /

Analog Input

The seam number of the respective welding process is specified using this value,

for example for documentation purposes.

For more detailed information regarding weld seam documentation, please refer

to Documentation mode (Documentation mode) - Single Biton page 19.

Additional information for TWIN systems:

The seam number for both power sources is specified at the same time.

This value is used to transmit the robot's TCP speed.

Additional information for TWIN systems:

The TCP speed for both power sources is transmitted at the same time.

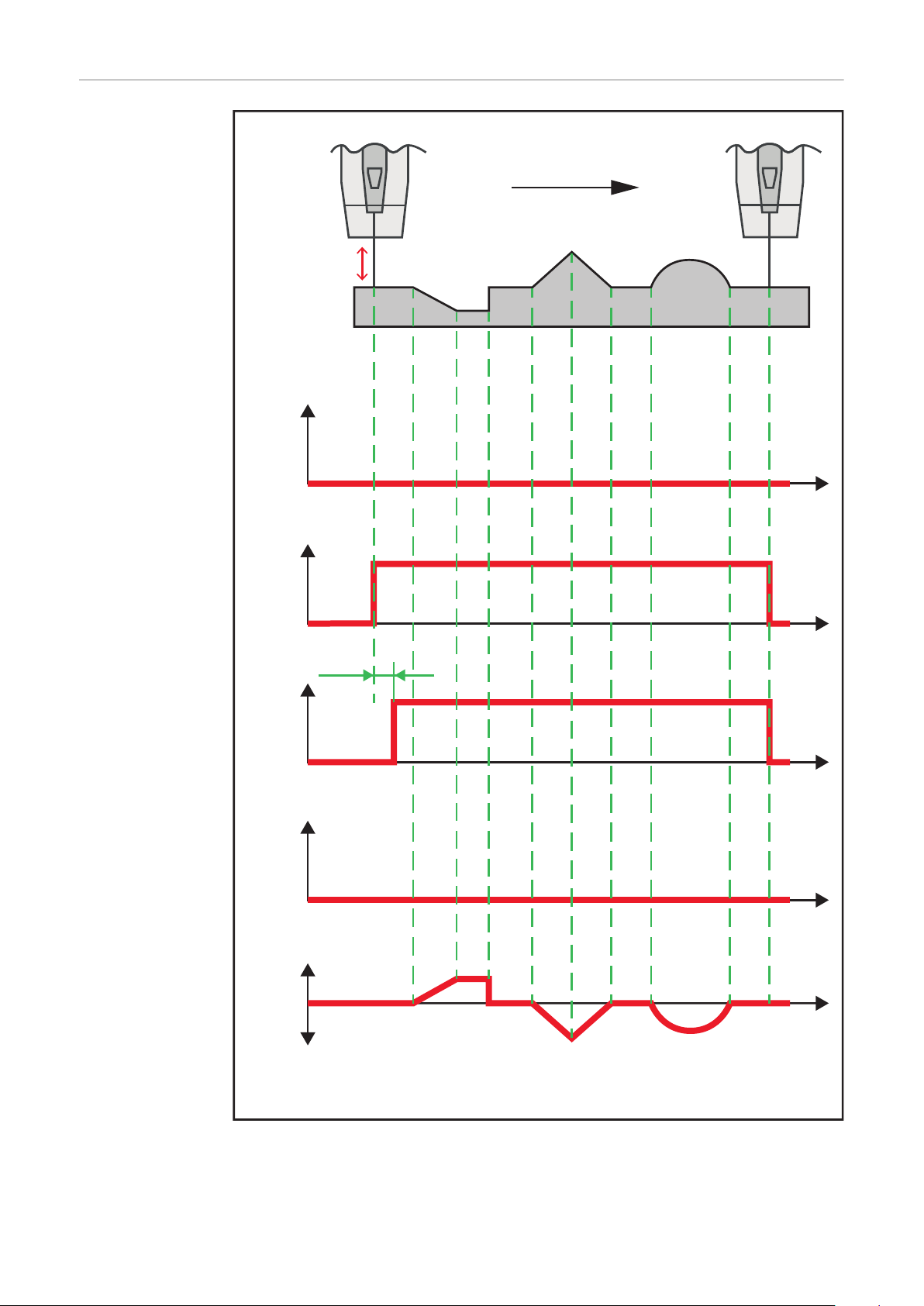

Contour detection (= WireSense - Sensing Mode):

If a value less than 0.5 mm (0.019 inches) is specified with the WireSense

-

edge detection signal, the WireSense start signal is used for contour detection.

The surface of the component is scanned cyclically by the wire electrode

-

and the measured height value is output continuously.

The Touch signal is not active at the same time.

-

Edge detection (= WireSense - Edge Detection Mode):

If a value of 0.5 - 20 mm (0.019 - 0.787 inches) is specified with the Wire-

-

Sense edge detection signal, the WireSense start signal is used to detect and

measure a single edge.

The specified value (threshold value) defines the minimum edge height that

-

can be detected by the power source.

For example, if you use a 2 mm (0.039 inch) thick sheet that is welded

-

with an overlap joint, it is recommended to use this signal to specify 1.5

mm (0.059 inches) (it is not recommended to always set the minimum

value of 0.5 mm (0.019 inches), as this setting may cause false detection.

For example, this may be caused by welding spatter, inaccurate robot

movements, etc.).

The Touch signal is output when an edge is detected.

-

Digital Interface:

The threshold value for edge detection is specified by entering a value between

0 and 200 (UINT 16).

Value range Designation Min./max. possible value

0 Threshold 0 mm (0 inches)

200 Threshold 20 mm (0.787 inches)

For more information on WireSense, see section WireSense - more information

from page 56.

24

Additional information for TWIN systems:

In single wire mode, only the wire electrode of the active process line is used

-

for WireSense edge detection .

In TWIN mode, both wire electrodes are used for WireSense edge detection .

-

The touch signal is only ever generated and output by the Lead-power

source.

The two wire electrodes from the TWIN system can only be used for the

-

same WireSense-function:

Both wire electrodes for either contour detection or edge detection.

-

EN-US

Wire forward /

backward length

(length specification wire

threading / wire

retraction) Group Input /

Analog Input

Signal behavior:

The signal is active as soon as a value greater than or equal to 1 mm (0.039

-

inches) is entered (0 = signal inactive).

If a value greater than or equal to 1 mm (0.039 inches) is specified, the wire

-

electrode is only fed by the specified value when the signal Wire forward is

set. After reaching the preset value, the end of wirefeeding takes place automatically.

As soon as the specified value is reached:

-

The Touch signal (WORD 0 / Byte 0 / Bit 7) is set

-

The signal Wire forward must be deactivated (otherwise the wire thread-

-

ing function remains active)

The signal Wire position is accompanied by an output defining how far

-

the wire electrode has been moved [the value remains set for 1 second;

+/- 1 mm (+/- 0.039 inches)]

If the wire electrode touches the workpiece before the preset value has been

-

reached, the Touch signal (WORD 0 / Byte 0 / Bit 7) and additionally the Arc

stable / Touch signal (WORD 0 / Byte 0 / Bit 5) are set. The end of wirefeeding takes place automatically.

The wire electrode can be conveyed a maximum of 50 m (164 feet 0.5

-

inches) (=safety stop).

If not all wire feeds of the welding system are synchronized (e.g. due to the combination of a Robacta Drive drive unit and a Stand Alone unwind wirefeeder), inaccuracies of +/- 5 mm (+/- 0.196 inches) may occur in the specification of the

wire electrode fed due to the system.

As described below, the set value can be specified on a Digital Interface or an

Analog Interface.

The following set value specifications apply to the MIG/MAG standard synergic,

MIG/MAG pulse synergic, MIG/MAG PMC, and MIG/MAG LSC welding processes.

Digital Interface:

The set value for the length of wire to be fed is specified by entering a value

between -32,768 and +32,767 (UINT 16).

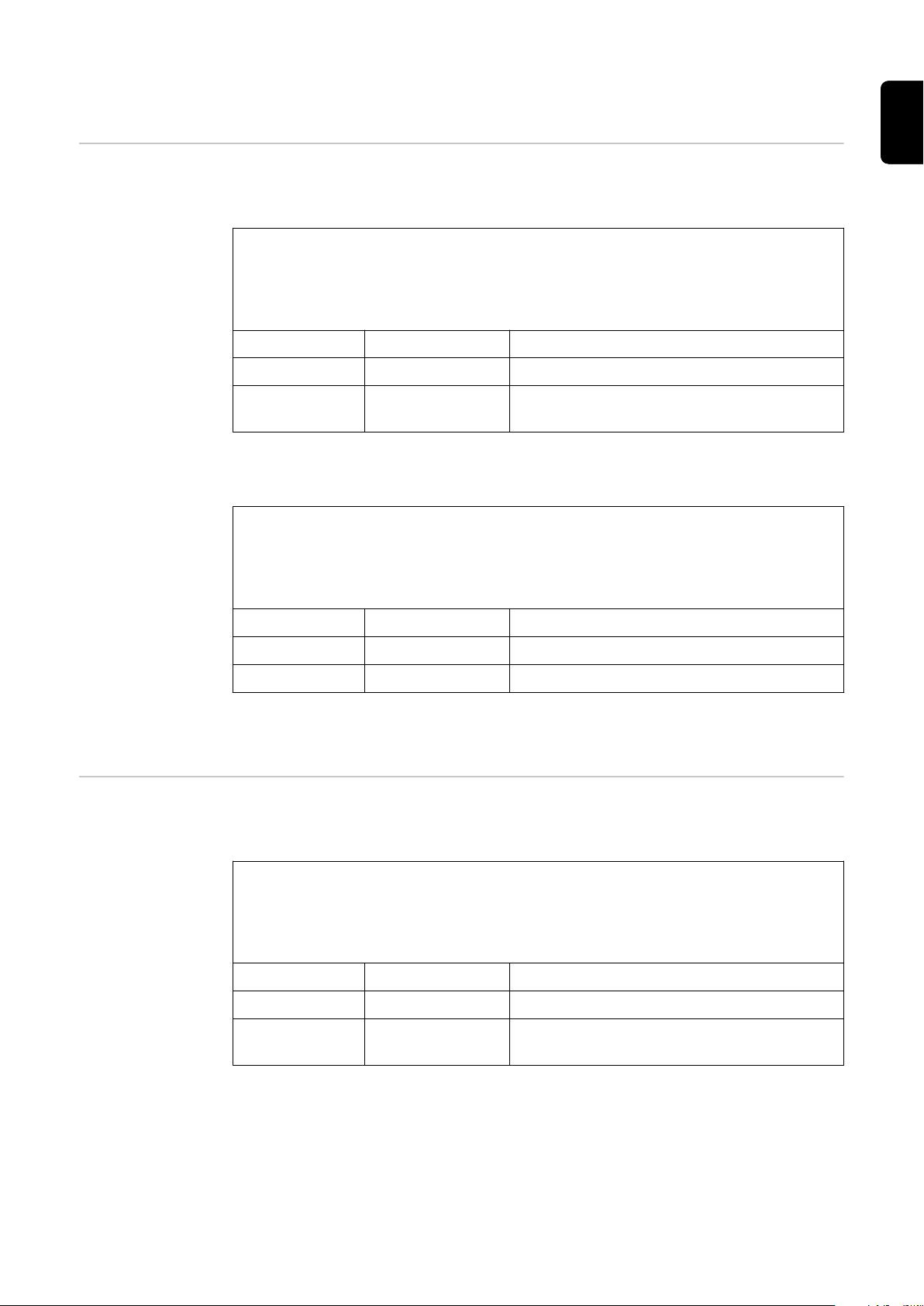

Value range Min./max. possible value

-32,768 1 mm (0.039 inches)

+32,767 10,000 mm (393.7 inches)

Additional information for TWIN systems:

The digital set value must be entered separately for both power sources.

Analog Interface:

The set value for the length of wire to be fed is specified by entering an analog

value of 0 to 10 V.

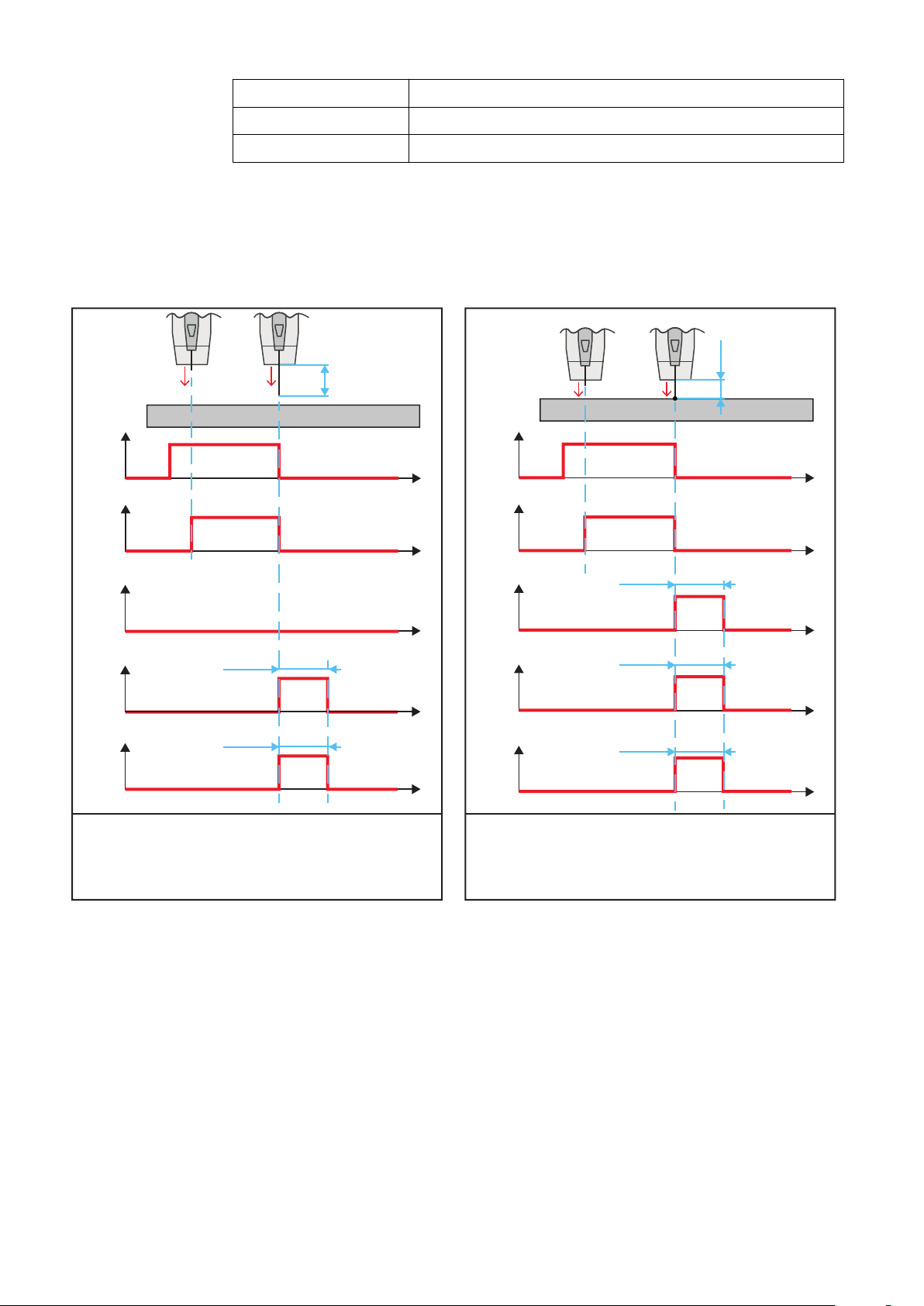

25

Value range Min./max. possible value

1 Second

1 Second

1

2

3

4

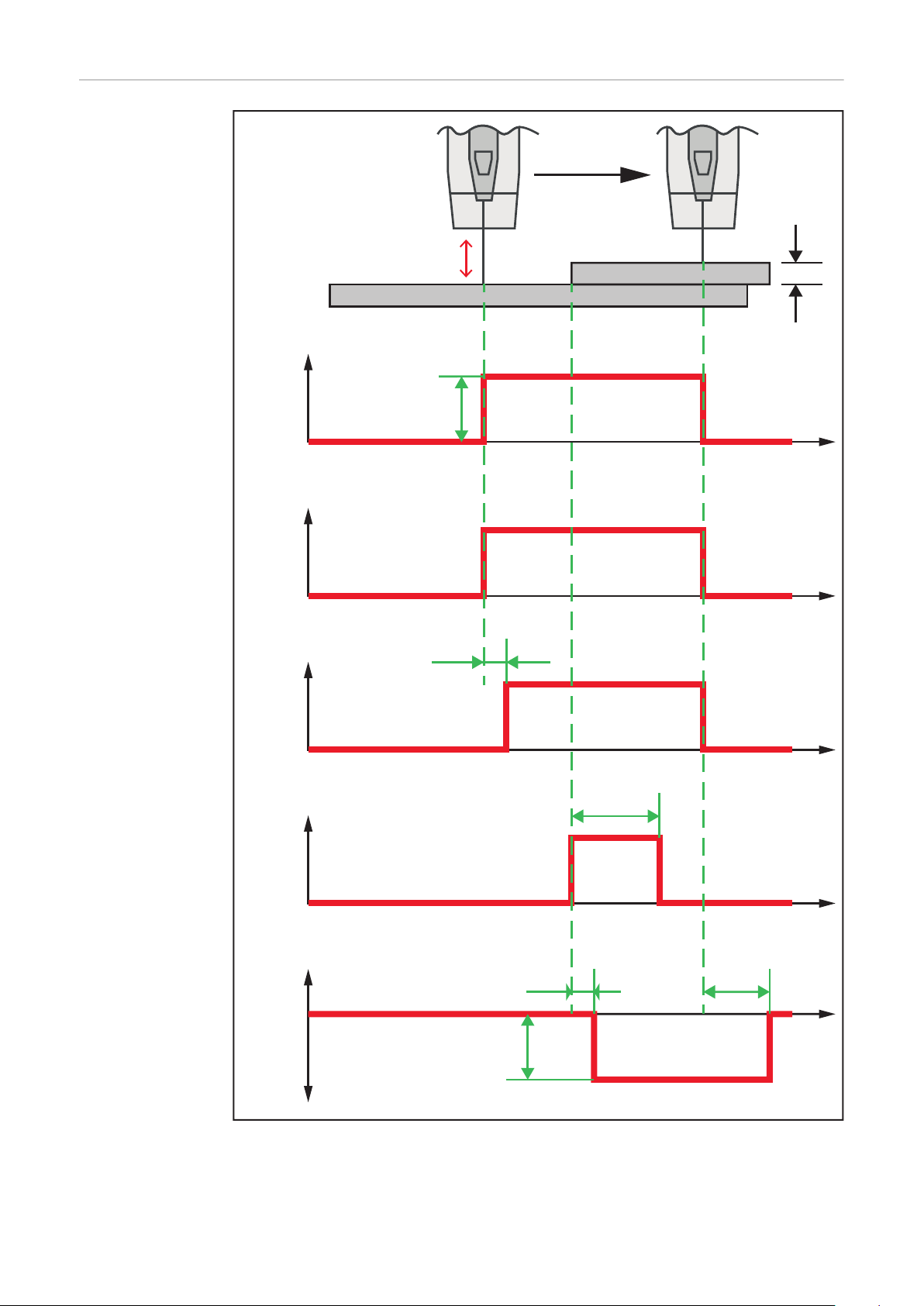

1 = Wire forward / backward length (Analog Input) | Bit 240 - 255

2 = Wire forward (Digital Input) | Bit 9

3 = Arc stable / Touch signal (Digital Output) | Bit 5

4 = Touch signal (Digital Input) | Bit 7

5 = Wire position (Analog Output) | Bit 256 - 271

t

t

t

t

5

t

25 mm

(0.984 inch)

t

t

t

1

2

3

4

5

1 = Wire forward / backward length (Analog Input) | Bit 240 - 255

2 = Wire forward (Digital Input) | Bit 9

3 = Arc stable / Touch signal (Digital Output) | Bit 5

4 = Touch signal (Digital Input) | Bit 7

5 = Wire position (Analog Output) | Bit 256 - 271

t

1 Second

15 mm

(0.591 inch)

t

1 Second

1 Second

0 V 1 mm (0.039 inches)

10 V 10,000 mm (393.7 inches)

Additional information for TWIN systems:

It is not possible to enter an analog set value on TWIN systems.

Signal course - set Wire forward length (= 25

mm / 0.984 inches) could be reached according to plan:

Signal course - workpiece contact occurs be-

fore the set Wire forward length (= 25 mm /

0.984 inches) could be reached:

26

Digital Outputs

(1) (2)

Definition Digital outputs are signals from the power source to the robot.

(1) Robot input

(2) Power source output

EN-US

Heartbeat power

source (Heartbeat power

source) - Single

Bit

Power source

ready (Power

source ready) Single Bit

Warning (Warning) - Single Bit

As soon as the interface creates an authenticated connection to the power

source, this signal changes its activity with a frequency of 1 Hz (1 second High, 1

second Low, 1 second High, etc.).

Additional information for TWIN systems:

As soon as the RI FB/i TWIN Controller establishes an authenticated connection

to both power sources, this signal changes its activity with a frequency of 1 Hz (1

second High, 1 second Low, 1 second High, etc.).

The signal is High when the power source is ready to weld.

-

The signal is Low, if a fault occurs on the power source (Error) or a notifica-

-

tion (Notification) is issued.

The signal can also be called a "common error", as it is set to Low for all

-

types of internal and external error.

Additional information for TWIN systems:

The signal is only set to High when both power sources are ready to weld.

The signal is High when the power source issues a warning.

-

The signal remains High until the reason for the warning has been rectified.

-

The signal automatically changes to Low, as soon as the reason for the warn-

-

ing has been eliminated.

The signal has no effect on the welding process or the operability of the

-

power source (welding can be started; running process is not interrupted,

etc.).

27

Additional information for TWIN systems:

I

t

t-S

t-E

High Low

(1)

Welding start

The signal is set to High as soon as one of the two power sources issues a warning.

Process active

(Process active)

- Single Bit

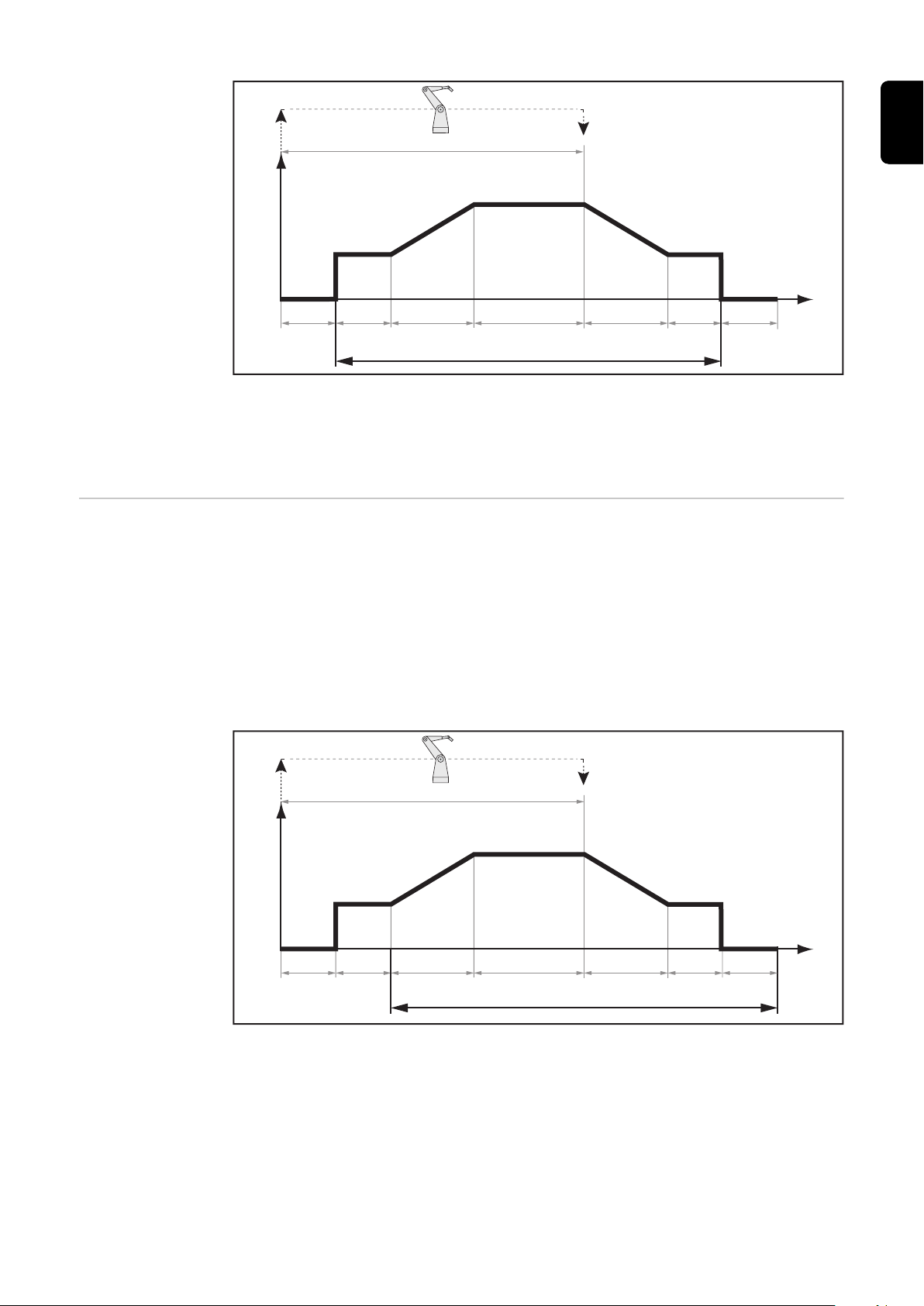

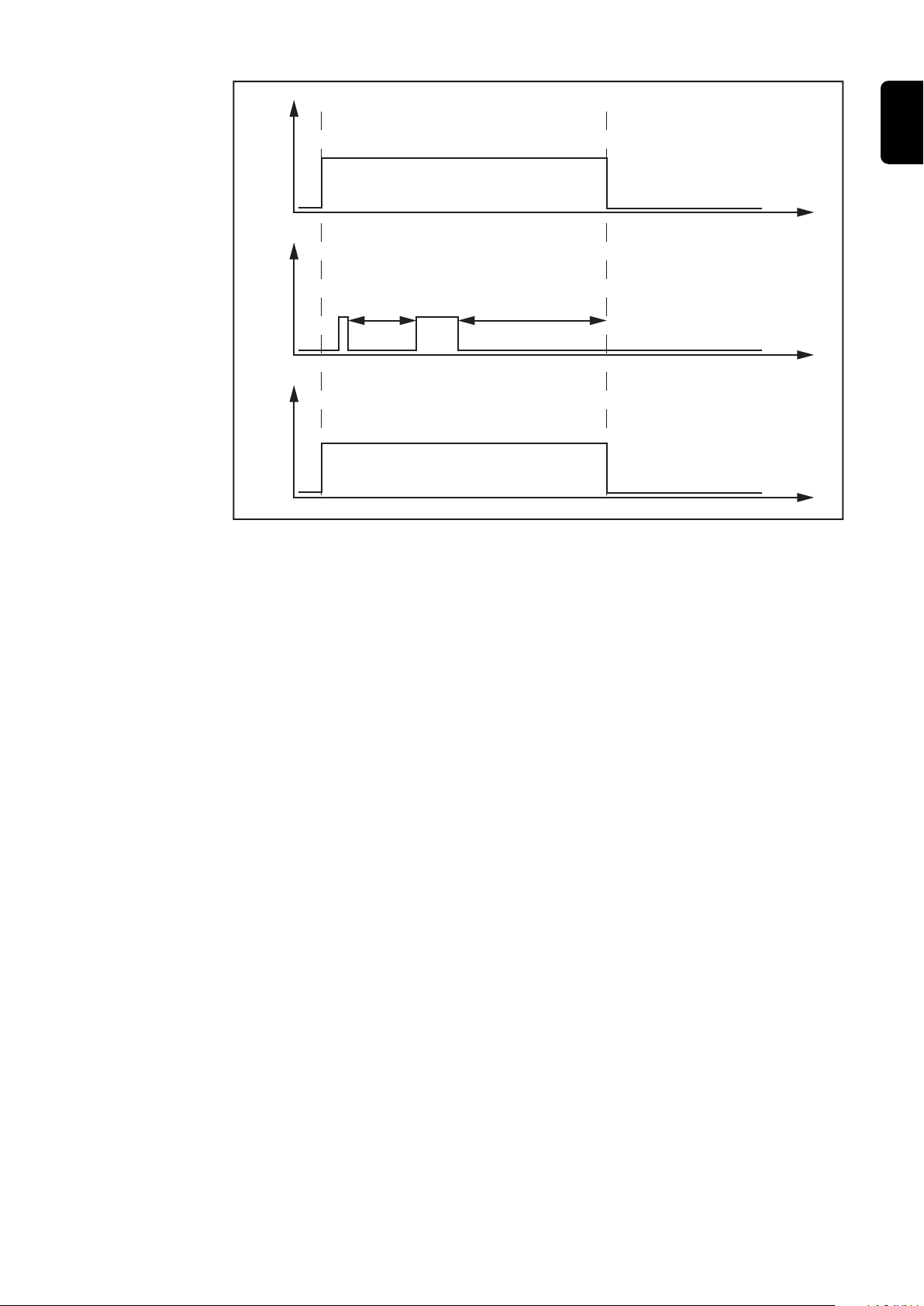

The Process active signal is set from the beginning of gas pre-flow to the end of

gas post-flow in order to inform the robot that welding is still taking place. This

means that, for example, the dwell time of the robot can be synchronized at the

end of the weld seam to ensure that there is an ideal gas shield.

If the Welding start signal is set, the gas pre-flow time begins to count down,

even before the arc is ignited.

After extinguishing the arc, the gas post-flow time begins to count down.

(1) Process active (process active)

Additional information for TWIN systems:

The signal is set as soon as one of the two power sources becomes active.

Current flow

(current flow) Single Bit

This signal is set as soon as the wire electrode touches the workpiece and current

begins to flow – the signal is High as soon as the workpiece is touched.

During welding the signal can fall to Low during all welding processes – the signal functions in the same way for all welding processes.

28

I

t

t-S

t-E

High Low

(1)

Welding start

(1) Current flow (current flow)

I

t

t-S

t-E

High Low

(1)

Welding start

Additional information for TWIN systems:

The signal is set to High as soon as one of the two wire electrodes becomes live.

EN-US

Robot motion release (Robot motion release) Single Bit

The signal is active from the end of the starting current to the end of the gas

post-flow.

The starting current time begins as soon as Current flow is High. Even if Current

flow is interrupted, the starting current time continues to run until the set end

(the starting current time does not reset).

If an arc monitoring time has been set, the Robot motion release signal is only

reset if the Current flow signal is inactive for longer than the set arc monitoring

time.

(1) Robot motion release (Robot motion release)

At the start of welding, the signal is set to High in the following instance:

Arc stable High.

-

Current flow High.

-

The starting current time has elapsed (not the slope time).

-

During welding, the signal is set to Low in the following instance:

Arc stable Low.

-

29

At the end of welding, the signal is set to Low in the following instance:

I

t

t-S

t-E

High Low

(1)

Welding start

Welding start Low.

-

The gas post-flow has ended.

-

Additional information for TWIN systems:

The signal is output separately for both process lines.

Arc stable /

Touch signal

(Arc stable/

touch signal) Single Bit

This signal is set as soon as the wire electrode touches the workpiece and

-

current flows, thus reporting to the robot controller that the arc is burning.

If the Arc stable / Touch signal is active, the arc monitoring is also active.

-

This is not the case for the Current flow signal.

If an arc monitoring time has been set, the Arc stable / Touch signal is only

-

reset if the Current flow signal is inactive for longer than the set arc monitoring time.

The Arc stable / Touch signal is active as long as the arc is burning.

-

The Arc stable / Touch signal is also set as soon as the wire electrode or the

-

gas nozzle comes into contact with the workpiece in Touch mode (Touch

sensing signal is active).

For more information about the Touch sensing signal, see Touch sensing

-

(TouchSensing) - Single Bit on page 12.

When using WireSense, the Arc stable / Touch signal is set as soon as the

-

wire electrode comes into contact with the workpiece for the first time and

the WireSense process runs stable (for example, when the WireSense Slaghammer function is automatically triggered, the Arc stable / Touch signal is only set after the WireSense - Slaghammer function has been successfully executed)

For more information on WireSense, see section WireSense start -

-

Single Bit from page 19.

When unwinding the wire electrode (Wire forward signal), the Arc stable /

-

Touch signal is set as soon as the wire electrode touches the workpiece.

(1) Arc stable / Touch signal (arc stable/touch signal)

30

The signal functions differently depending on the welding process. See below for

Ignition

(Start of Welding)

U

I

t

t

t

Current flowArc stable

Ignition

(Start of Welding)

U

I

t

t

t

Current flowArc stable

an overview of the function of the signal in conjunction with the different welding

processes.

MIG/MAG pulse synergic, MIG/MAG PMC, mixed processes:

Example of correct ignition at the start of welding.

EN-US

MIG/MAG pulse synergic, MIG/MAG PMC, mixed processes:

Example of incorrect ignition at the start of welding.

31

MIG/MAG standard synergic, MIG/MAG standard manual, MIG/MAG LSC,

Ignition

(Start of Welding)

U

I

t

t

Current flowArc stable

t

Ignition

(Start of Welding)

U

I

t

t

Current flowArc stable

t

150-200ms

MIG/MAG CMT, MIG/MAG CMT mixed processes:

Example of correct ignition at the start of welding.

MIG/MAG standard synergic, MIG/MAG standard manual, MIG/MAG LSC,

MIG/MAG CMT, MIG/MAG CMT mixed processes:

Example of incorrect ignition at the start of welding.

32

Additional information for TWIN systems:

I

t

t-S

t-E

High Low

(1)

Welding start

In single-wire operation, the following applies:

-

Once welding is started, the Arc stable / Touch signal is set as soon as

-

the wire electrode comes into contact with the workpiece and current

begins to flow.

In Touch mode, the Arc stable / Touch signal is set as soon as the wire

-

electrode touches the workpiece.

When using WireSense, the Arc stable / Touch signal is set as soon as the

-

WireSense-process is running stably (as soon as the Slaghammer is

ended).

In TWIN operation, the following applies:

-

Once welding is started, the Arc stable / Touch signal is set as soon as

-

both wire electrodes come into contact with the workpiece and current

begins to flow.

In Touch mode the Arc stable / Touch signal is set as soon as the wire

-

electrode of the lead power source or the gas nozzle touches the workpiece.

When unwinding the wire electrode (Wire forward signal), the Arc

-

stable / Touch signal is set as soon as one of the two wire electrodes

touches the workpiece.

When using WireSense, the Arc stable / Touch signal is set as soon as the

-

WireSense-process is running stably with both wire electrodes (as soon

as the Slaghammer is ended).

Additional information for ConstantWire:

In the case of operation with no earth connection, contact of the wire with

-

the workpiece is not detected.

The Arc stable / Touch signal is set automatically as soon as the gas pre-flow

-

is finished.

The Arc stable / Touch signal is automatically deactivated as soon as the

-

Welding start signal is deactivated.

EN-US

Main current signal (main current

signal) - Single

Bit

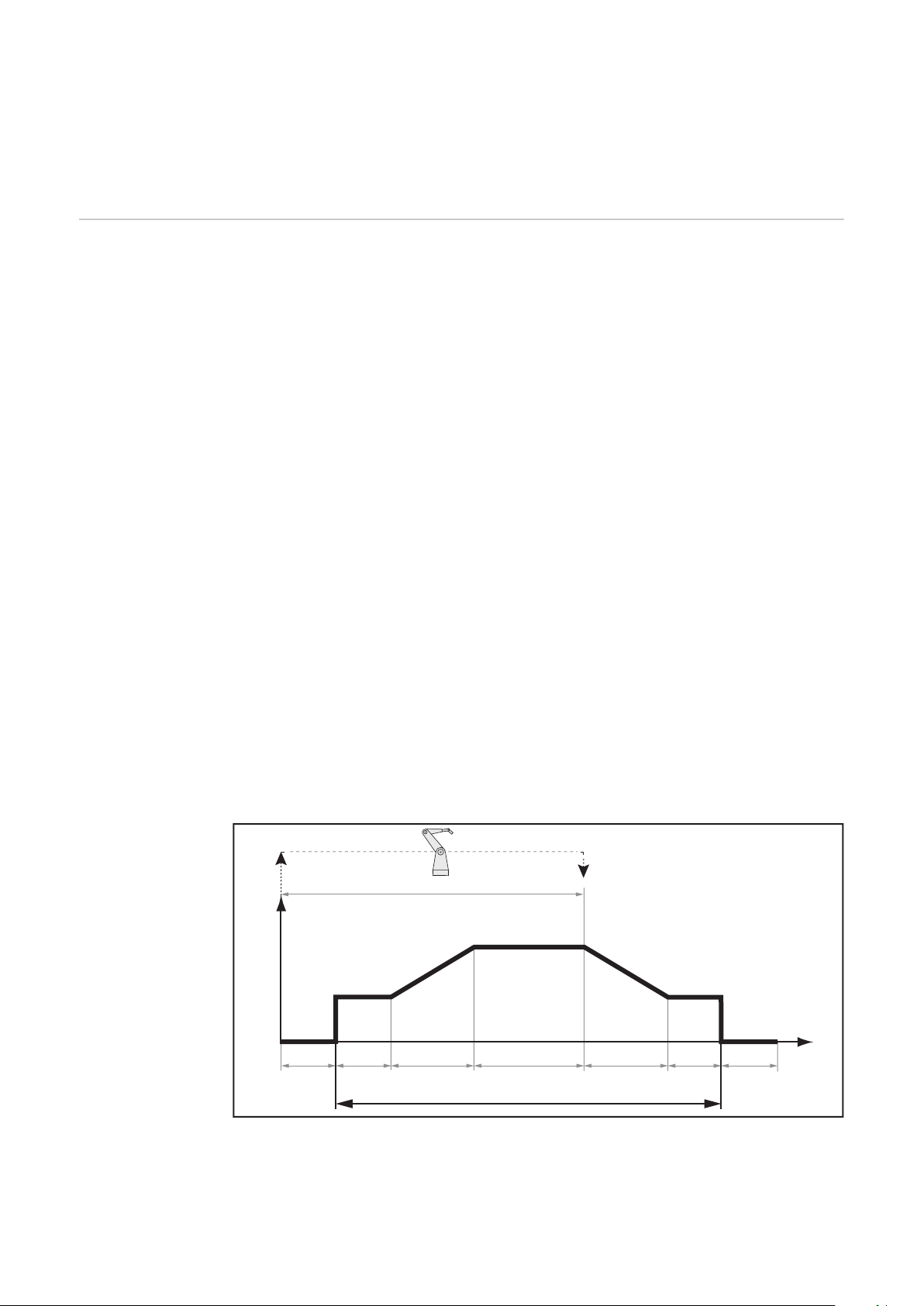

If welding is carried out with a defined starting current and a defined final current, the Main current signal is set between the end of the starting current and

the start of the final current phases.

(1) Main current signal (main current signal)

33

Additional information for TWIN systems:

In single wire mode, the signal is set as soon as the active process line starts

-

welding using the main current.

In TWIN mode, the signal is set as soon as both process lines start welding

-

using the main current.

Collisionbox active (CrashBox

active) - Single

Bit

Torchbody

gripped (Torch

body gripped) Single Bit

Command value

out of range (set

value out of

range) - Single

Bit

If a collision occurs (with the workpiece, clamping device, etc.) while using the

CrashBox, the contact of the CrashBox is opened and the Collisionbox active signal is set to Low.

In this case, it is recommended that:

Immediate shutdown of the robot is initiated.

-

The welding process is ended.

-

The signal has no effect on the power source.

This signal indicates that a Fronius torch body has been registered in the system.

This signal indicates that the „Wire feed speed command value“ input is outside

of the possible range.

The signal is High if, for example:

The possible range is limited by the wirefeeder:

-

Selected wirefeeder set value = 25 m/min (984.25 inches/min)

-

Maximum wirefeeder set value based on characteristic = 25 m/min

-

(984.25 inches/min)

Maximum possible speed of the wirefeeder = 15 m/min (590.55 inches/

-

min).

The possible range is limited by the characteristic:

-

Selected wirefeeder set value = 25 m/min (984.25 inches/min)

-

Maximum wirefeeder set value based on characteristic = 15 m/min

-

Maximum possible speed of the wirefeeder = 30 m/min (1181.1 inches/

-

min).

Correction out

of range (Correction out of

range) - Single

Bit

Process Bit (Process bit) - Group

Output

34

Additional information for TWIN systems:

The signal is set as soon as one of the two process lines exceeds a defined range.

This signal indicates that at least one of the selected corrections (for example,

Arc length correction) is outside of the specified range.

Additional information for TWIN systems:

The signal is set as soon as one of the selected corrections exceeds the defined

range.

These signals indicate which welding process has been selected.

Value range for welding process:

OPT/i RI

FB REL

(1)

External

Device

(2) (3)

Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Description

0 0 0 0 0 No internal mode selection or process

0 0 0 0 1 MIG/MAG pulsed synergic

0 0 0 1 0 MIG/MAG standard synergic

0 0 0 1 1 MIG/MAG PMC

0 0 1 0 0 MIG/MAG LSC

0 0 1 0 1 MIG/MAG standard manual

0 0 1 1 0 Electrode

0 0 1 1 1 TIG

0 1 0 0 0 CMT

0 1 0 0 1 ConstantWire

EN-US

ExtOutput 1-8

(External output

1-8) - Single Bit

Outputs used to control options, such as OPT/i RI FB REL.

Max. voltage = DC 113 V / AC 68 V

-

Max. current load 2 A

-

Example outputs: ExtOutput1 = OPT_Input 1.

(1) Robot input

(2) Power source output

(3) Options input

Additional information for TWIN systems:

TWIN systems are only compatible with the OPT/i RI FB REL EXT 8I/8O op-

-

tion

If an input signal is set on one of the two power sources, the signal is also set

-

on the fieldbus output

35

Touch signal

(Touch signal) Single Bit

The signal is used for various functions and indicates that:

In Touch mode the gas nozzle or the wire electrode touches the workpiece

-

(depending on the system configuration).

In Teach mode the wire electrode touches the workpiece.

-

During unwinding (Wire forward signal) the wire electrode touches the work-

-

piece.

When using the function for WireSense edge detection, the set threshold

-

value has been reached and thus the required edge has been successfully

detected.

For more information on WireSense, see section WireSense - more in-

-

formation from page 56.

Additional information for TWIN systems:

In single-wire operation, the following applies:

-

In Touch mode the touch signal is set as soon as the wire electrode or

-

the gas nozzle of the active power source touches the workpiece.

When unwinding the wire electrode (Wire forward signal), the Touch sig-

-

nal is set as soon as the wire electrode of the active power source

touches the workpiece.

When using the Teach mode, the touch signal is set as soon as the wire

-

electrode of the active power source touches the workpiece.

When using WireSense edge detection, the Touch signal is set as soon as

-

an edge has been detected by the active power source.

In TWIN operation, the following applies:

-

In Touch mode the Touch signal is set as soon as the wire electrode of

-

the Lead-power source or the gas nozzle touches the workpiece.

When unwinding the wire electrode (Wire forward signal), the Touch sig-

-

nal is set as soon as the wire electrode of the Lead-power source touches

the workpiece (the Trail-power source is ignored).

When using the Teach mode, the Touch signal is set as soon as the wire

-

electrode of the Lead-power source touches the workpiece (the Trailpower source is ignored).

When using WireSense edge detection, the Touch signal is set as soon as

-

an edge is detected by the Lead-power source (the Trail-power source is

ignored).

Characteristic

number valid

(Characteristic

number valid) Single Bit

Sensor Status 1

(sensor status 1)

- Single Bit

36

If the signal is High, the selected characteristic and the selected process are approved and can be used.

This signal indicates the status of the wire end option 4,100,869.

Signal level Description

High Wire electrode present

Low No wire electrode present

The signal is output as soon as the sensor of the option is detected in the system.

If there is no sensor in the system, the signal is set to High.

Additional information for TWIN systems:

The signal is output separately for both process lines.

Sensor Status 2

(sensor status 2)

- Single Bit

This signal indicates the status of the wire end option 4,100,879.

EN-US

Signal level Description

High Wire electrode present

Low No wire electrode present

The signal is output as soon as the sensor of the option is detected in the system.

If there is no sensor in the system, the signal is set to High.

Additional information for TWIN systems:

The signal is output separately for both process lines.

Sensor Status 3

(sensor status 3)

- Single Bit

Sensor Status 4

(sensor status 4)

- Single Bit

This signal indicates the status of the wire end option 4,100,878.

Signal level Description

High Wire electrode present

Low No wire electrode present

The signal is output as soon as the sensor of the option is detected in the system.

If there is no sensor in the system, the signal is set to High.

Additional information for TWIN systems:

The signal is output separately for both process lines.

The signal indicates the status of the wire buffer set CMT TPS/i 4,001,763 option.

Signal level Description

High Wire buffer is not empty

Low Wire buffer is empty

Wire stick workpiece (Wire stick

workpiece) Single Bit

The signal is output as soon as the sensor of the option is detected in the system.

If there is no sensor in the system, the signal is set to High.

Additional information for TWIN systems:

The signal is output separately for both process lines.

The signal is High if a wire stick is detected on the workpiece. This signal is always

output regardless of other settings.

Additional information for TWIN systems:

The signal is set to High as soon as one of the two wire electrodes sticks.

37

Short circuit

contact tip (contact tip short circuit) - Single Bit

This signal is set to High as soon as a short-circuit between the contact tip and

the gas nozzle has been detected during the Touch mode (short circuit due to

contamination between the contact tip and the gas nozzle, for example due to

welding spatter).

In order for the this signal to be available, the TouchSense Adv. option must be

installed in the welding system.

Additional information for TWIN systems:

This signal is set to High as soon as a short-circuit between the contact tip of the

lead power source and the gas nozzle has been detected during the Touch mode

(short circuit due to contamination between the contact tip and the gas nozzle,

for example due to welding spatter).

In addition, this signal is set High when the input signal Contact tip short circuit

detection on is set to High and a short circuit between the two contact tips is detected (short circuit due to contamination between the contact tips, for example

due to welding spatter).

Parameter selection internally

(Internal parameter selection)

- Single Bit

This signal indicates whether the parameter selection has been set to "internal".

This setting can be applied:

Using the Working mode signal/internal parameter selection, or

-

On the power source itself: Defaults/Interface setup/Welding parameter.

-

The following signals can be set on the power source itself if the Parameter selection internally High signal is active:

Welding process (MIG/MAG pulse synergic, MIG/MAG standard synergic,

-

etc.)

Operating mode (2-step mode, etc.)

-

Characteristic/job number (depending on the welding process)

-

Wirefeeder

-

Arc length correction

-

Pulse/dynamic correction

-

Wire retraction

-

Process-dependent correction

-

SynchroPulse on/off

-

Additional information for TWIN systems:

The signal is set to High as soon as parameter selection is set to "internal" on one

of the two process lines.

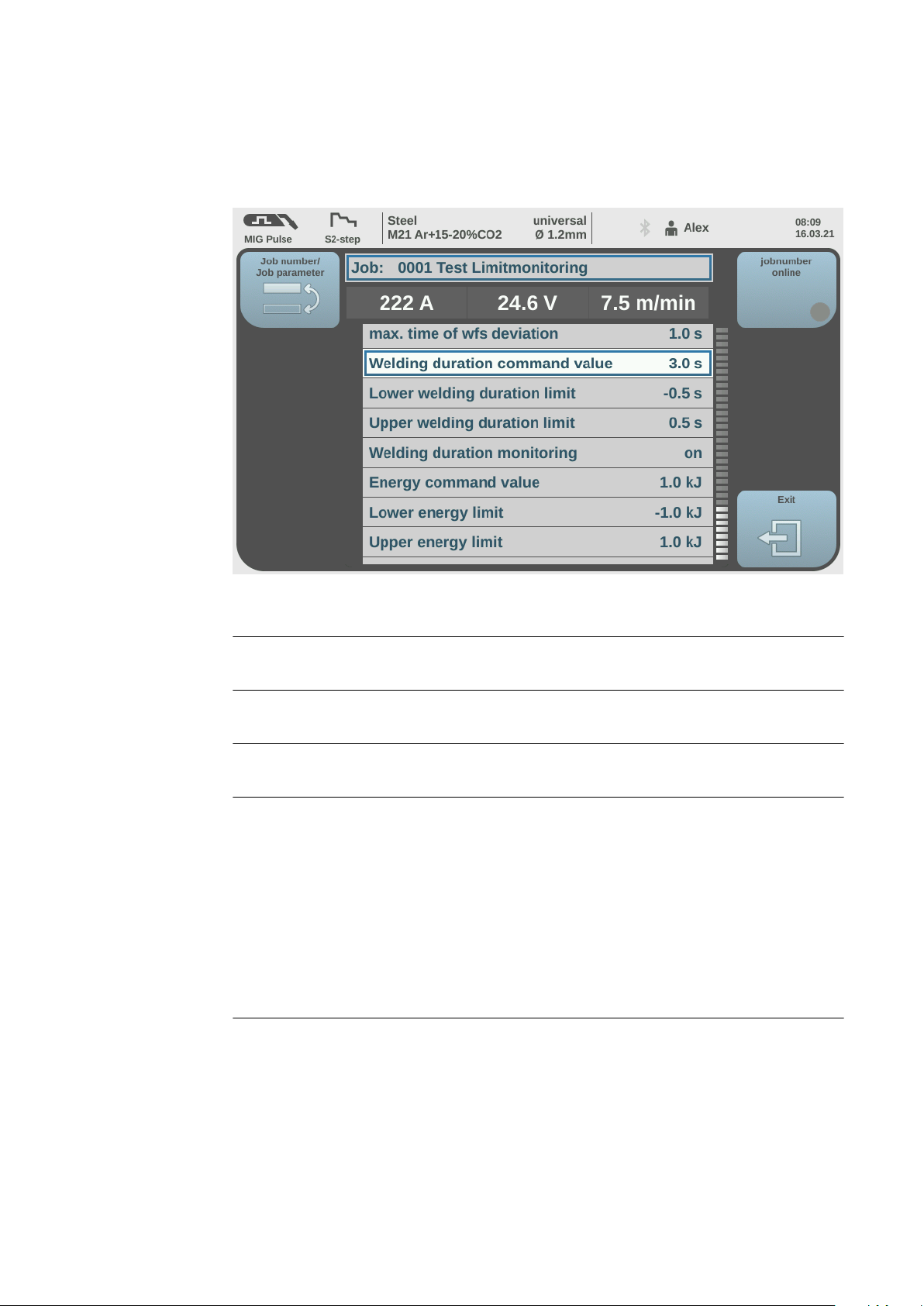

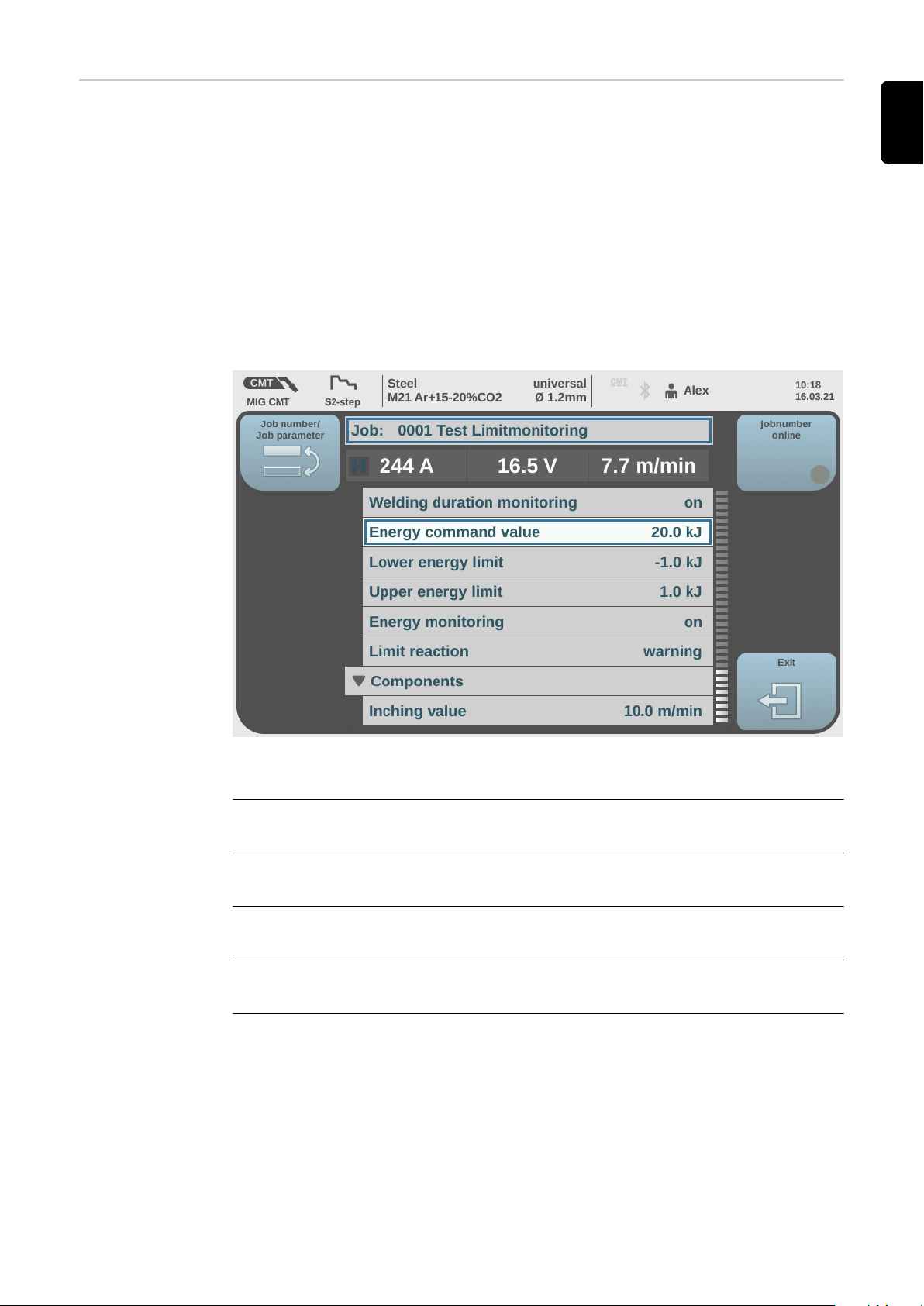

Limitsignal (Limit signal) - Single

Bit

38

This signal indicates that the set limits for voltage, current, wirefeeder, welding

time, and energy input have been exceeded or not reached.

This signal is only available in Job Mode.

Requirements

In the menu on the power source "Process parameters/Job/Optimize Job/

-

Limit monitoring/Limit reaction", the reaction is set to "Warning" or "Error".

OPT/i Limit Monitoring approved for the power source.

-

Additional information for TWIN systems:

The signal is output separately for both process lines.

For more information on Limit Monitoring see section:

Limit Monitoring - functions and activation from page 68 and

-

Limit Monitoring - details on the individual welding parameters from page

-

71.

EN-US

Main supply

status (Mains

voltage status) Single Bit

Safety status Single Bit

This signal indicates whether a phase error has occurred on the power source (incorrect power supply to the power source).

If this error has occurred, the error numbers 6451 or 6515 will be shown on the

display of the power source or transmitted to the robot via the interface as an Error number signal.

Additional information for TWIN systems:

The signal is set to High as soon as a phase error occurs on one of the two power

sources.

This signal indicates the status of the OPT/i Safety Stop PL d and OPT/i TPS External Stop options.

Bit 1 Bit 0 Description

0 0 Reserve

0 1 Hold

1 0 Stop

1 1 Not installed/active

Twin synchronization active Single Bit

System not

ready - Single Bit

The signal indicates that the synchronization between the two power sources is

active.

This signal indicates whether the welding system is ready for use:

This signal is Low if there are no error messages in the welding system (all er-

-

ror sources must be eliminated for the signal to change to Low.

This signal is High as soon as a component of the welding system outputs an

-

error message.

Examples of when this signal changes to High:

A component of the welding system performs an update.

-

Occurrence of an emergency stop.

-

In conjunction with wire sensors (ring sensor, sensor on wire drum, etc.), for

-

example, errors 16828, 16837, 16838.

If the following exceptions occur, the signal remains Low despite the error messages:

The Robot ready signal is Low.

-

During the welding process, a welding torch detection problem occurs (BID

-

error).

39

Touch signal gas

nozzle - Single

Bit

The Touch signal gas nozzle is set to High as soon as a short circuit between

-

the gas nozzle and the workpiece is detected during Touch. mode

The Touch signal gas nozzle is set in addition to the following signals:

-

Arc stable / Touch signal

-

Touch signal.

-

In order for the Touch signal gas nozzle to be available, the TouchSense Adv. option must be installed in the welding system.

The Touch signal gas nozzle in Touch mode allows the user to determine whether

there has been workpiece contact by the wire electrode or gas nozzle.

Notification (Notification) Single Bit

The signal is High when the power source issues a notification.

-