Fronius prints on elemental chlorine free paper (ECF) sourced from certified sustainable forests (FSC).

/ Perfect Charging / Perfect Welding / Solar Energy

Robacta TSS /i

Operating instructions

EN-US

42,0426,0000,EA 009-28012022

Table of contents

Safety Instructions 6

Explanation of Safety Instructions 6

General 6

Intended Use 7

Environmental Conditions 7

Obligations of the Operating Company 7

Obligations of Personnel 7

Particular hazard areas 7

Personal Protection and Protection of Others 8

EMC Device Classifications 8

Safety Measures at the Setup Location and During Transport 8

Safety Measures in Normal Operation 9

Maintenance and repair 9

Safety Inspection 9

Disposal 10

Safety symbols 10

Data backup 10

Copyright 10

General 11

General 13

Device Concept 13

Applications 13

Warning Notices on the Device 14

Types of Parting Agent and Their Use 15

Options 15

Detailed Information on the Optional Equipment 16

Transport 17

Transport Instructions on the packaging 17

Transport 17

EN-US

Operating controls, connections and mechanical components 19

Operating controls, connections and mechanical components 21

Detailed Information on the Optional Equipment 21

Safety 21

Connections and mechanical components 21

Connector pin assignments and signal descriptions 24

Safety 24

Assignment of standard I/O connection for robot control 24

Optional Connections Robot Control Unit (Fieldbus) 26

Assignment of external optional equipment connection 26

Installation and Startup 29

Safety 31

Detailed Information on the Optional Equipment 31

Safety 31

Before installation 33

Operating personnel, maintenance personnel 33

Setup Regulations 33

Specifications for the Compressed Air Supply 33

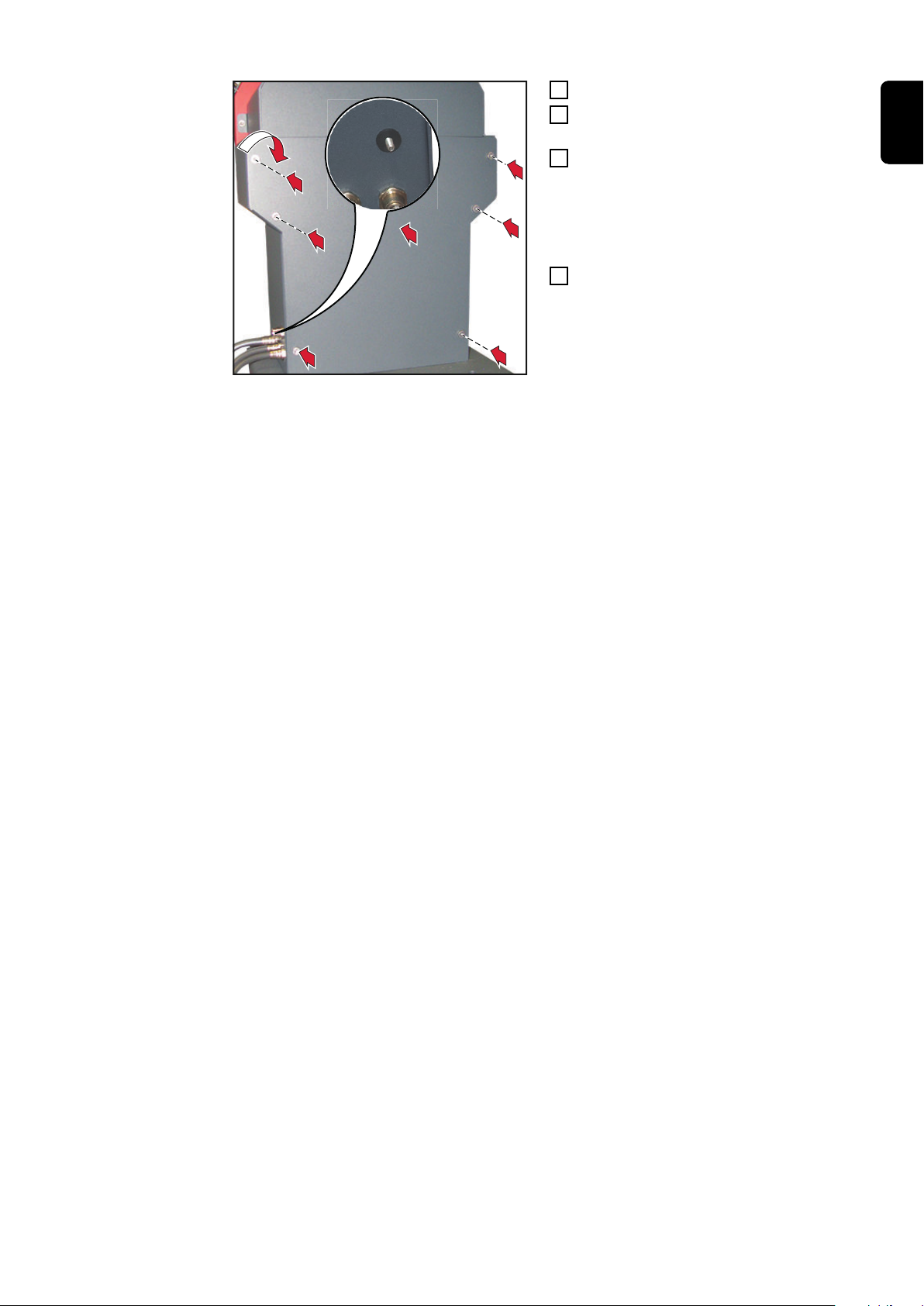

Bolting the Welding Torch Service Station to the Surface 34

Bolting the Welding Torch Service Station to the Surface 34

Installing Optional Equipment 35

Optional Equipment on Delivery 35

Installing optional equipment - overview 35

1. Installing Touch Sense 36

Tools required 36

Installing Touch Sense 36

3

2. Installing the wire cutter 40

Tools Required 40

Additionally required 40

Installing the Wire Cutter 40

Operating Instructions 41

3. Installing the Robacta TC 2000 cleaning unit 42

General 42

Tools required 42

Additionally Required 42

Installing the Robacta TC 2000 Cleaning Unit 42

4. Installing the level sensor 44

Tools Required 44

Installing the Level Sensor 44

5. Inserting the parting agent container 46

Inserting the Parting Agent Container 46

6. Installing the TCP Tip 47

Tools Required 47

Installing the TCP Tip 47

7. Installing the Robacta Reamer V Easy / Robacta Reamer V 70 Han12P cleaning unit 48

General 48

Tools required 48

Additionally required 48

Installing the Reamer V Easy / Robacta Reamer V 70 Han12P cleaning unit 48

Starting Up the Welding Torch Service Station 52

General 52

Opening the Welding Torch Service Station 52

Requirements for Starting Up 52

Starting Up the Welding Torch Service Station 52

Cleaning Program Sequence 55

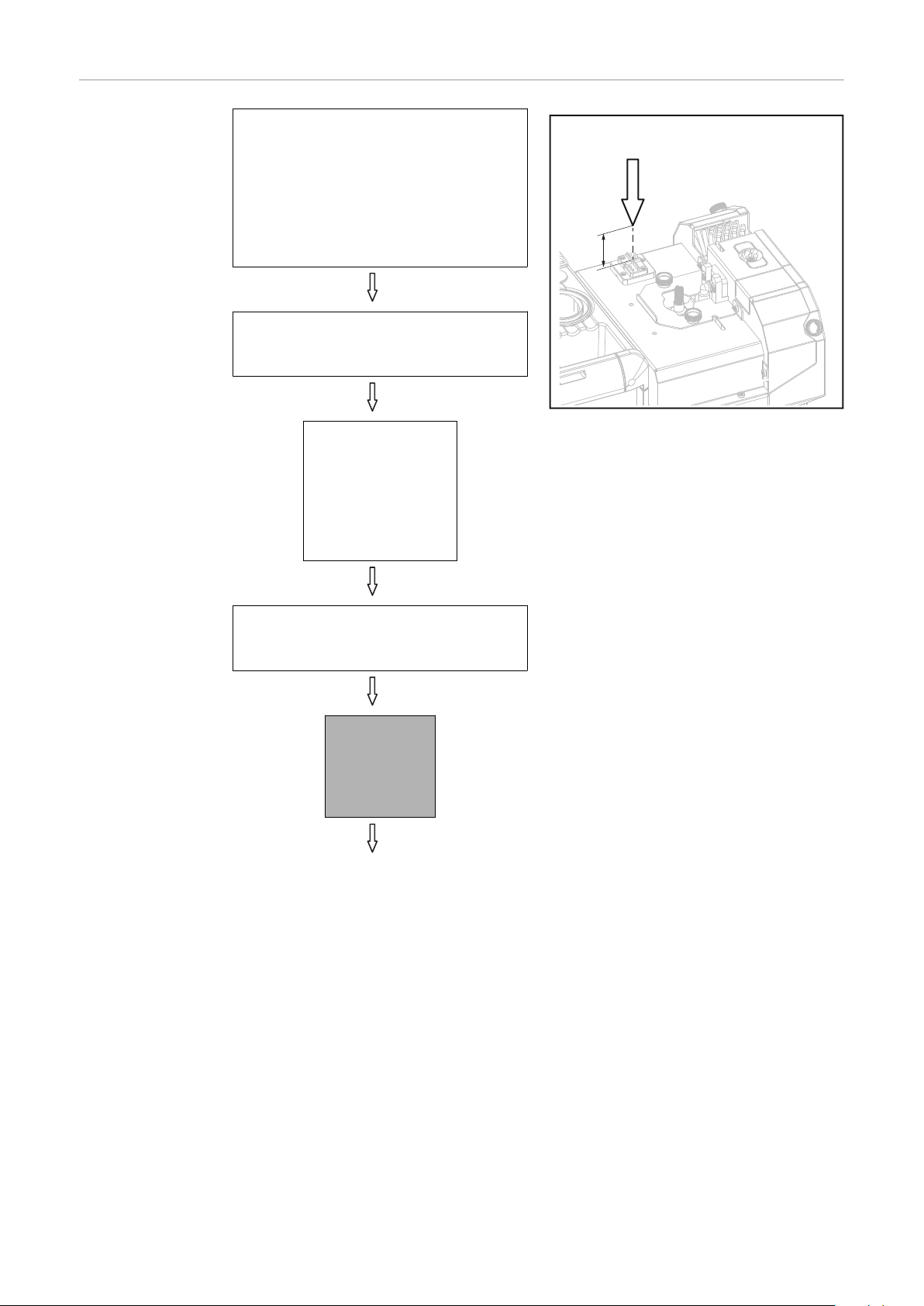

Program sequence—overview 57

Detailed Information on the Optional Equipment 57

Program Sequence—Overview 57

General information 59

Wire cutter 59

TC 2000 dipping bowl 59

Robacta TC 2000 59

Specification of the Parting Agent Volume 59

Cleaning End without Touch Sense Option 59

Program sequence 60

Wire cutter program sequence 60

Robacta TC 2000 dipping bowl program sequence 62

TC 2000 program sequence 63

High-pressure gas purging with parting agent program sequence (1st contact tip) 64

Outer gas nozzles cleaning brush program sequence 66

Inner gas nozzle cleaning brush program sequence 68

High-pressure gas purging with parting agent program sequence (2nd contact tip) 70

Touch Sense (option) program sequence 72

Wire cutter - cleaning end program sequence 73

Troubleshooting, Maintenance, and Disposal 75

Safety 77

Detailed Information on the Optional Equipment 77

Safety 77

Troubleshooting 79

Detailed Information on the Optional Equipment 79

Troubleshooting 79

Service, maintenance and disposal 81

Detailed Information on the Optional Equipment 81

Releasing Pressure before Maintenance Work 81

Before Every Start-up 81

4

Daily 81

Weekly 82

Monthly 82

Every 6 Months 82

Every 12 Months 82

Disposal 82

Change cleaning brushes and nozzle for the high-pressure gas purging 83

Releasing Pressure before Maintenance Work 83

Replacing the Outer Gas Nozzle Cleaning Brushes 83

Replacing the inner gas nozzle cleaning brush 84

Changing the nozzle for the high-pressure gas purging 85

Appendix 87

Technical data 89

Detailed Information on the Optional Equipment 89

Robacta TSS /i 89

EN-US

5

Safety Instructions

Explanation of

Safety Instructions

DANGER!

Indicates an immediate danger.

Death or serious injury may result if appropriate precautions are not taken.

▶

WARNING!

Indicates a possibly dangerous situation.

Death or serious injury may result if appropriate precautions are not taken.

▶

CAUTION!

Indicates a situation where damage or injury could occur.

Minor injury or damage to property may result if appropriate precautions are not

▶

taken.

NOTE!

Indicates the possibility of flawed results and damage to the equipment.

General The device has been manufactured using state-of-the-art technology and according to

recognized safety standards. If used incorrectly or misused, however, it can cause

- injury or death to the operator or a third party,

- damage to the device and other material assets belonging to the operating company,

- inefficient operation of the device.

All persons involved in the commissioning, operation, maintenance, and servicing of the

device must

- be suitably qualified,

- have knowledge of automated welding and

- have read these Operating Instructions and any system component operating instructions in full and follow them carefully.

The Operating Instructions must always be at hand wherever the device is being used. In

addition to the Operating Instructions, all applicable local rules and regulations regarding

accident prevention and environmental protection must also be followed.

All safety and danger notices on the device must

- must be kept in a legible state

- not be damaged/marked

- not be removed

- not be covered, pasted, or painted over

For the location of the safety and danger notices on the device, refer to the section

headed "General" in the Operating Instructions for the device.

Before switching on the device, remove any faults that could compromise safety.

Your personal safety is at stake!

6

Intended Use The device is to be used exclusively for its intended purpose.

The device is intended exclusively for the cleaning of Fronius welding torches.

Utilization for any other purpose, or in any other manner, shall be deemed to be “not in

accordance with the intended purpose.” The manufacturer accepts no liability for any

damage resulting from improper use.

Proper use also means

- Reading and adhering to all instructions in the Operating Instructions

- Reading and adhering to all safety instructions and danger notices

- Carrying out all the specified inspection and servicing work

The device is designed for operation in industry and business. The manufacturer shall

not be liable for any damage resulting from use in a living area.

The manufacturer shall also not be liable for faulty or incorrect work results.

EN-US

Environmental

Conditions

Obligations of the

Operating Company

Operation or storage of the device outside the stipulated area will be deemed as not in

accordance with the intended purpose. The manufacturer is not responsible for any damage resulting from improper use.

Temperature range of the ambient air:

- During operation: 0°C to + 40°C (32°F to 104°F)

- During transport and storage: -25°C to +55°C (-13°F to 131°F)

Relative humidity:

- Up to 50% at 40°C (104°F)

- Up to 90% at 20°C (68°F)

Ambient air: free of dust, acids, corrosive gases or substances, etc.

Altitude above sea level: up to 2000 m (6500 ft.)

The operating company must only allow persons to work with the device if they

- Are familiar with the basic occupational safety and accident prevention regulations

and are trained in handling the device

- Have read and understood these Operating Instructions, especially the section

"Safety Rules," and have confirmed this with their signature

- Are trained according to the requirements for the work results

The safety-conscious work of the personnel must be checked regularly.

Obligations of

Personnel

Particular hazard

areas

All persons who are assigned to work with the device must do the following before beginning the work:

- Follow the basic regulations for occupational safety and accident prevention

- Read these Operating Instructions, especially the section "Safety Rules," and confirm that they have understood and will follow them by signing

Before leaving the workplace, ensure that no personal injury or property damage can occur in one's absence.

Do not linger in the operating area of the robot.

Always integrate the device into a higher-level safety system in a secured area.

7

If this area has to be accessed for preparatory or maintenance work, ensure that

- the entire system is shut down for the duration of access to this area

- and remains shut down to prevent unintended operation, e.g., as a result of a control

error

In addition to these Operating Instructions, the safety rules of the robot manufacturer

must be followed.

Covers and side parts must only be opened/removed during maintenance and repair

work.

During operation:

- Ensure that all covers are closed and all side parts have been mounted properly.

- Keep all covers and side parts closed.

Personal Protection and Protection of Others

EMC Device Classifications

Magnetic fields generated by high amperage may eject ferromagnetic parts, such as

spatter accumulations, from the cleaning aperture. To prevent injury, always wear protective goggles with side protection and never look into the cleaning aperture when the

device is switched on.

Keep persons, especially children, away during the operation of the devices and during

the welding process. If persons are in the vicinity, however:

- Instruct them about all dangers (blinding hazard due to arcs, injury hazard due to flying sparks, welding fumes hazardous to health, noise exposure, possible hazard due

to grid current or welding current, possible hazard due to electromagnetic fields,

possible hazard due to the magnetic field of the cleaning aperture, moving mechanical parts, compressed air/parting agent mixture discharged from the cleaning aperture, flying chips or similar, etc.),

- Provide suitable protective equipment or

- Construct suitable protective walls and curtains.

Devices in emission class A:

- Are only designed for use in industrial settings

- Can cause line-bound and radiated interference in other areas

Devices in emission class B:

- Satisfy the emissions criteria for residential and industrial areas. This is also true for

residential areas in which the energy is supplied from the public low-voltage grid.

Safety Measures

at the Setup Location and During

Transport

8

EMC device classification as per the rating plate or technical data.

A toppling device can be deadly! Set up the device securely on an even, solid surface

- A tilt angle of no more than 10° is permitted.

Special regulations apply in areas at risk of fire or explosion

- Follow the appropriate national and international regulations.

Use instructions and checks within the company to ensure that the vicinity of the workplace is always clean and organized.

Only set up and operate the device in accordance with the degree of protection shown

on the rating plate.

Install the device with an all-round clearance of at least 0.5 m (19.69 in.) to walls, neighboring devices, or other objects.

Install the device at a minimum distance of 1 m (40 in.) away from IT equipment and control lines, as well as from the welding process.

Safety Measures

in Normal Operation

Set up the device in such a way that welding spatter cannot hit the cleaning device.

Before transporting the device, always completely drain the parting agent.

Take care to ensure that the applicable national and regional guidelines and accident

prevention regulations are observed when transporting the device, especially guidelines

concerning hazards during transport and shipment.

It is essential to conduct a visual inspection of the device to check for damage after it has

been transported but before it is commissioned. Have any damage repaired by trained

service technicians before commissioning the device.

Only operate the device when all safety devices are fully functional. If the safety devices

are not fully functional, there is a danger of:

- Injury or death to the operator or a third party

- Damage to the device and other material assets belonging to the operating company

- Inefficient operation of the device

Safety devices that are not fully functional must be repaired before the device is started

up.

Never bypass or disable safety devices.

Before starting up the device, ensure that no one can be put in danger.

EN-US

Maintenance and

repair

The device must be examined at least once a week for externally detectable damage

and functionality of the safety devices.

- Only use appropriate original parting agents from the manufacturer.

- When handling parting agents, observe the information on the parting agent safety

data sheets. The parting agent safety data sheets can be obtained from your service

center or via the manufacturer’s website.

- Do not mix parting agents from the manufacturer with other parting agents.

- If damage occurs due to the use of other parting agents, the manufacture is not liable for this and all warranty claims are forfeited.

- Properly dispose of used parting agents according to national and international regulations.

It is impossible to guarantee that bought-in parts are designed and manufactured to meet

the demands made of them, or that they satisfy safety requirements.

- Use only original spare and wearing parts (also applies to standard parts).

- Do not carry out any modifications, alterations, etc. to the device without the manufacturer's consent.

- Components that are not in perfect condition must be replaced immediately.

- When ordering, please give the exact designation and part number as shown in the

spare parts list, as well as the serial number of your device.

The housing screws provide the ground conductor connection for earthing the housing

parts.

Only use original housing screws in the correct number and tightened to the specified

torque.

Safety Inspection The manufacturer recommends that a safety inspection of the device be performed at

least every 12 months.

9

A safety inspection by a certified electrician is recommended:

- after changes

- after alterations

- after repair, care, and maintenance

- at least every 12 months.

For the safety inspection, follow the appropriate national and international standards and

guidelines.

You can obtain more information about the safety inspection and calibration from your

service center. The service center will provide the necessary documents upon request.

Disposal Do not dispose of this device with normal domestic waste! To comply with the European

Directive on Waste Electrical and Electronic Equipment and its implementation as national law, electrical equipment that has reached the end of its life must be collected separately and returned to an approved recycling facility. Any device that you no longer require

must be returned to your dealer, or you must locate the approved collection and recycling

facilities in your area. Ignoring this European Directive may have potentially adverse affects on the environment and your health!

Safety symbols Devices with the CE label satisfy the essential requirements of the low-voltage and elec-

tromagnetic compatibility directive (e.g., relevant product standards of the EN 60974

series).

Fronius International GmbH declares that the device complies with Directive

2014/53/EU. The full text of the EU Declaration of Conformity is available on the following website: http://www.fronius.com

Devices marked with the CSA test mark satisfy the requirements of the relevant standards for Canada and the USA.

Data backup The user is responsible for backing up any changes made to the factory settings. The

manufacturer accepts no liability for any deleted personal settings.

Copyright Copyright of these Operating Instructions remains with the manufacturer.

Text and illustrations were accurate at the time of printing. Fronius reserves the right to

make changes. The contents of the Operating Instructions shall not provide the basis for

any claims whatsoever on the part of the purchaser. If you have any suggestions for improvement, or can point out any mistakes that you have found in the Operating Instructions, we will be most grateful for your comments.

10

General

11

12

General

EN-US

Device Concept

Robacta TSS /i with the options wire cutter and

Robacta TC 2000

Applications The welding torch service station is used in automated MIG/MAG applications in a robot

cell:

- In the automotive and supply industry

- In equipment engineering

- In chemical plant construction

- In mechanical engineering

- In rail vehicle construction

- In shipyards

The Robacta TSS /i welding torch service

station is a complete system for the cleaning of a wide range of MIG/MAG robot

welding torches.

All optional equipment required for effective welding torch cleaning can be installed

directly on the welding torch service station.

13

Warning Notices

Type

Art.No.

Chargen No.

U1

I1

Wels - Austria

p

max

24 V

0.25 A

6 bar (87PSI)

on the Device

NOTE!

The welding torch service station is equipped with warning notices and a rating

plate.

These warning notices and the rating plate must not be removed or painted over.

14

Warning Notices on the Device

WARNING! Risk of serious injuries due to:

- moving mechanical parts

- compressed air/parting agent mixture discharged from the parting-agent injection

nozzles

- flying debris (chips, etc.)

- compressed air stored at 16 bar in the pressure booster

Release stored compressed air before maintenance and servicing!

During maintenance and servicing, keep the device de-energized and de-pressurized.

Do not use the functions described here until you have fully read and understood the following documents:

- these Operating Instructions

- all Operating Instructions for system components, especially the safety rules

For indoor use only

Wear eye protection

EN-US

Types of Parting

Agent and Their

Use

Options

Warning before the device switches on automatically

NOTE!

The parting agents are not included in the scope of supply.

Types of parting agent and their use:

- “Robacta Reamer” parting agent for spraying the welding torch after the cleaning

process

It is recommended that the welding torch be sprayed with the “Robacta Reamer” parting

agent for all applications.

OPT/i Robacta TSS BK Profinet 4,101,127,CK

OPT/i Robacta TSS BK Profibus 4,101,179,CK

OPT/i Robacta TSS BK DeviceNet 4,101,180,CK

OPT/i Robacta TSS BK EtherCAT 4,101,181,CK

OPT/i Robacta TSS BK Ethernet IP 4,101,236,CK

OPT/i TSS TCP Touch Sense 4,001,003,CK

OPT/i TSS/i TCP tip 4,001,072,CK

OPT/i TSS level sensor 4,001,014,CK

15

Parting agent canister 10 l 42,0411,8042

Robacta TC 2000 cleaning unit *

TC 1000/2000 0.85 m connection cable 43,0004,5929

OPT/i TSS TC2000 ** 4,001,012,CK

Twin wire cutter 44,0450,1027

OPT/i TSS Wire Cutter ** 4,001,098,CK

OPT/i TSS /i parting agent screen 4,001,106,CK

Robacta Reamer cleaning unit *

OPT/i TSS Reamer Twin ** 43,0004,5928

Reamer Twin 600 mm connection cable 4,001,109

Robacta Reamer Twin cleaning unit 44,0450,1282

Detailed Information on the Optional Equipment

Robacta Reamer V Easy (Single) cleaning unit

Robacta Reamer V 70 Han12P cleaning

unit

OPT/i TSS Reamer Single ** 4,001,123

OPT/i TSS Reamer V70 ** 4,001,133

Reamer Single 600 mm connection cable 43,0009,6290

* depending on the system configuration

** installation set; required for the installation of the respective device

NOTE!

For detailed information on the optional equipment, consult the available installation instructions or Operating Instructions for the optional equipment.

44,0450,1444

44,0450,1961

16

Transport

1

1

EN-US

Transport Instructions on the

packaging

Transport

CAUTION!

Danger due to improper transport.

This can result in damage to property.

Follow the transport instructions on the device packaging.

▶

WARNING!

Danger from machines toppling over or falling.

May result in serious injuries or death.

When transporting the device by counterbalanced lift truck or lift truck, secure the

▶

device to prevent it from falling

Do not turn, brake, or accelerate in a sudden, jerking manner

▶

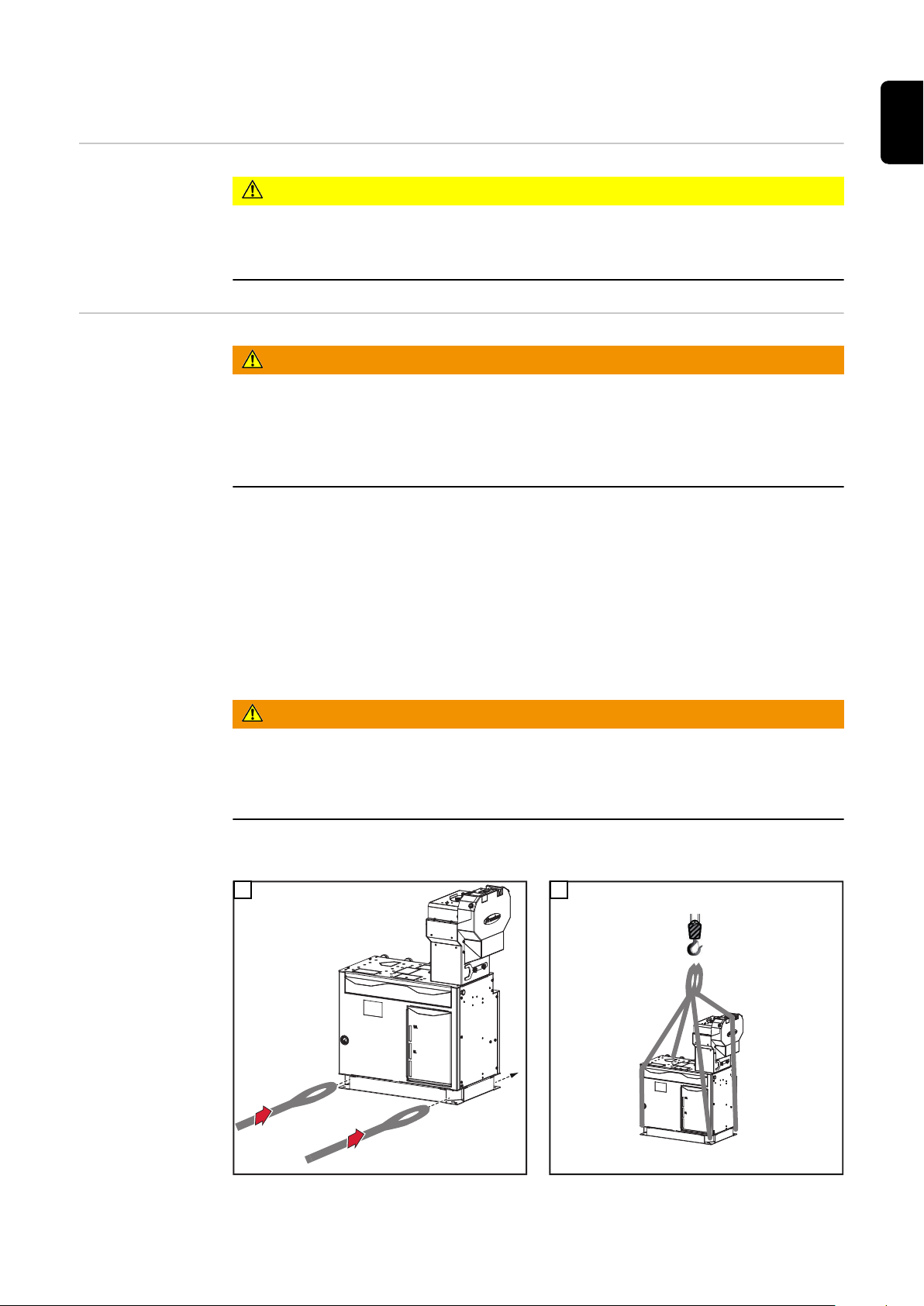

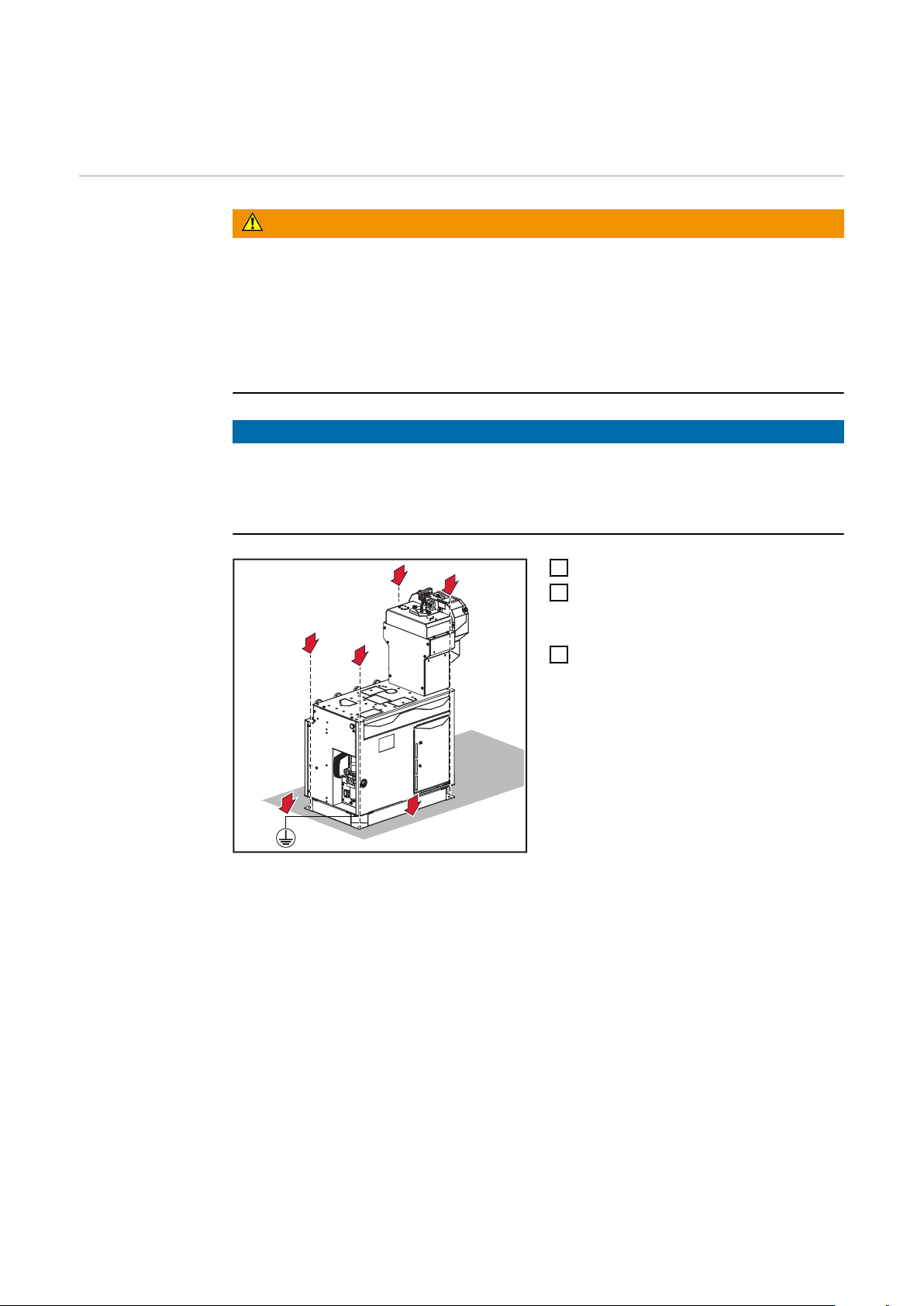

The welding torch service station can be transported as follows:

- manually, by at least two people

- on a pallet using a low lift truck

- on a pallet using a counterbalanced lift truck

The welding torch service station can be lifted from the pallet and positioned at the installation site using a crane and two belts.

When selecting the belt length for this, ensure that the welding torch service station will

not be damaged when lifting down from the pallet.

WARNING!

Danger from falling objects.

May result in serious injuries or death.

The only form of crane transport permitted is lifting the device down from the pallet

▶

using a crane and belts.

Lifting Welding Torch Service Station from the Pallet using Crane and Belts

1 2

17

18

Operating controls, connections and

mechanical components

19

20

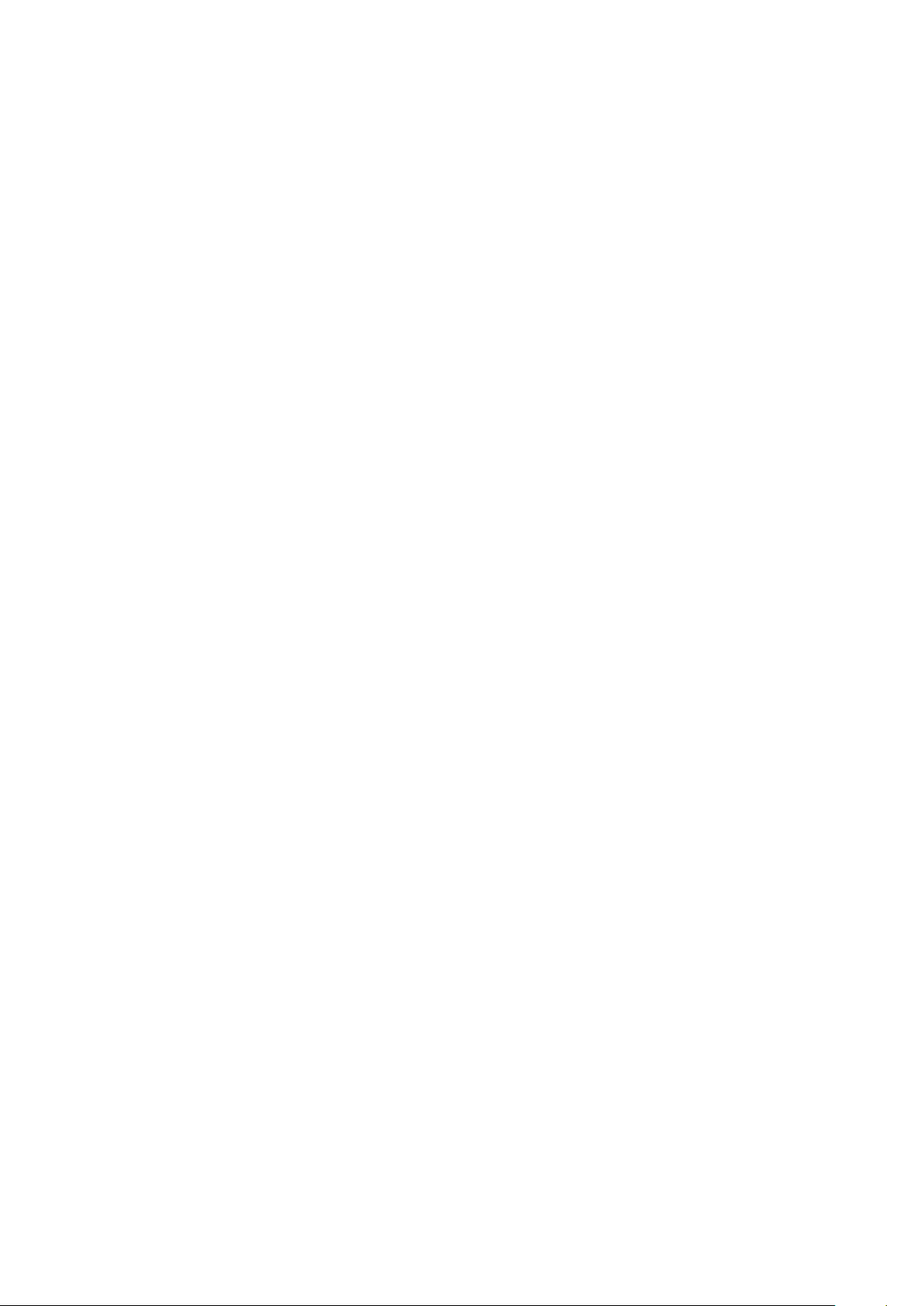

Operating controls, connections and mechanical

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

B

A

1

components

Detailed Information on the Optional Equipment

Safety

NOTE!

For detailed information on the optional equipment, consult the available installation instructions or Operating Instructions for the optional equipment.

Danger due to incorrect operation.

This can result in severe personal injury and damage to property.

▶

▶

EN-US

WARNING!

The functions described may only be used by trained personnel.

Do not perform the work described below until you have thoroughly read and under-

stood the following documents:

This document

All Operating Instructions for system components, especially the safety rules.

Connections and

mechanical components

(1) Outer gas nozzle cleaning brush

The second outer gas nozzle

cleaning brush can be released by

breaking away the metal parts

21

(2) High-pressure gas purging

1

1

(10)

(9)

Std. I/O

with parting agent

The opening for the high-pressure gas purging can be enlarged by breaking

away the metal parts, e.g., for oval gas nozzles.

(3) Inner gas nozzle cleaning brush

for cleaning the contact tip

(4) Collecting tray

(5) Flap for parting agent container

(6) Manometer

(7) Ground connection

(8) Installation area for optional equipment

(9) Robot control unit connection

Standard I/O, 37-pin

(10) Pressure regulator

Connection devices—supply air

Operating pressure 5.5–6 bar

View A

22

(16)

(15)

(14)

(13)

(12)

(11)

(18)

(17)

(19)

(21)

(20)

(11) External optional equipment

connection

(12) External optional equipment

connection

(13) External optional equipment

connection

(14) External optional equipment

connection

The 37-pin connections (11)–(14) for external optional equipment are equal.

EN-US

View B

(17) Compressed air connection

Nominal pressure 6 bar

(18) Compressed air connection

Nominal pressure 6 bar

(19) Compressed air connection

Nominal pressure 6 bar

(20) Parting agent connection

(21) Compressed air connection

Gas purging through hosepack, 16 bar

(15) Compressed air connection

Nominal pressure 6 bar

(16) Compressed air connection

Nominal pressure 6 bar

23

Connector pin assignments and signal descriptions

1234

9 8 7 6 5

101112131415

22 21 20 19 18 17 16

28 27 26 25 24 23

33 32 31 30 29

37 36 35 34

Safety

Assignment of

standard I/O connection for robot

control

WARNING!

Danger from incorrect operation and work that is not carried out properly.

This can result in serious personal injury and damage to property.

All the work and functions described in this document must only be carried out by

▶

technically trained and qualified personnel.

Read and understand this document in full.

▶

Read and understand all safety rules and user documentation for this equipment

▶

and all system components.

WARNING!

Danger due to machines starting automatically.

This can result in severe personal injury and damage to property.

The device must only be supplied with power using an emergency stop voltage cir-

▶

cuit.

CAUTION!

Danger from overcurrent.

Damage to the bearings may result.

Provide the power supply with 1.5 A fuse protection against overcurrent.

▶

To avoid interference, keep the line length between the welding torch service station and the robot control unit as short as possible.

Pin Signal

I 1 + 24 V DC

I 2 GND

NOTE!

I = Input:

from the robot control unit to the welding

torch service station

O = Output:

from the welding torch service station to

the robot control unit

24

I 3 High-end gas purging (from the front)

I 4 High-end gas purging (through the hosepack)

I 5 External valve brush cleaning

I 6 Internal valve brush cleaning

I 7 Pump for parting agent

8 NC

O 9 Pressure switch

O10 Parting agent fill level (optional)

11 Reserved

12 Reserved

O13 Gas nozzle free / cleaning ready (Braze +) / motor bottom / ready (TC

devices) - check, which signal belongs to which device

14 Reserved

I 15 Start cleaning (devices with 6-pin connector)

Clamp gas nozzle / cleaning motor on (devices with 17-pin connector)

16 Reserved

EN-US

I 17 Reserved

I 18 Reserved

O19 Reserved

O20 Reserved

O21 Cleaning error (TC devices); cleaning motor is running (RRV)

I 22 Spray In (TC devices);

spray parting agent at RRV (Twin / 70Han12P / Comfort);

adjust the measuring head on RRB+

O23 Ready (TC devices);

gas nozzle free at RRV (Twin / 70Han12P / Comfort);

gas nozzle free / motor bottom / cleaning ready for other devices

I 24 TC start cleaning

O25 TC parting agent low level OK

I 26 TC quick stop

27 NC

O28 RR Twin gas nozzle free

29 Reserved

30 Reserved

I 31 RR Twin start cleaning

32 Reserved

33 Reserved

25

I 34 WC cut wire electrode

1234

9 8 7 6 5

101112131415

22 21 20 19 18 17 16

28 27 26 25 24 23

33 32 31 30 29

37 36 35 34

I 35 Reserved

36 Reserved

37 NC

TC = Robacta TC 2000

WC = wire cutter

RR = Robacta Reamer

RRV = Robacta Reamer V

RRB+ = Robacta Reamer Braze+

Optional Connections Robot Control Unit (Fieldbus)

Assignment of

external optional

equipment connection

If the welding torch service station is equipped with an optional fieldbus as a robot control unit connection, then the connection is described in the separate Operating Instructions for the fieldbus:

42,0410,2245 ... ProfiNet Robacta TSS /i

42,0410,2434 … DeviceNet Robacta TSS /i

42,0410,2435 … ProfiBus Robacta TSS /i

42,0410,2436 … EtherCAT Robacta TSS /i

42,0410,2550 ... Ethernet IP Robacta TSS/i

CAUTION!

Danger from overcurrent.

Damage to the bearings may result.

Provide the power supply with 1.5 A fuse protection against overcurrent.

▶

NOTE!

To avoid interference, keep the line length between the welding torch service station and the robot control unit as short as possible.

26

I = Input:

from the optional equipment to the welding

torch service station

O = Output:

from the welding torch service station to

the optional equipment

Pin Signal

O 1 + 24 V DC

O 2 GND

3 NC

4 Occupied

5 Occupied

6 Occupied

7 Occupied

8 NC

9 Occupied

10 Occupied

I 11 Signal Gas OK Single

I 12 Signal Gas OK Twin

I 13 RR Single gas nozzle free

14 Reserved

O15 RR Single start cleaning

EN-US

16 Reserved

O17 Reserved

O18 Reserved

I 19 Reserved

I 20 Reserved

I 21 TC cleaning error

O22 TC spraying

I 23 TC ready

O24 TC start cleaning

I 25 TC agent low level OK

O26 TC quick stop

27 NC

I 28 RR Twin gas nozzle free

I 29 Reserved

30 Reserved

O31 RR Twin start cleaning

I 32 RR motor bottom

I 33 RR motor top

O34 WC / RR cut wire electrode

27

O35 RR clamp gas nozzle

O36 RR lifting device upwards

O37 Reserved

TC = Robacta TC 2000

WC = wire cutter

RR = Robacta Reamer

28

Installation and Startup

29

30

Safety

EN-US

Detailed Information on the Optional Equipment

Safety Please follow the safety rules below during all the tasks described in the "Installation and

NOTE!

For detailed information on the optional equipment, consult the available installation instructions or Operating Instructions for the optional equipment.

Commissioning" chapter.

WARNING!

Danger from incorrect operation and work that is not carried out properly.

This can result in severe personal injury and damage to property.

All work listed in these Operating Instructions may only be performed by trained spe-

▶

cialist personnel.

All functions described in these Operating Instructions may only be used by trained

▶

specialist personnel.

Do not perform the work or use the functions described below until you have thor-

▶

oughly read and understood the following documents:

these Operating Instructions,

all Operating Instructions for system components, especially the safety rules.

WARNING!

Danger due to machines starting automatically.

This can result in severe personal injury and damage to property.

In addition to these Operating Instructions, observe the safety rules of the robot

▶

manufacturer and welding system manufacturer.

For your personal safety, make sure that all protective measures have been taken in

▶

the robot's operating area and remain in effect while you are in this area.

WARNING!

Danger due to mechanically moving parts.

Serious injuries may result.

Before starting any work on the welding torch service station or the system compon-

▶

ents connected to it, disconnect the welding torch service station from the existing

compressed air supply, disconnect the existing options from the grid.

Ensure that the available compressed air supply to the welding torch service station

▶

and the electrical supply to the connected system components remain disconnected

until all work is finished.

31

WARNING!

Danger due

to flying parts (chips, metal particles, etc.),

escaping compressed air/parting agent mixture,

electrically supplied, activated options.

If compressed air is supplied to the welding torch service station, serious injury can result.

If work needs to be carried out on the device while the welding torch service station is

being supplied with compressed air or the optional equipment is being supplied with

electricity:

if there are TC cleaning units, keep all ferromagnetic parts (e.g., tools) away from

▶

the device

keep hands, hair, the face, items of property, and all items of clothing away from the

▶

optional devices

wear hearing protection

▶

wear protective goggles with side protection

▶

WARNING!

Danger due to insufficient ground conductor connection!

Serious injury or damage to property can result.

The housing screws are a suitable ground conductor connection for grounding the housing.

The housing screws must not under any circumstances be replaced by other screws

▶

without a reliable ground conductor connection.

32

Before installation

EN-US

Operating personnel, maintenance personnel

Setup Regulations

WARNING!

Danger due to machines starting automatically.

This can result in severe personal injury and damage to property.

In all situations, the device must only ever be operated by one person. In addition,

▶

make sure that there are no other people in the device's operating area while it is in

operation.

In all situations, the device must only ever be maintained by one person. In addition,

▶

make sure that there are no other people in the device's operating area while work

on it is ongoing.

The device has been tested according to protection class IP21. This means:

- Protection against contact with the fingers, protection against penetration of solid

foreign bodies with a diameter of more than 12.5 mm (0.49 in.)

- Protection against dripping water falling vertically

The device can be operated in accordance with protection class IP21.

Direct moisture (e.g. from rain) must be avoided.

NOTE!

Install the device at a minimum distance of 1 m (40 in.) away from IT equipment

and control lines, as well as from the welding process.

Specifications for

the Compressed

Air Supply

NOTE!

Install the device with an all-round clearance of at least 0.5 m (19.69 in.) to walls,

neighboring devices, or other objects.

NOTE!

Set up the device so that

welding spatter cannot hit the cleaning device,

▶

the device is accessible from all sides for maintenance and service work.

▶

To ensure the proper functioning of the cleaning device, fulfill the following specifications

for the compressed air supply:

- Set up a compressed air supply using the pressure relief valve and compressed air

filter

- Guarantee the compressed air quality in accordance with ISO 8573-1:2001, class 7

4 3, instrument air

-

Solid particle concentration £ 10 mg/m

- Pressure concentration point vapor £ + 3°C

-

Oil concentration £ 1 mg/m

3

3

33

Bolting the Welding Torch Service Station to the

2

2

2

2

3

1

Surface

Bolting the Welding Torch Service

Station to the

Surface

WARNING!

Danger due to the welding torch service station toppling over.

It can cause injuries.

Even out any unevenness in the floor

▶

Set the service station up on an even, solid, and vibration-free surface or a corres-

▶

ponding base

Only set up the service station so that it is horizontal

▶

Use four screws to anchor the service station to the surface

▶

NOTE!

Depending on the surface, different dowels and screws may be required to anchor

the service station to the surface.

Therefore, dowels and screws are not part of the scope of supply for the service station.

The system installer is responsible for selecting the proper dowels and screws.

Position the service station

1

Use four dowels and four screws ap-

2

propriate for the surface to anchor the

service station to the surface

Ground the service station at its base

3

34

Installing Optional Equipment

EN-US

Optional Equipment on Delivery

Installing optional equipment overview

Depending on the configuration, optional equipment is installed on the welding torch service station on delivery.

The following installation descriptions apply for a welding torch service station without

optional equipment or for the retrofitting of the optional equipment.

The installation of the optional equipment available for the welding torch service station

is made up of the following sections:

1. Installing Touch Sense

2. Installing the wire cutter

3. Installing the cleaning unit

Robacta TC 2000

Robacta Reamer Twin

4. Installing the level sensor

5. Inserting the parting agent container

6. Installing the TCP tip

7. Installing the Robacta Reamer V Easy / Robacta Reamer V 70 Han12P

IMPORTANT! Follow the order listed here when installing the individual pieces of optional equipment!

35

1. Installing Touch Sense

2

1

1

2

2

2

2

3

2

6x TX25

5

4

Tools required - Torx screwdriver TX20

- Torx screwdriver TX25

- Size 17 mm wrench

- 4 mm Allen key

- Cable ties

- Diagonal cutting pliers

- Slotted screwdriver

- Hammer

Installing Touch

Sense

Knock out the side round opening

1

Remove the 6 TX25 screws

2

Remove the cover

3

Knock out the top round opening

4

Remove the knocked-out material

5

from above

36

6

2 x TX20

7

7

Position the Touch Sense on the

9

8

10

10

2x TX20

1,4

1,8

2,2

2,6

1,4

1,8

2,2

2,6

1,4

1,8

2,2

2,6

1,4

1,8

2,2

2,6

6

plastic support

Secure the Touch Sense with 2 TX20

7

screws

Secure the cable to the bottom of the

8

Touch Sense with a 3 mm Allen screw

Insert the cable into the knocked-out

9

opening

EN-US

NOTE!

When installing the Touch Sense, do

not pinch, kink, shear off, or otherwise

damage the cable!

Install the Touch Sense on the service

10

station with 2 TX20 screws

The Touch Sense can be installed in

all 90° positions.

37

12

13

Insert the plastic insert into the open-

(1)

(2)

(3)

15

1

4

16

16

11

ing from the outside inwards

Use hexagonal nuts and wrench to at-

12

tach the plastic insert to the housing

wall

size 17 mm

Arrange serrated washer and cable

13

lug on the Allen screw according to

the diagram:

cable lug (1)—serrated washer (2)—

screw (3)

Screw the Allen screw into the plastic

14

insert

size 4 mm and then tighten

Fix the cable in place using 2 cable

15

ties

Trim cable ties

16

38

17

18

18

18

18

18

18

6x

TX25

*

Position cover

17

Install cover using 6 TX25 screws

18

Apply cable lug of an additional cable

19

to the screw protruding out of the

housing and use the serrated washer

and 8 mm hexagonal nut from the

scope of supply to secure the OPT/i

TSS TCP Touch Sense

Use the additional cable to establish a

20

connection to the workpiece/ground

EN-US

39

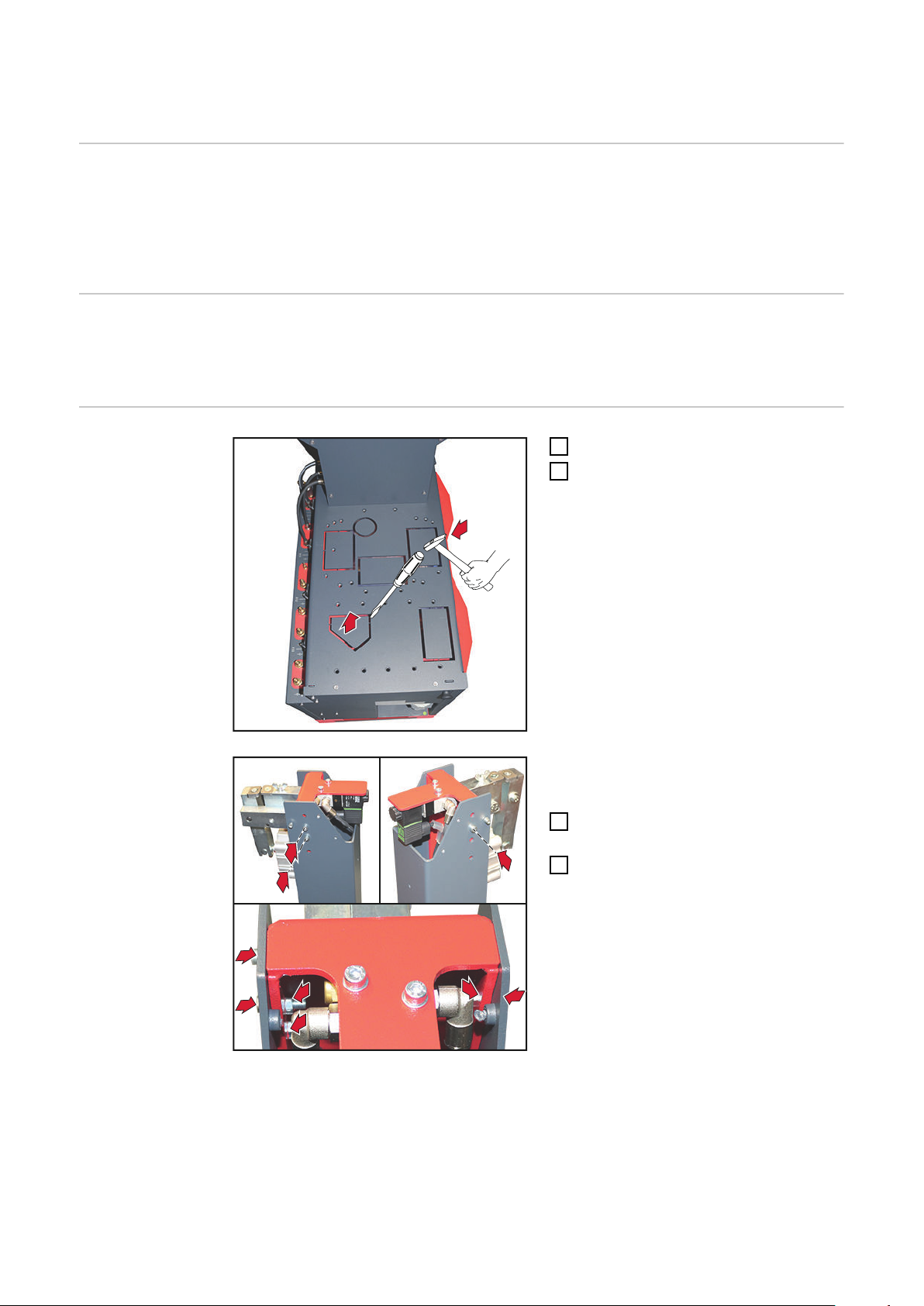

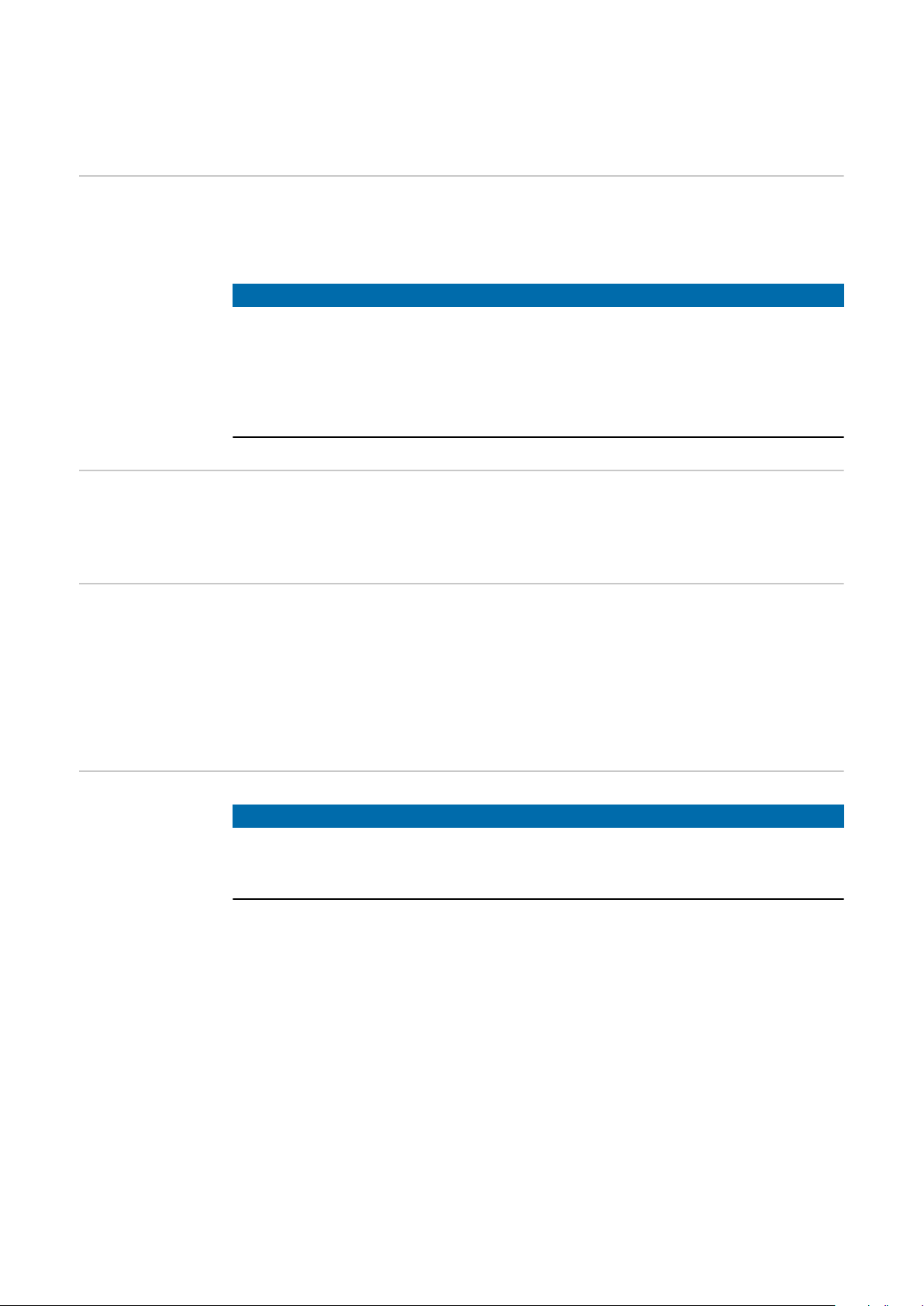

2. Installing the wire cutter

1

2

3

3

4

3

3

4

4

3

3

Tools Required - Slotted screwdriver

- Hammer

- 5 mm Allen key

- 6 mm Allen key

- 10 mm wrench

Additionally required

Installing the

Wire Cutter

The following accessories are required for attaching a wire cutter to the welding torch

service station:

OPT/i TSS Wire Cutter (installation set for wire cutter) ... 4,001,098,CK

Knock out the opening

1

Remove the knocked-out material

2

from above

Install the wire cutter on the wire cutter installation set:

using two 5 mm Allen screws and two

3

10 mm hexagonal nuts

using one 5 mm Allen screw and one

4

10 mm hexagonal nut

40

5

6

5

7

7

7

4x

Lay the control cable and compressed

8

10

9

5

air hose of the wire cutter backwards

through the recess

IMPORTANT! When positioning the

wire cutter, ensure that the control

cable and compressed air hose are

not pinched, kinked, cut, or otherwise

damaged.

Position the wire cutter according to

6

the diagram

Use four 6 mm Allen screws and four

7

washers to install the wire cutter on

the service station

Connect the control cable

8

Connect the compressed air hose

9

Apply the cover

10

EN-US

Operating Instructions

The wire cutter can be used to cut two wire electrodes with a diameter of up to 1.6 mm

(0.063 in.).

With the 0° welding torch, the wire electrodes must be cut one after the other.

The wire cutter is grounded.

41

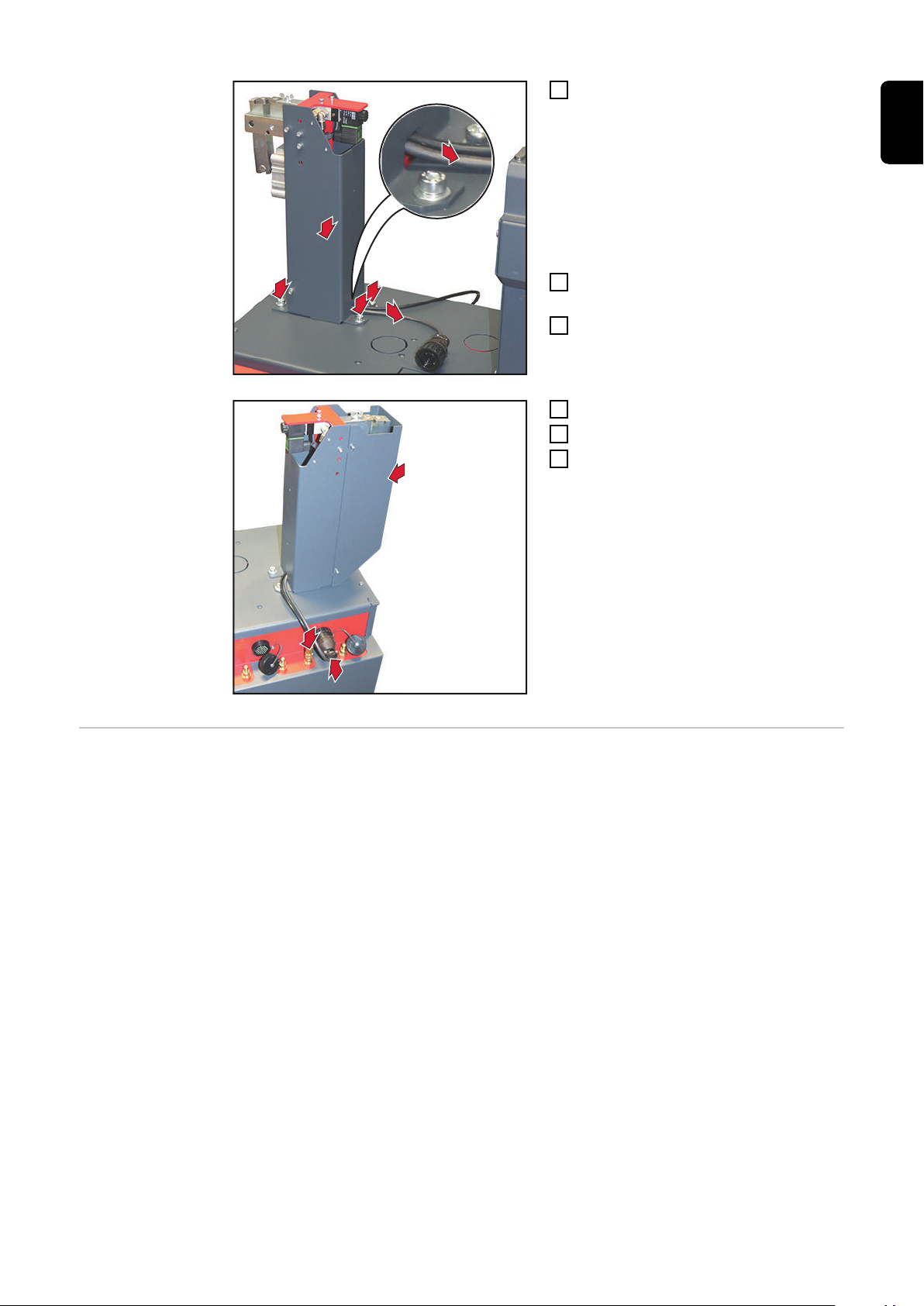

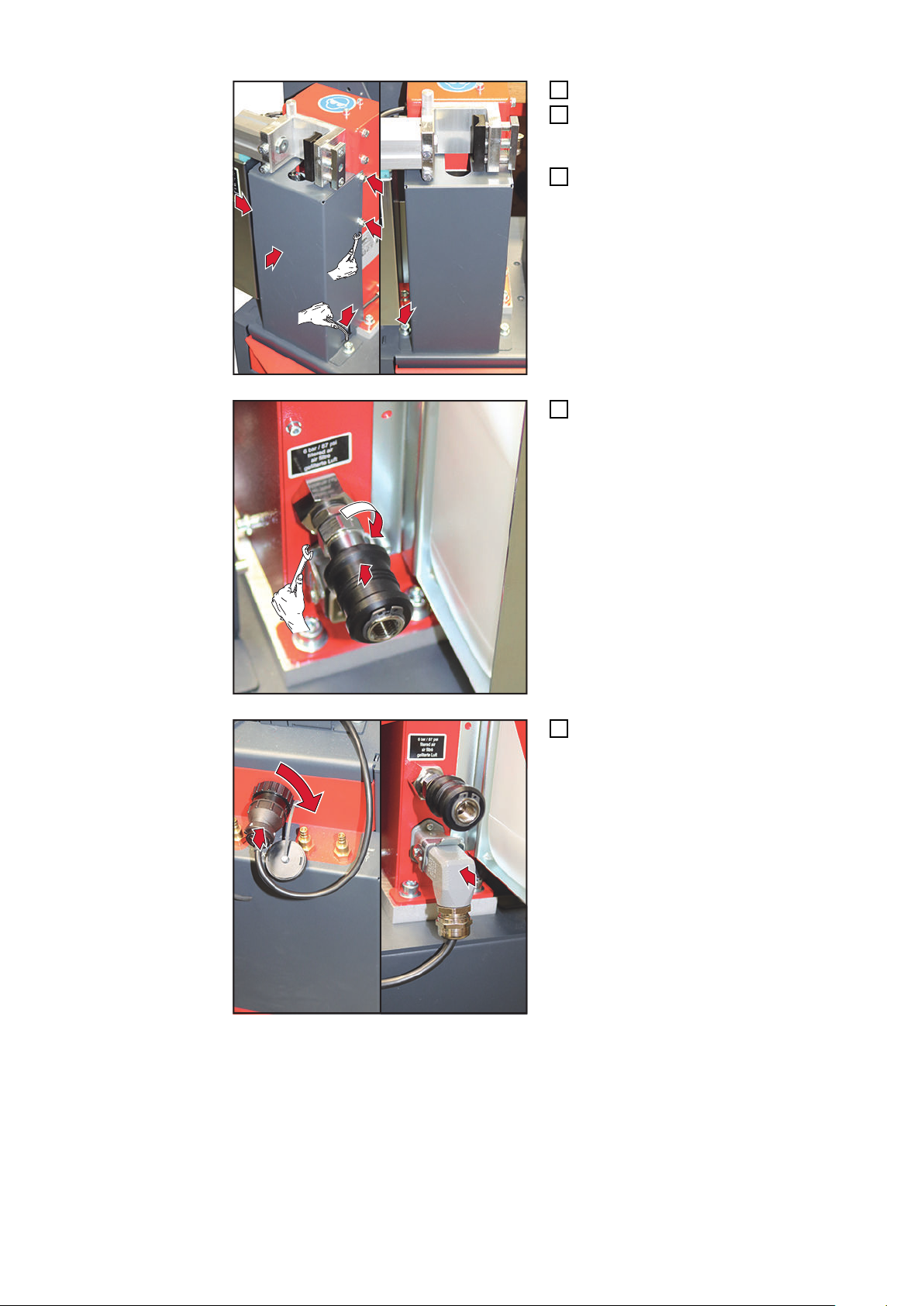

3. Installing the Robacta TC 2000 cleaning unit

1

1

2

3

3

3

3

General A Robacta TC 2000 cleaning unit or a Robacta Reamer Twin cleaning unit can be moun-

ted on the service station.

Tools required - Torx screwdriver TX25

- 6 mm Allen key

- Slotted screwdriver

- Hammer

Additionally Required

Installing the

Robacta TC 2000

Cleaning Unit

The following accessories are required for installing a Robacta TC 2000 cleaning unit on

the welding torch service station:

OPT/i TSS TC2000 (installation set for Robacta TC 2000) ... 4,001,012,CK

Knock out the round opening

1

Position the mounting plate

2

Use four 6 mm Allen screws and four

3

washers to install the mounting plate

42

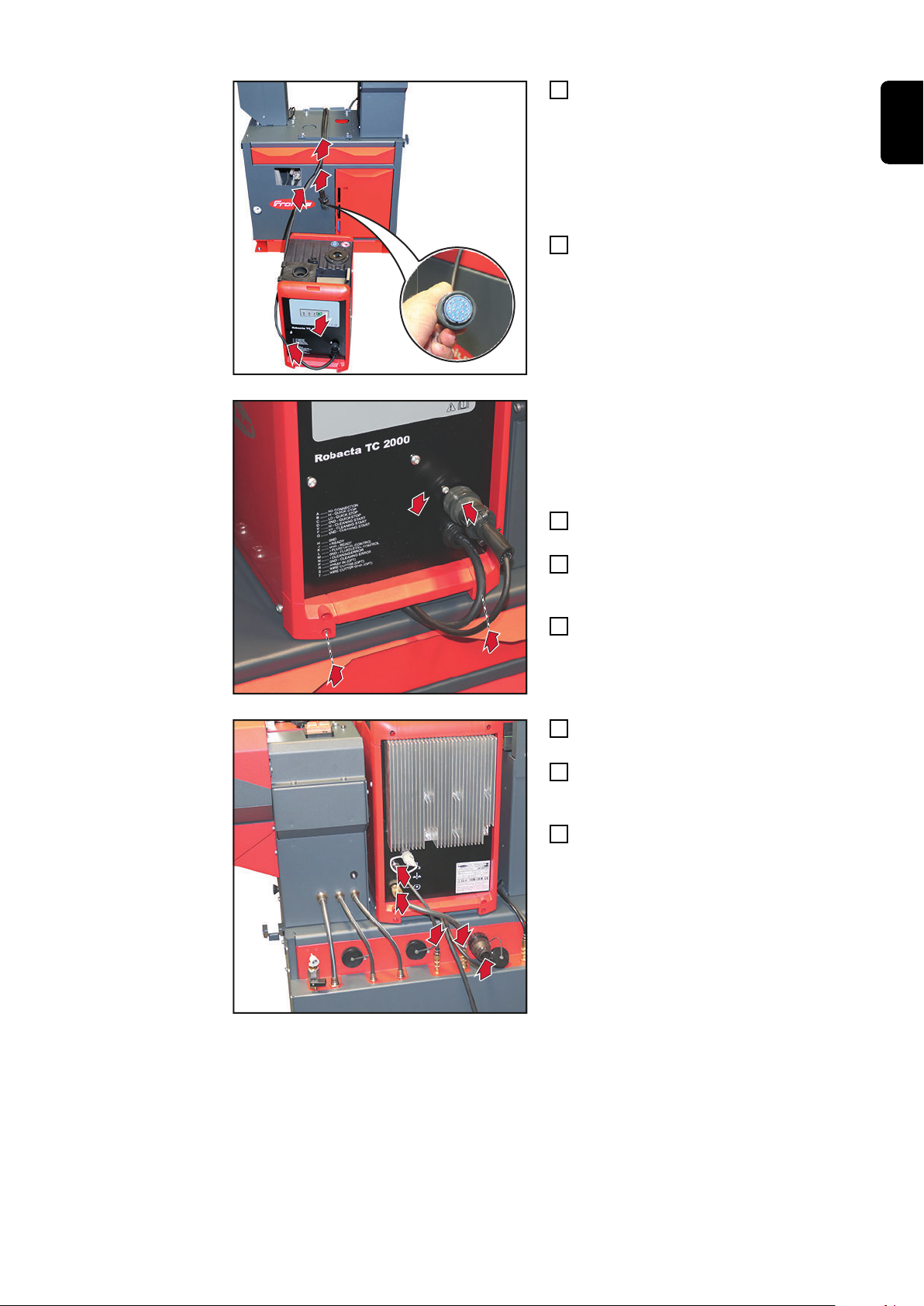

5

5

5

4

5

Place Robacta TC 2000 cleaning unit

6

8

7

7

4 x TX25

9

11

10

1

0

11

4

in front of the service station

IMPORTANT! When laying the control

cable, ensure that the correct cable

end is on the side of the TC 2000

cleaning unit.

Lay mains cable and control cable in

5

the mounting plate to the rear

IMPORTANT! When positioning the

Robacta TC 2000 cleaning unit, ensure

that the mains cable and control cable remain in the middle of the recess.

Apply Robacta TC 2000 cleaning unit

6

to the mounting plate

Use four TX25 screws to secure

7

Robacta TC 2000 cleaning unit to the

mounting plate

Connect control cable to the TC 2000

8

cleaning unit

EN-US

Attach control cable to the service sta-

9

tion

Connect hose for parting agent to the

10

service station and to the Robacta TC

2000 cleaning unit

Connect hose for compressed air to

11

the service station and to the Robacta

TC 2000 cleaning unit

43

4. Installing the level sensor

1

2

2

2

3

2

2

2

3

3

3

3

3

4

5

4

6

7

7

Tools Required - Torx screwdriver TX25

- 5 mm wrench

Installing the

Level Sensor

Pull the spring pins of the collecting

1

tray to the left and right and swing collecting tray out

Remove three TX25 screws on the left

2

Remove three TX25 screws on the

3

right

Remove frame

4

Open flap for parting agent container

5

Apply level sensor to the threaded pin

6

on the flap

Use two 5 mm hexagonal nuts to se-

7

cure the level sensor

44

9

8

9

Guide the sensor cable through the re-

10

11

12

12

13

14

14

14

13

13

15

13

13

13

14

14

14

8

cess to the other side

Attach the sensor cable to the avail-

9

able cable piece

Close flap for parting agent container

10

IMPORTANT! When inserting the frame,

ensure that the metal strap is positioned in

the recess.

EN-US

Insert the frame

11

Lift up the frame

12

Use three TX25 screws to secure the

13

frame on the right

Use three TX25 screws to secure the

14

frame on the left

Pull spring pins and insert collecting

15

tray

Carry out the commissioning of the level sensor in accordance with the "Commissioning

level sensor" instructions (42,0410,2553).

The instructions are included in the scope of delivery of the level sensor.

45

5. Inserting the parting agent container

1

3

2

4

7

5

6

6

Inserting the

Parting Agent

Container

Open flap for parting agent container

1

Carefully pull hose out of the flap

2

Insert parting agent container until it

3

reaches the stop

Open the parting agent container

4

Insert the hose into the parting agent

5

container

Secure the cap of the hose

6

NOTE!

When closing the flap, ensure that the

hose is not pinched, kinked, cut, or otherwise damaged

Close flap for parting agent container

7

46

6. Installing the TCP Tip

2

2 x TX20

1

1

Tools Required - Torx screwdriver TX20

EN-US

Installing the TCP

Tip

TCP = Tool Center Point

Instead of the Touch Sense, a TCP tip can also be fitted.

This can be done without knocking out the round holes on the side and top.

Use 2 TX20 screws to install the TCP

1

tip on the service station

Unscrew the protective cap for opera-

2

tion

47

7. Installing the Robacta Reamer V Easy / Robacta

Reamer V 70 Han12P cleaning unit

General In addition to the Robacta TC 2000 or Robacta Reamer cleaning units, a Robacta Ream-

er V Easy cleaning unit or a Robacta Reamer V 70 Han12P cleaning unit for single welding torches can be mounted on the service station.

NOTE!

If the Robacta Reamer and Robacta Reamer V Easy / Robacta V 70 Han12P cleaning units are available on the service station, both cleaning units are always activated at the same time!

Robacta Reamer and Robacta Reamer V Easy / Robacta V 70 Han12P are both always

active.

Which of the two cleaning units is started up depends on the robot program.

▶

Tools required - 6 mm Allen key

- 10 mm wrench

- 19 mm wrench

Additionally required

Installing the

Reamer V Easy /

Robacta Reamer

V 70 Han12P

cleaning unit

The following accessories are required for installing a Robacta Reamer V Easy cleaning

unit on the welding torch service station:

OPT/i TSS Reamer Single... 4,001,123

The following accessories are required for installing a Robacta Reamer V 70 Han12P

cleaning unit on the welding torch service station:

OPT/i TSS Reamer V70 ... 4,001,133

NOTE!

The assembly of Robacta Reamer V Easy and Robacta Reamer V 70 Han12P is

identical.

All work steps for Robacta Reamer V Easy also apply to Robacta Reamer V 70 Han12P.

48

1

Example: Service station with Robacta reamer and

2

3

3

3

3

4

5

4

4

6

wire cutter

Position the intermediate plate over

1

the 4 holes

Place the Robacta Reamer V Easy on

2

the intermediate plate

Use four 6 mm Allen screws and four

3

washers to install the Robacta Reamer V Easy on the service station

EN-US

Remove three 10 mm hexagonal bolts

4

Remove the cover

5

Knock out the rectangular opening

6

49

7

8

8

9

8

9

Fit the new cover

10

11

11

7

Install the new cover on the Robacta

8

Reamer V Easy with three 10 mm

hexagonal bolts

Secure the new cover to the service

9

station with two 6 mm Allen screws

Install spool valve

10

Size 19 mm

Connect the control cable to the ser-

11

vice station and Robacta Reamer V

Easy

50

1

2

12

Connect the compressed air supply

12

EN-US

51

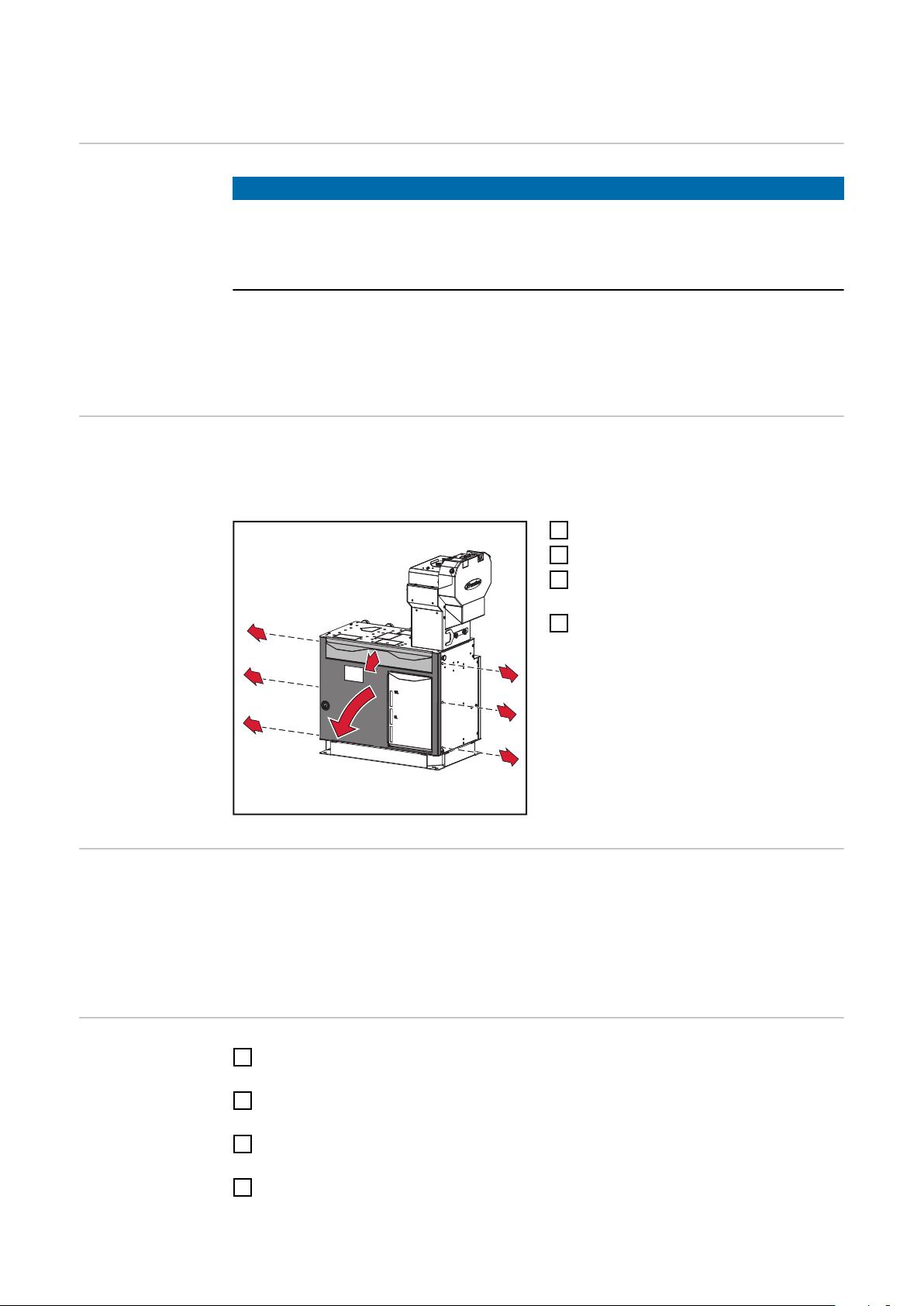

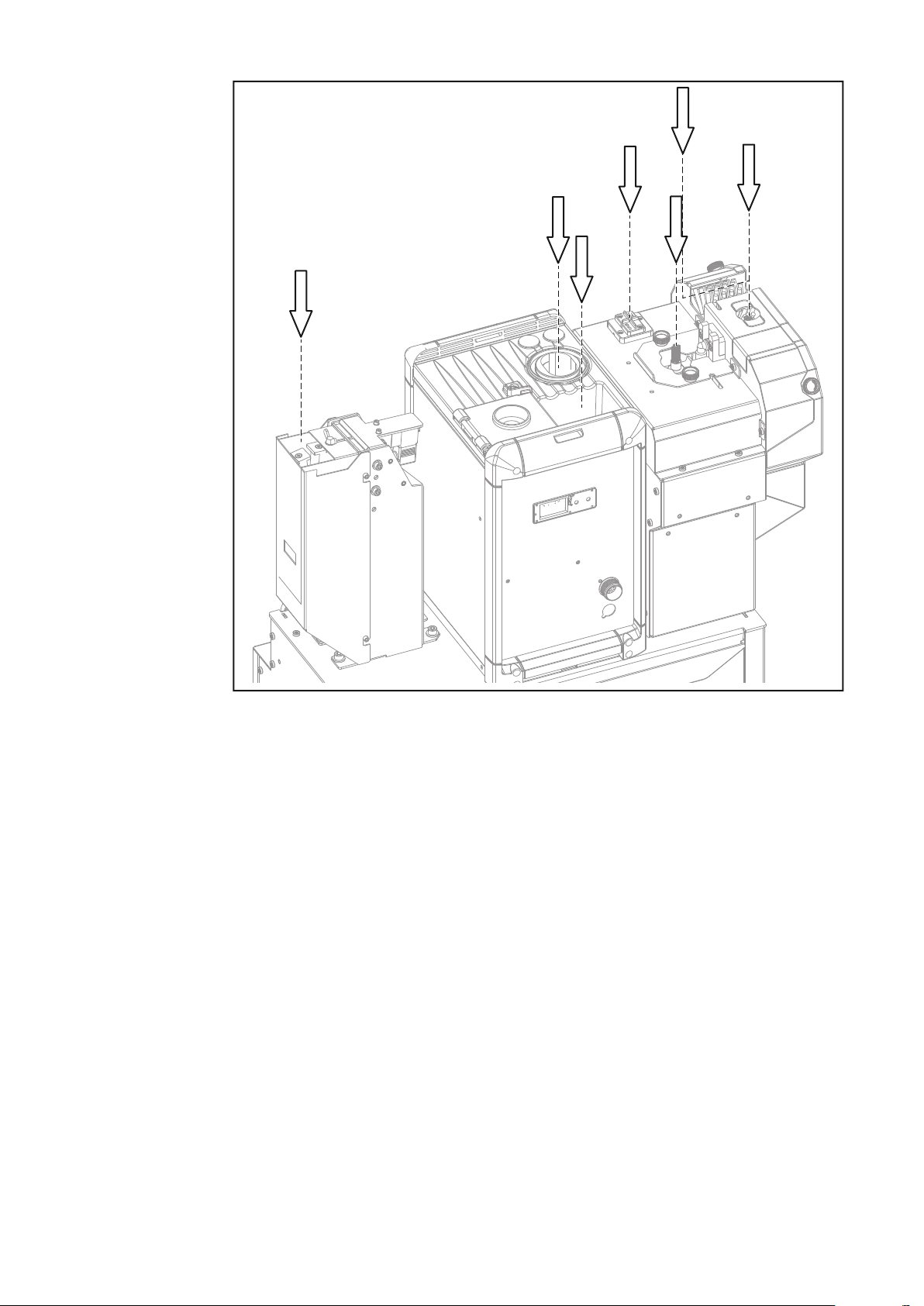

Starting Up the Welding Torch Service Station

*

4

3

2

1

3

3

2

2

General

Opening the

Welding Torch

Service Station

NOTE!

If wetting agent has not been applied to the inside of the welding torch, this may

lead to the permanent contamination of the welding torch when welding begins.

Always wet the inside of the welding torch with the manufacturer's "Robacta Reamer"

parting agent before starting an automatic application.

To achieve optimum cleaning results, observe the following points:

- Always wet the inside of the welding torch with parting agent

- Adhere to the specified cleaning procedures

- Adhere to the specified cleaning positions

If the welding torch service station is equipped with an optional fieldbus as a robot control unit connection, the service station for connecting the robot control unit and for fault

diagnosis of the fieldbus must be opened as follows:

Remove collecting tray

1

Remove three TX25 screws on the left

2

Remove three TX25 screws on the

3

right

Remove frame

4

* Position of the bus coupler

Requirements for

Starting Up

The following requirements must be met in order to commission the cleaning device:

- Securely bolt the welding torch service station to the surface

- Any available optional equipment installed on the welding torch service station, supplied with compressed air and connected to the grid if necessary

- Compressed air supply to the welding torch service station established

- Cleaning device connected to the robot control unit

Starting Up the

Welding Torch

Service Station

Check whether all optional equipment is correctly connected to the welding torch

1

service station

Connect welding torch service station to the robot control unit

2

max. length of the control cable = 30 m

Establish electrical supply to the optional equipment

3

max. length of the mains cable = 30 m

Establish compressed air supply

4

max. length of the compressed air supply line = 30 m

52

Adjust pressure on the manometer: 5.5–6 bar

5

Check that all equipment parts and covers are correctly installed

6

IMPORTANT! Before welding for the first time, a complete cleaning process must be car-

ried out.

EN-US

53

54

Cleaning Program Sequence

55

56

Program sequence—overview

EN-US

Detailed Information on the Optional Equipment

Program Sequence—Overview

NOTE!

For detailed information on the optional equipment, consult the available installation instructions or Operating Instructions for the optional equipment.

The following program sequence is described using the example of a service station with

wire cutter, Robacta TC 2000 cleaning unit, and dipping bowl.

For other configurations, refer to the Operating Instructions of the components.

- Welding

Pos. A Wire cutter + retract wire

Pos. B Robacta TC 2000 dipping bowl

Pos. C Robacta TC 2000

Pos. D High-pressure gas purging with parting agent (1st contact tip)

Pos. E Outer gas nozzle cleaning brush (2x)

Pos. F Inner gas nozzle cleaning brush (1st and 2nd contact tip )

Pos. D High-pressure gas purging with parting agent (2nd contact tip)

Pos. G Touch Sense + wire threading

or

Pos. A Wire cutter + wire threading

- Welding

57

A

B

C

D

E

F

G

58

General information

max. 75 mm

(2.95 in.)

(1)

Wire cutter The wire cutter can be used to cut two wire electrodes with a diameter of up to 1.6 mm

(0.063 in.)

The opening and closing of the wire cutter is triggered by an active signal from the robot

controls.

EN-US

TC 2000 dipping

bowl

The use of the dipping bowl is recommended in the case of:

- gas-cooled welding torches

- water-cooled welding torches in the higher power range (hot gas nozzles)

Advantages:

- The spatter accumulation on the gas nozzle loosens.

- The welding torch is also cooled.

- The anti-stick agent contained in the parting agent prevents new contaminations.

NOTE!

Immerse welding torch a maximum of

75 mm (2.95 in.) into the dipping bowl.

The gas holes (1) must remain dry.

▶

Robacta TC 2000 Robacta TC 2000 is an electromagnetic cleaning unit for welding torch cleaning in steel

applications.

After 50 seconds of charging time, the maximum magnetic flux density is available for

the cleaning process.

The cleaning process (discharge process) is initiated by the “Cleaning start” signal.

Specification of

the Parting Agent

Volume

Cleaning End

without Touch

Sense Option

In the case of high-pressure gas purging with parting agent, the parting agent volume is

specified via the duration of the external “Pump for parting agent” signal.

The longer the signal is present, the more parting agent is injected.

If the Touch Sense option is not installed on the service station, then the cleaning process is ended at the wire cutter.

59

Program sequence

A

50 mm

1.97 in.

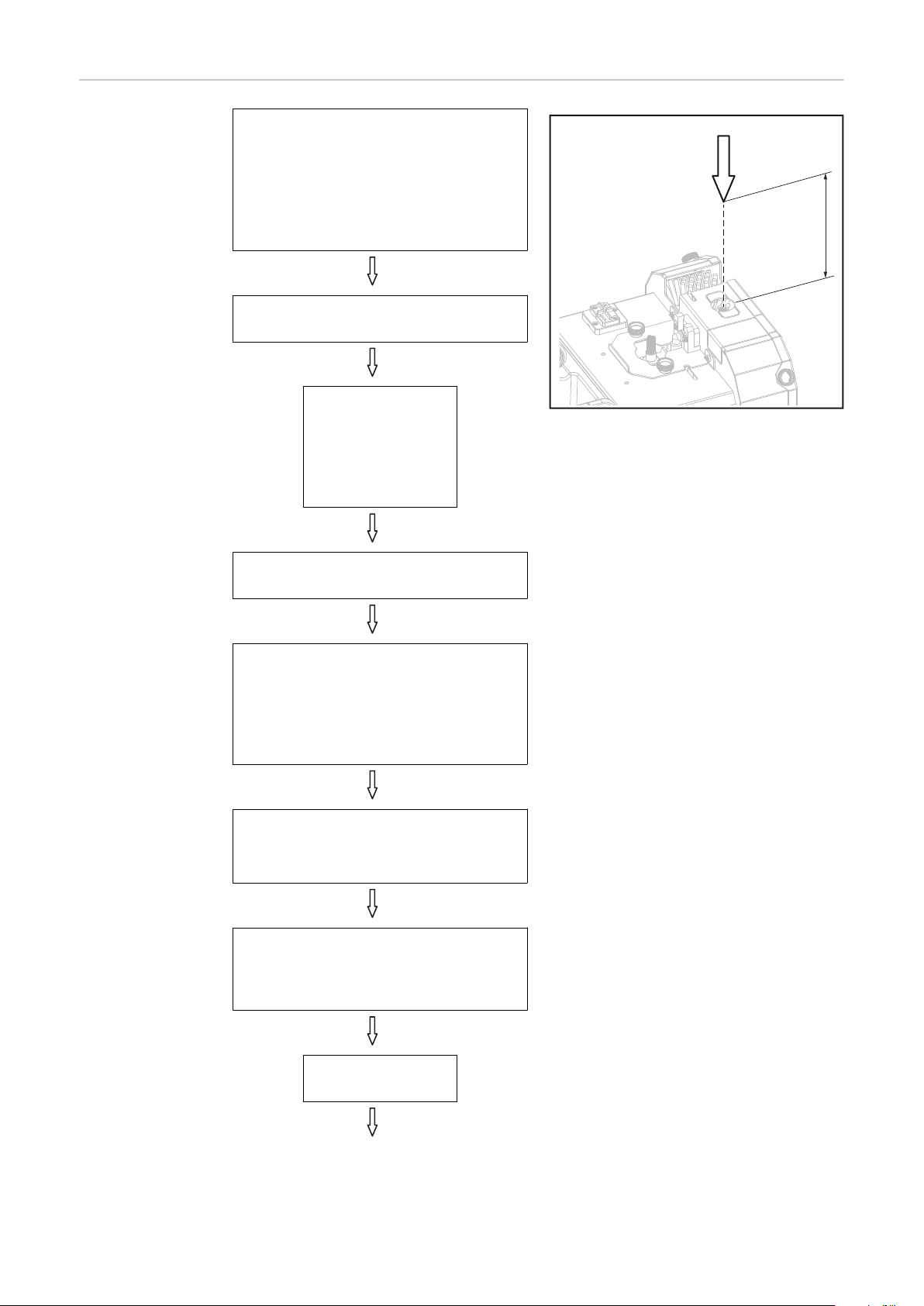

Wire cutter program sequence

Start

Move to position A

approx. 50 mm/1.97 in. above wire cutter (between blades and sheet metal

cover)

Speed: High-speed mode

Set

"Start wirefeeding" signal on the power

source

Wait approx. 0.5

seconds

Reset

"Start wirefeeding" signal on the power

source

Move in with the wire electrode in the

wire cutter blade

Speed: 50 cm/min (19.69 ipm)

Set

external signal "Cut wire electrode"

Move straight up

approx. 50 mm/1.97 in. above wire cutter blades

Speed: 50 cm/min (19.69 ipm)

Wait 0.5 seconds

60

Reset

external signal "Cut wire electrode"

Set

"Retract wire electrode" signal on the

power source

Reset

"Retract wire electrode" signal on the

power source

Wait approx. 2-3

seconds

EN-US

61

Robacta TC 2000

B

50 mm

1.97 in.

75 mm

2.95 in.

dipping bowl program sequence

Move to position B

approx. 200 mm/7.9 in. centrally above

dipping bowl

Speed: High-speed mode

Move into dipping bowl

max. speed: 50 cm/min / 19.69 ipm

max. insertion depth: 75 mm / 2.95 in.

Wait 2-3 seconds

Move to position B

approx. 200 mm/7.9 in. centrally above

dipping bowl

max. speed: 50 cm/min (19.69 ipm)

Set

gas purging through welding torch (option)

Reset

Wait 0.5 seconds

Max. insertion depth

gas purging through welding torch (option)

62

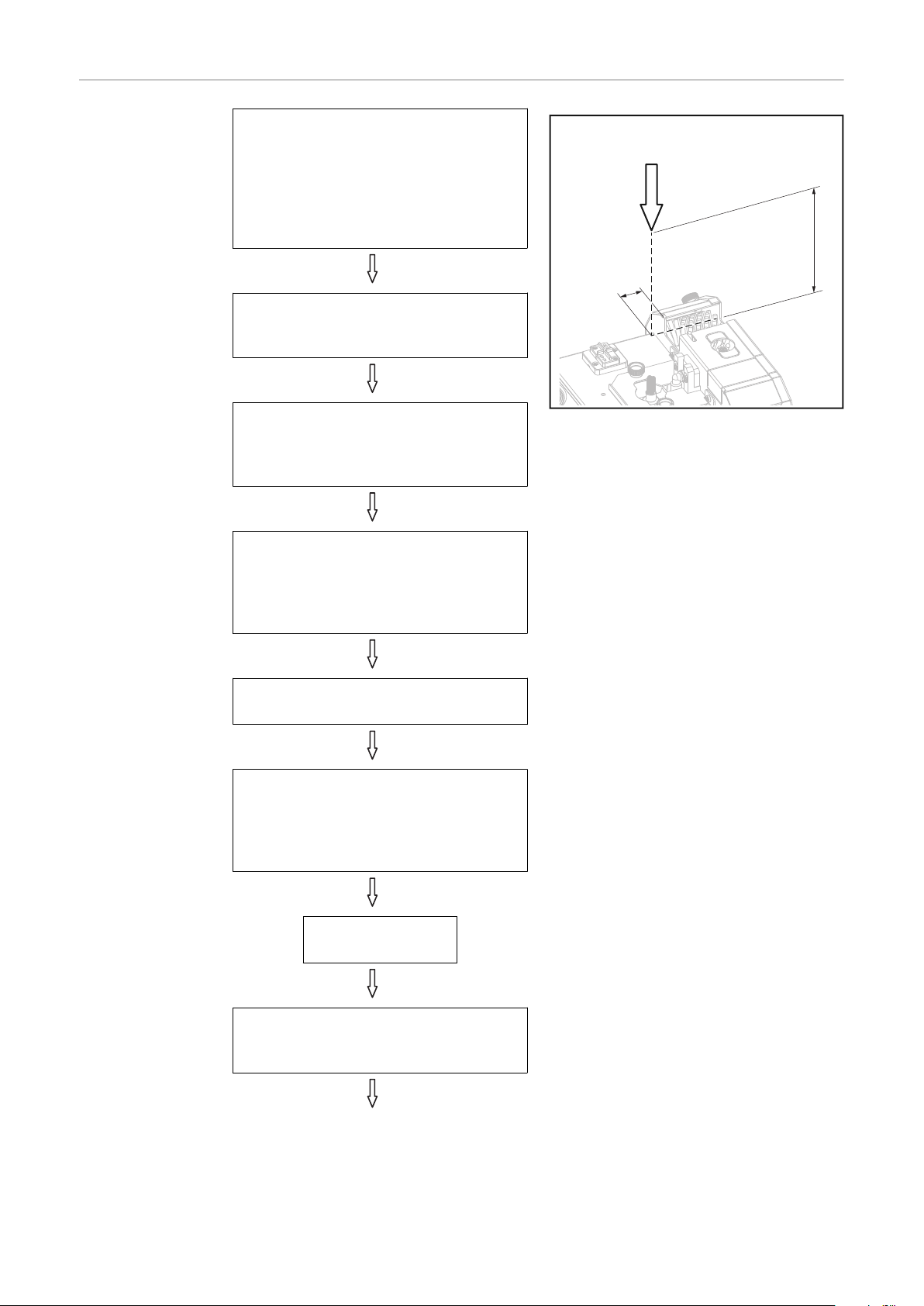

TC 2000 program

C

50 mm

1.97 in.

sequence

Move to position C

approx. 50 mm/1.97 in. centrally above

cleaning coil

Speed: High-speed mode

EN-US

Move into TC 2000

max. speed: 50 cm/min / 19.69 ipm

Insertion depth: 54 mm / 2.13 in. *)

Set

external signal "Start cleaning"

Wait 0.5 seconds

Reset

external signal "Start cleaning"

Move to position C

approx. 50 mm/1.97 in. centrally above

cleaning coil

max. speed: 50 cm/min (19.69 ipm)

*) Insertion depths for coil shapes

other than Twin as per Robacta

TC 2000 Operating Instructions

63

High-pressure

D

50 mm

1.97 in.

gas purging with

parting agent

program sequence (1st contact tip)

Move to position D

1

approx. 50 mm/1.97 in. centrally above

the opening for the high-pressure gas

purging

Contact tip 1 vertical to the service station

Speed: High-speed mode

Set

external signal "Pump for parting agent"

Wait 0.2-0.3

seconds

specification of the

parting agent

volume via the dur-

ation

Reset

external signal "Pump for parting agent"

Move into the high-pressure gas purging

max. speed: 50 cm/min / 19.69 ipm

Select insertion depth so that the distance between contact tip and nozzle is

3 mm / 0.12 in.

Set

64

external signal "External valve brush

cleaning"

Set

external signal "High-end gas purging

(from front)"

Wait 0.5 - 1.5

seconds

Reset

external signal "High-end gas purging

(from front)"

EN-US

Reset

external signal "External valve brush

cleaning"

Wait 1 second

65

Outer gas

E

50 mm

1.97 in.

20 mm

0.79 in.

nozzles cleaning

brush program

sequence

Move to position E

approx. 50 mm/1.97 in. centrally above

the outer gas nozzle cleaning brush and

approx. 20 mm/0.79 in. in front of the

housing of the service station

Position welding torch at an angle

Speed: High-speed mode

Set

external signal "External valve brush

cleaning"

Move into the external gas nozzle

cleaning brush

max. speed: 50 cm/min / 19.69 ipm

max. insertion depth: 12 mm / 0.47 in.

Pass through the external gas nozzle

cleaning brush x2

forwards and backwards

max. speed: 50 cm/min / 19.69 ipm

max. insertion depth: 12 mm / 0.47 in.

Turn welding torch 180°

*)

Pass through the external gas nozzle

cleaning brush x2

forwards and backwards

max. speed: 50 cm/min / 19.69 ipm

max. insertion depth: 12 mm / 0.47 in.

*) Alternative:

Break the second cleaning brush free

and pass through each cleaning brush x

1

66

Wait approx. 2-3

seconds

Reset

external signal "External valve brush

cleaning"

Move to position E

approx. 50 mm/1.97 in. centrally above

the outer gas nozzle cleaning brush and

approx. 20 mm/0.79 in. in front of the

housing of the service station

max. speed: 50 cm/min (19.69 ipm)

EN-US

67

Inner gas nozzle

50 mm

1.97 in.

F

cleaning brush

program sequence

Move to position F

1

approx. 50 mm/1.97 in. centrally above

the inner gas nozzle cleaning brush

Contact tip 1 vertical to the service station

Speed: High-speed mode

Set

external signal "Internal valve brush

cleaning"

Move into the inner gas nozzle cleaning brush

max. speed: 50 cm/min / 19.69 ipm

max. insertion depth: 1/3 of the brush

length

Wait 2-3 seconds

Move to position F

2

approx. 50 mm/1.97 in. centrally above

the inner gas nozzle cleaning brush

Contact tip 2 vertical to the service station

max. speed: 50 cm/min (19.69 ipm)

Move into the inner gas nozzle cleaning brush

max. speed: 50 cm/min / 19.69 ipm

max. insertion depth: 1/3 of the brush

length

Wait 2-3 seconds

Move to position F

approx. 50 mm/1.97 in. centrally above

the inner gas nozzle cleaning brush

Contact tip 2 vertical to the service station

max. speed: 50 cm/min (19.69 ipm)

68

Reset

external signal "Internal valve brush

cleaning"

EN-US

69

High-pressure

D

50 mm

1.97 in.

gas purging with

parting agent

program sequence (2nd contact tip)

Swivel to position D

2

Contact tip 2 vertical to the service station

max. speed: 50 cm/min (19.69 ipm)

Set

external signal "Pump for parting agent"

Wait 0.2 - 0.3

seconds

specification of

the parting agent

volume via the

duration

Reset

external signal "Pump for parting agent"

Move into the high-pressure gas purging

max. speed: 50 cm/min / 19.69 ipm

Select insertion depth so that the distance between contact tip 2 and nozzle

is 3 mm / 0.12 in.

Set

external signal "High-end gas purging

(from front)"

Set

external signal "External valve brush

cleaning"

Wait 0.5 - 1.5

seconds

Reset

external signal "High-end gas purging

(from front)"

70

Wait 1 second

Reset

external signal "External valve brush

cleaning"

Move to position D

2

approx. 50 mm/1.97 in. centrally above

the opening for the high-pressure gas

purging

Contact tip 2 vertical to the service station

max. speed: 50 cm/min (19.69 ipm)

EN-US

71

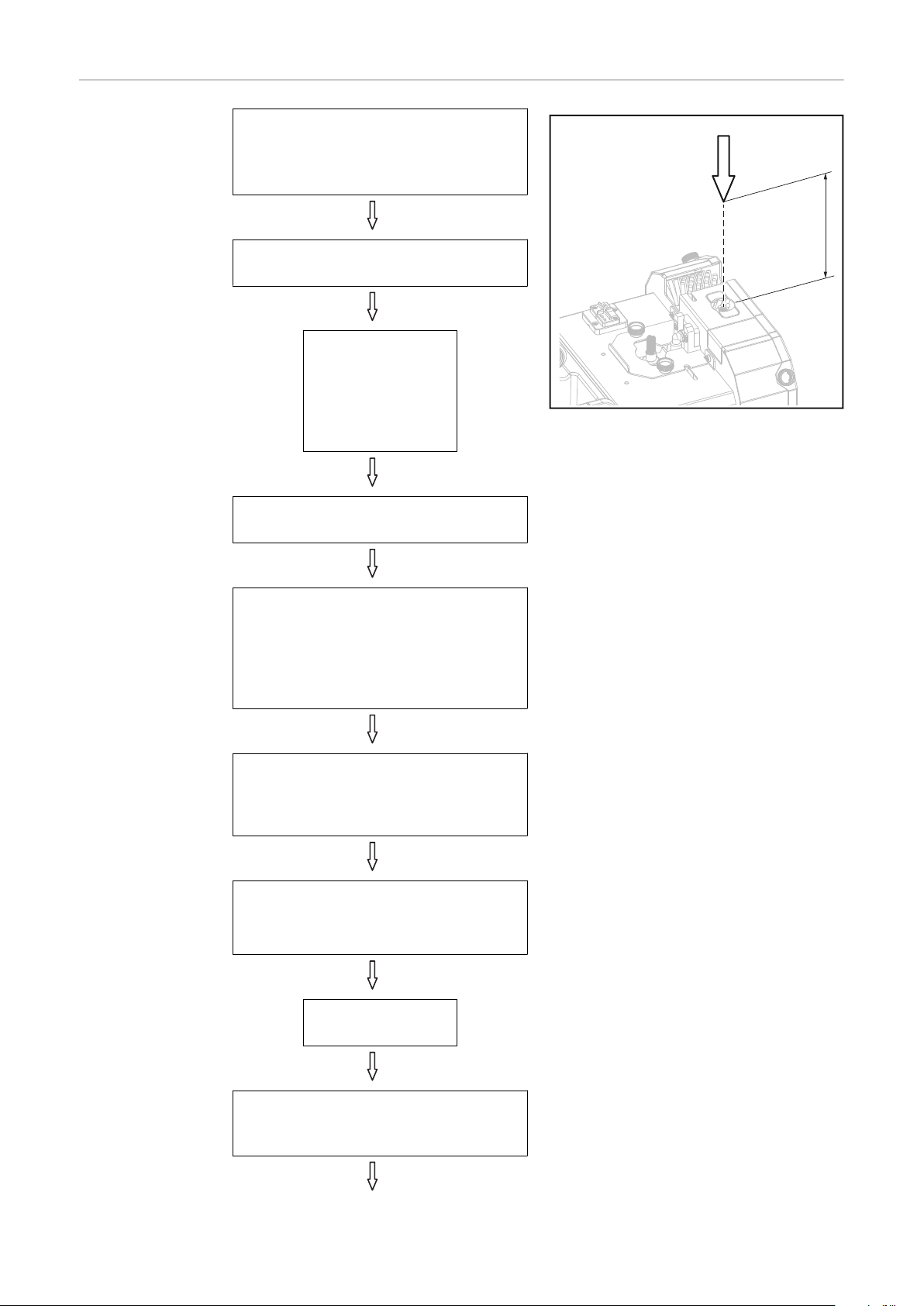

Touch Sense (op-

G

x mm

x in.

tion) program sequence

Move to position G

x mm/x in. centrally above the Touch

Sense option

x = stick out of the wire electrodes depending on application

Speed: High-speed mode

Set

"Wirefeeding on" signal on the power

source

Wait until the wire

electrode touches

the Touch Sense

option - the

wirefeeding is

automatically

stopped

Reset

"Wirefeeding on" signal on the power

source

End of the

cleaning

process

Welding

72

Wire cutter -

A

50 mm

1.97 in.

cleaning end program sequence

Inner gas nozzle cleaning brush

EN-US

Move to position A

approx. 50 mm/1.97 in. above wire cutter (between blades and sheet metal

cover)

Speed: High-speed mode

Set

"Start wirefeeding" signal on the power

source for approx. 2.5—4.5 seconds

(approx. 20% longer than retracting the

wire)

Wait 2.5 - 4.5

seconds

Reset

"Start wirefeeding" signal on the power

source

Move into wire cutter

insertion depth = x mm above the cutting tool

x = stick out of the wire electrodes depending on application

max. speed: 50 cm/min (19.69 ipm)

Set

external signal "Cut wire electrode"

Wait 0.5 seconds

Move straight up

approx. 50 mm/1.97 in. centrally above

wire cutter blades

Speed: 50 cm/min (19.69 ipm)

73

Reset

external signal "Cut wire electrode"

End of the

cleaning

process

Welding

74

Troubleshooting, Maintenance, and

Disposal

75

76

Safety

EN-US

Detailed Information on the Optional Equipment

Safety Please follow the safety rules below during all the tasks described in the "Installation and

NOTE!

For detailed information on the optional equipment, consult the available installation instructions or Operating Instructions for the optional equipment.

Commissioning" chapter.

WARNING!

Danger from incorrect operation and work that is not carried out properly.

This can result in severe personal injury and damage to property.

All work listed in these Operating Instructions may only be performed by trained spe-

▶

cialist personnel.

All functions described in these Operating Instructions may only be used by trained

▶

specialist personnel.

Do not perform the work or use the functions described below until you have thor-

▶

oughly read and understood the following documents:

these Operating Instructions,

all Operating Instructions for system components, especially the safety rules.

WARNING!

Danger due to machines starting automatically.

This can result in severe personal injury and damage to property.

In addition to these Operating Instructions, observe the safety rules of the robot

▶

manufacturer and welding system manufacturer.

For your personal safety, make sure that all protective measures have been taken in

▶

the robot's operating area and remain in effect while you are in this area.

WARNING!

Danger due to mechanically moving parts.

Serious injuries may result.

Before starting any work on the welding torch service station or the system compon-

▶

ents connected to it, disconnect the welding torch service station from the existing

compressed air supply, disconnect the existing options from the grid.

Ensure that the available compressed air supply to the welding torch service station

▶

and the electrical supply to the connected system components remain disconnected

until all work is finished.

77

WARNING!

Danger due

to flying parts (chips, metal particles, etc.),

escaping compressed air/parting agent mixture,

electrically supplied, activated options.

If compressed air is supplied to the welding torch service station, serious injury can result.

If work needs to be carried out on the device while the welding torch service station is

being supplied with compressed air or the optional equipment is being supplied with

electricity:

if there are TC cleaning units, keep all ferromagnetic parts (e.g., tools) away from

▶

the device

keep hands, hair, the face, items of property, and all items of clothing away from the

▶

optional devices

wear hearing protection

▶

wear protective goggles with side protection

▶

WARNING!

Danger due to insufficient ground conductor connection!

Serious injury or damage to property can result.

The housing screws are a suitable ground conductor connection for grounding the housing.

The housing screws must not under any circumstances be replaced by other screws

▶

without a reliable ground conductor connection.

78

Troubleshooting

*

2

3

4

1

EN-US

Detailed Information on the Optional Equipment

NOTE!

For detailed information on the optional equipment, consult the available installation instructions or Operating Instructions for the optional equipment.

Troubleshooting Make a note of the serial number and configuration of the device, and provide the ser-

vice team with a detailed error description if:

- Errors occur that are not covered in this document

- The troubleshooting measures provided in this document are unsuccessful

Parting agent is not injected

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Parting agent container is empty

Insert new parting agent canister

Injection quantity too low

Set injection quantity (injection time)

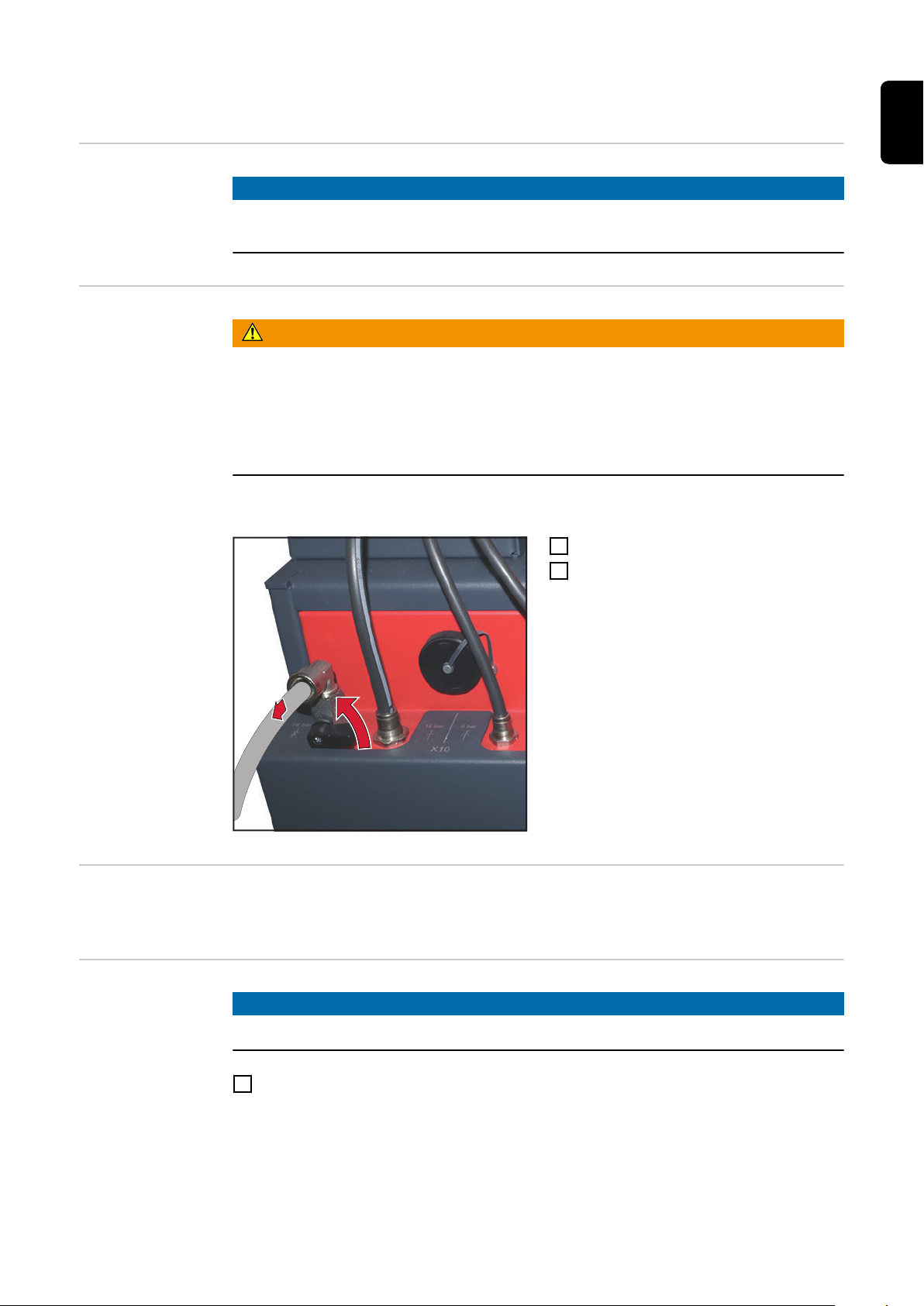

Intake filter in "Robacta Reamer" parting agent container dirty

Blow out the intake filter in the "Robacta Reamer" parting agent container

from the inside out with compressed air using the intake hose:

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Parting agent hose kinked

Remove kink, if necessary replace hose

Parting agent pump faulty

Contact After-Sales Service

No signal at the parting agent pump

Check programming;

Check connections to the robot control unit

Non-return value faulty

Contact After-Sales Service

Compressed air supply interrupted

Set up the compressed air supply

Compressed air supply line faulty or dirty

Clean compressed air supply line and replace if necessary

79

Cleaning brushes do not run

Cause:

Remedy:

Compressed air supply interrupted

Set up the compressed air supply

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

High-pressure gas purging not working

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Compressed air supply line faulty or dirty

Clean compressed air supply line and replace if necessary

Brush motor faulty

Inform service team

Valve faulty

Inform service team

No signal at the valve

Check programming;

Check connections to the robot control unit

Compressed air supply interrupted

Set up the compressed air supply

Compressed air supply line faulty or dirty

Clean compressed air supply line and replace if necessary

Pressure regulator not set correctly

Check pressure at pressure regulator, set pressure to 5.5 - 6 bar

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Cause:

Remedy:

Pores in the weld seam

Cause:

Remedy:

Cause:

Remedy:

Pressure booster faulty

Contact After-Sales Service

Inlet pressure at the pressure booster too low

Check inlet pressure

Valve faulty

Contact After-Sales Service

Nozzle blocked

Clean nozzle, replace if necessary

Too much parting agent in the inside of the welding torch

Remove residues of parting agent by blowing out the inside of the welding

torch. Ensure supply of compressed air

Too much parting agent in the inside of the welding torch

Reduce parting agent injection quantity (shorten duty cycle of pump for parting agent)

80

Service, maintenance and disposal

2

1

EN-US

Detailed Information on the Optional Equipment

Releasing Pressure before Maintenance Work

NOTE!

For detailed information on the optional equipment, consult the available installation instructions or Operating Instructions for the optional equipment.

WARNING!

Danger due to compressed air stored at 16 bar in the pressure booster.

Serious injuries may result.

Switch off the compressed air supply and release stored compressed air before

▶

maintenance and servicing.

During maintenance and servicing, keep the device de-energized and depressur-

▶

ized.

Release pressure:

Disconnect compressed air supply

1

Open valve

2

Fully release pressure

Before Every

Start-up

Daily

- Check the fill level in the parting agent container and top up if necessary

- Check cleaning brushes for contamination and wear; replace them if necessary

NOTE!

Only clean the devices with cleaning products that are free of solvents.

Remove any deposited parting agent and contamination from the outside of the base

1

unit and cleaning unit.

81

Weekly - Empty collecting tray;

clean screen for collecting tray if available

- Blow out the intake filter in the parting agent container from the inside out with compressed air using the intake hose

- Drain water in the pressure booster (press red button on the glass tank)

Monthly - Open the dirt deflector under the round brushes and clean with compressed air

Every 6 Months

Risk of damage to electronic parts.

▶

1

Every 12 Months

Disposal Materials should be disposed of according to valid local and national regulations.

1

CAUTION!

Do not blow electronic parts clean from a short distance away.

Open the welding torch service station and blow clean with dry and reduced compressed air

Have a Fronius service technician perform a safety inspection on the cleaning device

82

Change cleaning brushes and nozzle for the high-

2

1

2

1

1

pressure gas purging

Releasing Pressure before Maintenance Work

Danger due to compressed air stored at 16 bar in the pressure booster.

Serious injuries may result.

▶

▶

Release pressure:

WARNING!

Switch off the compressed air supply and release stored compressed air before

maintenance and servicing.

During maintenance and servicing, keep the device de-energized and depressurized.

Disconnect compressed air supply

1

Open valve

2

Fully release pressure

EN-US

Replacing the

Outer Gas Nozzle

Cleaning Brushes

Loosen knurled screws

1

Remove cover

2

83

3

Remove installation wrench

6

4

5

7

2

1

1

3

Place the installation wrench behind

4

the right-hand cleaning brush

Undo the 17 mm hexagonal bolt

5

Remove hexagonal bolt and fixing

6

washer

Remove right-hand cleaning brush

7

Replacing the inner gas nozzle

cleaning brush

Repeat steps 4 - 7 for the left-hand

8

cleaning brush

NOTE!

Always replace both cleaning brushes!

The assembly of the cleaning brushes is carried out in reverse order.

Loosen knurled screws

1

Remove cover

2

84

3

4

Press and hold locking button

2

1

1

3

4

3

Remove cleaning brush from above

4

Changing the

nozzle for the

high-pressure

gas purging

IMPORTANT! During installation, press

and hold the locking button and insert the

cleaning brush until it engages.

Loosen knurled screws

1

Remove cover

2

EN-US

Pull out spring bolt

3

Remove the nozzle from above

4

85

Fitting the nozzle:

IMPORTANT! When fitting the nozzle, ensure that:

- The O-ring on the nozzle is present and OK

- The O-ring is greased

CAUTION!

Danger from nozzle being thrown out of the device.

An incorrectly secured nozzle can be thrown out of the device when compressed air is

supplied and cause a variety of injuries.

The sequence of the following steps must be observed.

▶

Always insert the nozzle as far as it will go.

▶

Check that the nozzle is correctly secured.

▶