/ Perfect Charging / Perfect Welding / Solar Energy

Robacta

Robacta Twin

MTB /i

MTB /d

Operating Instructions

ENZH

MIG/MAG robot welding torch

䈤᰾Җ

MIG/MAG ᵪಘӪ✺⛜

42,0410,1933 003-07112019

Dear reader,

Thank you for the trust you have

placed in our company and congratulations on buying this high-quality

Fronius product. These instructions

will help you familiarise yourself

with the product. Reading the

instructions carefully will enable

you to learn about the many

different features it has to offer.

This will allow you to make full use

of its advantages.

Please also note the safety rules

to ensure greater safety when

using the product.

ZHEN

1

General

The Robacta and Robacta Twin

robot hose packs are available in

numerous versions, and are used

in automated series production.

They are particularly suitable for

welding steel and CrNi.

Connections with external or

internal water connections, as well

as a large number of torch neck

versions are available.

For hose pack lengths up to 6

metres (19 ft. 8.22 in.), the Robacta and Robacta Twin robot hose

packs represent a low-cost alternative to the motorised Robacta Drive

or Robacta Drive Twin robot hose

packs.

ZHEN

ES

2

Safety

WARNING! Work perfor-

med incorrectly can cause

serious injury and damage. The activities described

must only be carried out by

trained and qualified personnel.

Pay particular attention to the

enclosed „Safety rules“ docu-

WARNING! An electric

shock can be fatal. Only

carry out the activities described

if

- the power source mains

switch is in the „O“ position,

- the power source is un-

plugged from the mains.

ZHEN

3

Safety

WARNING! An electric

shock can be fatal. There

is also a risk of injury from filler

wire emerging. Switch the power

source mains switch to the „O“

position before cleaning the

welding torch and checking its

components.

CAUTION! When a

welding torch becomes

extremely hot from use, it

represents a fire risk. The

welding torch must only be

cleaned and its components

checked when it is cool.

ZHEN

4

Safety

CAUTION! Danger of

scalding by hot coolant.

Never check the water connections until they have cooled

down.

CAUTION! Risk of injury

from unsatisfactory

connections. All cables, leads

and hose packs must be properly secured, undamaged, insulated and adequately dimensioned.

NOTE! Never operate a

water-cooled welding

torch without coolant. The manufacturer shall not be liable for any

damage resulting from such

improper use. In addition, all

warranty claims will be forfeited.

ZHEN

5

1

VD (m/min)

**

Fdi

*

1

1 2 2,5 3 4 5

t (s)

6

Controls and connections

* „Feeder inching“ button

for feeding in the filler wire with

no accompanying flow of gas

or current. As long as the

feeder inching button is held

down, the filler wire is fed in.

The feeder inching speed

depends on the length of time

that the feeder inching button

is held down (Fig. 2).

** Collision box cable

for connecting the cable to the

BNC socket on the collision

box. If the welding torch

collides with an obstacle, the

collision box stops the feeding

movement of the robot and

also stops the welding process.

ZHEN

7

1

2

3

1

4

3

5

1

1

2

2

1

2

2

4

3

5

2

1

3

8

Fitting the clamp/adjusting clip

Important! The Robacta Twin

comes with a clamp fitted as

standard.

The Robacta clamp and Robacta

adjusting clip are for fitting the

Robacta hose pack to the robot or

to the welding machine.

The adjusting clip supports TCP

correction on the robot. The Robacta adjusting clip can be adjusted in

such a way that the position of the

arc is maintained during a corrective movement by the robot. The

robot therefore needs no additional

corrective movement in the x or y

direction.

ZHEN

9

2

Drill /

Ø5,8

Reamer /

Ø6G7

3

10

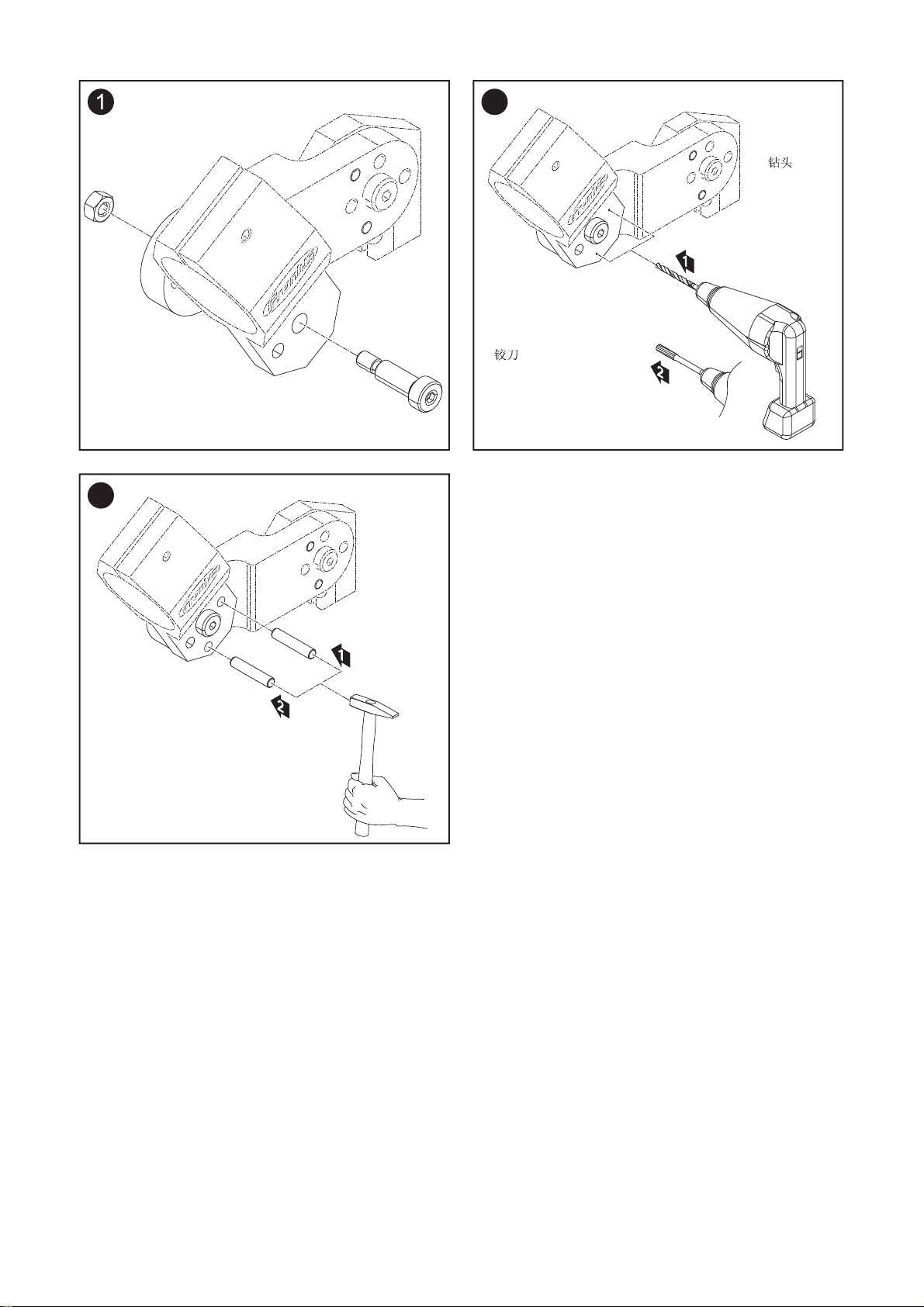

Fitting the mounting

bracket (standard)

WARNING! Work perfor-

med incorrectly can cause

serious injury to people and

damage to property. This installation must only be carried out

by trained and qualified personnel. Observe the safety rules in

the power source operating

instructions.

Important! Drill a Ø5.8 mm hole

for the mounting bracket and use a

reamer to enlarge the hole so it

can accommodate the dowel pin

(Ø6G7).

Important! The mounting bracket

must be fitted using an M8 shoulder screw and an M6 screw. After

screwing the mounting bracket in

place, another dowel pin (Ø6 mm)

must be driven in to secure it.

ZHEN

11

2

Drill /

Ø5,8

Reamer /

Ø6G7

3

12

Fitting the mounting

bracket (individually)

WARNING! Work perfor-

med incorrectly can cause

serious injury to people and

damage to property. This installation must only be carried out

by trained and qualified personnel. Observe the safety rules in

the power source operating

instructions.

Important! Drill a Ø5.8 mm hole

for the mounting bracket and use a

reamer to enlarge the hole so it

can accommodate the dowel pin

(Ø6G7).

Important! The mounting bracket

must be fitted using an M8 shoulder screw. The required bracket

must then be positioned and two

dowel pins (Ø6 mm) driven in to

secure it.

ZHEN

13

1

1

1

2

1

4

3

2

4

3

1

2

4

3

2

5

14

Robacta torch necks dismantling and assembling

NOTE! Risk of coolant

escaping through loose

union nut. When fitting the torch

neck, ensure that the union nut is

securely fastened: Tighten union

nut using a flat spanner.

For a defined, reproducible tightening torque, use a flat spanner and

torque wrench, ideal tightening

torque = 18 ±2 Nm.

ZHEN

15

1

2

1

3

2

1

54

6

7

3

3

1

2

1

5

3

5

6

4

2

4

5

16

6

x.3

x.2

x.1

2

1

x.3

x.1

x.2

3

Dismantling and assembling Robacta

Twin torch necks

NOTE! Risk of coolant

escaping through loose

union nuts. When fitting the Twin

torch neck, ensure that the union

nuts are securely fastened: Tighten

union nuts using flat spanner and

torque wrench, tightening torque =

18 ±2 Nm.

NOTE! When connecting

and terminating lines,

observe the following sequence:

1. Blow-out line x.1

2. Water flow x.2 (blue)

3. Water return x.3 (red)

ZHEN

17

1

1

2

3

*

4

5

18

Connecting the robot

hose pack

* Connection for torch blow-off

option

NOTE! Shielding gas

mixed with extraneous air

has an adverse effect on welding

results.

- The end of the hose must be

sealed off with the stopper

supplied if the torch blow-off

connection is not in use

- Do not connect the hose if no

compressed air is connected

to the solenoid valve for the

blow-off function. Seal hose

with stopper.

ZHEN

19

Loading...

Loading...