Page 1

/ Perfect Charging /Perfect Welding / Solar Energy

ROBACTA CTC Operating Instructions

Spare parts list

Contact Tip Changer

- 4,050,001 Robacta CTC ø25 M6

- 4,050,002 Robacta CTC ø25 M8x1,5

- 4,050,003 Robacta CTC ø27 M6

- 4,050,004 Robacta CTC ø27 M8x1,5

Version: 2021/05

Revision: 1.2

42,0426,0373,EN

Fronius prints on elemental chlorine free paper (ECF) sourced from certified sustainable forests (FSC).

Page 2

KYOKUTOH Europe GmbH

©

Radlkoferstraße 2

81373 München/Germany

Phone: +49-89-741185-313

Fax: +49-89-741185-315

Office Unna

Max-Planck-Straße 4

59423 Unna/Germany

Phone: +49-2303-93615-00

Fax: +49-2303-93615-29

info@kyokutoh.de

www.kyokutoh.de

Page 3

Foreword

Foreword

This operating manual contains all information pursuant to § 3 Equipment Safety Act "Conditions for

putting into circulation" (in conjunction with Machinery Directive 2006/42/EC as amended).

The operating manual is intended for persons who will be/are tasked with working on/with the

machine described here.

Only through knowledge of this operating manual can errors be avoided at the machine and fault-free

operation guaranteed. It is therefore necessary that this operating manual be known to the responsible

persons.

The operating manual is part of the user information when putting the machine on the market and

must be stored in such a way that it is accessible to the operator and the user. Should the location of

the machine change, then the operating and/or user instructions (including those provided by the

supplier) must be moved with the machine. The instructions in the operating and/or user instructions

(including those provided by the supplier) must be adhered to during all phases of product life.

Carefully read through the corresponding chapter in the operating manual before commencing work.

We accept no liability for damages and faults that arise as the result of failure to adhere to this

operating manual.

IT must be clearly and unequivocally established in-house who is responsible for the machine

(operator) and who is permitted to work at it (users).

For the staff deployed for the transport, installation, preparation, set-up, operation, care, maintenance

and repair, the corresponding responsibilities must be clearly established.

The PLUG & PLAY SETs from Tipman Co., Ltd, which belongs to the KYOKUTOH Group, are robust and

reliable complete systems for changing contact tips. They are easy and quick to integrate. Thanks to

their compact design the Contact Tip Changer can be operated intuitively. Highest quality and

durability, easy maintenance and reliable contact tip change, even under the most demanding

conditions guarantee the greatest possible economic and simplify maintenance.

Equipped with remover and fastening units for both nozzle inserts, a cutting device to shorten the

worn down welding wire, a mechanically changing magazine for ten contact tips including monitoring

sensor and a rotating cleaning unit for cleaning the contact tip.

I

Page 4

Table of Content

Table of content

1 Declaration of Conformity ............................................................................................................... 1

2 Technical Specifications ................................................................................................................... 2

2.1 Type ......................................................................................................................................... 3

2.2 Dimension ................................................................................................................................ 4

2.3 Sensor Technology .................................................................................................................. 5

3 Basic Saftey Instructions .................................................................................................................. 7

3.1 Explanation of symbols and instructions ................................................................................. 7

3.2 Proper use ............................................................................................................................... 8

3.3 Improper use ........................................................................................................................... 8

3.4 Obligation to instruct .............................................................................................................. 9

3.5 Safety devices .......................................................................................................................... 9

3.6 Systems with servo- and frequency inverters ......................................................................... 9

3.7 Inspection obligation ............................................................................................................... 9

3.8 Conduct in case of hazards and faults .................................................................................... 10

3.9 Information regarding residual risks ..................................................................................... 10

3.10 Special hazard points ............................................................................................................. 10

3.11 Safety and protection devices ............................................................................................... 10

3.12 Special safety instructions ..................................................................................................... 11

3.13 Hazards during maintenance, repair and similar work .......................................................... 12

3.14 Product monitoring ............................................................................................................... 12

4 SETUP AND ASSEMBLY .................................................................................................................. 13

4.1 Place of installation, place of use .......................................................................................... 13

4.2 Alignment and mounting ....................................................................................................... 13

4.3 Protective conductor connection on the stand..................................................................... 13

5 COMMISSIONING / SETUP ............................................................................................................. 14

5.1 Safety requirements .............................................................................................................. 14

5.2 Initial commissioning ............................................................................................................. 14

5.3 Preparation for operation ..................................................................................................... 15

5.3.1 Tolerance for centering and parallelism ....................................................................... 15

5.3.2 Process preparation for teaching .................................................................................. 16

5.3.3 Signals ............................................................................................................................ 17

5.3.4 Spacer ............................................................................................................................ 17

5.3.5 Change Spacer ............................................................................................................... 19

5.4 Teaching process ................................................................................................................... 20

II

Page 5

Table of Content

5.4.1 Preparation process....................................................................................................... 20

5.4.2 Confirmation of engine running .................................................................................... 21

5.4.3 Cut off welding wire ...................................................................................................... 22

5.4.4 Turn off and remove the nozzle .................................................................................... 24

5.4.5 Cleaning the contact tip ................................................................................................ 26

5.4.6 Actuation of the magazine (revolver) ............................................................................ 27

5.4.7 Remove contact tip ....................................................................................................... 27

5.4.8 Contact tip attachement ............................................................................................... 30

5.4.9 Attachment nozzle ......................................................................................................... 31

6 STORAGE AND TRANSPORT ........................................................................................................... 35

6.1 Safety regulations .................................................................................................................. 35

6.2 Symbols on the cargo ............................................................................................................ 35

6.3 Transport type ....................................................................................................................... 35

6.4 Handover and Inspection ...................................................................................................... 36

6.5 Unpacking and Storage .......................................................................................................... 36

7 Maintenance and Repair ............................................................................................................... 37

7.1 Maintenance.......................................................................................................................... 37

7.2 Cleaning ................................................................................................................................. 39

7.3 Repair .................................................................................................................................... 39

7.4 Safety regulations .................................................................................................................. 39

8 Decommissioning/Dismantling...................................................................................................... 41

8.1 Safety regulations .................................................................................................................. 41

8.2 Decommissioning .................................................................................................................. 41

9 SPAREPARTS .................................................................................................................................. 42

9.1 Patrlist ................................................................................................................................... 43

10 SERVICE ...................................................................................................................................... 44

10.1 Troubleshooting .................................................................................................................... 44

11 APPENDIX .................................................................................................................................. 46

11.1 Data on the different contact tips ......................................................................................... 46

11.2 Data on different nozzles ...................................................................................................... 47

11.3 Elektronic ............................................................................................................................... 48

III

Page 6

Table of Content

Rev. Description

Date

Editor

Department

Revision of chap. 5

- various corrections

05.10.2020

M. Swientek

Technology

Correction / addition chap. 9

– Ballplunger added,

05.10.2020

M. Swientek

Technology

Supplement chap. 10.1

- alarm 46 added

05.10.2020

M. Swientek

Technology

E-Plan change chap. 11.3

- Lin

05.10.2020

M. Swientek

Technology

Change chap. 2.1 Contact & Gas Nozzle

21.05.2021

G.Heimann

Technology

Change chap. 5.3.4 Fronius

item number added

t. 21.05.2021

G.Heimann

Technology

Change chap. 9.1 List of spare parts

21.05.2021

G.Heimann

Technology

Amendment Appendix E

-

Plan updated

21.05.2021

G.Heimann

Technology

1.1

1.2

corrected wire brush

e filter added, additional information added

IV

Page 7

1. Declaration of Conformity

1 Declaration of Conformity

EG-Konformitätserklärung

nach der EG-Maschinenrichtlinie 2006/42/EG

EC-Declaration of Conformity

Hiermit erklärt die

Herewith we

dass die nachfolgend bezeichneten Maschinen, aufgrund ihrer Konzeption und Bauart, soweit

in der von uns in Verkehr gebrachten Ausführung, den einschlägigen grundlegenden

Sicherheits– und Gesundheitsanforderungen der EG-Richtlinie entspricht.

Bei einer nicht mit uns abgestimmten Änderung der Maschinen, verliert diese Erklärung ihre

Gültigkeit.

declare that the machinery designated below, on the basis of its design and construction in the form brought onto the market by

us is in accordance with the relevant safety and health requirements of the EC Council Directive on Machinery.

If alterations are made to the machinery without prior consultations with us, this declaration becomes invalid

KYOKUTOH Europe GmbH

Radlkoferstraße 2

D –81373 München

Produktbezeichnung: Stromkontaktdüsen Wechsler

Designation Auto Contact Tip Changer

Maschinentyp: CTC-Serie Robacta

Machinery type CTC-Series Robacta

Einschlägige EG-Maschinenrichtlinie (2006/42/EG)

EG-Maschinenrichtlinien:

Relevant EC Council Directives

EC-Low Voltage Directive (2014/35/EU)

EC-Machinery Directive (2006/42/EG)

EG-Niederspannungsrichtlinie (2014/35/EU)

EG-Richtlinie Elektromagnetische Verträglichkeit (2014/30/EU)

EMC-Guideline (2014/30/EU)

EMV Geräteklasse: Klasse A für den Einsatz in industrieller

Umgebung

EMC – Device Class: Class A for use in an industrial environment

Hersteller-Unterschrift:

Signature

Datum: 05.09.2020

Date:

Angaben zum Unterzeichner: Johannes Okubo, Prokurist

Details signee Johannes Okubo, authorised Officer

KYOKUTOH Europe GmbH

info@kyokutoh.de

1

Page 8

2. Technical Specifications

Motor designation

BLM460SHP

-

GFV

Supply voltage

0-

240V/AC

Control voltage

24V/

DC

Power supply

connection

Without plug (cable)

Rotation sensor

Indu

c

tive

Power line 24V

Without plug (cable)

Motor Power

60 W

Torque

about

34Nm

Type of drive

electrical

Confirmation sensor

Electric motor

tips

Holder for contact

Mechanical magazine

Cleaning unit /

Wire cutter

2 Technical Specifications

CTC-001 Contact Tip Changer

Splash guard

Gearbox

Removal unit for nozzle

Removal unit for contact

tips

switch

wire brush

2

Page 9

2. Technical Specifications

Robacta CTC ø27 M6

Robacta CTC

Robacta CTC

Robacta CTC

Nozzle

Nozzle

Nozzle

Nozzle

Contact tip

Contact tip

Contact tip

Contact tip

2.1 Type

ø27 M8x1,5

ø25 M6

ø25 M8x1,5

3

Page 10

2. Technical Specifications

2.2 Dimension

4

Page 11

2. Technical Specifications

Note

!

E3T Photoelectric

E3Z photoelectric sensor /

Lower blade does

Upper

blade

Lower blade

does

2.3 Sensor Technology

Please pay attention to the correct cable connection.

sensor /

magazine query

1- E2E:

Determining the position of the cutter before cutting the welding wire in the cutting unit. (Output

signal: SS1)

not block the

insertion of the

welding wire.

The insertion into

the cutting position

is possible!

Lower

blade /

rotating

control request

block the insertion

of the welding wire.

The insertion into

the cutting position

is not possible!

Gear shaft

E2E proximity sensor /

cutter query

Proximity

sensor

5

2 x Sensor detector

Page 12

2. Technical Specifications

2- E3Z:

To check the presence of nozzle and contact tip.

To check the complete removal of nozzle and contact tip.

For checking incomplete fastening of the contact tip up to 0.5 mm with the mounting thread.

(Output signal: LS)

*For example, if the length of the thread of the contact tip is 7.0mm, the sensor determines the contact

tip from 6.5 to 7.0mm to the tip body.

3- E3T:

For checking the magazines for complete filling with contact tips. To check if the magazine cover is in

closed position. (Output signal: SS2)

6

Page 13

3. Basic Saftey Instructions

Note!

Warning: hazard point!

Warning: hazardous electrical voltage!

Warning: rotating parts

Wear eye protection

Wear gloves

Wear protective footwear

3 Basic Saftey Instructions

The health and safety of employees can only be guaranteed provided the described safety measures

are adhered to during all phases of life (construction, transport, installation etc.). Generally speaking,

the usual accident prevention regulations (Accident prevention regulations, UUV) apply, in particular the

UUV regarding safety at machines.

The operator is obliged to adhere to the valid laws and regulations, in particular in case of use outside

of the EU. This applies in particular if enhanced requirements must be implemented on account of

corresponding changes to laws and regulations.

3.1 Explanation of symbols and instructions

This symbol indicates general information for users

This symbol indicates a threatened or imminent danger to the life and health of

people. Failure to heed this warning instruction can result in material damage and

minor injuries but may also result in severe adverse health effects to lifethreatening injuries.

Failure to heed this notice may result in serious injuries or death!

Failure to heed this notice may result in serious injuries!

Appropriate eye protection must be worn. Failure to adhere to this instruction can

result in serious injuries!

Appropriate protective equipment must be worn. Failure to adhere to this

instruction can result in injuries!

Protective footwear with a steel toecap and oil-proof safety soles.

7

Page 14

3. Basic Saftey Instructions

Note!

Caution!

3.2 Proper use

The operational safety of the supplied machine is only guaranteed in case of proper

use.

This product is only for use to change specified contact tips.

Proper use also includes adherence to the operating and/or user instructions (including those provided

by the supplier) and adherence to all maintenance and service intervals.

Structural and technical changes to the machine and its accessories generally require written approval

from KYOKUTOH Europe GmbH. In case of infringements, any liability on the part of the manufacturer

and any manufacturer warranties shall become void!

No other objects (e.g. screwdrivers etc.), which are not explicitly intended for this purpose and

included within the scope of delivery, may be present in the machine (e.g. mix-ups in the parts listed

above, etc.); likewise, no non-production parts may be present around the machine. These objects can

cause damage to people and machinery. KYOKUTOH Europe GmbH accepts no liability for resulting

damage. In case of damage, liability remains with the operator and cannot be transferred to KYOKUTOH

Europe GmbH. This product should only be used for the milling of the identified electrodes.

3.3 Improper use

Warranty and liability claim in case of personal injury and material damage are

excluded if they are the result of one or more of the following causes:

– Improper installation, commissioning, operation and maintenance of the machine

– Operation of the machine while in faulty condition, without protective cover

– Installation in explosive areas

– Improper use of devices, accessories, peripherals etc.

– Operation without safety devices

– Operation with safety devices that are not in flawless condition, are short-circuited or out of

service

– Use of operating materials that are not approved by the manufacturer

– Insufficient monitoring of machine parts that are subject to wear

– Improperly performed repairs

– Emergencies caused by the impact of foreign bodies and force majeure

– Self-performed structural changes to the machine

– Self-performed changes to the

speeds, air pressure, engine speed…)

performance characteristics

(e.g. drive conditions, cylinder

8

Page 15

3. Basic Saftey Instructions

Caution!

Warning!

3.4 Obligation to instruct

The operator must instruct his employees regarding the possible risks, residual risks and the measures

to be taken in order to avoid these risks prior to the initial commissioning. This instruction must be

issued to every employee who operates the system or is in immediate proximity of these hazards.

3.5 Safety devices

The machine may only be operated if all safety devices are in functional condition.

The removal, bypassing and/or rendering ineffective of these safety devices is prohibited. The safety

devices also include the safety program contained in the software. Changes to this safety program are

prohibited.

All components of the machine, especially safety components, may only be replaced with original

components or other components subject to the written consent of KYOKUTOH Europe GmbH. In the

event that faults, and defects are identified in the safety devices, the machine must be shut down

immediately.

The safety devices must undergo the following checks prior to each time the machine is switched on,

or daily, and following every fault correction:

- Visual inspection of the safety devices, regarding the general appropriate condition and

functional safety (e.g. any bridging must be removed immediately)

- Checking of all locking systems, if present. With each check of the safety devices, it must be

ensured that no body parts or objects protrude into the hazard areas exposed by the opened

covers and that no parts can escape from the machine.

3.6 Systems with servo- and frequency inverters

We expressly point out that the integrated “Safe restart lock” does not interrupt

the power supply to the motor.

It only stops the development of a rotating field and thus safely prevents the startup of the motor. If

electrical work is carried out on the motor, then the mains power supply must be cut off using a mains

contactor or main switch. Also note the intermediate circuit discharge time of at least 5 minutes before

electrical work can be performed. LEDs switching off are no indication that the voltage supplies are

switched off and that the intermediate circuit has discharged to below 24V!

3.7 Inspection obligation

With the handover of the machine by the operator, responsibility regarding the maintenance and

inspection obligation, and in particular regarding the safety devices, is transferred to the operator of

the machine!

9

Page 16

Warning!

Warning!

3.8 Conduct in case of hazards and faults

Shut down system using EMERGENCY STOP.

Additional measures must be specified by the operator.

In the event of hazards or faults (irregularities) stop working; shut down the system and wait until it is

stationary. If there is no visual contact with the main switch, this must be secured against being

switched on again using a lock. In addition, a sign must be posted referring to the work on the system.

Correct the fault and if necessary, inform a manager / customer service / the service department.

3.9 Information regarding residual risks

Ensure the complete dissipation of residual energy.

The power supply to the control panel and ultimately to the main switch is always live.

Even when the main switch is switched off, individual components in the control cabinet may be live.

Live parts in the control cabinet and junction boxes are designed to be finger-safe, however touching

them with tools still poses the risk of contact with live parts. If work on live parts is required for

troubleshooting purposes, a second supervisor with electrical engineering training must be

brought in as an observer, in accordance with BGV A2, who will switch off the main switch and

seek help if necessary.

– Pneumatics components may drop to their starting position when the compressed air is switched

off. (Caution – residual energy!)

3.10 Special hazard points

– Entire electrical area

– Entire pneumatics area (N/A)

– Entire hydraulics area (N/A)

3.11 Safety and protection devices

– Protective doors with safety switches (safe)

– Emergency stop switch

– Main switch

10

Page 17

3. Basic Saftey Instructions

Note!

Caution!

3.12 Special safety instructions

Adhere to any user manuals for individual components that may be included in

the appendix.

Never place your hand or finger into the terminal opening while the machine is in

operation. This will result in serious injury.

This special manual is a significant component of this overall operating manual and must be observed

and adhered to. In this special manual you will find any safety instructions that protect against

potentially fatal hazards.

1. Attempt to limit contact with water as far as possible. Consequences could include operating

malfunctions (short circuit), electric shocks or short circuits.

2. Note that weld spatter does not damage the wiring. This prevents the melting of the wire

membrane and electric shock.

3. Remove any oil that accumulates on the tip dresser. Weld spatter can result in short circuits and

potential injuries.

4. Do not use any power supply other than that stated. Excessive heat can result in malfunctions and

short circuits.

5. Ensure that the power supply cable has the correct capacity. (10A/1 unit) Incorrect cabling can

result in malfunctions or short circuits.

6. Use a cable with a sufficient thickness (2 mm² or more). An incorrect cable can result in

malfunctions and short circuits.

7. Ensure that the power supply wiring is not damaged. Damaged cabling can result in malfunctions

and short circuits.

8. Secure the tip dresser firmly on the stand. If the tip dresser is not securely fixed, defective milling

operations and other problems can occur.

9. Ensure that the motor is not blocked. This could result in overheating and a potential short circuit.

10. Do not install the welding machine in the vicinity of the thermal generation source. This may result

in problems and accidents.

11. Do not install between a welding machine and a transformer. Strong magnetic forces and heat can

be dangerous and may cause malfunctions and short circuits.

11

Page 18

3. Basic Saftey Instructions

Caution!

Caution!

Note!

3.13 Hazards during maintenance, repair and similar work

Immediately after the completion of repair work, the safety devices must be

reinstalled and checked regarding their effectiveness.

All repairs and maintenance work may only be carried out if the main switch of the machine is set to

the “0” (OFF) position and locked with a padlock.

The operator is obliged to instruct the operating staff regarding the setup, effect and function of the

safety devices, as well as residual risks and conduct in accordance with occupational health & safety

regulations.

Any working step that affects the safety of the machine must be refrained from. The operator must

ensure that no unauthorized persons who have not been appropriated trained and briefed on the

requirements in the operating manual work on the machine or stay in their vicinity. Safety devices

must not be removed or placed out of service.

3.14 Product monitoring

The operator must check the machine for faults at regular intervals and analyse

the fault statistics that are compiled.

The operator must inform the manufacturer immediately of faults detected in this way, in order that

the manufacturer can correct the faults as quickly as possible.

- In the time between fault detection and the complete correction of the fault, it is the

responsibility of the operator to decide as to whether the machine

- is operated normally

- is operated with restrictions (with warning notices and instructions from the operator that are

specifically tailored to the problem in hand [cf. Equipment Usage Directive])

- is taken out of service.

In case of doubt, immediately decommission the machine

!

12

Page 19

4

. Setup and Assembly

Note!

4 SETUP AND ASSEMBLY

The machine must be set up in accordance with the planner’s installation plan.

4.1 Place of installation, place of use

Explosion areas are not permitted for this machine.

Observe the maximum load-bearing capacity of the installation area (statics).

A special foundation is not necessary.

Ensure that there is a sufficient work and traffic area!

This should be an area of at least 1m around the machine.

Connections (cables, pipes) between the systems must be laid in such a way that they do not present

a tripping hazard.

4.2 Alignment and mounting

Ensure that the machine is installed on a level, horizontal service (otherwise it may distort). All supply

connections may only be established by qualified personnel. All screws are to be tightened with the

respective tightening torques according to DIN 912.

4.3 Protective conductor connection on the stand

To fix the stand to the floor, 4 holes with Ø13mm are provided on the base plate.

13

Page 20

5. Commissioning / Setup

Caution!

Note!

Warning!

Note!

5 COMMISSIONING / SETUP

The commissioning of the machine may only be performed when wearing

suitable safety clothing.

As a rule, this machine may only be operated by authorized operating personnel,

who fulfill the requirements regarding training, briefing and qualifications.

5.1 Safety requirements

Correct faults immediately. Immediately shut down the machine in the event of

malfunctions and secure it against unintentional or unauthorized start-up.

Report any modification to the responsible body or supervisor immediately. Record all faults and

Modifikation.

5.2 Initial commissioning

Familiarize yourself with the handling and operation of the switches and controls.

Commission the machine for the first time as follows:

– Compare the specification regarding the electrical voltage supply in the control cabinet with the

available mains voltage

– Compare the specification regarding the pneumatic supply in the operating manual with the

available pneumatic system. If both details match up, then:

– Set the electrical main switch to “0” (OFF)

– Insert the mains connector into the mains socket

This process must be repeated each time you reposition the machine. This process must also be

completed if the machine has been temporarily disconnected from the supply units and then

connected to them again.

14

Page 21

5. Commissioning / Setup

5.3 Preparation for operation

Warning!

The disconnection of the electrical connection between the mains supply

and the control cabinet must be ensured.

The following steps are necessary to successfully remove and attach the nozzle and contact tip:

Before teaching:

1- Ensure that the unit is securely attached to the stand.

2- Please make sure that the I/O signals are connected to the robot or PLC.

When teaching:

1- The nozzle should be centered on the nozzle removal unit.

2- The nozzle should be aligned parallel to the unit.

3- The removal process cannot be performed due to the tilted insertion of the nozzle into the removal

unit.

4- If the above conditions are not considered, it can damage the components.

5.3.1 Tolerance for centering and parallelism

The tolerances for centering the nozzles

– Tolerance for centering the nozzle with the removal- and attaching unit (ø 1 mm)

– Tolerance for centering the contact tip with the removal unit (ø 1mm)

– Tolerance for centering the contact tip with the contact tip holder (ø 0.4mm)

The tolerance specifications for parallelism

– Tolerance between nozzle, contact tip and the removal, - attaching units (± 1 °)

15

Page 22

5. Commissioning / Setup

Tilted position of

the nozzle to the cleaning unit

Position of the nozzle parallel to the cleaning unit

5.3.2 Process preparation for teaching

1- Use the cleaning unit as a reference point / level for parallel alignment of the torch (see picture

below).

2- If the torch is parallel to the cleaning unit, move the torch horizontally to each unit.

3- Make sure that nozzle and contact tip are centered in the removal and attaching units so that

tolerances are the lowest.

16

Page 23

5. Commissioning / Setup

Output

Signals

(from

Robot

-PLC): Input

Signals

(to Robot

-

PLC):

- MC (

Magnetic Switch)

- OUT0 /

TLC (

torque control

)

Speed

setting

1 2 3 4

Caution

!

Speed [rpm]

2000 4

000 800 1000

M0 OFF ON OFF ON

M1 OFF OFF ON ON

Name:

Item number:

Verwendung:

FS-17,8L

42,0411,0350

Nozzle

Outer

- Ø 25 mm

FS-32,8L

42,0411,0352

Nozzle

Outer

- Ø 25 mm

FS-35L 42,0411,0354

Nozzle

Outer

- Ø 25

mm

FS-26,8L

42,0411,0351

Nozzle

Outer

- Ø 27 mm

FS-33,8L

42,0411,0353

Nozzle

Outer

- Ø 27 mm

Item Number

Nozzle Outer

- Ø 25 mm:

Spacer

:

42,0001,4487

FS-

17,8L

42,0001,4534

FS-

17,8L

42,0001,4902

FS-

17,8L

42,0001,4486

FS-

17,8L

42,0001,5023

FS-

17,8L

42,0001,4640

FS-

32,8L

If the robot and the contact tip changer are installed correctly on the same level (e.g. floor) and the

burner is aligned in the vertical alignment and measured as a tool in the robot controller, the

parallelism is normal.

A visual inspection of the gap dimensions can also be achieved by inserting the torch into the nozzle

removal point with a low immersion depth and complete immersion depth.

Note - WAIT commands may be necessary between the individual commands. This depends on the

programmed robot speed and how quickly the commands are processed by the robot controller. For

example, - Robot moves to a position the next command lines are already being processed during

the movement Activating the commands ahead of time can lead to problems!!!

5.3.3 Signals

Achtung: Vor dem Prozessbeginn alle Signale auf die Funktionstüchtigkeit überprüfen

- IN0 / FWD (Direction of rotation remover unit left)

- IN1 / REV (Direction of rotation remover unit right)

- IN2 / TL (Torque limiter)

- IN3 / M0 (rotation speed)

- IN4 / M1 (rotation speed)

- +24V & -0V

- OUT1 / VA (Ready)

- LS (Photoelectric barrier)

- SS1 (Proximity sensor, wire

cutter)

- SS2 (Magazine query)

- 1A (Auxiliary contact of the

magnetic connector)

When checking TLC (by hand), TL

must be switched off (OFF signal).

5.3.4 Spacer

Each CTC Fronius SET is delivered with a selection of spacers as standard. The spacer provides the right

distance to optimally remove the gas nozzle.

Depending on the used nozzle, the spacer must be installed by the customer. The table shows which

spacer is intended for which gas nozzle.

17

Page 24

5. Commissioning / Setup

42,0001,4048

FS-

32,8L

42,0001,4051

FS-

32,8L

42,0001,4474

FS-

32,8L

42,0001,4496

FS-

32,8L

42,0001,4080

FS-

32,8L

42,0001,4086

FS-

32,8L

42,0001,4497

FS-

32,8L

42,0001,4639

FS-

32,8L

42,0001,4045

FS-

32,8L

42,0001,4047

FS-

32,8L

42,0001,4475

FS-

32,8L

42,0001,4495

FS-

32,8L

42,0001,4788

FS-

32,8L

44,0350,2028

FS-

32,8L

42,0001,4085

FS-

32,8L

42,0001,4087

FS-

32,8L

42,0001,4088

FS-

32,8L

42,0001,4049

FS-

35L

42,0001,4050

FS-

35L

42,0001,4476

FS-

35L

42,0001,4494

FS-

35L

42,0001,4641

FS-

35L

44,0350,3936

FS-

35L

42,0001,4054

FS-

35L

42,0001,4043

FS-

35L

42,0001,4053

FS-

35L

42,0001,4043

FS-

35L

42,0001,4049

FS-

35L

42,0001,4050

FS-

35L

42,0001,4053

FS-

35L

42,0001,4054

FS-

35L

42,0001,4476

FS-

35L

42,0001,4494

FS-

35L

42,0001,4641

FS-

35L

44,0350,3936

FS-

35L

Item Number Nozzle Outer

- Ø 27 mm:

Spacer

:

44,0350,0222

FS-

26,8L

44,0350,2020

FS-

26,8L

44,0350,2021

FS-

26,8L

44,0350,0753

FS-

26,8L

44,0350,2004

FS-

33,8L

44,0350,1991

FS-

33,8L

44,0350,1995

FS-

33,8L

44,0350,0533

FS-

33,8L

44,0350,0752

FS-

33,8L

18

Page 25

5. Commissioning / Setup

- Remove the 4 fastening screws. Put

- Remove the entire nozzle removal

- Remove the jaws from the nozzle

- Remove the jaw guide ring.

- The spacer can now be removed.

5.3.5 Change Spacer

the cover aside.

unit.

removal unit.

The unit is reassembled in reverse

order.

19

Page 26

5. Commissioning / Setup

P

rocess

Details

5.4 Teaching process

5.4.1 Preparation process

-> Start

(Unless otherwise specified, turn all signals OFF)

-> Reset the robot signal

- Start

1

-> MC (Output): ON / (Motor drive: Power ON)

Preparation

-> after a second

(The magazine can be filled with a total of 10 contact tips. To refill, the magazine must

be turned back to its original position after changing the contact tip ten times)

The following monitoring is carried out using the SS2 photoelectric sensor:

1- The magazine is turned back to its original position

2- The complete filling of the contact tips

3- Protective cover is closed

-> SS2 Signal (Output)

-> SS2 Signal (Output) ON:

(The signal remains ON as long as the contact tips are present and remains OFF as long

as there are no contact tips)

-> True (ON) -> operational

-> continue to step (3)

from the contact nozzles

2- Confirmation of filling the magazine

-> False (OFF) -> not ready to operate

-> Stop robot

-> confirm

-> back to step (2)

20

Page 27

5. Commissioning / Setup

(Before

preforming

the change process, it must be checked that the permissible engine

5.4.2 Confirmation of engine running

load is not exceeded when idling, e.g. if foreign objects have penetrated the interior and

become noticeable, or that resistance has increased due to the wear of parts)

(Speed setting 4 = 1000rpm, Torque limit= lower than 25%

Do not perform the change process if the engine load exceeds 25%)

-> “Torque limit“ IN2 (TL) / (Input): OFF

-> “Speed setting 4“ IN3 (M0) / (Input): ON

IN4 (M1) / (Input): ON

-> “Reverse Rotation“ IN1 (REV) (Input): ON

-> (VA Signal Output: ON (When the speed signal is active)

-> TLC (Output): OFF

(Waiting for the signal: 5 Sec.)

The signal remains OFF as long as the torque limit is not exceeded.

Otherwise the signal is switched to ON.

For testing, the rotating round part can be held at the bottom at the front of the device,

in this case it is important that the TL (input) is OFF.

-> True (ON) -> “Reverse Rotation” IN1 (REV) / (Input): ON

-> “Speed setting 4“: ON

-> IN3 (M0) (Input): ON

-> IN4 (M1) (Input): ON

3- Confirmation of engine running

-> “Torque limit” IN2 (TL) / (Input): OFF

-> Continue to step (4)

-> False (OFF) -> Stop the engine

-> “Reverse Rotation” IN1 (REV) / (Input): ON

-> “Speed setting 4“: ON

-> IN3 (M0) (Input): ON

-> IN4 (M1) (Input): ON

-> “Torque limit” IN2 (TL) / (Input): ON

-> Stop robot

-> No further step possible

-> Checking the machine (CTC)

21

Page 28

5. Commissioning / Setup

5.4.3 Cut off welding wire

Requirements for cutting welding wire:

1- The welding wire must be pulled out at least 10 mm from the tip of the contact tip to

enable cutting.

2- Distance between the cutting position and the nozzle tip: 30mm

3- Rotation speed „Speed setting 1“: 2000rpm

4- Direction of rotation: (Reverse Rotation)

5- Motor “Torque limit”: Max (IN2 (TL) / (Input): ON)

-> “Torque limit” IN2 (TL) / (Input): ON

(To set the torque limit of the motor to the maximum value)

-> “Speed setting 1“: IN3 (M0) / (Input): OFF

IN4 (M1) / (Input): OFF

-> “Reverse Rotation“ IN1 (REV) / (Input): ON (Motor rotates)

-> SS1 Signal (Output): ON “Proximity sensor E2E monitors the cutter blade position”

“Reverse Rotation“ IN1 (REV) / (Input): OFF (Motor stop)

Move the welding torch and guide the electrode wire into position (2).

Query of the signals welding system ready / power source ready / wire feed unit

ready (see Fronius Interface operating instructions)

4- Cutting welding wire

-> Hold the electrode wire in place and guide it out of the nozzle

(Note: The electrode wire tip must not hit the housing surface of the cutting unit. This

can lead to a cutting error) (see right picture below)

22

Page 29

5. Commissioning / Setup

-> Guide the electrode wire to position (3)

Note - If a Fronius Wire Brake Device is installed in the welding system, it can be used to

hold the wire in place during the cutting process.

Include 2s waiting time for activation of the wire brake!

Include 3s waiting time for deactivation!

This process is not necessary because the wire cutting process works without holding the

wire electrode.

(The welding wire should be in contact at the groove at position 3)

-> “Reverse Rotation “ IN1 (REV) (Input): ON (Motor rotates)

(The cutting of the welding wire starts)

-> After approx. one second, “Reverse Rotation “ IN1 (REV) / (Input): OFF (stopping

the cutting process)

Alternative: if SS1 (Output) is OFF and then ON again, the blade has rotated through 360 °.

-> “Torque limit” IN2 (TL) / (Input): OFF

-> Wait 0,5s

-> Guide the welding torch out in reverse order (3-2-1).

-> Query of signals welding system ready / power source ready /

Wire feed unit ready

-> Pull the welding wire back into the nozzle

(Attention: Before the next step begins – “unscrewing the gas nozzle”, the wire should

be pulled back into the fastening body (see picture below).

4- Cutting welding wire

Otherwise, do not follow the steps below!

Note: If the inside diameter of the contact tip is larger than the outside diameter of the

wire, the cutting process cannot be performed without problems.

23

Page 30

5. Commissioning / Setup

Requirements for turning off

and removing the gas nozzle:

-> After inserting the gas nozzle “Forward Rotation”

IN0 (

FWD

) / (Input):

OFF

5.4.4 Turn off and remove the nozzle

1- In principle, when the nozzle is inserted into the removal unit and the unit is pressed

down, the clamping jaws extend mechanically. In this case, however, the jaws are not in

the actual clamping position. The nozzle is gripped by the clamping jaws by rotating the

removal unit REV.

2- Rotation speed “Speed setting 2“: (High Speed) 4000rpm

3- Direction of rotation of the removal unit when attaching the nozzle: (Forward Rotation)

4- Direction of rotation of the removal unit when removing the nozzle: (Reverse Rotation)

5- Engine torque: Max. (IN2 (TL) / (Input): ON

(Note: Before inserting the nozzle, check whether the jaws are retracted or pinched!)

-> “Speed setting 2“ IN3 (M0) / (Input): ON

IN4 (M1) / (Input): OFF

-> “Torque limit” IN2 (TL) / (Input): ON

-> “Forward Rotation” IN0 (FWD) / (Input): ON

-> VA Signal (Output): ON (when the speed detection signal is activated)

-> Insert the nozzle into the removal unit until the nozzle contacts the cone of the spacer.

The nozzle is not yet clamped in this position.

(Insert speed: 100cm/min od. 16mm/s)

(Pull back the jaws to easily insert the gas nozzle into the opening)

(Start changing the gas nozzle in the same time)

-> Wait 0,5s

5- Turn off and remove the nozzle

(Do not push the removal unit at the time)

24

Page 31

5. Commissioning / Setup

->

Move the torch to the stop of the spacer.

Push the nozzle

8mm

further down

.

During

this movement, the clamping jaws are extended, and the nozzle is clamped more and

more.

Spacer stop

Push 8 mm down

300cm/min or slower (48mm/s)

-> Wait 0,5s

-> “Reverse Rotation“ IN1 (REV) / (Input): ON (Motor rotates)

(Start the process of removing the nozzle)

-> Raise the welding torch after approx. 1 second

(Lifting speed: 50cm/min or 8mm/s until the nozzle is completely separated)

5- Turn off and remove the nozzle

-> After visually checking the separation of the nozzle, pull the welding torch out of the

removal unit at a speed of 416.6mm / s-10mm.

Then run the torch down at a speed of 166.6mm / s - 5mm.

Then move the burner out (the speed can be varied individually).

-> “Reverse Rotation“ IN1 (REV) / (Input): OFF (Motor stop)

-> “Speed setting 2” IN3 (M0) / (M0) (Input): OFF

-> “Torque limit” IN2 (TL) / (Input): OFF

Check the complete removal of the nozzle using LS-E and LS-R sensors).

25

Page 32

5. Commissioning / Setup

5.4.5 Cleaning the contact tip

Requirements for cleaning the contact tip:

1- Cleanability of the contact tip

2- Rotation speed “Speed setting 2“: (High Speed) 4000rpm

3- Direction of rotation of the cleaning unit when cleaning: (Reverse Rotation)

4- Engine torque: Max. (IN2 (TL) / (Input): ON)

(Note: When teaching, turning the motor REV is recommended to enable a better insertion

of the contact nozzle into the cleaning unit. Then move the welding torch up and down.)

-> “Torque limit “ IN2 (TL) / (Input): ON

-> “Speed setting 2” IN3 (M0) (Input): ON

IN4 (M1) (Input): OFF (High Speed)

-> “Reverse Rotation” IN1 (REV) / (Input): ON

-> VA Signal (Output): ON (when the speed detection signal is activated)

6- Cleaning the contact tip

Insert the contact tip into the cleaning unit.

(Insertion speed: 1m / min or 16mm / s)

When cleaning the gas holes, foreign objects are blown away with gas that is released from

the gas holes.

-> Query of signals welding system ready / power source ready /

Wire feed unit ready

-> Welding system interface signal "blow out" or "gas test" for the time of

Activate the cleaning procedure.

-> Pull out the welding torch

(Pull out speed: 700cm/min or. slower 116mm/s)

-> “Reverse Rotation “ IN1 (REV) / (Input): OFF

-> “Speed setting 2” IN3 (M0) / (Input): OFF

-> “Torque limit” IN2 (TL) / (Input): OFF

26

Page 33

5. Commissioning / Setup

5.4.6 Actuation of the magazine (revolver)

The magazine (revolver-shaped rotating unit)

(To avoid bending the welding torch, the mechanical switch should not be pressed down

more than 8mm.)

7- Actuation of the magazine (revolver)

-> Press the switch down about 7 mm

(Push down speed: 300cm/min or 48mm/s)

-> Pull out the welding torch after approx. 0.5 seconds

(Pull out speed: 2500cm/min or 417mm/s)

-> Remove the welding torch

5.4.7 Remove contact tip

1- When the contact tip removal unit rotates FWD, the clamping jaws withdraw. When

rotating REV, the clamping jaws are rotated into the clamping position and the contact

nozzle is clamped in.

2- Rotating speed: Speed setting 2 (High speed: 4000rpm)

3- Direction of rotation when retracting the jaws: FWD (forward rotation)

4- Direction of rotation when clamping the contact tip: REV (reverse rotation)

5- Engine torque: Max. (IN2 (TL) (Input): ON)

Requirements for removing the contact nozzle:

8- Remove contact tip

(Note: Before teaching and inserting the contact nozzles, check that the clamping jaws

are retracted or in the clamping position.)

-> ”Speed setting 2“ IN3 (M0) / (Input): ON

IN4 (M1) / (Input): OFF

-> “Torque limit” IN2 (TL) / (Input): ON

-> “Forward rotation” IN0 (FWD) / (Input): ON (Opening the clamping jaws)

27

Page 34

5. Commissioning / Setup

-> After about a second “Forward rotation” IN0 (FWD) / (Input): OFF

-> Stop engine

-> Insert the contact nozzle into the contact tip removal unit

(Insertion speed: 300cm/min or. slower 48mm/s)

-> Insert the contact tip so far that the clamping jaws can grip over the entire circumference.

The retaining head must not come into contact with the clamping jaws.

(This position is important for the start of the process)

(If the jaws are jammed, lower the tip of the contact nozzle towards the twist-off unit.

Then raise the welding torch by approx. 1 mm. This is the correct position for starting the

process.)

8- Remove contact tip

-> After approx. 0.5 sec. “Reverse rotation“ IN1 (REV) / (Input): ON

(Start of the removing process to remove the contact tip)

-> After a second, lift the welding torch. Set the speed as follows: (In connection with

different contact nozzles)

- M6 x 1 -> 10 cm/min (1,7mm/s)

- M8 x 1,25 -> 12,5 cm/min (2,1mm/s)

- M10 x 1,5 -> 15 cm/min (2,5mm/s)

28

Page 35

5. Commissioning / Setup

-> The direction of rotation (REV) and simultaneous lifting of the welding torch.

8- Remove contact tip

(After visual inspection that the contact nozzle has been removed.)

-> “Reverse rotation“ IN1 (REV) / (Input): OFF

(The height at which the contact nozzle is completely removed corresponds to thread

length + an excess length approx. 0.5 mm.)

(When the contact tip has been completely removed, the welding torch can be raised with

a higher speed.)

-> “Forward rotation“ IN0 (FWD) / (Input): ON

-> After approx. 0.5 sec “Forward rotation“ IN0 (FWD) / (Input): OFF

(The clamping jaws open and the used contact tip is removed as a result.)

-> “Torque limit“ IN2 (TL) / (Input): OFF

-> “Speed setting 2” IN3 (M0) / (Input): OFF

Use the LS-E and LS-R sensors to check the removal of the contact tip.

29

Page 36

5. Commissioning / Setup

Requirements

for

attaching

contact

tip:

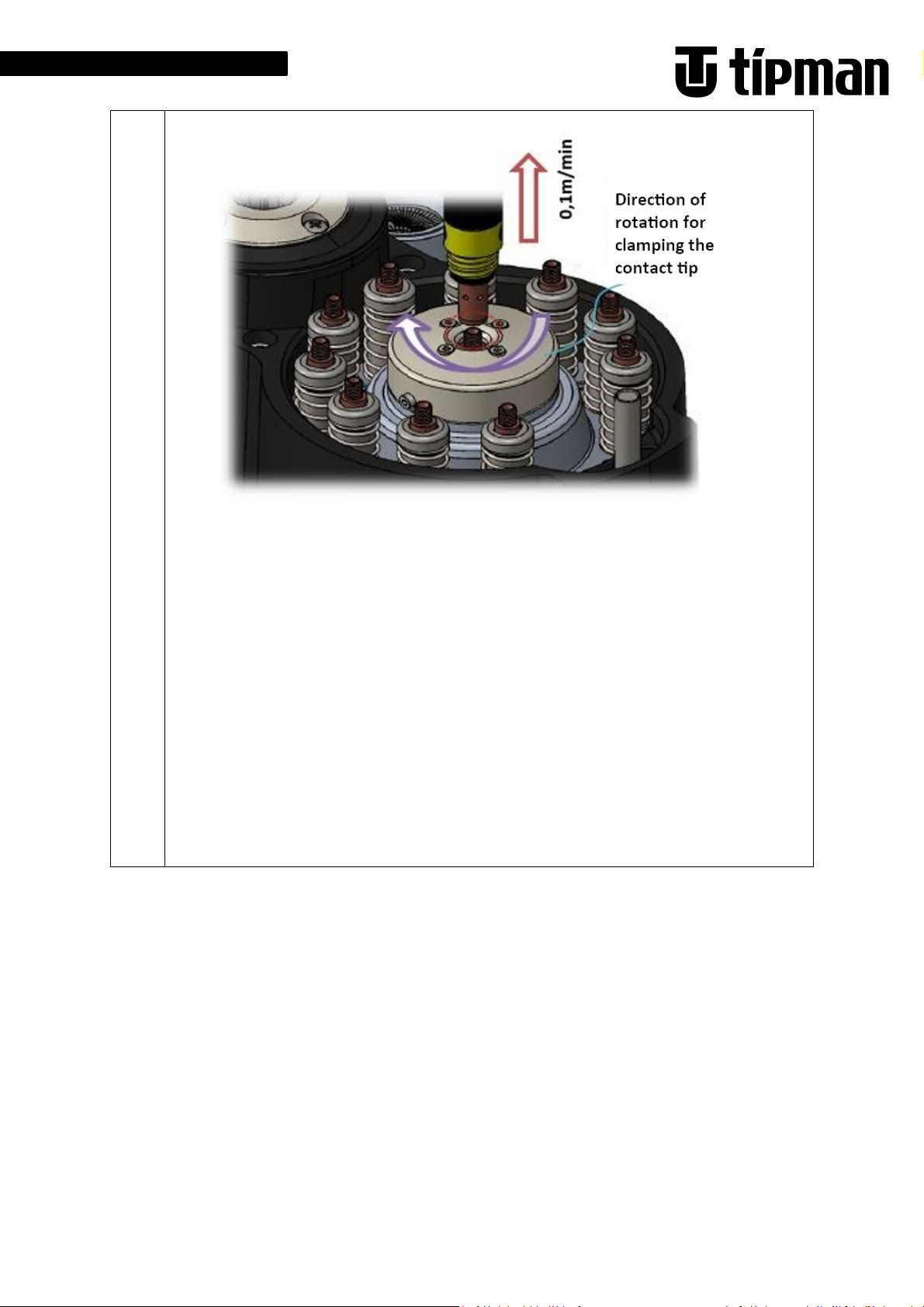

5.4.8 Contact tip attachement

1- Basically, if the contact tip holder is pressed 5 - 7 mm downwards, a connection with the

rotating unit is created.

2- Rotating speed: Speed setting 1 (Medium speed: 2000rpm)

3- Engine torque: restriction (IN2 (TL) / (Input): OFF

4- Direction of rotation of the motor when attaching contact tip: REV

-> “Torque limit“ IN2 (TL) / (Input): OFF (torque is existing)

-> “Speed setting 1“ IN3 (M0) / (Input): OFF

IN4 (M1) / (Input): OFF

-> “Reverse rotation” IN1 (REV) / (Input): ON

-> VA Signal (Output): ON (when the speed detection signal is activated)

-> Align the retaining head in the contact tip magazine

(The speed of insertion depends on the contact nozzle):

Approaching the pre-position that the retaining head of the welding torch is not yet

touching the contact tube in the contact tip magazine High approach speed

e.g. 400mm /s

Approaching the pre-position that the retaining head of the welding torch lightly touches

the contact tip in the contact tip magazine. Approach speed slightly reduced approx.

9- Contact tip attachment

200 mm /s.

Move the welding torch down another 5 mm In this position, the contact tip holder is

just not gripping the gear unit of the drive unit.

Approach speed approx. 50mm /s

Depending on the thread length of the contact tip, press the welding torch down further.

Speed depending on the thread pitch.

= Thread pitch x 10 cm/min (Thread pitch x 1.67 mm/s)

* M6 x 1 -> 10 cm/min (1,7 mm/s)

* M8 x 1,25 -> 13 cm/min (2,1 mm/s)

* M10 x 1,5 -> 15 cm/min (2,5 mm/s)

30

Page 37

5. Commissioning / Setup

Requirements for attaching the nozzle:

1-

Basically, when the clamping unit

(The distance of pushing down should correspond to the condition of the fully tightened

contact nozzle: 9-10mm)

-> TLC signal (Output): ON (With active torque detection signal)

-> Wait 0.5s

-> “Reverse rotation” IN1 (REV) / (Input): OFF

-> Wait 0.5s

-> Raise the welding torch (lifting speed: 100 cm/min or. 16mm/s)

Use the LS-E and LS-R sensors to check the contact tip.

5.4.9 Attachment nozzle

is pressed down, the nozzle is

clamped by the clamping jaws

2- Rotating speed (two stages):

Speed setting 1 (Medium speed:

2000rpm)

Speed setting 3 (Low speed: 800rpm)

3- Engine torque:

restriction (IN2 (TL) / (Input): OFF)

4- Direction of rotation of the

10- Attachment nozzle

attaching unit when fastening the

nozzle: FWD

(Note: Tightening the nozzle with the help of third-party tools or a higher rotational

speed can lead to the knurling of the nozzle being damaged or breaking the insulating

material.)

31

Page 38

5. Commissioning / Setup

-> Drive the torch down until the insulating part comes into light contact with the gas

nozzle. Caution: Do not push the unit down

(Insertion speed: 300cm / min or slower 48mm / s)

-> Drive the welding torch into the unit at a lower speed of 100 cm / min (16 mm / s)

Distance so that the nozzle is not yet pressed down by the welding torch. (Check

beforehand that the gas nozzle front edge is in contact with the inner pressure device

noticeable due to the spring-loaded bearing)

Thread welding torch small distance about 1mm or less to thread gas nozzle

32

Page 39

5. Commissioning / Setup

-> ”Torque limit“ IN2 (TL) / (Input): OFF (Torque limit available)

-> “Speed setting 1” IN3 (M0) / (Input): OFF

IN3 (M0) / (Input): OFF (Medium speed)

-> ”Forward rotation“ IN0 (FWD) / (Intput): ON

-> VA signal (Output): ON (when the speed detection signal is activated)

-> Drive the welding torch approx. 8mm deeper into the entire jaw device. Speed depending

on the thread pitch.

The inner clamping device is not yet in this position, but the jaws are extended during this

movement. (Total distance of the inner clamping device = 13mm).

The nozzle is screwed on at medium speed (2000 rpm / torque limit 45-55%).

(The speed of insertion depends on the gas nozzle):

= Thread pitch x 10 cm/min (Thread pitch x 1.67 mm/s)

* Pitch 2 -> 20 cm/min (3,3 mm/s)

* Pitch 3 -> 30 cm/min (5,0 mm/s)

* Pitch 4 -> 40 cm/min (6,6 mm/s)

10- Attachment nozzle

(The speed should be reduced to low before it is fully attached, which is the best way to

tighten the gas nozzle.)

-> “Speed setting 3” IN3 (M0) / (Input): OFF

IN4 (M1) / (Input): ON (Low speed)

-> Drive the welding torch approx. another 7mm down the device. After 5mm of the

distance, the inner clamping device is at a stop (8mm + 5mm = 13mm total distance of the

inner clamping device).

After the complete distance of 7mm has been immersed, the entire clamping device

should be sunk approx. 2-3mm from the upper edge of the housing only visible in teach

mode or only briefly recognizable if the nozzle has not yet been fully screwed on in

operational mode.

The distance when pressing down should correspond to the condition of the gas nozzle

fully tightened.

The nozzle is screwed on at a slow speed (800 rpm / Torque limit 35-45%)

33

Page 40

5. Commissioning / Setup

-> TLC signal (Output): ON (when the torque detection signal is activated)

-> ”Forward rotation“ IN0 (FWD) / (Input): OFF

-> Speed setting 3” IN4 (M1) (Input): OFF

-> Extend the torch at a speed of 200 cm/min or. (33 mm/s)

-> Check the complete intake of the nozzle using LS-E and LS-R sensors.

-> MC (Output): OFF (Motor drive: switch off)

-> End

When the alarm indicator (ARM) is lit, turn the driver off and on again until the CHARGED

11. Turn off

LED (charging indicator) switches off.

* If the steps 1-10 contain errors, carry out a teaching correction!

Notes for ongoing operations:

It is recommended to clean the thread of the nozzle and the thread on the welding torch at regular

intervals. Due to unfavorable conditions, welding spatter can penetrate this area and cause the

threads to wear prematurely.

The thread can be cleaned when refilling the contact tips.

34

Page 41

6. Storage and Transport

Caution!

Caution!

6 STORAGE AND TRANSPORT

During all transportation, lifting or moving work, all safety regulations must be adhered to. This also

includes that only tested and suitable lifting tools may be used!

Failure to heed the following instructions in the event of damage may void your

insurance cover.

6.1 Safety regulations

All power, supply and disposal connections may only be disconnected by qualified

personnel.

Only use suitable, undamaged, and fully functional transport equipment with sufficient load-bearing

capacity. Only attach transport / slinging equipment to the points intended for this purpose.

Transport the system carefully, do not lift, support or push onto/against delicate components such as

the control panel, levers, paneling etc.!

Transport preparation:

– Remove tools from the holder or spindle/magazine

– Secure moving machine parts

– Clean the machine

– Close open line ends

6.2 Symbols on the cargo

Fragile, handle

with care

This way up

Keep dry Use no hooks

Keep away

from heat

Sling here

6.3 Transport type

The machine can be moved with a pallet truck or with a forklift and transport rollers. Transport by

lorry, rail or ship:

– Screw the machine foot to the transport surface or the bottom of the box

– Securely fasten control cabinets

– Protect against humidity and corrosion

– Secure provided accessories against slipping

35

Page 42

6. Storage and Transport

Note!

Caution!

6.4 Handover and Inspection

Suitable transport equipment must be provided during handover (e.g. forklift

truck, pallet truck).

Check the packaging after delivery:

– For transport damage

– For other abnormalities

– Document identified damage immediately (sketch, digital / instant camera, description of the

damage).

– Have the damage confirmed in writing on-site by the carrier!

– Forward the corresponding documents immediately Fronius International GmbH!

6.5 Unpacking and Storage

Transport locks, transport aids and packaging should only be removed after

positioning the machine

Dispose of the packaging material in an environmentally friendly manner or re-use it!

Specific transport aids and transport locks are retained by the customer. Store these if the system is to

be moved again.

Check the system after unpacking:

– for transport damage

– for completeness (see delivery note)

– for other abnormalities

– Document identified damage immediately (sketch, digital / instant camera, description of the

damage).

– Forward the corresponding documents immediately to Fronius International GmbH!

In case of interim storage, ensure the following:

– Suitable storage area e.g. dry, clean, heated, measures taken to prevent corrosion

– Store level, horizontally (to prevent distortion)

– Check pneumatic hoses and lines for abrasion points and leaks.

36

Page 43

8. Decommissioning / Dismantling

Note!

7 Maintenance and Repair

Maintenance, repair and cleaning must be carried out by appropriately qualified

personnel (in keeping with the respective task).

7.1 Maintenance

1- Check the attachment, removal unit and nozzle holder for correct functionality

2- Check the unlocking of the contact tip removal unit for correct functionality

3- Check the plain bearings for correct functionality

4- Remove dust and dirt from the guide pins

5- Under no circumstances open the gearbox

37

Page 44

7. Maintenance and Repair

38

Page 45

7. Maintenance and Repair

Note!

Caution!

Caution!

Warning!

Warning!

7.2 Cleaning

Only clean the machine using suitable auxiliary materials.

Switch the machine off before cleaning and secure against unauthorized restart.

It goes without saying that you should clean and care for your machine regularly. How often you must

clean it depends primarily on your work and environment. If you have no visual contact with the main

switch during cleaning work, it must be secured with a lock to prevent it from being switched on again.

In addition, information signs referring to the work must be displayed on the machine.

7.3 Repair

Be sure to adhere to accident prevention regulations! Repairs may only be

performed by commissioned specialist personnel

Be sure to allow residual energy to safely dissipate.

7.4 Safety regulations

Switch the machine off prior to performing maintenance work and secure against

unauthorized restart. In addition, information signs must be displayed referring to

the work on the machine.

Work on electrical devices may only be carried out by skilled electricians, specialist in specific electronic

activities or staff with electrical engineering training.

Live parts in the control cabinet and junction boxes are designed to be finger-safe, however touching

them with tools still poses the risk of contact with live parts.

Servicing, cleaning, etc. may only be performed with the system switched off and stationary.

In case of servicing or maintenance work:

– Switch off the power supply

– Wait for the machine to come to a stop

– Safe dissipation of residual energy (e.g. pressure accumulator, electronics)

– Do not overestimate your own strength – get help or use lifting equipment if necessary, e.g. pallet

truck.

39

Page 46

7. Maintenance and Repair

– Do not clean the machine using high-pressure cleaning equipment.

– Supply parts must be maintained in accordance with manufacturer specifications.

– Maintain a clean and tidy environment during all servicing work.

– Keep traffic routes clear.

– Restore safe operating conditions once service work is complete, i.e. check e.g. that loosened

screw connections are secure, safety devices are fully mounted and functional, connections / lines

are not leaking

– All service work must adhere strictly to the described sequence.

– Only use approved auxiliary and operating materials

– Only use original replacement parts.

.

40

Page 47

8. Decommissioning / Dismantling

Caution!

Warning!

Note!

Warning!

8 Decommissioning/Dismantling

Be sure to adhere to accident prevention regulations!

Be sure to allow residual energy to safely dissipate.

8.1 Safety regulations

Decommissioning may only be performed by commissioned specialist personnel.

Switch the machine off prior to decommissioning and secure against unauthorized

restart. In addition, information signs must be displayed referring to the work on

the machine.

Work on electrical devices may only be carried out by skilled electricians, specialist in specific electronic

activities or staff with electrical engineering training

Live parts in the control cabinet and junction boxes are designed so as to be finger-safe, however

touching them with tools still poses the risk of contact with live parts.

Do not overestimate your own strength – get help or use lifting equipment if necessary, e.g. forklift

truck.

8.2 Decommissioning

Shutdown

– Switch off, disconnect power and operating material lines

– Drain liquid and pressure containers

Cleaning

– Cleaning prior to storage

Preservation

– Apply corrosion protection

– Fill tanks and containers with corrosion protection and/or anti-freeze agent

– Replace lubricant

41

Page 48

9. Spareparts

Note!

Caution!

9 SPAREPARTS

Non-original or faulty replacement parts can cause damage or machine

malfunctions.

Replacement parts may only be replaced, or repairs performed by specialist

personnel, as there is a risk of injury on account of stored residual energy.

In order that valuable production time is not lost in the event of the failure of components that are

subject to wear and to minimize downtime, we recommend that you keep a stock of replacement parts.

Purchased parts can be taken from the enclosed sets of drawings. All components of the machine,

especially safety components, may only be replaced with original components or other components

subject to the written consent of KYOKUTOH Europe GmbH. All screws are to be tightened with the

respective tightening torques according to DIN 912

42

Page 49

9. Spareparts

Robacta Model:

4,050,001

4,050,002

Item no.:

42,0411,0357

42,0411,0358

Quantity:

4 4

Treibwerk für

4,050,001

Item no.:

42,0411,0359

Quantity

: 1

Robacta Model:

4,050,001

4,050,003

Item no.:

42,0411,0355

42,0411,0356

Quantity

: 4 4

Robacta Model:

4,050,001

Item no.:

42,0411,0362

Quantity

: 1

Robacta Model:

4,050,001

Item no.:

42,0411,0360

Quantity

: 1

Ball Plunger for

Robacta

4,050,001

Item no.:

42,0411,0361

Quantity

: 4

9.1 Partlist

Sparepart list

Clamping jaws

for contact tip

Driving finger

for contact tip

holder

Clamping jaws

for the removal

and attaching

unit of the

nozzle

Cleaning unit for

contact tips

Kontaktdüsenmagazin:

4,050,003

4,050,002

4,050,003

4,050,004

4,050,002

4,050,002

4,050,003

4,050,004

4,050,004

4,050,004

Lower blade for

welding wire

cutting

guiding gas nozzle

Model:

4,050,002

4,050,003

4,050,004

4,050,002

4,050,003

4,050,004

43

Page 50

10. Service

Note!

Warning!

Caution!

Warning!

Trouble

Possible causes

Elimination

– The power supply is interrupted

– Check connection

– The nozzle is stuck between the

– Correct the position during

– The contact tip tuck between

– Correct the position during

10 SERVICE

The penetration of cooling water from the welding grippers into the transmission

housing can result in the damage of the intake gearwheel incl. the bearings in the

transmission area, depending on operating conditions.

Be sure to regularly lubricate the transmission! (See Maintenance)

There is a risk of becoming trapped or injured as a result of the movement of the

components.

All power, supply and disposal connections may only be disconnected by qualified

personnel.

Risk of injury when troubleshooting due to residual energy (e.g. in the pneumatics

system). There is the risk that the cutting edge will suddenly start moving. Never

place your fingers in the cutting area.

10.1 Troubleshooting

A rotating unit

does not rotate

The nozzle cannot be

removed

The contact tip cannot

be removed

– Alarm mode switched on

– Nozzles are stuck

– Signals for different directions of

rotation switch on

simultaneously

jaws

– The speed of rotation is not

enough

– Foreign objects in the unit

– Insufficient torque limit when

(TL) is off

– Wrong direction of rotation

the jaws

– The jaws and contact tip are not

correctly aligned

– The speed of rotation is not

enough

– Wrong direction of rotation

– Clear alarm

– Perform teaching correction

– Cancel signals

teaching

– Extend rotation time

– Clean the unit

– Torque limit signal (TL)

– Check and switch on

– Check the direction of rotation

teaching

– Compare the diameter of the

contact tips and jaws and replace

if necessary

– Extend rotation time

– Check the direction of rotation

44

Page 51

10. Service

– Welding wire was not pulled out

– Pull the Welding wire out of the

–

The nozzle is not stuck properly

– Pay

attention to the correct

The robot's shock

– -Re-teachen

– The power was

turned on again

– Turn on the power after turning

– Control position is switched OFF

– Pay attention to the correct

– The

blade

is worn

– Exchange for new blade

– The brush is worn out

– Exchange for new ones

Trouble – Possible causes – Elimination

The contact tip is not

pinched

The nozzle is not

pinched

sensor switches off

Alarm 46 displayed on

FC screen

Malfunction of the

sensors

of the contact tip attachment

– insufficient push-down distance

– Not centered

between the jaws

– Not enough time

– Foreign objects in the unit

– Not centered or positioned

vertically

– Wrong direction of rotation

when the FWD input or REV

input was being ON.

– Unsuitable time (0.2 seconds or

more)

– Damage

– Connection Error

contact tip attachment

– Reposition and re-teach

– Pay attention to the correct

position during re-teaching

position during re-teaching

– Increase times

– Clean the unit and remove foreign

objects

– Set the correct direction of

rotation

both the FWD input and REV input

OFF.

position during re-teaching

– Correct the time

– Exchange for a new sensor

– Check the connection and

eliminate the problem

Burr after cut off the

welding wire

Contact tip is not

cleaned

In the event of faults, questions or spare parts deliveries, please contact your Fronius contact person.

– The lower blade and the surface

of the wire do not touch

– Re-teach so that there is a contact

45

Page 52

11. Appendix

C

ontact tips with wrench size

Outer diameter

ØA:

Wrench size

B:

Length

C:

Thread length

D:

Distance between the tip of the thread length

C

ontact tips with

out wrench size

Outer diameter

ØA:

Length

C:

Thread length

D:

Distance

between the tip of the thread length

11 APPENDIX

11.1 Data on the different contact tips

and the flange E:

Ø7 – Ø10

6 - 9

„0“ If without flange

and the flange E1:

Ø6 und Ø8

46

Page 53

11.

Appendix

Threaded nozzle

Shape

: Straight

(S

) /

Conical

(T

) /

Stepped

(D)

Outer diameter

ØF: Ø34mm or smaller

Length

H:

Knurling length

l: 60mm

or smaler

11.2 Data on different nozzles

47

Page 54

11.

Appendix

Speed Control Motor spec

Frame Size

80 mm

Rated Output Power

60 W

Gearhead Ratio

20:1

Power Supply

AGE11513

Single Phase 200~240 VAC

Frequency (Hz)

50/60

Rated Torque (Gearhead Shaft)

3,4 Nm

Maximum Instantaneous Torque (Gearhead

7,5 Nm

Speed Control Range (Gearhead Shaft)

100~200 r/min

Multi Speed Operation

Min. 3 speeds

Input

Speed Control: Rotational Speed 1, Rotational

FWD

and

REV (DIR)

Torque Limit (TL)

Output

Torque Limit Signal [TLC]

11.3 Elektronic

Motor Specification – Speed Control Motor CTC

(Frequency converter type BLE2D60-C)

Shaft)

I/O

Dimensions for installation screws

Three Phase 200~240 VAC

Speed 2 and Rotational Speed 3

Or Rotation Signal [MOVE]

48

Page 55

11.

Appendix

49

Page 56

FRONIUS INTERNATIONAL GMBH

Froniusstraße 1, A-4643 Pettenbach, Austria E-

Mail: sales@fronius.com www.fronius.com

Under www.fronius.com/contact you will find the addresses of all Fronius

Sales & Service Partners and locations

50

Loading...

Loading...